Method for synthesizing isooctyl nitrate and microchannel reactor

A microchannel reactor, the technology of isooctyl nitrate, applied in the directions of nitrate preparation, organic chemistry, etc., can solve the problems of rising raw material cost, increase of operation steps and subsequent separation steps, etc., to save equipment cost and improve space-time yield , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

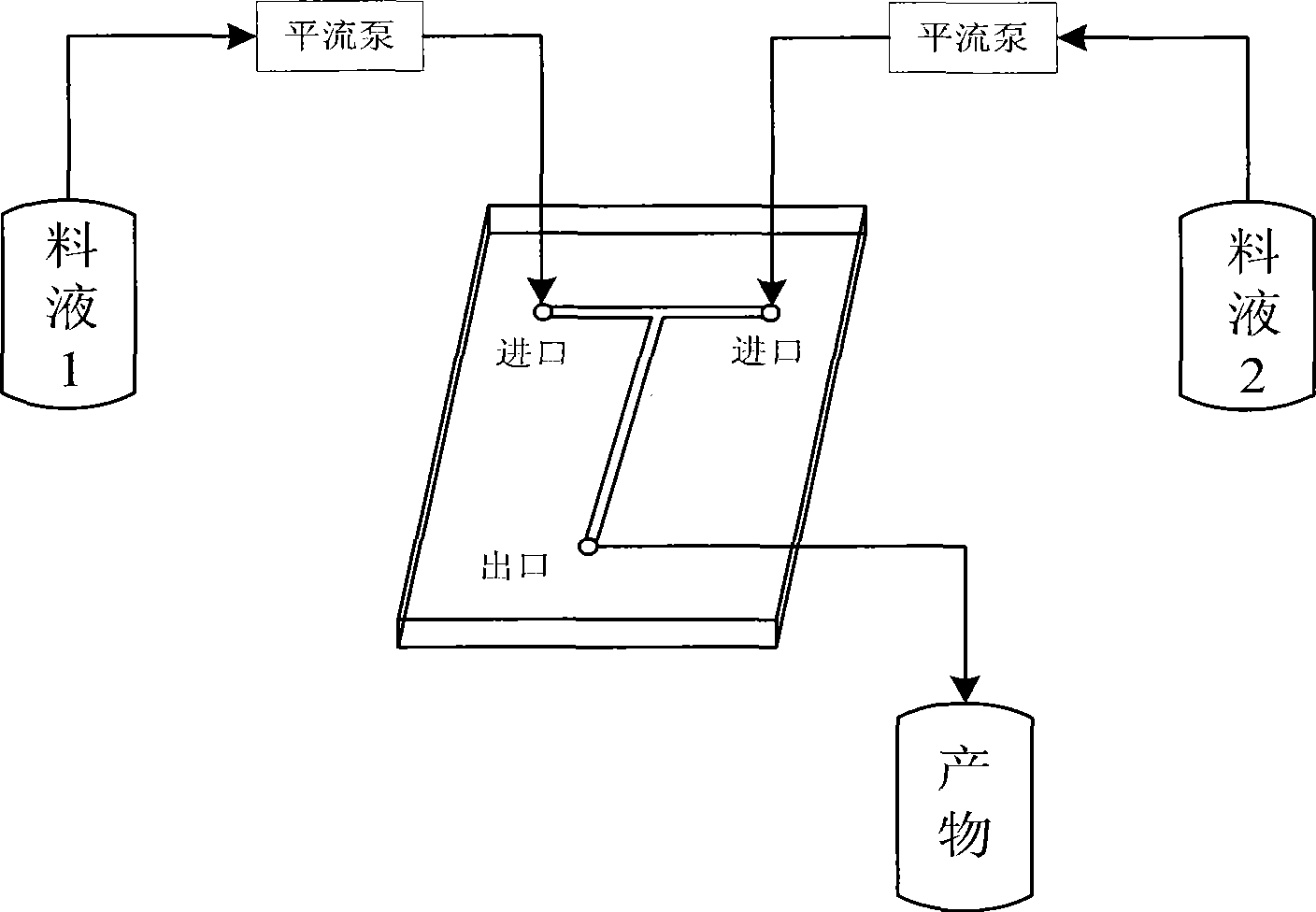

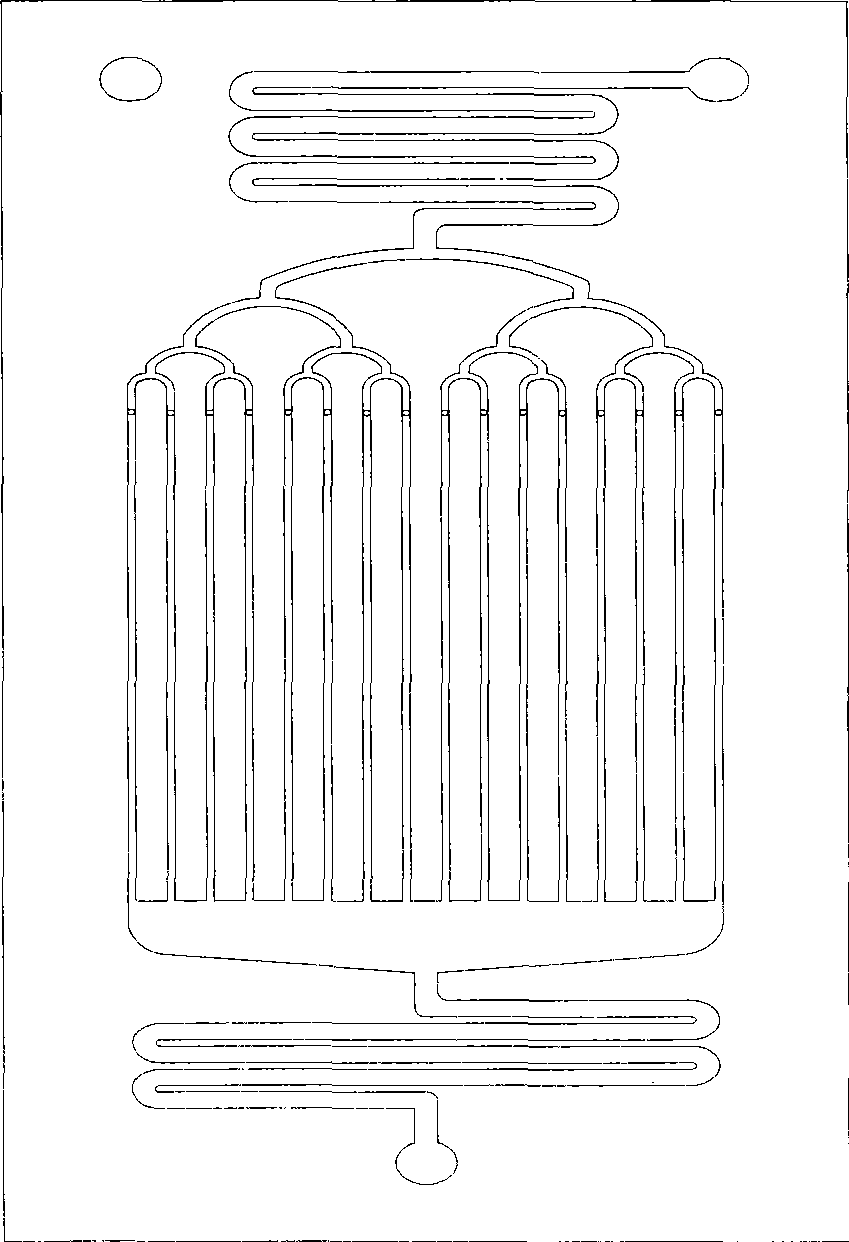

Method used

Image

Examples

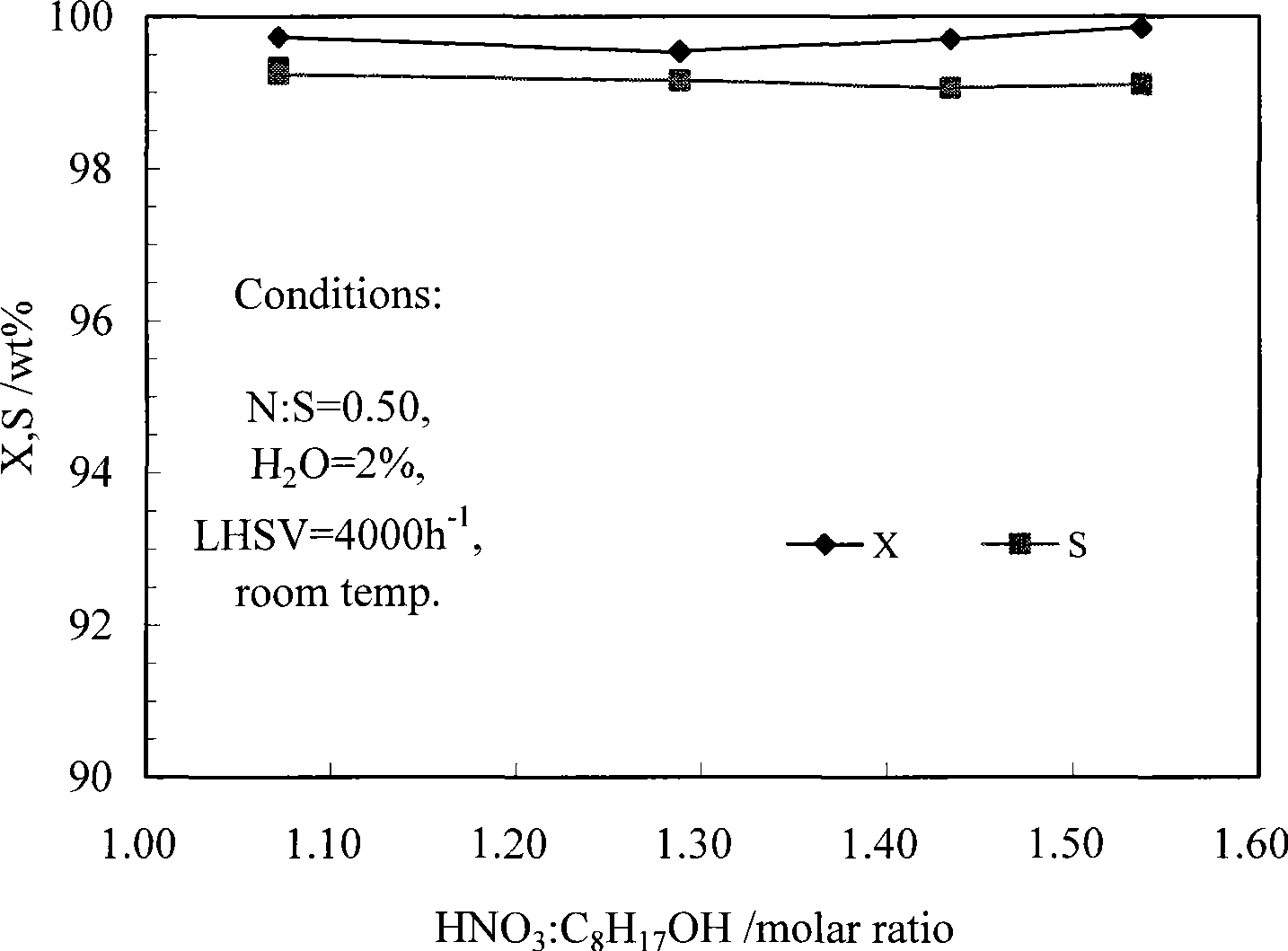

Embodiment 1

[0048]Use 98% nitric acid and 98% concentrated sulfuric acid to prepare a mixed acid with a molar ratio of nitric acid and sulfuric acid of 1:2, and the temperature during the preparation of the mixed acid can be controlled below 35°C. Under normal temperature conditions, the mixed acid and liquid isooctyl alcohol are continuously pumped into the microreactor by a micro-advection pump and react in the microchannel. The molar ratio of nitric acid and isooctyl alcohol is controlled to be 1.3:1, and the liquid hourly space velocity of the reactor is 4000h -1 . The reaction product flows out of the reactor continuously, and is collected in the collector at normal temperature, and the layers are statically separated, and the acid solution is separated, and the ester layer is washed with water, alkali and water until neutral. The purity of the product isooctyl nitrate reaches 99.5%, and the yield is 98.9%.

Embodiment 2

[0050] The process is the same as in Example 1, the molar ratio of nitric acid and sulfuric acid is fixed at 1:2, and only the molar ratio of nitric acid and isooctyl alcohol is changed: nitric acid and isooctyl alcohol are fed in a stoichiometric ratio of 1:1. The purity of isooctyl nitrate reaches 99.5%, and the yield is 99.1%.

Embodiment 3

[0052] The process is the same as in Example 1, only the molar ratio of nitric acid and sulfuric acid is changed: the molar ratio of nitric acid and sulfuric acid is 1:1. The purity of isooctyl nitrate reaches 99.7%, and the yield is 98.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com