Patents

Literature

1493 results about "Microreactor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A microreactor or microstructured reactor or microchannel reactor is a device in which chemical reactions take place in a confinement with typical lateral dimensions below 1 mm; the most typical form of such confinement are microchannels. Microreactors are studied in the field of micro process engineering, together with other devices (such as micro heat exchangers) in which physical processes occur. The microreactor is usually a continuous flow reactor (contrast with/to a batch reactor). Microreactors offer many advantages over conventional scale reactors, including vast improvements in energy efficiency, reaction speed and yield, safety, reliability, scalability, on-site/on-demand production, and a much finer degree of process control.

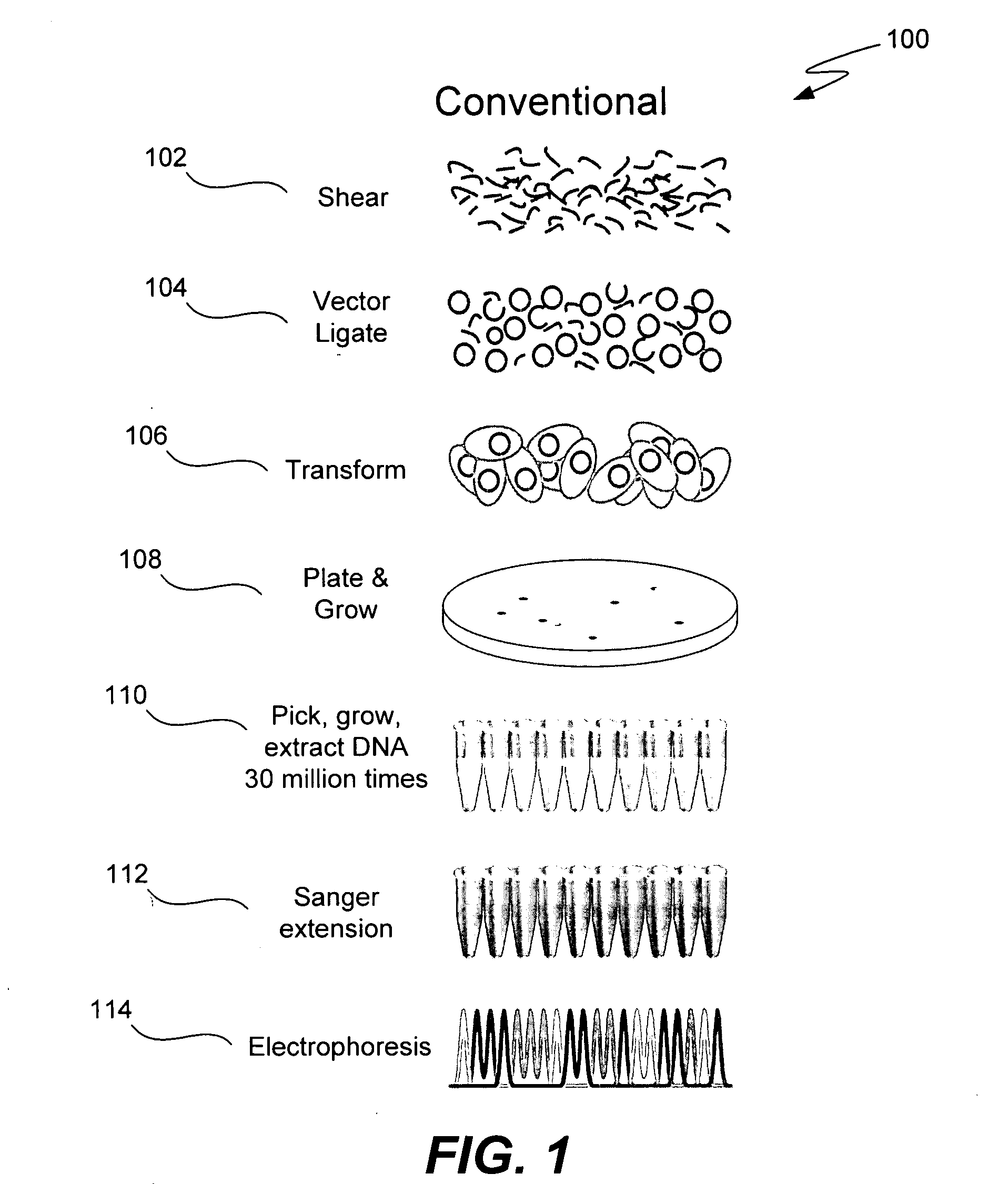

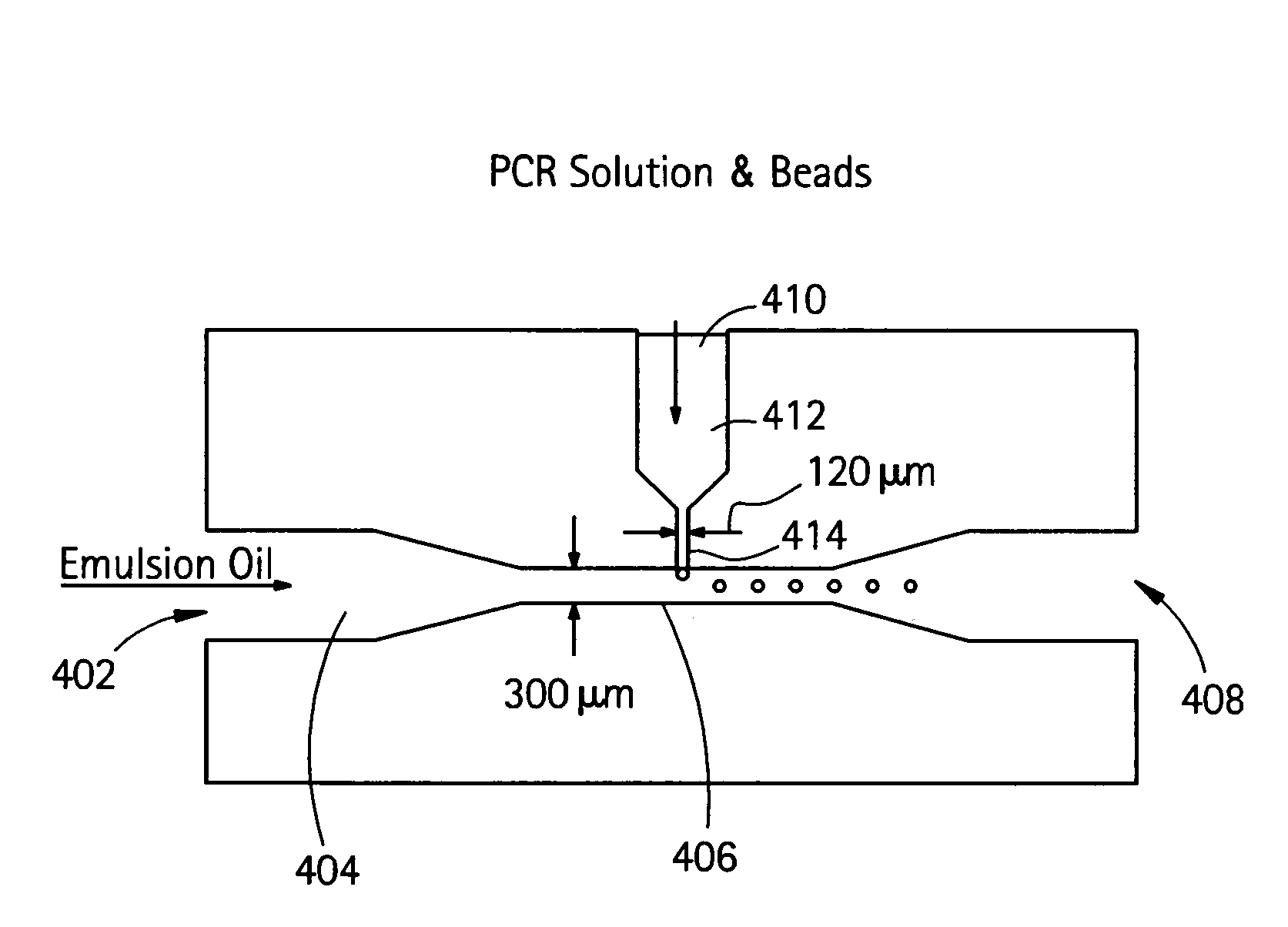

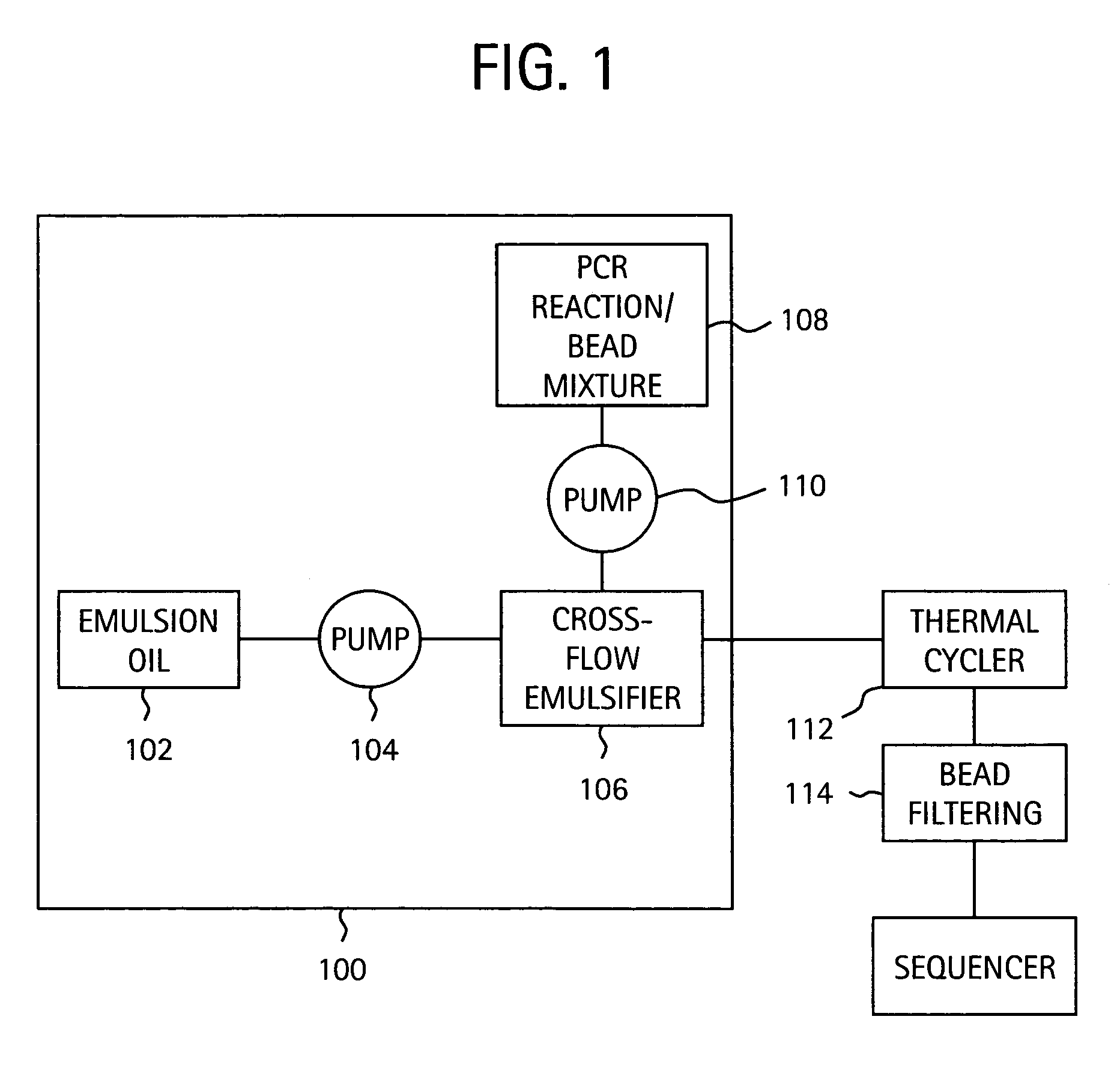

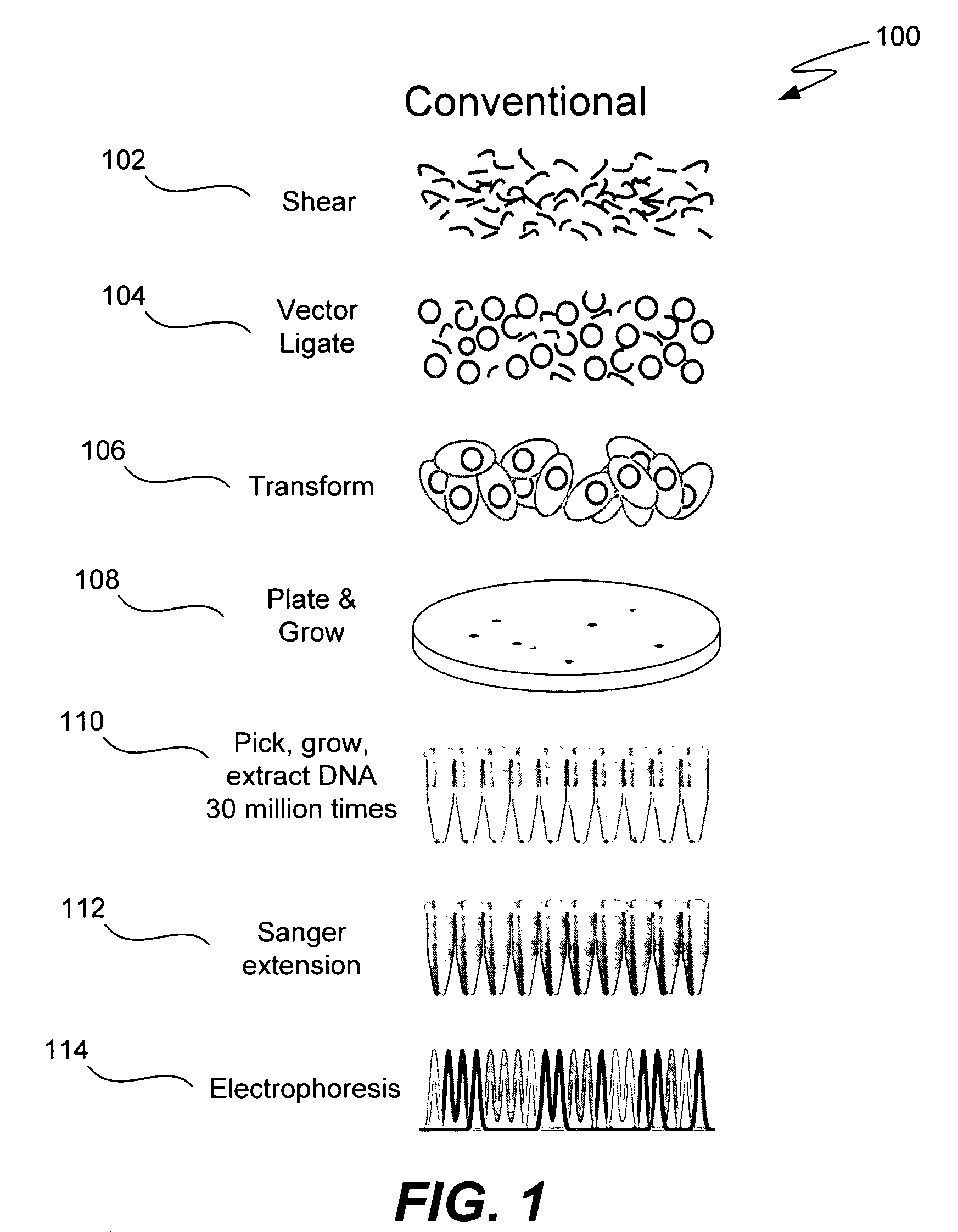

Nucleic acid amplification with continuous flow emulsion

InactiveUS20050227264A1Rapid and economical mannerReduce nozzle cloggingHeating or cooling apparatusFlow mixersMicroreactorGenetic Materials

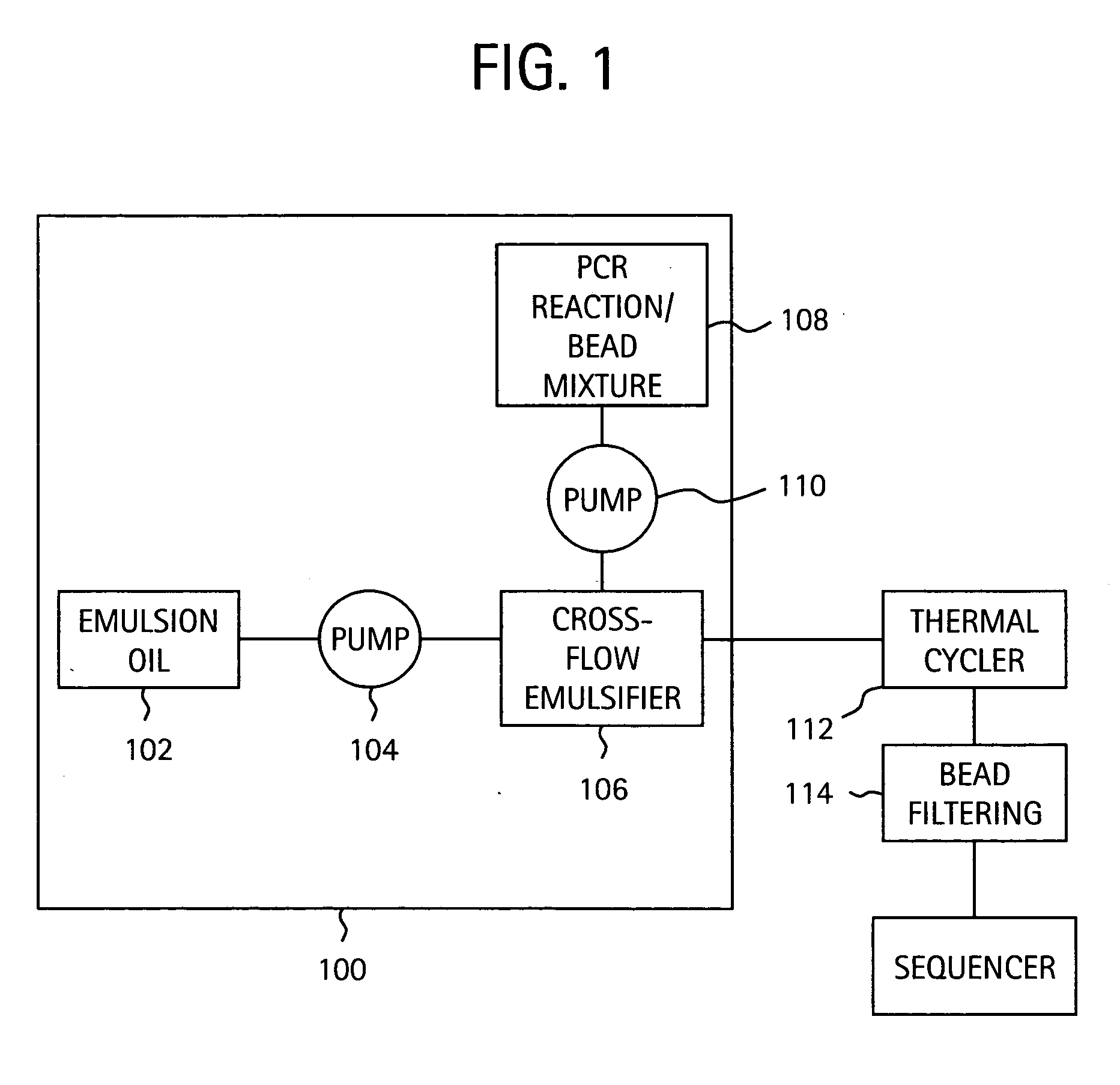

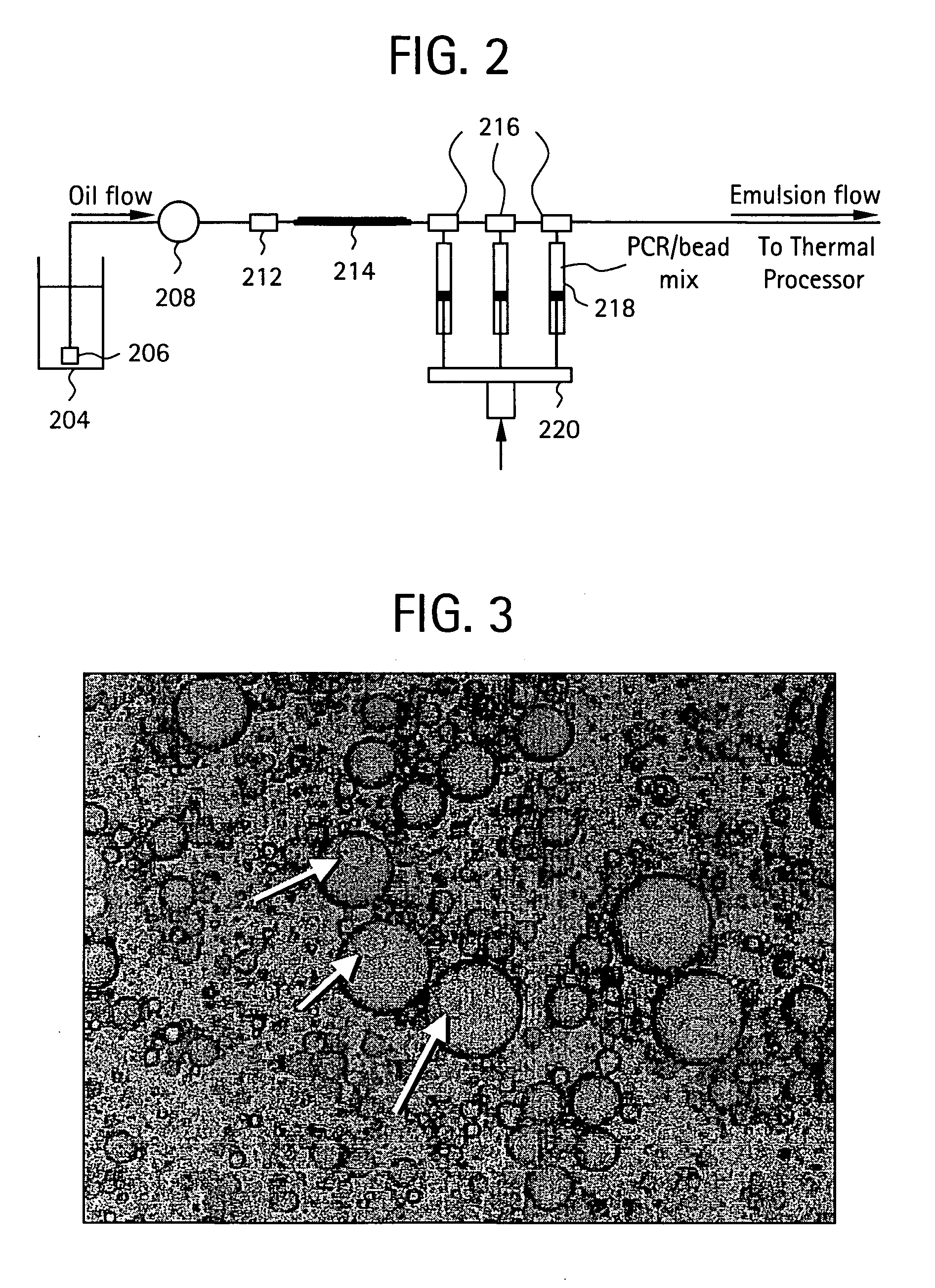

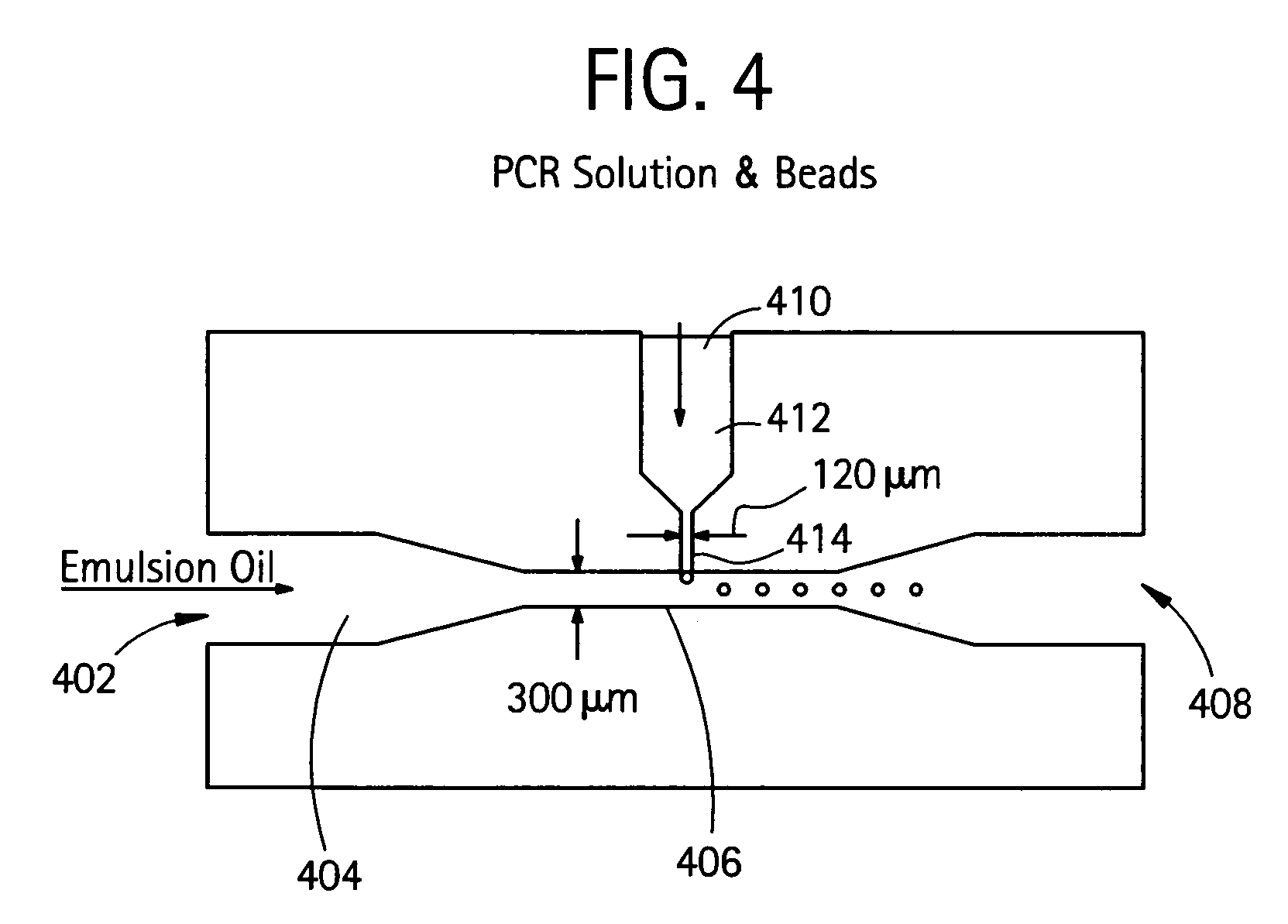

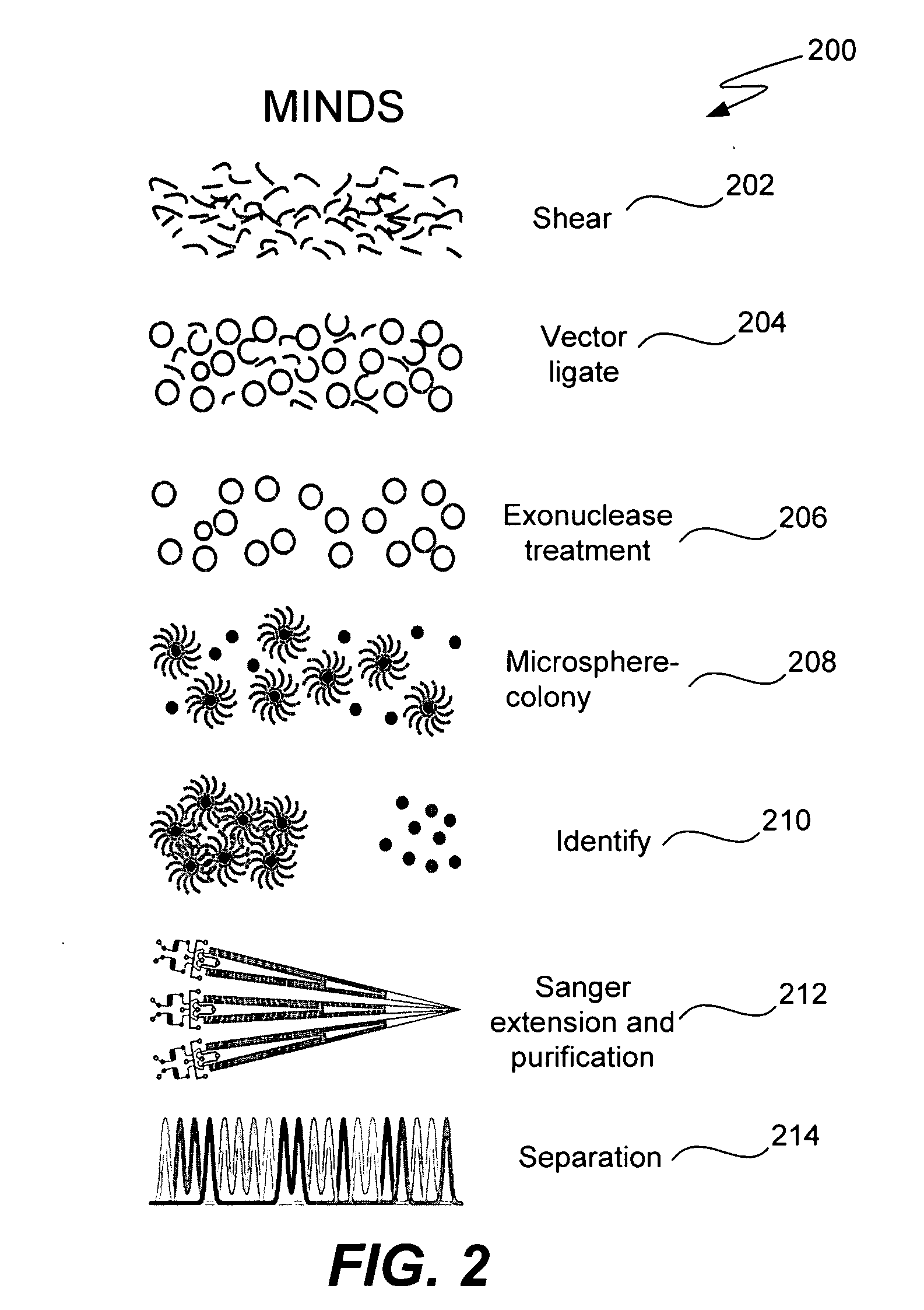

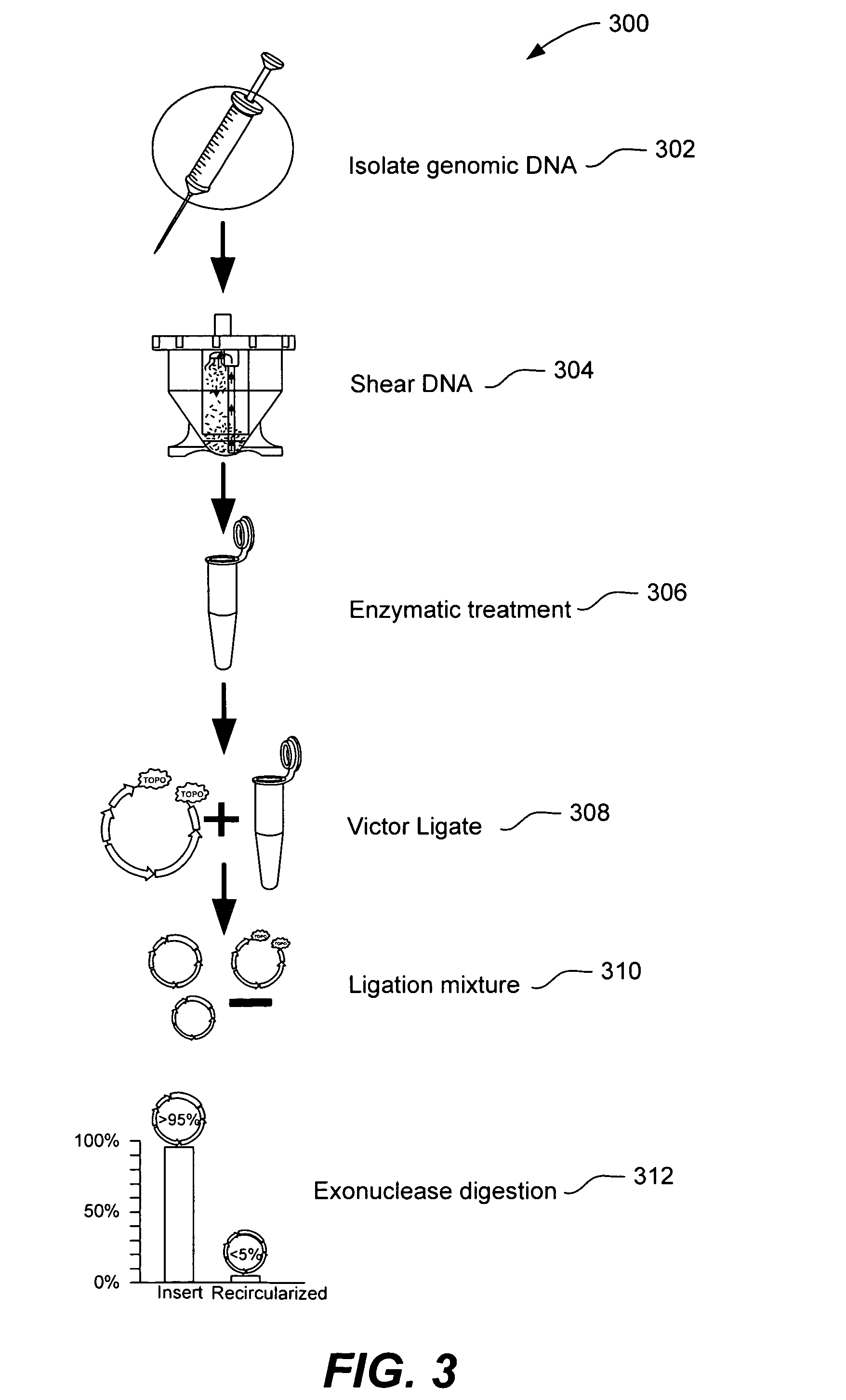

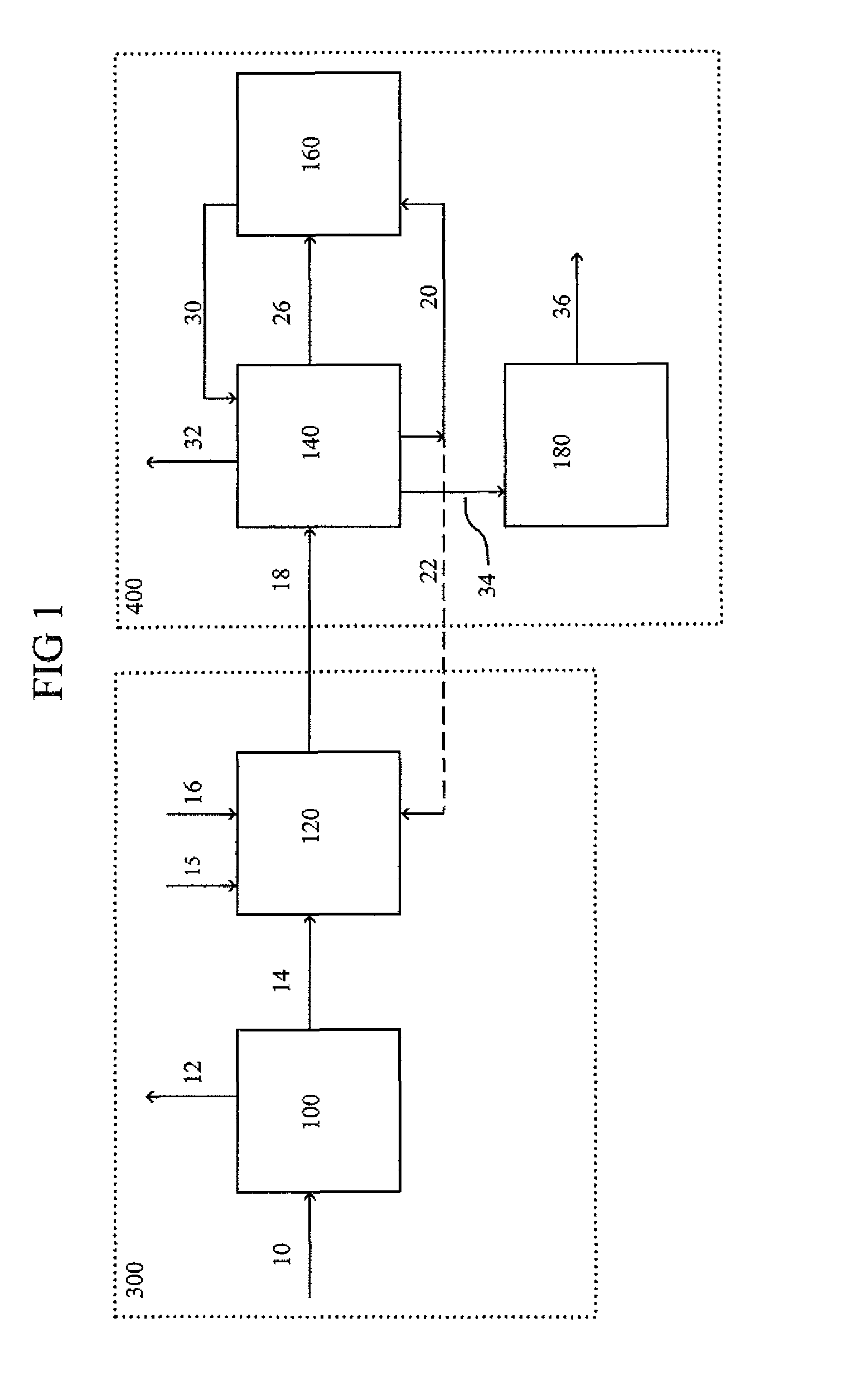

Embodiments of the present invention are directed to methods and devices / systems for amplifying genetic material and may include providing a water-in-oil emulsion in a continuous flow. The emulsion may include a plurality of water droplets comprising microreactors. Each of the plurality of microreactors may include a single bead capable of capturing a nucleic acid template, a single species nucleic acid template and sufficient reagents to amplify the copy number of the nucleic acid template. The method also includes flowing the emulsion across a first temperature zone and a second lower temperature zone to thermally process the microreactors to amplify the nucleic acid template by polymerase chain reaction.

Owner:454 LIFE SCIENCES CORP

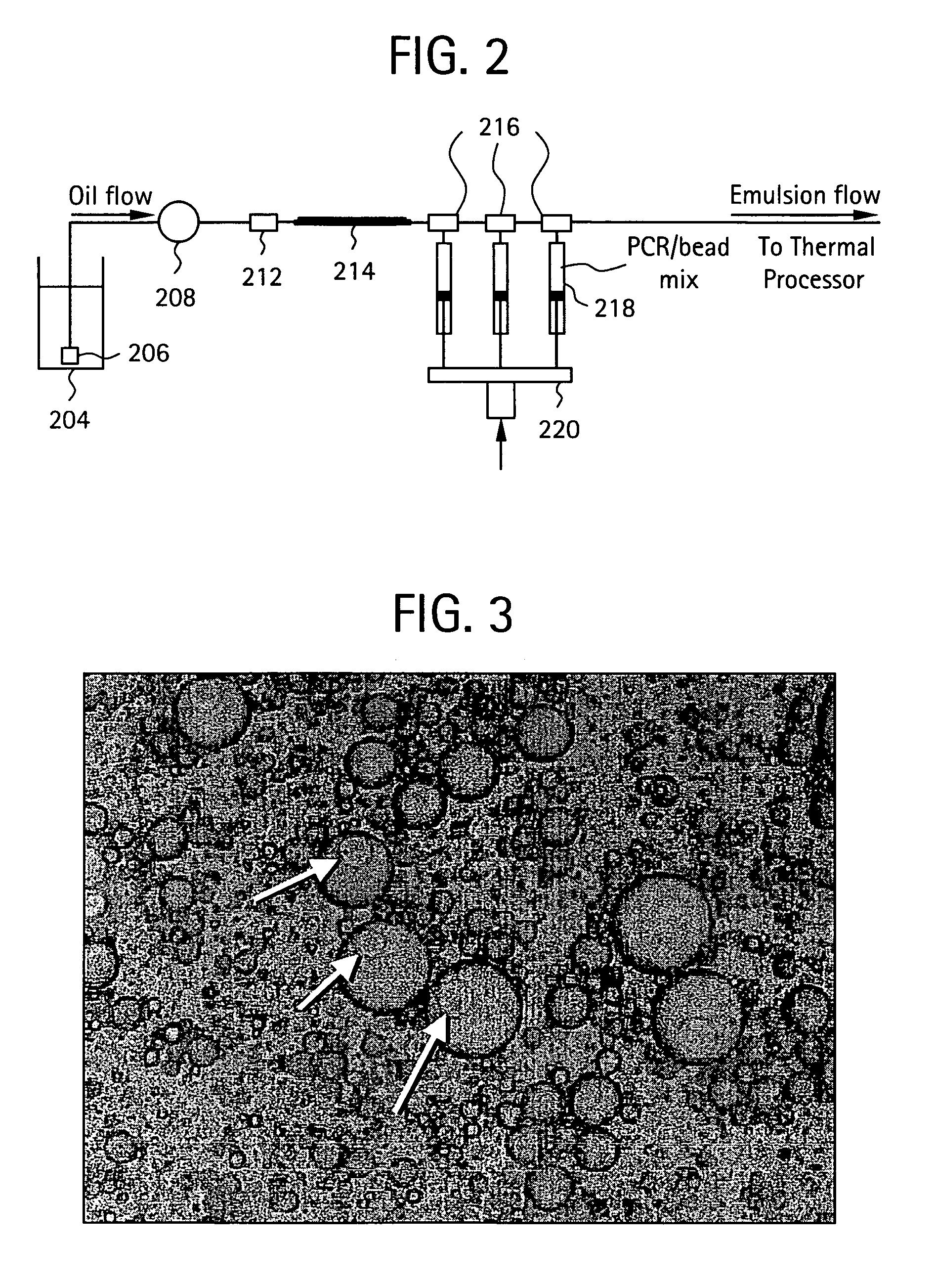

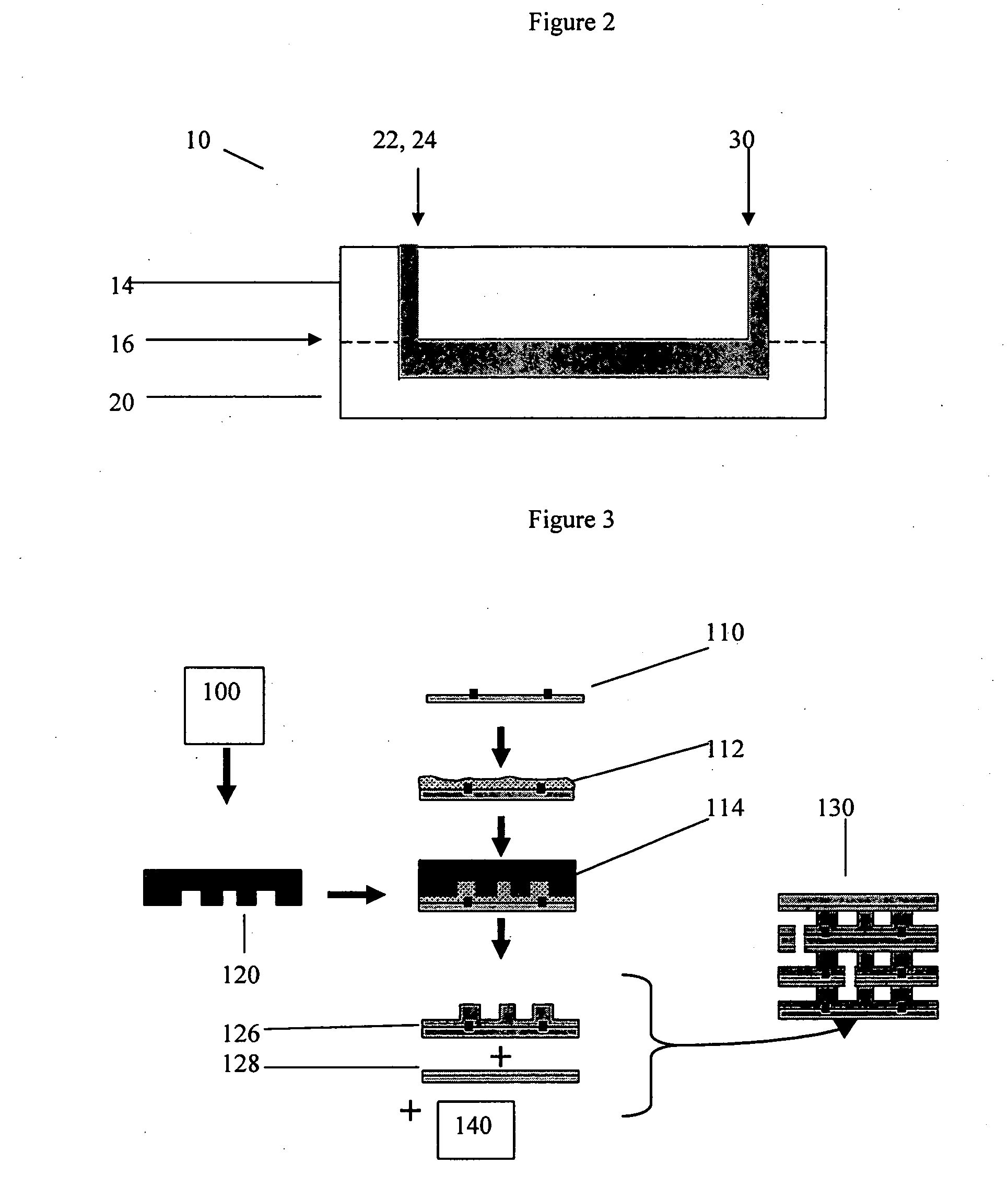

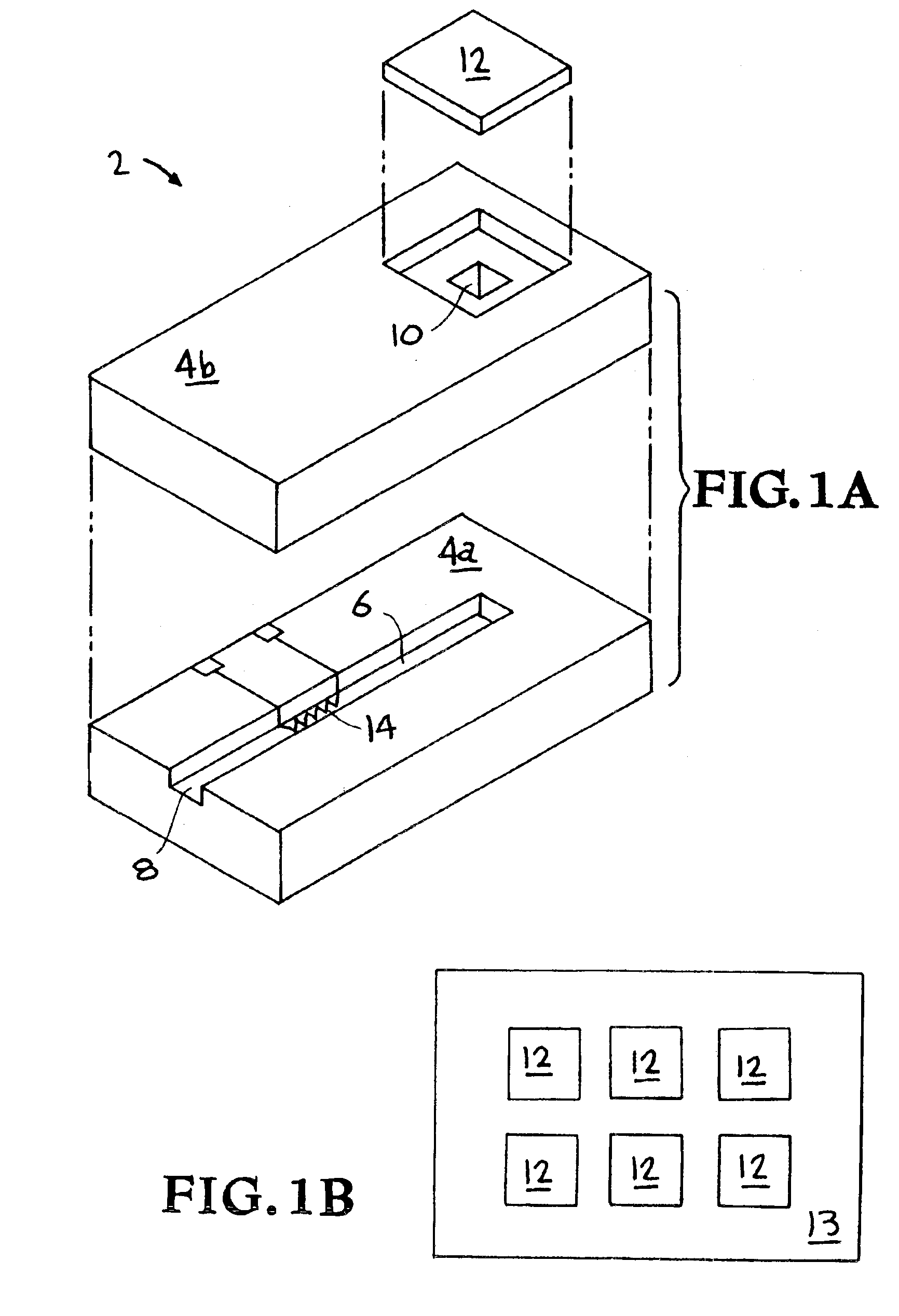

Microfabricated integrated DNA analysis system

ActiveUS20050287572A1Improve automationBig spaceBioreactor/fermenter combinationsElectrolysis componentsMicroreactorMicrosphere

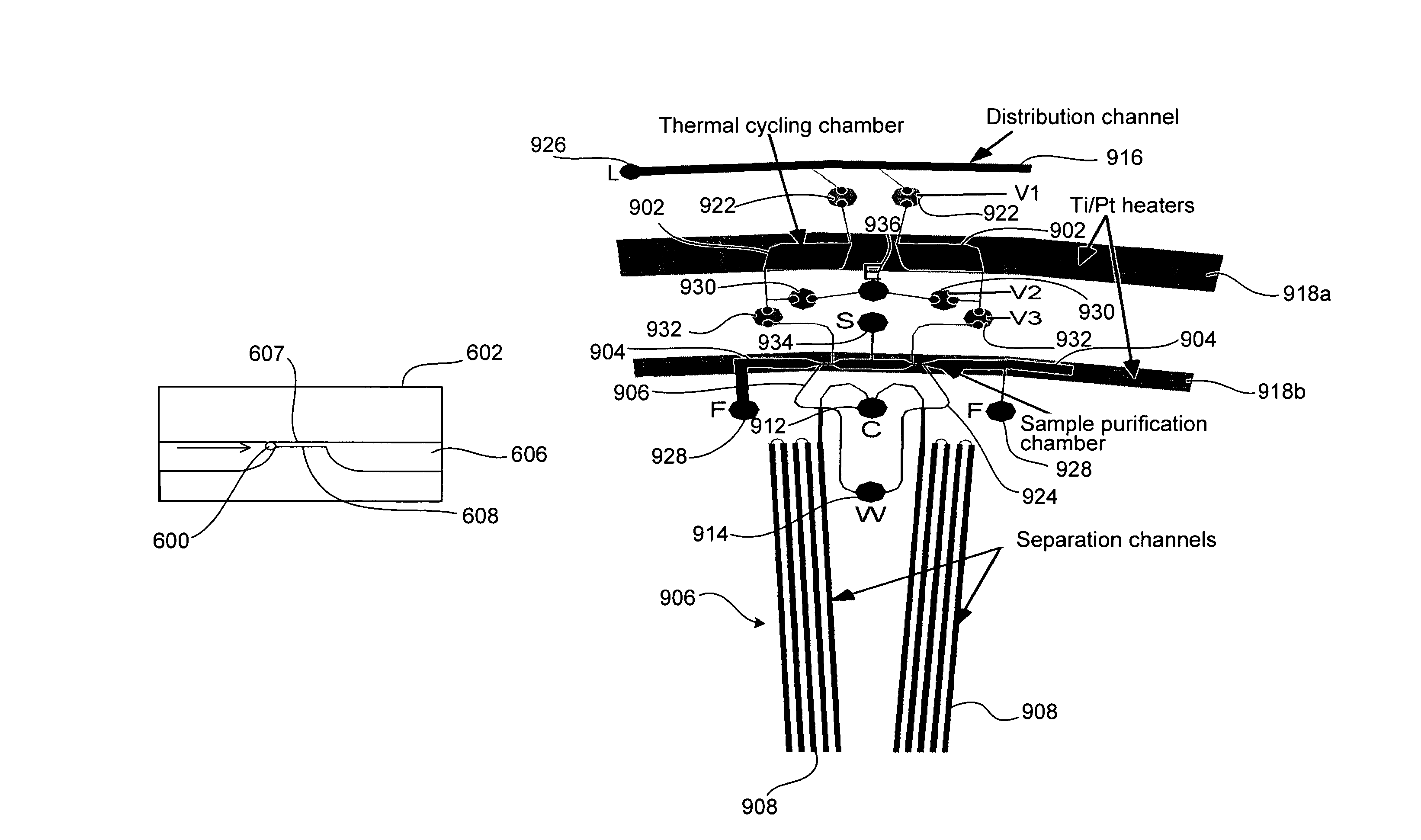

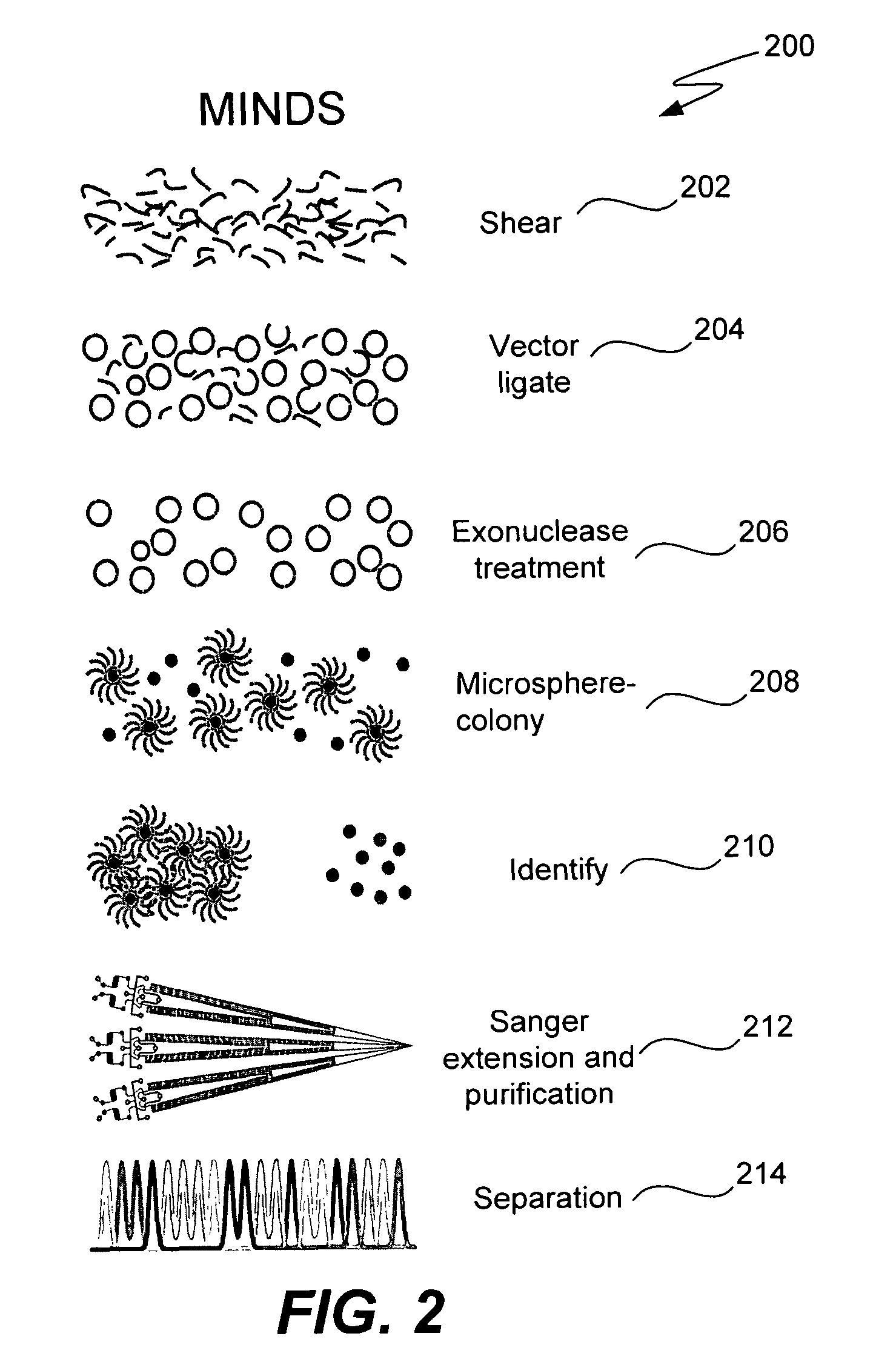

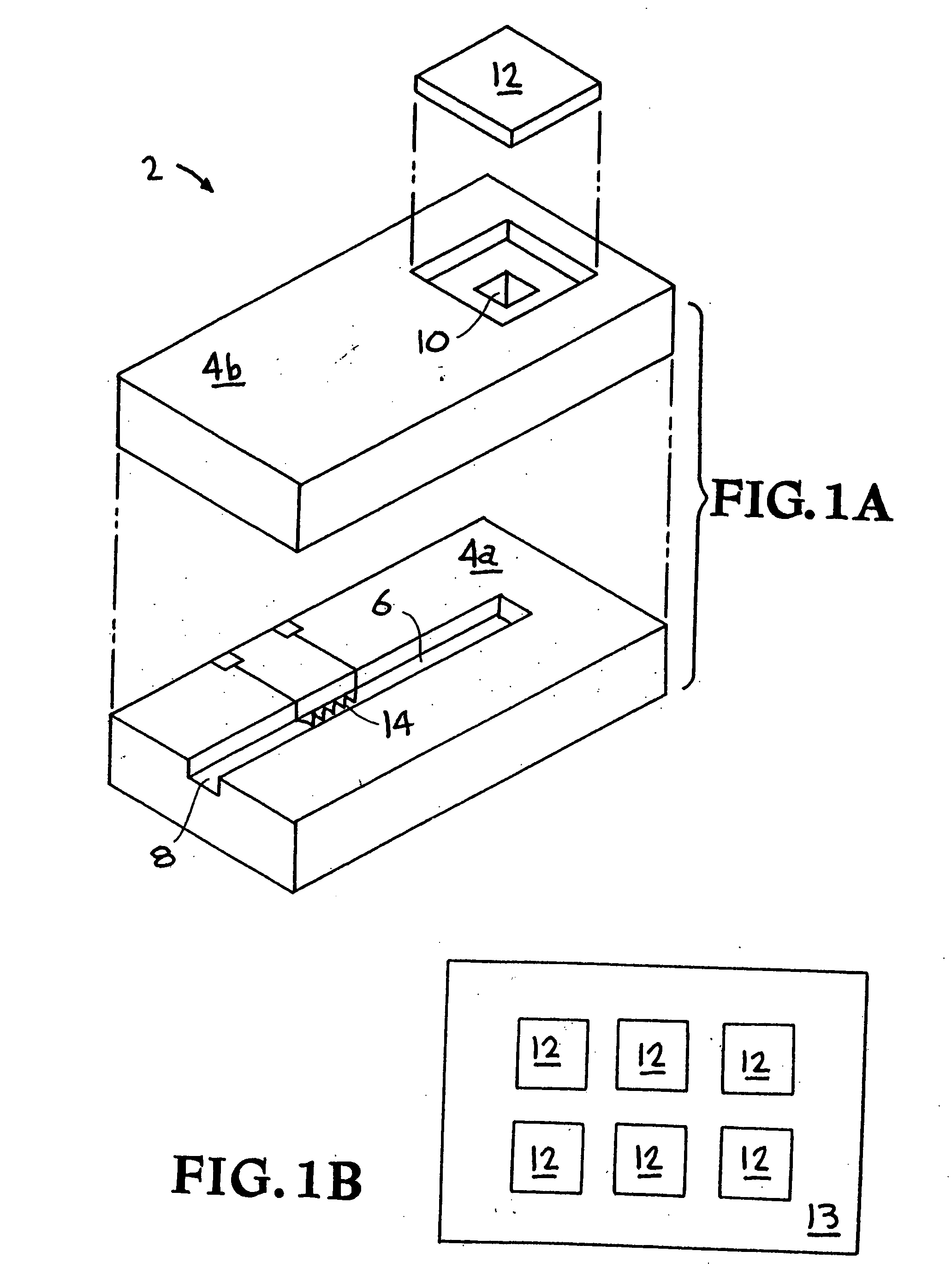

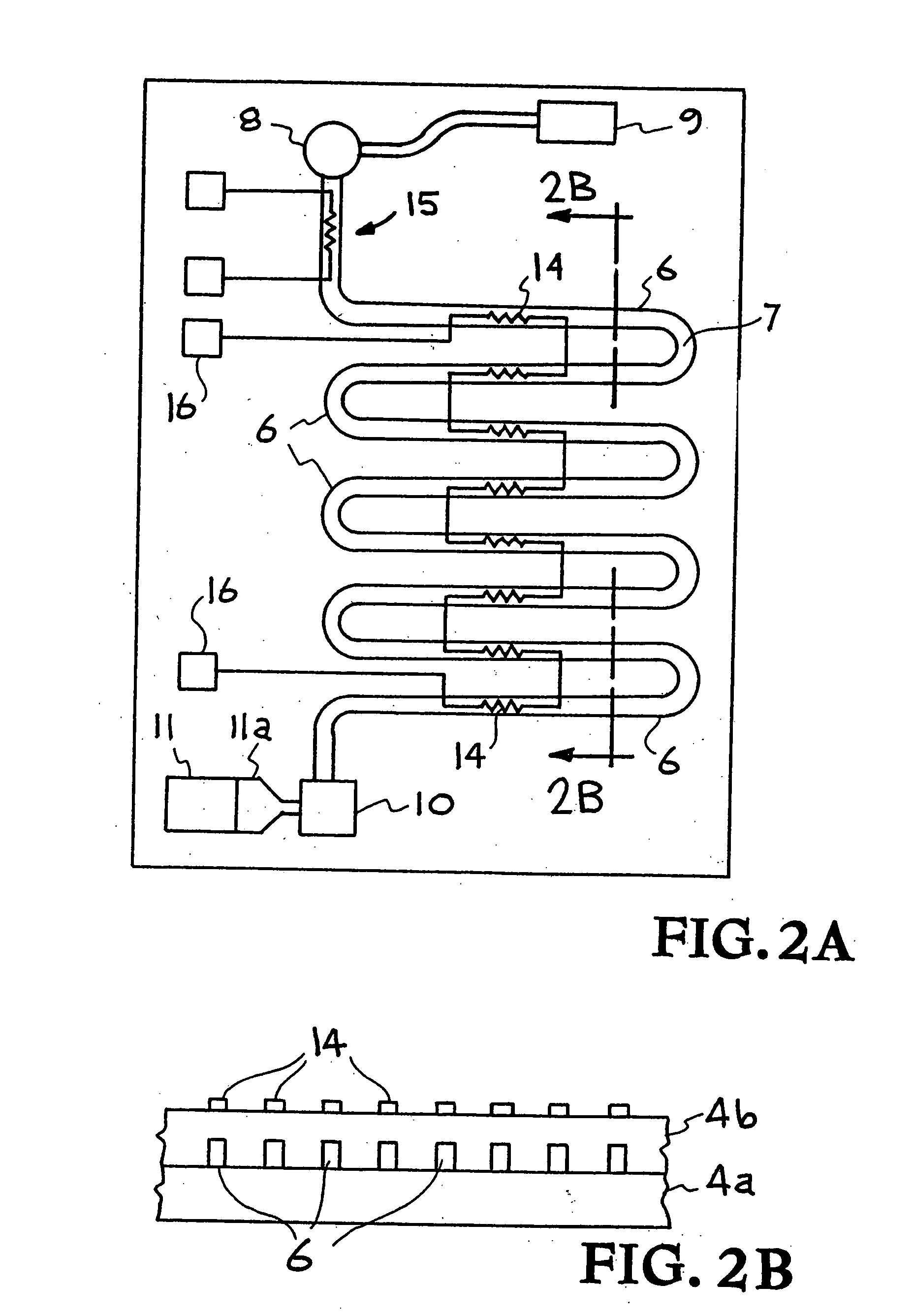

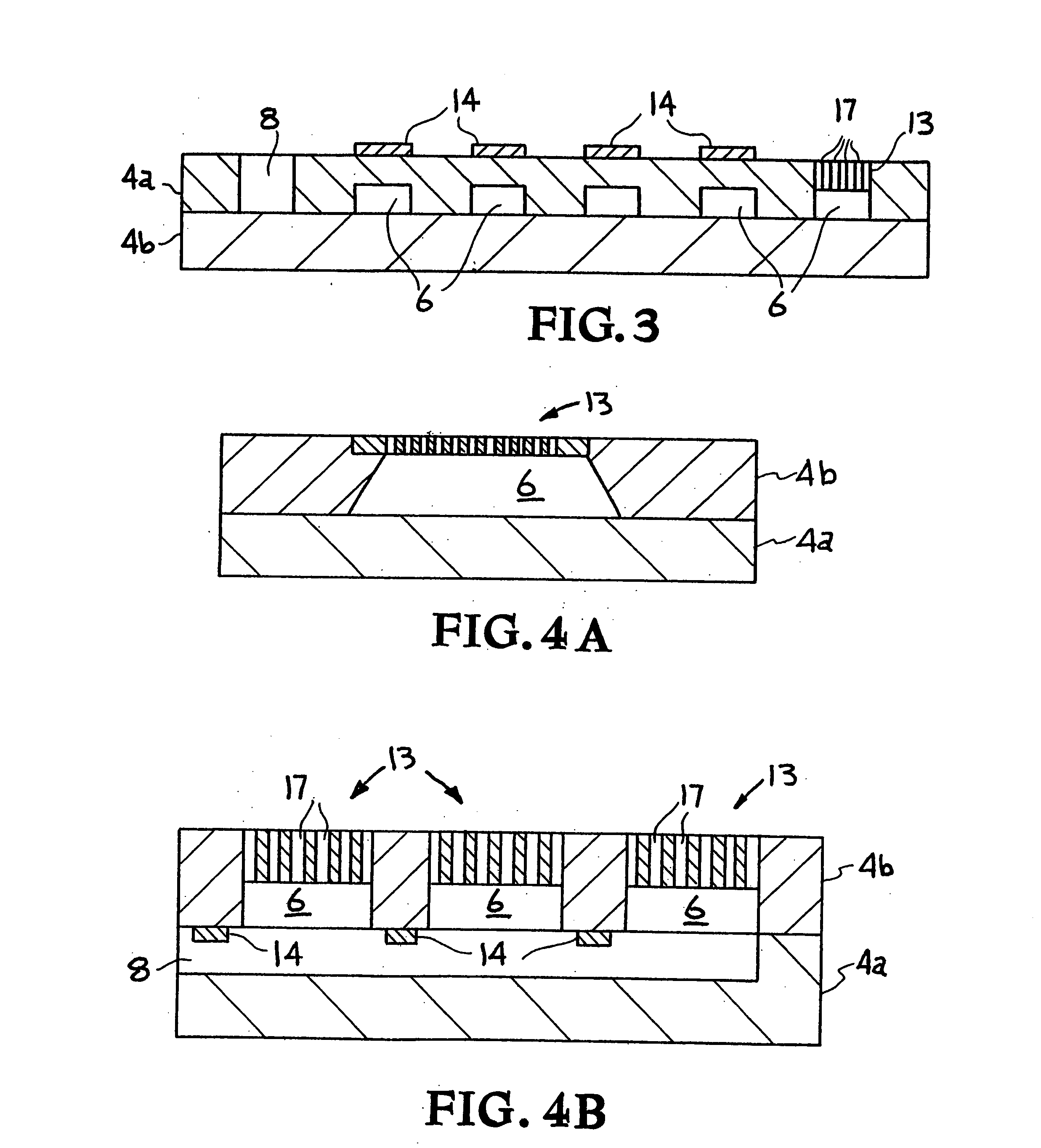

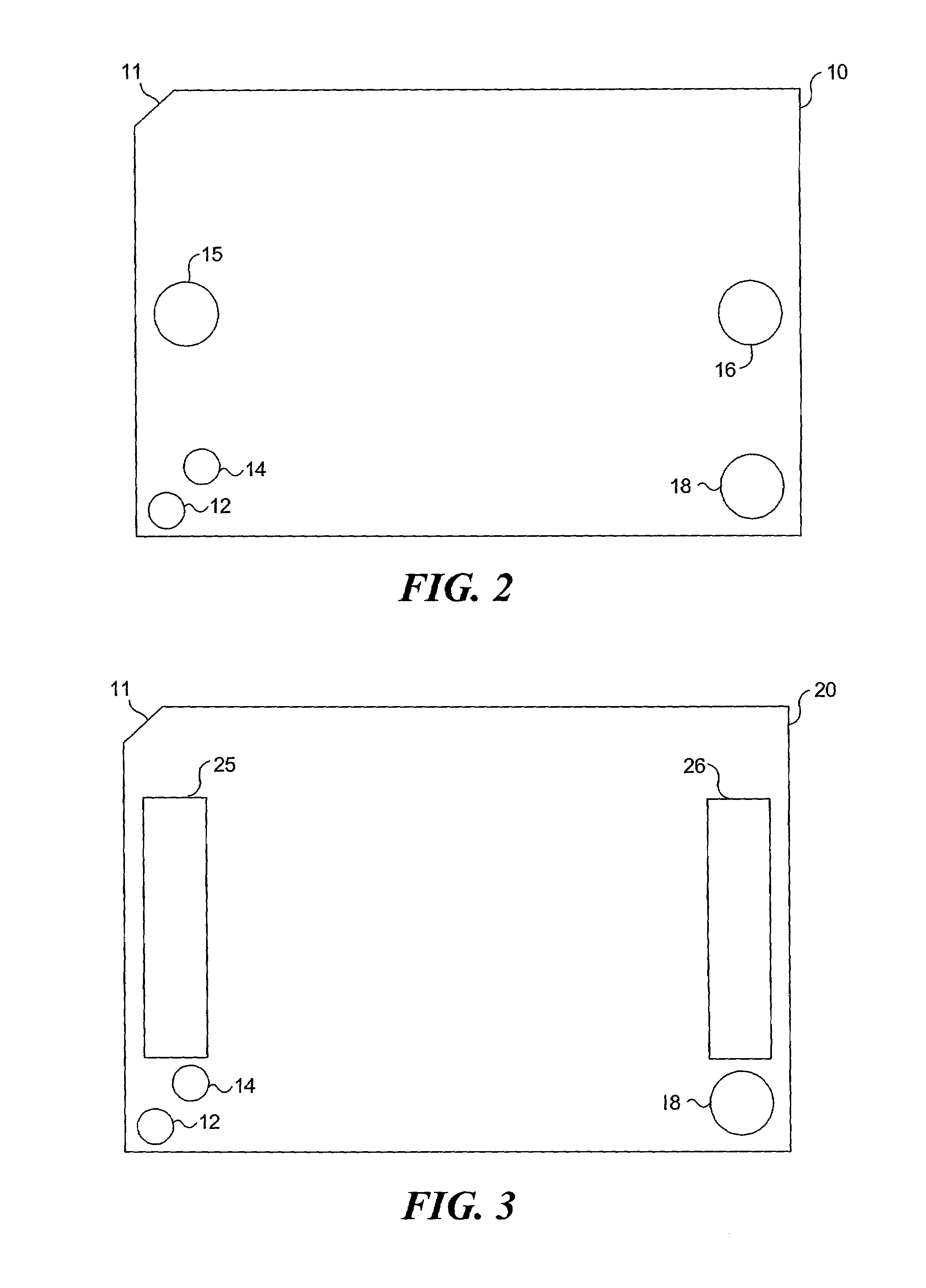

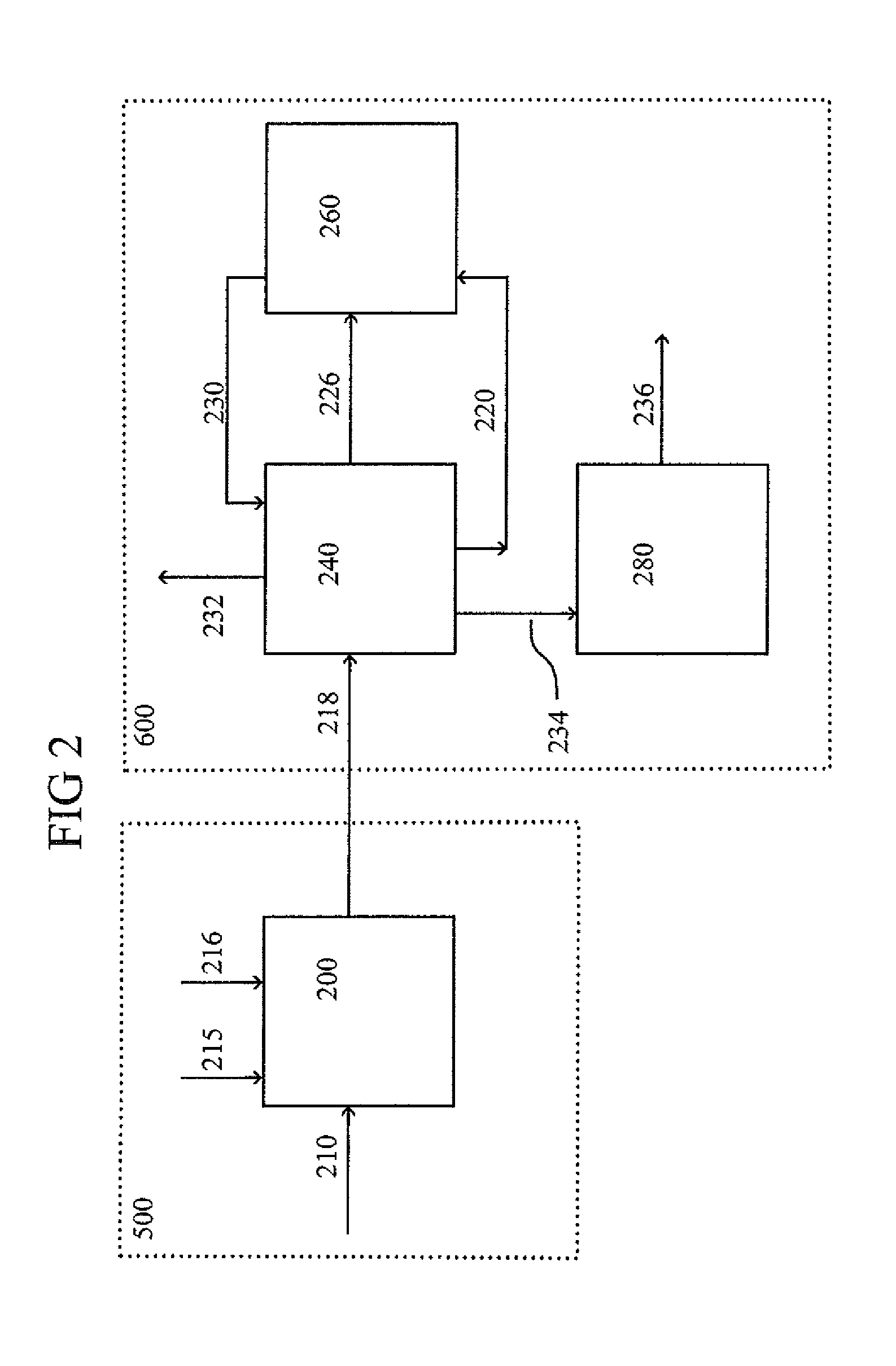

Methods and apparatus for genome analysis are provided. A microfabricated structure including a microfluidic distribution channel is configured to distribute microreactor elements having copies of a sequencing template into a plurality of microfabricated thermal cycling chambers. A microreactor element may include a microcarrier element carrying the multiple copies of the sequencing template. The microcarrier element may comprise a microsphere. An autovalve at an exit port of a thermal cycling chamber, an optical scanner, or a timing arrangement may be used to ensure that only one microsphere will flow into one thermal cycling chamber wherein thermal cycling extension fragments are produced. The extension products are captured, purified, and concentrated in an integrated oligonucleotide gel capture chamber. A microfabricated component separation apparatus is used to analyze the purified extension fragments. The microfabricated structure may be used in a process for performing sequencing and other genetic analysis of DNA or RNA.

Owner:RGT UNIV OF CALIFORNIA

Droplet Microreactor

InactiveUS20080124252A1Improve purification effectInexpensive to fabricateChemical/physical/physico-chemical microreactorsMaterial analysis by electric/magnetic meansMicroreactorLab-on-a-chip

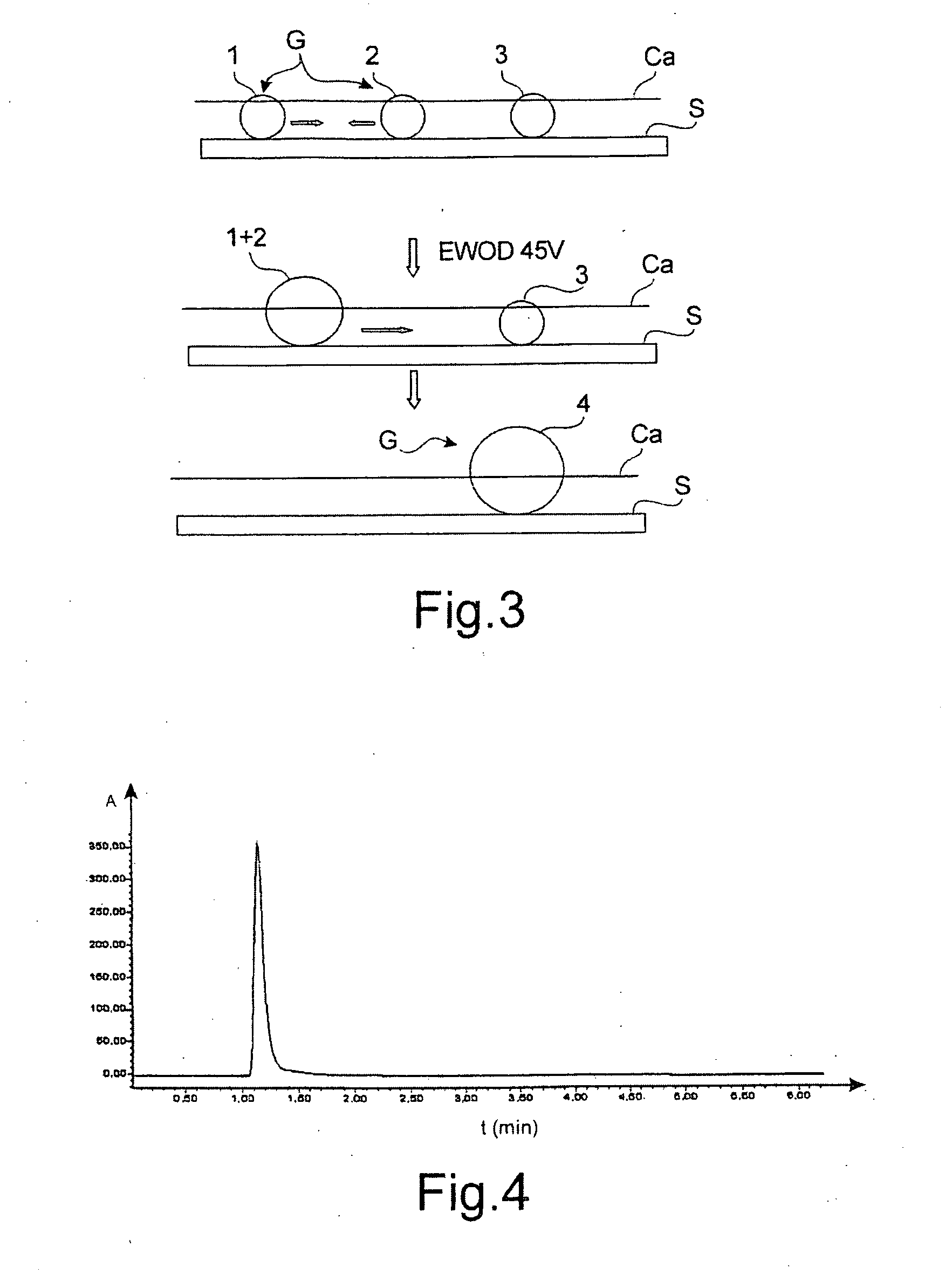

The present invention relates to a droplet microreactor, i.e. a microreactor consisting of a droplet of a specific liquid, the microreactor being wall-less, wherein the interface of the specific liquid with the ambient environment and with the support on which the droplet is deposited defines the limits of the microreactor. The microreactor is characterized in that it consists of a droplet comprising at least one ionic liquid. The present invention also relates to methods for carrying out chemical or biochemical reactions and / or mixes using said droplet microreactor, and also to a lab-on-chip comprising a microreactor according to the invention.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

Nucleic acid amplification with continuous flow emulsion

InactiveUS7927797B2Rapid and economical mannerReduce nozzle cloggingHeating or cooling apparatusFlow mixersMicroreactorGenetic Materials

Embodiments of the present invention are directed to methods and devices / systems for amplifying genetic material and may include providing a water-in-oil emulsion in a continuous flow. The emulsion may include a plurality of water droplets comprising microreactors. Each of the plurality of microreactors may include a single bead capable of capturing a nucleic acid template, a single species nucleic acid template and sufficient reagents to amplify the copy number of the nucleic acid template. The method also includes flowing the emulsion across a first temperature zone and a second lower temperature zone to thermally process the microreactors to amplify the nucleic acid template by polymerase chain reaction.

Owner:454 LIFE SCIENCES CORP

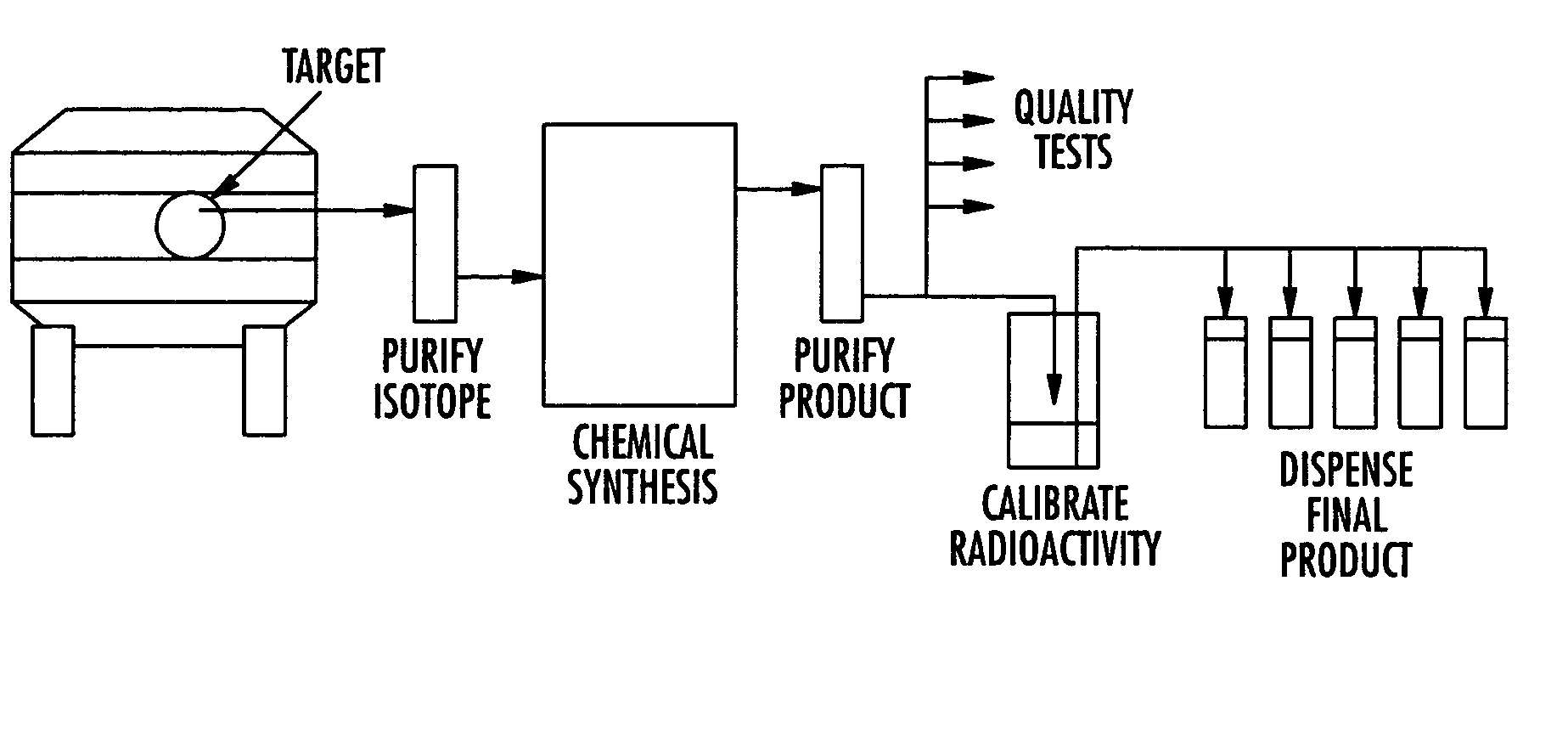

Biomarker generator system

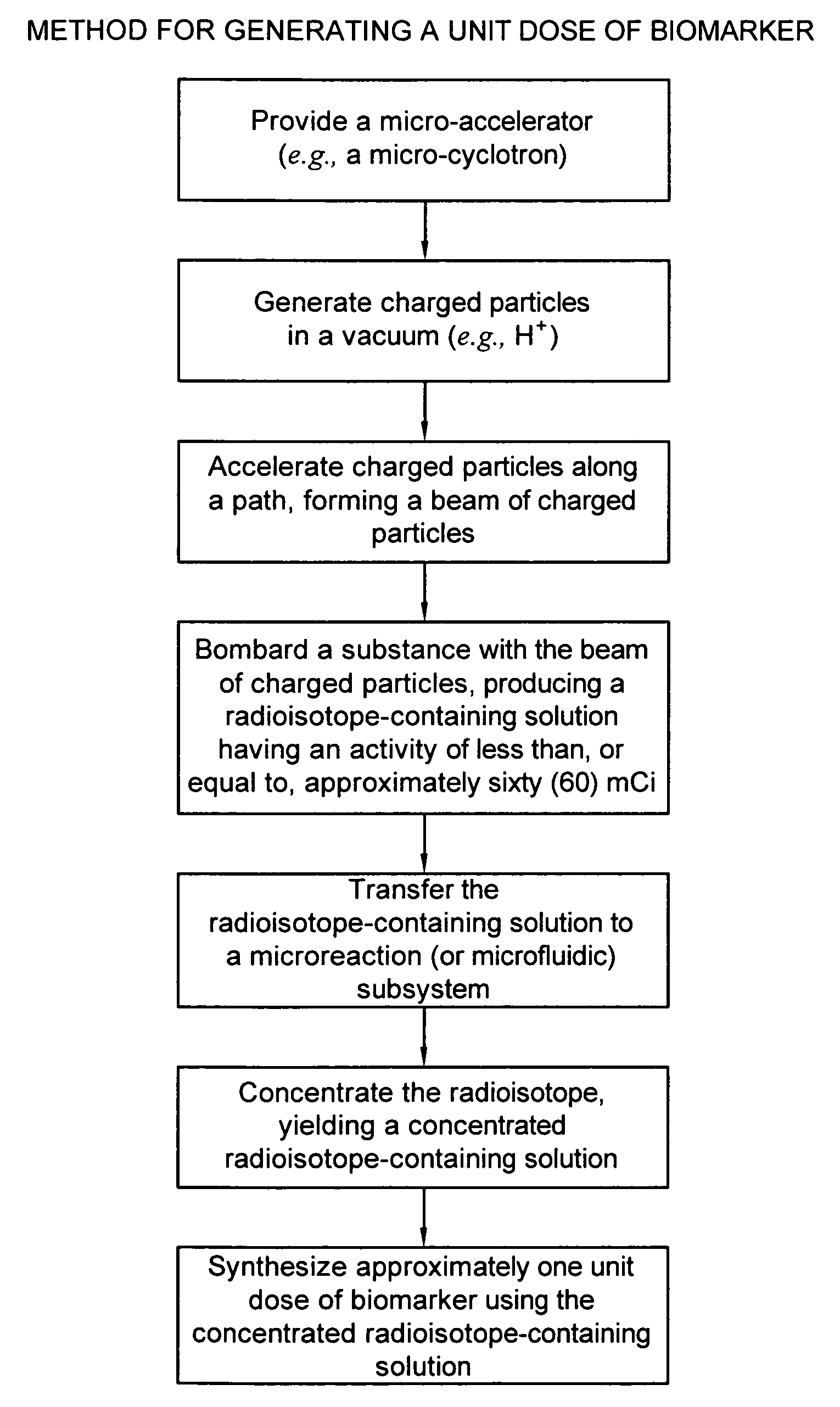

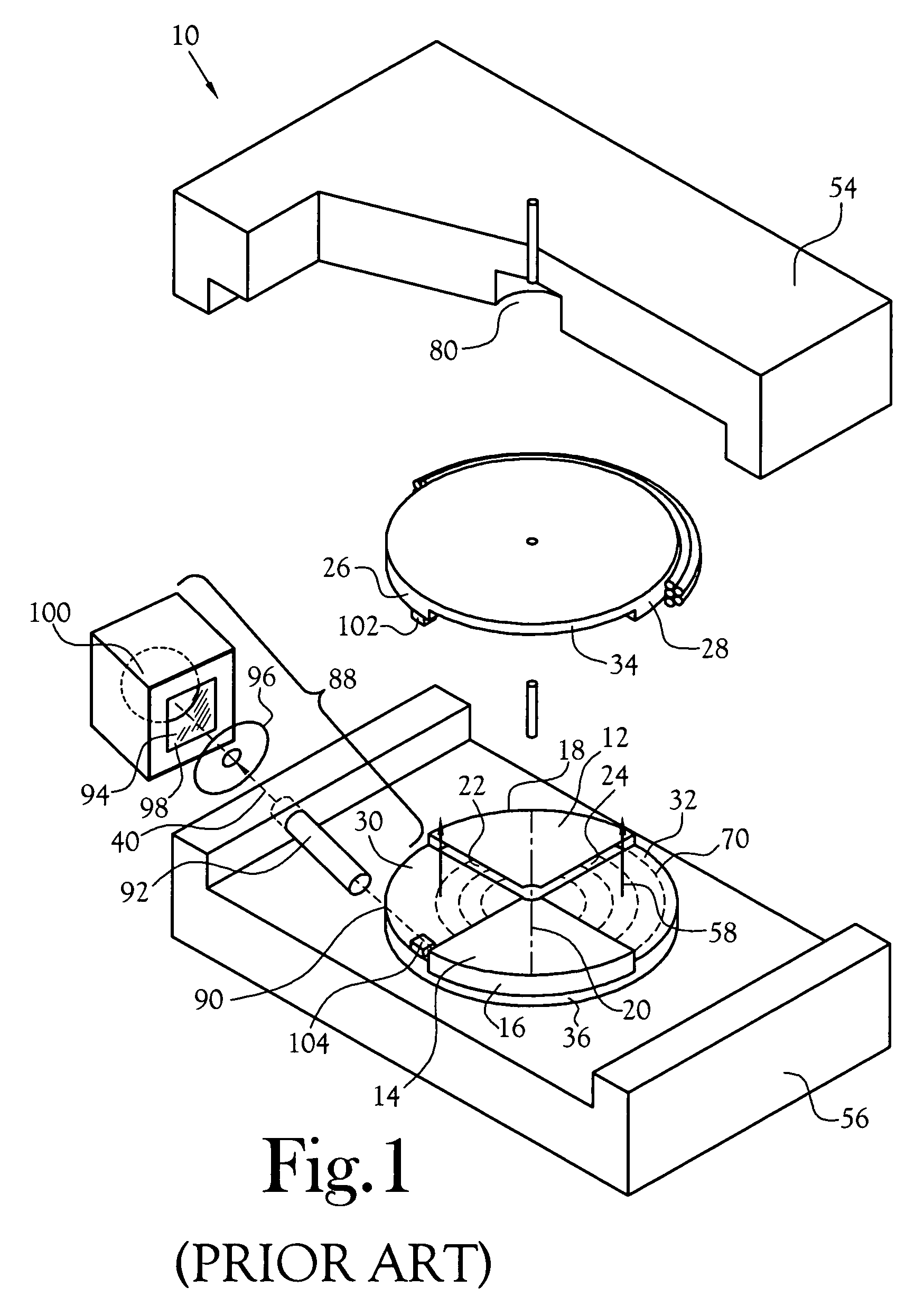

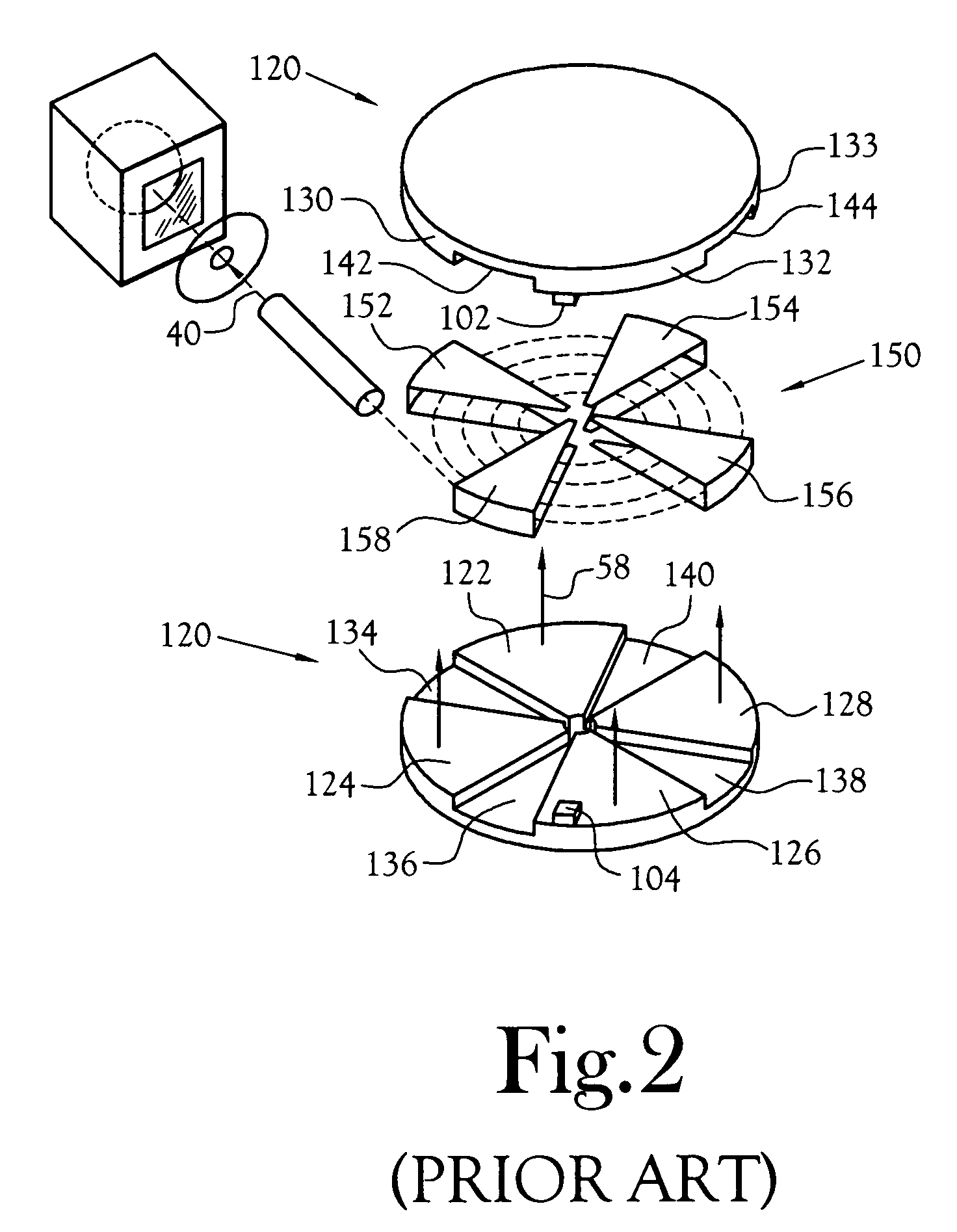

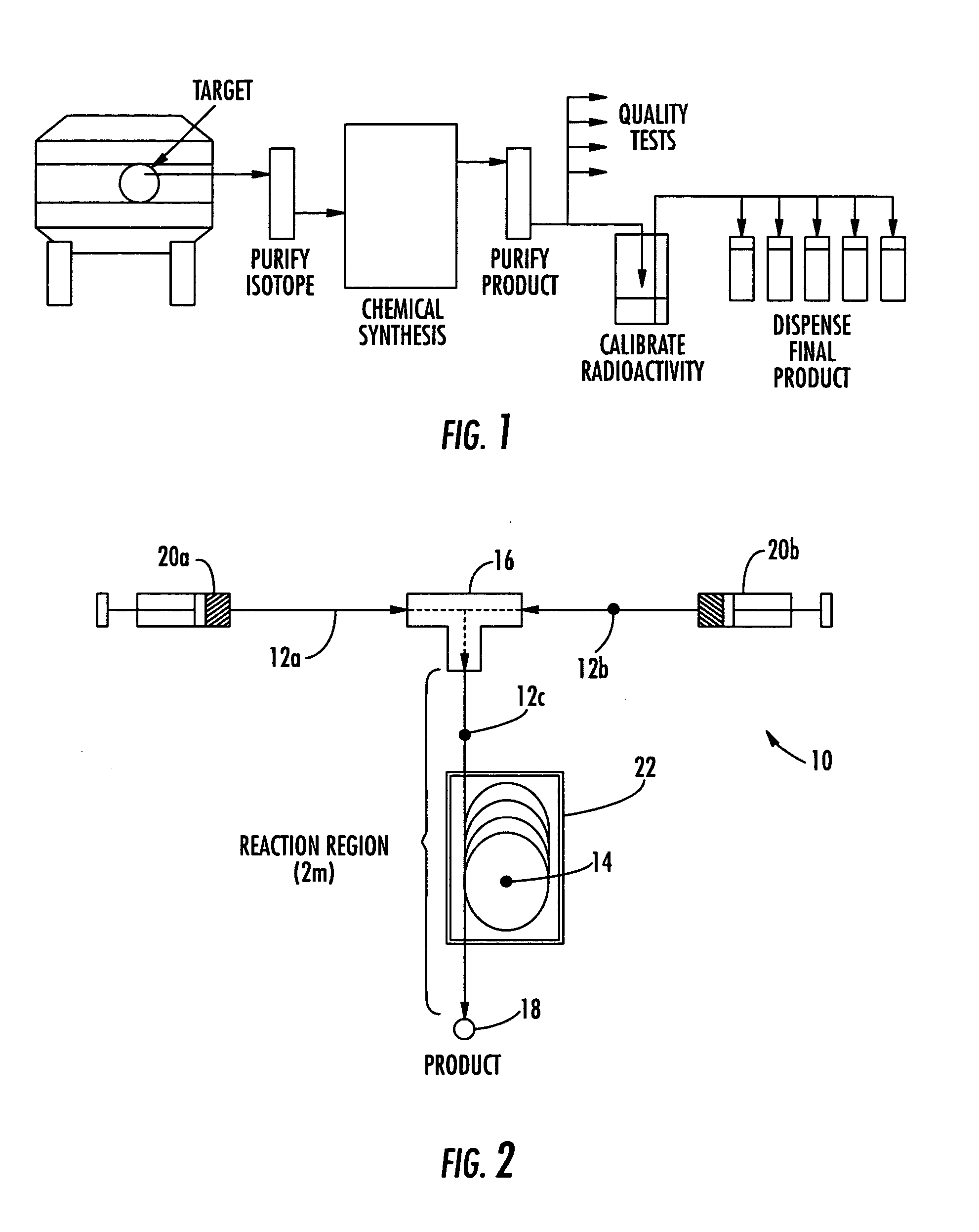

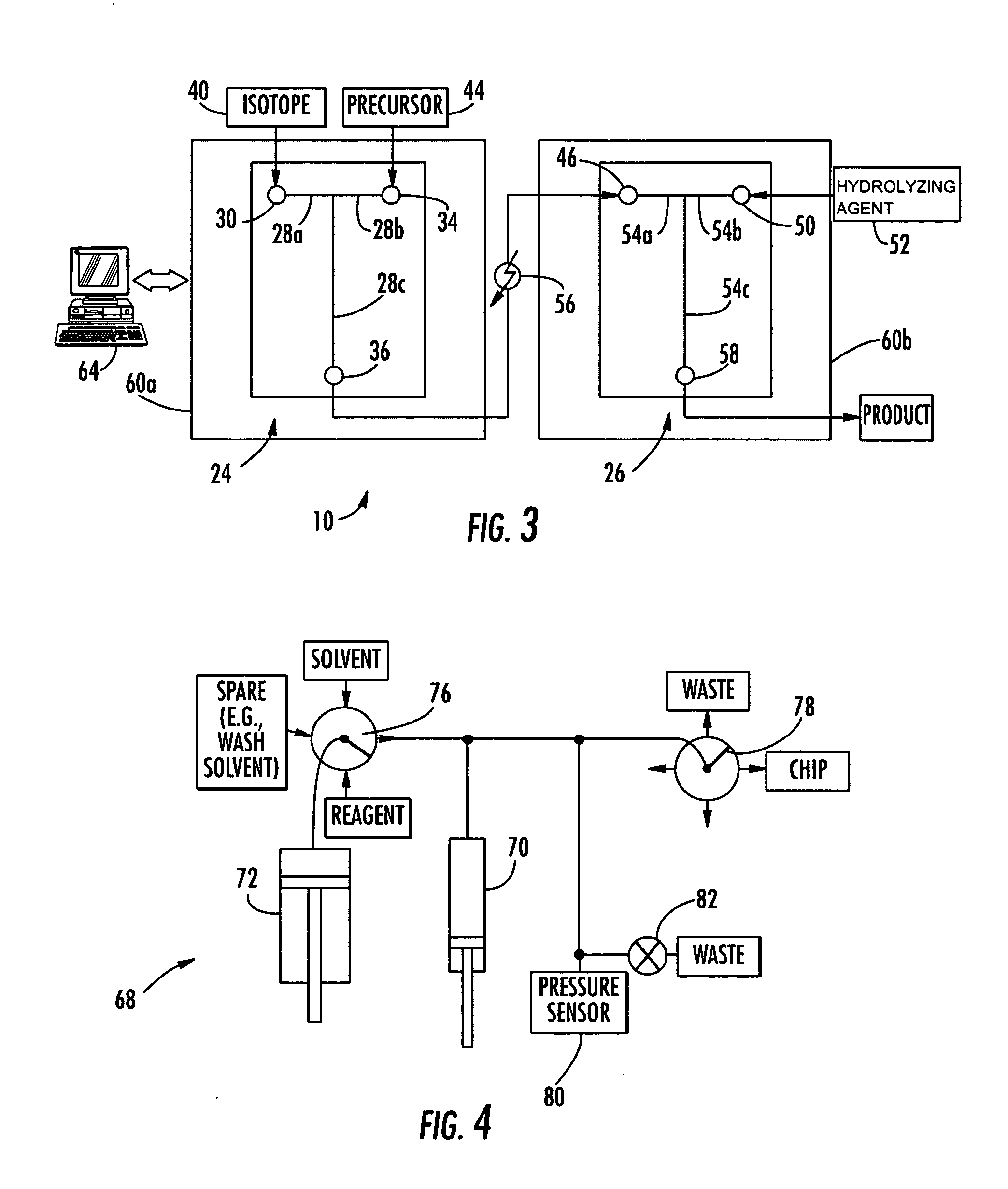

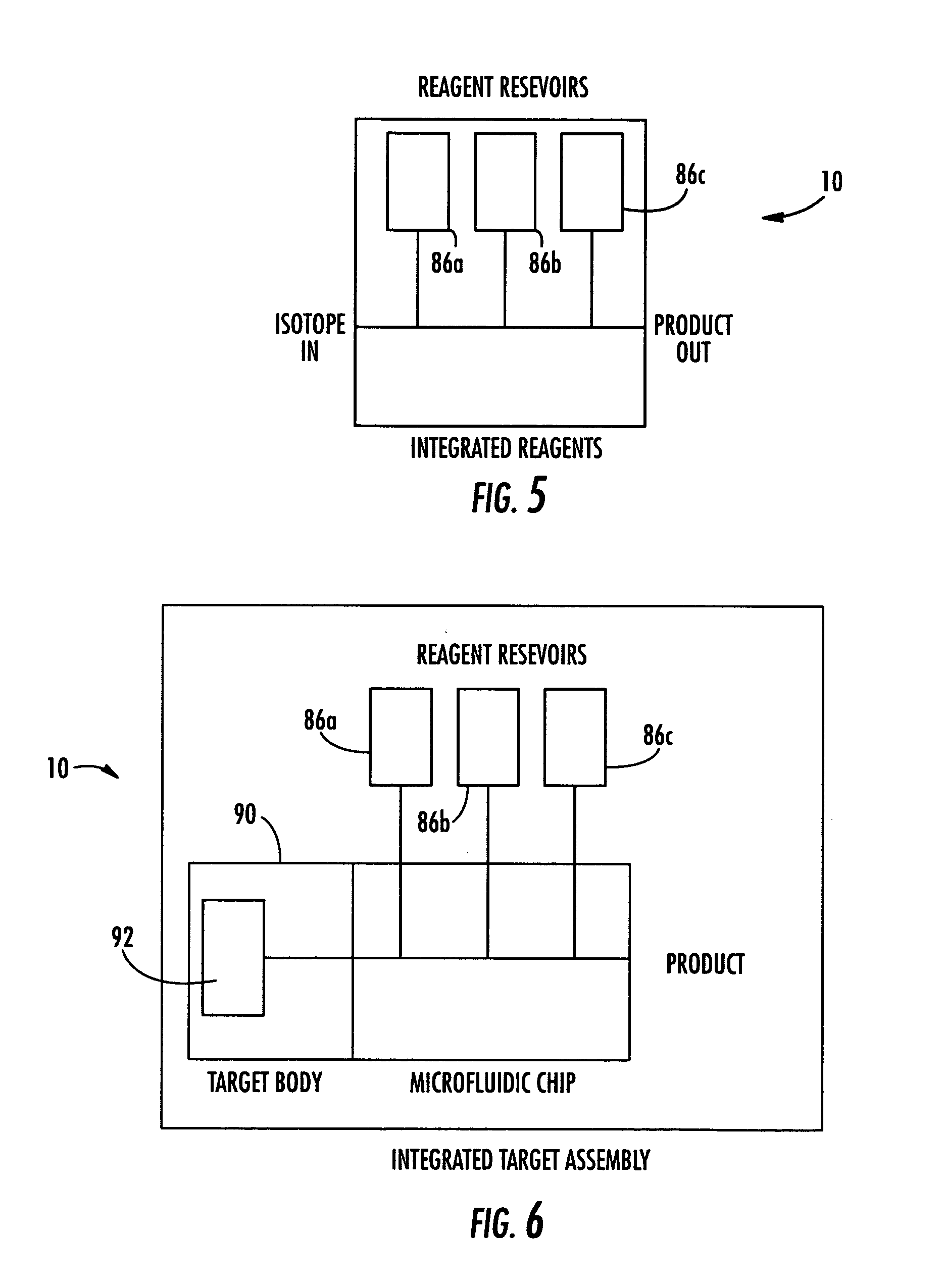

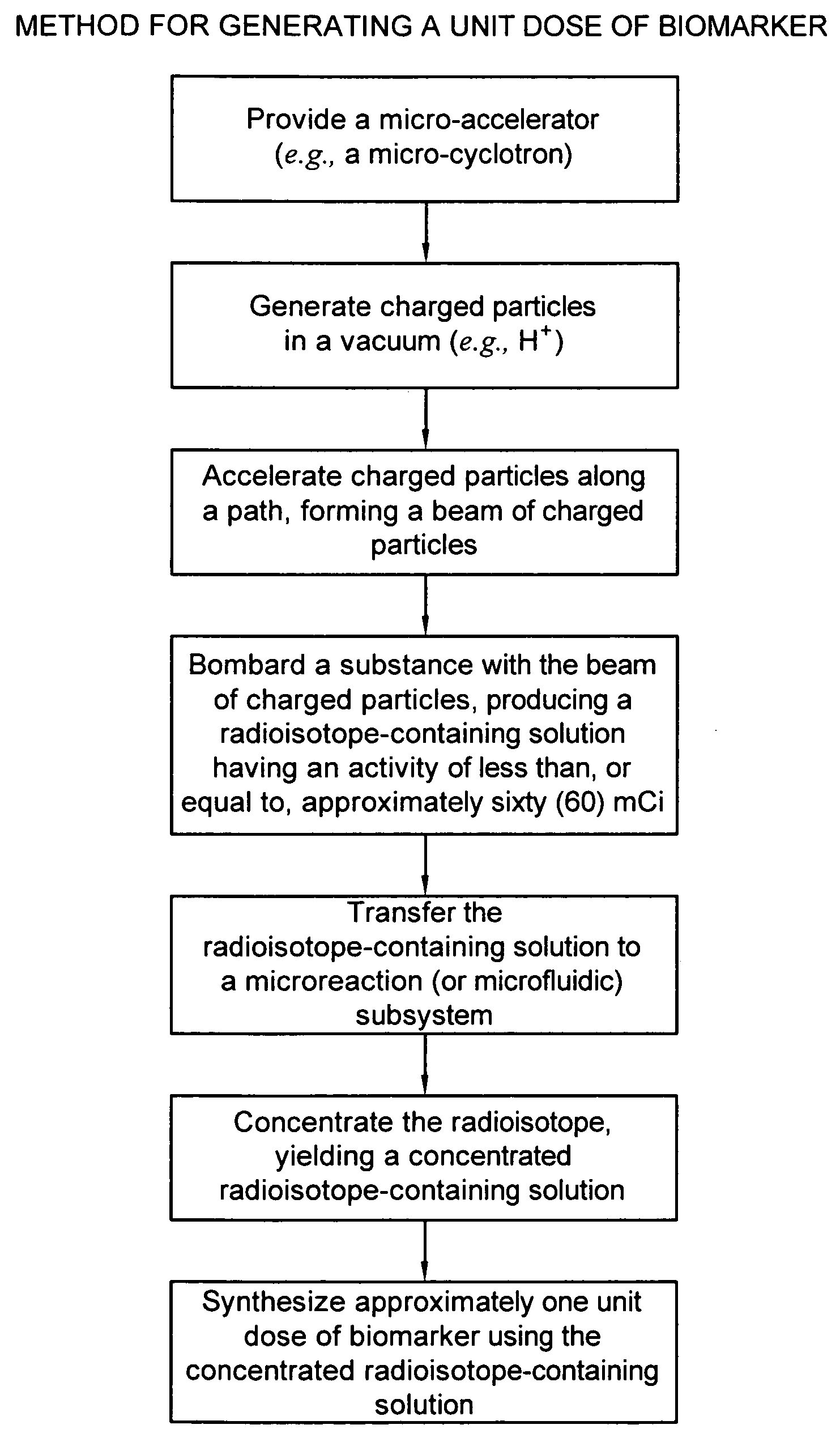

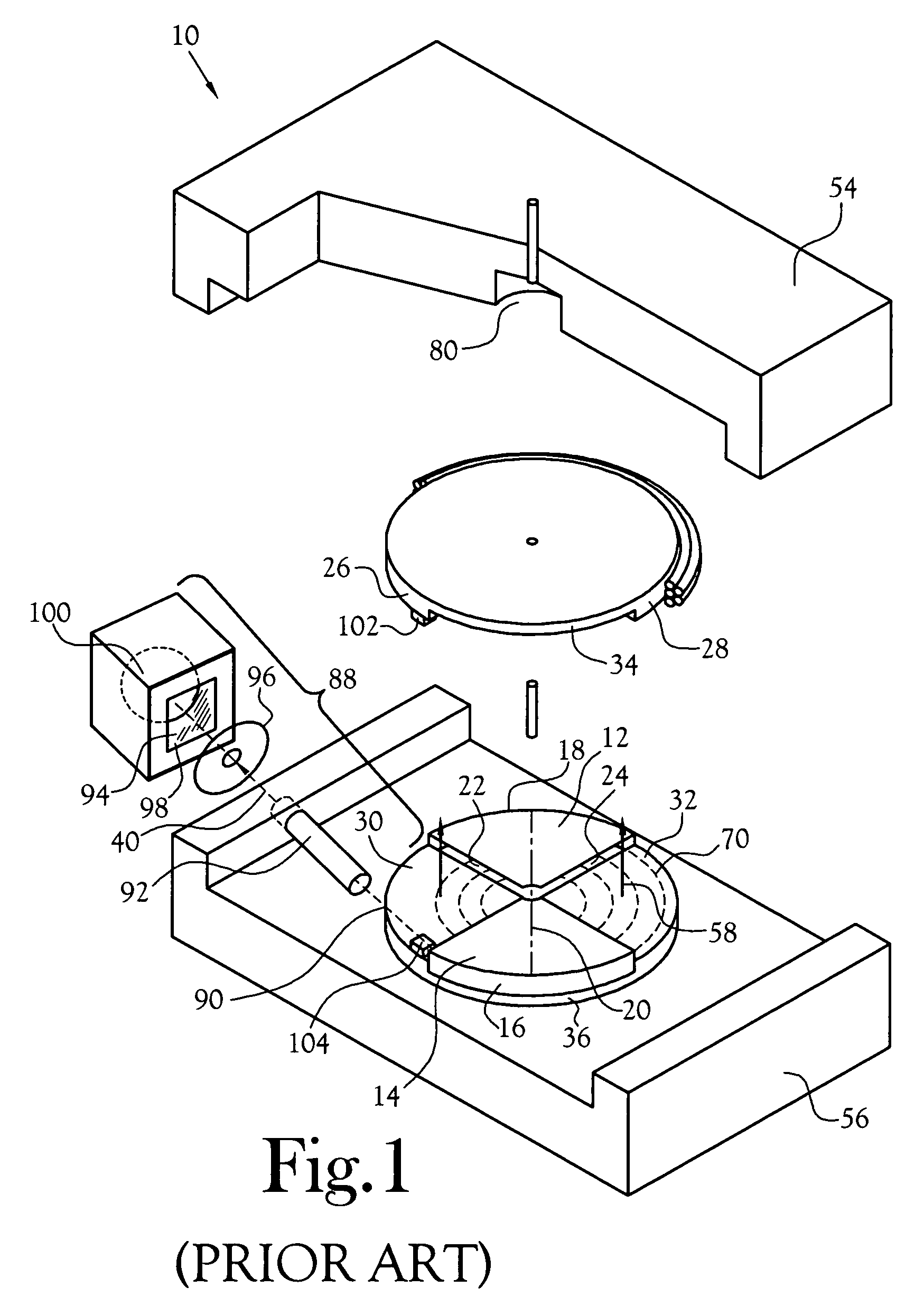

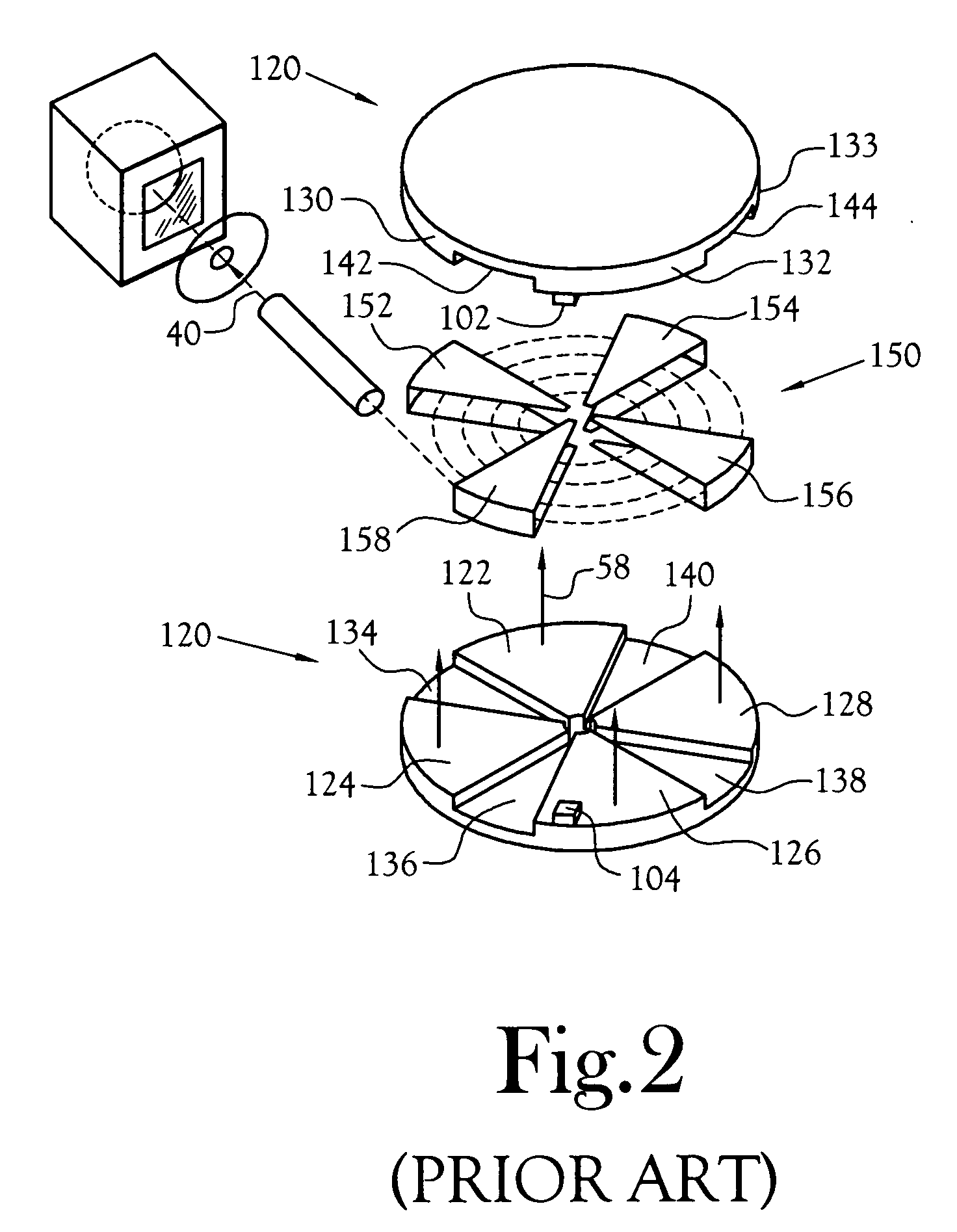

ActiveUS7476883B2Efficient dosingEfficient productionMaterial analysis using wave/particle radiationIsotope delivery systemsChemical synthesisMicroreactor

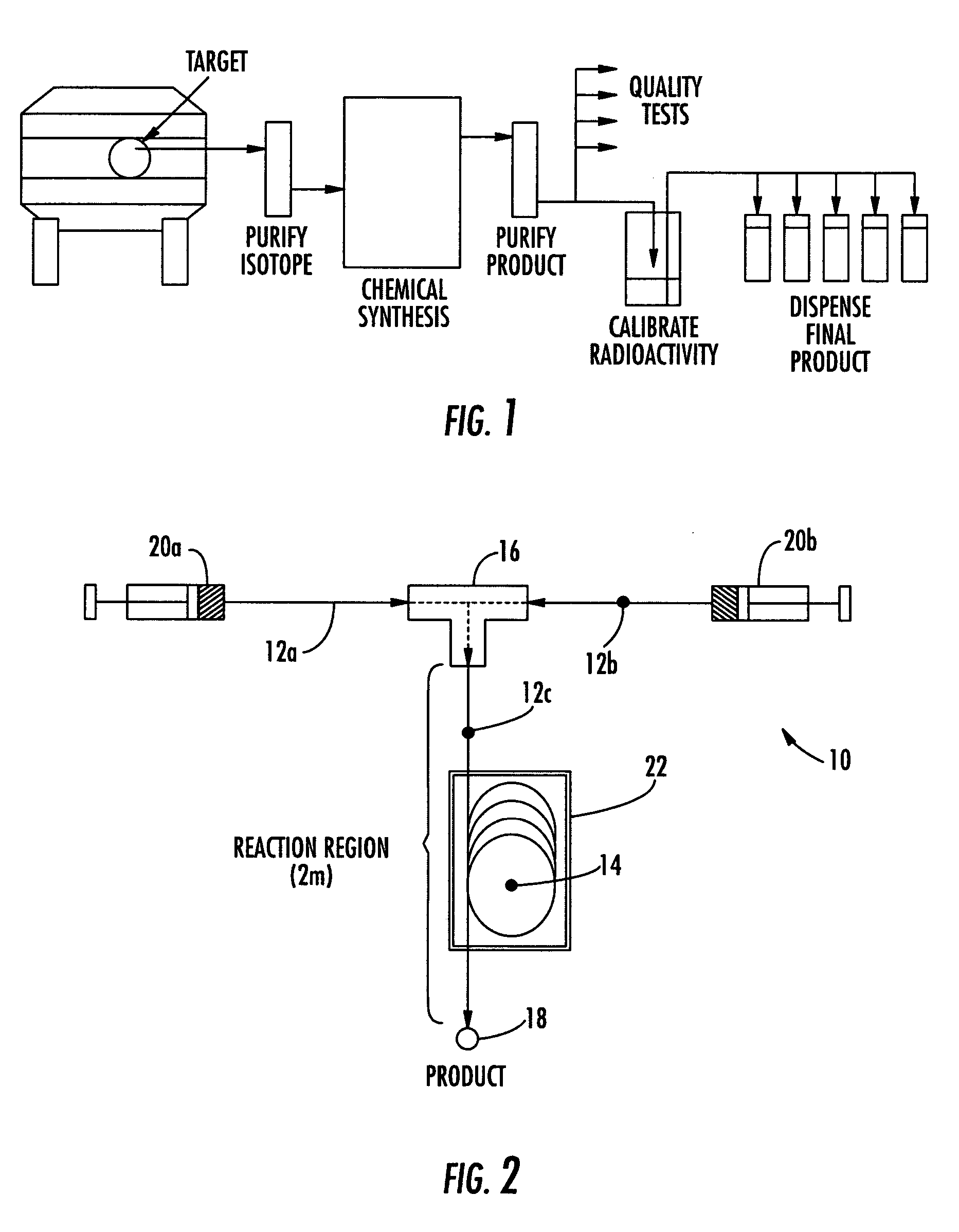

A biomarker generator system for producing approximately one (1) unit dose of a biomarker. The biomarker generator system includes a small, low-power particle accelerator (“micro-accelerator”) and a radiochemical synthesis subsystem having at least one microreactor and / or microfluidic chip. The micro-accelerator is provided for producing approximately one (1) unit dose of a radioactive substance, such as a substance that emits positrons. The radiochemical synthesis subsystem is provided for receiving the radioactive substance, for receiving at least one reagent, and for synthesizing the approximately one (1) unit dose of a biomarker.

Owner:BEST ABT INC

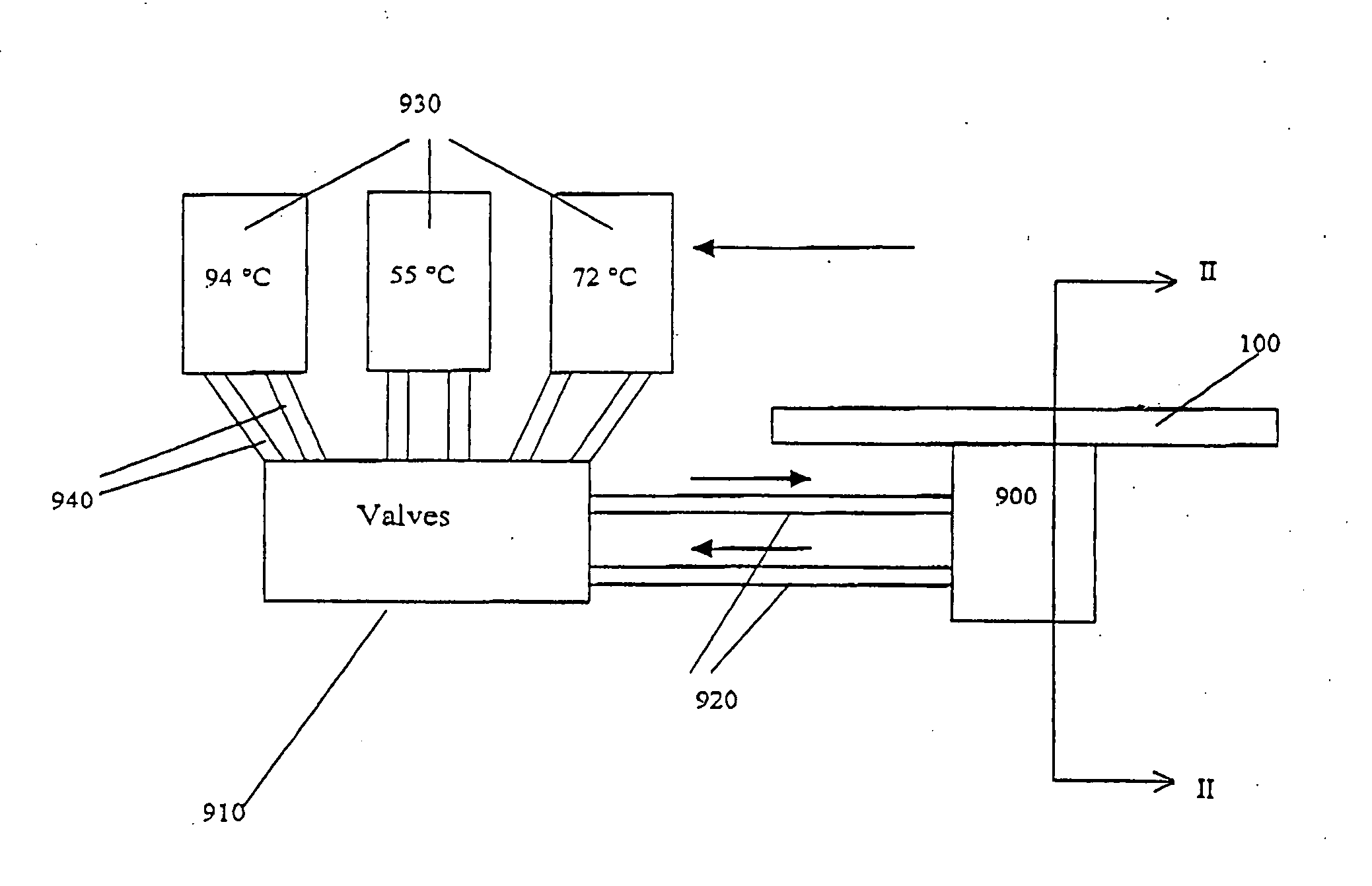

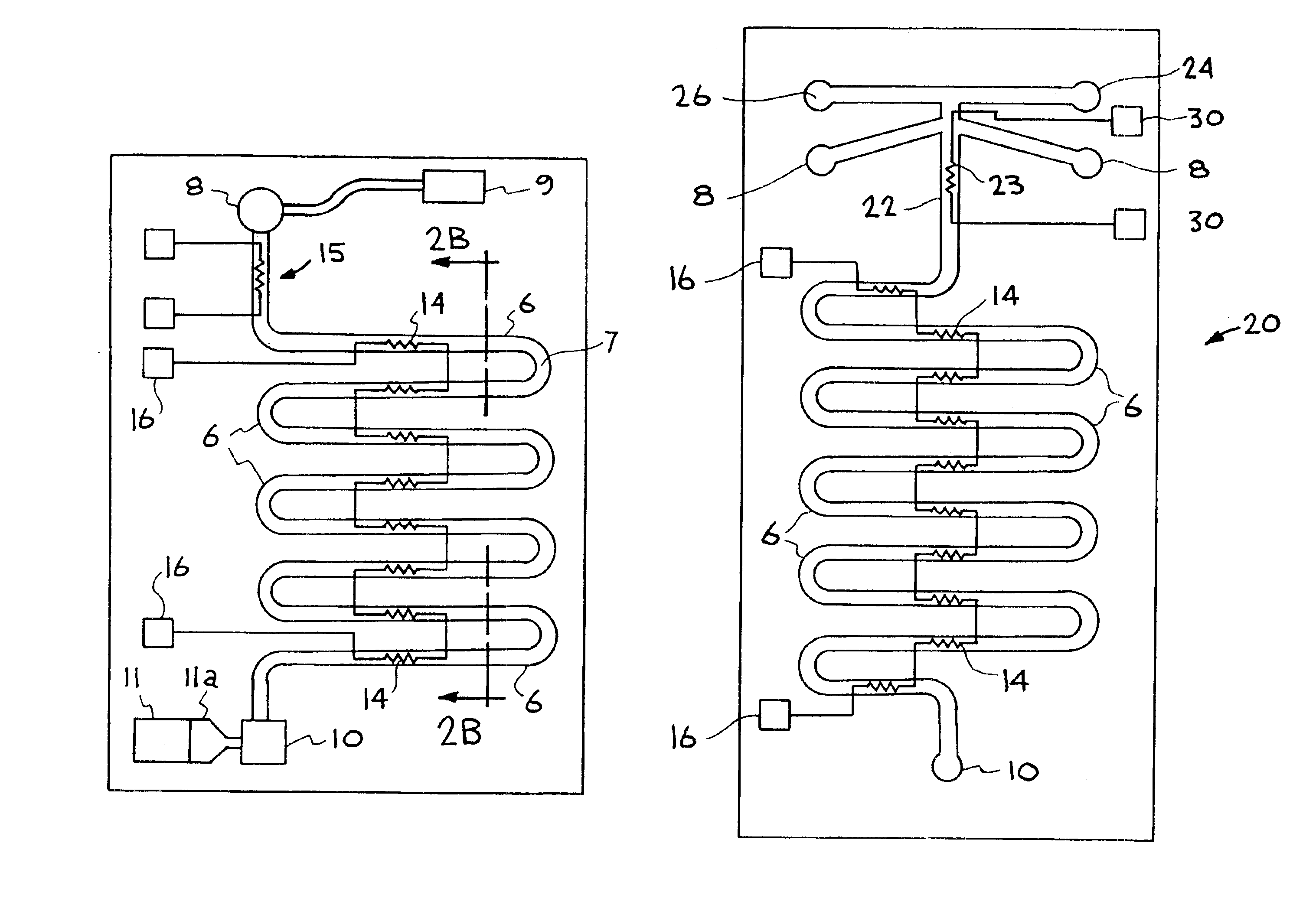

Method for carrying out a biochemical protocol in continuous flow in a microreactor

InactiveUS20050282224A1Reduce in quantityImprove throughputBioreactor/fermenter combinationsFixed microstructural devicesMicroreactorTwo temperature

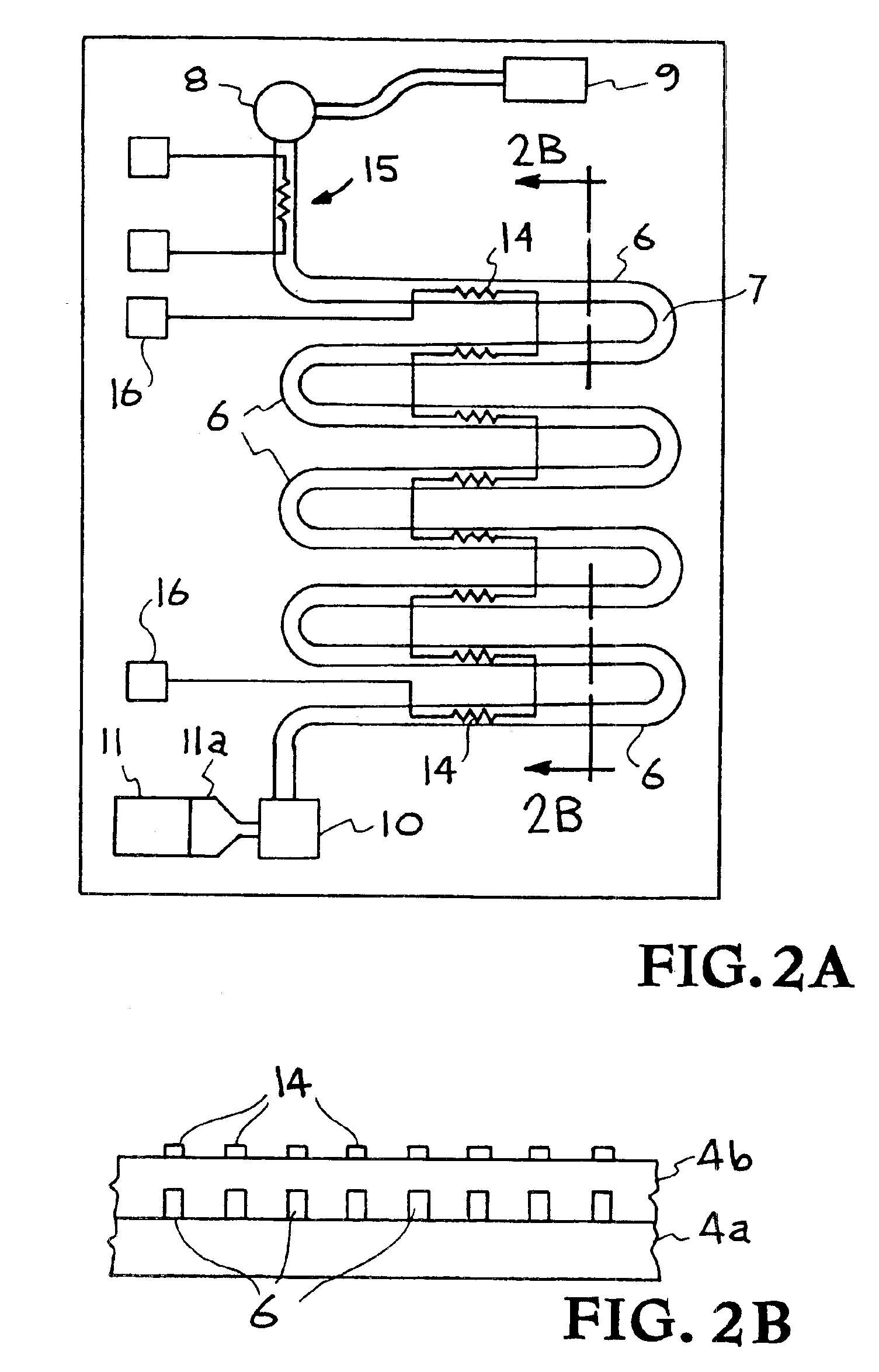

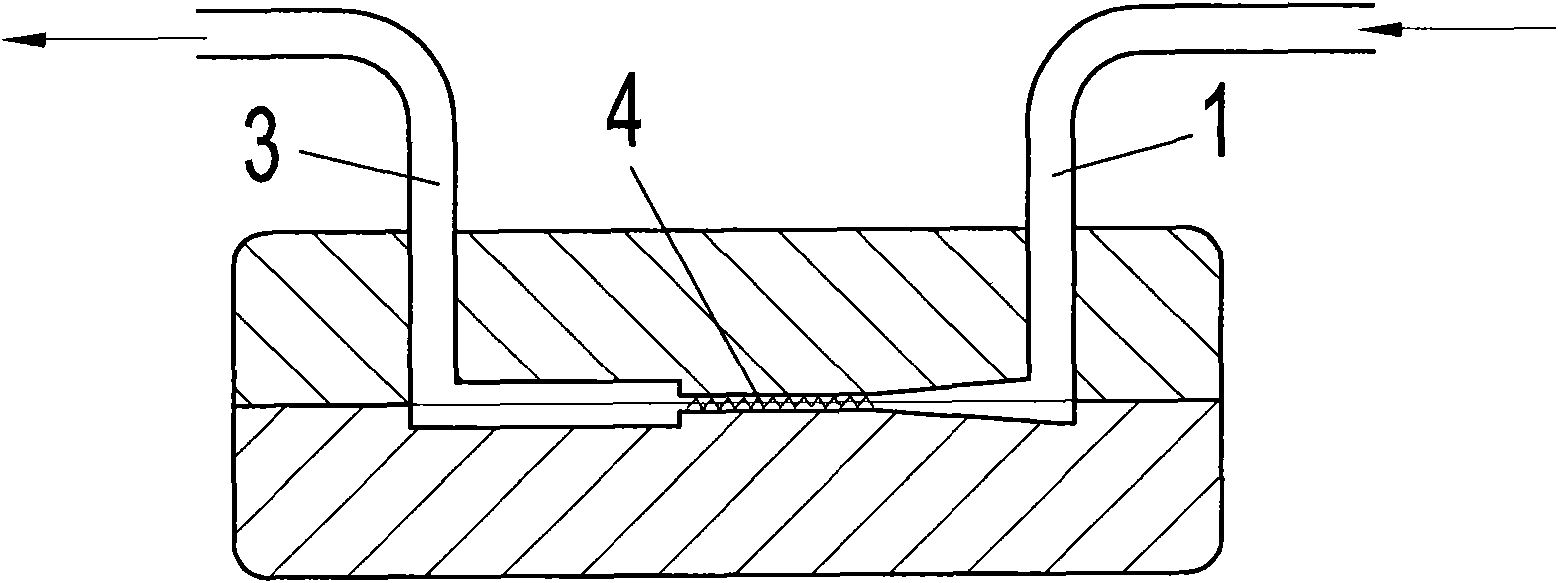

Devices and methods for carrying out a chemical or biochemical protocol are disclosed. In one embodiment, the chemical or biochemical protocol is performed by cycling at least one thermal transfer member between at least two temperatures while liquid samples on which the chemical or biochemical protocol is to be performed are continuously moving through at least one temperature regulated zone upon which the at least one thermal transfer member acts. In some embodiments, the device comprises a sample transport member that comprises liquid samples in sample receiving regions. The sample transport member moves the samples continuously through a temperature regulated zone which cycles between at least two temperatures while the liquid samples are moving through a temperature regulated zone on which at least one thermal transfer member acts. In some embodiments, the sample receiving regions comprise wells, hydrophillic films or hydrophillic filaments.

Owner:SERONO GENETICS INST SA +1

Microfabricated integrated DNA analysis system

ActiveUS7799553B2Improve automationBig spaceBioreactor/fermenter combinationsElectrolysis componentsMicroreactorMicrosphere

Methods and apparatus for genome analysis are provided. A microfabricated structure including a microfluidic distribution channel is configured to distribute microreactor elements having copies of a sequencing template into a plurality of microfabricated thermal cycling chambers. A microreactor element may include a microcarrier element carrying the multiple copies of the sequencing template. The microcarrier element may comprise a microsphere. An autovalve at an exit port of a thermal cycling chamber, an optical scanner, or a timing arrangement may be used to ensure that only one microsphere will flow into one thermal cycling chamber wherein thermal cycling extension fragments are produced. The extension products are captured, purified, and concentrated in an integrated oligonucleotide gel capture chamber. A microfabricated component separation apparatus is used to analyze the purified extension fragments. The microfabricated structure may be used in a process for performing sequencing and other genetic analysis of DNA or RNA.

Owner:RGT UNIV OF CALIFORNIA

Chemical microreactor and method thereof

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

Method for carrying out a biochemical protocol in continuous flow in a microreactor

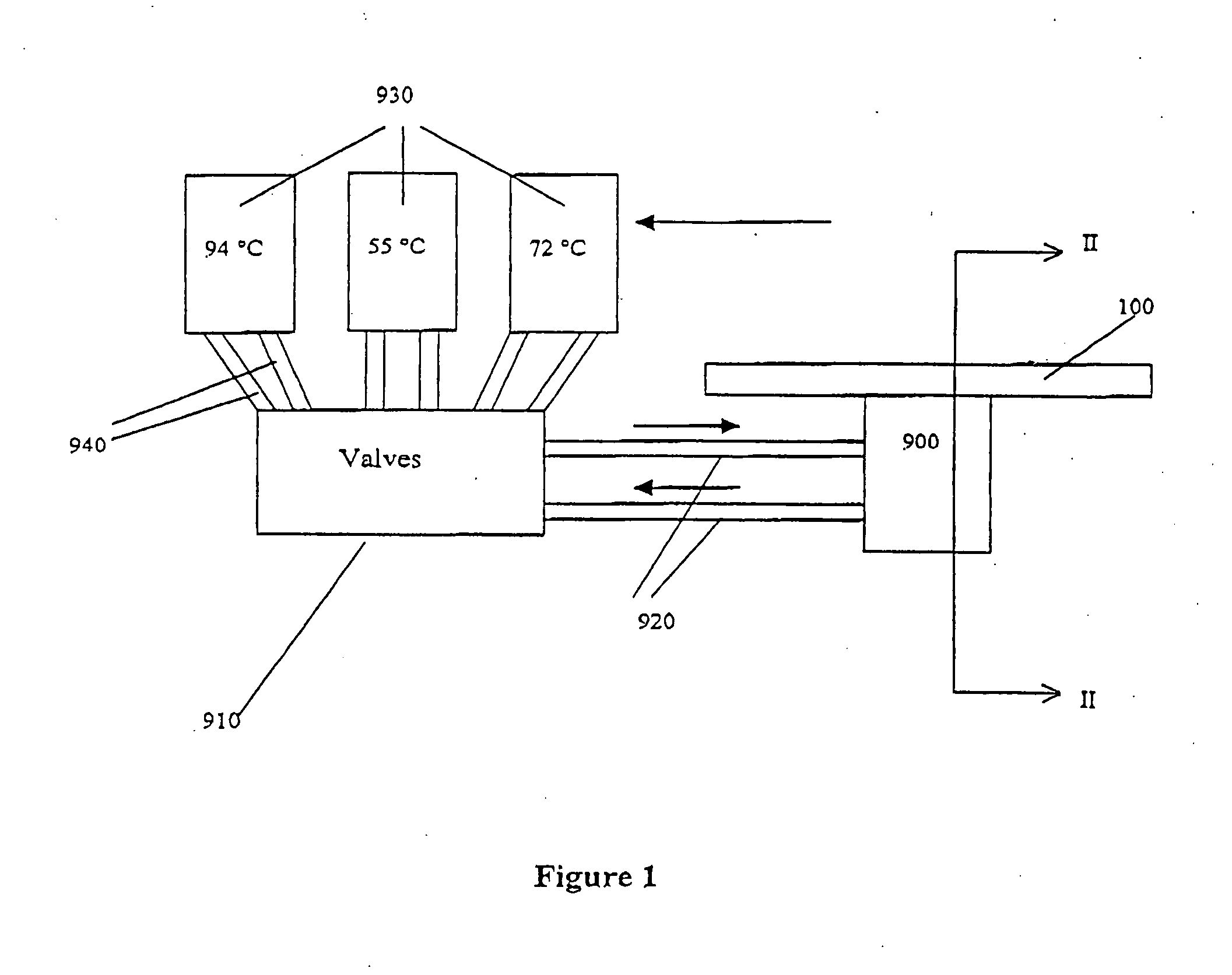

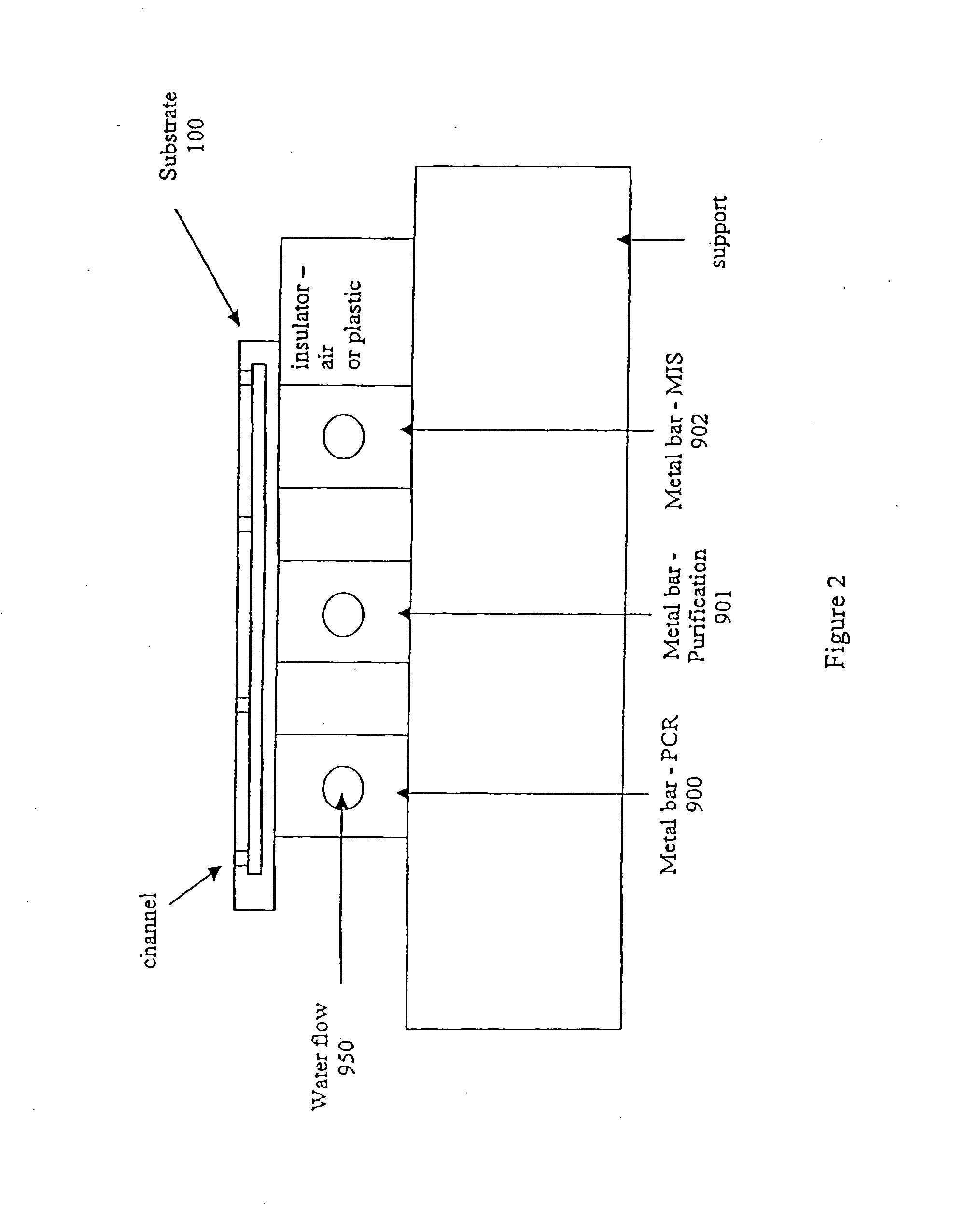

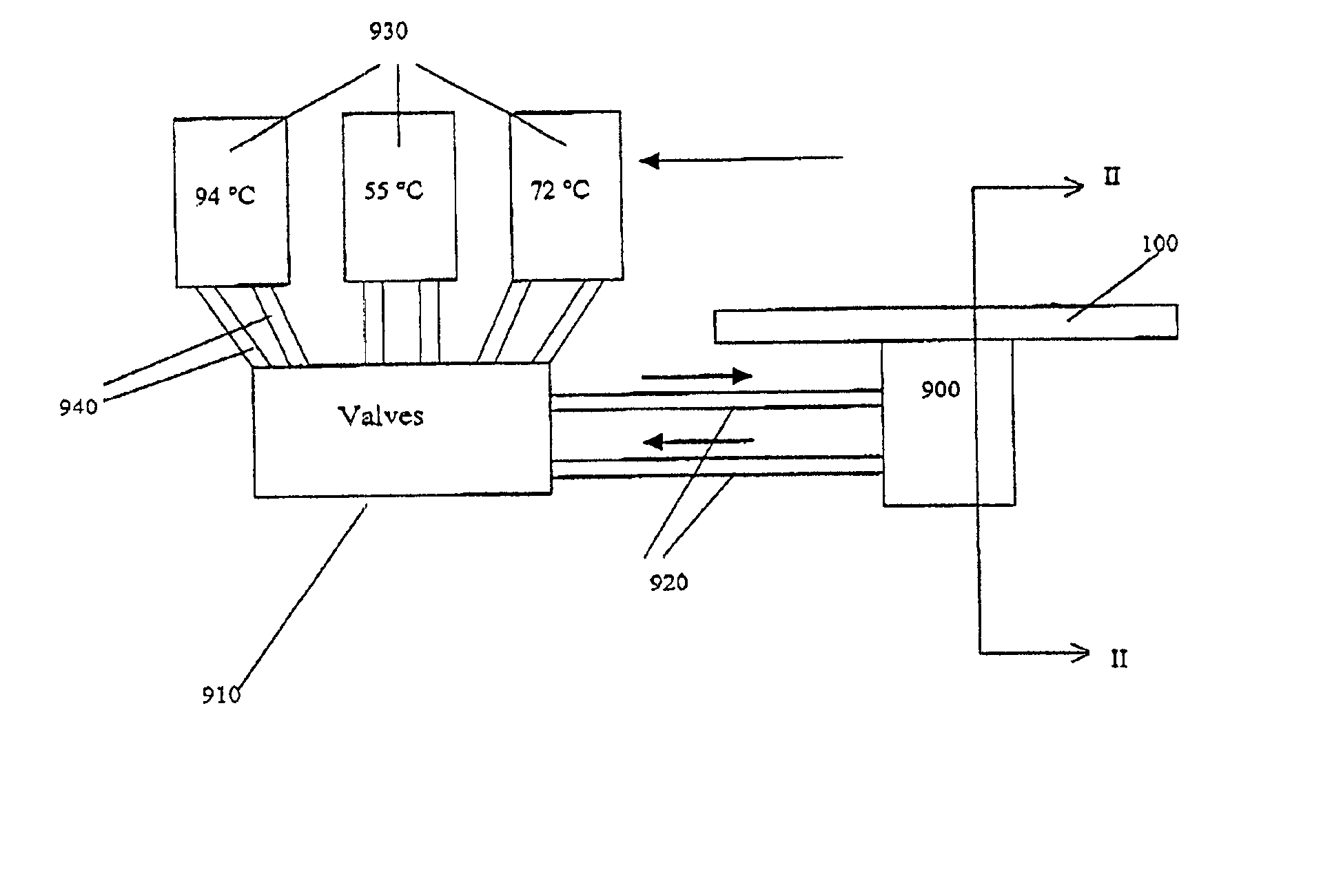

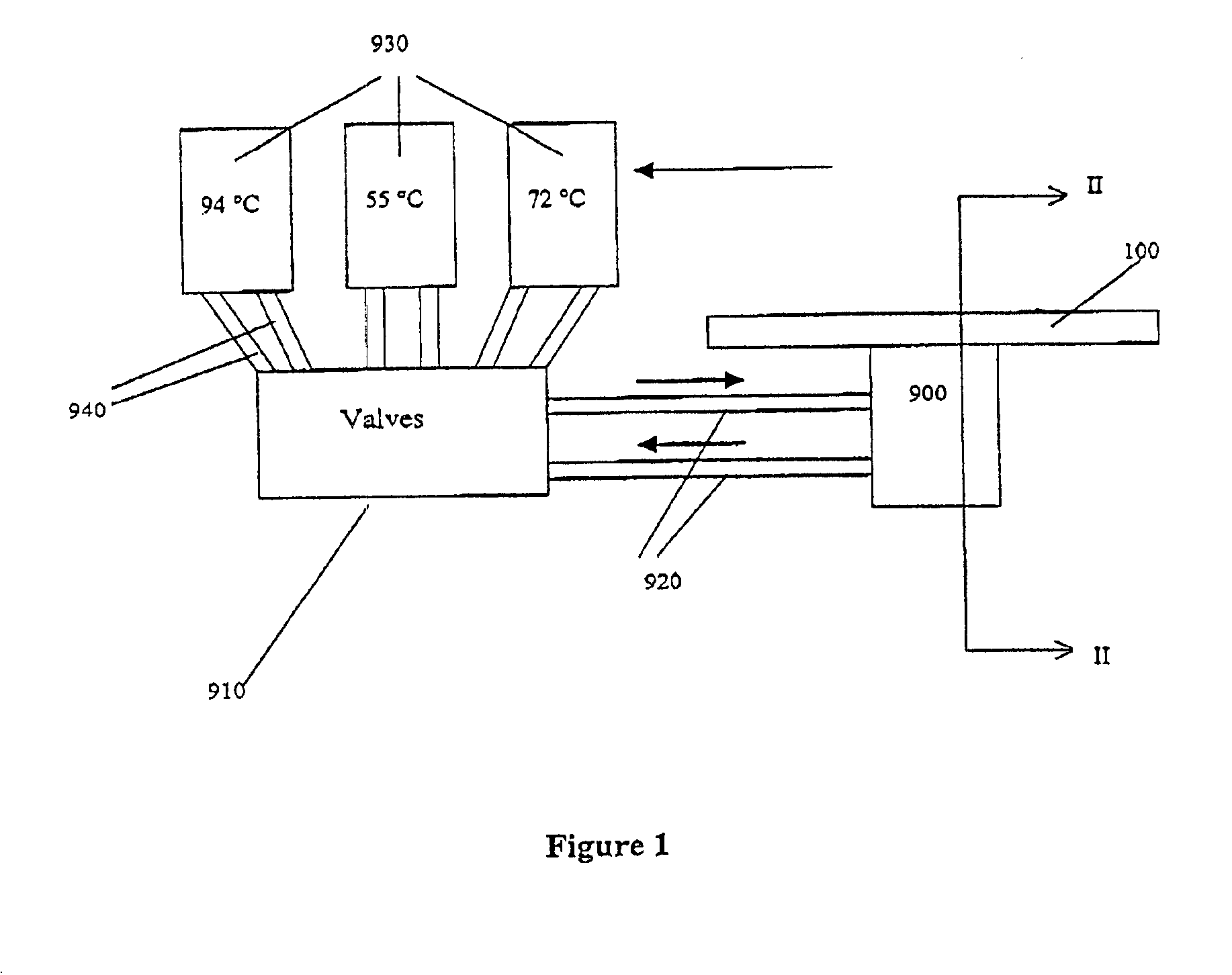

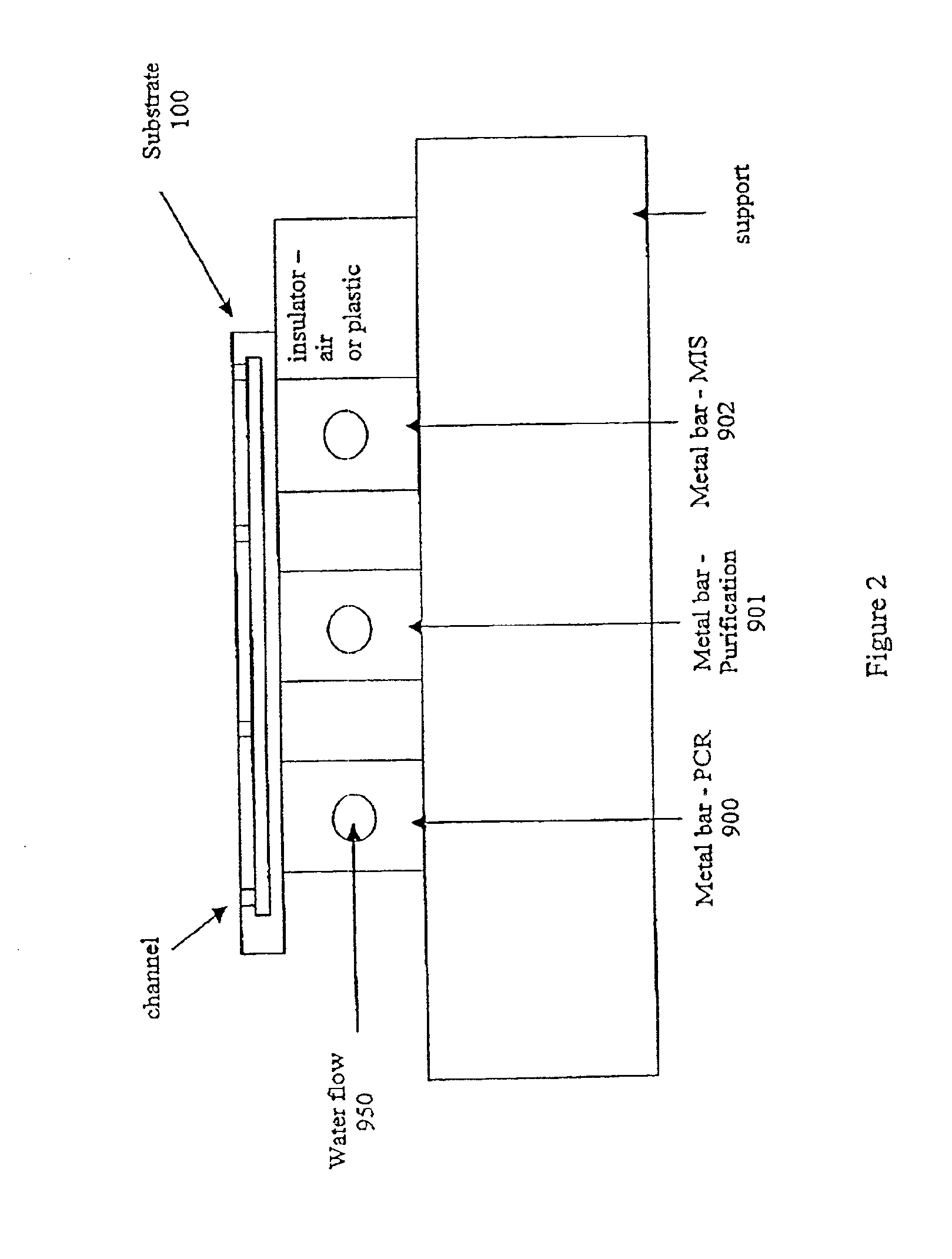

InactiveUS6977145B2Improve throughputReduce in quantityBioreactor/fermenter combinationsFixed microstructural devicesMicroreactorTwo temperature

Devices and methods for carrying out a chemical or biochemical protocol are disclosed. In one embodiment, the chemical or biochemical protocol is performed by cycling at least one thermal transfer member between at least two temperatures while liquid samples on which the chemical or biochemical protocol is to be performed are continuously moving through at least one temperature regulated zone upon which the at least one thermal transfer member acts. In some embodiments, the device comprises a sample transport member that comprises liquid samples in sample receiving regions. The sample transport member moves the samples continuously through a temperature regulated zone which cycles between at least two temperatures while the liquid samples are moving through a temperature regulated zone on which at least one thermal transfer member acts. In some embodiments, the sample receiving regions comprise wells, hydrophillic films or hydrophillic filaments.

Owner:SERONO GENETICS INST SA +1

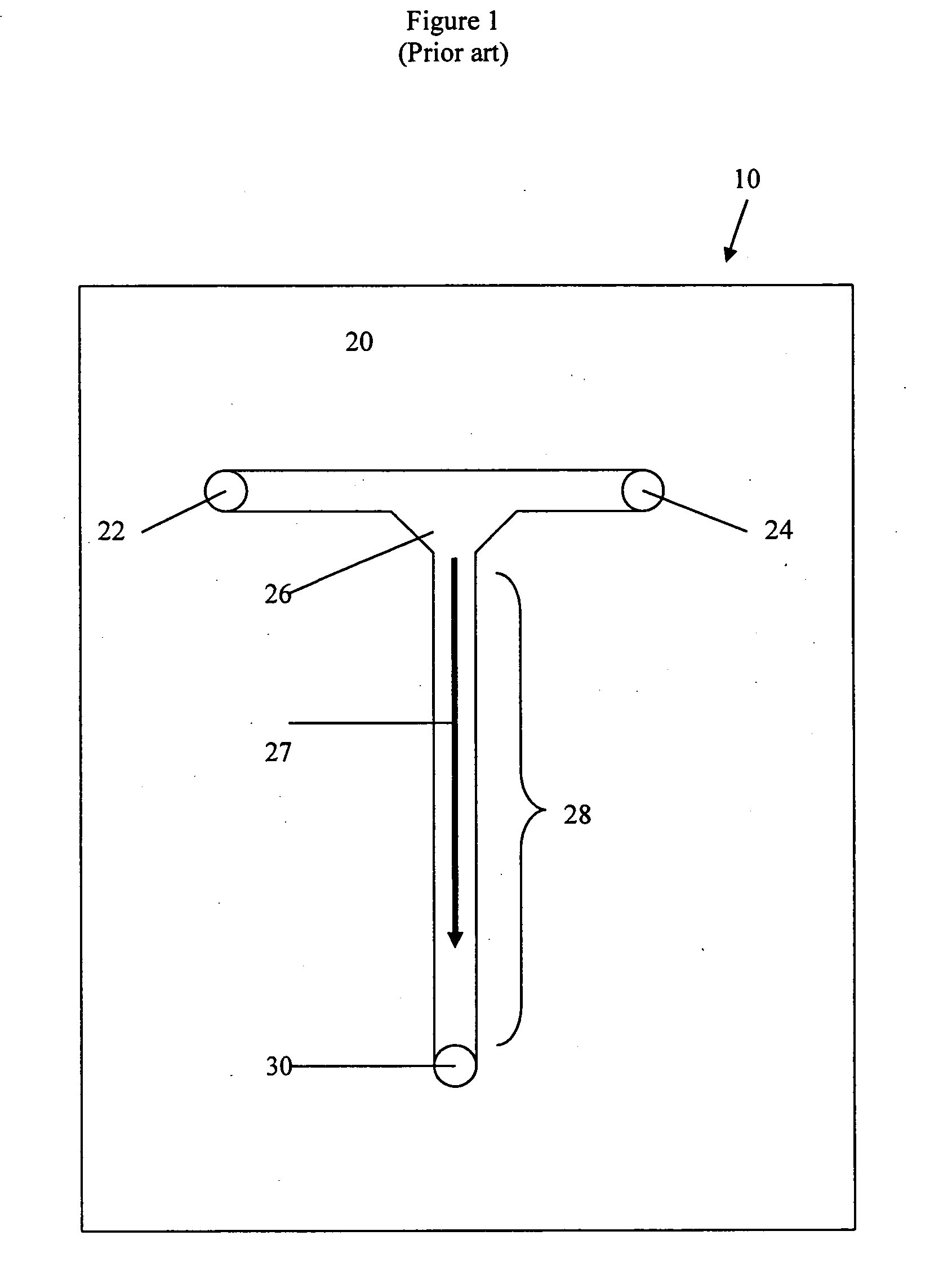

Microfluidic apparatus and method for synthesis of molecular imaging probes

InactiveUS20050232387A1Fast synthesis timeHigh synthetic yieldIn-vivo radioactive preparationsConversion outside reactor/acceleratorsMicroreactorMolecular imaging

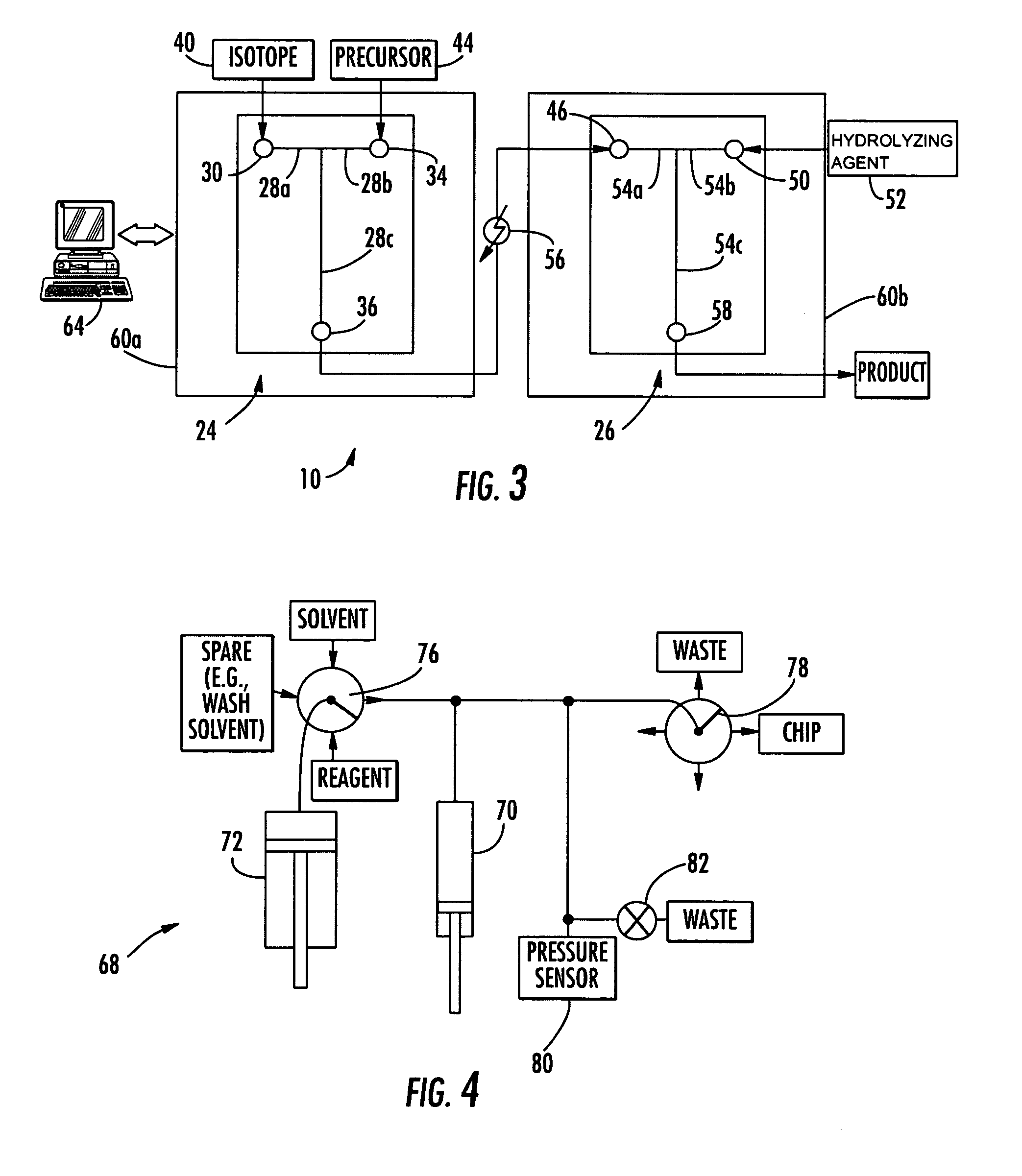

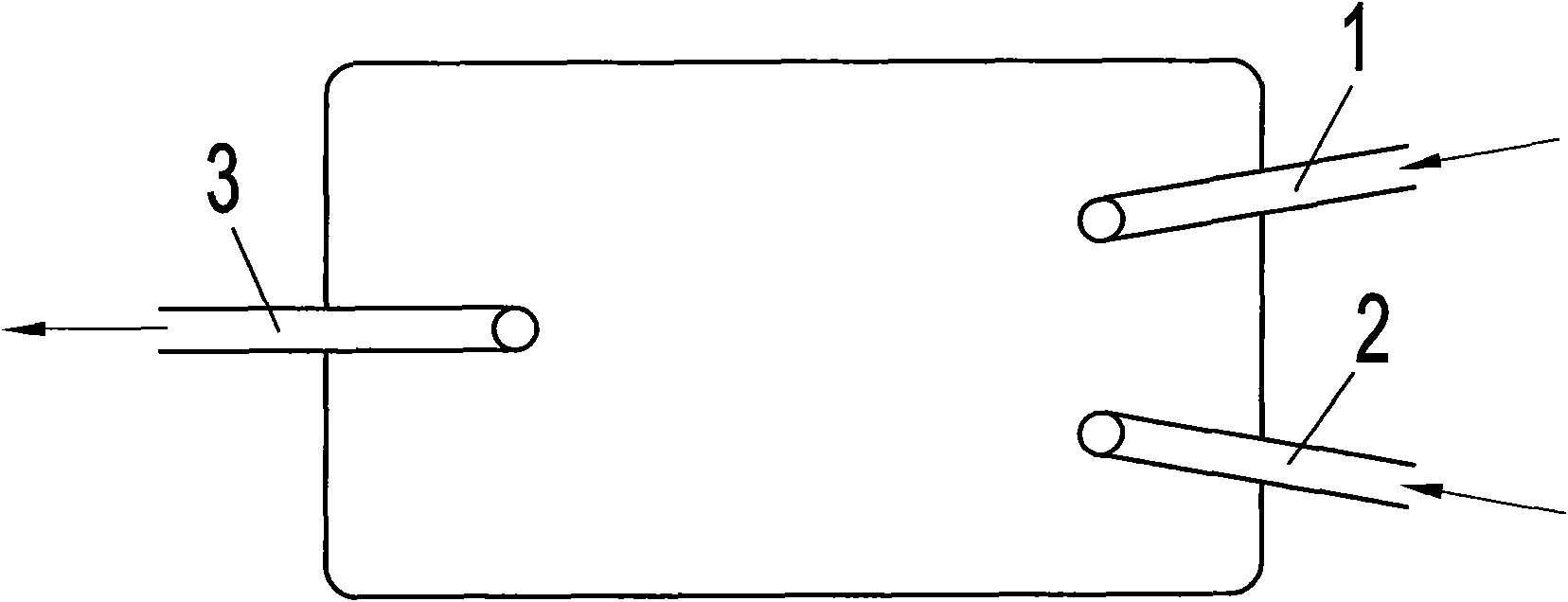

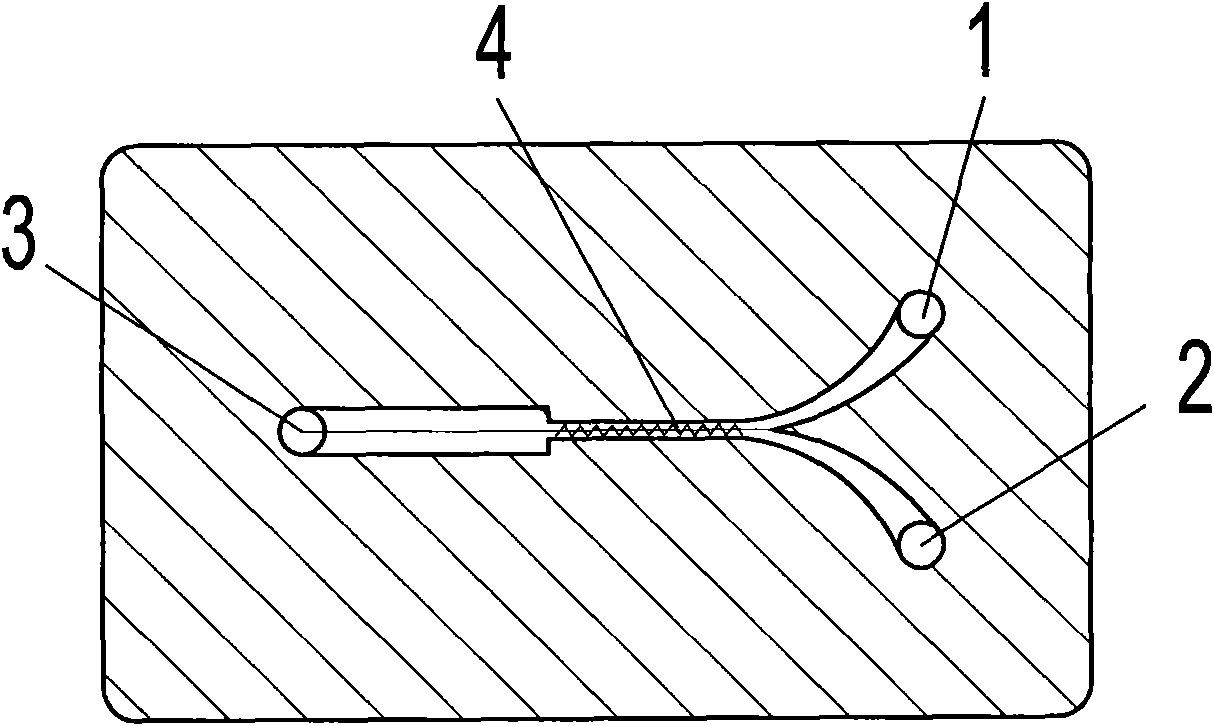

The invention provides a method and apparatus for preparation of radiochemicals, such as PET molecular imaging probes, wherein the reaction step or steps that couple the radioactive isotope to an organic or inorganic compound to form a positron-emitting molecular imaging probe are performed in a microfluidic environment. The method for synthesizing a radiochemical in a microfluidic environment comprises: i) providing a micro reactor comprising a first inlet port, a second inlet port, an outlet port, and at least one microchannel in fluid communication with the first and second inlet ports and the outlet port; ii) introducing a reactive precursor into the first inlet port of the micro reactor, the reactive precursor adapted for reaction with a radioactive isotope to form a radiochemical; iii) introducing a solution comprising a radioactive isotope into the second inlet port of the micro reactor; iv) contacting the reactive precursor with the isotope-containing solution in the microchannel of the micro reactor; v) reacting the reactive precursor with the isotope-containing solution as the reactive precursor and isotope-containing solution flow through the microchannel of the micro reactor, the reacting step resulting in formation of a radiochemical; and vi) collecting the radiochemical from the outlet port of the micro reactor.

Owner:MOLECULAR TECH

Crystallization-free glass frit compositions and frits made therefrom for microreactor devices

InactiveUS20070123410A1Low pour pointHigh acid resistanceLaboratory glasswaresChemical/physical/physico-chemical processesMicroreactorFrit

The invention is directed to a glass composition that can be used to make glass frits suitable for use in the manufacturing of microreactors. The glass compositions, after final sintering to produce a finished microreactor, have a surface crystalline layer of 30 μm or less, or are completely amorphous throughout. Generally, the borosilicate glasses of the invention have a composition of B2O3=12-22 mol %; SiO2=68-80 mol % and additional components selected from the group consisting of either (a) Al2O3=3-8 mol % and Li2O=1-8 mol %, or (b) K2O=0-2 mol % and Na2O=0-2 mol %, except that both K2O and Na2O cannot both equal zero at the same time. One borosilicate glass has a composition, in mole percent (mol %) of B2O3=18-22 mol %, SiO2=75-80 mol %, K2O=0-2 mol %, and Na2O=0-2 mol %, except that both K2O and Na2O cannot both equal zero at the same time.

Owner:CORNING INC

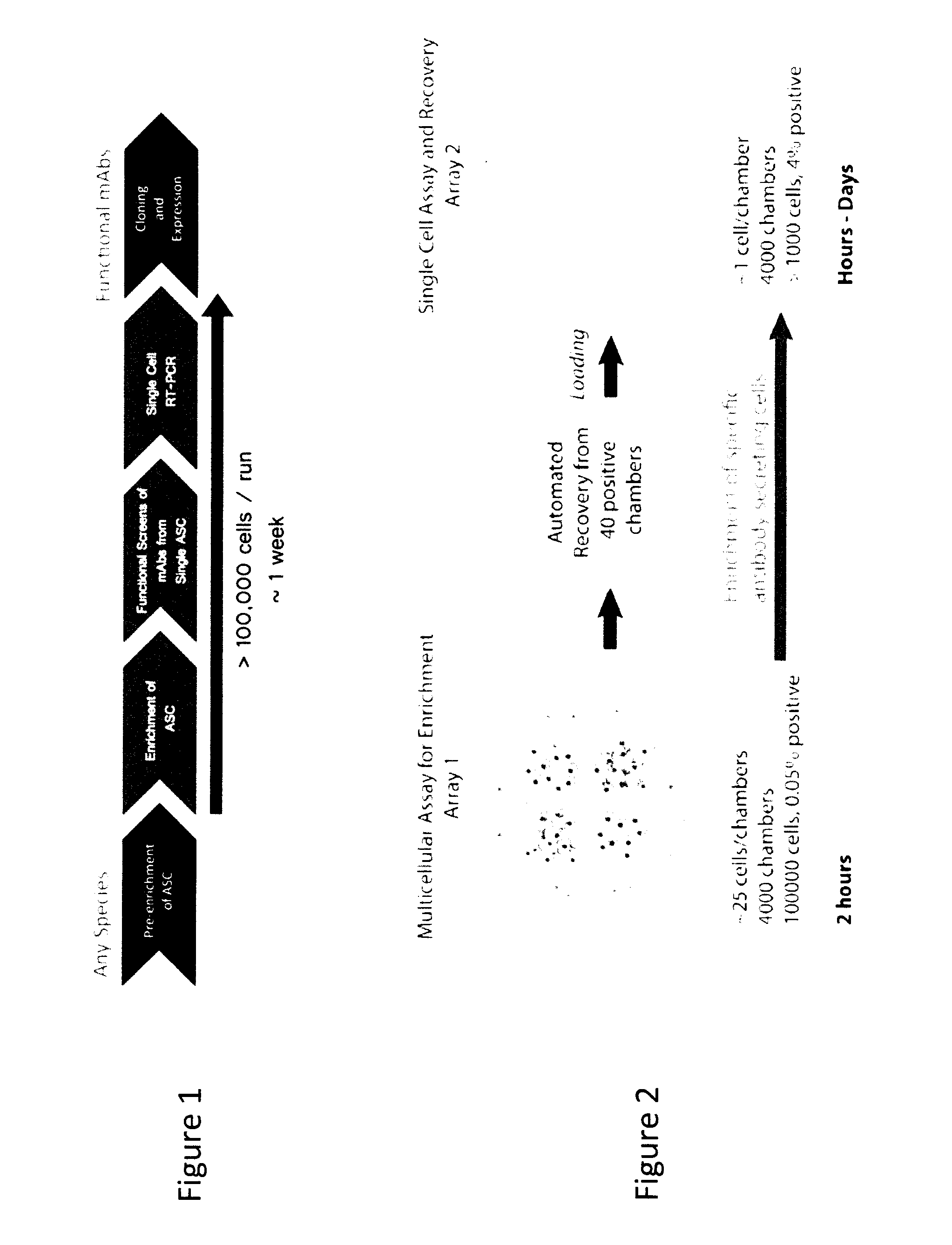

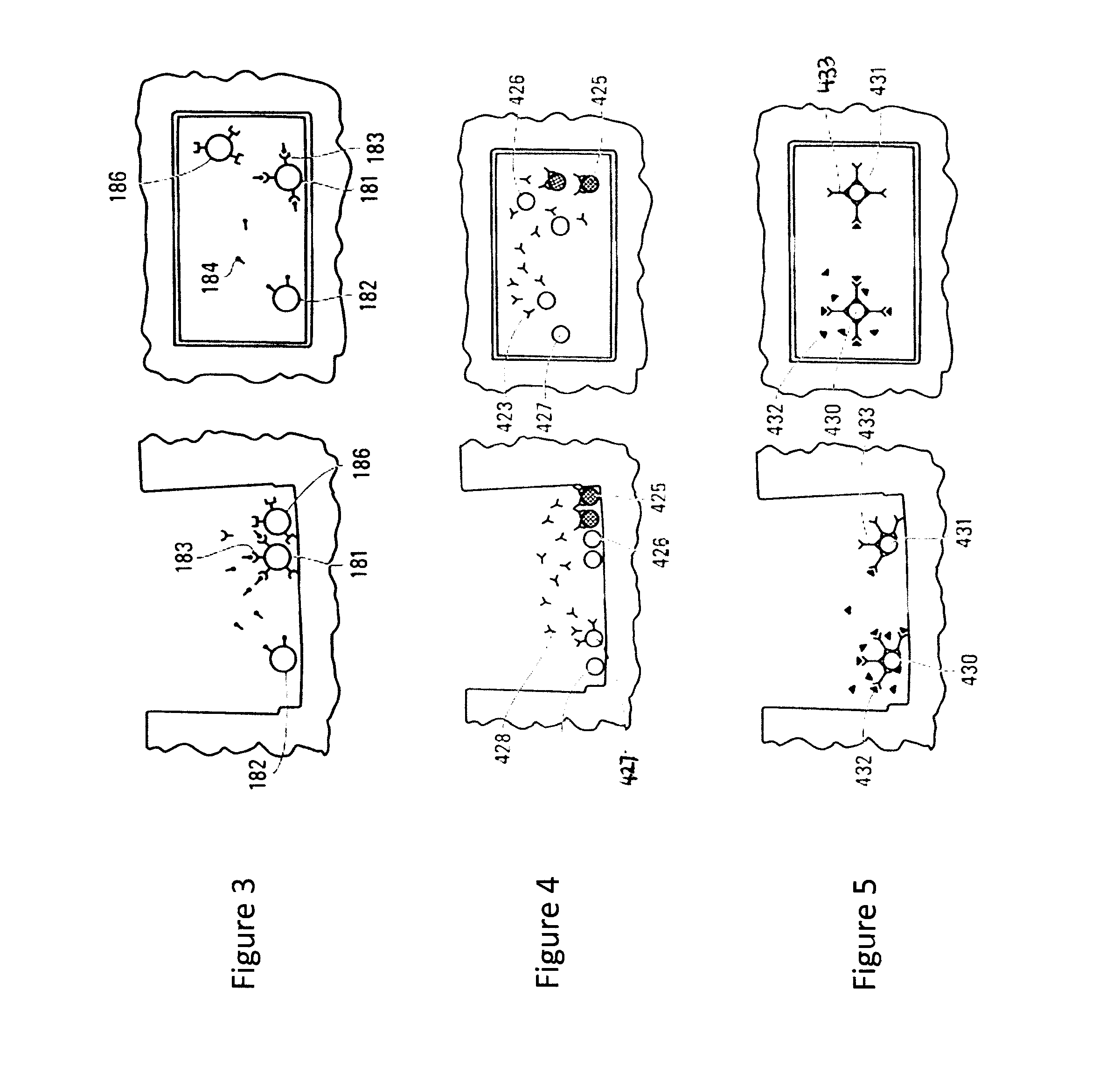

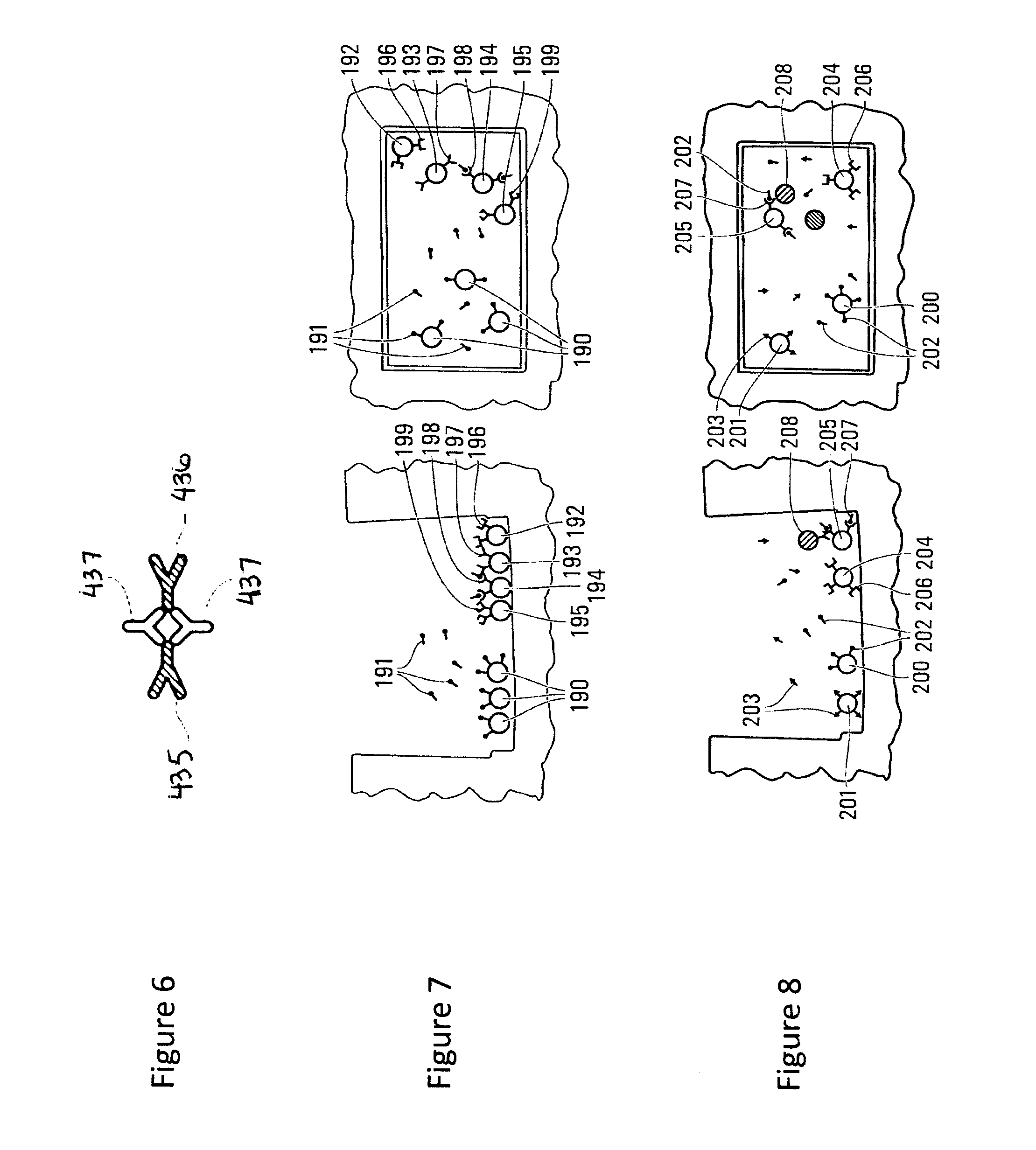

Microfluidic Devices and Methods for Use Thereof in Multicellular Assays of Secretion

ActiveUS20160252495A1Microbiological testing/measurementLaboratory glasswaresMicroreactorEffector cell

Methods and devices are provided herein for identifying a cell population comprising an effector cell that exerts an extracellular effect. In one embodiment the method comprises retaining in a microreactor a cell population comprising one or more effector cells, wherein the contents of the microreactor further comprise a readout particle population comprising one or more readout particles, incubating the cell population and the readout particle population within the microreactor, assaying the cell population for the presence of the extracellular effect, wherein the readout particle population or subpopulation thereof provides a direct or indirect readout of the extracellular effect, and determining, based on the results of the assaying step, whether one or more effector cells within the cell population exerts the extracellular effect on the readout particle. If an extracellular effect is measured, the cell population is recovered for further analysis to determine the cell or cells responsible for the effect.

Owner:THE UNIV OF BRITISH COLUMBIA

Alkoxylations in microstructured capillary reactors

InactiveUS20050245628A1High uniformity and purityIncrease conversion rateOrganic chemistryOrganic compound preparationMicroreactorPolymer science

The invention relates to a process and to an apparatus for preparing polyether alcohols by alkoxylating alcohols, and also long-chain polyether alcohols having a narrow product distribution. The process is preferably carried out continuously in the liquid phase in a microstructured reactor. An alkylene oxide or different alkylene oxides are metered at one or more points into the channels of the microreactor. The channels are cooled with the aid of a cooling medium or heated with the aid of a heating medium.

Owner:EVONIK DEGUSSA GMBH

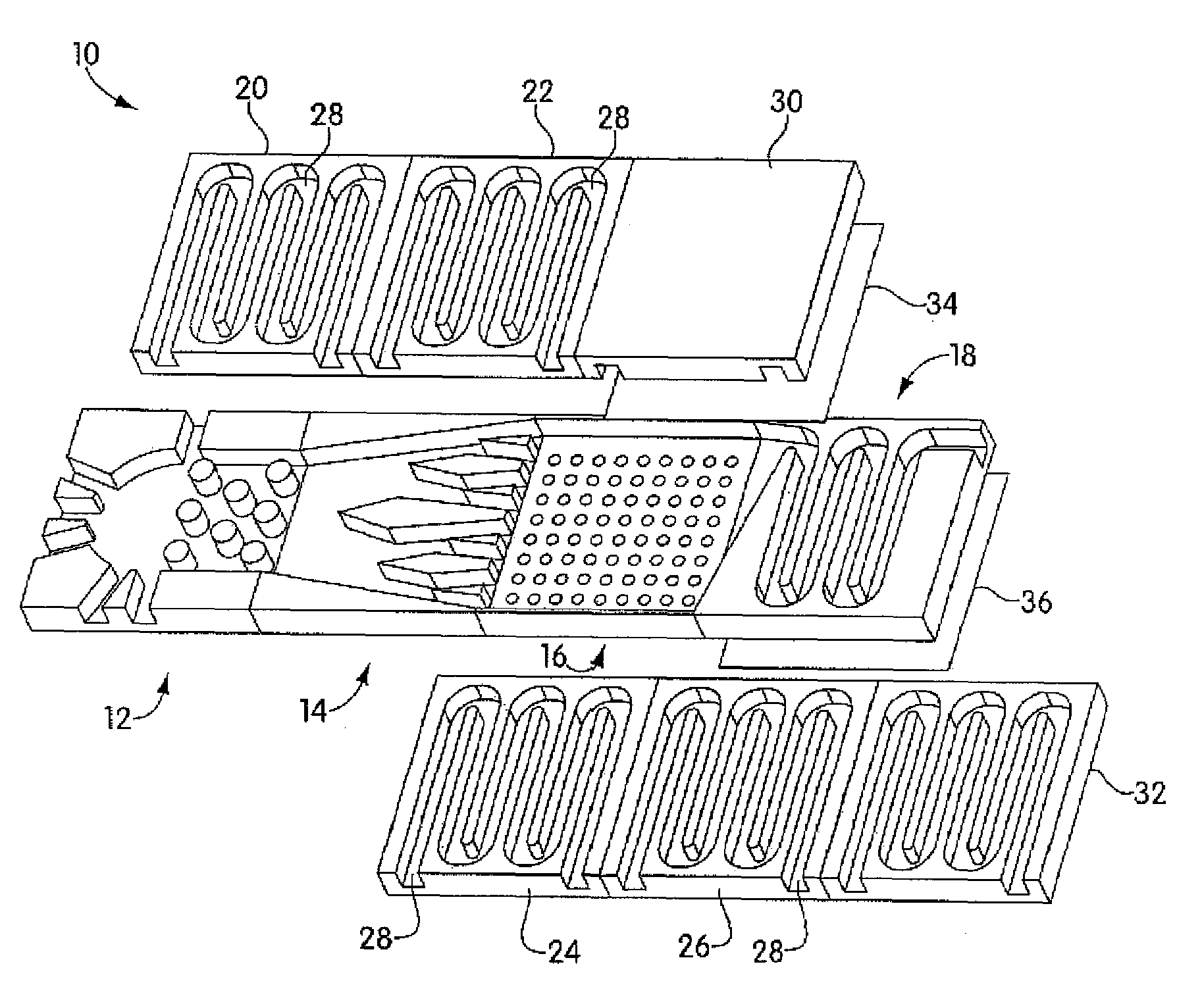

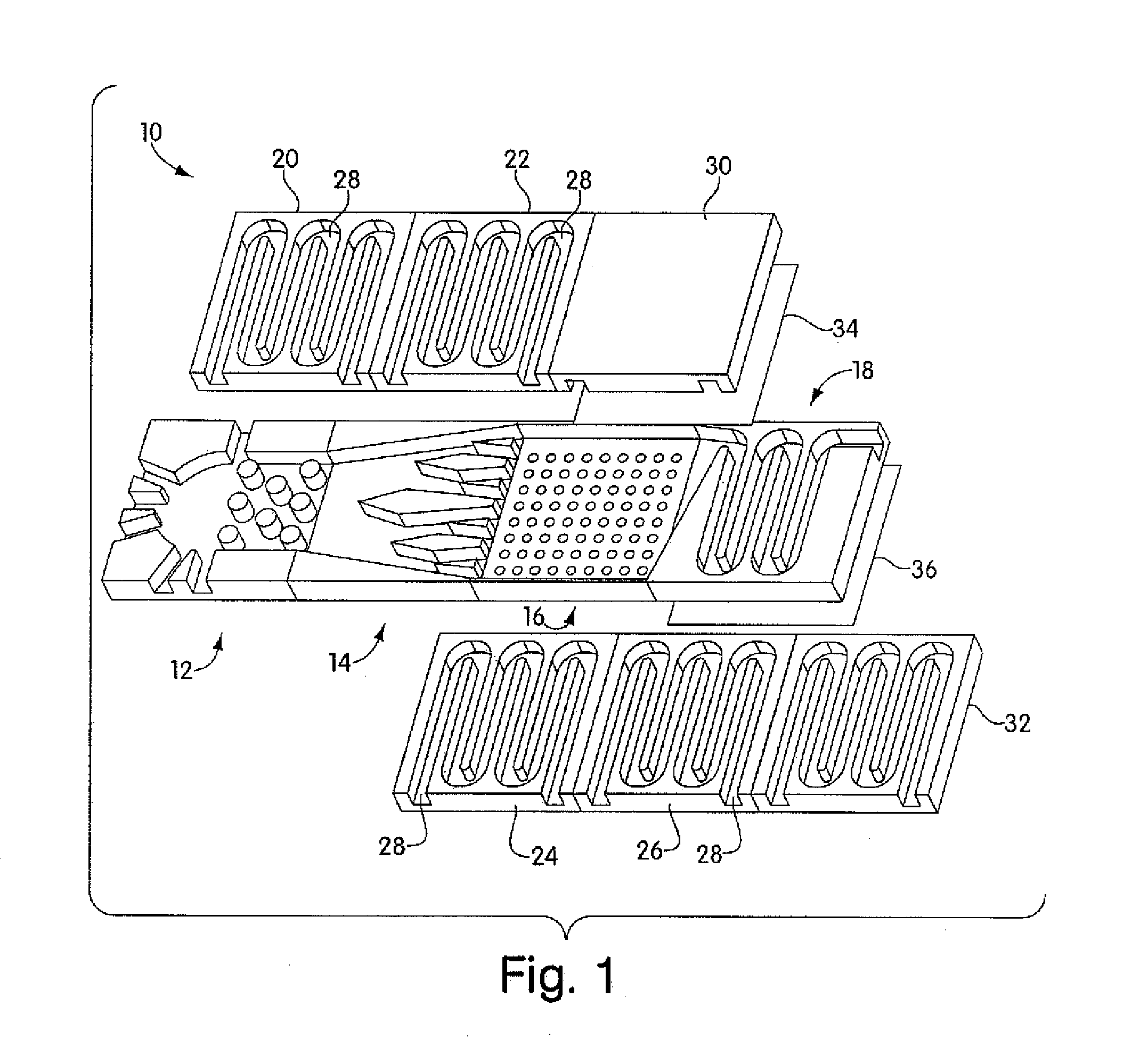

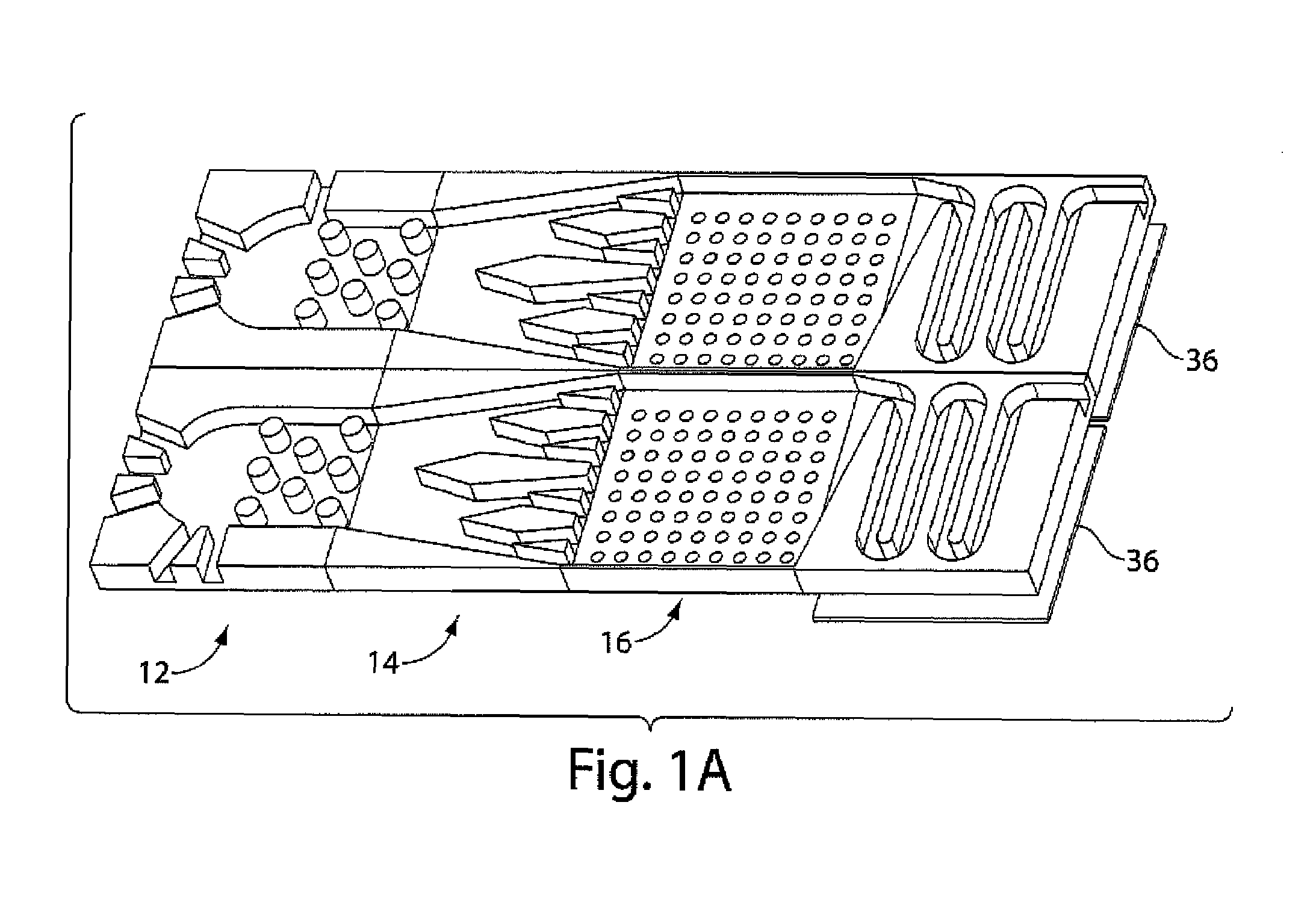

Enhancing fluid flow in a stacked plate microreactor

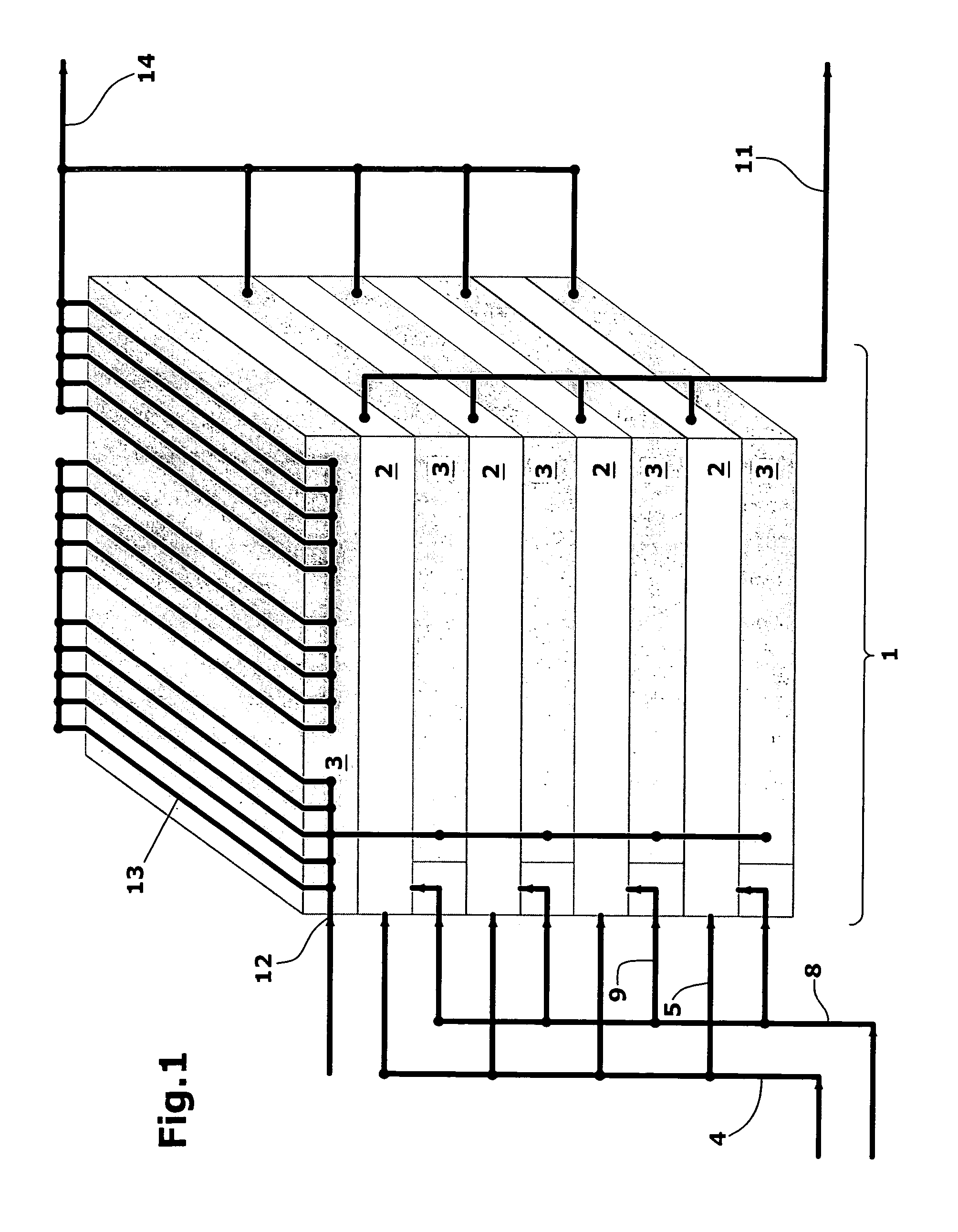

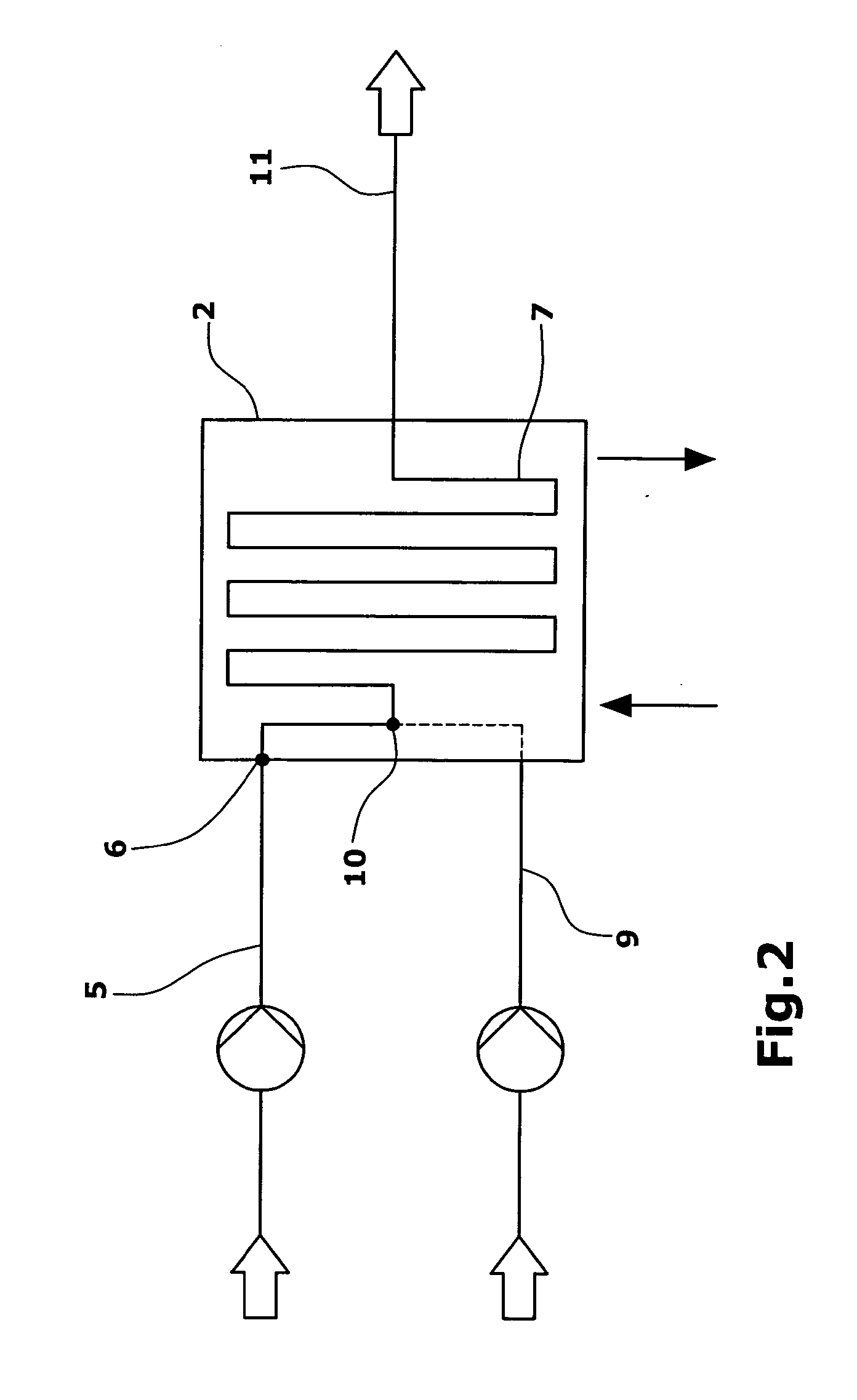

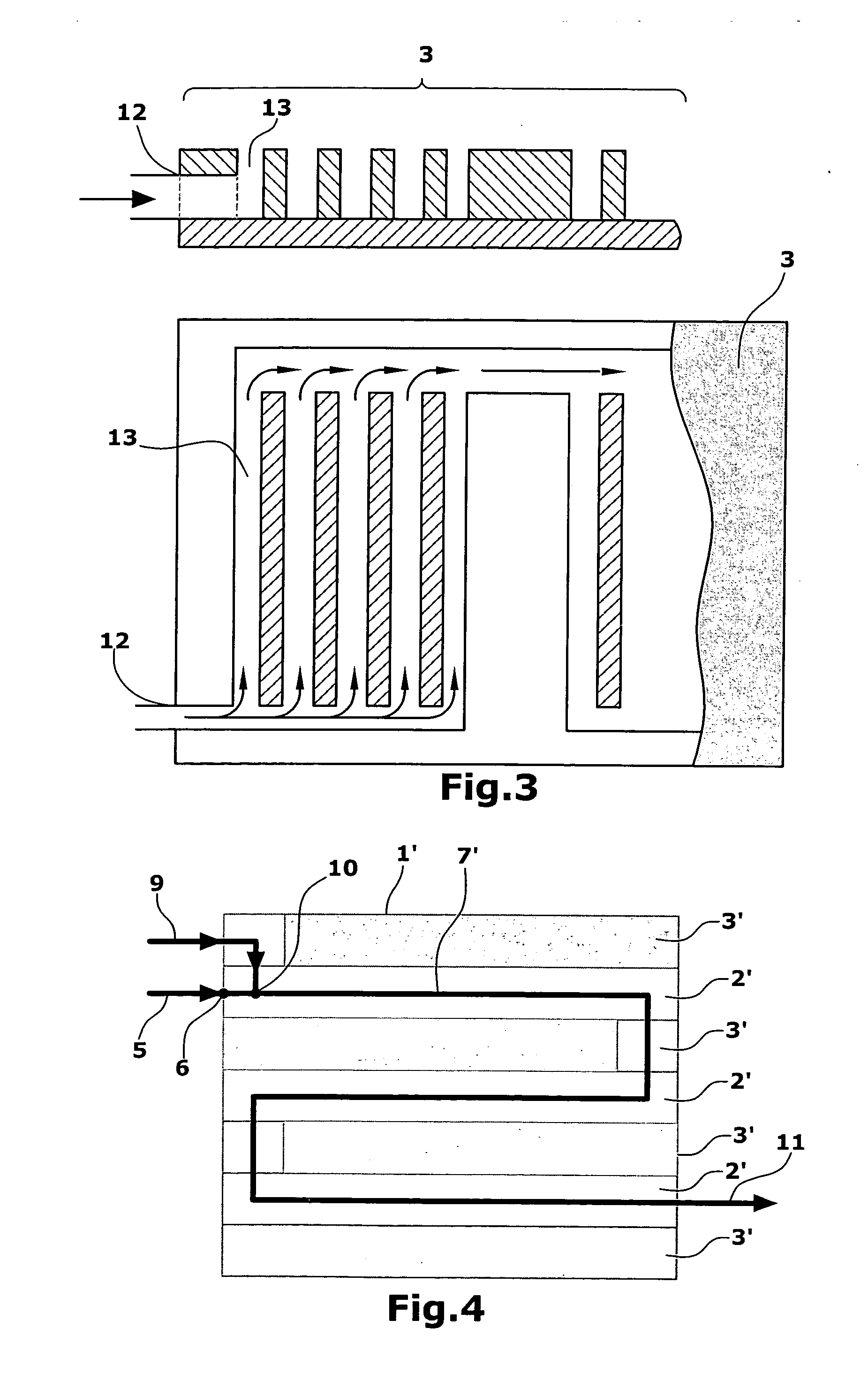

InactiveUS7241423B2Easy to reconfigureFree of scratchesFlow mixersTransportation and packagingMicroreactorChemical reaction

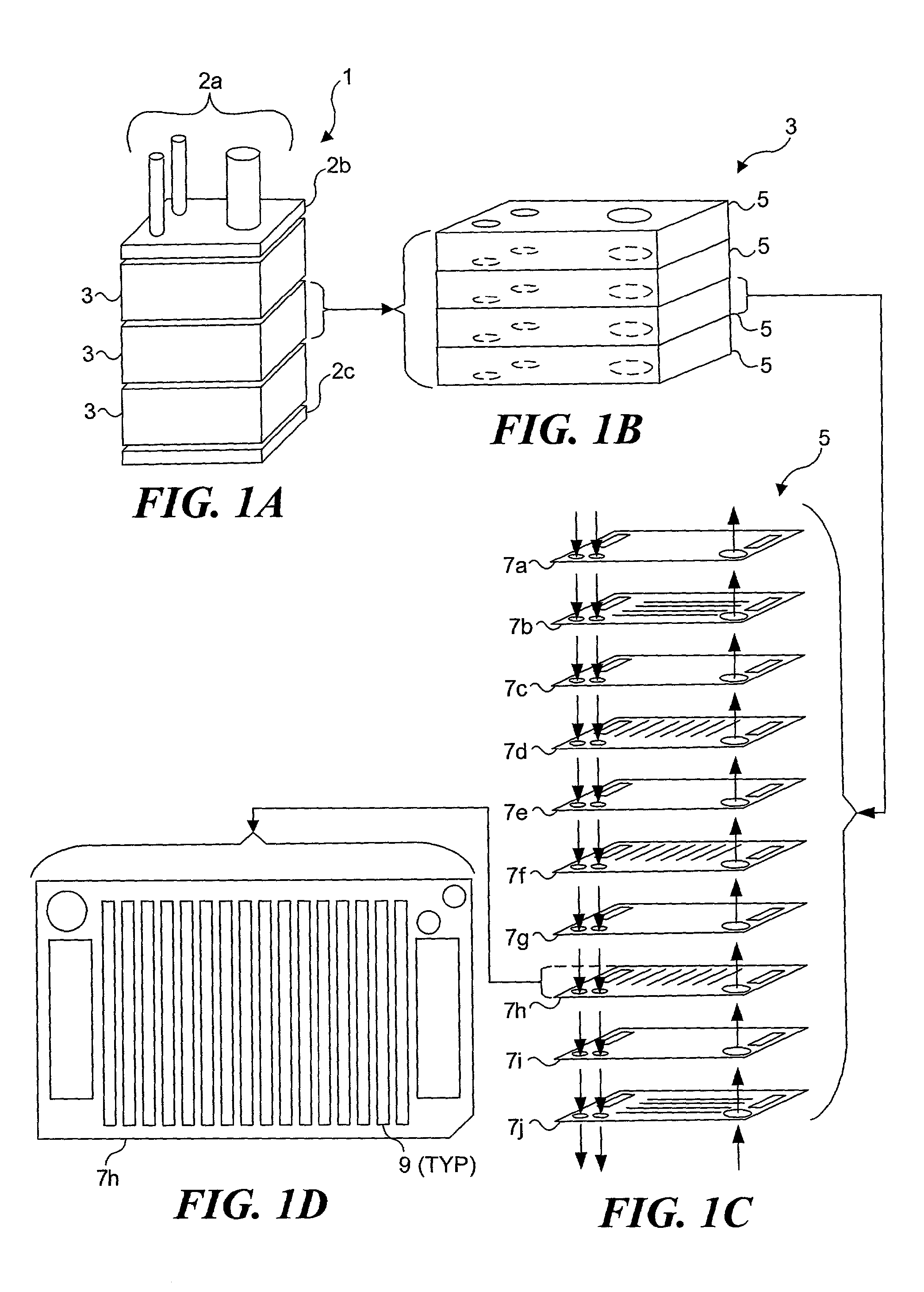

A stacked plate chemical reactor in which simple plates are stacked together to form the reactor. When openings in adjacent plates are properly aligned, fluid pathways and processing volumes are defined for chemical reactants, heat transfer medium, and a product. In one embodiment of the invention, an n-fold internal array is achieved by providing a first group of simple plates defining a reaction unit that includes bypass fluid channels and reaction fluid channels for each reactant, such that a portion of each reactant is directed to subsequent groups of simple plates defining additional reaction units. A chemical reactor with variable output is obtained in a preferred embodiment by reversibly joining reactor stacks comprising irreversibly joined reaction units, these reaction units consisting of a plurality of simple plates. Other embodiments employ at least one of an array of parallel fluid channels having different widths, bifurcated fluid distribution channels to achieve a substantially even flow equipartition for fluids with varying viscosities flowing within the fluid channels of each reaction unit.

Owner:EHRFELD MIKROTECHNIK BTS GMBH

Microfluidic apparatus and method for synthesis of molecular imaging probes including FDG

InactiveUS20050232861A1Fast synthesis timeHigh synthetic yieldIsotope introduction to sugar derivativesIn-vivo radioactive preparationsMicroreactorMolecular imaging

The invention provides a method and apparatus for preparation of radiochemicals wherein the reaction that couples the radioactive isotope to the reactive precursor to form a positron-emitting molecular imaging probe is performed in a microfluidic environment. The method comprises: providing a micro reactor; introducing a liquid reactive precursor dissolved in a polar aprotic solvent into an inlet port of the micro reactor, the reactive precursor adapted for reaction with a radioactive isotope to form a radiochemical; introducing a solution comprising a radioactive isotope dissolved in a polar aprotic solvent into another inlet port of the micro reactor; contacting the reactive precursor with the isotope-containing solution in a microchannel of the micro reactor; reacting the reactive precursor with the isotope-containing solution as the reactive precursor and isotope-containing solution flow through the microchannel of the micro reactor, wherein the reacting step is conducted at a temperature above the boiling point of the polar aprotic solvent at 1 atm and at a pressure sufficient to maintain the polar aprotic solvent in liquid form; and collecting the resulting radiochemical from the micro reactor.

Owner:MOLECULAR TECH

Biomarker generator system

ActiveUS20080067413A1Efficient dosingEfficient productionIsotope delivery systemsMaterial analysis using wave/particle radiationMicroreactorParticle accelerator

A biomarker generator system for producing approximately one (1) unit dose of a biomarker. The biomarker generator system includes a small, low-power particle accelerator (“micro-accelerator”) and a radiochemical synthesis subsystem having at least one microreactor and / or microfluidic chip. The micro-accelerator is provided for producing approximately one (1) unit dose of a radioactive substance, such as a substance that emits positrons. The radiochemical synthesis subsystem is provided for receiving the radioactive substance, for receiving at least one reagent, and for synthesizing the approximately one (1) unit dose of a biomarker.

Owner:BEST ABT INC

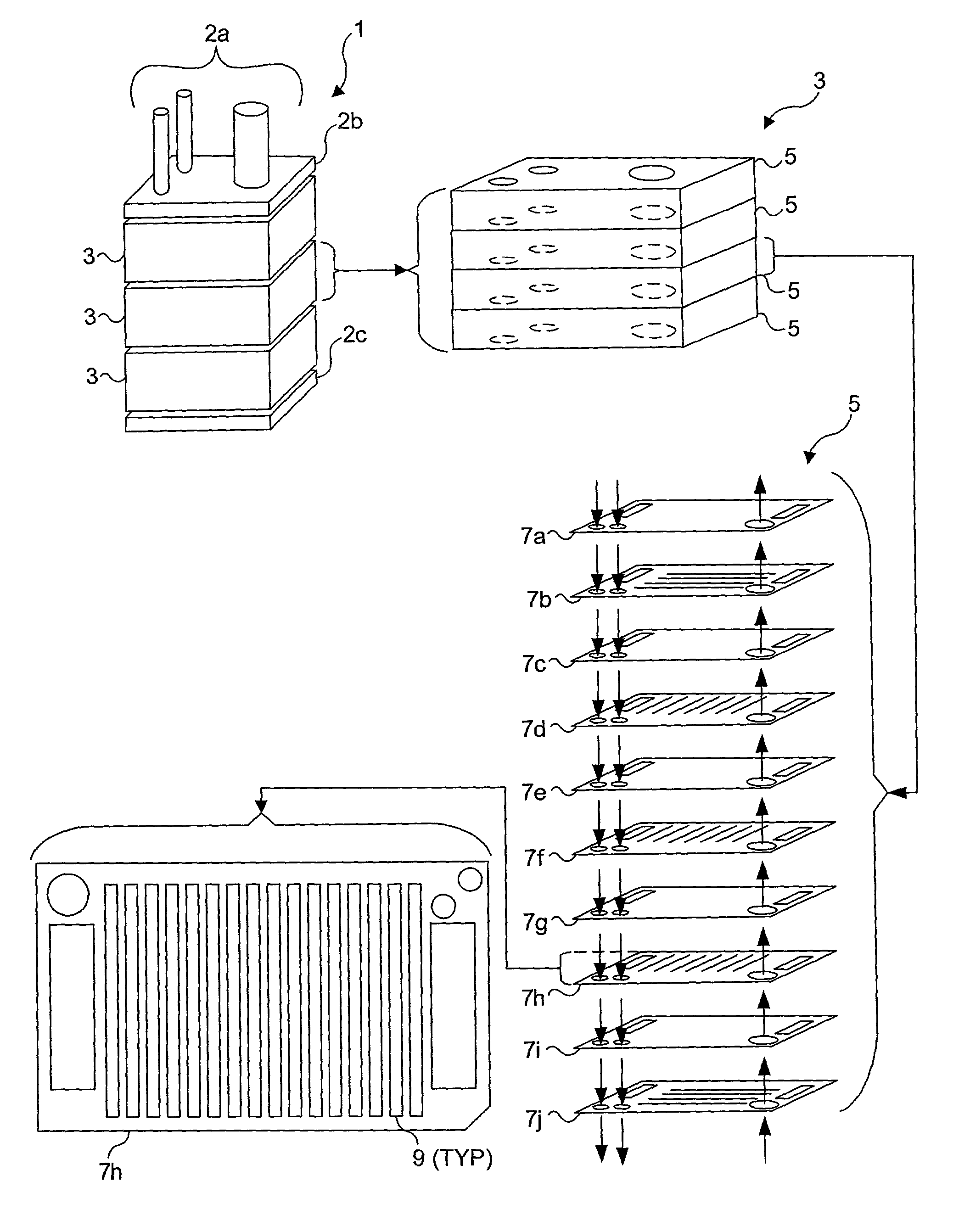

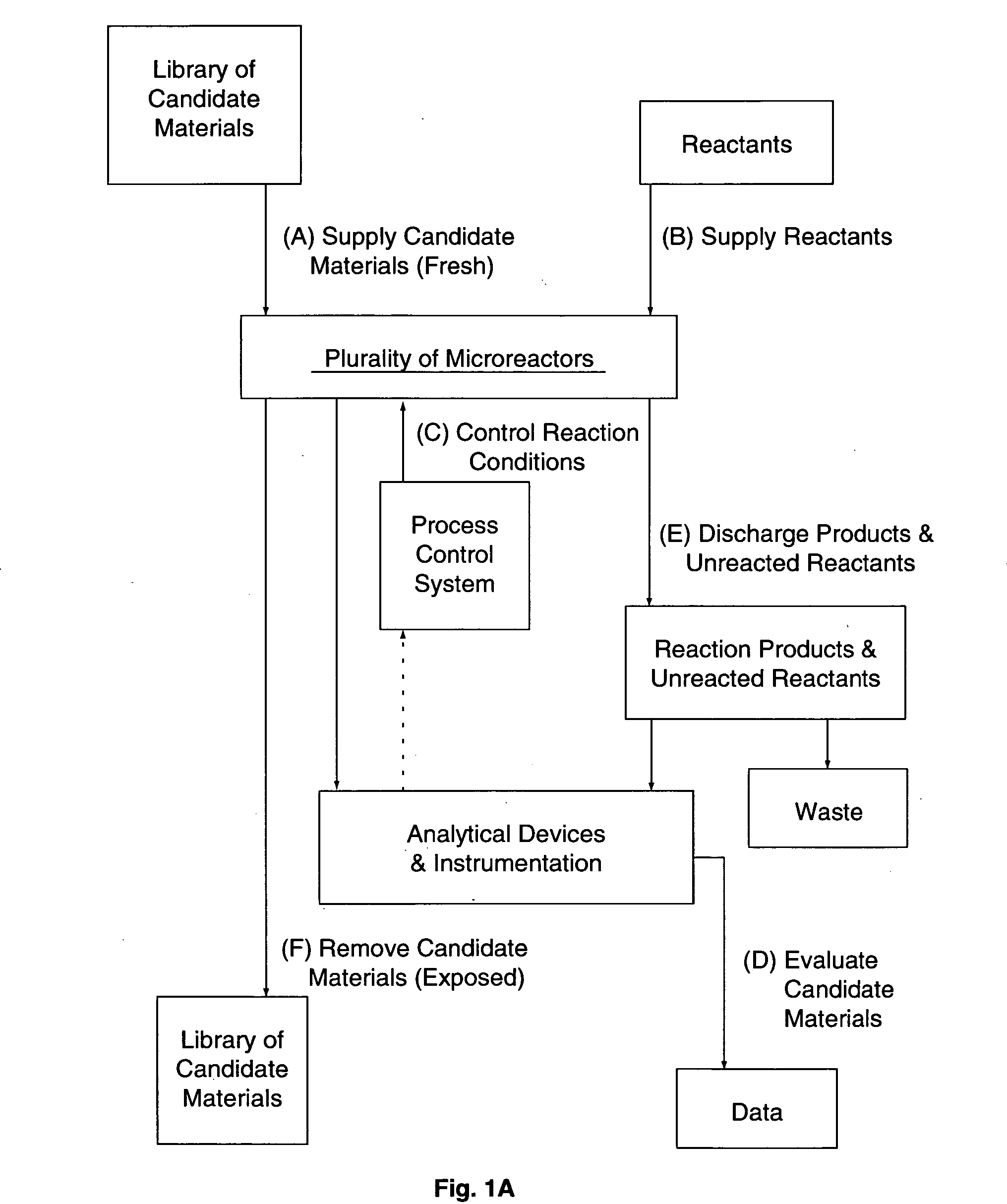

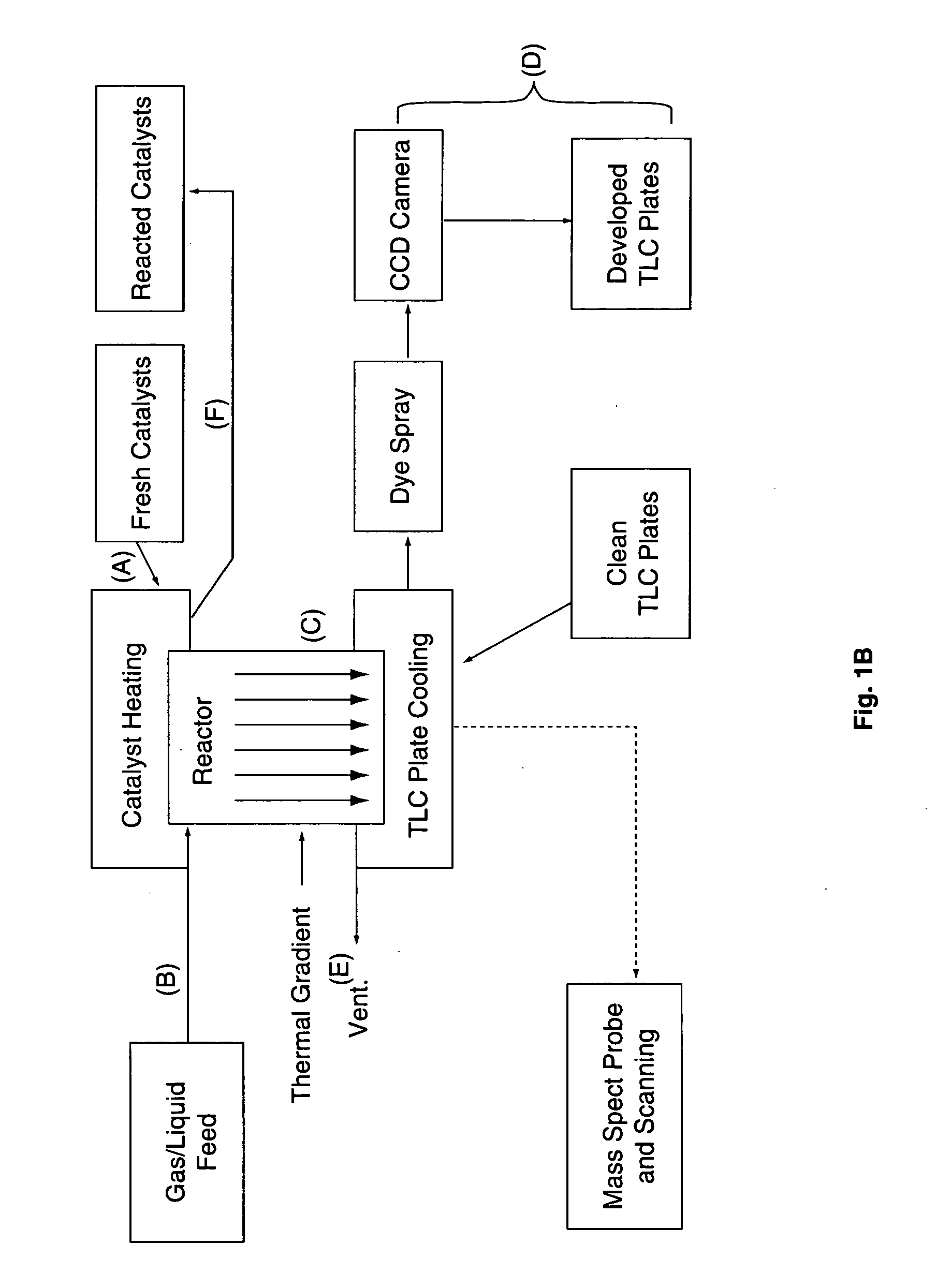

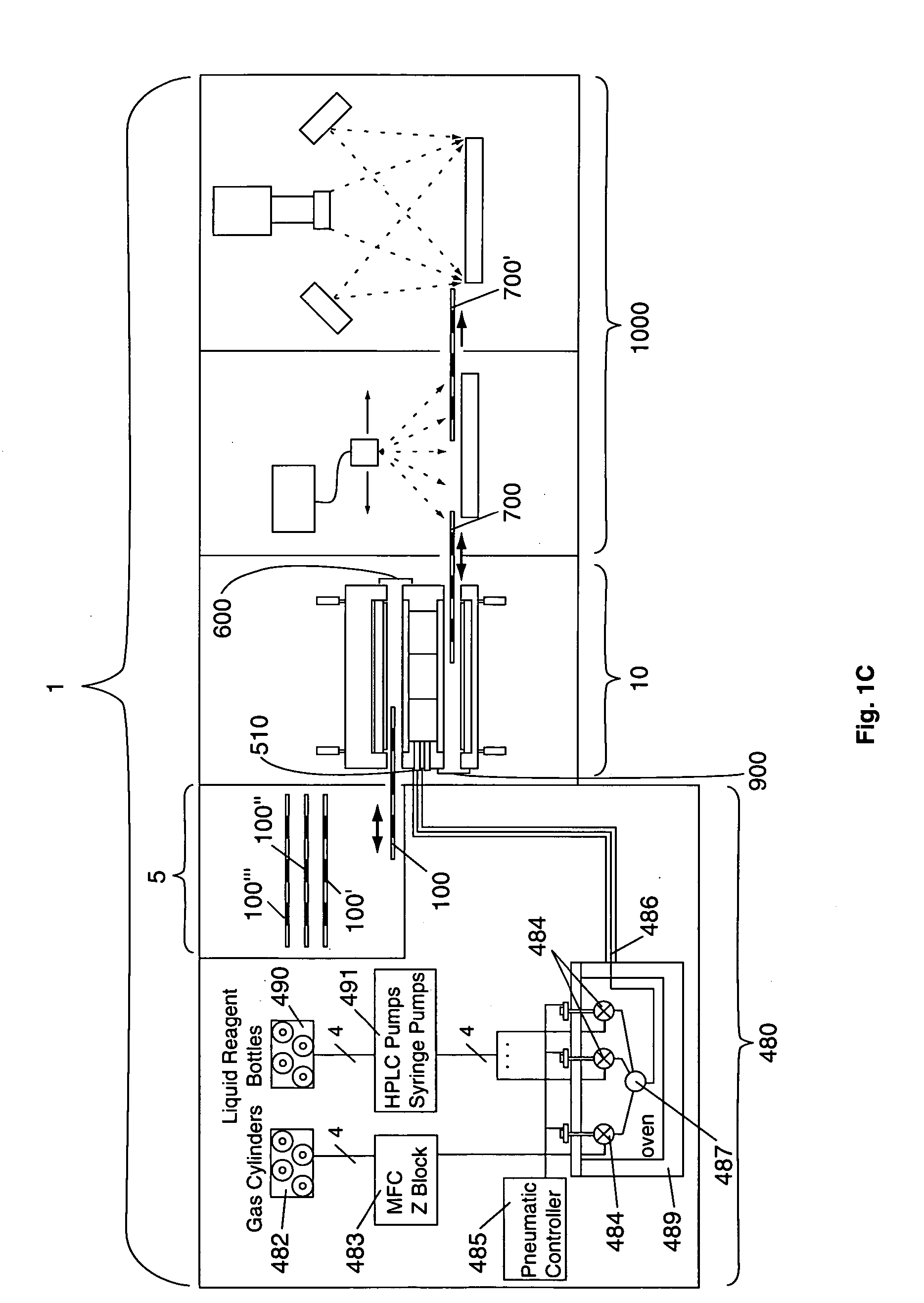

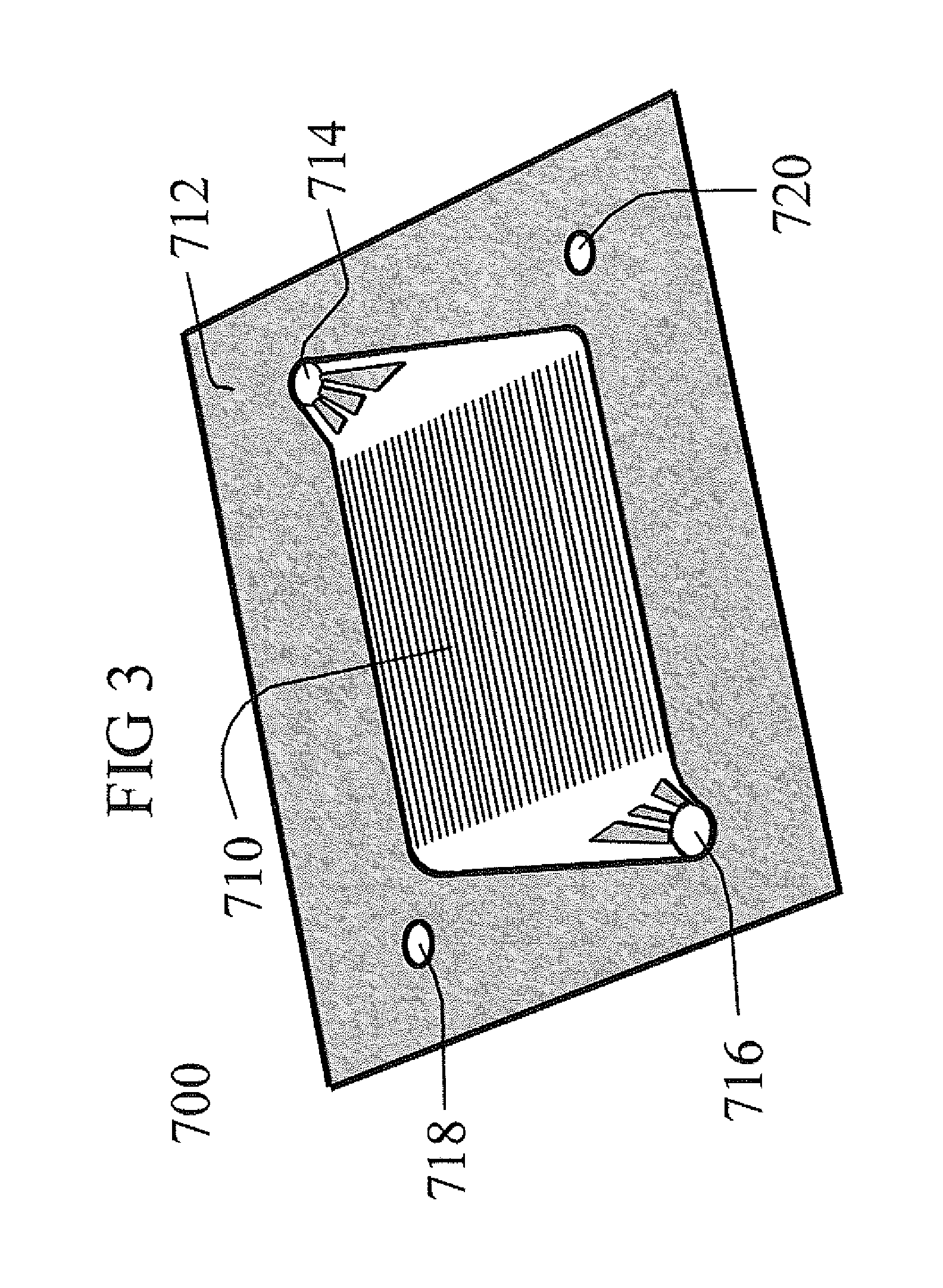

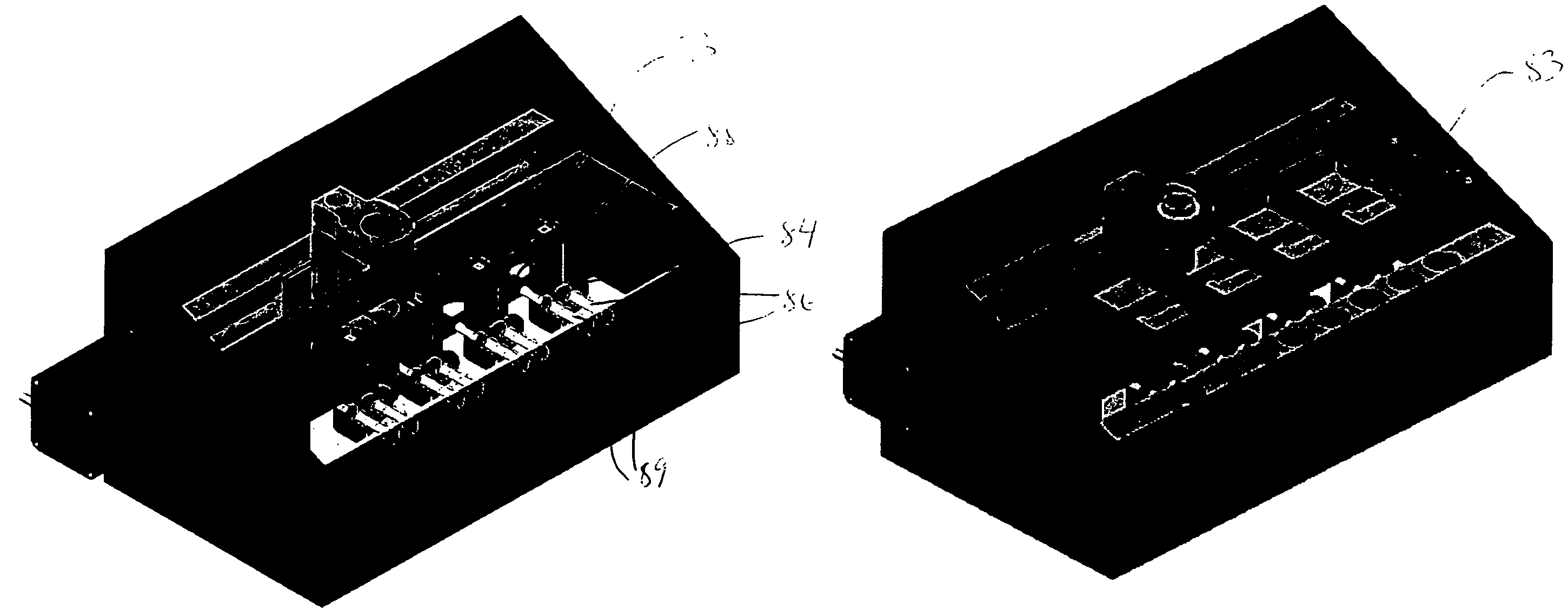

Chemical processing microsystems comprising high-temperature parallel flow microreactors

InactiveUS20050009175A1Large degree of analytical flexibilityReduce manufacturing costBioreactor/fermenter combinationsSequential/parallel process reactionsChemical treatmentMicroreactor

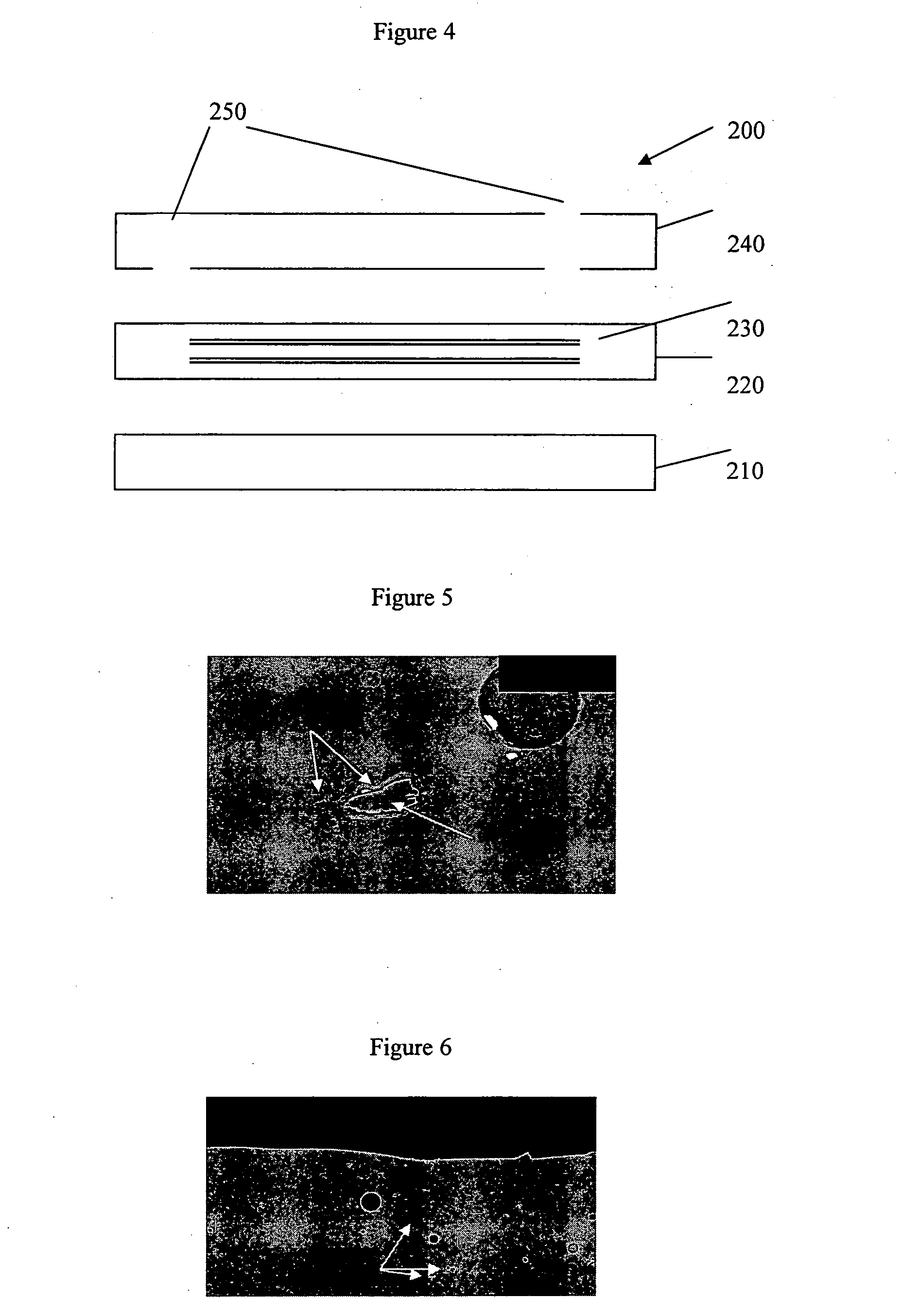

A chemical processing microsystem useful for identifying and optimizing materials (e.g., catalysts) that enhance chemical processes or for characterizing and / or optimizing chemical processes is disclosed. The chemical processing microsystem comprises a plurality of microreactors 600 and, in a preferred embodiment, a plurality of microseparators 900 integral with the chemical processing microsystem 10. The microreactors 600 are preferably diffusion-mixed microreactors formed in a plurality of laminae that include a modular, interchangeable candidate-material array 100. The material array 100 comprises a plurality of different candidate materials (e.g., catalysts), preferably arranged at separate, individually addressable portions of a substrate (e.g., wafer). The microseparators 900 are similarly formed in a plurality of laminae that include a modular, interchangeable adsorbent array 700. The adsorbent array 700 comprises one or more adsorbents, preferably arranged at separate, individually addressable portions of a substrate to spatially correspond to the plurality of different candidate materials. Modular microfluidic distribution systems are also disclosed. The chemical processing microsystem can be integrated into a material evaluation system that enables a comprehensive combinatorial material science research program.

Owner:FREESLATE

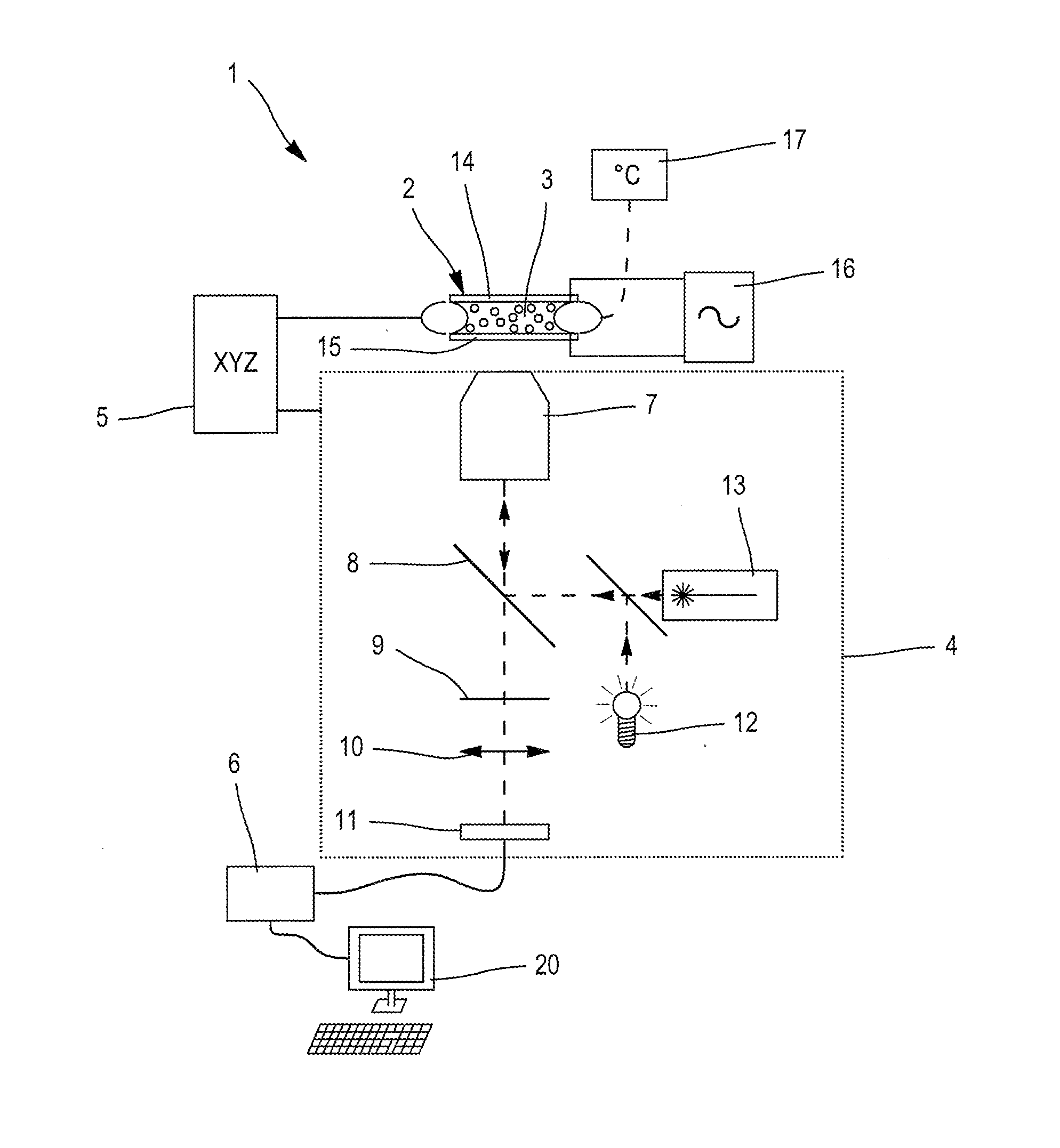

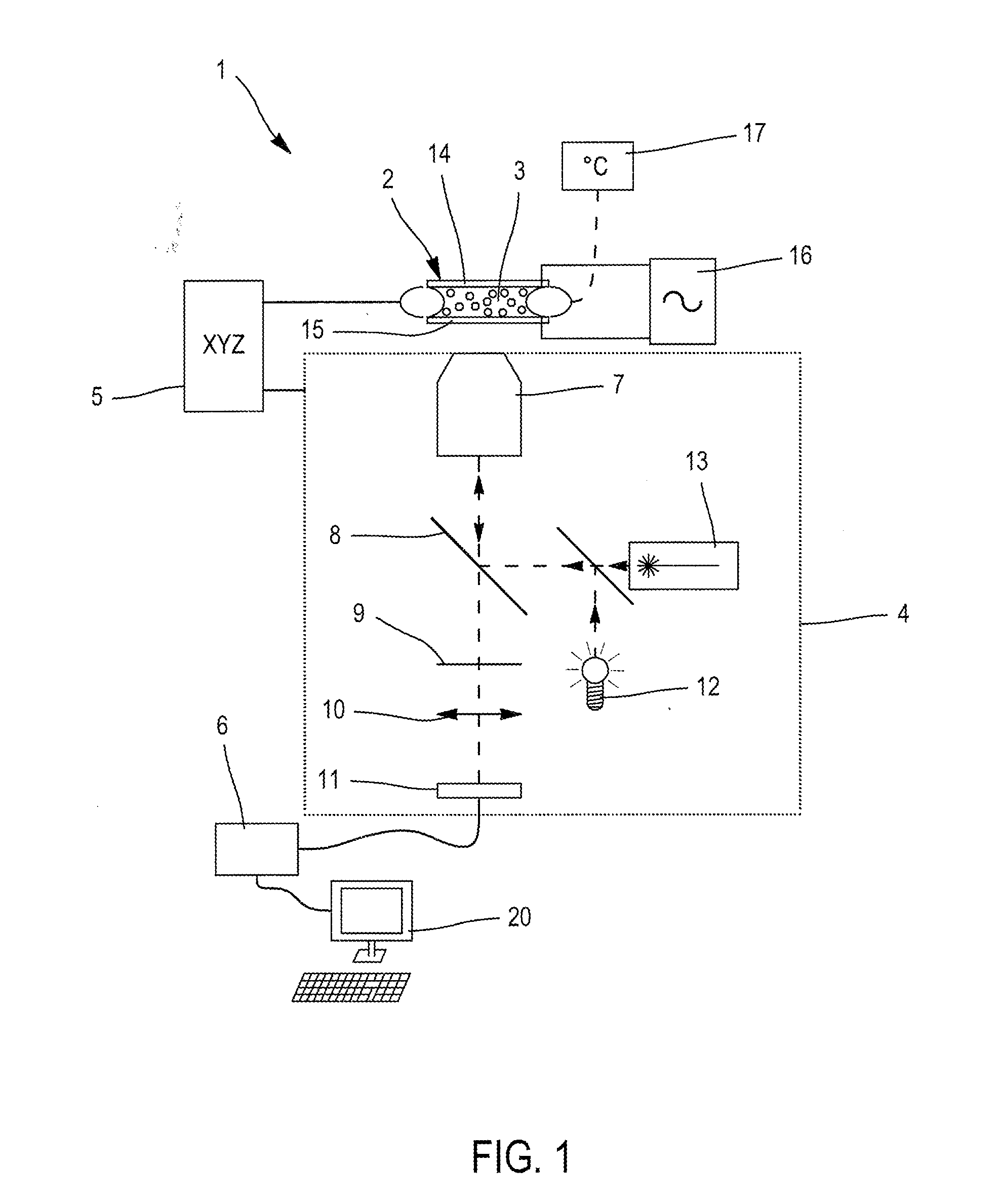

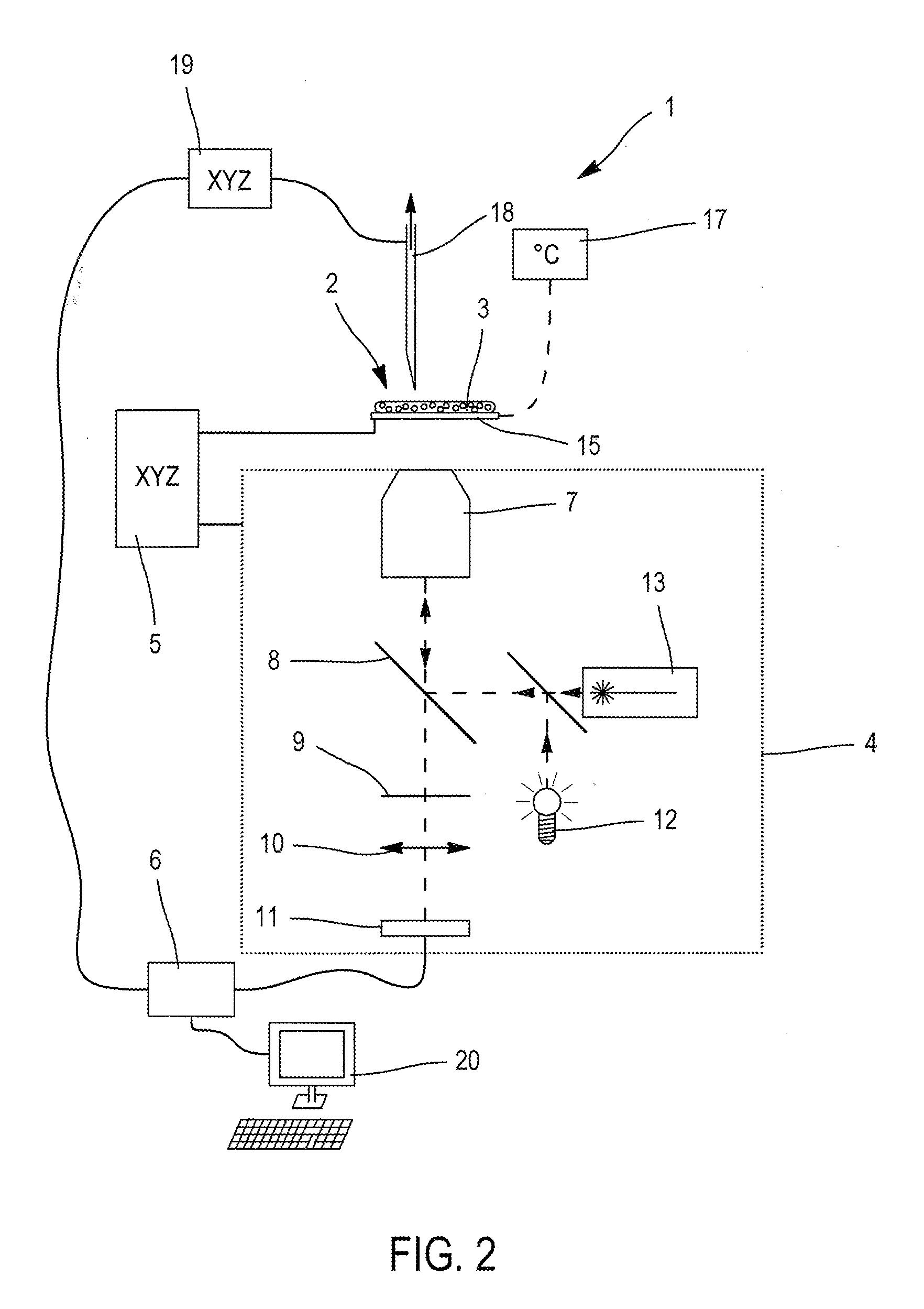

Method and device for reading an emulsion

ActiveUS20110188717A1Character and pattern recognitionMonitoring particle agglomerationMicroreactorComputer science

A method for reading an emulsion (3) including droplets and a continuous phase surrounding the droplets, the method includes:two-dimensional scanning of the emulsion (3), andconstruction of a two-dimensional image of the emulsion (3) based on the scanning. Preferably, the droplets do not move during scanning, for example by solidifying the continuous phase or by using a two-dimensional compact or semi-compact network of droplets. The method can further include time-based monitoring of a chemical or biological reaction taking place in at least one of the droplets. A device implementing this method is also described. The method is applicable for the detection and / or sorting of microdroplets performing the role of microreactors or containing specific cells or molecules, in fields such as gene expression or diagnosis.

Owner:ECOLE SUPERIEURE DE PHYSIQUE & DE CHIM IND DE LA VILLE DE PARIS +1

Chemical microreactor and method thereof

InactiveUS6960235B2Physical/chemical process catalystsHydrogen separationMicroreactorSteam reforming

A chemical microreactor suitable for generation of hydrogen fuel from liquid sources such as ammonia, methanol, and butane through steam reforming processes when mixed with an appropriate amount of water contains capillary microchannels with integrated resistive heaters to facilitate the occurrence of catalytic steam reforming reactions. One such microreactor employs a packed catalyst capillary microchannel and at least one porous membrane. Another employs a porous membrane with a large surface area or a porous membrane support structure containing a plurality of porous membranes having a large surface area in the aggregate, i.e., greater than about 1 m2 / cm3. The packed catalyst capillary microchannels, porous membranes and porous membrane support structures may be formed by a variety of methods.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

Process for toluene and methane coupling in a microreactor

InactiveUS8071836B2Hydrocarbon by hydrogenationChemical/physical/physico-chemical microreactorsMicroreactorMethane

A process for making ethylbenzene and / or styrene by reacting toluene with methane in one or more microreactors is disclosed. In one embodiment a method of revamping an existing styrene production facility by adding one or more microreactors capable of reacting toluene with methane to produce a product stream comprising ethylbenzene and / or styrene is disclosed.

Owner:FINA TECH

Method for preparing high-stability mesoporous molecular sieve

ActiveCN104891526APolycrystallineActs as a templating agentFaujasite aluminosilicate zeoliteMolecular sieveMicroreactor

The invention provides a method for preparing a high-hydrothermal-stability mesoporous molecular sieve. The method includes the following steps: (1) preparation of a first Y-type molecular sieve precursor; and (2) crystallization: adding a seed crystal to the first Y-type molecular sieve precursor, adjusting the pH value to 0.5-5, stirring for 10 h-24 h at the temperature of 20 DEG C-50 DEG C, then aging for 2 h-24 h at the temperature of 20 DEG C-50 DEG C, to obtain an assembled product, transferring the assembled product into a microreactor with a polytetrafluoroethylene lining, then transferring together with the reactor into a high-pressure reaction kettle, crystallizing for 10 h-48 h at the temperature of 100 DEG C-200 DEG C, filtering, washing, drying, and thus obtaining the high-stability mesoporous molecular sieve. Firstly, the microporous molecular sieve precursor is prepared, a mesoporous-microporous molecular sieve as the seed crystal is used for preparation of the mesoporous molecular sieve, the molecular sieve precursor assembly method and the seed crystal method are combined, and the high-stability mesoporous molecular sieve is obtained under the condition without use of an organic template agent. Not only is the preparation cost of the molecular sieve reduced greatly, but also the process of calcination of the template agent is omitted so as to reduce the energy consumption.

Owner:PETROCHINA CO LTD +1

Apparatus and methods for simultaneous operation of miniaturized reactors

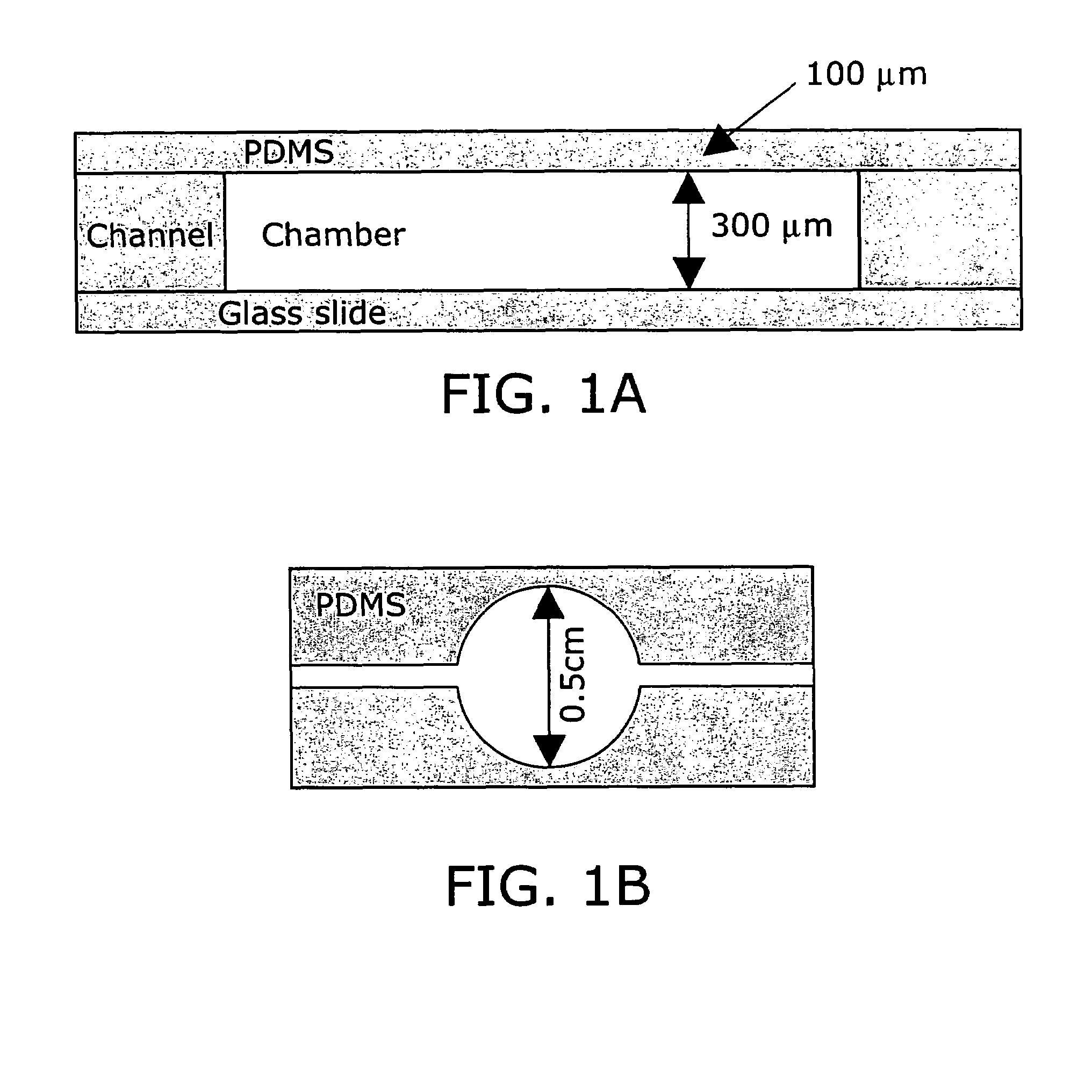

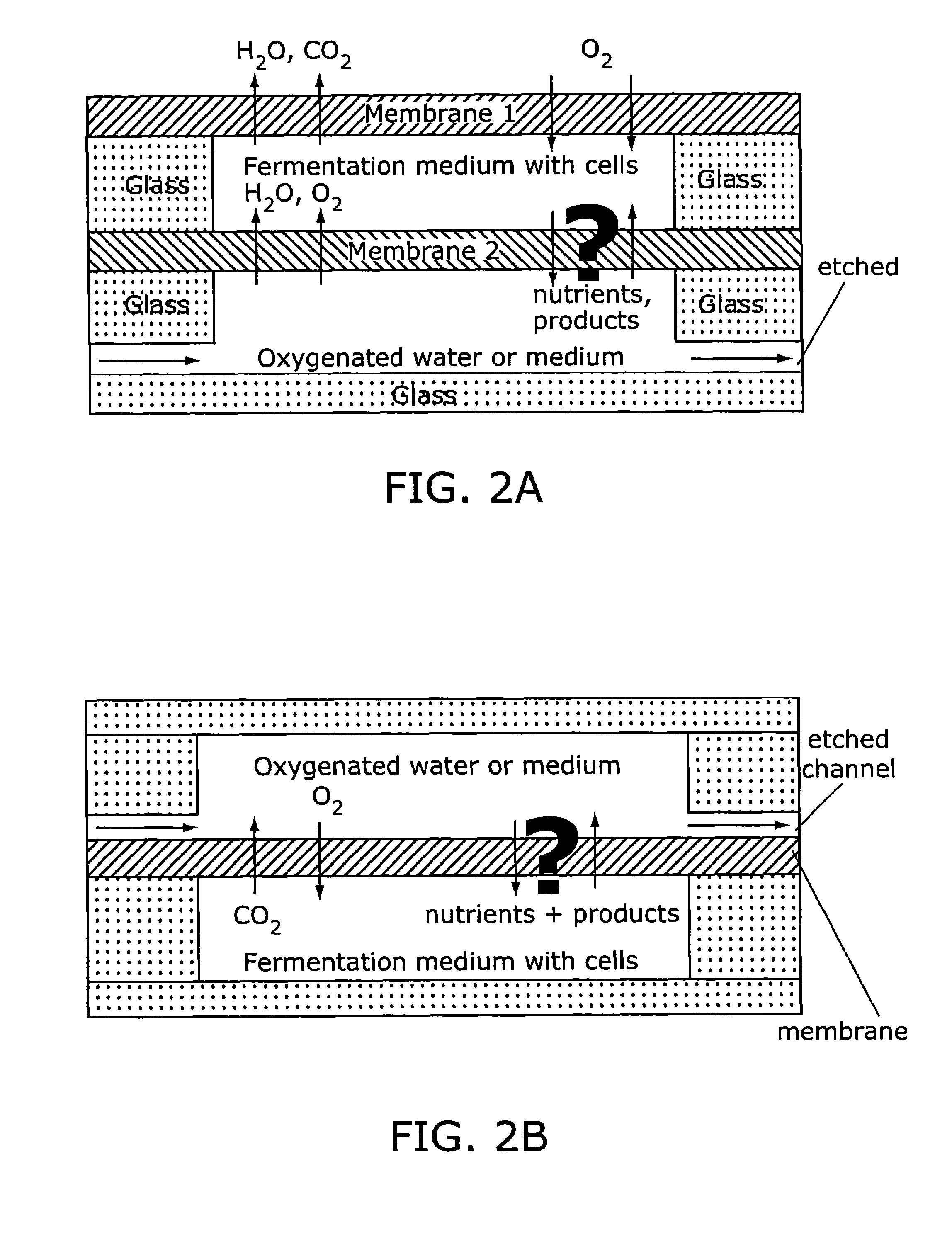

InactiveUS7507579B2Bioreactor/fermenter combinationsBiological substance pretreatmentsMetabolitePh control

The present invention provides a variety of microscale bioreactors (microfermentors) and microscale bioreactor arrays for use in culturing cells. The microfermentors include a vessel for culturing cells and means for providing oxygen to the interior of the vessel at a concentration sufficient to support cell growth, e.g., growth of bacterial cells. Depending on the embodiment, the microfermentor vessel may have various interior volumes less than approximately 1 ml. The microfermentors may include an aeration membrane and optionally a variety of sensing devices. The invention further provides a chamber to contain the microfermentors and microfermentor arrays and to provide environmental control. Certain of the microfermentors include a second chamber that may be used, e.g., to provide oxygen, nutrients, pH control, etc., to the culture vessel and / or to remove metabolites, etc. Various methods of using the microfermentors, e.g., to select optimum cell strains or bioprocess parameters are provided. The invention provides microreactors having a variety of different designs, some of which incorporate active stirring and / or have the capability to operate in batch or fed-batch mode. The invention further provides an apparatus and methods for simultaneous operation of a plurality of microreactors, with monitoring of the individual microreactors during a run. The invention further provides methods of performing gene expression analysis on cells cultured in microreactors.

Owner:MASSACHUSETTS INST OF TECH

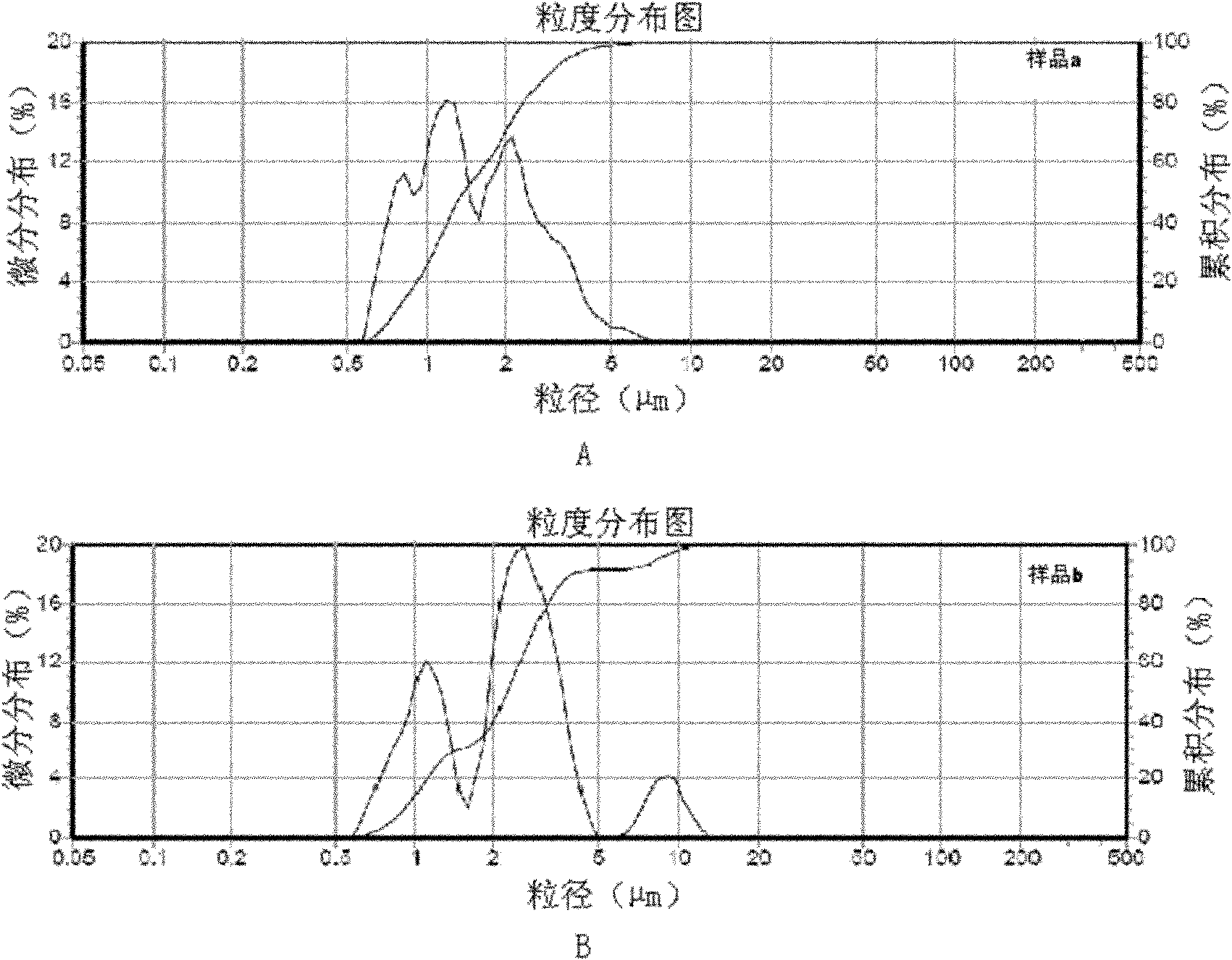

Lithium ion phosphate positive electrode material of nanometer core shell structure and preparation method thereof

InactiveCN102420324AShape is easy to controlControllable granularityCell electrodesPhosphateMixed materials

The invention discloses a lithium ion phosphate positive electrode material of a nanometer core shell structure. The positive electrode material is provided with an inner core active material and a conductive outer shell structure; a conductive agent is an outer shell material; the active material is of an inner core structure; and the structure formula of the inner core active material is LiFe[1-x]MxP[1-y]AyO4, wherein x is greater than or equal to 0, y is less than or equal to 0.1, M is a transition metal element, and A is silicon. Additionally, the invention also discloses a preparation method of the lithium ion phosphate positive electrode material. According to the preparation method in the invention, a porous material is adopted as a synthesis microreactor, and a lithium ion phosphate precursor is loaded and filled in holes, namely, the inner core active precursor reversely wraps a porous precursor so as to form a special nanometer core shell structure, thus the topography granularity of primary granule is controlled; and the lithium ion phosphate positive electrode material of the nanometer core shell structure is prepared by adopting a liquid phase mixed material and solid phase sintering technology. According to the invention, on the premise that the electrical performance of the positive electrode material is not influenced, a nanometer core shell structured active substance with uniform and controllable topography and granularity is synthesized; and the preparation method disclosed by the invention has lower technology, devices and control costs, which is beneficial to large-scale production.

Owner:SHANGHAI PYLON TECH CO LTD

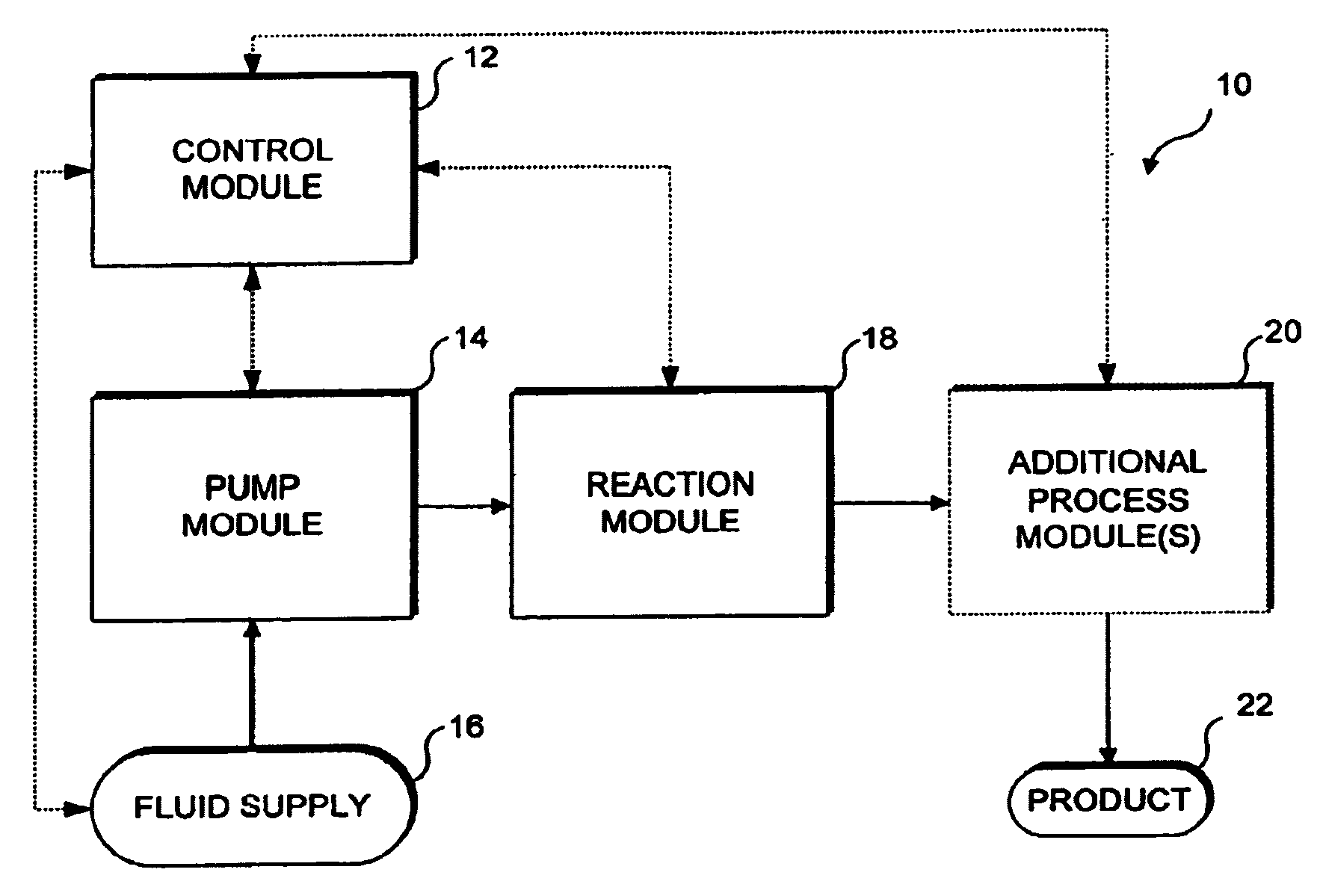

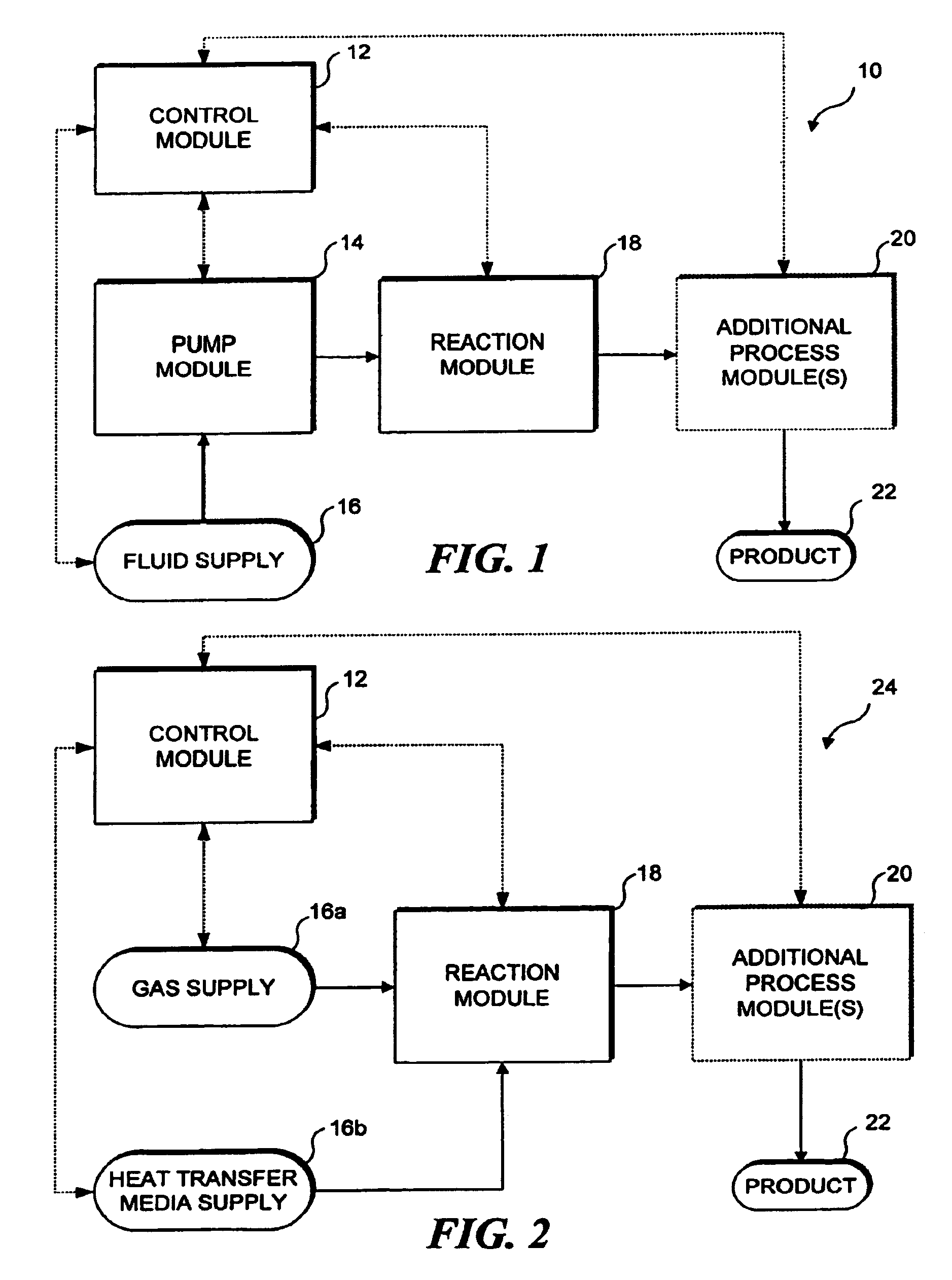

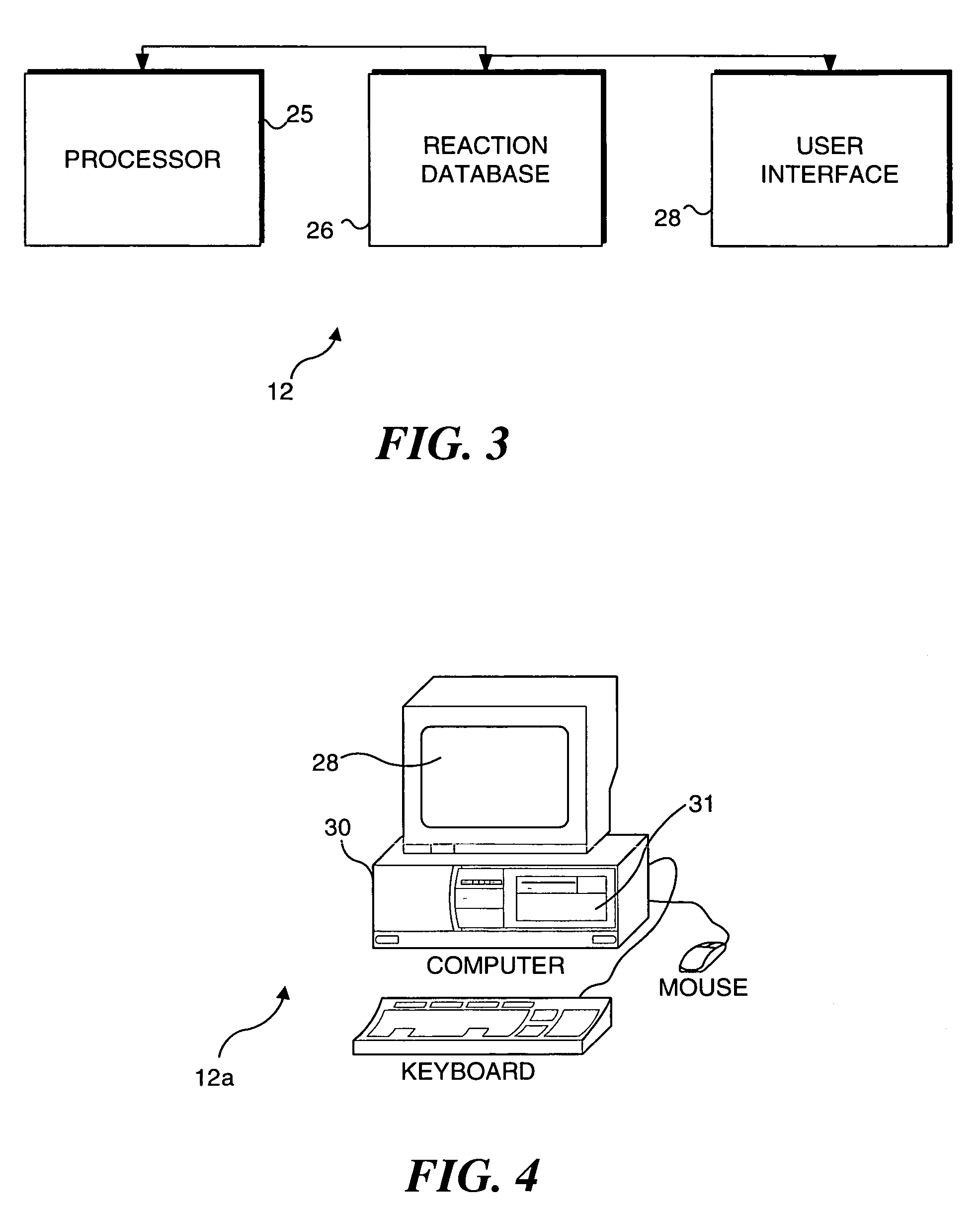

Modular chemical production system incorporating a microreactor

InactiveUS7056477B1Facilitate single stepEasy to completeExhaust apparatusTemperatue controlMicroreactorOperational system

A modular chemical production system that preferably includes a microreactor for producing a product by reacting two or more reactants. Modularization enables components such as controllers, pumps, valves, microreactors, and processing modules to be added or removed from the system as required to produce a desired product. A minimum system includes a control module and a reaction module, which has a mixing volume and a reaction volume. Various pumping modules and residence time modules may also be included in the system. Modules can be changed if malfunctioning, or for producing a different product, or to change a quantity of the chemical produced. The control module preferably accesses a database in which data define parameters for a plurality of different reactions that are optimized for the production of different chemical products. The user selects the product desired and the amount of the product, provides the reactants, solvents, and heat transfer media supplies, and the control module operates the system to automatically produce the product until the desired amount is obtained. The reaction module preferably includes a microreactor, which can be replaced with a microreactor of a different configuration to produce a different product. Connections between modules are designed to enable quick connection and disconnection of modules, and fluid lines are self sealing to prevent leakage of fluids when changing modules.

Owner:YMC

Microreactor

Chemical and biological reactors, including microreactors, are provided. Exemplary reactors include a plurality of reactors operable in parallel, where each reactor has a small volume and, together, the reactors produce a large volume of product. Reaction systems can include mixing chambers, heating / dispersion units, reaction chambers, and separation units. Components of the reactors can be readily formed from a variety of materials. For example, they can be etched from silicon. Components are connectable to and separable from each other to form a variety of types of reactors, and the reactors can be attachable to and separable from each other to add significant flexibility in parallel and / or series reactor operation.

Owner:BIOPROCESSORS CORP

Method for preparing aliphatic polyisocyanurate by using microreactor

The invention discloses a method for preparing aliphatic polyisocyanurate by using a microreactor, which comprises the following steps: adding isocyanurate and a catalyst compound system formed by quaternary ammonium salt and inert alcohol solvent to enable the isocyanurate to generate a polymerization reaction; then feeding a formed material flow into a dynamic reactor for continuously carrying out a polymerization reaction; and enabling reaction solution obtained by the reaction to pass through a second-stage evaporator to obtain a polyisocyanurate product. The method can well control the reactivity of the catalyst, so that a trimerization reaction of the isocyanurate is finished under a mild condition to obtain a tripolymer product with excessively-high quality.

Owner:WANHUA CHEM GRP CO LTD +1

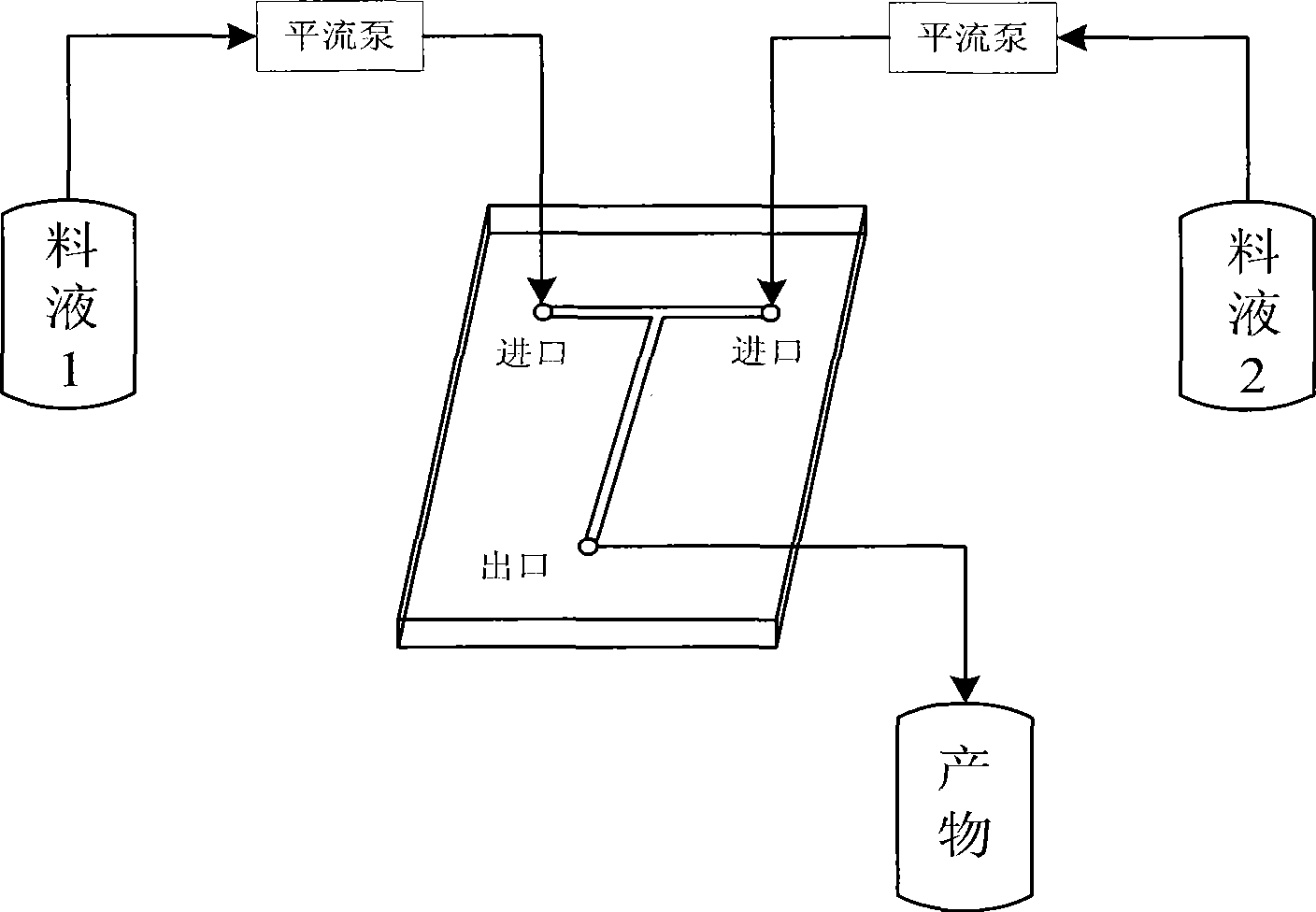

Method for synthesizing isooctyl nitrate and microchannel reactor

ActiveCN101462962AAvoid production accidentsLow costNitric acid ester preparationSynthesis methodsSolvent

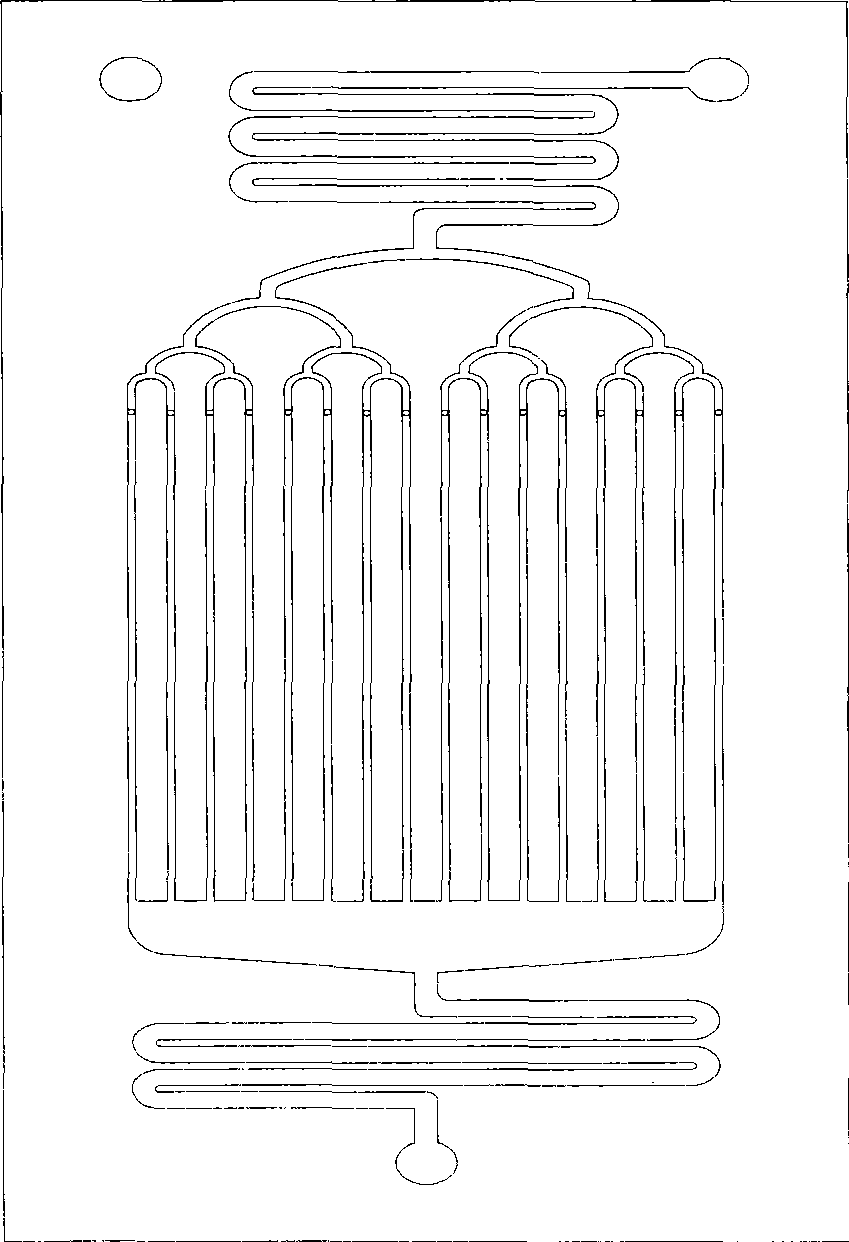

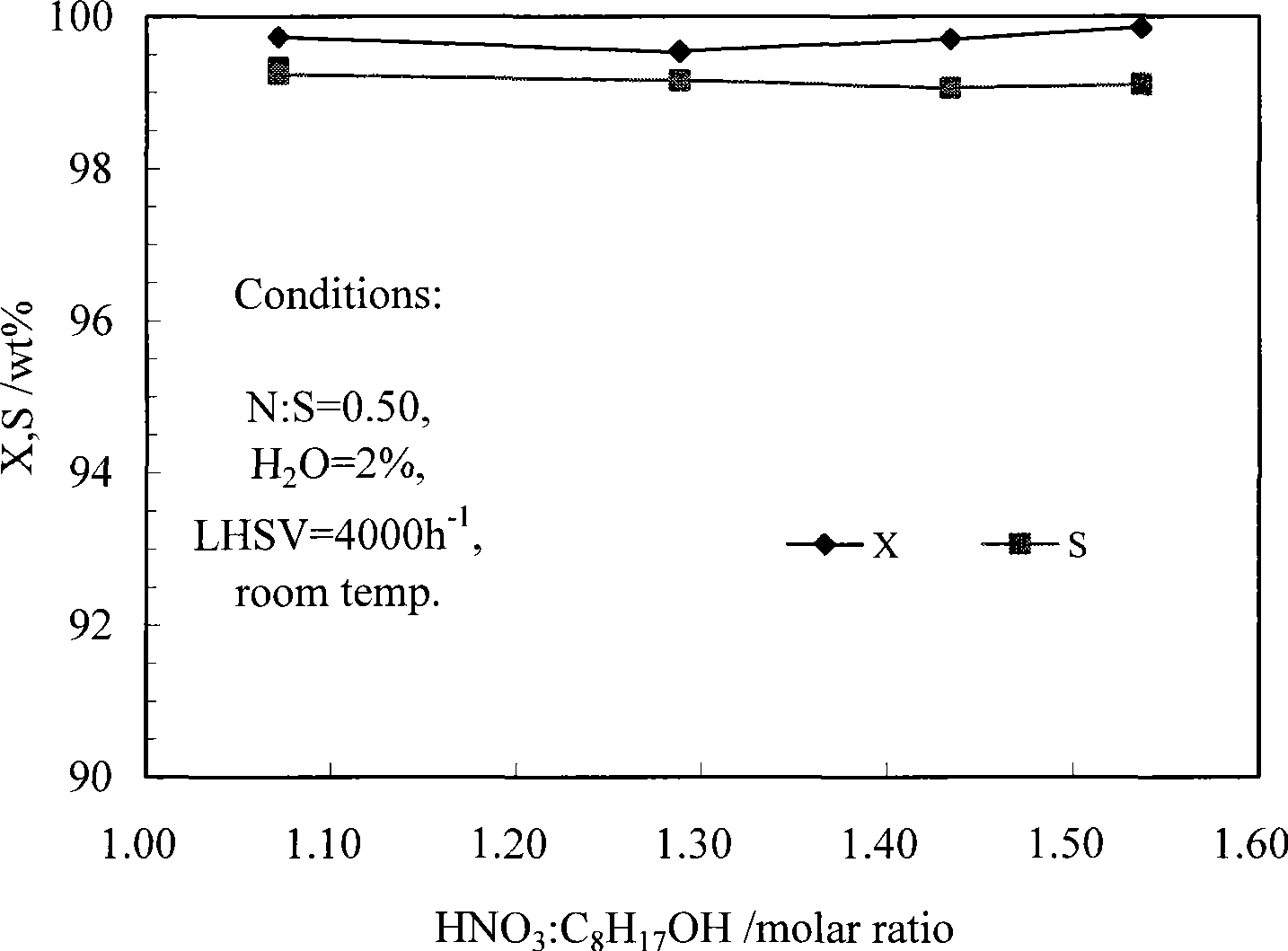

The invention relates to the synthesis of isooctyl nitrate; in particular to a synthesis method of isooctyl nitrate and a microchannel reactor. Isooctyl alcohol is taken as raw material and an acid mixture of nitric acid and sulphuric acid is taken as nitrating agent, and the raw material and the nitrating agent are pumped into the microchannel reactor at normal temperature and pressure to carry out direct esterification. The process needs no catalyst or solvent, makes full use of the efficient heat and mass transfer capability of the microchannel as well as the characteristic of direct amplification and adopts two microreactors, of which one is a single-channel microreactor and the other is a multichannel microreactor; liquid hourly space velocity in the microreactor is 3000-10000h<-1>, the once-through conversion ratio of isooctyl alcohol is higher than 99% and the yield coefficient of isooctyl nitrate is higher than 98%. The process has high operation safety and high selectivity and can realize approximate isothermal operation in the reaction. The reactor is small in volume, is easy to integrate and amplify and space-time productive rate is high, thus being significant for strengthening and guaranteeing the safe production of isooctyl nitrate.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing naphthalene sulphonic acid by sulfonating sulfur trioxide in microreactor

InactiveCN101607925ALarge specific surface areaImprove heat transfer performanceChemical/physical/physico-chemical processesSulfonic acid preparationReaction temperatureNitromethane

The invention relates to a method for preparing naphthalene sulphonic acid by sulfonating sulfur trioxide in a microreactor, belonging to methods for preparing dye intermediates in the field of fine chemical engineering. The method comprises the following steps: taking alkyl halide and nitromethane as an organic solvent, naphthalene and derivative thereof as the raw material and organic solution of liquid sulfur trioxide as a sulfonating agent, preparing a solution according to the mol ratio of the organic solvent, the raw material and the sulfonating agent of 19-74:1:1-3 in the microreactor of with channel with the diameter of 10-50 microns, and sulfonating the reaction solution to prepare the naphthalene sulphonic acid by controlling the sulfonation reaction temperature to be between 17DEG C below zero and90 DEG C. The method adopts a continuous flow reactor, solves the problem of impossible transient mixing in the conventional reactor, prevents secondary reaction caused by local excess, and is especially suitable for strong exothermic reaction, fast reaction and flammable and explosive reaction. Compared with the preparation technology in the traditional batch reactor, the invention has the advantages of no generation of waste water and waste acid, clean and environment-friendly technology, consumption of sulphonic acid close to the theoretical quantity, fast reaction speed, low sulfonation temperature, high product yield, good repeatability, high labor productivity and low equipment cost.

Owner:SPECIAL CHEM CO LTD DALIAN FIRSTAR

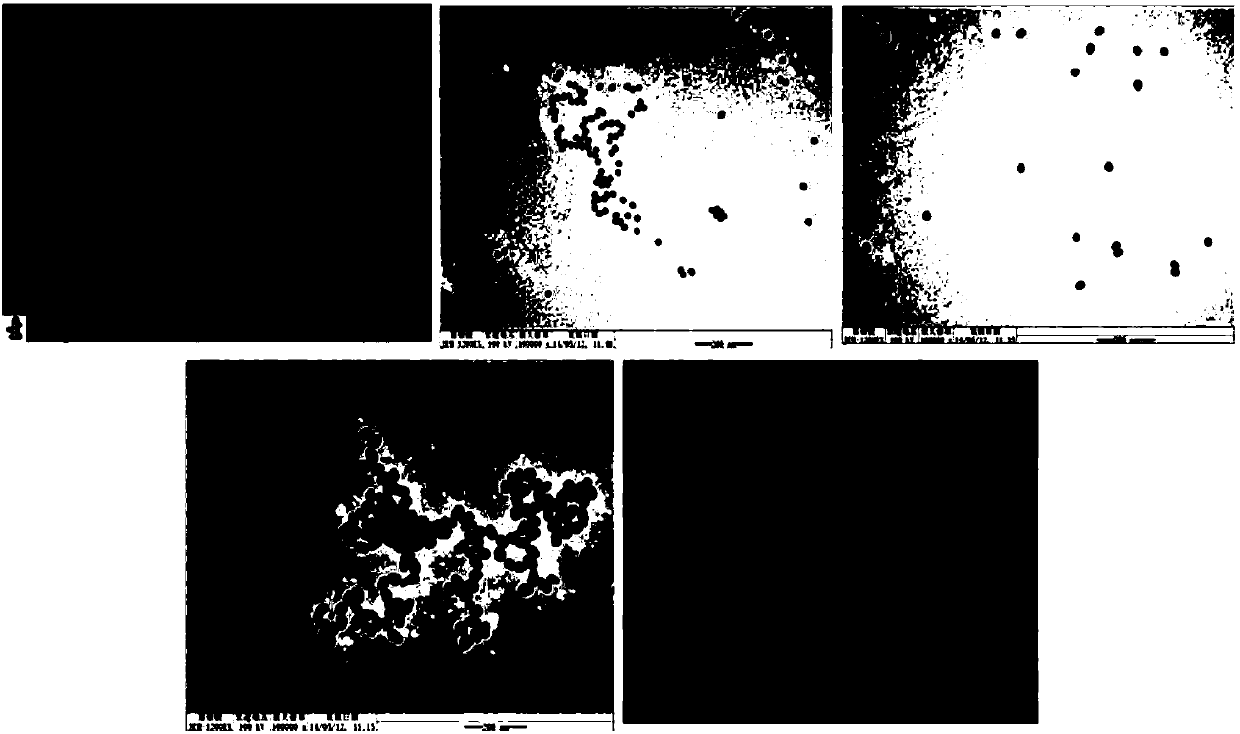

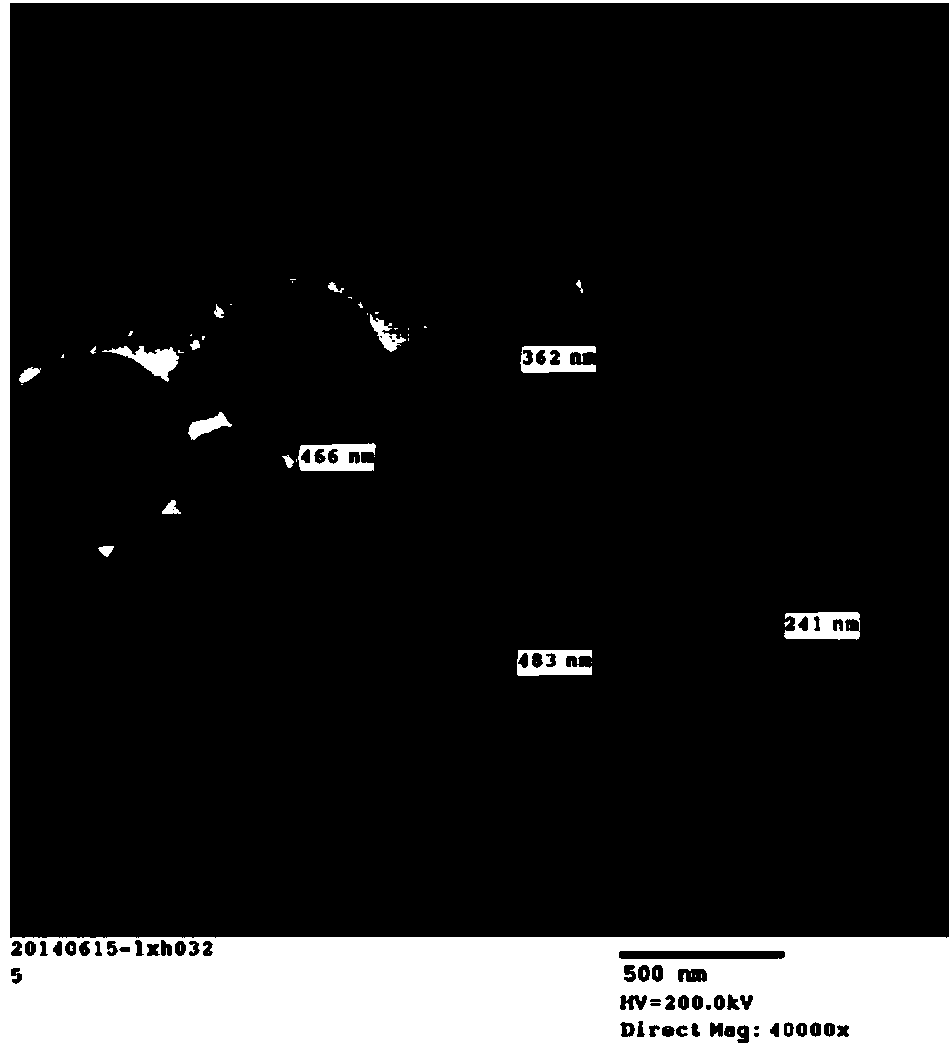

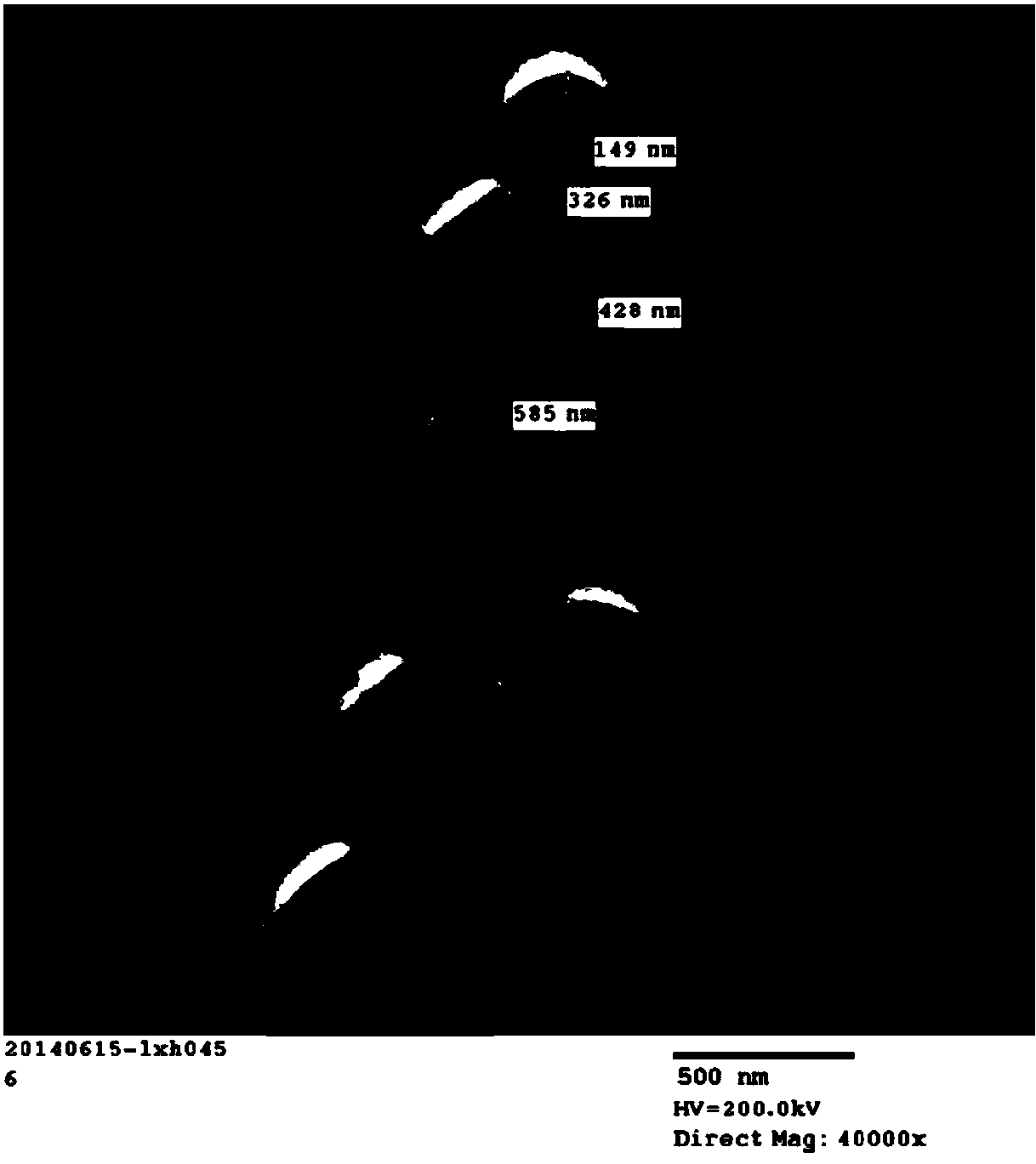

Preparation method and application of nano material monolithic column immobilized enzyme biological micro-reactor

InactiveCN104195042AFast catalytic efficiencyHigh catalytic efficiencyEnzyme production/based bioreactorsMicroorganism fixing/supporting apparatusMicroreactorFunctional monomer

The invention discloses a preparation method and an application of a nano material monolithic column immobilized enzyme biological micro-reactor. The preparation method comprises the following steps of firstly, preparing a porous organic polymer monolithic column by using a mixed solution of a functional monomer, a crosslinking agent, a pore forming agent and an initiating agent through in-situ thermal-initiated or light-initiated polymerization in the column, and then bonding a nano material after functional modification to obtain a nano material monolithic column; and secondly, realizing immobilization of the enzyme on the monolithic column by using the nano material as an intermediate ligand to obtain the nano material monolithic column immobilized enzyme biological micro-reactor. The biological micro-reactor is successfully applied to proteomic analysis, medicament chiral resolution and catalyzed ester exchange reactions. The biological micro-reactor disclosed by the invention has the following advantages that the preparation method is simple, the immobilization amount of the enzyme is large, the catalytic activity is high, the enzymolysis speed is high, the efficiency is high, the service life is long, and the biological micro-reactor can be reused.

Owner:BEIJING UNIV OF CHEM TECH

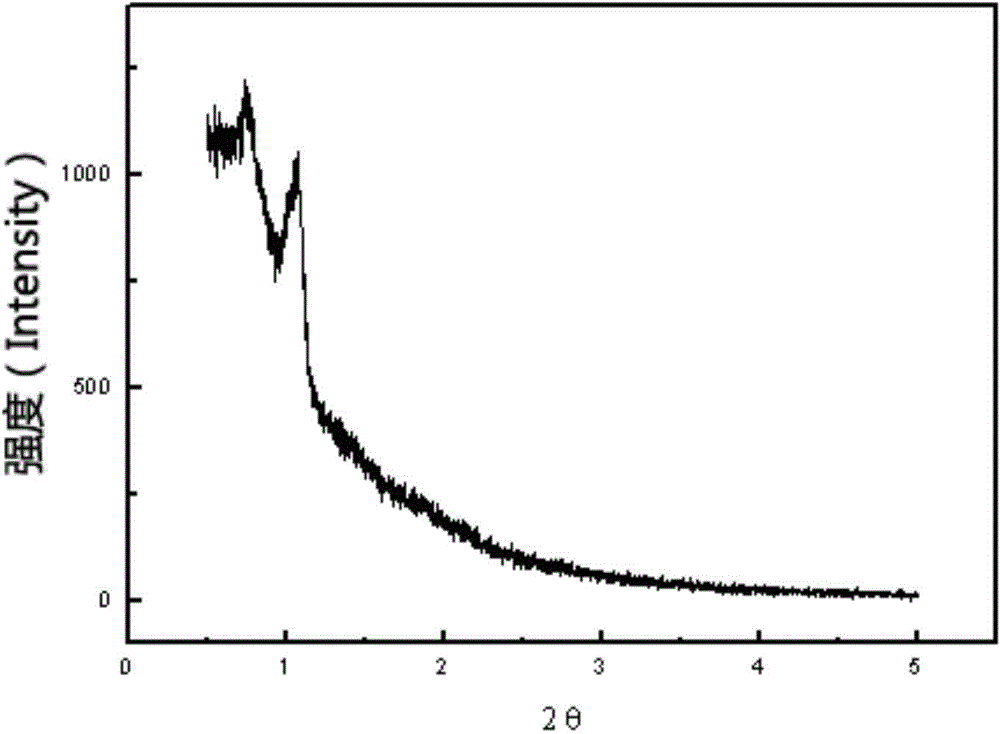

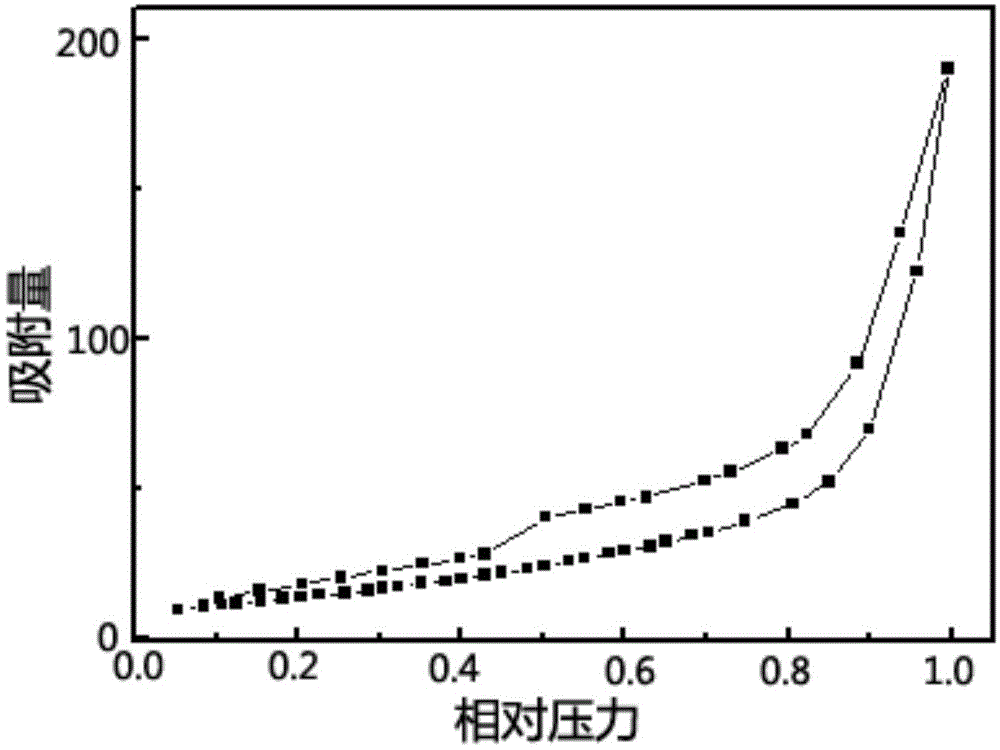

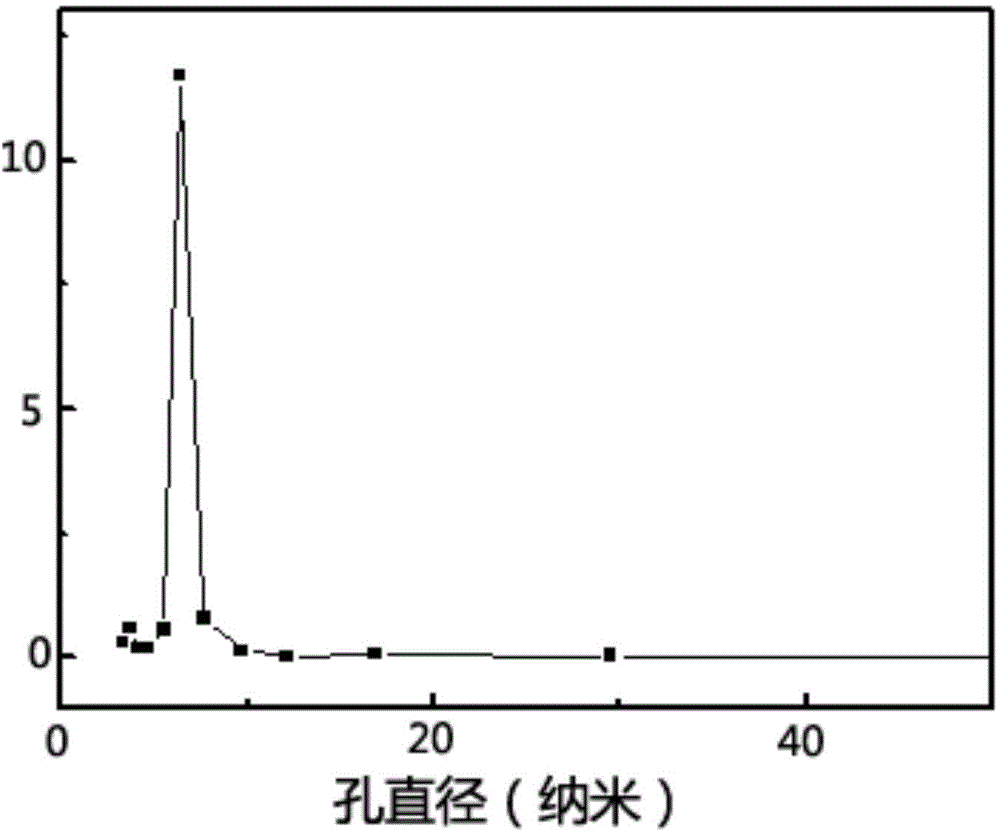

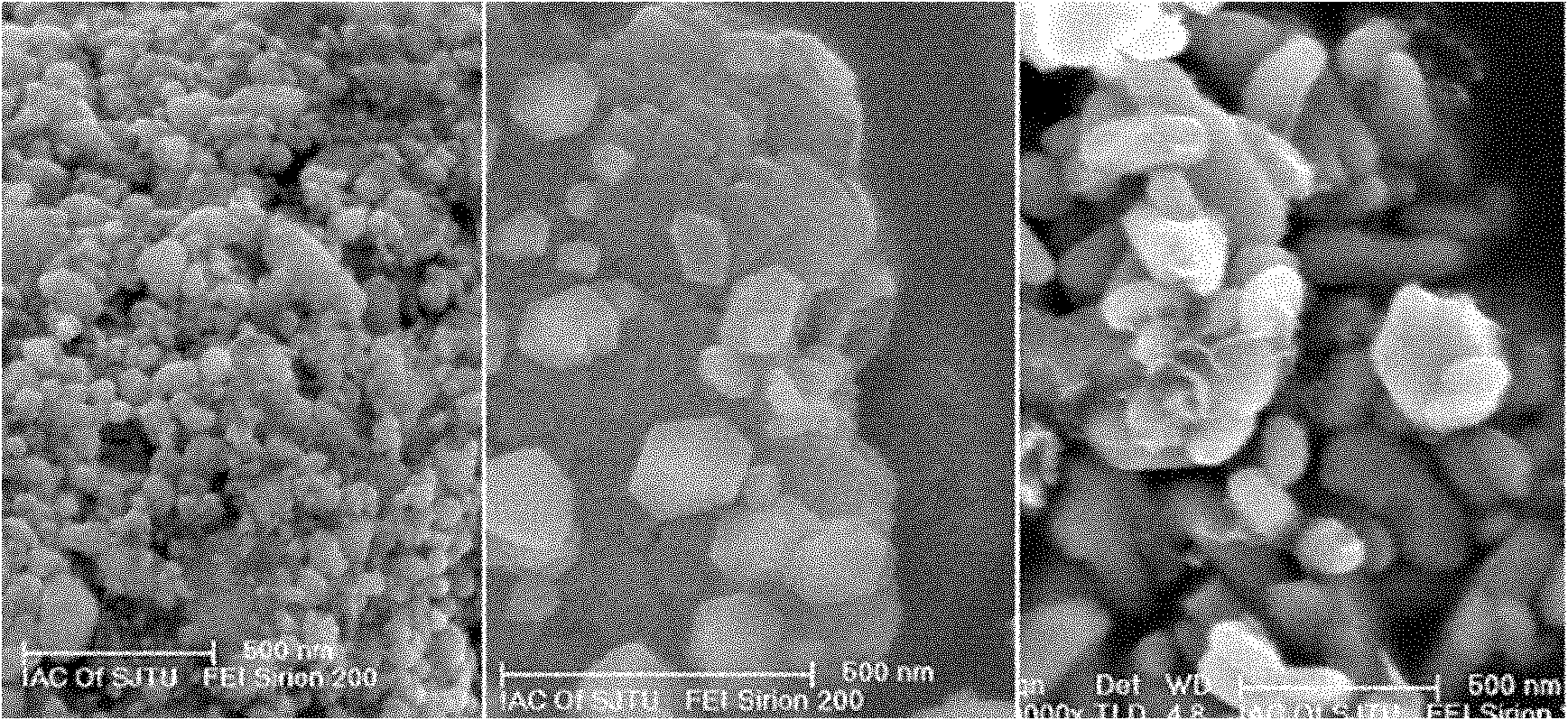

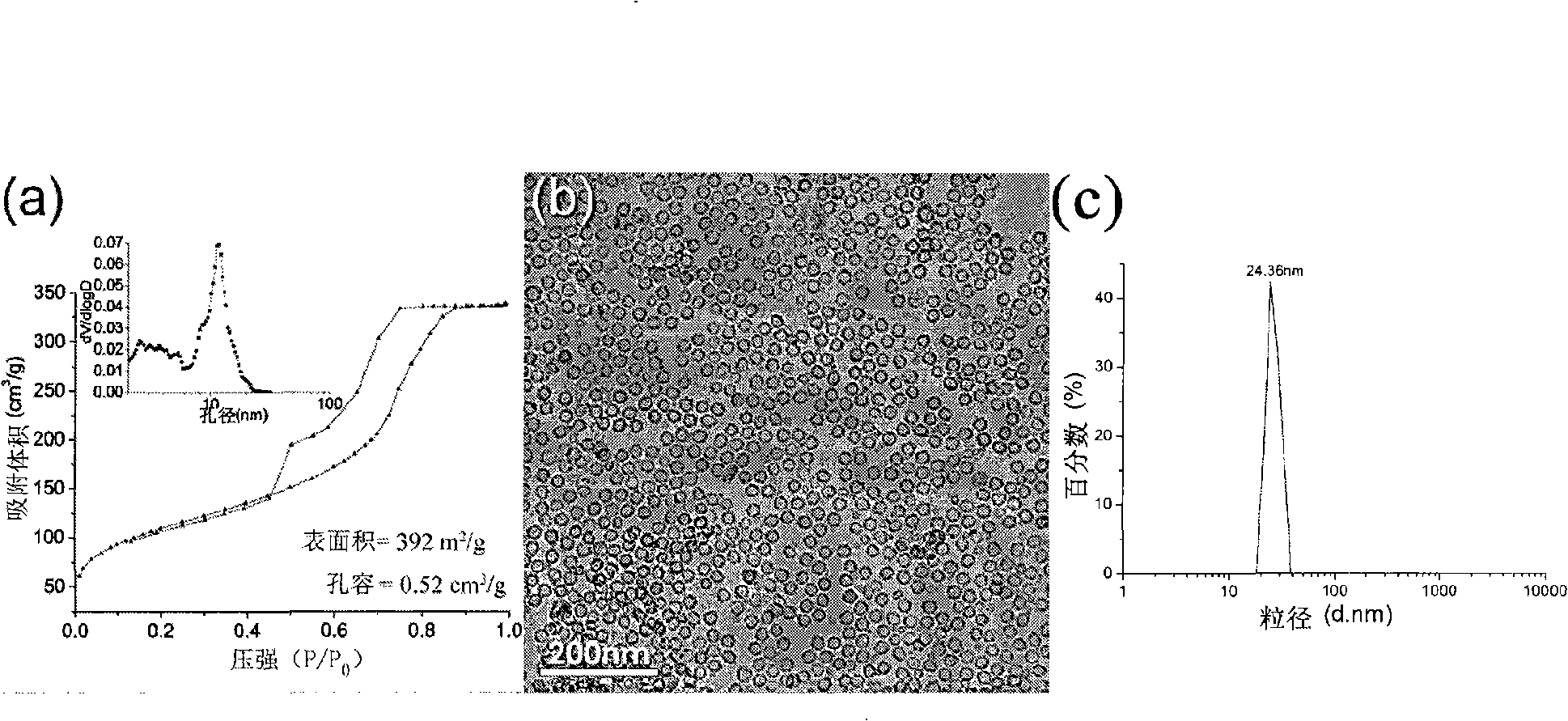

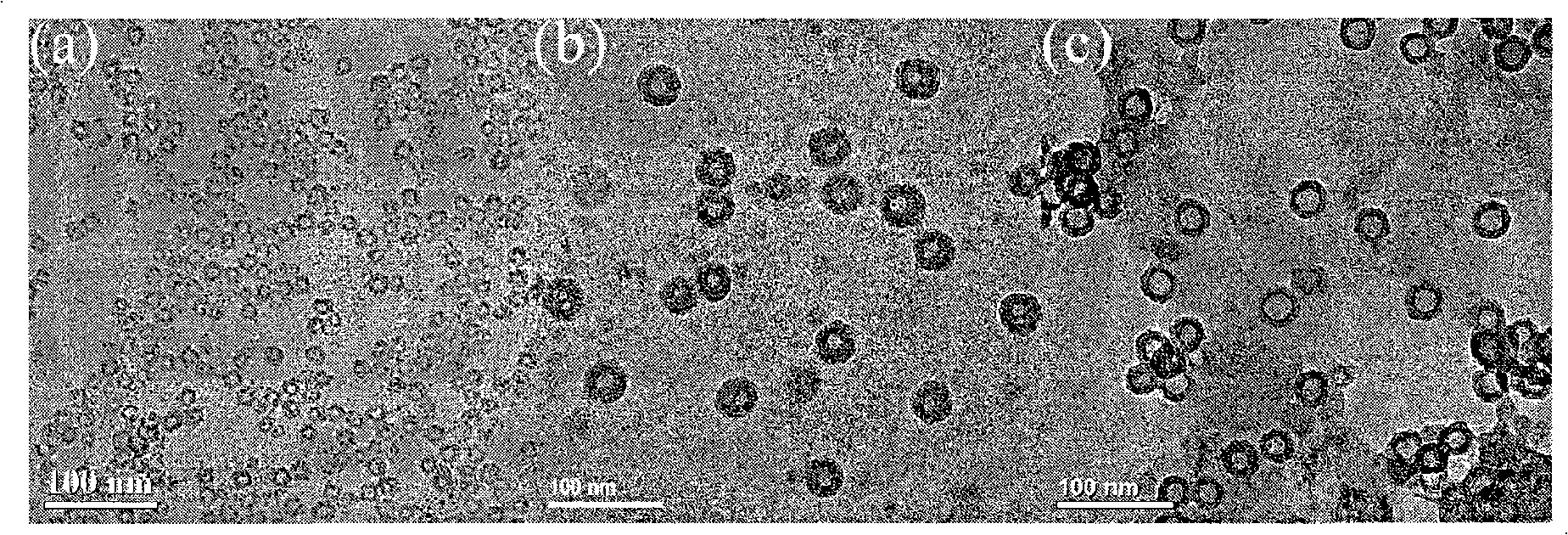

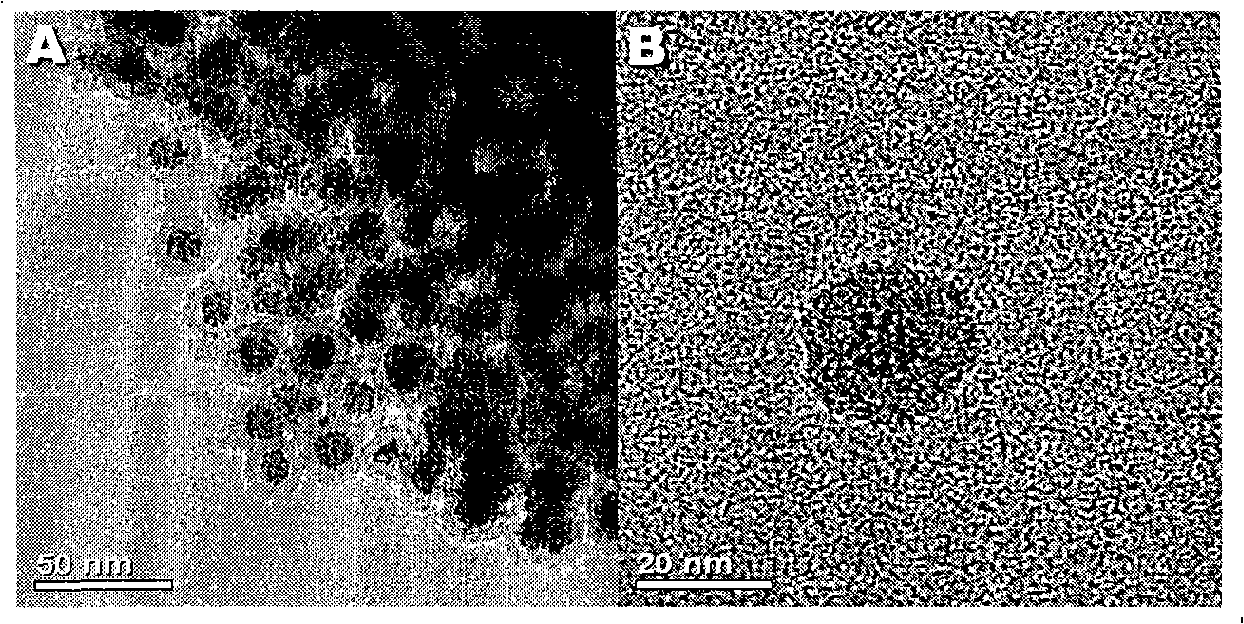

Nano-silicon dioxide hollow sphere material and method of preparing the same

InactiveCN101343065AGood monodispersityReaction raw materials are cheap and easy to obtainSilicaReaction temperatureSilicon dioxide

The invention relates to a material of a nanometer silica hollow sphere and a synthesizing method thereof, belonging to the technical field of nanometer material. Wherein, a novel material of a nanometer silica hollow sphere is synthesized by the sol-gel method under the guidance of micelle, and is characterized in that the size is super small, particles are distributed evenly (the deviation of the particle size is less than 3 percent), the pore diameter is 5 to 20 nm, the wall thickness is 5 to 20 nm, and the particle size is adjustable. The synthesizing method comprises procedures of self-assembling, monodisperse controlling, dialyzing, drying and removing a template agent, etc. of the silica hollow sphere under the guidance of the micelle. The material has the advantages that the reaction conditions are mild, the operation is simple and easy, and the ultimate material is cheap and easily available. The physicochemical properties of the particle size and the pore diameter, etc. of the material can be modified by changing conditions of the raw material ratio, added expansion reagents, reaction temperatures and reaction time, etc. The nanometer silica hollow sphere has wide application prospect in the field of adsorption, drug sustained release, the catalyst carrier, the microreactor, and cell intervention targeted diagnosis and treatment.

Owner:FUDAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com