Patents

Literature

149results about How to "Small molecular weight distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acrylonitrile copolymer spinning solution with high molecular weight and narrow distribution and preparation method thereof

InactiveCN101805936AHigh molecular weightHigh solid contentMonocomponent synthetic polymer artificial filamentPolymer scienceAlcohol

The invention discloses an acrylonitrile copolymer spinning solution and a preparation method thereof. The spinning solution is a mixed solvent solution of an acrylonitrile copolymer; the acrylonitrile copolymer is formed by polymerization of a first acrylonitrile monomer and a comonomer, and the comonomer comprises unsaturated carboxylic acid monomers; the mass of the first acrylonitrile monomer is 90-99.5% of the total mass of monomers, and the mass of the comonomer is 0.5-10% of the total mass of monomers; the mixed solvent is a mixture comprising dimethyl sulfoxide and at least one of water, alcohol solvents and ketone solvents; and the mass percent concentration of the monomers in the spinning solution is 15-30%. In the invention, the mixed solvent of the dimethyl sulfoxide is adopted in the process of acrylonitrile copolymerization, and the proportion of each solvent is controlled to carry out copolymerization reaction in homogeneous phases; and meanwhile, the second comonomer is continuously replenished in a certain time of reaction to stabilize the instantaneous composition of the acrylonitrile copolymer to obtain the polyacrylonitrile copolymer spinning solution with high molecular weight, narrow molecular weight distribution and uniform chain structure.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Method for preparing water-soluble solid styrene/acrylic resin and application thereof

InactiveCN101575397AAvoid it happening againAvoid cloggingInksCoatingsAcrylic resinUnsaturated monomer

The invention discloses a method for preparing water-soluble solid styrene / acrylic resin and application thereof. The method prepares the required resin by simultaneously performing free radical polymerization reaction and esterification reaction on an aromatic vinyl unsaturated monomer, an aliphatic vinyl unsaturated monomer, an unsaturated carboxylic acid monomer, fat alkanol, an initiating agent and an alpha-methyl styrene dimer in a reactor. In the method, the alpha-methyl styrene dimer is added as a chain transfer agent to reduce the branching degree and avoid the generation of gel and the blockage of the reactor; and simultaneously, the added fat alkanol performs esterification reaction with acroleic acid to inhibit the esterification reaction between an alcohol ether solvent and the acroleic acid, thus the viscosity of the reaction mixture is controlled effectively, and the finally prepared resin has narrow molecular weight distribution (Mw / Mn is less than 2.0), low molecular weight (Mw is less than 10,000), few organic volatile matters, and good wetting dispersion of pigment, and can be applied to preparing water color ink, coating or oil polish.

Owner:SUN YAT SEN UNIV

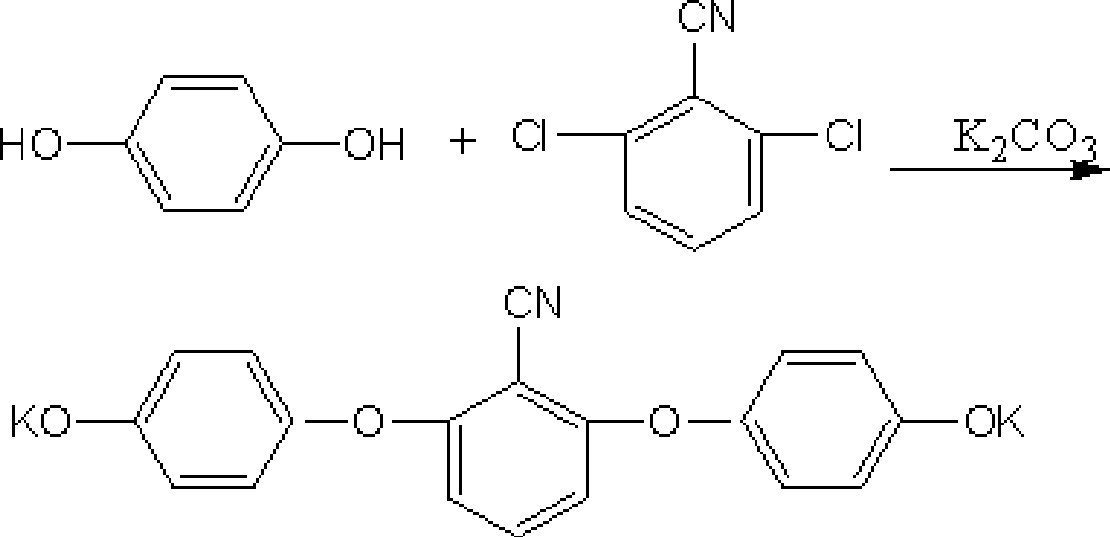

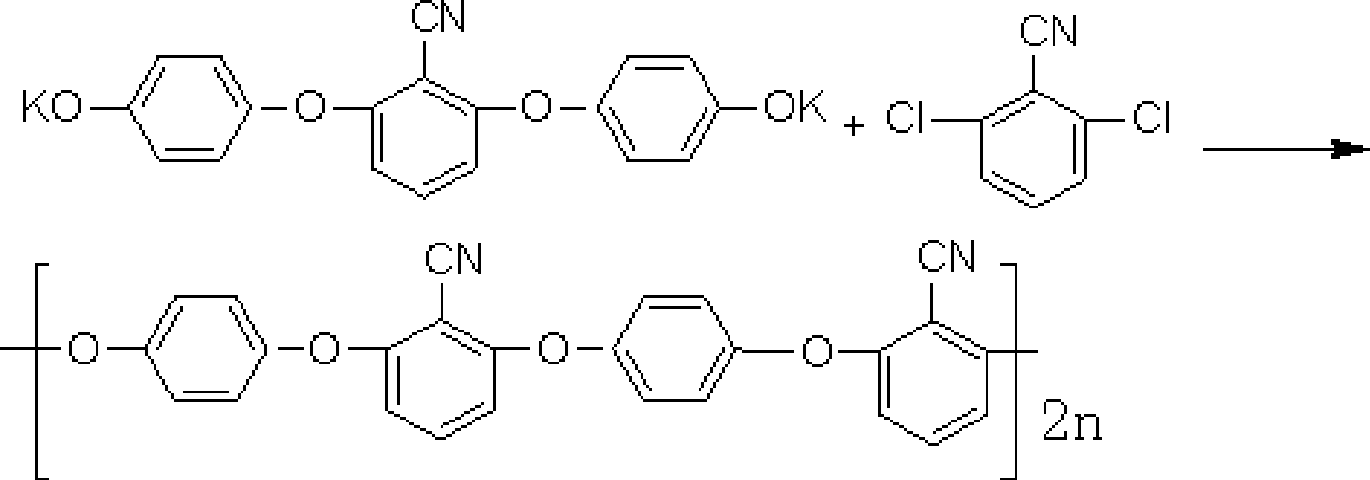

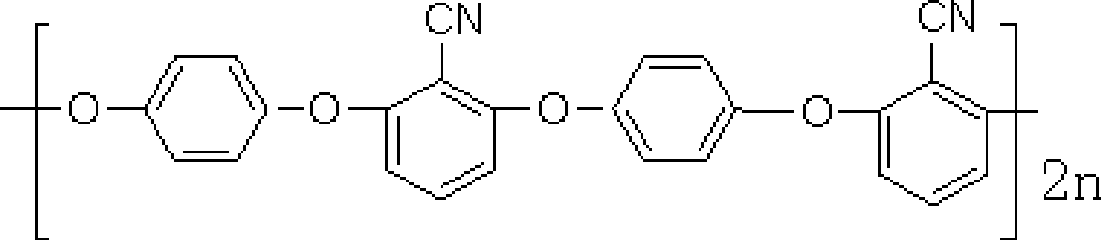

Industrial production method of semi-crystalline poly aryl ether nitrile

The invention relates to an industrial production method for semi-crystal poly(aromatic ether nitrile), which belongs to the field of polymer material. The method comprises the following steps: 2, 6-dichloro benzonitrile and hydroquinone are taken as raw materials; anhydrous potassium carbonate is taken as a catalyst; in the presence of a solvent and a dehydrating agent, the raw materials and the catalyst react under atmospheric pressure to obtain the poly(aromatic ether nitrile) homopolymer with low molecular weight and regular chain segments; and then the molecular weight of polymer is increased through pressurization, so as to obtain the semi-crystal poly(aromatic ether nitrile) polymer with high molecular weight. Due to the increase of crystallinity and molecular weight, the mechanical properties and heat resistance of the semi-crystal poly(aromatic ether nitrile) polymer are obviously improved.

Owner:SICHUAN FEIYA NEW MATERIAL

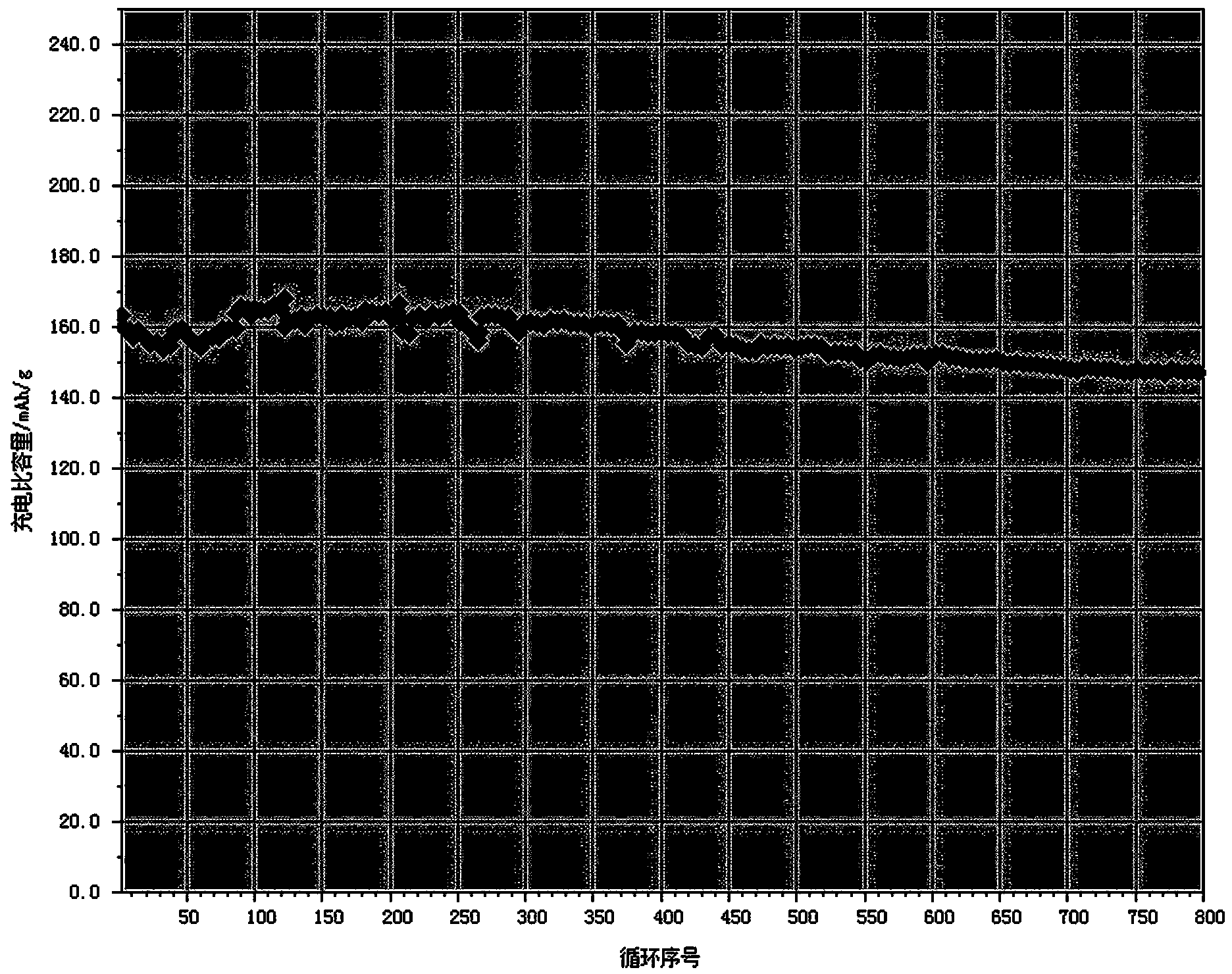

Method for preparing carbon-coated lithium titanate negative electrode material for lithium battery

ActiveCN103730649AMolecular weight controllableSmall molecular weight distributionCell electrodesCarbon layerPolymer science

The invention discloses a method for preparing a carbon-coated lithium titanate negative electrode material for a lithium battery. The method comprises the following steps: preparing a polymer with controllable molecular weight by adopting living polymerization, performing ball milling and mixing with raw materials of lithium titanate, and sintering to obtain a lithium titanate material coated with a conductive carbon layer. The adopted polymerization method has the advantages that range of optional monomers is wide, polymers of different carbon chain lengths can be obtained by adjusting the raw material ratio, the carbon chain length distribution is uniform, and the finally obtained carbon-coated lithium titanate material is uniform and stable in performance. Moreover, the initial charge specific capacity of the obtained lithium titanate material reaches over 160mAh / g under the rate of 1C (1C=175mA / g), and the capacity is kept over 90 percent due to cycle of 800 times.

Owner:中国东方电气集团有限公司

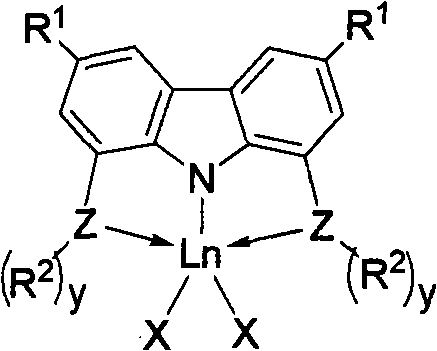

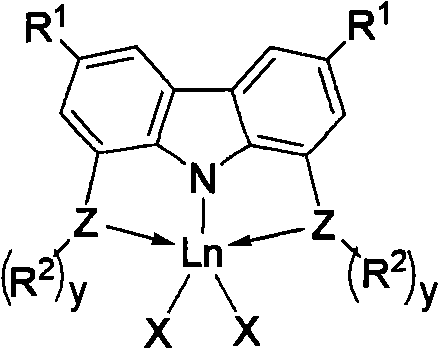

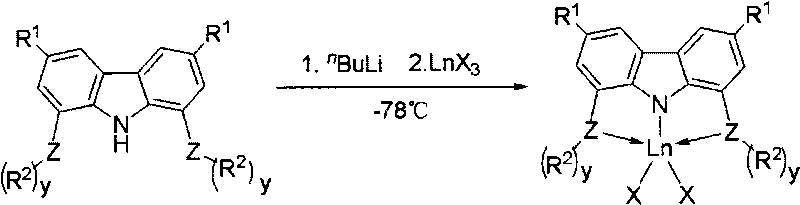

Application of rare-earth complexes chelated by tridentate carbazolyl in conjugated diene and polar monomer copolymerization catalyst system

InactiveCN101693754ASmall molecular weight distributionGroup 4/14 element organic compoundsGroup 5/15 element organic compoundsConjugated dieneAlkyl transfer

The invention relates to application of rare-earth complexes chelated by tridentate carbazolyl in a conjugated diene and polar monomer copolymerization catalyst system. The catalyst system comprises the rare-earth complexes chelated by the tridentate carbazolyl, organic boron salt and an alkylation agent by the molar ratio ranging from 1:1:0 to 1:1:100. The catalyst system catalyzes copolymerization between conjugated diene and polar monomer; chain segment compositions and molecular weight of obtained copolymers can be regulated and controlled by changing molar ratio between two monomers and the catalyst system and the molar ratio between the two monomers; the molar ratio between a conjugated diene monomer and the catalyst system is 500-10000:1; and the molar ratio between the polar monomer and the catalyst system is 100-10000:1.The content of segmental cis 1,4 of poly-conjugated-diene of the obtained copolymers ranges from 97% to 99.9%, number-average molecular weight is within the range from 5 to 2 million, and molecular weight distribution is smaller than 3.0.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

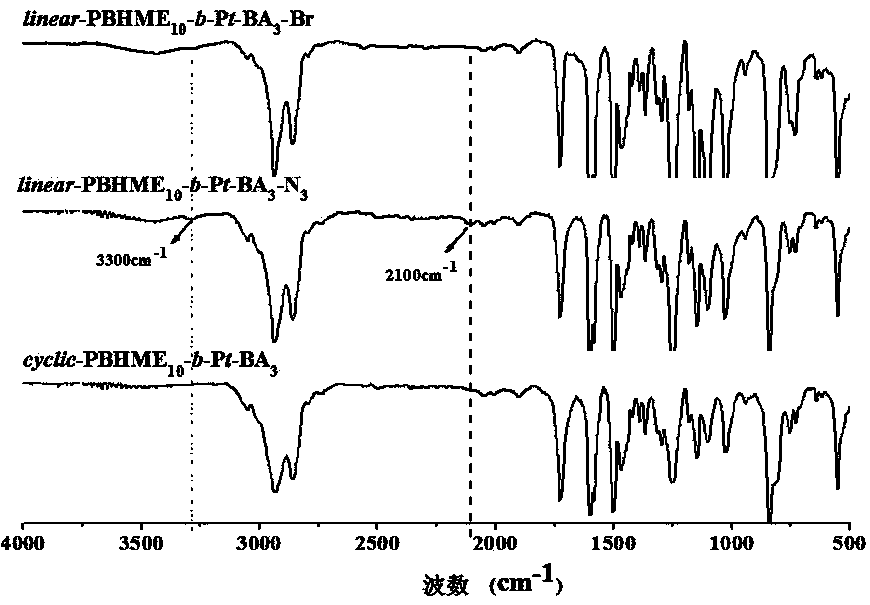

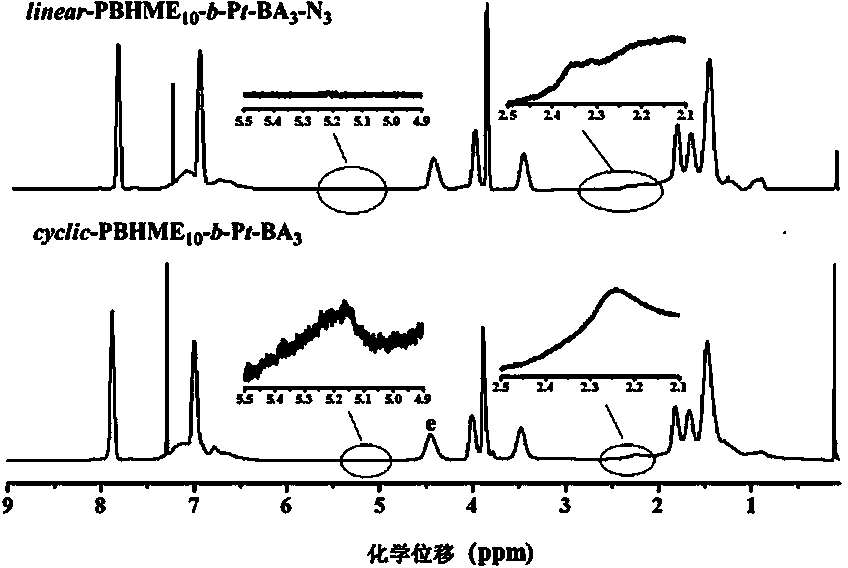

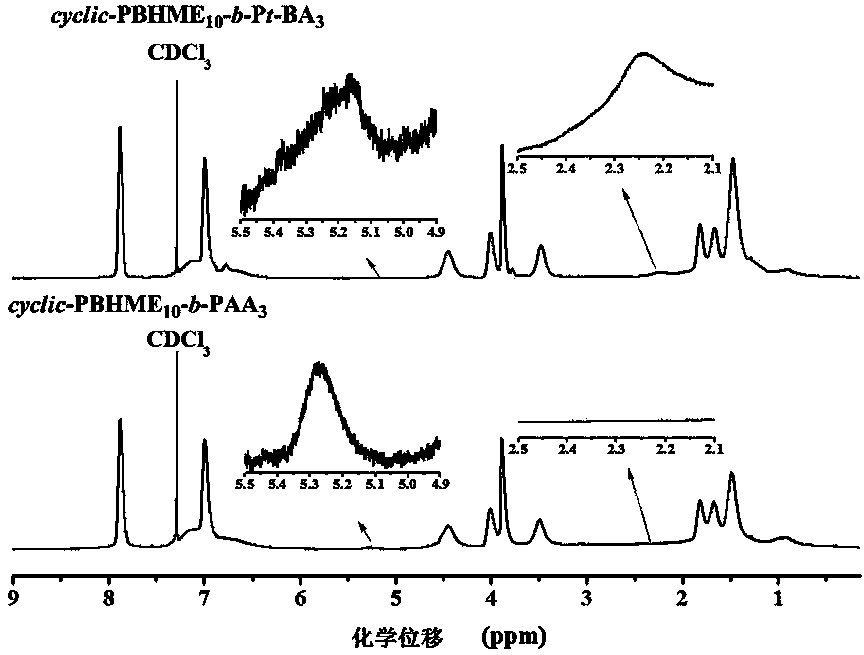

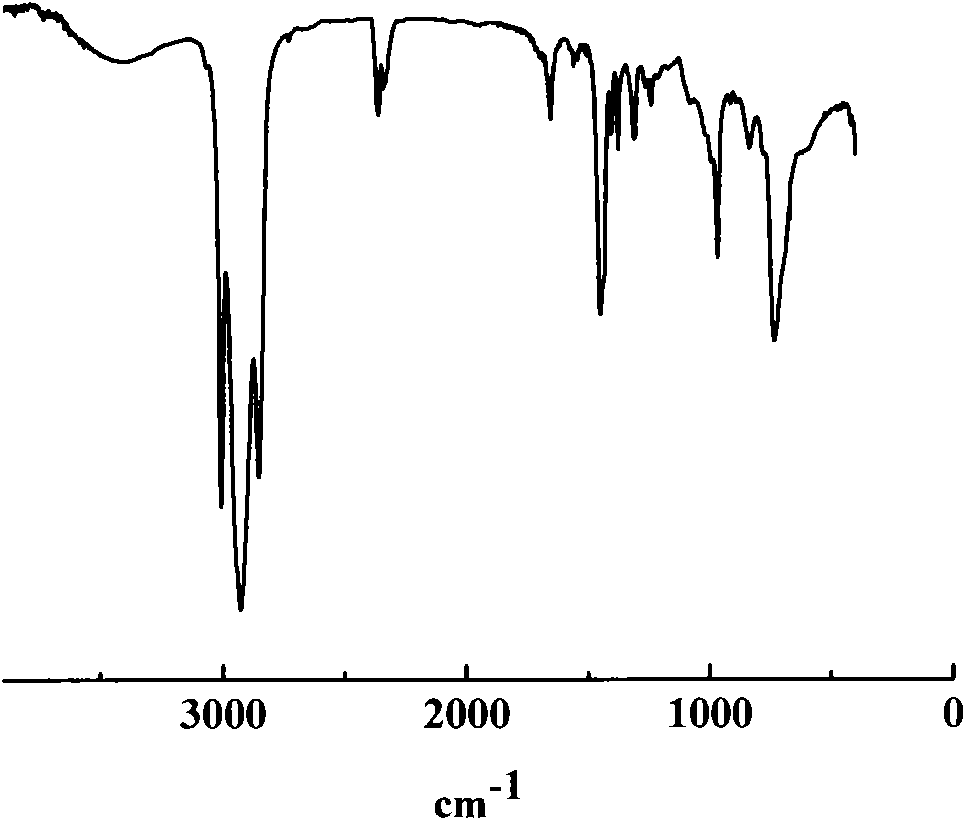

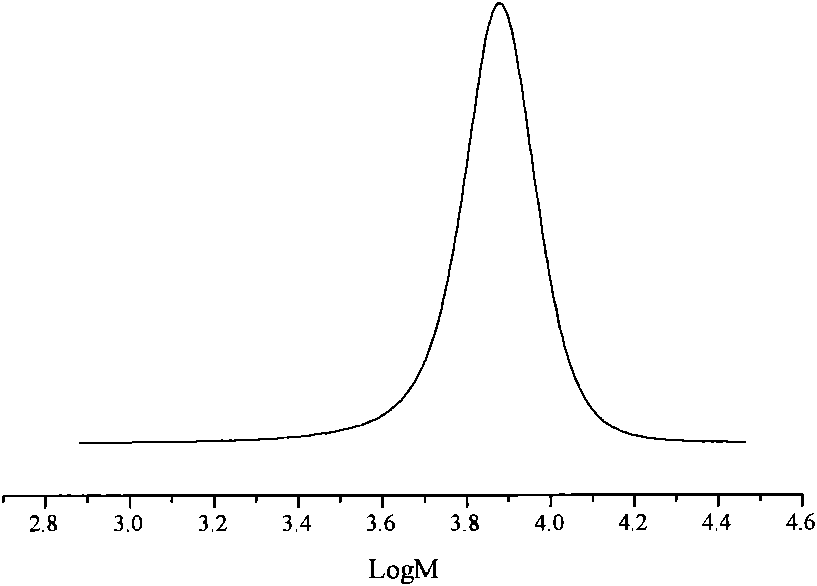

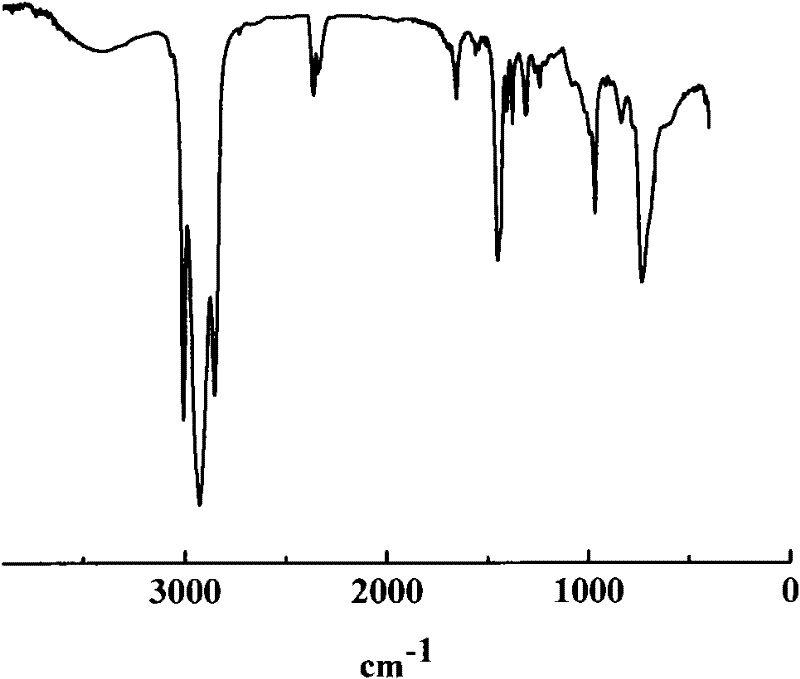

Cyclic azobenzene amphiphilic segmented copolymer and its preparation method

ActiveCN103819584APhotoresponsiveSmall molecular weightOrganic chemistryPolymer scienceIsomerization

The invention discloses a cyclic azobenzene amphiphilic segmented copolymer and its preparation method. The preparation method is concretely characterized in that the cyclic azobenzene amphiphilic segmented copolymer with controllable molecular weight, molecular weight distribution and ratio of a hydrophilic segment to a hydrophobic segment is obtained by combining through controllable atom transfer radical polymerization (ATRP) and an efficient CuAAC reaction. Compared with linear polymers having a same molecular weight, the cyclic polymer disclosed in the invention has the advantages of high Tg, fast photo-isomerization, sensitive light and pH response performances in an alkaline medium, and wide application potential in medicine release, surfactants, coatings, adhesives and separation films.

Owner:SUZHOU UNIV

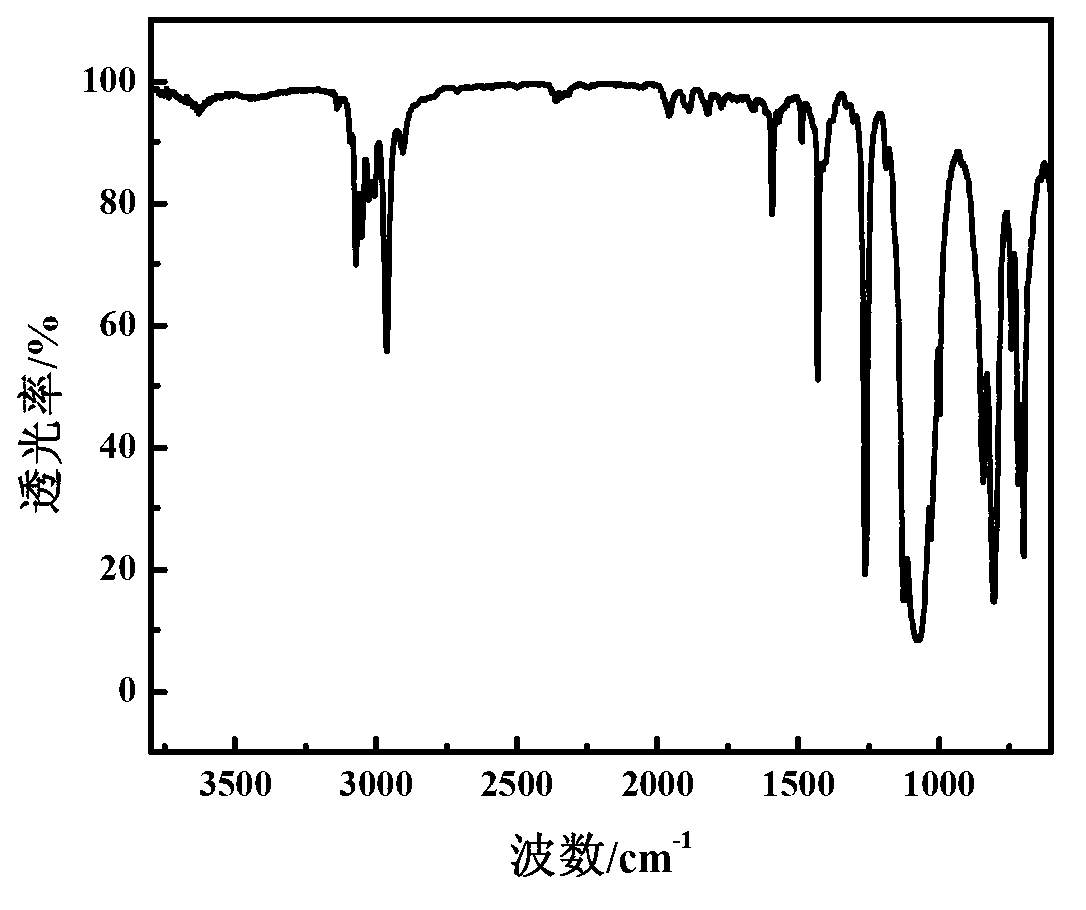

Method for preparing butadiene-isoprene copolymer

The embodiment of the invention discloses a method for preparing butadiene-isoprene copolymer, which comprises the steps of: reacting a reaction monomer under the action of a catalyst so as to obtain a solution A; and adding an ethanol solution to the solution A so as to condense butadiene and isoprene copolymer, wherein the mol ratio of the reaction monomer to the catalyst is 100 to 4000:1. In the invention, the molecular weight and the molecular weight distributions of the butadiene-isoprene copolymer are controlled by controlling the mol ratio of the reaction monomer to the catalyst, and a polymerization reaction is terminated through hydroxyl in ethanol. The experimental result proves that the butadiene-isoprene copolymer prepared by the invention has the advantages of low molecular weight and narrow molecular weight distributions, wherein the molecular weight of the butadiene-isoprene copolymer is 1,000 to 120,000, and Mw / Mn is 1.1 to 2.0.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Method for preparing butadiene-isoprene copolymer

The embodiment of the invention discloses a method for preparing butadiene-isoprene copolymer, which comprises the steps of: reacting a reaction monomer under the action of a catalyst so as to obtain a solution A; and adding an ethanol solution to the solution A so as to condense butadiene and isoprene copolymer, wherein the mol ratio of the reaction monomer to the catalyst is 100 to 4000:1. In the invention, the molecular weight and the molecular weight distributions of the butadiene-isoprene copolymer are controlled by controlling the mol ratio of the reaction monomer to the catalyst, and apolymerization reaction is terminated through hydroxyl in ethanol. The experimental result proves that the butadiene-isoprene copolymer prepared by the invention has the advantages of low molecular weight and narrow molecular weight distributions, wherein the molecular weight of the butadiene-isoprene copolymer is 1,000 to 120,000, and Mw / Mn is 1.1 to 2.0.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

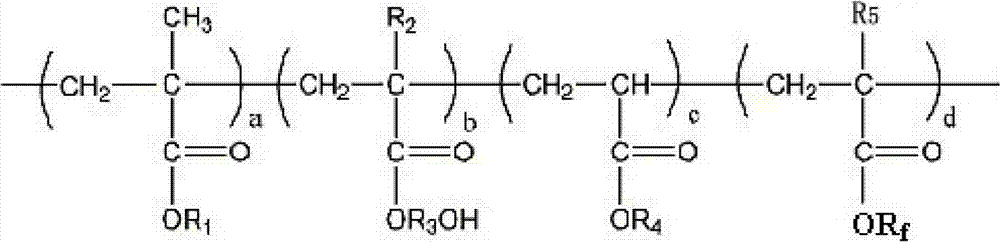

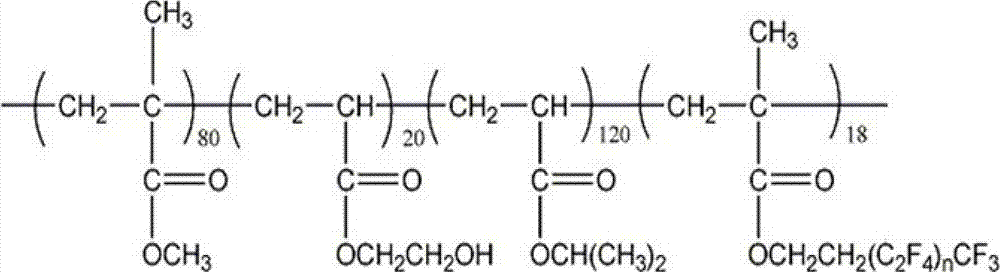

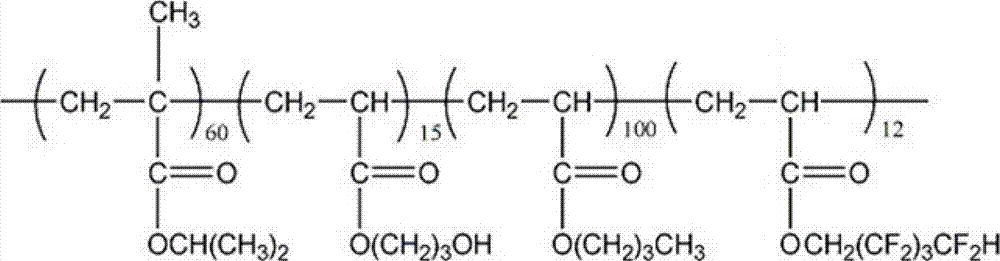

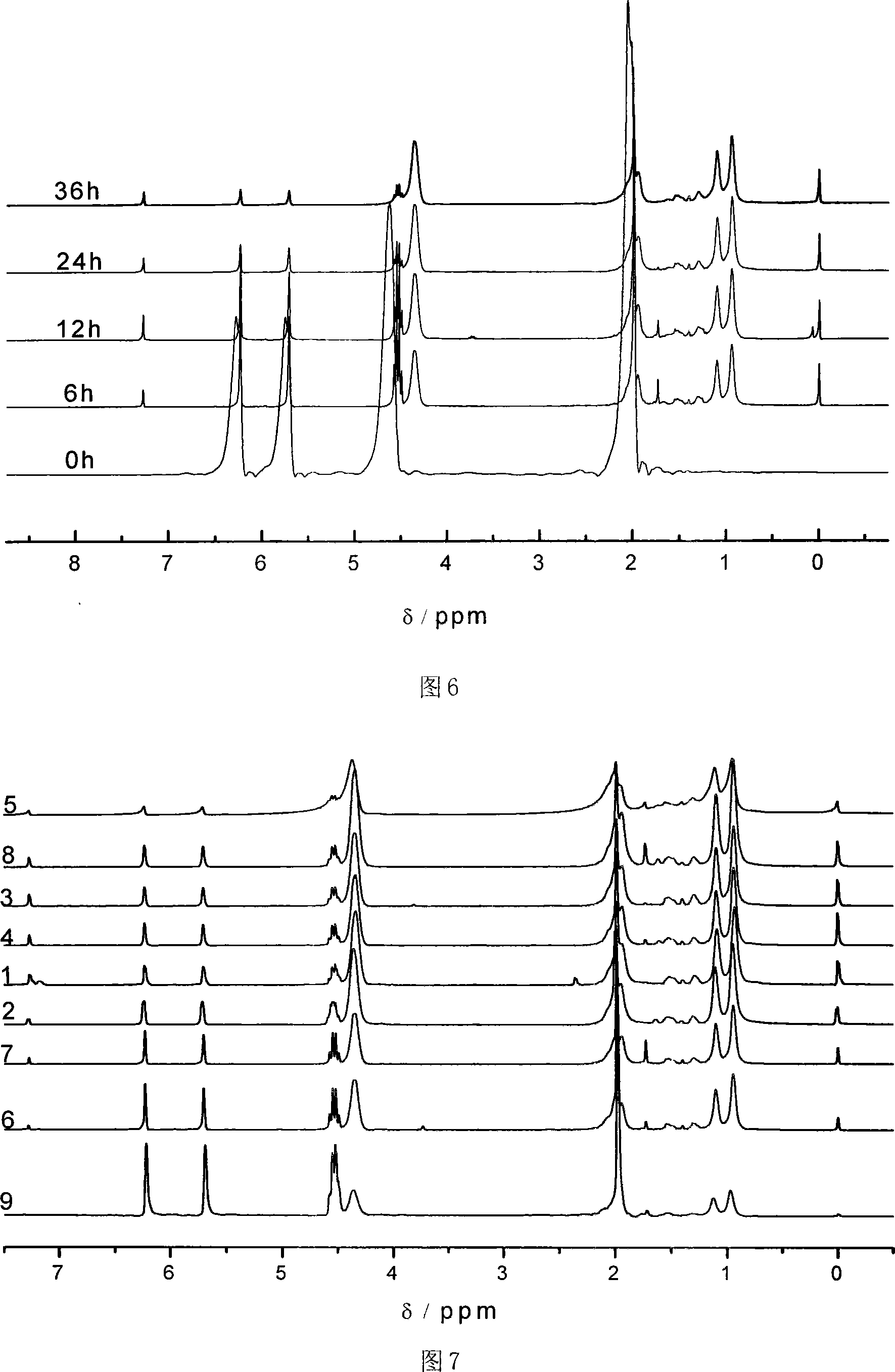

Cross-linked fluorine (methyl)-containing acrylic segmented copolymer and its preparation method and use

InactiveCN102827335AStrong process controllabilitySmall molecular weight distributionPolyurea/polyurethane coatingsCross-linkPolymer science

The invention discloses a cross-linked fluorine (methyl)-containing acrylic segmented copolymer and its preparation method and use, and belongs to the field of chemical materials. The preparation method comprises that various (methyl) acrylate functional monomers are copolymerized into the cross-linked fluorine (methyl)-containing acrylic segmented copolymer by an atom transfer radical polymerization (ATRP) method. A structure, molecular weight and molecular weight distribution of the cross-linked fluorine (methyl)-containing acrylic segmented copolymer can be controlled. The molecular weight of the cross-linked fluorine (methyl)-containing acrylic segmented copolymer is in a range of 10000 to 35000 and the molecular weight distribution is less than 1.4. The cross-linked fluorine (methyl)-containing acrylic segmented copolymer is mixed with a curing agent according to a certain ratio and the mixture self-assembles in a selective solvent so that a micellar solution having an average particle size of about 100 to 450nm is formed. Through a solvent evaporation film-forming method, the micellar solution is prepared into a super-hydrophobic coating film having a contact angle of more than 150 degrees, hardness H and second-level adhesion. The preparation method has simple and feasible operation processes, a low cost and a wide application prospect in the field of water-proofing and moisture-proofing coatings.

Owner:SOUTH CHINA UNIV OF TECH

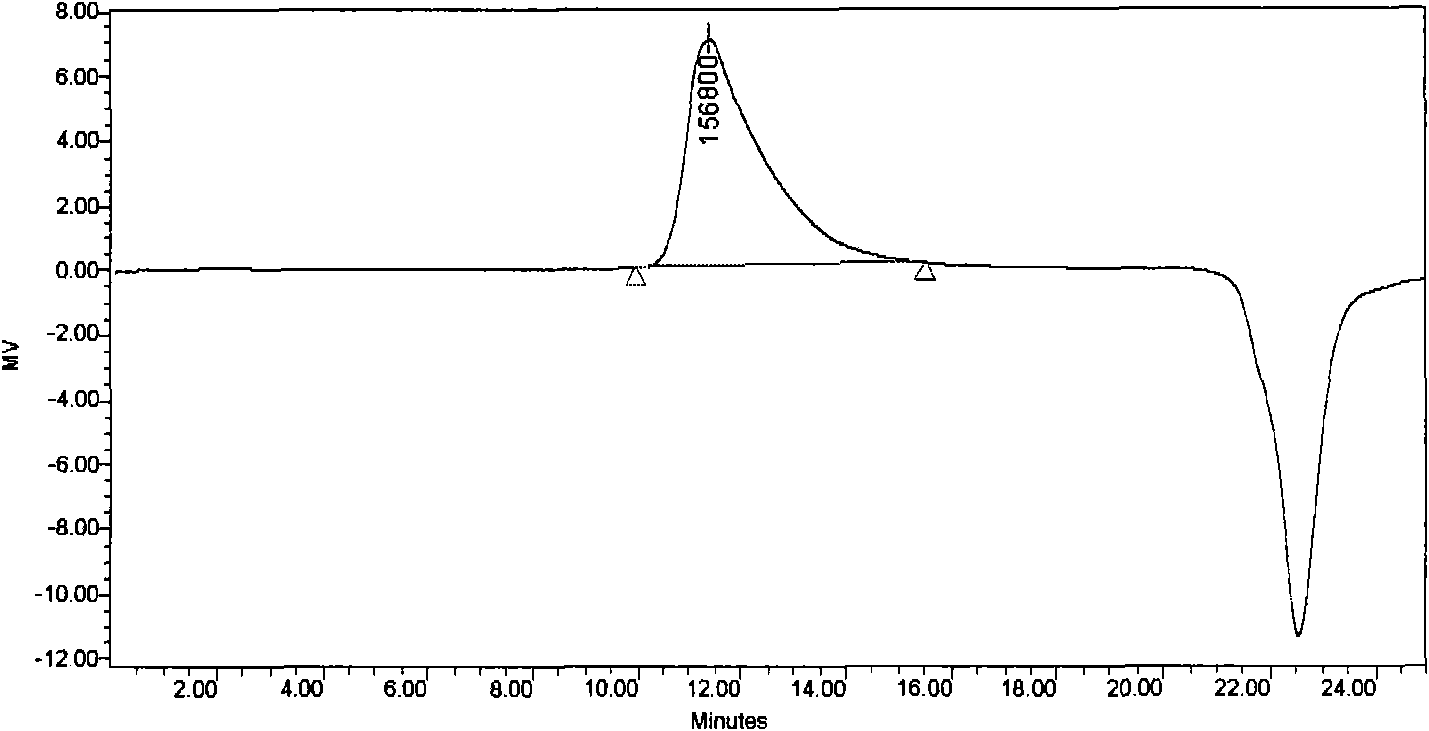

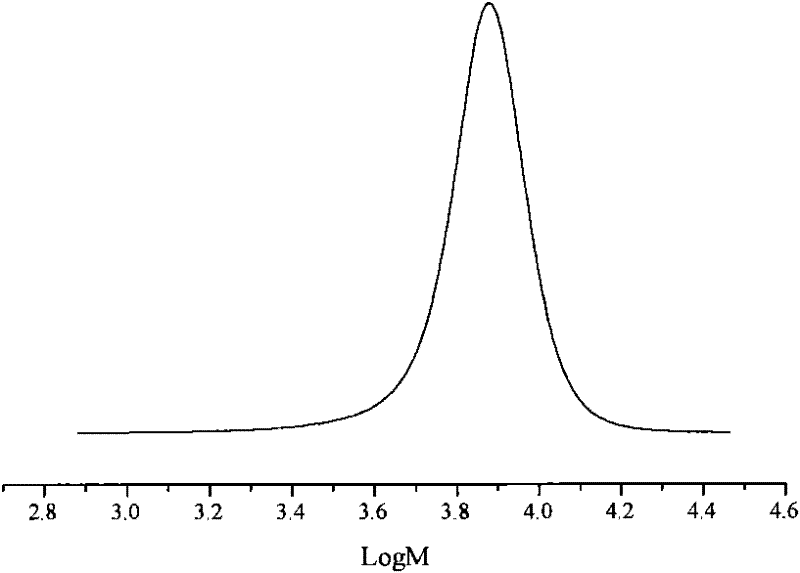

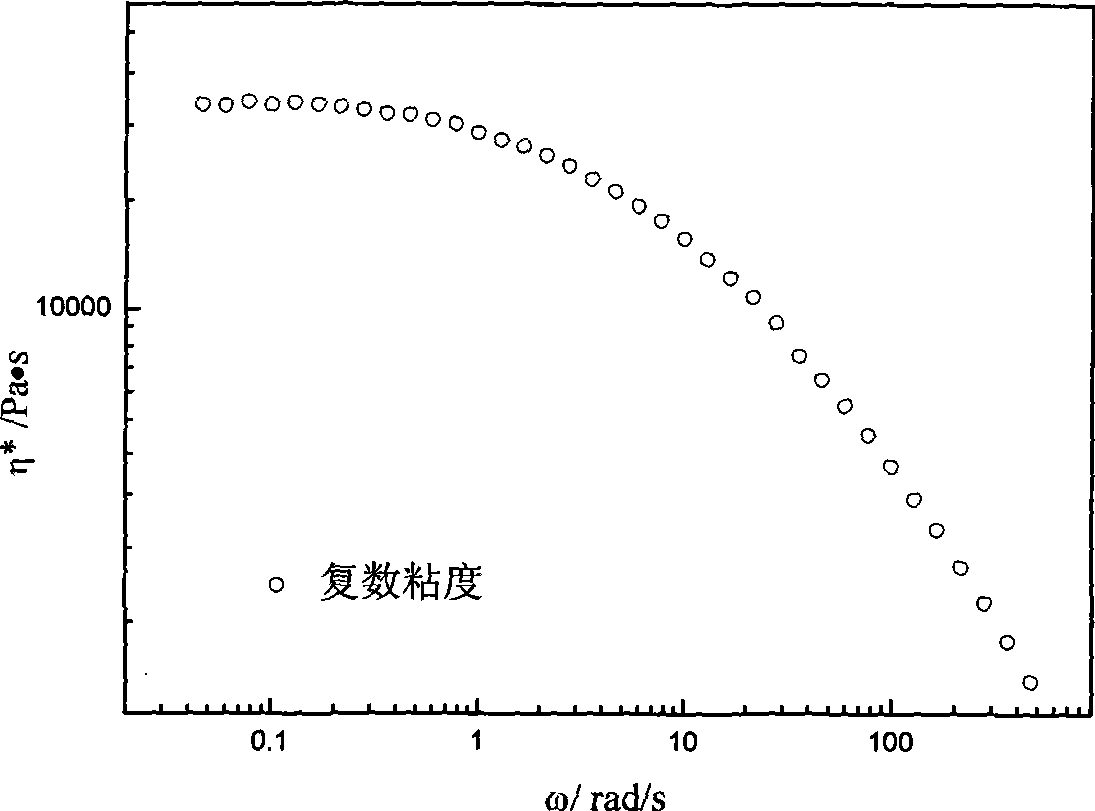

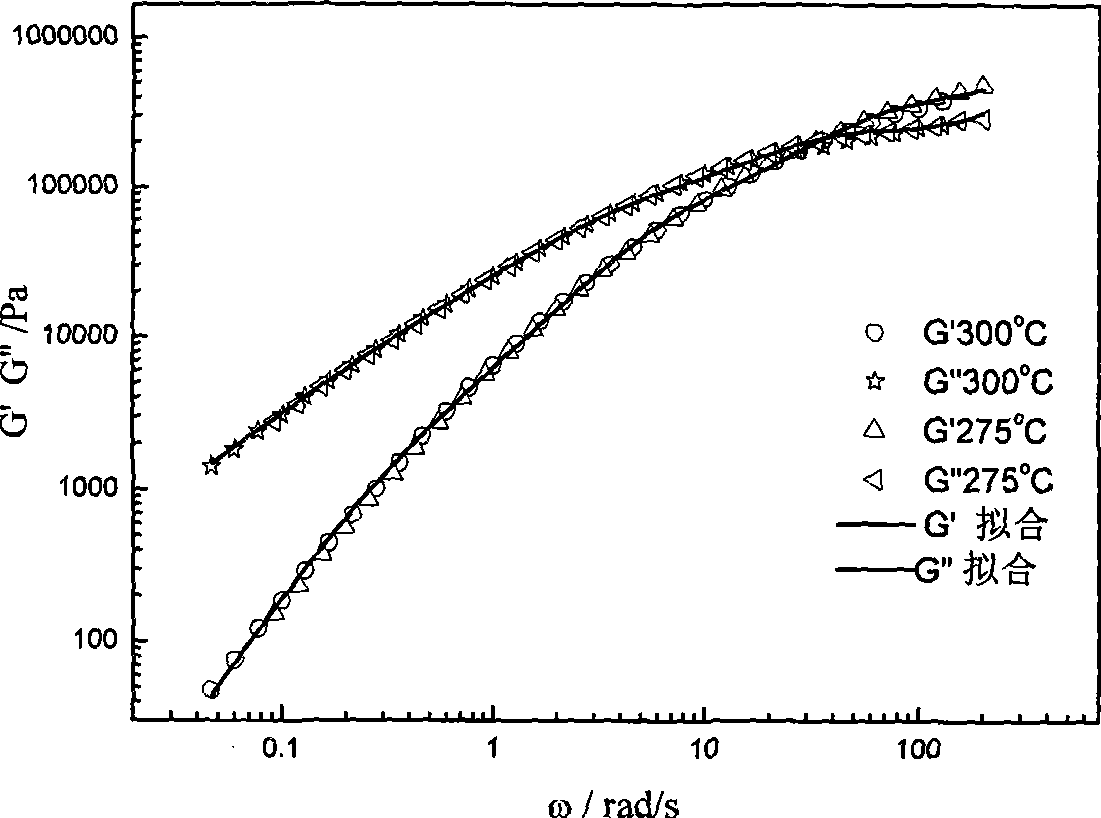

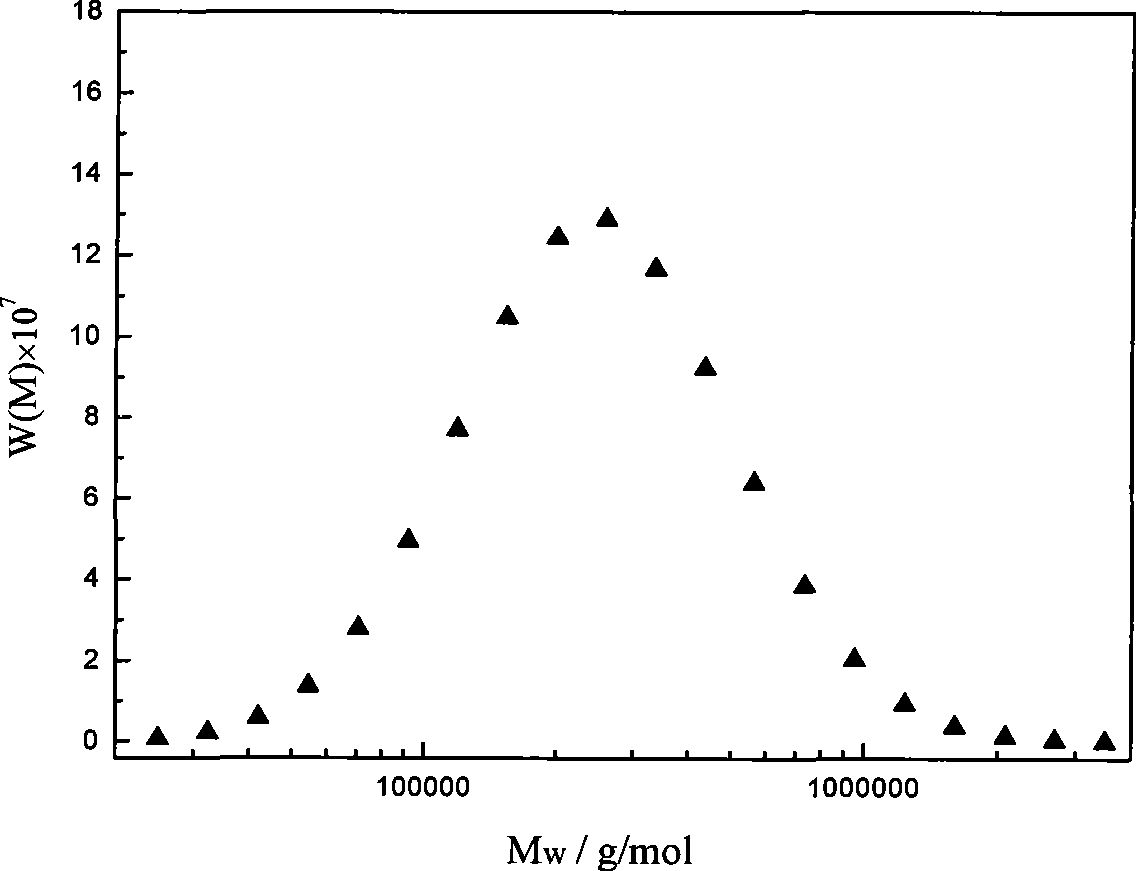

Method for measuring molecular weight distribution of linear polymer

InactiveCN101458246AReduce measurementSmall molecular weight distributionFlow propertiesPolymer dissolutionMathematical model

The invention relates to a method for measuring molecular weight distribution of a linear polymer. Rheological behavior of the polymer is measured by a dynamic rheological test, and a dynamic storage modulus curve is converted into a weight integral distribution curve of the molecular weight according to a mathematical model, and the integral distribution curve is differentiated to obtain the molecular weight distribution of the linear polymer. The method is based on the rheology, does not need dissolution of the polymer, overcomes the limit that the molecular weight of insolubles or indissolubles can not be or is difficult to be measured by the traditional measurement method without dissolution of the polymer based on the rheology, and help cheaply, rapidly and reliably measure the molecular weight distribution of linear polymers with environmental protection. The method can be programmed and embedded in rheological test software to expand the application range of a rheometer.

Owner:ZHEJIANG UNIV

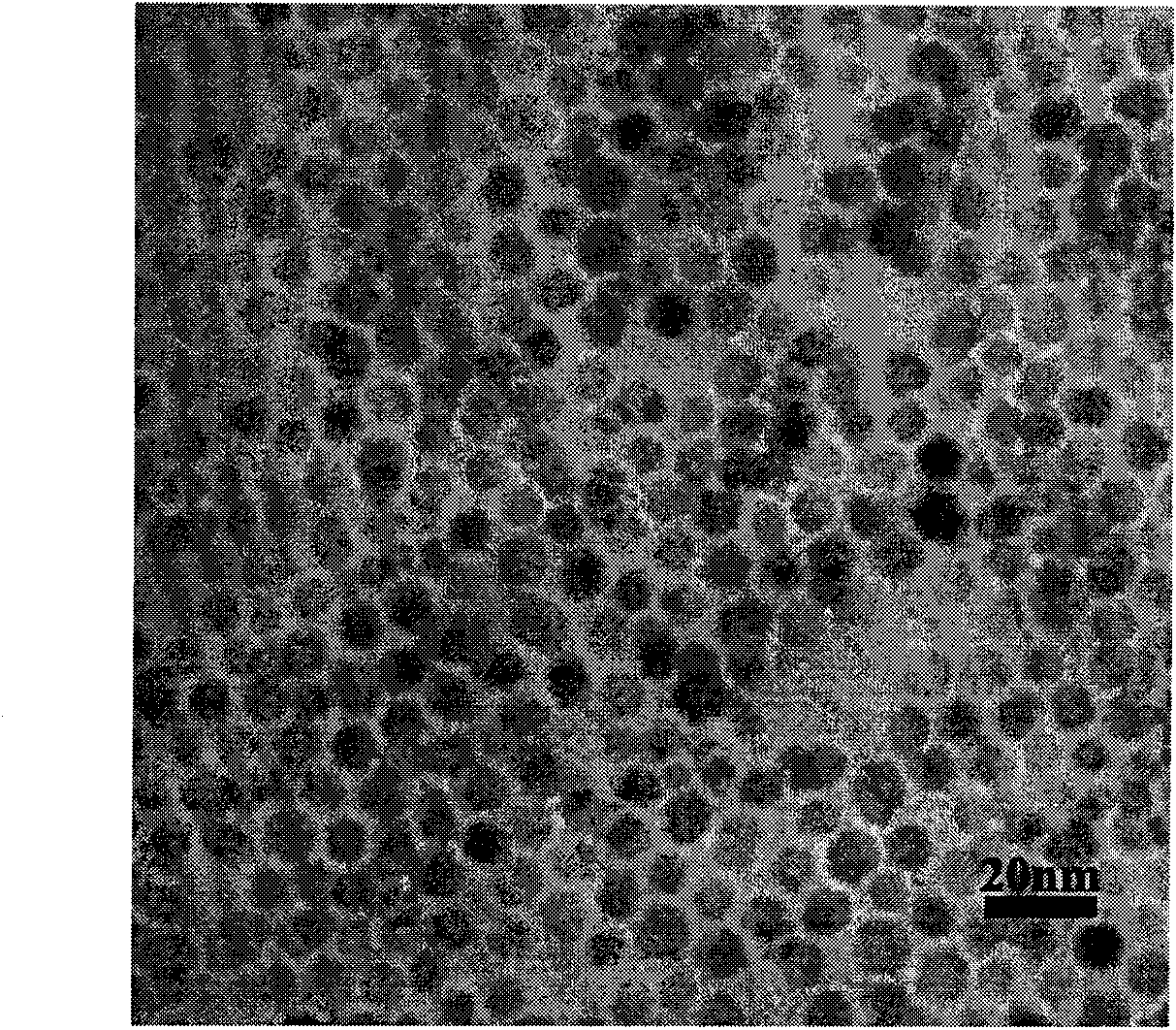

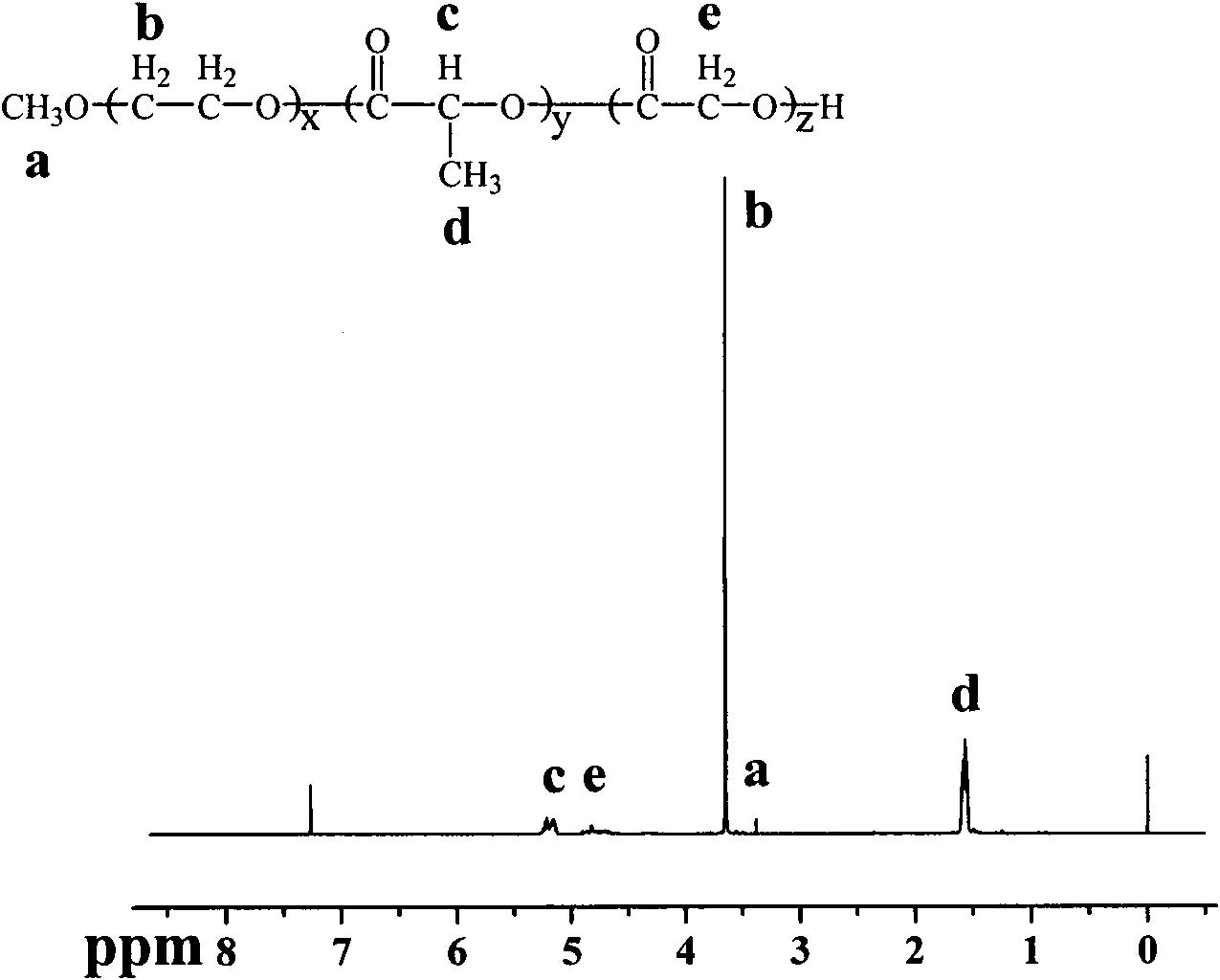

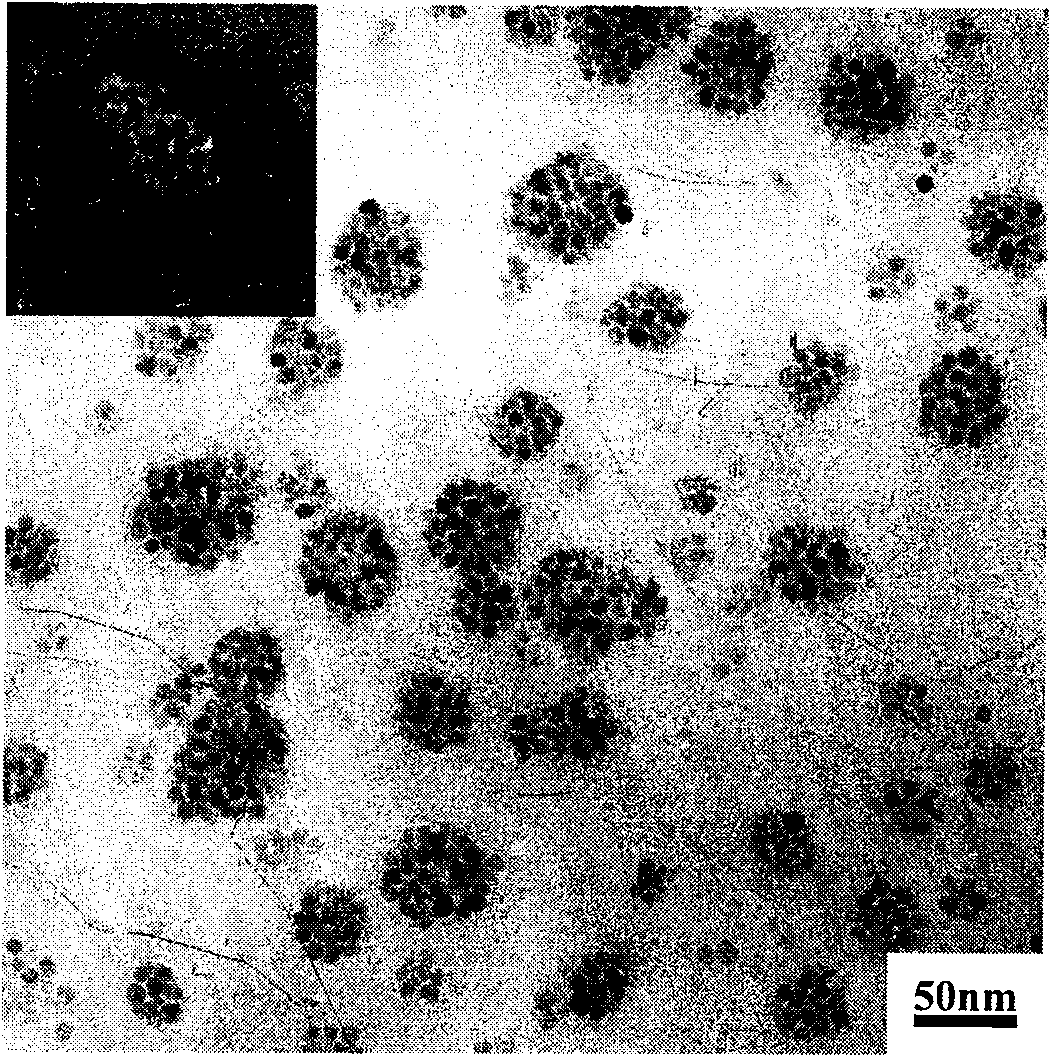

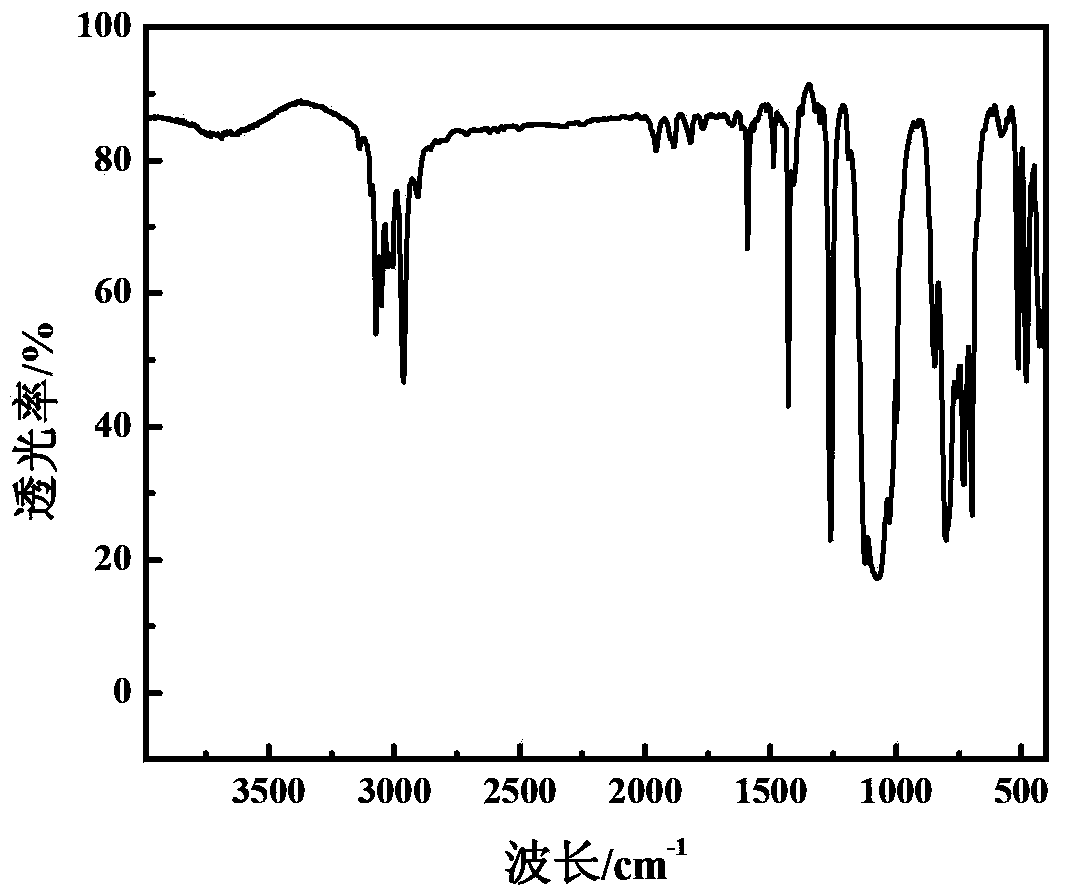

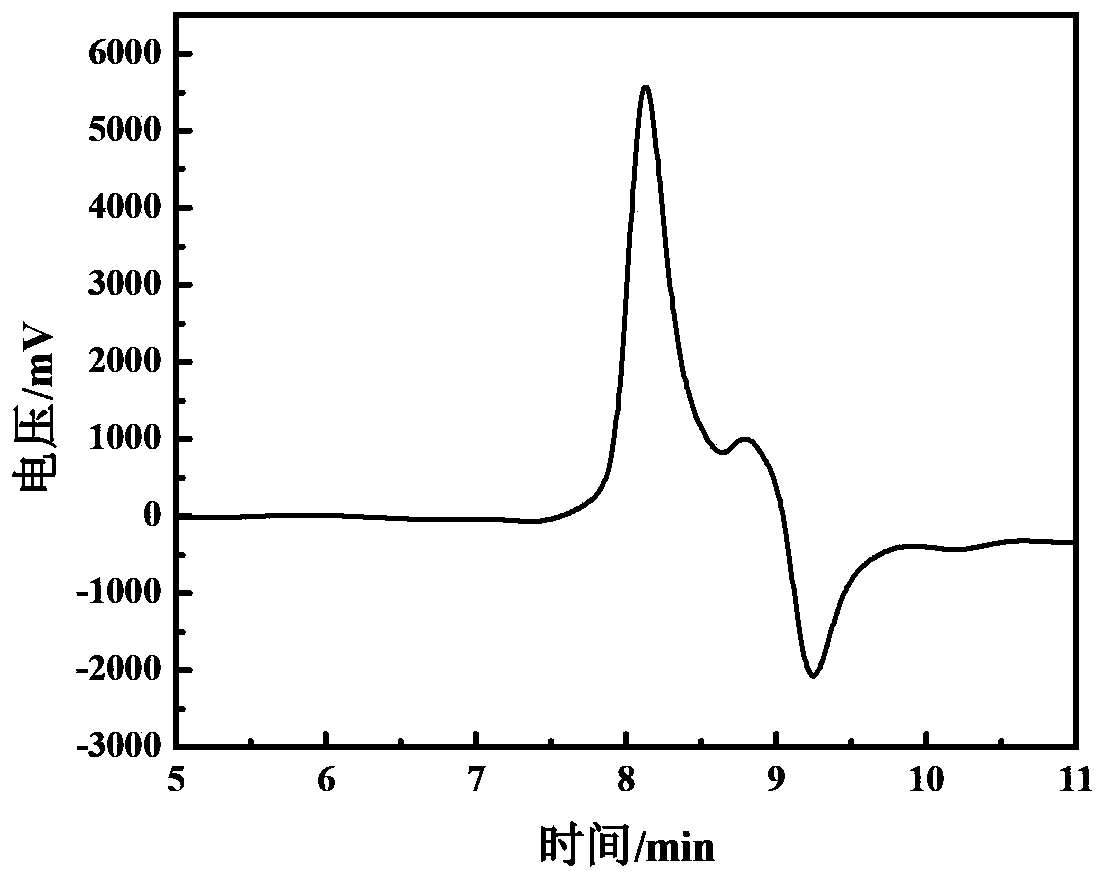

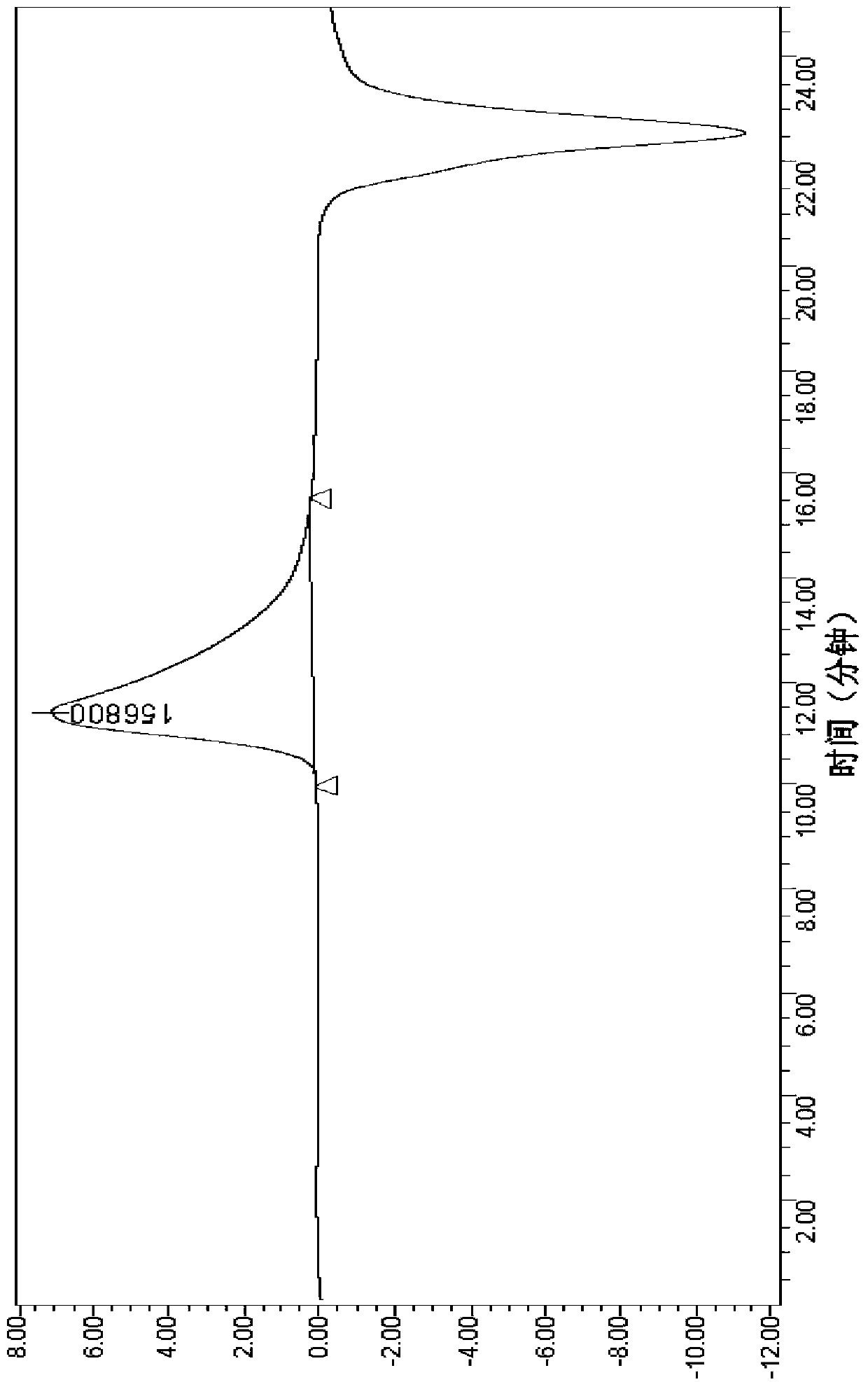

Magnetic nano-carrier with targeted hydrophobic drug delivery to tumor and preparation method thereof

InactiveCN101632834ASolve solubilityReduce usageInorganic non-active ingredientsIn-vivo testing preparationsNanocarriersSide effect

The invention belongs to the technical field of biomedical polymer material and nanobiomaterial, particularly relates to a magnetic nano-carrier with targeted hydrophobic drug delivery to tumor and a preparation method thereof. The magnetic nano-carrier is formed by encapsulating superparamagnetic nano-particles with amphiphilic segmented copolymer methoxy polye thylene glycol-poly(lactide- glycolide) (MePEG-PLGA) micelles. First, a large amount of MePEG-PLGA with good dispersion is synthesized by the improved solution polymerization process, and then the MePEG-PLGA is used as raw materials to encapsulate Fe3O4 nano-particles by the solvent evaporation process to obtain a magnetic nano drug carrier. The carrier is expected to solve the solubility problem of insoluble drugs, achieves slow release of drugs, and achieves the passive-targeting of the drugs by the EPR effect of tumor; Fe3O4 nano-particles are used in the active-targeting of the drugs to reduce the dosage and the side effect and improve the treatment efficiency; besides, the carrier can be used in the magnetic resonance imaging (MRI) of tumor.

Owner:JILIN UNIV

Preparation method of methyl phenyl silicone oil with high refractive index

The invention relates to a preparation method of methyl phenyl silicone oil with high refractive index, and belongs to the technical field of organosilicon synthesis. The method is as below: using dimethyl dichlorosilane, diphenyl dichlorosilane and dichloromethyl phenylsilane as polymerization monomers; adding the monomers into a solvent while stirring at 30 DEG C; uniformly stirring; dropwise adding a proper amount of a hydrolysate; continuing to react until the end of hydrolysis; standing for layering; separating out a lower layer of acid water; washing an upper layer organic phase to a neutral state to obtain a siloxane prepolymer; adding a proper amount of an end-capping reagent and a condensation catalyst into the siloxane prepolymer to carry out a condensation reaction; after the reaction, washing out the catalyst to a neutral state; and steaming out the solvent of xylene and low-boiling-point substances under reduced pressure to obtain the silicone oil. The methyl phenyl silicone oil prepared by the invention is a clarified transparent oily liquid with high refractive index, good product uniformity, high purity and good high temperature resistance; and the preparation technology is simple and easy for industrialization.

Owner:JIANGSU UNIV

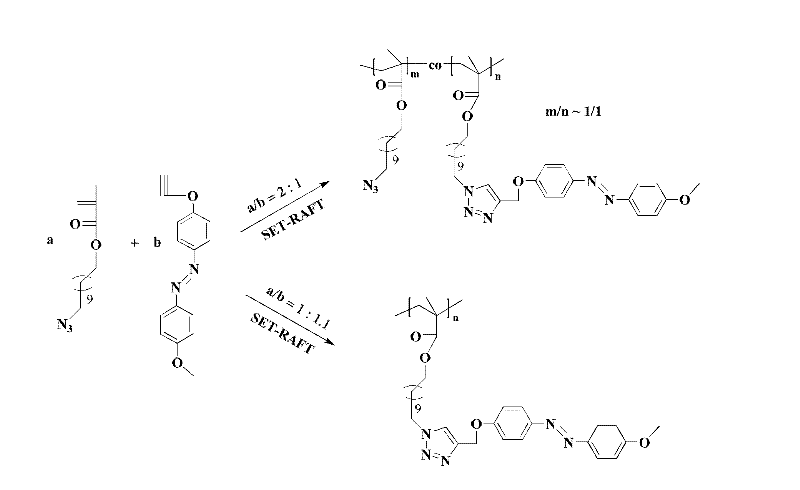

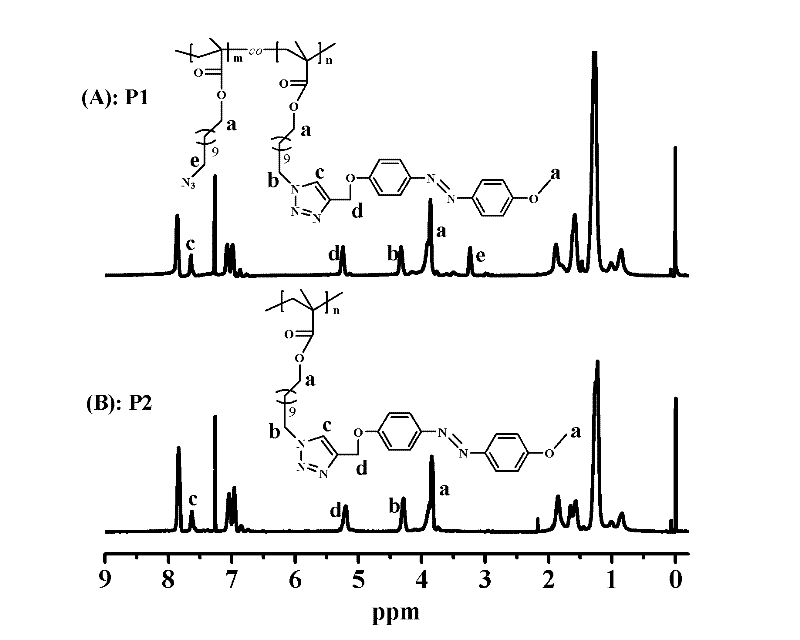

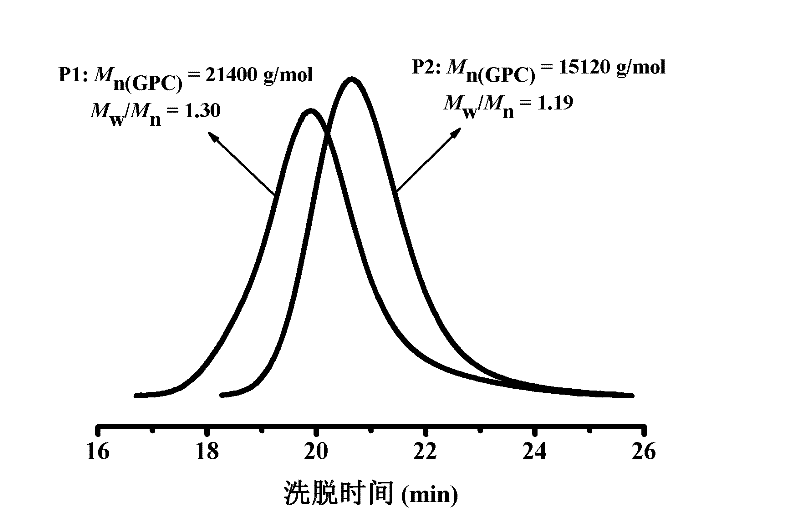

Side chain functional polymer and preparation method thereof

The invention discloses a side chain functional polymer and a preparation method thereof. A polymerization system consists of a monomer, an initiator, a chain transfer agent, a catalyst, a coordination agent and a coupling component, wherein the monomer is undecyl azidomethacrylic ester; the catalyst is copper; the coordination agent is N,N,N',N'',N''-pentamethyldiethylenetriamine; the coupling component is 4-methyoxyl-4'-propynyloxy azobenzene; single electron transfer (SET) is adopted for initiation to produce a free radical; polymerization reaction of the monomer is performed by a method for performing chain propagation in a reversible addition fragmentation chain transfer (RAFT) mode; meanwhile, click chemical reaction is performed; and monovalent copper is used for catalyzing an azide group and an alkynyl group in the coupling component to perform cycloaddition reaction so as to obtain the side chain functional polymer. Since the SET-RAFT method and the click chemical method are combined, the side chain functional polymer can be obtained by only one-step reaction; and thus, the reaction steps are reduced, the waste rate of the raw materials is reduced, rational utilization ofthe resources is realized, side reaction is basically avoided, and troublesome purification operation is avoided.

Owner:SUZHOU UNIV

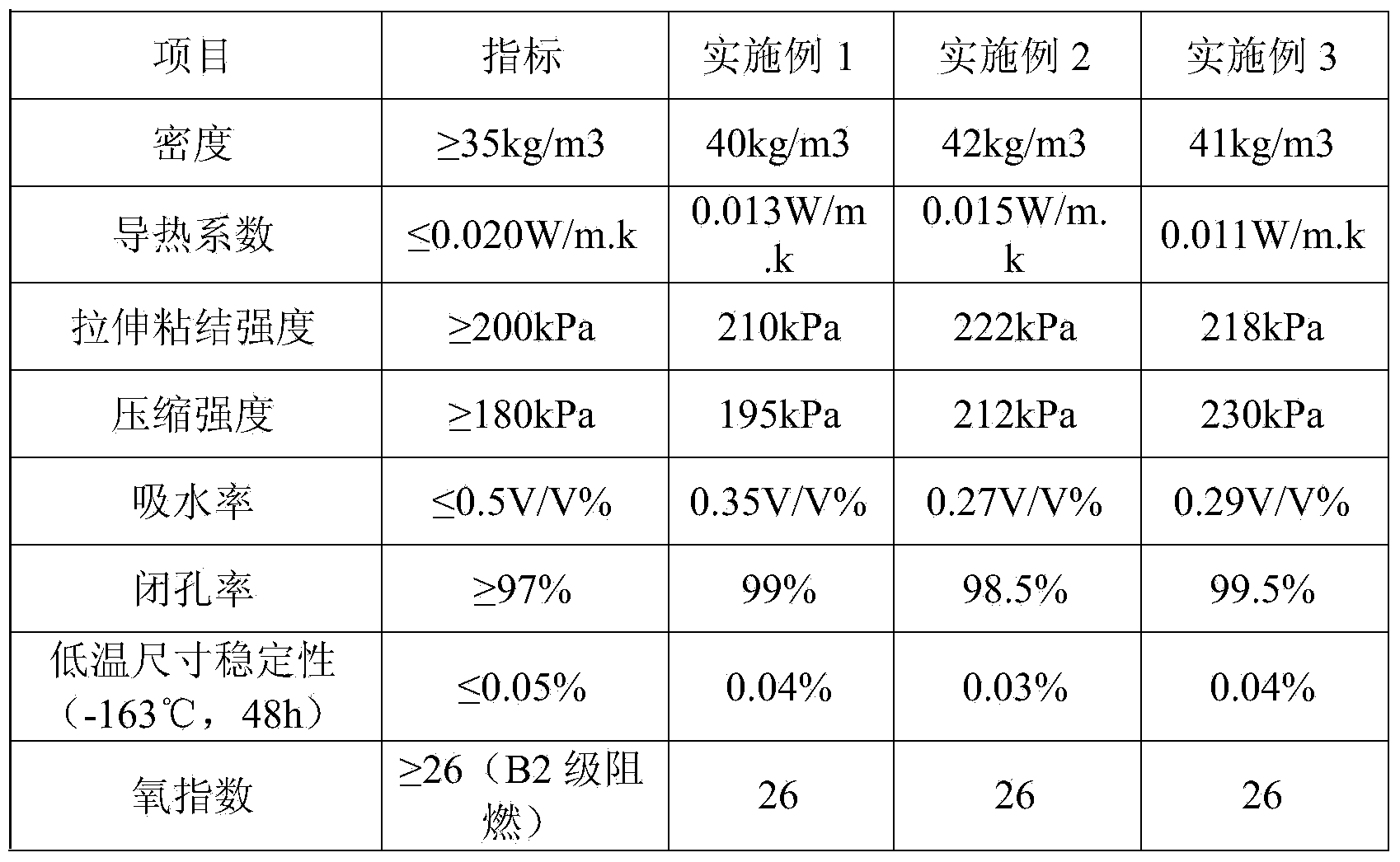

Modified polyurethane spraying composite material for cold insulation of ultralow temperature liquefied natural gas (LNG) storage tank and preparation method of composite material

ActiveCN103709355ASmall molecular weight distributionGood dimensional stability at low temperaturePolyurea/polyurethane coatingsFire retardantHigh pressure

The invention relates to a modified polyurethane spraying composite material for cold insulation of an ultralow temperature liquefied natural gas (LNG) storage tank and a preparation method of the composite material. The composite material consists of a component A and a component B at a weight ratio of 1: (1-1.05), wherein the component A includes polyether glycol A, polyether glycol B, modified polyether glycol, a foam stabilizer A, a foam stabilizer B, a chemical foaming agent, a physical foaming agent, a catalyst, a fire retardant and other auxiliaries, and the component B is polymethenyl polyphenyl polyisocyanate; the preparation method comprises the steps of sequentially adding the ingredients of the component A in a reaction kettle, stirring for 0.5-1 hour at a high temperature for completely mixing; and uniformly mixing the component A and the component B at weight ratio of 1: (1-1.05) through a high-pressure spraying machine, atomizing and foaming so that foam is rapidly formed and ripened, thus obtaining a finished product. The foam prepared by the invention is quite strong in low-temperature size stability, and is free from contraction crack in a cryogenic environment, so as to guarantee a perfect cryogenic cold insulation effect; and the composite material is specifically applicable to cold insulation construction of the LNG storage tank.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

Method for preparing hexafluoropropylene oxide oligomer

InactiveCN104513390AEffective control of molecular weightImprove conversion rateProduction effectBiological activation

The invention discloses a method for preparing hexafluoropropylene oxide oligomer. Alkali-metal fluoride salt, aprotic inertia polarity organic solvents, fluorine-containing organic solvents and perfluoro(2-methyl-3-oxahexanoyl)fluoride are used for preparing a homogeneous activation initiator, the homogeneous activation initiator is used for initiating a hexafluoropropylene oxide monomer to have a polymerization reaction, and then the hexafluoropropylene oxide oligomer with a high molecular weight is obtained. Meanwhile, a part of products and related solvents are recycled, and an environment-friendly recycle production effect is achieved.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

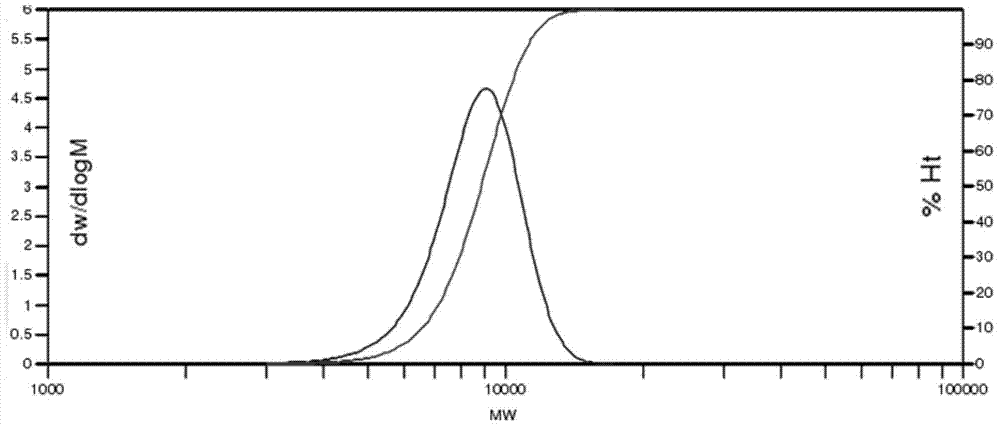

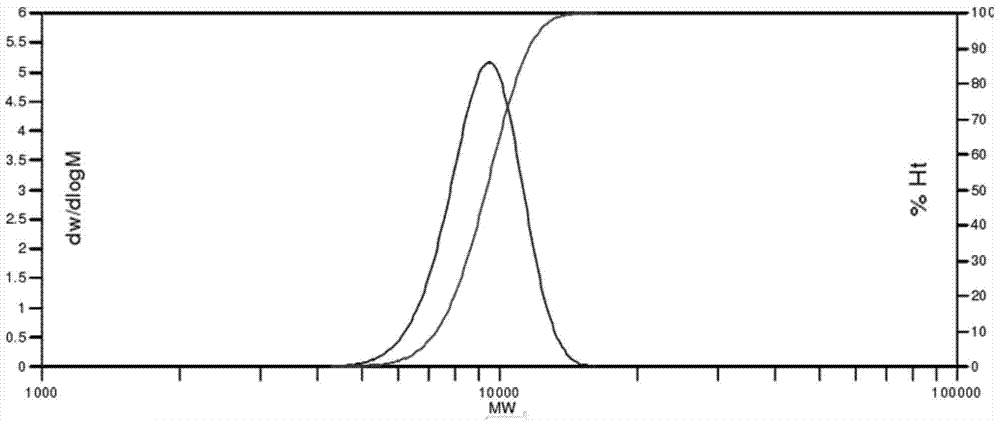

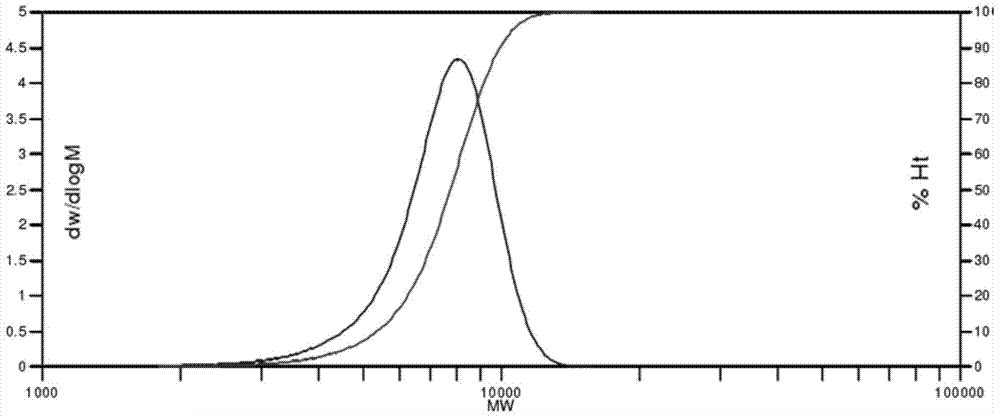

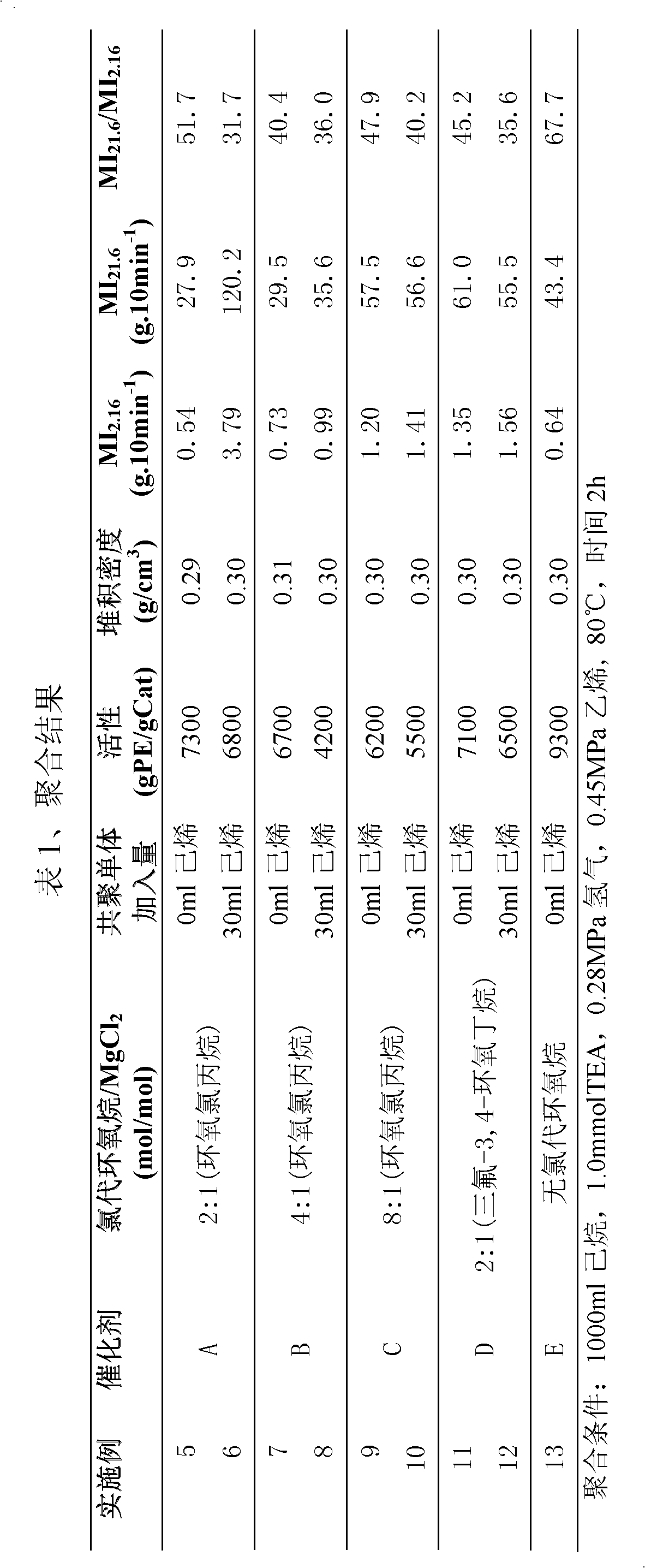

Polyethylene catalyst component with narrow molecular weight distribution, preparation method and application

ActiveCN103044591ASmall molecular weight distributionHigh ethyleneBulk chemical productionZiegler–Natta catalystSilica gel

The invention relates to a Ziegler-Natta catalyst component which comprises a Ti compound, MgCl2, silica gel, and halogenated alkylene oxide. The catalyst has a relatively high activity when used for ethylene polymerization or copolymerization, and can produce polyethylene resin with relatively narrow molecular weight distribution.

Owner:CHINA PETROLEUM & CHEM CORP +1

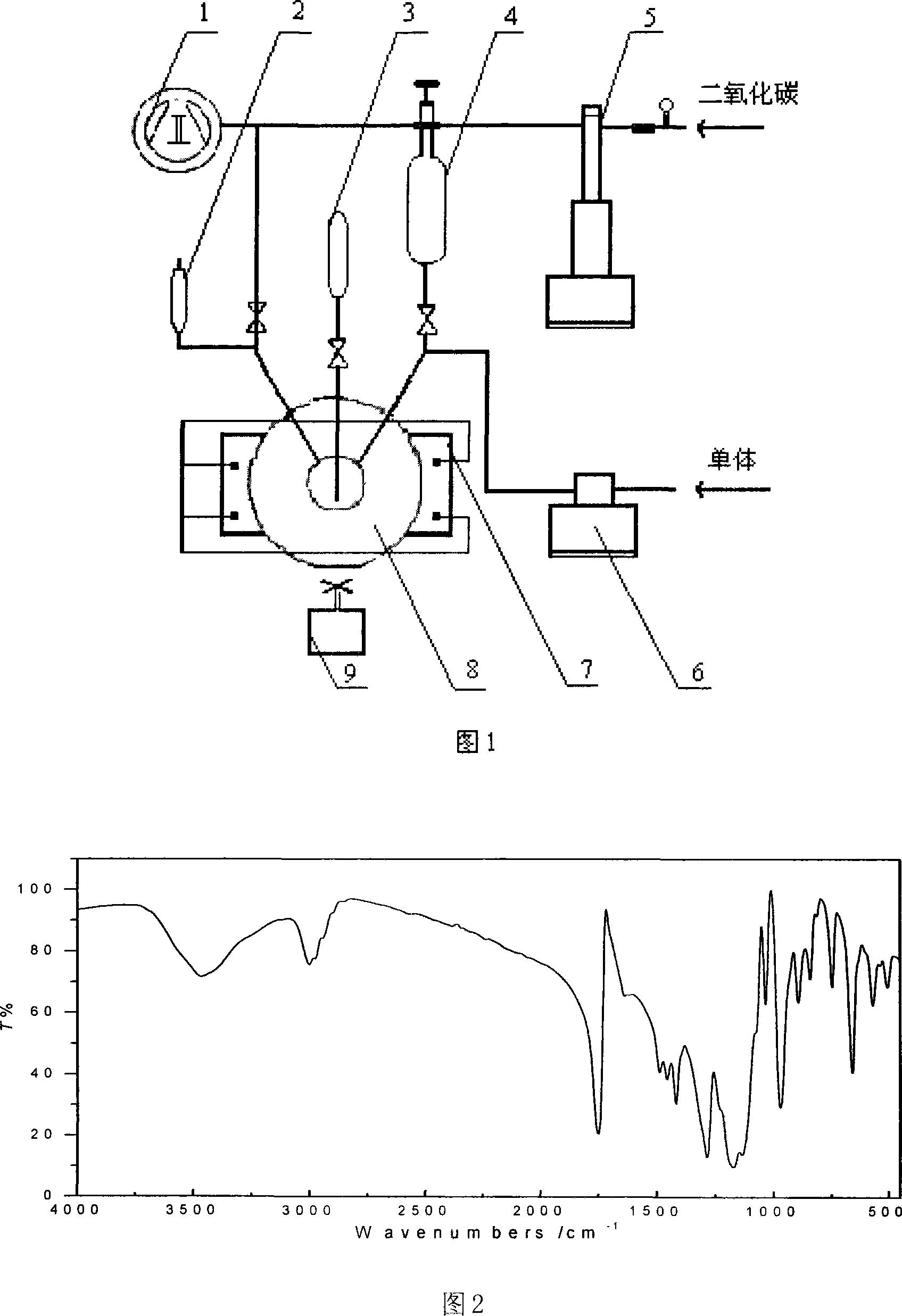

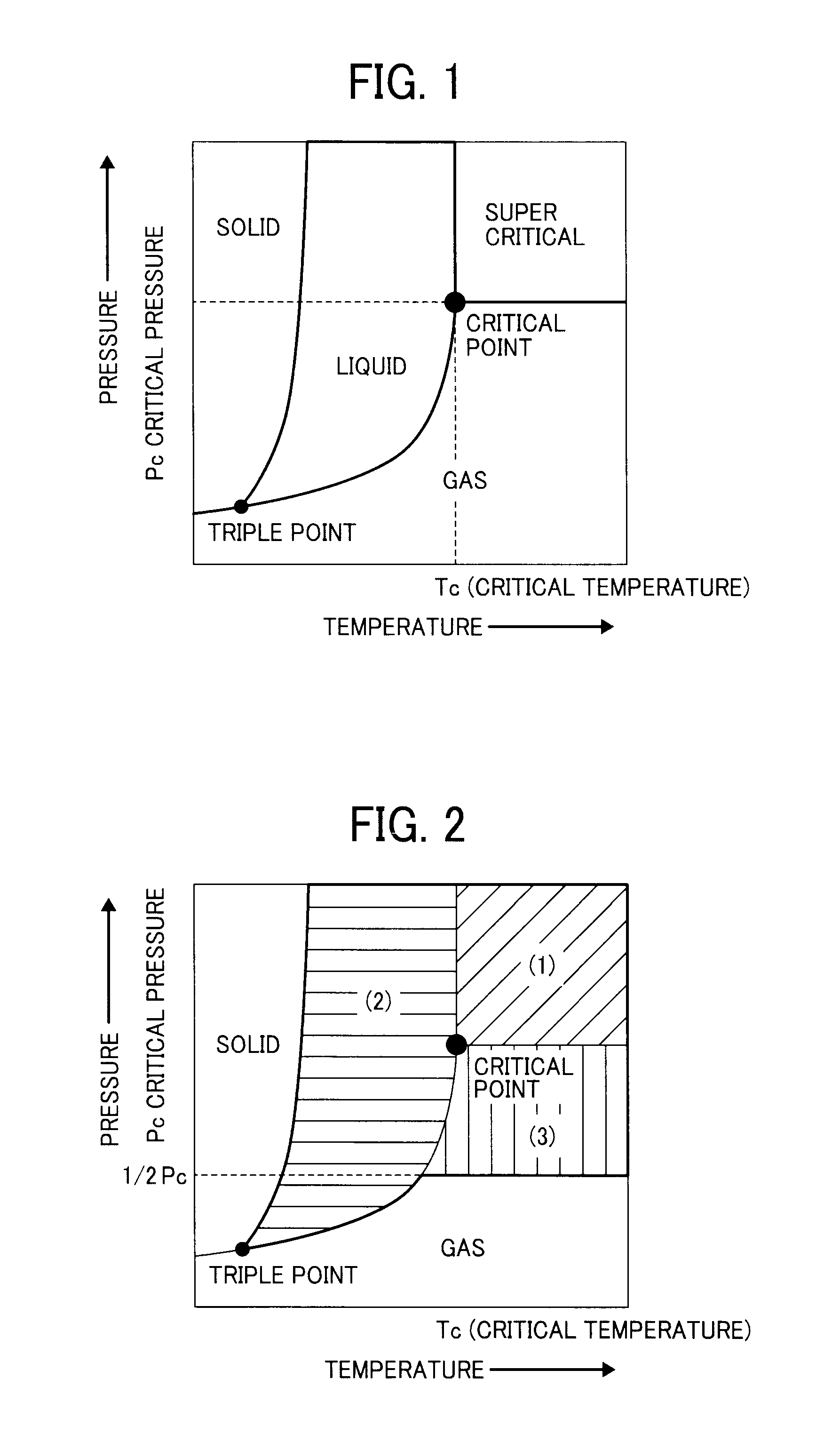

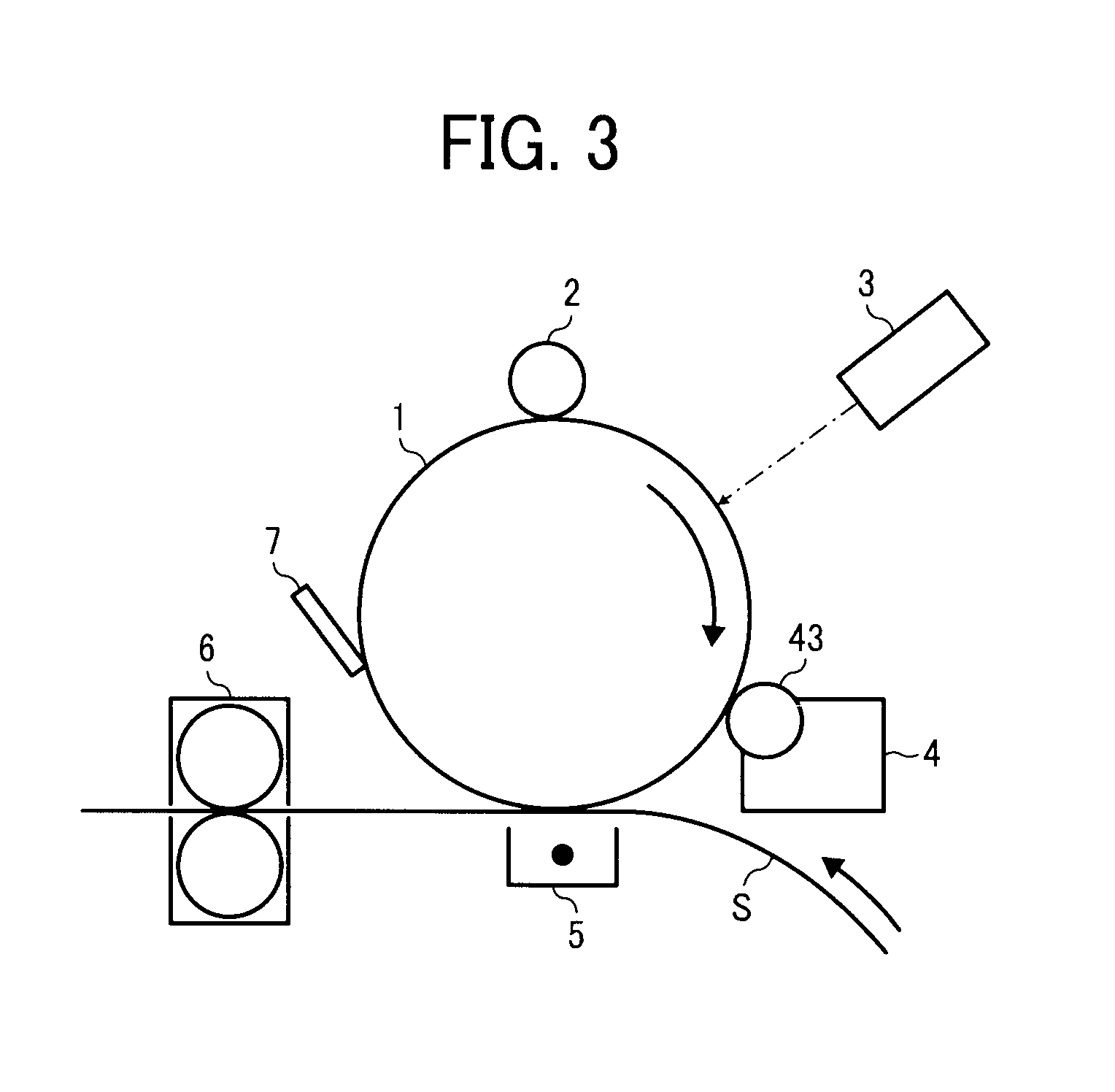

Method for preparing polythene derivative in supercritical fluid

InactiveCN101121760ASmall molecular weight distributionReduce lossBulk chemical productionReaction temperatureReaction step

The utility model relates to a preparation method of polyethylene derivatives in supercritical fluid. The utility model consists of a polymerization reaction step and a purification step by means of a reaction axe 8, and a vacuum pump 1 used for vacuumizing. Compared with the existing preparation method of polyethylene derivatives in supercritical fluid, the utility model takes use of the vacuum pump 1 to vacuumize the reaction axe 8. And then monomer is added into the reaction axe 8. When the reaction axe 8 is heated to the reaction temperature, initiator is added into the reaction axe 8 for polymerization reaction. Through a large number of laboratory research, the experiment results indicate that the processing steps of the utility model reduces the loss of raw materials in the reaction process, the environmental pollution, as well as the polymer molecule distribution, enhances the yield rate of the polymerization reaction products and improves the performance of the products. The utility model also reduces the production cost. The utility model can be used for the preparation of polyethylene derivatives after the medium enlarging experiment.

Owner:SHAANXI NORMAL UNIV

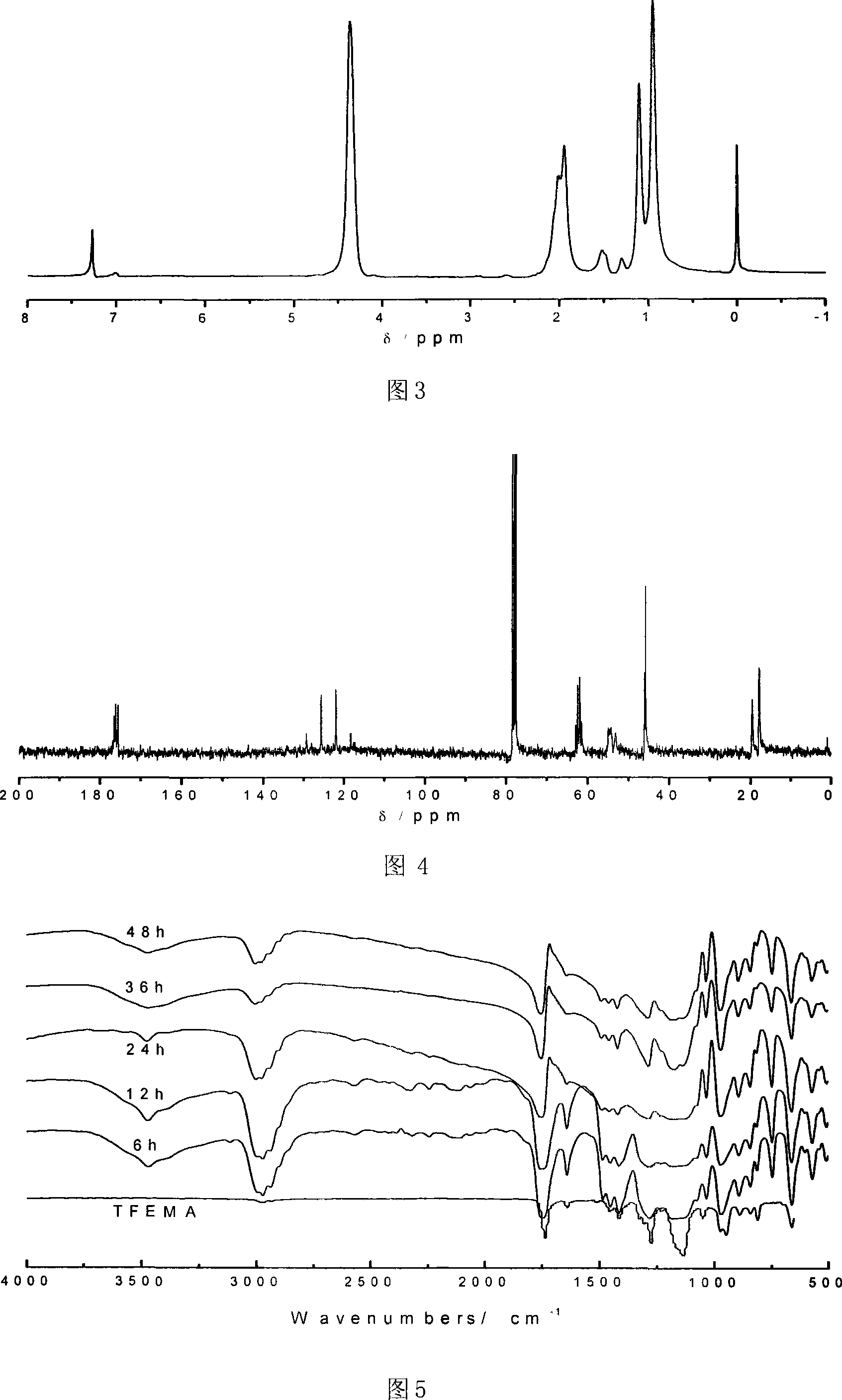

Method for preparing polyacrylonitrile spinning stoste

InactiveCN1710159AStable concentrationSmall molecular weight distributionMonocomponent synthetic polymer artificial filamentYarnPolymer science

The poly-acrylonitrile spinning stost is prepared by mixing acrylonitrile, azobisisobutyronitrile and dimethyl sulfoxide according to a certain weight proportion, stirring uniformly, leading in nitrogen gas under the stirring speed of 230-290 turn / min., making them react under reaction temp. of 52-65 degree C, continuously feeding in acryamide solution to react for 8-13 hours in which the ratio of feed amount per min. to container volume is 2x10-5 -1x10-4 min-1 , then demonomorizing and defoaming. Advantages: obviously reduced poly-acrylonitrile molecular weight distribution, improved spinning property of polymer and the oxidisability of raw yarn and simple process etc..

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

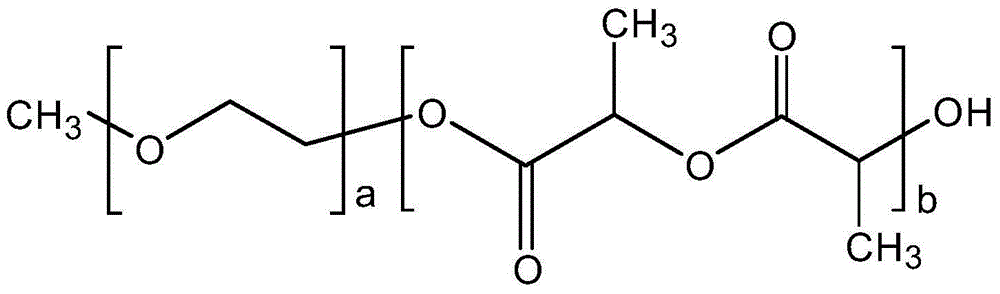

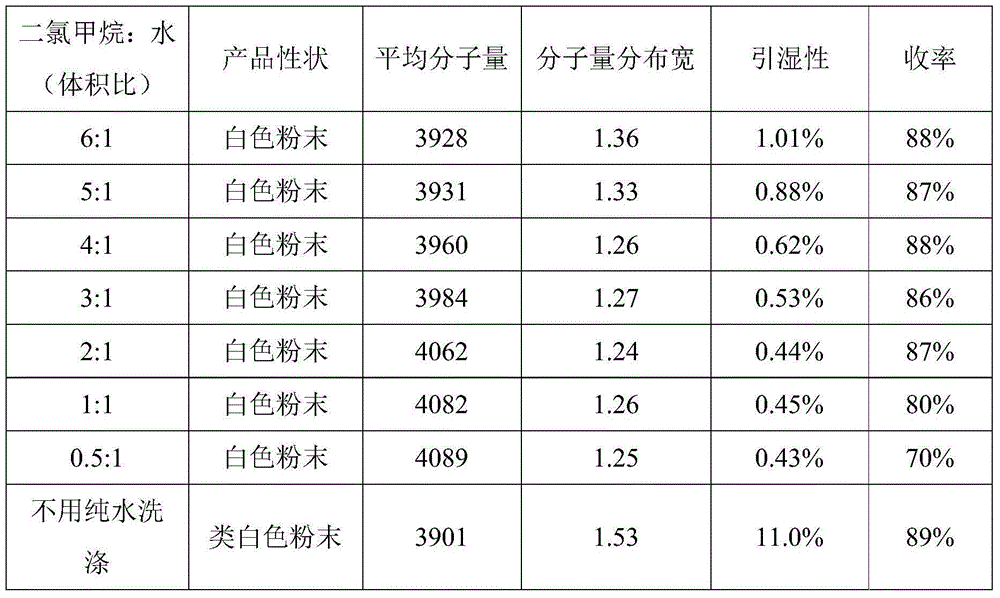

Preparation method of polyethyleneglycol monomethyl ether-polylactic acid block copolymer

InactiveCN104892909ASmall molecular weight distributionIncrease humidityOrganic active ingredientsAerosol deliveryDissolutionDiethyl ether

The invention provides a preparation method of a polyethyleneglycol monomethyl ether-polylactic acid block copolymer, which comprises the following steps: reacting raw materials polyethyleneglycol monomethyl ether and D,L-lactide by melt polycondensation by using stannous octoate as a catalyst; and after the reaction finishes, carrying out after-treatment by a 1-4-time dichloromethane dissolution-aether crystallization process, wherein the product to be purified is dissolved by the dichloromethane and washed with pure water in the first or second crystallization process to remove more low-molecular impurities, thereby obviously narrowing the molecular weight distribution of the product. The hydroscopic property of the product is obviously improved, and the flowability is higher and is more suitable for preservation and use of the product.

Owner:深圳万乐药业有限公司

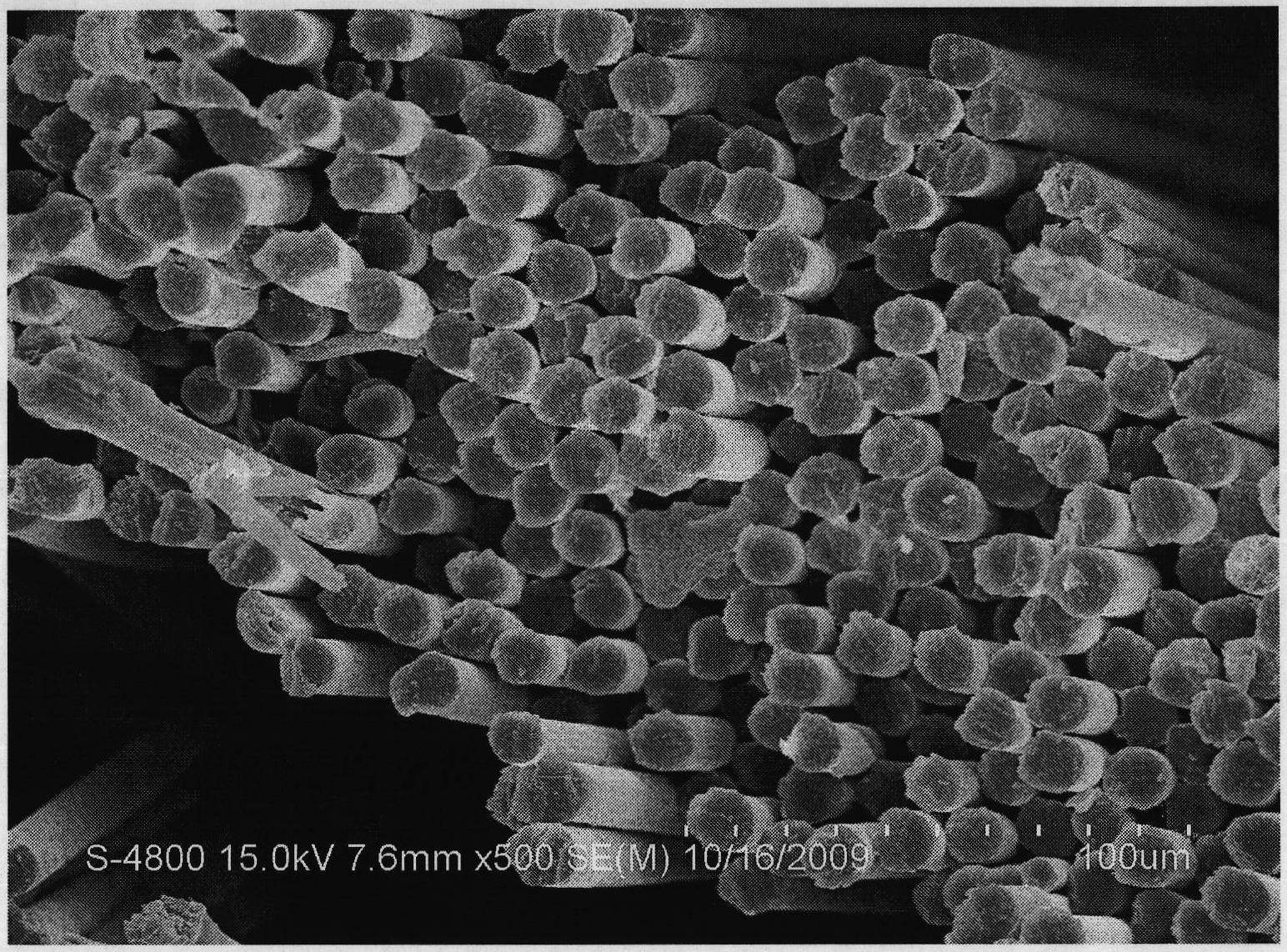

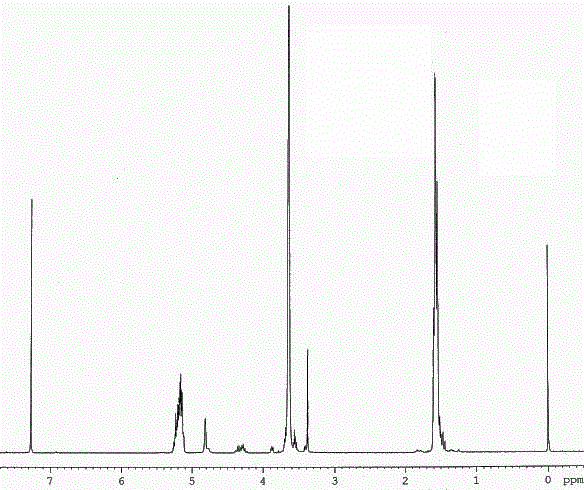

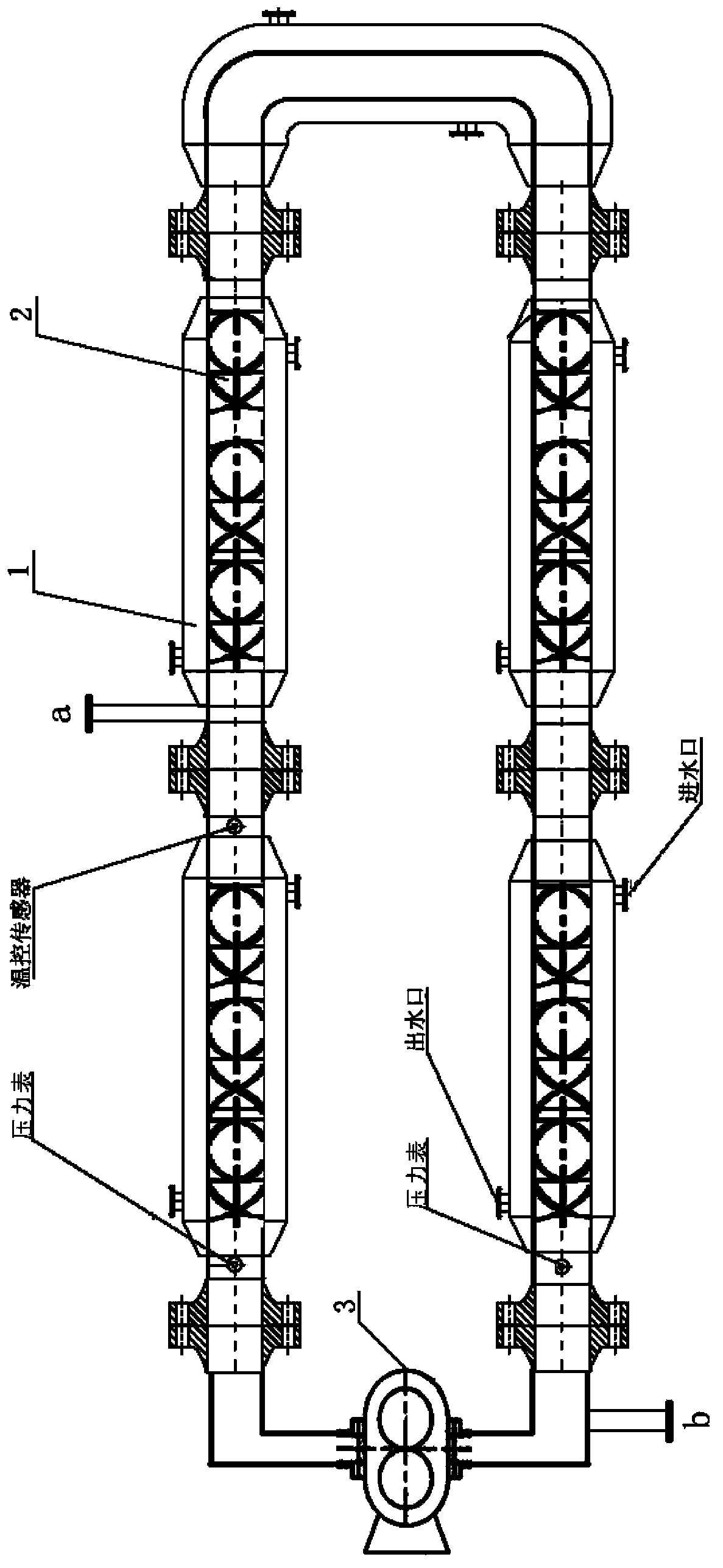

Polyacrylonitrile copolymer spinning solution and preparation method thereof

ActiveCN103421141AImprove the forceEnhanced mass transferFibre chemical featuresSpinning solutions preparationPolymer scienceAcrylonitrile

The invention relates to a polyacrylonitrile copolymer spinning solution and a preparation method thereof. In the invention, copolymerization reaction is performed on acrylonitrile in a tubular reactor containing a static mixer component; the tubular reactor, which contains the static mixer component and has the characteristics of mass transfer, efficient heat transfer, continuous and stable reaction and no mechanical stirring, is adopted to prepare the polyacrylonitrile copolymer spinning solution with high molecular weight and narrow molecular weight distribution. The polyacrylonitrile copolymer spinning solution is obtained after copolymerization reaction is performed on reaction liquid composed of monomers, a radical initiator and a solvent, wherein the percent concentration by weight of the monomers in the reaction liquid is 15% to 20%; the weight of the radical initiator is 0.4% to 1% of that of the monomers; the solvent is in balancing amount; the monomers are an acrylonitrile monomer and a comonomer. The dynamic viscosity of the polyacrylonitrile copolymer spinning solution provided by the invention is 200 to 800 Pa.S, and the molecular weight distribution is 1.5 to 2.6.

Owner:INST OF CHEM CHINESE ACAD OF SCI

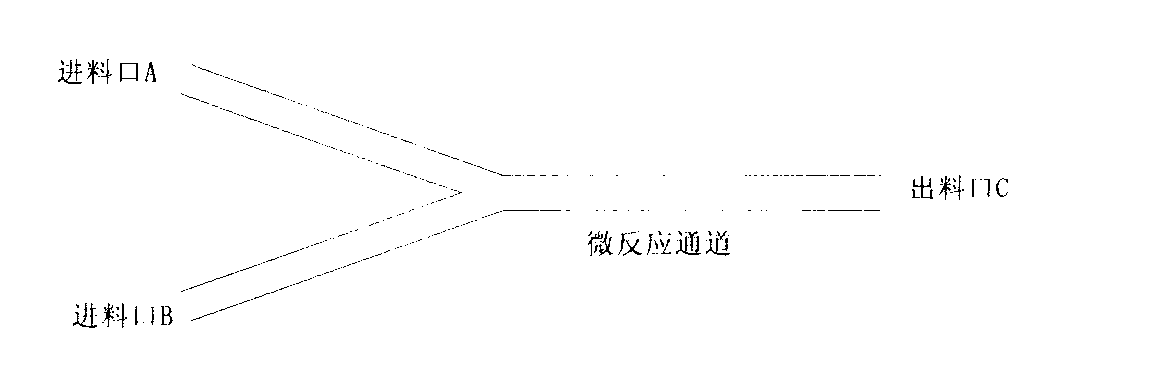

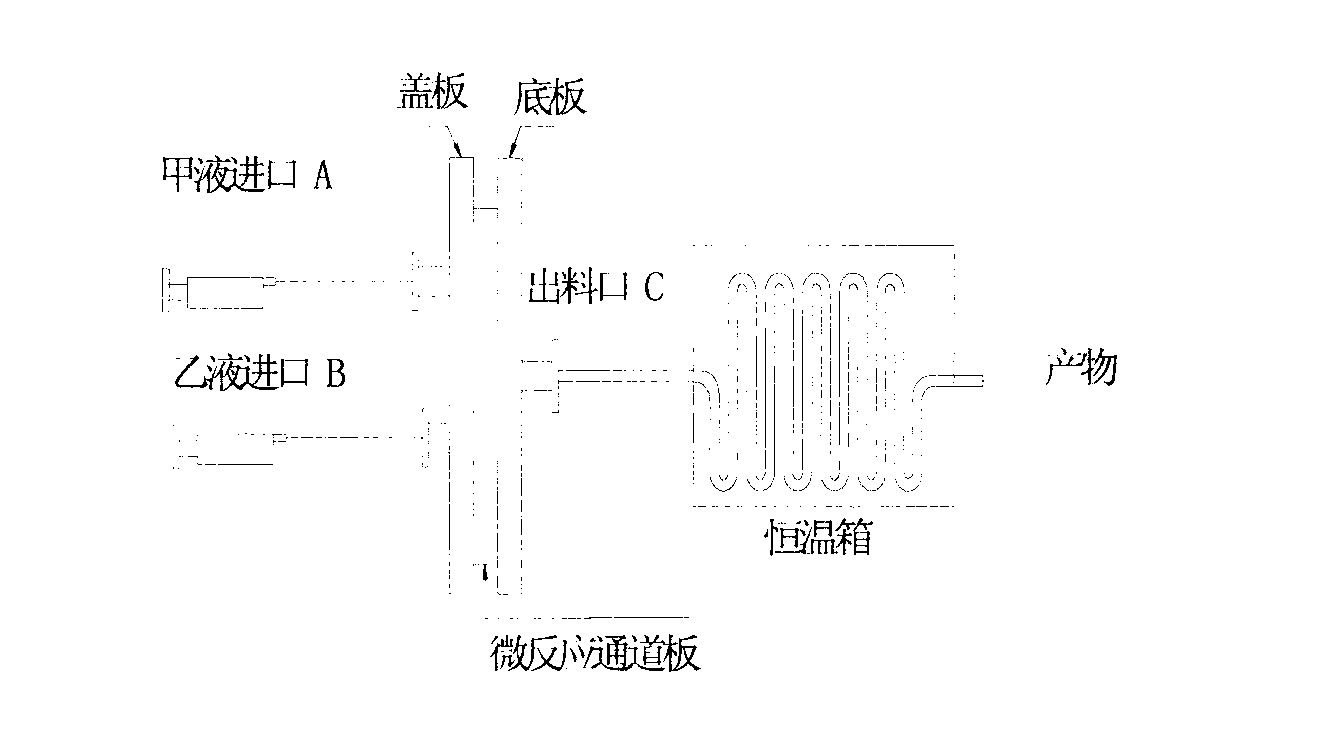

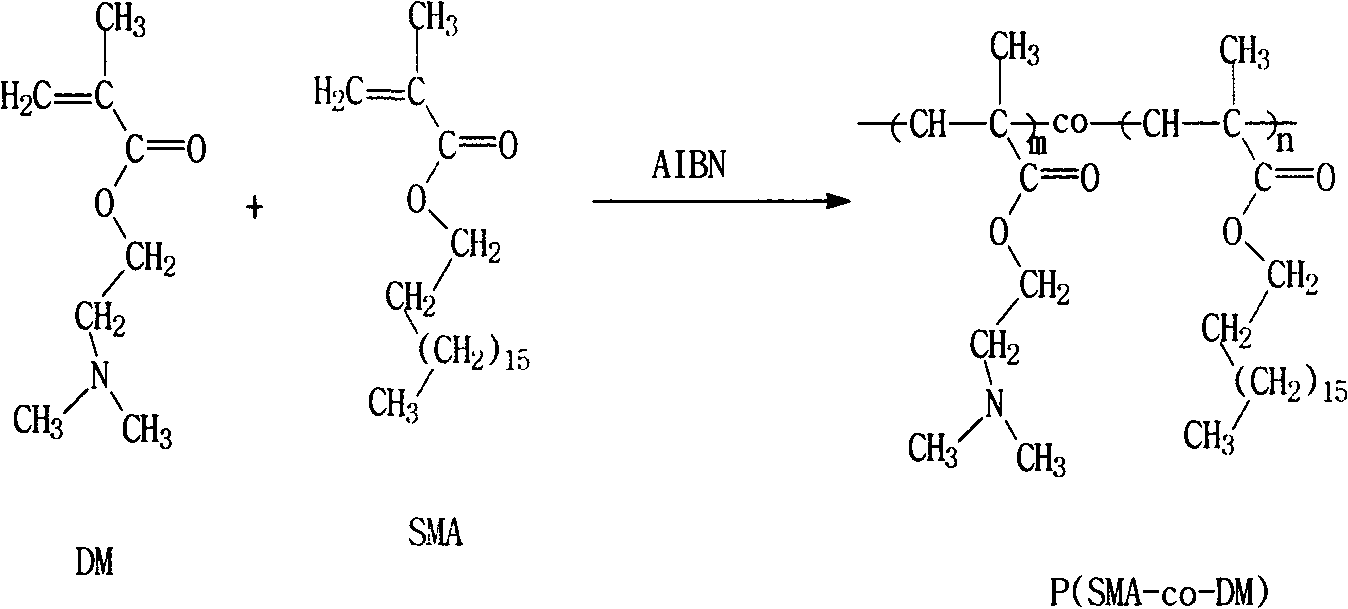

Method for preparing P(SMA-co-DM) in micro-reactor through free radical polymerization

The invention belongs to the field of random copolymer preparation, and particularly relates to a method for preparing an amphiphilic random copolymer P(SMA-co-DM) in a micro-reactor through free radical polymerization. A hydrophobic monomer SMA in the P(SMA-co-DM) has a long chain pendant group, such that the polymer easily forms a vesicle-shaped micelle in the subsequent self-assembly, and the property can be used in drug slow-release carriers, biomolecules and other fields; and a hydrophilic monomer DM has pH sensitivity and temperature sensitivity, and a morphology of a micelle can be controlled in copolymer self-assembly by changing a pH value and a temperature so as to provide a good prospect. In the prior art, amphiphilic random copolymer preparation is simple, but a series of problems such as low conversion rate, wide molecular weight distribution and the like exist. The micro-reactor provides great advantages in amphiphilic random copolymer preparation. In addition, a linear size of the channel is reduced to a micron size, and the whole volume of the micro-reactor is small, such that the operation is controllable, the safety is strong, and the operation is flexible.

Owner:JIANGNAN UNIV

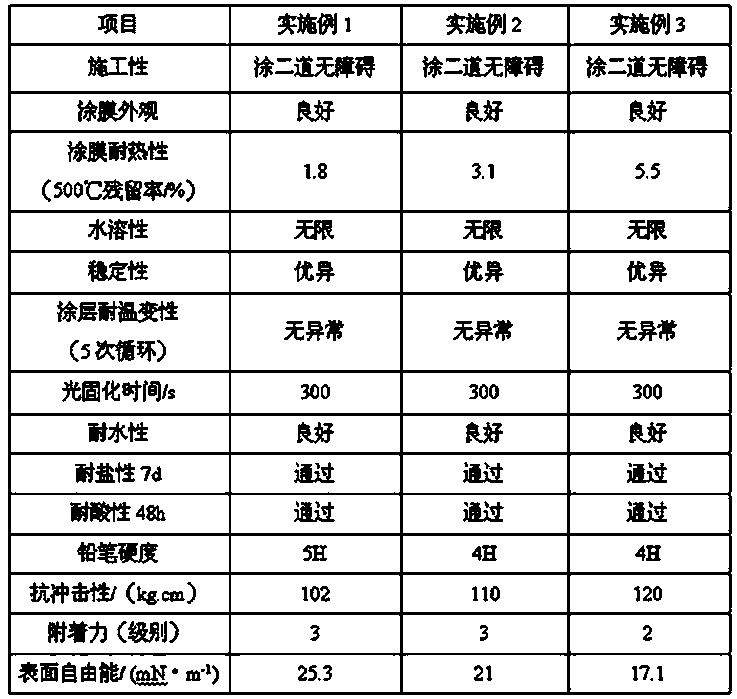

Aqueous UV (ultraviolet)-curable fluorine-alcohol-modified epoxy resin coating and preparation method thereof

ActiveCN103396722AImprove curing efficiencyGood weather resistanceEpoxy resin coatingsEpoxyResin coating

The invention particularly discloses an aqueous UV (ultraviolet)-curable fluorine-alcohol-modified epoxy resin coating and a preparation method thereof. The preparation method comprises the following steps of: firstly reacting a fluorine-containing terminal hydroxy compound with a diisocyanate monomer by utilizing a solution polymerization method so as to prepare mono-isocyanate terminated fluorine-containing isocyanate; carrying out a directed grafting reaction on epoxy resin containing hydroxy groups by utilizing the mono-isocyanate terminated fluorine-containing isocyanate so as to prepare fluorine-alcohol-modified epoxy resin Fn-EP, and further reacting maleic anhydride monomers with epoxy groups at two ends of the Fn-EP to prepare aqueous ultraviolet-curable fluorine-alcohol-modified epoxy resin Fn-EMA; and salifying the obtained Fn-EMA resin by adding a neutralizer, and uniformly mixing the obtained salt with water, so as to obtain the coating. The aqueous UV (ultraviolet)-curable fluorine-alcohol-modified epoxy resin coating has good photo-curing performance and excellent heat resistance, weather fastness and pollution resistance, is a high-performance environment-friendly coating and can be applied to the fields of household daily carpentry, building walls and steel components.

Owner:GUANGDONG UNIV OF TECH

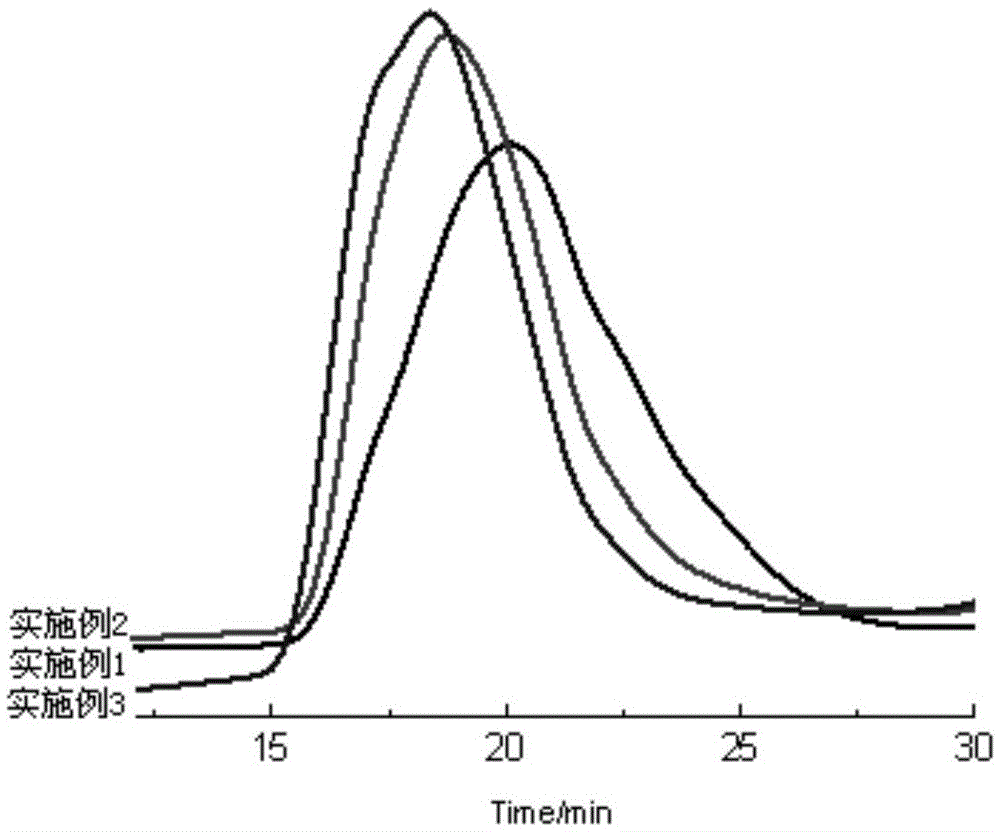

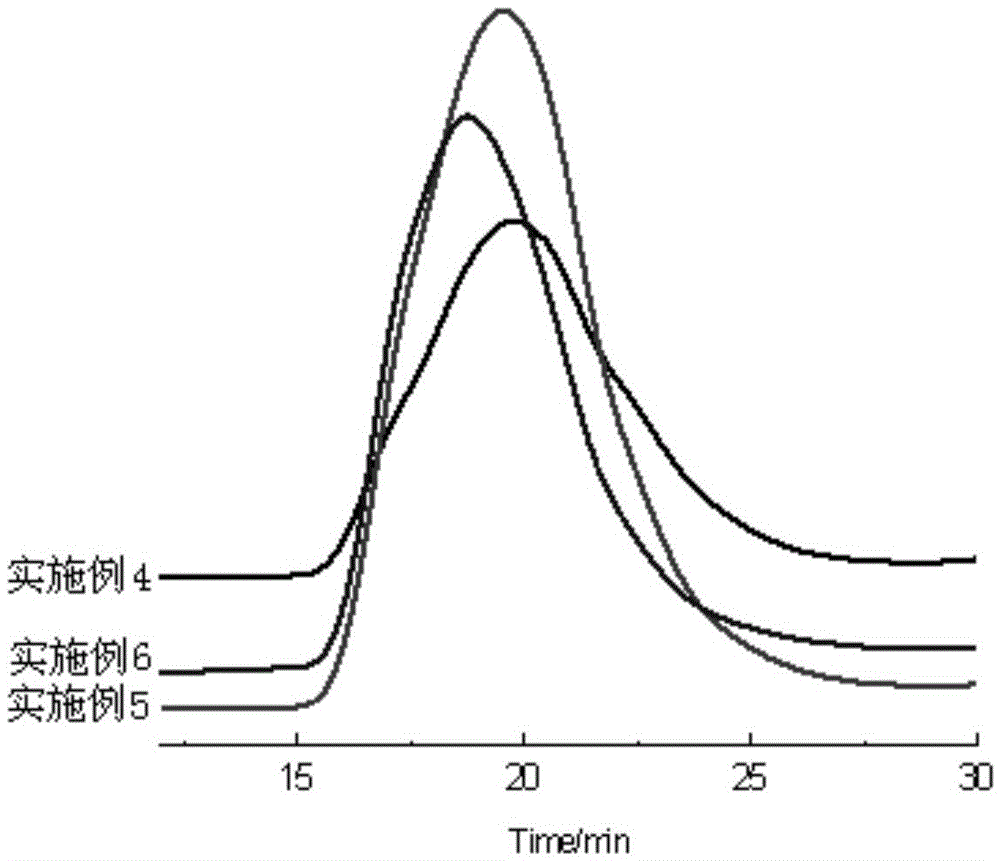

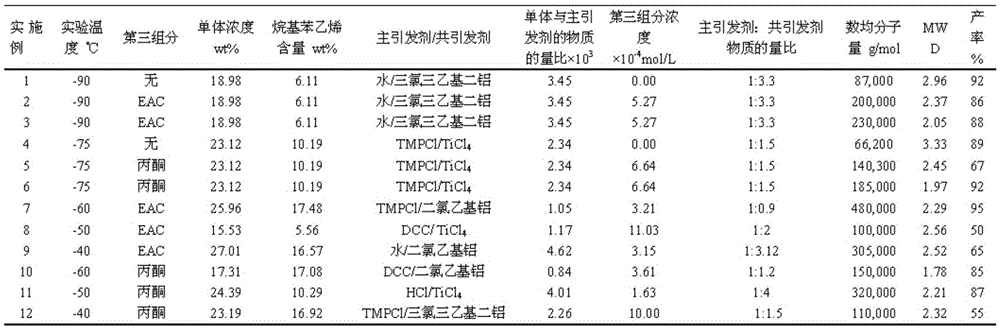

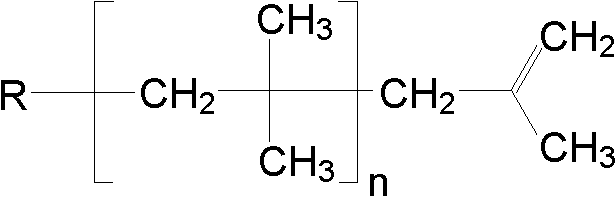

Preparation method of isobutene-alkyl styrene random copolymer

The invention discloses a preparation method of an isobutene-alkyl styrene random copolymer, and belongs to the technical field of macromolecular copolymer synthesizing methods. The preparation method comprises the steps of reactor feeding, initiator system preparing and polymer synthesizing and particularly comprises the two forms that a third component is added into a reactor along with a monomer raw material or the third component is added into the reactor after being aged together with a coinitiator and a main initiator. According to the preparation method, an ester compound or a ketone compound is taken as the cationic copolymerization third component, therefore, the cationic activity center can be stabilized, the reaction speed can be controlled, the molecular weight of the polymer can be increased, the molecular weight distribution can be reduced, and the reaction temperature can be increased, so that a reaction is performed at the higher temperature to achieve the effects of energy conservation and emission reduction. The property of the synthesized isobutene-alkyl styrene random copolymer is the same as that of a copolymer synthesized at the lower temperature, and the isobutene-alkyl styrene random copolymer can serve as a tire inner liner and a vibration-absorptive material or damping material.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

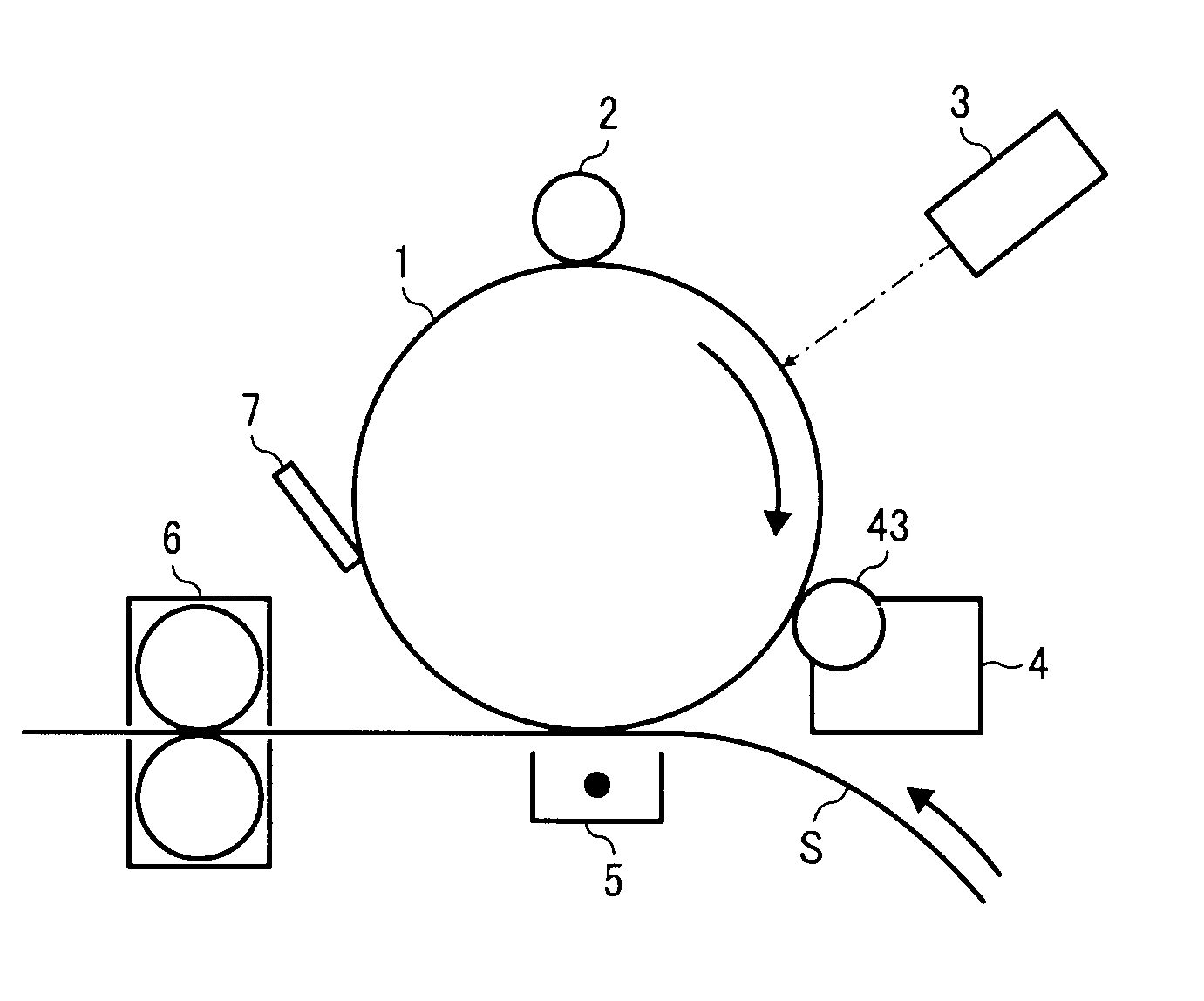

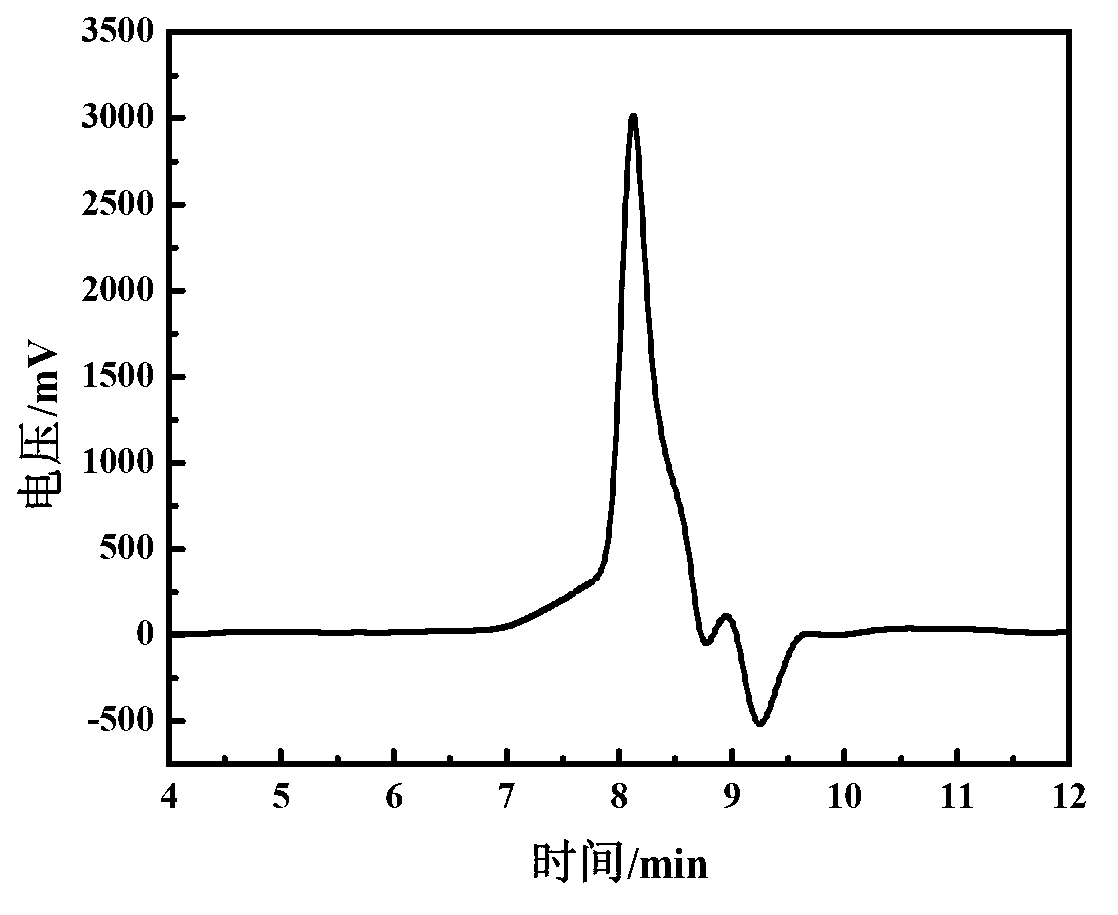

Toner

A toner prepared by a method comprising granulating while polymerizing a ring-opening polymerizable monomer with a catalyst under the presence of a surfactant and a colorant in a compressible fluid.

Owner:RICOH KK

Preparation method of methyl phenyl silicone oil

The invention relates to a preparation method of methyl phenyl silicone oil, which belongs to the technical field of organic silicon synthesis. The preparation method comprises the following steps of: adding dimehtyl silane dichloride and diphenyl silane dichloride monomers of a certain proportion to a solvent mixture of dimethyl benzene and acetone for uniformly mixing; dropwise adding a hydrolysate mixture of acetone and water to the solvent mixture by adopting a reverse hydrolysis method; adding a certain amount of end-capping reagent after dropwise adding, continuously reacting for a certain time at 30 DEG C to end up the hydrolysis; stewing and layering, separating out lower-layer acid water, and washing the upper-layer hydrolysate to neutral by using hot distilled water to obtain siloxane prepolymer; adding a certain amount of condensation catalyst to the siloxane prepolymer to carry out the condensation reaction, and washing the crystal to neutral by using the hot distilled water; evaporating out solvent dimethyl benzene and low-boiling-point substance under the reduced pressure to obtain the methyl phenyl silicone oil. The methyl phenyl silicone oil prepared by the preparation method disclosed by the invention is clear semi-transparent oil liquid, good in product uniformity, high in purity, simple in preparation process condition, capable of recycling the solvent and easy for the industrial production.

Owner:JIANGSU UNIV

Preparation method of complete biogenetic derivation benzoxazine resin and application thereof

The invention relates to a preparation method of complete biogenetic derivation benzoxazine resin and application thereof. A complete biogenetic derivation benzoxazine prepolymer is simple in process,high in reaction efficiency, high in product purity, narrow in molecular weight distribution, uniform in solidified product structure and complete in network structure. The complete biogenetic derivation benzoxazine resin obtained by the final procedure, heating for solidification, of the prepolymer has excellent heat resistant property, mechanical property, flame retardant property and dielectric property, has excellent high frequency dielectric property, and can be applied to the fields of high frequency and high speed circuit board base materials, microwave and millimeter wave communication, vehicle-borne radar and the like. While because the solidified resin has developed cross-linked network, and relatively high nitrogen content, and the carbonized complete biogenetic derivation benzoxazine resin can be applied as a functional material, and can be applied to the aspects of electricity storage, drug loading, pollutant treatment, gas adsorption and the like.

Owner:淮北绿洲新材料有限责任公司

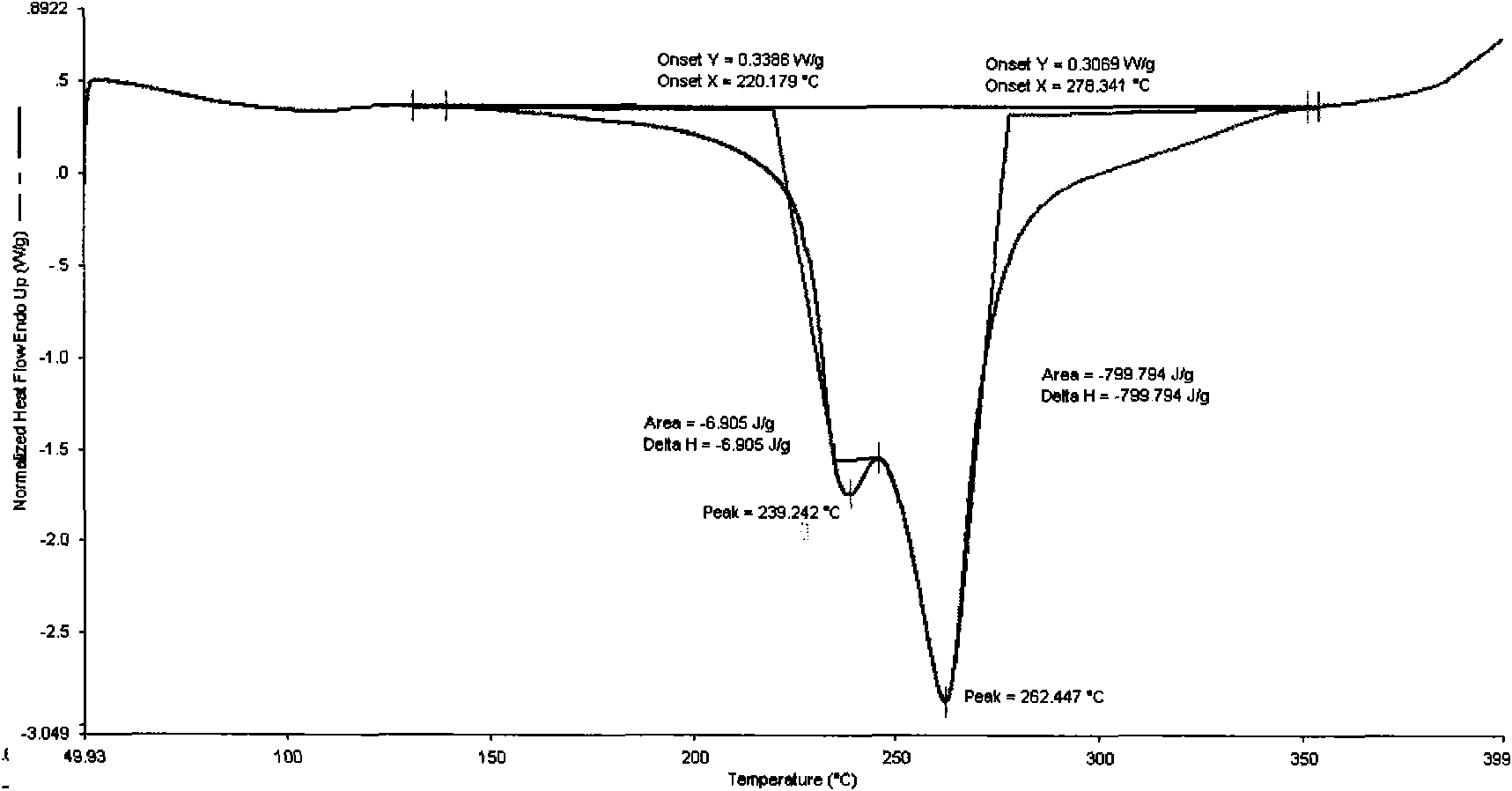

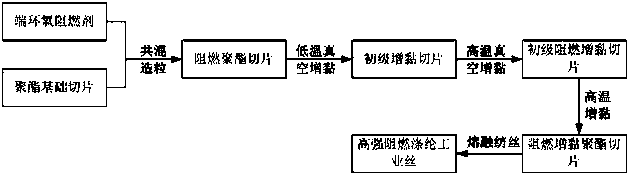

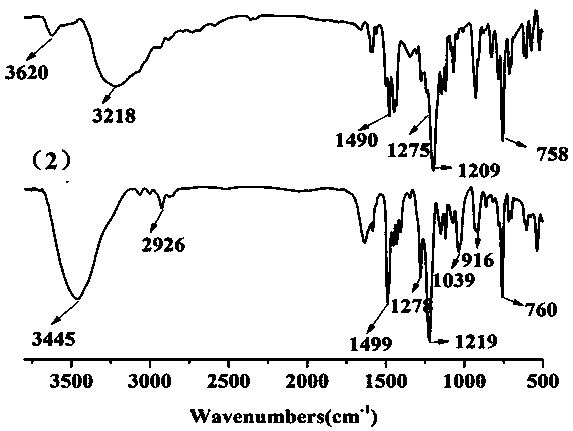

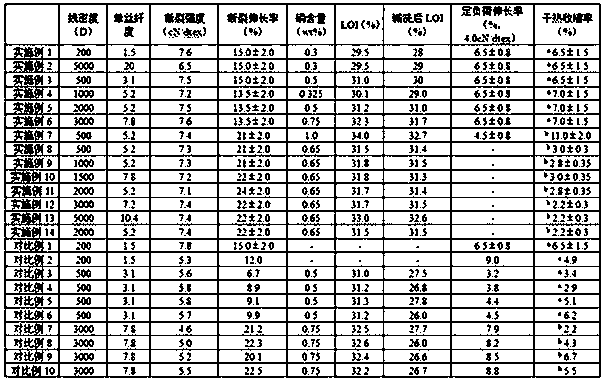

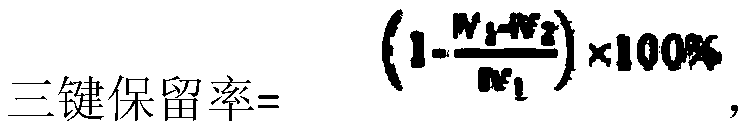

High-strength antiflaming polyester industrial filaments and preparation method thereof

ActiveCN110528109AHigh melting pointHigh melting enthalpyFlame-proof filament manufactureMonocomponent polyesters artificial filamentPolyesterIntrinsic viscosity

The invention relates to high-strength antiflaming polyester industrial filaments and a preparation method thereof. Particularly, by utilizing processes of low-temperature vacuum viscosity improvement, high-temperature viscosity improvement and high-temperature solid-phase viscosity improvement, phosphorus-containing viscosity-improvement polyester chips are prepared, and by utilizing a melt spinning process of the antiflaming viscosity-improvement polyester chips, high-strength antiflaming polyester industrial filaments are prepared. The intrinsic viscosity of the antiflaming viscosity-improvement polyester chips is 1.05-1.25 dL / g, the terminal carboxyl group content is 12-22 mmol / kg, the average molecular weight is 35,000-45,000, the molecular weight distribution coefficient PDI is 1.05-1.08, the phosphorus content is 0.3-4.0 wt%, and the limit oxygen index is 28-36%; the linear density of the high-strength antiflaming polyester industrial filaments is 200-5,000 D, the single filament fineness is 1.5-20 dpf, the breaking strength is 6.5-7.6 cN / dtex, the content of phosphorus in fibers is 0.3-1.0%, the limit oxygen index is 28-34%, and after a plain weave fabric is washed with 0.1mol / L sodium hydroxide for 15 minutes at 80 DEG C, the limit oxygen index is greater than or equal to 28%. The high-strength antiflaming polyester industrial filaments have high strength, excellent antiflaming performance and good washable performance, are used for the fields of advertising cloth, fire-fighting hoses, oil containing bags of military boxes and the like and have an important application prospect.

Owner:WUXI SUOLIDE TECH DEV CO LTD

Preparation method of tert-alkynol polyether

ActiveCN109970964ASmooth responseMild conditionsEther preparation by compound dehydrationReaction temperatureFine chemical

The invention relates to a preparation method of tert-alkynol polyether, and belongs to the field of fine chemical engineering. The preparation method comprises following steps: (1) adding a catalystand tert-alkynol into a reactor, carrying out degassing for 1 hour at a certain temperature under a certain pressure, controlling the reaction temperature and reaction pressure, slowly and evenly adding part of olefin oxide into the reactor within a certain period, and after addition, maintaining the temperature until the pressure becomes stable; and (2) keeping on adding olefin oxide at a certaintemperature until the reactions are finished, maintaining the temperature until the pressure becomes stable, cooling to remove a little of unreacted olefin oxide, adding an acid to carry out neutralization, and discharging obtained tert-alkynol polyether. The invention provides a preparation method of tert-alkynol polyether, which has the advantages of light color, high unsaturation degree, narrow distribution, low residual raw materials, and low PEG / PPG content.

Owner:ZHEJIANG HUANGMA TECH +3

Initiation system for preparation of high reaction activity polyisobutylene and application

ActiveCN102775534AHigh molecular weightThe polymerization process is stable and controllablePolymer scienceCationic polymerization

The invention relates to an initiation system for preparation of high reaction activity polyisobutylene and application. The initiation system consists of SnCl4, water and an organic compound containing oxygen, nitrogen and / or sulphur. The initiation system is added into an isobutene-containing polymerization raw material to induce cationic polymerization. The polymerization temperature is controlled at -60-30DEG C, and the polymerization reaction is stable and easy to control. Optimally, the terminal group alpha-double bond content can reach 98%. And according to needs, the initiation system can be used to prepare high reaction activity polyisobutylene with a number average molecular weight of 500-5000, a molecular weight distribution index up to 1.3 and an alpha-double bond content greater than 80%mol, a low molecular weight and narrow molecular weight distribution, and high reaction activity polyisobutylene with a number average molecular weight of 8000-15000, a molecular weight distribution index up to 1.6, an alpha-double bond content over 80%mol, a medium molecular weight and narrow molecular weight distribution.

Owner:BEIJING UNIV OF CHEM TECH

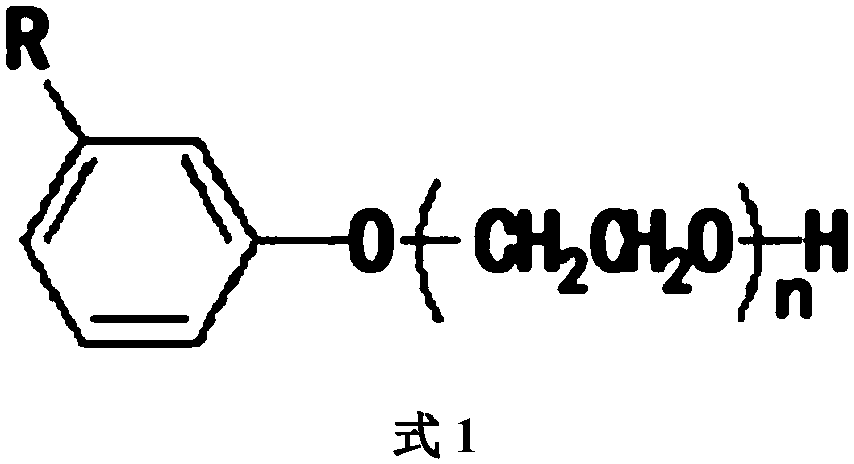

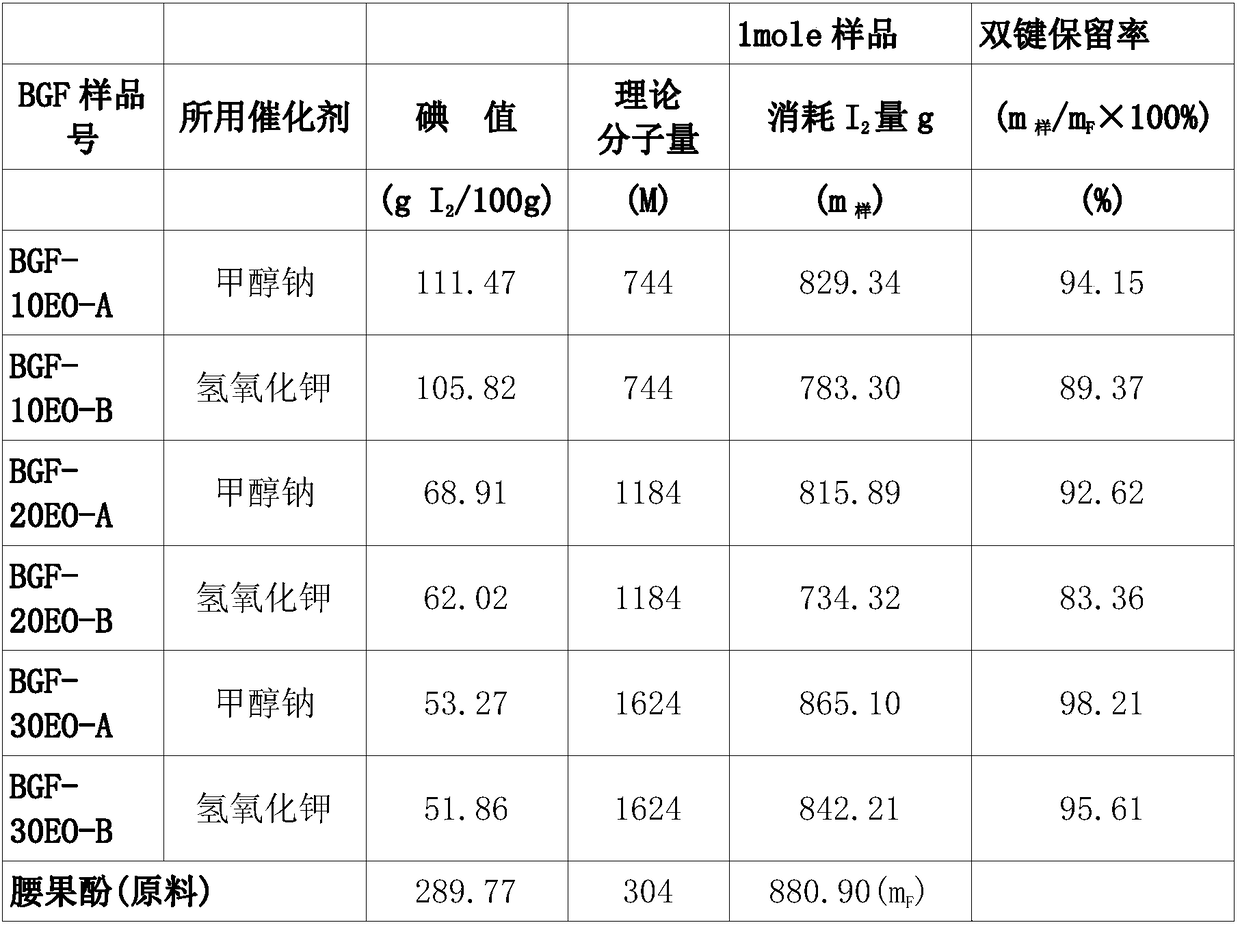

Method for preparing cardanol polyoxyethylene ether

InactiveCN108129651ALow viscosityLower viscosity, lower molecular weight distributionEther preparation from oxiranesAcetic acidEthylene oxide

The invention provides a method for preparing cardanol polyoxyethylene ether. The method comprises the following steps of, in a pressure-resistant reactor, enabling raw materials cardanol and ethyleneoxide, under the action of an alkoxide catalyst, in heating and pressurizing conditions, to complete a polymerization reaction within 2h to 4h; afterwards, cooling reaction materials, and neutralizing by using lactic acid, so that the cardanol polyoxyethylene ether is prepared. As alkoxide is used as the catalyst to replace a conventional inorganic strong base (such as NaOH and KOH) and the lactic acid is used as a neutralizer to replace usually used acetic acid, the polymerization reaction is enabled to be stable and controllable; an obtained product is light in color and luster, narrower inmolecular weight distribution and good in rheological characteristic, and therefore, has favorable application performance. The method provided by the invention is high in adaptability to the raw materials. A commercially available unsaturated cardanol raw material can be directly used. According to application demand, the molecular number of the ethylene oxide needing to be added can be adjusted, and thus, the hydrophile-lipophile balance (an HLB value) of the product is regulated, so as to prepare functional products of an emulsifier, a wetting and dispersing agent, a washing agent, a leveling agent and the like, which are applicable to corresponding fields.

Owner:上海邦高化学有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com