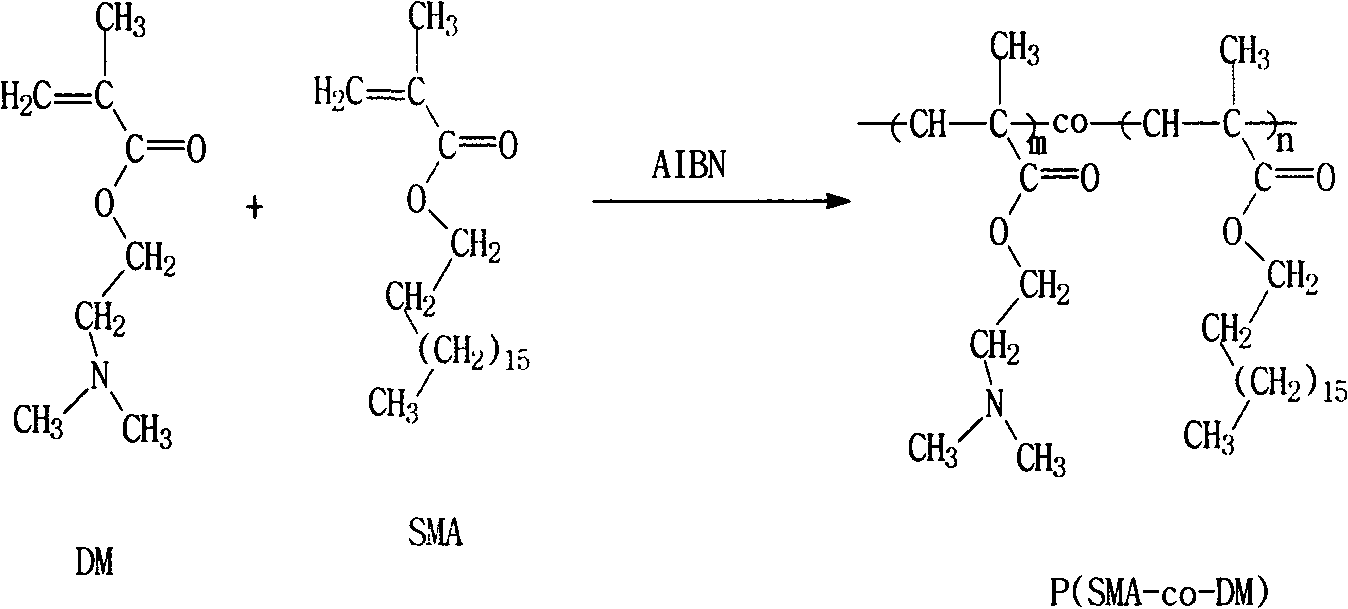

Method for preparing P(SMA-co-DM) in micro-reactor through free radical polymerization

A micro-reactor, sma-co-dm technology, applied in the field of polymer materials, can solve the problems of wide molecular weight distribution and low conversion rate, and achieve the effect of reducing power loss and simplifying structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

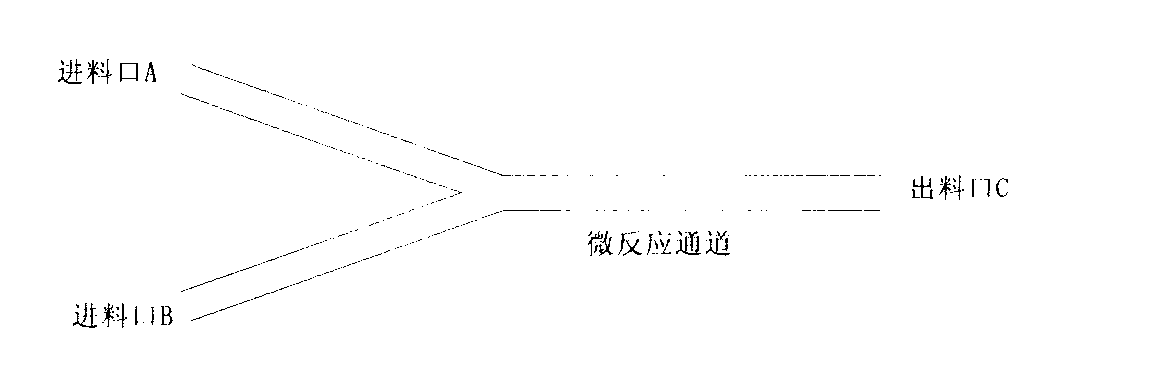

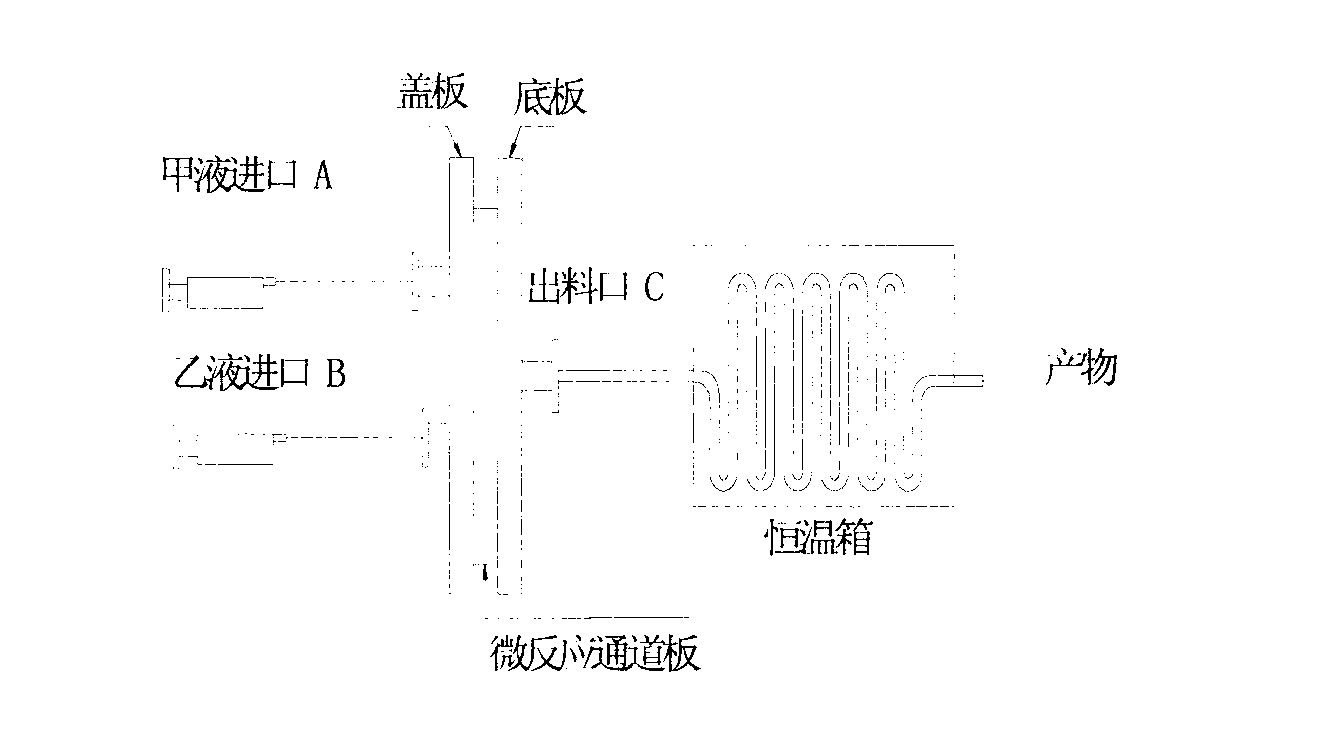

Method used

Image

Examples

example 1

[0024] Take by weighing hydrophobic monomer SMA 5mmoL, measure solvent dioxane 10mL, dissolve evenly, obtain A solution; Take by weighing initiator AIBN0.7mmoL, DM 30mmoL, and initiator is dissolved in hydrophilic monomer DM, obtain B liquid; the reaction materials, liquid A and liquid B, are respectively sent to the two injection ports of the microreactor synchronously through a single-channel micro-injection pump, and the flow rate of liquid A is set to 15ml / h, and the flow rate of liquid B is set to 10ml / h. Reaction 24h in constant temperature water bath, the conversion rate of product is 95%, the M of GPC survey w =25100, M n =22800, M w / M n = 1.1.

example 2

[0026] Take by weighing hydrophobic monomer SMA 6mmoL, measure solvent dioxane 12mL, dissolve evenly, obtain A solution; Take by weighing initiator AIBN0.8mmoL, DM 34mmoL, and initiator is dissolved in the hydrophilic monomer DM, obtain B liquid; the reaction materials, liquid A and liquid B, are respectively sent to the two injection ports of the microreactor synchronously through a single-channel micro-injection pump, and the flow rate of liquid A is set to be 13ml / h, and the flow rate of liquid B is set to be 8ml / h. Reaction 24h in constant temperature water bath, the conversion rate of product is 96%, the M of GPC survey w =24000, M n =21400, M w / M n = 1.12.

example 3

[0028] Take by weighing hydrophobic monomer SMA 6mmoL, measure solvent dioxane 14mL, dissolve evenly, obtain A liquid; Take by weighing initiator AIBN0.6mmoL, DM 24mmoL, and initiator is dissolved in hydrophilic monomer DM, obtain B liquid; the reaction materials, liquid A and liquid B, are respectively sent to the two injection ports of the microreactor synchronously through a single-channel micro-injection pump, and the flow rate of liquid A is set to be 13ml / h, and the flow rate of liquid B is set to be 7ml / h. Reaction 24h in constant temperature water bath, the conversion rate of product is 93%, the M of GPC survey w =23000, M n =21300, M w / M n = 1.08.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com