Nanometer colloid particle-assembled high-strength self-repairing injectable composite colloid gel material and preparation method and application thereof

A nanoparticle, high-strength technology, applied in non-active medical preparations, non-active polymer compounds, prostheses, etc., can solve the problem of inability to accurately control drug release, weak mechanical strength, and difficult to take into account biocompatibility and biodegradability, etc., to achieve the effect of enhancing mechanical strength, high mechanical strength, and high self-healing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

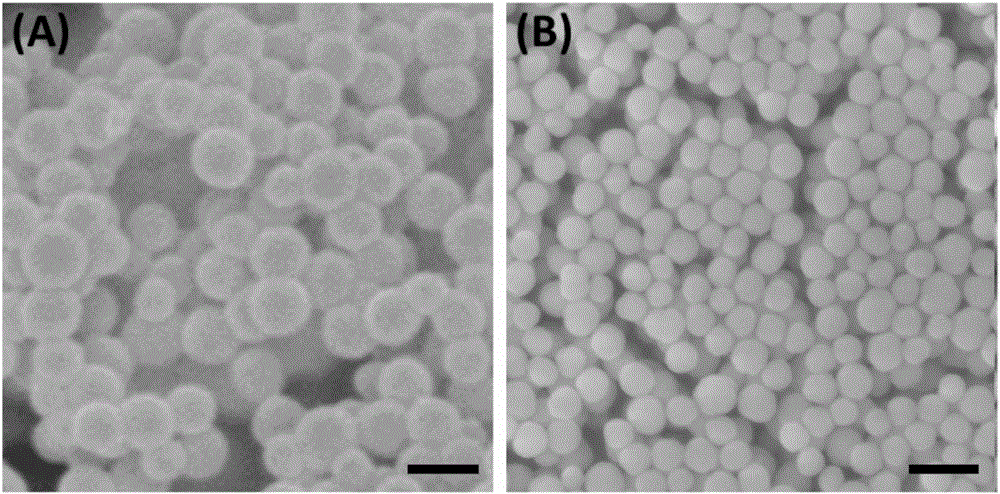

[0060] (1) gelatin microspheres:

[0061] In this example, gelatin nanospheres were prepared by desolvation method[7,8] to obtain the appearance of gelatin nanospheres as follows figure 2 As shown in A, the particle size of the nanospheres is about 100 nm, and the surface Zeta potential of the microspheres is about +10 mV measured in a pH7 aqueous solution.

[0062] (II) Silica microspheres:

[0063] In this example, silica microspheres were prepared by the Stober method [9]. The surrounding morphology of the obtained silica microspheres is as follows: figure 2 As shown in B, the particle size of the nano-microsphere is about 80nm, and the surface Zeta potential of the microsphere is about -40mV measured in the pH7 aqueous solution.

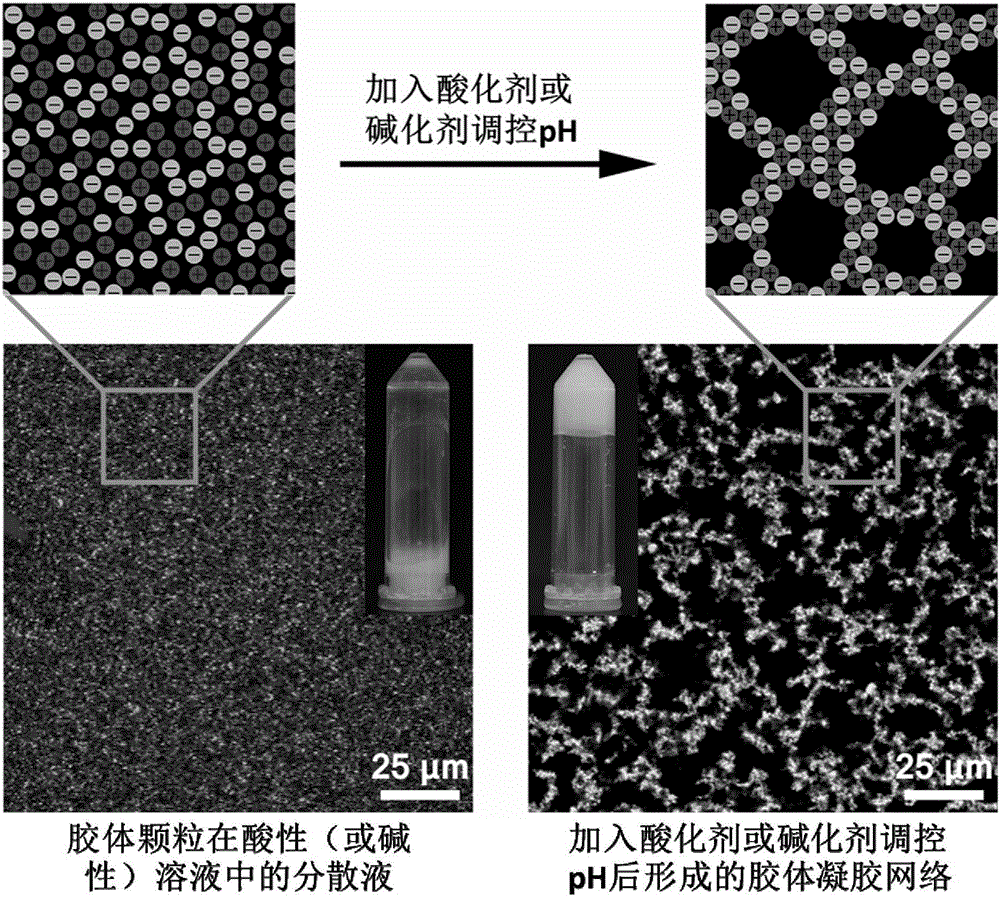

[0064] (III) Silica / gelatin composite colloidal gel:

[0065] Gelatin and silicon dioxide particles were respectively dispersed in a certain volume of NaOH (20mM) aqueous solution, and the volume of colloidal particles in the two suspension...

Embodiment 2

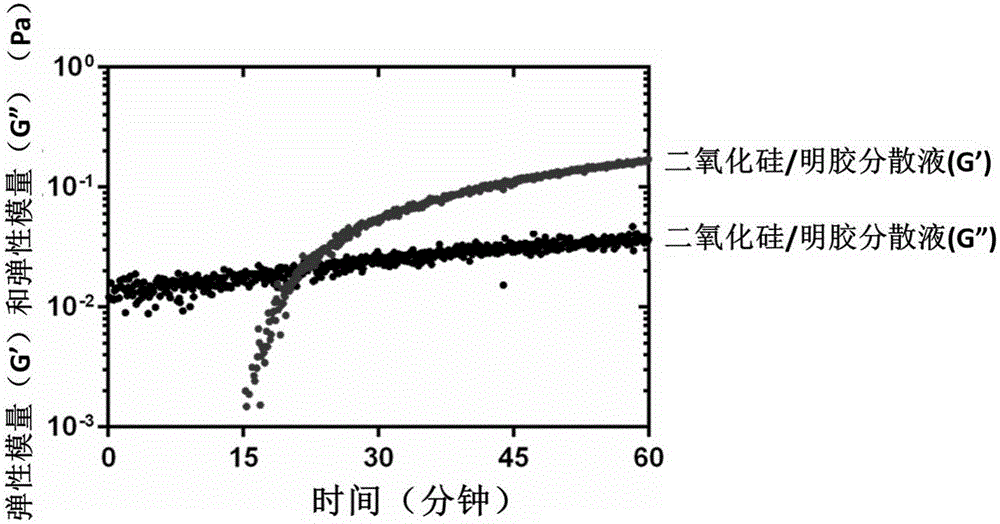

[0071] Using the gelatin and silica microspheres in Example 1, the gelatin and silica microspheres are respectively dispersed in a certain volume of HCl (20mM) aqueous solution, the volume of colloidal particles accounts for the percentage of the total volume of the suspension in the two suspensions Then the gelatin of the same concentration (i.e. the volume fraction concentration) and the suspension of inorganic particles were directly mixed and stirred quickly to obtain a uniformly dispersed two-phase colloidal particle suspension. After mixing, the volume of all colloidal particles accounted for the suspension The percentage of the total volume of the liquid is 5%; the mixing ratio of the two-phase colloidal particles is the number ratio of the two-phase particles to silicon dioxide / gelatin=5. Add alkalizing agent urea and urease powder to the two-phase colloidal dispersion, wherein the concentration of urea is 50 mM, and the concentration of urease is 30 U / ml, and the gelat...

Embodiment 3

[0073] Use the gelatin and silicon dioxide microspheres in embodiment 1, and it is respectively dispersed in the NaOH (20mM) aqueous solution of certain volume with gelatin and silicon dioxide microspheres, in two kinds of suspensions, colloid particle volume accounts for suspension The percentage of total volume is 5%, obtains the colloidal particle suspension of homogeneous dispersion; Then the gelatin of identical concentration (being volume fraction concentration) and inorganic particle suspension are directly mixed and mixed rapidly, two-phase colloidal particle mixing ratio Respectively, the ratio of the number of two-phase particles to silica / gelatin=1, 5, 10, 20, 50, to obtain a colloidal suspension in which the two-phase colloidal particles are uniformly mixed, and the percentage of the volume of all colloidal particles to the total volume after mixing is still 5 %. Add acidulant gluconolactone powder to the biphasic colloidal dispersion to a final concentration of 80...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com