Patents

Literature

1158results about How to "Evenly mixed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

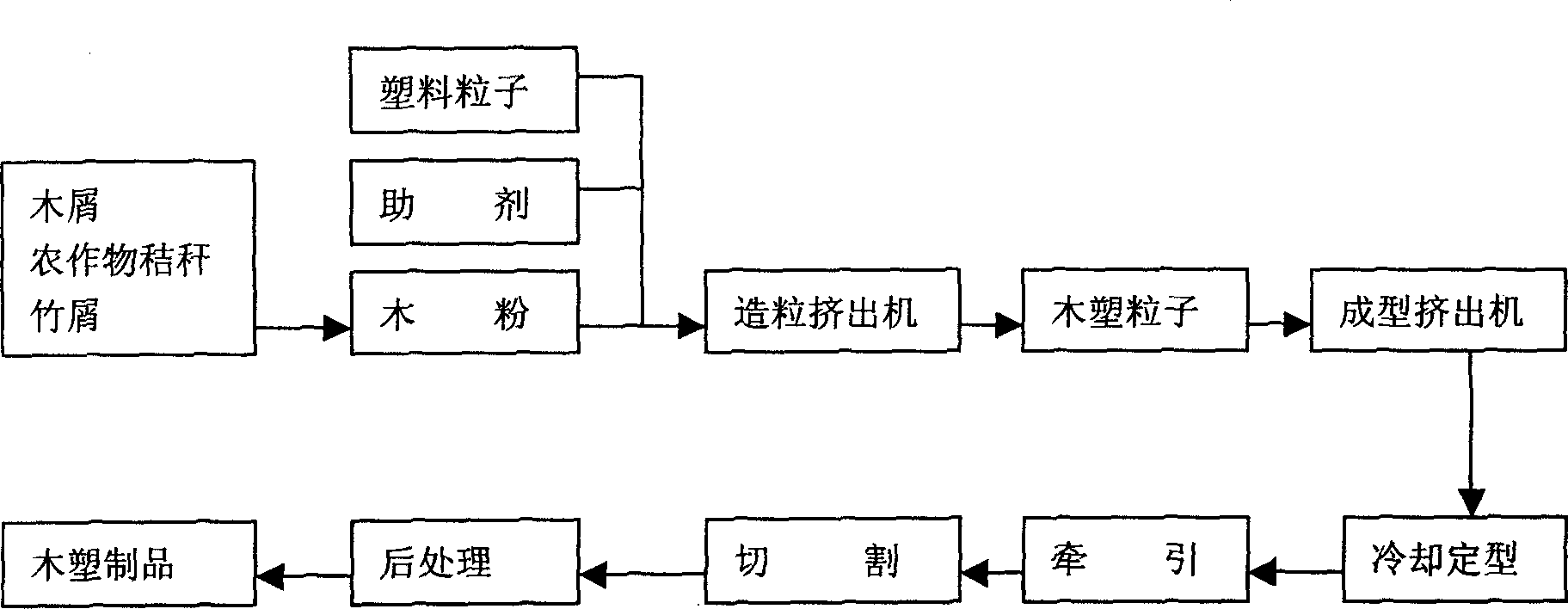

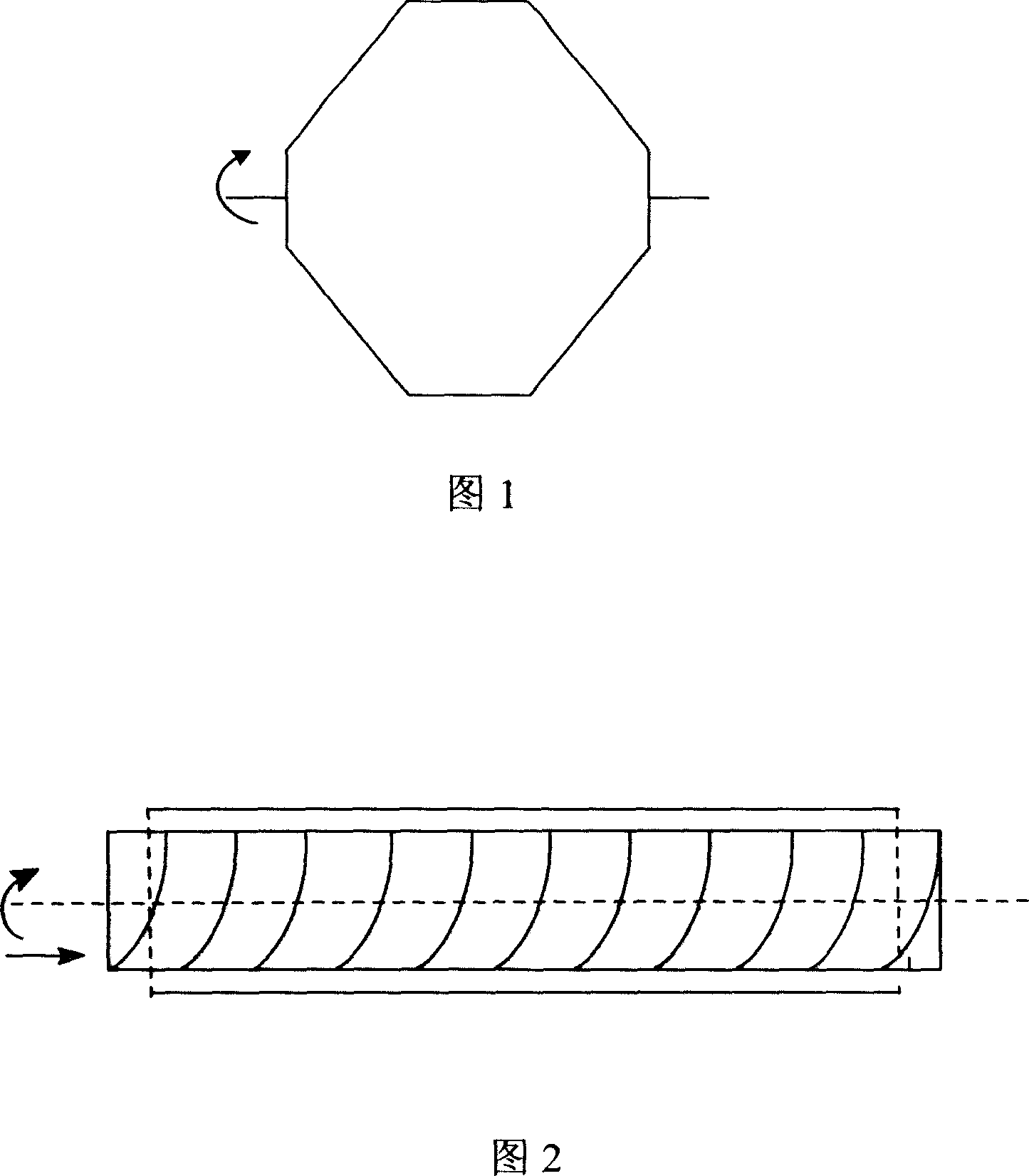

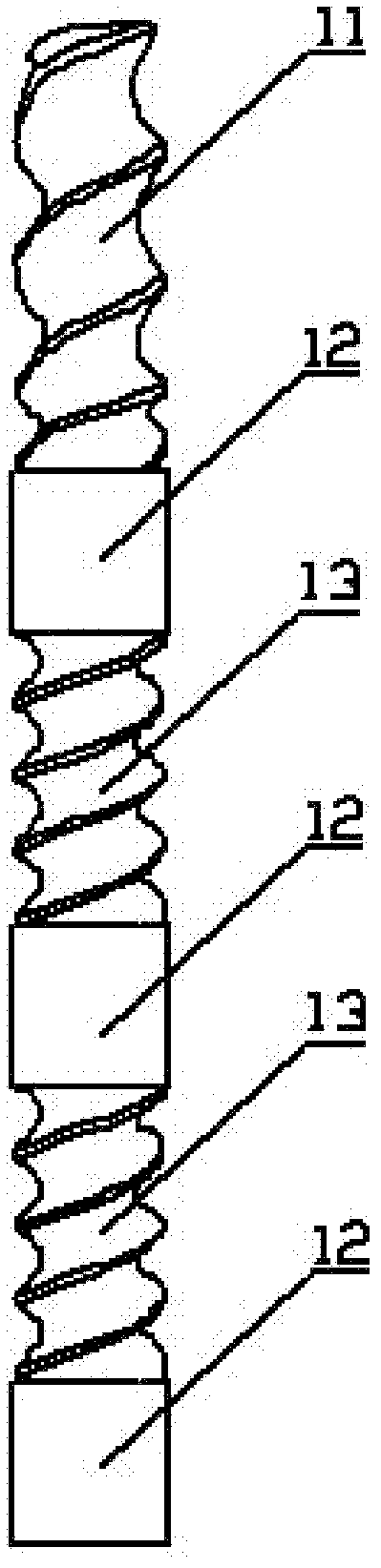

Making process of compound wood-plastic material product

The present invention discloses the making process of compound wood-plastic material product. Un-dried wood powder, plastic grain, compatibilizing agent, coupler, antioxidant, reinforcer, color powder and lubricant in certain proportion are fed to a pelletizing extruder for form granular material; and the granular material is extruded in a forming extruder and further processed through cooling to settle, drawing, cutting and decorating to produce the wood-plastic product. The present invention has the advantages of simple process, high production effect and rich material resource, and the product has timber-like texture, excellent performance and environment friendship.

Owner:浙江诚信包装有限公司

Method for preparing porcelain granules by using fly ash

InactiveCN101585698AImprove protectionSave natural resourcesFluid removalCeramic materials productionExpanded clay aggregateSlurry

The invention discloses a method for preparing porcelain granules by using fly ash, which comprises the following steps: putting fly ash, potassium feldspar and quartz as raw materials into a ball mill respectively, dry-milling the raw materials, sieving the milled raw materials respectively, removing iron from the sieved fly ash, putting the fly ash after iron removal, the sieved potassium feldspar and quartz and kaolin into the ball mill, and wet-milling and evenly mixing the materials to form mixed slurry; and granulating the mixed slurry by adopting a pressure type spray granulator, putting the granules into an alumina crucible, placing the alumina crucible into a silicon-carbon rod resistance furnace, sintering and naturally cooling the granules, and taking out the granules to obtain the high-strength porcelain granules. The method for preparing the porcelain granules by using the fly ash is not only favorable for saving natural resources and reducing the production cost, but also favorable for environmental protection. The fly ash does not need to be crushed by a high-power crusher, and the fly ash is mixed evenly. The production process is easy to control, and has little energy consumption; the strength of the prepared fly ash porcelain granules can reach 60 to 120MPa; and the porcelain granules have good properties of light weight, high temperature resistance, corrosion resistance and the like, and can be used as a fracturing propping agent for middle and deep layer oil-gas fields.

Owner:SHAANXI UNIV OF SCI & TECH

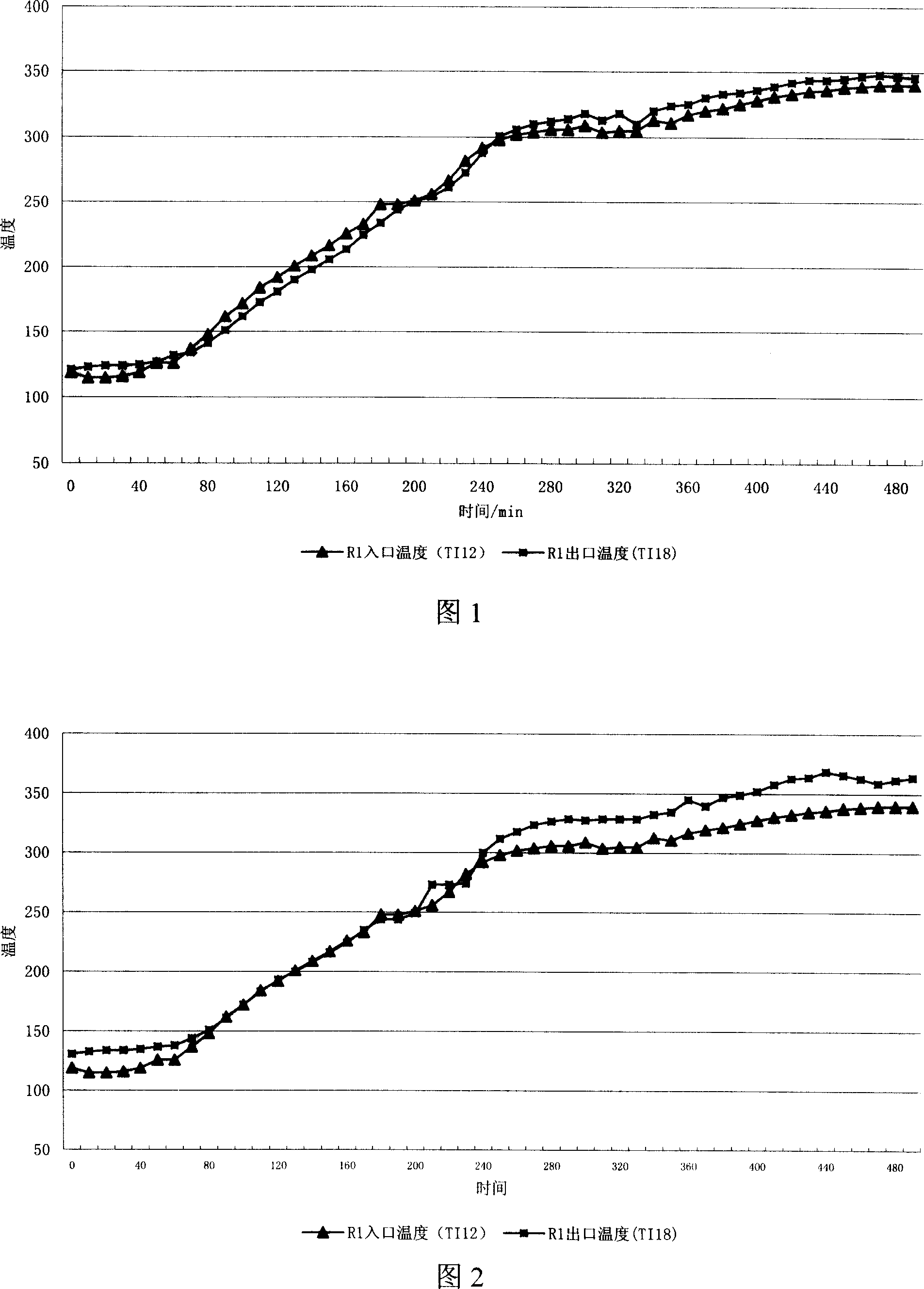

Prepn process of vulcanized hydrogenation catalyst

ActiveCN101088619AFull and even contactEvenly mixedCatalyst activation/preparationRefining by selective hydrogenationSulfurNitrogen

The present invention relates to one kind of vulcanized hydrocarbon oil hydrogenating catalyst and its preparation process. The preparation process includes the first supporting certain amount of VI and VIII metal precursor oxide, the subsequent introducing sulfur and heat treatment in dynamic heating equipment, and final adding the residual VI and VIII metal precursor oxide and drying treatment. The present invention combines the pre-vulcanizing into the preparation process of catalyst, and the catalyst has raised reaction performance, and is suitable for hydrocarbon oil hydroprocessing, especially light fraction oil desulfurizing reaction, hydrodenitrogenation reaction, arene hydrogenating saturation and other catalytic reaction process.

Owner:CHINA PETROLEUM & CHEM CORP +1

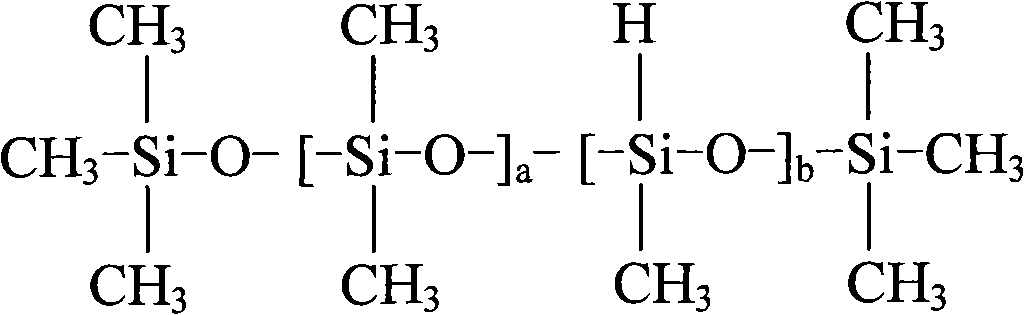

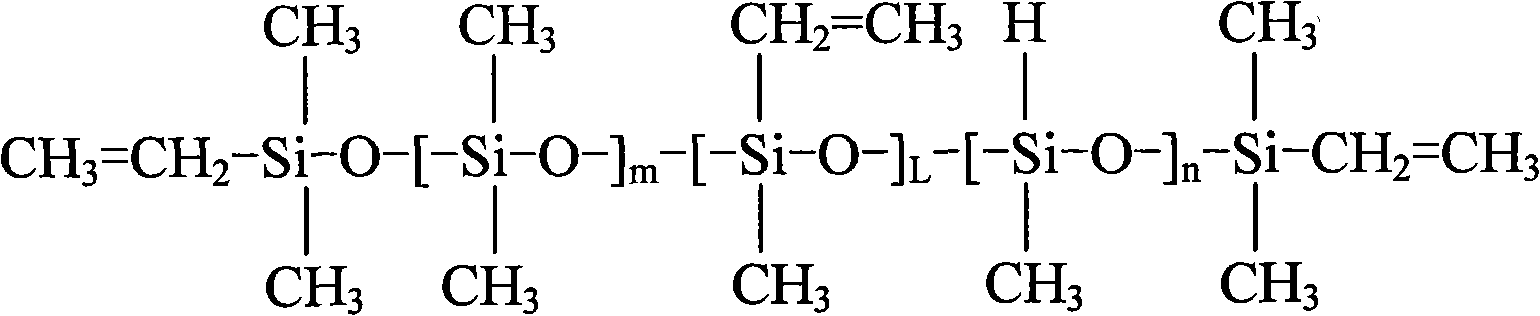

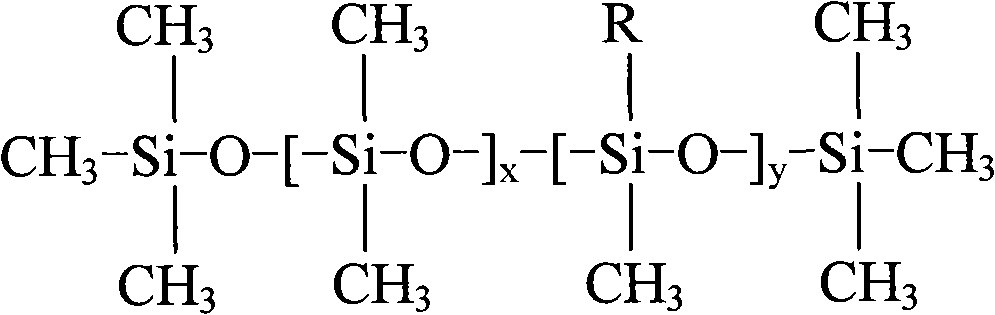

Silastic composition and preparation method thereof

The invention relates to a silastic composition and a manufacturing method thereof. The silastic composition comprises a component A and a component B, the component A is composed of mixing base adhesive and platinum coordination complex, whereas the component B is composed of the mixing base adhesive, hydrogen-containing silicone oil, a thickening agent and a depressor; the mixing mass ratio is: component A: component B is 0.5-99:1-99.5. The silastic composition of the invention is a solid-state mixing silastic containing platinum curing ingredient, so no curing ingredient is needed in the process of molding, besides, the vulcanization effect is good, the vulcanization moulding temperature is low, thus saving electricity, reducing exhaust emission and improving productivity; moreover, the silastic product is odorless and has fine physical and mechanical properties.

Owner:东莞市贝特利新材料有限公司

Method for increasing retention rate of calcium carbonate in paper-process reconstituted tobacco sheets

The invention relates to a method for increasing the retention rate of calcium carbonate in paper-process reconstituted tobacco sheets. The purpose of the invention is to solve the problems that: since the prior art directly adds calcium carbonate, the bonding force between the calcium carbonate and tobacco fibers is weak, as a result, loss is severe, the material utilization rate is low, the amount of waste water to be treated is large, and the treatment cost is high. The technical point is that: needed chemical constituents are extracted from tobacco material, residue is ground into pulp after extraction, and the concentration of the pulp is regulated between 3 percent and 25 percent; the solution of soluble carbonate accounting for 4 percent to 40 percent of the weight of dry fibers in the pulp is added into the pulp, and is fully stirred and uniformly mixed, and impregnation is then carried out for 20 to 150 minutes, so that the fibers of the pulp can be impregnated with the soluble carbonate; the solution of soluble calcium salt, the molar mass of which is approximately equal to the molar mass of the soluble carbonate, is added into the impregnated pulp, and is fully stirred and uniformly mixed, static reaction is then carried out for 30 to 180 minutes, and the reaction temperature is controlled at 5 DEG C to 50 DEG C; and after the static reaction, the pulp is made into reconstituted tobacco sheets by papermaking equipment.

Owner:GUANGDONG JINKE REFORGING TOBACCO LEAF CO LTD

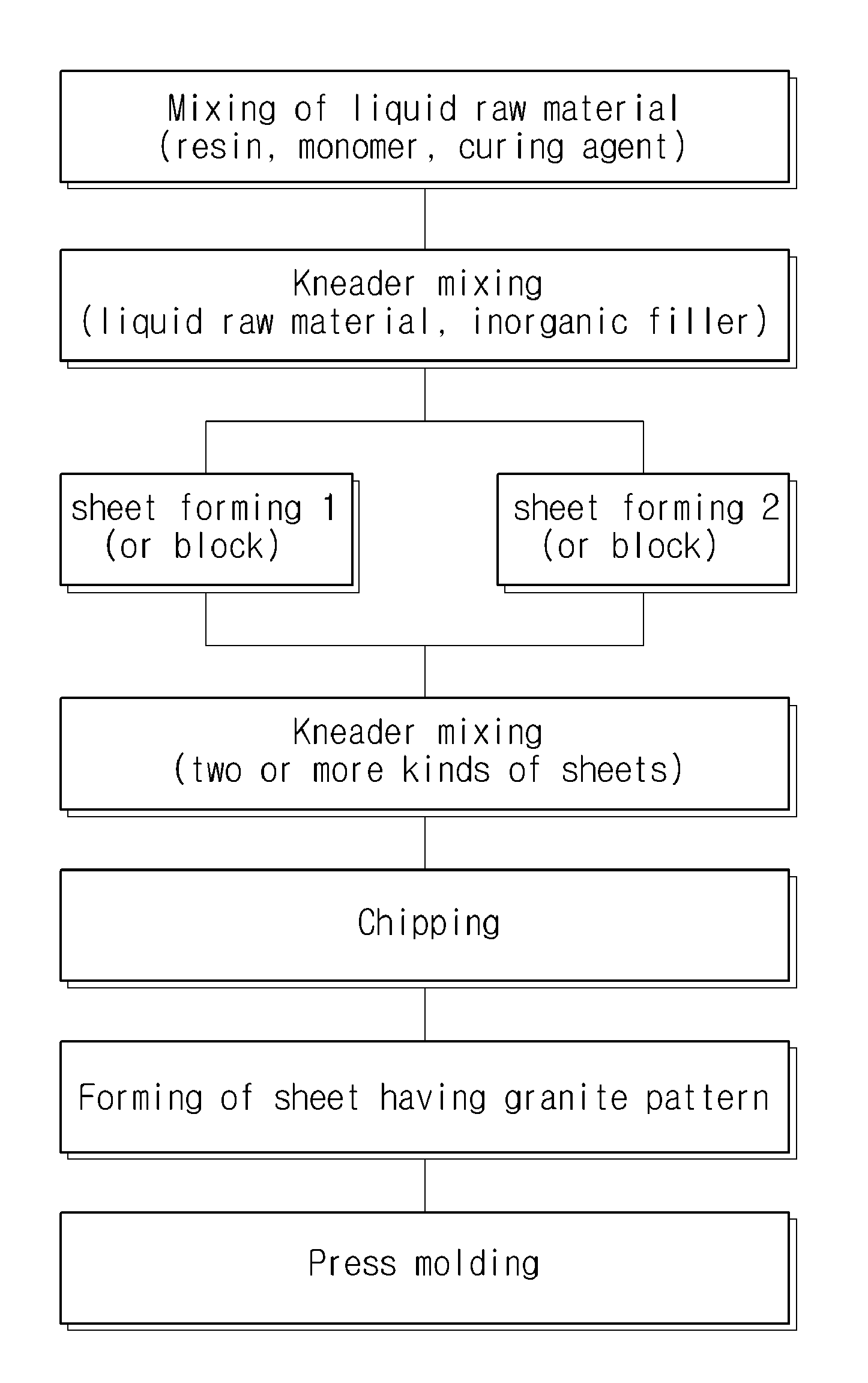

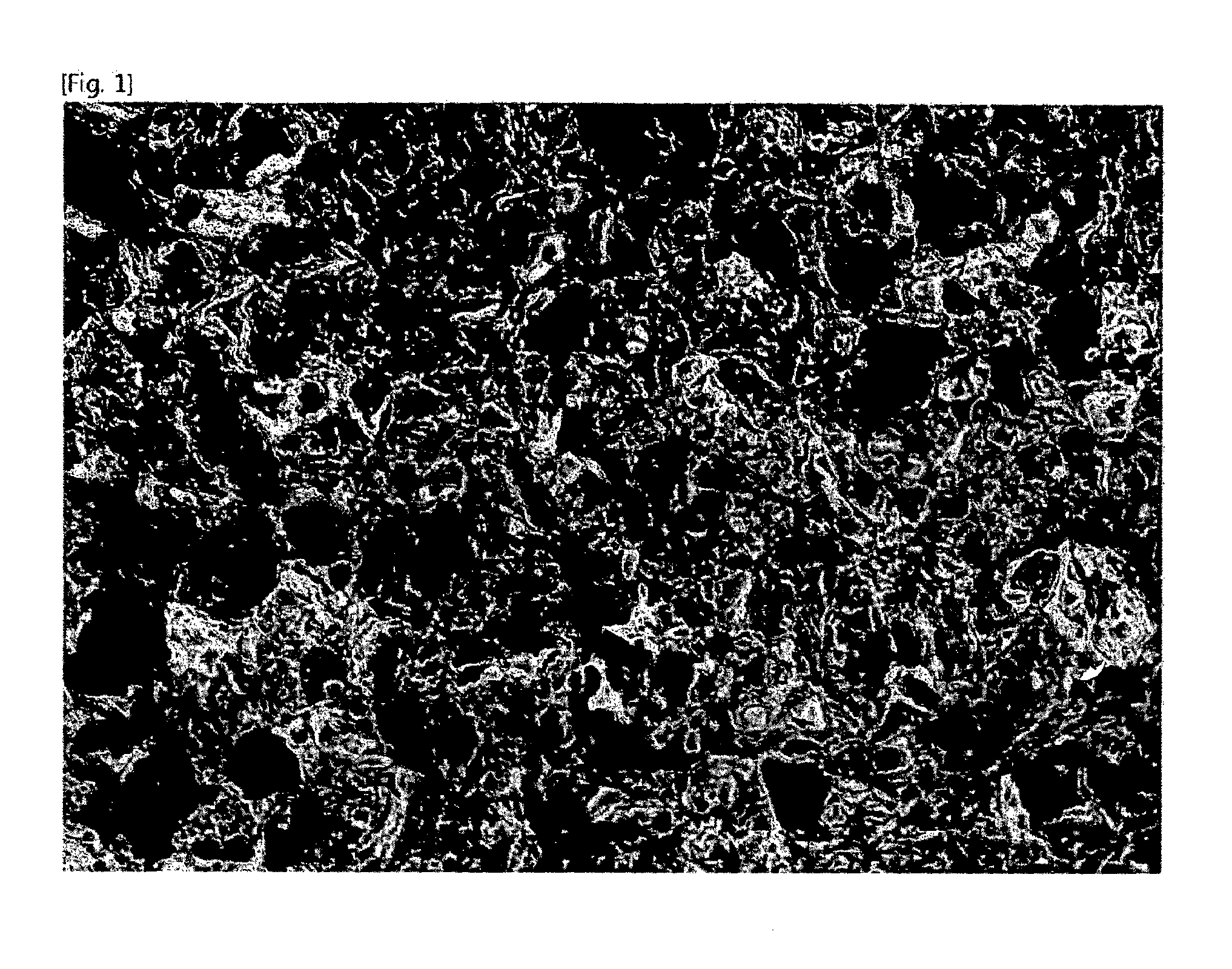

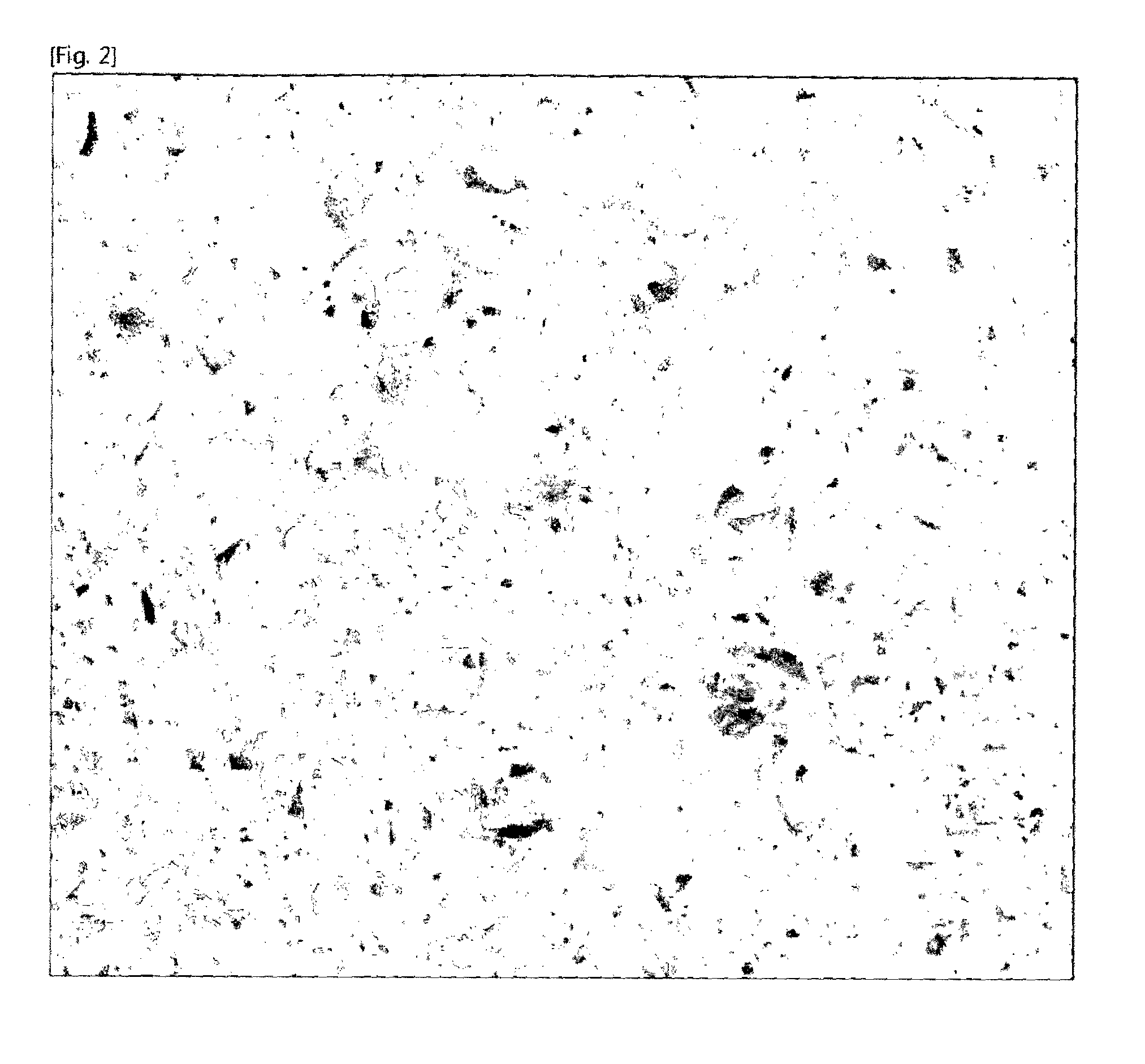

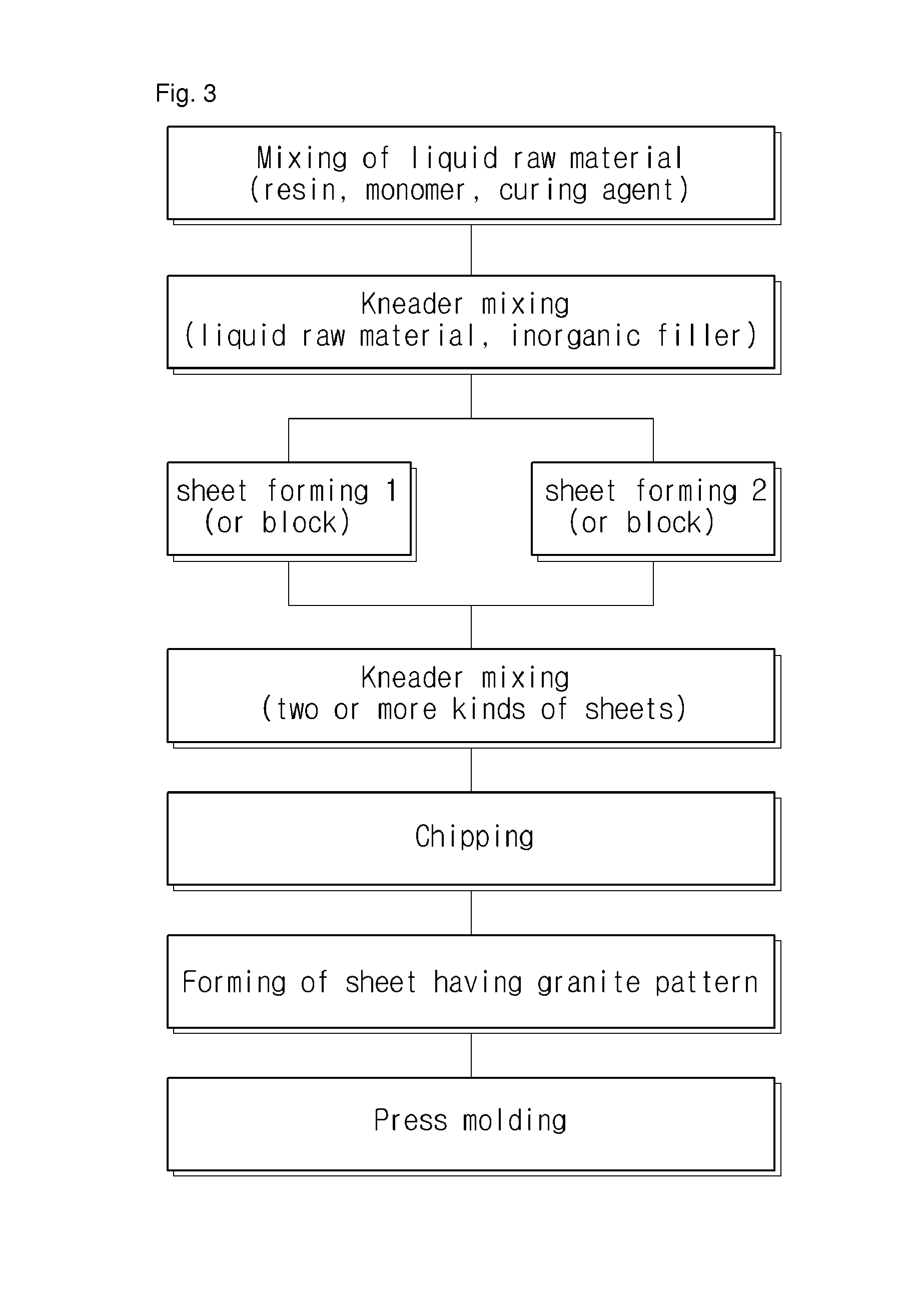

Acrylic artificial marble having granite pattern and method of manufacturing the same

InactiveUS20130137810A1Well mixedDesired patternNatural patternsNon-woven fabricsShell moldingGranolithic

The present invention relates to an acrylic artificial marble having a granite pattern and a method of manufacturing the same, which can provide a natural marble effect by mixing and molding two or more compounds having different colors and thus can obtain a granite pattern in which patterns of the two or more compounds are smoothly mixed, and which can obtain a desired pattern remarkably similar to a pattern of natural stone by using a multicolor chip sheet.

Owner:LG HAUSYS LTD

Process of treating hydrogenation catalyst before application

ActiveCN101088615AImprove performanceSolve the problem of concentrated heat releaseCatalyst activation/preparationRefining by selective hydrogenationAs elementOrganic acid

Owner:CHINA PETROLEUM & CHEM CORP +1

Prepn process of vulcanized catalyst

ActiveCN101088620AImprove vulcanization effectImprove hydrogenation reaction performanceCatalyst activation/preparationRefining by selective hydrogenationChemistryThiram

The present invention relates preparation process of vulcanized catalyst. During the preparation process, thiram in 0.5-25 wt% of the catalyst, sulfur element in 30-150 % of the theoretic sulfur demand of the catalyst and organic solvent in 0.1-50 wt% of the catalyst are first introduced into the catalyst in oxide state, and the catalyst is then heat treated in dynamic heating apparatus. The catalyst has raised sulfur holding rate, smooth heat release, shortened vulcanizing period and raised production efficiency. The method of the present invention may be used in the treatment of various kinds of hydrogenating catalyst before application.

Owner:CHINA PETROLEUM & CHEM CORP +1

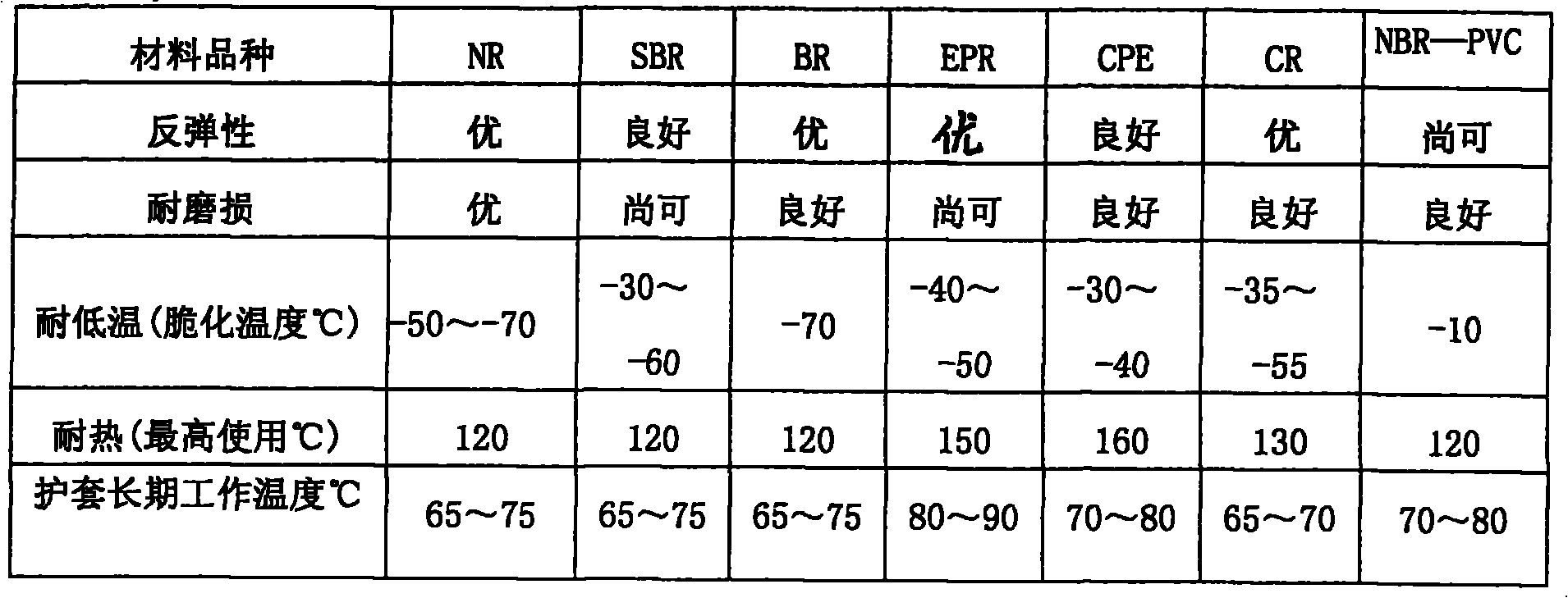

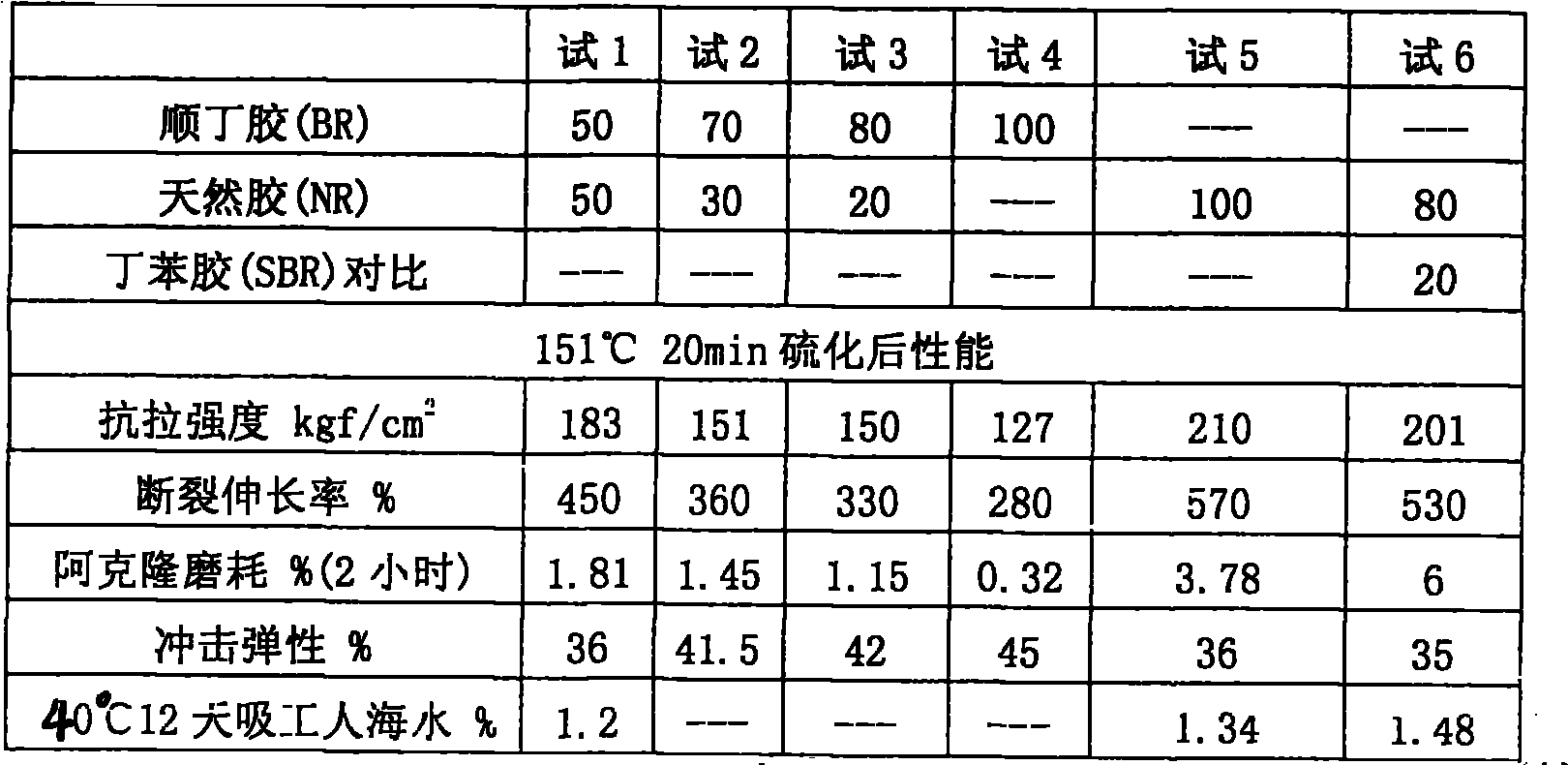

Cable jacket rubber and preparation method

ActiveCN101580606AScorch slowFast vulcanizationRubber insulatorsInsulated cablesTetramethylthiuram disulfideElectricity

The invention relates to a cable jacket rubber and a preparation method, wherein the cable jacket rubber has high elastic resilience, softness and abrasive resistance at a low temperature. The cable jacket rubber is characterized in that a base material of the rubber is formed by mixing 30 to 50 weight percent of natural gum and 50 to 70 weight percent of cis-butadiene rubber; a vulcanizing system in a rubber compounding agent is a low-sulfur high-accelerant vulcanizing system, the addition of sulfur is 0.3 to 0.6 weight percent of that of the base material of the rubbere, the addition of the accelerant tetramethylthiuram disulfide is between 1.0 and 1.3 weight percent, the addition of the accelerant N-cyclohexyl-2-benzothiazole sulfonamide is between 1.8 and 2.2 weight percent, and the addition of the accelerant diphenyl disulfide benzothiazole is between 0.6 and 0.9 weight percent. The cable jacket rubber has wide range of working temperature, and can be bent and distorted randomly without cracking at a long-term usage temperature of between 50 DEG C below zero and 70 DEG C, the impact elasticity is high and can reach 42 percent, the specific elongation is more than 350 percent, and the Akron abrasion loss is less than 2 percent, thus the cable jacket rubber is particularly suitable for wind-power generated electricity tower tube cables.

Owner:WUXI HUAMEI CABLE

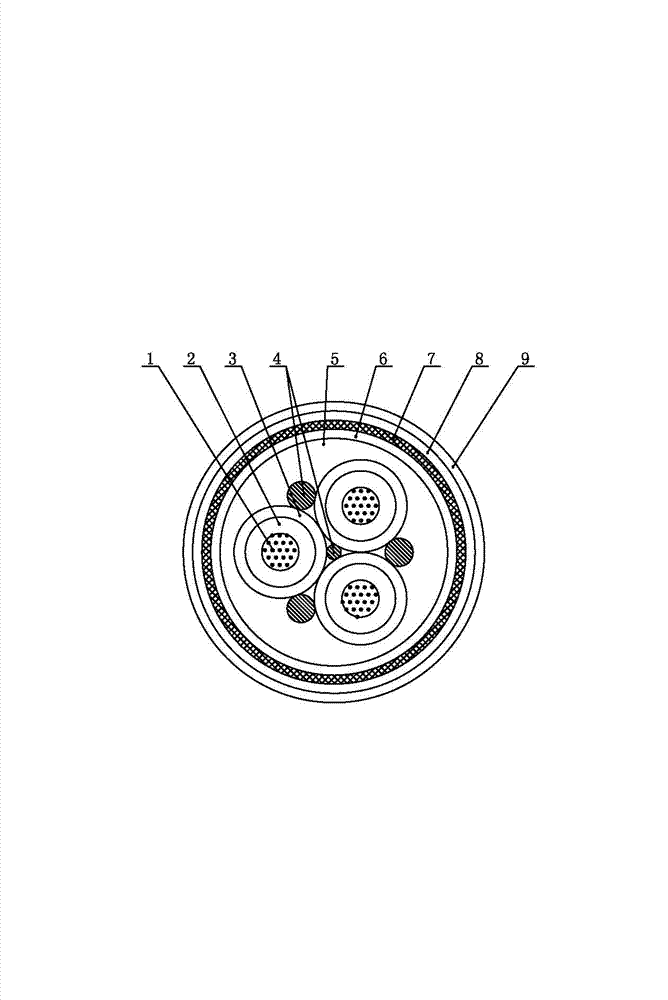

Shielding longitudinal watertight degaussing cable and production method thereof for ships

ActiveCN102855982AEnsure watertight effectImprove sealingInsulated cablesCable/conductor manufactureCopper conductorVulcanization

The invention discloses a shielding longitudinal watertight degaussing cable and a production method thereof for ships. A tinned copper wire is impregnated with a sealant and then twisted into a twisted copper conductor which is impregnated with a conductor sealant layer on the periphery, an electro-insulating rubber layer is extruded on the periphery of the conductor sealant layer to form insulation core wires, chloroprene rubber filling bars are filled into gaps between the insulation core wires, and a plurality of insulation core wires are twisted wholly into a cable core. A cable core inner sealant layer, an inner jacket rubber layer, an armor shielding layer and an outer jacket rubber layer are sequentially arranged on the periphery of the cable core. A single wire of the cable conductor is impregnated with the sealant, the twisted copper conductor is impregnated with the conductor sealant layer on the periphery, the cable core inner sealant layer is extruded on the periphery of the cable core to form multiple sealing, the chloroprene rubber filling bars swell during follow-up vulcanization and can fill in the gaps inside the cable core completely, and tangency between the insulation core wires can be avoided, so that the sealant can permeate to the inside of the cable core to guarantee the watertight effect when the cable core inner sealant layer is extruded.

Owner:嘉兴顾翔制冷设备有限公司

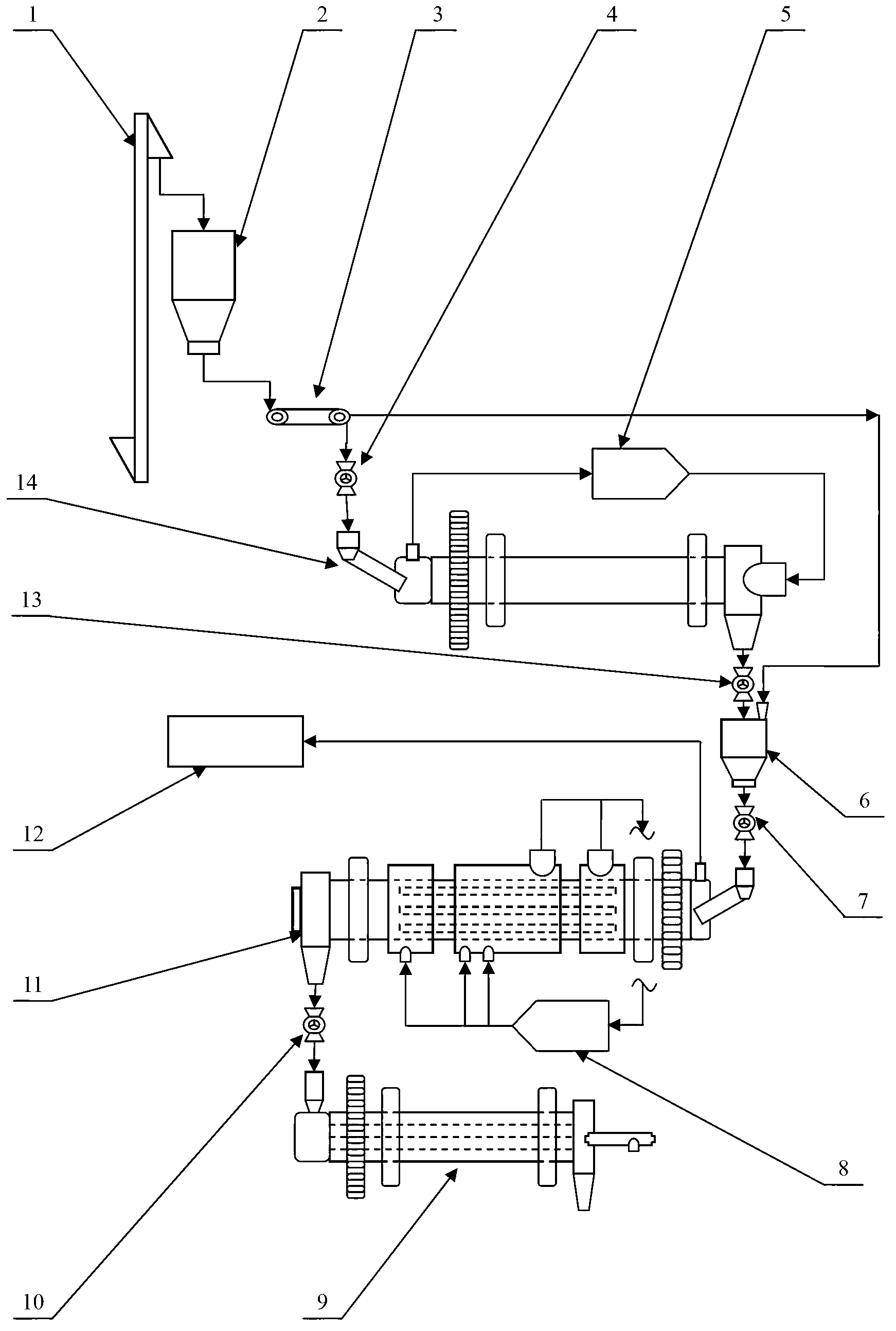

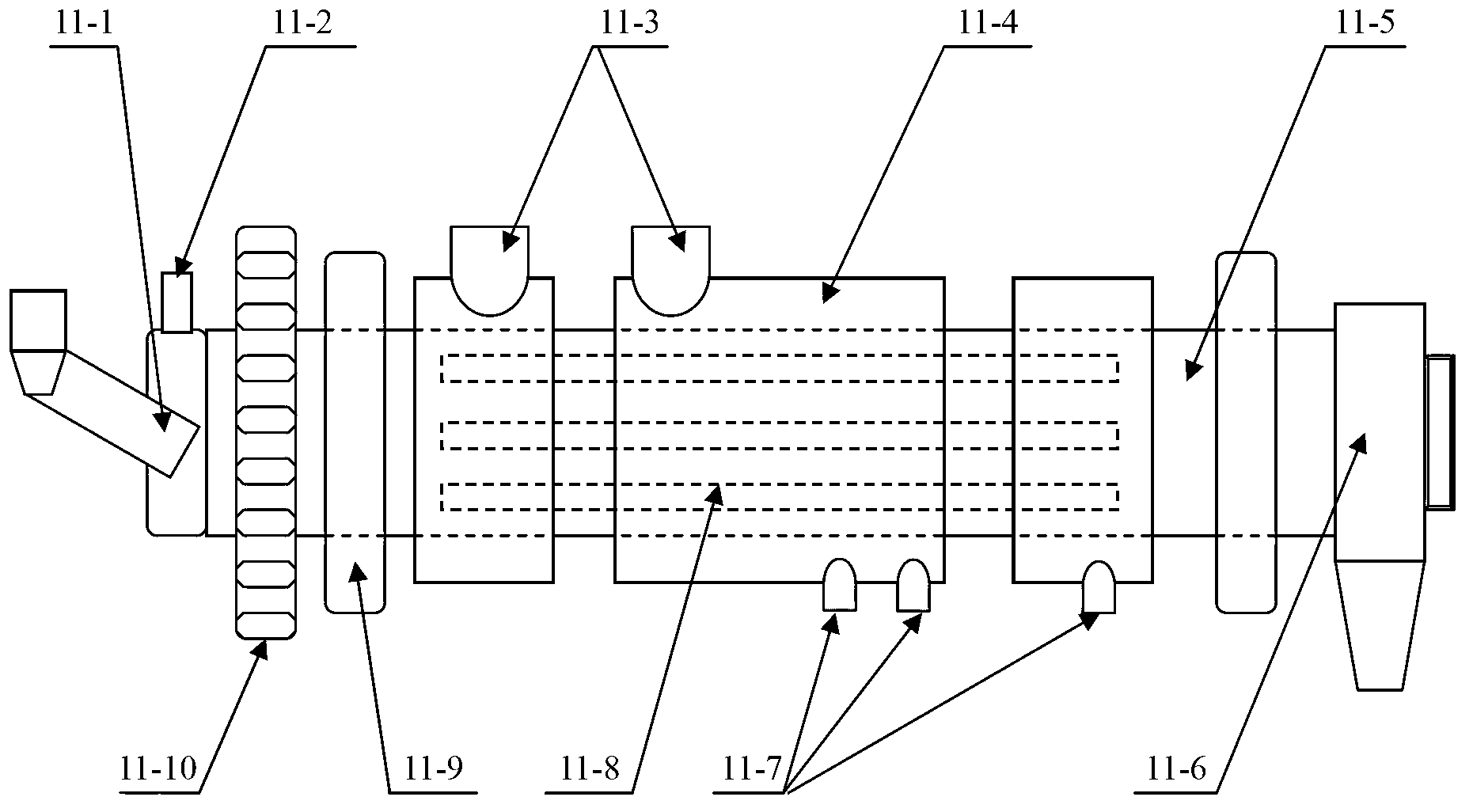

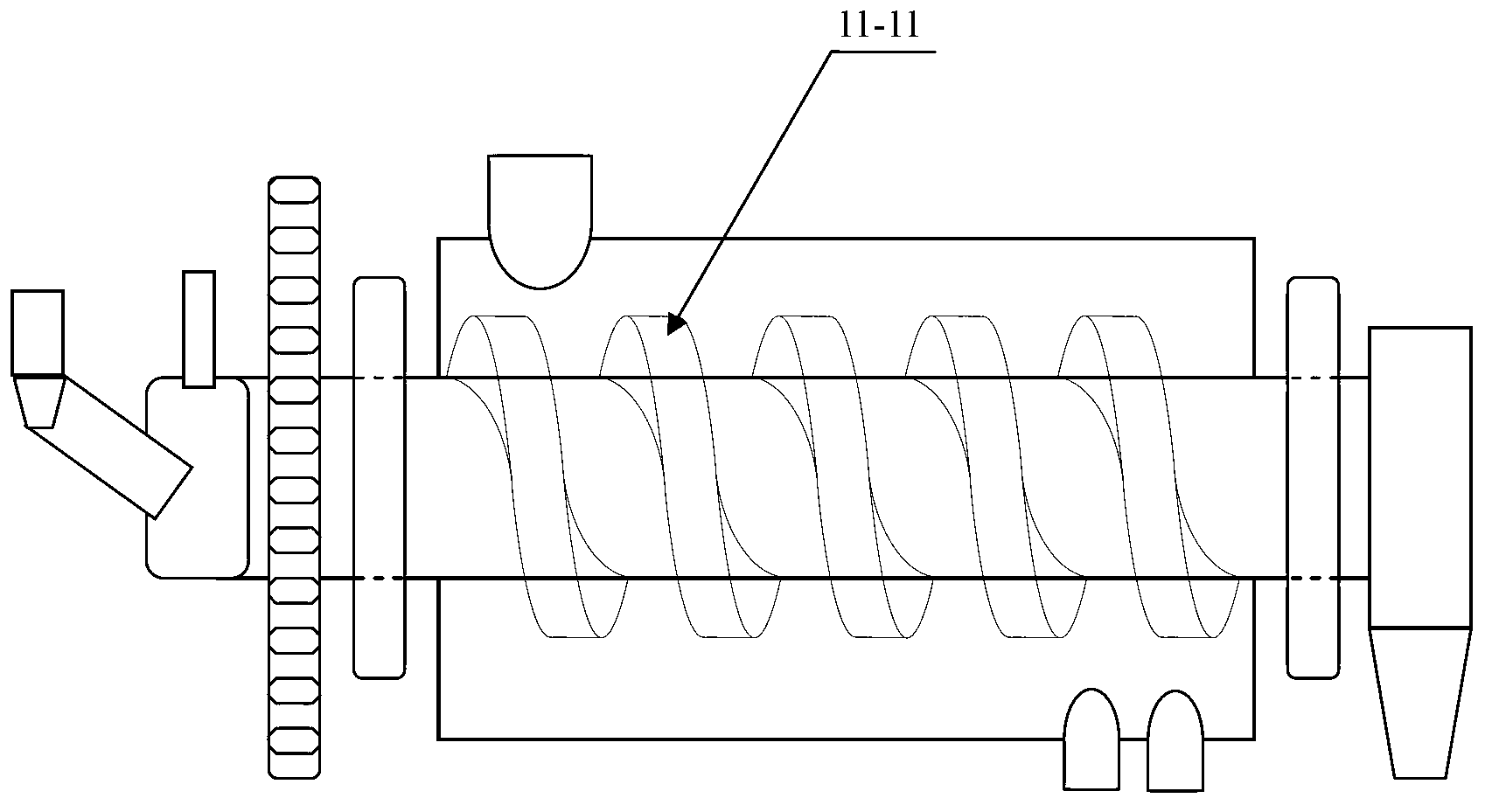

Low-temperature carbonization apparatus and method for oil sand, oil sludge, oil shale and biomass

ActiveCN103160301AIncrease profitReduce energy consumptionDirect heating destructive distillationBiofuelsCarbonizationOil shale gas

The invention discloses a low-temperature carbonization apparatus and method for oil sand, oil sludge, oil shale and biomass. The apparatus comprises a delivery apparatus, a storage bin, a metering apparatus, a drying furnace and a surge bin. The method comprises the following steps: drying, preheating, carbonizing, and cooling. The core of the invention is an external heating type rotary carbonization furnace which realizes the pyrolysis of oil sand, oil shale, oil sludge (oil sludge on the ground, oil sludge at the bottom of a tank and oil-containing sludge from oil refinery) and biomass, and the product is high in purity and low in loss. The invention effectively solves the problems of solid materials such as adhesion, wall accretion and the like in the pyrolysis process by material returning. The technology provided by the invention is simple in process and reliable and stable in operation, and has obvious advantages in the treatment of small particle materials such as oil shale, oil sand, oil sludge (oil sludge on the ground, oil sludge at the bottom of a tank and oil-containing sludge from oil refinery), biomass and the like.

Owner:何建祥

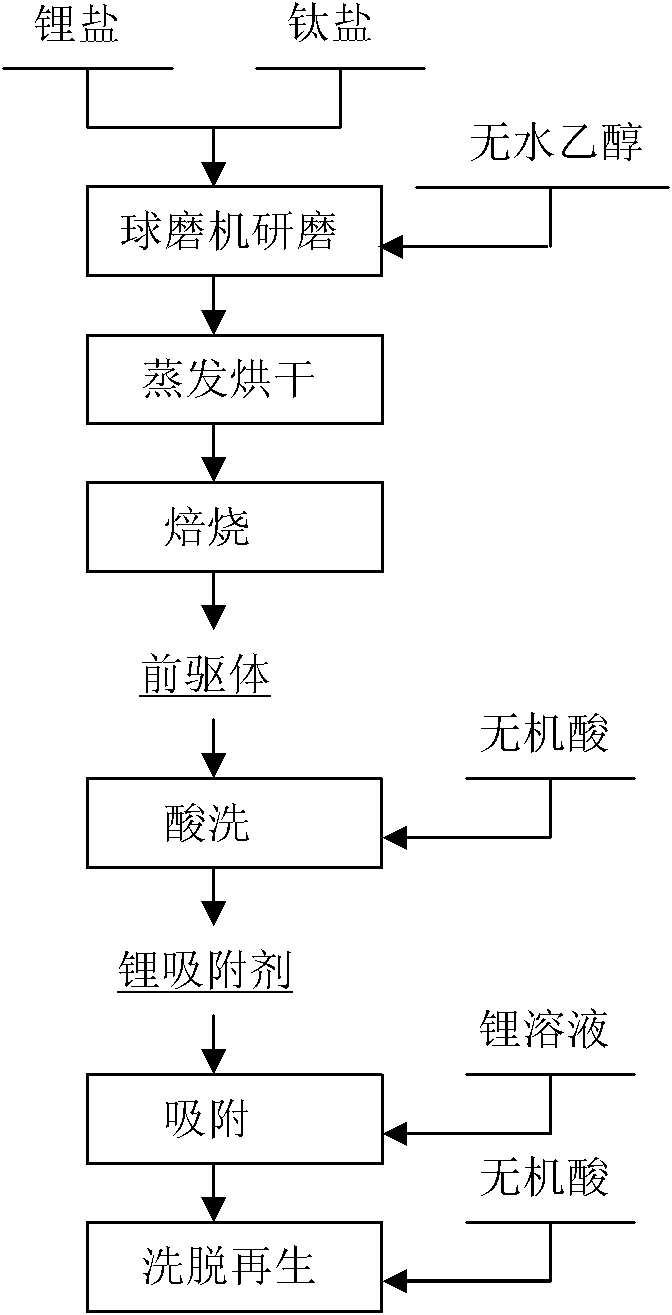

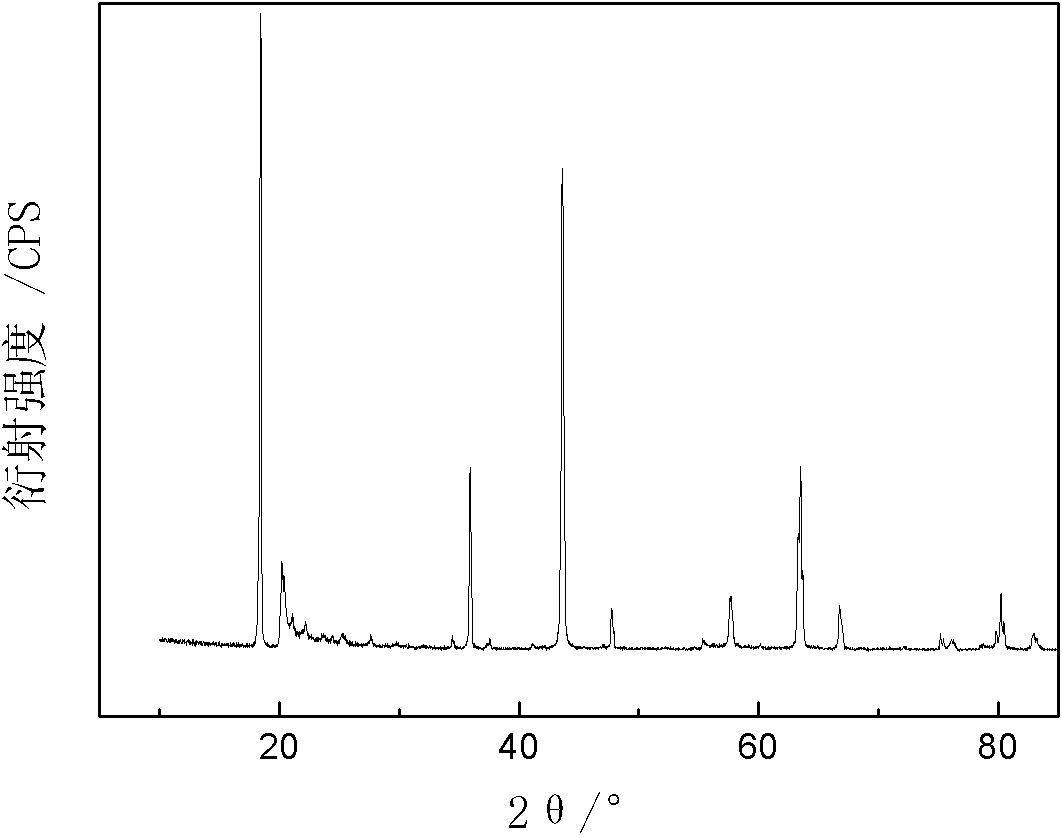

Lithium-titanium oxide type lithium ion sieve absorbent and method for preparing precursor thereof

InactiveCN101944600AWell mixedIncrease contact surfaceCell electrodesTitanium compoundsSalt lake brineTitanium oxide

The invention discloses a lithium-titanium oxide type lithium ion sieve absorbent and a method for preparing a precursor thereof, and relates to a method for preparing an inorganic absorbent for absorbing enriched lithium from salt lake brine, seawater and other liquid lithium resources. The method is characterized in that: titanium dioxide and lithium salt are taken as raw materials, ground by a ball grinder and dried so as to prepare a precursor Li2TiO3 of an ion sieve through a high-temperature solid-phase roasting method; and the lithium is eluted from the precursor Li2TiO3 by inorganic acid to prepare an ion sieve H2TiO3. The method has the advantage of simple technology, and the obtained ion sieve has the advantages of low solution loss and high adsorption capacity.

Owner:CENT SOUTH UNIV

Method for preparing manganese lithium phosphate/carbon composite material by manganese phosphate

ActiveCN101673819ALow costThe synthesis process is simpleElectrode manufacturing processesCarbon compositesManganese

The invention discloses a method for preparing manganese lithium phosphate / carbon composite material by manganese phosphate, belonging to the technical field of energy material, comprising the following steps: firstly, preparing active manganese phosphate (MnPO4), secondly mixing the active manganese phosphate with lithium source and adding carbon source, ball milling and spray drying the materials, conducting heat treatment on the dried powder in the presence of protective atmosphere, heating to 300-850 DEG C and roasting for 2-12 hours and naturally cooling to obtain the manganese lithium phosphate / carbon composite material. The preparation method has low cost and simple synthesis technology, is applied to industrial production; the prepared manganese lithium phosphate / carbon composite material has a primary particle average diameter of 40-500 nm; the synthetic manganese lithium phosphate / carbon composite material has good electrochemical property when taken as the anode material ofthe lithium battery, high specific capacity and nice circulating performance at the conditions of room temperature and large current density; and the specific discharge capacity with 0.1 C multiplyingpower is more than 130 mAh / g.

Owner:TSINGHUA UNIV

Waterproof and anti-corrosion repair mortar for polymer cement-based concrete structure

The invention relates to a waterproof and anti-corrosion repair mortar for a polymer cement-based concrete structure, in particular to a cement concrete repair material for a cement concrete structure, which is used for carrying out bonding reinforcement and repair on defects of municipal roads, municipal services, bridges and water conservancy projects (dams and gates). The waterproof and anti-corrosion repair mortar is prepared by mixed materials and water, and the mixed materials comprise the following components in parts by weight: 20-30 parts of portland cement, 0.01-0.05 part of high-performance water-reducing agent, 1-5 parts of high-aluminum cement, 15-30 parts of quartz sand, 25-60 parts of gravel and 1-3 parts of acrylic adhesive powder, 1-3 parts of fiber material, while the using amount of water accounts for 5-14% of the total parts of the mixed materials. Due to the adoption of the technical scheme, the waterproof and anti-corrosion repair mortar has the characteristics of good pressure resistance, high flexural strength, high bonding strength, good durability, convenient and fast construction, fast setting and early strength shrinkage control, and can greatly shorten the repair time and quickly resume the traffic in particular to roads.

Owner:卢建华

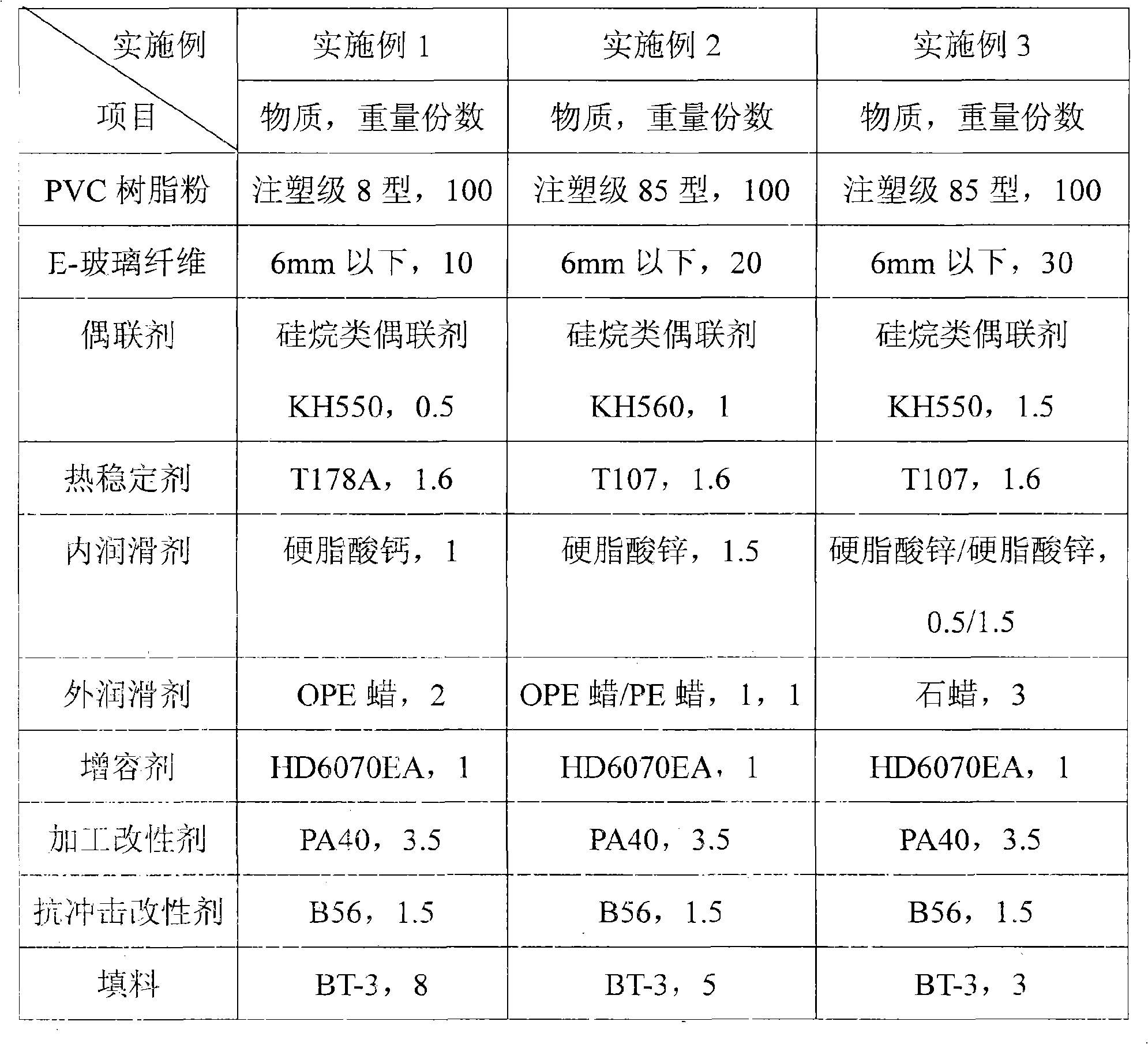

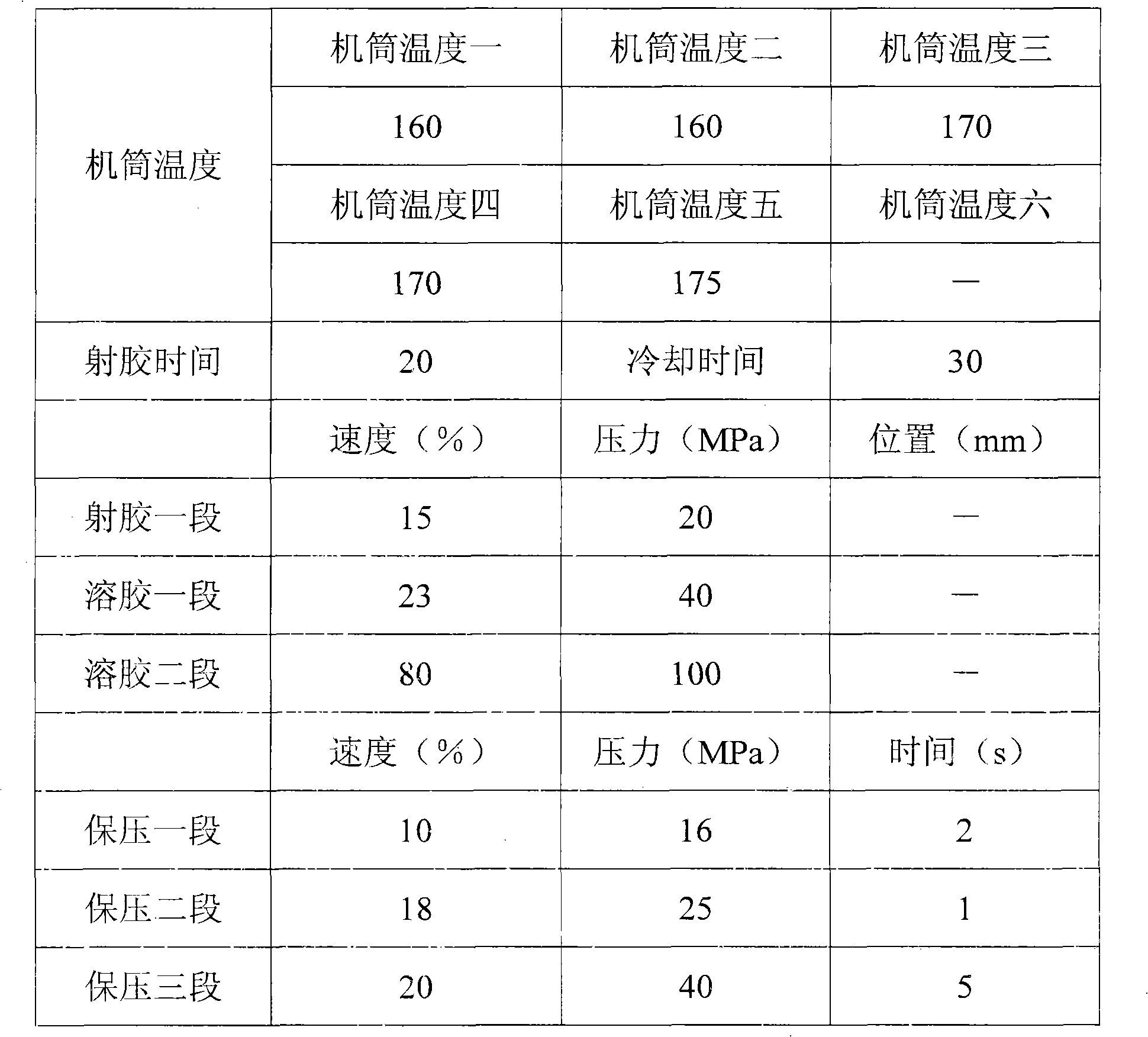

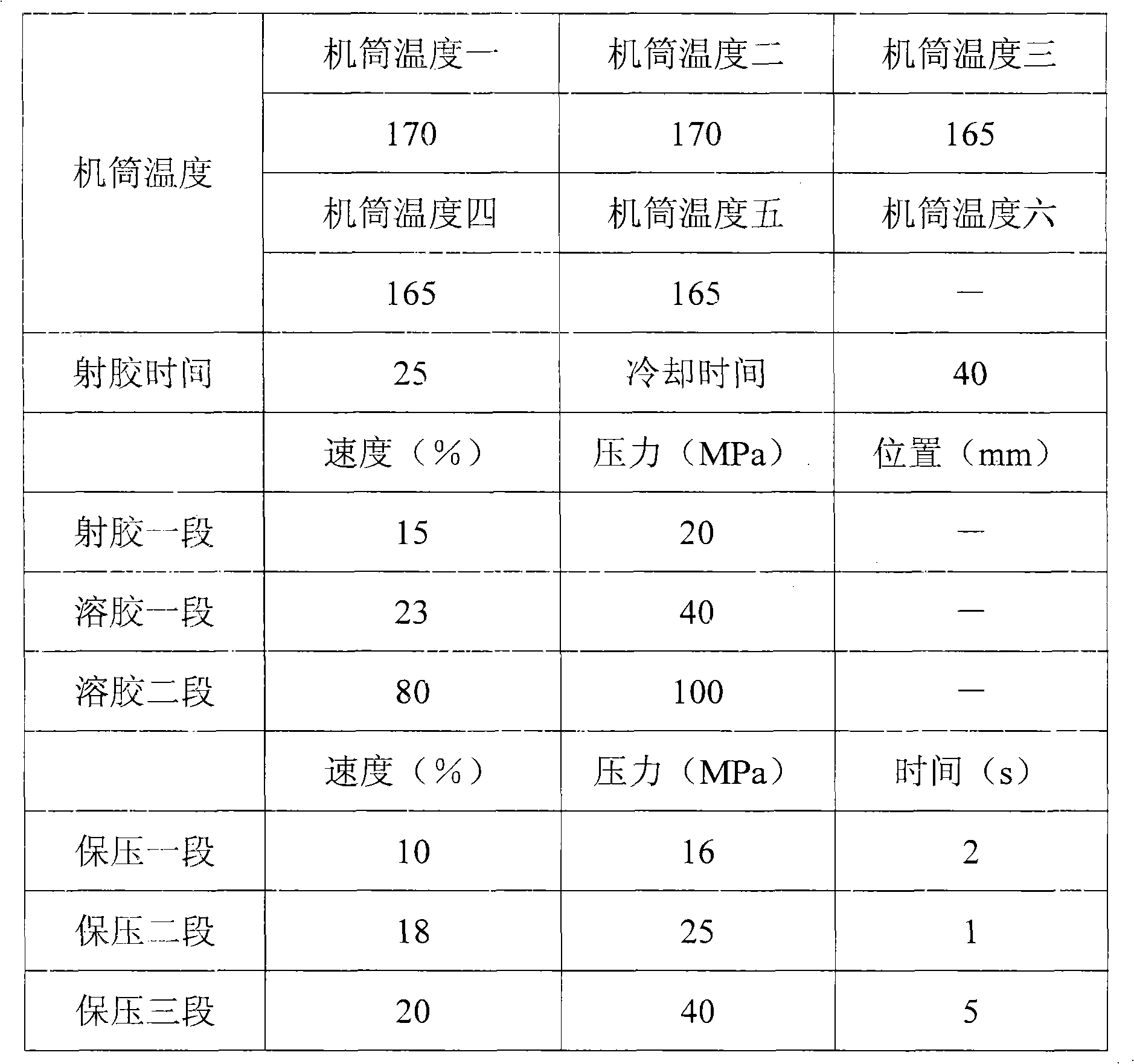

Glass fiber reinforced unplasticised polyvinyl chloride material and preparation thereof

The invention discloses a glass fiber enhanced hard polyvinyl chloride material and a preparation method. The material comprises PVC resin powder, glass firber, coupling agents, heat stabilizer, compatibilizer, lubricant, processing modifier, anti-impact modifier, filler and other components, and the weight proportion of the components is 100:1-50:0.1-10.0:0.5-3.0:0.5-5.0:0.2-5.0:0.1-5.0:0.1-10.0:1.0-10.0. Through the coupling compatibility and compatibilization-granulation technology, the preparation method ensures that the glass fiber and polyvinyl chloride resin are directly mixed, granulated, injection-molded and made into the glass fiber enhanced hard polyvinyl chloride material having higher water-pressure resistance, higher heat resistance and other advantages. The preparation method solves the problems that subsequent PVC composite material s are difficult to mix, process and blank in the prior high-speed mixing method, which is favorable for processing and molding the subsequent PVC composite materials.

Owner:GUANGDONG LIANSU TECH INDAL

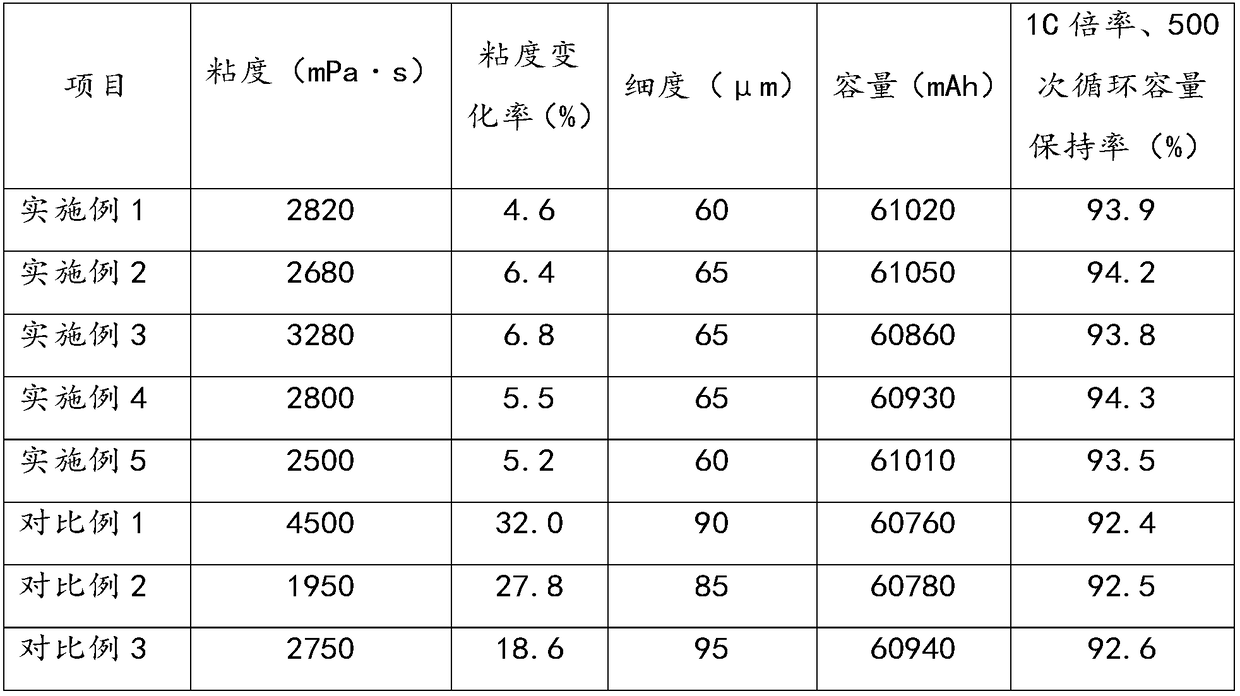

Preparation process of lithium ion battery negative paste, lithium ion battery negative pole plate and lithium ion battery

ActiveCN108305987AEvenly dispersedQuality improvementElectrode manufacturing processesElectrode carriers/collectorsPhysical chemistrySodium-ion battery

The invention belongs to the technical field of a lithium ion battery, and relates to a preparation process of lithium ion battery negative paste, a lithium ion battery negative pole plate and a lithium ion battery. The preparation process of the lithium ion battery negative paste comprises the following steps of (a) mixing a negative active substance, a conductive additive, a dispersion agent anda thickening agent in a dried way to obtain mixed powder; (b) adding a solvent, performing uniform mixing to obtain primary paste with solid content being 67-69wt%; (c) adding the solvent again, performing uniform mixing to obtain secondary paste with solid content being 58-62wt%; (d) adding the solvent again, performing uniform mixing to obtain third paste with solid content being 54-56wt%; and(e) adding a binding agent into the third paste, and performing uniform mixing to obtain the lithium ion battery negative paste. The process is simple and is easy to operate, the preparation time canbe remarkably prepared, the equipment utilization ratio is improved, meanwhile, the mixing is uniform, and the dispersion performance, the consistency and the fineness of the paste are improved.

Owner:BEIJING NAT BATTERY TECH

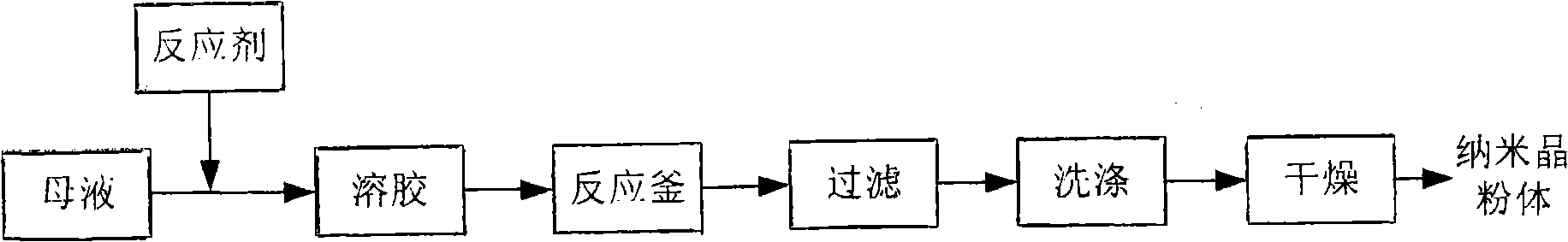

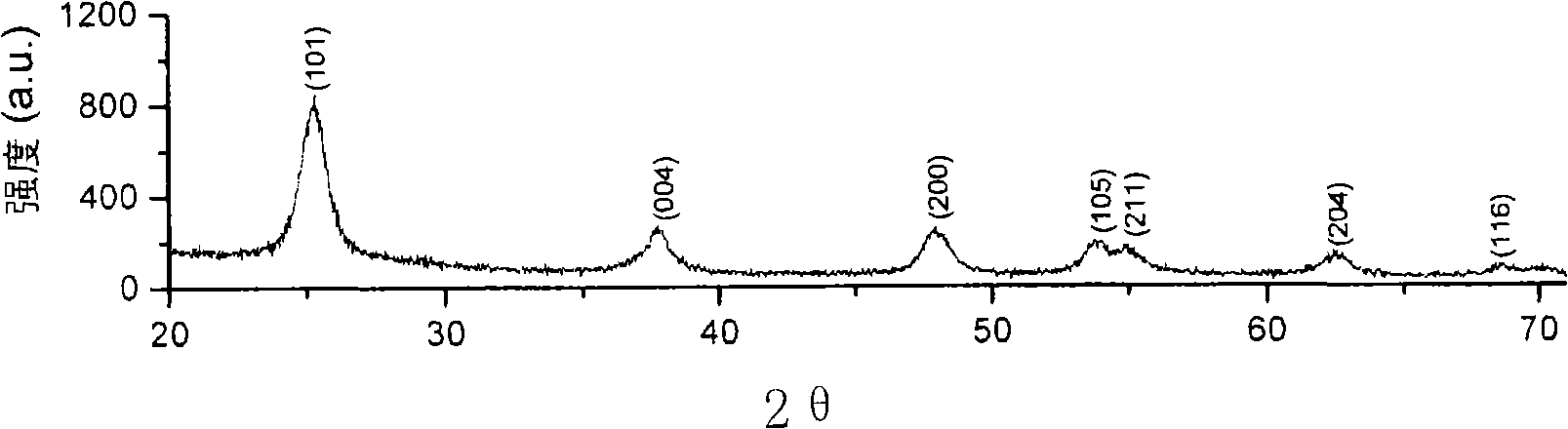

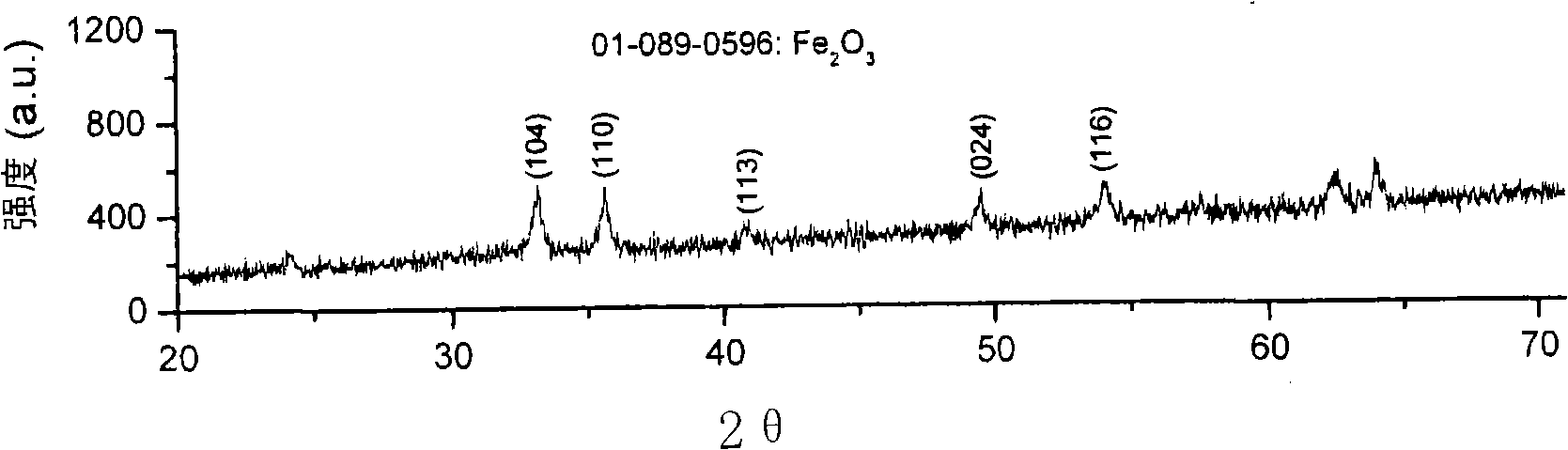

Sol-solvent-thermal method for synthesizing nanocrystalline oxide powder

InactiveCN101348240AUniform particle sizeNarrow distributionOxide/hydroxide preparationIron oxides/hydroxidesInorganic saltsLiquid medium

The invention provides a sol-solvent thermal method for synthesizing a nanocrystalline oxide powder. The method comprises the following: (1) a step of preparation of inorganic salt mother liquids, during which the inorganic salt taken as a material is dissolved in an organic liquid medium or water to prepare a mother liquid of the inorganic salt with definite concentration; (2) a step of preparation of a precipitation reactant liquid, during which alkali is dissolved in an organic liquid medium or water, proper quantity of surfactants are added to prepare the precipitation reactant liquid with definite concentration; (3) a step of preparation of sols, during which, at a certain temperature, while stirring, the prepared reactant liquid is slowly added in the prepared mother liquid of the inorganic salt, the reactant liquid and the mother liquid of the inorganic salt are kept reacting for a period of time after adding the reactant liquids in the mother liquid of the inorganic salt, and the transparent sols are obtained; and (4) a step of solvent thermal reaction of the sols, during which the prepared sols are put in a reaction kettle and reacted for a period of time under a certain temperature and pressure, the products obtained are subjected to filtering, washing and drying, and the nanocrystalline oxide powder is obtained.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

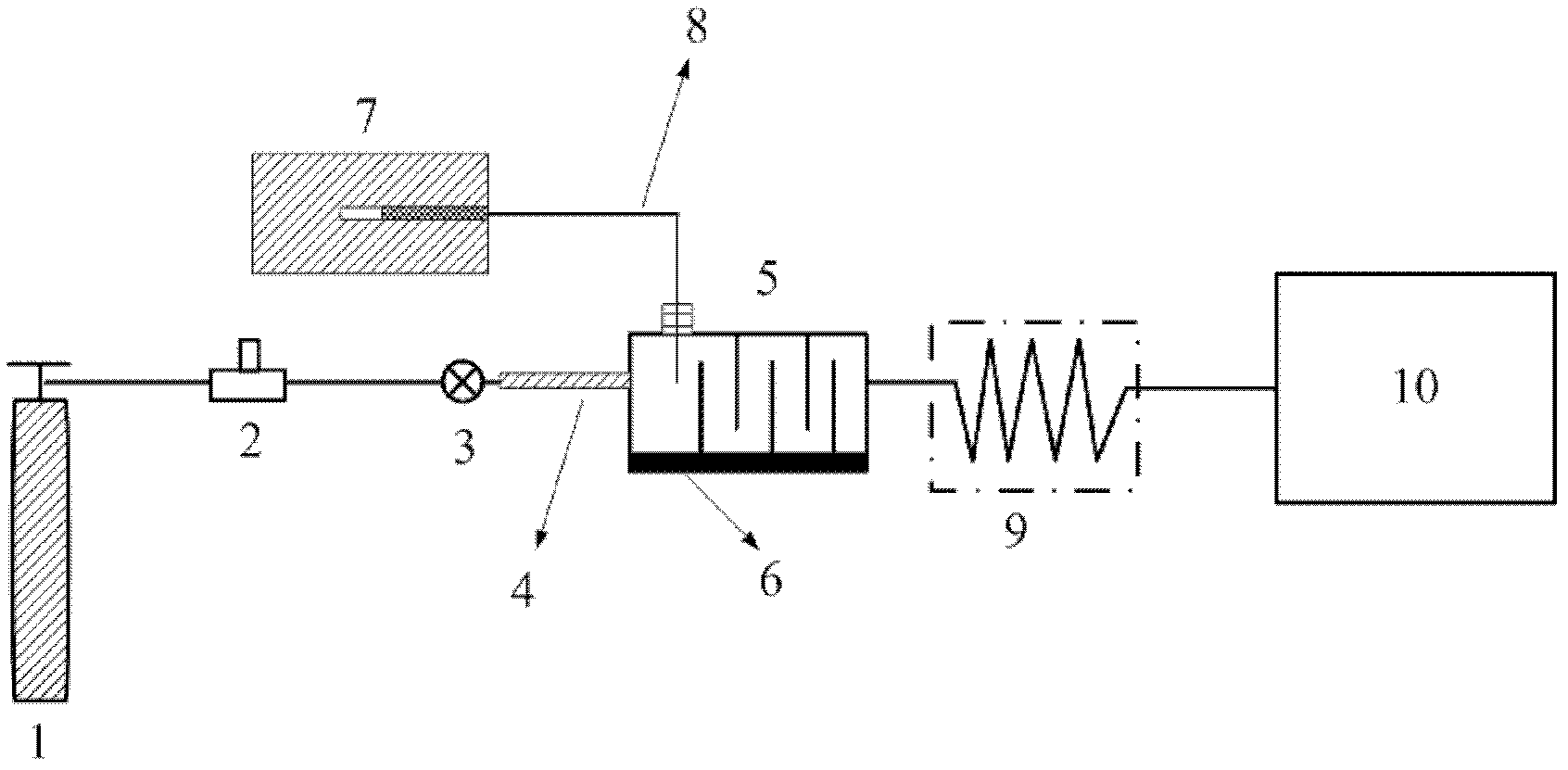

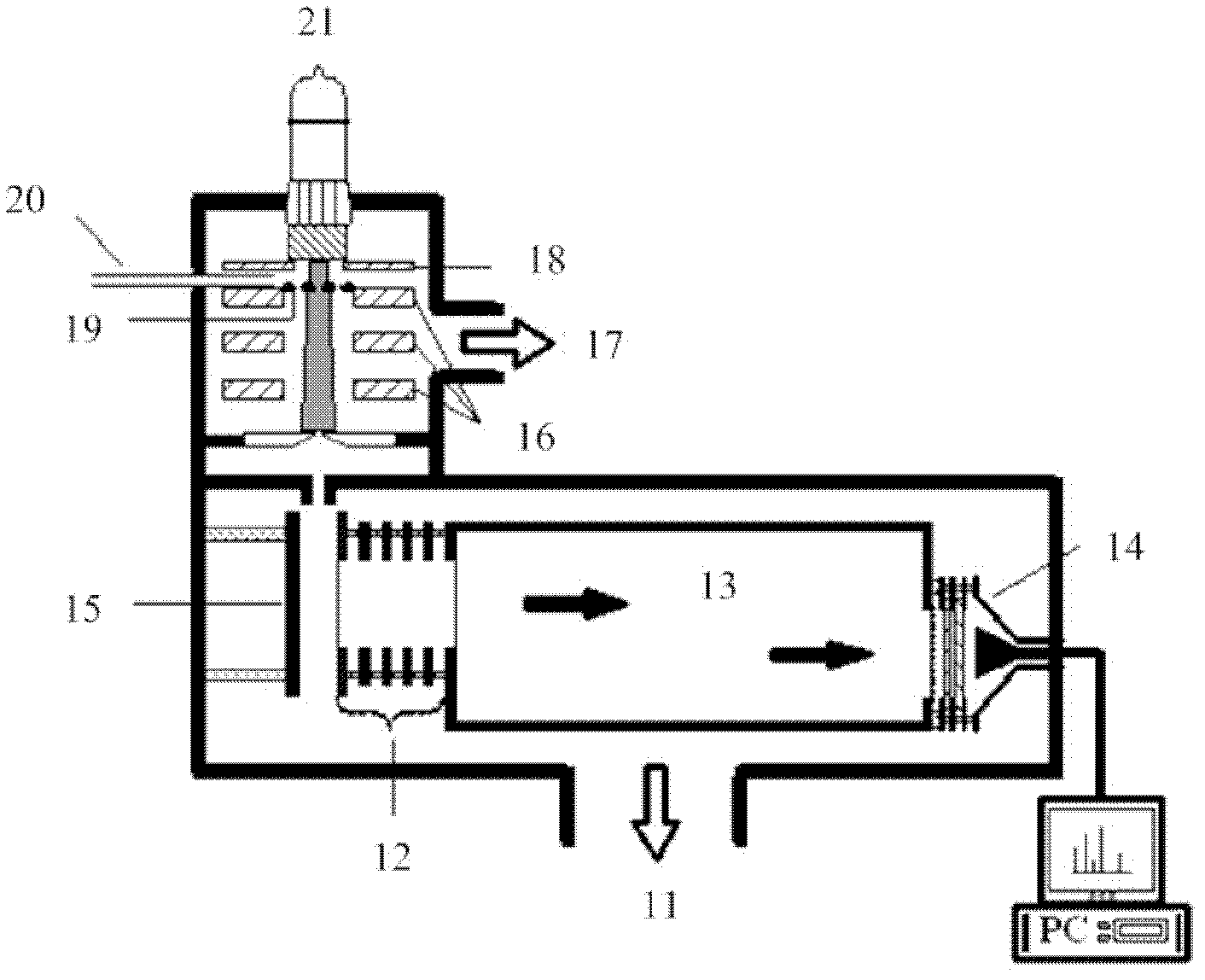

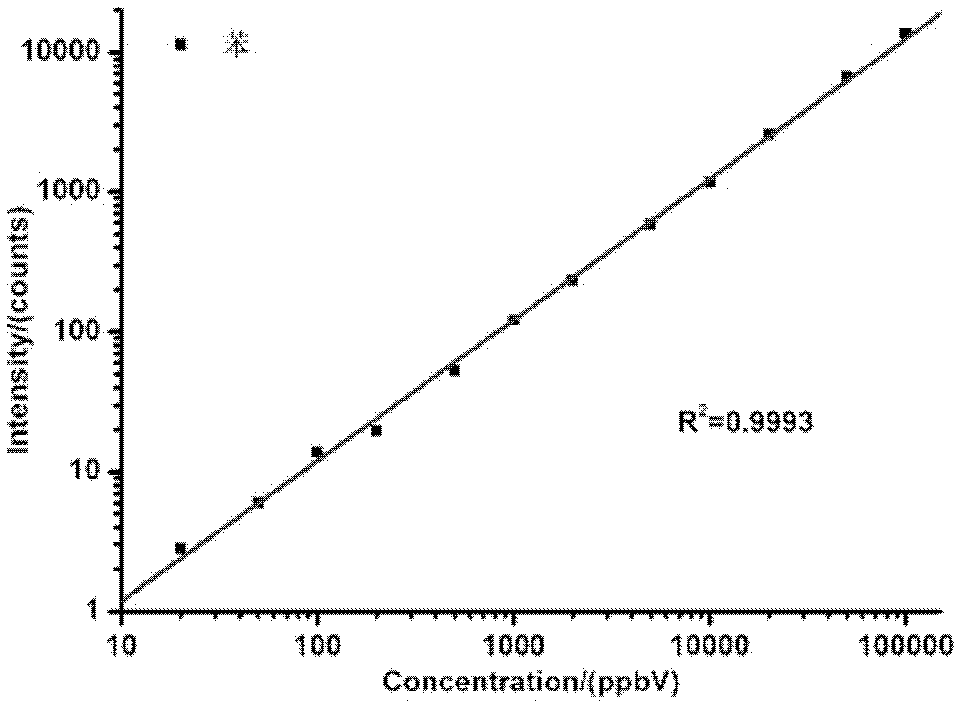

Solid phase and liquid phase compound dynamic gas preparation device and gas preparation method

InactiveCN103163007AEasy to operateShorten the timeComponent separationPreparing sample for investigationGas analysisFlow ratio

The invention provides a solid phase and liquid phase compound dynamic gas preparation device and a gas preparation method. The gas preparation system comprises a diluted gas supplying portion, a diluted gas preheating portion, a sample standard liquid micro-scale control sample injector, a gas mixing portion and a gas analysis device. According to the gas preparation method, diluted gas passes through the diluted preheating device and enters a liquid evaporating device in a certain flow, meanwhile sample standard liquid enters the liquid evaporating device to mix with the diluted gas, finally the mixed gas passes through the gas mixing portion for being mixed evenly, a part of gas enters the gas analysis device for analysis and other gas is exhausted as tail gas. The flow ratio of sample gas and the diluted gas can be effectively controlled due to change of flow of the micro-scale sample injector and flow of the diluted gas so that the mixed gas with different concentrations can be obtained without preparation of the sample standard liquid in all concentration points and preparation efficiency and accuracy of solid phase and liquid phase compound standard gas are improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

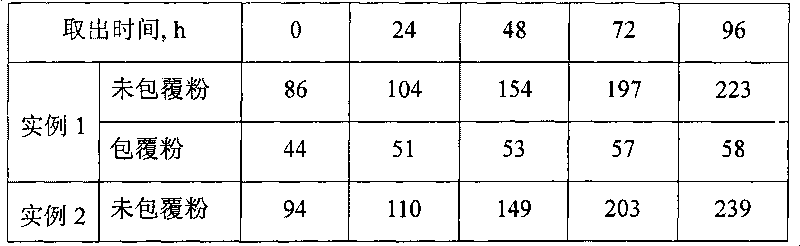

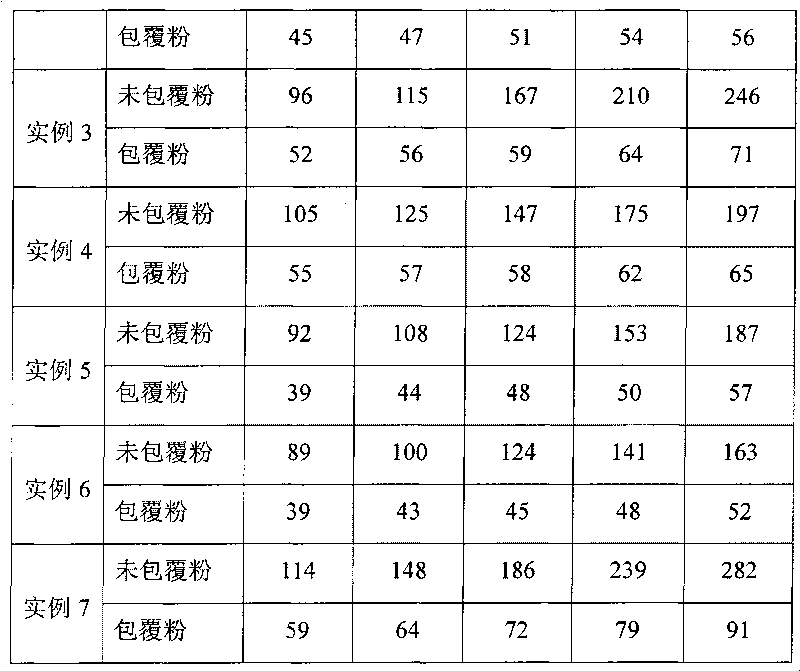

Method for preparing antioxidant soldering powder

ActiveCN101745636AExtended shelf lifeLow costWelding/cutting media/materialsSoldering mediaSolventActive agent

The invention relates to a method for preparing antioxidant soldering powder, comprising the following steps: adding soldering powder to solution containing 5-25 percent by weight of active agent and 2-20 percent by weight of coating agent; stirring the active agent, the coating agent and the soldering powder at the temperature of 30-80 DEG lower than the soldering powder melting point so that the soldering powder suspending in the solution for 10-90 min; and filtering the solution, eluting the solution with solvent and drying the solution in vacuum to obtain the antioxidant soldering powder. The invention is suitable for coating the alloy soldering powder such as SnPb soldering powder, SnPbAg soldering powder, SnPbBi soldering powder, SnBi soldering powder, SnCu soldering powder, SnBiCu soldering powder, SnAg soldering powder, SnAgCu soldering powder and SnZn soldering powder of any particle size and is particularly suitable for coating the alloy soldering power of small particle size or the alloy soldering power which is easily oxidized. The soldering powder is coated by removing an oxidation layer on the surface of the soldering powder, thus the effect of coating the soldering power with the coating agent is improved, the shelf life of the soldering powder is prolonged, the requirements for the package, the storage and the transportation of the soldering powder are lowered, the cost is saved and the waste of the resources is reduced.

Owner:BEIJING COMPO ADVANCED TECH

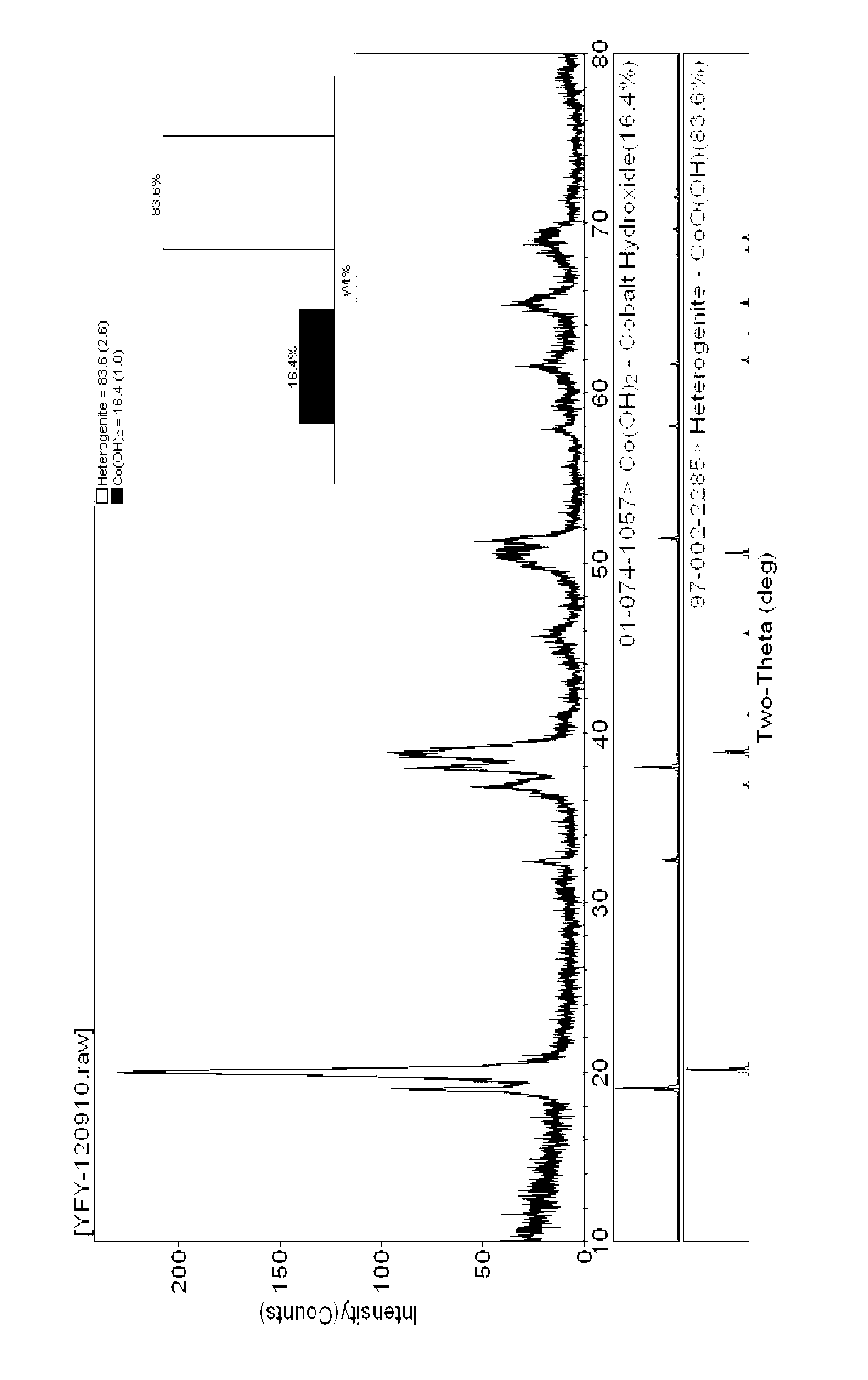

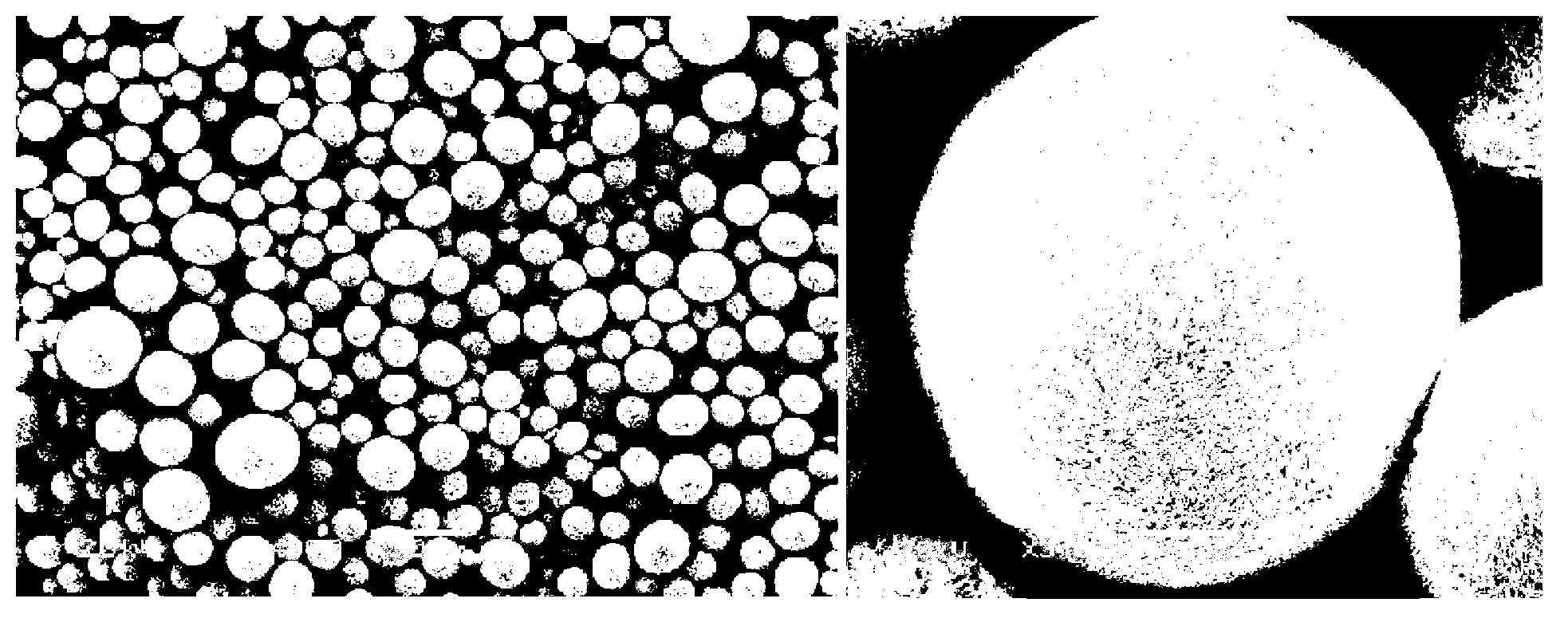

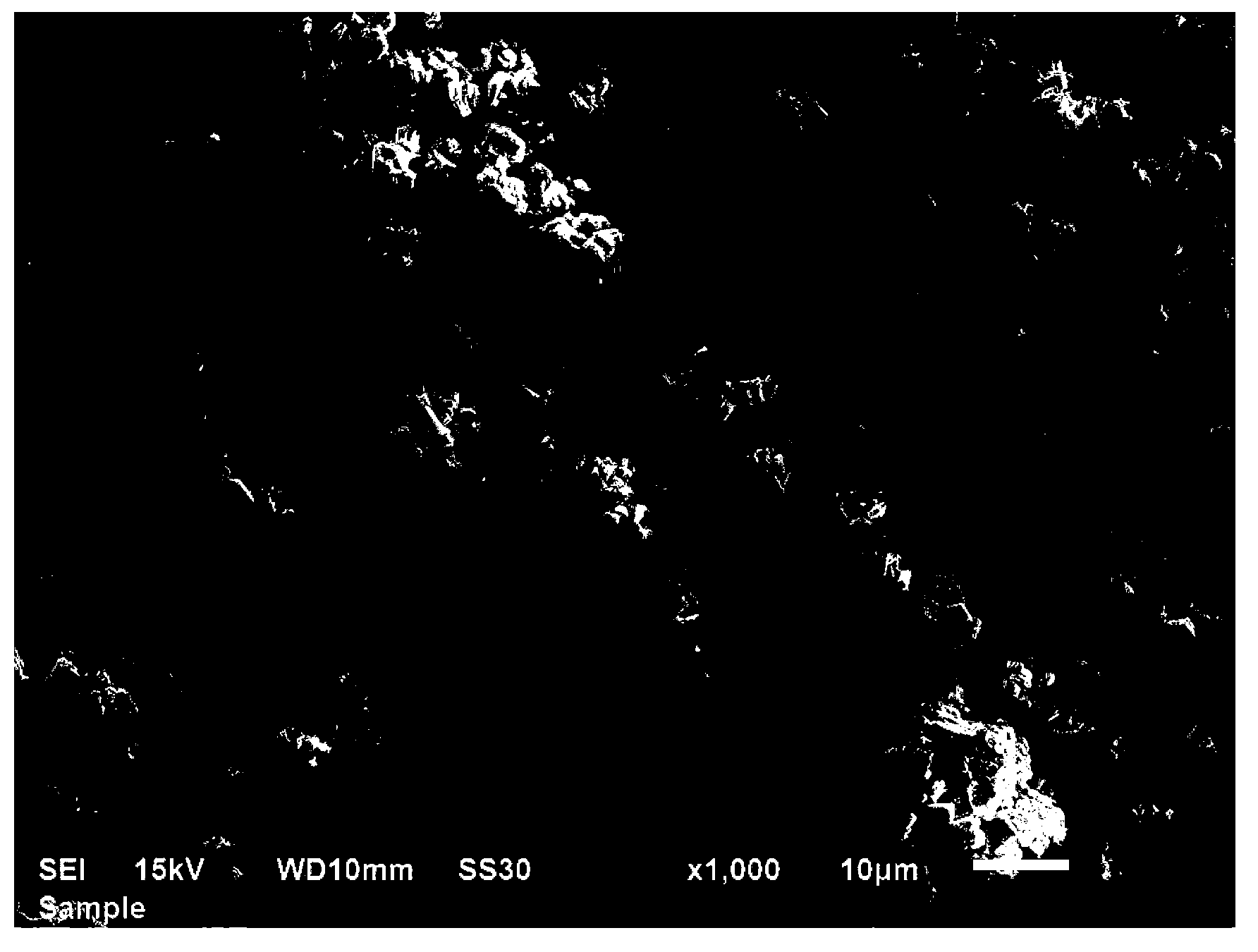

Preparation method for large-grained spherical cobalt oxyhydroxide

The present invention provides a preparation method for large-grained spherical cobalt oxyhydroxide. The specific method is as follows: (1) preparing a 0.5-2.0mol / L cobalt salt solution and a 5-10mol / L sodium hydroxide solution, and adding a complexing agent and a reducing agent in the sodium hydroxide solution; (2) under the protection of nitrogen, simultaneously pumping the cobalt salt solution and the sodium hydroxide solution prepared in the step (1) into a reaction vessel for a continuous reaction, wherein a pH value is controlled to be in a range of 10-12 by adjusting the flow rate of the sodium hydroxide solution, and a slurry particle size is controlled to be in a range of 15-20 microns; (3) obtaining cobalt hydroxide with good sphericity and crystallinity, washing and filtering, controlling a water content in a range of 10-30%, transferring into an oxidation reactor, and blowing air in for oxidation; and (4) placing the oxidized slurry into a blast oven for drying to obtain the large-grained spherical cobalt oxyhydroxide.

Owner:HUNAN YACHENG NEW MATERIAL CO LTD

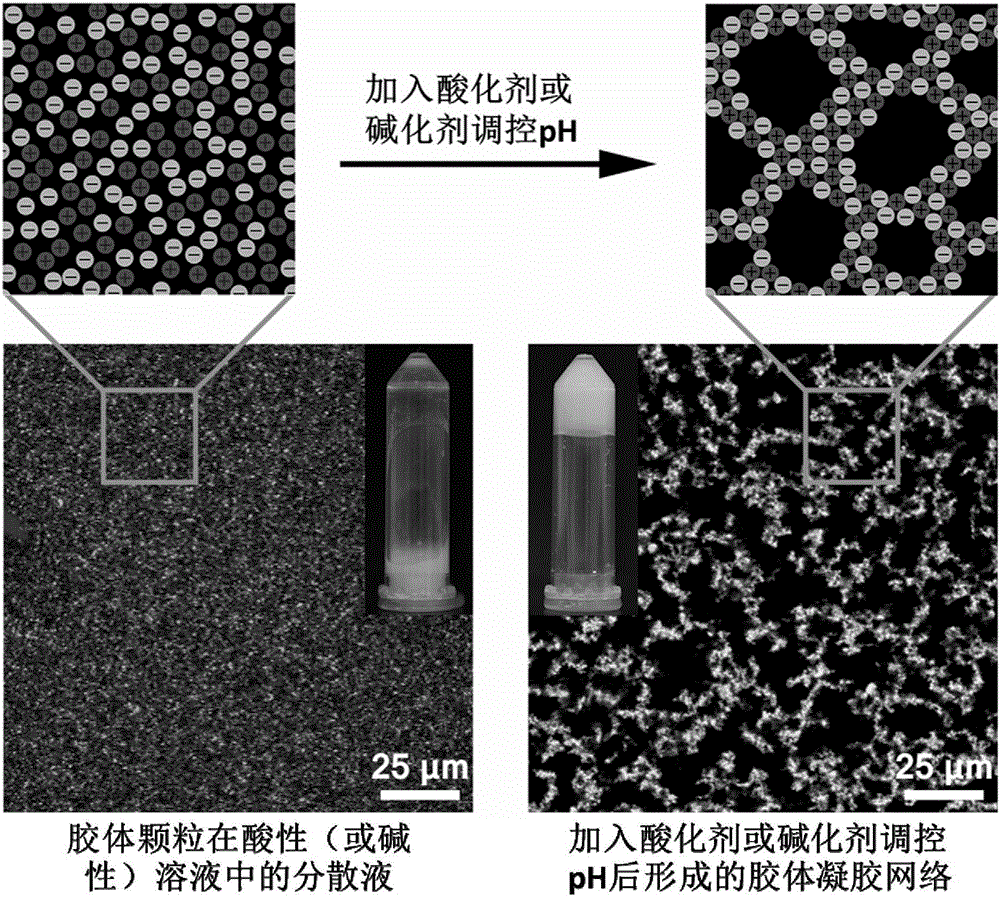

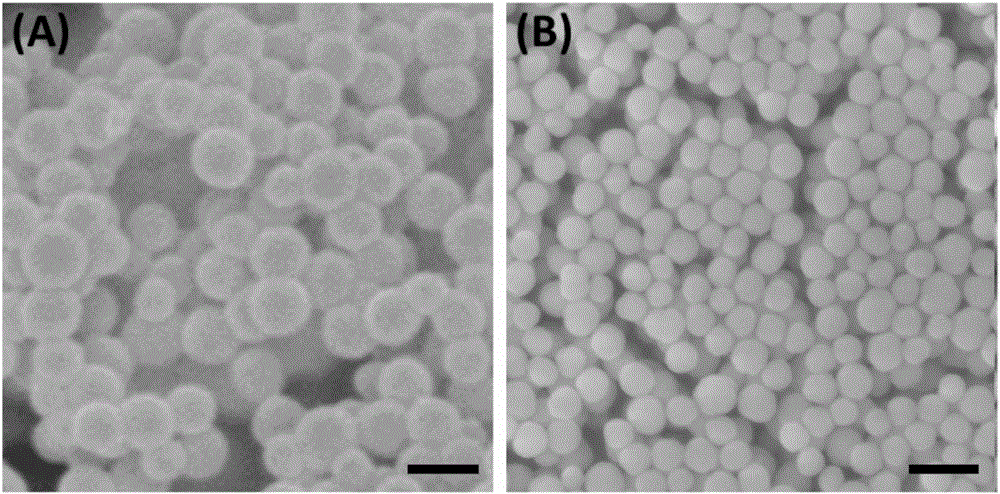

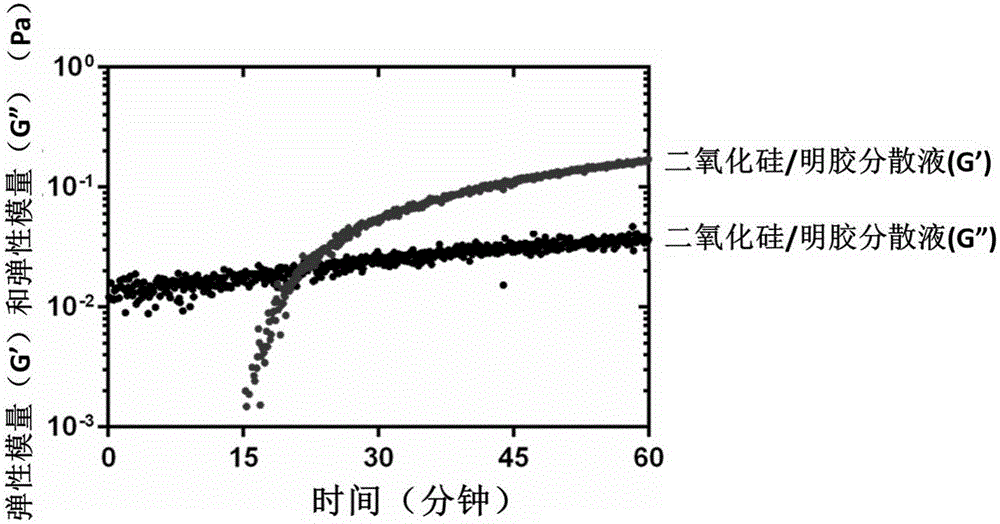

Nanometer colloid particle-assembled high-strength self-repairing injectable composite colloid gel material and preparation method and application thereof

InactiveCN105796478AHigh strengthImprove self-healing abilityAerosol deliveryInorganic non-active ingredientsBiological materialsSilicon dioxide

The invention discloses a nanometer colloid particle-assembled high-strength self-repairing injectable composite colloid gel material and a preparation method and application thereof. According to the preparation method, two-phase colloid particles with opposite electric charges are uniformly blended in an alkaline or acidic environment, an acidifying agent or alkalizing agent is added to induce the pH of the solution to recover the neutrality, electrostatic self-assembly among the two-phase colloid particles is initiated, and a uniformly-dispersed composite gel network is formed, wherein the gel is high in mechanical strength and wide in regulation and control range, the elasticity modulus of the gel can be regulated and controlled within the range of 10 Pa-100 kPa, and the self-repairing efficiency of the gel is higher than or equal to 100%. The silicon dioxide-gelatin composite colloid gel which has both the high mechanical strength and the self-repairing performance is finally and successfully prepared, and it is verified that the composite gel still can quickly recover the mechanical strength after being broken by shear force many times; in addition, the composite gel has the excellent injectable property and plasticity and can be used for an in-vitro cell culture matrix material by serving as an injectable biological material.

Owner:SHENZHEN HUA NOVA BIOTECH LTD

Method for preparing lithium ferrous silicate or carbon ferrous silicate cathode material for lithium ion battery

InactiveCN102664262AEvenly mixedHigh tap densityCell electrodesAlkali metal silicatesCarbon sourceCarbon composites

The invention discloses a method for preparing a lithium ferrous silicate or carbon ferrous silicate cathode material for a lithium ion battery, relates to a method for preparing a cathode material for a lithium ion battery and aims to solve the problems that the conventional prepared lithium ferrous silicate or carbon ferrous silicate composite is low in purity, inhomogeneous in granularity, and poor in electrochemical cycling stability. The method comprises the following steps of: 1, weighing a lithium salt compound, a ferric salt compound, a nano silica and a carbon source compound; 2, dispersing the weighed materials in the step 1 into a dispersing agent by a ball mill or ultrasonic dispersion method to obtain mixed liquor; 3, drying the mixed liquor by a spray drying method to obtain precursor powder; and 4, heating, namely heating the precursor powder obtained in the step 3 under the protection of inert gas in a certain flow rate, cooling naturally to room temperature, and thus obtaining the lithium ferrous silicate or carbon ferrous silicate cathode material for the lithium ion battery. The method is mainly applied to preparation of the lithium ferrous silicate or carbon ferrous silicate cathode material for the lithium ion battery.

Owner:HARBIN INST OF TECH

Method for preparing modified nano montmorillonite

InactiveCN102485805AEvenly mixedPigment treatment with macromolecular organic compoundsMontmorilloniteChloride

The invention relates to a method for preparing modified nano montmorillonite, characterized by using an intercalation / coupling secondary modification technique, using an acid composite intercalation solution as a dispersing agent, dispersing montmorillonite through using the salvation of the intercalating agent solution, then adding a certain amount of a titanate coupling agent dropwisely in the montmorillonite for surface modification, then modifying the montmorillonite by secondary intercalation through using acrylate monomers, and further dispersing the nano montmorillonite through initiating the polymerization of the acrylate monomers between the montmorillonite layers to obtain the modified nano montmorillonite finally. The modified nano montmorillonite can effectively increase the thermal stability of polrvinyl chloride (PVC).

Owner:GUANGDONG GAOKEDA TECH IND

Technique for smelting vanadium iron from calcium vanadate

A production of ferrovanadium concerned with calcium vanadate is carried out by smelting calcium vanadate, Al and ferrous powder at weight ratio of 100: (23-28): (23-27). The said calcium vanadate is selected from m-calcium vanadate, p-calcium vanadate or o-calcium vanadate, one of them at least, with V content of 24-43%. It has high recovery rate and no wastewater pollution.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES

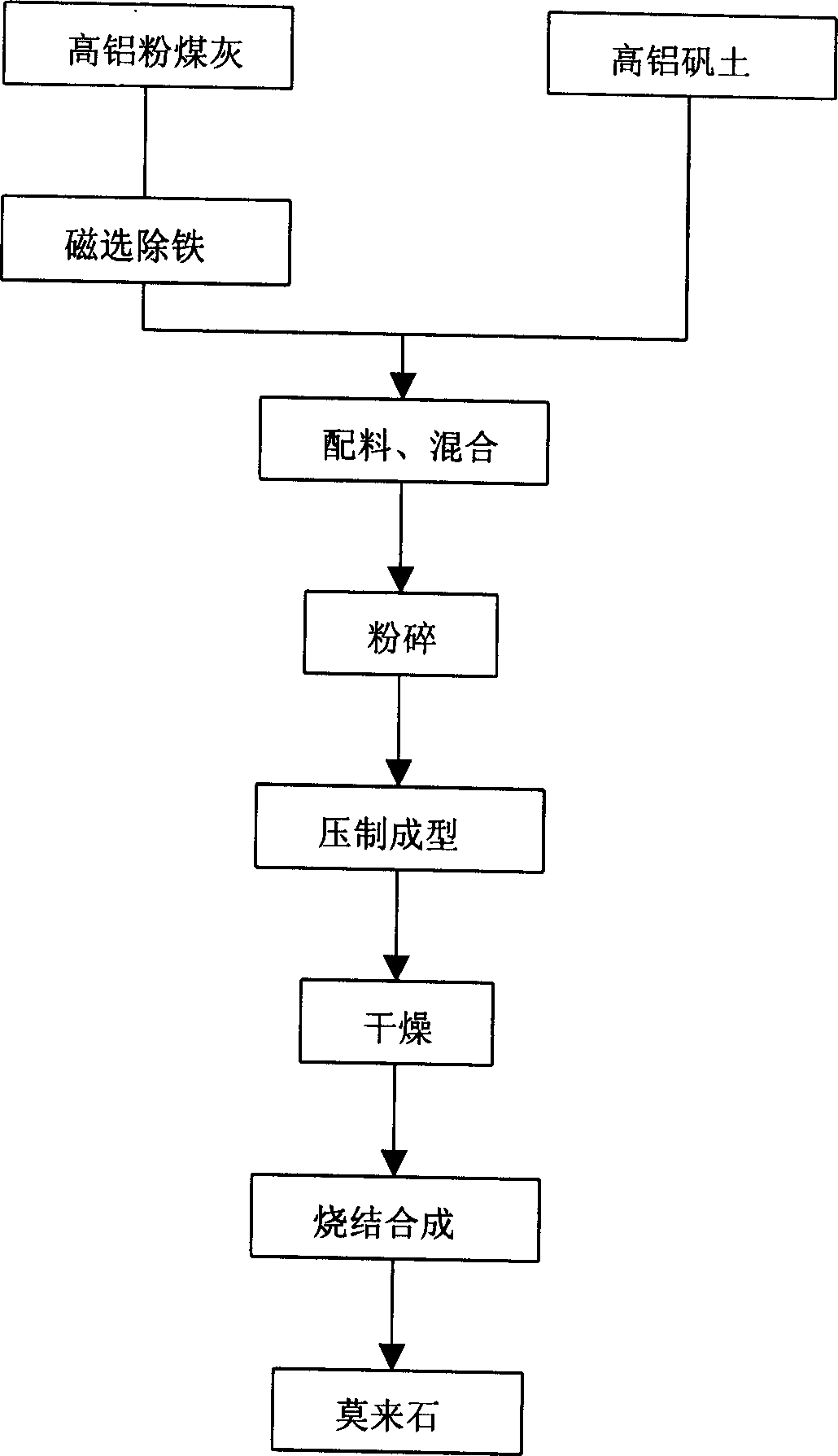

Agglomeration method for synthesizing mullite by using high aluminous fly ash

ActiveCN1696075ARealize comprehensive utilizationReduce manufacturing costTunnel kilnPolymer science

Owner:TSINGHUA UNIV +1

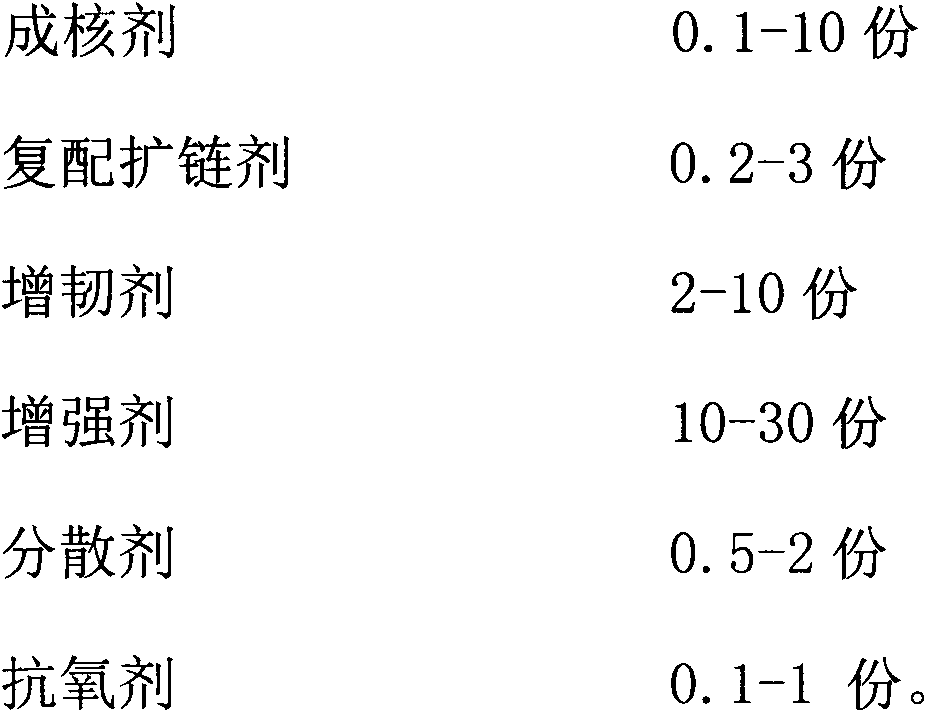

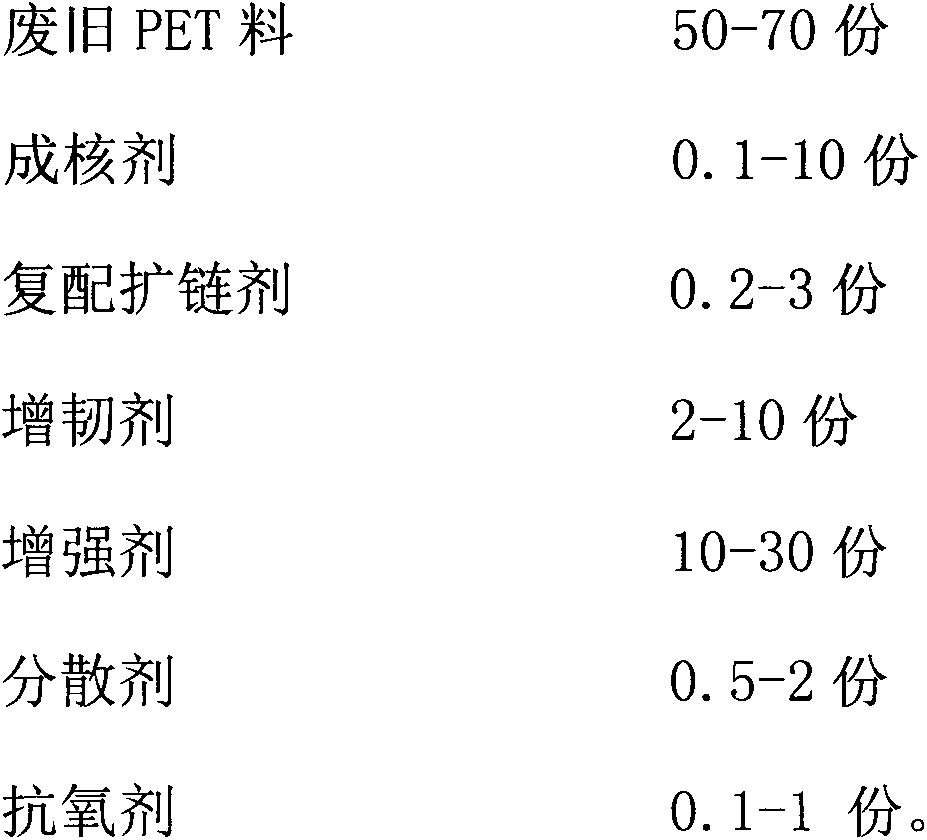

Waste PET (Polyester) heat-proof tackifying and reinforcing composite material and preparation process thereof

InactiveCN103146159AThe preparation process is simple and convenientGood mechanical propertiesPolyesterAntioxidant

The invention discloses a waste PET (Polyester) heat-proof tackifying and reinforcing composite material and a preparation process thereof. The preparation raw materials of the waste PET heat-proof tackifying and reinforcing composite material include a waste PET material, a nucleating agent, a compound chain extender, a toughening agent, a reinforcing agent, a dispersant and an antioxidant. When the waste PET heat-proof tackifying and reinforcing composite material is prepared, a first mixture formed by mixing the waste PET material and the toughening agent is added from a main feed port, the nucleating agent, the compound chain extender, the dispersant and the antioxidant are added from a powder side beside the main feed port in a feeding way, and the reinforcing agent is added from the feed port positioned at an extruder side, so that a small amount of powdery auxiliary agent and a main material can be uniformly mixed and the quality of a finished material is enhanced in such a unique charging way. The preparation process of the waste PET heat-proof tackifying and reinforcing composite material, which is disclosed by the invention, has the advantages of simple process and easiness for industrialization; and the waste PET heat-proof tackifying and reinforcing composite material disclosed by the invention has the advantages of high crystallization rate, high heat-proof temperature and excellent mechanical property.

Owner:江苏中再再生资源有限公司

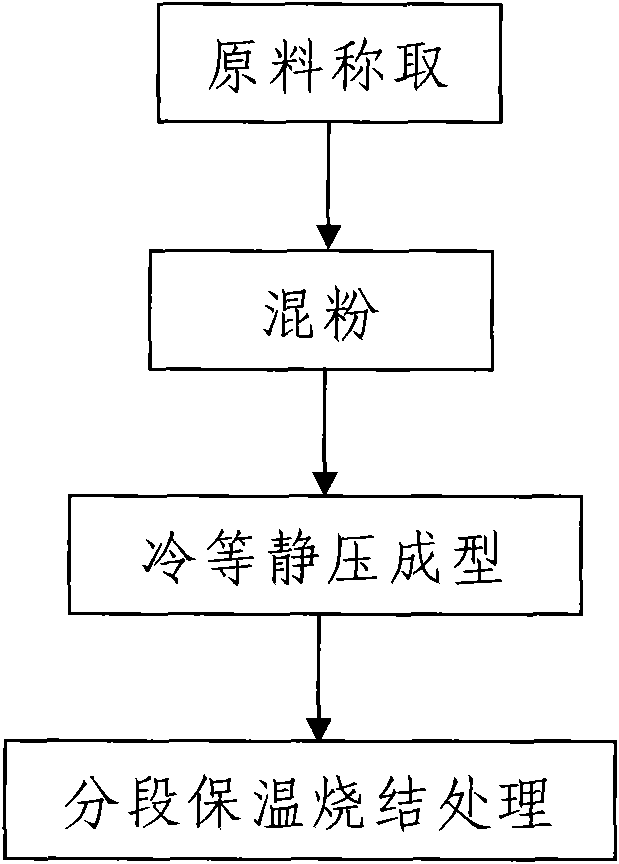

Method for preparing large powder metallurgy TZM blank with uniform carbon and oxygen distribution

The invention discloses a method for preparing a large powder metallurgy TZM blank with uniform carbon and oxygen distribution, which comprises the following steps of: 1, weighing raw materials; 2, mixing powder, namely mixing the weighed four raw materials twice under vacuum or the protection of inert gas, mixing titanium hydride powder, zirconium hydride powder and carbon black powder to prepare mixed powder, adding a volatile organic solvent into the mixed powder, uniformly stirring to prepare suspension, adding the weighed molybdenum powder into the suspension for uniform mixing, and adding residual molybdenum powder for uniform mixing; 3, performing cold isostatic pressing; and 4, sintering by keeping the temperature at stages, namely adopting a vacuum sintering furnace and sintering at three stages, wherein the process comprises the following steps of: raising the temperature at the first stage, raising the temperature at the second stage, and sintering at high temperature. The preparation method has the advantages of reasonable design, simple and convenient operation, and good using effect. The carbon content in the center and on the surface of the prepared larger-size TZM blank can be controlled to be approximately consistent, and the oxygen content in the center and on the surface of the TZM blank also can be reduced to a lower level.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Acrylic artificial marble having granite pattern and method of manufacturing the same

InactiveUS9012532B2Well mixedEvenly mixedNatural patternsCeramic shaping apparatusShell moldingGranolithic

The present invention relates to an acrylic artificial marble having a granite pattern and a method of manufacturing the same, which can provide a natural marble effect by mixing and molding two or more compounds having different colors and thus can obtain a granite pattern in which patterns of the two or more compounds are smoothly mixed, and which can obtain a desired pattern remarkably similar to a pattern of natural stone by using a multicolor chip sheet.

Owner:LG HAUSYS LTD

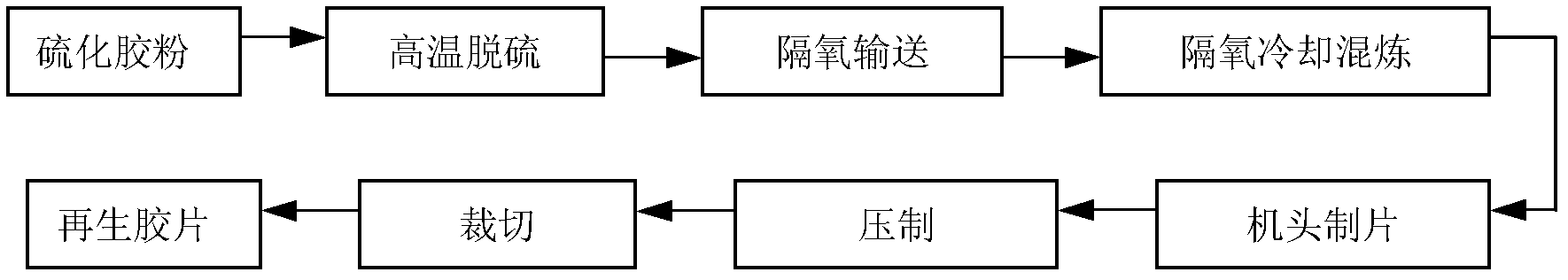

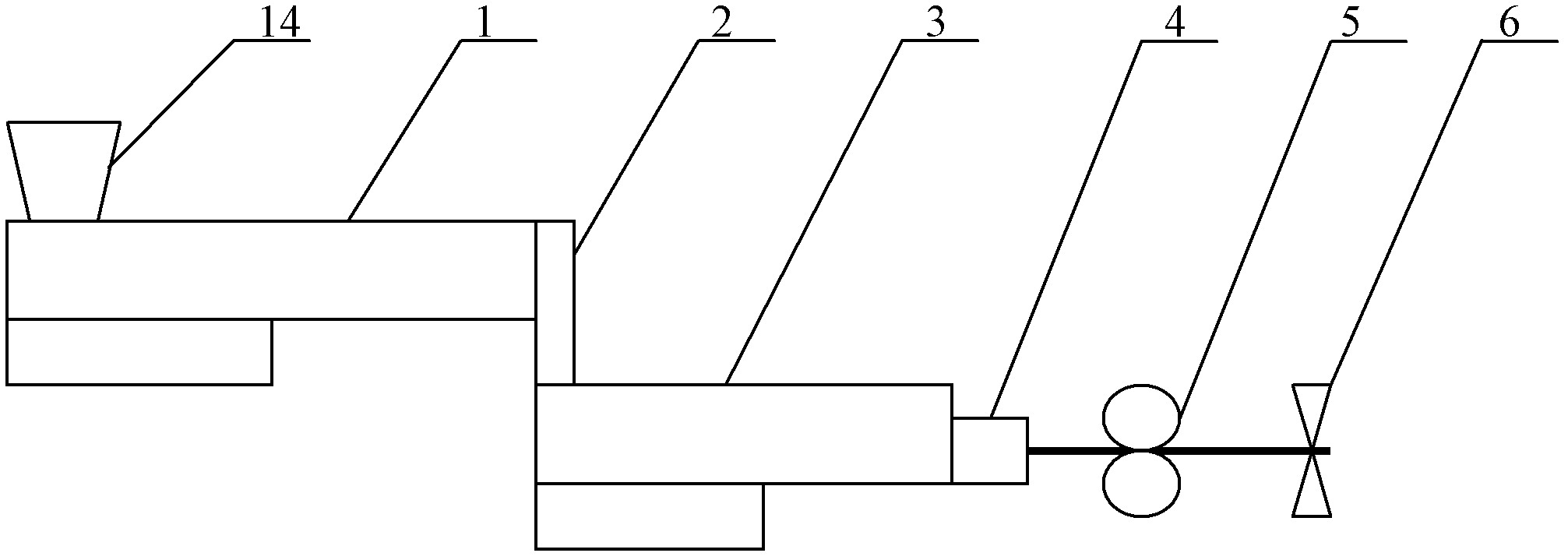

Device and method for directly preparing regenerated rubber sheet by continually cooling and mixing desulfurized rubber powder

The invention relates to device and method for preparing a regenerated rubber sheet by continually cooling and mixing desulfurized rubber powder. The device comprises a continuous production line consisting of a rubber desulfurizing device with a hopper, a transition conveyer, a single-screw oxygen isolating cooling device, a sheet handpiece, a pair of compression rollers and a shearing device, wherein the discharging hole of the rubber desulfurizing device is connected with the feeding hole of the single-screw oxygen isolating cooling device through the transition conveyer; and the discharging hole of the single-screw oxygen isolating cooling device is connected with the feeding hole of the sheet handpiece. In the invention, a double-screw rubber desulfurizing device is meshed in the same direction, so that mixing is uniform and the energy consumption is low. The preparation method comprises the following process steps of: (a) desulfurizing; (b) conveying in an oxygen isolating way; (c) cooling and mixing in an oxygen isolating way; (d) sheeting; (e) pressing; and (f) cutting. Due to the adoption of the oxygen isolating conveying as well as oxygen isolating cooling and mixing, high-temperature oxidation of high-temperature desulfurizing rubber powder is prevented, the mechanical property of the regenerated rubber is improved, the production is continuous and safe, and no waste is discharged.

Owner:溧阳常大技术转移中心有限公司

Method for preparing foamed ceramic insulation board by coal ash

InactiveCN101597178AImprove protectionSave natural resourcesSolid waste disposalCeramic shaping apparatusSlurryBall mill

The invention relates to a method for preparing a foamed ceramic insulation board by coal ash. The coal ash and potash feldspar are respectively put into a ball mill for dry grinding and then sieved by a 1000-mesh sieve, iron in the sieved coal ash is removed, the coal ash after iron removal, potash feldspar after dry grinding and sieving, kaolin and cerium oxide are put into the ball mill for wet grinding to be even, so as to form mixed slurry; the mixed slurry is dried by a pressure GLZ, the dried powder material is put into a steel mould to be pressed into a flat green body; and the pressed green body is put into an aluminum oxide sagger which is evenly spread with aluminium oxide powder at the bottom, sintered in a silicon carbon rod resistance furnace and cooled naturally, thus obtaining the foamed ceramic insulation board for building. The coal ash is used for preparing the foamed ceramic insulation board, which is not only beneficial for saving natural resources and reducing production cost but also beneficial for environmental protection. The coal ash contains a great amount of hollow cenospheres and melikaria and has low heat conductivity and thermostability characteristic. The cerium oxide is used as foaming agent, which can lower sintering temperature of the foamed ceramic and reduce energy consumption.

Owner:SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com