Patents

Literature

1038 results about "Mechanical efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

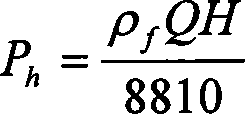

Mechanical efficiency is a dimensionless number that measures the effectiveness of a machine in transforming the power input to the device to power output. A machine is a mechanical linkage in which force is applied at one point, and the force does work moving a load at another point. At any instant the power input to a machine is equal to the input force multiplied by the velocity of the input point, similarly the power output is equal to the force exerted on the load multiplied by the velocity of the load.

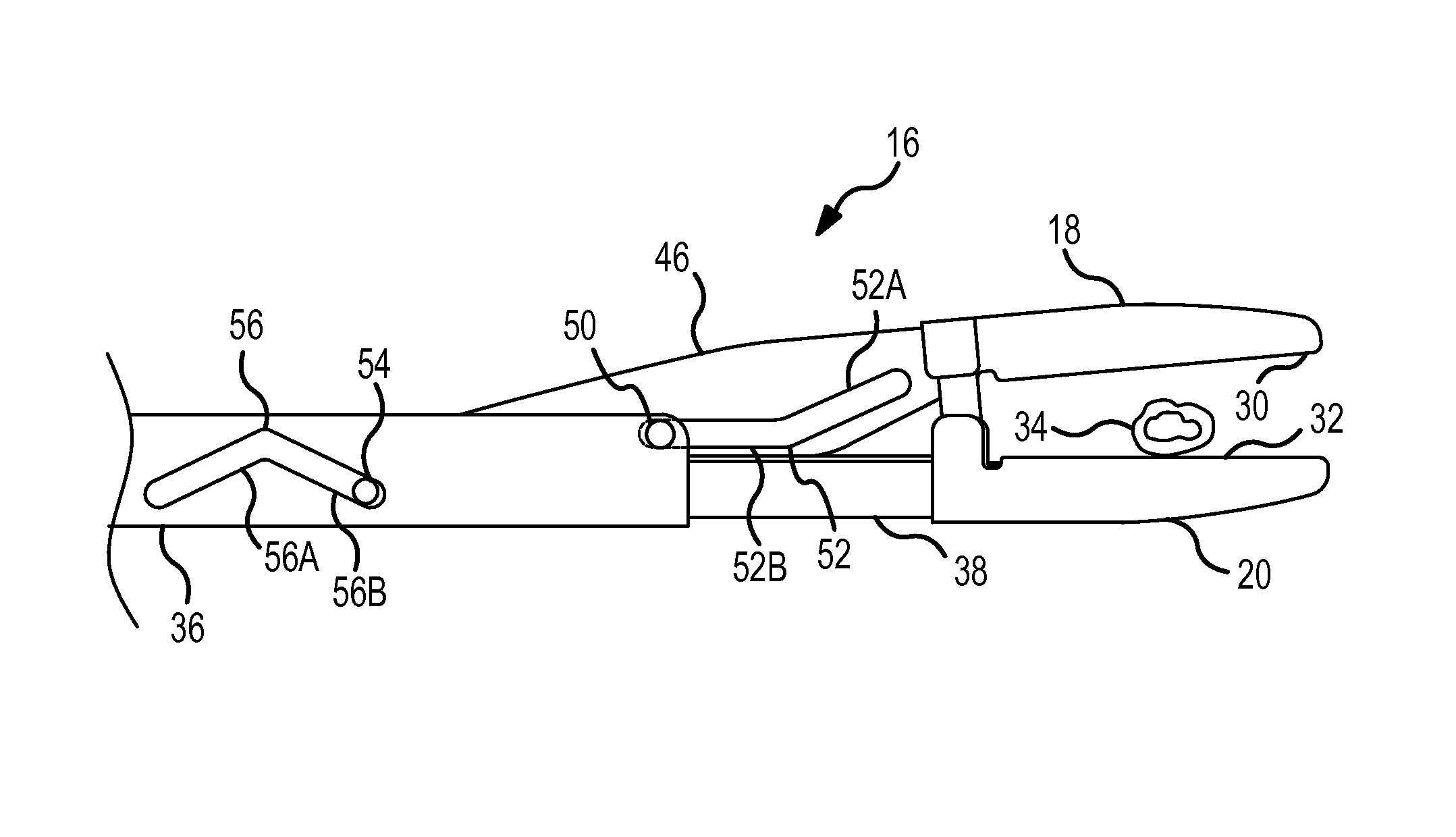

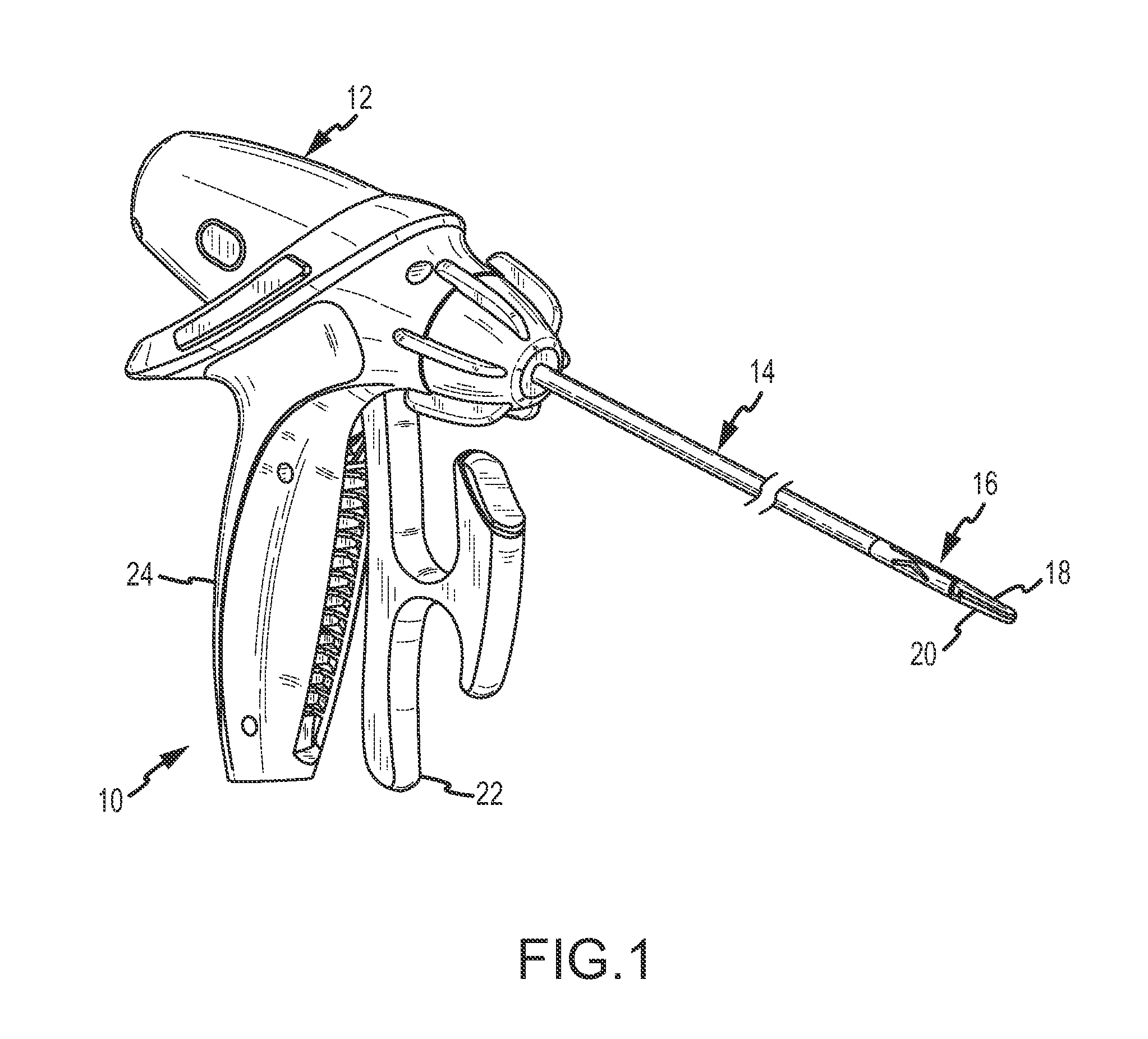

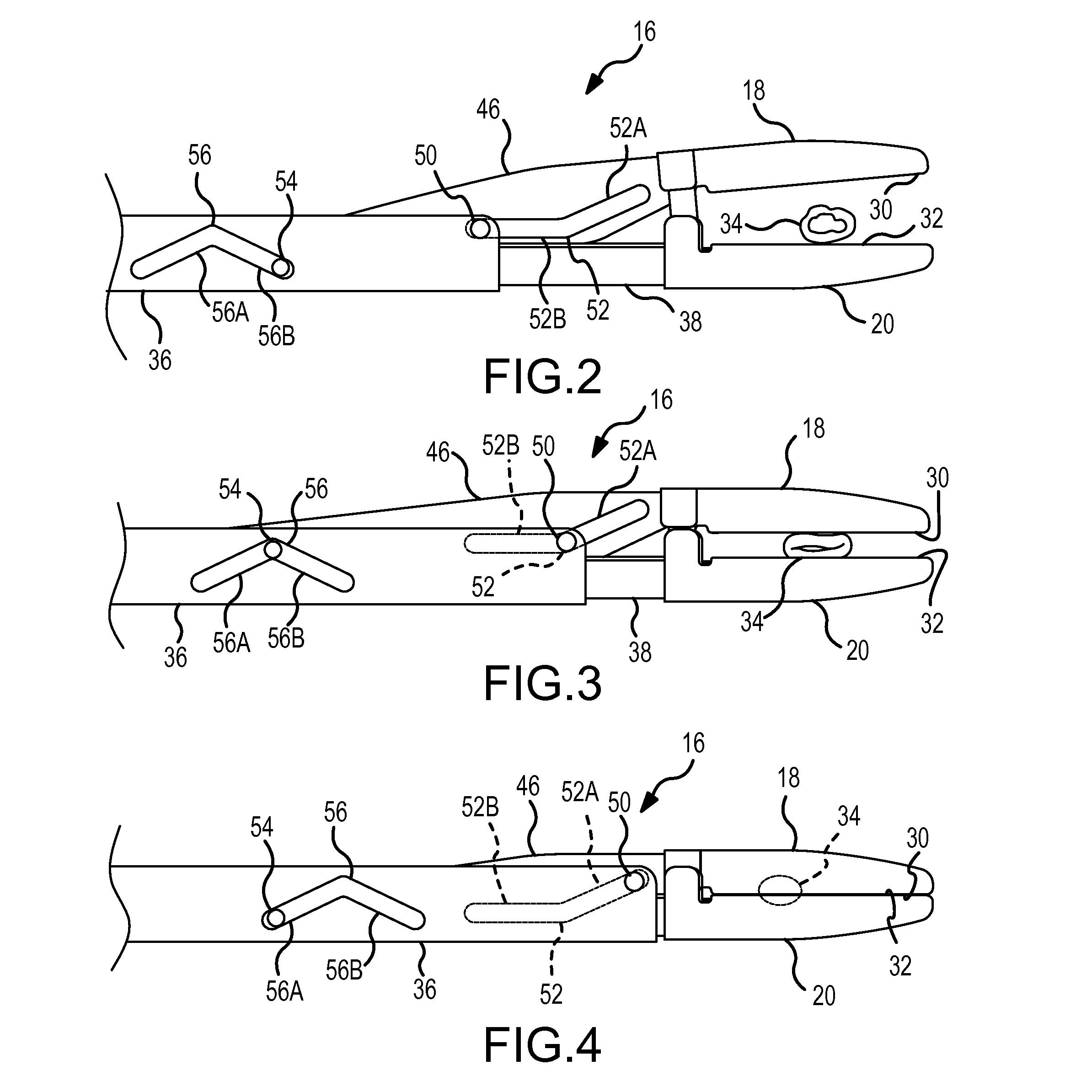

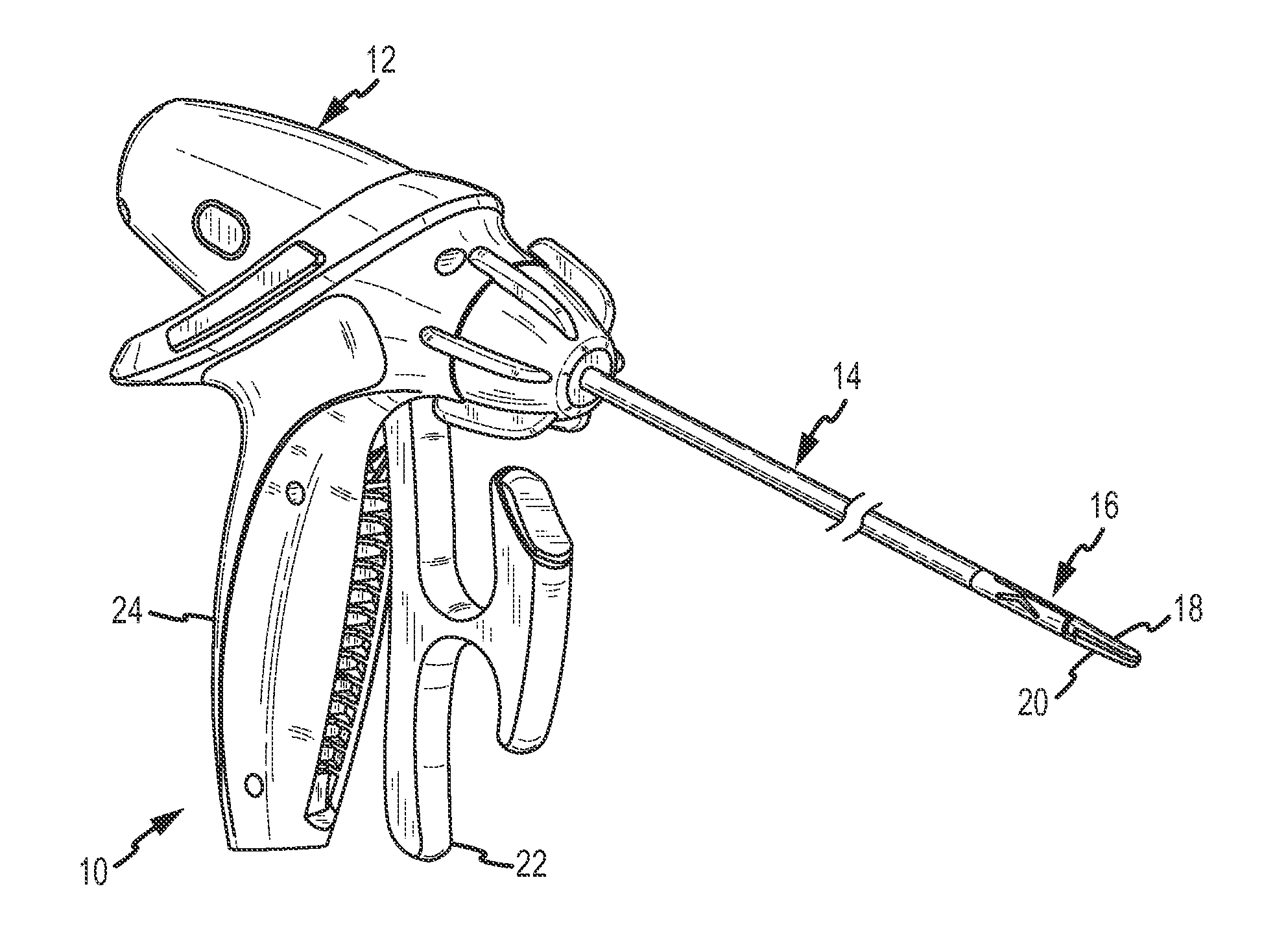

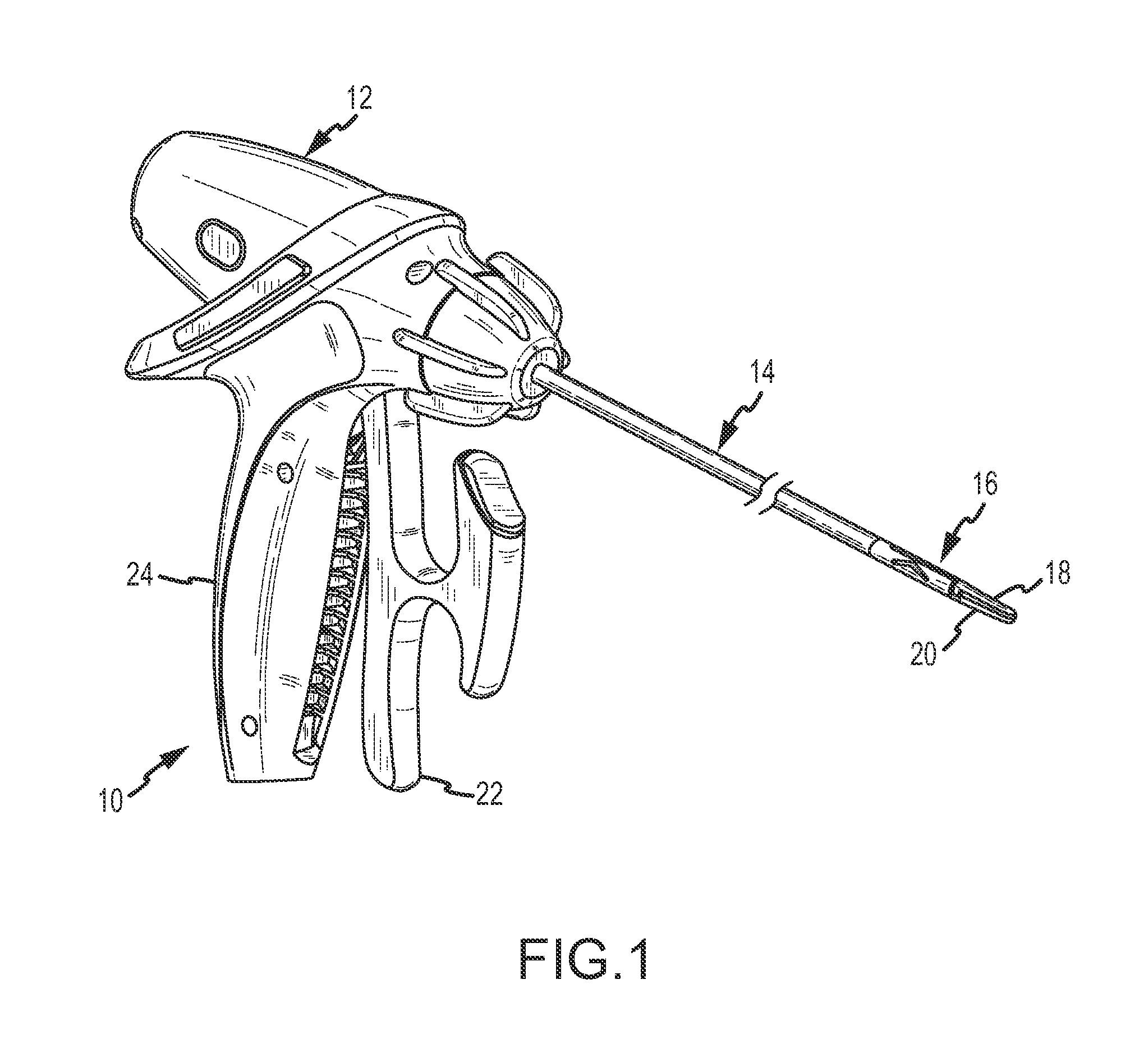

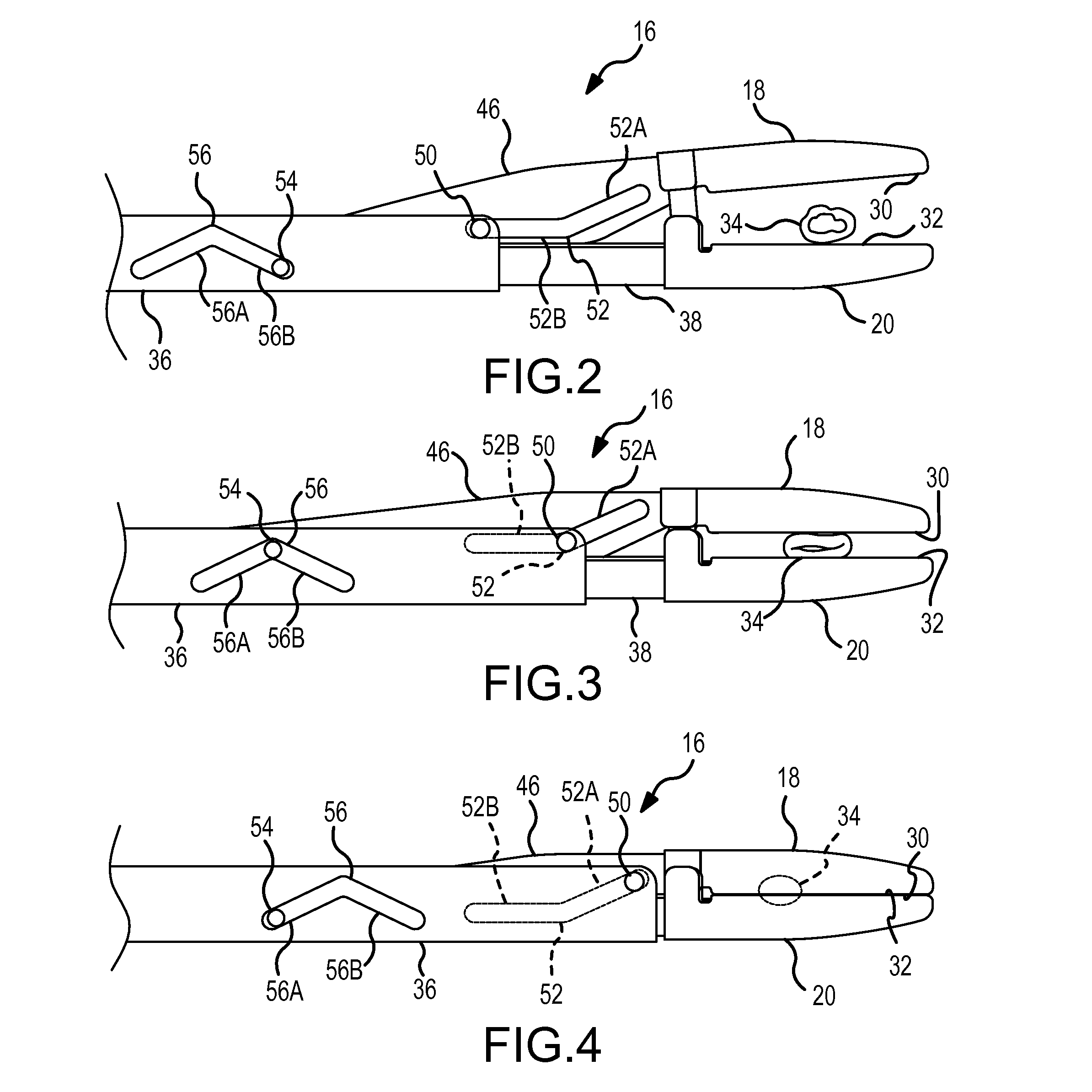

Jaw movement mechanism and method for a surgical tool

ActiveUS8663270B2Reduce the amount requiredEnhances mechanical force transferring capability and efficiencyPliersSurgical instrument detailsEngineeringJaw movement

A jaw movement mechanism for surgical tools has improved mechanical efficiency and other advantages. The jaw movement mechanism controls the orientation and position of a movable jaw relative to a fixed jaw through a range of movement of the movable jaw. The jaws maintain a parallel orientation throughout a portion of the range of movement of the movable jaw. The jaws maintain an angular relationship throughout a portion of the range of movement of the movable jaw.

Owner:CONMED CORP

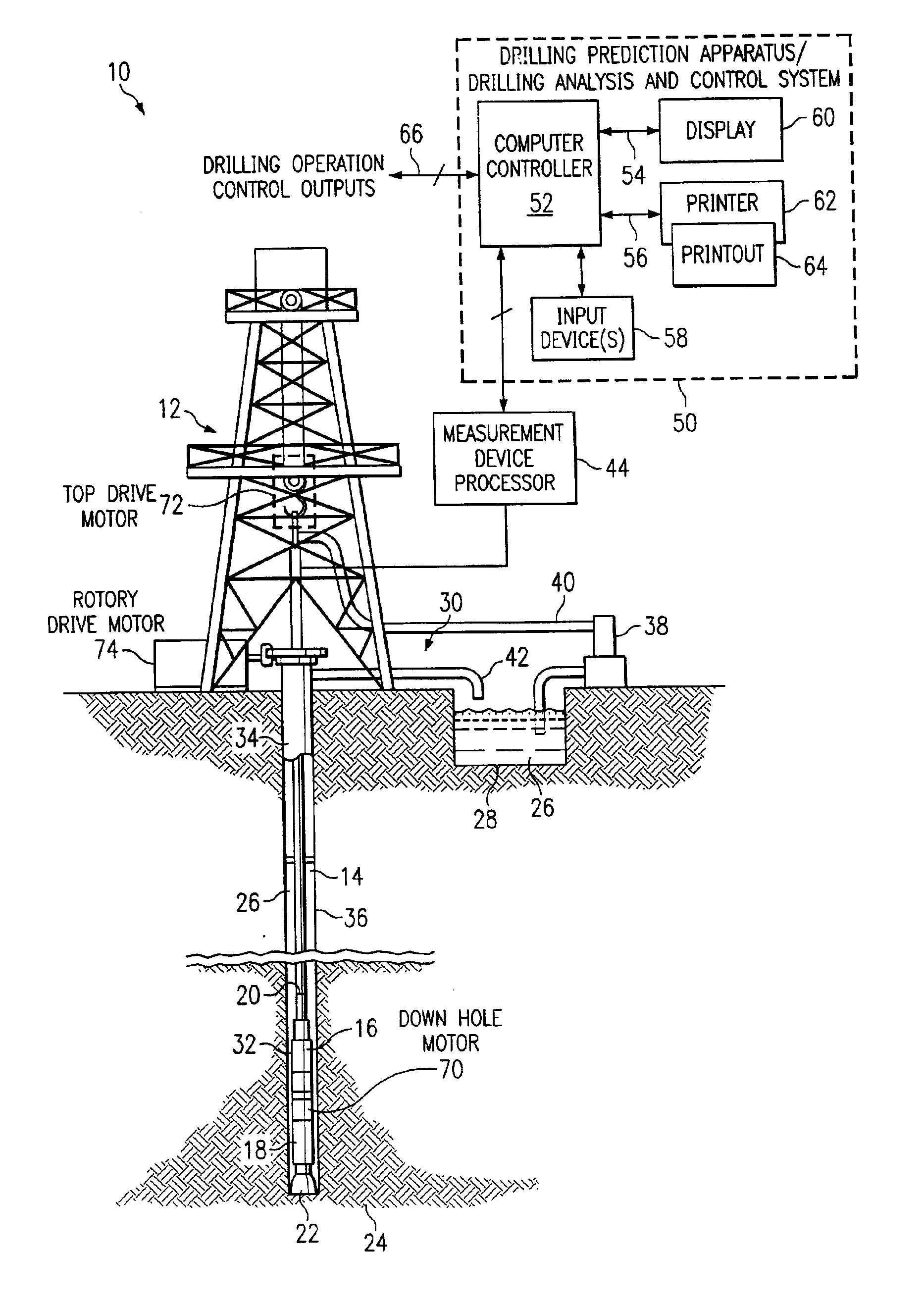

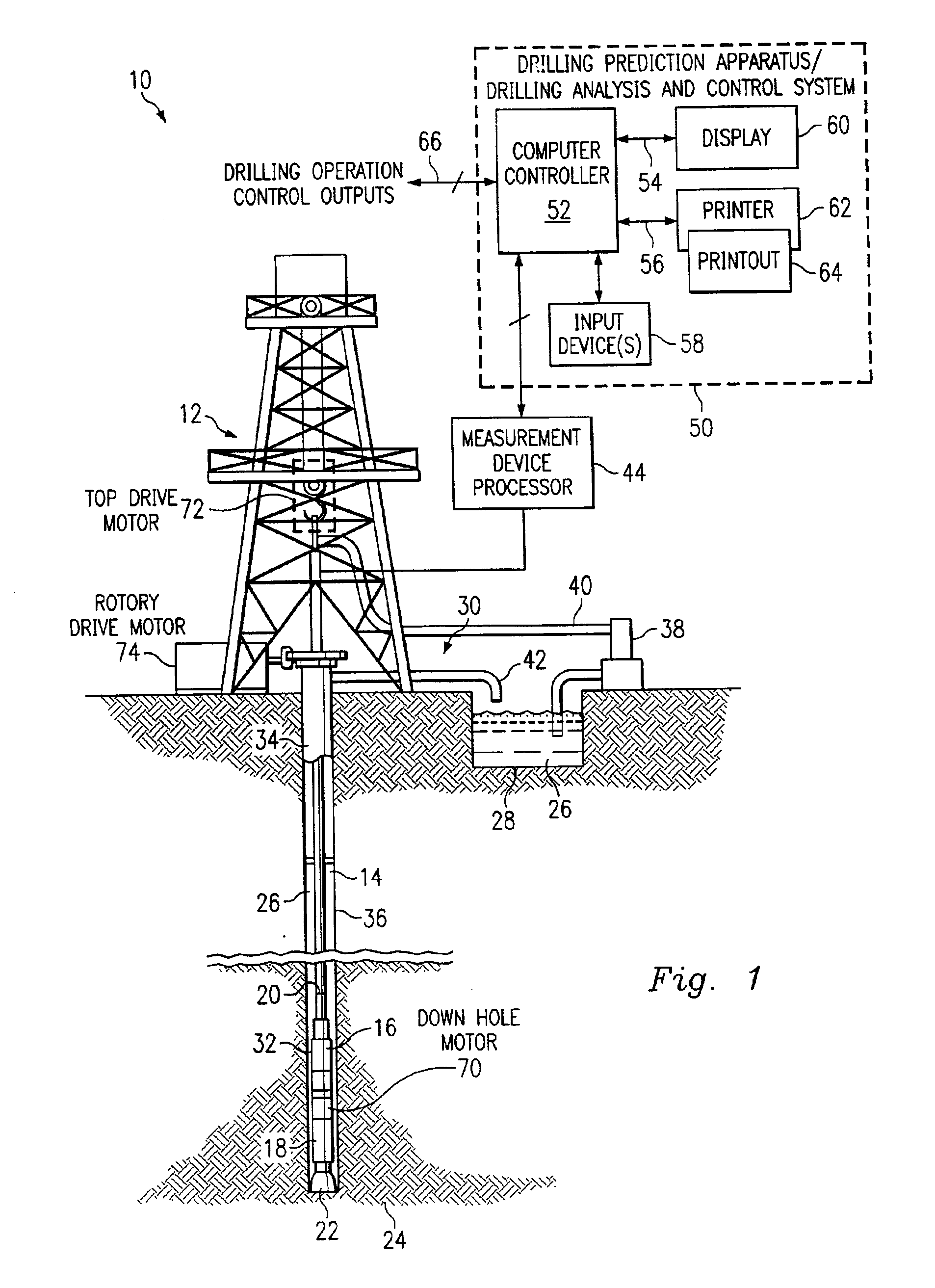

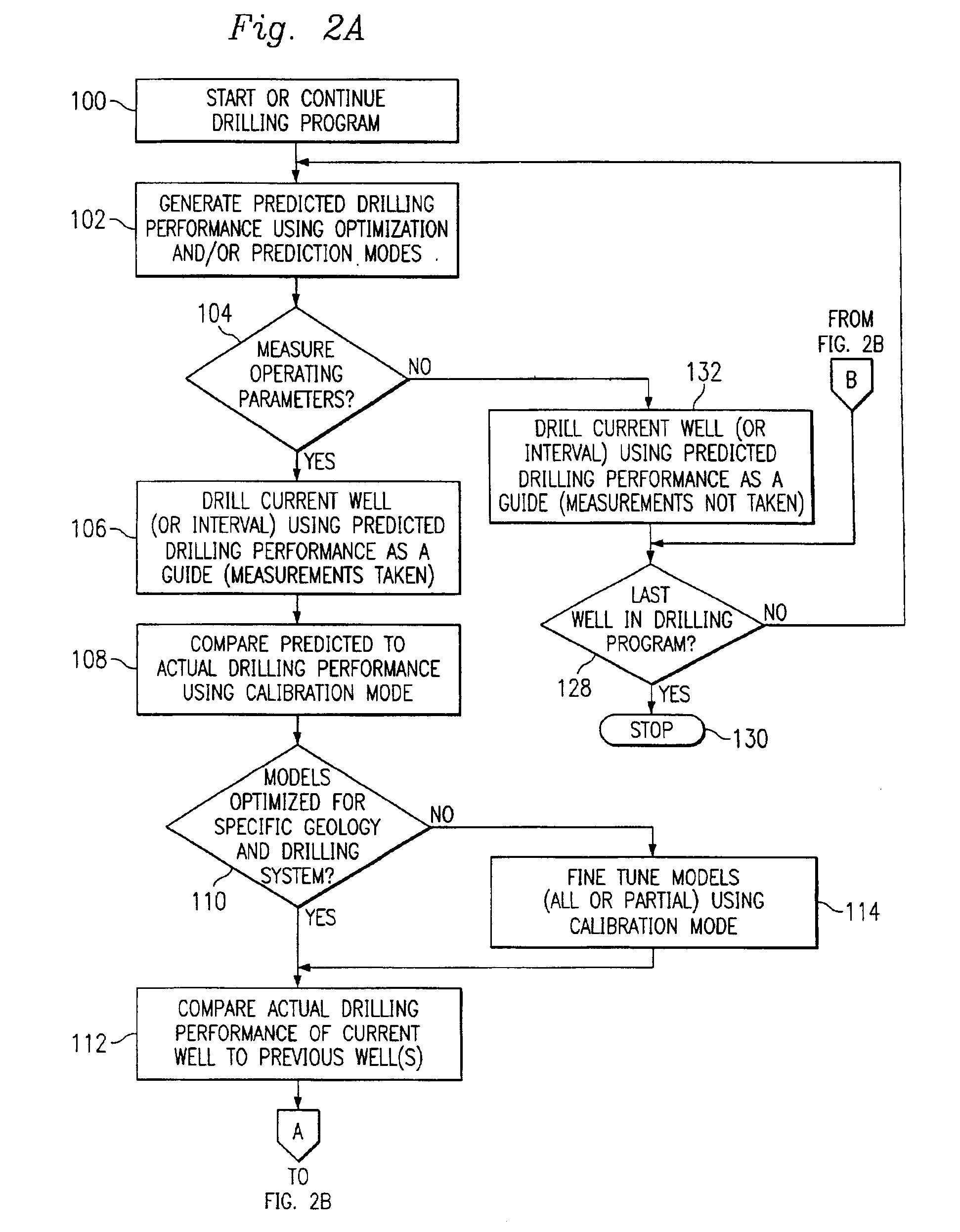

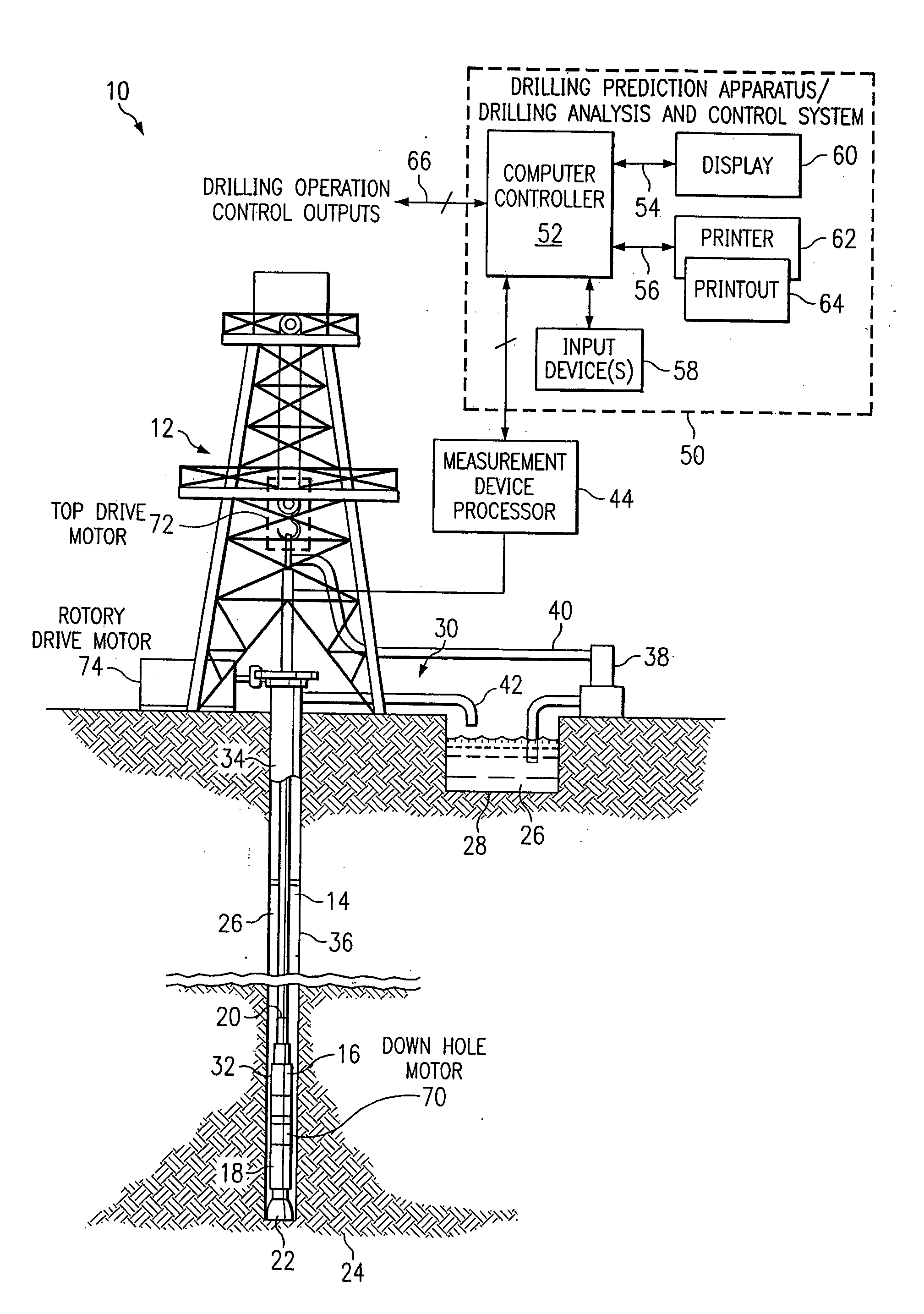

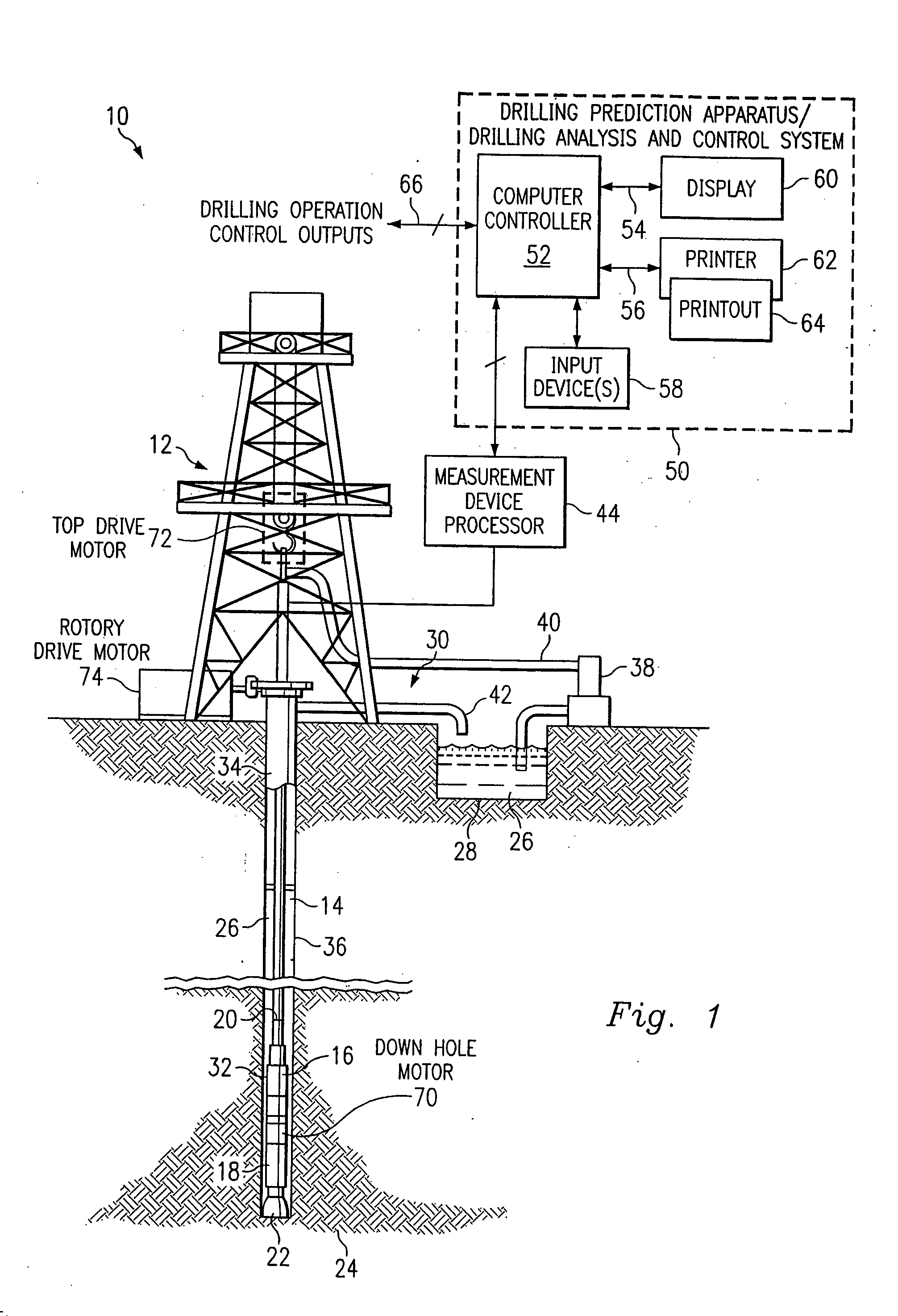

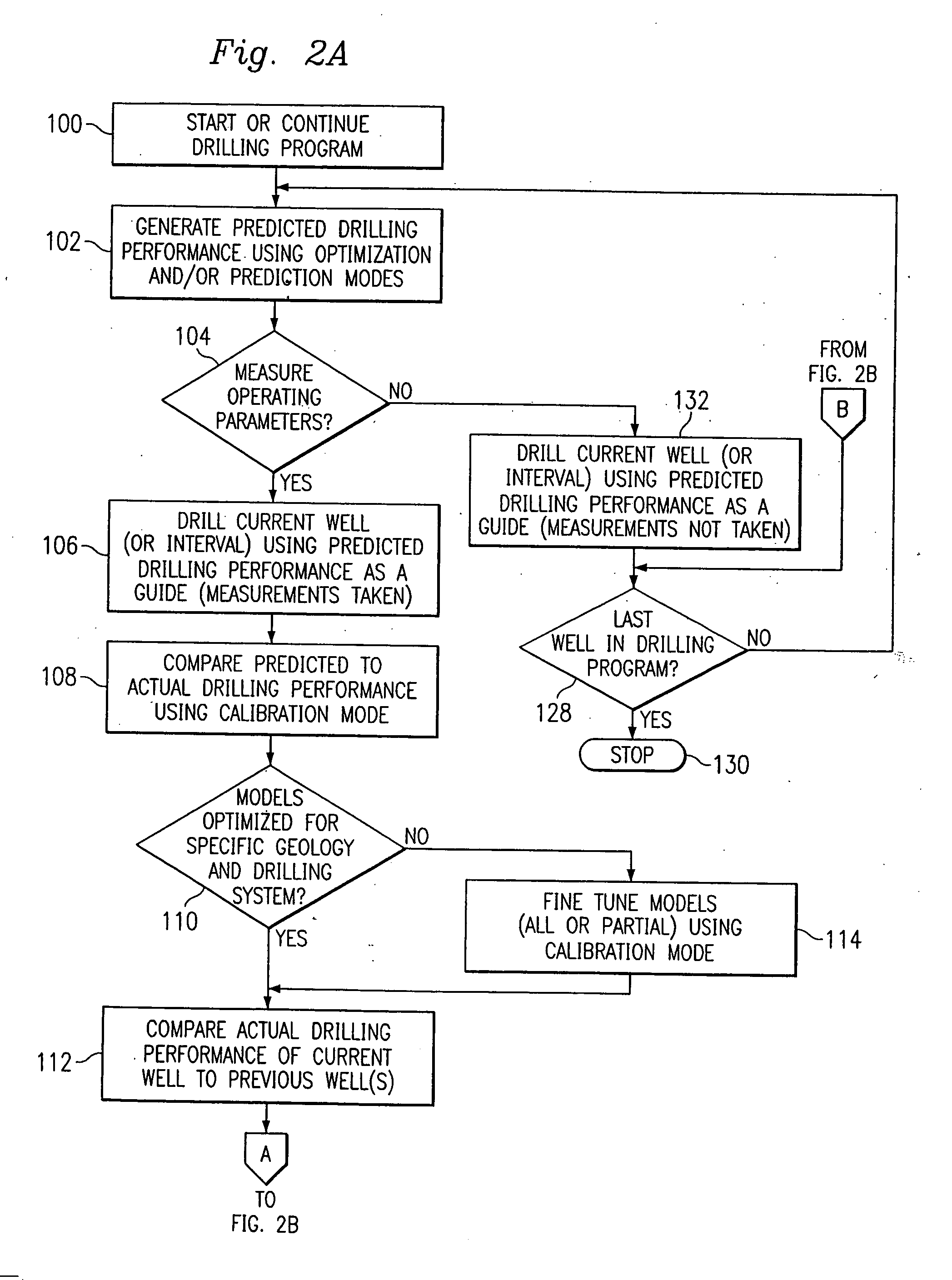

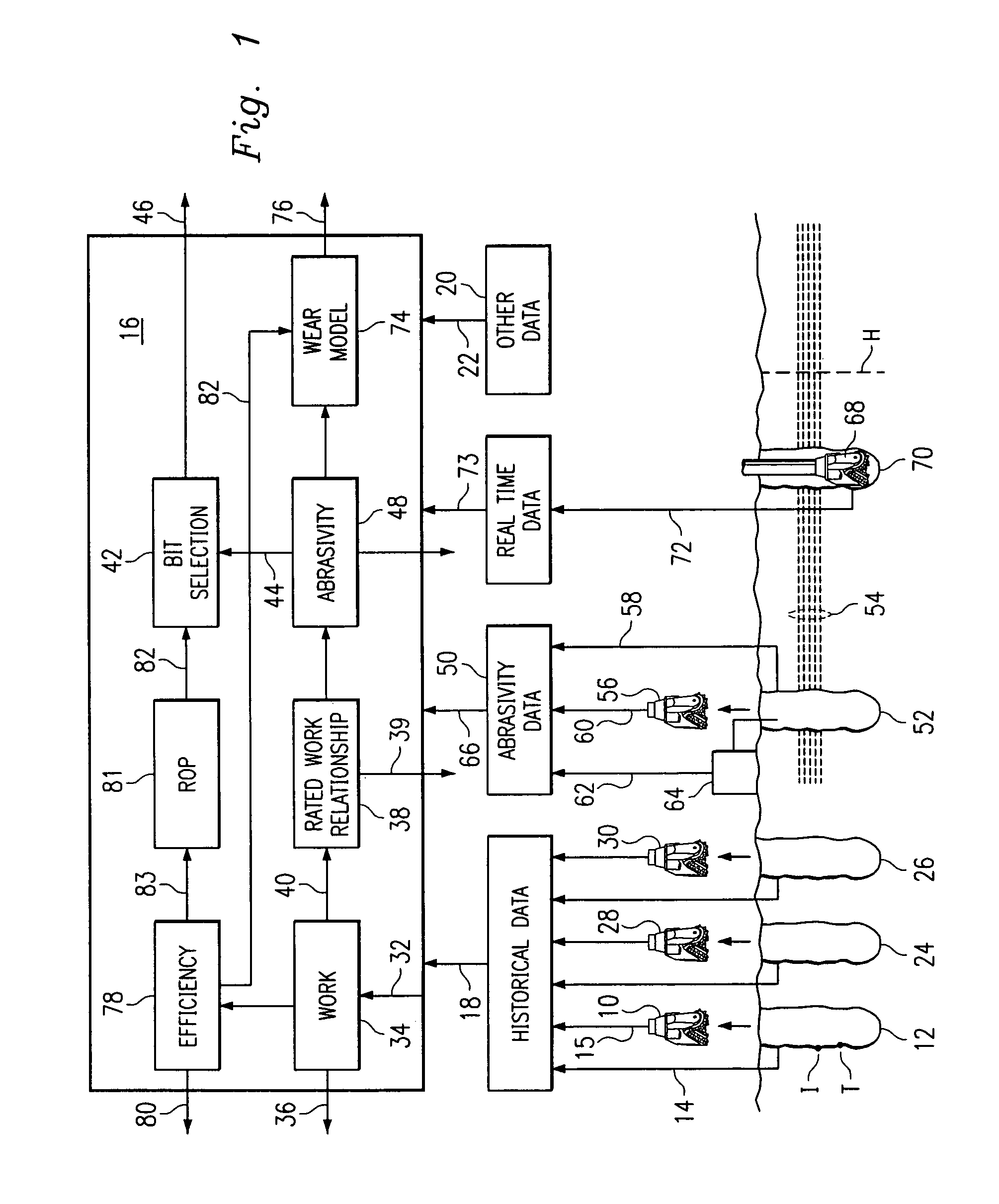

Method and system for predicting performance of a drilling system of a given formation

InactiveUS7032689B2Electric/magnetic detection for well-loggingEarth drilling toolsComputer printingDisplay device

A method and apparatus for predicting the performance of a drilling system for the drilling of a well bore in a given formation includes generating a geology characteristic of the formation per unit depth according to a prescribed geology model, obtaining specifications of proposed drilling equipment for use in the drilling of the well bore, and predicting a drilling mechanics in response to the specifications as a function of the geology characteristic per unit depth according to a prescribed drilling mechanics model. Responsive to a predicted-drilling mechanics, a controller controls a parameter in the drilling of the well bore. The geology characteristic includes at least rock strength. The specifications include at least a bit specification of a recommended drill bit. Lastly, the predicted drilling mechanics include at least one of bit wear, mechanical efficiency, power, and operating parameters. A display is provided for generating a display of the geology characteristic and predicted drilling mechanics per unit depth, including either a display monitor or a printer.

Owner:HALLIBURTON ENERGY SERVICES INC

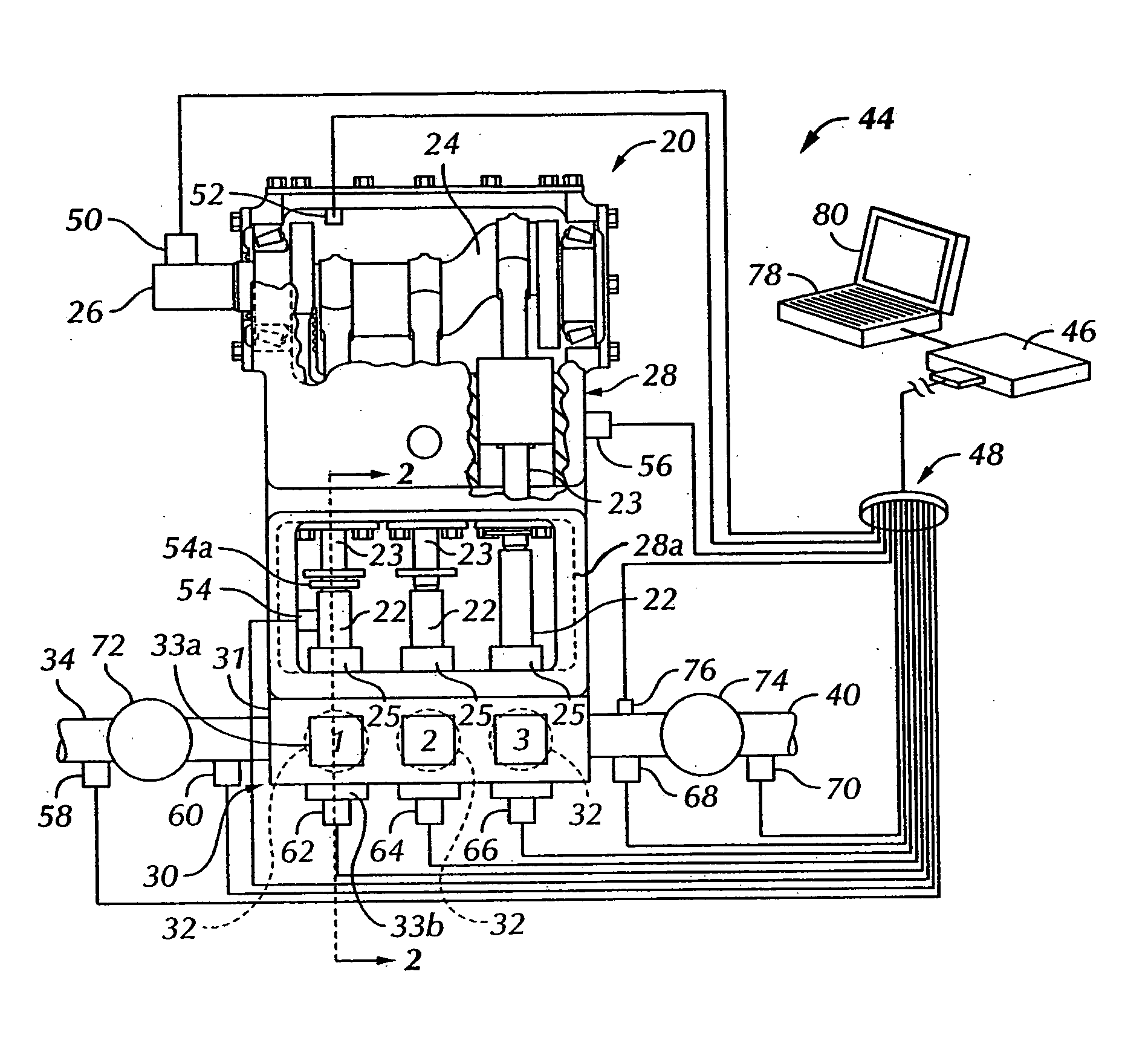

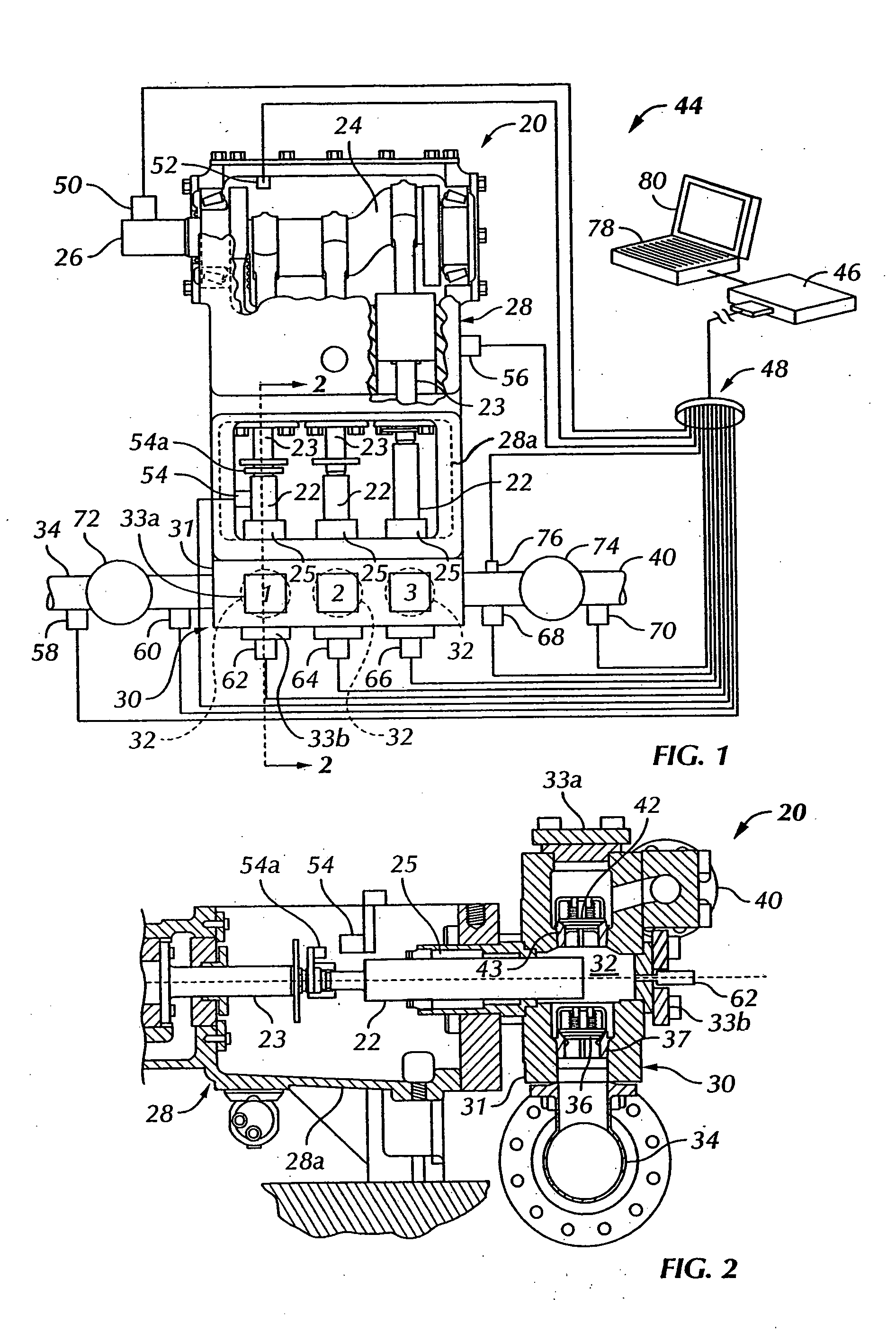

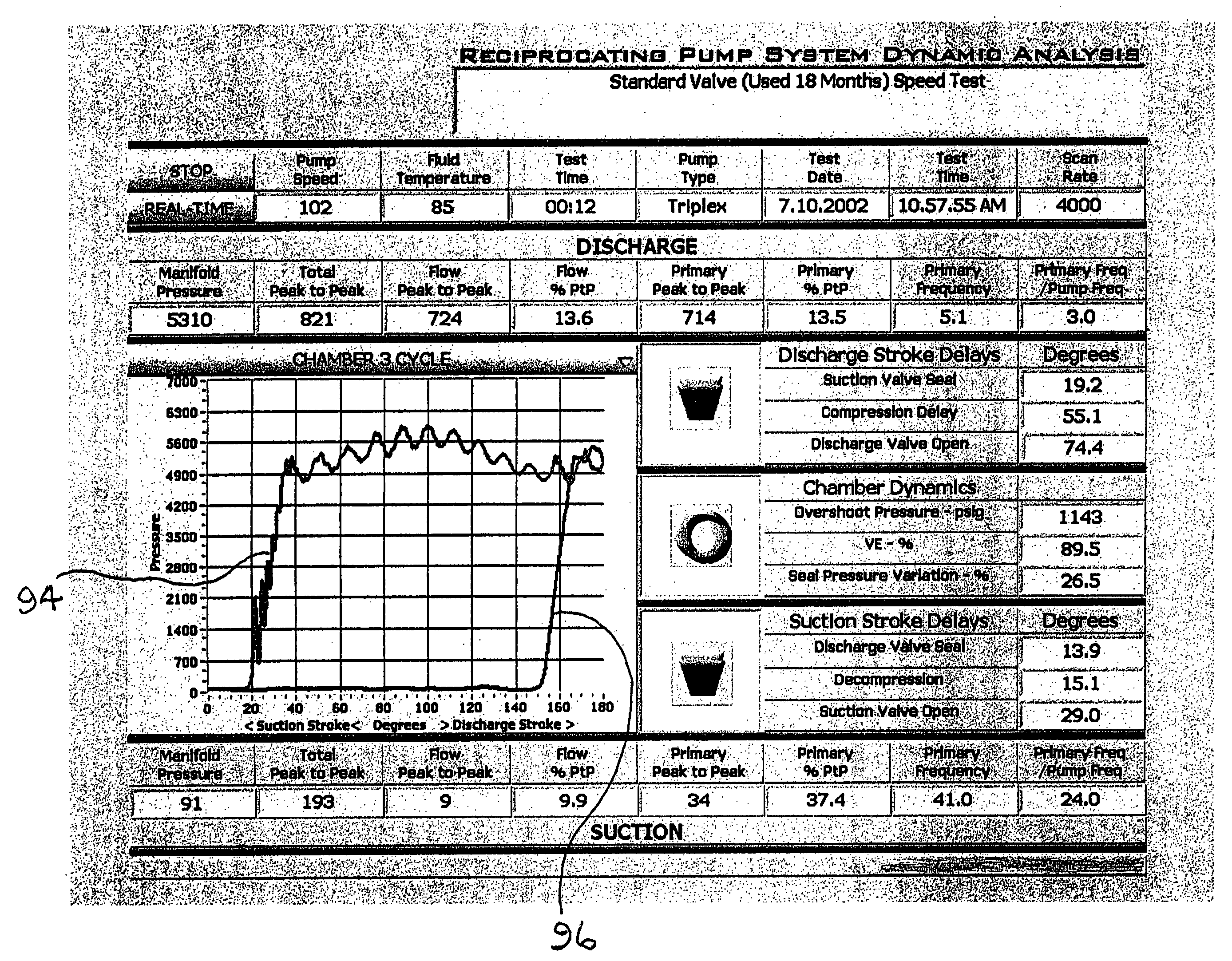

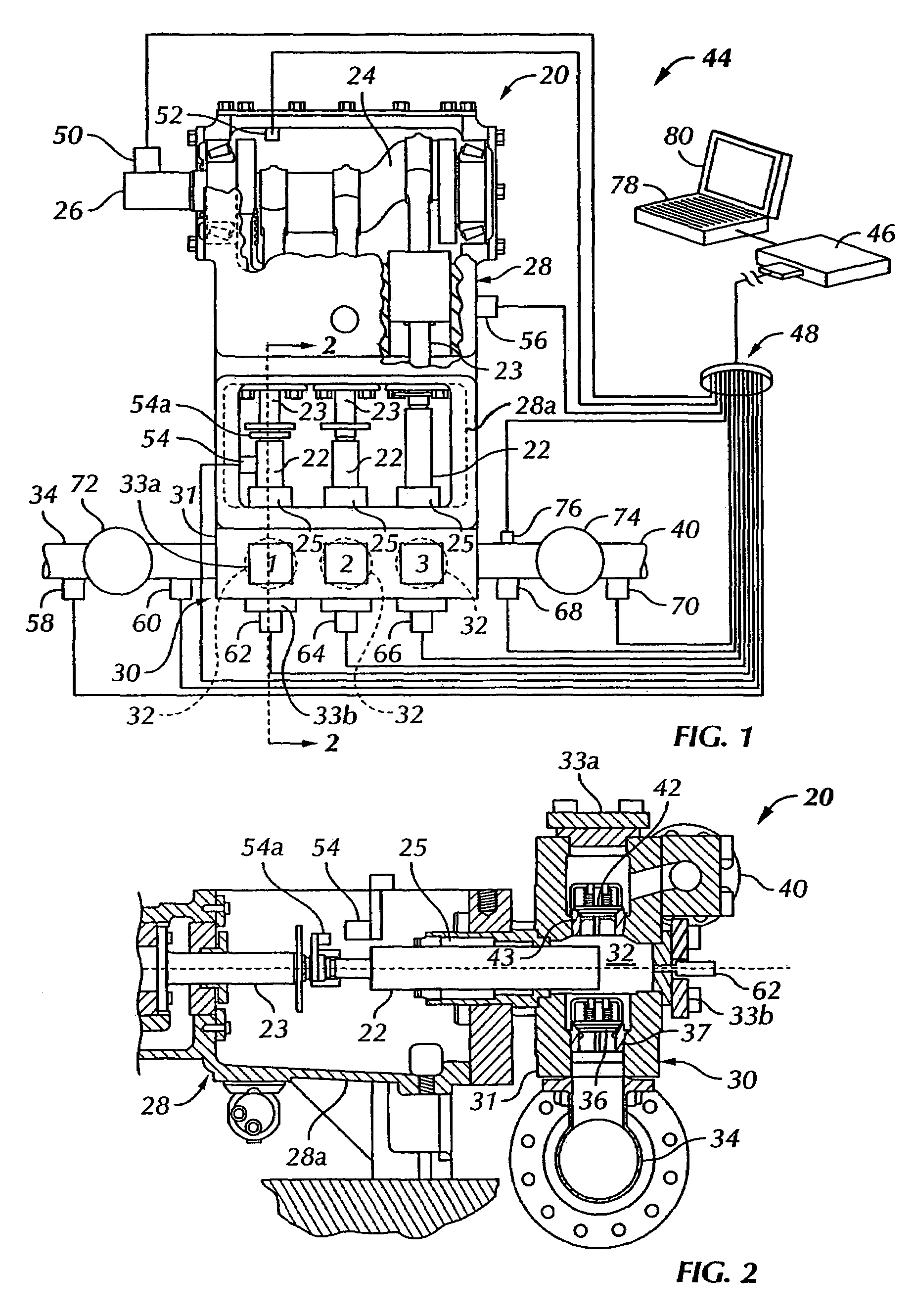

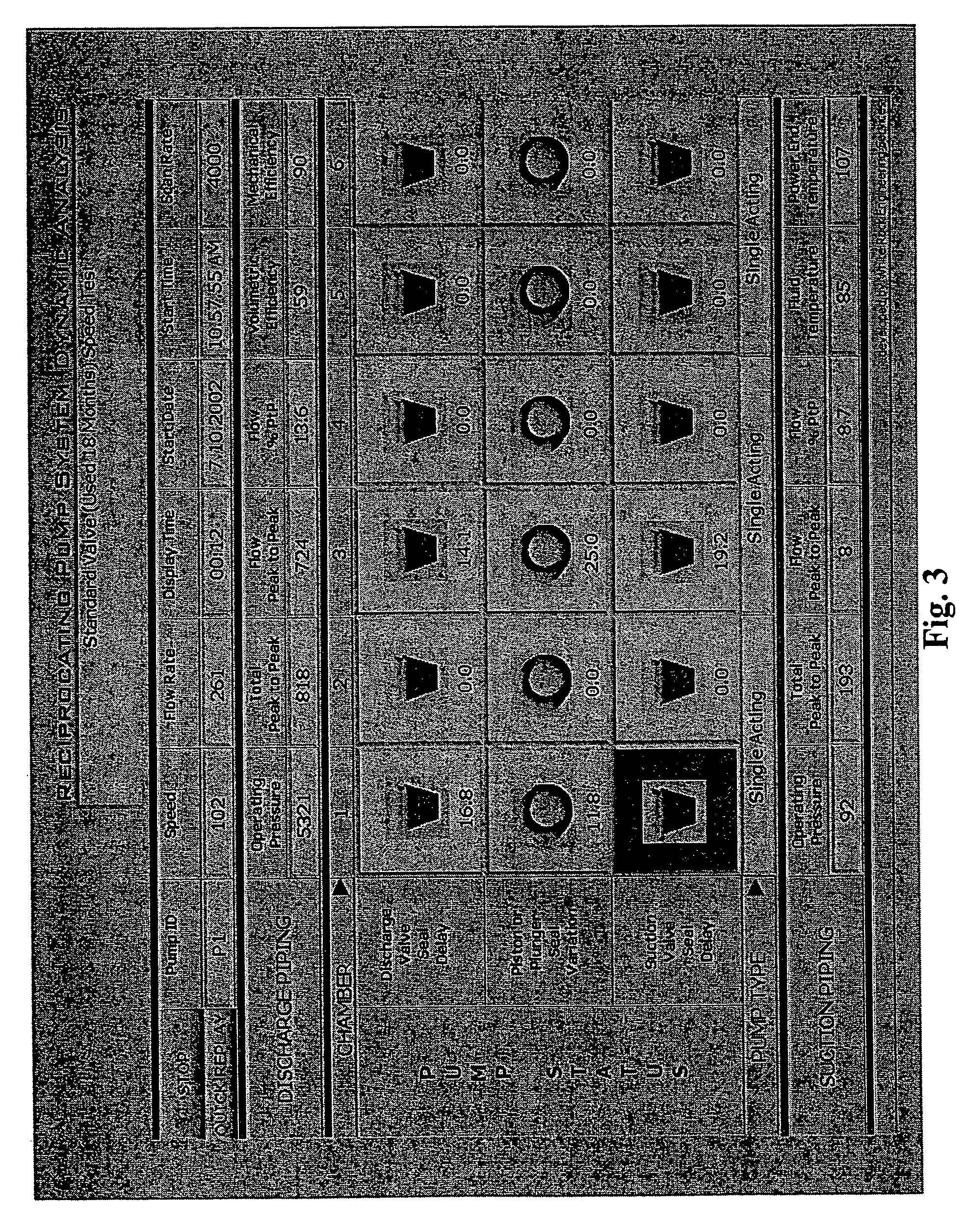

System and method for power pump performance monitoring and analysis

InactiveUS20050180868A1Easy to useEasy to provideTime indicationProgram control using stored programsDisplay deviceEngineering

A power pump performance analysis system includes a signal processor connected to pressure sensors for sensing pressures in the cylinder chambers and inlet and discharge piping of a single or multi-cylinder pump. Pump speed and piston position are determined by a crankshaft position sensor. Pump vibration, fluid temperatures, and power input may also be measured by sensors connected to the processor. Performance analyses, including determination of pump volumetric efficiency, mechanical efficiency, suction and discharge valve sealing delay, valve and piston seal leakage, flow induced pressure variations, acceleration induced pressure detection, hydraulic resonance detection and pulsation dampener performance may be measured and selected parameters displayed on a visual display connected to the processor directly or via a network.

Owner:MHWIRTH

System and method for power pump performance monitoring and analysis

InactiveUS7623986B2Easy to useEasy to provideTime indicationProgram control using stored programsEngineeringStreamflow

A power pump performance analysis system includes a signal processor connected to pressure sensors for sensing pressures in the cylinder chambers and inlet and discharge piping of a single or multi-cylinder pump. Pump speed and piston position are determined by a crankshaft position sensor. Pump vibration, fluid temperatures, and power input may also be measured by sensors connected to the processor. Performance analyses, including determination of pump volumetric efficiency, mechanical efficiency, suction and discharge valve sealing delay, valve and piston seal leakage, flow induced pressure variations, acceleration induced pressure detection, hydraulic resonance detection and pulsation dampener performance may be measured and selected parameters displayed on a visual display connected to the processor directly or via a network.

Owner:MHWIRTH

Method and system for predicting performance of a drilling system for a given formation

InactiveUS20050284661A1Electric/magnetic detection for well-loggingEarth drilling toolsWell drillingDisplay device

A method and apparatus for predicting the performance of a drilling system for the drilling of a well bore in a given formation includes generating a geology characteristic of the formation per unit depth according to a prescribed geology model, obtaining specifications of proposed drilling equipment for use in the drilling of the well bore, and predicting a drilling mechanics in response to the specifications as a function of the geology characteristic per unit depth according to a prescribed drilling mechanics model. Responsive to a predicted drilling mechanics, a controller controls a parameter in the drilling of the well bore. The geology characteristic includes at least rock strength. The specifications include at least a bit specification of a recommended drill bit. Lastly, the predicted drilling mechanics include at least one of bit wear, mechanical efficiency, power, and operating parameters. A display is provided for generating a display of the geology characteristic and predicted drilling mechanics per unit depth, including either a display monitor or a printer.

Owner:HALLIBURTON ENERGY SERVICES INC

Jaw Movement Mechanism and Method for a Surgical Tool

ActiveUS20120022584A1Reduce the amount requiredEnhances mechanical force transferring capabilitySurgical instrument detailsSurgical forcepsRange of motionEngineering

A jaw movement mechanism for surgical tools has improved mechanical efficiency and other advantages. The jaw movement mechanism controls the orientation and position of a movable jaw relative to a fixed jaw through a range of movement of the movable jaw. The jaws maintain a parallel orientation throughout a portion of the range of movement of the movable jaw. The jaws maintain an angular relationship throughout a portion of the range of movement of the movable jaw.

Owner:CONMED CORP

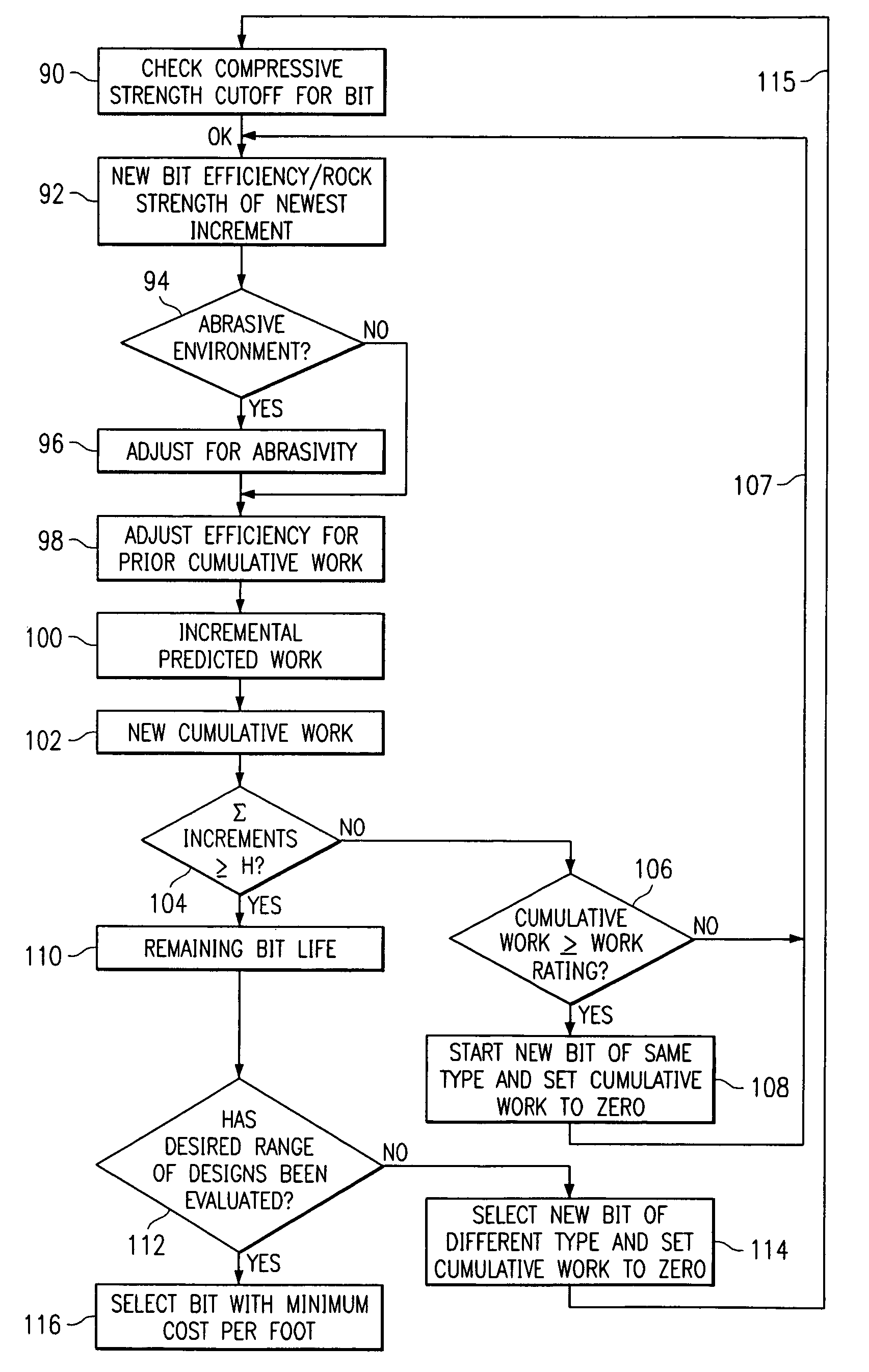

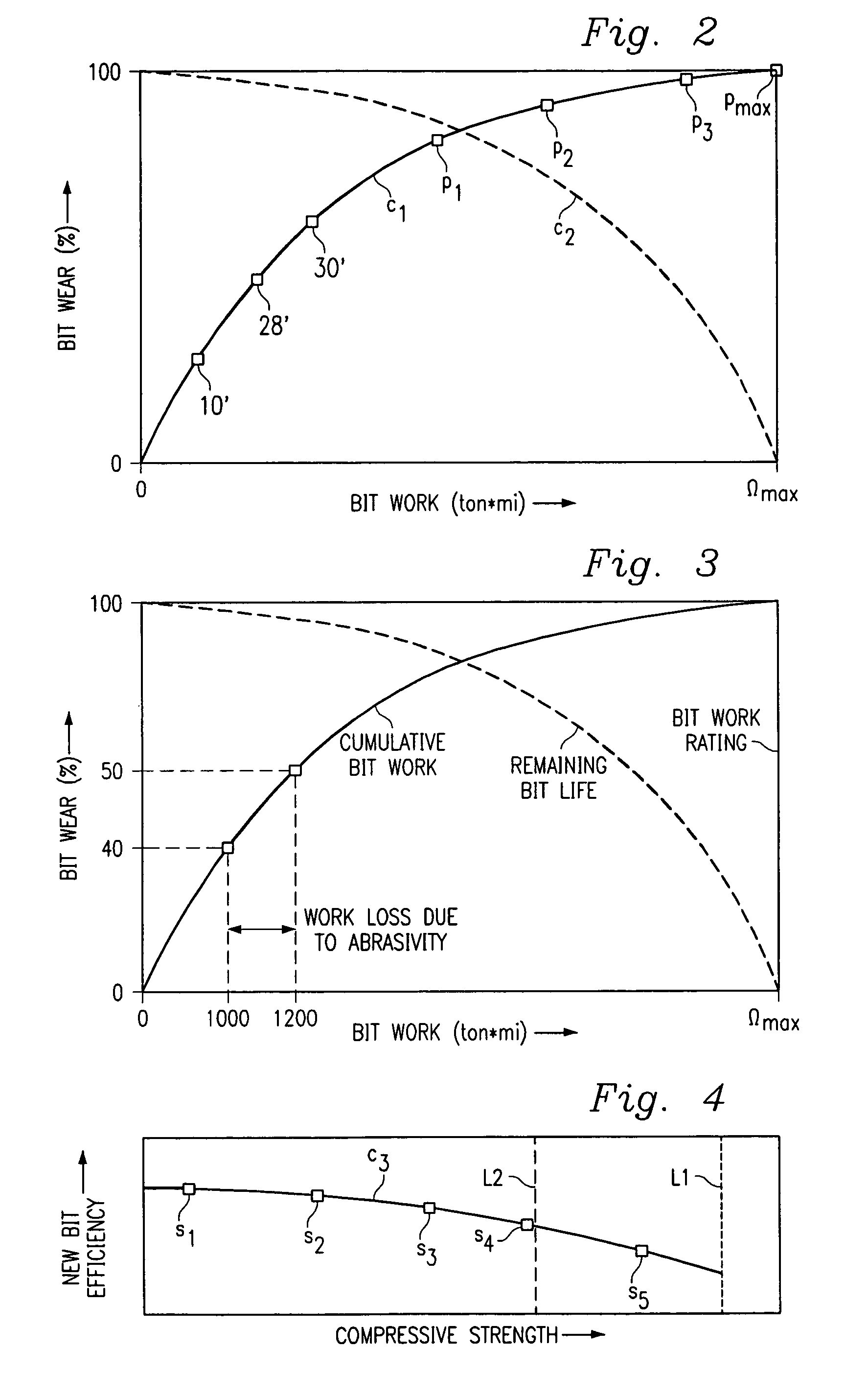

Method of assaying downhole occurrences and conditions

InactiveUS7035778B2Earth drilling toolsElectric/magnetic detection for well-loggingBit wearUltimate tensile strength

A method of assaying work of an earth boring bit of a given size and design including establishing characteristics of the bit of given size and design. The method further includes simulating a drilling of a hole in a given formation as a function of the characteristics of the bit of given size and design and at least one rock strength of the formation. The method further includes outputting a performance characteristic of the bit, the performance characteristic including a bit wear condition and a bit mechanical efficiency determined as a function of the simulated drilling.

Owner:HALLIBURTON ENERGY SERVICES INC

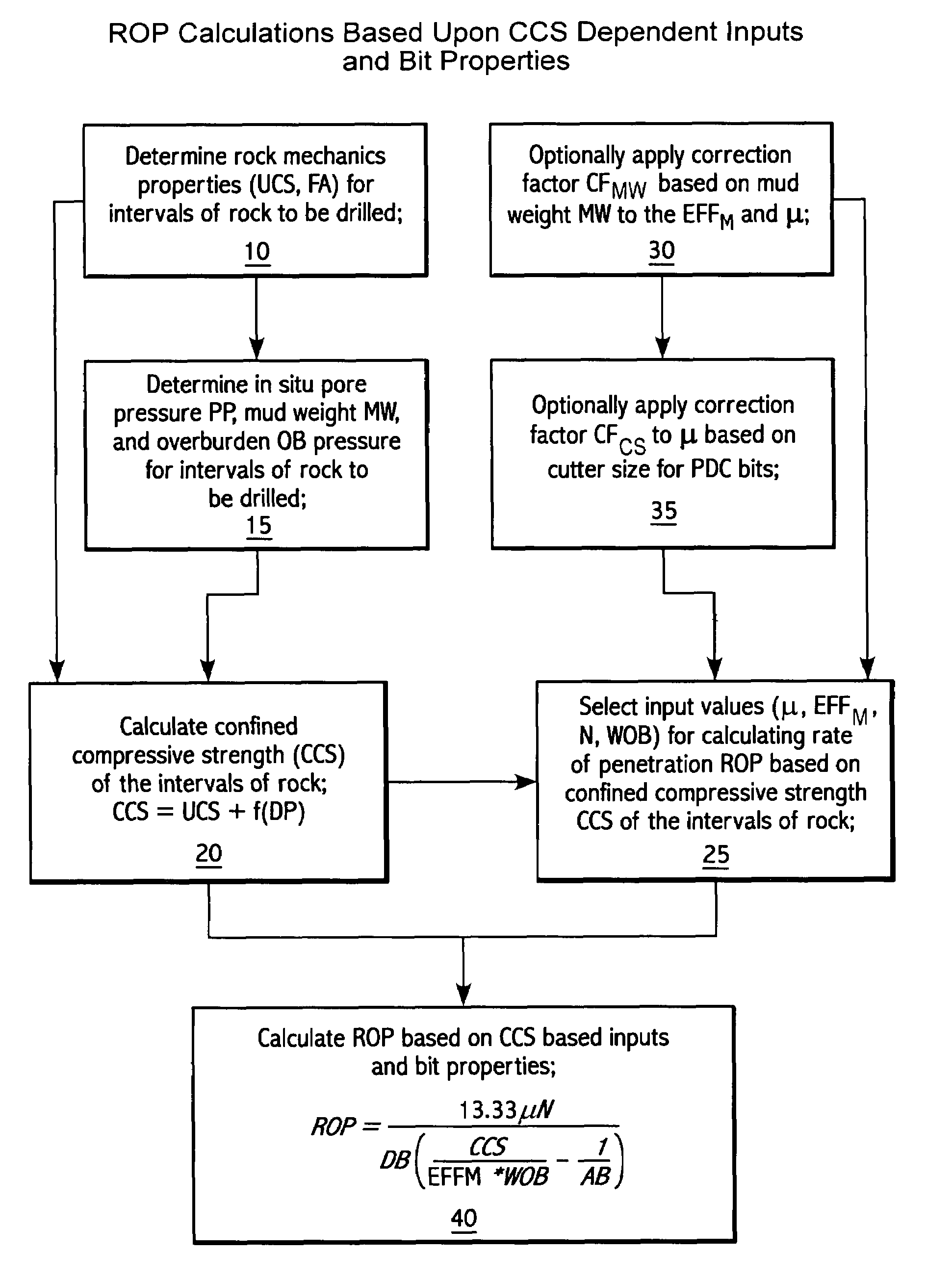

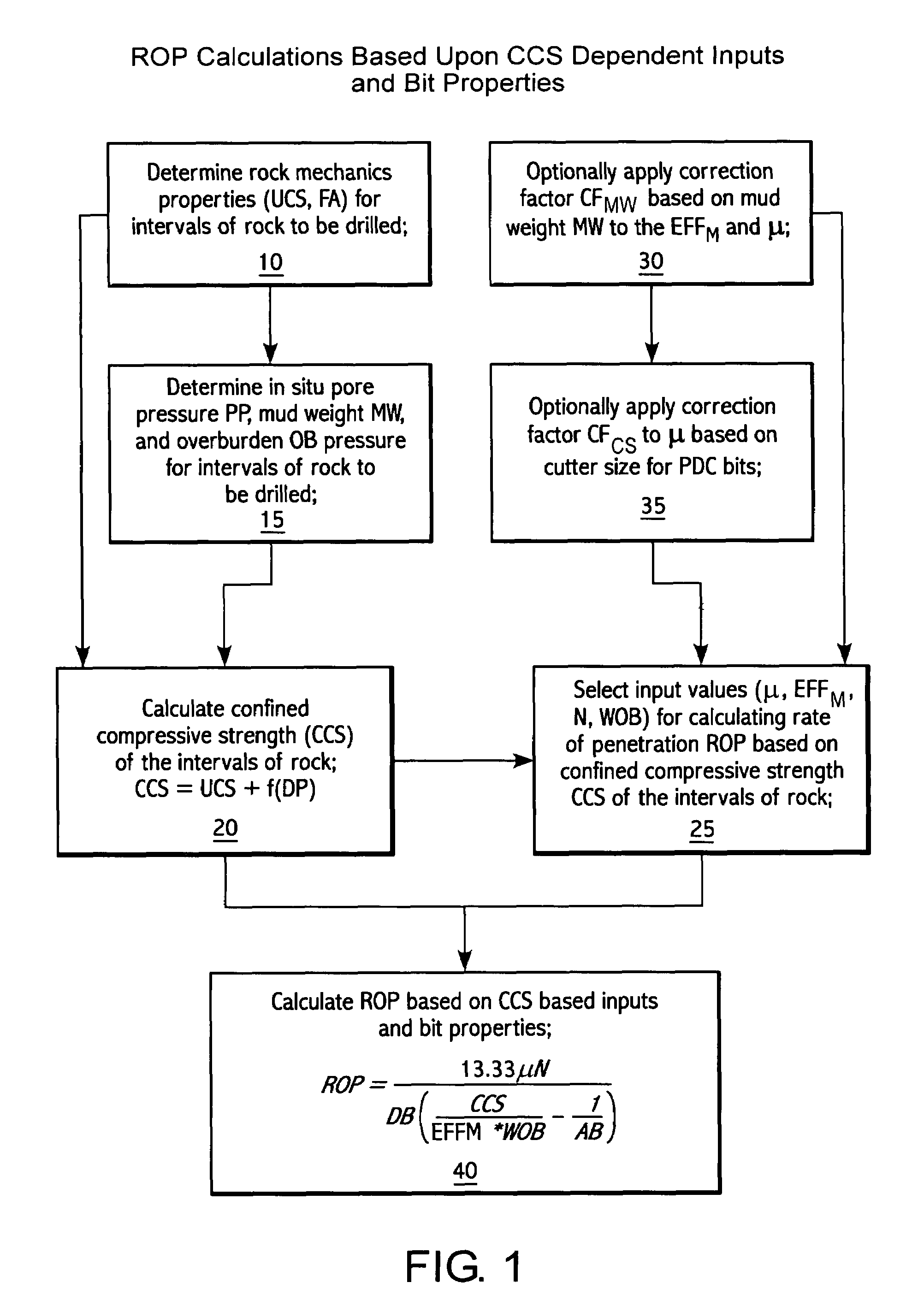

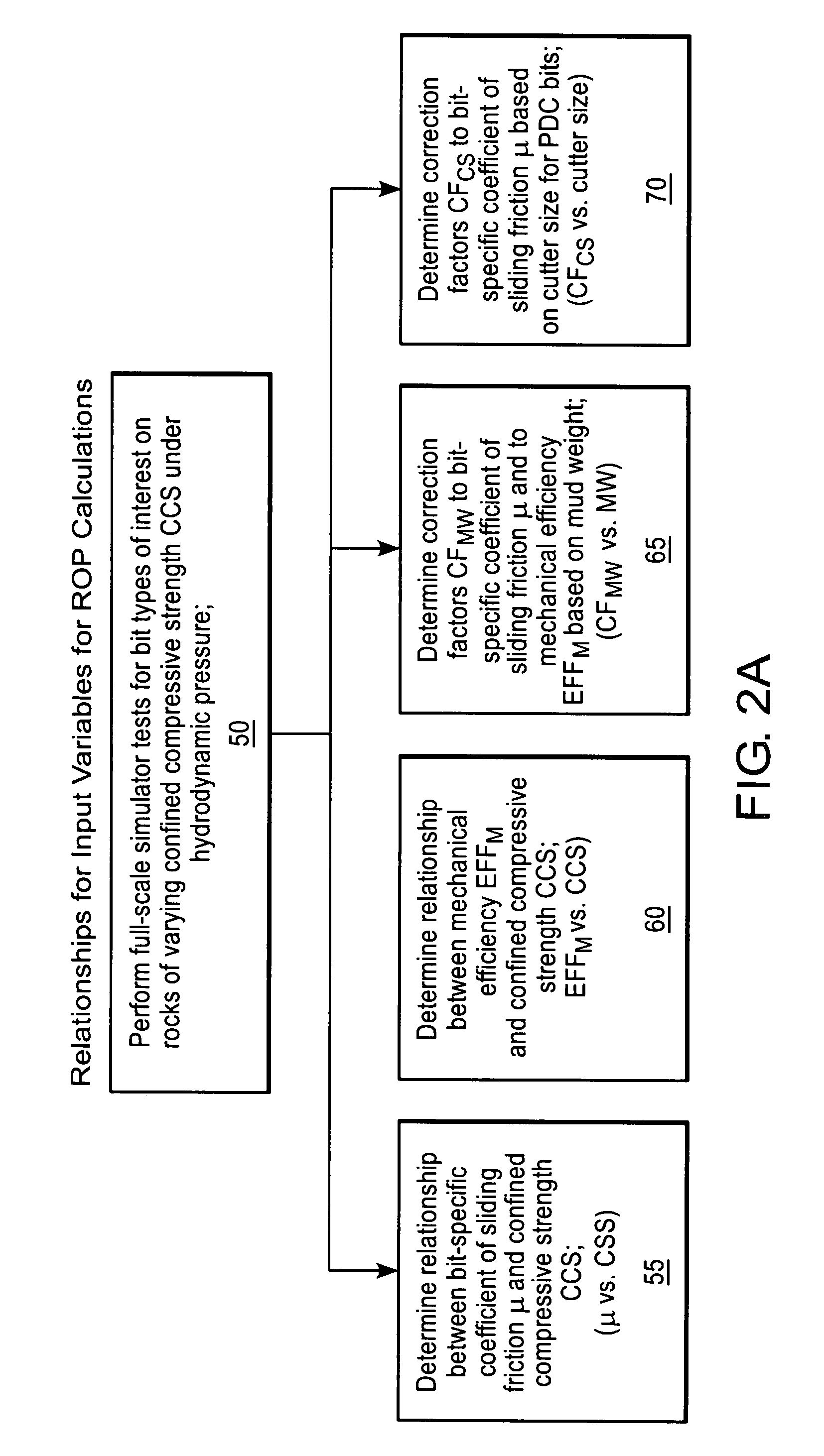

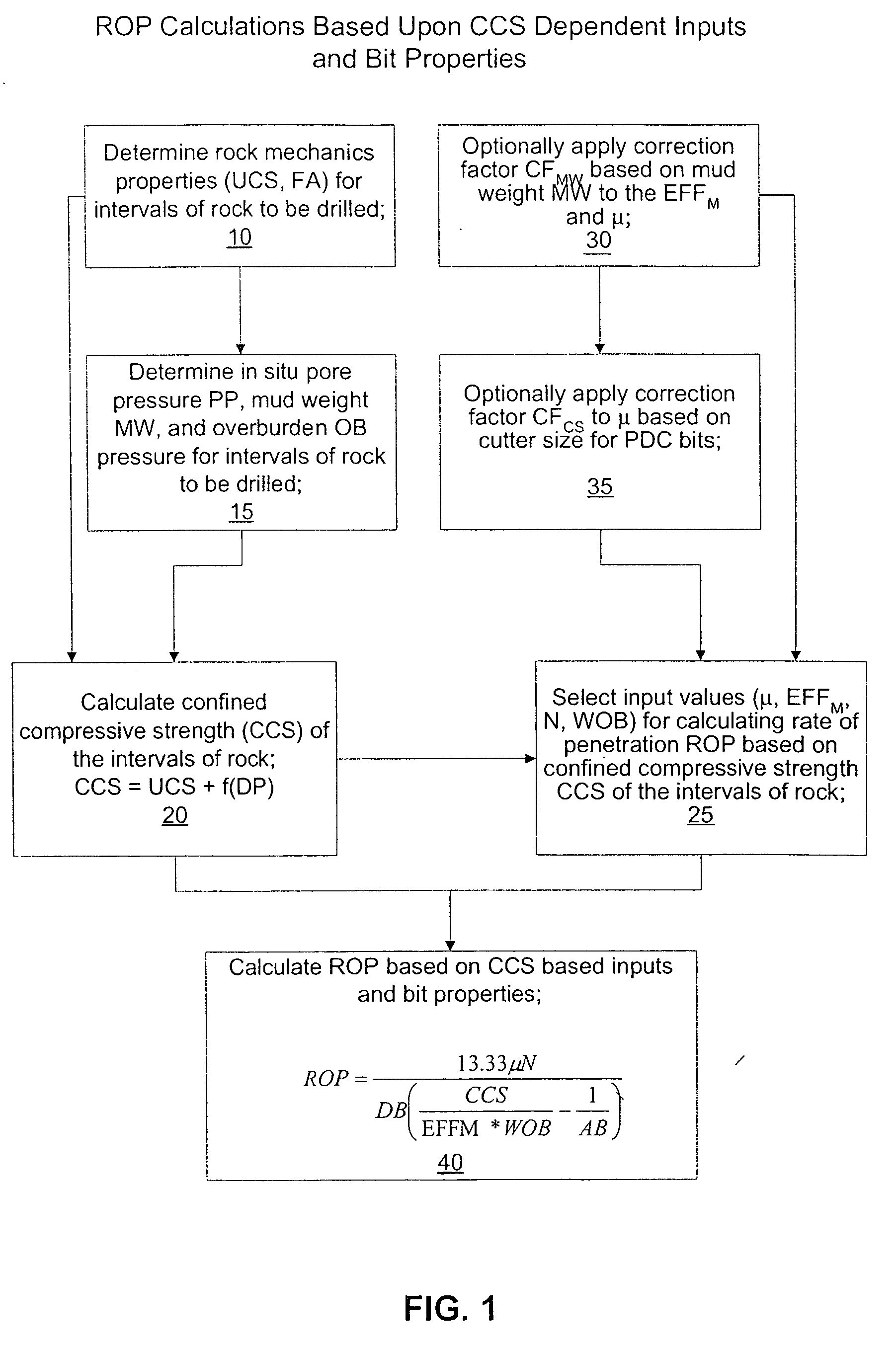

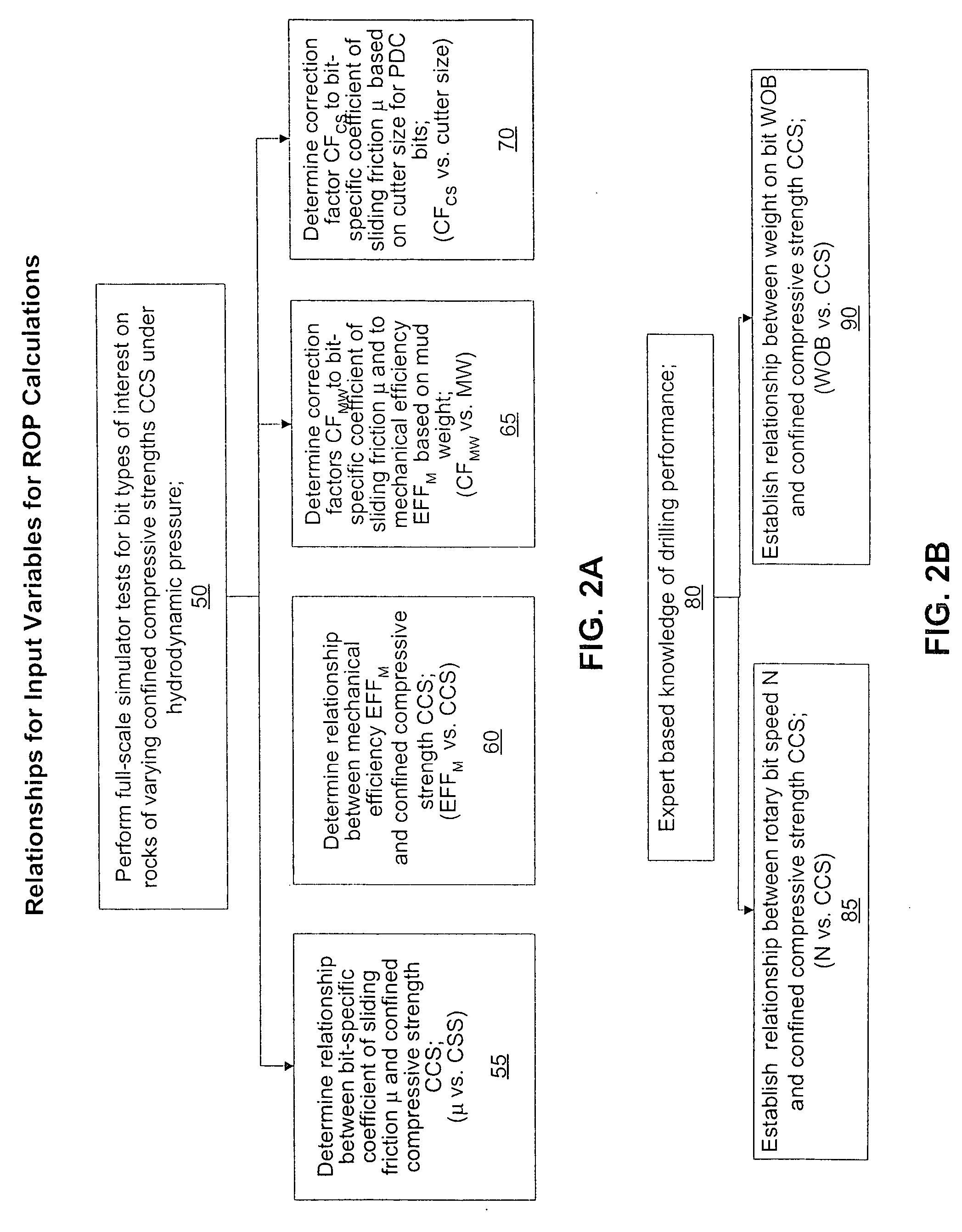

Method for predicting rate of penetration using bit-specific coefficient of sliding friction and mechanical efficiency as a function of confined compressive strength

InactiveUS7412331B2Electric/magnetic detection for well-loggingSeismology for water-loggingRate of penetrationCompressive strength

A method for predicting the rate of penetration (ROP) of a drill bit drilling a well bore through intervals of rock of a subterranean formation is provided. The method uses an equation based upon specific energy principles. A relationship is determined between a bit-specific coefficient of sliding friction μ and confined compressive strength CCS over a range of confined compressive strengths CCS. Similarly, another relationship for the drill bit is determined between mechanical efficiency EFFM and confined compressive strength CCS over a range of confined compressive strengths CCS. Confined compressive strength CCS is estimated for intervals of rock through which the drill bit is to be used to drill a well bore. The rate of penetration ROP is then calculated utilizing the estimates of confined compressive strength CCS of the intervals of rock to be drilled and those determined relationships between the bit-specific coefficient of sliding friction μ and the mechanical efficiency EFFM and the confined compressive strengths CCS, as well as using estimated drill bit speeds N (RPM) and weights on bit (WOB).

Owner:CHEVROU USA INC

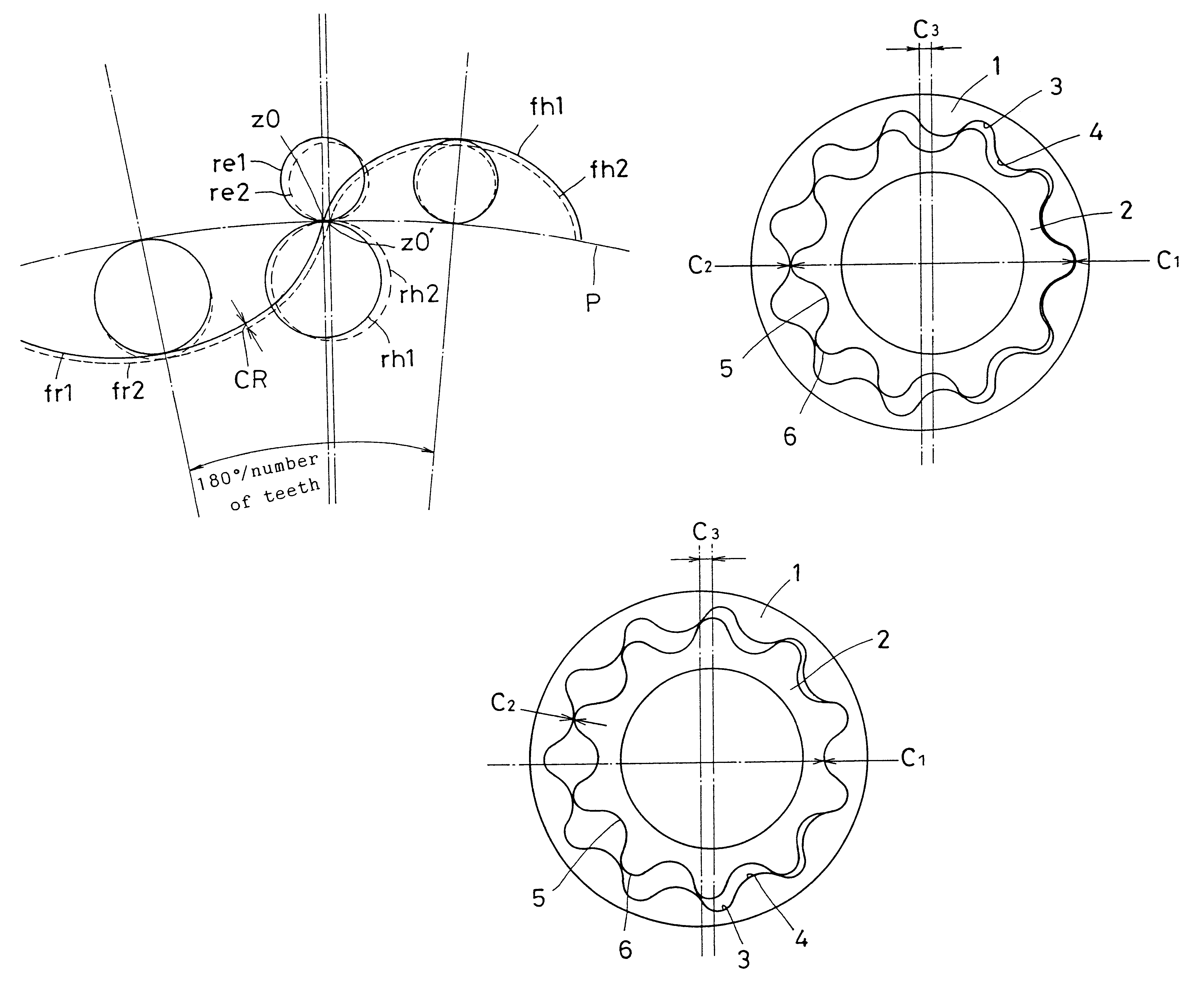

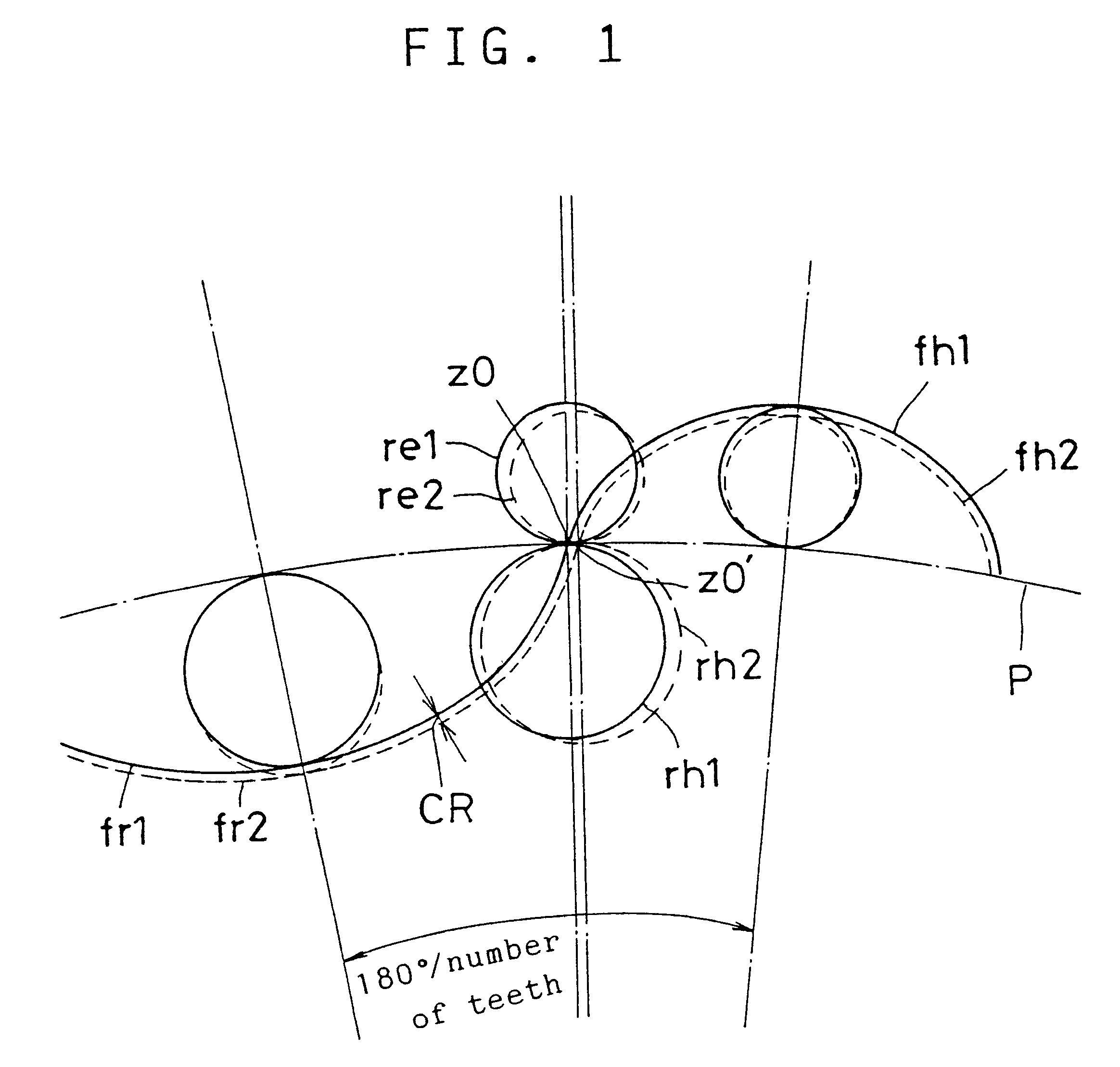

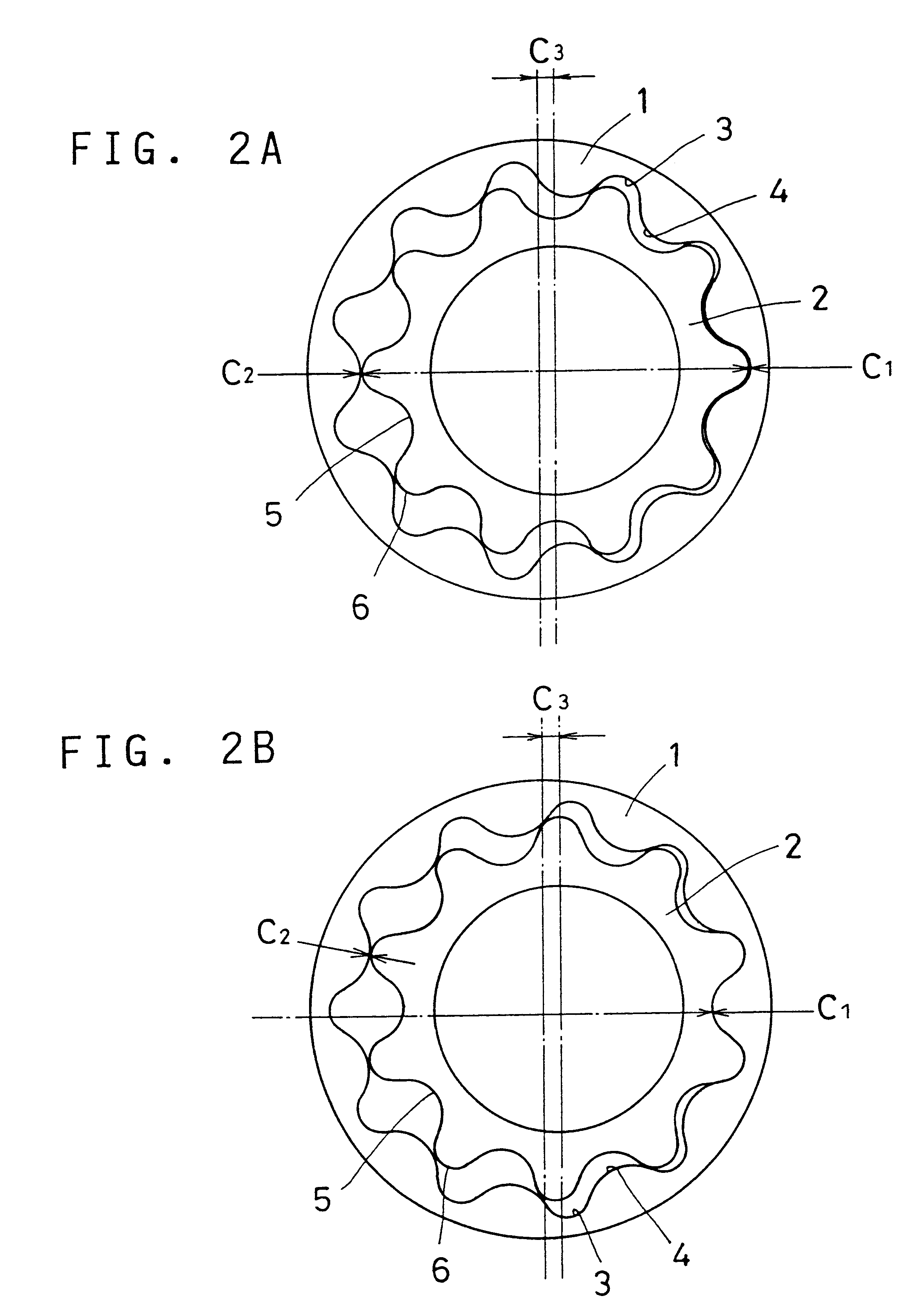

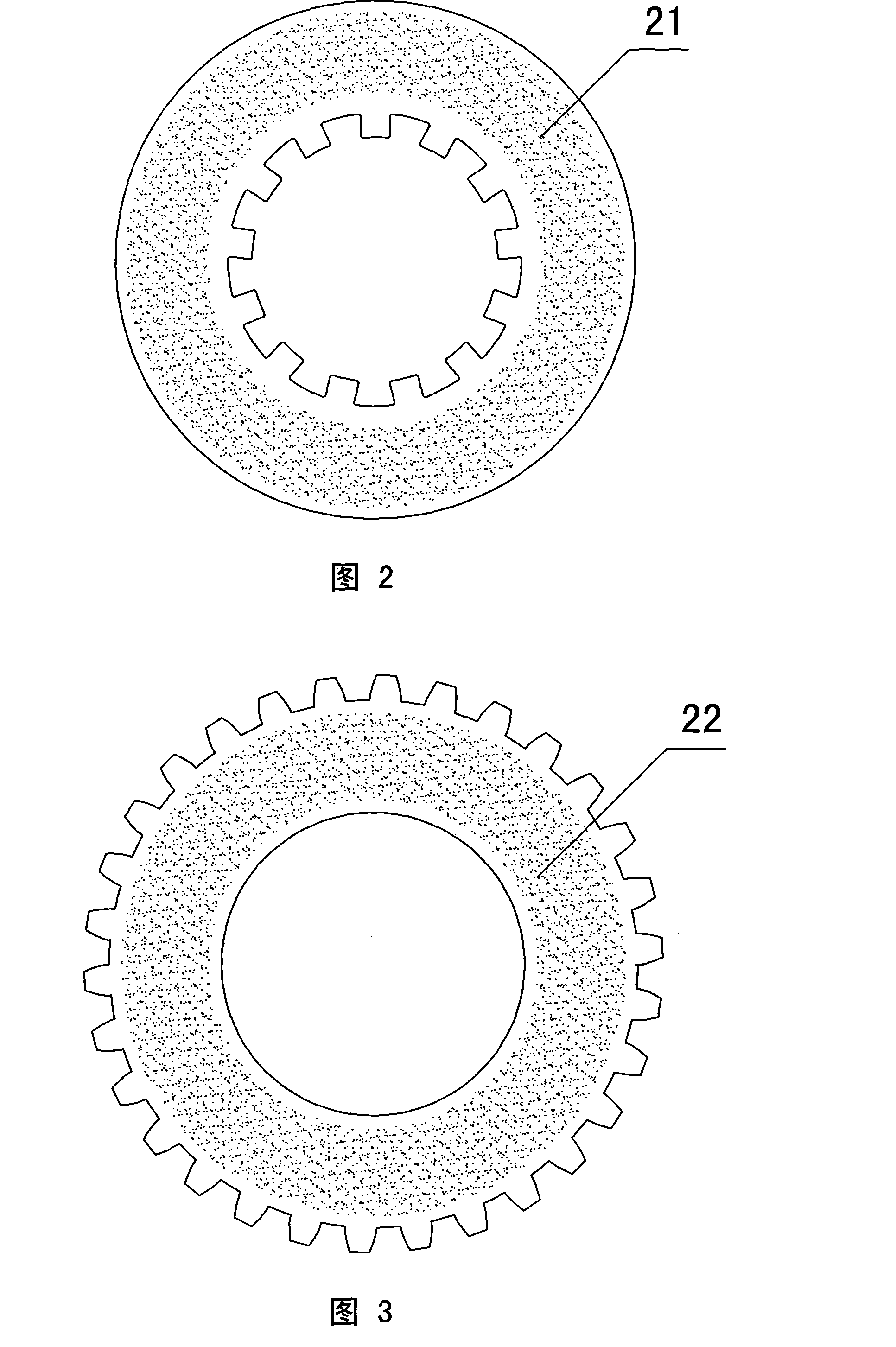

Internal gear pump

InactiveUS6244843B1Oscillating piston enginesEngine of intermeshing engagement typeGear pumpEngineering

An internal gear pump which improves the mechanical efficiency and the life and reduces noises by eliminating non-uniformity of the gaps between teeth. In the internal gear pump wherein the tooth spaces of the outer gear and the tooth tips of the inner gear form an epicycloid and the tooth tips of the outer gear and the tooth spaces of the inner gear form a hypocycloid, these cycloids are formed by four circles that roll on the pitch circle of each gear such that the gap between teeth in a region where the outer and inner gears mesh most deeply with each other is substantially equal to the gap between teeth in a region where the depth of mesh between the outer and inner gears are the shallowest.

Owner:SUMITOMO ELECTRIC SINTERED ALLOY LTD

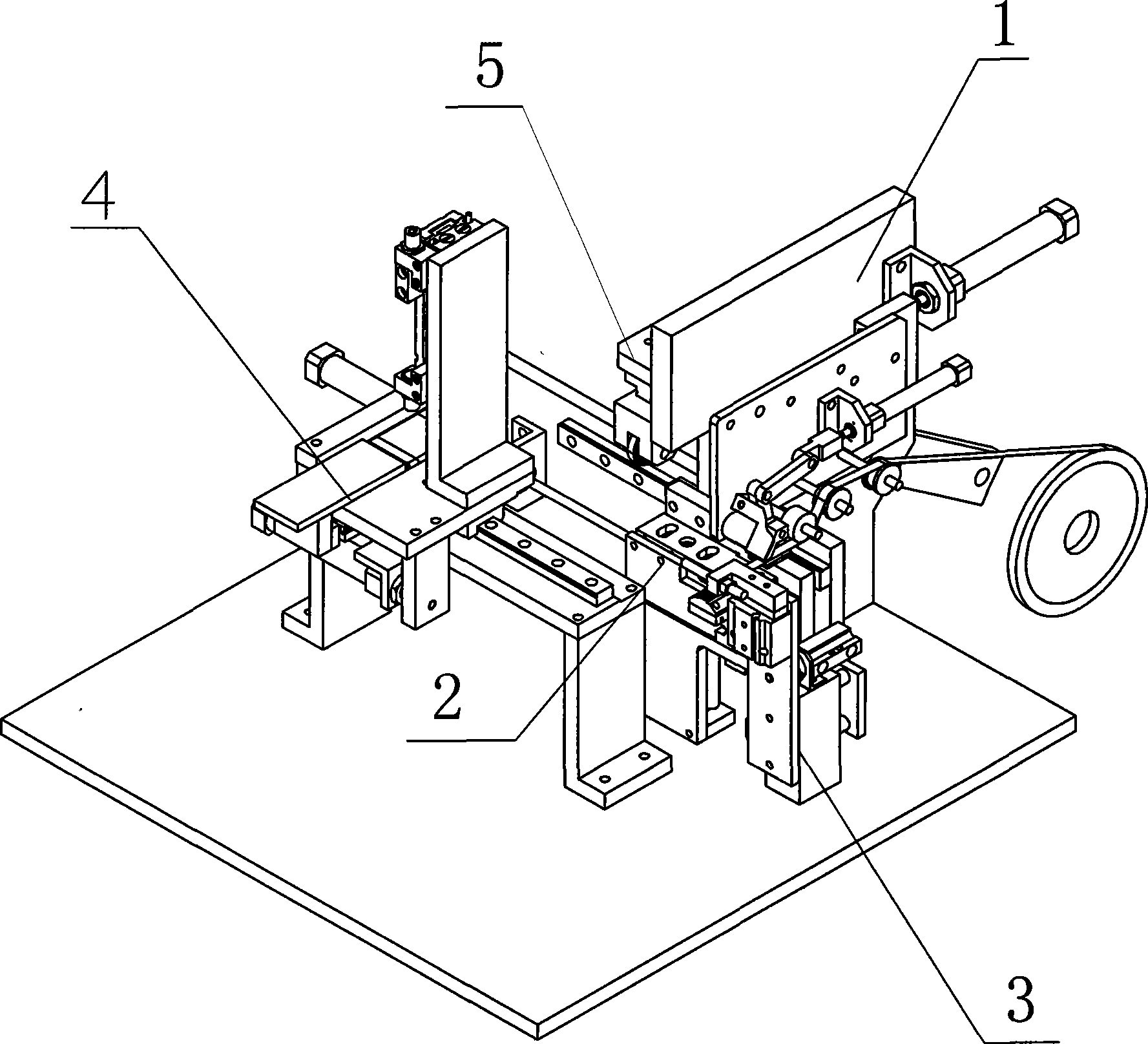

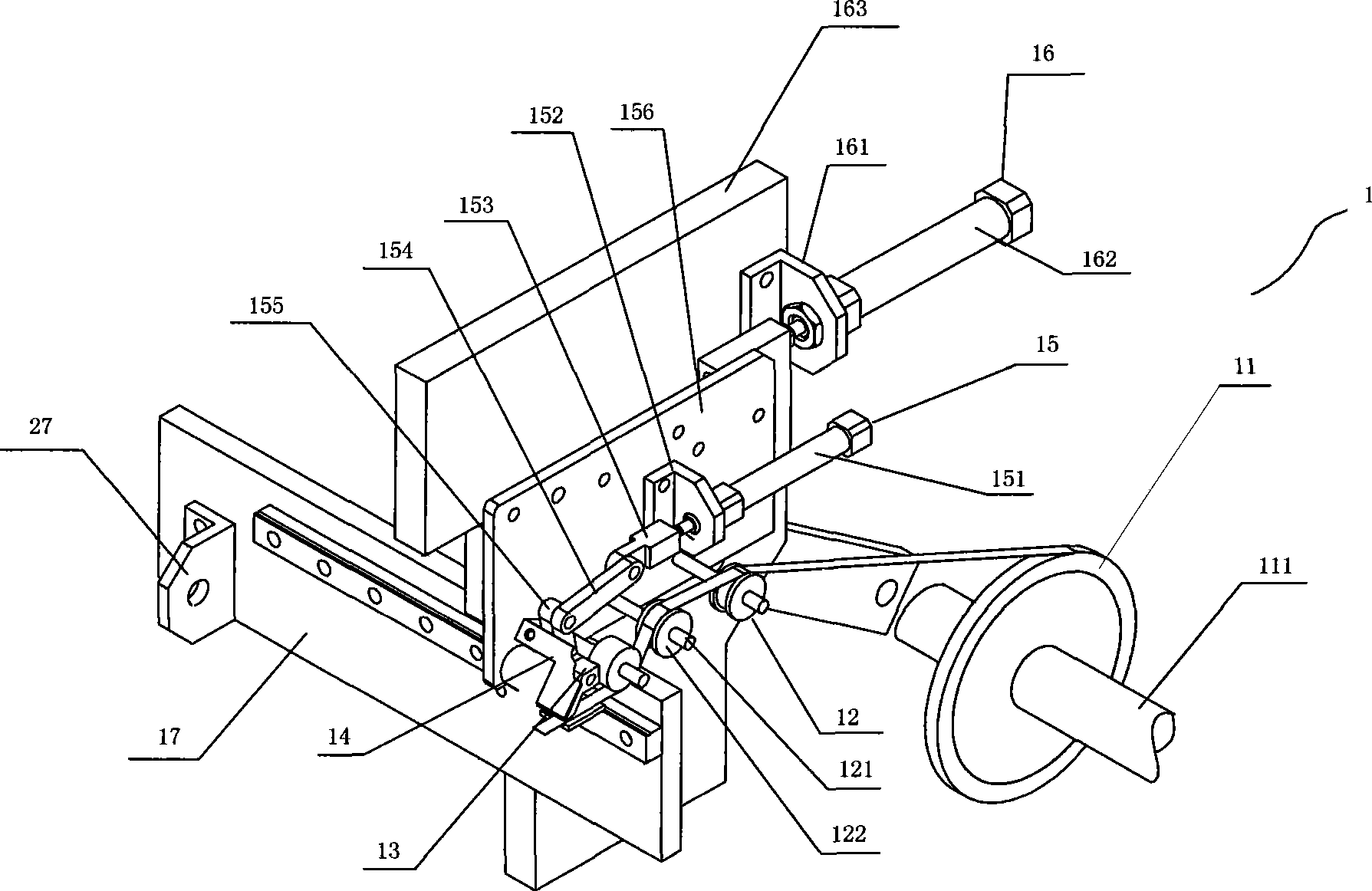

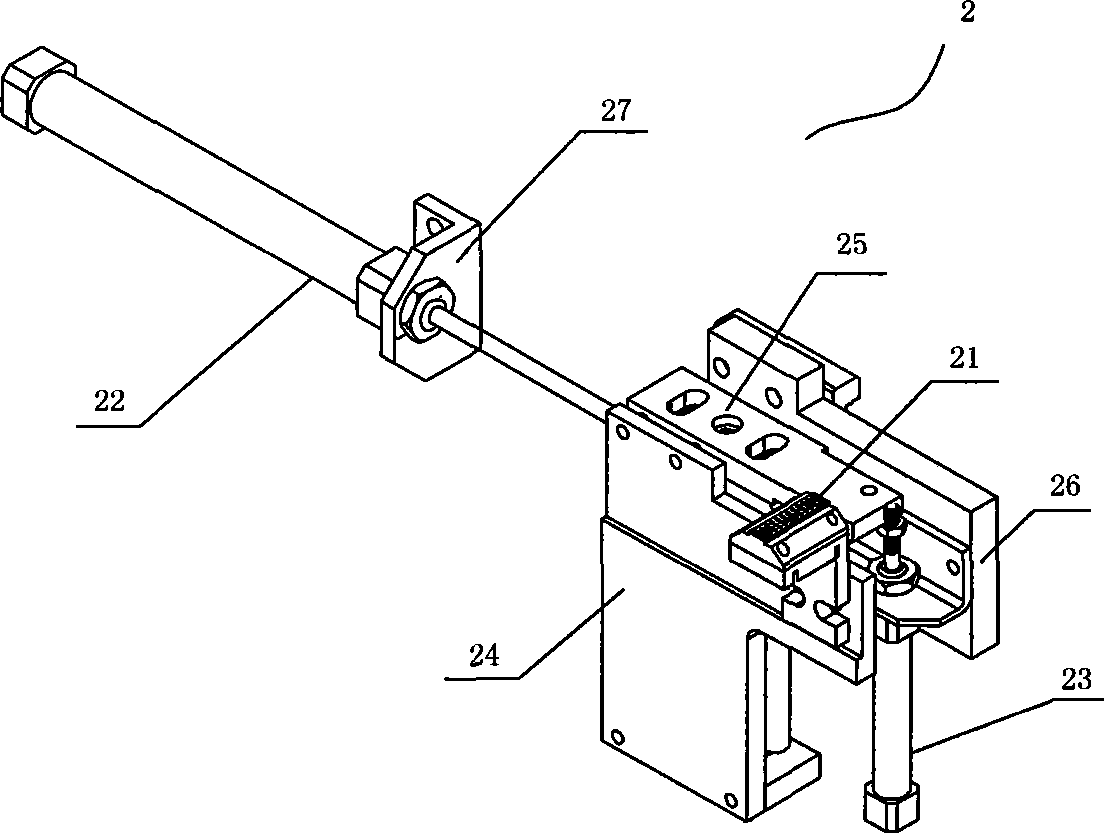

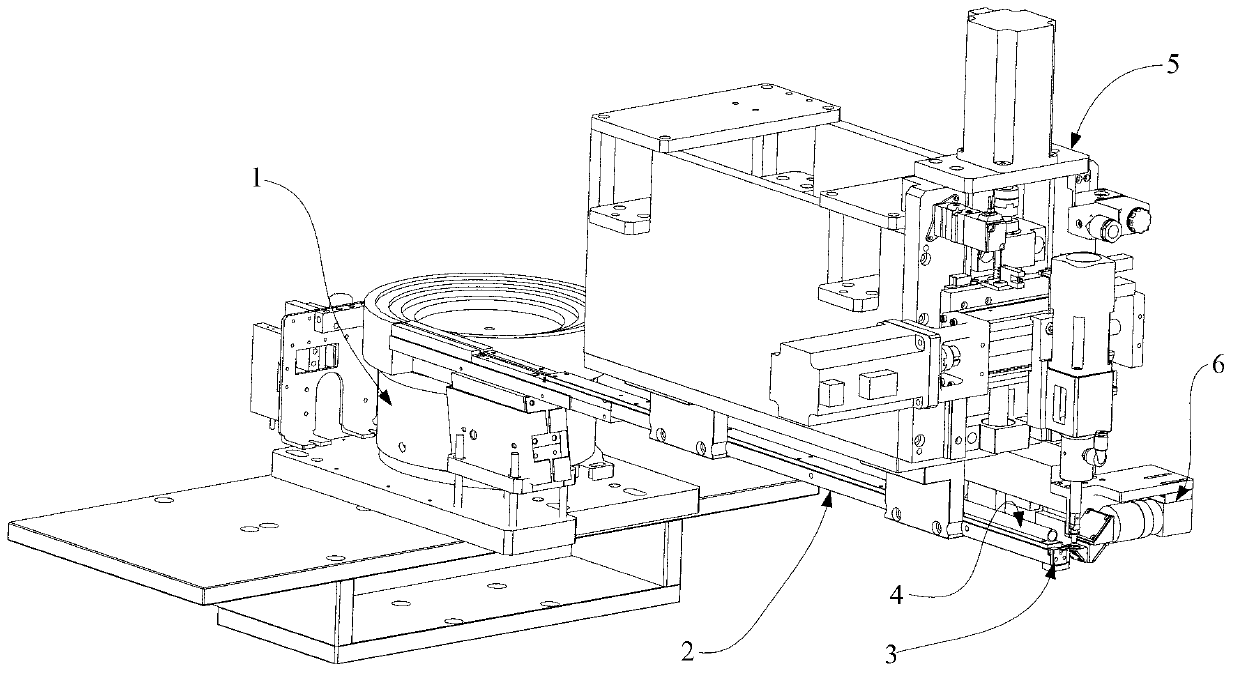

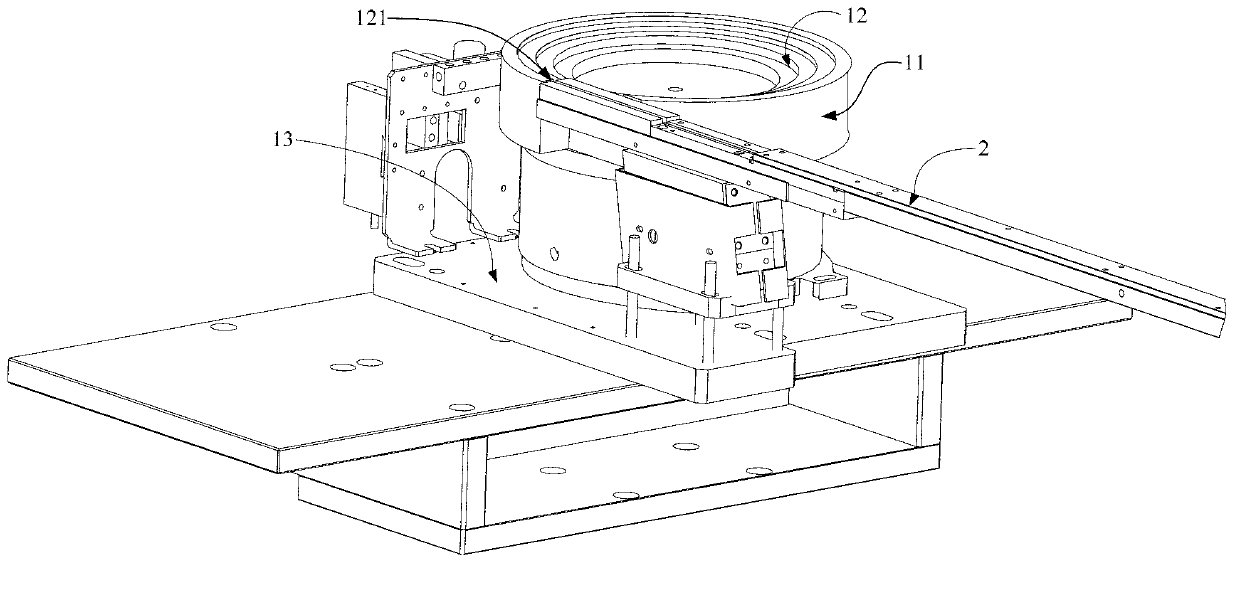

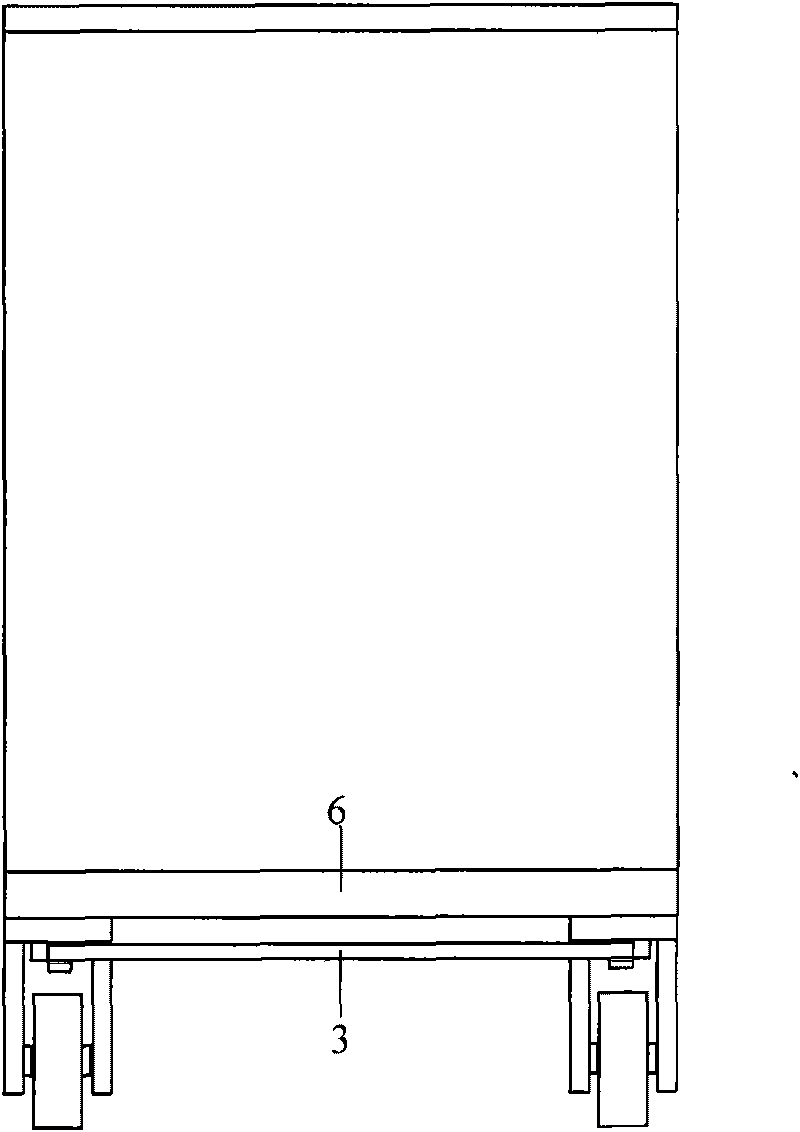

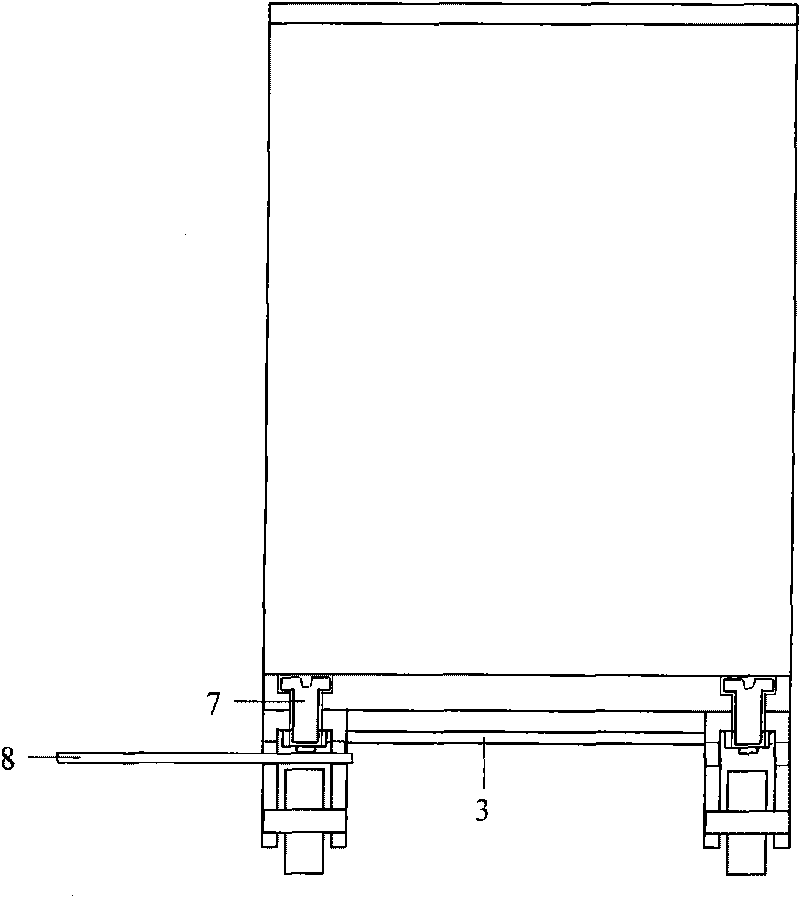

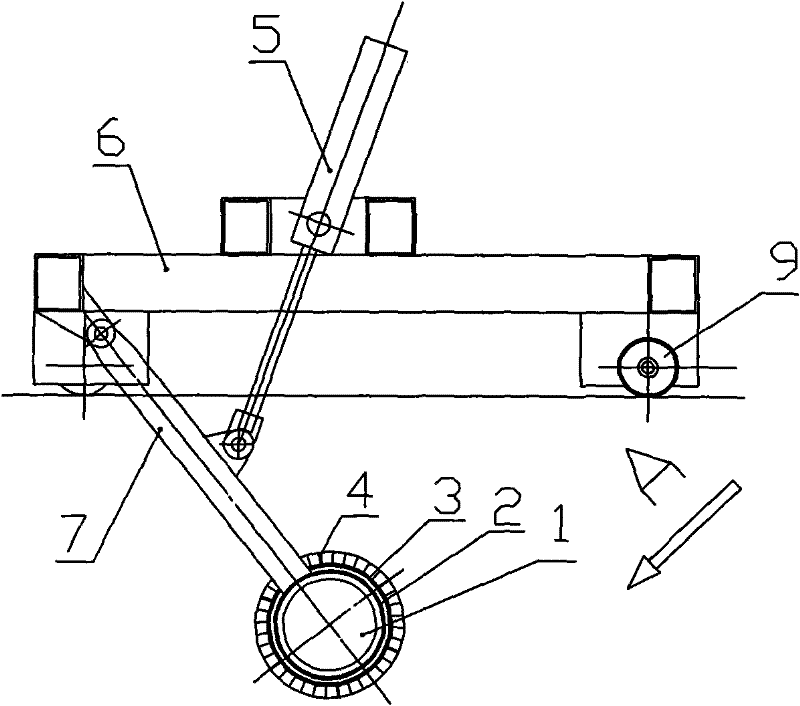

Gummed paper adhering machine

ActiveCN101394000AImprove mechanical efficiencyShorten the timeNon-aqueous electrolyte cellsFinal product manufacturePulp and paper industryPaper sheet

A gummed paper sticking machine is characterized in that the gummed paper sticking machine comprises a gummed paper delivering part used for delivering a disk-shaped gummed paper roll to a gummed paper cutting work station through a driving piece; a gummed paper pressing part used for compressing and cutting the delivered gummed paper head; a gummed paper moving part used for delivering the cut gummed paper to a gummed paper sticking work station and butted with a workpiece; a workpiece positioning part used for delivering the workpiece to the gummed paper sticking work station, and a gummed paper sticking part used for sticking the gummed paper on the workpiece. The gummed paper delivering part is driven by a hauling mechanism to move; the gummed paper pressing part and the gummed paper moving part are positioned on the gummed paper cutting work station, and correspondingly arranged in front of the gummed paper delivering part; the workpiece positioning part is moveably positioned in the side surface positions of the gummed paper pressing part and the gummed paper moving part, and butted with the gummed paper sticking part in a fitting manner; the gummed paper sticking part is positioned on the side surface of the gummed paper delivering part. In the invention, the preset mechanical automation is completely realized in the processes from cutting the gummed paper to sticking the gummed paper, the mechanical efficiency is high, the time and a large amount of labor are saved, and the cost is reduced to a certain extent.

Owner:ZHENGZHOU BAK BATTERY CO LTD

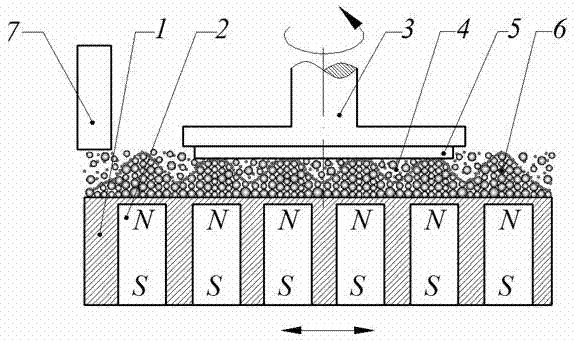

Combined machining method for chemistry cluster magneto-rheological of monocrystal silicon carbide wafer

The invention provides a combined machining method for chemistry cluster magneto-rheological of a monocrystal silicon carbide wafer. The method based on the magneto-rheological effect comprises the following steps: a monocrystal silicon carbide wafer is pasted on an antimagnetic tool head through a binder; the antimagnetic tool head is mounted on a motor spindle, and swings to a certain extent relatively to a polishing disc while the antimagnetic tool head and the polishing disc rotate around respective axial lines of the antimagnetic tool head and the polishing disc; grinding material and acid-base chemical reagent both mixed into magneto-rheological fluid are used as polishing working solution; small grinding heads with the magneto-rheological effect are produced based on a magnetic substance to limit gathered free grinding material; a flexible polishing film is formed by the array combination of multipoint small grinding heads with the magneto-rheological effect based on the cluster action principle; the distance between a workpiece and an antimagnetic polishing disc and the relative rotating speed of the workpiece to the polishing disc can be controlled to reduce surface defect and layer damage of the monocrystal silicon carbide wafer; and a super smooth surface with high quality can be obtained. According to the invention, the method integrates the advantages of high mechanical efficiency of cluster magneto-rheological and chemocatalysis of chemical polishing; and the polishing efficiency is high.

Owner:GUANGDONG UNIV OF TECH

Method for predicting rate of penetration using bit-specific coefficient of sliding friction and mechanical efficiency as a function of confined compressive strength

InactiveUS20060149478A1Electric/magnetic detection for well-loggingSeismology for water-loggingRate of penetrationCompressive strength

A method for predicting the rate of penetration (ROP) of a drill bit drilling a well bore through intervals of rock of a subterranean formation is provided. The method uses an equation based upon specific energy principles. A relationship is determined between a bit-specific coefficient of sliding friction μ and confined compressive strength CCS over a range of confined compressive strengths CCS. Similarly, another relationship for the drill bit is determined between mechanical efficiency EFFM and confined compressive strength CCS over a range of confined compressive strengths CCS. Confined compressive strength CCS is estimated for intervals of rock through which the drill bit is to be used to drill a well bore. The rate of penetration ROP is then calculated utilizing the estimates of confined compressive strength CCS of the intervals of rock to be drilled and those determined relationships between the bit-specific coefficient of sliding friction μ and the mechanical efficiency EFFM and the confined compressive strengths CCS, as well as using estimated drill bit speeds N (RPM) and weights on bit (WOB).

Owner:CHEVROU USA INC

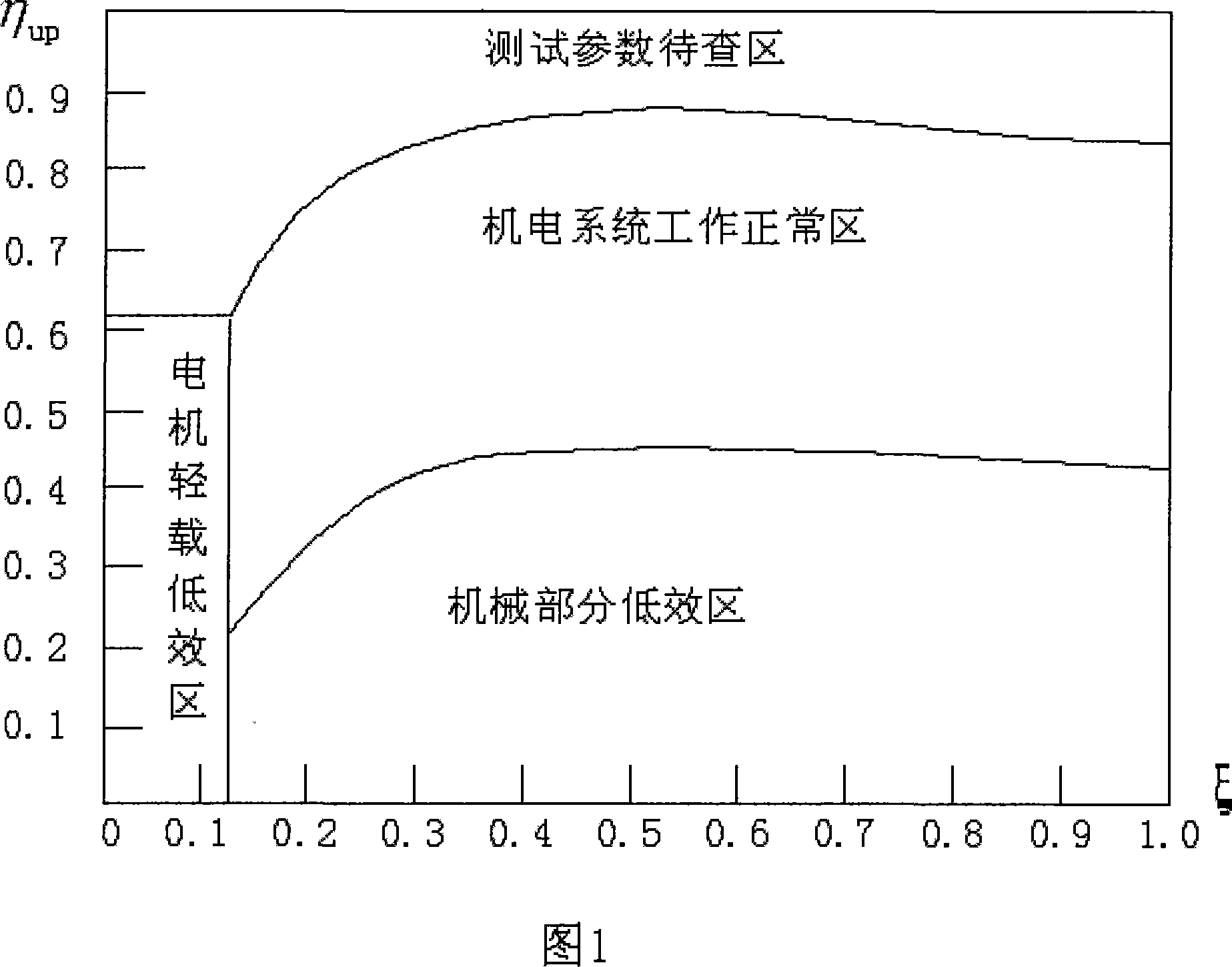

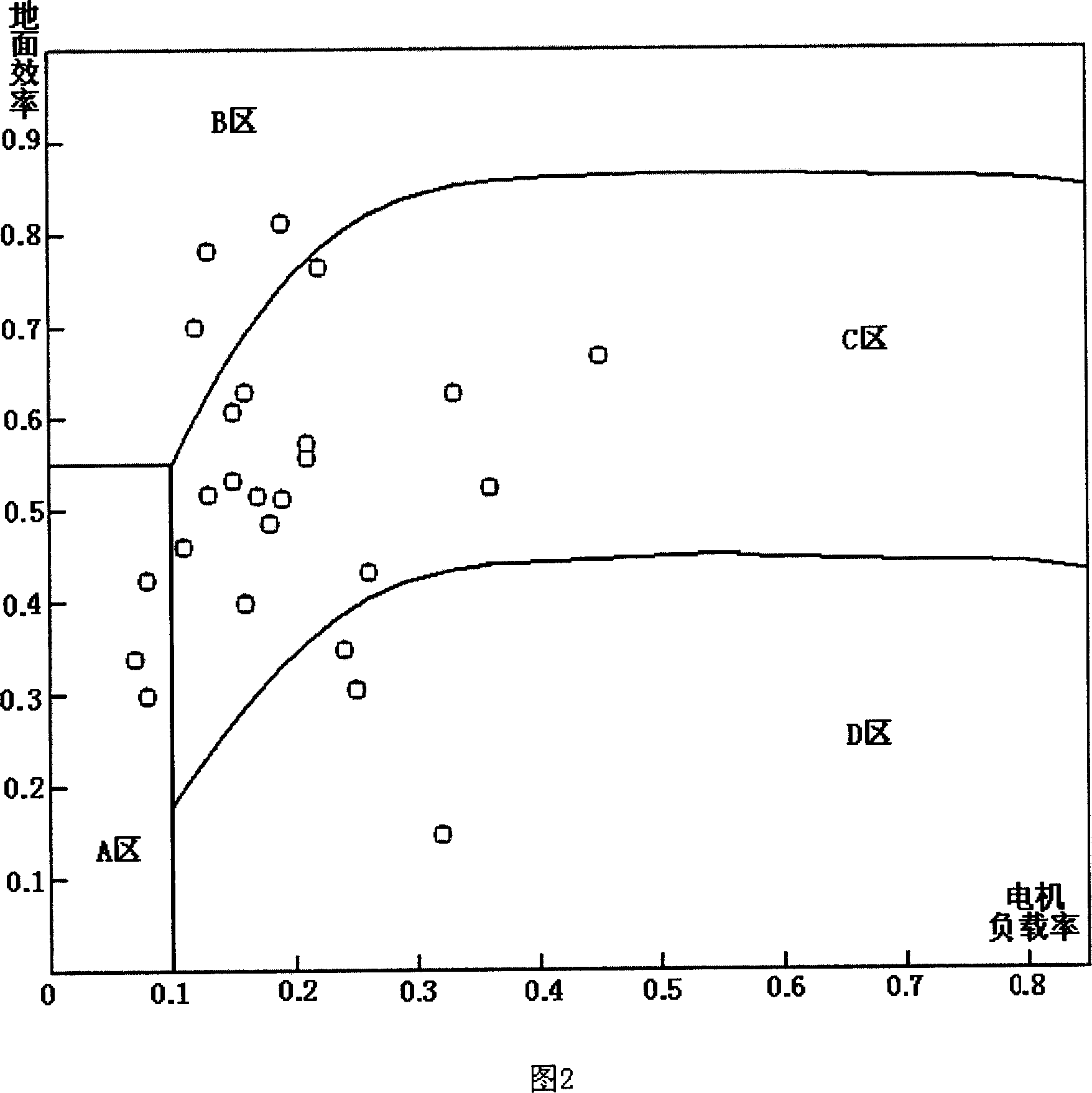

Oil pumping with lever system ground facilities efficiency evaluate method

ActiveCN101135910AComprehensive evaluationRepair in timeFlexible member pumpsElectric testing/monitoringLow loadUnit system

The method comprises: a) drawing a operating condition graph, and dividing the operating condition graph into four areas which are an area of test parameter under investigation, an area of normal working, an area of low mechanical efficiency, and an area of motor low load and load efficiency; b) determining the location of individual well in the graph: testing the motor running parameter, pumping unit well suspension parameter, and using diagram of work fluidounce metering to fast measure the fluidounce yield; calculating the motor input and output power, motor load rate, pumping unit polished rod power and pumping unit system ground efficiency; filling the obtained motor load rate, pumping unit system ground efficiency data into the ground electromechanical system operating condition graph.

Owner:PETROCHINA CO LTD

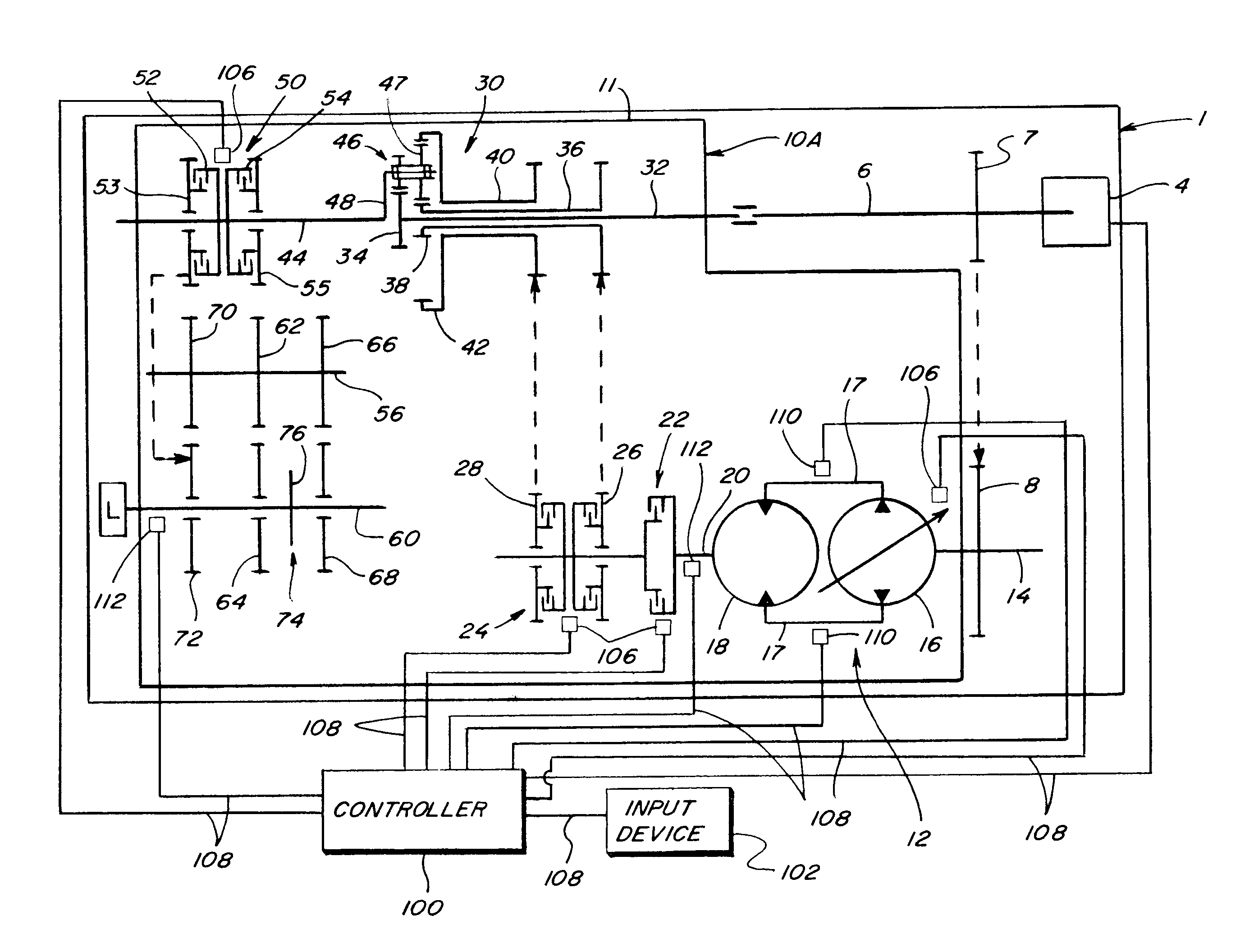

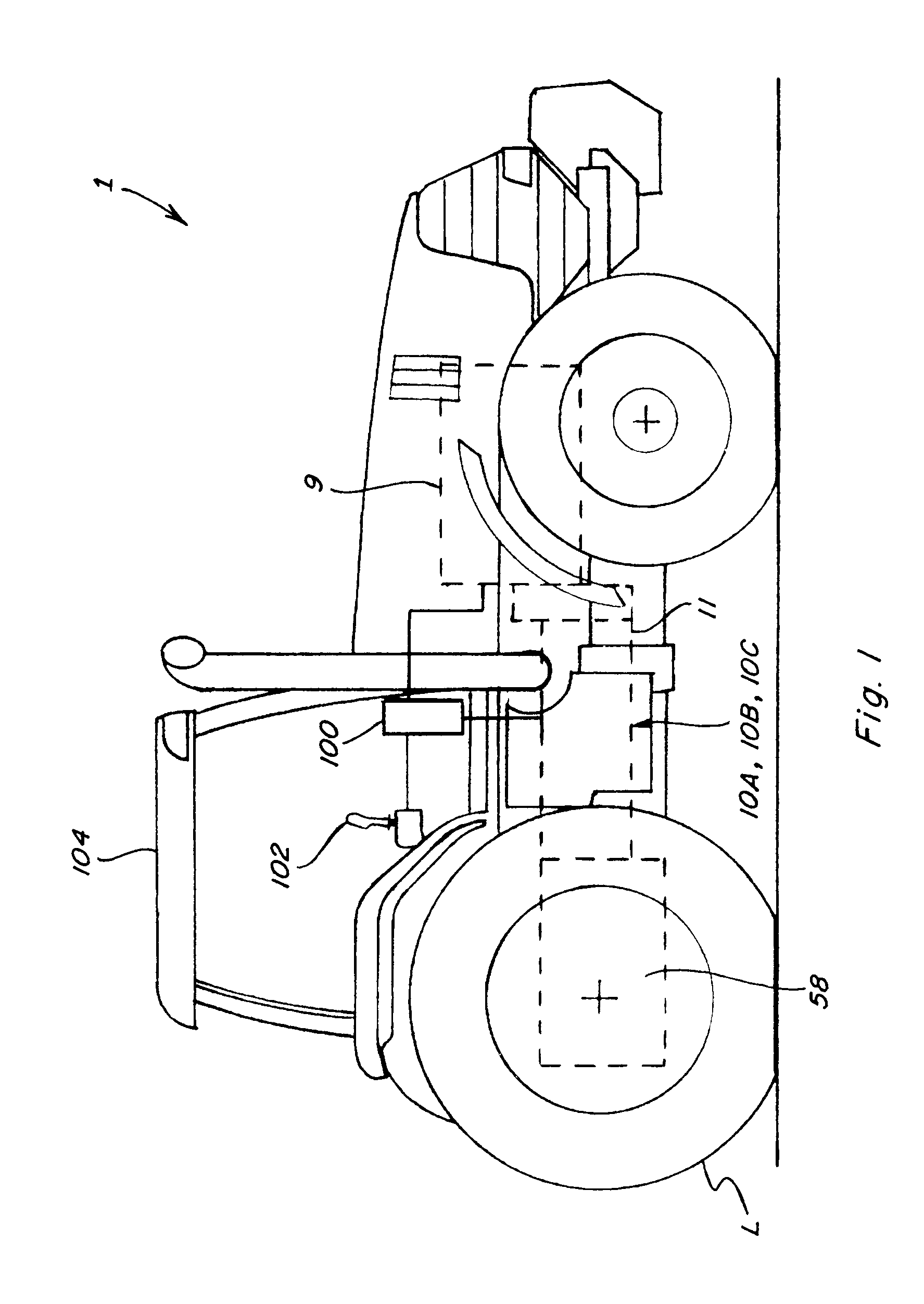

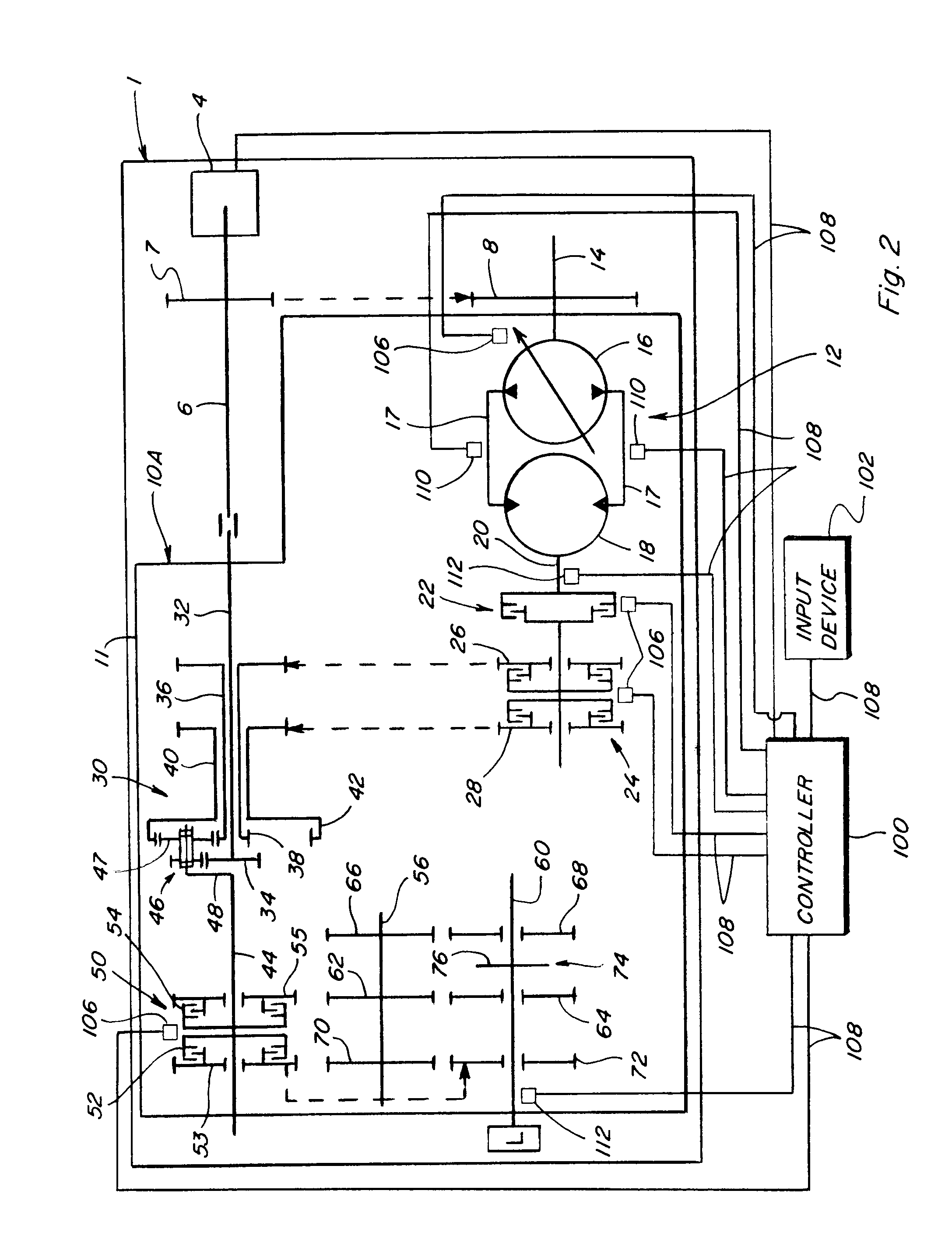

Method for estimating and controlling driveline torque in a continuously variable hydro-mechanical transmission

ActiveUS20110166752A1Reduce torqueReducing engine speedAnalogue computers for trafficGearing controlHydraulic machineryControl theory

The method of estimating and controlling driveline torque in a continuously variable hydro-mechanical transmission uses pressure data and other metrics of a hydrostatic power unit of the transmission in lieu of actual driveline torque data. A mechanical efficiency of the transmission is determined as a function of whether the power unit is operating in a power generation or regeneration mode, and the torque output of the power unit is estimated from that and other hydrostatic parameters. This is used to estimate a torque output of a planetary power unit of the transmission, and the torque on an output member of the driveline is then estimated using that value, and appropriate corrective action taken.

Owner:BLUE LEAF I P

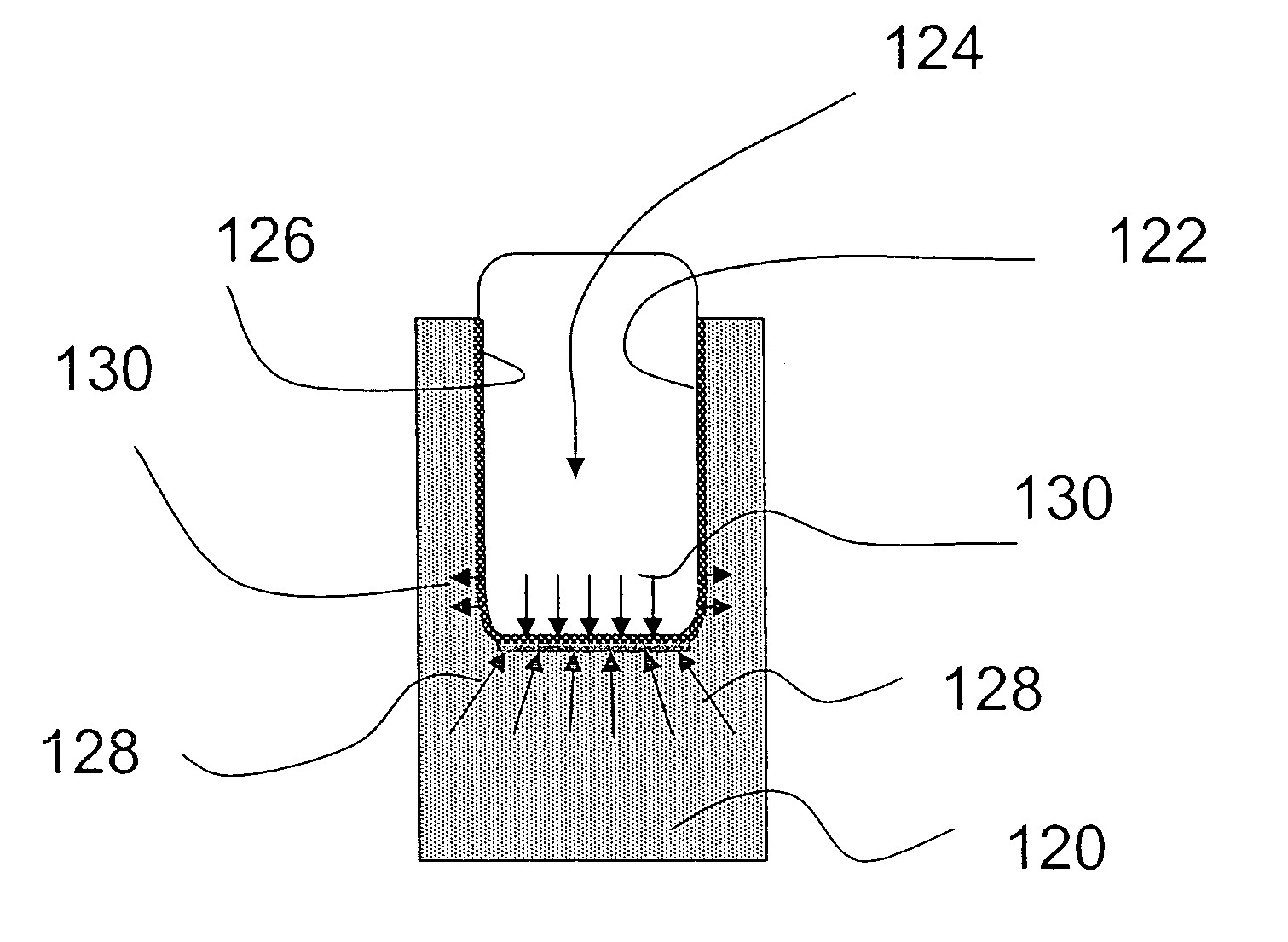

Automatic chip mounting device and chip mounting method

ActiveCN103281872ATape programSimple processPrinted circuit assemblingControl systemElectronic component

The invention discloses an automatic chip mounting device and a chip mounting method. The automatic chip mounting device comprises a plate loading mechanism, a feeding mechanism, an element taking and mounting mechanism, a position information collecting mechanism and a control system, wherein the plate loading mechanism is used for loading, positioning and unloading a PCB (printed circuit board); the feeding mechanism is used for automatically completing the primary sorting, transmission and test action of electronic elements in bulk; the element taking and mounting mechanism comprises a taking head and is used for controlling the taking head to rotate and to move in the horizontal direction and vertical direction; and the control system is used for positioning the PCB and the electronic elements on the taking head according to original position information data of the PCB and the position information data of the electronic elements collected by the position information collecting mechanism, so that the electronic elements can be accurately mounted on corresponding positions of the PCB. By adopting the automatic chip mounting device, the mechanical operating range can be greatly shortened, the process flow is simplified, the mechanical efficiency is improved, and the mounting precision is improved.

Owner:汤良安

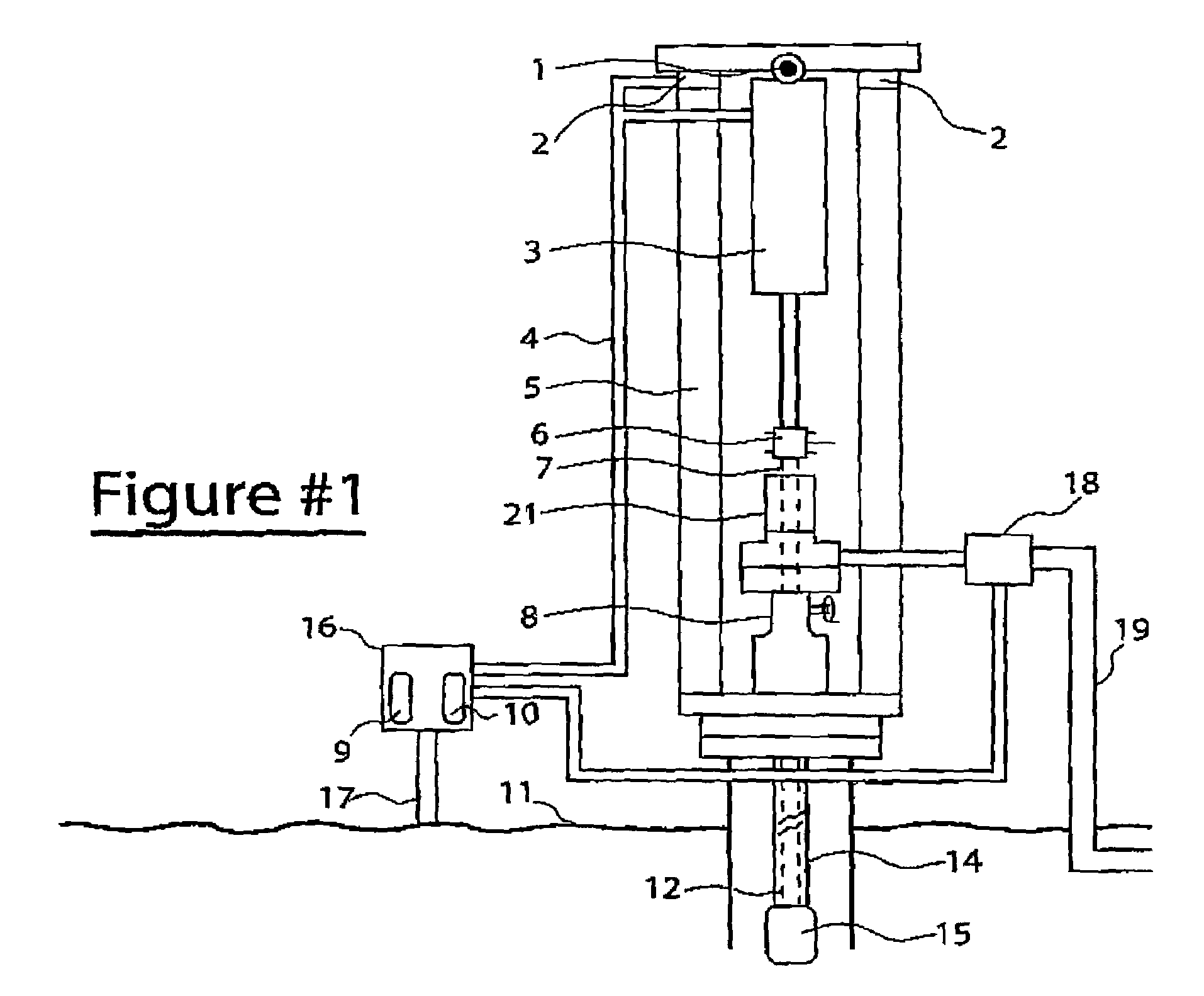

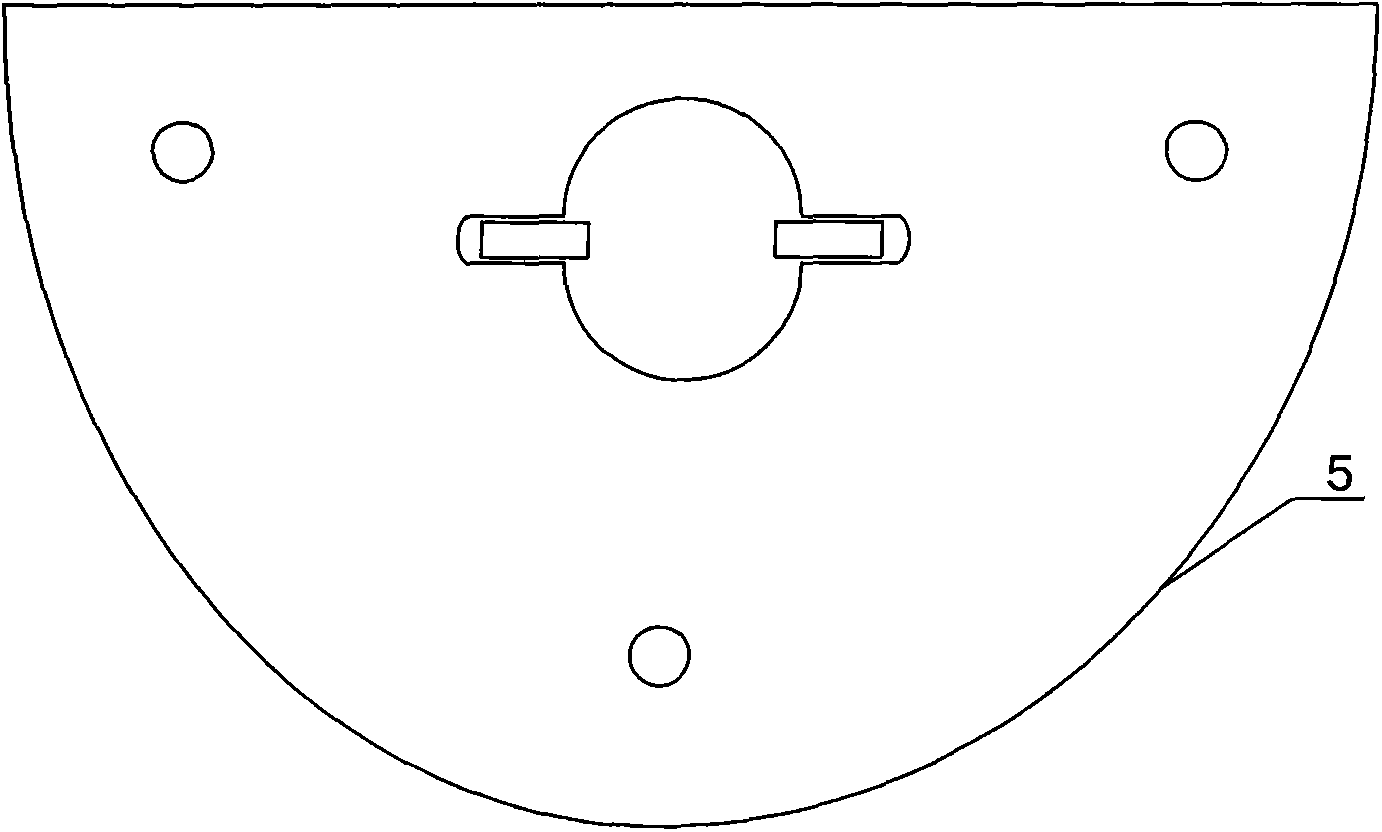

Pump jack and method of use

InactiveUS7373971B2Improve efficiencyReduce energy costsFlexible member pumpsFluid removalProcess engineeringOil well

An electromagnetic ram for use in artificially lifting fluid from a well and in particular an oil well. The disclosure also teaches a method and system employing the ram. The use obviates existing systems used today in terms of cost, environmental concerns, optimized mechanical efficiencies and maximizing overall production of wells on a case by case basis.

Owner:CROSTEK MANAGEMENT CORP

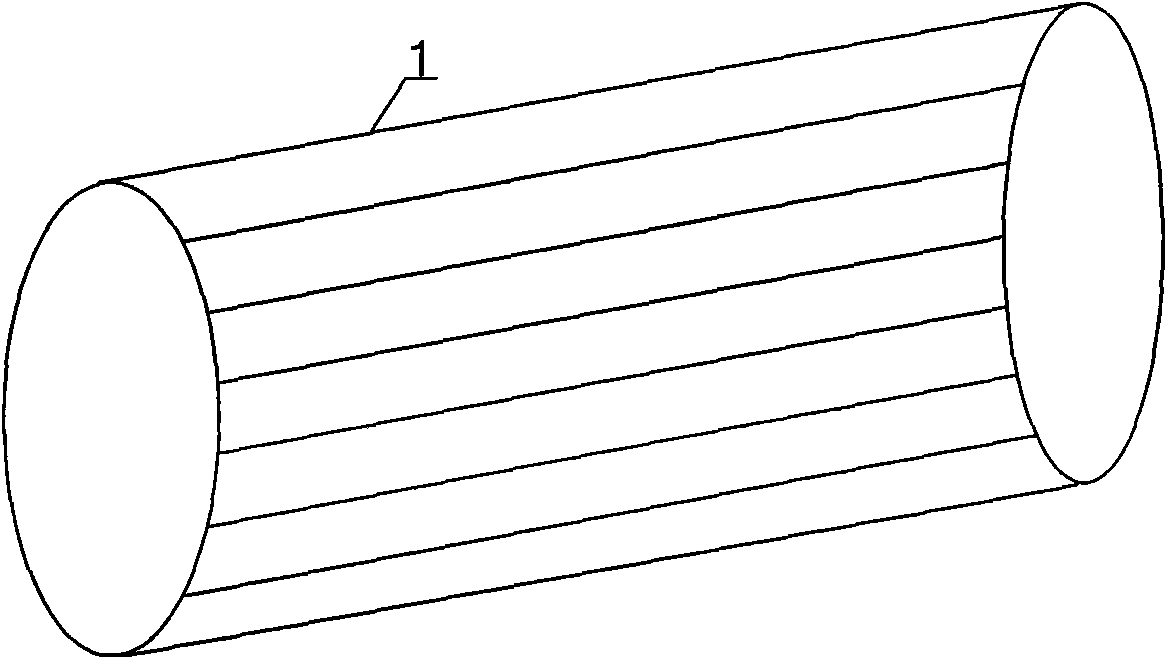

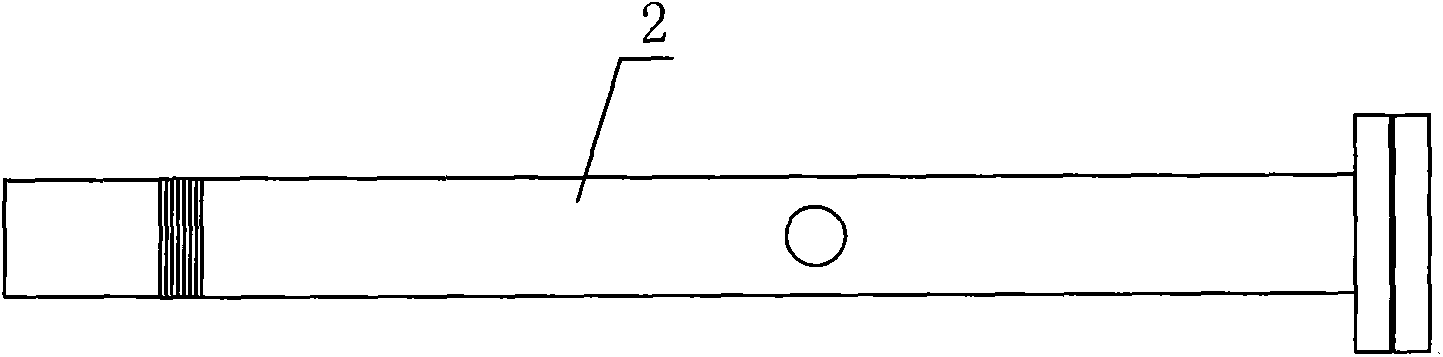

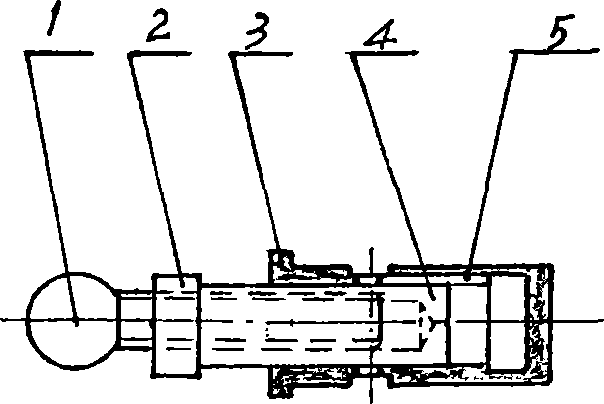

Linear reciprocating motor

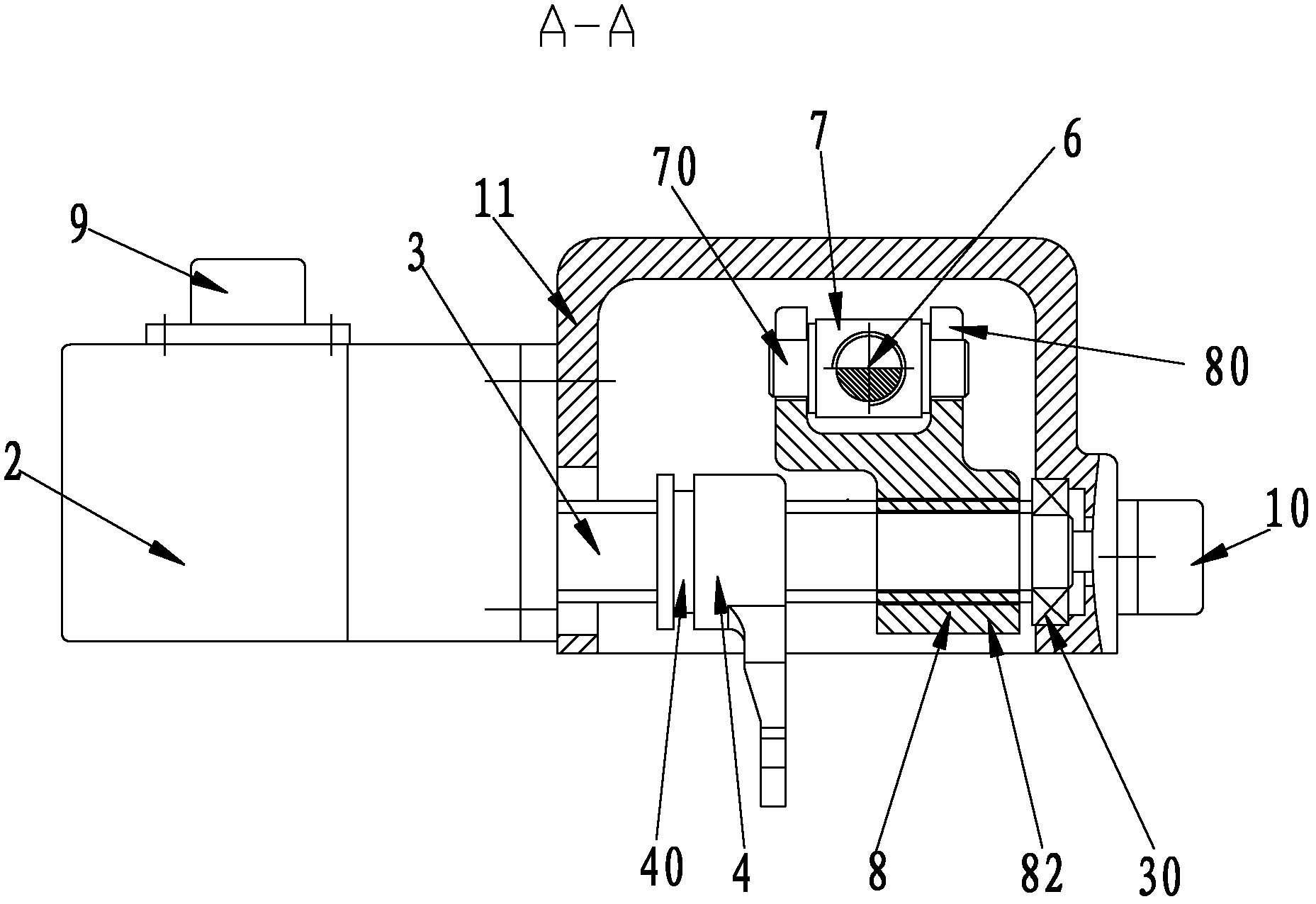

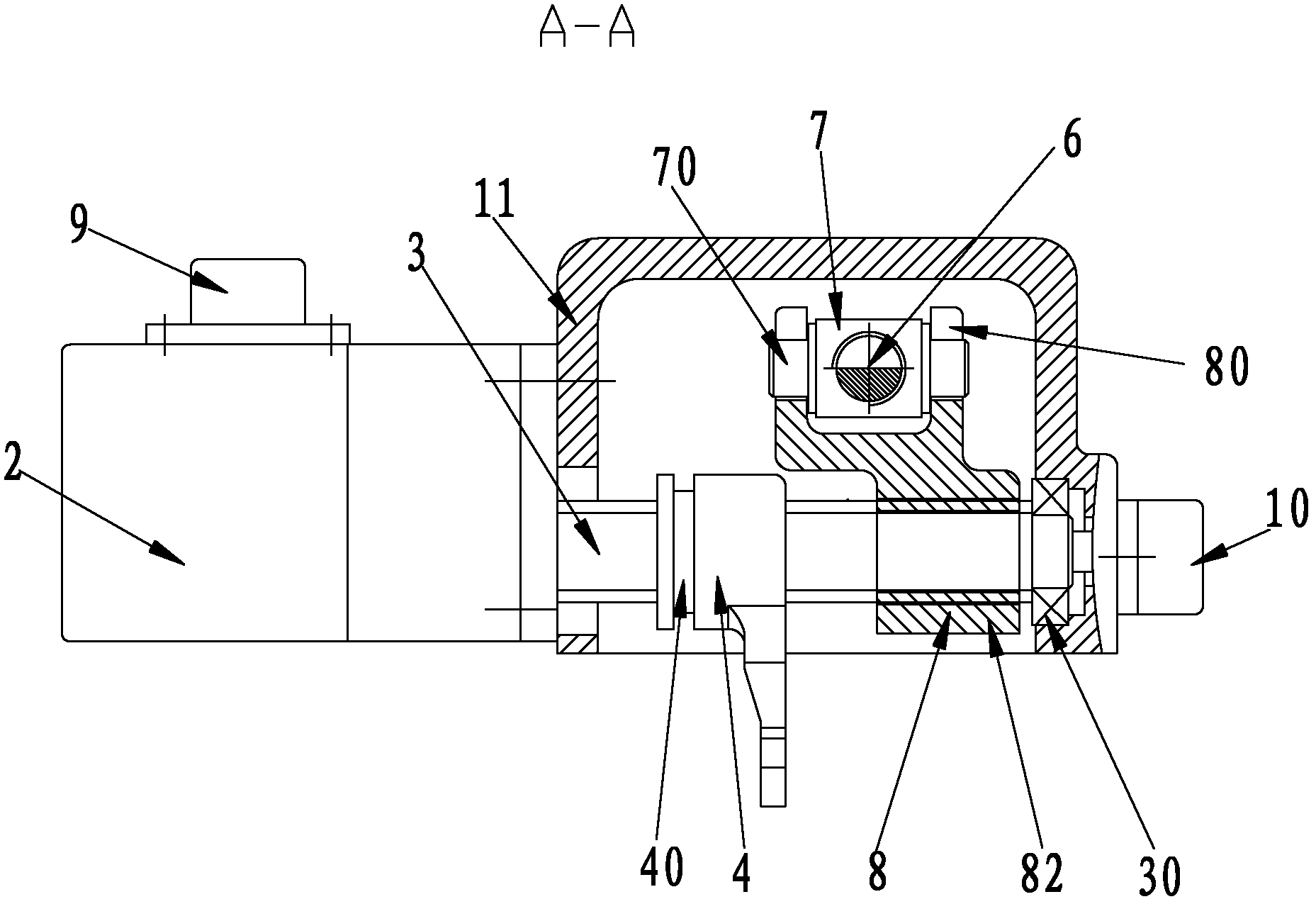

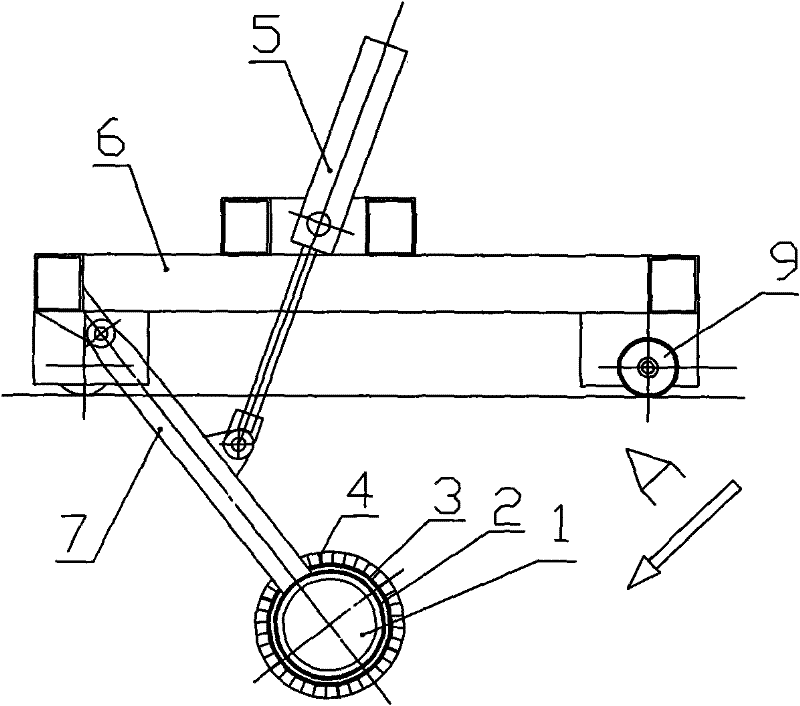

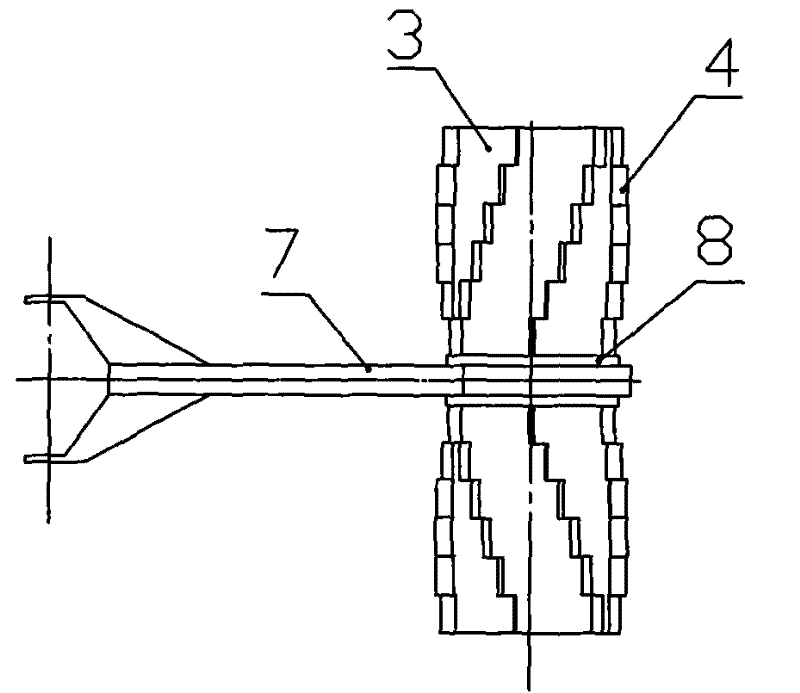

InactiveCN103715858AReduce the transmission linkImprove mechanical efficiencyPropulsion systemsReciprocating motionEngineering

The invention discloses a linear reciprocating motor. The linear reciprocating motor comprises a reciprocating screw rod (4) which is sleeved with a hollow shaft (2), a small round hole is formed in the side wall of the hollow shaft (2), a guide block (3) is placed in the small round hole of the hollow shaft and makes contact with a bidirectional sliding groove of the reciprocating screw rod (4), the hollow shaft (2) provided with the guide block (3) is sleeved with a rotor (1), and the rotor (1) is sleeved with a motor stator. According to the linear reciprocating motor, the guide block is arranged in the small round hole in the hollow shaft arranged outside the reciprocating screw rod in a sleeved mode, then the rotor is arranged uniformly, and after installation is finished, the hollow shaft rotates to drive the guide block to move in the reciprocating screw rod so that front and back linear reciprocating motion of the reciprocating screw rod can be achieved under the action of the guide block. Thus, the linear reciprocating motor can be applied to various occasions needing the reciprocating motion, the number of transmission links is reduced, mechanical efficiency is improved, production cost is reduced, and the linear reciprocating motor is simplified substantially.

Owner:刘开超

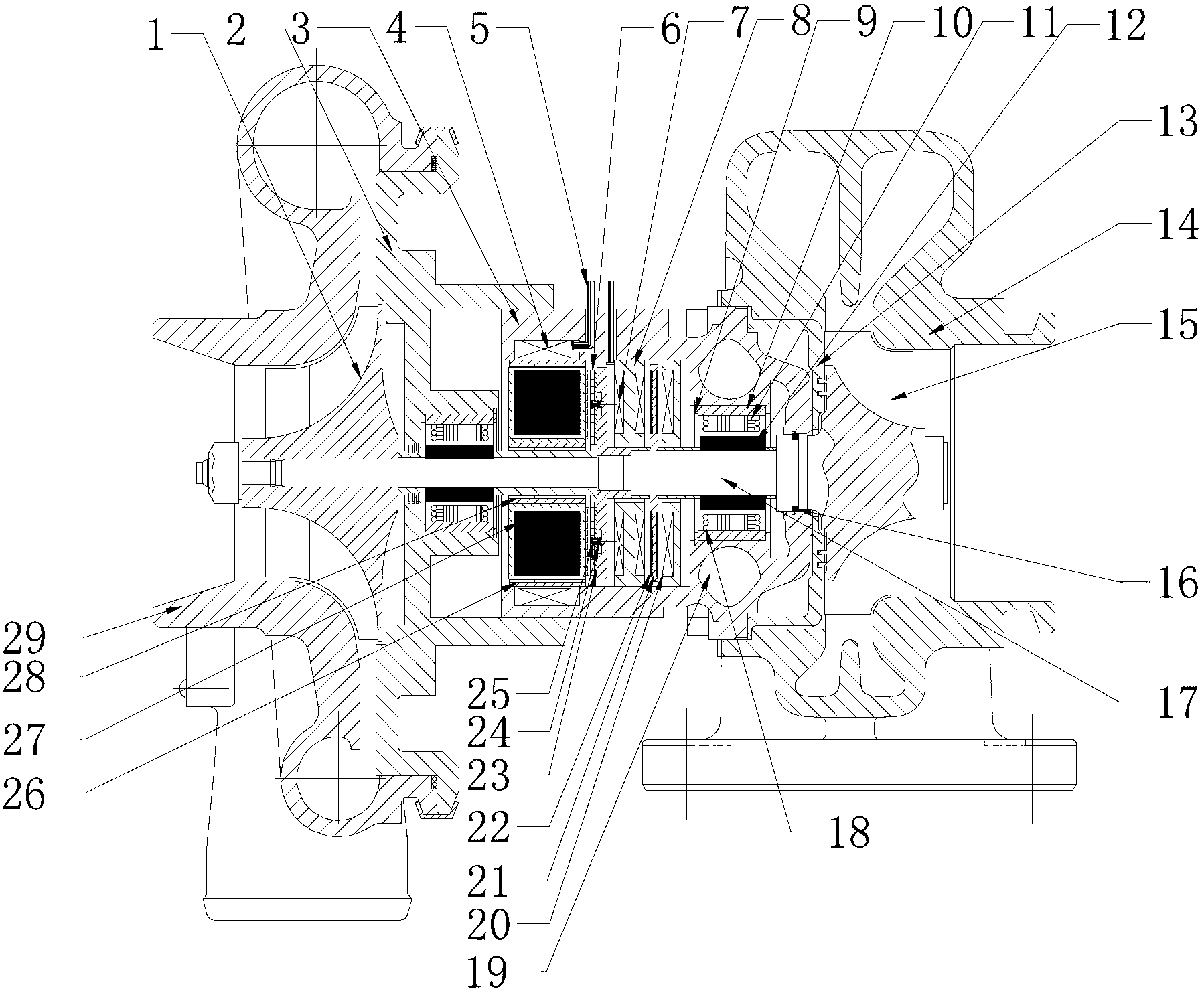

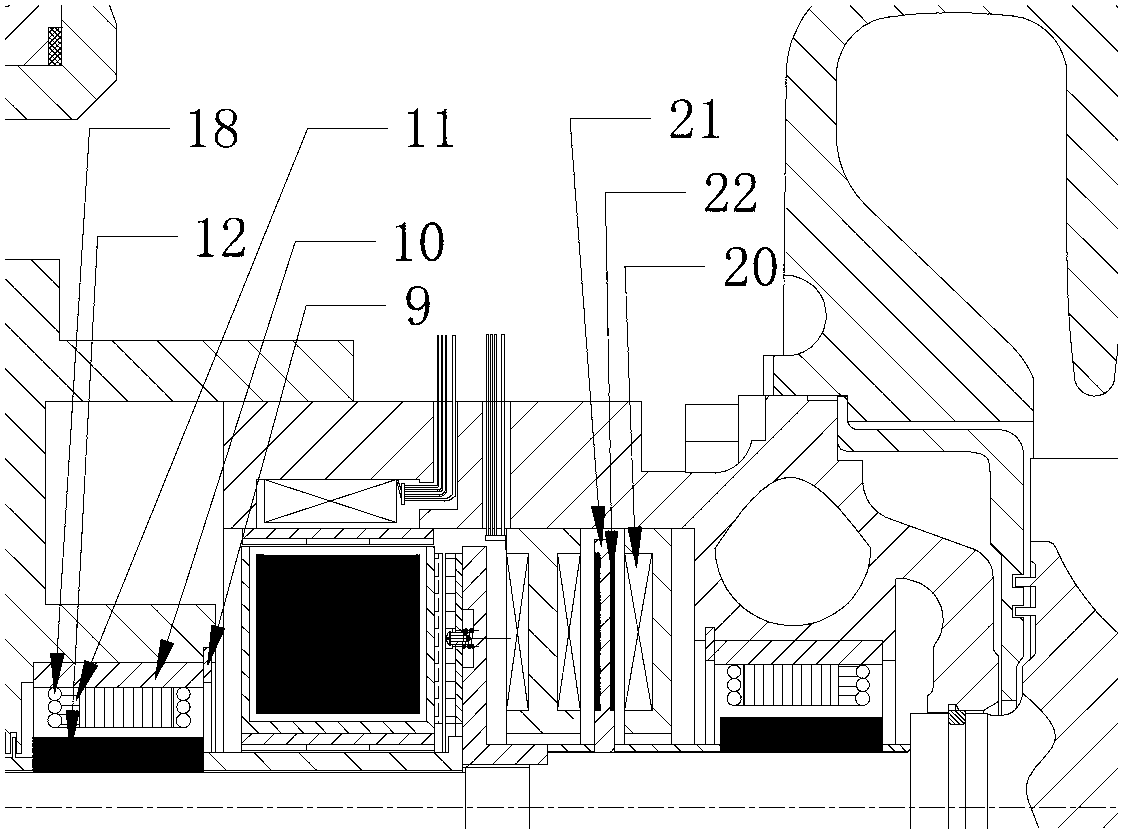

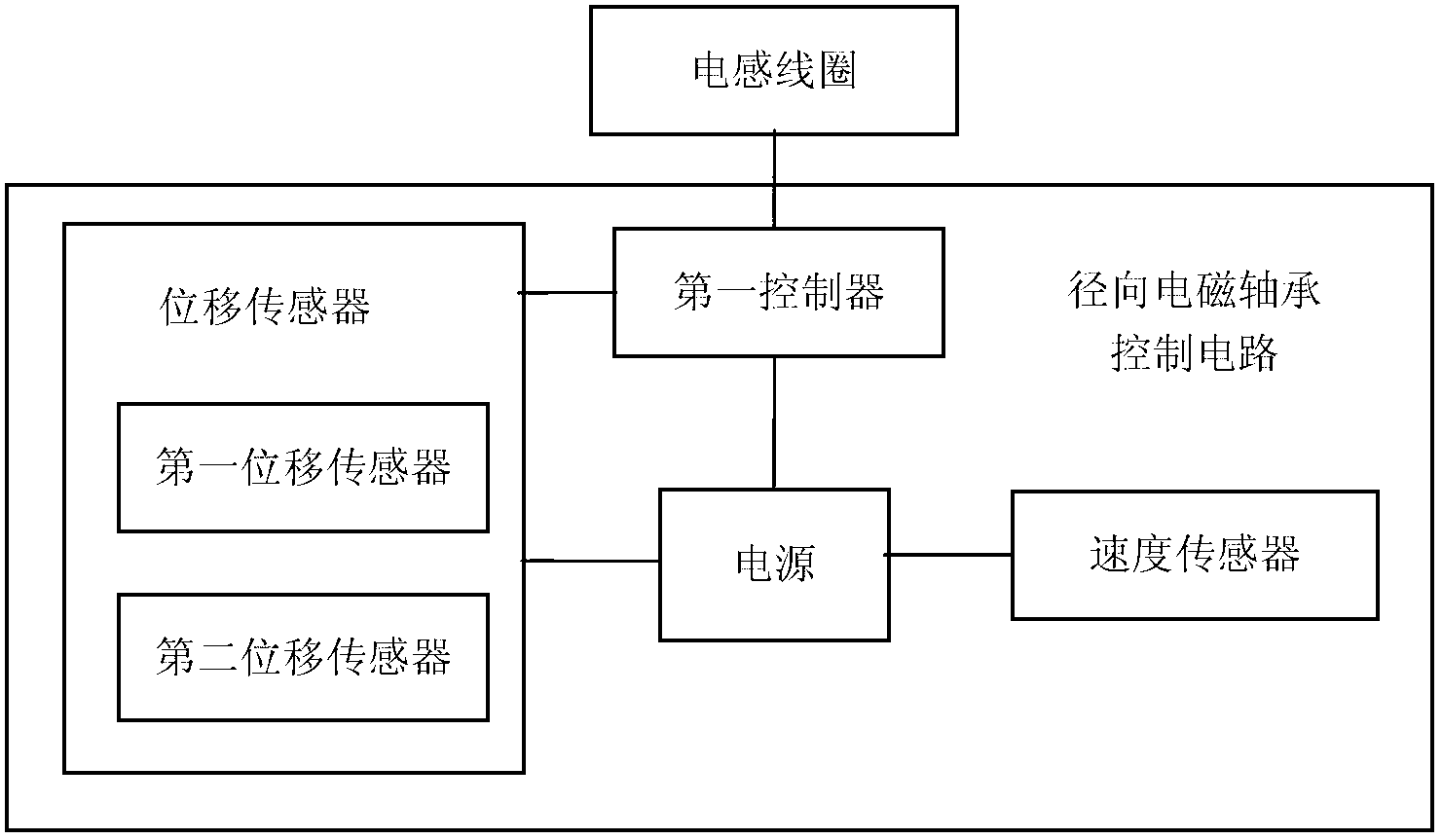

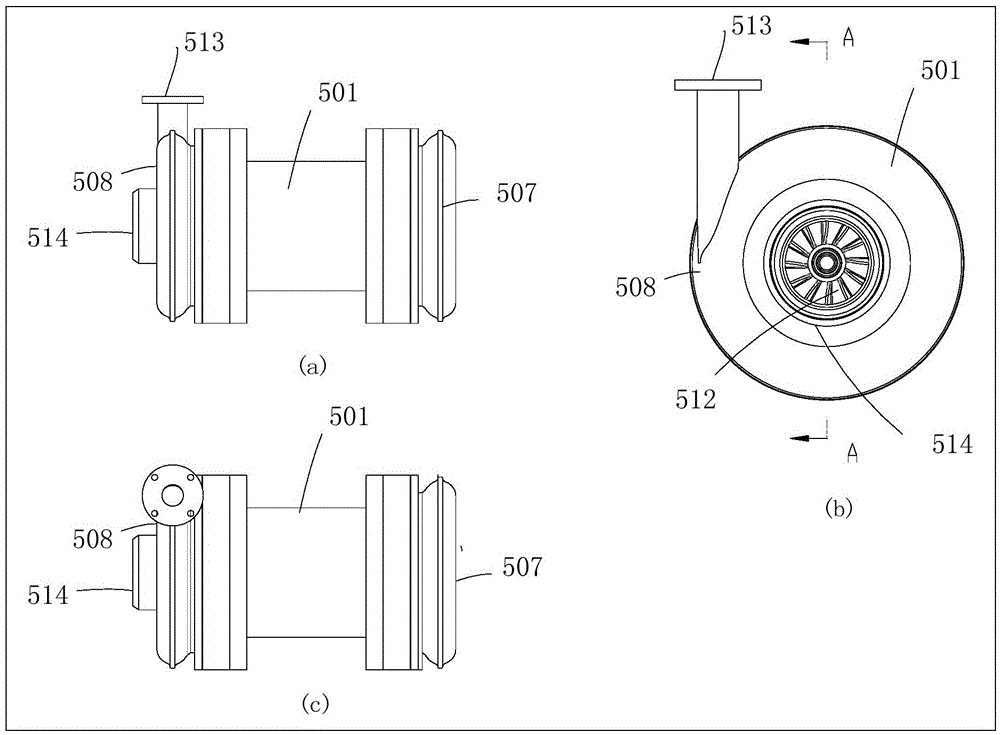

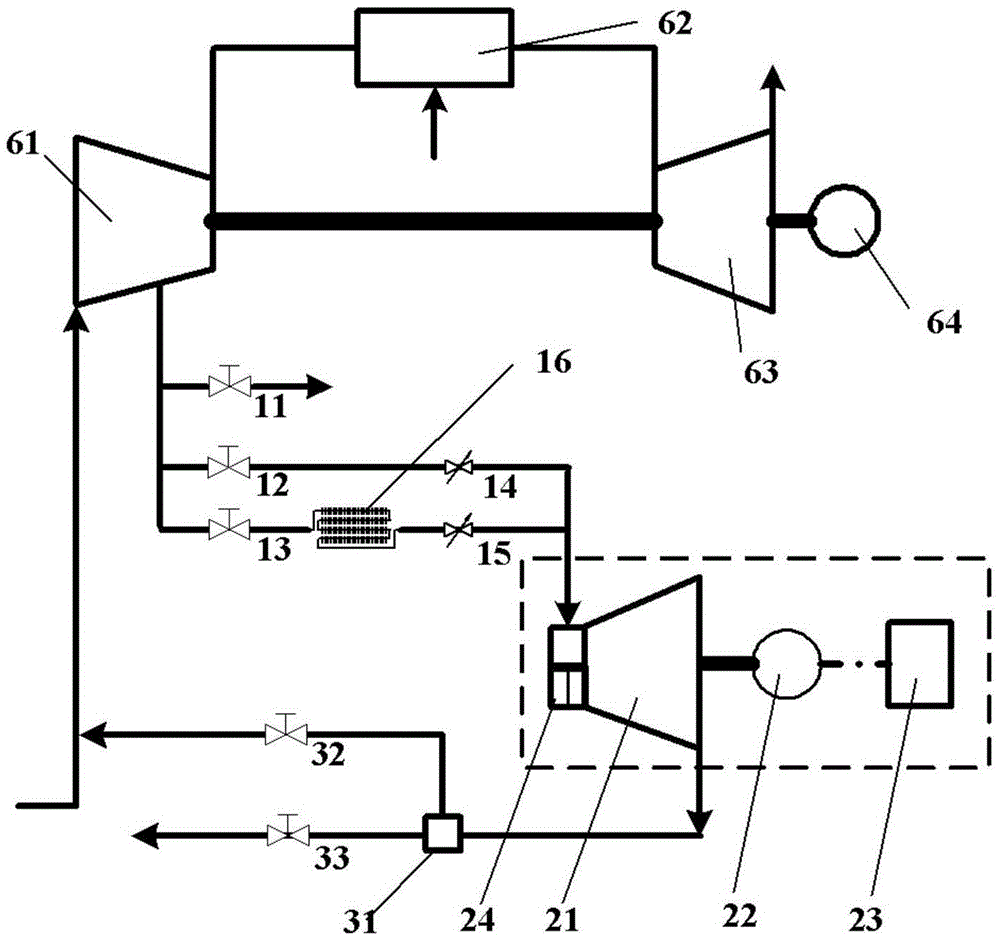

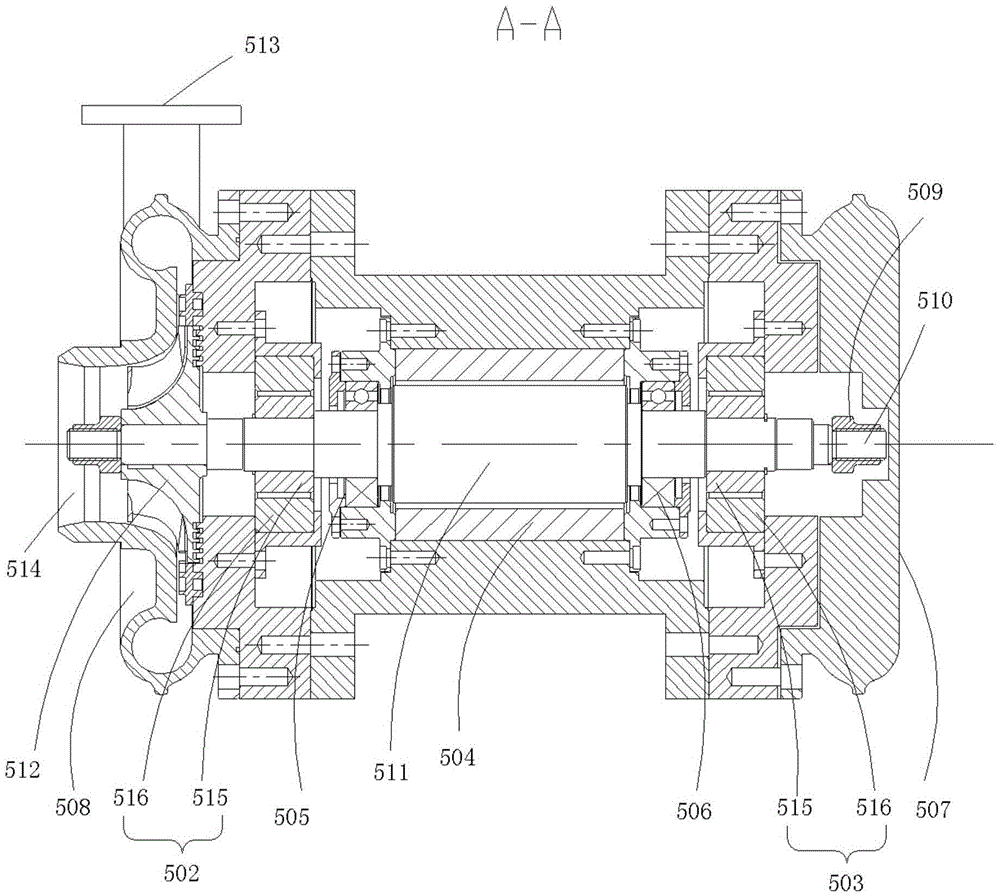

Electric turbocharger

ActiveCN103061869AImprove efficiencyImprove reliabilityInternal combustion piston enginesShaftsMagnetic bearingClutch control

The invention relates to an electric turbocharger which comprises a radial electromagnetic bearing, a radial electromagnetic bearing control circuit, an axial electromagnetic bearing, an axial electromagnetic bearing control circuit, a motor generator, a clutch device and a clutch control system. The motor generator, the clutch device, the radial electromagnetic bearing and the axial electromagnetic bearing are located in a space formed by an intermediate, a compressor back plate and a turbine shell and disposed around a turbine rotor. The clutch device is used for controlling combination and separation of the motor generator and the turbine rotor. The motor generator and the clutch device are controlled by the clutch control system. The radial electromagnetic bearing is controlled by the radial electromagnetic bearing control circuit. The axial electromagnetic bearing is controlled by the axial electromagnetic bearing control circuit. By the electric turbocharger, active control of dynamic features of a bearing-rotor system is realized, lubricating oilway is omitted, airtightness is achieved, mechanical efficiency of turbochargers is improved, utilization rate of waste gas is increased, and turbine lag is solved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Axial variable displacement plunger pump of swash plate

InactiveCN101487458APositive-displacement liquid enginesMulti-cylinder pumpsEngineeringHigh pressure

The invention provides a power element used in a hydraulic transmission system. A swash plate variable axial plunger pump consists of a swash plate, a plunger cylinder body and a port plate. The angle-variable swash plate rotates with a drive rotating shaft which is connected by a hinge, and the swash plate drives the plunger to only have reciprocating motion in a fixed cylinder barrel, thus avoiding the disadvantages of large rotating inertia, large friction surface of port surface and easy leakage of a common swash plate axial plunger pump. The swash plate can be divided into a manual swash plate, a hydraulic-control swash plate and a hydraulic-control and spring combined variable swash plate. The swash plate can be conveniently adjusted by a window above a variable shell. The plunger pump has various uses and advantages of small rotating inertia, little friction surface, and high mechanical efficiency and volumetric efficiency, and being insensitive to pollution, generating little heat, being capable of taking as an economical combination pump with 'low pressure and large flow or high pressure and small flow' and the like. Besides as a common pump, the axial plunger pump can also be used in the superhigh pressure and synchronous cylinder field. The axial plunger pump has the advantages of general working accuracy and low production cost.

Owner:张全根

Modified gear oil

A modified gear oil can be used for extreme worm oil, open industrial gear oil and closed industrial gear oil in traffic transportation, machinery, metallurgical, chemical industries. In the mineral lube-oil or synthetic lube-oil, modified nano-carbon with average grain size 2-6nm is added as extreme anti-scuff agent and oily agent, quality fraction is 2X10-5-1X10-2, nano-diamond occupies 10-99%, wear rate is decreased by 46.7%, mechanical efficiency improves by 2.84%, polishing scratch depth is decreased from 4.94 mu m to 0.07 mu m.

Owner:TIANJIN CHANYU SUPERHARD SCI TECH CO LTD

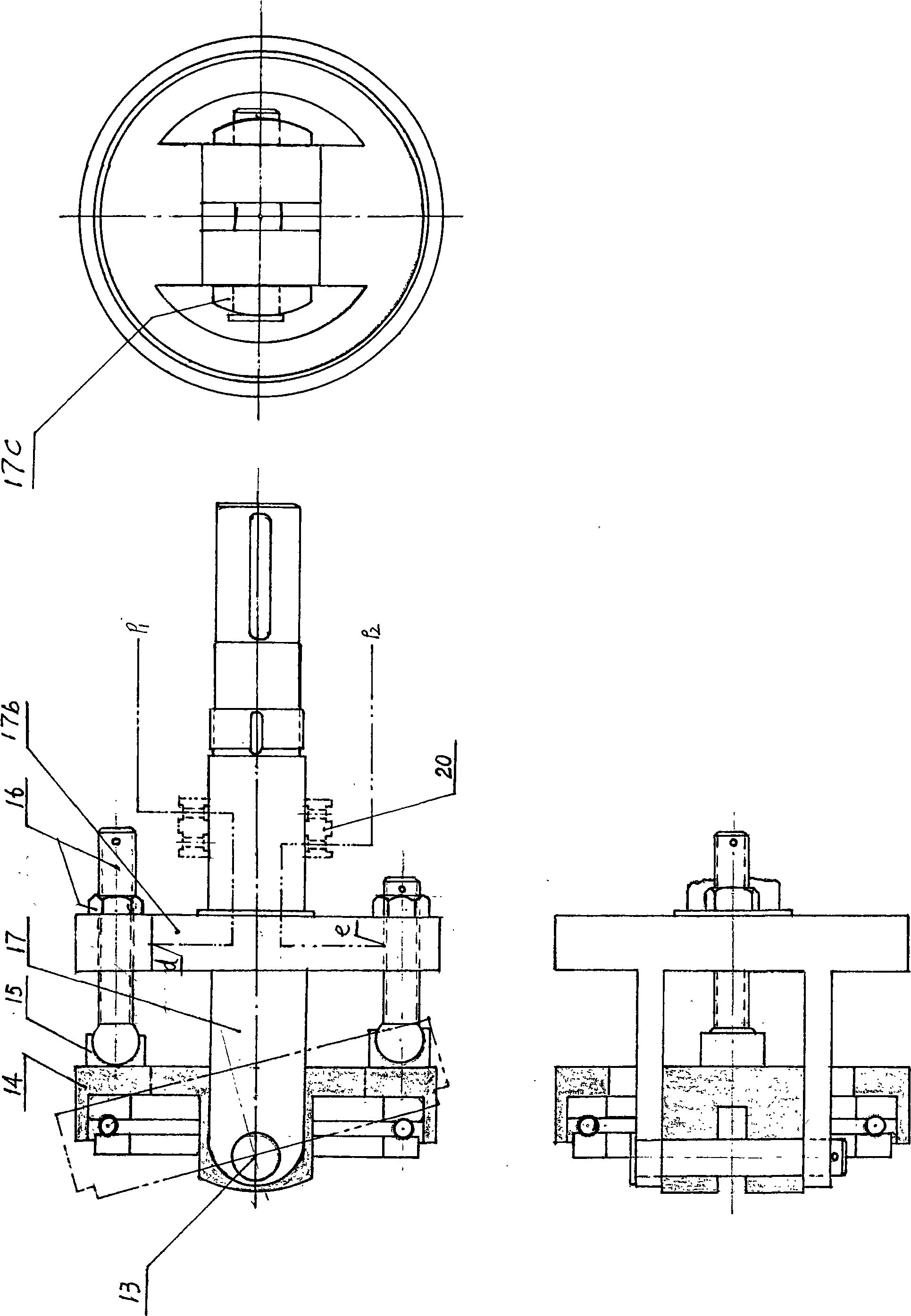

Hydraulic pressure reel cart with clutch at transmission last level

The invention discloses a hydraulic winch which is provided with a clutch at the transmission terminal. The hydraulic winch which is provided with a clutch at the transmission terminal comprises a hydraulic motor, a hydraulic brake, a planetary gear speed reducer, a hydraulic clutch, a winding drum and a hydraulic control loop which controls the work of the winding drum, wherein the hydraulic clutch arranged in the winding drum is arranged at the terminal of a system transmission chain; the planetary gear speed reducer is arranged in the winding drum, and the output end at the right side of the terminal planetary frame at the terminal of the planetary gear speed reducer is a spline shaft which is connected with a multi-plate type friction clutch; the right end of the spline shaft is the piston of a clutch control cylinder, and the planetary frame of the planetary gear speed reducer, the spline shaft of the clutch and the piston is an integrative structure. The invention effectively overcomes the problems that the present hydraulic winch is complex in connecting structure, difficult in processing and assembly, unbalance in the stress of dynamic shaft, easily worn in the connection part where a frame bearing shaft force, low in mechanical efficiency and short in service life, etc.

Owner:INI HYDRAULIC

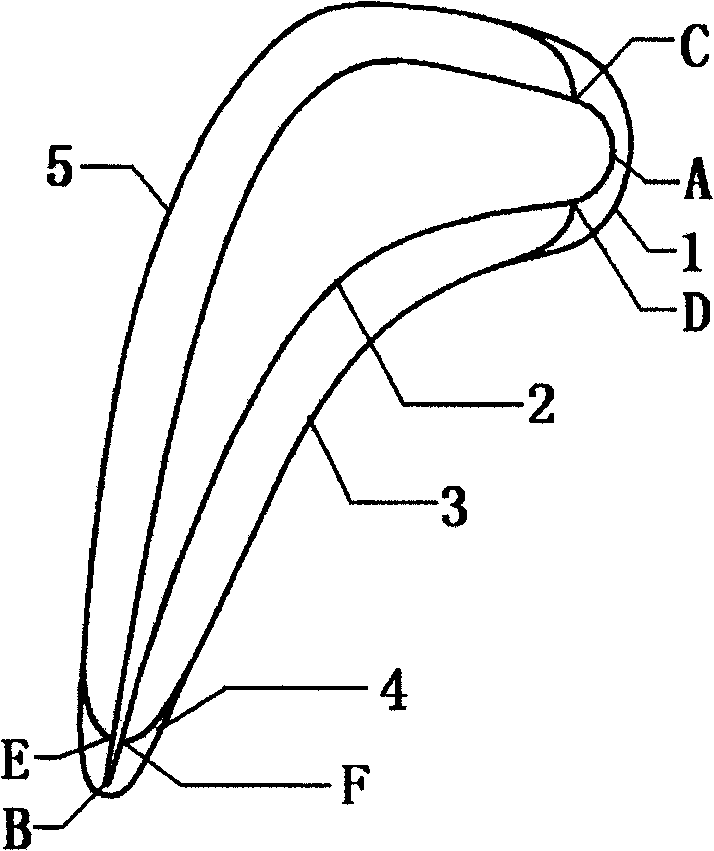

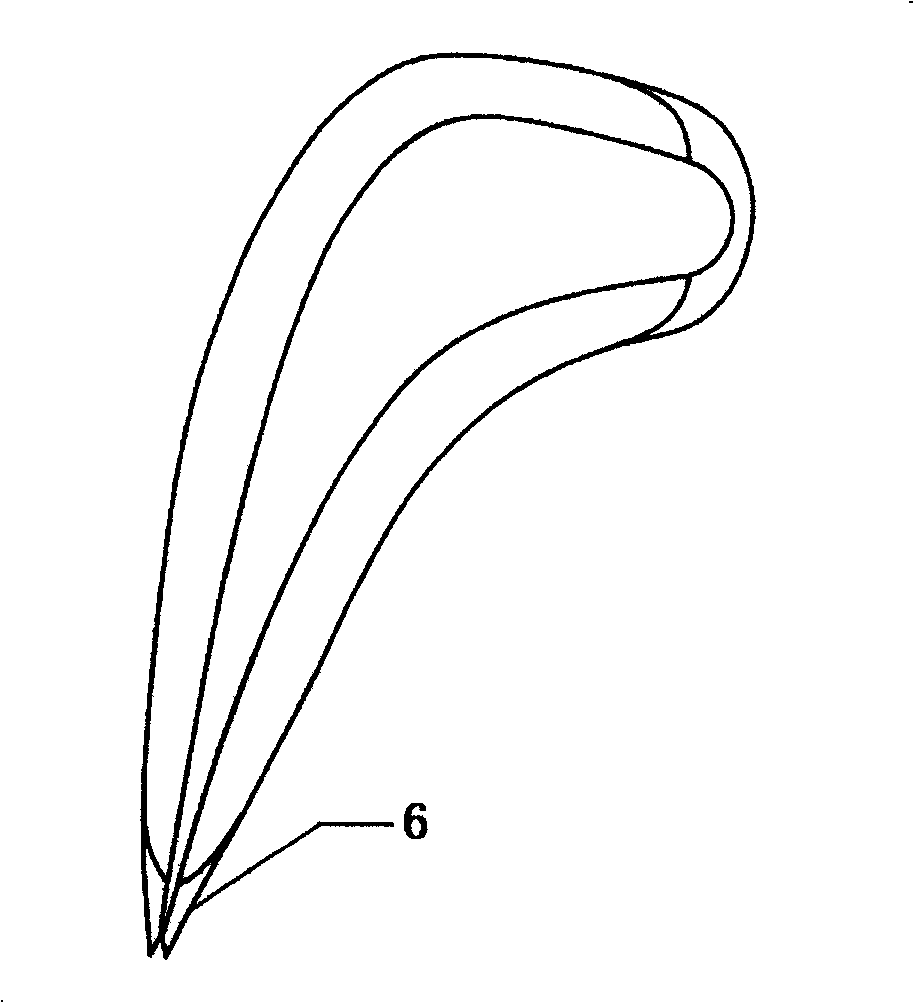

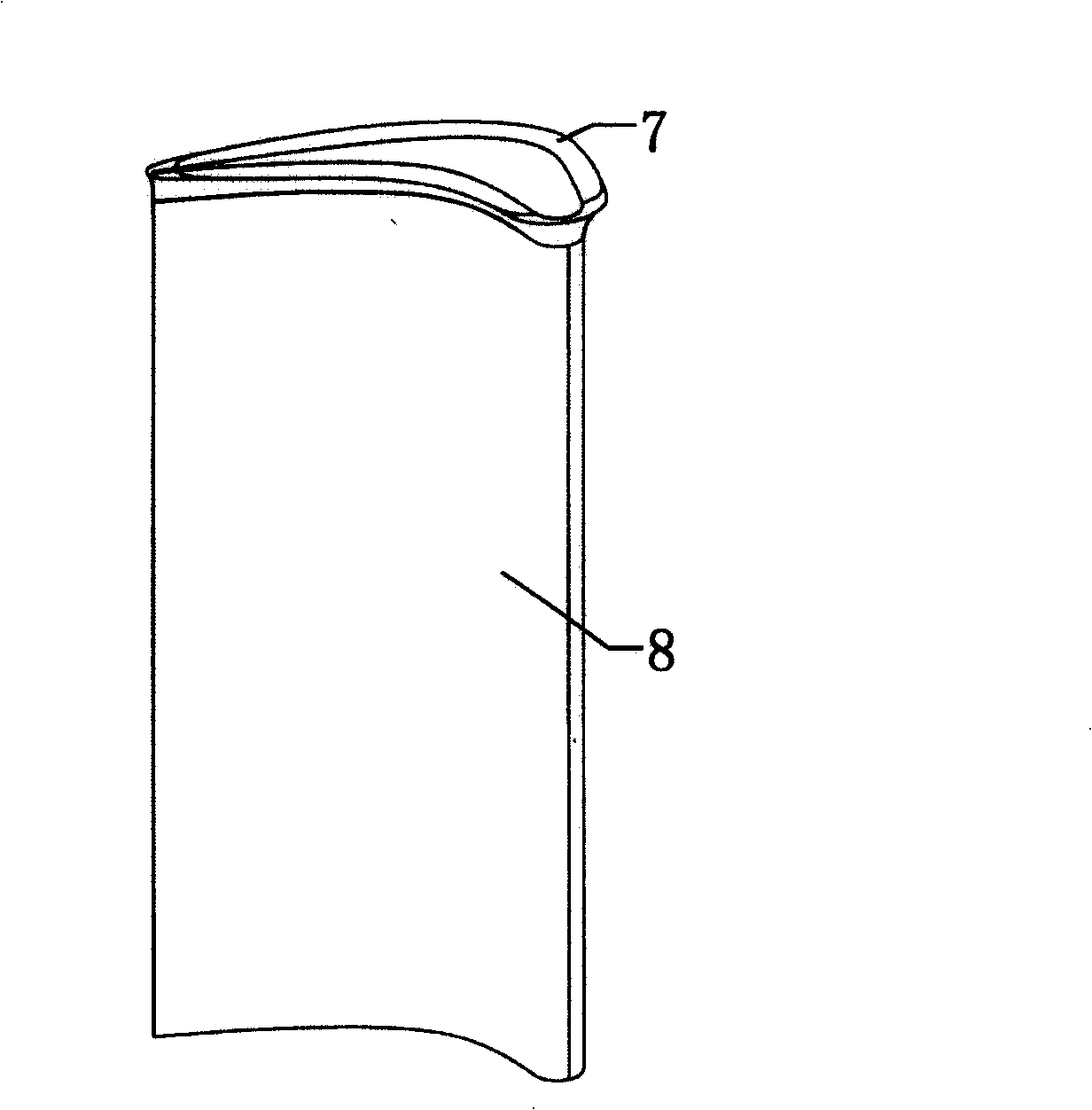

Blade tip alula of turbine or steam turbine moving-blade

The present invention provides a tip vane of guided vane of turbine or steam turbine related to field of turbomachine. The tip vane comprises a front edge wing, a pressure surface wing, a suction surface wing and a tail edge wing, the pressure surface wing and the suction surface wing are little vanes expended between front edge point A and tail edge point B of leaf along circumference, front edge point D and C of pressure surface wing and suction surface wing are lied on front edge point A or between front edge point A and most thickness part of guided vane; the tail edge point F and E of the pressure surface wing and the suction surface wing are arranged on tail edge point B or between tail edge point B and the most thickness part of guided vane; the front edge wing and tail edge wing are connected smoothly with the pressure surface wing and suction surface wing, and the front edge wing and the tail edge wing are extended parts of pressure surface wing and suction surface wing at front edge and tail edge. The present invention reduces effect of flow field in channel by tip leakage, tip leakage vortex and scraping gyres, improves cascade flow field, and enhances mechanical efficiency of impeller at the same time.

Owner:DALIAN MARITIME UNIVERSITY

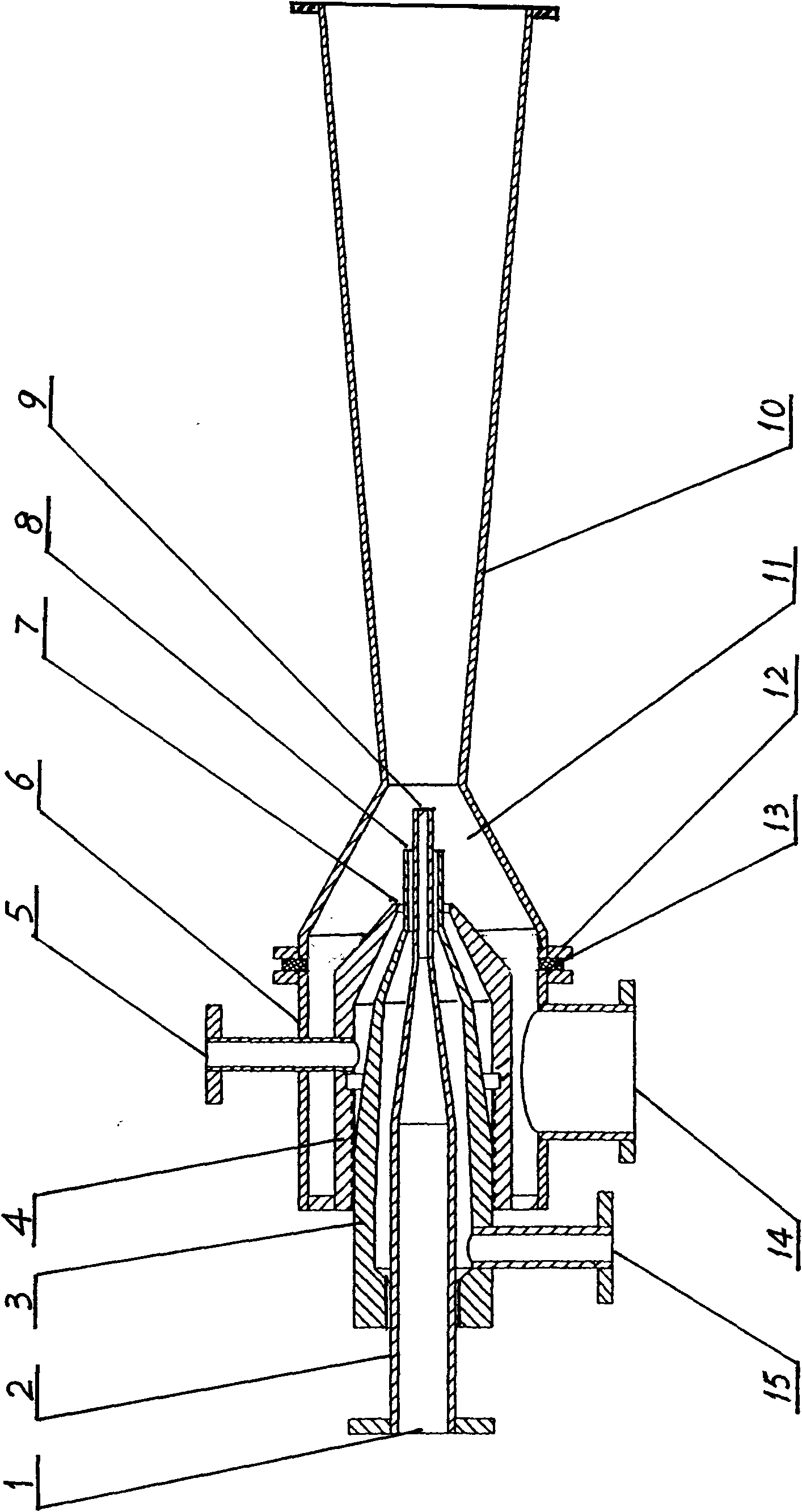

Adjustable multi-streaming type steam jet heat pump

InactiveCN101625000AImprove energy utilizationReduce flow impact lossJet pumpsMachines/enginesFront edgeDiffusion tube

The invention discloses an adjustable multi-streaming type steam jet heat pump. One or more than one conical-cylindrical surrounding nozzle with annular nozzle mouths are coaxially sleeved at the outer side of a conical-cylindrical central nozzle positioned in the center of a pump body, a nozzle mouth of the central nozzle is positioned at the topmost end and is in stepped arrangement with the annular nozzle mouths of the surrounding nozzles, the surrounding nozzles are respectively provided with a working steam inlet, a jet steam inlet is arranged on the lateral wall of the pump body, a cavity body at the front part of the pump body and the outer side of the nozzle mouth is of a steam mixed chamber, and the outer end of the steam mixed chamber is connected with the small mouth end of a diffusion tube. Working steam is jetted from the central nozzle in high speed, other strands of working steams are jetted from the nozzle mouths of the surrounding nozzles, a plurality of strands of steams form a certain-speed distribution field and act together so as to ensure that the pressure intensity at the nozzle mouths is reduced, and the jet steam is sucked in, and the steams are mixed through the steam mixed chamber, and slowed down and pressurized by the diffusion tube to generate jet stream with adjustable speed gradient, thereby the flow impact loss at the front edges of the nozzle mouths is effectively reduced, the energy loss is decreased, and the mechanical efficiency is improved.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

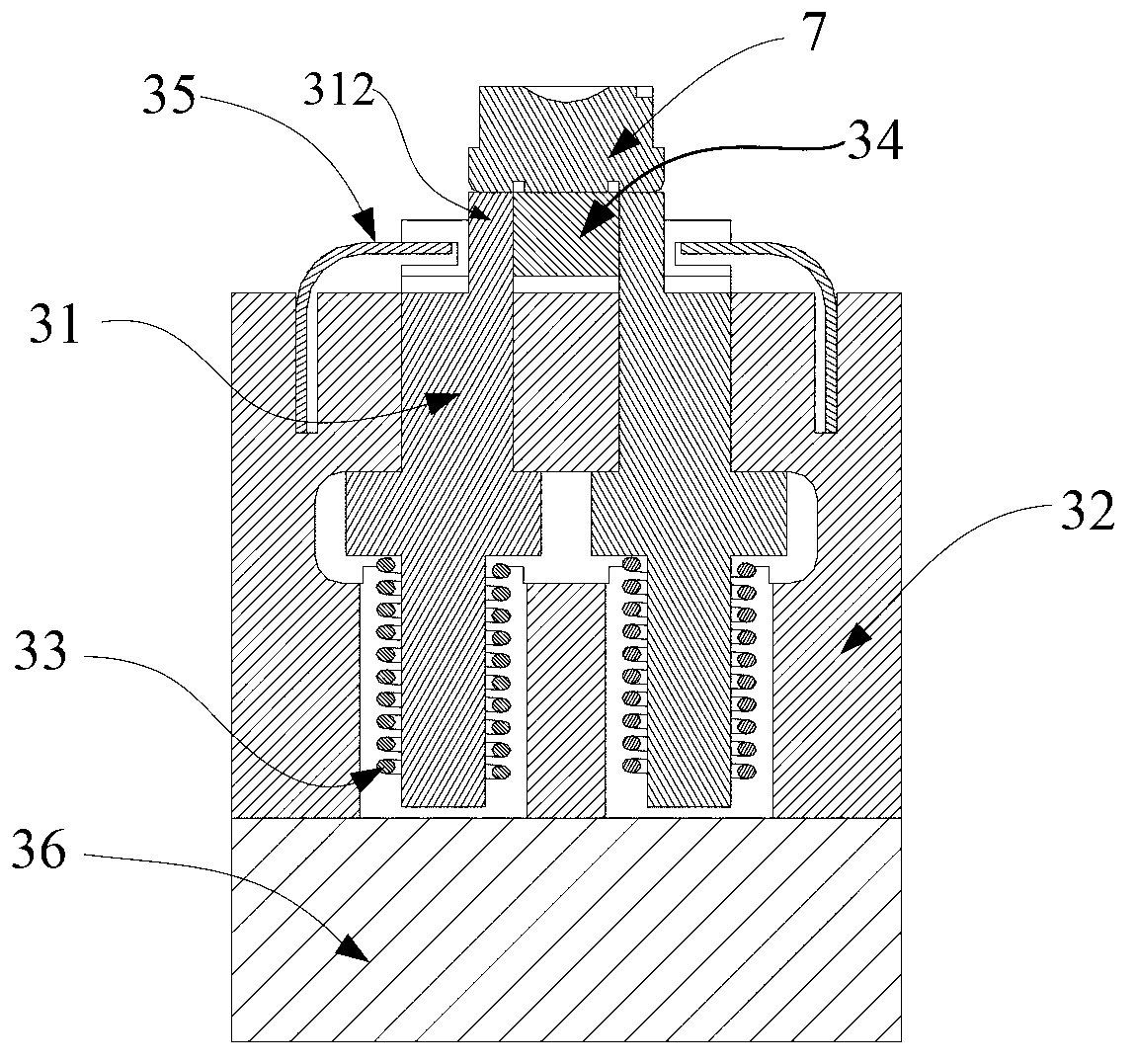

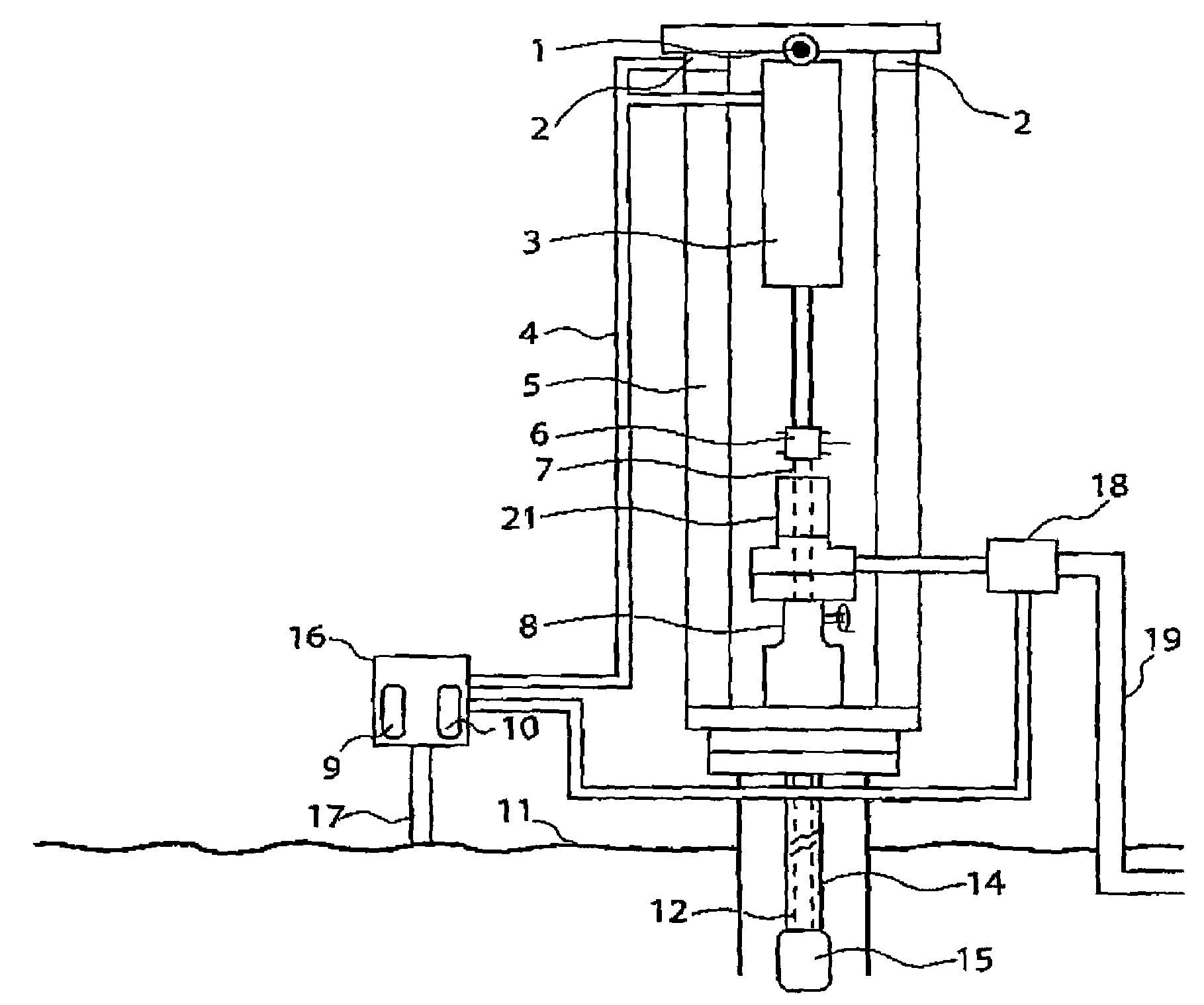

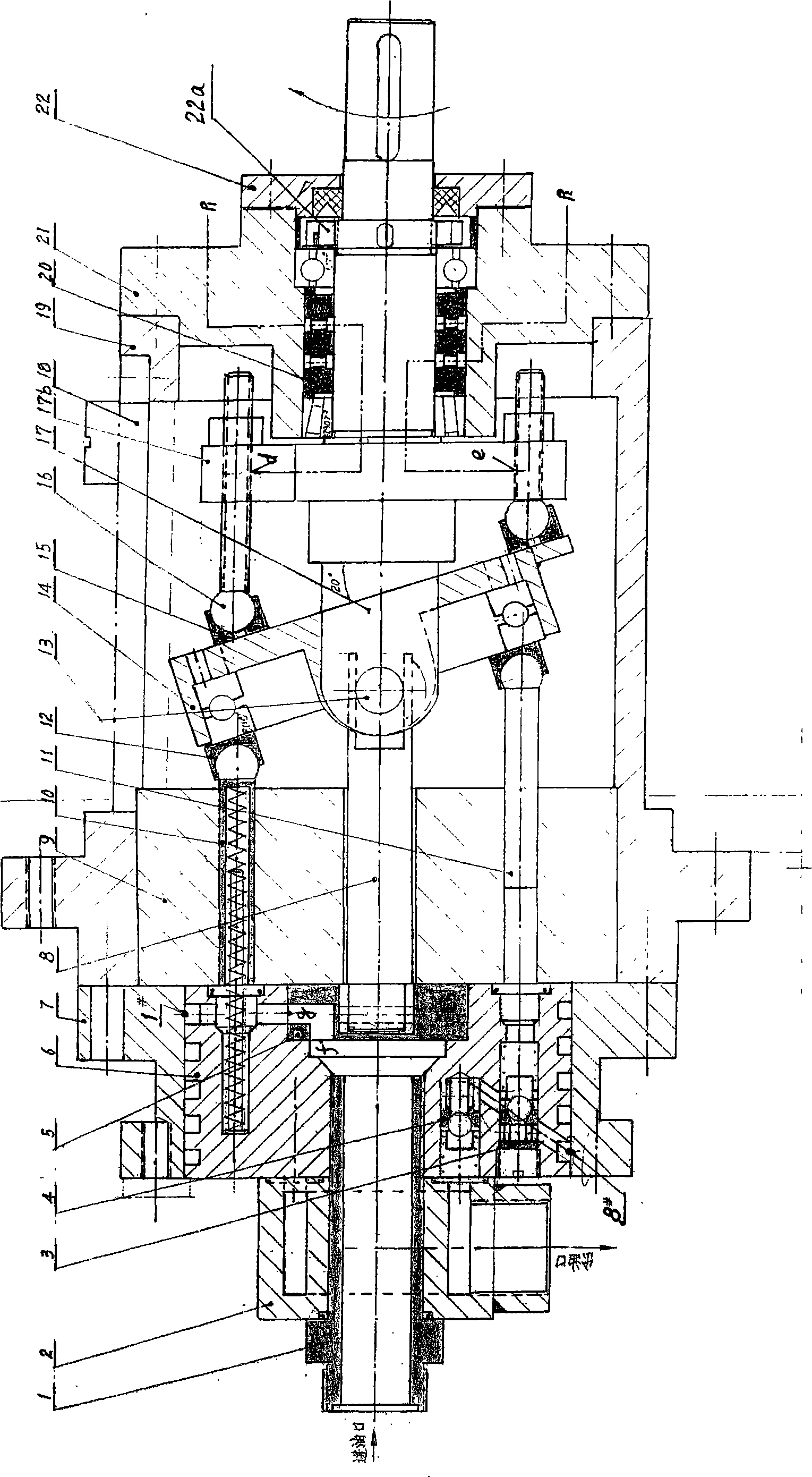

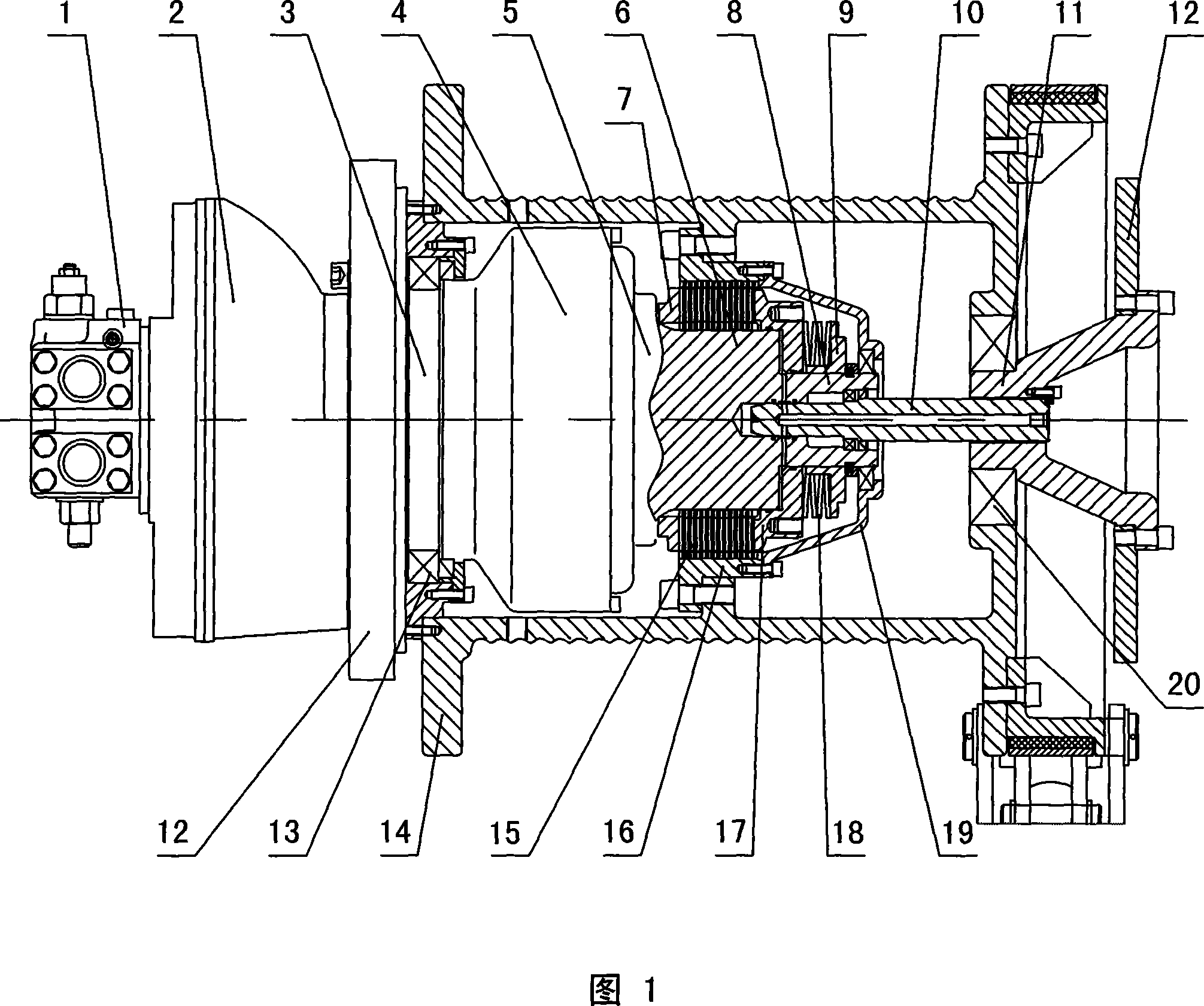

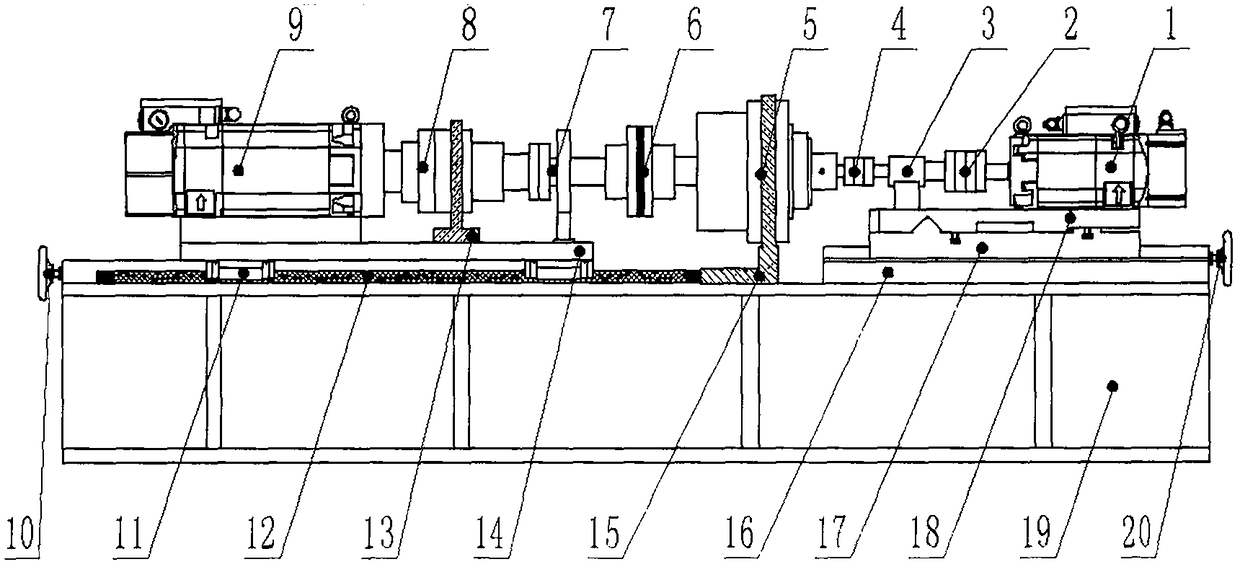

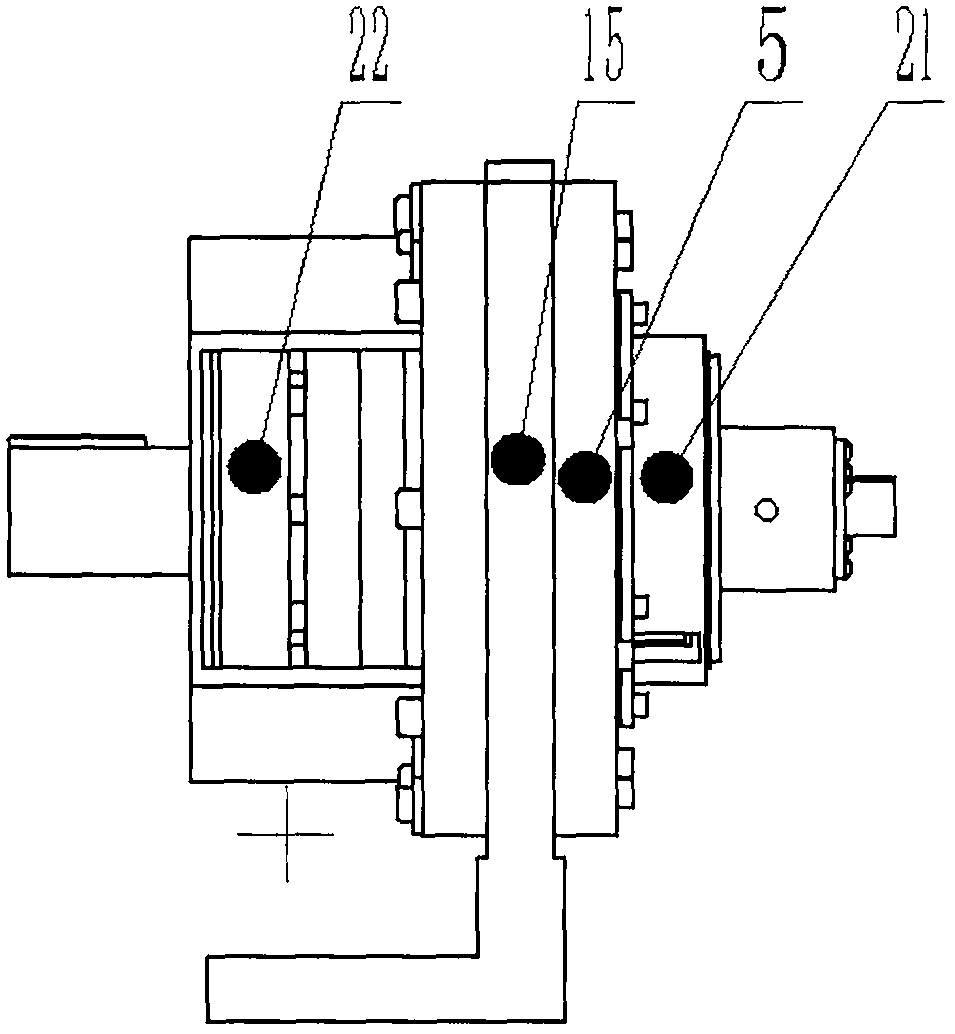

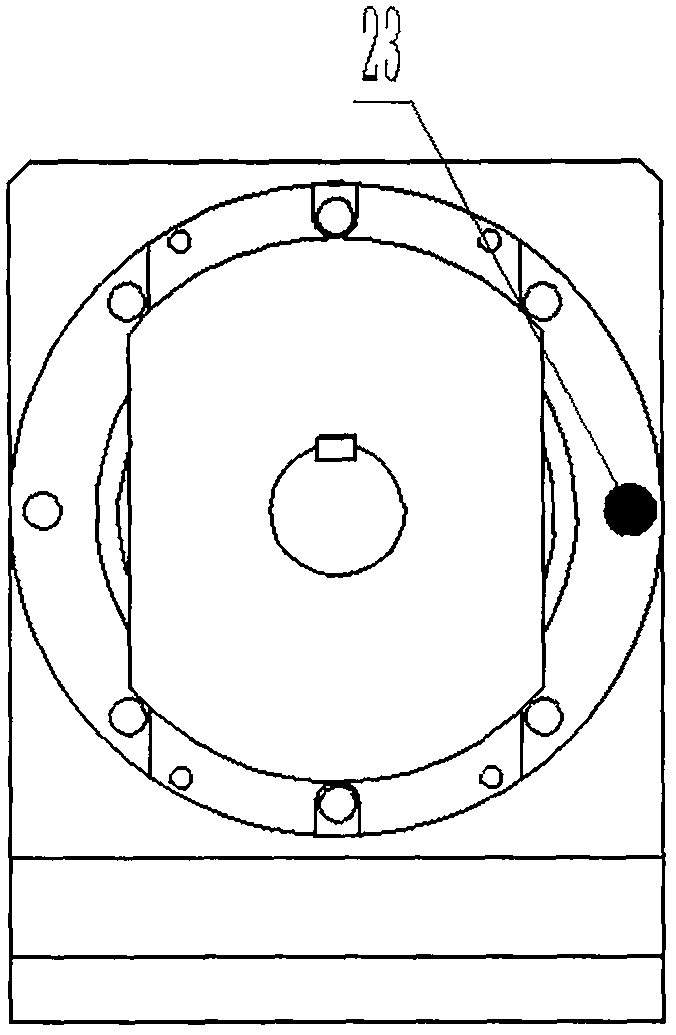

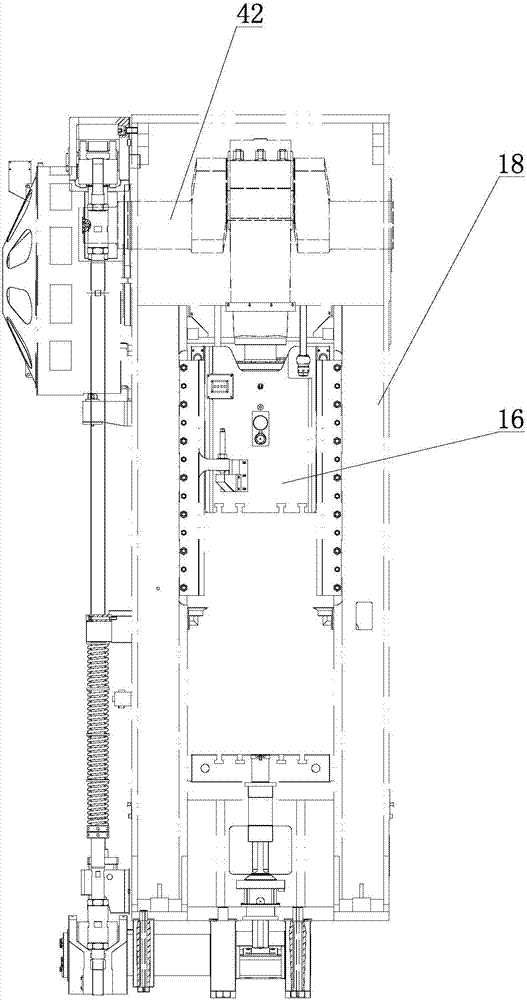

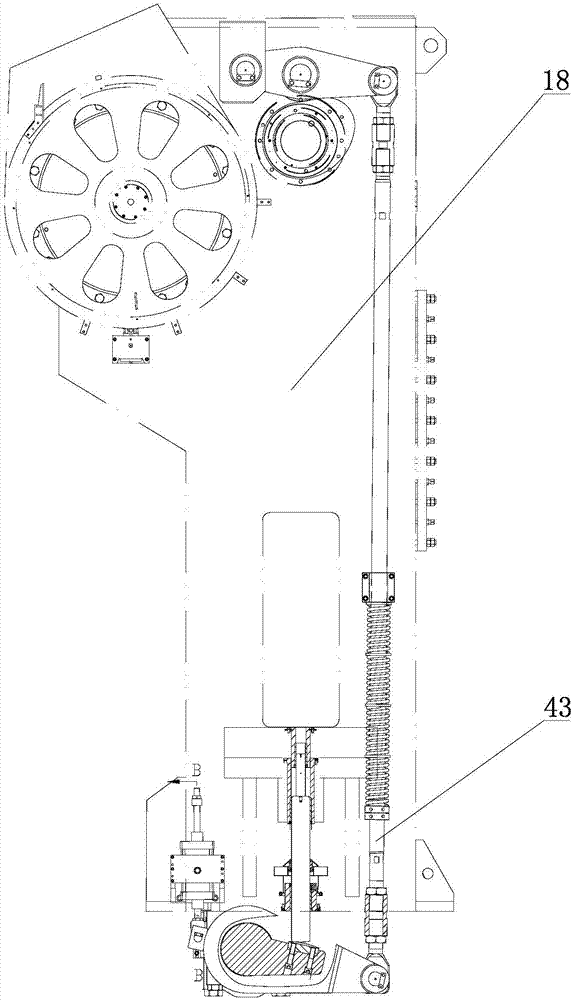

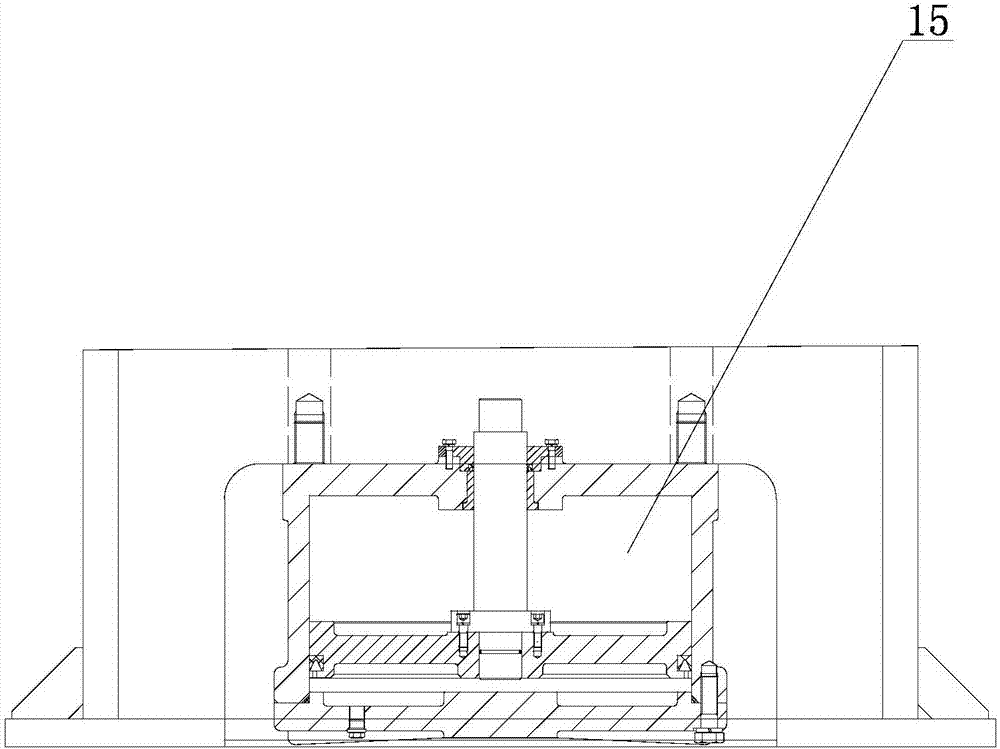

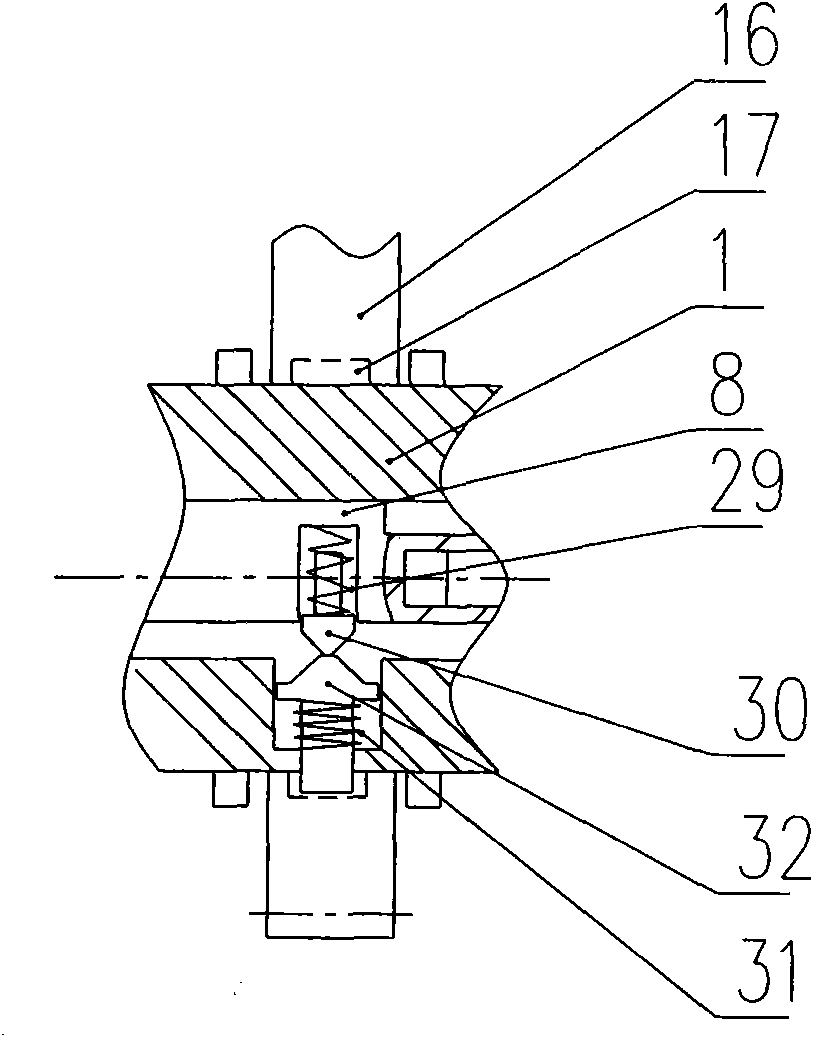

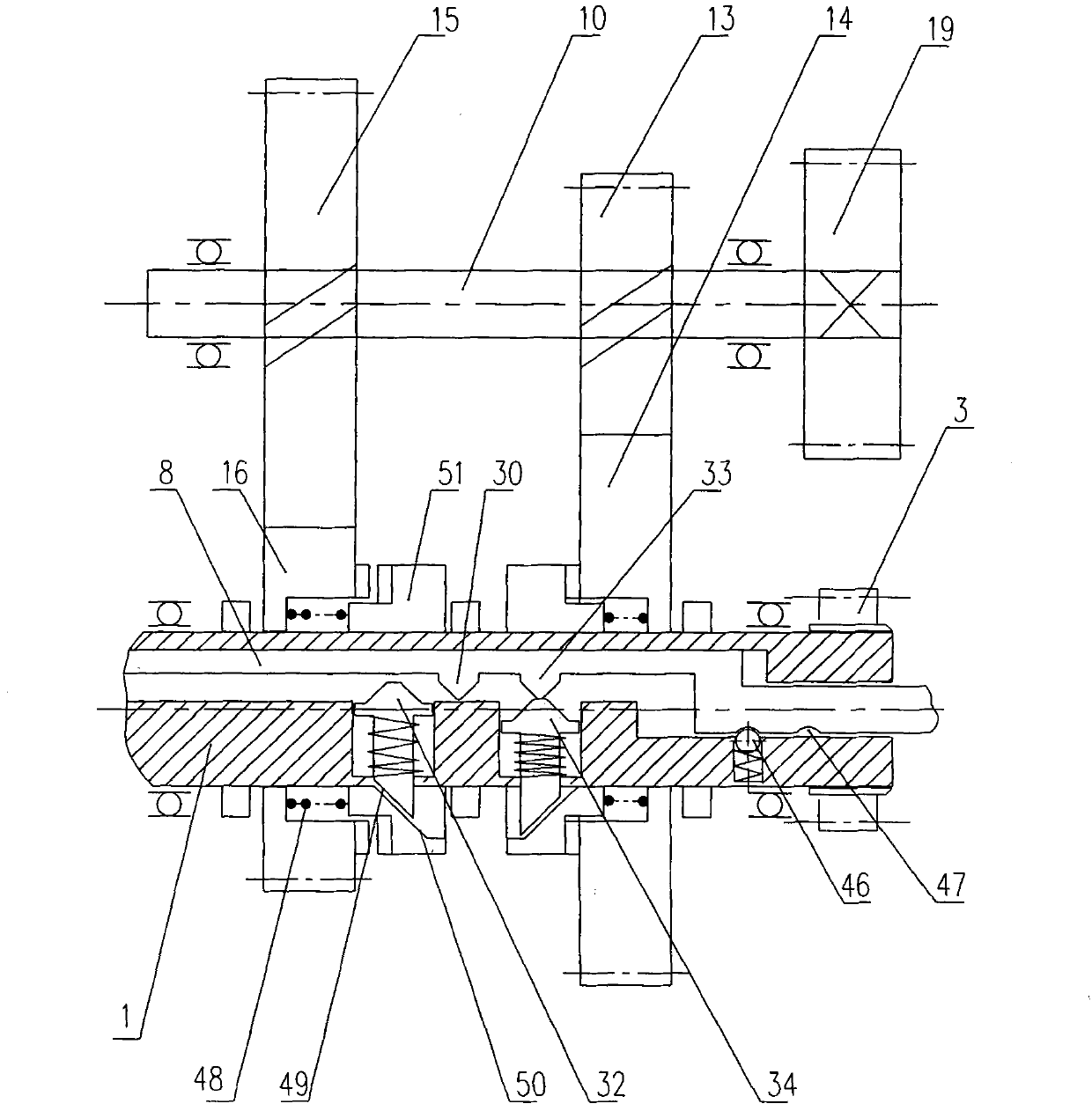

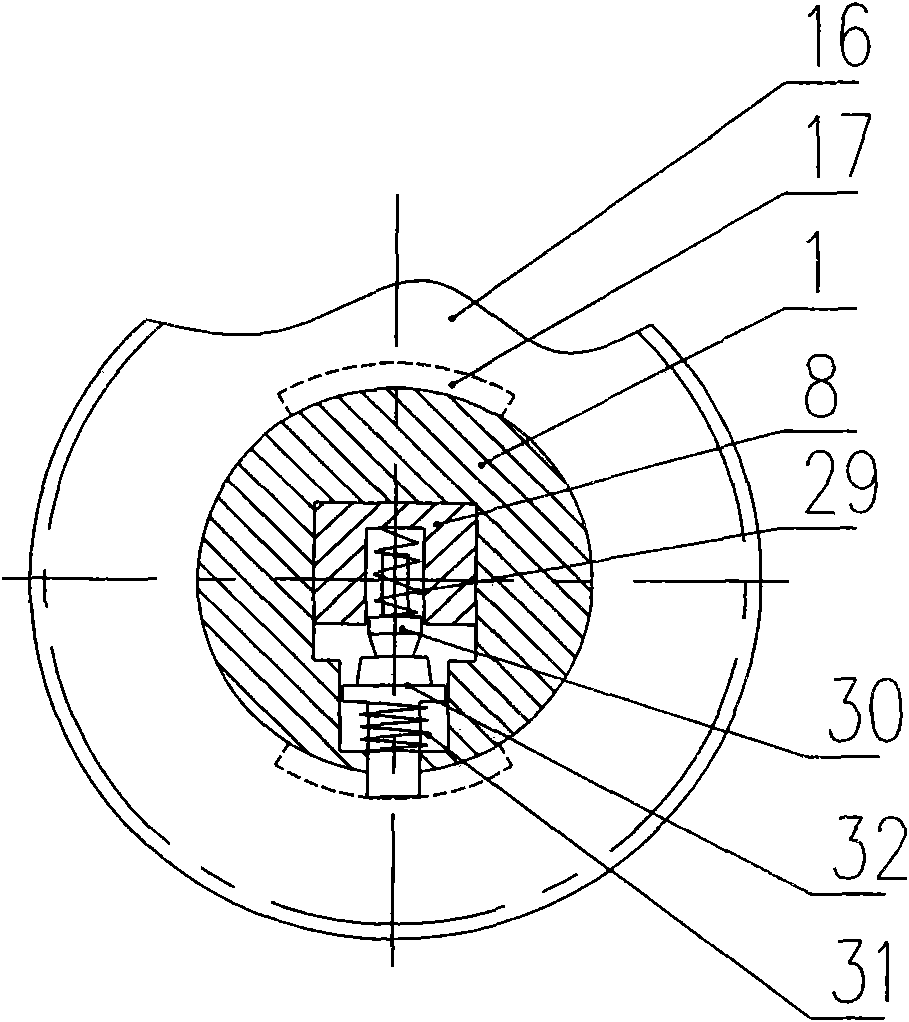

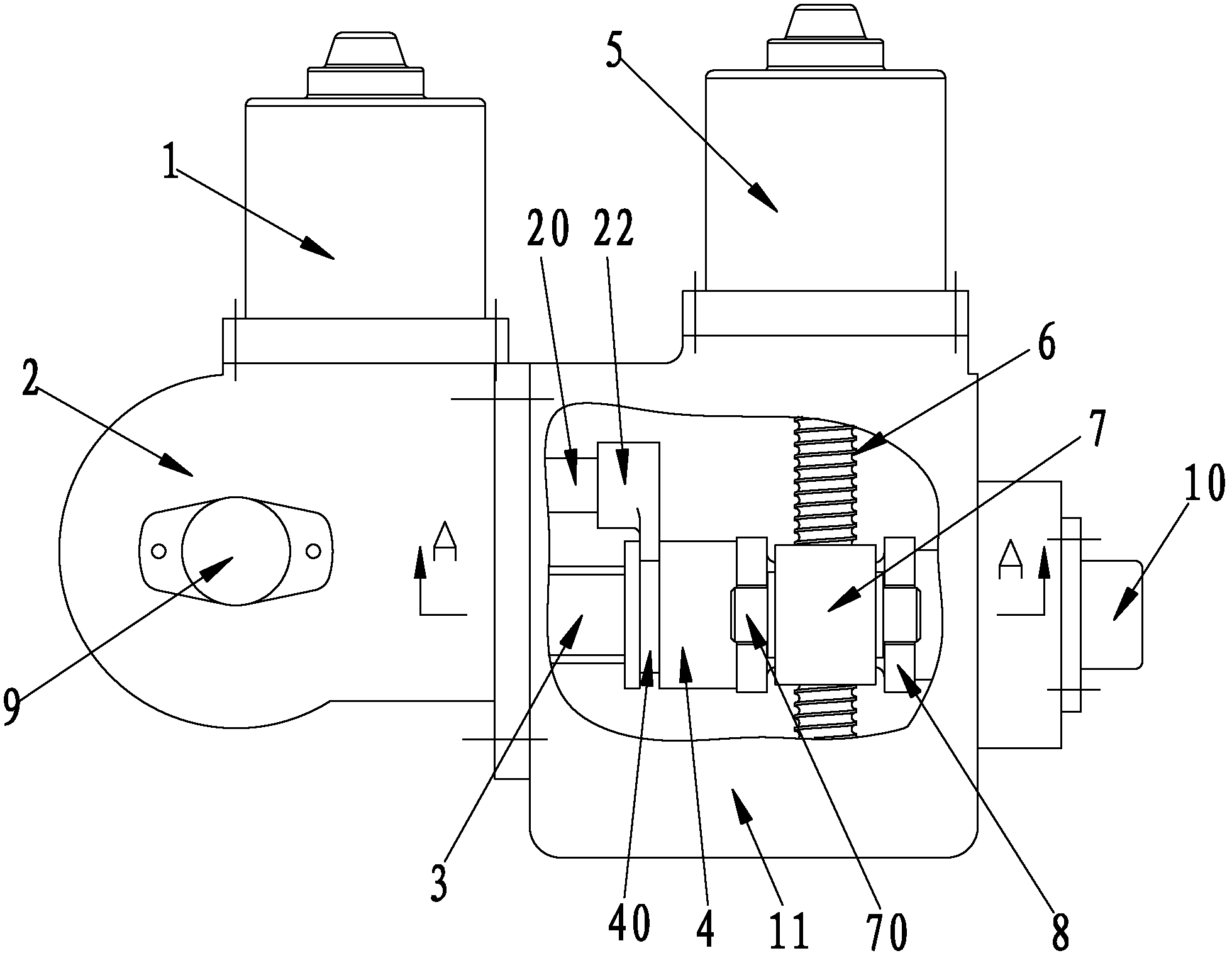

Precision speed reducer accuracy and performance comprehensive test bed

InactiveCN108225766AImprove general performanceComprehensiveMachine gearing/transmission testingTest efficiencyFriction torque

The invention discloses a precision speed reducer accuracy and performance comprehensive test bed. A driving motor 1, a first coupler 2, an input end torque sensor 3, a second coupler 4, an input endangle measuring module 21, a tested speed reducer 5, an output end angle measuring module 22, a third coupler 6, an output end torque sensor 7, a speed increasing machine 8 and a loading motor 9 are sequentially connected on a bed base 19 along the same axis, the driving unit is fixedly connected on an X-axis driving and supporting platform 18, the input end angle measuring module, the output endangle measuring module and the tested speed reducer 5 are connected on a mounting and clamping support 15, and a loading unit is fixedly arranged on a loading and supporting platform 14. The test bedmeets the testing requirements of transmission performances such as precision speed reducer angle transmission errors, torsion rigidity, back clearances, return differences, retrace errors, no-load starting torques, no-load friction torques, reverse starting torques, mechanical efficiency, temperature rising and no-load running-in, on-load tests and overload tests, and the test bed is high in testing function comprehensiveness and high in testing efficiency and testing accuracy.

Owner:中机生产力促进中心有限公司

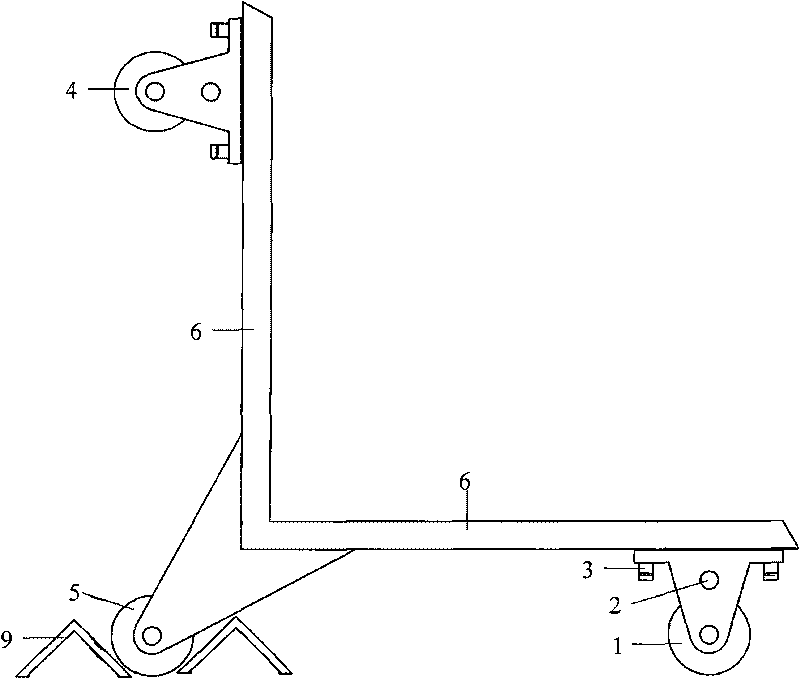

Device for hoisting prefabricated reinforced concrete column on site and walking technology thereof

InactiveCN101713254AShorten the timeUprighting vertical process is stableBuilding material handlingLoad-engaging elementsReinforced concrete columnEconomic benefits

The invention relates to the field of building operations, in particular to a device for hoisting prefabricated reinforced concrete column on site and a walking technology thereof. The purpose of the invention lies in providing a simple yet effect walking technology for hoisting prefabricated reinforced concrete column on site and the device for realizing the technology; the design is simple and the operation is effective. To achieve the purpose, the invention provides the following technical proposal: the device of the invention is composed of a wheeled supporting plate, steel sheets and braking angle iron and has the following characteristics: the supporting plate is a right-angle structure, the top of the right angle is provided with deflectable rolling-over wheels, the two ends of the supporting plate far away from the top of the right angle are respectively provided with deflectable wheels, rotary connecting rods are arranged on a deflectable wheel seat. With the device of the invention adopted, mechanical efficiency can be effectively improved, construction productivity can also be enhanced, thus accelerating construction progress and enjoying extremely noticeable economic benefits and comprehensive benefits.

Owner:DALIAN ZHUCHENG CONSTR GRP

Lever type mechanical downward pushing device of mechanical press

ActiveCN107214284AEasy to grabIncrease profitForging/hammering/pressing machinesEjection devicesEngineeringMechanical press

A lever type mechanical downward pushing device of a mechanical press comprises a sliding block mounted on a machine body. Supports are mounted on the two sides of the sliding block correspondingly to be connected with vertical upper pull rods. The upper pull rods are connected with lower pull rods through adjusting nuts. The lower ends of the lower pull rods are fixedly connected with pull rod connectors. The pull rod connectors are rotatably and slidably connected with the outer ends of horizontally-arranged levers. The middles of the levers are rotatably connected with fulcrum seats arranged on the machine body. The other ends of the levers are in rolling connection with the lower bottom faces of a pushing seat. The upper end of the pushing seat is vertically and movably arranged in the machine body. A through hole is formed in the center of the pushing seat. An air cylinder is arranged at the bottom of the pushing seat. A piston rod of the air cylinder is mounted in the through hole. The upper end of the pushing seat is in matched connection with the lower end of an upper pushing rod. The upper end of the upper pushing rod is in matched connection with a worktable. The lever type mechanical downward pushing device has the advantages that synchronization is good, symmetrical balance is achieved, ejecting force is large, structure is simple, compactness is achieved, mechanical efficiency is high, manufacturing cost is low, maintenance is easy, environmental friendliness and energy saving are achieved.

Owner:RONGCHENG HUADONG METAL FORMING MACHINERY

Speed changer

InactiveCN101818804AReduce speed differenceGuaranteed smoothnessToothed gearingsGearing controlPush and pullDrive shaft

The invention discloses a speed changer capable of solving the problems of large size, complex operation, high maintenance cost, and the like of the traditional speed changer. The speed changer has about 97 percent of transmission mechanical efficiency and easy and convenient operation and is characterized in that a power input gear can be fixed with a jacket; a sliding sleeve is matched with thejacket through a helical rack and is matched with a gear shaft through a spur rack; a pin shaft of the sliding sleeve contacts with a push rod of a gear shift shuttle; a crank arm is movably connected with a lug through the pin shaft; a shifting fork forks on a shaft rod of a push-and-pull rod; a hollow cavity or a sliding chute of the gear shaft is internally provided with the gear shift shuttle; the gear shift shuttle is provided with a top bulge; the gear shaft is provided with a sliding key and is assembled with an angle gear matched with a chamfered groove strip and a plurality of gearshift gears; the gearshift gears can be respectively meshed with a driven gear; the driven gear is assembled on a driven shaft; and the driven shaft is fixed with a power output gear. The invention can be used for an epicyclic gear train and realize the full-automatic speed change from two gears to more than ten gears.

Owner:HUNAN JINLONG MOTOR

Anti-surge air escape energy recycling system of gas turbine

ActiveCN105626266AImprove economyImprove work efficiencyGas turbine plantsEngine componentsEnergy recoveryAir compressor

The invention provides an energy recycling system by using anti-surge air escape of a gas turbine of an integrally integrated turbine generator set; and the anti-surge air escape energy recycling system of the gas turbine comprises an intake subsystem, a turbine power generation subsystem and an exhaust subsystem. The system performs the energy recycling for the anti-surge air escape of the gas turbine, improves the economy of an air escape anti-surge measure, adopts a pressure buffer device to improve the working efficiency of the turbine generator set and the recovery effect, uses the recovered anti-surge air escape energy for intake cooling of an air compressor, and reduces the power consumption of the air compressor; the integral turbine generator set needs no complex control system; the power loss caused by bearing friction is reduced; the power density of a rotating shaft is higher; the size of the set is smaller; a permanent magnetic motor rotor is arranged on the rotating shaft, and shares the same rotating shaft with a turbine rotor; speed reducing and connecting mechanisms in middle are reduced; and the mechanical efficiency is higher.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Automatic shifting device and method for speed change of vehicles

ActiveCN102384262AFirmly connectedSimple structureControlled membersGearing controlReducerEngineering

The invention relates to an automatic shifting device and a method for speed change of vehicles. The device comprises a shift selection motor, a shift selection reducer which is connected with the shift selection motor and is used for speed reduction, a spindle, a dial head sleeved on the spindle, a shift motor, a lead screw connected with the output of the shift motor, a nut sleeved on the lead screw, a shifting fork which is sleeved on the spindle and is in transmission fit with the nut, a shift selection position sensor arranged on the shift selection reducer, a shift position sensor connected with the spindle, and a shell which is positioned between the shift selection reducer and the shift motor and covers the spindle. The invention has the advantages that: the device has a simple structure, is light and has high mechanical efficiency; the device can realize trip stop, is convenient to install, and is small in mechanical occupied space; the device can realize the stable transmission of power, is accurate in position, can realize program control easily, and is safe and reliable, and shift selection and changing actions are accurate; and the device is low in cost and is easy to implement.

Owner:SUZHOU LVKON TRANSMISSION TECH CO LTD

Drum-type turner

ActiveCN102126602AQuality improvementHigh strengthThrowing machinesSludge treatmentFriction lossSludge

The invention discloses a drum-type turner which is characterized in that a motor is arranged in a roller; and the roller is directly arranged on a power output shaft of a speed reducer. The drum-type turner has the advantages of compact structure, high mechanical efficiency, stable operation and no noise; a stepped web plate is adopted; the cutting edge is sharp; the friction loss is less and the scarifying and material smashing operation quality is good; and the turner is provided with a feed distribution cabin and a lifting workbench, thus various types of work, such as material paving, detection and the like can be finished simultaneously. The equipment can be used for processing solid wastes, such as rubbish, excrement, mud and the like.

Owner:BEIJING ZHONGKE BOLIAN ENVIRONMENT ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com