Patents

Literature

7551results about "Shearing machine accessories" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

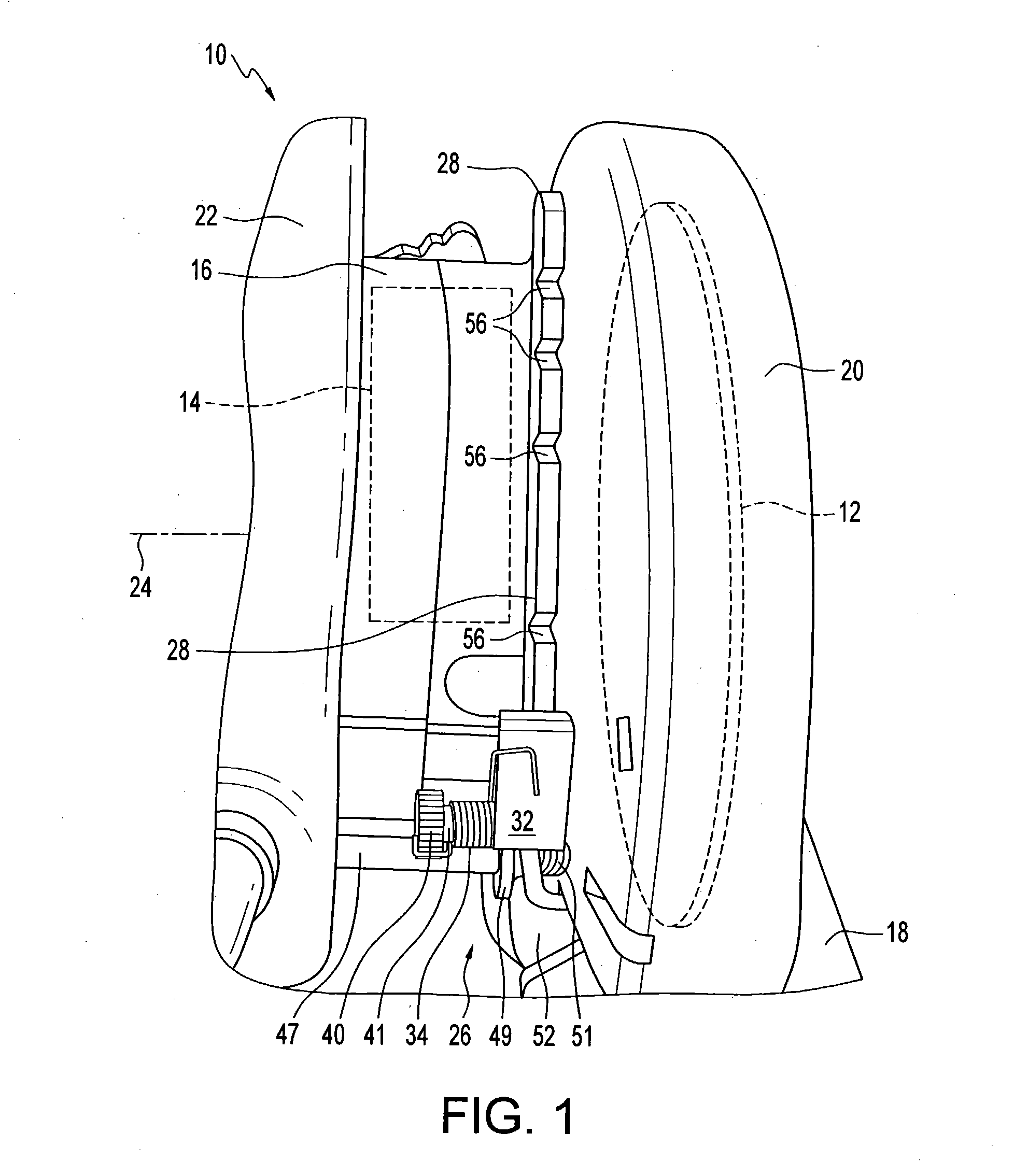

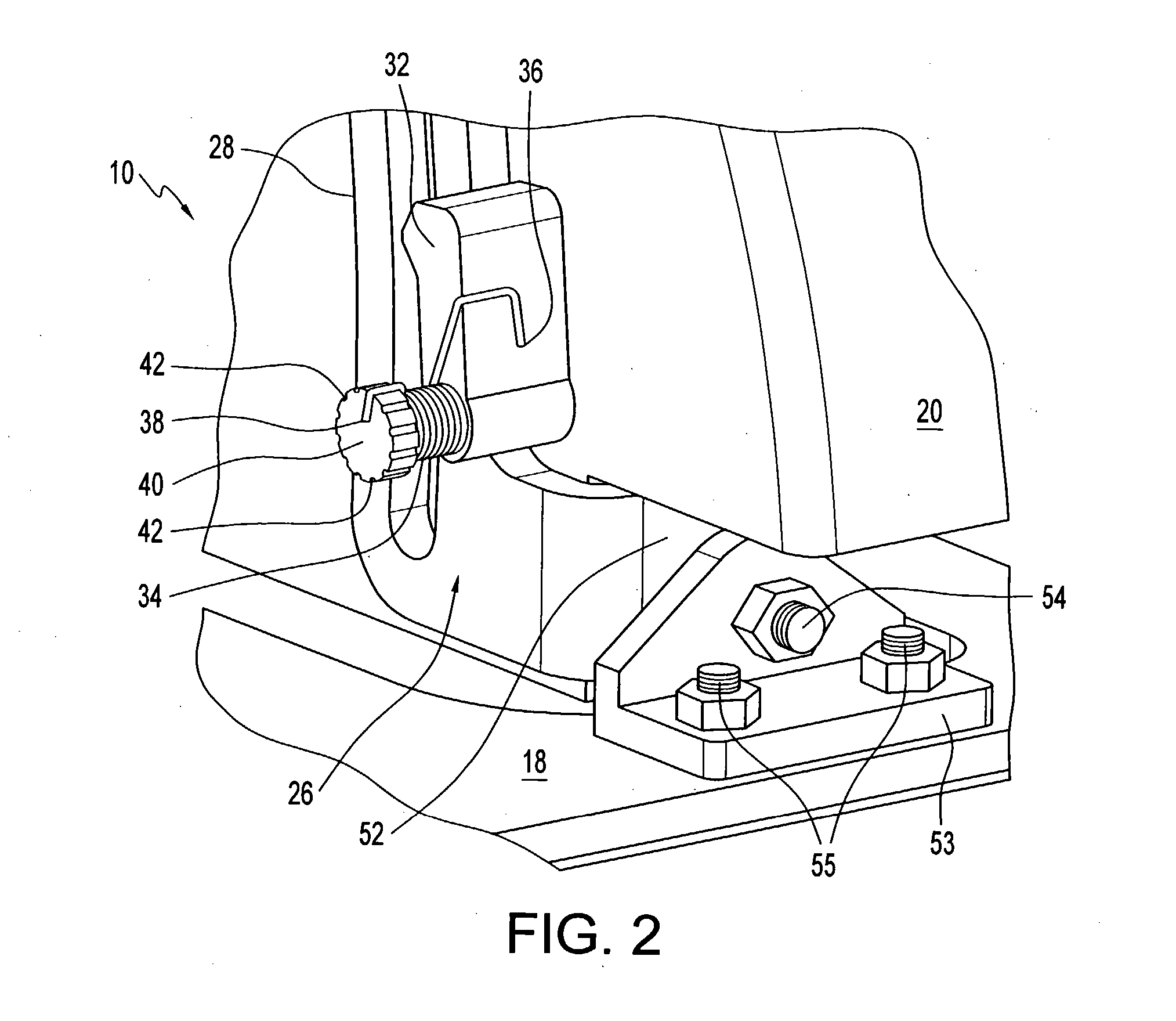

Brake positioning system

InactiveUS6857345B2Multi-purpose machinesEngineering safety devicesEngineeringMechanical engineering

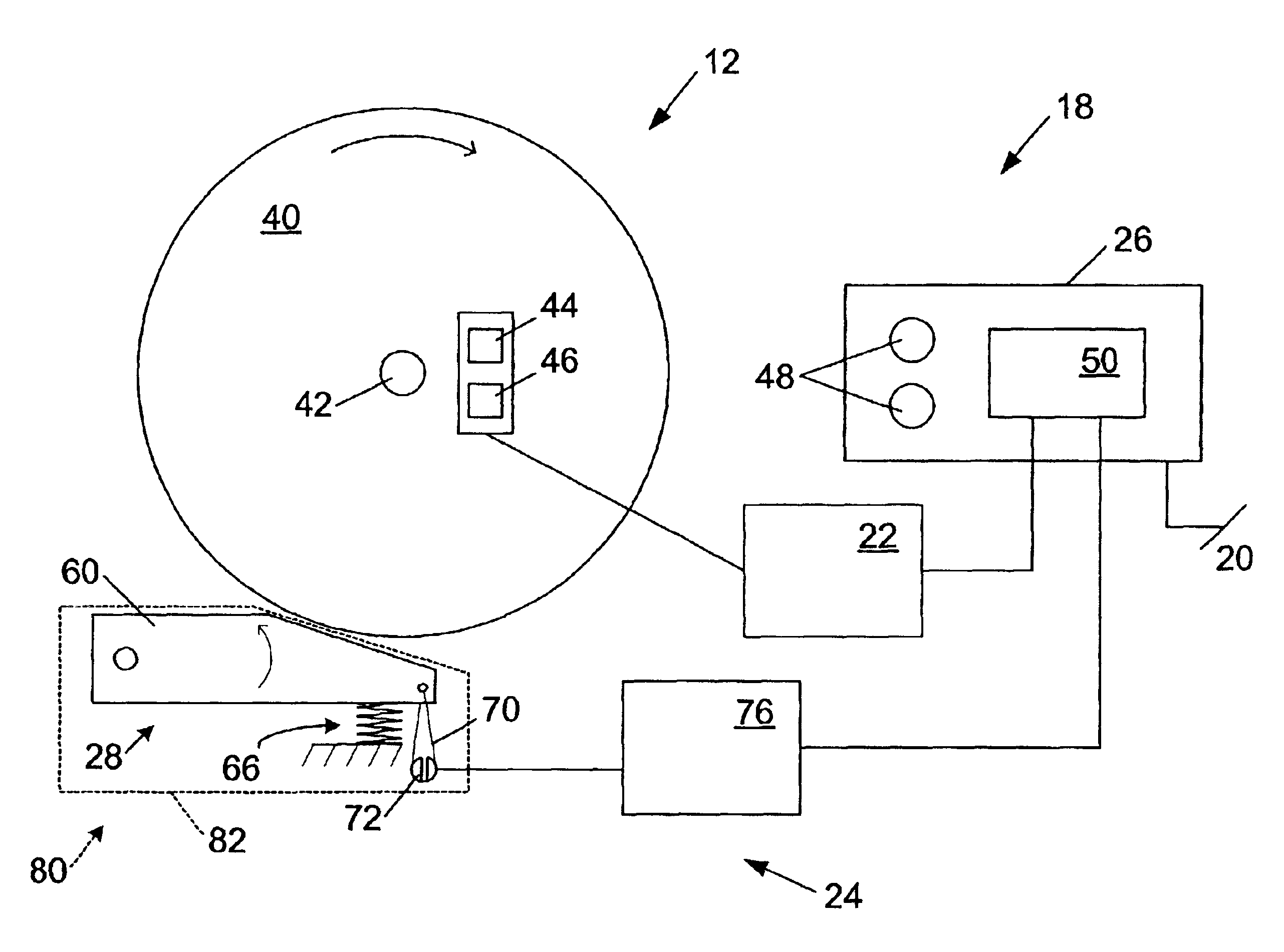

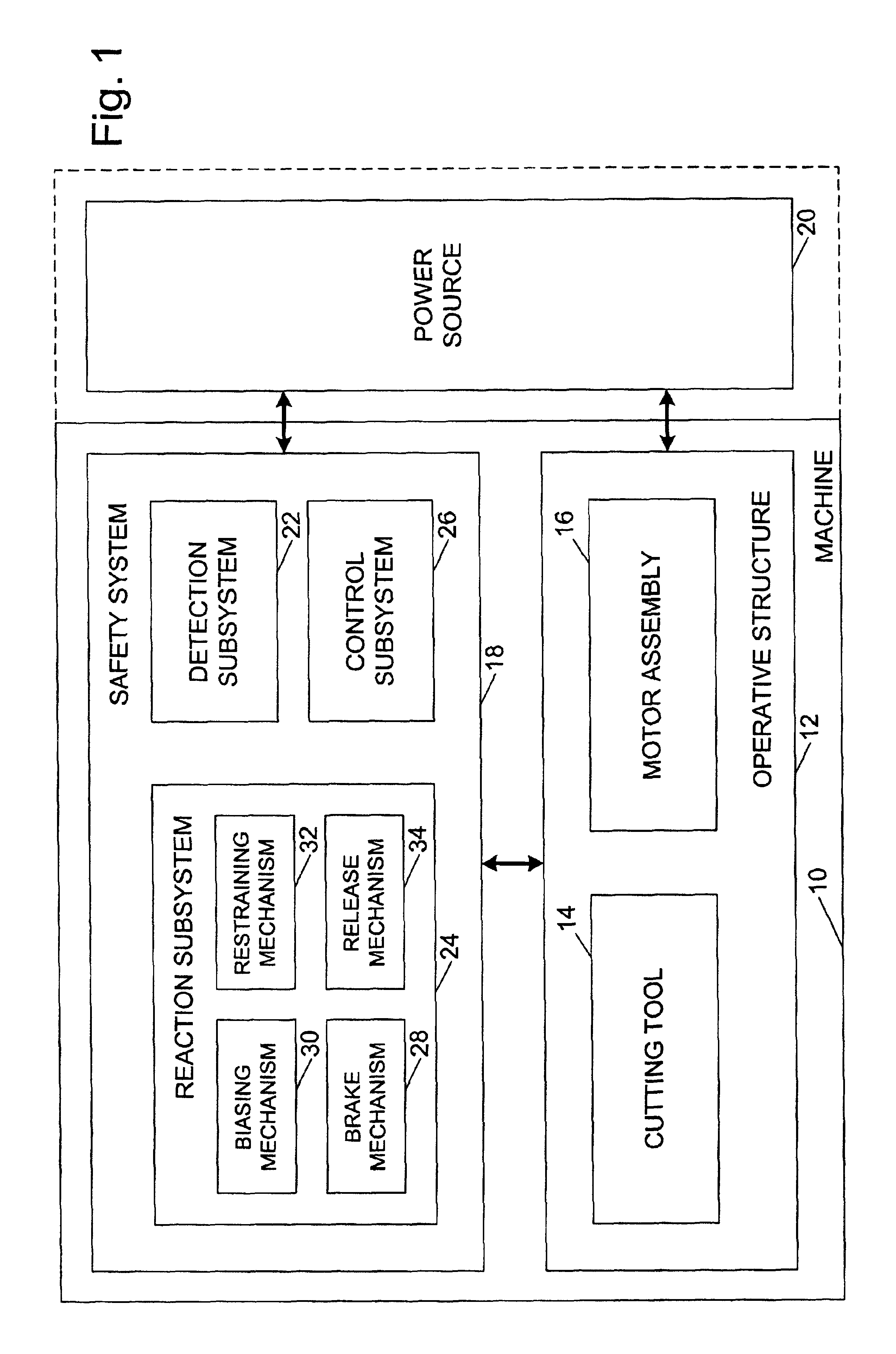

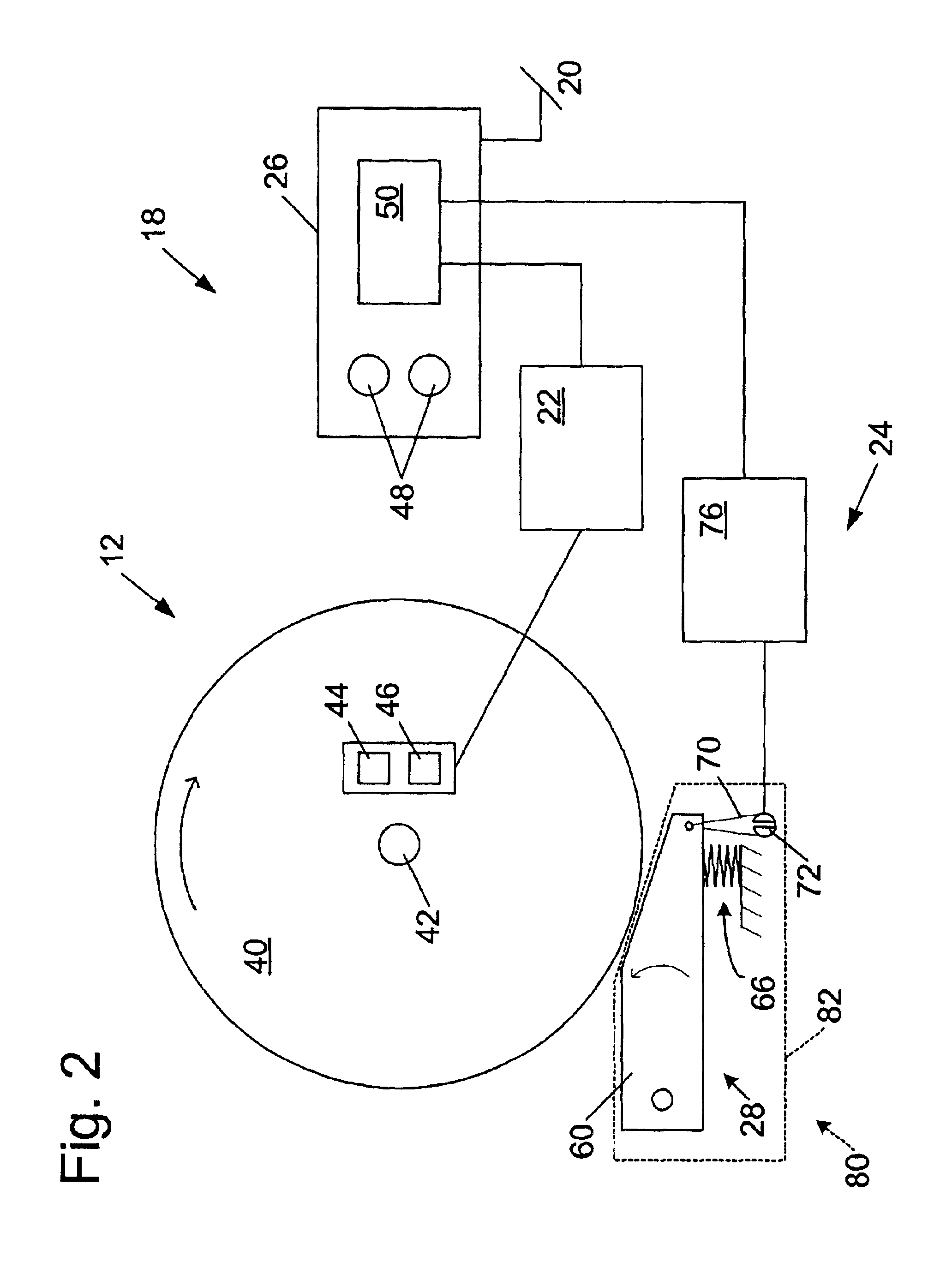

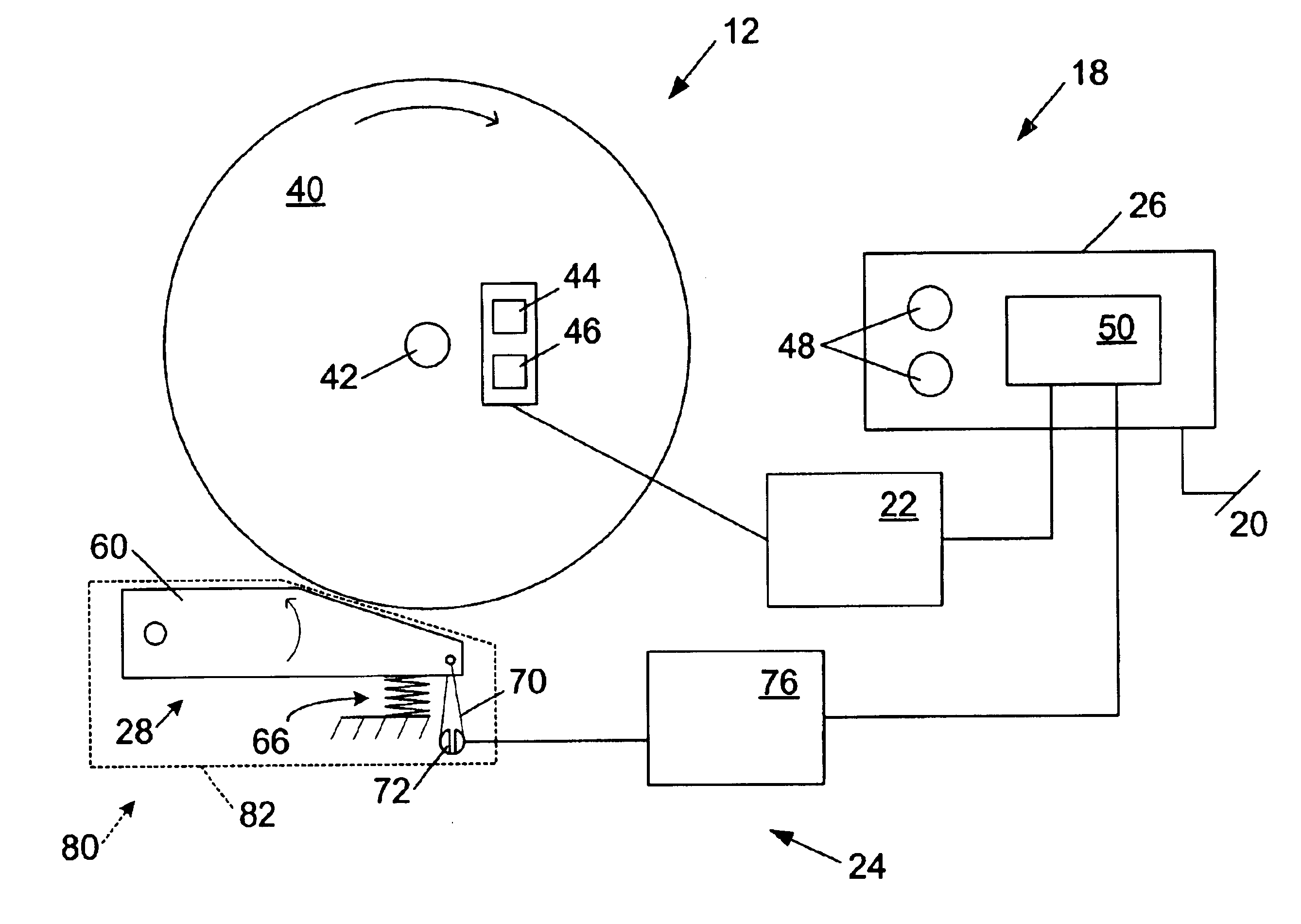

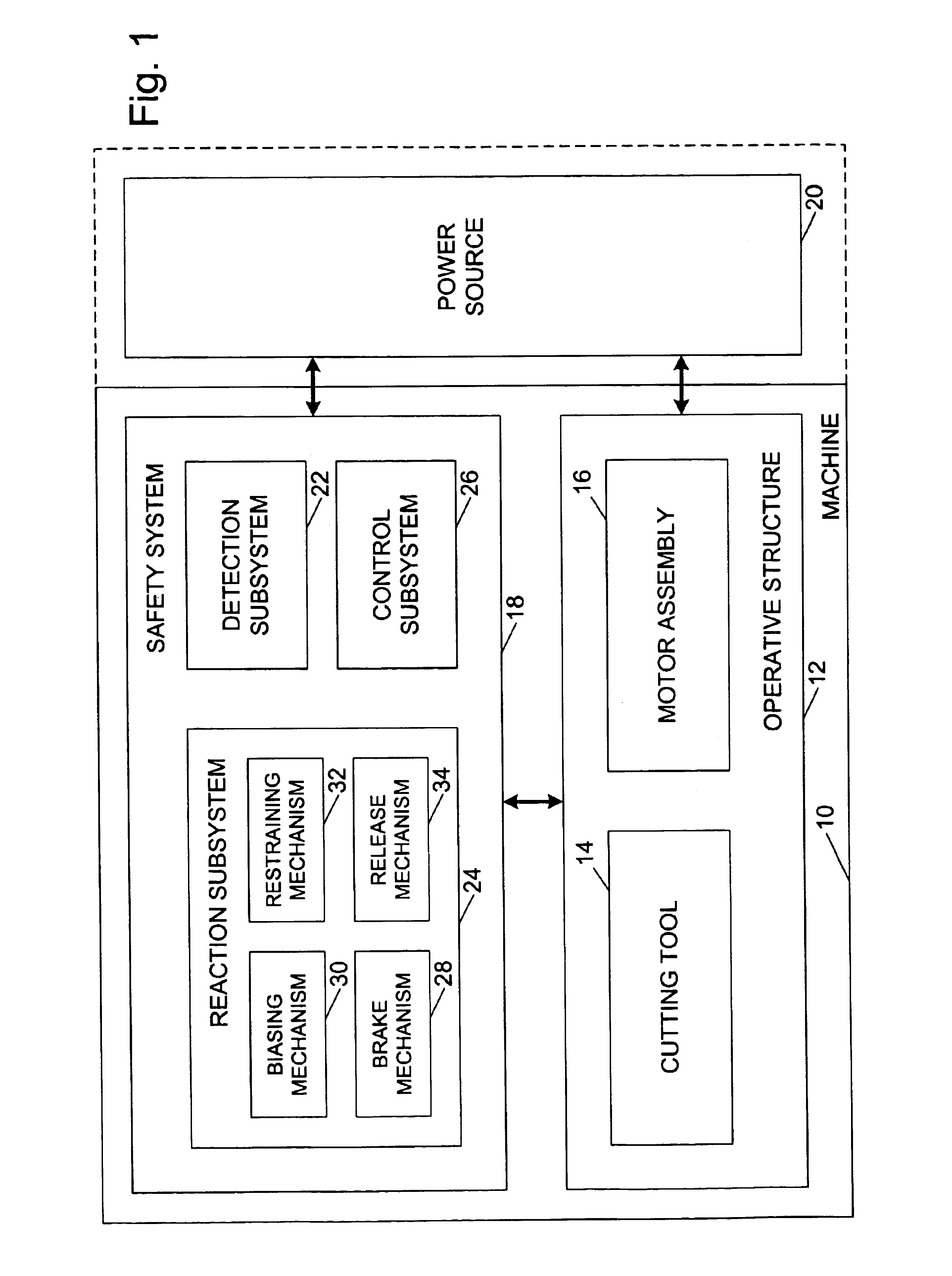

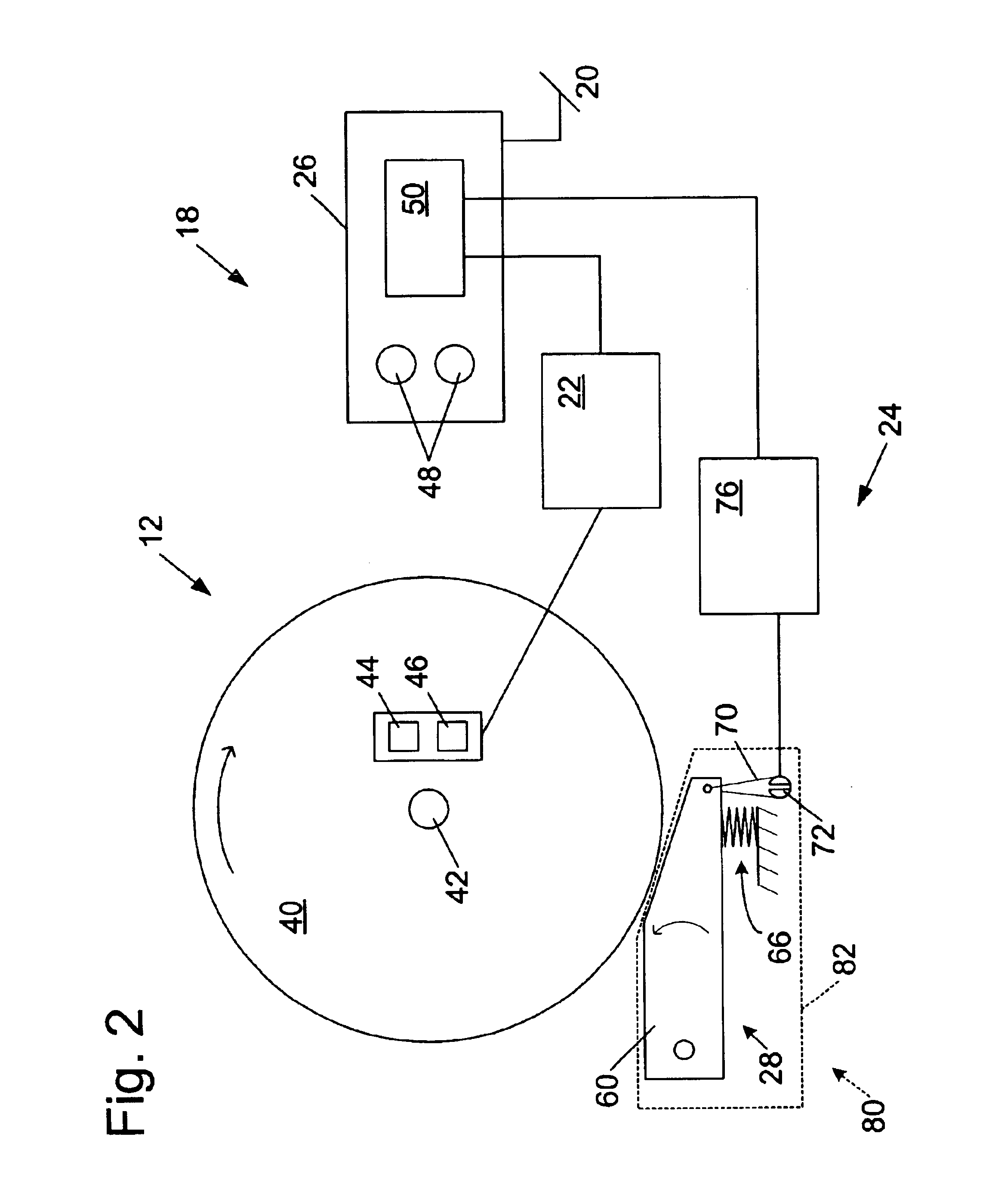

A saw is disclosed having a detection system adapted to detect a dangerous condition between a person and a saw blade, and a brake adapted to stop the saw blade in response to detection of the dangerous condition. The saw further includes a brake positioning system that allows the brake to be positioned in at least two different operable positions to accommodate at least two different blade diameters. The saw may include a system to detect brake-to-blade spacing.

Owner:SAWSTOP HLDG LLC

Safety systems for power equipment

A saw with a safety system is disclosed. The safety system includes a detection system adapted to detect contact between a person and a blade while the blade is moving. The safety system further includes a brake system adapted to engage the blade and to stop the blade when the detection system detects contact between the person and the blade.

Owner:SAWSTOP HLDG LLC

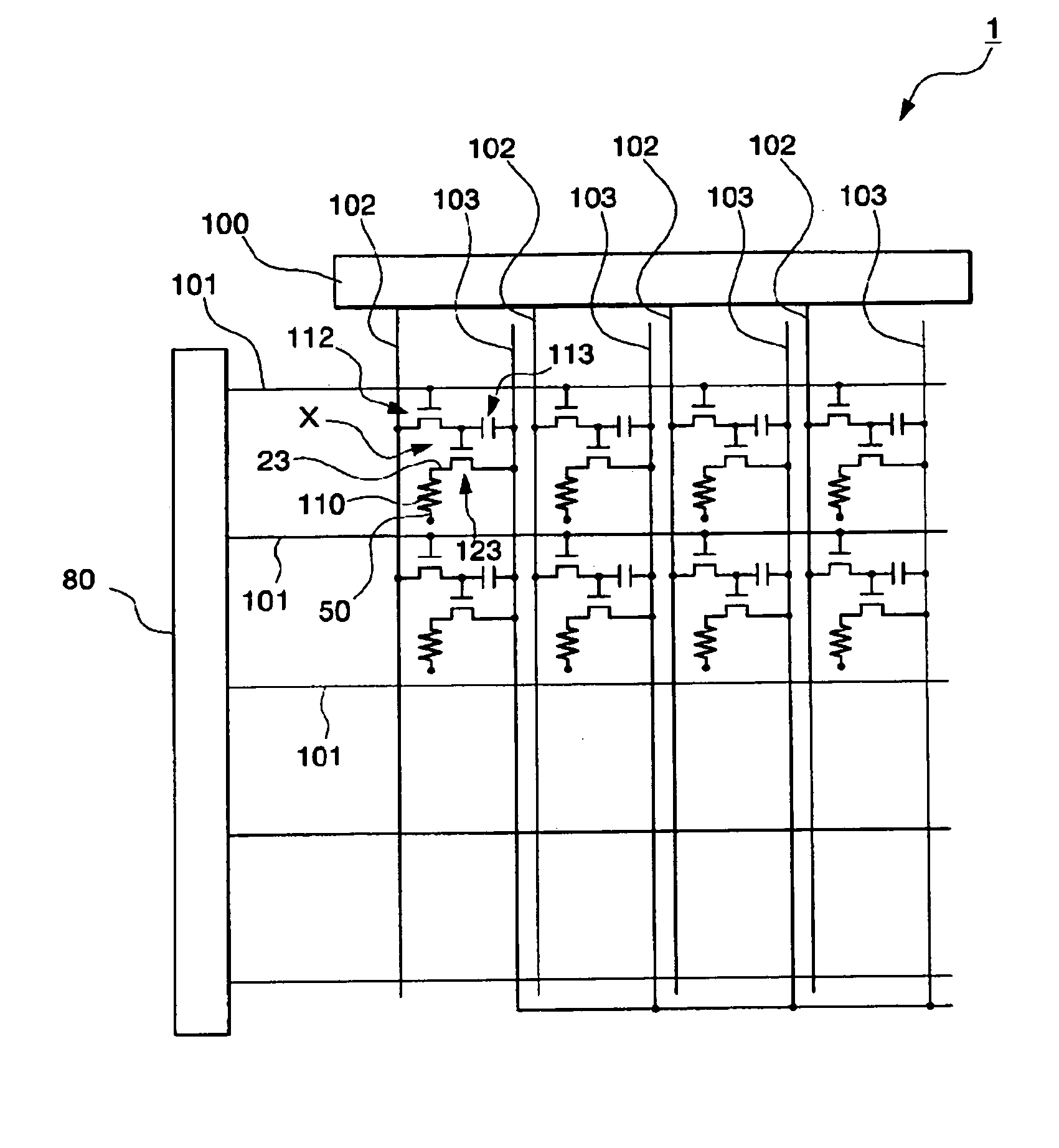

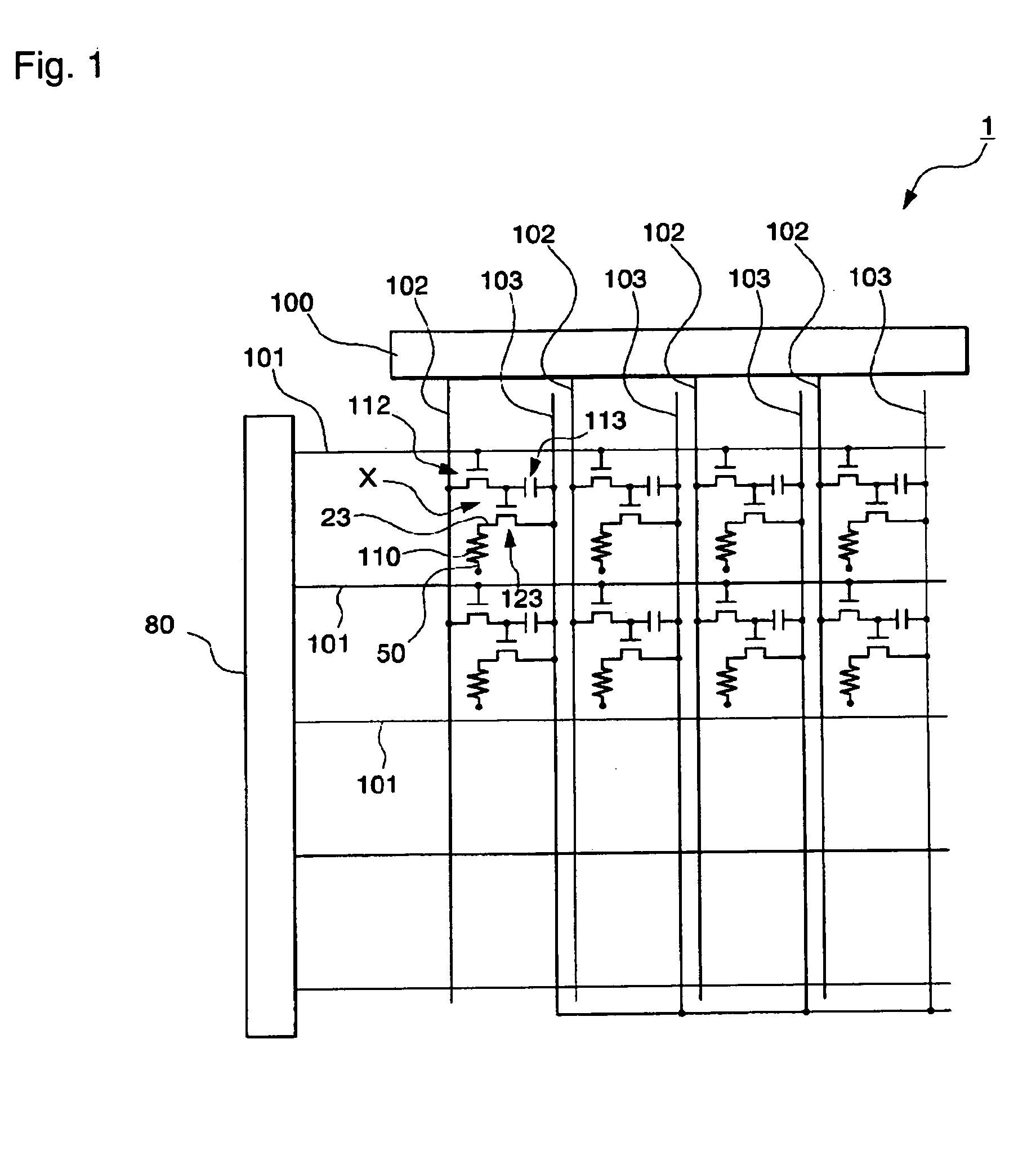

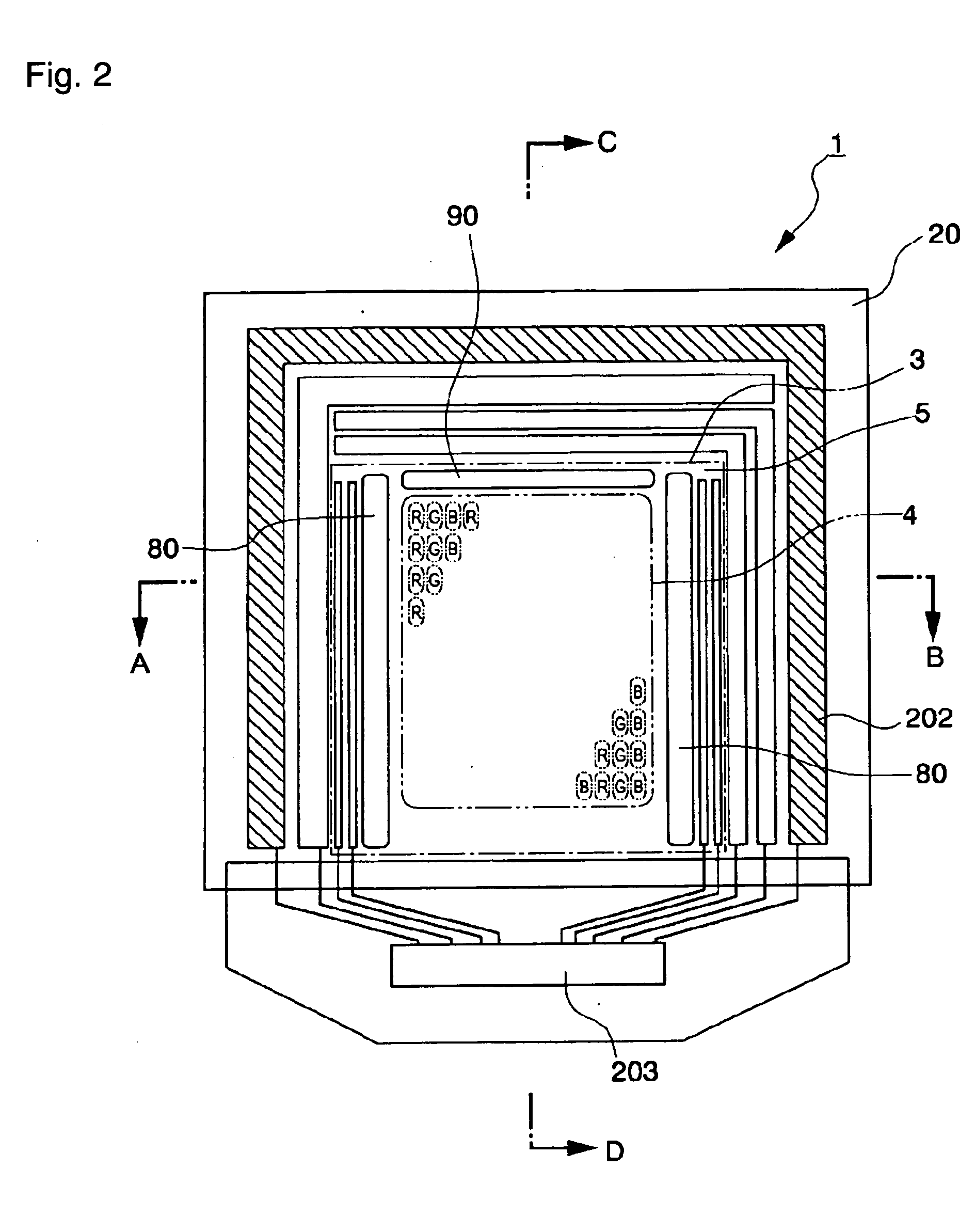

Electro-optical device, method of manufacturing the same, and electronic apparatus

ActiveUS20040212759A1Reduced or prevented from being deterioratedQuality improvementElectroluminescent light sourcesSolid-state devicesUltravioletEngineering

Owner:SEIKO EPSON CORP

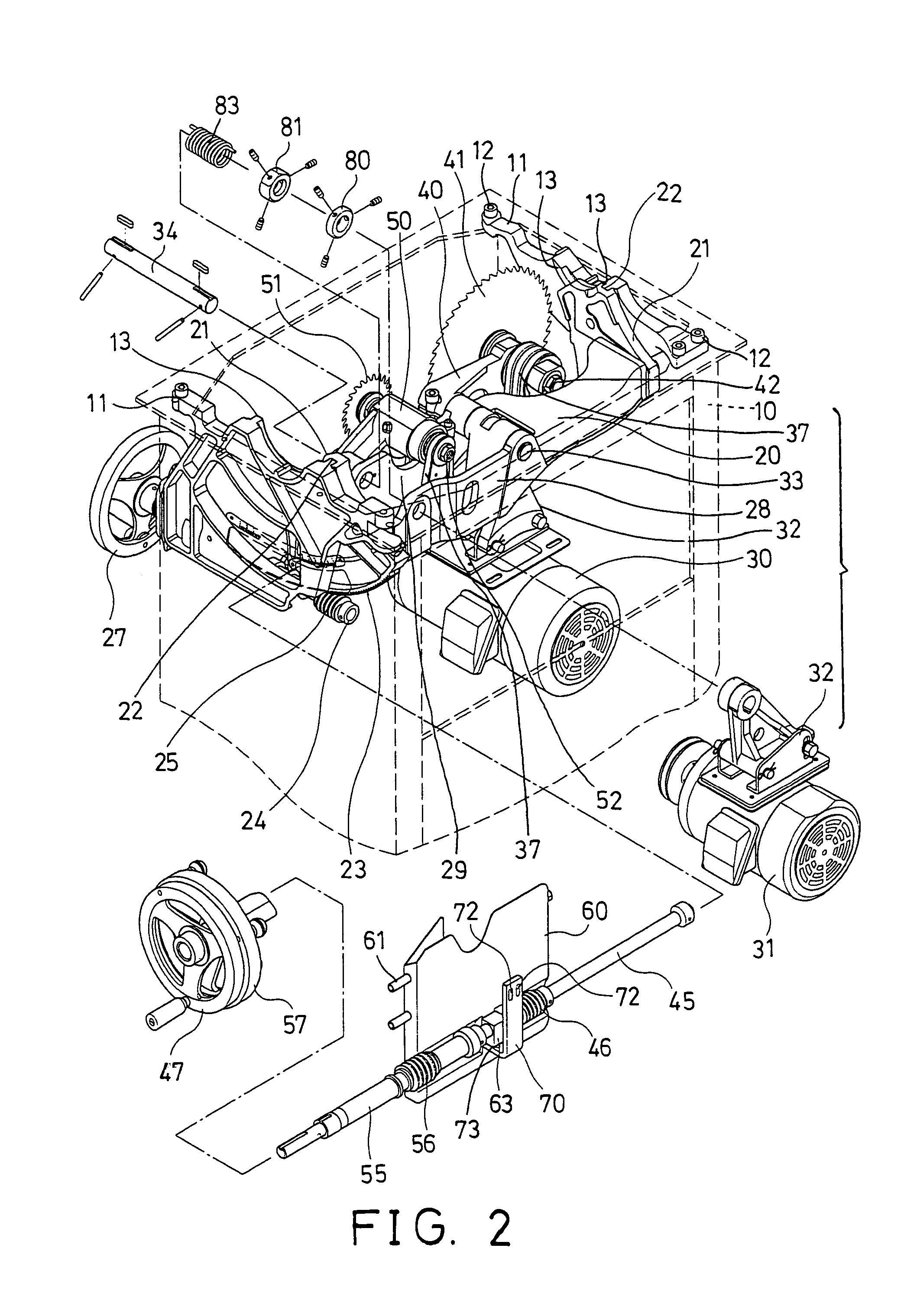

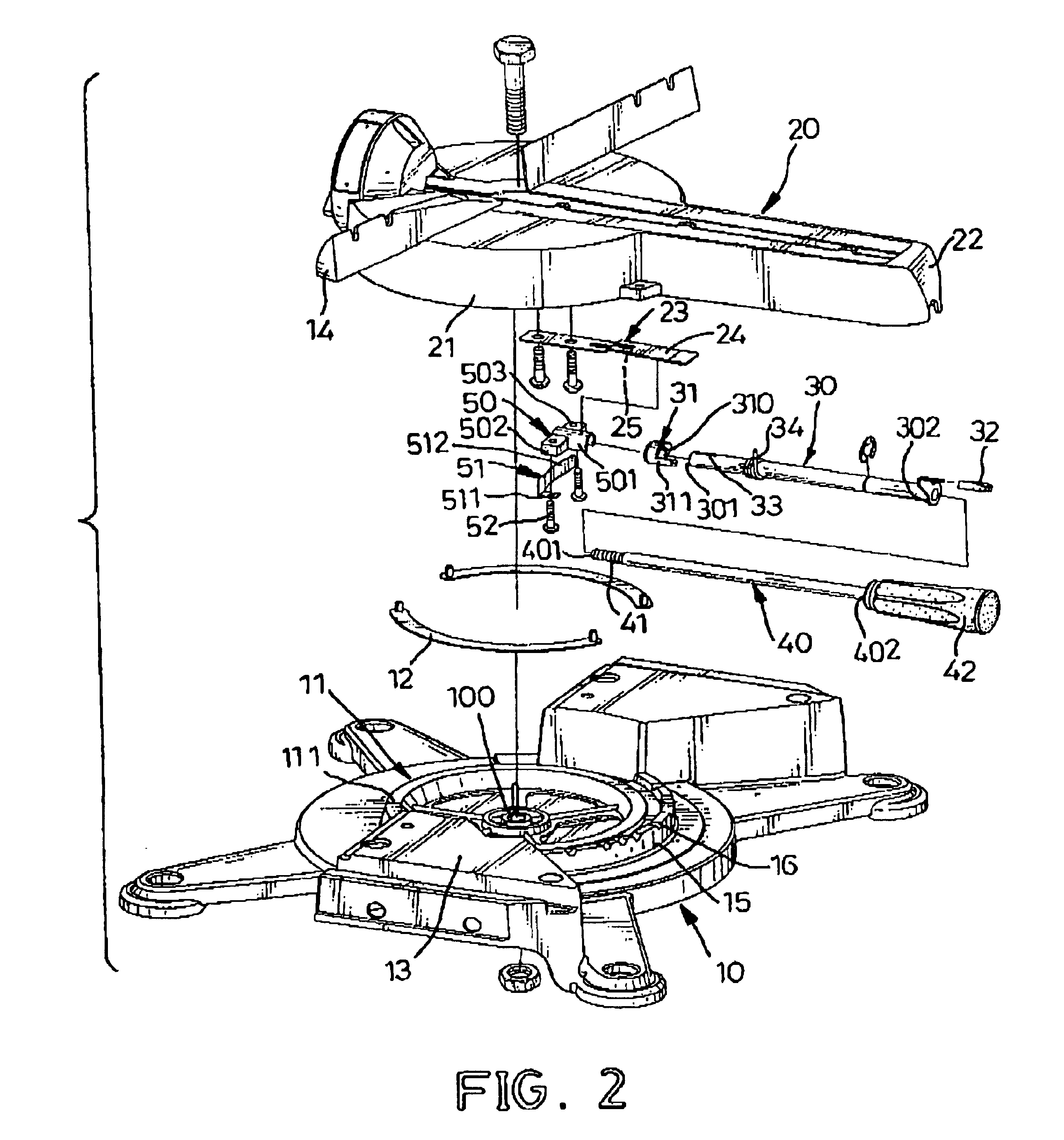

Cutting machine with built-in miter cutting feature

A miter cutting arrangement for a cutting machine is provided to accommodate cutting work at an angle or a bevel for precisely cutting on a work piece. It includes a platform support arm longitudinally mounting to a cutting head support bracket, a platform pivot arm transversely extended from the platform support arm, a head platform pivotally connected with the platform pivot arm to support a motor, a miter supporting unit, and a locker device for selectively locking the cutting head at the normal position and the slanted position. The miter supporting unit includes a miter support provided at an outer side of the head platform and a miter stopper provided at an outer end of the platform pivot arm to block the miter support when the head platform is rotated at the slanted position.

Owner:LEE WY PERON

Circular cutter with a friction-provided plate

InactiveUS6874397B2Clamp tightlyPrevent rotationMetal sawing devicesGuide fencesScrew threadFriction force

Owner:P & F BROTHER INDAL

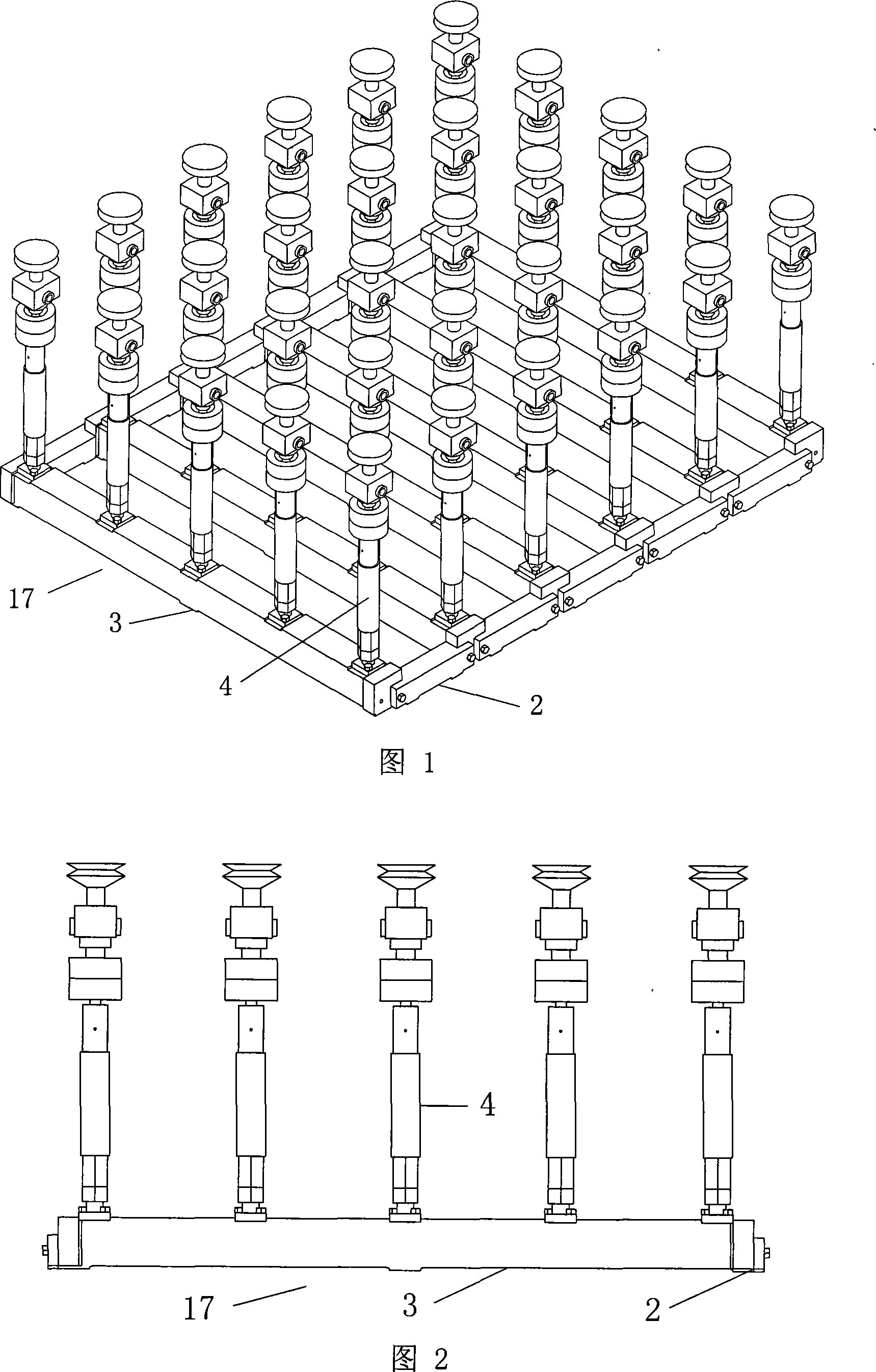

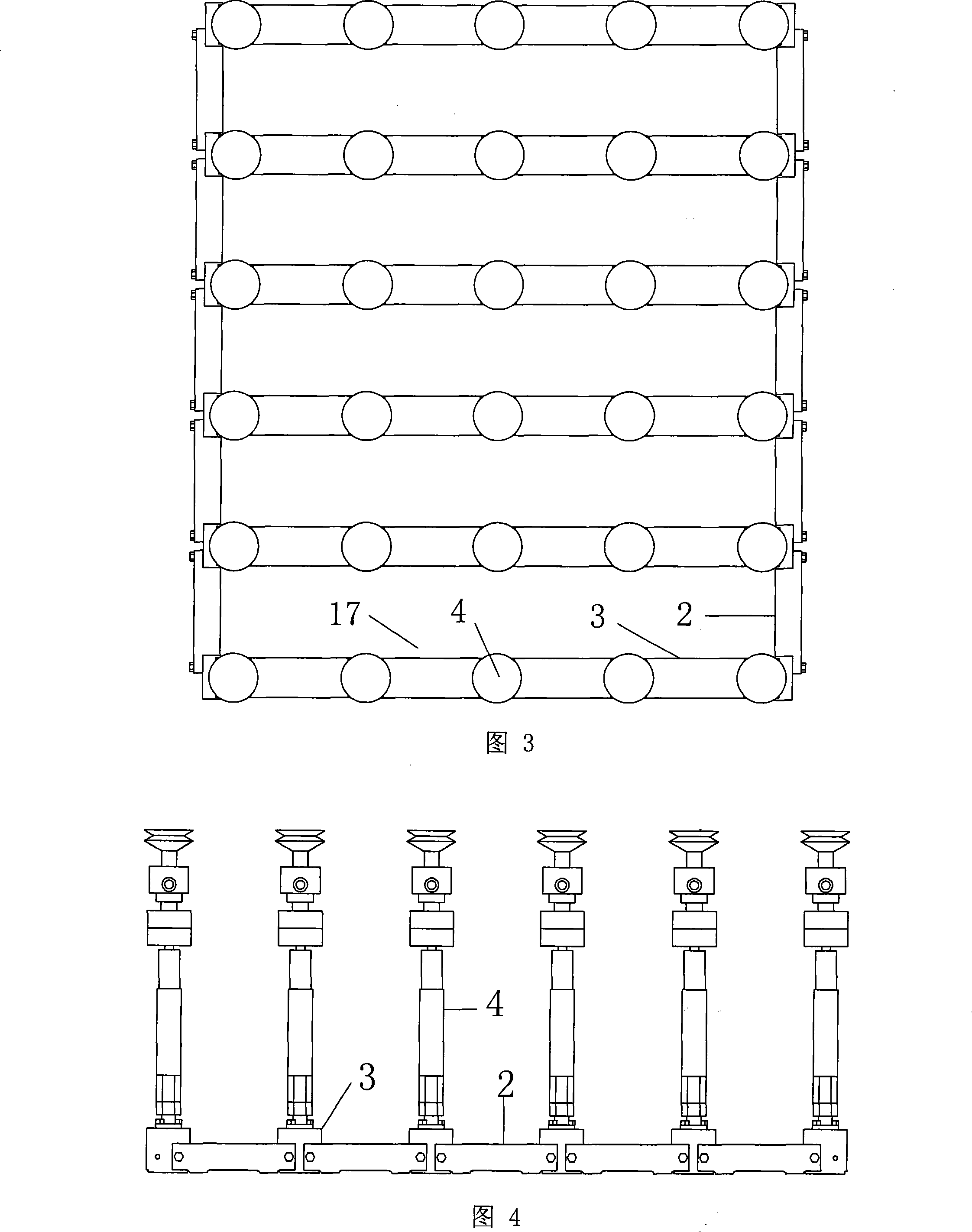

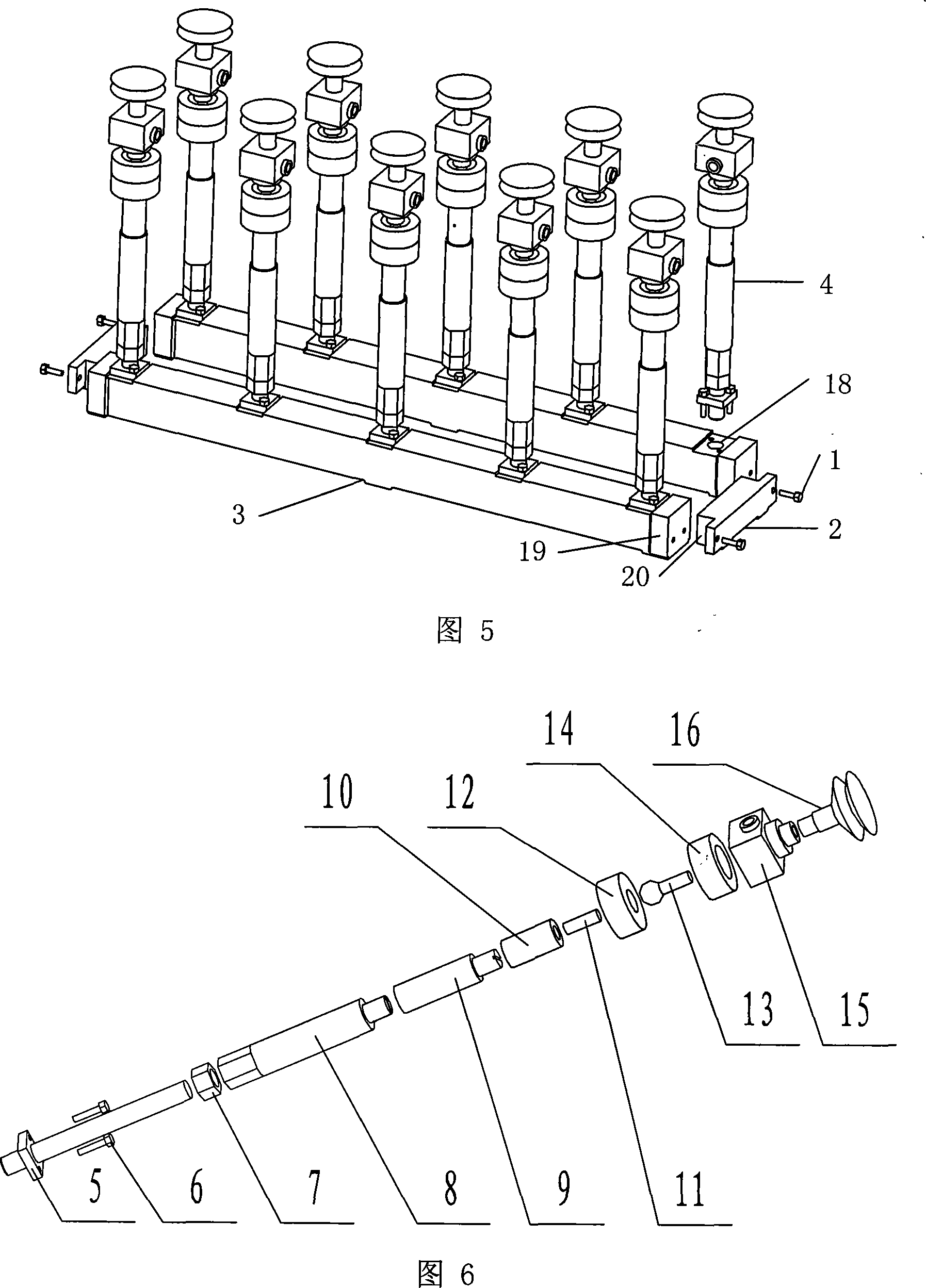

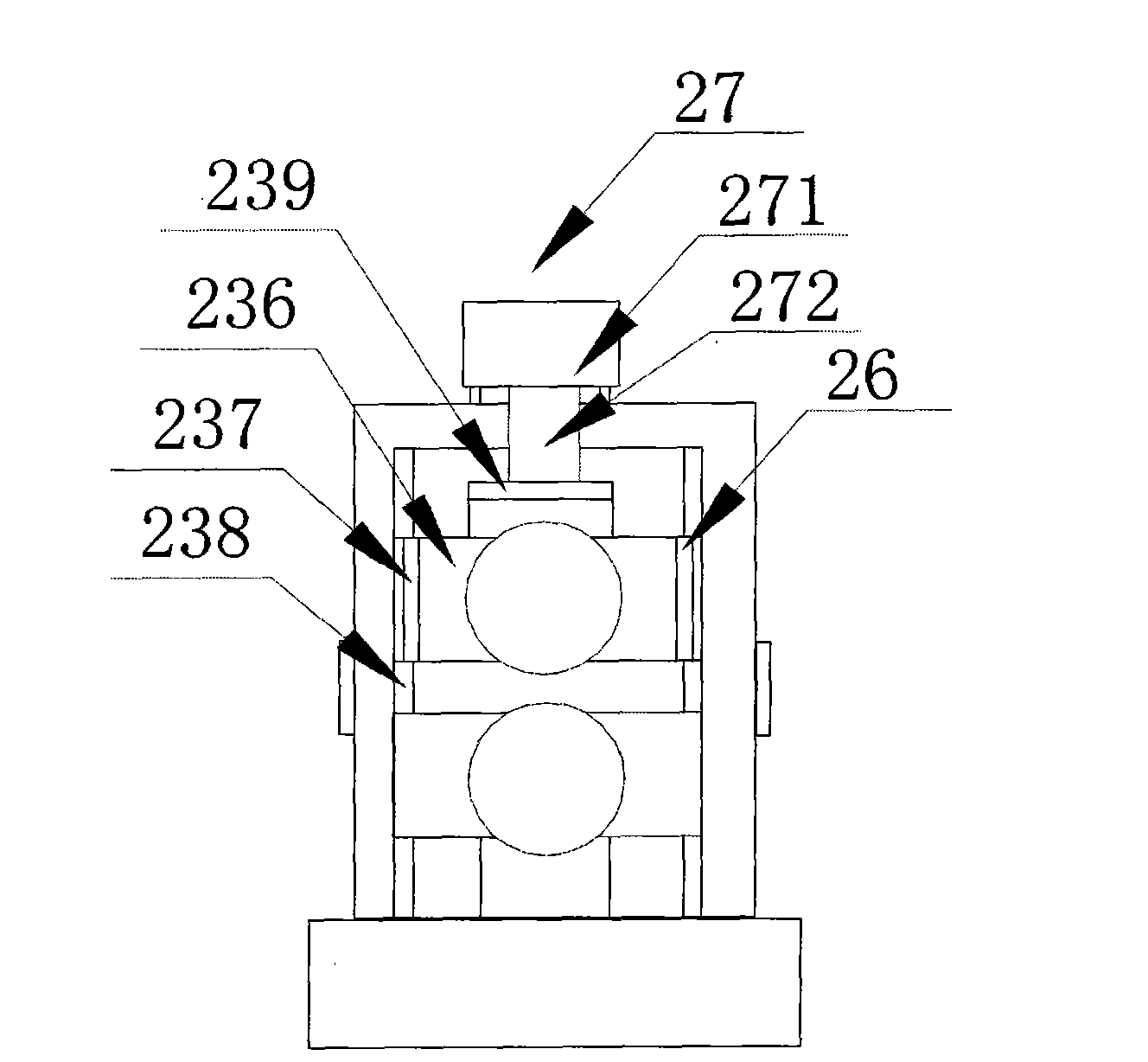

Combined type thin-gauge skin moulding surface trimming cut flexibility multi-supporting equipment

InactiveCN101229598AReduce in quantityEasy to assembleWelding/cutting auxillary devicesWork holdersEngineeringLocknut

The invention relates to a combination flexible multipoint support device with skin and trimming, which consists of a plurality of positioning plates and a plurality of adjusting components; the positioning plates is flat T-shape and a threaded hole and a matching surface are arranged on the positioning plates; the adjusting components consist of a basioccipital and a nail height adjusting unit; the adjusting components are put in parallel in an X direction and the interval between centers is fixed; the positioning plates are divided into two symmetrical rows in a Y direction; each positioning plate is connected with the same end of two adjacent adjusting components; the basioccipital shapes like a rectangular and locating holes, a threaded hole and a matching surface are arranged on the basioccipital; the locating holes are evenly distributed in a line on the basioccipital and the nail height adjusting unit is fixed in the locating holes; the nail height adjusting unit consists of a large double-screw bolt, a bolt, a locknut, a rotary nail, a replaceable nail sleeve, a joint cylinder, a universal device, a vacuum generator and a vacuum chuck. The device of the invention realizes flexible holding, reduces special clamping devices and frocks and has remarkable economic and time benefits.

Owner:BEIHANG UNIV

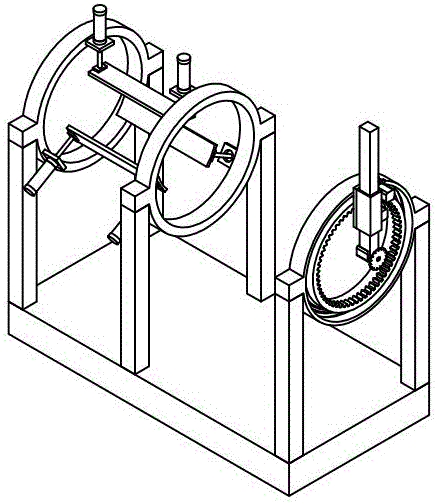

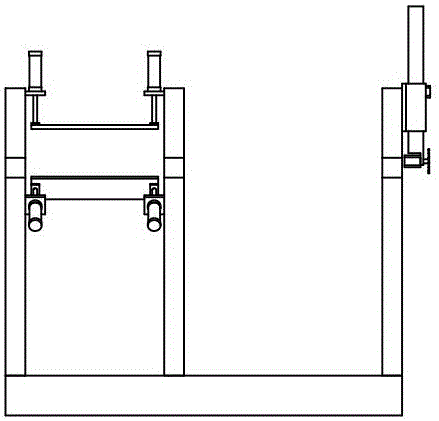

Saw machine having two saw blades

A saw machine includes a seat disposed in a housing, two frames rotatably secured to the seat with pivot pins and each having a sector gear and a saw blade, and a driving device for driving the saw blades. A shaft is rotatably secured to the seat and has a worm engaged with the sector gear of one of the frames, to rotate and adjust the frame relative to the seat. A conduit is rotatably engaged on the shaft and has a worm engaged with the sector gear of the other frame, to adjust the other frame relative to the seat. A support device includes a block having an orifice to rotatably receive the shaft and to stably support and retain the shaft to the seat.

Owner:YU HSI HUI

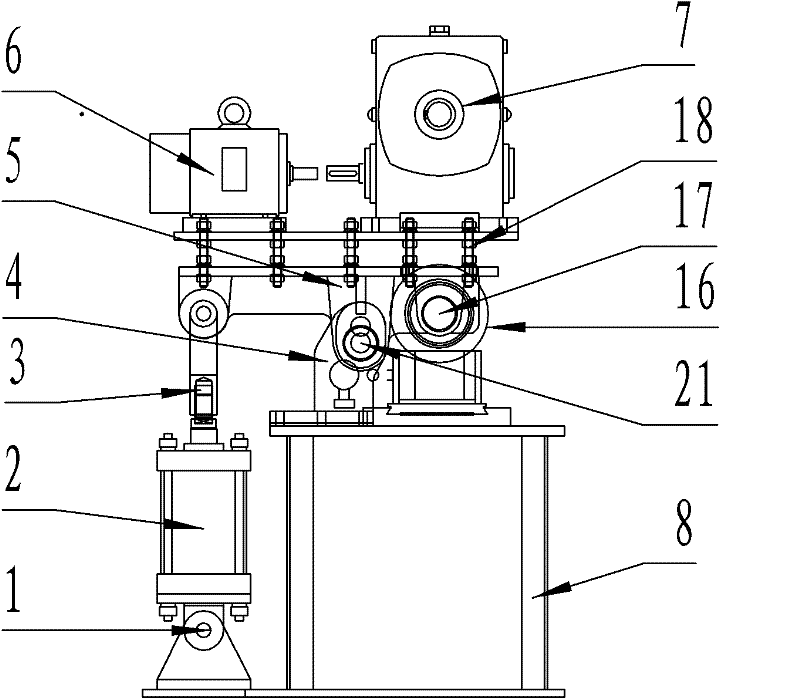

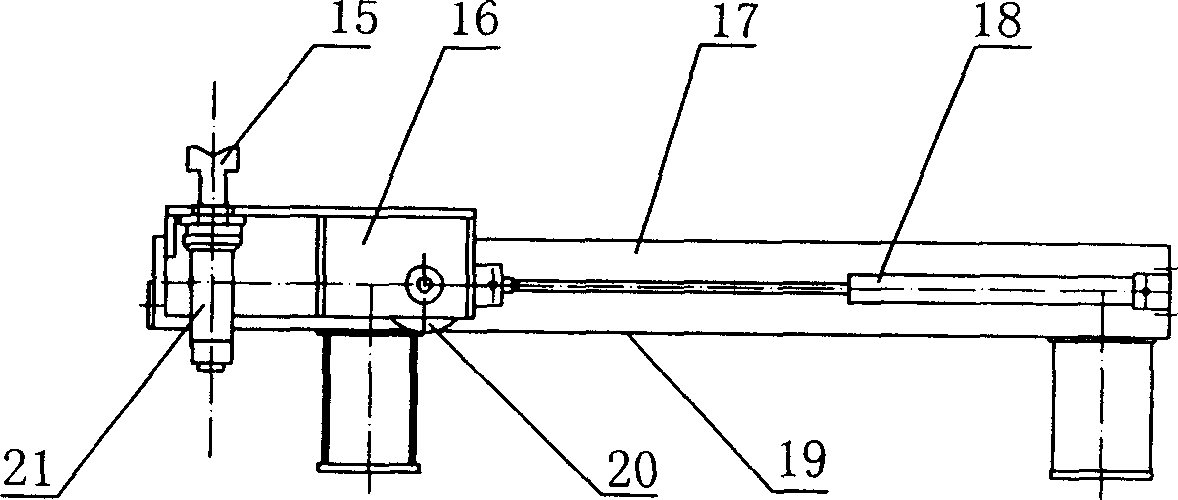

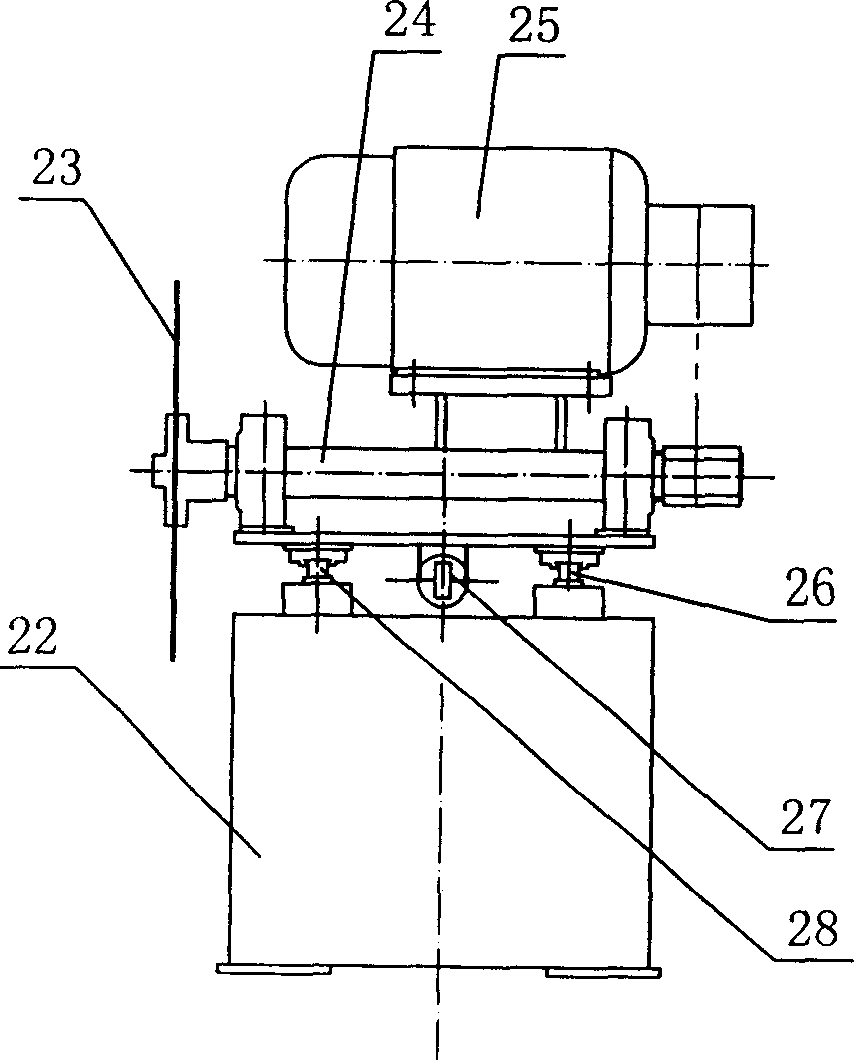

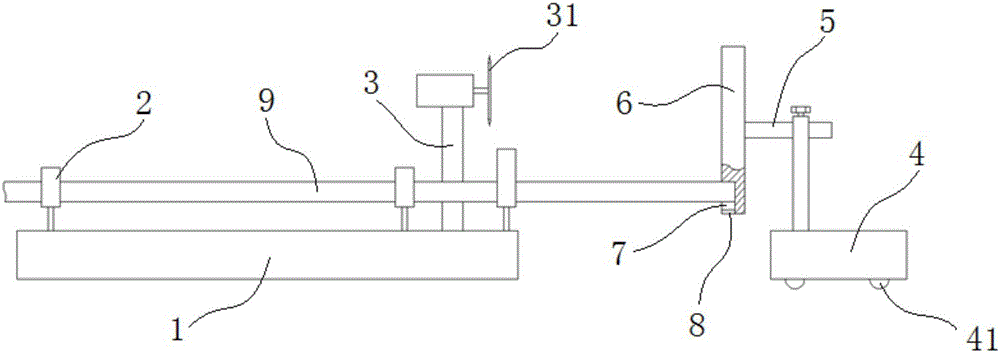

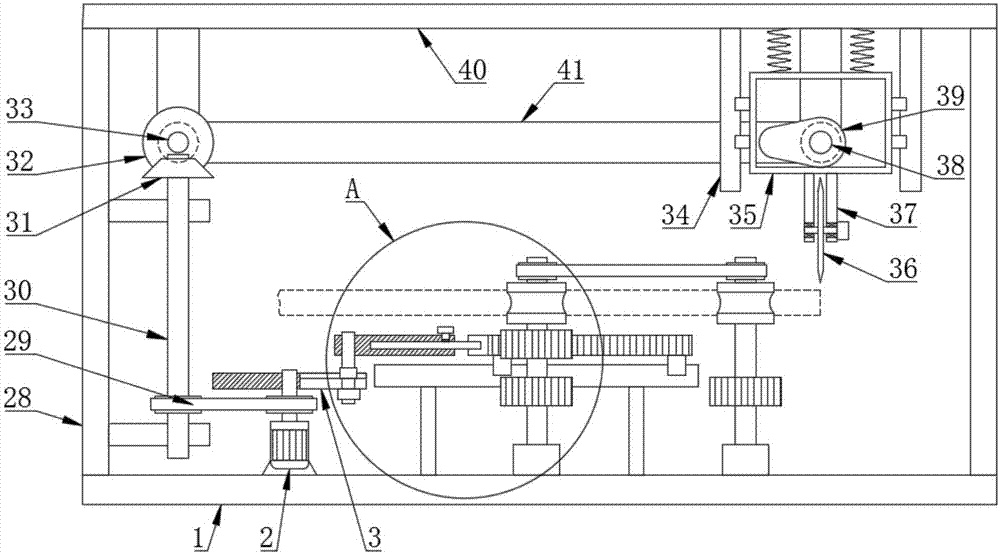

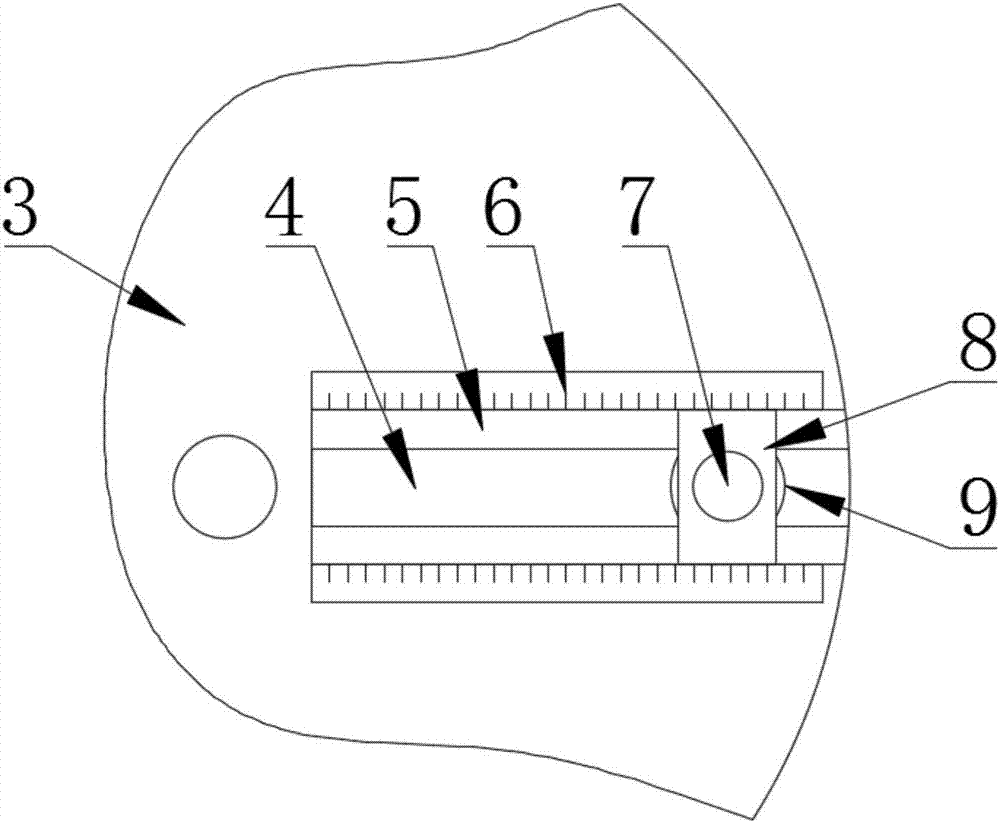

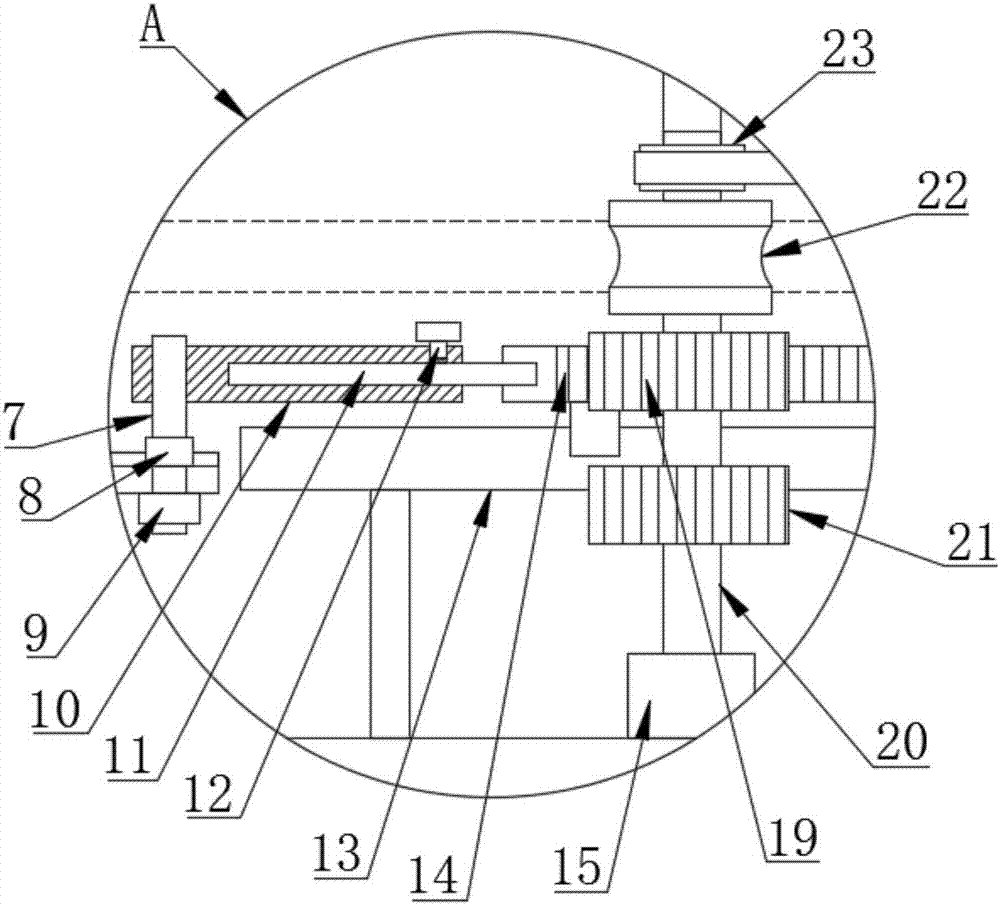

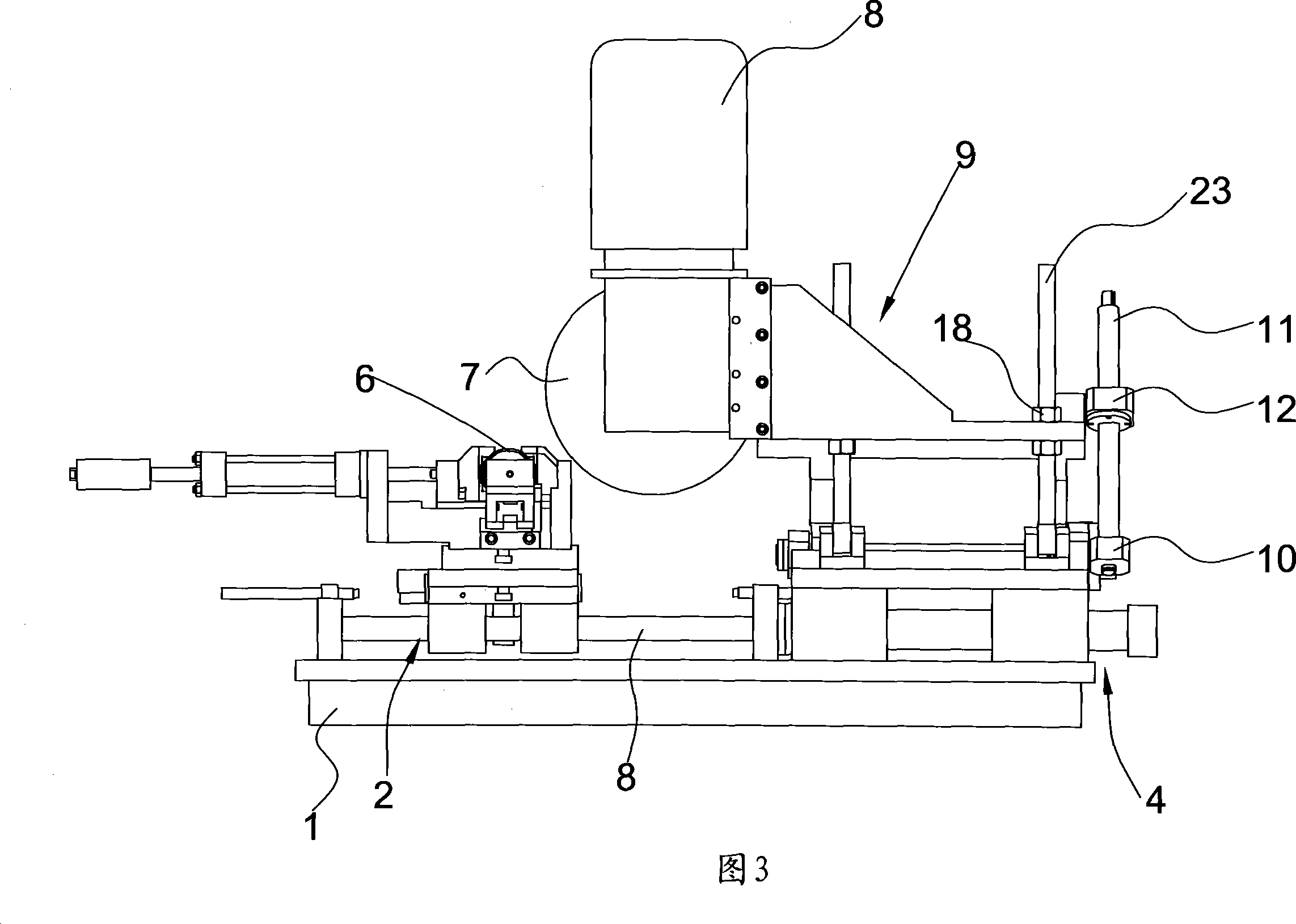

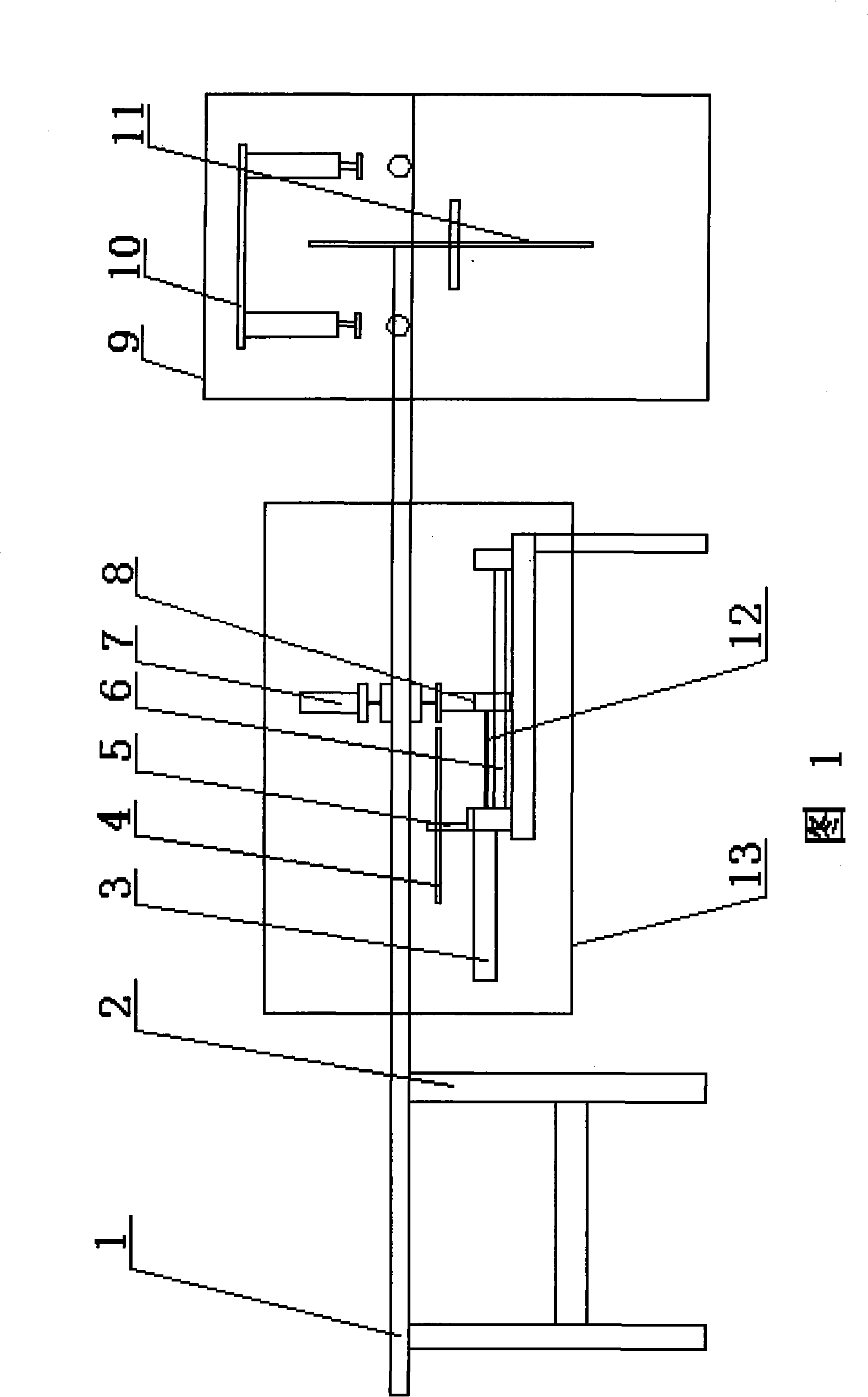

Full-automatic fixed-length cutting device of metallic hose

InactiveCN101623780ARealize fixed-length automatic cuttingIncrease productivityMetal-working feeding devicesTube shearing machinesFixed lengthMetal hose

The invention relates to a full-automatic fixed-length cutting device of a metallic hose, comprising a base, a strip conveyer and a conveying chute. The strip conveyer is used for conveying the metallic hose and is erected on the base; the conveying chute vertically penetrates through the strip conveyer which is provided with a positioning mechanism, a conveying mechanism and a clamp, wherein the conveying mechanism sends the metallic hose into the clamp and pulls the metallic hose away for a certain distance, and then, the metallic hose is cut by a cutting mechanism which is arranged on the base. The invention realizes the automatic fixed-length cutting of the metallic hose, greatly improves the production efficiency, and achieves higher consistency degree of a cut product.

Owner:严光辉

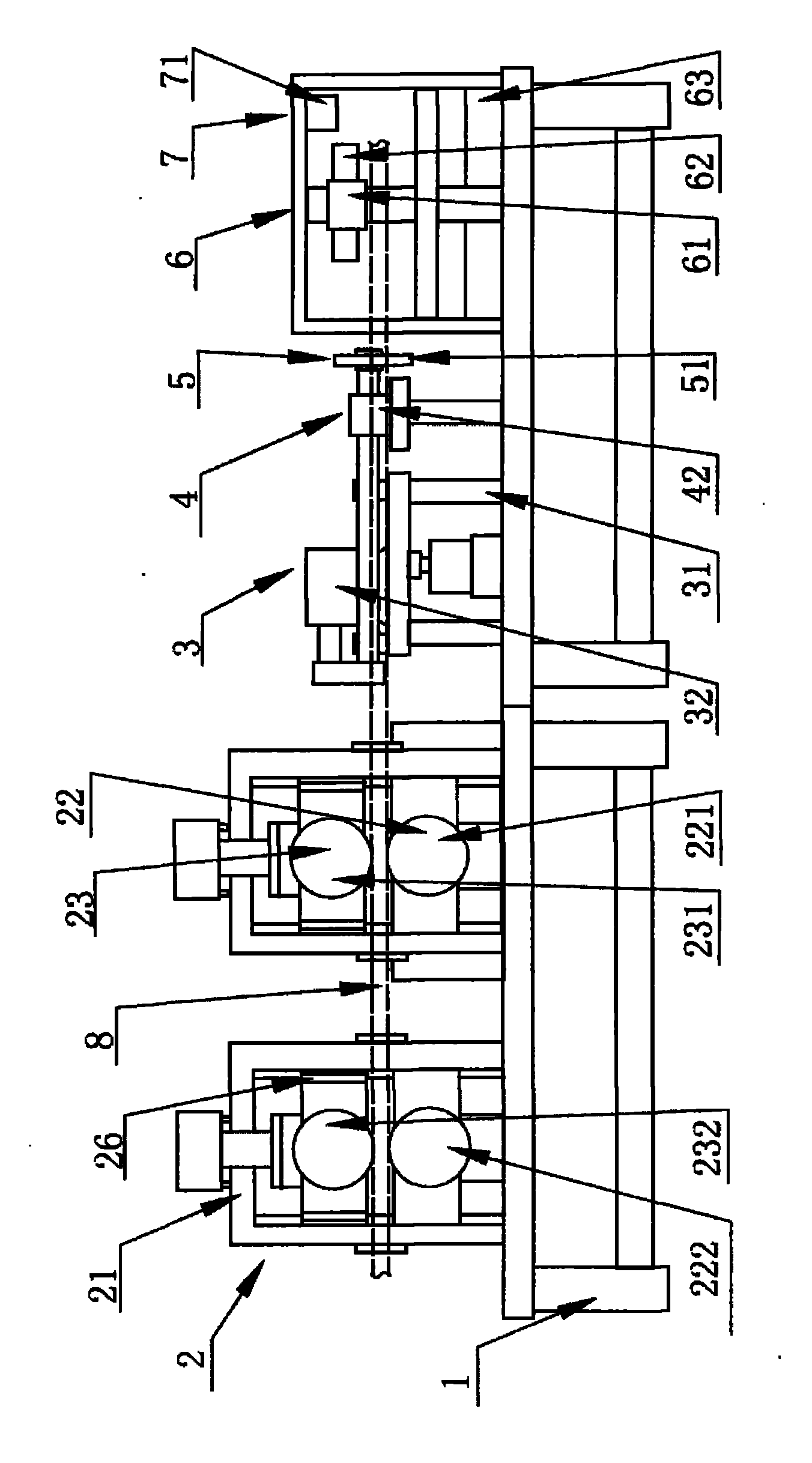

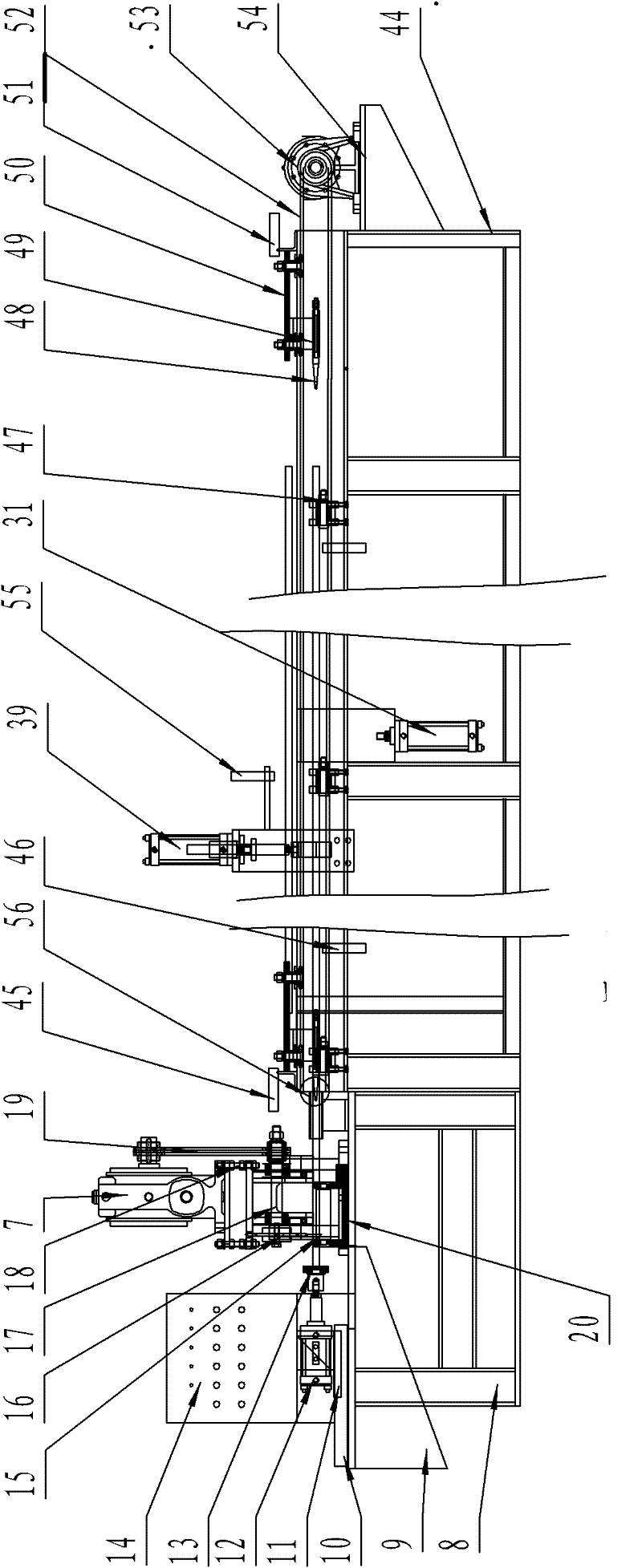

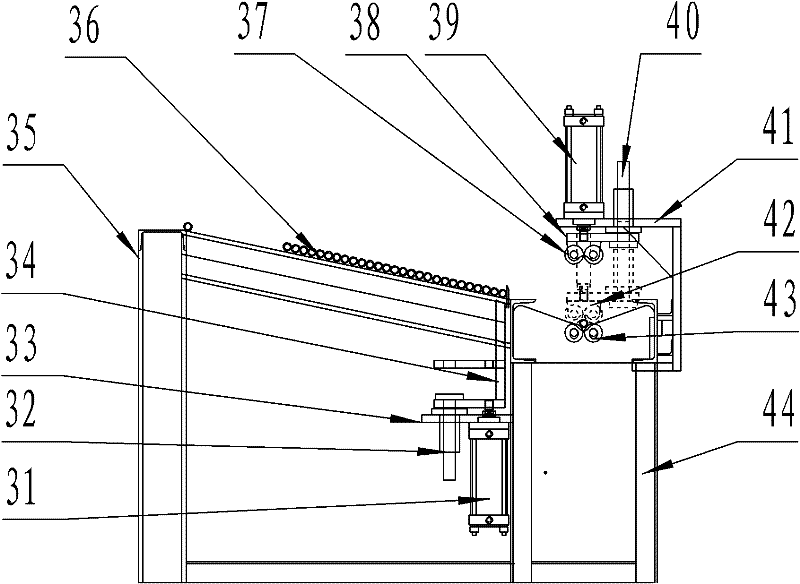

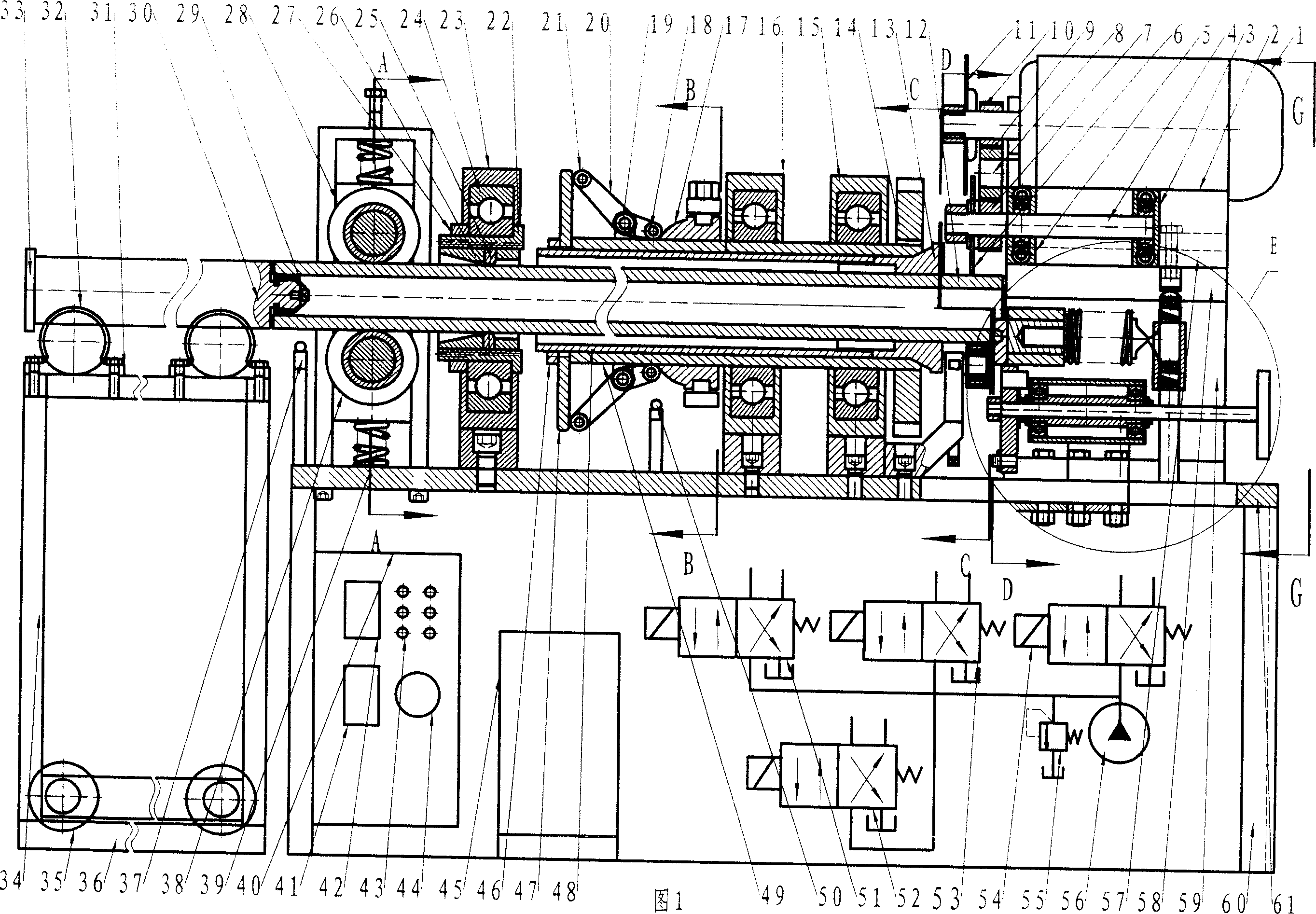

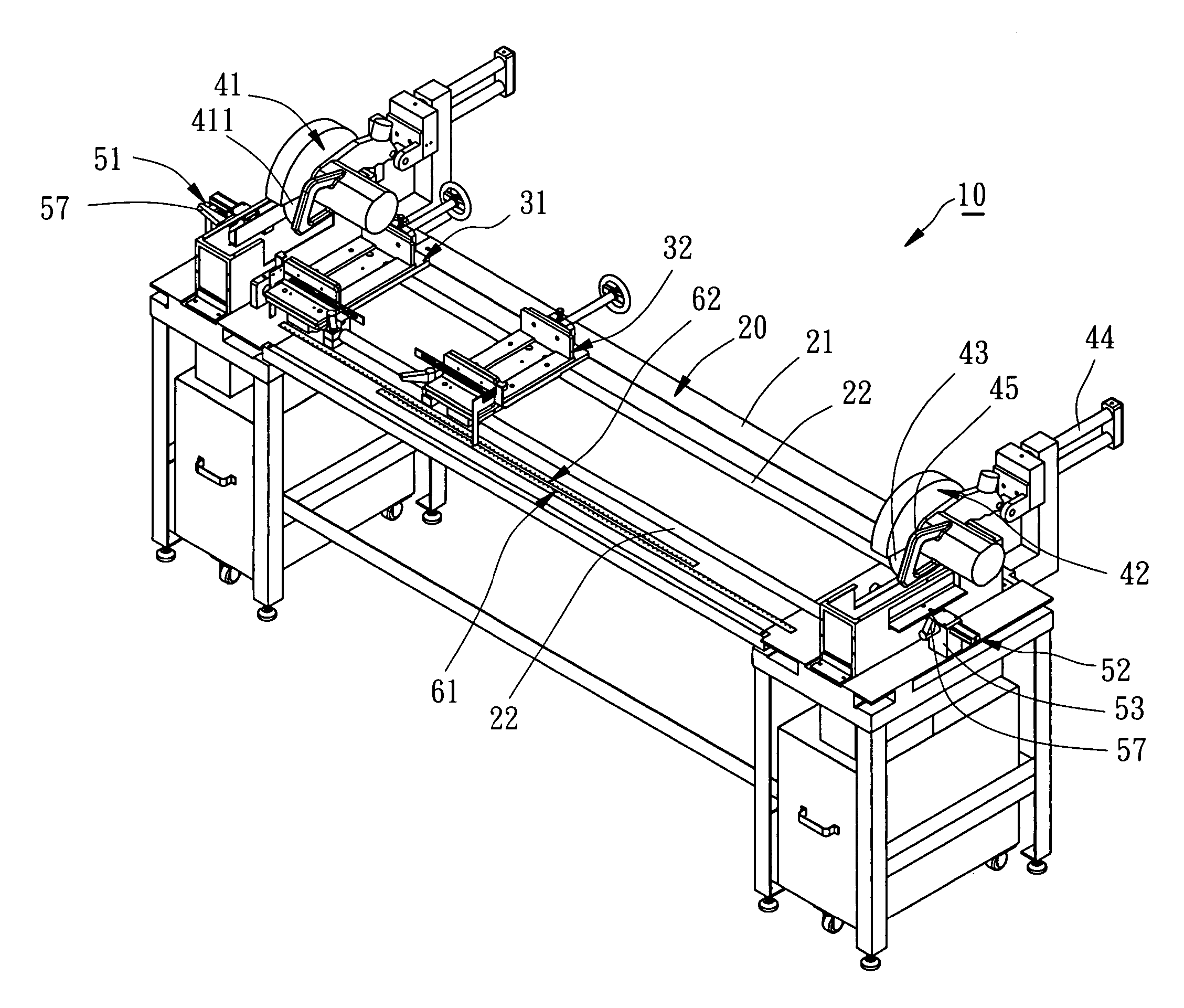

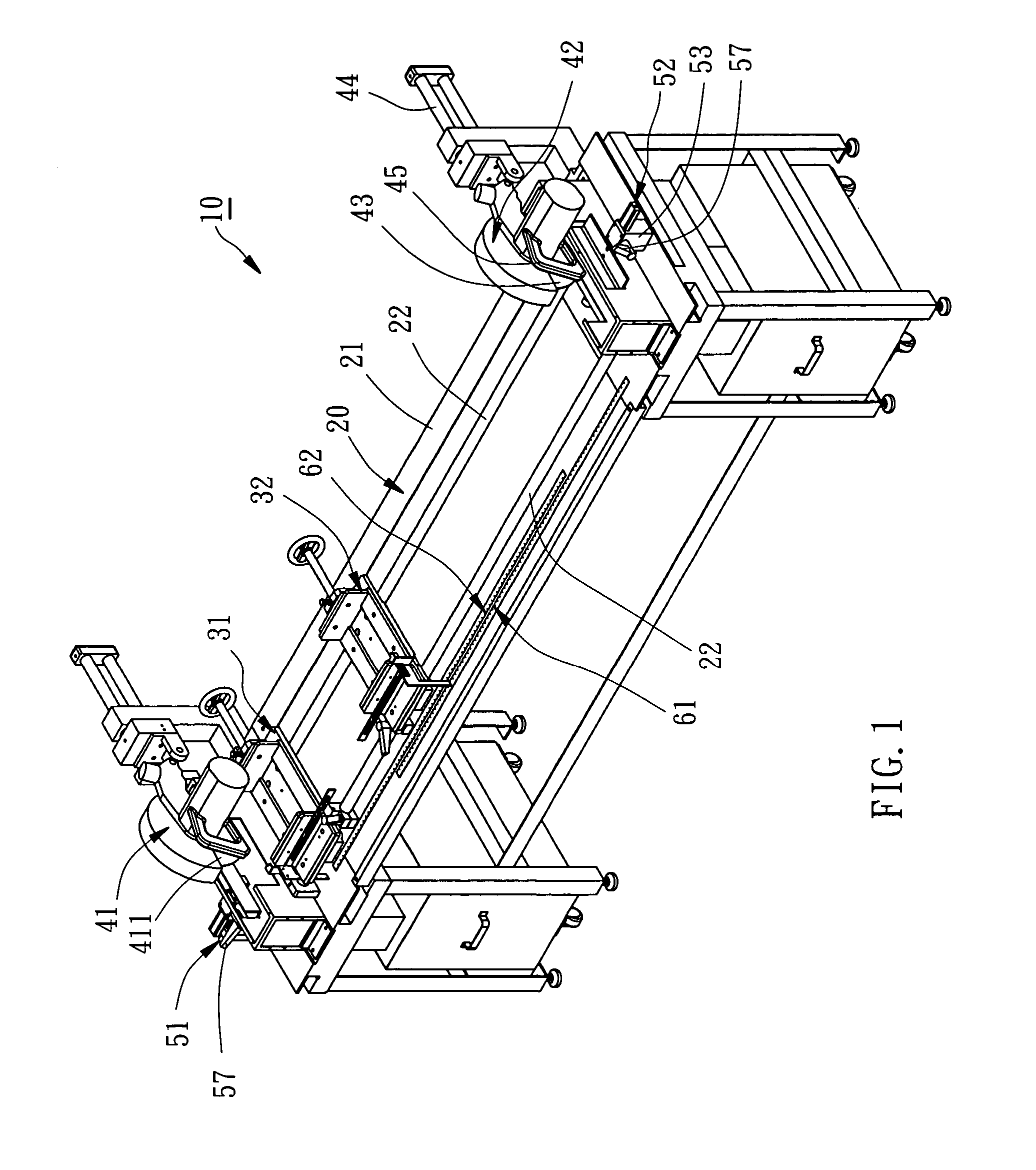

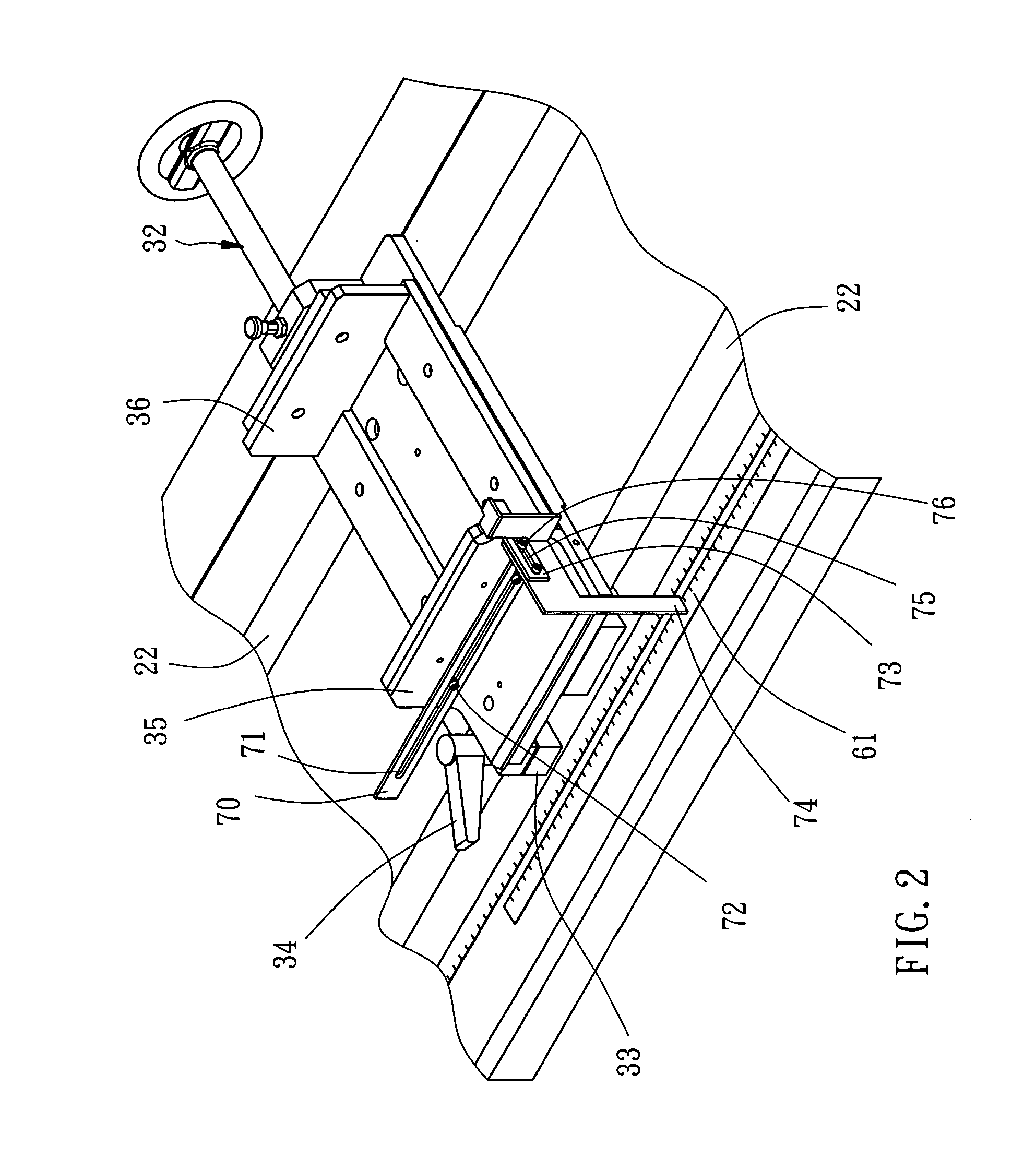

Full automatic pipe cutting machine

InactiveCN102179562AHigh degree of automationImprove cutting efficiencyTube shearing machinesShearing machine accessoriesEngineeringLength measurement

The invention discloses a full automatic pipe cutting machine. The pipe cutting machine comprises a feeding drive part, a cutting drive part, a pipe clamping part, a cutting part, an unloading part and a cutting measurement part which are sequentially arranged on an operating platform, wherein the feeding drive part conveys pipes to the cutting part by a driving wheel and a rolling wheel, then the pipes are cut off by a cutting tool driven by the cutting drive part; the driving wheel of the pipe cutting machine is driven by a stepping motor, and the lengths of the cut pipes can be accurately detected and controlled according to the electrical signals of stepping quantity of the stepping motor and the data of radius of the driving wheel; and in addition, the operating platform is also provided with an infrared distance measurement sensor, and the length accuracy of the cut pipe is jointly ensured by the electrical distance measurement signals and the movement detection signals of the stepping motor. By adopting the clamping feeding structure, the automatic cutting structure, the automatic clamping structure, the automatic unloading structure and the automatic cut pipe-length measurement and control mechanism, the degree of automation of the pipe cutting machine is improved.

Owner:中臻工业有限公司

Automatic blanking machine for steel pipes

ActiveCN102126045AExact lengthFully automatedTube shearing machinesShearing machine accessoriesElectrical controlSlide plate

The invention discloses an automatic blanking machine for steel pipes, belongs to the field of cutting-off equipment of the steel pipes and particularly relates a steel pipe cutting-off device with a mechanical automatic material supply device and a cutting-off device. The automatic blanking machine for the steel pipes is characterized by mainly comprising a fixed scale cutting-off system, a steel pipe conveying system and an electrical control system, wherein the steel pipe conveying system and the electrical control system are connected with the fixed scale cutting-off system, wherein the fixed scale cutting-off system comprises a steel pipe fixed scale device mounted on a transverse sliding track at the left end of a lathe bed and the cutting-off device mounted on the lathe bed, a front positioning sliding plate is mounted on a front positioning sliding plate seat fixed on the transverse sliding track of the steel pipe fixed scale device, a steel pipe fixed scale cylinder is arranged on the sliding plate, a steel pipe fixed scale detection switch is arranged at the front end of the cylinder, and the steel pipe conveying pipe comprises a steel pipe storage device and a steel pipe feed device. The automatic blanking machine for the steel pipes has the beneficial effects of realizing automation of supply, compression and fixed scale cutting-off of the steel pipes, not only improving the working efficiency and reducing the labor intensity, but also ensuring the precise length of the steel pipes which are cut off, and being suitable for being used in occasions which need to cut the steel pipes into steel pipe sections with equal length.

Owner:济南玛钢钢管制造有限公司

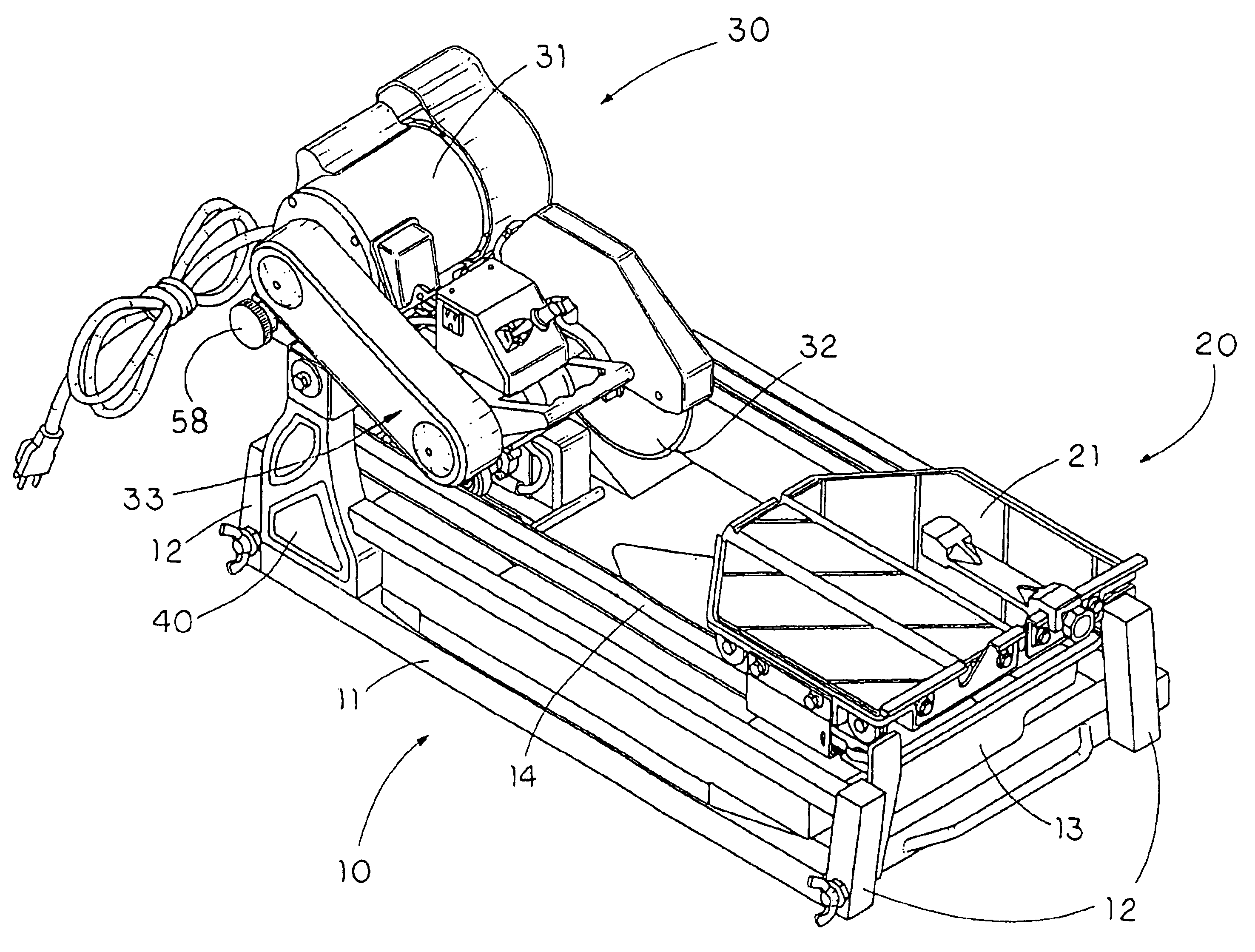

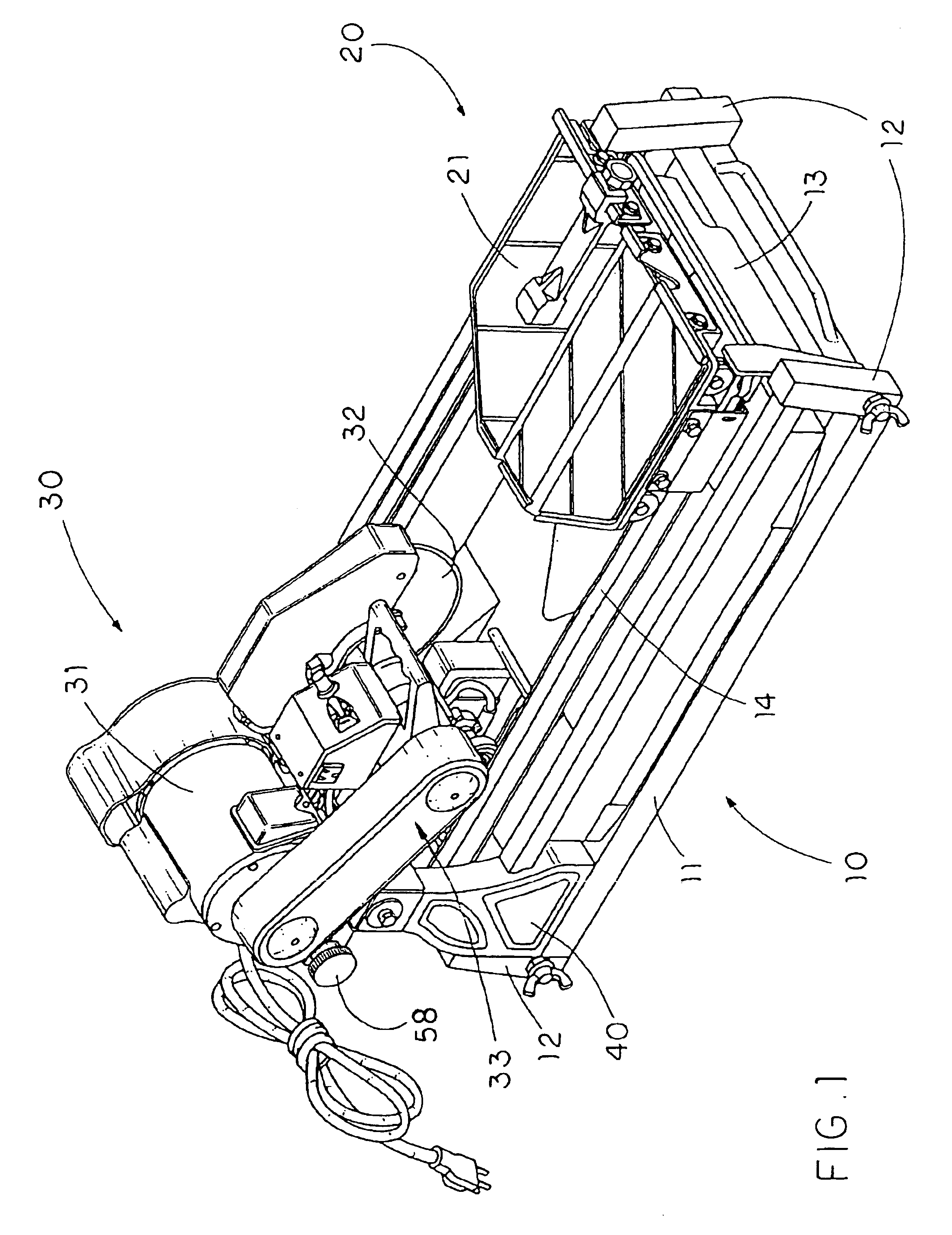

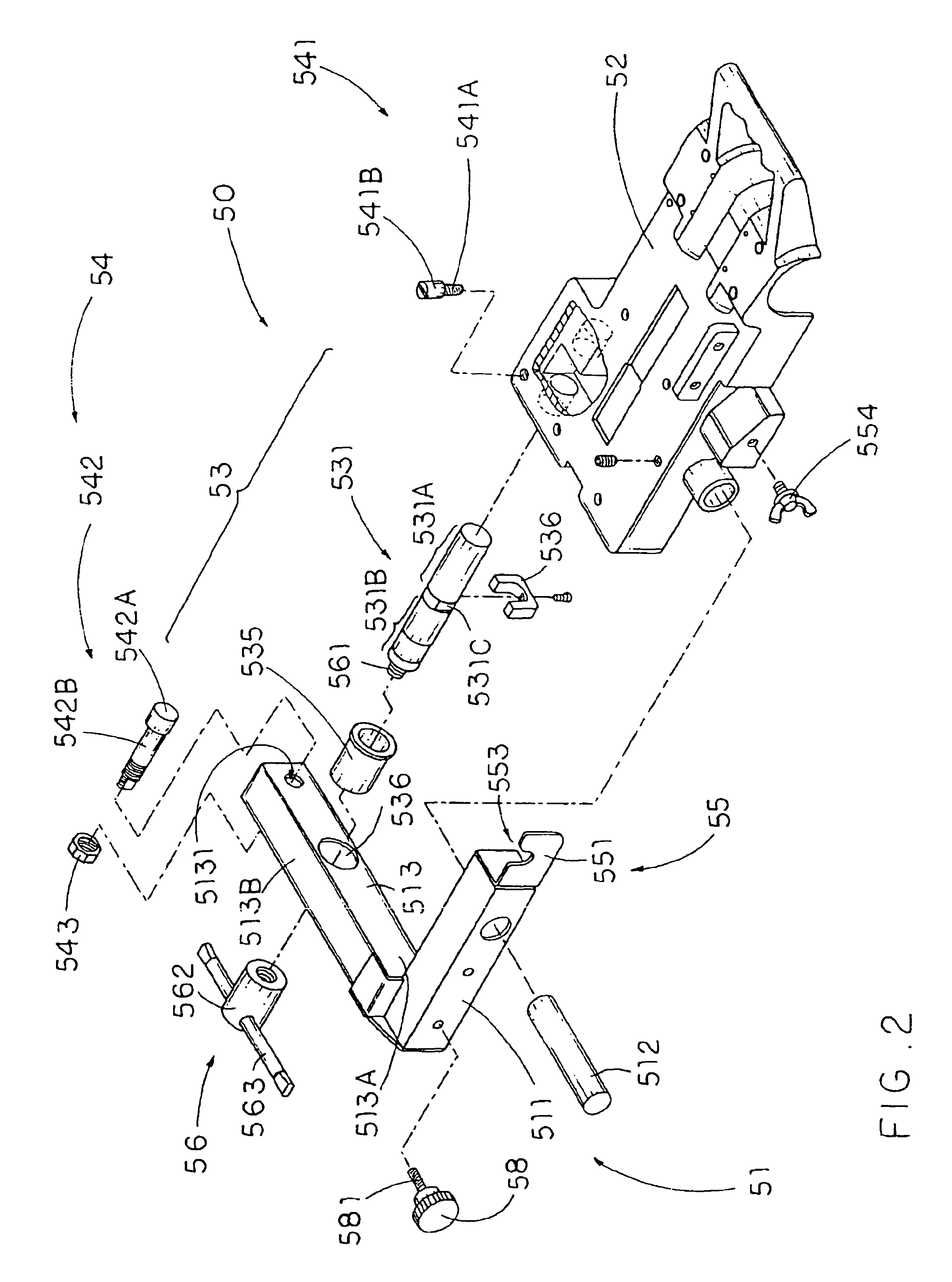

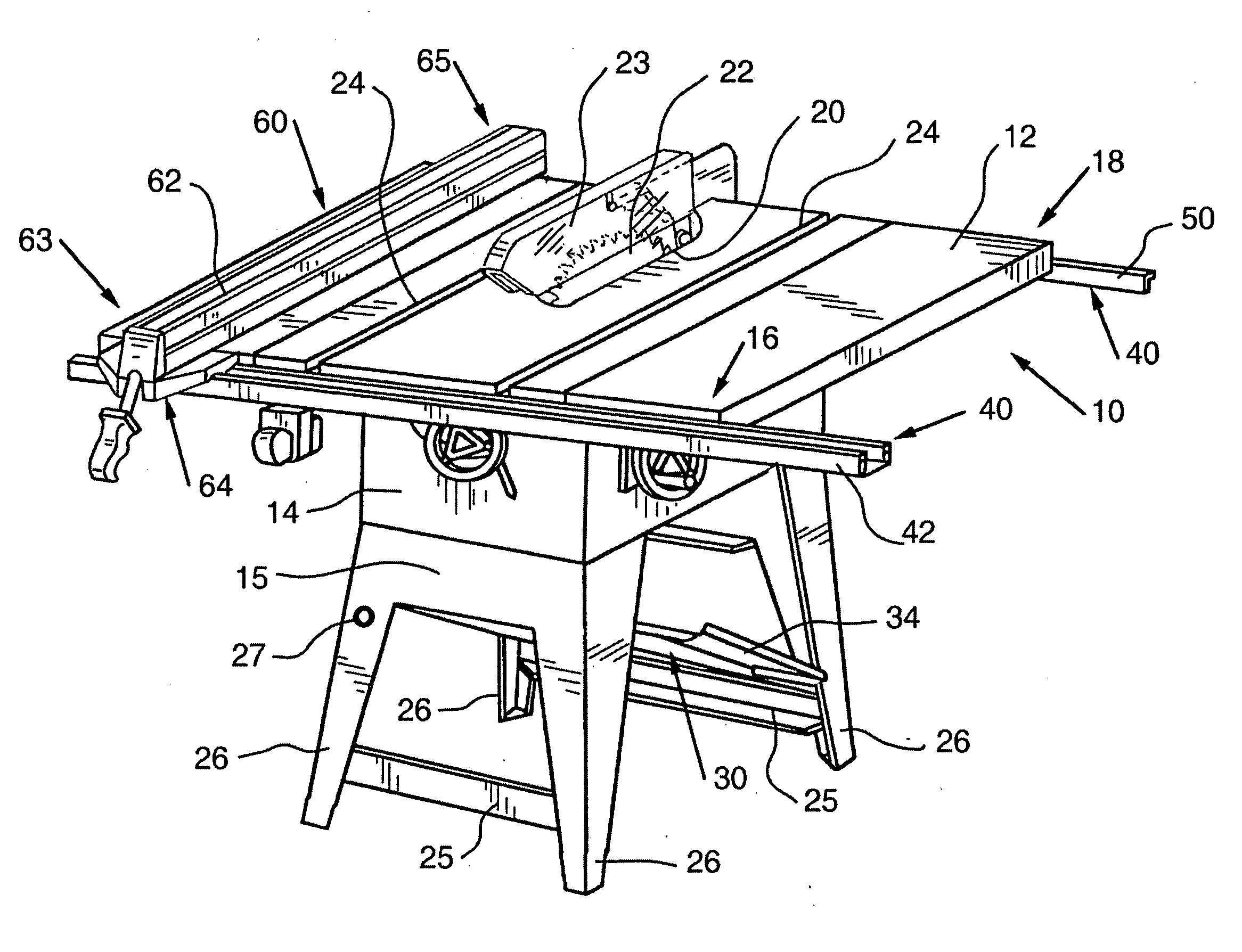

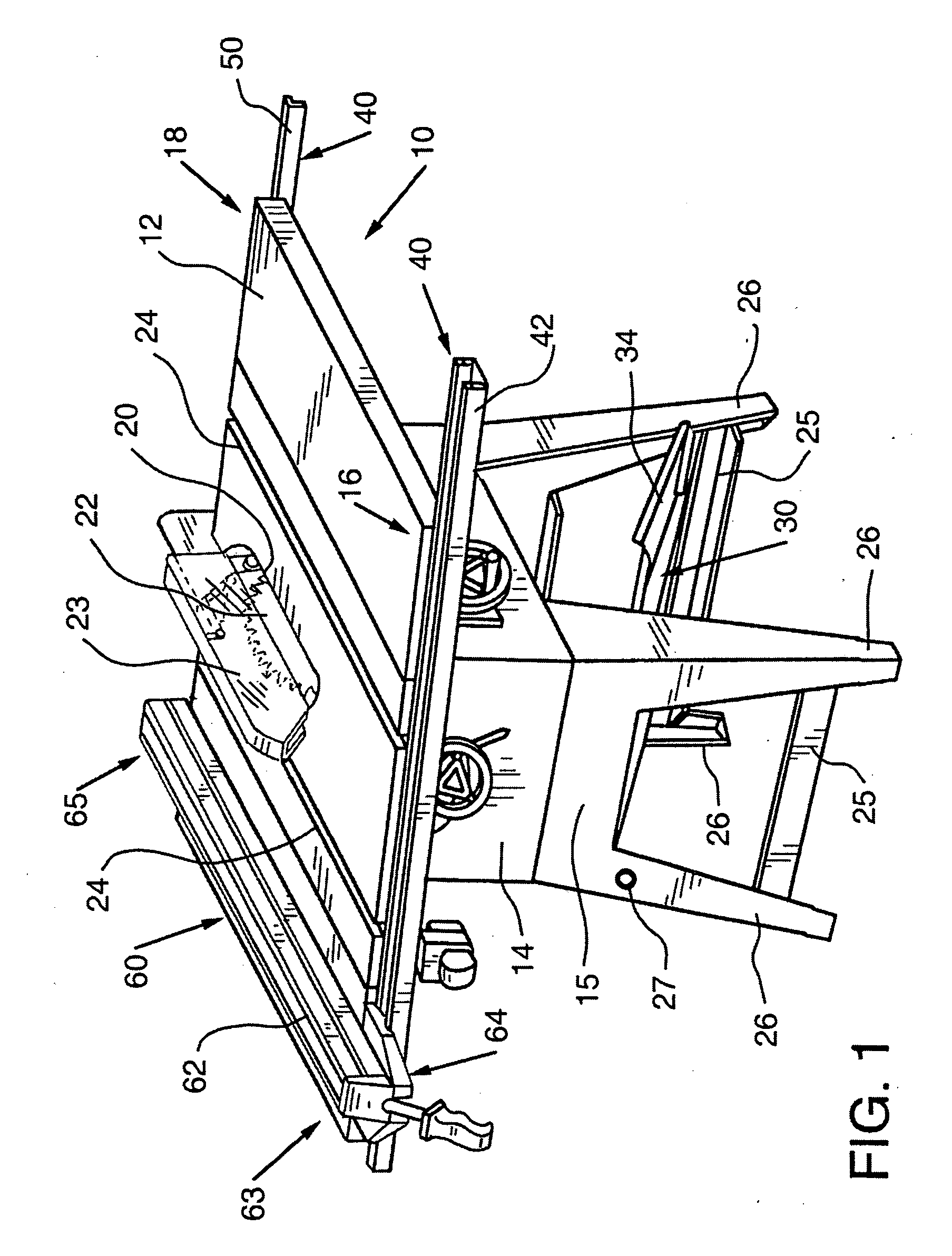

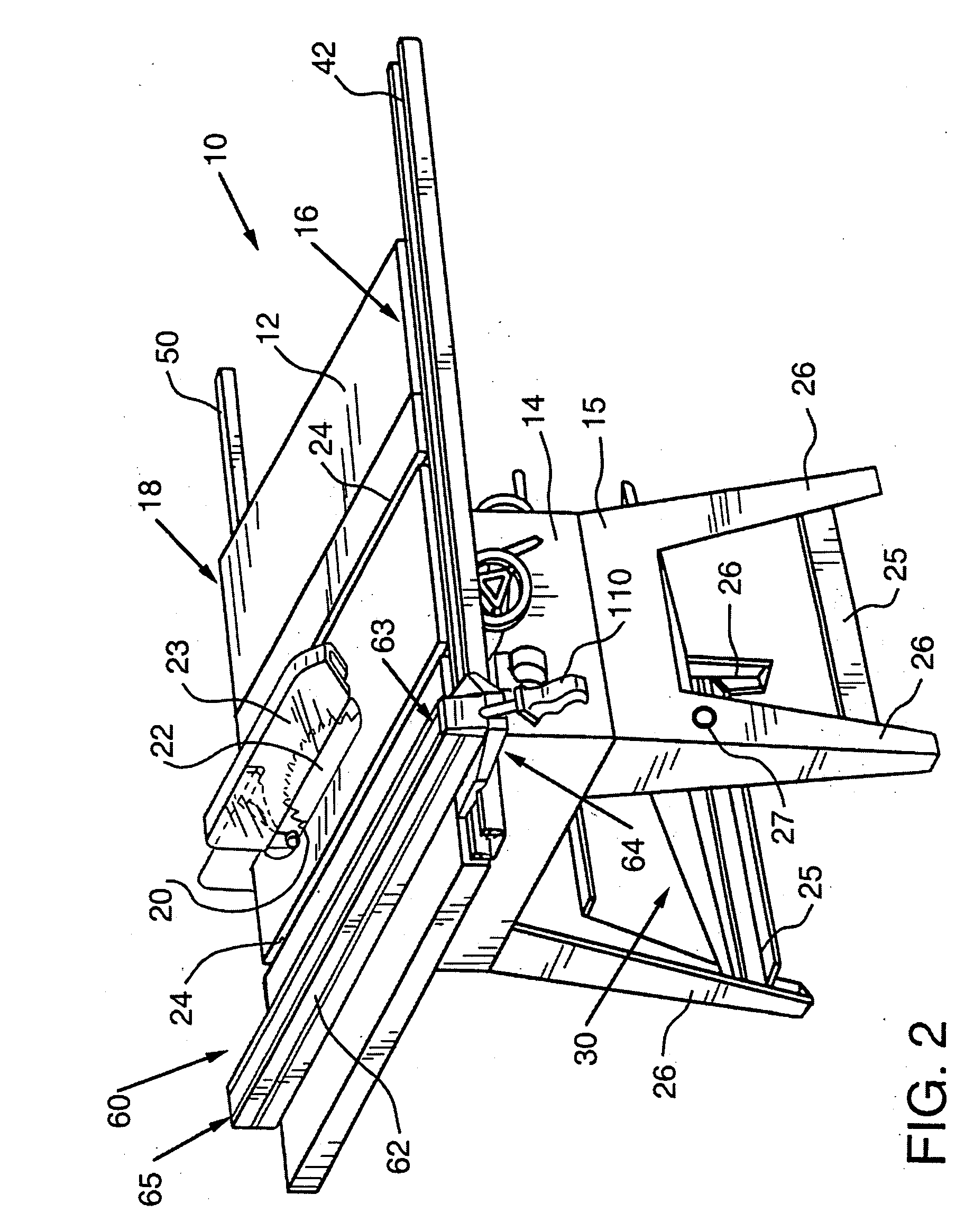

Sawing apparatus and saw fence system

InactiveUS20050087049A1Consistent supportEasy to adjustMetal sawing devicesMetal sawing accessoriesCollection systemEngineering

A sawing apparatus and a saw fence. The saw apparatus may include a work surface. The saw may include a rail system disposed along the edges of the work surface, for the attachment of accessories thereto. The saw may be provided with workpiece guide adapted to be attached to the rail system for guiding workpieces during the operation of the saw. The workpiece guide may also be provided with an infeed extension that rides on the rail system and is capable of supporting workpieces during the operation of the saw. The infeed extension may be adjustable relative to the work surface of the saw. The saw may further be provided with a debris collection system for the collection of debris produced by the cutting operations of the saw.

Owner:DELTA INT MACHINERY

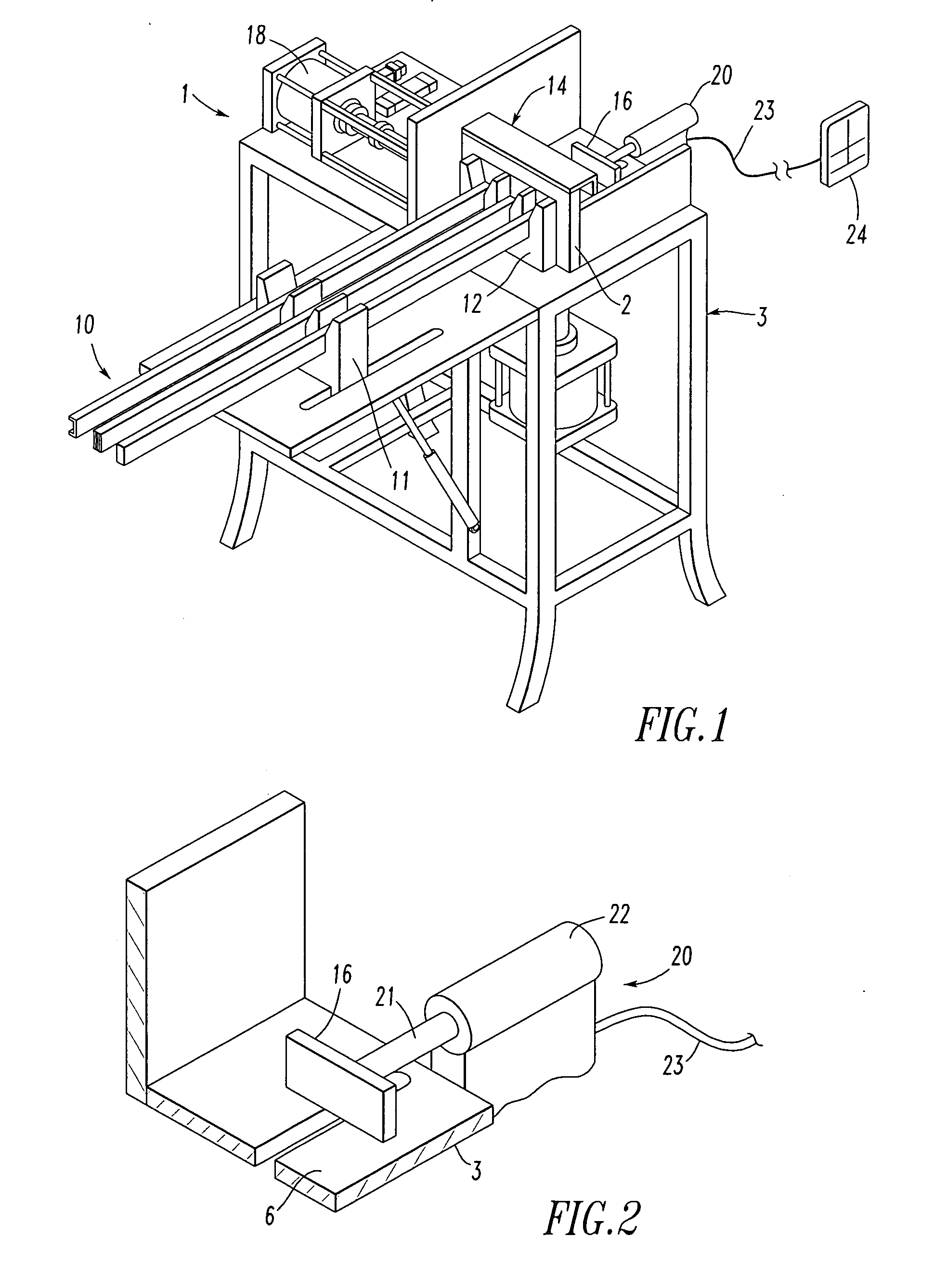

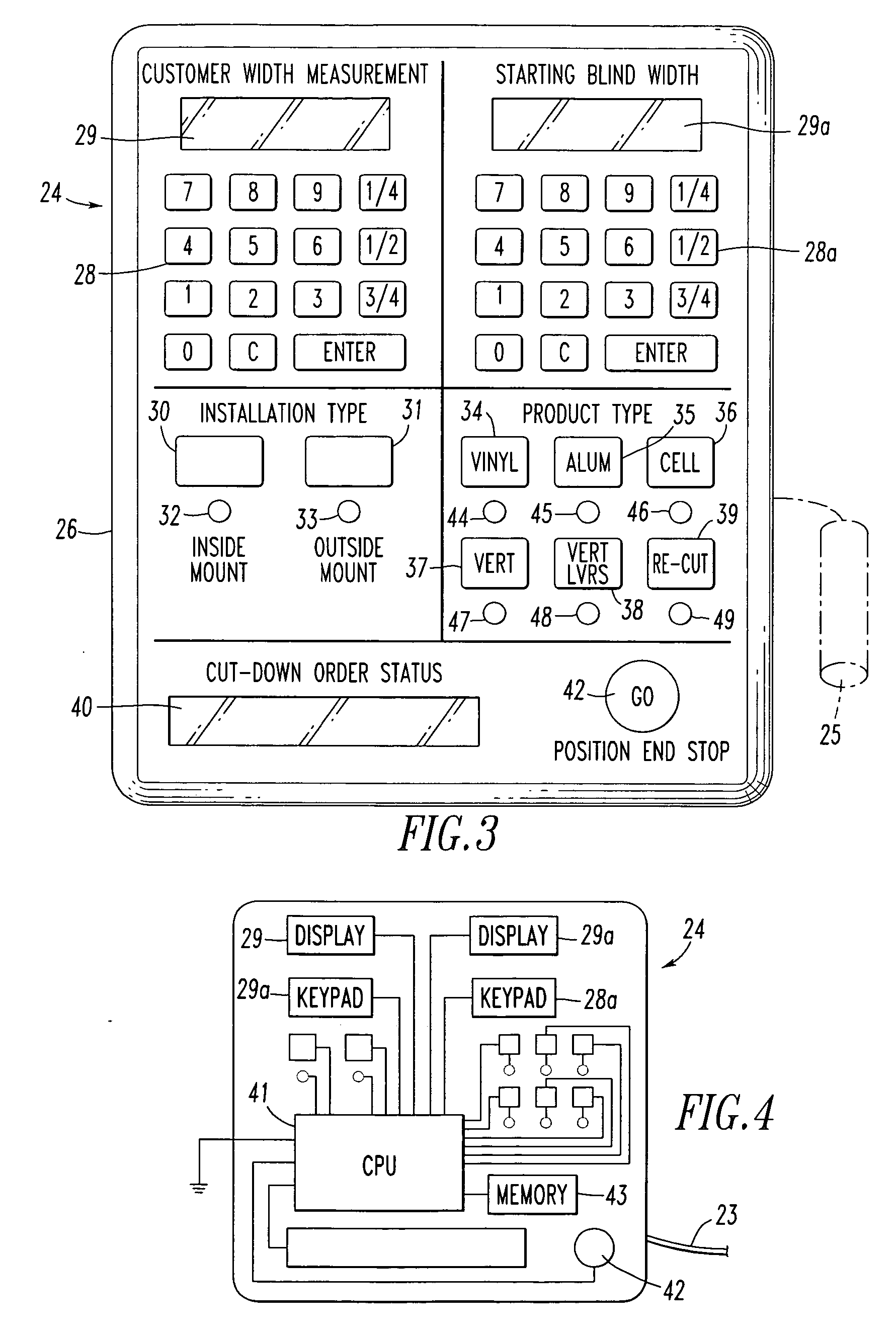

Blind cutting machine

An improved blind cutting machine has a work surface on which a blind to be cut is placed and at least one end stop against which an end of the blind to be cut rests prior to being cut by a cutting mechanism. An actuator is connected to the end stop. The actuator moves the end stop relative to the work surface and the cutting mechanism in response to signals from a controller. An operator enters information about the blind to be cut and the dimensions of an opening over which the blind to be cut is to be mounted into the controller. The controller then calculates the location where the end stop should be so that a sufficient amount of material can be trimmed from an end of the blind to be cut to enable the blind to fit the opening. Then the controller sends a signal to the actuator that causes the actuator to move the end stop to that location. In alternative embodiments the end stop is fixed and the actuator moves the cutting mechanism or a work surface on which the blind to be cut has been placed.

Owner:LUMINO

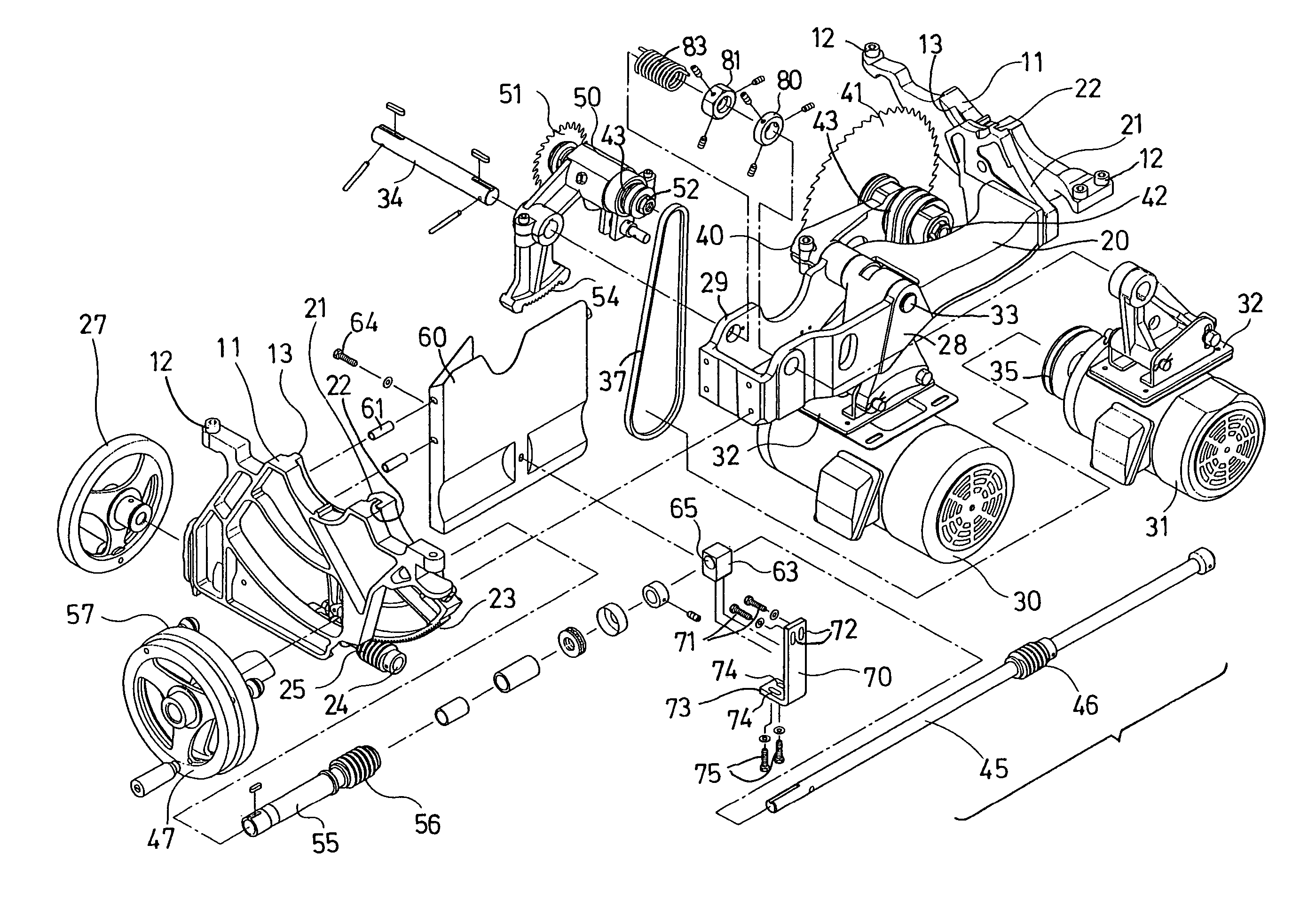

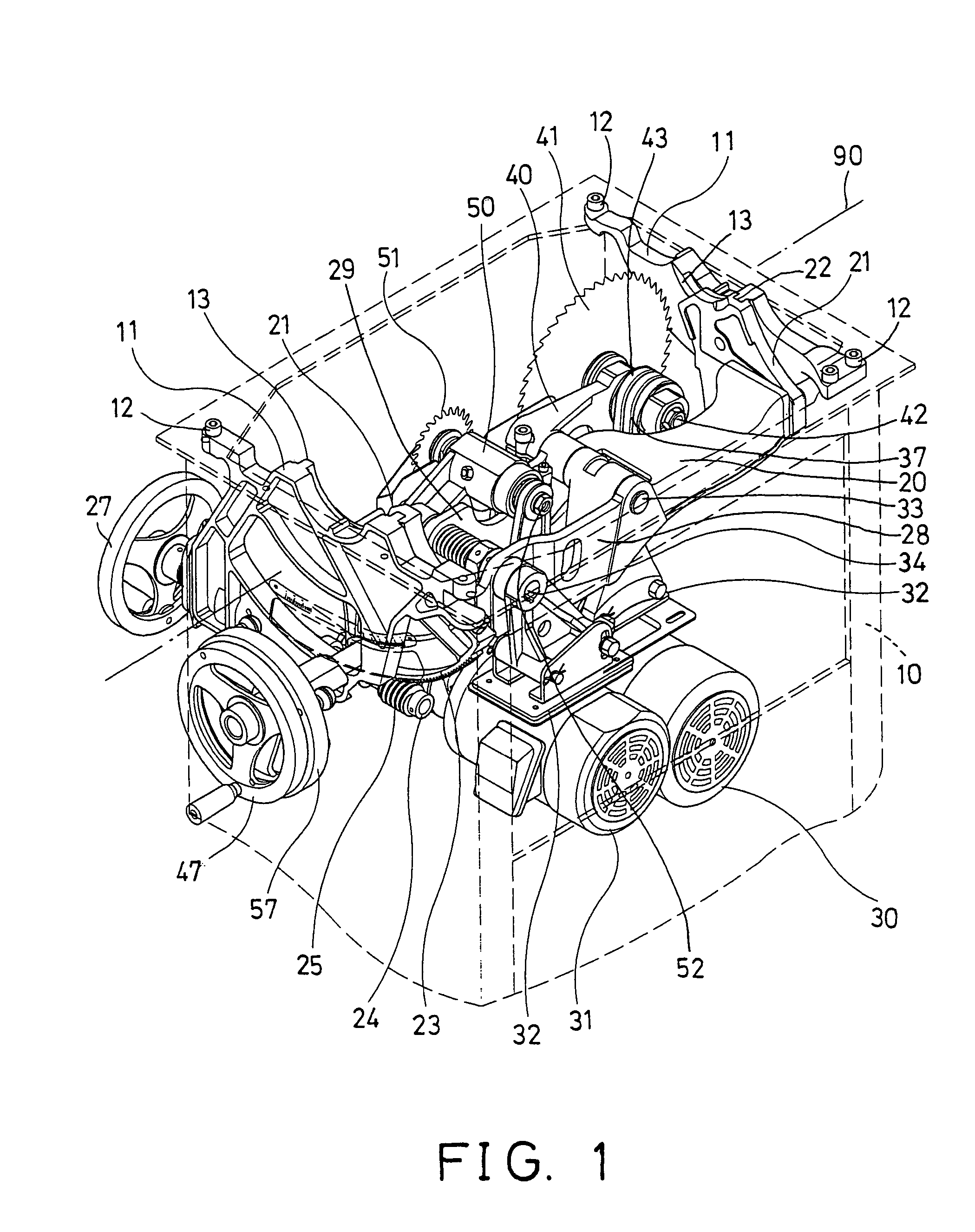

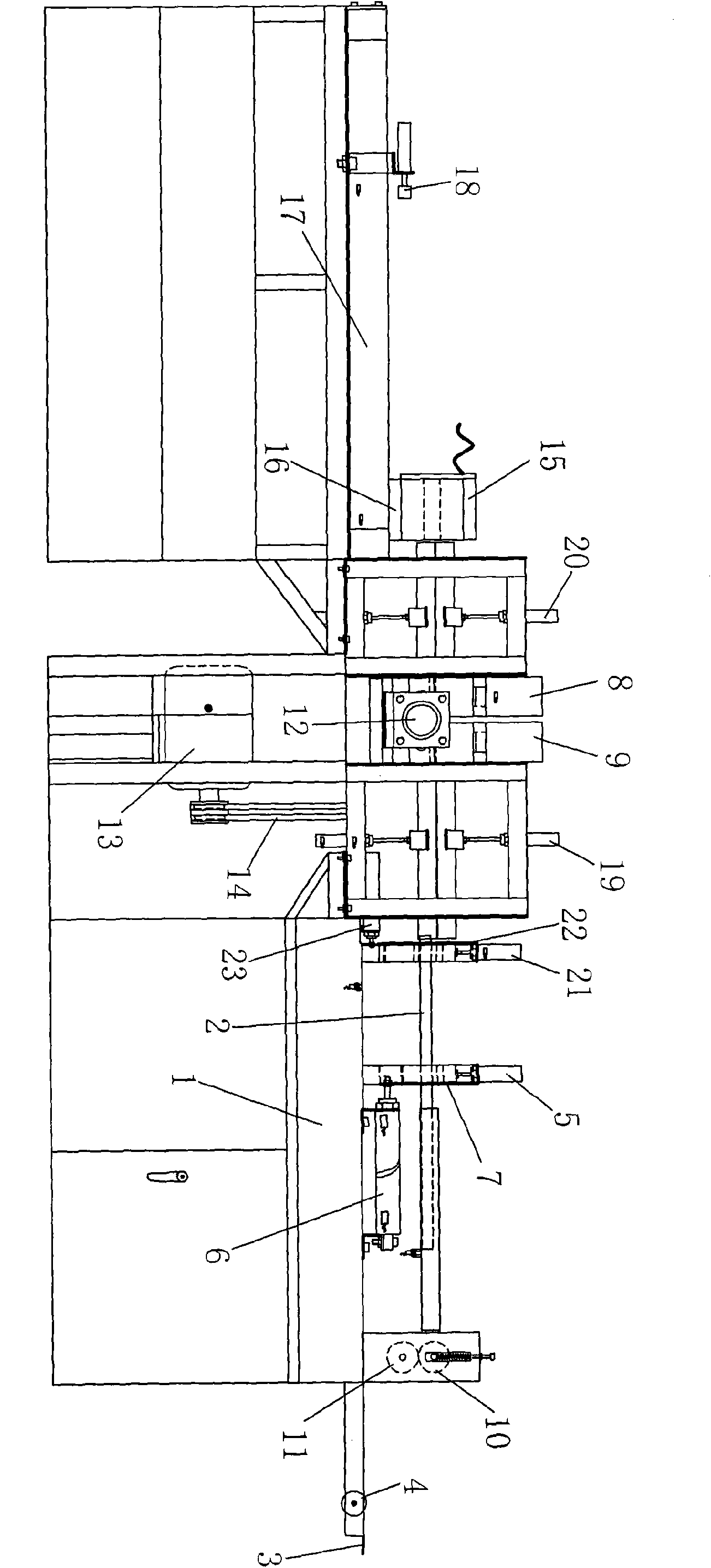

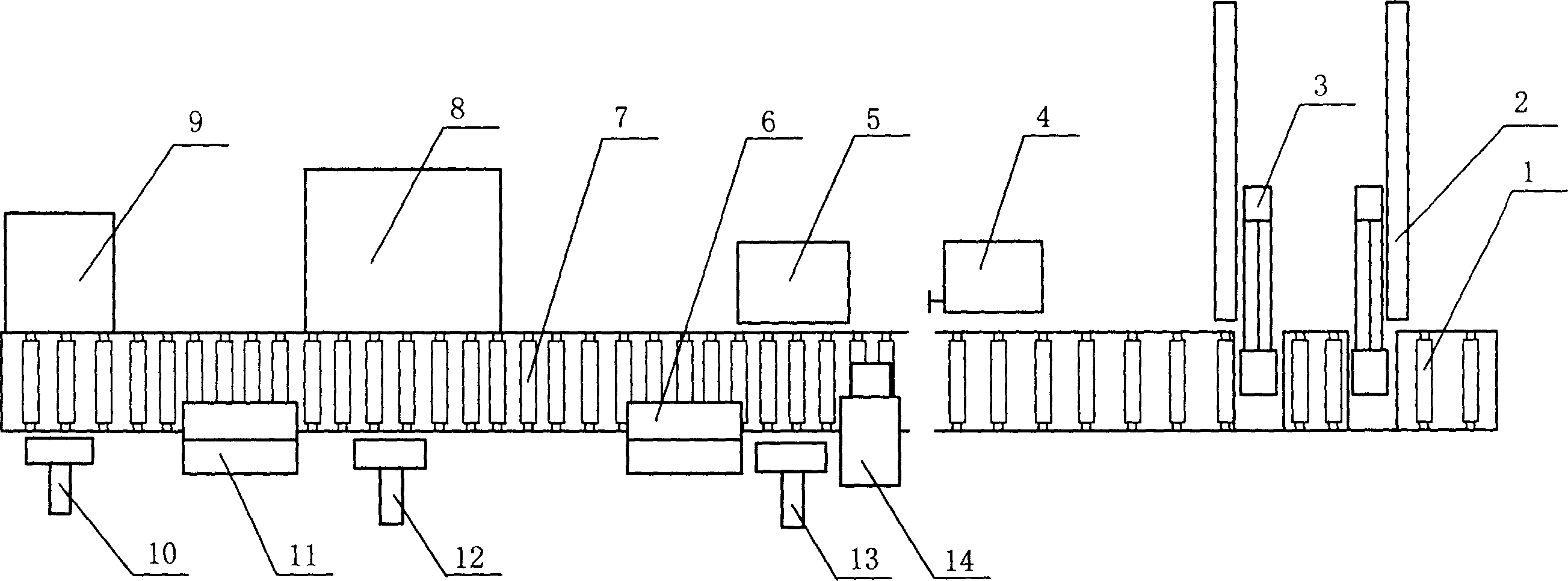

Automatic sawing, cutting and stacking machine for aluminum alloy bar

ActiveCN1899719ARealize automatic controlFree laborMetal-working feeding devicesPositioning devicesAutomatic controlStack machine

The automatic sawing, cutting and stacking machine for aluminum alloy bars includes conveying roller bed comprising conveying rollers and chain wheel driving mechanism, operating stations set along the conveying roller bed, material feeding mechanism, material setting mechanism, cutting mechanism, sizing mechanism, stacking mechanism, side aluminum bar pushing mechanism, power mechanism and control mechanism. The present invention has power mechanism and control mechanism, and can realize PLC automatic control and automatic operation of feeding, sizing, cutting and stacking aluminum alloy bars, and possesses high production efficiency.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

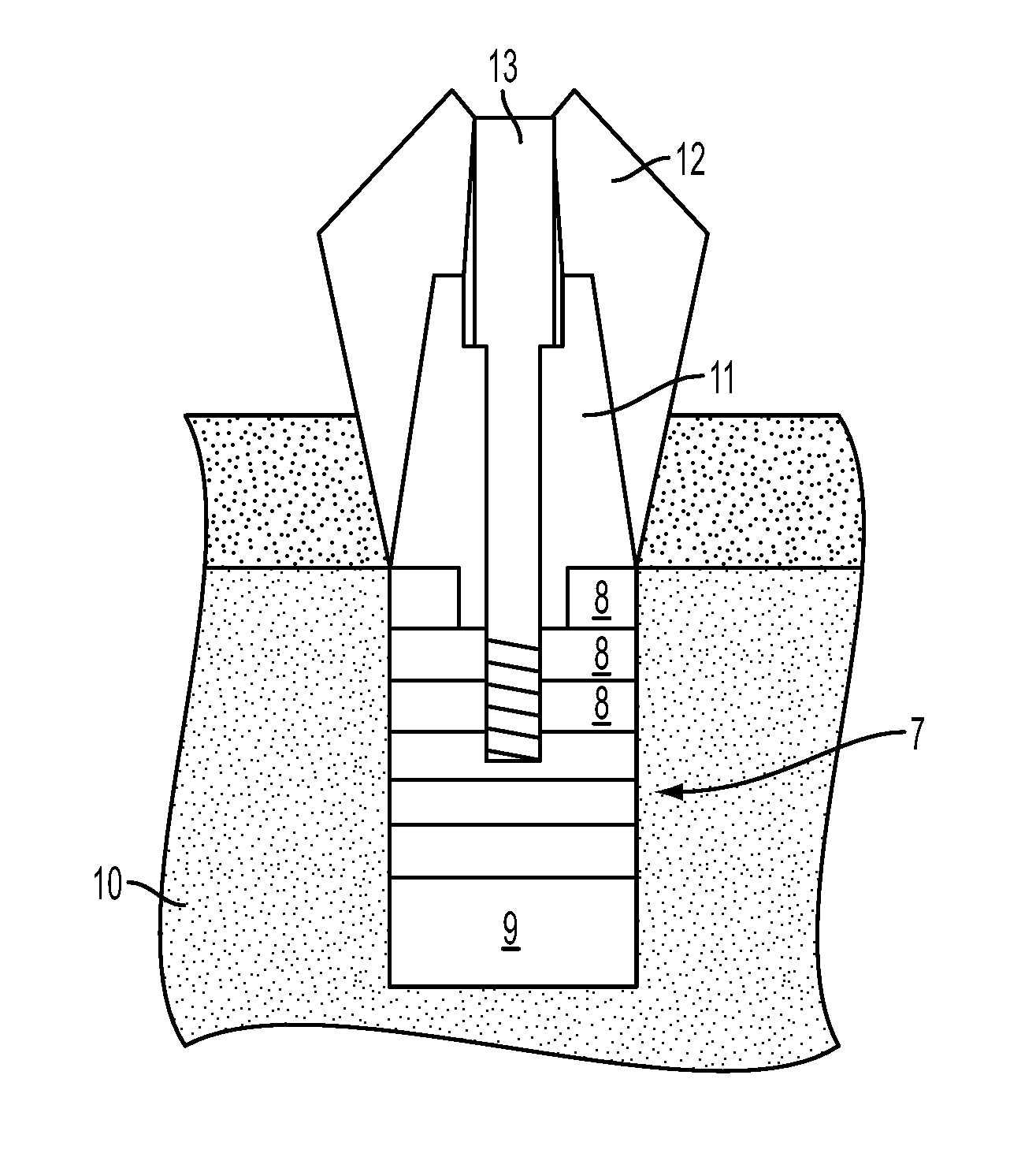

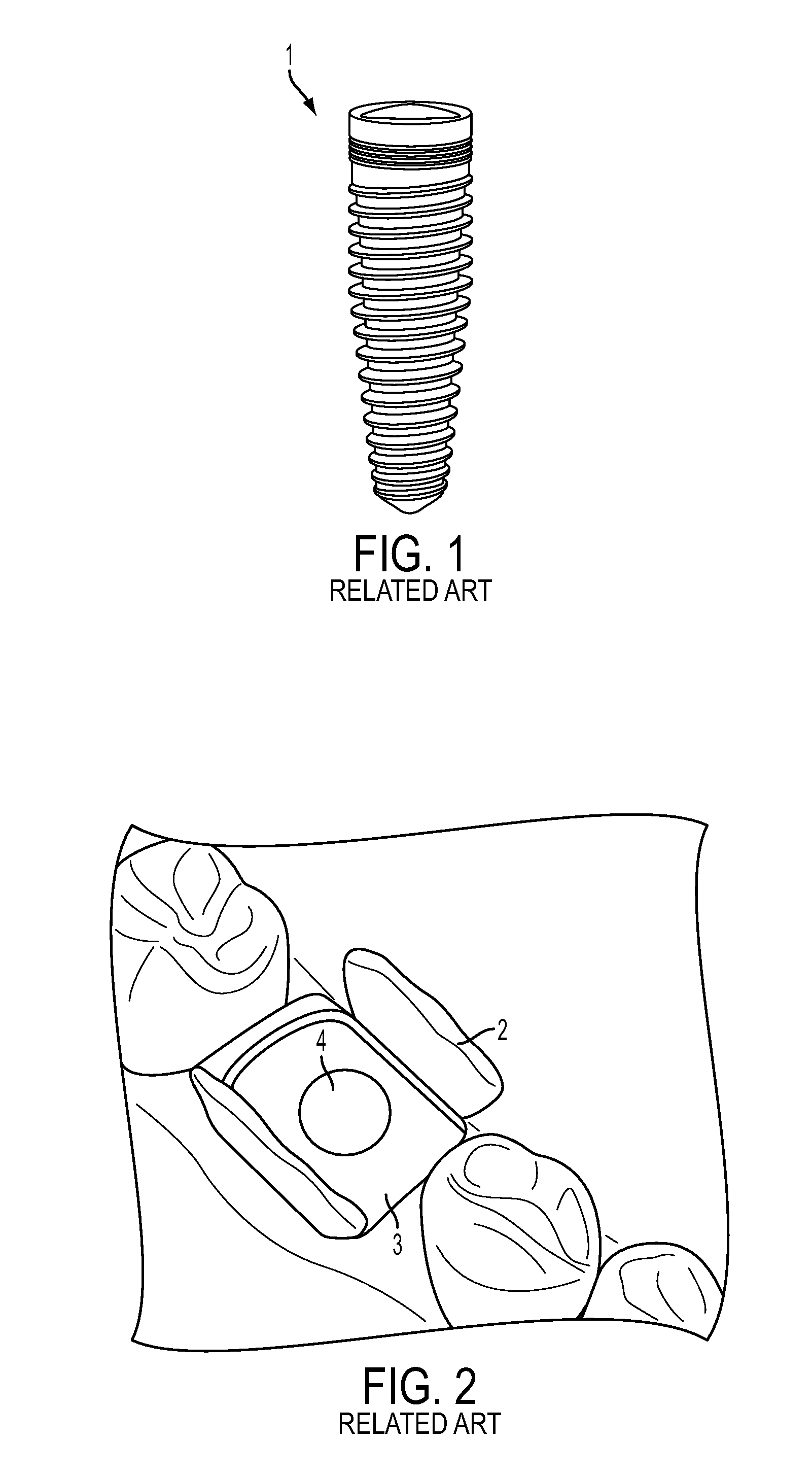

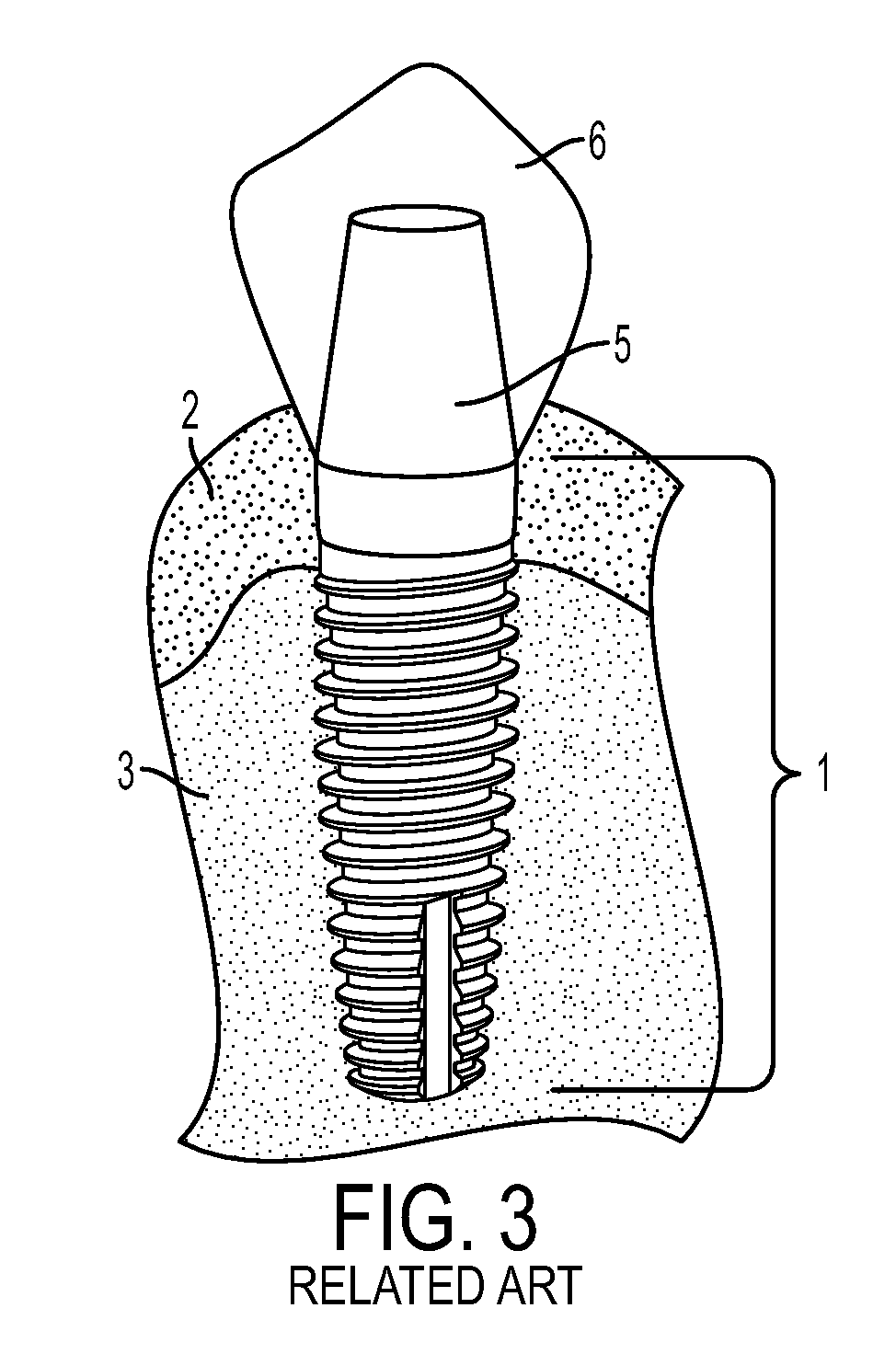

System and method for prevention and treatment of peri-implant infection

ActiveUS20120156645A1Convenient treatmentDental implantsFastening prosthesisImplant InfectionDentistry

A system, method and device design to prevent, treat and maintain dental periimplant infections including a dental implant to be inserted into a jawbone of a patient that includes a base segment provided at one distal end of the implant which is configured to be put inside and come in contact with the jawbone, an abutment portion provided on an end opposite to the one distal end of the implant to which an artificial tooth is configured to be attached, and a plurality of removable segments which are configured to be put inside and come in contact with the jawbone and are removably attached to the base segment. If an infection is diagnosed around an implant site, infected removable segments can be extracted while maintaining positioning of the uninfected removable segments and the base segment. The infected removable segments are replaced with cleaned or sterilized removable segments.

Owner:JACOBY BENNETT

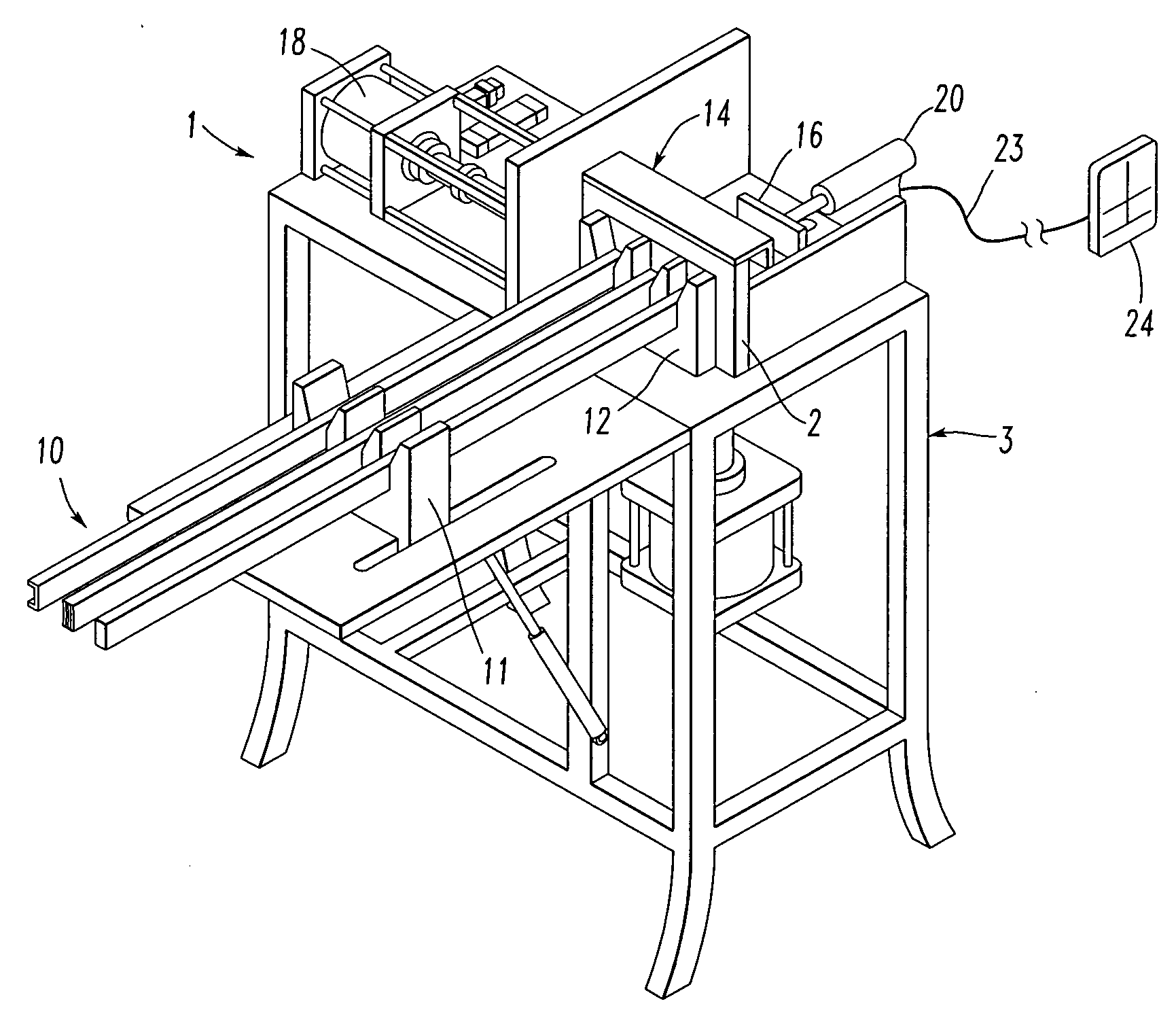

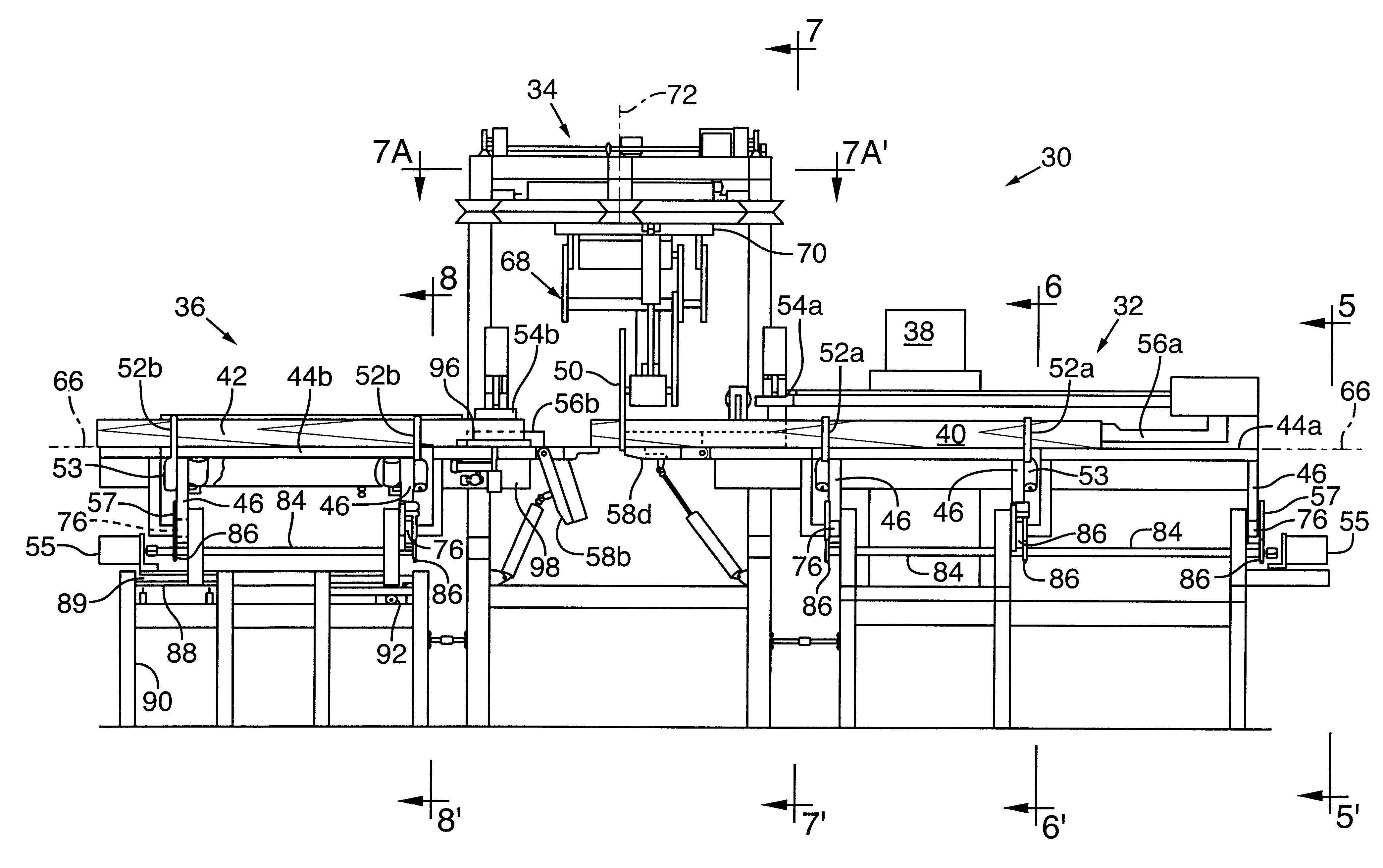

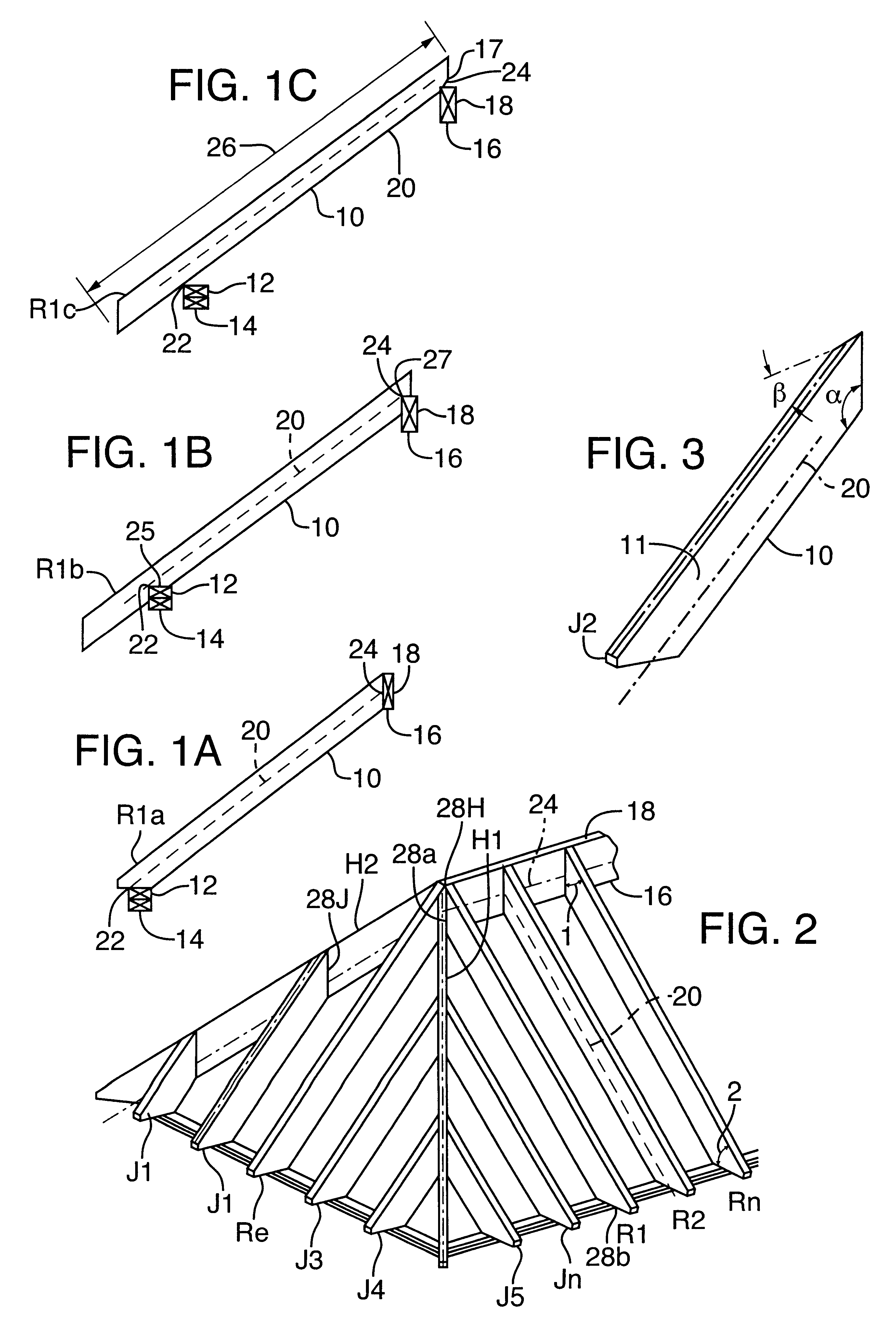

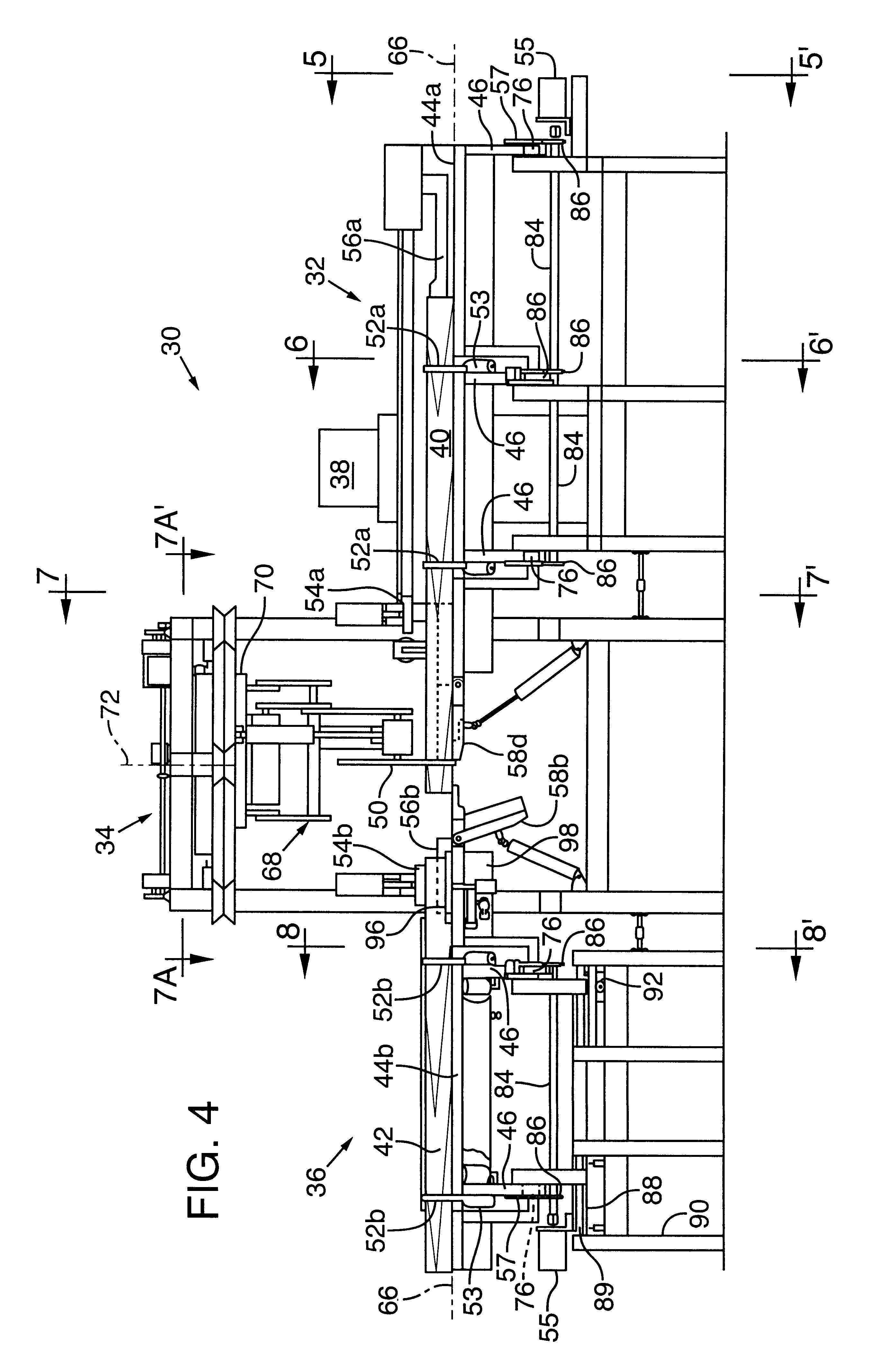

Tiltable infeed and outfeed saw table

InactiveUS6212983B1Precise positioningMinimum elapsed timeMetal sawing devicesAutomatic control devicesCircular sawEngineering

An apparatus for sequentially and automatically cutting a piece of dimension lumber at a number of predetermined angles to produce a building component, such as a rafter or truss web or chord, with composite or compound angles, is disclosed. The apparatus includes infeed and outfeed tables tiltable about a longitudinal axis and equipped with fences along which a workpiece moves longitudinally via moving devices. Clamps hold the workpiece at different positions relative to a cutting station during a cutting operation. A cutter, which for example includes a circular saw blade, is mounted for a positioning movement about a vertical axis at the cutting station, as well as for vertical movement to cut a workpiece at a predetermined composite or compound angle. The entire lumber cutting process at both ends of the workpiece, including lumber movement on the table past the cutting station, angular cutter and table adjustment, cutter movement, and clamping and unclamping, is under the control of a programmable computer operating in conjunction with appropriate sensors and pulse counters on the equipment.

Owner:STODDARD H PYLE REVOCABLE LIVING TRUST DATED JULY 17 1991

Pipe cutter

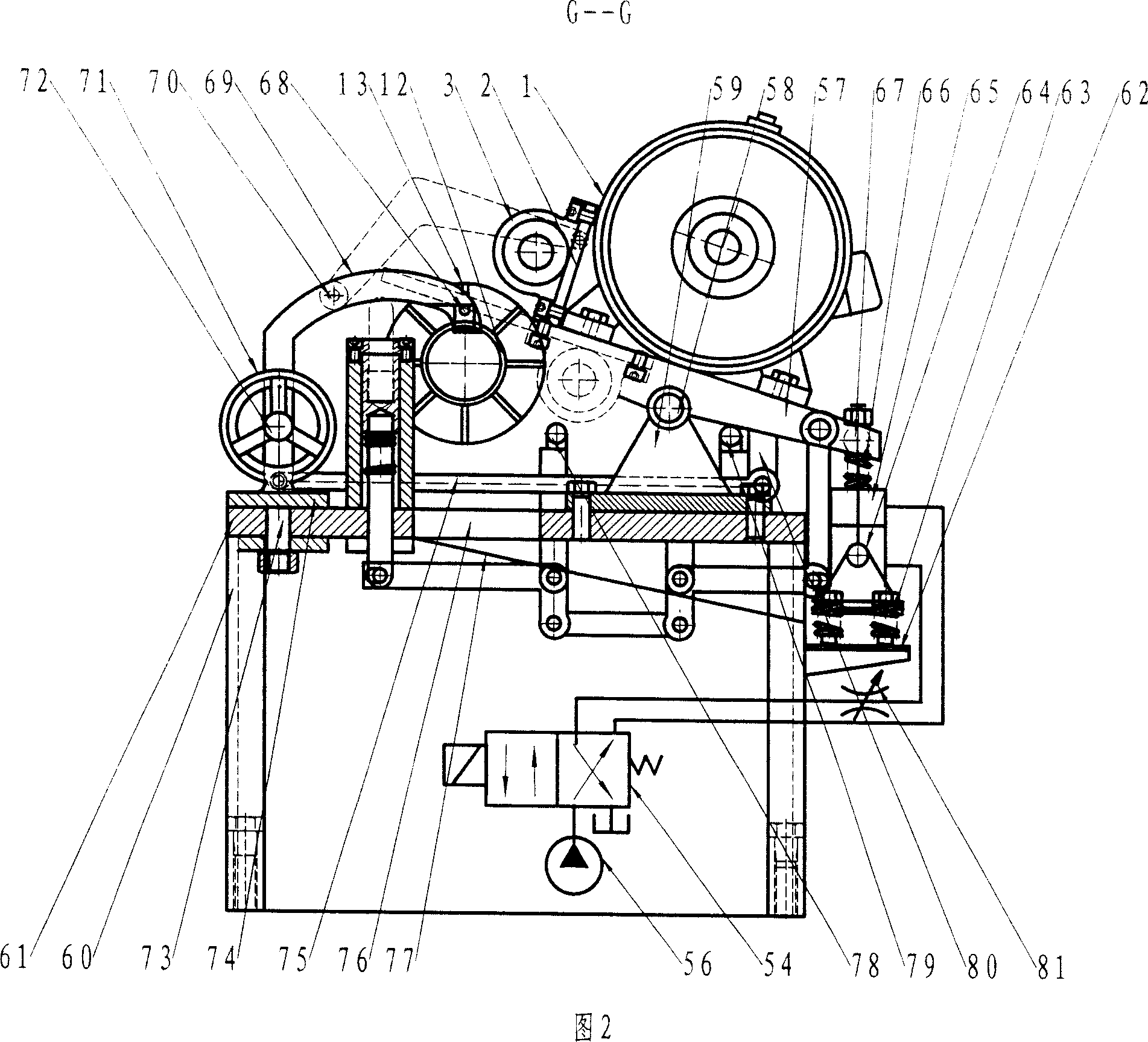

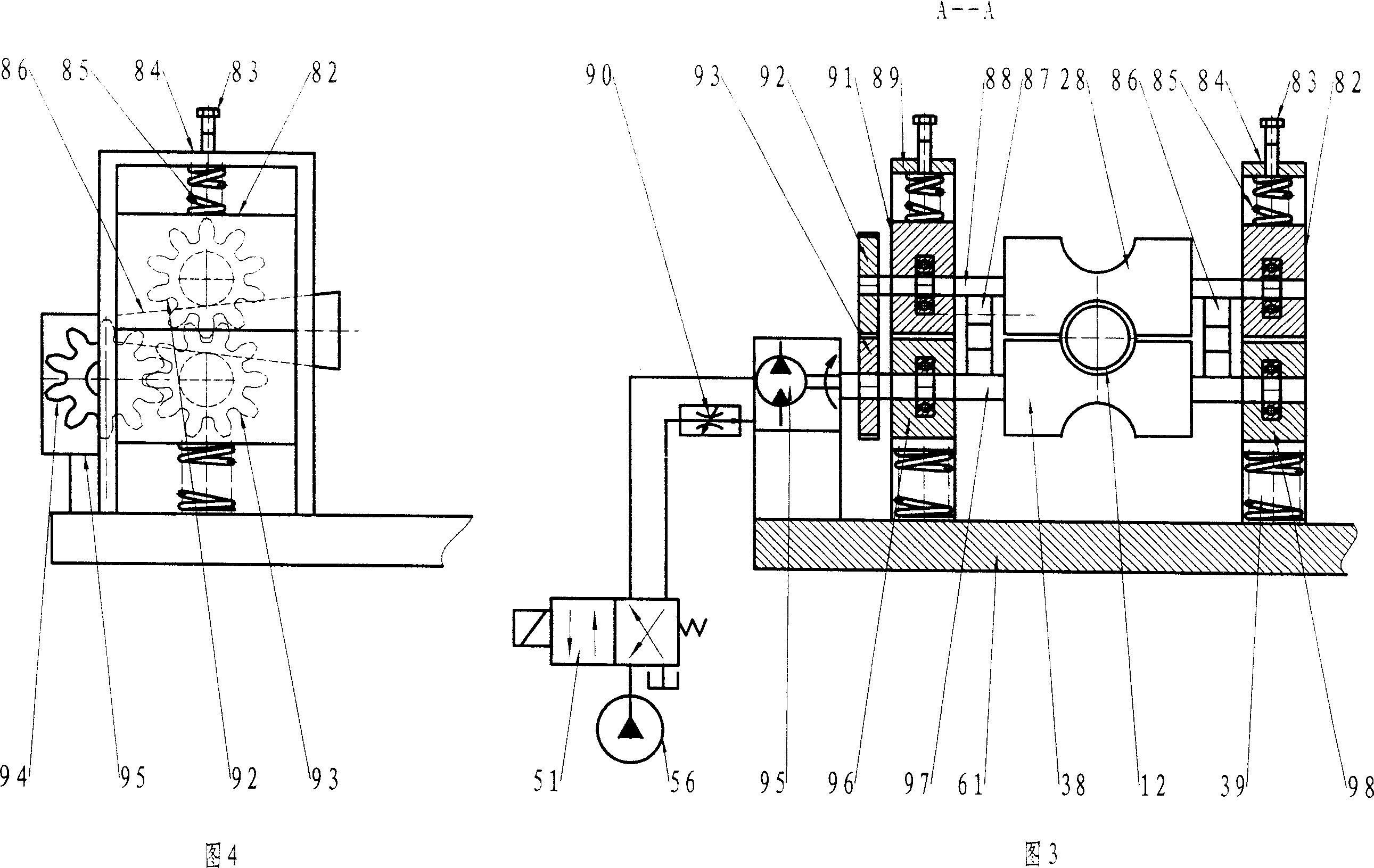

InactiveCN1951616AImprove verticalityImprove machining accuracyMetal-working feeding devicesOther manufacturing equipments/toolsSizingIndustrial engineering

The invention relates to a pipe cutter, which comprises: frame (60), work table (61), aerated or hydraulic device, connecting tube valve, cutting motor (1) axially mounted at one end of work table (61), and the cutter driven by said motor (1). Wherein, the work table (61) and frame (60) are mounted with a device for moving cutting motor (1) and cutter up and down, and a device for rotating the pipe (12) around its axle; the end of work table (61) far from the motor (1) has automatic pipe feeder; the work table (61) between cutter and pipe feeder is mounted with pipe guide support and pipe automatic clamper; one side of motor (1) has pipe (12) automatic sizing device under. The invention has high vertical degree between cutting surface and pipe axle, with high efficiency and low cost.

Owner:陈永真

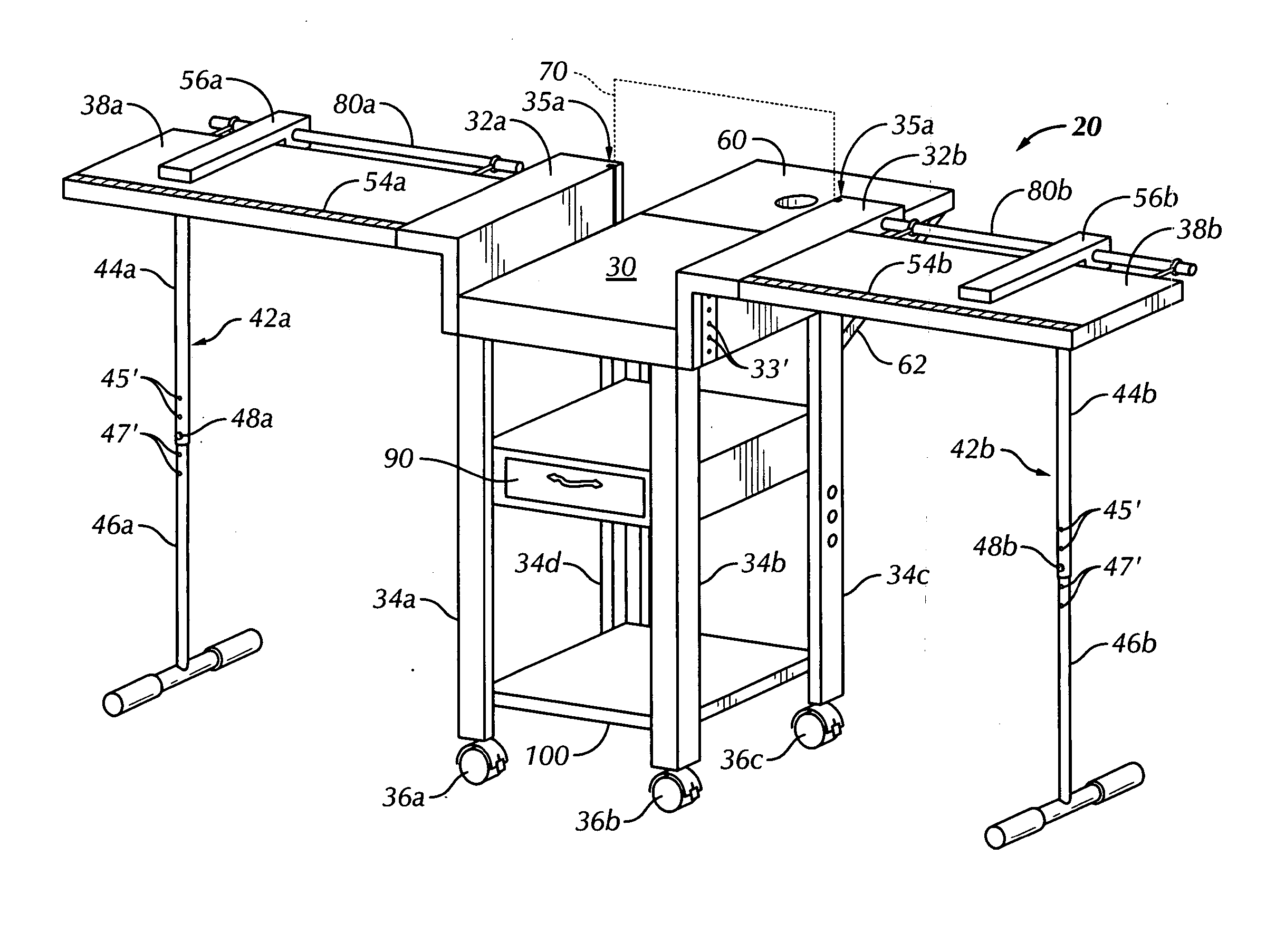

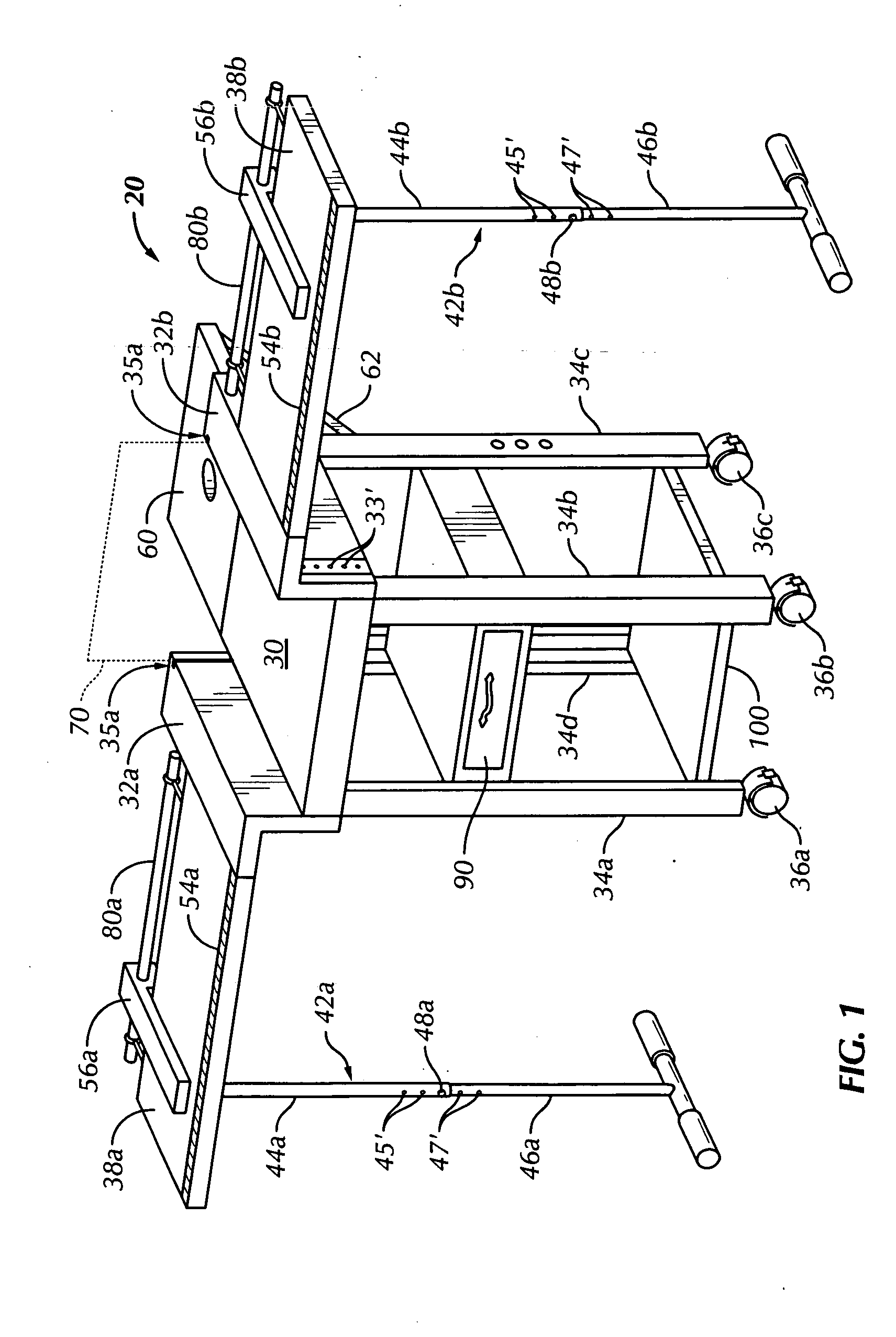

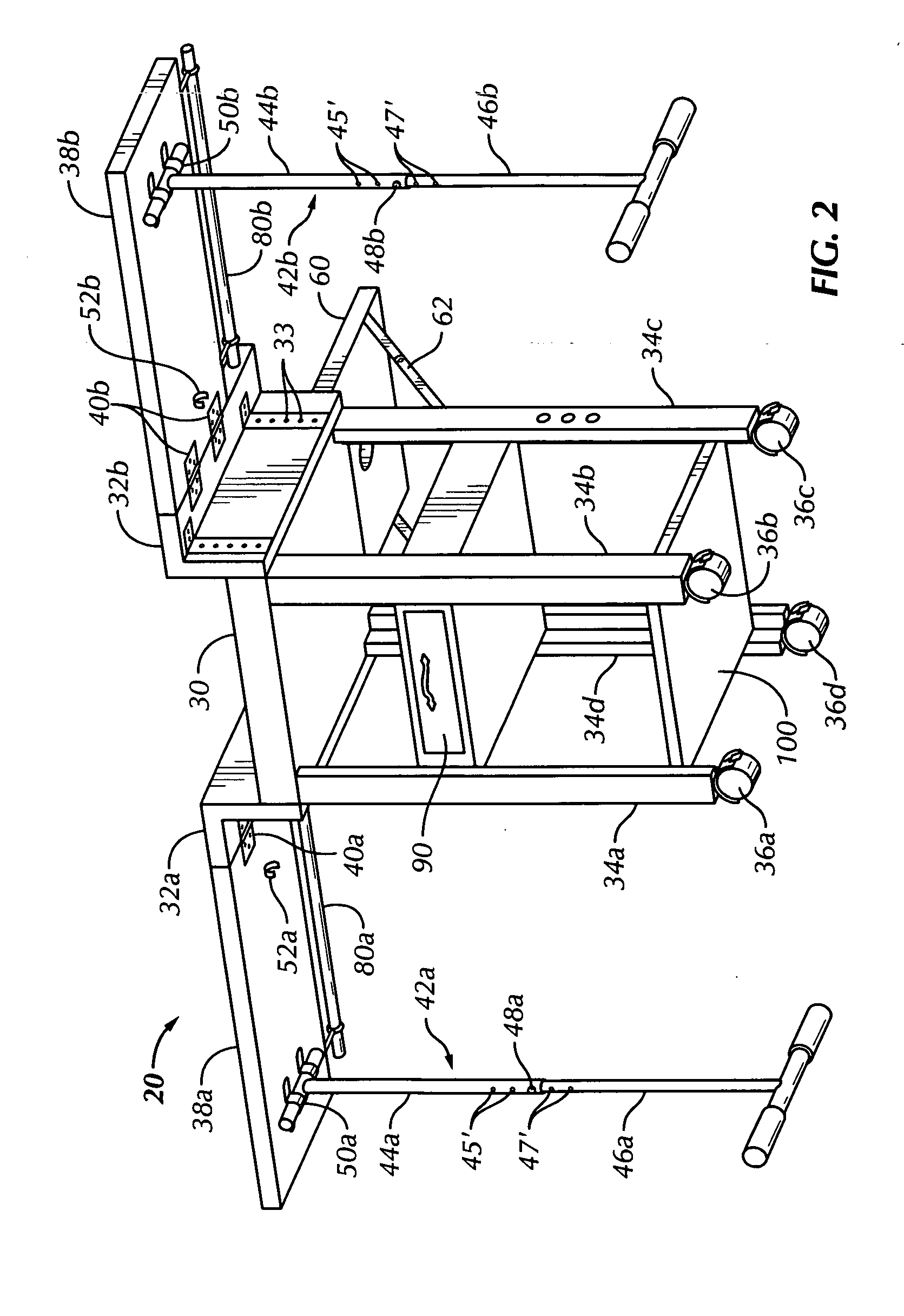

Portable, dual-station, expandable carpenter's work bench

A portable, expandable carpenter's workbench which has the capability of accommodating two separate saws simultaneously. The height of the workpiece supports of the primary table saw work area can be adjusted from flush with the table saw support plate to various heights above the table saw support plate. The workpiece supports each have collapsible workpiece extension wings which allow a means of supporting longer workpieces and can optionally house means for measuring and bracing the workpiece for accuracy in cutting.

Owner:LAIRD R WAYNE

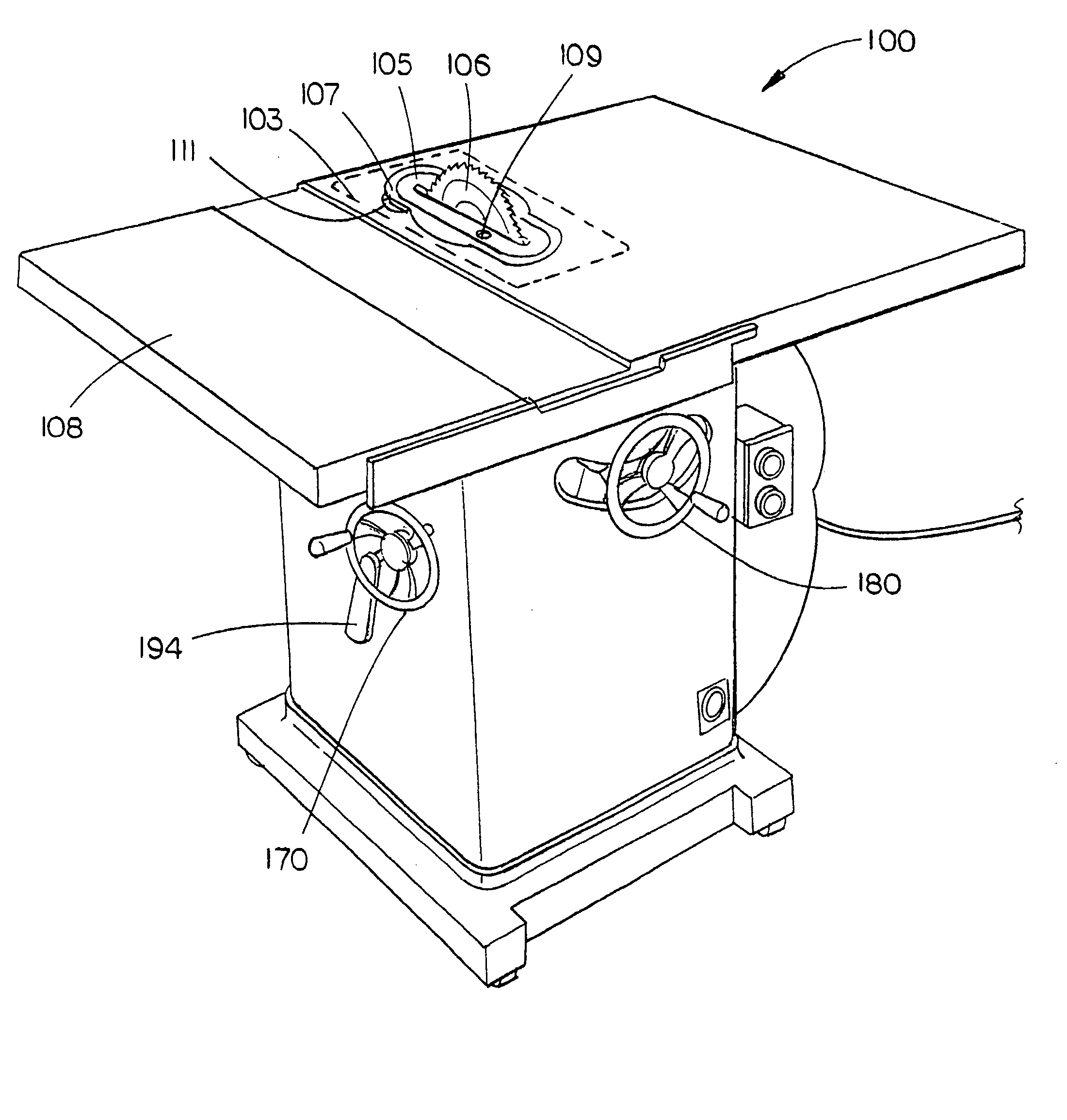

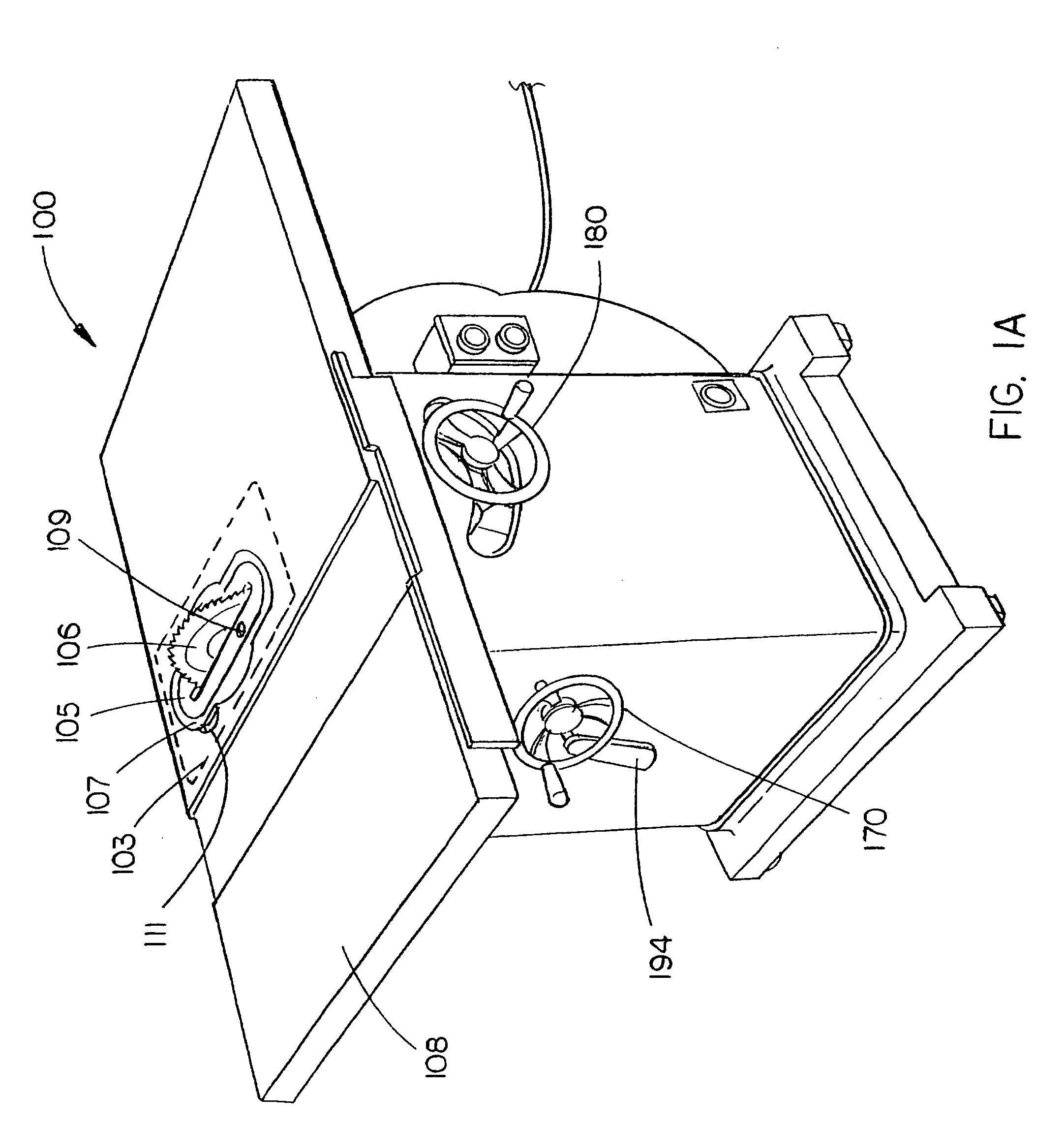

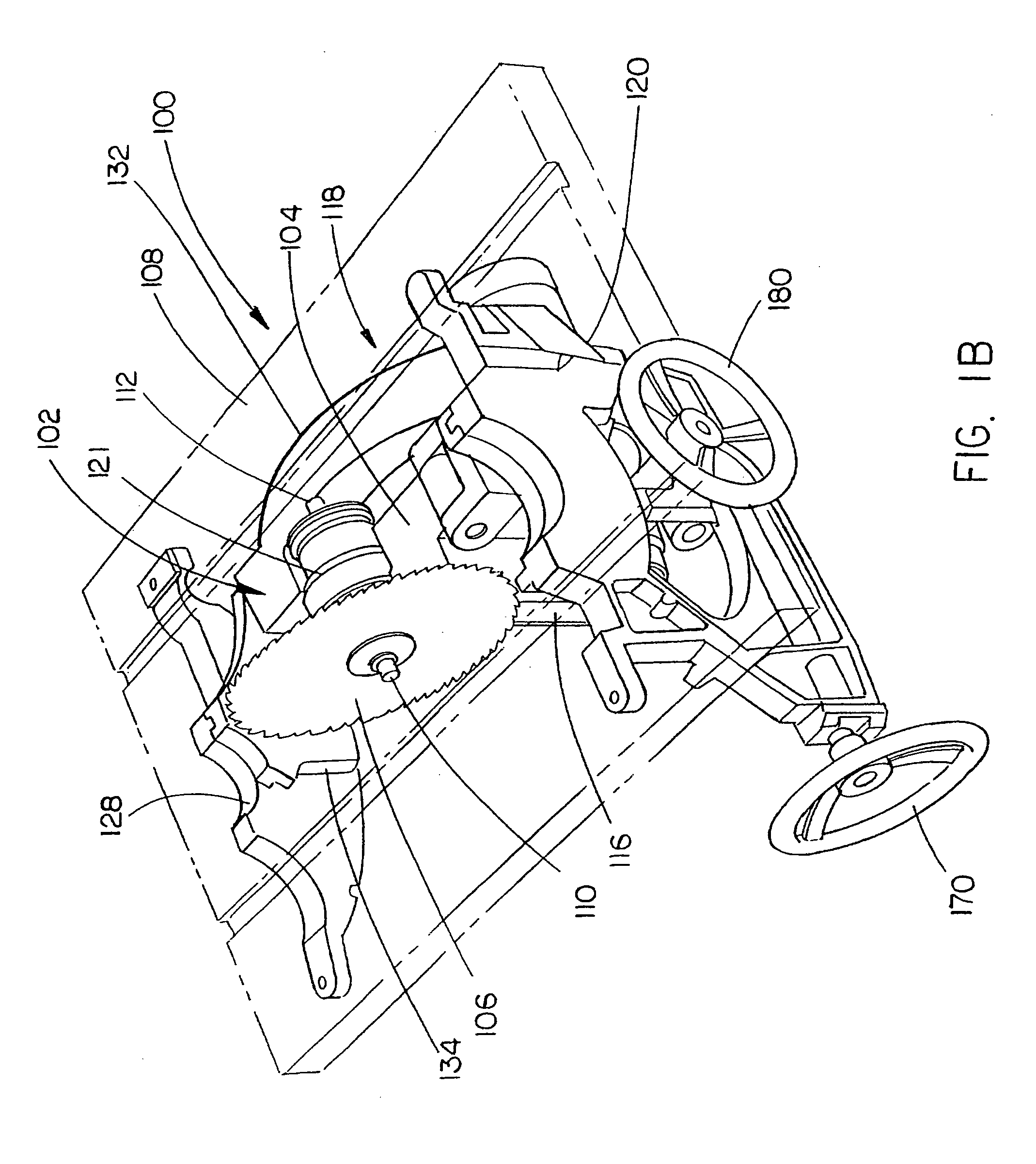

Dual bevel table saw

InactiveUS20050160895A1Efficient use ofMaximizing functional capabilityMetal sawing devicesShearing machinesEngineeringMechanical engineering

A dual bevel table saw provides a table saw enabled with a dual sided arbor assembly and a bi-directional bevel assembly. The dual sided arbor assembly coupled with the bevel assembly further provides for the positioning of a motor and a saw blade to allow for the full range of angular adjustment to be enabled without having to sacrifice any of the cutting features of the saw blade such as depth of cut. The dual bevel table saw may further include a companion saw assembly to provide increased functionality provided by the dual bevel table saw.

Owner:BLACK & DECKER INC

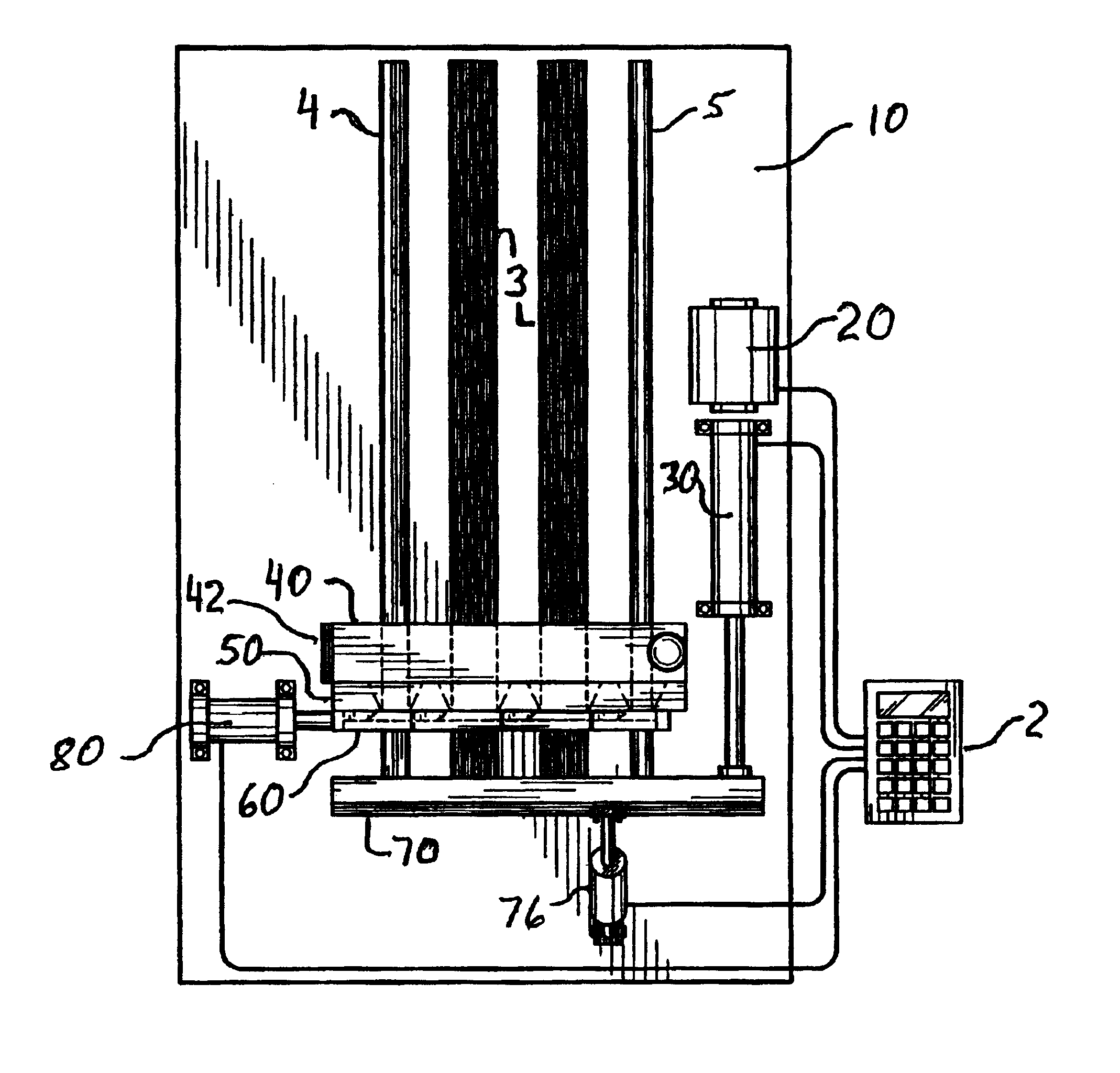

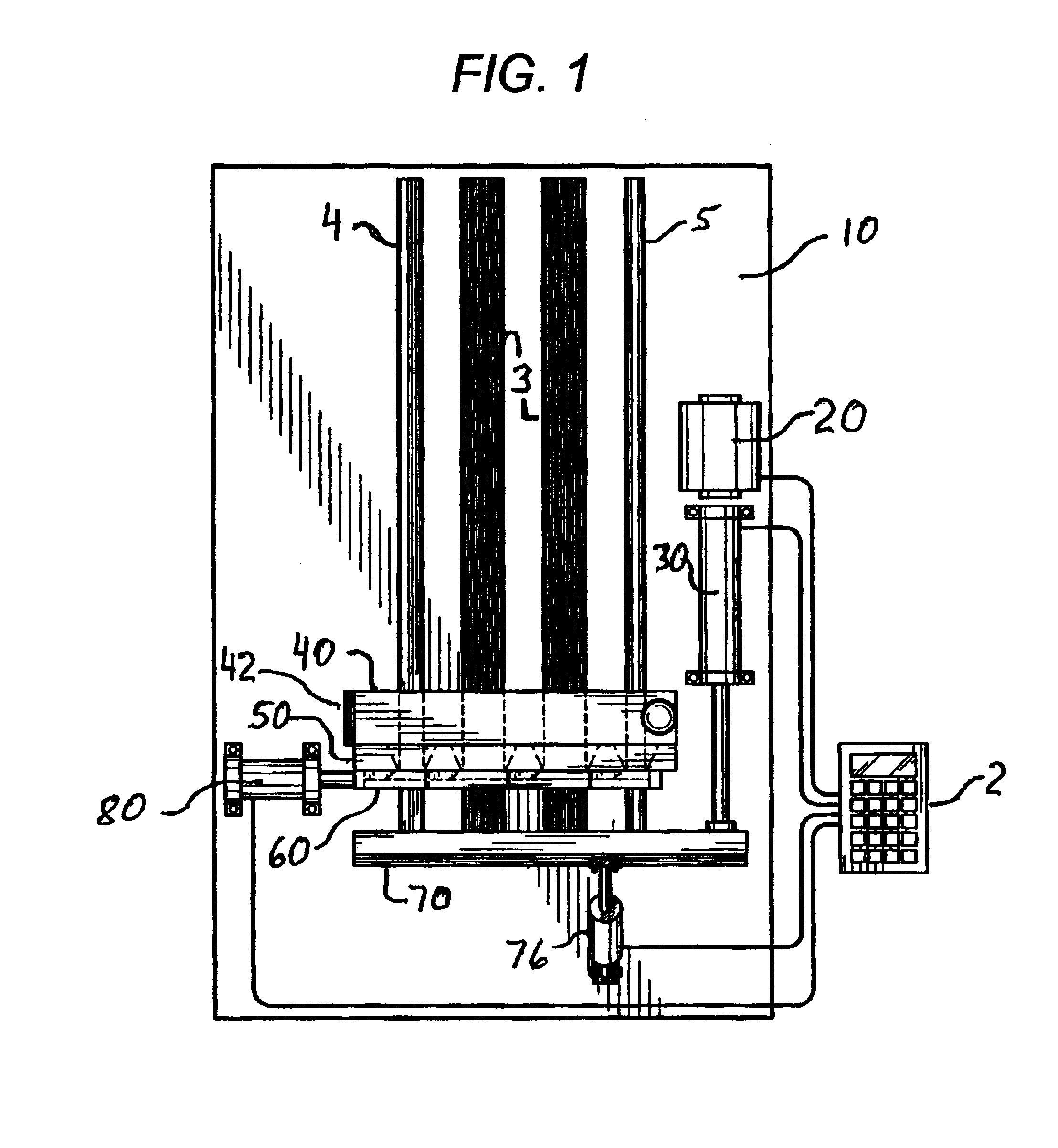

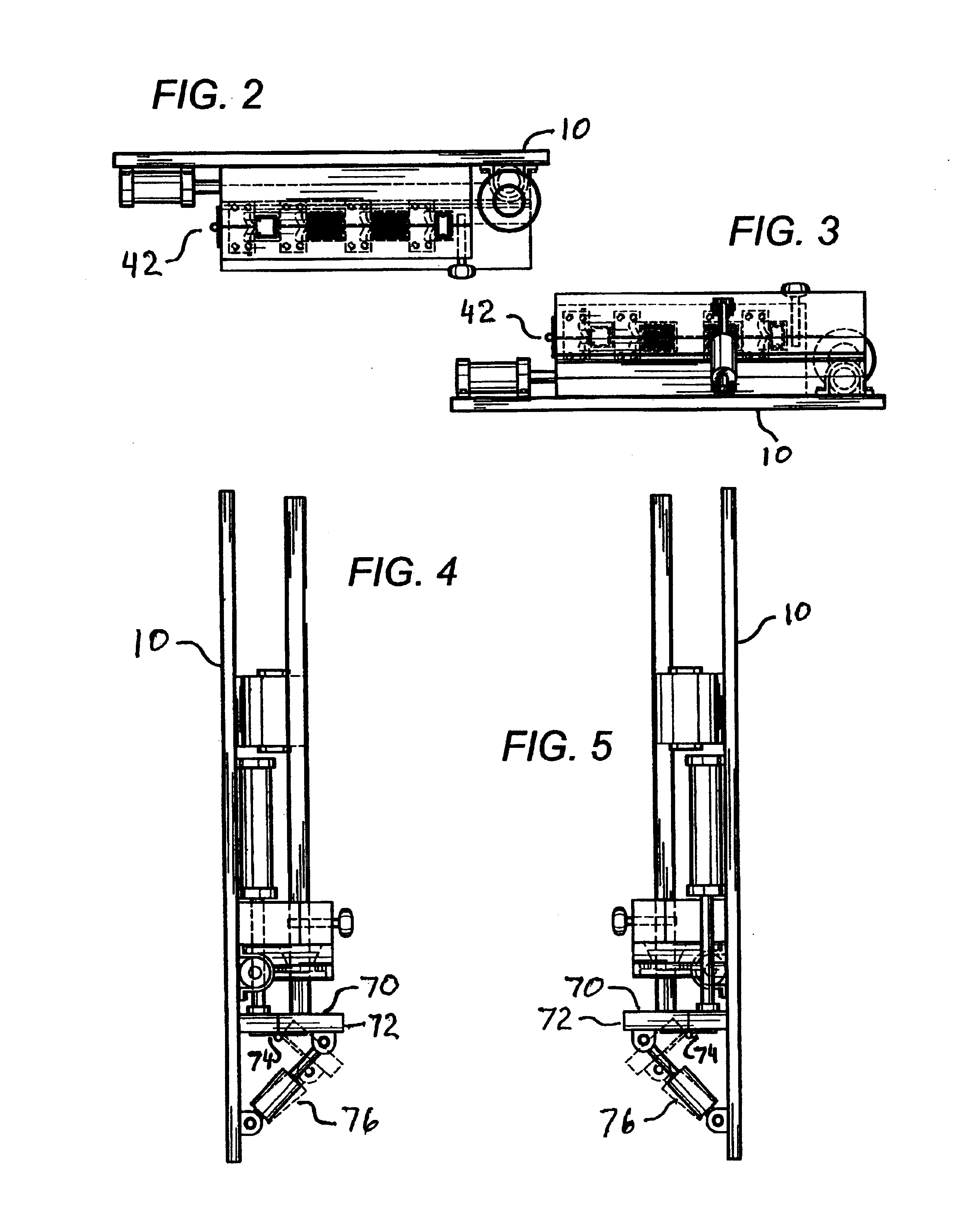

Automated blind cutting machine

InactiveUS6945152B2Reduce the amount requiredEasy to useLight protection screensStock shearing machinesElectrical controlEngineering

The present invention is a method and apparatus for automatically cutting a blind. The blind cutting apparatus comprises a framework, a die assembly, a cutting assembly, a clamp assembly, a blind support base, an integral measuring assembly, an electrical control assembly, and a displacement mechanism. The blind is cut to the exact dimensions by the operator who inputs the dimensions of the window and the size of the blind.

Owner:JABBARI ABBAS +1

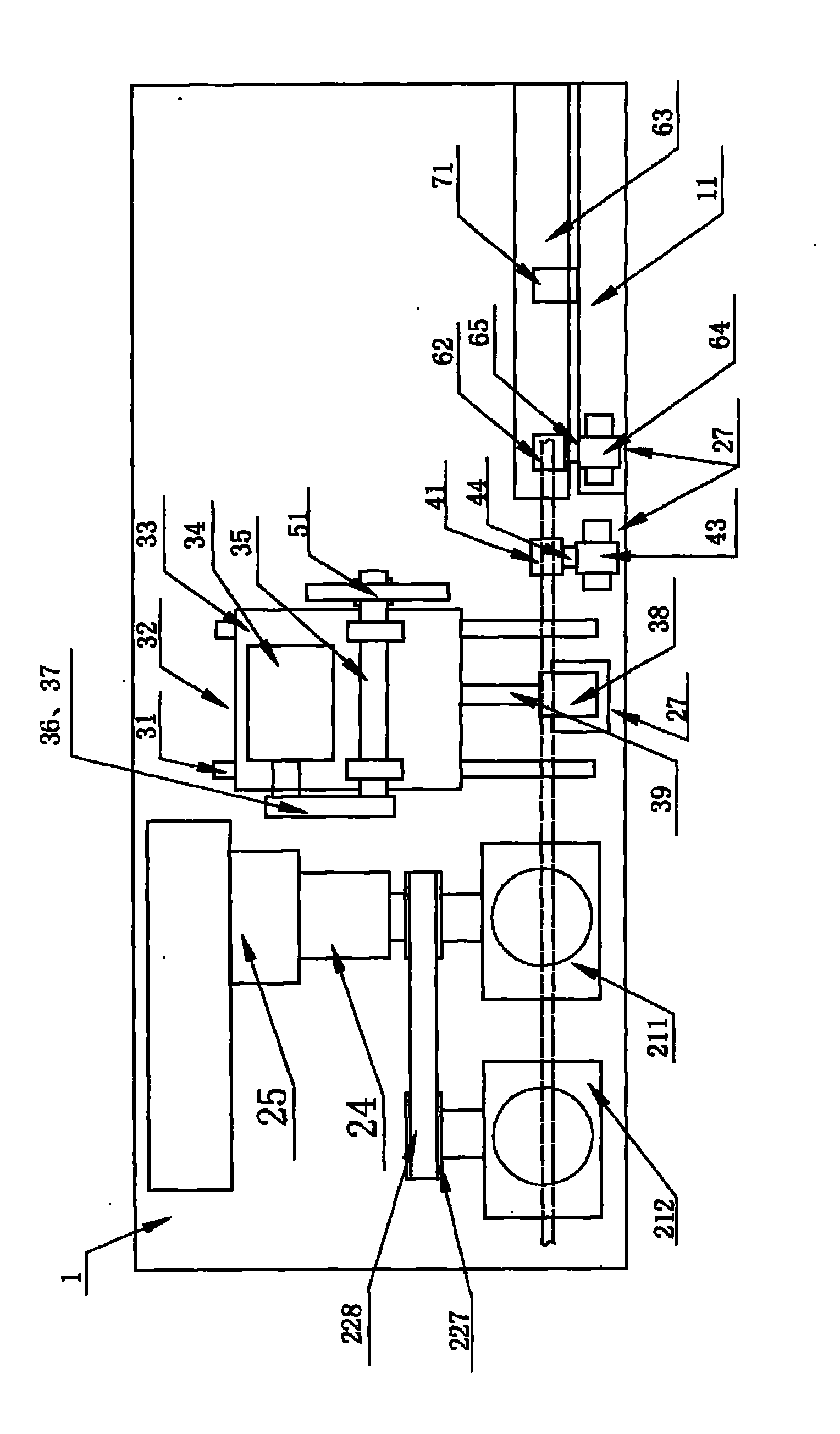

Fixed-length cutting device for tubes

ActiveCN105689788AEasy to cut to lengthImprove securityTube shearing machinesMetal working apparatusEngineeringMechanical engineering

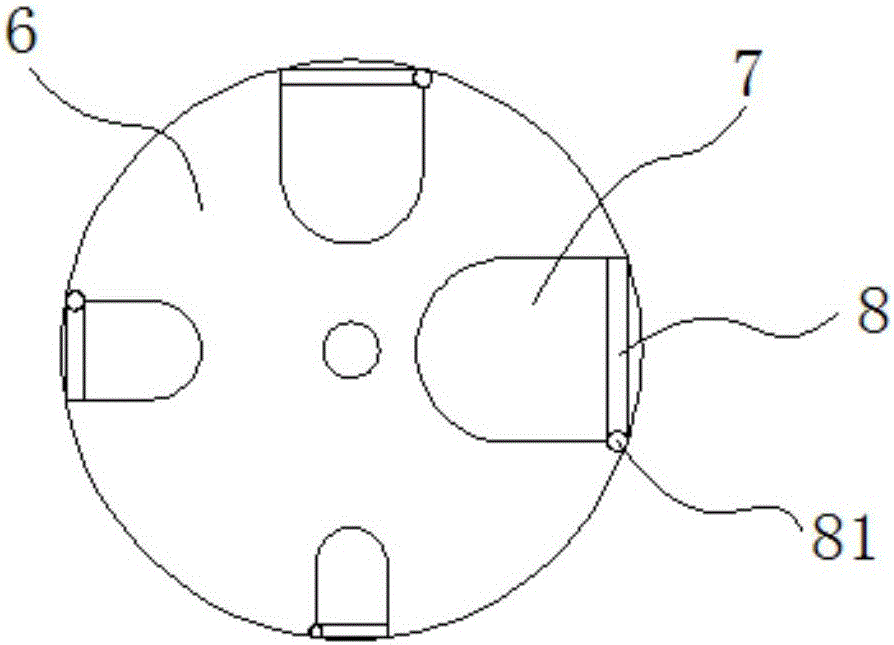

The invention discloses a fixed-length cutting device for tubes. The fixed-length cutting device comprises a cutting table, a cutting device, support elements, a location table, a support shaft, a location disc and baffles, wherein the cutting device is arranged at the front end of the cutting table; the plurality of support elements are arranged on the cutting table along the same straight line, wherein the support element at the forefront is located in front of the cutting device; the location table is arranged in front of the cutting table; the support shaft is erected on the location table in a manner of being capable of sliding forwards and backwards; the location disc is rotatably arranged at the rear end of the support shaft in a sleeving manner, a plurality of U-shaped grooves are arranged in the rear end surface of the location disc in a sinking manner along a peripheral direction, and the opening of each U-shaped groove penetrates through the sidewall of the location disc; one baffle is arranged at the opening of each U-shaped groove in a covering manner; and one end of each baffle is hinged at one side of the opening of the corresponding U-shaped groove through a pin shaft, and a torsional spring is arranged on each pin shaft in a sleeving manner. The fixed-length cutting device disclosed by the invention is capable of conveniently carrying out fixed-length cutting on the tubes, safe and efficient in cutting process, and low in cost.

Owner:海宁经开产业园区开发建设有限公司

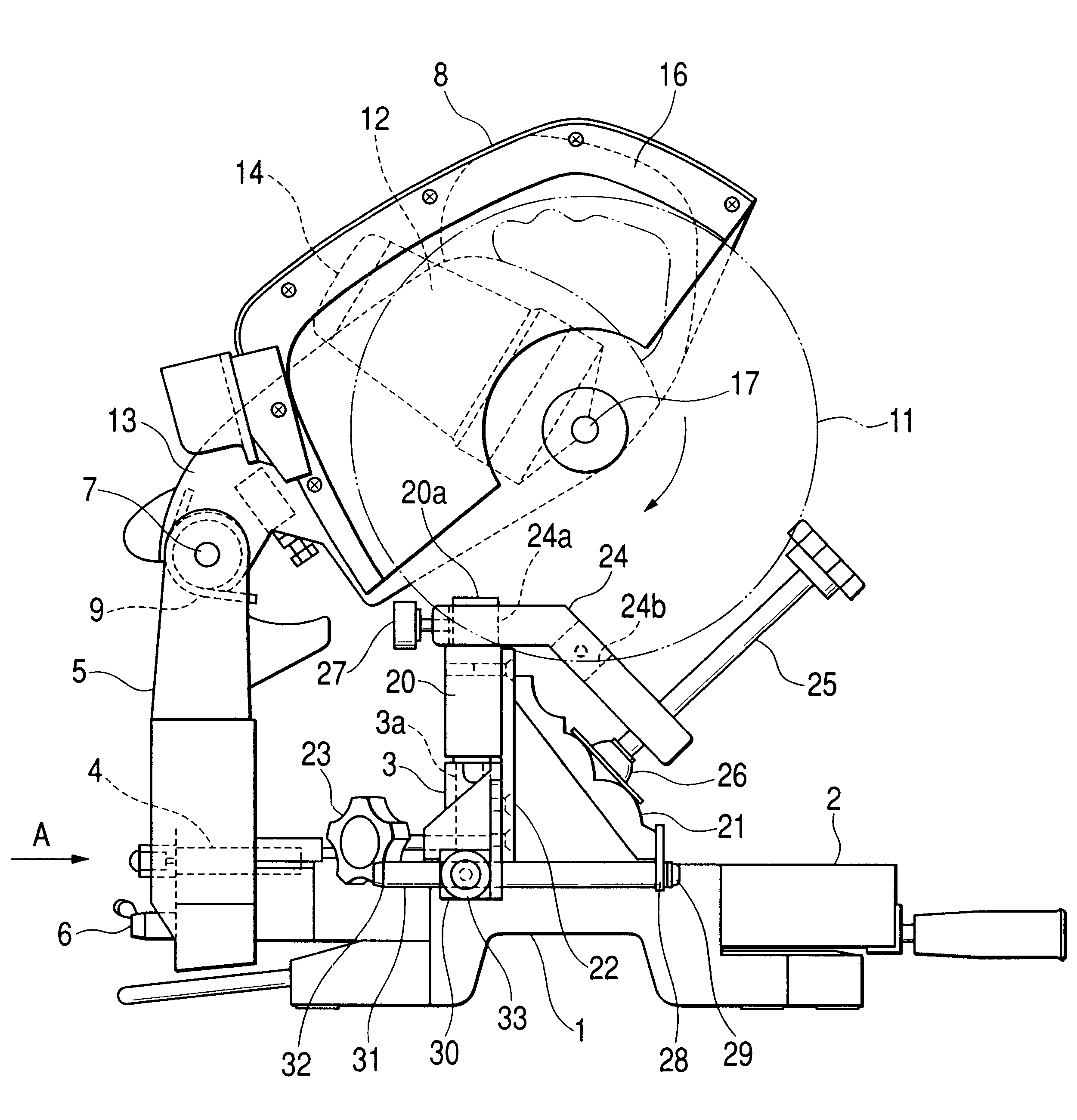

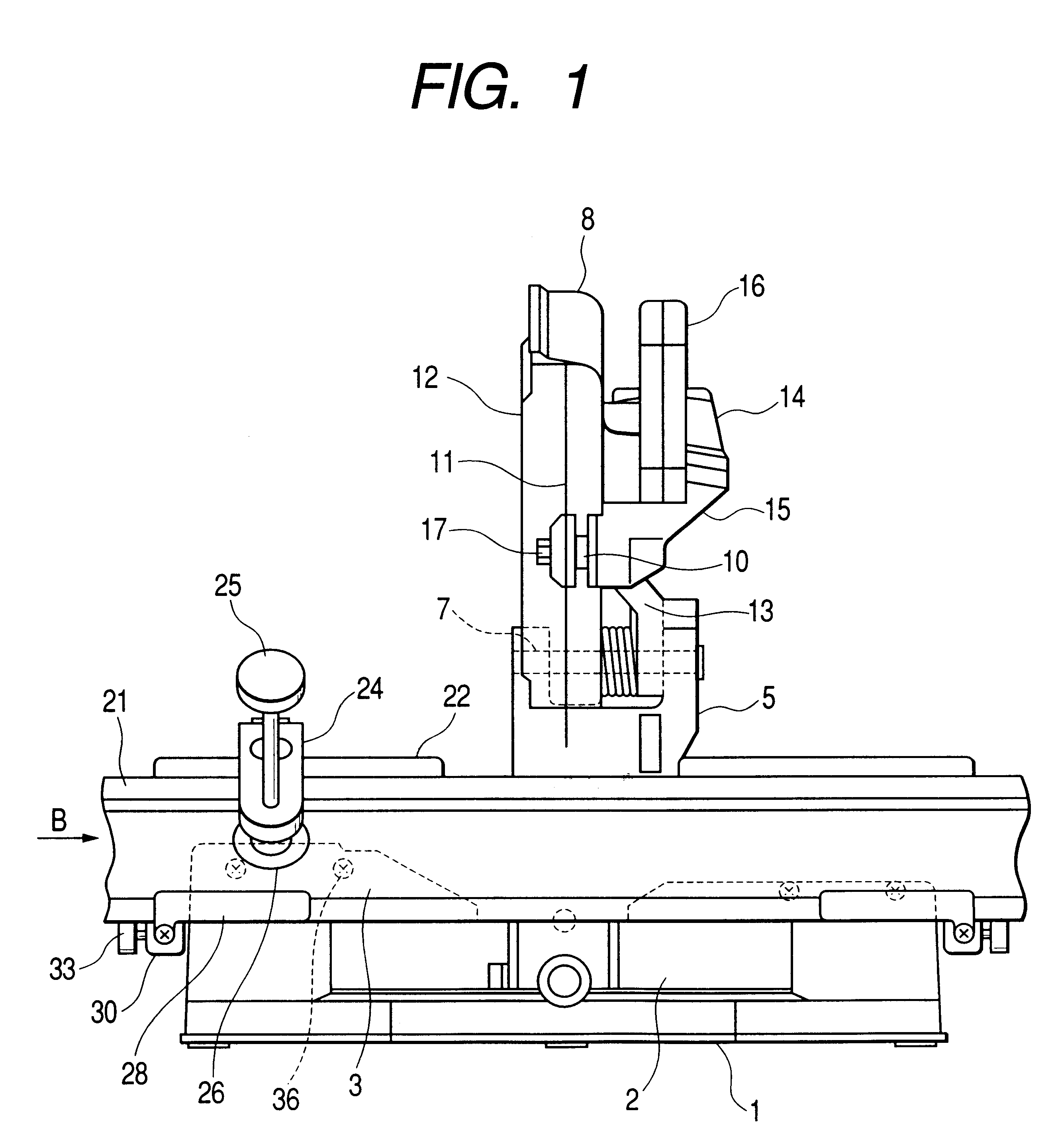

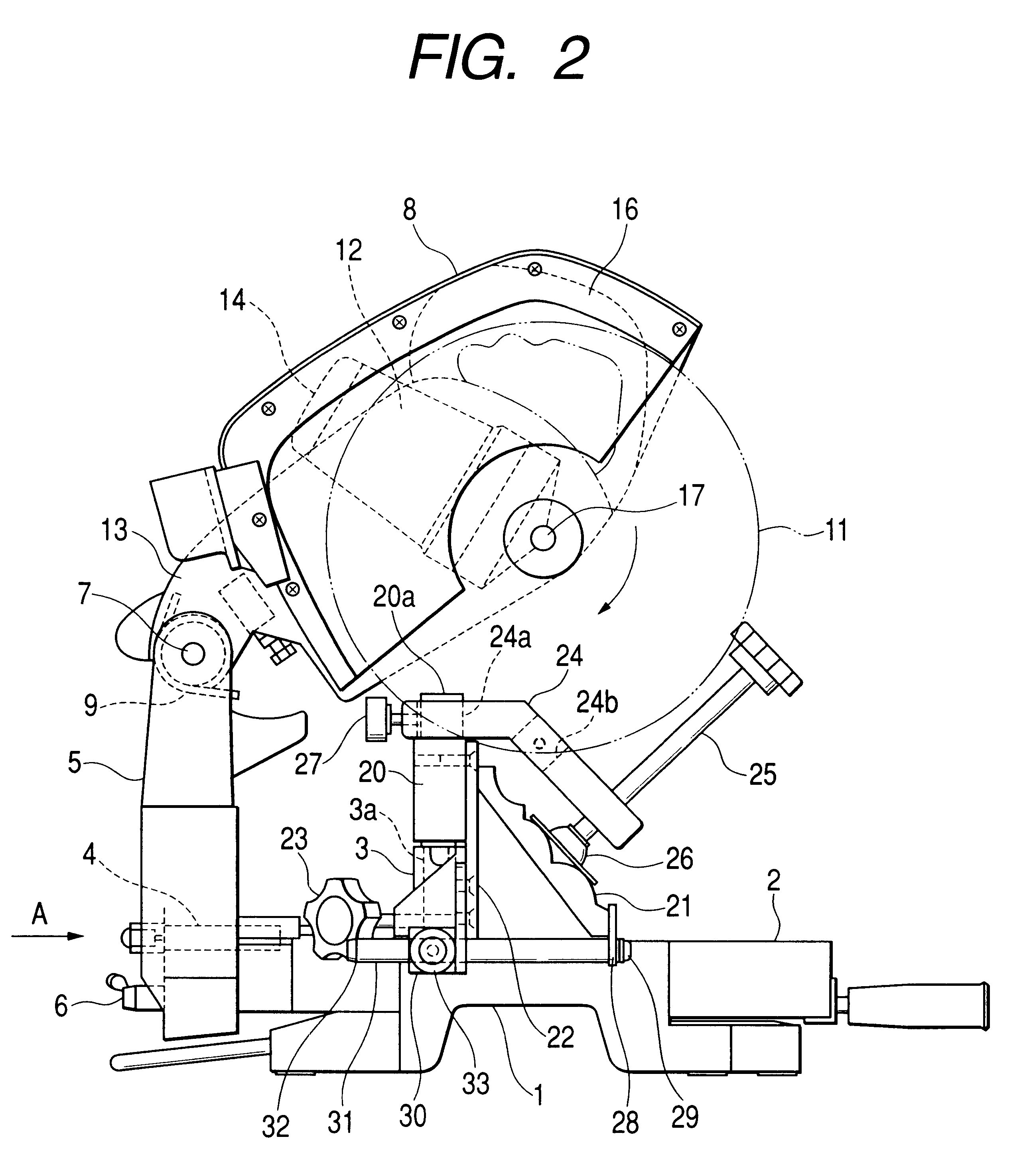

Vice device in compound miter saw

Owner:KOKI HLDG CO LTD

Adjustable equal-length automatic steel pipe cutting device

ActiveCN107570784AAdjust feed lengthAdjustable lengthTube shearing machinesShearing machine accessoriesTorsion springMotor shaft

The invention discloses an adjustable equal-length automatic steel pipe cutting device. A first rack on the upper side is rotationally connected with a first rotating shaft, and multiple elastic plates are evenly hinged to the positions, located at the first gear, of the side wall of the first rotating shaft through torsion springs. Inclined grooves matched with the elastic plates are evenly formed in the inner wall of the first rack of the upper side. A moving sliding rail is fixedly arranged on the top of a base through a support. The moving sliding rail is connected with a rack in a slidingmanner through a sliding block. The rack is located on the rear side of the first rack on the upper side and is engaged with the first rack on the upper side. The top of the base is further providedwith a speed reduction motor. A rotary disc is installed at the top of the speed reduction motor through a motor shaft. A bar-shaped hole is formed in the right side of the rotary disc. A sliding groove is further formed in the top of the right side of the rotary disc. A limiting block is connected to the sliding groove in a sliding manner, and a pin shaft is fixedly connected to the limiting block. By means of the adjustable equal-length automatic steel pipe cutting device, the first rack on the upper side only drives the first rotating shaft to rotate forwards, and therefore a steel pipe isdriven to be fed progressively; and due to the feeding length of the steel pipe, a plate can be covered, manual feeding control is not needed, and operation is convenient.

Owner:阪神机器(徐州)有限公司

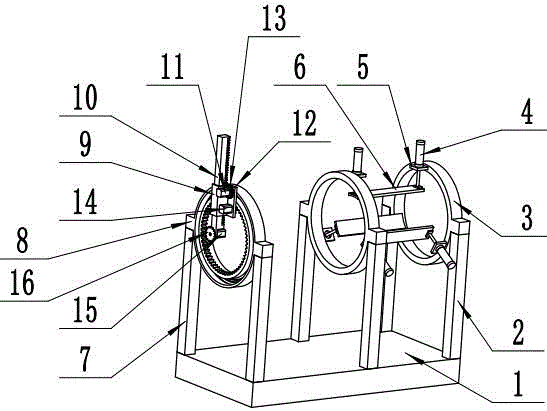

Outer-pipe circular cutting robot for steel pipe

ActiveCN106001735AImprove cutting efficiencyFast cutting speedTube shearing machinesShearing machine accessoriesGear wheelElectric machinery

The invention relates to an outer-pipe circular cutting robot for a steel pipe. The robot comprises a base, a steel pipe pressing plate, a circular cutting frame, an expansion link sleeve, an expansion link, an expansion link motor, a cutting mechanism fixing plate, a rotary motor, a cutting blade, an electric brush, an expansion link rack and an expansion link cutting motor fixing frame, wherein steel pipe frame stand columns of the expansion link motor fixing plate is fixedly arranged on the base, a steel pipe fixing sleeve is fixedly arranged on the steel pipe frame stand columns, the circular cutting frame is fixedly arranged on circular cutting frame stand columns, and the circular cutting frame stand columns are fixedly arranged on the base; the expansion link is arranged on the expansion link sleeve in a sliding way, the expansion link motor is fixedly arranged on the expansion link motor fixing plate, a stretching motor gear is fixedly arranged on an expansion link motor shaft, and the stretching motor gear is meshed with the expansion link rack; and the cutting motor is fixedly arranged on the expansion link cutting motor fixing frame, and the cutting blade is fixedly arranged on the cutting motor shaft. The robot can improve the steel pipe cutting efficiency, and is high in cutting speed, trim in notches and good in effect.

Owner:青岛昊坤机械制造有限公司

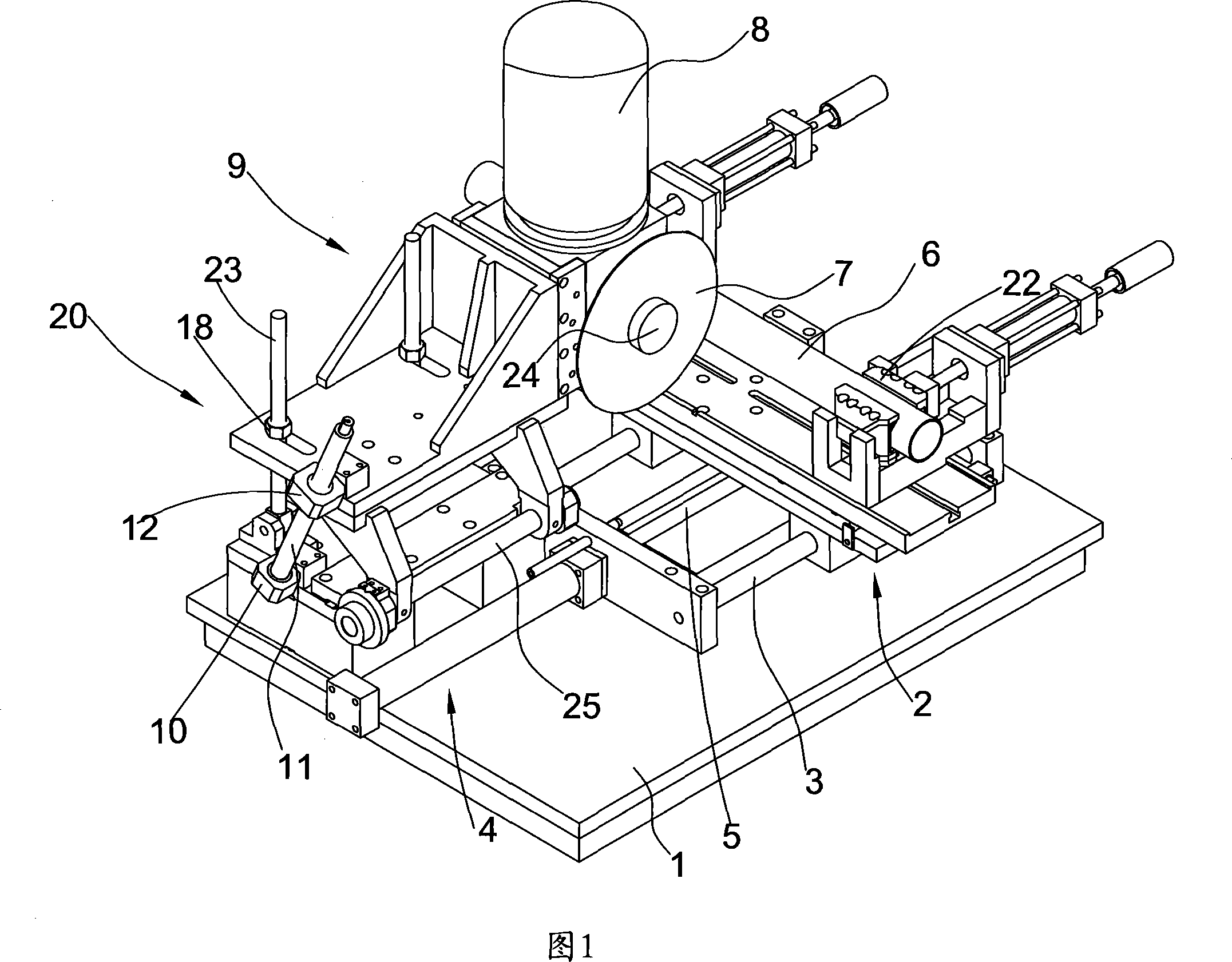

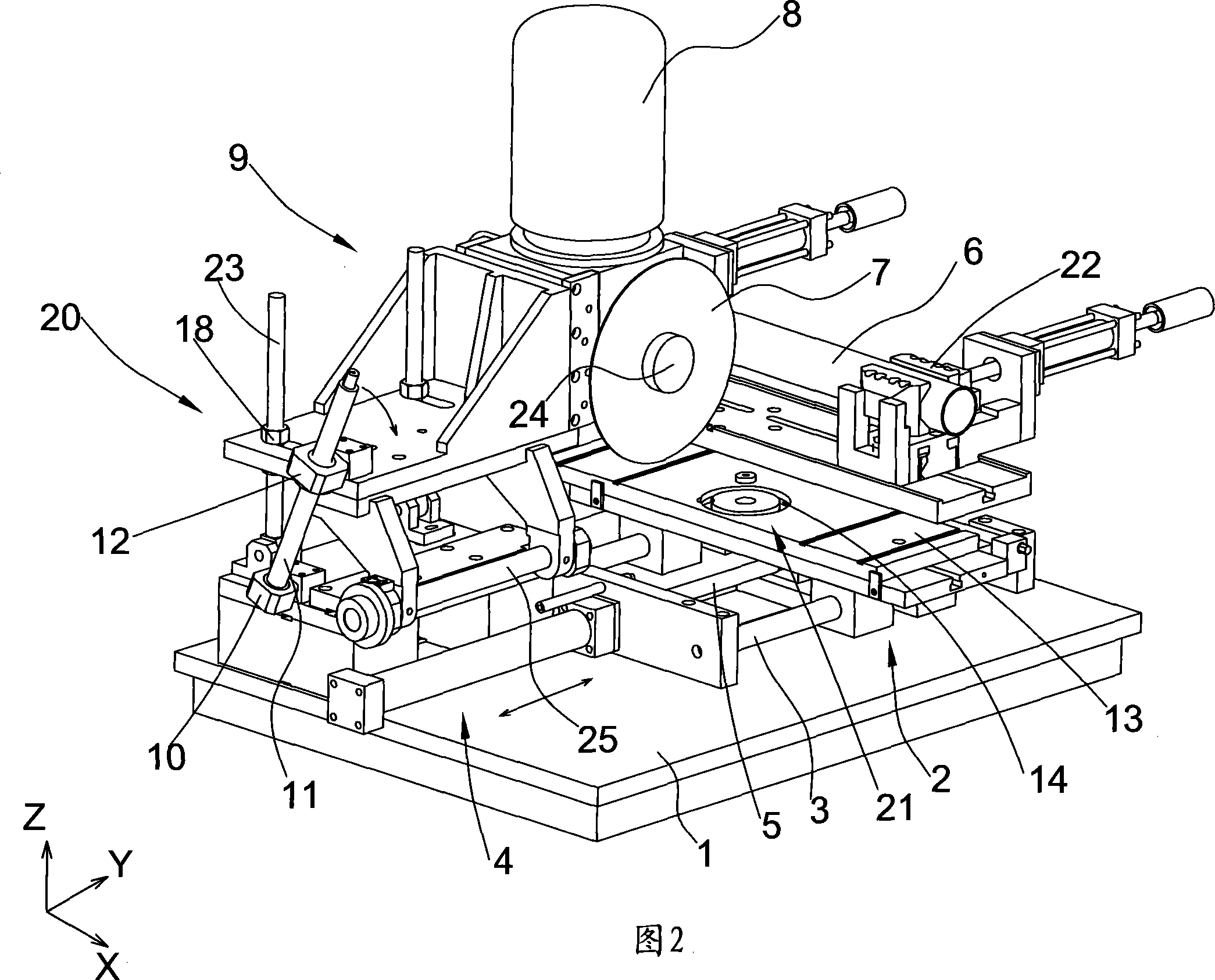

Three-dimensional pipe cutter

The invention is concerned with a kind of three-dimensional machine to cut pipe, relating to machine rack, holding equipment, fixing seat for drill. The drill connects with the fixing seat in moving, and the holding equipment sets on the machine rack in sliding. The drill connects on the first running axis extending to the axis of X and the machine rack has guiding rail extending along the level direction and the holding equipment set on this guiding rail in sliding. The machine rack has the second running axis extending along the axis of Y that being upright to axis of X and the drill seat connects with the second running axis in sliding. There is the first lock equipment between the drill fixing equipment and machine rack, and the holding equipment relates to the sliding seat connecting with guiding rail and worktable on the sliding seat moving around the axis of Z, and the sliding seat and worktable can match and slide with each other and there is the second lock equipment between the sliding seat and worktable. The three-dimensional relationship between the drill and pipe piece to cut the pipe piece from multi-angle, and the adjustment is easy to cut the strange shape of pipe piece or cut for many times.

Owner:庄添财

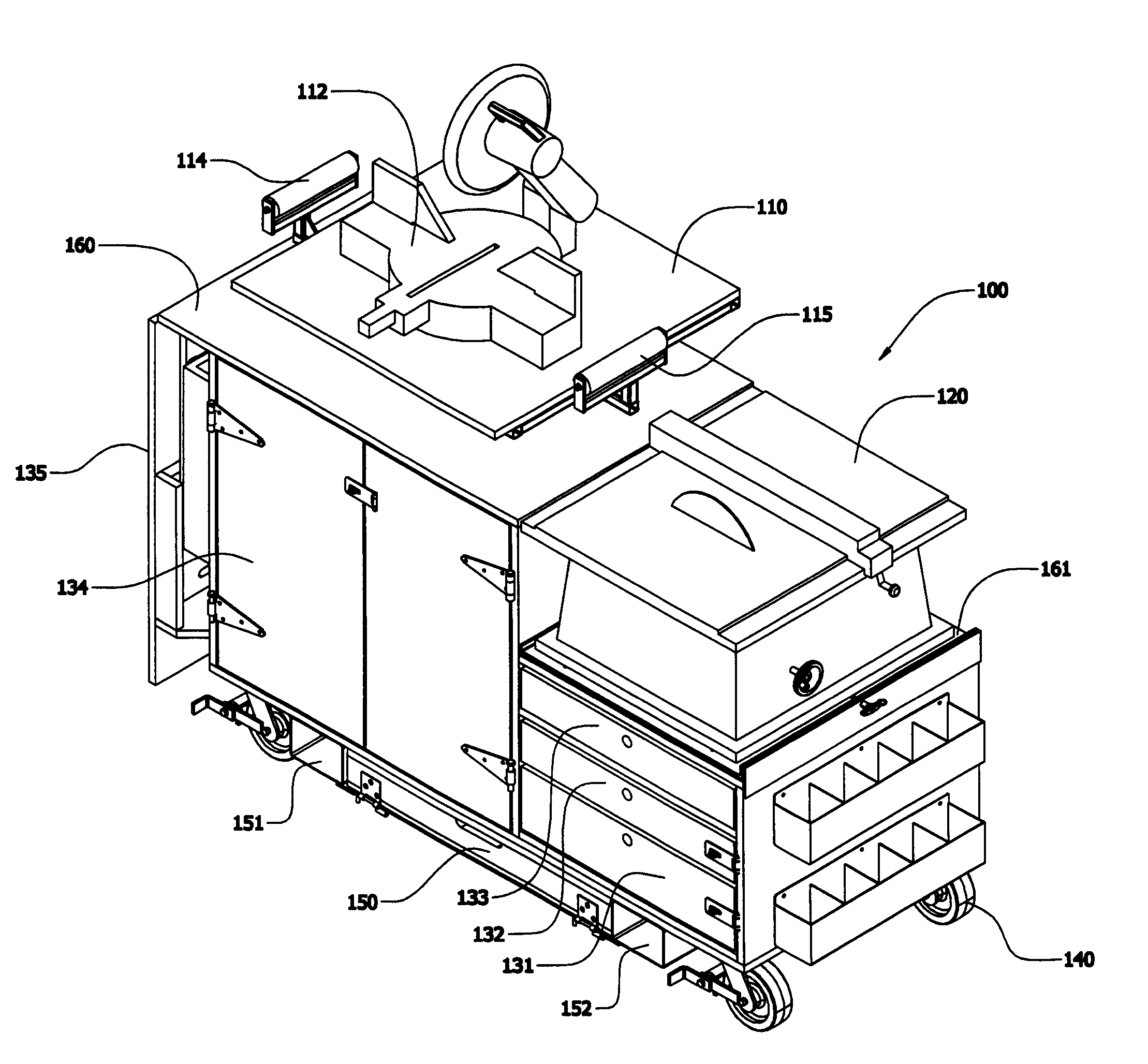

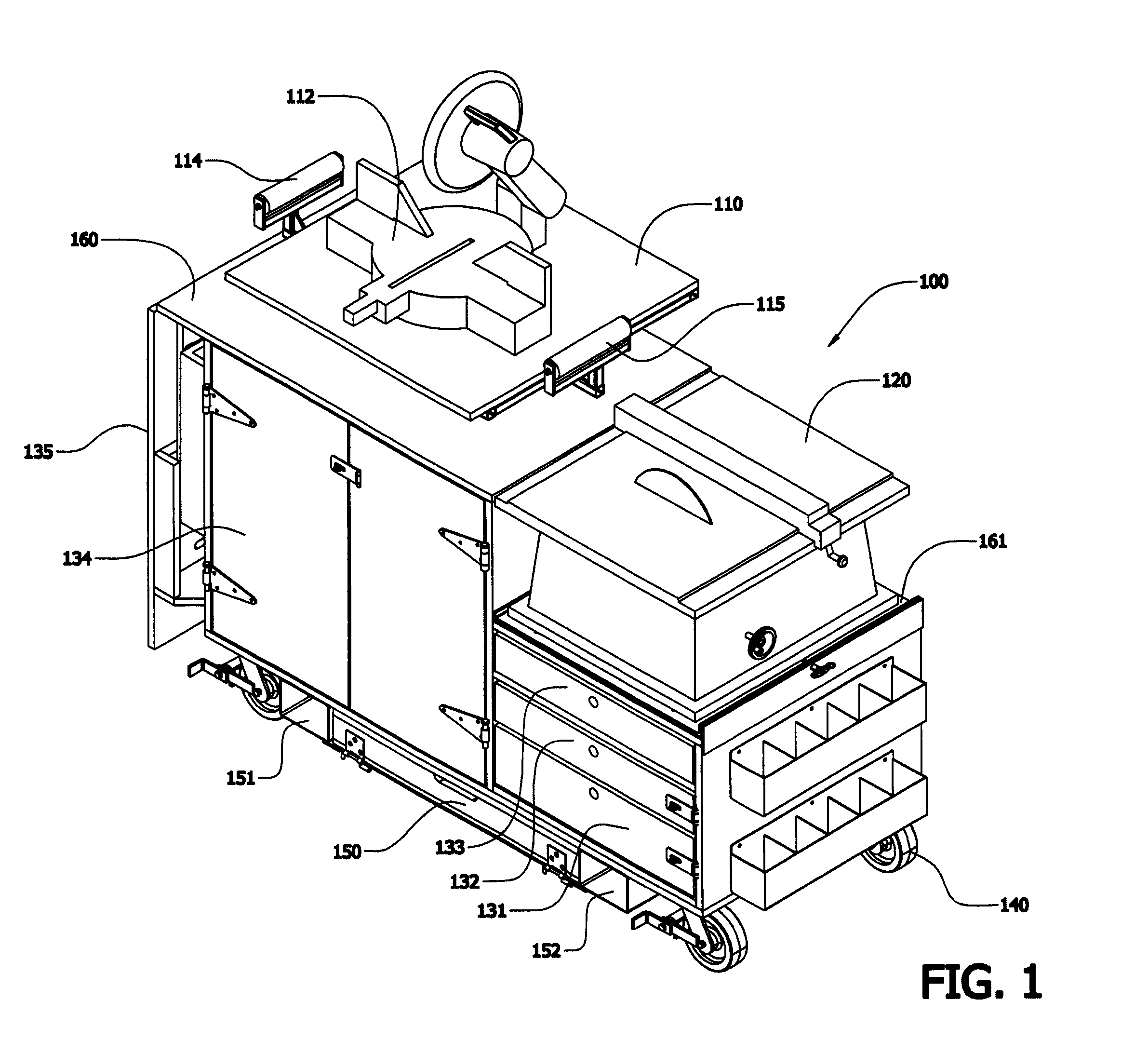

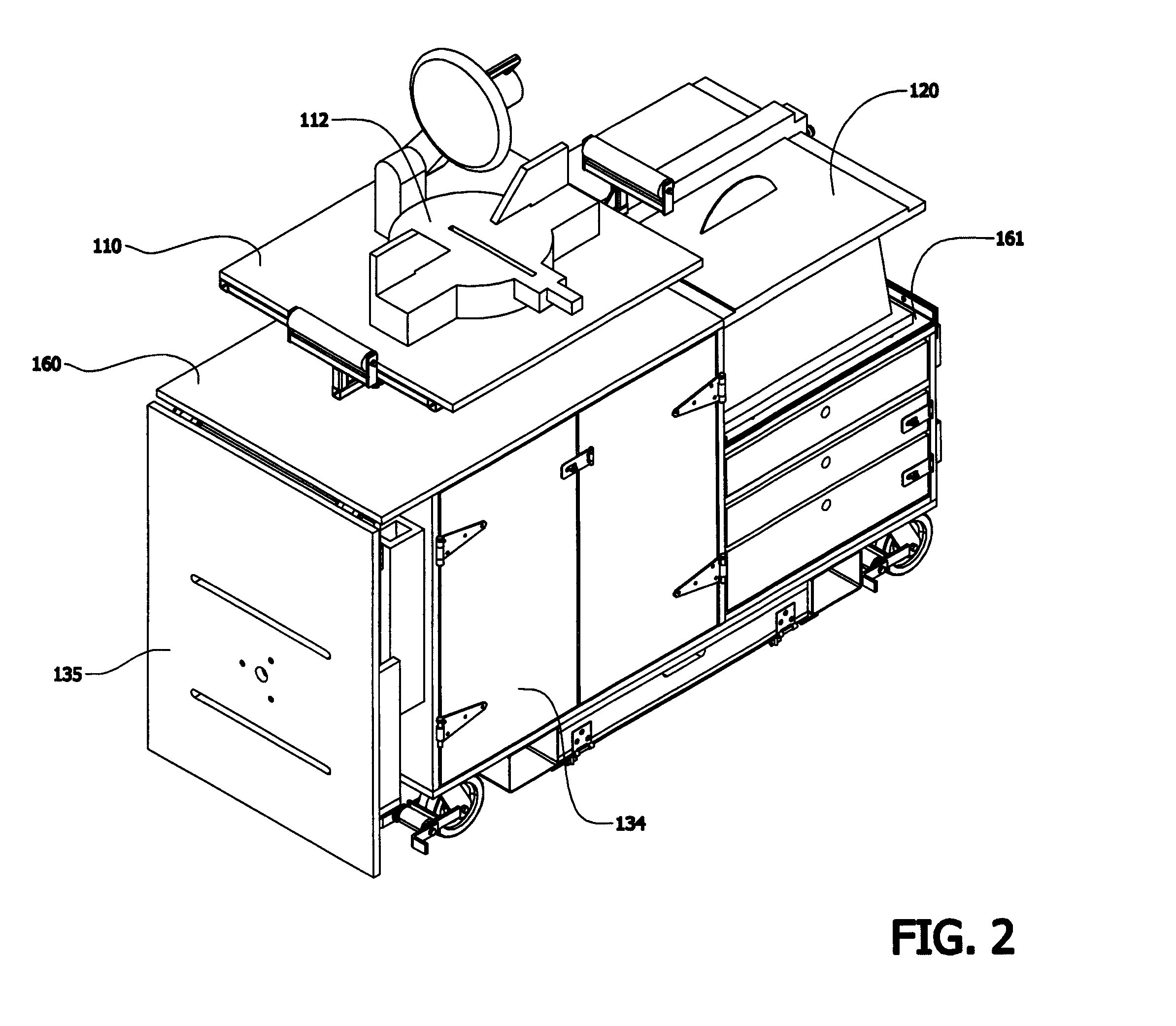

Portable carpentry workshop

InactiveUS7647956B1Easy to transportImprove mobilityGuide fencesShearing machinesEngineeringPower tool

A portable rolling carpentry workshop includes a table saw mounted on a sliding means to allow the blade of the saw to be shifted to the left or to the right of the longitudinal centerline of the workshop so that more supporting surface is available on either side of the blade to allow cutting large workpieces on a relatively narrow tabletop surface. The workshop of the invention is sized to allow easy maneuvering through the narrow hallways of apartment buildings but affords the functionality of larger worktables due to this unique ability to slide the table saw. Also provided is an extendable miter saw table located above the main tabletop surface and allowing passing of the longer workpieces underneath thereof when ripping with table saw. Therefore the use of both the table saw and the miter saw can be accomplished at the same time without the need to rearrange the configuration of the power tools on the workshop.

Owner:CONA FRED MR

Full automatic aluminium section bar cutter device

InactiveCN101352770AImprove accuracyReduce randomnessMetal sawing devicesMetal-working feeding devicesAssurance qualityEngineering

The invention discloses a full-automatic aluminum cutting device which aims at solving the problem of low manual feeding efficiency of the existing aluminum cutting device and provides a safe and convenient full-automatic aluminum cutting device which can ensure the quality. The device of the invention includes: a feed device, a bracket and a cutting saw arranged on the bracket; the feed device includes an upper clamping part, a lower clamping part, a horizontal feed part and a locating part. The device fully uses machines to replace manual operation, thus not only enhancing the accuracy, increasing the efficiency, reducing the cost, but also saving the human labor and materials as well as enhancing the safety performance.

Owner:TIANJIN SANTROLL ELECTRIC SCI & TECH

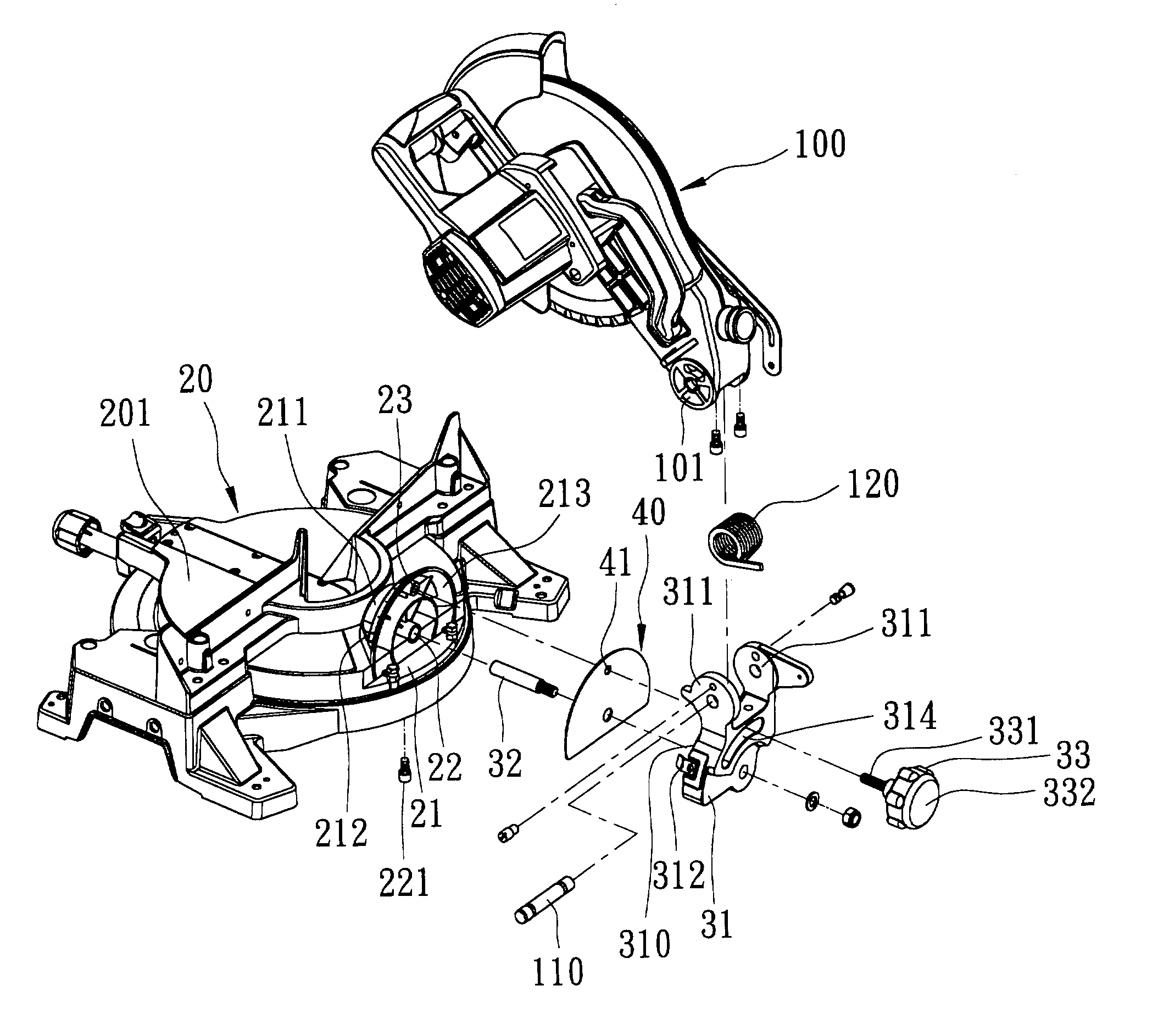

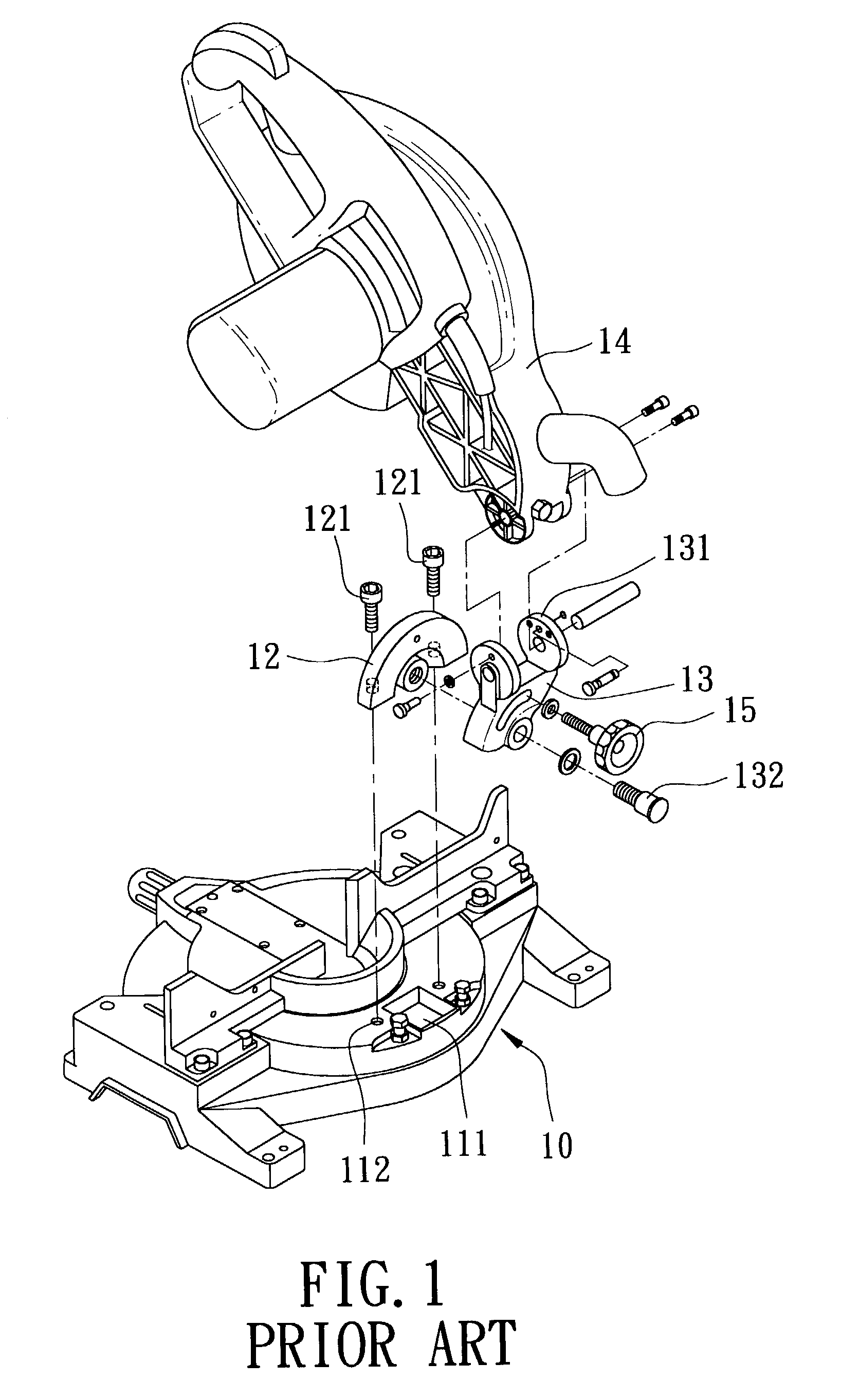

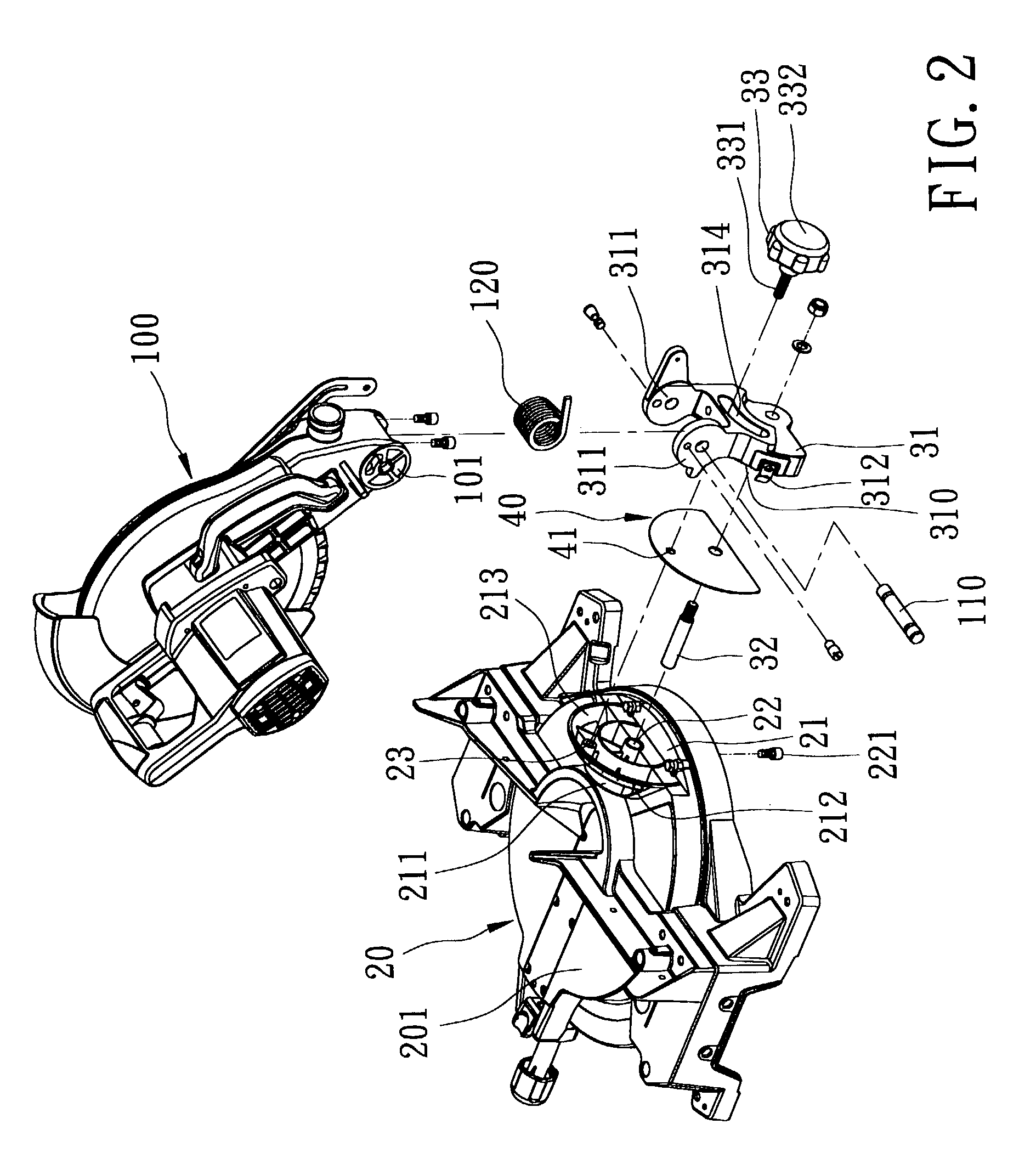

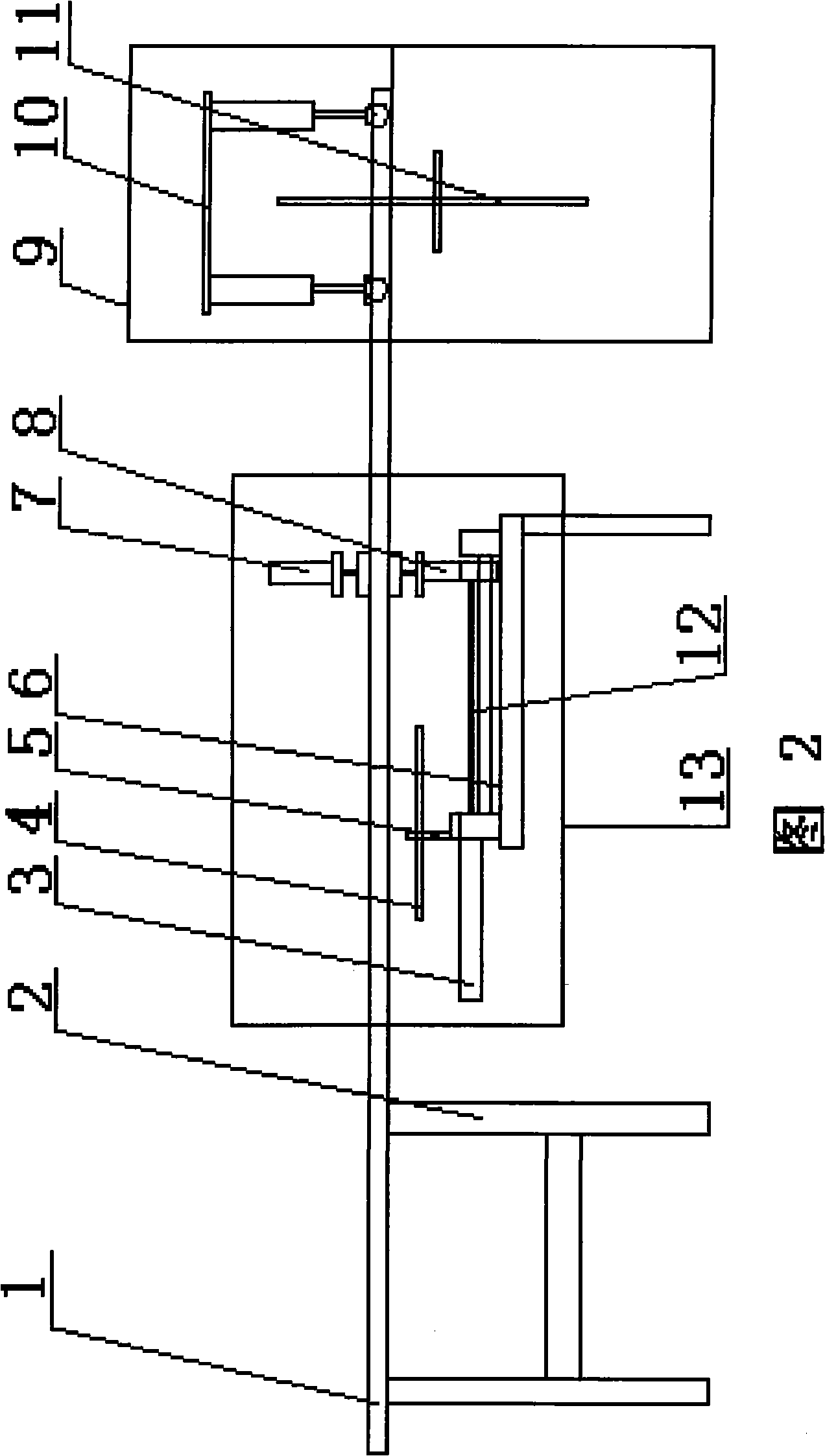

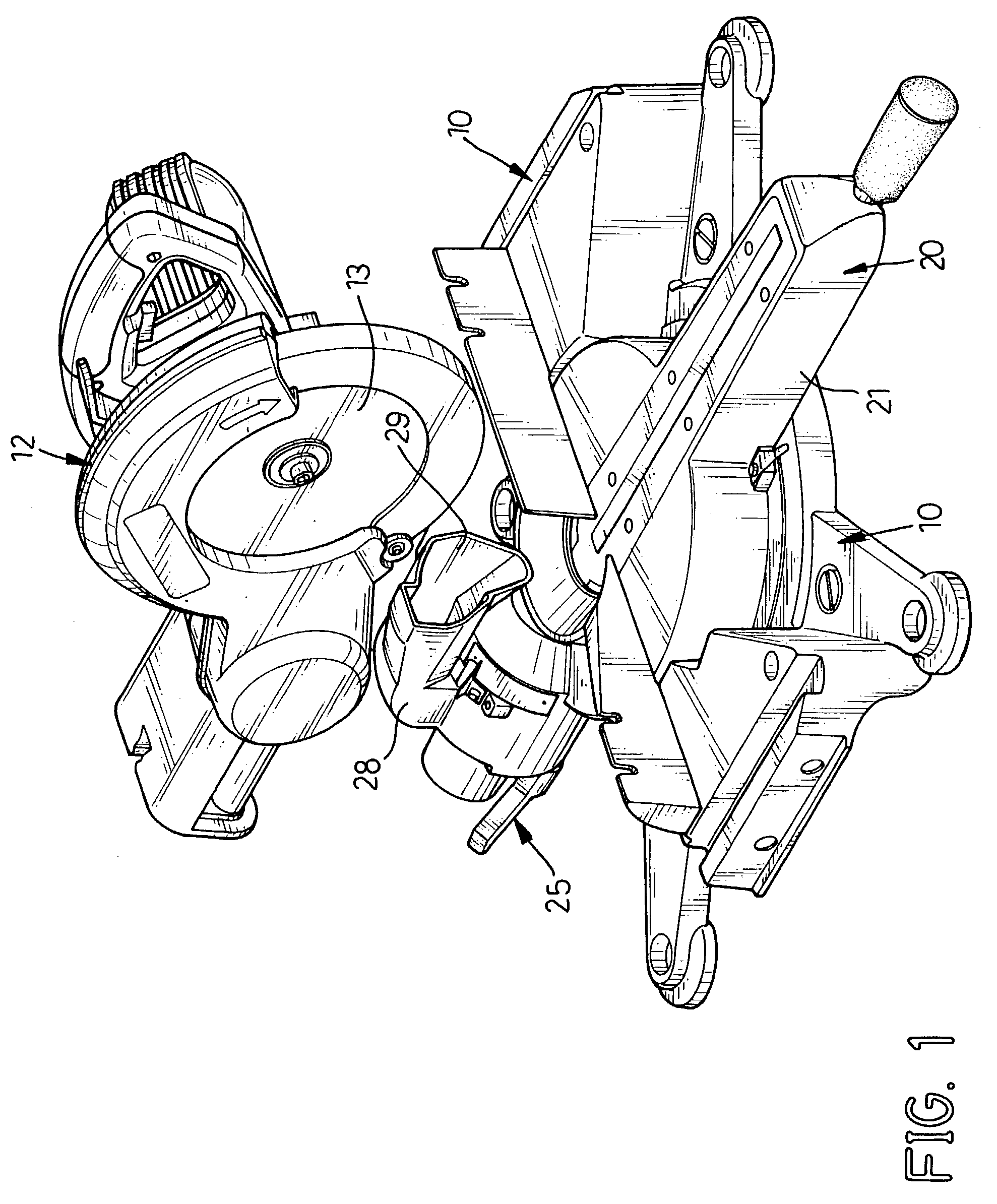

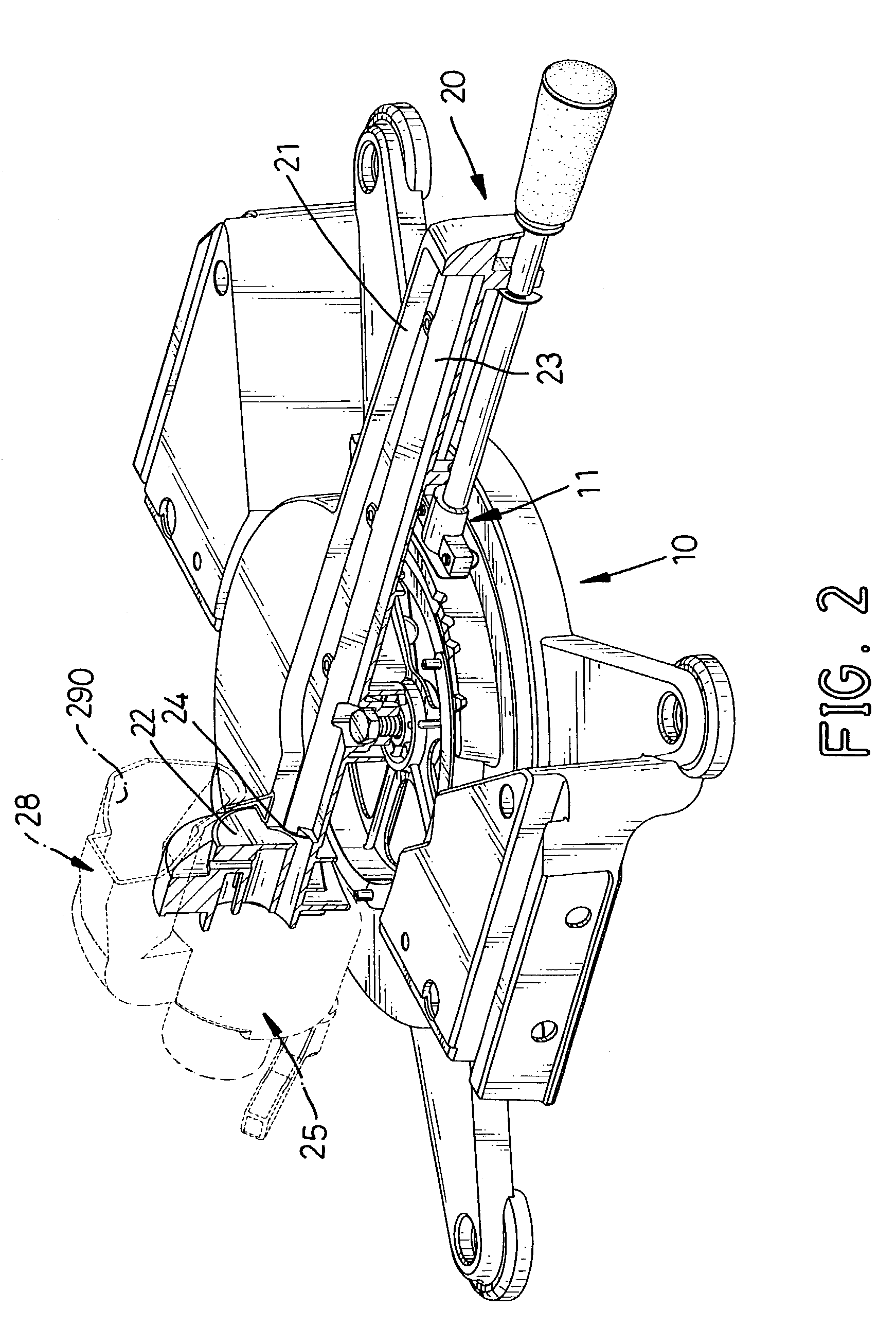

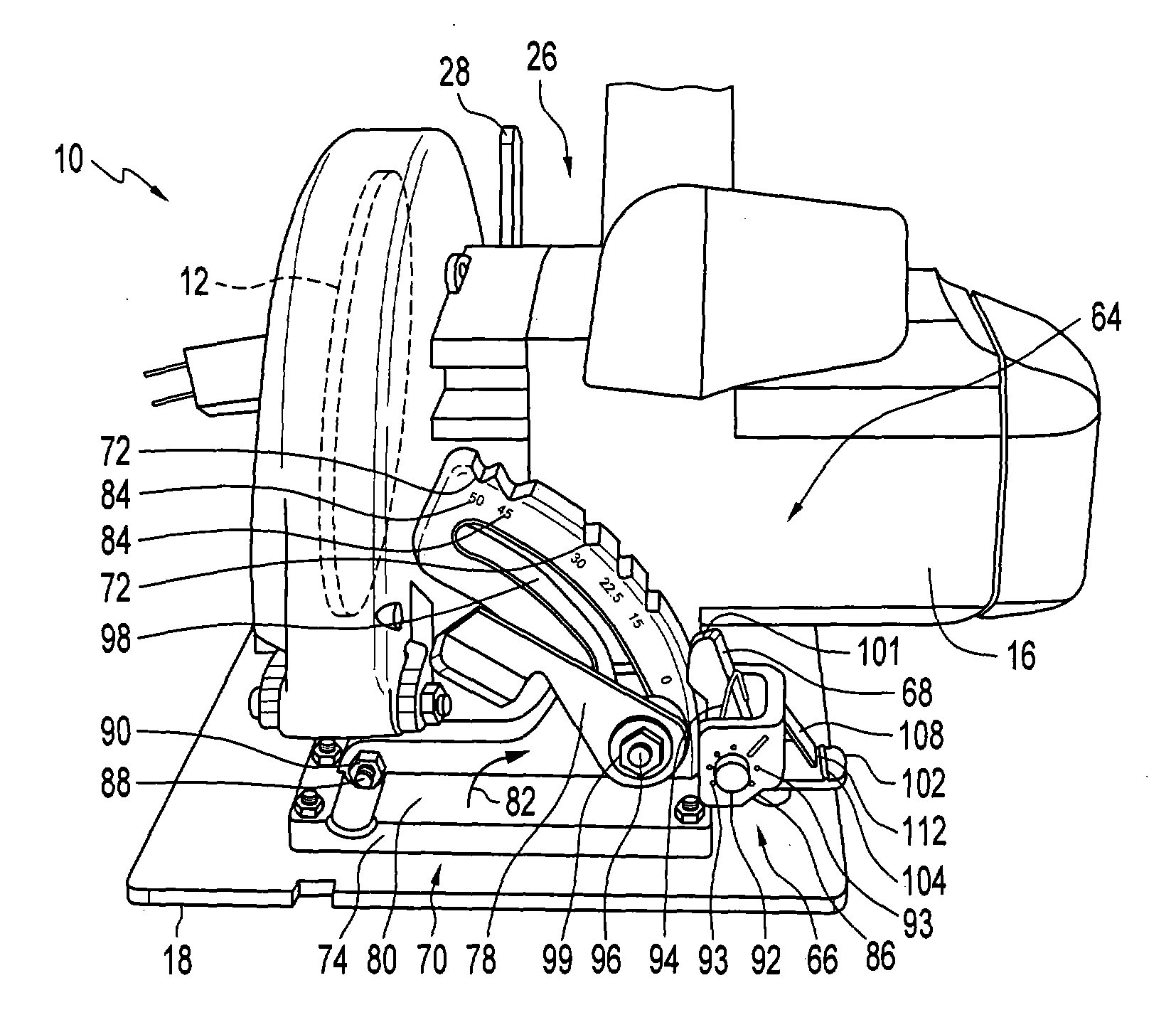

Adjustment device for a compound miter saw

An adjustment device for a compound miter saw includes a base having a top and a miter lip with detents, a turntable having a bottom and a miter assembly. The turntable is rotatably mounted on the top of the base, and the miter assembly is attached to the bottom of the turntable. The miter assembly includes a resilient biasing member having an engaging stop corresponding to the detents, a releasing rod rotatably mounted in the turntable, and an eccentric rotator having an eccentric portion and attached to the releasing rod corresponding to the resilient biasing member. The releasing rod rotates the eccentric rotator so the eccentric portion will push the engaging stop upward to disengage it from the detents to allow the turntable to be adjusted.

Owner:P & F BROTHER INDAL

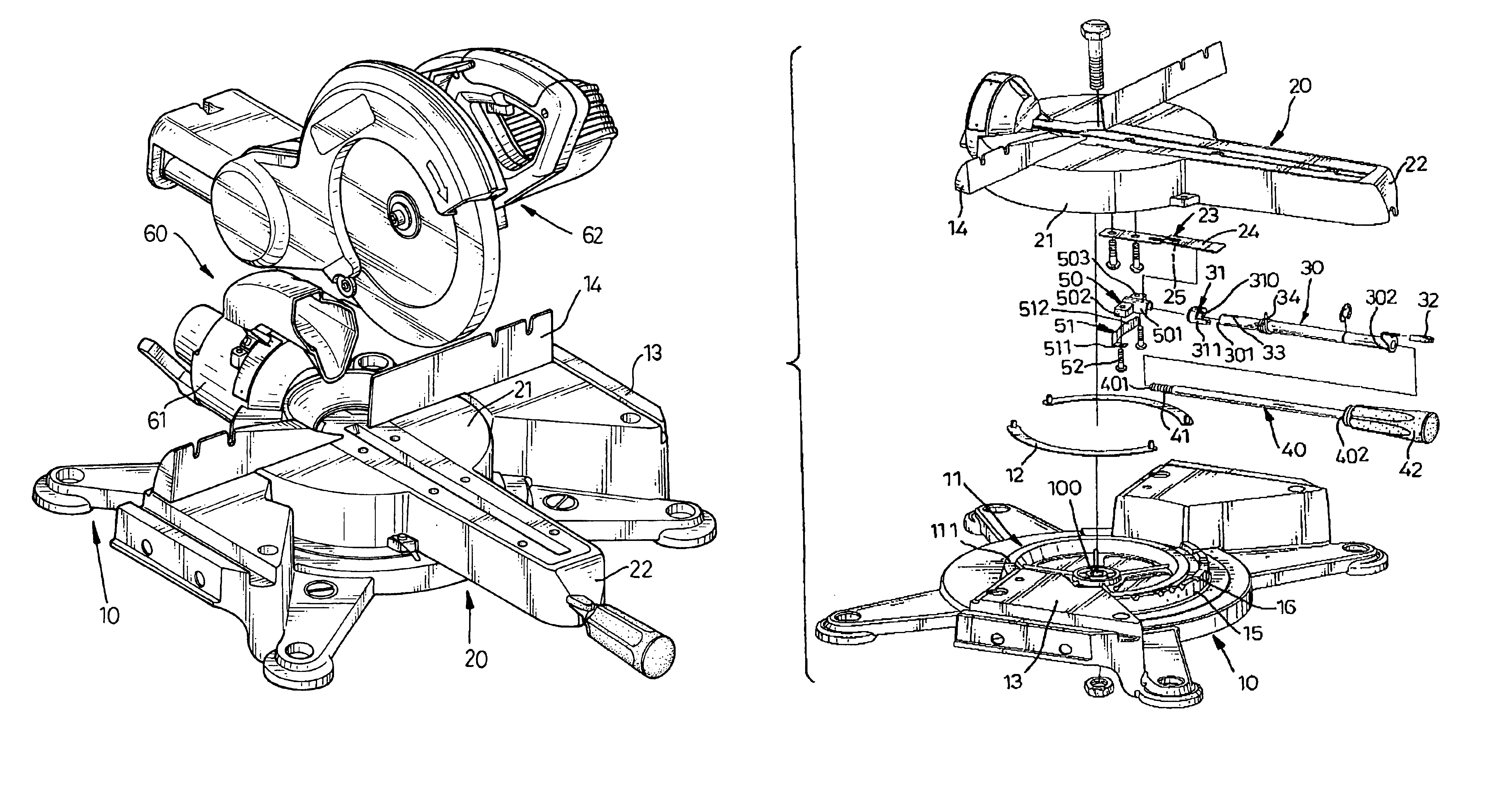

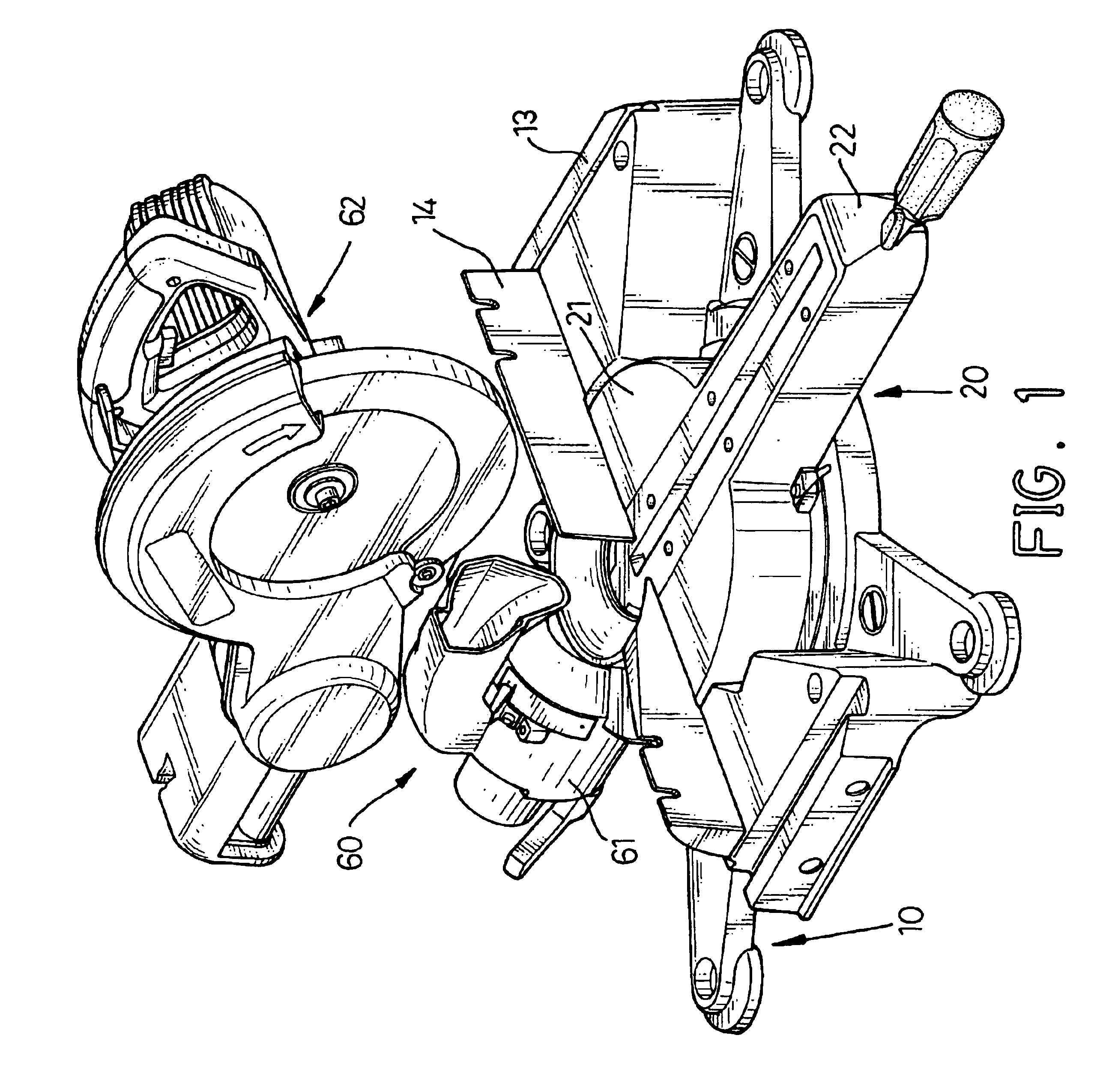

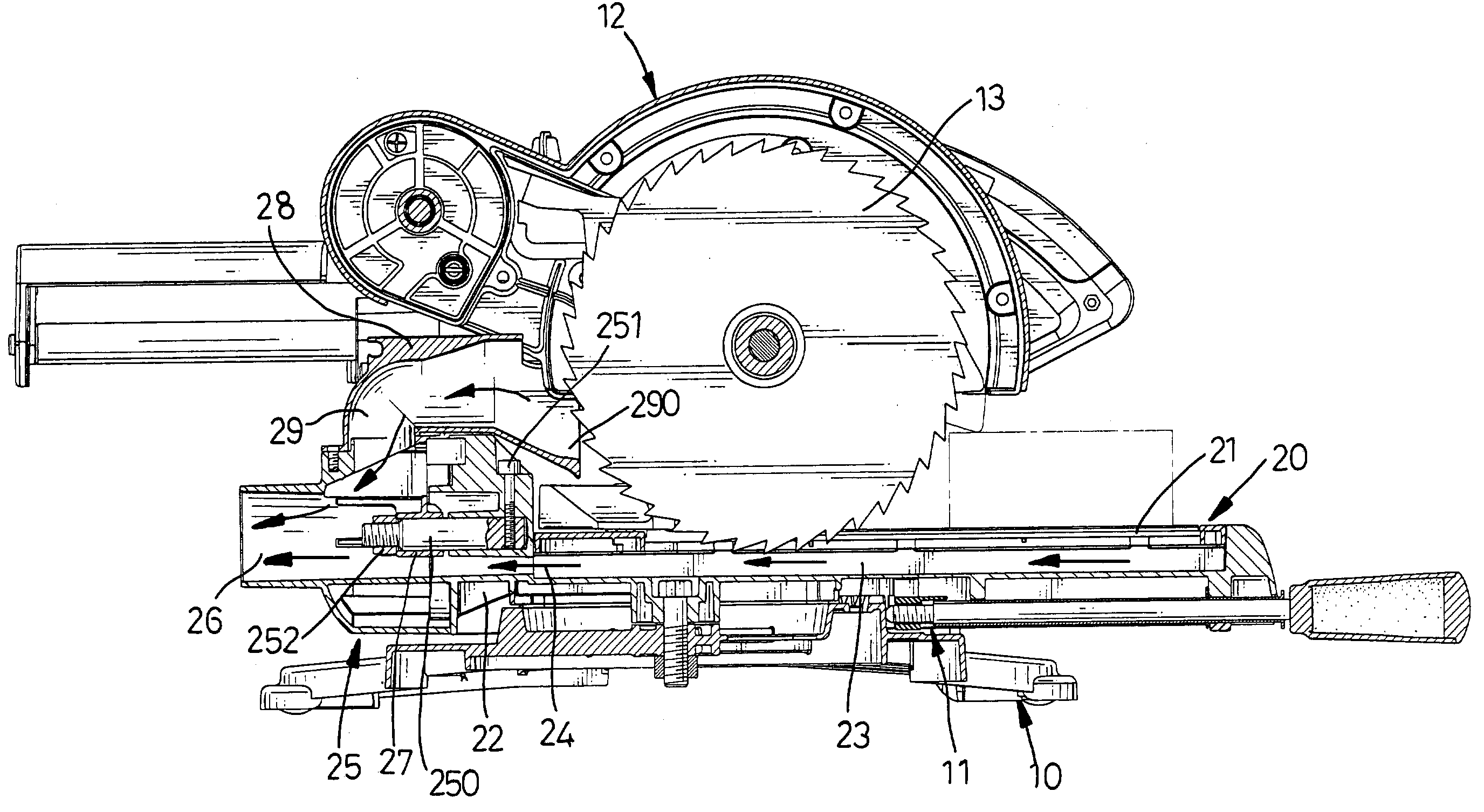

Sawdust collection assembly for a compound miter saw

InactiveUS20040060405A1Metal sawing devicesMetal sawing accessoriesEngineeringMechanical engineering

A sawdust collection apparatus for a compound miter saw includes a turntable and a sawdust collection assembly. The turntable is rotatably mounted on a base and has a cutting groove defined in the turntable and a sawdust guide communicating with the cutting groove. The sawdust collection assembly has a hollow sawdust duct with a sawdust channel communicating with the sawdust guide and a hollow sawdust entry duct with a sawdust entry port to receive sawdust and debris and a sawdust passage to communicate with the sawdust entry port. The sawdust channel is connected to a vacuum cleaner to efficiently pull sawdust and debris out of the miter saw through the sawdust channel and the sawdust passage.

Owner:P & F BROTHER INDAL

Window blind cutting machine

InactiveUS7024977B2Easy to controlDesired sizeDoor/window protective devicesStock shearing machinesEngineeringReference line

Owner:NIEN MADE ENTERPRISE CO LTD

Circular saw having bevel and depth of cut detent system

A circular saw having a saw blade depth adjustment detent mechanism for facilitating rapid positioning of a saw blade at predetermined depth positions includes a housing enclosing a motor disposed therein that rotates a circular saw blade. The circular saw includes a foot which rides on a workpiece to guide the saw blade during cutting operations. The saw blade depth adjustment detent mechanism pivotally interconnects the foot to said housing such that the circular saw blade is adjustable to the foot through a number of saw blade depth settings within a range of saw blade depth of cuts relative to the foot. The saw blade depth adjustment detent mechanism includes a saw blade depth detent and a second member having a plurality of spaced saw blade depth recesses that are each matingly engageable with the saw blade depth detent to provide the range of saw blade depths.

Owner:CREDO TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com