Slide palte deformed tooth stepless engagement adjustable gear

A technology of deformed teeth and slides, which is applied to gear transmissions, belts/chains/gears, V-shaped belts, etc., can solve the problems of low mechanical efficiency, narrow speed range, and low transmission power, and achieve low machining accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

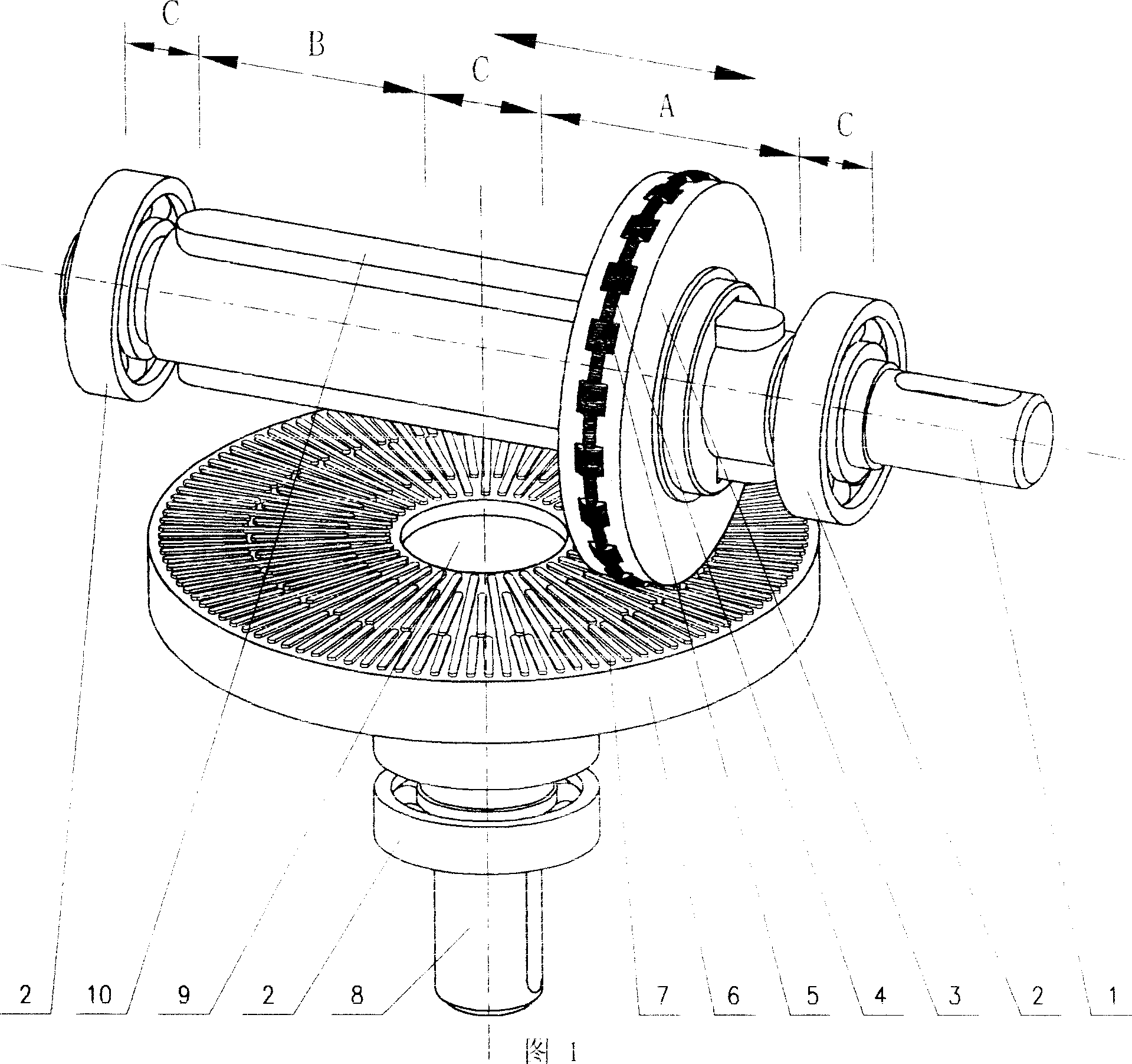

[0109] Cylindrical movable gear continuously variable transmission series

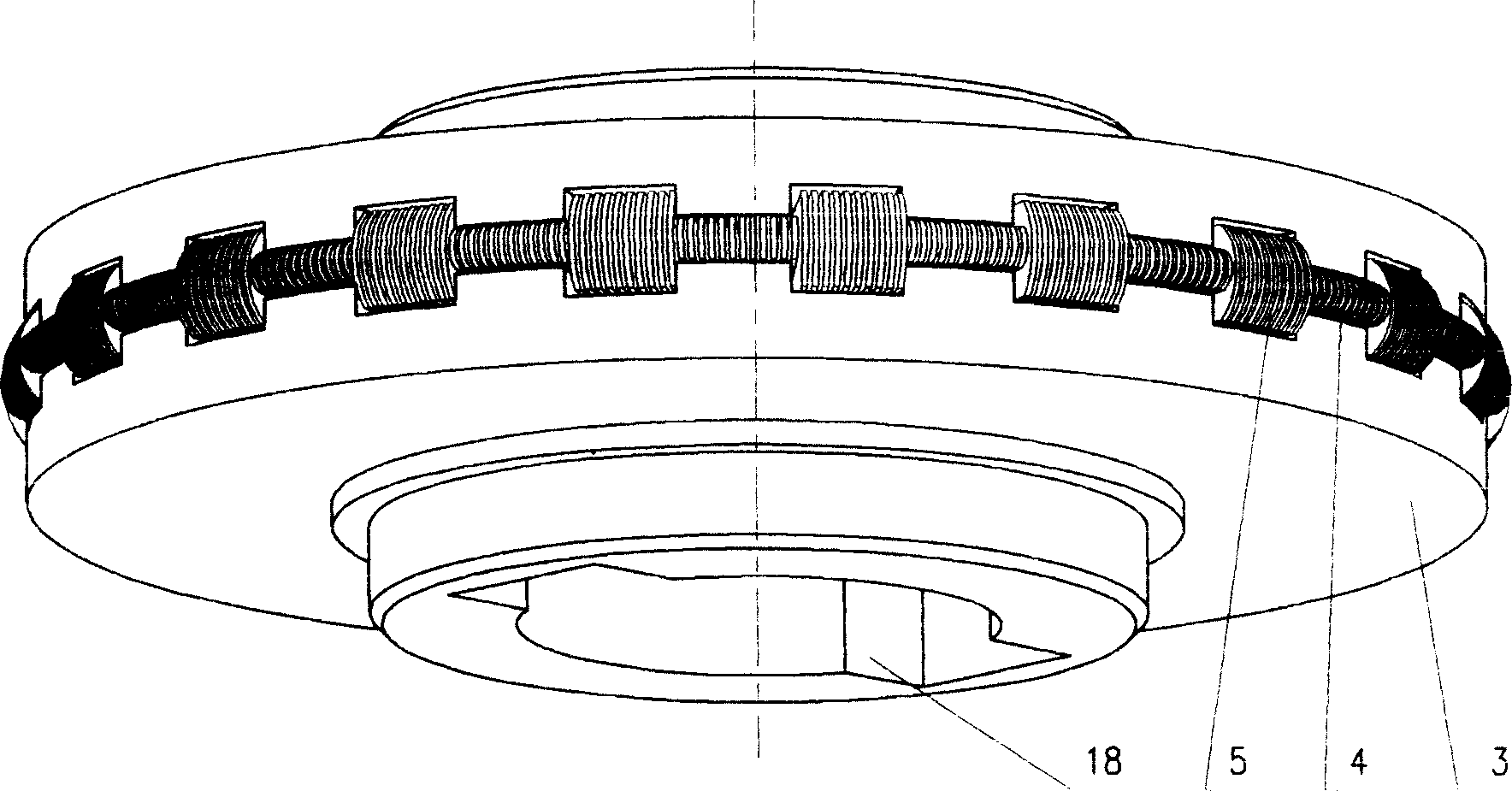

[0110] Figure 1. Structural diagram of cylindrical live gear continuously variable transmission figure 2 , Structural diagram of cylindrical movable gear

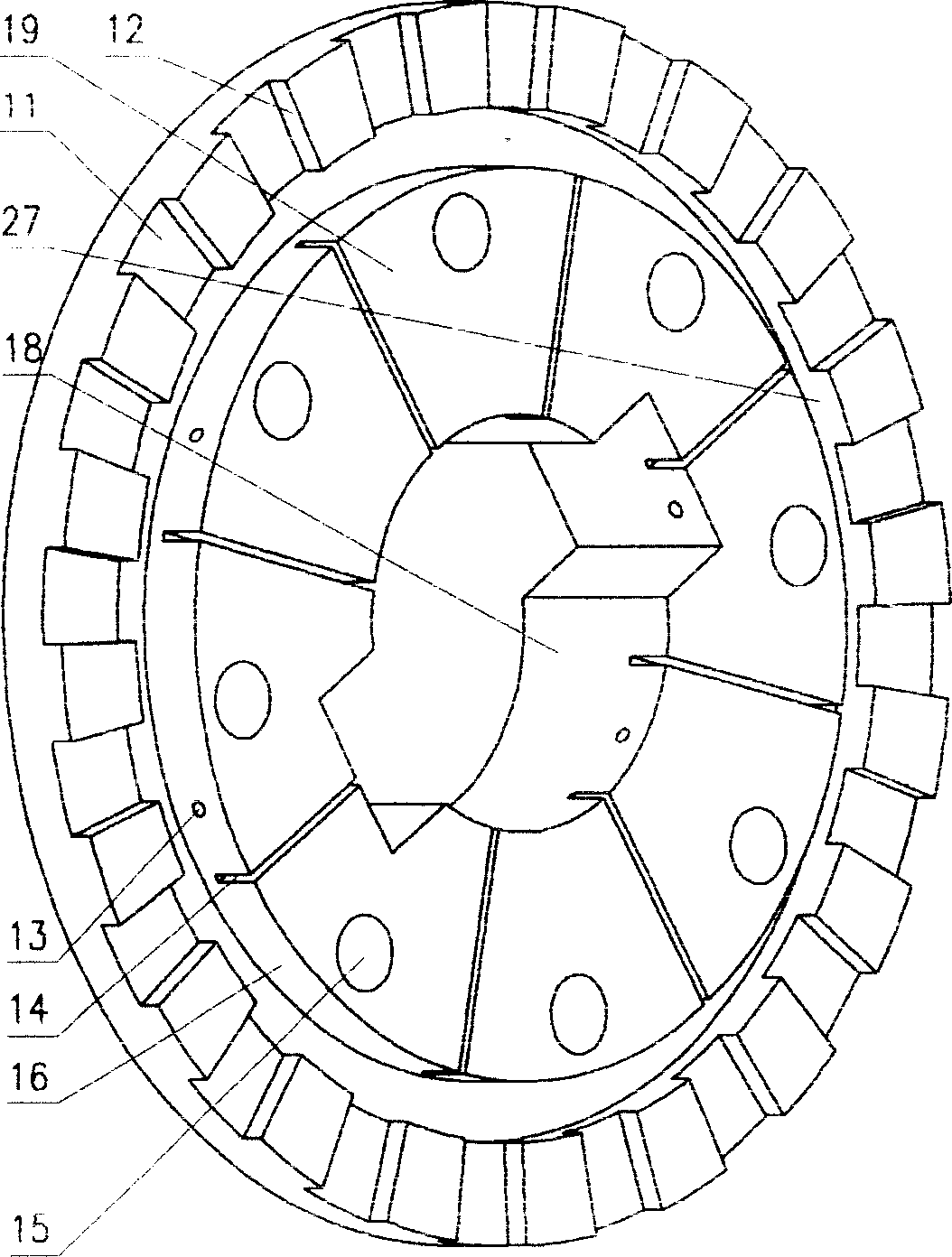

[0111] image 3 , Structural Diagram of Cylindrical Live Gear Wheel Figure 4, Structural Diagram of Sliding Plate for Cylindrical Live Gear

[0112] Figure 5, Internal structure diagram of cylindrical movable gear Fig. 6, Plan view of internal structure of cylindrical movable gear

[0113] As shown in the figure: the input shaft is connected to the cogged wheel, and the movable gear is connected to the output shaft through a guide key or a spline, which can freely move axially while transmitting torque, and the meshing radius with the cogged wheel can be changed steplessly. Stepless speed change (in Fig. 1: A, B, C represent respectively: forward gear zone, reverse gear zone, neutral gear zone).

[0114] The structure of the cylindrical liv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com