Patents

Literature

1492results about "V-belts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

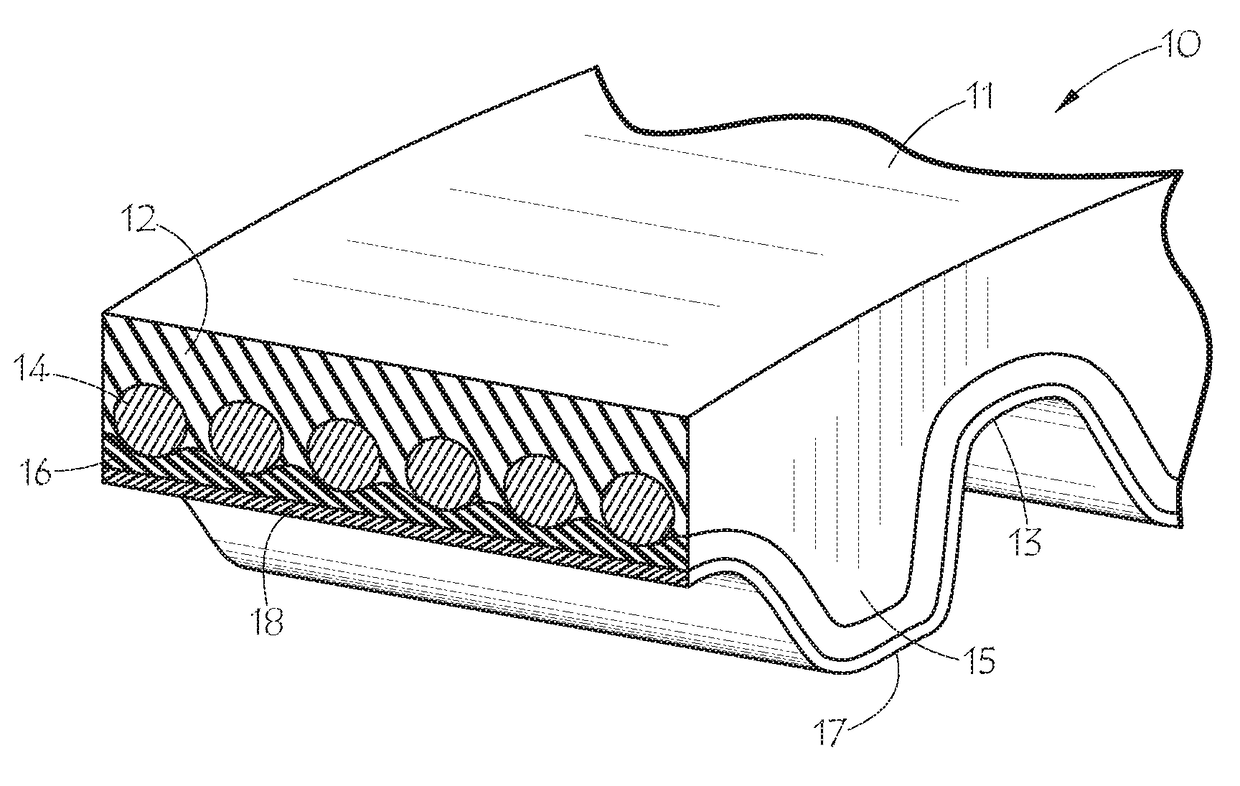

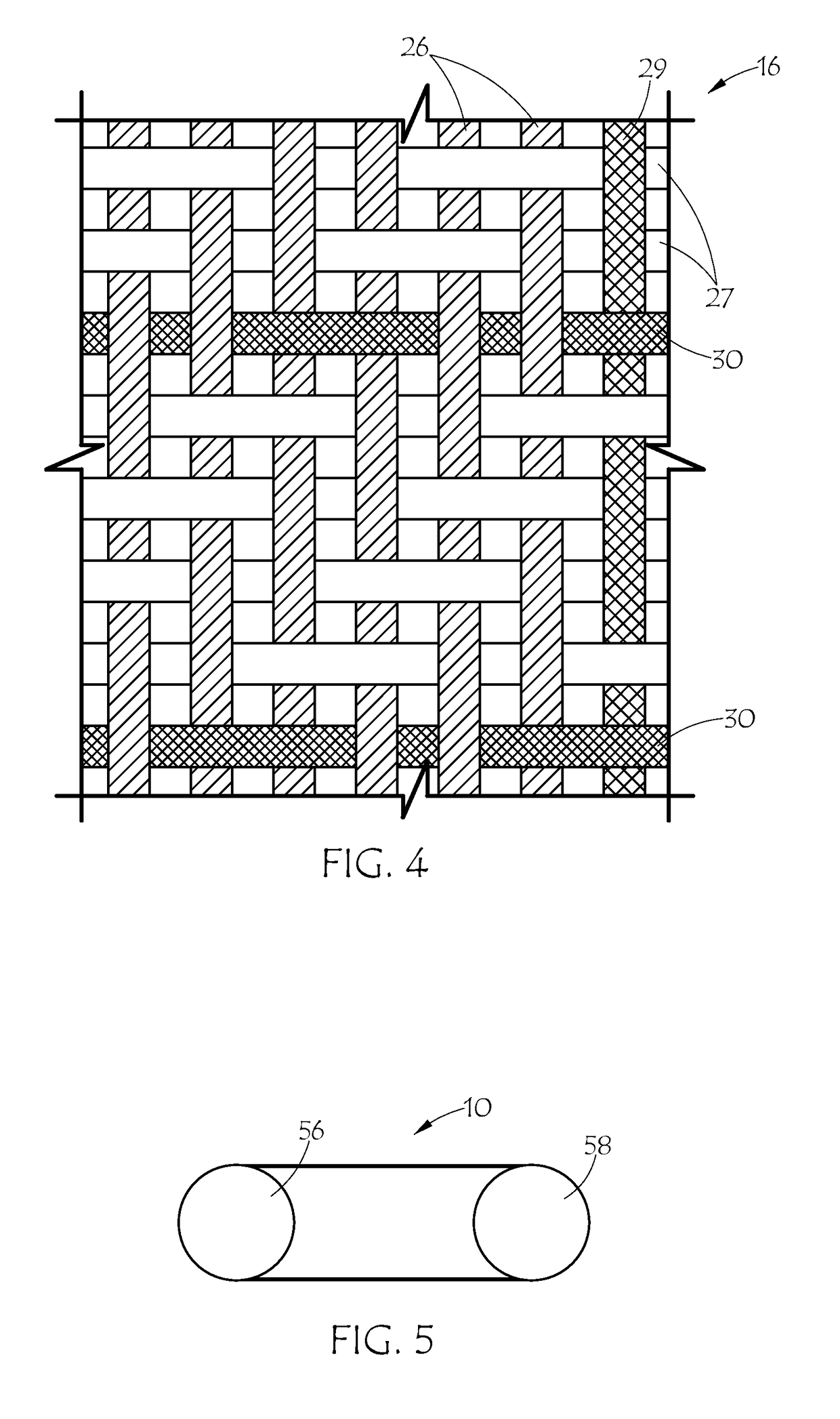

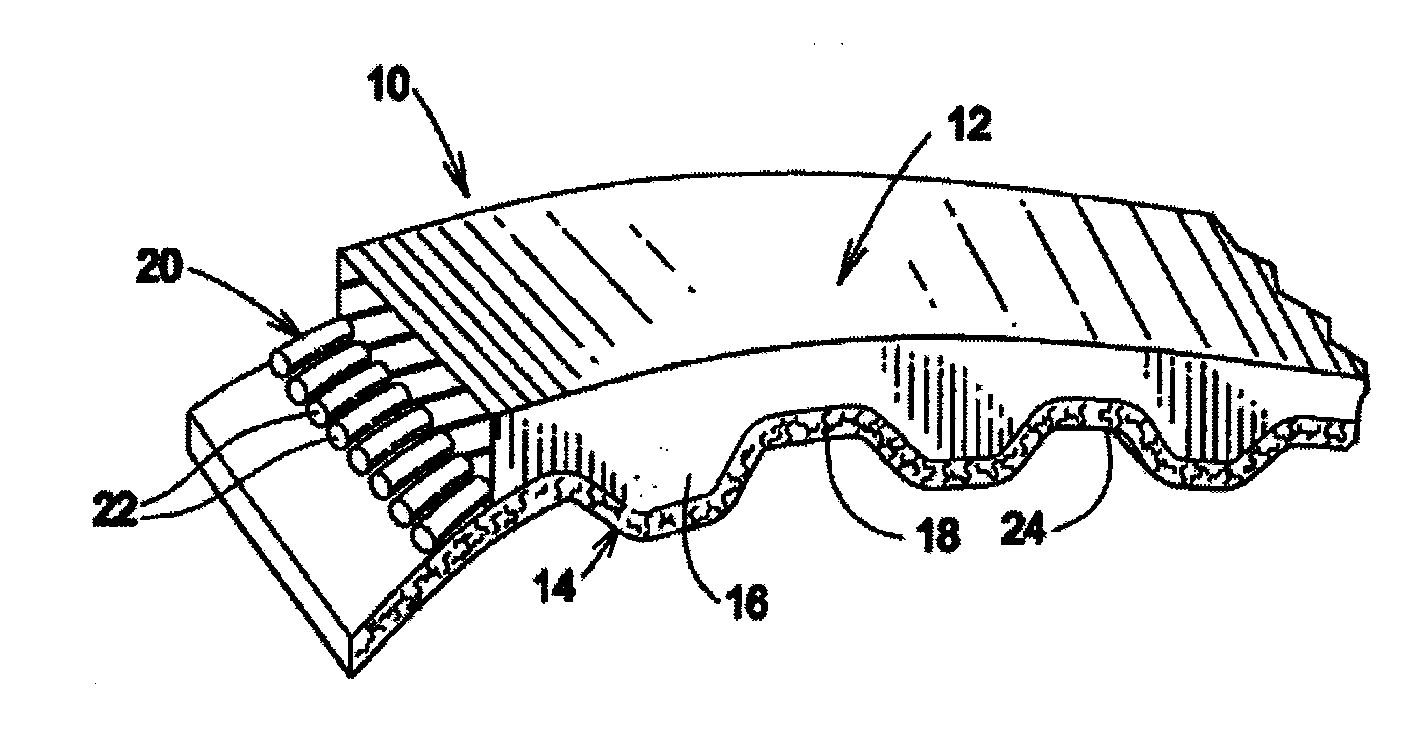

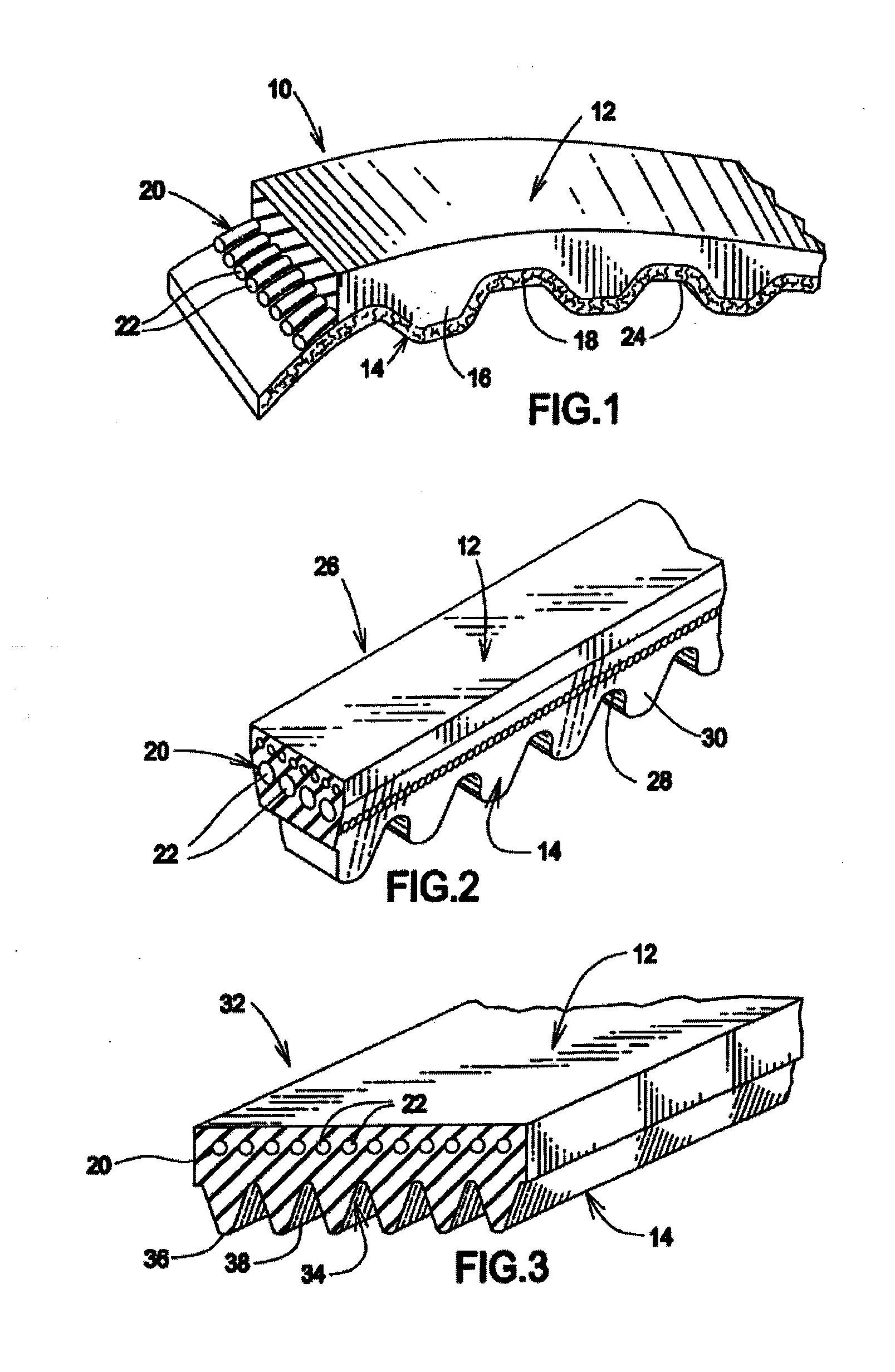

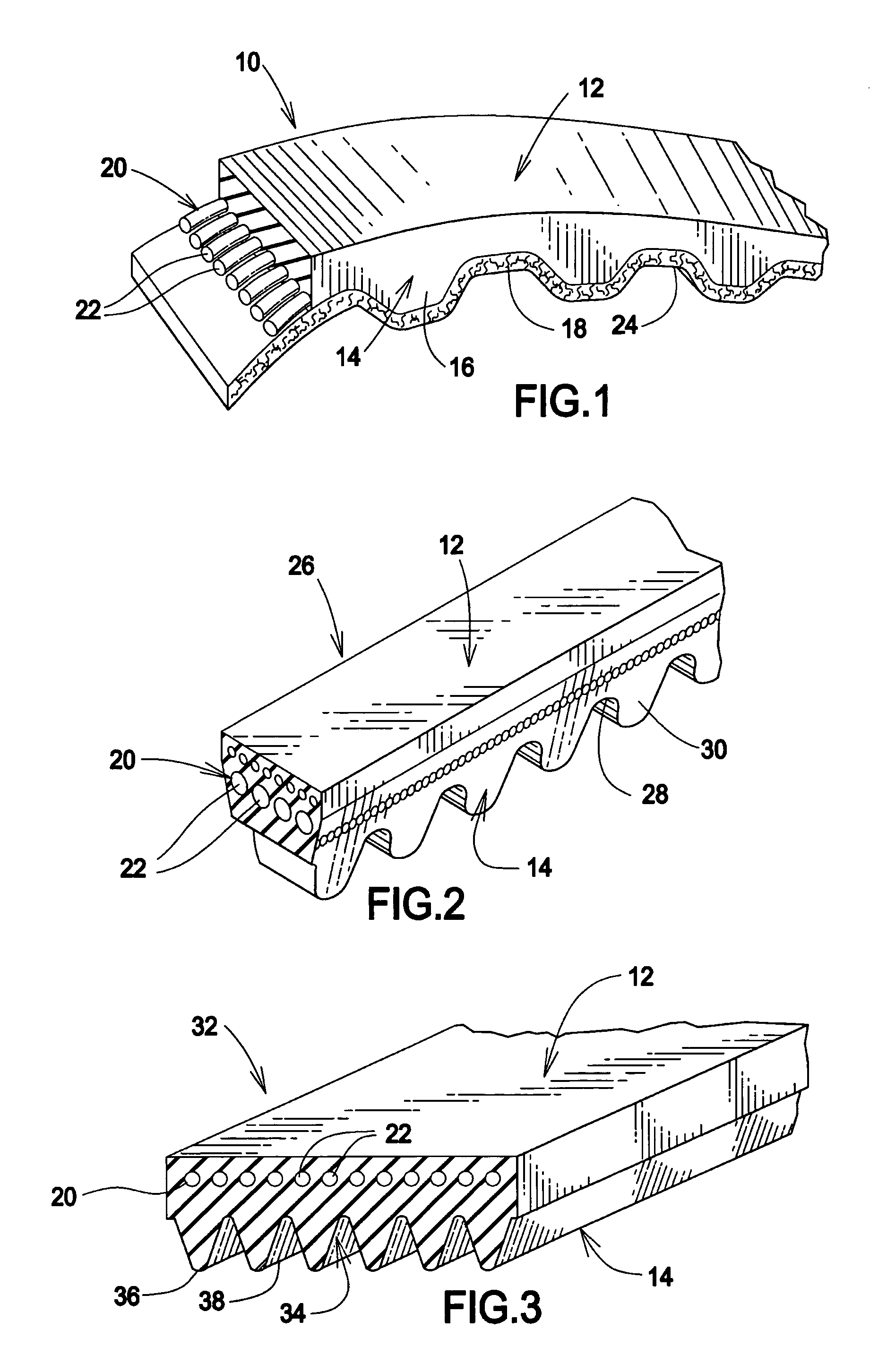

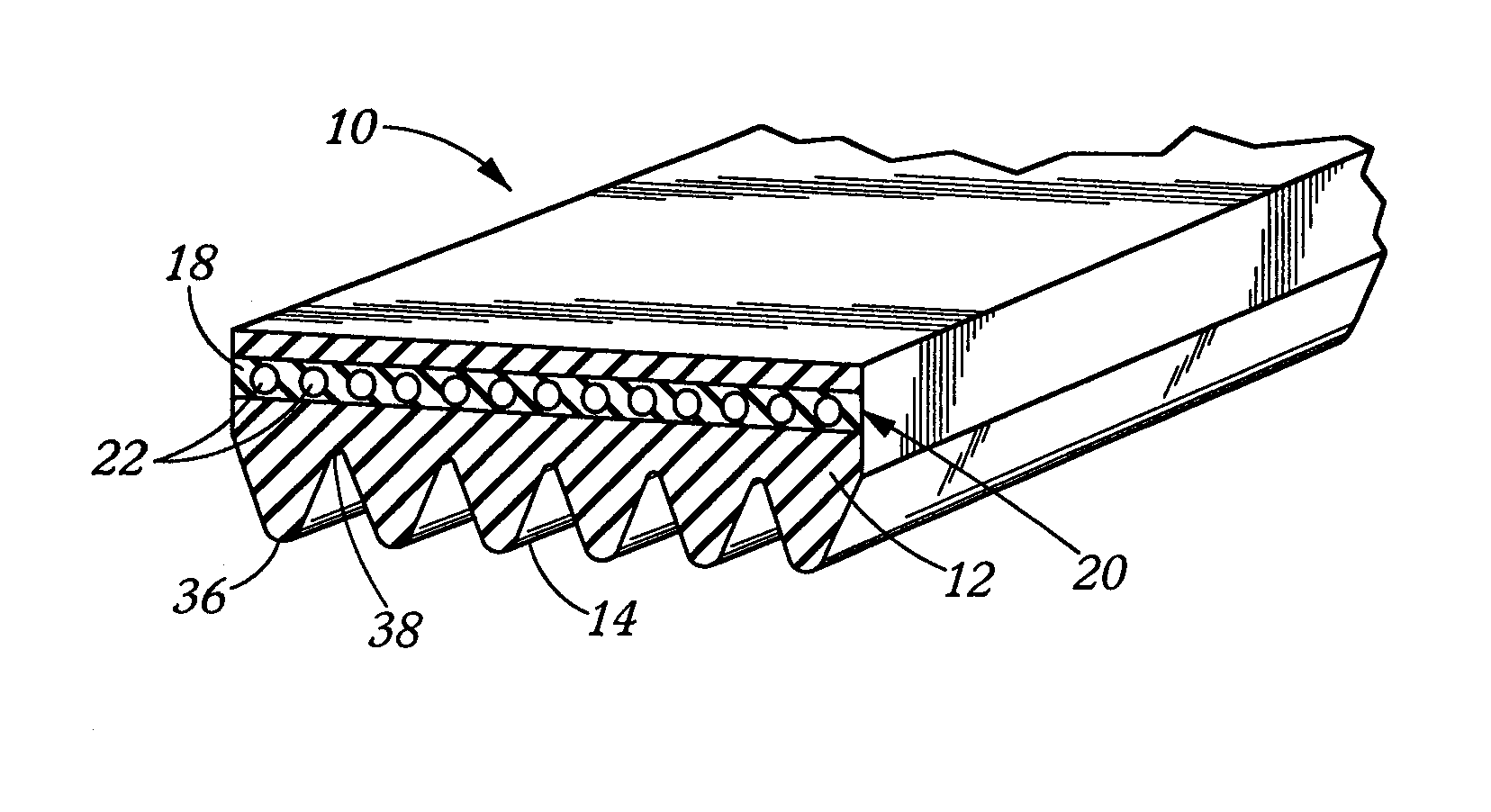

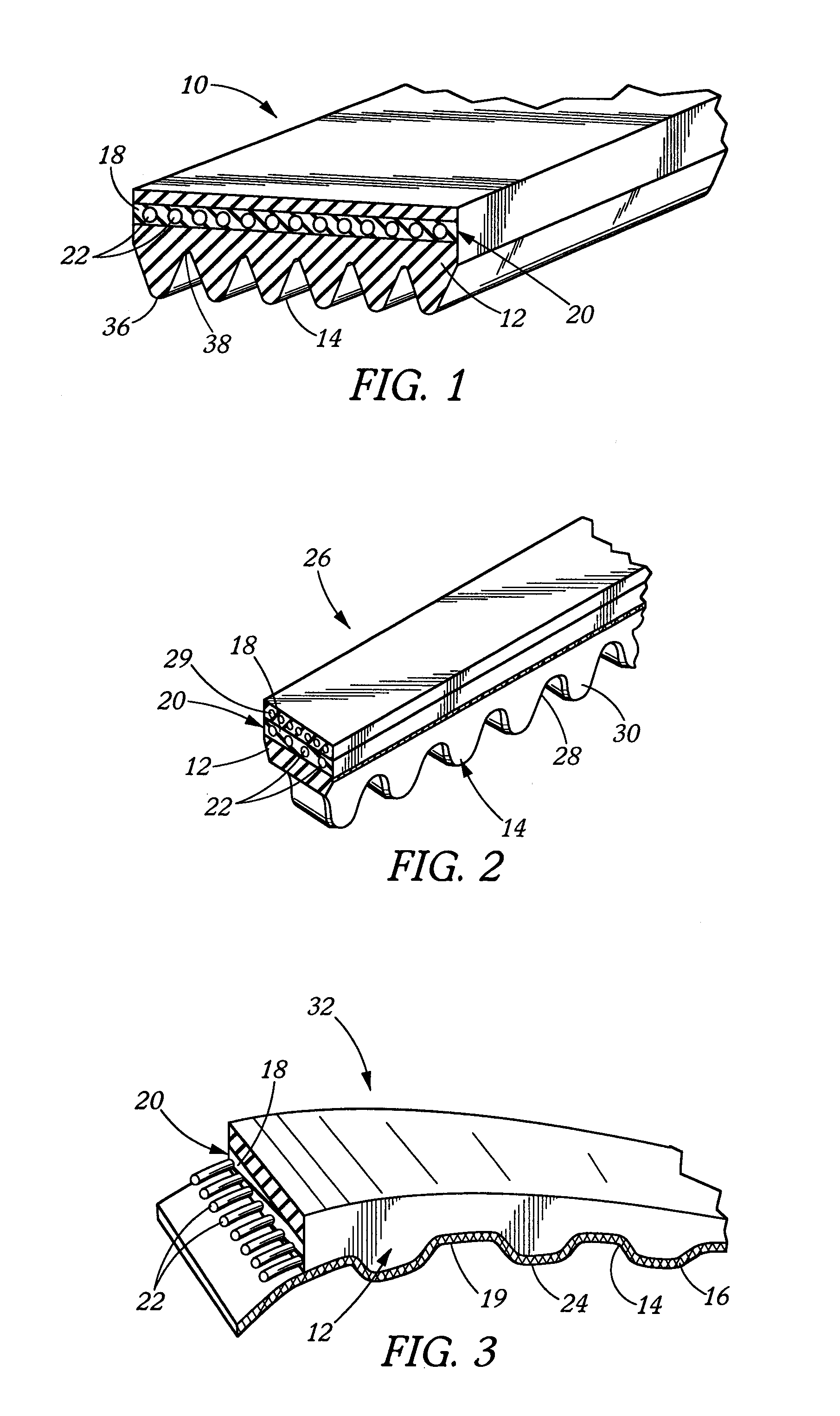

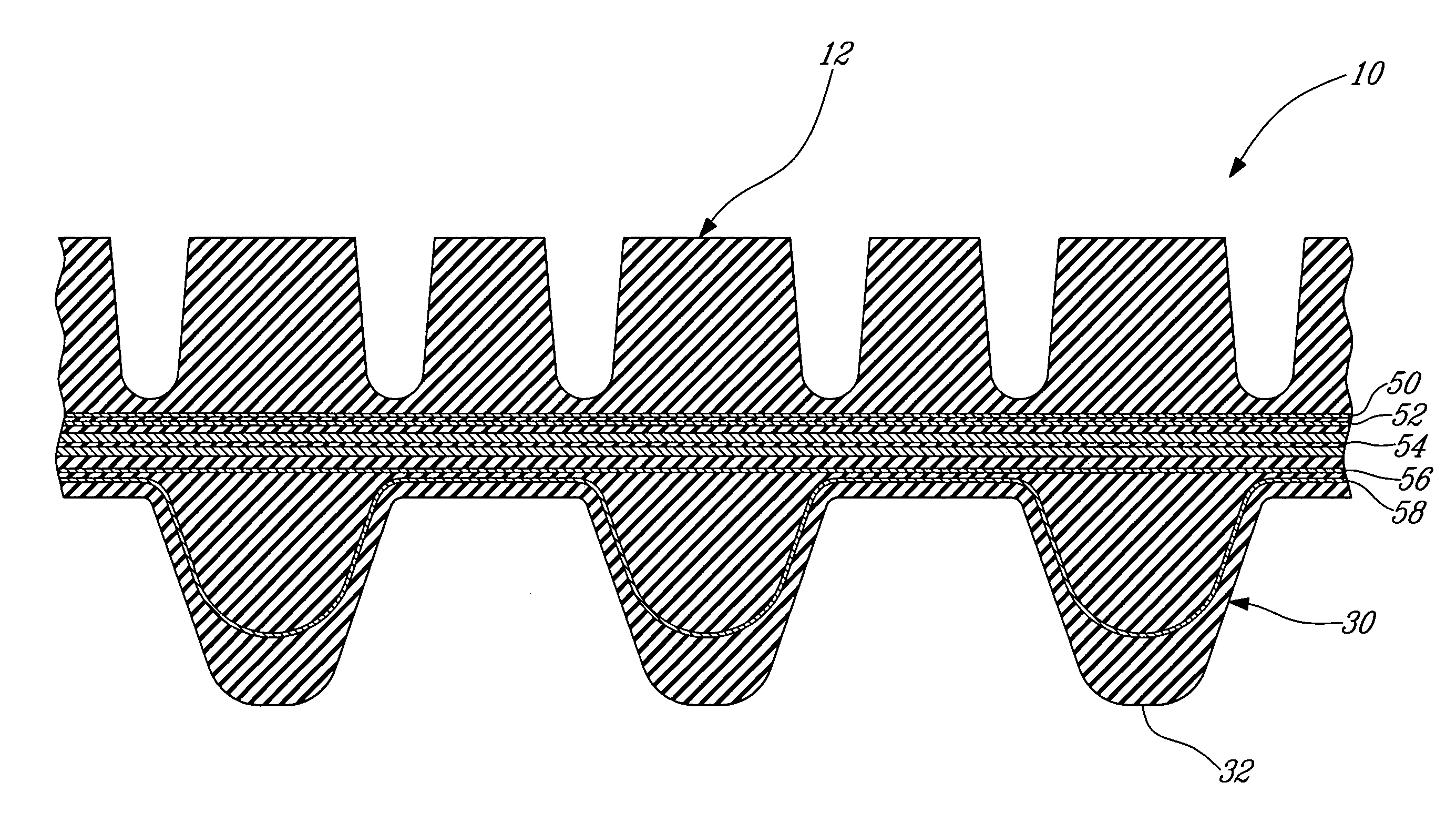

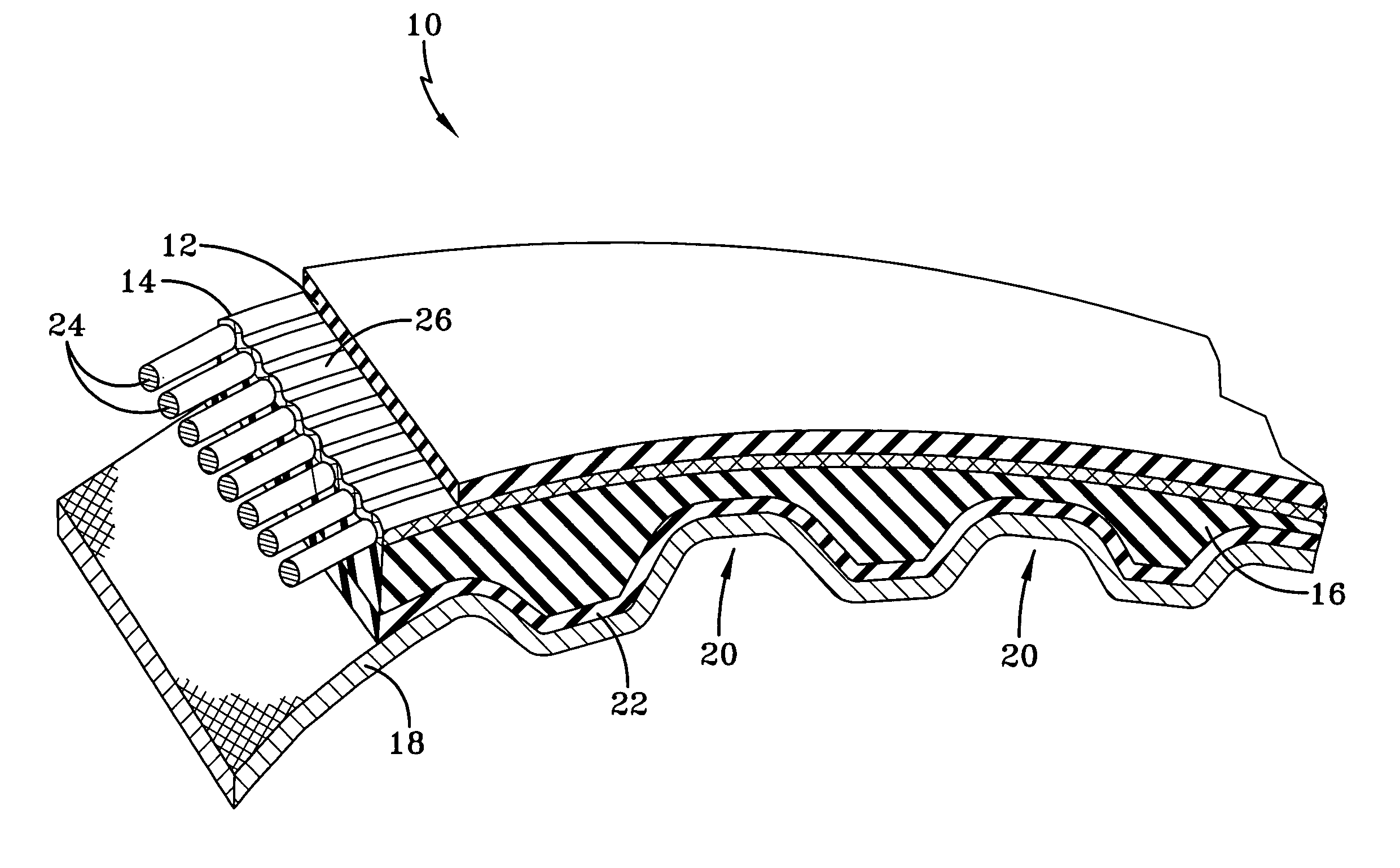

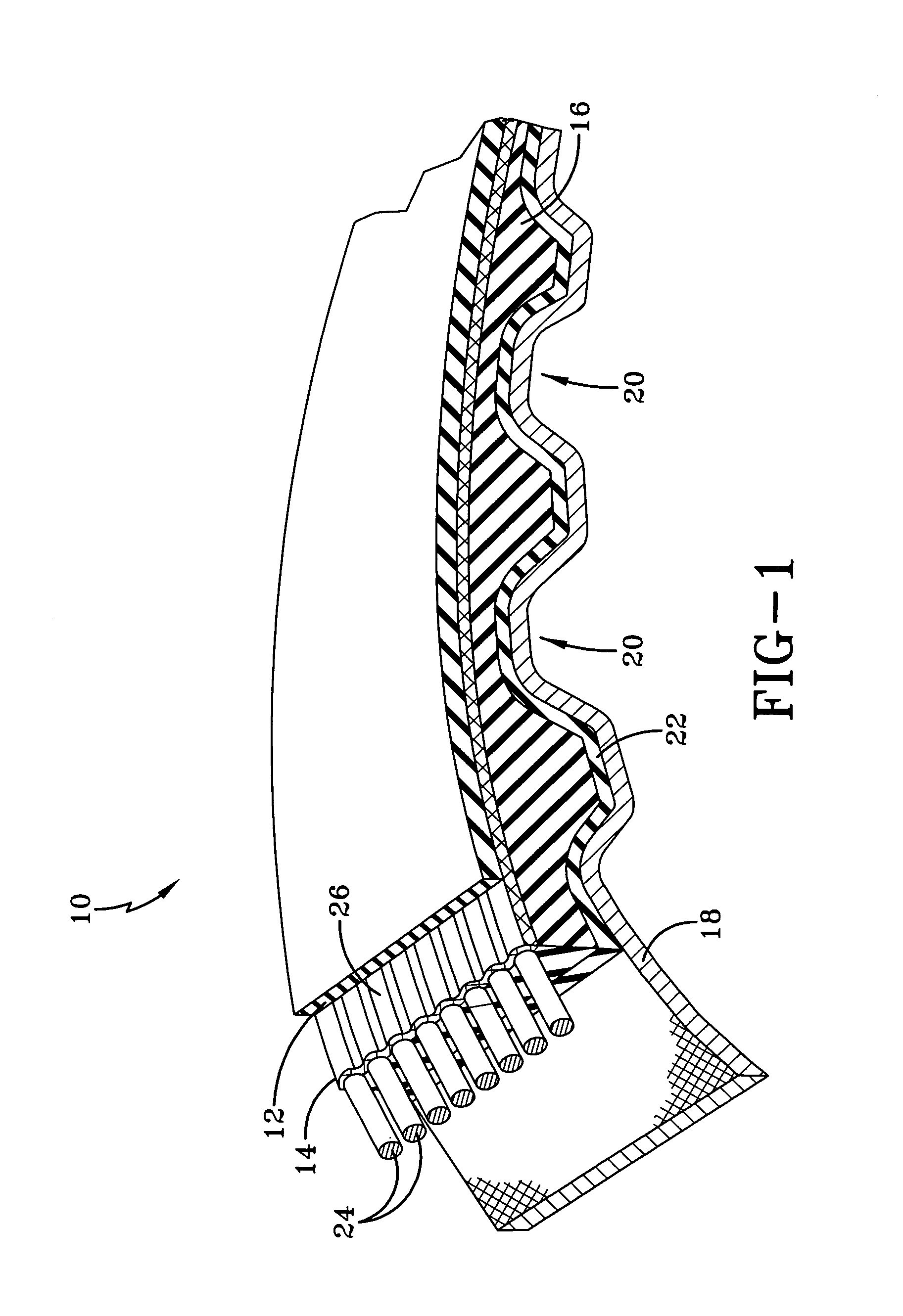

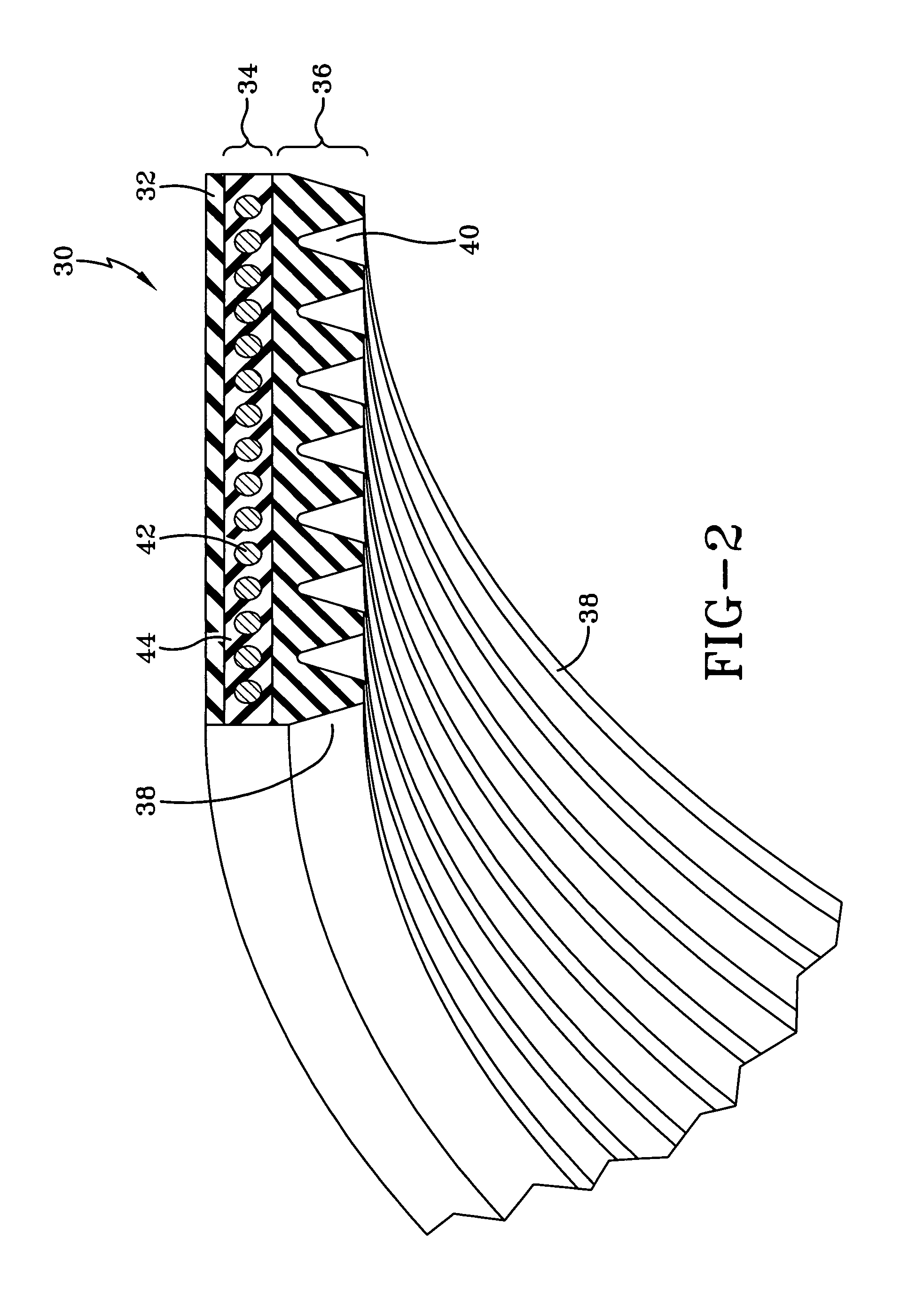

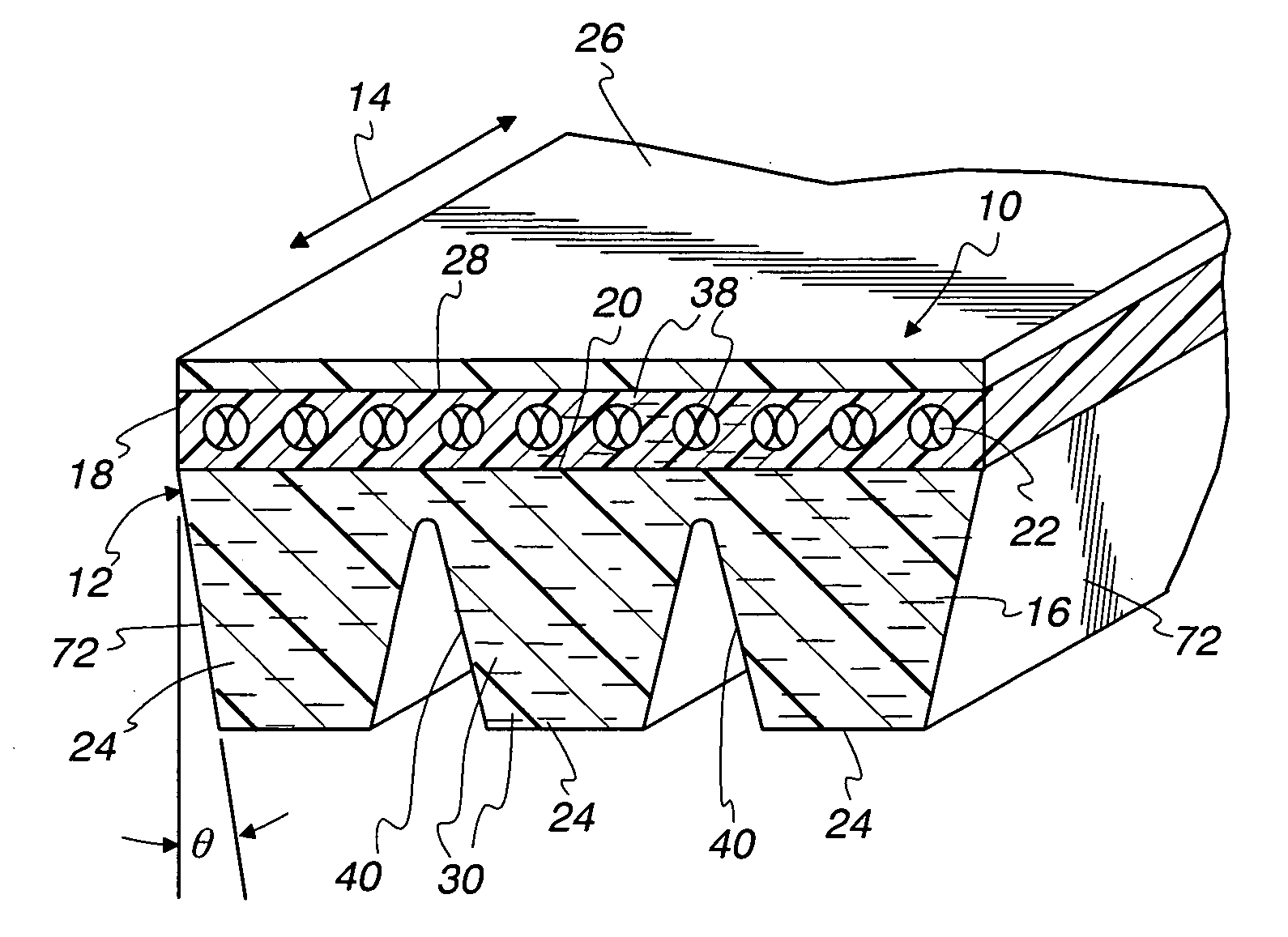

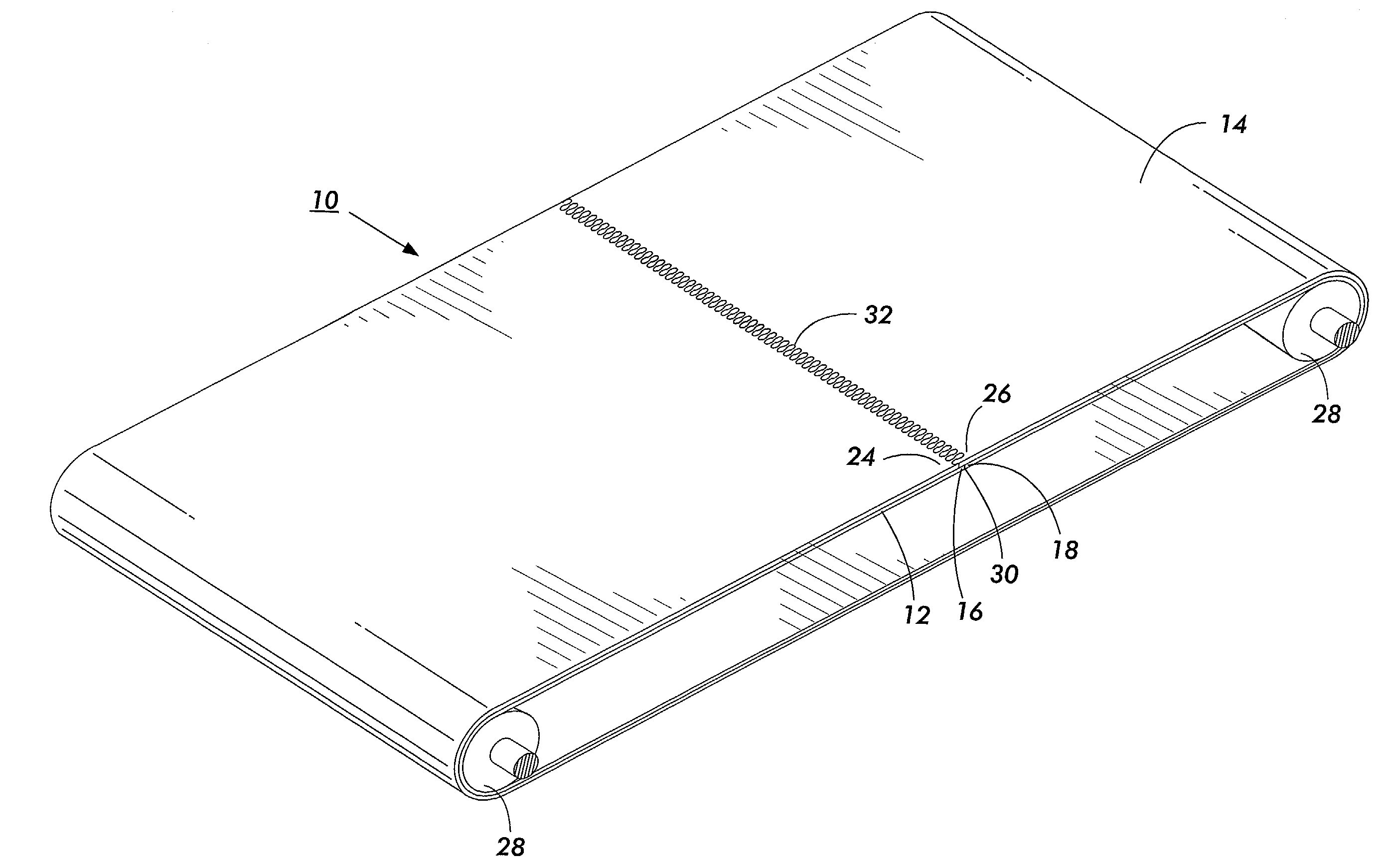

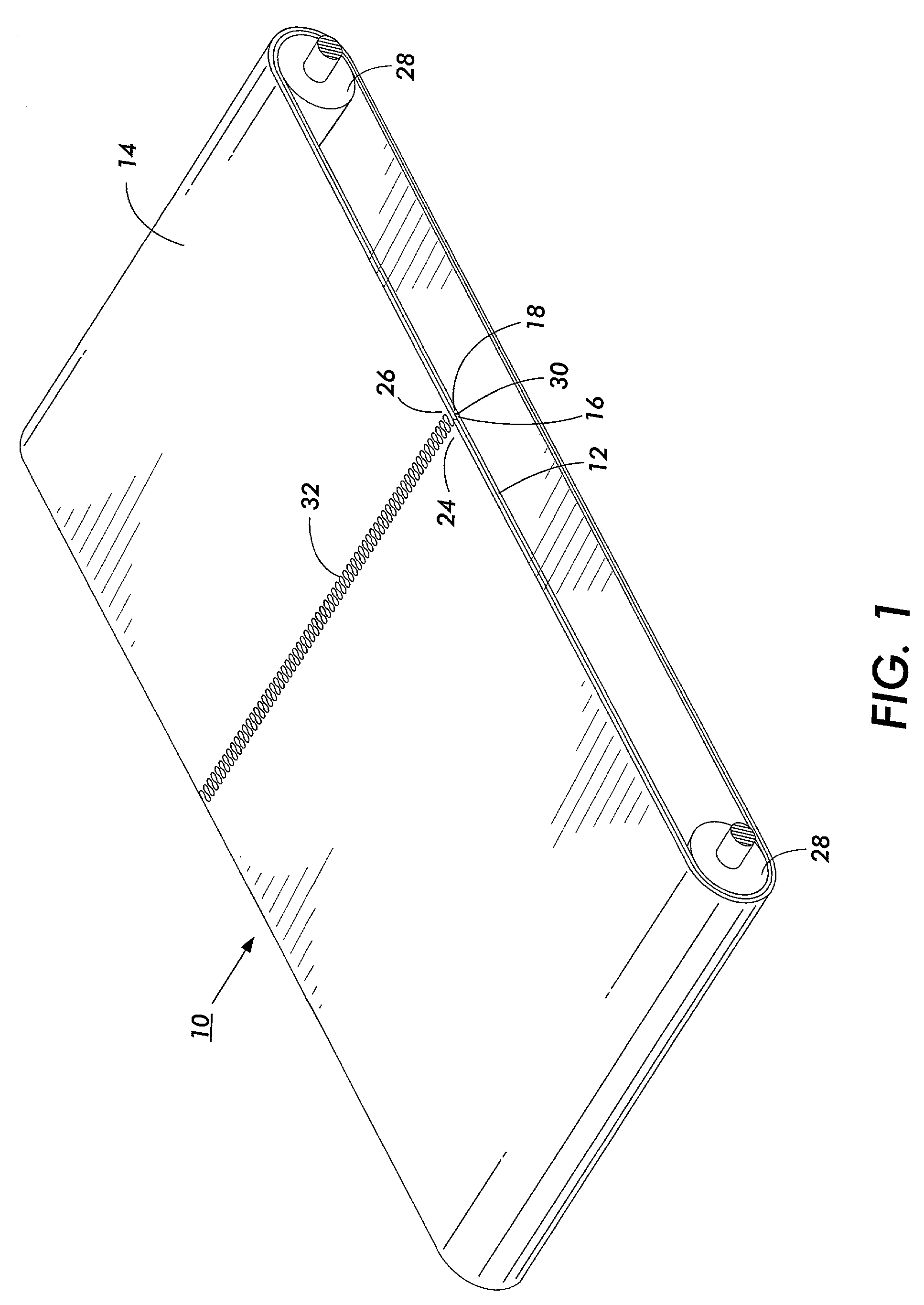

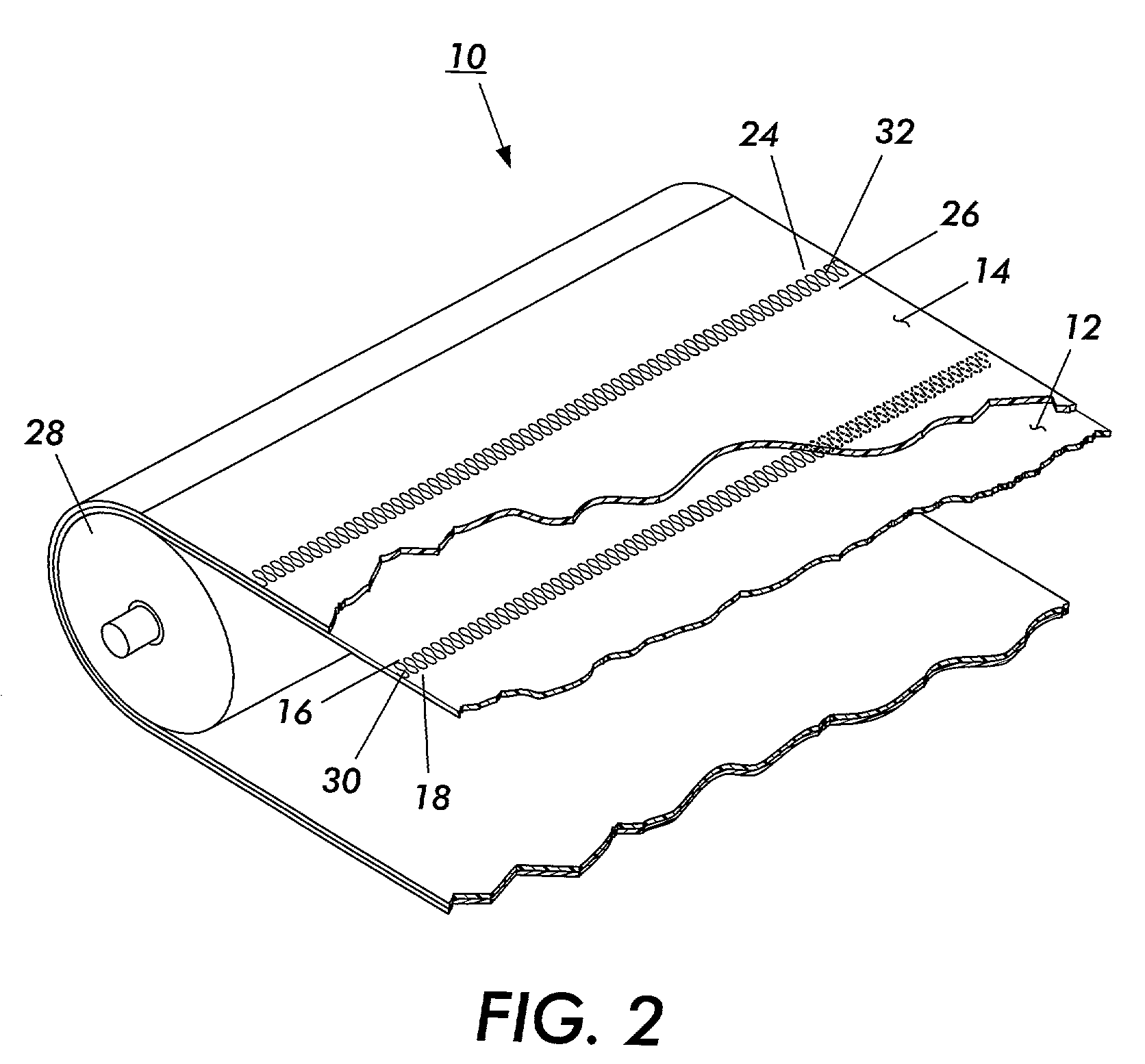

Electrically conductive power transmission belt

A belt made up of an elastomeric belt body, an electrically conductive tensile cord such as carbon fiber cord in a cord layer reinforcing the belt body, an outer layer of electrically conductive thermoplastic material such as polypropylene film, and an electrically conductive fabric layer residing between the tensile cord layer and the outer layer and providing electrical continuity between the outer layer and the tensile cord. An electrically conductive thread may be woven in the fabric and may present at both surfaces of the fabric and contact both the outer layer and the tensile cord to provide the electrical continuity there between.

Owner:THE GATES CORP

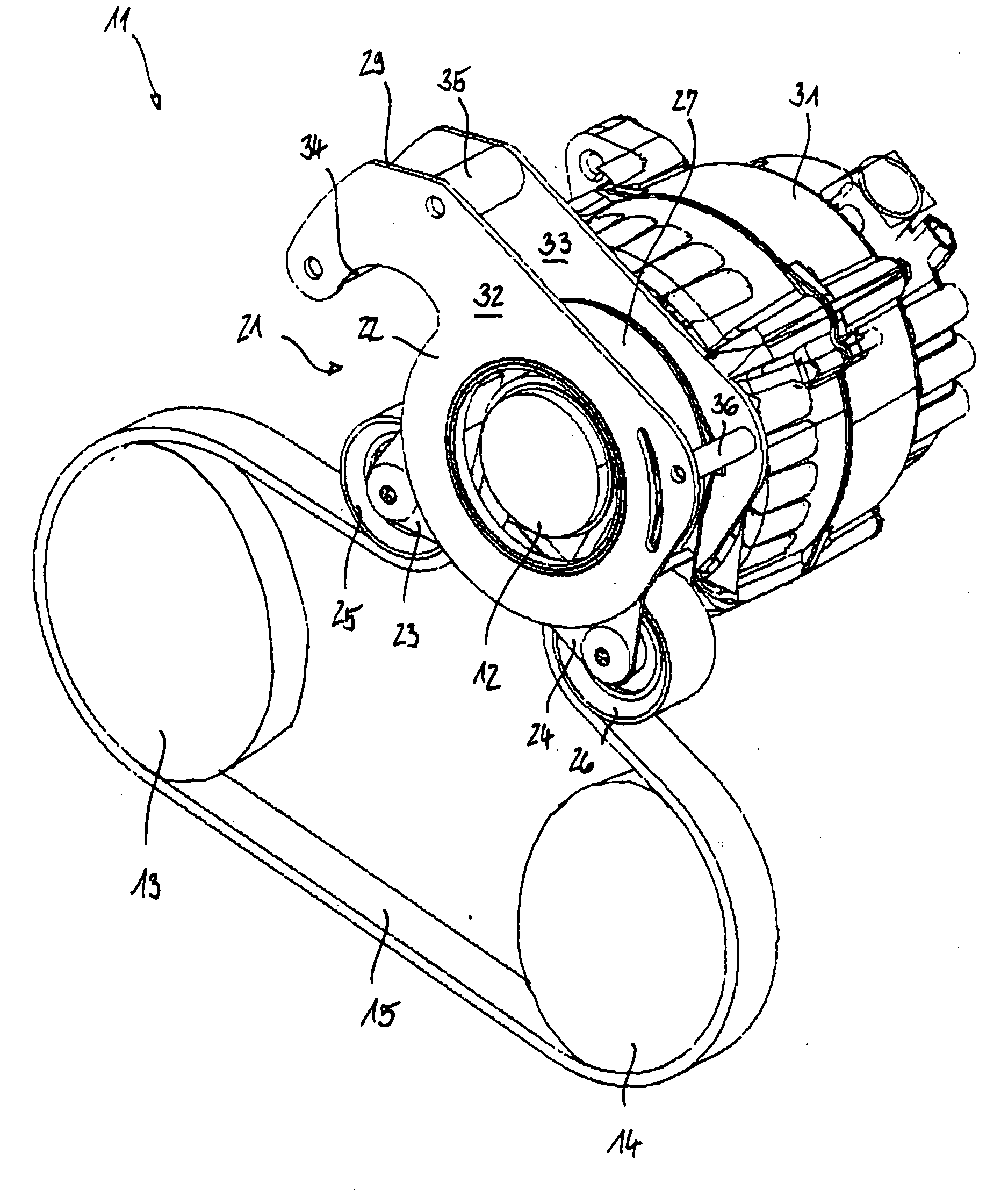

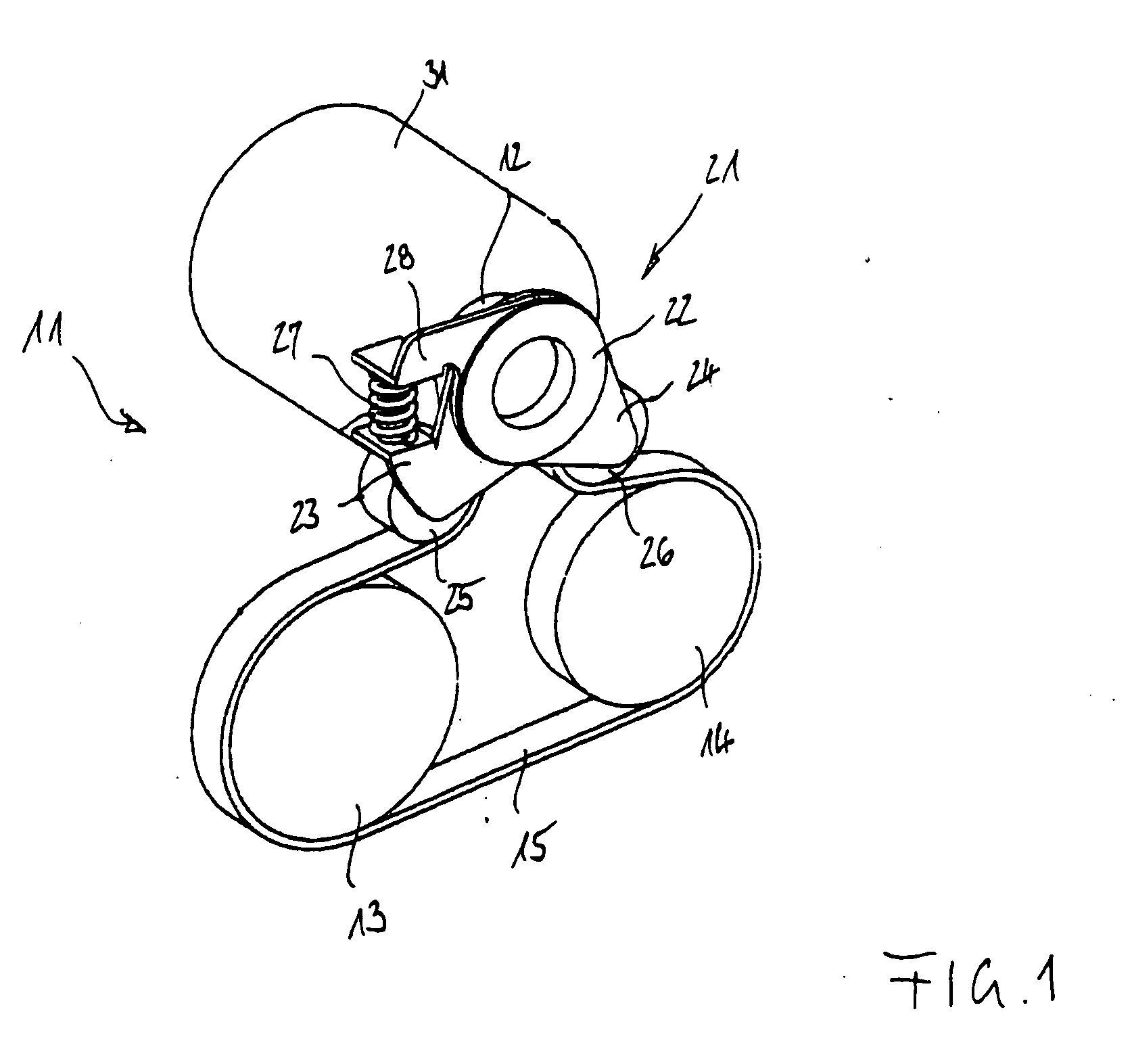

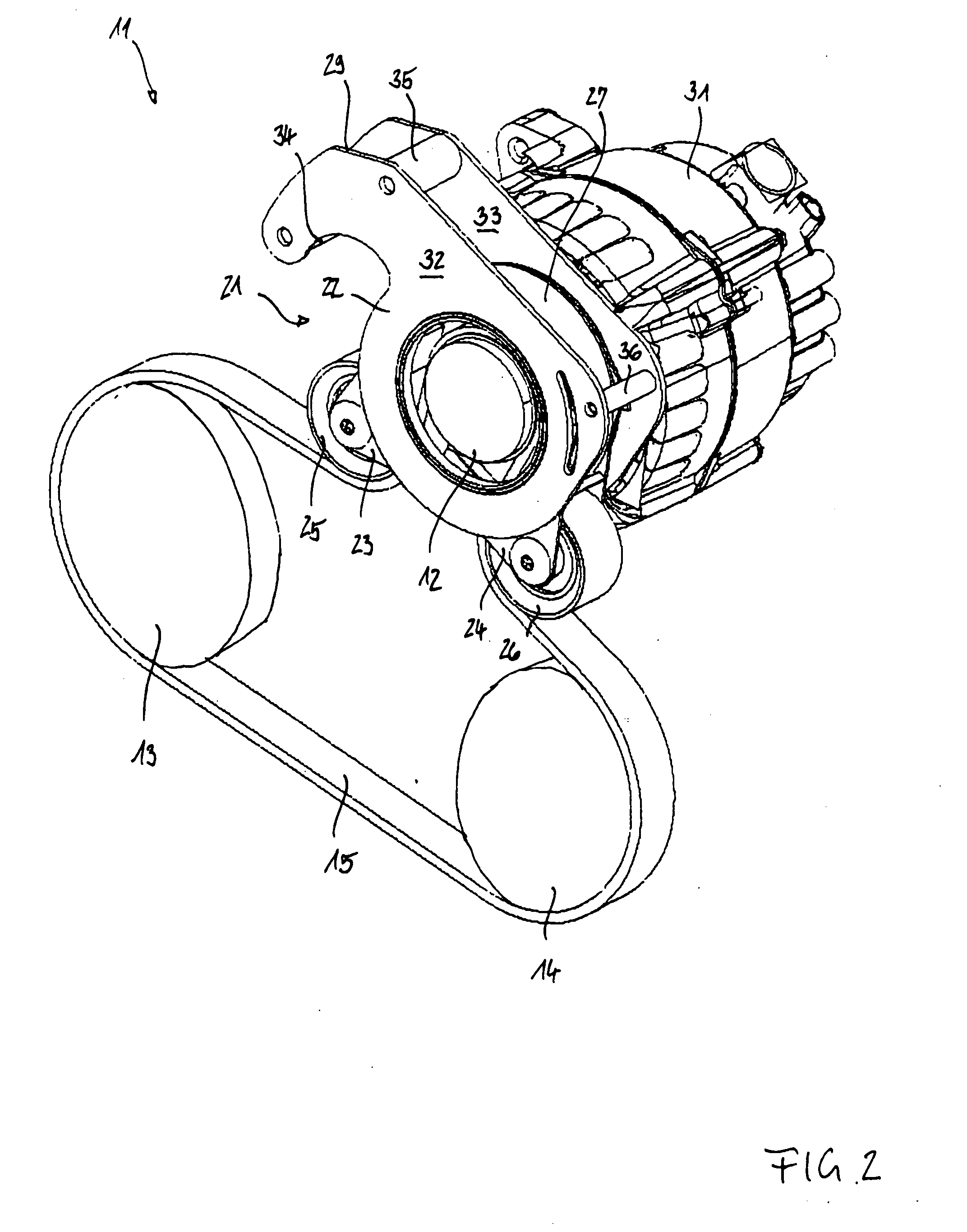

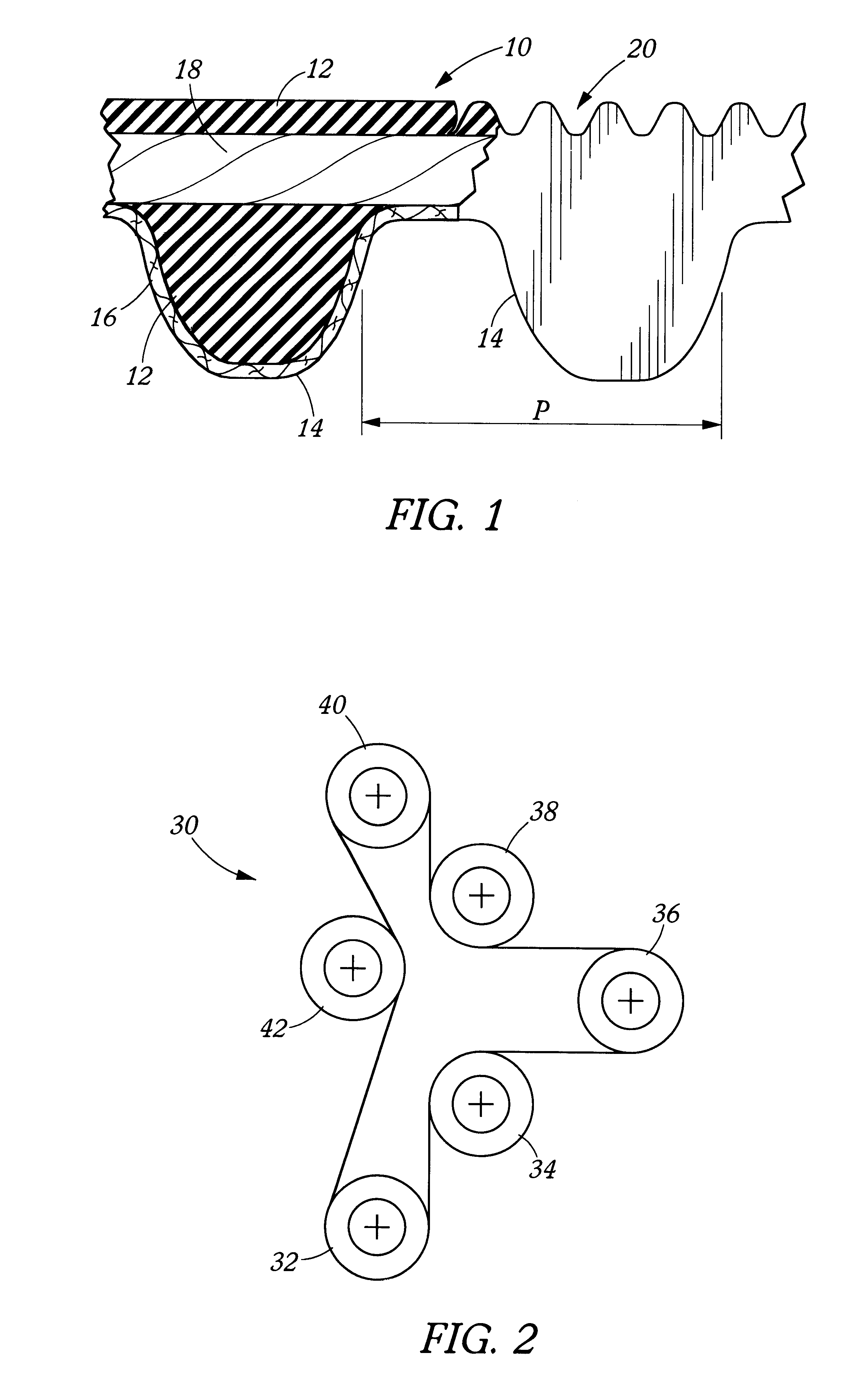

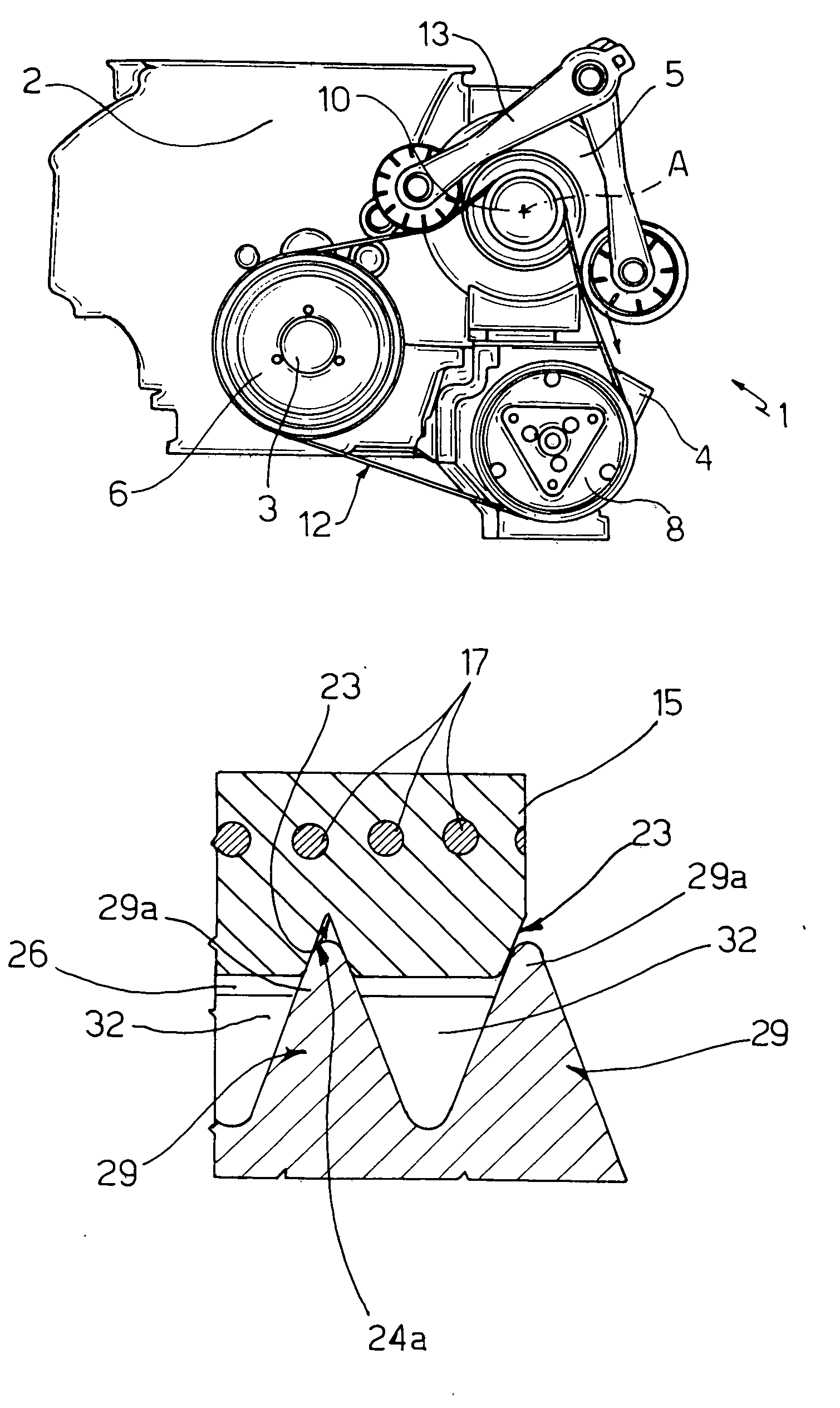

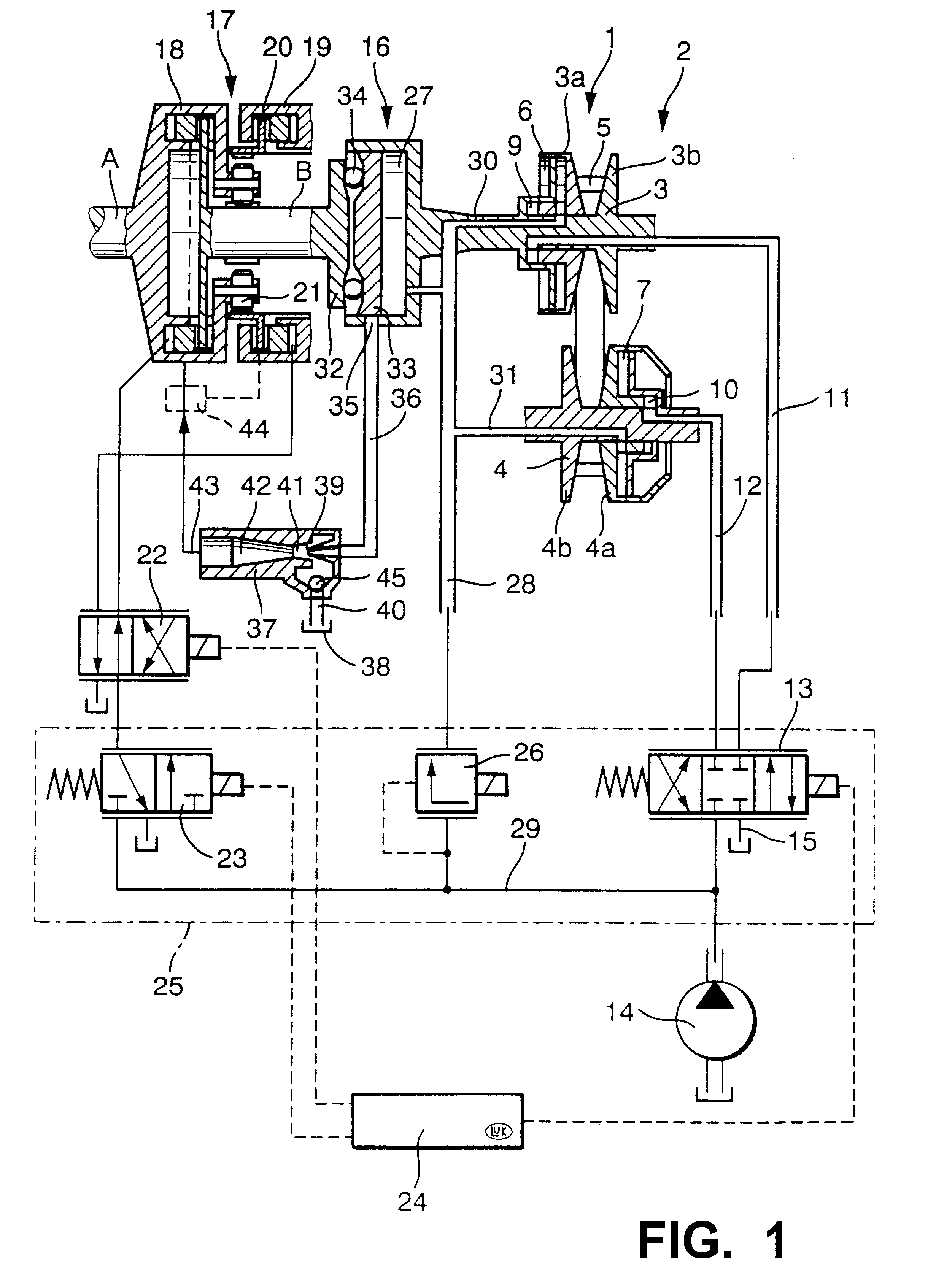

Belt tensioning device for being used with a starter generator

A belt tensioning device for a belt drive which comprises a driving machine with a driving belt pulley drivable by a driveshaft around a driving axis, and a plurality of further belt pulleys and with an infinite belt which is wrapped around the driving belt pulley and the further belt pulleys wherein the belt tensioning device comprises a housing in which two tensioning arms are supported so as to be pivotable around a common pivot axis, in which tensioning arms there are supported tensioning rollers with axes of rotation extending parallel to the driving axis, wherein the tensioning arms are supported relative to one another by spring means, wherein, with the driving belt pulley mounted at the driving machine, the housing can be mounted in that, in an annular region surrounding the driveshaft of the driving belt pulley, the housing is contact-free relative to the driving machine.

Owner:MUHR UND BENNDER KG

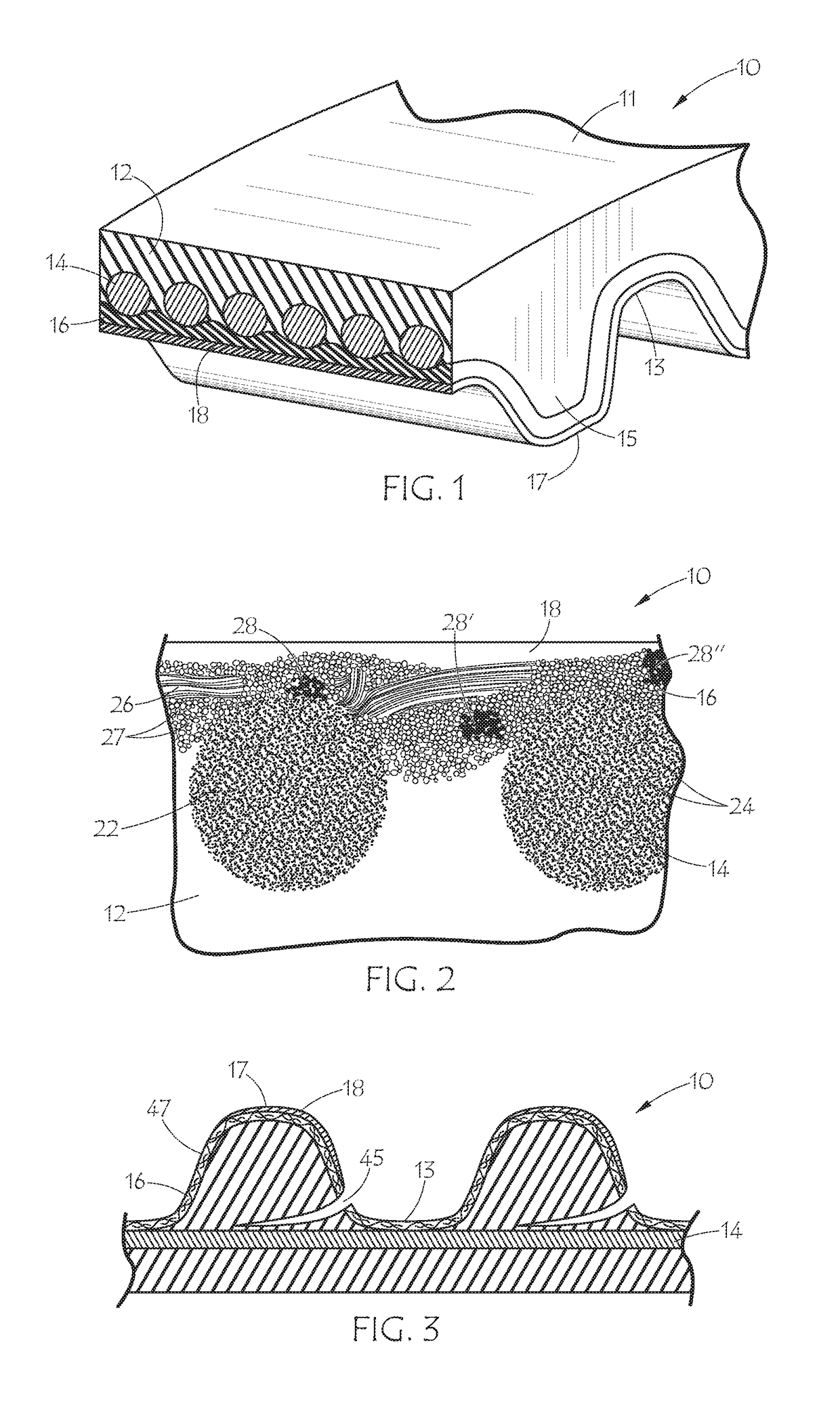

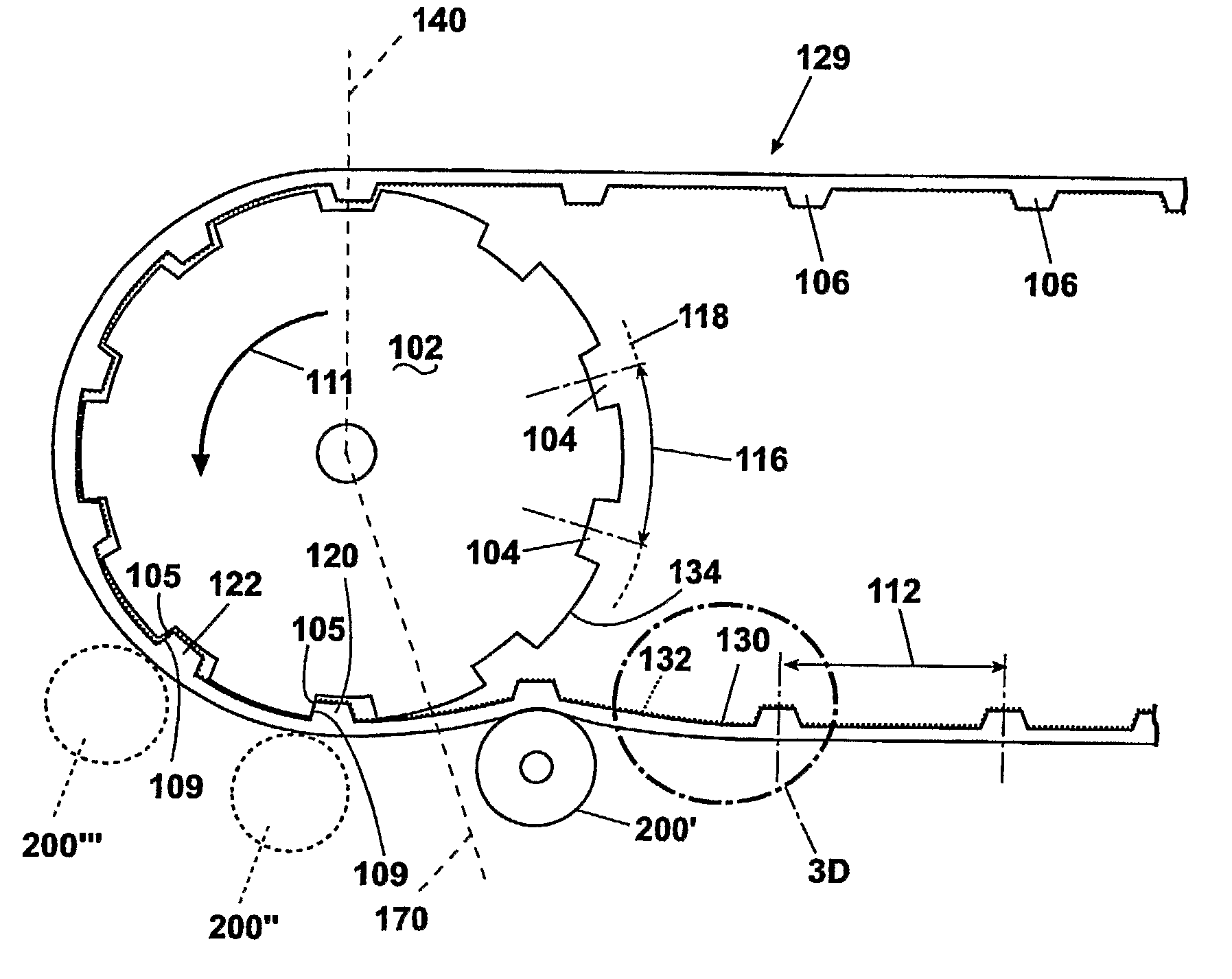

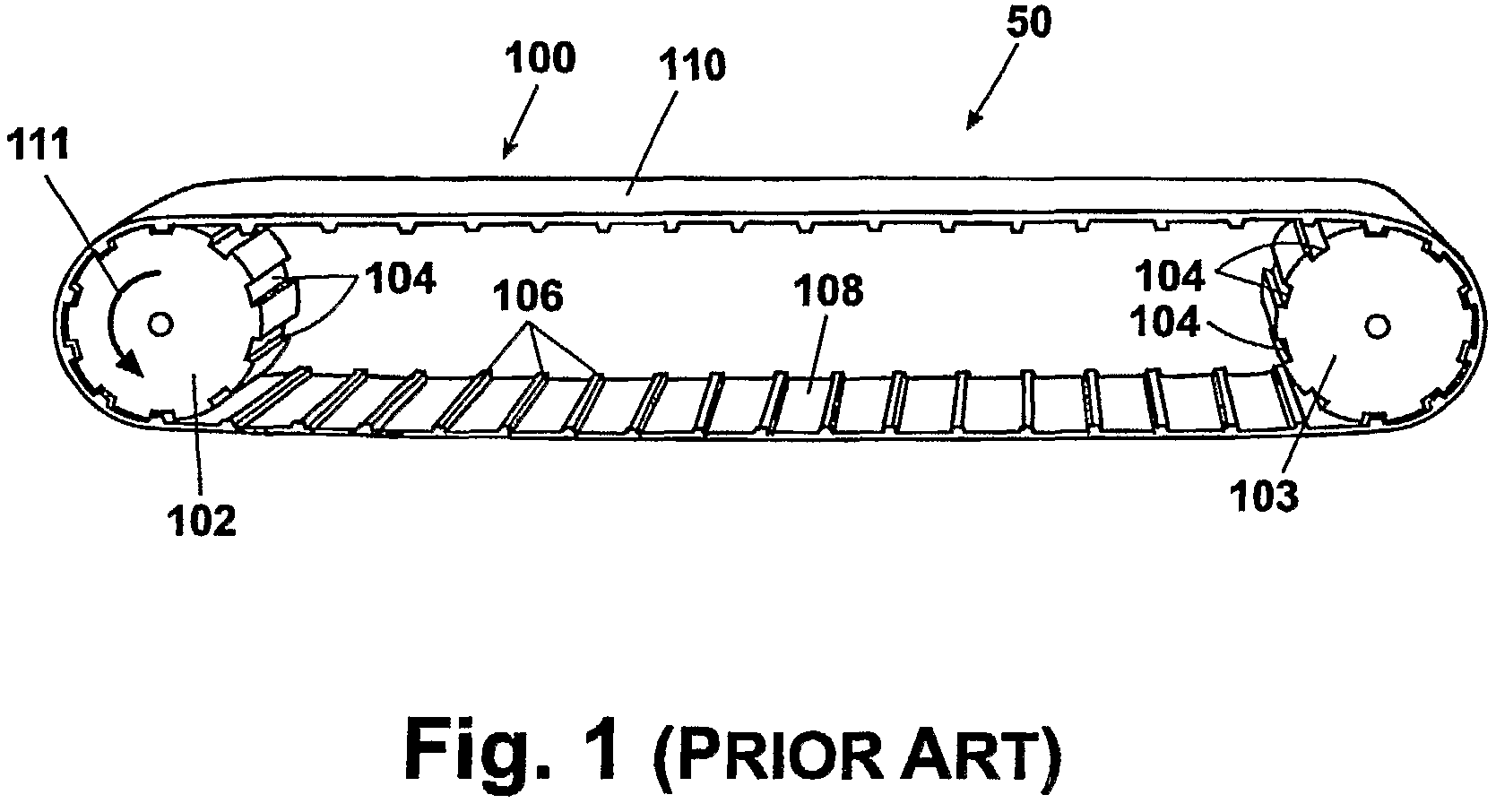

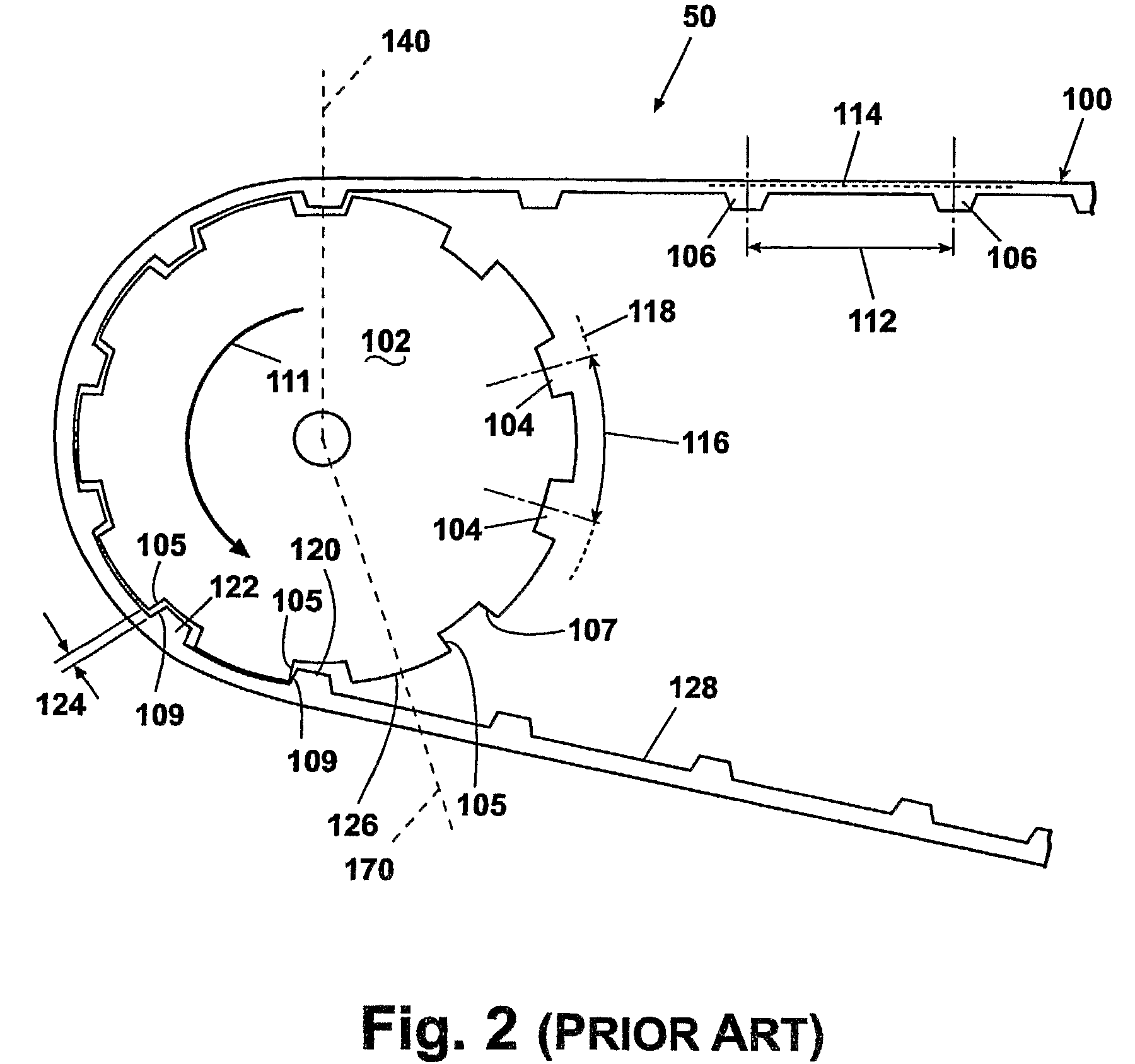

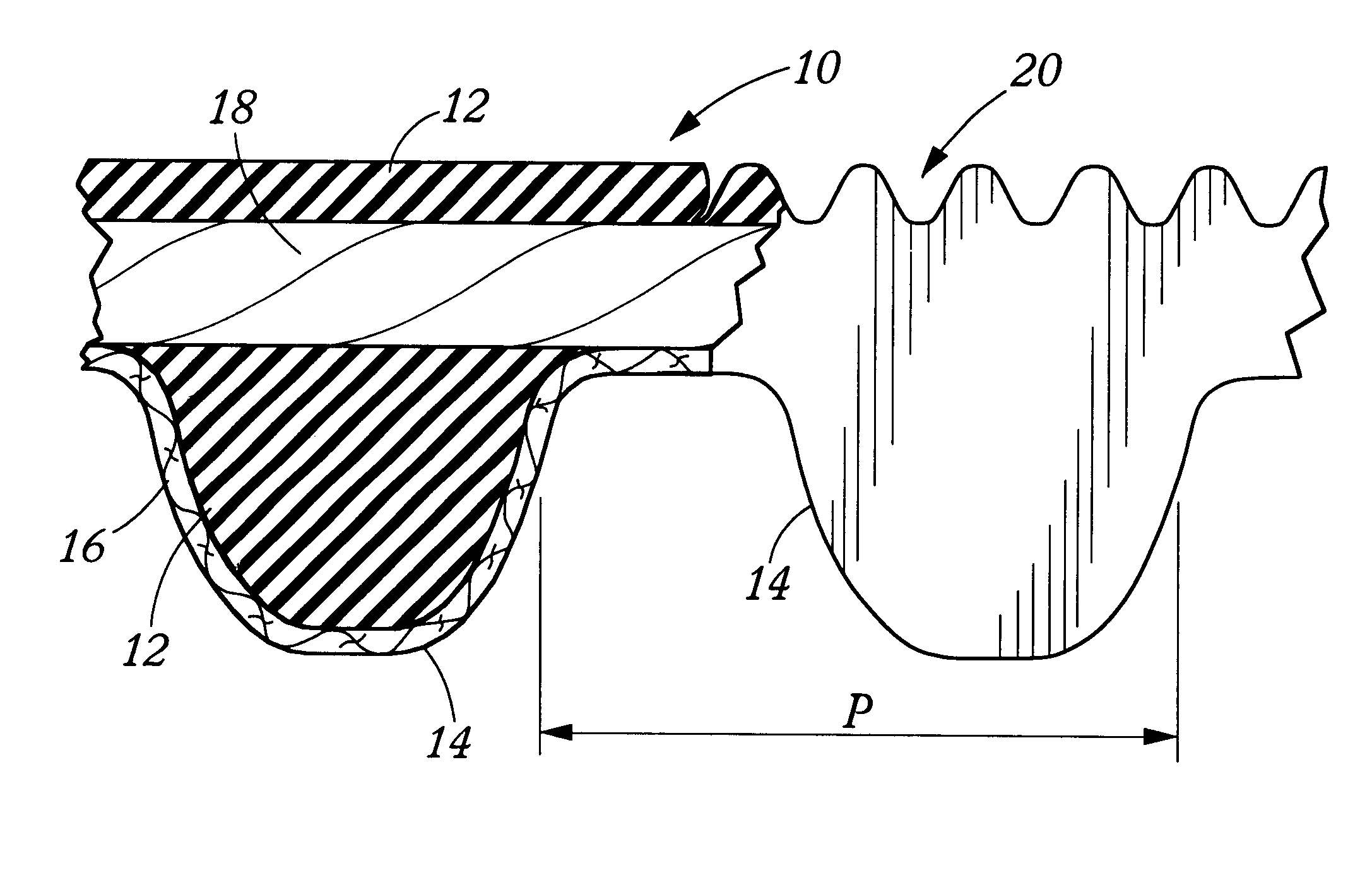

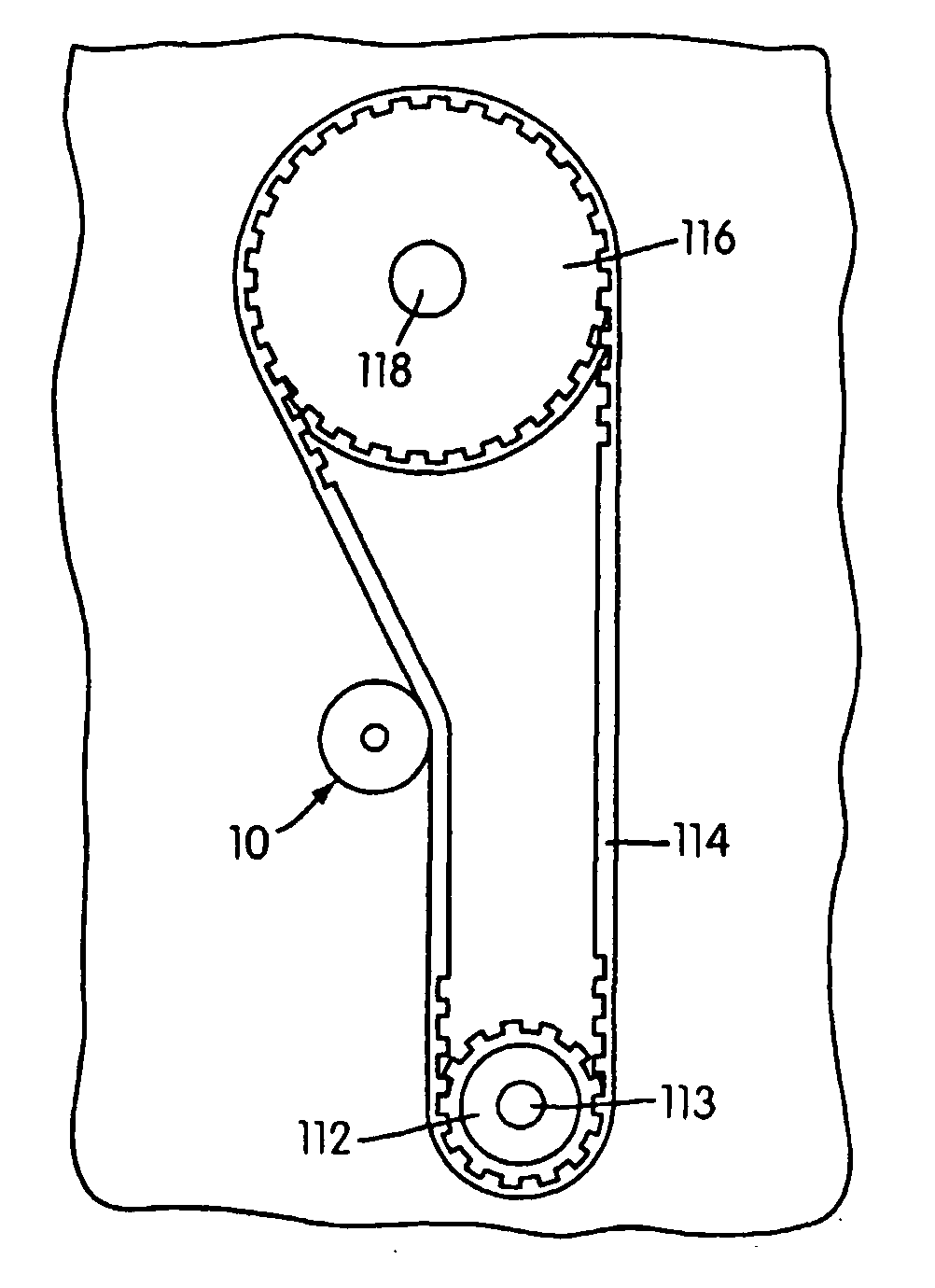

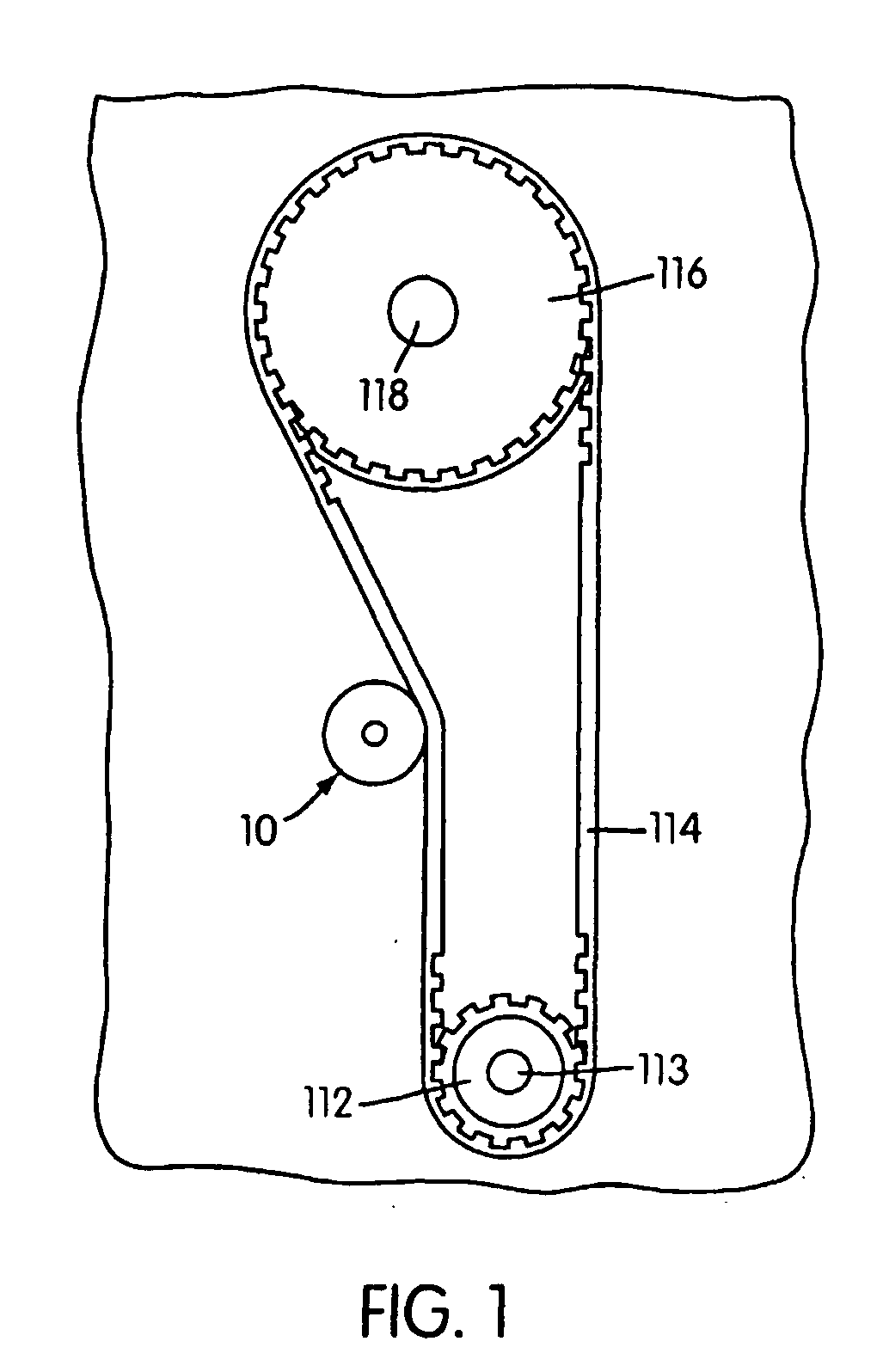

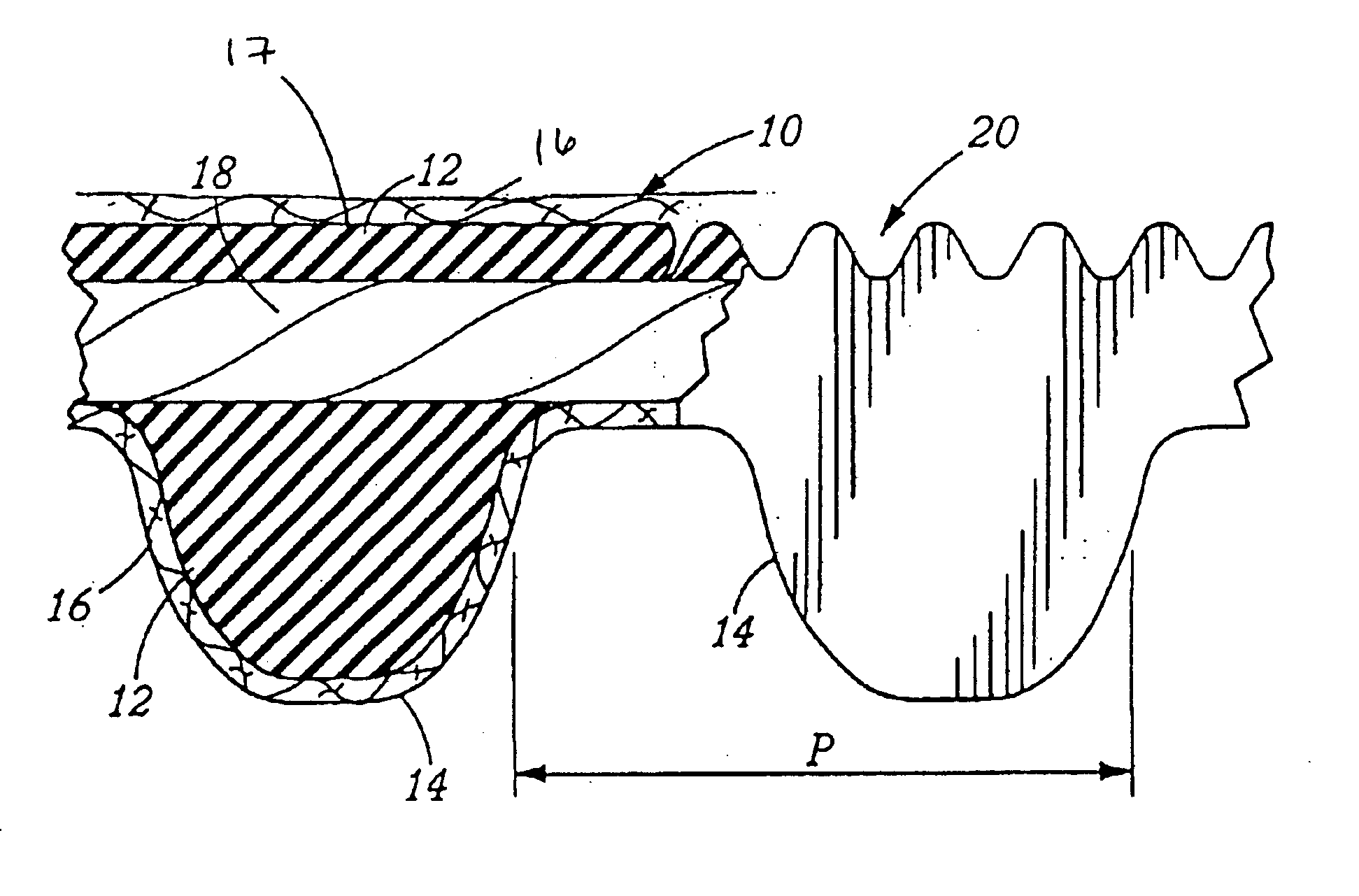

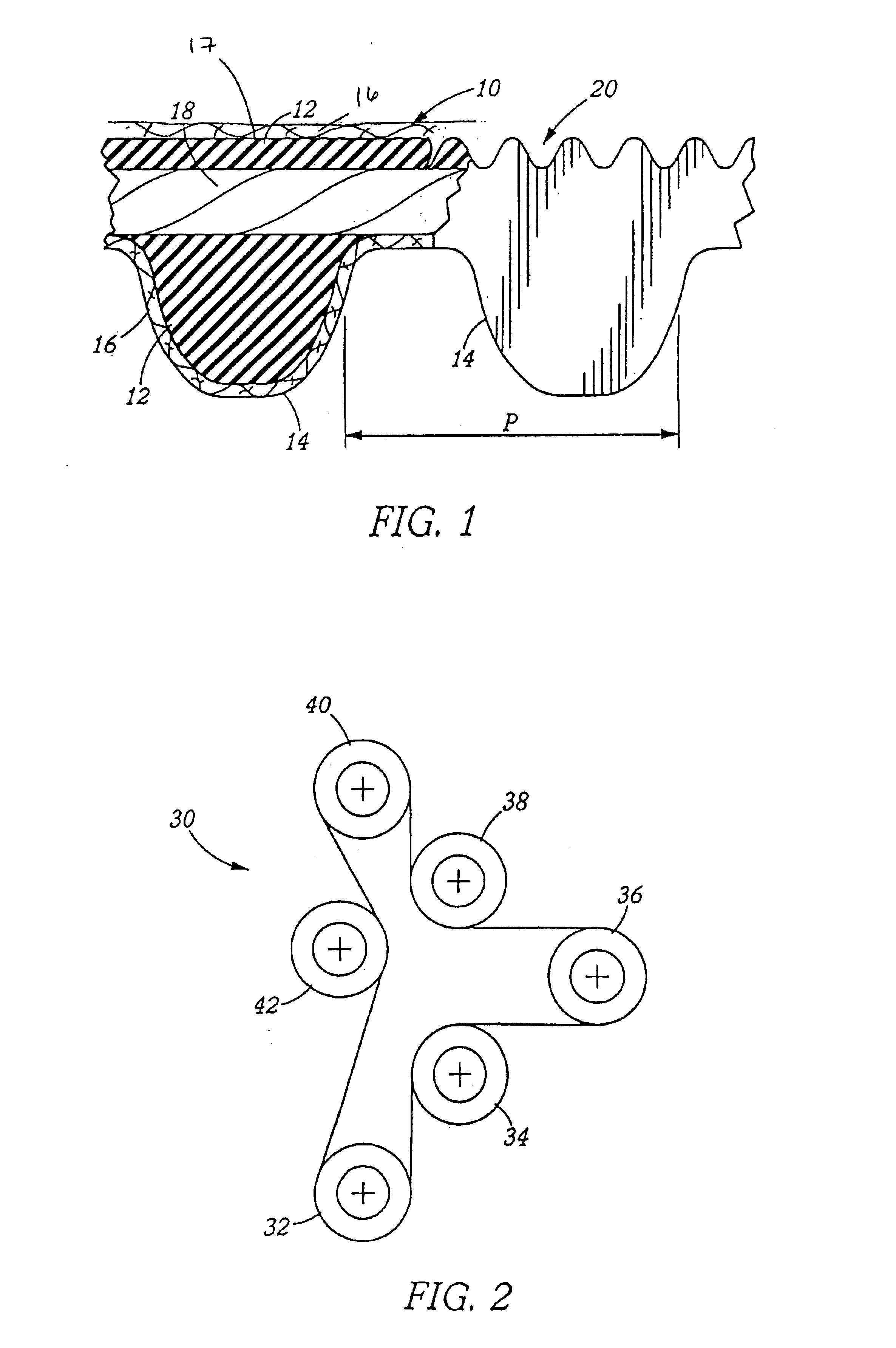

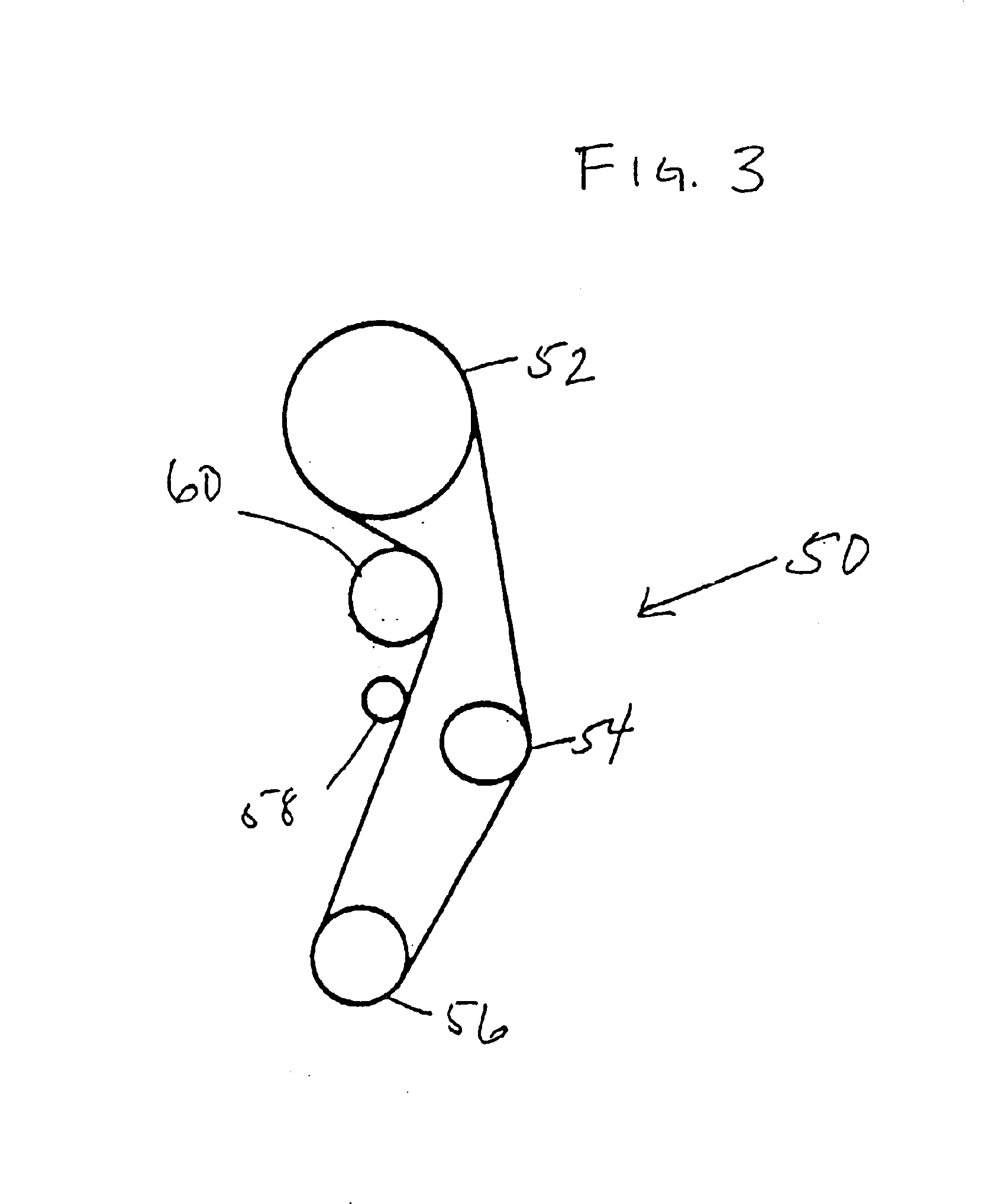

Low friction, direct drive conveyor belt

A thermoplastic endless belt (100) has a smooth outer surface substantially free of discontinuities and an inner surface with a plurality of teeth (106) at a given belt pitch. The teeth are adapted to engage a pulley (102) with circumferentially spaced sheaves (104) at a pulley pitch greater than the belt pitch. The belt is slightly stretchable so that the pulley can drive the endless belt when engaging the teeth within a range of load on the belt. Means (132, 136, 138) are provided to minimize friction between the belt and the drive pulley. Also, a position limiter (200) ensures that the driven tooth stays engaged optimally with the drive sheave.

Owner:LAITRAM LLC

Prepreg and fiber-reinforced rubber materials

The object is to provide a carbon fiber-reinforced rubber material which is superior in heat resistance, water resistance, and dimensional stability and exhibits resistance to fatigue from flexing at a practical level. The present invention relates to a prepreg comprising a liquid rubber composition having a viscosity in a range of 0.01 Pa.s to 100 Pa.s at 70° C. and substantially containing no solvent, the liquid rubber being impregnated into a reinforcing fiber, and relates to a fiber-reinforced rubber material comprising the prepreg in which the liquid rubber is crosslinked. Also, the present invention relates to a fiber-reinforced rubber material comprising a substrate comprising a rubber component, the substrate being reinforced by a core material comprising a prepreg of a reinforcing fiber impregnated with the same rubber component.

Owner:TORAY IND INC

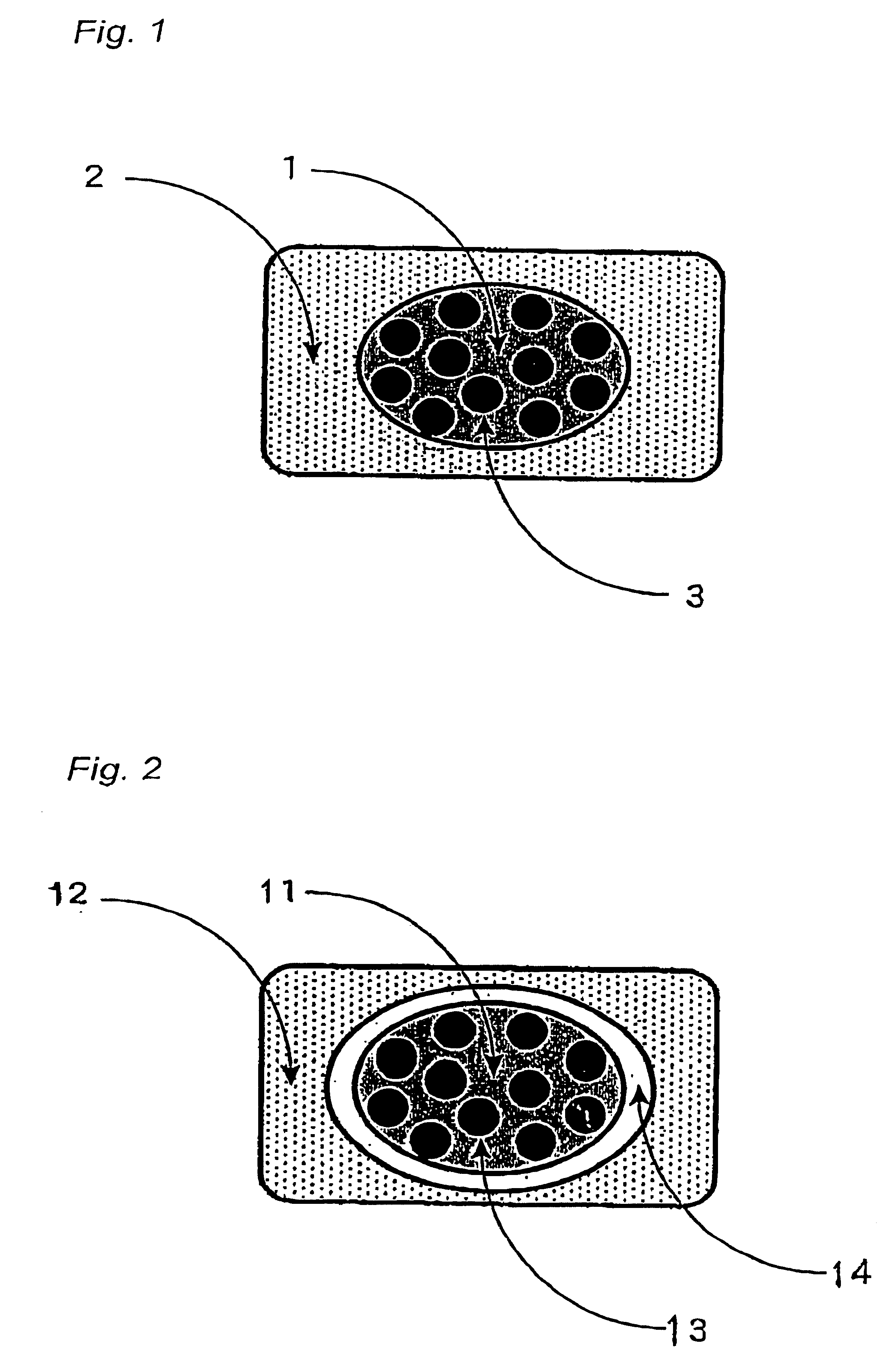

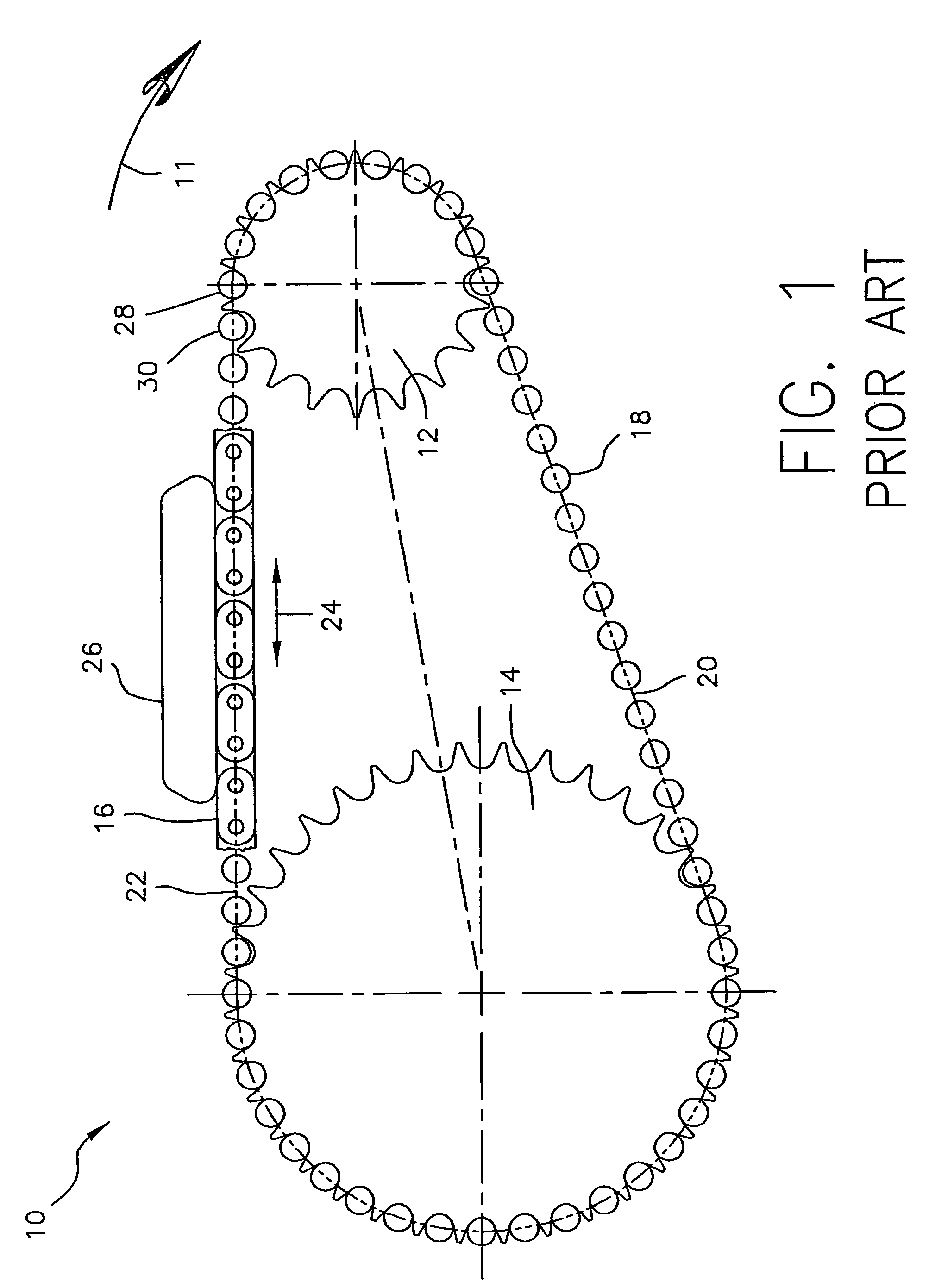

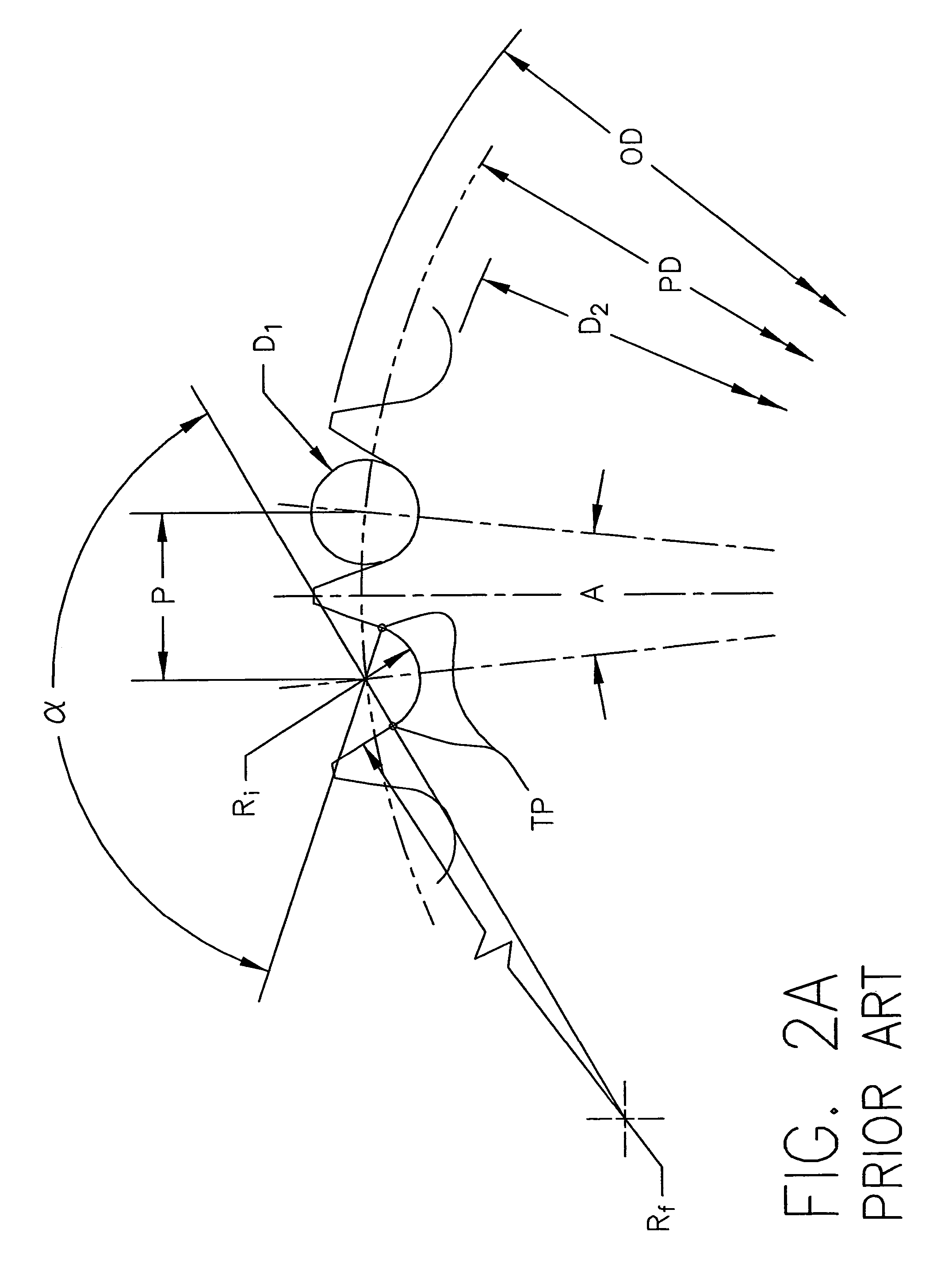

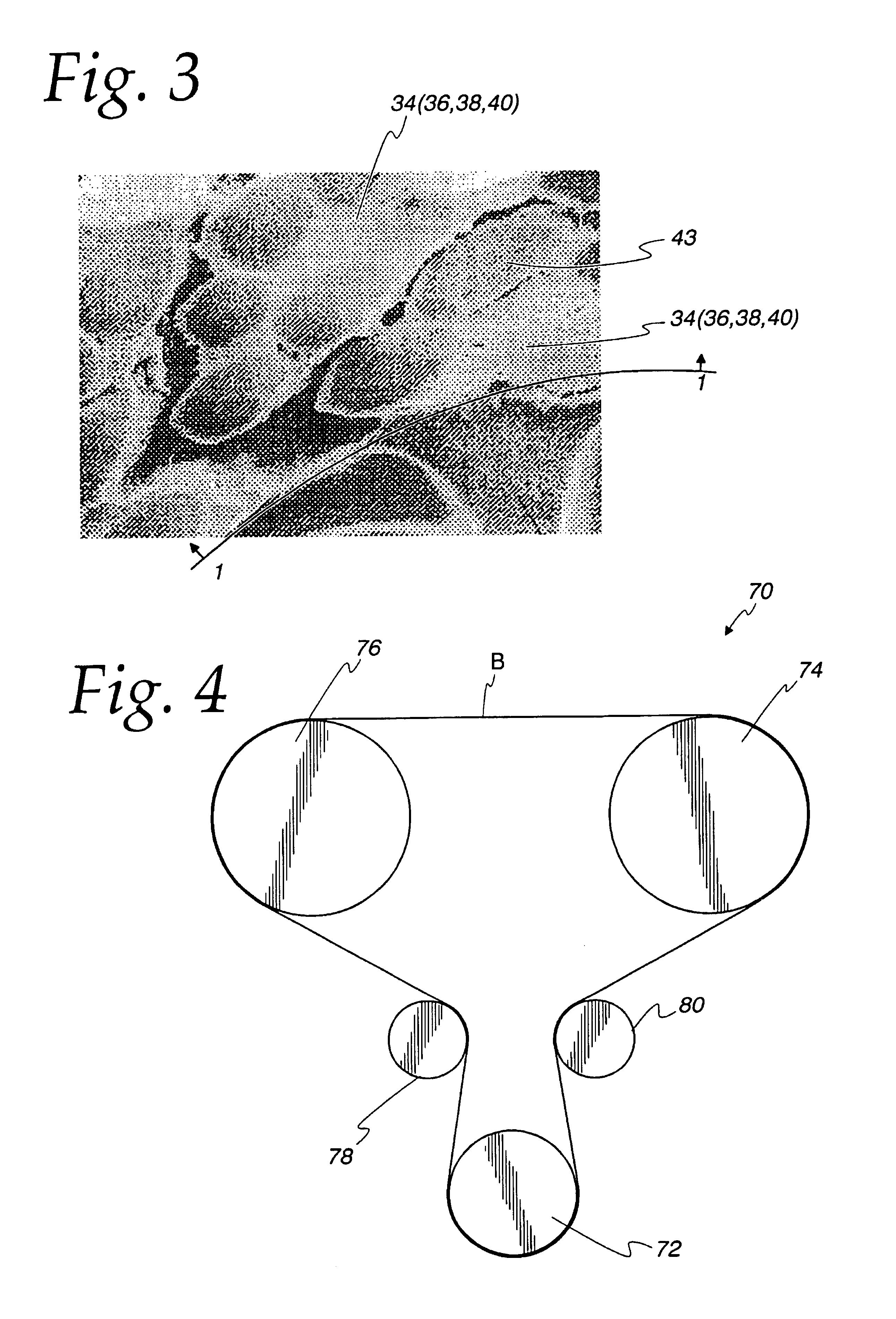

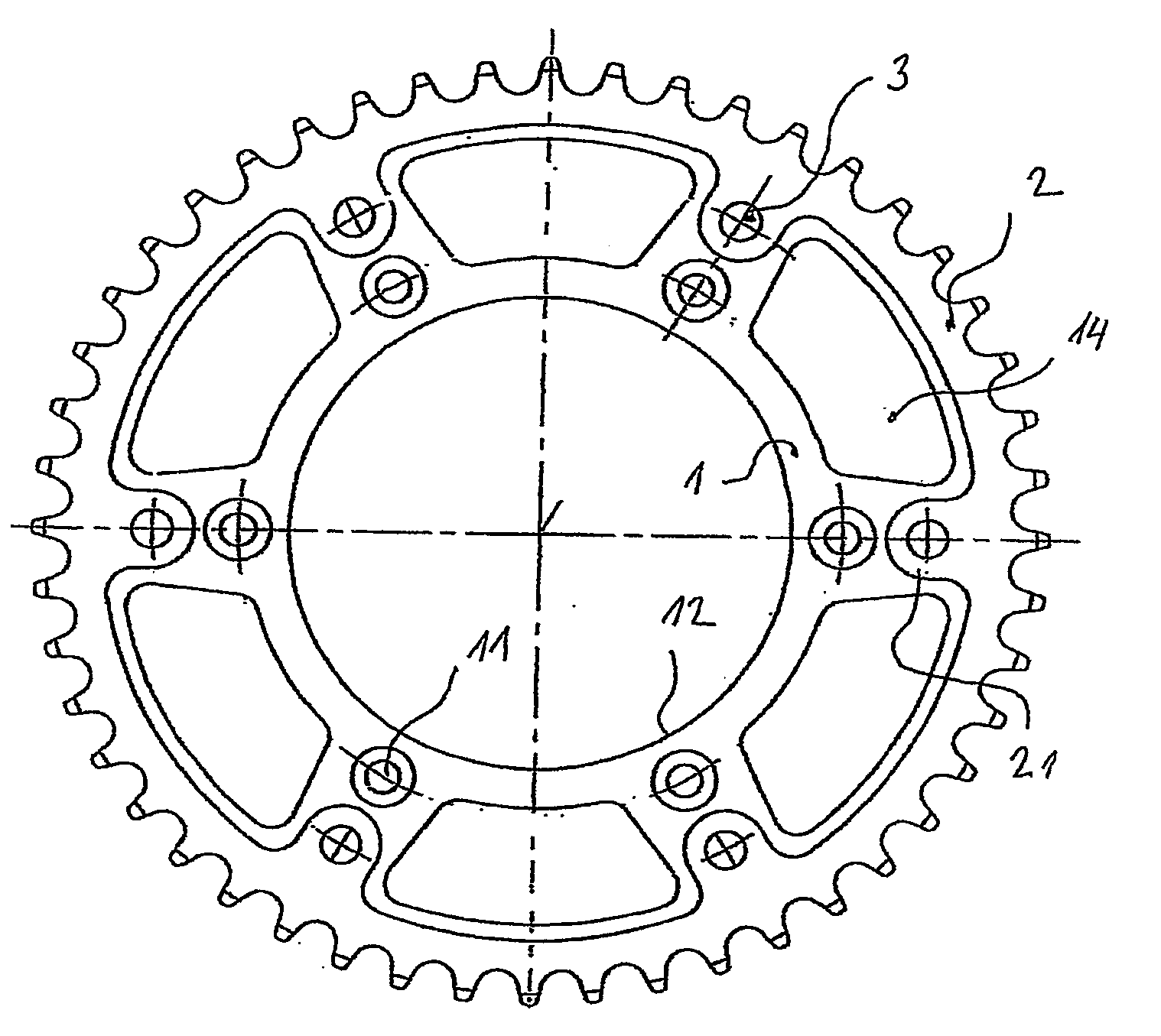

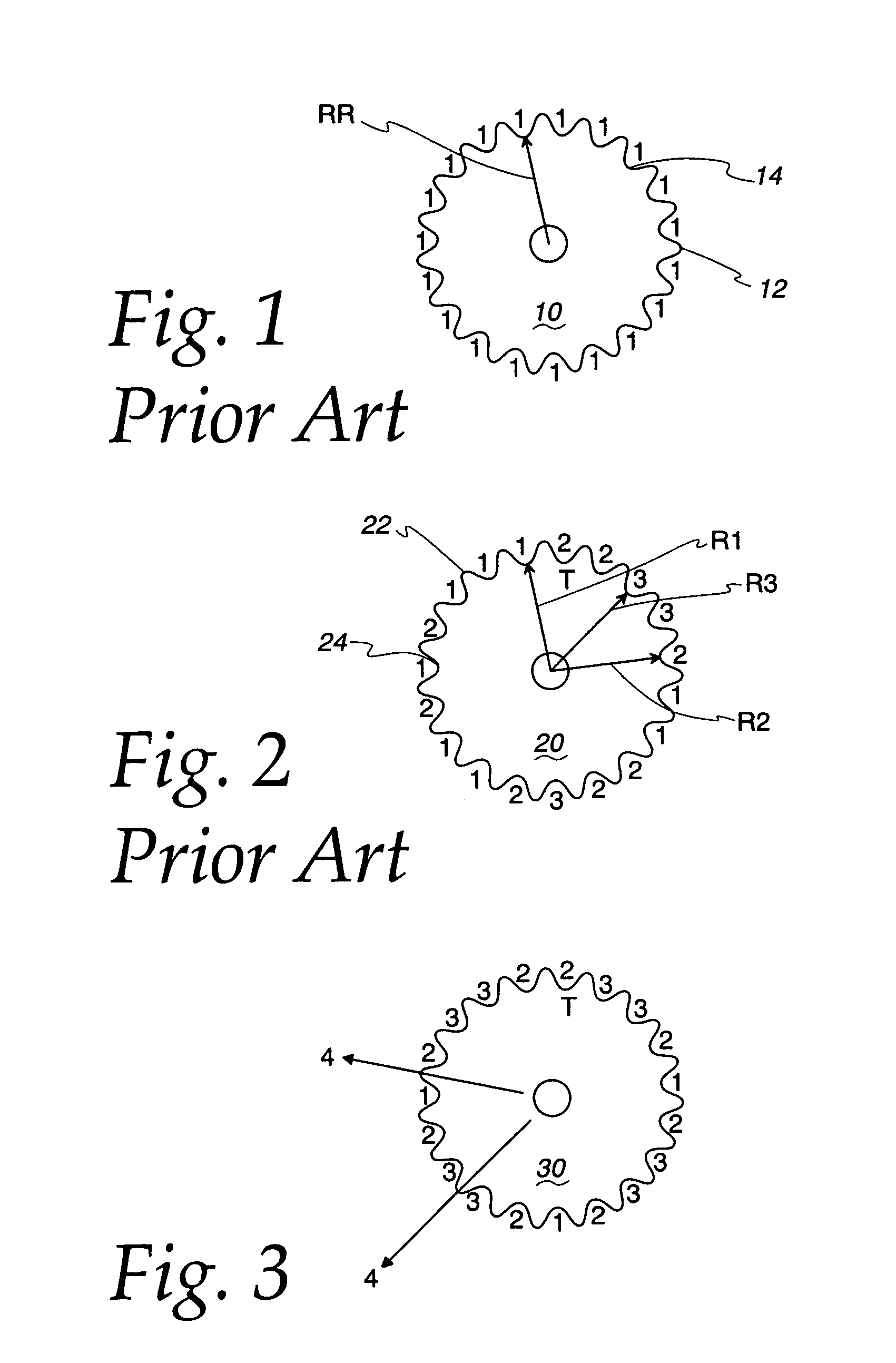

Random engagement roller chain sprocket and timing chain system including same

A sprocket and a roller chain drive system including same are disclosed. The sprocket is a random engagement sprocket comprising a first plurality of A-profile teeth formed with a first asymmetric profile and a second plurality of B-profile teeth formed with a second asymmetric profile. The A-profile teeth each define a first pressure angle and the B-profile teeth each define a second pressure angle that is at least 5 degrees greater than said first pressure angle so that a minimum separation Δ is defined. The sprocket is defined with added chordal pitch reduction of 0.2% up to 1% relative to the link pitch of the associated roller chain. The sprocket can be defined with root relief and / or can comprise resilient cushion rings. Initial roller contacts made with the A-profile and B-profile teeth are modulated owing to the pressure angle separation and added chordal pitch reduction.

Owner:HH CLOYES INC

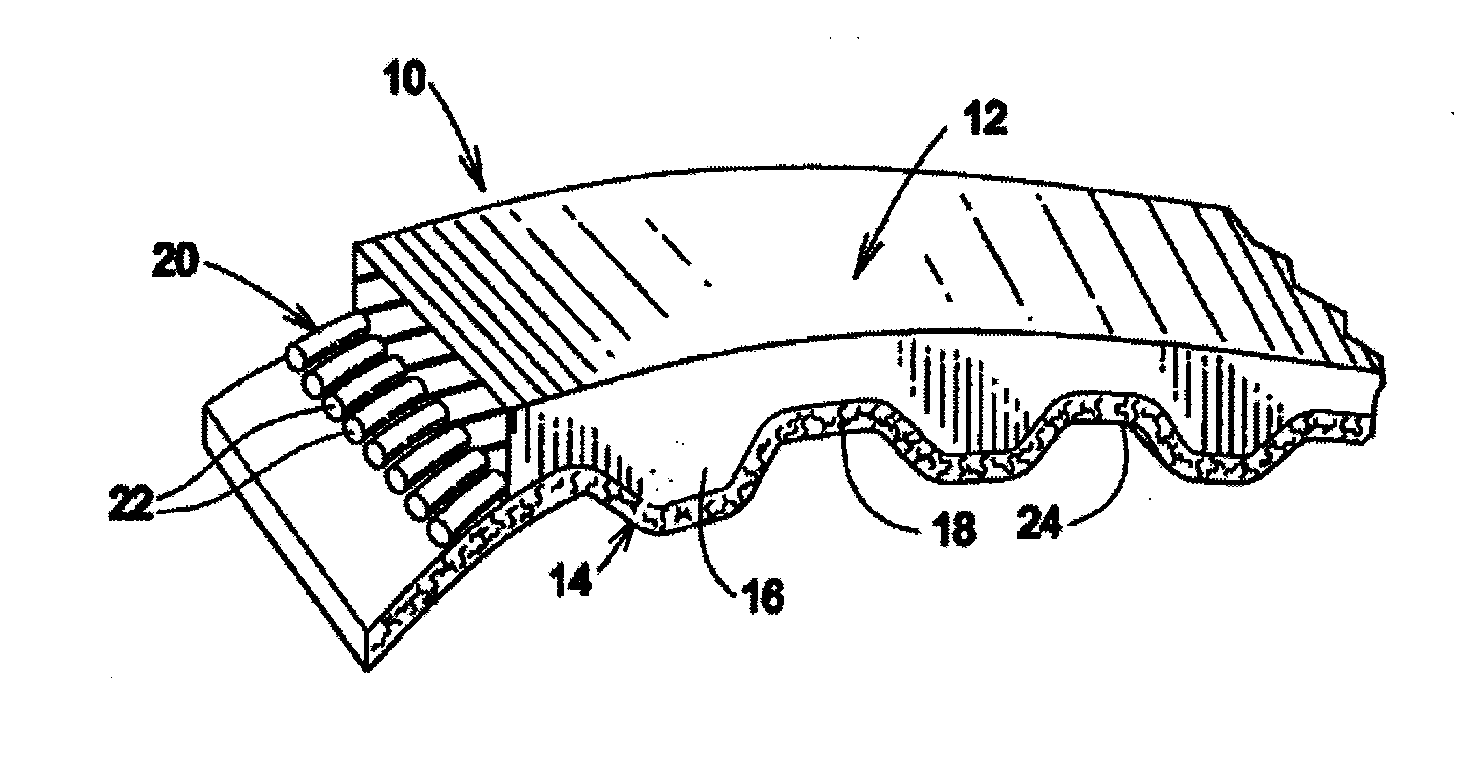

Polyurethane power transmission belt

ActiveUS20090227406A1Increase load capacityIncrease resistanceV-beltsRopes and cables for vehicles/pulleyElastomerFiber

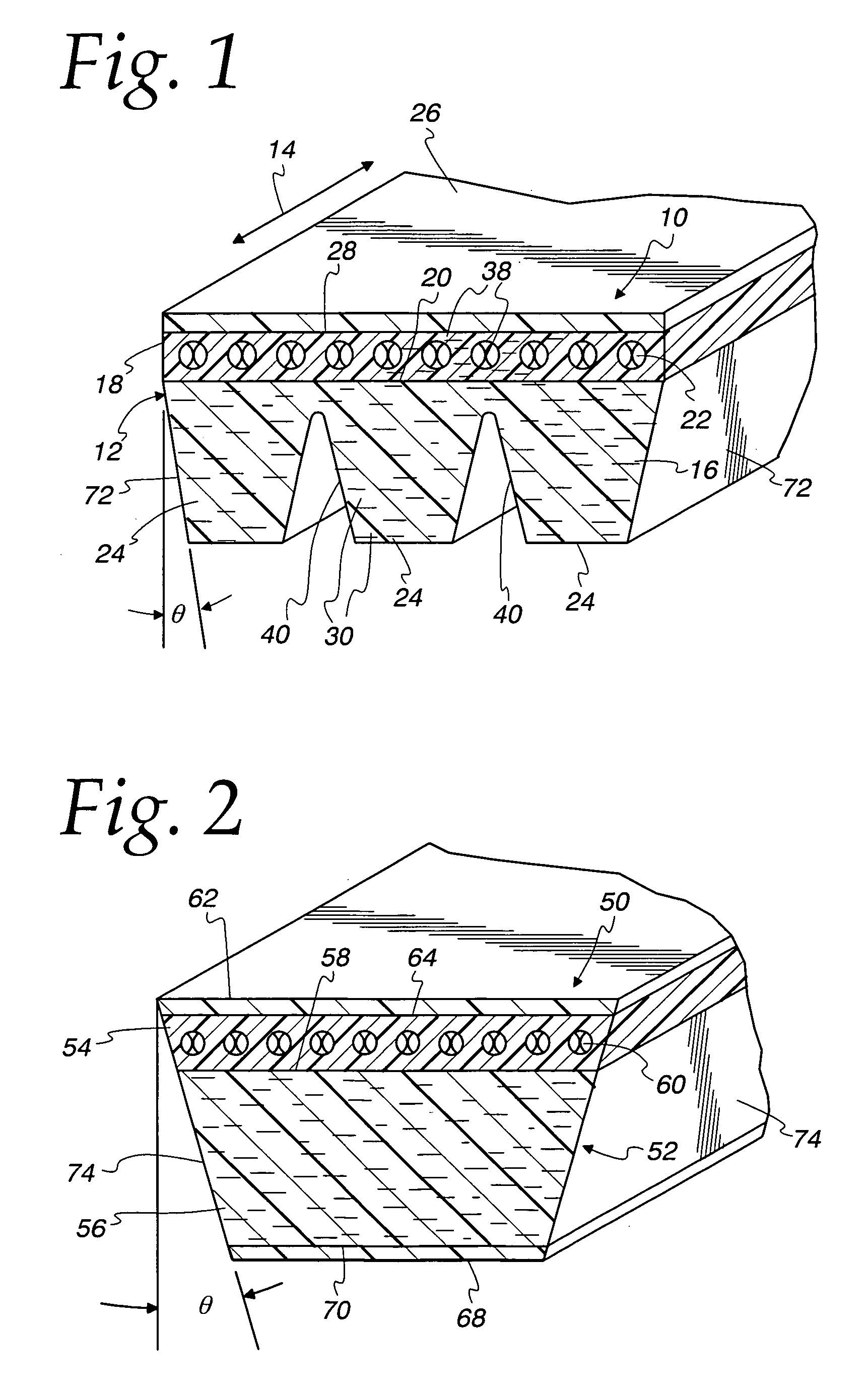

A power transmission belt having a main belt body portion of elastomeric material, a tensile reinforcement such as carbon fiber cord, disposed in said body portion, and a sheave contact portion integral with said main body portion. The elastomeric material includes the reaction product of a polyisocyanate prepolymer composition and a chain extender. The polyisocyanate prepolymer composition is prepared by reacting a diisocyanate and a polyol substantially free of moieties oxidative at less than about 150° C. and at least one triol crosslinker selected from the same group of polyols. Either before or after reacting the prepolymer, a plasticizer selected from the group consisting of alkyl-ether di-alkylesters such as polyethylene glycol di-alkylester is added thereto. The chain extender is an aromatic symmetric primary or secondary diamine chain extenders.

Owner:THE GATES CORP

Polyurea-Urethane Cord Treatment for Power Transmission Belt and Belt

ActiveUS20110129647A1Improve adhesionGood compatibilityV-beltsPolyureas/polyurethane adhesivesPolyesterElastomer

A belt with a tensile cord embedded in an elastomeric body, having a polyurea-urethane adhesive composition impregnating the cord and coating the fibers. The composition is reaction product of a polyurethane prepolymer and a diamine curative or water. The prepolymer is a reaction product of a compact, symmetric diisocyanate and a polyester, polyether, or polycarbonate polyol. The belt body may be of cast polyurethane, vulcanized rubber, or thermoplastic elastomer. The cord may have an adhesive overcoat.

Owner:THE GATES CORP

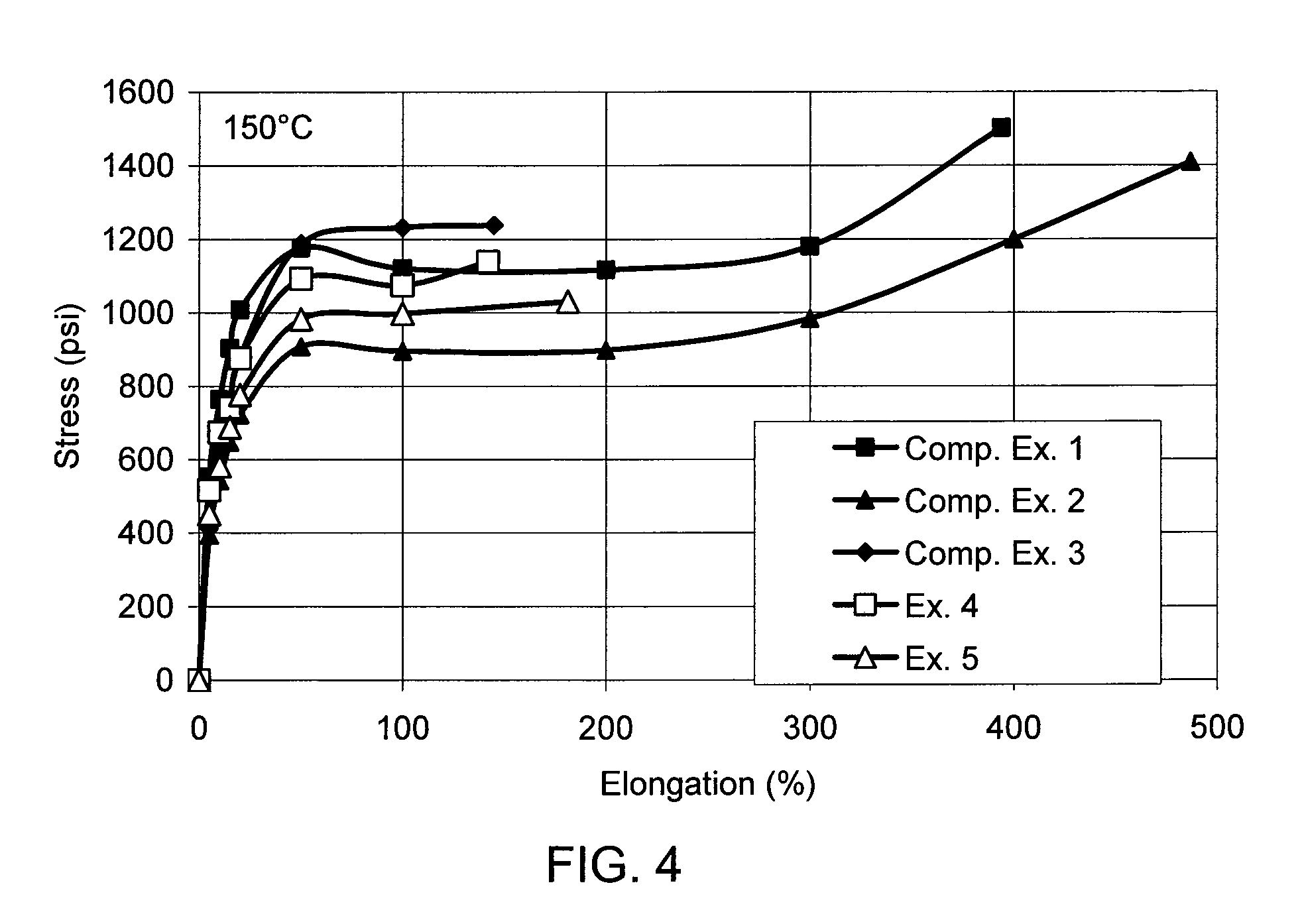

High temperature polyurethane/urea elastomers

InactiveUS6964626B1High and low temperature resistance propertiesHigh and low temperature resistance propertyV-beltsRopes and cables for vehicles/pulleyElastomerPolyester

The present invention relates to molded polyurethane / urea elastomers, and specifically to improved polyurethane / urea elastomers having high temperature stability to about 140–150° C. and low temperature flexibility at about −35–(−40)° C., for use in dynamic applications. These elastomers are particularly useful for application in belts, specifically in automotive timing or synchronous belts, V-belts, multi V-ribbed or micro-ribbed belts, flat belting and the like. The polyurethane / urea elastomers of the present invention are prepared by reacting polyisocyanate prepolymers with symmetric primary diamine chain extenders, mixtures of symmetric primary diamine chain extenders and secondary diamine chain extenders, or mixtures of symmetric primary diamine chain extenders and non-oxidative polyols, which are all chosen to eliminate the need for catalysts via standard molding processes, and to improve phase separation. The polyisocyanate prepolymers are reaction products of polyols which are nonoxidative at high temperatures, such as polycarbonate polyols, polyester polyols, or mixtures thereof, with organic polyisocyanates which are either compact, symmetric and aromatic, such as para-phenylene diisocyanate, 1,5-naphthalene diisocyanate, and 2,6-toluene diisocyanate, or are aliphatic and possess trans or trans,trans geometric structure, such as trans-1,4-cyclohexane diisocyanate and trans,trans-4,4′-dicyclohexylmethyl diisocyanate.

Owner:THE GATES CORP

Power transmission belt and cord adhesive system and adhesion method

ActiveUS20090142572A1Improve balanceLow costV-beltsRopes and cables for vehicles/pulleyPolyesterElastomer

Owner:THE GATES CORP

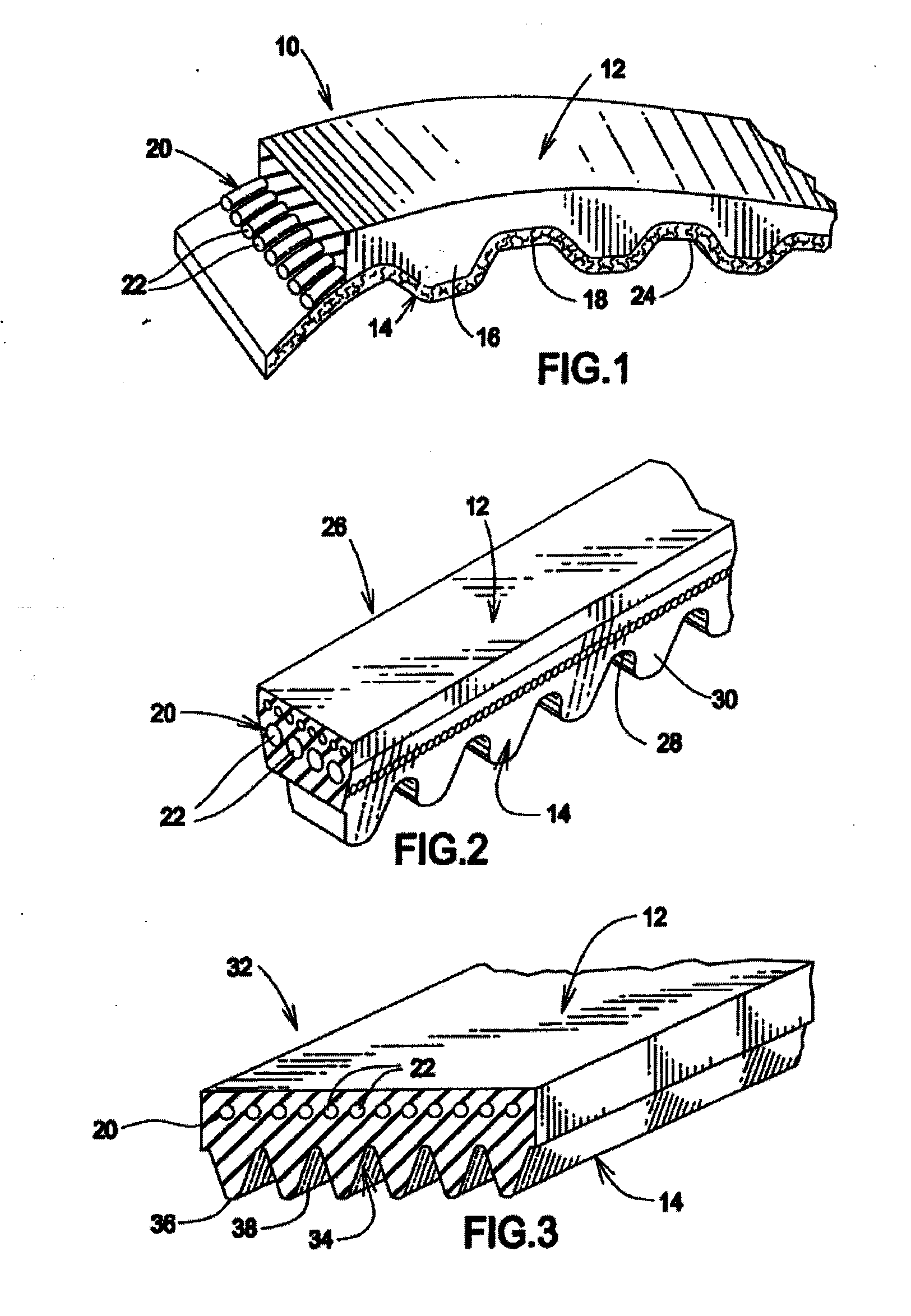

Low growth power transmission belt

A power transmission belt, and more particularly a toothed power transmission belt, comprising a longitudinally extending tensile member composed of one or more carbon fiber cords, wherein the belt exhibits belt growth of not more than 0.1% based on its original length after 48 hours under High Temperature Belt Growth Analysis performed at 100° C., and a method for producing such belts exhibiting reduced belt growth.

Owner:THE GATES CORP

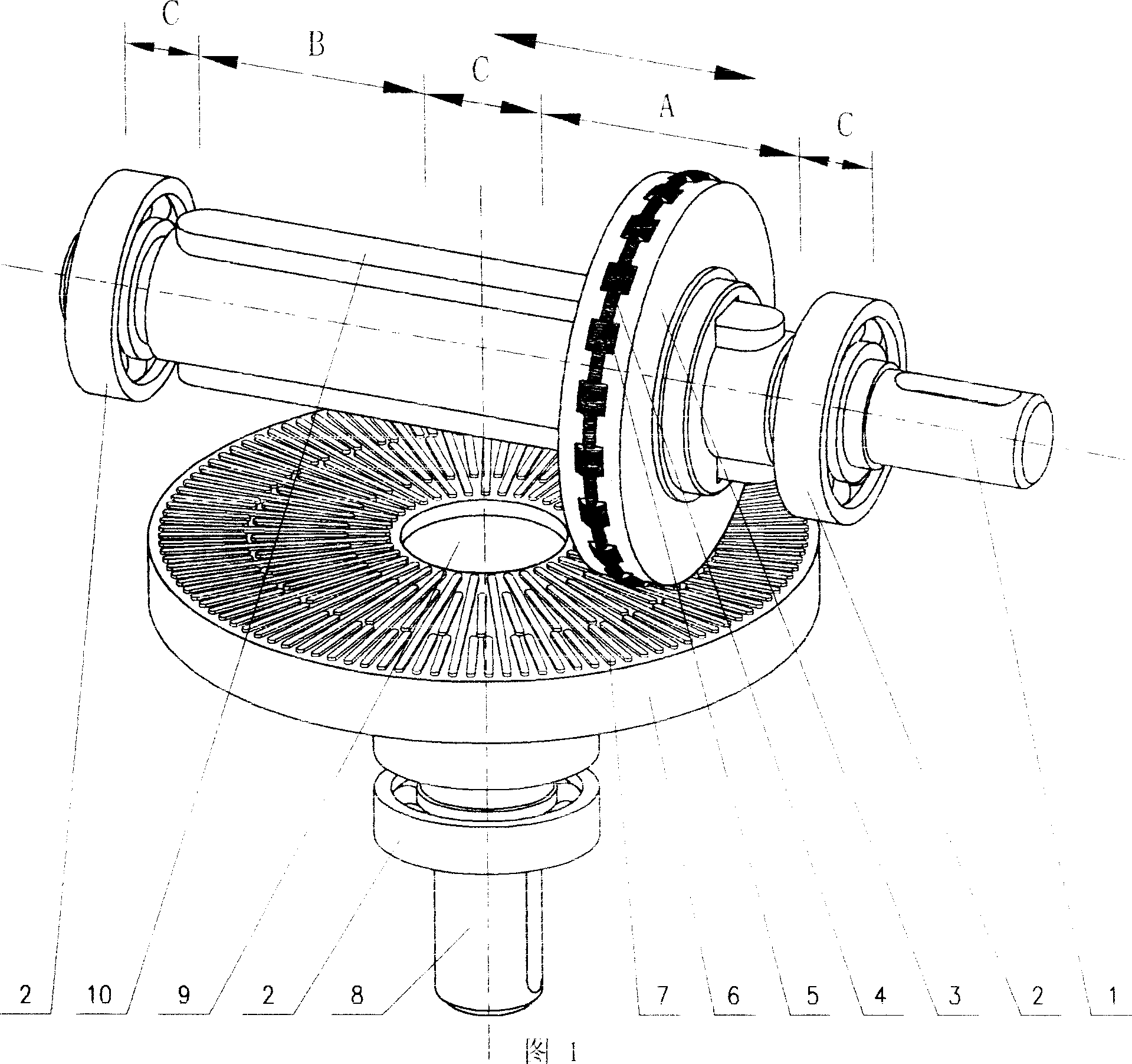

Slide palte deformed tooth stepless engagement adjustable gear

InactiveCN1752479AReduced precision requirementsHigh outputV-beltsSolid-state devicesGear driveGear wheel

The oscillating tooth gear is designed according to the ''sliding vane stepless deformation principle'', its working surface is made up by coinciding lots of sliding vanes (sliding needles), it can utilize sliding vane free stepless slippage to form any shaped meshed tooth profile. Because the slippage direction of sliding vane is different from its stress direction, the sliding vane can be freely deformed with current meshed tooth profile, and the stress direction when the power is trans ferred is perpendicular to free slippage direction or its included angle is in the equivalent frictional angle, so that said sliding vane has the self-locking property, and when the stress is borne by it, it does not change tooth profile form, all the sliding vanes can be formed into an integrated elastic closed ring, therefore it has strong bearing capacity and high transmission efficiency.

Owner:王国斌

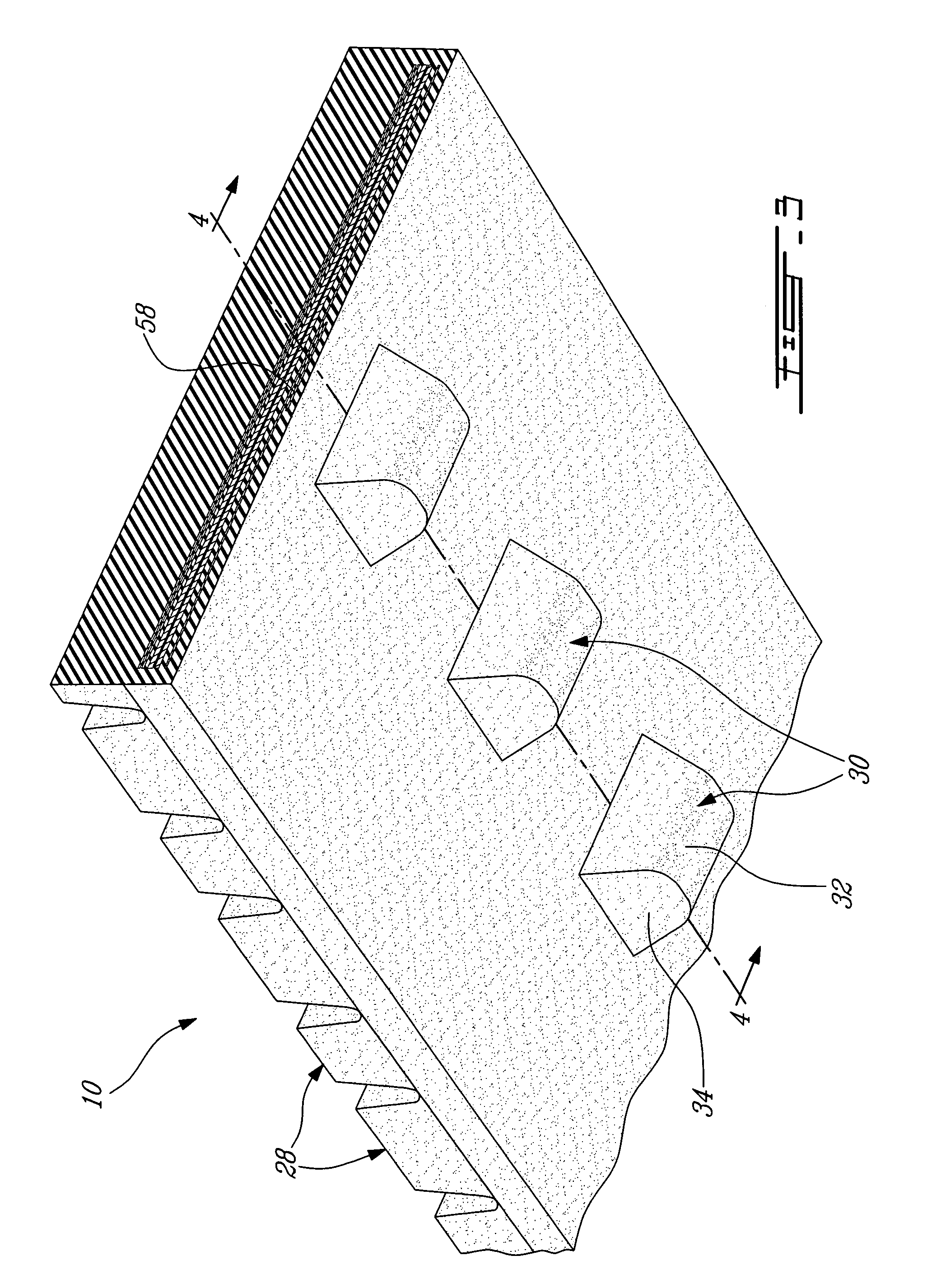

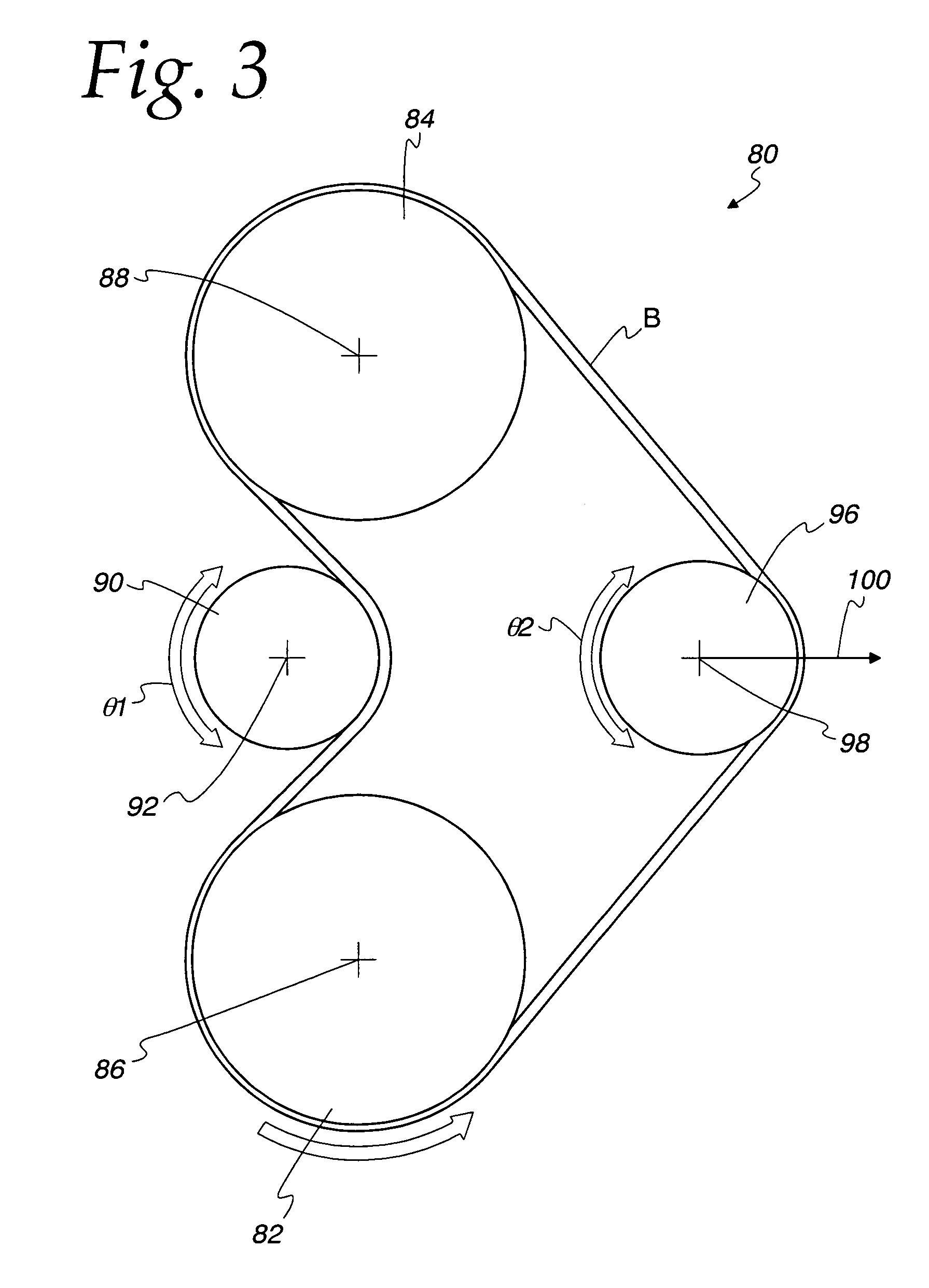

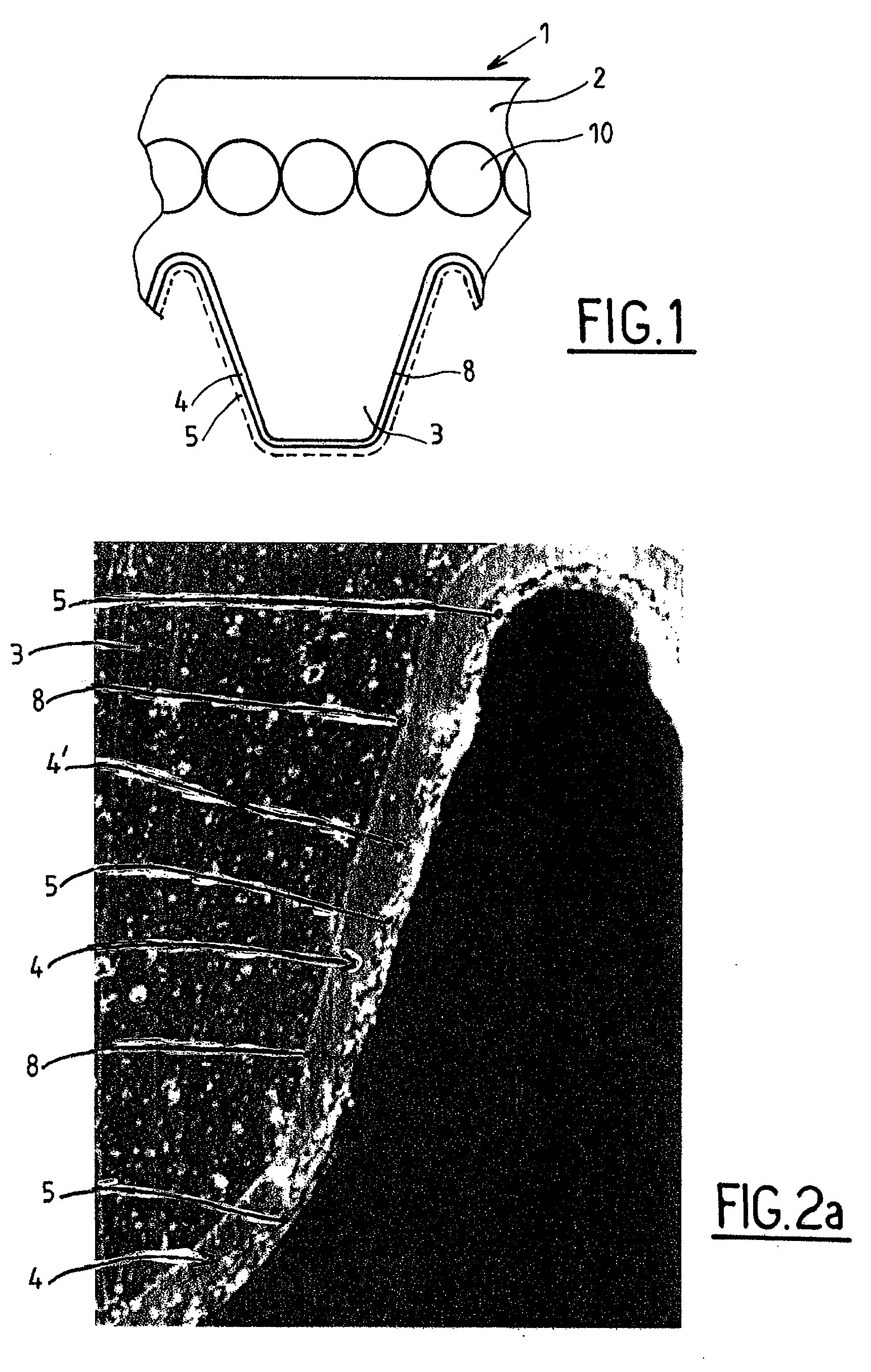

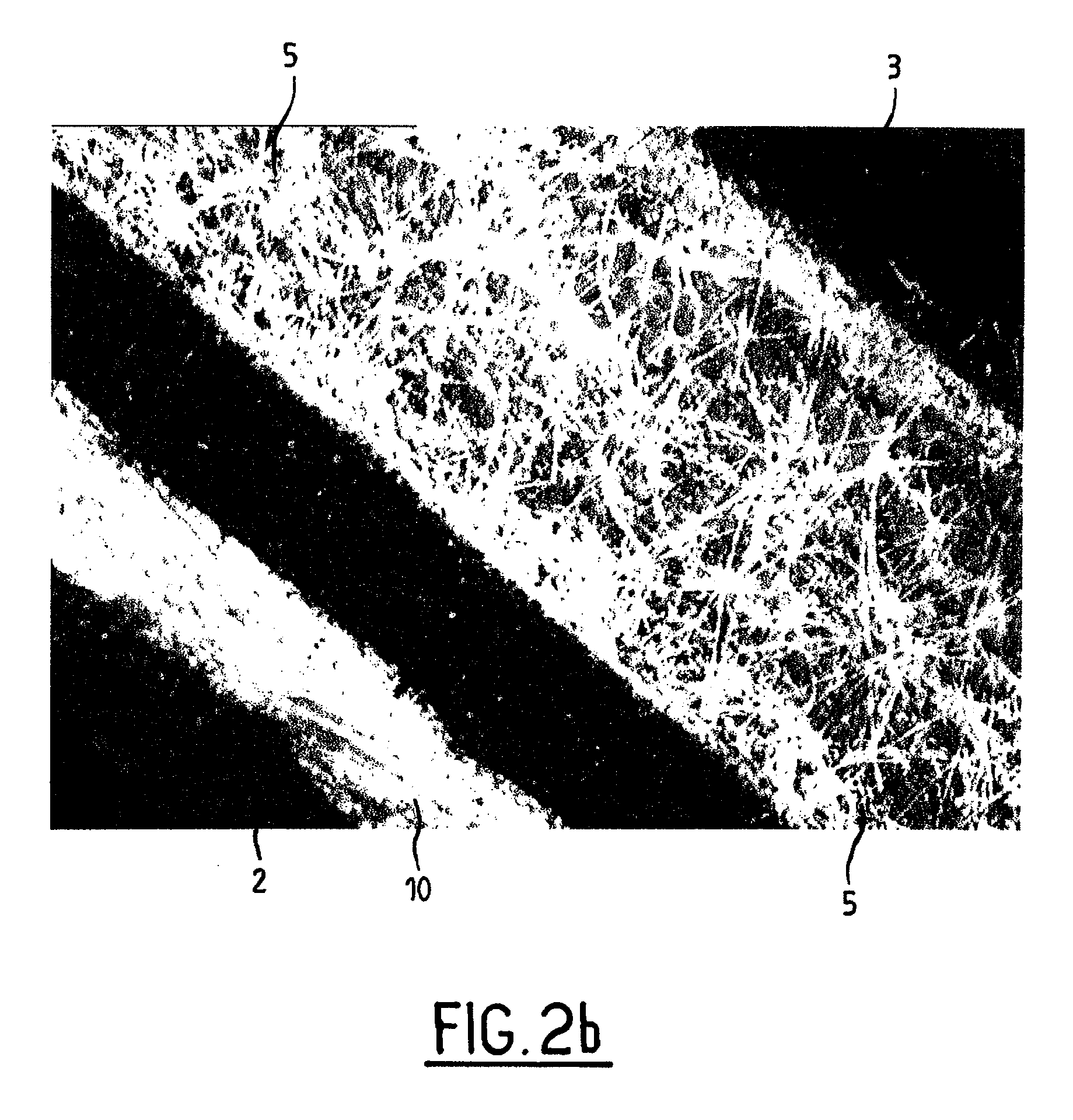

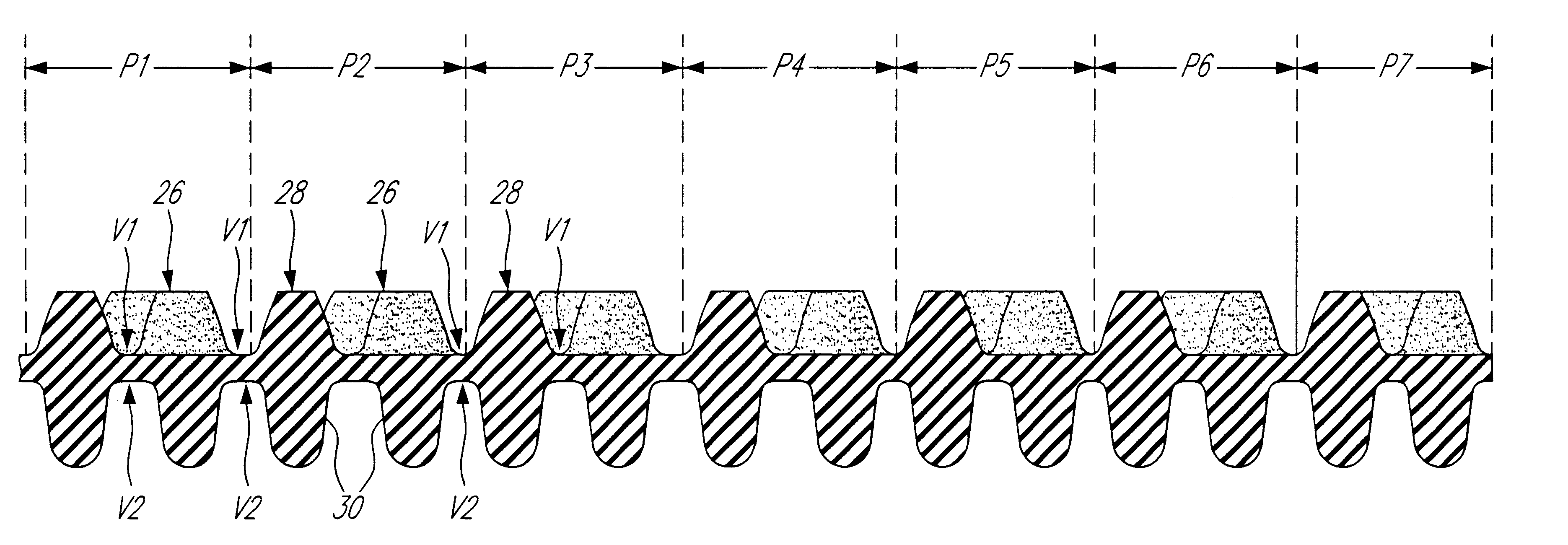

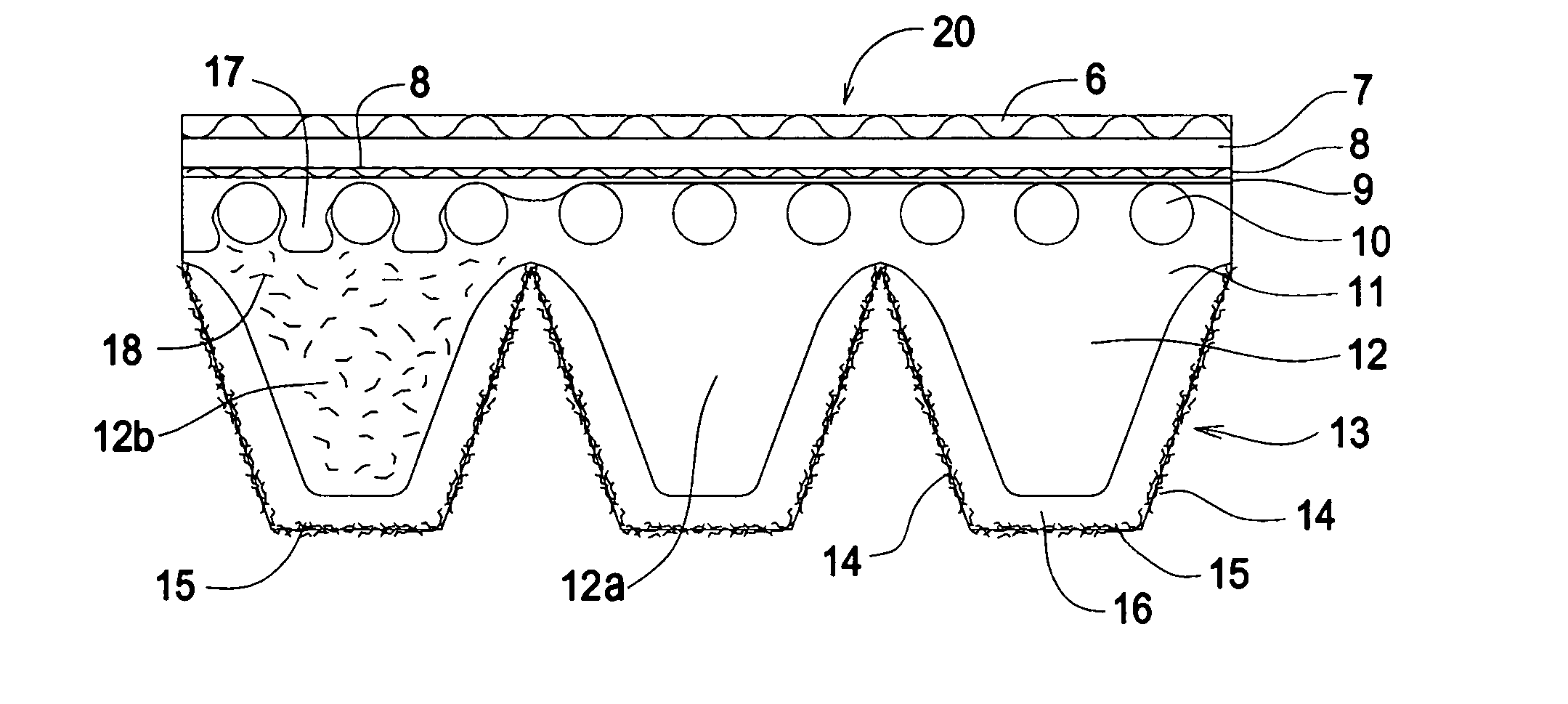

Endless track for industrial or agricultural vehicles

Described is an endless track for an industrial or agricultural vehicle consisting of a body formed of a rubber material having an outer surface displaying a series of ground engaging profiles longitudinally spaced along the surface and an inner surface displaying a series of longitudinally spaced drive lugs adapted to be engaged by drive sprockets on the vehicle driving assembly. The body of the endless track is fabric reinforced. One layer of fabric longitudinally extends at a distance from the inner surface of the track and has a width slightly less than the width of the drive lugs so that the fabric may extend inside the drive lugs to increase their rigidity.

Owner:CAMOPLASY INC

Power transmission belt and method of manufacturing the power transmission belt

A power transmission belt having a body defined by rubber and having an exposed outer surface, a fiber layer on at least a part of the exposed outer surface of the body, and a mixture including a resin adhesive ingredient, a rubber ingredient, and a lubricant that is a fluorine resin powder that is applied to the fiber layer.

Owner:MITSUBOSHI BELTING LTD

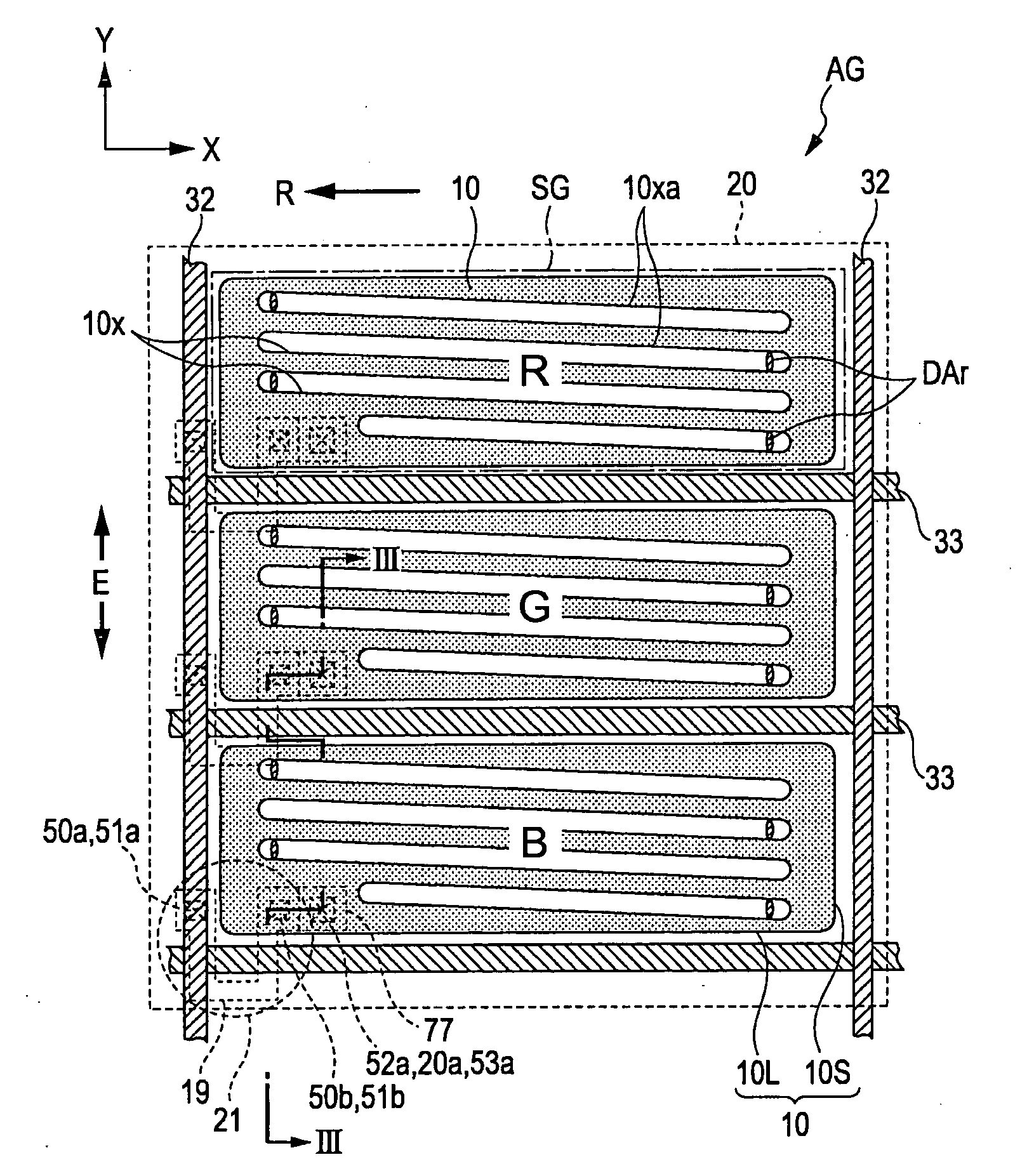

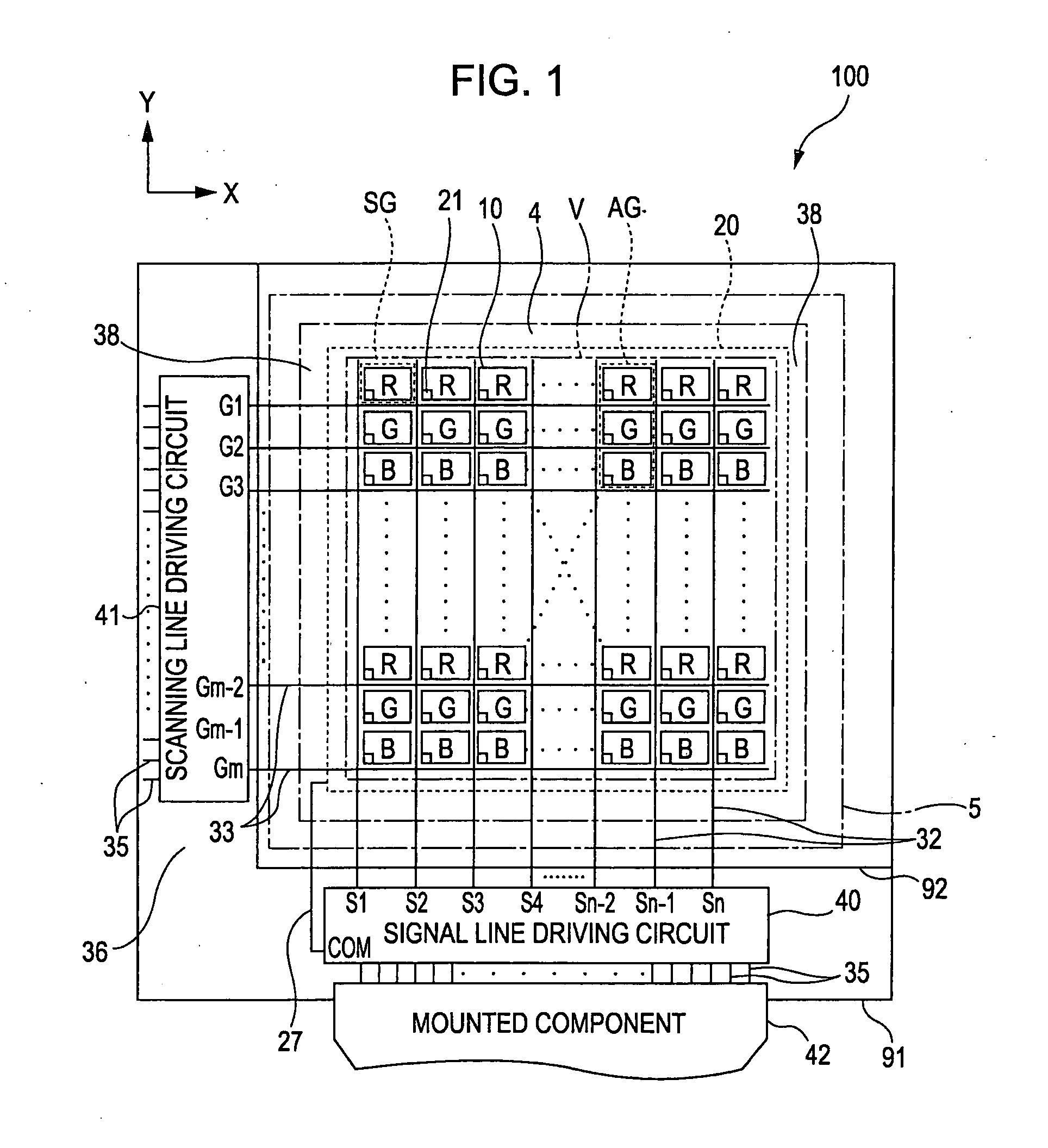

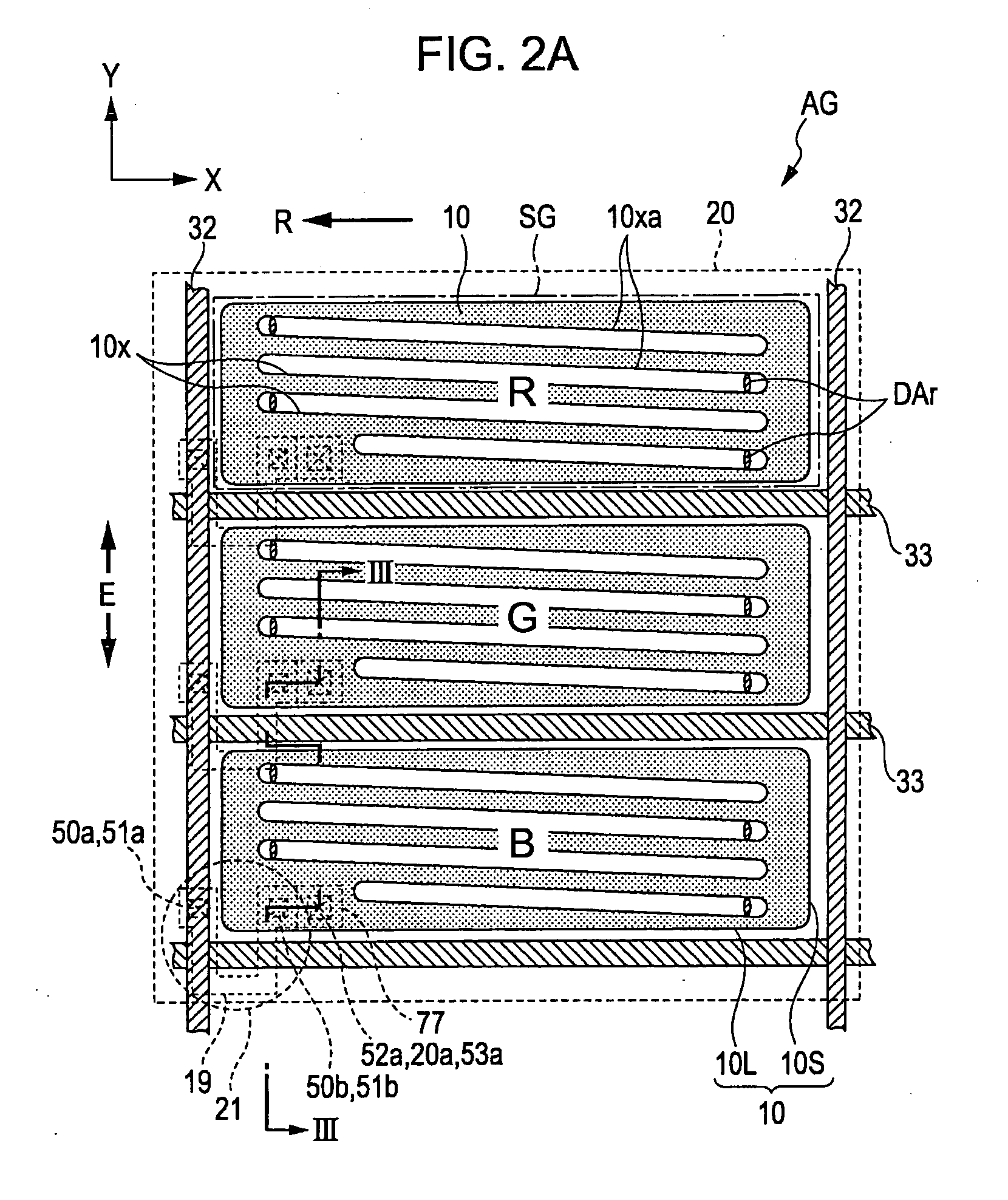

Liquid crystal device and electronic apparatus

1. A liquid crystal device includes a substrate including unit pixels each composed of a plurality of sub pixels arranged in a plurality of rows and one column and having a long side in the row direction and a short side in the column direction, wherein the substrate includes switching elements, an insulating film provided on at least the upper side of each of the switching elements, at least one first transparent electrodes provided on the upper side of the insulating film, other insulating film provided on the upper side of the first transparent electrodes, and at least one second transparent electrode formed on the upper side of the other insulating film and having a plurality of slits formed for each of the sub pixels and generating an electric field, the electric field being generated between the first transparent electrode and the second transparent electrode through each of the slits, and the extending direction of the long side of each of the slits is defined in a direction not the same as the extending direction of the short side of the sub pixels.

Owner:EPSON IMAGING DEVICES CORP

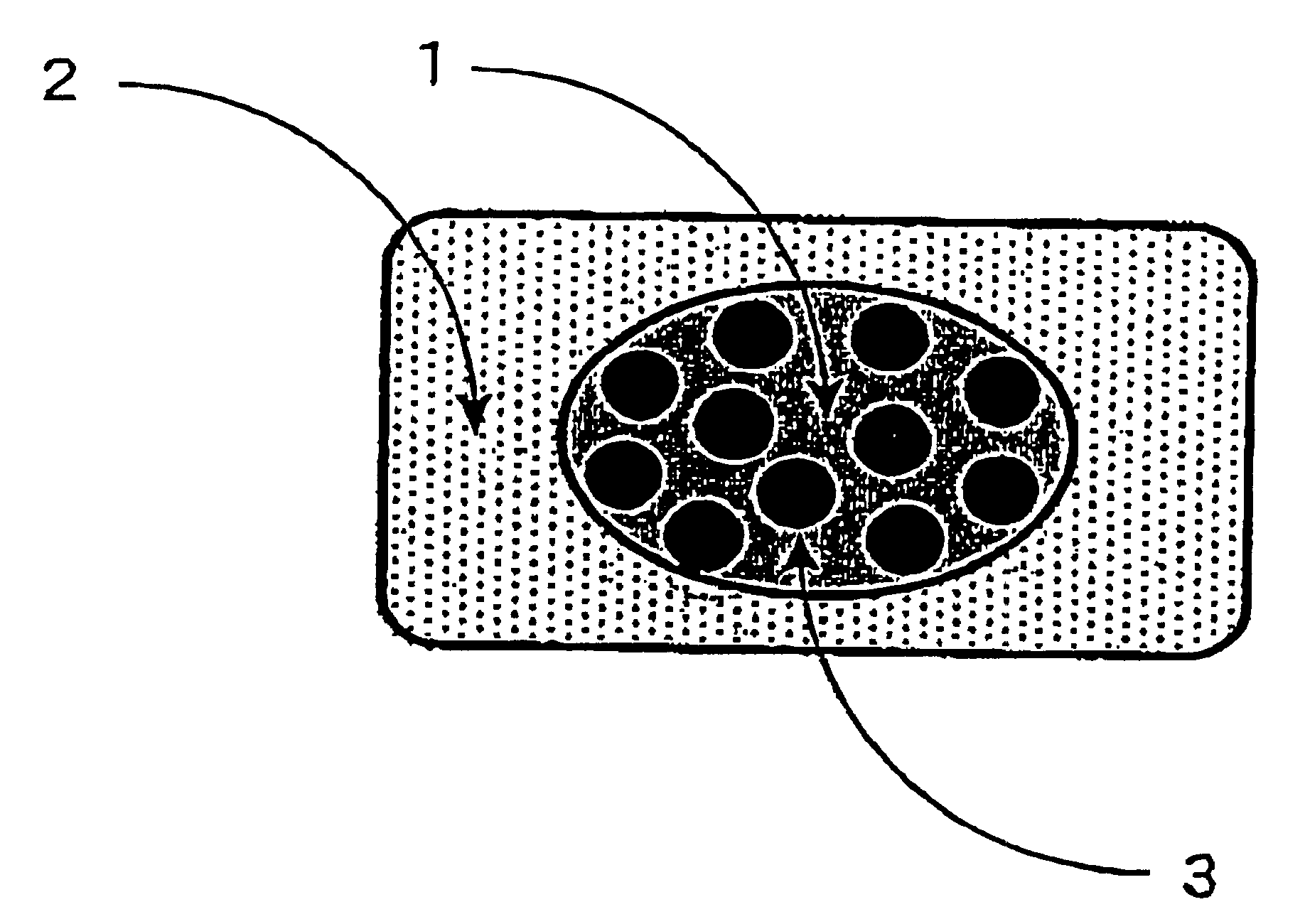

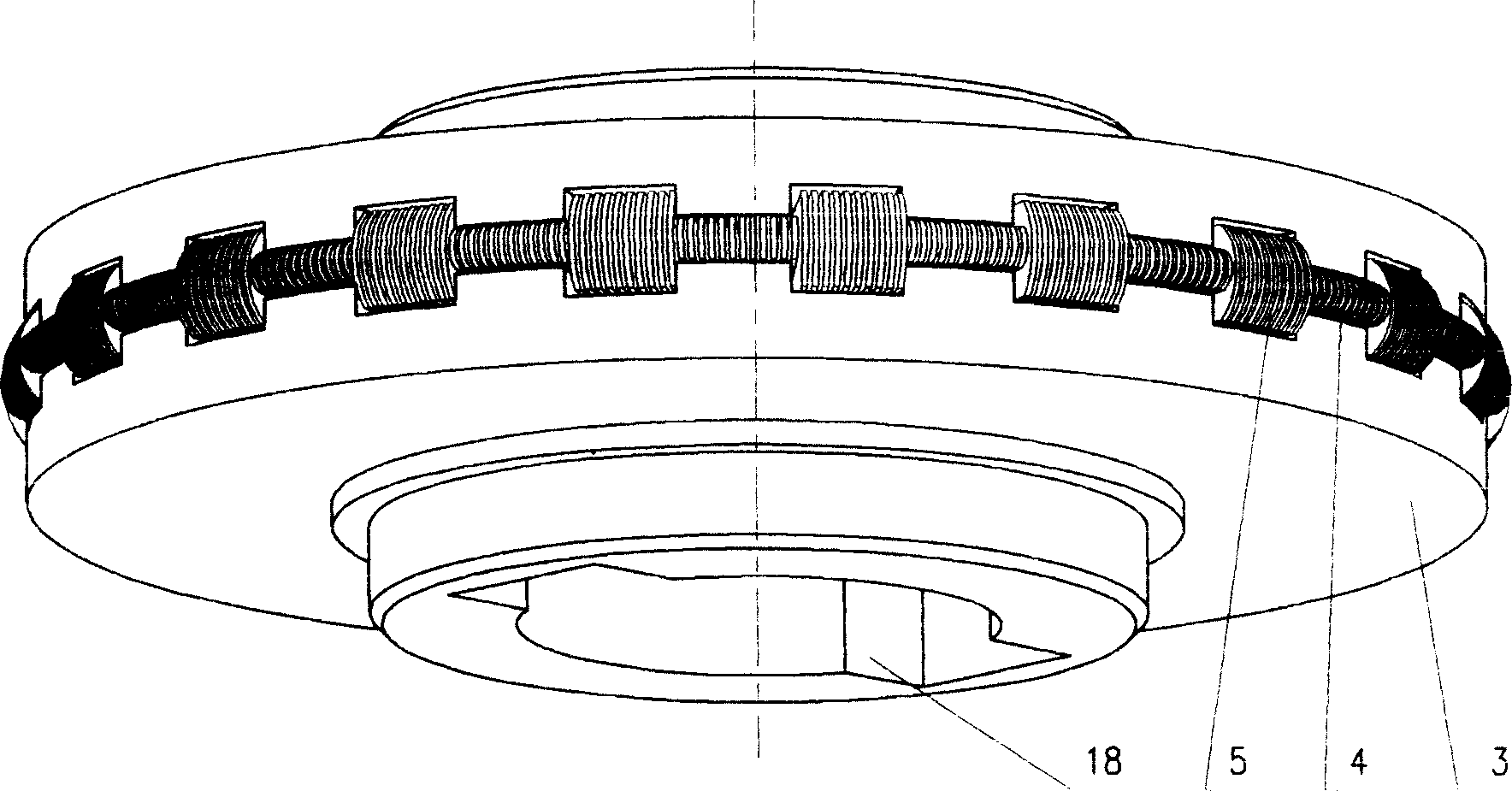

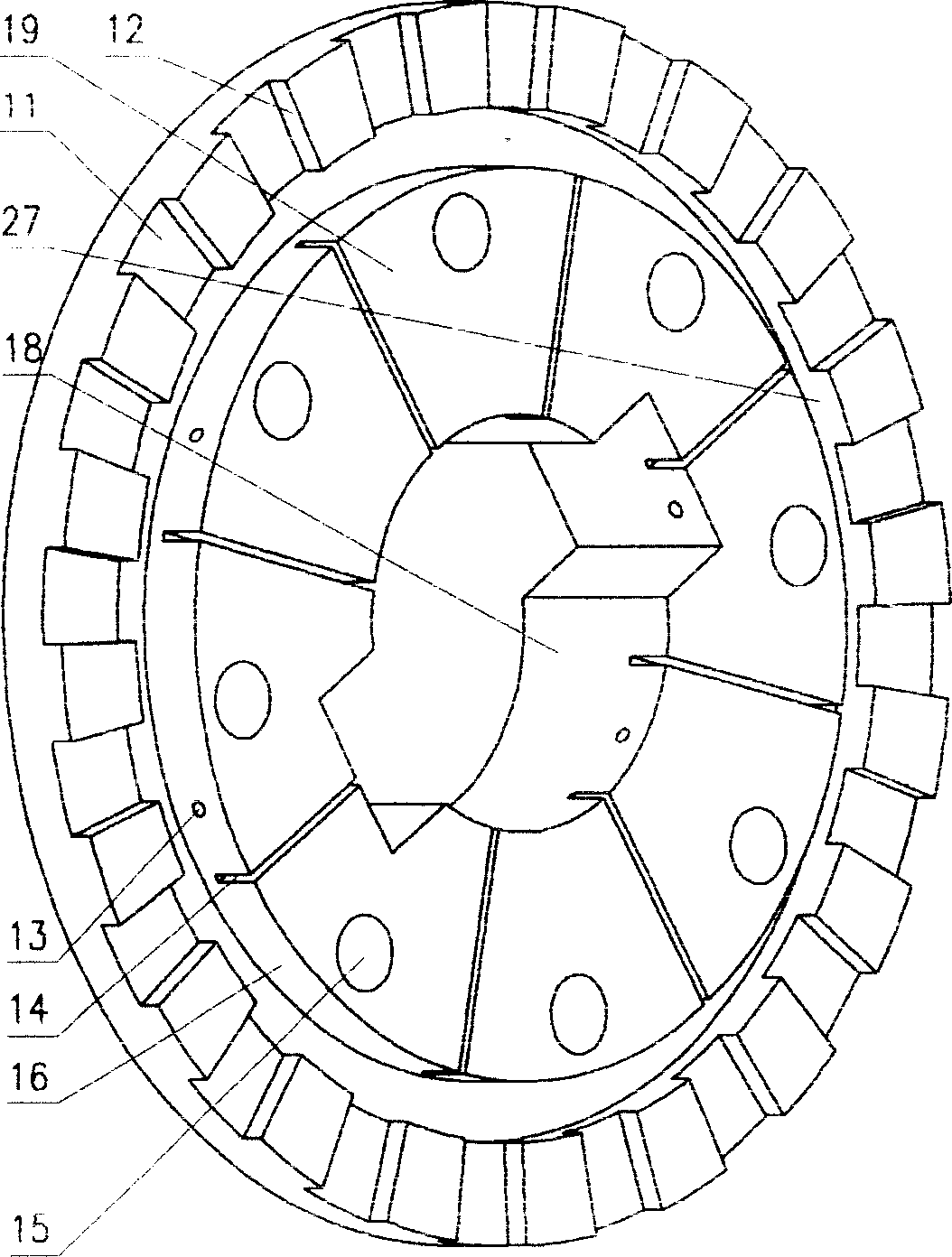

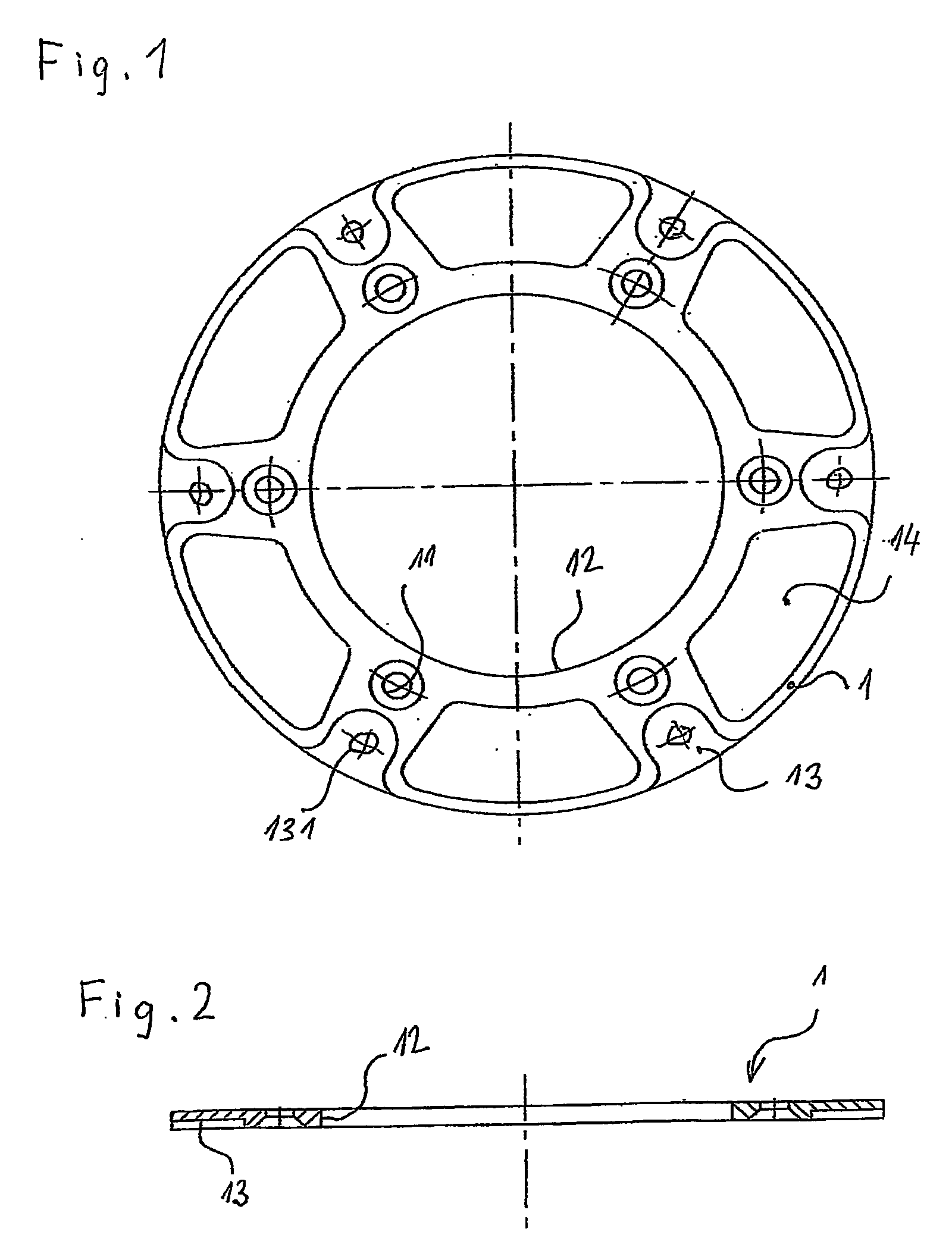

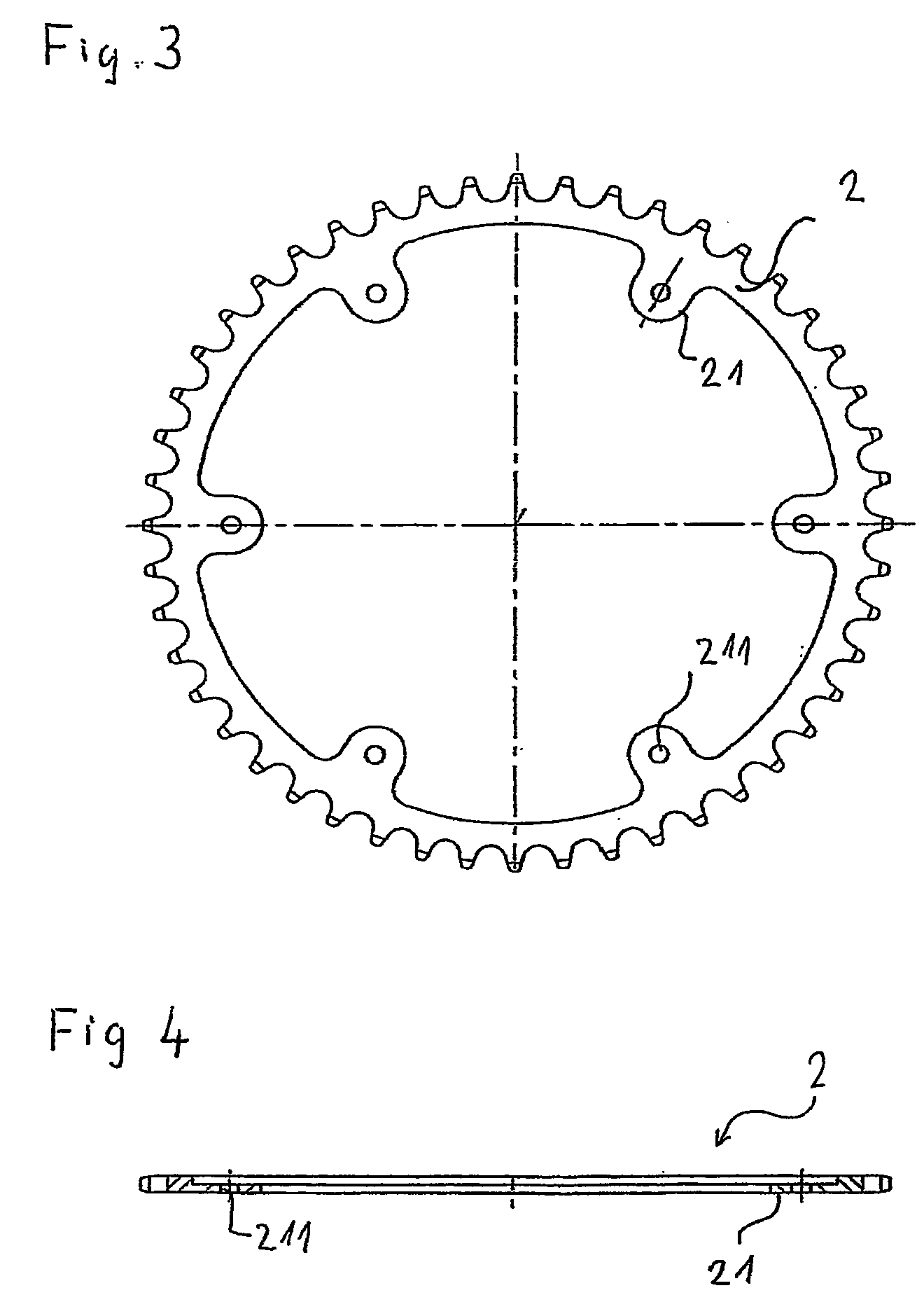

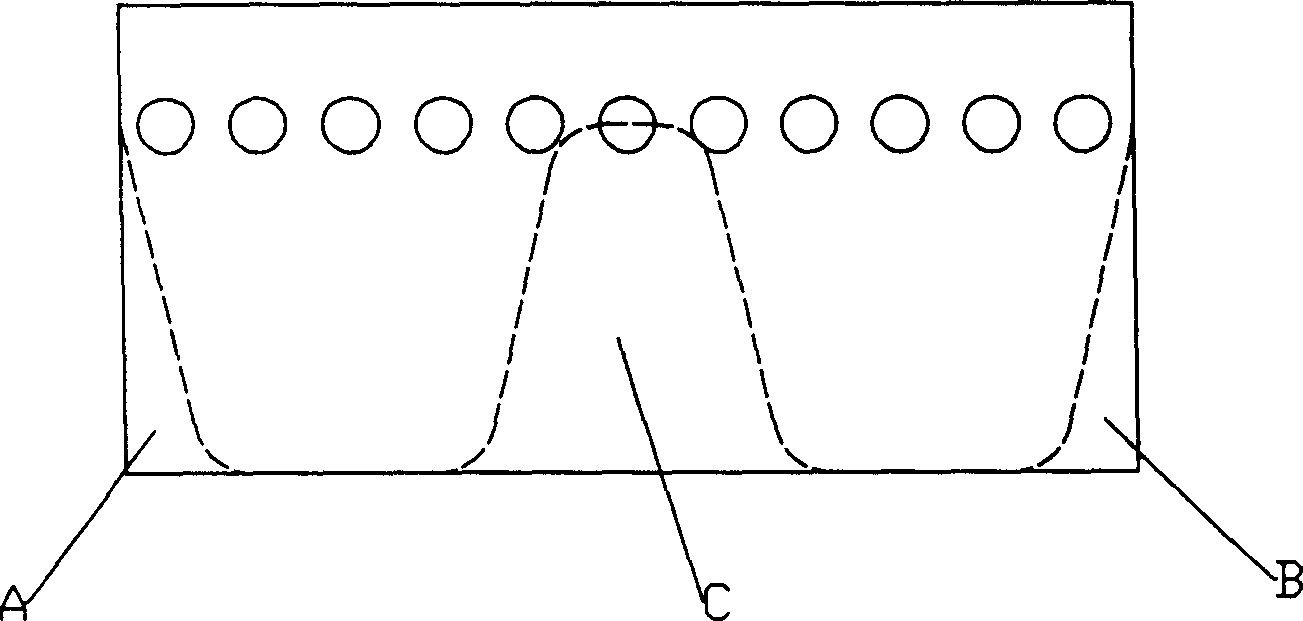

Lightweight sprocket

ActiveUS20050233850A1Lightweight and economical in construction and operationExtended service lifeV-beltsChain/belt transmissionSprocketEngineering

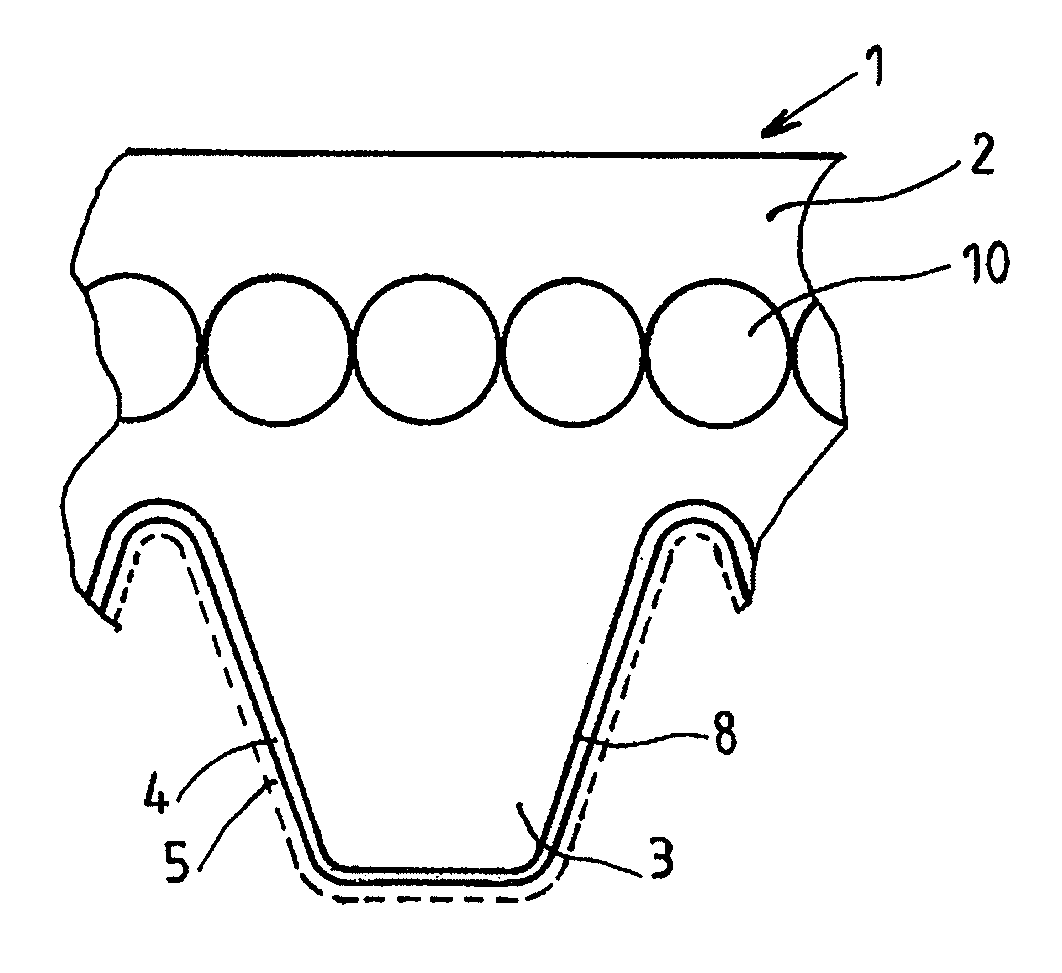

The present invention relates to lightweight sprocket, consisting of a central portion (1) made from light metal alloy, to which a peripheral toothed portion (2) made from ferrous alloy is joined, using rivets (3) for joining said portions (1,2), where said joining is created between radial beams (21) of the peripheral toothed portion (2) and pocket-like recess (13) in the central portion (1), radial beams (21) being overlapped across bottoms of pocket-like recesses (13), and where a thickness of radial beams (21), at least over the joining area, is decreased by 10 to 60%, in relation to full thickness of said toothed peripheral portion (2), and a thickness of a bottom of the pocket-like recess (13) in the central portion (1) is decreased by 20 to 70%, in relation to full thickness of the central portion (1) of the sprocket.

Owner:SUPERSPROX

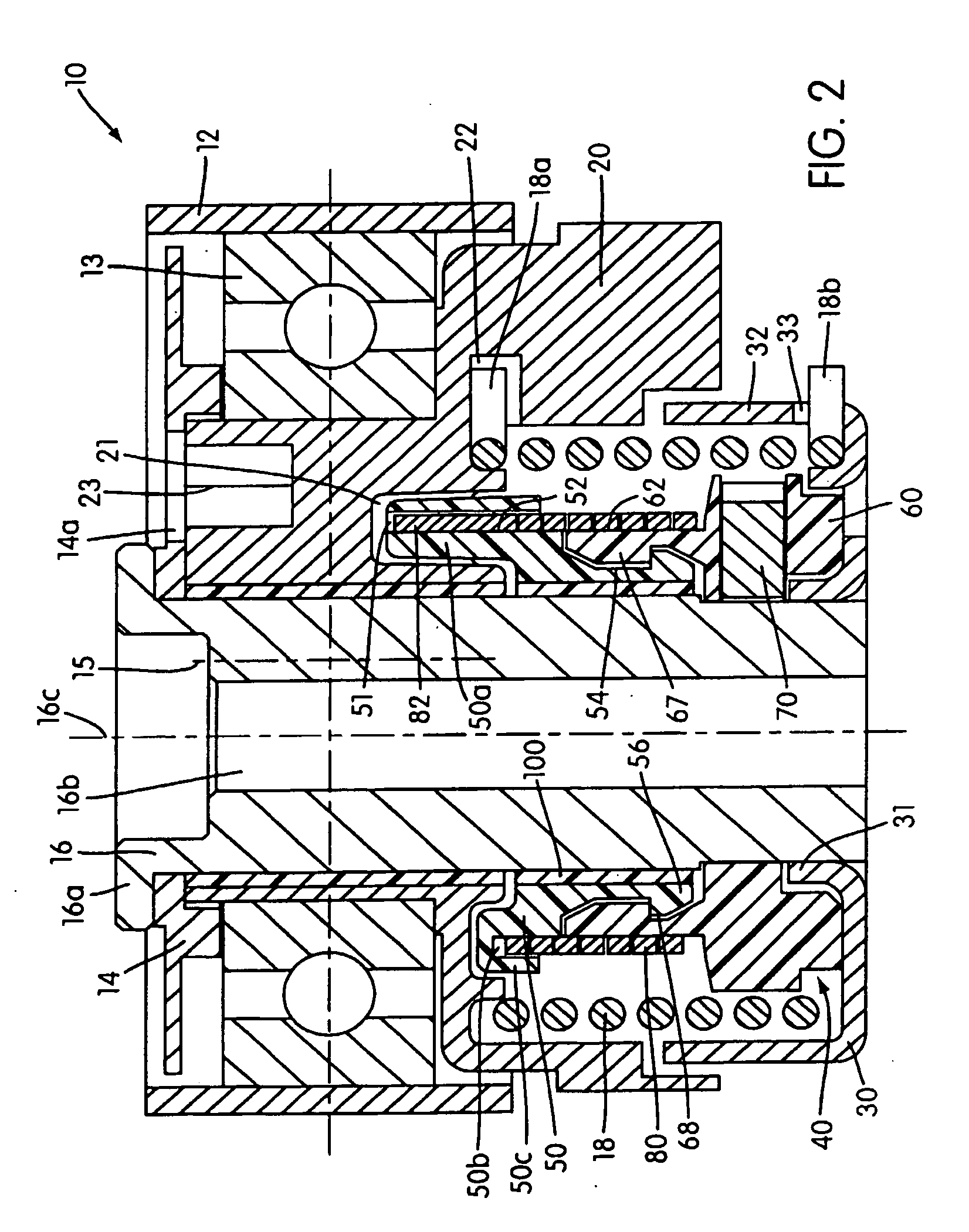

Timing belt tensioner with stops controlled by frictional brake

ActiveUS20060035740A1Easy to installEasy constructionV-beltsRopes and cables for vehicles/pulleyFree rotationCoupling

A tensioner (10) features a backstop device (40) which allows free rotation of the pivot arm (20) in one direction but not the other. Reverse rotation is prevented by friction that is able to resist torque on the pivot arm (20) under ordinary operating conditions which otherwise could permit belt tooth-skip to occur. In disclosed embodiments, the backstop device (40) includes a stop sleeve (50) and a clamp holder (60) which are axially interlocked and are able to rotate relative to each other. A clutch spring (80) surrounds permits relative rotation between the stop sleeve (50) and the clamp holder (60) in one direction but not the other. A clamp (70) retained within the clamp holder (60) frictionally engages the pivot shaft. A viscous coupling may be used in place of the frictional clamp.

Owner:LITENS AUTOMOTIVE INC

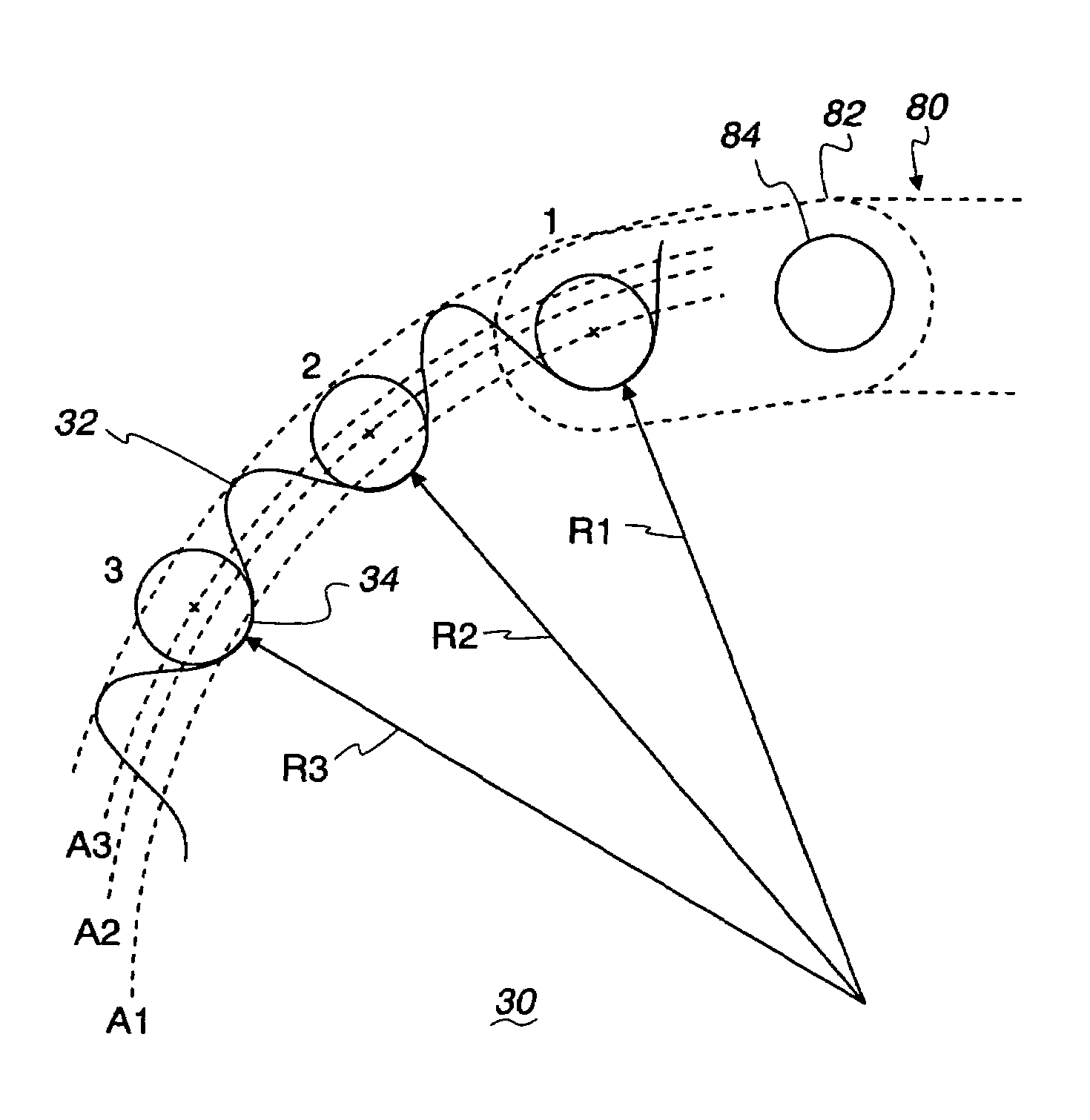

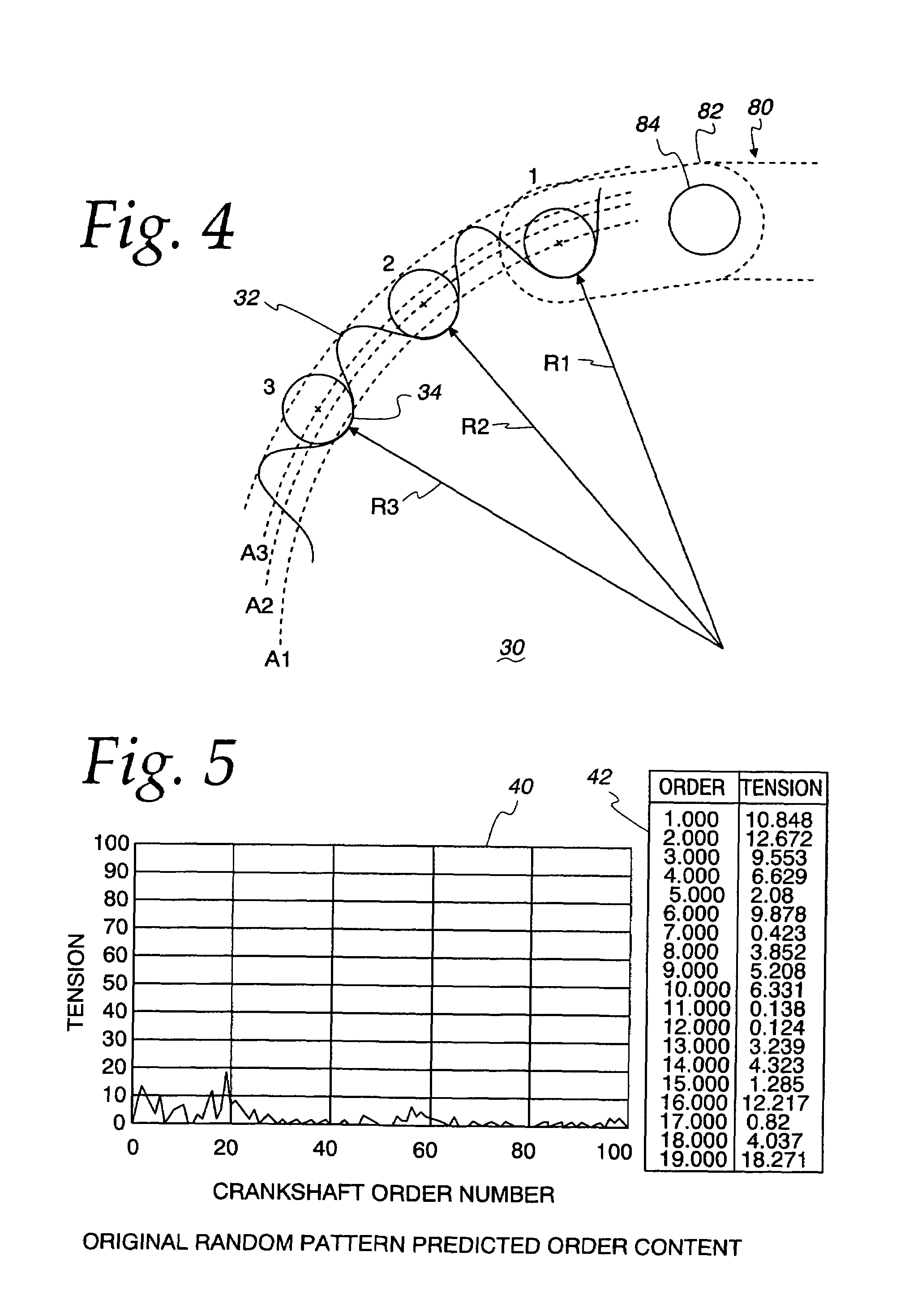

Tension-reducing random sprocket

InactiveUS7125356B2Promotes reduced and controlled chain tensionReduce noiseV-beltsGearingEngineeringSprocket

A sprocket is provided having a plurality of teeth around its circumference. Adjacent teeth are separated by roots each having a root radius defined as the distance between the center of the sprocket and a point along the root closest to the sprocket center in a radial direction. In one aspect of the invention, the sprocket comprises at least two different root radii arranged in a pattern effective to redistribute tensions imparted to a chain by the sprocket at one or more predetermined sprocket orders.

Owner:BORGWARNER INC

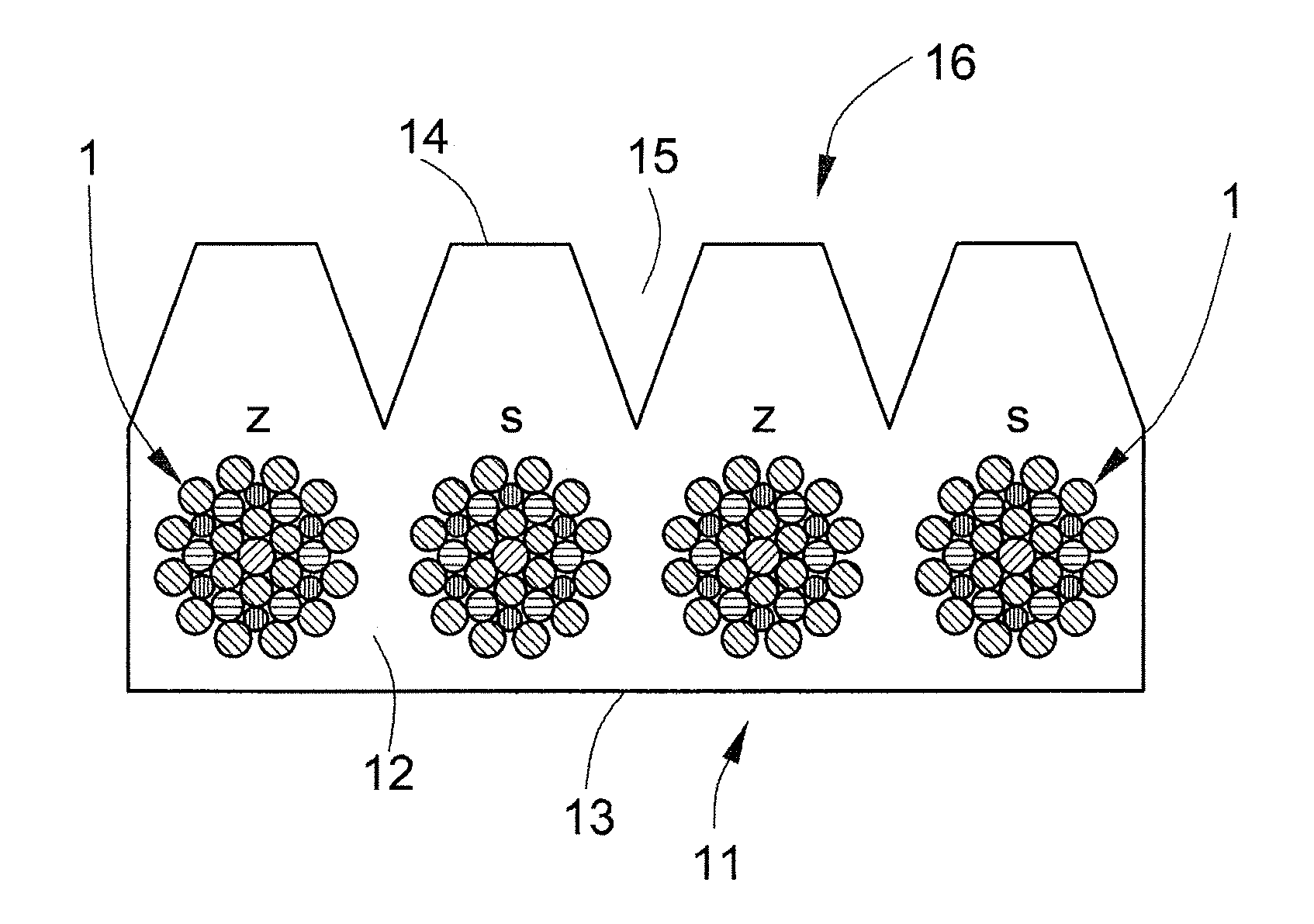

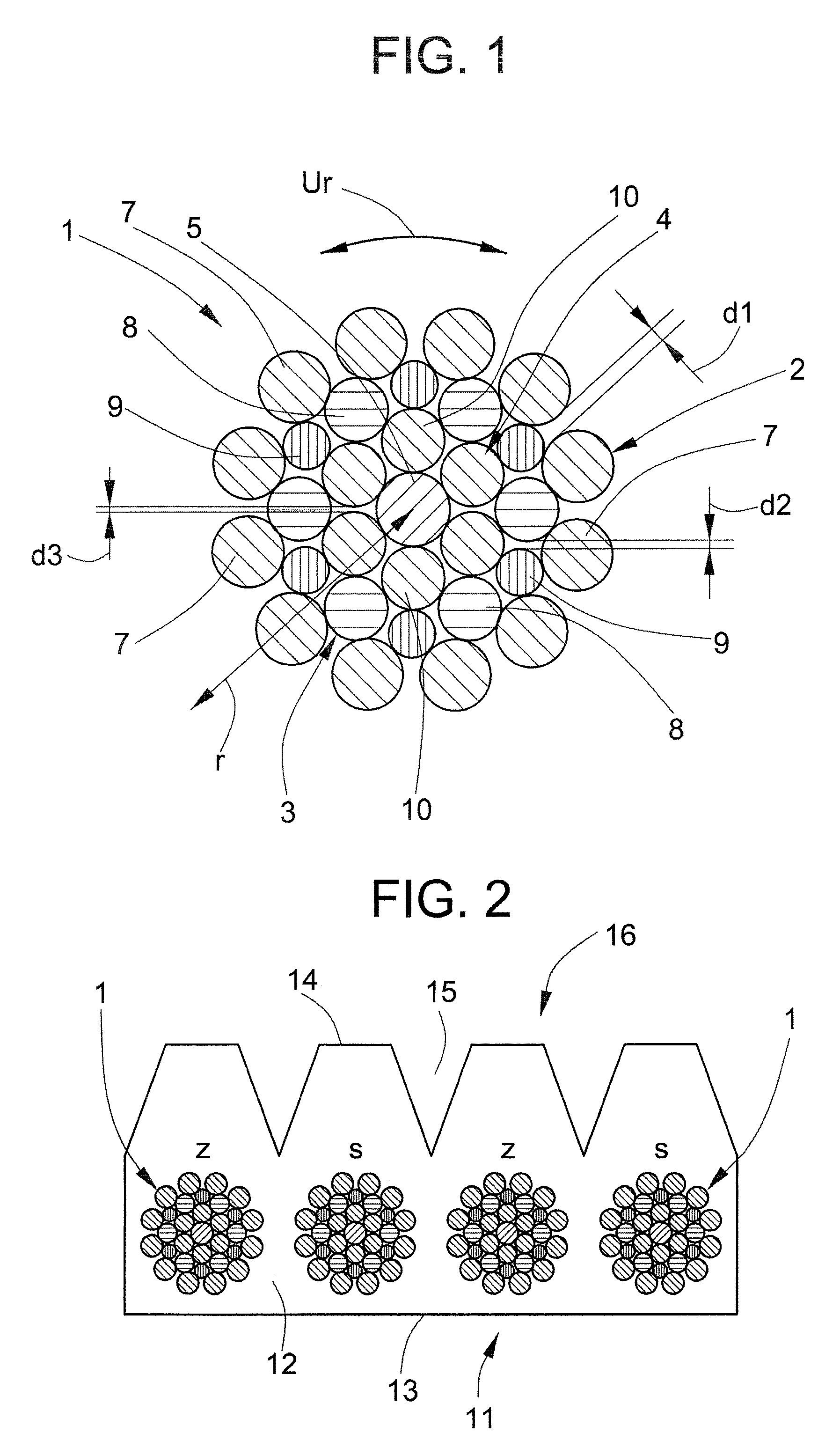

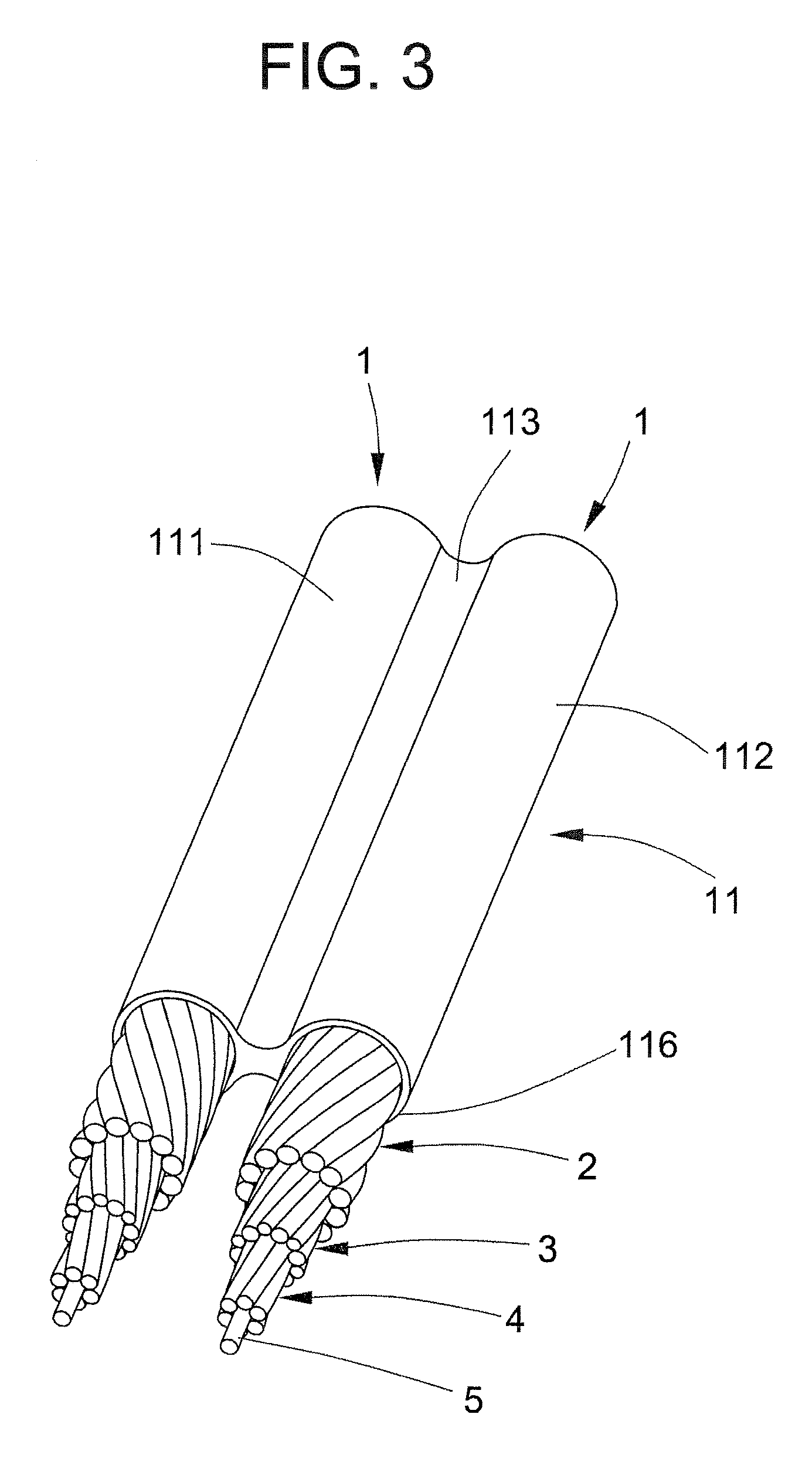

Flat-belt-like supporting and drive means with tensile carriers

ActiveUS20080081721A1Reduce bending stressDeflecting pulleyV-beltsRopes and cables for vehicles/pulleyPull forceBand shape

A supporting and drive belt including a belt body or sheathing which encloses tensile carriers. The running surface of the belt can be flat and parallel to the belt back or have trapezium-shaped or semicircular ribs and grooves, wherein the profile of a drive pulley or of a deflecting pulley is approximately complementary to the running surface of the belt. One or more tensile carriers are provided for each rib, wherein the tensile carriers are laid or stranded alternately in the “Z” direction and the “S” direction.

Owner:INVENTIO AG

Power transmission belts

InactiveUS8142316B2Improve propertiesV-beltsRopes and cables for vehicles/pulleyElastomerEngineering

A belt has a compression section, a tension section, and a load carrying section disposed between the compression section and the tension section. The belt has an elastomeric / thermoplastic material, the elastomeric / thermoplastic material has 50 to 90 parts per hundred of an elastomer and 10 to 50 parts per hundred thermoplastic.

Owner:CONTITECH USA INC

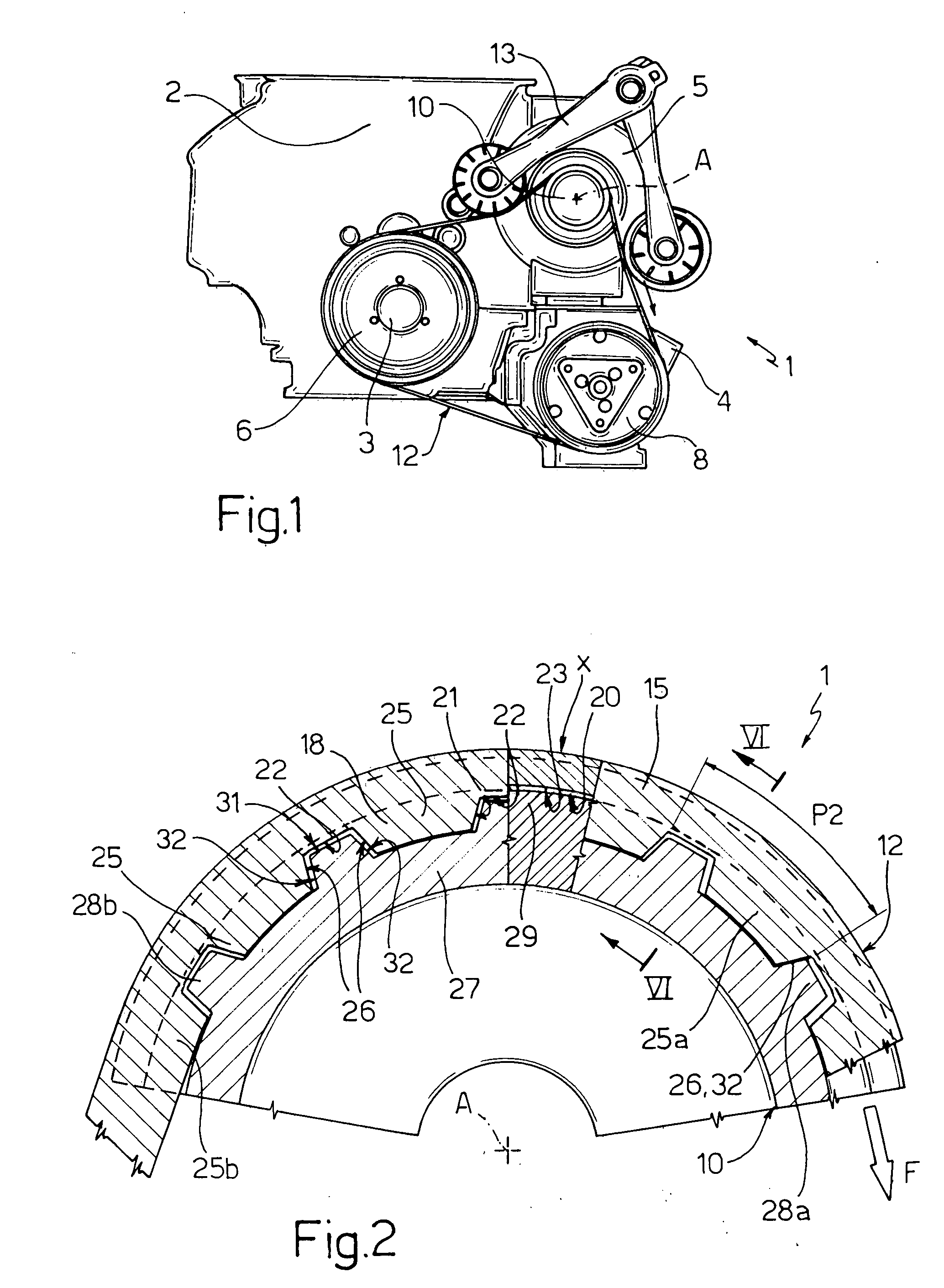

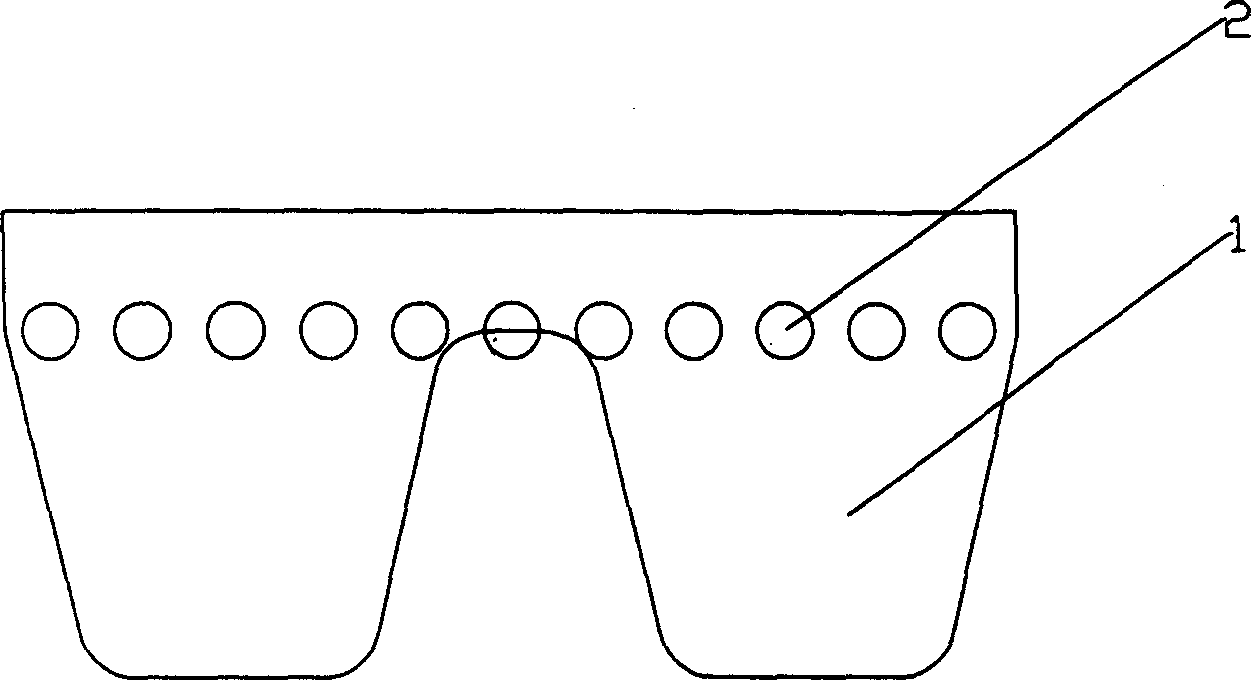

Belt drive assembly for driving accessory parts of an internal combustion engine, drive belt and pulleys suited to be used in said assembly

InactiveUS20060100051A1Effective and simple and economic solutionV-beltsRopes and cables for vehicles/pulleyElectric machineEngineering

Belt drive assembly for driving accessory parts of an internal combustion engine comprising a reversible electric machine, comprising a belt with a plurality of longitudinal ribs alternating with grooves and with a plurality of cavities spaced at equal distances from each other longitudinally and obtained transversely with respect to the ribs in such a way as to interrupt them; the pulley comprises a plurality of ribs suited to engage the grooves of the belt and a plurality of teeth transverse with respect to the ribs, spaced at equal distances from each other on the circumference and suited to engage the respective cavities of the belt. The cavities of the belt have a depth at the most equal to the height of the ribs of the belt itself, and the ribs of the pulley have a radial height larger than the teeth, so as to cooperate with the belt continuously along the whole winding arc.

Owner:DAYCO EURO

Link chain

InactiveUS6478704B1Simple and inexpensiveExcellent substituteV-beltsGearingParallel plateEngineering

An endless link chain, particularly for use in a continuously variable transmission in the power train of a motor vehicle, has composite links and pintles which articulately connect neighboring links to each other. At least one of the links is assembled of at least two types of parallel plate-like components which differ from each other in size, shape, material and / or strength. The purpose of such selection of the plate-like components is to enhance one or more characteristics of the chain, for example, to reduce or eliminate vibration, to reduce the bulk and / or to properly position the pintles. The distribution of components in one or more links can be selected with a view to influence the above-enumerated and / or other characteristics, such as the resistance to deformation, of the chain.

Owner:LUK LAMELLEN & KUPPLUNGSBAU BETEILIGUNGS KG

Rubber composition and power transmission belt incorporating the rubber composition

ActiveUS20050037882A1Easy to processIncreased durabilityV-beltsRopes and cables for vehicles/pulleyFiberPolymer science

Owner:MITSUBOSHI BELTING LTD

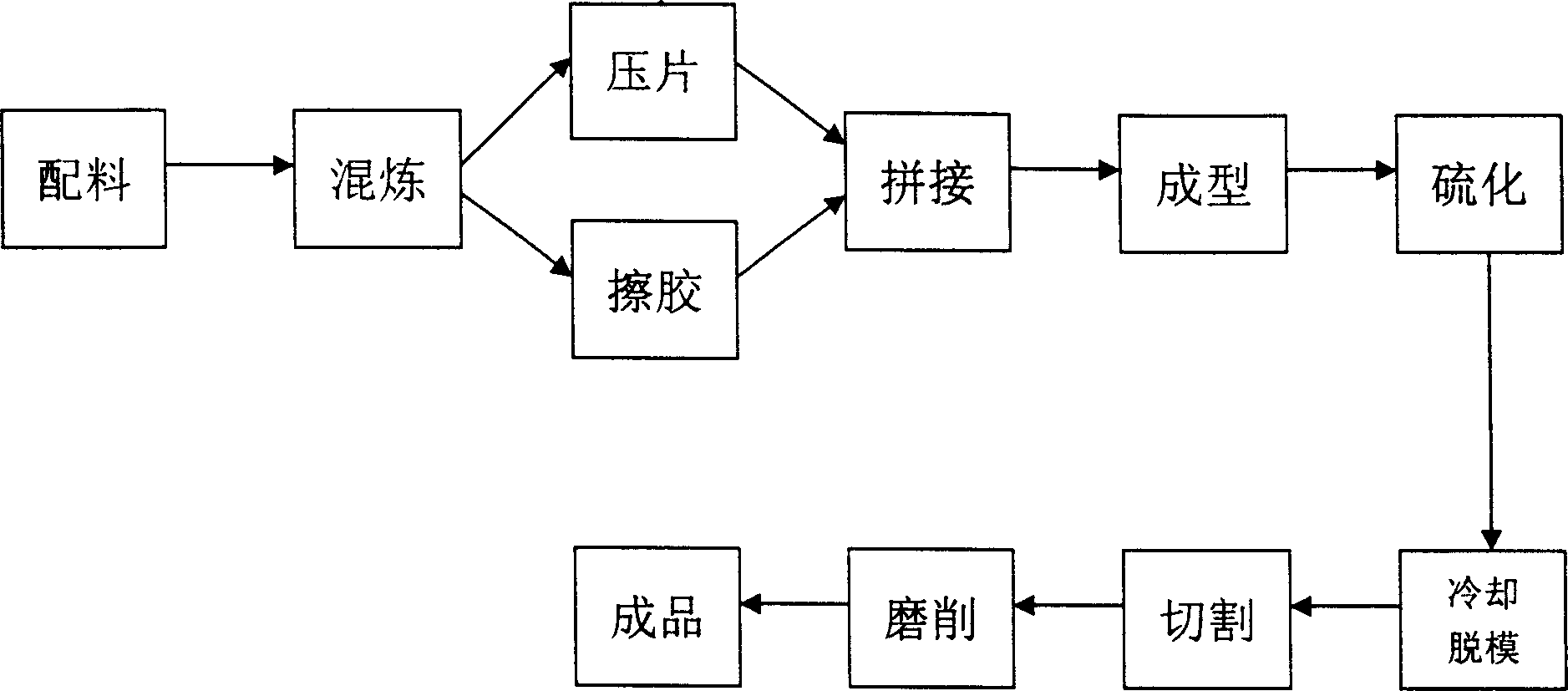

Joined raw-edge V-belt and manufacturing method thereof

The combined edge-cutting V-belt is one combined structure of two or more parallel V-belts, and has lower toothed part, upper flat part, inside skeleton in the transition part between the toothed part and the upper flat part, and flat part connection between adjacent V-belts. The V-belt is made of chloroprene rubber and the skeleton is hard polyester string. The technological process includes the steps of compounding material, mixing, pressing sheet, splicing, forming, sulfurizing, cooling and demolding, cutting, grinding, etc. The combined edge-cutting V-belt has simple structure, easy installation, balanced stress, homogeneous transmission, smooth operation and convenient replacement, simple production process and low production cost.

Owner:王彩霞

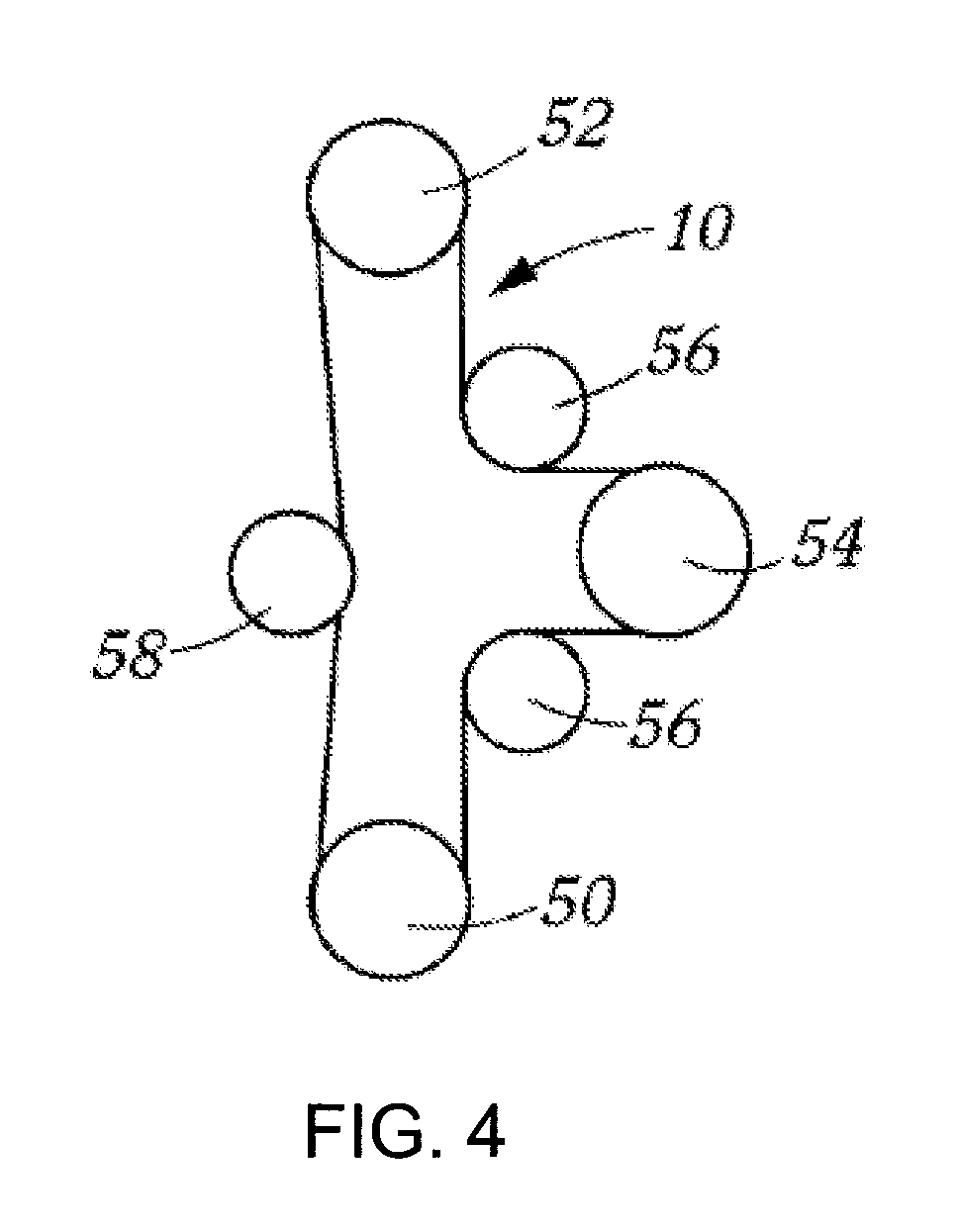

Power transmission belt and method

A power transmission belt, and more particularly a toothed power transmission belt, comprising a longitudinally extending tensile member composed of one or more carbon fiber cords, wherein the belt exhibits belt growth of not more than 0.1% based on its original length after 48 hours under High Temperature Belt Growth Analysis performed at 100° C., a method for producing such belts exhibiting reduced belt growth, and a method for reducing the angular vibration of a camshaft in relation to a crankshaft in an internal combustion engine wherein the camshaft is driven by a timing belt.

Owner:THE GATES CORP

Seamed, conformable belt and method of making

InactiveUS7052426B2Eliminates “ bump ”Easy to replaceV-belt fasteningsV-beltsElectrical and Electronics engineering

Owner:XEROX CORP

Power transmission belt

ActiveUS20100075793A1Avoid disadvantagesV-beltsRopes and cables for vehicles/pulleyElastomerEngineering

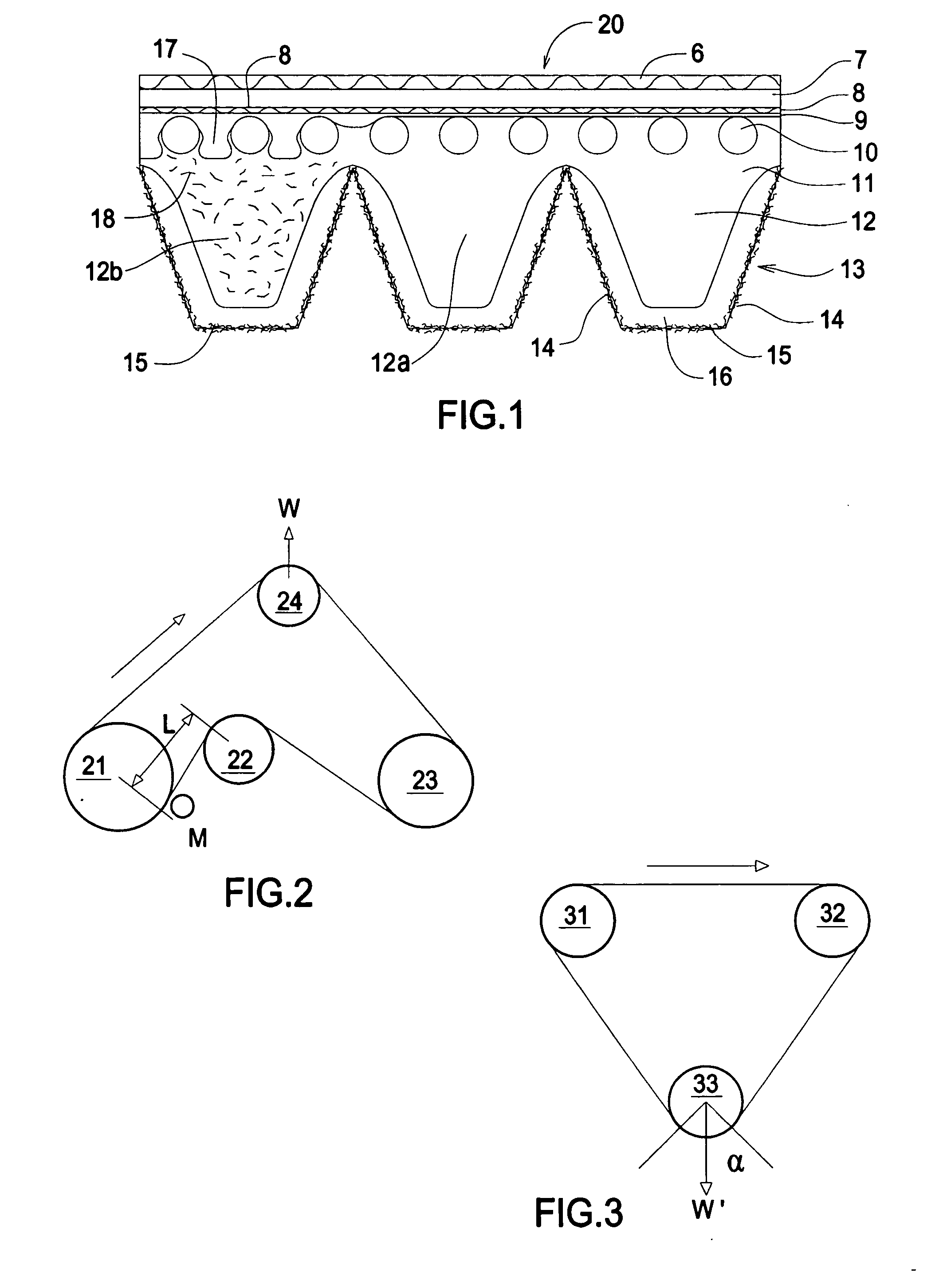

The invention relates to a power transmission belt presenting elastomer teeth based on ethylene alpha olefin elastomer provided with an outer woven or non-woven covering. According to the invention the teeth are covered in a barrier layer, in particular of a thermoplastic material, and said outer covering, at least on the flanks of the teeth, is partially included in a portion of the thickness of the barrier layer.

Owner:HUTCHINSON SA

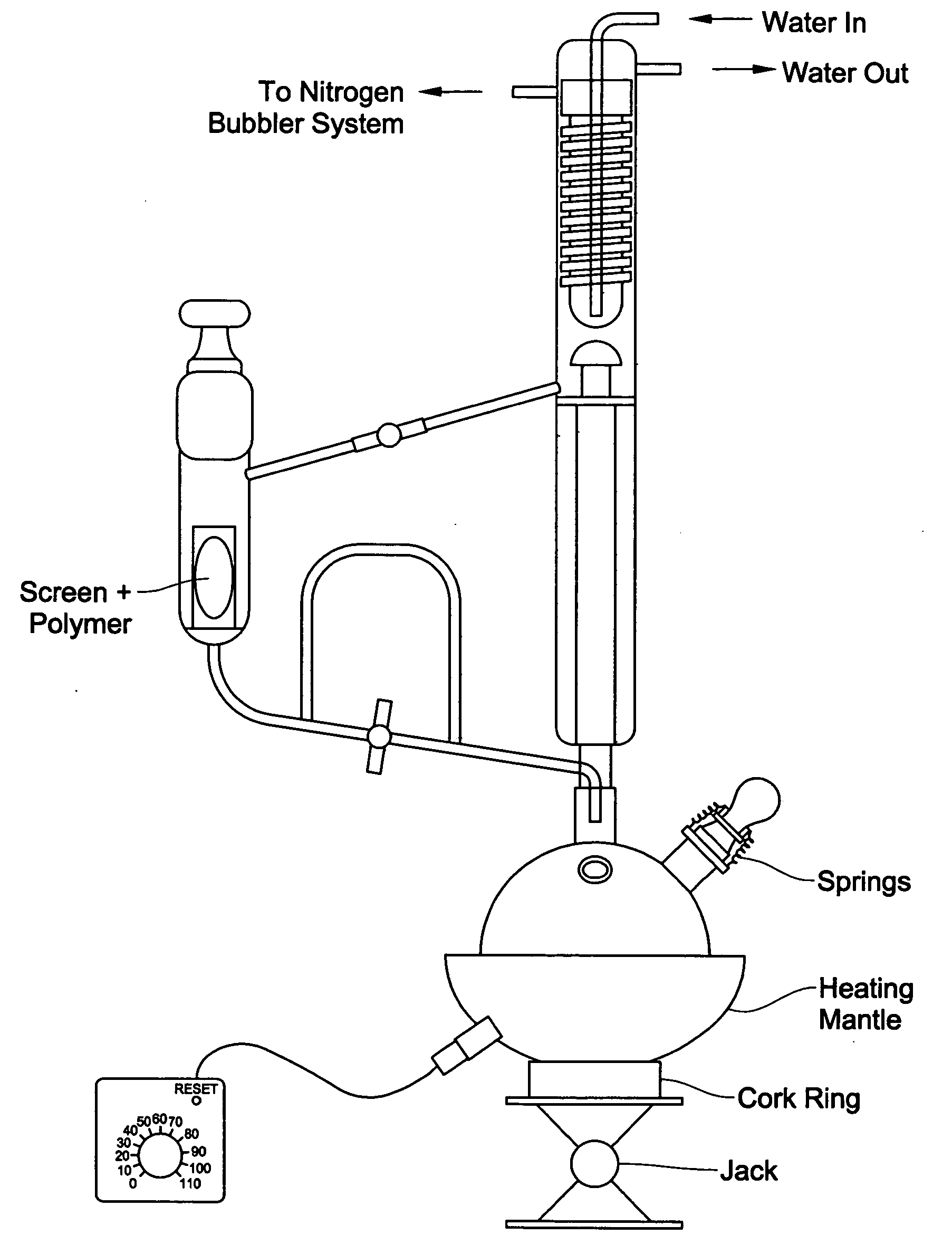

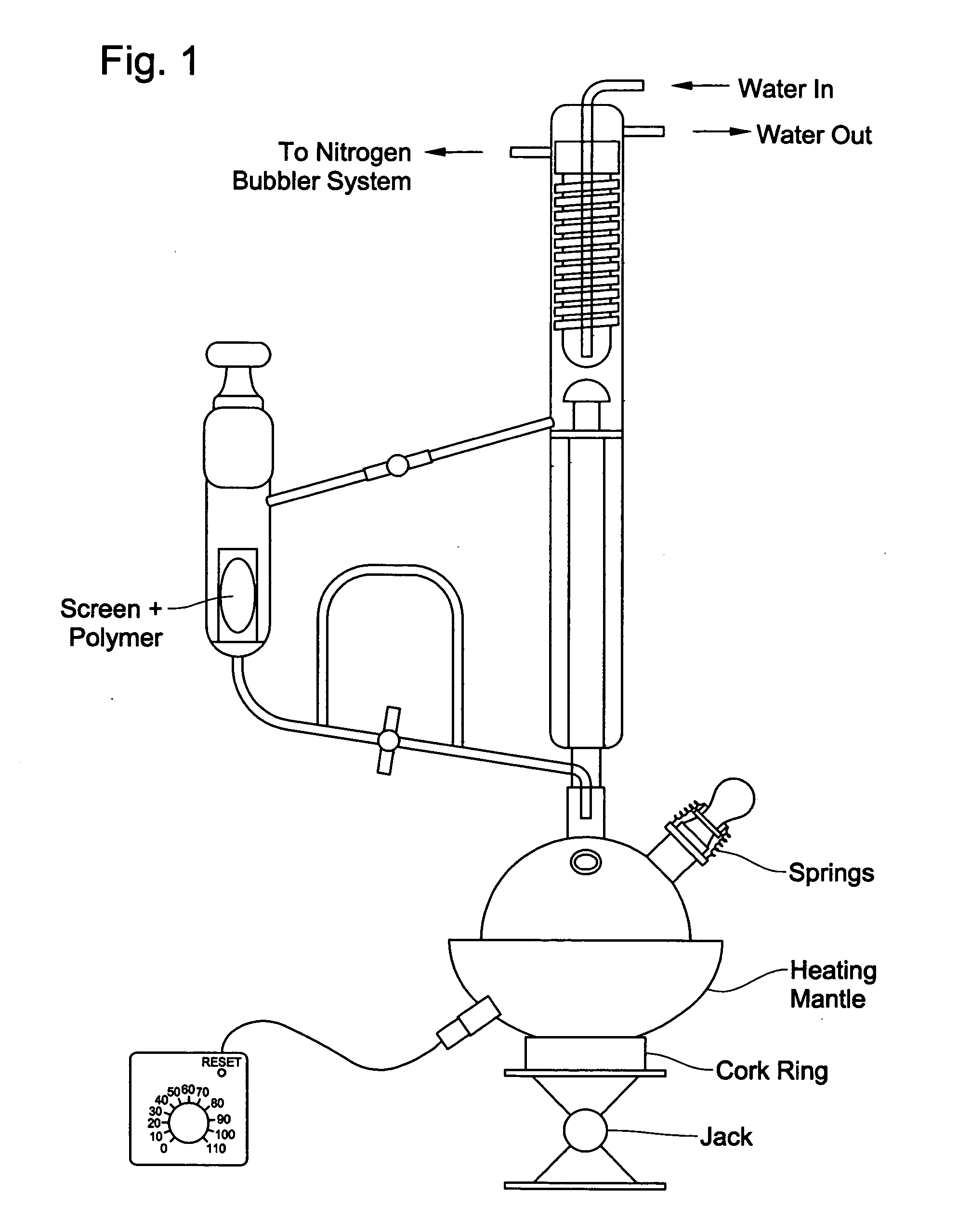

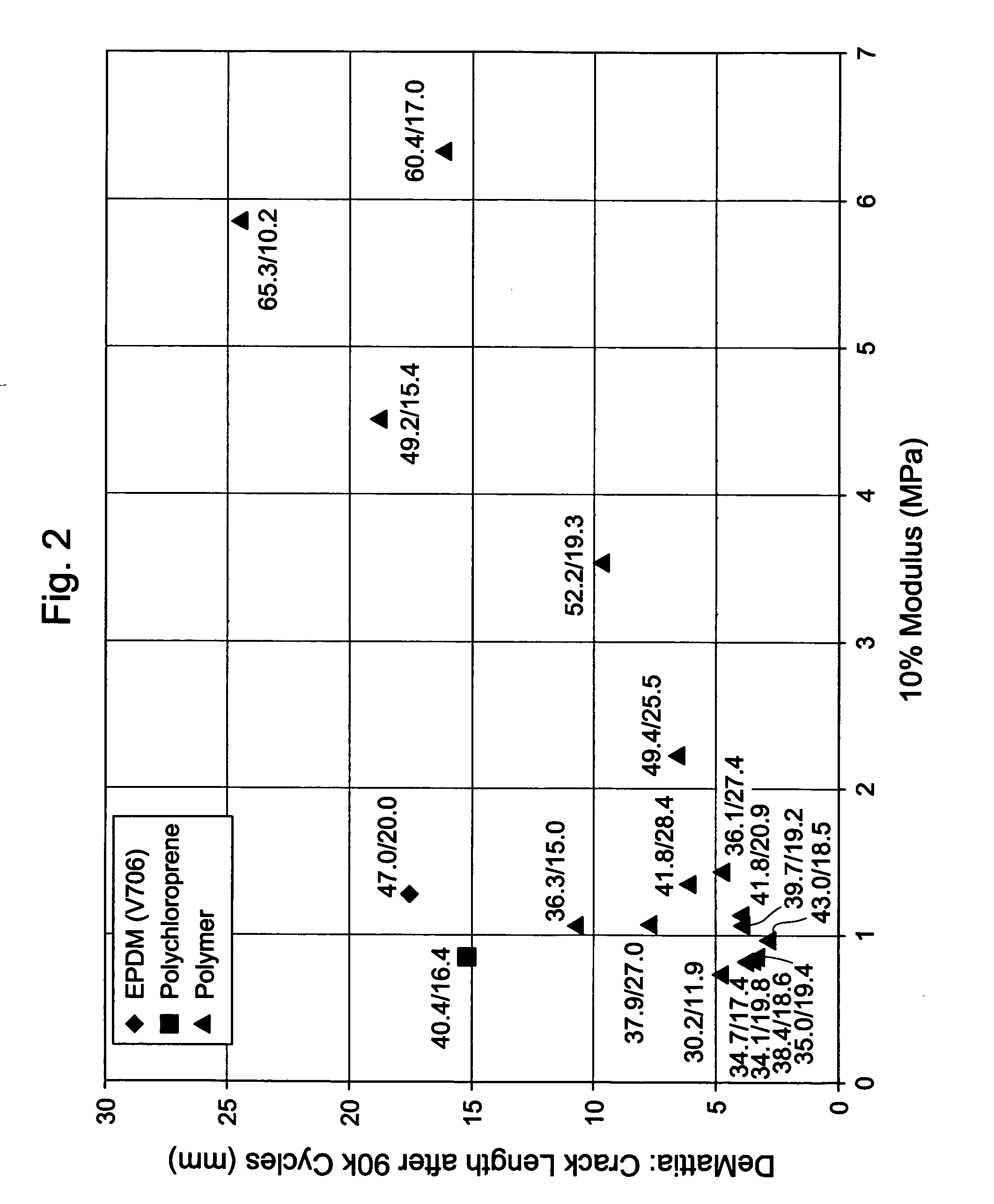

Process for making dynamically-loaded articles comprising propylene-based elastomers, composition for use in such processes, and article made using such processes

The invention relates to a process for making an article subject to dynamic loading, the process comprises: (i) shaping a polymer-containing composition in the green state, the composition comprising (a) a continuous phase of a polymeric component of at least 15 wt %, based on the total weight of the polymer component of a propylene elastomer having a heat of fusion of less than 70 J / g and an isotactic triad tacticity of 50 to 99% and optionally containing units derived from a diene, the polymeric component having a density of less than 0.9 g / cm3 and (b) from 20 to 120 phr, preferably 30 to 100 phr, most preferably 40 to 90 phr based on the total weight of the polymer component of a reinforcing filler component; and (c) a peroxide curative. The composition is combined with a fibrous reinforcement which is then cured to a cure state as determined by ODR @ 170° C., 30 min MH-ML of from 5 to 80 dNm. The invention especially relates to such processes when providing under Demattia testing conditions a crack length of less than 15 mm at room temperature over 90K cycles, preferably 10 mm, more preferably 7 mm, and most preferably 4 mm, and a 10% modulus of 0.7 to 10 MPa, preferably 1.4 to 9 MPa and most preferably 2 to 8 MPa.

Owner:EXXONMOBIL CHEM PAT INC

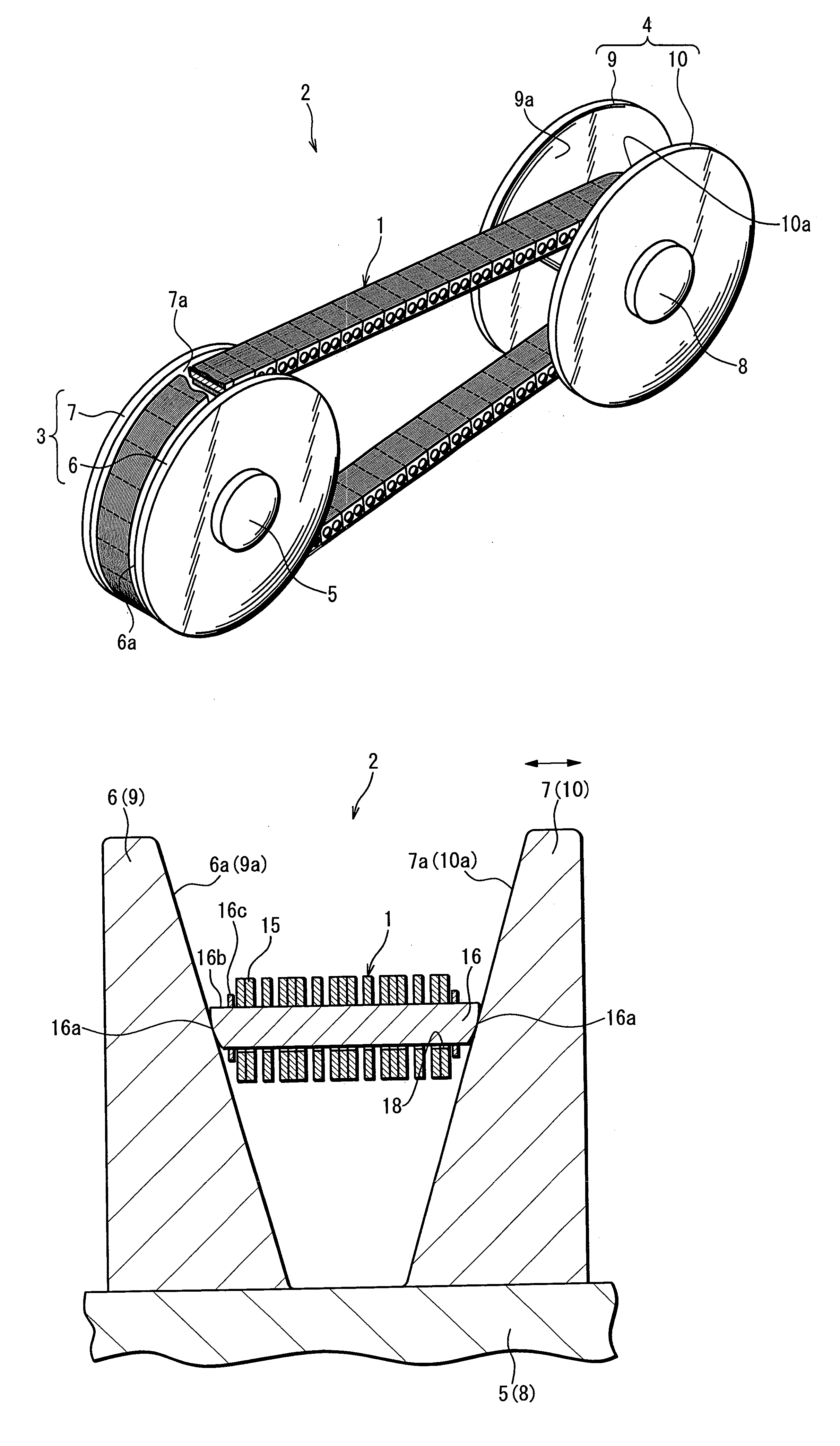

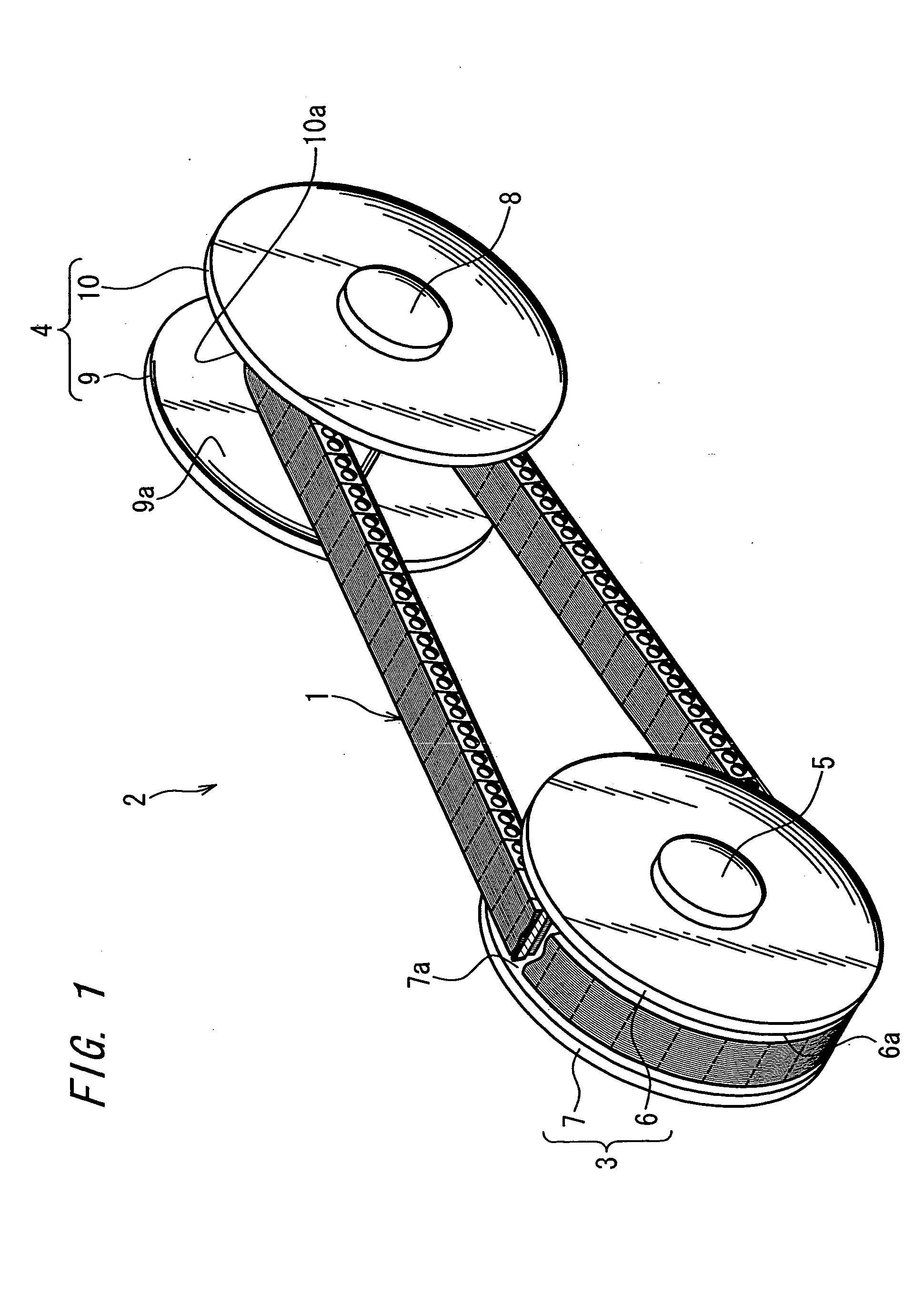

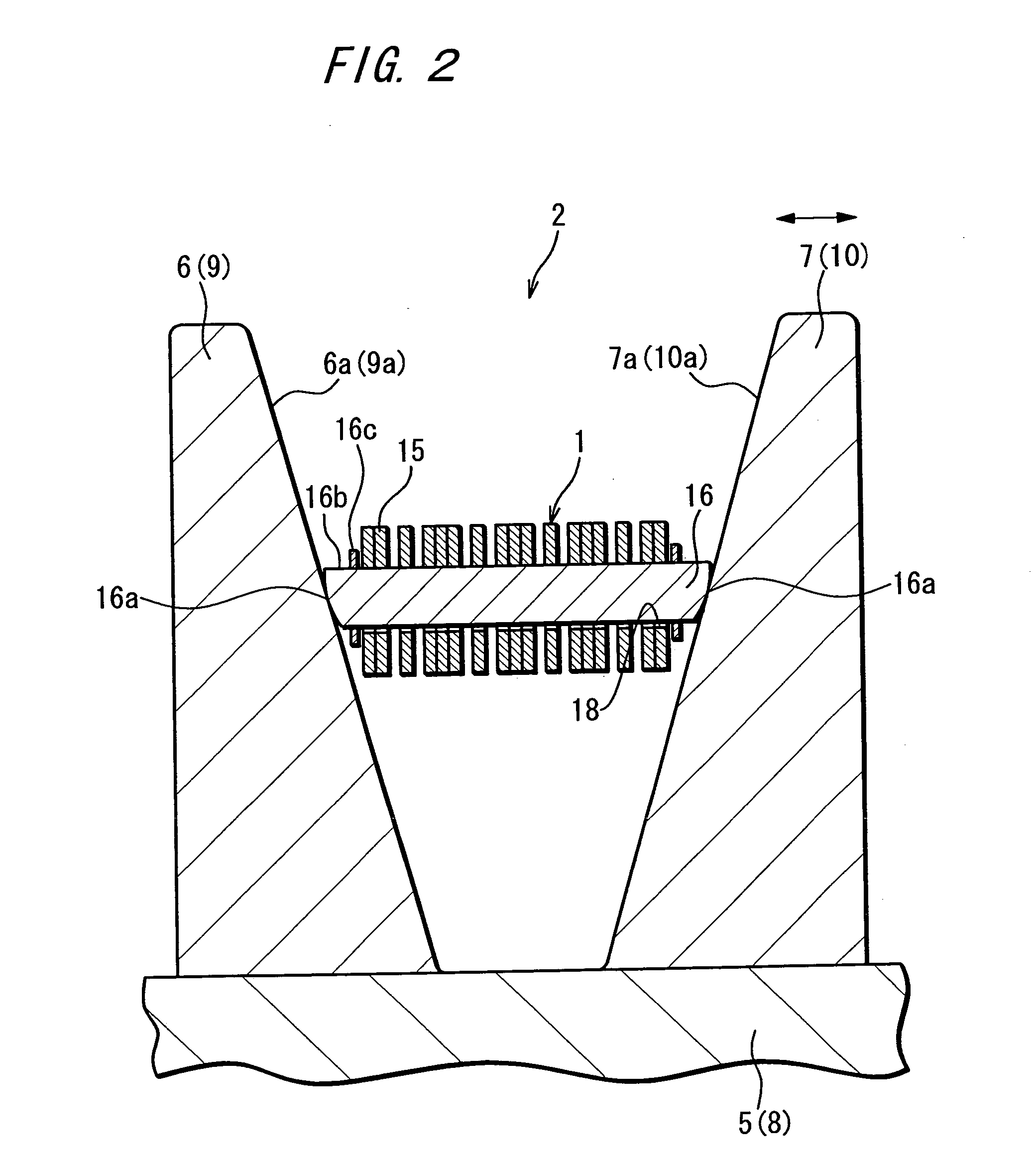

Power transmission chain and power transmission apparatus using same

This power transmission chain has a plurality of links, and a plurality of pins mutually joining this plurality of links. The power transmission chain is used to span a first pulley having a sheave face of conical shape, and a second pulley having a sheave face of conical shape, and power is transmitted by contact of both end faces of the pins, and the sheave faces of the first and second pulleys. Contact points are formed at both ends of this pin such as to contact the sheave face forward of the center position of the relevant end face.

Owner:JTEKT CORP

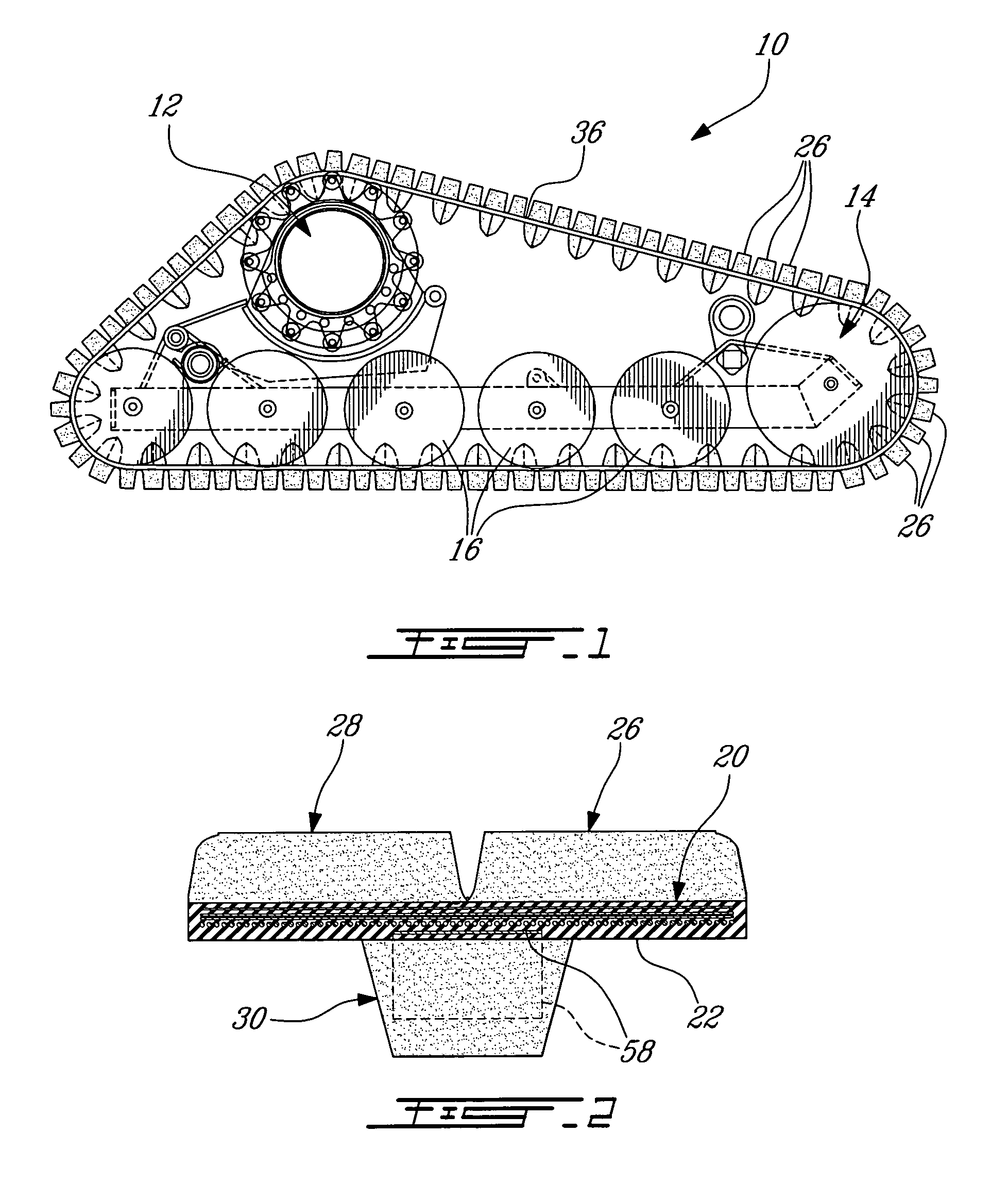

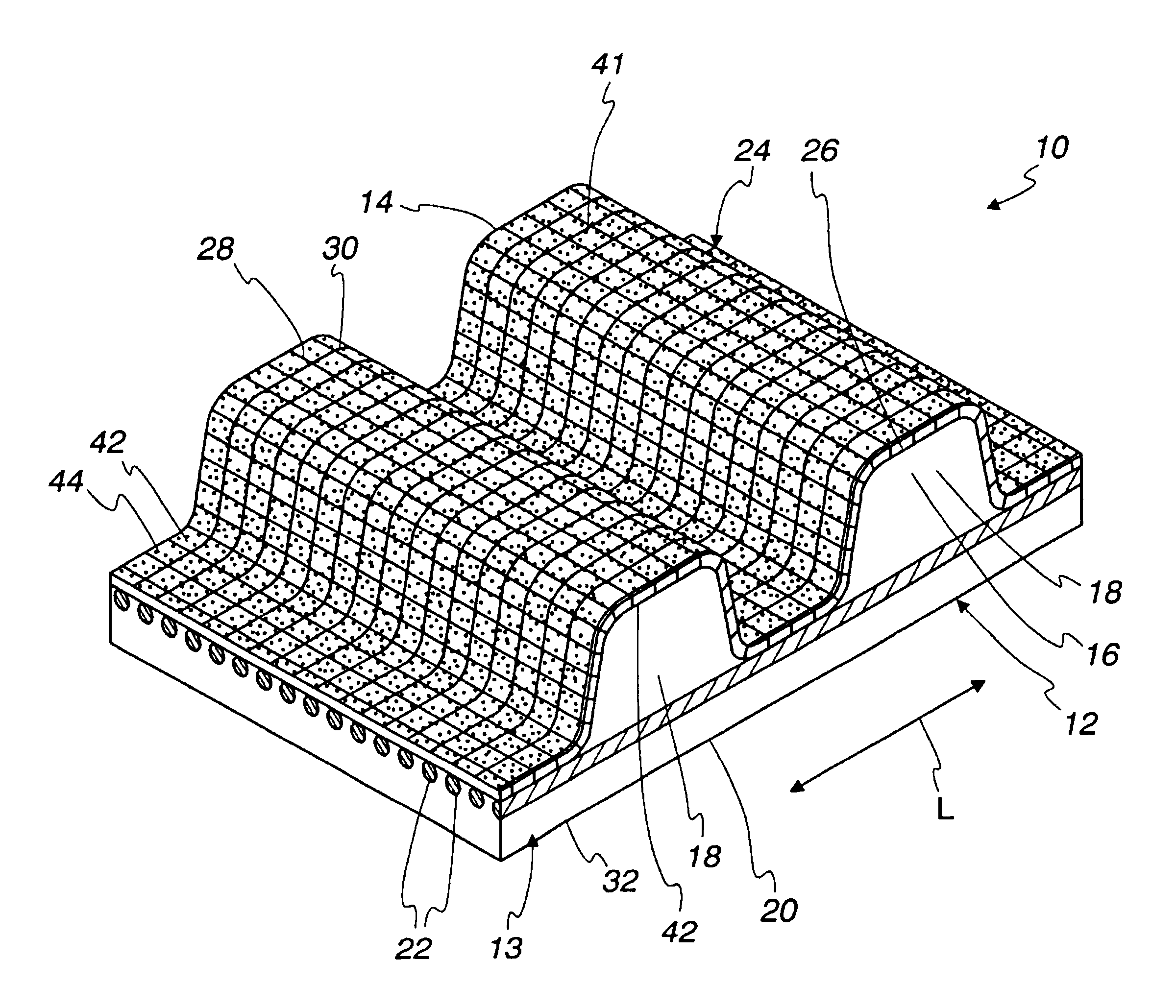

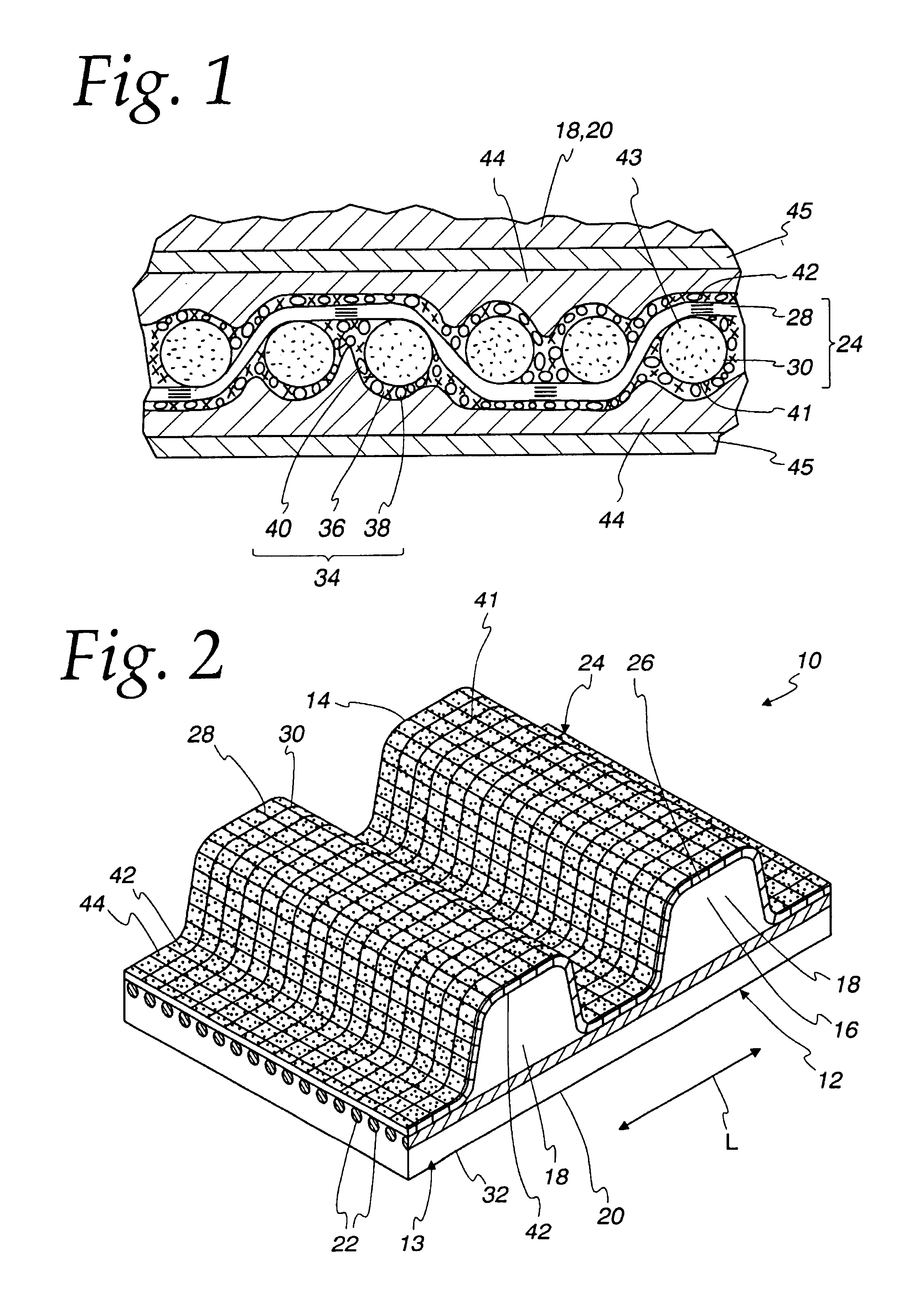

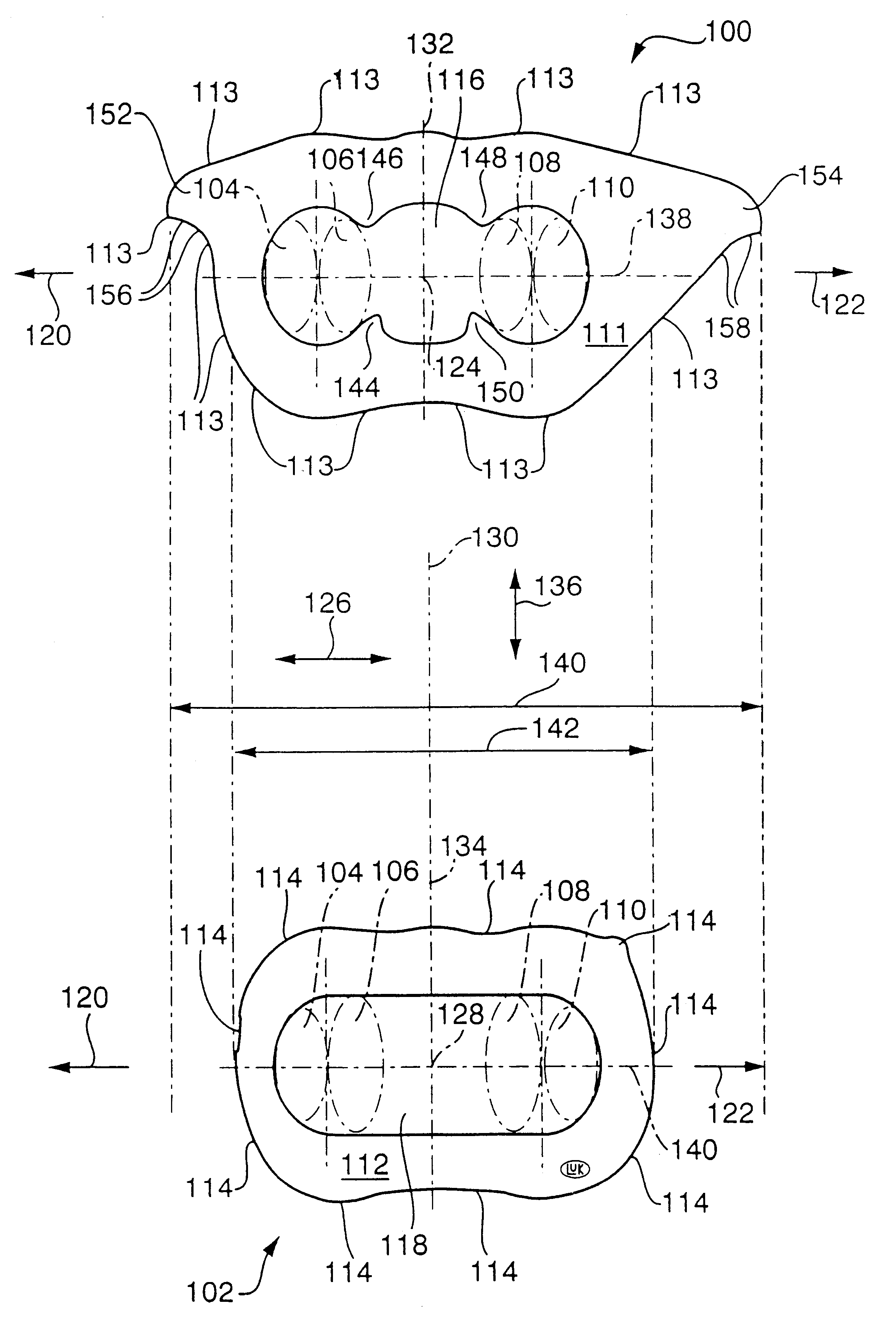

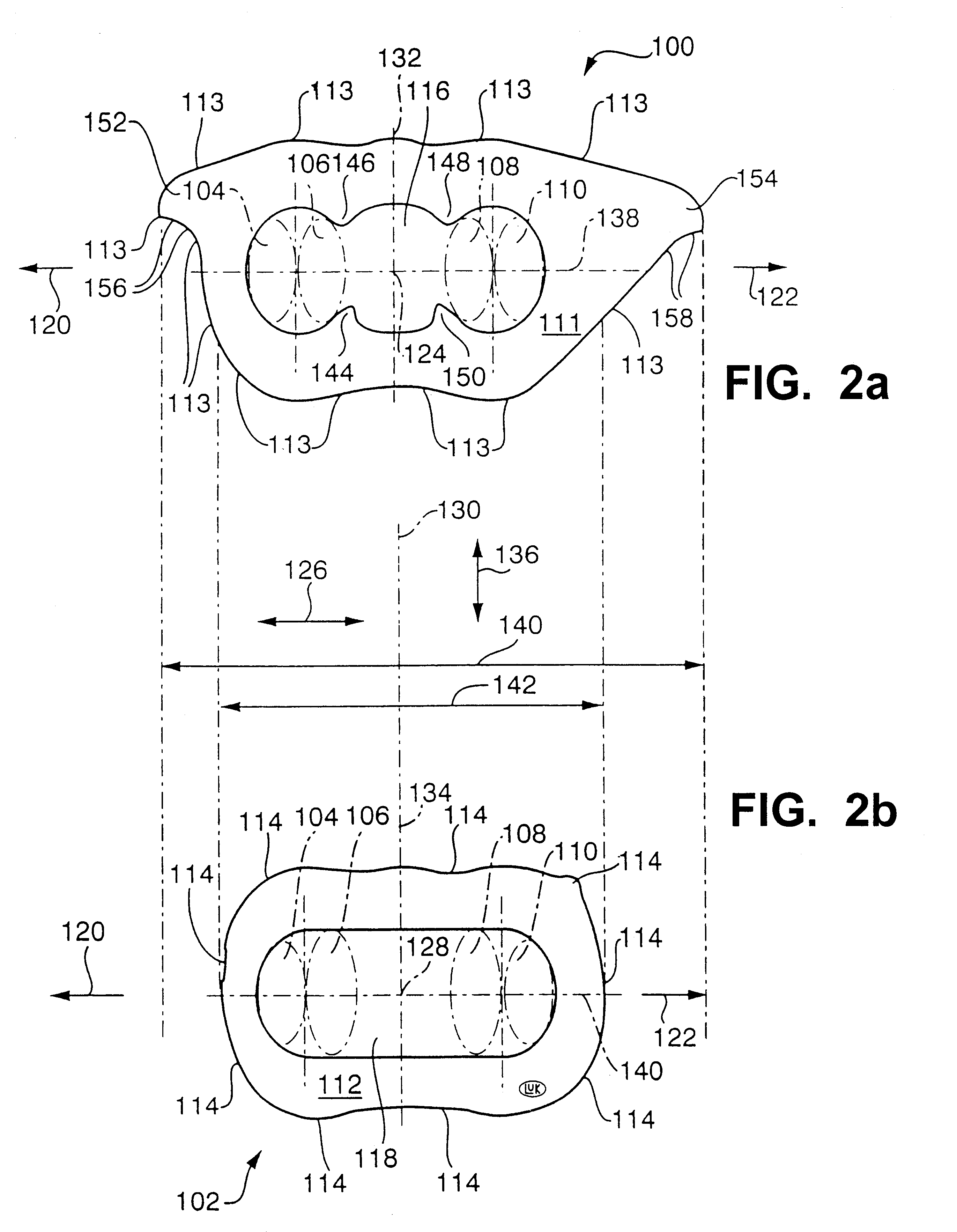

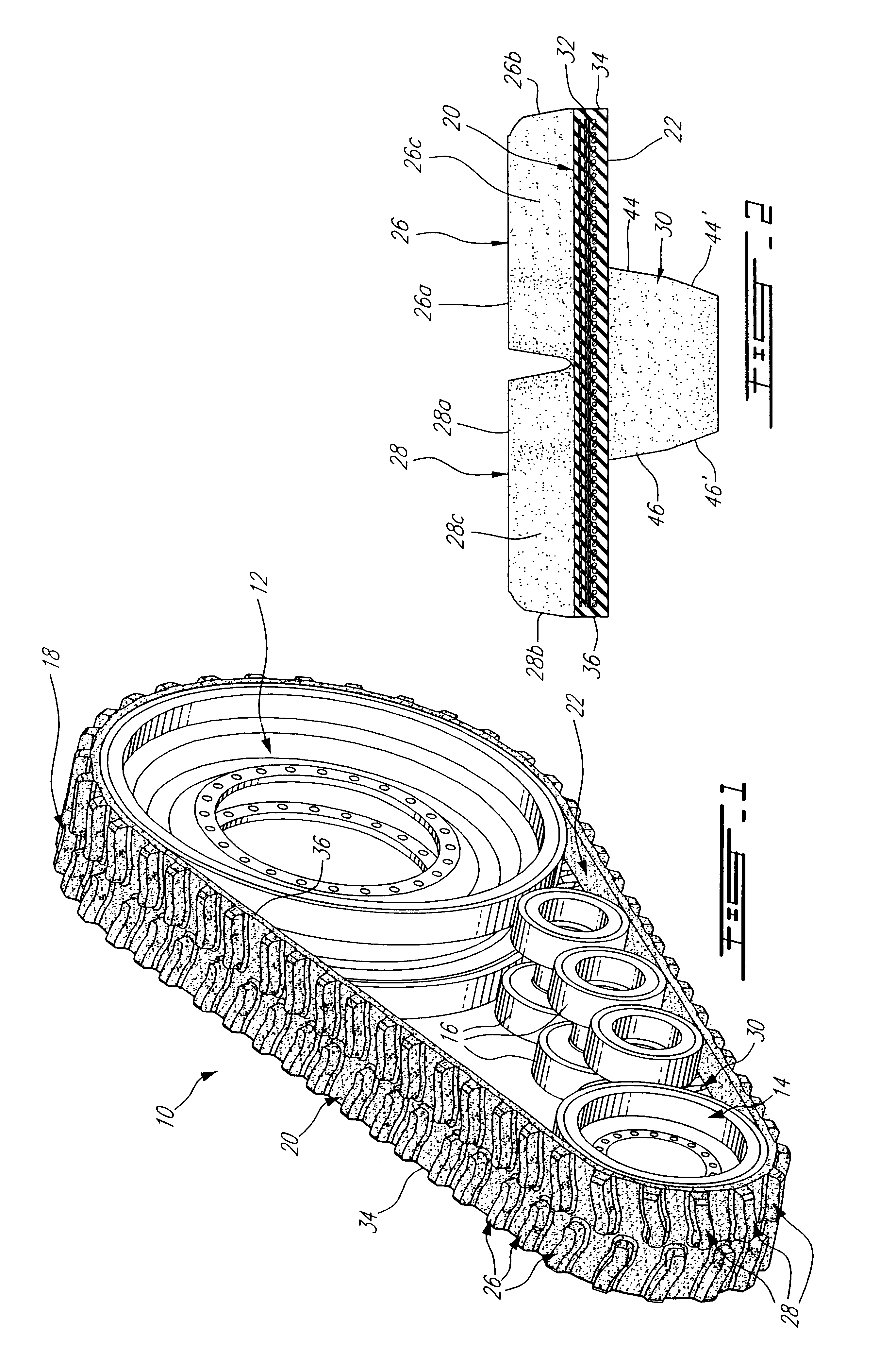

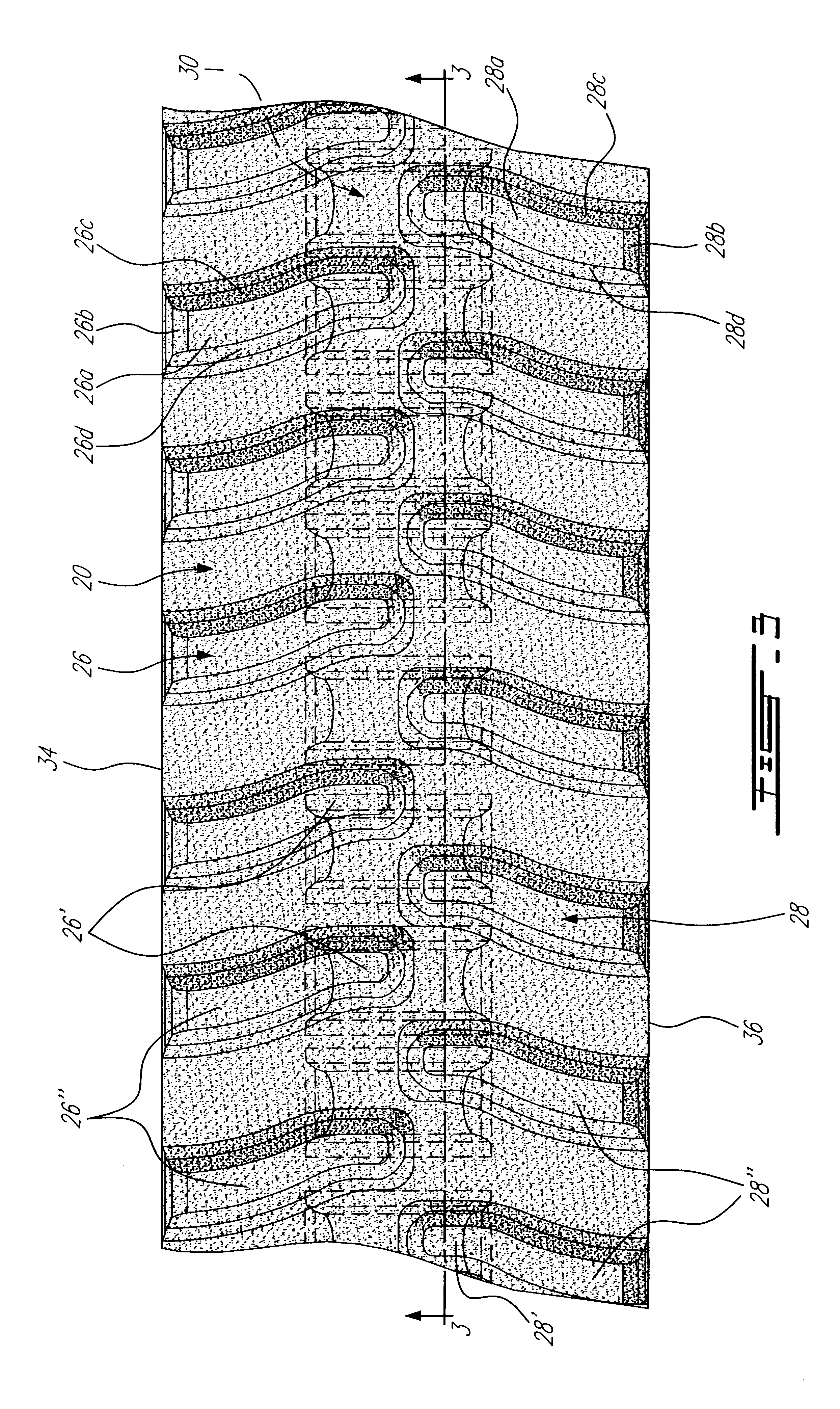

Endless belt for use with heavy duty track vehicles

InactiveUS6402268B1Reduce stress exertedAccurate locationV-beltsRopes and cables for vehicles/pulleyVertical alignmentHeavy duty

An endless belt for use with a heavy duty track vehicle comprises a body made of polymeric material wherein a series of longitudinally spaced guide members are integrally formed to the inner surface thereof while two rows of longitudinally spaced tread members are integrally formed to the outer surface thereof. Each tread member in each row has an outer edge area adjacent the outer edge of the body and an inner edge area terminating substantially at mid-section of the body. Each tread member of the first row is longitudinally offset relative to an adjacent tread member of the second row. Each inner edge area of the tread members is in vertical alignment with a corresponding one of the guide members of the inner surface of the body. Also, the pitch defined by two successive guide members differs in value from other pitches along the outer surfaces of the belt. This particular geometry of tread members and drive members is such as to reduce slitting damages to the track when driven as well as vibration.

Owner:CAMOPLASY INC

Power transmission belt

A power transmission belt comprising a body comprising a first elastomeric material and having tensile members running in a longitudinal direction, the body having a pulley engaging region having a profile; characterized in that the pulley engaging region comprises a surface region and a subsurface region; the subsurface region comprising a second elastomeric material having a friction modifying agent; and the surface region comprising a nonwoven fabric material co-mingled with the second elastomeric material.

Owner:THE GATES CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com