Patents

Literature

4810results about "Ejection devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

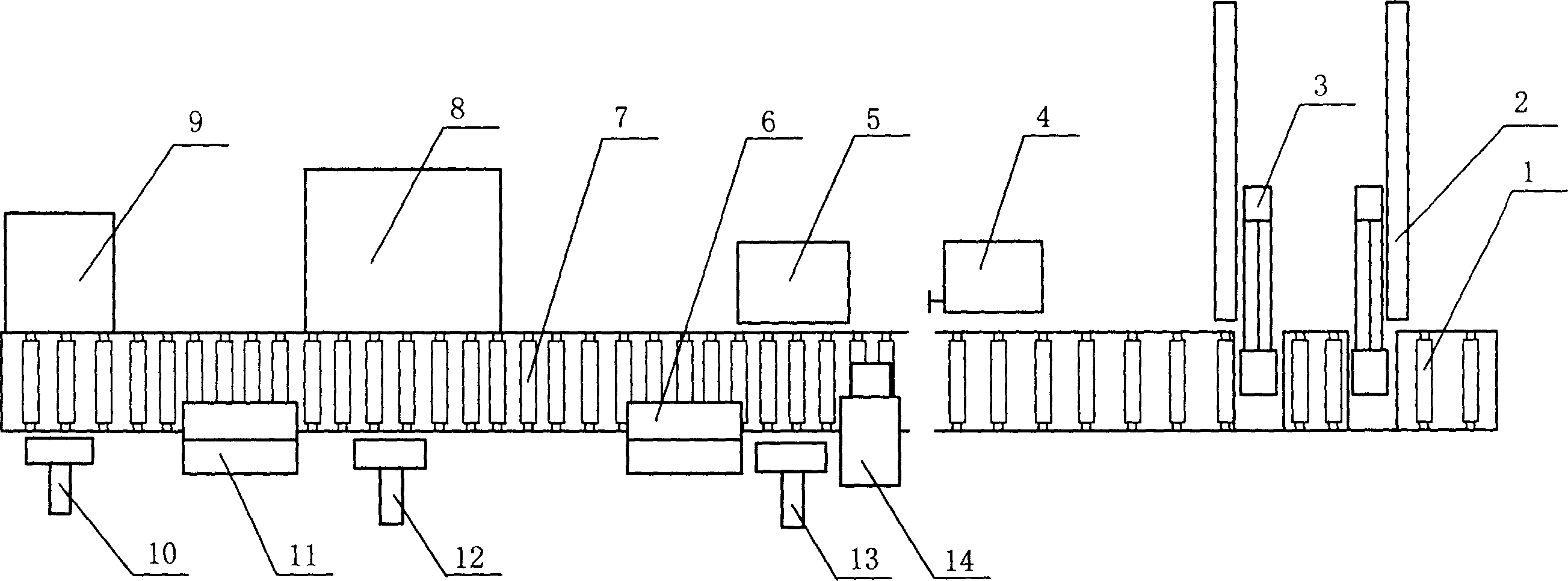

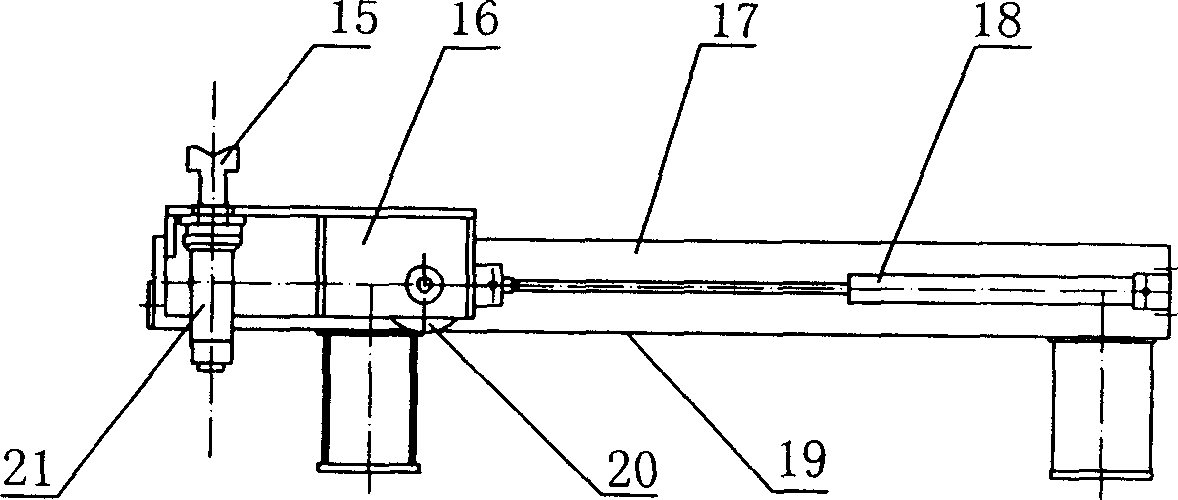

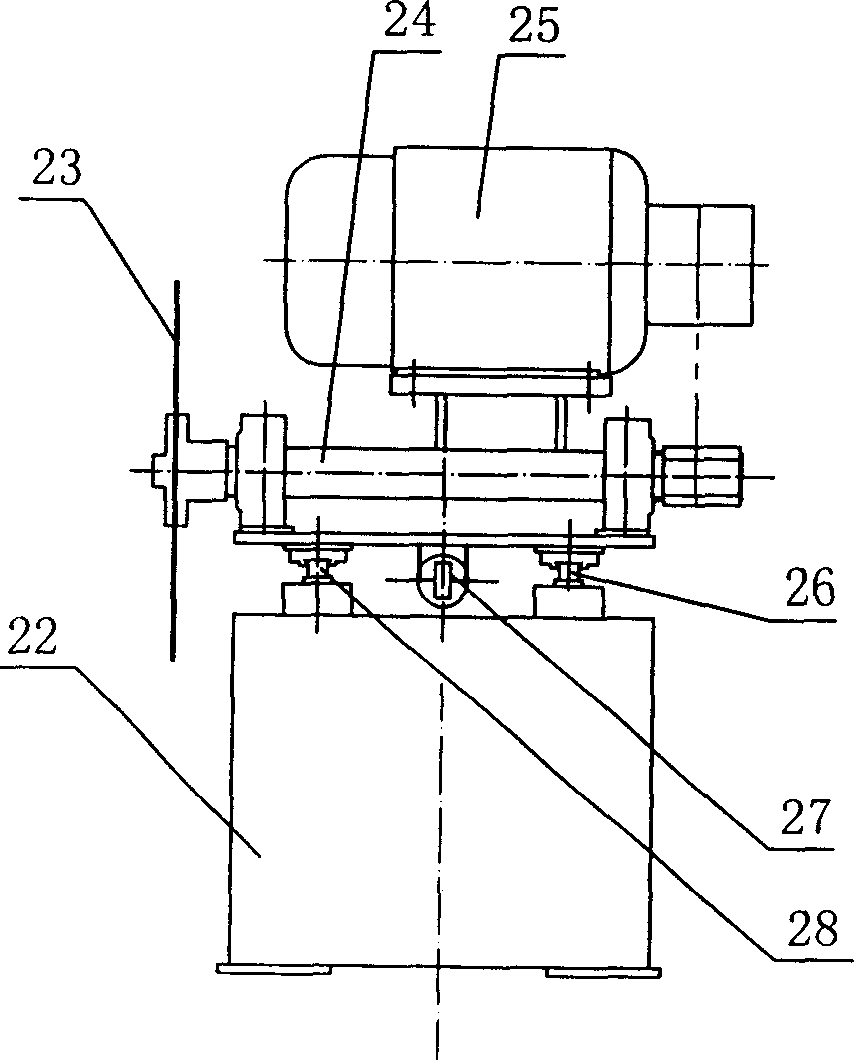

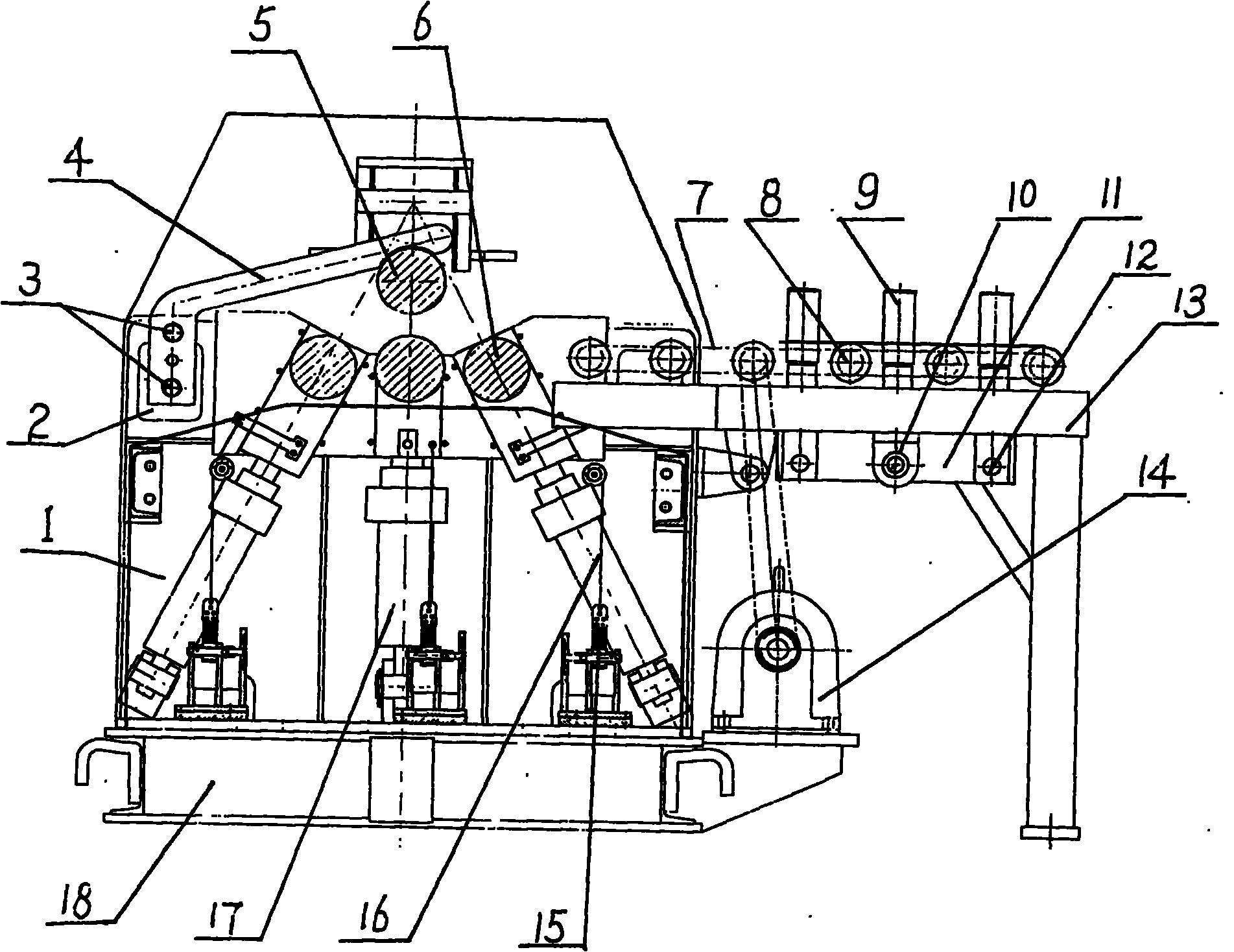

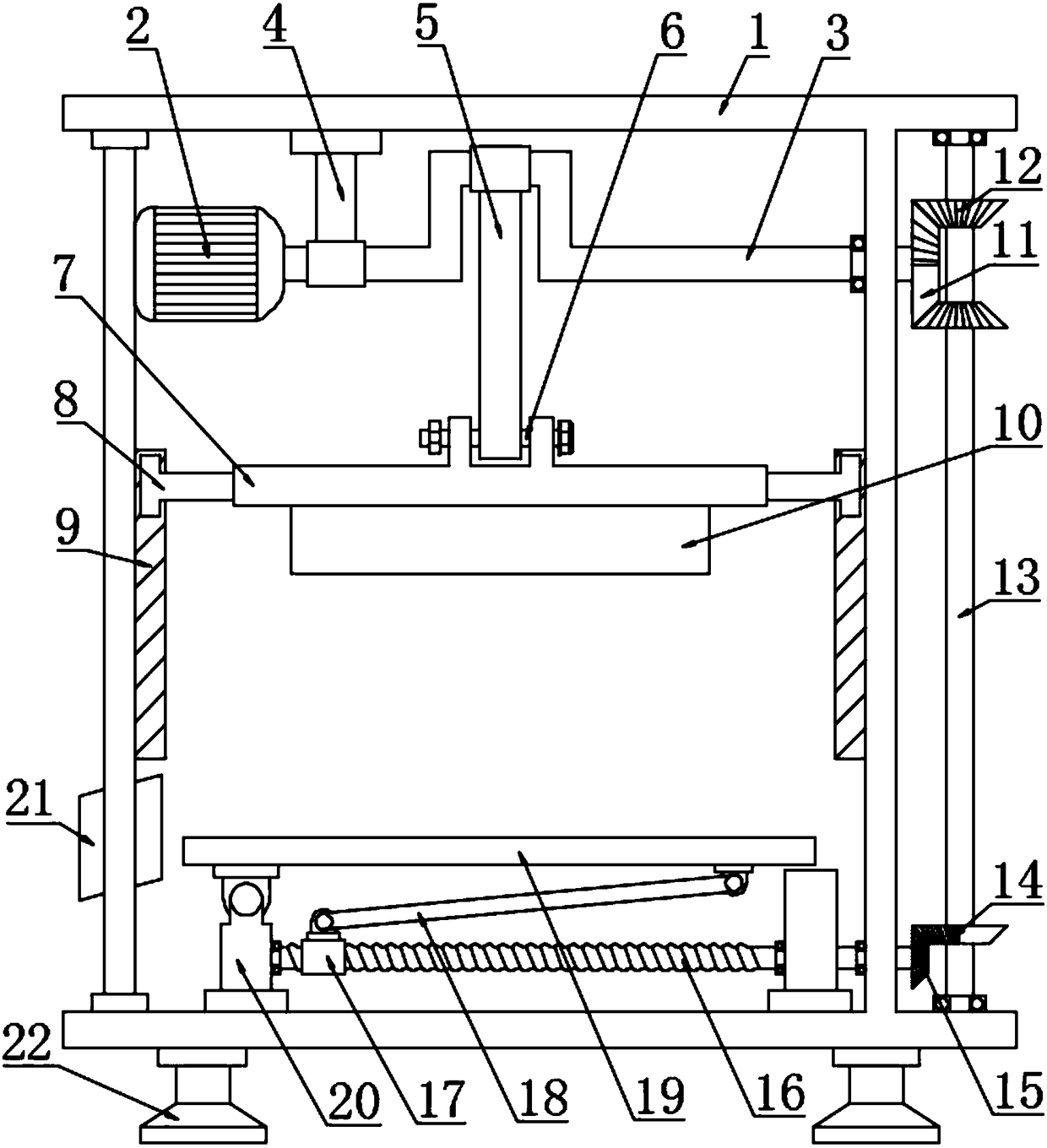

Automatic sawing, cutting and stacking machine for aluminum alloy bar

ActiveCN1899719ARealize automatic controlFree laborMetal-working feeding devicesPositioning devicesAutomatic controlStack machine

The automatic sawing, cutting and stacking machine for aluminum alloy bars includes conveying roller bed comprising conveying rollers and chain wheel driving mechanism, operating stations set along the conveying roller bed, material feeding mechanism, material setting mechanism, cutting mechanism, sizing mechanism, stacking mechanism, side aluminum bar pushing mechanism, power mechanism and control mechanism. The present invention has power mechanism and control mechanism, and can realize PLC automatic control and automatic operation of feeding, sizing, cutting and stacking aluminum alloy bars, and possesses high production efficiency.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

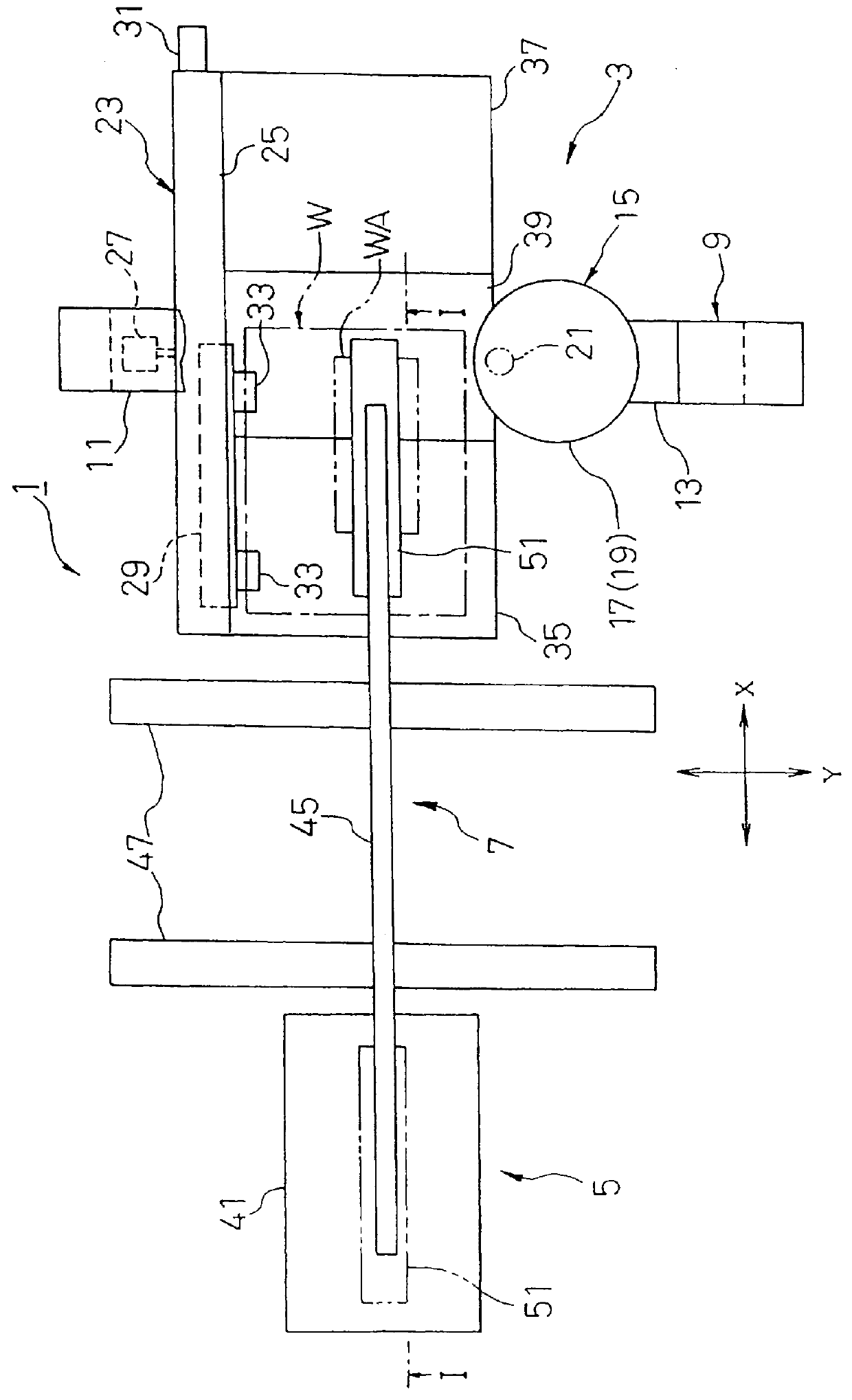

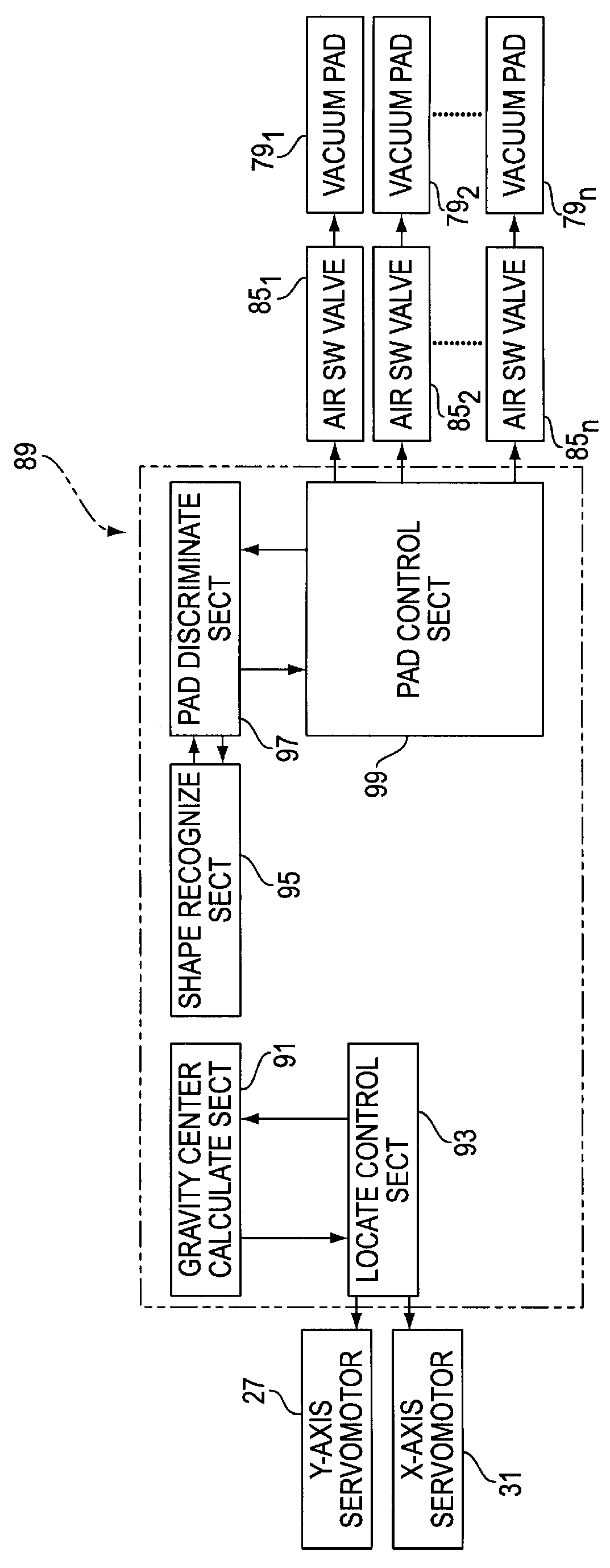

Punched plate material carrying-out system

InactiveUS6055895AReduce in quantitySmall sizeAutomatic control devicesMetal-working feeding devicesPunch pressManufacturing data

A slider of the punch carry out unit is moved in the X-axis direction adjacent a punching section of the punch press machine before or after a plate material is punched into a punched product by a punch press machine. At the same time, a gravity center and a shape of the punched product are calculated and recognized on the basis of the manufacturing data. On the basis of the obtained gravity center and the shape of the punched product, the gravity center of the punched product is moved under the lift arm by the X- and Y-axis locating mechanism. Vacuum pads located just over the punched product are selected or discriminated. Then, the lift arm is lowered and the punched product is held by actuating only the discriminated vacuum pads. During this lift motion, it is preferable to bend one end of the punched product slightly upward to easily separate the punched product from the remaining flat plate material. After the punched product has been lifted, the punched product is moved horizontally away from the punch press, and is then lowered on the punched product supporting unit by releasing only the actuated vacuum pads. Since only the vicinity of the gravity center of the punched product is held by a minimum possible number of the vacuum pads, irrespective of the size and shape of the punched products, the number of the vacuum pads can be reduced.

Owner:U S AMADA

Feeding and discharging mechanical arm and device for stamping process

InactiveCN104785655AAutomatic and flexible reclaimingAutomatic and flexible feedingProgramme-controlled manipulatorMetal-working feeding devicesElectricitySingle process

The invention discloses a feeding and discharging mechanical arm and device for the stamping process. The feeding and discharging mechanical arm structurally comprises an electric control cabinet, a rack, a main rotating shaft, a fixing base, a vertical shaft, a first mechanical arm body, a second mechanical arm body, a first mechanical claw and a second mechanical claw. The included angle between the first mechanical arm body and the second mechanical arm body ranges from 90 degrees to 120 degrees, and the first mechanical arm body and the second mechanical arm body can move vertically along with the vertical shaft. The vertical shaft and the fixing base can rotate horizontally along with the main rotating shaft. The main rotating shaft, the vertical shaft, the first mechanical arm body and the second mechanical arm body are driven by different motors, and all the motors are electrically connected with the electric control cabinet. The feeding and discharging mechanical arm has the functions of taking and placing materials automatically and flexibly, is suitable for single-process stamping as well as whole-line multi-station stamping, solves the technical problems that existing equipment is low in applicability, low in working efficiency and likely to cause industrial accidents, and improves working efficiency, flexibility and safety.

Owner:FOSHAN IROBOT AUTOMATIC

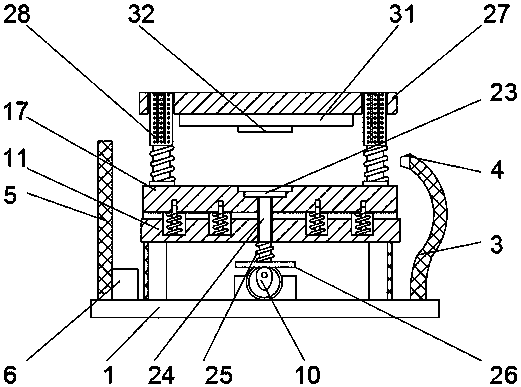

Self-discharging type stamping and forming all-in-one machine

InactiveCN111001720ARealize automatic feeding processSustainable workMetal-working feeding devicesPositioning devicesPunchingElectric machinery

The invention relates to a stamping and forming all-in-one machine, in particular to a self-discharging type stamping and forming all-in-one machine. The self-discharging type stamping and forming all-in-one machine can achieve automatic feeding, can continuously work, can save time, is easy and convenient to operate and can also avoid stamping accidents. The self-discharging type stamping and forming all-in-one machine comprises a chassis, a rack, an arc-shaped plate, a supporting column, an L-shaped block, a motor and the like. The rack, the supporting column and the motor are fixedly arranged on the chassis, the rack is located on the right side of the supporting column, and the motor is located below the rack. According to the invention, a stamped workpiece can be pushed out through apushing mechanism, and the other workpiece in a discharging frame can be pushed into a punching frame, so that people can take down the punched workpiece, the workpiece does not need to be placed manually, automatic feeding and continuous work can be achieved, a large amount of time is saved, operation is easy and convenient, and punching accidents can be avoided.

Owner:申继州

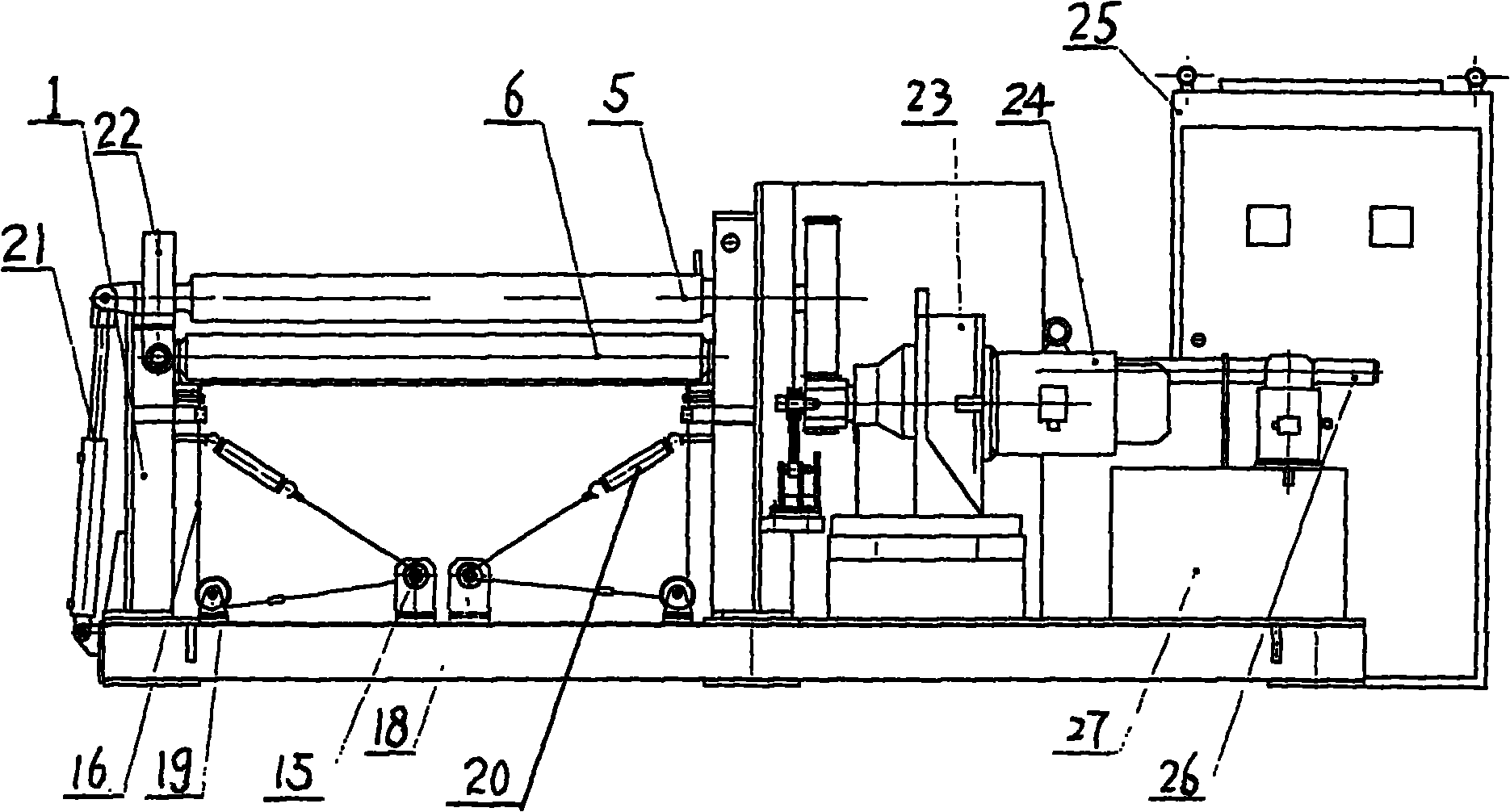

Full-automatic plate bending machine and control method thereof

ActiveCN101773955AReduce labor intensityIncrease productivityMetal-working feeding devicesPositioning devicesHydraulic motorHydraulic cylinder

The invention relates to a full-automatic plate bending machine and a control method thereof. The plate bending machine comprises a machine body, a main motor or a hydraulic motor, a speed reducer, a fixed driving roll, a movable driven roll, a coiling press roll movable shaft seat and a movable shaft seat opening-closing hydraulic cylinder, wherein the front part and the rear part of the machine body are connected with an automatic loading device and an automatic unloading mechanism respectively; the lower part of the machine body is provided with a plurality of displacement sensing mechanisms correspondingly connected with the movable driven roll; one side of the machine body is provided with an automatic control device; and the automatic control device is connected with the main motor or the hydraulic motor, a lifting hydraulic cylinder, the automatic loading device, the automatic unloading mechanism and the displacement sensing mechanisms respectively through signal transmission lines. The full-automatic plate bending machine realizes the automatic machine-shaping of metal plate blank winding drums by using an intelligent automatic control method so as to greatly improve the production efficiency and greatly reduce the labor intensity for operators, and can reliably guarantee the quality of products.

Owner:郑州得力齿轮有限公司

Full-automatic necking machine

InactiveCN106111826AImprove diameter reduction efficiencyReduce labor costsMetal-working feeding devicesMetal working apparatusEngineeringPipe support

The invention provides a full-automatic necking machine and belongs to the technical field of automatic machines. By the adoption of the full-automatic necking machine, the problem that in the prior art, the steel pipe necking efficiency is low is solved. The full-automatic necking machine comprises a machine frame, a hopper and a necking mold. A movable steel pipe supporting frame and a fixed steel pipe supporting frame are arranged between the feeding side and the discharging side of the necking mold device, wherein the moving direction of the movable steel pipe supporting frame is the same as the moving direction of a feeding pull frame, and the fixed steel pipe supporting frame and the movable steel pipe supporting frame are arranged side by side in the same direction. The fixed steel pipe supporting frame and the movable steel pipe supporting frame are each provided with a plurality of grooves distributed at equal intervals. A discharging guide plate is arranged corresponding to an unfilled-corner oblique plane and provided with a rotating mechanism used for controlling the guide plate to rotate. The full-automatic necking machine is simple in structure and low in cost, and the steel pipe necking efficiency can be greatly improved.

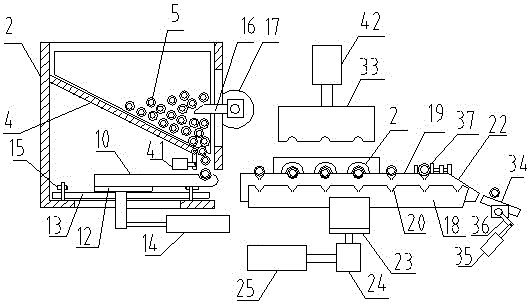

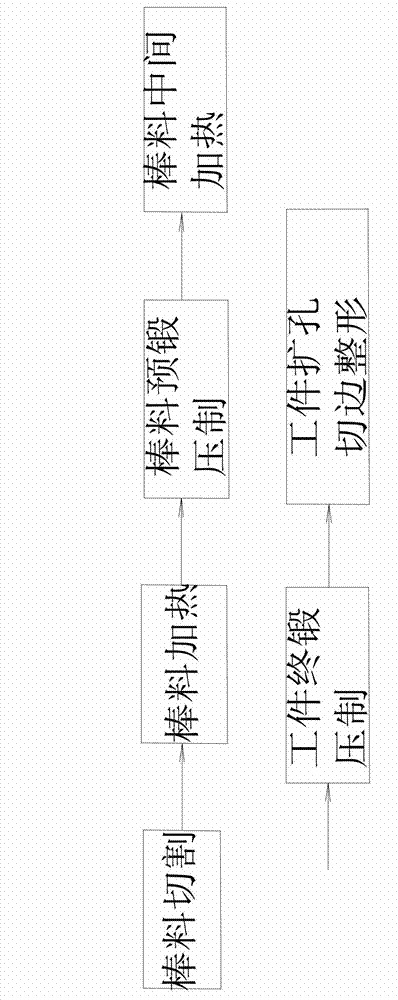

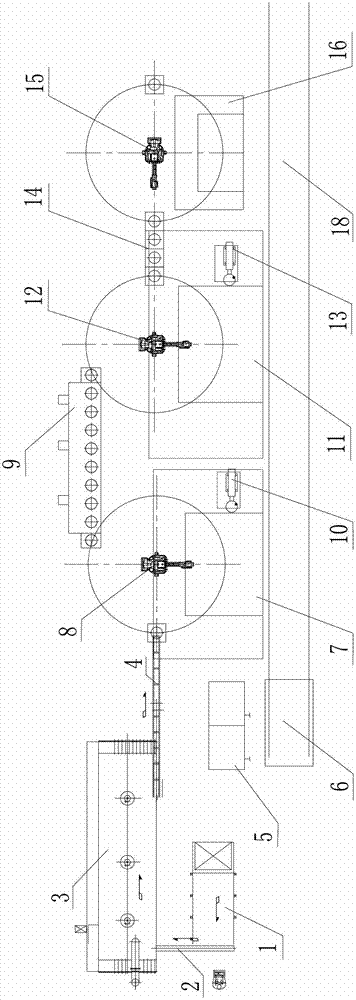

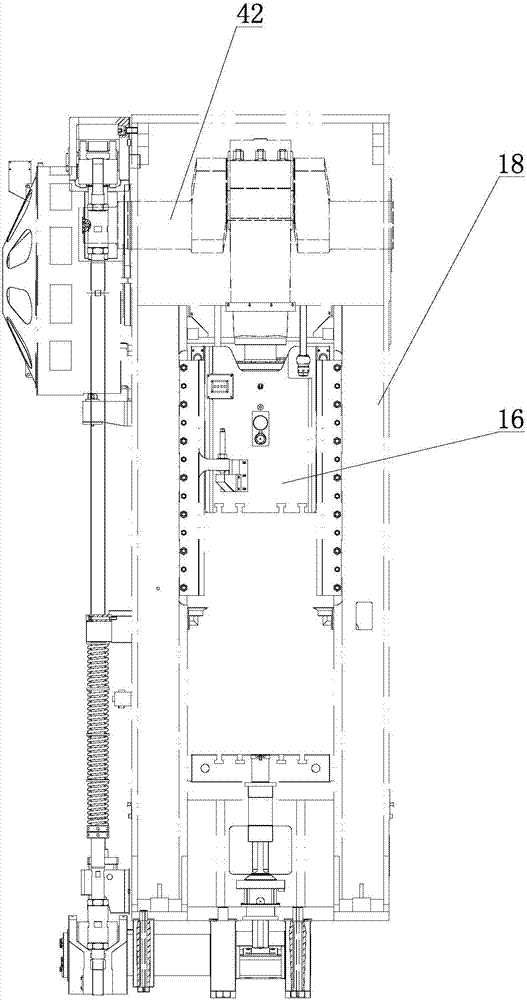

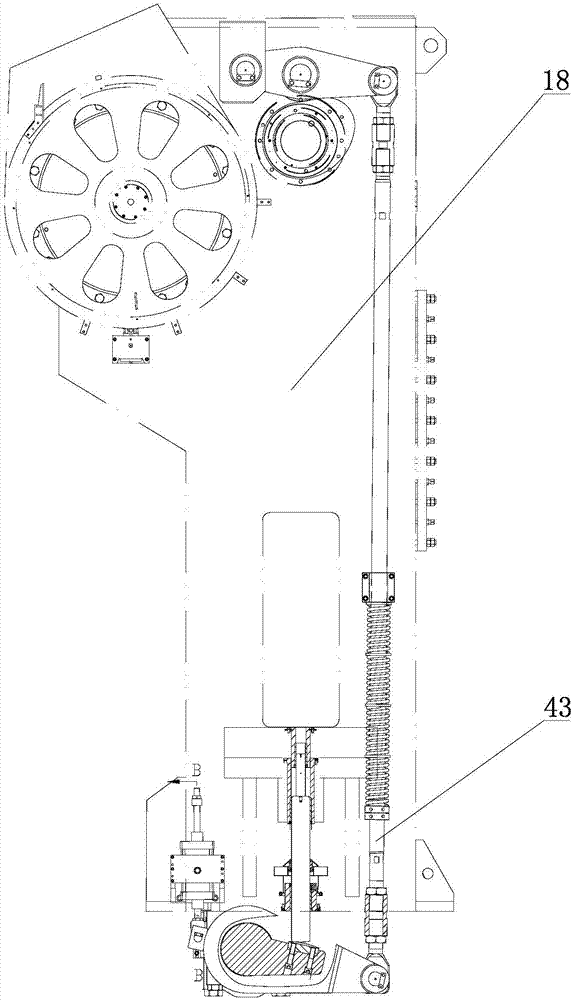

Forging process of large aluminum alloy hub

ActiveCN102873252ASimplify the pressing processWeight optimizationWheelsEjection devicesThermal insulationHeating furnace

The invention relates to a forging process of a large aluminum alloy hub. The forging process is a processing process using a production line of the large aluminum alloy hub and is characterized by including the steps of cutting an aluminum alloy bar, heating the bar, performing pre-forging and compacting to a blank by a hydraulic pre-forging machine, performing secondary heating and thermal insulation to a workpiece, performing final forging and compacting to the workpiece by a hydraulic hub final-forging machine, and performing hole expanding, edge cutting and reshaping to the workpiece. The production line comprises a bar cutting machine, a bar heating stove, workpiece clamping manipulators, the hydraulic pre-forging machine, the hydraulic hub final-forging machine, a hydraulic hub hole-expanding and edge cutting machine and a hub compacting die. The forging process for the large aluminum alloy hub has the advantages that mechanical performance, physical performance and yield of a finished hub can be increased greatly, cost, time and manpower for secondary processing and reshaping are economized greatly, and safety and operation efficiency of a device in production and manufacturing are increased. The forging process is high in automation degree, and a modern production and manufacturing process for aluminum alloy hubs can be met.

Owner:TIANJIN TIANDUAN PRESS CO LTD

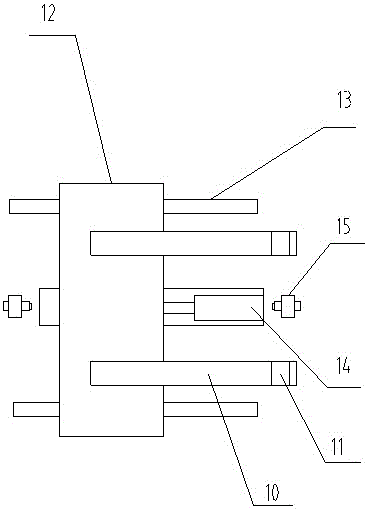

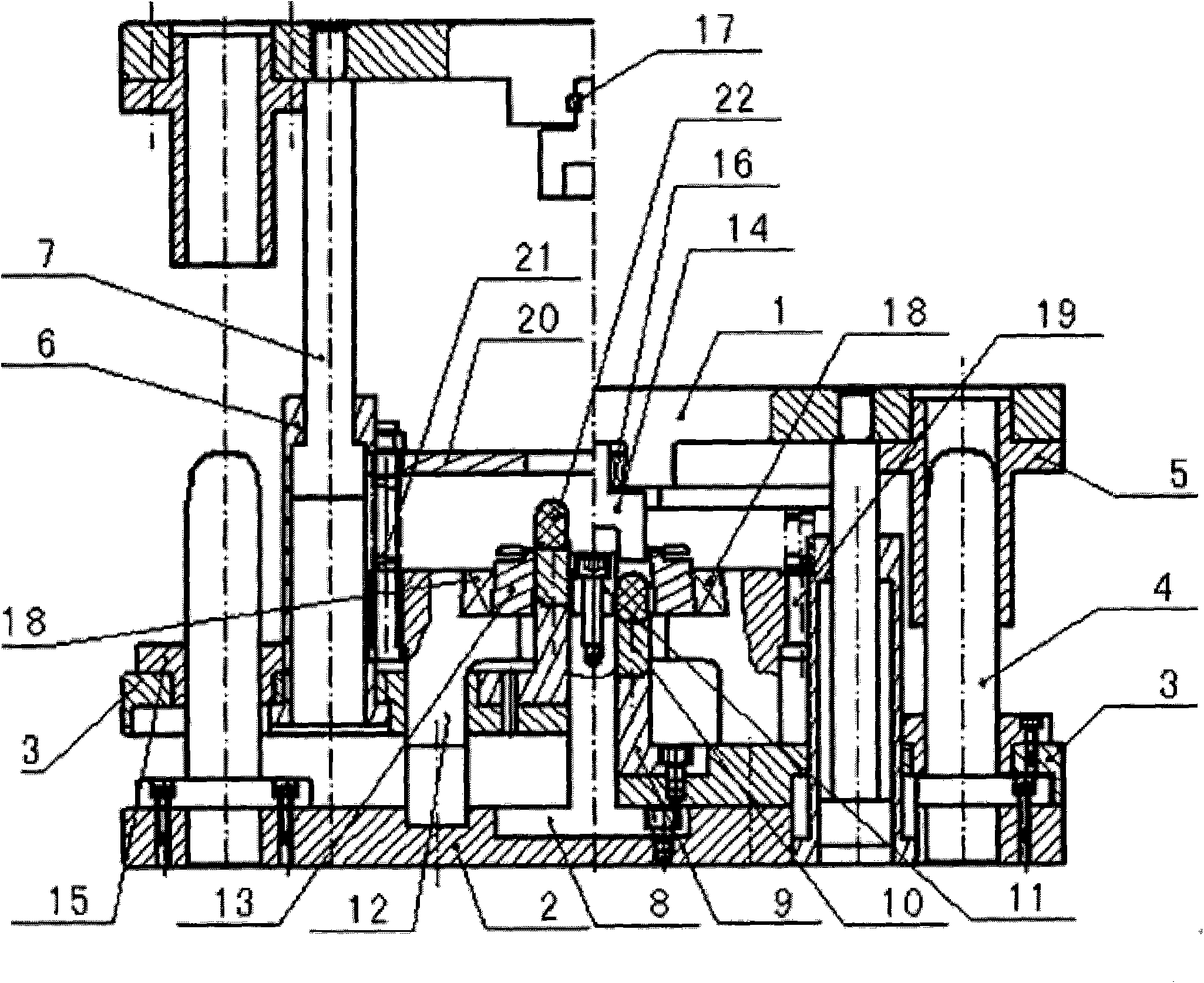

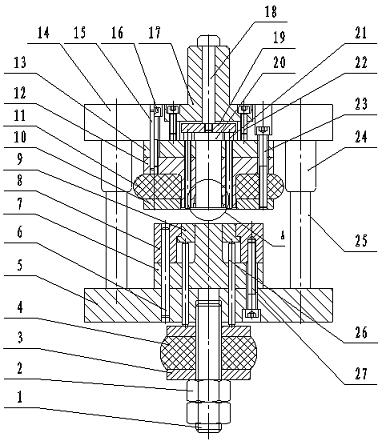

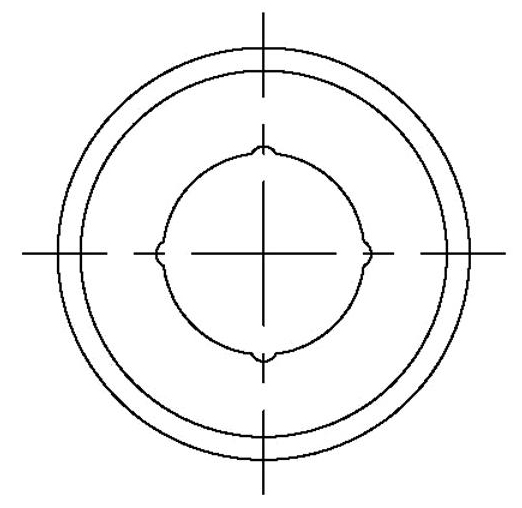

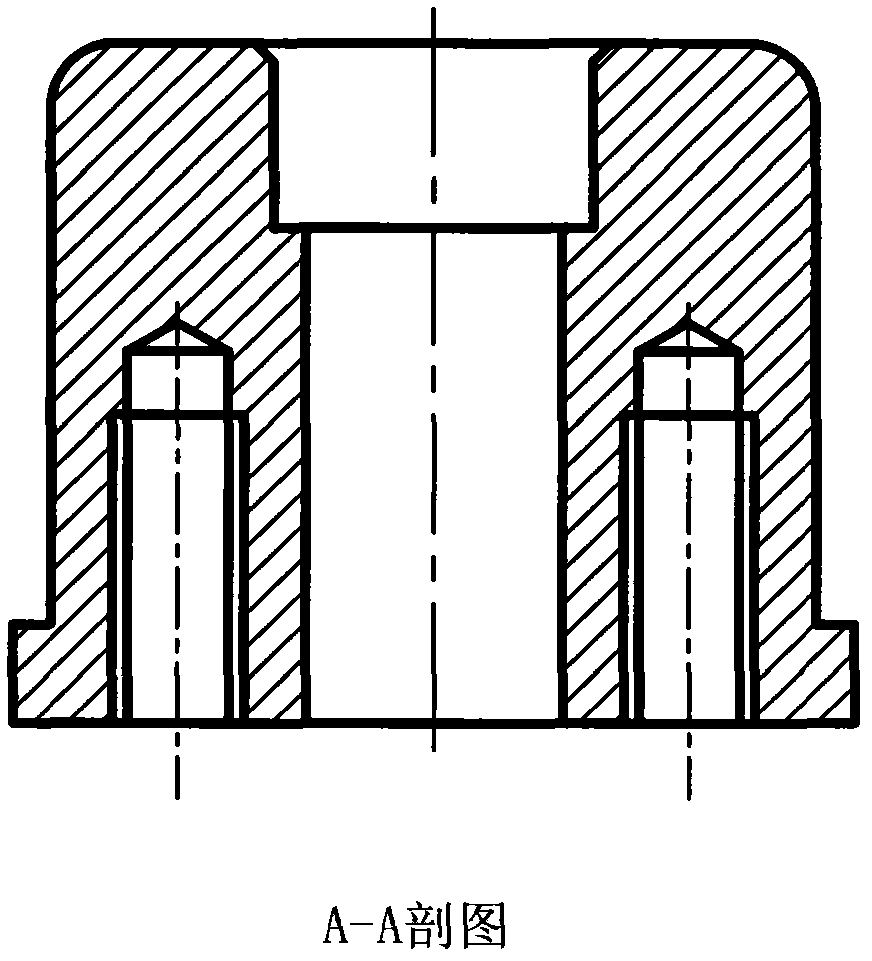

Ring forge piece punching and cutting composite type mould

ActiveCN102029323ACompact structureReasonable structureShaping toolsPerforating toolsPunchingEngineering

The invention relates to a ring forge piece punching and cutting composite type mould which is used on a mechanical press, in particular to the ring forge piece punching and cutting composite type mould. In the conventional mechanical manufacturing industry, inner hole punching and outer edge cutting in a forging and forming process of a forging ring of a transmission chain are performed in two steps, the production efficiency is low and the cost is high. The mould consists of an upper mould, an ejector, a lower mould and a material returning and outer burr removing part, wherein an upper mould plate is provided with a guide sleeve, connecting rods and an edge cutting punch head; a lower mould plate is provided with guide posts, an edge cutting female die seat, an edge cutting female die, a punching punch head seat and a punching punch head; a movable plate is provided with a connecting sleeve, an ejector seat and an ejector head and positioned and guided by two guide posts and the guide sleeve; and four connecting rods drive the connecting sleeve, the movable plate and the ejector part to rise so as to eject a finished punched workpiece. The composite mould is matched with a guide post guide sleeve structure, so accurate positioning of the upper mould, the lower mould and the ejector part is realized, the dimensional accuracy of a product is guaranteed, and the mould is suitable for simultaneous edge cutting and punching of a ring forge piece.

Owner:CHINA COAL ZHANGJIAKOU COAL MINING MACHINERY

Die stamping device with turnover workbench

InactiveCN108058418AImprove work efficiencyReasonable structural designPress ramEjection devicesDrive motorEngineering

The invention discloses a die stamping device with a turnover workbench. According to the die stamping device, a driving motor is fixedly connected to the upper part of the left end of a device body;a crankshaft is connected to the right side of the driving motor in a rotating mode; the left side of the crankshaft is sleeved with the lower end of a lifting rod; the upper end of the lifting rod isfixedly connected to the device body; a bearing on the right side of the crankshaft is connected to the device body in a rotating mode; the middle of the crankshaft is sleeved with the upper end of apush rod; the lower end of the push rod is connected to the middle of a pin shaft in a rotating mode; the two ends of the pin shaft are connected to the upper ends of a transverse plate in a rotatingmode; the lower end of the transverse plate is fixedly connected to a stamping die; the right end of the crankshaft is fixedly connected to a first semi-bevel gear; and two first bevel gears are arranged at the upper part and the lower part of the first semi-bevel gear. According to the die stamping device, the transverse plate is driven to move up and down along guide grooves in a reciprocatingmode through the crankshaft so as to drive the stamping die to move up and down to complete the stamping action, meanwhile, the second bevel gear which intermittently rotates forwards and reversely ina reciprocating mode drives a screw to intermittently rotate forwards and reversely in a reciprocating mode so as to drive the workbench to preform intermittent swing discharging through a connectingrod. The die stamping device has the advantages of being reasonable and practical in structural design and capable of realizing automatic discharging and saving the labor force.

Owner:ZHENGZHOU MOORE ELECTRONICS INFORMATION TECH CO LTD

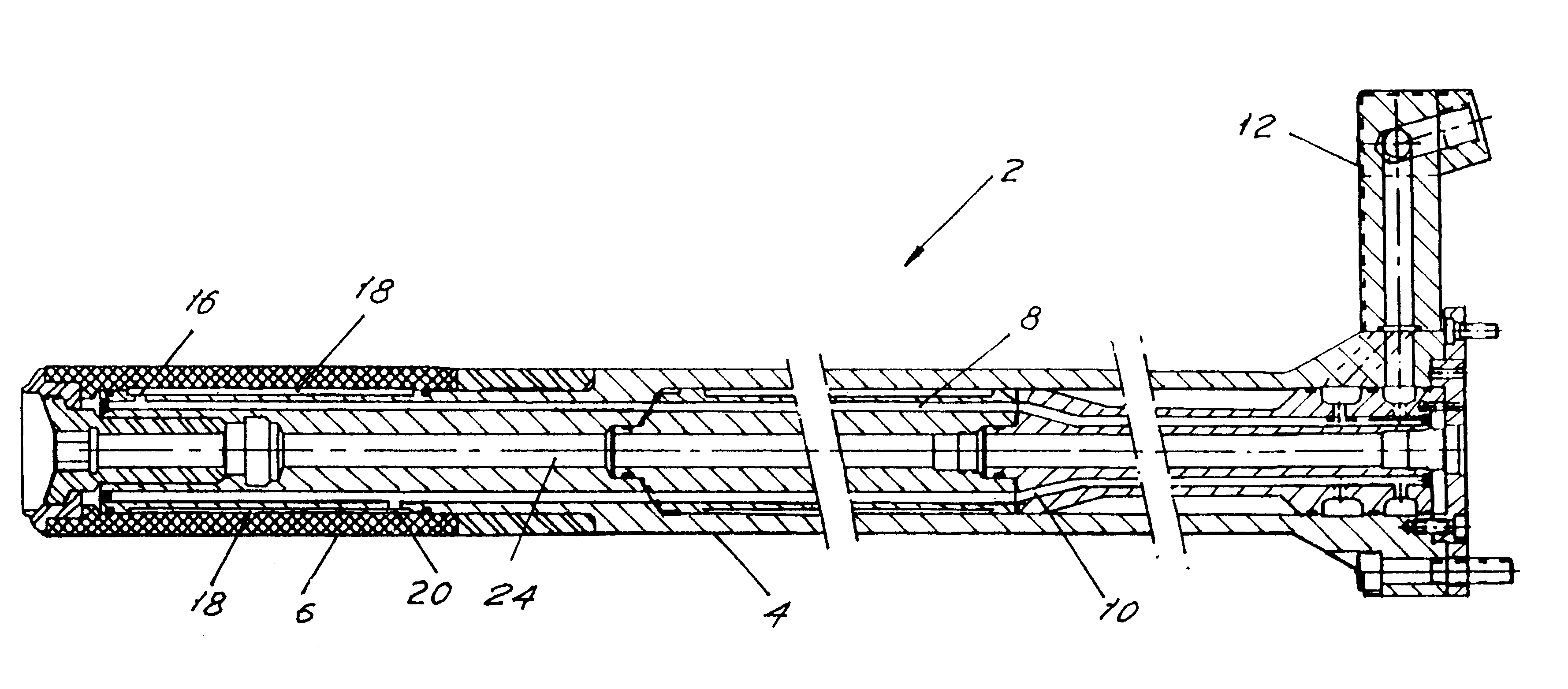

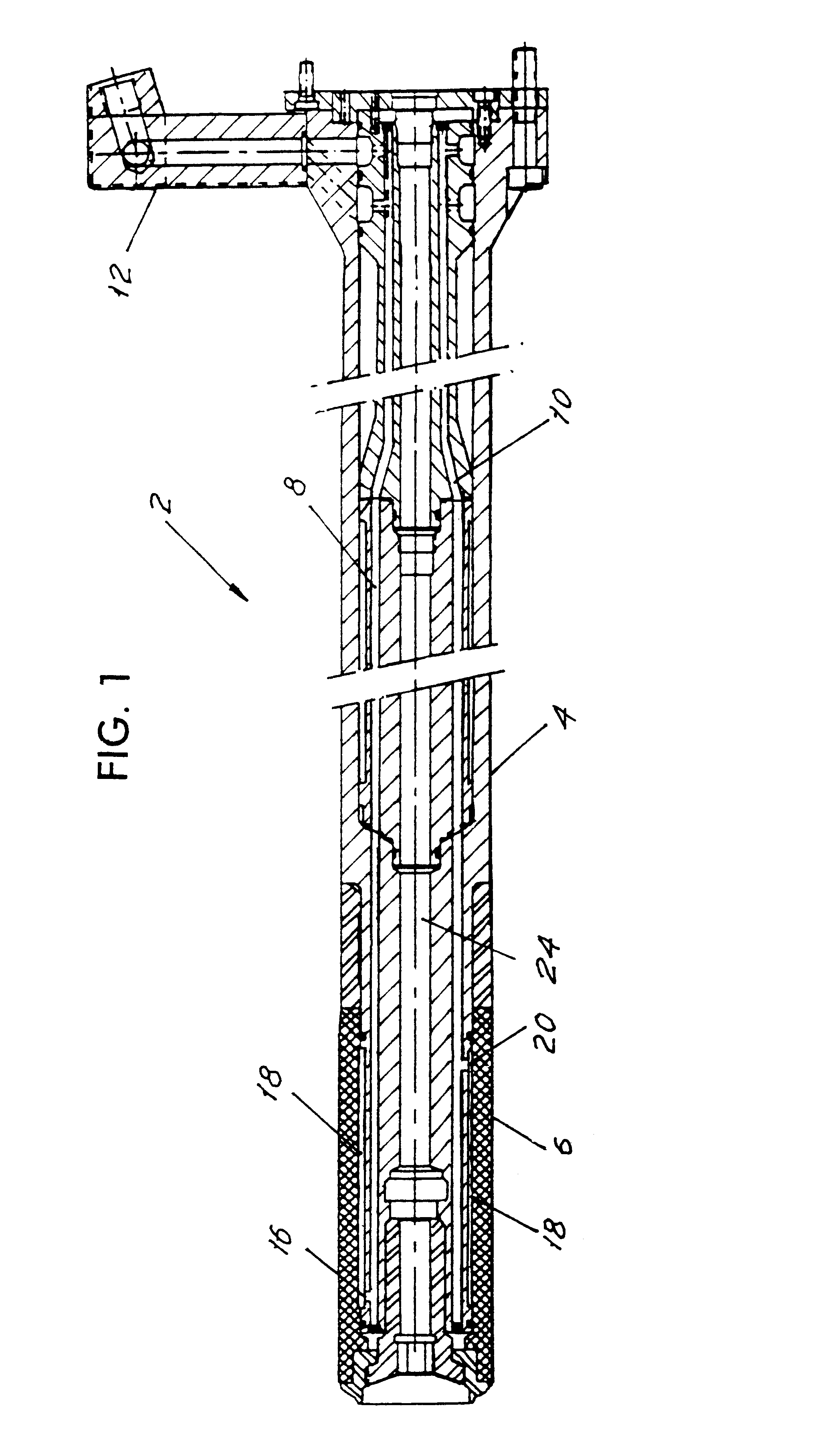

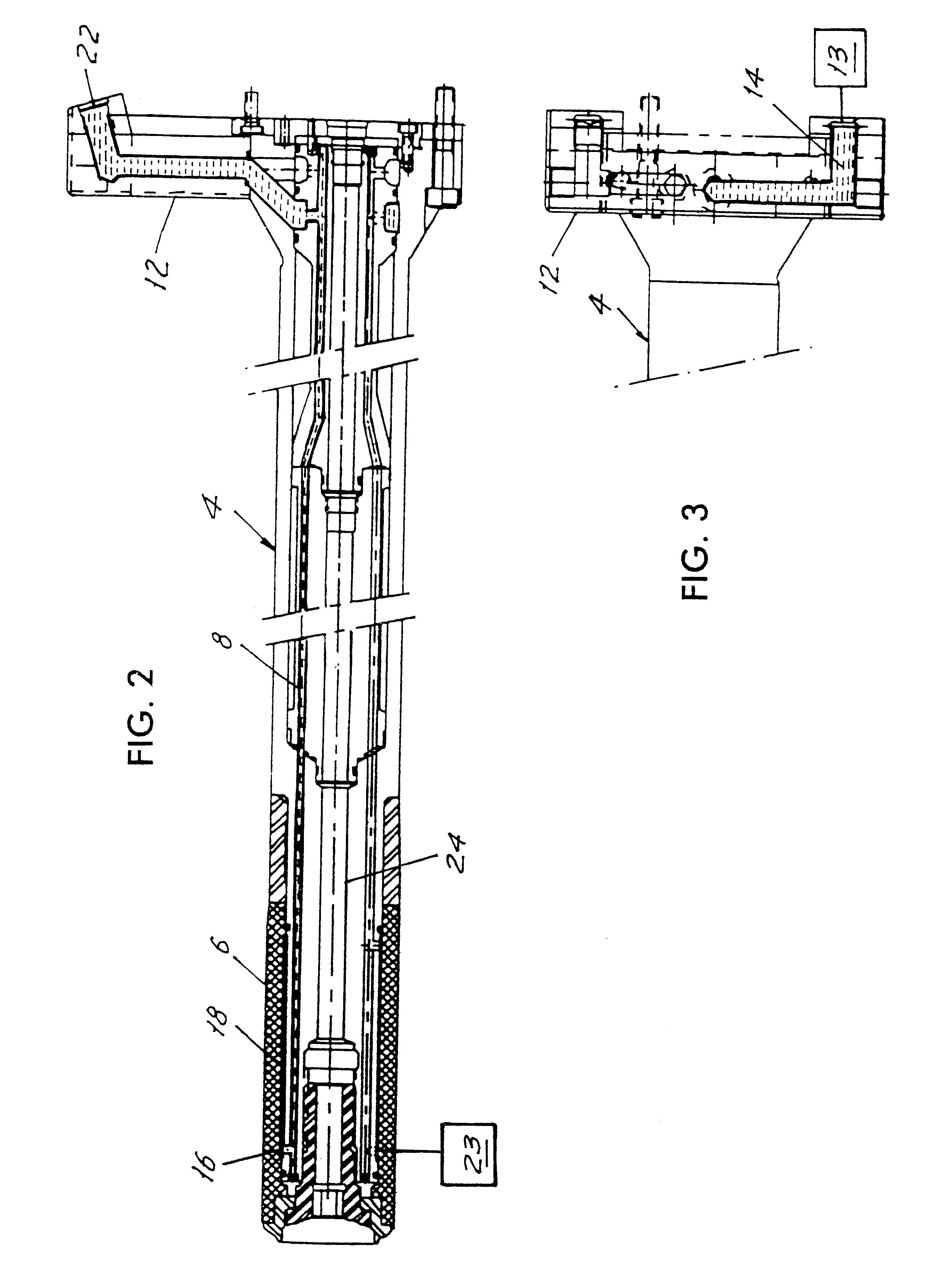

Internally cooled punch

An internally cooled punch disposed on the end of a ram in a can forming machine. Internal fluid cooling means in the ram avoids the need for externally applied cooling fluids. A plurality of parallel fluid transfer tubes is arranged annularly within the ram. Cooling medium flows through inlet tubes to radial inlet ports which supply the cooling medium to the inner surface of the punch where the medium flows rearwardly through a channel at the inner surface of the punch to radial outlet ports leading to outlet tubes through the ram. Discharged cooling media flows back along the ram and out through a manifold. The transfer tubes are arranged symmetrically in an alternating array circumferentially around the ram to reduce radial temperature gradients within the ram. A central port allows air flow through the ram to aid in stripping the formed container from the punch.

Owner:STOLLE MACHINERY

Swing stamping mechanism

ActiveCN102319786AReduce cutting processReduce wasteMetal-working feeding devicesManufacturing stator/rotor bodiesNumerical controlEngineering

The invention relates to a swing stamping mechanism, which comprises a stamping machine, wherein the stamping machine comprises a stamping frame, a lifting stamping die arranged on the stamping frame as well as a lifting control device for driving the lifting stamping die to carry out stamping work. The swing stamping mechanism is characterized by further comprising a numerical control device and a deflection feeding machine arranged at the rear side of the stamping machine; the deflection feeding machine comprises a fixed bracket, a movable stand, a transverse translation driving device and a material forward conveying device, wherein the movable stand is arranged on the fixed bracket and can be used for transversely translating along a direction vertical to the forward direction of materials relative to the fixed bracket; the transverse translation driving device is connected between the fixed bracket and the movable stand and is used for driving the movable stand to transversely translate; the material forward conveying device is arranged on the movable stand and can be used for conveying the materials to move along the forward direction of the materials; and the numerical control device is respectively connected with the lifting control device, the transverse translation driving device and the material forward conveying device for transmitting a control command. According to the swing stamping mechanism disclosed by the invention, work procedures can be reduced, the production efficiency can be improved and the waste of raw materials can be reduced.

Owner:靖江市易凯通风设备有限公司

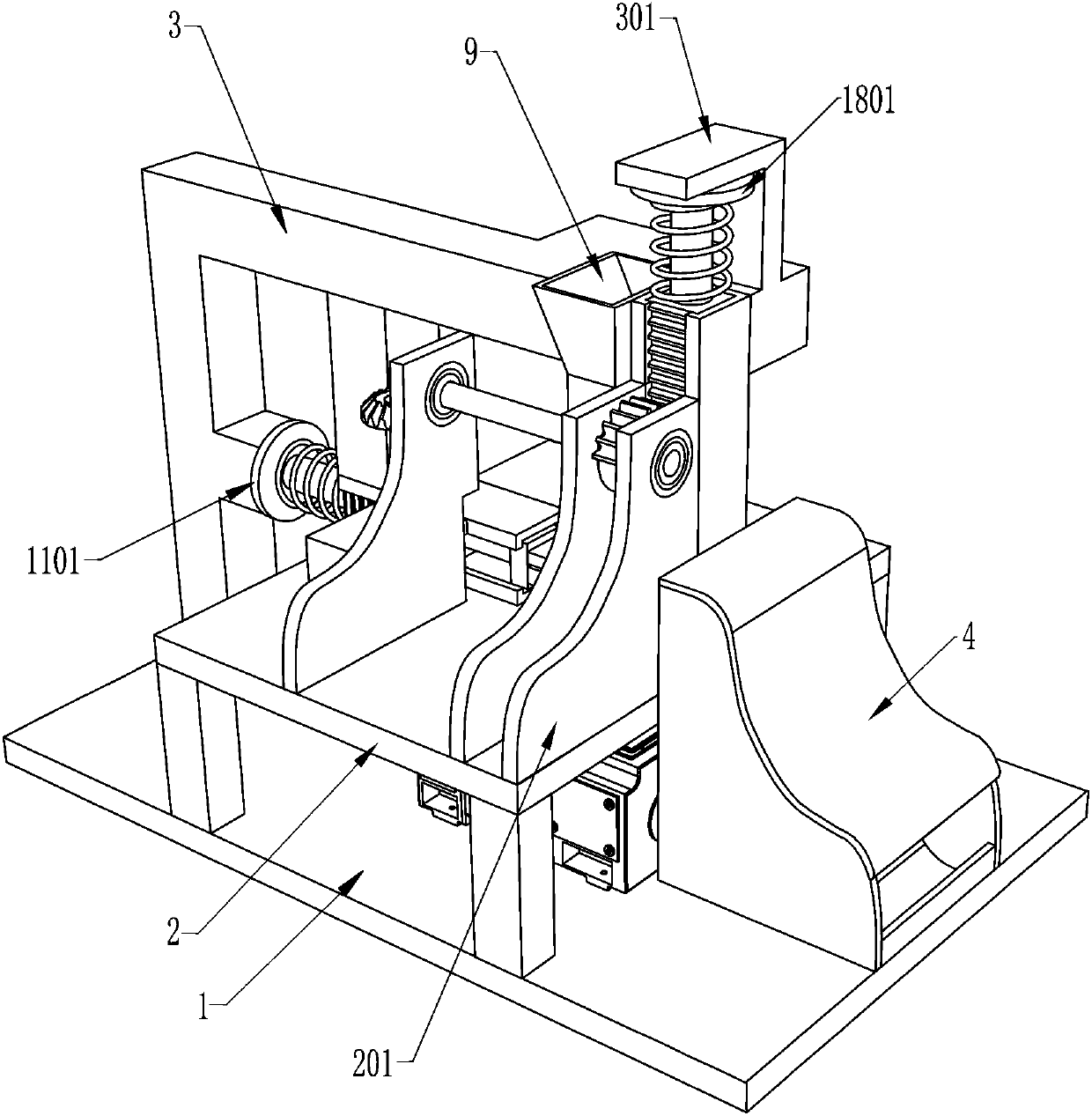

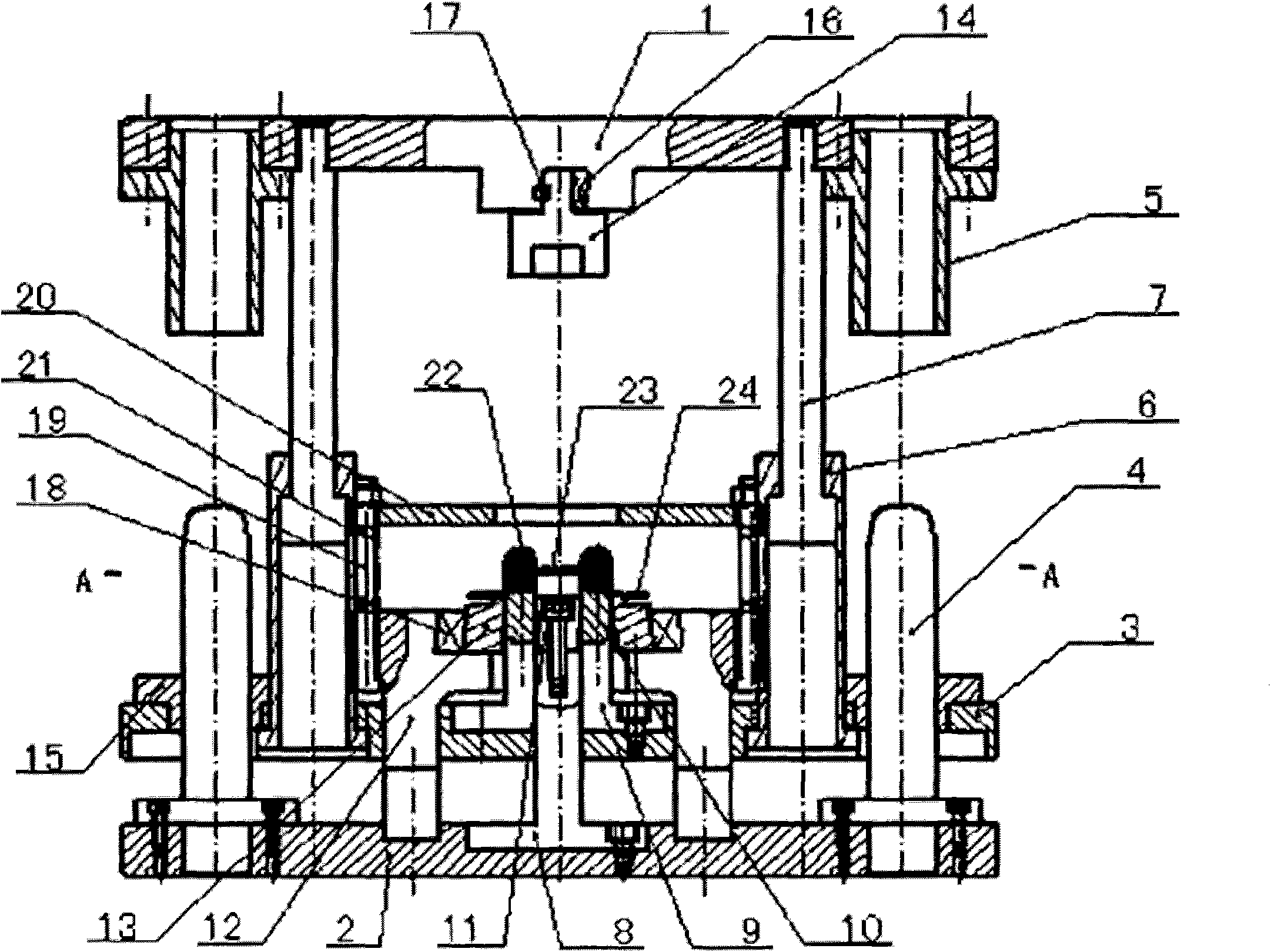

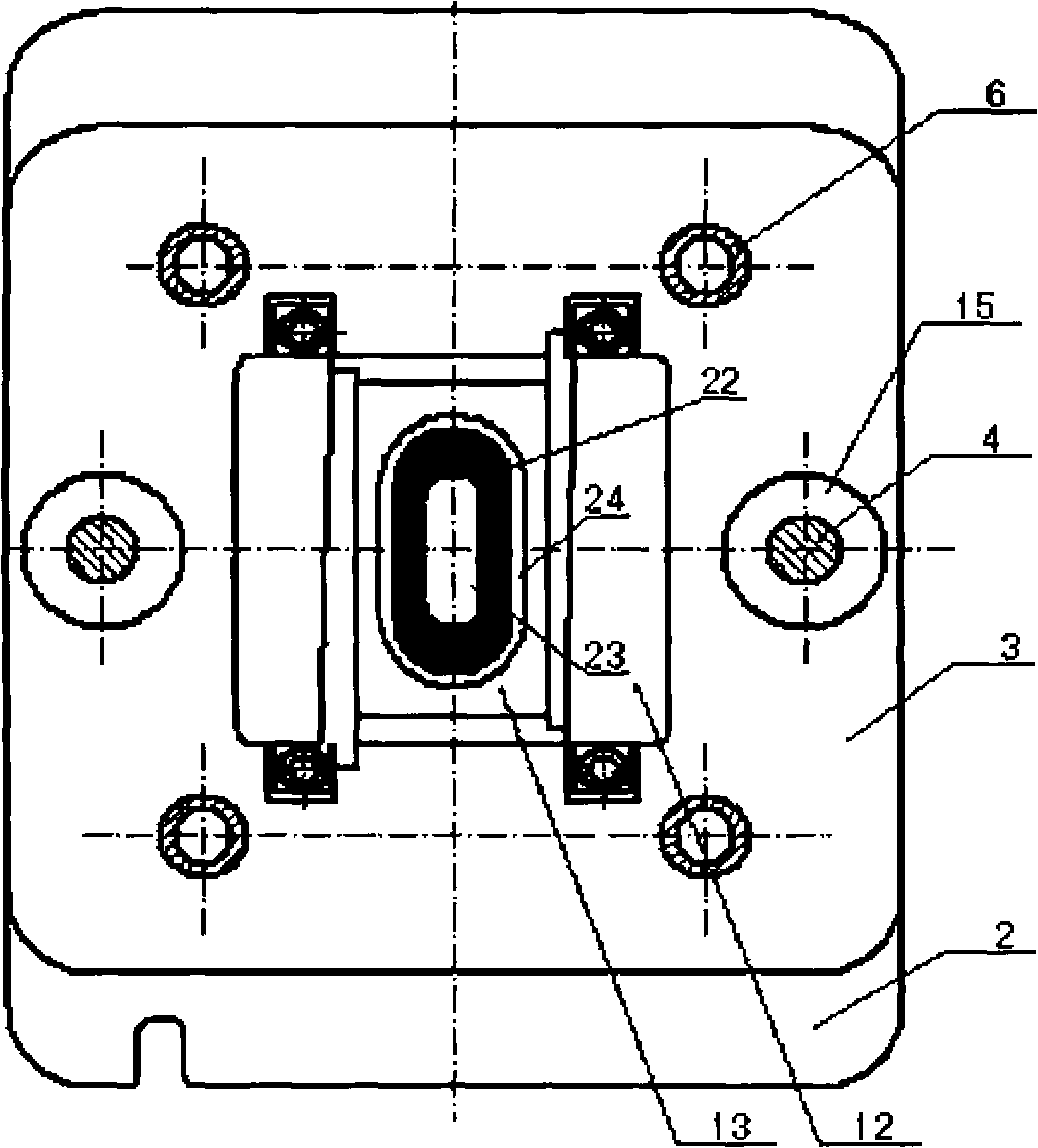

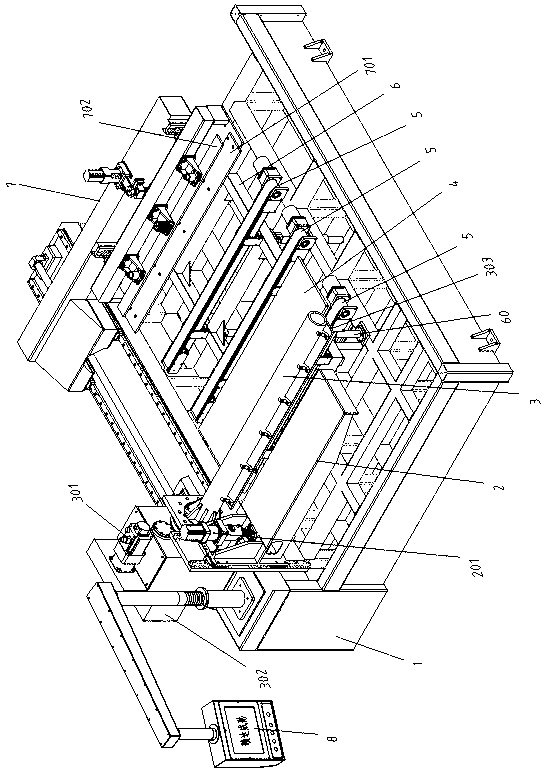

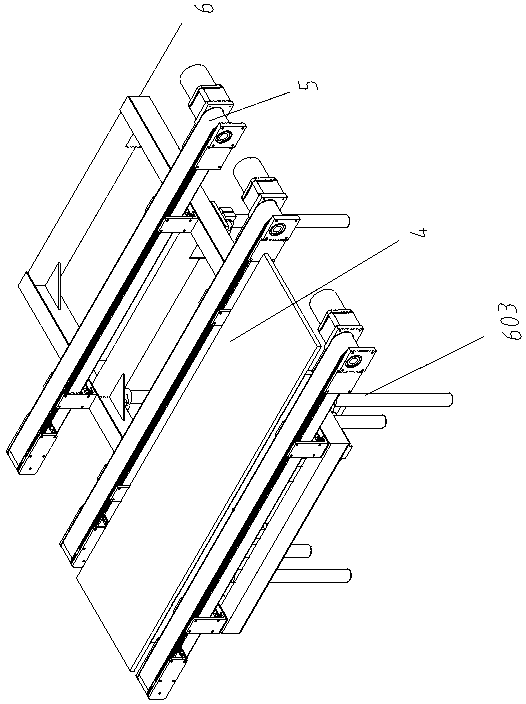

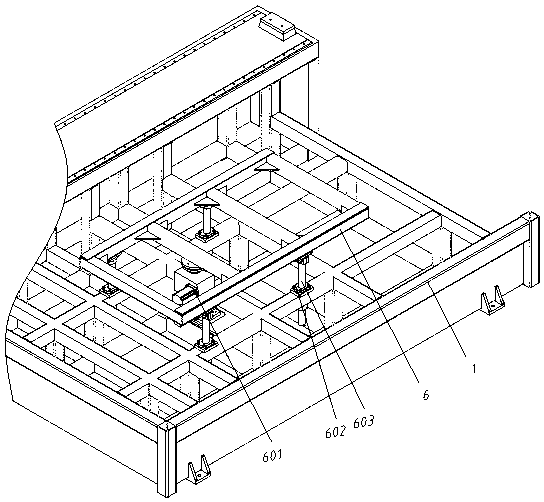

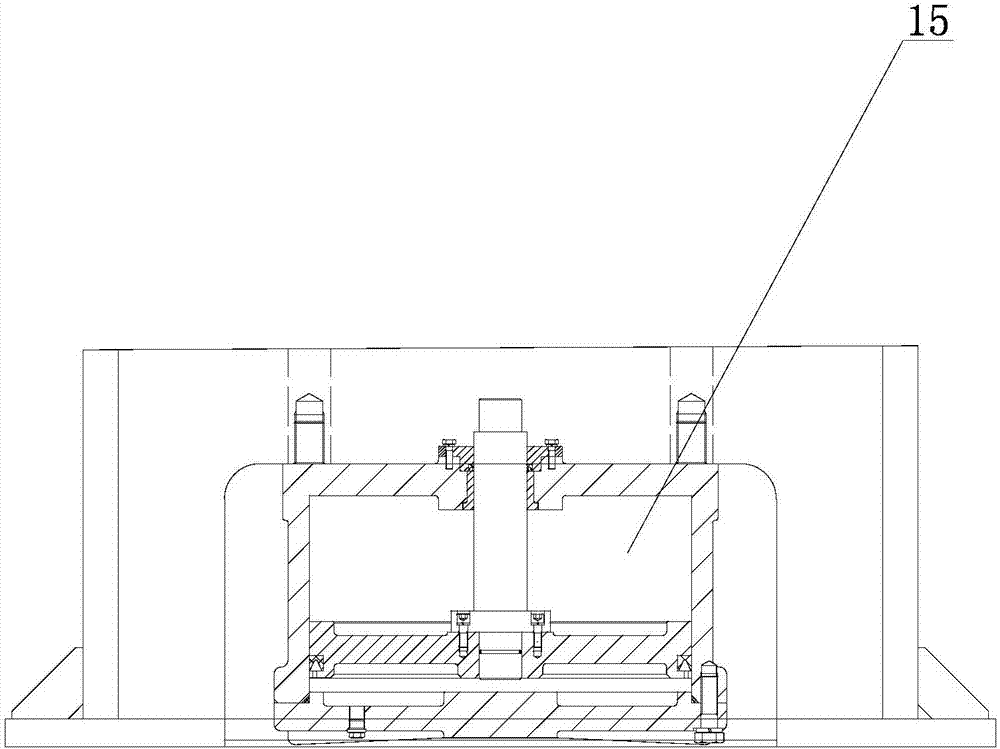

Disposable arc-rolling and forming die

The invention discloses a disposable arc-rolling and forming die, relating to the technical field of motor production. The disposable arc-rolling and forming die comprises a lower template (1) and a lower template accessory device, an upper template (21) and an upper template accessory device, and also comprises a movable plate device, a slideway device, a pressing device and a positioning device. The disposable arc-rolling and forming die can ensure that a plate cylinder motor shell is once coiled and formed, thus accumulated errors are avoided, collision and deformation of the products in machining and conveying processes are avoided, uniformity of sizes of final products is greatly improved, mechanical automation degree is increased, working efficiency is improved, yield and quality ofthe products are increased, and input of equipment resources and manpower resources is also reduced.

Owner:JIANGSU CHAOLI ELECTRIC

Pipe bending machine

ActiveCN103878267AImprove work efficiencySave human effortShaping toolsEjection devicesManipulatorBend Material

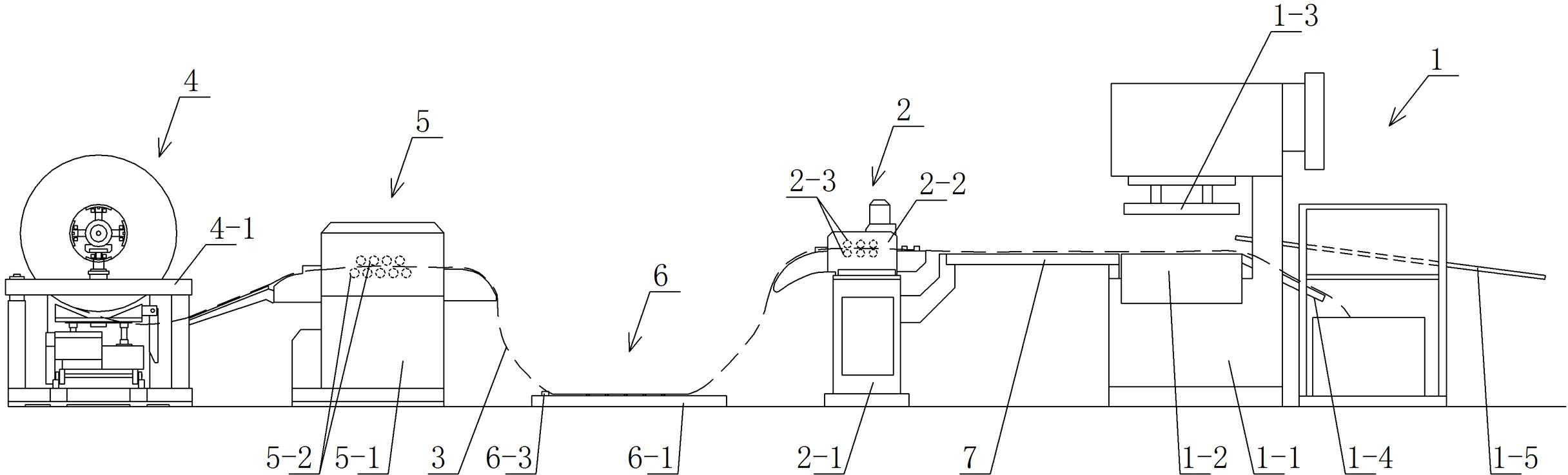

The invention discloses a pipe bending machine which comprises a rack. A straightening mechanism is arranged on the rack, a feeding mechanism is arranged at an output end of the straightening mechanism, a cutting mechanism is arranged at an output end of the feeding mechanism, a moving mechanism is arranged at an output end of the cutting mechanism and can move material pipes cut by the cutting mechanism to a pipe bending feeding mechanism arranged beside the feeding mechanism, a bending mechanism capable of bending the material pipes fed by the pipe bending feeding mechanism is arranged at an output end of the pipe bending feeding mechanism, a discharging mechanism for discharging is arranged at an output end of the bending mechanism, the pipe bending feeding mechanism comprises a sliding rail, a feeding seat is arranged on the sliding rail, a rotating clamping head, a rotating positioning motor and a clamping cylinder driving the rotating positioning head to clamp the material pipes is arranged on the feeding seat, and a pushing device capable of pushing the bent material pipes out of the rotating clamping head is arranged on the feeding seat. By the pipe bending machine, small-specification bend material pipes that a discharging manipulator cannot grab can be pushed out of the pipe bending machine to complete automatic discharging, so that working efficiency is improved, manpower is saved, and production cost is lowered.

Owner:OMS MASCH CO LTD

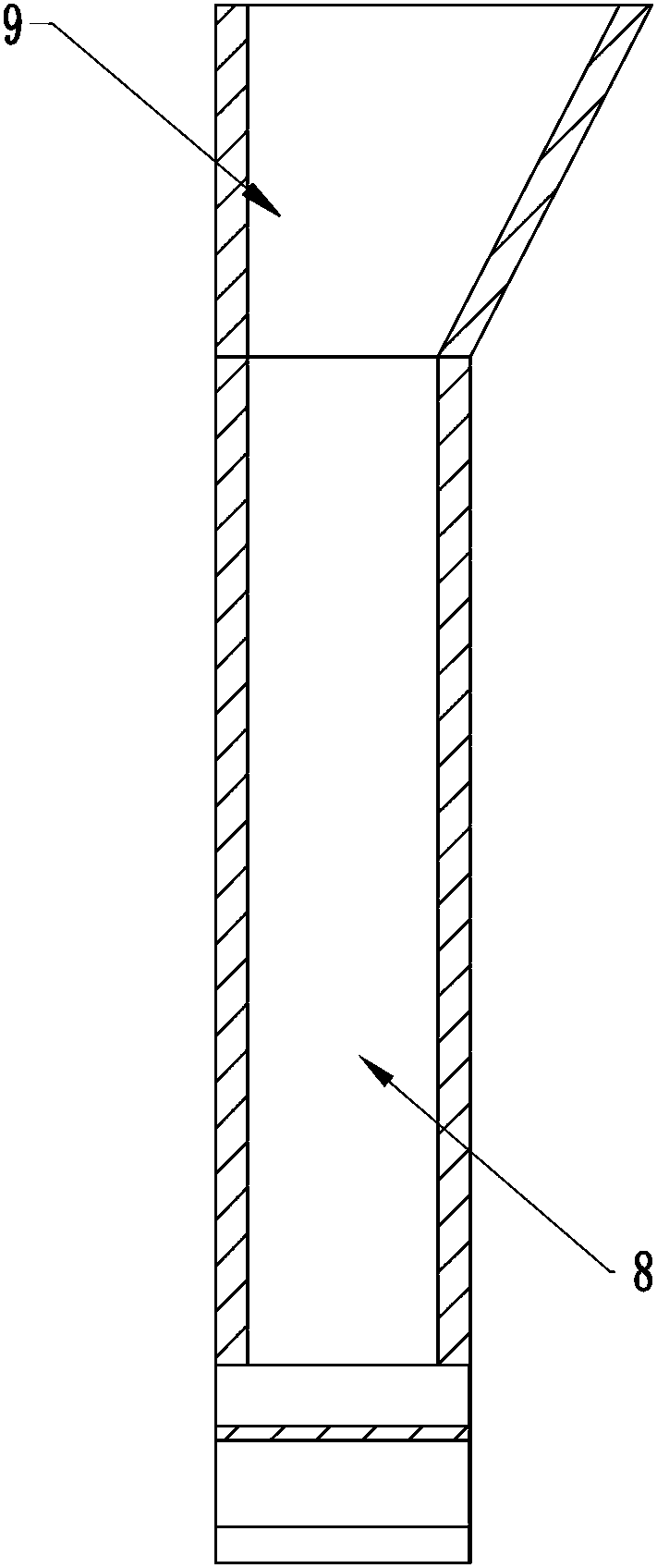

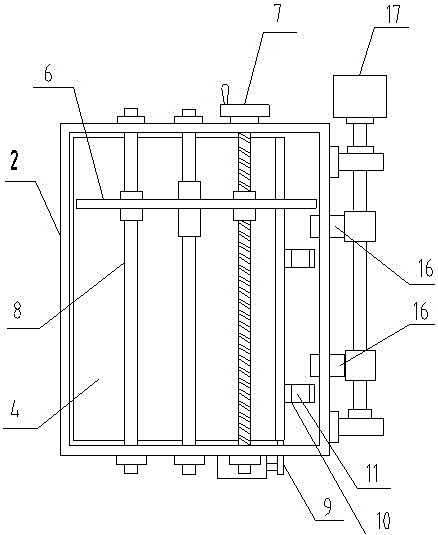

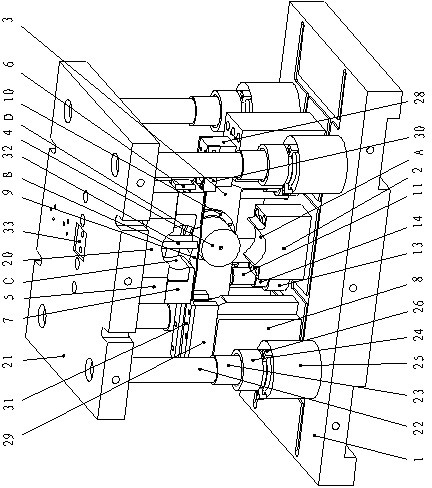

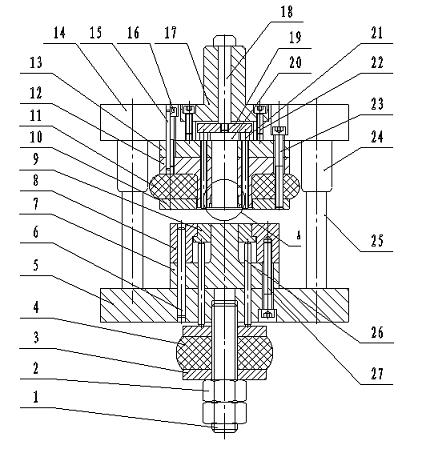

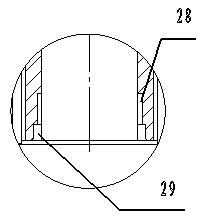

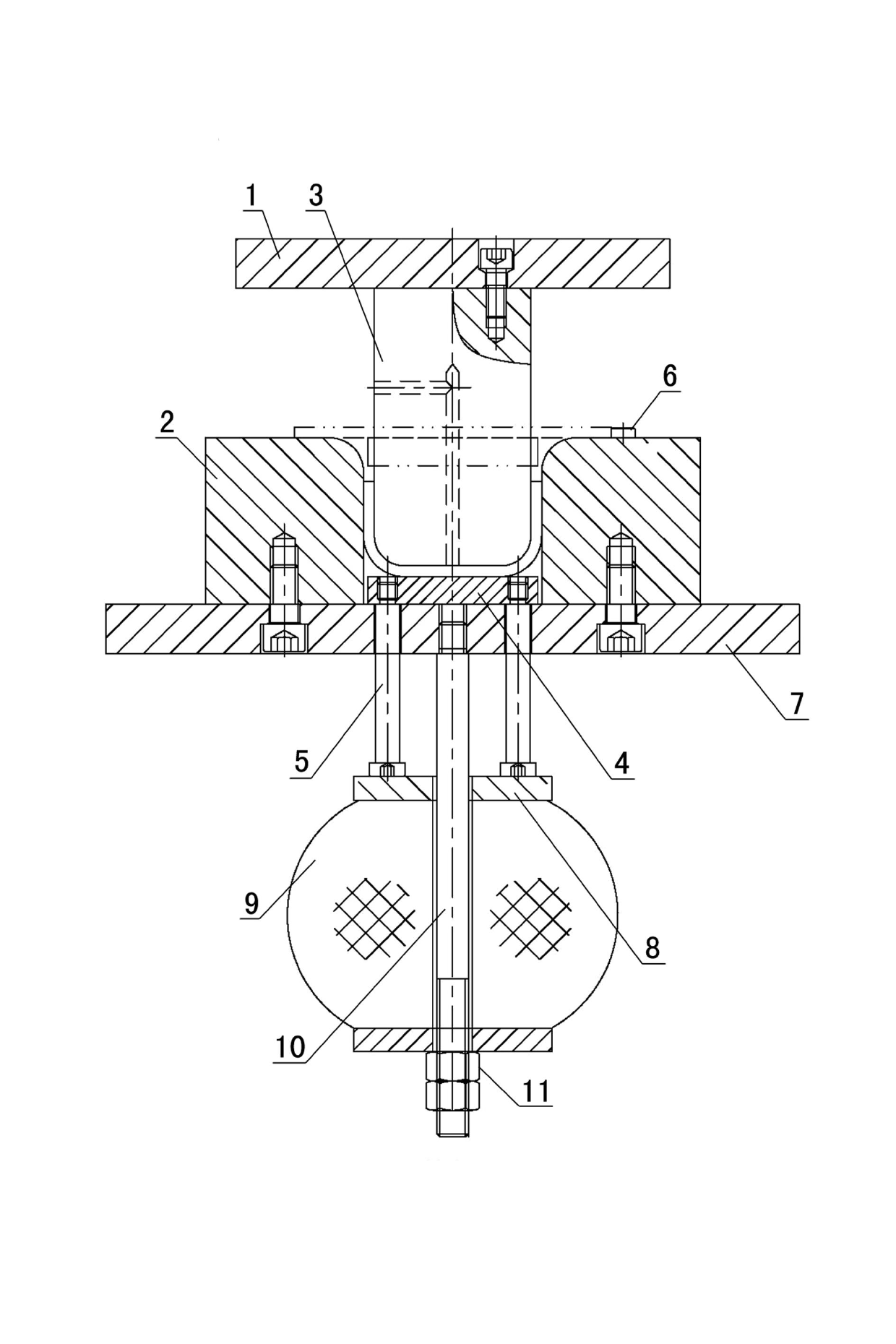

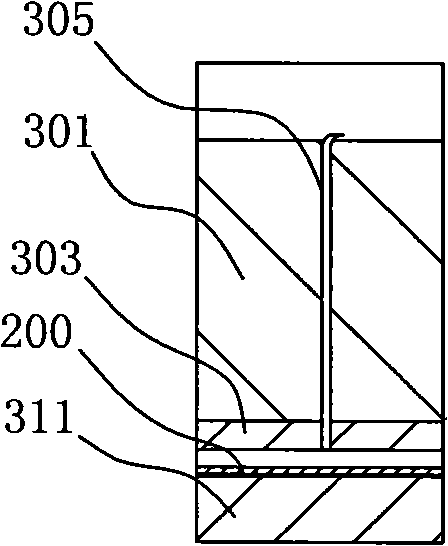

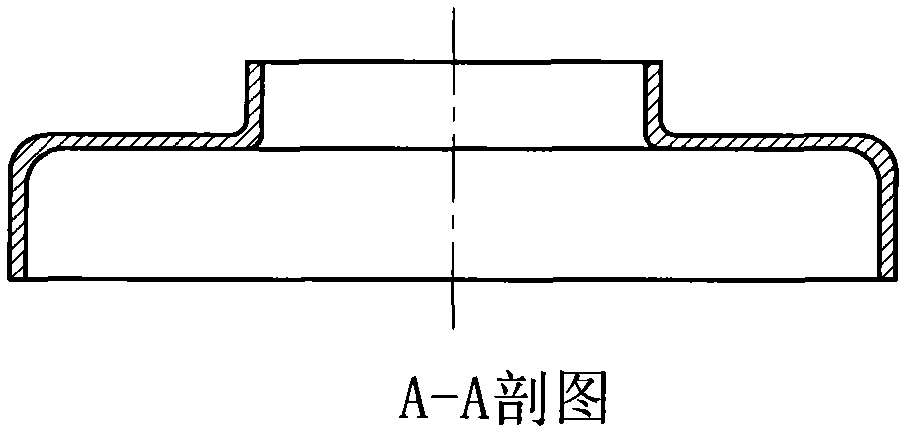

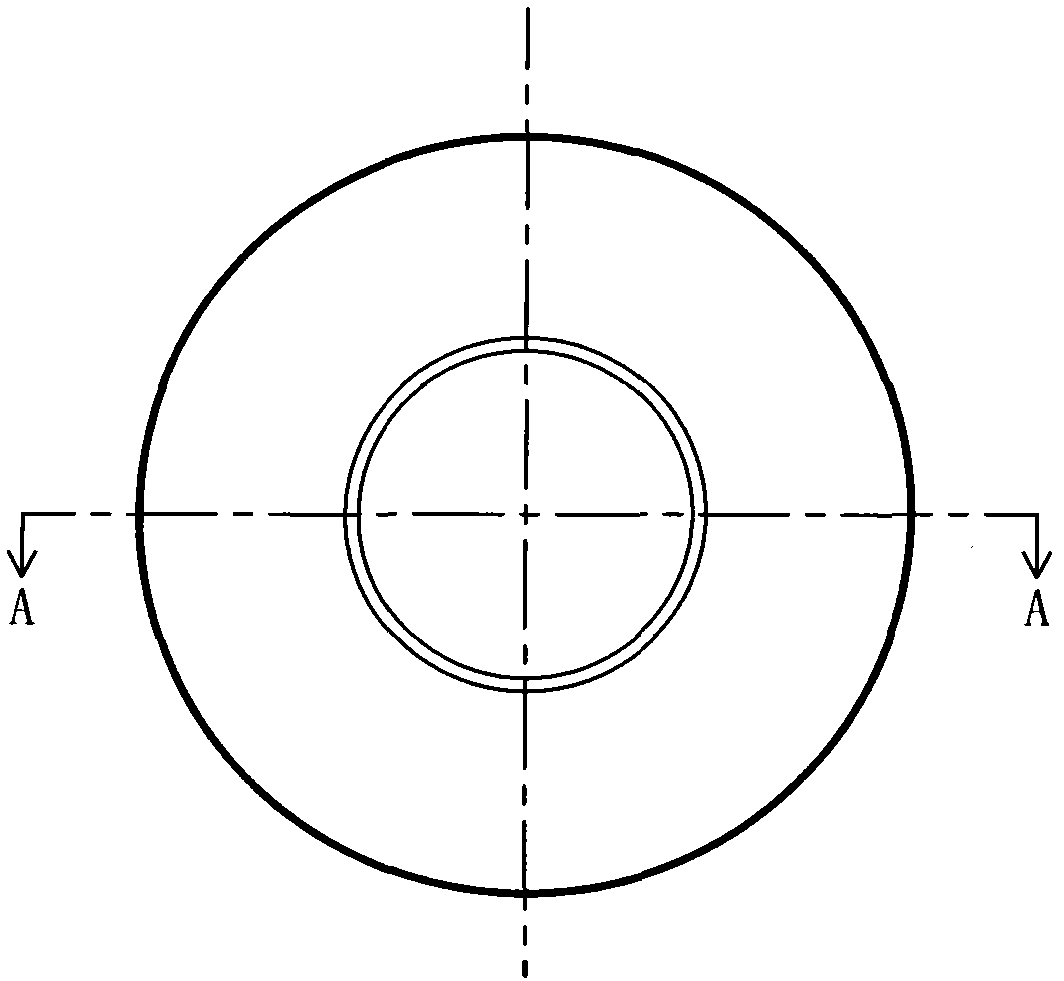

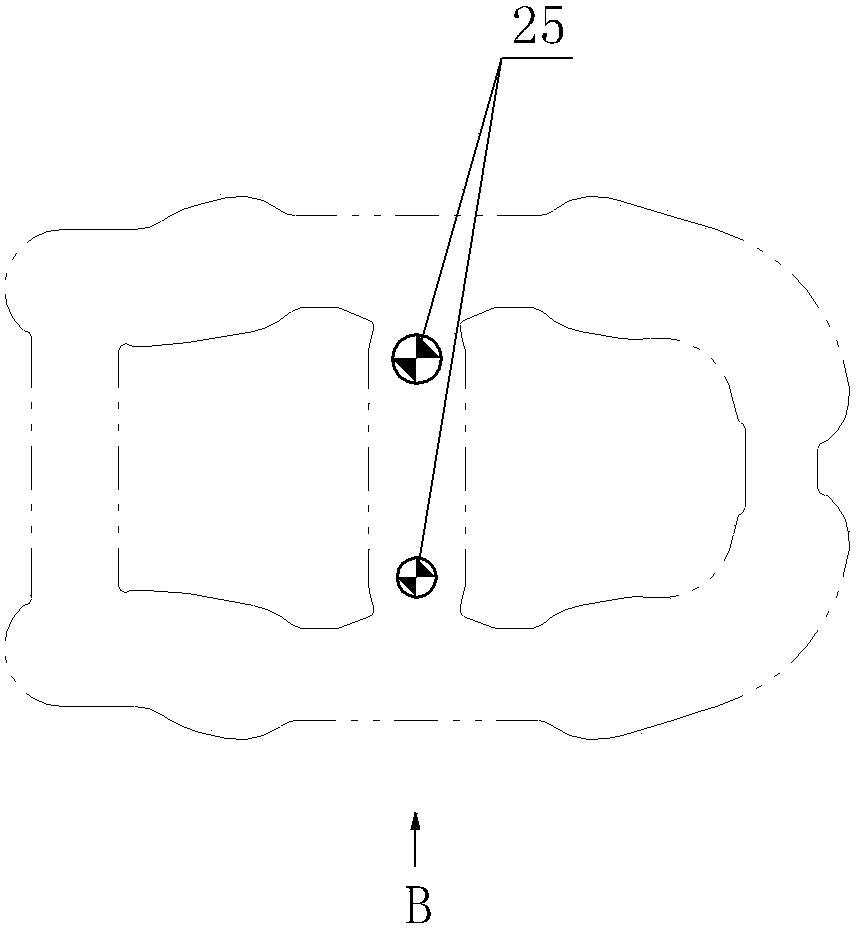

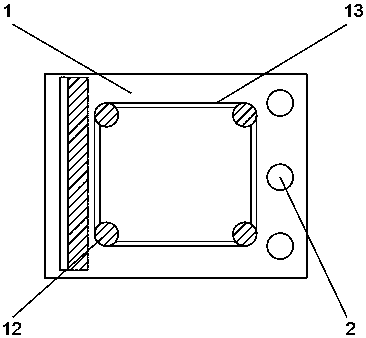

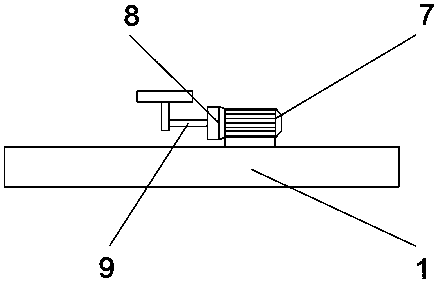

Composite mould for machining parts such as short flanged washers

InactiveCN102430652ASimple structureReduce the difficulty of assemblyShaping toolsEjection devicesMachine partsPunching

The invention belongs to the technical field of moulds and provides a composite mould for machining parts such as short flanged washers. The composite mould mainly comprises an upper mould plate (14), a lower mould plate (5), guide pillars (25), guide sleeves (24), a punch-matrix (12), a blanking die (8), a drawing cut-off punch (7), an unloading mechanism, an ejecting mechanism and a beating mechanism. The upper mould plate (14) is connected with the lower mould plate (5) through the guide pillars (25) and the guide sleeves (24), the punch-matrix (12) is connected to the lower end face of the upper mould plate (14) and is a structure with the center of the lower end face protruding downwards, a punching groove (28) and a drawing groove (29) are respectively arranged on the inner wall surface of the lower end of the through hole of the punch-matrix (12) from top to bottom, and the blanking die (8) and the drawing cutoff punch (7) are arranged on the upper end face of the lower mould plate (5). The composite mould has the advantages that mould structures are simplified, assembling difficulty and manufacturing cost of moulds are reduced, and service lives of moulds are prolonged.

Owner:CRRC LUOYANG CO LTD

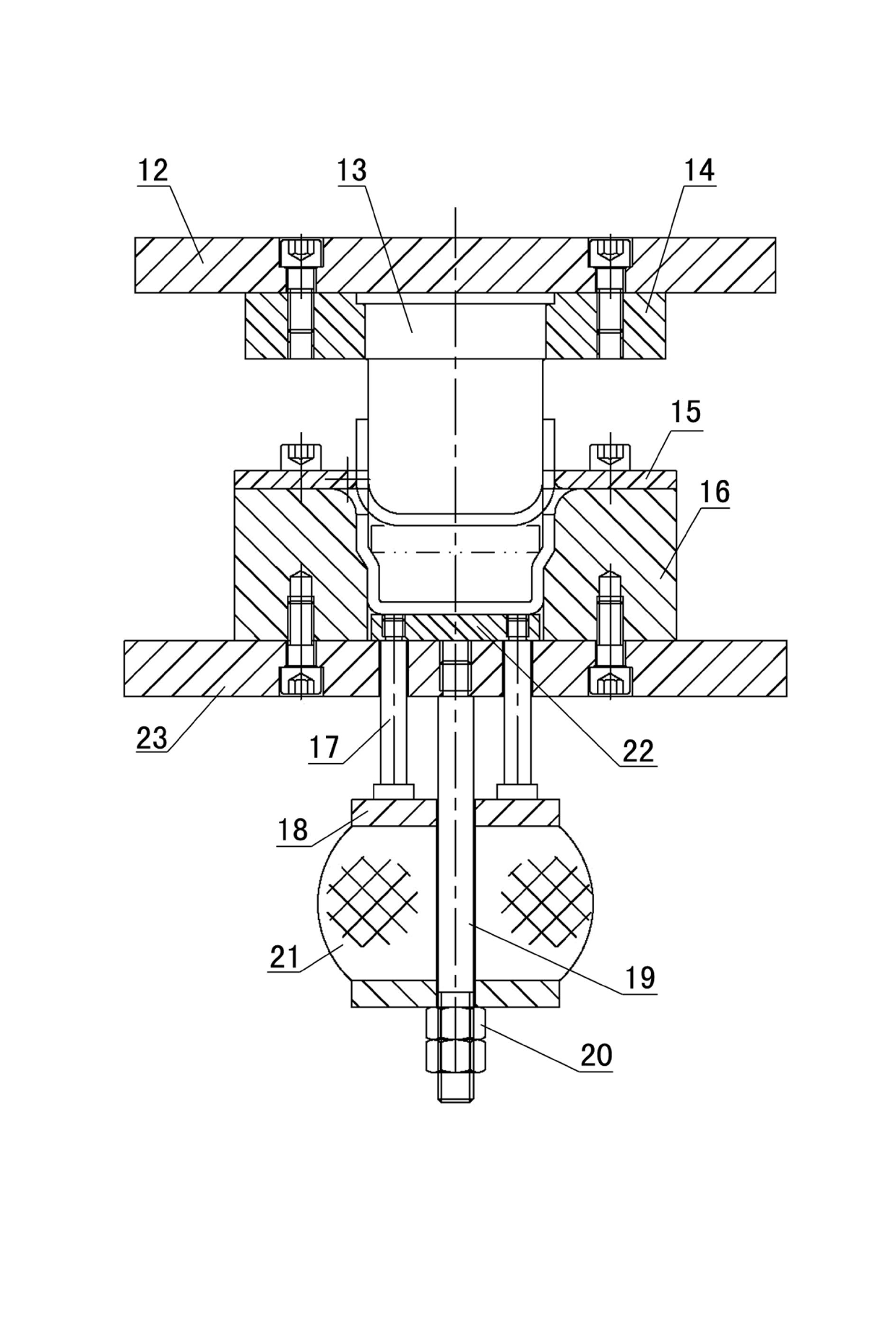

Stepped cylindrical component die for medium plate

InactiveCN101767154ASimple structureEasy to manufactureShaping toolsPerforating toolsEngineeringScrew thread

The invention relates to a stepped cylindrical component die for a medium plate, which consists of a primary drawing die, a drawing dressing die and a punch die. The primary drawing die consists of an upper drawing die, a lower drawing die and a drawing die material returning device. The drawing dressing die consists of an upper dressing die, a lower dressing die and a dressing die material returning device. The punch die consists of an upper punch die, a lower punch die and a punch die guide pair. Only three sets of the stepped cylindrical component dies for the medium plate can press a die plate with middle thickness into a stepped cylindrical component. The three sets of dies have the advantages of simple structure, simple and easy manufacturing, convenient maintenance, reasonable layout, stable performance and long service life. The design standardization degree of the three sets of dies is high. Connecting bolts, material returning bolts, discharge rods and the like are all selected from standard components easily purchased on the market. The three sets of dies all adopt threaded connection and do not adopt the non-removable mode such as riveting, welding and the like so as to be convenient for later maintenance and convenient disassembling.

Owner:BEIJING SANXING AUTOMOBILE

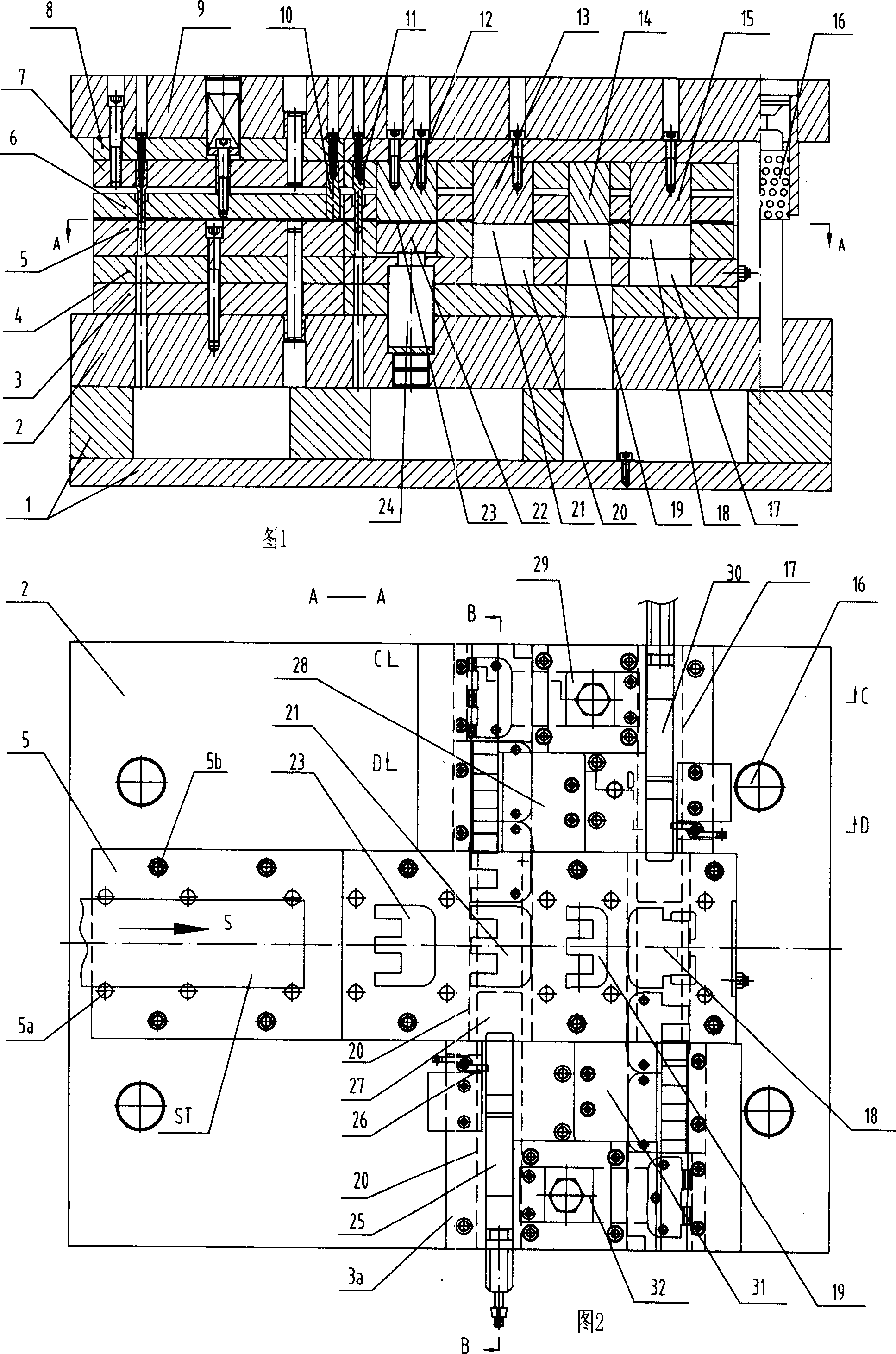

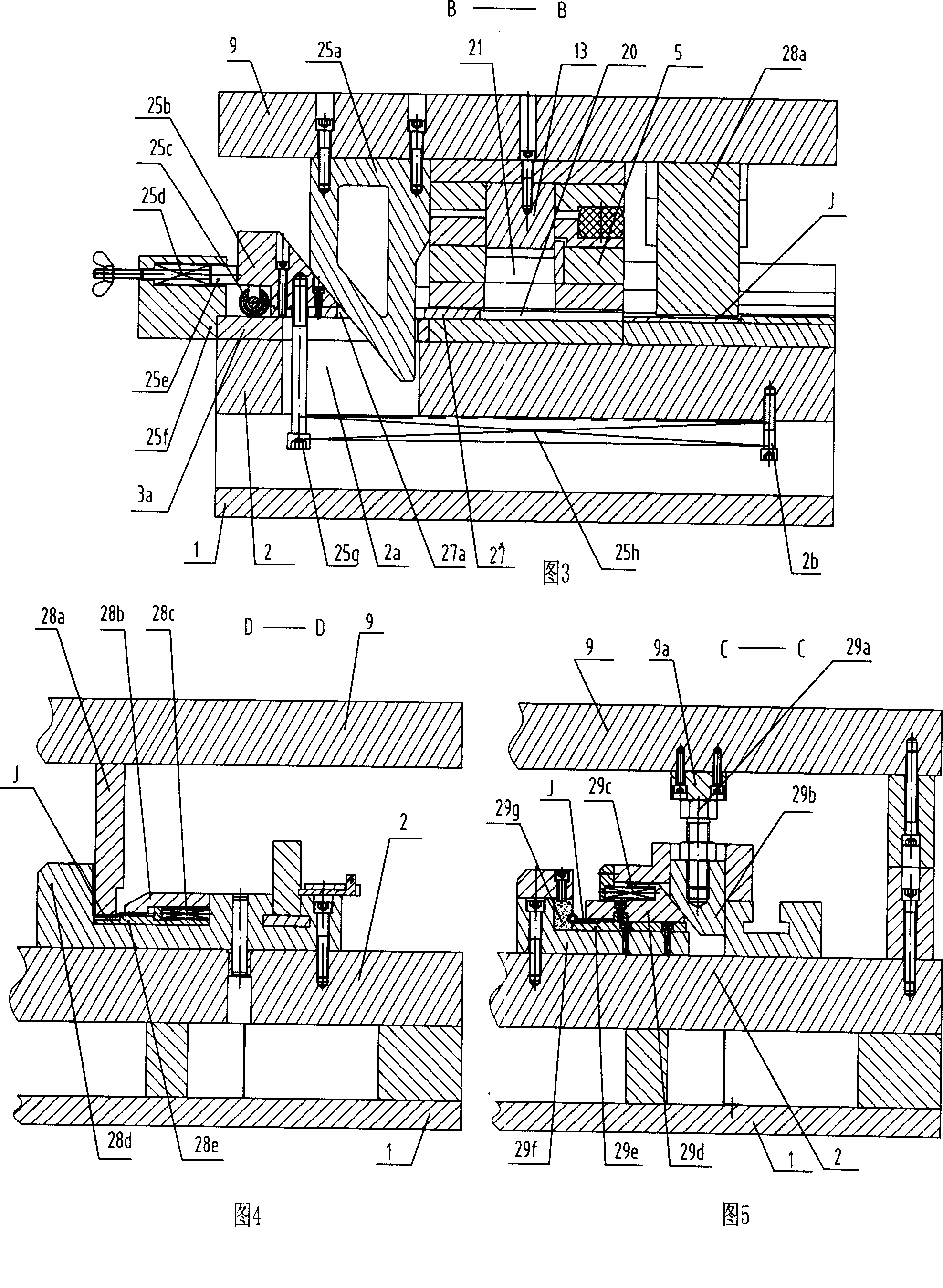

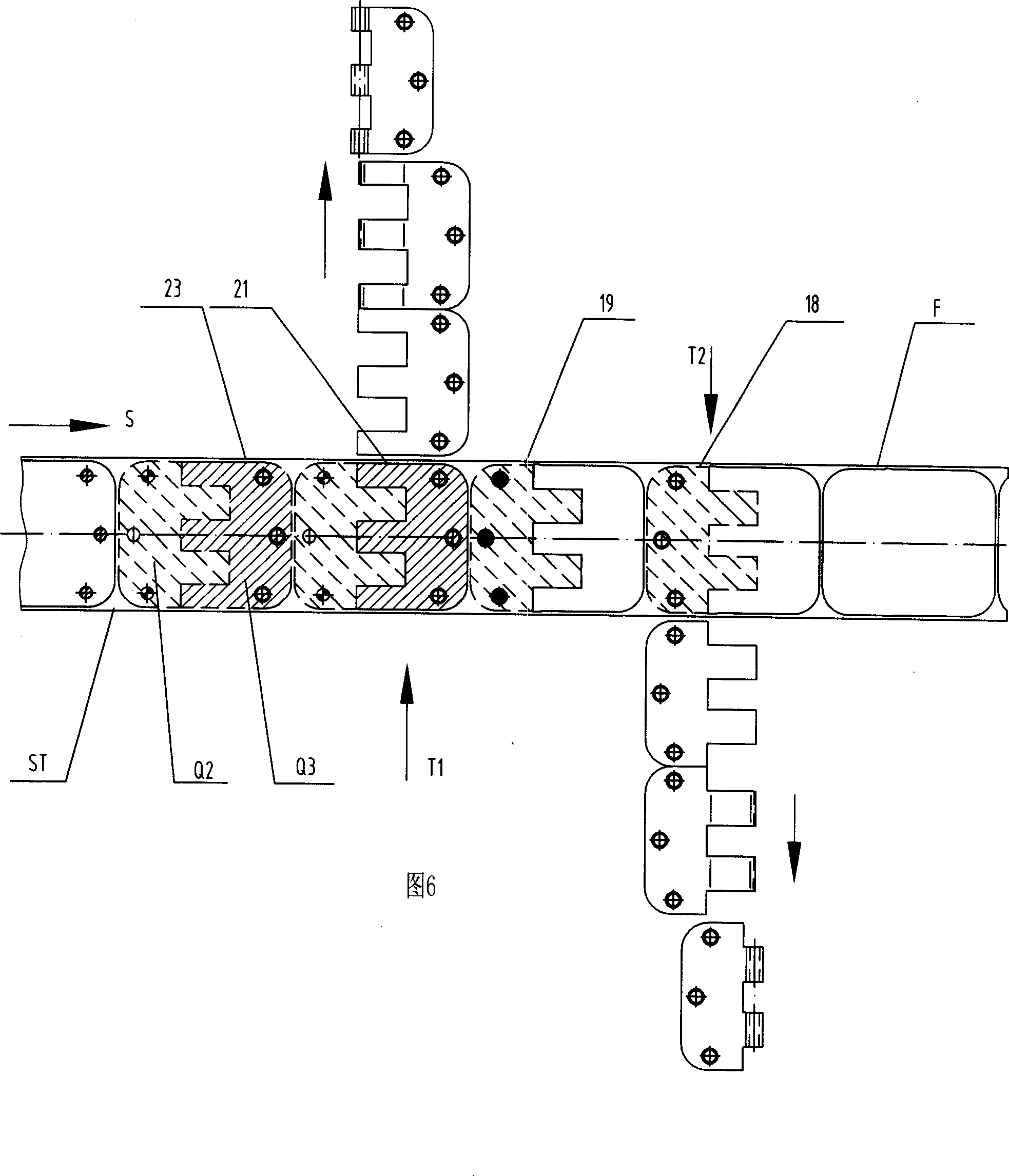

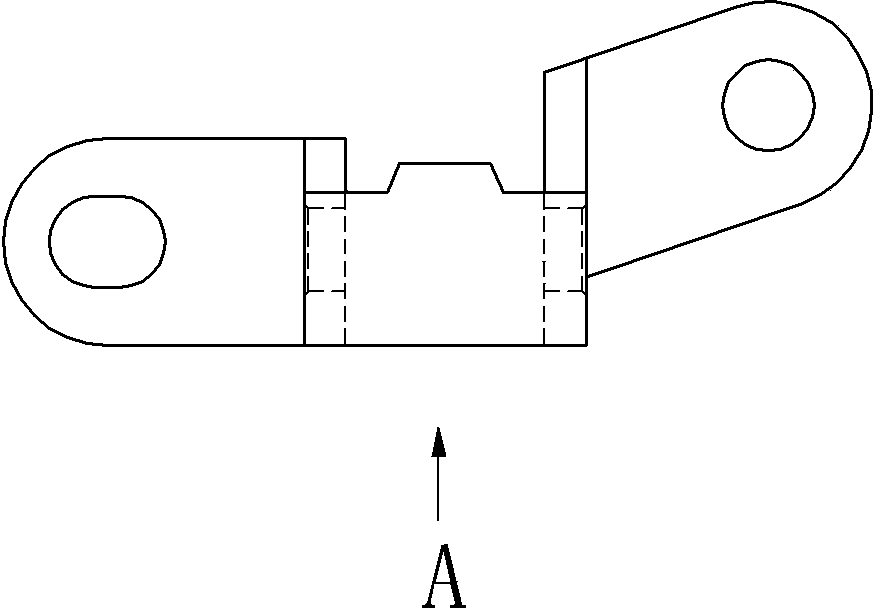

Complete cutting type belt coil pipe stepped mould for hinger

InactiveCN101011716AGuaranteed utilizationRealize one-time moldingShaping toolsMetal-working feeding devicesPunch pressStirrup

A hinge blade nest cutting winding progressive die comprises up die and bottom die and the connecting guide post, with the up die having stirrup punch head, three claw punch head and two claw punch head, with the bottom die having stirrup, three claw die and two claw die, with the later tow having a horizontal slide path, one side of which having a discharge device linked with the up die, bending die linked with the up die on the other side, and the winding die. It realizes the one time forming with the stirrup, shear cutting, bending and winding, with precision and improved production efficiency and reduced cost. One set of die, a punch machine and an operator will get everything done.

Owner:伟业重工(安徽)有限公司

Automatic material pushing type stainless steel circular sheet forming device

ActiveCN106862356AEasy to install and disassembleAchieve demouldingShaping toolsMetal-working feeding devicesEngineeringSupport plane

The invention discloses an automatic material pushing type stainless steel circular sheet forming device which comprises a rack; an upper supporting frame is fixedly arranged on the top surface of a top plate of the rack; a stamping oil cylinder is fixedly arranged at the middle part of the top surface of a top plate of the upper supporting frame; a push rod of the stamping oil cylinder penetrates through the top plate of the upper supporting frame and is fixedly provided with an upper connecting plate; an upper die is fixedly arranged at the middle part of the bottom surface of the upper connecting plate; a plurality of stamping bumps are uniformly formed at the bottom surface of the upper die; connecting plates are fixedly arranged at the bottom surfaces of the edges of the two sides of the upper connecting plate; guide sleeves are fixedly arranged at the bottom surfaces of the connecting plates; guide rods are inserted into the guide sleeves; upper pressing plates are fixedly arranged at the bottom ends of the guide rods; buffer springs are arranged on the guide rods and the guide sleeves in a sleeving manner; the upper ends of the buffer springs are fixed to the connecting plates; and the lower ends of the buffer springs are fixed to the top surfaces of the upper pressing plates. The automatic material pushing type stainless steel circular sheet forming device can clamp and fix a to-be-machined stainless steel plate before stamping, bolt fixing by using a pressing plate and the like manually is not required, and the automatic material pushing type stainless steel circular sheet forming device is convenient to mount and dismount, and can be lifted through an arc-shaped limiting block.

Owner:江门市新会区金长利实业有限公司

Connecting rod punch press

ActiveCN104226768AReduce connection gapsGuaranteed stabilityPress ramEjection devicesPunch pressDynamic balance

The invention discloses a connecting rod punch press, comprising a rack, a crankshaft, a lower slide block, and a crankshaft rotation drive device, wherein the lower slide block is in sliding fit with the rack. The connecting rod punch press is characterized in that an upper slide block is arranged inside the rack; the upper end of the rack is provided with a dynamic balance connecting mechanism of the upper slide block; a first link transmission mechanism is arranged among the crankshaft, the lower slide block and the upper slide block; the rack is provided with an upper slide block adjusting mechanism which is used for adjusting the height of the mold. The connecting rod punch press has the advantages that the upper slide block is arranged inside the rack, the rack is provided with the upper slide block adjusting mechanism which is used for adjusting the height of the mold, and the upper and lower positions of the upper slide block can be adjusted through the adjusting mechanism, thus the height of the mold of the connecting rod punch press is adjusted, meanwhile, the internal structure of the lower slide block is also reduced, the structure of the lower slide block is simplified, the condition that the lower slide block can bear good punching, and does not deform when the connecting rod punch press is used for punching at high temperature is ensured, the punching stability of the punch press and the accuracy of a punched product are ensured, and the connecting rod punch press can be applicable to high-temperature punching.

Owner:NINGBO CITY COSTON PRECISION MACHINERY

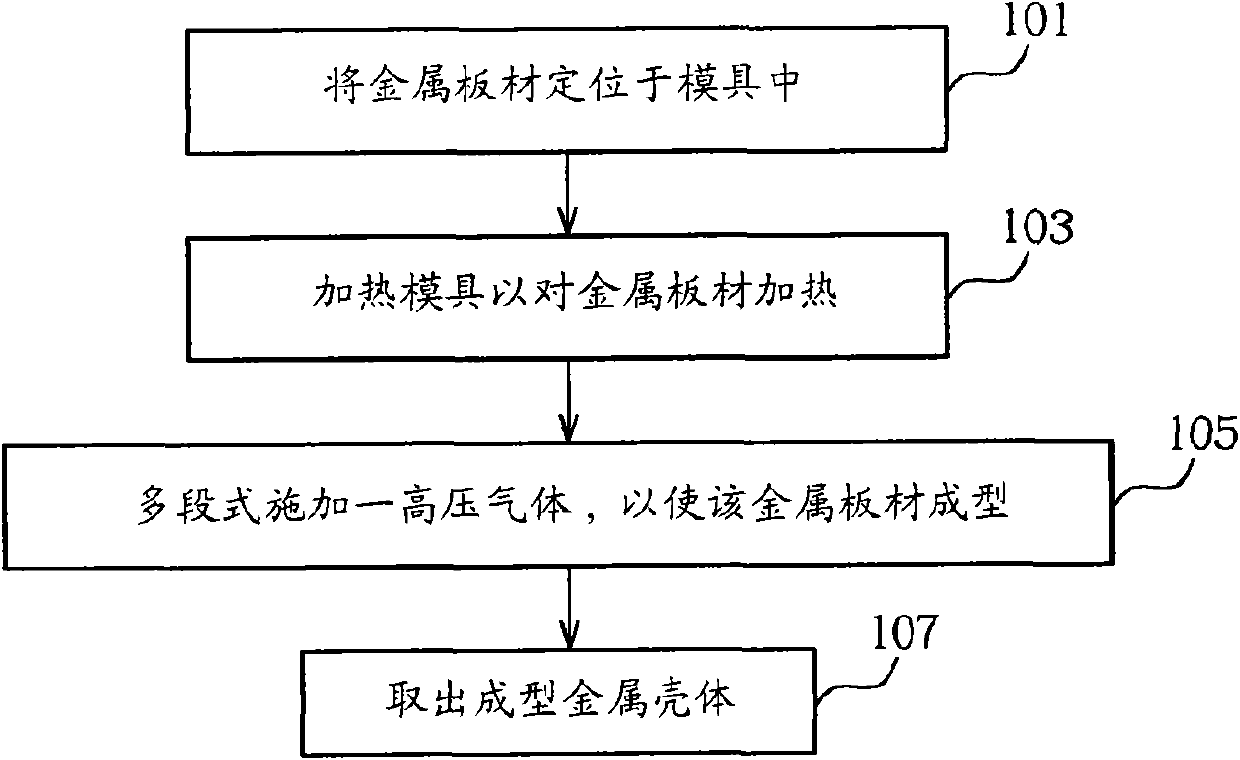

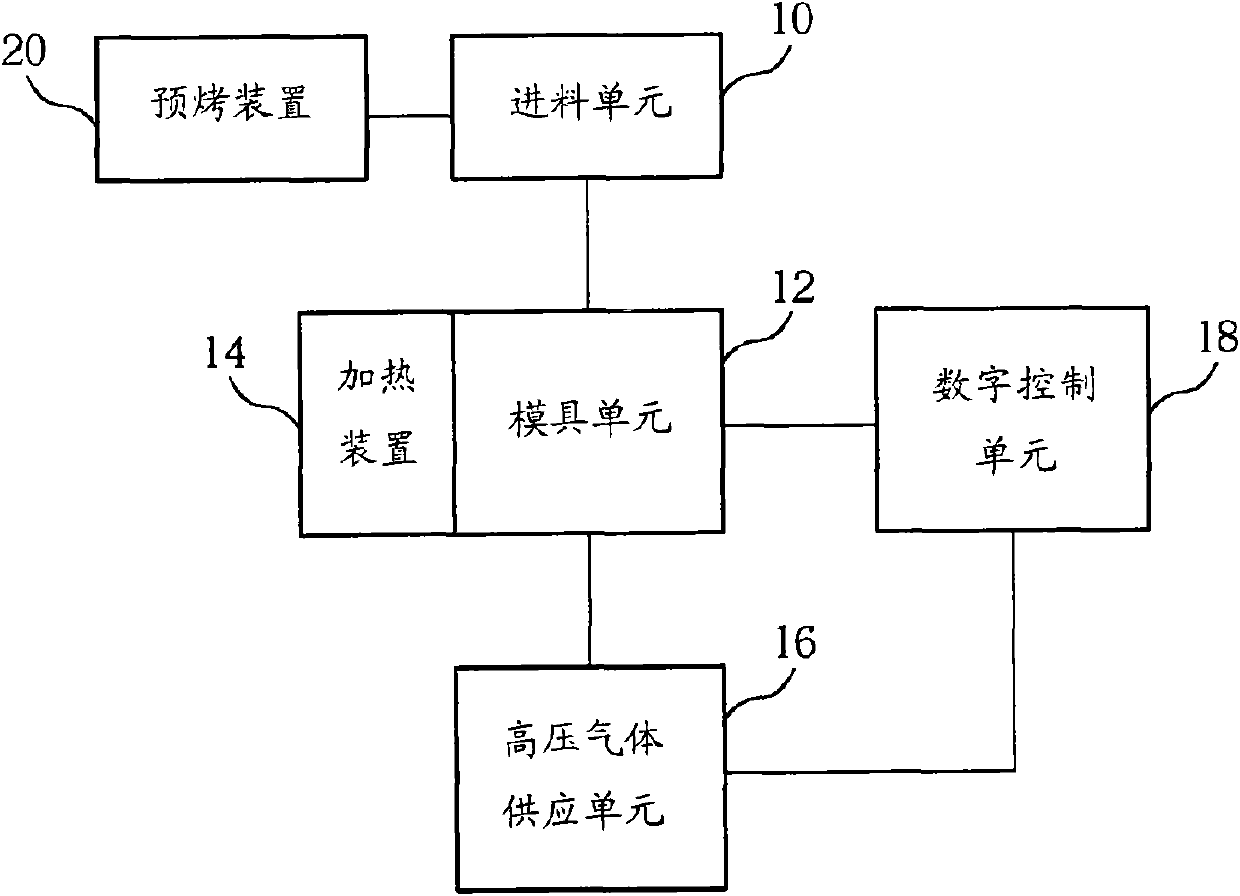

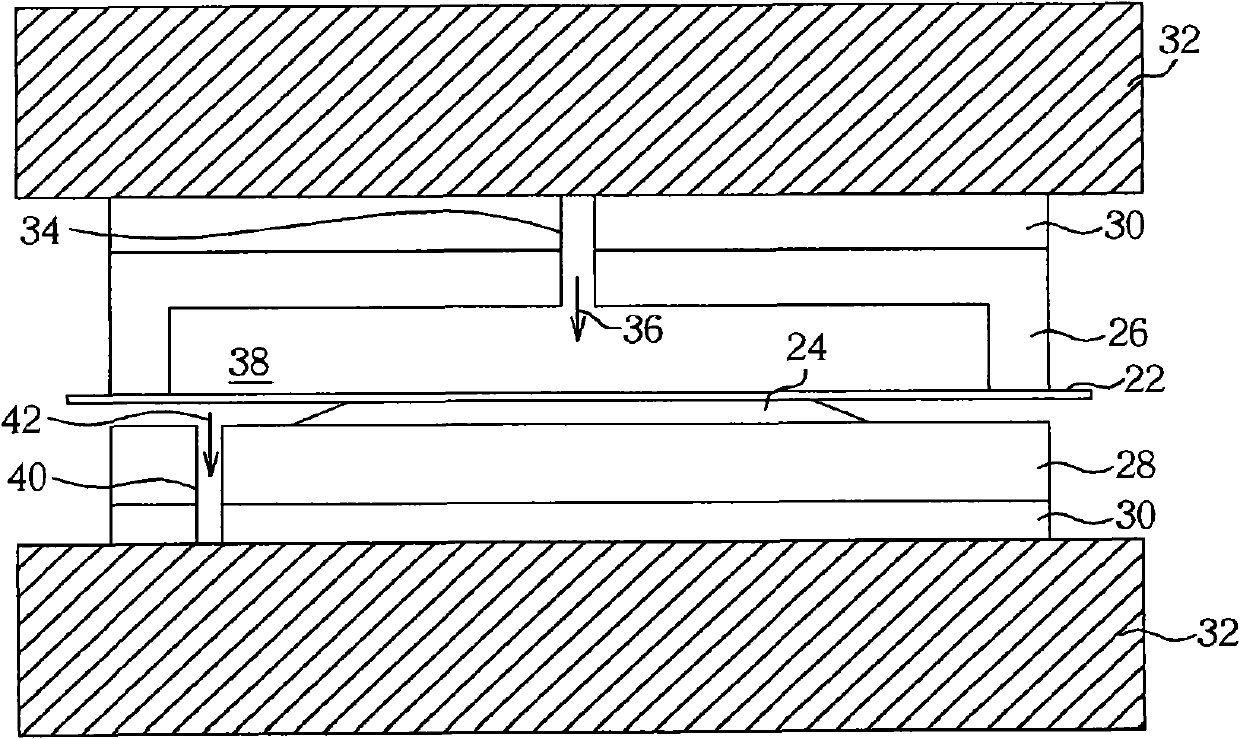

Metal shell forming method and device

The invention discloses a metal shell forming method and device, wherein a metal shell high-pressure forming method comprises the following steps: locating a metal plate in a die including an upper die, a lower die and a die core, and locating the metal plate on the die core; heating the die by a heating device to heat the metal plate; and applying high-pressure gas in multi-level mode to the metal plate so as to drive the metal plate to be pressed on a surface of the die core and form the metal shell. On the other hand of the invention, a metal shell high-pressure forming device particularly comprises the heating device combined with an external surface of the die and used for heating the die and the metal plate, a high-pressure gas supply unit for applying the high-pressure gas to the metal plate, and a digital control unit for controlling the high-pressure gas supply unit in digital form to apply the high-pressure gas to the metal plate in multi-level mode to form the metal shell.

Owner:ICHIA TECH

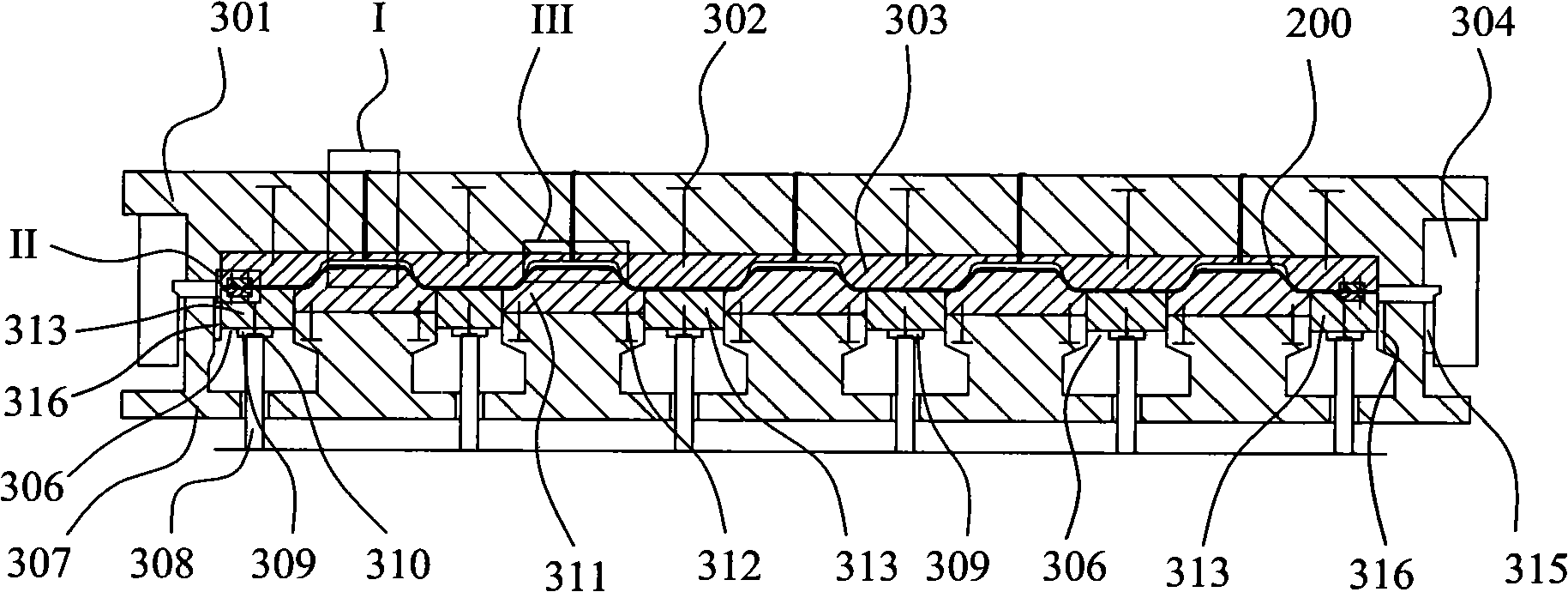

Container top board forming mold

ActiveCN101301670AIncrease productivityDimensionally stableShaping toolsEjection devicesMaterial removalContainer tops

The invention relates to a container top plate forming die. The container top plate forming die is provided so as to solve the problems in the prior art that the container top plate forming device has low production efficiency and unstable dimension of the finished products. The container top plate forming die comprises an upper die, a lower die, and a material removal plate; the upper die comprises an upper die seat and a concave die which is arranged on the upper die seat; the lower die comprises a lower die seat and a convex die which is arranged on the lower die seat and matched with the concave die; the concave die comprises at least two concave troughs which are intermittently arranged; the convex die comprises convex die embeddings which have the same quantity with the concave troughs on the concave die and match with the concave troughs; the material removal plate is hollowly provided with a trough where the convex die embedding can move up and down; the lower die seat is provided with a die cavity; the material removal plate is arranged in the die cavity and slide up and down by matching with and guiding the die cavity. The container top plate forming die of the invention has the advantages of high production efficiency and saving material; meanwhile, the operators during the production process can be greatly reduced correspondingly to the previous condition; furthermore, a plurality of top plate bosses are formed in one-step forming, thus having the advantages of stable dimension.

Owner:CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD

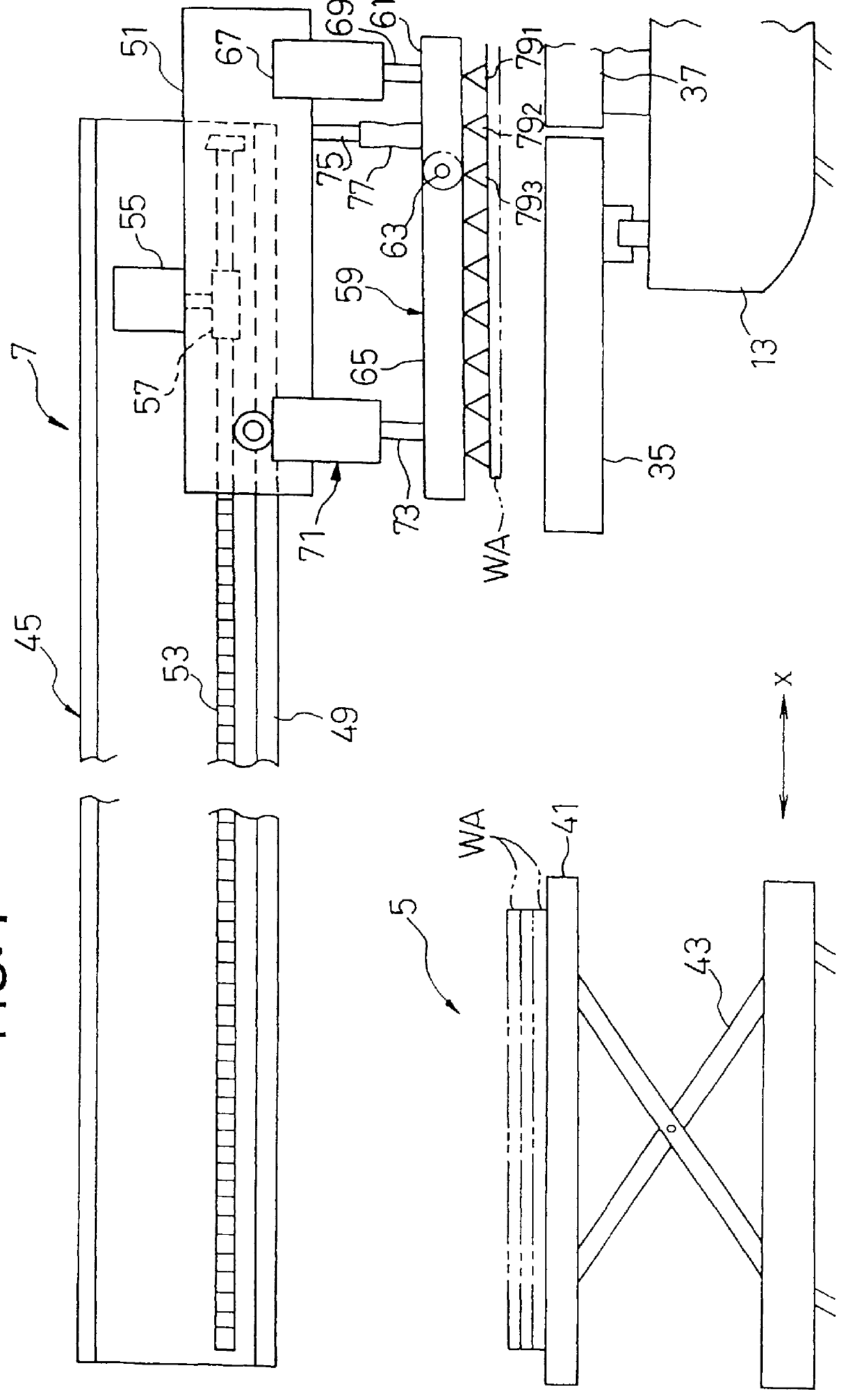

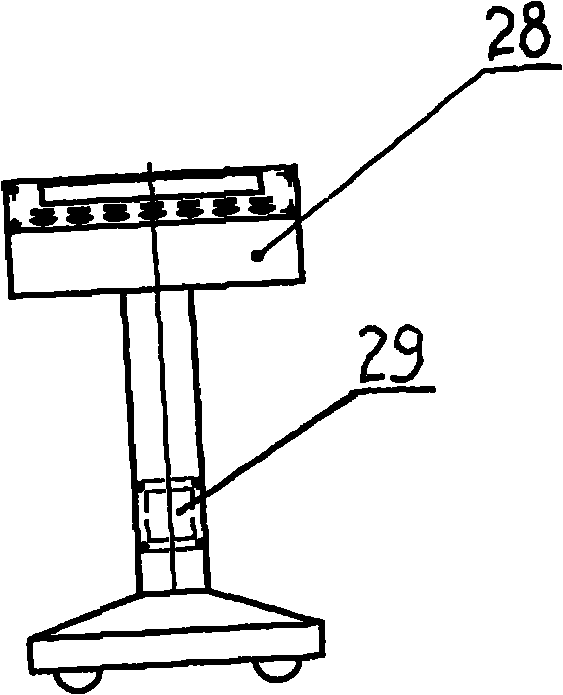

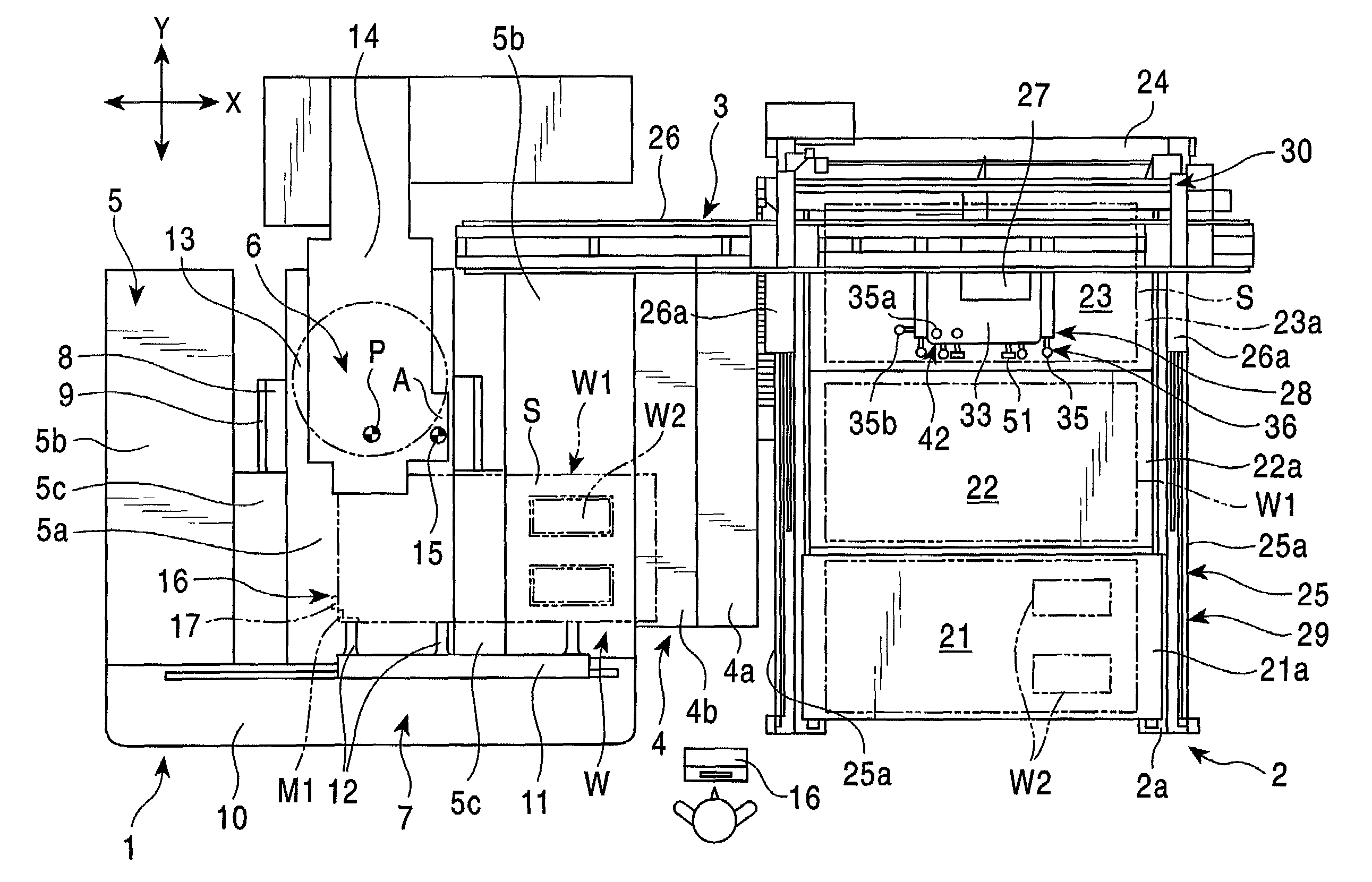

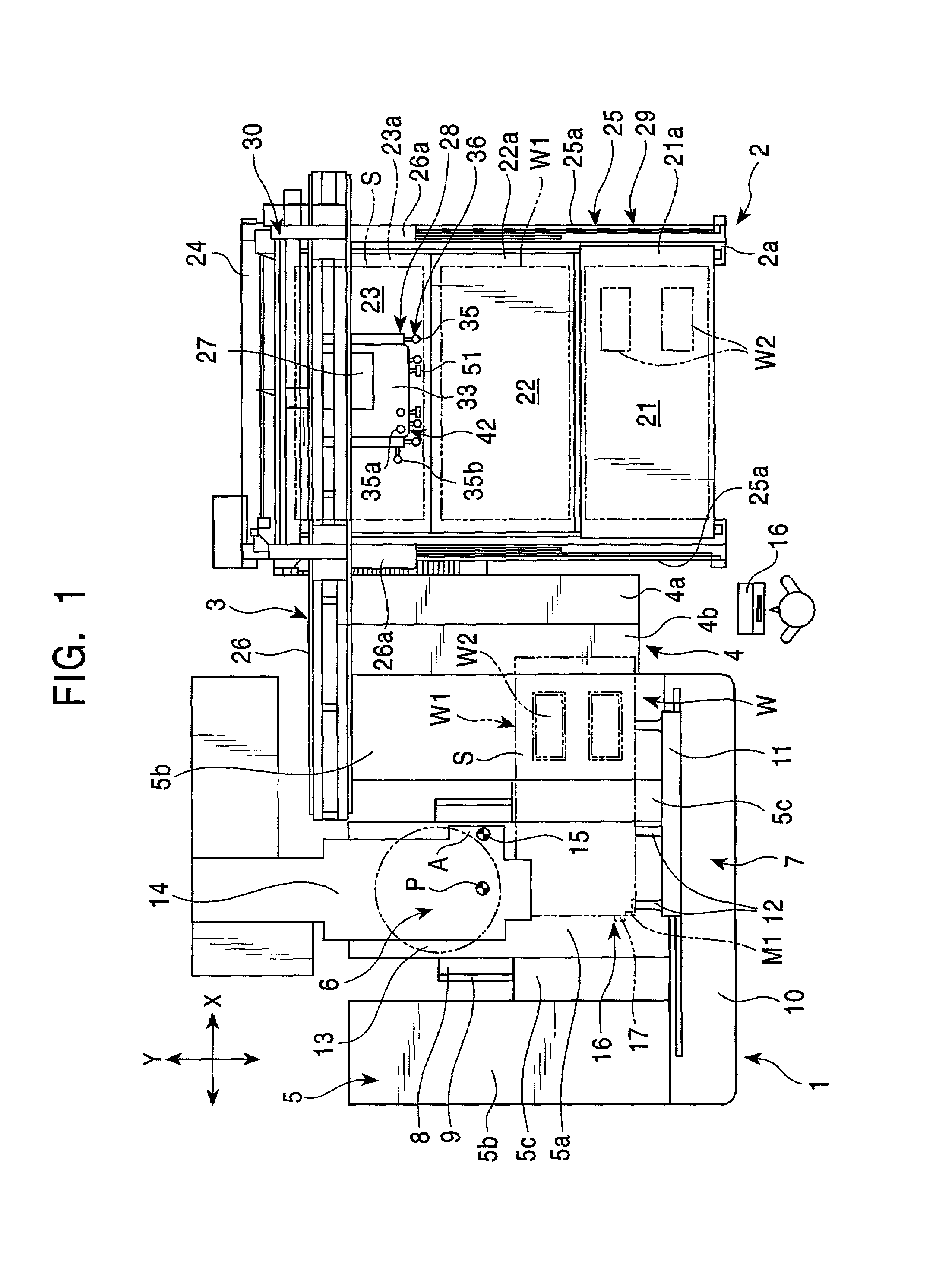

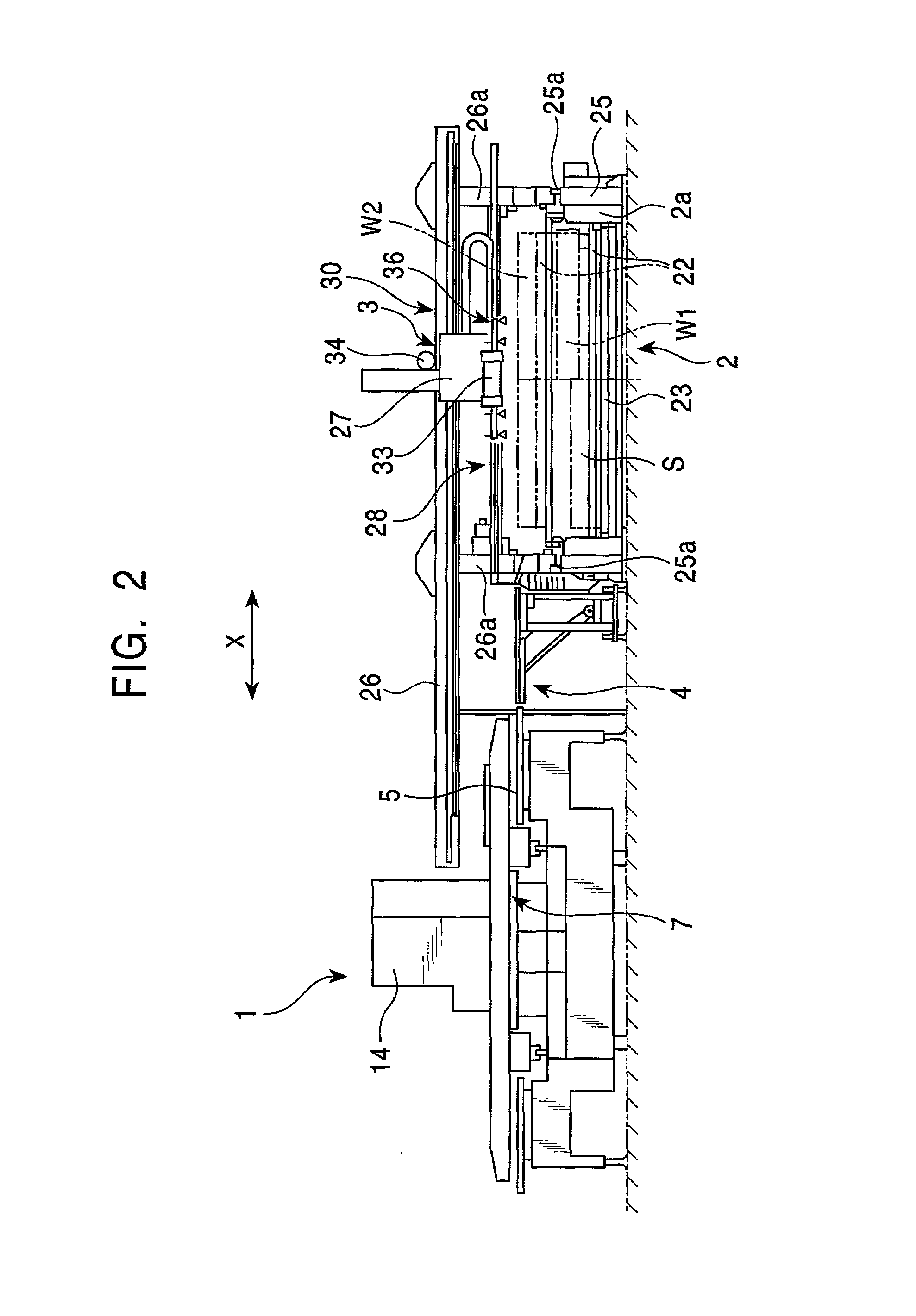

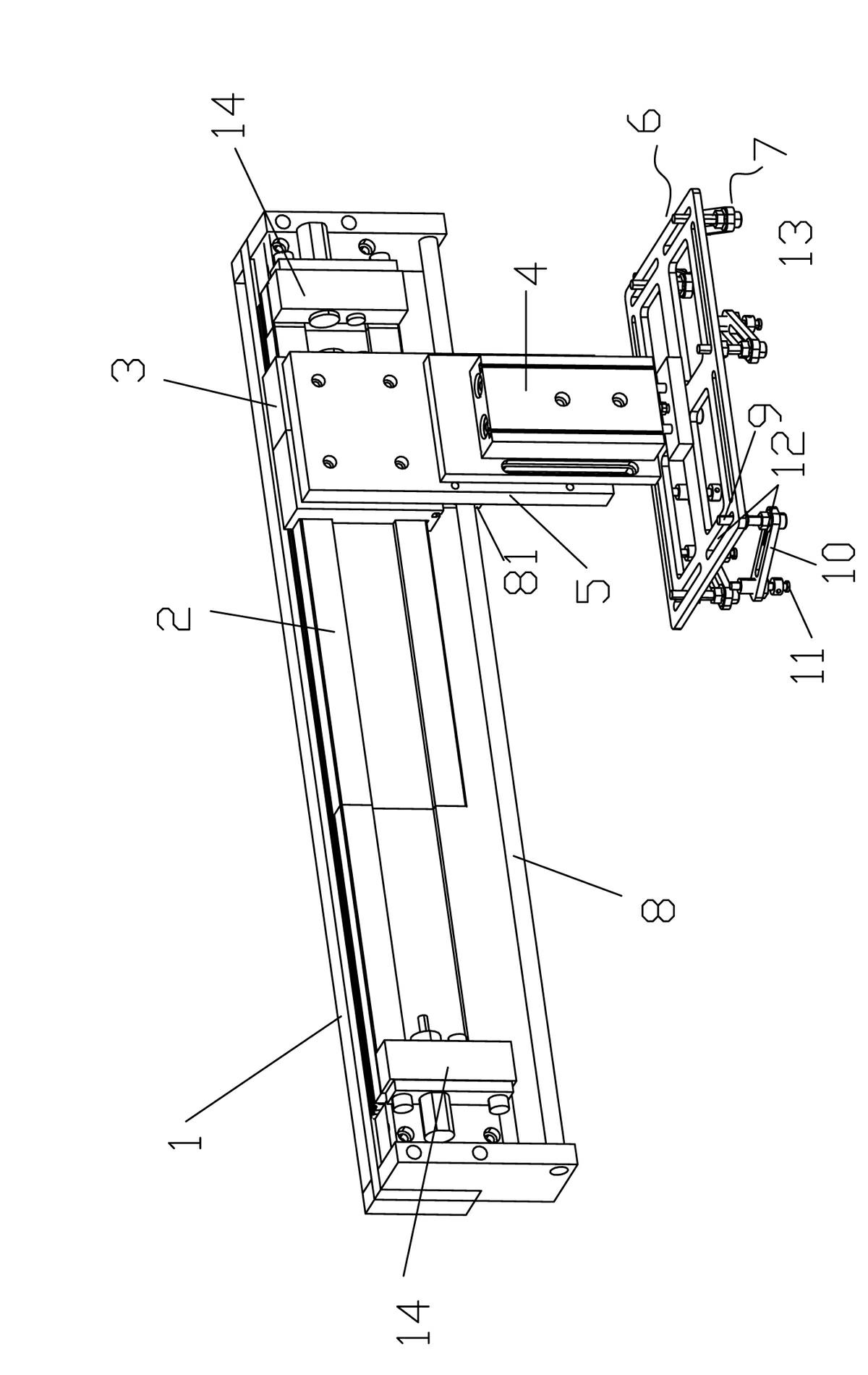

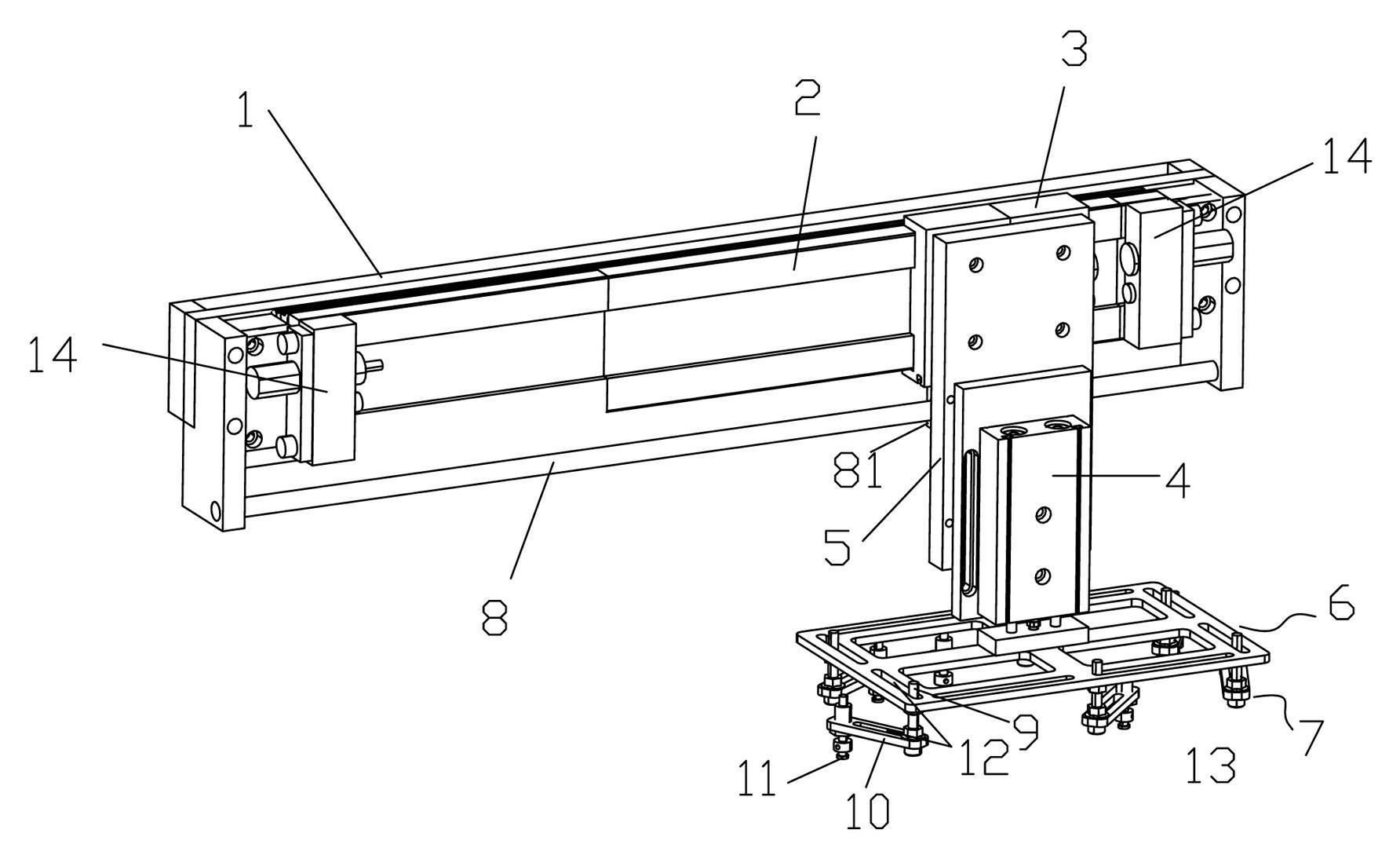

Workpiece-transfer device

InactiveUS7131361B2Easy to useSimple configurationMetal-working feeding devicesWork holdersRectangular coordinatesEngineering

The present invention provides a workpiece-transfer device that has functions for both loading and unloading workpieces, without requiring a workpiece-storage device to enable a function for replacing material and product workpieces with each other, and that requires only a simple configuration and low costs. A workpiece-transfer device loads a material workpiece W1 in a workpiece-machining device 1 and unloads a product workpiece W2 from the workpiece-machining device 1. A movement means with a rectangular coordinate system 30 is provided to move a traveling body 27 in a first direction along the direction in which the workpiece-machining device 1 and a workpiece-storage device 2 stand in a line (direction X) as well as in a second horizontal direction orthogonal to the first direction (direction Y). The traveling body 27 includes a gripping means 28 for gripping a material or product workpiece W1 and W2.

Owner:MURATA MASCH LTD

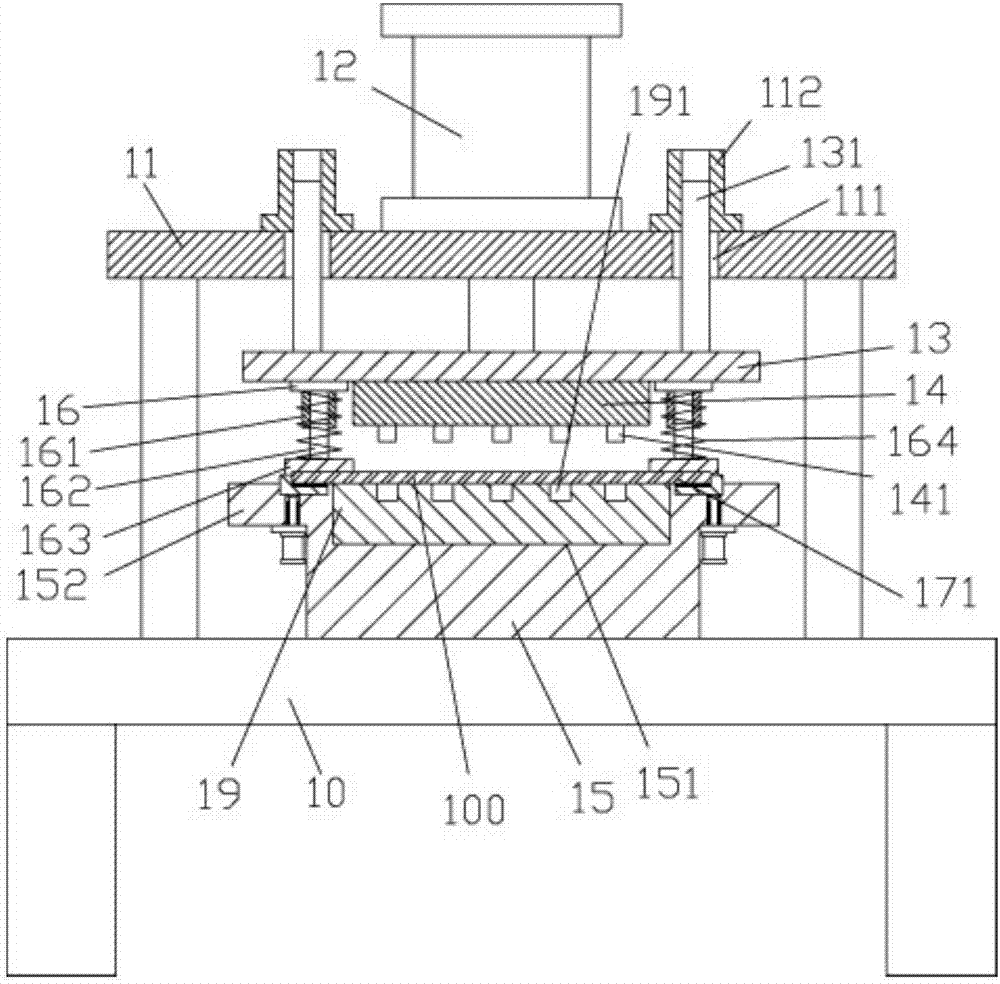

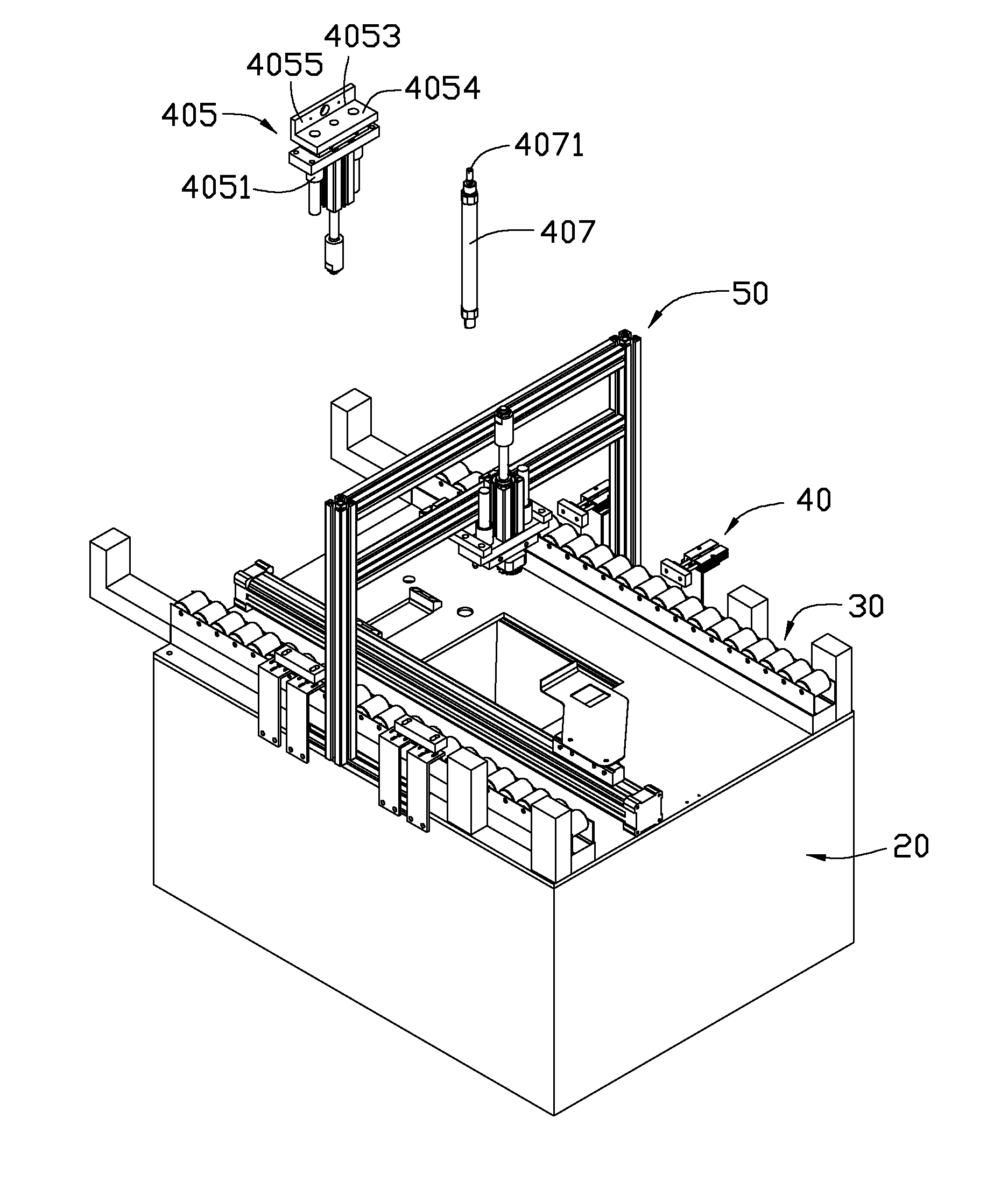

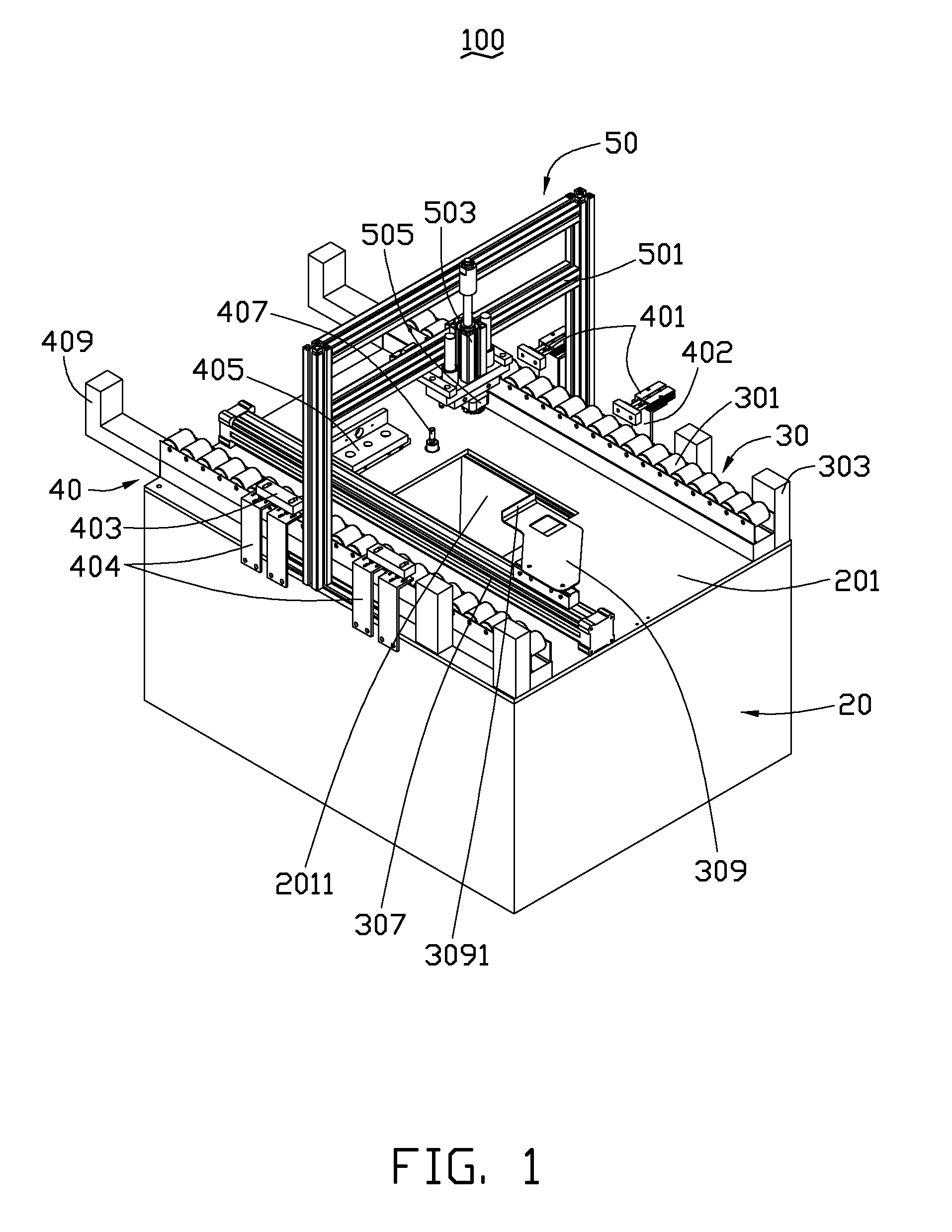

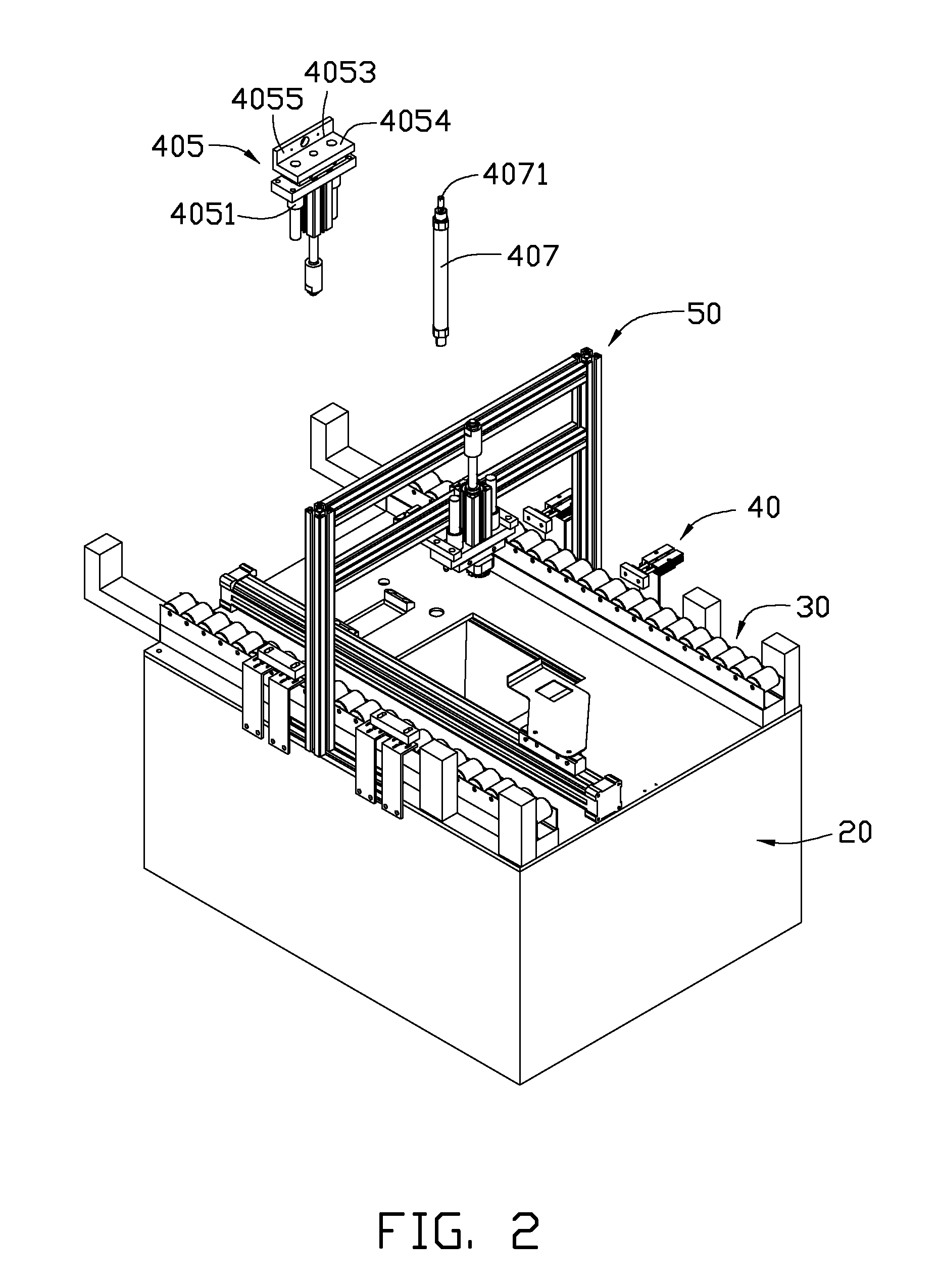

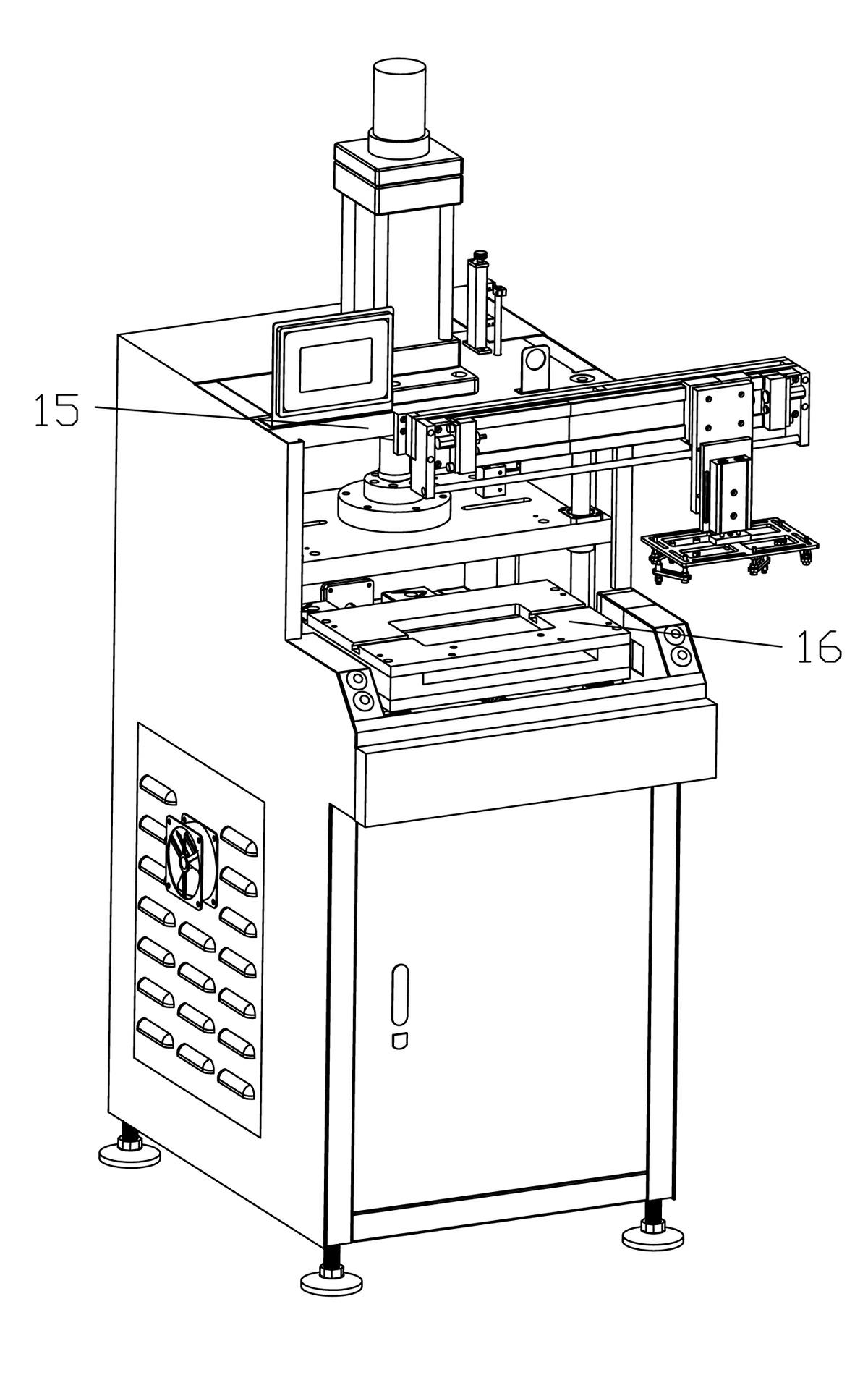

Punch device

A punch device includes a mounting platform, a punch mechanism, a feeding mechanism, and a positioning and ejecting mechanism. The punch mechanism is mounted over the mounting platform for punching a pre-punched workpiece positioned on the mounting platform. The feeding mechanism is mounted on the mounting platform for conveying the pre-punched workpiece. The positioning and ejecting mechanism is mounted on the mounting platform and positioned under the punch mechanism, for positioning the pre-punched workpiece during a punching process, and ejecting the punched workpiece after the punching process is performed, thereby facilitating an operator to take away the punched workpiece.

Owner:FU TAI HUA IND SHENZHEN +1

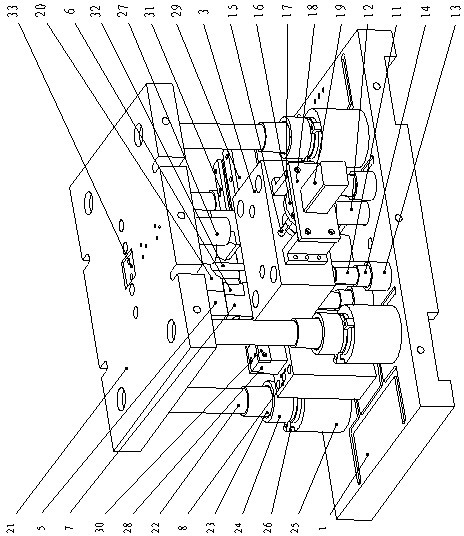

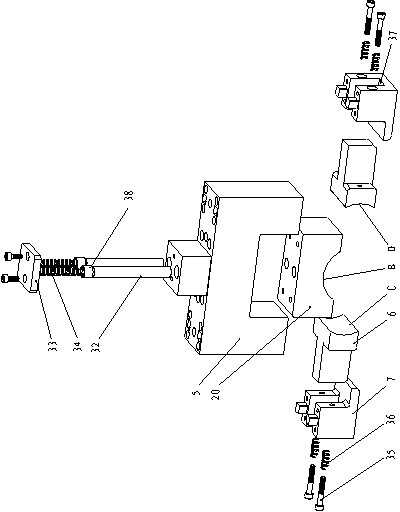

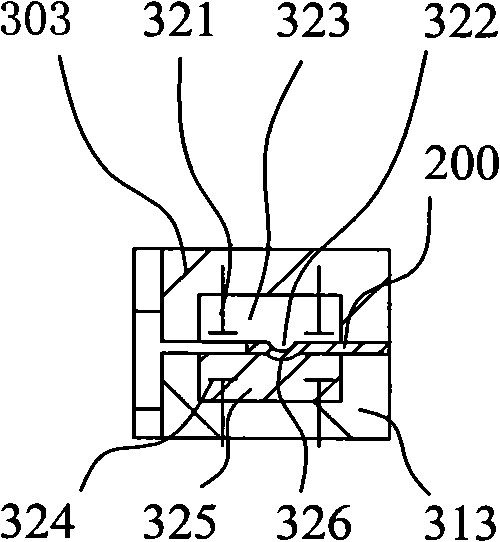

Multi-procedure punching compound die

InactiveCN103372605ASimple and fast operationIncrease productivityShaping toolsMetal-working feeding devicesPunchingHigh volume manufacturing

The invention provides a multi-procedure punching compound die, and belongs to the technical field of punching compound dies. Four procedures of blanking, punching, deep drawing and flanging can be finished synchronously, and continuous production is realized. The multi-procedure punching compound die comprises an upper die part and a lower die part. Mutual feeding is adopted, a blank guide pin is adopted by a blank guiding device, a blank stopping pin (33) is adopted for controlling feeding step pitches, spring unloading rigid striking parts are adopted by the die, a standard buffer mounted under a working bench of a punch machine is utilized to provide blank holding force. Guide manners of the upper die and the lower die are considered, the requirement of the size accuracy is general, large-scale production can be realized, correct punching and positioning of the upper die and the lower die are completed through matching a guide column with a guide sleeve, the production efficiency and quality of products are high, wear resistance, toughness, hardness and thermal stability of the die are good, matching accuracy and location of each part are good, assembling can be successful and no interference occurs, maintenance and disassembling are facilitated, a JC23-40F open-type punch machine can be selected to use for producing, and the multi-procedure punching compound die is particularly adaptable to large-scale production and automatic production.

Owner:刘雨欣

Flexible plate punching machine manipulator

InactiveCN102179808ARealize transportationAchieve normal workProgramme-controlled manipulatorMetal-working feeding devicesPunch pressControl manner

The invention discloses a flexible plate punching machine manipulator which comprises an installing seat, a horizontal guide rail, a sliding table, a lifting and releasing cylinder, a cylinder installing plate, a suction nozzle fixing disc and a plurality of suction nozzle pieces. In the invention, a flexible plate is sucked up and released by the suction nozzle pieces in an adsorption manner; through controlling the matching process of a sliding table drive piece, the lifting and releasing cylinder and the suction nozzle pieces, the flexible plate can be transported, located and placed, and thus the troubles caused by manually operating the flexible plate are avoided and safety accidents can be prevented; in addition, because the actions of the sliding table drive piece, the lifting and charging cylinder and the suction nozzle pieces can be accurately controlled in a controlled manner, the precision of the action of taking and placing the flexible plate can be ensured; and compared with a mode of manually placing the flexible plate, the flexible plate punching machine manipulator has greatly-improved quality of punched products.

Owner:李亮

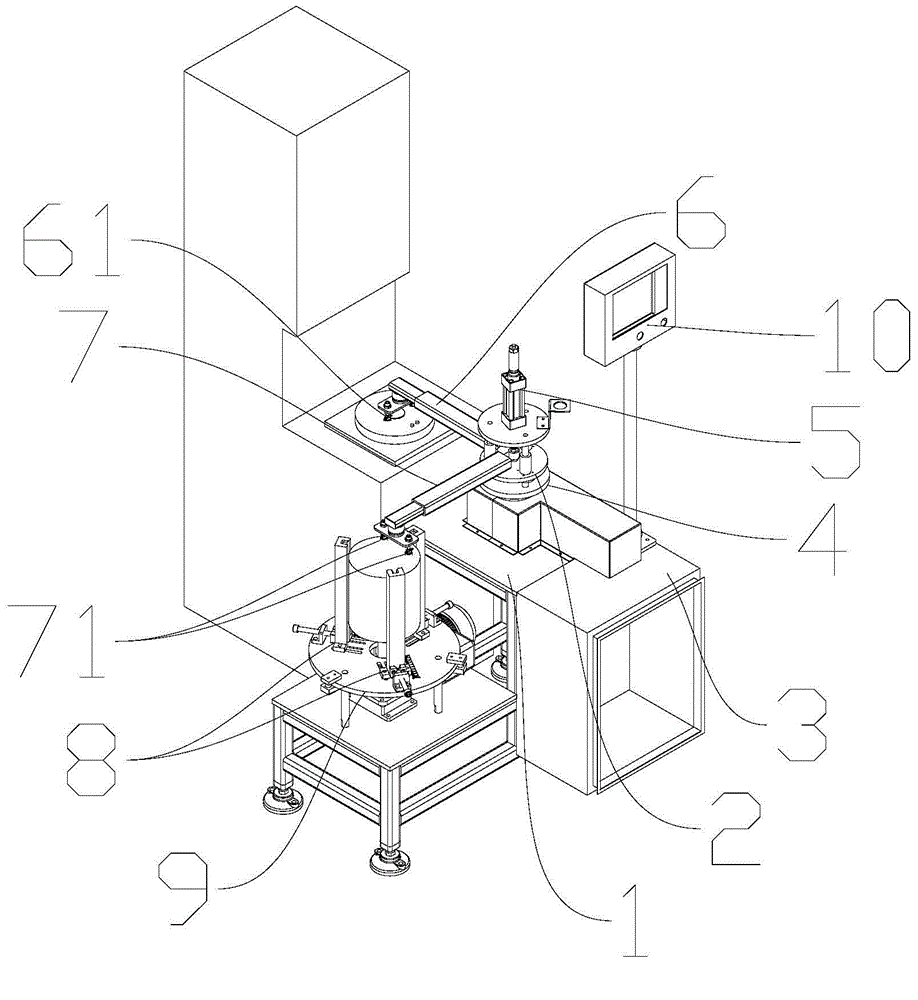

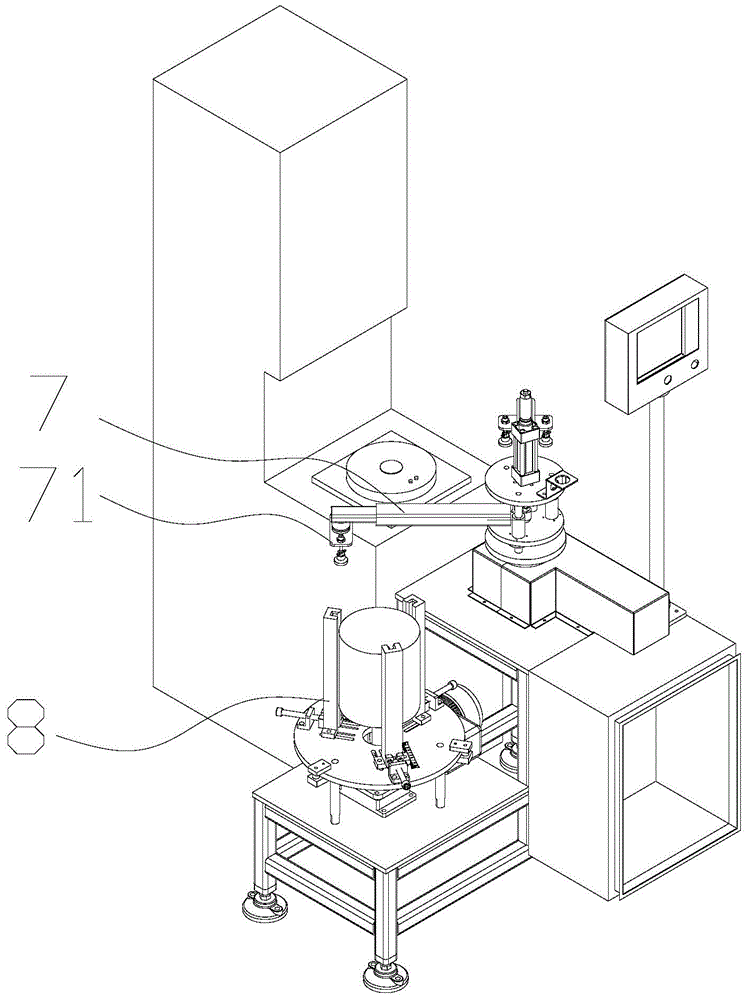

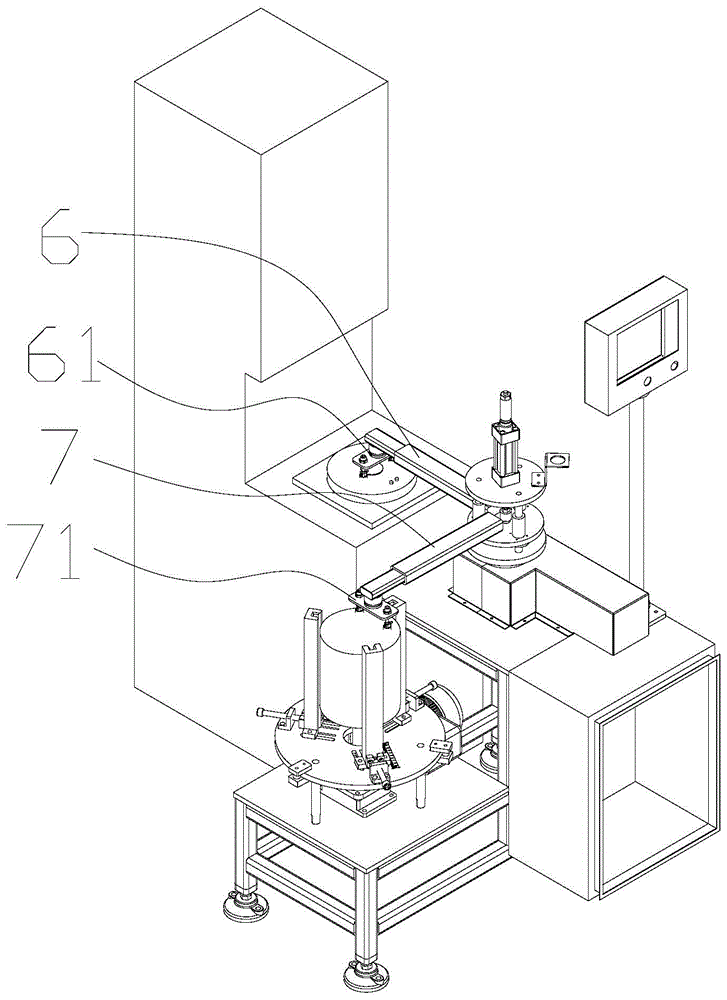

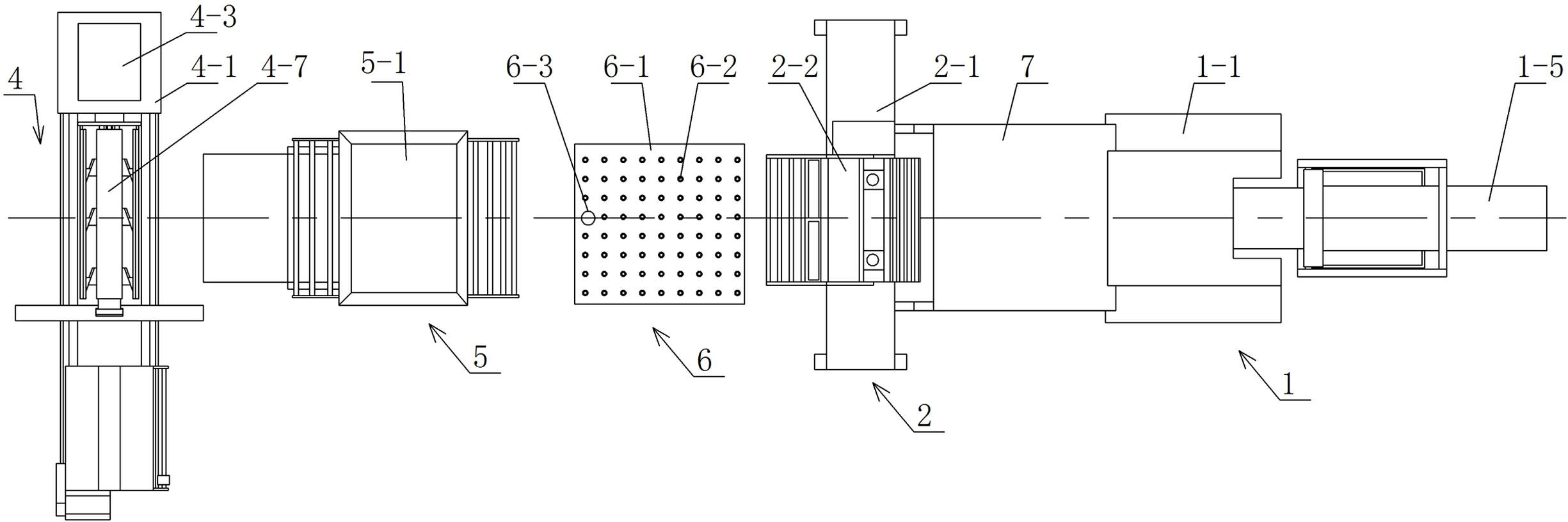

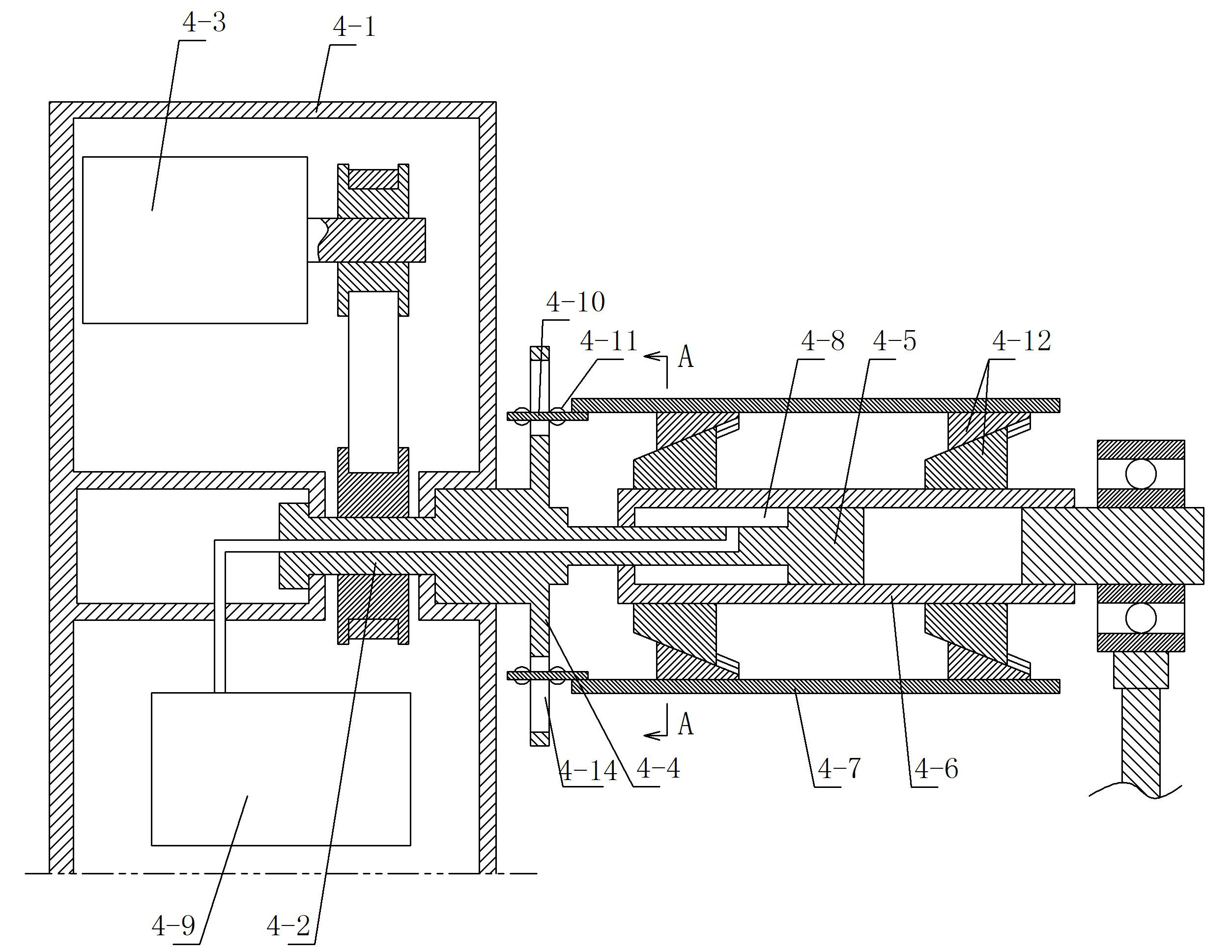

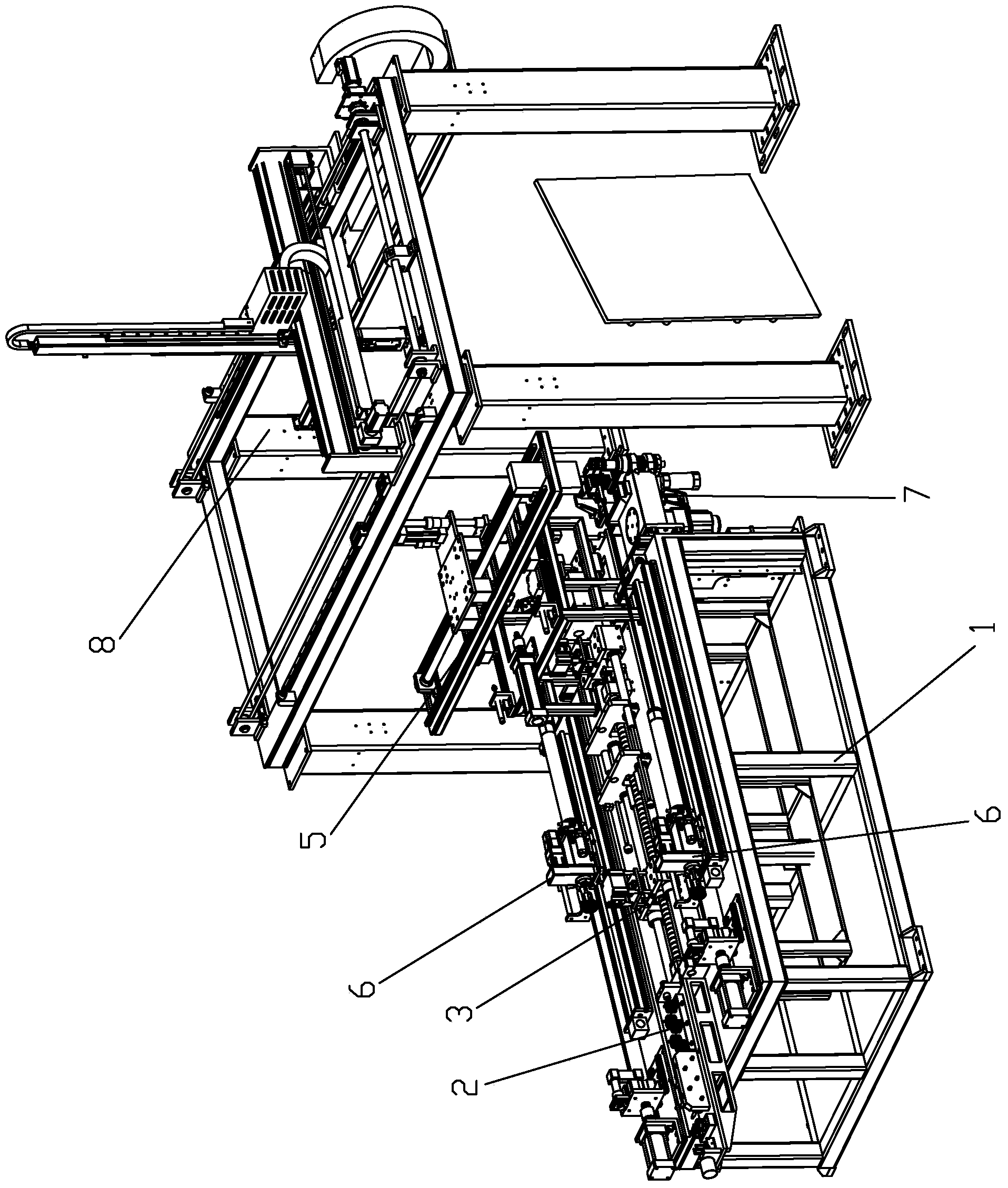

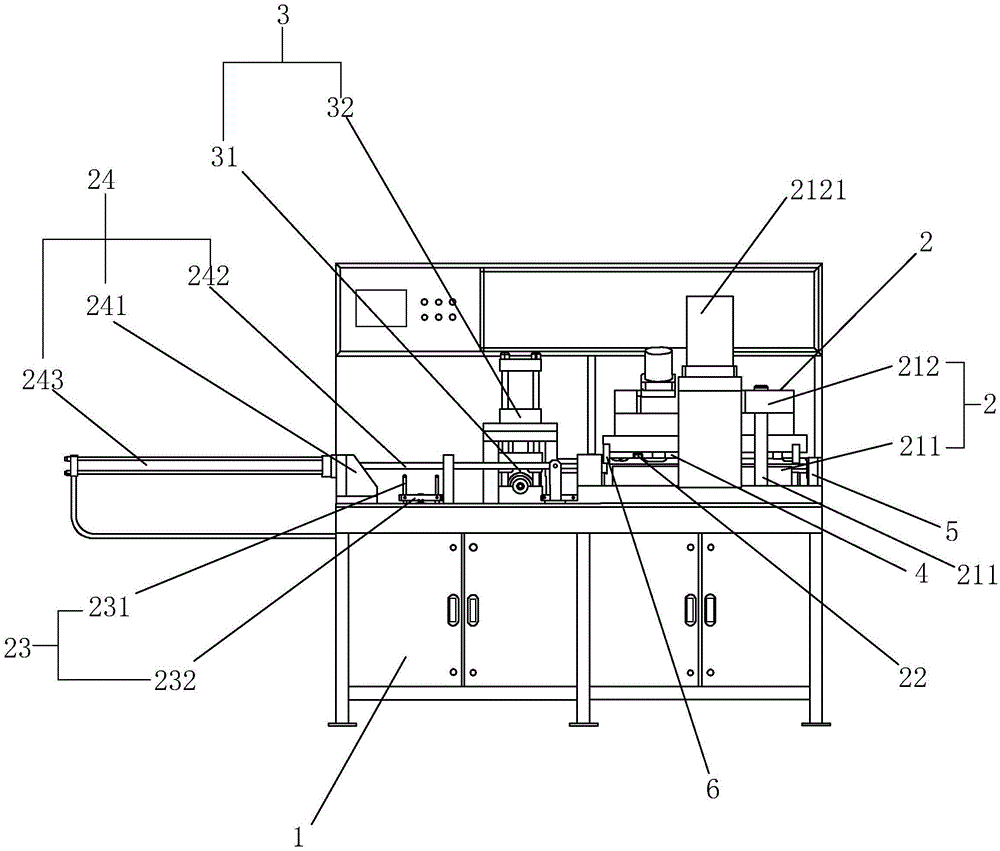

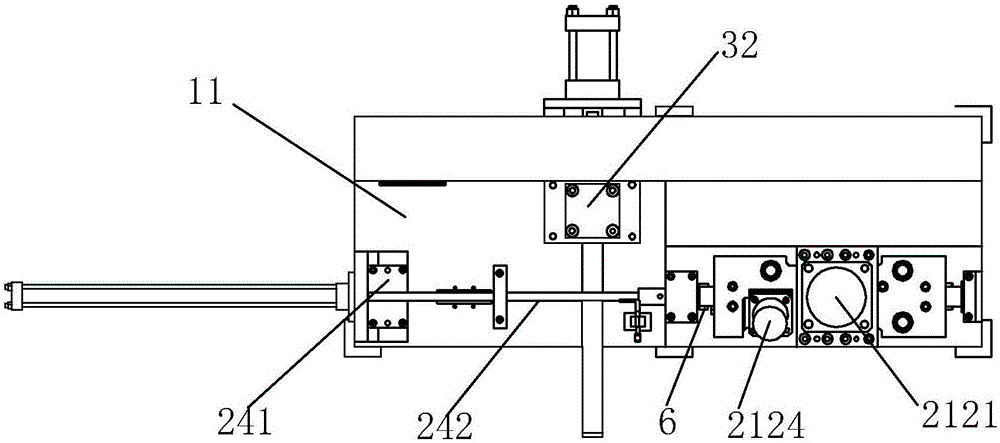

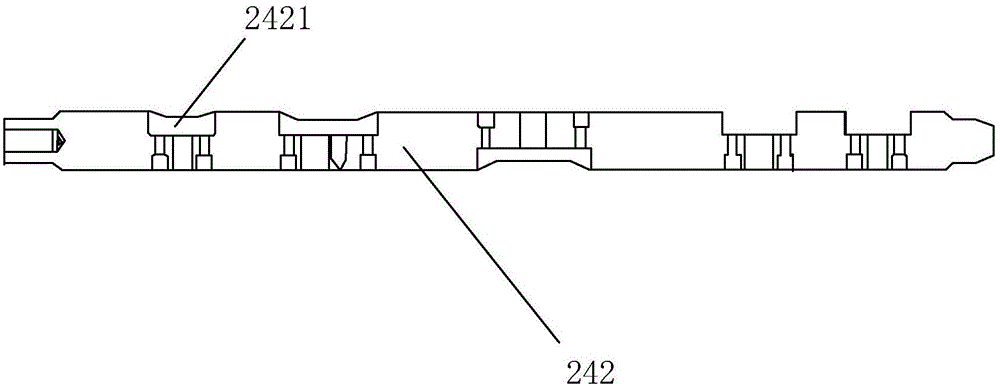

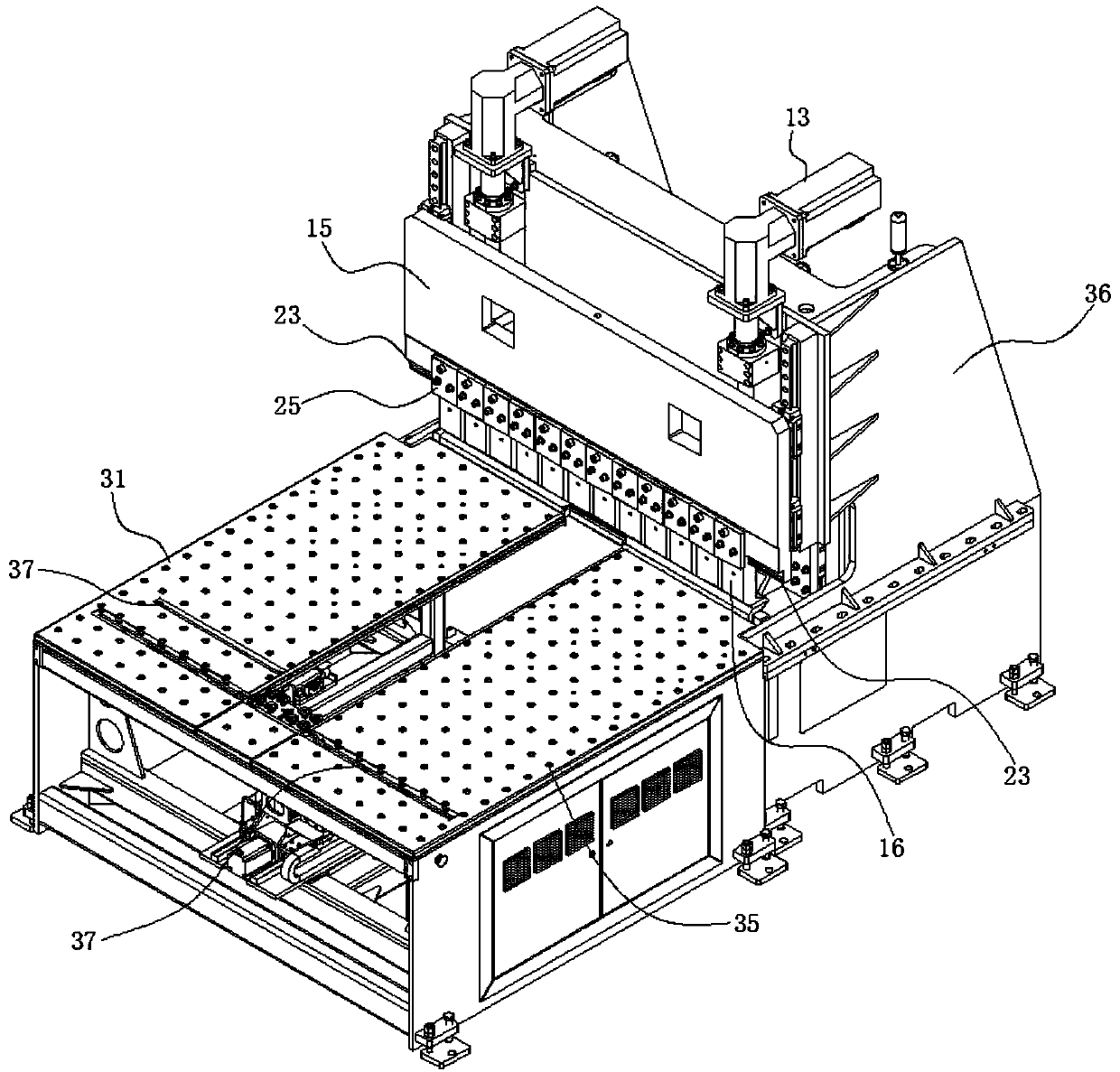

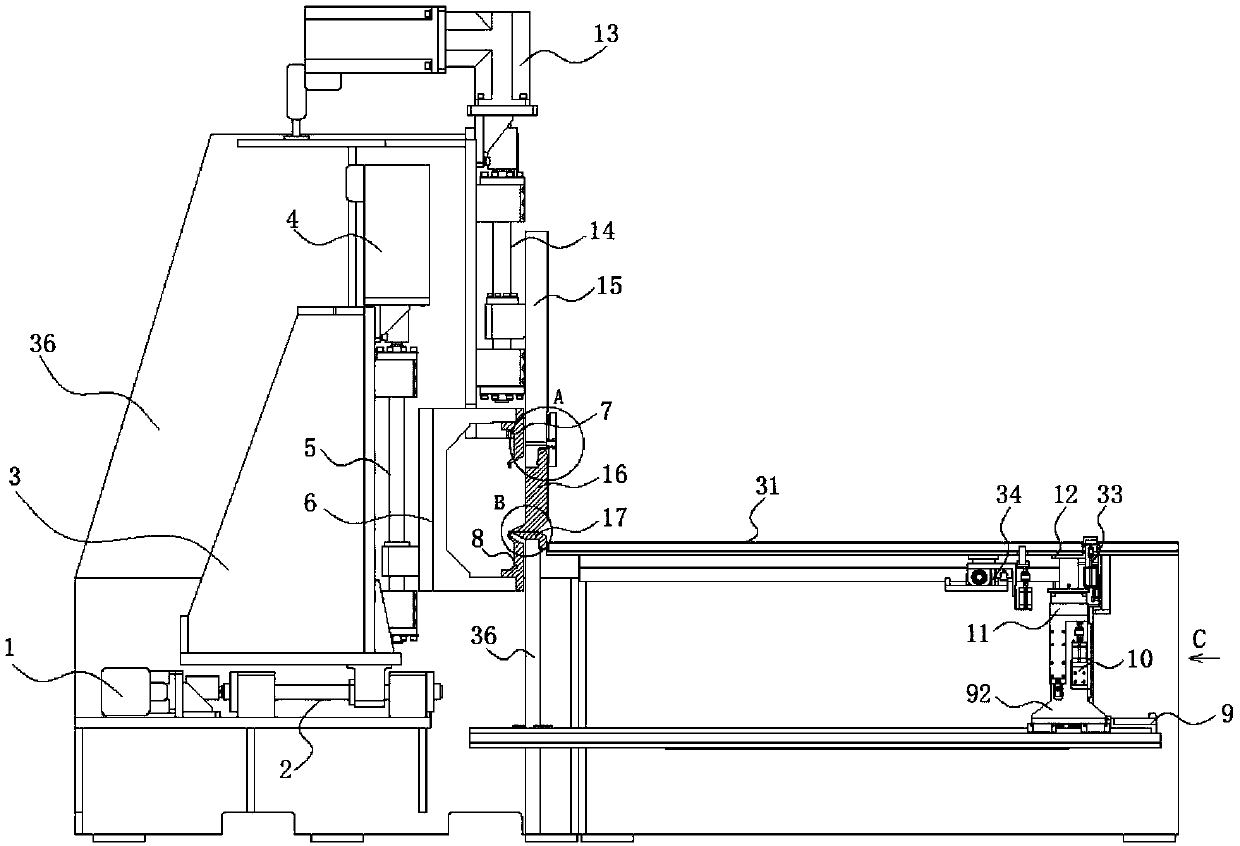

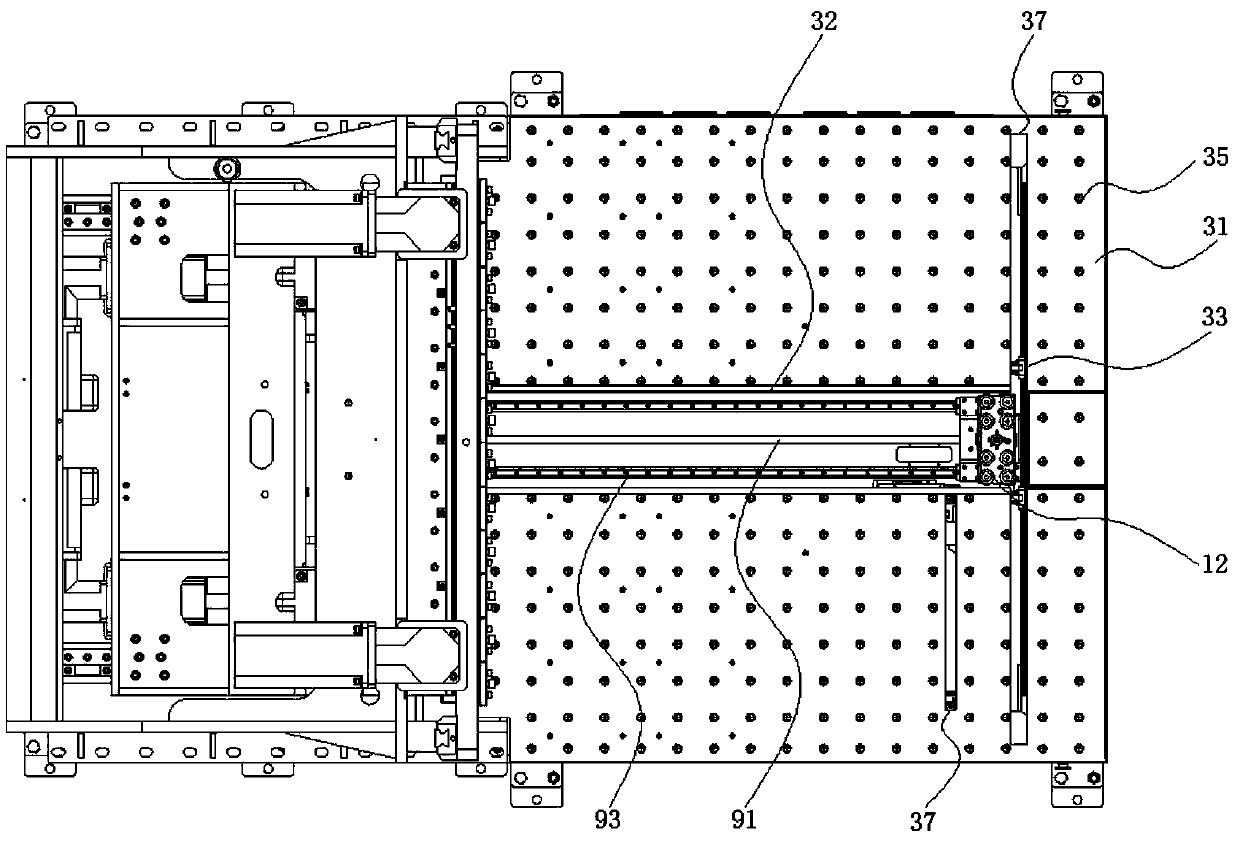

Multifunctional pipe fitting forming all-in-one machine and machining process thereof

The invention discloses a multifunctional pipe fitting forming all-in-one machine and a machining process thereof, belongs to the technical field of pipe fitting forming, and aims at providing equipment capable of carrying out multi-procedure machining on the same workbench surface simultaneously by virtue of the same control system, and a process method. Compared with a complete set of forming production line for pipe fittings in the prior art, the multifunctional pipe fitting forming all-in-one machine disclosed by the invention is small in floor area, saves the cost of the control system and the management cost, and increases the working efficiency; wastes can be automatically discharged, thus further increasing the working efficiency while improving the safety; and moreover, simultaneous punching for a plurality of holes can be realized in a punching mechanism of the multifunctional pipe fitting forming all-in-one machine disclosed by the invention, thus improving the punching accuracy, and improving the forming quality of the pipe fittings.

Owner:ZHEJIANG MOTORBACS TECH

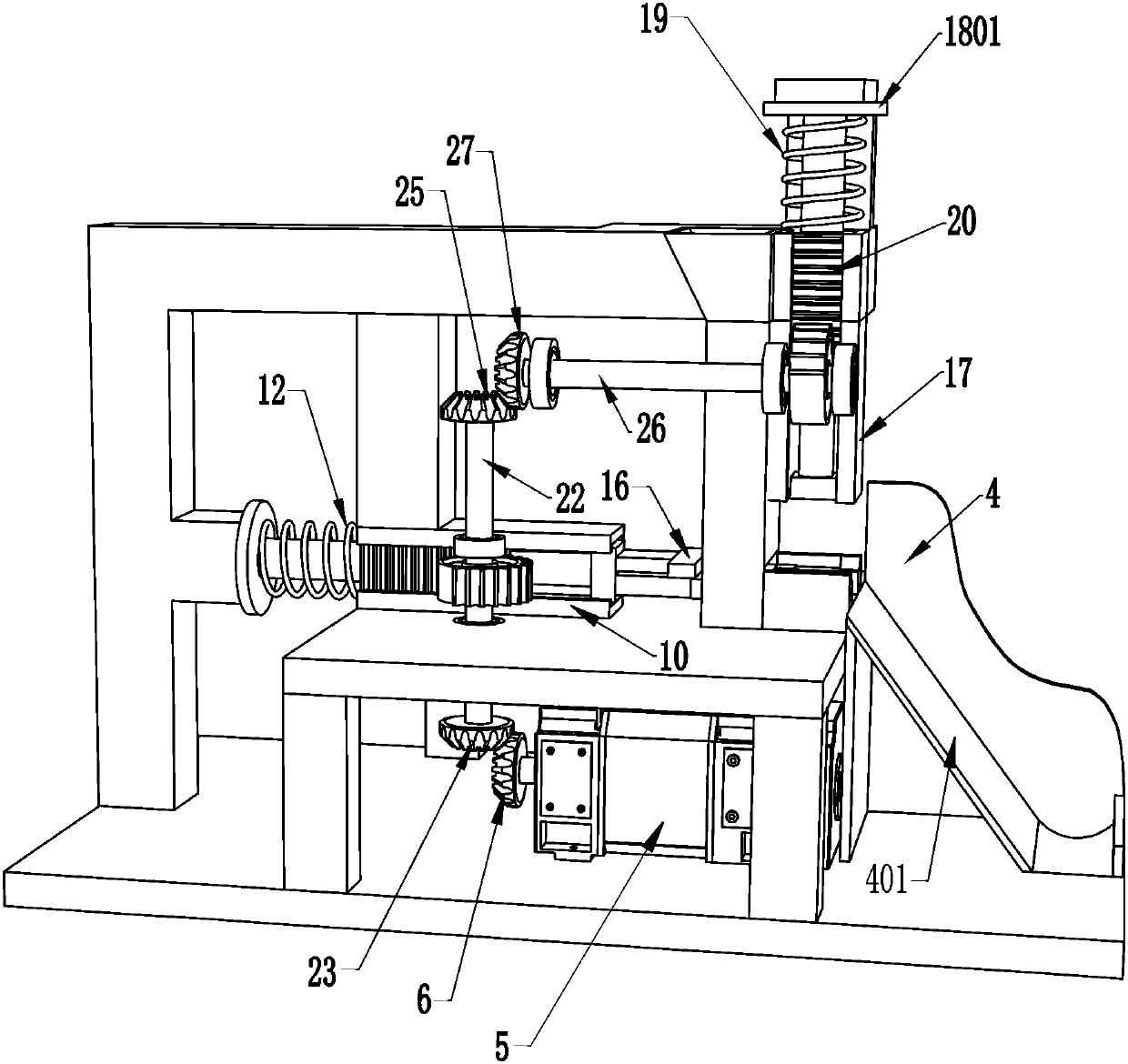

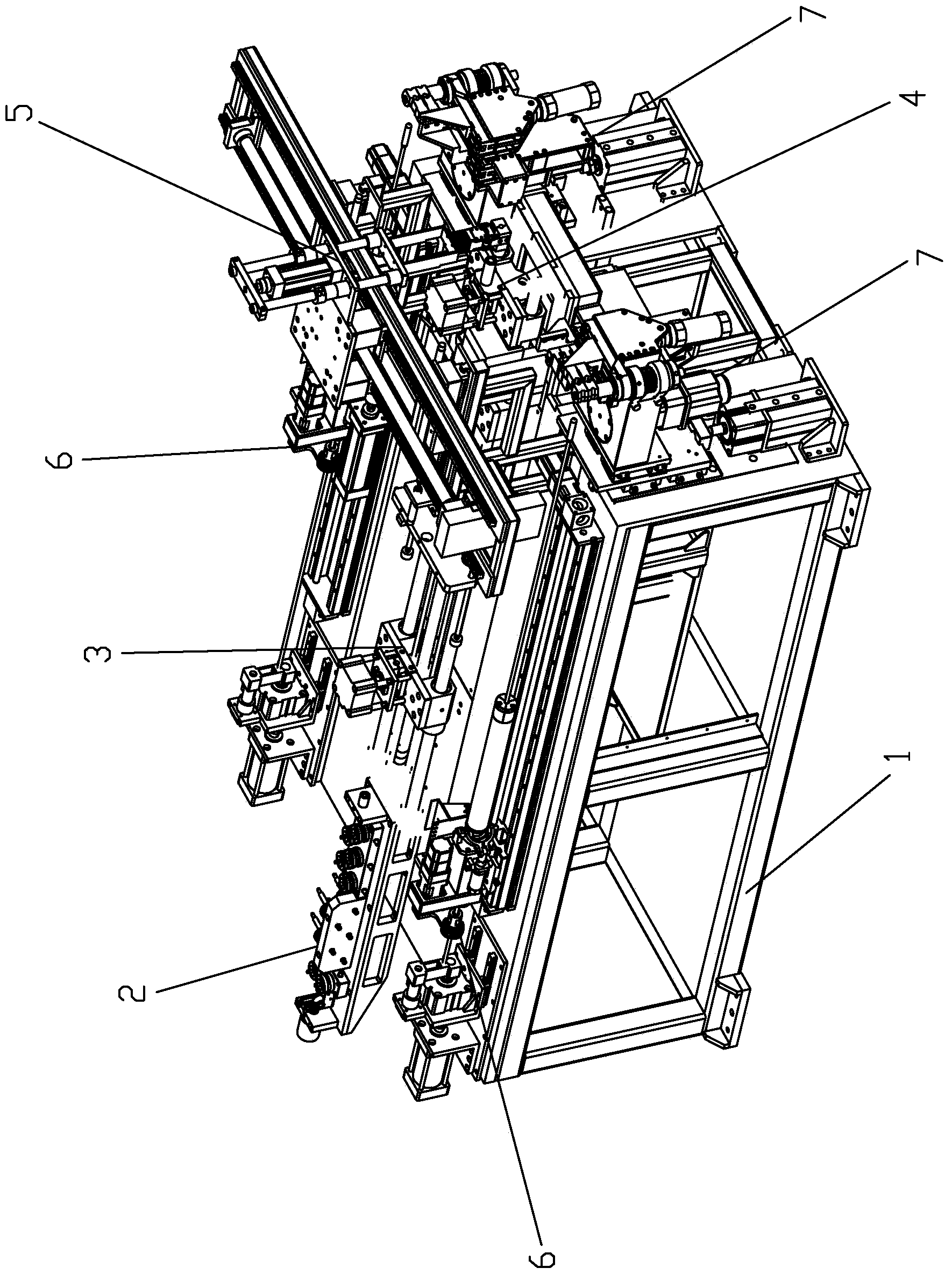

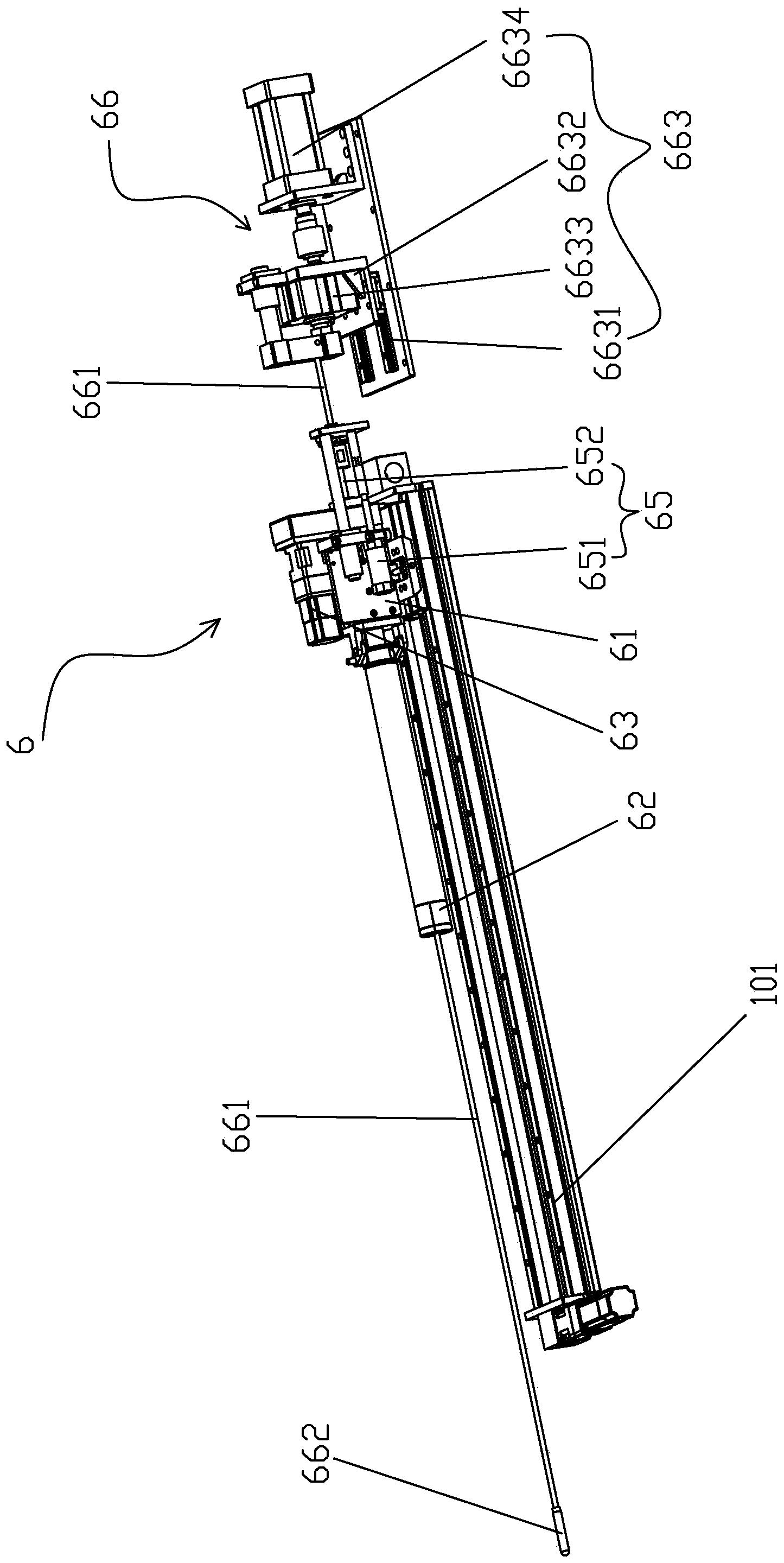

Multi-shaft drive bending machine and bending method thereof

PendingCN110538899AImprove work efficiencyReasonable and reliable structureShaping toolsMetal-working feeding devicesDischarge - actionPress brake

The invention discloses a multi-shaft drive bending machine which comprises a bending system and an integrated feeding and discharging system. The bending system comprises a horizontal bending drive device. A horizontal bending shaft arranged in the horizontal direction is installed on the horizontal bending drive device. A linkage support is installed on the horizontal bending shaft. An up and down bending drive device is further arranged at the upper end of the linkage support. An up and down bending shaft installed in the vertical direction is installed on the up and down bending drive device. A bending cutter support is installed at the shaft end of the up and down bending shaft. An upper bending cutter and a lower bending cutter are installed at the upper end and the lower end of thebending cutter support correspondingly, wherein the upper bending cutter and the lower bending cutter correspond in upper and lower position. According to the multi-shaft drive bending machine, by means of coordinative matching and adjusting of bending drive, the upper bending cutter and the lower bending cutter can reach different positions, a down pressing drive lifting device cooperates to control down pressing fixing and loosening of an upper pressing cutter and feeding and discharging action of feeding and discharging drive, and bending of bent parts in any shape, at any angle and with any flexible radian is completed.

Owner:南京蓝昊智能科技有限公司

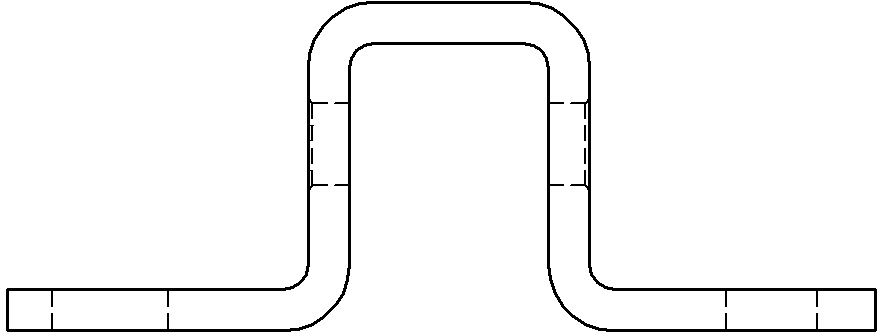

Horizontal bending machine

InactiveCN103121053AIncrease forward momentumEasy to bend multiple timesMetal-working feeding devicesPositioning devicesRelative pressureLayer thickness

The invention relates to a horizontal bending machine which comprises a machine body, a controller, a bending mechanism and a follower plate. The bending mechanism is horizontally arranged on the machine body. The follower plate is arranged in a workpiece feeding direction of the bending mechanism. In time of bending, the controller controls a workpiece to moving into the follower plate and the position of the workpiece is limited by the follower plate and the bending mechanism. The bending mechanism bends the workpiece and acts synchronously with the follower plate. The bending precision is improved, a bending die can rotate independently so that restoring is convenient and multiple bending of the workpiece is facilitated. A whole bending process of the workpiece is fully automatic so that the production efficiency of the bending machine is improved, labor intensity of operators is relived and at the same time, quality and stability of products can be improved. In time of material pressing, the bending machine can be suitable for clamping heat exchangers with different layer thickness and layer numbers so that application range is wide. Synchronous action of the bending mechanism and the follower plate in time of bending can be achieved, friction when the workpiece is bent is reduced and quality of the workpiece is improved. The workpiece can be bended in a delamination mode, required bending moment is little, relative pressure among heat exchanger fins and the bending die and among layers of the heat exchanger is small and the heat exchanger fins are not prone to fall.

Owner:JDM JINGDA MASCH (NINGBO) CO LTD

Bending and shaping die for automobile upper door hinge brackets

InactiveCN103817231AGuaranteed accuracyPrecise positioningShaping toolsMetal-working feeding devicesPunchingRejection rate

The invention provides a bending and shaping die for automobile upper door hinge brackets. The bending and shaping die comprises an upper die structure and a lower die structure. The upper die structure comprises an upper die plate, an upper padding plate is mounted under the upper die plate, and upper padding feet are mounted on the upper die plate. The lower die structure comprises a lower die plate, a lower padding plate is mounted on the lower die plate, a mounting plate is mounted under the lower die plate through lower padding feet, and die assembling is performed through a sliding guide post component between the upper die plate and the lower die plate. The bending and shaping die is characterized in that a shaping male die is mounted under the upper padding plate, a female die frame is mounted on the lower padding plate, an ejecting plate is embedded in the female die frame, a positioning nail is vertically mounted in the ejecting block and penetrates the ejecting block from bottom to top, an ejecting mechanism is mounted under the ejecting block and penetrates the lower die plate, the lower padding plate from bottom to top to be connected with the bottom surface of the ejecting block, and a limiting hole is formed in the position of the shaping male die and directly facing the positioning nail. By the bending and shaping die, the problem about inaccurate positioning of a workpiece in processing of simple punching dies can be solved, processing quality can be improved, and rejection rate can be lowered.

Owner:WUXI AIBO METAL PROD

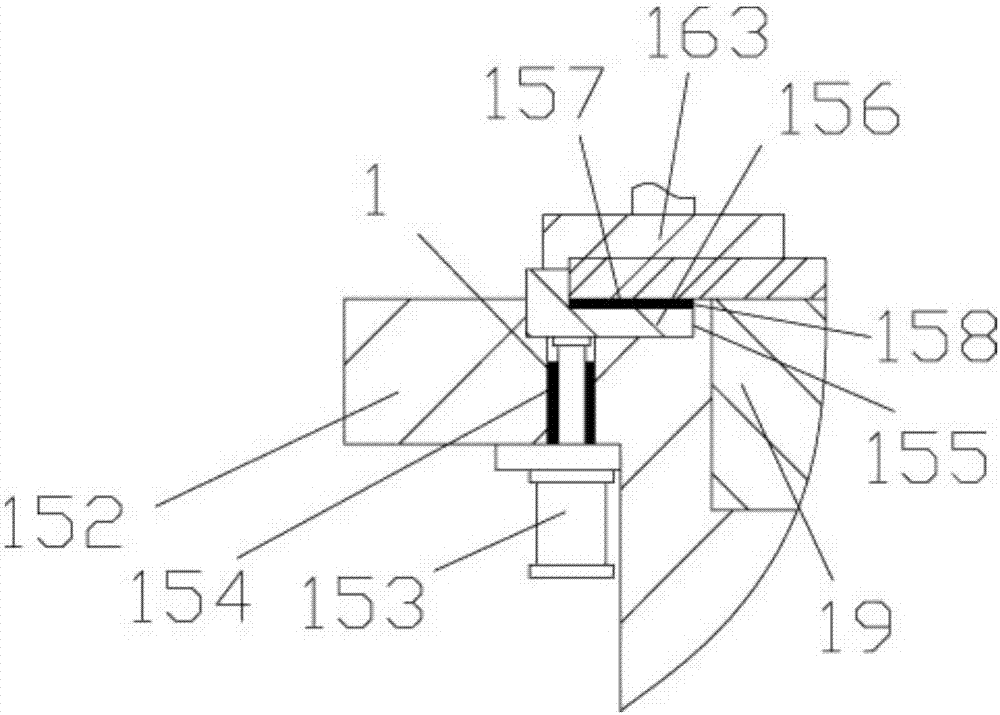

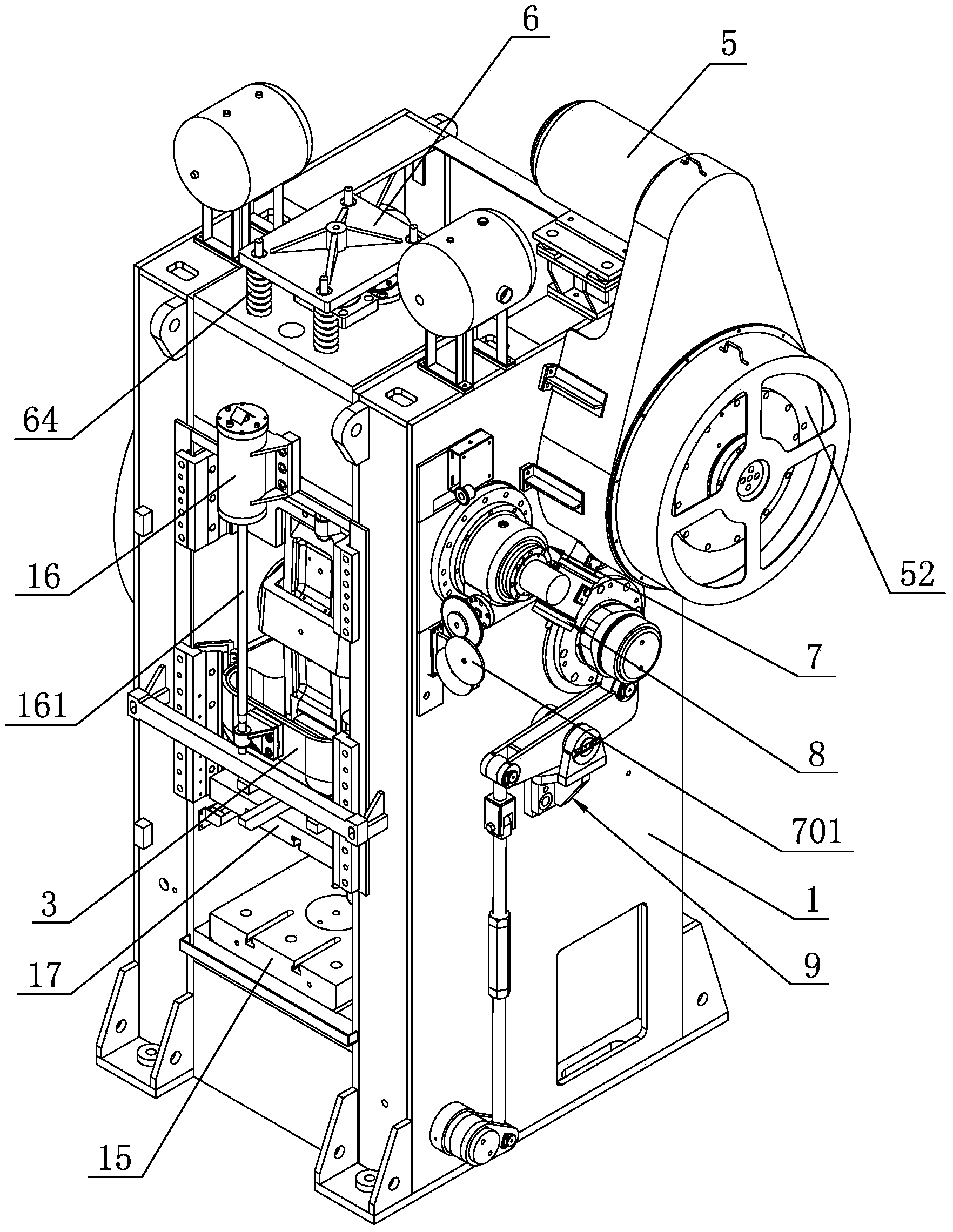

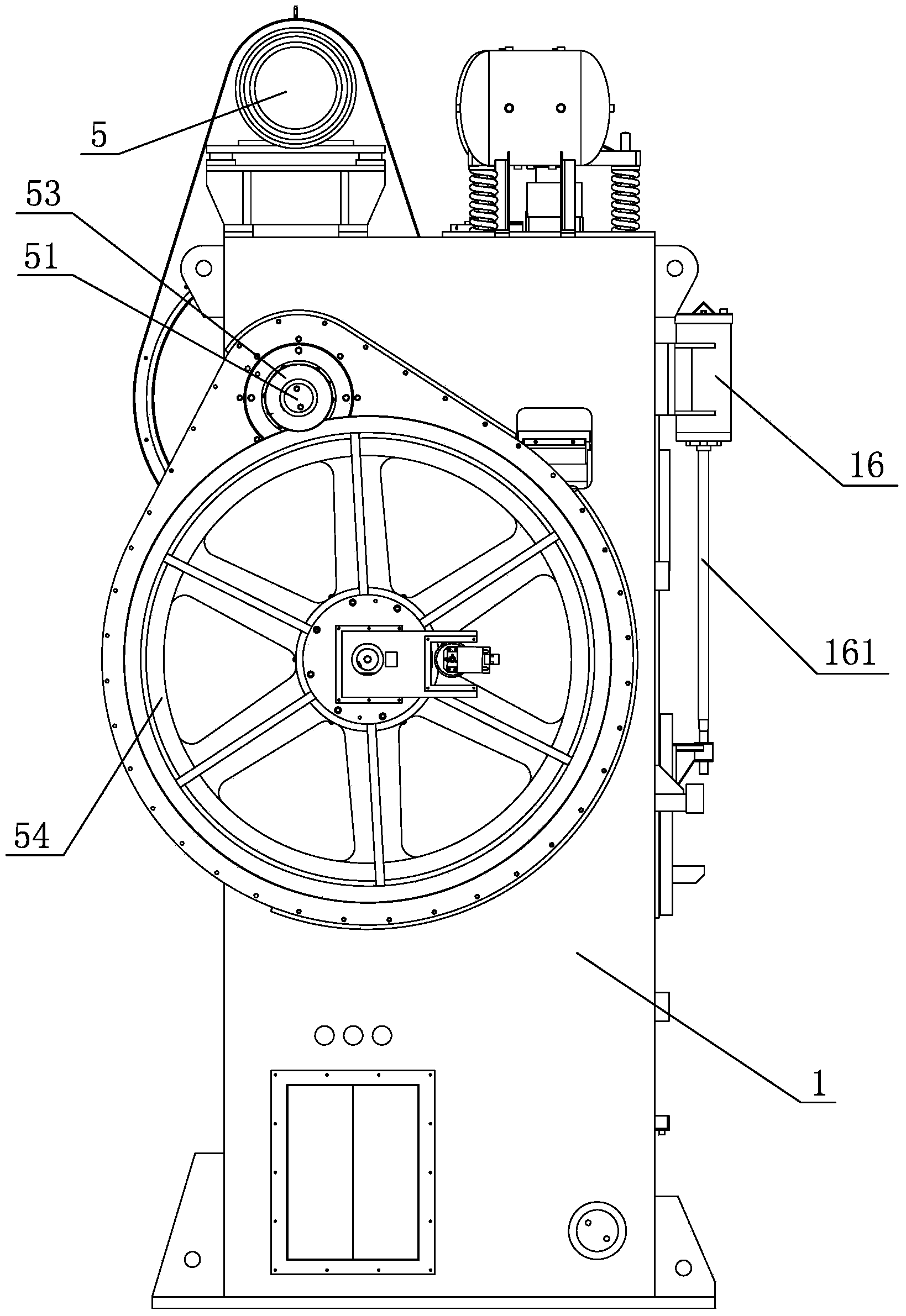

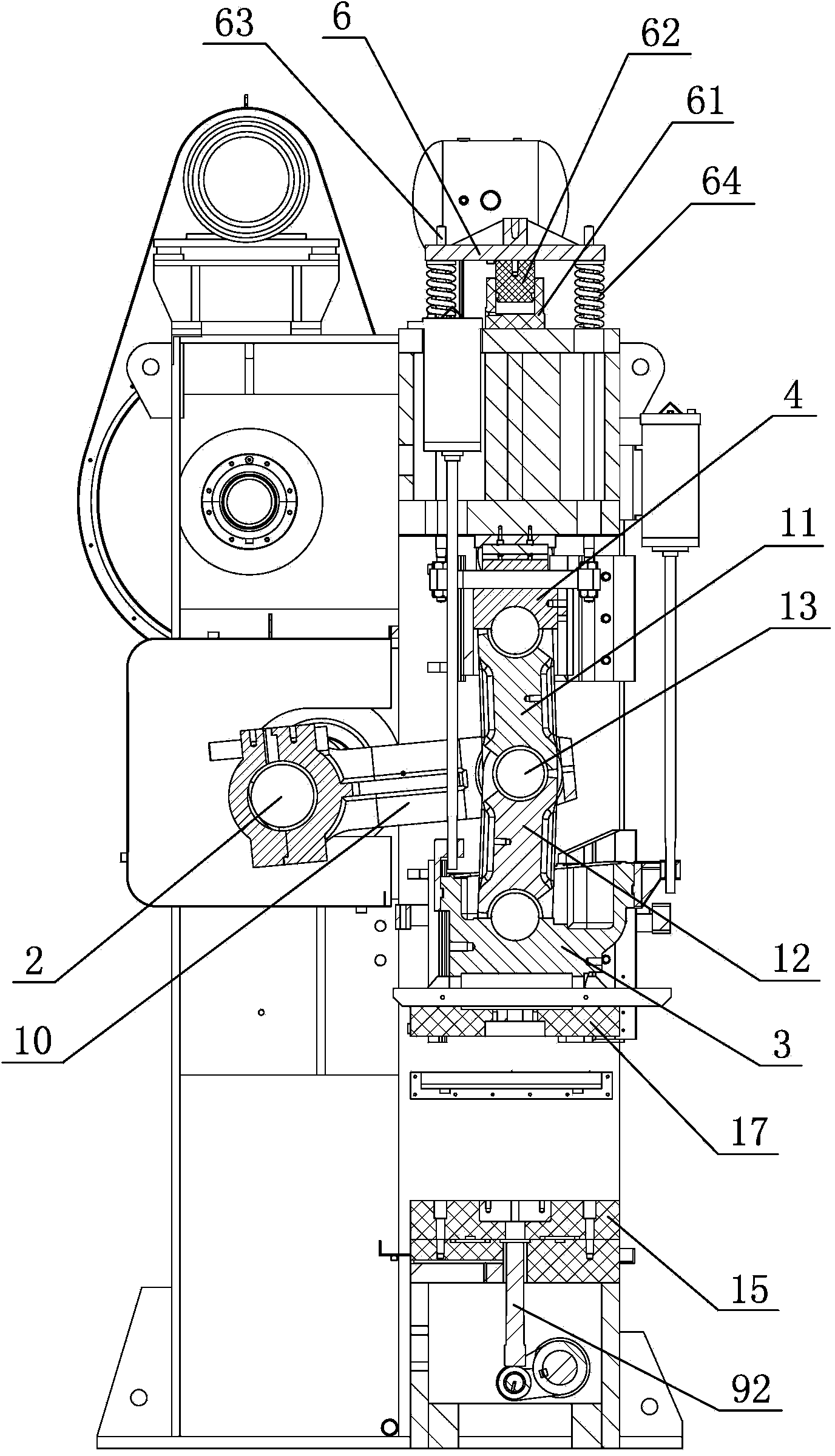

Lever type mechanical downward pushing device of mechanical press

ActiveCN107214284AEasy to grabIncrease profitForging/hammering/pressing machinesEjection devicesEngineeringMechanical press

A lever type mechanical downward pushing device of a mechanical press comprises a sliding block mounted on a machine body. Supports are mounted on the two sides of the sliding block correspondingly to be connected with vertical upper pull rods. The upper pull rods are connected with lower pull rods through adjusting nuts. The lower ends of the lower pull rods are fixedly connected with pull rod connectors. The pull rod connectors are rotatably and slidably connected with the outer ends of horizontally-arranged levers. The middles of the levers are rotatably connected with fulcrum seats arranged on the machine body. The other ends of the levers are in rolling connection with the lower bottom faces of a pushing seat. The upper end of the pushing seat is vertically and movably arranged in the machine body. A through hole is formed in the center of the pushing seat. An air cylinder is arranged at the bottom of the pushing seat. A piston rod of the air cylinder is mounted in the through hole. The upper end of the pushing seat is in matched connection with the lower end of an upper pushing rod. The upper end of the upper pushing rod is in matched connection with a worktable. The lever type mechanical downward pushing device has the advantages that synchronization is good, symmetrical balance is achieved, ejecting force is large, structure is simple, compactness is achieved, mechanical efficiency is high, manufacturing cost is low, maintenance is easy, environmental friendliness and energy saving are achieved.

Owner:RONGCHENG HUADONG METAL FORMING MACHINERY

Hardware stamping die

InactiveCN107838295ANot easy to damageNot easy to shiftShaping toolsNon-rotating vibration suppressionDrive shaftAir pump

The invention discloses a hardware stamping die. The hardware stamping die comprises a base, a metal hose, a spray nozzle, a scrap blocking plate, an electromagnet, a cam, a vibration damper plate, damping springs, a buffer cushion, a material push plate, a sleeve and heat dissipation slots. One end of the metal hose is provided with the spray nozzle, the side face of the lower portion of the scrap blocking plate is provided with the electromagnet, and one end of an electromotor is provided with a speed reducer. One end of a transmission shaft is connected with the cam in a sleeved manner, thedamping plate is arranged above the base, the damping plate is connected with the base through supporting rods, and positioning pillars are sleeved with the vibration damper springs. The bottom faceof the material push plate is connected with a push rod, the bottom end of the push rod is connected with a push plate, and the outer side of the sleeve is uniformly provided with the heat dissipationslots. The electromotor is utilized to drive the cam to push the material push plate, materials are taken conveniently, and a workpiece is not prone to be damaged; the vibration damper springs in thedamping plate are utilized to absorb vibration generated in the stamping process, vibration reduction performance is good, and the die is not prone to be damaged; and scraps are blown away through the metal hose connected with an air pump and blocked by the scrap blocking plate, and stamping and cleaning are facilitated.

Owner:梅州华盛辉科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com