Patents

Literature

172 results about "Length distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

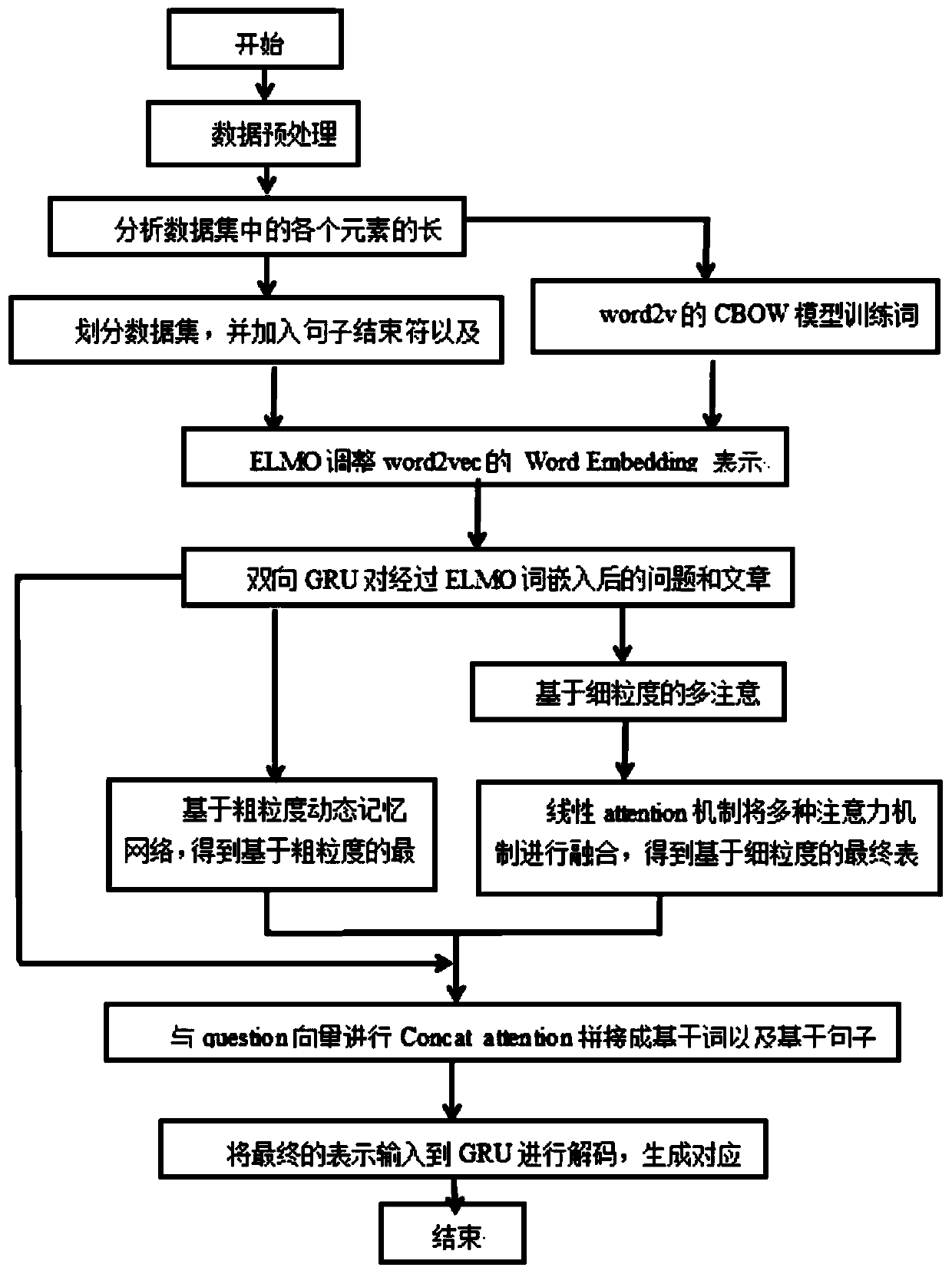

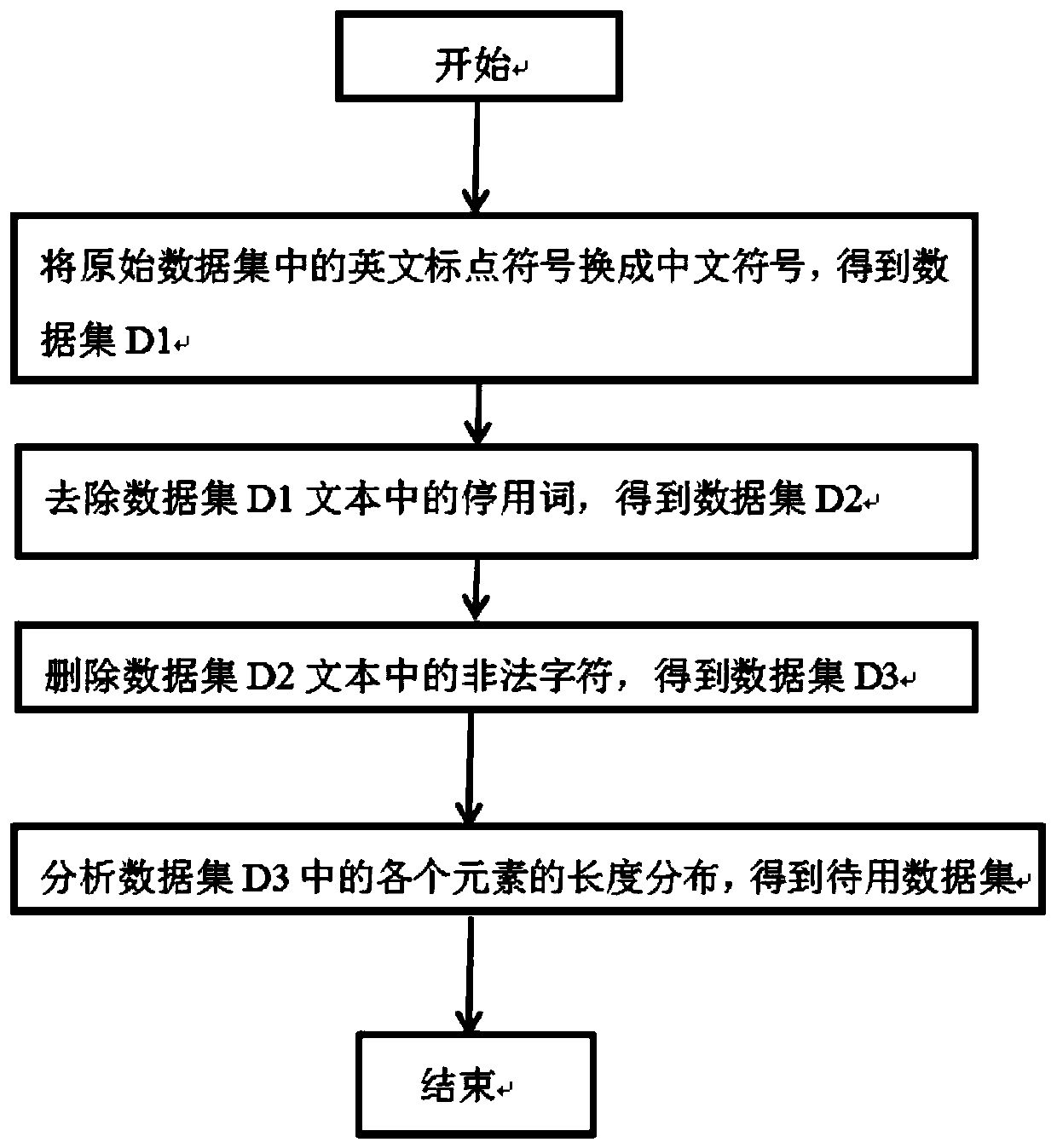

Implementation method for fusing network question and answer system based on multi-attention mechanism

ActiveCN110134771AEnhanced Representational CapabilitiesImprove accuracyDigital data information retrievalNatural language data processingData setOriginal data

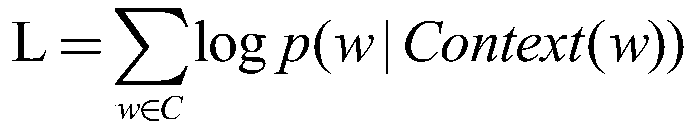

The invention discloses an implementation method of a fusion network question and answer system based on a multi-attention mechanism, which comprises the following steps of constructing a question andanswer system network model, preprocessing an original data set to obtain a standby data set, and performing text length distribution analysis; subjecting text in standby data set to one-hot vector representation, using a CBOW model to train one-hot word vector and forming a word2vec word list; adjusting the sequence length of each sentence in the text, and adding a sentence end mark; training the word2vec vector by using an ELMO language model to obtain an ELMO word vector; encoding the ELMO vector to obtain a sentence vector; performing coarse-fine granularity attention on the sentence vectors respectively to obtain memory vectors and attention vectors based on each word; carrying out vector splicing to obtain expression vectors based on words and sentences; and decoding an answer representing the vector generation question sentence. According to the method, the representation ability of sentences is improved through an ELMO language model; and various attention mechanisms are fused, so that the decision making accuracy of the system is improved, and the interpretability of the system is enhanced.

Owner:GUANGDONG UNIV OF TECH

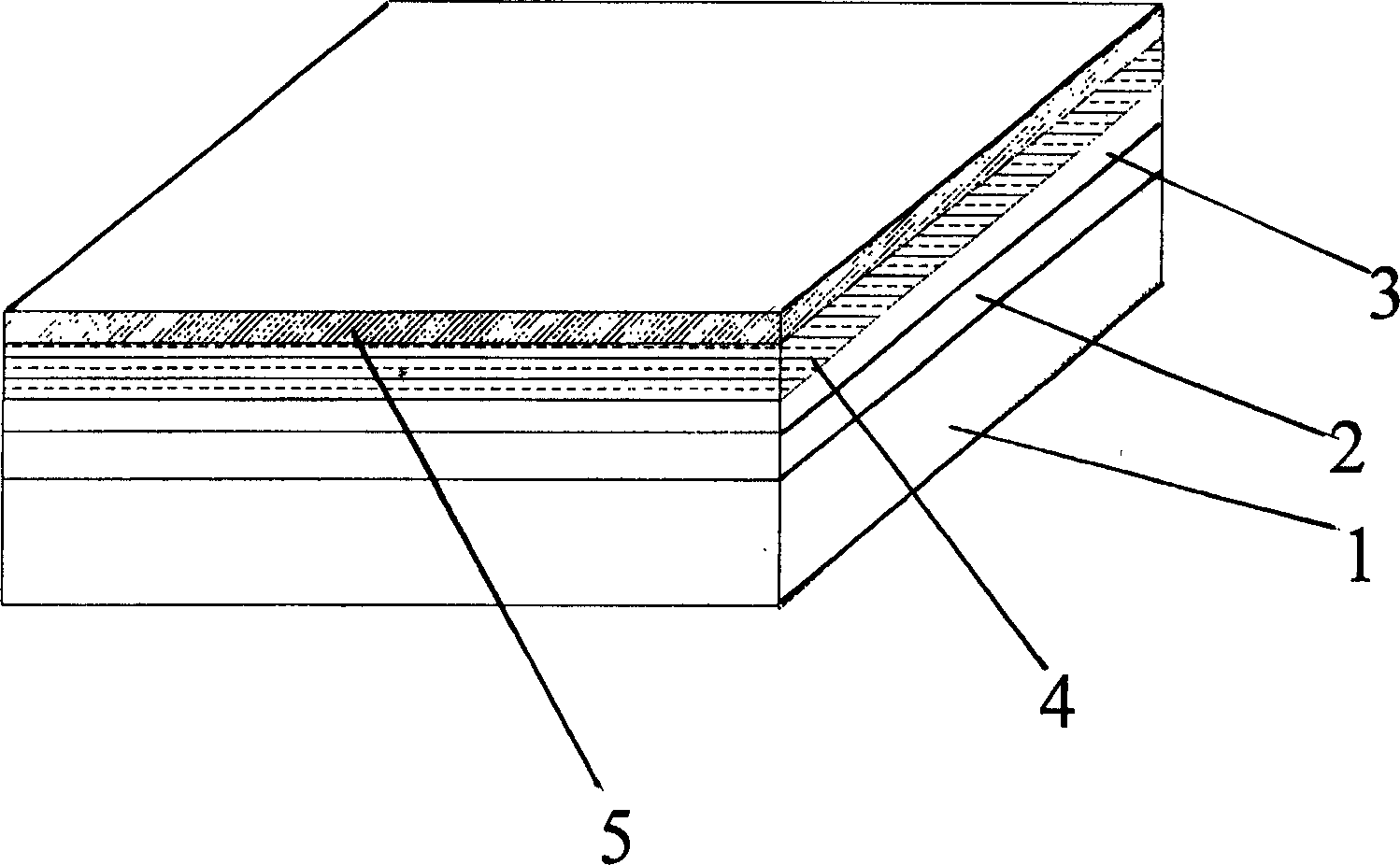

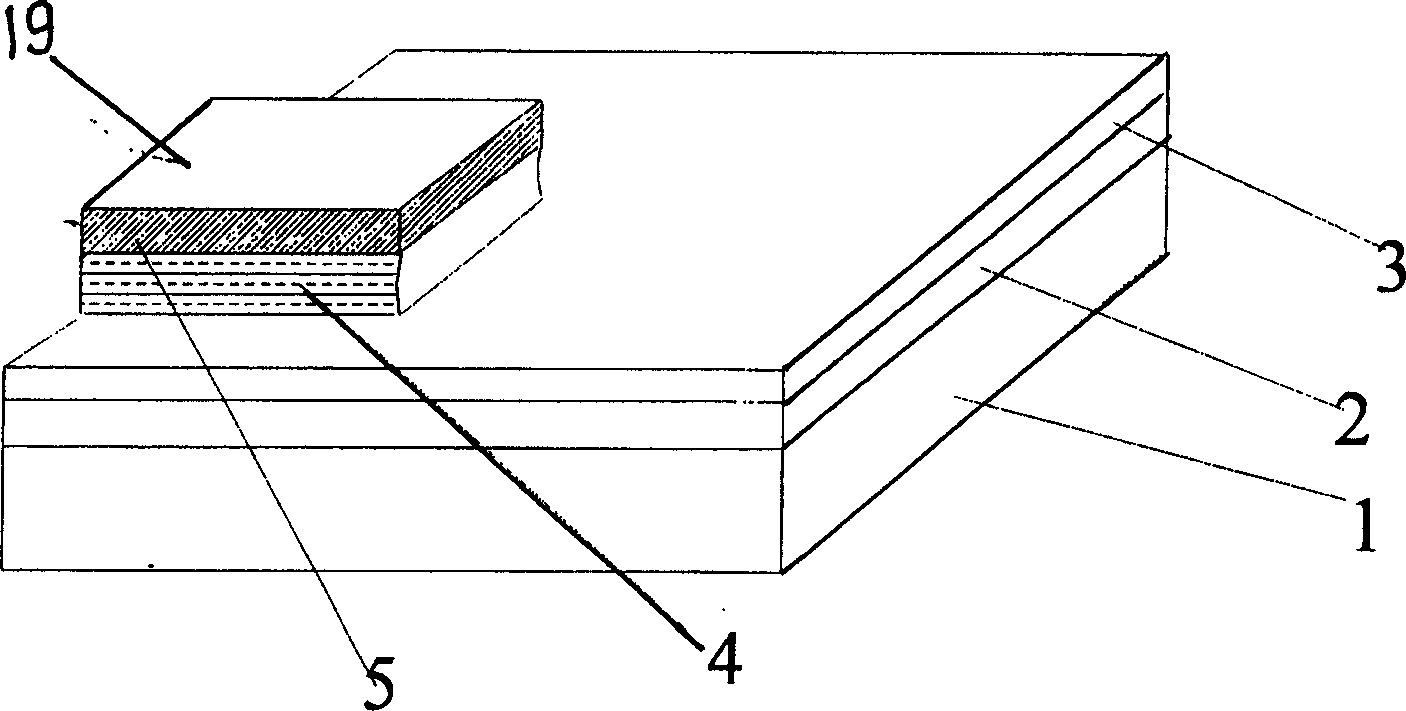

Fiber-reinforced thermoplastic resin molded article

ActiveUS7858172B2Improve accuracyGood lookingLamination ancillary operationsSynthetic resin layered productsHeat resistanceUltimate tensile strength

Provided is a fiber-reinforced thermoplastic resin molded article, which contains reinforcing fibers having a given flattened cross-sectional profile, in which the fiber length distribution of the reinforcing fibers is shifted on the side of long fibers, and which is excellent in mechanical strength, heat resistance, dimensional accuracy such as warpage resistance, and surface appearance.

Owner:MITSUBISHI ENG PLASTICS CORP

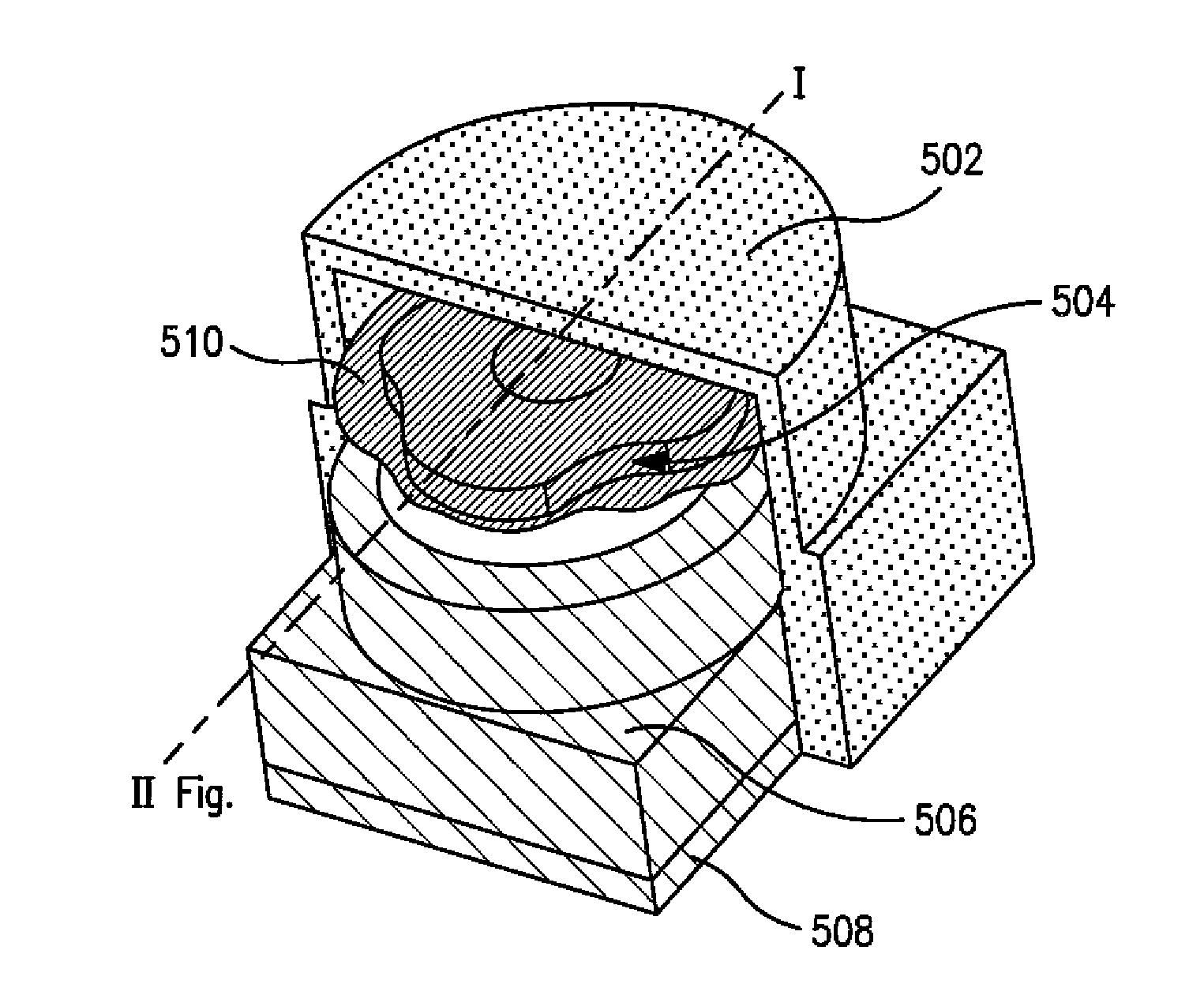

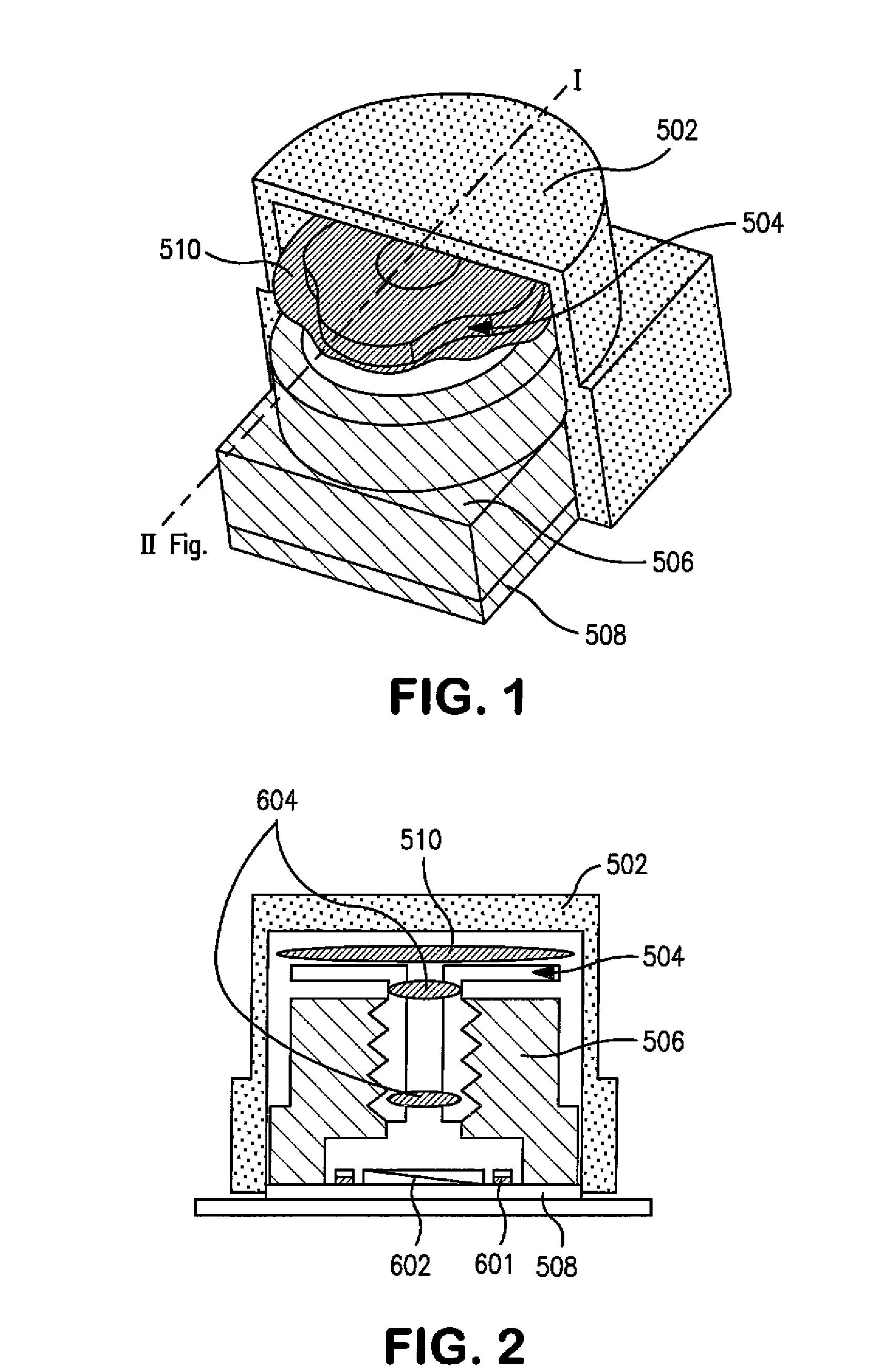

Compact camera module

Owner:TICONA LLC

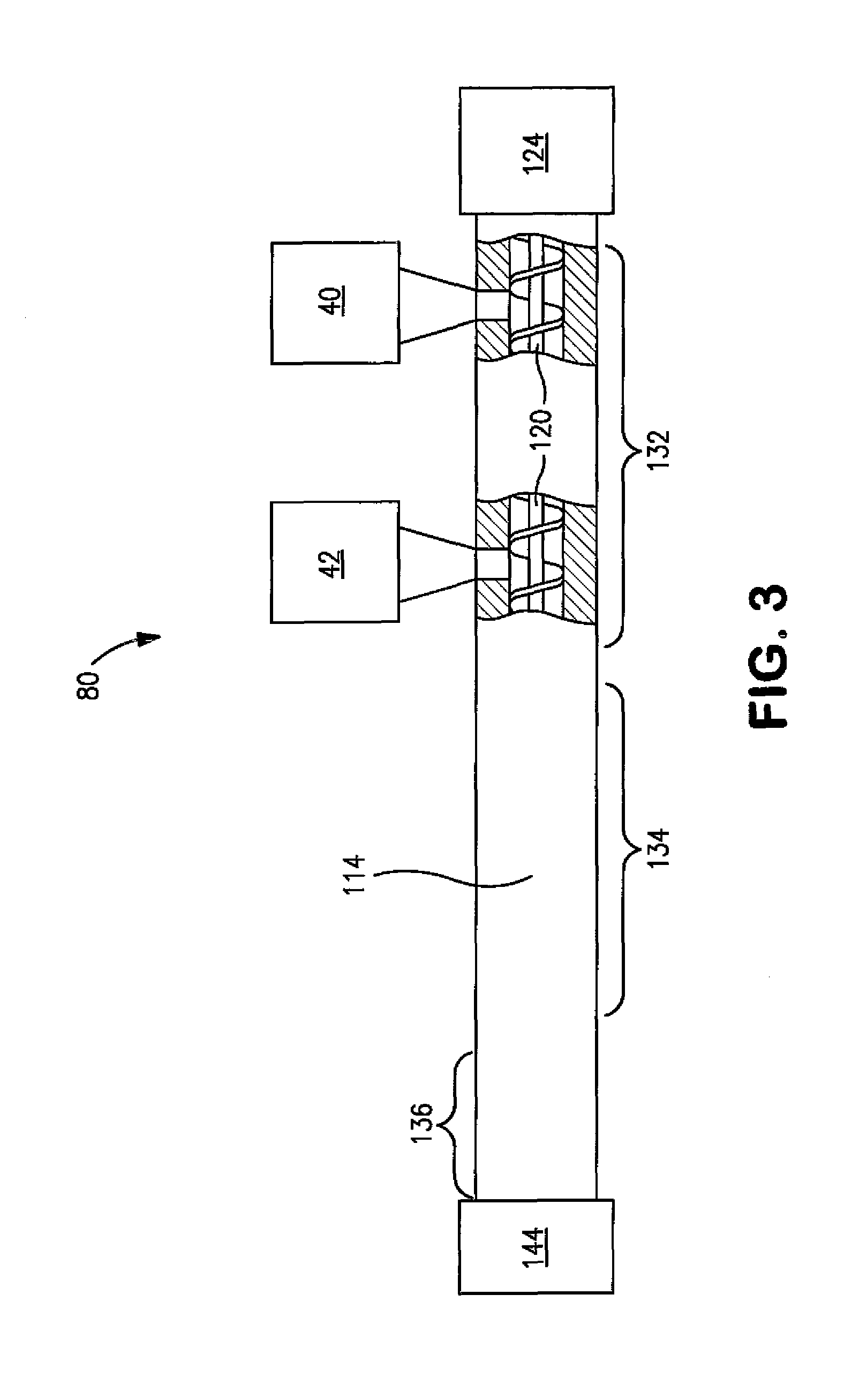

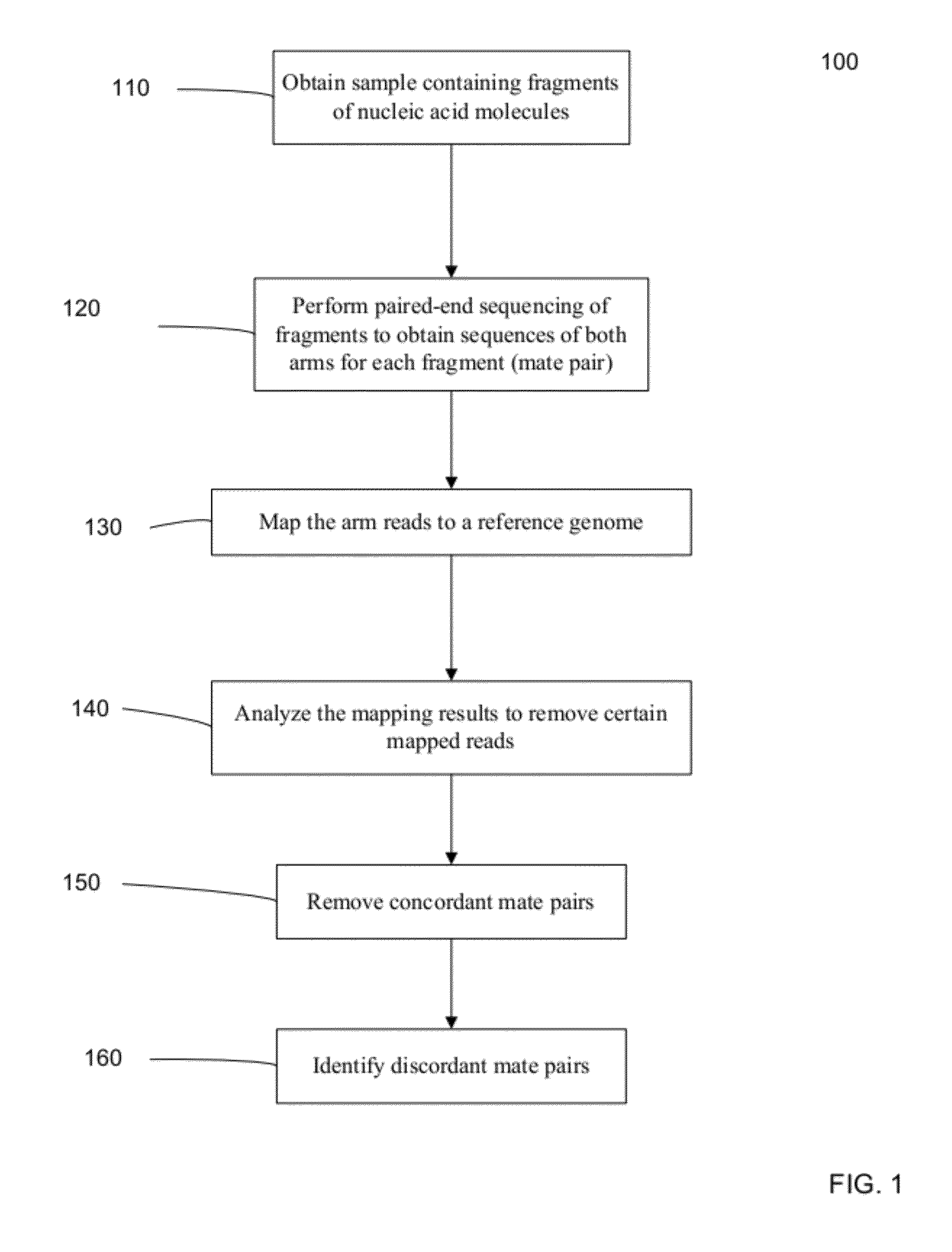

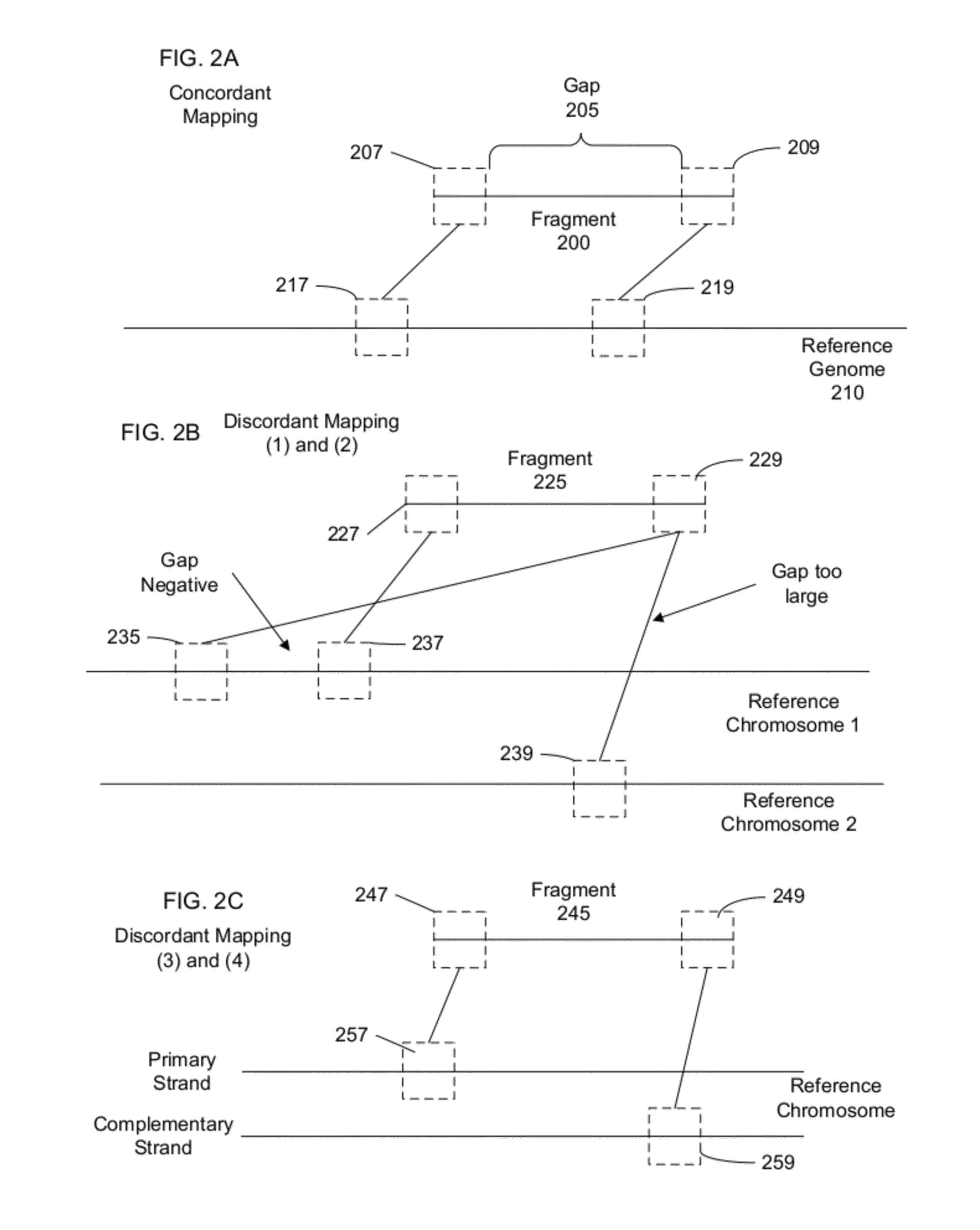

Identifying rearrangements in a sequenced genome

Methods, apparatuses, and systems for identification of junctions (e.g., resulting from large-scale rearrangements) of a sequenced genome with respect to a human genome reference sequence is provided. For example, false positives can be distinguished from actual junctions. Such false positives can result from many sources, including mismapping, chimeric reactions among the DNA of a sample, and problems with the reference genome. As part of the filtering processes, a base pair resolution (or near base pair resolution) of a junction can be provided. In various implementations, junctions can be identified using discordant mate pairs and / or using a statistical analysis of the length distributions of fragments for local regions of the sample genome. Clinically significant junctions can also be identified so that further analysis can be focused on genomic regions that may have more of an impact on the health of a patient.

Owner:COMPLETE GENOMICS INC

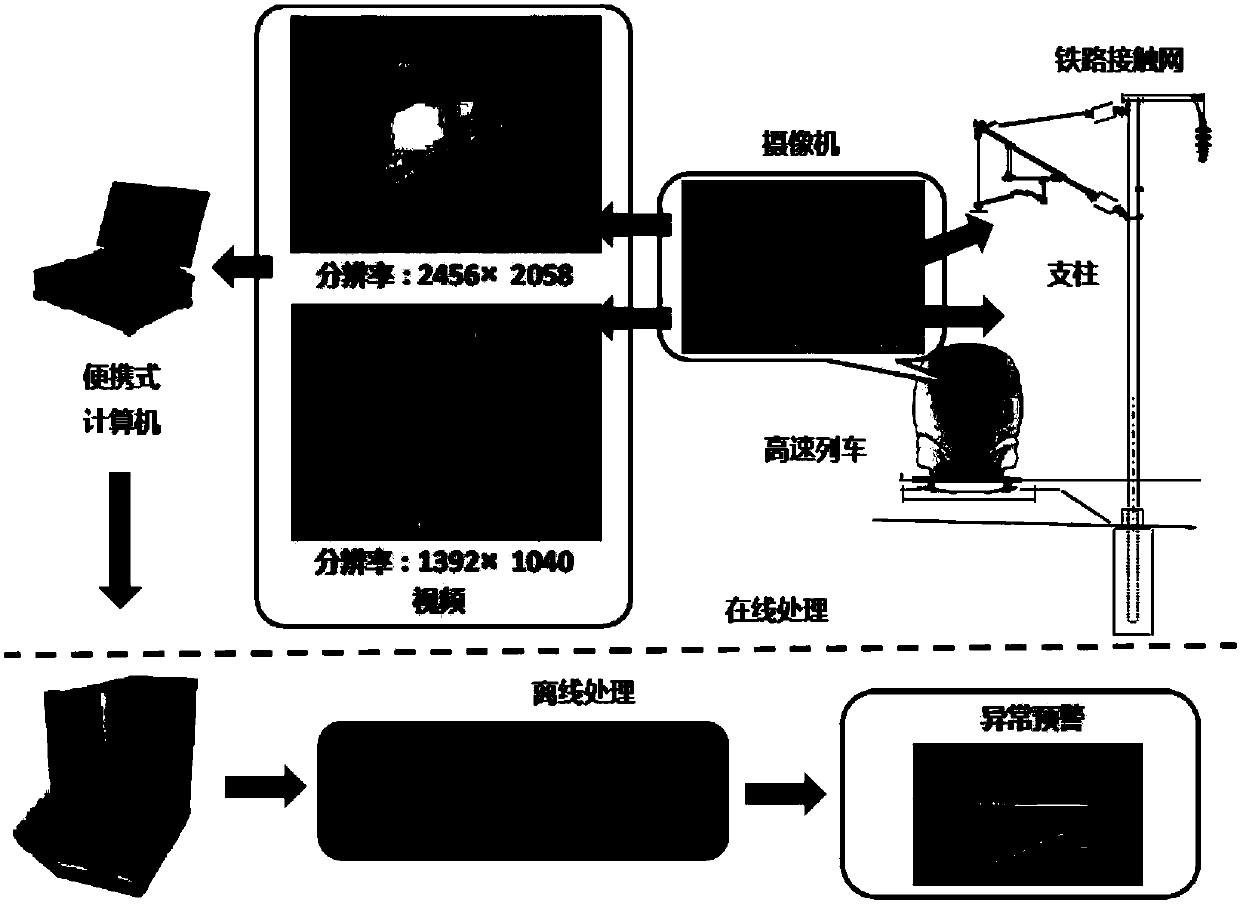

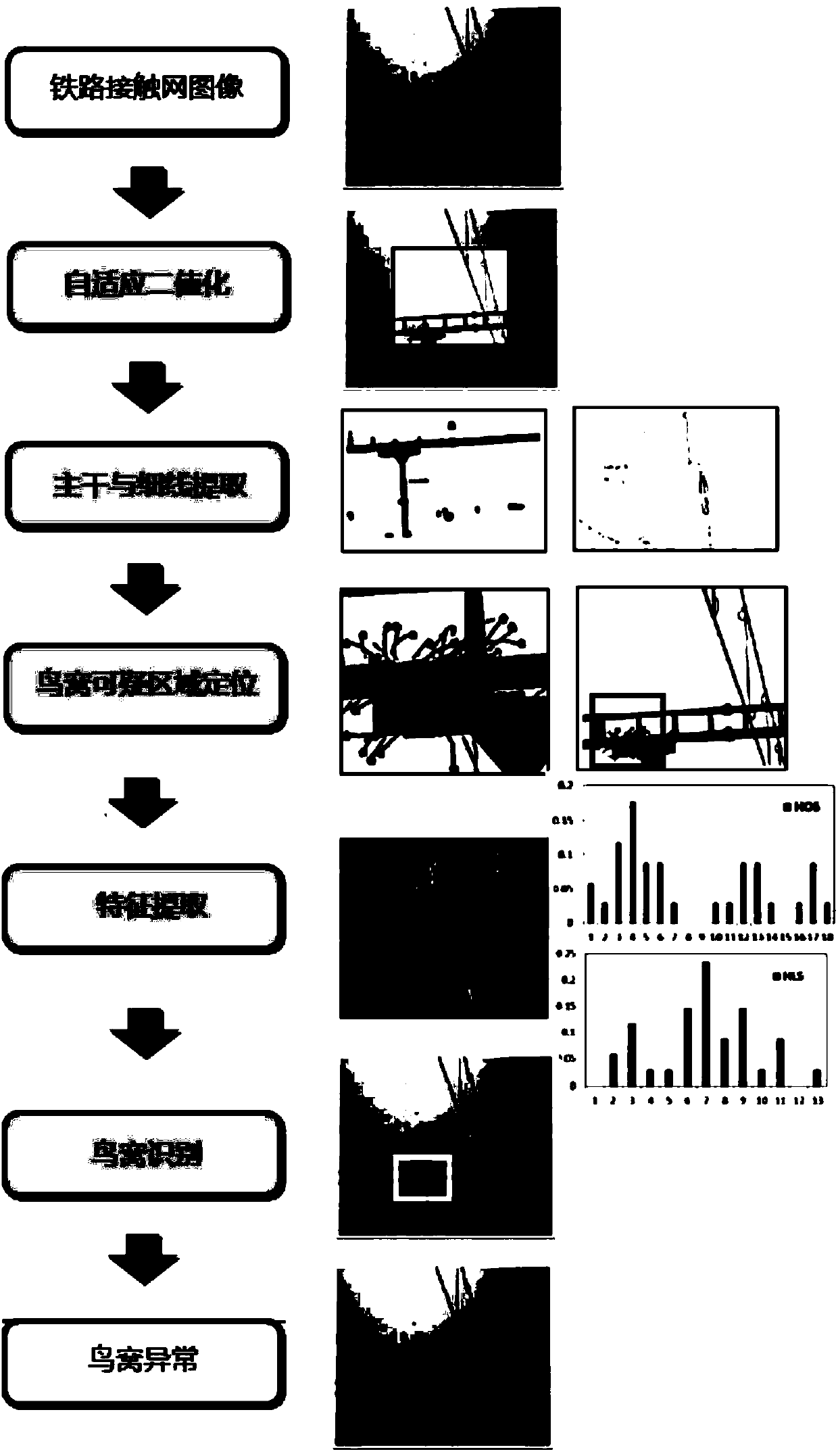

Image-based railway contact net bird-nest abnormal condition detection method

ActiveCN103745224AHold image informationConvenience to workCharacter and pattern recognitionFine lineFeature extraction

The invention discloses an image-based railway contact net bird-nest abnormal condition detection method. According to the invention, an abnormal condition that there exists a bird nest in a railway contact net patrol image is automatically identified by a digital image processing method. The method provided by the invention comprises the following main steps: 1) image binaryzation of the railway contact net; 2) extraction of pillar main parts and fine lines of the contact net; 3) bird nest suspicious area location based on suspension point detection; 4) feature extraction of linear direction histogram and length histogram of a bird nest suspicious area; and 5) bird nest identification based on linear direction and length distribution characteristics. By the method provided by the invention, bird nest abnormal condition detection and identification of the railway contact net are carried out efficiently and automatically. The method has great safety significance as well as practical application value, is suitable for automatic inspection of high-speed rail and common railway contact nets, can effectively help an inspector rapidly find whether there exists a bird nest on a support of a contact net and troubleshoot potential safety hazard, is adopted to raise work efficiency of inspectors and avoid huge manpower consumption caused by manual interpretation.

Owner:SOUTHWEST JIAOTONG UNIV

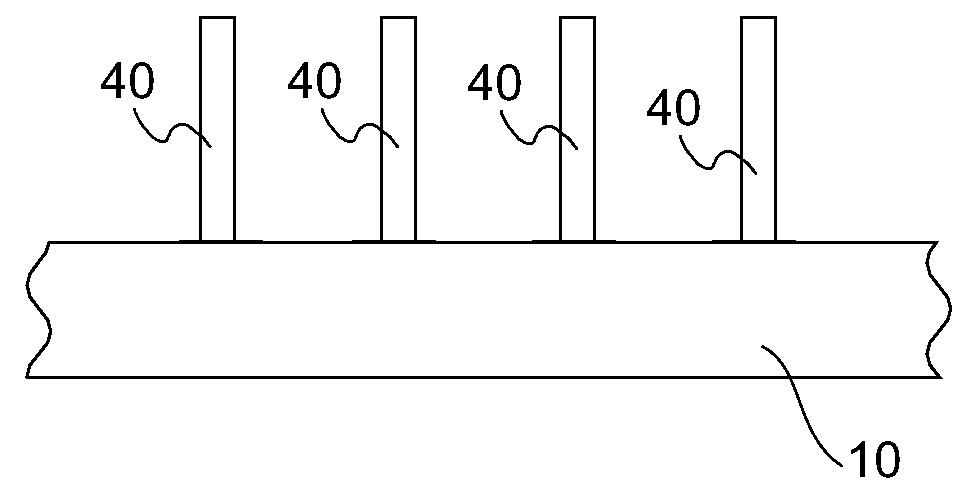

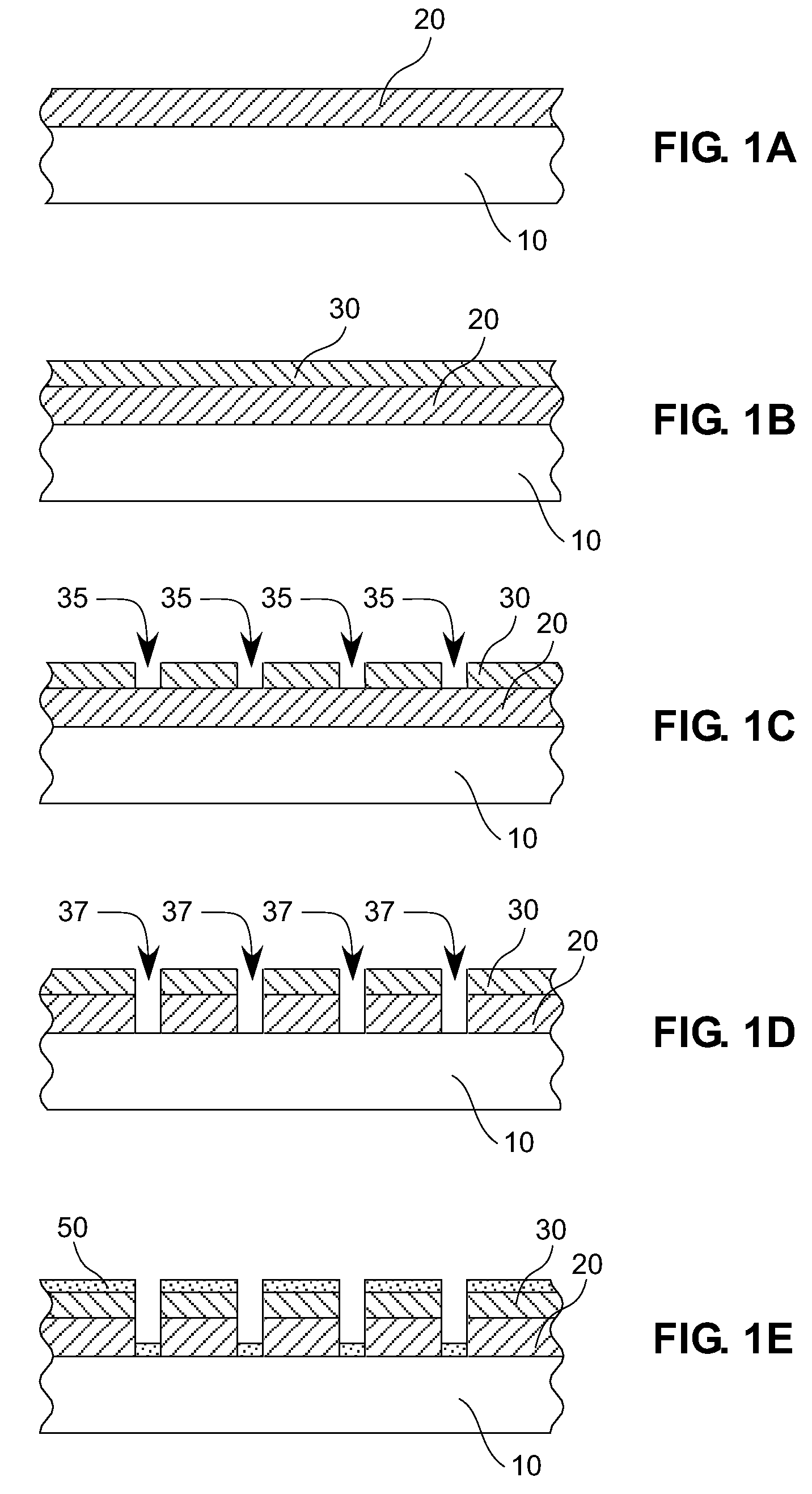

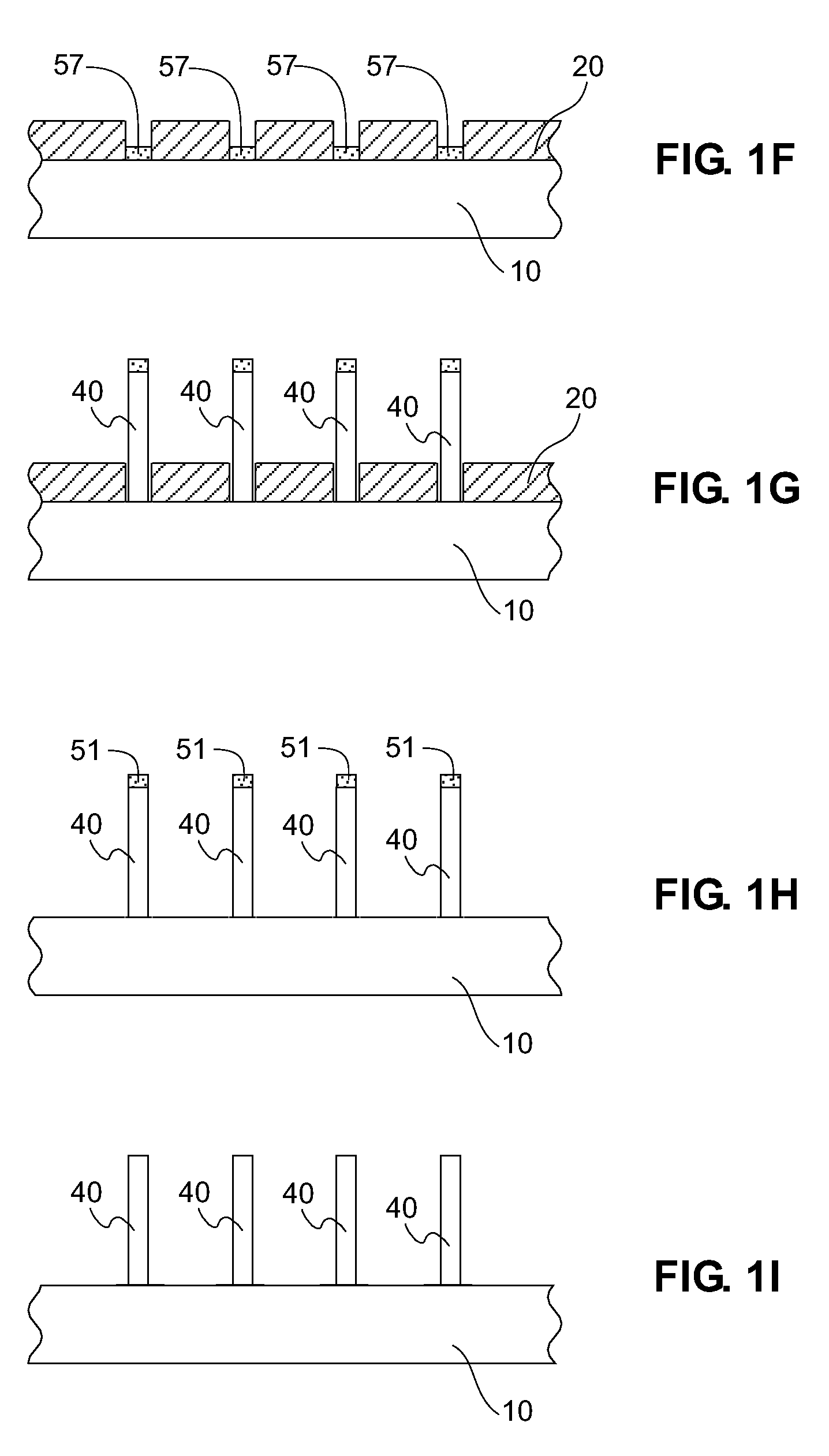

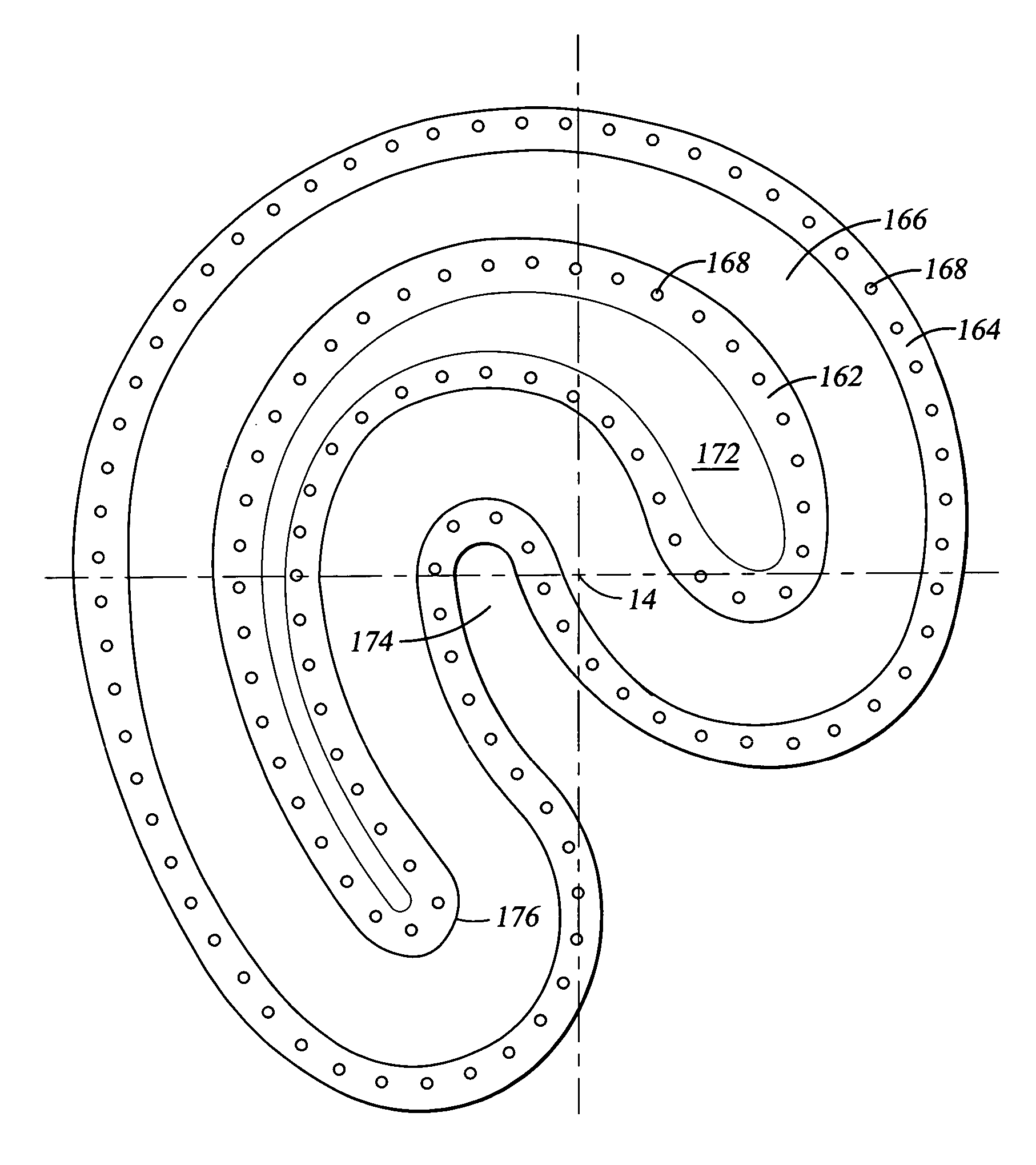

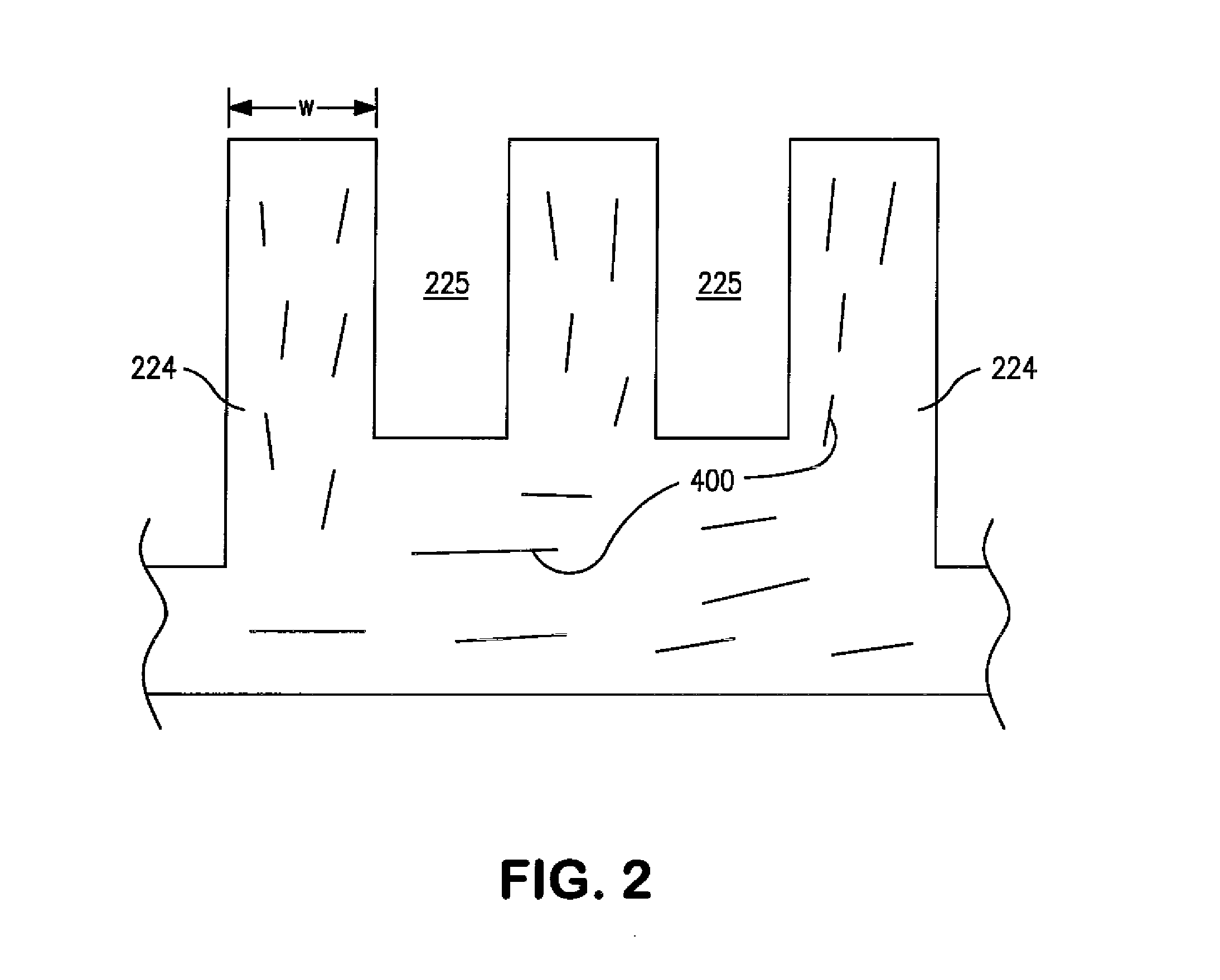

STRUCTURES OF AND METHODS FOR FORMING VERTICALLY ALIGNED Si WIRE ARRAYS

ActiveUS20090020853A1Narrow diameterNarrow length distributionMaterial nanotechnologyPolycrystalline material growthEngineeringLength distribution

A structure consisting of vertically aligned wire arrays on a Si substrate and a method for producing such wire arrays. The wire arrays are fabricated and positioned on a substrate with an orientation and density particularly adapted for conversion of received light to energy. A patterned oxide layer is used to provide for wire arrays that exhibit narrow diameter and length distribution and provide for controlled wire position.

Owner:CALIFORNIA INST OF TECH

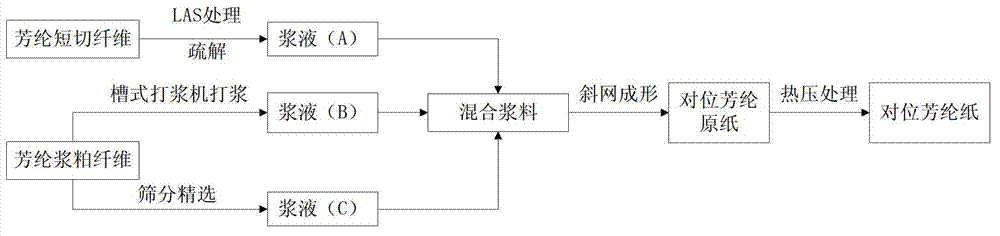

Para-aramid paper and preparation method thereof

ActiveCN102864677AReduce water repellencyImprove dispersion compatibilitySynthetic cellulose/non-cellulose material pulp/paperPapermakingAramid

The invention discloses Para-aramid paper and a preparation method thereof. By adding Para-aramid pulp size, sieved and selected from pulp fiber, of 50-100 meshes to form mixed size, fiber length and width distribution span of aramid pulp fiber is reduced, and obtained pulp fiber is concentrated in length distribution and width distribution, and have larger specific surface area. When the obtained pulp fiber is used with chopped fiber for papermaking with pulp, the obtained pulp fiber can be served as filler to combine with the chopped fiber better, paper sheet gap is filled, combination of fiber after hot pressing is tighter, combination of fiber is enhanced, paper sheet gap is reduced, evenness of finished paper is increased evidently, mechanical strength and compression strength of aramid paper are improved, paper breaking during papermaking is reduced, speed of a paper machine is increased, production efficiency is improved, and adverse effects to paper sheet performance due to introduction of a third binding fiber is avoided.

Owner:SHAANXI UNIV OF SCI & TECH

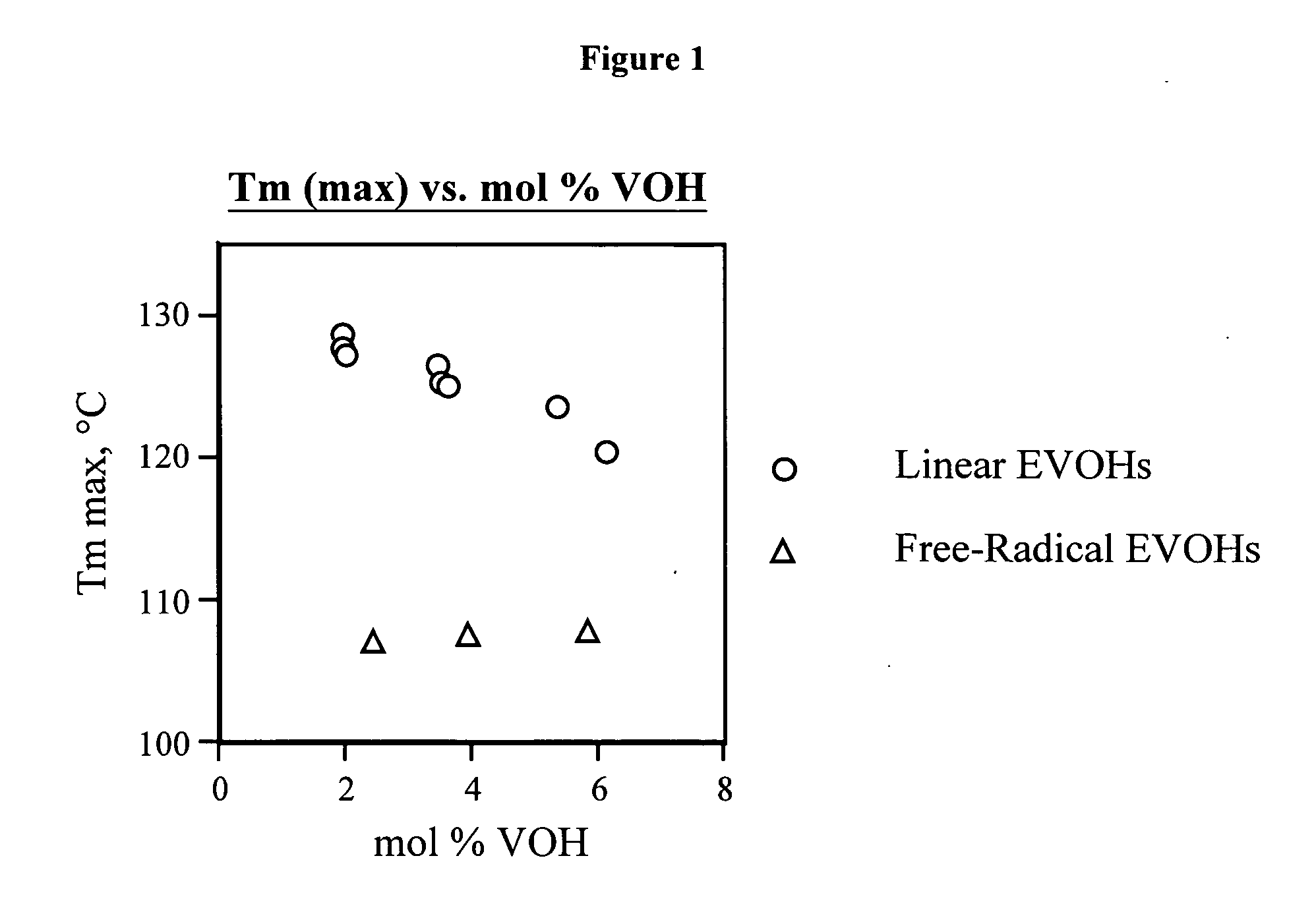

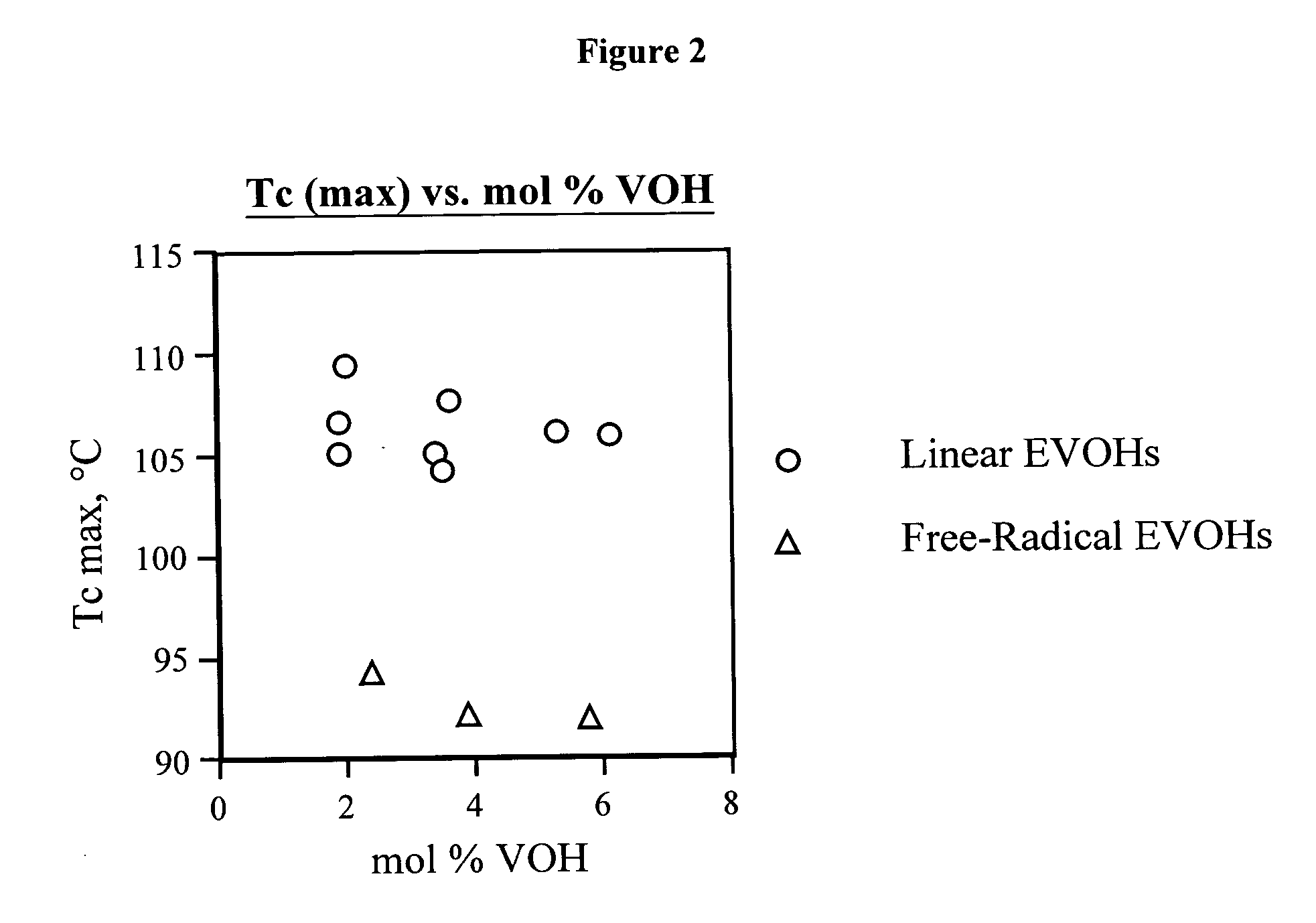

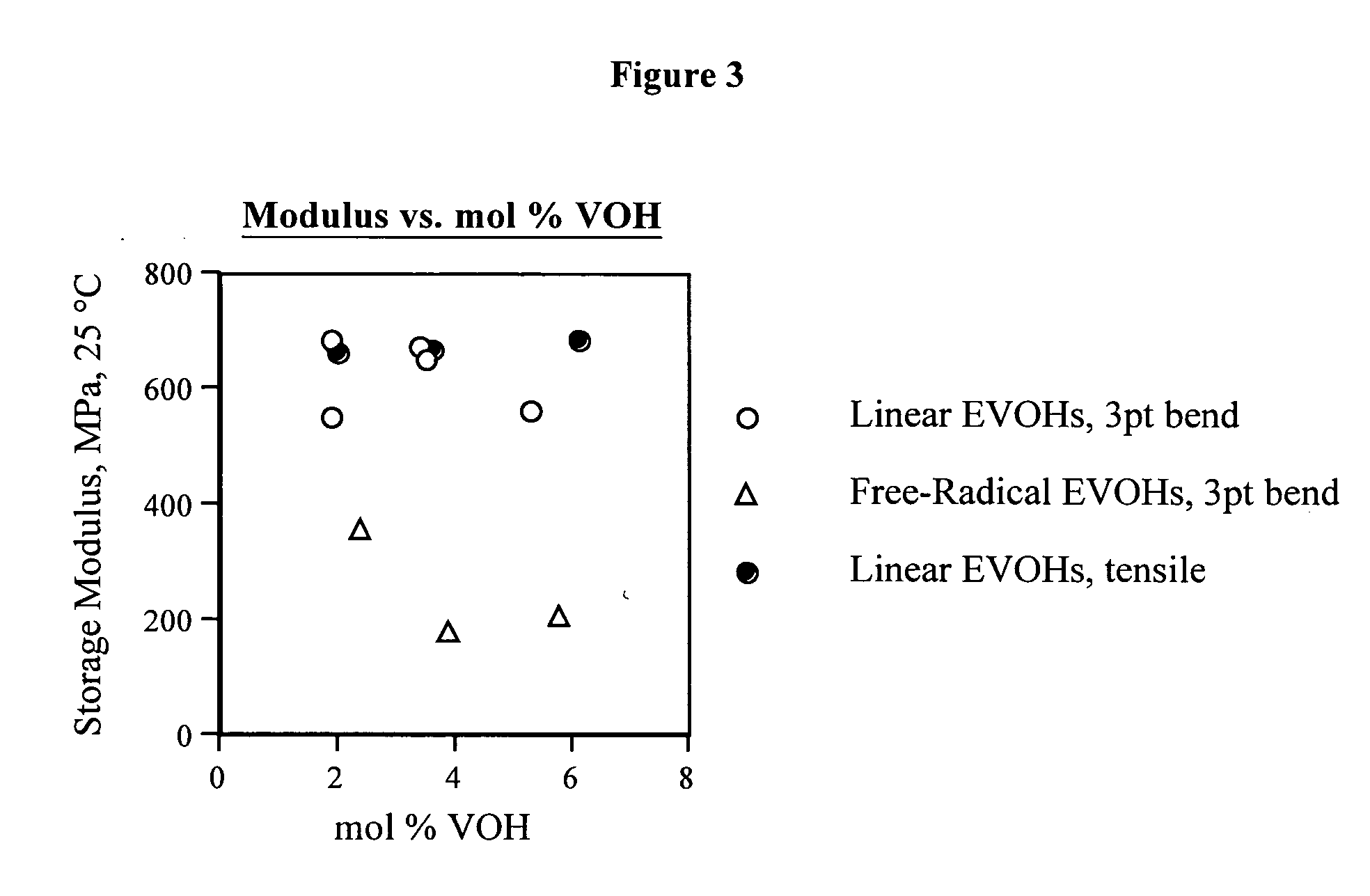

Linear functional copolymers of ethylene with precise and minimum run length distributions and method of making thereof

The present invention is related to a linear functional polymer having repeating units A, B and D. Unit A represents —CH2—, unit B represents and unit D represents where R1 represents a polar functional group. There are at least four A units separating each B unit, each D unit, and each B and D unit. The value y represents the total number of B units and is an integer greater than or equal to 1. The total number of D units is represented by h and is an integer greater than or equal to 0. And x represents the total number of A units and is an integer sufficient that the molar fraction of the B and D units in the linear functional polymer is represented by a value j defined by the equation: j=y+hx+y+h≤0.032.The present invention is also directed to a method for preparing such linear functional polymers by copolymerizing a first polar substituted monomer and a second non-polar unsubstituted monomer.

Owner:EXXON RES & ENG CO

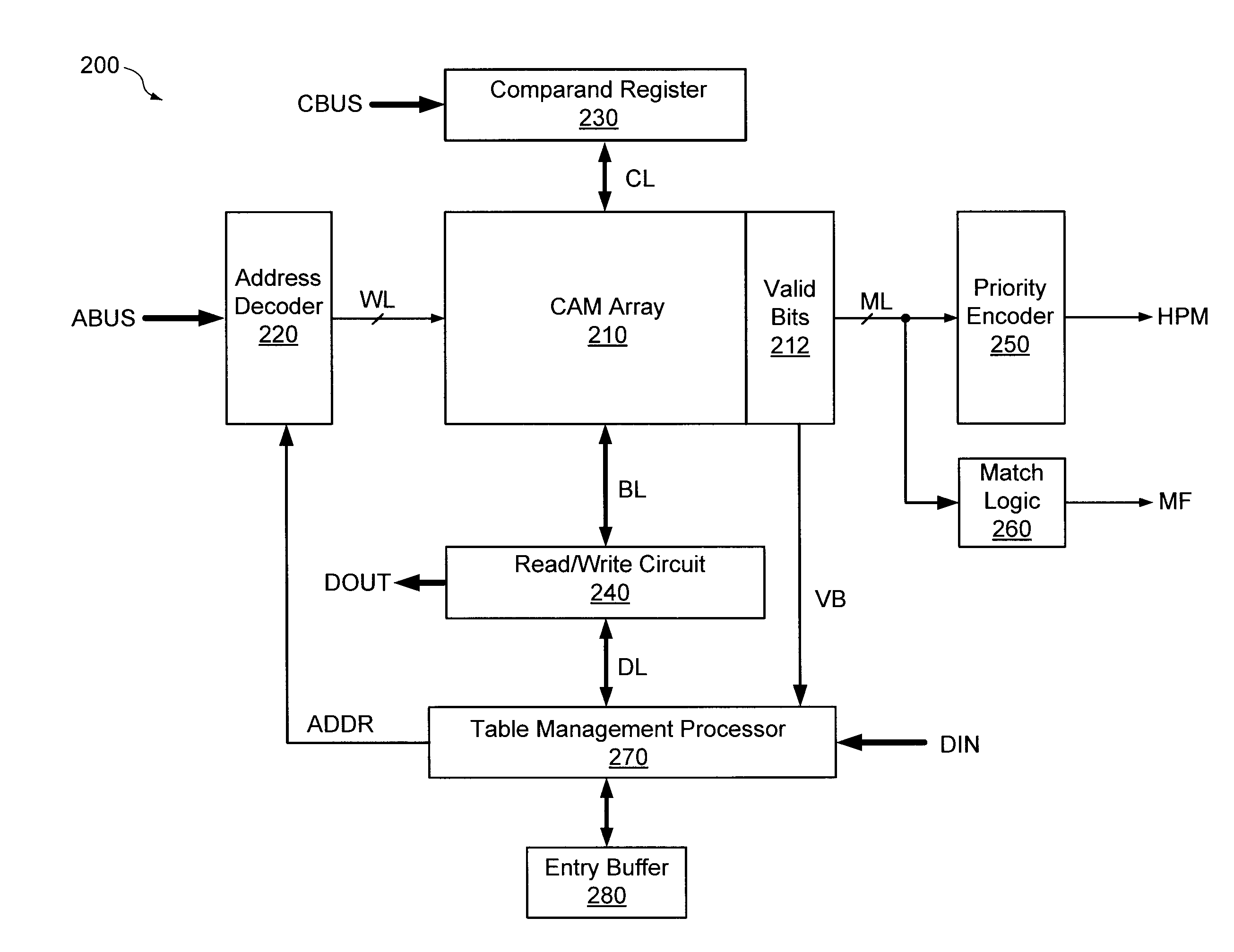

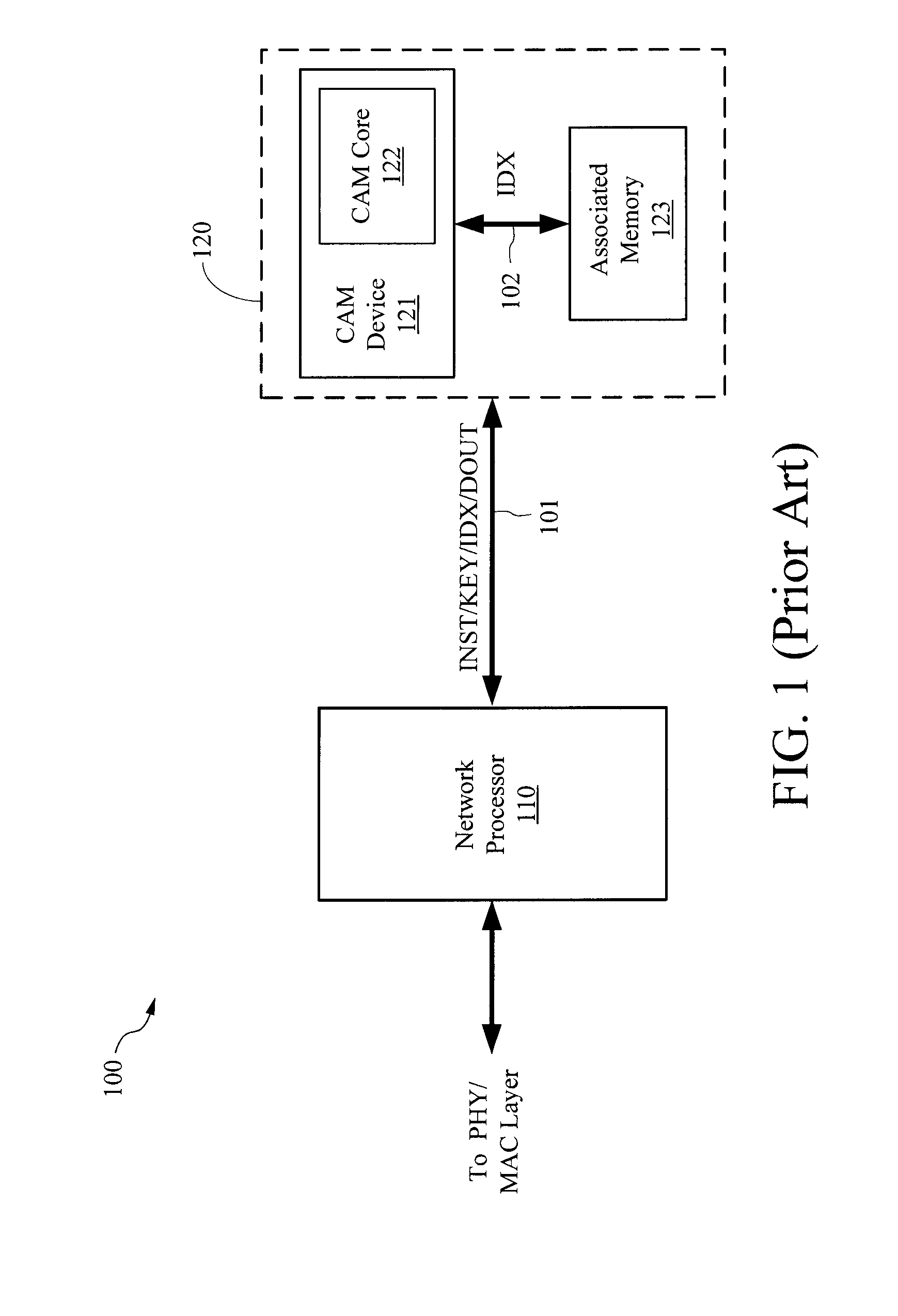

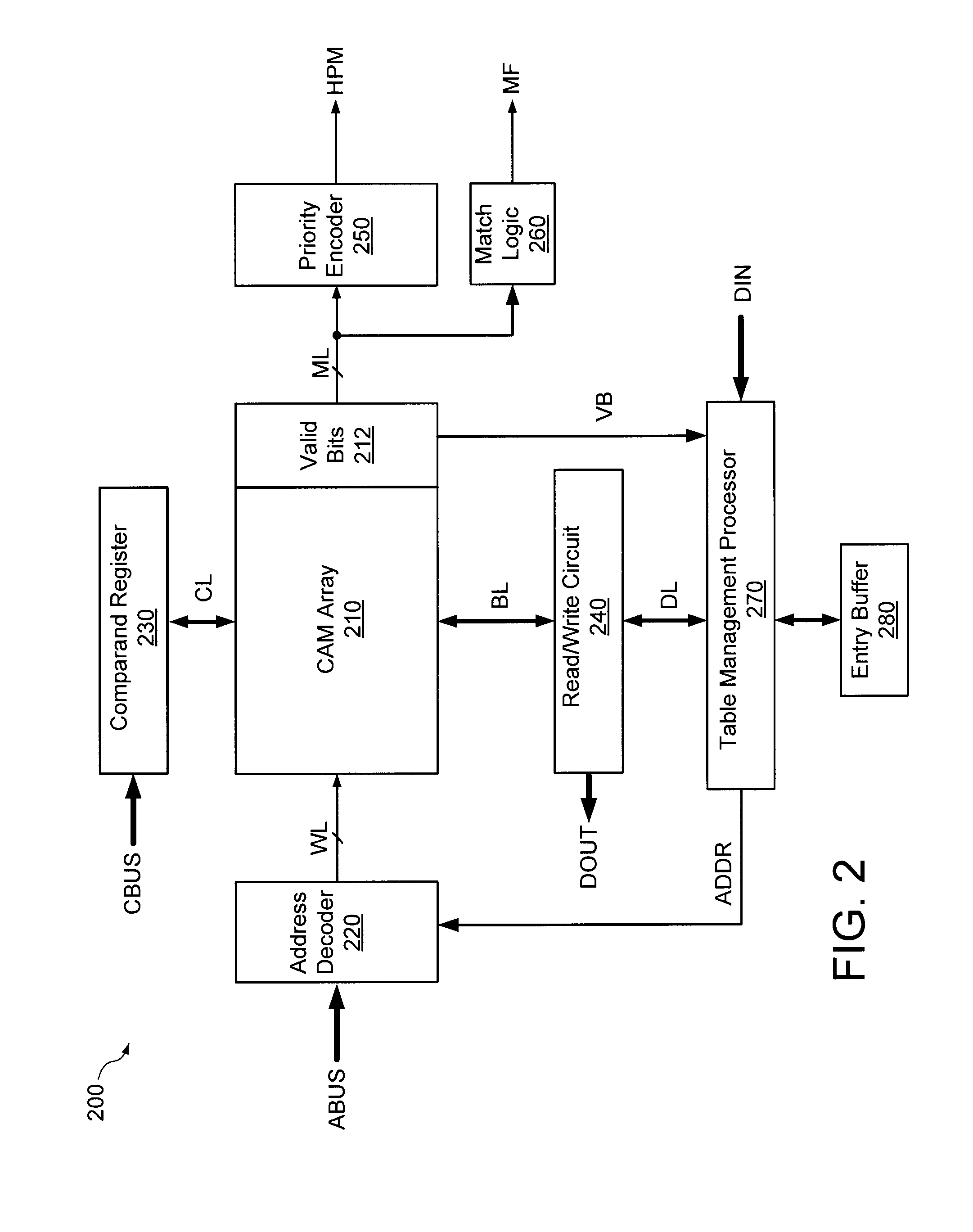

Updating cam arrays using prefix length distribution prediction

InactiveUS20110283061A1Digital storageMemory systemsTheoretical computer scienceTernary content addressable memory

A method and apparatus for ordering a plurality (P) of entries having various prefix lengths for storage in a number (T) of available storage locations in a content addressable memory (CAM) array according to the prefix lengths is disclosed. Initially, a first number (N) of the entries of selected and used to generate a distribution graph of their prefix lengths. Then, for each unique prefix length, a corresponding subset of the T storage locations in the CAM array are allocated according to a predicted prefix length distribution indicated by the distribution graph. Then, all of the entries are stored in the corresponding allocated storage locations according to prefix length.

Owner:AVAGO TECH WIRELESS IP SINGAPORE PTE

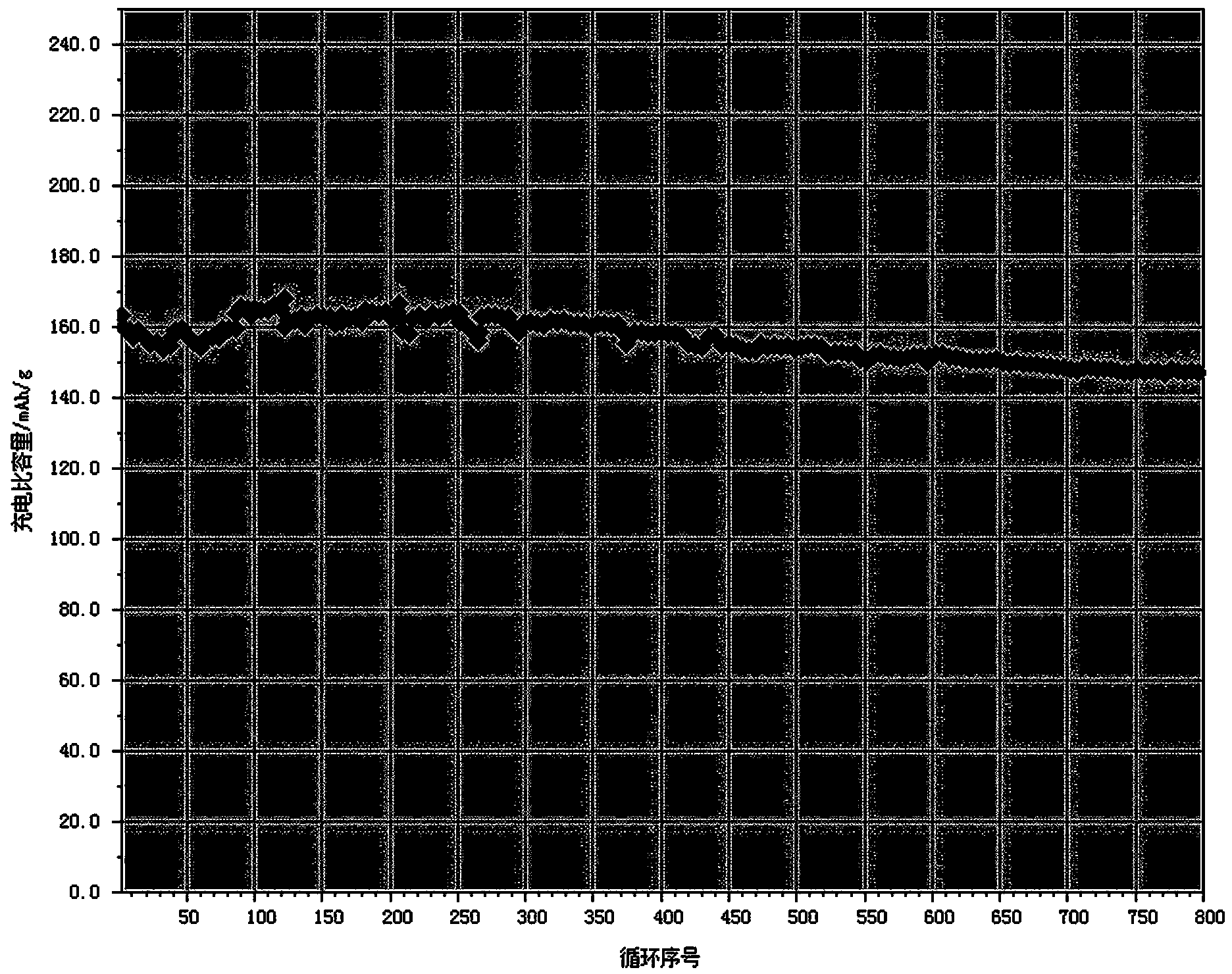

Method for preparing carbon-coated lithium titanate negative electrode material for lithium battery

ActiveCN103730649AMolecular weight controllableSmall molecular weight distributionCell electrodesCarbon layerPolymer science

The invention discloses a method for preparing a carbon-coated lithium titanate negative electrode material for a lithium battery. The method comprises the following steps: preparing a polymer with controllable molecular weight by adopting living polymerization, performing ball milling and mixing with raw materials of lithium titanate, and sintering to obtain a lithium titanate material coated with a conductive carbon layer. The adopted polymerization method has the advantages that range of optional monomers is wide, polymers of different carbon chain lengths can be obtained by adjusting the raw material ratio, the carbon chain length distribution is uniform, and the finally obtained carbon-coated lithium titanate material is uniform and stable in performance. Moreover, the initial charge specific capacity of the obtained lithium titanate material reaches over 160mAh / g under the rate of 1C (1C=175mA / g), and the capacity is kept over 90 percent due to cycle of 800 times.

Owner:中国东方电气集团有限公司

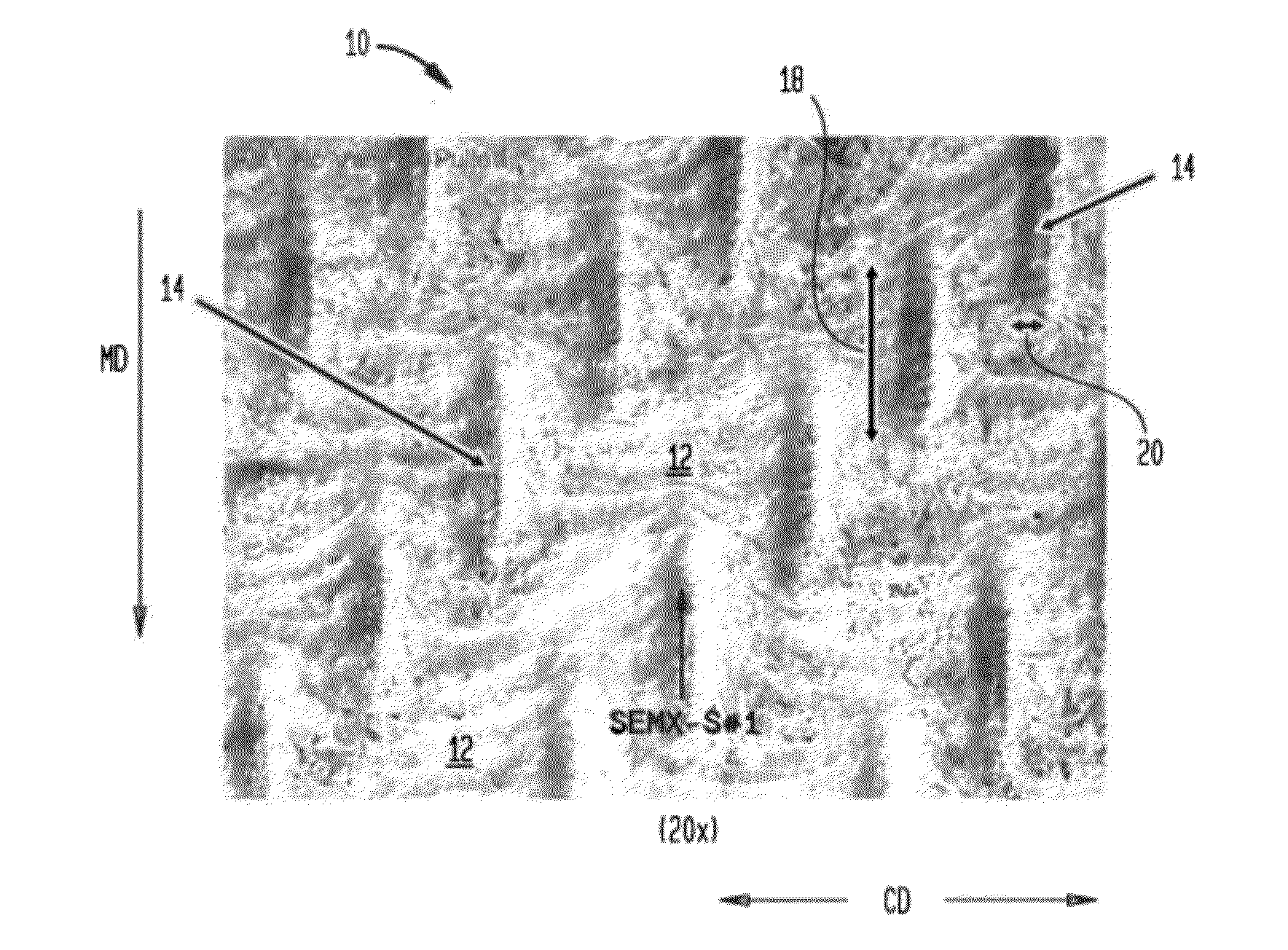

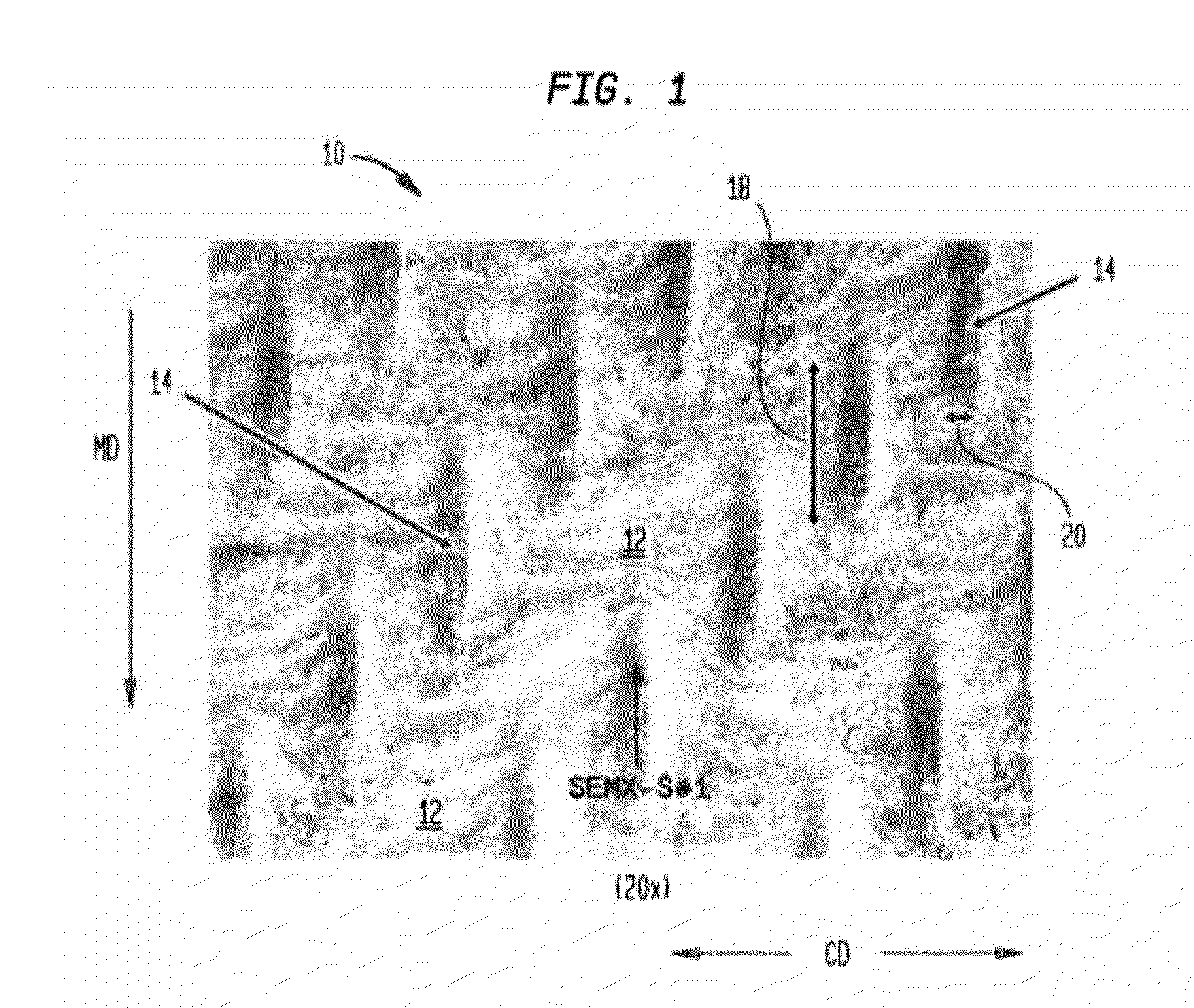

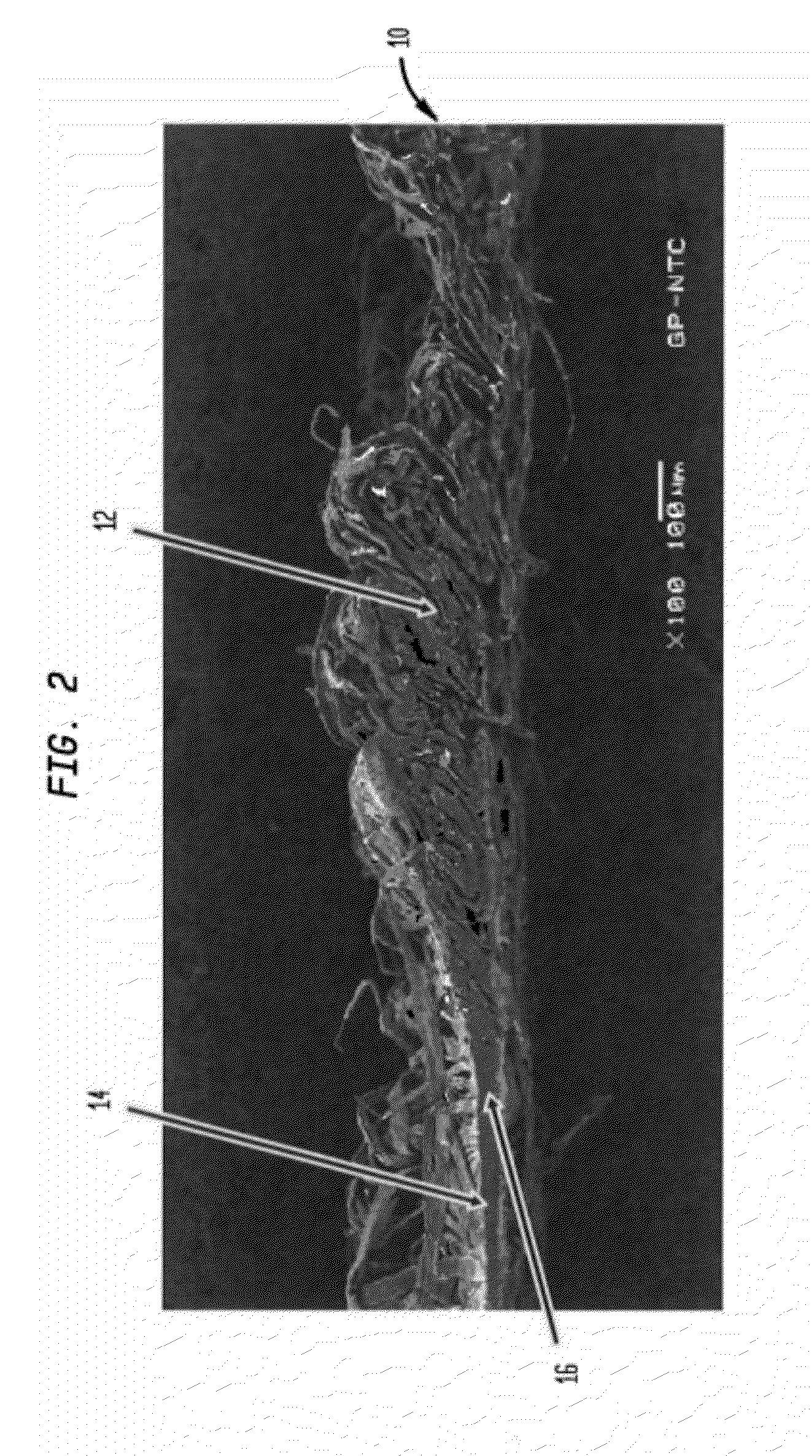

Absorbent Sheet of Cellulosic Fibers

ActiveUS20120145342A1Improve water absorptionSurprising softnessCellulosic pulp after-treatmentNon-fibrous pulp additionCellulose fiberEngineering

An absorbent sheet of cellulosic fibers includes a mixture of hardwood fibers and softwood fibers arranged in a reticulum having (i) a plurality of pileated fiber enriched regions of a relatively high local basis weight each extending a distance in the cross-machine direction (CD) of the sheet and interconnected by way of (ii) a plurality of lower local basis weight linking regions that each extend a distance in the machine direction (MD) of the sheet and whose fiber orientation is biased along the direction between pileated regions interconnected thereby. The relative basis weight, degree of pileation, hardwood to softwood ratio, fiber length distribution, fiber orientation, and geometry of the reticulum are controlled such that the sheet exhibits a percent CD stretch that is at least about 2.75 times the machine direction to cross-machine direction (MD / CD) dry tensile ratio of the sheet.

Owner:GPCP IP HLDG LLC

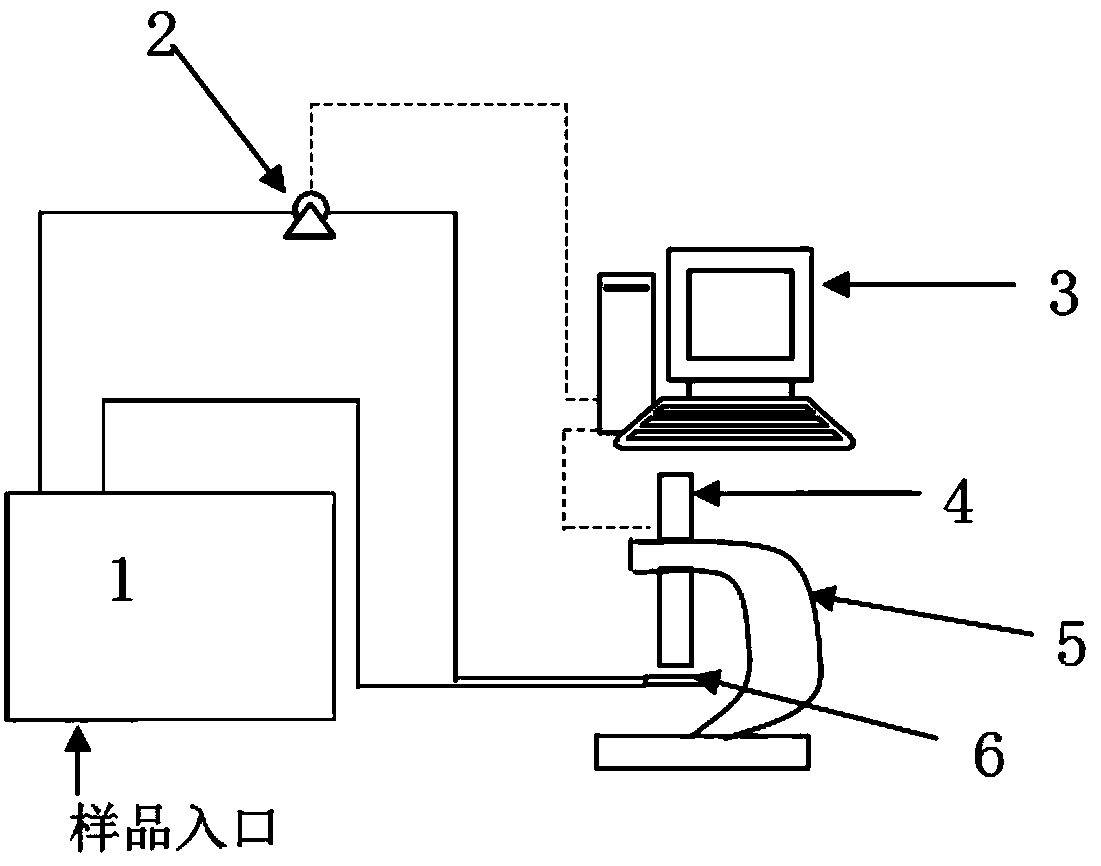

Active sludge online computer image analysis early warning system and an active sludge online computer image analyzing and early warning method thereof

InactiveCN103630473ARapid quantitative assayReduce subjectivityParticle size analysisActivated sludgePeristaltic pump

The invention relates to an active sludge online computer image analysis and early warning system and an active sludge online computer image analysis and early warning method thereof. The system consists of a sample diluter, a peristaltic pump, a computer, a high-speed camera, a microscope and a sample chamber. The method comprises the steps of acquiring a morphological image of a sample firstly and then processing the acquired image; analyzing floc size distribution and filamentous bacterium length distribution; associating the floc particle size distribution and filamentous bacterium length distribution of active sludge with settling properties of the active sludge so as to perform early warning on the settling effect of the active sludge.

Owner:YANGZHOU UNIV

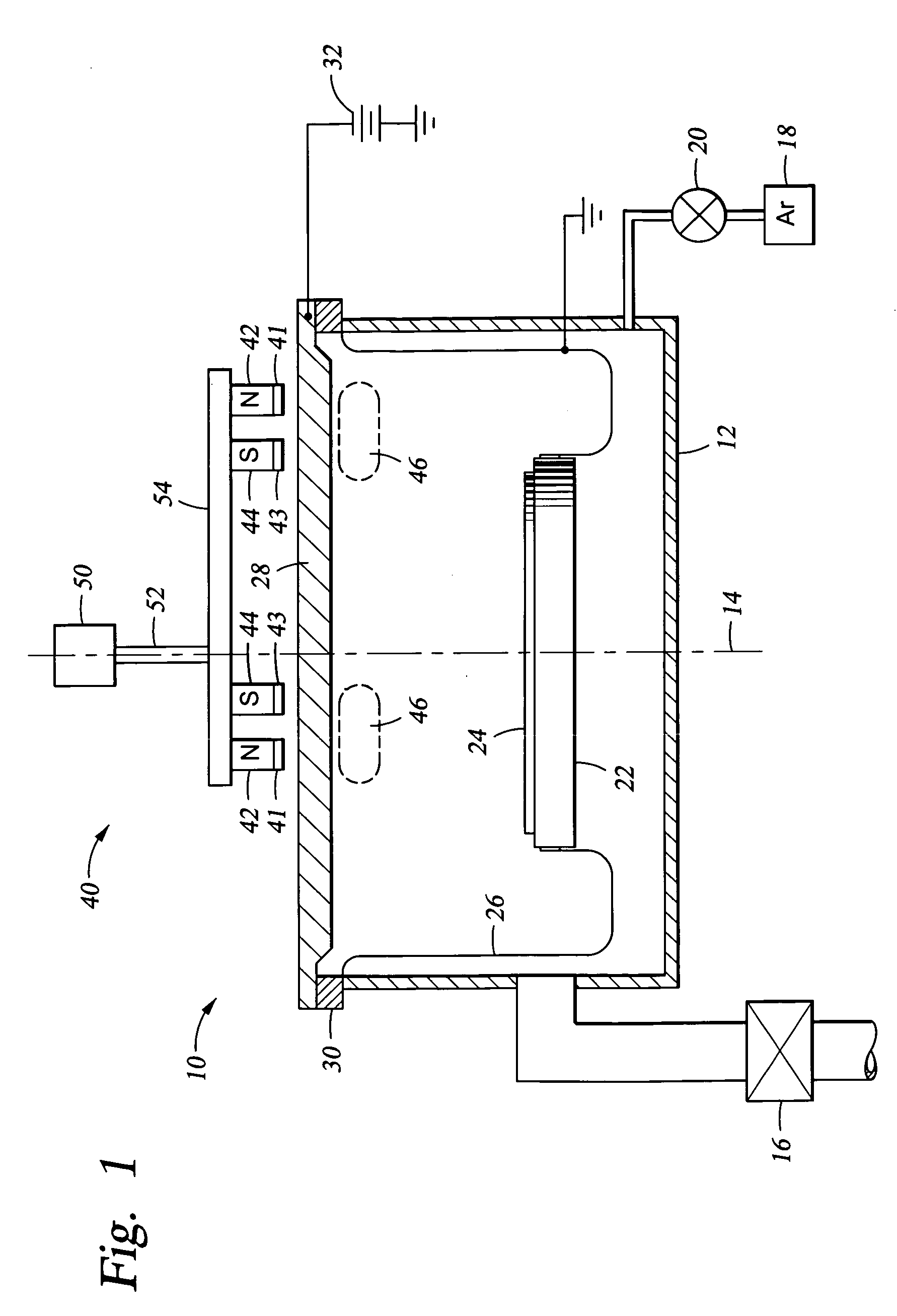

Multi-track magnetron exhibiting more uniform deposition and reduced rotational asymmetry

Owner:APPLIED MATERIALS INC

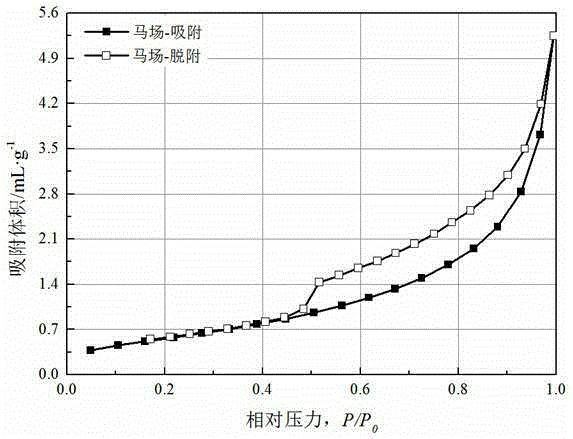

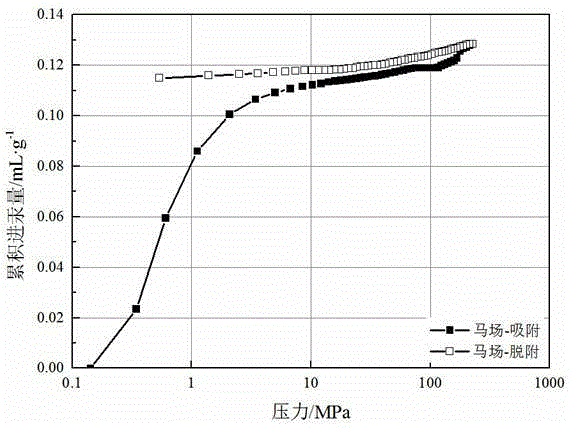

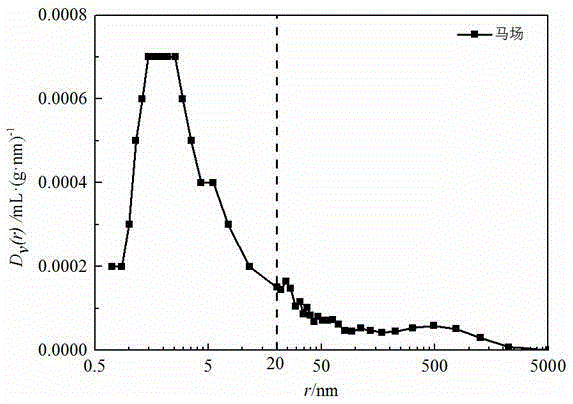

Coal full-pore-diameter measuring and pore shape semi-quantifying method

The invention discloses a coal full-pore-diameter measuring and pore shape semi-quantifying method. A mercury intrusion method and a liquid nitrogen adsorption method are organically combined to analyze the change condition of the coal pore volume along with the grain size change, a mercury intrusion method is selected for measuring the pore diameter section larger than 20 nm, a liquid nitrogen adsorption method is used for measuring the pore diameter section smaller than 20 nm, a theoretical calculation method is adopted for obtaining the number of particles contained in each gram of coal, then the full-pore-diameter pore volume distribution characteristic of single-particle coal is obtained, the pore length distribution data of the single-particle coal are obtained through a theoretical calculation formula, and a semi-quantitative coal pore shape is obtained through the coal pore shape distribution characteristic. A more visual observation method is provided for researching adsorption or desorption in gas in coal.

Owner:TAIYUAN UNIV OF TECH

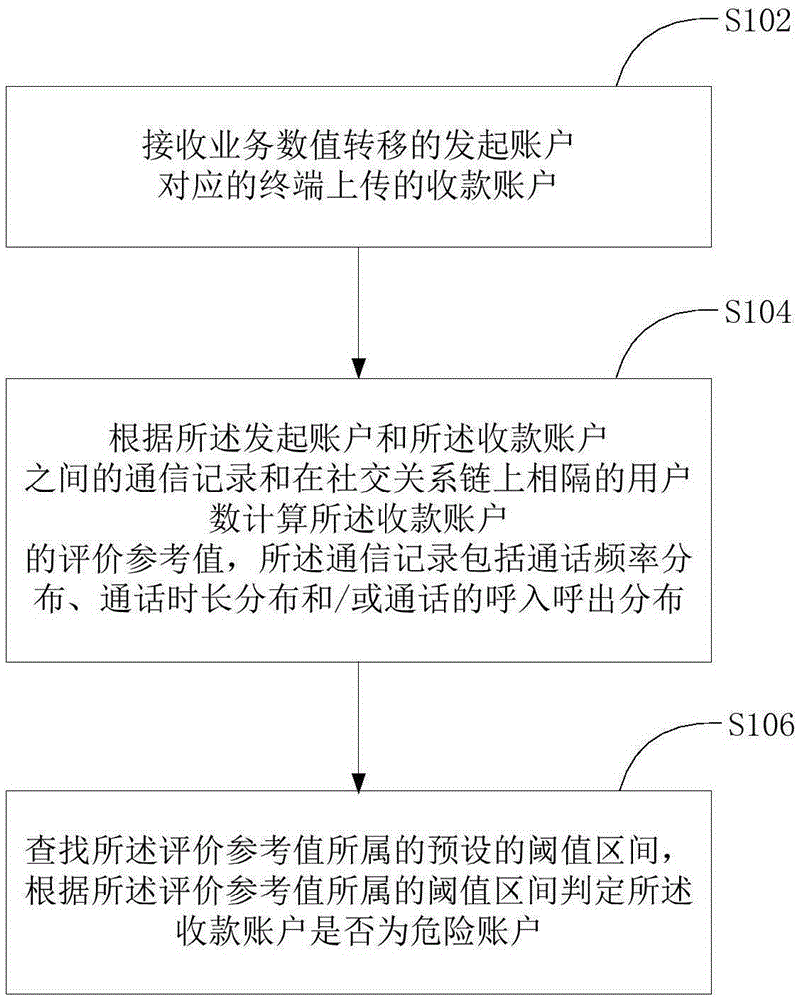

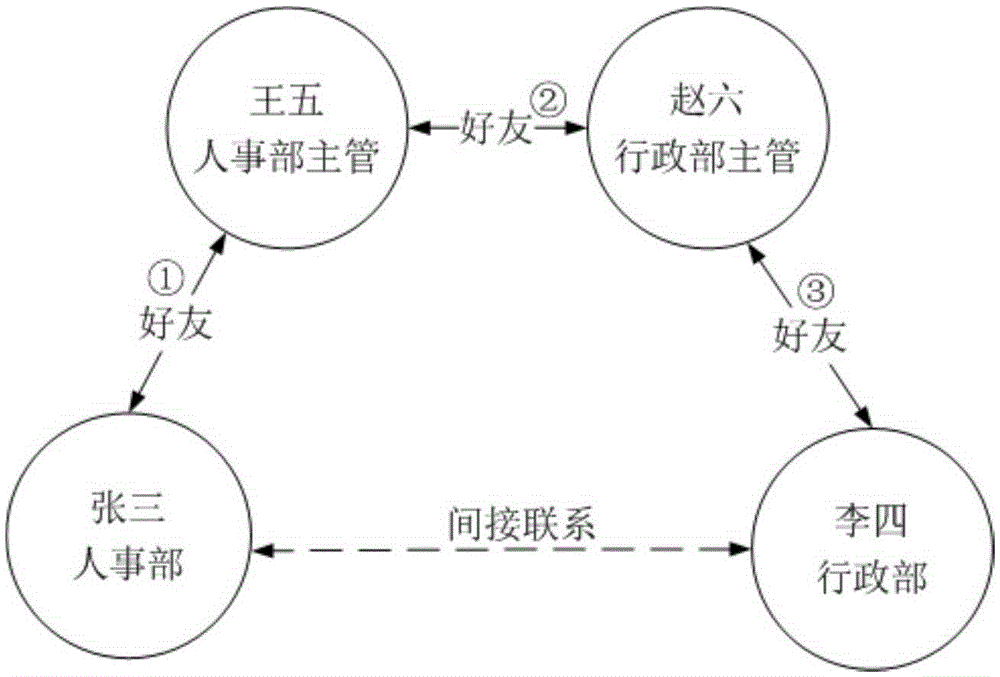

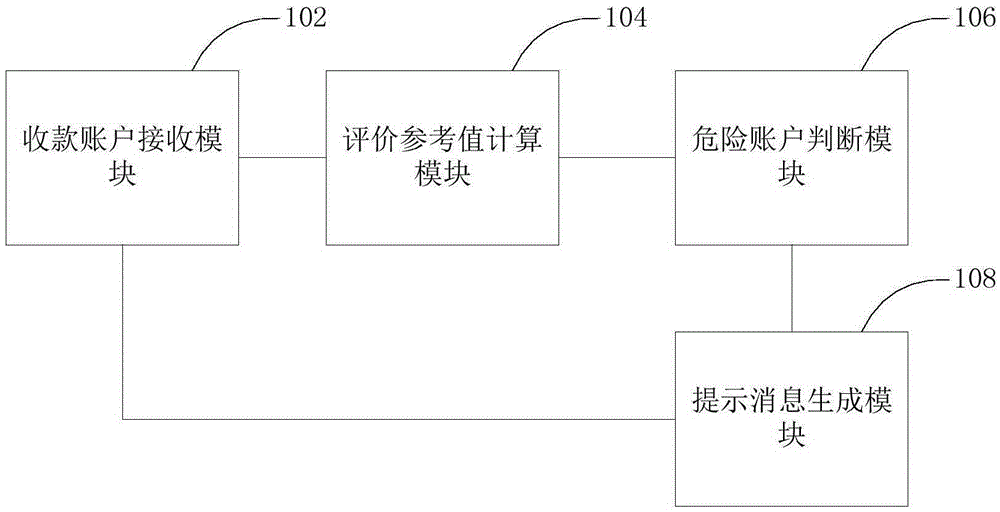

Risk account identification method and device

ActiveCN105429948AAccurate identificationImprove accuracyInterconnection arrangementsTransfer mechanismsIdentification deviceComputer terminal

The embodiment of the invention discloses a risk account identification method, comprising: receiving a terminal uploading collection account corresponding to a business value transfer initiation account; calculating the evaluation reference value of the collection account according to the communication record between the initiation account and the collection account, and user numbers separated on a social relation chain, the communication record comprising conversation frequency distribution, conversation time length distribution and / or conversation incoming and outcoming distribution; and searching for a preset threshold zone to which the evaluation reference value belongs, and determining whether the collection account is a risk account according to the threshold zone to which the evaluation reference value belongs. The invention also correspondingly discloses a risk account identification device. The risk account identification method and device can more accurately identify a risk account, and improve the risk account identification accuracy in business value transfer.

Owner:DONGGUAN COOLPAD SOFTWARE TECH

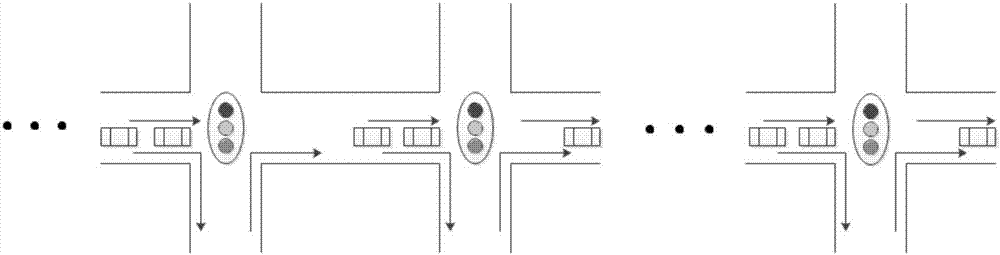

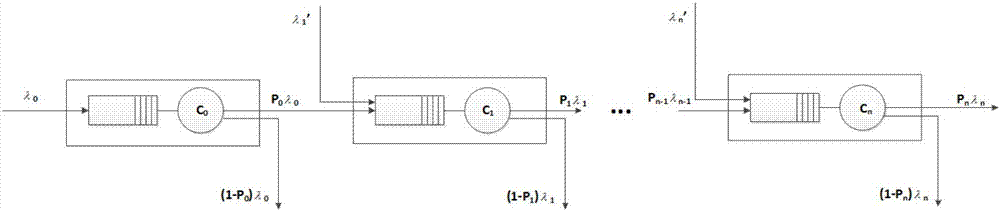

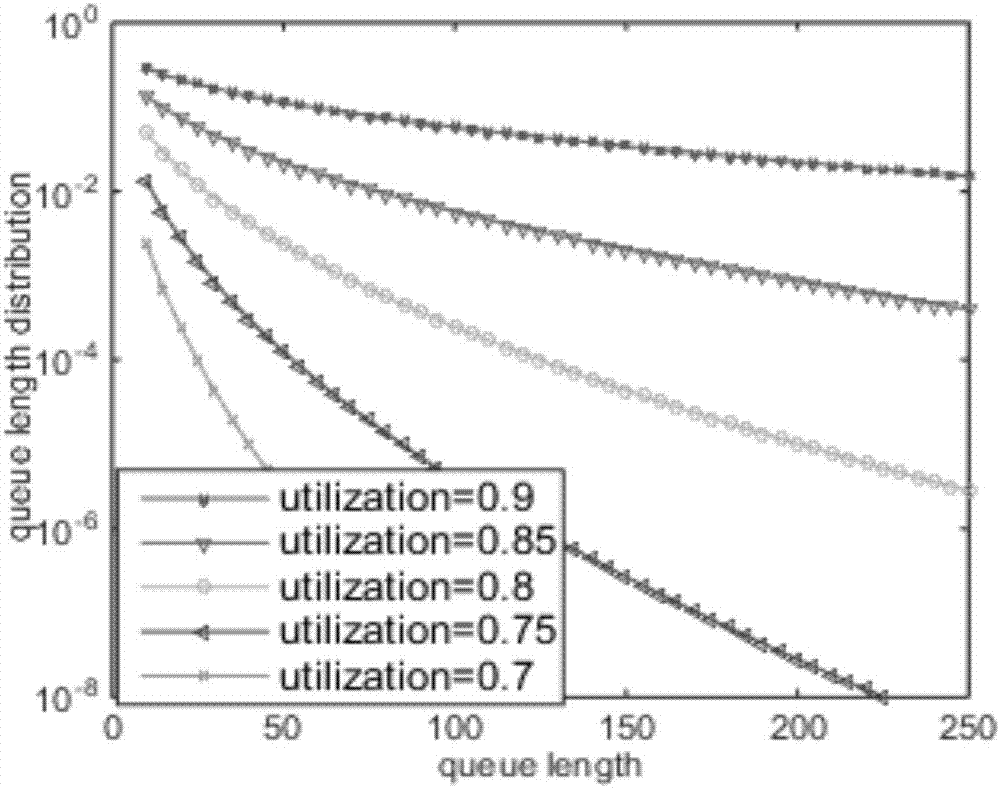

Queuing theory-based continuous traffic node congestion degree prediction model, system and method

ActiveCN106887141APredict the level of traffic congestionDetection of traffic movementForecastingTraffic capacityTraffic congestion

The present invention discloses a queuing theory-based continuous traffic node congestion degree prediction model, a system and a method. The model comprises a plurality of continuous traffic nodes. The length distribution of queues is adopted as an index for evaluating the traffic node congestion condition. The queue length distribution of each traffic node is constructed based on the queuing theory and the flow of the self-similarity. According to the invention, the method is directed to the prediction of the continuous traffic node congestion degree. Based on the method, firstly, the traffic congestion degree of each single node is predicted based on the flow that reaches the above single traffic node. Secondly, the traffic congestion degrees of multiple continuous traffic nodes connected with a current traffic node are predicted according to the flow of the current traffic node. Therefore, the traffic system is reasonably adjusted by related government departments according to the congestion degree information of the system.

Owner:SHANDONG UNIV

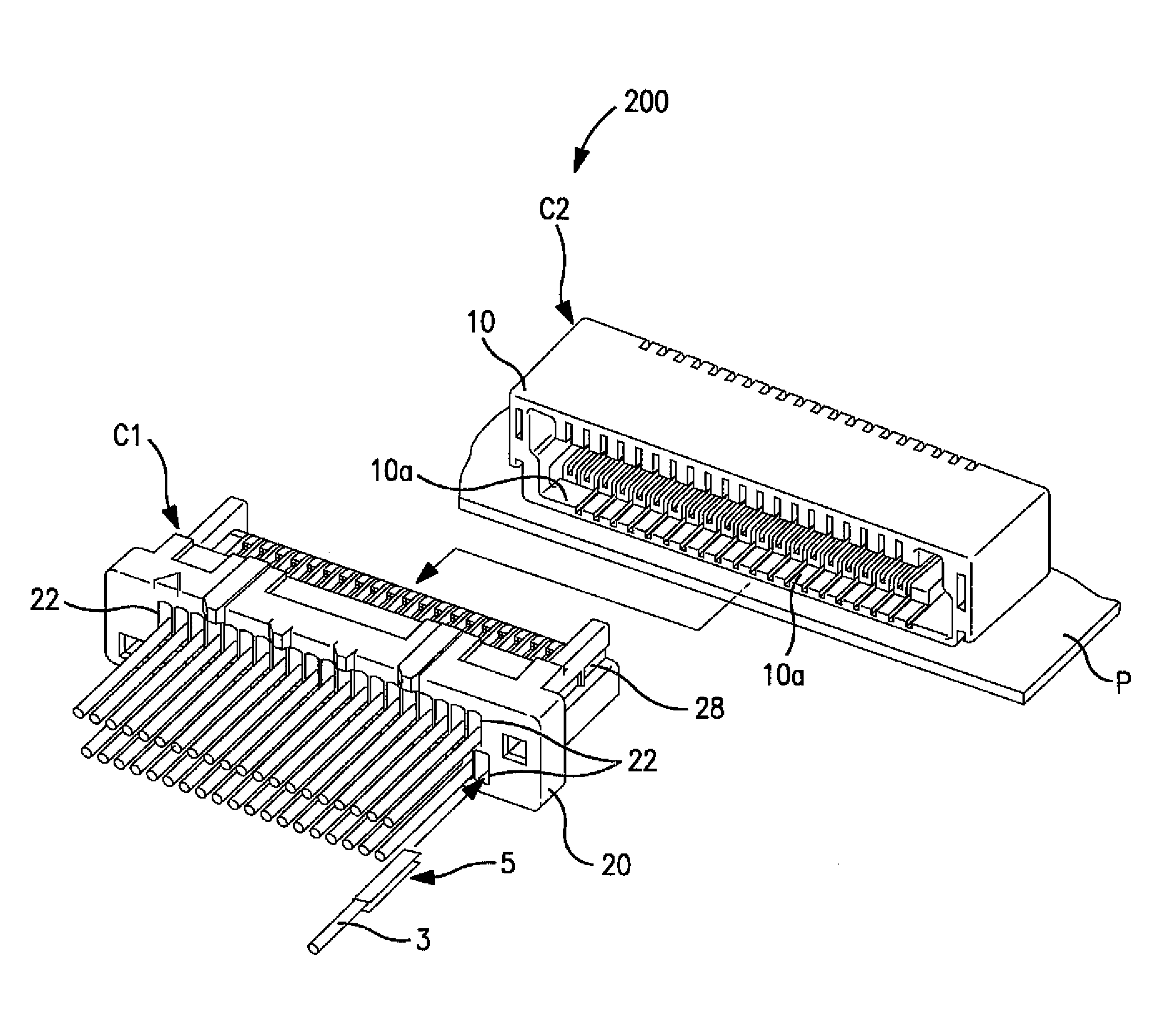

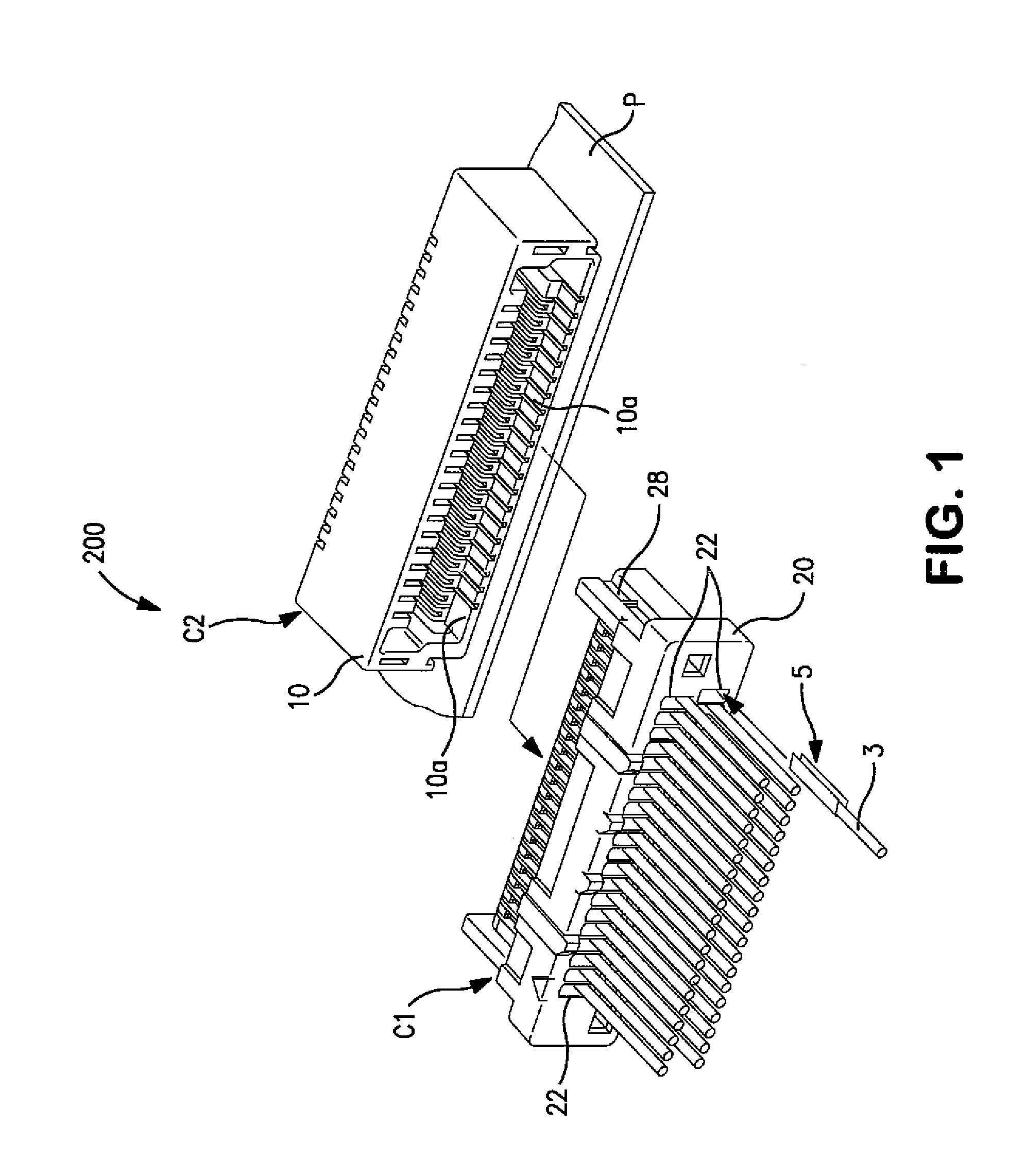

Fine Pitch Electrical Connector and a Thermoplastic Composition for Use Therein

A thermoplastic composition for use in a fine pitch electrical connector is provided. The thermoplastic composition contains a liquid crystalline polymer and a plurality of fibers. The volume average length of the fibers in the thermoplastic composition is selectively controlled according to the present invention so that it is within a certain range, such as from about 80 to about 250 micrometers. The fibers also have a narrow length distribution. That is, at least about 70% by volume of the fibers have a length within a certain range. Through the use of a liquid crystalline polymer and fibers of a certain weight average length and narrow length distribution, the present inventors have discovered that the resulting thermoplastic composition is able to achieve a desirable combination of strength and flowability, which enables it to be uniquely suited for the walls of a fine pitch connector.

Owner:TICONA LLC

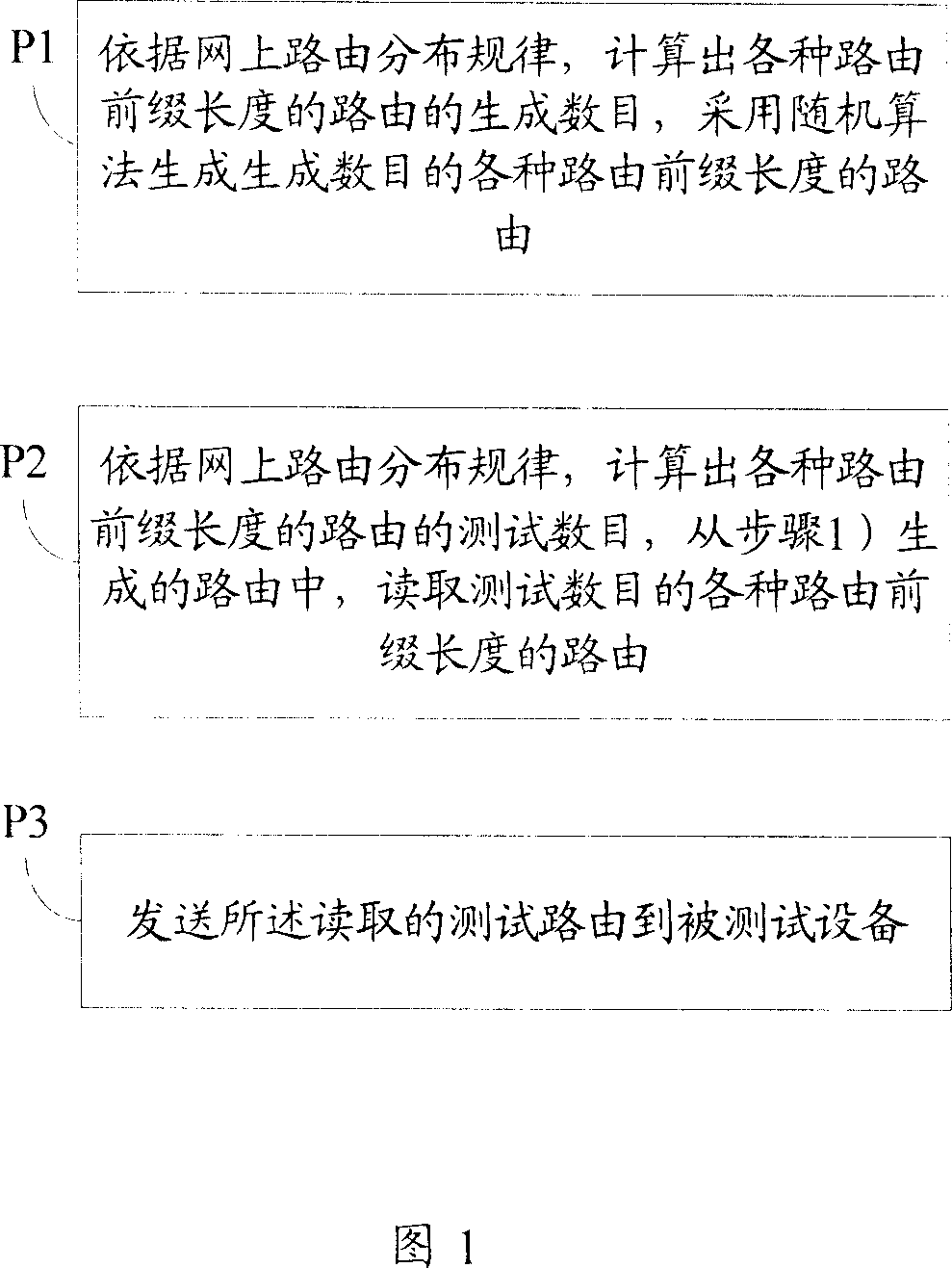

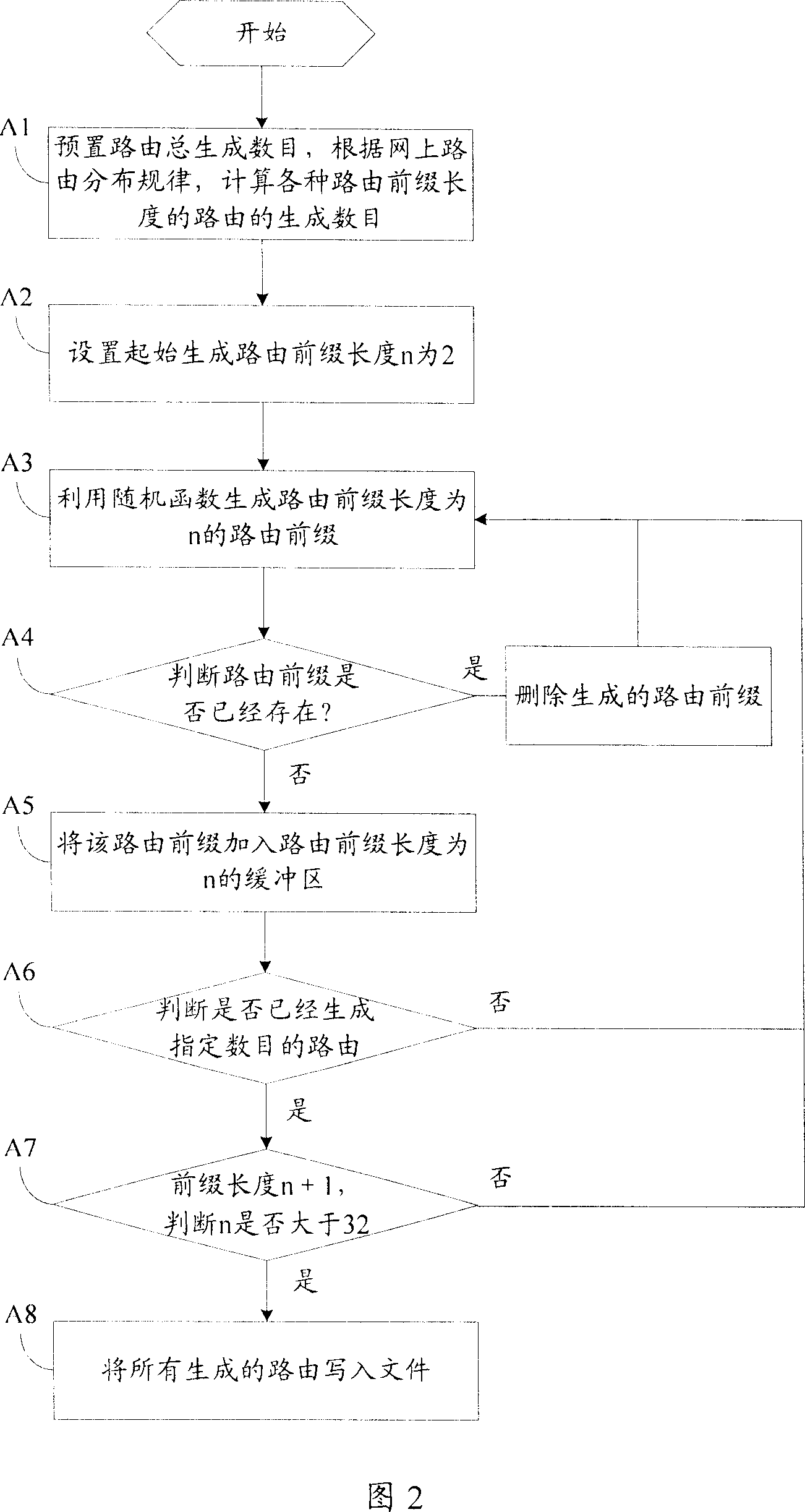

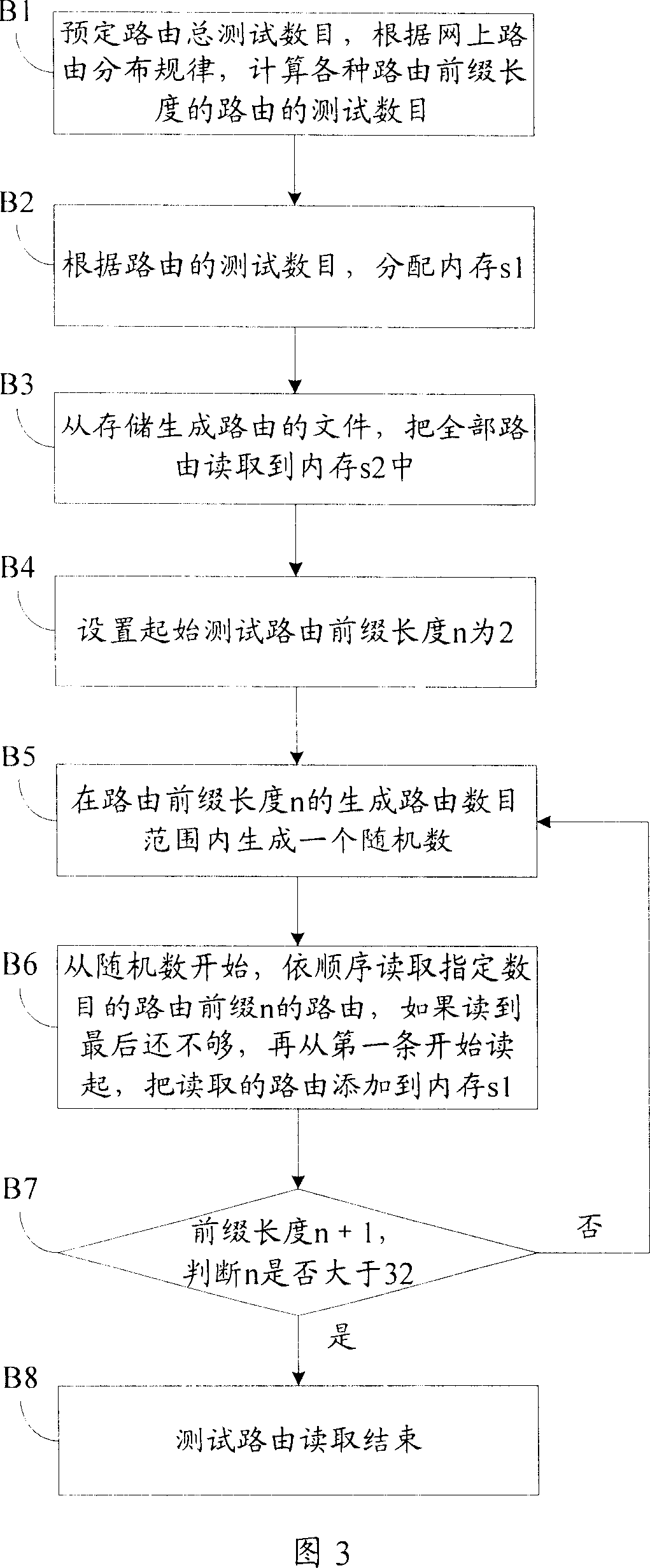

Method and system for transmitting test route

InactiveCN101047571AHas random propertiesTest accuratePulse modulation television signal transmissionTelevision system scanning detailsThe InternetLength distribution

A method for sending test route includes generating random route in according with prefix length distribution law of route on network first, then fetching out test route from generated routes and sending said test route to tested device.

Owner:HUAWEI TECH CO LTD

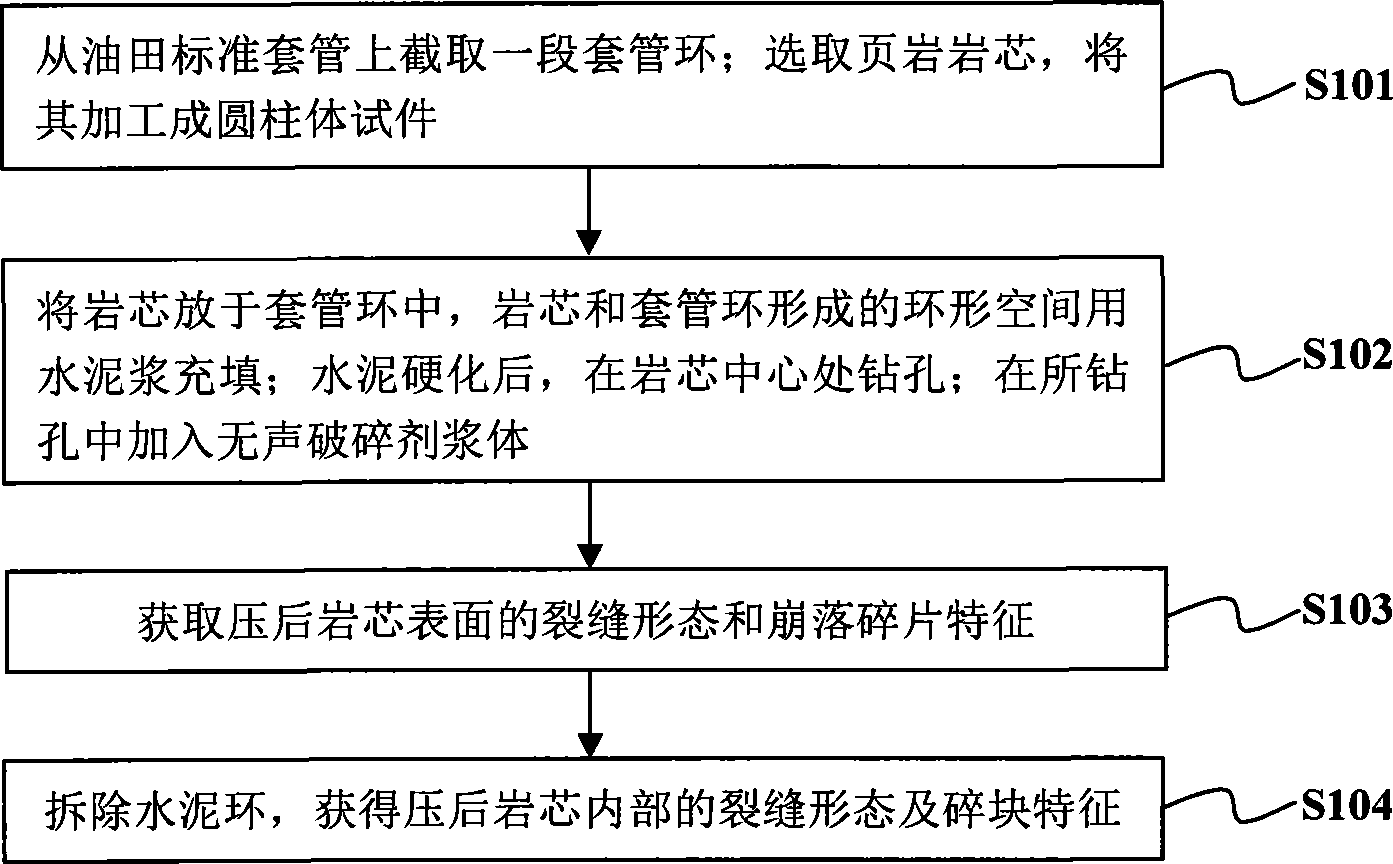

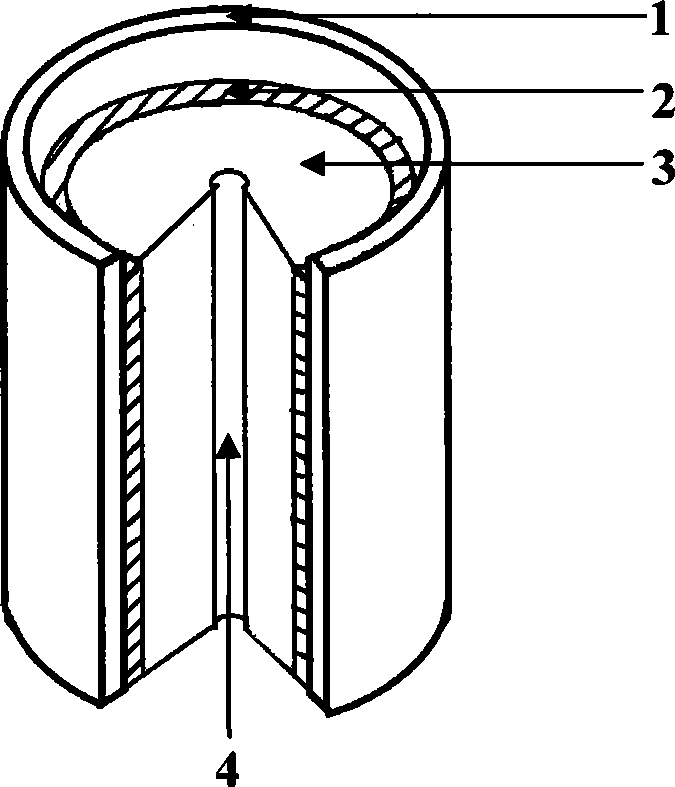

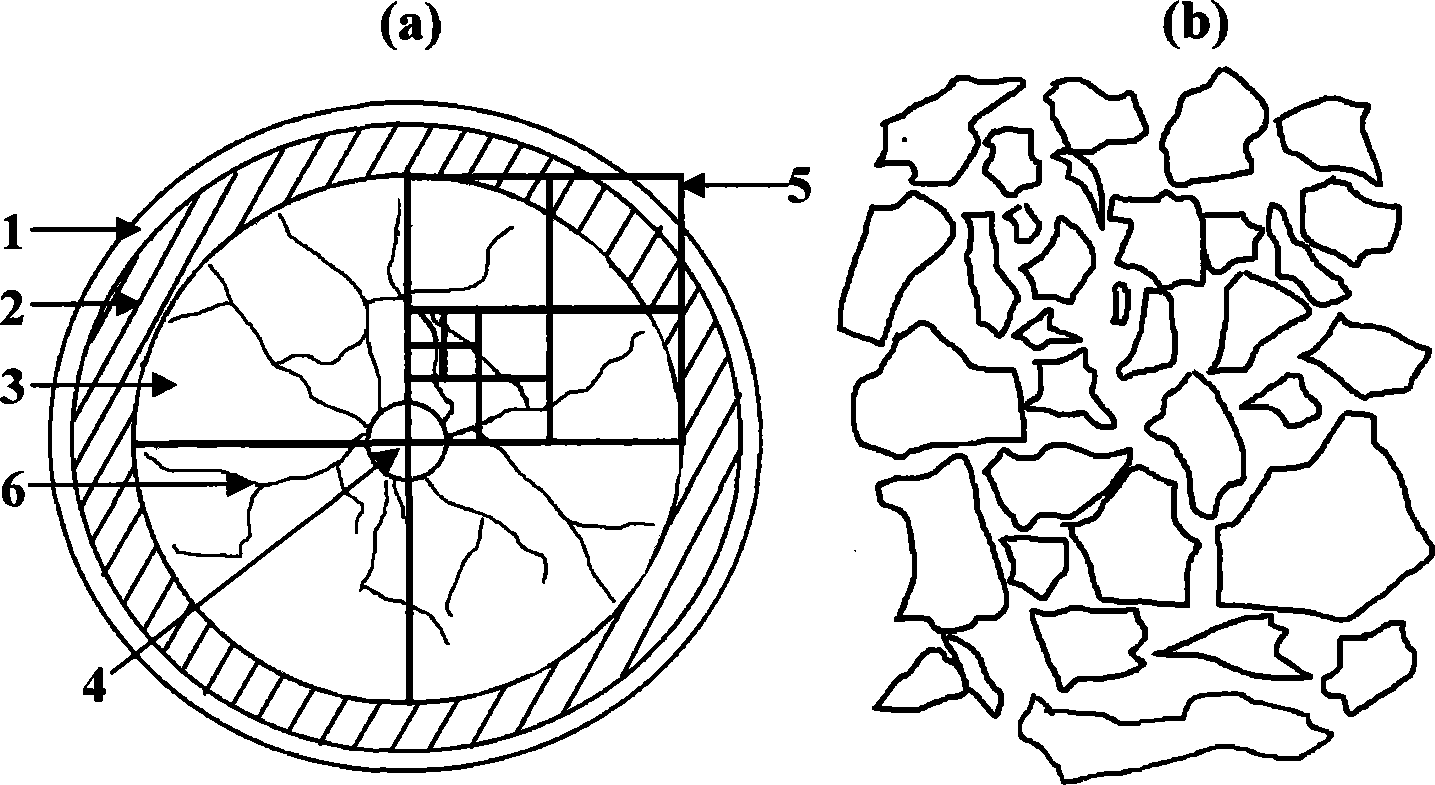

Experiment method for evaluating shale fracturing crack mesh forming capability

InactiveCN104131803AComprehensive embodying brittlenessComprehensive reflection of hardnessFluid removalOil fieldCement slurry

The invention provides an experiment method for evaluating the shale fracturing crack mesh forming capability. The method comprises the following steps that: (a) a section of sleeve ring is intercepted from an oil field standard sleeve, and a shale core is selected and is processed into a cylinder test piece; (b) the shale core is placed into the sleeve ring, and an annular space formed by the shale core and the sleeve ring is filled with cement slurry; a hole is drilled in the center part of the shale core after the cement is hardened; and soundless breaking agent slurry is added into the drill hole; (c) the fractal dimension of the crack structure surface trace length distribution, the surface density and the crack number are used for carrying out quantitative characterization on the crack form of the pressed shale core surface, and the size and the number of breaking fragments are evaluated; and (d) a cement ring is dismounted, the crack number inside the pressed shale core, the bulk density and the size and the number of the fragments are obtained. The experiment method integrally reflects the brittleness of the shale and the natural crack system (and deposition stratification) characteristics, and is used for judging the crack mesh forming capability of the pressed shale; visualized effects and reliability are realized; in addition, the operation is simple; and the experiment method is suitable to be applied in an oil field site.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

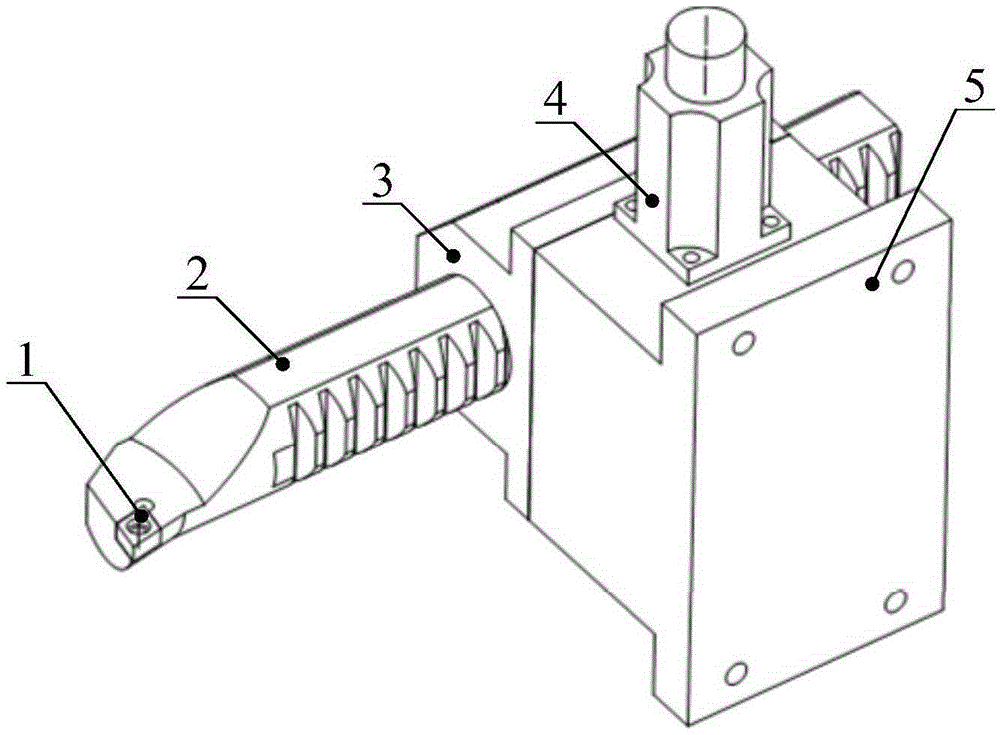

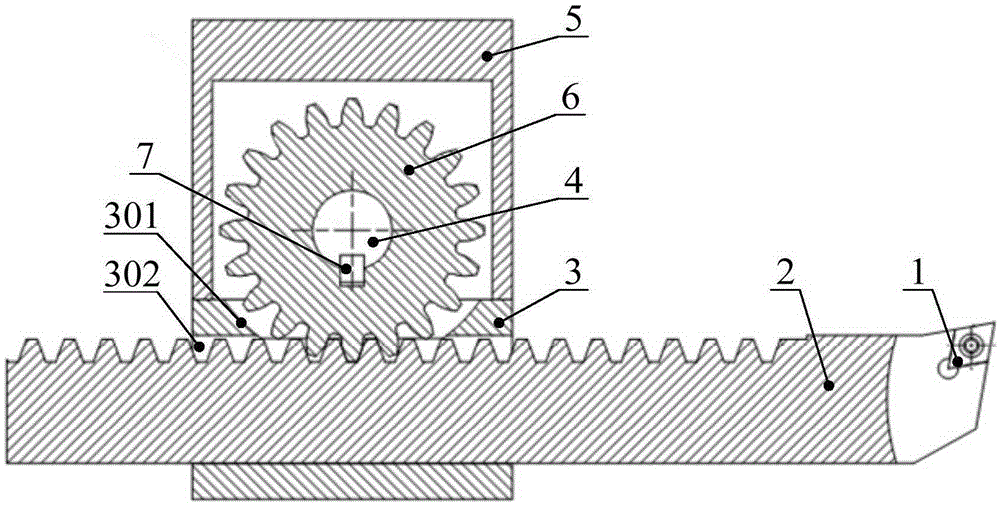

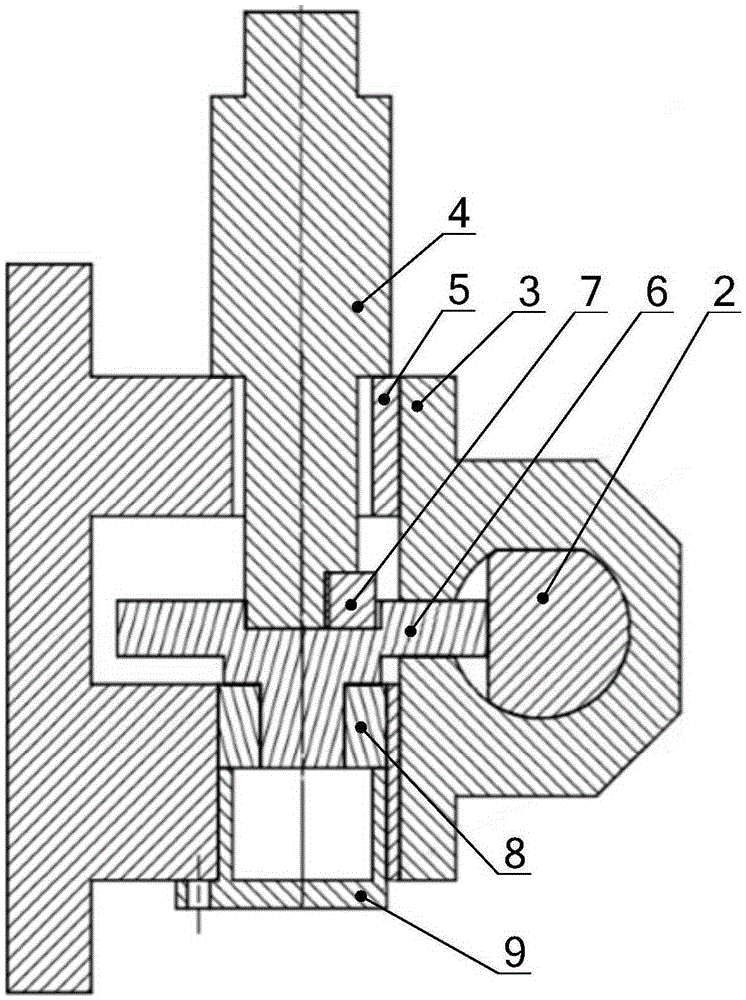

Anti-vibration tool rest with adjustable cutter bar extended length for deep hole turning

The invention discloses an anti-vibration tool rest with adjustable cutter bar extended length for deep hole turning, belongs to the technical field of mechanical processing, and aims to solve the problems that in the prior art, cutter bar extended length cannot be automatically regulated, a cutting chattering phenomenon is severe, efficiency is affected by tool changing and tool setting errors are easily caused. The anti-vibration tool rest with adjustable cutter bar extended length for deep hole turning comprises a combined type blade, a cutter bar, a cutter bar supporting base and a power drive unit, wherein the blade is arranged at one end part of the cutter bar; the other end of the cutter bar penetrates through a cutter bar slot of the cutter bar supporting base; and the cutter bar realizes stretching out and drawing back by virtue of the power drive unit. According to the anti-vibration tool rest with adjustable cutter bar extended length for deep hole turning disclosed by the invention, the principle of restraining cutting chattering is mainly realized by regulating extended length of the cutter bar, and improving dynamic rigidity of the cutter bar under the same cutting condition. For a hole with greater depth, a mode of gradually increasing extended length distribution of the cutter bar to process to the final depth is adopted, so that the cutting chattering phenomenon generated when directly adopting cutter bar extended length bigger than or equal to hole depth can be avoided.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Carbon fibre cloth for gaseous diffusion layer of fuel cell electrode

InactiveCN101492895ASpread evenlyOvercoming the resistivity of carbon paperSynthetic cellulose/non-cellulose material pulp/paperCellulose material pulpingFiberPorosity

The invention relates to carbon fiber paper for an electrode gas diffusion layer of a fuel cell, and is characterized in that carbon fibers are cut short, the length of the cut short carbon fibers is between 0.5mm and 5.0mm, and the average length thereof is between 1.0mm and 3.0mm; less than 1 percent of dispersant is used for dispersing the short carbon fibers into a water phase to form pulp stock, wherein the content of the carbon fiber is between 97.1 and 99.1 percent by weight percentage; and a carbon fiber paper material is prepared by a wet papermaking forming method. The length distribution of the short carbon fibers is between 0.5 and 5.0 millimeters, the average length thereof is between 1.0mm and 3.0mm, and the content thereof is 97.1 to 99.1 percent by weight percentage; the thickness of the carbon fiber paper is between 0.14mm and 0.22mm, the porosity is more than 70 percent, the volume density is 0.36-0.52 g / cm, the gas transmission rate is less than or equal to 50mmH, the electric conductivity passing through the carbon paper is less than or equal to 0.16OHMcm, the area weight is 40-80 g / m, and the specific resistance is 0.04-0.05 Omega.cm.

Owner:程显军

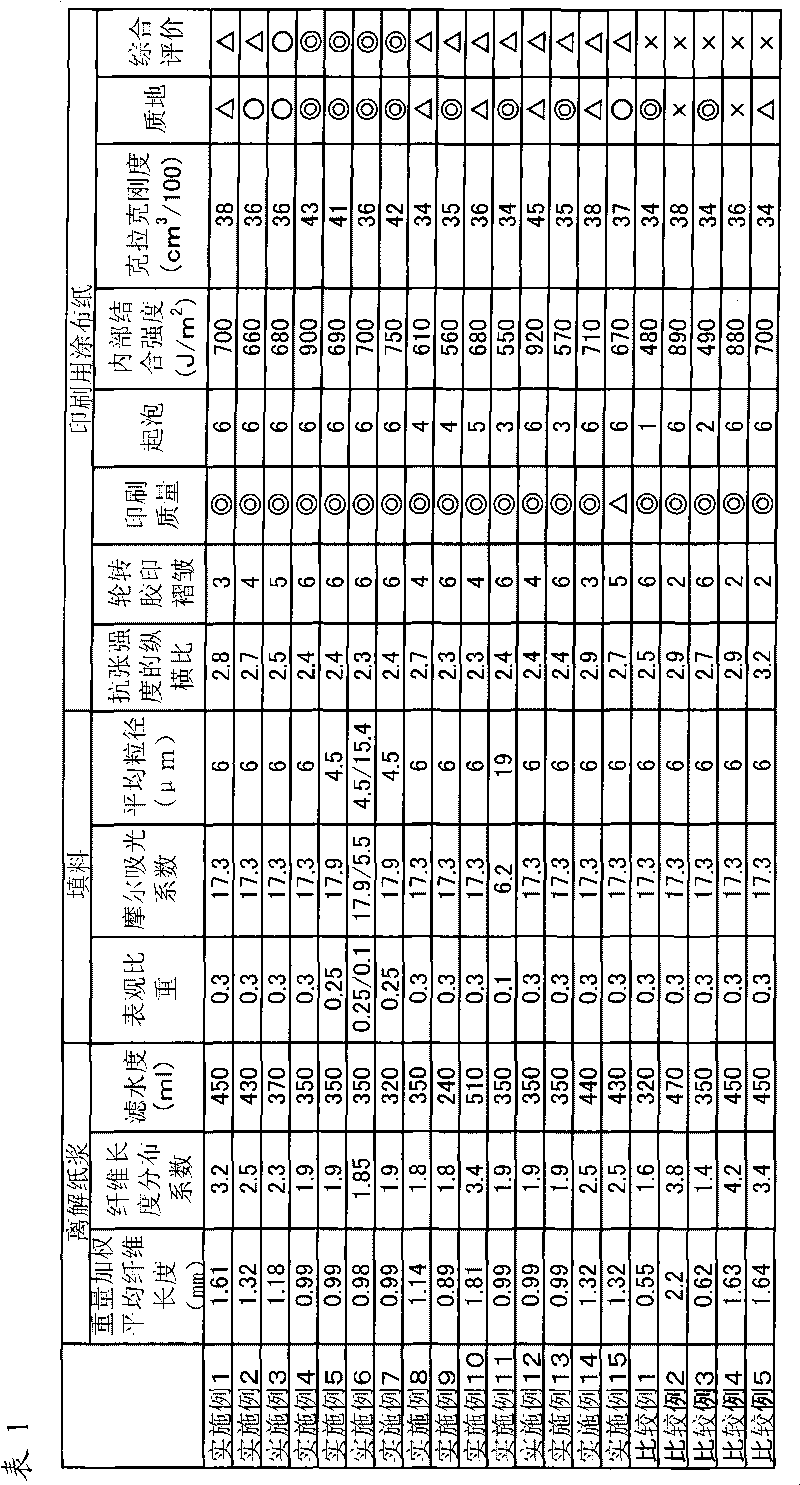

Coating paper for printing

ActiveCN101725081AImprove textureGood printabilityCoatings with pigmentsDryer sectionFiberUltimate tensile strength

The invention provides a coating paper for printing obtained by a twin-wire former type paper machine with excellent texture, paper interlayer intensity, rigidity and printing aptitude, characterized in that: more than 50 weight% of bleached pulp uses eucalypt material or acacia material as the raw material and the bleached pulp is pulped by gradually adding cooking liquor and subjected to many segments of bleaching processing steps. The coating paper for printing is produced by the following steps: forming a wet paper; squeezing the wet paper; drying the squeezed paper; setting more than one paint coating layer. The weighted mean fiber length of the dissociated paper pulp is 0.6-2.0mm and the fiber length distribution coefficient is 1.5-4.0 and the aspect ratio of the tensile strength of the coating paper is below 3.0.

Owner:OJI HLDG CORP

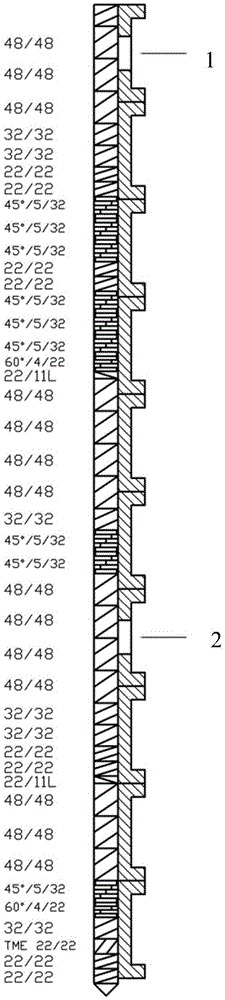

High performance short glass fiber enhanced polypropylene composite material and preparation method thereof

The invention discloses a high performance short glass fiber enhanced polypropylene composite material, which is composed of the following components in percentage by weight: 50 to 85% of polypropylene, 2 to 8% of modified polypropylene, 10 to 40% of modified short-cut glass fiber, 0.1 to 5% of antioxidant, and 0.5 to 5% of lubricant, wherein the modified polypropylene is prepared by modifying polypropylene with dicumyl peroxide and a silane coupling agent, and the modified short-cut glass fiber is prepared by modifying short-cut glass fiber with dicumyl peroxide and a silane coupling agent. Through the formula mentioned above, the provided composite material has the advantages of high modulus, high strength, and high impact strength. The invention also discloses a preparation method of the high performance short glass fiber enhanced polypropylene composite material. According to the preparation method, a same direction double-screw extruder is adopted, a specific screw combination is used to ensure that the length of glass fiber is short and the length distribution is in a narrow range, and thus a high performance polypropylene material is obtained.

Owner:CGN JUNER NEW MATERIALS +1

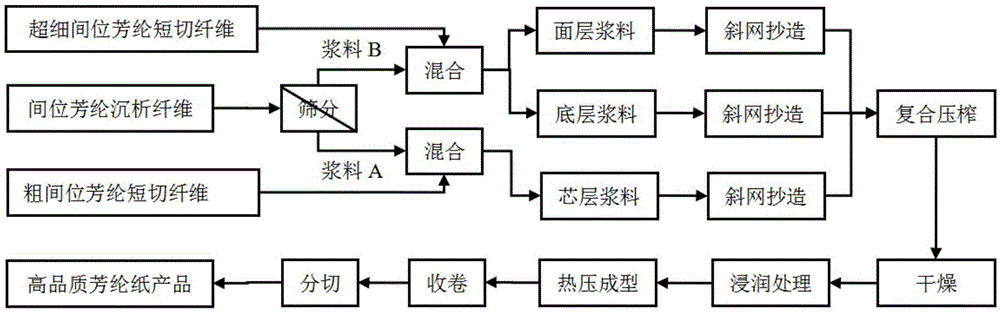

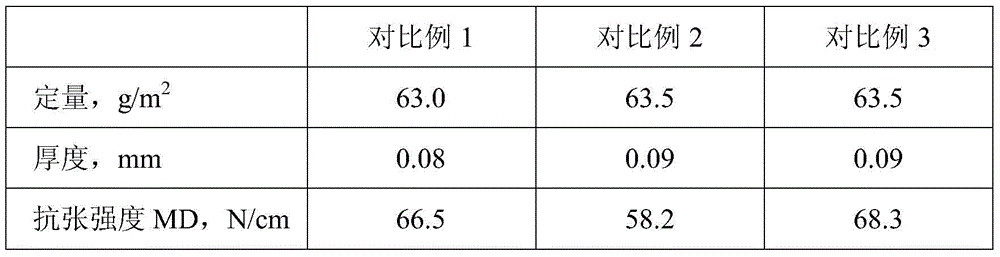

Method for preparing high-smoothness poly-m-phenyleneisophthalamide paper for insulation

ActiveCN105603802AIncrease contentSolve the difficult problem of wet copyingNon-fibrous pulp additionMechanical paper treatmentSurface layerSlurry

The invention relates to a method for preparing high-smoothness poly-m-phenyleneisophthalamide paper for insulation. The method comprises the steps of screening slurry A with the fiber length distribution greater than or equal to 100 meshes and slurry B with the fiber length distribution less than 100 meshes out of poly-m-phenyleneisophthalamide precipitation fibers; sufficiently mixing the slurry A with thick poly-m-phenyleneisophthalamide chopped fibers, conducting dispersion, and conducting formation paper-making, so that a core-layer wet paper web is obtained; sufficiently mixing the slurry B with superfine poly-m-phenyleneisophthalamide chopped fibers, conducting dispersion, and conducting formation paper-making, so that a surface-layer wet paper web and a bottom-layer wet paper web are obtained; compositing the surface-layer wet paper web, the core-layer wet paper web and the bottom-layer wet paper web in sequence from top to bottom, and then conducting squeezing and drying, so that raw aramid paper is obtained, then conducting infiltration treatment, and conducting thermo-compression formation on the infiltrated raw aramid paper, so that the high-smoothness poly-m-phenyleneisophthalamide paper for insulation is obtained. The aramid paper prepared through the method is high in surface smoothness, the problem that the surface gets shaggy easily is solved, excellent mechanical strength of the paper is guaranteed, while dielectric properties of the aramid paper are improved, and meanwhile energy consumption in the thermo-compression process is remarkably lowered.

Owner:YANTAI METASTAR SPECIAL PAPER

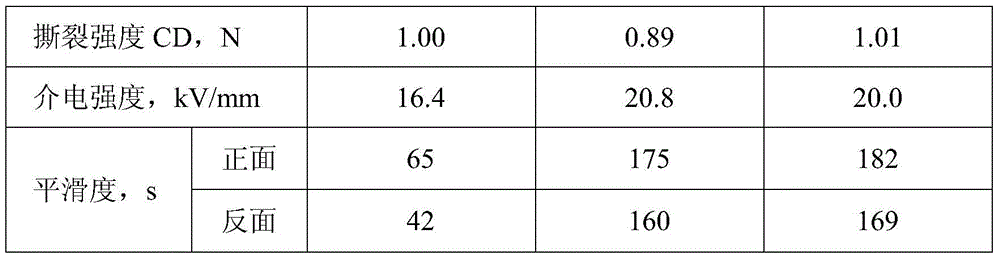

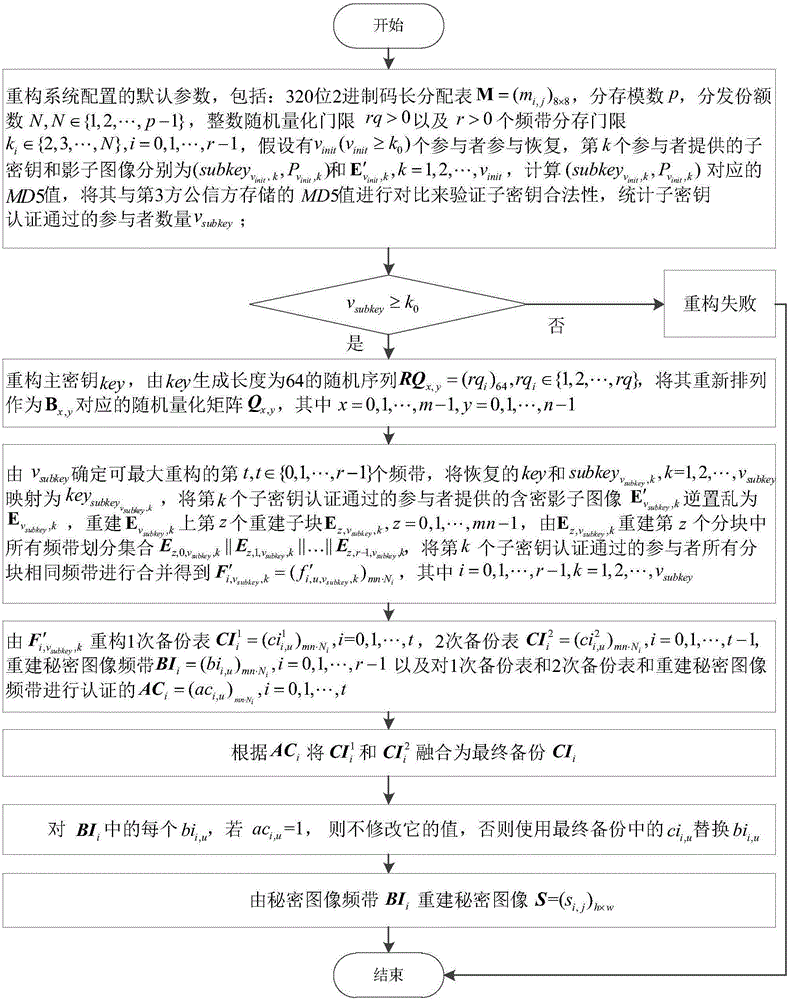

GF(2<6>) finite-field multi-threshold progressive secrete image sharing and reconstruction methods

ActiveCN106683053AImprove certification accuracyEnhanced Image Restoration CapabilitiesImage enhancementKey distribution for secure communicationReconstruction methodGlyph

The invention provides GF(2<6>) finite-field multi-threshold progressive secrete image sharing and reconstruction methods. A secret key is shared by combining a random participation value, and an MD5 value corresponding to the shared secrete key and participation value is published to prevent cheating; 8*8 frequency domain transformation is carried out on a secret image, sub-block frequency domain coefficients are quantified randomly, a specific code length distribution list is represented in a binary manner, multiple division frequency bands are formed according to a similar Z-shaped scanning sequence and frequency band recombination, and a frequency band backup is formed by scrambling; and frequency band, frequency band backup and authentication information is shared in multiple thresholds in the GF(2<6>) finite-field, and 2-bit authentication information is added to reconstruct a distribution shadow image. During recovery, the MD5 value is detected, a reconstructable frequency band is determined by combining the multiple thresholds, primary and secondary frequency band backup tables are reconstructed via dual authentication, a corresponding frequency band is reconstructed, and the reconstructed frequency band is used to reconstruct a secret image. Compared with existing methods, the distribution shadow image can be used fully to share the secret image progressively, and the visual reconstruction quality is improved.

Owner:SHAANXI NORMAL UNIV

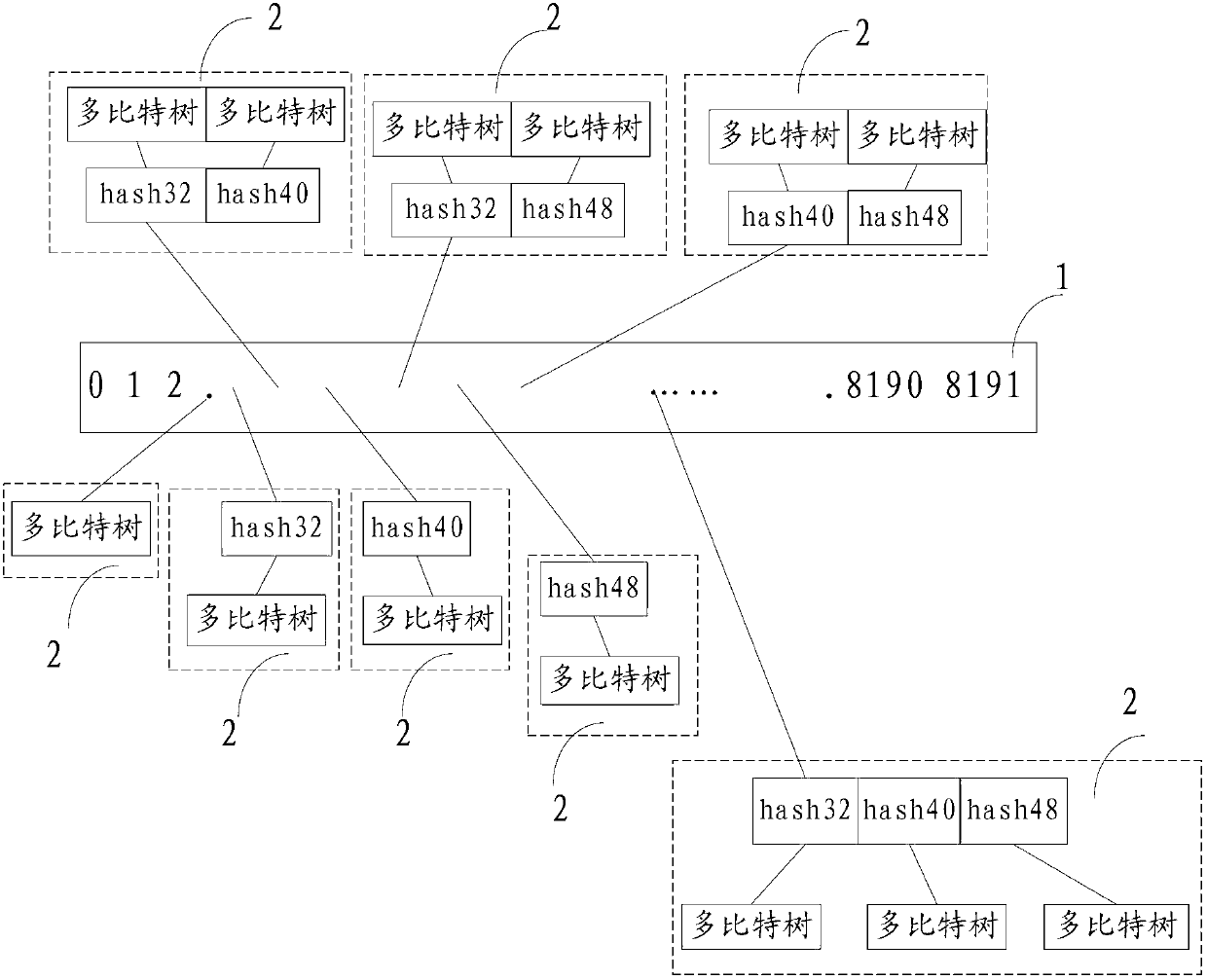

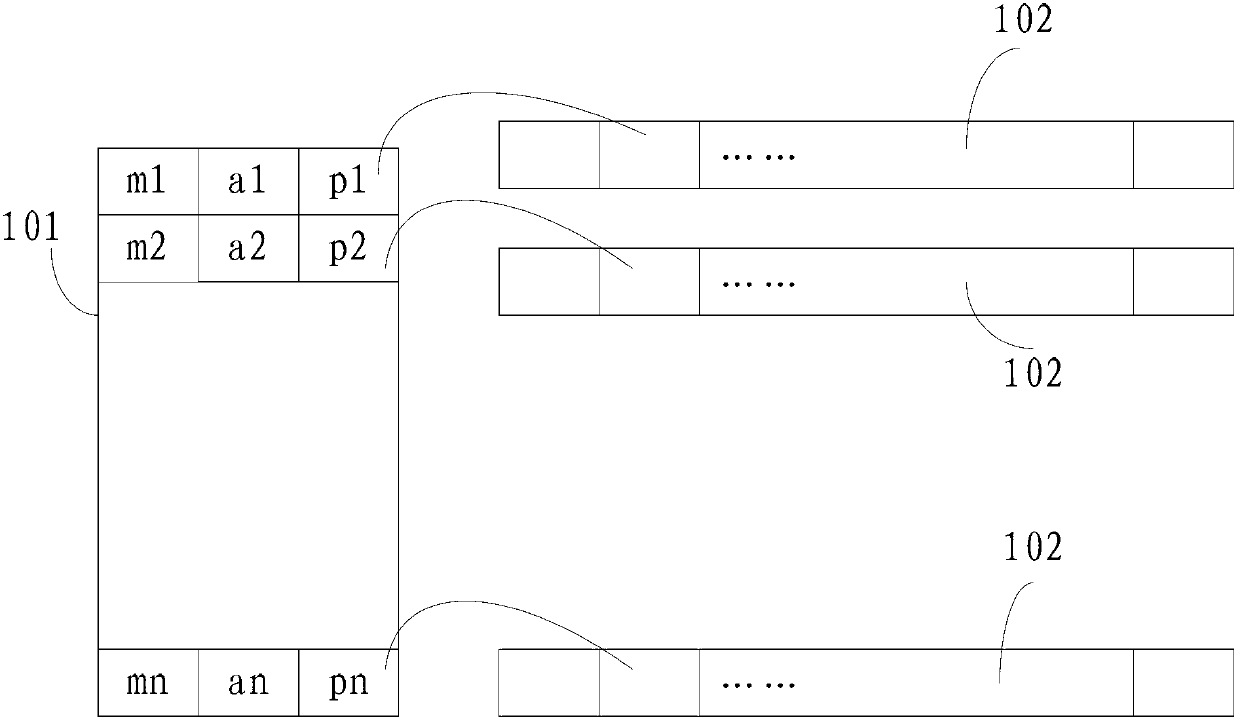

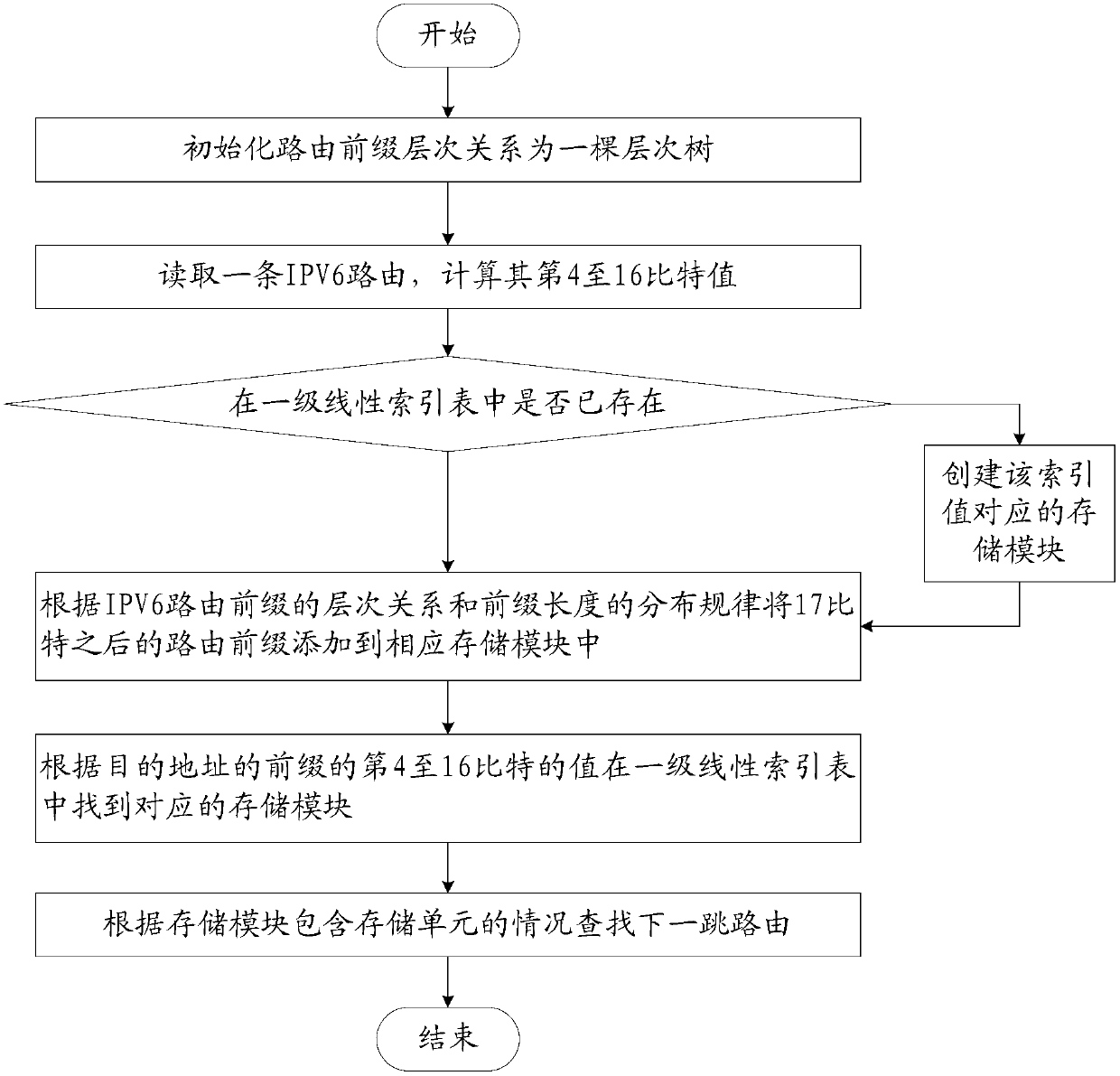

System and method of quick searching Internet protocol version 6 (IPV6) route

ActiveCN103107945AImprove search efficiencyImprove stabilityData switching networksRoute search16-bit

The invention relates to a system and a method of quick searching an Internet protocol version 6 (IPV6) route. The system of quick searching the IPV6 route comprises a route storage list, wherein the route storage list comprises a first level linear index table and more than one storage module, the first level linear index table is used for storing more than one index value, and each index value is corresponding to a storage module, wherein the each index value is the value of 4-16 bit of a route prefix, the storage module is used for storing route prefixes after 17 bit, the method of the quick searching the IPV6 route adds the route prefixes after 17 bit to corresponding storage modules according to the hierarchical relation of the IPV6 route prefixes and the length distribution law of the IPV6 route prefixes. The system and the method of quick searching the IPV6 route improve the efficiency of route searching due to the fact that the first level linear index table is provided, and reduce the number of comparison times due to the fact that a conflict-free hash table and a multiple bit tree are chosen according to the length distribution law of the IPV6 route prefixes and the hierarchical relation of the IPV6 route prefixes. The method of quick searching the IPV6 route is good in stability.

Owner:INST OF INFORMATION ENG CAS +1

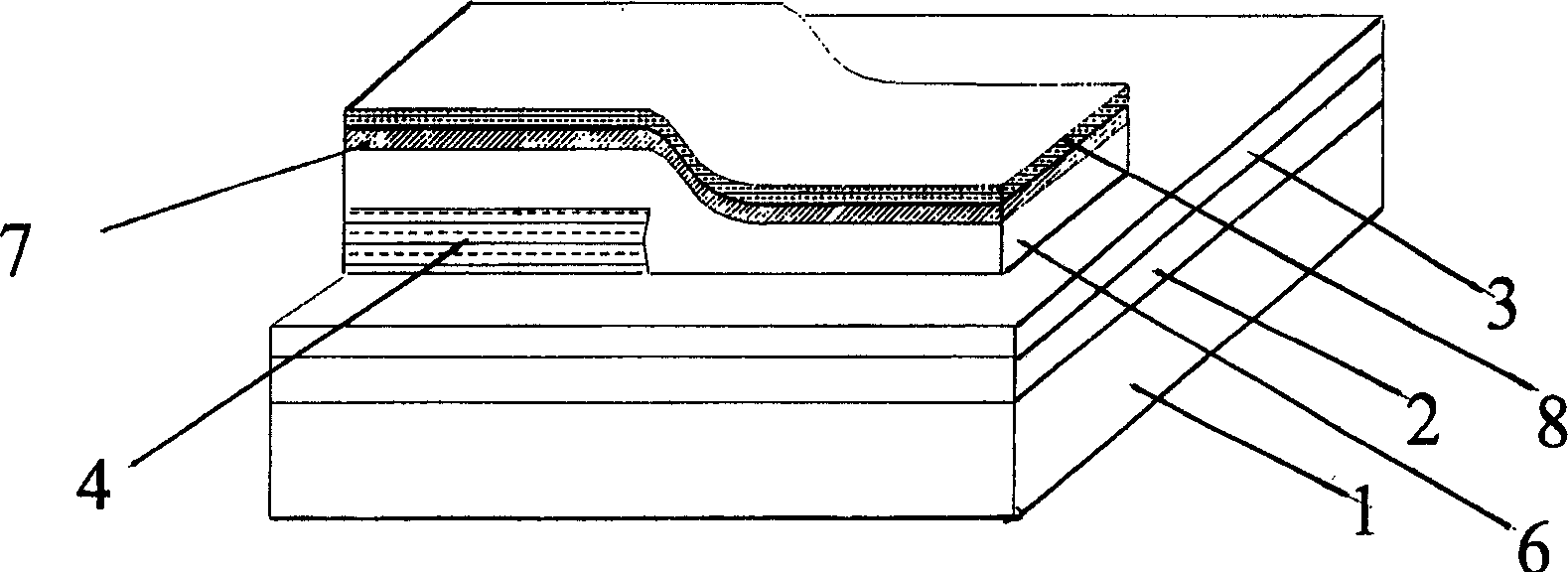

Method for producing adjustable wave length distribution Bragg reflective laser

InactiveCN1492550ALow costQuality improvementLaser detailsSemiconductor lasersGratingElectrode Contact

A method for processing wave length tunable distribution Bragg reflection laser includes the following steps:1) epitaxing a multiple quantum well layer structure on a n-type InP substrate, 2) corroding the multiple quantum well layer out of an active region by mask photoetching, 3) epitaxing InGaAsP material and a layer of indium phosphide, 4) depositing a layer of medium film to mask the grating window and selecting to corrode the indium phospbide layer, 5) taking the complete plate as the uniform Bragg grating, 6) epitaxially growing the grating cover layer and an electrode contact layer, 7) photoectching rib strips to mask photoetching electro isolation zone to deposit SiO2 layer and applying ionic implantation in the isolation ditch to form high isolation resistor zone, 8) sputtering P and N sides electrodes.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Method of producing glass-fiber-reinforced thermoplastic resin molded object and glass-fiber-reinforced thermoplastic resin molded object obtained by the method

Provided are a method of producing a glass-fiber-reinforced thermoplastic resin molded object by which a special glass-fiber-reinforced thermoplastic resin molded object excellent in mechanical strength and aesthetic appearance can be easily produced, and a glass-fiber-reinforced thermoplastic resin molded object obtained by the method. Glass fiber chopped strands subjected to a surface treatment with at least one of a urethane-based sizing agent and an acrylic urethane-based sizing agent, the glass fiber chopped strands each having a fiber length of from 1.2 mm to 1.8 mm, and a thermoplastic resin are each directly loaded into an injection molding machine, and are subjected to injection molding to produce the following special glass-fiber-reinforced thermoplastic resin molded object. The resin molded object shows a specific fiber length distribution and shows a specific tensile strength, and unopened glass fibers are absent on the surface of the resin molded object.

Owner:SUMITOMO RIKO CO LTD

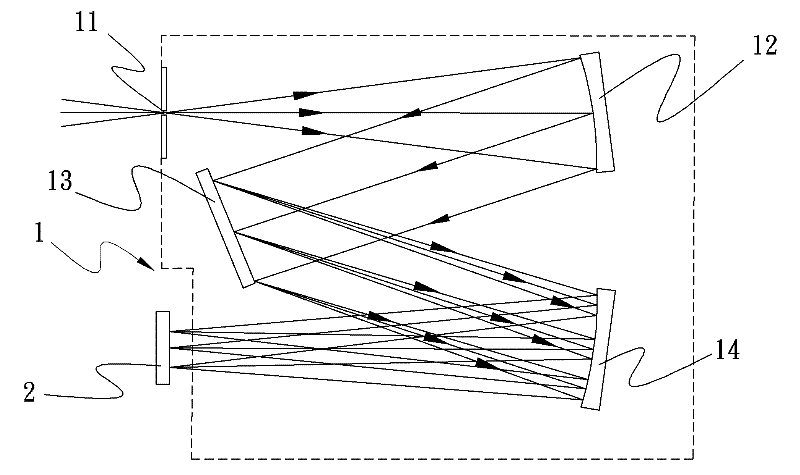

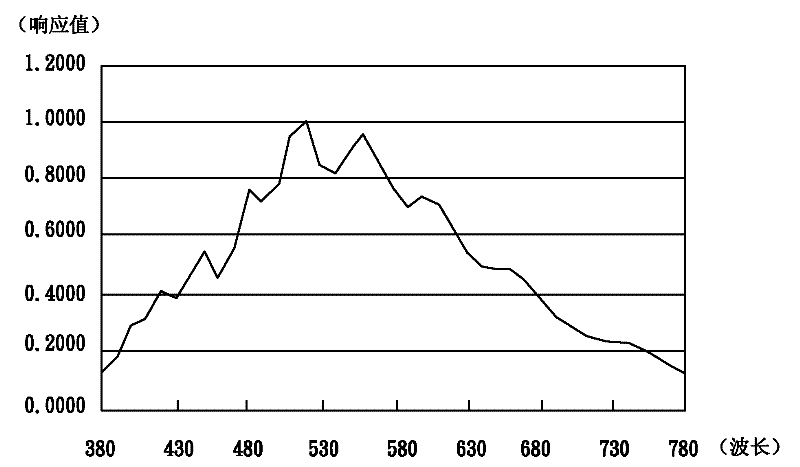

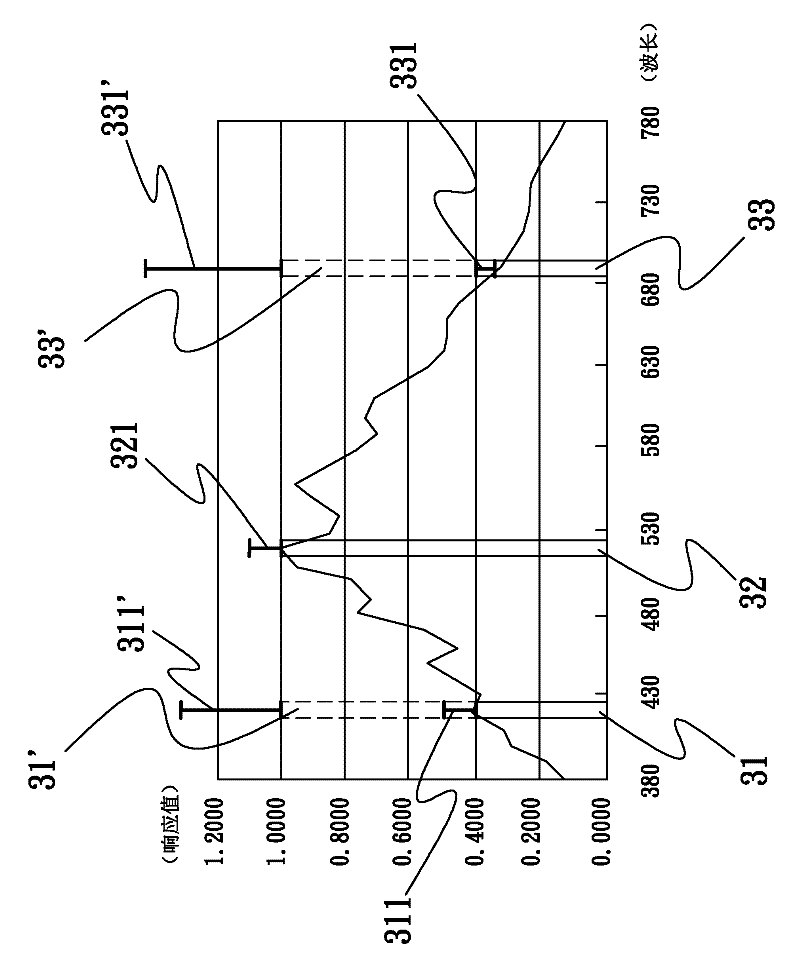

Light-splitting spectrum type measurement system

InactiveCN102445271AUniform wavelength responseAccurate measurementSpectrum investigationSpectrum generation using diffraction elementsOptical transmittanceSpectral responsivity

The invention relates to a light-splitting spectrum type measurement system, mainly comprising a light-splitting device, a light detecting device and a filtering device, wherein the light-splitting device is used to decompose light to be measured according to wave length distribution, and the filtering device is used to change light transmittance with different wave length components in advance, so that the penetration rate of the part of the light detecting device, with high spectral response part, is reduced, the penetration rate of the components with low spectral response is maintained to be high, various wave length components measured by the light detecting device are homogenized, errors caused by instrument equipment and environment can not cause unequal interference due to different wave lengths of all components; moreover, the compatibility of the structure and the known technology is high, the manufacturing cost is hardly increased and the accuracy of the spectrum measurement is increased.

Owner:致茂电子(苏州)有限公司

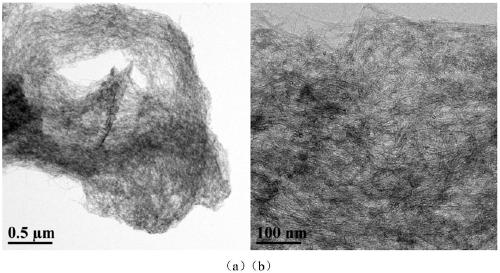

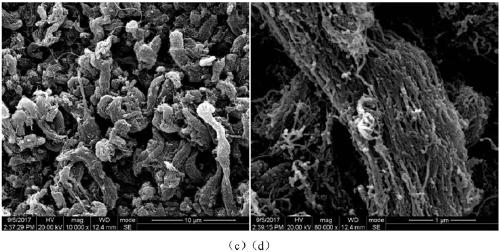

Method for preparing multi-wall carbon nanotubes

InactiveCN109665512AOvercoming the inability to prepare low wall numbersOvercome limitationsCatalyst activation/preparationMulti-walled nanotubesFreeze-dryingMicrometer

The invention relates to a preparation method of multi-wall carbon nanotubes, in particular to a method for directly preparing multi-wall carbon nanotubes with high specific surface area by using a chemical vapor deposition method. The method comprises the steps of preparing a catalyst with excellent catalytic performance by adopting a precipitation freeze-drying method, and cracking C1 hydrocarbon to grow carbon nanotubes in a reactor by using the catalyst. The specific surface area of the multi-walled carbon nanotubes directly prepared by the method is as high as 800-900 m<2> / g, the tube diameter distribution is in a range of 3-5 nm, the length distribution is in the range of several to dozens of micrometers, the purity of a crude product can be greater than or equal to 90 wt%, the purity can further be greater than or equal to 98 wt% after simple pickling, and the obtained carbon nanotubes have the advantages of high quality, low cost and easiness in operation and implementation.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com