Patents

Literature

306results about "Vegetable fibre separation from seeds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

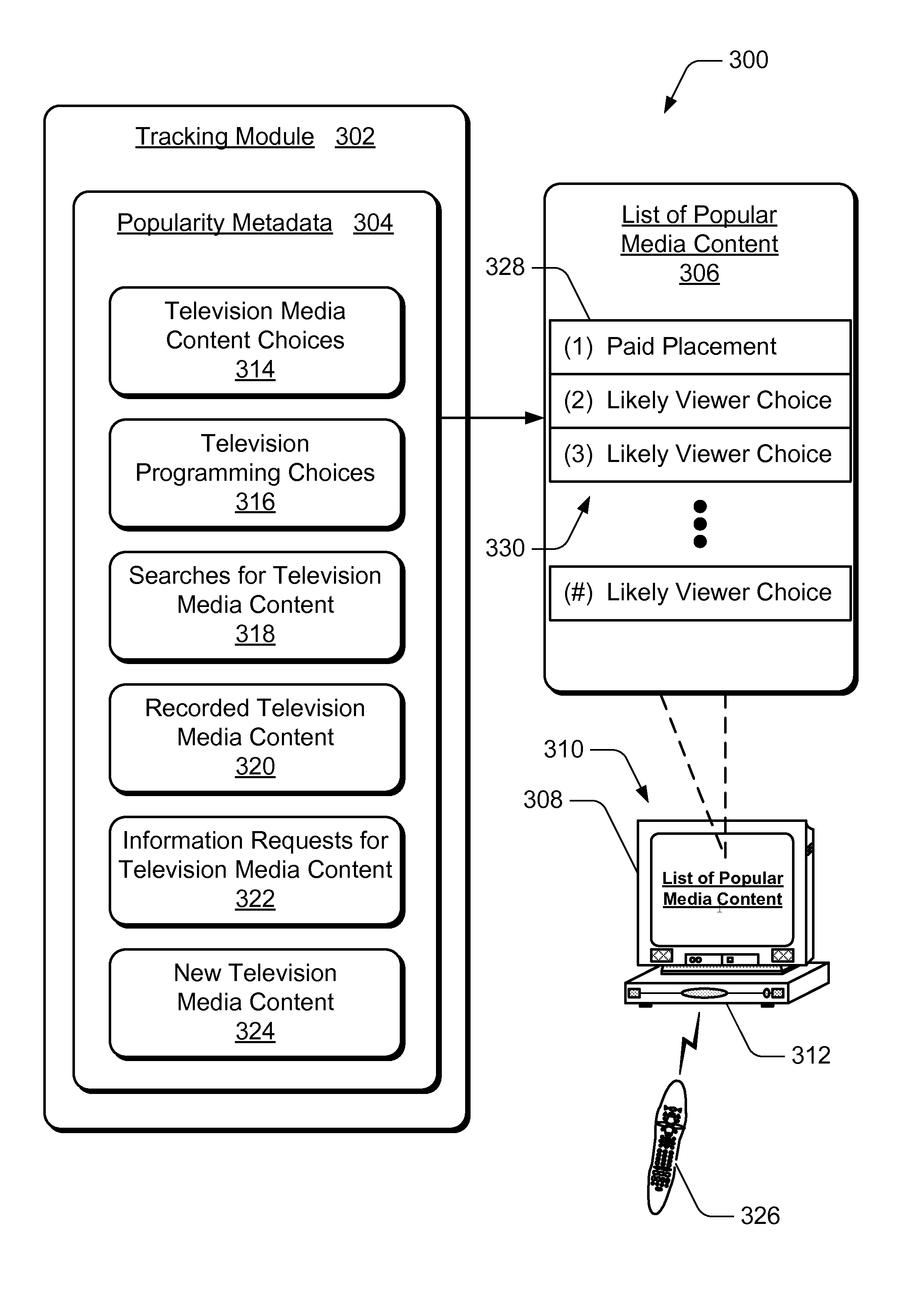

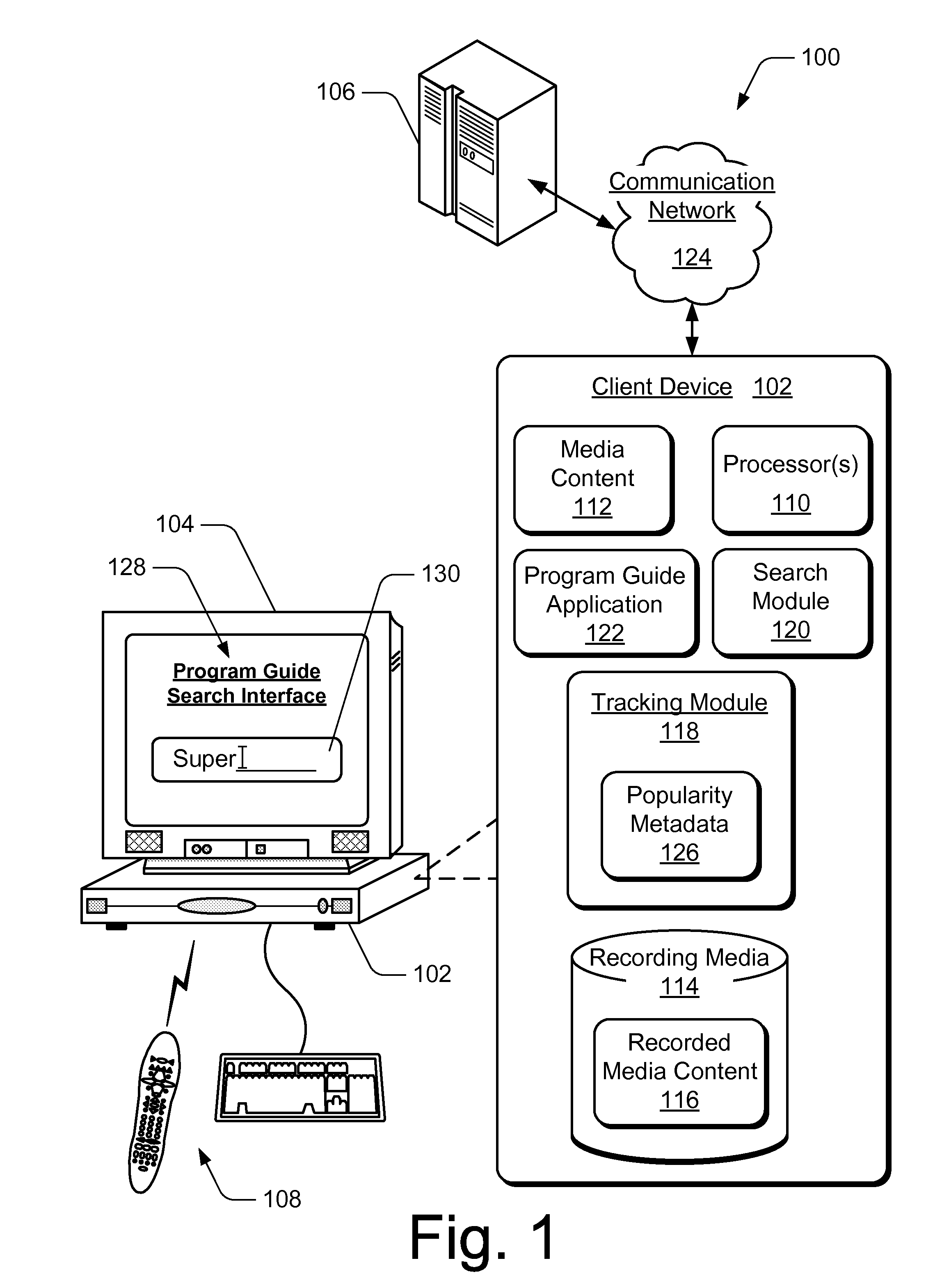

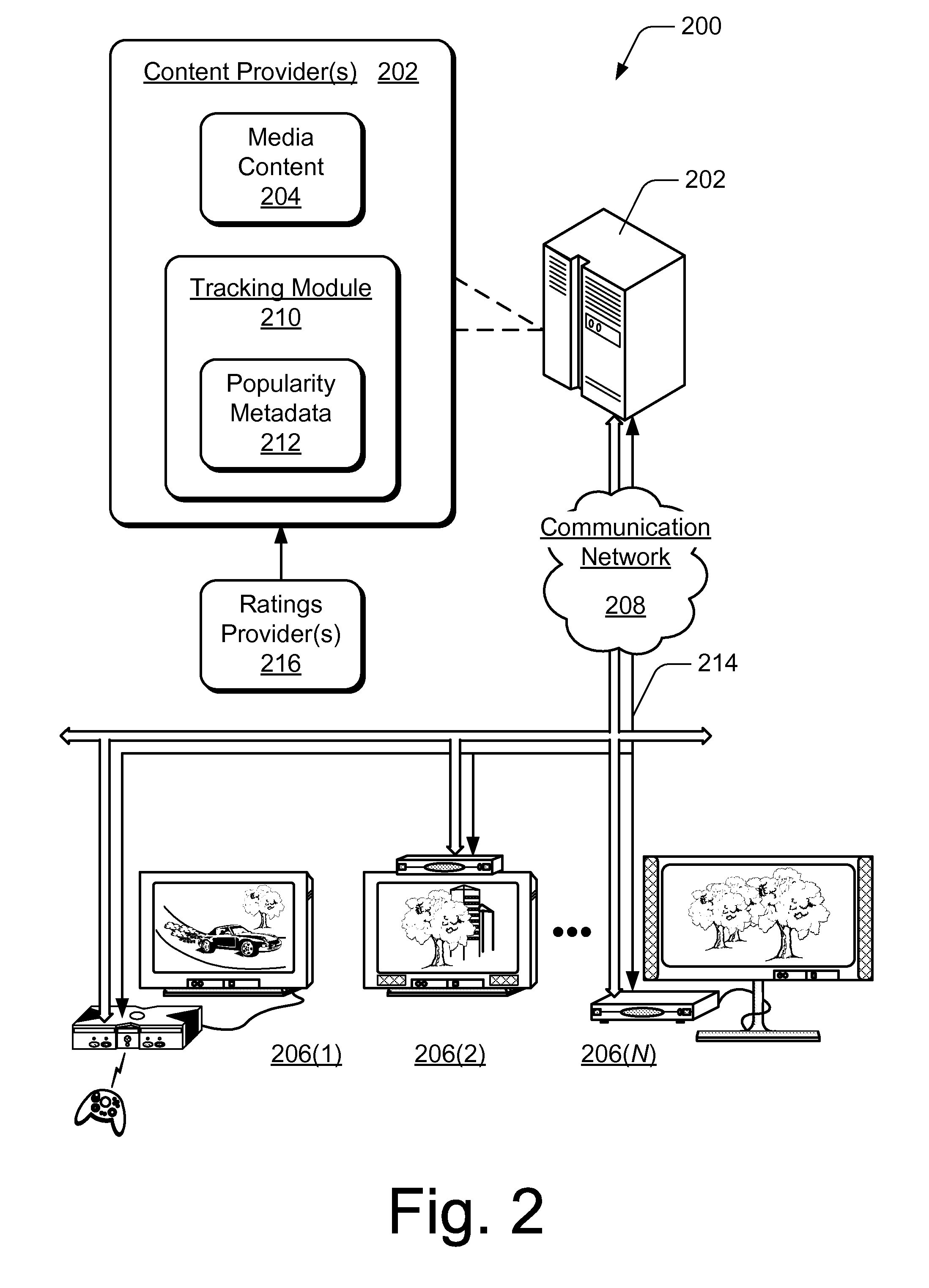

Media content search results ranked by popularity

ActiveUS8478750B2Television system detailsDigital data information retrievalRankingInformation retrieval

Media content search results ranked by popularity is described. In embodiment(s), a search request for television media content can be initiated by a viewer, and television media content that is relevant to the search request can be identified. The relevant television media content can then be ranked based on a popularity rating and the relevant television media content can be displayed in an ordered list that is ordered by popularity rankings.

Owner:ROVI TECH CORP

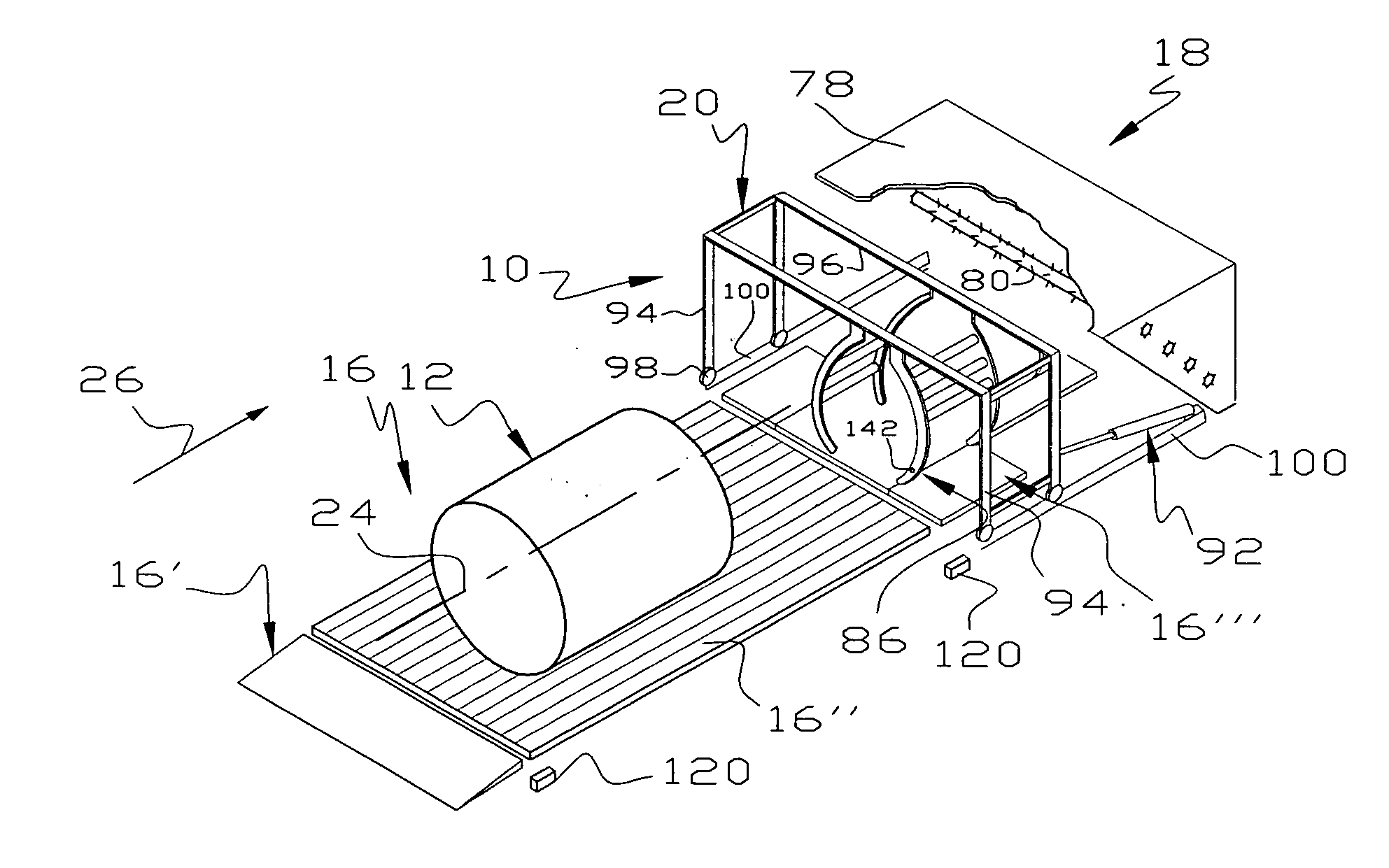

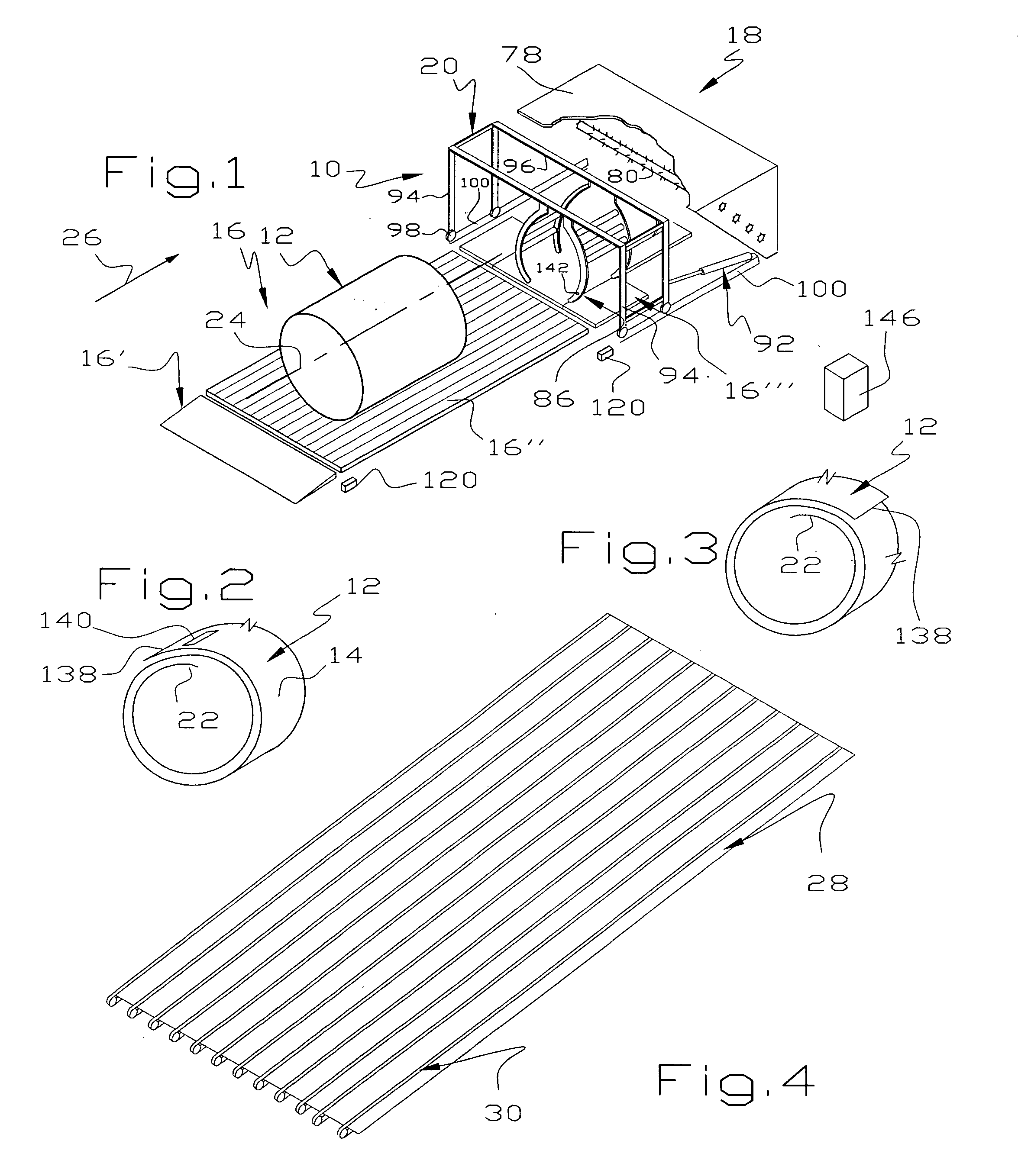

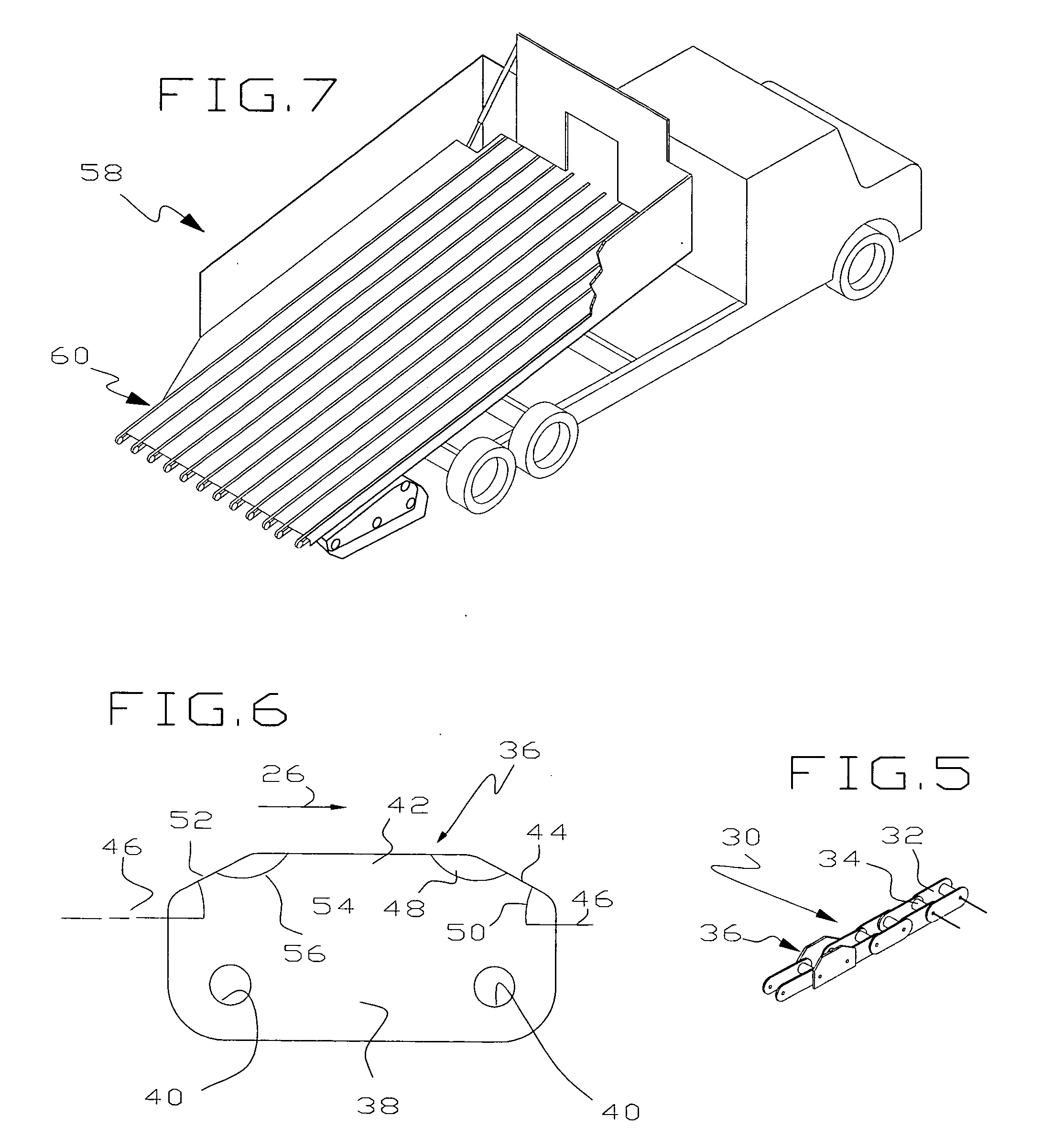

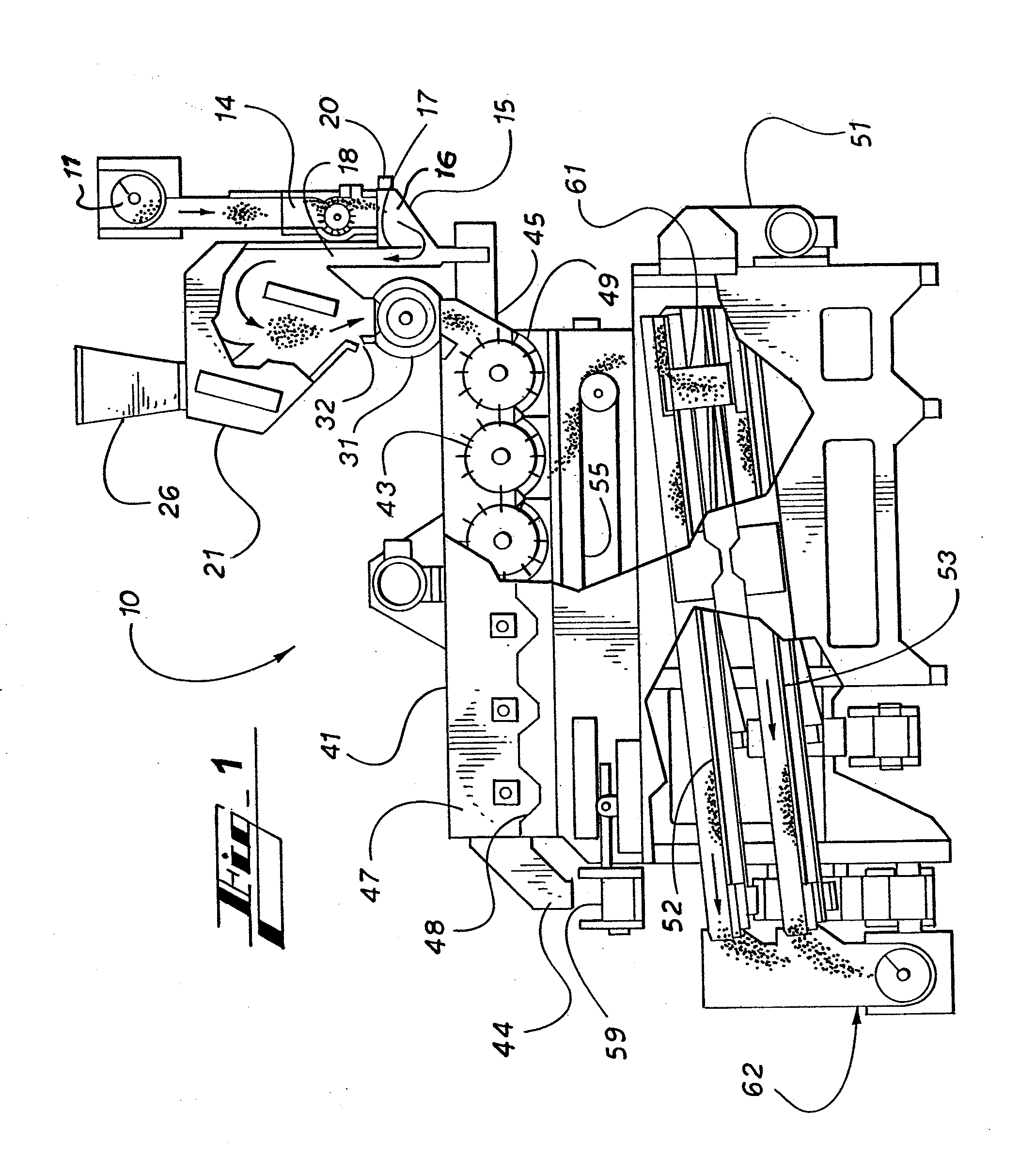

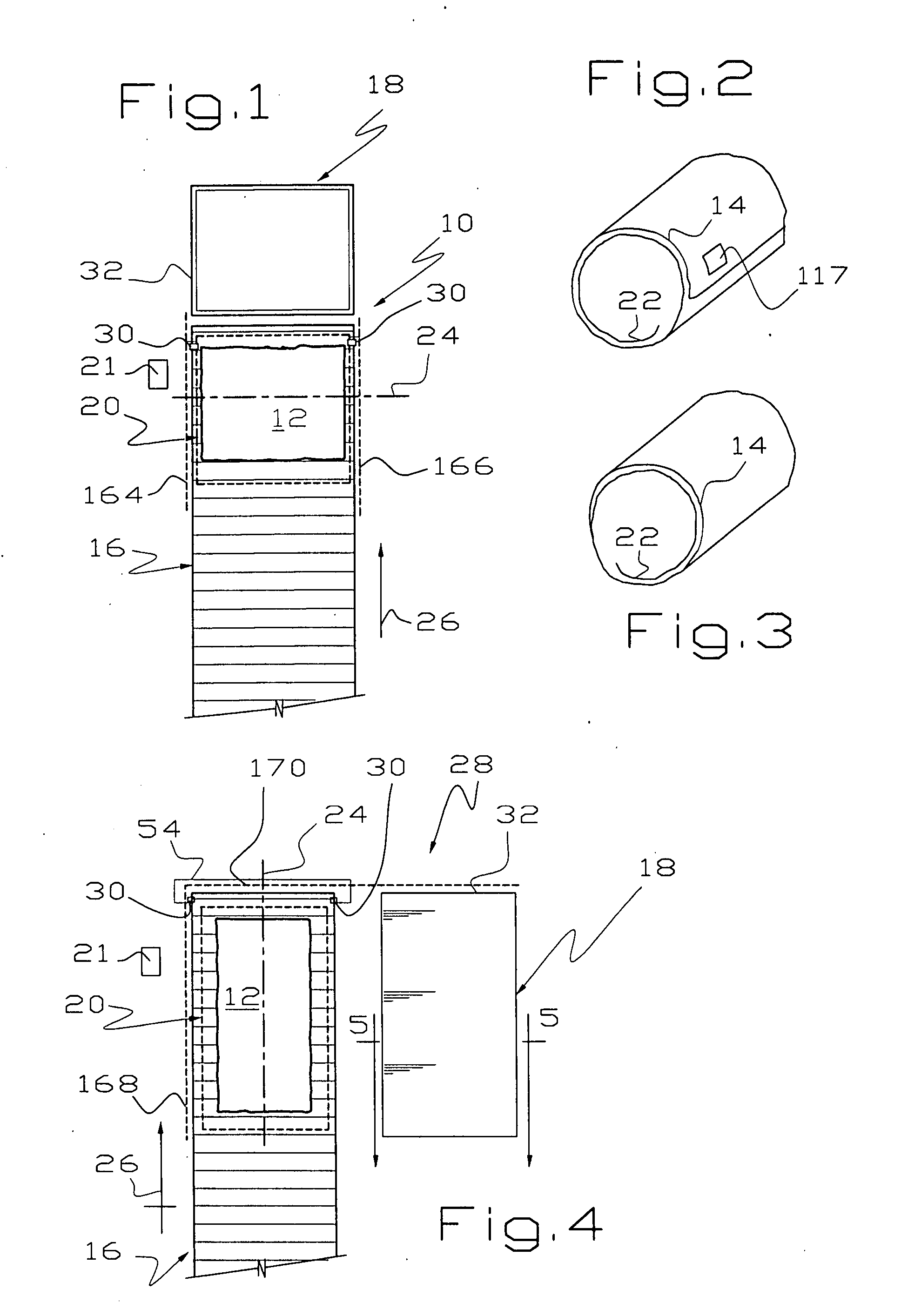

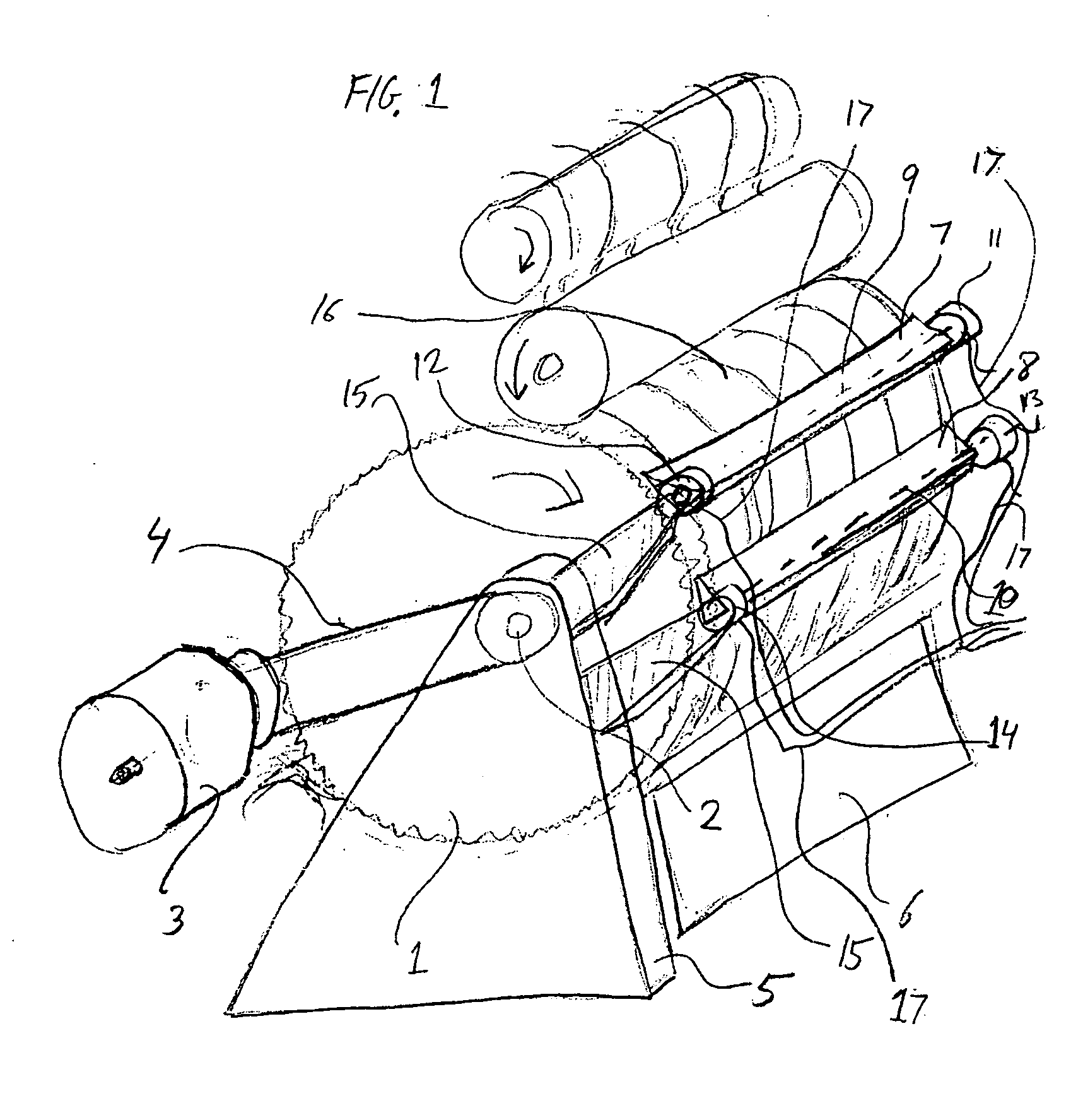

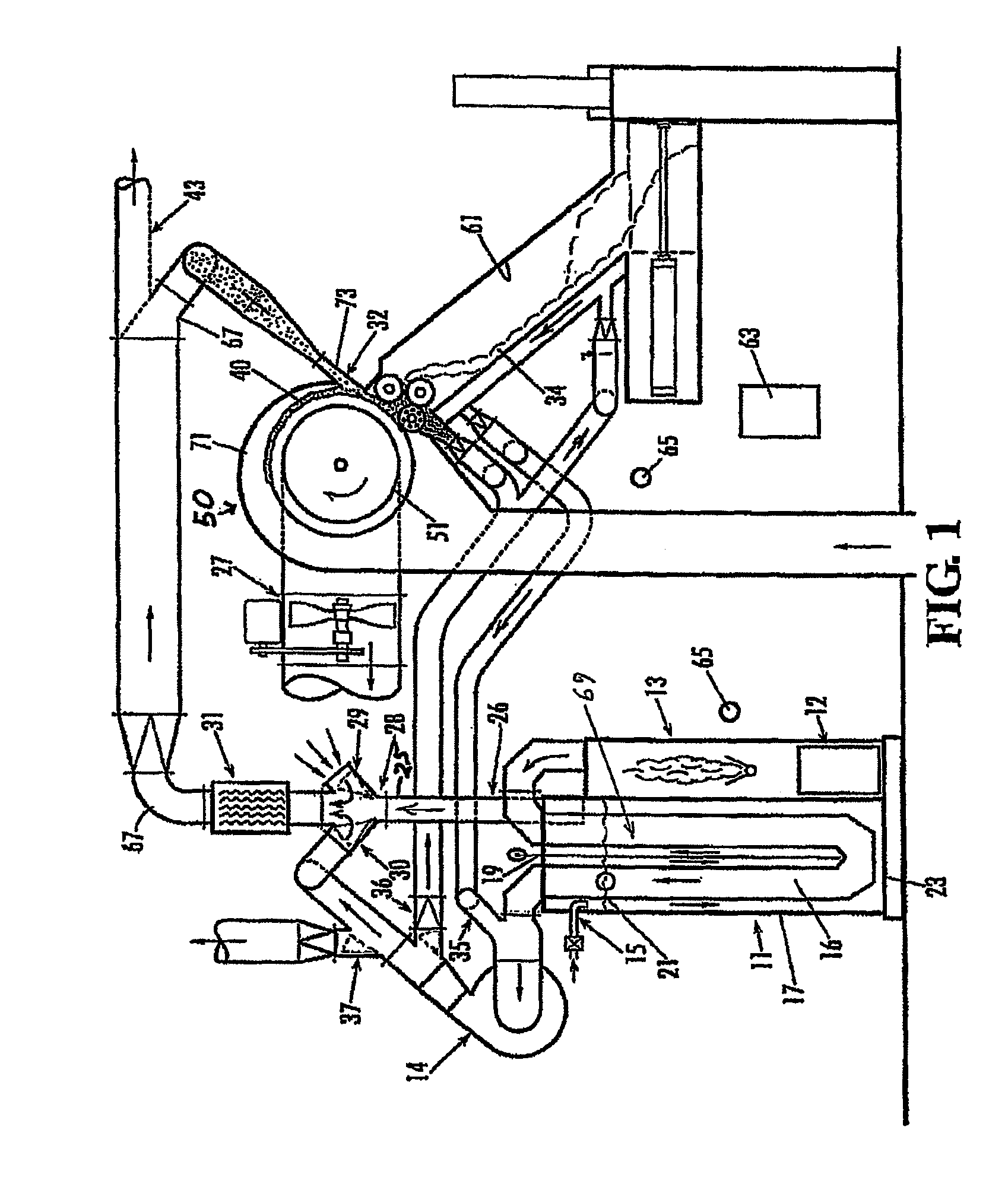

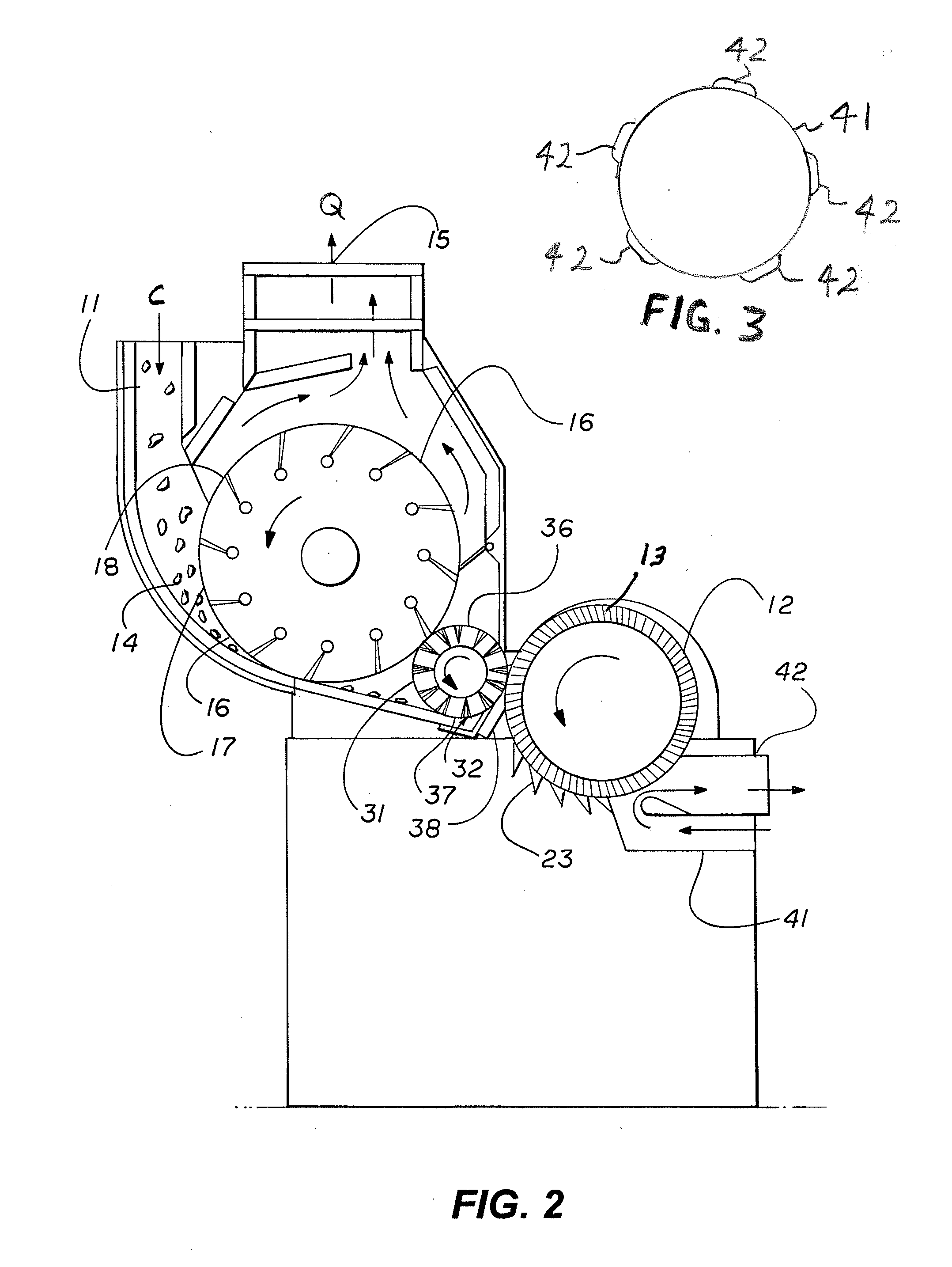

Technique for removing a cover from cylindrical modules

In one embodiment, a system for removing a plastic wrap from a cylindrical module includes a conveyor transporting the cylindrical module toward a disperser with the cylindrical axis of the module parallel to the direction of conveyor movement. In another embodiment, the disperser is a travelling head disperser thereby providing relative movement between the modules and the disperser. The direction of the wrap around the module is determined and the cover is removed during rotation of the module, either by unwrapping the plastic or by slitting the plastic and then rotating the module. The equipment used to handle a cylindrical module is moved out of the path of movement of a conventional rectangular module so an installation can handle both rectangular and wrapped cylindrical modules.

Owner:STOVER EQUIP

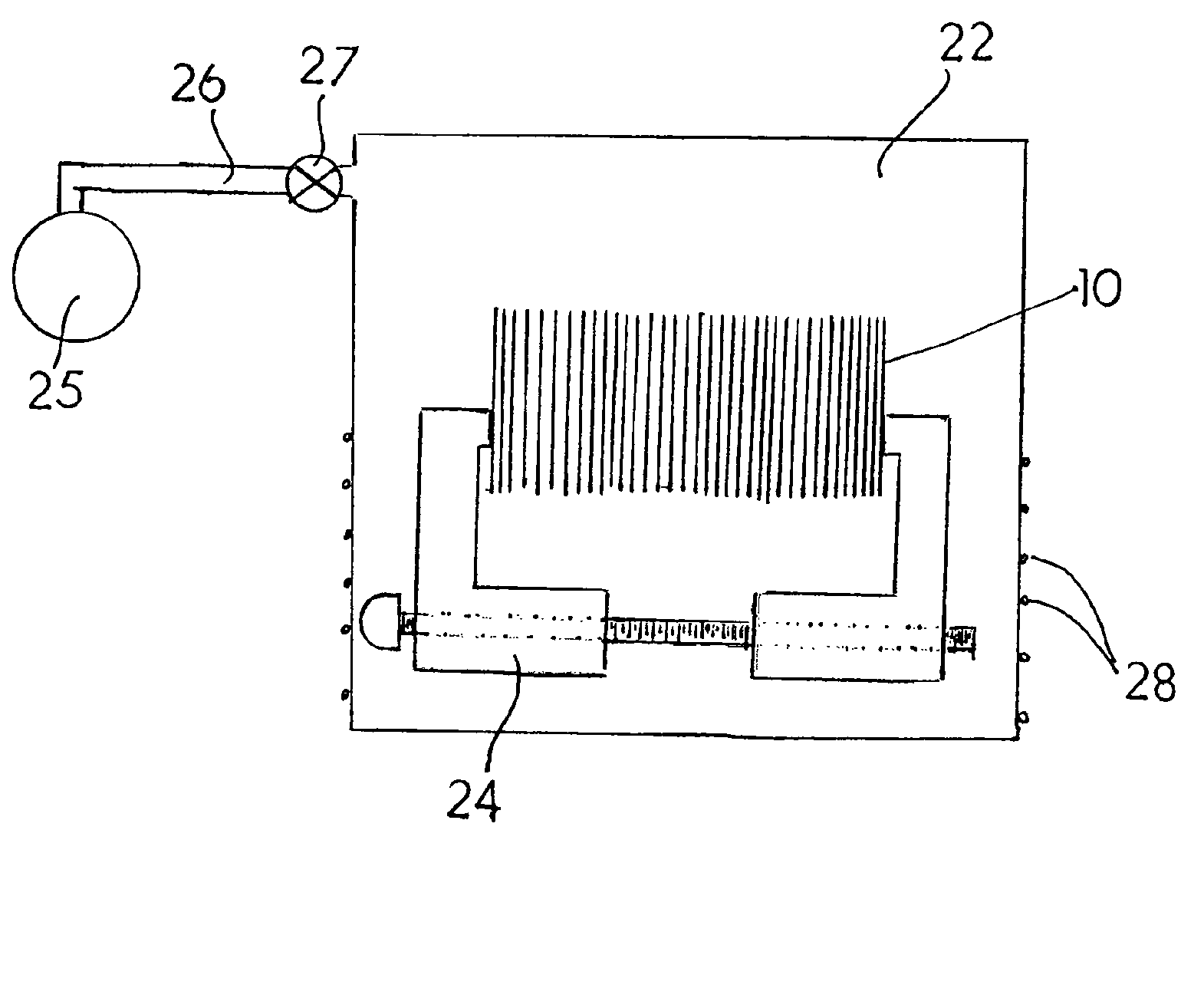

Seed cotton foreign fiber separator

ActiveCN101570905AEfficient removalImprove cleanlinessVegetable fibre separation from seedsFibre cleaning/openingFiberState of art

The invention discloses a seed cotton foreign fiber separator which comprises a separating chamber consisting of an electrode plate set and a case body, a feeding port, a discharge port, an impurity discharge port, a fan and a wind chamber. The electrode plate set consists of an anode plate and a cathode plate. The electrode plate of the electrode plate set, which is positioned between the separating chamber and the wind chamber, is a wind-evening network-shaped structure. The seed cotton foreign fiber separator is characterized in that a stirring device is arranged between the anode plate and the cathode plate in the separating chamber, and at least one stirring and shifting roller constitutes a stirring and shifting roller set. Compared with the prior art, the seed cotton foreign fiber separator can effectively clear foreign fibers such as mulching films, and the like during cotton picking, and meanwhile can clear other impurities, and the clearing effect is good.

Owner:SHIHEZI UNIVERSITY

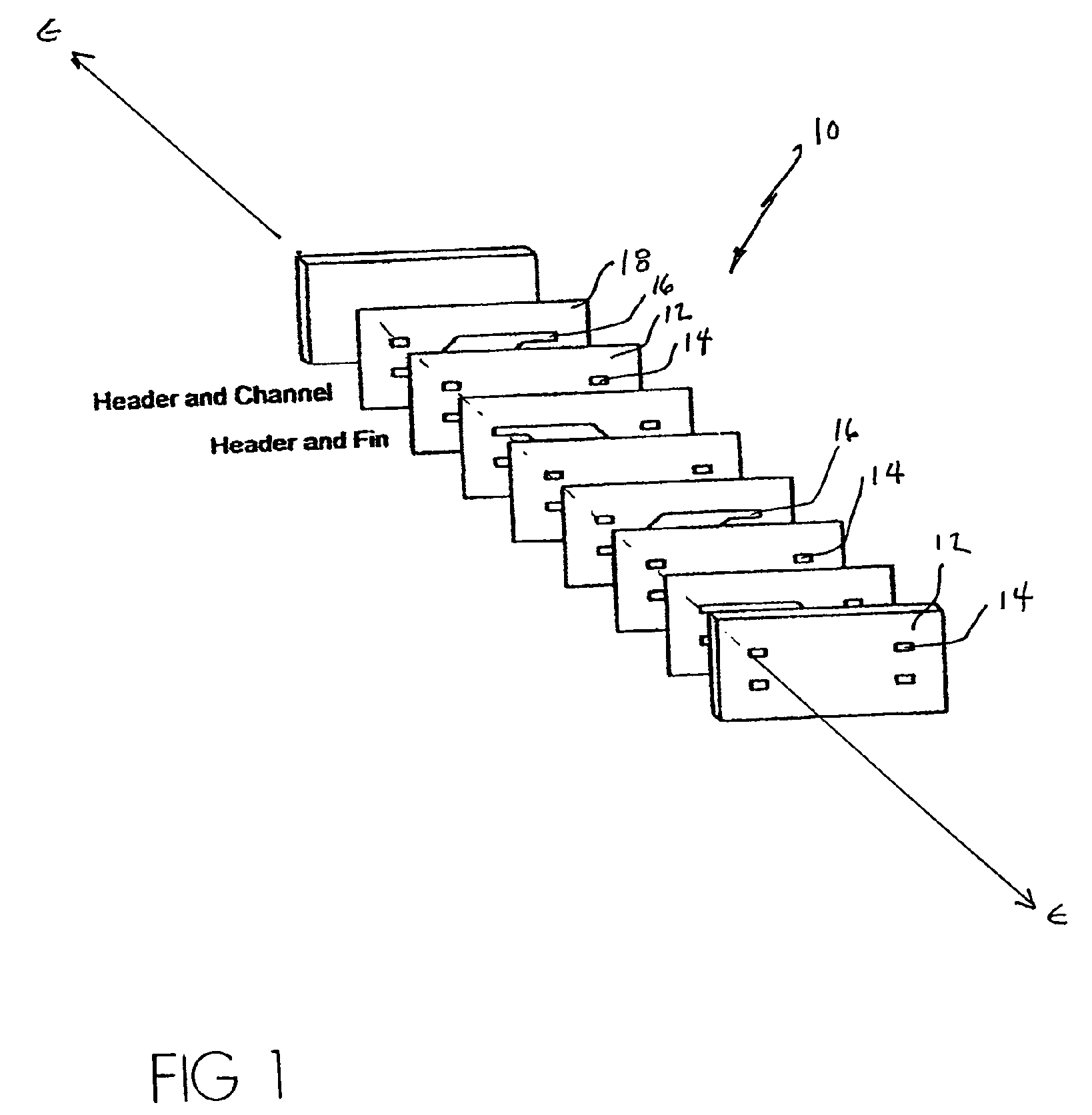

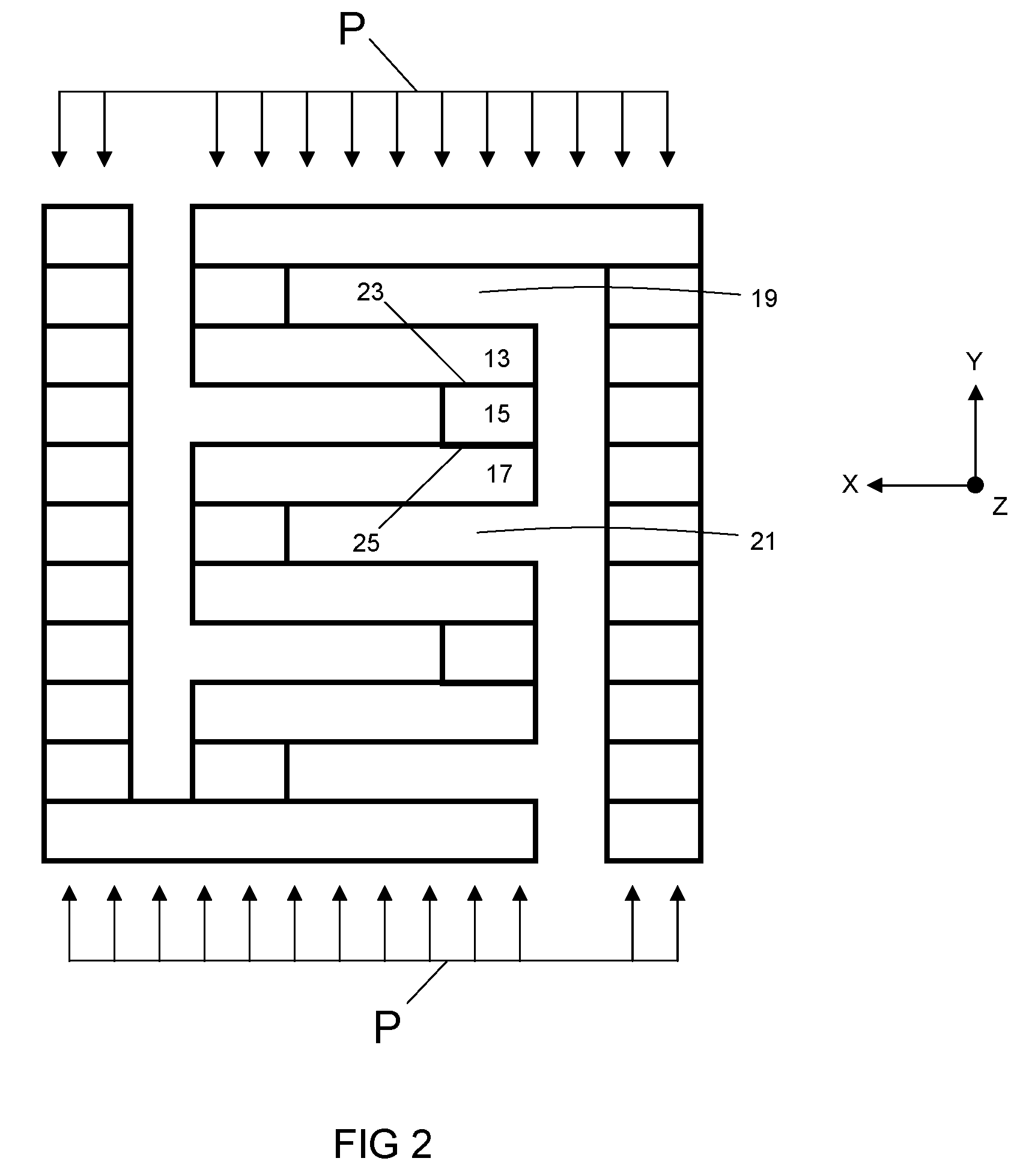

Method for producing components with internal architectures, such as micro-channel reactors, via diffusion bonding sheets

InactiveUS7900811B1Prevent collapseAvoid distortionAdhesive processesVegetable fibre separation from seedsCombustorChemical reactor

This invention relates to a method for producing components with internal architectures, and more particularly, this invention relates to a method for producing structures with microchannels via the use of diffusion bonding of stacked laminates. Specifically, the method involves weakly bonding a stack of laminates forming internal voids and channels with a first generally low uniaxial pressure and first temperature such that bonding at least between the asperites of opposing laminates occurs and pores are isolated in interfacial contact areas, followed by a second generally higher isostatic pressure and second temperature for final bonding. The method thereby allows fabrication of micro-channel devices such as heat exchangers, recuperators, heat-pumps, chemical separators, chemical reactors, fuel processing units, and combustors without limitation on the fin aspect ratio.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

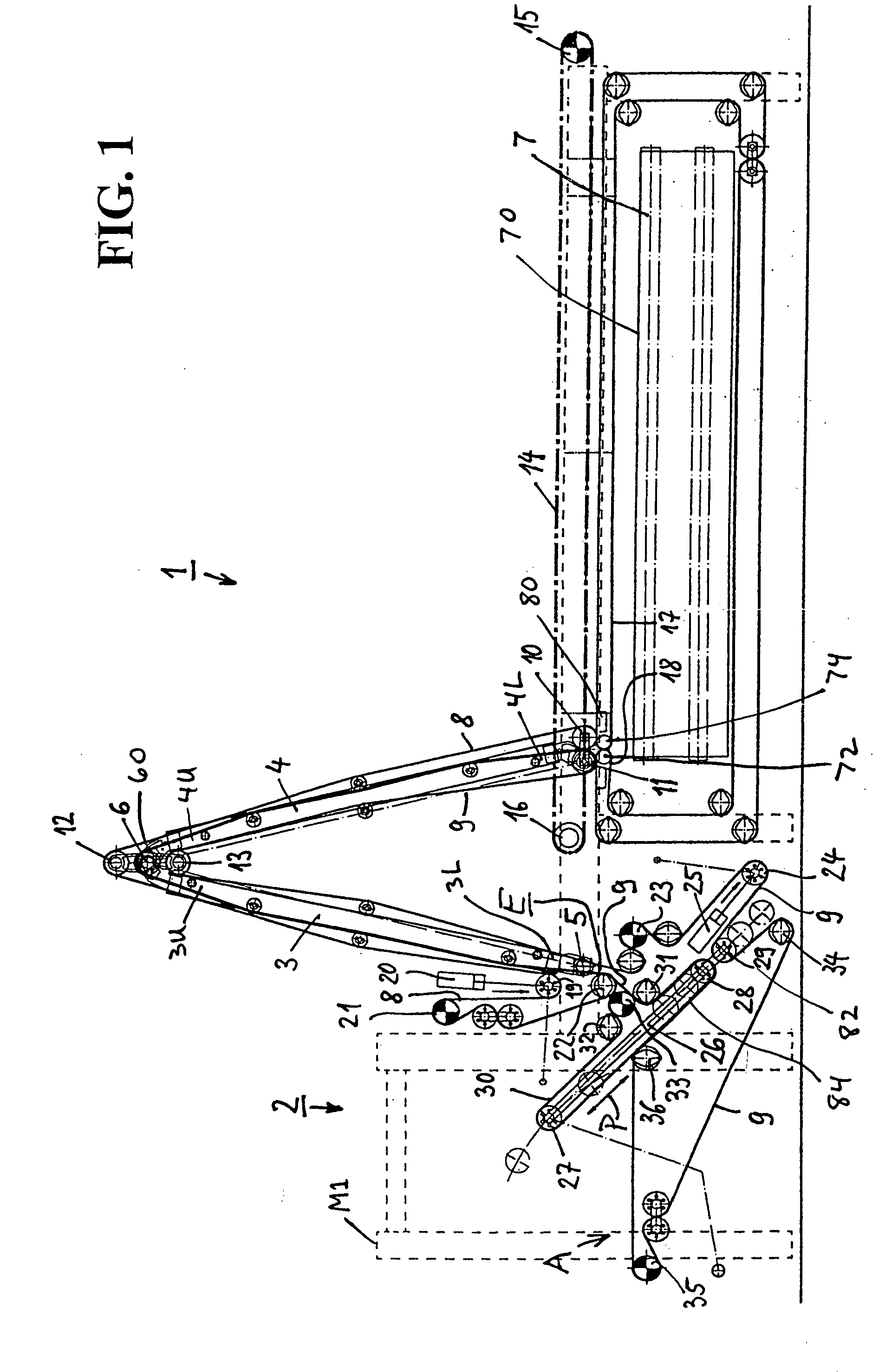

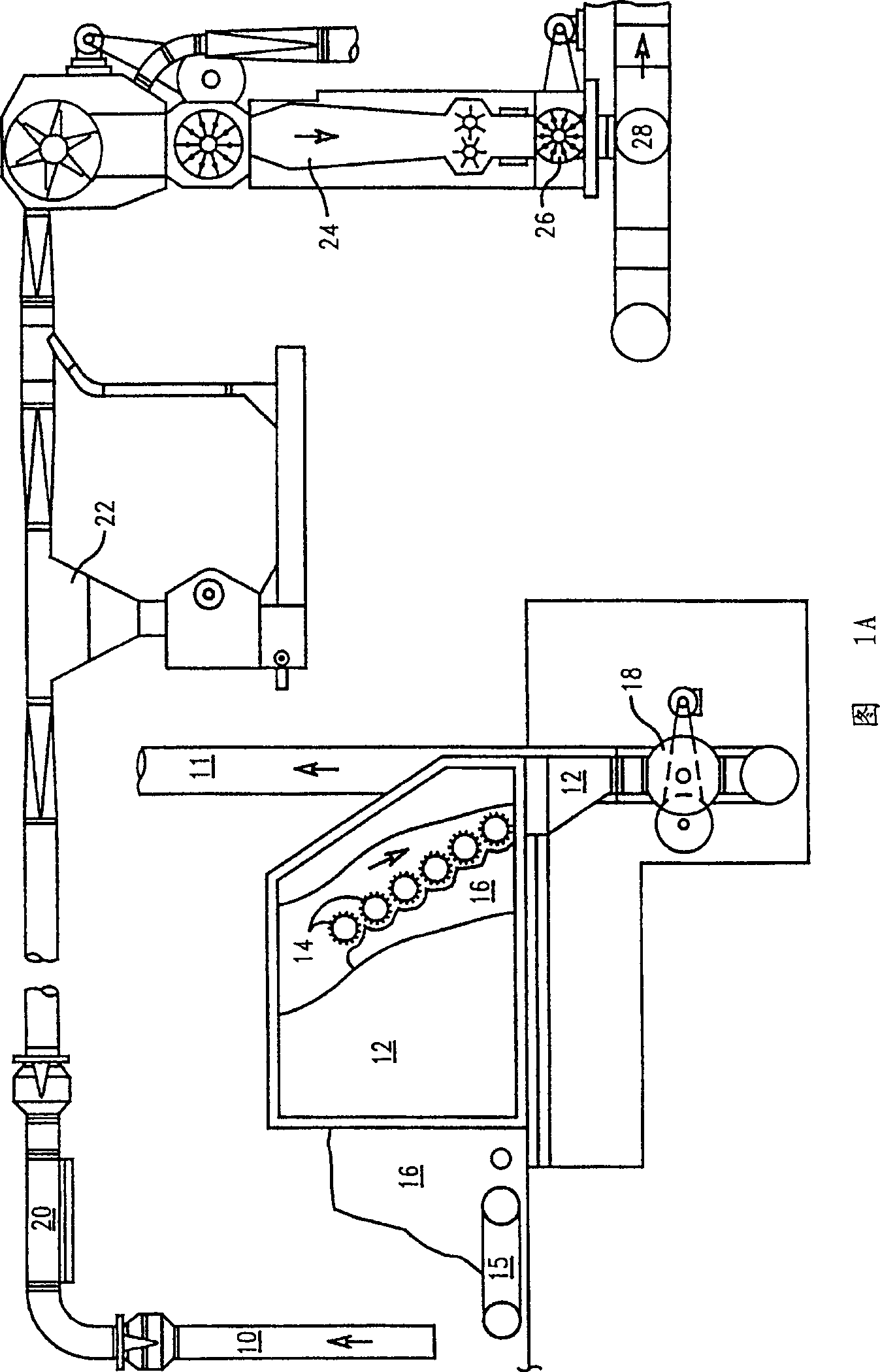

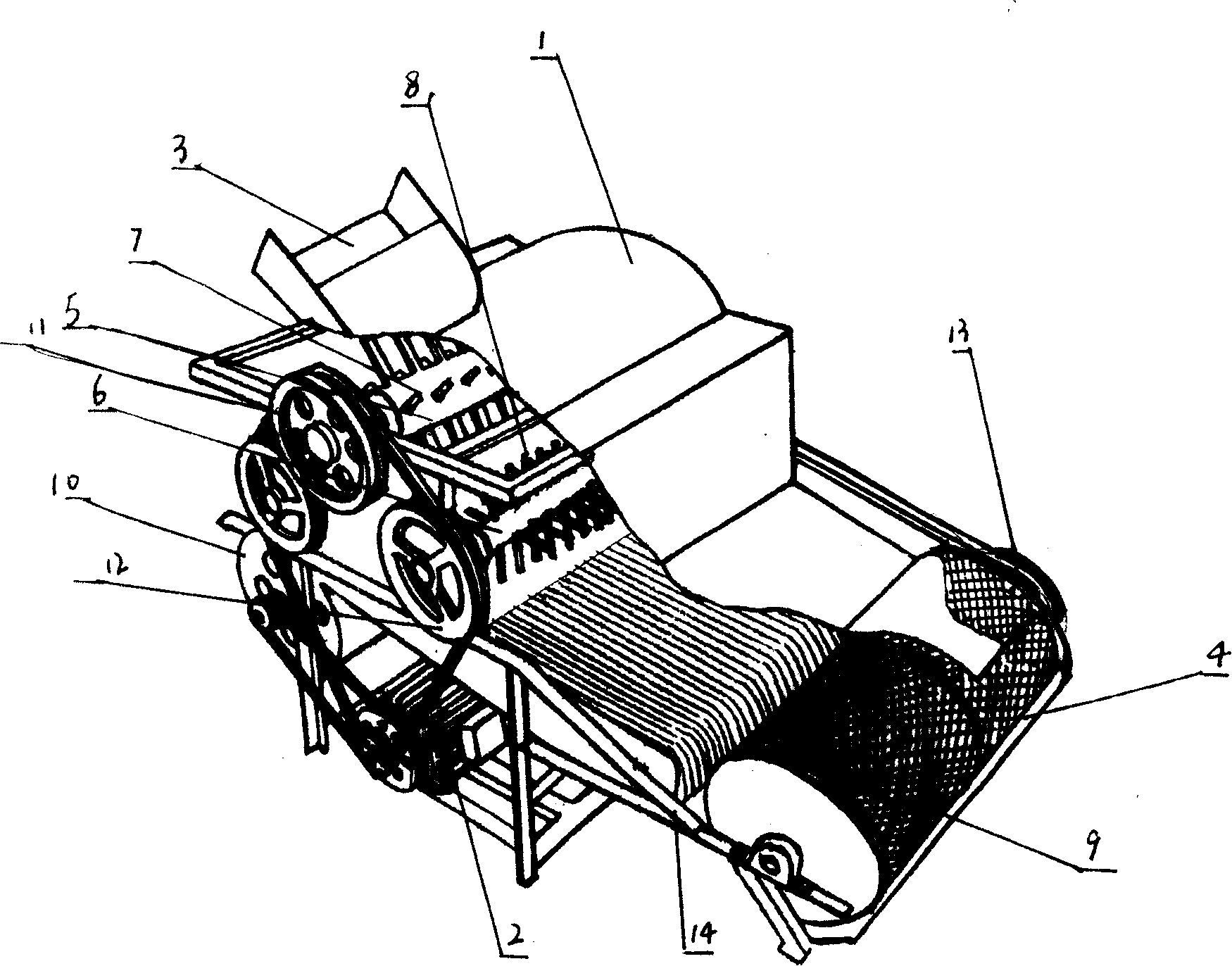

Seed Cleaner

ActiveUS20090194463A1Reducing cleaning rate and efficiencyIncrease capacitySievingVegetable fibre separation from seedsEngineeringCleaning agent

An improved seed cleaner utilizes a rock trap sequentially followed by an aspiration hood which performs preliminary cleaning before passing seed to a rotary seed cleaner mounted over a shaker to yield a cottonseed cleaning system has enhanced the removal of loose lint from the seed before the seed is passed over any shaker screens to prevent clogging of the shaker screens by the loose lint.

Owner:LUMMUS INDS

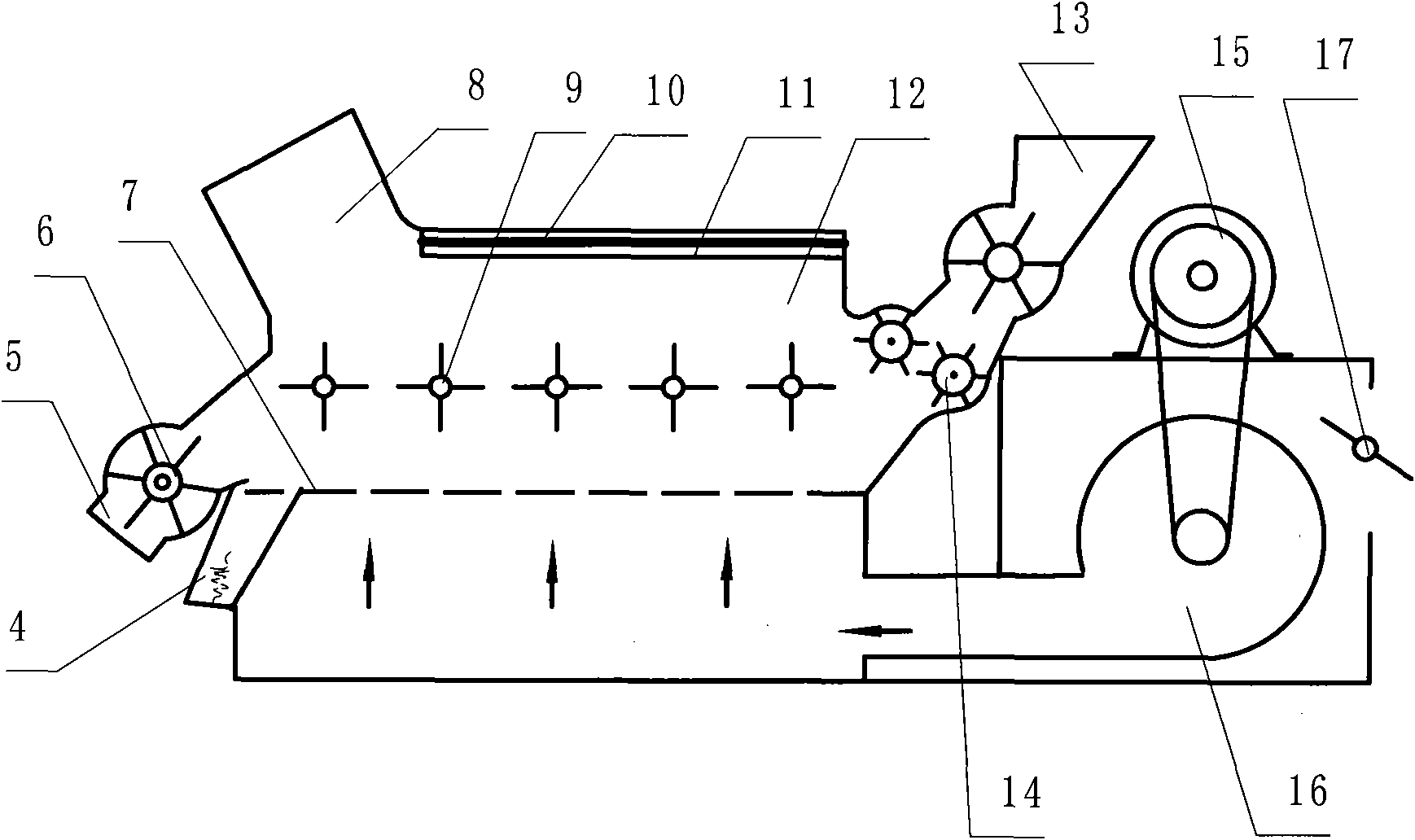

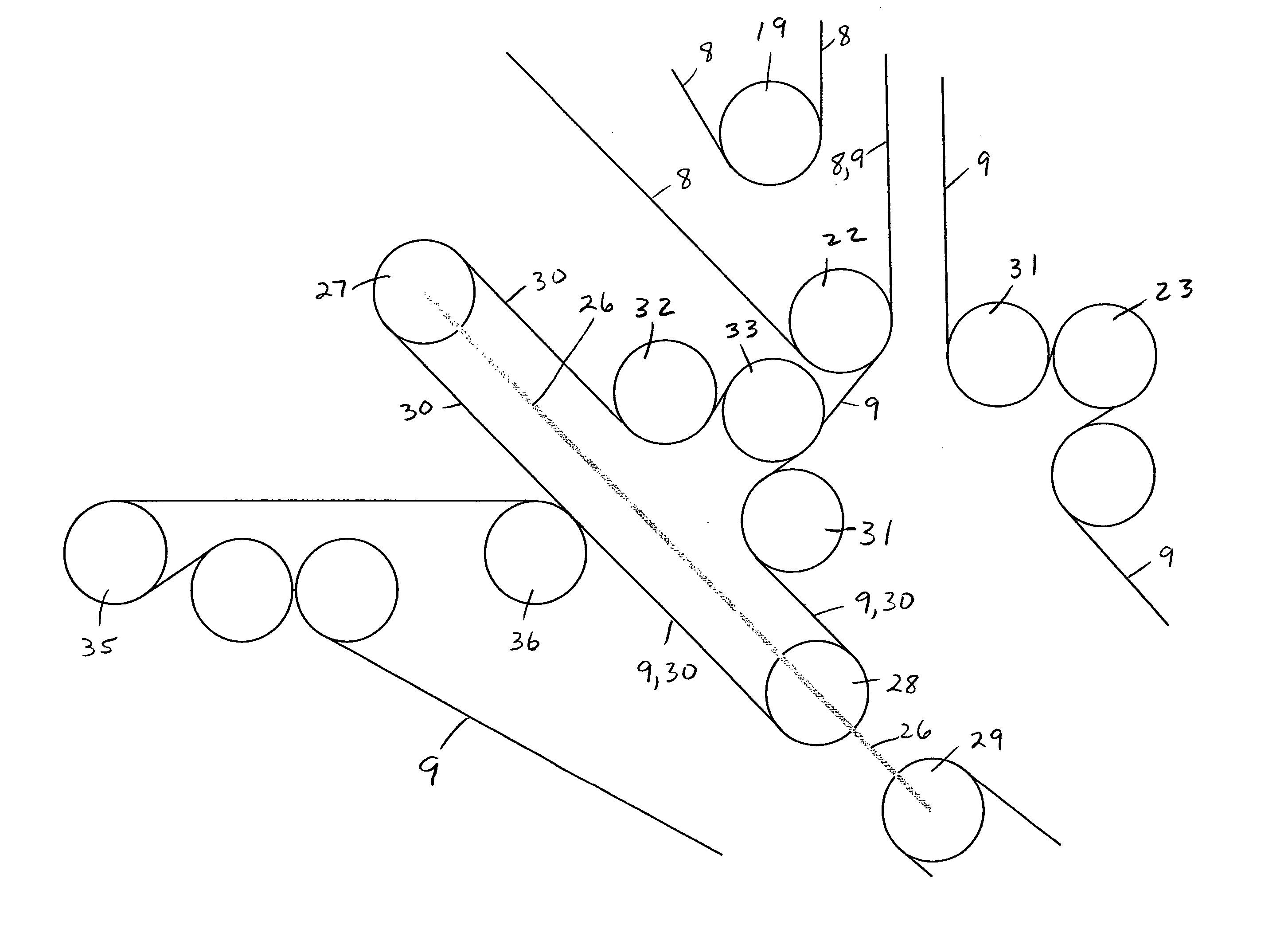

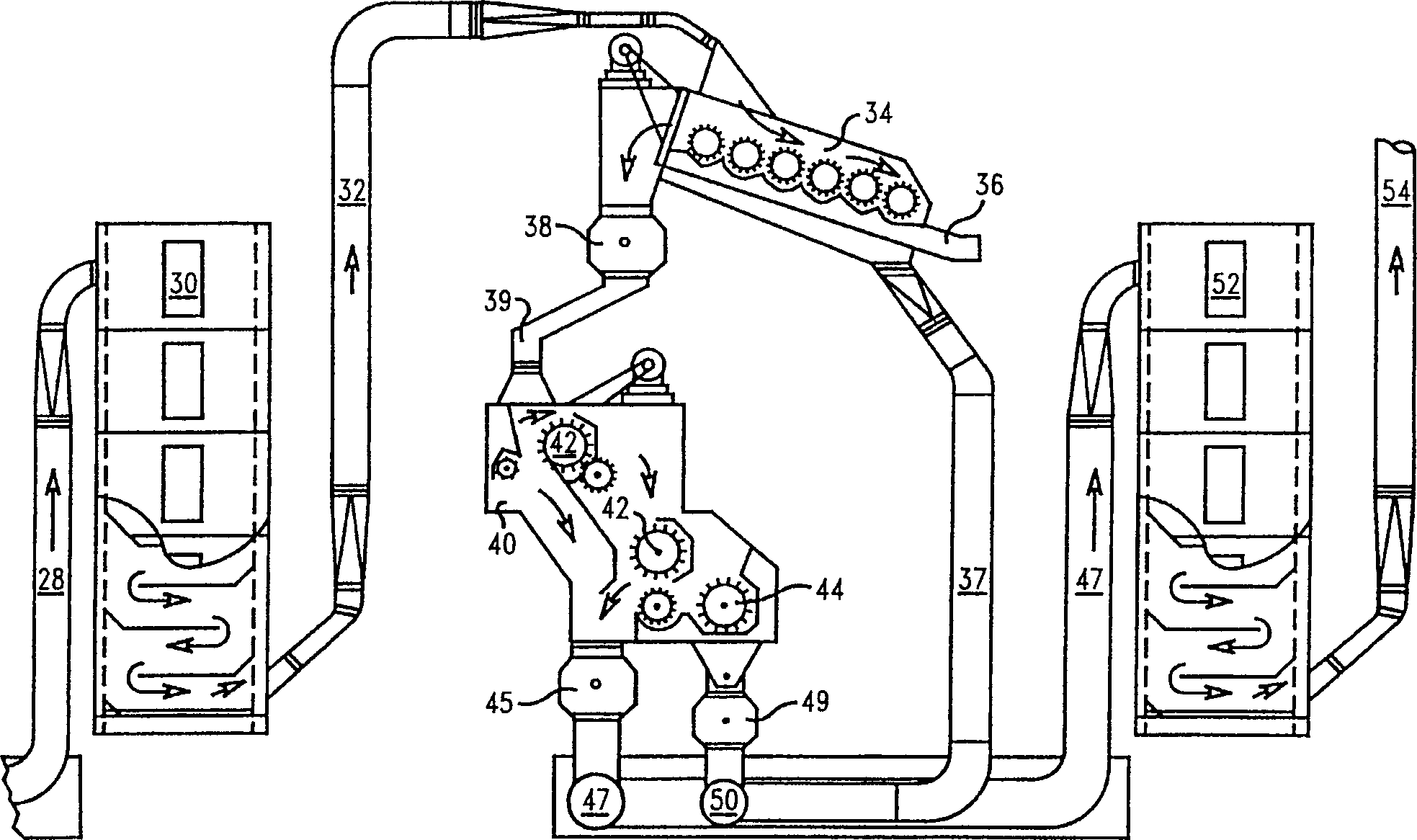

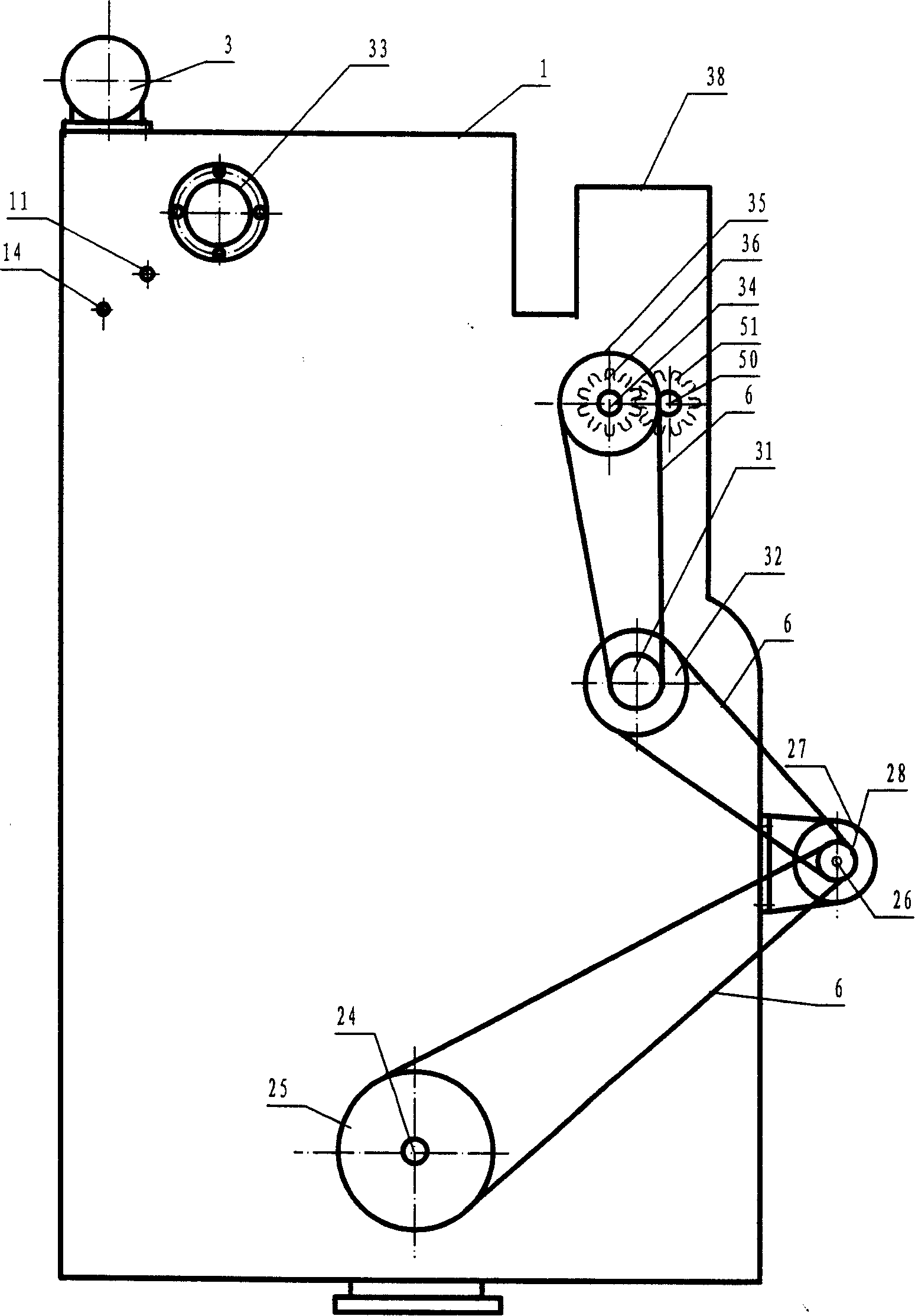

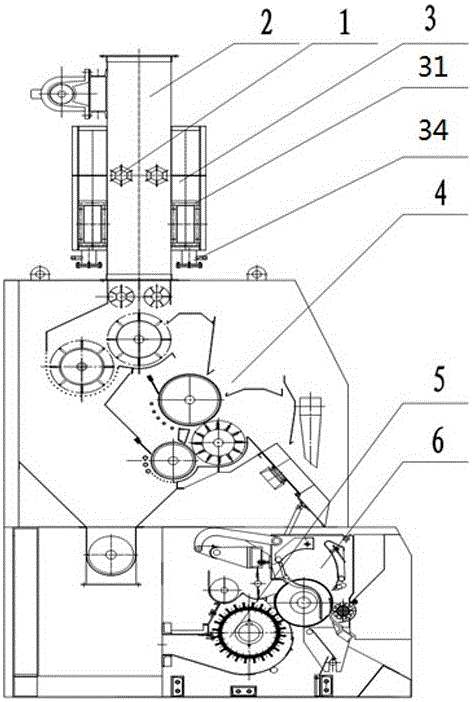

Fleece laying device

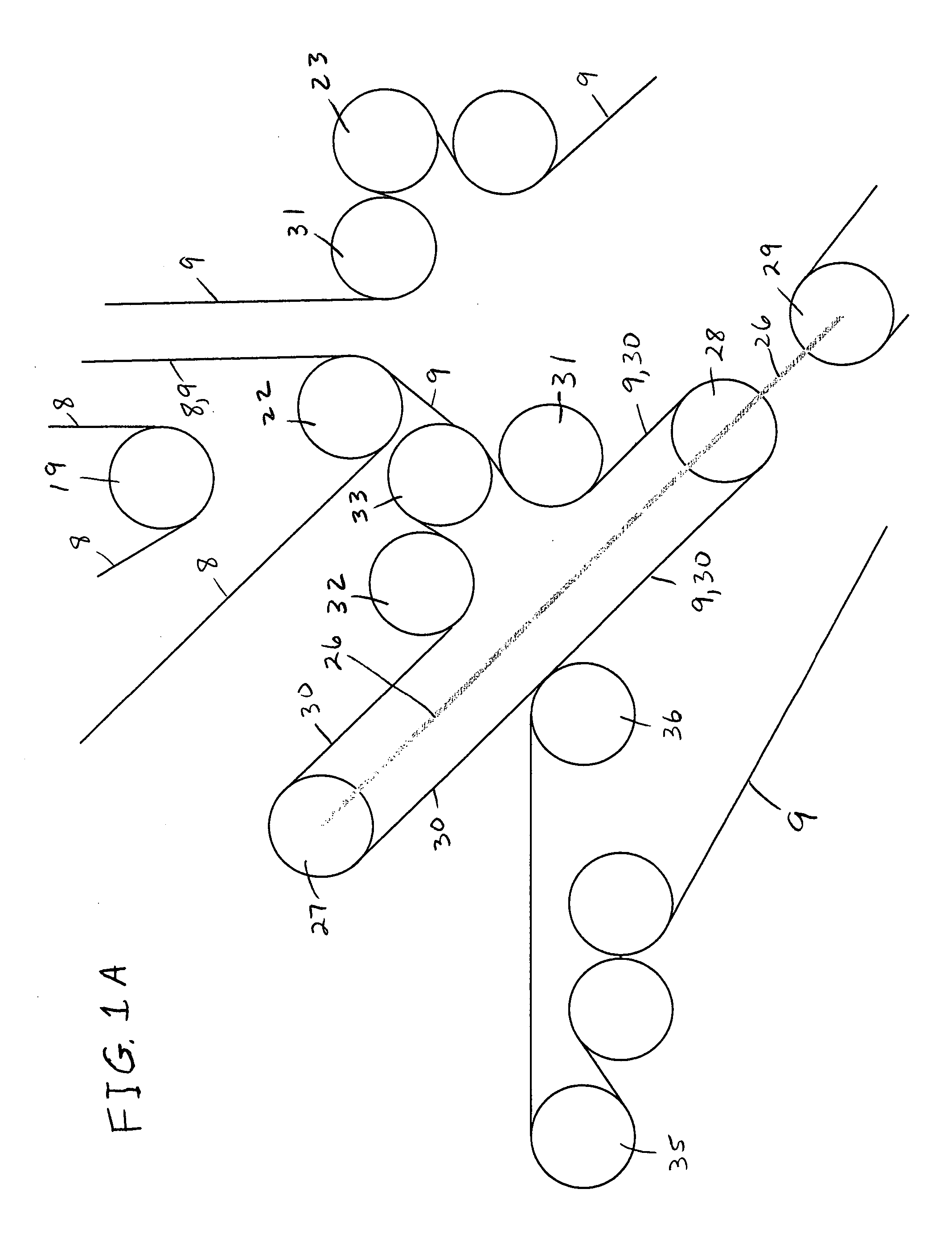

InactiveUS20050193525A1Reduce distortion problemsQuality improvementVegetable fibre separation from seedsLap-winding devicesFiberEngineering

A non-woven fiber web laying apparatus including (1) a camel back cross lapper having a supply arm, a layering arm connected thereto, and two delivery transport belts guided in juxtaposed fashion from an infeed zone to a lower end of the layering arm and (2) an upstream web buffering apparatus adapted to hold a web between two take-up transport belts at least one of which is one of the two delivery transport belts, the apparatus sandwiching the web substantially the entire path from the take-up site to the layering-arm lower end. While at least one of the two take-up transport belts of the web buffering apparatus is one of the delivery transport belts of the cross lapper, in one embodiment both of the take-up transport belts are the delivery transport belts. In another embodiment, only one of the take-up transport belts is a delivery transport belt, the other being a pressure belt operating only within the web buffering apparatus.

Owner:DILO MASCHF OSKAR

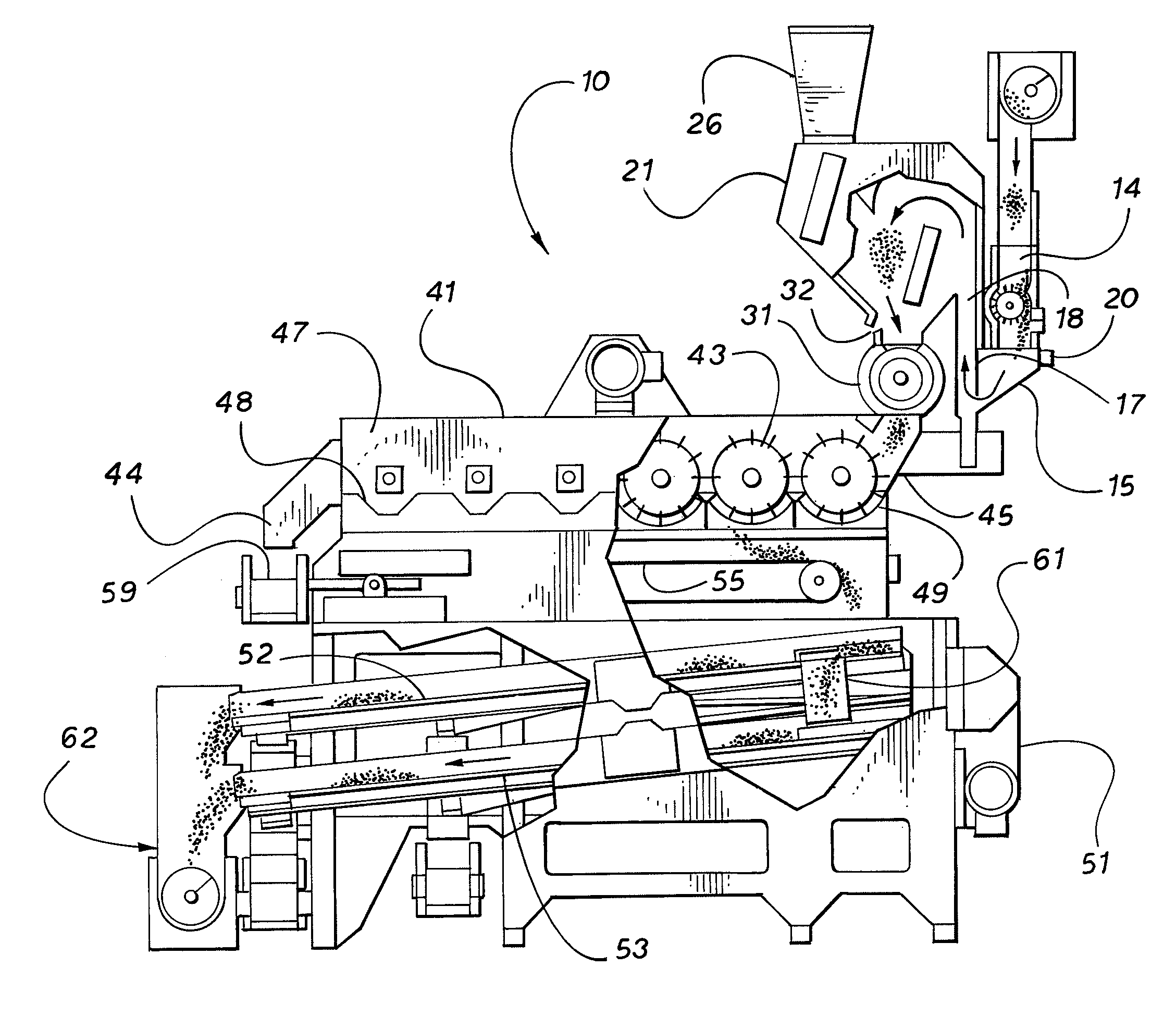

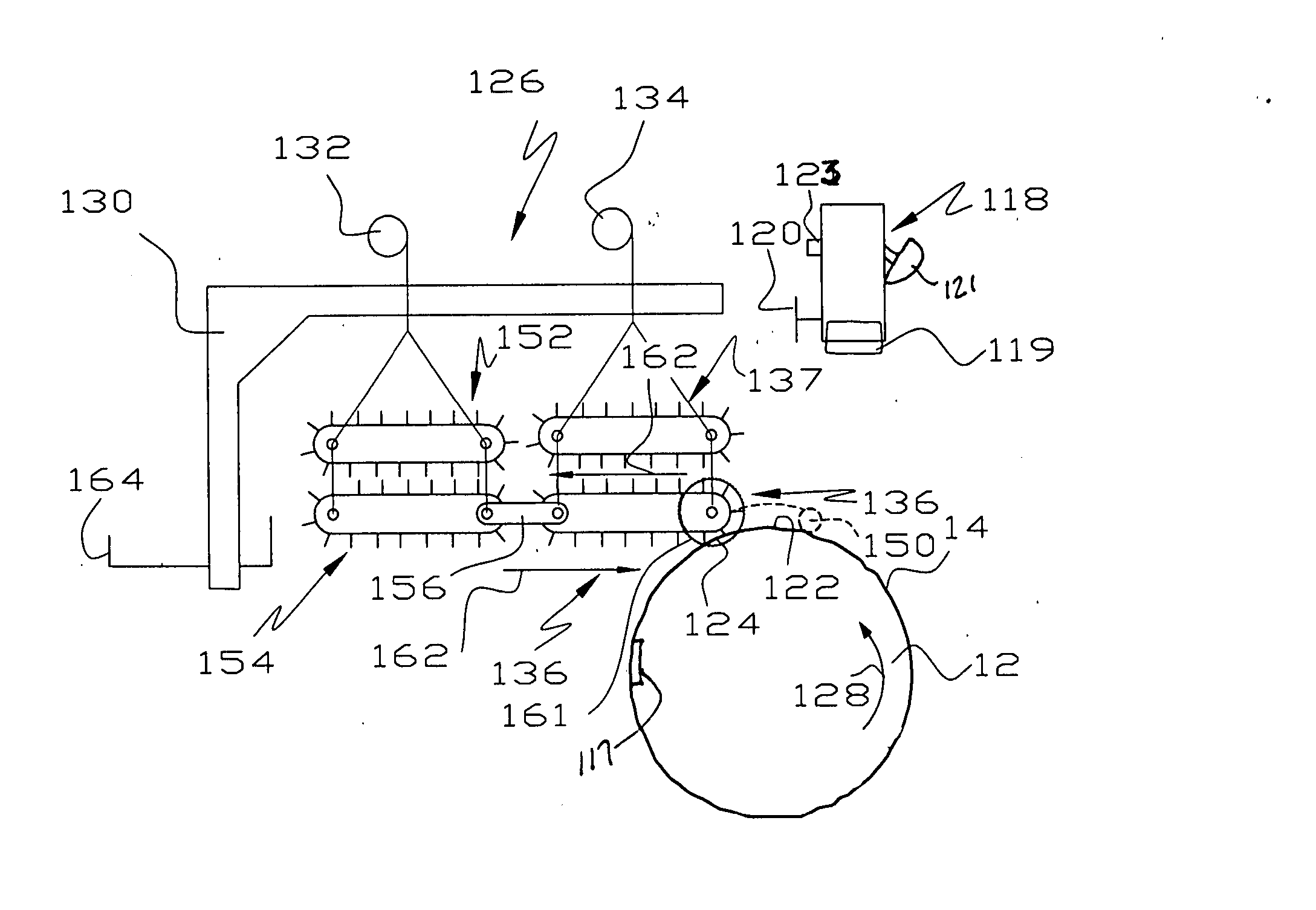

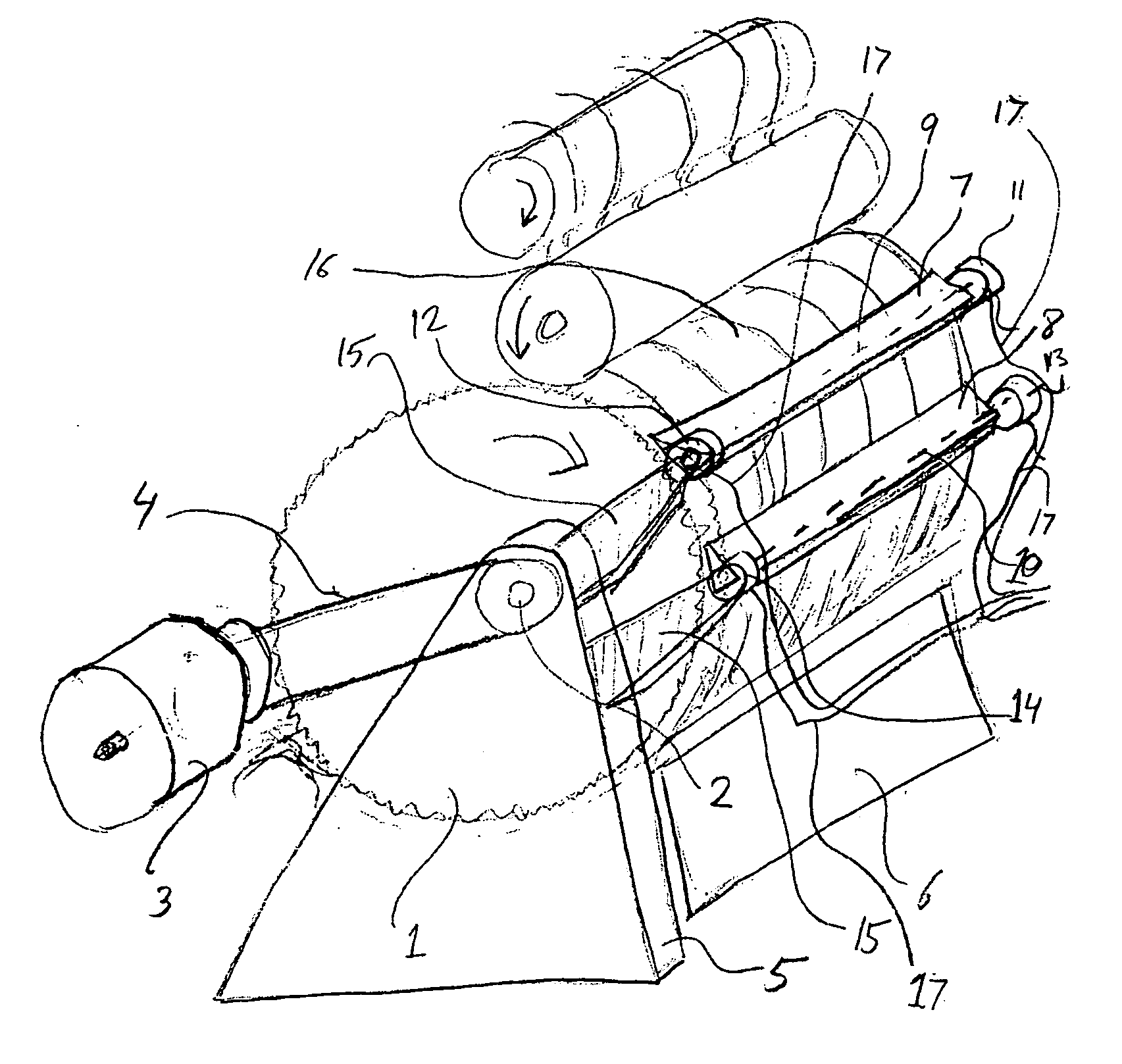

Digesting cylindrical modules

A conveyor delivers a series of cylindrical wrapped fibrous modules to a station where the module is lifted off the conveyor and an operation conducted on the module. One operation is to find a tail, or unattached segment, of the cover. Another operation is to remove the cover, by slitting and then unwinding it. The cover is delivered to a storage area and the contents of the module are delivered into a hopper, or in some embodiments, into a disperser. In some embodiments, a grabber moves the slit cover from adjacent a slitting position to a storage area and includes a guide wheel for moving a conveyor up and down in response to the configuration of the round module. In one embodiments, the plastic cover is removed manually by workers guiding the plastic wrap as it is unrolled by the unrolling device.

Owner:STOVER EQUIP

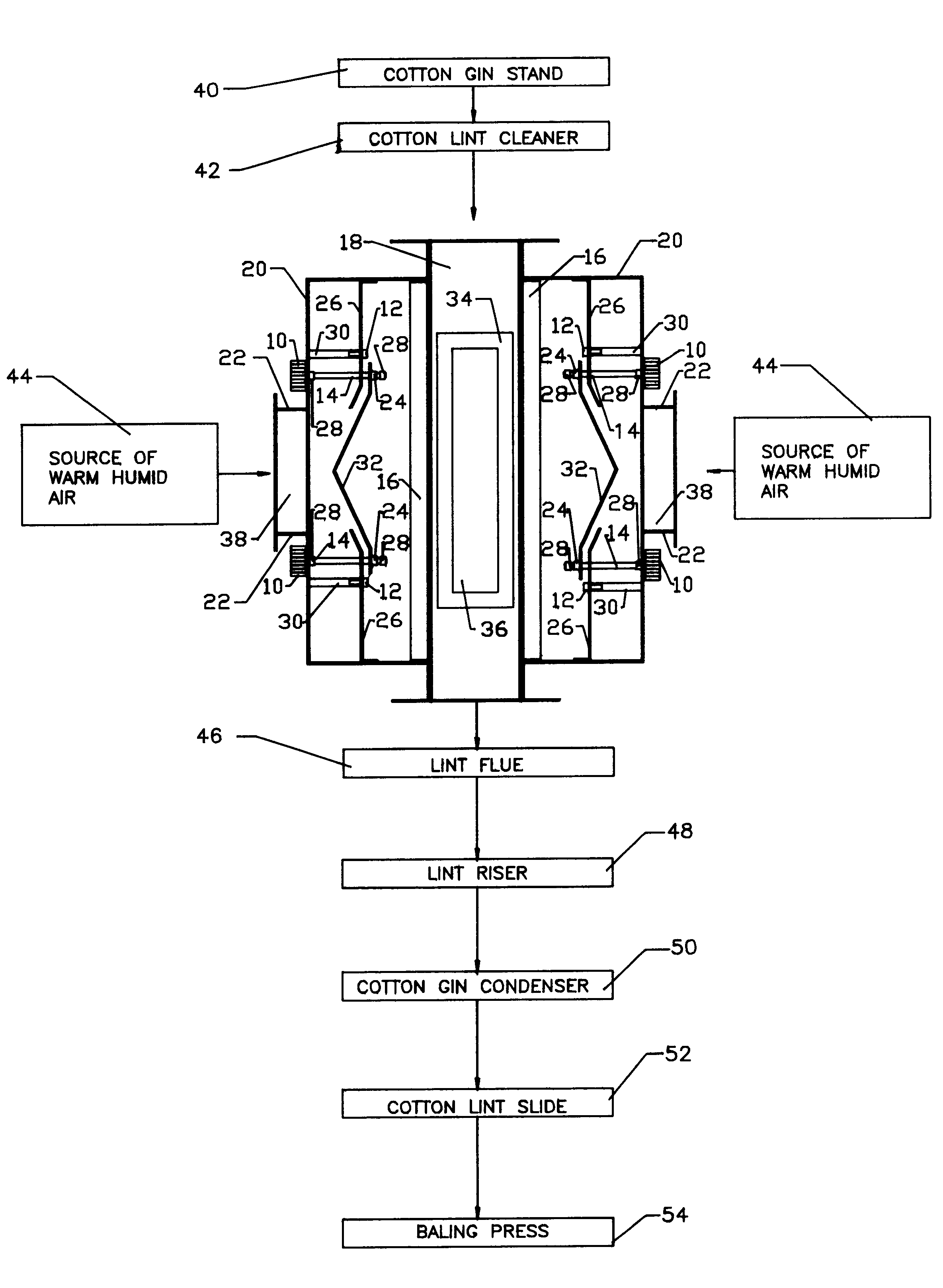

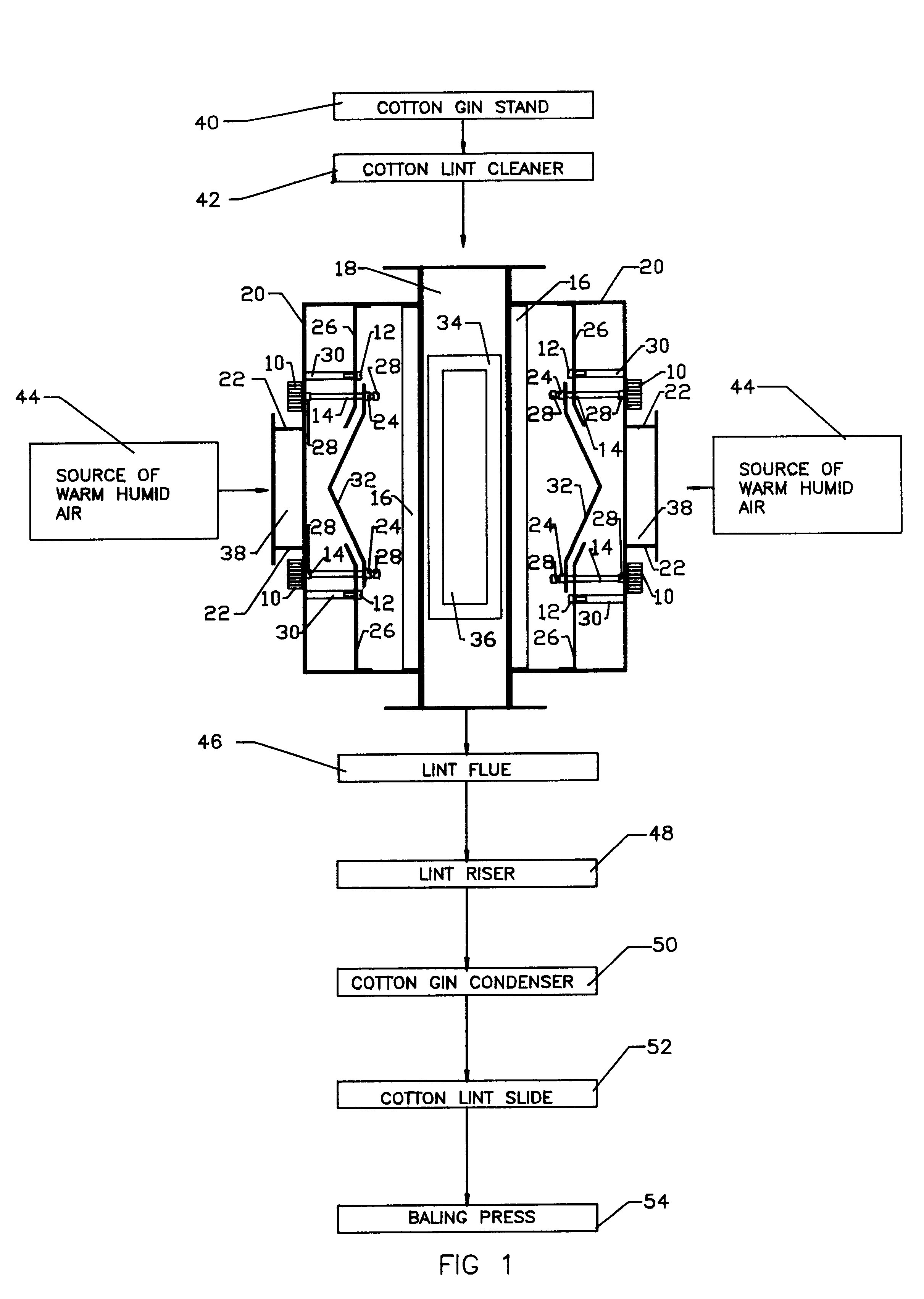

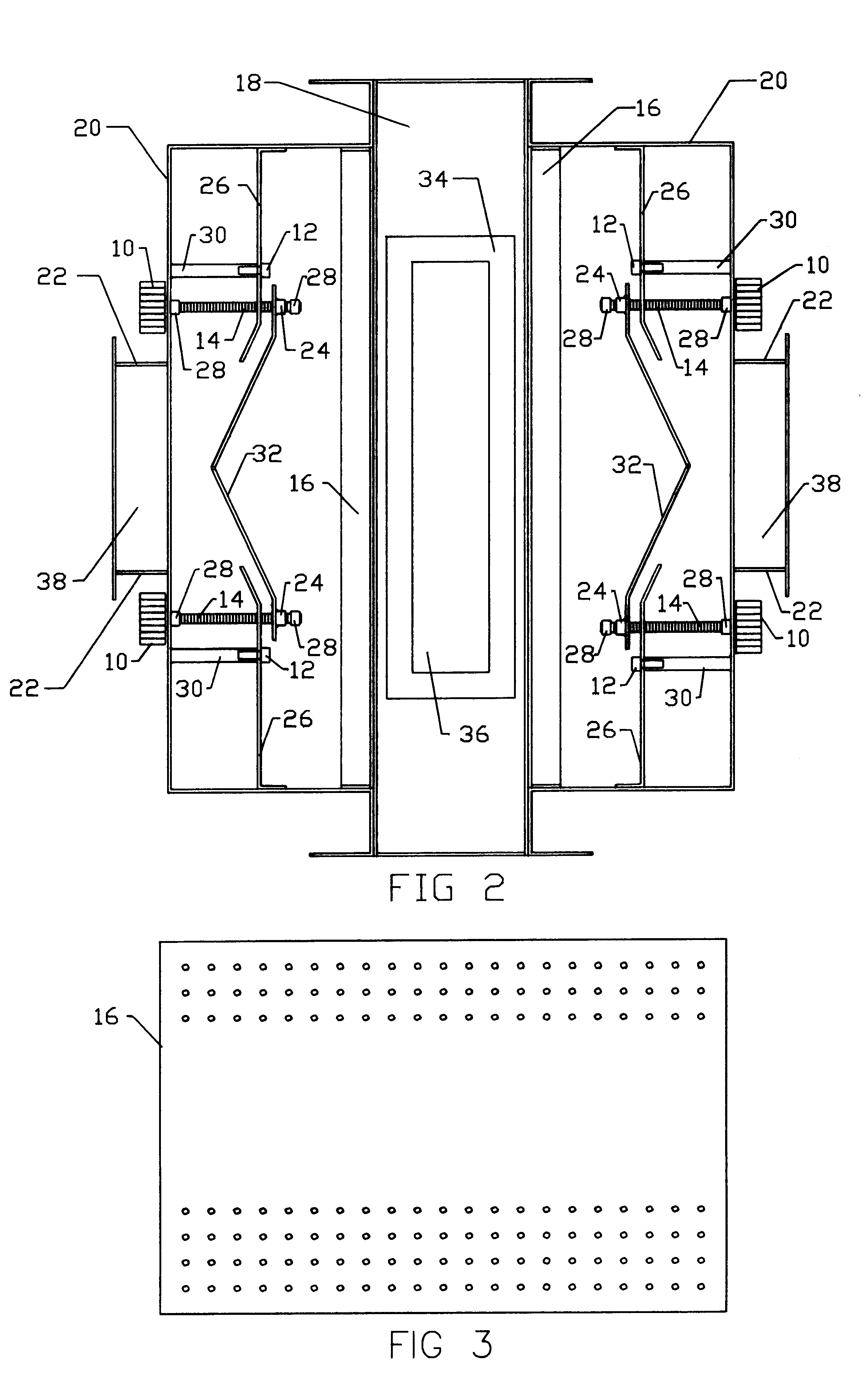

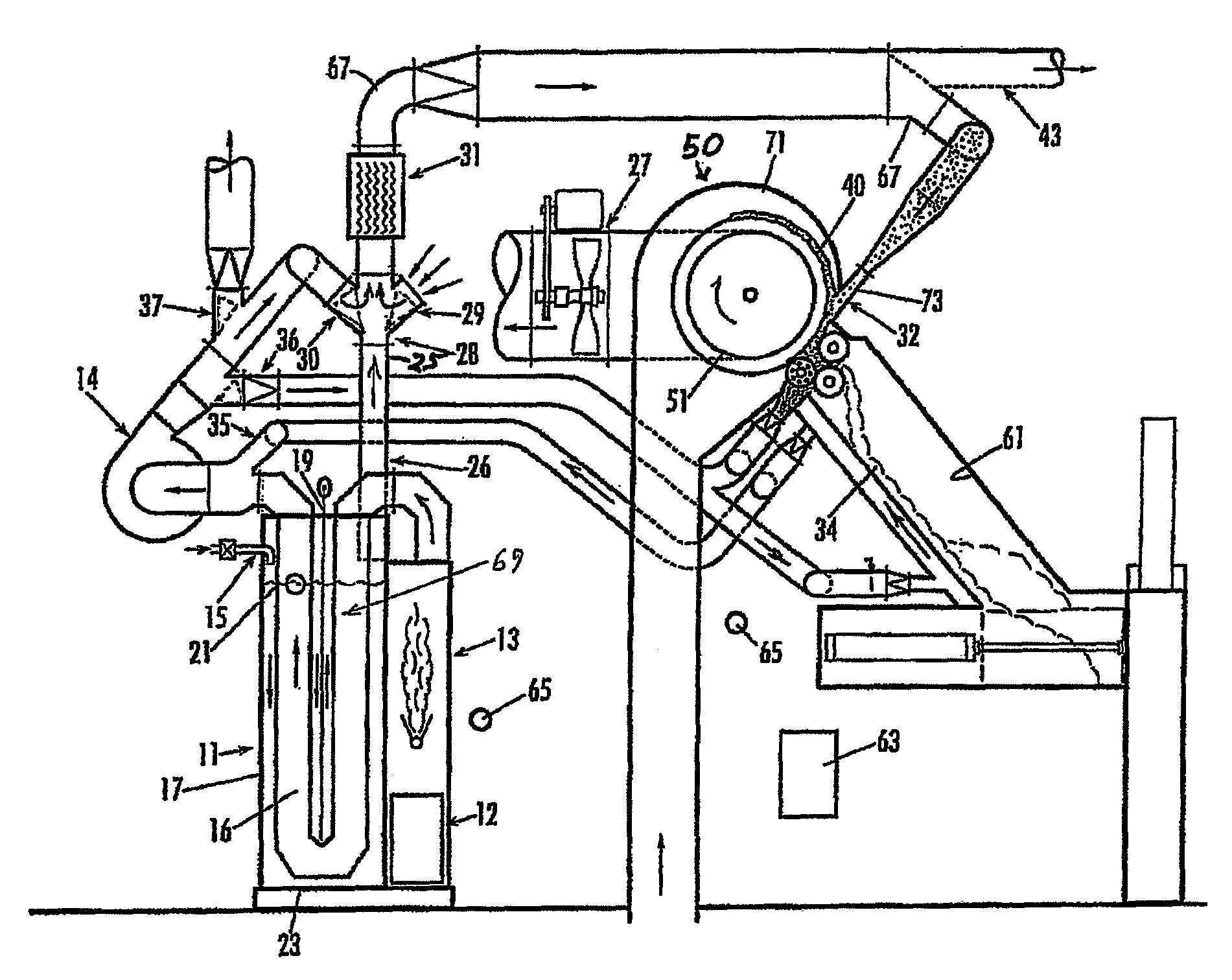

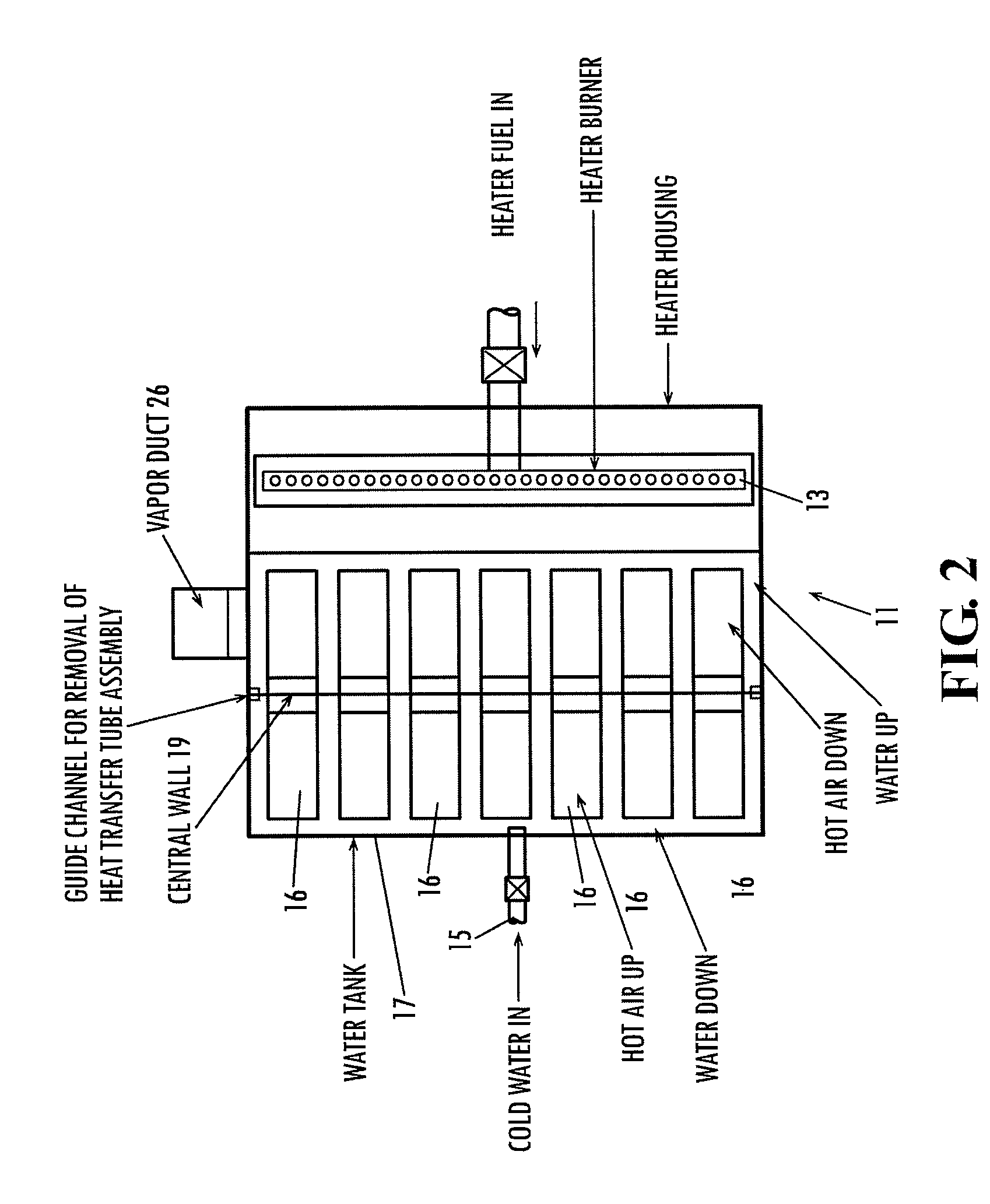

Fiber moisture cell for humidifying cotton and method

InactiveUS6237195B1Save resourcesEnergy efficiencyLubricating devicesVegetable fibre separation from seedsFiberEngineering

Apparatus for humidifying lint cotton in a cotton gin that has a cell arranged for receiving a fiber mass from a lint cleaner and controlling the movement of the fiber over a moist air inlet panel. Warm humid air introduced through an adjustable air inlet panel passes through the moist air inlet panel and, thus, through the cotton under negative pressure raising the moisture content of the fiber mass. The movement of the fiber mass thru the cell is controlled by the amount of warm moist air flowing under pressure through the moist air inlet screen.

Owner:SHOEMAKER THOMAS R

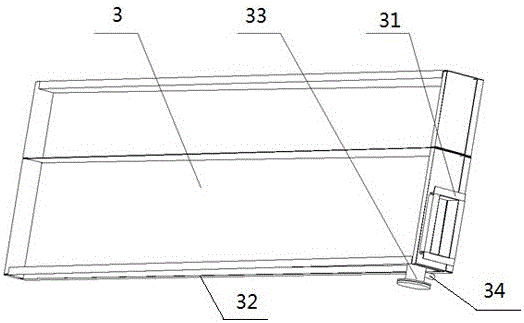

Technological process and apparatus for delinting of cotton seeds

InactiveCN1672483AEasily damagedReduce production efficiencyVegetable fibre separation from seedsSeed and root treatmentEngineeringMechanical engineering

The technological process of delinting cotton seeds features that cotton seeds are first delinted mechanically in a mechanical delinting device, then sprayed with certain amount of foamed dilute sulfuric acid, stoved in the stoving room and polished in one other mechanical delinting device, and finally washed. The mechanical cotton seed delinting apparatus includes rolling steel wire brush, sieving plate, lint extracting cover, and features the rolling steel wire brush and the sieving plate vertically set, the sieving plate with valve, and the delinting chamber with material inlet in the upper end and material outlet in the lower end. The mechanical cotton seed delinting apparatus has reasonable structure, good cotton seed flowability, high efficiency, low power consumption and other advantages.

Owner:王强

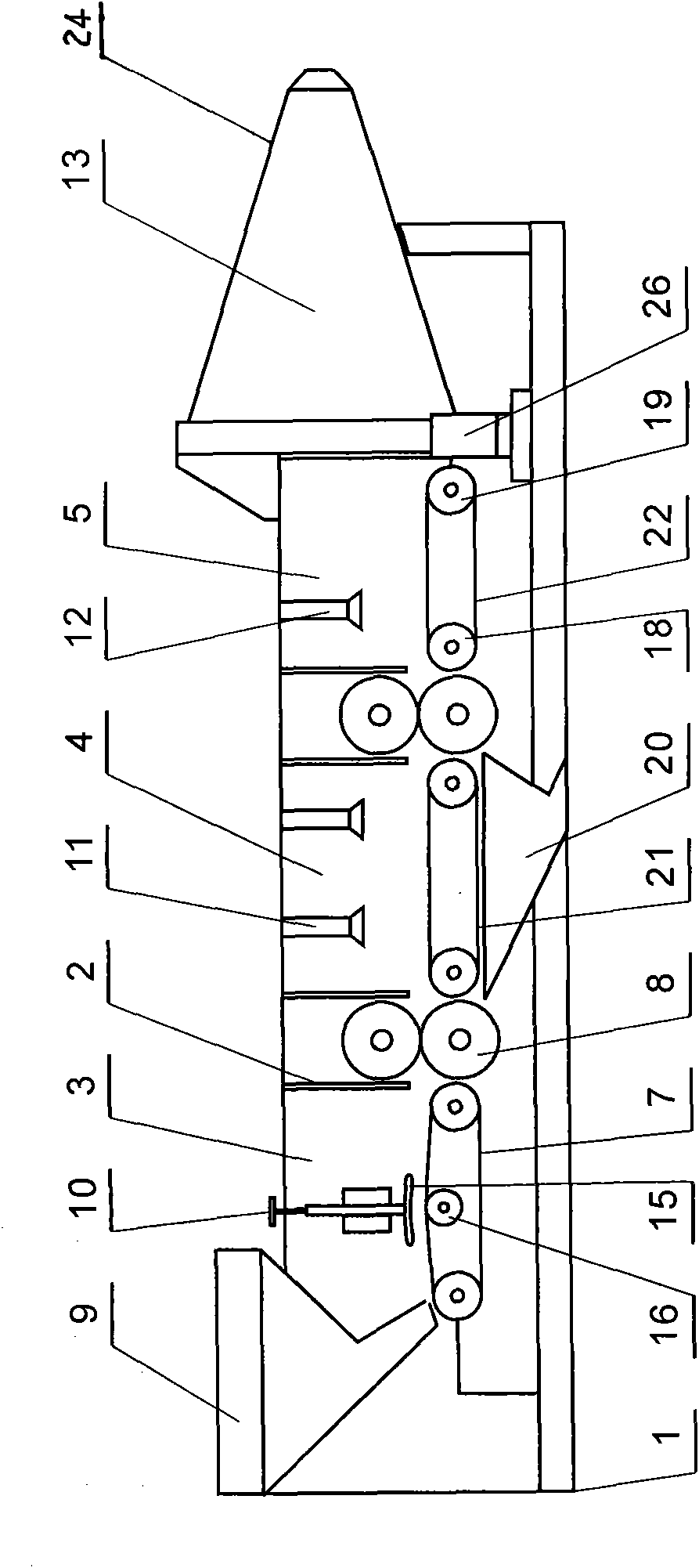

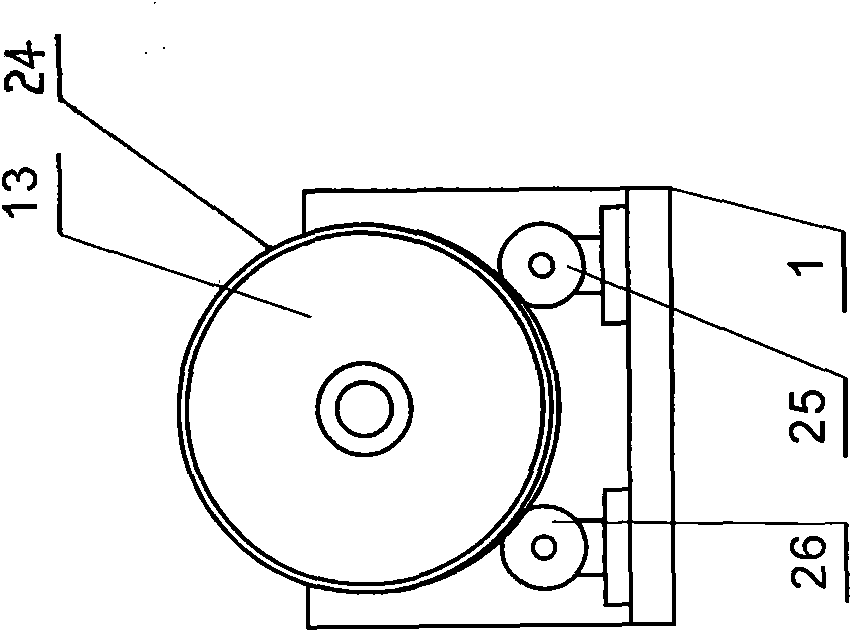

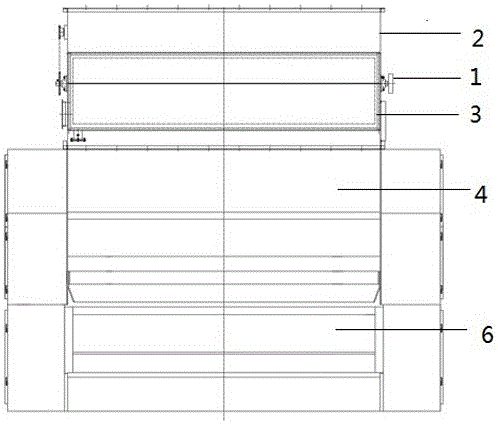

Mudar floss silver used for spinning, processing method and equipment thereof

InactiveCN101565860AEasy plantingLow costVegetable fibre separation from seedsLap forming devicesYarnFiber

The invention discloses a mudar floss silver used for spinning, a processing method and an equipment thereof, and is characterized in that the fruit of the mudar is adopted; after removing the seeds, the pappus fiber of the seed is taken and softened so that the fiber is softened and coiled as the silver; the processing equipment is characterized in that a cotton wadding chamber, a cleaning cotton chamber and a humidifying chamber are internally provided with a conveyor belt respectively and integrated in a long bar-shaped box; and engaged rollers connected with the three conveyor belts are arranged among the cotton wadding chamber, the cleaning cotton chamber and the humidifying chamber respectively. Compared with the prior art, the invention has the advantages that the mudar floss of the new spinning material is easily obtained, can compare the beauty with cotton and replace the cotton to be used for spinning yarns; and the weaved fabrics has the smooth sensing same as silk and the air-permeability and comfortableness similar to full cotton, supplements the shortages of cottons and petrochemical products, greatly improves the local entironment simultaneously, and is a spinning new fiber material which is ecologically environment-protective.

Owner:上海善道生物科技有限公司

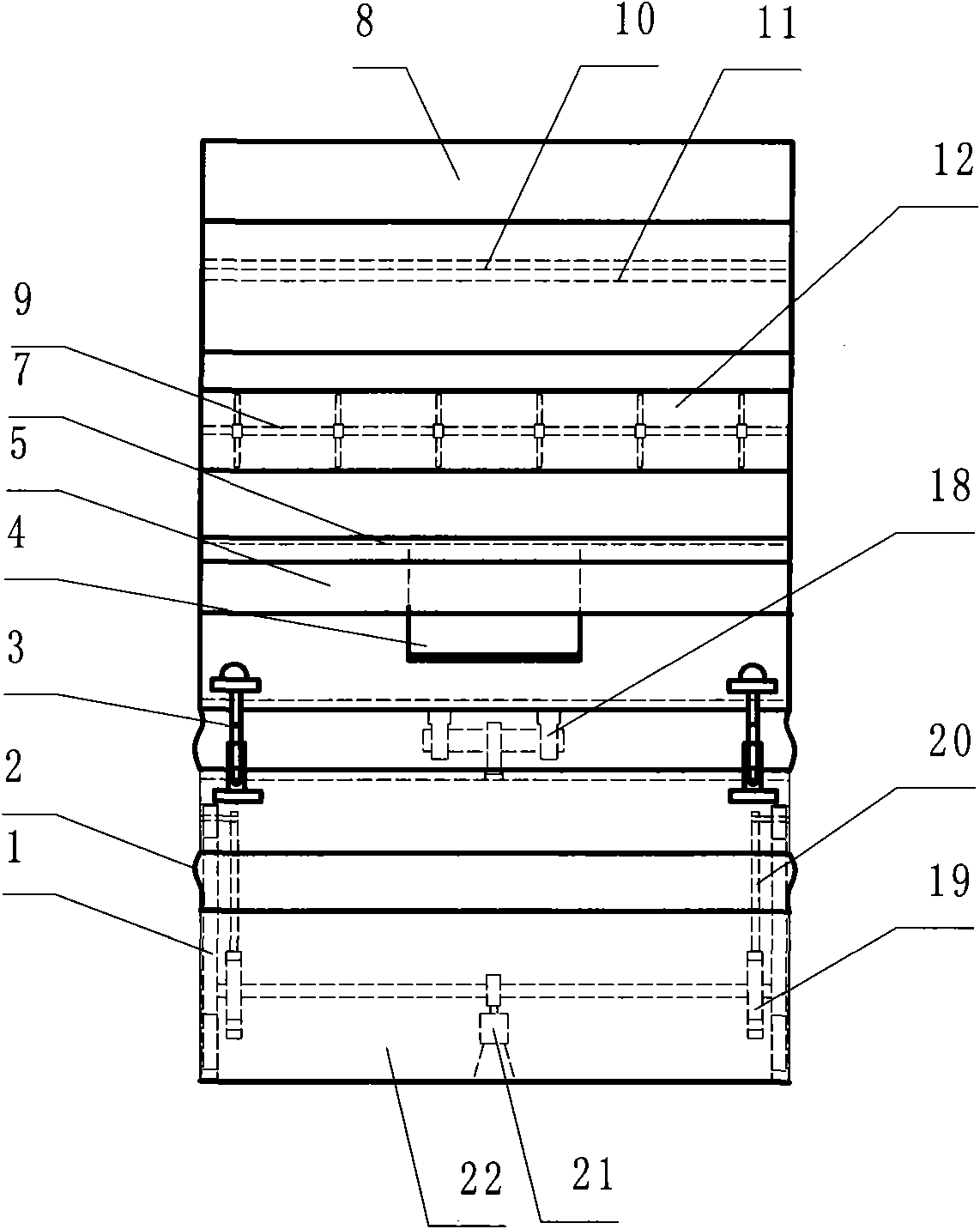

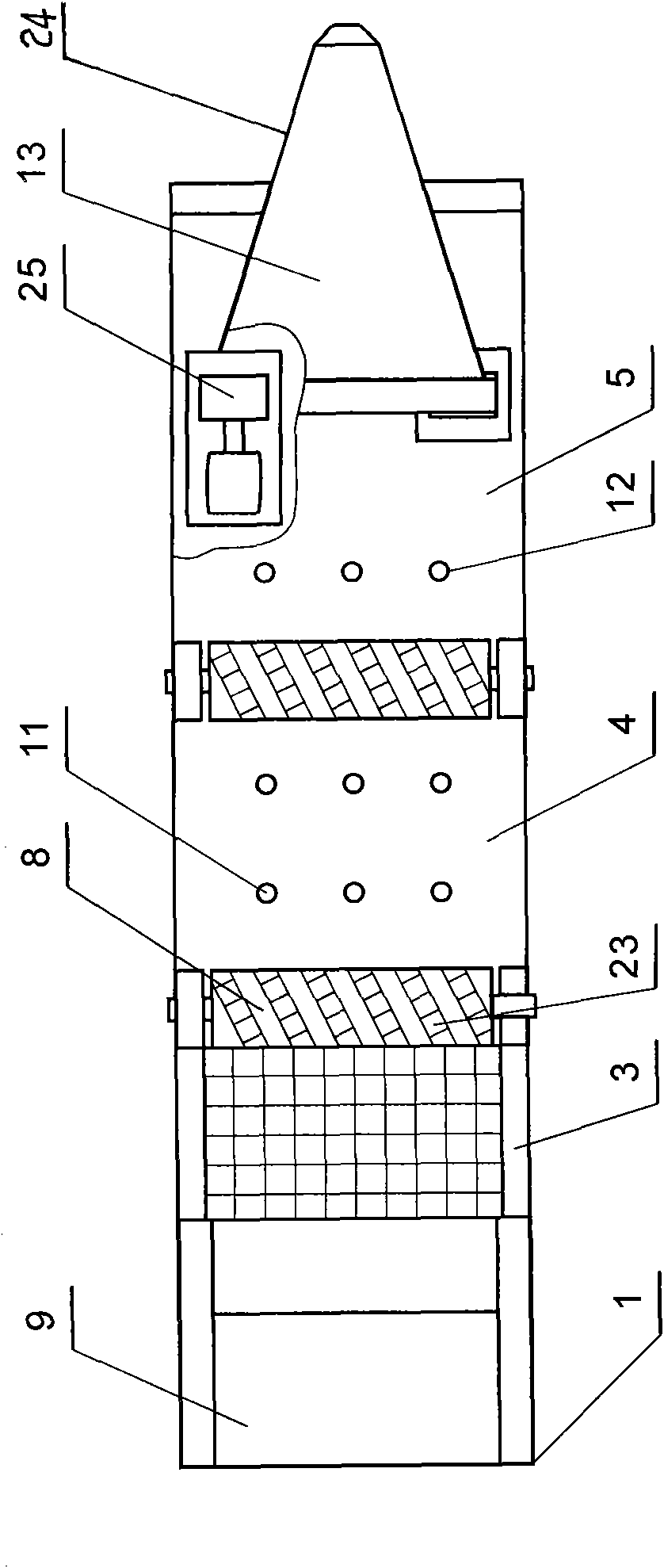

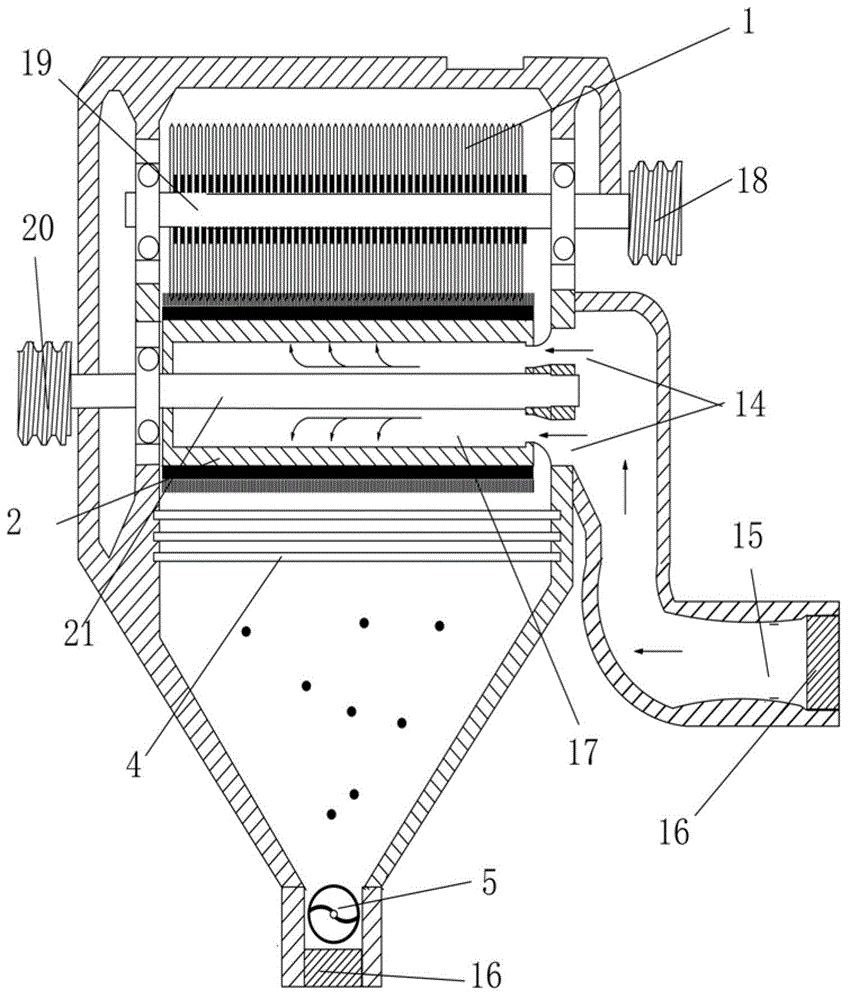

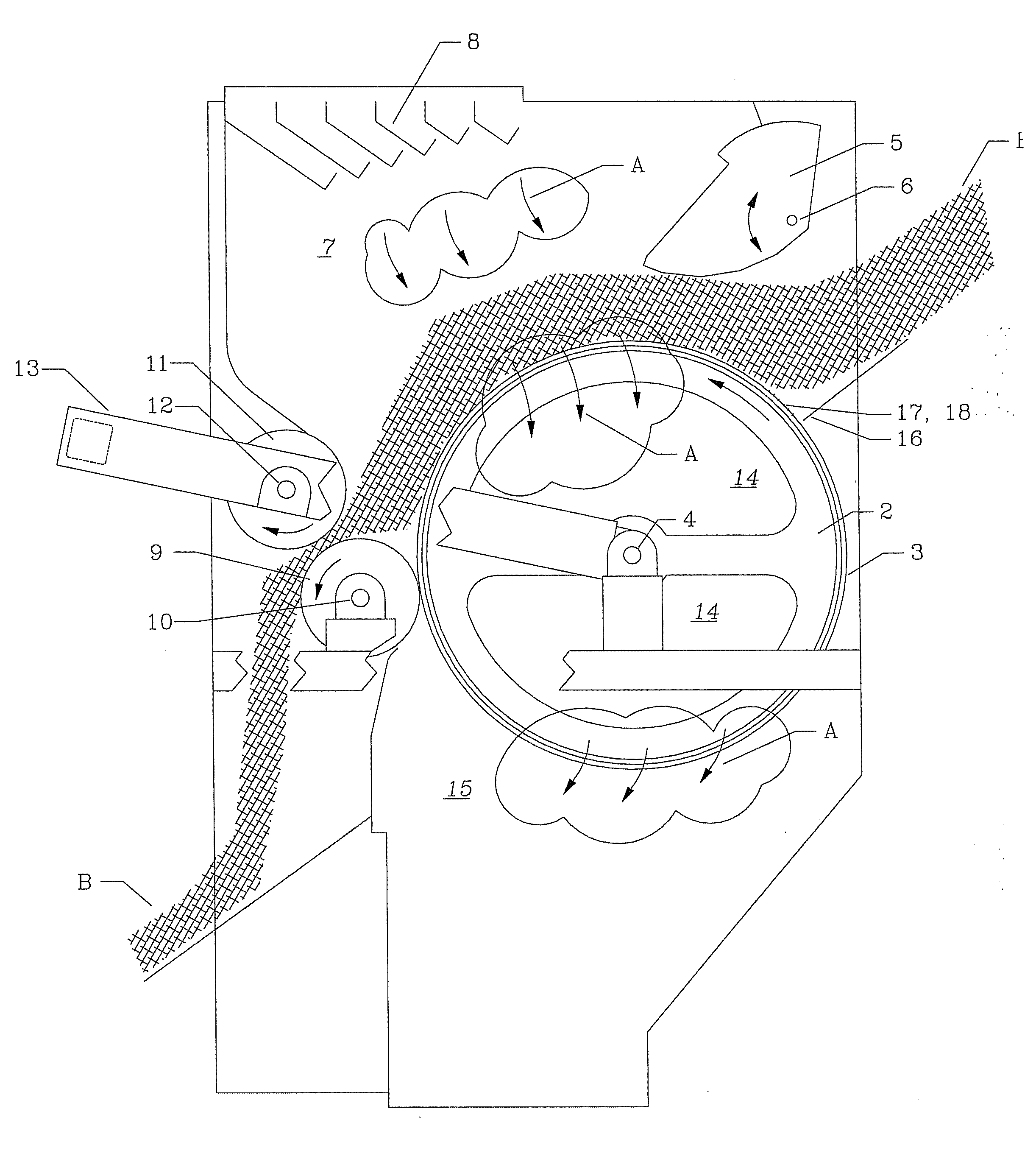

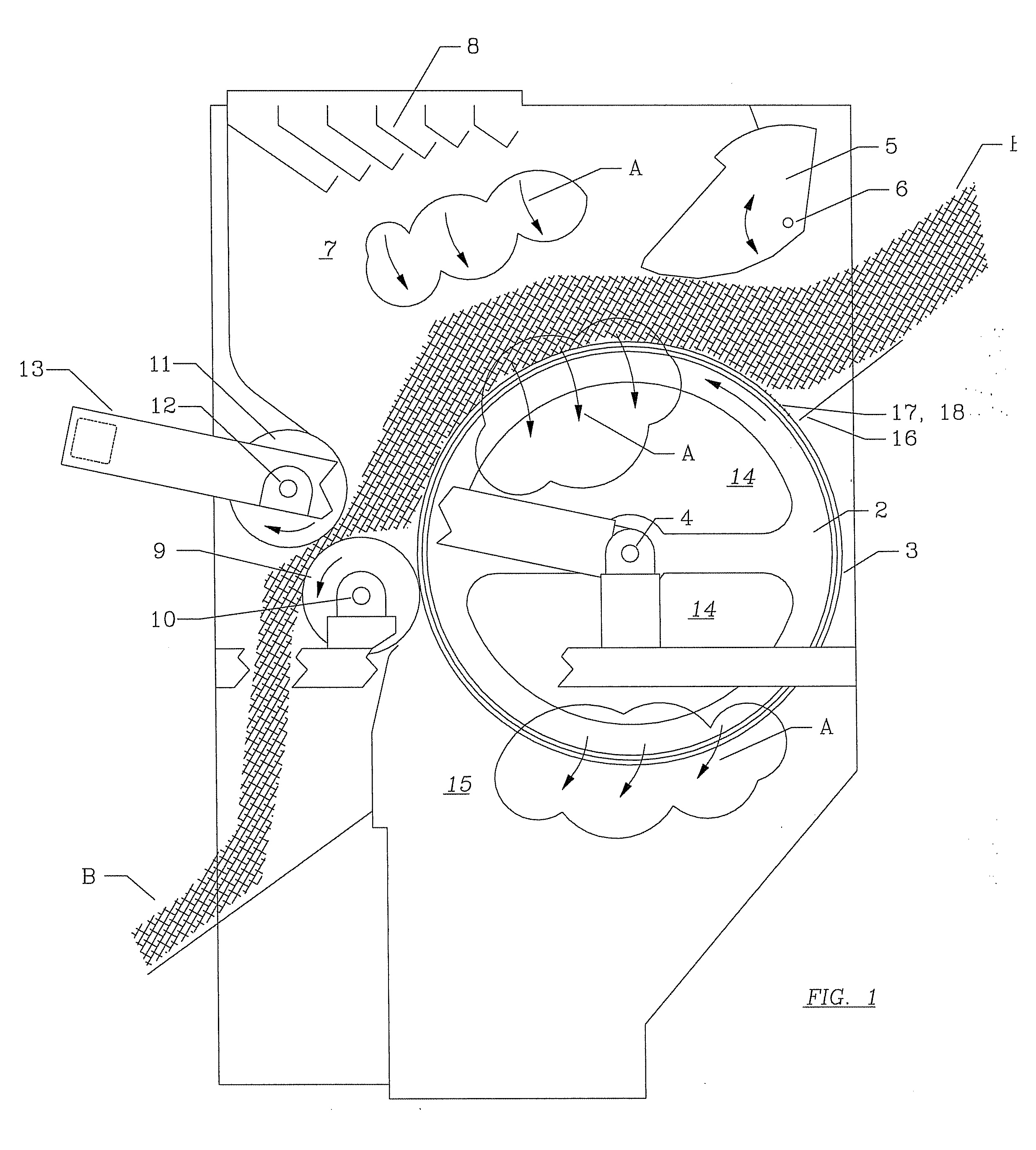

Back-suction-preventing high-efficiency embossing machine

InactiveCN103147134ASolve complexitySolve the cumbersomeFibre cleaning/opening by air draught arrangementsVegetable fibre separation from seedsFiberAir volume

The invention discloses a back-suction-preventing high-efficiency embossing machine. An air inlet (14) and an air quantity regulating device (16) are arranged on one end or two ends of a brush roll (2) of the embossing machine, and air outlets (11) among brush strips or cotton brushing plates are formed in the circumference of the roller of the brush roll (2); an impurity-removing combination comprises an impurity-removing lattice bar grid (4) and a lower impurity-removing stranding cage or an impurity-suction port (5), and is located on the outer side of the brush roll. According to the back-suction-preventing high-efficiency embossing machine disclosed by the invention, by means of changing the structure of the traditional roller, the roller under high-speed rotation not only has an air conveying function and an inertial centrifugal force, but also is free from a self back suction phenomenon, so that fibers and impurities locate at different positions of an air flow layer under the action of centrifugal force due to differences in self weight and connecting force, and are forced to be separated under the coordination of the impurity-removing combination, and moreover, the fibers can be prevented from being overflowed. Alternatively, by means of changing the traditional cotton supporting plate into the impurity-removing combination, the purpose of separating the fibers and the impurities can also be achieved by changing the air inlet position of the brush roll under the attraction of a proper quantity of air.

Owner:李通

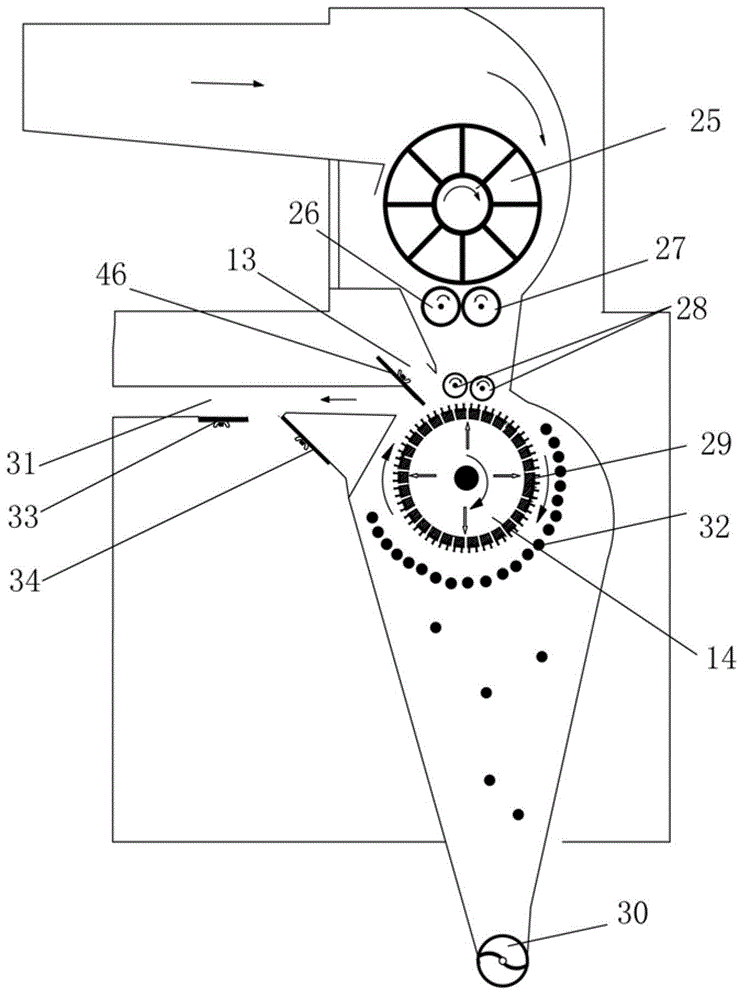

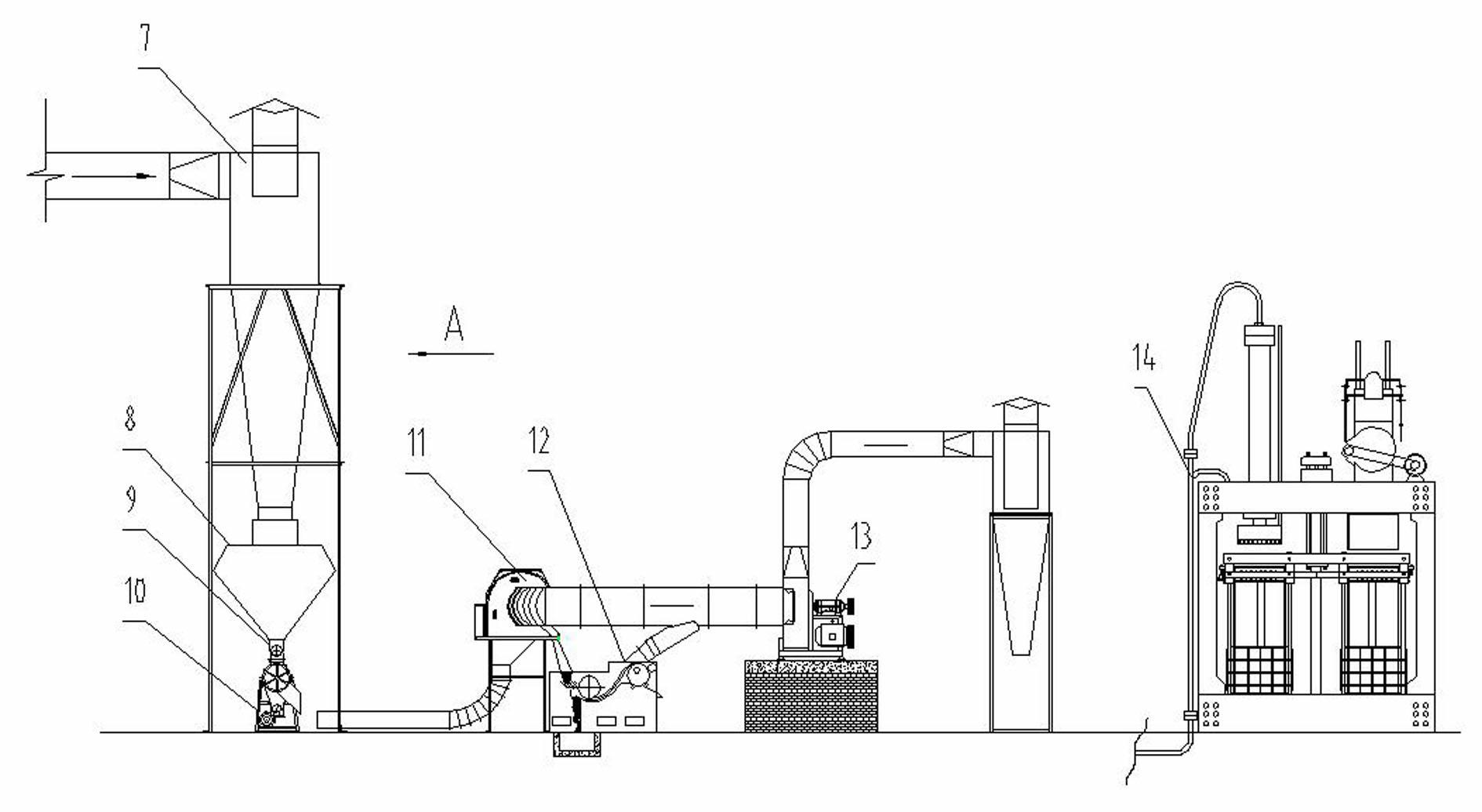

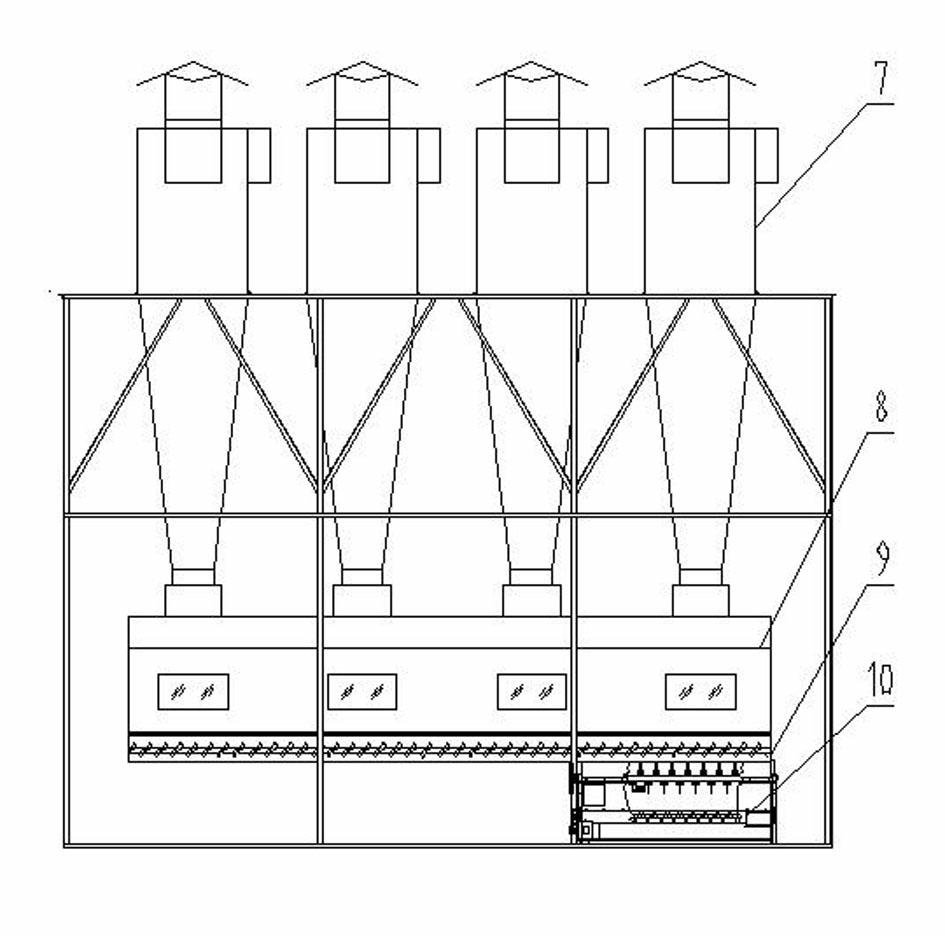

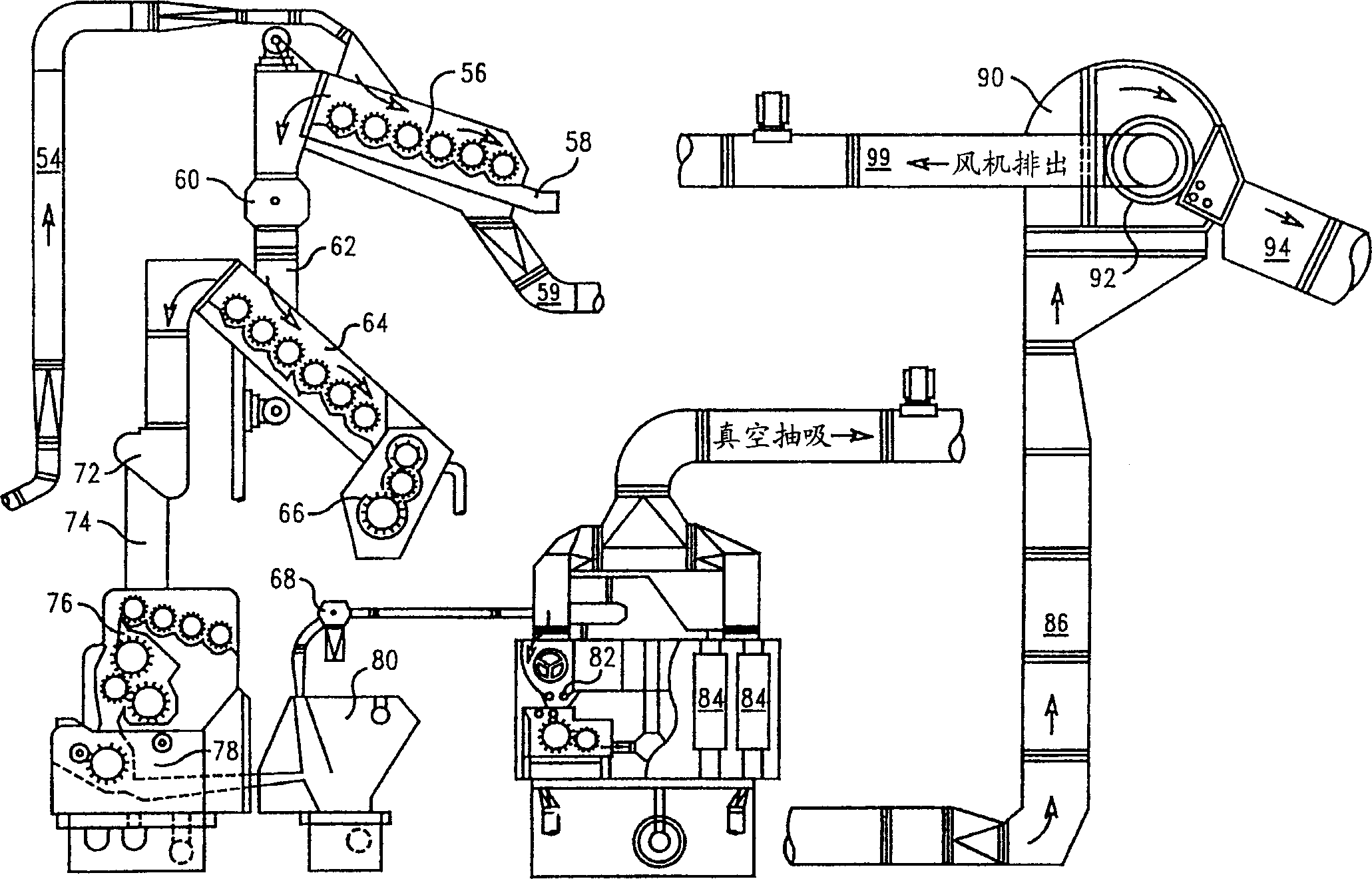

Leftovers cleaning and recovering process in cottonseed velvet peeling production line

ActiveCN102605481AReduce pollutionImprove resource utilizationVegetable fibre separation from seedsTextile disintegration and recoveryProduction lineResource utilization

The invention discloses a leftovers cleaning and recovering process in a cottonseed velvet peeling line, which is used for cleaning and recovering leftovers of a cyclone dust collector in the cottonseed velvet peeling line. The leftovers cleaning and recovering process includes the following steps of A) primarily separating the leftovers of short velvets carrying dust and with length smaller than 3mm, and separating partial dust and loose short-velvet dust mixture with first characteristics; B) gathering the short-velvet dust mixture with the first characteristics; C) feeding the short-velvet dust mixture with the first characteristics to a short-velvet cleaner, and separating short velvets and dust by a licker-in with linear speed ranging from 38m / s to 42m / s; and D) discharging the dust generated in the step C) and conveying separated short velvets to a packing machine by wind force to be packed. By the leftovers cleaning and recovering process, resource utilization rate is increased and environment pollution is reduced.

Owner:SHANDONG SWAN COTTON INDAL MACHINERY STOCK

Moisture conditioner for lint cotton

An apparatus for processing a fibrous material batt like lint cotton to increase the moisture content of the material and to compress the batt of humidified fibers to increase the batt density. A stream of warm humid air is passed through the moving batt of fiber that is constrained between a rotatable hollow cylinder and a stationary perforated screen. The air passing through the batt of figure removes debris from the batt and carries the debris to an associated plenum. The batt is doffed off the rotatable cylinder by a roller that serves to both doff and compress the batt. A roller doffs the fiber batt from the rotatable cylinder and doffs and compresses the batt against a compression roller.

Owner:COTTON PICKING MIND LP

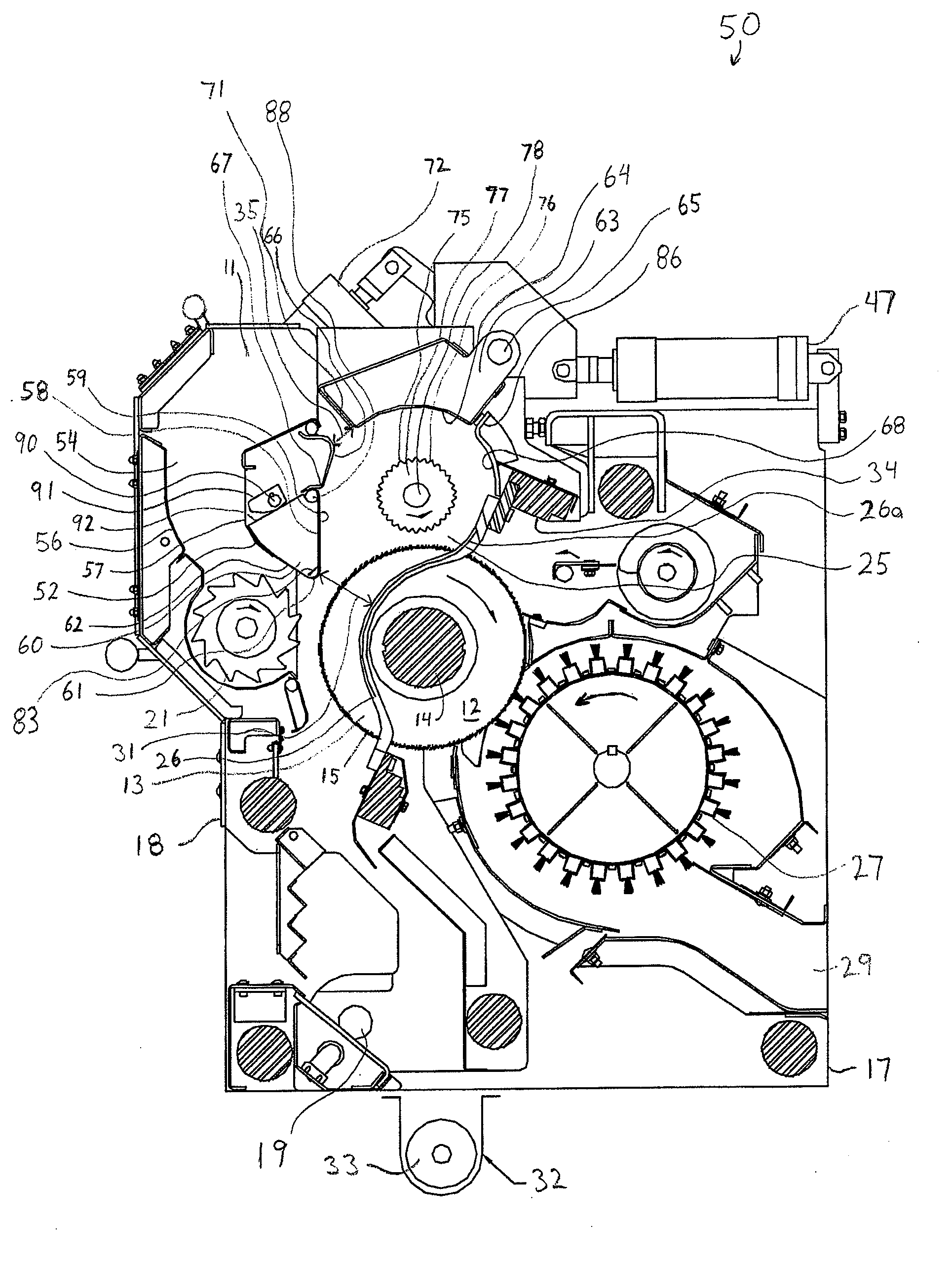

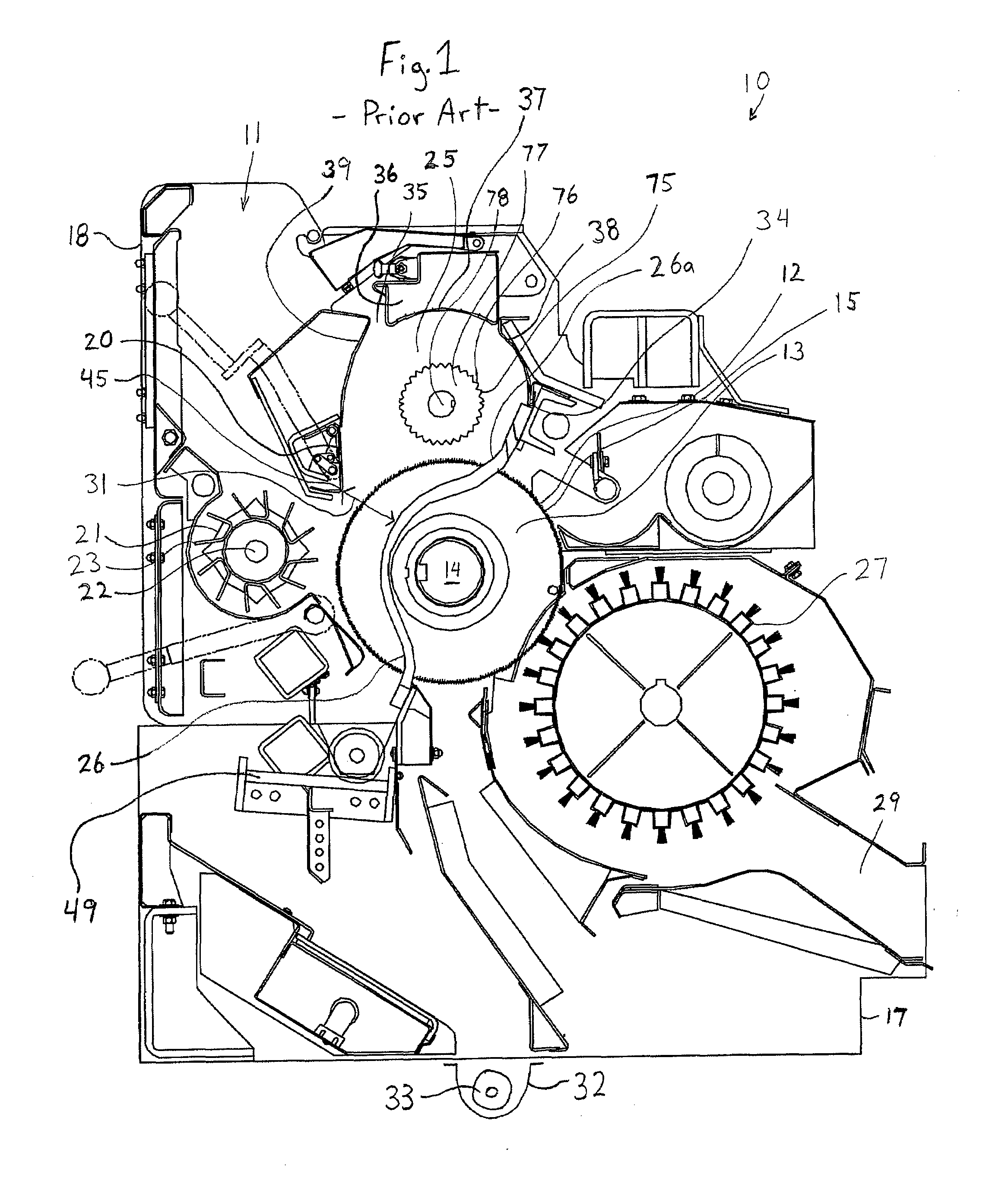

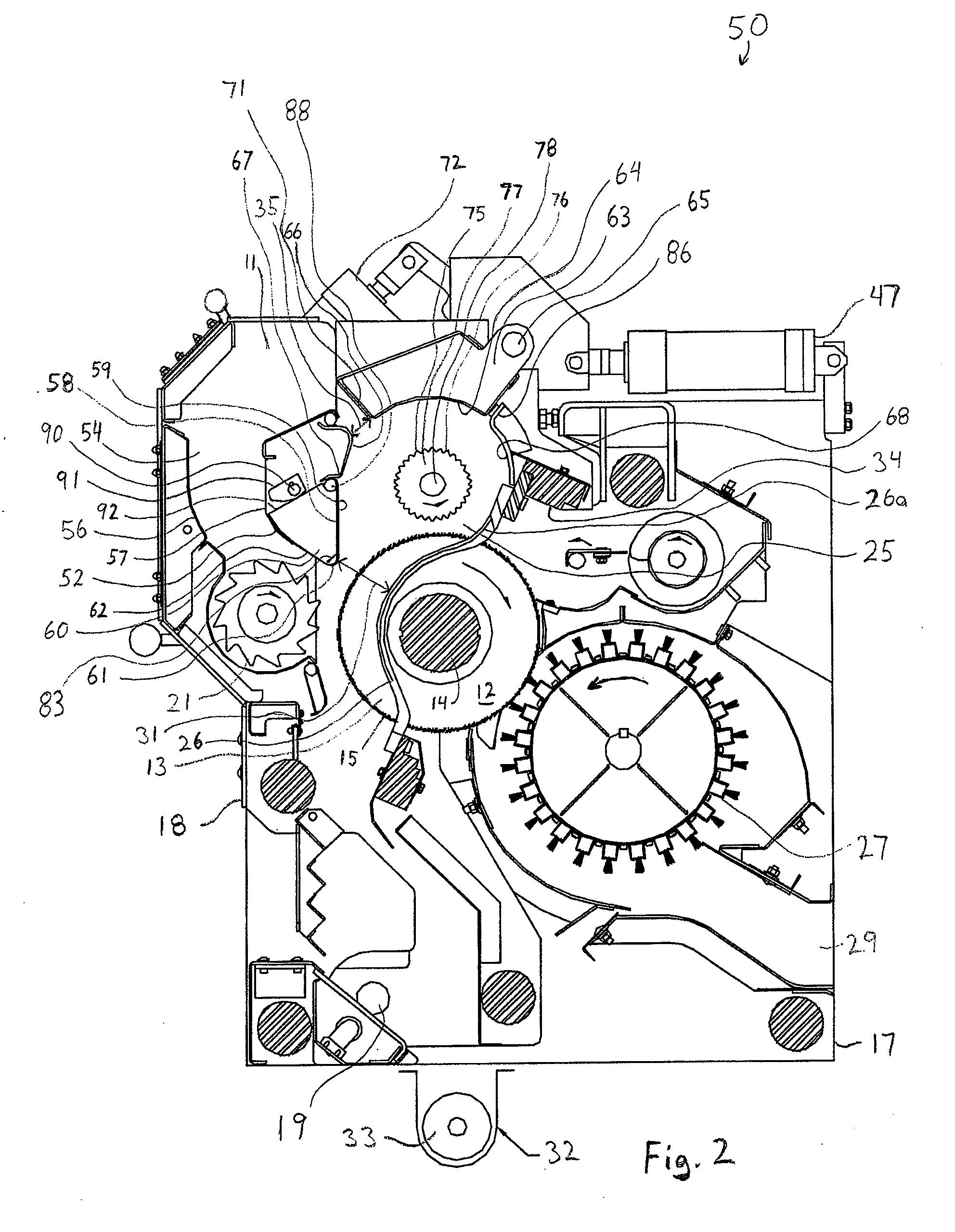

Gin Saw Stand With Adjustable Seed Roll Retaining Member

ActiveUS20100058559A1Improve performanceVegetable fibre separation from seedsEngineeringMechanical engineering

Owner:CHEROKEE FABTION

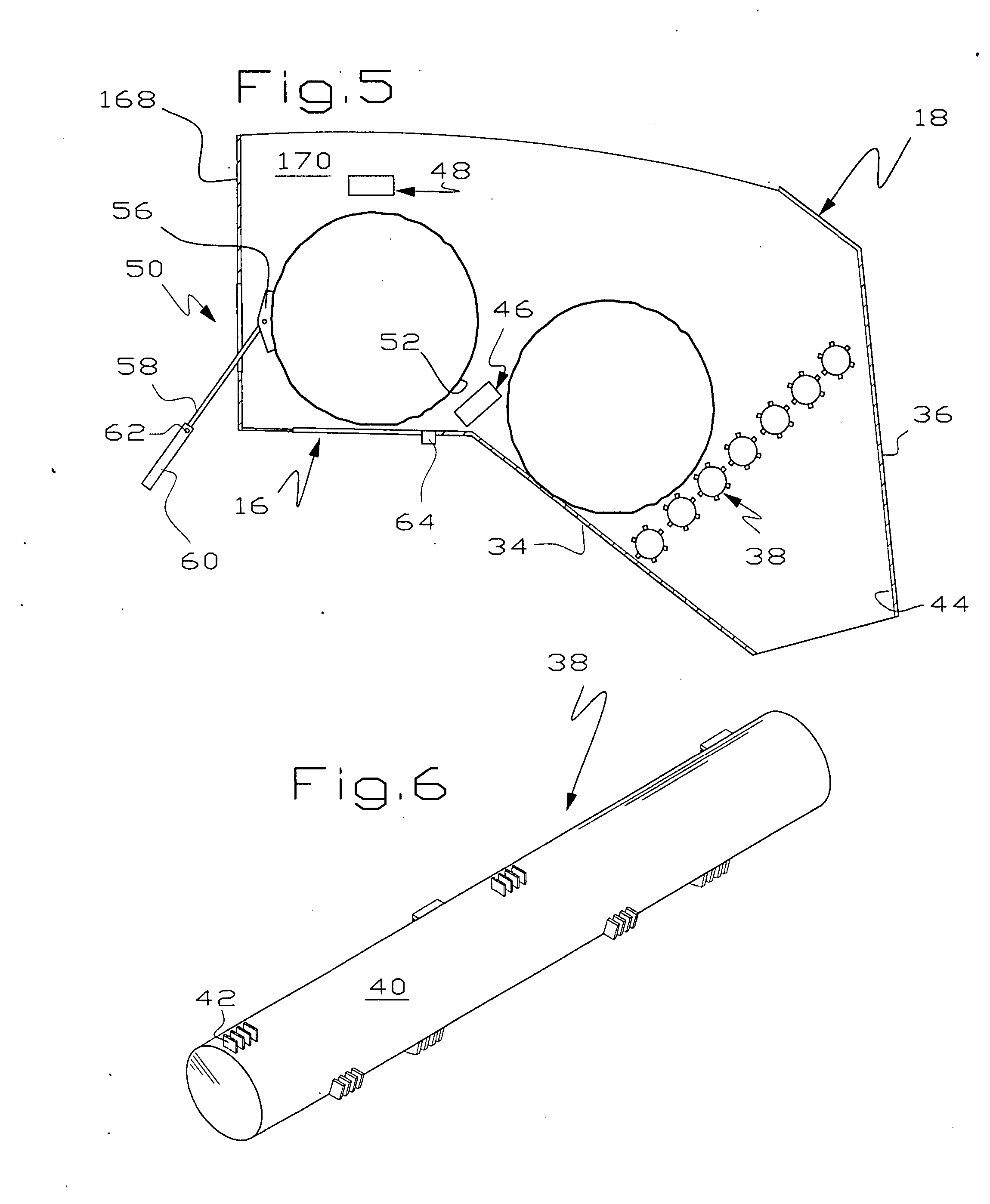

Apparatus and method for controlling the amount of trash in lint

InactiveUS20050217076A1Avoid possibilityVegetable fibre separation from seedsEngineeringMechanical engineering

An apparatus and algorithm for controlling the operation of a lint cleaner in a cotton gin having motorized grid bars, in which any one of the grid bars can be positioned in an engaged or disengaged position. When the grid bar is in the engaged position it functions as a lint cleaning instrument on a lint cleaning machine. When it is in the disengaged position it does not participate in the active cleaning process.

Owner:GVILI MICHAEL E +3

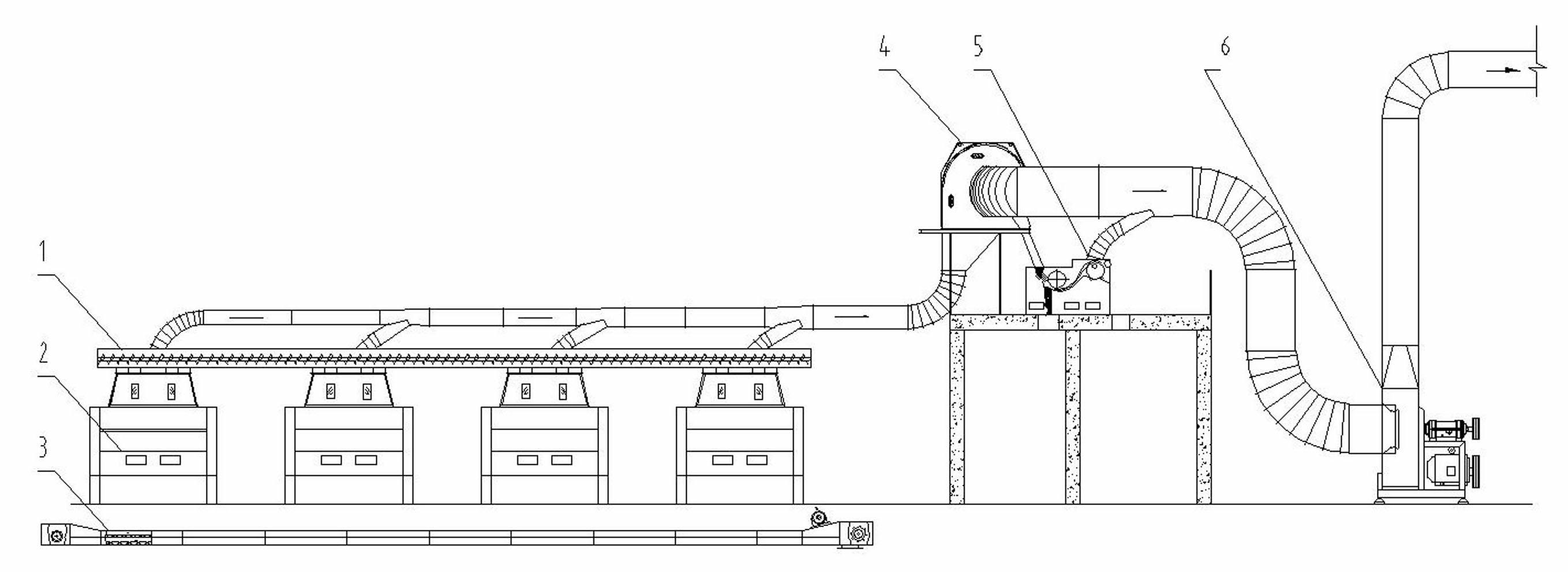

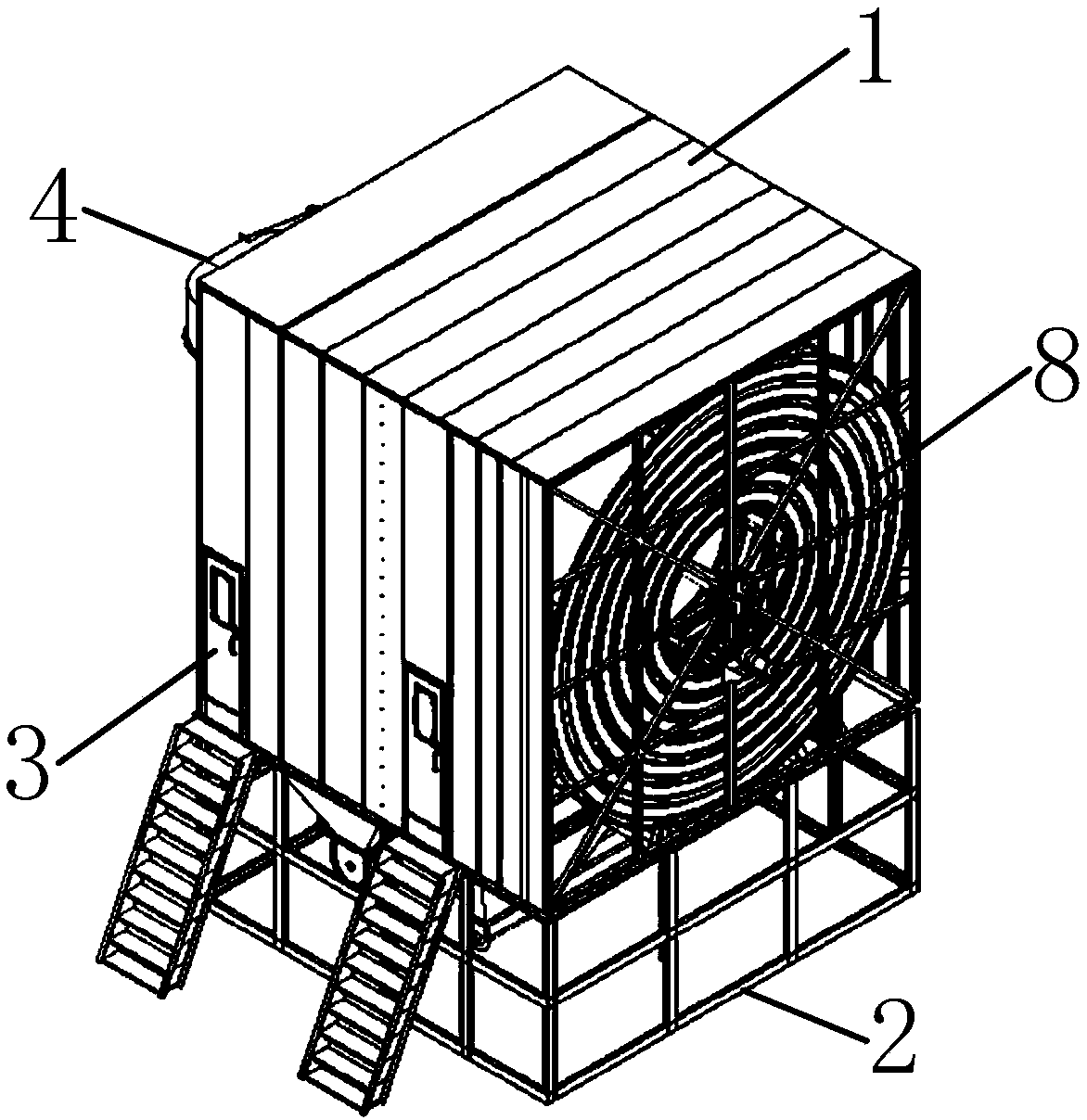

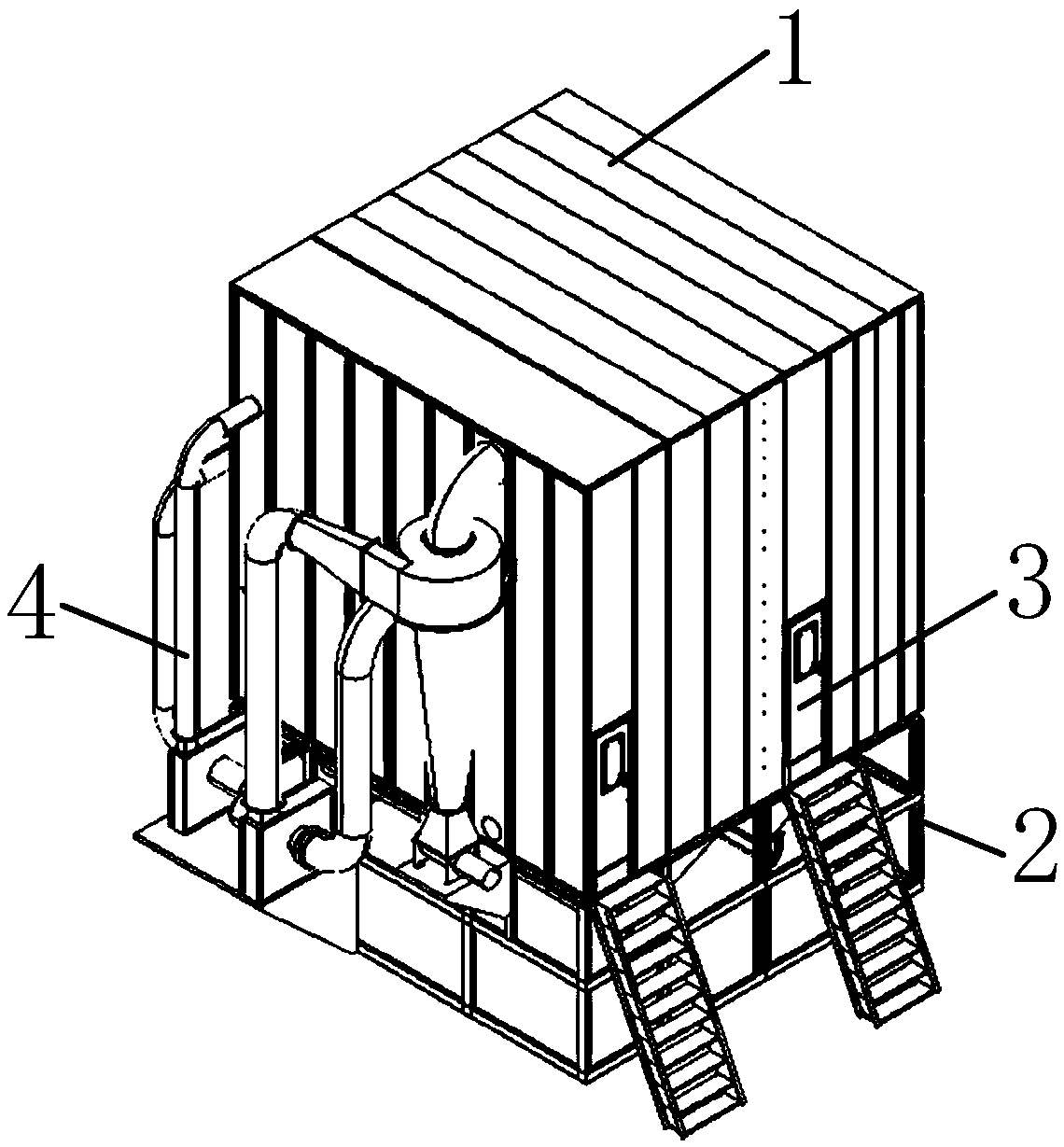

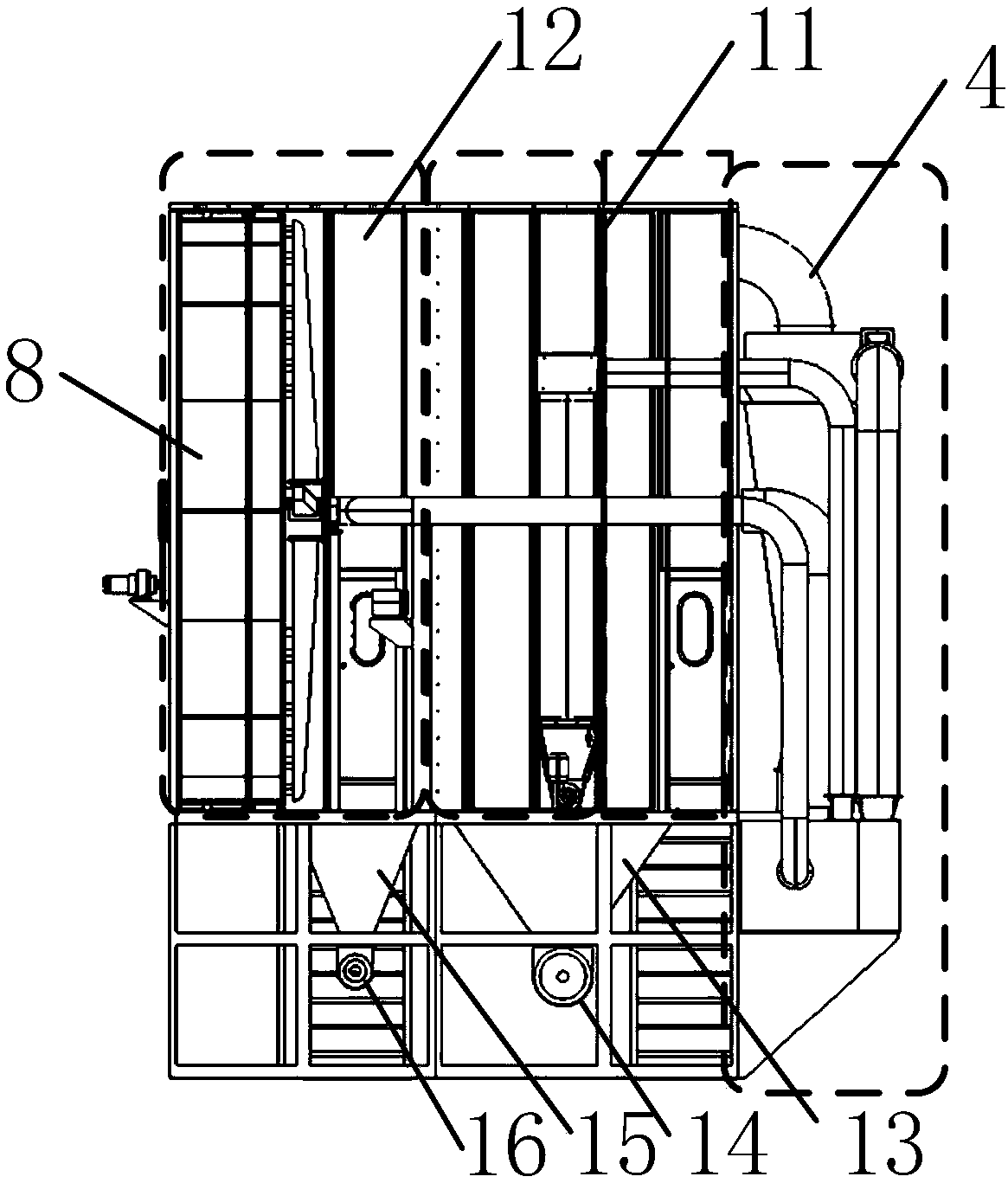

Cotton processing dust-removing machine set

PendingCN108434917ALarge amount of processingReduce resistanceCombination devicesVegetable fibre separation from seedsHigh concentrationFiltration

The invention relates to a cotton processing dust-removing machine set. A dust-removing chamber is arranged on an auxiliary support, and is divided into a first chamber and a second chamber; a second-stage dust-removing device is arranged between the first chamber and the second chamber; the second chamber is connected to the outside of the dust-removing chamber through a third-stage dust-removingdevice; the lower side of the second chamber is connected to a second impurity discharging device through a second impurity collecting hopper; an air inlet passage and a pressure relief valve are arranged on the side surface of the first chamber respectively; the lower side of the first chamber is connected to a first impurity discharging device through a first impurity collecting hopper; a first-stage dust-removing partition board is arranged on the side surface of the air inlet passage and on the inner side of the first chamber; a fan is arranged on the auxiliary machine set; the fan is connected with the second-stage dust-removing device through a first pipe; the fan is connected with the third-stage dust-removing device through a second pipe. The cotton processing dust-removing machine set has large processing capacity, achieves multi-stage filtration, has low resistance, low energy consumption, high dust-removing efficiency and a relatively small volume, reduces pollution, can treat high-concentration impurity dust and can automatically fall the dust.

Owner:JIANGSU JINGYA ENVIRONMENT TECH

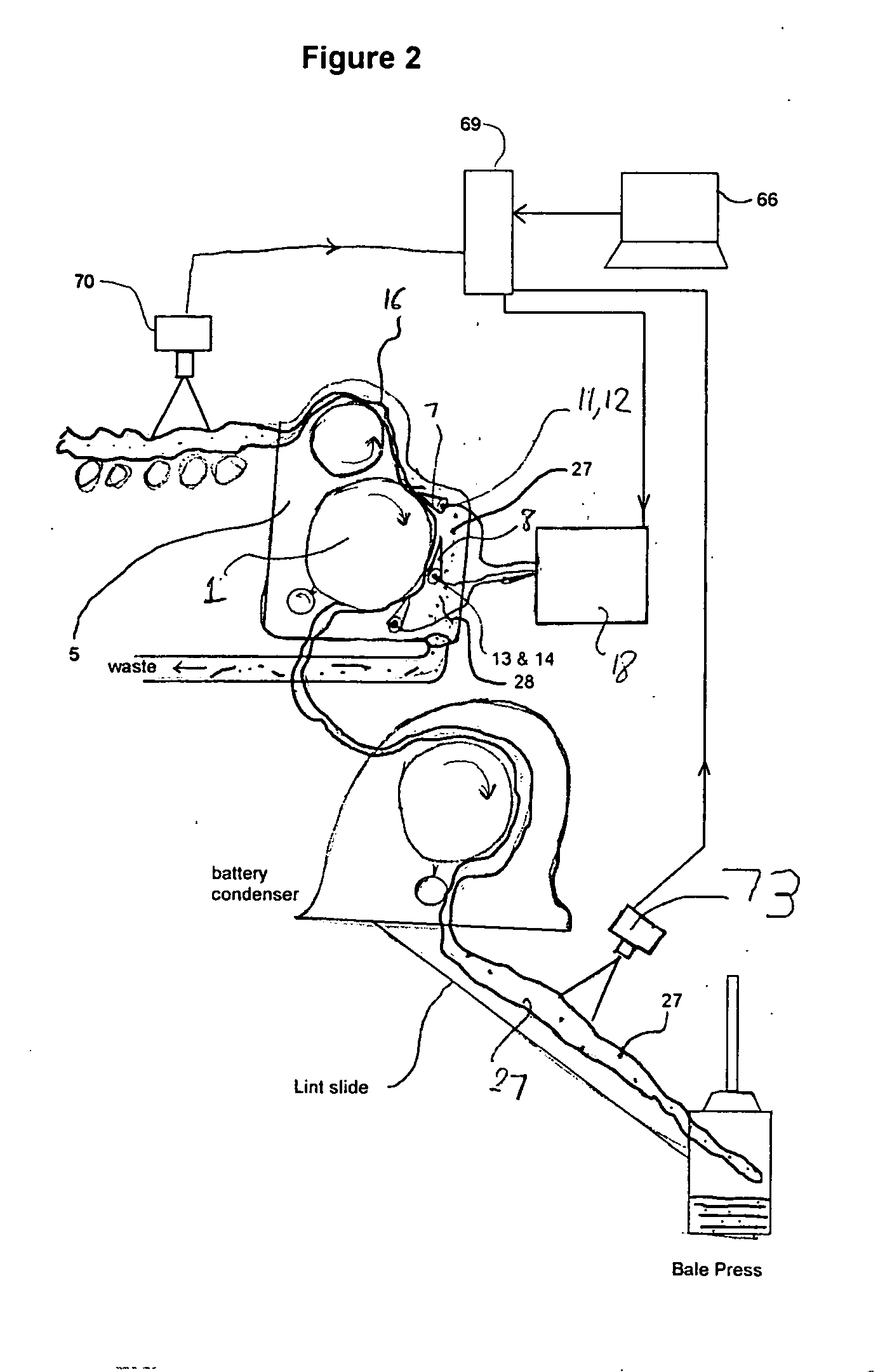

Fiber micronaire testing system

A gin process control system including sensing stations for sensing the physical properties of cotton as it progresses through a gin. A moisture sensor determines, over a wide range of values, the amount of moisture in the cotton. A quality monitor determines the color of the cotton, color distribution, and the amount and type of trash or other impurities which may be entrained in the cotton. A micronaire unit determines both micronaire and cotton maturity. A fiber length tester provides information on the length distribution, breaking strength, and elongation of the cotton fibers. Cotton samples are gathered from the gin flow stream and presented to the sensing stations in a variety of manual, semi-automated, and automated fashions. In a fully automated unit, the sensing stations are connected directly to the gin. The sensing stations are also in communication with the gin process control system, which uses the data from the sensing stations to automatically control the operation of the gin. Alternately, the sensing stations are assembled into a stand-alone unit. In a semi-automatic version of the stand-alone unit, samples are manually gathered and presented to the unit in cassettes for automated subsampling and testing by the sensing stations. In this semi-automatic version, the sensing stations may be in a configuration identical to that of the fully automatic, on-line unit. In a manual version of the stand-alone unit, the samples are manually gathered and manually placed into contact with the various sensing stations. The information reported by the stand-alone units can be used to manually control the operation of the gin.

Owner:USTER TECHNOLOGIES

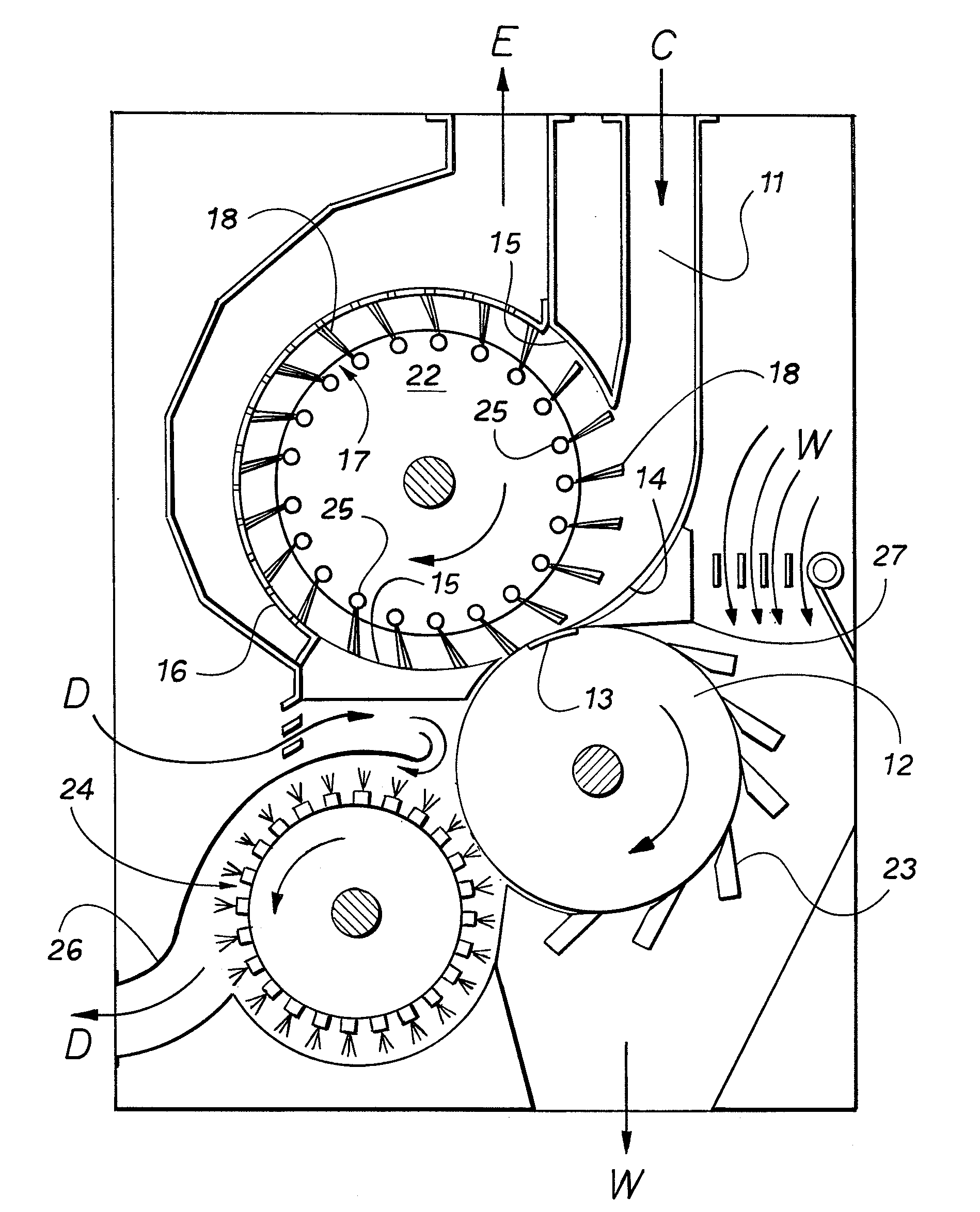

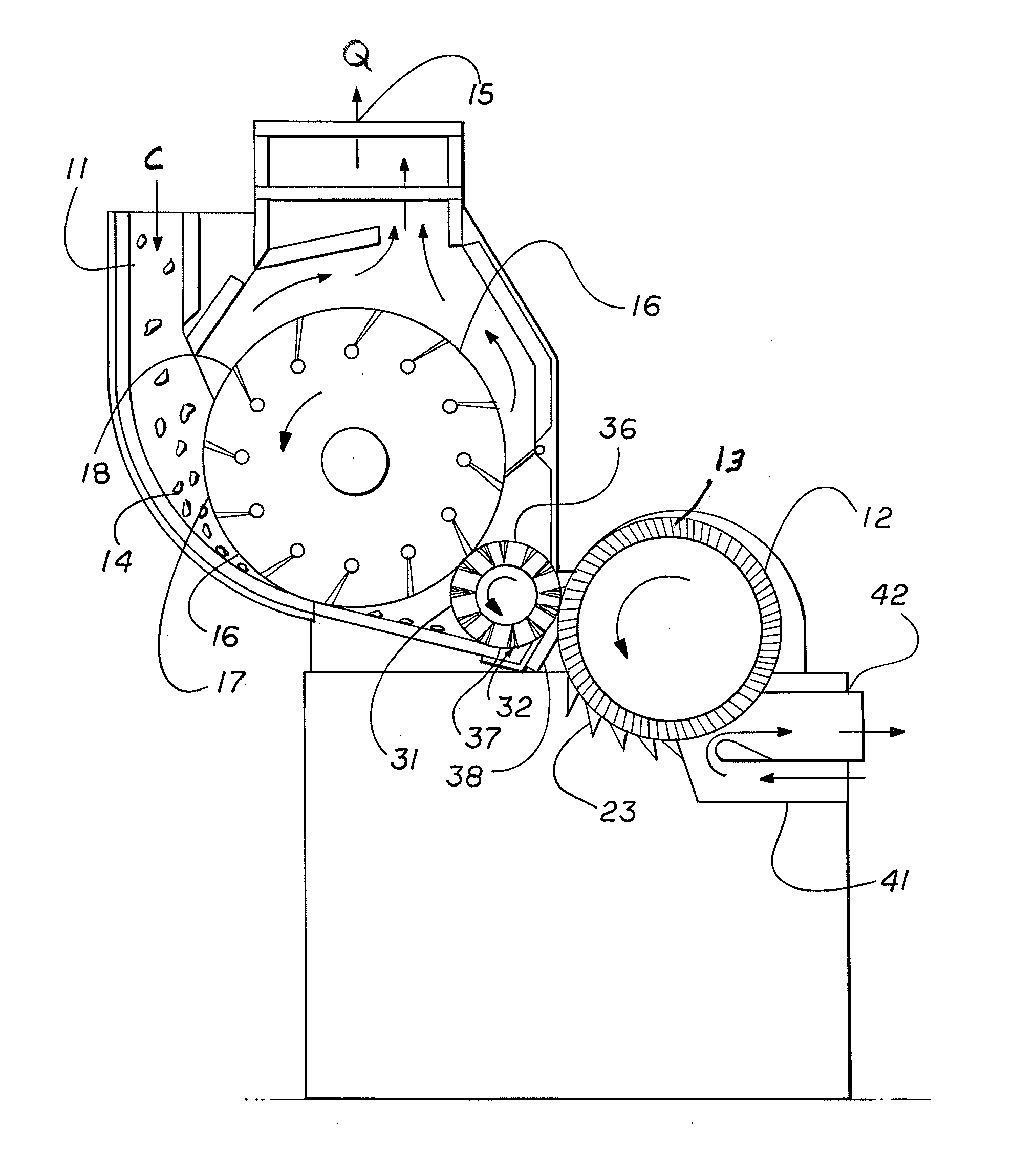

Method and Apparatus for Separating Foreign Matter From Fibrous Material

ActiveUS20090172918A1Simple methodEliminate needMechanical impurity removalLubricating devicesForeign matterFiber

An apparatus for cleaning foreign matter from separated tufts of fiber uses a revolving open reel type structure mounted within a porous housing to separate a conveying air stream from tufts of fiber conveyed thereby and deliver the tufts to a toothed cleaning cylinder which passes beneath a plurality of cleaning bars. The open reel utilizes brush like outer surfaces to sweep tufts of fiber from the housing back into the air stream adjacent the cleaning cylinder.

Owner:LUMMUS INDS

Method, apparatus and system for adding moisture to cotton fibers during the cotton ginning process

Owner:LUMMUS INDS

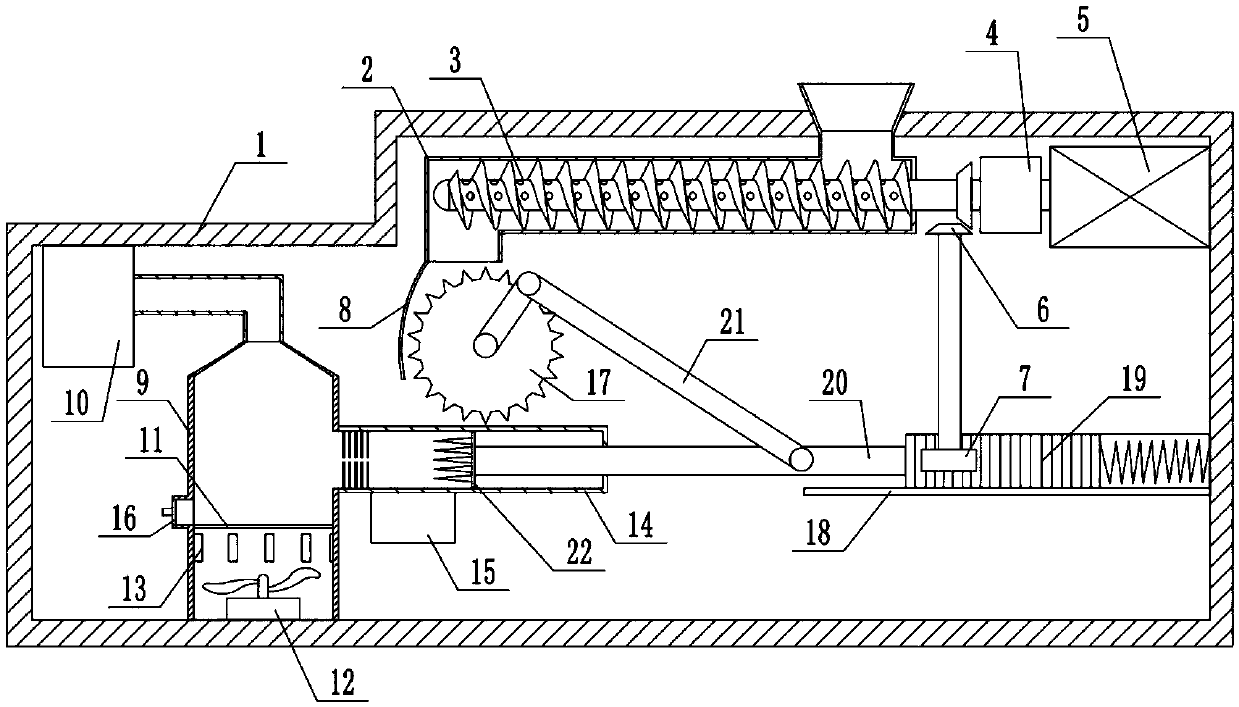

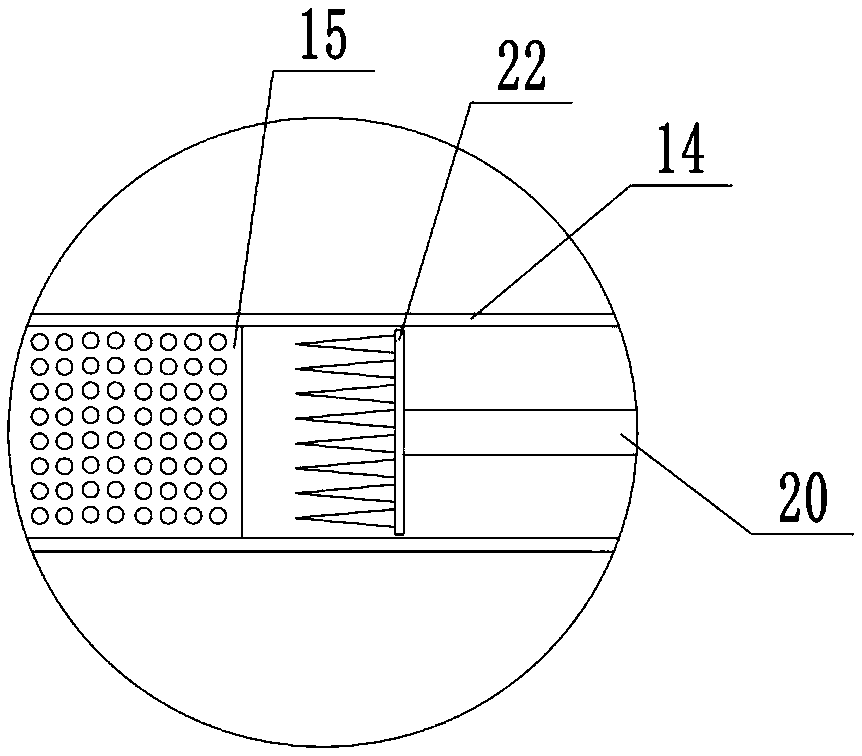

Cotton seed separating device

InactiveCN109652862AEasy to separatePrevent flutteringVegetable fibre separation from seedsFiberWood splinter

The invention relates to the field of textile, and discloses a cotton seed separating device which comprises a body. The inside of the body is provided with a feeding port, a feeding pipe, an operation barrel, a pressuring roller and a sliding rail, a screw rod is arranged in the feeding pipe and provided with a chamber, a through hole, a first bevel gear, a steamer and a motor, the first bevel gear is engaged with a second bevel gear, the second bevel gear is coaxially connected with an incomplete gear, a baffle plate is fixedly connected at the tail end of the feeding pipe, a conveying pipeis fixedly connected at the top of the operation barrel and connected with a treatment box, an air feeding plate, a plurality of heating pipes and a fan are arranged in the operation barrel, air outlet holes are densely formed in the air feeding plate, a separating tank is arranged on the operation barrel, a brush is arranged in a separating box, a collecting box is communicated with the bottom ofthe separating box, a rack and a spring are arranged in a guide rail, a pushing rod and a connecting rod mechanism are arranged on the rack, a needle plate is arranged on the pushing rod, iron splinters are densely distributed on the needle plate. By the aid of the technical scheme, the separating device solves the problems of low quality of cotton fibers separated by a ginning machine and more cotton dust in the prior art.

Owner:象山平悦环保科技有限公司

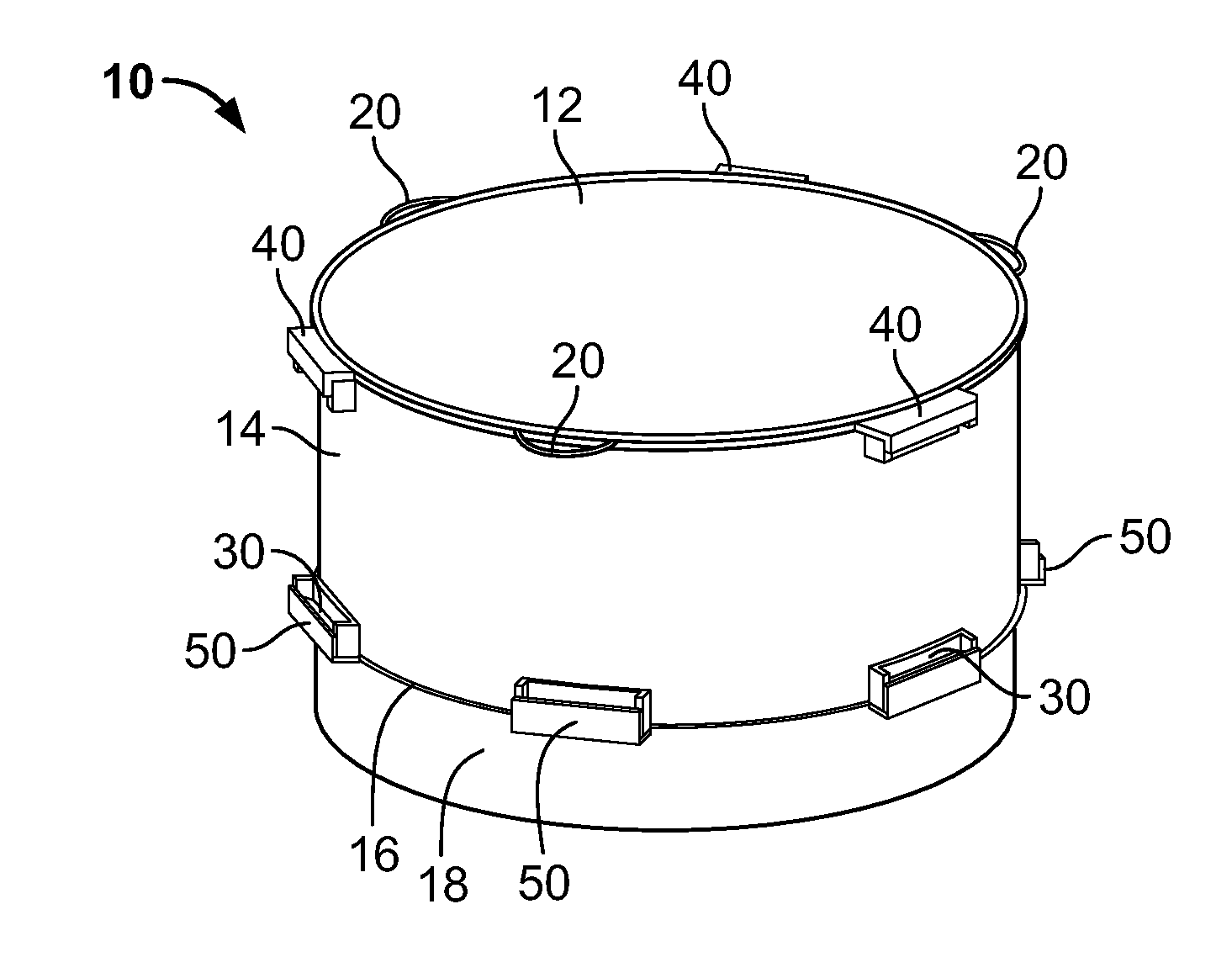

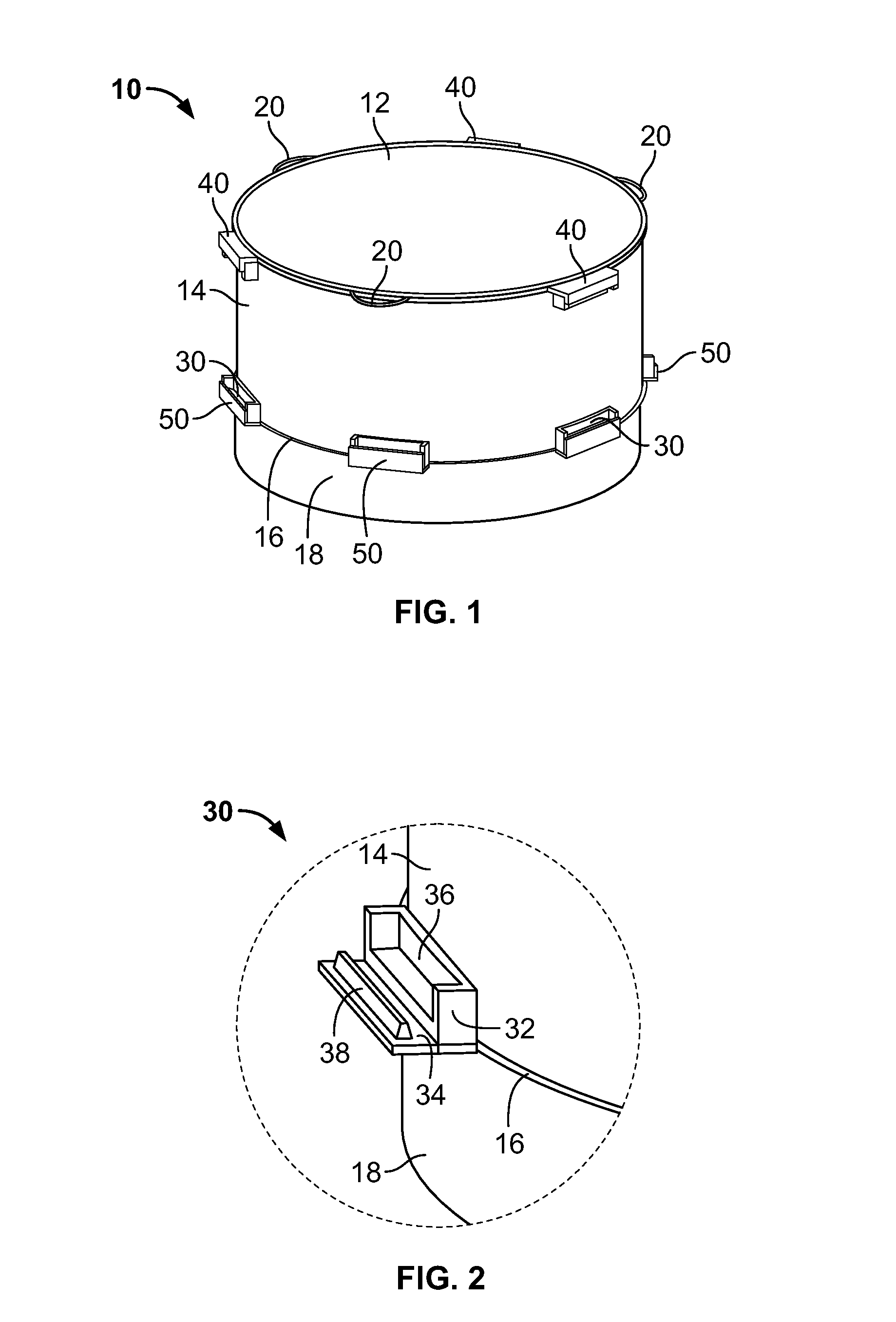

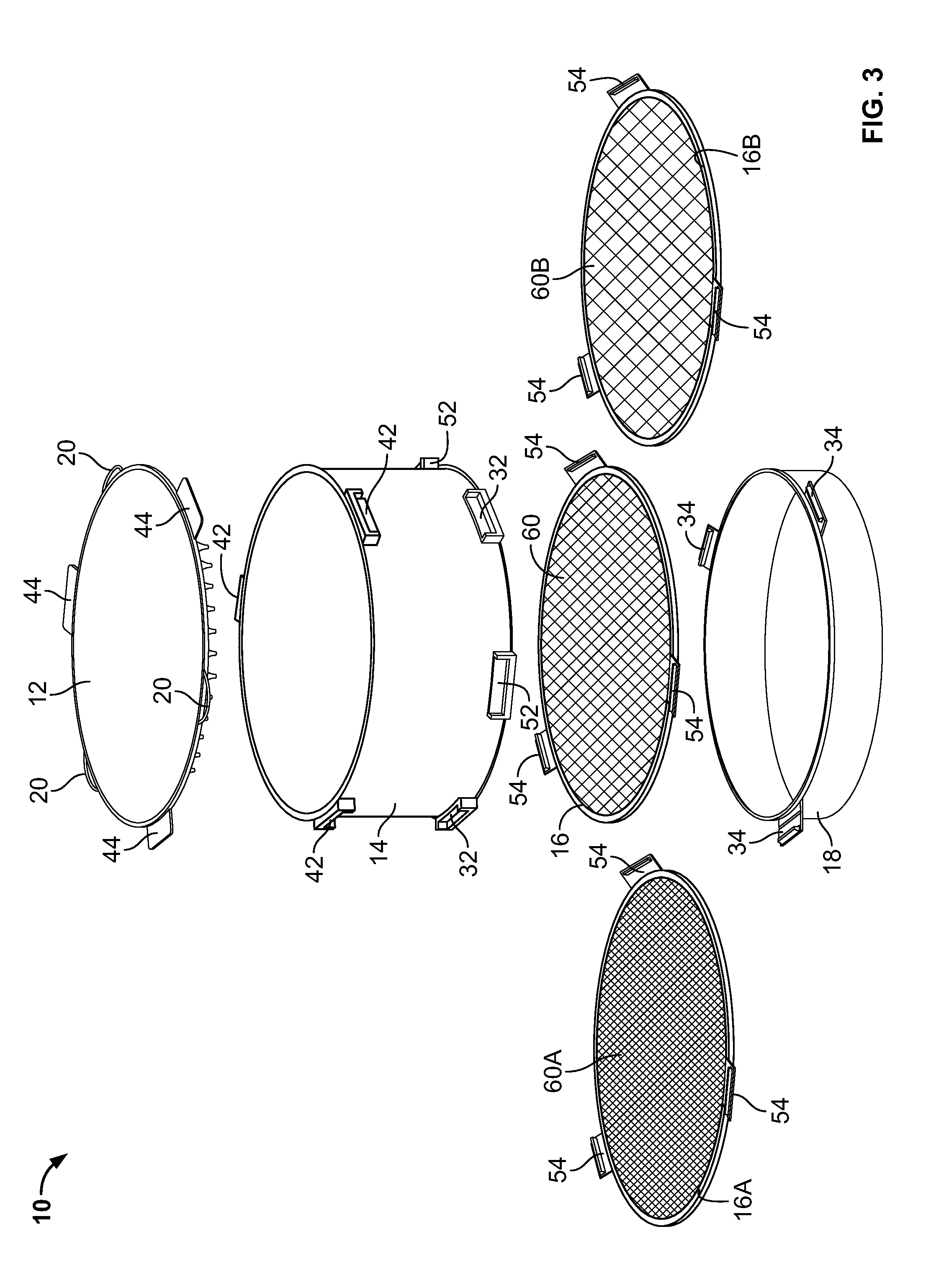

Multi-Part Sifter for De-Seeding and Sorting Plant Material

A multi-part sifter for de-seeding or sorting plant material includes an upper frame having an open top and an open bottom; a lid that covers the top of the upper frame; a screen that covers the bottom of the upper frame; a lower frame having an open top and a closed bottom; a lid latch to releasably hold the lid to the top of the upper frame; a screen latch to releasably hold the screen to the bottom of the upper frame; and a frame latch to releasably hold the bottom of the upper frame to the top of the lower frame with the screen in between the upper frame and lower frame.

Owner:ROSADO JAMES

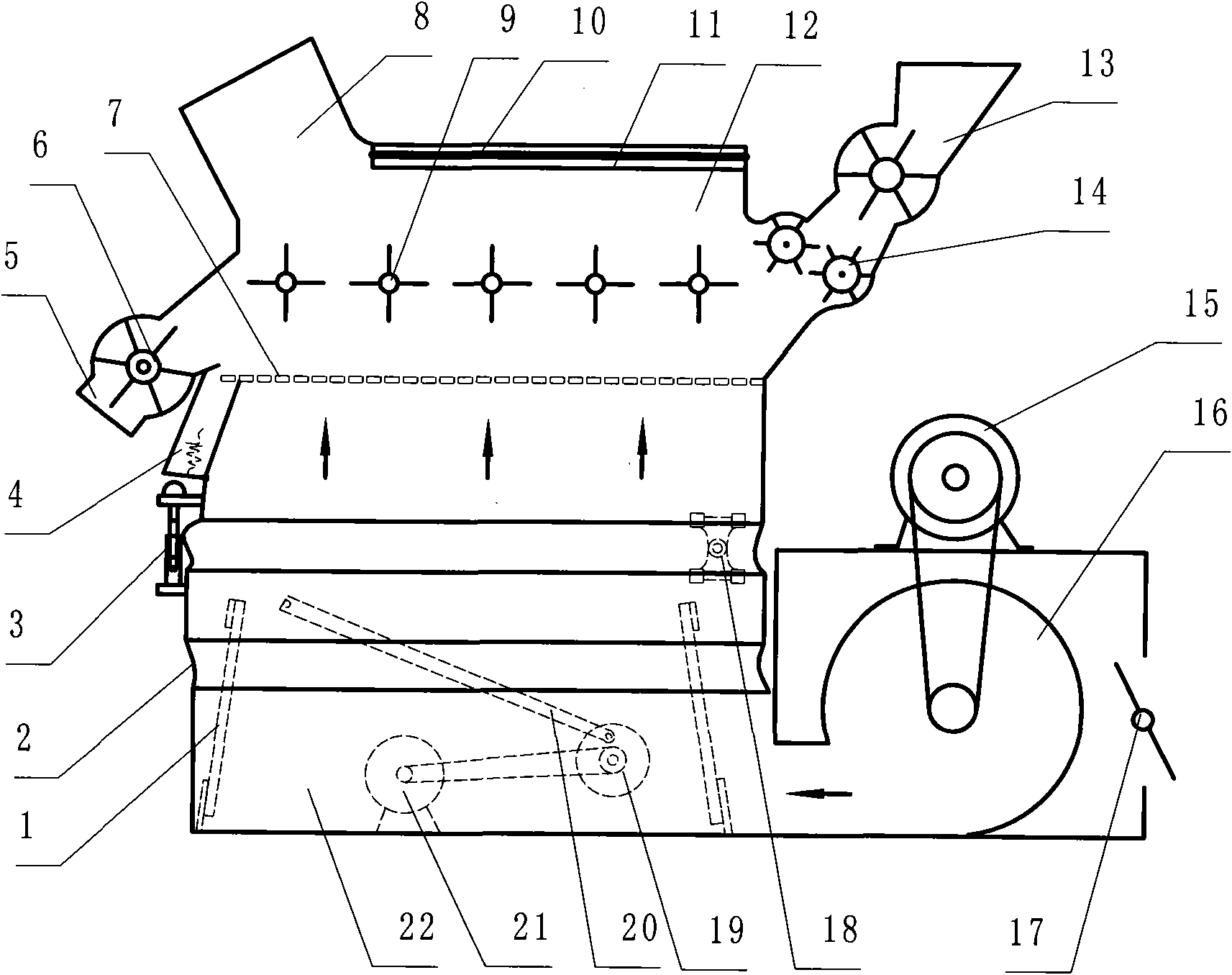

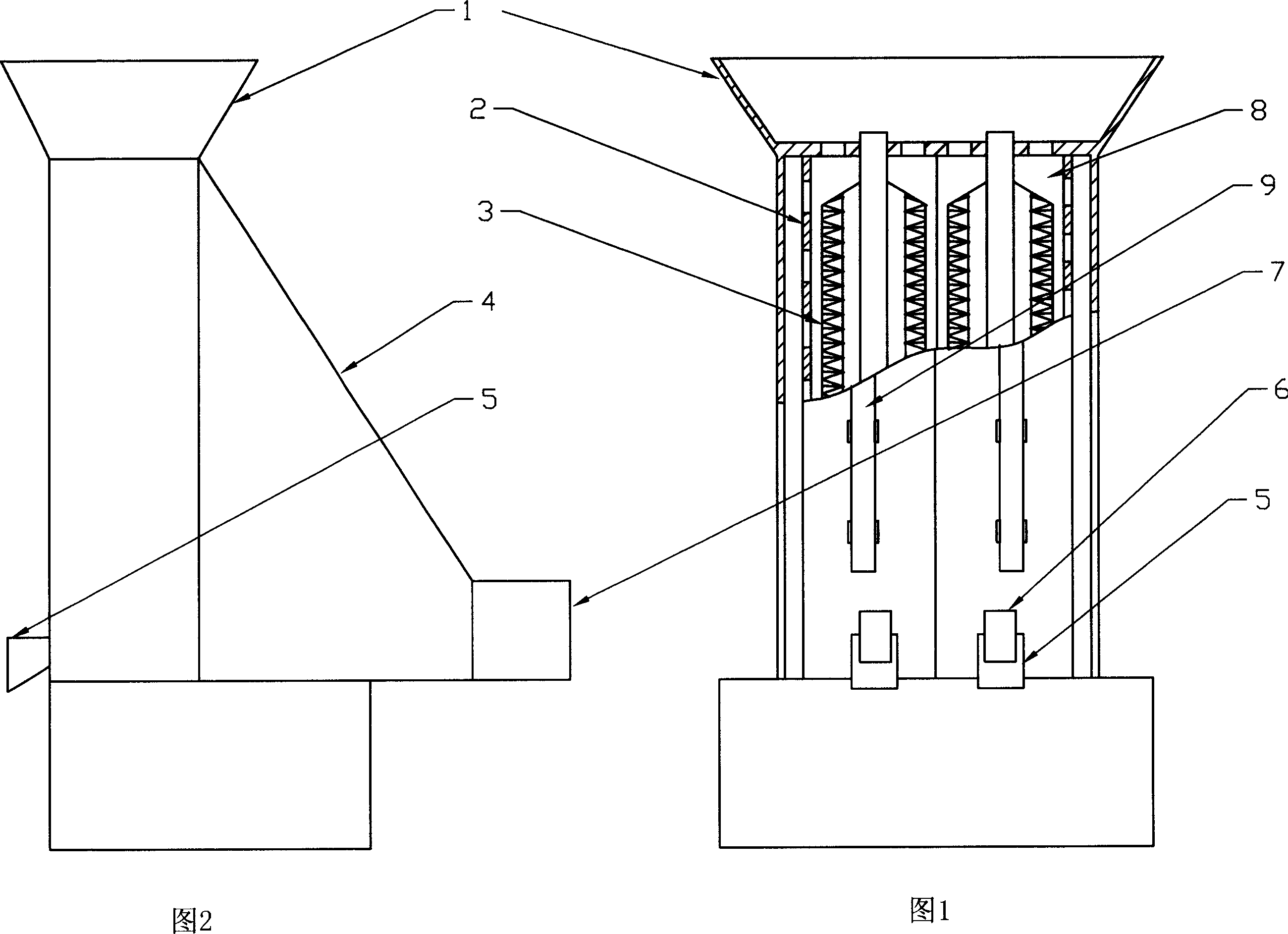

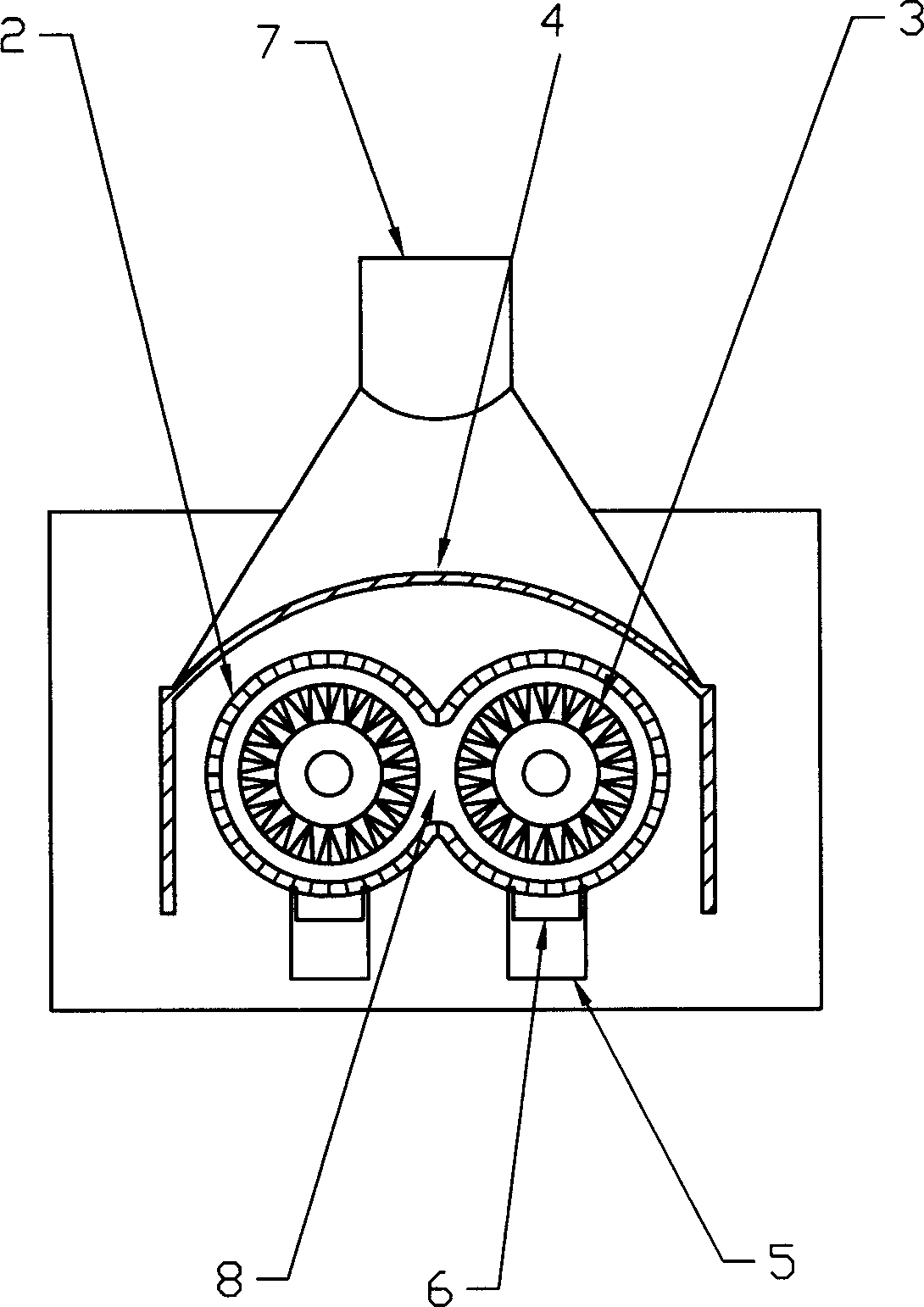

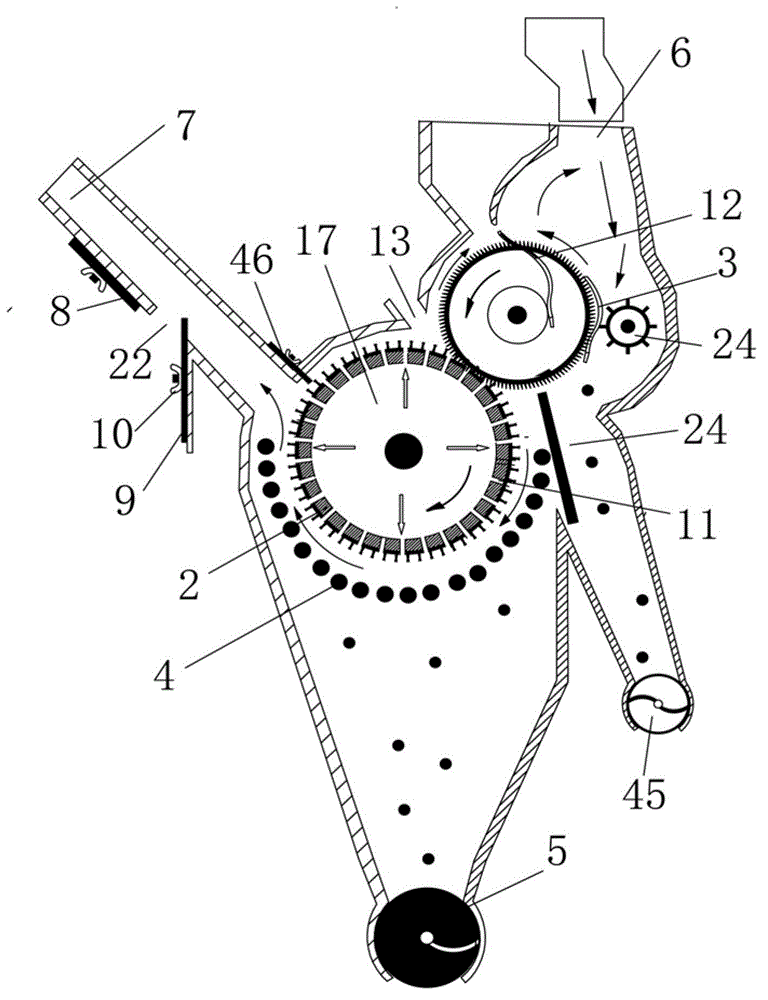

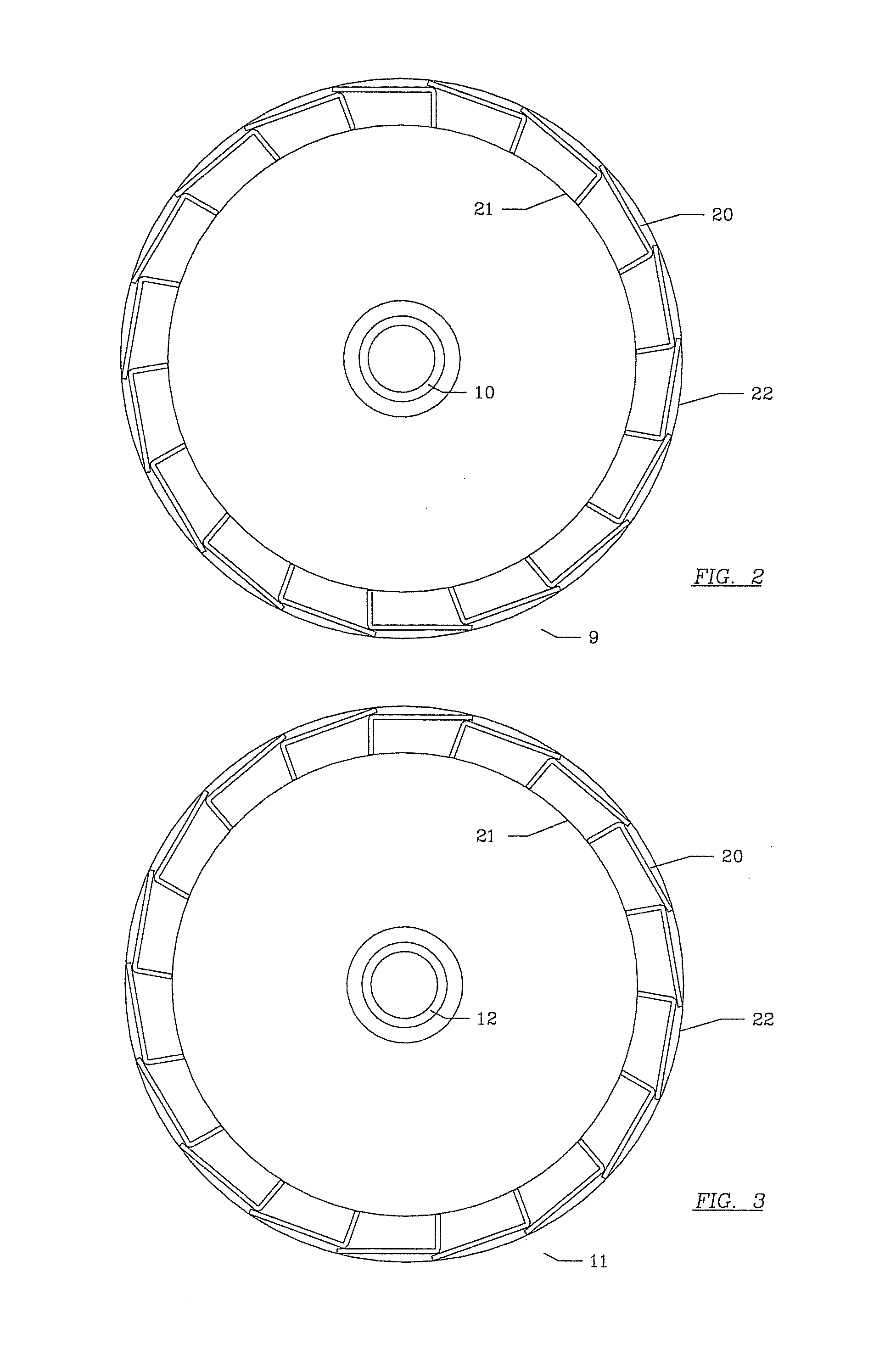

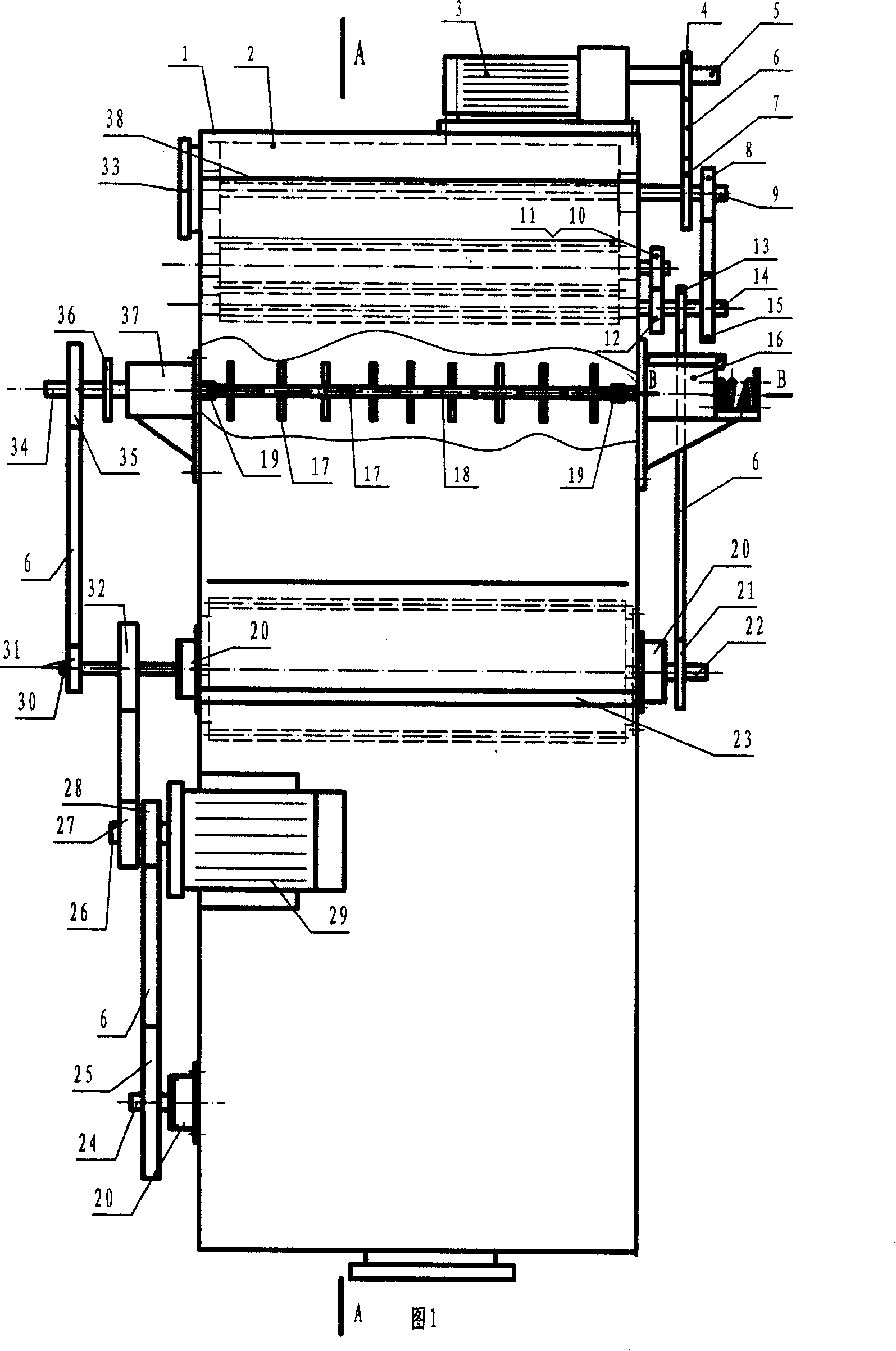

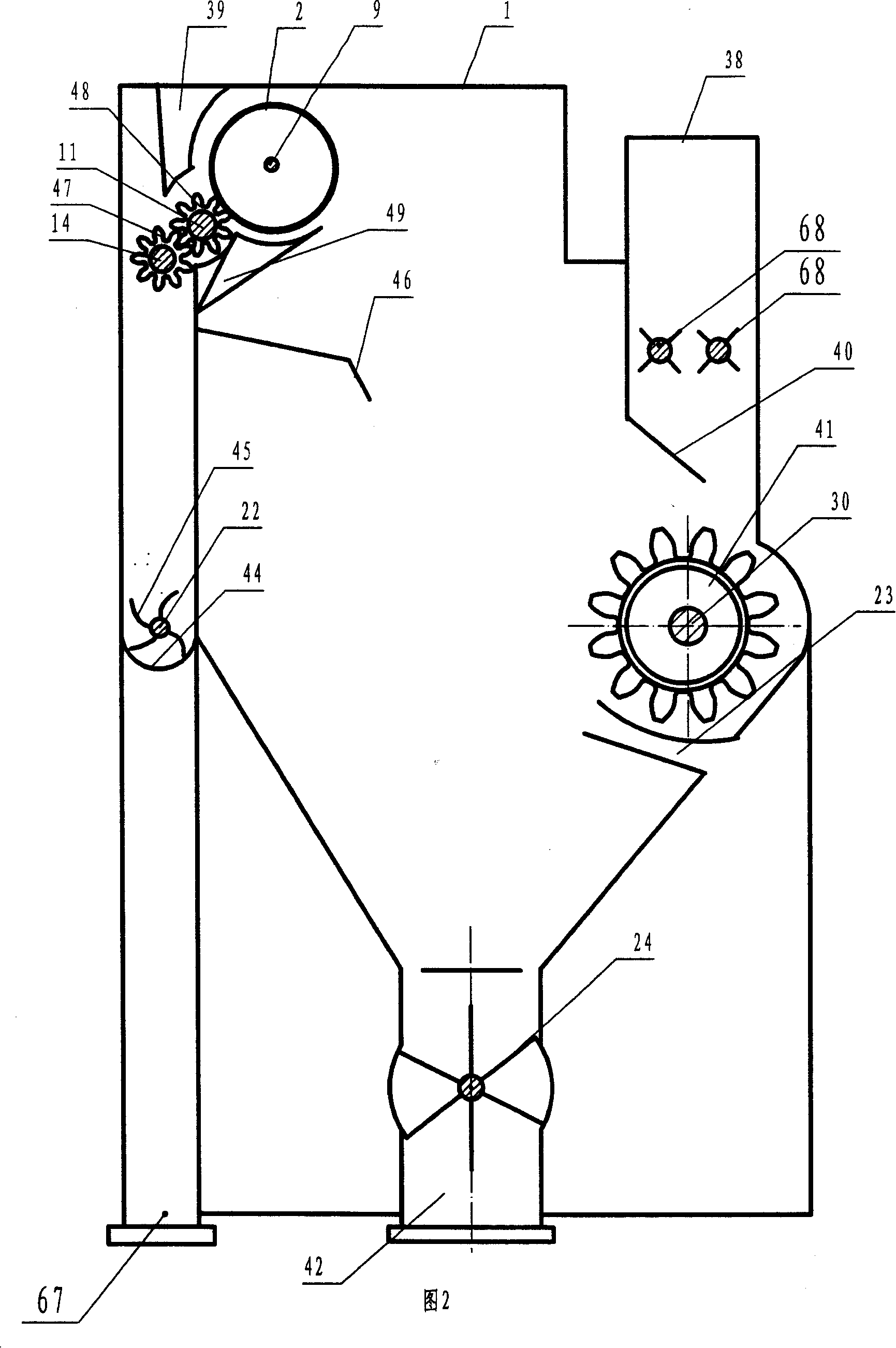

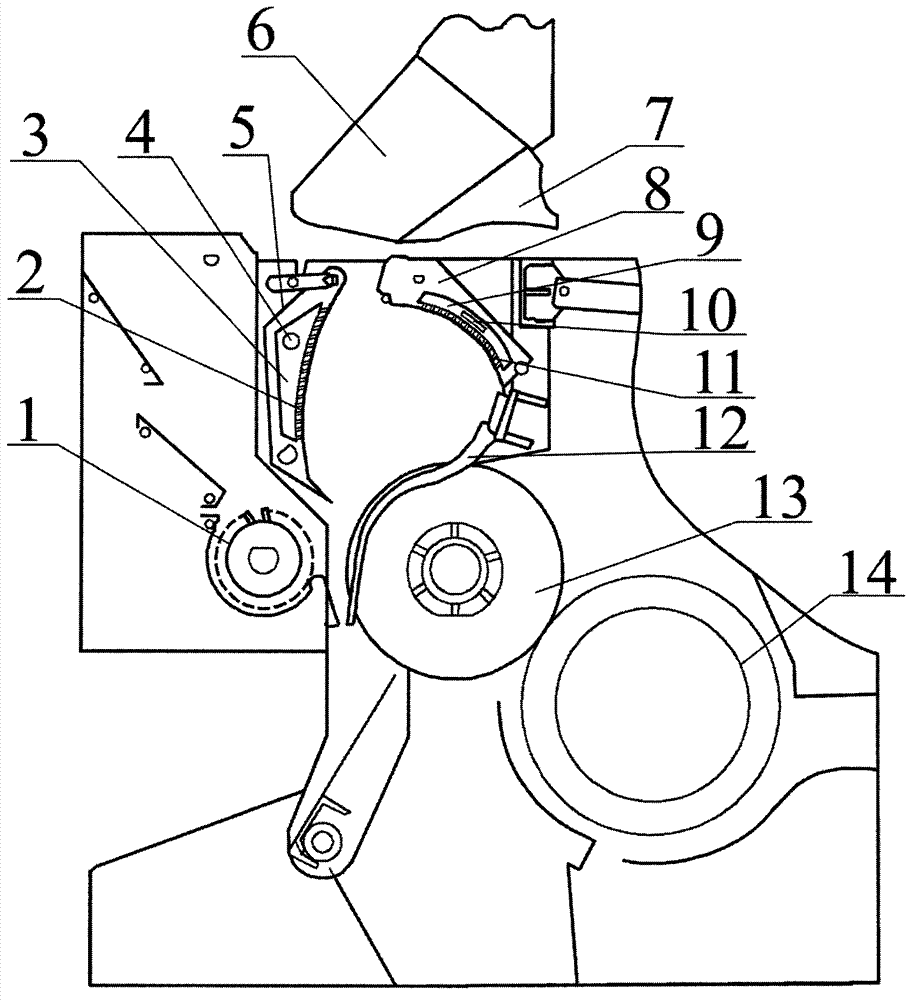

Seed cotton isomerism defibrator

InactiveCN101173370AIntegrity guaranteedEnsure comprehensivenessVegetable fibre separation from seedsFibre separationIsomerismsPulp and paper industry

The invention relates to a machine used for separating foreign fibre from seed cotton, which is characterized in that a plurality of winding rollers are arranged inside the intra-cavity under the inlet of the body and a guide plate is arranged on a longitudinal side of the winding rollers, a mass ejection roller is arranged under the outlet of the guide plate, and a makeup air port is arranged under the mass ejection roller; a net cage, a removing roller and a poking roller are arranged on the other side of the intra-cavity of the body, a wind screen and a wind limited plate are respectively arranged at the upper side and the lower side of the net cage and the removing roller, a back partition board is arranged under the wind limited plate, a screw conveyor and a screw conveyor groove are arranged under the poking roller, and a channel communicated with the foreign fibre outlet is arranged at the bottom of the screw conveyor groove; the lower part of the intra-cavity is funnel-shaped, and an airlock is arranged between the upper and lower ends of the lower outlet of the body. The invention has the advantages of significantly decreasing the textile cost, ensuring the continuity of scale production, sky-high running rate of equipments, consumedly reducing the human labor intensity, consumedly shortening the downtime, and significant rising of quality index of the produced lint cotton compared with other removing methods.

Owner:周义

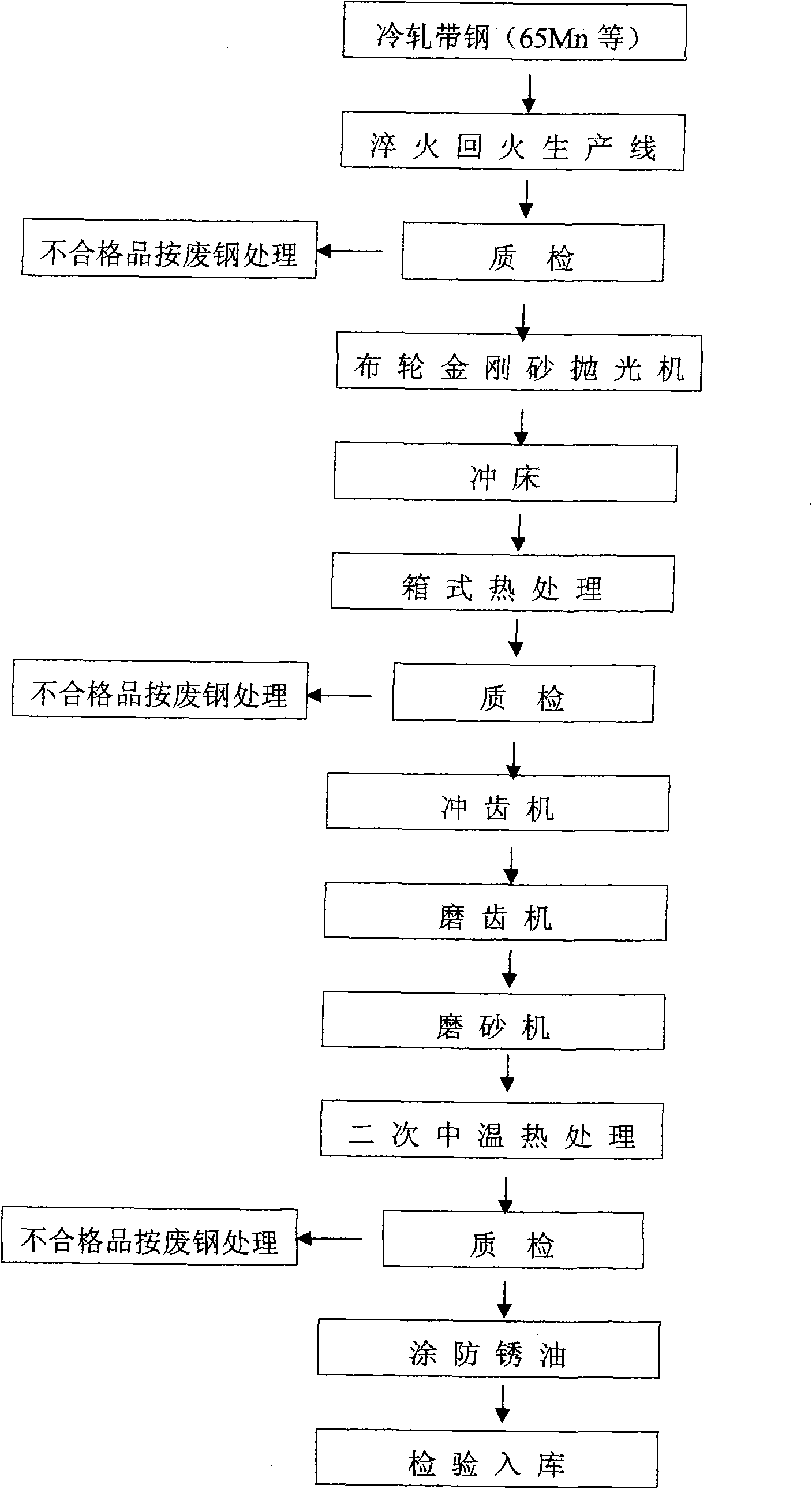

Method for producing traceless quenching and embossing saw blade

InactiveCN101333688AQuality improvementStable hardnessVegetable fibre separation from seedsMetal sawing tool makingProduction lineHardness

The invention discloses a production method of cotton ginning saw-blade, which directly uses the strip steel to firstly quench and temper and then subsequently process the strip steel. The process steps are as follows: selecting the strip, quenching the strip, inspecting the quality of the strip, polishing the surface of the strip, punching the strip into a blank of the saw-blade, heat treating the blank of the saw-blade, inspecting the quality of the blank, punching teeth on the blank by a sawtooth punching machine, grinding teeth, burring, heat treating the blank in moderate temperature, inspecting the quality of the finished product, packaging the finished product after coating antirust oil on the finished product, and inspecting and warehousing the finished product. The production method continuously produces the strip steel of 350mm and 430mm on quenching and tempering production lines, so the produced saw-blade has stable hardness, good toughness, good wear resistance and long service life.

Owner:HANDAN HANWU COTTON MACHINERY

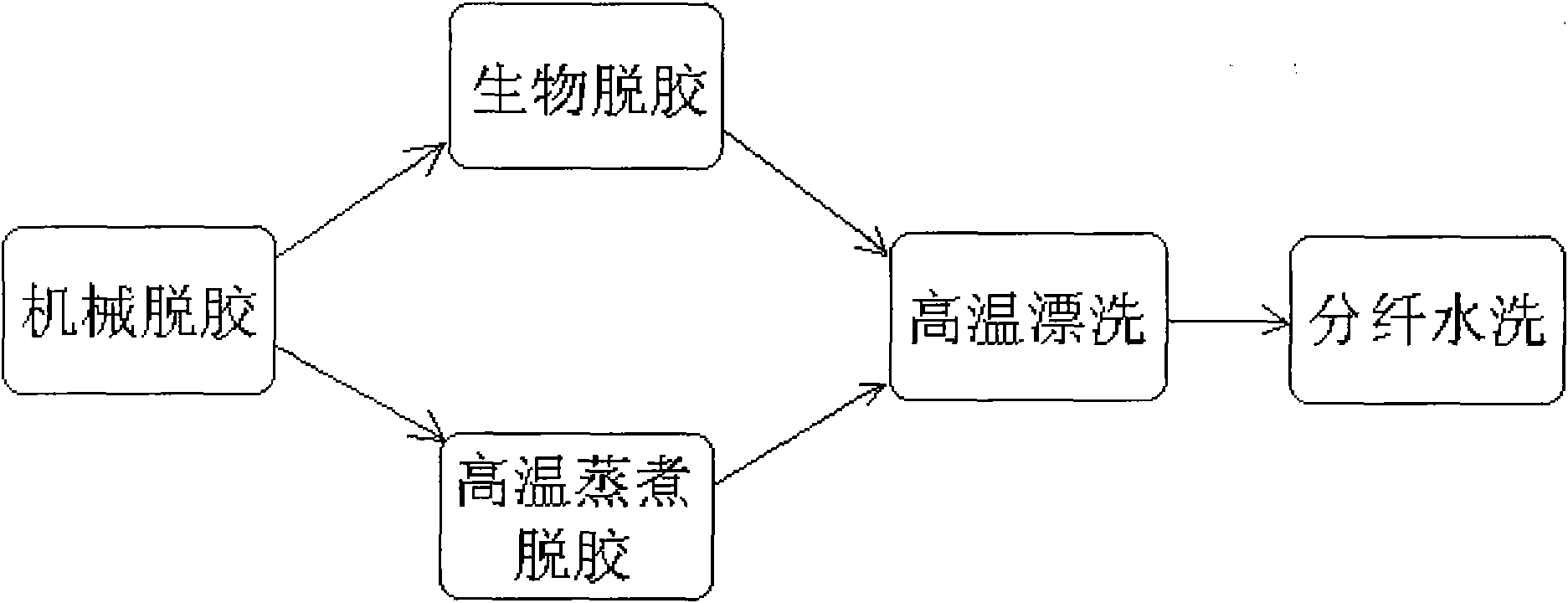

Degumming method and device for bast fibers

ActiveCN101851788AFully and evenly degummedImprove degumming effectVegetable fibre separation from seedsTextile treatment machine partsYarnEngineering

The invention relates to a degumming method and a degumming device for bast fibers. The degumming method comprises the following steps of: mechanically degumming, biologically degumming and / or degumming through high-temperature cooking, sintering at high temperature, and distributing fiber and washing with water; and the degumming device comprises a mechanical degumming device, an inoculated fermentation device, a high-temperature liquid circulating device, a fiber distributing and water washing device and a yarn hanging device. The method and the device have the advantages of reasonable procedures, obvious degumming effect, good homogenization and consistence, high degumming operating efficiency, strong controllability, and neat bulk fiber processed. The invention can effectively reduce environmental pollution, so the invention can be widely applied to the degumming process of various bast fibers.

Owner:WUHAN HEMP BIOLOGICAL TECH CO LTD +2

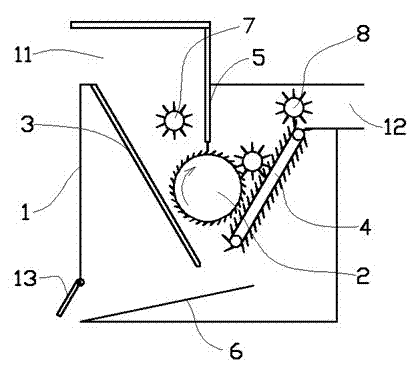

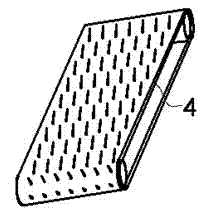

V-type cotton gin

The invention discloses a V-type cotton gin. The V-type cotton gin comprises a frame, a cotton ginning roller, a blanking plate and a discharge belt plate. A feed inlet and a discharge outlet are formed in the upper portions of the front position and the rear position of the frame; the blanking plate and the discharge belt plate are placed in a slant mode, the sections of the blanking plate and the discharge belt plate are V-type, and the feed inlet and the discharge outlet are connected with the feed inlet and the discharge outlet; the cotton ginning roller is placed between the blanking plate and the discharge belt plate; slant cotton stirring needles are densely distributed on the surface of the cotton ginning roller; the cotton ginning roller and the frame are assembled in a rotating mode; a baffle plate is installed on the upper portion of the cotton ginning roller; a belt conveying structure is adopted by the discharge belt plate; slant cotton feeding needles are arranged on the surface of the discharge belt plate. The mode that cotton is directly stirred through rotation of the cotton ginning roller is adopted, and therefore the V-type cotton gin is small in noise, simple and compact in overall structure, easy to manufacture and high in safety when being used because a main cotton ginning structure is assembled in the frame.

Owner:SUZHOU QISHANG TEXTILE

Method for improving embossing quality of sawteeth

InactiveCN102787365AImprove qualityInhibition of fractureVegetable fibre separation from seedsFiberEngineering

The invention relates to a method for reducing the binding force between cotton fibers and cotton seeds and improving the embossing quality of sawteeth by carrying out online humidifying and heating on the cotton seeds and belongs to the field of textile processing. According to the invention, gas inlet micropores which are uniformly distributed are arranged on a cotton flow-down plate in a feeding region of a sawtooth cotton gin; the cotton flow-down plate is connected with a steam passage; high temperature steam is filled into the cotton flow-down plate to carry out high temperature heat and wet treatment on seed cotton passing through the cotton flow-down plate; the processed seed cotton enters an embossing region and is subjected to further treatment by high temperature steam output by a first steam outlet hole and a second steam outlet hole; the binding force between the cotton fibers and cotton seed hulls is greatly reduced; under the tearing action of a high-speed rotating sawtooth wheel, the separation of the cotton fibers from the cotton seeds from the roots is implemented; the breakage of a great amount of fibers, which is caused by the case that the cotton fibers are randomly broken by the sawteeth, is fundamentally inhibited; the original fiber length of the cotton fibers on the embedded seed cotton is kept; and the embossing quality of the sawteeth is greatly improved. The method has the advantages of reasonable design and simple structure and is suitable for large-area transformation of the sawtooth cotton gin.

Owner:HUBEI HENGDA TEXTILE CO LTD

Cotton shucking machine

Owner:王有成

Spinning method for regenerated yarns

InactiveCN101634066AHigh strengthImprove evennessVegetable fibre separation from seedsYarnYarnEngineering

The invention provides a spinning method for regenerated yarns. The spinning method adopts specific operating process conditions, controls and adjusts speed and separation distance of each main process, adjusts the quantification of each process, improves the woven roving coefficient, and is favorable for pure yarns of a spun yarn process; and meanwhile, because the twist of the spun yarn process is improved, the strength of resultant yarns is further improved, the evenness level of the resultant yarns is improved, and the thin section, thick section and neps are reduced so that the resultant yarns achieve the requirement of subsequent weaving. The fabric woven by the yarns which are spun by the method has coarse and good moisture conducted breathability, and meanwhile has no stimulation to human skin, no pollution or toxic harm, so the fabric is favored by people.

Owner:SHANGHAI SHENAN TEXTILE

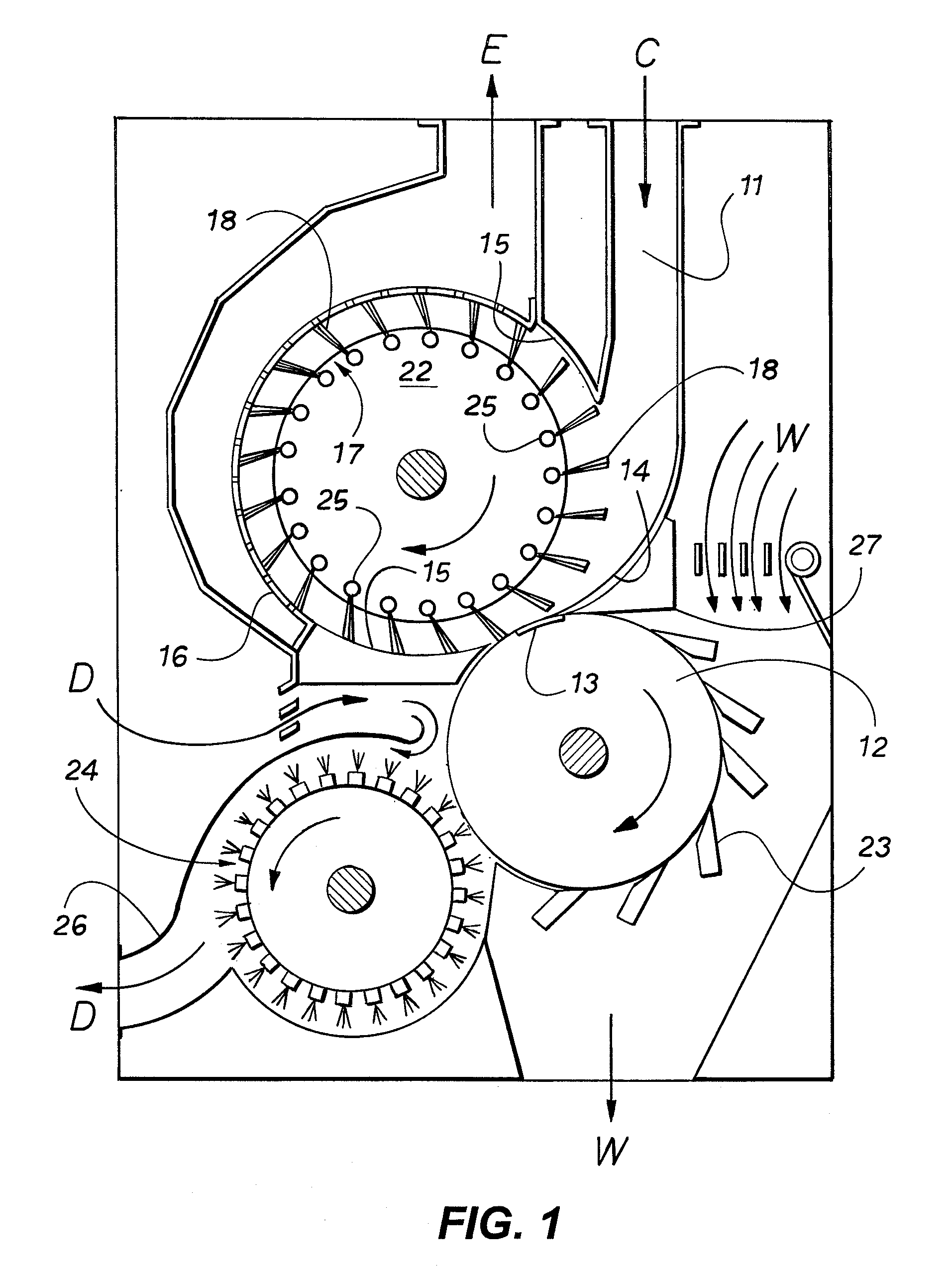

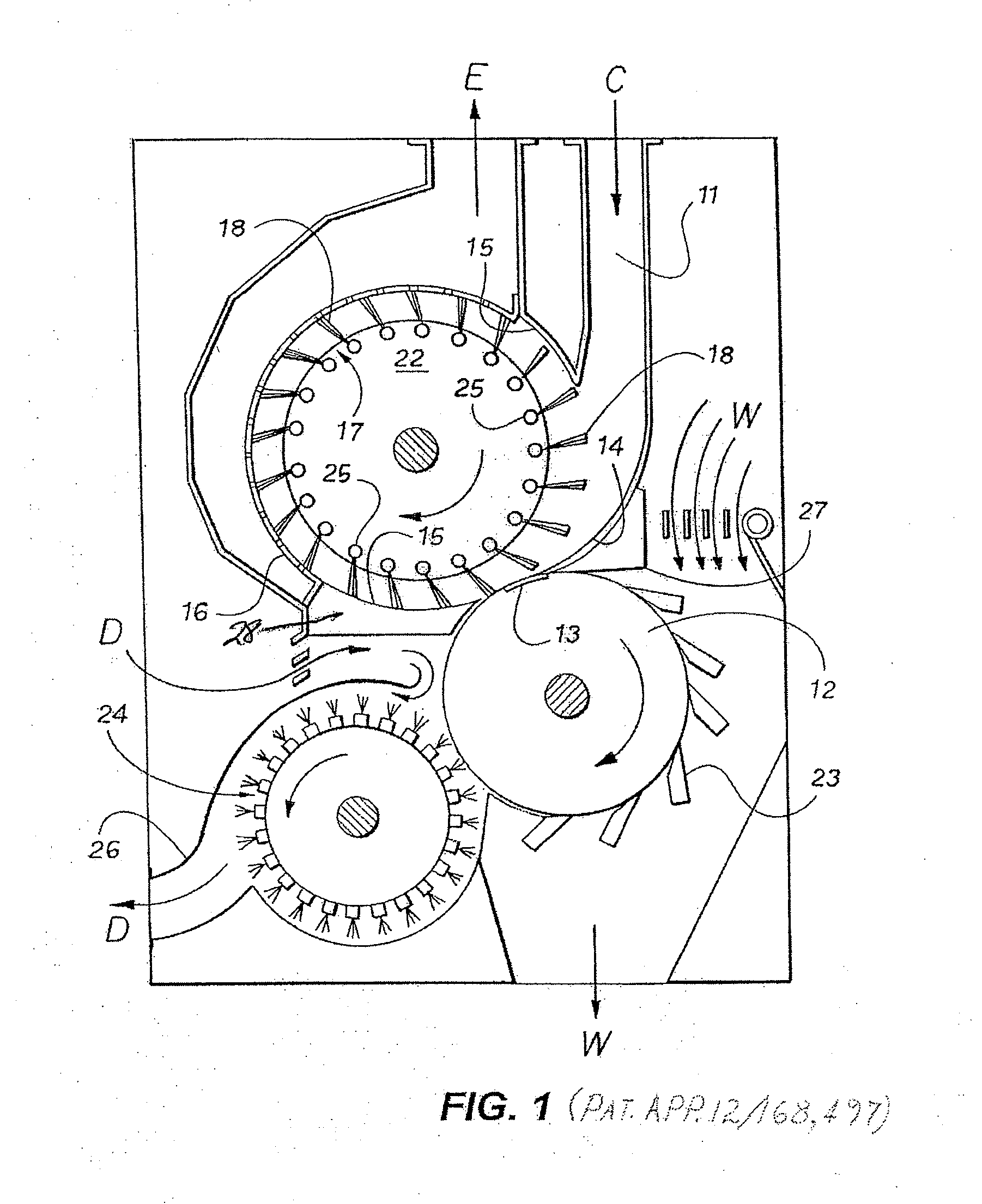

Method and Apparatus for Separating Foreign Matter from Fibrous Material

ActiveUS20100306966A1High speed separation and cleaningSimple methodMechanical impurity removalVegetable fibre separation from seedsForeign matterFiber

An apparatus for cleaning foreign matter from separated tufts of fiber uses a transfer cylinder intermediate a revolving open reel type structure mounted within a porous housing to separate a conveying air stream from tufts of fiber conveyed thereby and a toothed cleaning cylinder to separate air flow through said revolving reel from said cleaning cylinder such that air is not drawn through said cleaning cylinder into said porous housing.

Owner:LUMMUS INDS

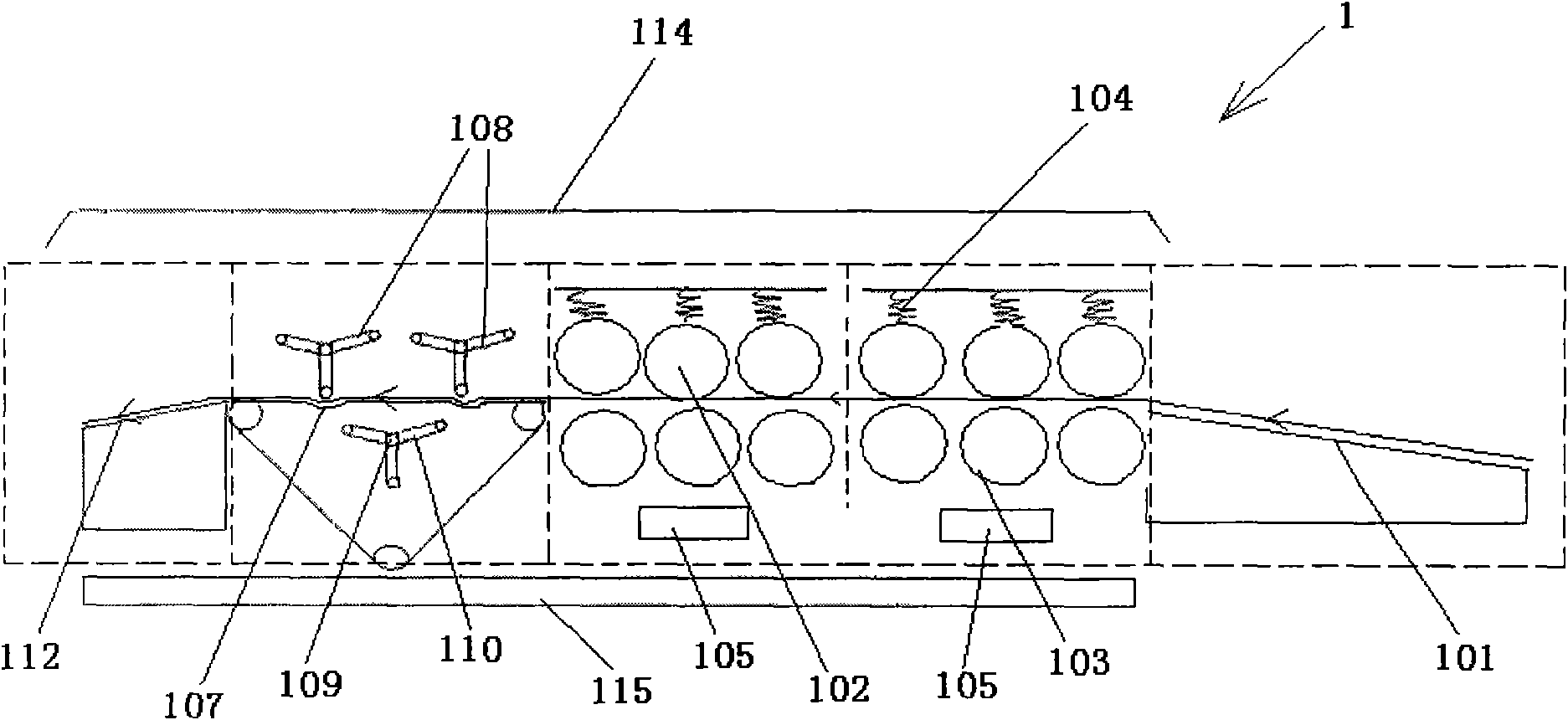

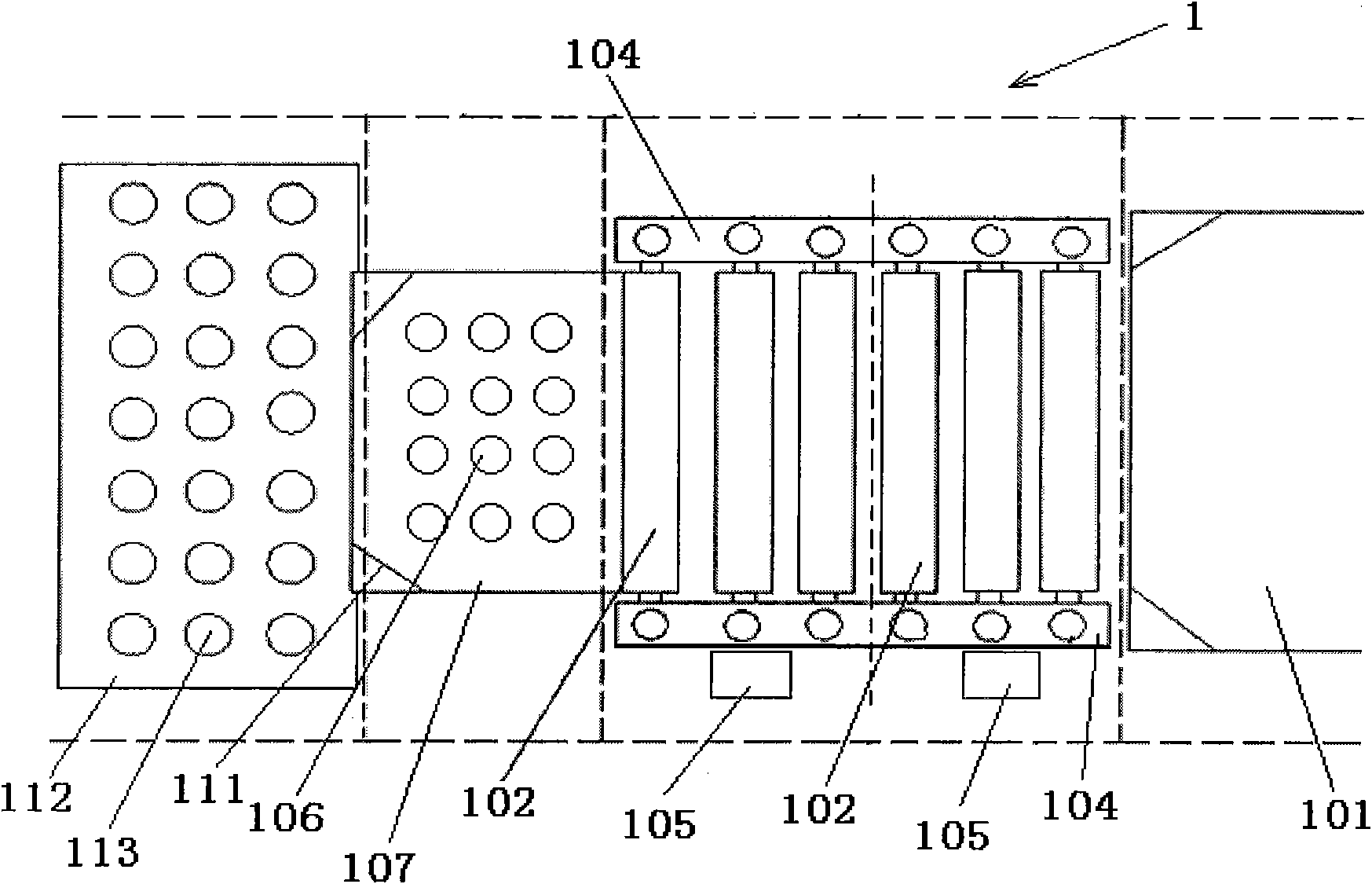

Cotton gin with humidifying function

ActiveCN106480509AImprove processing qualityFull and even humidificationVegetable fibre separation from seedsLiquid/gas/vapor fibres/slivers/rovings treatmentFiberEngineering

The invention provides a cotton gin with a humidifying function and belongs to the field of cotton processing. The cotton gin comprises a box, a seed cotton opening and feeding device, a seed cotton cleaning device, a cotton gin frame and a cotton ginning work box, wherein the box is supported on the cotton gin frame, the cotton ginning work box is arranged on one side of the cotton gin frame, the seed cotton cleaning device is arranged between the box and the cotton gin frame, the seed cotton opening and feeding device is arranged in the box, a cotton cleaning and opening mechanism and an impurity discharge mechanism are arranged in the seed cotton cleaning device, a cotton fiber cleaning mechanism and a saw blade separating mechanism are arranged on the cotton gin frame, a cotton fiber and cotton seed separating mechanism is arranged in the cotton ginning work box, a moisture box is arranged outside the box and communicated with the box, and a moisture inlet is formed in the moisture box. The cotton gin has the advantages that seed cotton can be humidified evenly, and the processing quality of the seed cotton is increased.

Owner:中棉集团邯郸物流园有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com