Patents

Literature

1500 results about "Steam distillation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steam distillation is a special type of distillation (a separation process) for temperature sensitive materials like natural aromatic compounds. It once was a popular laboratory method for purification of organic compounds, but has become less common due to the proliferation of vacuum distillation. Steam distillation remains important in certain industrial sectors.

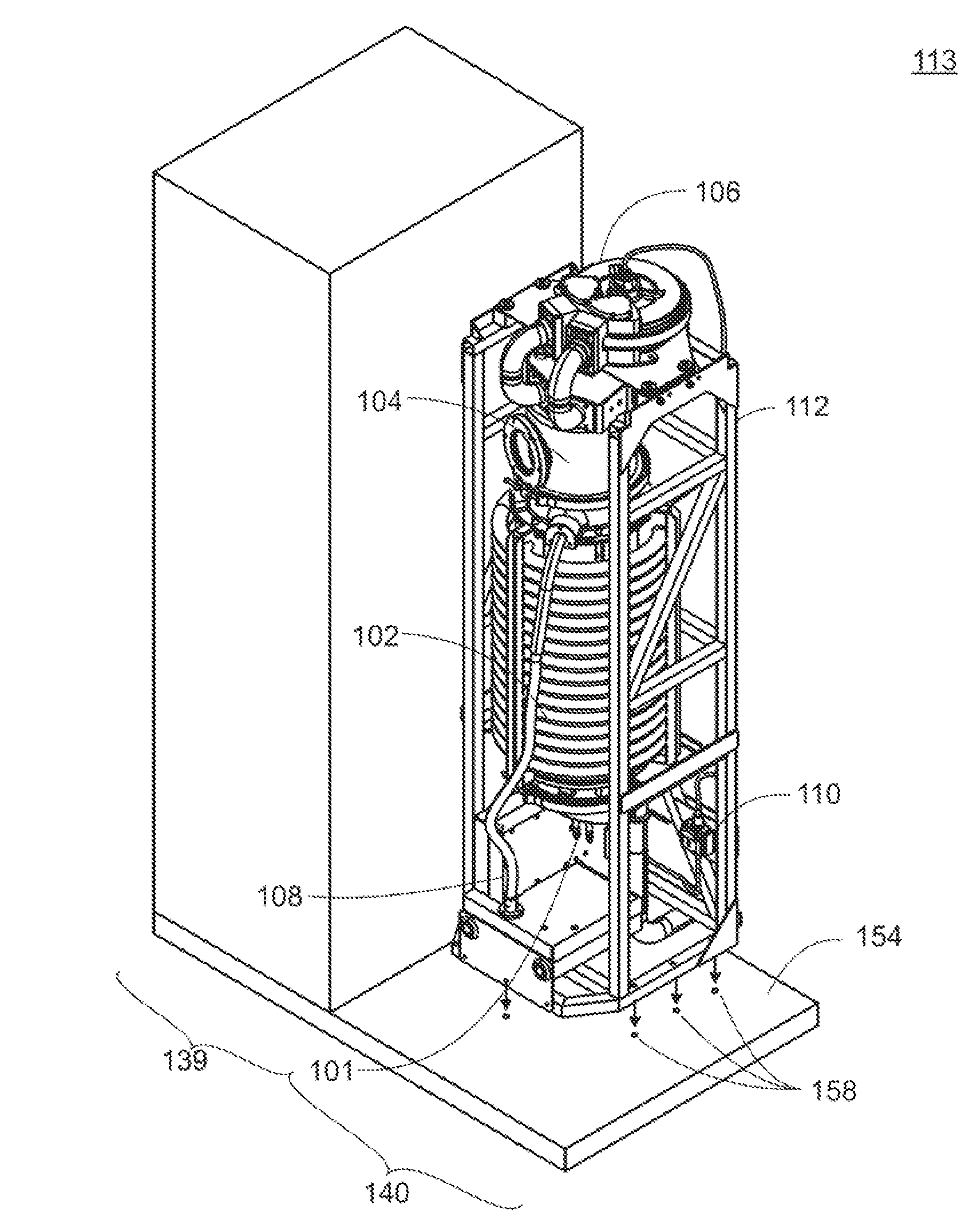

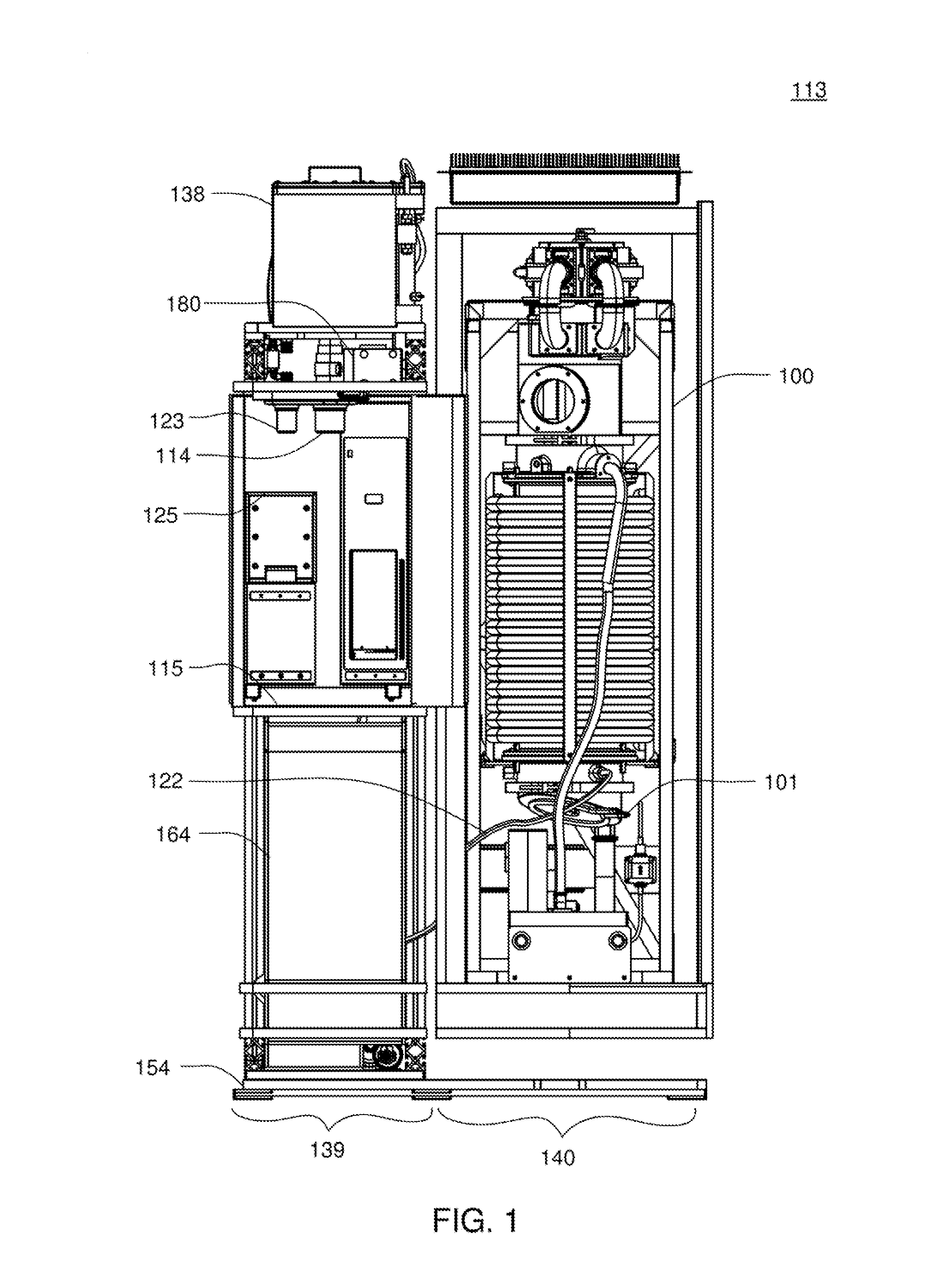

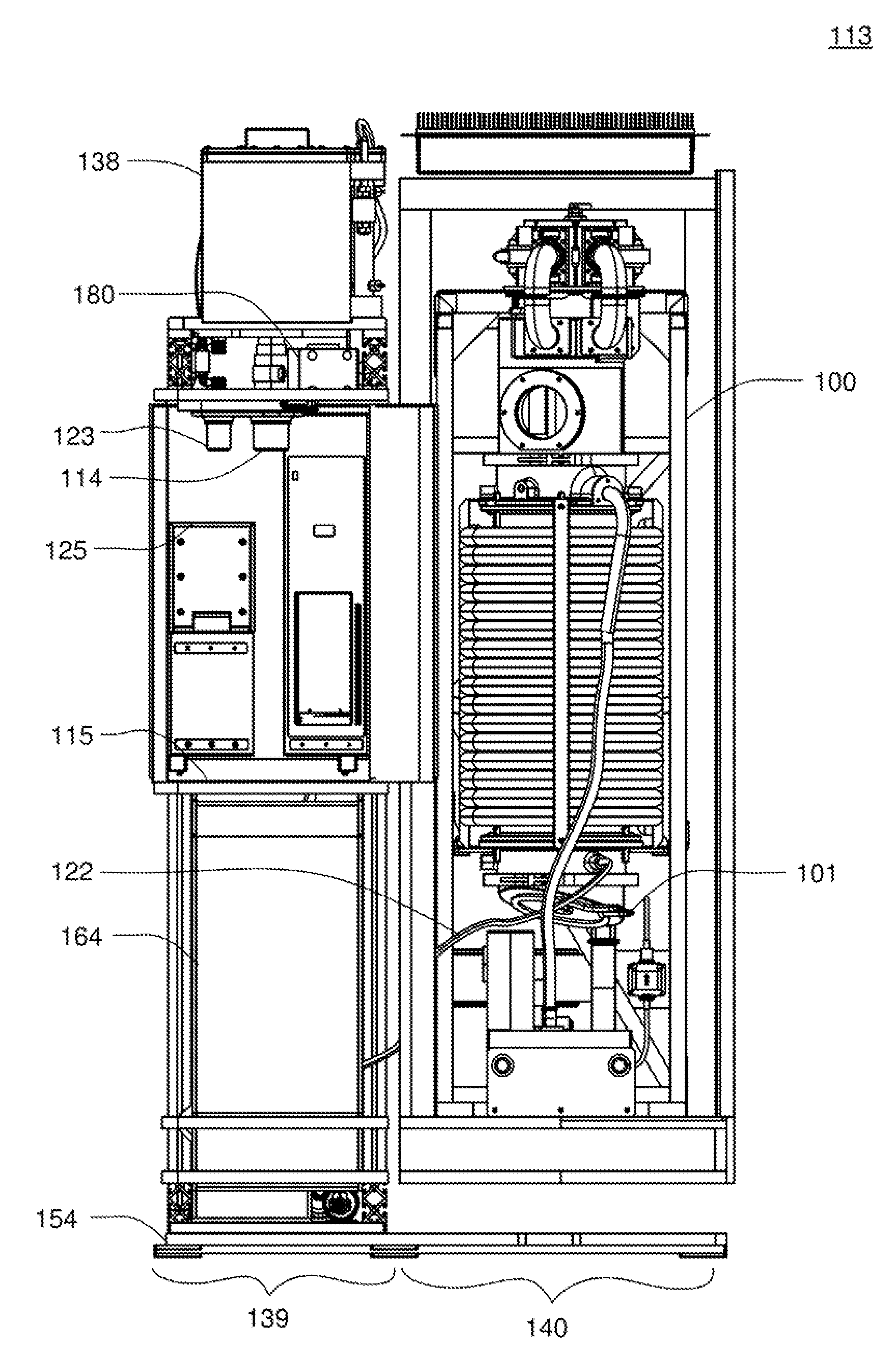

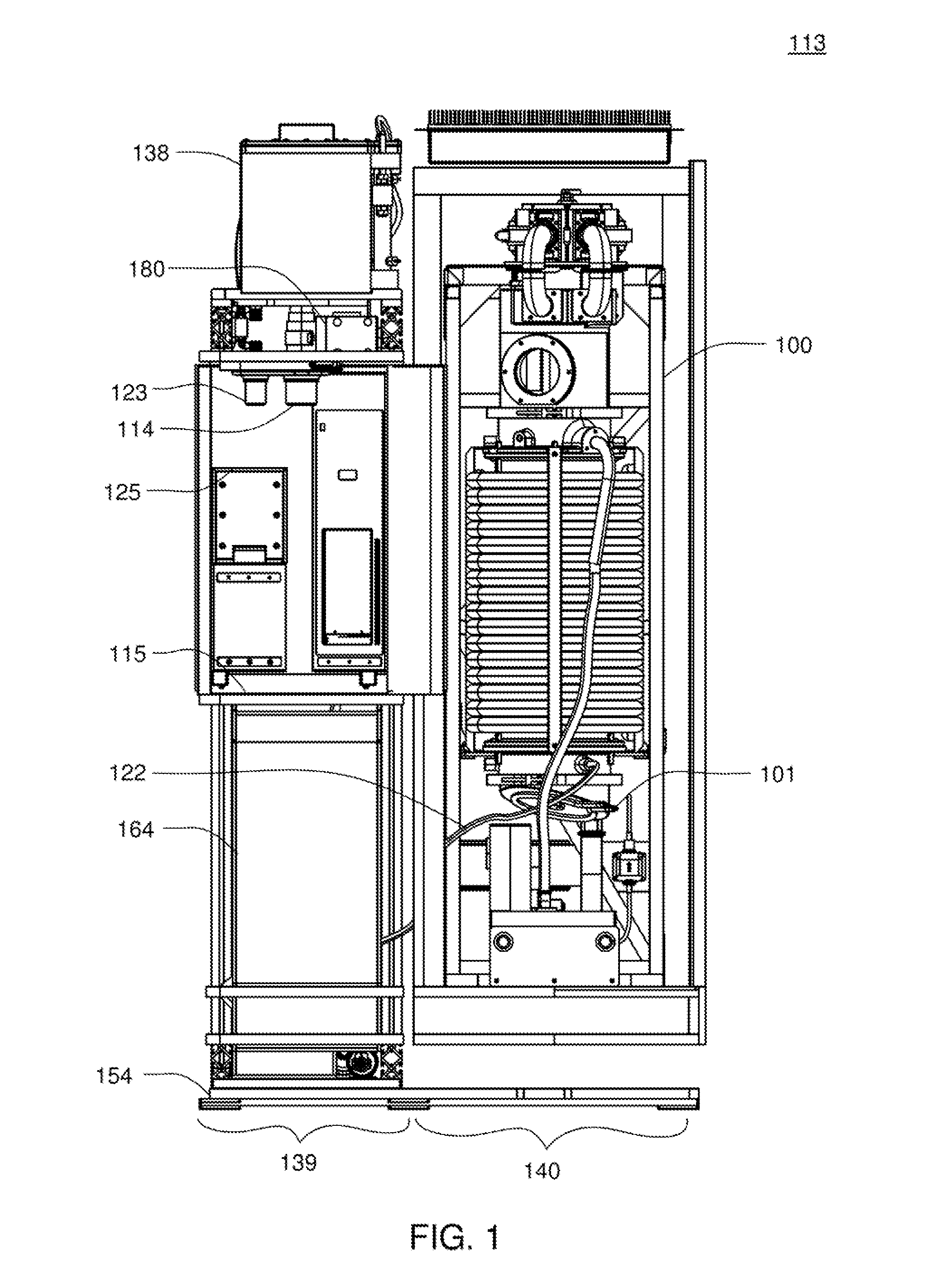

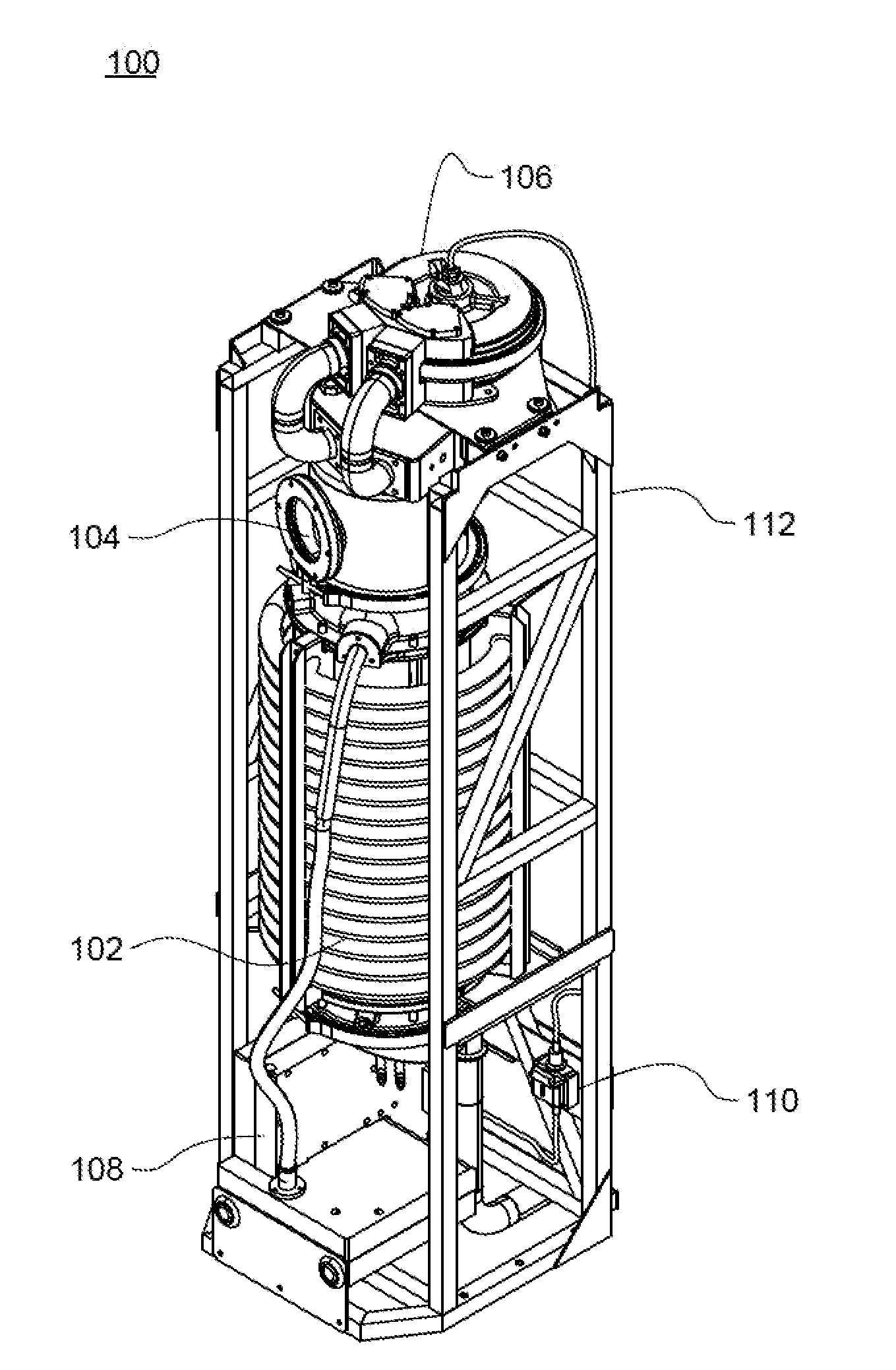

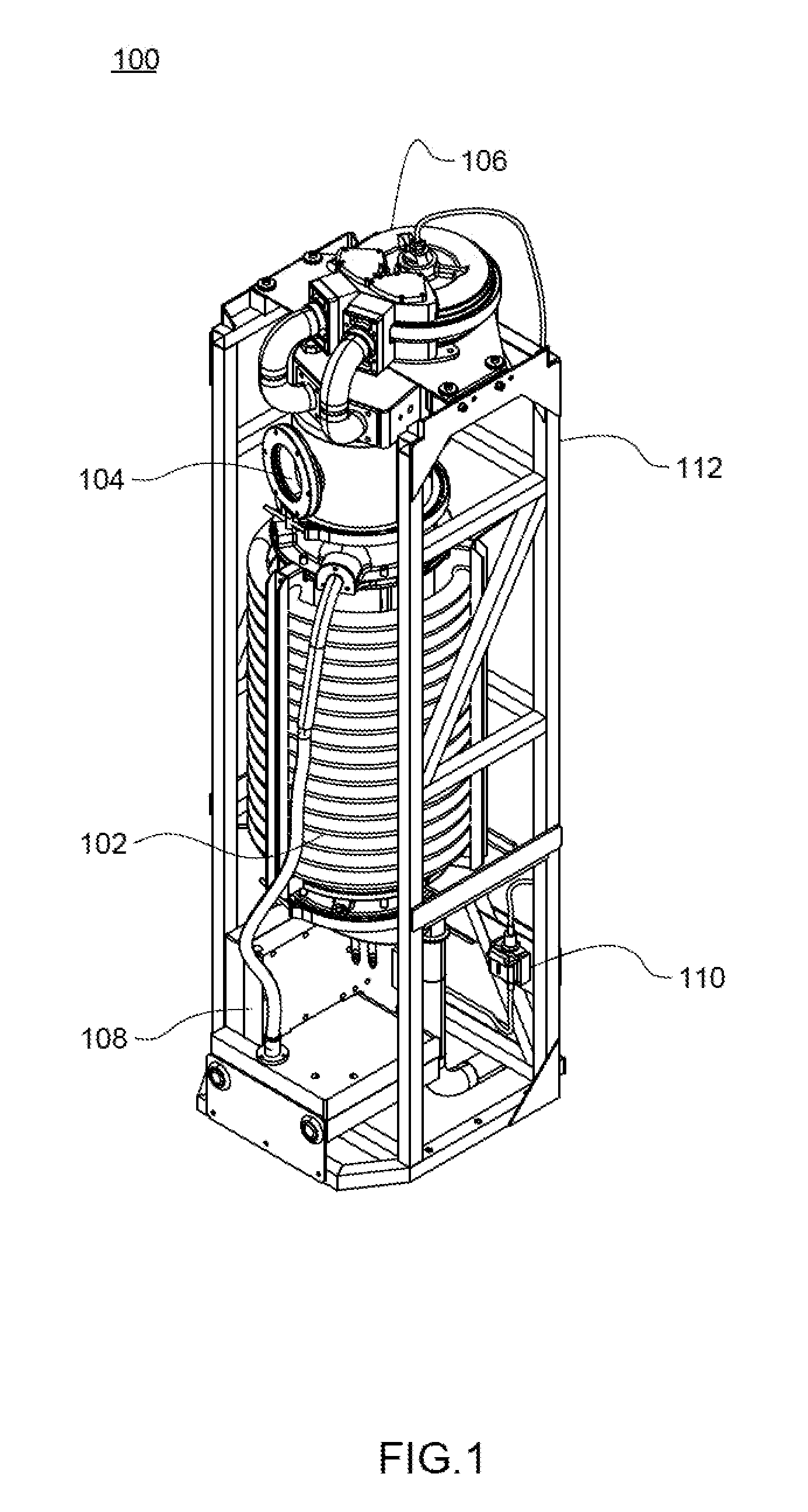

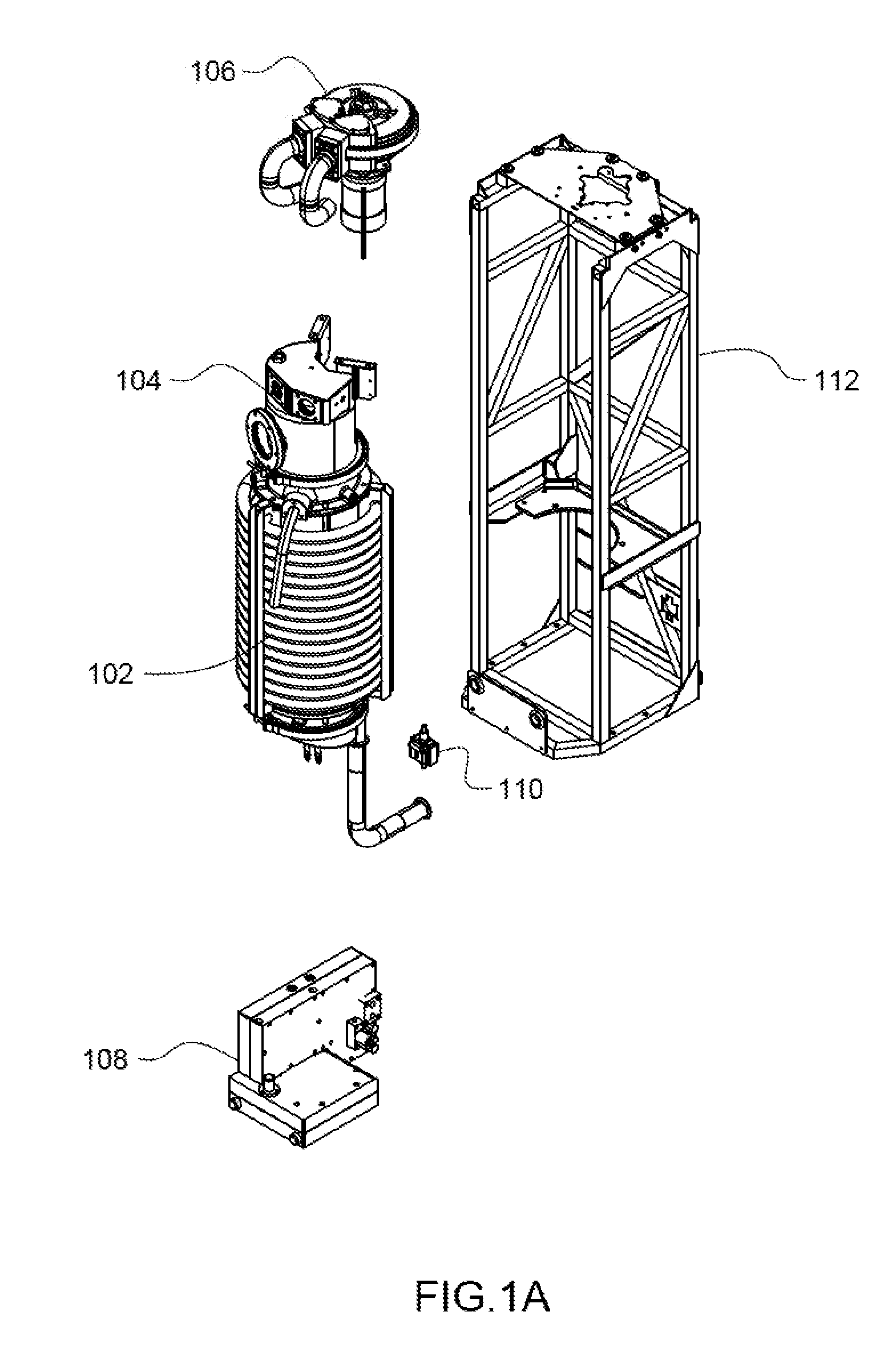

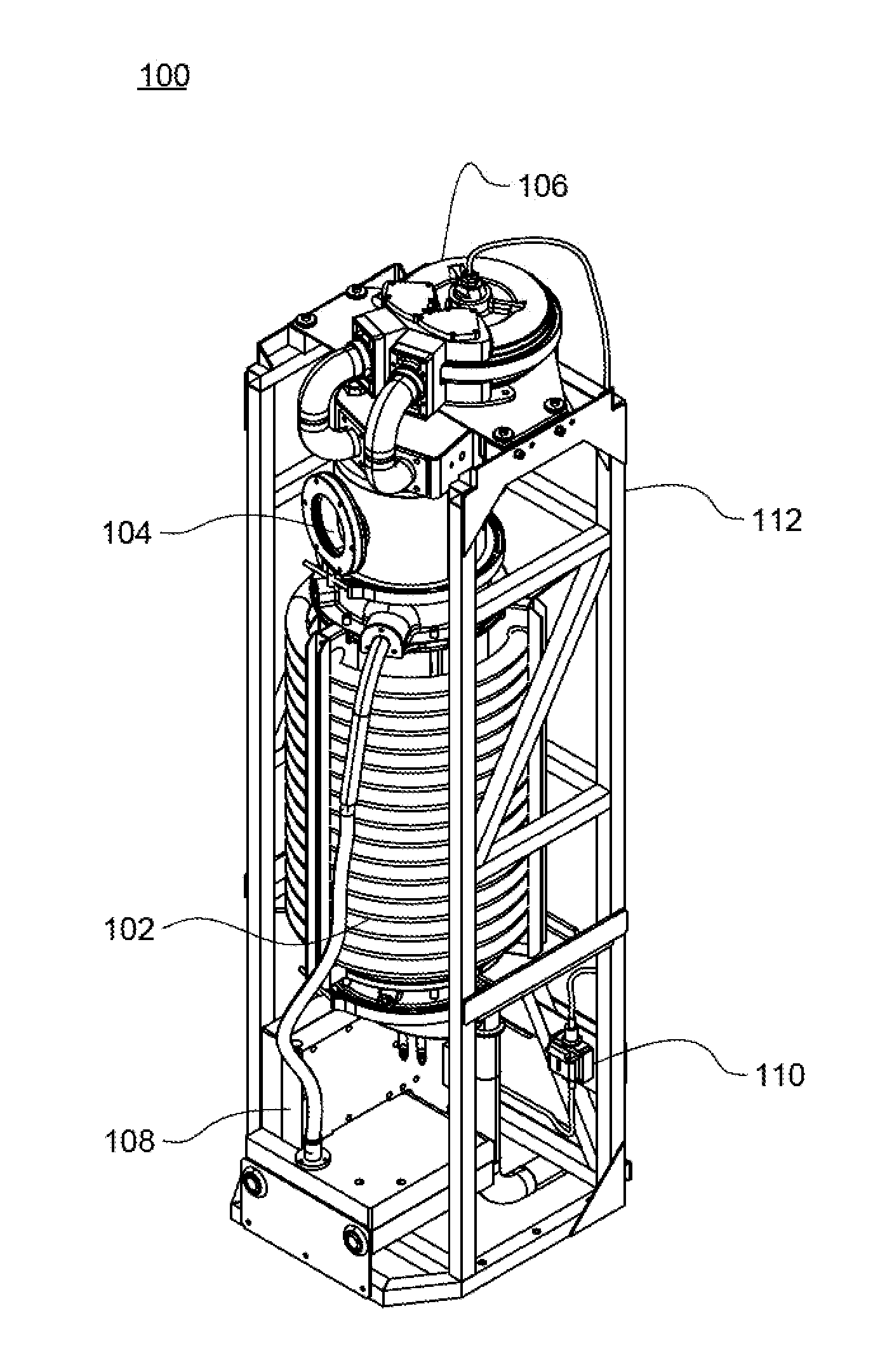

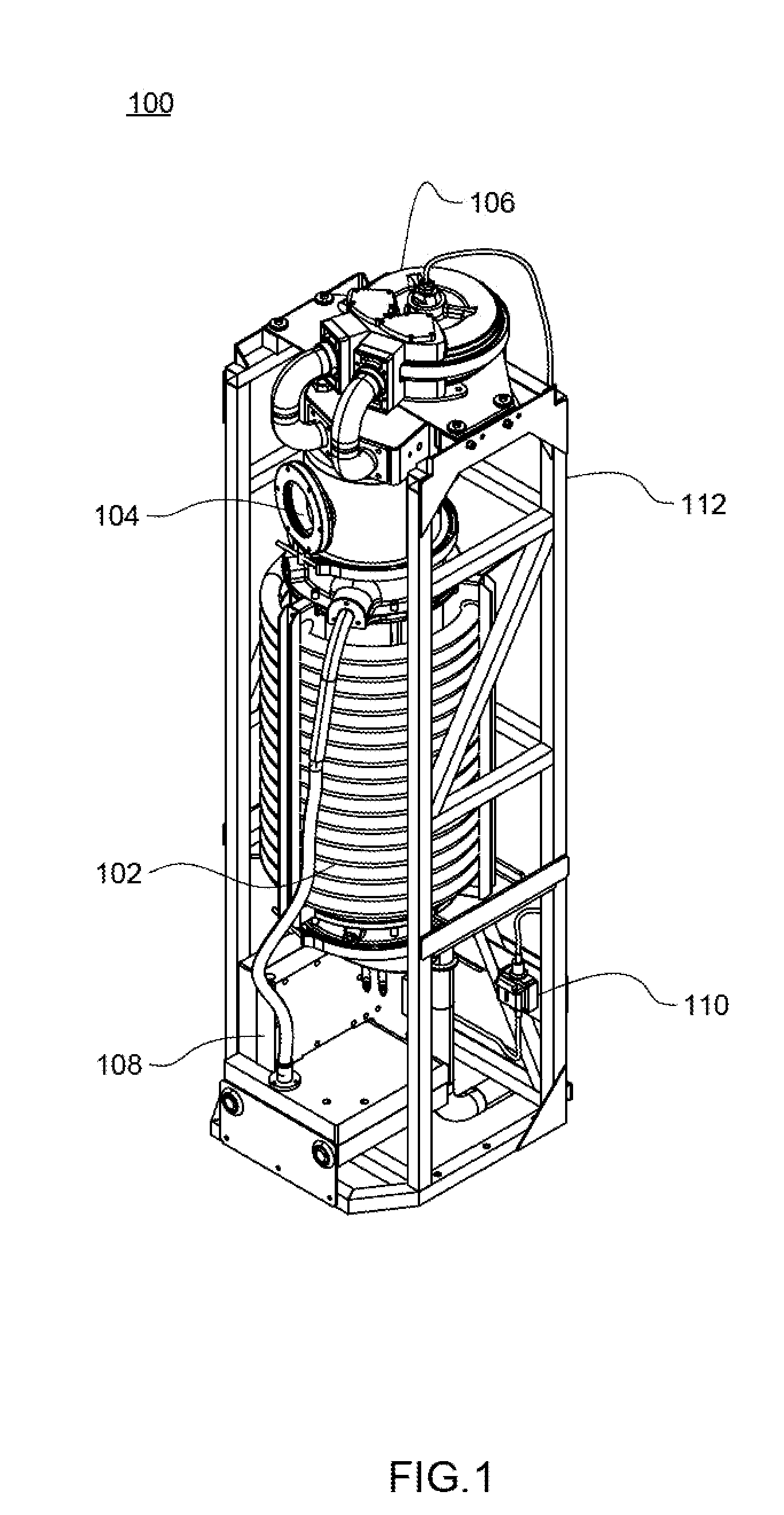

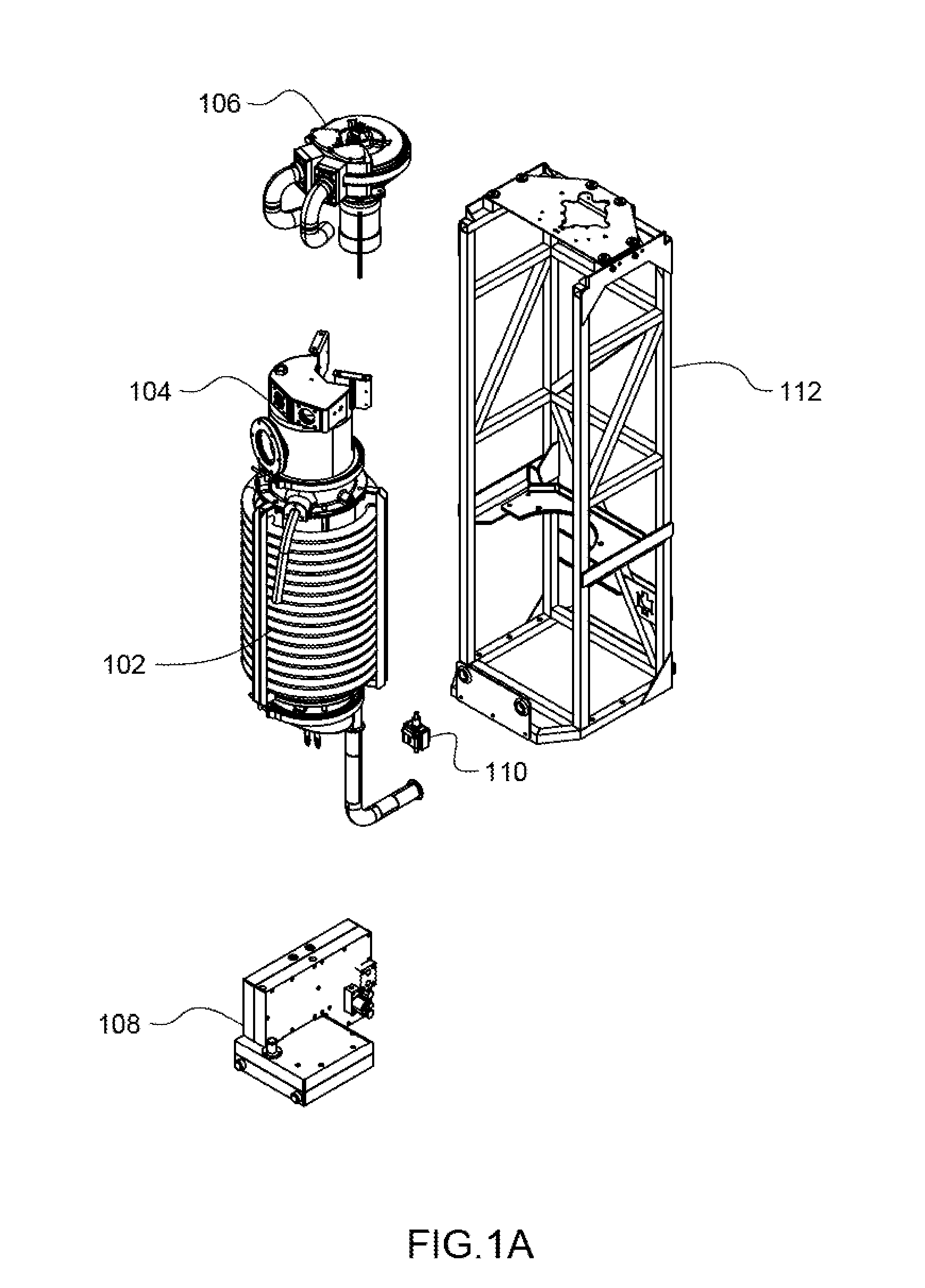

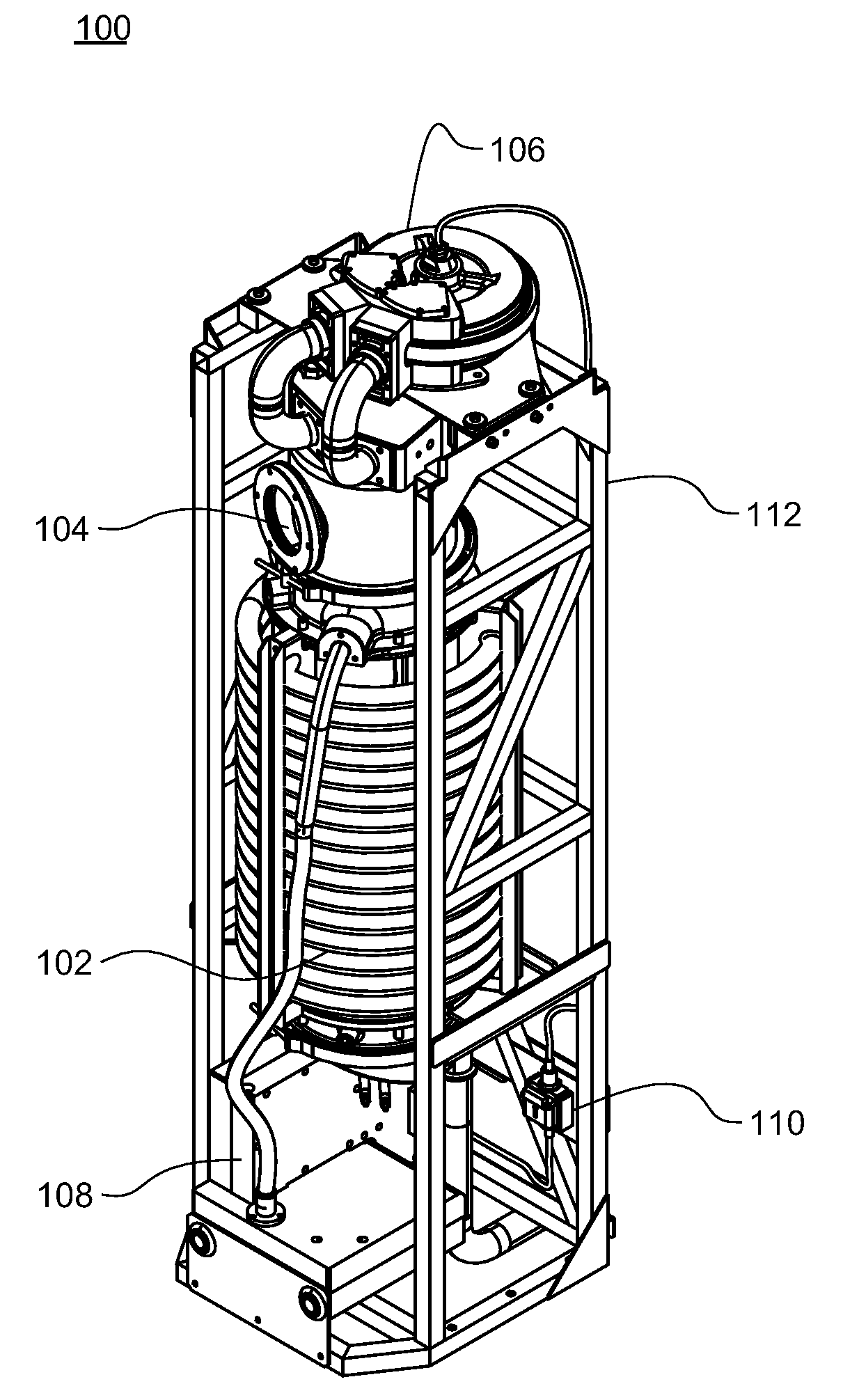

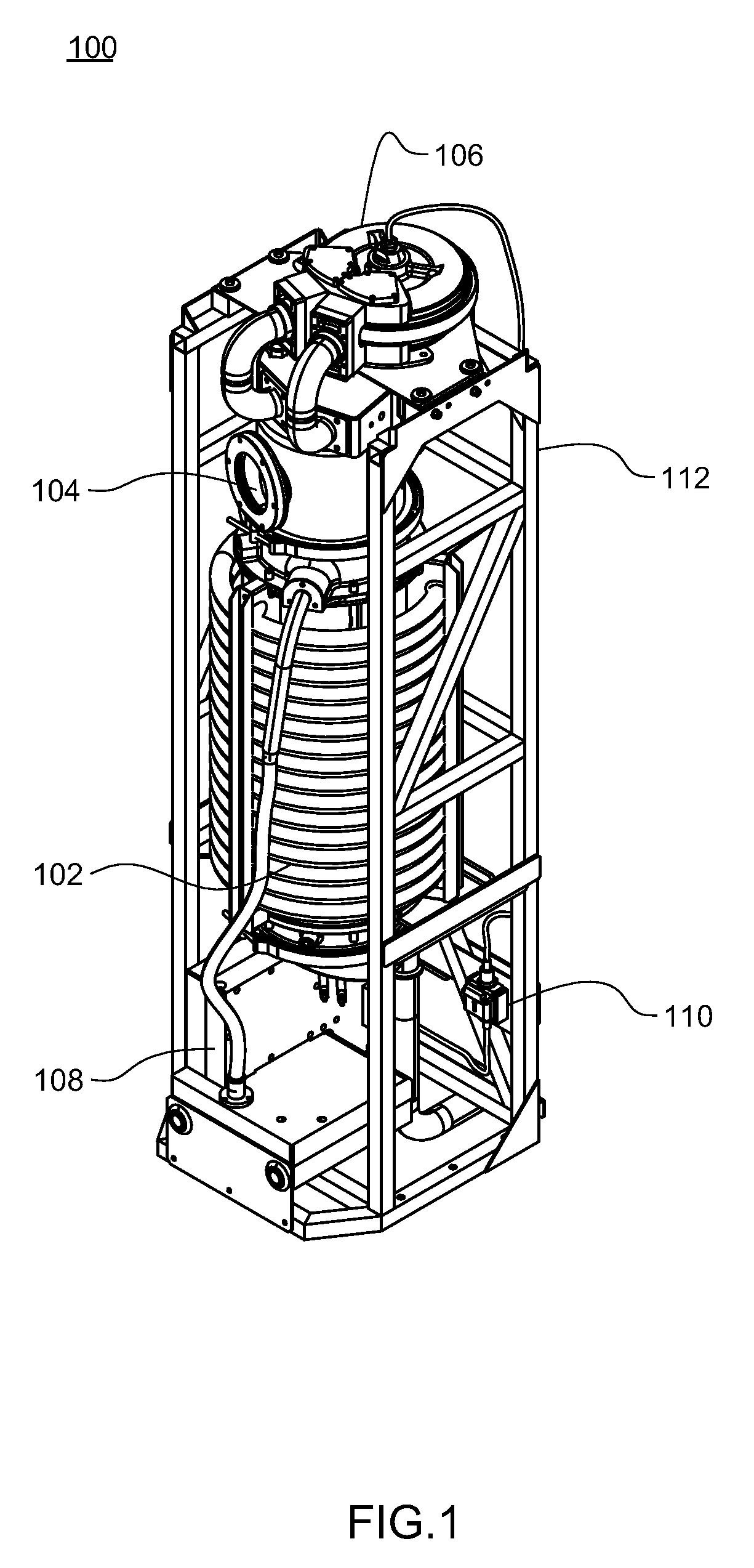

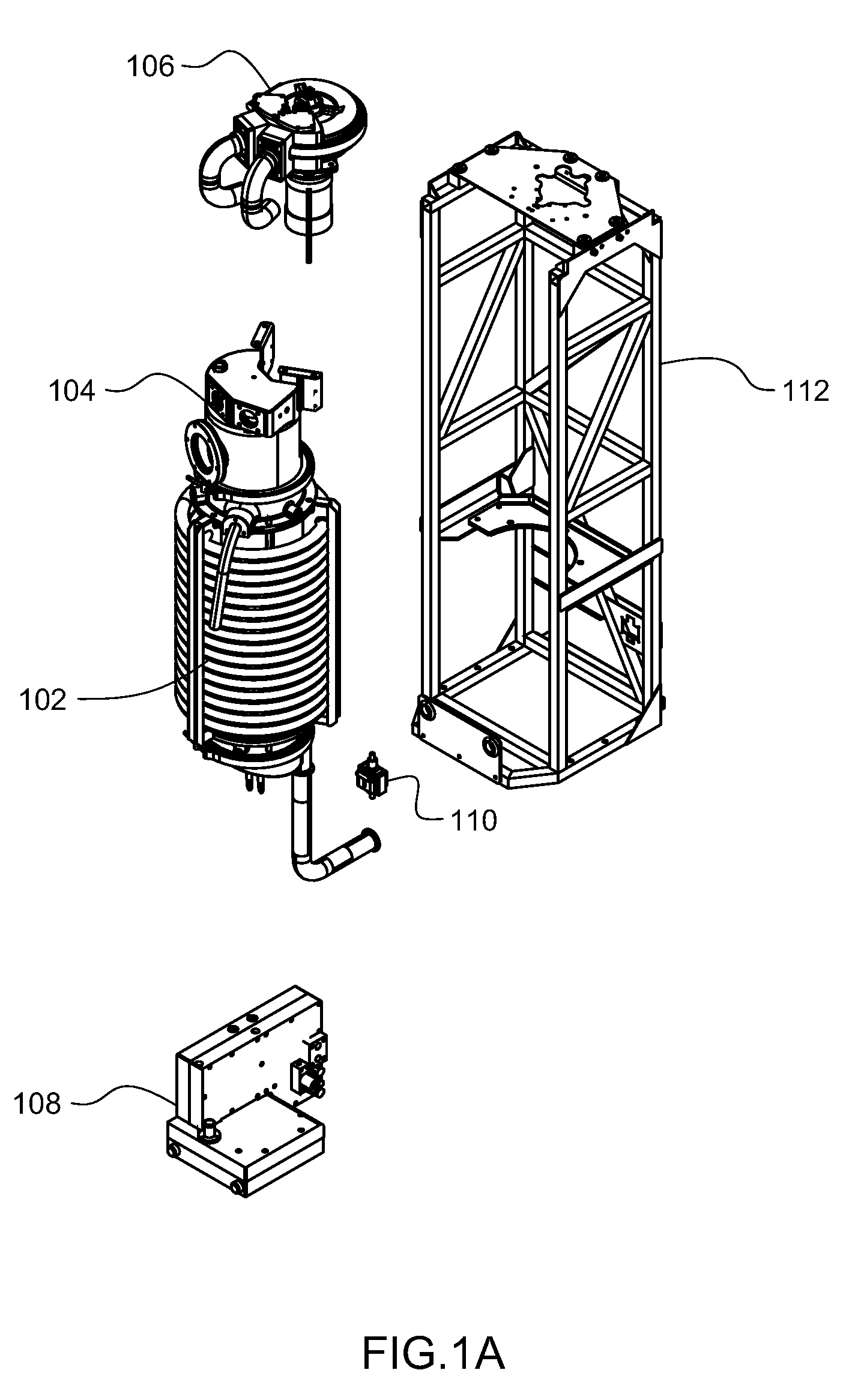

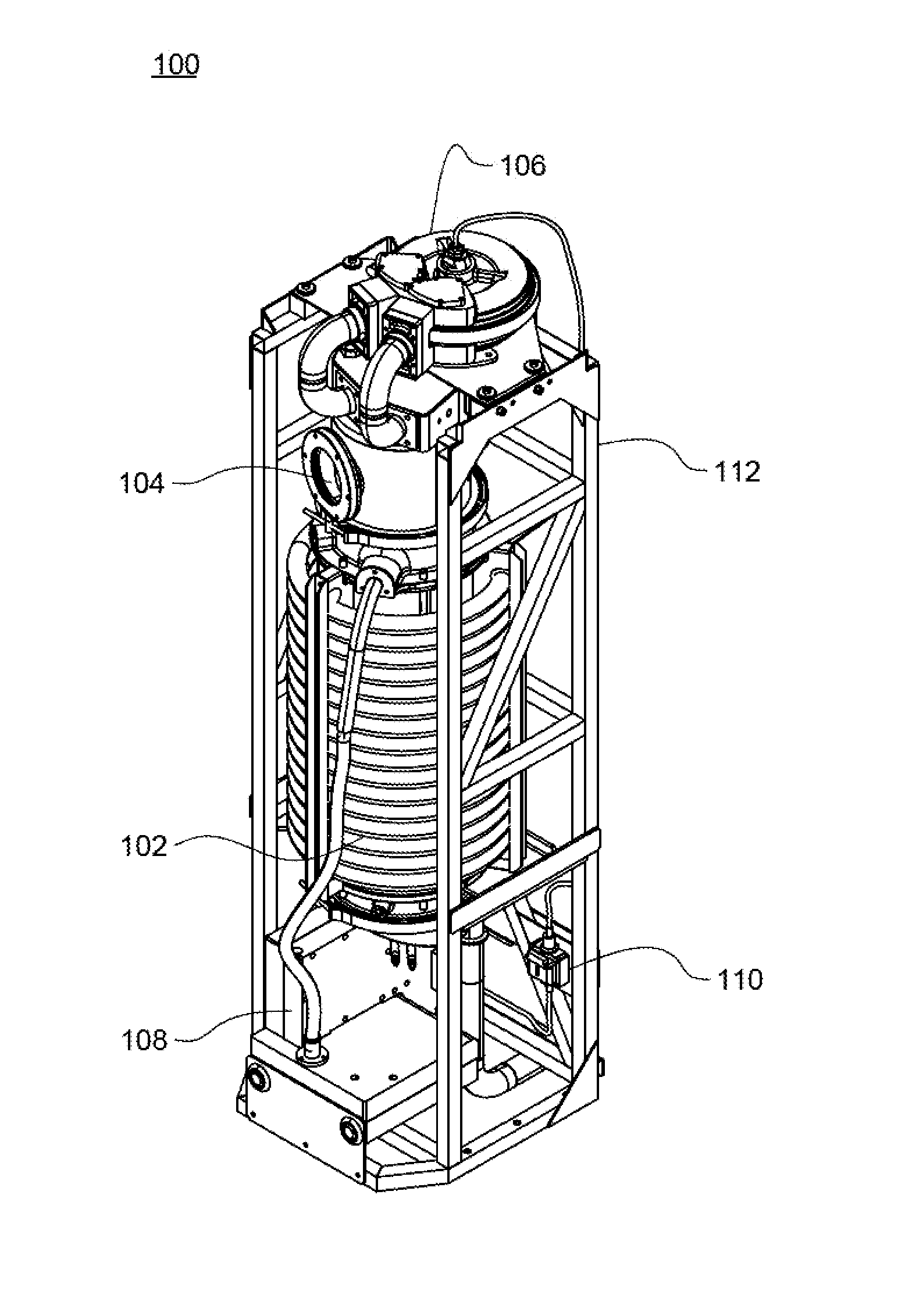

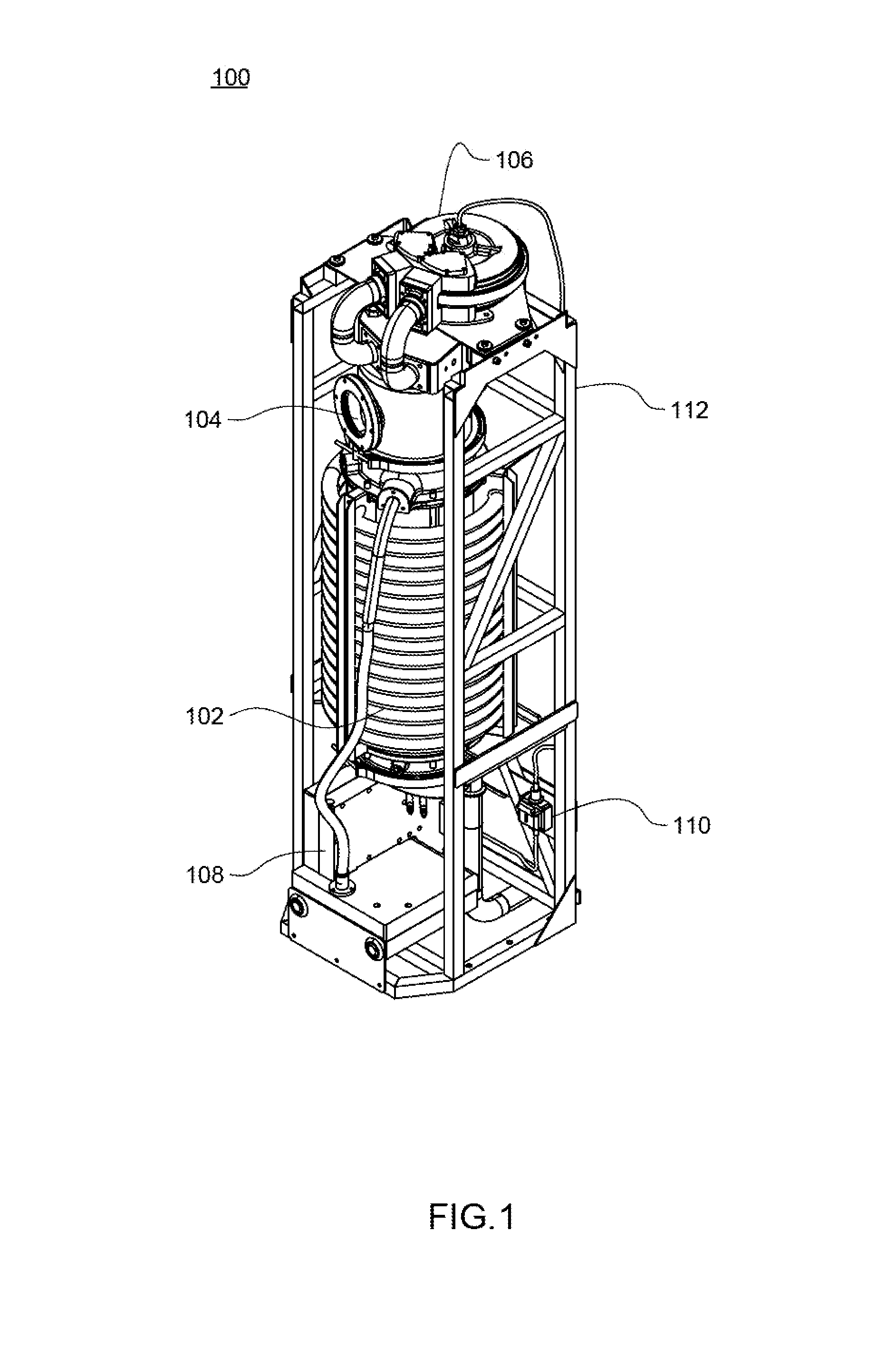

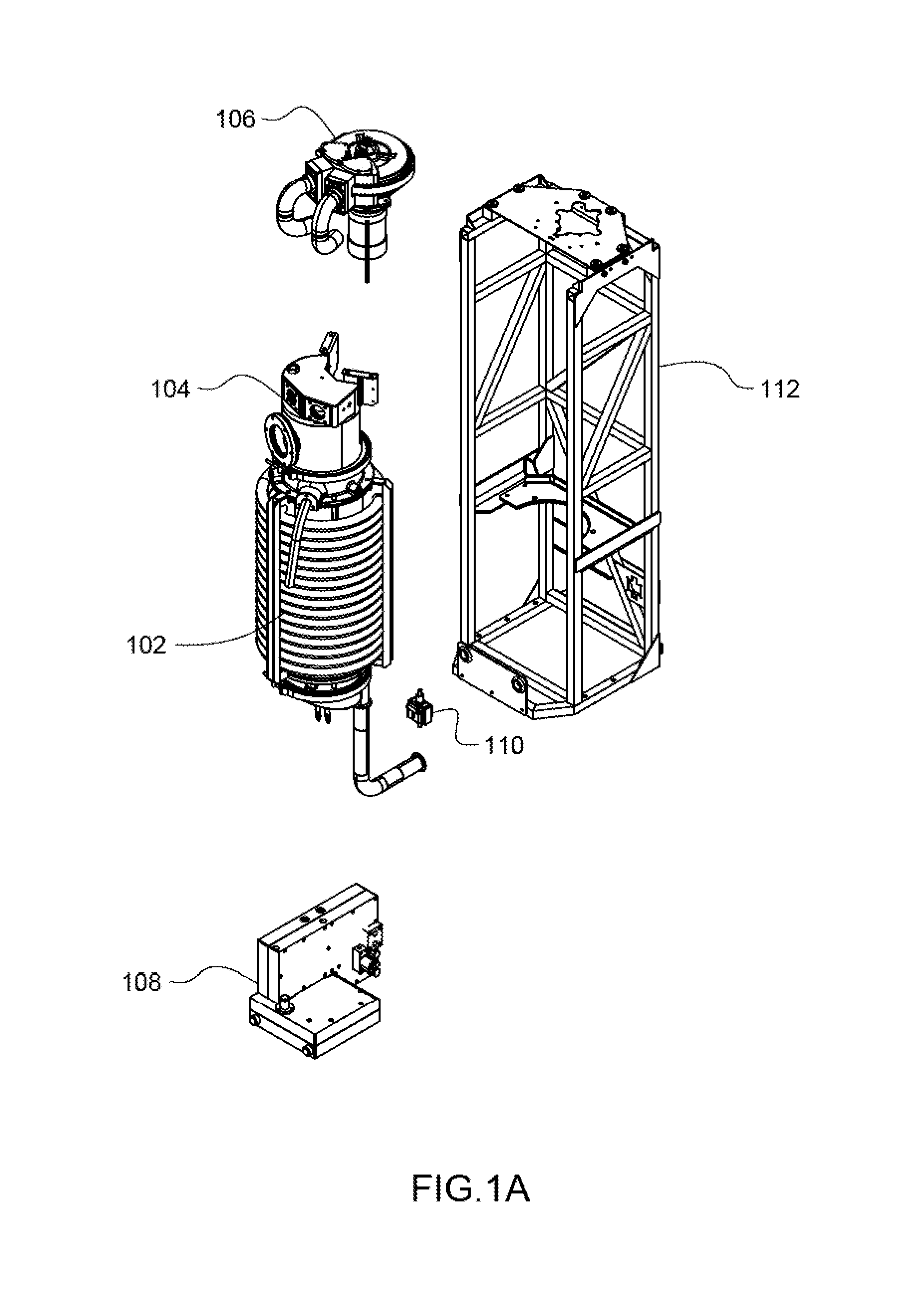

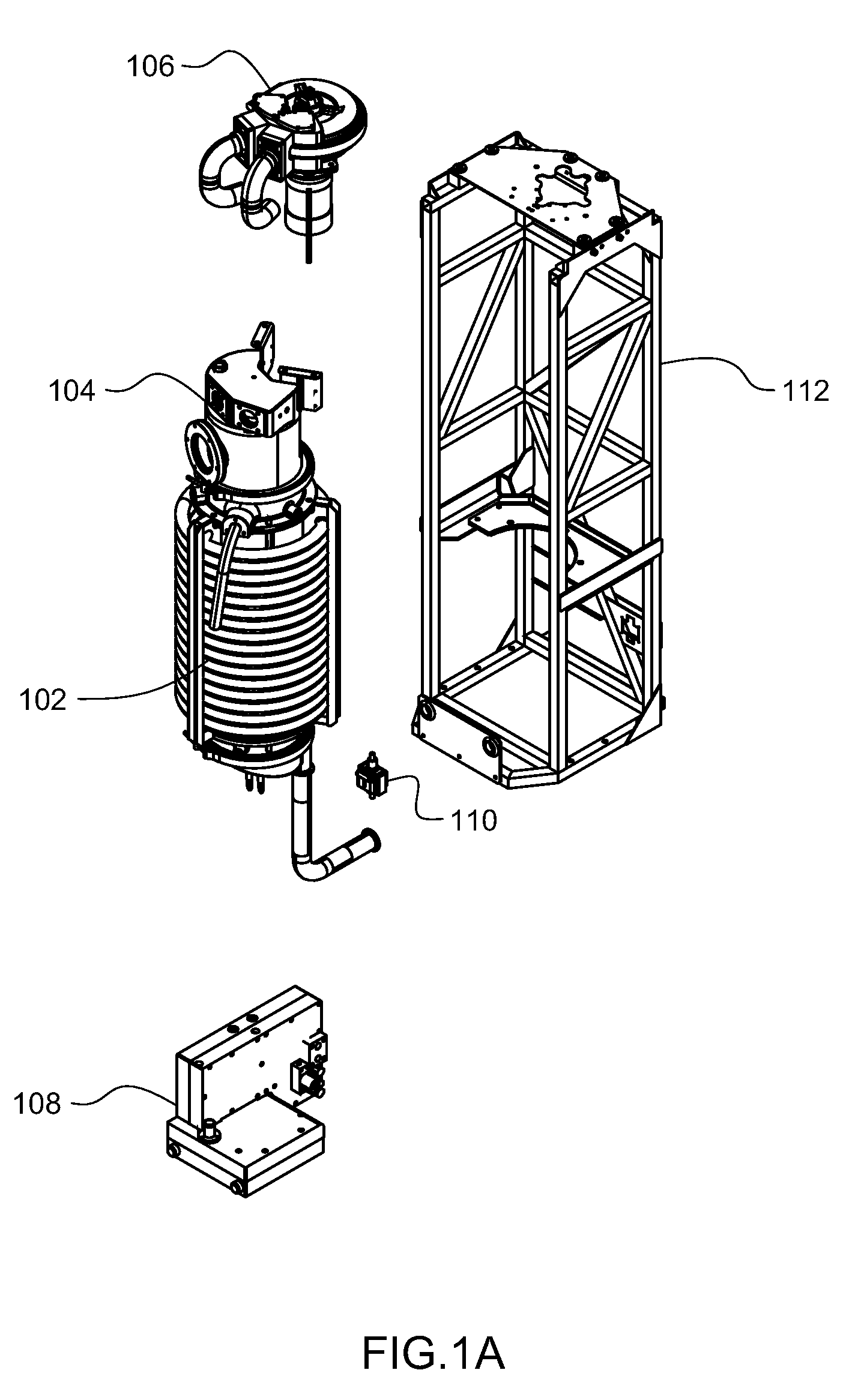

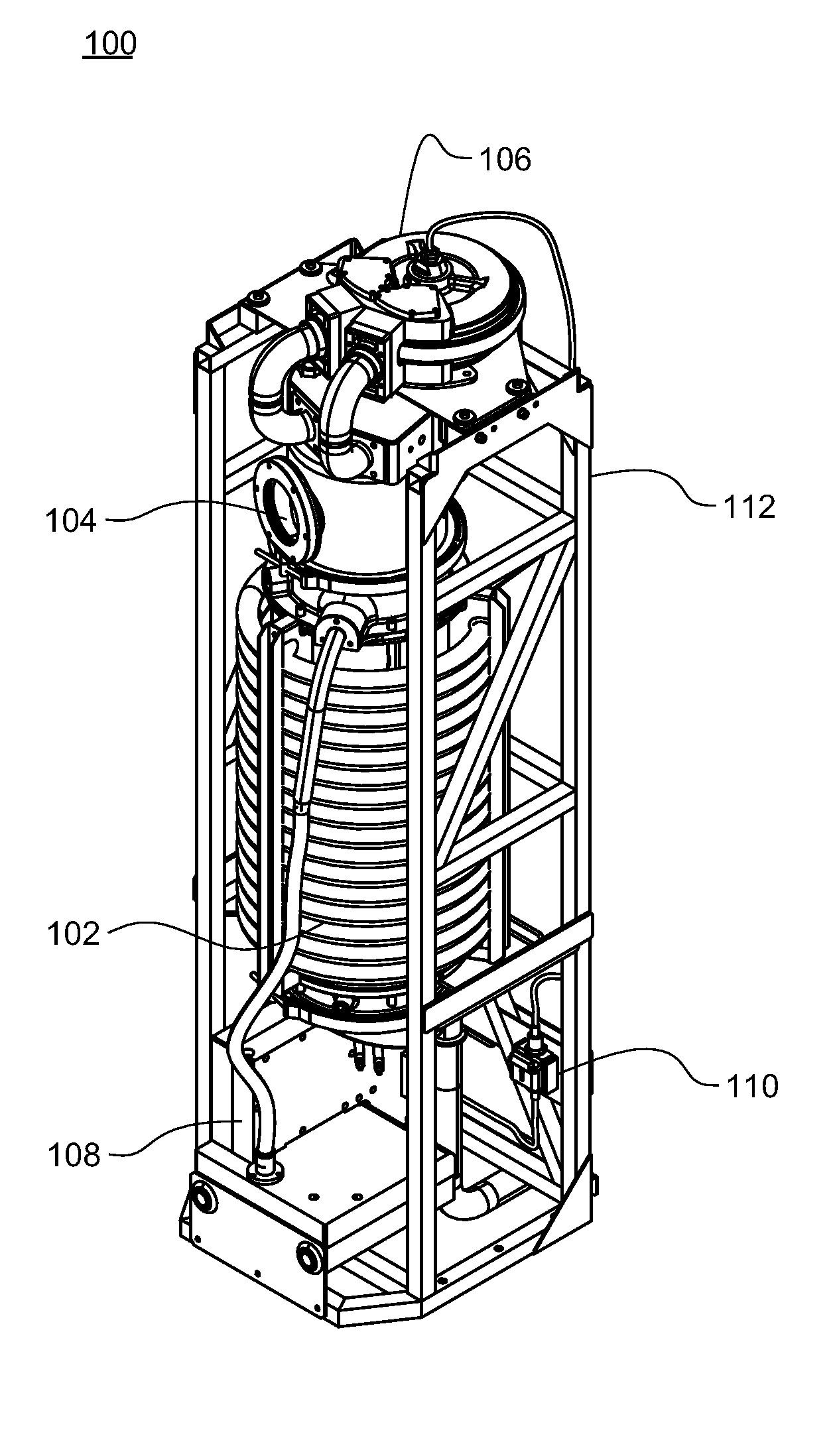

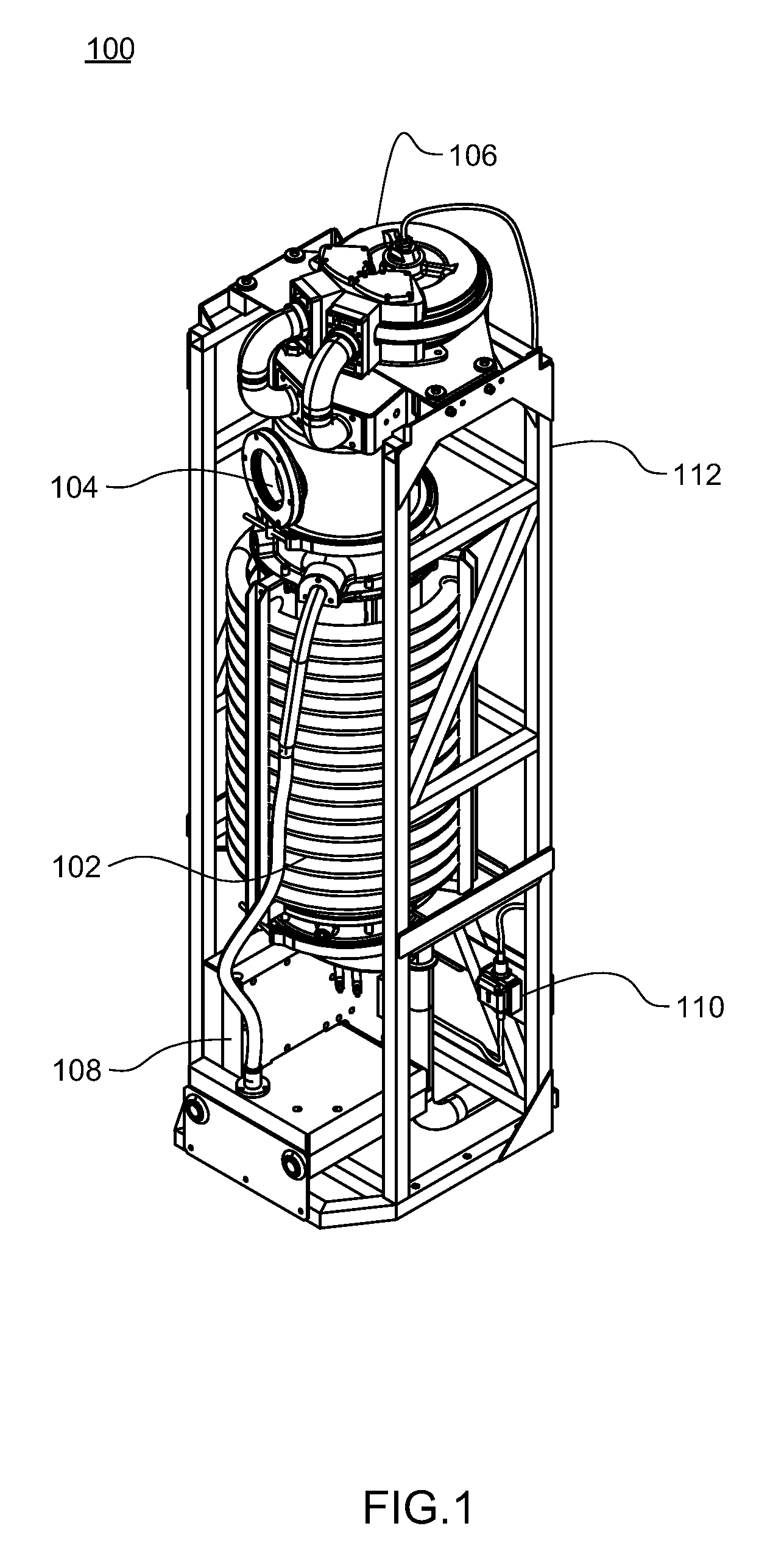

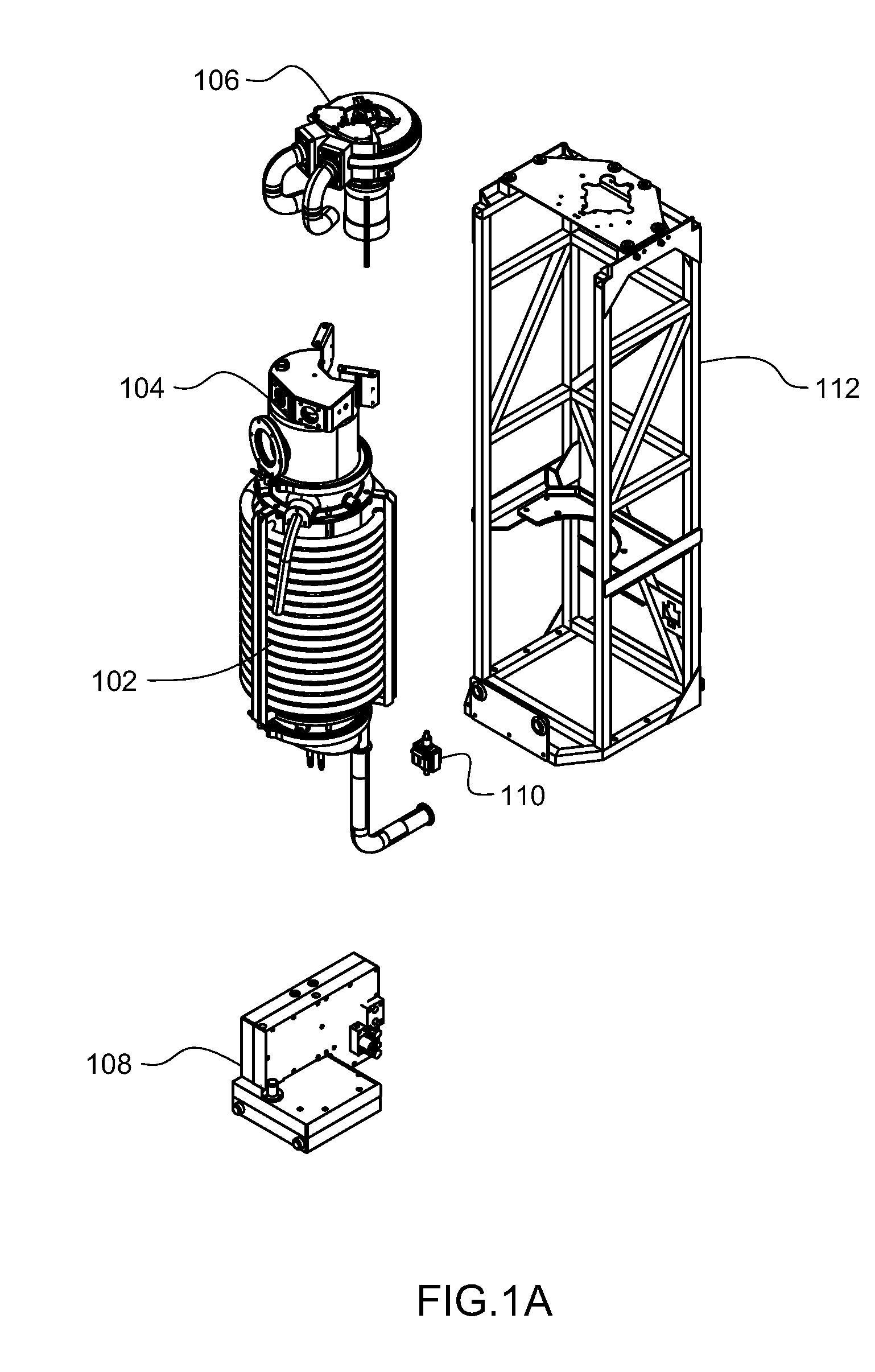

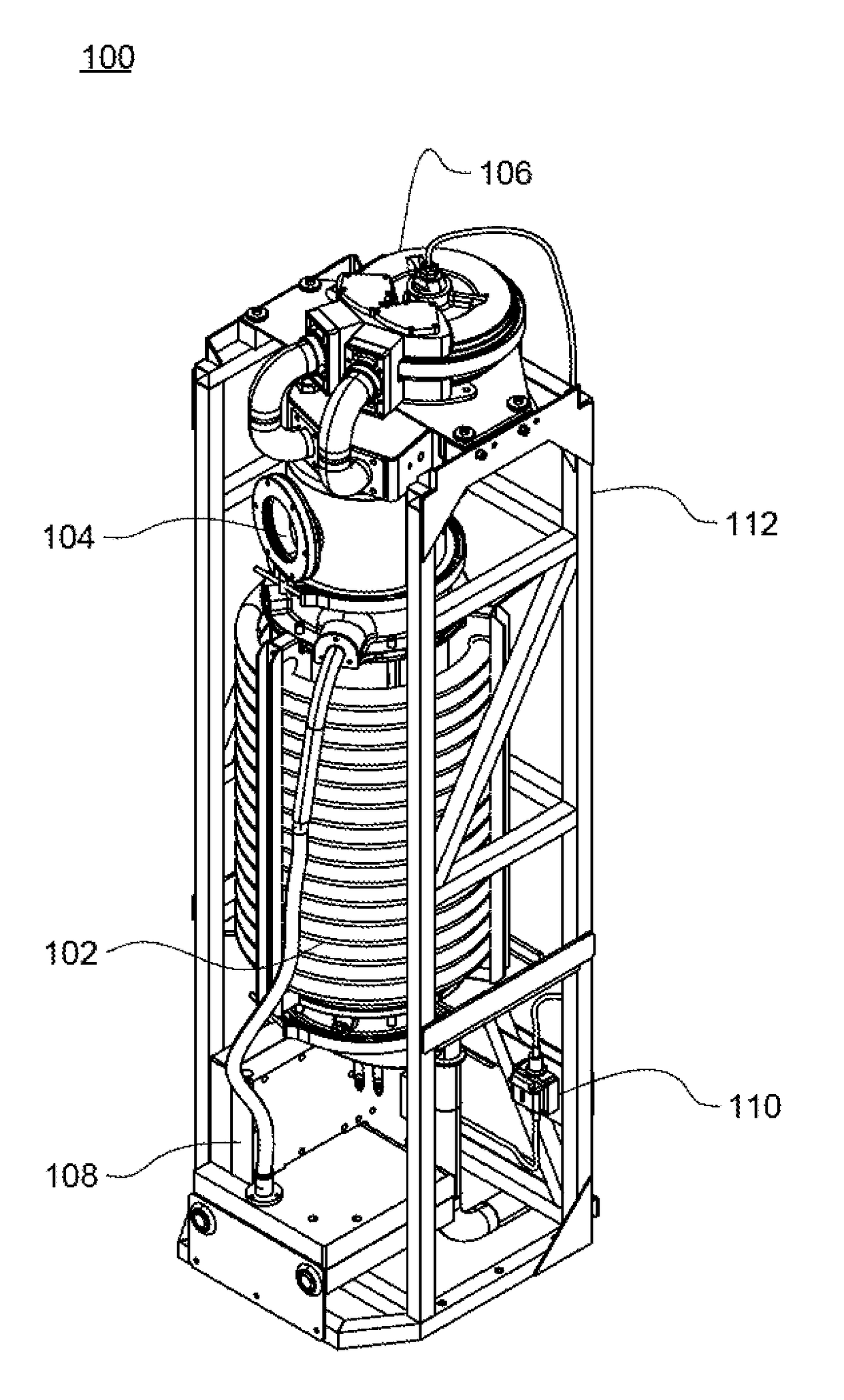

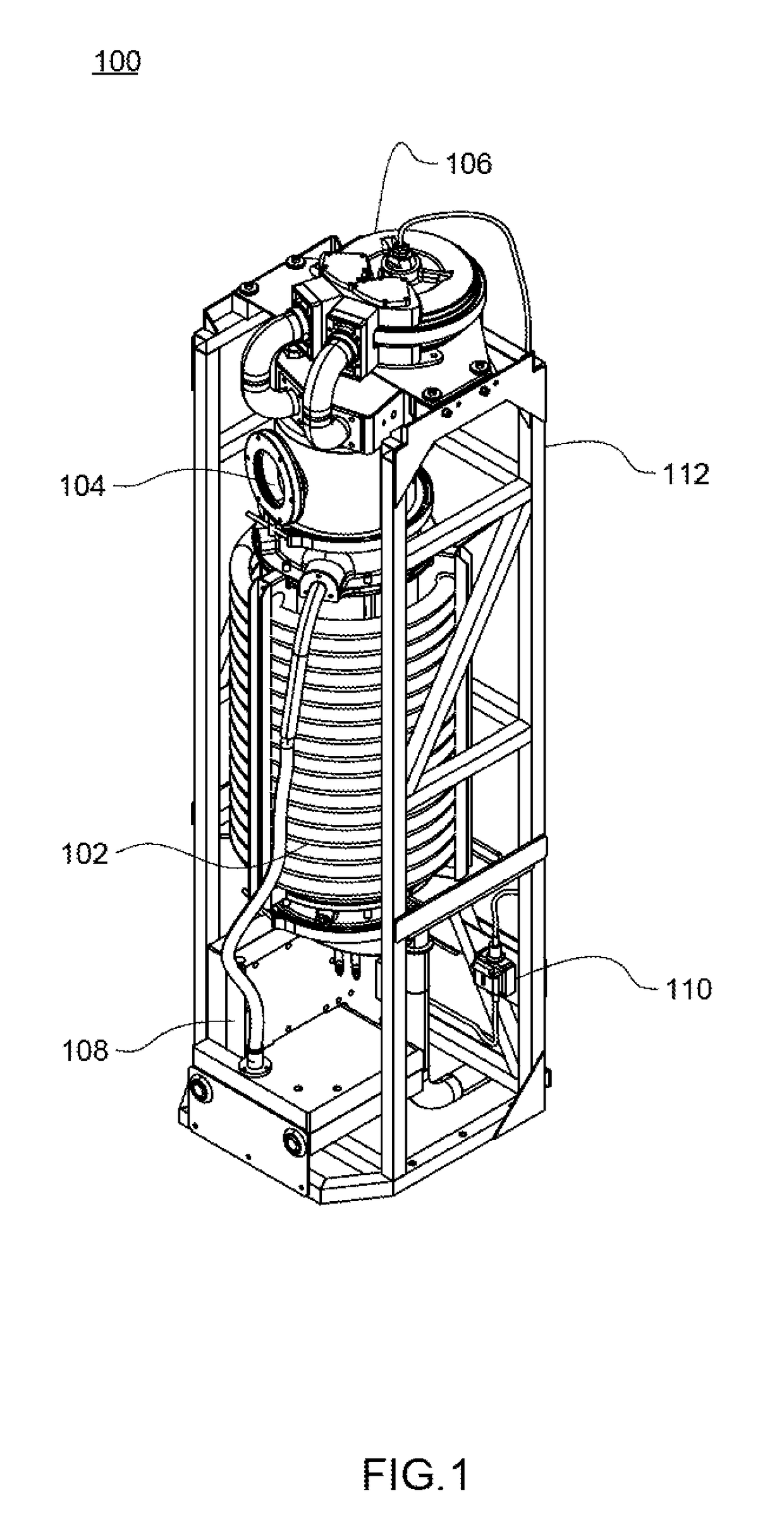

Water Vapor Distillation Apparatus, Method and System

ActiveUS20090025399A1Semiconductor/solid-state device detailsSolid-state devicesWater vaporEngineering

A fluid vapor distillation apparatus. The apparatus includes a source fluid input, and an evaporator condenser apparatus. The evaporator condenser apparatus includes a substantially cylindrical housing and a plurality of tubes in the housing. The source fluid input is fluidly connected to the evaporator condenser and the evaporator condenser transforms source fluid into steam and transforms compressed steam into product fluid. Also included in the fluid vapor distillation apparatus is a heat exchanger fluidly connected to the source fluid input and a product fluid output. The heat exchanger includes an outer tube and at least one inner tube. Also included in the fluid vapor distillation apparatus is a regenerative blower fluidly connected to the evaporator condenser. The regenerative blower compresses steam, and the compressed steam flows to the evaporative condenser where compressed steam is transformed into product fluid.

Owner:DEKA PROD LLP

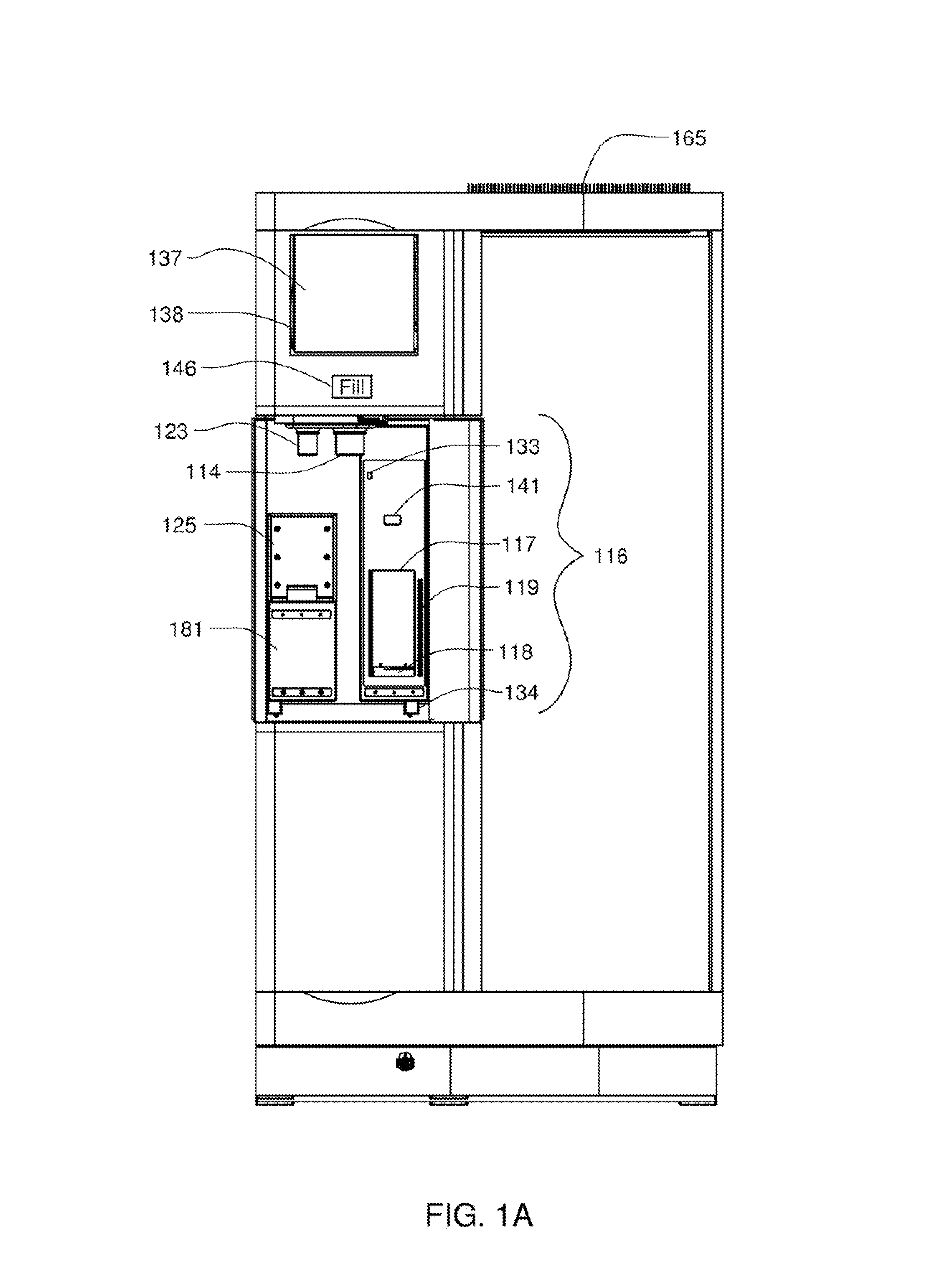

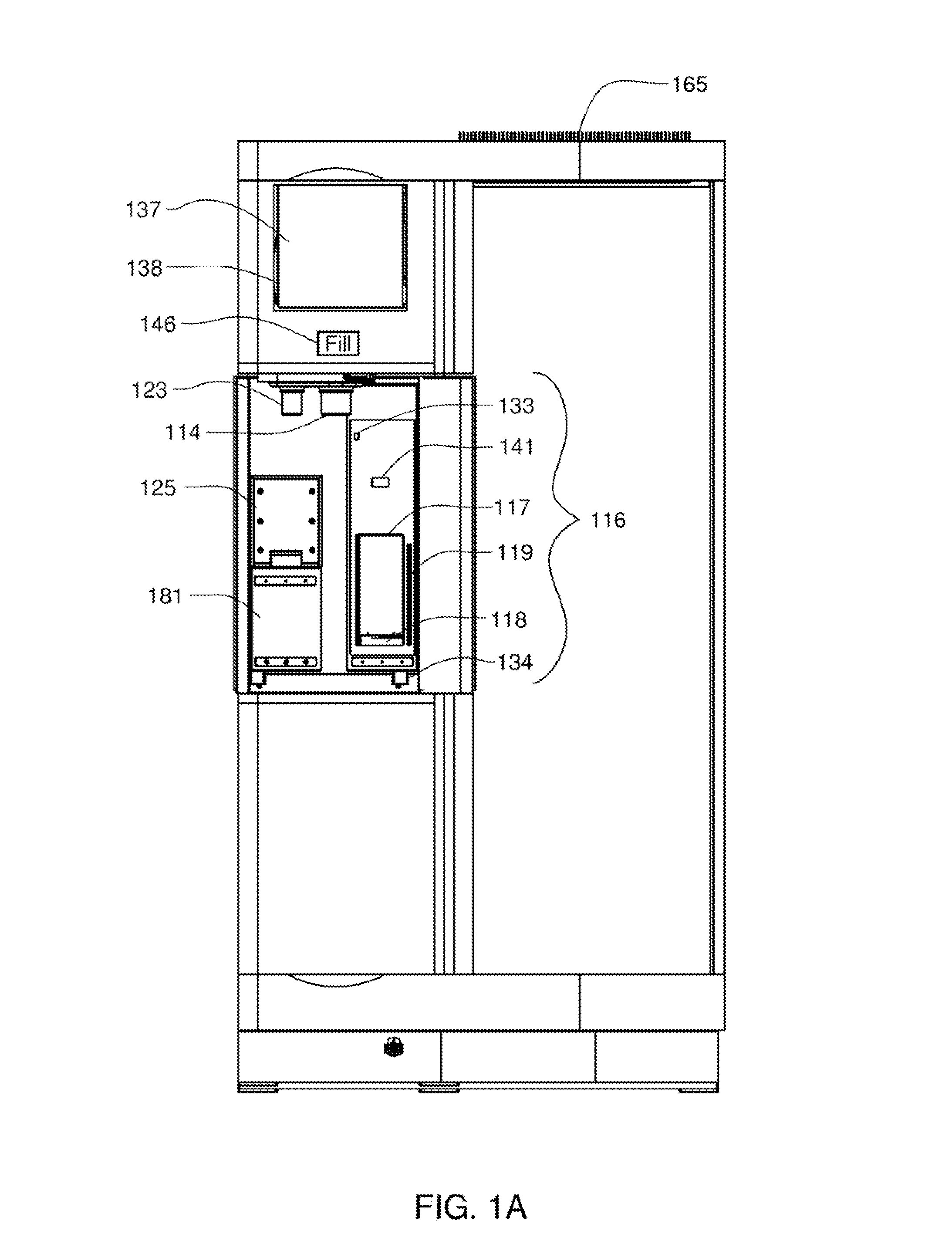

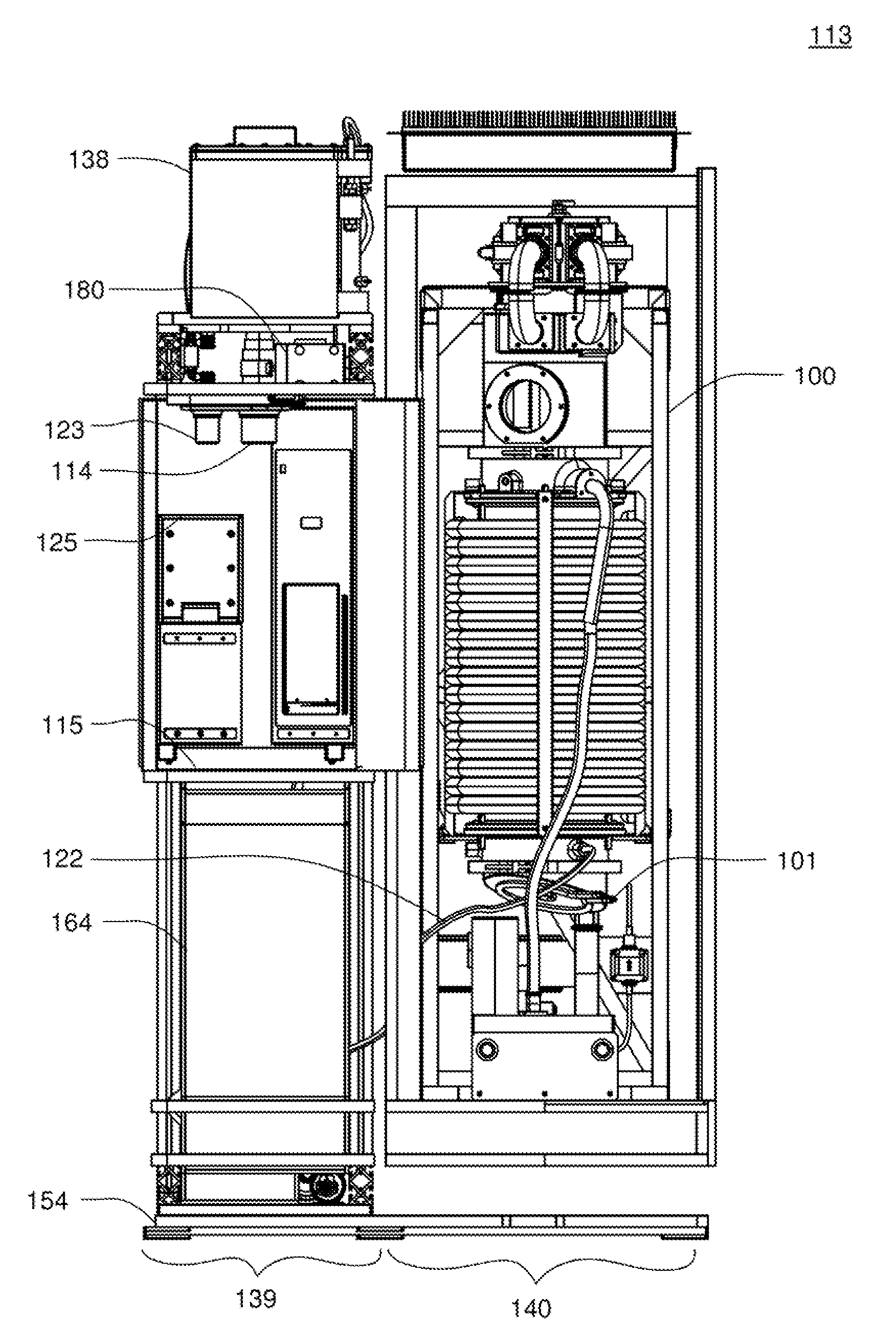

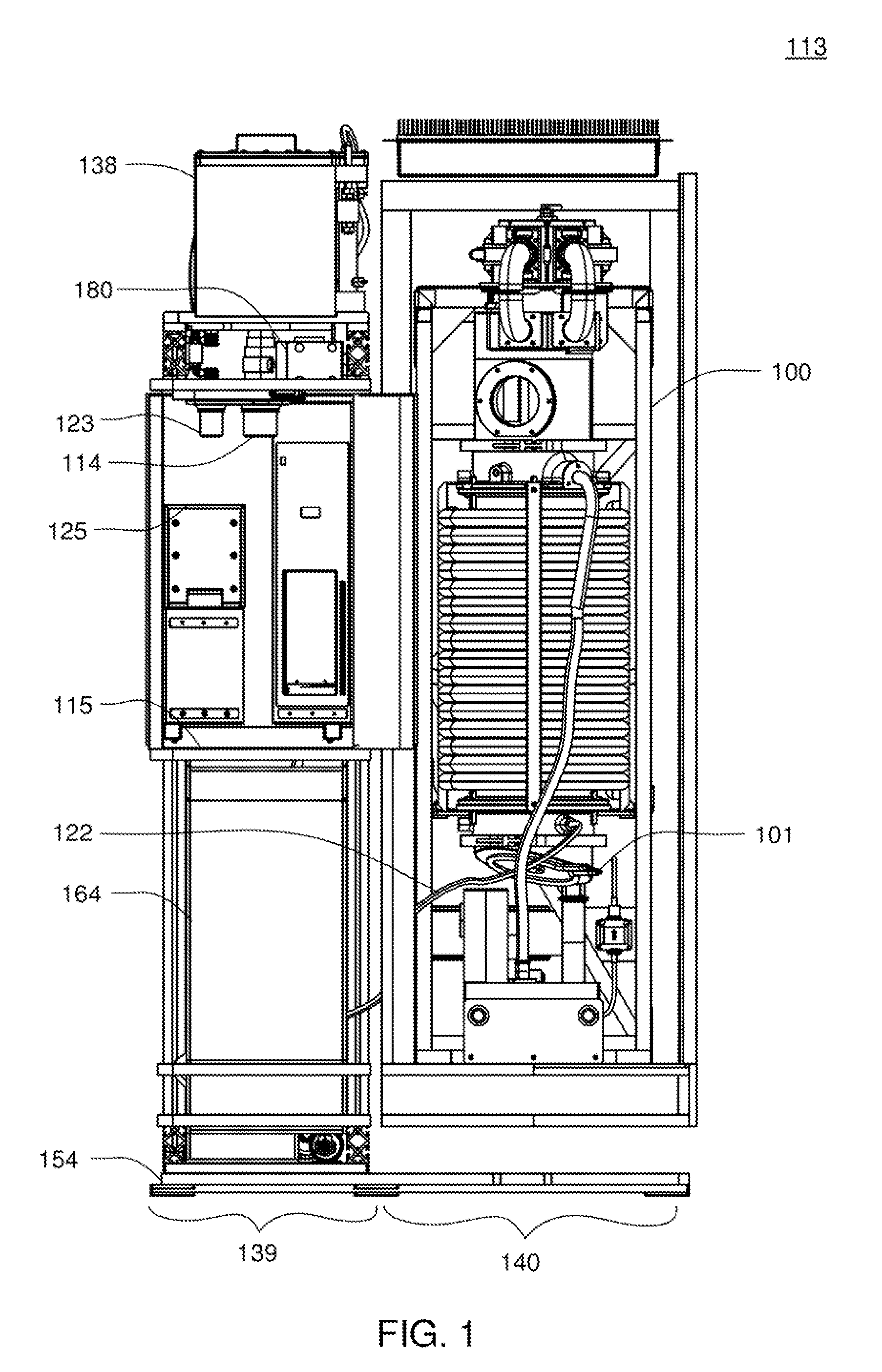

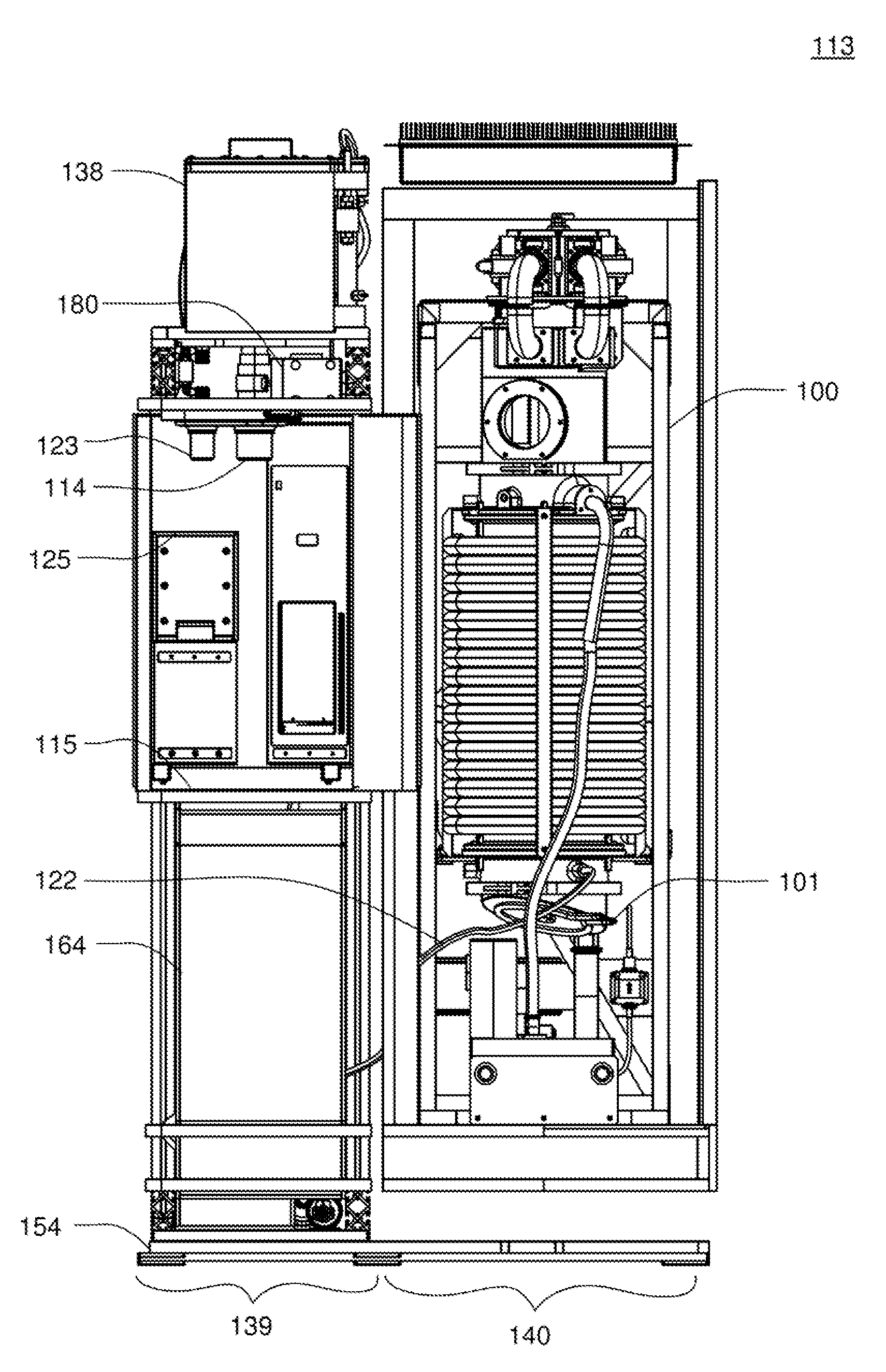

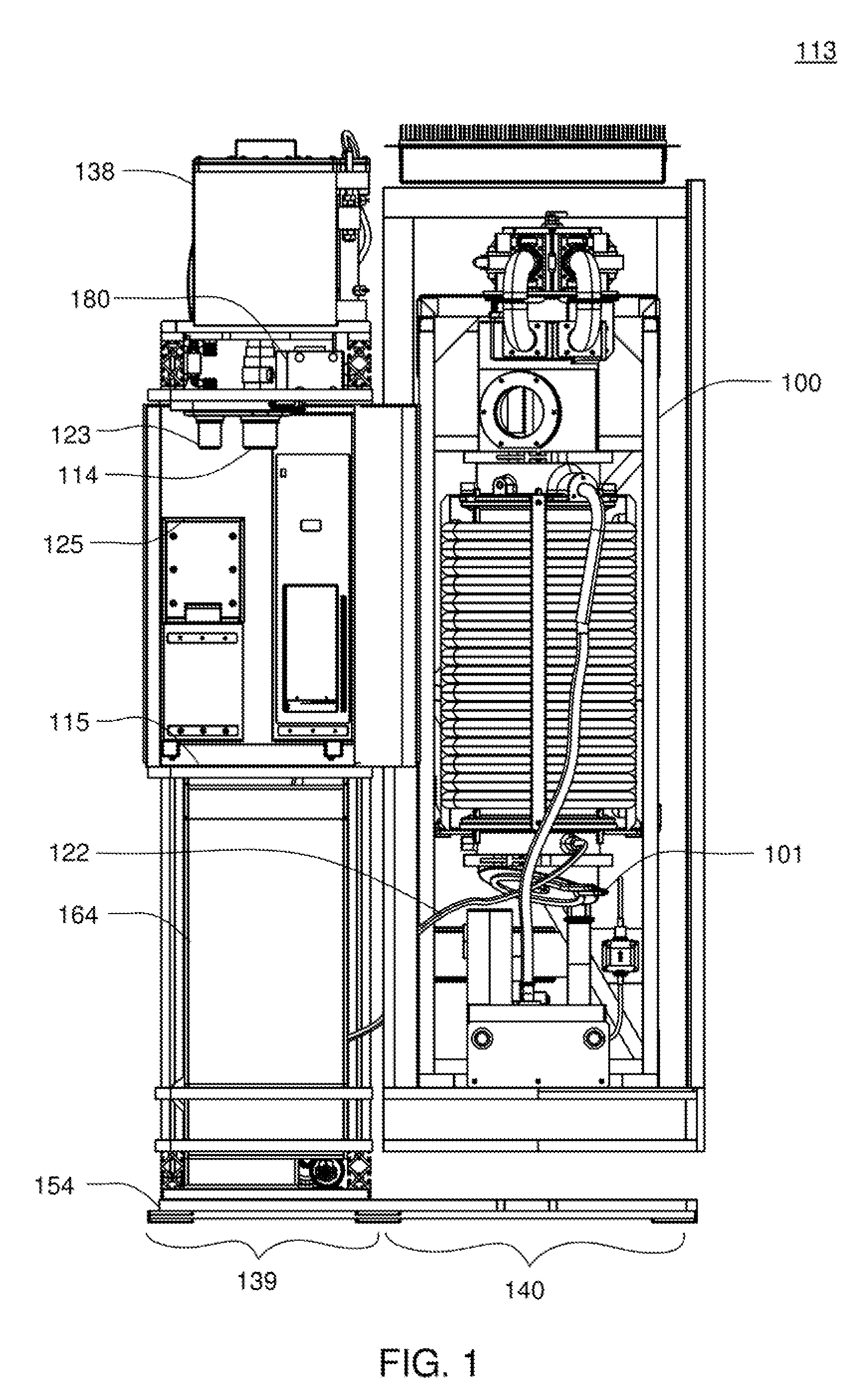

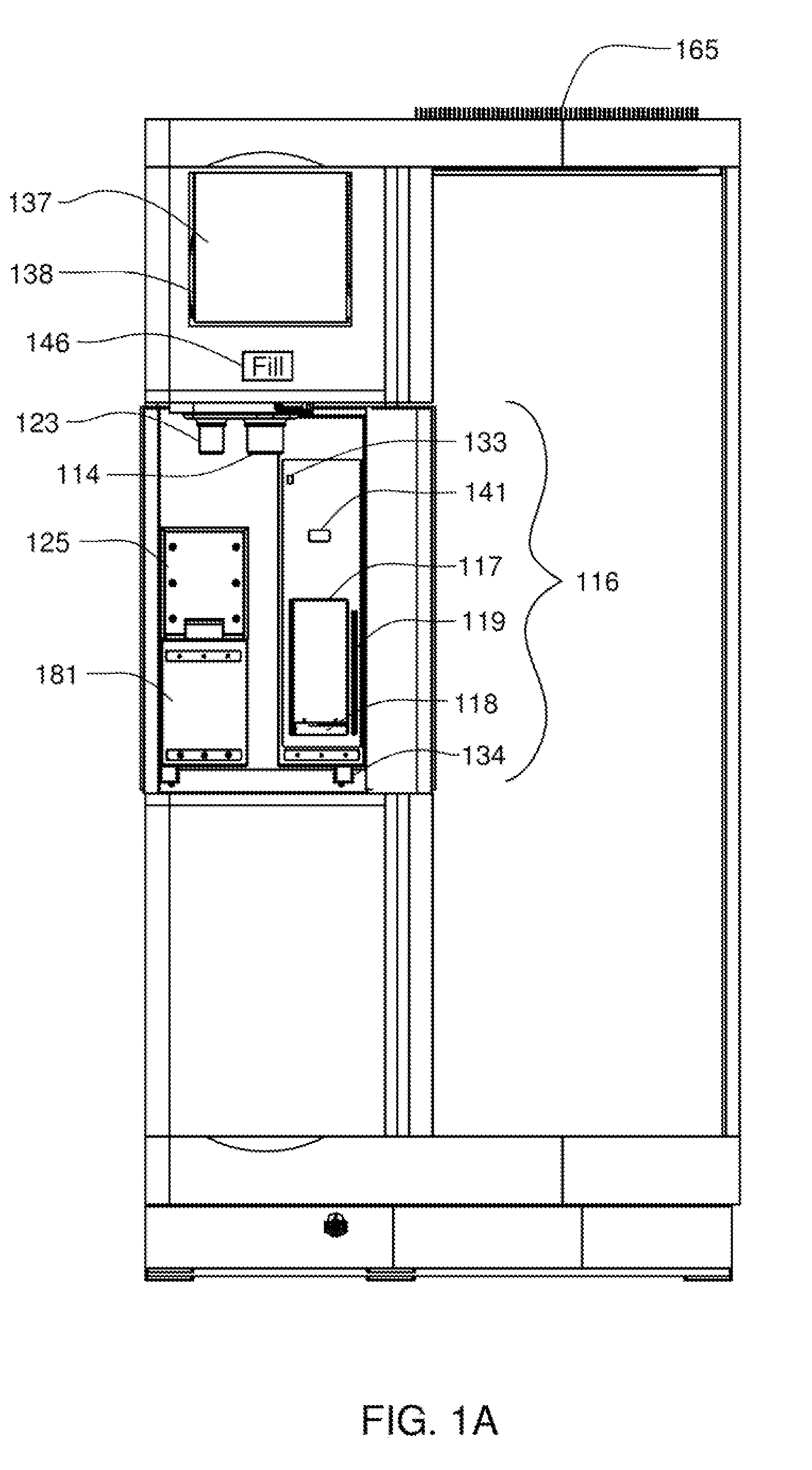

Water vending apparatus

ActiveUS20110147194A1Less production ratePrevents sediment buildupCharging-discharging device combinationsLighting and heating apparatusSteam distillationWater vapor

A water vending apparatus is disclosed. The water vending system includes a water vapor distillation apparatus and a dispensing device. The dispensing device is in fluid communication with the fluid vapor distillation apparatus and the product water from the fluid vapor distillation apparatus is dispensed by the dispensing device.

Owner:DEKA PROD LLP

Equipment and method for extracting perfume plant essential oil by reduced pressure steam distillation

InactiveCN102250689AWide applicabilityEasy and flexible operationEssential-oils/perfumesWater vaporOil phase

The invention provides a piece of equipment and a method for extracting volatile essential oil from natural perfume plants by using the technology of reduced pressure steam distillation extraction. The equipment provided in the invention comprises a steam distillation system and a vacuum system, wherein the steam distillation system is composed of a steam generator, a material retort, a condenser, an oil-water separator and connecting pipelines, and the vacuum system comprises a vacuum unit or a suction pump, a pressure regulator valve, connecting pipelines and the like. The method comprises the following steps that: plant raw materials to be extracted for essential oil in the material retort is controlled to be at a certain temperature and under certain pressure so as to reduce changes of aroma components in perfume plants in the process of extraction as much as possible; extracted volatile components of essential oil is mixed with steam to form mixed steam of water and oil; the mixed steam enters into the condenser for condensation and then enters into the oil-water separator for separation; an oil phase is collected after separation and the oil phase is plant essential oil; the separated water phase is flower water. The essential oil and flower water obtained by the extraction method have pure aroma, suffer little loss for head volatile thereof, and are applicable to the industries of perfumes, essence, cosmetics, daily chemicals, etc.

Owner:XINJIANG UNIVERSITY +2

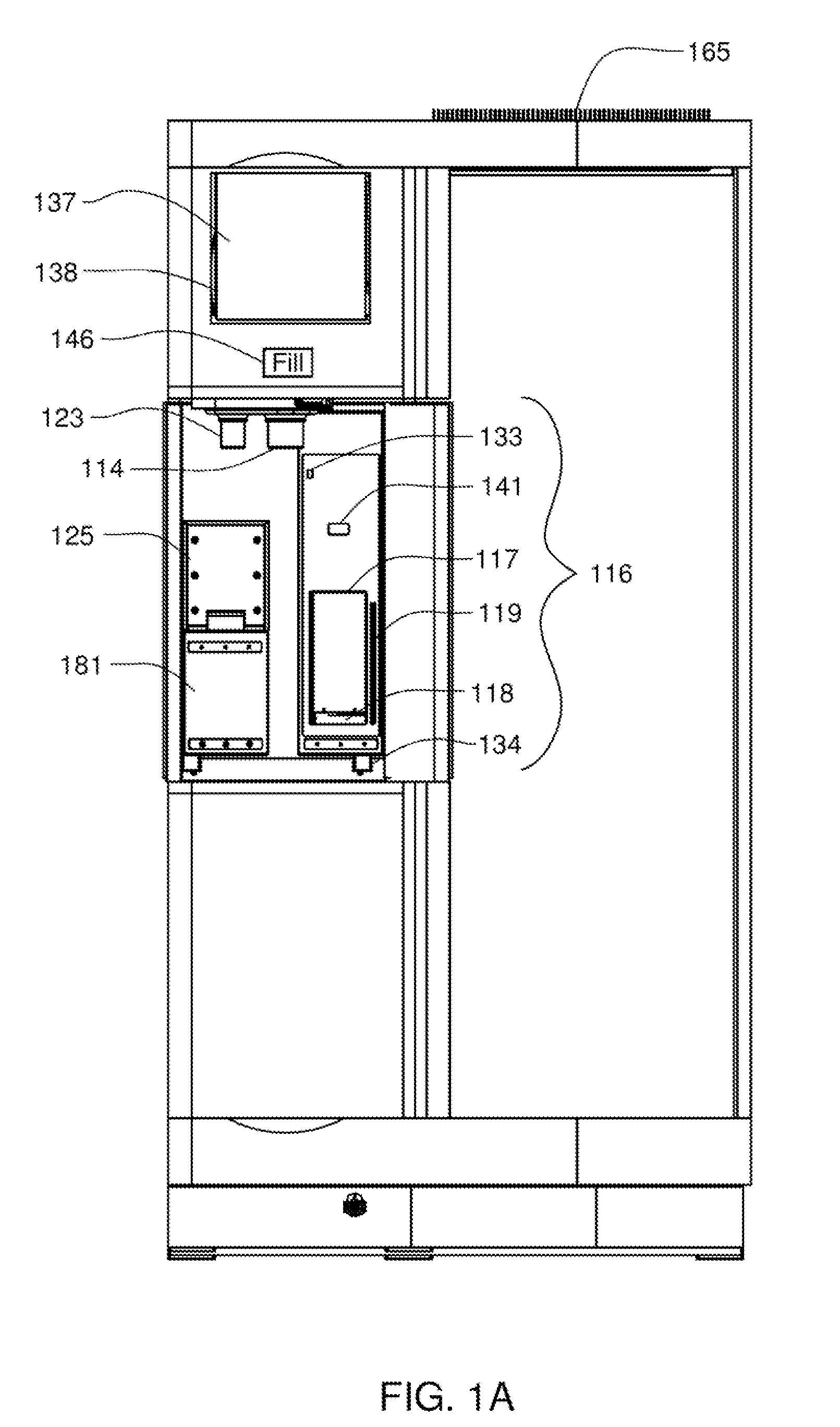

Aromatic plant essential oil ecological processing method

InactiveCN101157880AAchieve continuous recyclingSolve wasteEssential-oils/perfumesWater vaporWater resources

The invention relates to an ecological processing procedure of an aromatic plant essential oil. In the process of extracting plant essential oil by means of vapor distillation, a condenser is communicated with a cooling device of cycling water to realize the continuous circulating use of condensed water. While the aromatic plant essential oil is gained, the by-products, such as lixivium, residue, and aromatic water, generating in extraction of essential oil can be recycled and are convenient to store and utilize after the processing of the by-products so as to further make multiple high added value product. Affected by the cycle utilization of the condensed water in the course of processing essential oil and the recycling of the by-products, the invention can realize non-refuse release in manufacturing technique and complete ecological transition without water resource wasted.

Owner:SHANGHAI JIAO TONG UNIV

Natural tea essence prepared by using tea and preparation method thereof

ActiveCN101928639AFavorable for free precipitationEasily damagedEssential-oils/perfumesPectinaseWater vapor

The invention relates to a natural tea essence prepared by using tea and a preparation method thereof. The tea is taken as a raw material; high-purity natural tea essences with different tea aroma characteristics are prepared through compound enzymolysis, releasing, steam distillation under reduced pressure, cold trap recycling, low temperature freezing concentration, centrifugal oil-water separation, and trace moisture adsorption by using anhydrous sodium sulfate; and the compound enzymolysis and the releasing are realized by adding pectinase, cellulase or pectinase and cellulose complex enzyme, and beta-glucosidase. In the preparation method, a pectinase and cellulose complex enzyme method is adopted for enzymolysis to facilitate cracking cell walls of the tea so as to facilitate liberation and separation of aroma components from the tea, and improve the yield of the essence; therefore, the method is a method for industrially producing the natural tea essence which is energy-saving, low in cost, environmentally friendly and high in efficiency.

Owner:ZUNYI LUSHENG HEALTH SOURCE & TECH DEV

Water Vending Apparatus

ActiveUS20100101929A1Less production ratePrevents sediment buildupWater/sewage treatment by irradiationLighting and heating apparatusWater vaporSteam distillation

A water vending apparatus is disclosed. The water vending system includes a water vapor distillation apparatus and a dispensing device. The dispensing device is in fluid communication with the fluid vapor distillation apparatus and the product water from the fluid vapor distillation apparatus is dispensed by the dispensing device.

Owner:DEKA PROD LLP

Instant pu'er tea and its preparation method

The invention discloses a rapid-soluble Pu'er tea and preparing method to accelerate body to release energy, which comprises the following steps: blending Pu'er tea and ripe tea ( or black tea and green tea) according to certain proportion; grinding roughly; extracting through water; condensing; drying; adding beta-cyclodextrin; recycling aged perfume benzine ingredient through steam distilling method or super-critical extracting method; packing the benzine and rapid-soluble tea powder together; adding isomaltose hypgather, degrading factor and flavoring factor.

Owner:YUNNAN LONGRUN TEA TECH

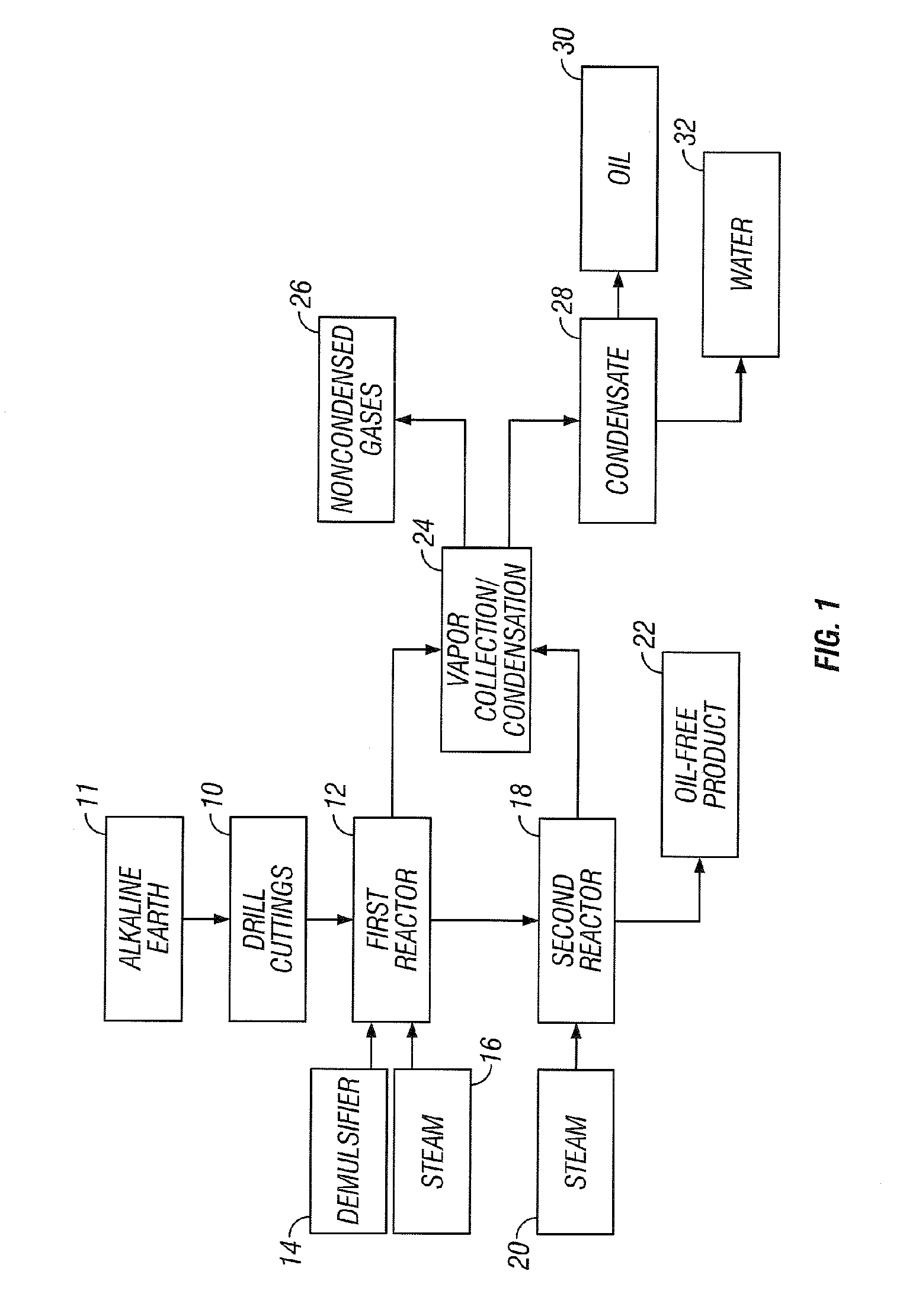

Water vapor distillation apparatus, method and system

ActiveUS9604858B2Water treatment parameter controlDistillation regulation/controlWater vaporControl system

A fluid vapor distillation system. The system includes a control system for controlling a fluid vapor distillation apparatus including a blow down controller for controlling a blow down valve, a source flow controller for controlling a source flow valve, and a blow down level sensor in communication with a blow down controller and a source flow controller, the blow down level sensor sends signals related to the blow down level to the blow down controller and the source flow controller indicative of the blow down level, wherein the source flow controller actuates the source flow valve based at least on the blow down level sensor signals, and wherein the blow down controller actuates the blow down valve based at least on the blow down level sensor signals, whereby the blow down level and the source flow level are maintained using the blow down level sensor signals as input.

Owner:DEKA PROD LLP

Method for extracting rose damascana and rose flower water from roses

InactiveCN101691522AReduce lossesImprove qualityCosmetic preparationsToilet preparationsWater vaporPetal

The invention relates to a method for extracting rose damascana and rose flower water from roses, belonging to the technical field of natural product chemistry. In the invention, the picked fresh roses and saline solution are placed into a pulp refiner with a certain ratio of material to liquid for homogenization and crushing after the stamens of the roses and impurities are removed, the sample is poured into a distillation still for dipping, a vent valve is opened, water steam flow rate is adjusted to carry out steam distillation, the temperature of a condenser is adjusted, oil-water mixed steam is condensed, the flowing-out liquid is collected until the volume of the flowing-out liquid and the weight of rose leaves form a certain proportion, the flowing-out liquid is placed still and layered at low temperature, rose damascana dehydrating agents are added in an upper layer of oil, and then the rose damascana is obtained after being dehydrated; the solution at the lower layer is the rose flower water. Compared with the prior art, the method has the advantages of little loss of top note of the extracted rose damascana, high product quality, simple operation and low production cost.

Owner:INST OF MEDICINAL PLANTS YUNNAN ACAD OF AGRI SCI

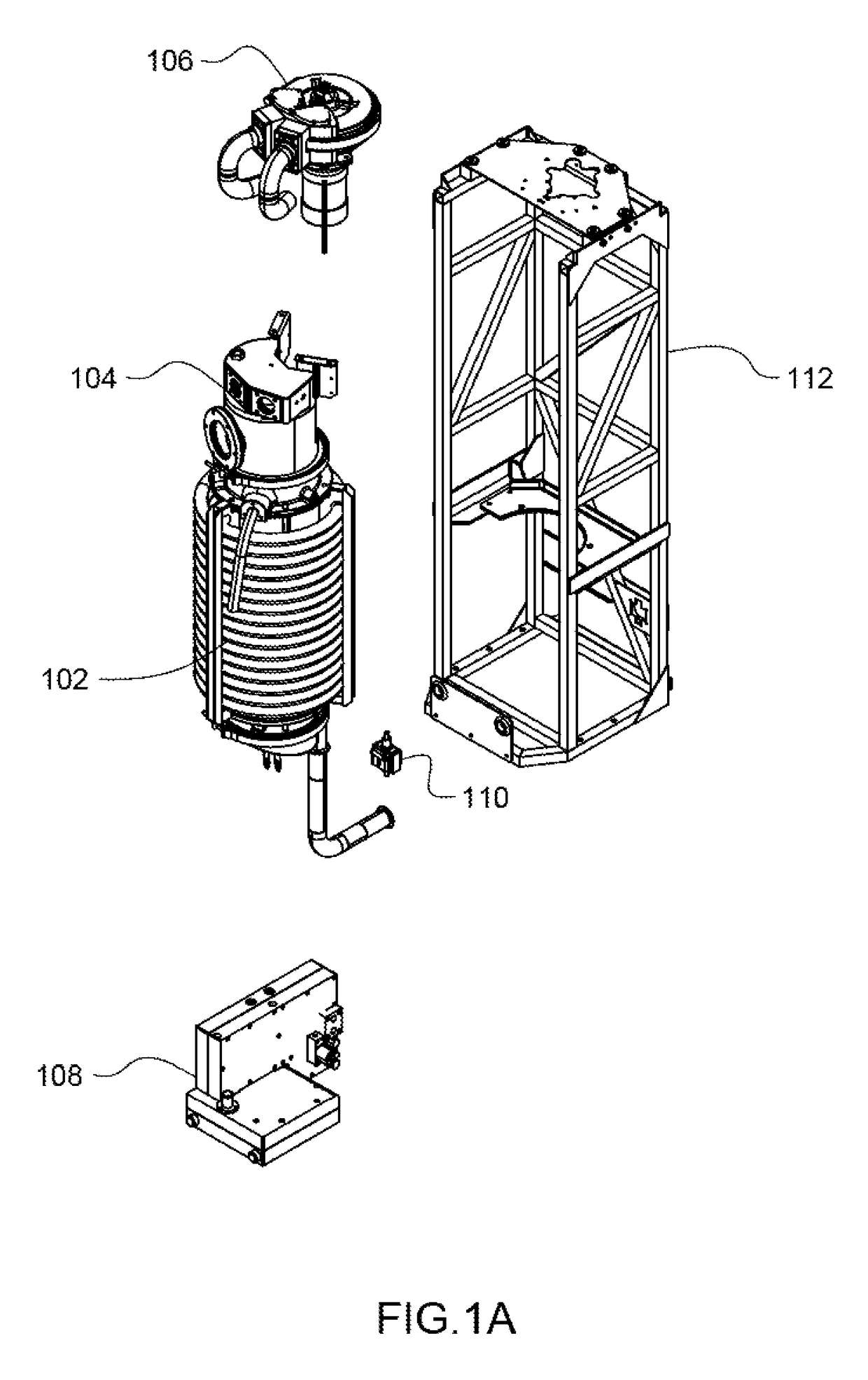

Oil contaminated substrate treatment method and apparatus

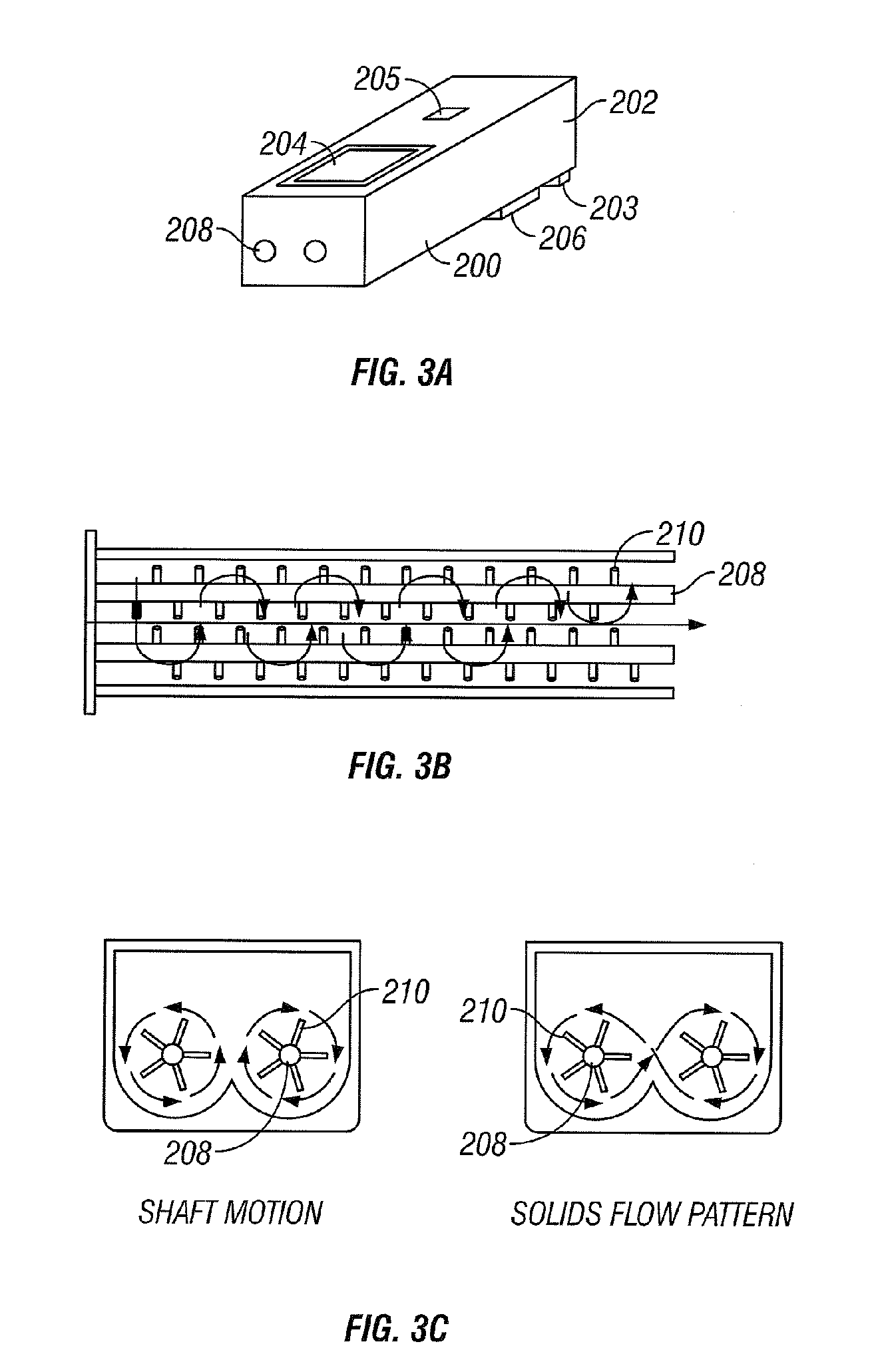

InactiveUS20050145418A1Rapid contaminant removalIncrease shearDewatering/demulsification with chemical meansSolid waste disposalEmulsionCollection system

A method and apparatus for treating for disposal oil contaminated substrates, such as drill cuttings from drilling with an oil-based mud, by steam distillation. If necessary, the contaminated substrate 10 can be pretreated with an emulsion breaker 14. The contaminated substrate 10 can be treated with steam 16 in a first mixing still 12. The substrate can be optionally treated with a second steam source 20 in a second mixing still 18. The steam provides heat to vaporize the oil, moisture to treat the substrate and water to the reaction mixture. Recoverable constituents in the vapor can be condensed in a vapor collection system 24. The treated substrate 22 is essentially free of oil and can have a controlled water content. The process exhibits low energy consumption, rapid treatment, compact equipment and a high degree of process control.

Owner:RACIONAL ENERGY & ENVIRONMENT

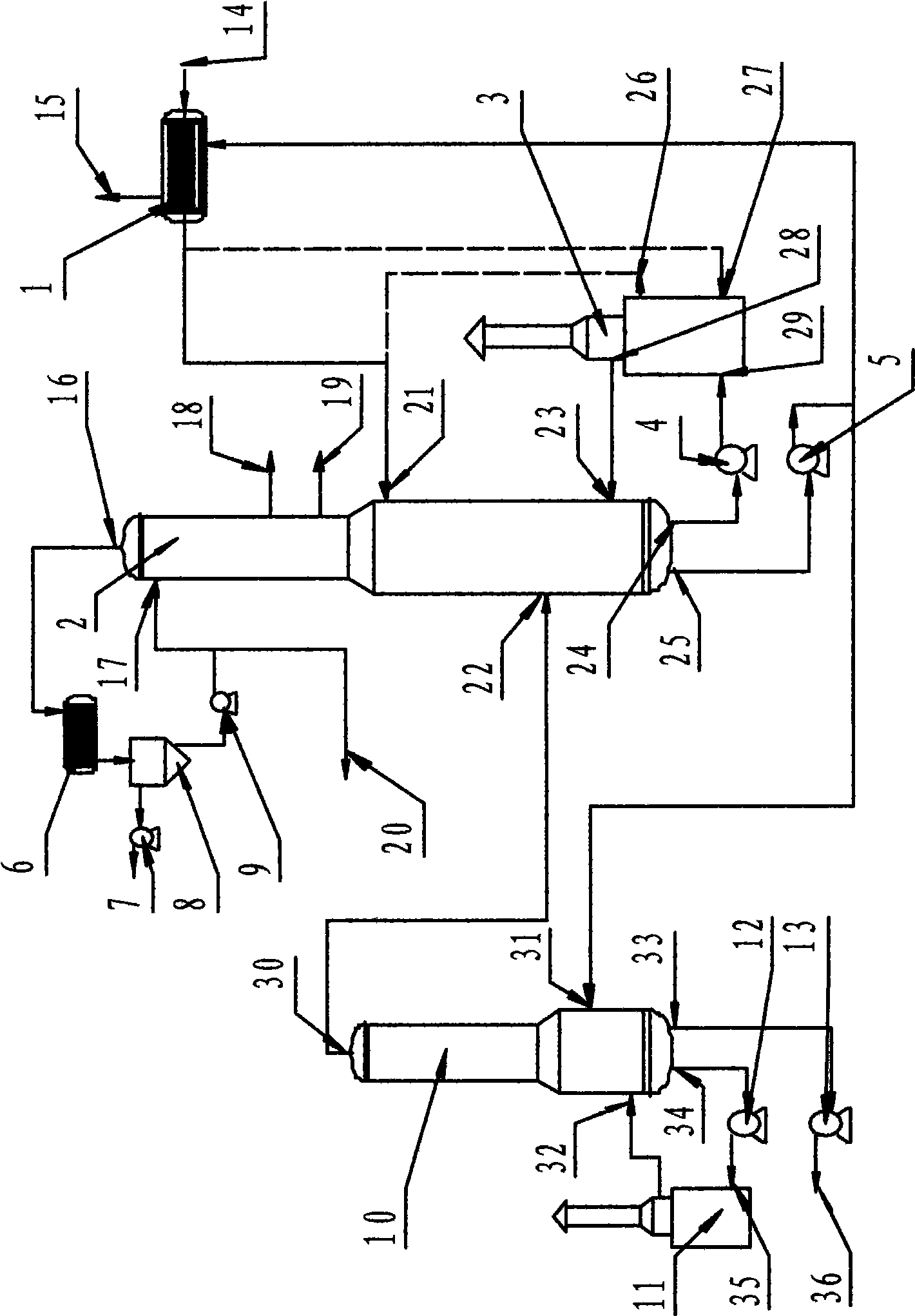

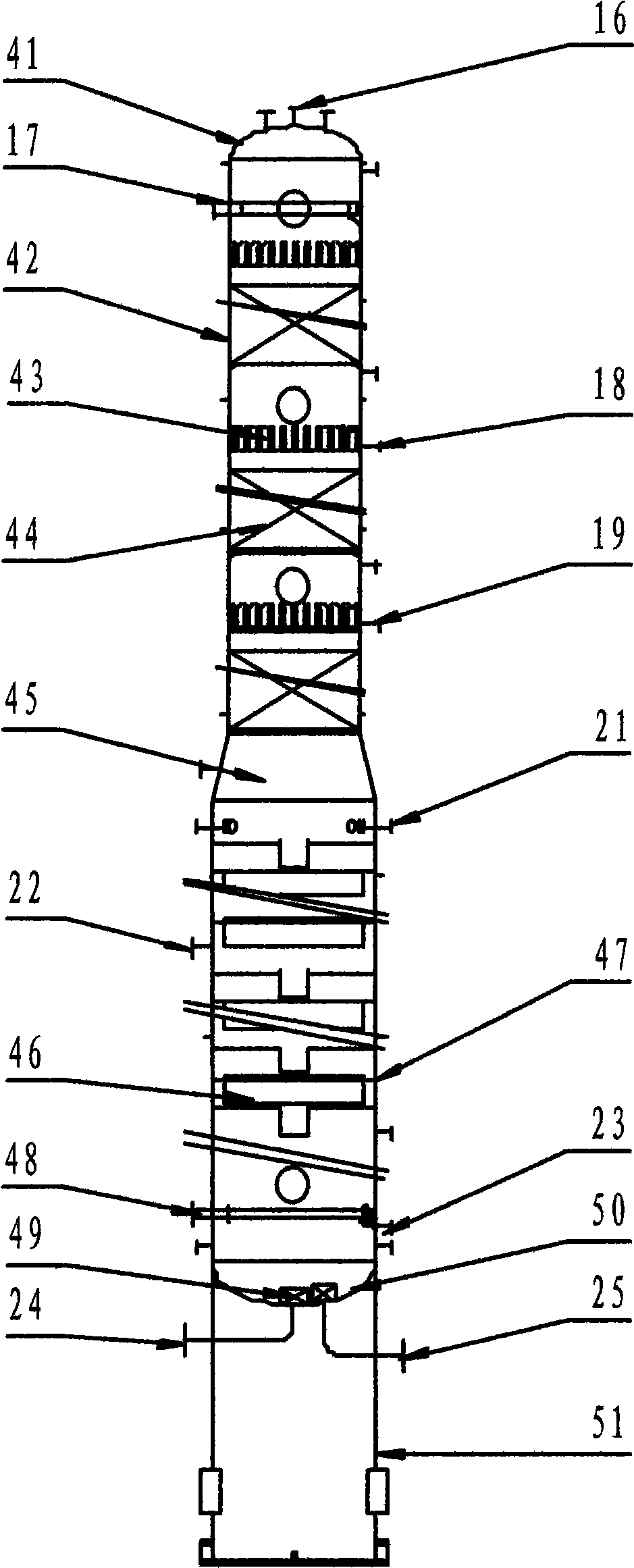

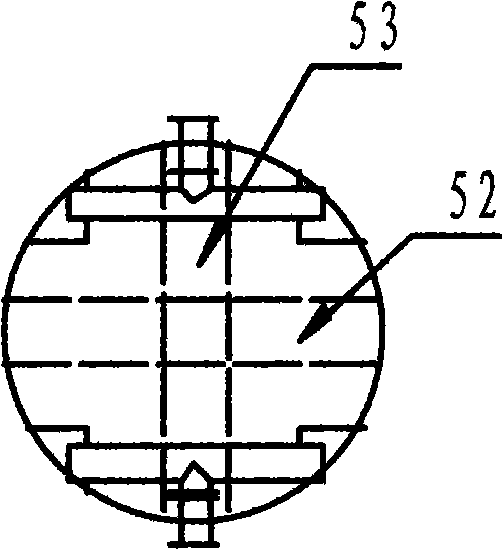

Process and equipment for negative pressure benzene removal

ActiveCN101544913ALow boiling pointReduce partial pressureCombustible gas purificationBenzeneThermodynamics

The invention discloses a process and equipment for negative pressure benzene removal , belonging to technology and equipment for recovering resultant in the coking industry, in particular to technology and equipment for removing and recovering benzene contained in coke gas. To solve the problems existing in the prior art, the invention develops the process for non-steam and non-distillation debenzolization under the negative pressure operation condition is developed and designs a novel debenzolization tower thus the disadvantages of equipment and process for benzene removal by adopting tubefurnace for heating rich oil under normal pressure can be overcome. The invention mainly has the advantages that firstly, as benzene is removed by the negative pressure process, the boiling point of the benzene and the partial pressure of the benzene in gaseous phase are lowered, and the benzene can be removed without using direct steam for steaming and blowing, thus waste water generated by the steam is reduced and the environment can not be polluted; secondly, the productive rate of dry coal due to benzene removal is increased to be more than 1.35 percent from the original 1 percent, and the recovery ratio of the benzene is increased to be more than 35 percent; and thirdly, compared with the existing benzene removal process, the process reduces the energy consumption by more than 20 percent.

Owner:JINAN METALLURGICAL CHEM EQUIP CO LTD

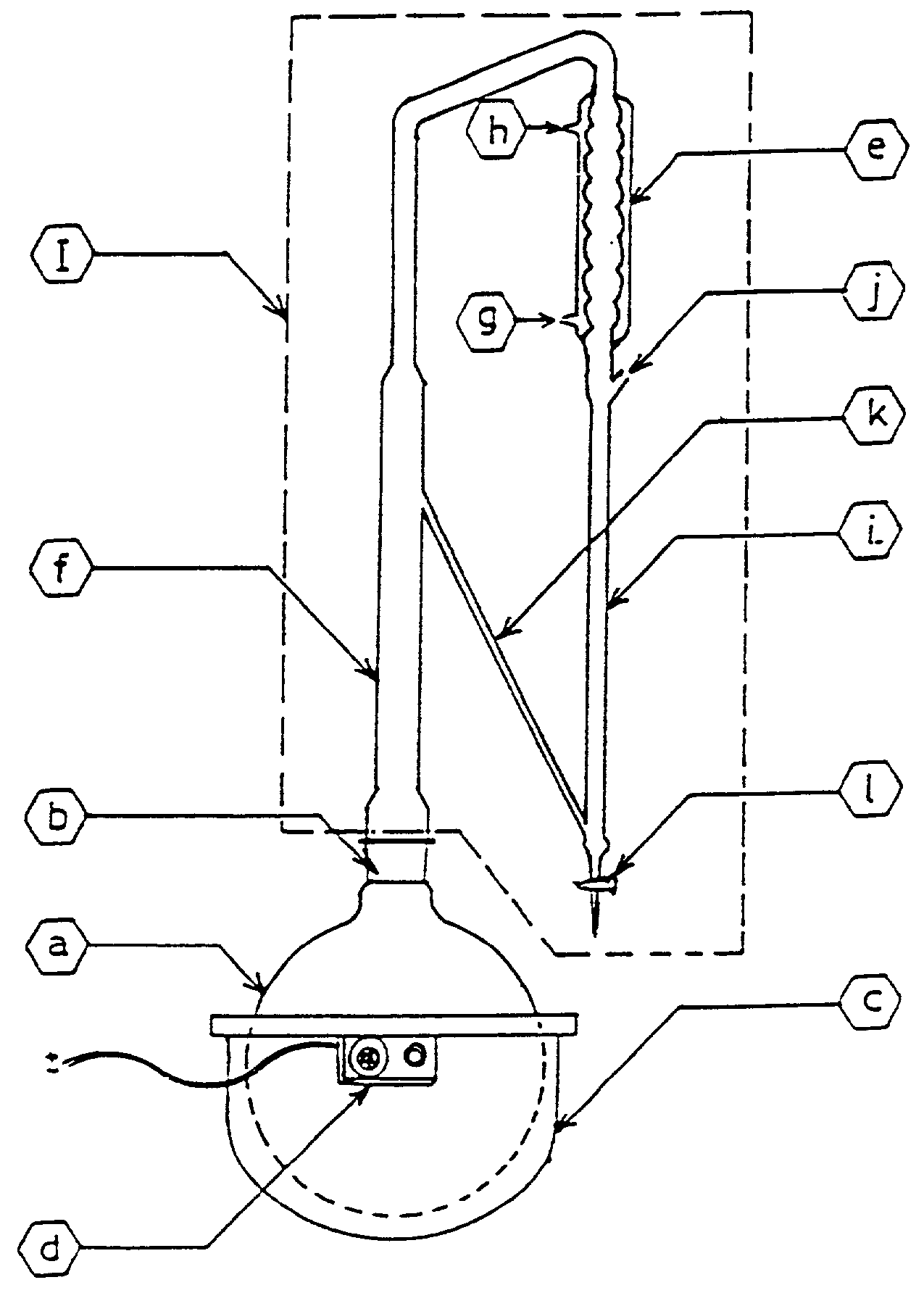

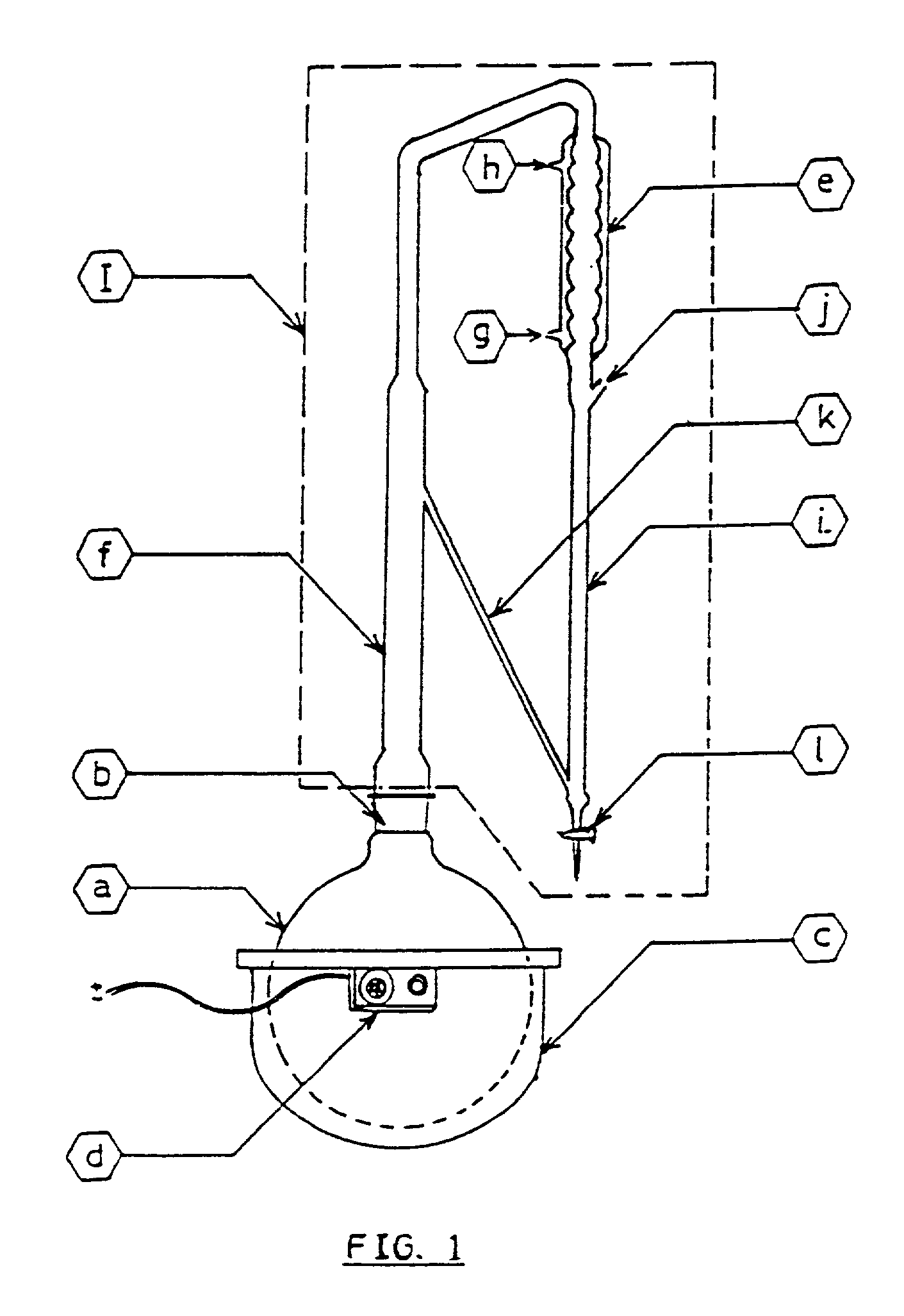

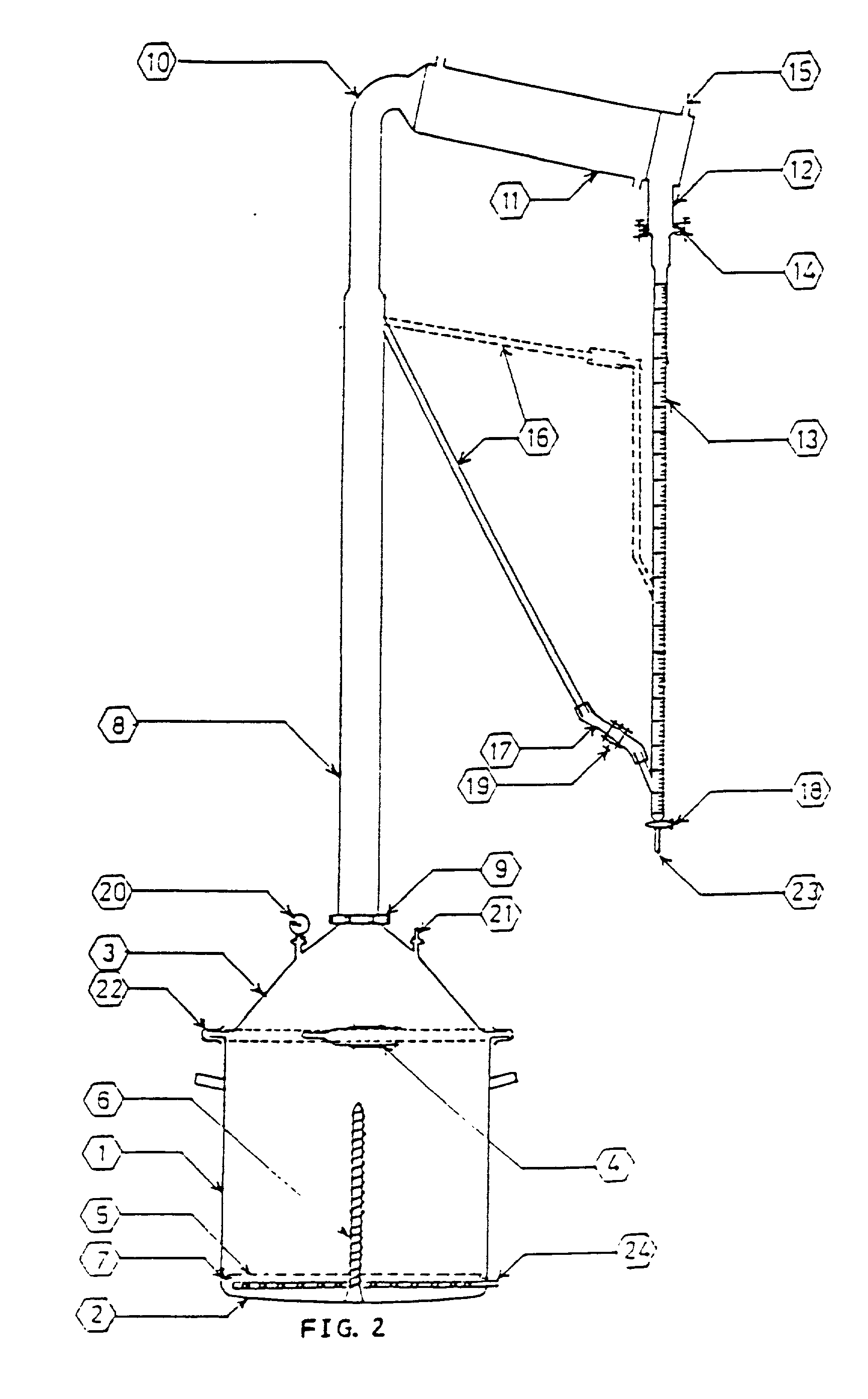

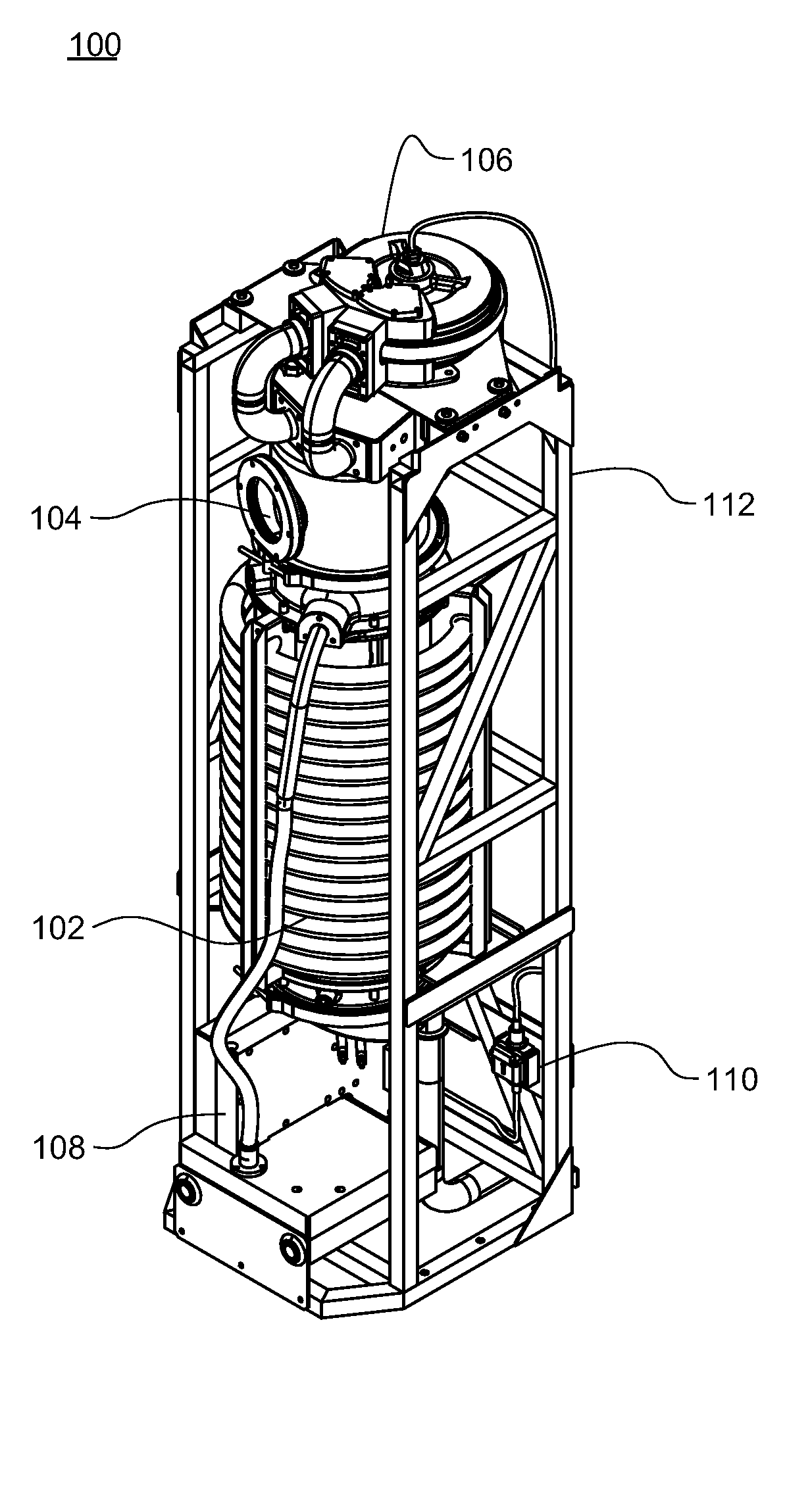

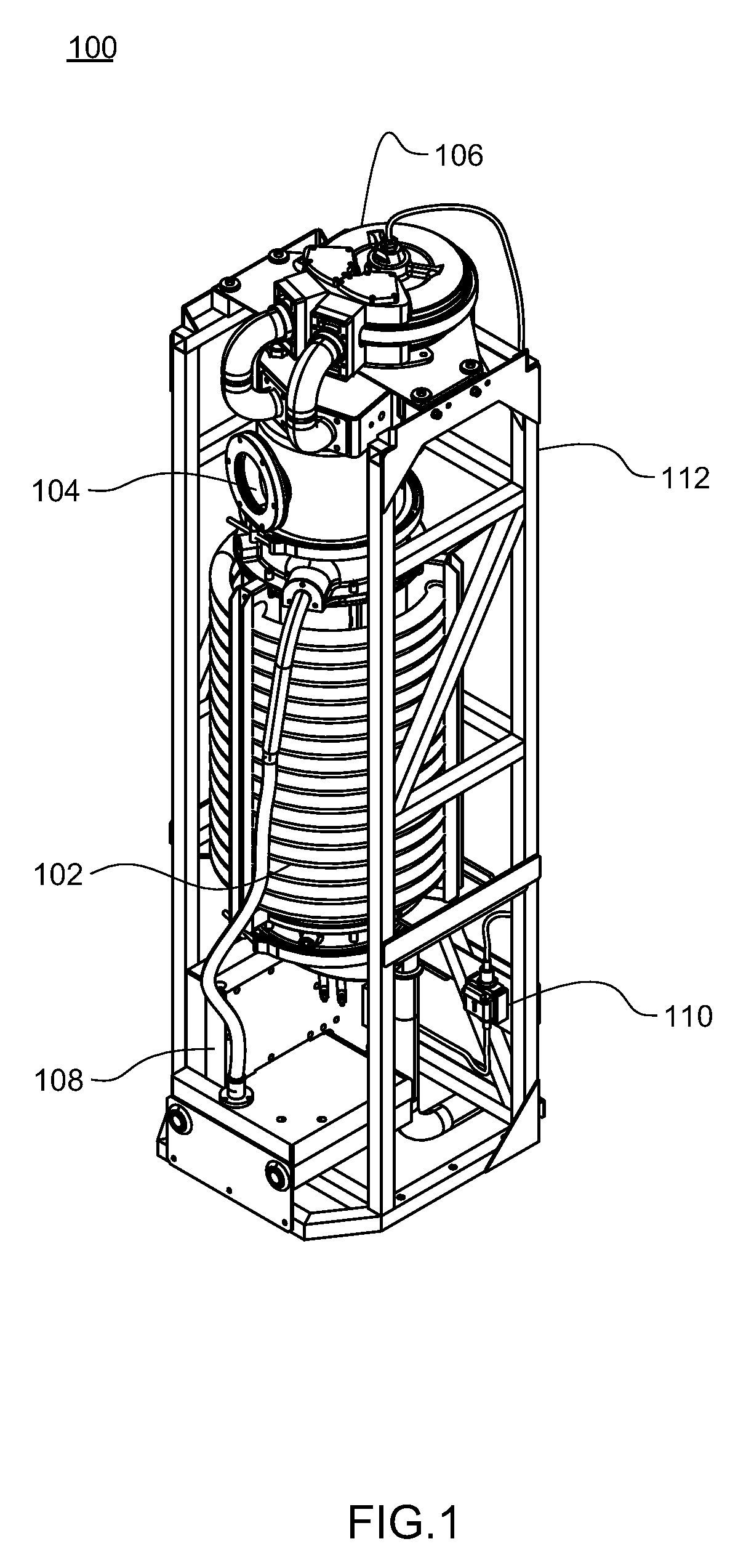

[Air and Water Conditioning System and Filter Media]

InactiveUS20050274663A1Efficiently exchange heatSimple self-regulatingLiquid separation auxillary apparatusSolvent extractionCelluloseWater filter

Disclosed is an air-water-catalyst-UV light contacting, air heating and cooling, humidifying and dehumidifying CHAMBER, which receives water that continuously recirculates through the water filtering, heating and cooling, (and deionizing) loop, which gets fresh outdoors air through the energy-efficient heat exchanger, which generates water from the atmospheric moisture, which stores and recirculates pure water through potable water holding tank, and to which is connected a novel design energy-efficient self-regulating steam distillation apparatus. Also, a water filtration system utilizing zwitterionic polymers as ion exchange and salt-absorbing and filtration media. Also disclosed are novel ionic and zwitterionic polymers, derived from cellulose.

Owner:ROITMAN LIPA LEON

Water vending apparatus

ActiveUS8359877B2Prevents sediment buildupLesser rateEvaporation with vapour compressionLighting and heating apparatusWater vaporSteam distillation

A water vending apparatus is disclosed. The water vending system includes a water vapor distillation apparatus and a dispensing device. The dispensing device is in fluid communication with the fluid vapor distillation apparatus and the product water from the fluid vapor distillation apparatus is dispensed by the dispensing device.

Owner:DEKA PROD LLP

Water vending apparatus

ActiveUS8511105B2Prevents sediment buildupLesser rateLighting and heating apparatusEvaporation with vapour compressionWater vaporSteam distillation

A water vending apparatus is disclosed. The water vending system includes a water vapor distillation apparatus and a dispensing device. The dispensing device is in fluid communication with the fluid vapor distillation apparatus and the product water from the fluid vapor distillation apparatus is dispensed by the dispensing device.

Owner:DEKA PROD LLP

Preparation method and application of Jin Tang tobacco essential oil

The invention provides a preparation method of Jin Tang tobacco essential oil. The preparation method is characterized in that by adopting the combined technologies of subcritical extraction and molecular distillation, the Jin Tang tobacco as a raw material is extracted and separated, so that the content of volatile aroma substances in the essential oil is effectively improved. By applying the Jin Tang tobacco essential oil into the cigarettes, the aroma quality and the mouthfeel of the cigarettes can be improved, and the sensory comfort of the cigarettes is improved; after the Jin Tang tobacco essential oil is applied to juice of electronic cigarettes, rich tobacco scent can be attached to the electronic cigarettes, so that the satisfaction is enhanced, and the disagreeable sweet feel of a solvent is reduced. The preparation method and the application have the greatest advantages that (1) compared with the steam distillation, the extraction rate of essential oil is greatly improved; (2) due to the combined use of the subcritical extraction and molecular distillation, the content of the nonvolatile macromolecular substances in the essential oil is reduced, the content of volatile aromatic substances is improved, wherein the contents of nicotine, solanone, neophytadiene, megastigmatrienone, farnesyl acetone, and the like are obviously improved compared with those in the essential oil extracted by the subcritical extraction technology, and therefore, the characteristic aroma of the tobacco is more outstanding.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Heart nourishing and nerve soothing functional electronic cigarette juice

ActiveCN104026731AMeeting smoking needsEnhance physical fitnessTobacco treatmentMedicineElectronic cigarette

The invention discloses heart nourishing and nerve soothing functional electronic cigarette juice which comprises, by mass, 50-70 percent of propylene glycol, 5-10 percent of glycerin, 5-15 percent of deionized water, 5-15 percent of heart nourishing and nerve soothing medicament, 2-6 percent of cigarette extract, 2-6 percent of tobacco essence and 2-6 percent of thickener. The heart nourishing and nerve soothing medicament is an extracting liquid obtained by extracting a plant mixture through steam distillation or through ethanol extracting, and the plant mixture is made of poria with hostwood, lavender, bodhi leaves, lily, jasmine, liquorice, cortex albiziae, chrysanthemum, spina data seeds, caulis Polygoni multiflori and agilawood. The heart nourishing and nerve soothing functional electronic cigarette juice can meet the smoking requirement of smokers, in addition, the efficacy of nourishing the heart and soothing the nerves is achieved, mental fatigue is relieved, and sleeping is improved.

Owner:CHINA TOBACCO ANHUI IND CO LTD

Water vapor distillation apparatus, method and system

ActiveUS20120006670A1Distillation regulation/controlSpecific water treatment objectivesWater vaporControl system

A fluid vapor distillation apparatus. The apparatus includes a source fluid input, and an evaporator condenser apparatus. The evaporator condenser apparatus includes a substantially cylindrical housing and a plurality of tubes in the housing. The source fluid input is fluidly connected to the evaporator condenser and the evaporator condenser transforms source fluid into steam and transforms compressed steam into product fluid. Also included in the fluid vapor distillation apparatus is a heat exchanger fluidly connected to the source fluid input and a product fluid output. The heat exchanger includes an outer tube and at least one inner tube. Also included in the fluid vapor distillation apparatus is a regenerative blower fluidly connected to the evaporator condenser. The regenerative blower compresses steam, and the compressed steam flows to the evaporative condenser where compressed steam is transformed into product fluid. The fluid vapor distillation apparatus also includes a control system.

Owner:DEKA PROD LLP

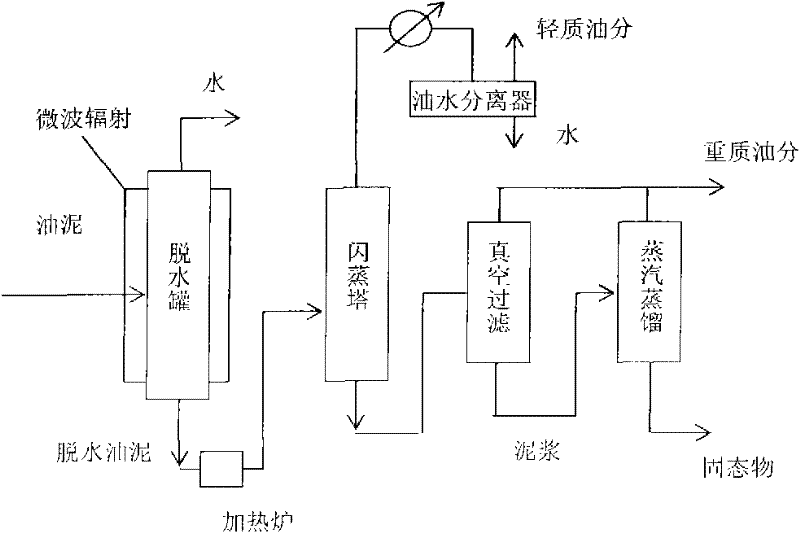

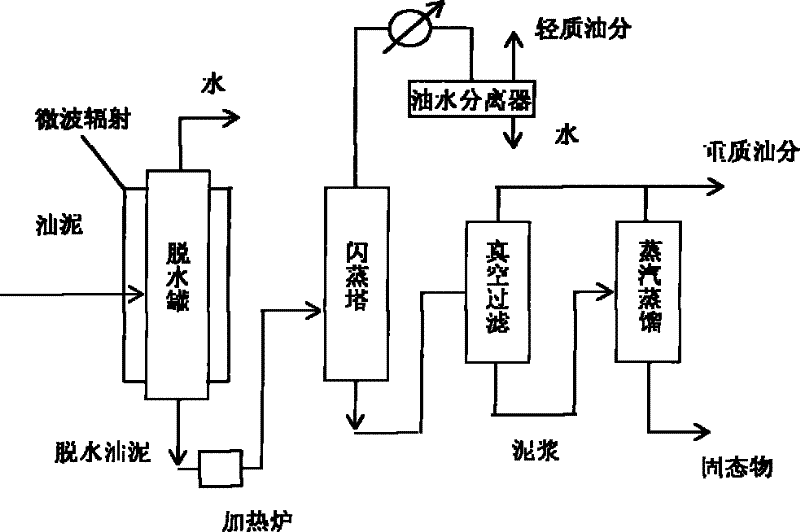

Method for treating oil sludge

ActiveCN102452776AImprove processing efficiencySmall scaleSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningFull recoveryOil sludge

The invention discloses a method for treating oil sludge. The method realizes oil sludge integrated treatment by utilization of microwave demulsification dehydration, heat treatment flash evaporation and steam distillation. Concretely, the method comprises the following steps of 1, carrying out a microwave pretreatment demulsification dehydration process on oil sludge to reduce water content of the oil sludge, 2, heating the oil sludge subjected to the microwave pretreatment demulsification dehydration process to a temperature of 100 to 300 DEG C in an oxygen-free environment, feeding the heated oil sludge into a separating column, carrying out a heat treatment flash evaporation process, through condensation, recovering a light oil component and water separated by the heat treatment flashevaporation, and taking out sludge comprising a heavy oil component and solids from the separating column, and 3, carrying out solid-liquid separation of the sludge in the bottom of the separating column, recovering the heavy oil component as a coking or catalytic cracking raw material, and carrying out a steam distillation process on the solids to further recover an oil component from the solids. The method can realize full recovery of various valuable components of oil sludge and has good industrial application economical efficiency.

Owner:CHINA PETROLEUM & CHEM CORP +1

Water Vapor Distillation Apparatus, Method and System

ActiveUS20140183025A1Water treatment parameter controlDistillation regulation/controlWater vaporControl system

A fluid vapor distillation system. The system includes a control system for controlling a fluid vapor distillation apparatus including a blow down controller for controlling a blow down valve, a source flow controller for controlling a source flow valve, and a blow down level sensor in communication with a blow down controller and a source flow controller, the blow down level sensor sends signals related to the blow down level to the blow down controller and the source flow controller indicative of the blow down level, wherein the source flow controller actuates the source flow valve based at least on the blow down level sensor signals, and wherein the blow down controller actuates the blow down valve based at least on the blow down level sensor signals, whereby the blow down level and the source flow level are maintained using the blow down level sensor signals as input.

Owner:DEKA PROD LLP

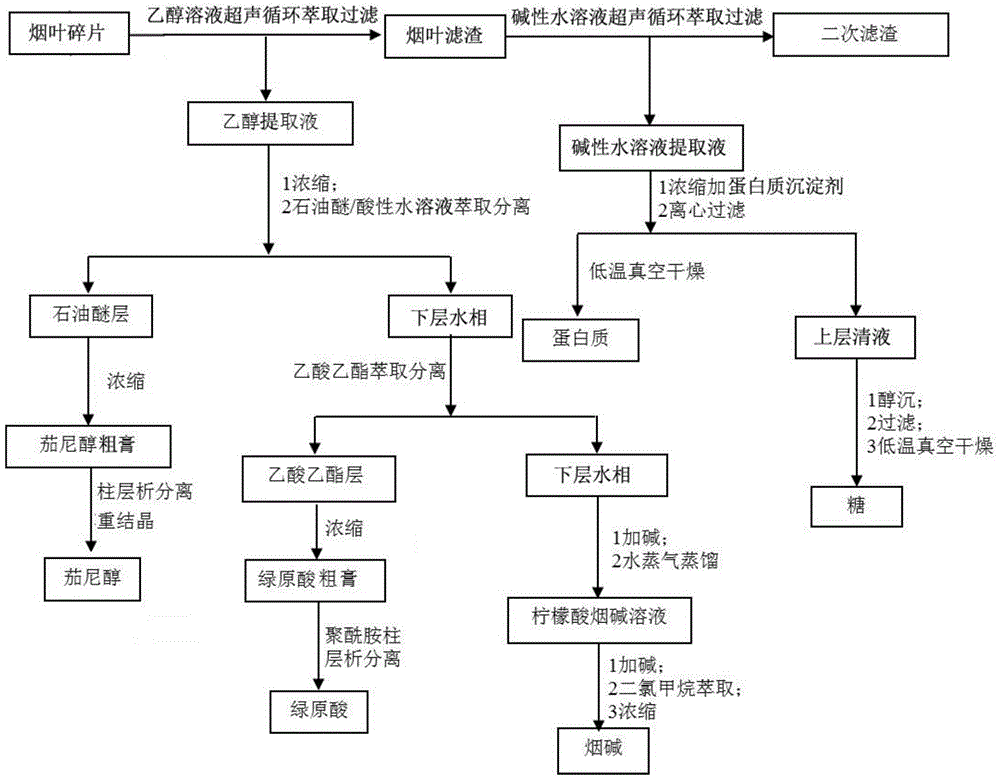

Method for comprehensively extracting multiple effective components from tobacco leaves

InactiveCN104151140AIncrease profitEmission reductionSugar derivativesPeptide preparation methodsChlorogenic acidPurification methods

The invention discloses a method for comprehensively extracting multiple effective components from tobacco leaves. The method comprises the following steps: performing twice ultrasonic circulation extraction on the tobacco leaves to respectively obtain crude ointment containing solanesol, nicotine and chlorogenic acid and an extract containing protein and sugar, and with the combination of separation and purification methods such as liquid-liquid two-phase extraction, column chromatography, recrystallization, steam distillation and precipitation, separating five effective components, namely, solanesol, nicotine, chlorogenic acid, protein and sugar from the tobacco leaves one by one. The method can continuously extract and separate the multiple effective components form the tobacco leaves, can greatly improve the utilization rate of a tobacco leaf raw material, has the advantages that the extraction efficiency is high, a great number of separation products are obtained and a small amount of wastes are discharged, and is an efficient and environment-friendly comprehensive tobacco leaf multi-component extraction technique.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Preparation method of low-odor polymer emulsion

The invention relates to a preparation method of a low-odor polymer emulsion, and is designed to solve the problems that the free mercaptan content in a copolymer emulsion is high and the copolymer emulsion easily sends out peculiar odor in the existing polymer emulsion preparation process using high-boiling-point mercaptan as molecular weight regulator. The method comprises the following steps: in the presence of emulsifier, initiator, pH buffer and mercaptan molecular weight regulator, performing emulsion polymerization on a vinyl monomer, an acrylate monomer and a functional monomer among alkenyl unsaturated monomers; and finally, performing reduced pressure distillation or steam distillation on the emulsion. The method is characterized in that after the emulsion polymerization reaction, a catalyst and peroxide are added, so that the unreacted free mercaptan in the polymer emulsion is converted into an odorless product. The prepared low-odor polymer emulsion can be used as ink powder for printers or duplicators. The technical process provided by the invention is simple and low in cost, can effectively reduce the peculiar odor of the polymer emulsion, and is suitable for serving as a preparation method of a low-odor polymer emulsion or an improvement of a similar method.

Owner:鼎龙(宁波)新材料有限公司

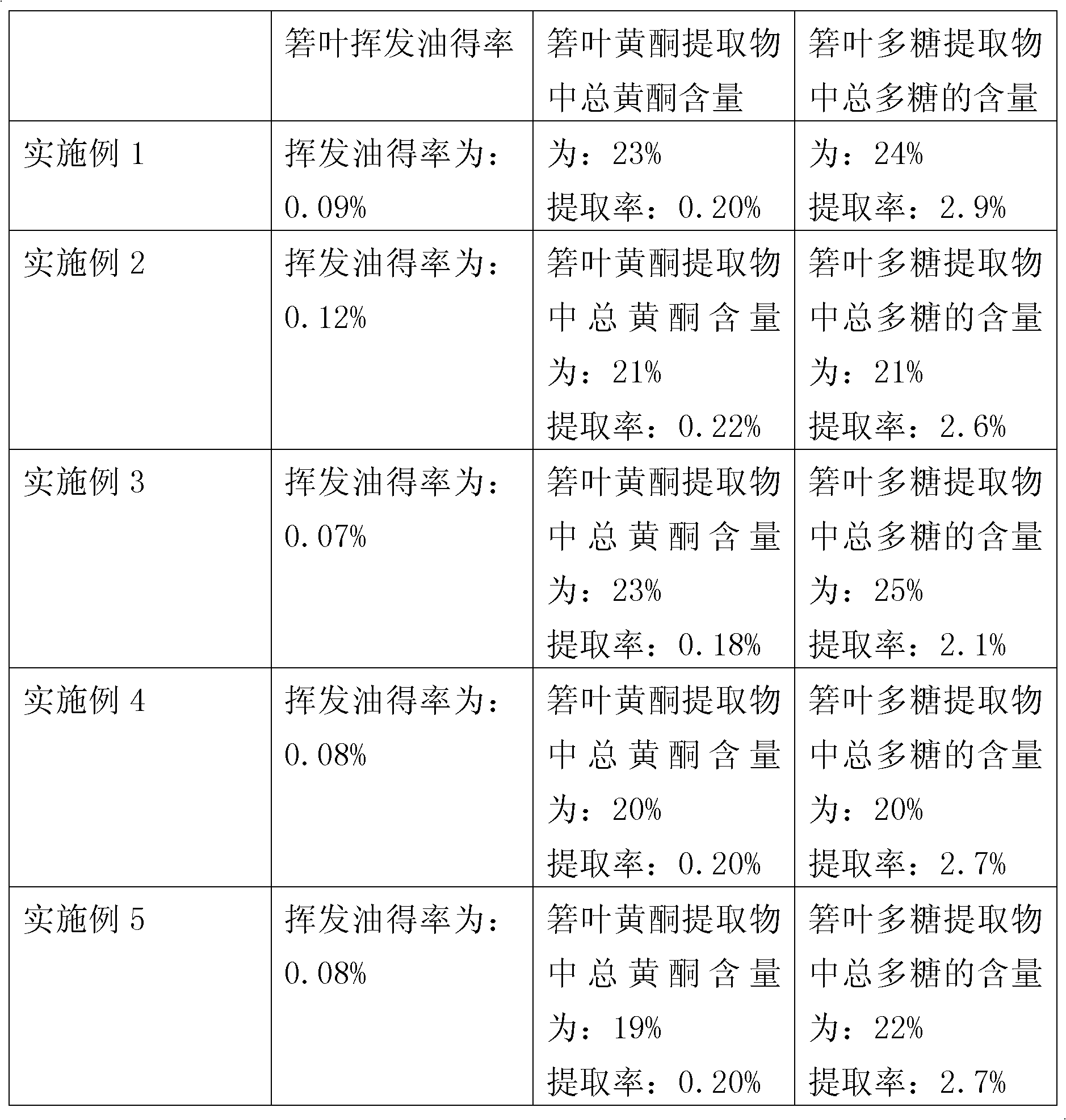

Method for simultaneously preparing indocalamus leaf volatile oil, total flavone and total polysaccharide

InactiveCN102671017AImprove resource utilizationAvoid wastingAntipyreticDigestive systemOrganic solventDissolution

The invention discloses a method for simultaneously preparing indocalamus leaf volatile oil, total flavone and total polysaccharide, which comprises the following steps: taking indocalamus leaf powder and adding water of 5-12 times in weight; dipping for 0-4h; extracting for 2-12h through a steam distillation method; extracting through organic solvent to obtain the volatile oil; keeping the extracted medicine liquid for later use; adding 20-50% of ethanol of 6-12 times in raw dose mass by weight into the medicine dreg; carrying out backflow extraction for 2-3 times of 0.5-1.5h each time; filtering; combining each extracted liquid and extracting the medicine liquid after extracting the volatile oil; depressurizing and concentrating so as to obtain the extractive; adding water for dissolution; making the concentration of the loading solution be 0.4-1.0 g / ml by raw dose mass; passing through macroporous resin, wherein the absorbing flow speed is 1-3 BV / h, and the resin column height ratio is 1:5-8; firstly eluting using water for 2-4 BV; depositing the eluting liquid using the ethanol; drying to obtain the polysaccharide; subsequently eluting using 40-90% of ethanol for 3-6 BV, wherein the elution flow speed is 0.8-2 BV / h; and concentrating the eluting liquid and drying to obtain the total flavone.

Owner:HUBEI CHANGYOU MODERN AGRI CO LTD

Simple portable mini distillation apparatus for the production of essential oils and hydrosols

This invention relates to a simple, convenient, portable mini-distillation apparatus for the production of essential oils and hydrosols, said apparatus is useful to distill essential oils and hydrosols such as rose water, ajowain water from fresh and dried plant material like leaves, flowers, roots and rhizomes by water distillation, water and steam distillations and as an optional, steam distillation can also be performed at atmospheric pressure as well as slightly higher and lower than atmospheric pressure, said apparatus can be heated on brick-clay furnace with small agro-waste, LPG cooking gas, electrically heated stove or kerosene / diesel burner etc. and requires minimum attention during handling; since the apparatus is made of stainless steel and glass, the essential oil distilled is of better quality.

Owner:COUNCIL OF SCI & IND RES

Water Vapor Distillation Apparatus, Method and System

A fluid vapor distillation apparatus. The apparatus includes a source fluid input, and an evaporator condenser apparatus. The evaporator condenser apparatus includes a substantially cylindrical housing and a plurality of tubes in the housing. The source fluid input is fluidly connected to the evaporator condenser and the evaporator condenser transforms source fluid into steam and transforms compressed steam into product fluid. Also included in the fluid vapor distillation apparatus is a heat exchanger fluidly connected to the source fluid input and a product fluid output. The heat exchanger includes an outer tube and at least one inner tube. Also included in the fluid vapor distillation apparatus is a regenerative blower fluidly connected to the evaporator condenser. The regenerative blower compresses steam, and the compressed steam flows to the evaporative condenser where compressed steam is transformed into product fluid.

Owner:DEKA PROD LLP

Method for extracting rose essential oil, rose water and rose aqueous extract from fresh rose flower

ActiveCN103666766ANatural aromaShort distillation timeEssential-oils/perfumesPlant ingredientsWater vaporAdditive ingredient

The invention discloses a method for extracting rose essential oil, rose water and a rose aqueous extract from fresh rose flowers. The method includes the following steps: (1) soaking freshly picked roses with softened water; (2) beating the system obtained in the step (1) to obtain a flower slurry; (3) sending the flower slurry from a feeding port of a rotating cone distillation column into the body and introducing steam from the bottom of the rotating cone distillation column, wherein the steam extracts volatile aroma components in the flower slurry during the rising process, then moves out of the rotating cone distillation column and is condensed to obtain a rose oil-water mixture; and acquiring the rose dreg and liquid mixture from the bottom of the rotating cone distillation column; (4) conducting oil and water separation on the rose oil-water mixture to obtain an upper layer separating medium rose essential oil and a lower layer separating medium rose water; and (5) filtering the rose dreg and liquid mixture to obtain a filtrate, and concentrating the filtrate to obtain the rose aqueous extract. The invention can avoid the degradation of recycled aroma substances or raw materials and solve the problem that steam distillation method for extracting essential oil produces stewing smell.

Owner:CHINA AGRI UNIV

Water Vapor Distillation Apparatus, Method and System

A water vapor distillation apparatus. The apparatus includes a source fluid input, an evaporator condenser whereby the source fluid input is fluidly connected to the evaporator condenser and the evaporator condenser transforms source fluid into steam and transforms compressed steam into product fluid, and a steam chest fluidly connected to the evaporator condenser, whereby the steam flows from the evaporator condenser into the steam chest, the steam chest comprising a foam mitigation device wherein the foam mitigation device mitigates foam in the water vapor distillation apparatus.

Owner:DEKA PROD LLP

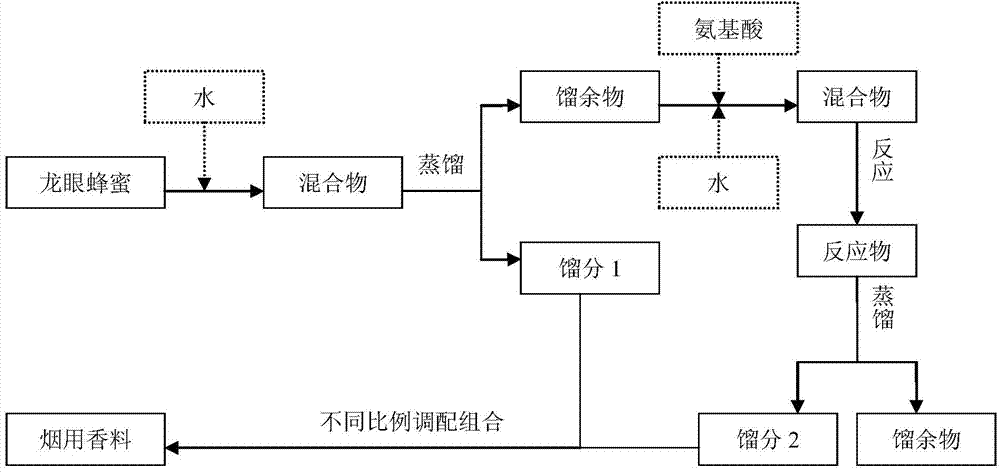

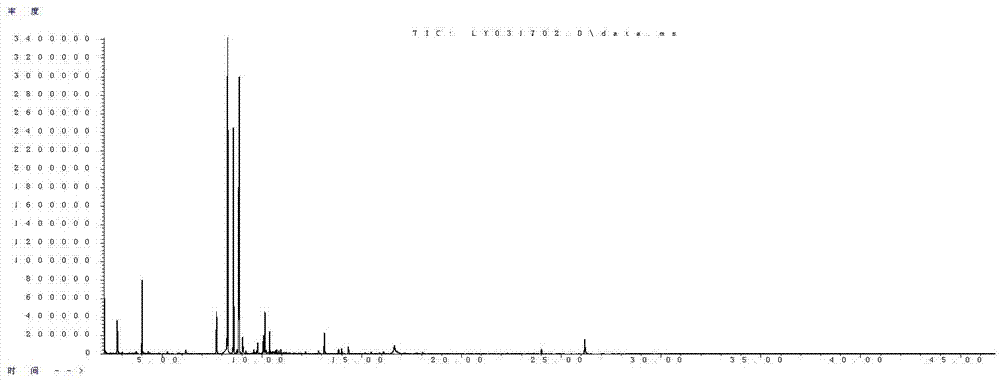

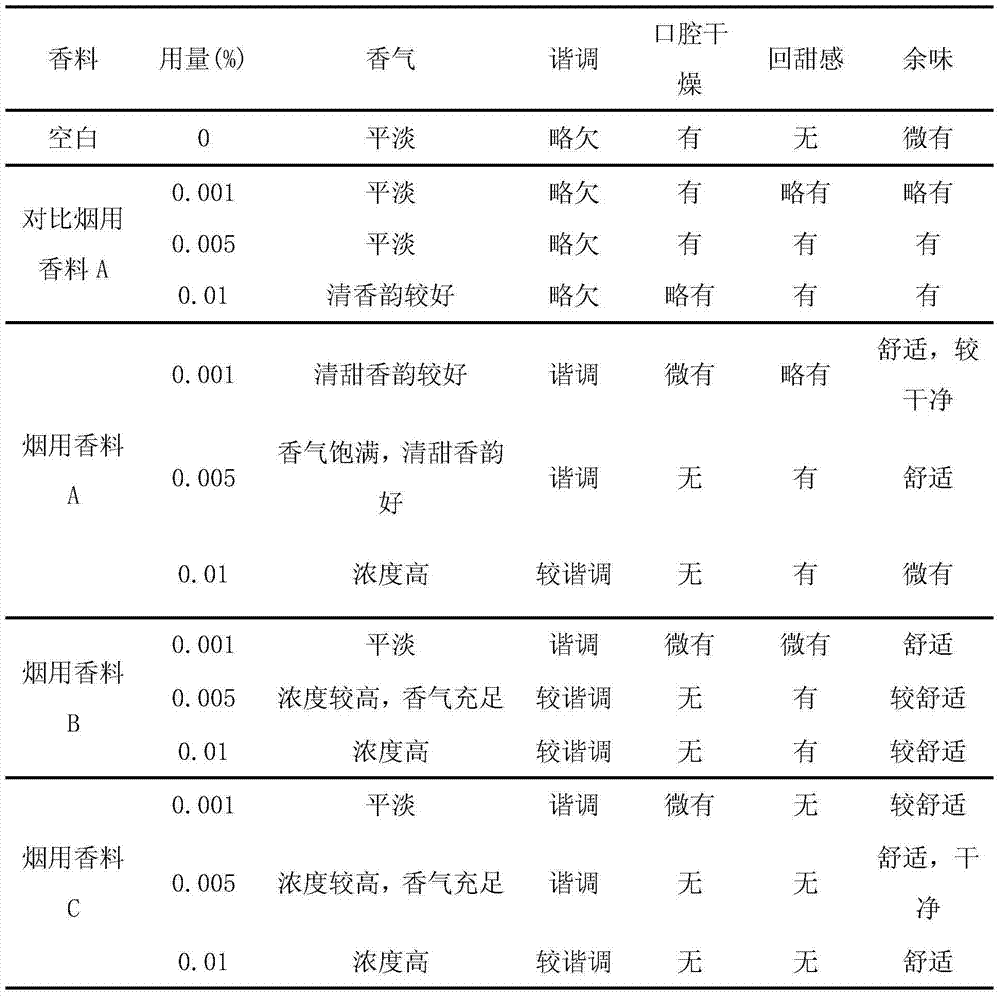

Spice for cigarettes and application thereof

InactiveCN104745303ASimple processThe process is simple and applicableTobacco treatmentEssential-oils/perfumesMaillard reactionAdditive ingredient

The invention discloses a spice for cigarettes and an application thereof. The spice is prepared in a manner that longan honey is subjected to steam distillation and a maillard reaction and mixed with ingredients. After the obtained spice is added to a flue-cured type cigarette leaf group, through a sense organ smoke panel test, the spice plays an important role in improving the quality of a cigarette. The spice is simple and convenient in method and technology; equipment is simple; the cost is low; the pollution is little; the extraction efficiency is high; composition analysis indicates that the contents of overall aroma-active components of a product are high; the aroma-active components are rich in variety; and through sensory evaluation, the product can effectively improve the smoke quality of the cigarette.

Owner:CHINA TOBACCO YUNNAN IND

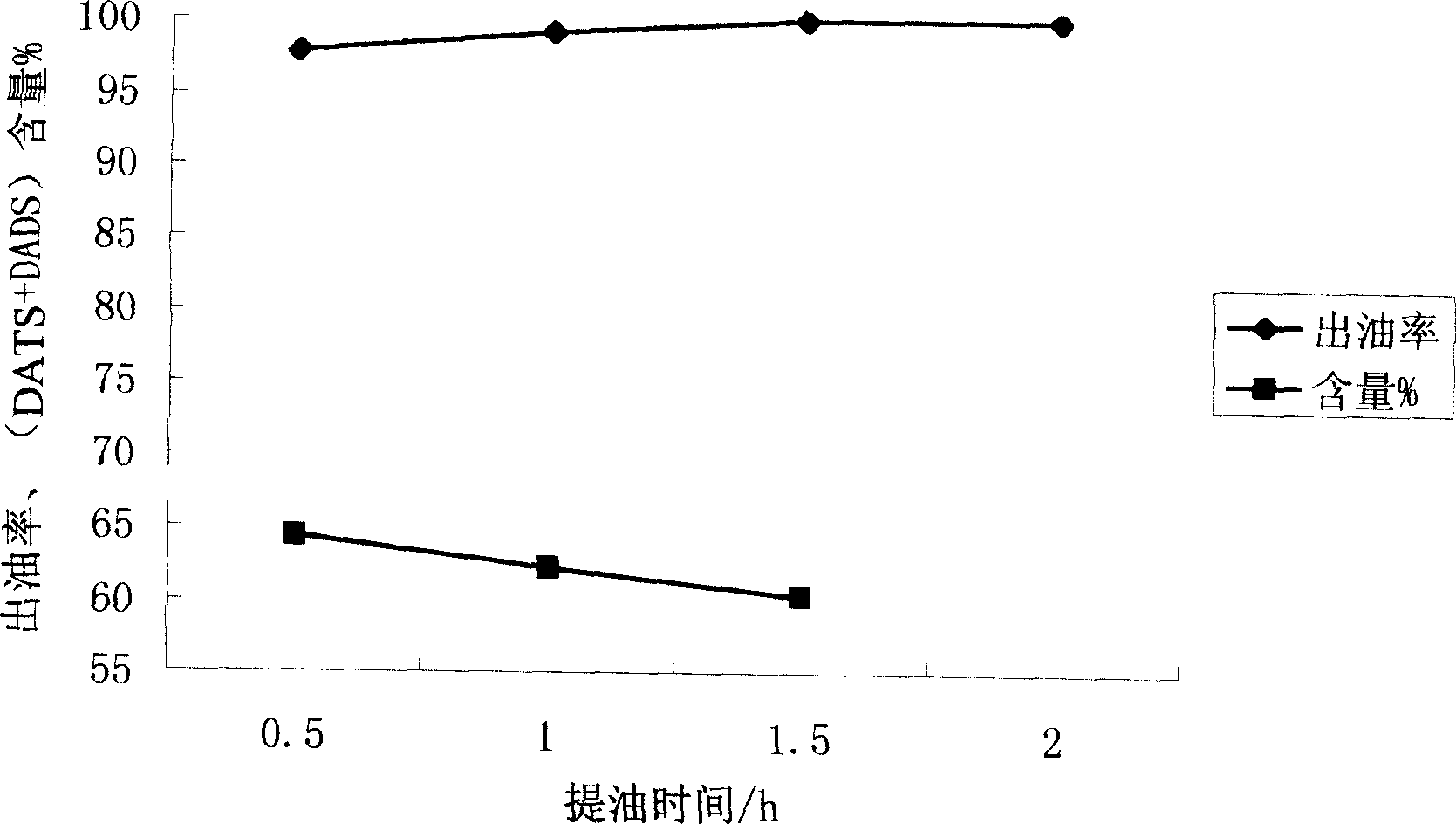

Extraction of garlic volatile oil

InactiveCN1895524AIncrease contentUniform contentFatty-oils/fats productionFermentationWater vaporGranularity

Owner:INST OF BASIC THEORY OF TCM CHINA ACADEMY OF CHINESE MEDICAL SCI

Preparation method of 4,6-dichloropyrimidine

InactiveCN102746237AReduce consumptionEasy to scale up productionOrganic chemistryOrganic solventPhysical chemistry

The invention discloses a preparation method of 4,6-dichloropyrimidine, which comprises the following steps: mixing 4,6-dihydroxypyrimidine and phosphorus oxychloride, dropwise adding triethylamine under the temperature of 40-65 DEG C, then heating up to 110-120 DEG C, carrying out heat preservation reaction, stopping the reaction until the content of 4,6-dihydroxypyrimidine is less than 1%, cooling reaction mixture to below 30 DEG C, dropwise adding sodium hydroxide solution while controlling the temperature not more than 30 DEG C until the pH is in the range of 6-6.5, conducting steam distillation, collecting distillate, separating solid and liquid, and drying solid to obtain the 4,6-dichloropyrimidine; The invention uses stoichiometric or slight excess of phosphorus oxychloride. There is no need to recover phosphorus oxychloride after the reaction. Material and energy consumption and loss of product are reduced. Separation methods such as organic solvent extraction, drying and dehydration, organic solvent recovering and the like are not used. There is no need to use and recover organic solvent. The preparation method provided by the invention is environment friendly, avoids loss of product, produces no extra solid waste, and is conducive to industrial scale production. The product has high yield and purity, and can reach the commercial requirement without being subjected to secondary purification. The production cycle is short and the production cost is low.

Owner:CHONGQING UNISPLENDOUR CHEM

Water vapor distillation apparatus, method and system

A fluid vapor distillation apparatus. The apparatus includes a source fluid input, and an evaporator condenser apparatus. The evaporator condenser apparatus includes a substantially cylindrical housing and a plurality of tubes in the housing. The source fluid input is fluidly connected to the evaporator condenser and the evaporator condenser transforms source fluid into steam and transforms compressed steam into product fluid. Also included in the fluid vapor distillation apparatus is a heat exchanger fluidly connected to the source fluid input and a product fluid output. The heat exchanger includes an outer tube and at least one inner tube. Also included in the fluid vapor distillation apparatus is a regenerative blower fluidly connected to the evaporator condenser. The regenerative blower compresses steam, and the compressed steam flows to the evaporative condenser where compressed steam is transformed into product fluid.

Owner:DEKA PROD LLP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![[Air and Water Conditioning System and Filter Media] [Air and Water Conditioning System and Filter Media]](https://images-eureka.patsnap.com/patent_img/7a12db92-c370-467d-80d1-4e4b53e06f22/US20050274663A1-20051215-D00000.png)

![[Air and Water Conditioning System and Filter Media] [Air and Water Conditioning System and Filter Media]](https://images-eureka.patsnap.com/patent_img/7a12db92-c370-467d-80d1-4e4b53e06f22/US20050274663A1-20051215-D00001.png)

![[Air and Water Conditioning System and Filter Media] [Air and Water Conditioning System and Filter Media]](https://images-eureka.patsnap.com/patent_img/7a12db92-c370-467d-80d1-4e4b53e06f22/US20050274663A1-20051215-D00002.png)