Patents

Literature

163results about How to "Avoid separability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing inorganic hydrous salt phase transition energy-storing material

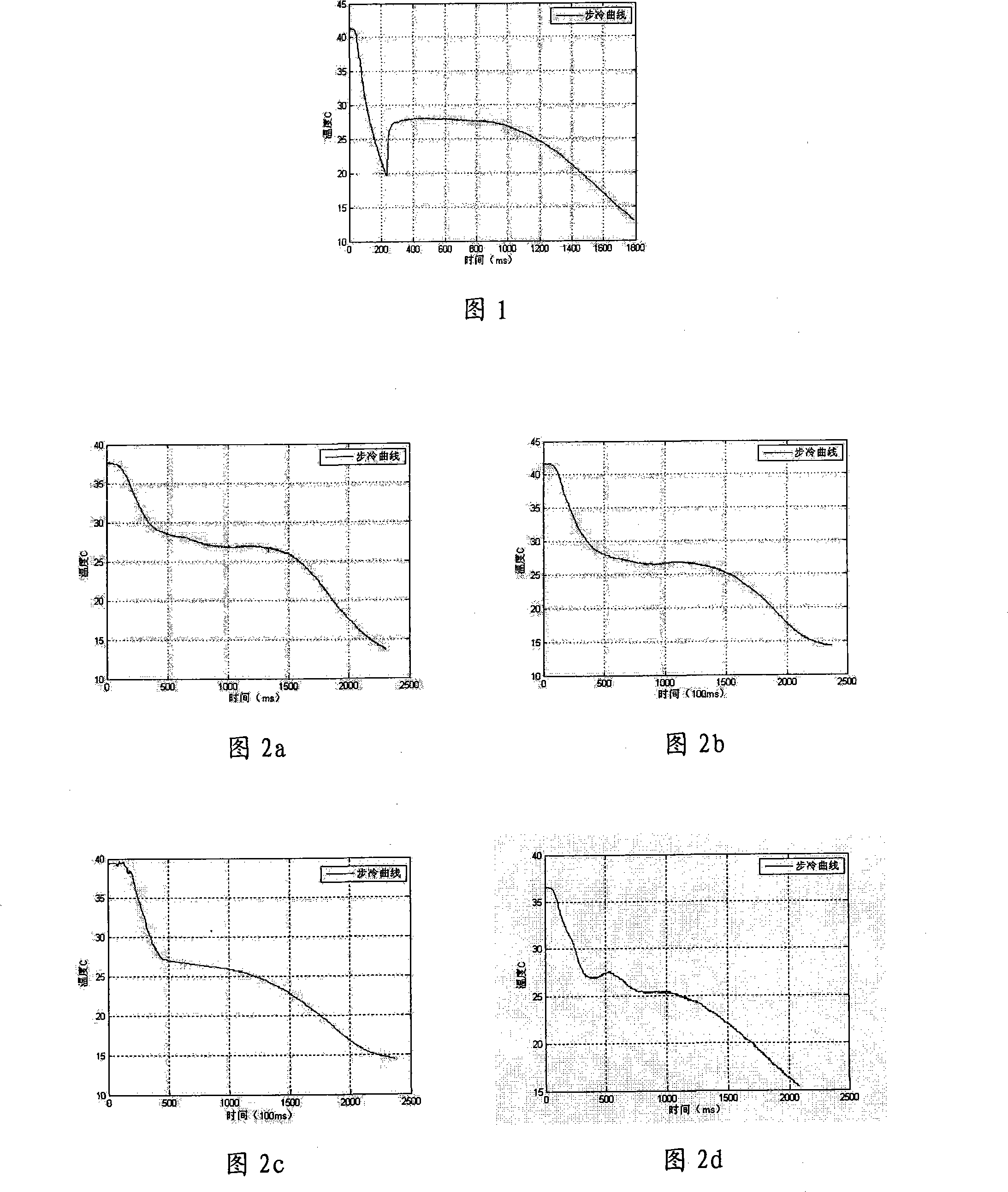

ActiveCN101235272APrevent overcoolingAvoid separabilityHeat-exchange elementsInorganic saltsPhase change

The invention discloses a preparation process of inorganic salt hydrate phase-change energy-storage material, comprises the following steps that adding 40-60g inorganic salt particles and 3-5g overcooling- resistance agent in 100g water, stirring and mixing to prepare hydrating inorganic salt solution, adding 5-10g poly-sodium acrylate in the hydrating inorganic salt solution, and stirring and mixing to prepare viscous hydrating inorganic salt mixed solution. The preparation process of hydrating inorganic salt phase-change material which is provided by the invention is added with overcooling- resistance agent and poly-sodium acrylate in the preparation process, which can effectively avoid the hydrating inorganic salt phase-change material from generating the phenomenon of over-cooling and phase separation in the phase change process, and ensures hydrating inorganic salt phase-change material to keep uniformity after repeated circulating.

Owner:SHENZHEN INST OF ADVANCED TECH

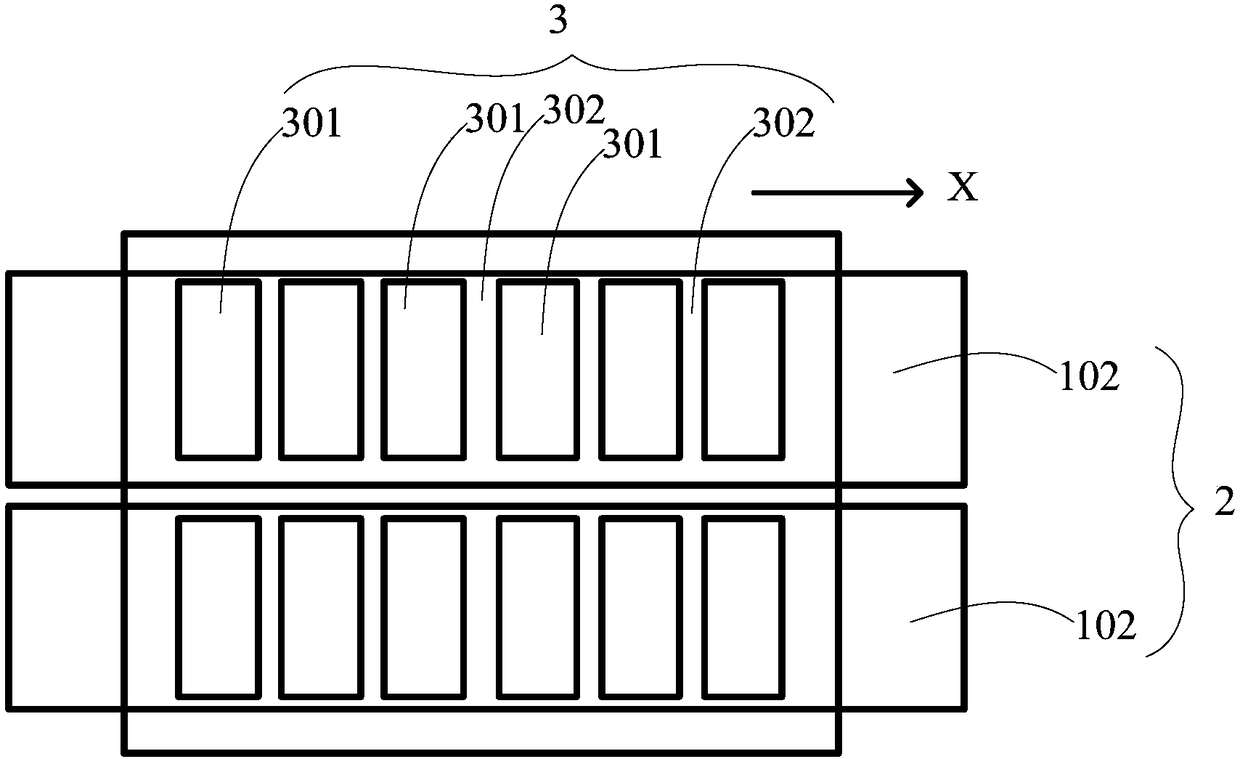

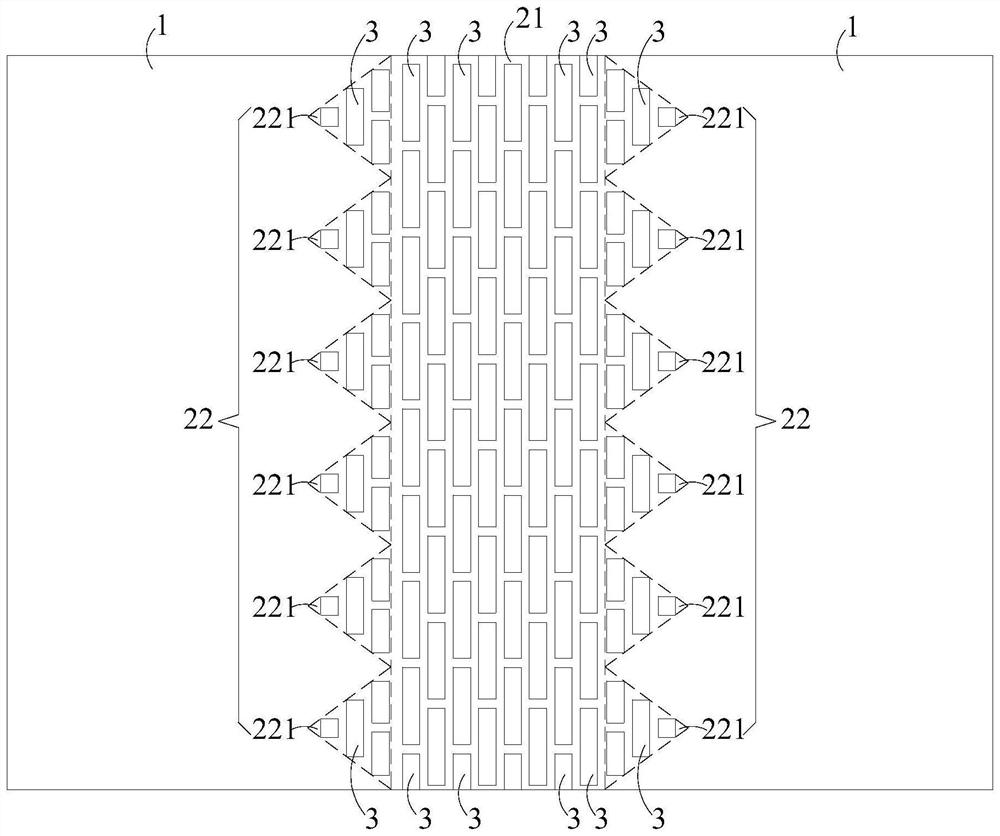

Flexible display screen

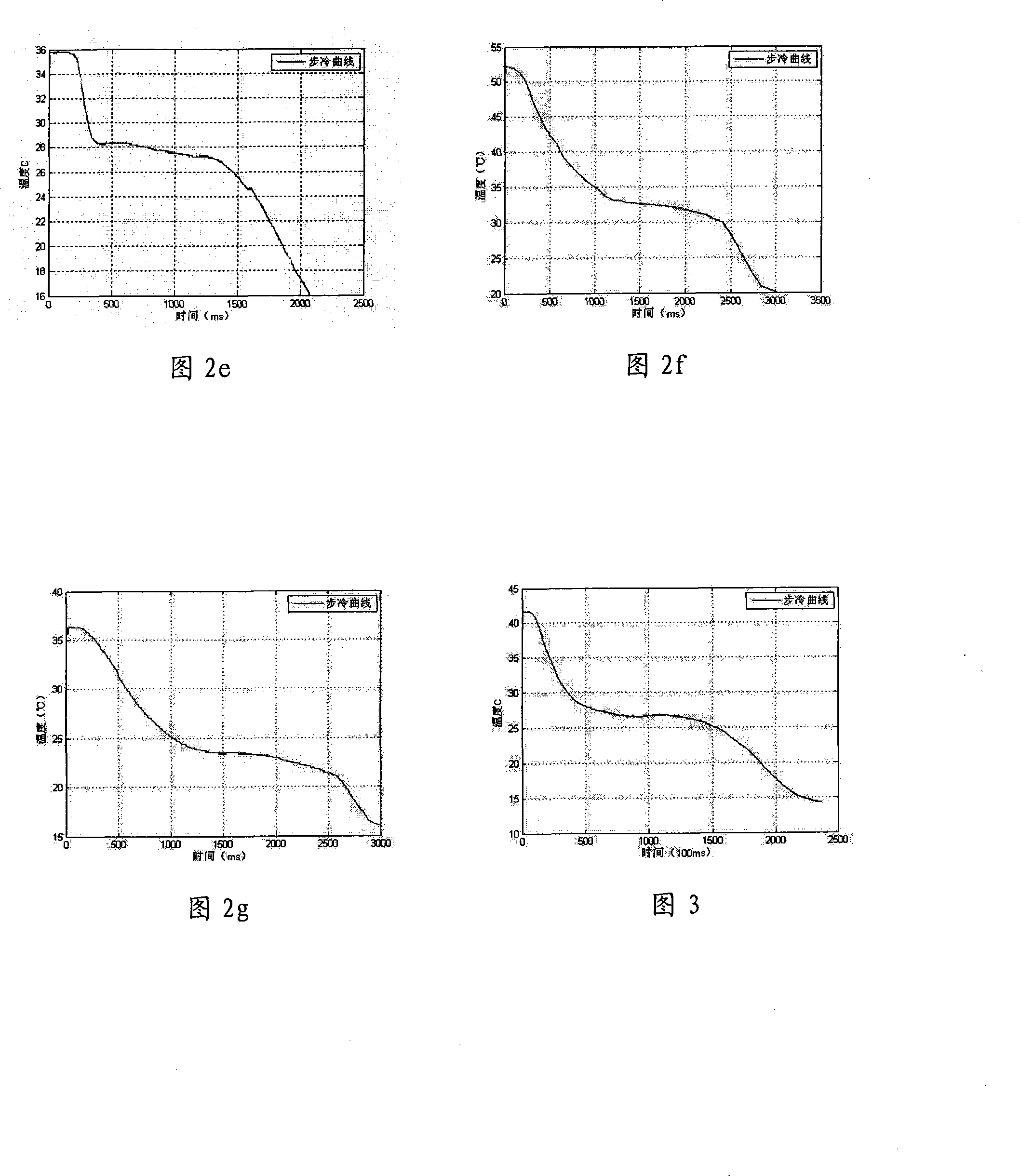

InactiveCN108155218AImprove reliabilityReduce bending stressSolid-state devicesSemiconductor/solid-state device manufacturingStress concentrationEngineering

The embodiment of the invention provides a flexible display screen. The screen comprises multiple functional film layers which are sequentially overlapped, wherein at least one functional film layer of the functional film layers comprises multiple sections of module material, clearances or grooves are formed in the positions between two adjacent sections of the module material, and elastic materials fill the clearances or the grooves. The contact area between the functional layer where the module material is located and the adjacent functional layer can be reduced by the grooves or the clearances, so that when the flexible display screen is bent, bending stress on the adjacent functional layer generated by the functional layer where the module material is located is reduced, and thereforeseparation or fracture between the adjacent functional layers is prevented. Moreover, the elastic materials fill the clearances or the grooves, concentration of the stress of the functional layers where the clearances or the grooves are located can be relieved when the flexible display screen is bent, and the bending stress is released to improve reliable performance of the flexible display screen.

Owner:YUNGU GUAN TECH CO LTD

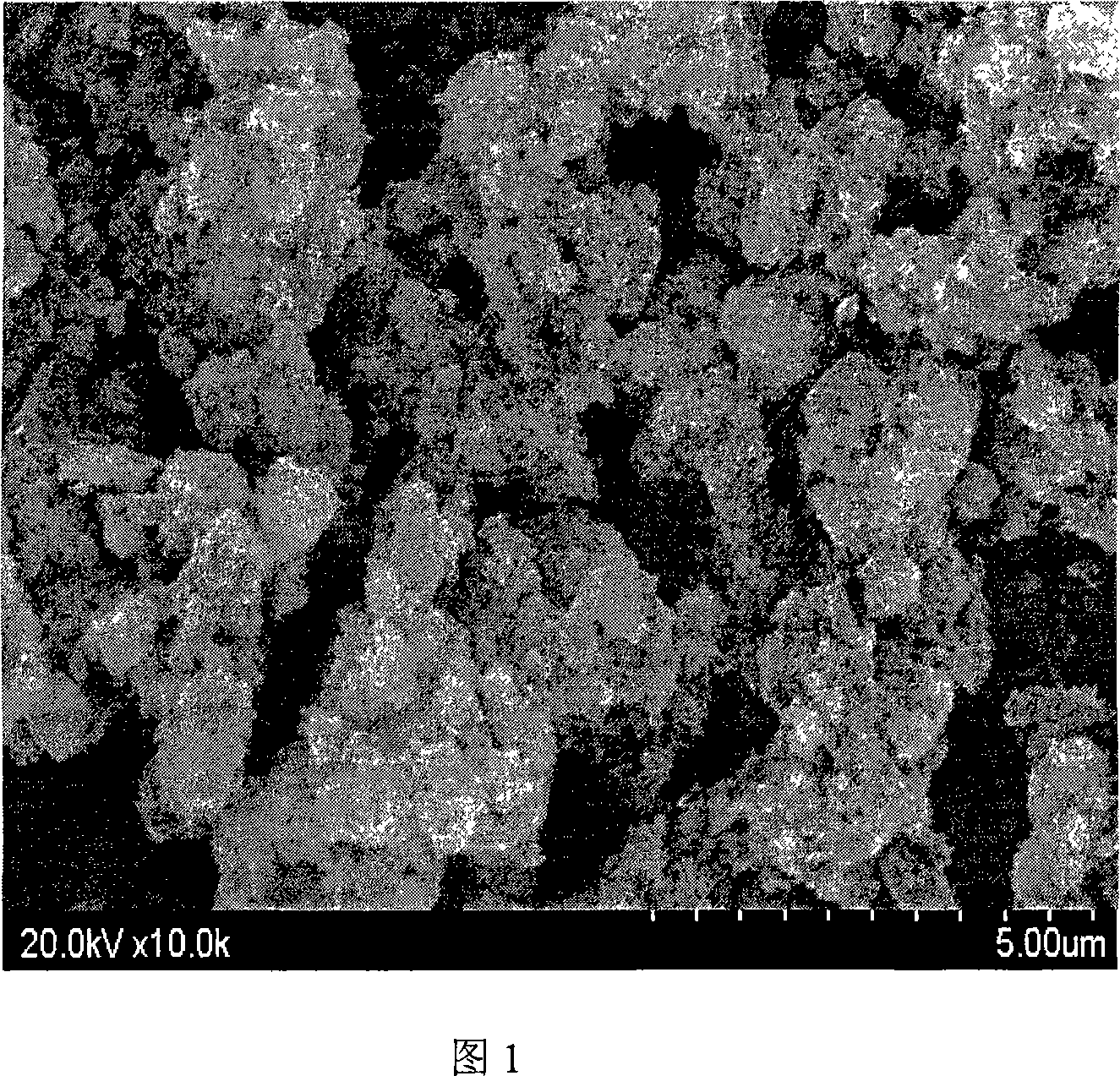

Carbon nano tube composite film and preparation method thereof

ActiveCN103435027AEvenly dispersedAvoid reunionMaterial nanotechnologyCarbon compoundsComposite filmCatecholamine

The invention discloses a preparation method for a carbon nano tube composite film. The method comprises the following steps: first, allowing a phenolic hydroxyl group, a quinonyl group and other functional groups to be introduced on the surface of a carbon nano tube through oxidation autopolymerization reaction of catecholamine under an alkalescence condition, so as to realize the modification for the surface of the carbon nano tube; then, using water-soluble polymers with amino groups or mercapto groups as raw materials to realize layer-by-layer self-assembly under the action of chemical bonds formed by Schiff base or Michael Addition reaction, thereby obtaining the carbon nano tube composite film. The method has the advantages of mild reaction condition, environmental protection, simplicity and feasibility, and is suitable for industrialized production. The carbon nano tube composite film prepared by the method has the advantages of excellent thermal and chemical stability, ductility, mechanical strength and transparency.

Owner:ZHEJIANG UNIV

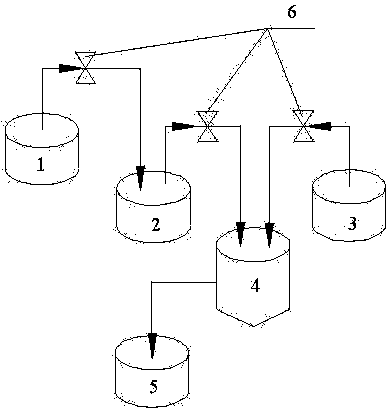

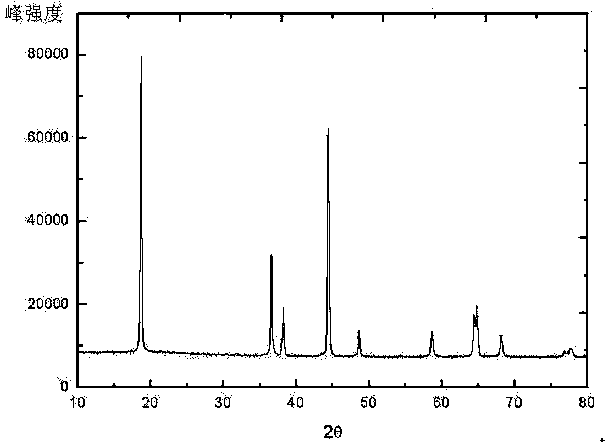

Lithium battery positive electrode material and preparation method thereof

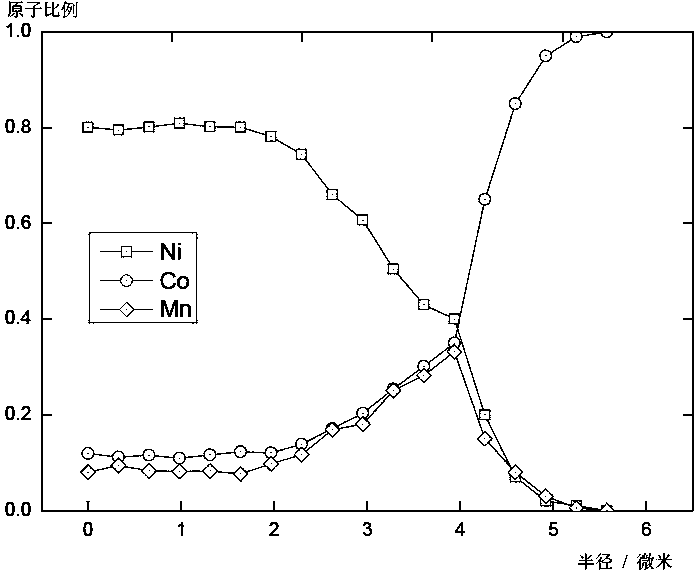

InactiveCN103904318AIncrease capacityImprove thermal stabilityCell electrodesSecondary cellsPrecipitationChemistry

The invention provides a lithium battery positive electrode material and a preparation method thereof. The preparation method of the lithium battery positive electrode material comprises the following steps: S1. pumping a solution A and an alkali solution into a reaction vessel at a constant speed to carry out co-precipitation reaction; S2. pumping a solution B into the solution A at the constant speed while performing the step S1, and drying after the reaction is ended to obtain a precursor; S3. mixing and firing the precursor with lithium salt. In the solution A, a mole ratio of Ni to Co to Mn is (1-2x):x:x, and x is greater than 0 and less than or equal to 0.25. In the solution B, a mole ratio of Ni to Co to Mn is (1-2y):y:y, and y is greater than or equal to 0.25 and less than 0.5; the solution A is different from the solution B; the alkali solution is an aqueous solution which contains a precipitating agent and a complexing agent; the precipitating agent is selected from one or more of water-soluble hydroxides; the complexing agent is ammonia water. The lithium battery positive electrode material has the advantages of high capacity, high heat stability, high cycle performance, high electrochemical performance and low cost.

Owner:HUIZHOU BYD BATTERY

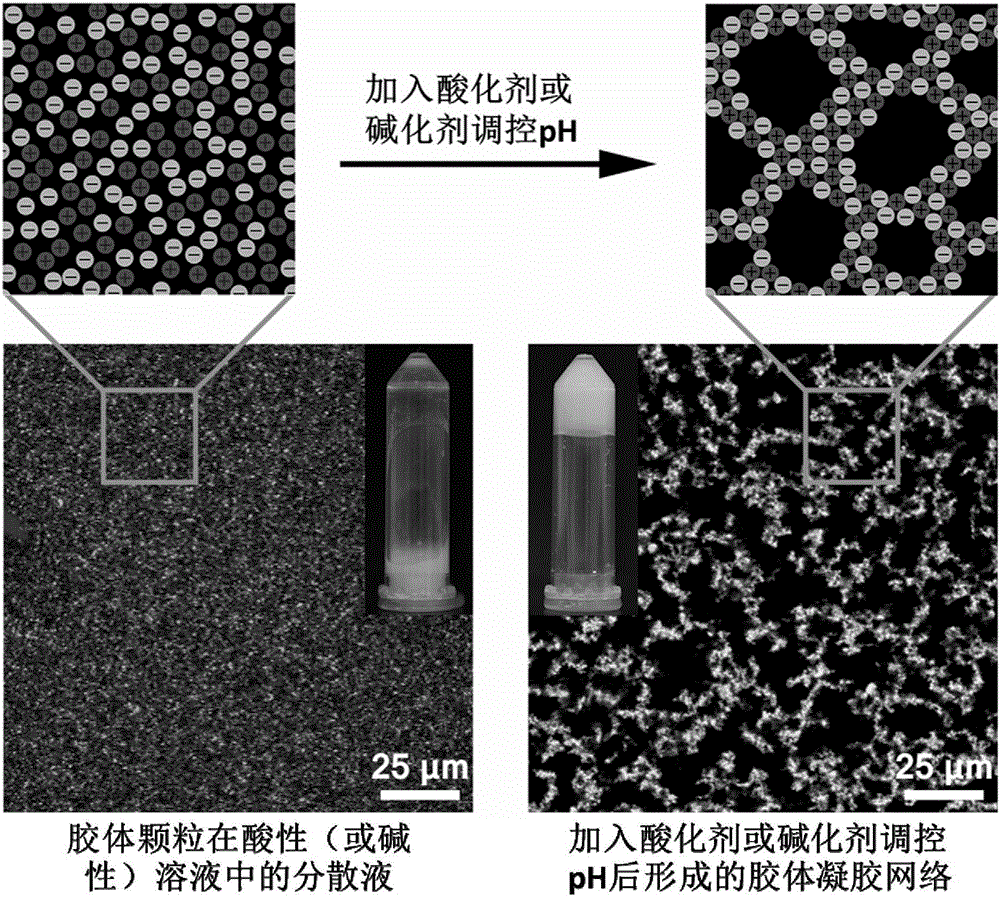

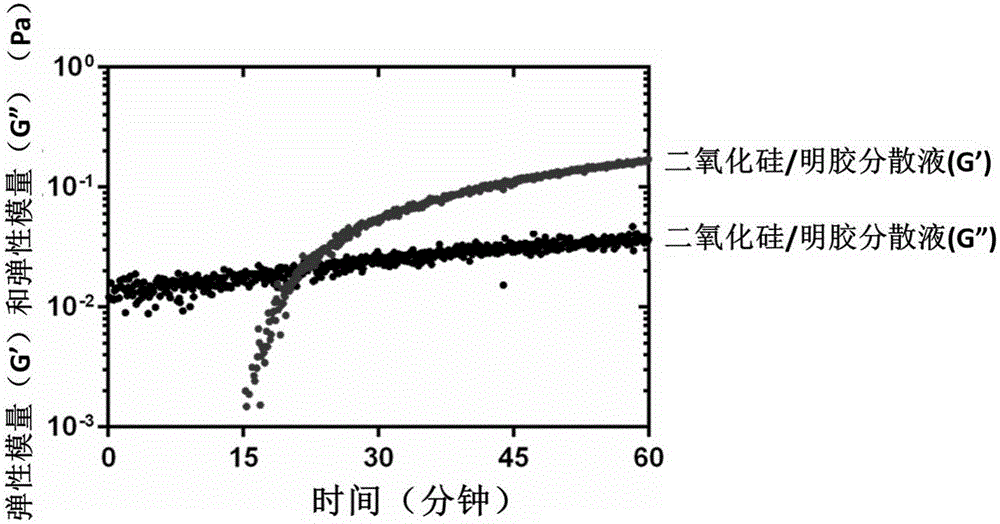

Nanometer colloid particle-assembled high-strength self-repairing injectable composite colloid gel material and preparation method and application thereof

InactiveCN105796478AHigh strengthImprove self-healing abilityAerosol deliveryInorganic non-active ingredientsBiological materialsSilicon dioxide

The invention discloses a nanometer colloid particle-assembled high-strength self-repairing injectable composite colloid gel material and a preparation method and application thereof. According to the preparation method, two-phase colloid particles with opposite electric charges are uniformly blended in an alkaline or acidic environment, an acidifying agent or alkalizing agent is added to induce the pH of the solution to recover the neutrality, electrostatic self-assembly among the two-phase colloid particles is initiated, and a uniformly-dispersed composite gel network is formed, wherein the gel is high in mechanical strength and wide in regulation and control range, the elasticity modulus of the gel can be regulated and controlled within the range of 10 Pa-100 kPa, and the self-repairing efficiency of the gel is higher than or equal to 100%. The silicon dioxide-gelatin composite colloid gel which has both the high mechanical strength and the self-repairing performance is finally and successfully prepared, and it is verified that the composite gel still can quickly recover the mechanical strength after being broken by shear force many times; in addition, the composite gel has the excellent injectable property and plasticity and can be used for an in-vitro cell culture matrix material by serving as an injectable biological material.

Owner:SHENZHEN HUA NOVA BIOTECH LTD

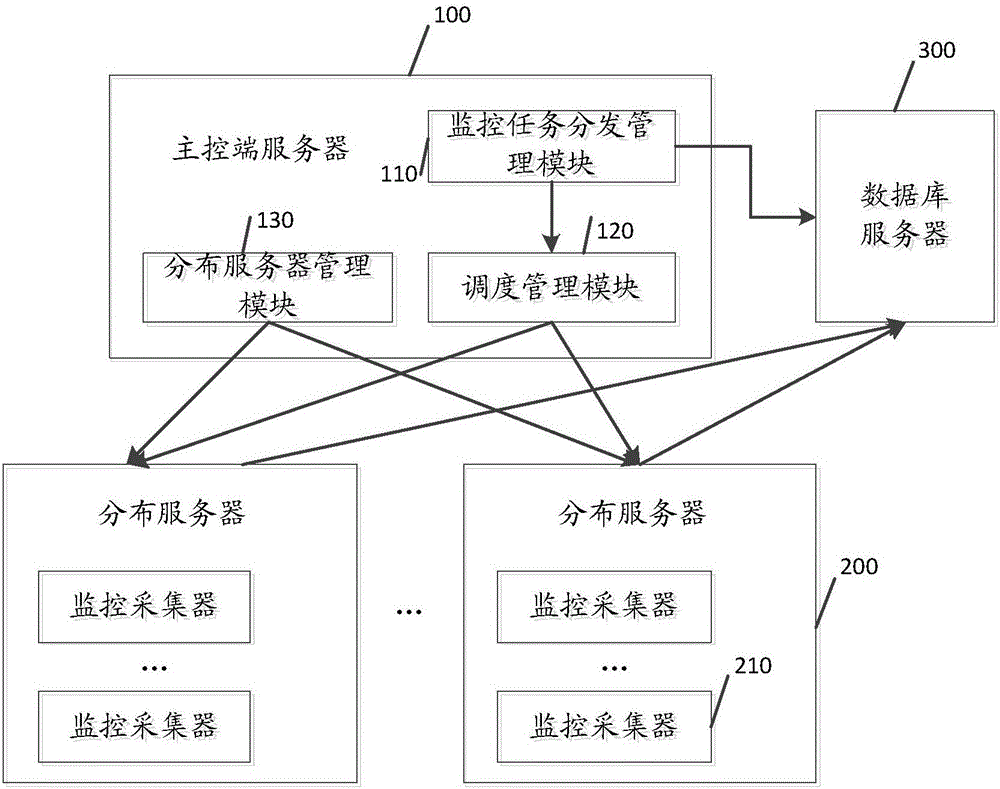

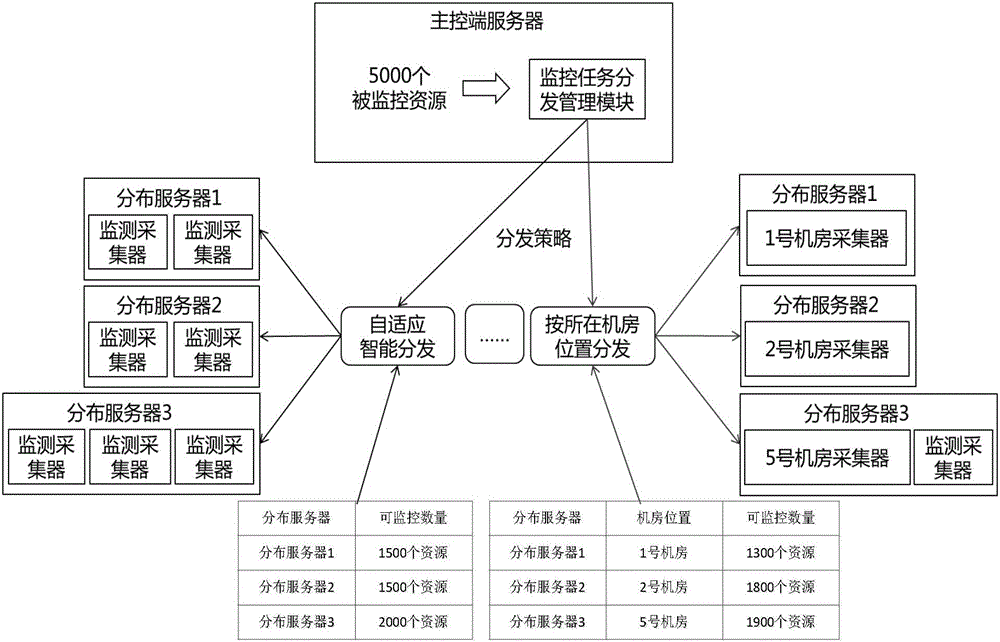

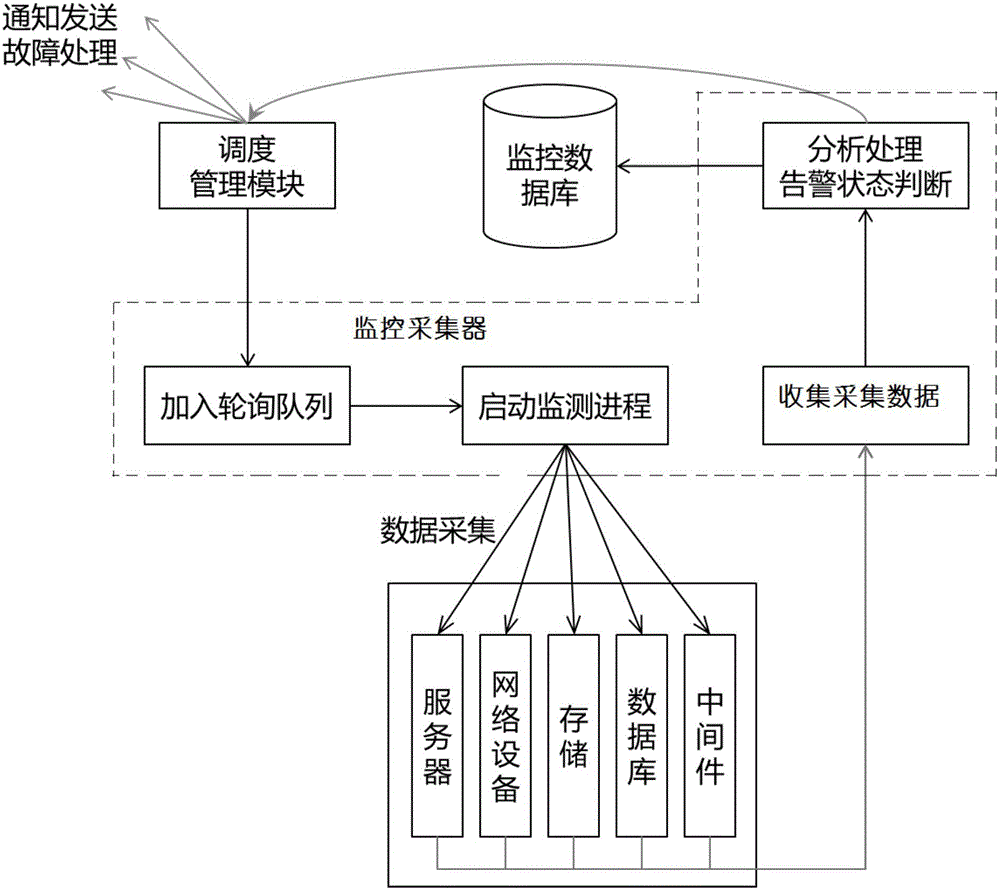

Data center monitoring system and method

InactiveCN106209482AGuaranteed uniform deploymentGuarantee managementData switching networksTerminal serverData center

The invention discloses a data center monitoring system and method. The system comprises a master control terminal server, wherein the master control terminal server comprises a monitoring task distribution management module which is used for distributing a monitoring task to a corresponding distribution server according to a selected monitoring task distribution strategy; a scheduling management module used for allocating the monitoring task to a monitoring collector of the corresponding distribution server, and processing received monitoring data; a distribution server management module used for supervising each distribution server through heartbeat connection; the distribution server comprises the monitoring collector, which adds the received monitoring task in a polling queue, orderly starts the monitoring process of the corresponding monitoring task to perform data acquisition in sequence, performs analysis and process and alarm status judgment on the data to obtain the monitoring data, and transmits the monitoring data to a database server and the scheduling management module; and the database server receives data transmitted by the monitoring collector. Therefore, the data center monitoring system provided by the invention improves the monitorable capacity of large-scale data center monitoring, and guarantees the allocation and management of the distribution server.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

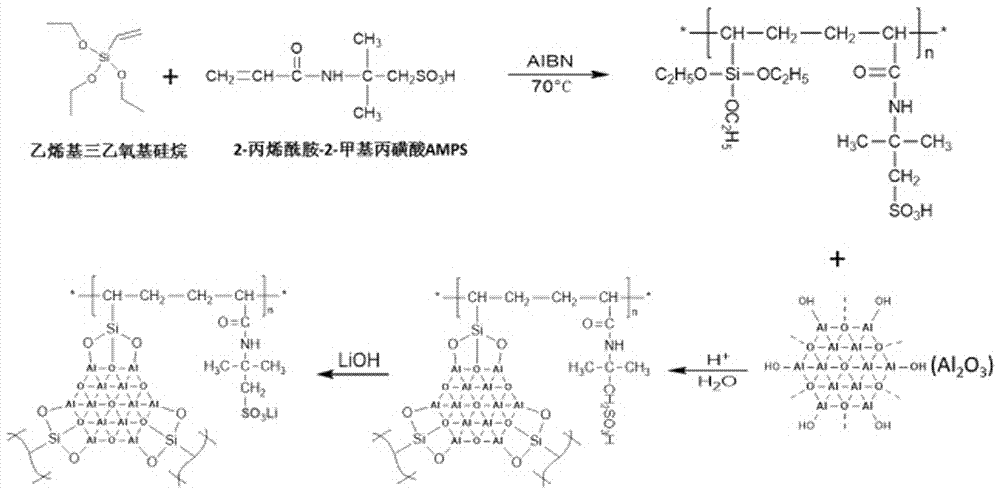

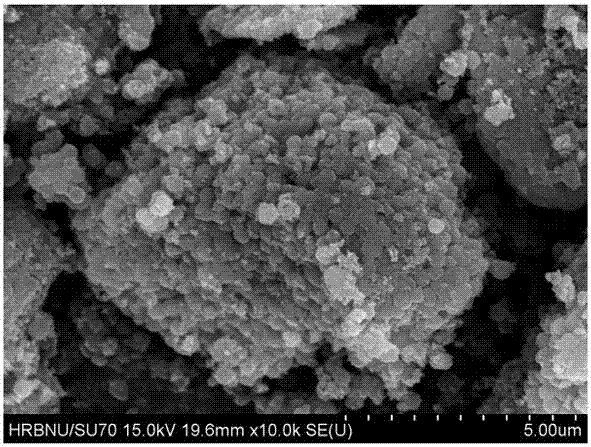

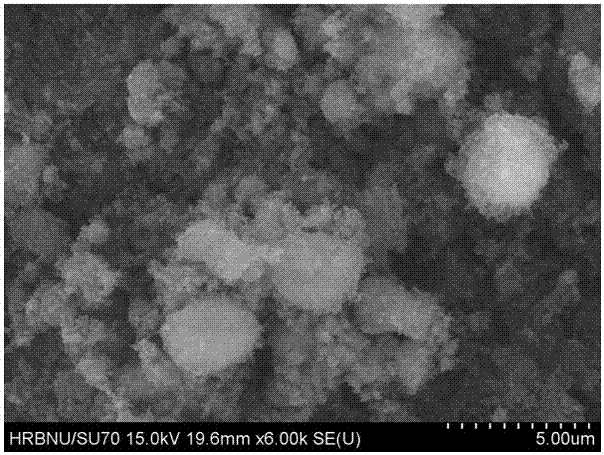

Surface-modified inorganic nanoparticles as well as preparation method and application thereof

ActiveCN107134590AGood dispersionEvenly dispersedMaterial nanotechnologySolid electrolytesDispersityMetal oxide nanoparticles

The invention discloses surface-modified inorganic nanoparticles as well as a preparation method and application thereof. The surface-modified inorganic nanoparticles are composed of a core of inorganic metal oxide nanoparticles and amphipathic organic segments grafted on the surface of the particles, wherein the amphipathic organic segments grafted on the surface of the particles account for 0.1-50% of total mass of the surface-modified inorganic nanoparticles; the inorganic metal oxide nanoparticles refer to one or several in aluminum oxide, silicon dioxide, titanium dioxide, zirconium dioxide and zinc oxide inorganic nanoparticles; and the amphipathic organic segments are produced from a vinyl silicane coupling agent and 2-acrylamido--methylpropane sulfonic acid through solution polymerization. The surface-modified inorganic nanoparticles can be used for preparing polymer electrolyte. Therefore, the inorganic nanoparticles are high in dispersity in a polymer matrix, and the prepared polymer electrolyte is high in lyotropic property, high in ionic conductivity and stable in electrochemical performance.

Owner:浙江久功新能源科技有限公司

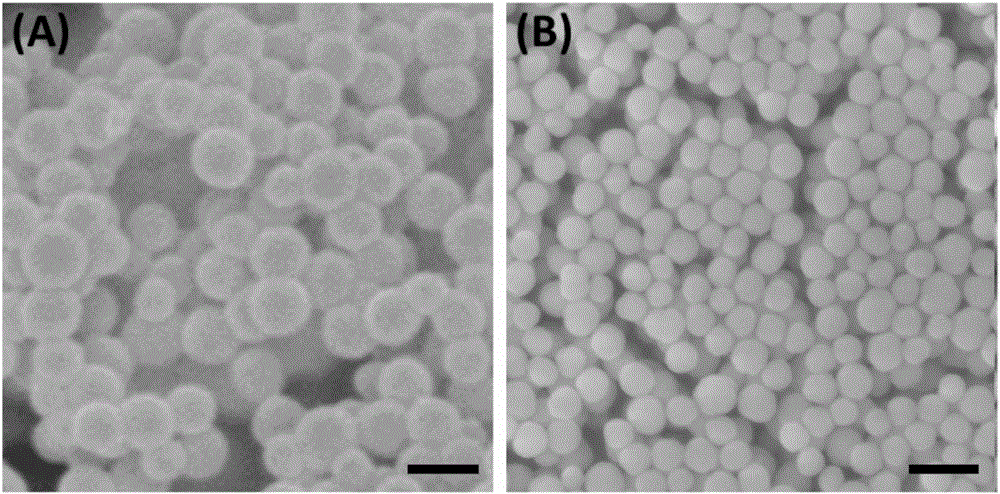

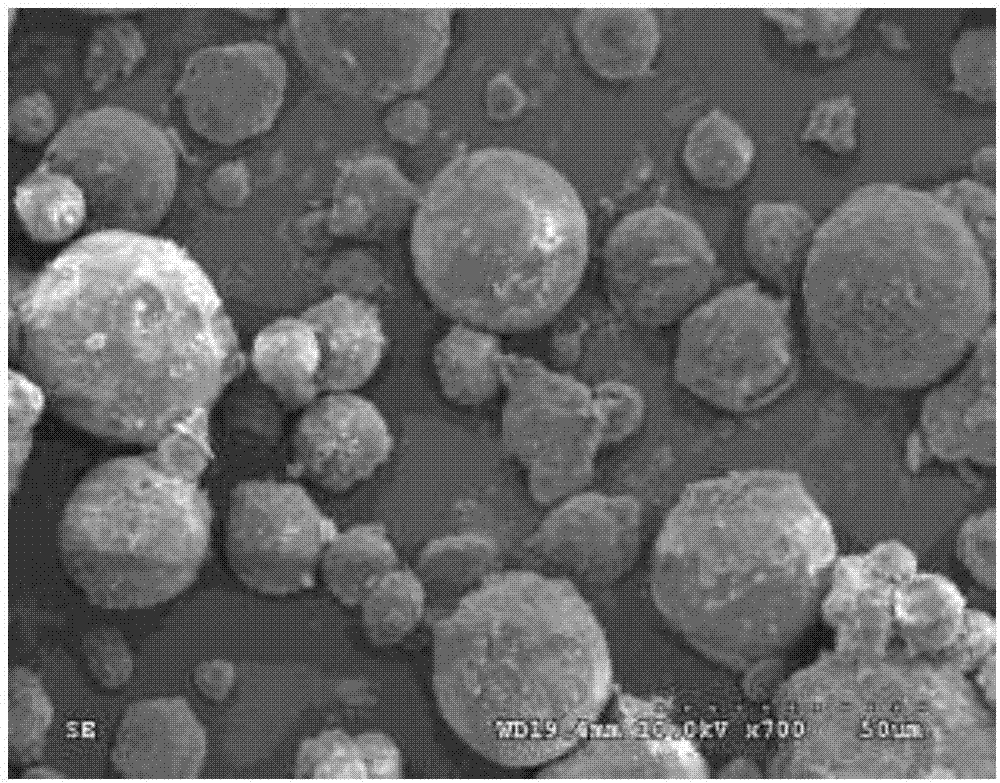

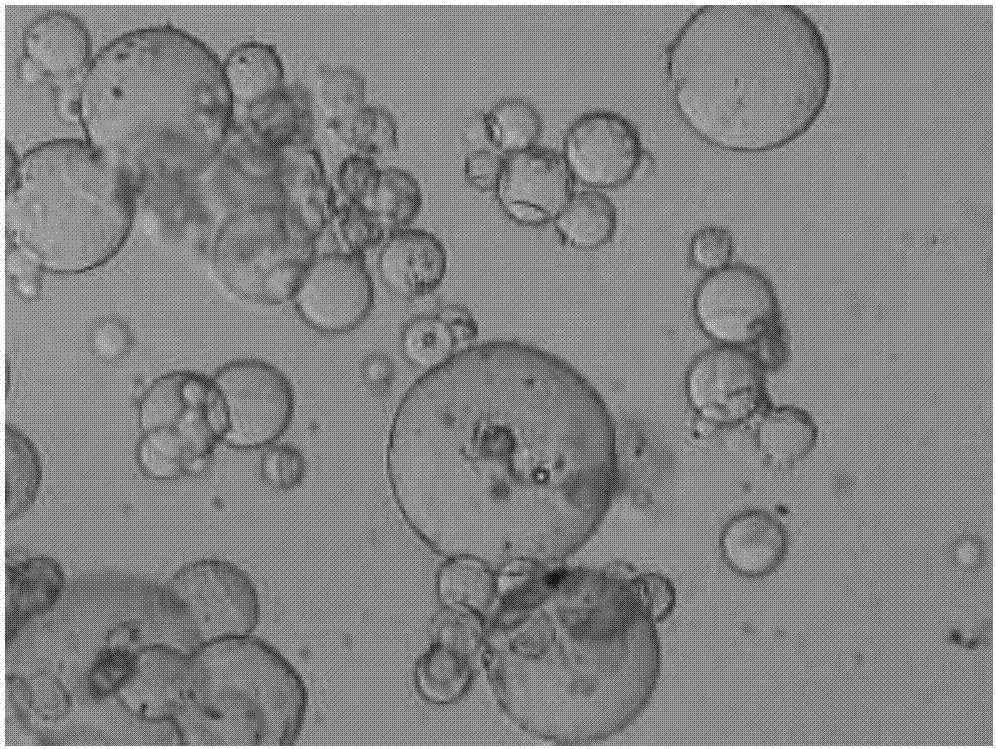

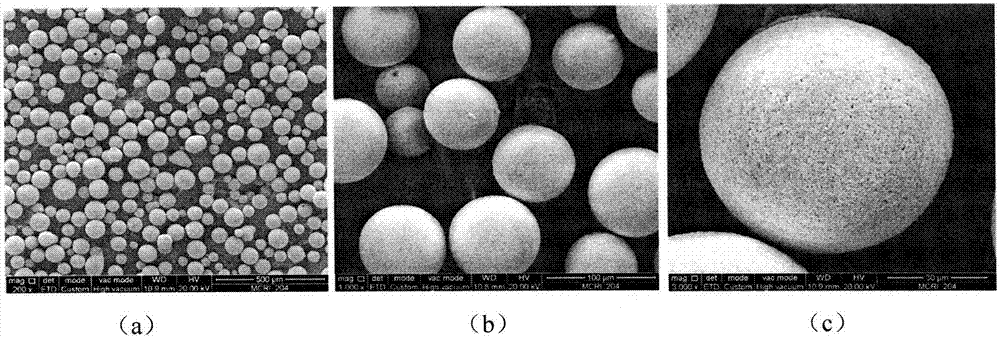

Preparation method of polyvinyl alcohol/hydroxyapatite (PVA/HA) composite microspheres

InactiveCN107376795AGood dispersionUniform internal structureCosmetic preparationsOther chemical processesFood additiveMicrosphere

A preparation method of polyvinyl alcohol / hydroxyapatite (PVA / HA) composite microspheres belongs to preparation methods of composite water-in-oil emulsion system microspheres. PVA and HA precursors are used as raw materials to prepare a clear and transparent mixed solution; the clear and transparent mixed solution is dispersed into an oil phase containing a surfactant to form a homogeneous water-in-oil microemulsion; and the PVA / HA composite microspheres can be finally obtained by successive crosslinking reaction under acid-catalyzed conditions, HA deposition under alkaline conditions, product centrifugation, washing, drying and other processes. The method has the advantages of simple process, good repeatability, low energy consumption and low cost, and effectively solves the problems that inorganic nanoparticles are easy to agglomerate in the microspheres to cause uneven structures and poor comprehensive performances and the like. The composite microspheres prepared by the method have the advantages of regular morphology, high dispersibility, uniform microstructure, good biocompatibility, biological activity and adsorption performance, and can be used as drug carrier materials, bone repair materials, environmental water treatment materials, cosmetics or food additives and the like.

Owner:CHINA UNIV OF MINING & TECH

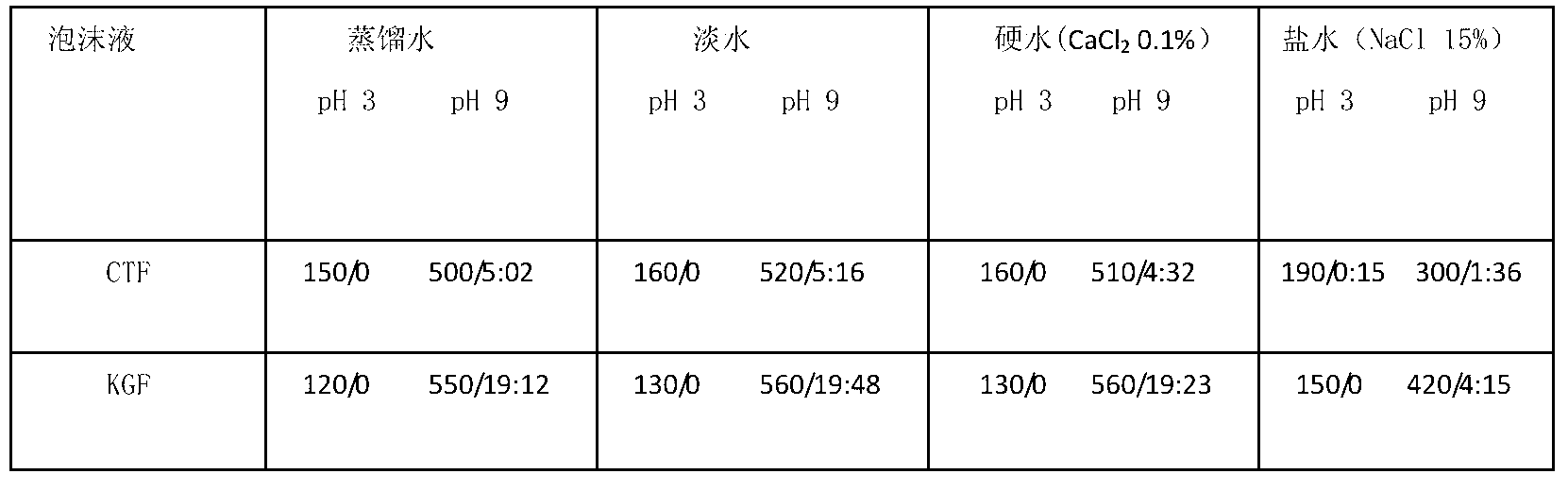

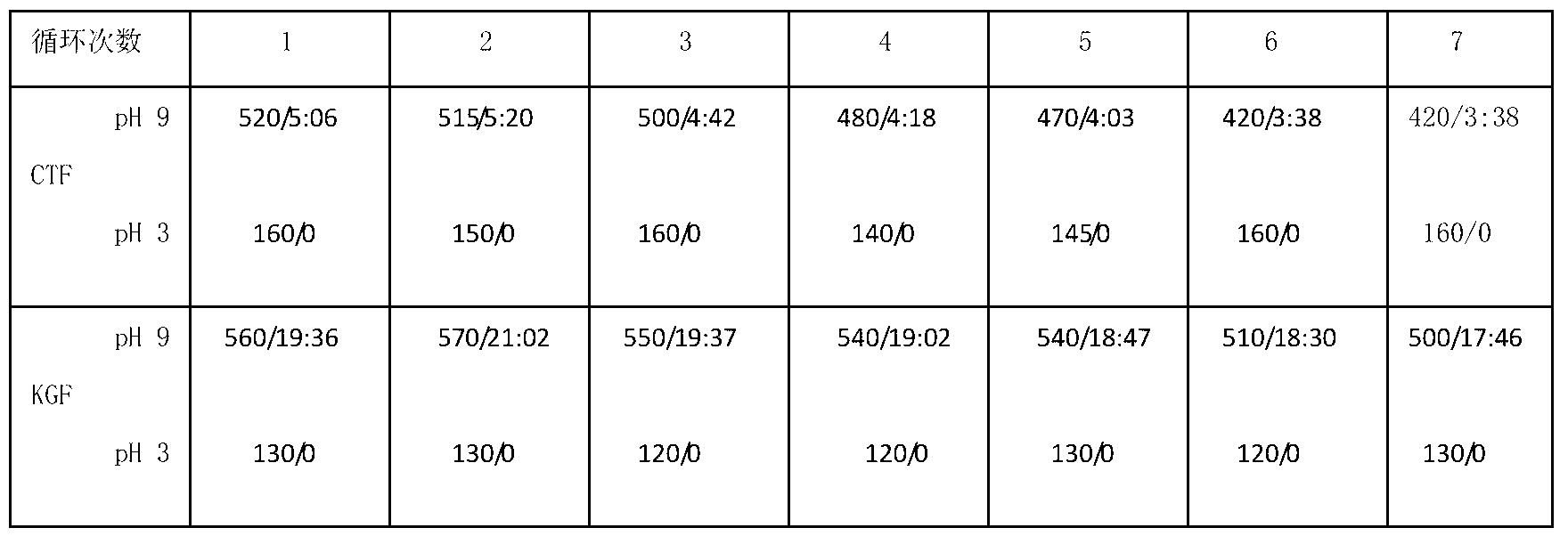

Switchable foaming solution for foam drilling and well cleanup on oil and gas field

The invention discloses an acid / alkali switchable foaming solution for foam drilling and well cleanup on an oil and gas field, which is prepared by complexing natural nonionic surfactant and anionic surfactant. When the pH value of the solution is higher than 8, stable and abundant foam is generated to take out drill cuttings and other particulate matters from the bottom of a well; when acid is added at a well mouth under the condition of stirring to ensure that the pH value of the solution is lower than 4, the solution is defoamed to become a water solution, and solid particles are separated out; and when the pH value of the separated solution is regulated to 8 or above with alkali, the solution reverts to a foaming solution having favorable property and can be injected to the bottom of the well to foam. Such cycle can be repeated multiple times. Thus, the invention lowers the use cost of chemical agents, saves water and solves the problems such as high separation difficulty, environment pollution and the like.

Owner:SOUTHWEST PETROLEUM UNIV

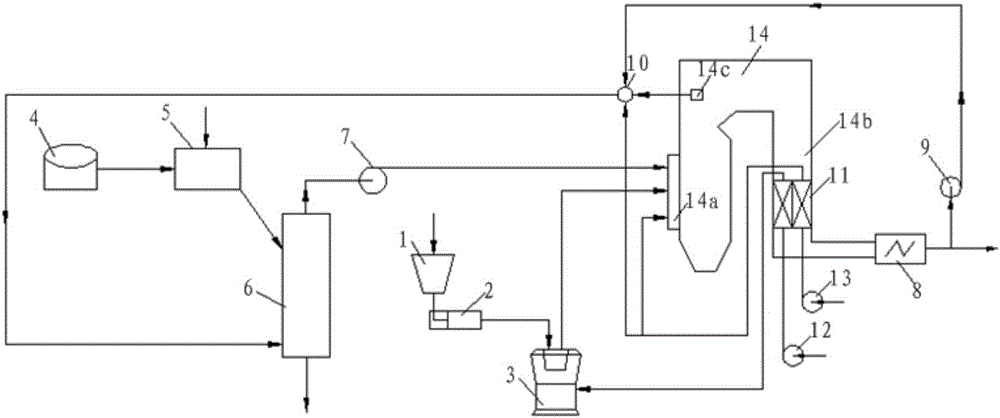

Coal and household garbage coupled combustion system

InactiveCN106247342ALarge amount of processingSimple processCombustion using gaseous and pulverulent fuelIncinerator apparatusCombustion systemSludge

A coal and household garbage coupled combustion system comprises a coal mill, a garbage storage pit, a feeder, a gasification furnace and a synthesis gas booster fan, wherein a discharge port of the coal mill is connected with a combustor of a pulverized coal boiler; the garbage storage pit is connected with a feed port of the gasification furnace via the feeder; and a discharge port of the gasification furnace is connected with the combustor of the pulverized coal boiler via the synthesis gas booster fan. The system achieves organic combining of fire coal power generation, sludge drying and combustion and has the advantages of large handling capacity, concise flow and good airtightness.

Owner:上海垒锦环境科技中心

Method for manufacturing high-grade artificial rutile by ilmenite concentrate

The invention relates to a preparation method of high-grade synthetic rutile by using ilmenite concentrate. The technological procedure is as followings in sequence: firstly, a ball milling is activated; the mechanical ball milling is implemented to the ilmenite concentrate with a ball mill so as to activate the ilmenite concentrate; secondly, atmospheric pressure leaching; with a ratio ranging from 1:3 to 1:5 in volume, the ilmenite concentrate and the hydrochloric acid solution are heated to 90 to 105 DEG C in atmospheric pressure to carry out the leaching reaction for 4 to 6 hours, thereby a front body of the synthetic rutile is obtained; thirdly, solid-liquid separation, after the reaction is completed, the ground paste is cooled down to 30 DEG C to 50 DEG C, and then the front body of the synthetic rutile is separated from the mother solution by adopting a vacuum filtration, the separated mother solution can be prepared into revival hydrochloric acid and cycled to be used in atmospheric pressure leaching procedures; fourthly, washing, drying and calcining; the front body of the separated synthetic rutile is washed and dried, and then is calcined for 2 to 4 hours at a temperature of 800 DEG C to 1000 DEG C, thereby the powder synthetic rutile is obtained.

Owner:SICHUAN UNIV

Lithium battery cathode material and preparation method thereof

ActiveCN104347866AIncrease capacityImprove cycle performanceCell electrodesSecondary cellsCobalt saltCoprecipitation

The invention provides a lithium battery cathode material and a preparation method thereof. The preparation method comprises the following steps: S1, performing coprecipitation reaction on a solution A and an alkali solution for 5-25 h; S2, pumping a solution B into the solution A at a constant speed, and continuing to perform coprecipitation reaction on the whole mixed solution and the alkali solution when the solution B is pumped; S3, continuing to perform coprecipitation reaction on a solution C and the alkali solution, and drying the obtained precursor after the reaction is terminated; and S4, mixing the precursor with a lithium salt, and sintering to obtain the lithium battery cathode material. The molar ratio of Ni, Co and Mn in the solution A is equal to (1-2x):x:x, and 0<x<=0.25; the molar ratio of Ni, Co and Mn in the solution B is equal to (1-2y):y:y, and 0.25<=y<0.5; and the solution C is an aqueous solution of a cobalt salt. The provided lithium battery cathode material has the advantages of high capacity, high heat stability, high cycle performance, high electrochemical performance and low cost, and has the first efficiency up to 92% or more.

Owner:BYD CO LTD

Attapulgite-graphite-like carbon nitride composite ceramic microfiltration membrane with photocatalytic performance and preparation method and application thereof

ActiveCN107008152AHas photocatalytic propertiesHigh selectivityMembranesUltrafiltrationPorosityChemical Linkage

The invention relates to an attapulgite-graphite-like carbon nitride composite ceramic microfiltration membrane with photocatalytic performance and a preparation method thereof and belongs to the field of ceramic membranes. The method comprises the steps of preparing casting solution slurry from titanate coupling agent modified attapulgite and melamine; and preparing a wet membrane of the ceramic microfiltration membrane through a dip-coating method, airing at a room temperature and roasting to prepare the attapulgite-graphite-like carbon nitride composite ceramic microfiltration membrane. A separation layer of the ceramic microfiltration membrane is prepared from attapulgite fibers and graphite-like carbon nitride and the attapulgite fibers are disorderly stacked into the separation layer, so that relatively large total porosity and superficial area are provided for the separation layer; coupling of photocatalysis and separation processes can be achieved by using the photocatalytic performance of the graphite-like carbon nitride, and self-cleaning of the membrane is achieved; and the graphite-like carbon nitride is uniformly and dispersedly immobilized on the surface of attapulgite of the membrane through the chemical bonding effect, so that the disadvantages that granular graphite-like carbon nitride is easy to aggregate, difficult to separate and difficult to reuse in the using process are effectively avoided.

Owner:HUAIYIN TEACHERS COLLEGE

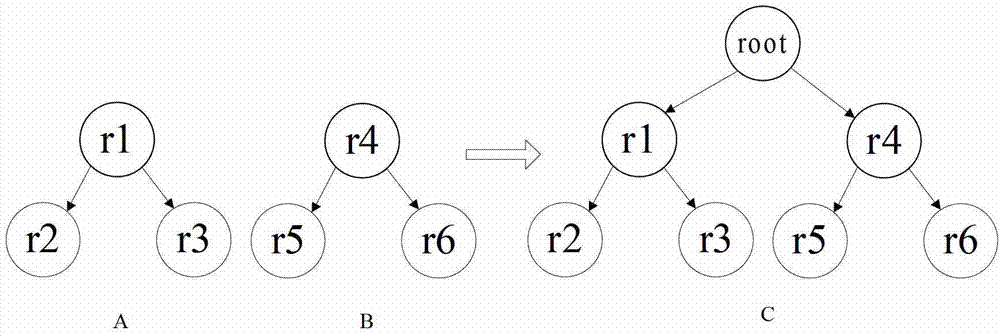

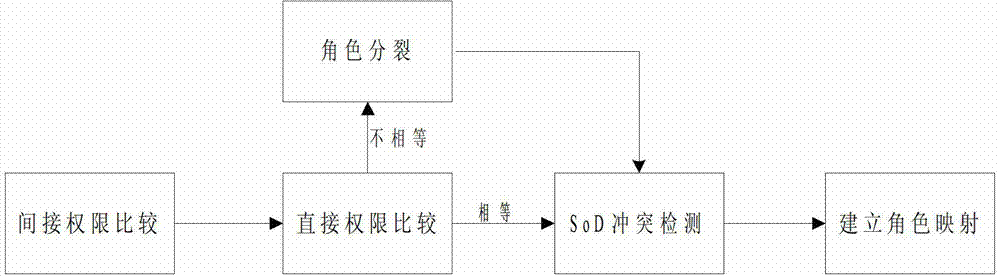

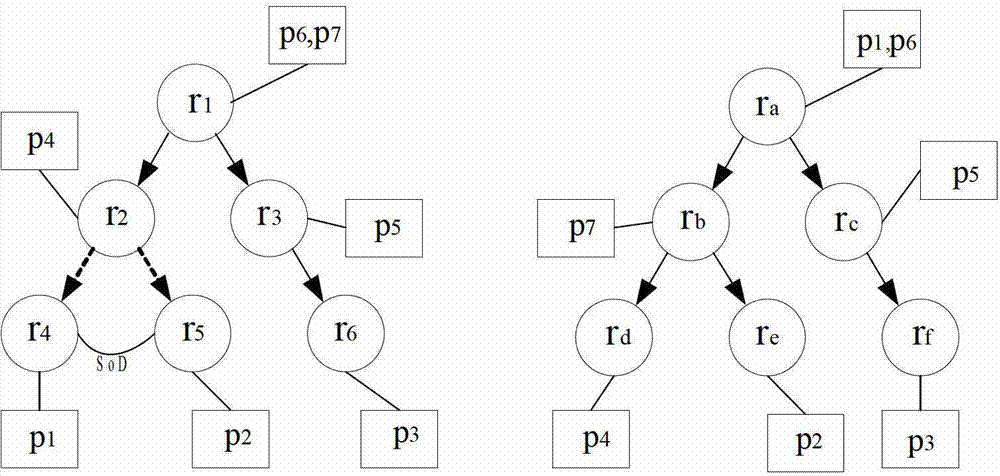

Multi-domain RBAC (Role-Based Access Control) model-based access control policy composition method

A multi-domain RBAC model-based access control policy composition method includes the following steps: tree merge is carried out in a single domain, indirect permission sets of roles, i.e. A inherited permission set and I inherited permission set, are then calculated, finally, the permission sets of the inter-domain rolles are recursively compared, the roles to be divided are determined, inter-domain role mapping is established, and a global access policy is generated. The multi-domain RBAC model-based access control policy composition method inputs the RBAC policies of multiple domains to be composed as a method, establishes inter-domain role mapping sets according to the role permission assignment relations, the role hierarchies and the inter-role SOD (Separation of Duties) constraints in the original domains, and generates and outputs a global access control policy.

Owner:SHANGHAI JIAO TONG UNIV

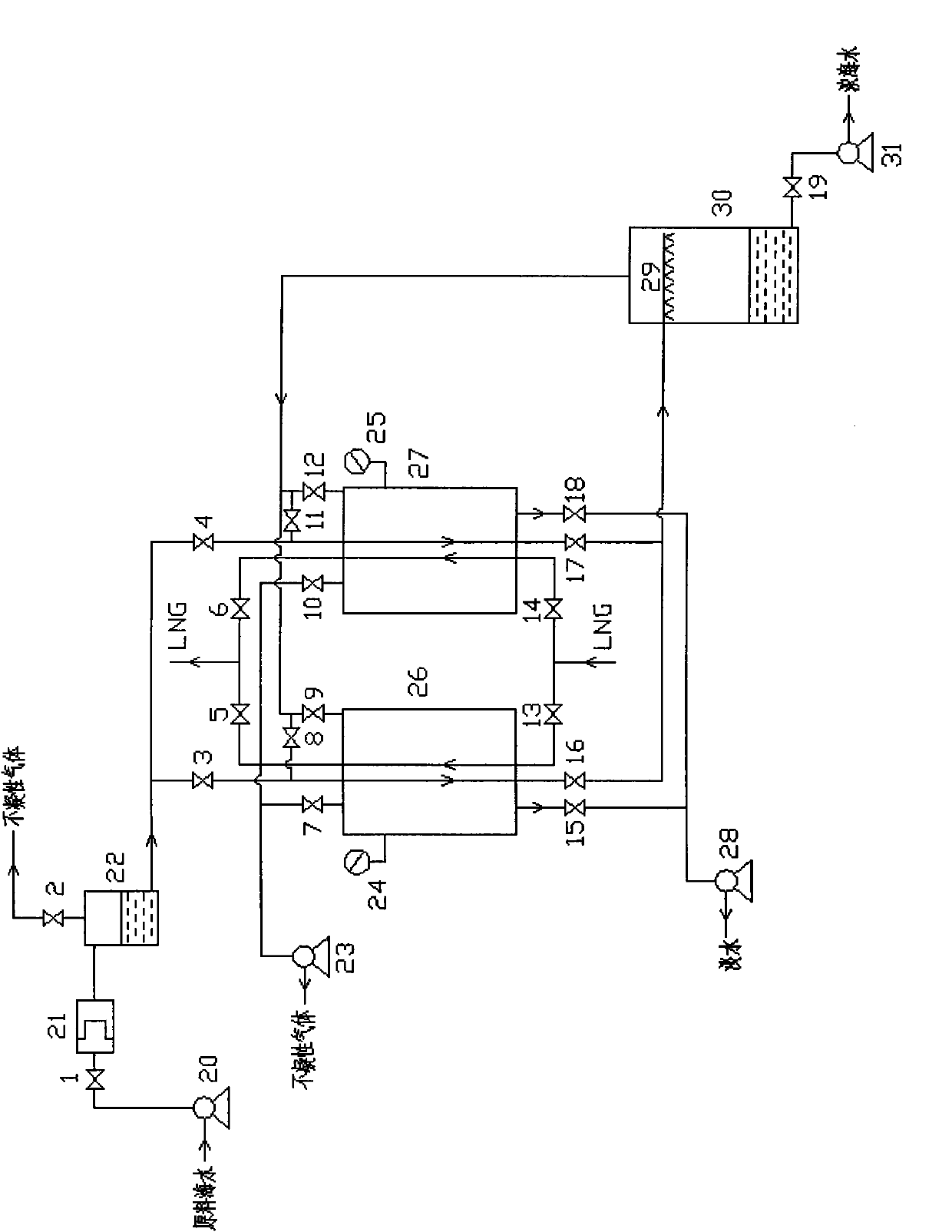

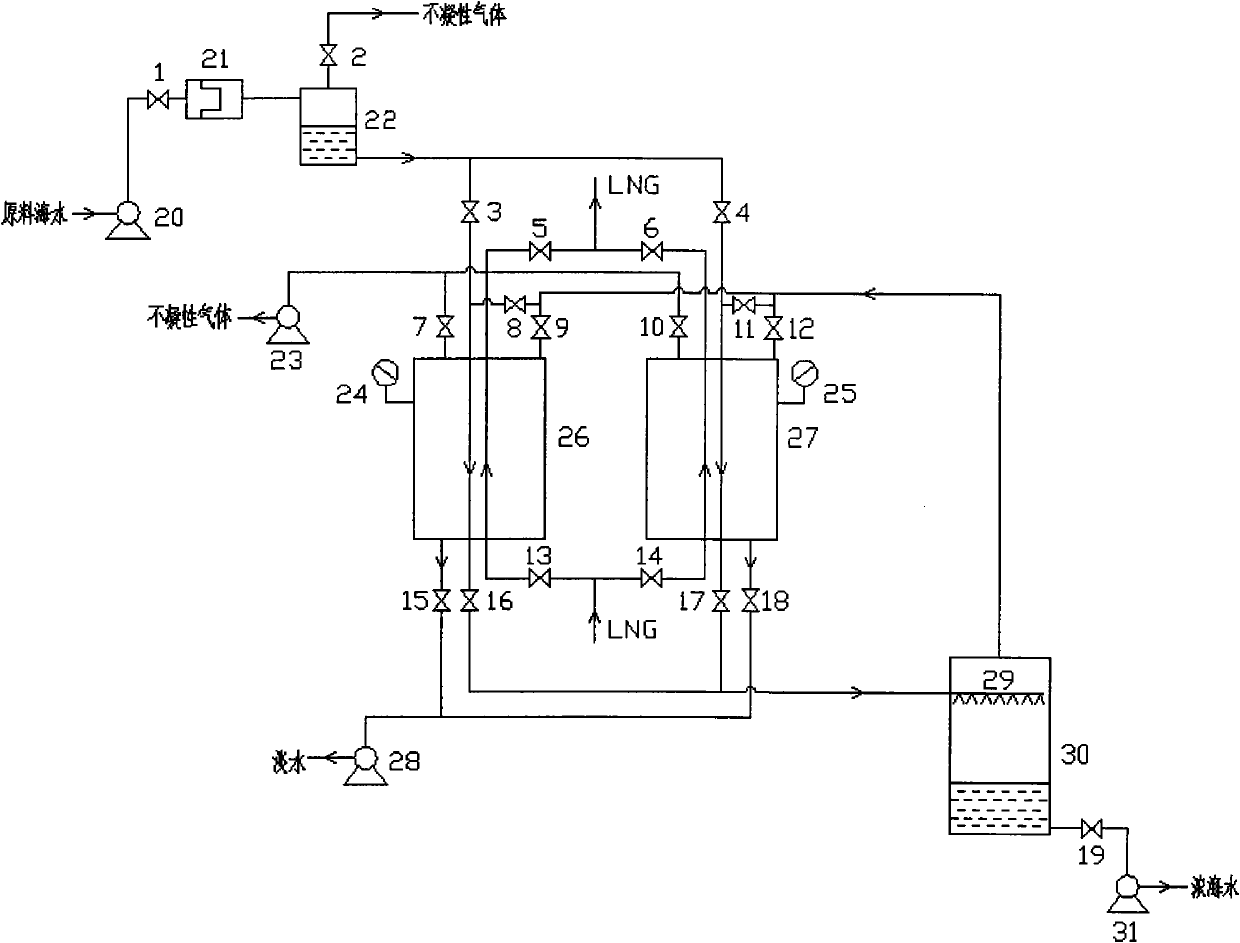

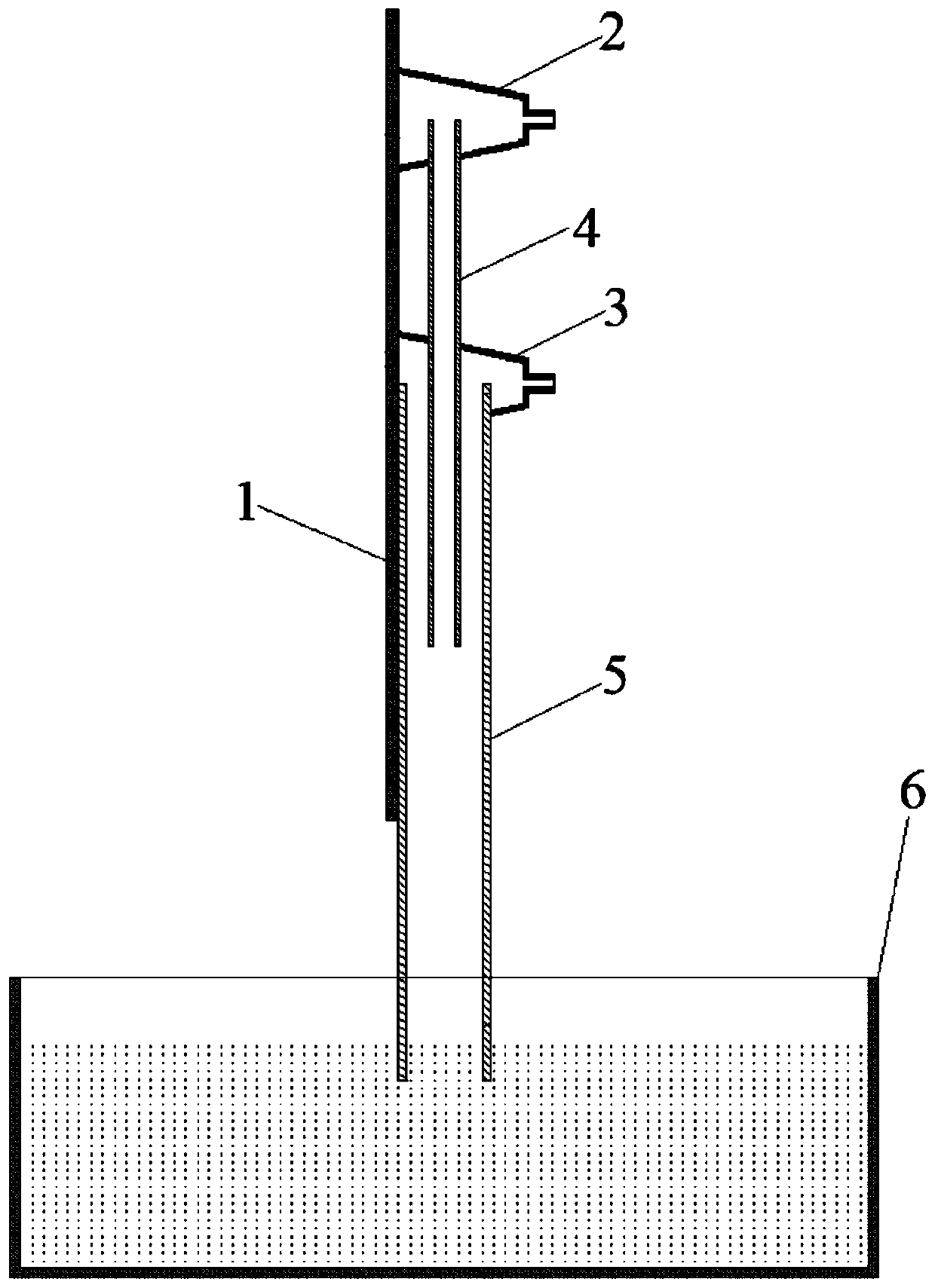

Device and method for desalting seawater by using cold energy of liquefied natural gas

InactiveCN101792193AAvoid Ice WashesAvoid separabilityGeneral water supply conservationDomestic cooling apparatusSeawaterLiquefied natural gas

The invention discloses a device and a method for desalting seawater by using cold energy of liquefied natural gas. The method promotes the seawater to gasify and solid in a crystallizer by using the balance pressure difference of vapor between a low temperature and room temperature so that the aim of desalting the seawater by using the cold energy of the liquefied natural gas is fulfilled. The device mainly comprises a water pump, a filter, a degassing tower, a vaporizer, the crystallizer and the vacuum pump. The device and the method are mainly characterized in that: the cold energy recovery of the liquefied natural gas and the seawater desalination are combined and the seawater is gasified at a temperature a little lower than the room temperature by using the low-temperature cold energy of the liquefied natural gas so as to realize the seawater desalination. The device and the method overcome the defects of the difficult ice crystal washing and separation and poor desalination effect and the like of the traditional refrigerated seawater desalination method and have the advantages that: the cold energy of the natural gas is rationally utilized, the cost is low, the pollution is little, the raw water is simply preprocessed; and the concentration range is wide, the corrosion on equipment is less, the scale is little, no secondary coolant is required, the fresh water product can meet the state drinking standards by simple treatment and the like.

Owner:ZHEJIANG UNIV

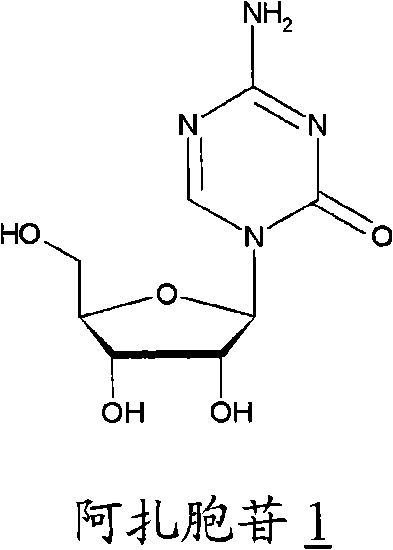

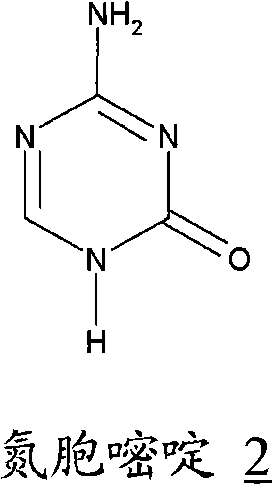

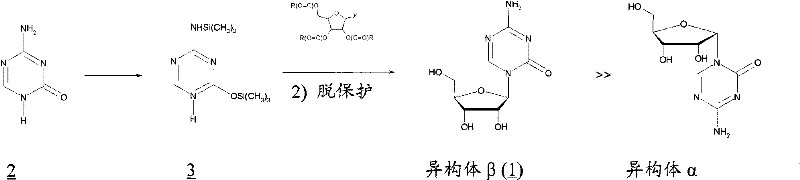

Process for the synthesis of azacitidine and decitabine

ActiveCN102206240AHigh yieldAvoid processing powerGroup 4/14 element organic compoundsSugar derivativesOrganic solventTrimethylsilyl

Described herein is a process for the synthesis of azacitidine or decitabine, comprising the silylation of azacytosine in the presence of N,O-bis-trimethylsilyl)-trifluoroacetamide. Such reaction is performed in an organic solvent, preferably aprotic, even more preferably selected from among dichloromethane, dichloroethane and / or acetonitrile. According to a further aspect of the process, 2 to 3 moles of N,O-bis-trimethylsilyl-trifluoroacetamide are used per mole of azacytosine, preferably from 2.2 to 2.5.

Owner:CHEMI SPA

Silicon carbide composite powder as well as preparation method and application thereof

The invention discloses silicon carbide composite powder as well as a preparation method and application thereof. A granulation method of the silicon carbide composite powder comprises the following steps: (1) uniformly mixing beta-SiC micropowder with water and a dispersing agent in a mass ratio of (0.1-0.2) to 1 to (0.03-0.08), putting the mixture into a sand mill, and carrying out circularly grinding, so as to obtain nano-beta-SiC slurry, wherein the average grain diameter of the beta-SiC micropowder is not more than 1.5 micron; (2) adding micron-scale alpha-SiC and a bonding agent into the nano-beta-SiC slurry, and uniformly stirring, so as to obtain mixed slurry, wherein the mass of micron-scale alpha-SiC is 0.8-0.9 of the mass of the mixed slurry, and the mass of the bonding agent is 0.03-0.05 of the mass of the mixed slurry; and (3) conveying the mixed slurry into a spray granulation machine through a peristaltic pump, so as to obtain silicon carbide composite granulated powder. By introducing nano-scale beta-SiC, the sintering temperature can be decreased, the tenacity and strength of ceramic can be increased, and more importantly, nano-scale beta-SiC can be gradually converted into alpha-SiC in a uniform phase during the sintering, so that the stability of the use performance of the silicon carbide ceramic is not degraded.

Owner:XIAN BOER NEW MATERIAL CO LTD

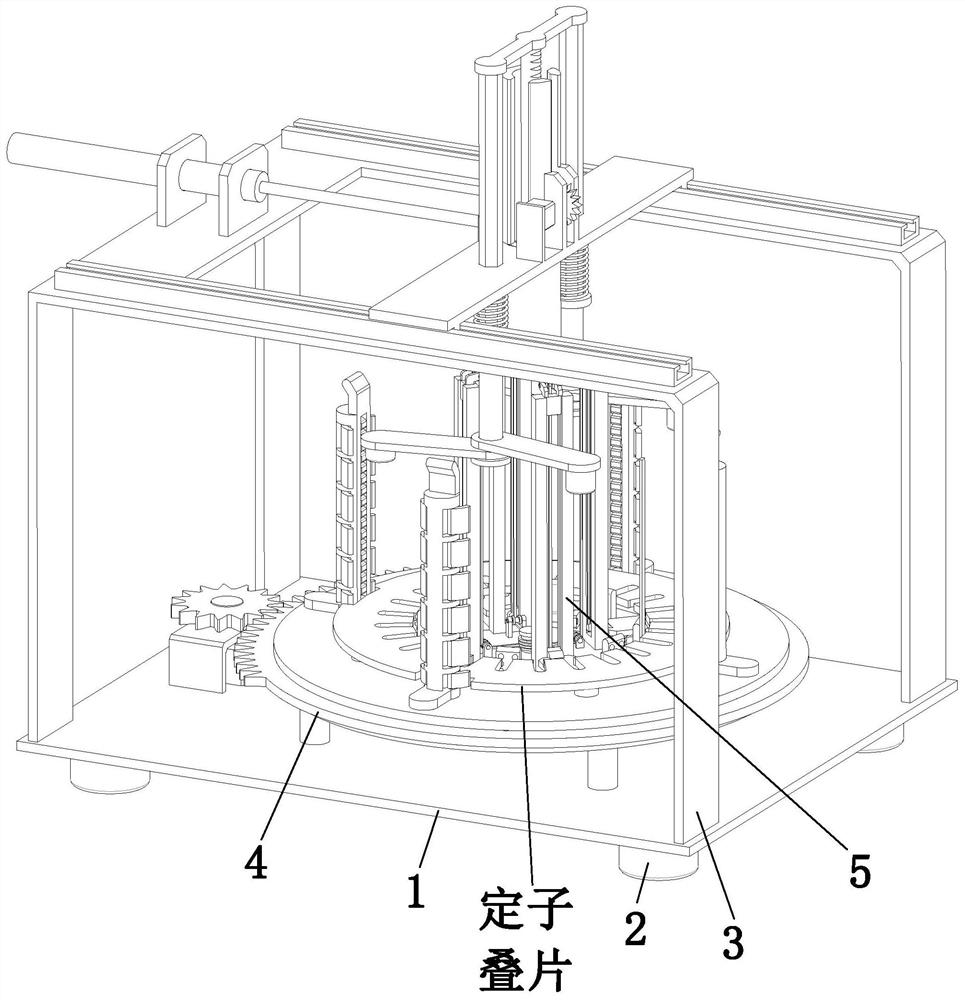

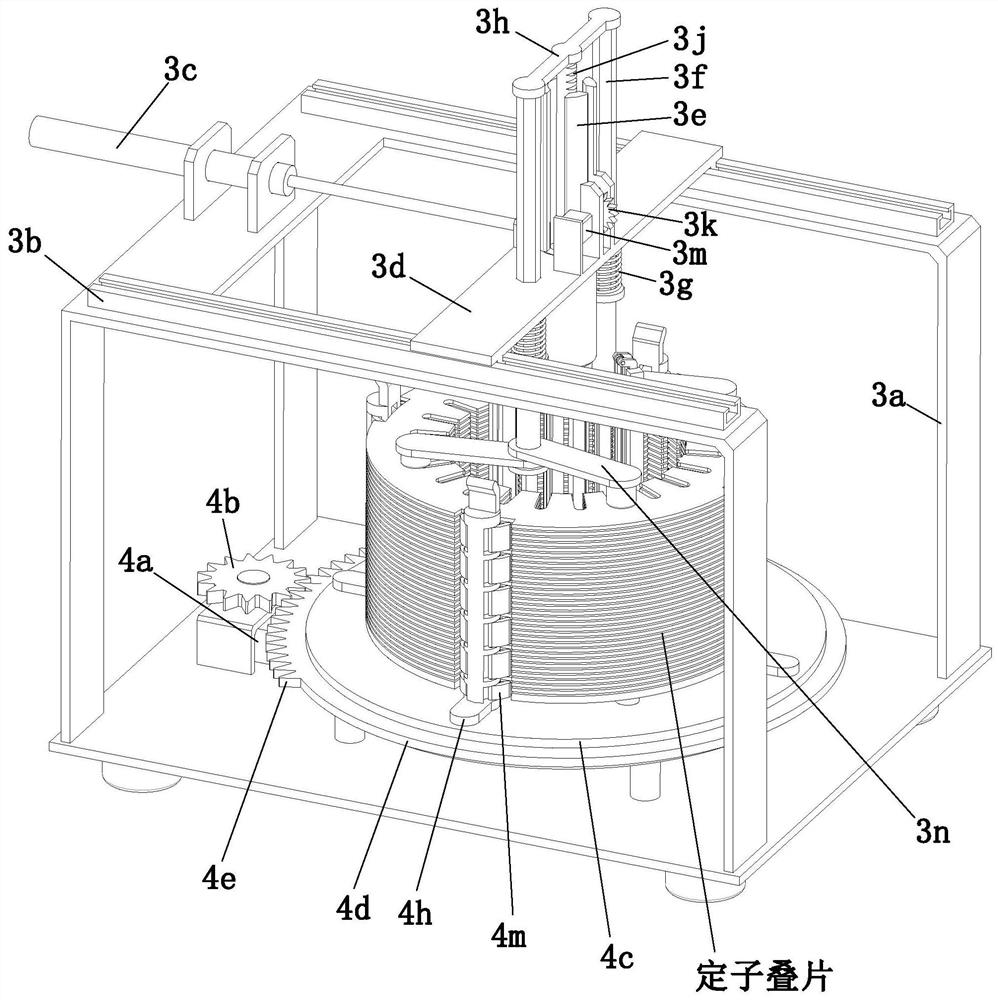

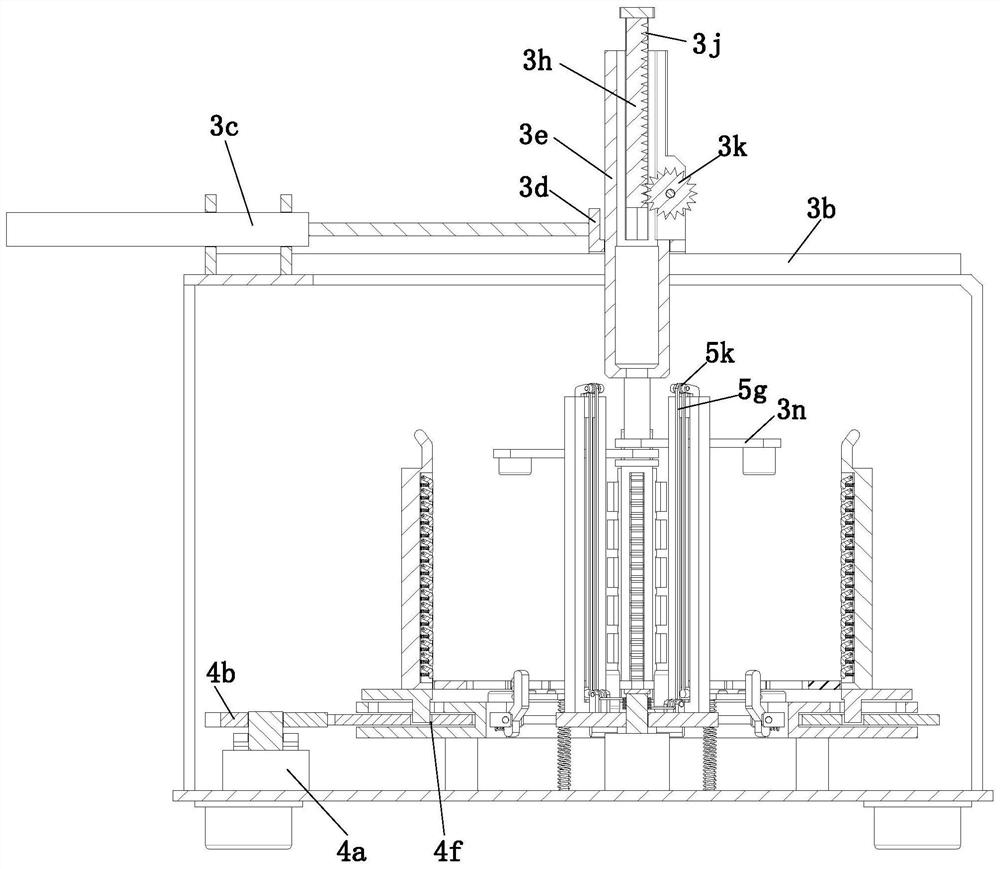

Motor stator punching sheet processing system

ActiveCN113098210AAvoid Rotation SkewImprove accuracyMetal-working feeding devicesManufacturing stator/rotor bodiesPunchingElectric machine

The invention provides a motor stator punching sheet processing system. The system comprises a mounting bottom plate, supporting legs, a positioning mechanism, an assembling mechanism and a supporting mechanism,solves the problem that the inner side and the outer side of a positioning punching sheet are difficult to support and abut synchronously during the lamination operation of the motor stator punching sheet, so that the concentricity of the positioning punching sheet is ensured, but the stator punching sheets which are stacked one by one are difficult to clamp and limit, avoids situations that the stator punching sheets are prevented from rotating and deflecting, the stacked positioning punching sheets are difficult to uniformly and repeatedly extrude, gaps between the motor stator punching sheet laminations are eliminated, and the motor stator punching sheet laminations are difficult to integrally move upwards, and avoids the problems of separation, fault and the like of the motor stator punching sheet lamination in the taking-out process.

Owner:佛山市顺德区致翔金属制品有限公司

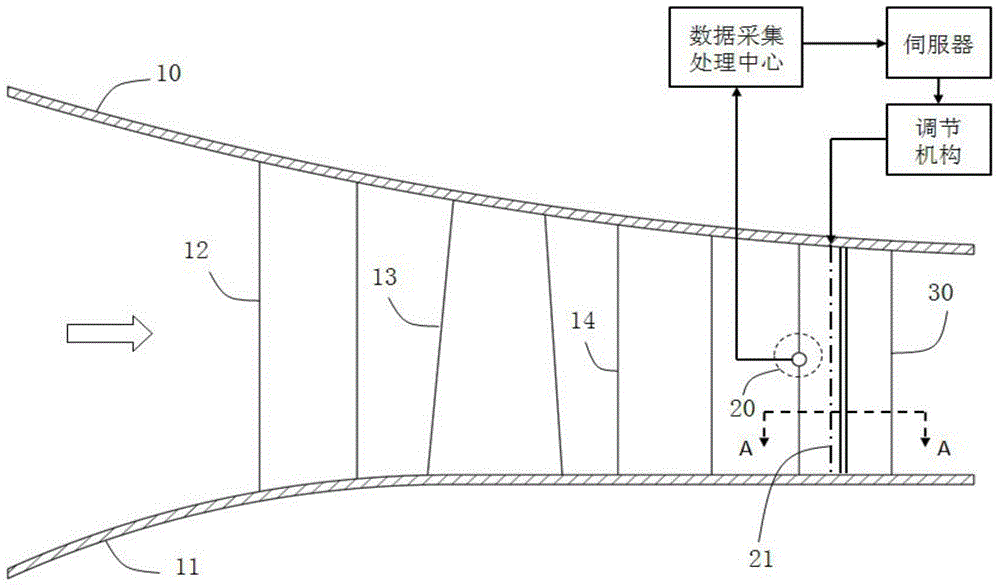

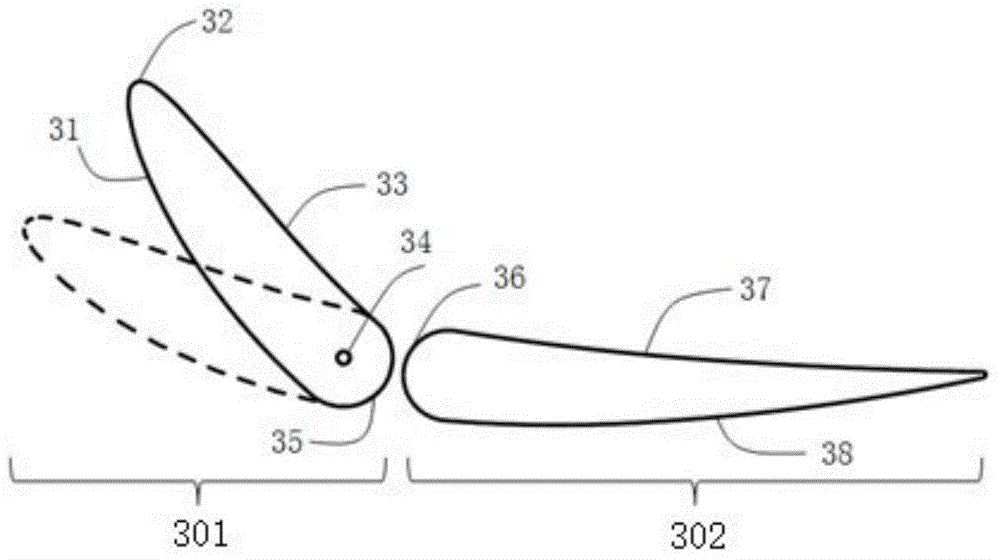

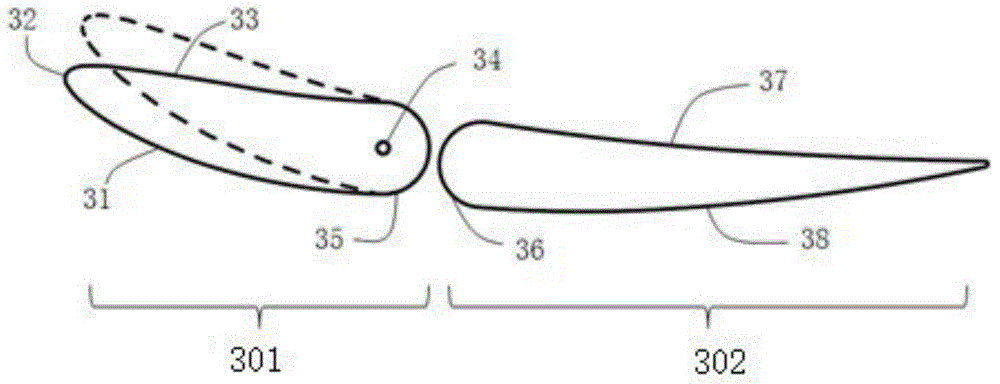

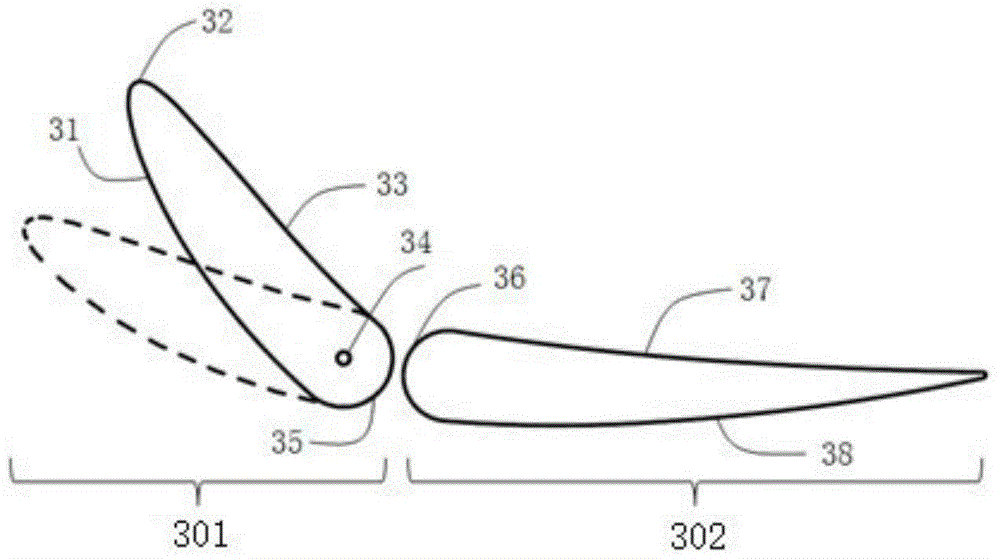

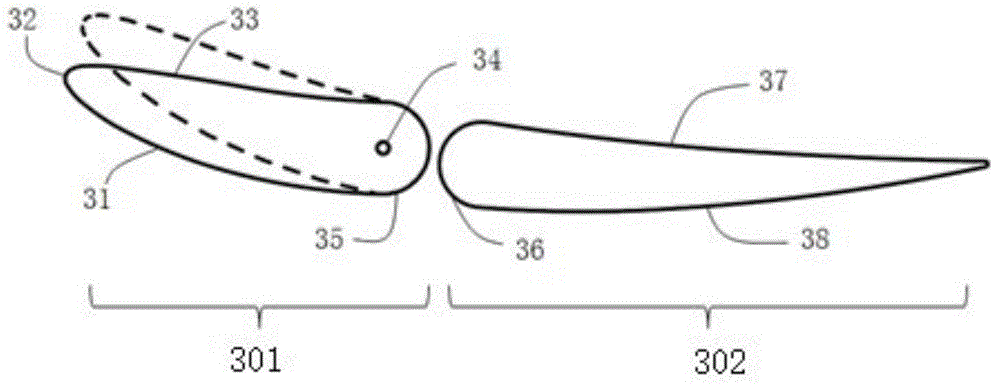

Variable geometric outlet vane

ActiveCN105715585AImprove efficiencyImprove outlet flow fieldPump componentsPumpsTurn angleCombustion chamber

The invention discloses a variable geometry outlet guide vane, the outlet guide vane includes an inlet adjustable section, an outlet fixed section, and there is a gap between the trailing edge of the inlet adjustable section and the front edge of the outlet fixed section; the gap is formed by Composed of two smooth curves, the pressure surface and the suction surface are connected through the gap. Using the pressure difference between the pressure surface and the suction surface, a small part of the air flows through the gap from the concave surface to the convex surface, so as to blow the boundary layer and reduce the loss. Increase the airflow turning angle. The variable geometry outlet guide vane of the compressor proposed by the present invention, by adjusting the position of the front part of the outlet guide vane, avoids flow separation or blockage due to the excessive The rear part of the guide vane remains stationary, and the rotation of the guide vane has little effect on the flow of the exhaust diffuser and the combustion chamber.

Owner:SHANGHAI ELECTRICGROUP CORP

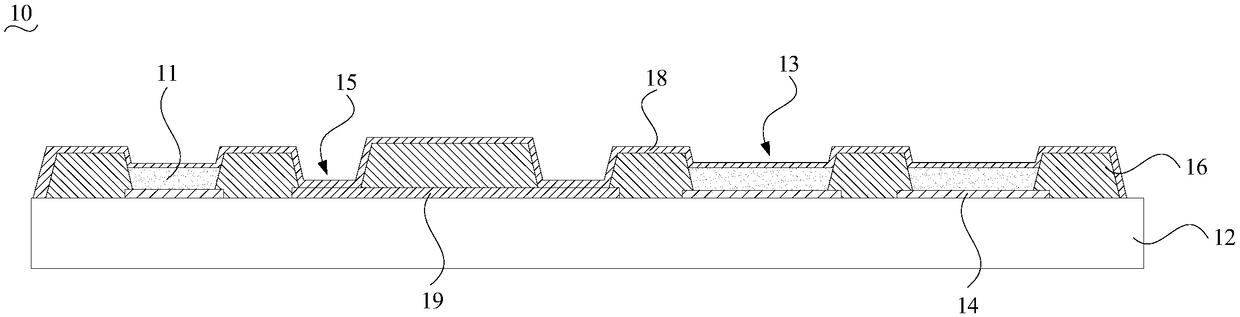

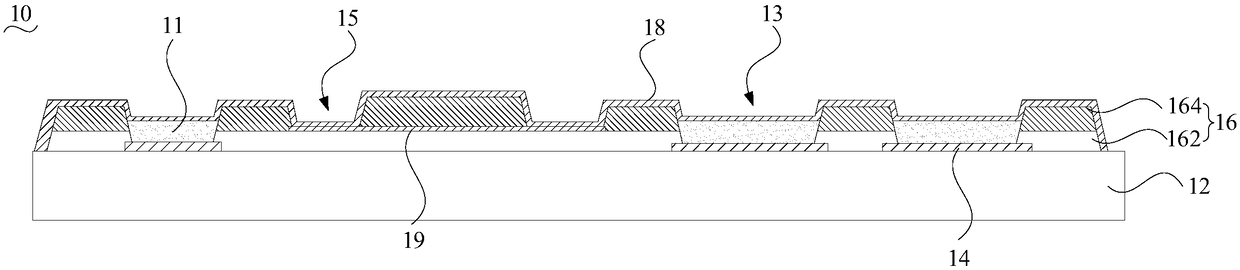

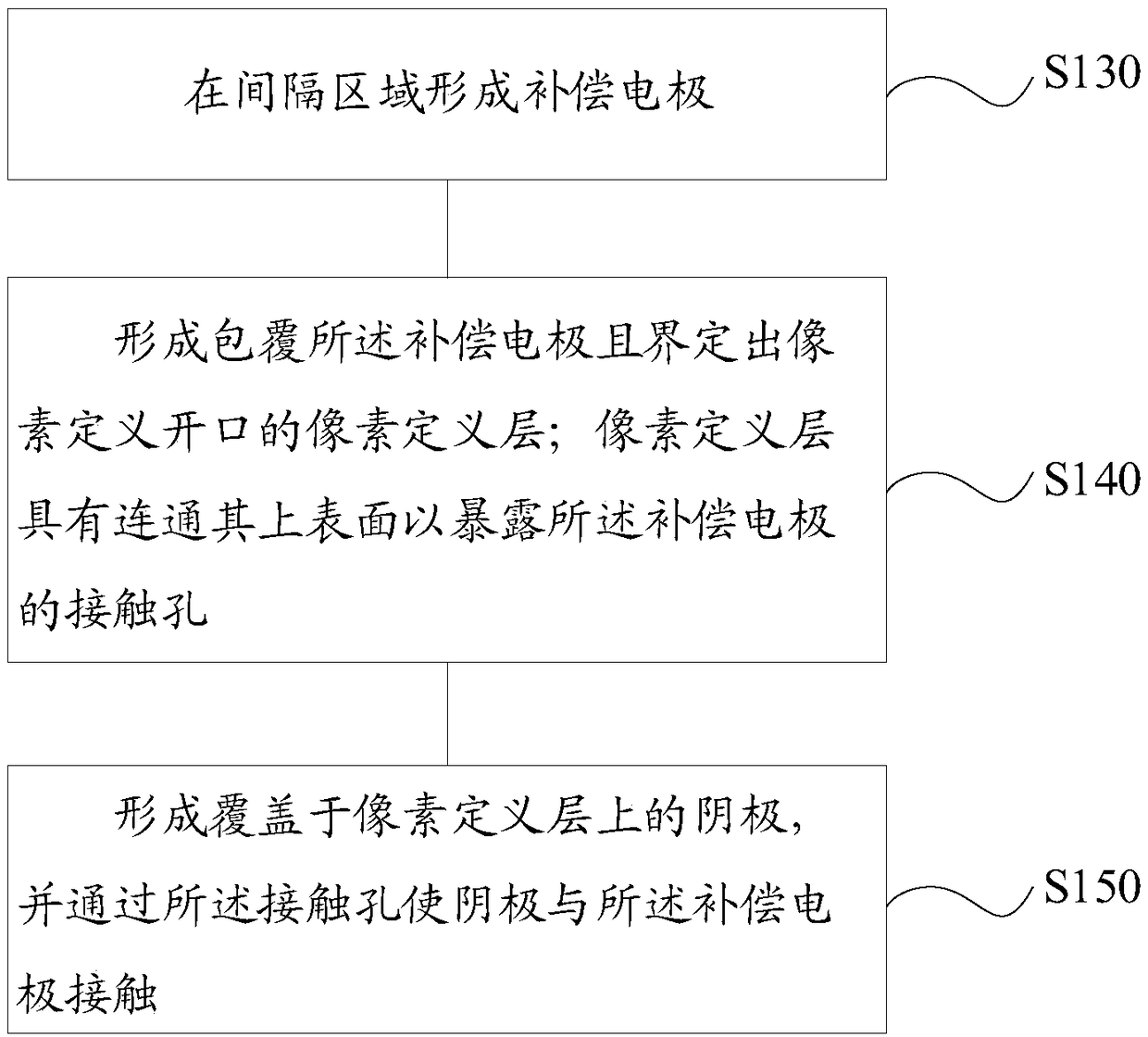

Display panel, manufacturing method thereof, and display device

ActiveCN109004005AImprove bending strengthAvoid breakingSolid-state devicesSemiconductor/solid-state device manufacturingDrop impactFlexural strength

The invention relates to a display panel, comprising a pixel definition layer, a cathode and a compensation electrode. The pixel definition layer defines a plurality of pixel definition openings and aspacing area between the pixel definition openings. A cathode is overlaid on the pixel definition layer. The pixel definition layer is configured to cover the compensation electrode and has a contacthole communicating with an upper surface thereof so that the cathode contacts the compensation electrode through the contact hole. As that display panel is subject to drop impact or multiple bending,The thin film encapsulation layer is bent downward along the direction of the applied force, and the impact force is transmitted to the cathode layer. The compensation electrode and the cathode layeroverlap each other through the contact hole to form a three-dimensional three-dimensional network structure, which can support the cathode layer and disperse the impact stress, thereby preventing thecathode from breaking or being separated from the organic light-emitting unit. Thus, the bending strength and the impact strength against drop of the display panel are improved. Also provided are a method for manufacturing a display panel and a display device.

Owner:YUNGU GUAN TECH CO LTD

High-structural-strength three-dimensional solid wood composite board and forming method thereof

The invention discloses a high-structural-strength three-dimensional solid wood composite board which comprises a hard base layer and further comprises a first capacity layer group, a second capacity layer group and a surface layer, wherein the first capacity layer group and the second capacity layer group are arranged on the two sides of the base layer, wherein each of the first capacity layer group and the second capacity layer group is provided with at least one flexible capacity layer; the surface layer is arranged on the surface of the first capacity layer; a decoration groove is formed in the surface layer; and the bottom of the decoration groove is embedded into the first capacity layer group. The hard base layer can provide enough mechanical strength for the whole board and support the capacity layers and the surface layer in the board, so as to prevent the board from deforming in the process of making the decoration groove under high pressure. The solid wood composite board provided by the invention has a brand-new structure different from that of a conventional board, has the characteristics of stereoscopic vision, high mechanical strength and long service life, further has the advantages of low formaldehyde release amount and environment friendliness in use and can be widely applied to the fields of home decoration, artwork processing, commercial place decoration and municipal construction.

Owner:SHENZHEN SONGBOYU TIMBERING

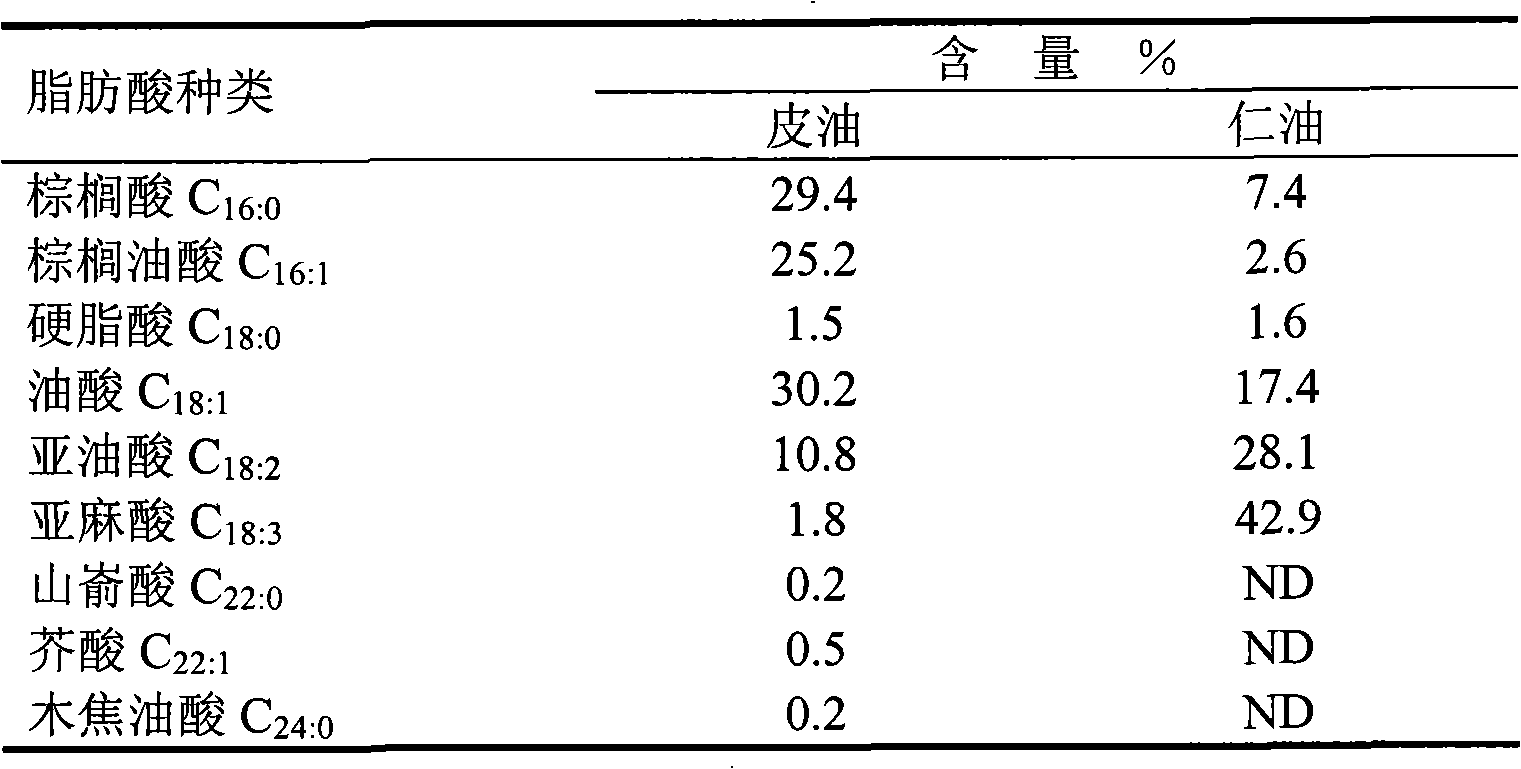

Technique for extracting seed capsule oil and kernel oil from Zanthoxylum bungeanum seeds using homogeneous solvent two-step extraction method

InactiveCN101326942AImprove qualityImprove use valueFood processingAnimal feeding stuffOil and greasePalm kernel oil

The invention discloses an extraction process of pepper seed oil. The husk oil and the kernel oil of pepper seed are extracted through a same solvent two-step extraction method, which effectively avoids the problems that pepper seed husk and kernel can not be separated throughly, raw materials are easily lost, etc., realizes the separate extraction of the pepper seed husk oil and kernel oil, and improves the utilization value of the husk oil and the quality of the kernel oil. The kernel oil extracted through the method can be used as edible oil after being refined and the husk oil can be used as industrial oil, which effectively solves the problems of low oil yielding rate, poor quality of kernel oil products, etc. of the prior art.

Owner:CHONGQING TECH & BUSINESS UNIV +1

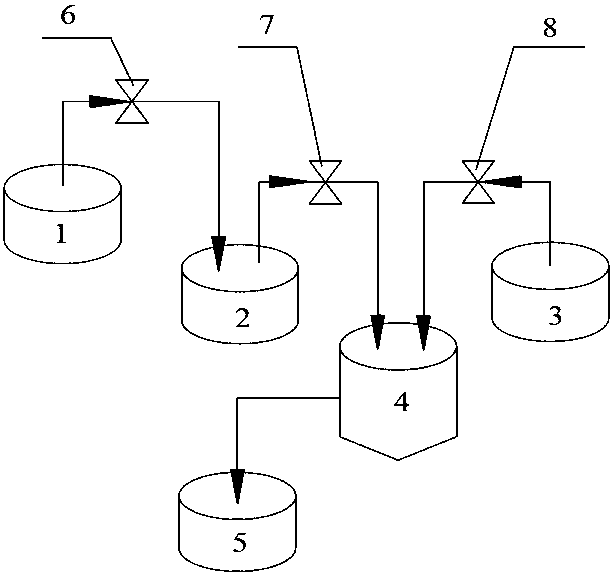

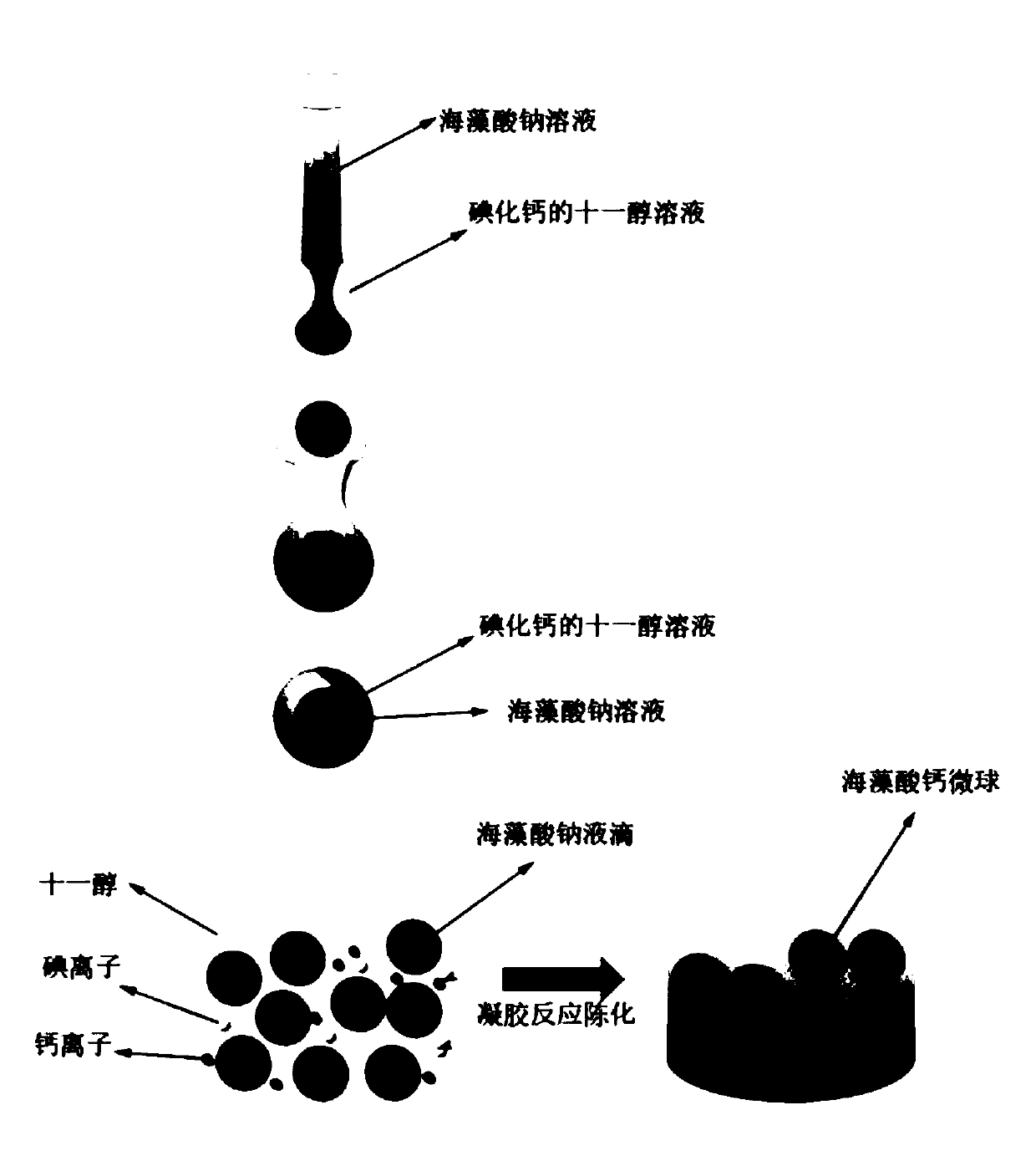

Device and method for preparing calcium alginate microspheres by using micro-reactor, and applications thereof

ActiveCN110639450AUniform particle sizeGood sphericityChemical/physical/physico-chemical microreactorsLaboratory glasswaresMicroreactorPetri dish

The invention relates to the technical field of calcium alginate microsphere preparation, and especially relates to a device and a method for preparing calcium alginate microspheres by using a micro-reactor, and applications thereof. The method comprises the following steps: (1) an outer-phase fluid is introduced into a second dispensing needle head, and then enters an outer-phase glass tube, andan inner-phase fluid is introduced through a first dispensing needle head and an inner-phase glass tube when the outer-phase fluid flows out of the outlet of the outer-phase glass tube; (2) the inner-phase fluid forms liquid drops coated with the outer-phase fluid at the outlet of the inner-phase glass tube under the action of shearing force of the outer-phase fluid, and the liquid drops flow intoa collecting culture dish along with the outer-phase fluid; and 3) the position of a chip is continuously moved during collection to separate the liquid drops collected in the culture dish from eachother, and the obtained liquid drops stands after the collection is completed in order to move the redundant outer-phase fluid and obtain the calcium alginate microspheres. The device and the method are realized by using the micro-reactor, and the calcium alginate microspheres prepared by utilizing an oil phase and a water phase have the characteristics of uniform particle size, good sphericity degree and controllable swelling ratio, and can well meet the applications in the fields of drug loading, catalysis and detection.

Owner:SHANDONG UNIV

Low-temperature prepn process of degradable efficient oil absorbent

InactiveCN1417263AEfficient use ofReduce pollutionOther chemical processesNatural resourceAcetic anhydride

The present invention relates to a low-temperature preparation process of degradable efficient oil absorbent. It is prepared through reaction of bagasse with acetic anhydride and N-bromo-succinimide in a reactor and the separation of reaction products. The process is simple and low in cost, and utilizes natural resource effectively. Needing no separation of organic solvent and residual product, the process has high yield and less environmental pollution. Compared wth prior production process, the process has decreased reaction temperature from 120 deg.c to 50-80 deg.c and this further reducesproduction cost. In addition, the low-cost catalyst is used, the product has high oil absorbing amount, the absorbed oil may be recovered via squeezing and the oil absorbent may be used repeatedly before natural degradation producing no environmental pollution.

Owner:SOUTH CHINA UNIV OF TECH

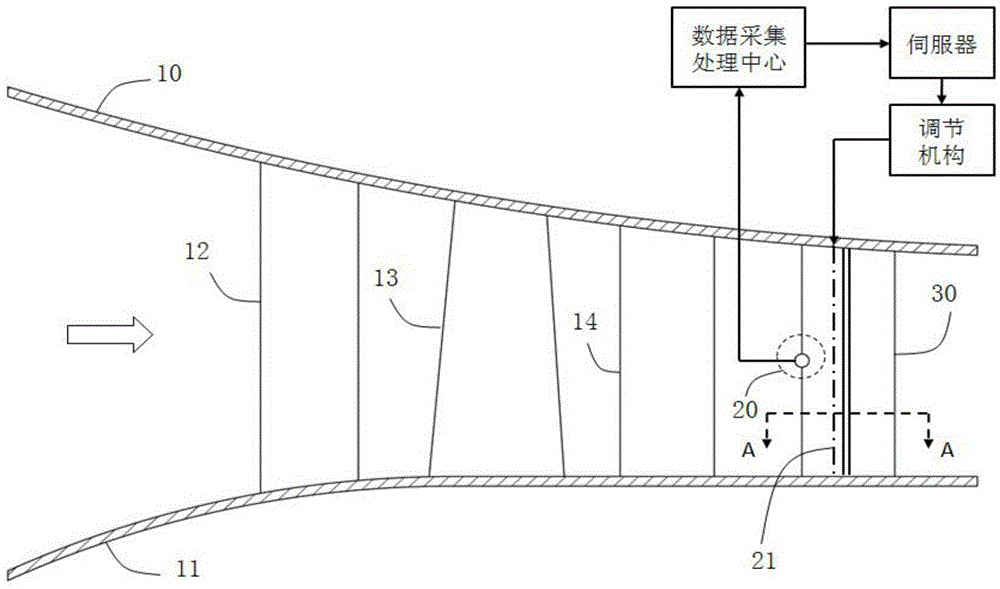

Vane regulation control device

ActiveCN105715574AImprove efficiencyUniform outlet flow fieldPump componentsPump controlTurn angleCombustion chamber

The invention discloses a vane regulation control device. The vane regulation control device comprises a variable geometric outlet vane and a corresponding data acquisition and processing system, wherein the outlet vane comprises an inlet adjustable section and an outlet fixed section, and a clearance is arranged between the tail edge of the inlet adjustable section and the front edge of the outlet fixed section; and the clearance consists of two sections of smooth curved lines, and a pressure surface communicates with a force absorption surface through the clearance. By utilizing pressure difference between the pressure surface and the force absorption surface, a small part of air is led into a convex surface from a concave surface through a seam so as to blow a boundary layer thin. Losses are reduced, and airflow turning angle is increased. According to the vane regulation control device provided by the invention, a regulation command is sent out by the data acquisition and processing system, the mounting angle of the front part of the outlet vane is adjusted in a stepping manner, and flow separation or blockage caused by too-large attach angle of a vane inlet when the vane runs under variable work conditions is avoided; and at the same time, as the rear of the vane is kept still, the rotating of the vane produces little influence on the flow of an exhaust diffusion section and a combustion chamber.

Owner:SHANGHAI ELECTRICGROUP CORP

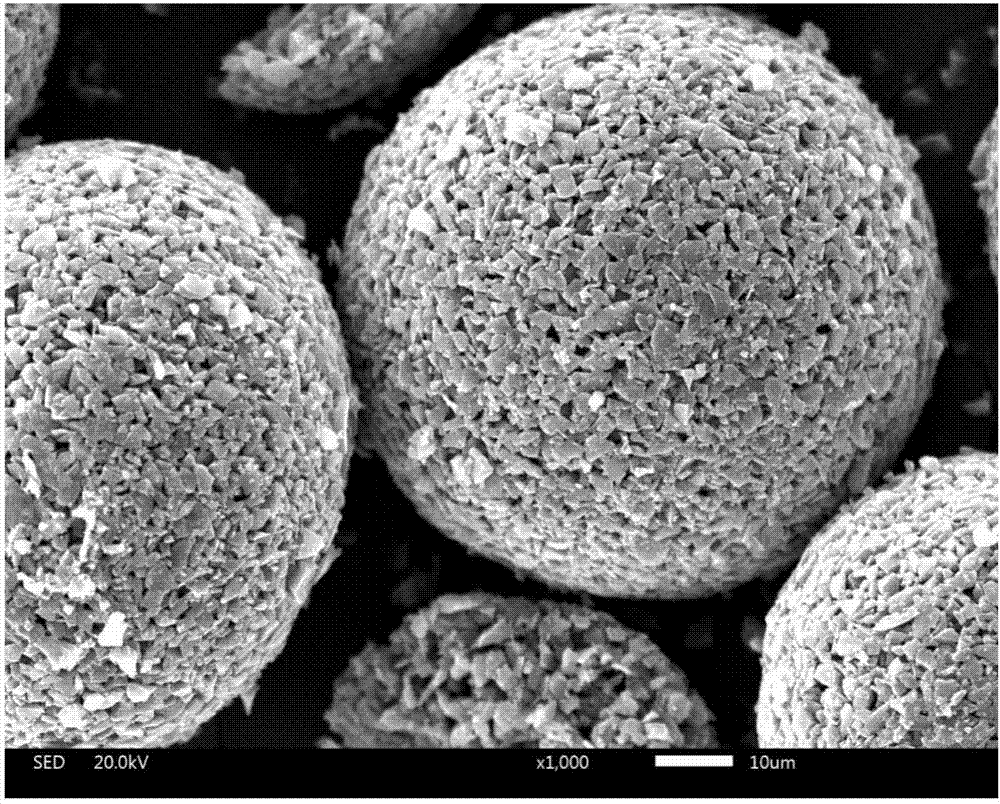

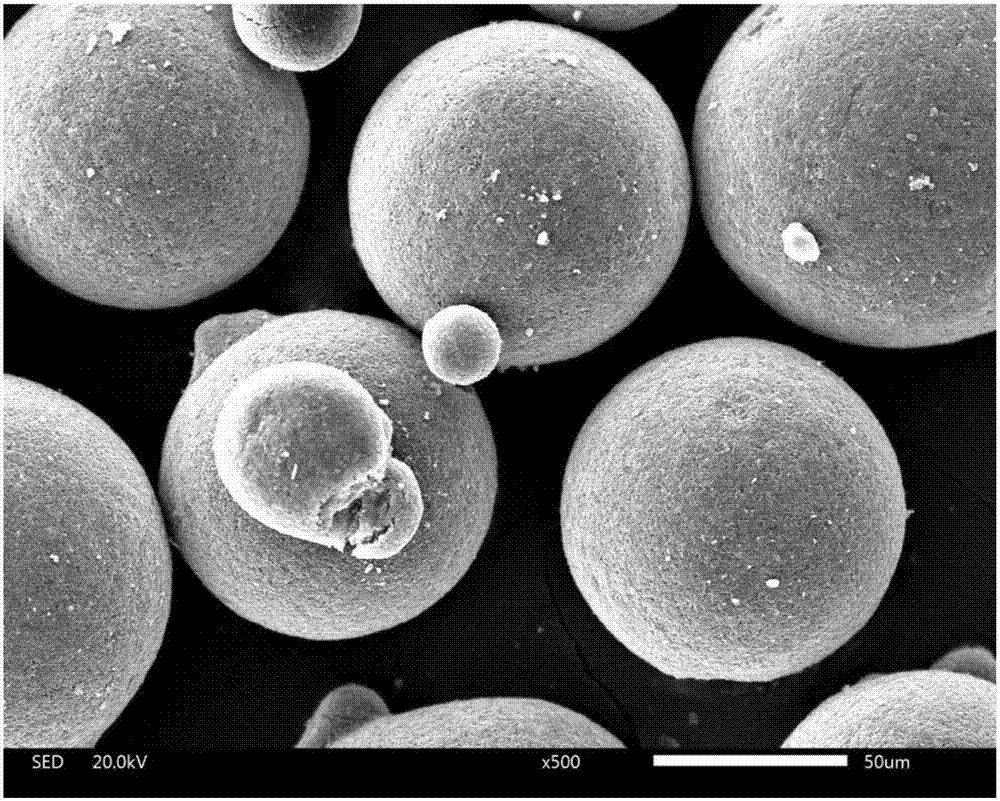

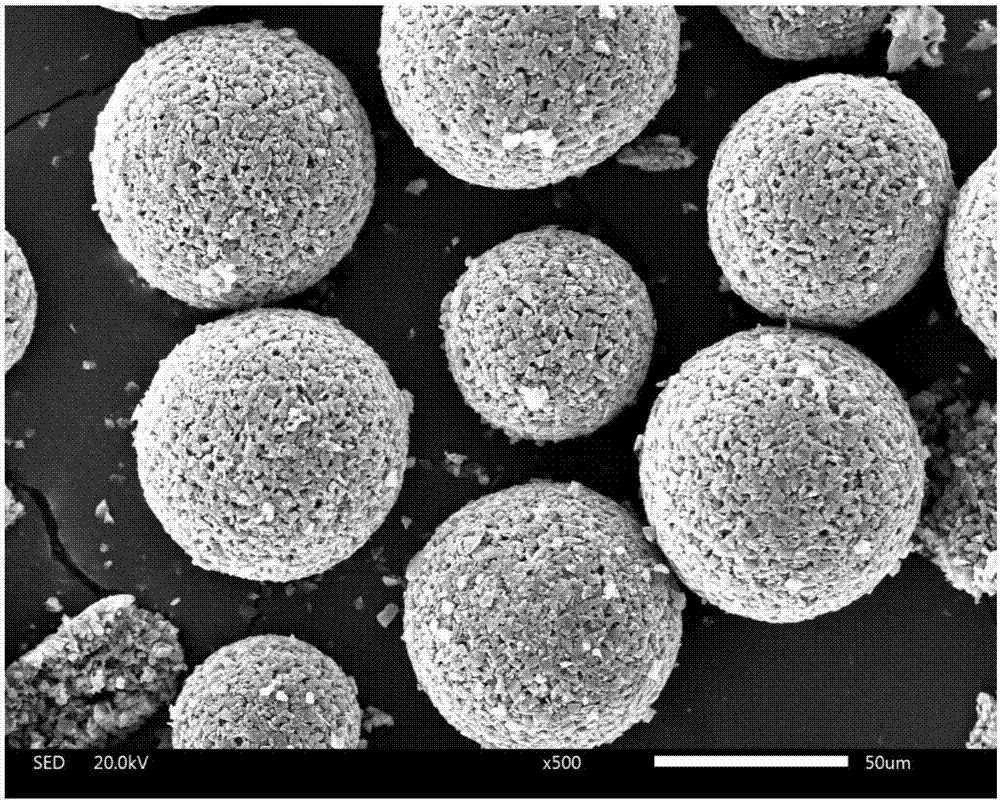

Method for preparing ultrafine boron carbide granulation powder by combining high-energy ball milling with spray drying technology

The invention relates to a method for preparing ultrafine boron carbide granulation powder by combining high-energy ball milling with a spray drying technology. The method comprises the following steps: firstly, burdening; secondly, preparing slurry: putting deionized water, a lubricant A, a lubricant B, a dispersing agent, a binder A and a binder B into a polytetrafluoroethylene ball mill tank, adding ball milling beads on a planetary ball mill to carry out ball milling mixing, then adding boron carbide micropowder into the ball mill tank and continuously carrying out ball milling for 0.5 hour, and then adding a binder C into the ball mill tank and carrying out ball milling for 12 to 18 hours; finally, adding a defoaming agent into the ball mill tank and carrying out ball milling for 10 minutes to obtain the slurry; thirdly, carrying out spray drying granulation: carrying out drying granulation on the slurry by using a spray drying granulator to obtain the ultrafine boron carbide granulation powder. According to the preparation method disclosed by the invention, the spherical granulation powder is obtained by combining wet high-energy ball milling with the spray granulation technology; the obtained powder is helpful to the forming of the boron carbide powder and the improvement on relative density of a biscuit.

Owner:WUHAN UNIV OF TECH

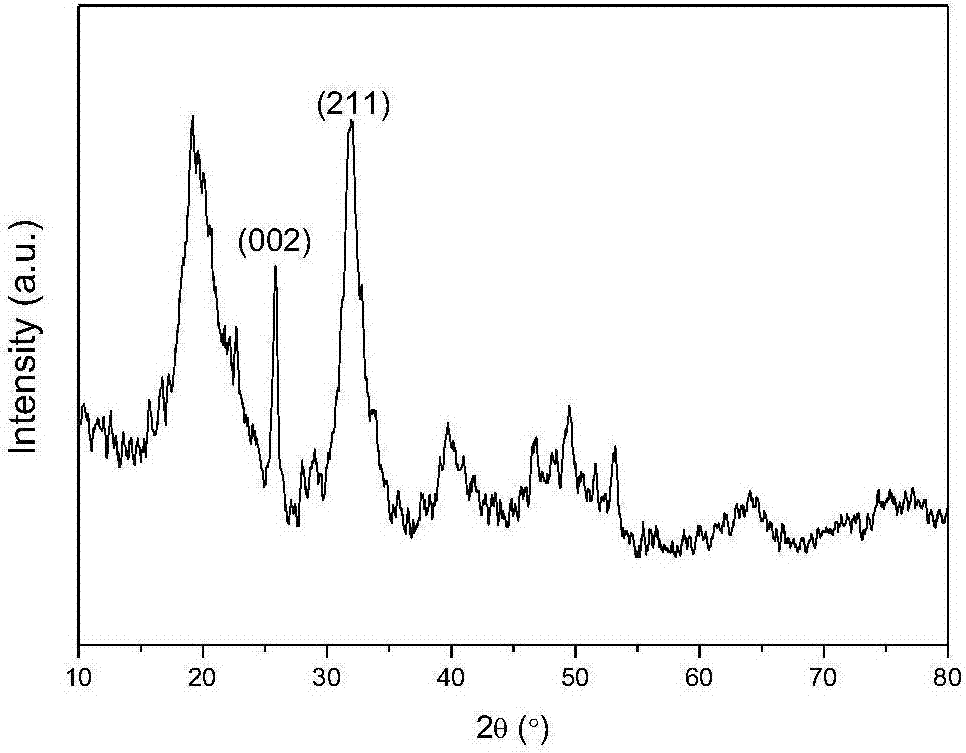

Method for preparating ethyl linoleate by catalysis of composite solid ultra-strong acid

InactiveCN101139288ALarge specific surface areaHigh catalytic activityPhysical/chemical process catalystsOrganic compound preparationMethyl linoleateAdditive ingredient

The present invention is a method of preparing the linoleic acid ethyl ester with the composite solid superacid catalyst. The production method the of linoleic acid ethyl ester in the existing industrialized production is the esterification reaction between the linoleic acid and the anhydrous ethanol ester with the concentrated sulfuric acid as the catalyst. The method has the problems of the large discharge of the acidic wastewater, the serious corrosion of the production equipment and so on. Therefore, the industrialized production urgently needs an environment-friendly solid acid catalyst. The method of preparing the linoleic acid ethyl ester with the composite solid superacid catalyst of the present invention is that the linoleic acid and the anhydrous ethanol with the molar ratio of 1 to between 1 and 10 are added into the reactor in order; the mixed solution is added with the SO42- / TiO2-SiO2, the composite solid superacid catalyst, whose weight is 1 to 10 percent of the weight of the linoleic acid; the mixed solution is stirred and heated with the protection of the nitrogen; the reaction is done for 2 to 10 hours at the return temperature of 40 DEG C; the solution is delaminated statically after the reaction; the products on the upper layer are decompressed and distilled under the pressure of minus 98.8 to minus 99.3 kPa; the distilled ingredients are collected at the temperature between 162 and 172 DEG C; then the refined inoleic acid ethyl ester can be got. The method of the present invention is suitable for the preparation of the linoleic acid ethyl ester in the industry.

Owner:HEILONGJIANG UNIV

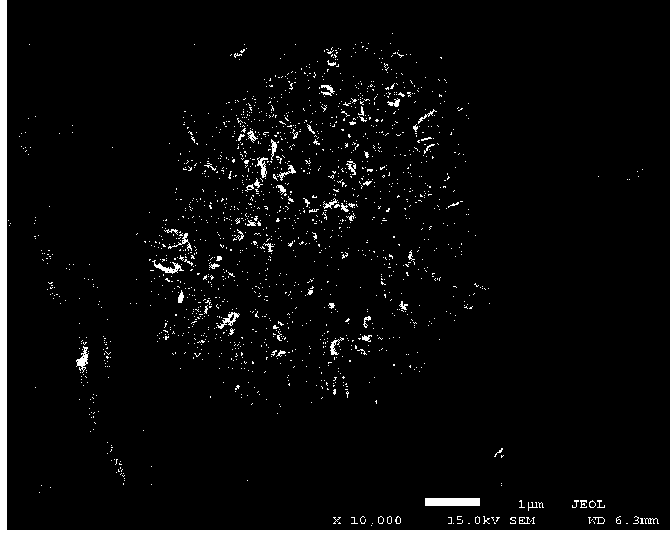

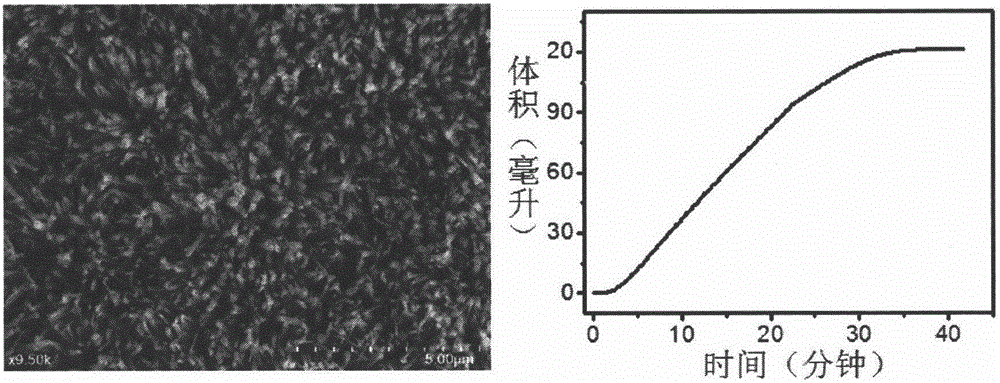

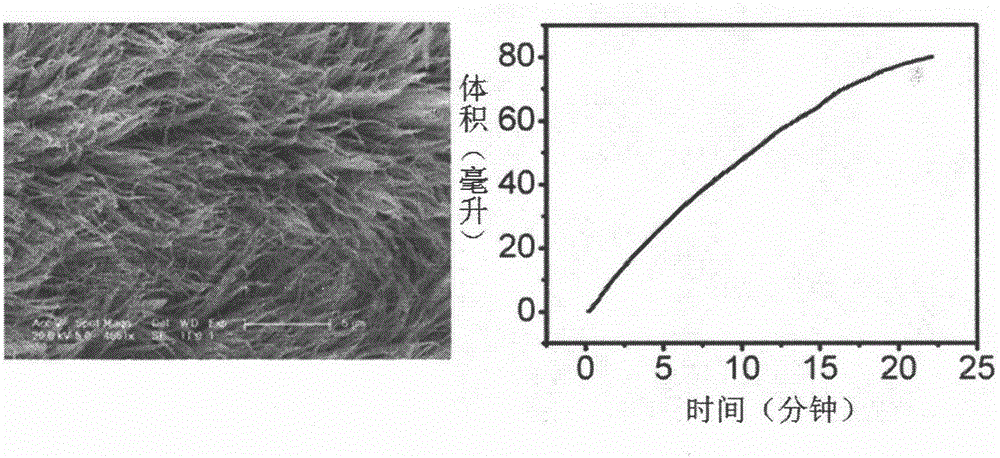

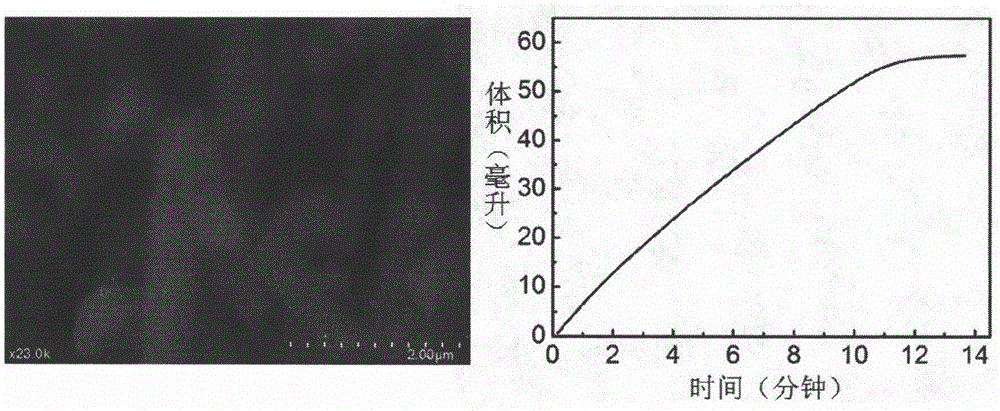

Application of three-dimensional transitional metal nanoarray used as catalyst for hydrogen production from hydroboron

InactiveCN105958086ARapid hydrolysis hydrogen productionEfficient hydrolysis hydrogen productionMaterial nanotechnologyCell electrodesNano catalystHydrolysis

The invention discloses an application of a three-dimensional transitional metal nanoarray used as a catalyst for hydrogen production from hydroboron, and belongs to the fields of hydrogen energy and fuel cells. Compared with the prior art, the three-dimensional transitional metal (elementary substance, hydroxide, oxide, nitride and carbide) nanoarray is initially taken as the overall catalyst used for the hydrolysis hydrogen production of the hydroboron; the catalyst has excellent catalytic activity and stability; due to the structure, the contact area between the solid catalyst and the reaction solution is greatly enlarged; the mass transfer between the reactant and the product is promoted; the problems that the nanocatalyst is easy to aggregate and it is hard to separate the nanocatalyst from hydrolysis by products can be avoided effectively; and therefore, the catalyst is suitable for a continuous hydrogen production process.

Owner:成都玖奇新材料科技有限公司

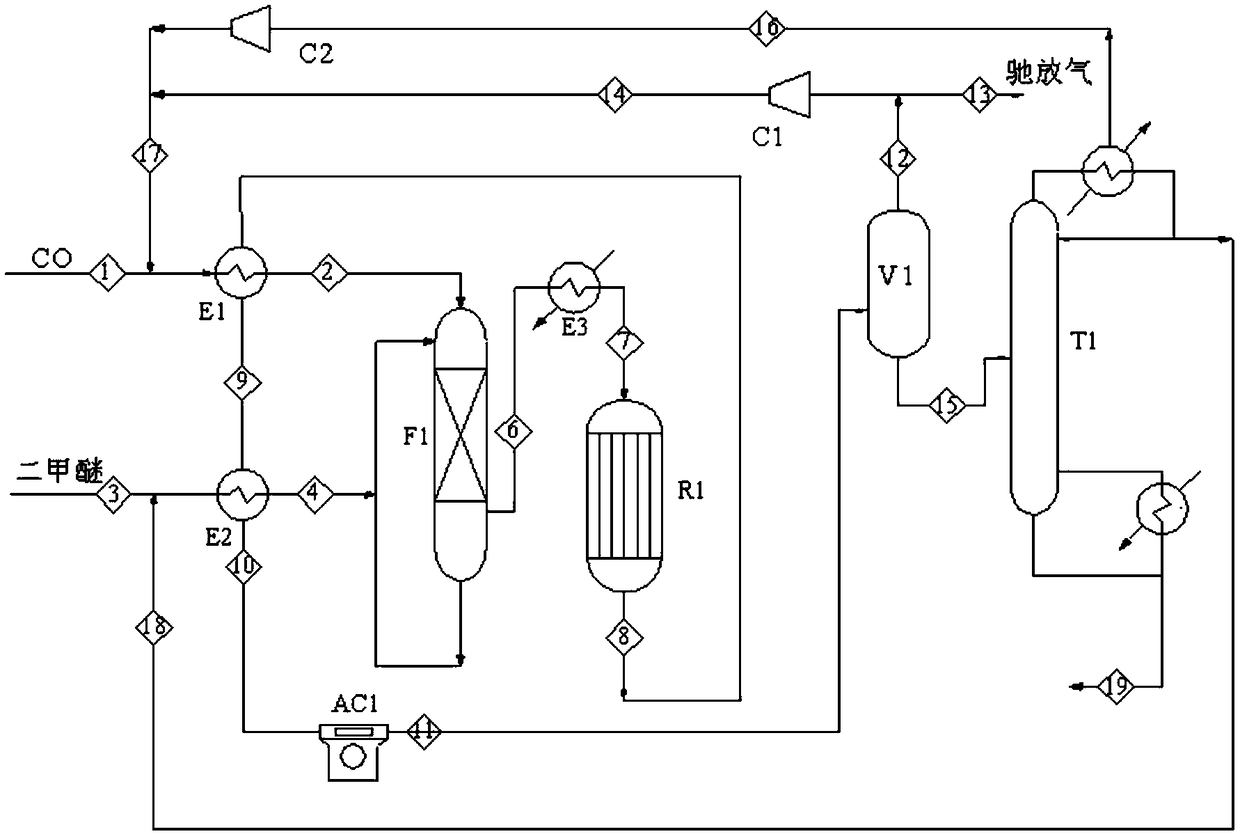

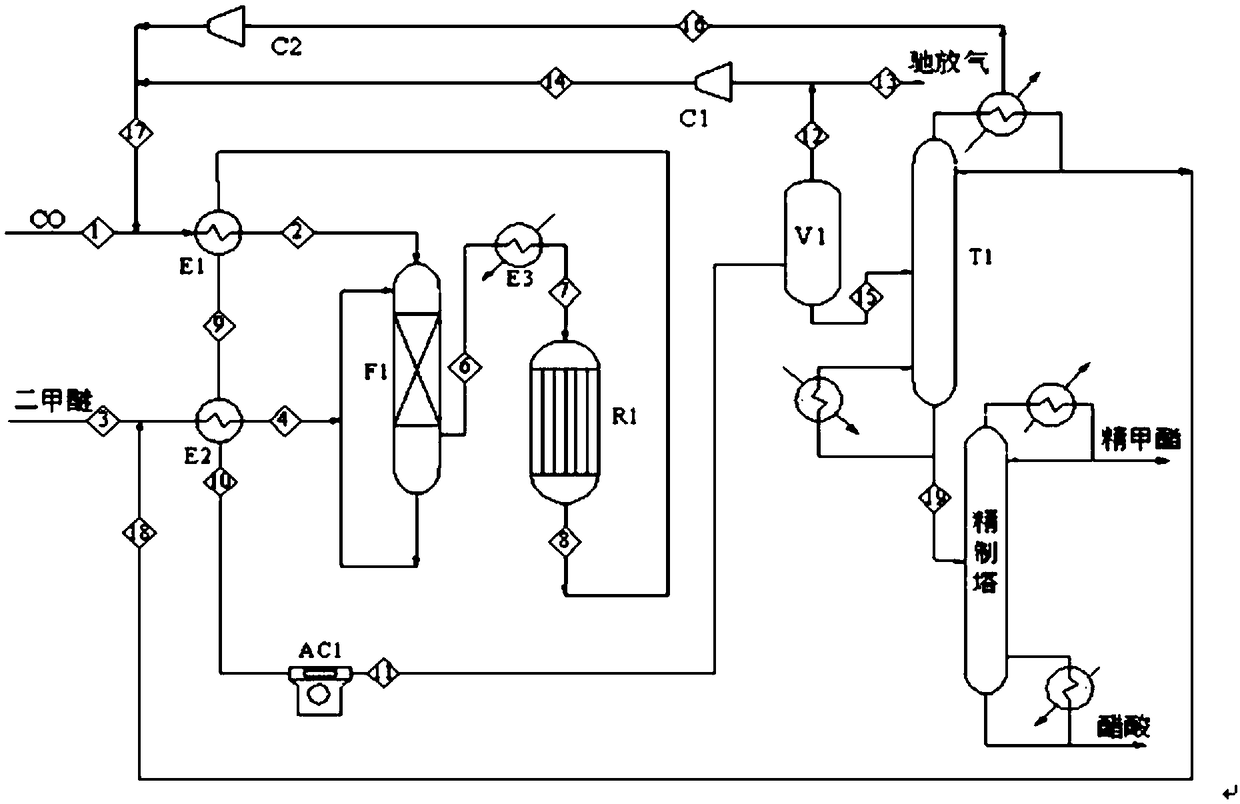

Process for indirectly producing ethanol from dimethyl ether

ActiveCN109503326AAvoid separabilityAvoid processing powerOrganic compound preparationHydroxy compound preparationHydrogenMethyl acetate

The invention provides a process for indirectly producing ethanol by dimethyl ether, and belongs to the technical field of ethanol preparation. In the process, firstly, the dimethyl ether and carbon monoxide are used as raw materials to prepare methyl acetate and acetic acid by carbonylation reaction, the methyl acetate and the acetic acid are catalytically hydrogenated with hydrogen, and the product is purified to obtain an ethanol product. In the process for indirectly producing the ethanol from the dimethyl ether in the invention, the dimethyl ether and the carbon monoxide are used as the raw materials to carry out the carbonylation reaction, and the product methyl acetate and acetic acid are further catalytically reacted with the hydrogen to produce the ethanol. The co-hydrogenation ofthe reacted product methyl acetate and acetic acid after the carbonylation reaction to produce the ethanol avoids the separate separation and treatment of by-product acetic acid as waste acid, reduces energy consumption, and also reduces emissions of three wastes (waste gas, waste water and industrial residue). At the same time, the heat pump rectification of a methanol column in the ethanol separation process further reduces the energy consumption of the device.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

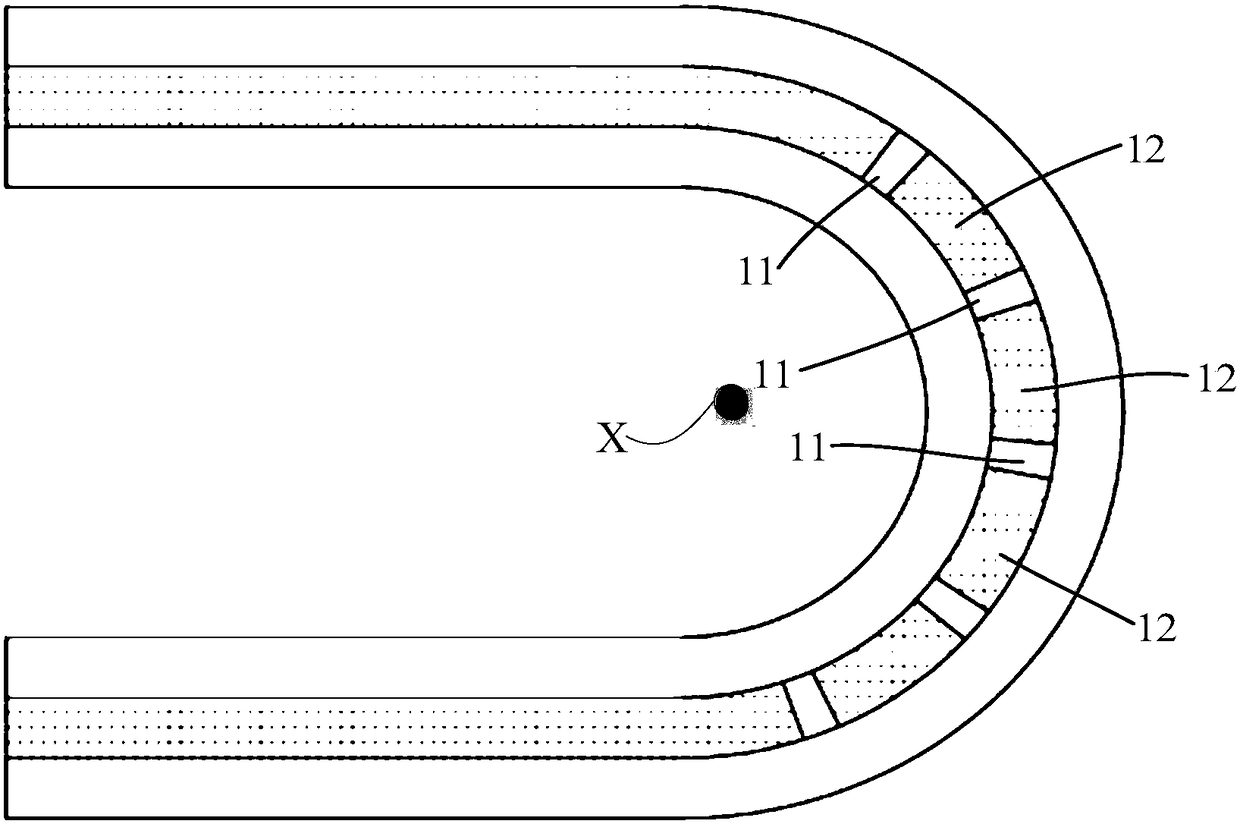

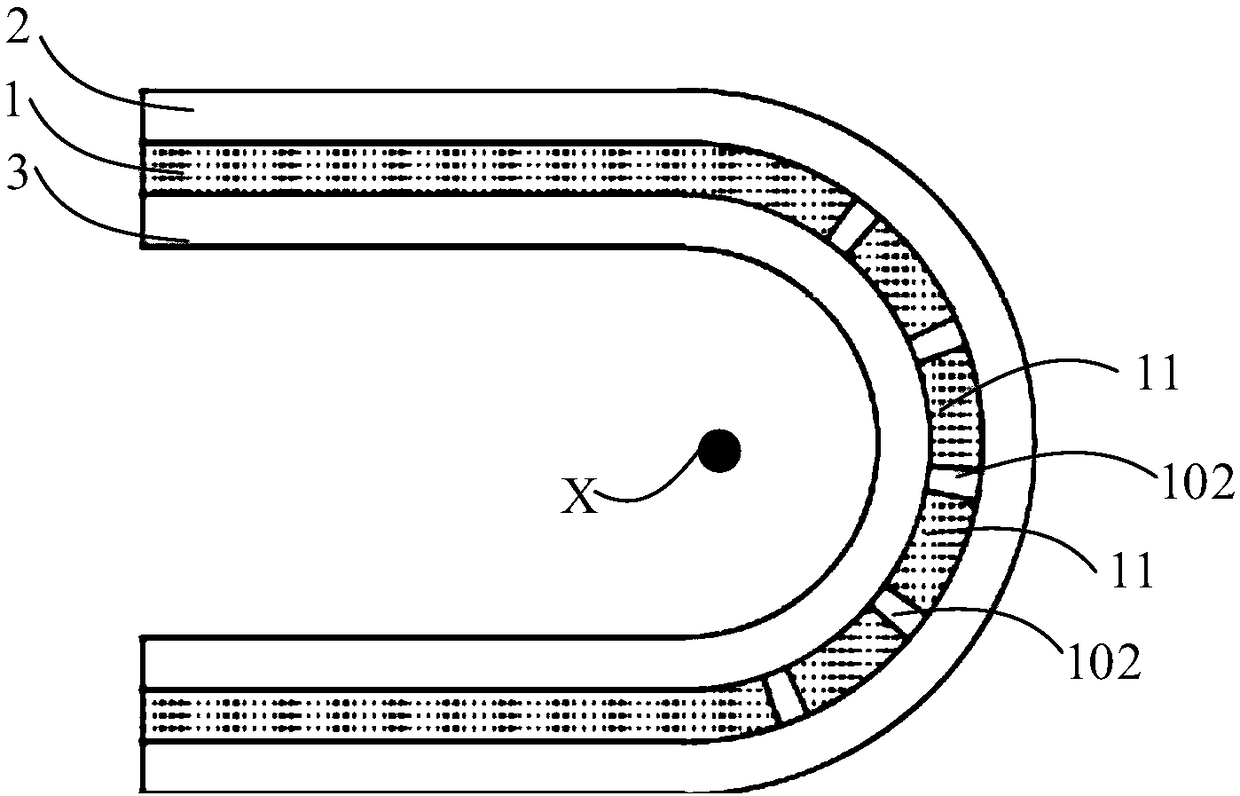

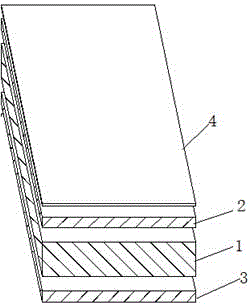

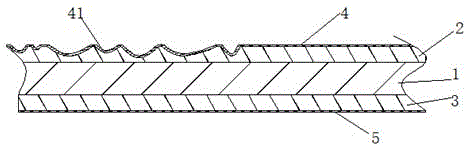

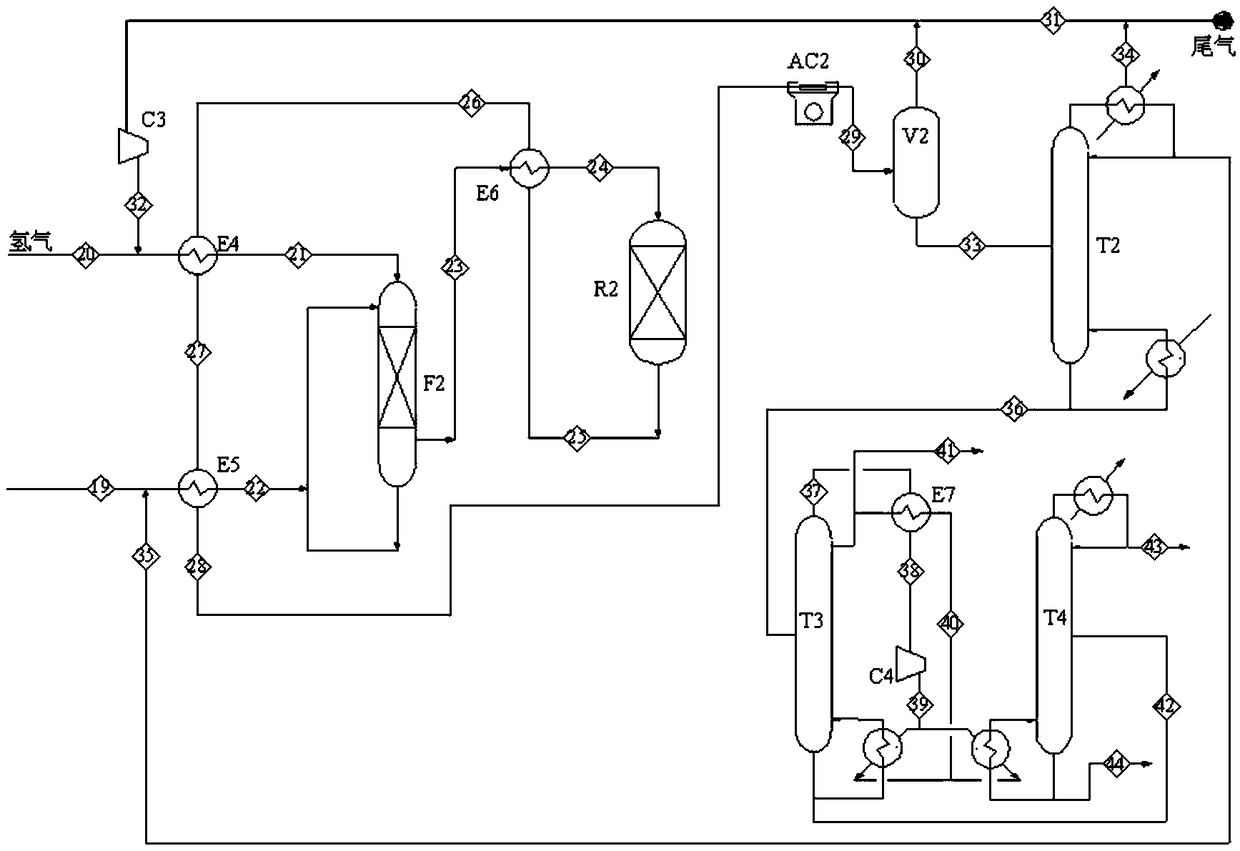

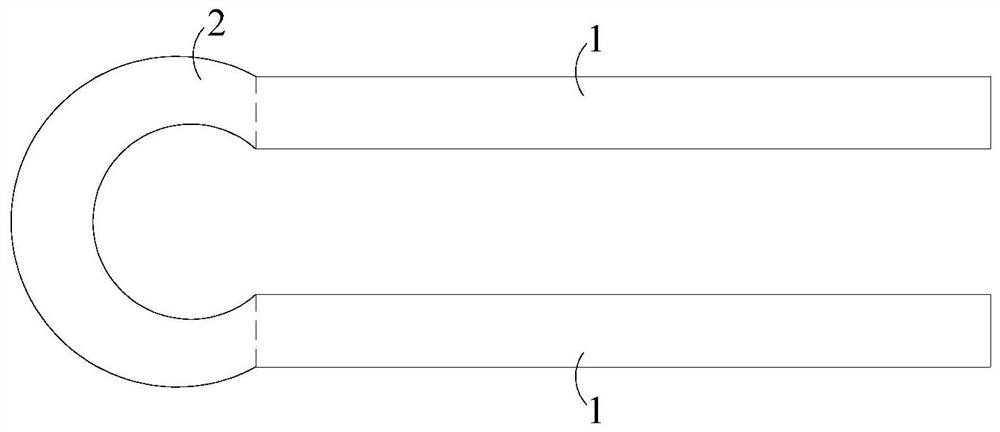

Flexible support plate and flexible display device

PendingCN112489564AAvoid separabilityAvoid crackingSolid-state devicesCasings/cabinets/drawers detailsEngineeringFlexible display

The invention relates to the technical field of display and provides a flexible supporting plate and a flexible display device. The flexible support plate comprises an open pore area and at least onesolid area arranged on at least one side of the open pore area, wherein a plurality of through holes are formed in the perforated area, the perforated area comprises a middle area and a transition area, the transition area is arranged between the middle area and the entity area, and the width of the transition area is reduced along with the increase of the distance between the transition area andthe middle area. When the flexible support plate is bent, deformation of the transition area is gradually changed, and the stress is also gradually changed without sudden change, i.e., the stress is uniformly changed, so that hard corner bending caused by sudden change of the stress during bending is avoided, and problems of film separation and cracks are avoided; in addition, the flexible displaypanel can be applied to a flexible display device with a small bending radius.

Owner:BOE TECH GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com