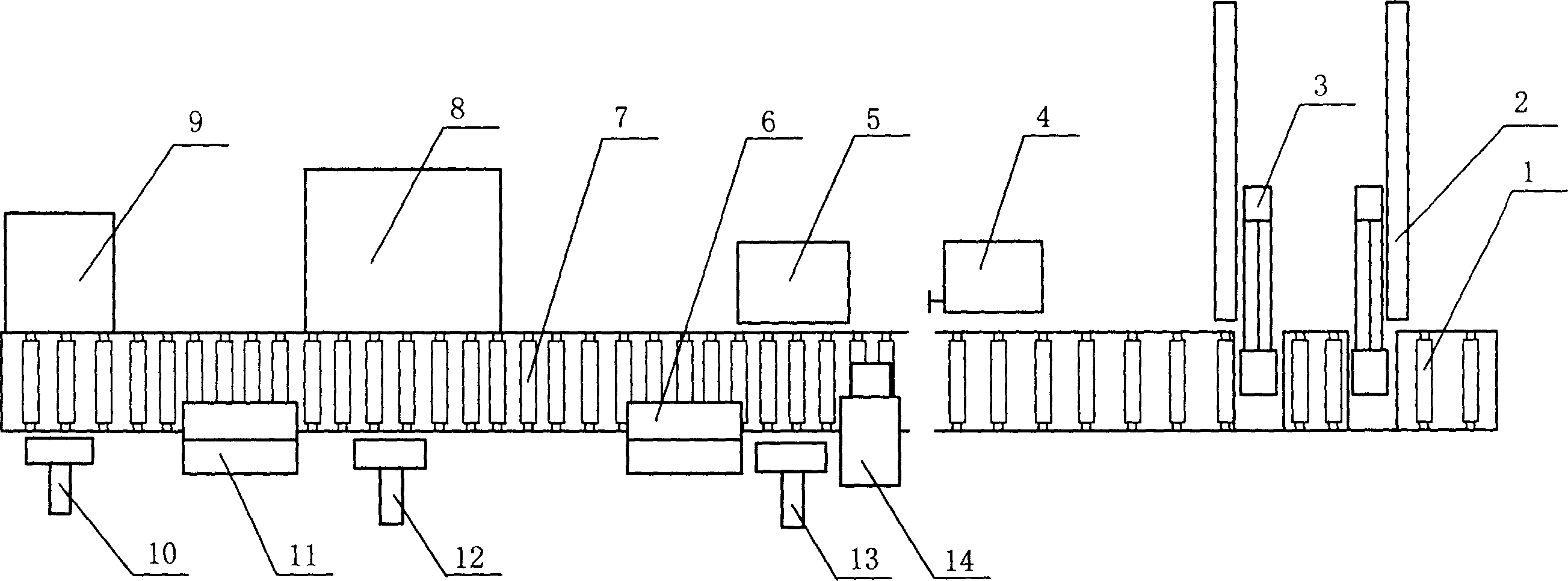

Automatic sawing, cutting and stacking machine for aluminum alloy bar

A technology of aluminum alloy and palletizer, which is applied in the field of automatic sawing and palletizing machine for aluminum alloy rods, can solve problems such as increased labor intensity, low production efficiency, and difficulty in realization, and achieve neat and orderly products, improve production efficiency, and liberate labor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings of the embodiments.

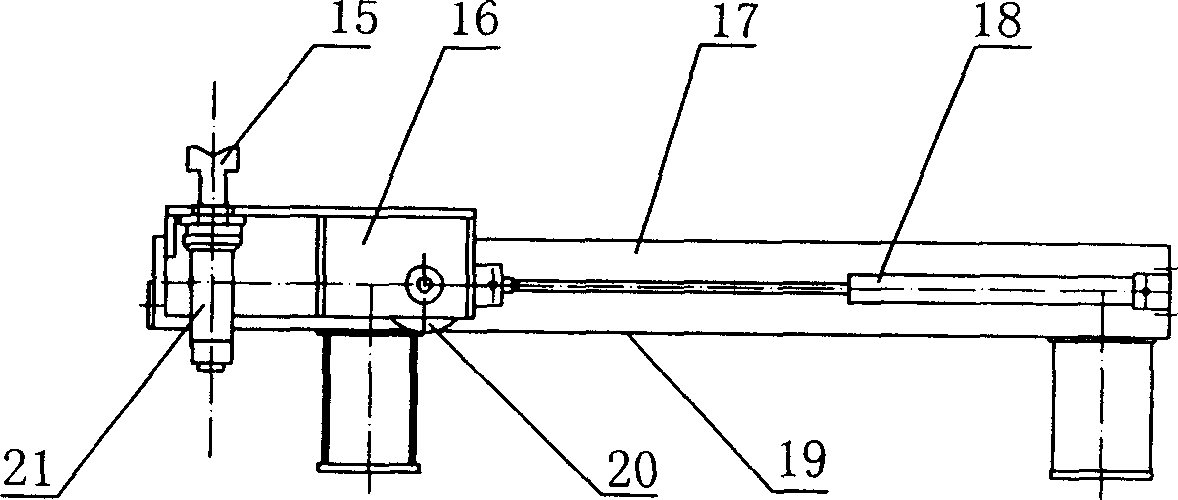

[0031] Such as figure 2 As shown, the feeding mechanism includes a rod support 15 and a mobile oil cylinder. The rod support 15 is arranged on the vertical oil cylinder 21, and the carrying vehicle body 16 of the vertical oil cylinder 21 is connected on the horizontal mobile oil cylinder 18, and the rollers 20 of the carrying vehicle body 16 are placed on the guide on track 19. When material needs to be loaded, move the oil cylinder 18 horizontally to drag the load-carrying body 16 and then move to the rod holder 15 to reach the position of the aluminum alloy rod. At this time, the vertical oil cylinder 21 moves to make the rod holder 15 lift the aluminum alloy rod to be sawed Raise, then, move the oil cylinder 18 horizontally and push the carrying car body 16 to move forward. When the aluminum alloy rod to be sawed reaches the position of the conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com