Cold and hot type adsorption-desorption device and adsorption-desorption method thereof

An adsorption-desorption, cold-heat technology, applied in separation methods, chemical instruments and methods, filter regeneration, etc., can solve the problems of increasing the cost of air containing oil vapor, reducing the service life of the adsorbent, and poor waterproof performance of the adsorbent. , to achieve the effect of shortening the vacuum desorption time, reducing the degree of damage, and reducing the requirements of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

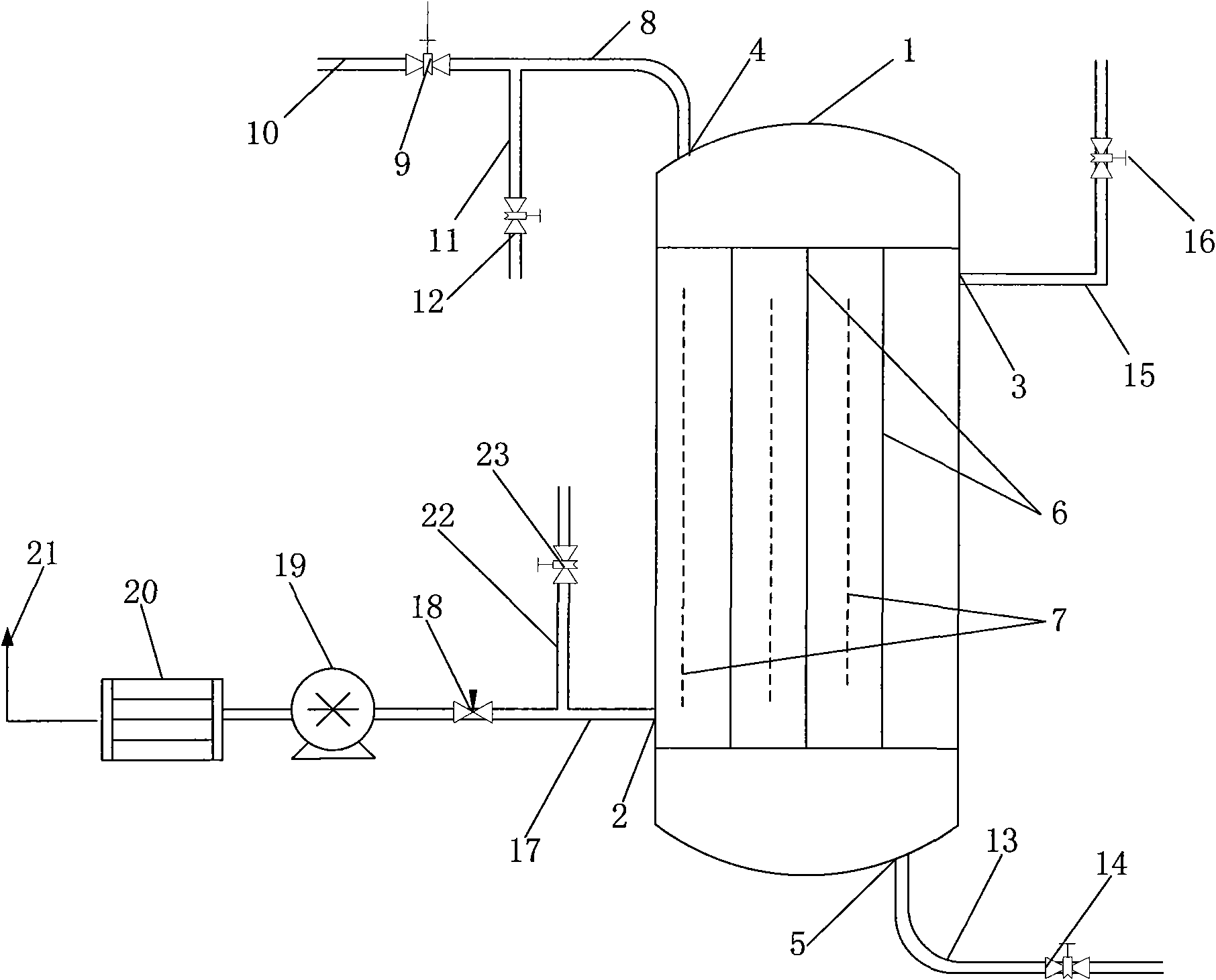

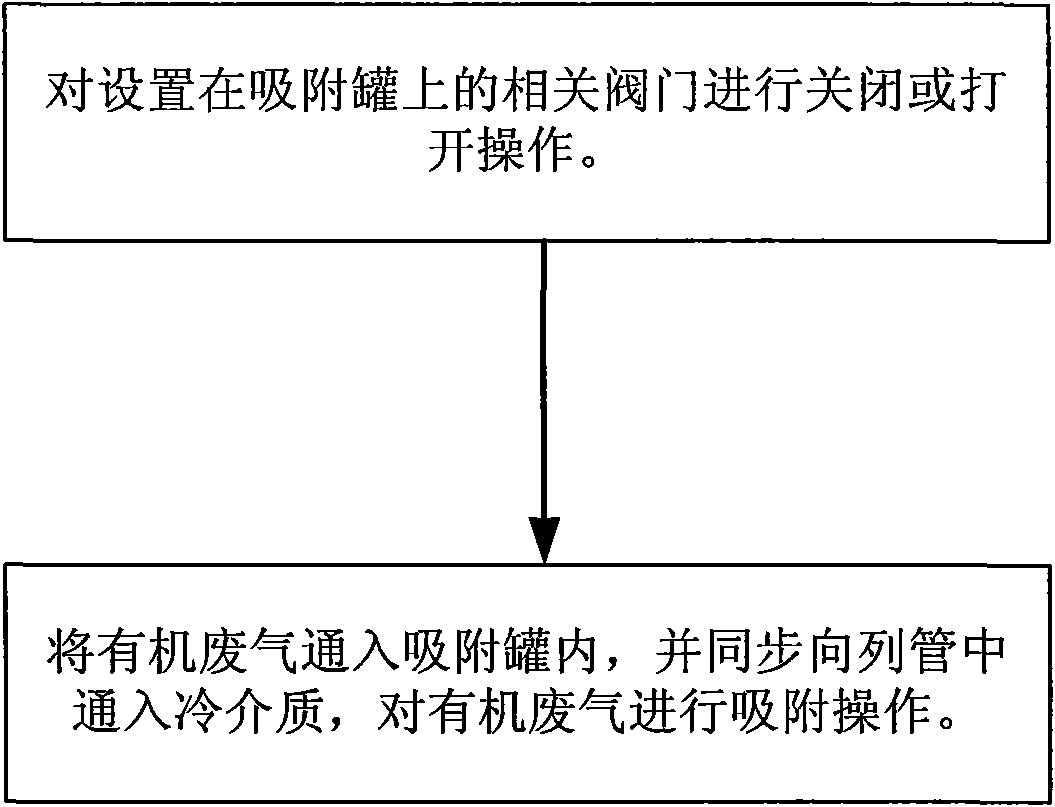

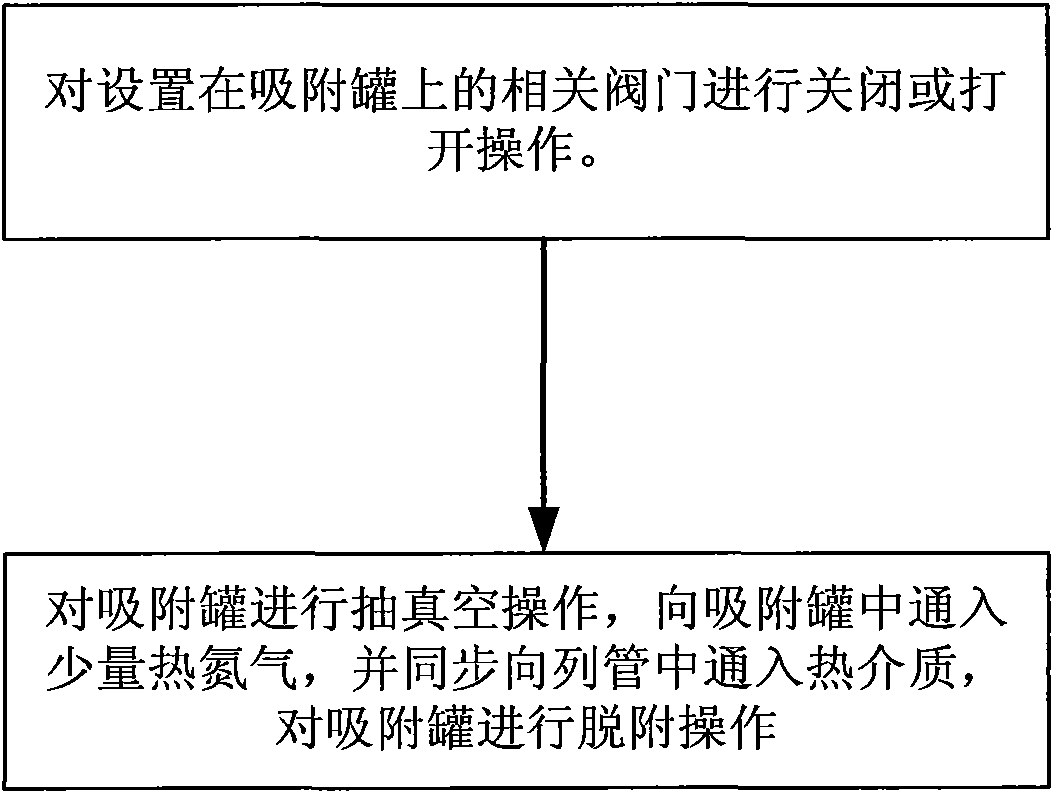

[0023] The invention provides a cold-heat type adsorption-desorption device and an adsorption-desorption method thereof. A series of tubes for connecting cold medium or hot medium is arranged in the adsorption tank, and the tubes are introduced into the tubes during the process of adsorption and desorption. Cold medium or hot medium can reduce the activity of organic waste or increase the activity of organic waste, thereby improving the adsorption efficiency and desorption efficiency of the adsorption and desorption device, improving the utilization rate of active substances, and reducing the impact on the equipment during the desorption process. requirements. Such as figure 1 As shown, the cold-heat adsorption and desorption device includes an adsorption tank 1, and the adsorption tank is provided with an opening 2 for introducing waste gas and vacuuming, a purified gas outlet 3, and a tube-side inlet 4 for introducing cold medium or heat medium With the tube-side outlet 5 u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com