Patents

Literature

177 results about "Cryo-adsorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

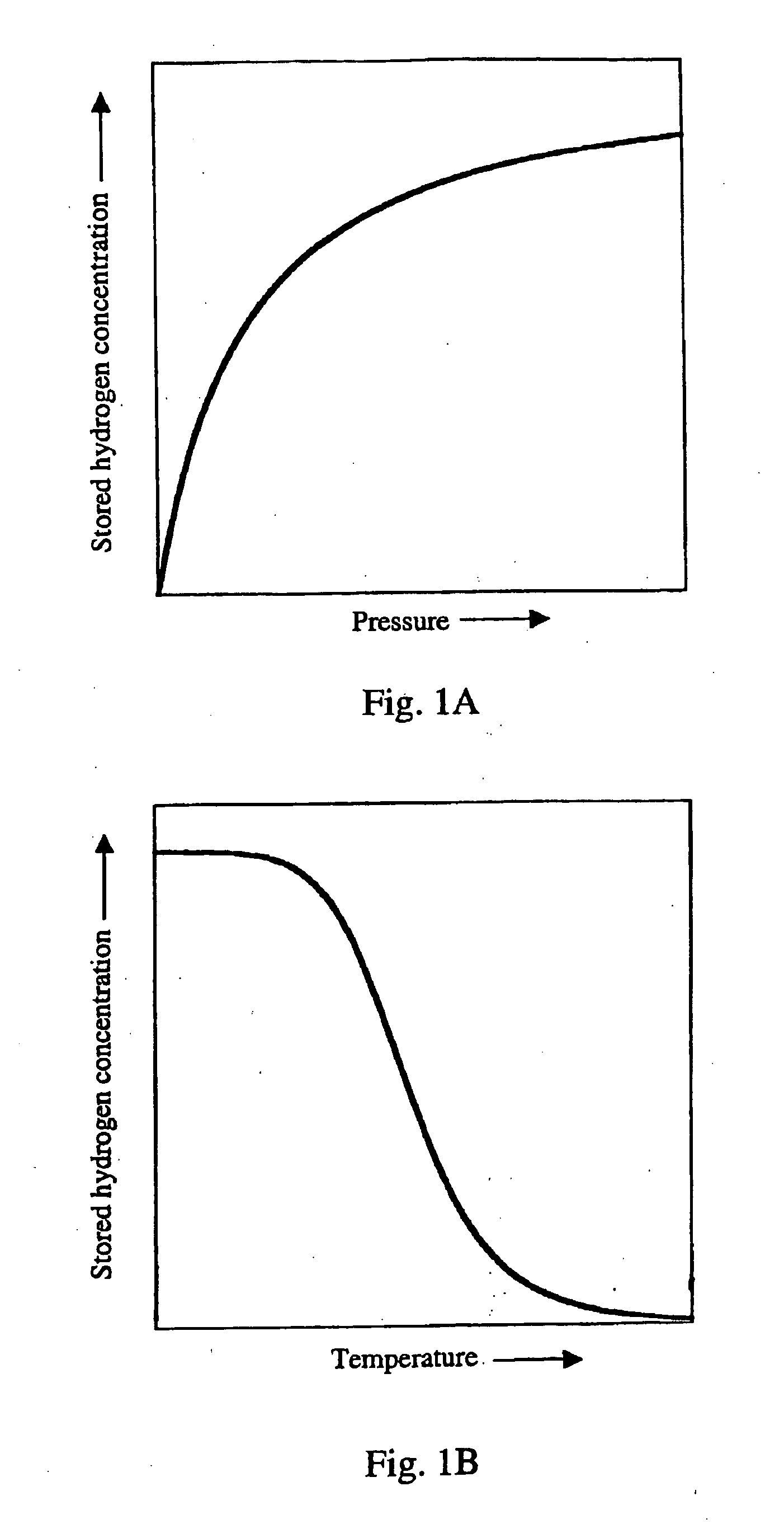

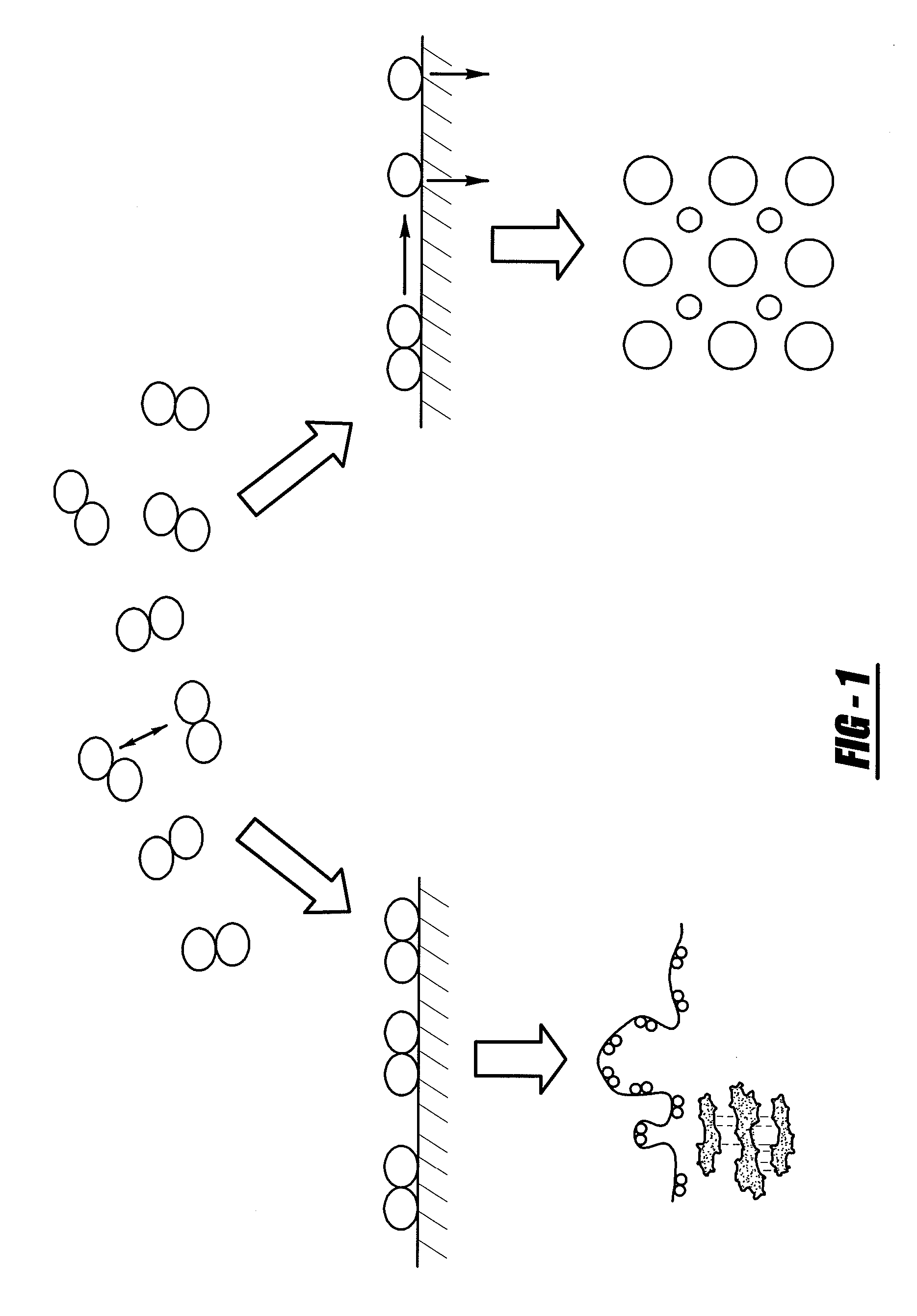

Cryo-adsorption is a method used for hydrogen storage where gaseous hydrogen at cryogenic temperatures (150—60 K) is physically adsorbed on porous material, mostly activated carbon. The achievable storage density is between liquid-hydrogen (LH₂) storage systems and compressed-hydrogen (CGH₂) storage systems.

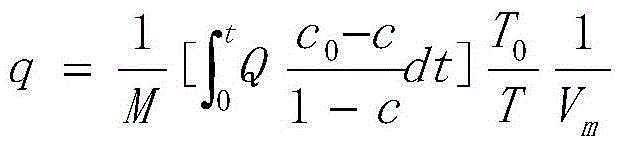

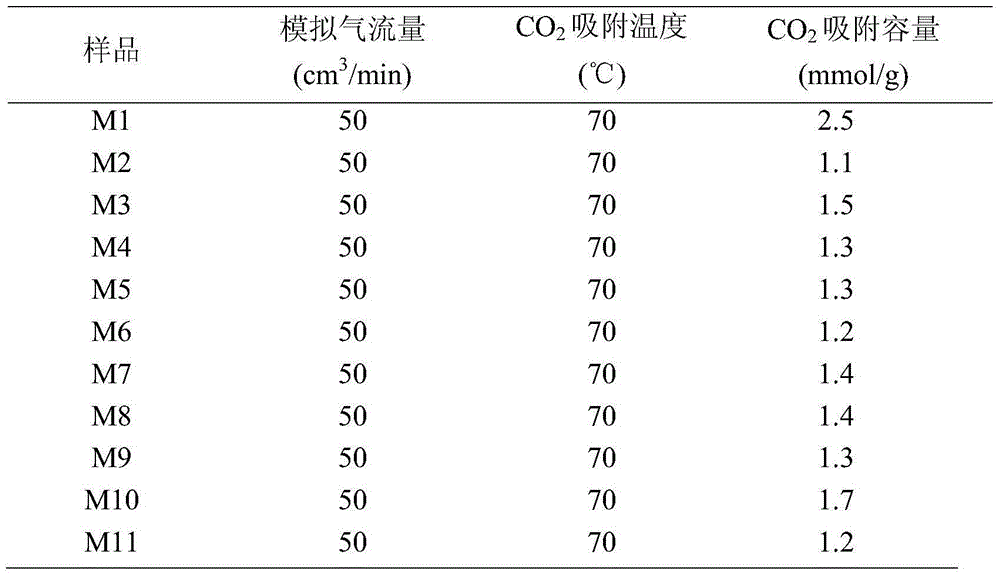

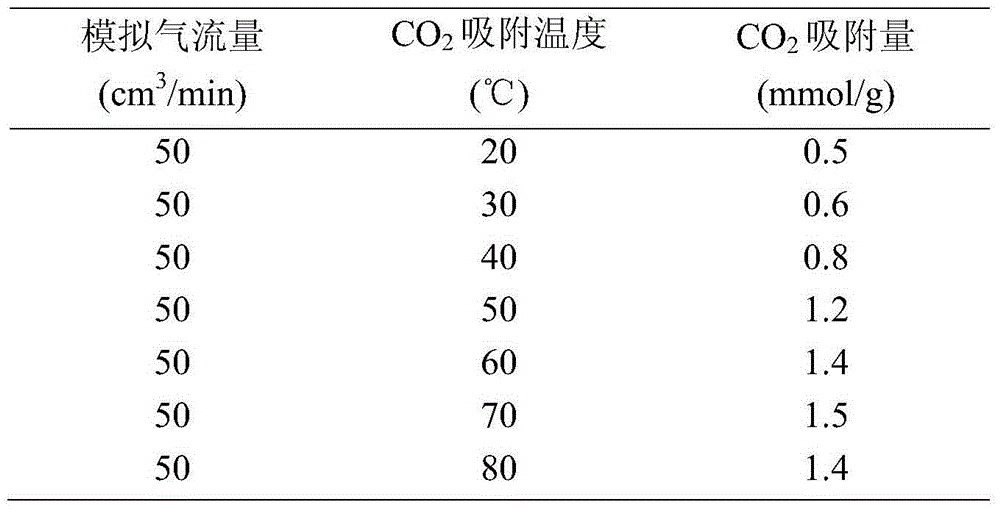

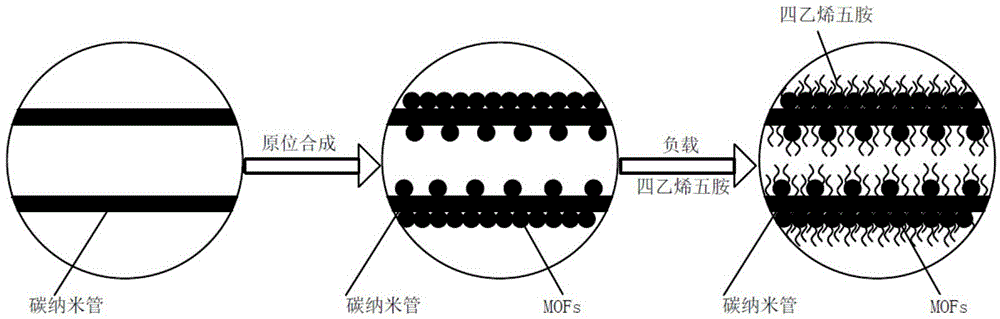

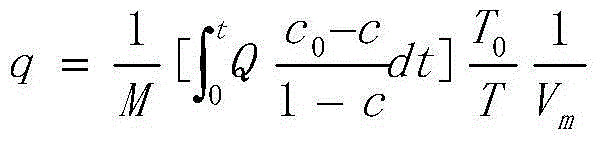

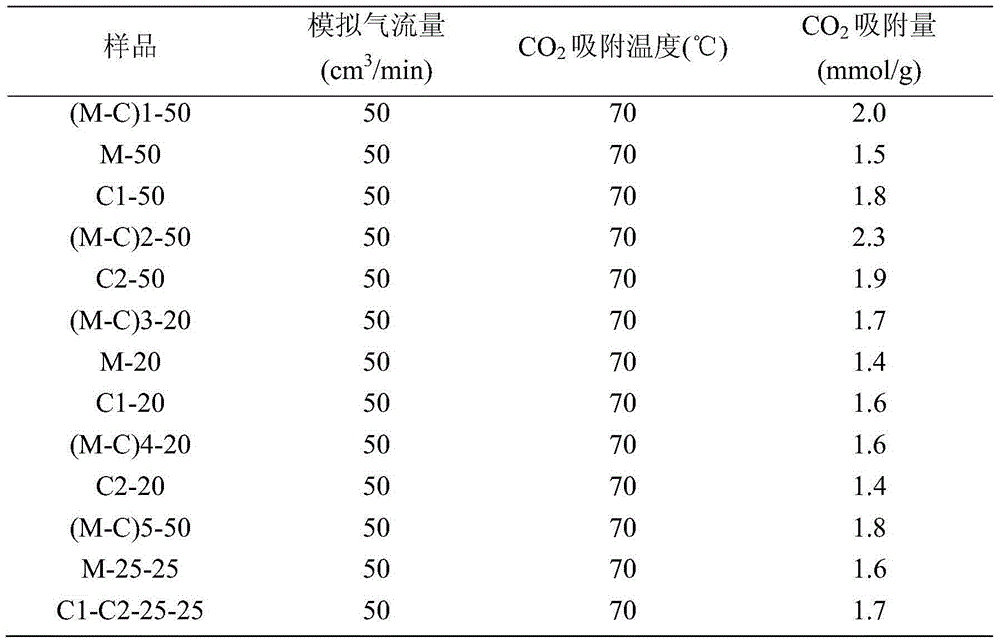

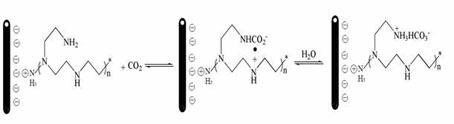

MOFs based carbon dioxide adsorbent, preparation method and application thereof

InactiveCN104056598ALarge specific surface areaStrong specific surface areaOther chemical processesDispersed particle separationSorbentFlue gas

The invention discloses an MOFs (metal-organic frameworks) based carbon dioxide adsorbent, which includes MOFs and organic amine loaded in the pore channels and on the surface of MOFs. The mass ratio of the MOFs to the organic amine is 0.1-10:1. The MOFs based carbon dioxide adsorbent provided by the invention realizes the combined action of physical adsorption and chemical adsorption and can adsorb and store carbon dioxide at medium and low temperature, and regeneration and reutilization of the adsorbent can be realized under certain condition. The MOFs based carbon dioxide adsorbent has good adsorption capacity, high selectivity and cycling stability on carbon dioxide, and can overcome the disadvantages of easy volatilization and easy corrosion of equipment in organic amine so as to meet the industrial processing requirements. The invention also discloses a preparation method of the MOFs based carbon dioxide adsorbent and application of the adsorbent in adsorption of carbon dioxide in flue gas.

Owner:ZHEJIANG UNIV

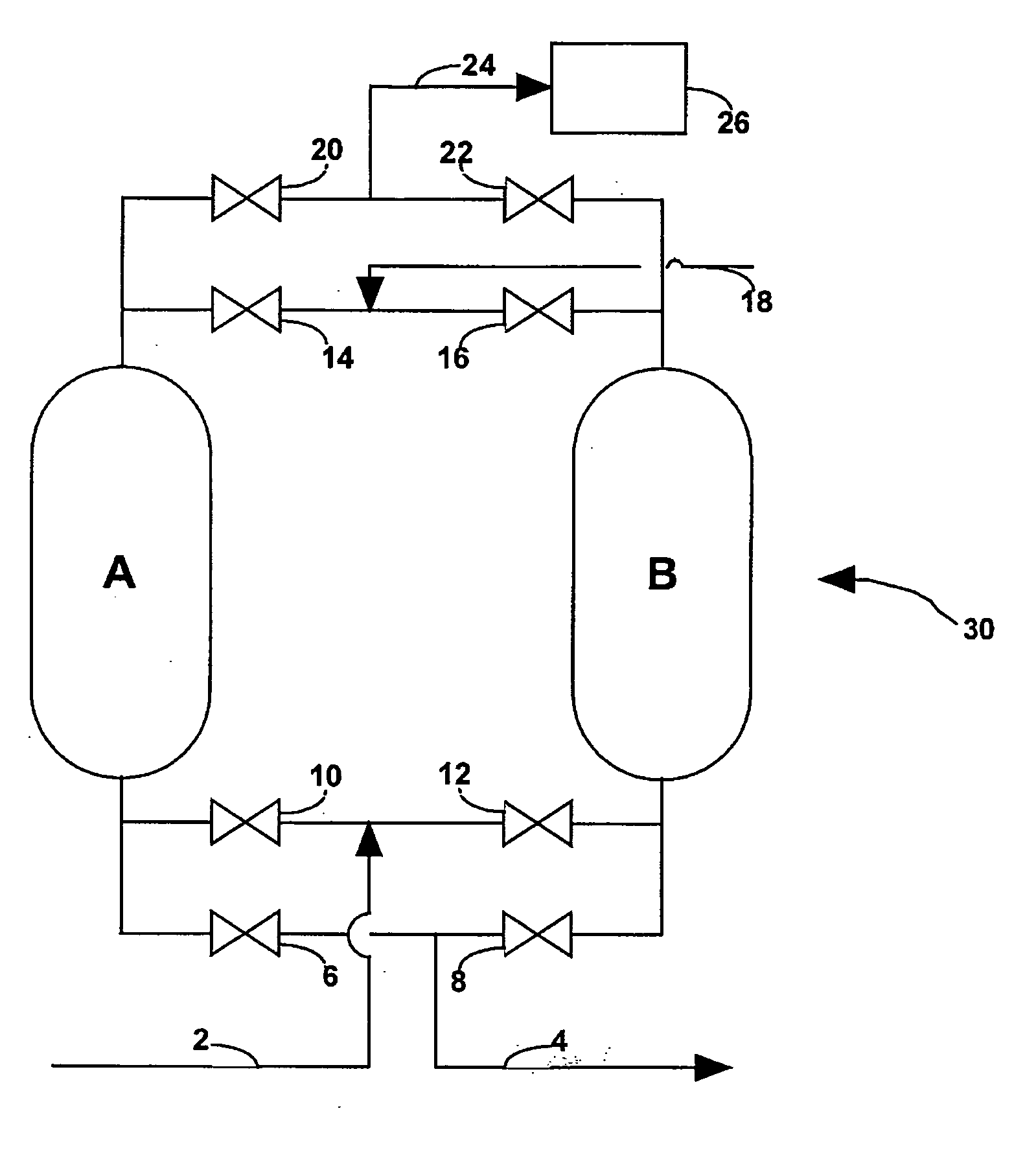

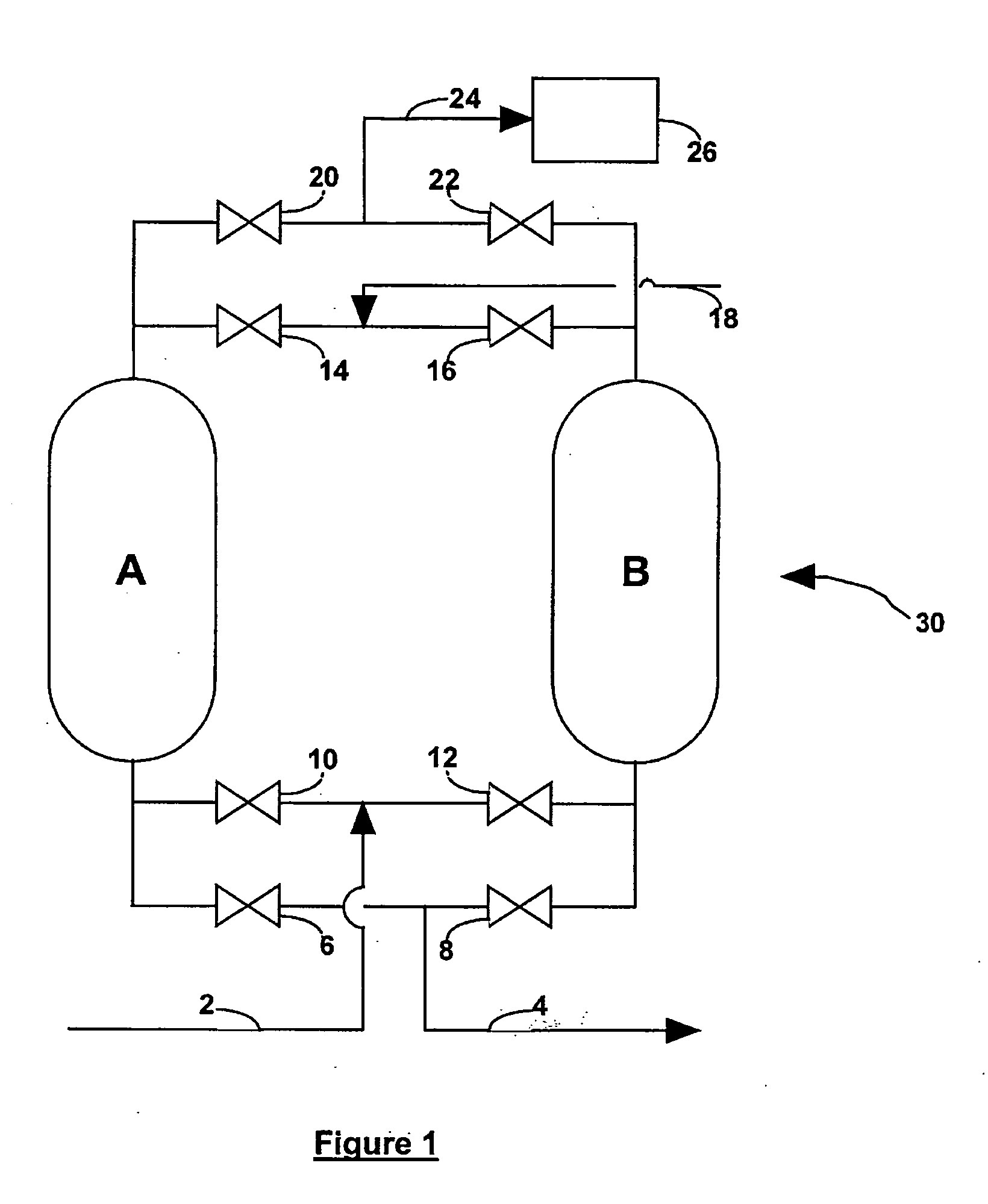

Process for gas purification

The present invention provides for a process for purifying carbon monoxide-containing gas streams that contain impurities such as hydrocarbons by using a cryogenic adsorption process. Preferably this process is a temperature swing adsorption process at cryogenic temperatures below −75° C. Alternatively, the carbon monoxide-containing gas streams may be purified using the cryogenic adsorption process with membrane separation units or vacuum swing adsorption units or cryogenic distillation.

Owner:BOC GRP INC

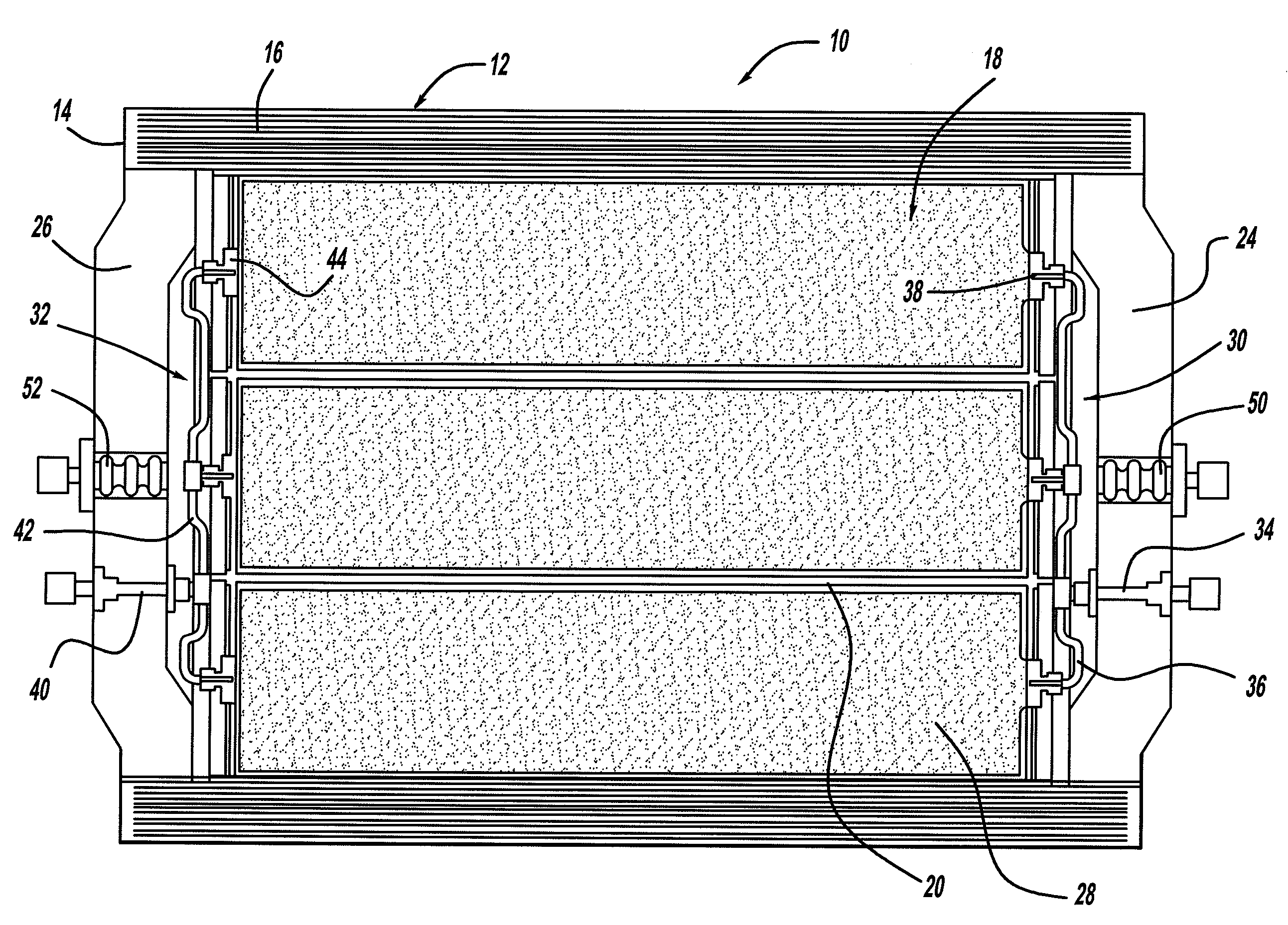

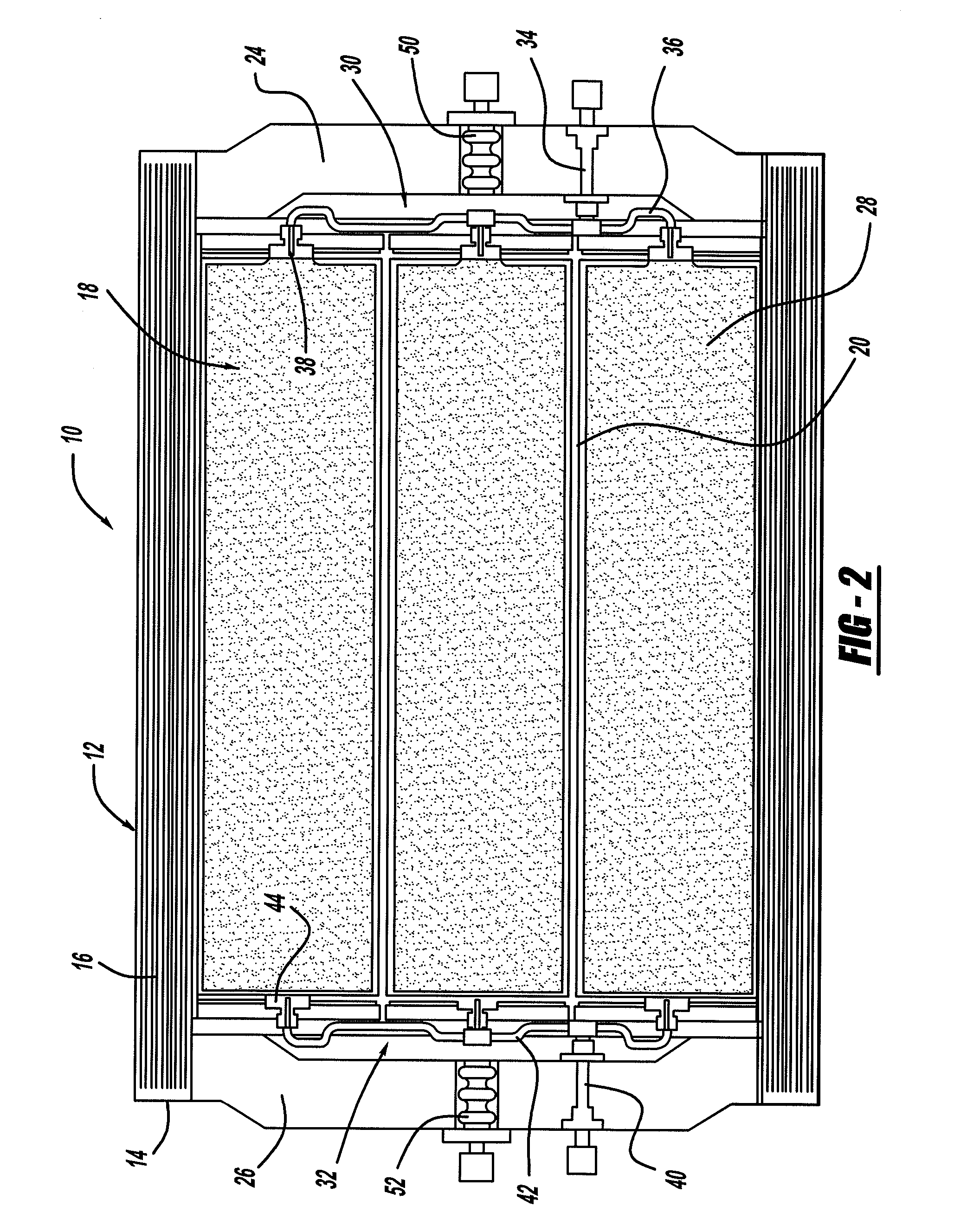

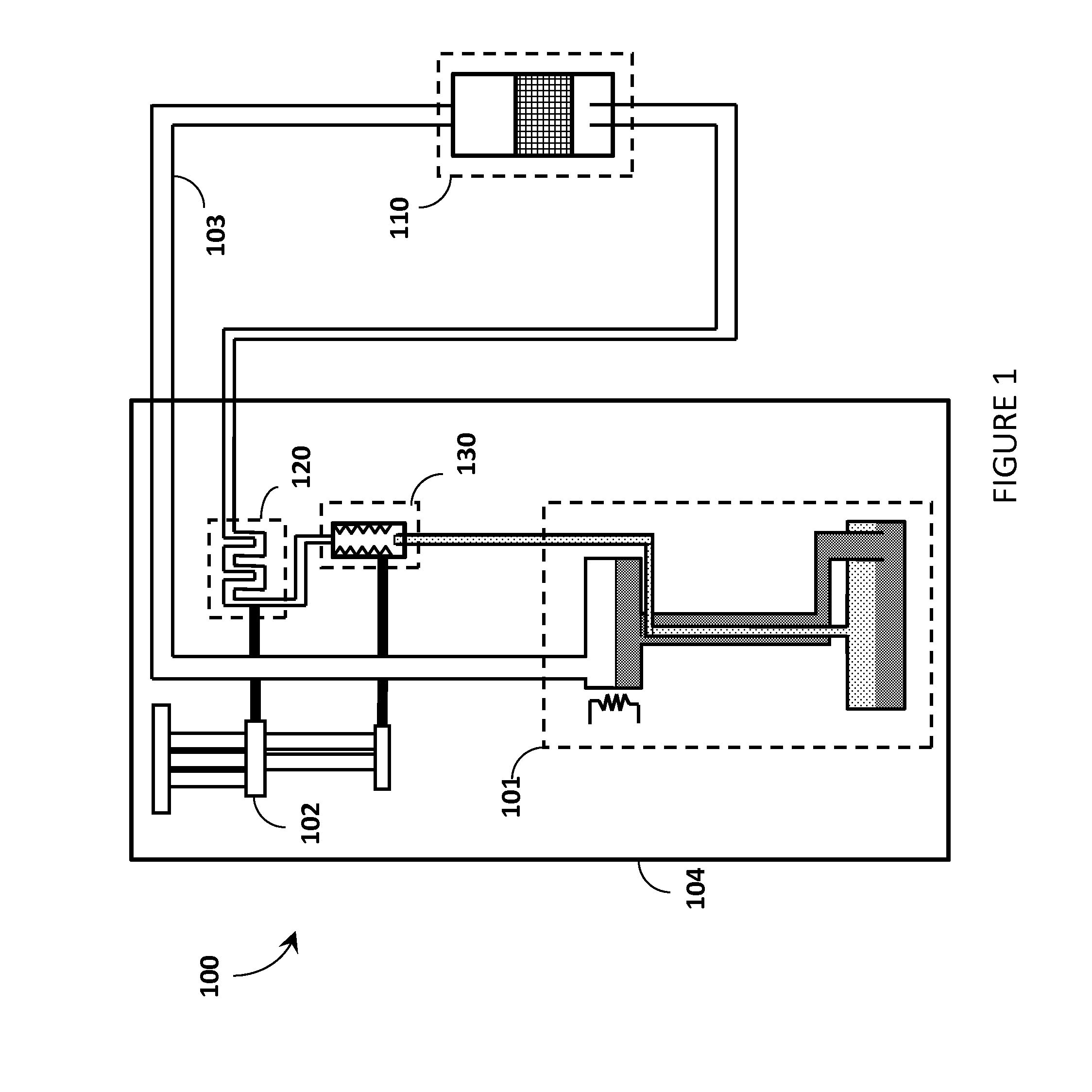

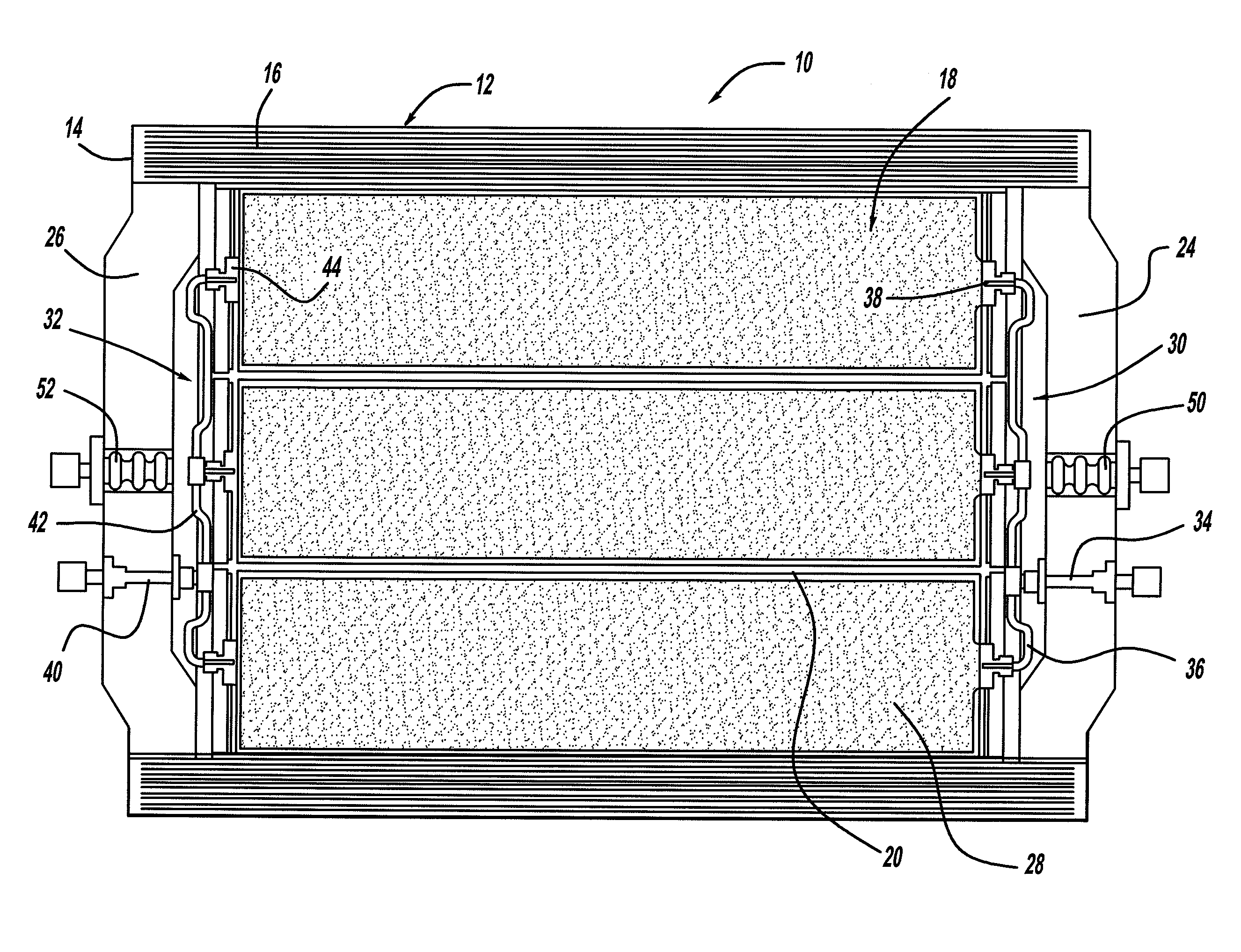

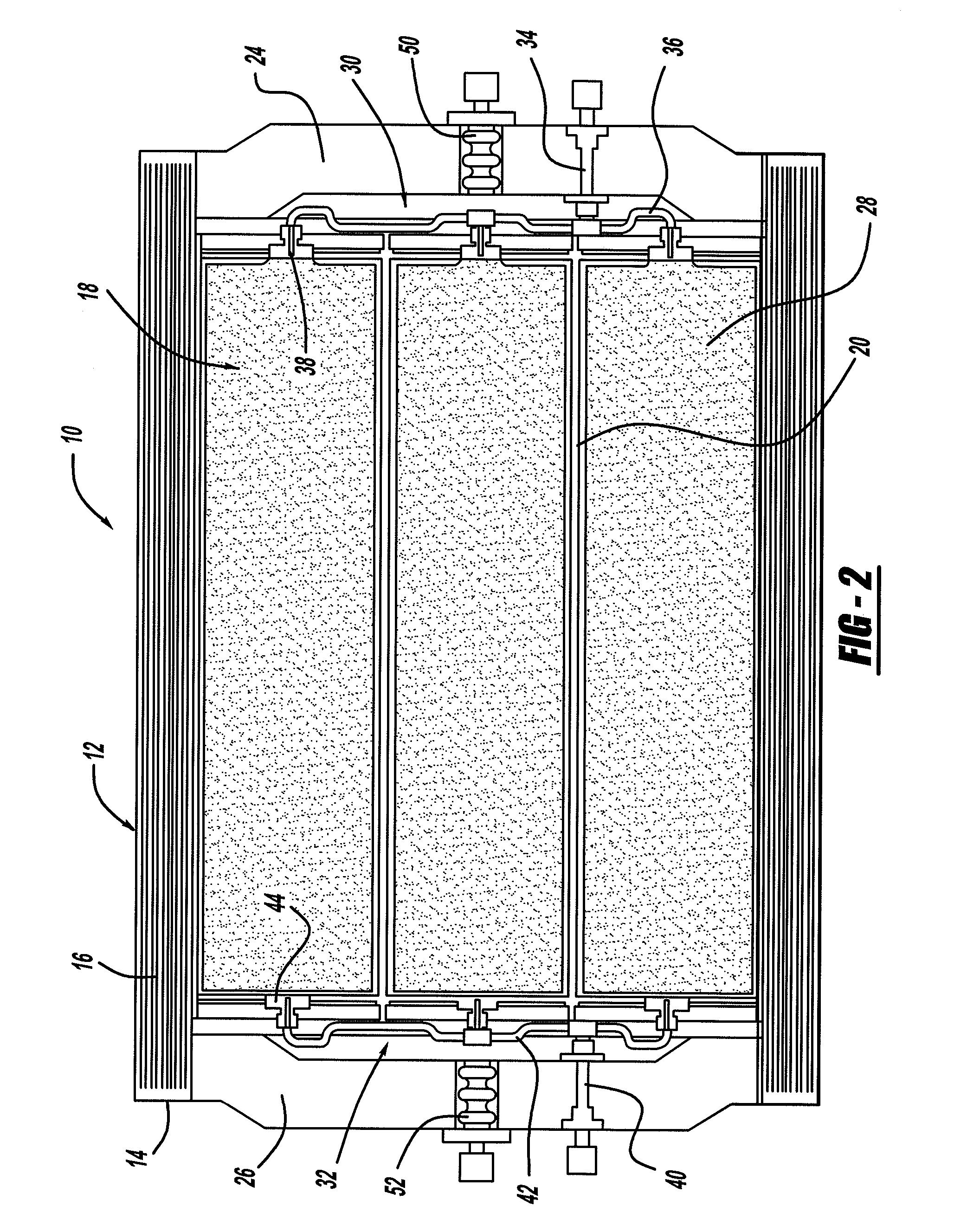

Hydrogen Storage Tank System Based on Gas Adsorption on High-Surface Materials Comprising an Integrated Heat Exchanger

A gas storage system that stores a gas by cryo-adsorption on high surface materials. The gas storage system includes an outer container having insulated walls and a plurality of pressure vessels disposed therein. Each of the pressure vessels includes a high surface material. A manifold assembly distributes the gas under pressure to the pressure vessels where the gas is adsorbed by cryo-adsorption using the high surface materials. A cooling fluid is provided within voids between the pressure vessels to remove heat as the pressure vessels are being filled with the gas.

Owner:GM GLOBAL TECH OPERATIONS LLC

Process for gas purification

The present invention provides for a process for purifying carbon monoxide-containing gas streams that contain impurities such as hydrocarbons by using a cryogenic adsorption process. Preferably this process is a temperature swing adsorption process at cryogenic temperatures below −75° C. Alternatively, the carbon monoxide-containing gas streams may be purified using the cryogenic adsorption process with membrane separation units or vacuum swing adsorption units or cryogenic distillation.

Owner:JAIN RAVI +1

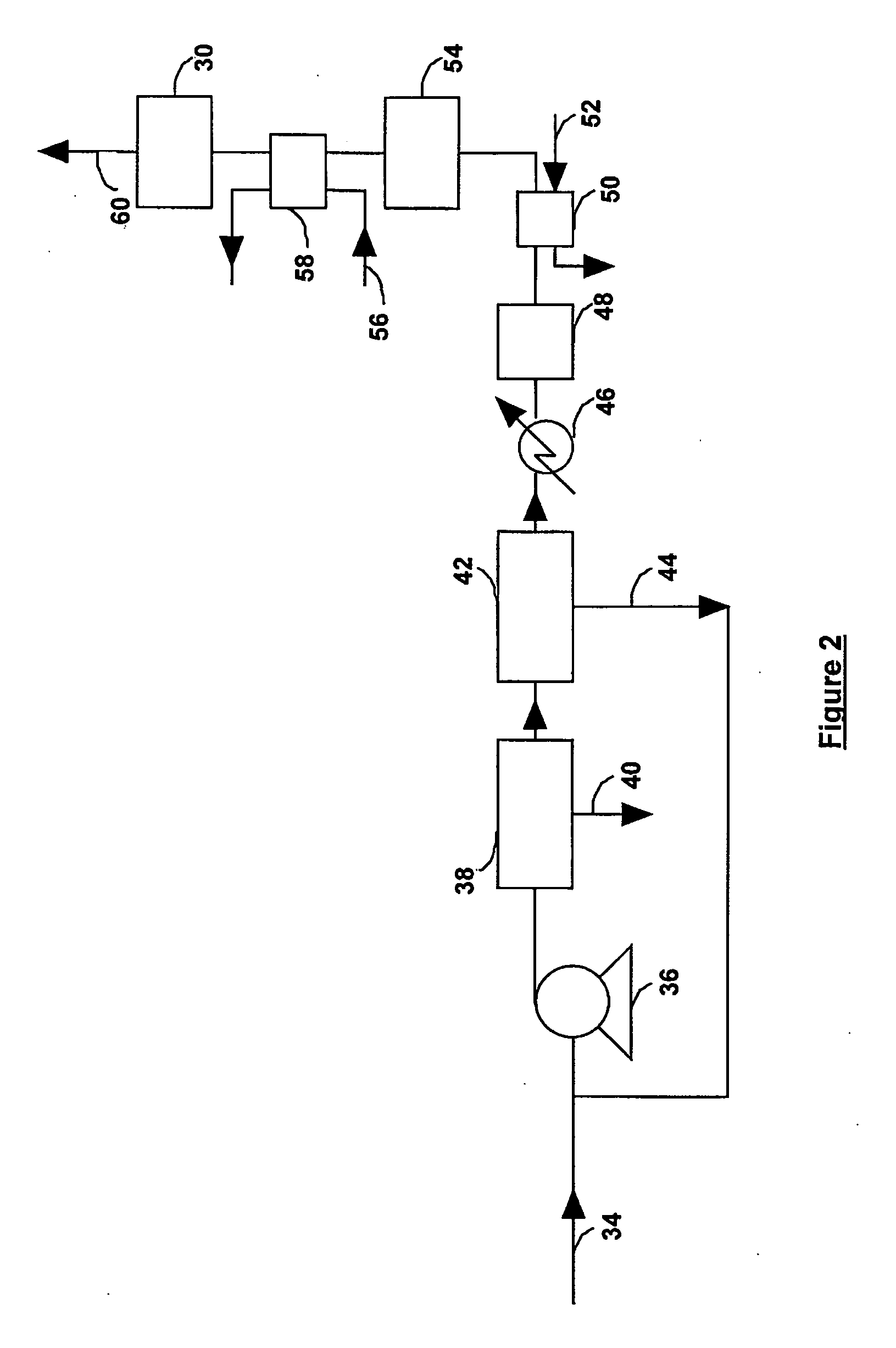

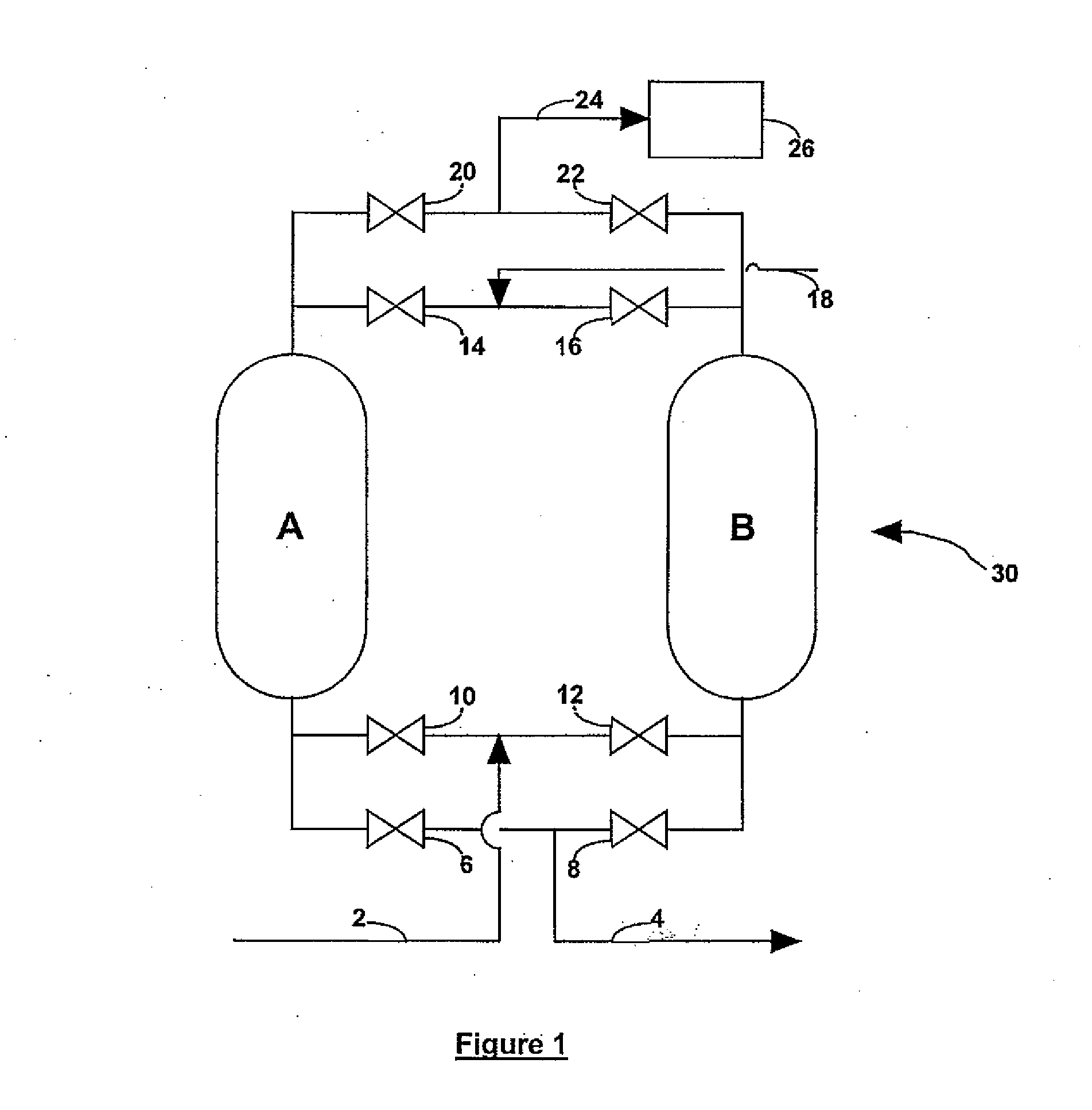

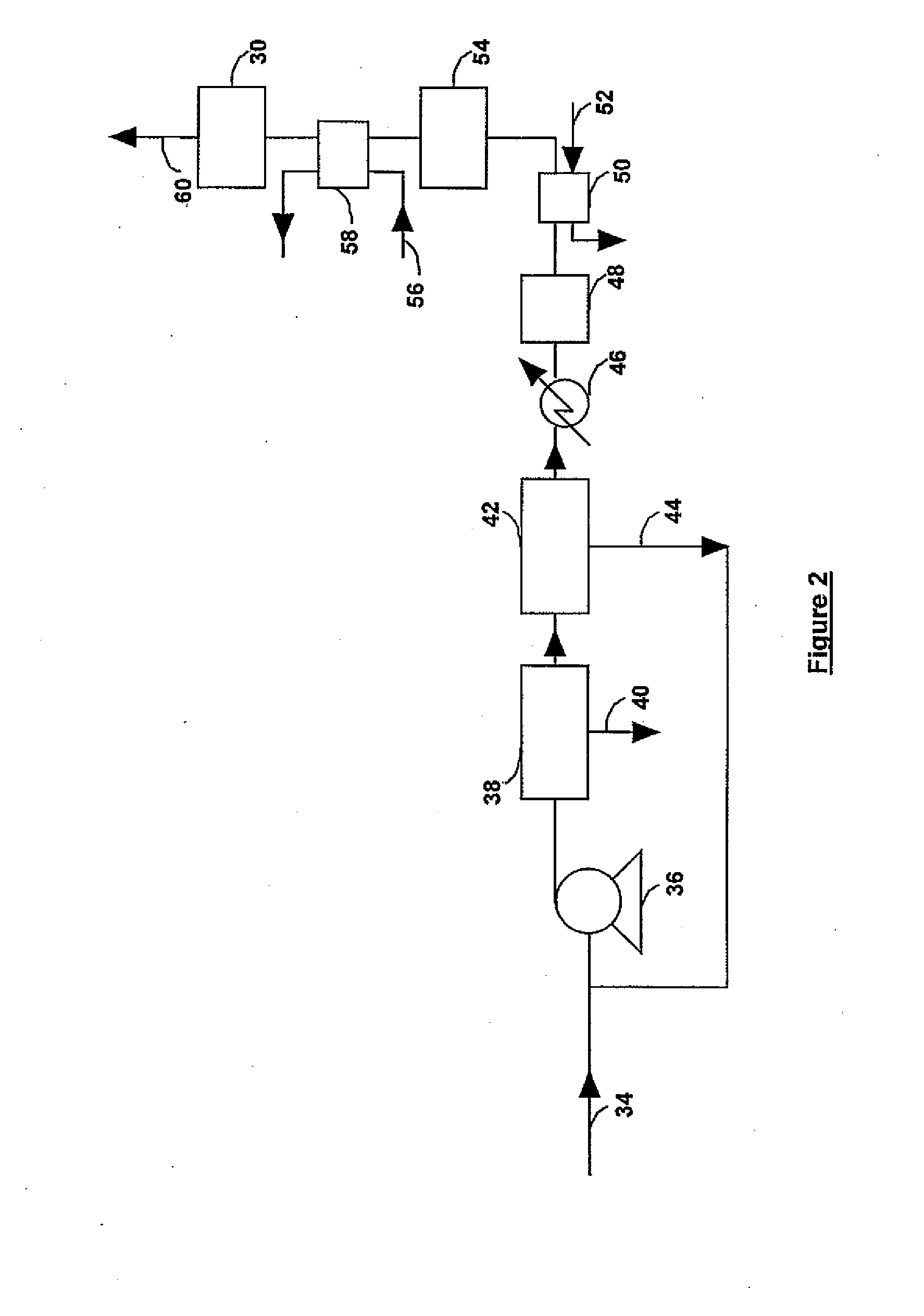

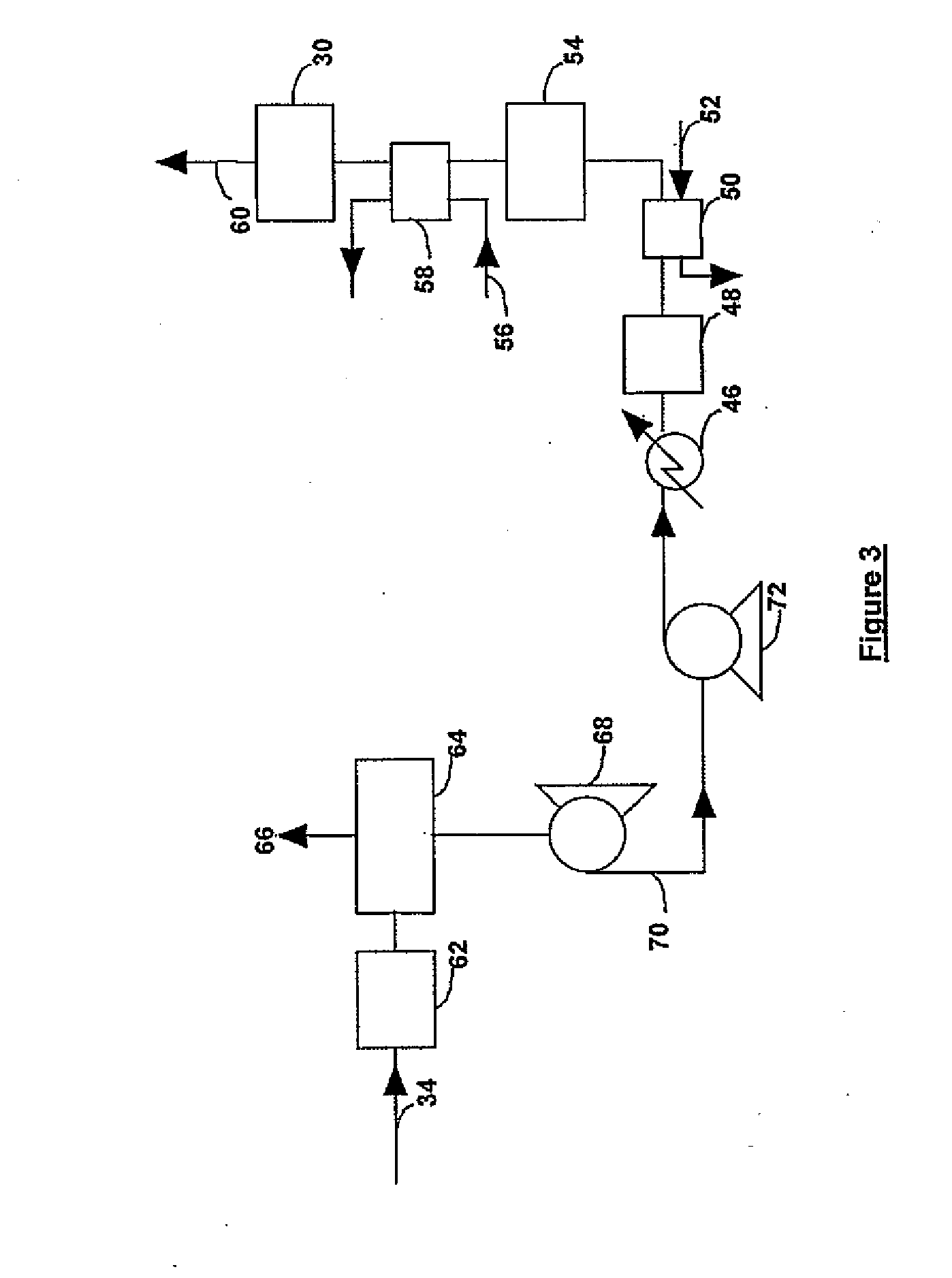

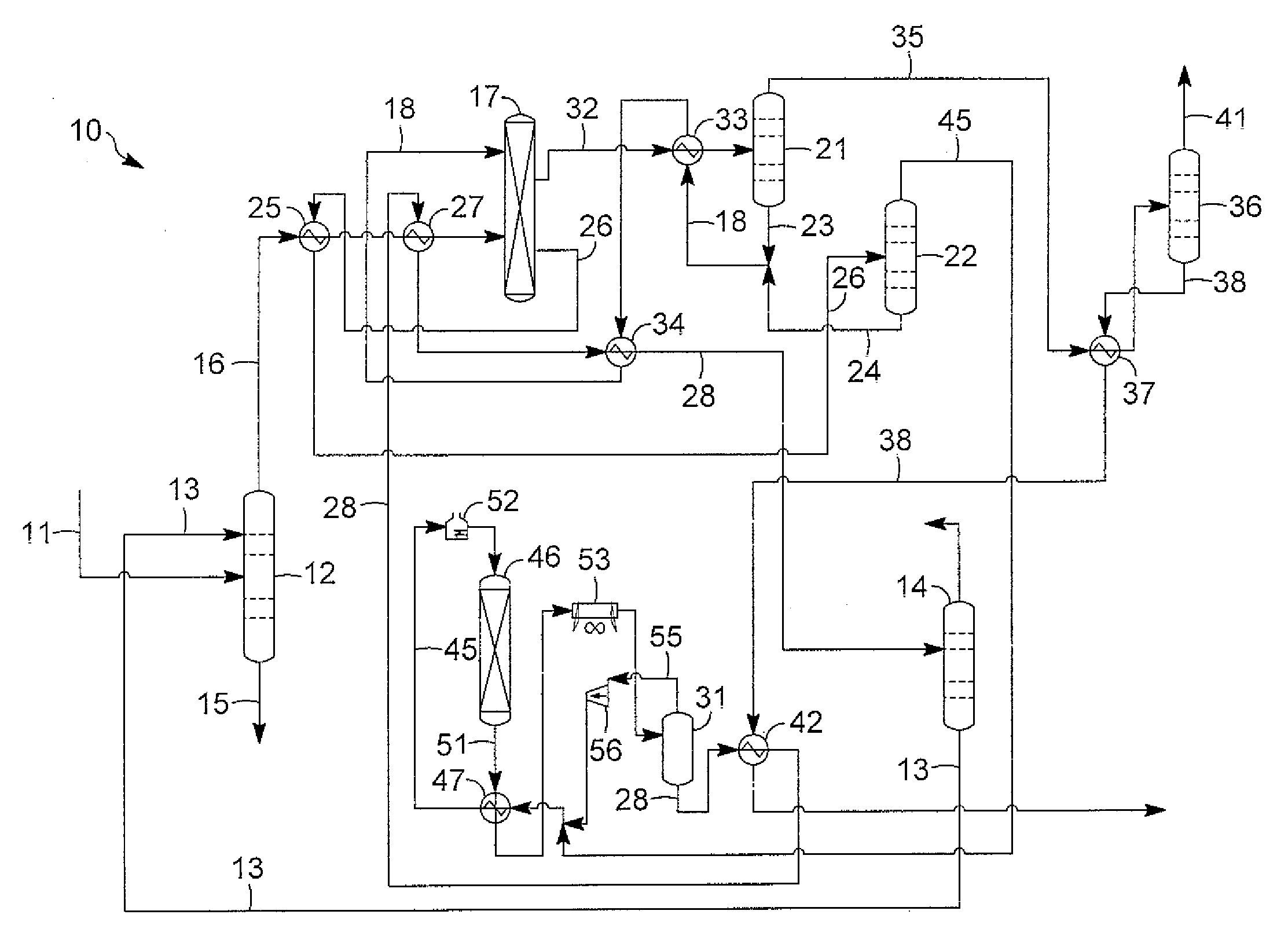

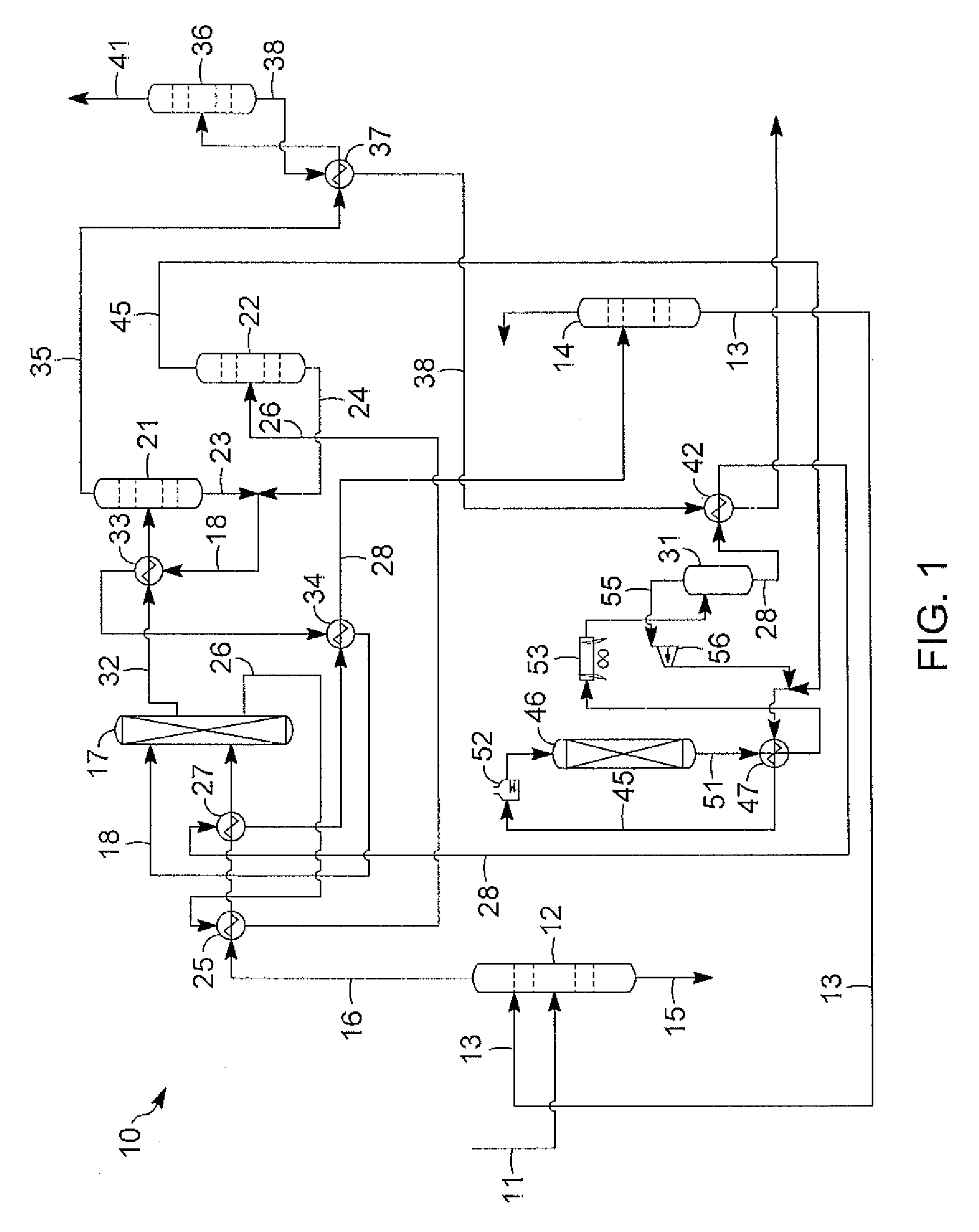

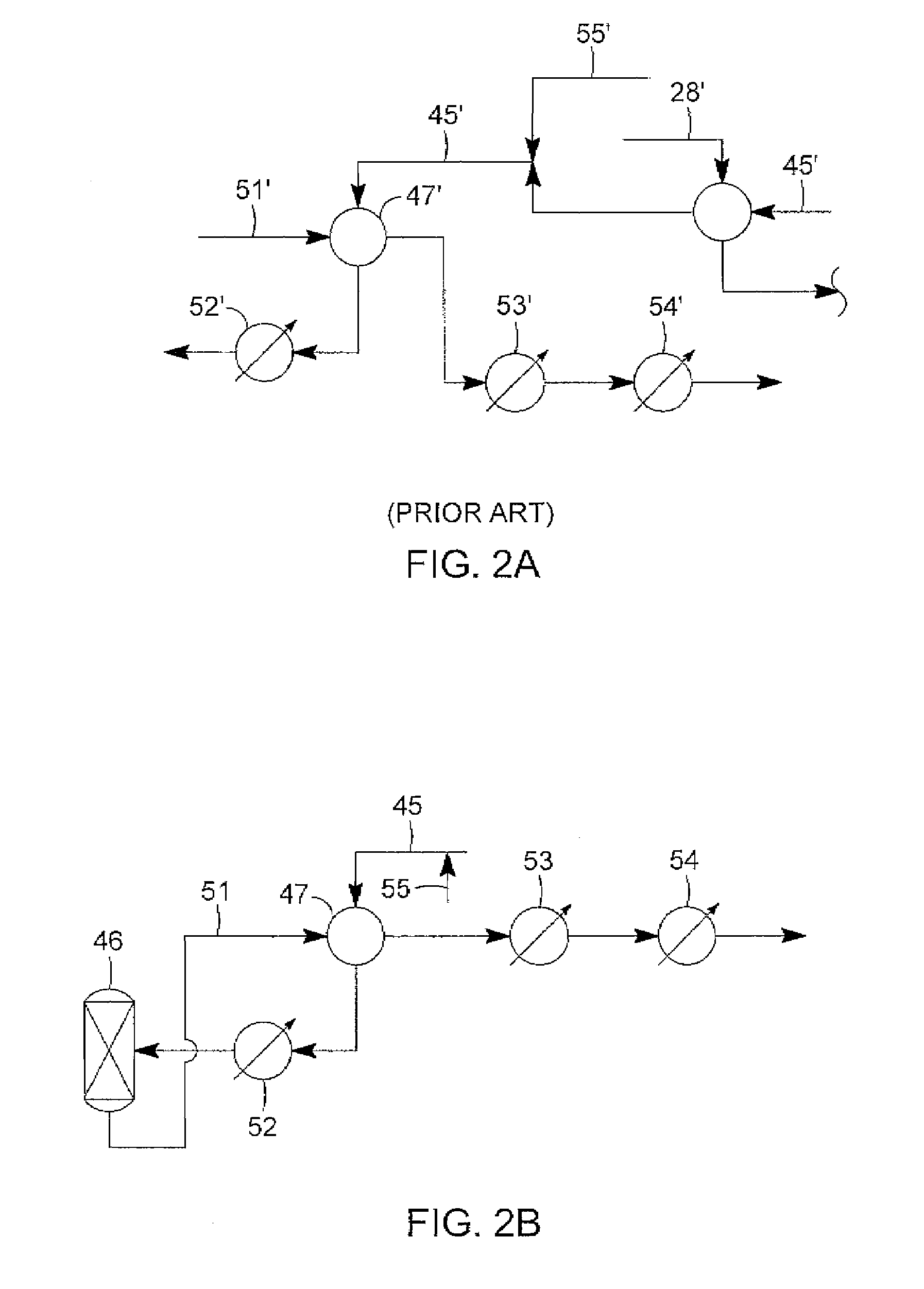

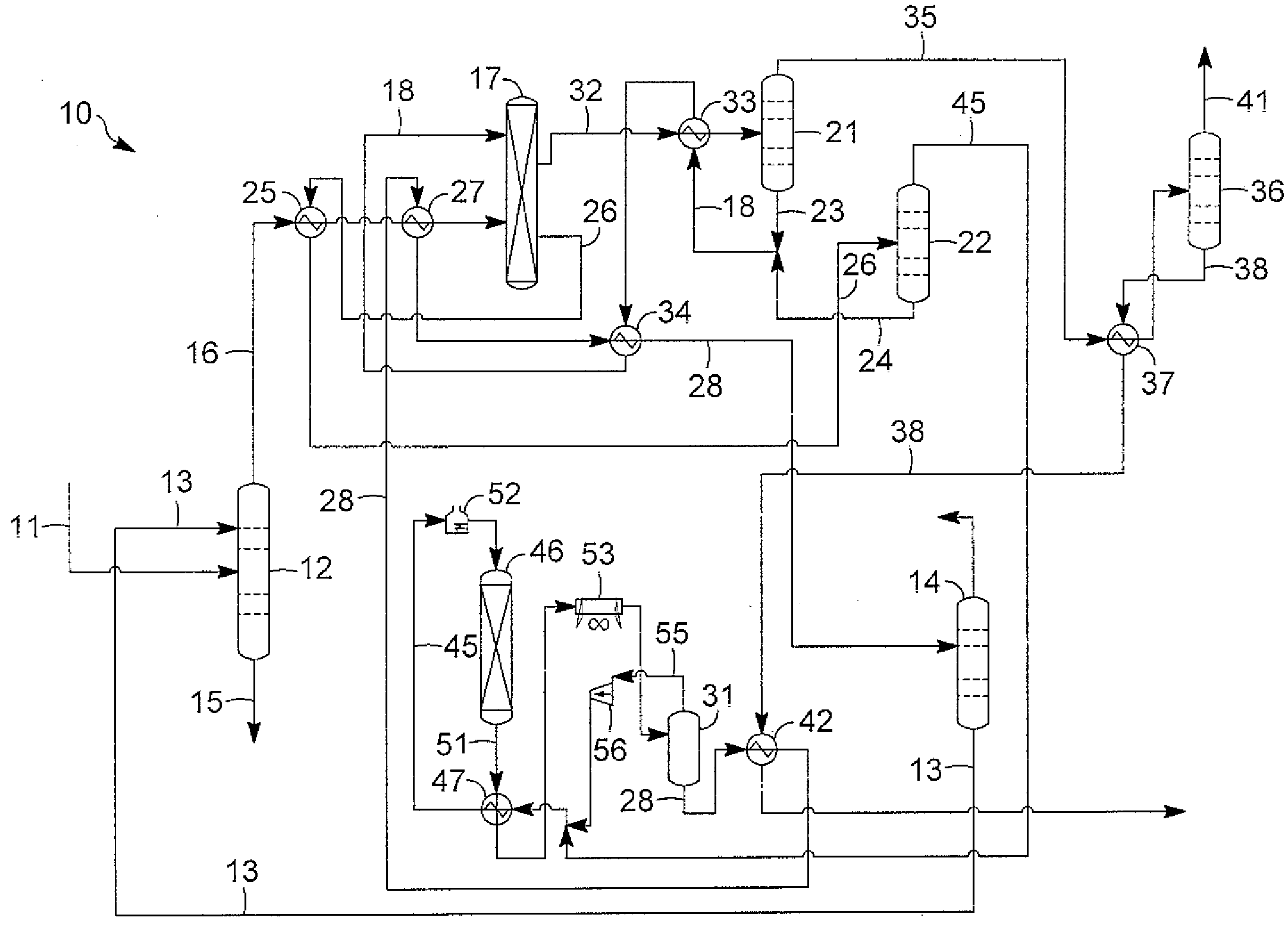

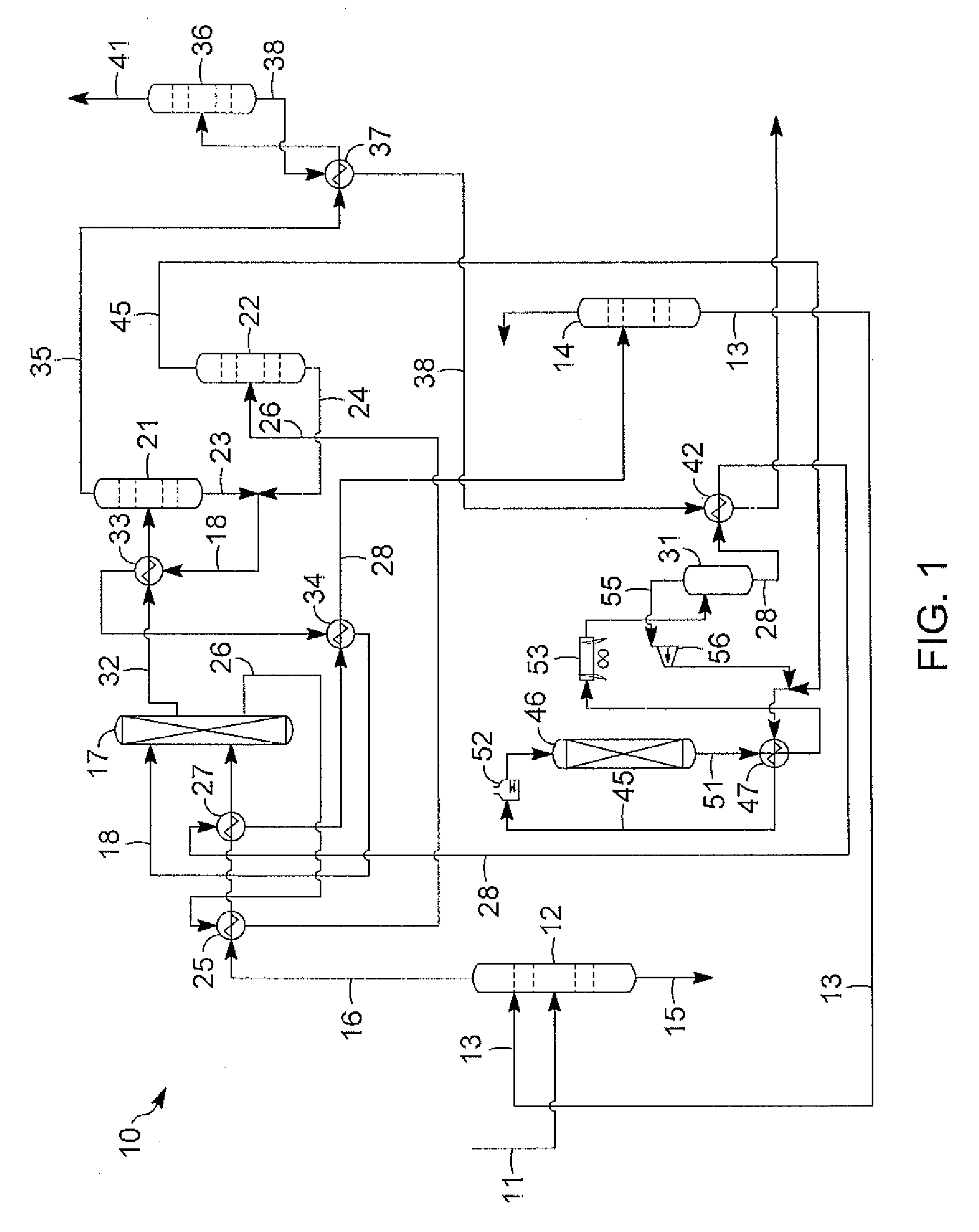

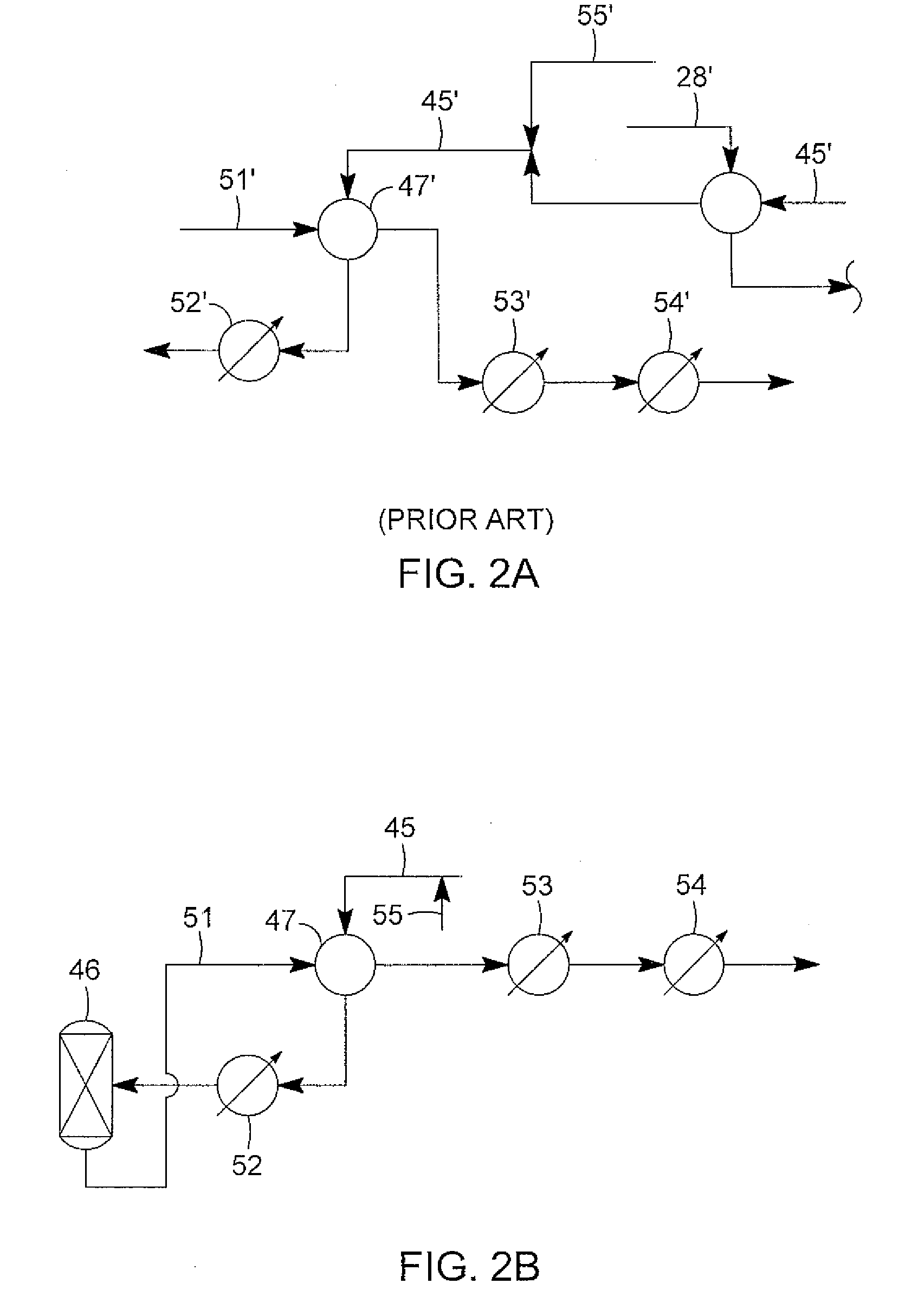

Low temperature process for recovering and producing para-xylene and heat exchange network therefore

ActiveUS7687674B2Increase and optimize capacitySaving in connectionHydrocarbon by isomerisationChemical industryIsomerizationExchange network

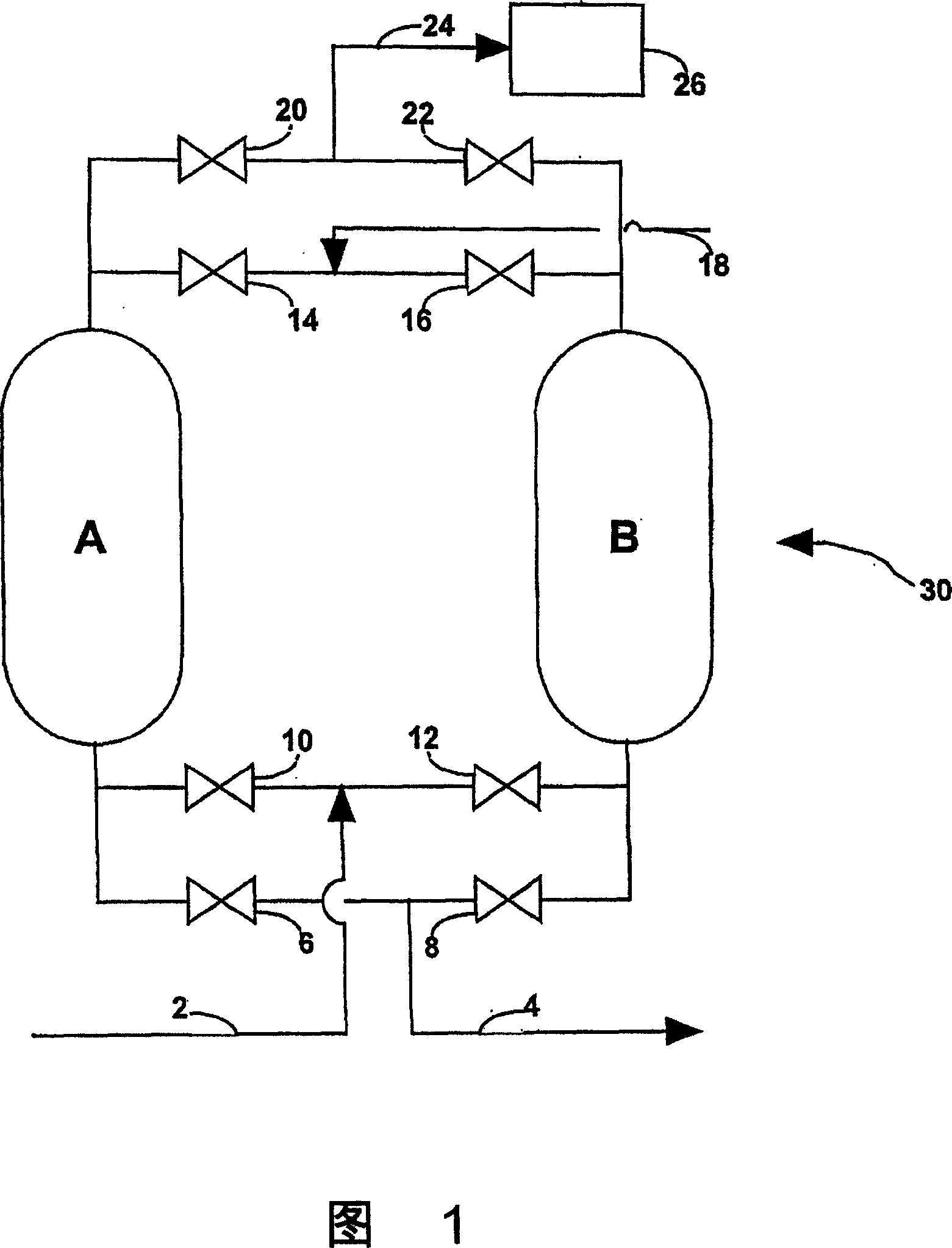

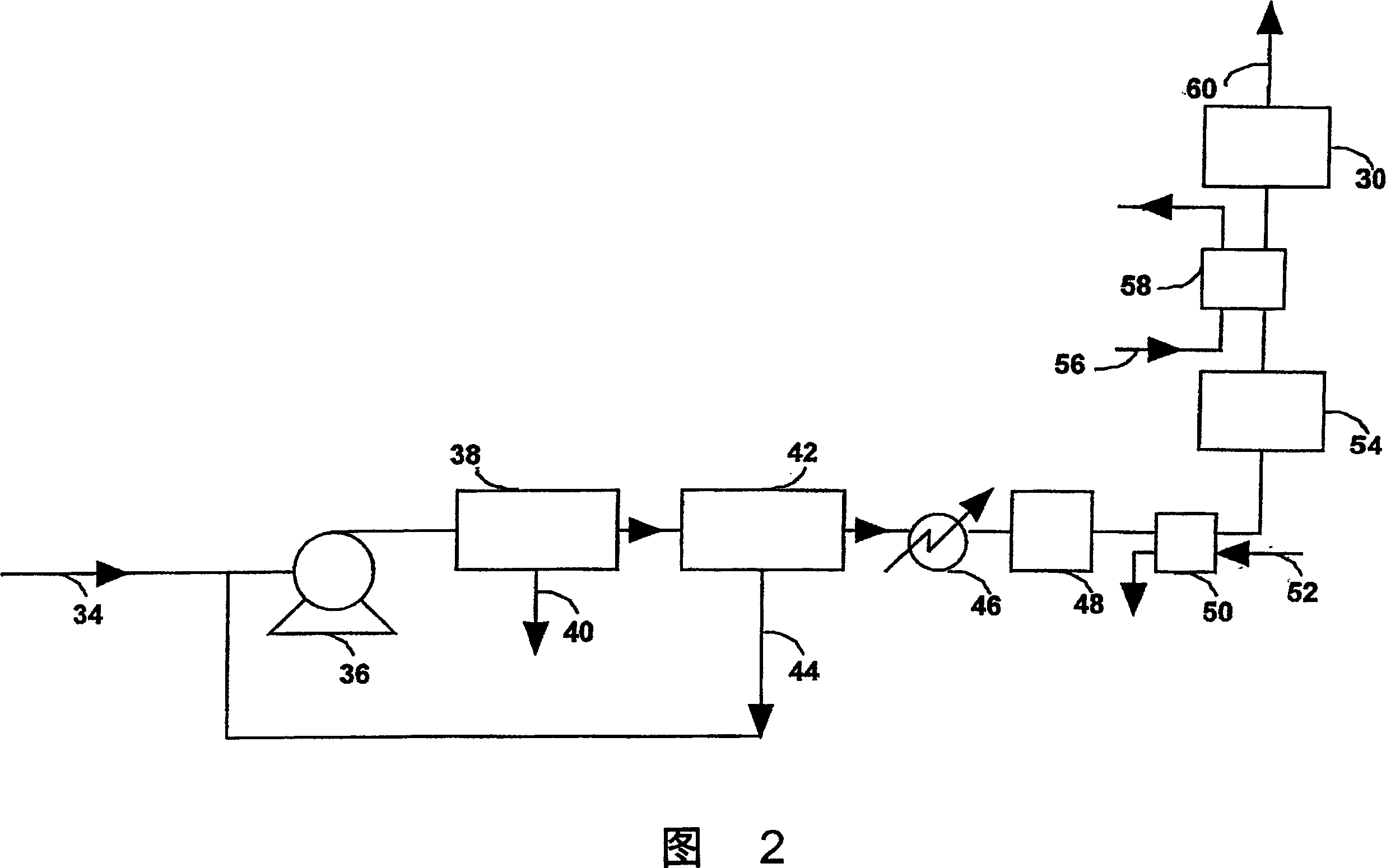

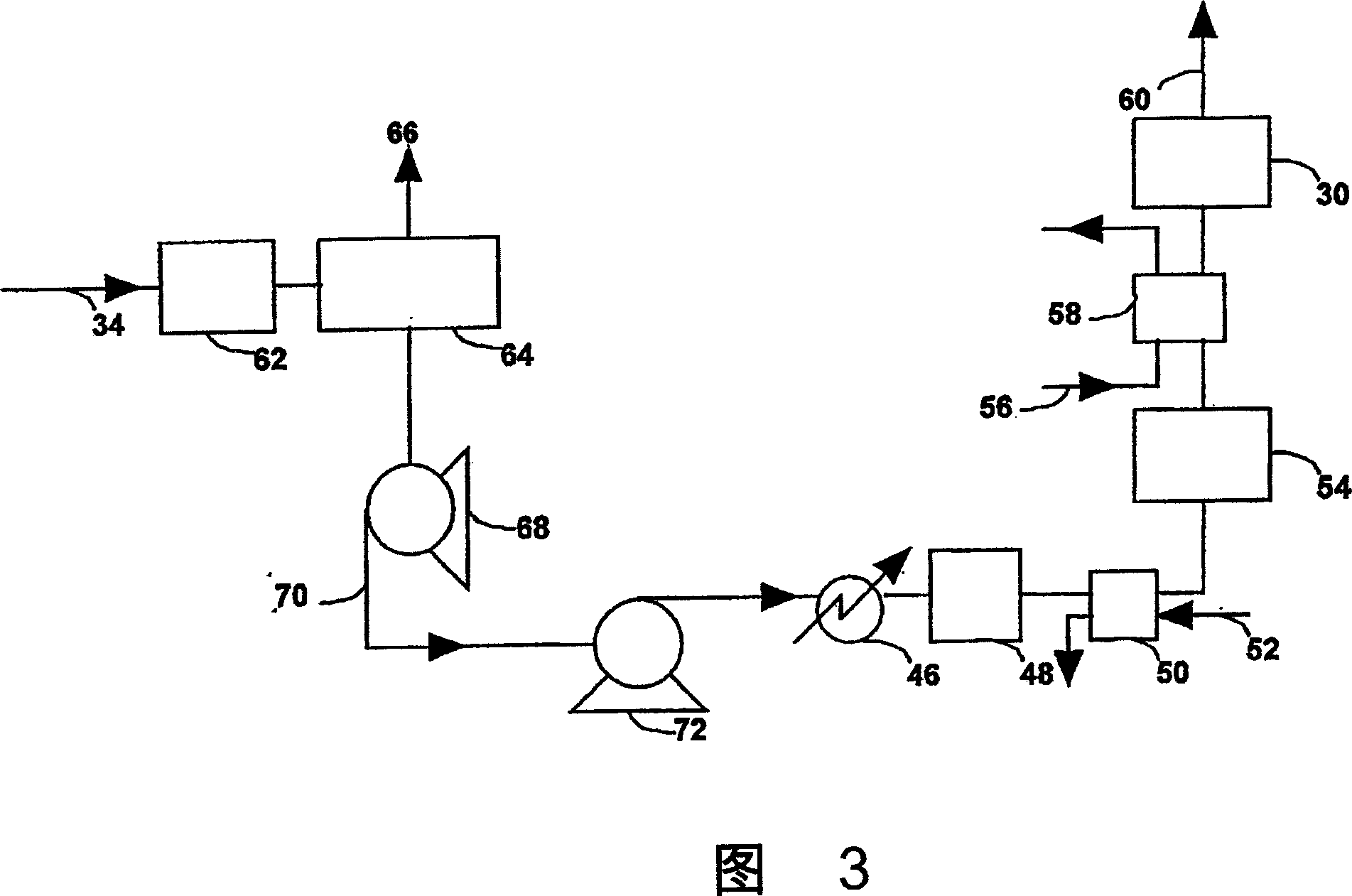

Recent experimental work with currently available adsorbents indicates that operating the adsorption section at lower temperatures improves the para-xylene productivity. As a result, an aromatics complex and heat recovery network for a low temperature adsorptive separation-isomerization loop is disclosed resulting in adsorbents savings in combination with higher capacity thereby enabling smaller adsorbents chambers, a smaller total heat exchanger area and a lower heat exchanger shell count.

Owner:UOP LLC

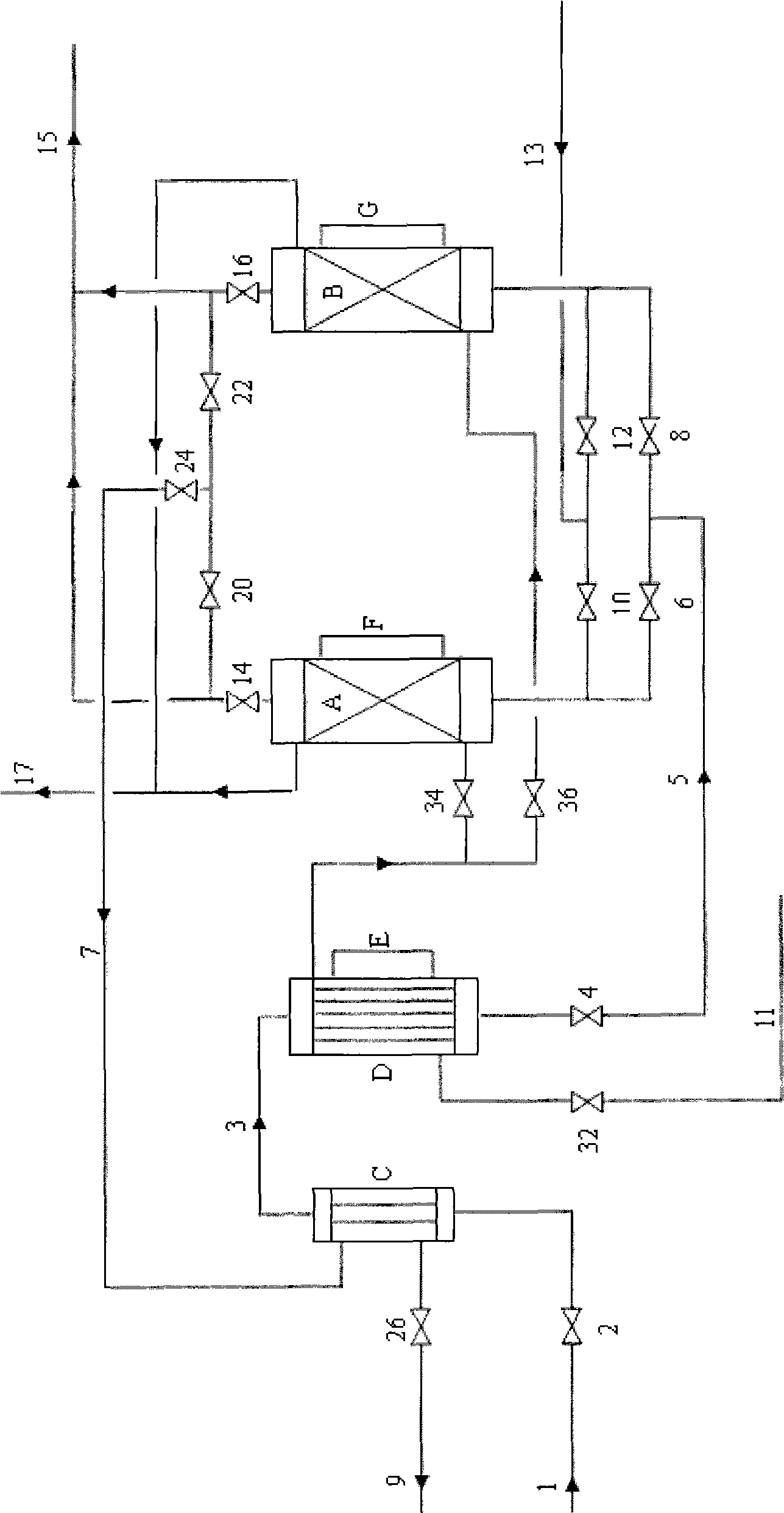

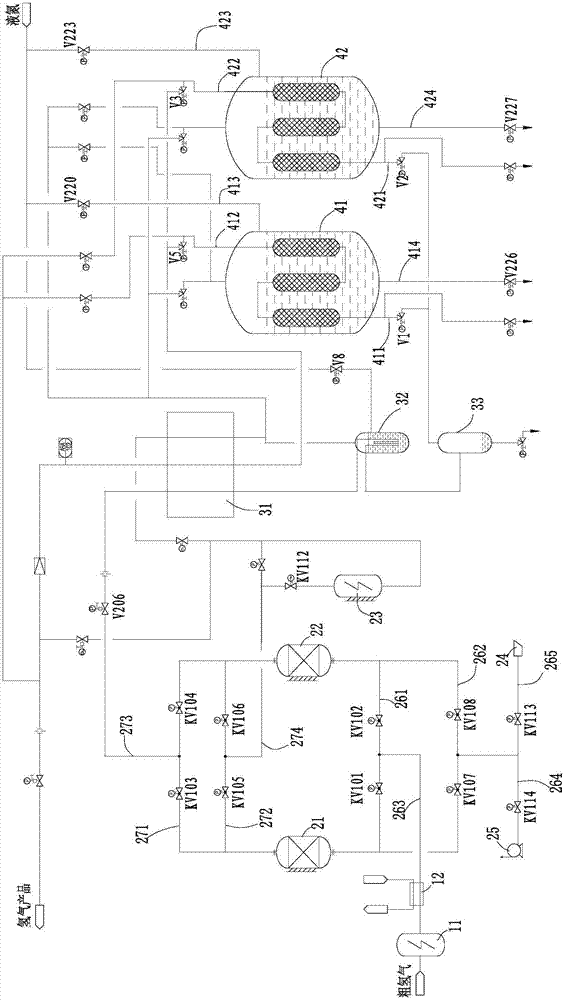

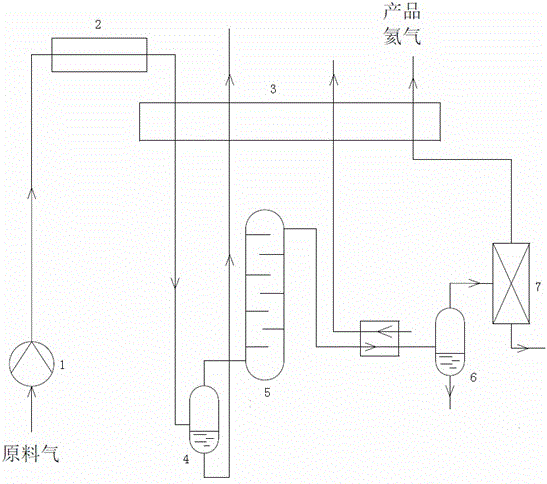

Low temperature adsorption method for continuously producing ultra-pure gas

InactiveCN101530717AEasy to operateReduce cooling lossDispersed particle separationEnergy recoveryOxygen

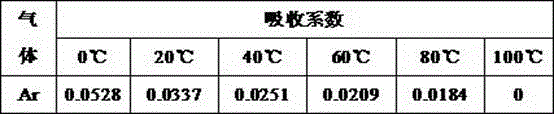

The invention provides a low temperature adsorption method for purifying impurity-containing gas, and continuously producing ultra-pure gas. The method uses liquid nitrogen as cold source, uses liquid nitrogen evaporator to cool raw material gas to required temperature, and uses low temperature adsorption tower group to adsorb to prepare ultra-pure gas with purity more than 6N. In addition, the method also includes cold energy recovery process of product gas and low temperature nitrogen. The method can be used for continuously producing ultra-pure hydrogen, deuterium, tritium, helium, neon, argon, nitrogen, oxygen, carbon monoxide and methane. The invention radically solves defects of directly putting an adsorption tower (column) into a liquid nitrogen groove, and realizes large-scale continuous production of ultra-pure gas.

Owner:中昊光明化工研究设计院有限公司

Low Temperature Process for Recovering and Producing Para-Xylene and Heat Exchange Network Therefore

ActiveUS20080161626A1Increase and optimize capacitySaving in connectionHydrocarbon by isomerisationChemical industryIsomerizationExchange network

Recent experimental work with currently available adsorbents indicates that operating the adsorption section at lower temperatures improves the para-xylene productivity. As a result, an aromatics complex and heat recovery network for a low temperature adsorptive separation-isomerization loop is disclosed resulting in adsorbents savings in combination with higher capacity thereby enabling smaller adsorbents chambers, a smaller total heat exchanger area and a lower heat exchanger shell count.

Owner:UOP LLC

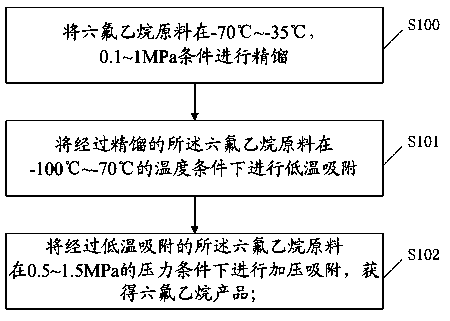

Hexafluoroethane purification method

ActiveCN103664501AHigh puritySolve storage problemsHalogenated hydrocarbon separation/purificationHexafluoroethanePurification methods

The invention discloses a hexafluoroethane purification method which comprises the following steps: rectifying a hexafluoroethane raw material under the conditions of (-70)-(-35) DEG C and 0.1-1 MPa; performing low-temperature adsorption on the rectified hexafluoroethane raw material under the temperature conditions of (-100)-(-70) DEG C; and performing pressurized adsorption on the hexafluoroethane raw material after low-temperature adsorption under the pressure conditions of 0.5-1.5 MPa, thus obtaining the hexafluoroethane product, wherein the CO2 volume concentration of the hexafluoroethane product is no more than 0.5 ppm, and the H2O volume concentration is no more than 1 ppm. According to the invention, the problem that potential safety hazard is caused due to insufficient CO2 and H2O removal depth and introduction of anhydrous HCl in hexafluoroethane is solved, the energy consumption is reduced, and the adsorption effect of adsorbent is enhanced; and the purity of the hexafluoroethane product is up to 99.9995% or above, thus meeting the requirements for electronic specific gas in the semiconductor and micro-electronics industry.

Owner:FOSHAN HUATE GASES +1

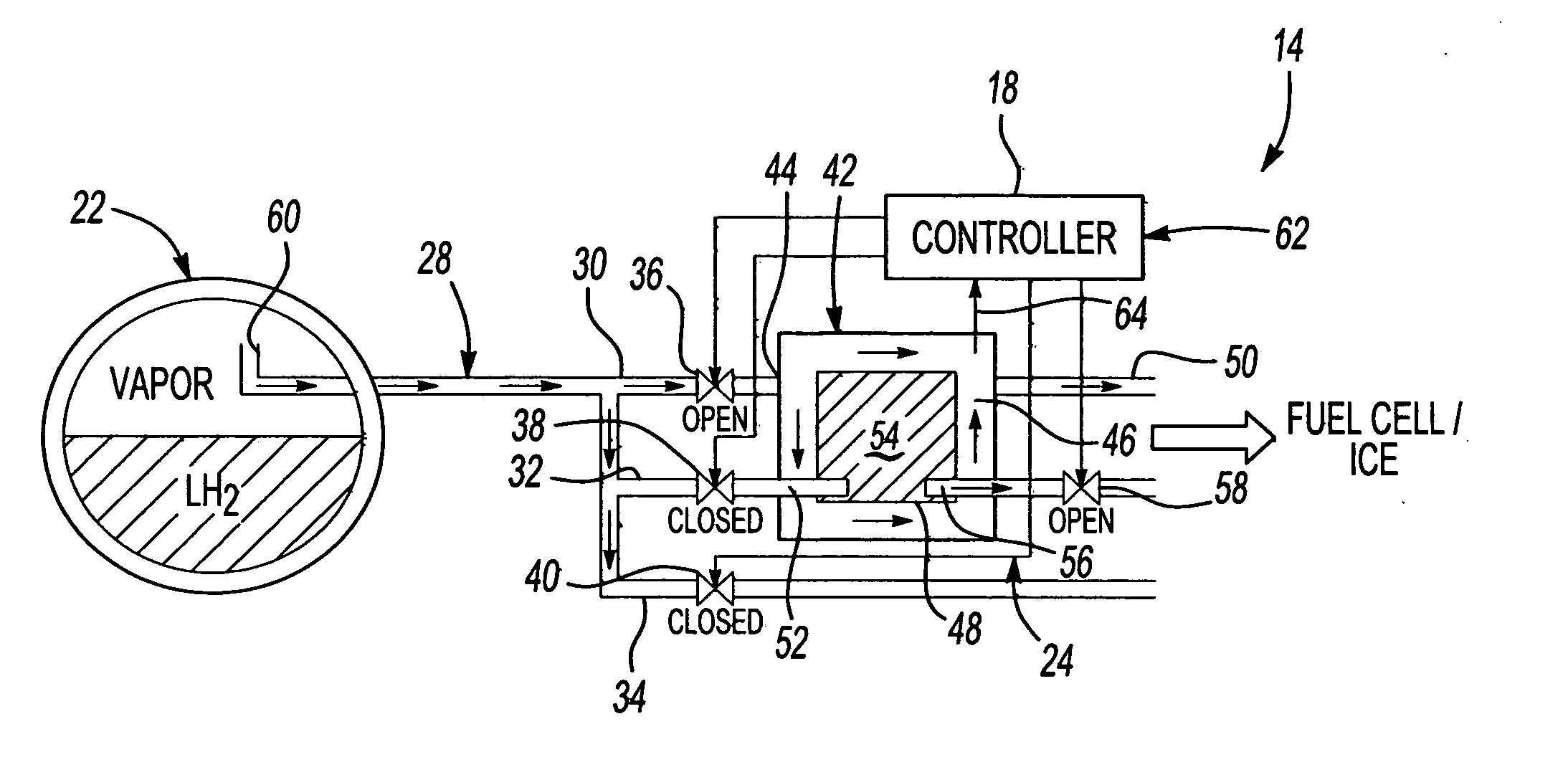

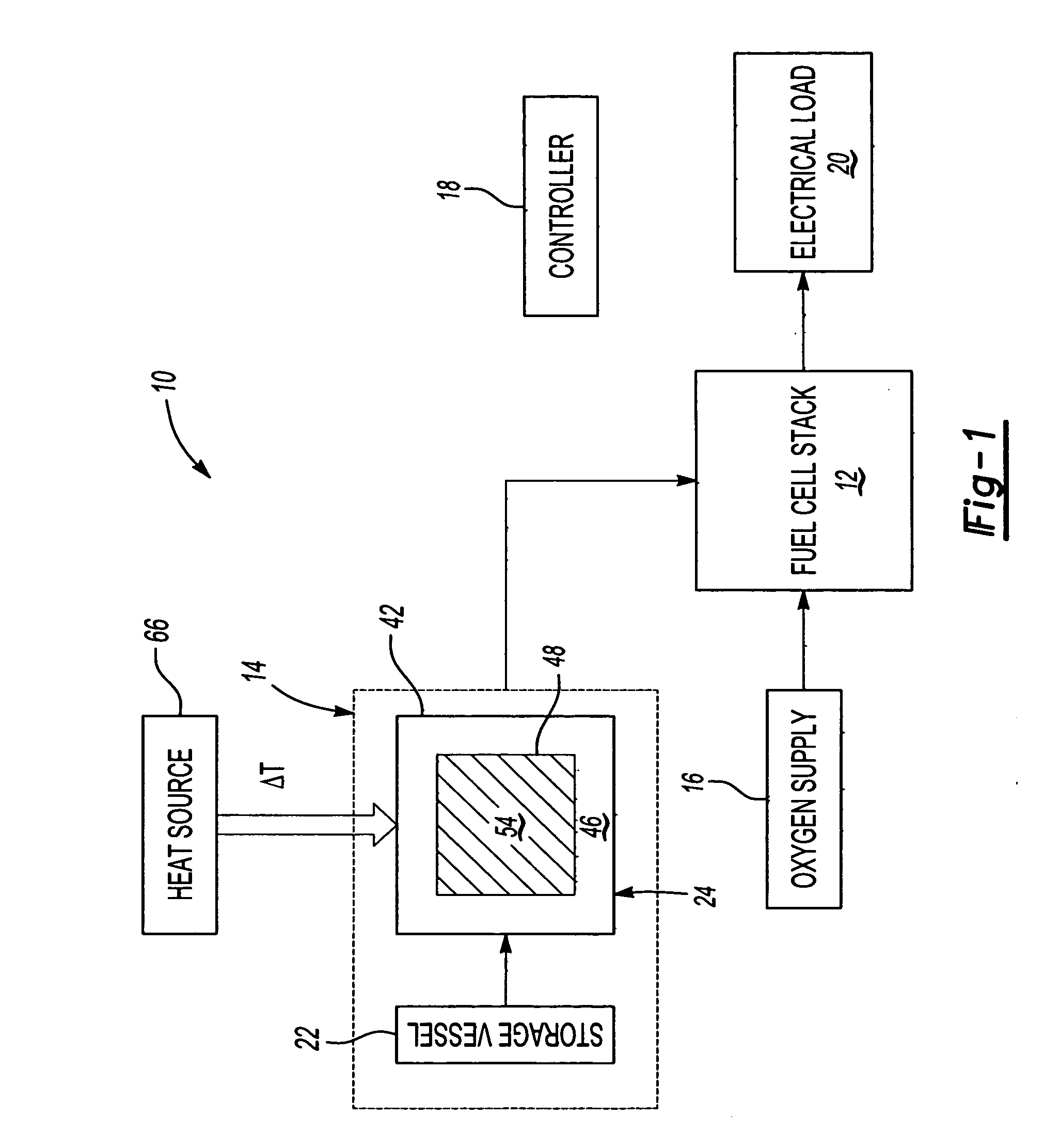

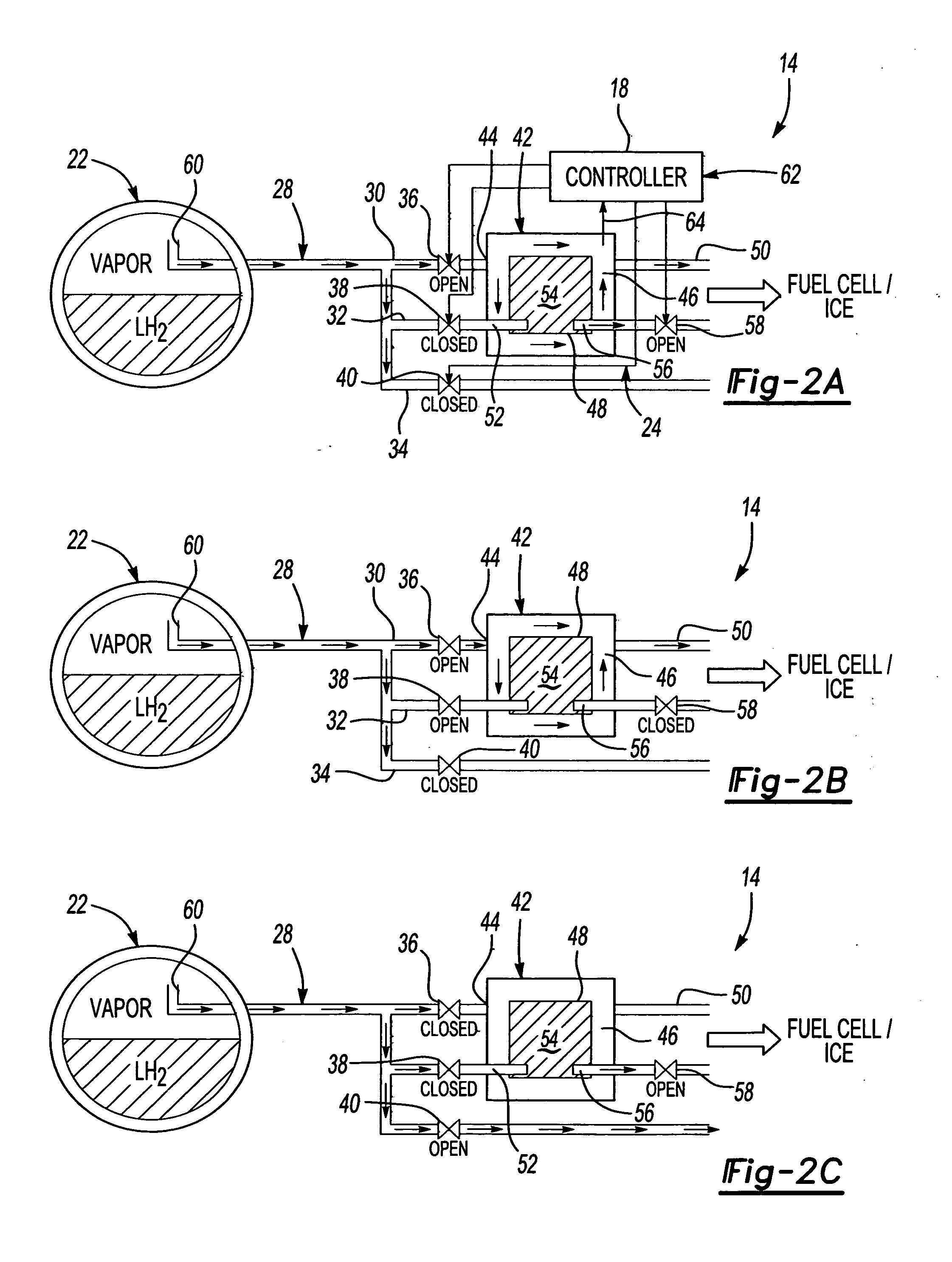

Boil-off compensating cryoadsorption container for liquid gas storage

InactiveUS20060199064A1Reactant parameters controlContainer filling methodsProcess engineeringLiquid hydrogen

A hydrogen-based propulsion system is provided for storing hydrogen feed gas which evaporates over time from a storage vessel containing liquid hydrogen as a fuel. In particular, this system enables the evaporated hydrogen feed gas to be stored for later use in the propulsion unit and also provides a system for enabling the stored hydrogen gas to be cooled by evaporated hydrogen feed gas in transit to the propulsion unit.

Owner:GM GLOBAL TECH OPERATIONS LLC

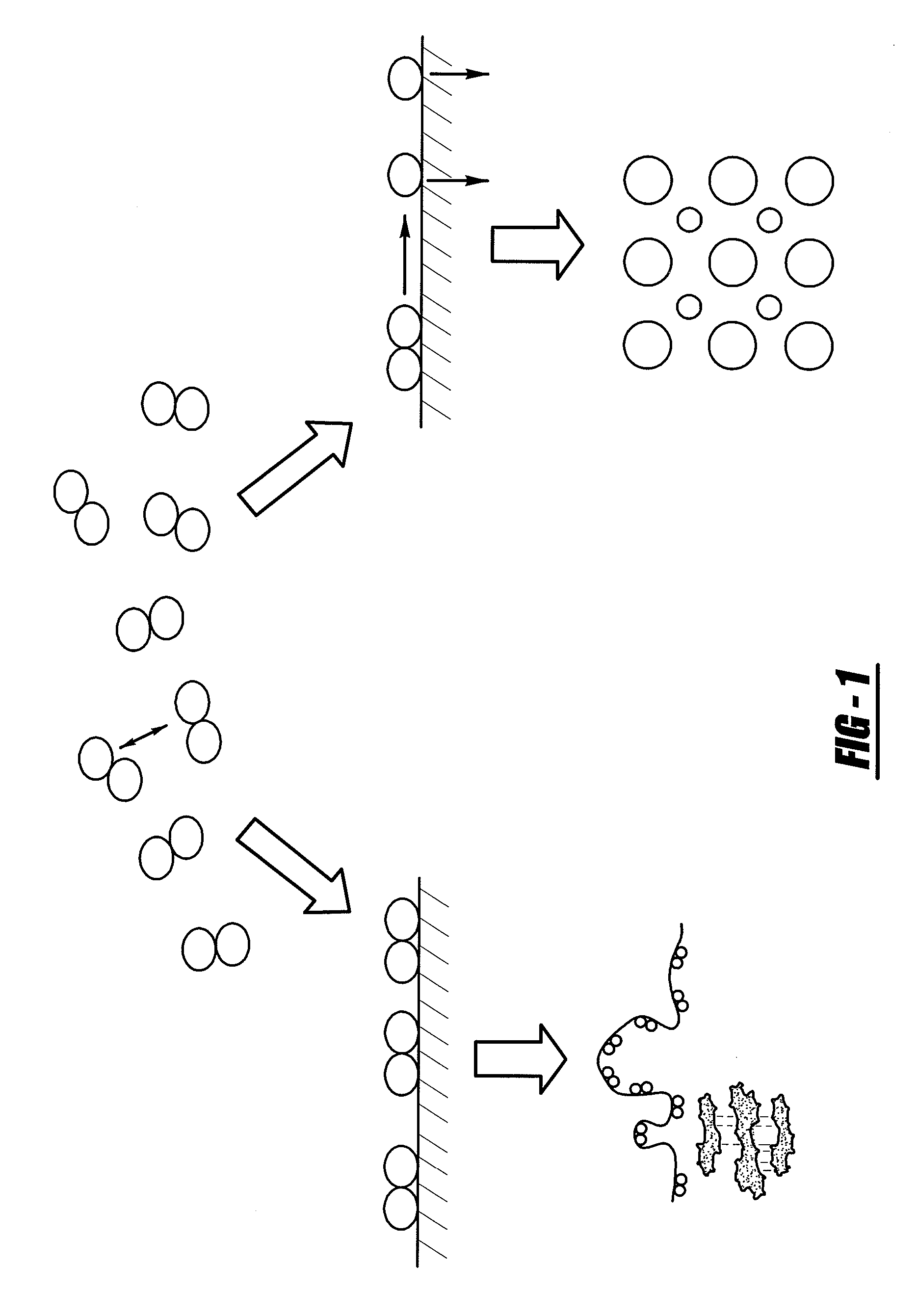

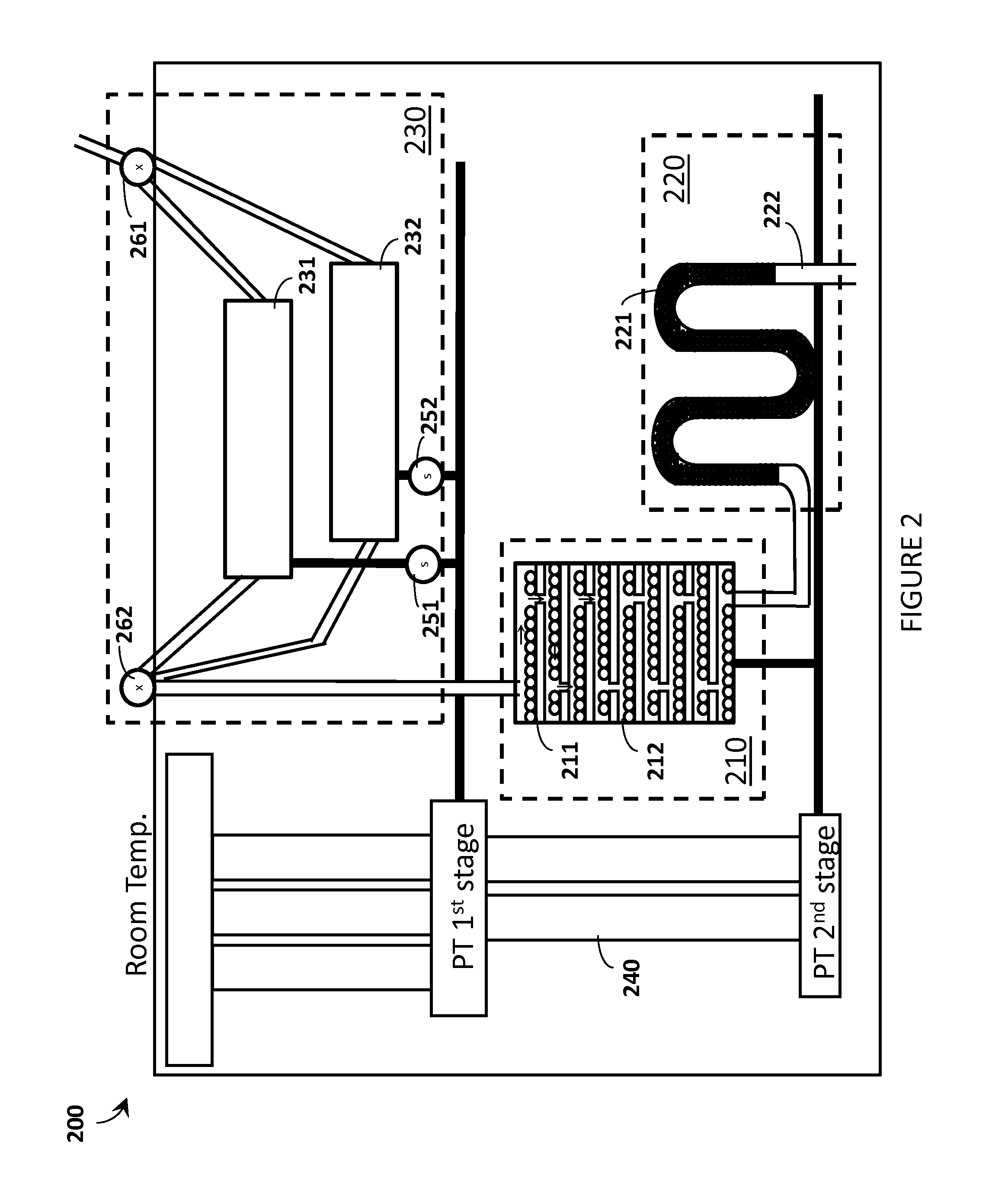

Systems and methods for cryogenic refrigeration

InactiveUS20140137571A1Increase surface areaImprove thermal conductivitySolidificationLiquefactionBinding energyDilution refrigerator

Systems and methods for improving the performance of dilution refrigeration systems are described. Filters and traps employed in the helium circuit of a dilution refrigerator may be modified to improve performance. Some traps may be designed to harness cryocondensation as opposed to cryoadsorption. A cryocondensation trap employs a cryocondensation surface having a high thermal conductivity and a high specific heat with a binding energy that preferably matches at least one contaminant but does not match helium. Multiple traps may be coupled in series in the helium circuit, with each trap designed to trap a specific contaminant or set of contaminants. Both cryocondensation and cryoadsorption may be exploited among multiple traps.

Owner:D WAVE SYSTEMS INC

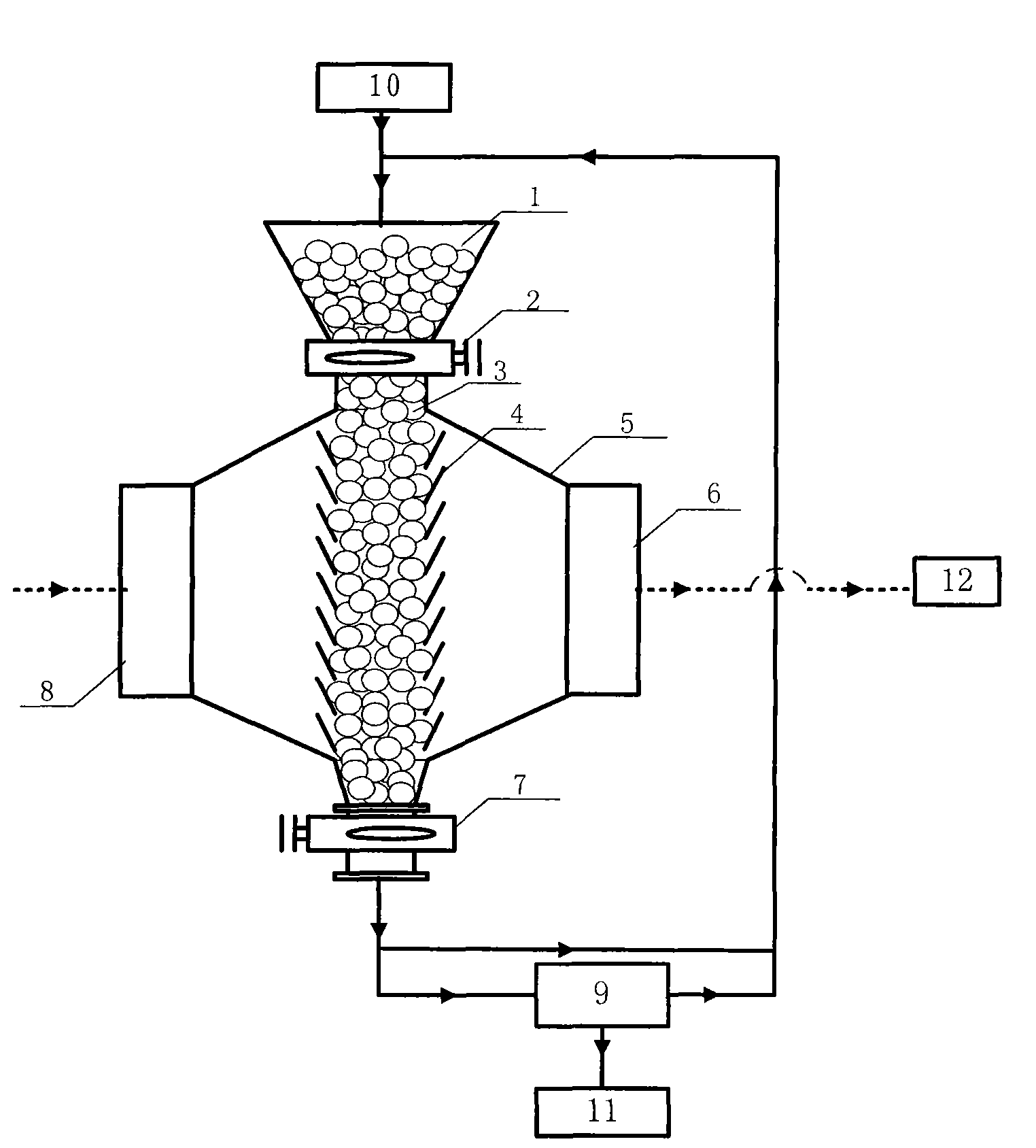

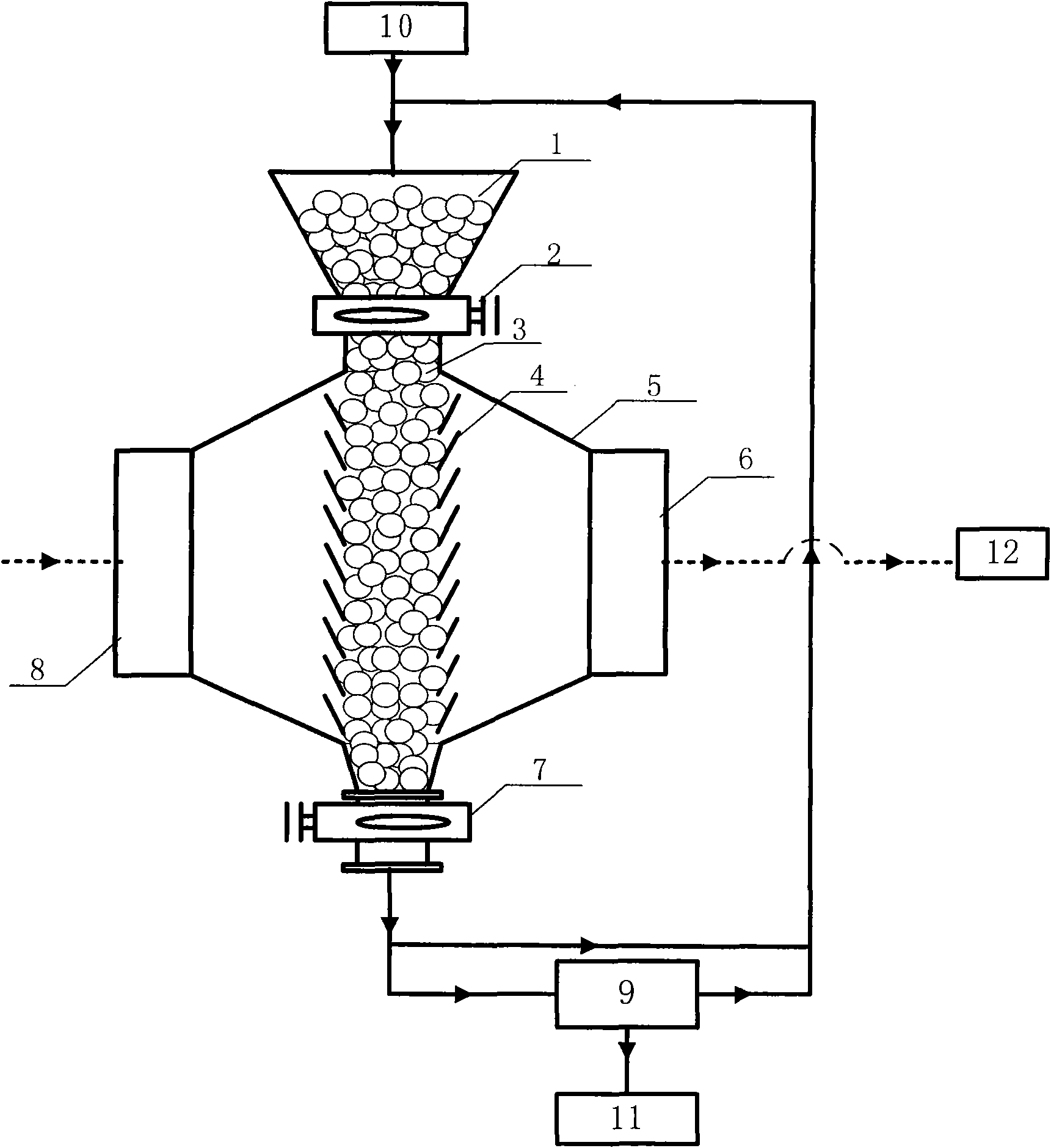

Device and method for removing harmful components from gas in cement kiln by utilizing cross-flow moving bed

ActiveCN101785953ASolve the problem of crust cloggingReduce firing heat consumptionDispersed particle separationHazardous substanceSulfur

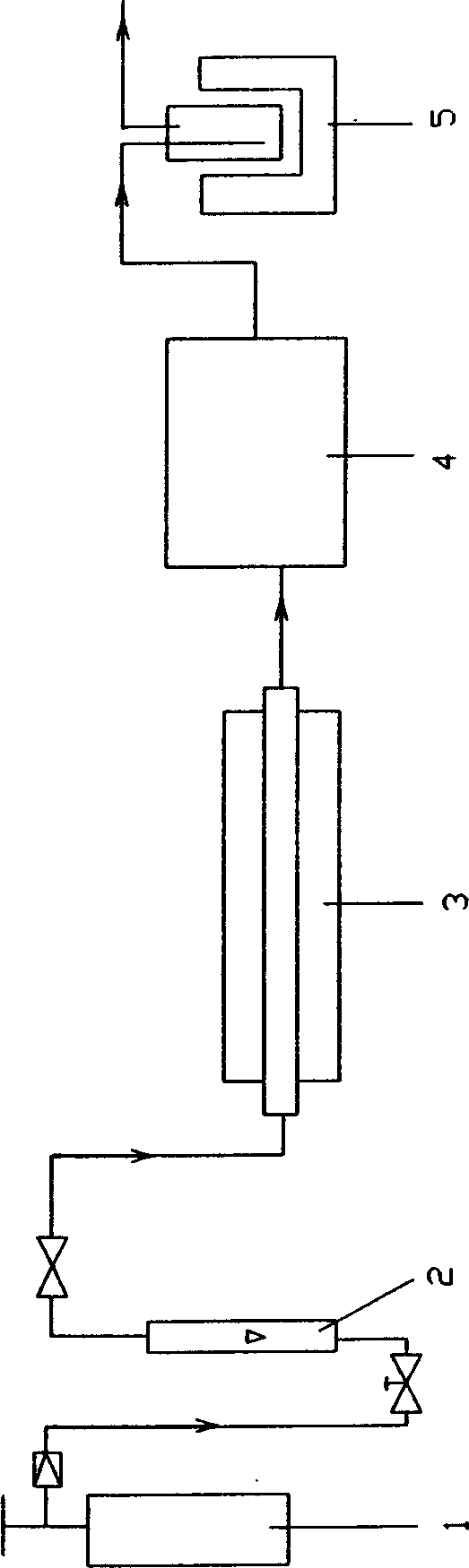

The invention discloses a device and a method for removing harmful components from gas in a cement kiln by utilizing a cross-flow moving bed. The device and the method are implemented by the following steps: adsorption carrier particles (3) fall into an absorber of the cross-flow moving bed (5) from a hopper (1); the high temperature gas enters the absorber of the cross-flow moving bed (5) and the low temperature adsorption carrier particles (3) for cross-flow flowing, and the harmful components in the gas are condensed onto the adsorption carrier particles (3); a discharge valve (7) controls the discharge rate of the adsorption carrier particles (3); a cleaning device (9) completes washing and drying the adsorption carrier particles (3) and delivers the adsorption carrier particles (3) back to the hopper (1) to realize the recycling of the carrier particles; and a supply bin (10) completes supplying the adsorption carrier particles (3). The device and the method can effectively solve the problems of crusting and blocking caused by circulation and enrichment of the harmful components such as alkali, chlorine and sulfur, avoid the increase of energy consumption due to evacuation, and simultaneously can separate harmful substances from the gas for resource recycling.

Owner:SOUTHEAST UNIV

Catalyst for purifying exhaust gases

InactiveUS7084086B2Excellent in HC purifying abilityImprove oxygen storage capacityMolecular sieve catalystsInternal combustion piston enginesCryo-adsorptionHigh heat

A catalyst for purifying exhaust gases exhibits not only effective purifying characteristics even in a low temperature range such as immediately after an engine starts but also high exhaust gas purifying ability. In the catalyst for purifying exhaust gases of a first aspect of the invention, HC adsorbed at low temperature are released at high temperature and the released HC are purified by a catalyst metal. This catalyst for purifying exhaust gases has an excellent advantage in purifying HC at low temperature as well as excellent exhaust gas purifying ability.

Owner:CATALER CORP

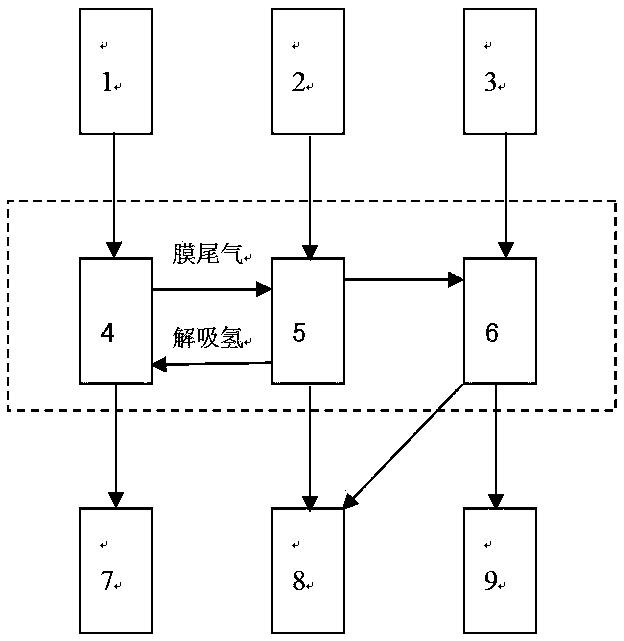

Hydrogen and helium gas mixture separation and recovery device

InactiveCN104340959AEfficient recyclingAchieve separationHydrogen separationDispersed particle separationWater storage tankCryo-adsorption

The invention provides a hydrogen and helium gas mixture separation and recovery device. The device characterized in that a high-concentration hydrogen and helium gas mixture in the device is connected with a membrane separator, and the membrane separator is connected with a low-temperature adsorption bed and a hydrogen gas storage tank respectively; a medium-concentration hydrogen and helium gas mixture is connected with the low-temperature adsorption bed, the low-temperature adsorption bed is connected with the membrane separator, a catalytic oxidation bed and a helium gas storage tank respectively, and the catalytic oxidation bed is connected with the helium gas storage tank and a water storage tank respectively; a low-concentration hydrogen and helium gas mixture is connected with the catalytic oxidation bed, and the catalytic oxidation bed is connected with the helium gas storage tank and the water storage tank respectively. By adopting the device provided by the invention, the separation and recovery of the hydrogen and helium gas mixtures of different volumetric concentrations can be realized.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

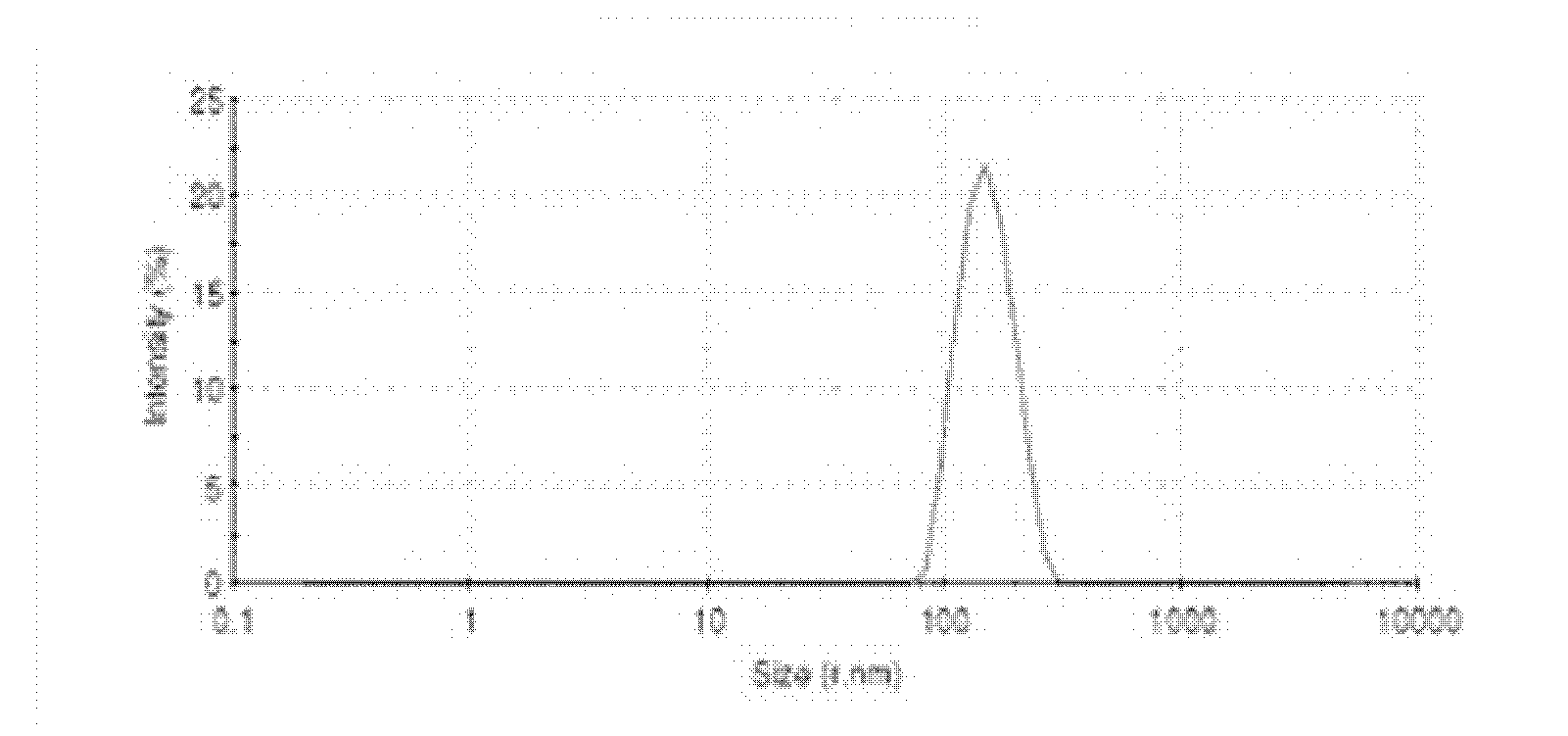

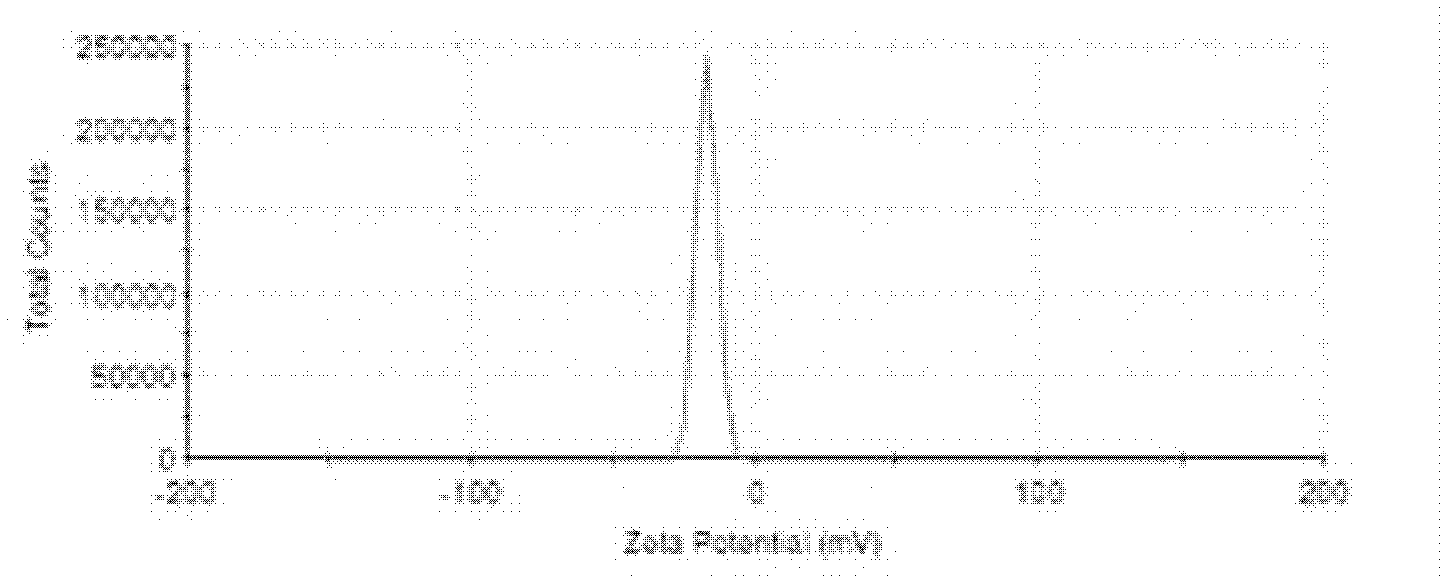

Composite carbon dioxide adsorption material, preparation method and application thereof

ActiveCN104056599AImprove adsorption capacityEasy to spreadOther chemical processesDispersed particle separationSorbentChemical adsorption

The invention discloses a composite carbon dioxide adsorption material, which includes an in-situ synthesized MOFs(metal-organic frameworks)-graphite based composite material and organic amine loaded on the MOFs-graphite based composite material. The mass ratio of the MOFs-graphite based composite material to the organic amine is 0.1-10:1. The composite carbon dioxide adsorption material provided by the invention realizes the combined action of physical adsorption and chemical adsorption, can adsorb and store carbon dioxide at medium and low temperature, and realizes regeneration and reuse of the adsorbent under certain conditions. The composite carbon dioxide adsorption material has good adsorption capacity, high selectivity and cycling stability on carbon dioxide, and can overcome the disadvantages of easy volatilization and easy corrosion of equipment in organic amine so as to meet the industrial processing requirements. The invention also discloses a preparation method of the composite carbon dioxide adsorption material and application in adsorption of carbon dioxide in flue gas.

Owner:ZHEJIANG UNIV

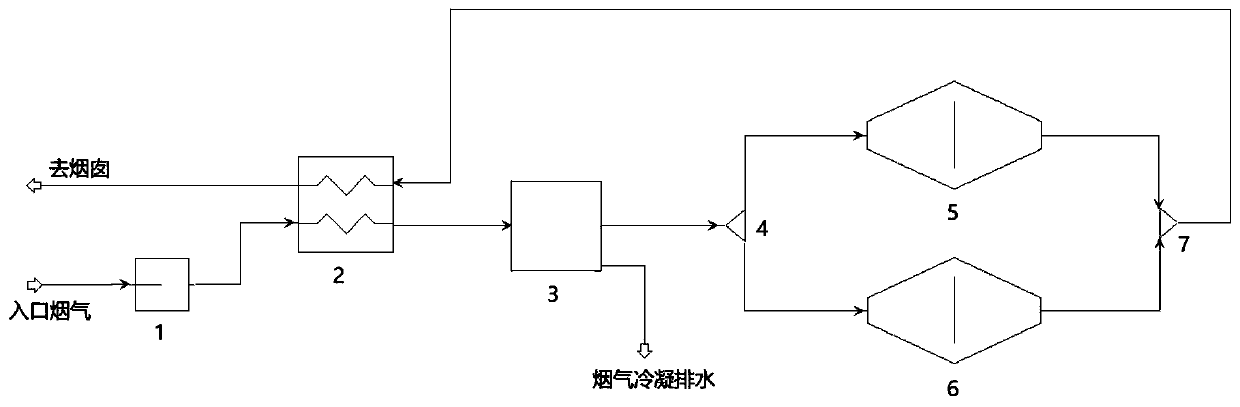

Low-temperature adsorption denitration system and process for smoke

InactiveCN110743312ARealize continuous denitrification operationImprove cooling utilizationGas treatmentDispersed particle separationCryo-adsorptionCooling capacity

The invention discloses a low-temperature adsorption denitration system and process for smoke. The low-temperature adsorption denitration system comprises a booster fan, a cooling capacity recoverer,a smoke cooling system, a smoke switching valve and denitration adsorption towers; an inlet of the booster fan communicates with an inlet smoke pipeline, the booster fan, the cooling capacity recoverer, the smoke cooling system, the smoke switching valve and the denitration adsorption towers sequentially communicate, an outlet of the smoke switching valve communicates with the first denitration adsorption tower and the second denitration adsorption tower, smoke outlets of the first denitration adsorption tower and the second denitration adsorption tower communicate with a smoke convergence device, and the smoke convergence device communicates with the cooling capacity recoverer. The two denitration adsorption towers are arranged to perform denitration and regeneration processes in turn, continuous denitration operation of the system can be achieved, the denitration efficiency is high, and adsorbed materials are desorbed and then recycled; and physical adsorption denitration is adopted,meanwhile NO2 and NO are directly adsorbed to be removed, preoxidation of the NO is not needed, strong oxidant and precious metal catalysis is not needed either, the denitration efficiency is high, and zero emission of NO<x> can be achieved.

Owner:CHINA HUANENG GRP CO LTD +1

Halloysite carbon dioxide adsorbent and preparation method thereof

InactiveCN102614832ARealize recycling and reuseImprove adsorption capacityProductsCarbon compoundsHalloysiteCarbon oxide

The invention discloses a halloysite carbon dioxide adsorbent and a preparation method thereof. The halloysite carbon dioxide adsorbent is characterized by comprising a halloysite nanometer pipe and an organic amine substance loaded on the inner surface and outer surface of the halloysite nanometer pipe, wherein the mass ratio of the halloysite nanometer pipe to the organic amine substance is (1-10):1. The halloysite carbon dioxide adsorbent has higher adsorptive property and adsorptive selectivity on carbon dioxide, can release carbon dioxide at high temperature by adsorbing and storing carbon oxide at low temperature so as to realize the regeneration and reutilization of an adsorbing agent, and can be used for overcoming the defects that organic amine is easy to volatilize and can etch equipment easily and meeting the requirements of industrial treatment; and in addition, the preparation process is simple and controllable.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

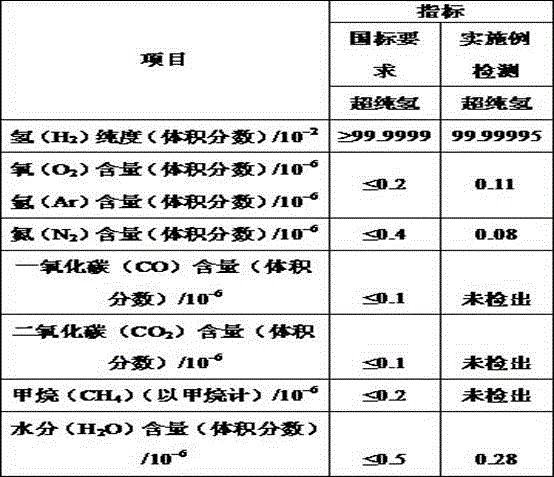

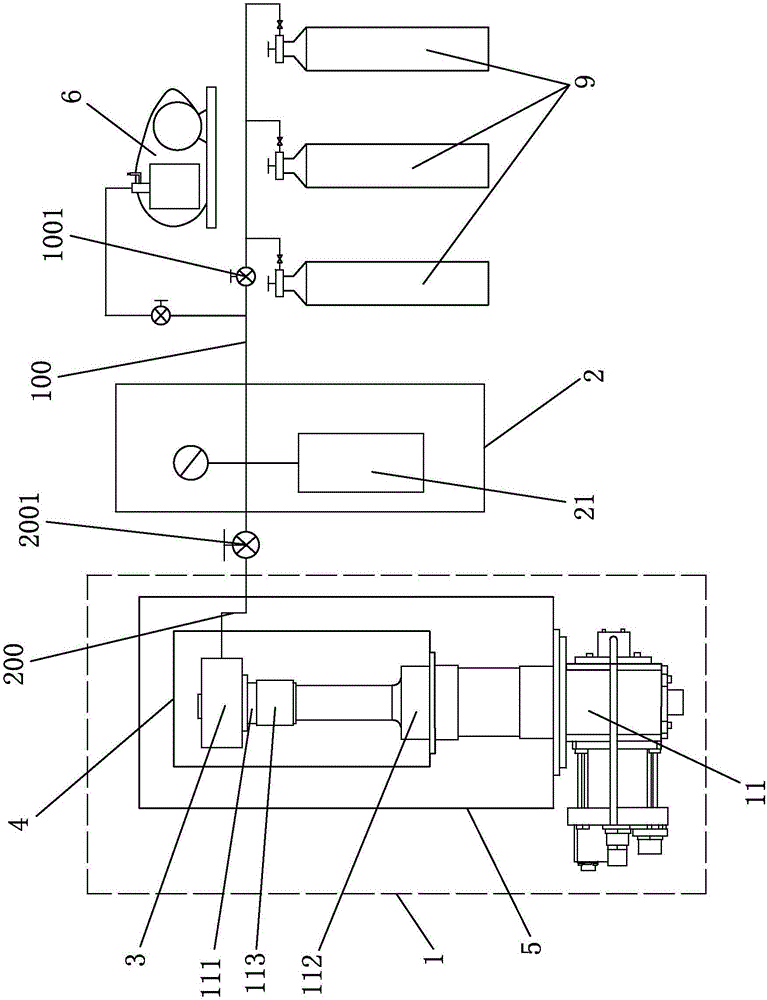

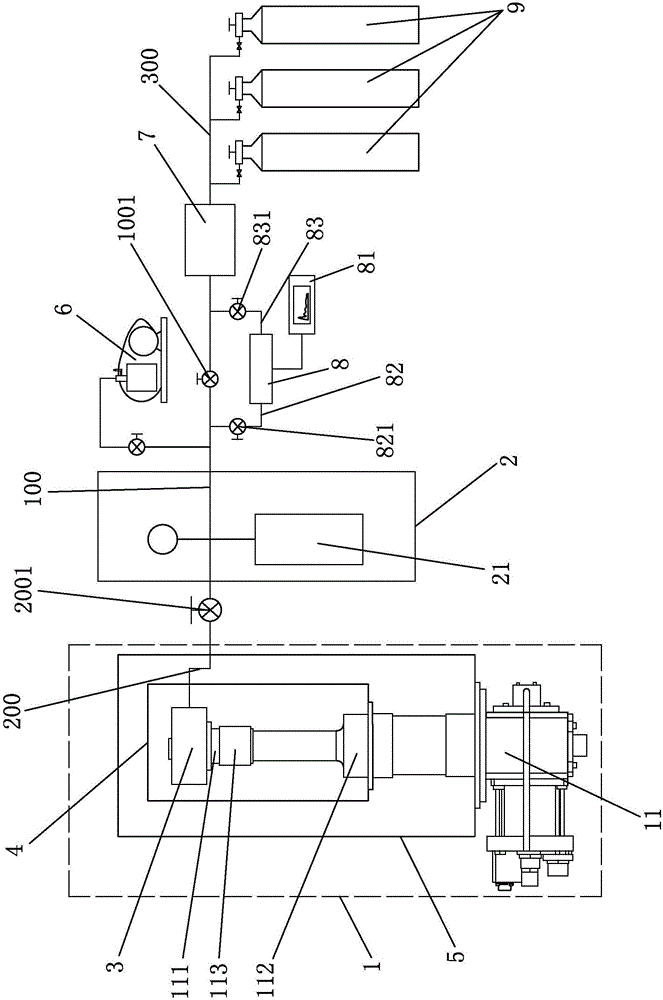

Low-temperature hydrogen purification device and control method

PendingCN107364832ALow oxygenReduce nitrogen contentHydrogen separation by selective and reversible uptakeHydrogen separation at low temperaturePhysical chemistryProcess engineering

The invention discloses a low-temperature hydrogen purification device which comprises a catalytic deoxidization device, a normal-temperature adsorption device, a low-temperature heat exchange device and a low-temperature adsorption device. Deoxidization is performed on crude hydrogen by the catalytic deoxidization device, the crude hydrogen is cooled to reach normal temperature by the catalytic deoxidization device, the normal-temperature adsorption device is used for adsorbing nitrogen in the crude hydrogen, the low-temperature heat exchange device is used for cooling the crude hydrogen, and the low-temperature adsorption device is used for adsorbing the nitrogen in the crude hydrogen. A gas inlet of the catalytic deoxidization device is connected with the crude hydrogen, a gas outlet of the catalytic deoxidization device is sequentially connected with the normal-temperature adsorption device, the low-temperature heat exchange device and the low-temperature adsorption device through pipelines, the normal-temperature adsorption device further can adsorb water and carbon dioxide in the crude hydrogen, and the low-temperature adsorption device further can adsorb micro-oxygen in the crude hydrogen. The invention further discloses a control method of the low-temperature hydrogen purification device. The low-temperature hydrogen purification device can obtain hydrogen with higher purity and better quality by the aid of tertiary purification technology, and the purification device further has the advantages of low operating cost, less equipment investment, convenience in operation, simplicity and convenience in maintenance and high reliability.

Owner:深圳市海格金谷工业科技有限公司

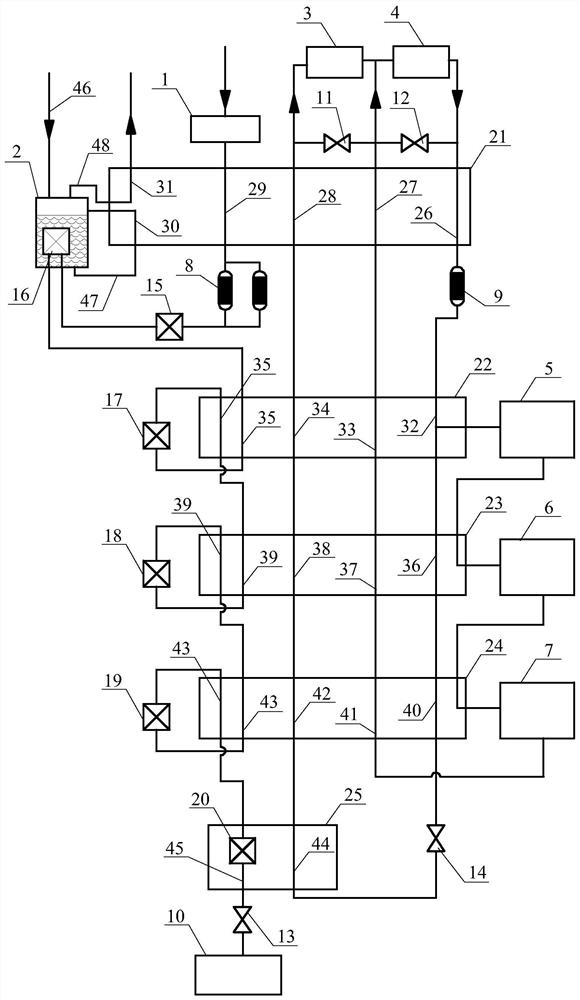

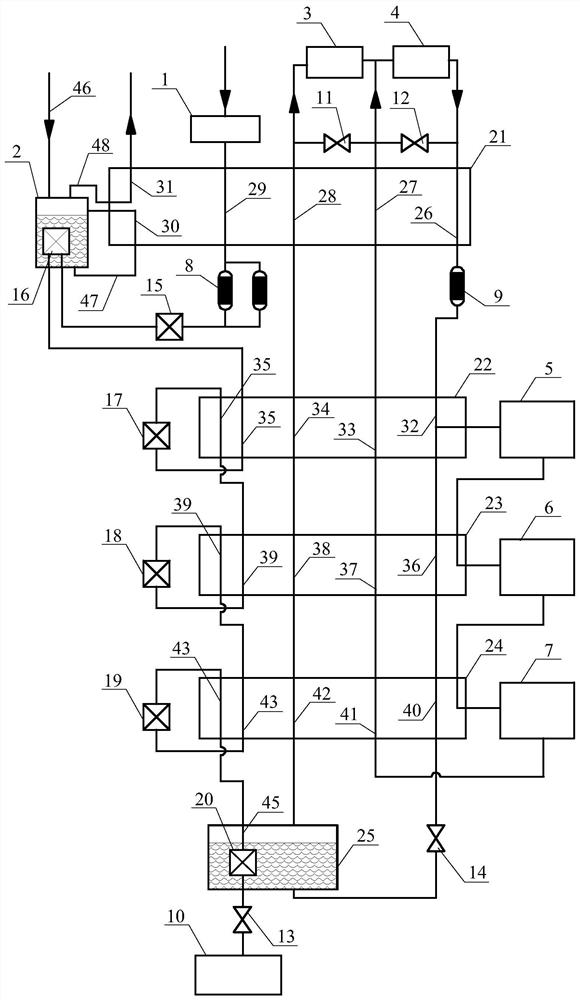

Hydrogen liquefaction equipment provided with three turbo expander units connected in series

PendingCN112361711AHigh hydrogen liquefaction efficiencyReduce energy consumptionSolidificationLiquefactionConvertersHydrogen compression

The invention discloses hydrogen liquefaction equipment provided with three turbo expander units connected in series. The hydrogen liquefaction equipment comprises a vacuum box, a hydrogen purification device, a pre-cooling device, a first hydrogen compressor unit, a second hydrogen compressor unit, a first turbo expander unit, a second turbo expander unit, a third turbo expander unit, a first low-temperature adsorber, a second low-temperature adsorber, heat exchangers, ortho-parahydrogen converters, regulating valves, throttle valves and a liquid hydrogen storage tank. According to the hydrogen liquefaction equipment, 5-10 tons of liquefied hydrogen can be produced every day, three turbo expander units are connected in series for refrigeration, a hydrogen refrigeration circulating systemconnected to high-pressure throttling refrigeration in parallel is adopted, raw material hydrogen is converted, cooled and liquefied through the multiple stages of ortho-parahydrogen converters, and the hydrogen liquefaction equipment has the advantages of being high in hydrogen liquefaction efficiency and low in energy consumption.

Owner:BEIJING INST OF AEROSPACE TESTING TECH +1

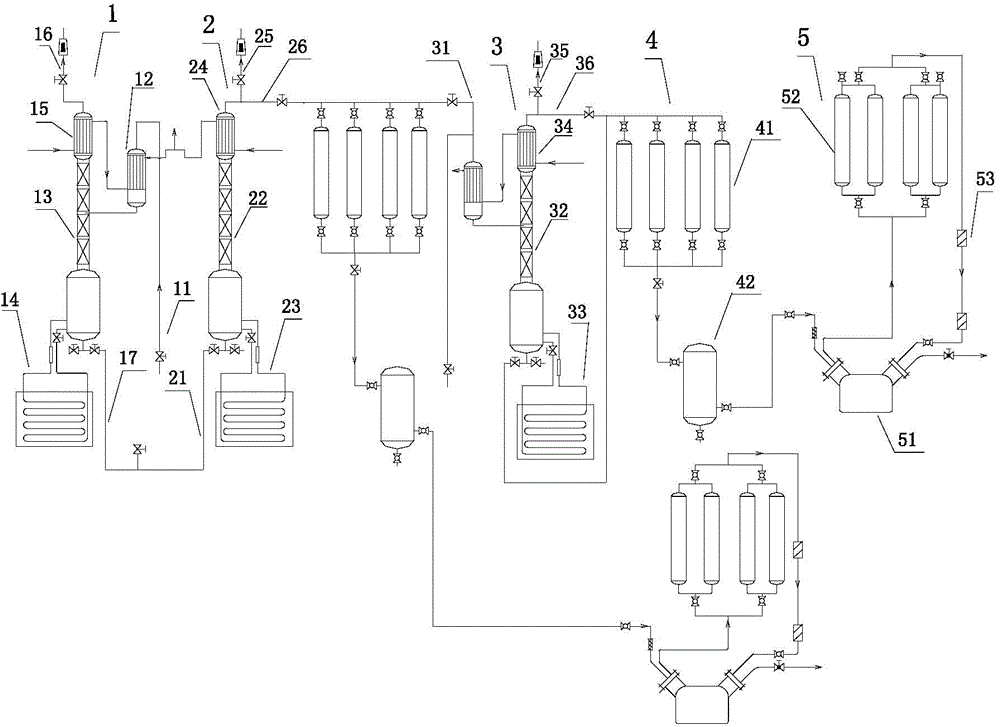

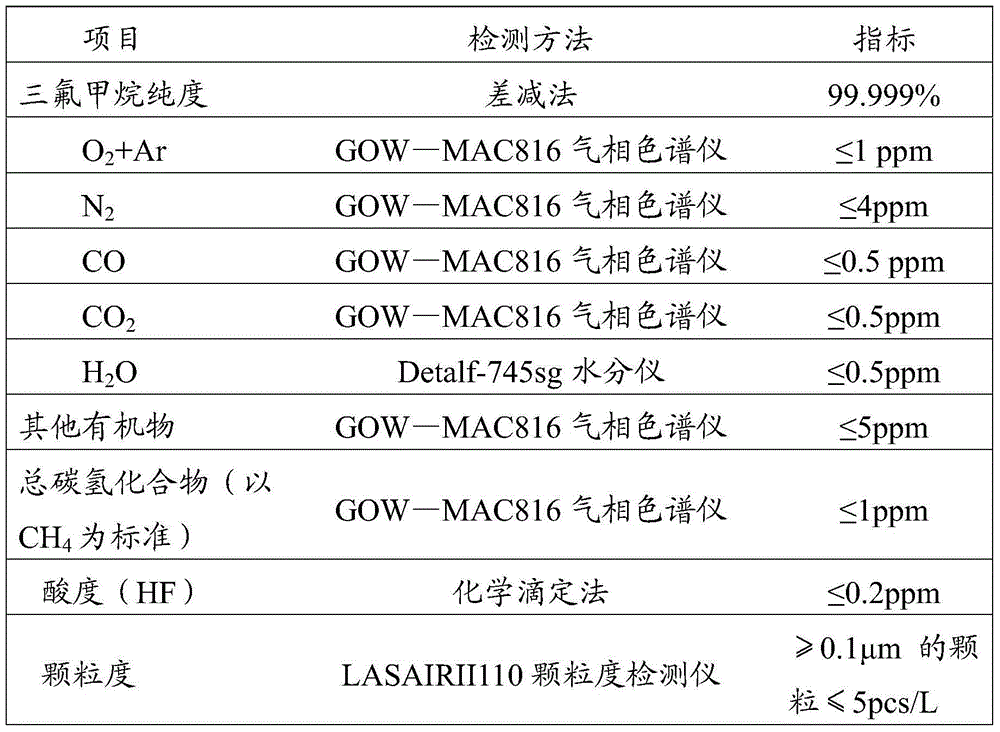

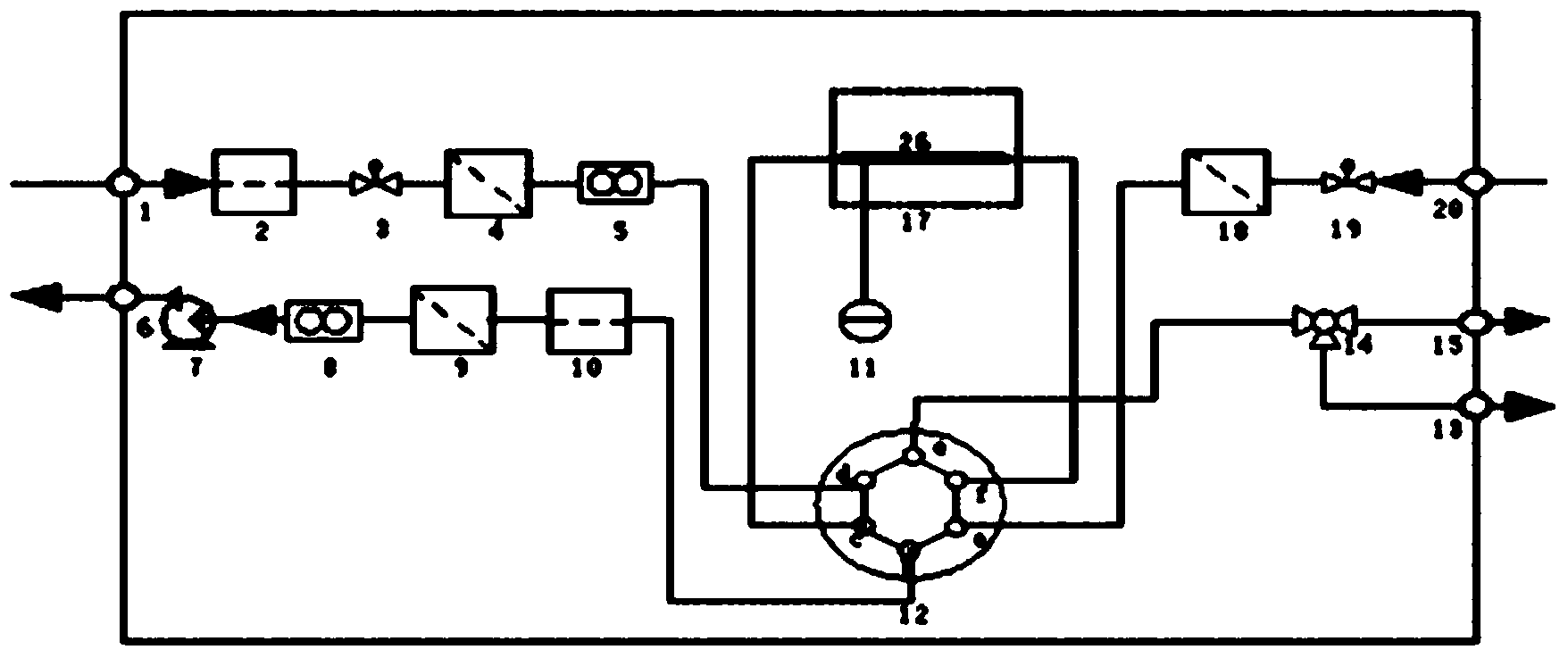

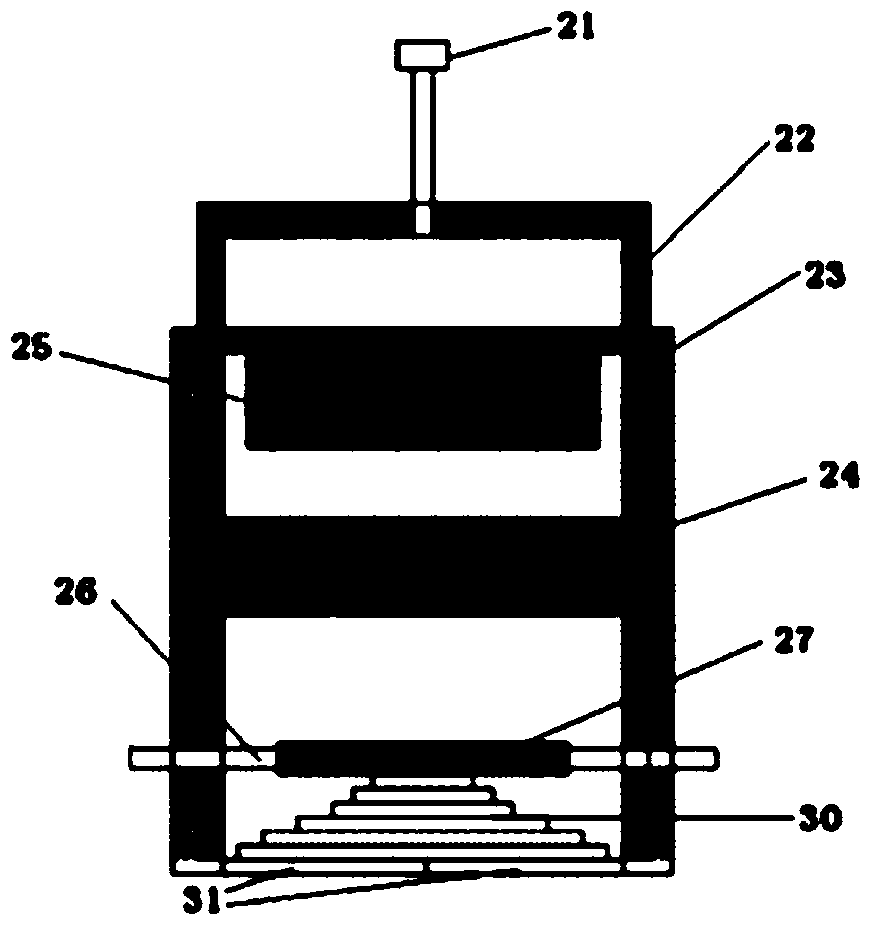

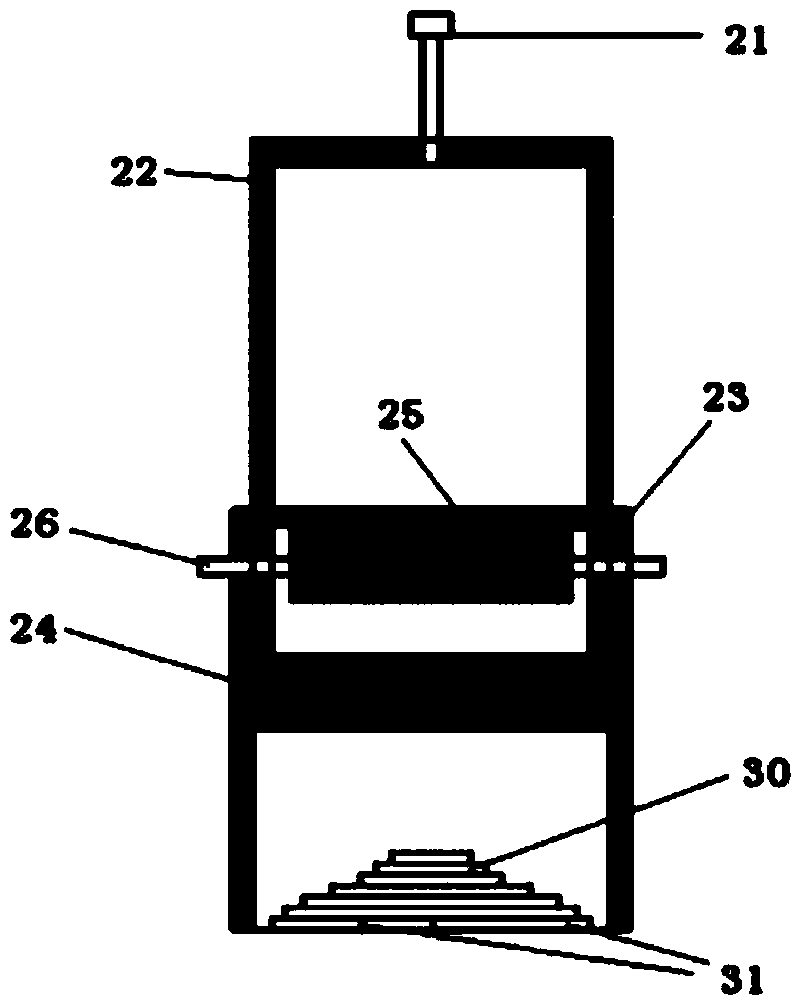

Device and method for purifying trifluoromethane

ActiveCN103951543AHigh purityMeet the requirementsHalogenated hydrocarbon separation/purificationPurification methodsCryo-adsorption

The invention discloses a device and a method for purifying trifluoromethane. The device comprises a rectification device and an adsorption device connected with the rectification device, wherein the rectification device comprises a first-stage rectification device, a second-stage rectification device and a third-stage rectification device which are connected in sequence; the adsorption device comprises a low-temperature adsorption device and a filling device which are connected in sequence; the low-temperature adsorption device of the adsorption device is connected with the rectification device. Compared with the prior art, the purity of trifluoromethane purified by adopting the device is relatively high, the device is easy to operate, and a purification process is complete, reliable and good in repeatability. The removal of conventional impurities is considered, difficultly removed carbon dioxide, monochlorodifluoromethane, pentafluoroethane, water and particles are removed to be in a qualified range, and the product purity is 99.999% and meets the use requirements of the semiconductor industry.

Owner:FOSHAN HUATE GASES

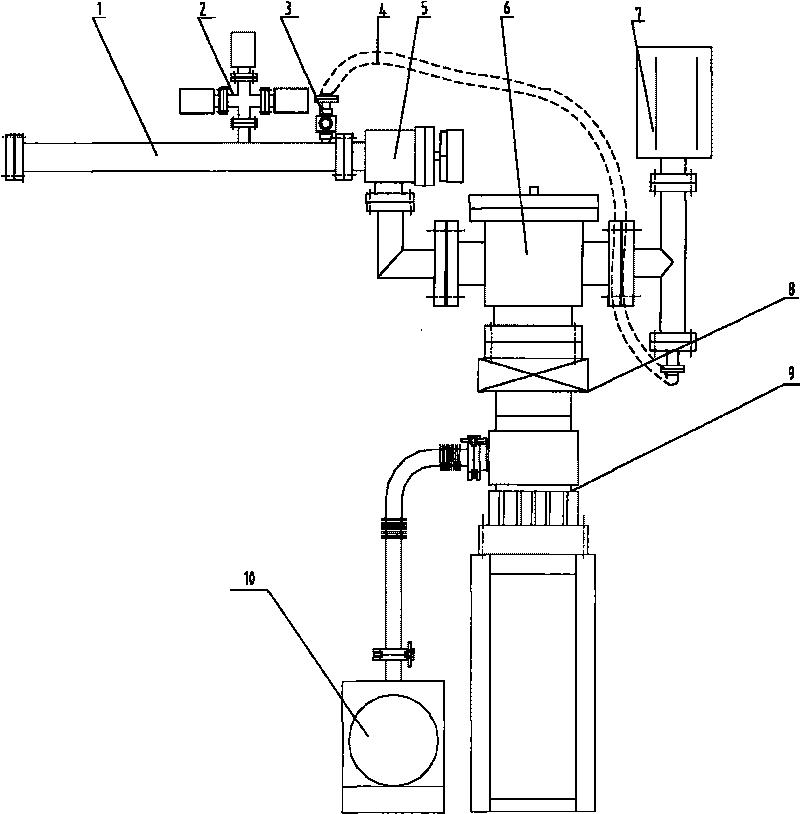

Mobile low-temperature adsorption concentration-thermal desorption device and application method thereof

InactiveCN103852370AEffective isolationSolve the fragilePreparing sample for investigationControl systemComputer module

The invention discloses a mobile adsorption concentration-thermal desorption device and an application method thereof. The device comprises a control system, a gas circuit part and a mobile cold trap consisting of a heating module, a refrigerating module and a mobile mechanism. The method comprises the steps of control system starting, operation of the refrigerating module, sample collection, operation of the heating module, sample desorption, pipeline cleaning, and the like. The device has the advantages that a refrigerating fin is easy to damage after long-time overheating, and the gas adsorption and gas enrichment efficiency is effectively improved. In comparison with the prior art, the device shortens the adsorption and analysis time, reduces the time consumption, lowers the cost and improves the concentration efficiency.

Owner:TIANJIN ACADEMY OF ENVIRONMENTAL SCI

Metal system for testing outgassing property of low-temperature material

The invention relates to a metal system for testing the outgassing property of low-temperature material, which belongs to the field of low-temperature materials. The system consists of a sample chamber, a capacitor gauge, a micro adjusting valve, a metal hose, a high vacuum angle valve, a liquid nitrogen cold trap, a mass spectrometer, an inserting plate valve, a molecular valve and a mechanical pump. A vacuum pumping system consisting of the mechanical pump and the molecular pump vacuumizes samples in the sample chamber, and the liquid nitrogen cold trap performs low-temperature absorption on oil steam generated by the system. When the pressure of the sample chamber is pumped to 1*10<-3> Pa, the high-vacuum angle valve and the inserting valve are closed, the capacitor is used for testing the changes of the pressure in the sample chamber in the specified time, and then the outgassing rate of the sample is calculated. After the outgassing rate test is finished, the micro adjusting valve is opened, the discharged gas of the sample is introduced into the mass spectrometer by the metal hose, the outgassing component of the sample is analyzed by the mass spectrometer, and then the outgassing component of the sample is determined. The system enhances the reliability and he accuracy of the system, and has reliable testing result.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

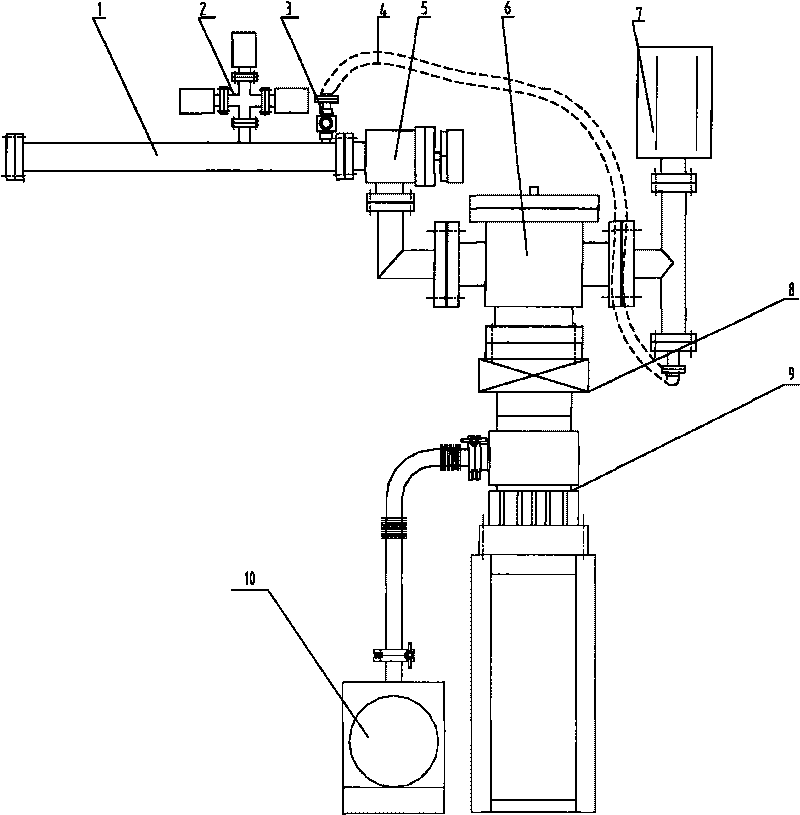

Method and apparatus for purifying helium by condensing method

The present invention relates to a method and an apparatus for recovering helium at low temperature by using cryogenic adsorption. The apparatus comprise a feed gas compressor and a cooling system thereof; and a set of external cryogenic cooling system placed in a small cold box uses a pressure mixed gas after refrigerant cooling pressurization. According to the invention, an absorption tower is arranged between a first-stage condensation and a second-stage condensation, and uses liquid nitrogen as a downstream liquid to absorb oxygen, argon and carbon monoxide in feed gas, so that the outlet feed gas only contains nitrogen impurity; and the nitrogen impurity can be removed directly by cryogenic adsorption. The helium purification apparatus provided by the invention is suitable for feed gas containing ingredients such as nitrogen, oxygen and argon; the absorption tower is arranged to simplify the process, and under the cooperation with multistage flash evaporation and cryogenic adsorption, the helium purity is up to higher than 99.999%. Therefore, the method and apparatus are very practical.

Owner:SHANGHAI QIYUAN GAS DEV

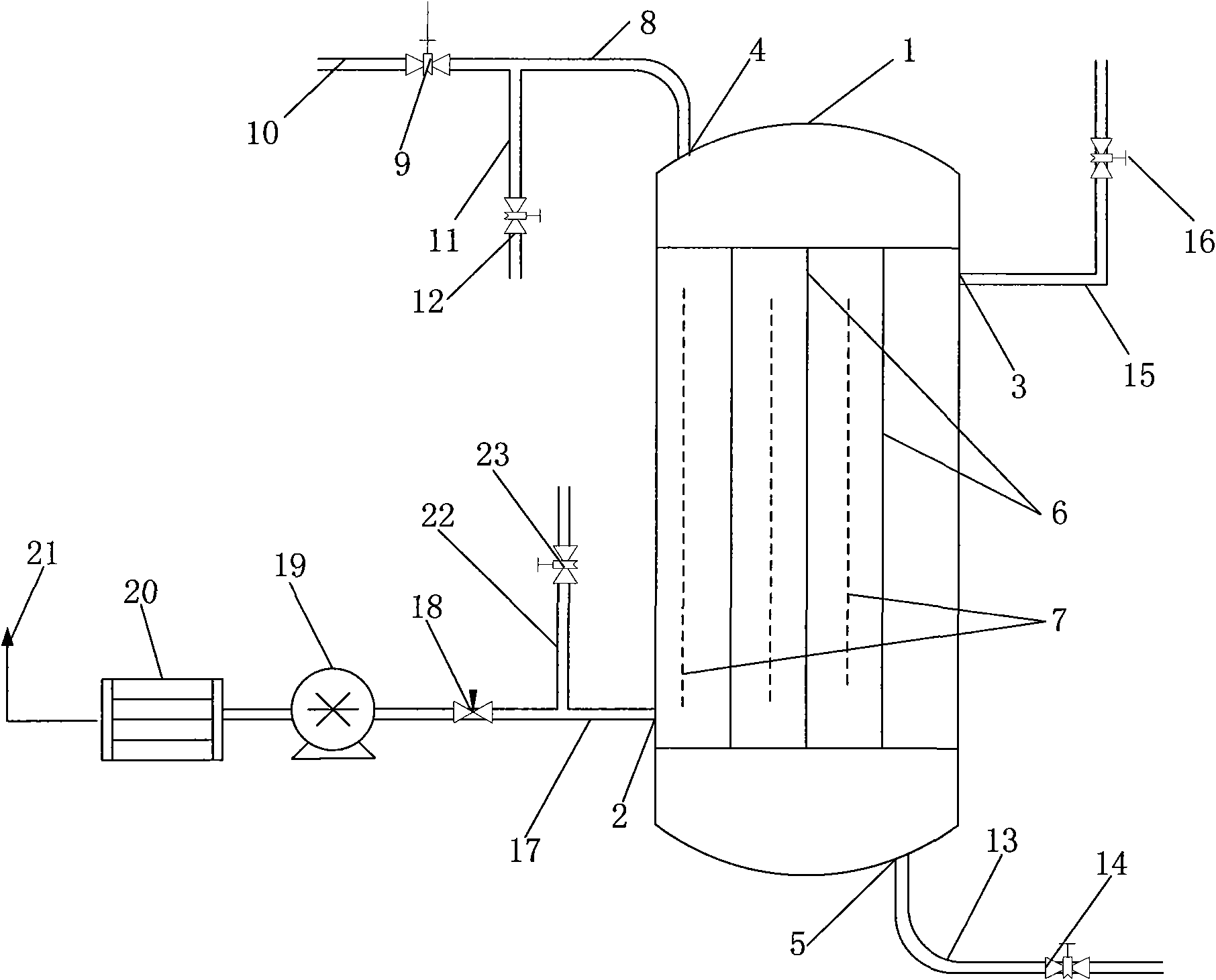

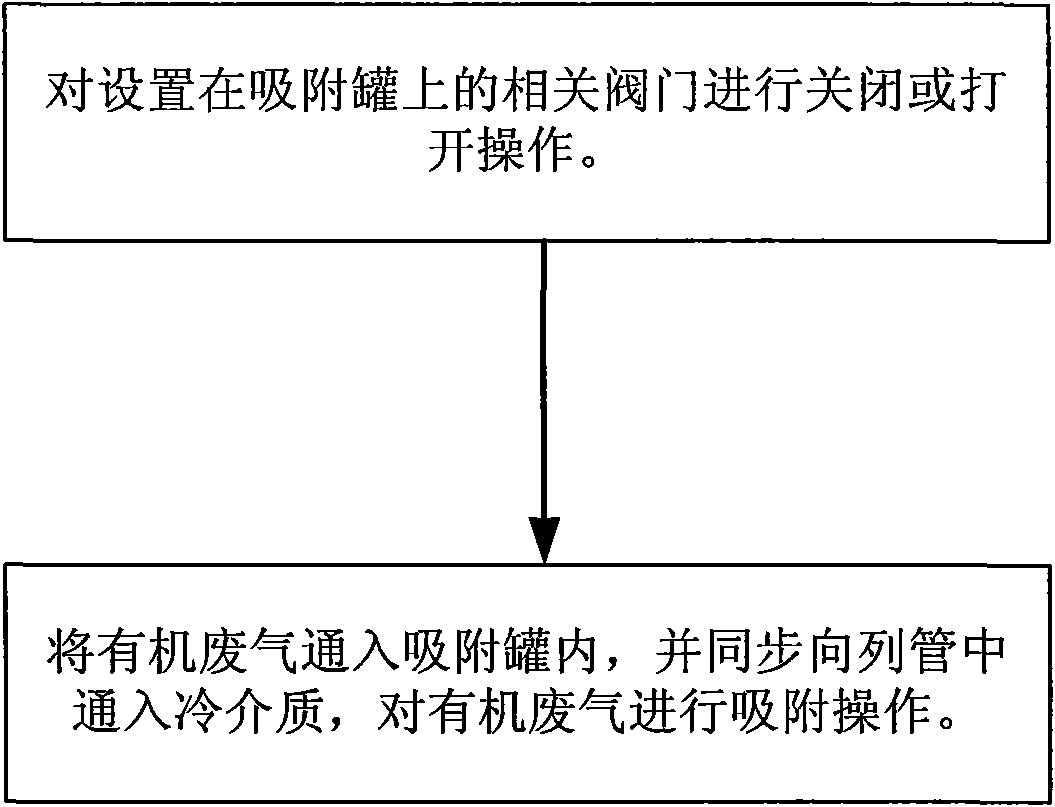

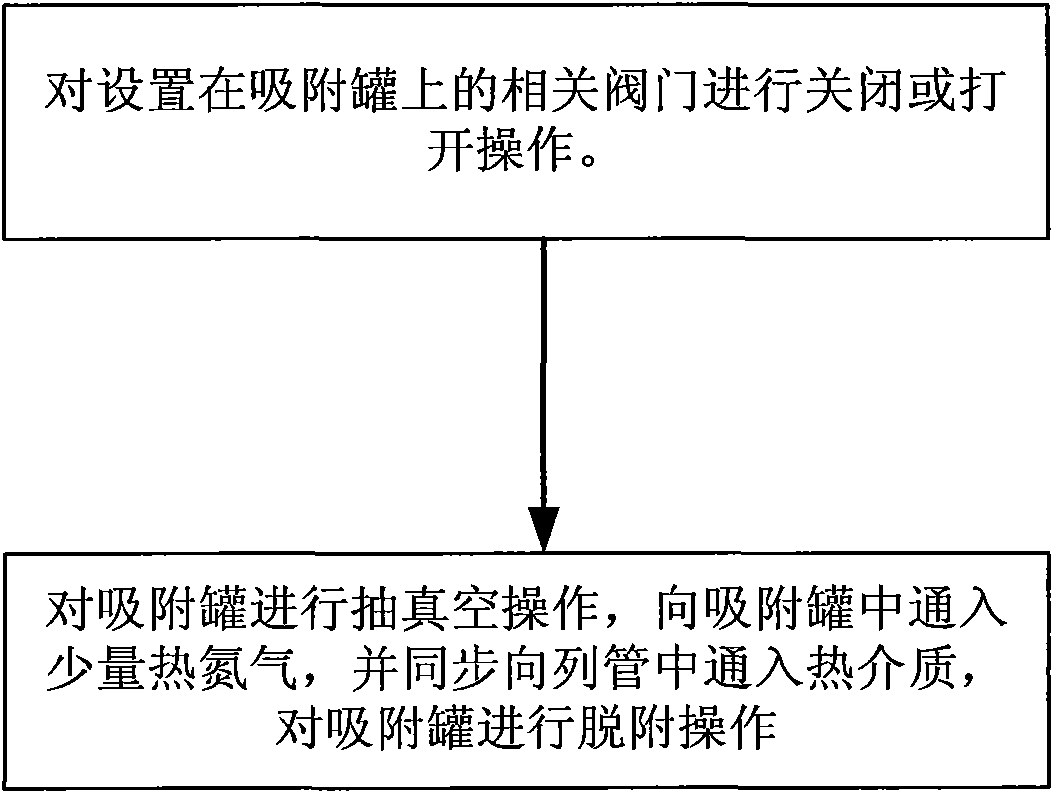

Cold and hot type adsorption-desorption device and adsorption-desorption method thereof

ActiveCN101648102AHigh adsorption capacityReduce damageDispersed particle separationCombustible gas purificationEngineeringCryo-adsorption

The invention discloses a cold and hot type adsorption-desorption device and an adsorption-desorption method thereof, belonging to a device and a method for treating organic waste gas. The device comprises an adsorption tank which is provided with an opening used for leading in waste gas and vacuumizing, a clean gas outlet, a tube pass inlet used for leading in cold medium or hot medium and a tubepass outlet used for leading out cold medium or hot medium; the adsorption tank is internally provided with tube arrays which are evenly distributed in the adsorption tank, and the two ends of the tube arrays are respectively communicated with the tube pass inlet and the tube pass outlet; a shell pass of the adsorption tank is internally filled with adsorbing medium which surrounds the tube arrays; and the adsorption tank also carries out low temperature adsorption and high temperature desorption operations. In the invention, the adsorption tank is provided with tube arrays, and cold medium or hot medium can be led into the tube arrays, thus realizing low temperature adsorption and high temperature desorption operations, reducing the level of vacuumizing, saving energy consumption, substantially reducing requirements on the device in the desorption process, improving the adsorption and desorption efficiency, prolonging the service life of the adsorption medium and saving production cost.

Owner:QINGDAO HSJ ENVIRONMENTAL PROTECTION TECH CO LTD

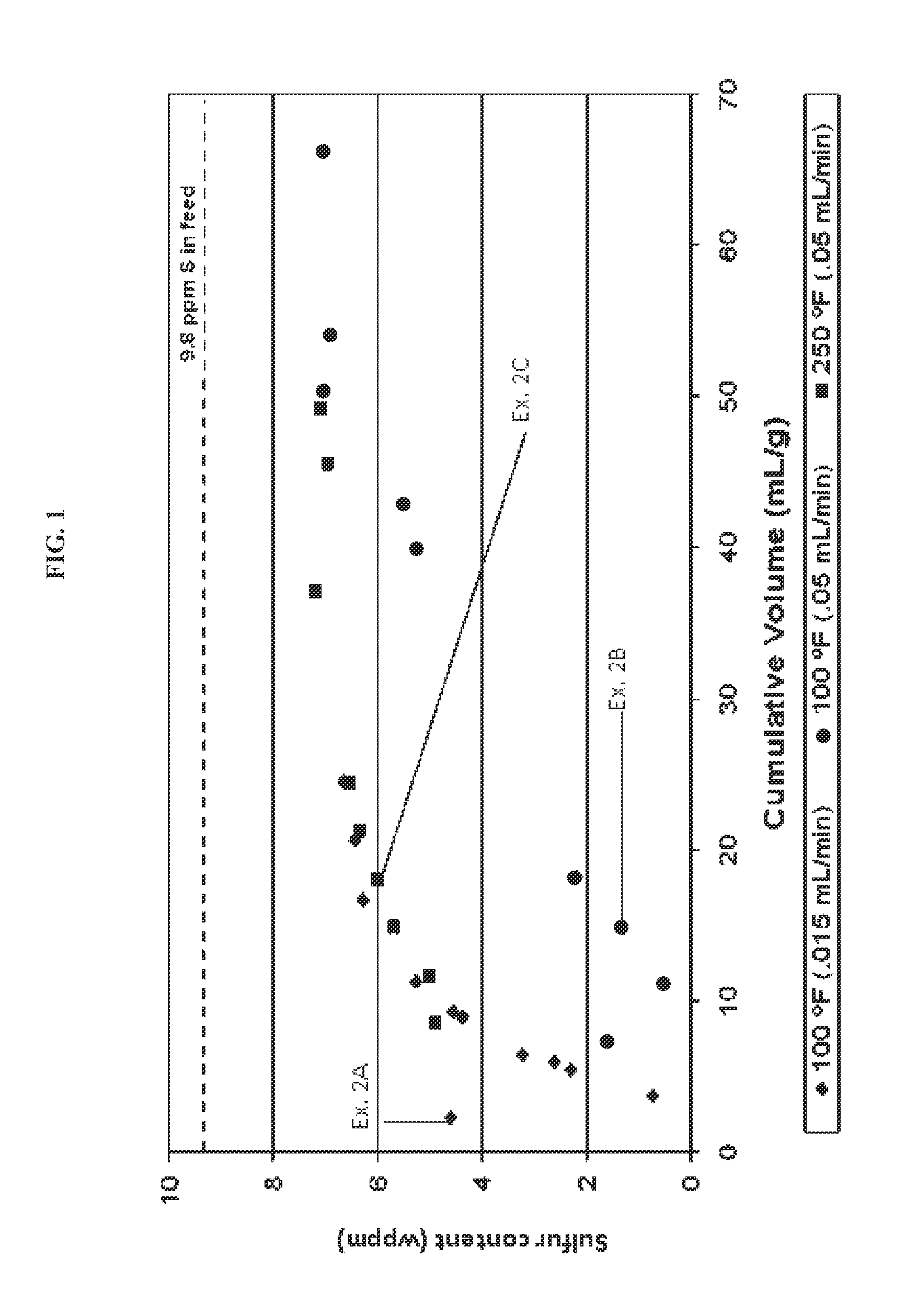

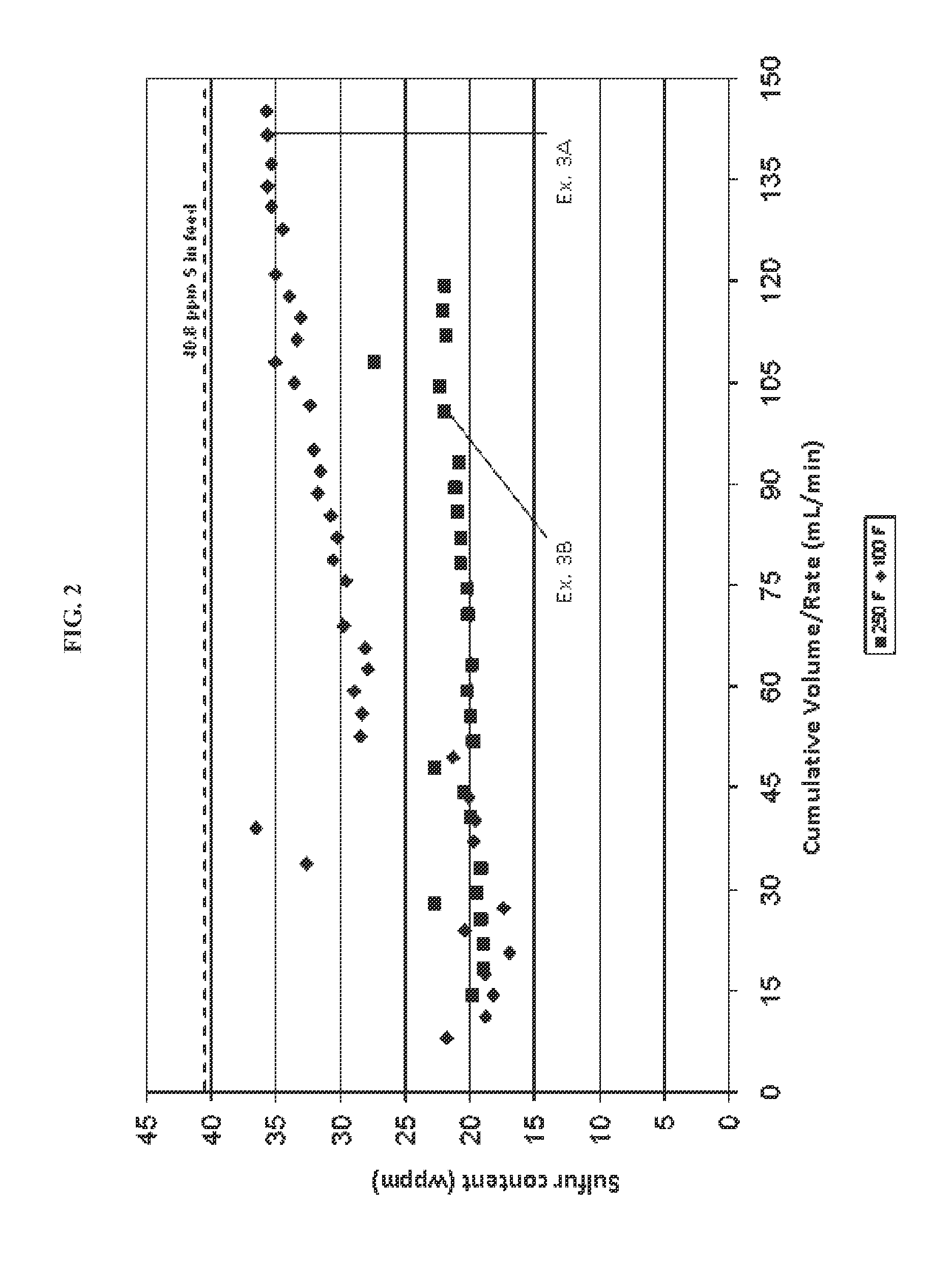

Low temperature adsorbent for removing sulfur from fuel

The present invention relates to methods for removing sulfur from a hydrocarbon fuel or fuel precursor feedstream, such as methods comprising contacting a hydrocarbon fuel or fuel precursor feedstream having a relatively low sulfur content with a sulfur sorbent material comprising an active copper component disposed on a zeolitic and / or mesoporous support under conditions sufficient to reduce the sulfur content by at least 20 wt % and / or to about 15 wppm or below, thus forming a hydrocarbon fuel product. In some advantageous embodiments, the contacting conditions can include a temperature of about 392° F. (about 200° C.) or less.

Owner:EXXON RES & ENG CO

Purification for separating feed gas in stabilized isotope 13C by low-temperature CO rectifying method

Purification for separating charge gas of 13C stable isotope by CO low-temperature rectifying method is carried out by taking CO as charge gas, normal-temperature adsorbing, chemical purifying and low-temperature adsorbing. The content of O2 is <=0.01ppm, the content of H20 is <=0.01ppm and the content of CO2 is <=0.01ppm, they accord with technology requirement. It is simple and cheap, has advanced technology and high purifying efficiency and can be used to separate stable isotope 13C and 180 by CO low-temperature rectifying method.

Owner:SHANGHAI RES INST OF CHEM IND

Gas purification method

The present invention provides for a method for purifying a carbon monoxide-containing gas stream that contains hydrocarbon impurities, such as methane, by using a cryogenic temperature swing adsorption method, at cryogenic temperatures below -75 DEG C. The carbon monoxide-containing gas stream may be pre-purified by membrane separation or vacuum swing adsorption or cryogenic distillation.

Owner:BOC GRP INC

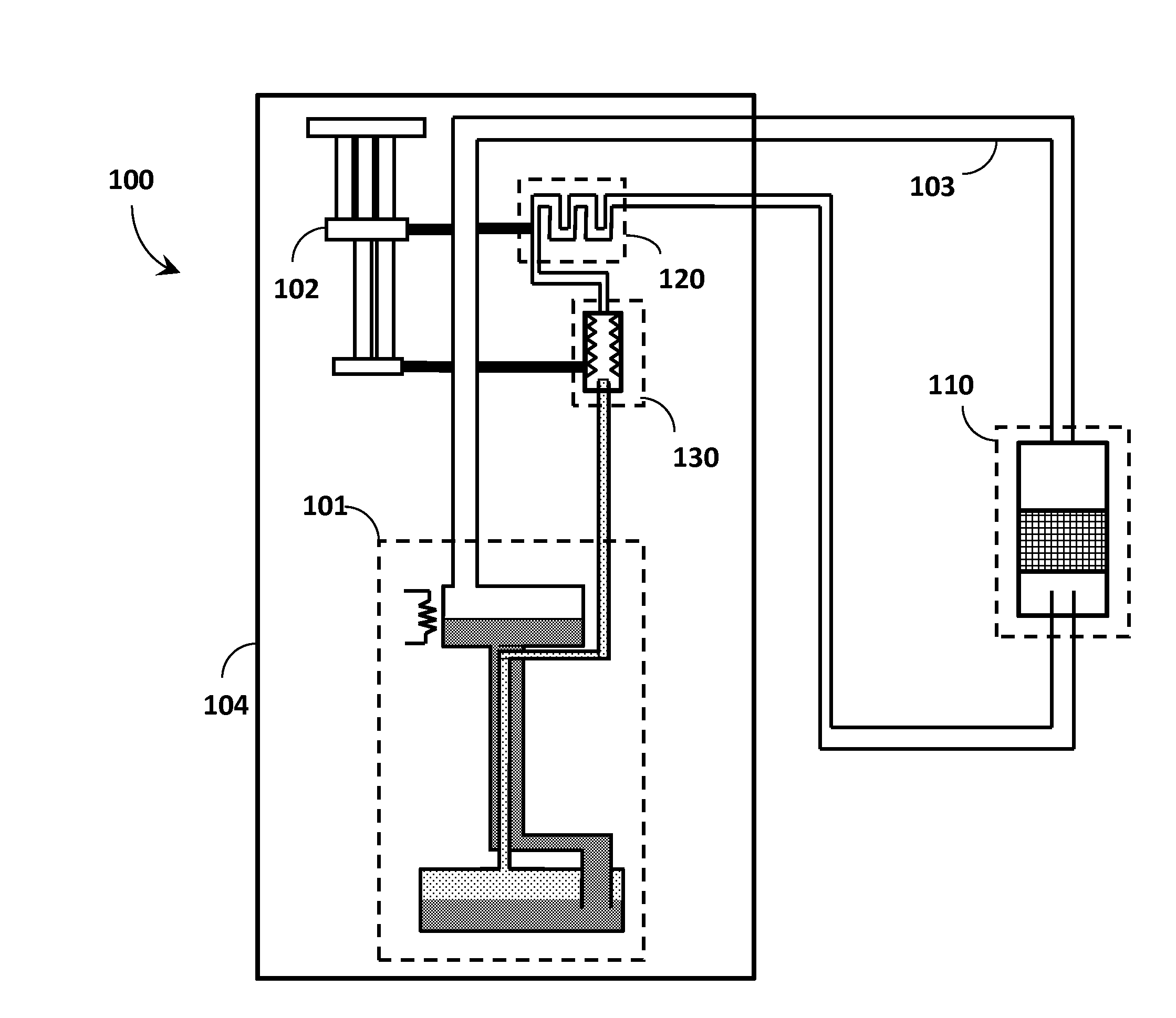

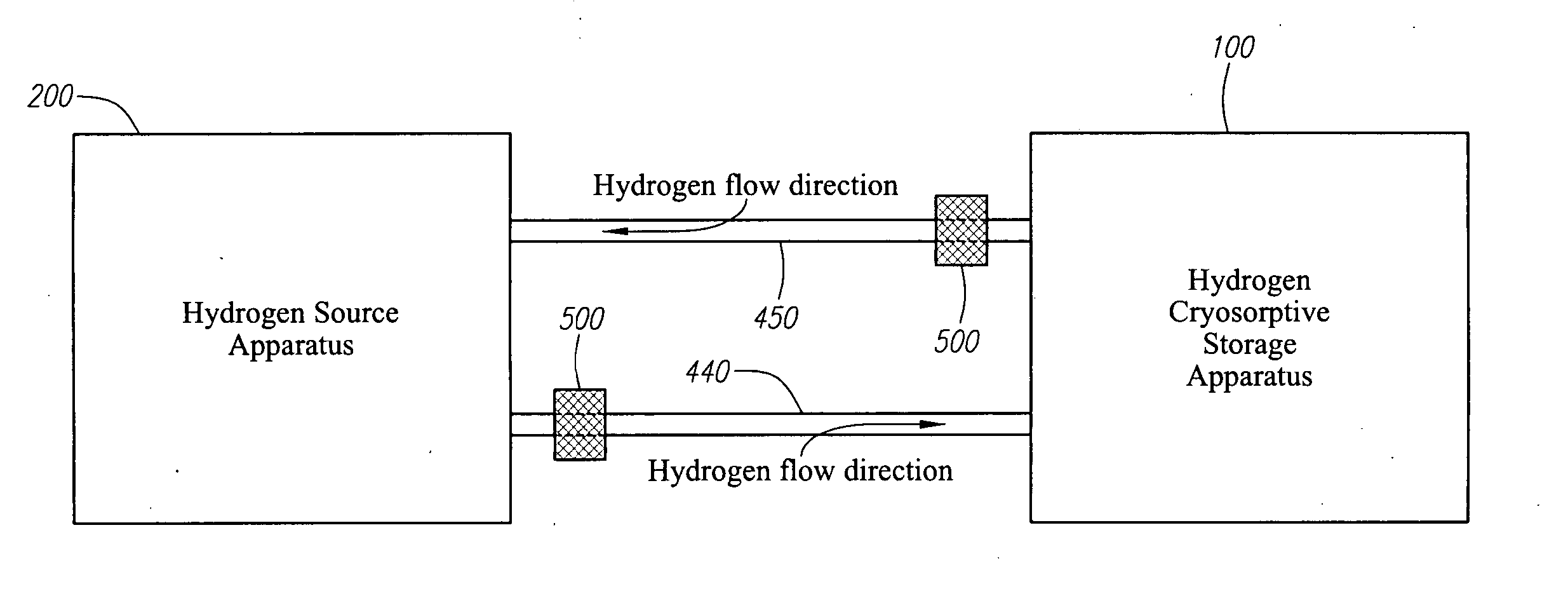

Hydrogen storage and supply system

InactiveUS20050183424A1Large specific surface areaData processing applicationsLiquid fillingPorous mediumProcess engineering

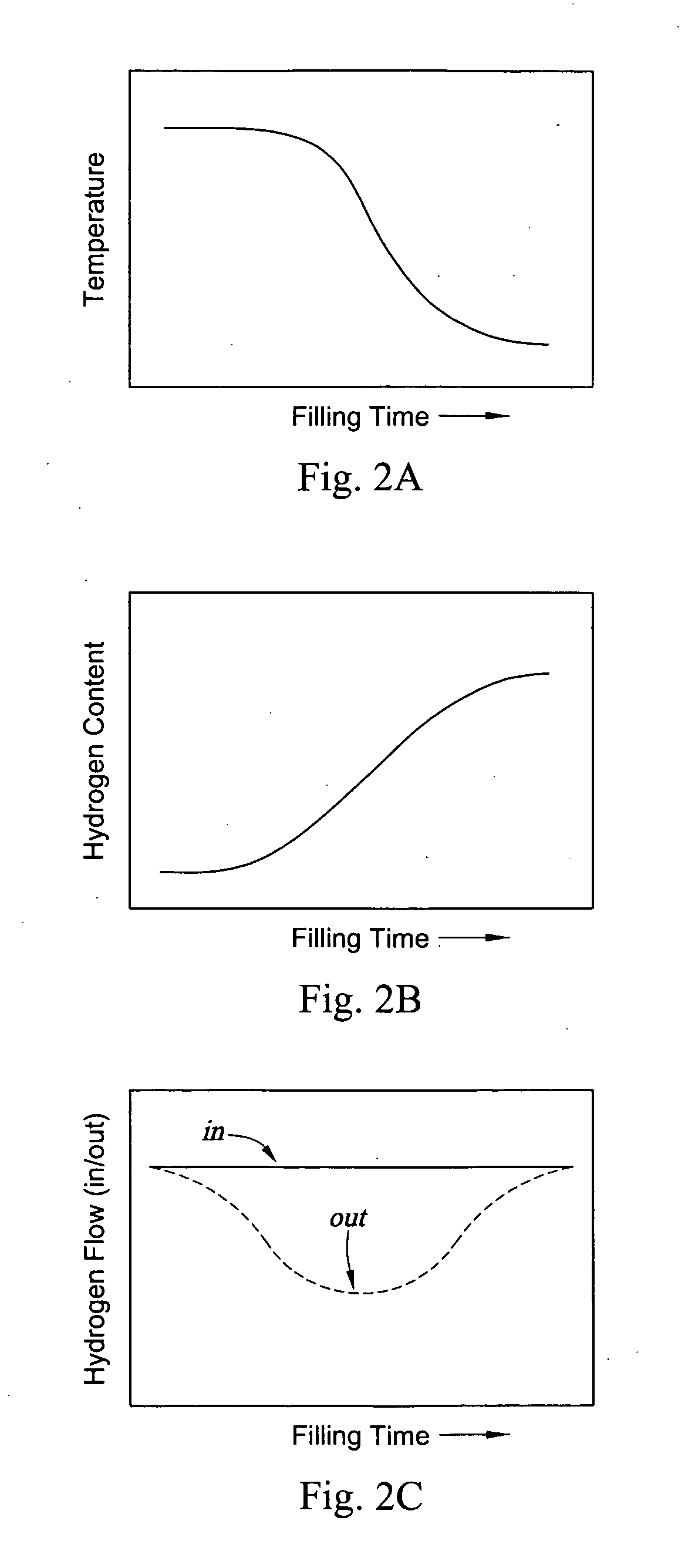

This invention provides for an apparatus and a method for operation of a cryogenic hydrogen storage system that contains a porous medium configured to adsorb hydrogen. The hydrogen storage and supply system includes a hydrogen source apparatus and a cryosorptive storage apparatus. Methods and devices that allow for an energy efficient filling of the cryosorptive apparatus from the hydrogen source apparatus are described. The cryosorptive hydrogen storage apparatus is filled with cold, pressurized hydrogen. During the course of filling, heat is generated in the cryosorptive storage device by the process of hydrogen adsorption on to the host medium. Methods and devices are provided for the removal the generated heat and the warm hydrogen. Further provided are devices and methods for the capture and recycle of escaped hydrogen within the hydrogen source apparatus.

Owner:NANOMIX

Method for preparing ultra-pure hydrogen

ActiveCN106283101ALow costEasy to operateElectrolysis componentsHydrogen separationElectrolysisSoftened water

The invention discloses a method for preparing ultra-pure hydrogen. The electrolytic hydrogen production process is adopted in the method. Softened water before electrolysis is pretreated, the softened water is heated, and various sorts of gases like N2 and Ar dissolved in the softened water are removed completely; high-purity oxygen is supplied for pressure maintaining; and then the ultra-pure hydrogen meeting 'GBT 3634.2-2011 pure hydrogen, high-purity hydrogen and ultra-pure hydrogen' requirements can be produced by the adoption of the catalyst catalytic deoxidation and molecular sieve dehydration process, filtering dust removal process and steel cylinder drying treatment process. The method for preparing the ultra-pure hydrogen has the beneficial effects that the defects that a palladium alloy diffusion film (pipe) separation method is high in cost and small in production amount, a hydrogen storage alloy absorbing and desorbing method is short in hydride service life and instable in production, a low-temperature adsorption method needs to use liquid nitrogen and thus the requirements for equipment are high are overcome successfully; and the characteristics of being low in production energy consumption, high in flow-path efficiency, simple in process, stable in production and the like are achieved.

Owner:山东泓达生物科技有限公司

Testing device for testing low-temperature adsorption performance of gas

ActiveCN106442895ASolve wastePrecise and controllable temperatureMaterial analysisProcess engineeringEngineering

The invention discloses a testing device for testing a low-temperature adsorption performance of gas. The testing device comprises a low-temperature device, a gas adsorption device and a gas inlet pipeline, wherein the low-temperature device comprises a refrigerating machine, a sample cavity which is arranged on a secondary cold head of the refrigerating machine and is used for storing a sample for testing, a shielding cover which covers the secondary cold head of the refrigerating machine and the sample cavity, and a vacuum cover which covers the shielding cover and enables a primary cold head of the refrigerating machine, the secondary cold head of the refrigerating machine and the sample cavity to be in a vacuum environment; the sample cavity is connected with an adsorption device reference cavity in the gas adsorption device through a gas conveying pipeline. According to the testing device provided by the invention, the refrigerating machine is used as a cold source, and problems that a low-temperature adsorption performance testing device excessively depends on low-temperature liquid so that experimental operations are complicated and a lot of raw materials of the low-temperature liquid are wasted in the prior art are solved.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Hydrogen storage tank system based on gas adsorption on high-surface materials comprising an integrated heat exchanger

A gas storage system that stores a gas by cryo-adsorption on high surface materials. The gas storage system includes an outer container having insulated walls and a plurality of pressure vessels disposed therein. Each of the pressure vessels includes a high surface material. A manifold assembly distributes the gas under pressure to the pressure vessels where the gas is adsorbed by cryo-adsorption using the high surface materials. A cooling fluid is provided within voids between the pressure vessels to remove heat as the pressure vessels are being filled with the gas.

Owner:GM GLOBAL TECH OPERATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com