Patents

Literature

1467 results about "Metal hose" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A metal hose is a flexible metal line element. There are two basic types of metal hose that differ in their design and application: stripwound hoses and corrugated hoses. Stripwound hoses have a high mechanical strength (e.g. tensile strength and tear strength). Corrugated hoses can withstand high pressure and provide maximum leak tightness on account of their material. Corrugated hoses also exhibit corrosion resistance and pressure tightness under the most extreme conditions, such as in aggressive seawater or at extreme temperatures such as found in space or when transporting cooled liquid gas. They are particularly well suited for conveying hot and cold substances.

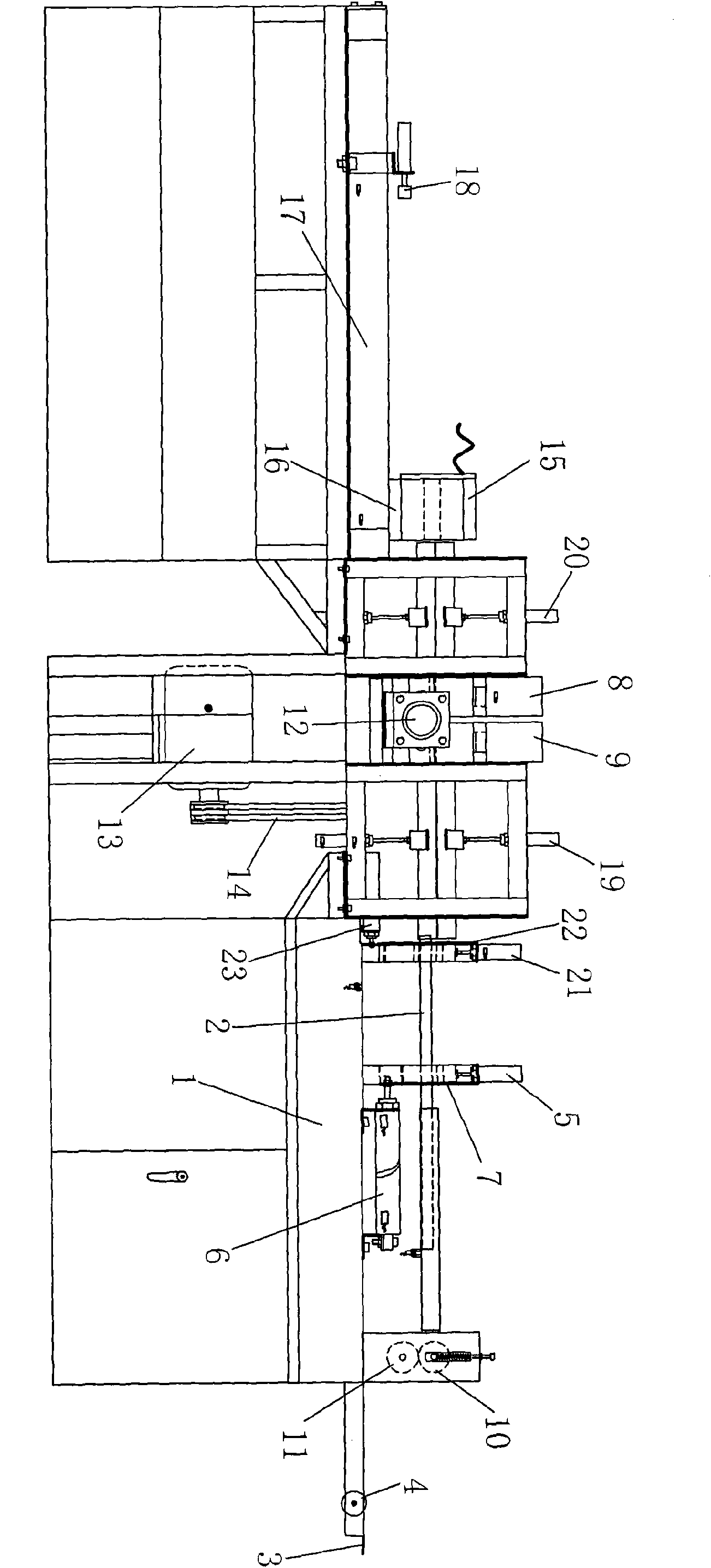

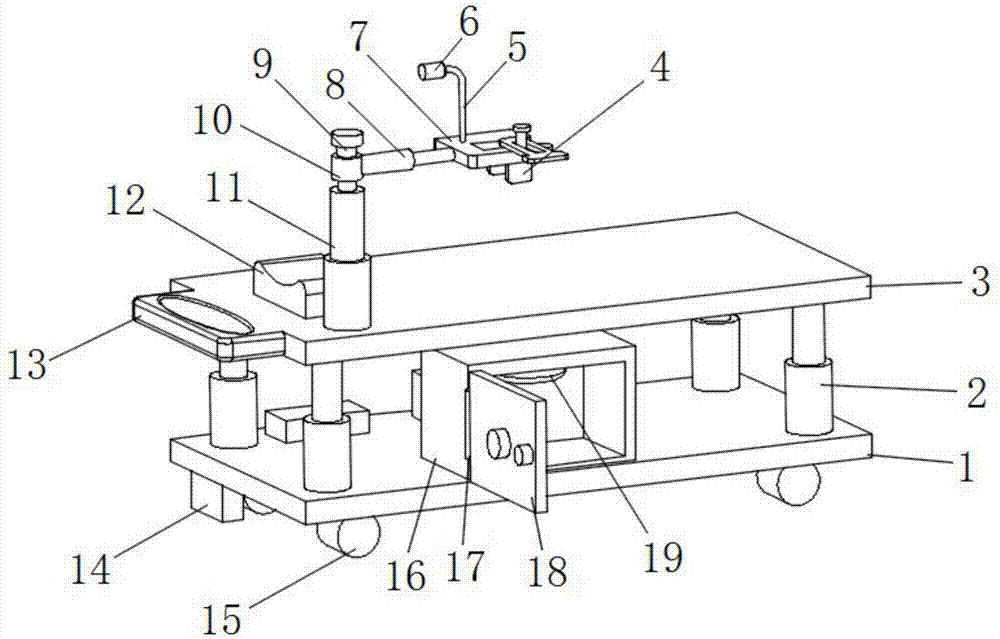

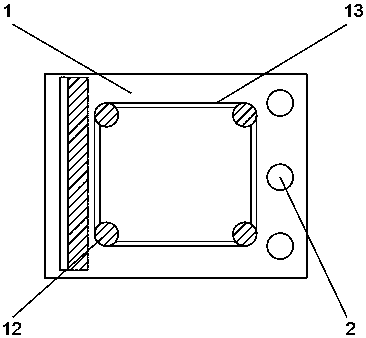

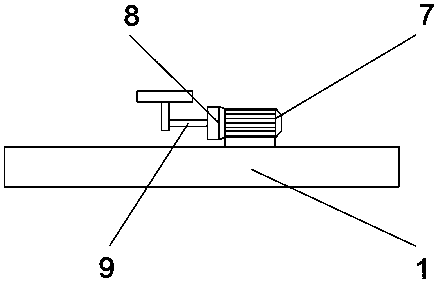

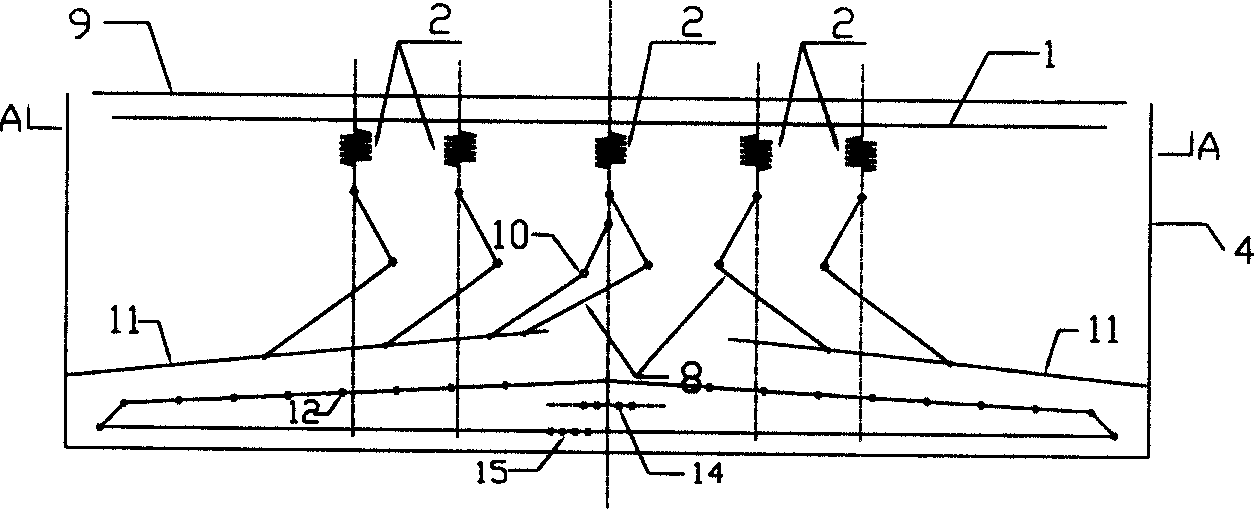

Full-automatic fixed-length cutting device of metallic hose

InactiveCN101623780ARealize fixed-length automatic cuttingIncrease productivityMetal-working feeding devicesTube shearing machinesFixed lengthMetal hose

The invention relates to a full-automatic fixed-length cutting device of a metallic hose, comprising a base, a strip conveyer and a conveying chute. The strip conveyer is used for conveying the metallic hose and is erected on the base; the conveying chute vertically penetrates through the strip conveyer which is provided with a positioning mechanism, a conveying mechanism and a clamp, wherein the conveying mechanism sends the metallic hose into the clamp and pulls the metallic hose away for a certain distance, and then, the metallic hose is cut by a cutting mechanism which is arranged on the base. The invention realizes the automatic fixed-length cutting of the metallic hose, greatly improves the production efficiency, and achieves higher consistency degree of a cut product.

Owner:严光辉

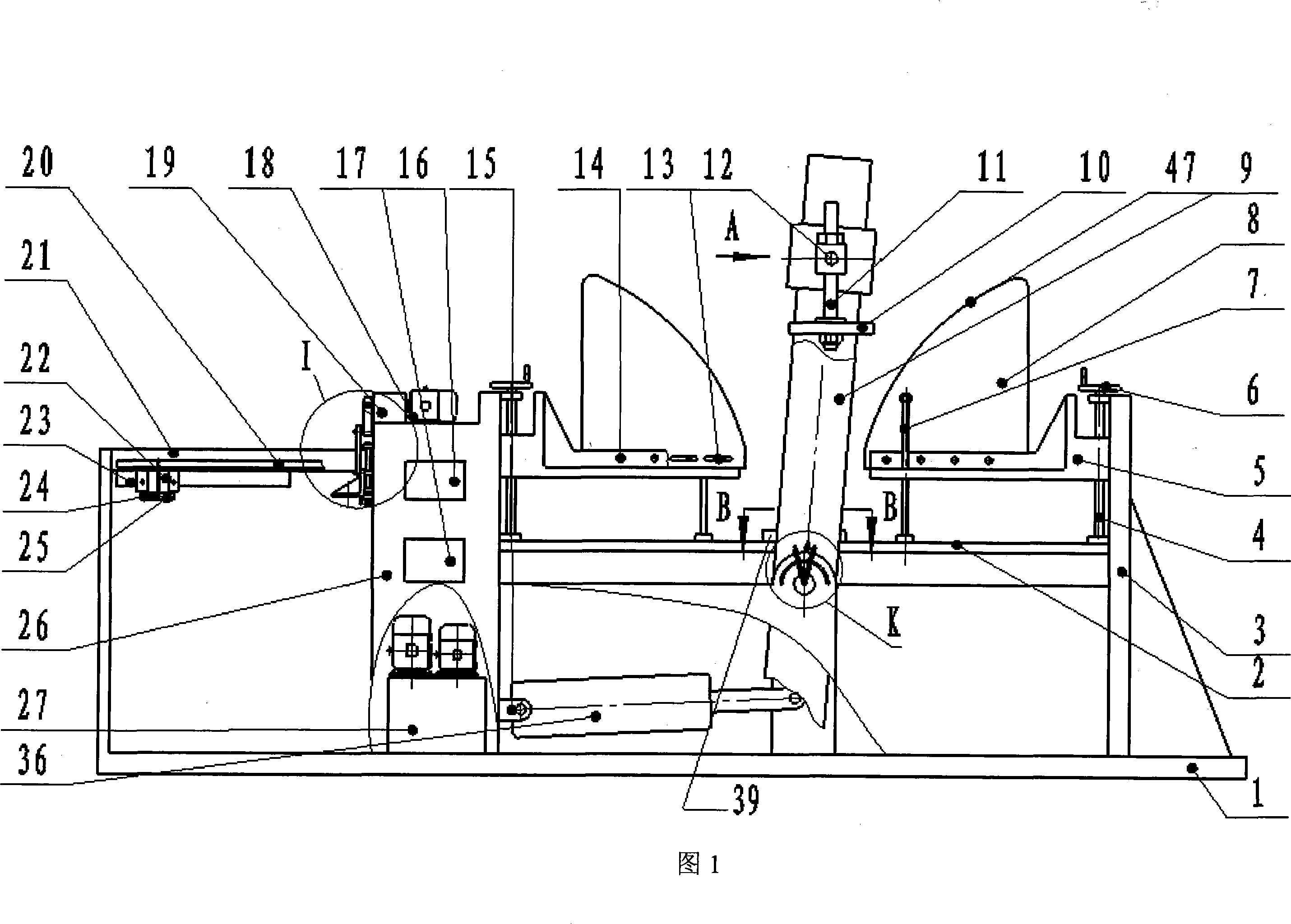

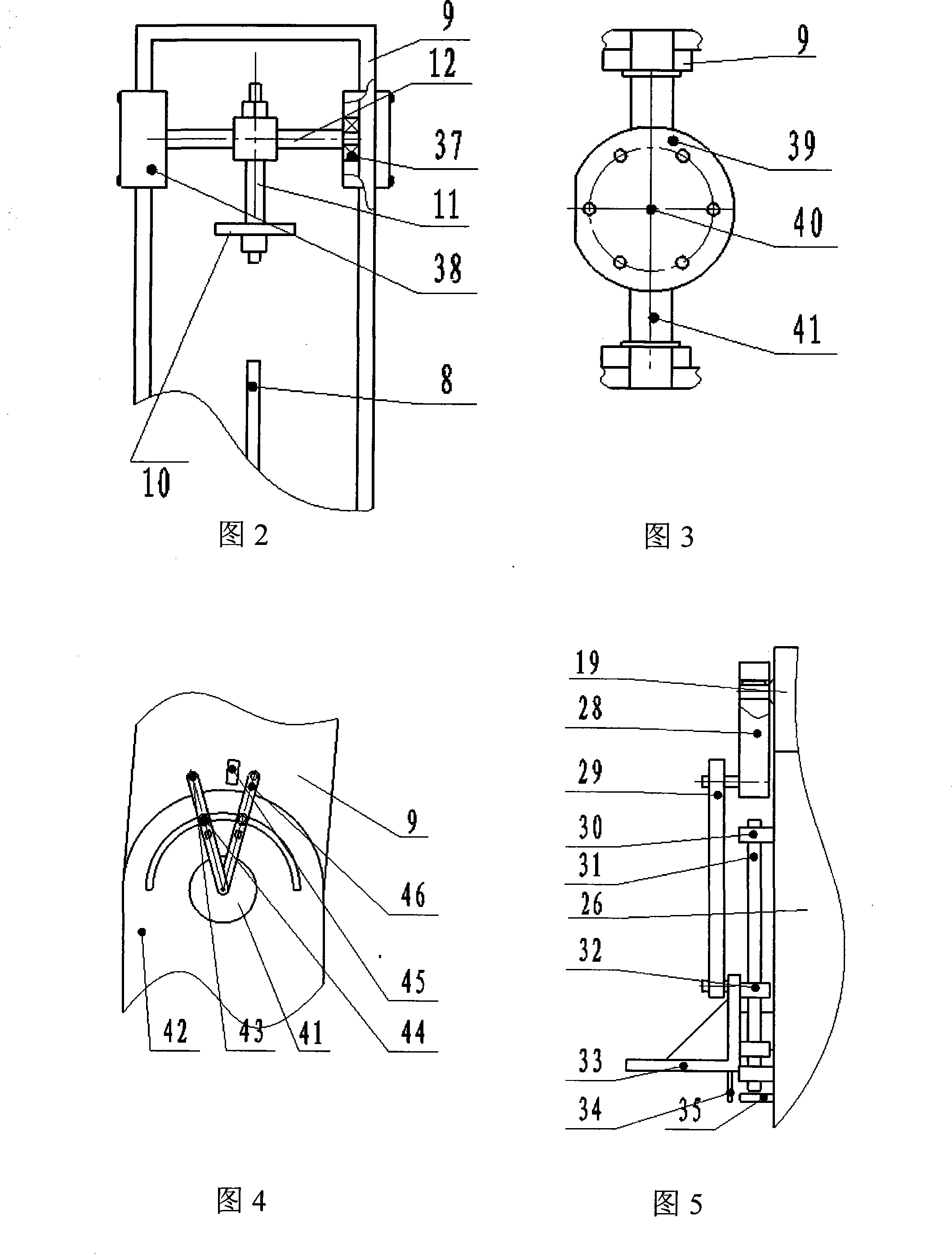

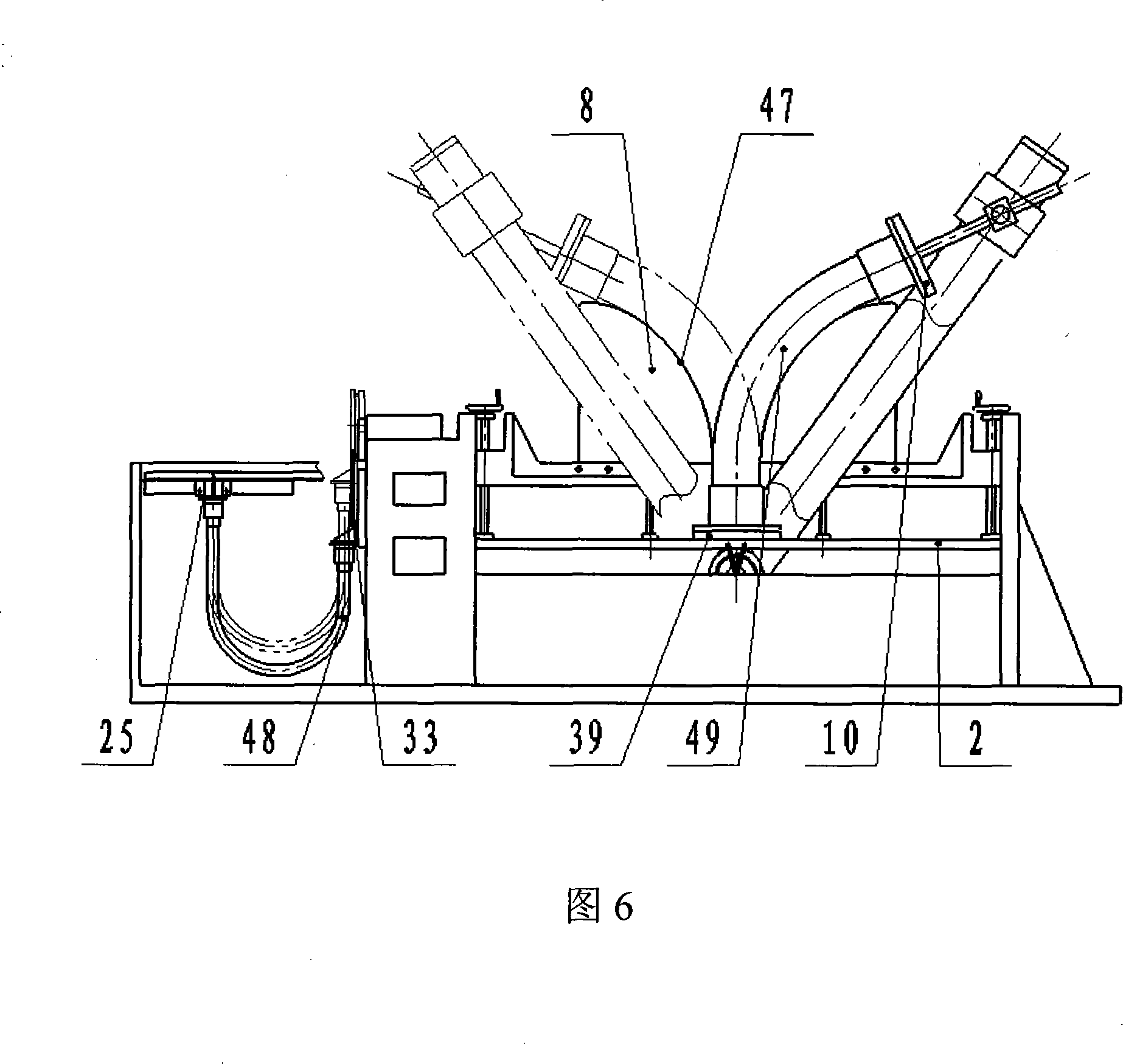

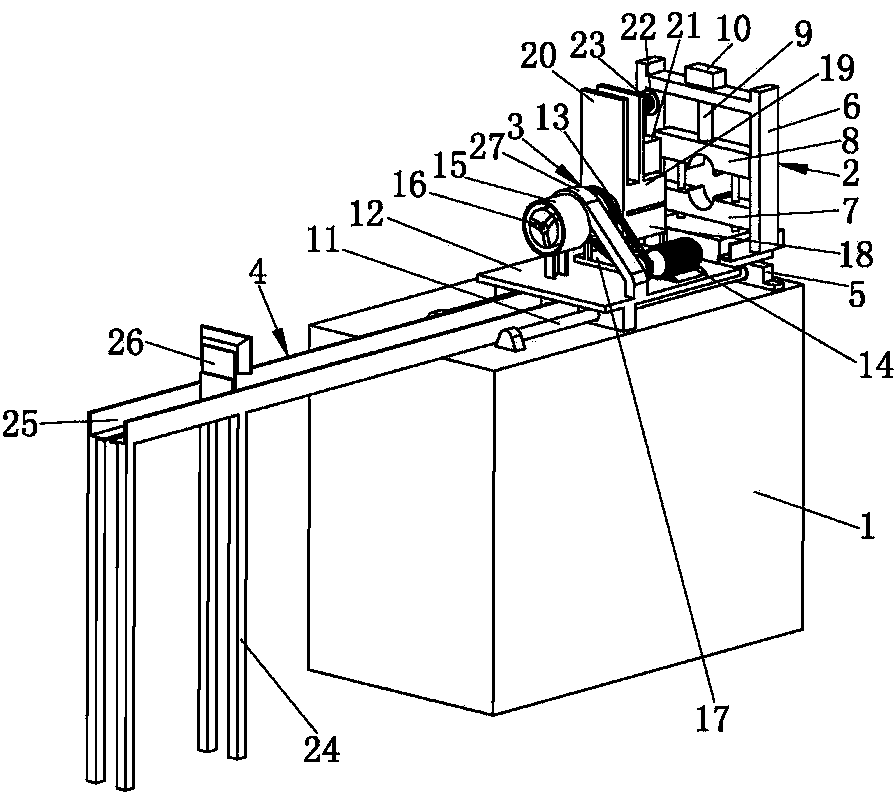

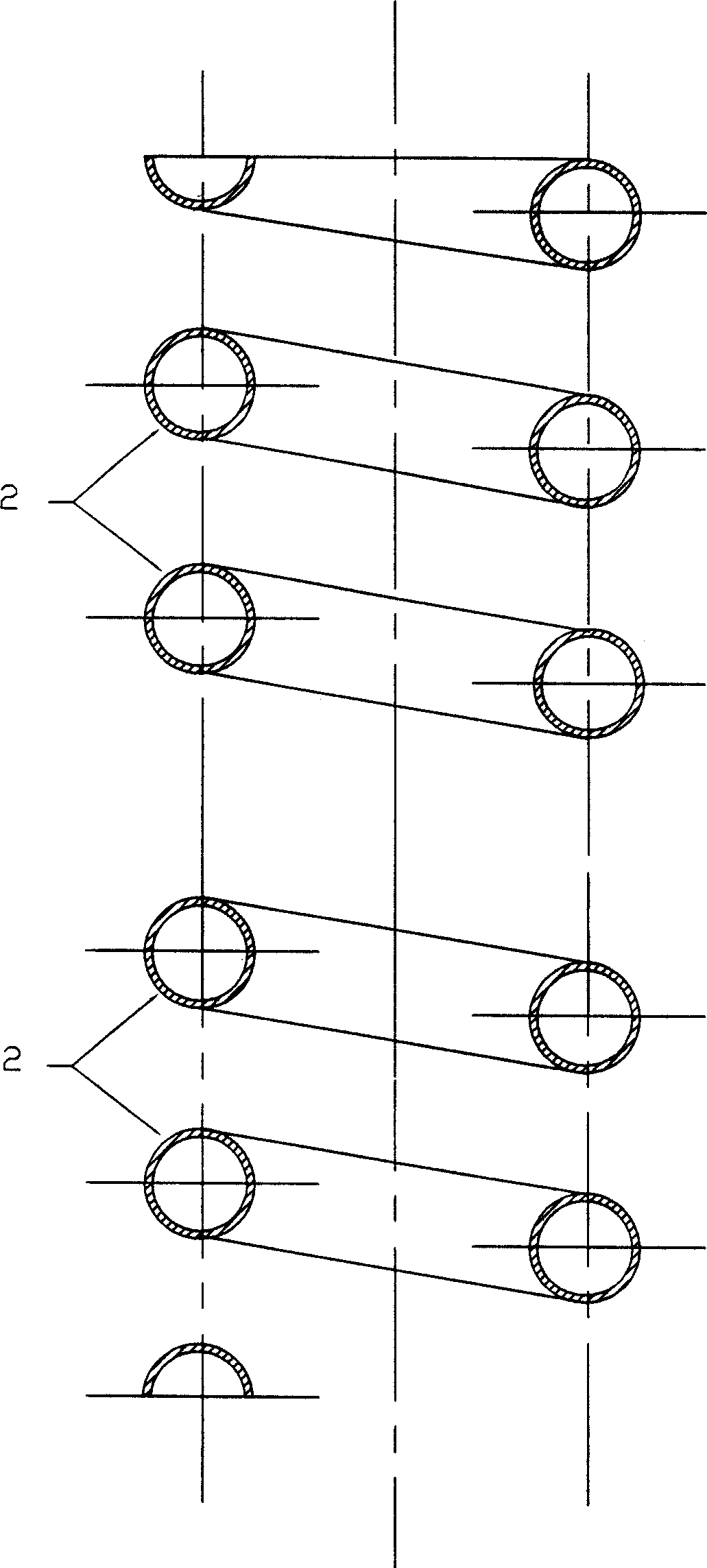

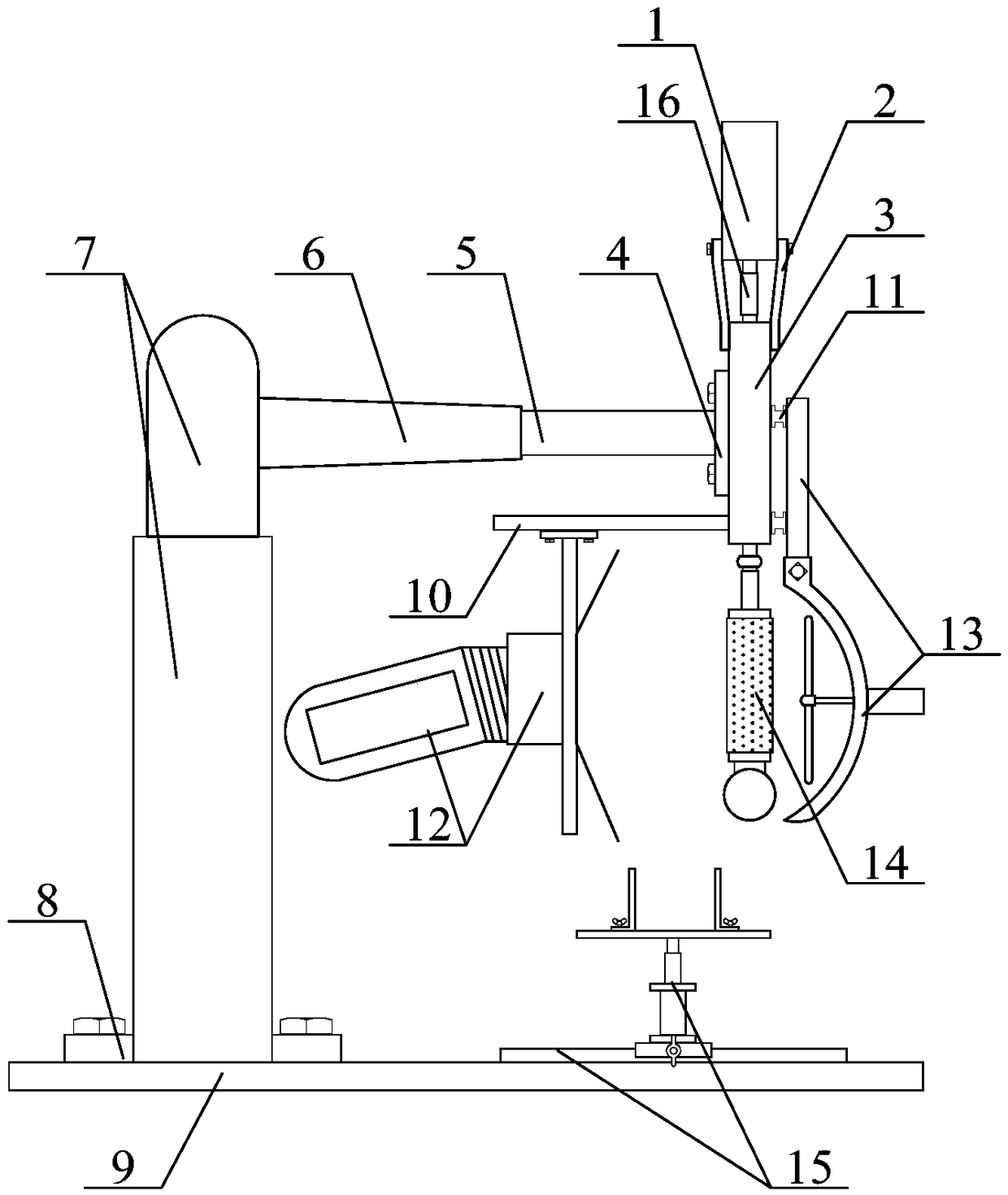

Flexural oscillation testing machine for metal flexible pipe

InactiveCN101196451AImprove test efficiencyRealize alternating constant displacement motionMaterial strength using repeated/pulsating forcesElectric machineElectrical control

A metal soft tube flexural oscillations tester for conducting life test is provided, which comprises a stander, a control cabinet, an electric control unit and a displaying unit. The technical points are that: a transmission oil cylinder, a rotating axle and a transmission arm are arranged in the stander, which are connected with an arm swinging link gear to compose the actuating unit of the equipment. and the hydraulic pressure machine set drive motor power structure drives the equipment to movement swinging arm; the two ends of the metal soft tube are installed on a fixing pressing base and a dynamic displacement compensation mechanism, and the metal soft tube movement trail is adjusted by an arc limiting structure; one end of the metal soft tube is connected fixedly with the arc limiting structure to realize bending and double-direction swinging function. Through an electric control unit, a starting dynamo, the alternate invariable displacement structure composed of an eccenter, a connecting bar, a linear guide and a movement end connected with base is driven by a reducer driven by electric engine, which makes the metal soft tube fixed on the connecting base of the moving end realize the curvature movement of invariable displacement.

Owner:SHENYANG ACAD OF INSTR SCI

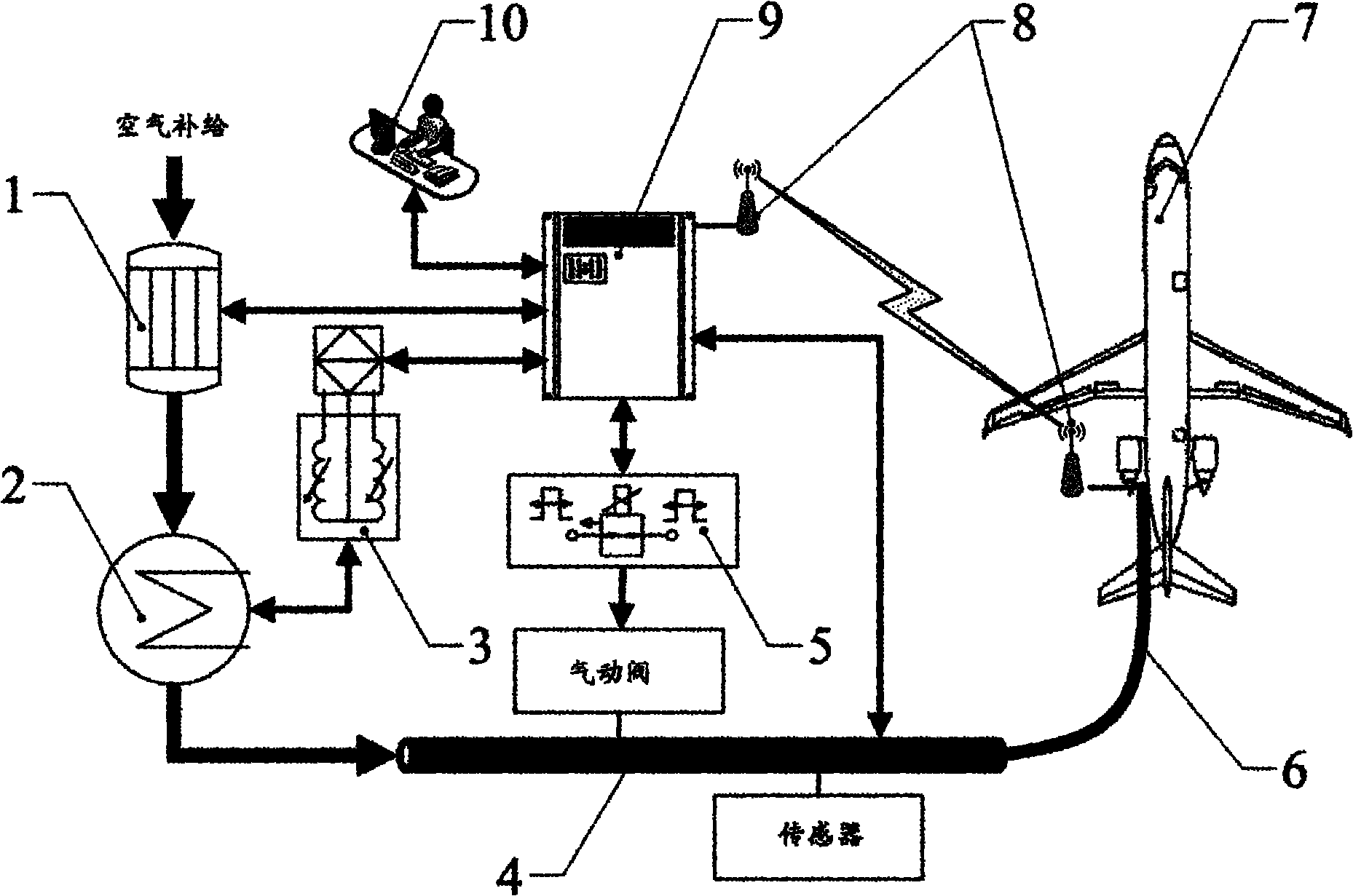

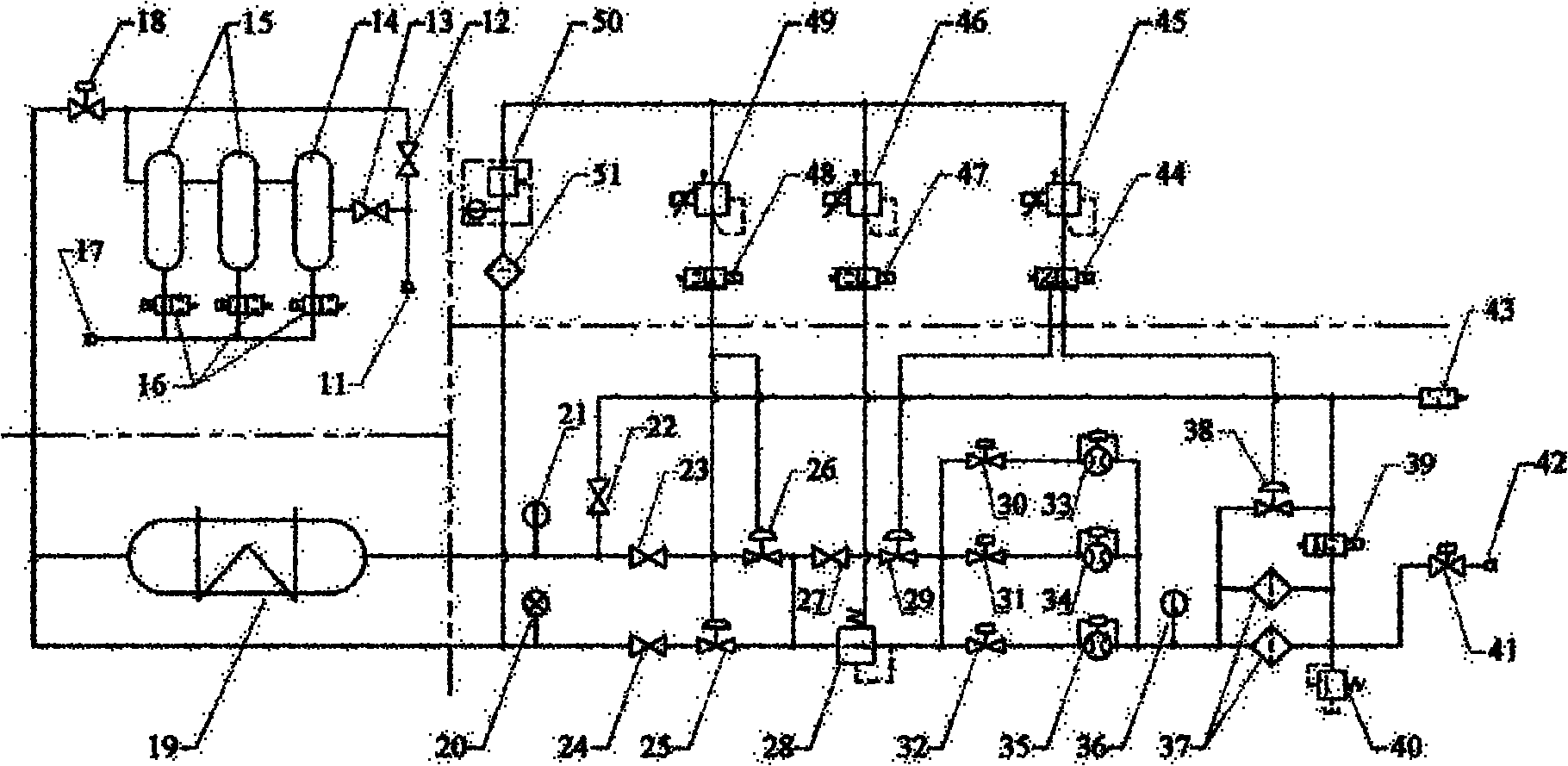

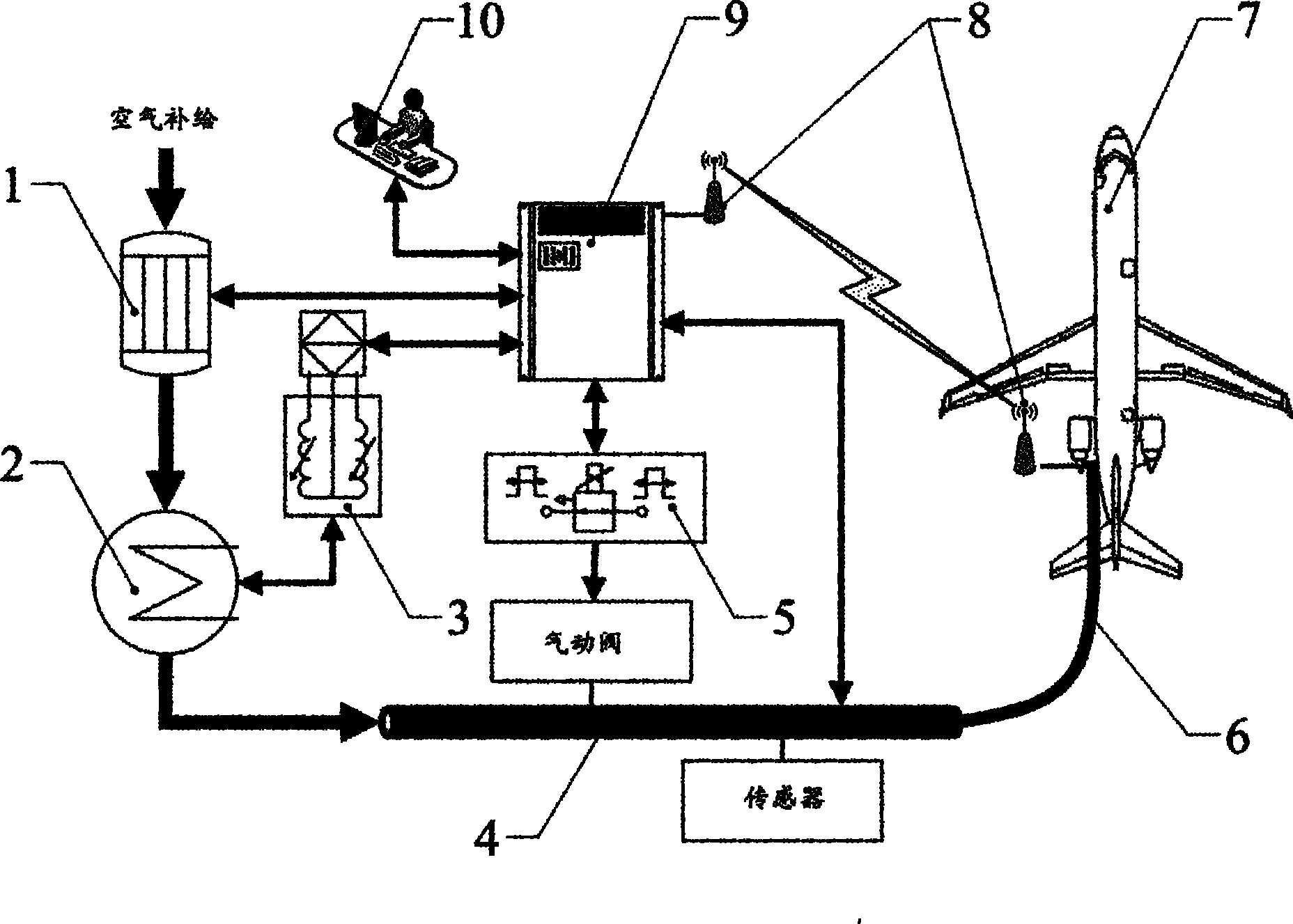

Automation device for use in civil aircraft environment control system function test

InactiveCN101916108AImprove test efficiencyRealize automatic collectionElectric testing/monitoringControl systemProgrammable logic controller

The invention relates to an automation device for use in a civil aircraft environment control system function test, which belongs to the technical field of aircraft manufacturing. The automation device comprises an air source processing component, an electric air heating furnace, an air heating furnace controller, a main pipeline system, a pneumatic valve control component, a metal hose component, a wireless sensing communication module, a programmable logic controller (PLC) control module and an upper machine monitoring computer. In the invention, an aircraft pressure cabin and air conditioner pipeline leakage amount test, a cabin pressure regulating system test, a cabin air temperature regulating system function test and an anti-ice system function test are carried out by using an on-spot air source of an aircraft assembly plant in place of an engine or an auxiliary power unit (APU) unit, so that a plurality of test items in the aircraft environment control function test can be completed, and the requirements of aircraft mass production on the quality and efficiency improvement on the environment control function test in a final assembly process are met.

Owner:SHANGHAI JIAO TONG UNIV +1

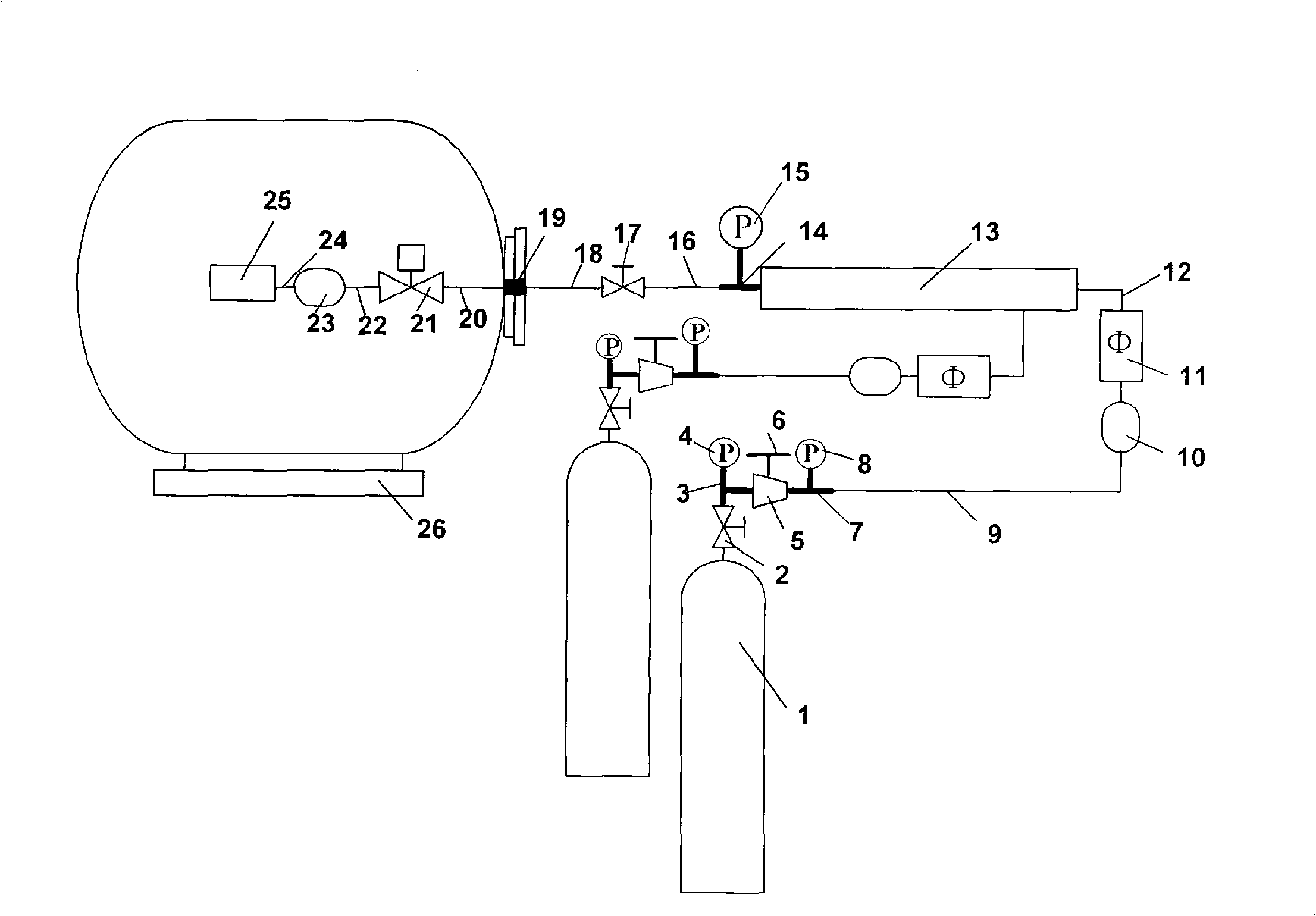

Electric propulsion testing platform gaseous-propellant supply device

InactiveCN101539482AConstant flow and constant pressureConstant pressureEngine testingEngineeringHigh pressure

The invention discloses an electric propulsion testing platform gaseous-propellant supply device which consists of a high pressure gas cylinder, a gas cylinder manual valve, a gas cylinder pressure gauge, a discompressor, a discompressor valve, a discompressor pressure gauge, a metallic hose, a filter in front of a flow controller, the flow controller, a premixing cavity, a pressure sensor, a penetration front manual valve, a penetration flanged joint, an electromagnetic valve, a filter in front of an engine, a tee joint and a stainless steel canaliculus tubule. The gaseous-propellant supply device can propel gas which has single component in certain flow rate and pressure intensity, provides mixed gas propelling agent with certain mixing ratio, and has the advantages of stable work and accurate control of the flow rate.

Owner:BEIHANG UNIV

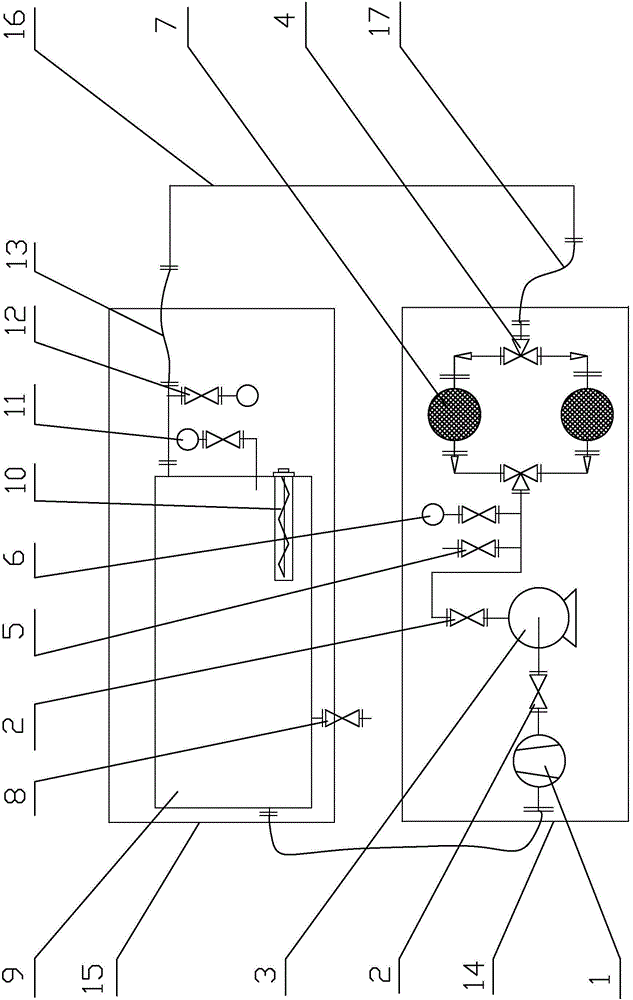

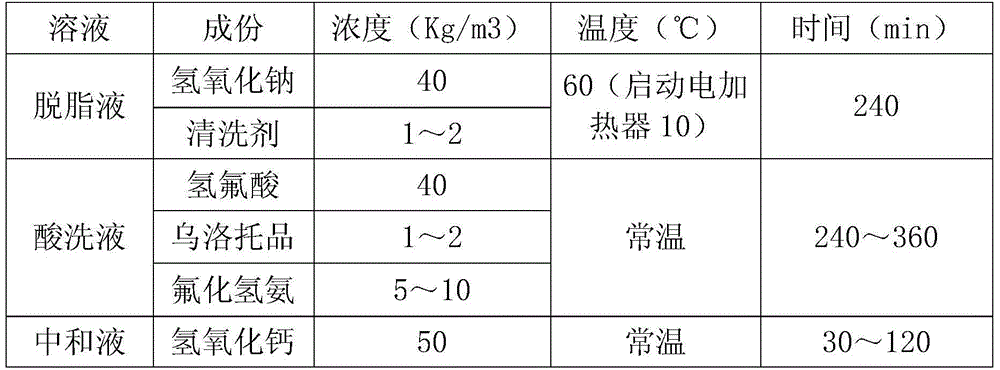

Cleaning and oil flushing device and method for unit lubricating oil system pipeline

The invention discloses a cleaning and oil flushing device and method for a unit lubricating oil system pipeline, which are used for performing cleaning and oil flushing on the pipeline, which is arranged on site, of a unit separately and out of the unit. Namely, the unit pipeline and the device form a loop by using a metal hose, and large-flow circulating flushing is performed by using chemical cleaning agent, water and flushing oil, so that cleaning and purification requirements on the inside of the unit pipeline are met, and the problems of the traditional cleaning process of the existing petrochemical unit lubricating oil system that the cleaning process is complex, the cleaning cycle is long, the cleaning is not thorough, the unit is contaminated, safety loopholes exist and the like are solved. According to the invention, the same device is adopted to finish performing the cleaning and oil flushing of the pipeline, which is arranged on site, of the large unit separately and out of the unit, the cleaning cycle is short, the cleaning and purification are thorough, the construction is pollution free, the practicability is high, and the device and the method are especially applicable to moving construction.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

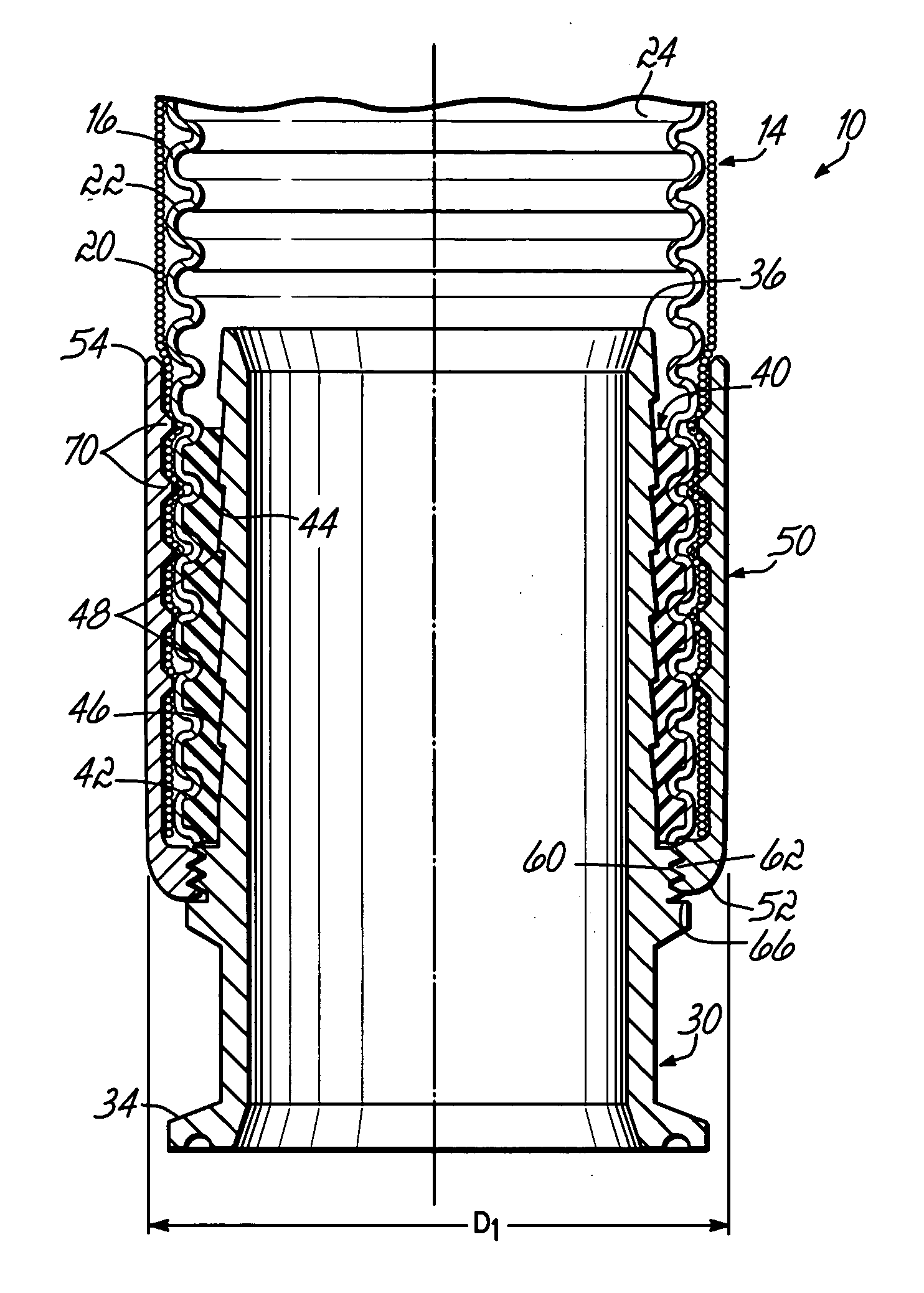

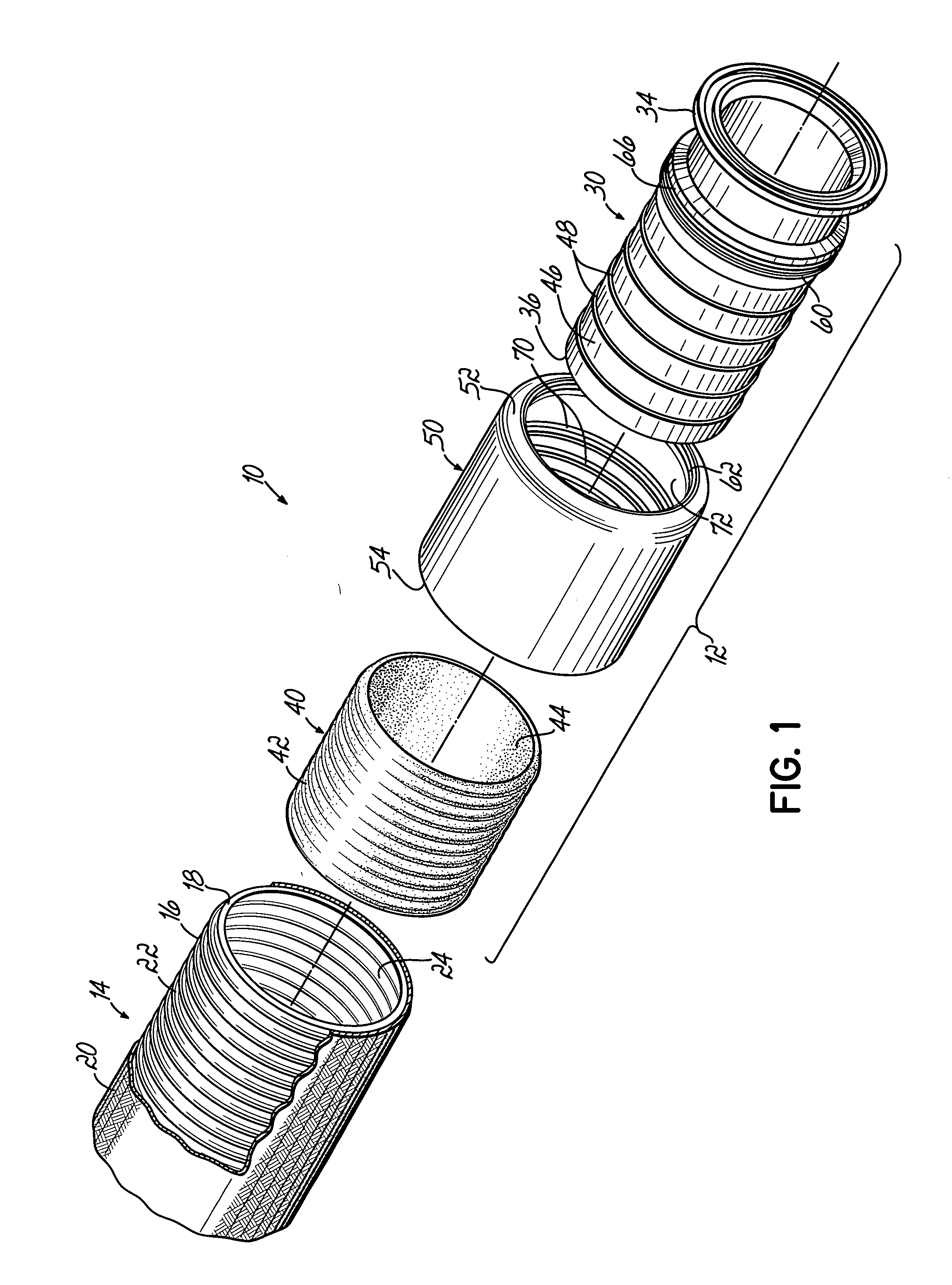

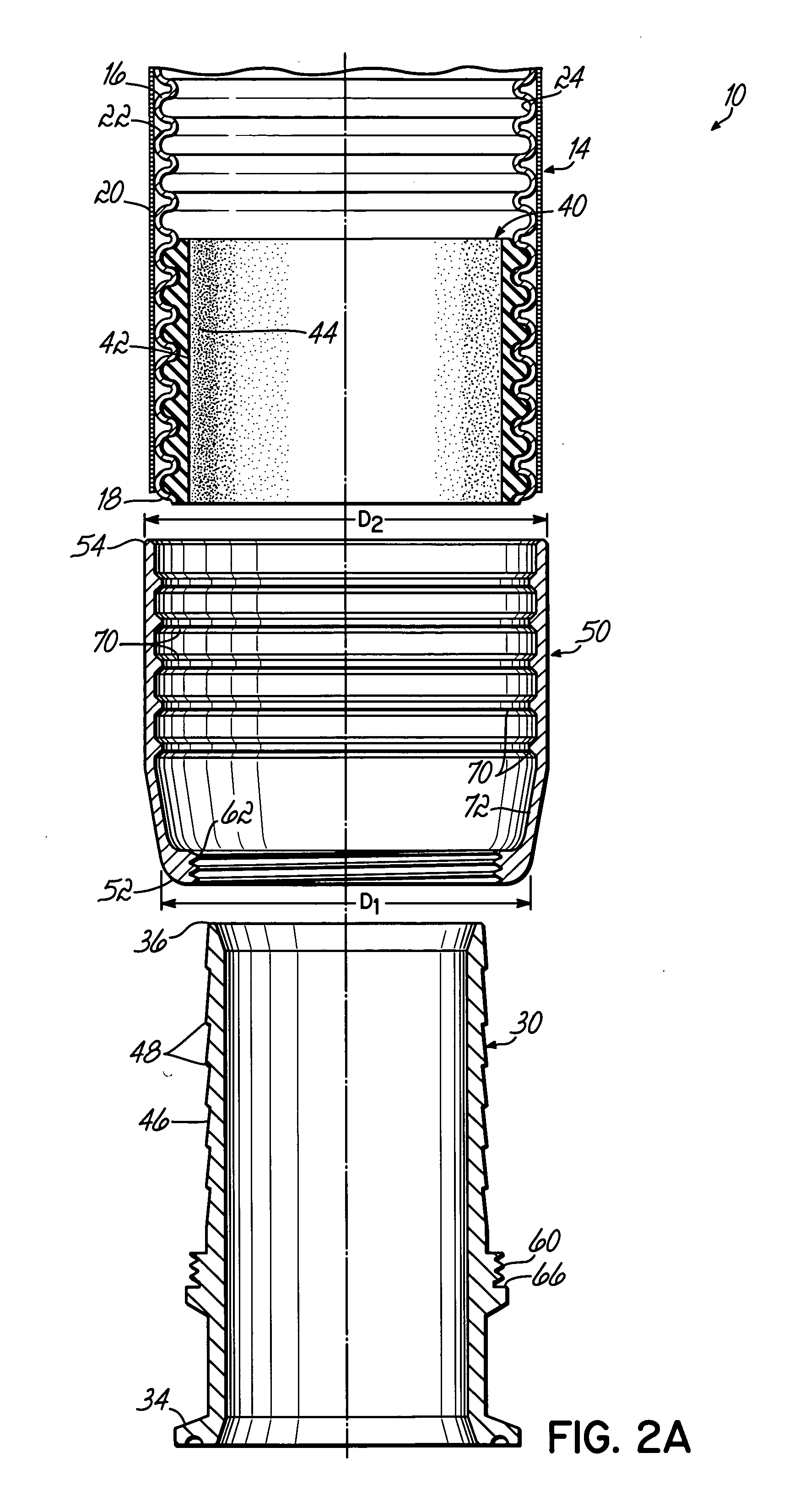

Fitting for a flexible metal hose

A flexible hose formed from corrugated metal tube has a fitting permanently crimped to the end of the hose. The fitting includes an elongated stem having a first end adapted to be coupled to an appropriate fitting surface and a second end configured to be received within the hose. A sealing member disposed on the second end of the stem seals the fitting between the corrugated metal tube and the stem. A ferrule is placed over the hose and is crimped to compress the hose and sealing member between the ferrule and stem.

Owner:CHARLES C ASHDOWN ESQ AND J THOMAS MELLOTT ESQ CO TRUSTEES UNDER THE FULLBECK PATENT TRUST

Clinical examination device for internal emergency department

The invention discloses a clinical examination device for emergency medicine, comprising a base, a brake and a universal wheel are arranged on the lower surface of the base, a first electric telescopic rod is arranged on the upper surface of the base, and a The position of the rear side is provided with a power storage device and a control switch group, the side of the power storage device is provided with a charging jack, the end of the first electric telescopic rod is provided with a reclining board, and one end of the upper surface of the reclining board is provided with a reclining board. With a headrest, the emergency medical clinical examination device has a reasonable structure and strong practicability. The universal wheel and brake are convenient for the movement and braking of the device, and the bite plate and tongue depressor are convenient for medical staff to carry out inspections in the cavity and irradiation. The lamp and the metal snakeskin hose are convenient for irradiating the patient's mouth and eyes at any angle, the first aid box is convenient for placing the medical aids needed for first aid, and the first electric telescopic rod is convenient for adjusting the height of the device, which is suitable for popularization.

Owner:苏强

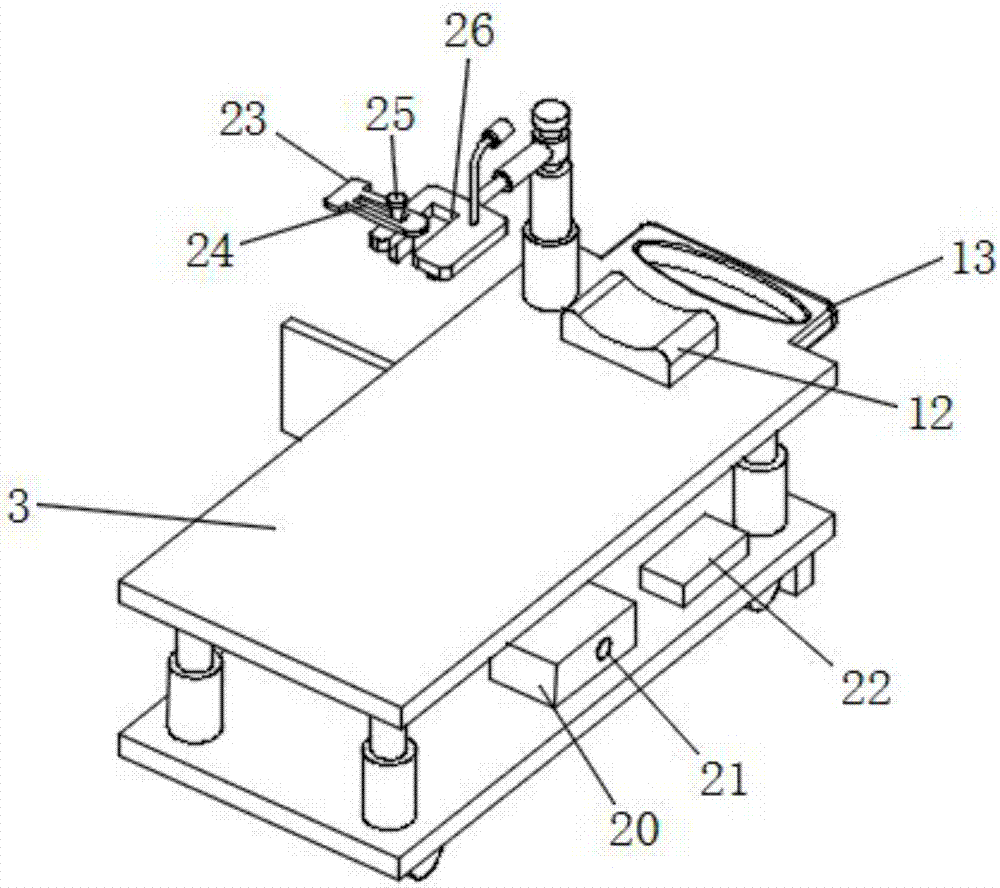

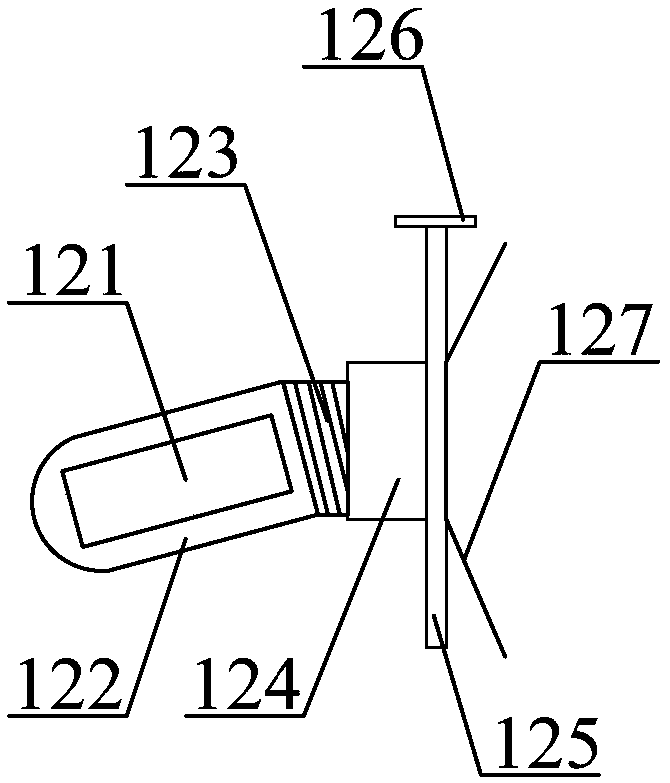

Cutting equipment capable of conveniently cutting off flexible pipe

ActiveCN103357946AUniform lengthEasy to cut offMeasurement/indication equipmentsTube shearing machinesMeasurement devicePipe fitting

The invention relates to the technical field of pipe equipment, in particular to cutting equipment capable of conveniently cutting off a flexible pipe. The cutting equipment comprises a rack, wherein a clamping device is arranged on the right part of the upper end of the rack; a cut-off device which is correspondingly connected with the clamping device is arranged in the middle of the upper end of the rack; and a measurement device is correspondingly arranged at one end of the cut-off device. When the cutting equipment is used, a required cut-off length of a metal flexible pipe is preset, and the metal flexible pipe is tightly clamped by the clamping device and a holding device, so that one end of the metal flexible pipe is fixed on the clamping device while the other end of the metal flexible pipe is pressed against the measurement device; and a motor drives a cut-off roller to rotate so as to rotationally cut off the metal flexible pipe through cut-off blades in the cut-off roller. Therefore, the metal flexible pipe can be cut off conveniently and quickly, and metal flexible pipe sections which are cut off are uniform in length.

Owner:NINGBO HONGWU PIPE IND

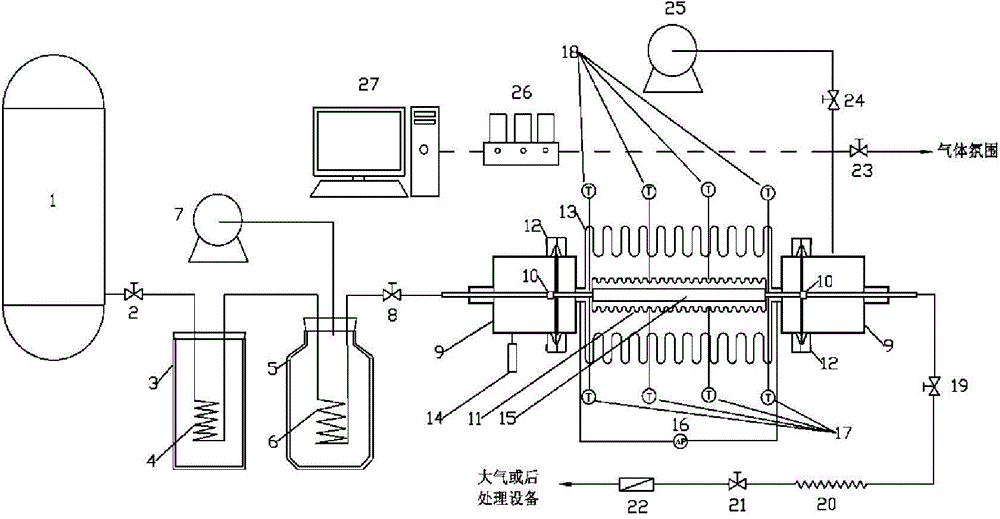

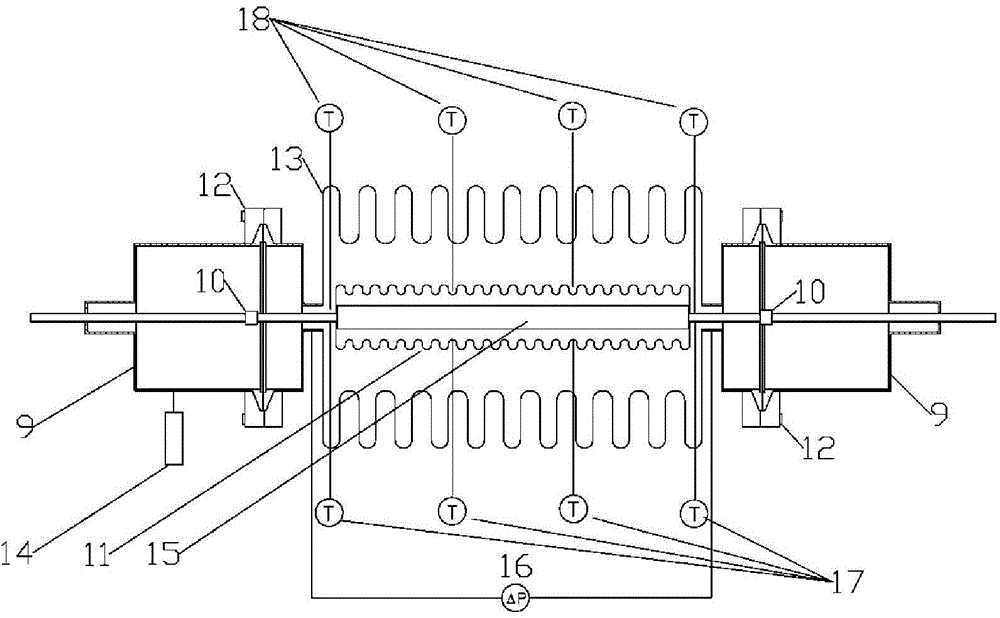

Flow resistance and temperature distribution testing device for low-temperature fluid inside heat insulating corrugated pipes

ActiveCN104697739ARealize the measurement functionEasy to replaceHydrodynamic testingFlow resistivityEngineering

The invention relates to a flow resistance and temperature distribution testing device for low-temperature fluid inside heat insulating corrugated pipes. The low resistance and temperature distribution testing device for the low-temperature fluid inside the heat insulating corrugated pipes comprises a low-temperature self-pressurization storage tank, a two-stage supercooler, a corrugated pipe testing section, a vaporizer and a gas flowmeter which are connected through metal hoses. The corrugate pipe testing section is communicated with an inflating and exhaust pipe, which adjusts the internal vacuum degree of the corrugated pipe testing section; the inside of the corrugated pipe testing section is provided with a temperature and pressure measuring unit and a vacuum degree measuring unit, and the flow resistance and the temperature distribution of the low-temperature fluid inside the heat insulating corrugated pipe can be obtained according to the temperature, pressure and vacuum degree data inside the heat insulating corrugated pipes. Compared with the prior art, the flow resistance and temperature distribution testing device for the low-temperature fluid inside the heat insulating corrugated pipes is simple in structure, convenient to operate, safe, reliable and applicable to experiment measurement of the flowing and heat transfer characteristics of the low-temperature fluid inside the heat insulating corrugated pipes at different inclinations.

Owner:SHANGHAI JIAO TONG UNIV

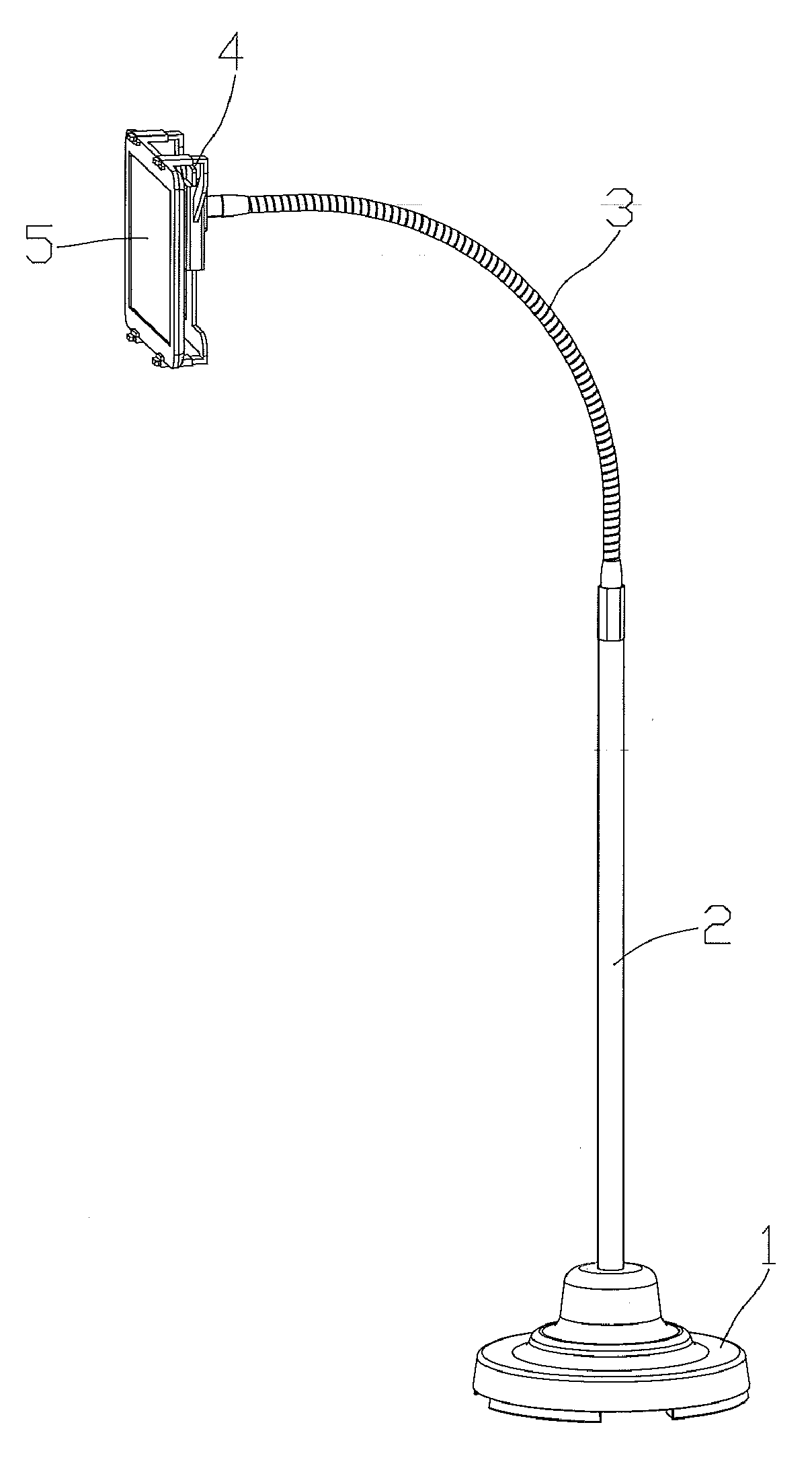

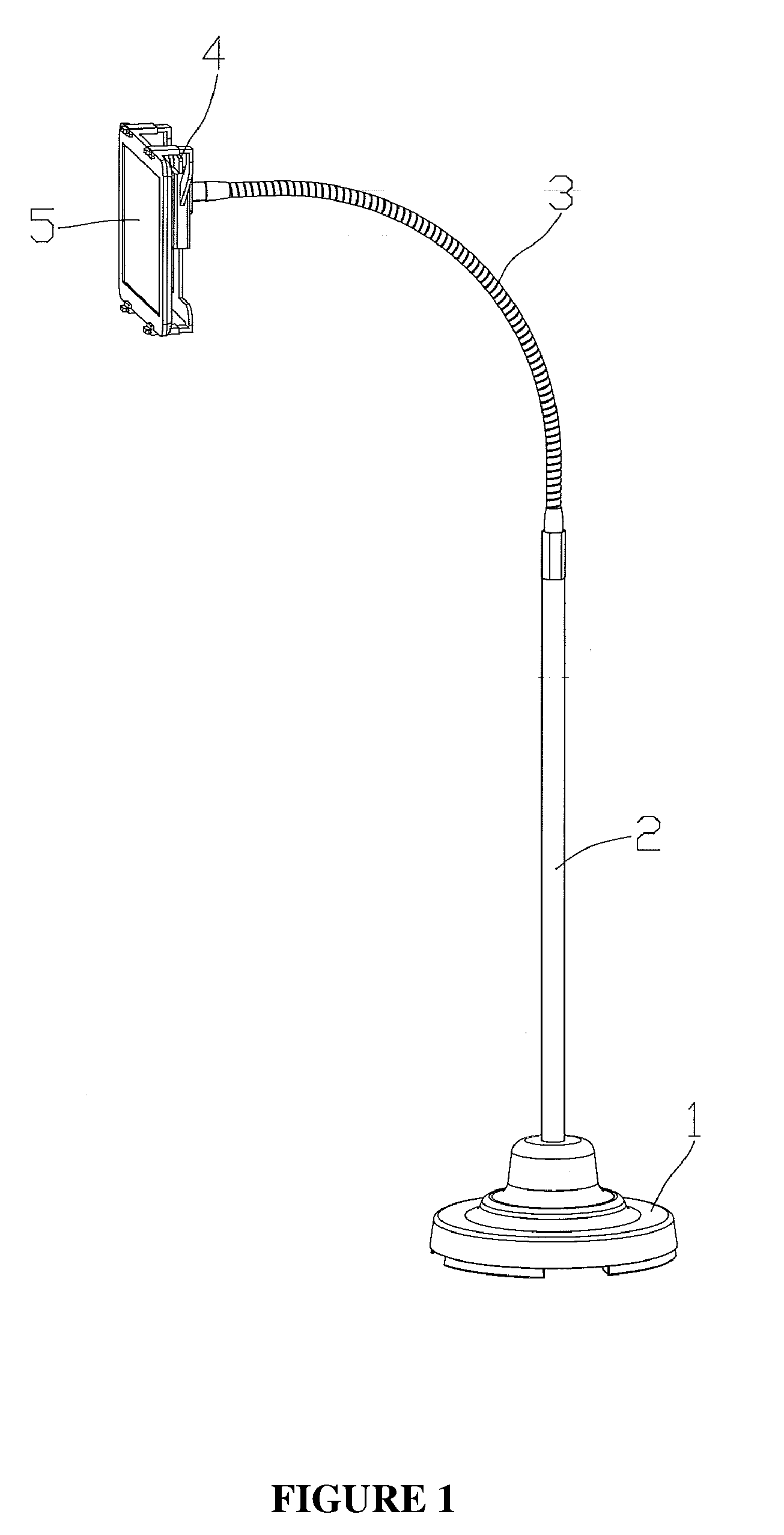

Tablet PC Stand

InactiveUS20120187257A1Prevent eyesSpace minimizationStands/trestlesKitchen equipmentWhole bodyEngineering

A computer accessory for provides a fixing stand for tablet PC or other e-book products such as “ipad®” comprising: a base; a height rod, which is vertical to the base; a metal hose, at which one end of the hose is fixed to the top end of the height rod; and a fixing holder, connecting to the other end of the metal hoses for clamping tablet PC or e-book. For user's convenience, the tablet PC stand can be moved with the whole body. Users can bend the metal hoses as like. The fixing holder can be rotated at 360 degrees to adjust tablet PC or e-book's best place in height, horizontal and angle and make users in the best comfortable gestures.

Owner:ZOU JIANHUA

Exhaust pipe for motor vehicle

InactiveCN103925056ASimple structureSimple preparation processExhaust apparatusSilencing apparatusExhaust pipeMetal hose

The invention discloses an exhaust pipe for a motor vehicle. The direction of the exhaust pipe for the motor vehicle can be changed flexibly according to requirements. According to the technical scheme, a metal hose is additionally arranged at the tail end of the exhaust pipe for the motor vehicle. The exhaust pipe for the motor vehicle comprises an exhaust pipe body, the metal hose and a screw, wherein the exhaust pipe body is fixedly connected with the metal hose through the screw, and the metal hose is connected to the tail end of the exhaust pipe body in a sleeved mode. By the adoption of the technical scheme, the exhaust pipe is simple in structure, the manufacturing technique is simple and convenient to realize, using is convenient, and the direction of the exhaust pipe of the motor vehicle can be changed flexibly according to requirements.

Owner:胡素芳

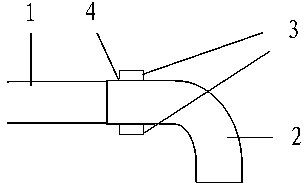

Liquid steel temperature fast response infrared continuous measuring device

InactiveCN101021439ALow densityQuick responsePyrometry using electric radation detectorsPyrometry using radiation pressureFiberPower cable

An infrared device can measure quick-response of liquid steel temperature continuously. It contains temperature tube, temperature gun, tubular conical connecter packaged on open end of temperature tube and measuring probe equipped in center of upper cavity. Upper open end of temperature gun is connected with a protective metal hose, which both as the delivery channel of cooling gas and laying channel of fiber optic cable, communication and power cable. Cavity outside protective shell of inner measuring probe of temperature gun is cooling gas channel. In the middle of temperature gun set a measuring locator with gas caulking ring. Tubular measuring locator is under gas caulking ring and there are many blow holds on their joint. A microtubule honeycomb duct spirals on central port of caulking ring. The conical connecter inserts in the measuring locator. The invention adopts special function of training temperature gun and monolayer temperature tube with high temperature conductivity to realize except baking, quick response and precious dynamic measuring of the temperature tube.

Owner:MAGANG (GROUP) HOLDING CO LTD

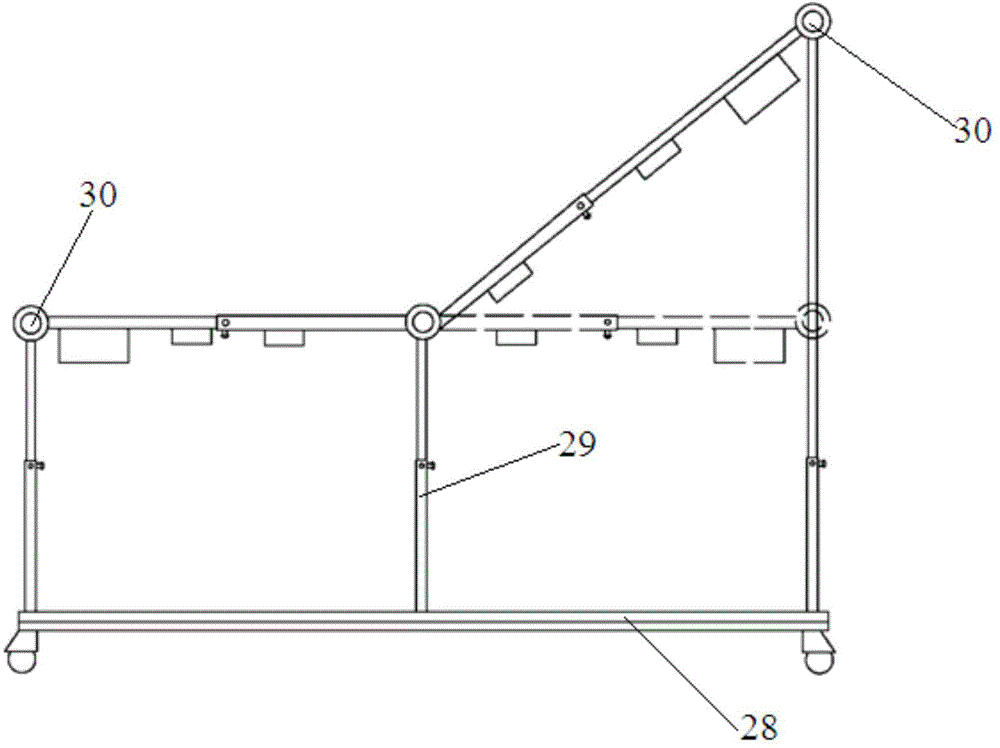

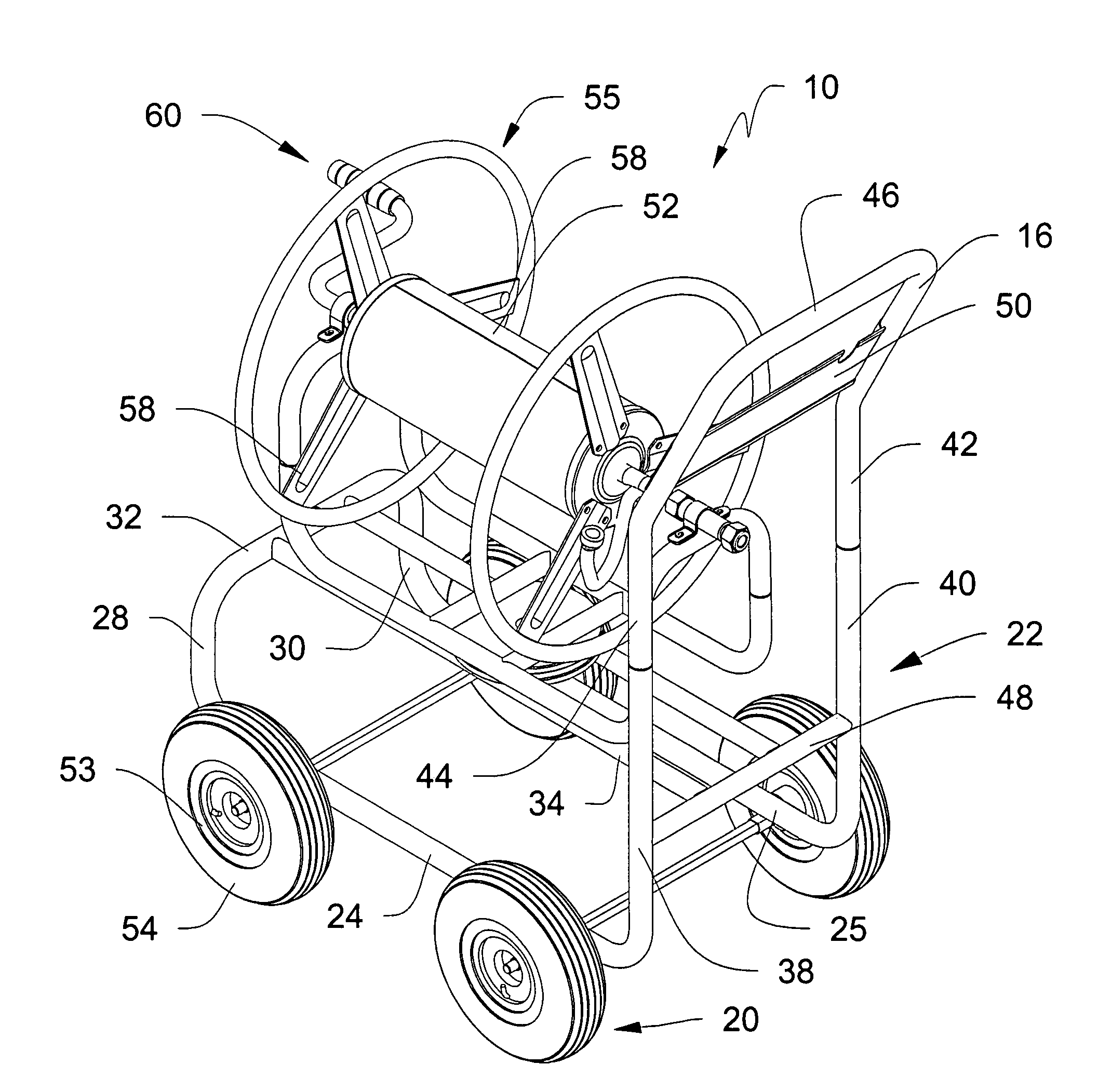

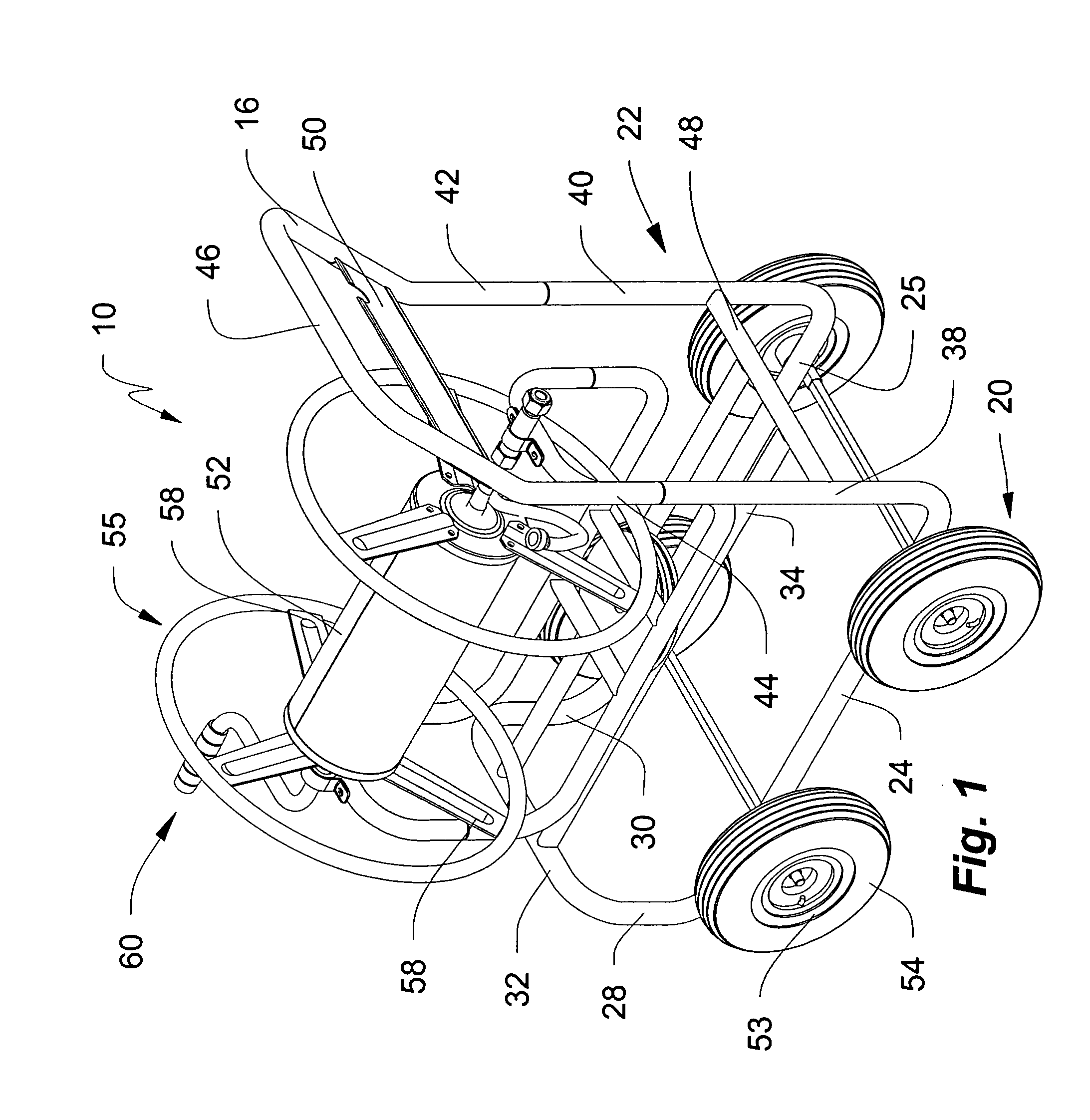

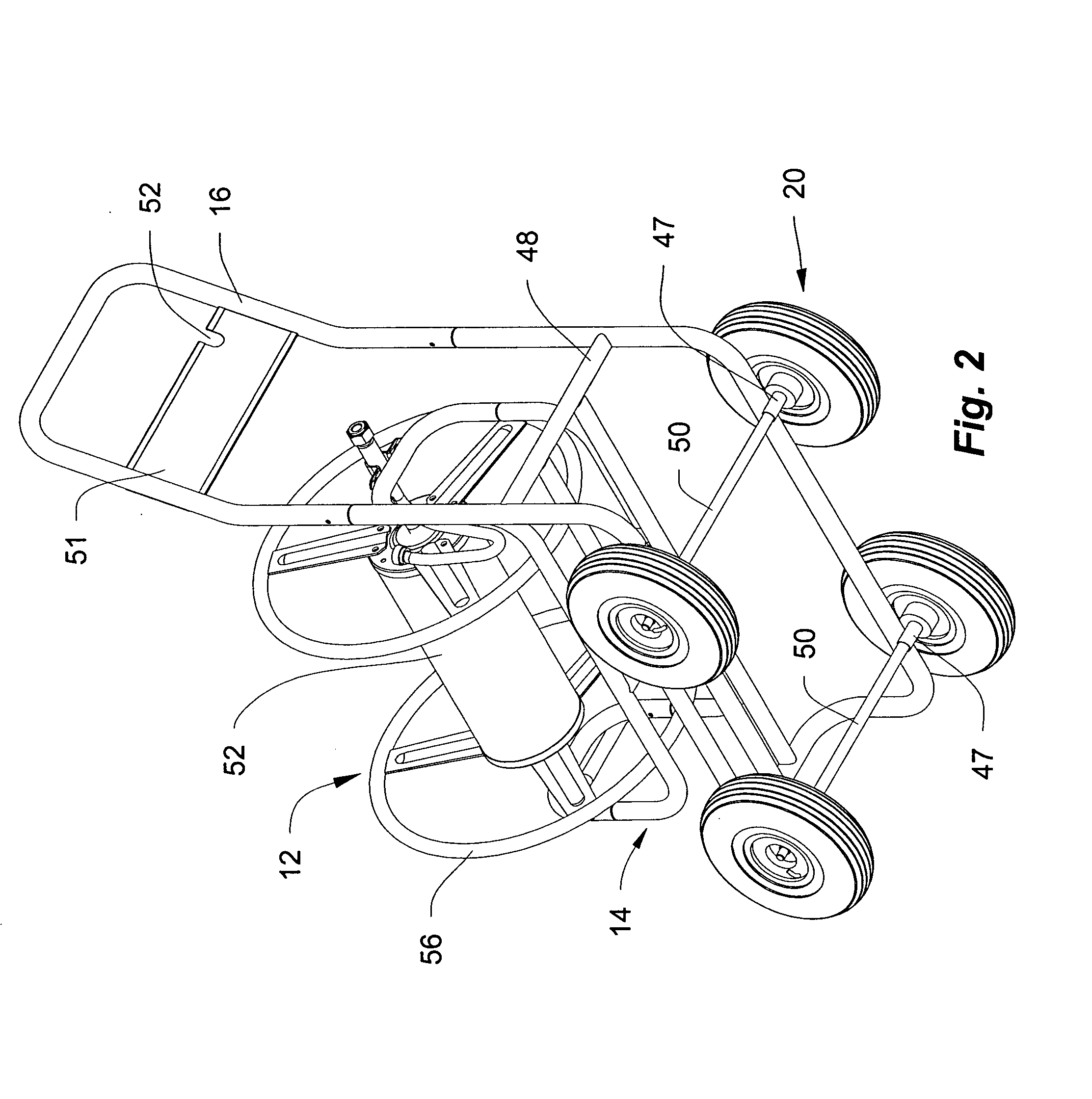

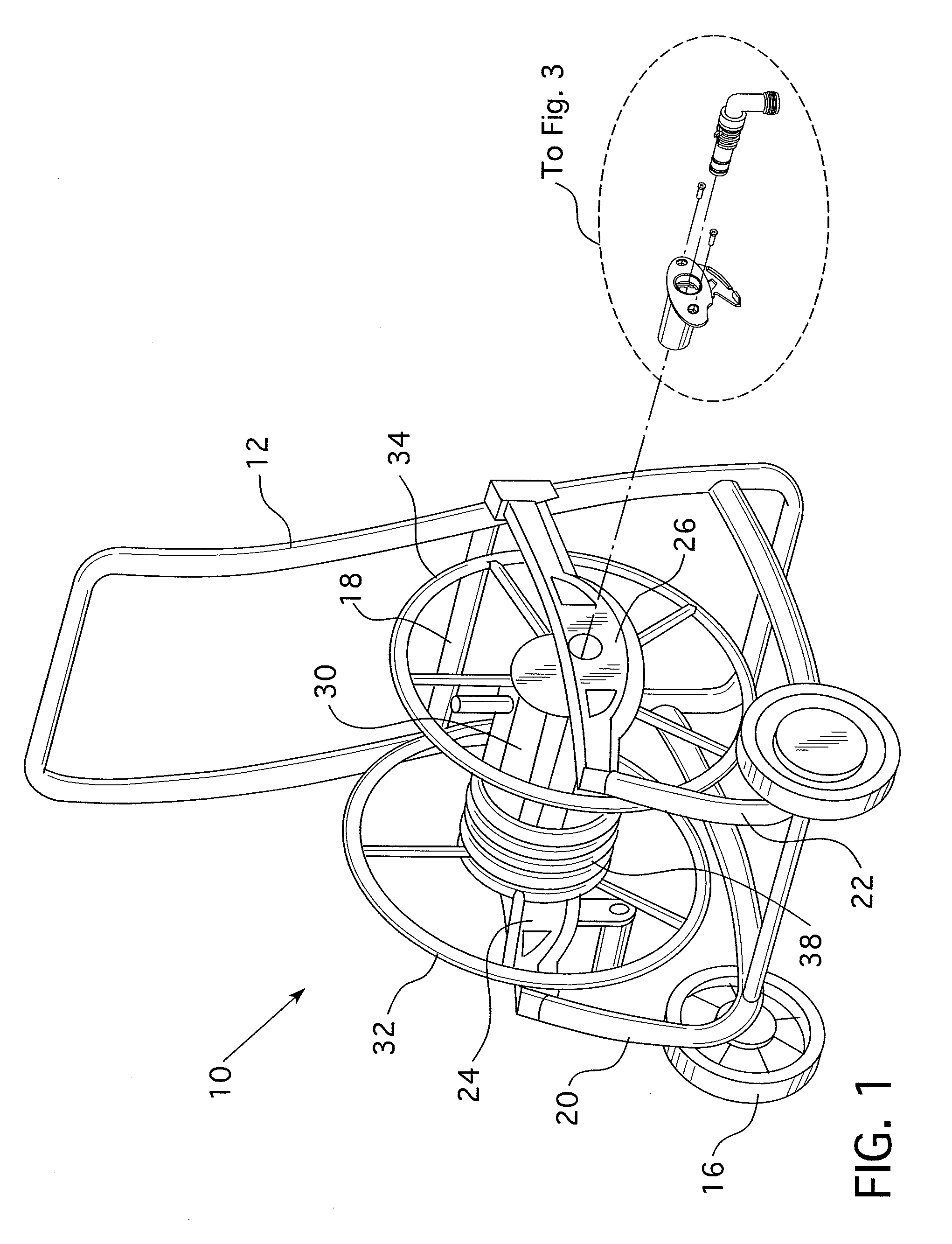

Swivel metal hose cart

InactiveUS20080066808A1Increased durabilityImprove stabilityTank vehiclesWatering devicesMetal hoseCart

A hose reel cart utilizes metal and coated metal component construction for increased durability and stability while still remaining lightweight for increased hose capacity and maneuverability. Additionally the hose reel can pivot about an axis which is substantially perpendicular to the horizontal rotary axis of the hose reel thereby enabling the hose to be readily removed from the hose reel irrespective of the location of the user without the danger of the hose reel cart tipping over. This pivoting ability of the hose reel also permits the hose to be wound onto the hose reel evenly irrespective of the location of the hose without the user having to constantly reposition the hose reel cart. This pivoting ability also enables the use of a wider than normal hose reel thereby increasing the capacity of the length of hose which can be carried on the reel. Further, the hose is wound around the reel by use of a crank which provides a direct rotational link between the crank and the winding of the reel.

Owner:SUNCAST

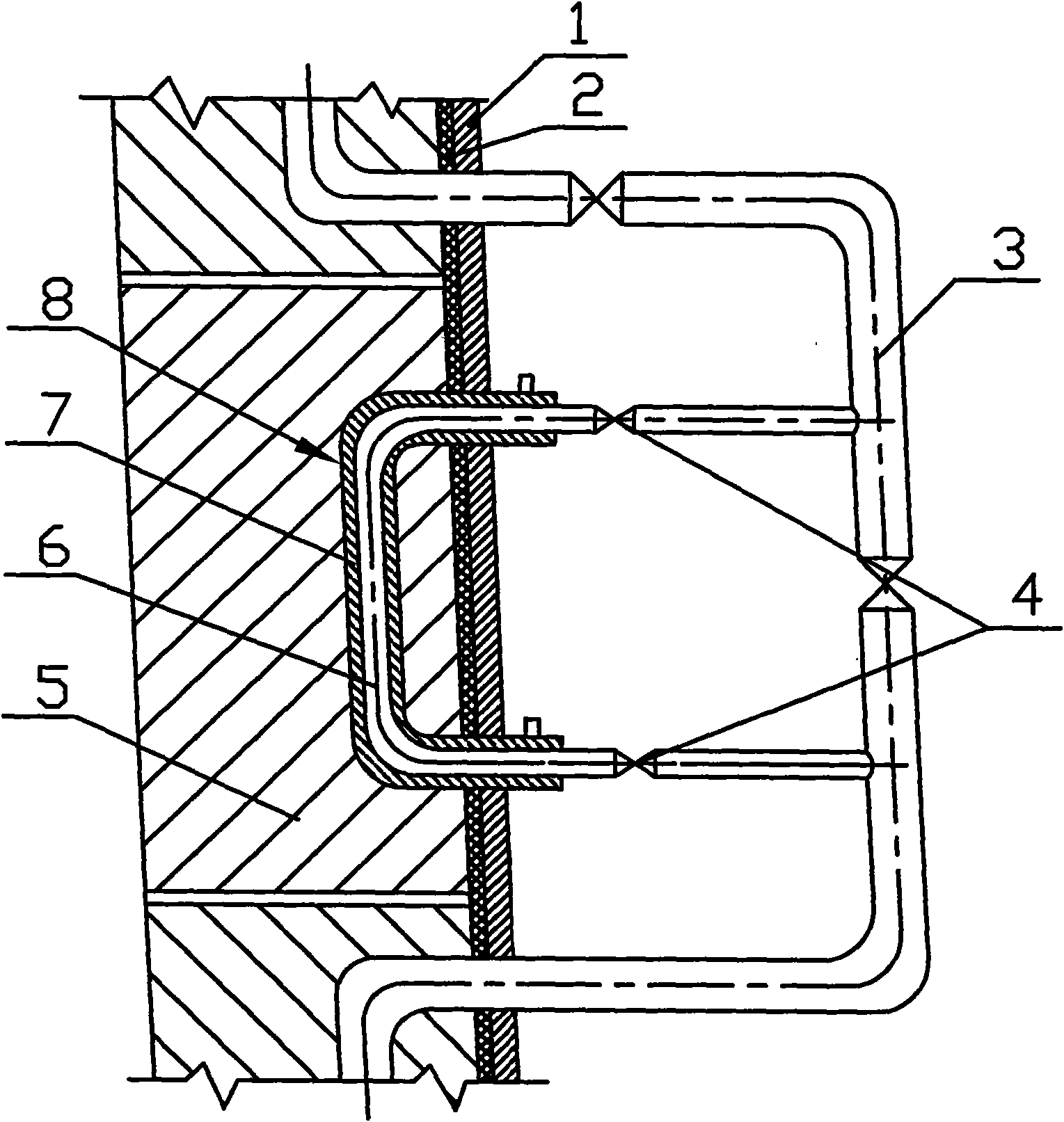

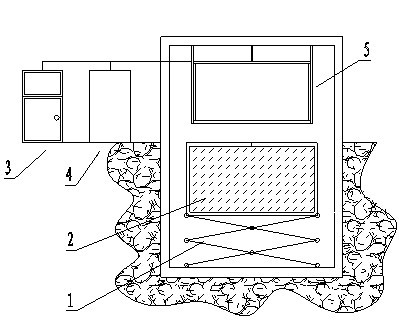

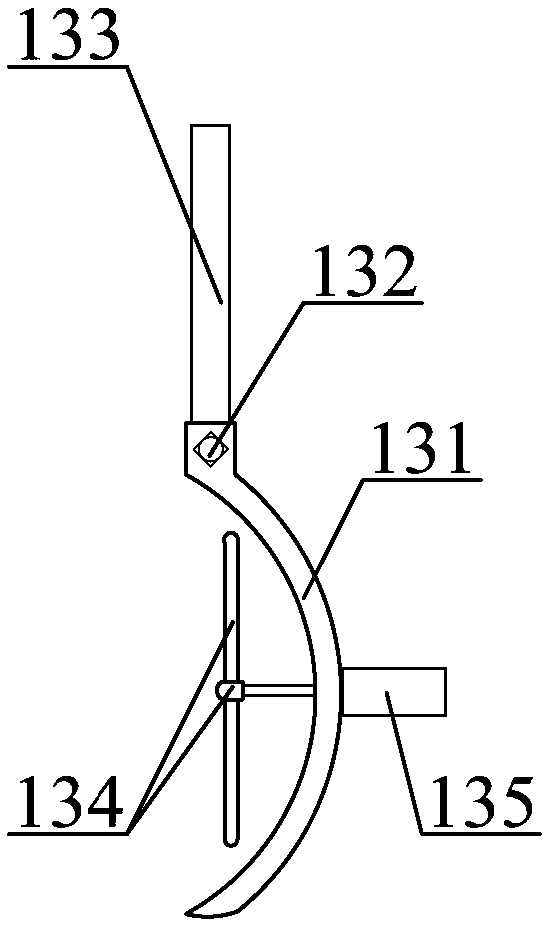

Method for preparing water cooling system of blast furnace cooling wall

The present invention relates to a method for preparing water cooling system of blast furnace cooling wall. A technical scheme is that: the cooling system includes a cooling water pipe (8) and an outer water pipe (3), the cooling water pipe (8) communicates with the outer water pipe (3), the cooling water pipe (8) is beset on the blast furnace cooling wall (5) passing through a furnace shell (1) and a filling agent layer (2). When the cooling water pipe (8) is broke and water leakage in the blast furnace cooling wall (5), the cooling water pipe (8) disconnects with the outer water pipe (3) on the furnace shell (1), then a metal flexible pipe (6) passes through the cooling water pipe (8), and two ends of the metal flexible pipe (6) communicates with the disconnected out water pipe (3). The metal flexible pipe (6) located on the furnace shell outside is equipped with a valve for controlling, grouting material (7) is filled between the metal flexible pipe (6) and the furnace shell (1). The method has characteristics of convenient operation, safety, low cost and superior integrality which can be widely used for preparing the water pipe with water leakage in the blast furnace cooling wall system.

Owner:WUHAN WINNING TECH

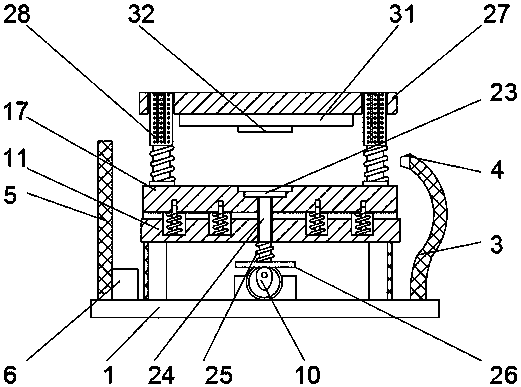

Hardware stamping die

InactiveCN107838295ANot easy to damageNot easy to shiftShaping toolsNon-rotating vibration suppressionDrive shaftAir pump

The invention discloses a hardware stamping die. The hardware stamping die comprises a base, a metal hose, a spray nozzle, a scrap blocking plate, an electromagnet, a cam, a vibration damper plate, damping springs, a buffer cushion, a material push plate, a sleeve and heat dissipation slots. One end of the metal hose is provided with the spray nozzle, the side face of the lower portion of the scrap blocking plate is provided with the electromagnet, and one end of an electromotor is provided with a speed reducer. One end of a transmission shaft is connected with the cam in a sleeved manner, thedamping plate is arranged above the base, the damping plate is connected with the base through supporting rods, and positioning pillars are sleeved with the vibration damper springs. The bottom faceof the material push plate is connected with a push rod, the bottom end of the push rod is connected with a push plate, and the outer side of the sleeve is uniformly provided with the heat dissipationslots. The electromotor is utilized to drive the cam to push the material push plate, materials are taken conveniently, and a workpiece is not prone to be damaged; the vibration damper springs in thedamping plate are utilized to absorb vibration generated in the stamping process, vibration reduction performance is good, and the die is not prone to be damaged; and scraps are blown away through the metal hose connected with an air pump and blocked by the scrap blocking plate, and stamping and cleaning are facilitated.

Owner:梅州华盛辉科技有限公司

Replacement method for cooling water pipe of cooling wall of blast furnace

InactiveCN102534078AThe replacement method is simple and easyEasy to operateCooling devicesFurnace temperatureWater leakage

The invention provides a replacement method for a cooling water pipe of a cooling wall of a blast furnace. A broken cooling water pipe is disconnected with a front cooling water pipe and a rear cooling water pipe; and the front cooling water pipe and the rear cooling water pipe are connected through an external water pipe, so that cooling water is directly circulated across the broken cooling water pipe. Meanwhile, a metal hose is penetrated in the broken cooling water pipe and is connected to a replaced cooling water pipe, which is communicated with an external water source, through seamless steel pipes at the two ends, so that cooling water in the metal hose independently forms a passage to continuously realize a cooling function. By using the method, quick replacement of the broken cooling water pipe is realized without affecting normal water supply cooling of other cooling water pipes, the water leakage phenomenon in the blast furnace is eliminated, the problem of increased coke ratio caused by reduced furnace temperature is prevented, the cooling function of the broken cooling water pipe is restored, the cooling effect of the cooling wall is guaranteed, and the service life of the cooling wall can be prolonged.

Owner:ANGANG STEEL CO LTD

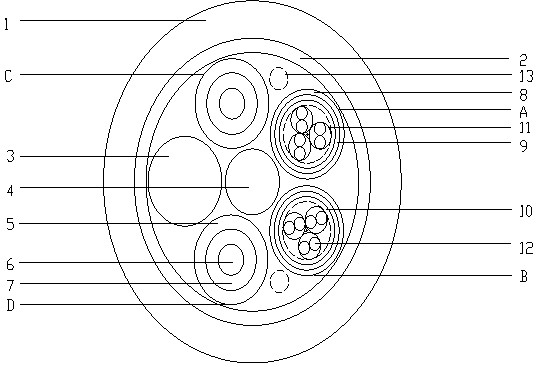

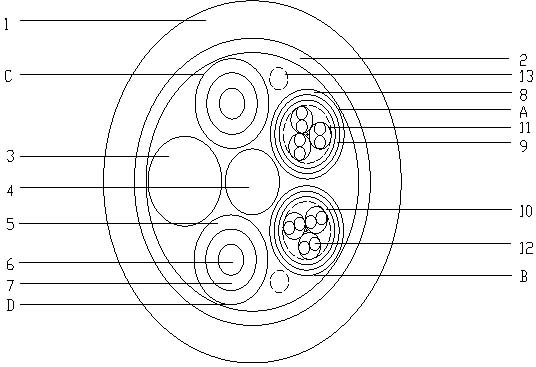

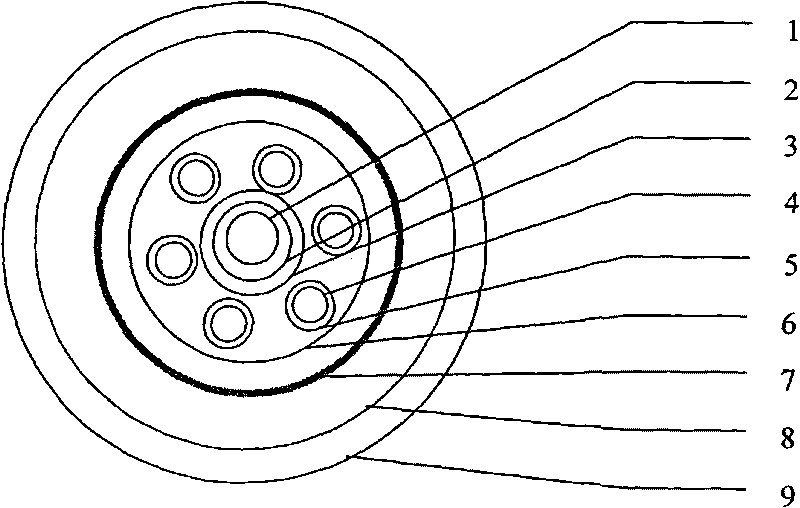

Photoelectric combination cable

The invention relates to a photoelectric combination cable, which comprises an optical unit, a feeder line unit and a center reinforcement. The photoelectric combination cable is characterized in that the optical unit is provided with a plurality of dual-core semi-tight tube optical fiber protection layers, dual-core full-chromatograph optical fibers are arranged in the dual-core semi-tight tube optical fiber protection layers, multiple strands of aramid fiber reinforced yarns are longitudinally wrapped outside the dual-core semi-tight tube optical fiber protection layers, stainless steel metal hoses are spirally wrapped on the outer parts of the multiple strands of aramid fiber reinforced yarns, polyurethane jackets are extruded on the outer parts of the stainless steel metal hoses to form protection layers, a copper conductor is arranged in the center of the feeder line unit, a plurality of insulation layers are arranged on the copper conductor, polyurethane jackets are arranged on the outer parts of the insulation layers to form protection layers, the outer diameter of the optical unit is equal to that of the feeder line unit, the optical unit, the feeder line unit and a filling rope are twisted around a non-metal center reinforcement, water-stopping yarns are filled in a gap of the cable core, a water-stopping band is arranged outside the water-stopping yarns and an outer jacket is arranged on the outer part of the water-stopping band. The photoelectric combination cable has the advantages of reasonable design, compact structure, good flexibility, high mechanical strength, weather resistance, pressure resistance, good heat resistance, excellent fire resistance, high safety and wide application range.

Owner:宏安集团有限公司

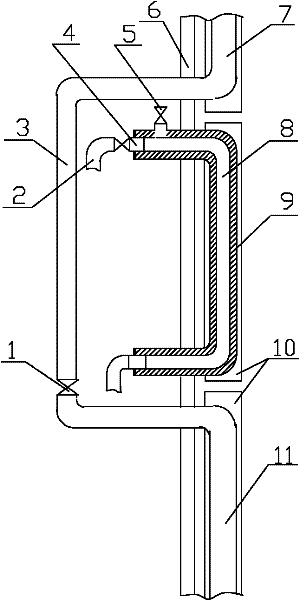

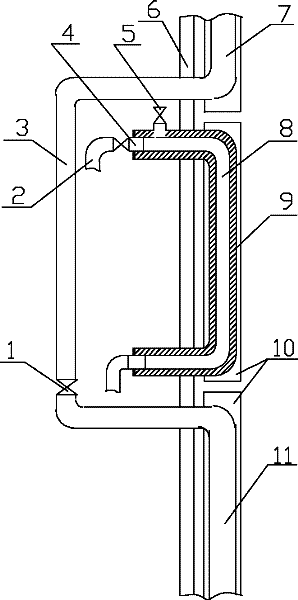

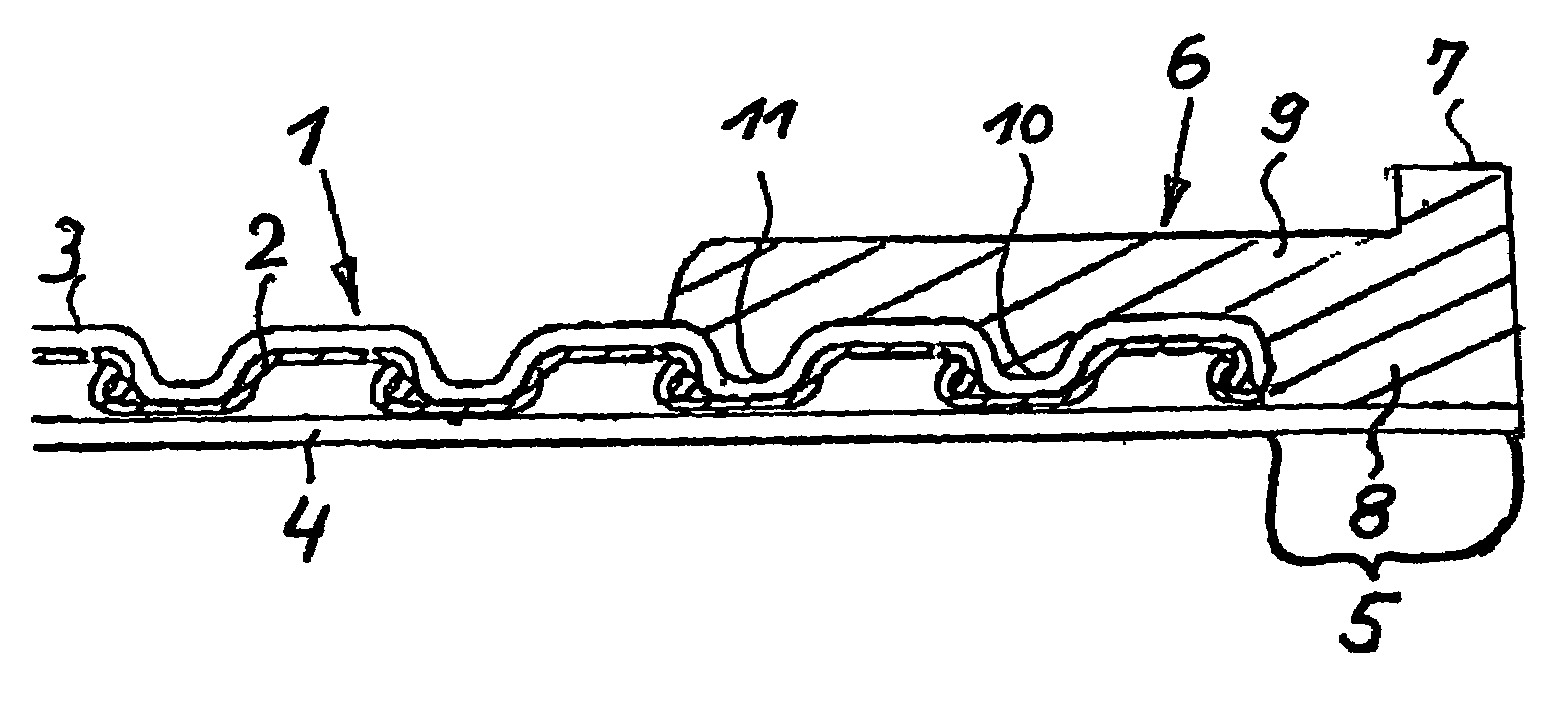

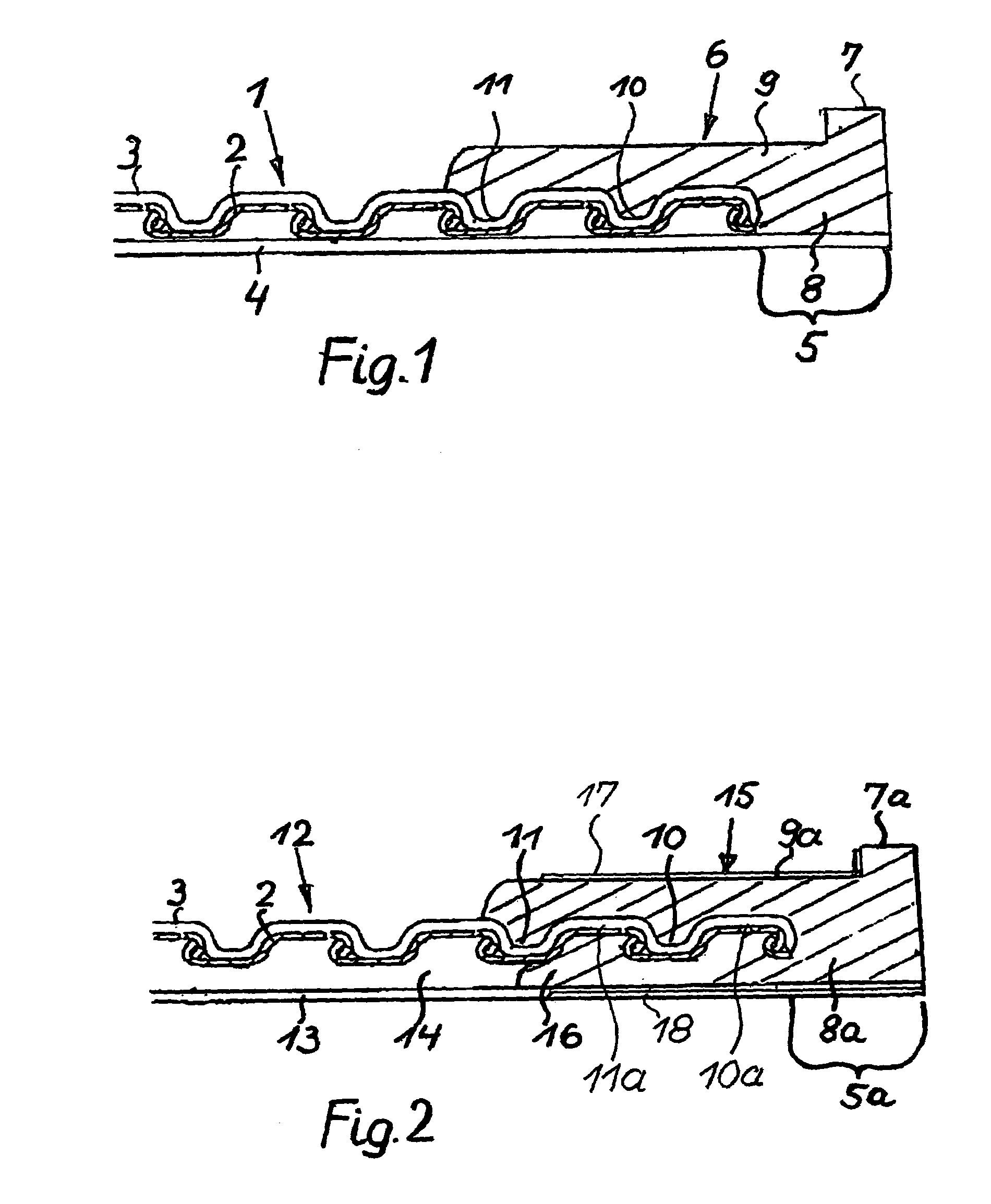

Flexible conduit, particularly for sanitary purposes

InactiveUS6971414B2Reduction in flow areaImprove sealingDomestic plumbingPipe elementsCouplingMetal hose

A flexible conduit includes a metal hose provided with a helical groove having a plurality of turns; a plastic jacket surrounding the metal hose and conforming to the helical groove thereof; a plastic inner hose received in the metal hose and having a projecting length portion extending beyond an end of the metal hose. The conduit further includes a plastic coupling part which surrounds the metal hose. The coupling part includes a cylindrical collar surrounding the projecting length portion and having a material-to-material bond therewith; and an overlapping portion adjoining the cylindrical collar and extending away therefrom. The overlapping portion surrounds the jacket and extends into the helical groove. The overlapping portion and the plastic jacket have a material-to-material bond with one another.

Owner:VOHRAN PATENTVERW

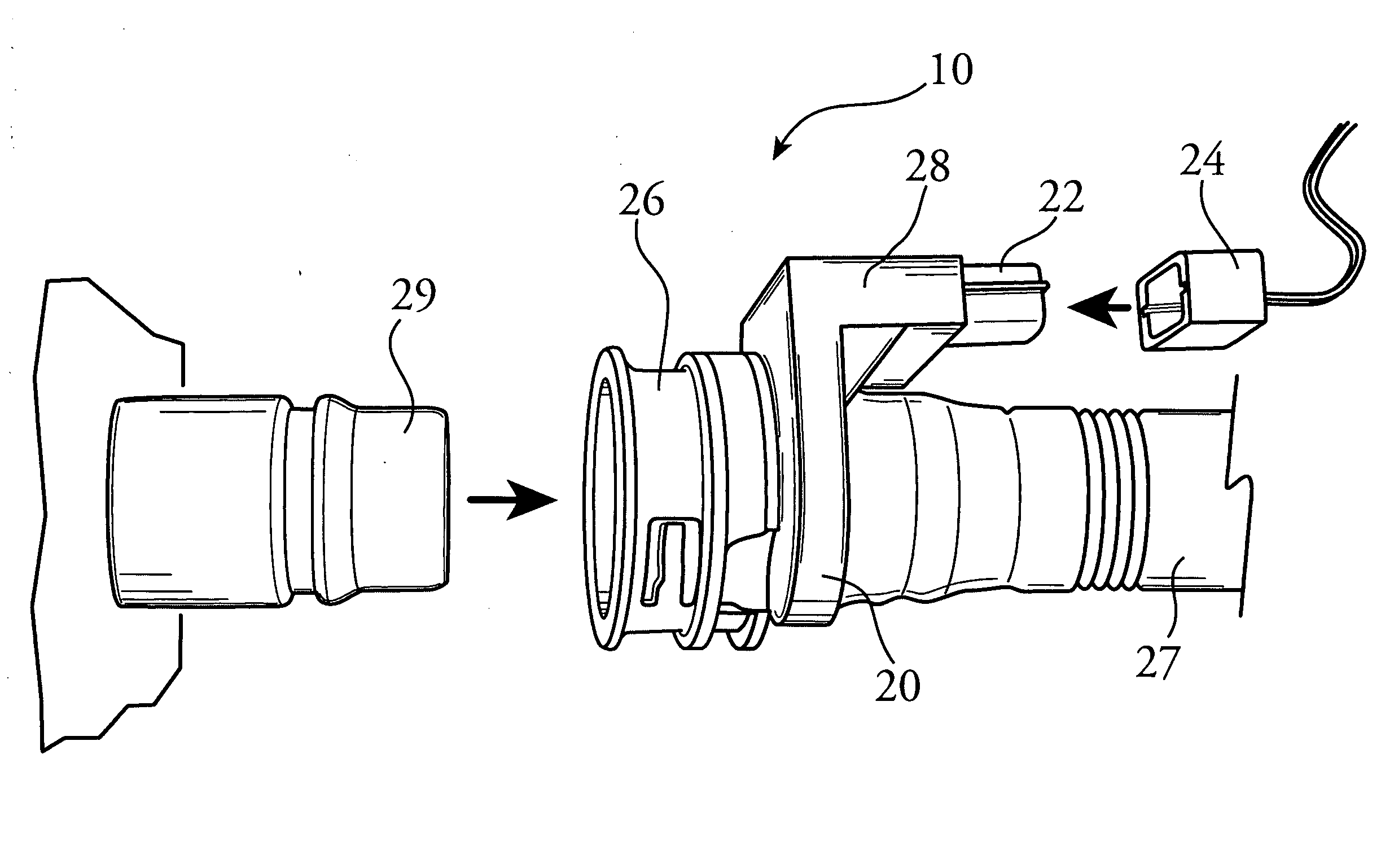

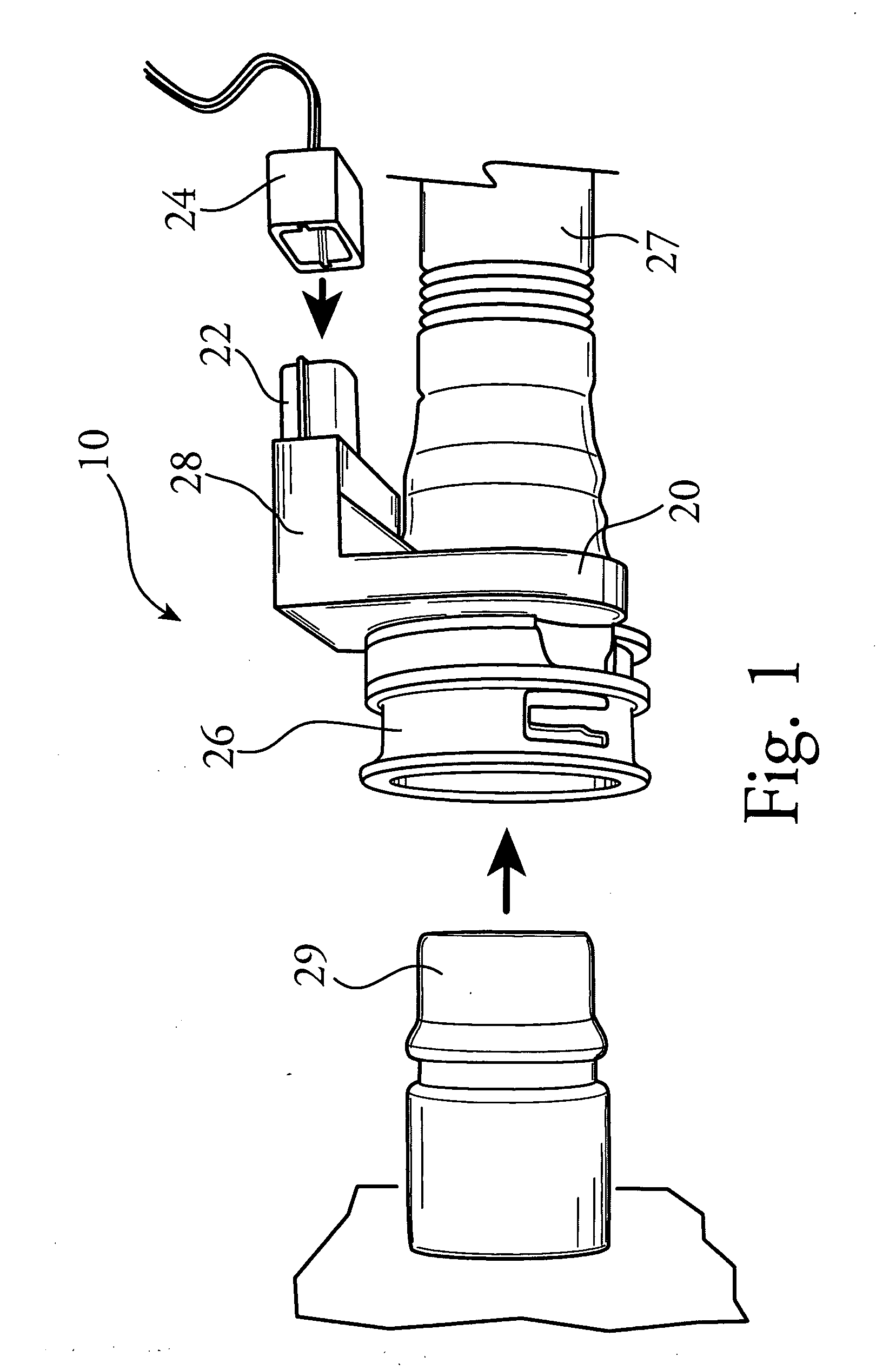

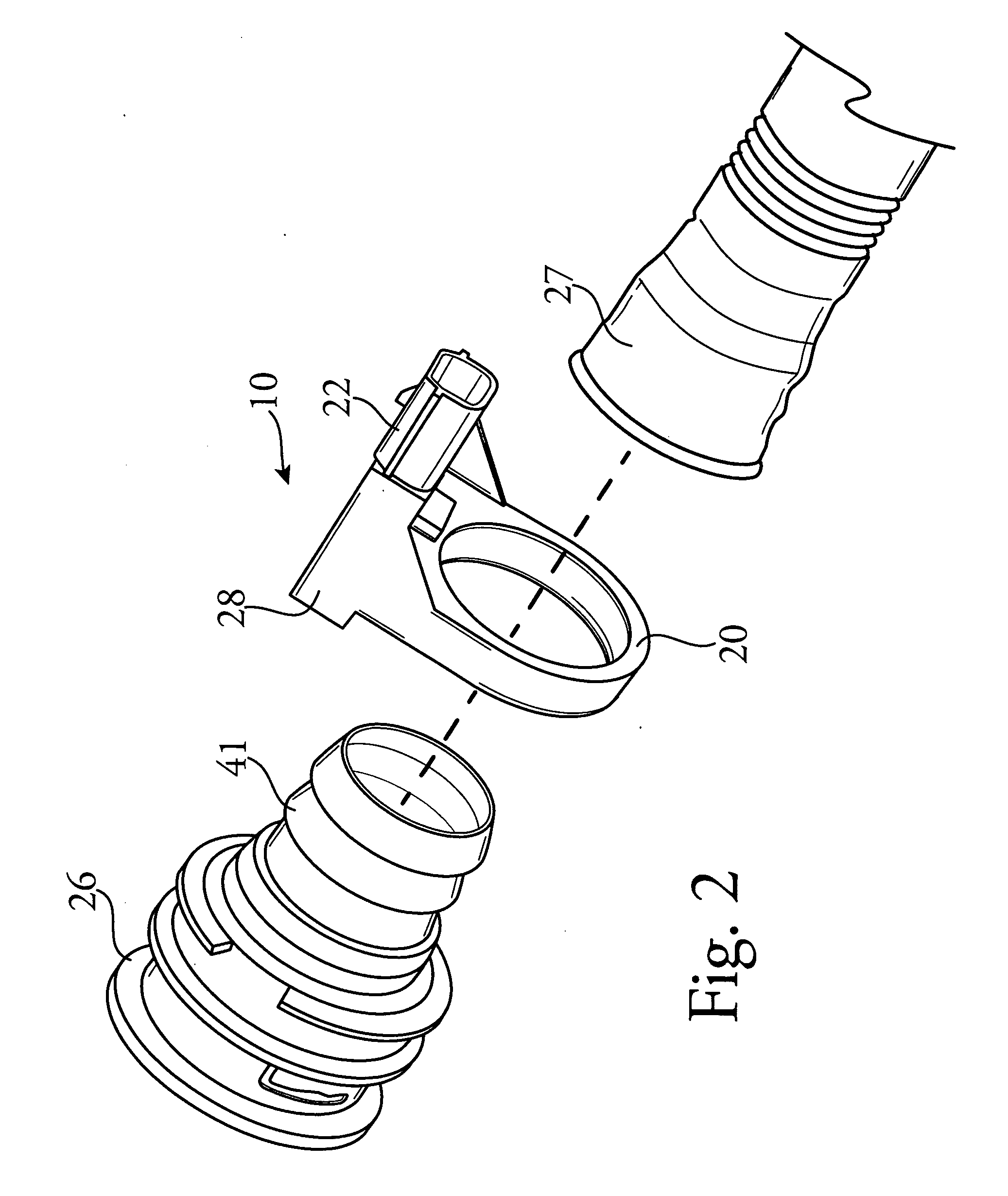

Quick connect sensor apparatus

InactiveUS20110133759A1Simple circuit designResistance/reactance/impedencePipe couplingsInductanceComparator

An electronic sensor for determining if a metal hose connector is fully snapped into its mating plastic connector. This sensor detects the metal hose in position by having a coil in position over the plastic connector and at the end of the metal hose when it is in correct position. The metal of the hose interacts with the magnetic field of the coil to both increase the inductance and greatly reduce the ‘Q’ because of the “shorted turn” effect of the round metal hose. The sensor inherently detects faults in its own circuit because of the comparator voltage window. Faults such as an open coil, oscillator or rectifier failure will appear at the output as “hose disconnected” which is the desirable failure mode. The invention also detects external faults because of the two non-zero, non-line voltages seen during normal operation.

Owner:STANDEX INT CORP

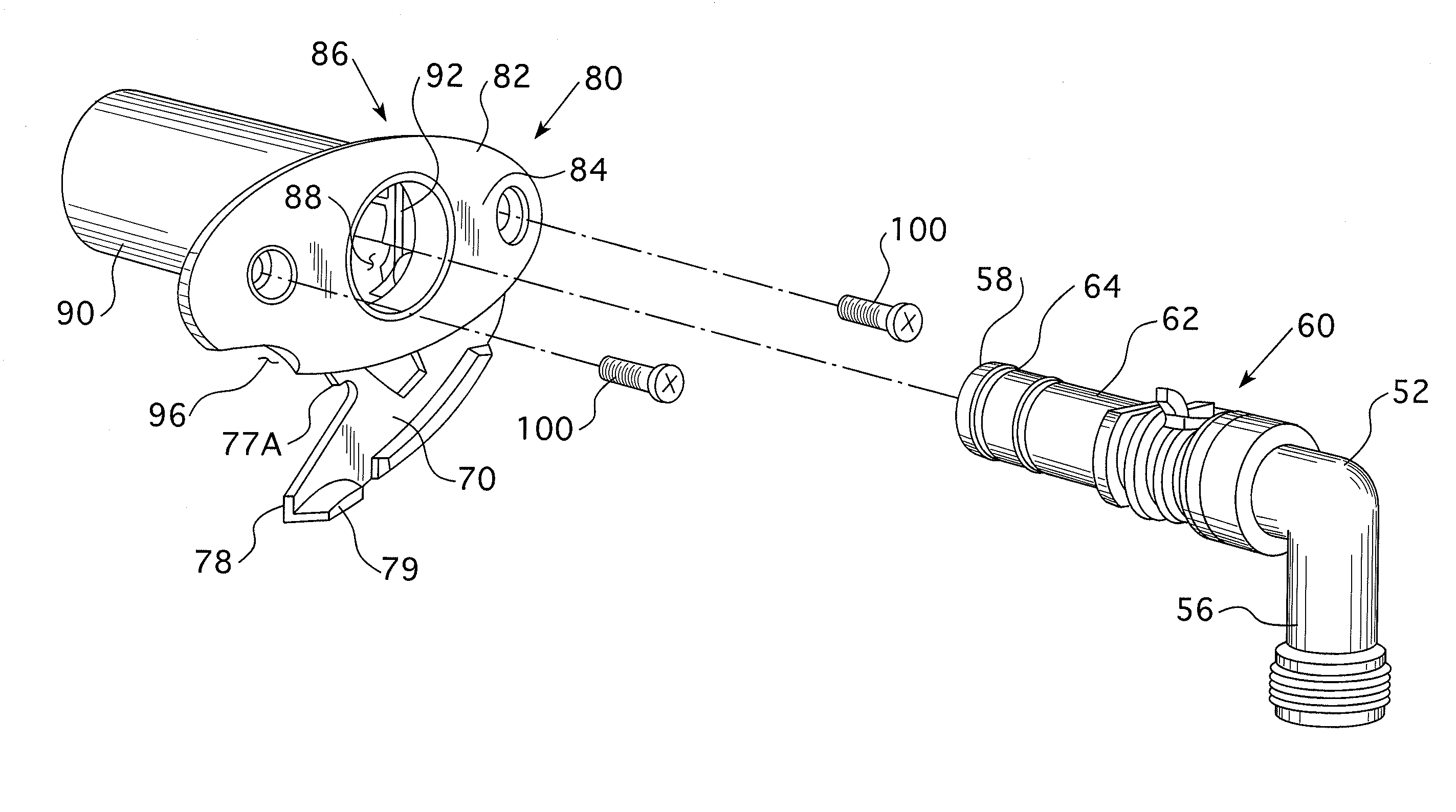

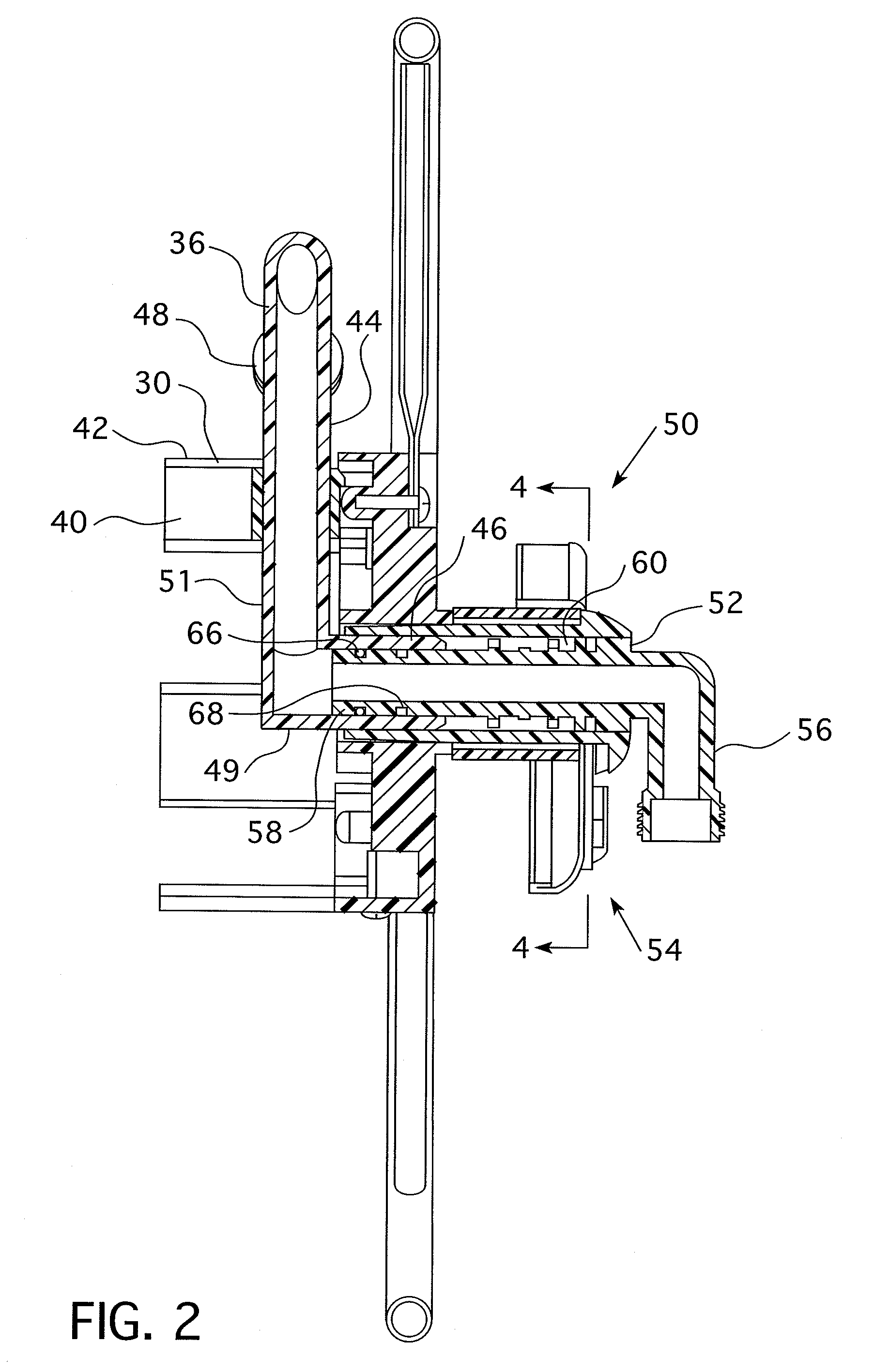

Metal hose reel water system

ActiveUS20090121067A1Quickly and easily actuateEasy to removeAdjustable jointsCouplings for rigid shaftsBiomedical engineeringMetal hose

An inlet conduit assembly for a hose reel assembly includes a clip assembly that is structured to be accessible from the outer side of the frame assembly. The clip assembly is structured to be operated without the use of tools. The clip assembly, essentially, prevents the inlet conduit assembly from being moved axially once installed. In this configuration, a user may quickly and easily actuate the clip assembly to release or engage the inlet conduit assembly. Thus, a user may quickly and easily remove the inlet conduit assembly.

Owner:IAMS

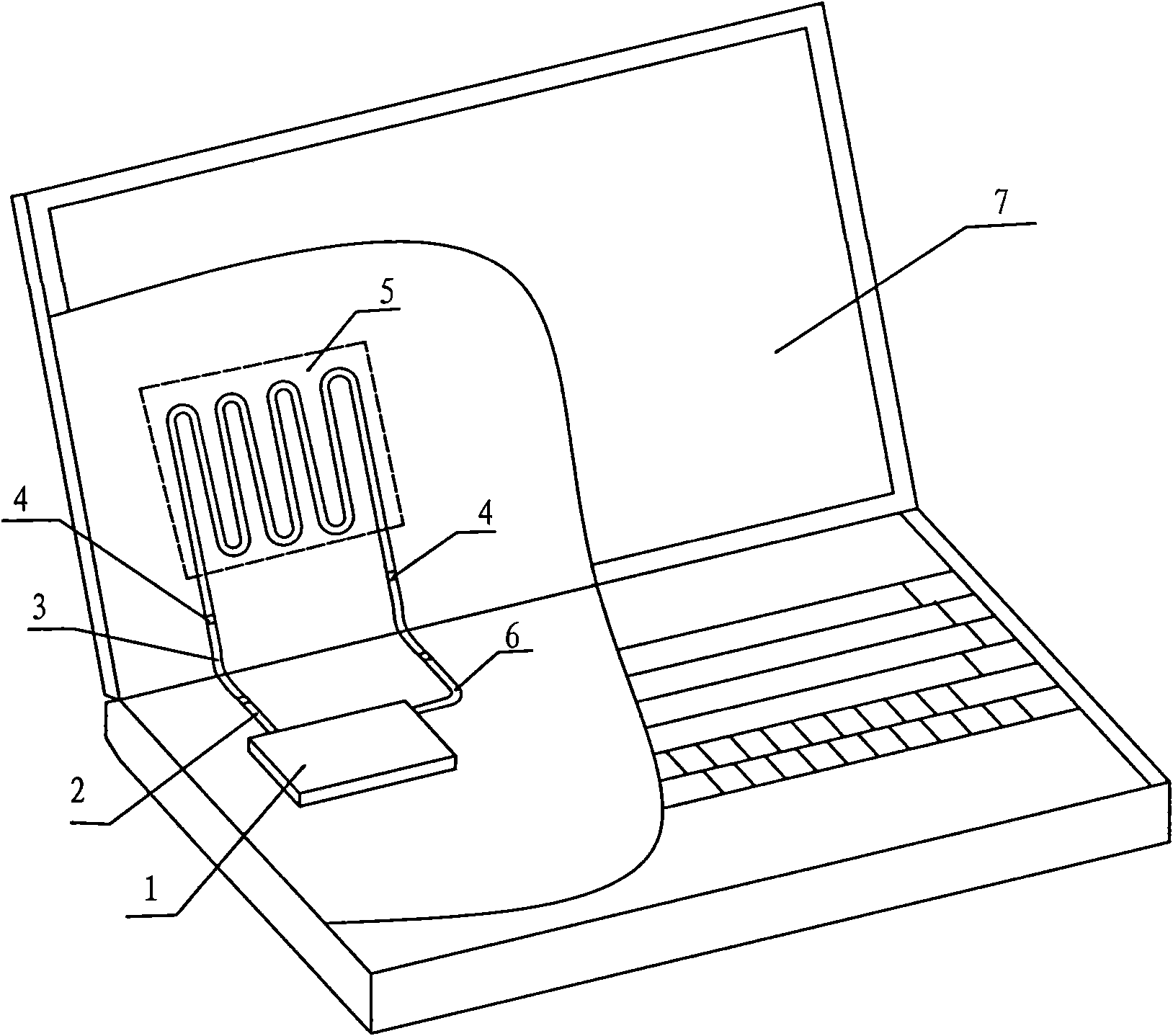

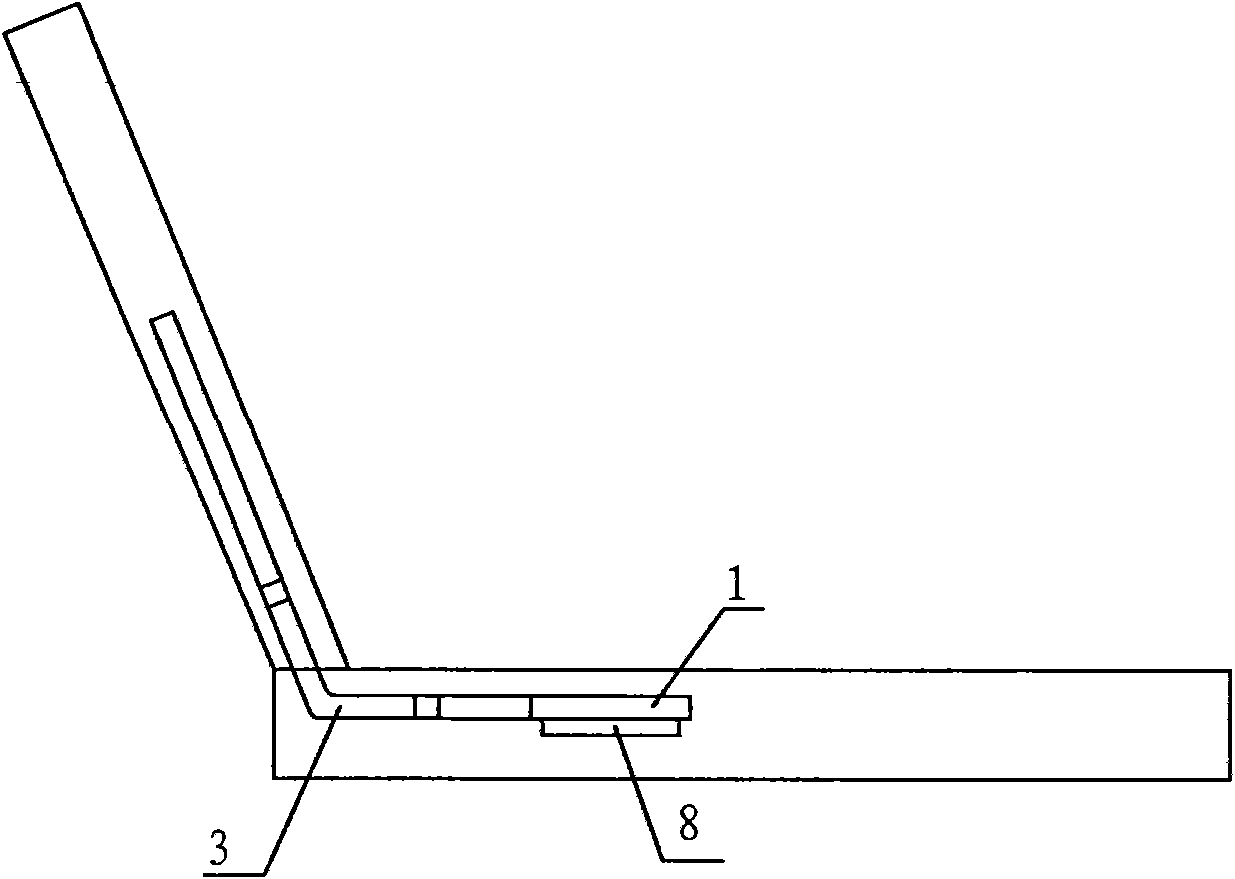

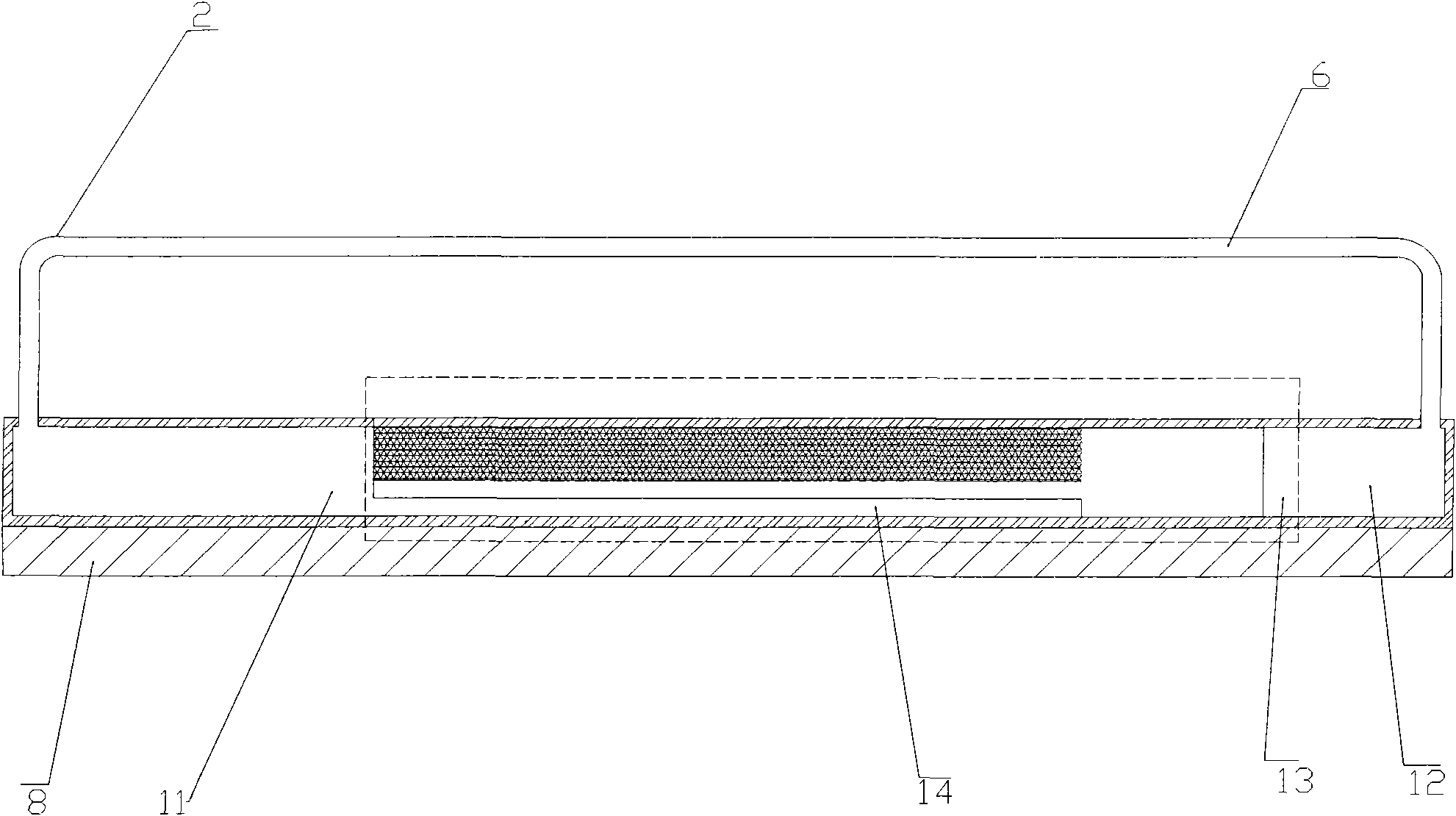

Heat dissipation device for notebook computer

InactiveCN101901036ASolve the cooling problemSatisfy the pursuit of thin and light requirementsDigital data processing detailsIndirect heat exchangersWorking fluidHeat conducting

The invention discloses a heat dissipation device for a notebook computer, which comprises a screen, an evaporation cavity, a liquid phase pipeline, a vapor phase pipeline, a flexible pipeline and a condensation section. The evaporation cavity is tightly connected with a chip by heat conducting silica gel; the condensation section consists of a bent pipeline loop and is positioned at the back of the screen of the notebook computer, and two joints of the pipeline loop of the condensation section are communicated with the vapor phase pipeline and the flexible pipeline respectively to form a circulation pipeline which is provided with working fluid, and the flexible pipeline is positioned at a connection part of a host of the notebook computer and the screen, and is made from a corrugated metal hose. Heat energy on the chip of the notebook computer is transferred to the condensation section at the back of the screen under the condition of no additional power, and the back of the screen is used as a heat dissipation surface so as to quickly dissipate the heat energy to the environment, and the flexible pipeline cannot be broken off when the notebook computer normally opens and closes. Thus, the stable operation of the notebook computer is guaranteed.

Owner:SOUTH CHINA UNIV OF TECH

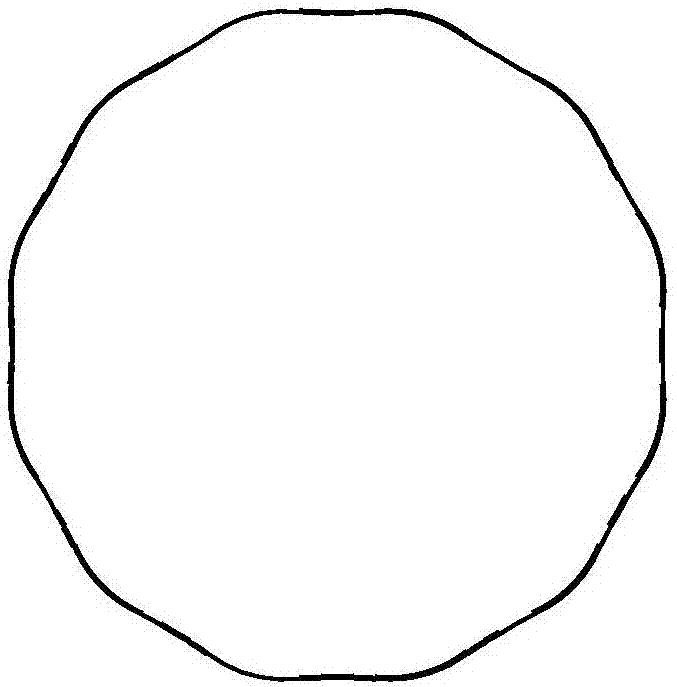

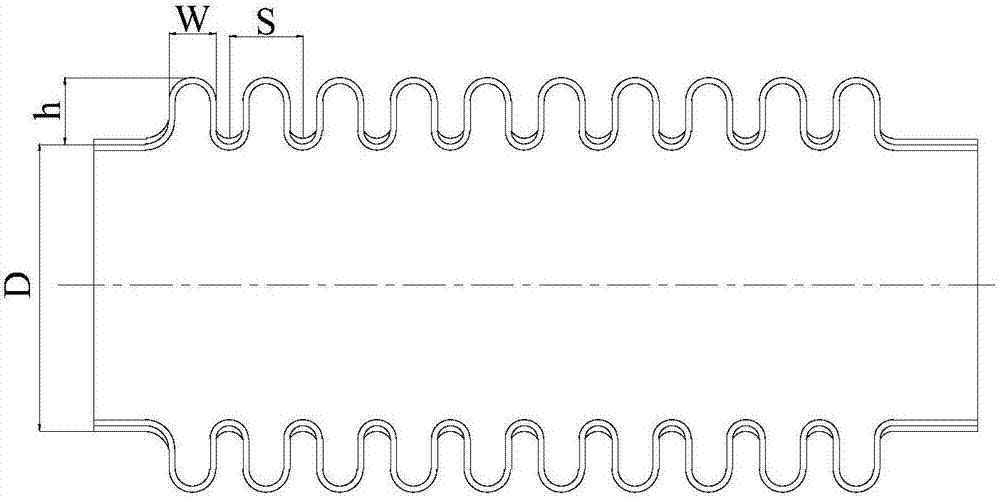

Metal bellows with axial stiffeners, and forming method

ActiveCN107413882AHigh bending deformation stiffnessExtended service lifeFlexible pipesEngineeringMetal

The invention provides a metal bellows with axial stiffeners. The metal bellows is a corrugated metal hose with the axial stiffeners at the wave trough position. The forming method of the corrugated metal hose comprises the steps of rolling plates to form corrugation, then curling and welding, and finally bulging on a bulging machine; flat expanding axial waves at the wave peak position so that the wave peak position has no the axial stiffeners, while the axial stiffeners at the wave trough position are reserved, so that the corrugated metal hose with the axial stiffeners at the wave trough position is obtained. The bending deformation rigidity of the corrugated metal hose is high; in case of axial elongation deformation, the deformation mainly focuses on the wave peak position, while the wave trough position is hardly deformed; and the service life of the corrugated metal hose is prolonged effectively.

Owner:JIANGSU HONGYUAN PIPES

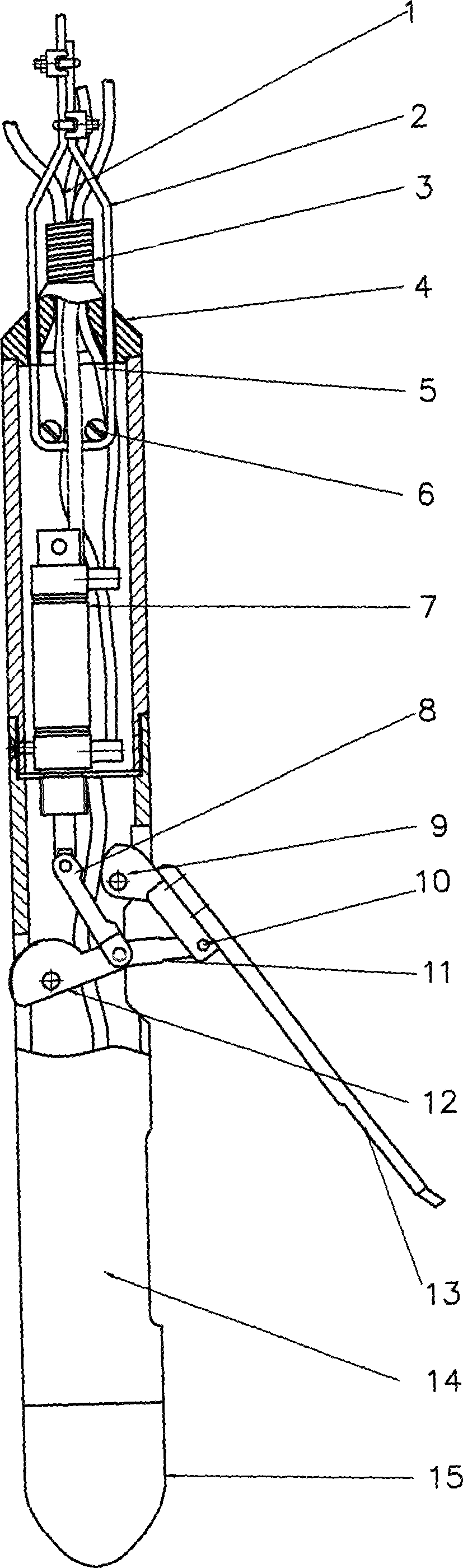

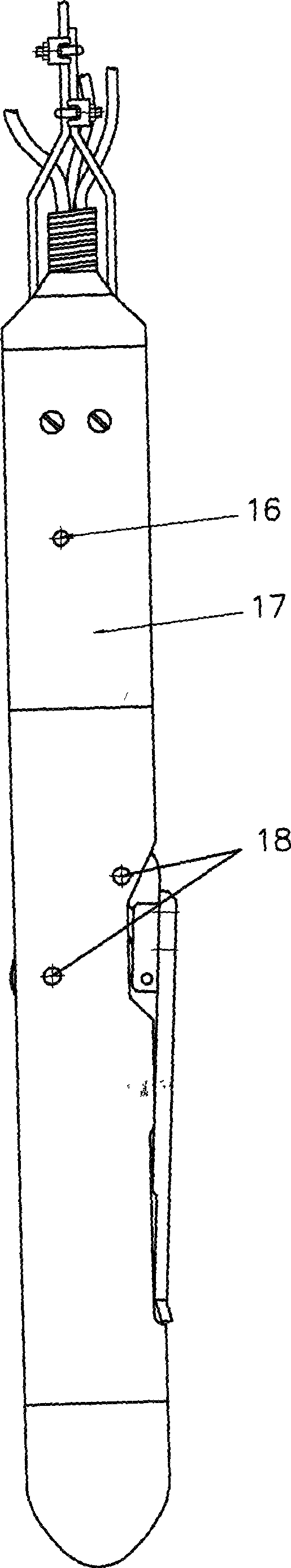

Well logging detector device

InactiveCN101545980ASimple structureAccurate receptionSeismic signal receiversSeismology for water-loggingWave detectionWell logging

The invention relates to a well logging detector device, which comprises a main body internally provided with a cylindrical structure, a weight body, a signal receiving device, a push-support device , a lift-pull device and a metal hose, wherein the signal receiving device is internally sealed with three detectors which are connected with a seismic apparatus on the ground by a cable along the main body and the inner wall of the metal hose; the push-support device is formed by a double-action circular cylinder, a supporting arm and a four-link mechanism; the link mechanism comprises a piston rod, a push rod, a supporting arm fixed block and a rotary block; a wire rope of the lift-pull device is fixed on a mandrel of the main body; and the metal hose is connected with an upper end cover of the main body. The push-support device adopts a mechanical push arm mode, has the characteristics of simple structure, convenient operation and accurate push-support position, and is convenient to gather and use in next construction. The well logging detector device is suitable for well logging and wave detection of oil seismic exploration, geological mining, constructional engineering, and the like.

Owner:WEIHAI SUNFULL GEOPHYSICAL EXPLORATION EQUIP

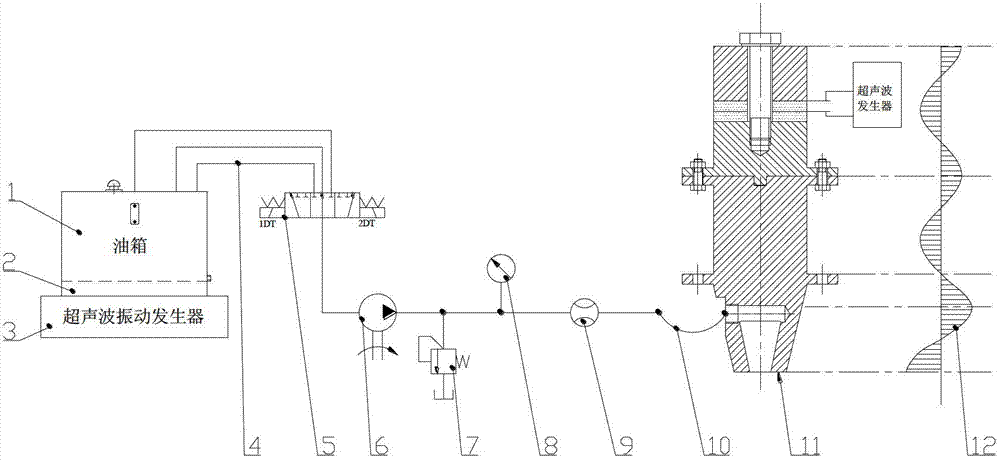

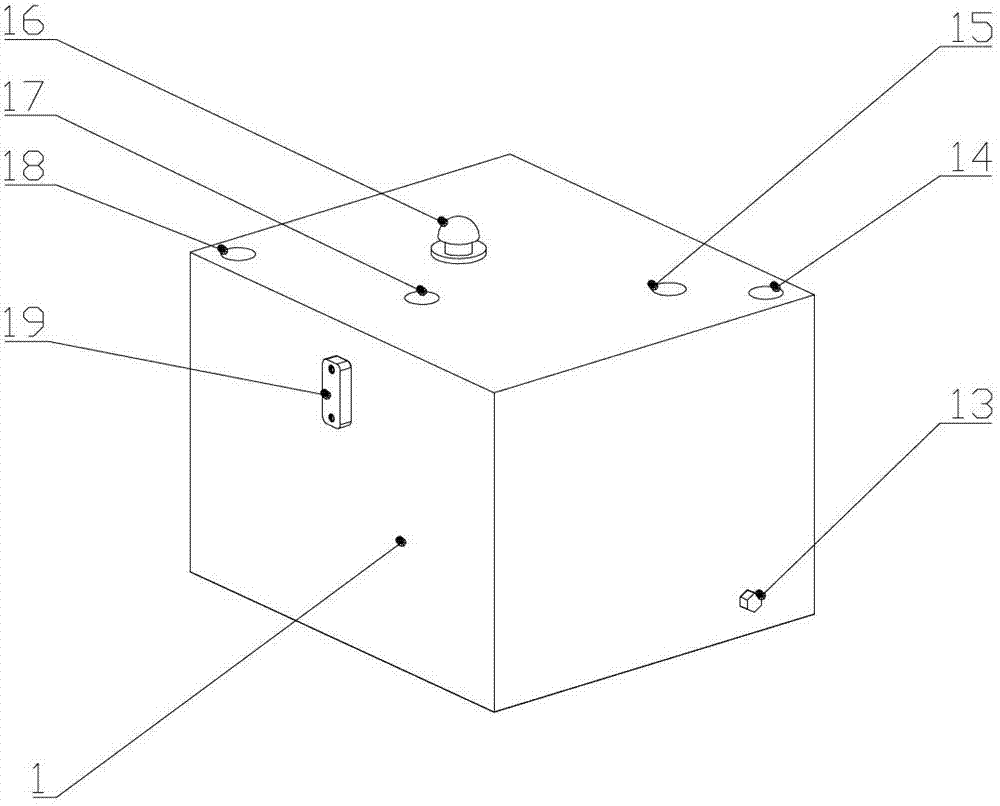

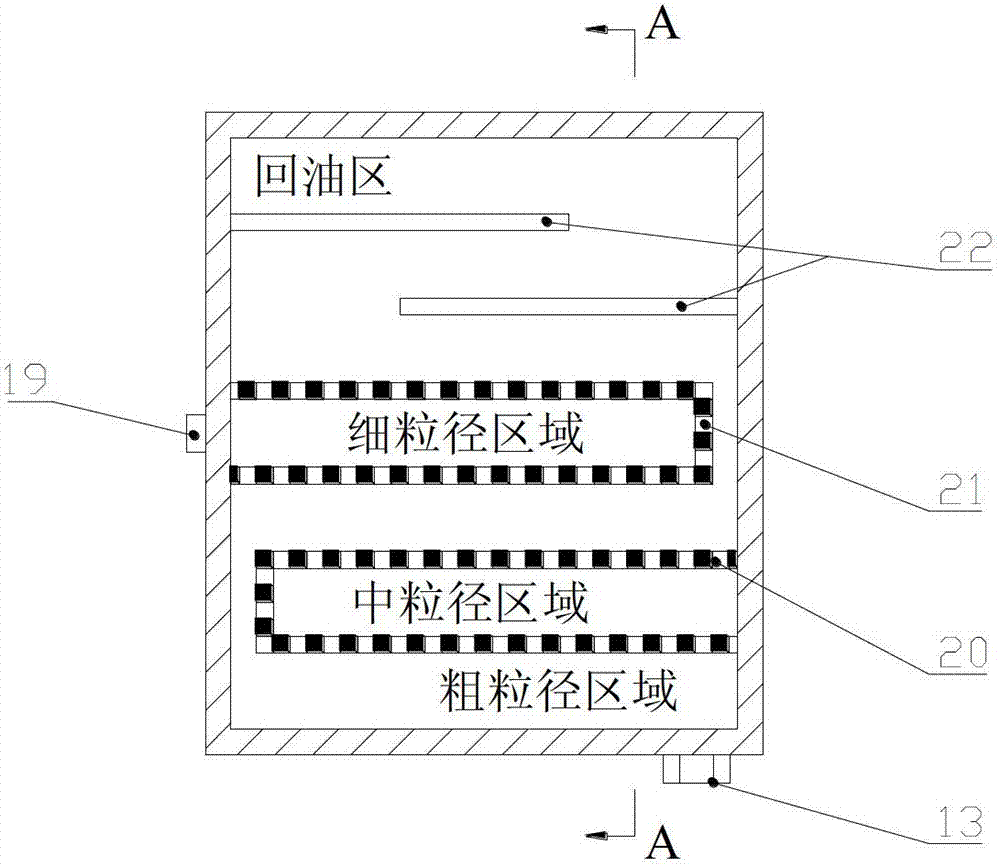

Solid particle grinding fluid combined machining process and device

ActiveCN102729101AImprove abilitiesImprove sharpening effectGrinding/polishing apparatusFuel tankResource saving

The invention relates to a solid particle grinding fluid combined machining process and a solid particle grinding fluid combined machining device. The device comprises an oil tank, wherein the oil tank is connected with an ultrasonic vibration generator through an electromagnet; a coarse particle size region, a middle particle size region and a fine particle size region are formed inside the oil tank; each region is provided with a corresponding oil supply opening and connected with a corresponding hydraulic pipeline; the hydraulic pipelines are connected with an electromagnetic directional valve; an outlet of the electromagnetic directional valve is connected with a slurry pump and an overflow valve through the hydraulic pipelines; the overflow valve is connected with an ultrasonic vibration spray nozzle through a metal hose; and both the ultrasonic vibration generator and the electromagnet are connected with a controller. By the process and the device, workpieces are ground, lapped and polished and subjected to combined machining by an in-process dressing grinding wheel continuously; the advantages that solid particles are high in cooling performance and impact machining performance are fully utilized; grinding burn is effectively avoided; the surface integrity and machining accuracy of the workpieces are improved; a high-efficiency, low-consumption, environment-friendly and resource-saving low-carbon clean production process is realized; and the process and the device have an important significance.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Metal system for testing outgassing property of low-temperature material

The invention relates to a metal system for testing the outgassing property of low-temperature material, which belongs to the field of low-temperature materials. The system consists of a sample chamber, a capacitor gauge, a micro adjusting valve, a metal hose, a high vacuum angle valve, a liquid nitrogen cold trap, a mass spectrometer, an inserting plate valve, a molecular valve and a mechanical pump. A vacuum pumping system consisting of the mechanical pump and the molecular pump vacuumizes samples in the sample chamber, and the liquid nitrogen cold trap performs low-temperature absorption on oil steam generated by the system. When the pressure of the sample chamber is pumped to 1*10<-3> Pa, the high-vacuum angle valve and the inserting valve are closed, the capacitor is used for testing the changes of the pressure in the sample chamber in the specified time, and then the outgassing rate of the sample is calculated. After the outgassing rate test is finished, the micro adjusting valve is opened, the discharged gas of the sample is introduced into the mass spectrometer by the metal hose, the outgassing component of the sample is analyzed by the mass spectrometer, and then the outgassing component of the sample is determined. The system enhances the reliability and he accuracy of the system, and has reliable testing result.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

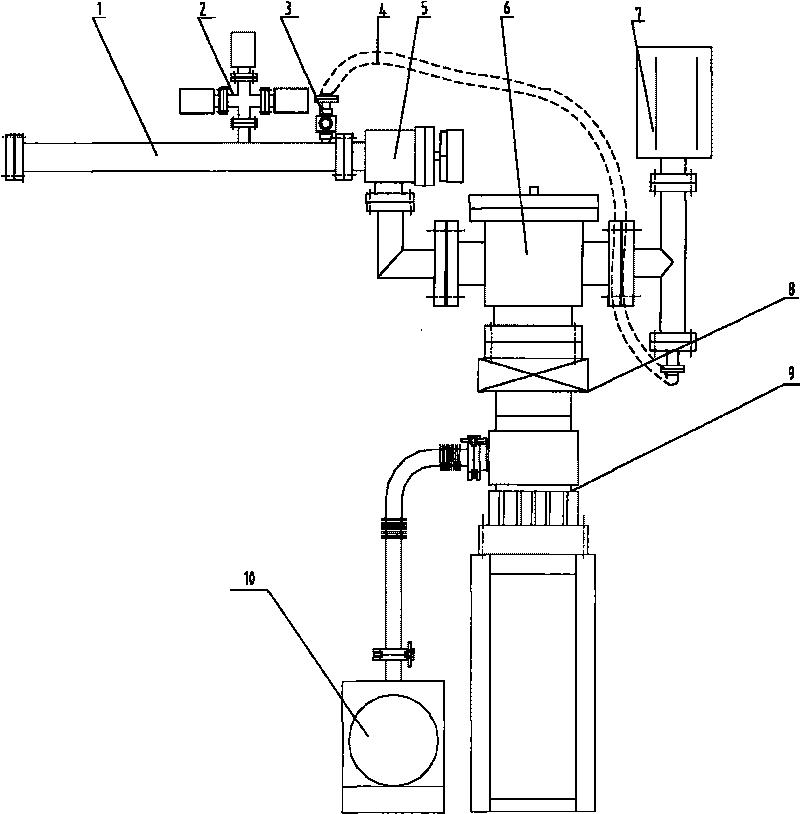

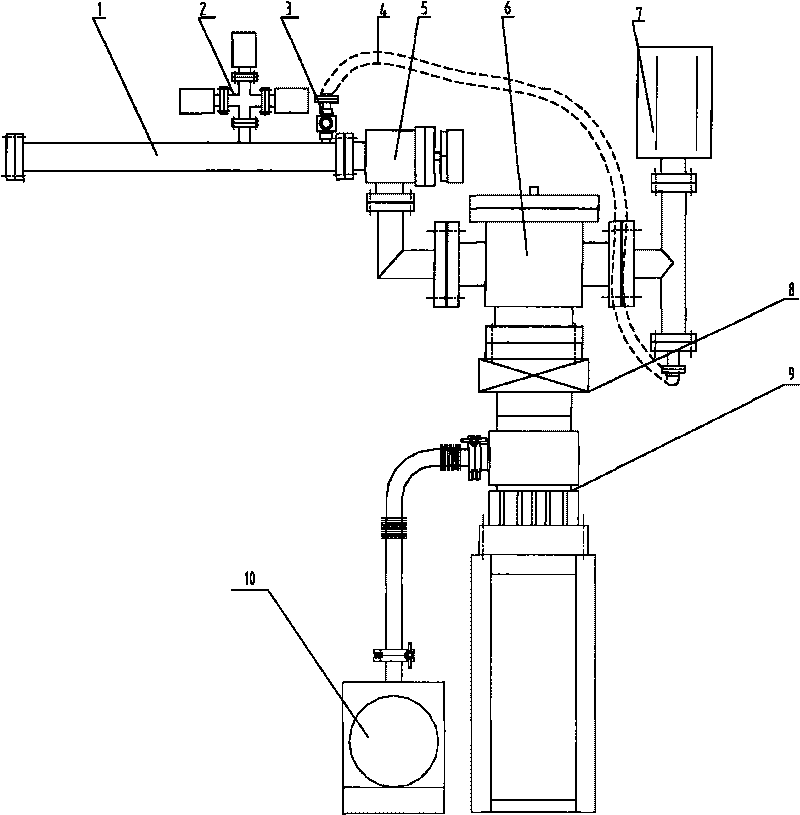

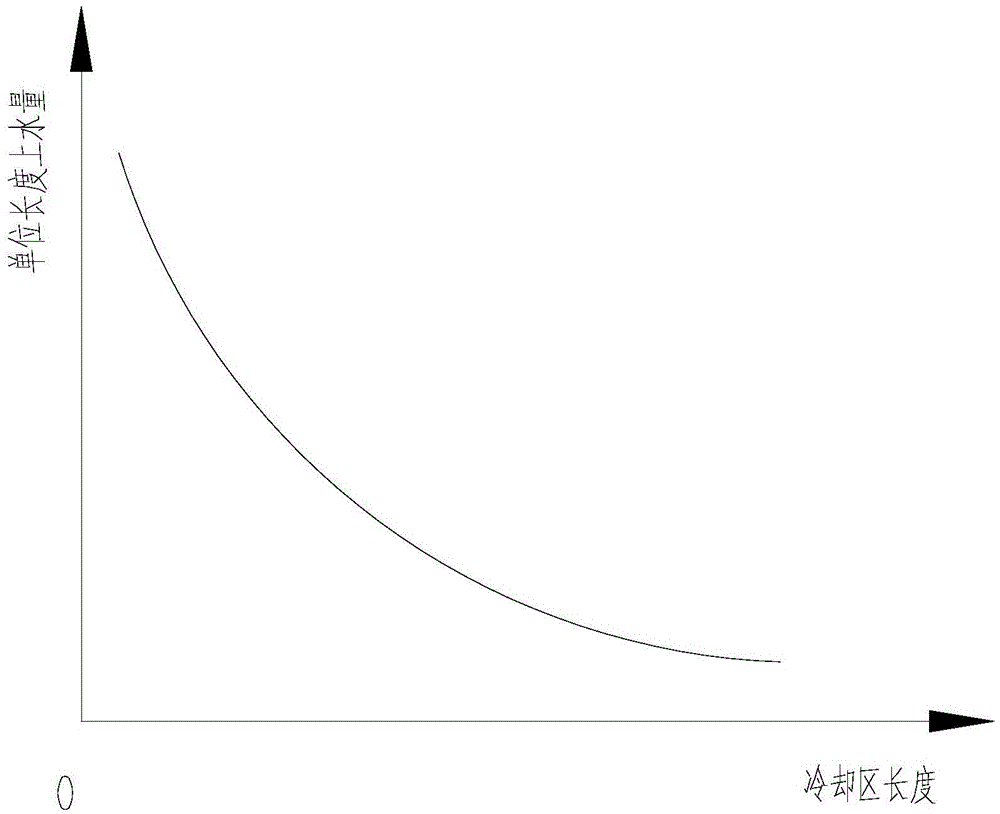

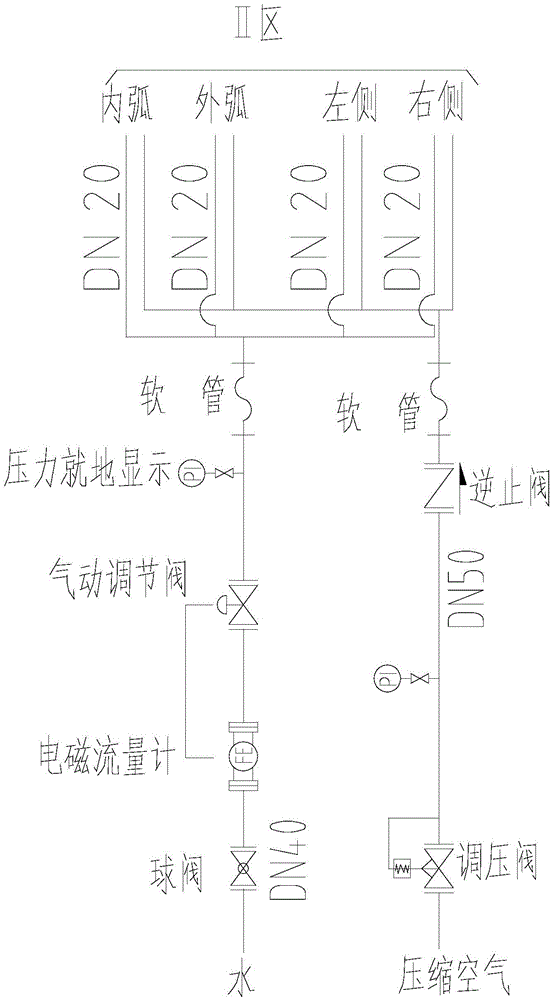

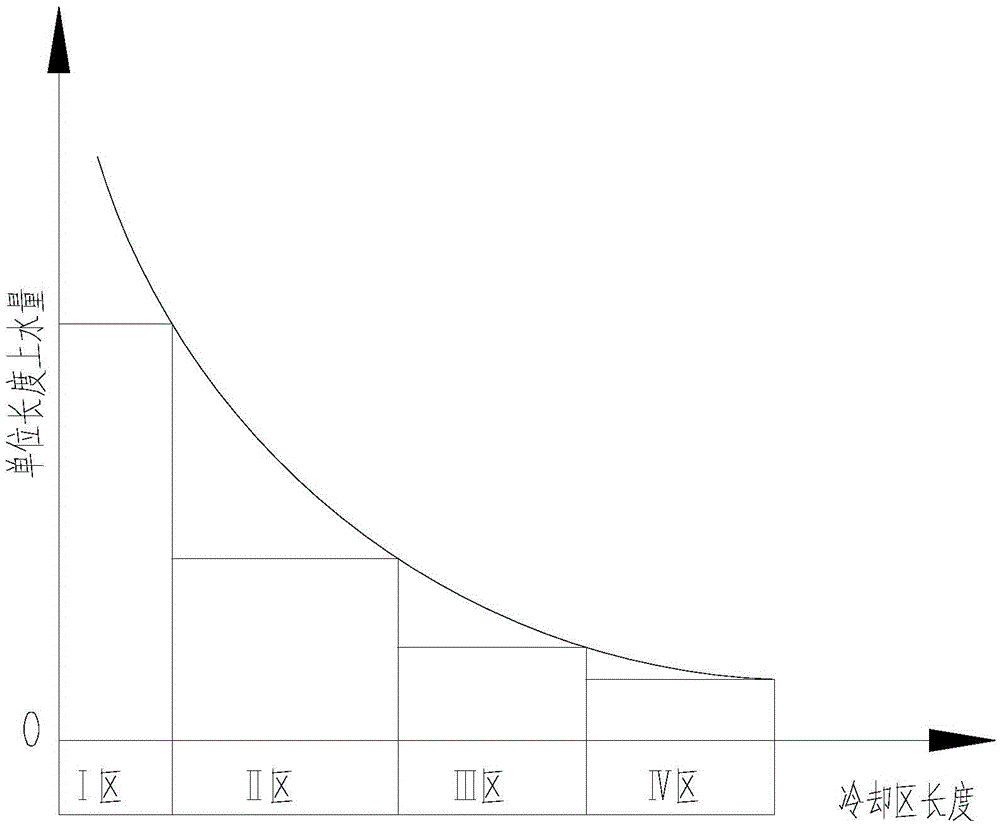

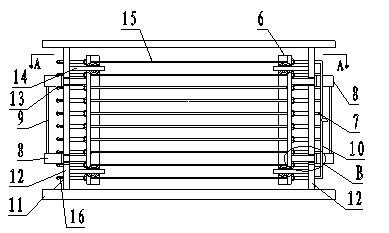

Novel square billet continuous casting secondary cooling water adjusting structure

The invention discloses a novel square billet continuous casting secondary cooling water adjusting structure which comprises a spraying rack capable of adjusting secondary cooling water, wherein the spraying rack comprises an inner arc spraying rack and an outer arc spraying rack; a plurality of inner and outer arc nozzles of which ejection holes are opposite to one another are perpendicularly formed in the inner arc spraying rack and the outer arc spraying rack; left spraying racks and right spraying racks are respectively arranged on the left sides and the right sides of the inner arc spraying rack and the outer arc spraying rack; a plurality of left nozzles and right nozzles, of which ejection holes are opposite to one another, are perpendicularly arranged on the left spraying racks and the right spraying racks; a water inlet tube connector and an air inlet tube connector connected with workshop tubes are arranged at the end part of each spraying rack. When being used, the spraying racks are connected with the workshop tubes through metal hoses, so that water-air communication can be achieved; the problems that the quantity of cooling water cannot be finely adjusted and the cooling effect is poor as a secondary cooling zone cannot be divided into a plurality of small zones because of problems such as machining, manufacturing, assembling, disassembling, repairing and equipment cost can be solved; by adopting the novel square billet continuous casting secondary cooling water adjusting structure, on the premise that the cost is reduced, the quantity of water can be finely adjusted, the actual water flow density of secondary cooling water is approximate to theoretic water flow density as much as possible, and the quality of a cast blank can be remarkably improved.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

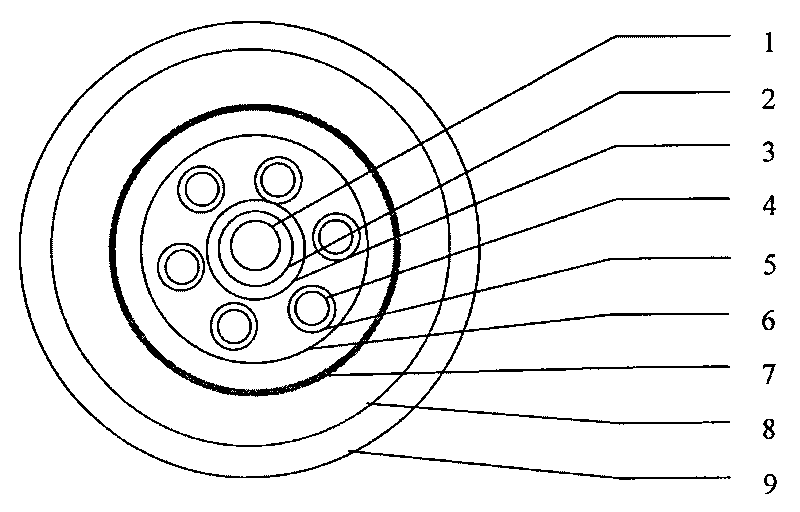

Electro-optic compound cable for towing and manufacturing method thereof

ActiveCN101714425AReasonable designCompact structureCommunication cablesFibre mechanical structuresPolyesterSilver plate

The invention relates to an electro-optic compound cable for towing, which is an electro-optic compound cable capable of retracting and releasing repeatedly in special occasions, and used for transmitting optical signals and electrical signals. The cable core is formed by twisting high temperature silver-plated leads and optical fiber, and is protected by spiral metal hose at outside, and polyurethane material is extruded outside the steel tube. The cable is composed of a plurality of silver-plated leads, tight tube optical fiber, polyester belting, a spiral stainless steel hose, an aramid fiber twisted layer and a polyurethane jacket; the tight tube optical fiber and the silver-plated leads are twisted into the cable core in an S twisting form, the cable core is wrapped and fixed by the polyester belting, the spiral stainless steel hose is arranged outside the polyester belting, the aramid fiber twisted layer is arranged outside the spiral stainless steel hose, and the polyurethane jacket is extruded outside the aramid fiber twisted layer.

Owner:ZHONGTIAN BROADBAND TECH +1

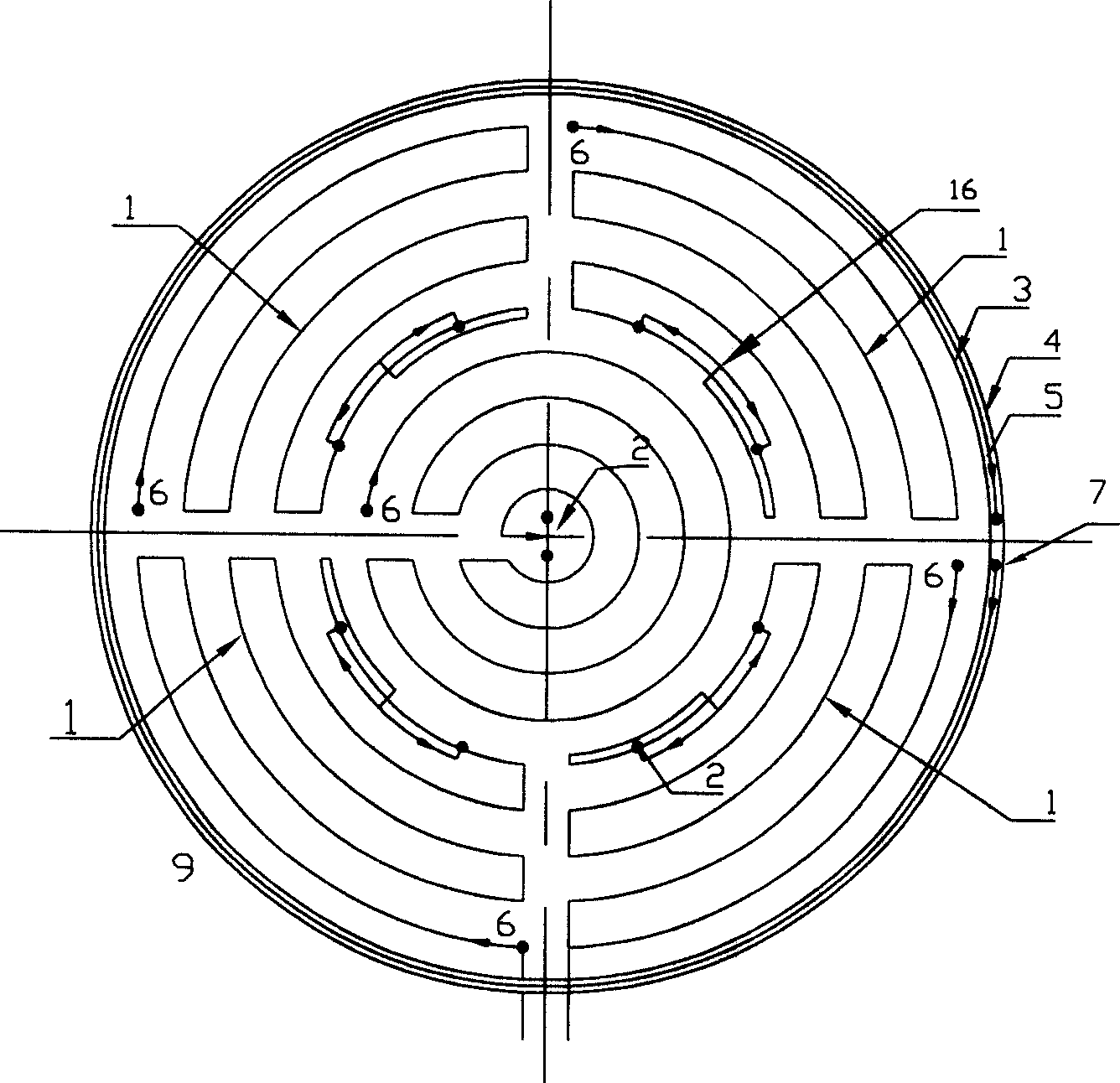

High-solidified oil floating-roof oil tank space heating device

The present invention relates to a high solidification high-viscosity wax-containing petroleum product floating-roof-tank low-temp. stored space heating equipment. It is characterized by that on the tank bottom a bottom portion steam tube heater is mounted, under the floating roof a top horizontal steam tube heater is mounted, and is connected with 9-13 vertical helical steam tube heaters which are uniformly distributed in the oil tank, and the lower portion of vertical helical steam tube is connected with metal hose, then is connected to the water-discharging header of bottom portion.

Owner:PIPECHINA SOUTH CHINA CO

Leakage check device for metal hoses in batch

ActiveCN102607777AFast loadingEasy to removeDetection of fluid at leakage pointMaterial strength using tensile/compressive forcesTest efficiencyElectricity

The invention discloses a leakage check device for metal hoses in batch, which is used for solving the problems of high labor intensity and low testing efficiency existing in leakage check of the metal hoses. The leakage check device consists of a control part, an air channel part, an elevating water groove and a hose supporting and locking mechanism, wherein the elevating water groove is positioned on the lower part of the hose locking mechanism; the lower part of the elevating groove is provided with an elevating frame; and the control part is electrically connected with the air channel part, the hose supporting and locking mechanism and the elevating frame. Matched pressure testing parts are selected according to different metal hose specifications, so that pressure test is performed in batch. The metal hose locking mechanism in the device is designed according to the structural characteristics of joint positions at the two ends of each metal hose, so that the metal hose can be clamped or detached rapidly and conveniently; and in a testing process, the pressure is controlled by using a computer, data are recorded according to a testing result, and unqualified products are automatically distinguished according to visual observation and a pressure value fed back by using a pressure sensor. The leakage check device has the advantages of high automatic degree, greatly-improved production efficiency and accurate and reliable detection result.

Owner:石家庄巨力科技股份有限公司

Multifunctional robot polishing equipment

ActiveCN108655911ATimely collectionAdd collection functionGrinding carriagesGrinding machinesCouplingEngineering

The invention provides multifunctional robot polishing equipment. The multifunctional robot polishing equipment comprises a polishing motor, a fixed plate, a fixed sleeve, a connecting plate, a robotpower arm, a robot extension arm, an ER50-3200 six-axle robot, a fixed clamping base, a base, a support plate, an I-shaped frame, a waste chip and dust collecting environmental-protection barrel structure, an adjustable dust and waste chip blowing machine structure, a quick polishing replacement rod structure, a height-adjustable clamping plate structure and a sleeve coupling. Through arrangementof a collecting barrel, a metal hose, a dust guide pipe, a joint base, a support lining base and a dust guide hopper, dust and waste chips generated by polishing are timely collected, the collecting function is added, the pollution is prevented, and the environment is protected; through arrangement of a transparent piece, the collecting condition of the dust and the waste chips in the collecting barrel can be timely determined to achieve replacement or cleaning; and through arrangement of fan blades and a blowing motor, the waste chips and the dust generated by polishing are timely blown out to guarantee the polishing efficiency.

Owner:柳州中科机器人自动化股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com