Prepn process of vulcanized catalyst

A catalyst and vulcanization-type technology, which is applied in the field of preparation of hydrogenation catalyst compositions, can solve problems such as self-heating of sulfided catalysts, unfavorable industrial application of catalysts, low catalyst production efficiency, etc. For large-scale use, the effect of improving the vulcanization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The commercial hydrodesulfurization catalyst FH-5A (developed by Fushun Petrochemical Research Institute and produced by Wenzhou Huahua Group Co., Ltd.) was selected. The main composition and properties are shown in Table 1.

[0033] The specific pre-sulfurization process is as follows:

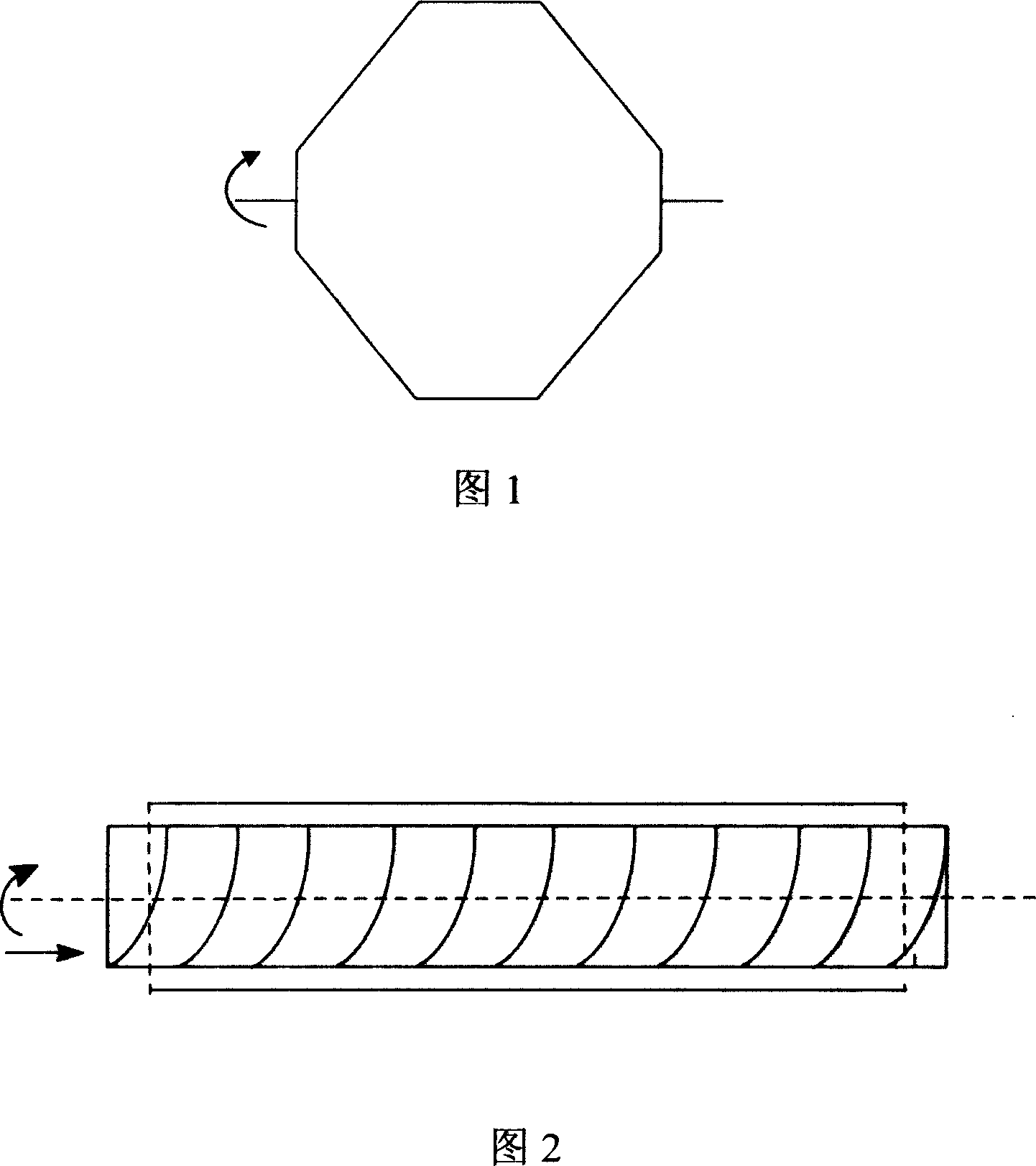

[0034] The molten elemental sulfur is introduced into the oxidation state catalyst, and the introduced amount of the elemental sulfur is 105% of the theoretical sulfur requirement of the catalyst. Then tetrabutylthiuram disulfide (TBTD) was mixed with coked diesel oil, and the mixture was introduced into the catalyst containing elemental sulfur. The amount of TBTD was 3% by weight of the catalyst, and the amount of coked diesel oil was 40% by weight of the catalyst. Finally, it was treated at 160°C for 5 hours at normal pressure and in a stagnant air atmosphere. The heat treatment equipment used the biconical rotary heat processor described in Figure 1, and the speed was 5 rpm to obtai...

Embodiment 2

[0036] The catalyst in the oxidation state is the same as in Example 1, which is FH-5A.

[0037] The specific pre-sulfurization process is as follows:

[0038] 1. Dissolving tetramethylthiuram disulfide (TMTD) in benzene, evenly impregnating it on the oxidized state FH-5A catalyst, the addition of TMTD is 5% of the weight of the catalyst, to obtain a catalyst supporting TMTD.

[0039] 2. Dispersing the elemental sulfur in a solvent with a volume ratio of catalytic cracking gasoline and rapeseed oil of 8:1, the amount of solvent is 12% of the catalyst weight, and the amount of elemental sulfur is 90% of the theoretical sulfur content of the catalyst containing metal. The elemental sulfur solvent impregnates the TMTD-supported catalyst obtained in step 1. Heat treatment was performed in a closed device at 180°C for 5 hours, and the final pressure was 0.4 MPa (gauge pressure). The heat treatment equipment used the double-cone rotary heat processor described in Figure 1, and the ...

Embodiment 3

[0045] The catalyst in the oxidation state is the same as in Example 1, which is FH-5A.

[0046] The specific pre-sulfurization process is as follows:

[0047] 1. Dissolve dithiodimethyldiphenylthiuram in acetone and introduce it into the catalyst in an oxidized state. The amount of dithiodimethyldiphenylthiuram is 20% of the catalyst weight, and then at 105°C Under treatment for 3 hours, a catalyst containing dithiodimethyldiphenylthiuram was obtained.

[0048] 2. The volume ratio of vacuum distillate oil and peanut oil is a miscible solvent of 1: 2. The solvent consumption is 0.5% of the catalyst weight, and then mixed with the elemental sulfur solid powder. The elemental sulfur consumption is 40% of the metal-containing theoretical sulfur requirement of the catalyst.

[0049] 3. The material obtained in step 2 was treated at 180° C. for 3 hours under normal pressure and in a stagnant air atmosphere. The heat treatment equipment used the double-cone rotary heat processor de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com