Patents

Literature

161 results about "Full recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and apparatus providing system availability during DBMS restart recovery

InactiveUS6185699B1Redundant operation error correctionTransaction processingFull recoveryData consistency

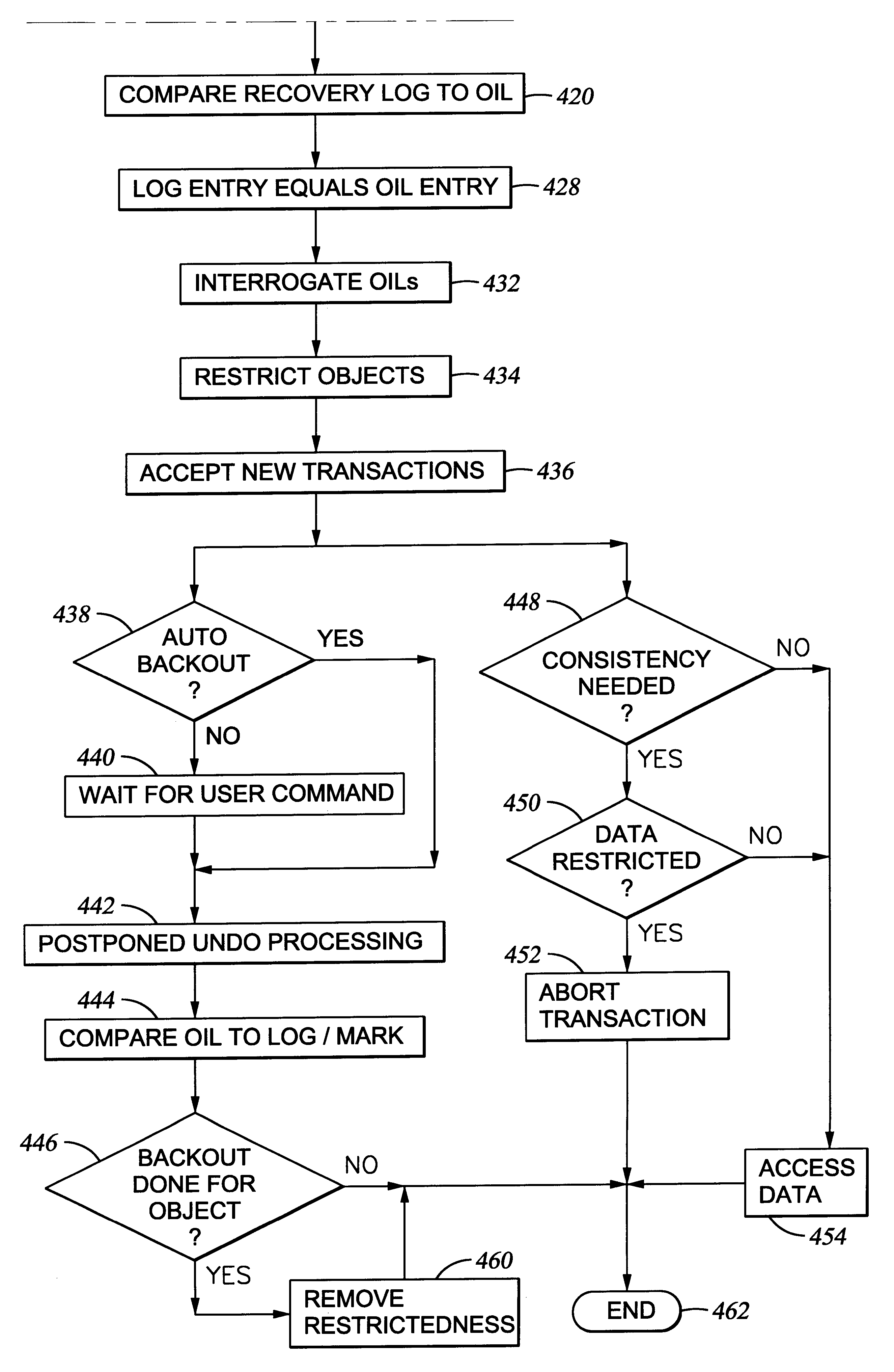

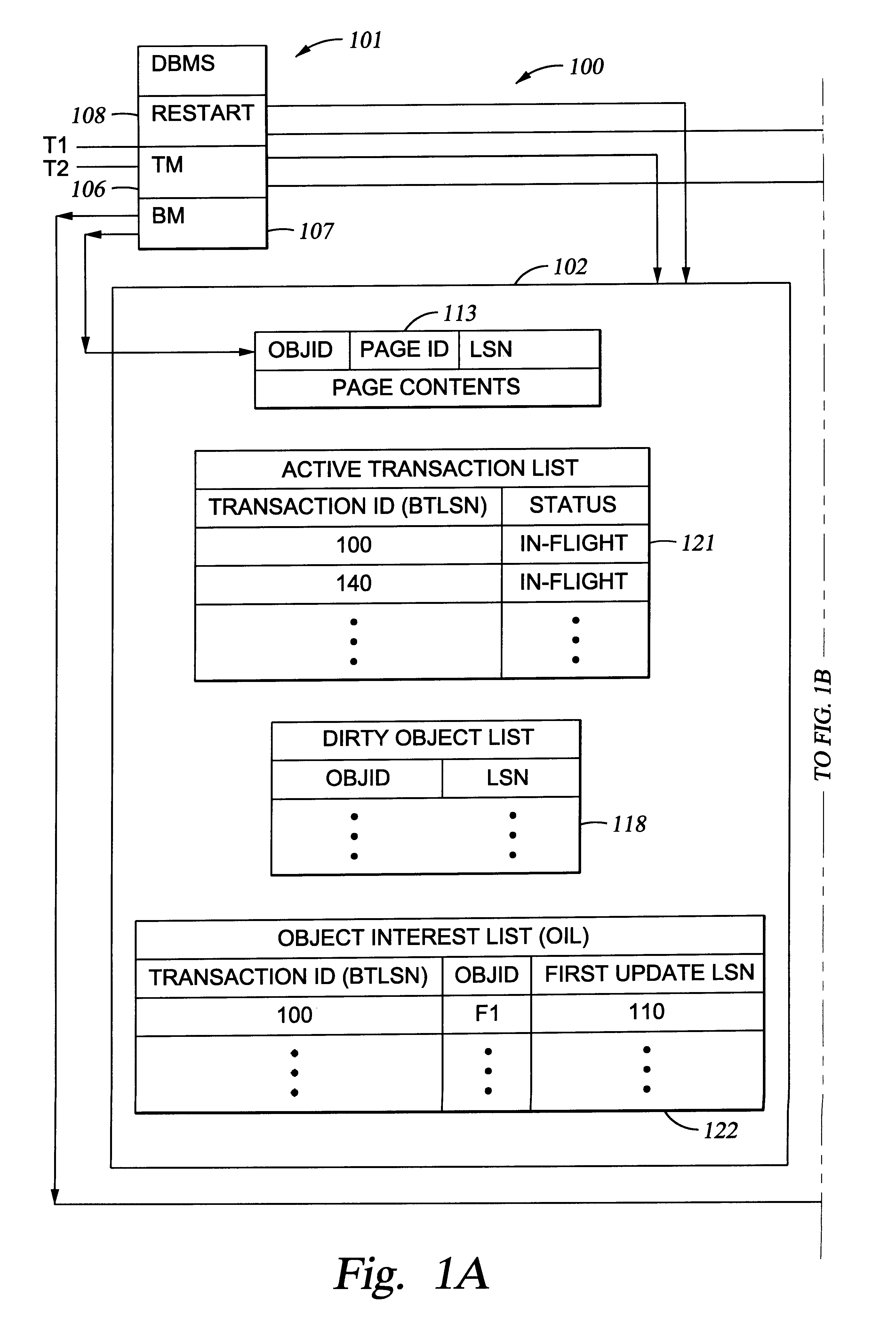

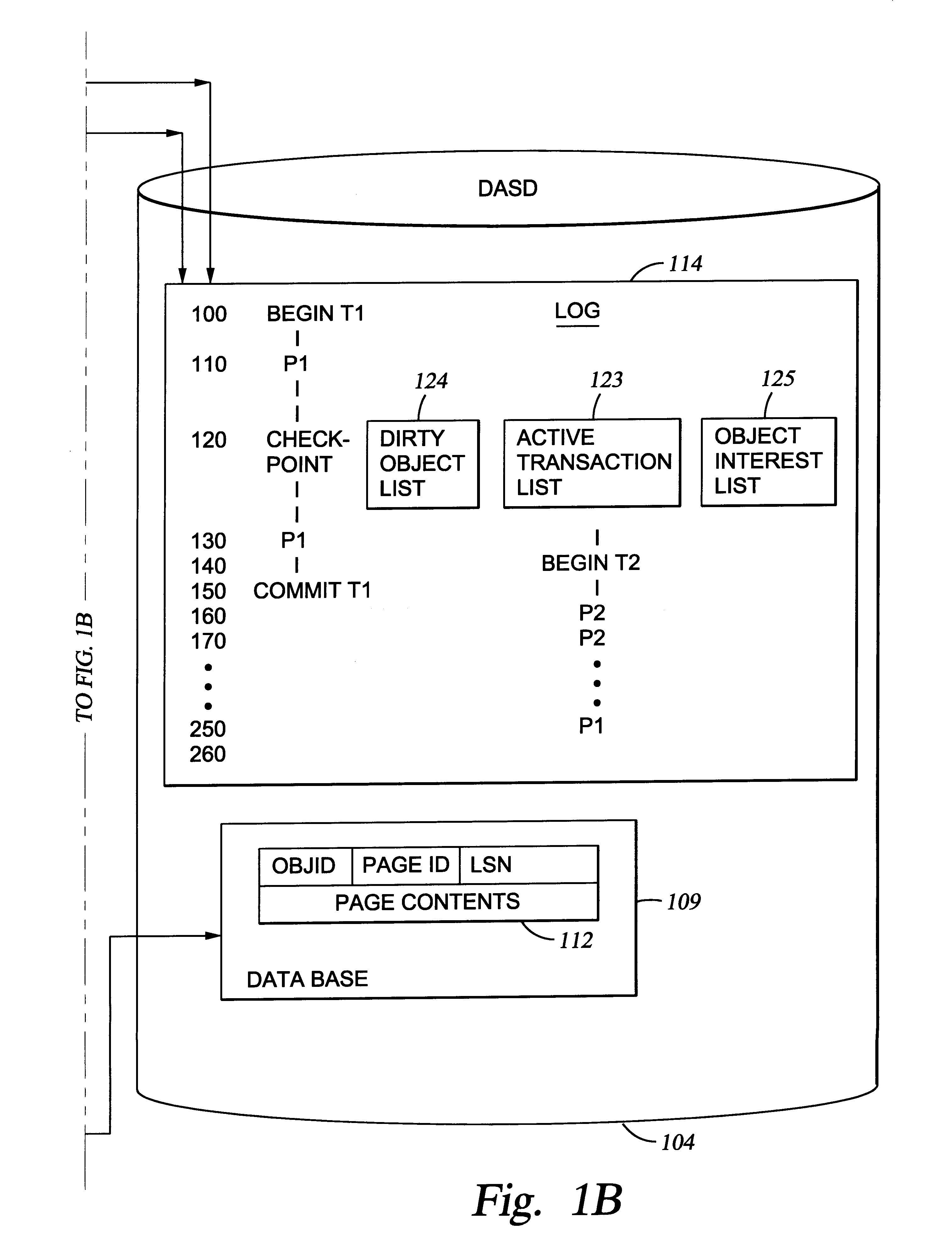

A method and apparatus to provide DBMS restart recovery that allows transactions to access data that does not have restart recovery work pending. Access to data requiring restart recovery work to be performed is restricted, and a transaction is denied access to this data. In another embodiment, the invention allows certain transactions to access restricted data that has restart recovery work pending. These transactions are transactions that do not require data consistency. Regardless of the embodiment, the invention allows full recovery to be completed concurrent to the processing of new transactions requiring access to the database. An amount of restart recovery processing may be postponed until after the DBMS has begun accepting new work requests.

Owner:IBM CORP

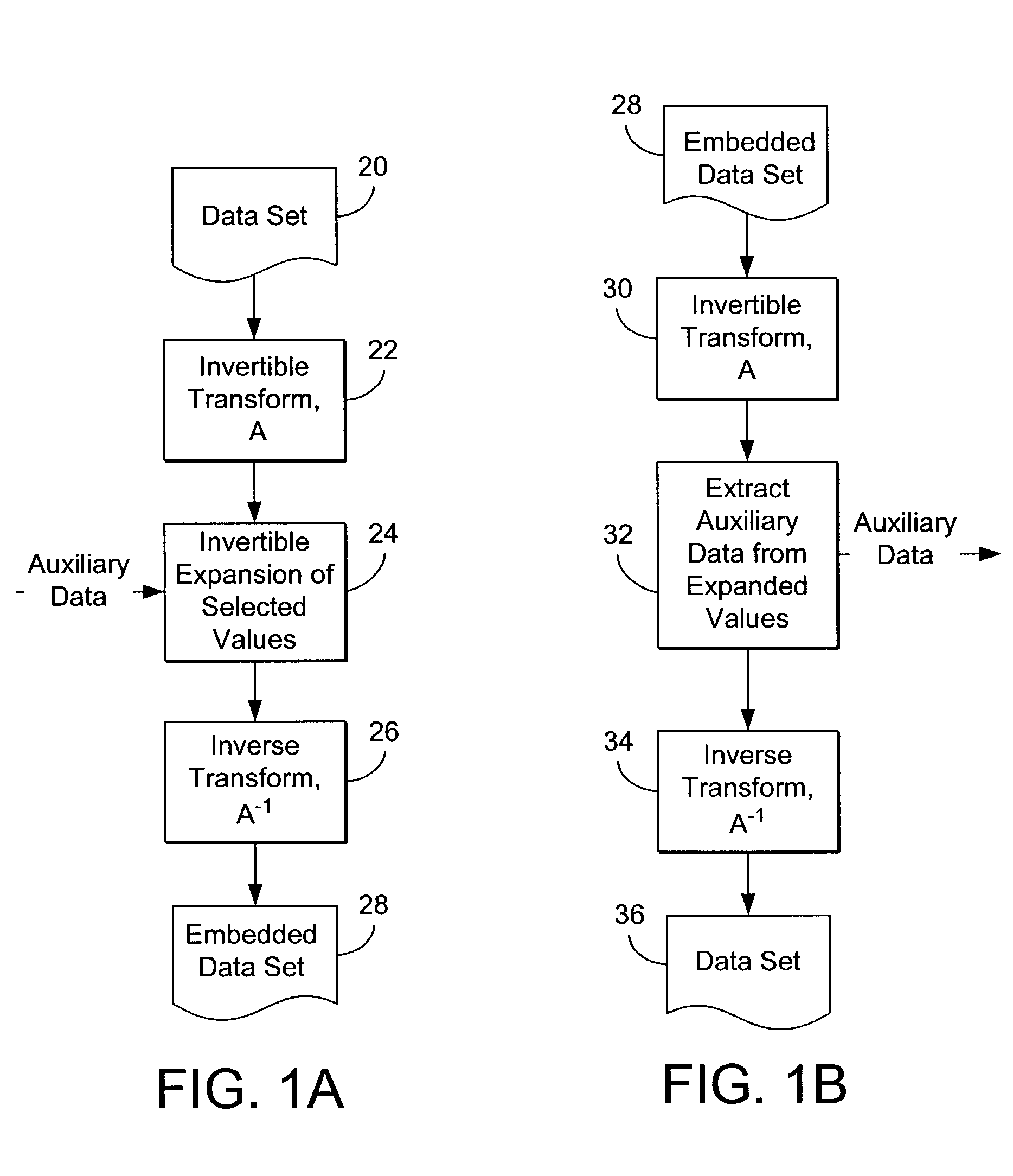

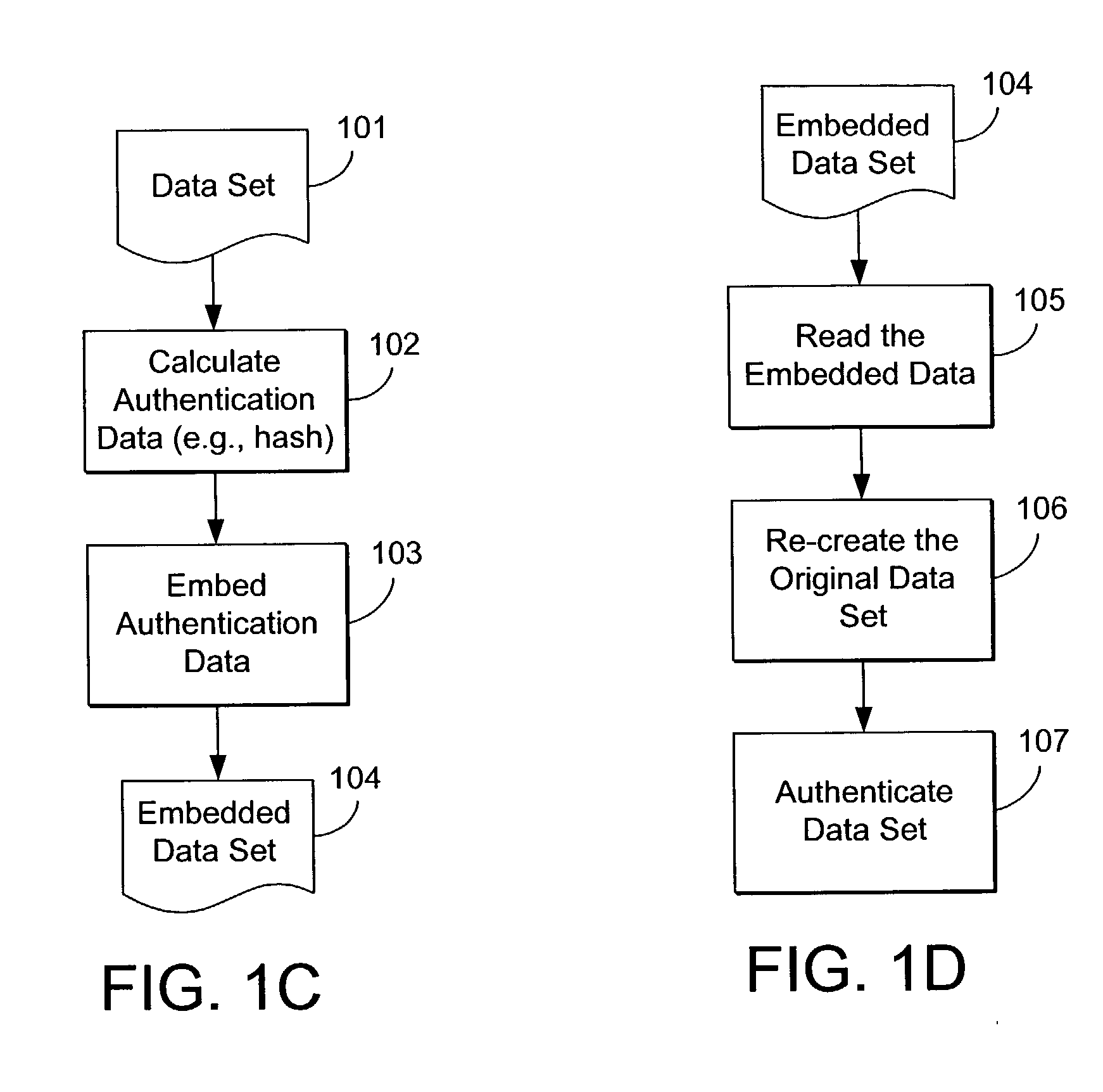

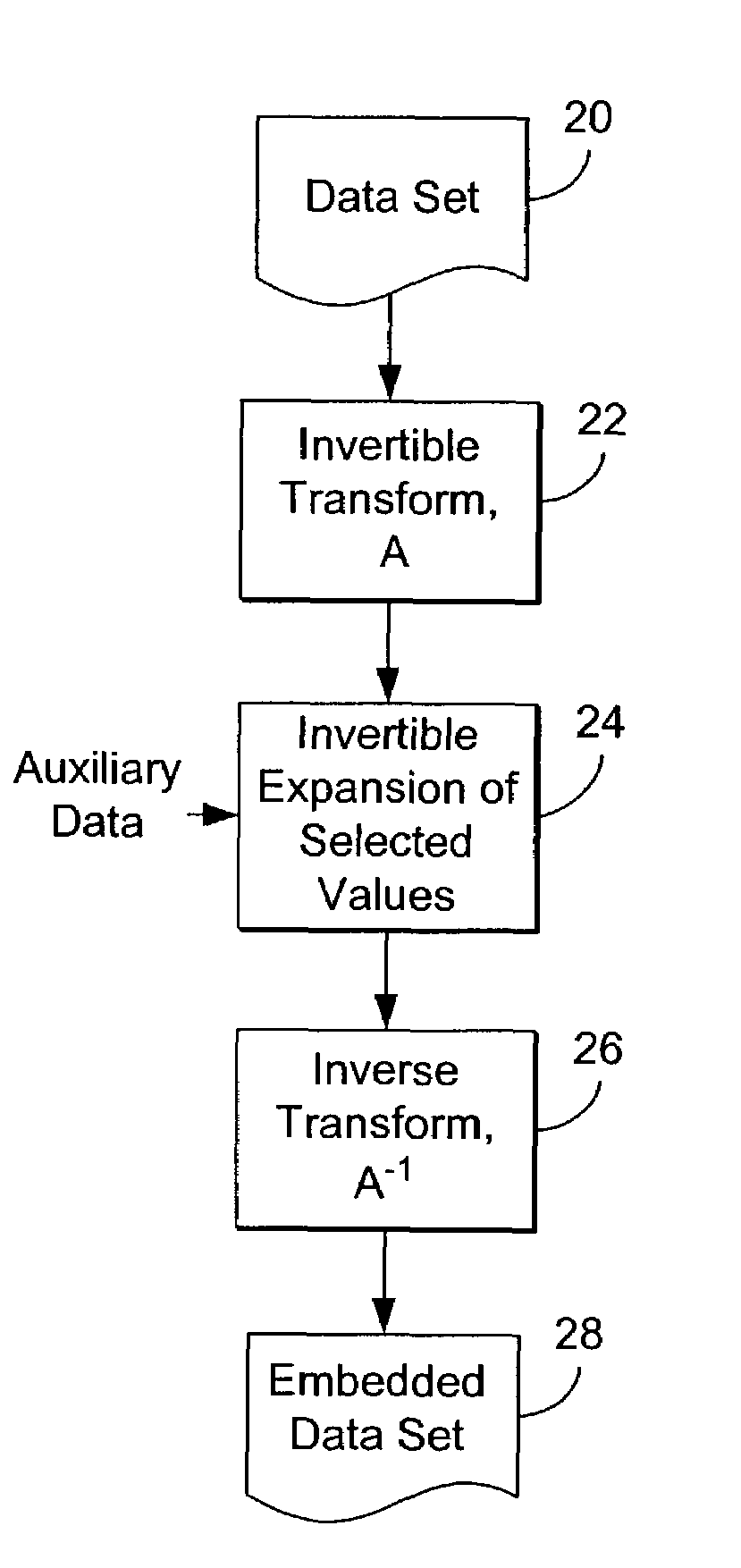

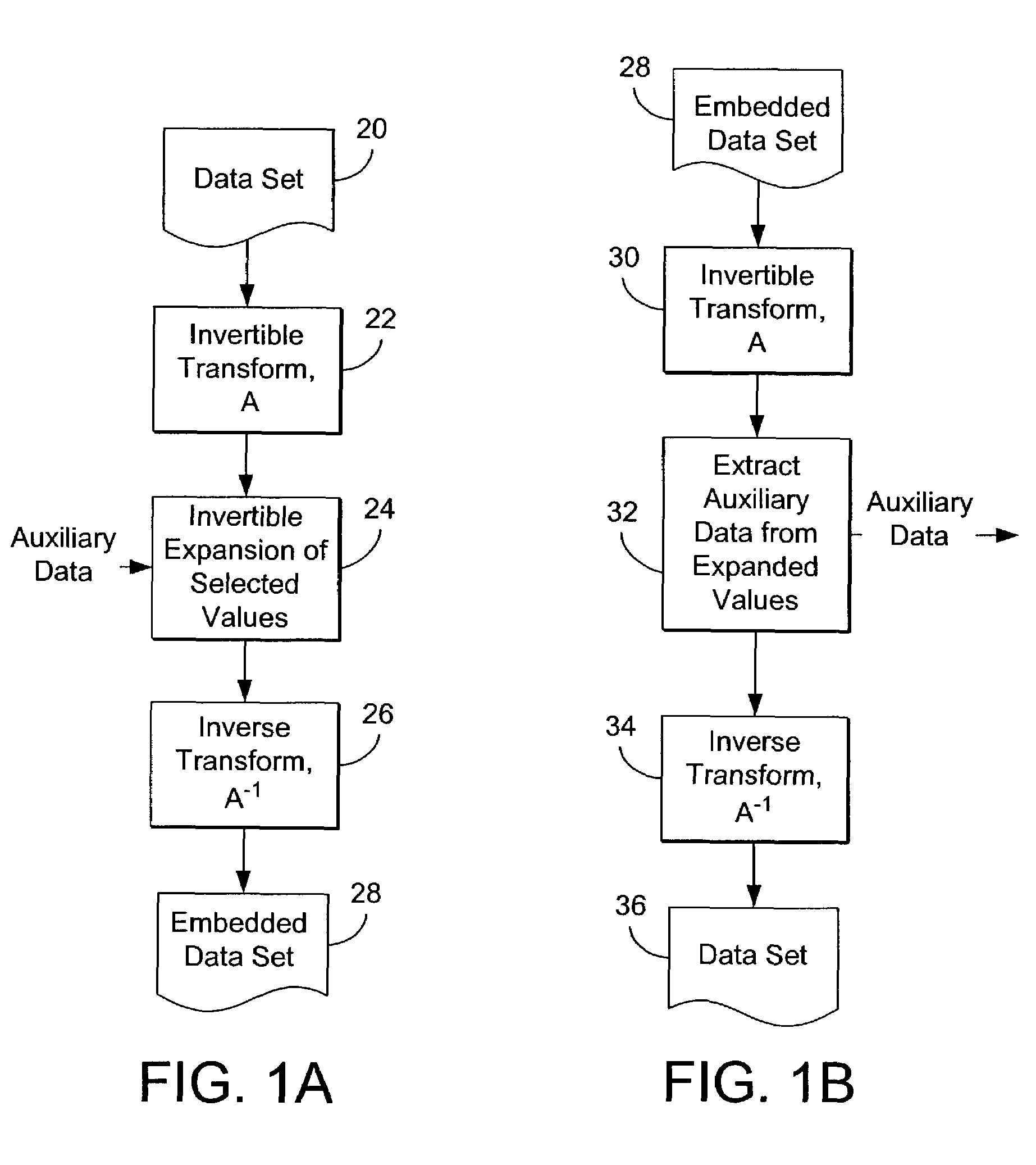

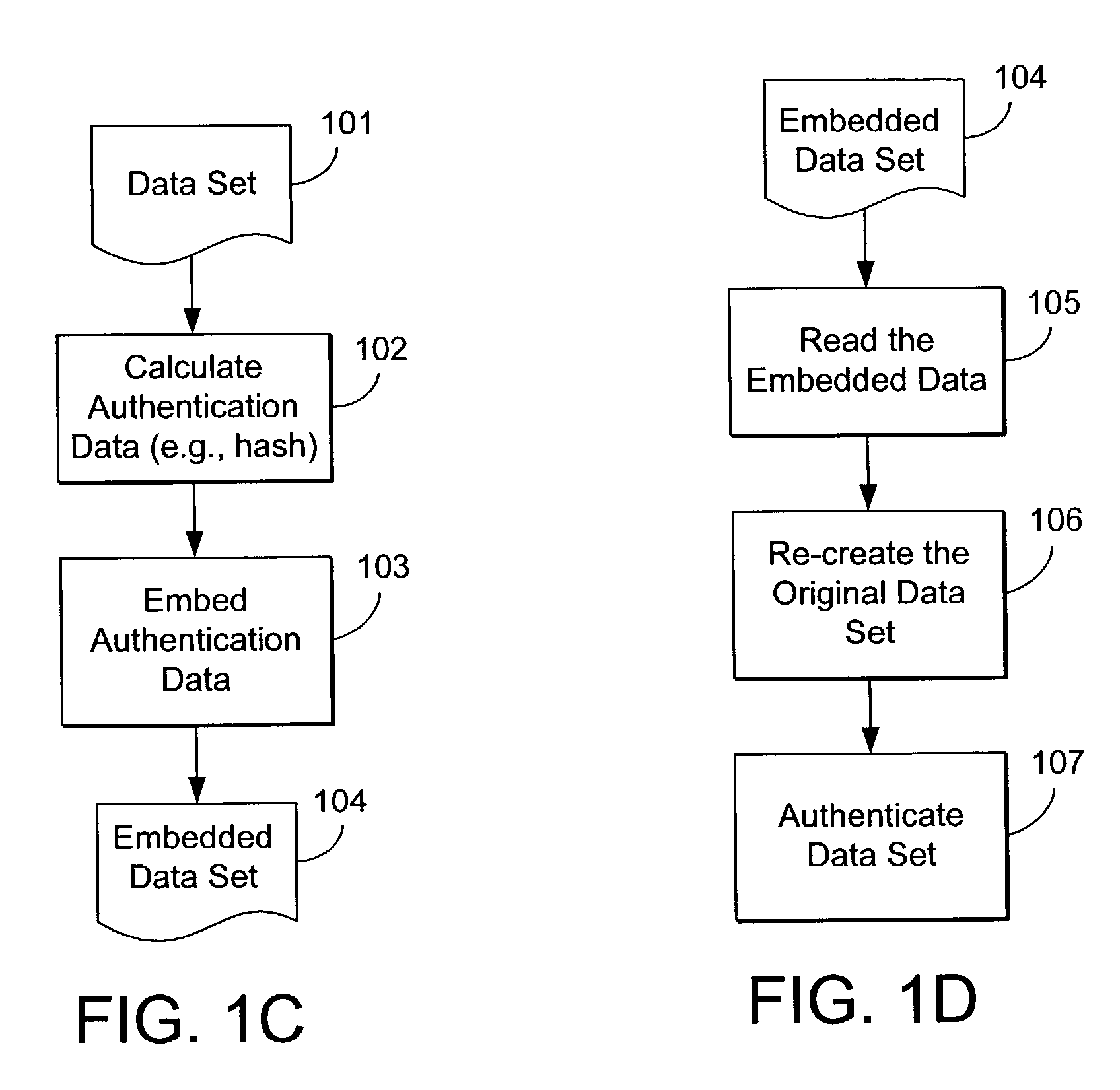

Reversible watermarking

ActiveUS20030149879A1Improve performanceIncrease capacityUser identity/authority verificationSpeech analysisData setFull recovery

A reversible watermarking method embeds auxiliary data into a data set, such as an image, audio, video or other data, in a manner that enables full recovery of the original, un-modified data set. This method may be used to determine whether the data set has been tampered. To improve embedding capacity without the need for compression of the auxiliary data, the method uses an expansion technique. One particular approach exploits the correlation or redundancy within the data set to convert the data to a set of small, expandable values, such as difference values. These small values are then expanded by inserting auxiliary data as one or more additional bits, increasing the number of bits without causing an underflow or overflow. This approach also uses a property of the data set that is invariant to the embedding operation to identify embedding locations, obviating the need for separate data to identify where data is embedded in a data set.

Owner:DIGIMARC CORP

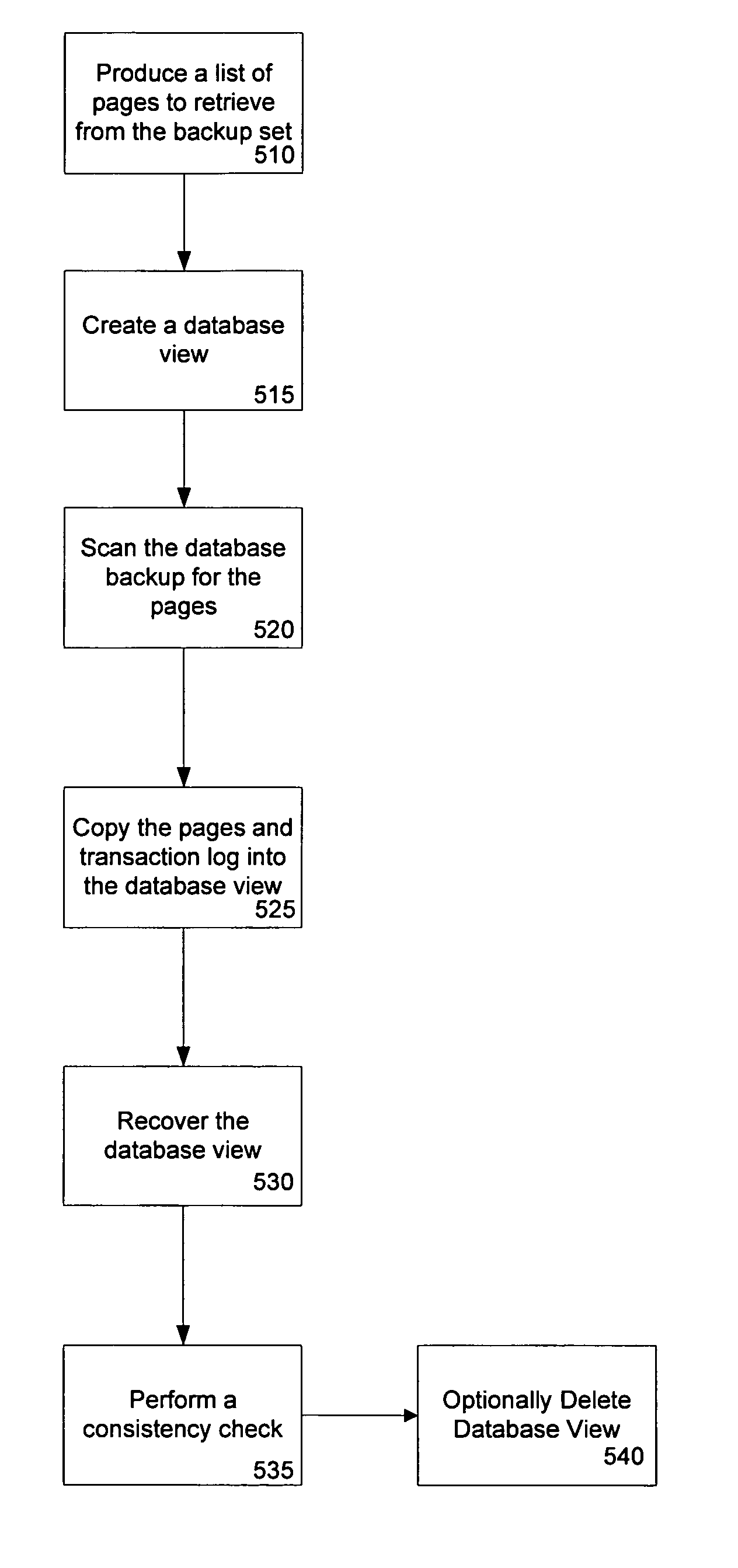

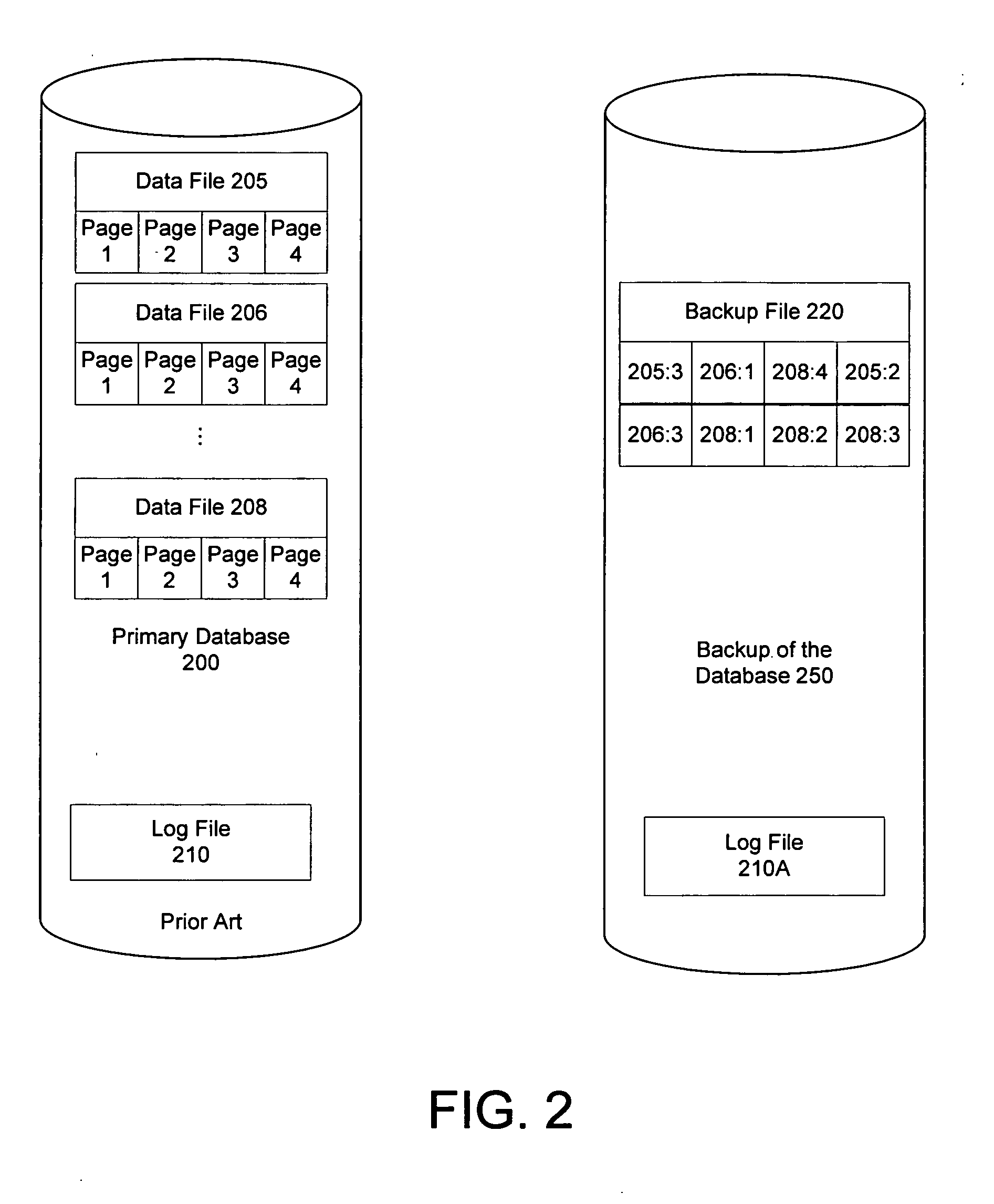

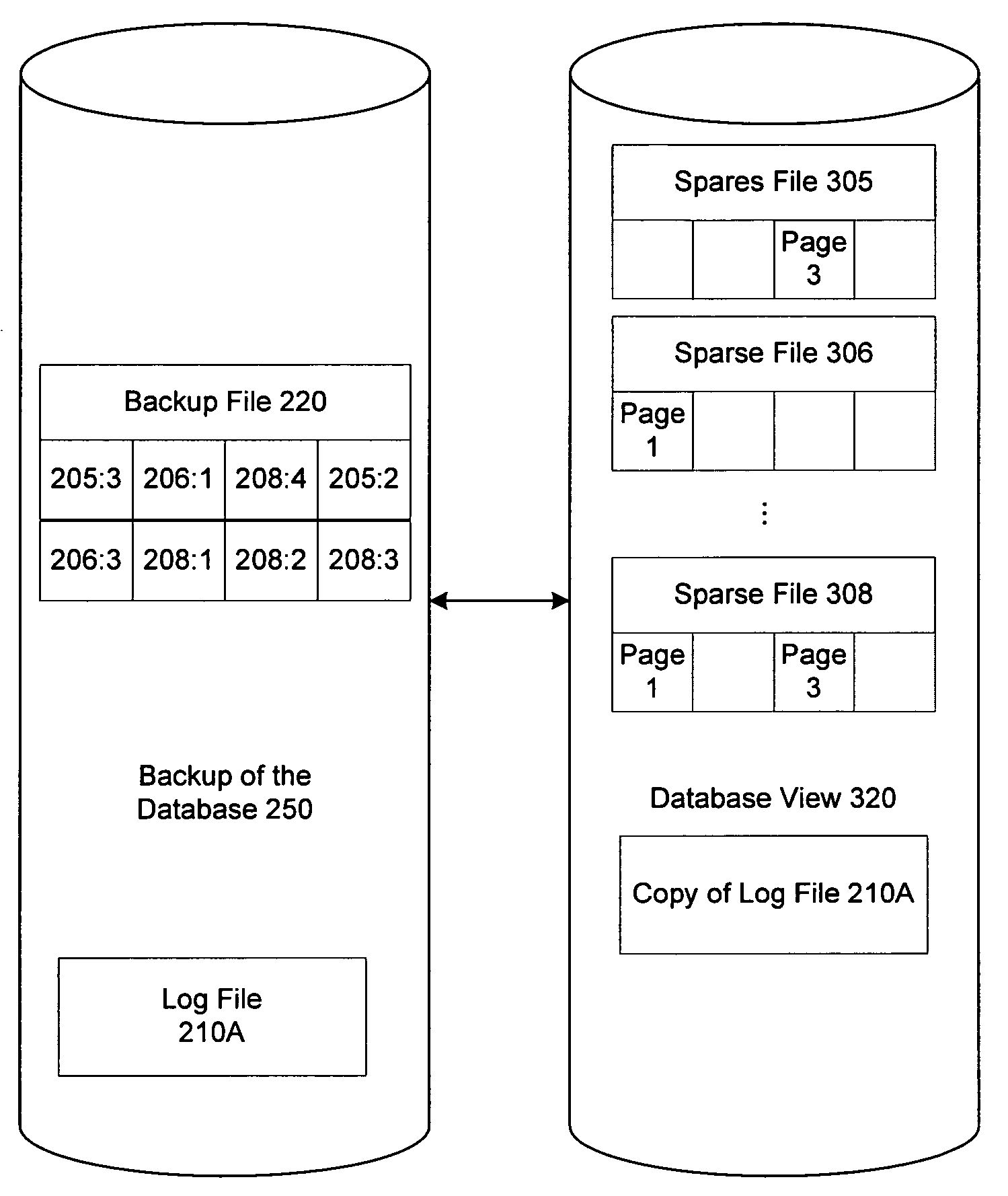

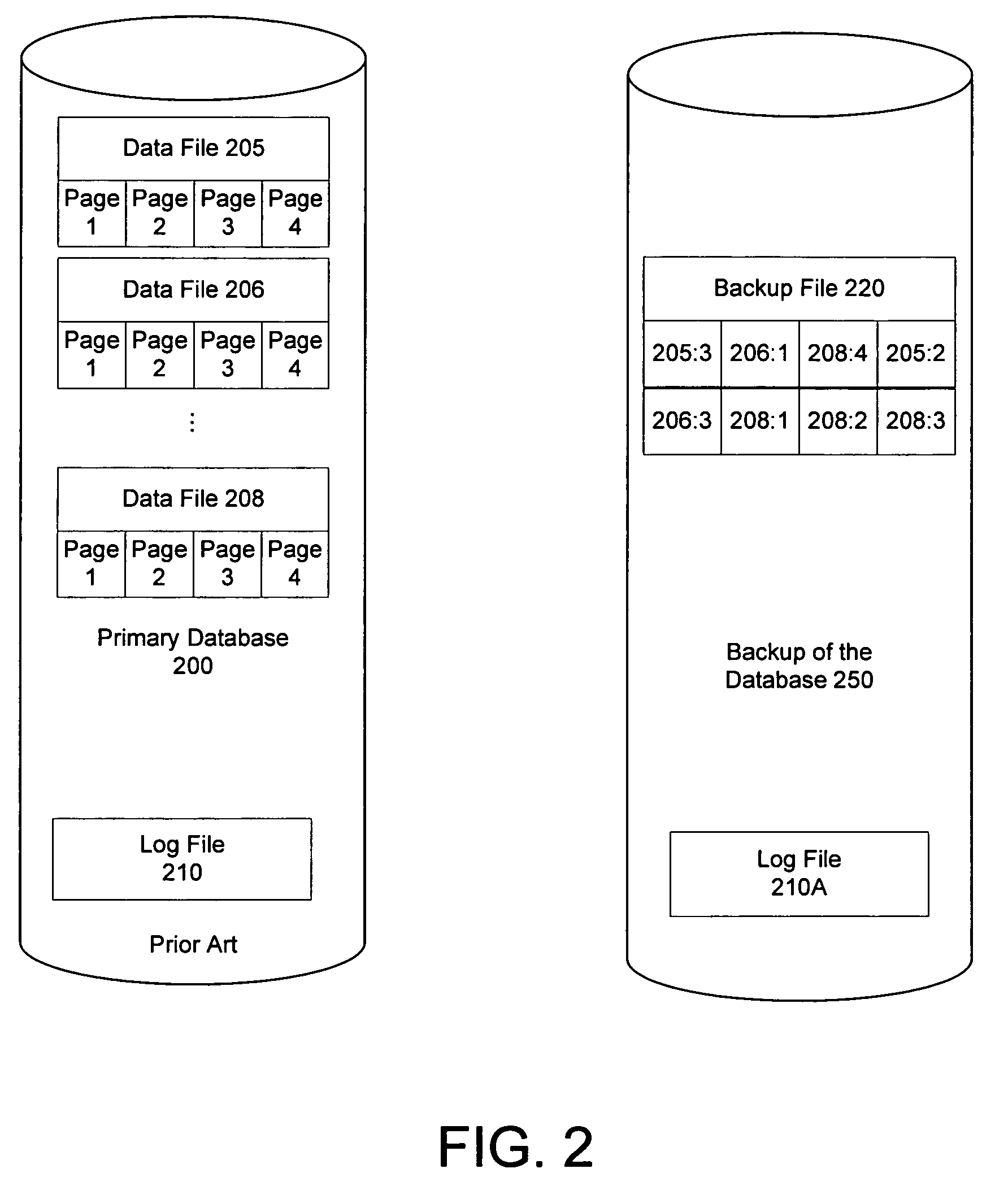

System and method for a consistency check of a database backup

InactiveUS20050223043A1LessReliability in measurement is increasedData processing applicationsDigital data processing detailsFull recoveryDatabase backup

A method for performing a consistency check on a database backup of a database is performed without requiring a full recovery of the original database from the database backup. Instead, a database view may be used as a smaller storage requirement tool for providing a transaction-consistent view of portions of an existing full database backup. The database view, in combination with the database backup and transaction log, contains all the information necessary to perform a consistency check on the database backup without a full reconstitution of the original database from the database backup. The consistency check may be run on the database view along with the database backup to verify the integrity of the full database backup to add improved reliability to a database recovery scheme.

Owner:MICROSOFT TECH LICENSING LLC

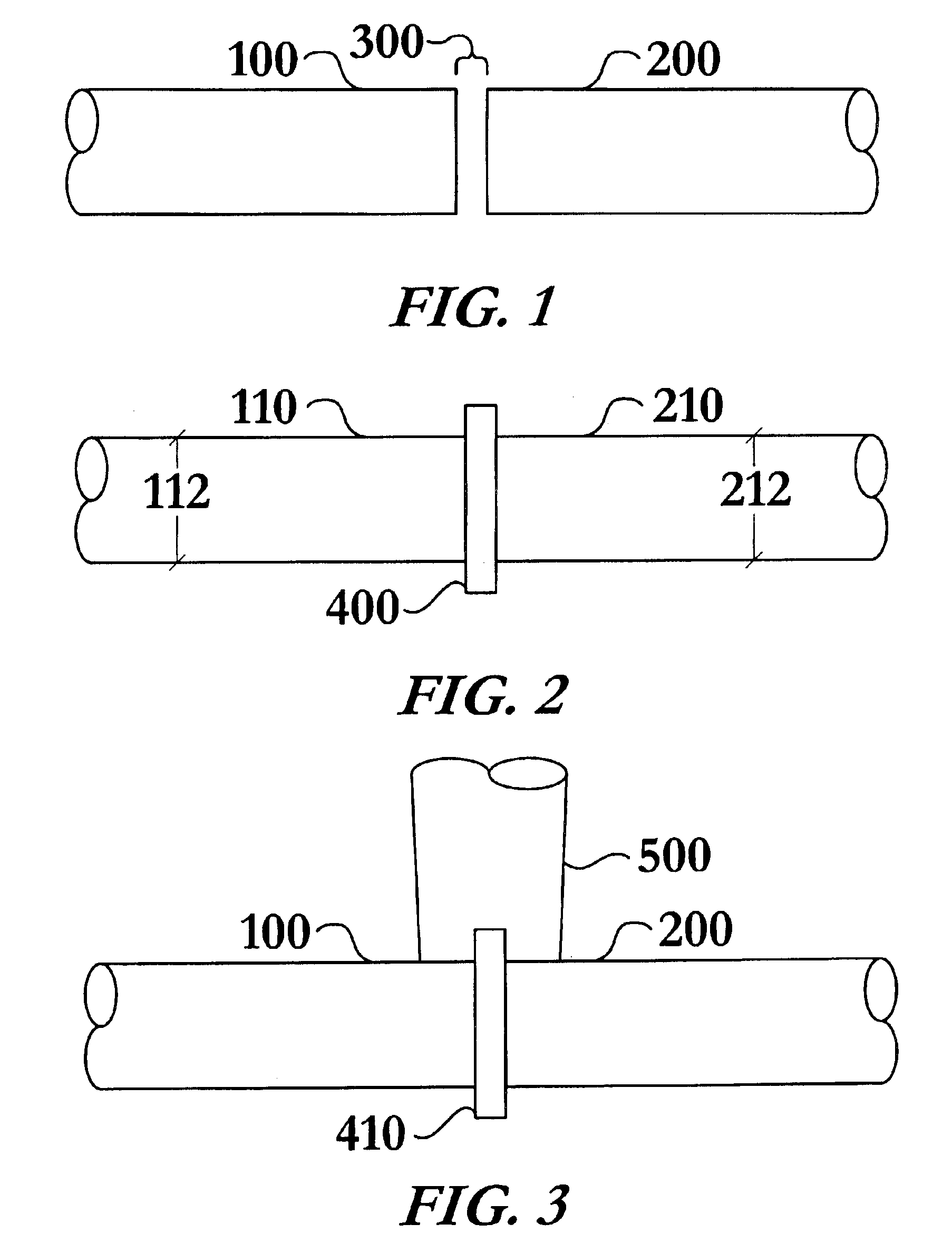

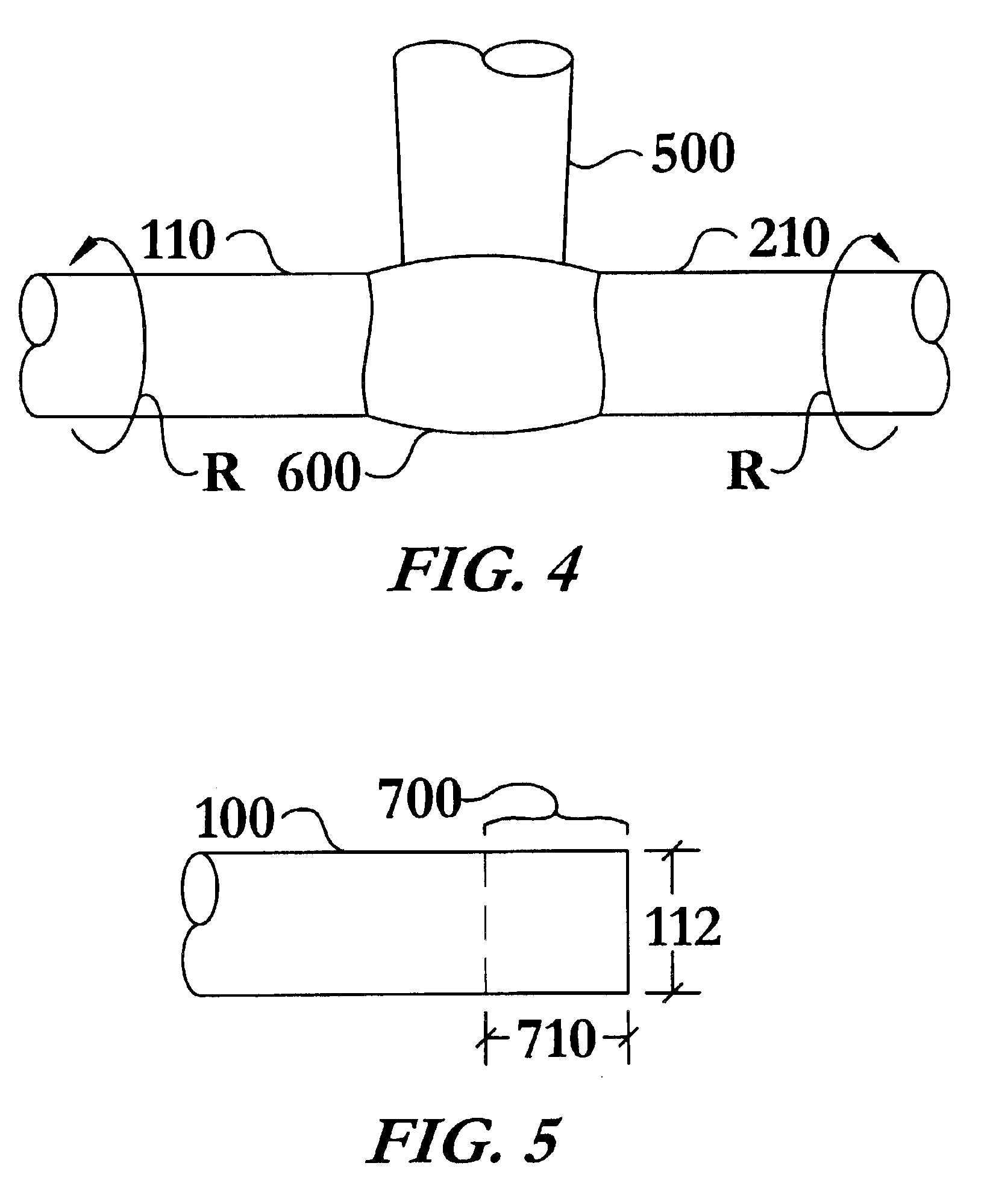

Method of welding titanium and titanium based alloys to ferrous metals

InactiveUS6875949B2Welding/cutting media/materialsWelding/soldering/cutting articlesFull recoveryPoor quality

A method of welding titanium, and titanium based alloys, to ferrous metals is described. Welding of titanium, and titanium based alloys, is plagued with poor quality and highly brittle welds, substantially due to formation of Ti—Fe intermetallics in the weld pool. The instant invention provides supplementary filler material to alter the proportions of various elements in the weld pool. Certain fillers, such as nickel or iron, added to the weld pool enable high quality welds to be fabricated utilizing a wide variety of fusion welding techniques, including laser welding, between titanium, or titanium based alloys, and ferrous metals, including but not limited to the welding of nickel-titanium and stainless steel. Filler material may be supplied in various forms, including foil, wire, powders, preformed gaskets, and numerous others. Optionally, the titanium or titanium based alloy may be stress relieved to achieve full recovery of the shape memory strain prior to welding.

Owner:EDISON WELDING INSTITUTE INC

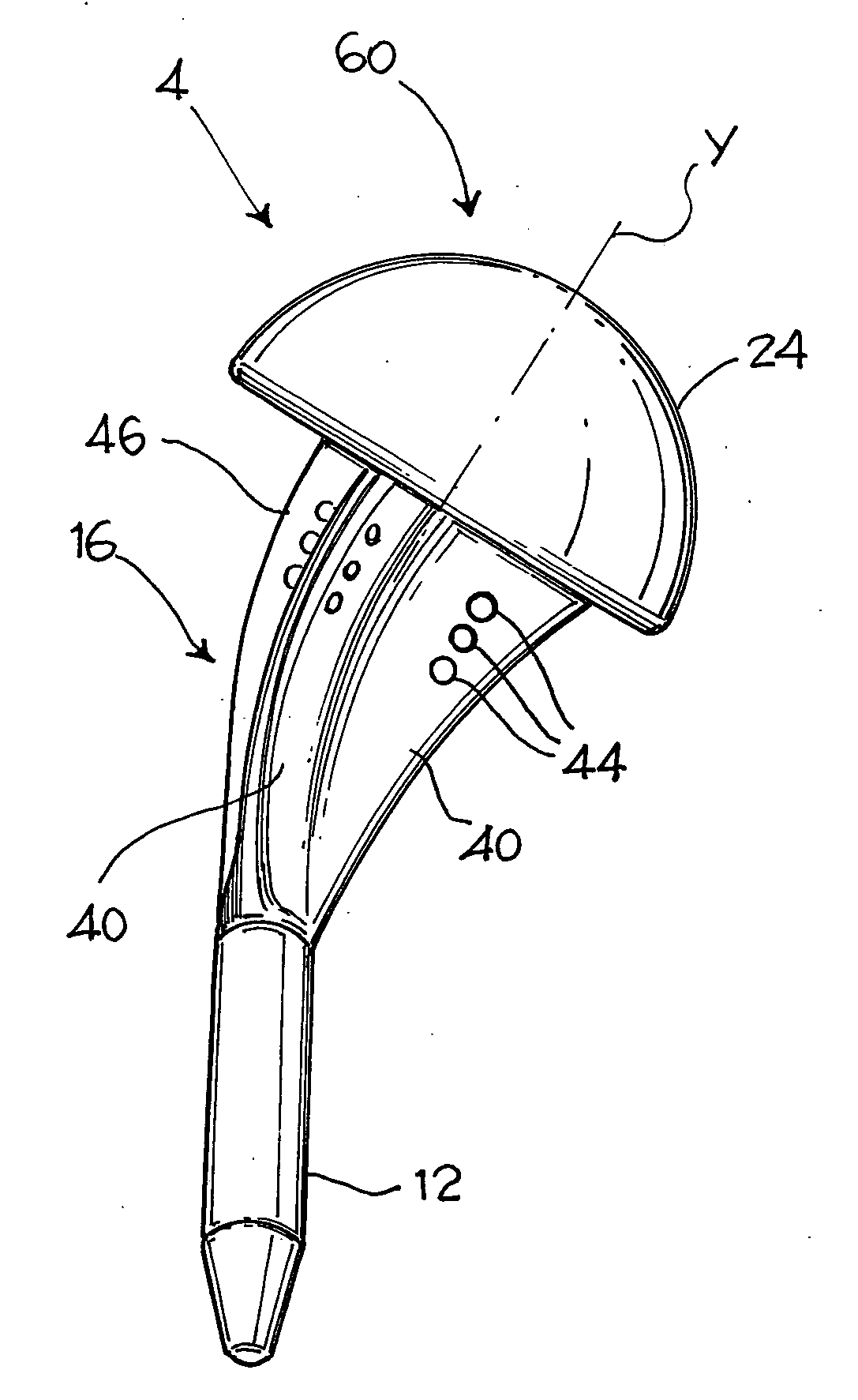

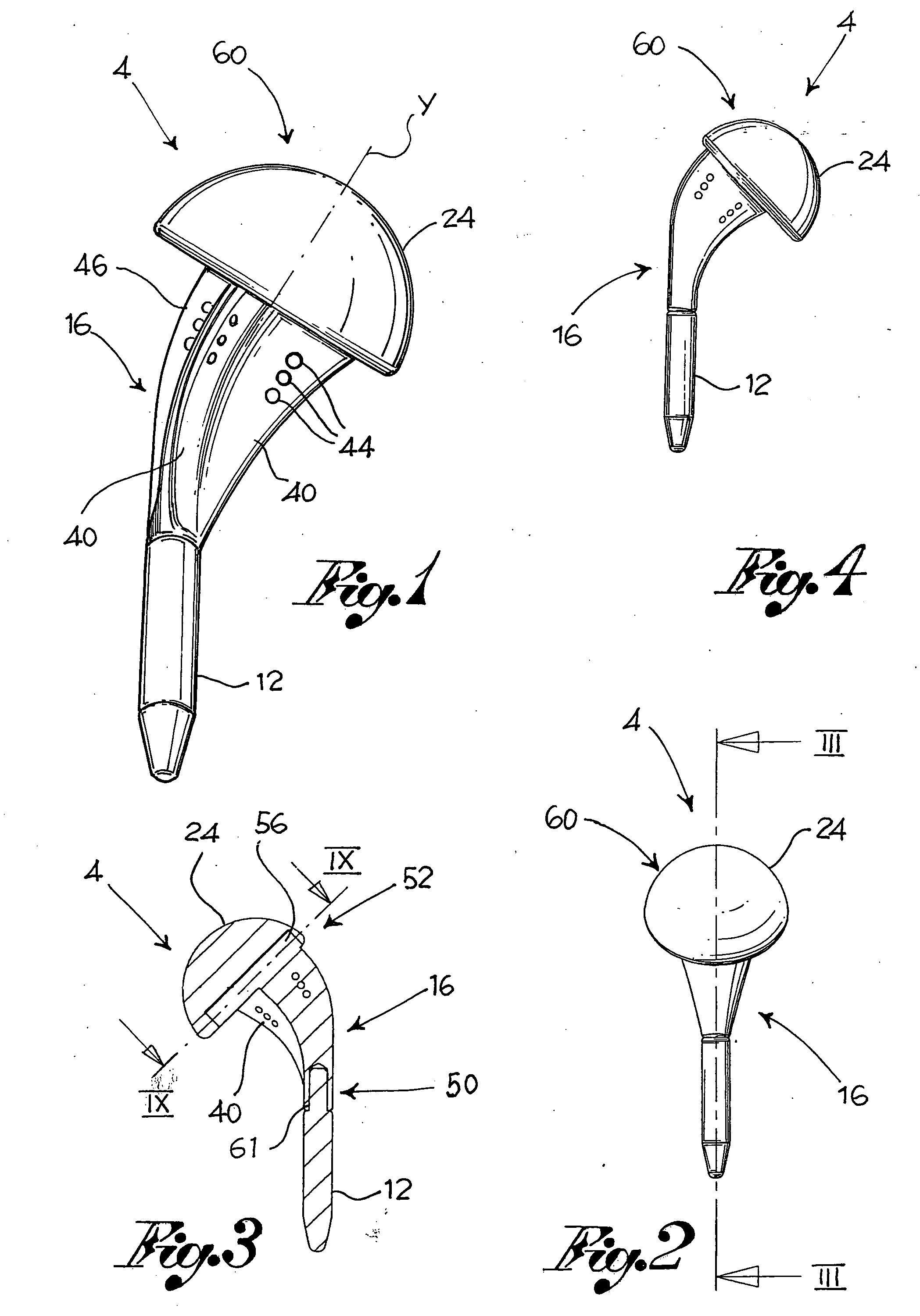

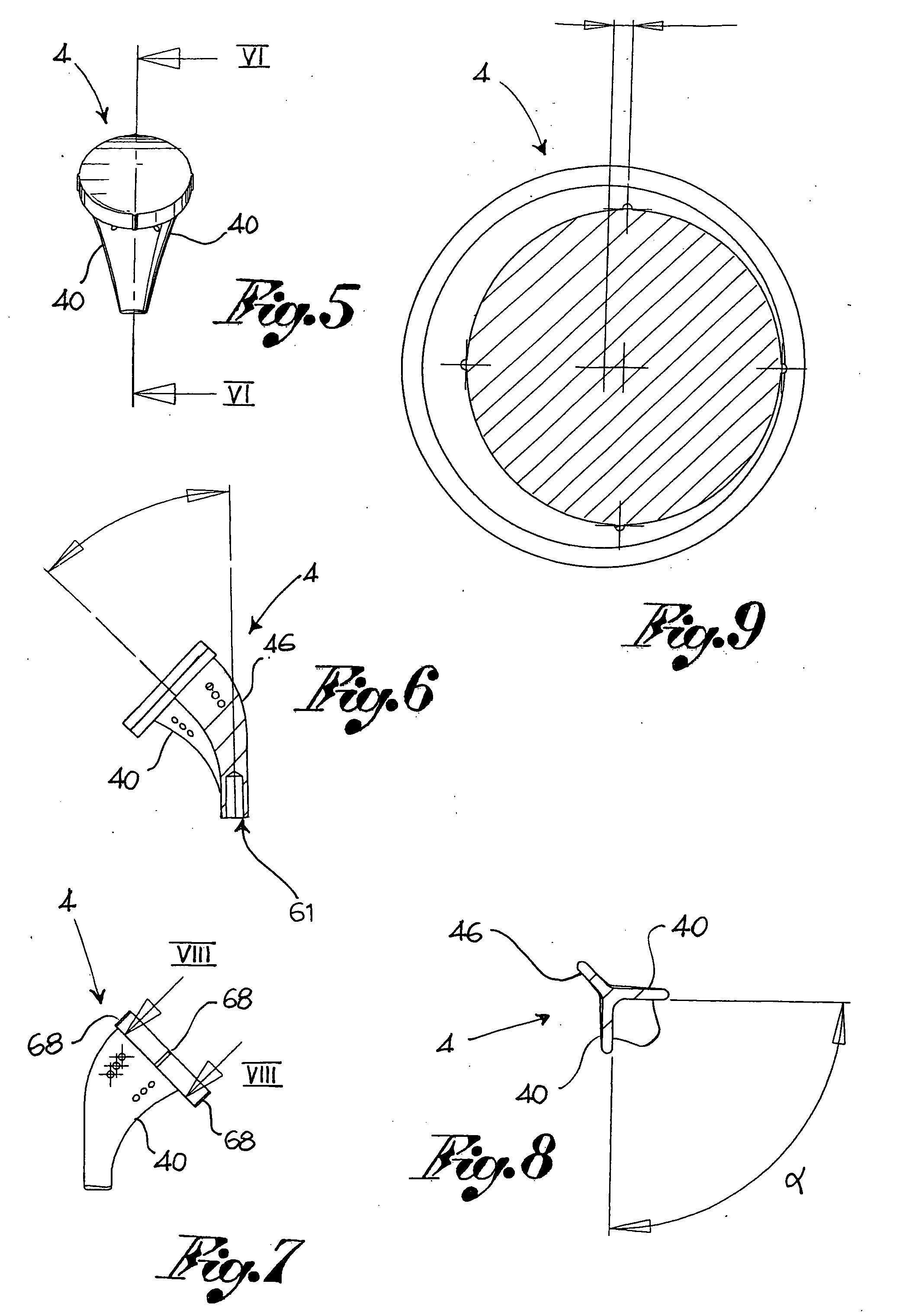

Shoulder Prosthesis

A shoulder prosthesis of a modular type adapted to changing from a direct configuration to an inverted configuration. The prosthesis is particularly non-invasive and has a large modular capacity, permitting full recovery of the articular function following the implant thereof.

Owner:PLUSTEK

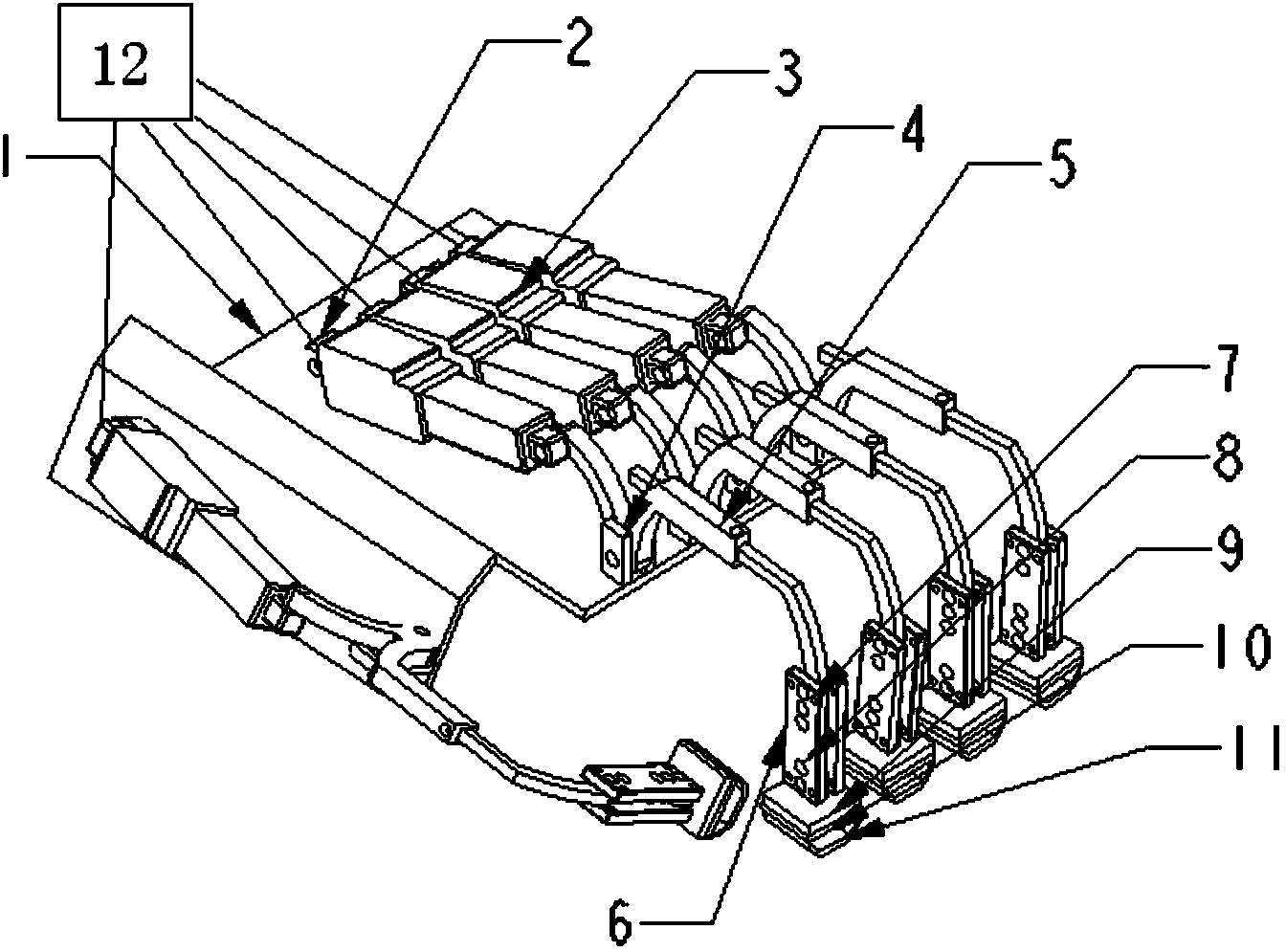

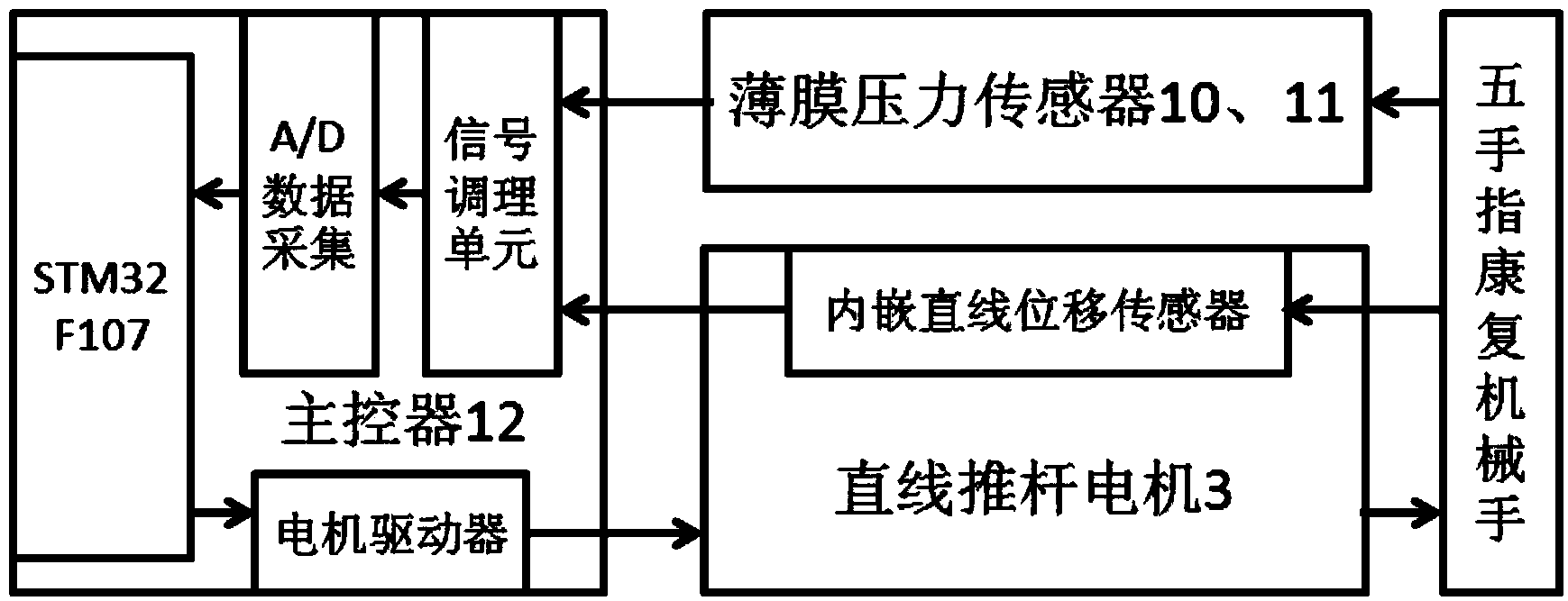

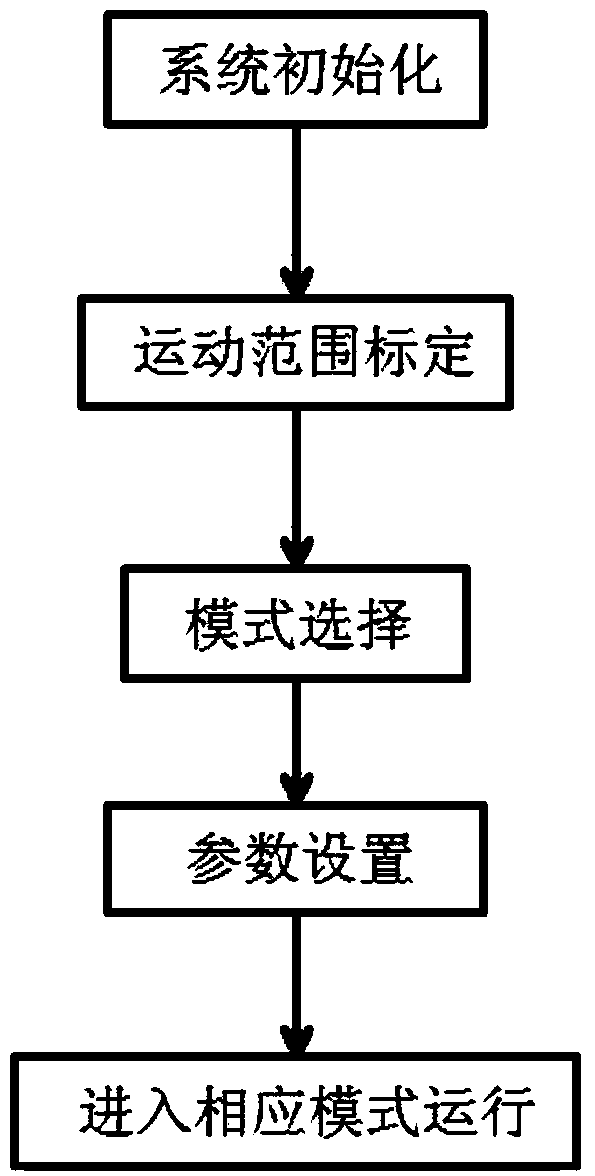

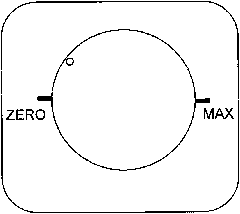

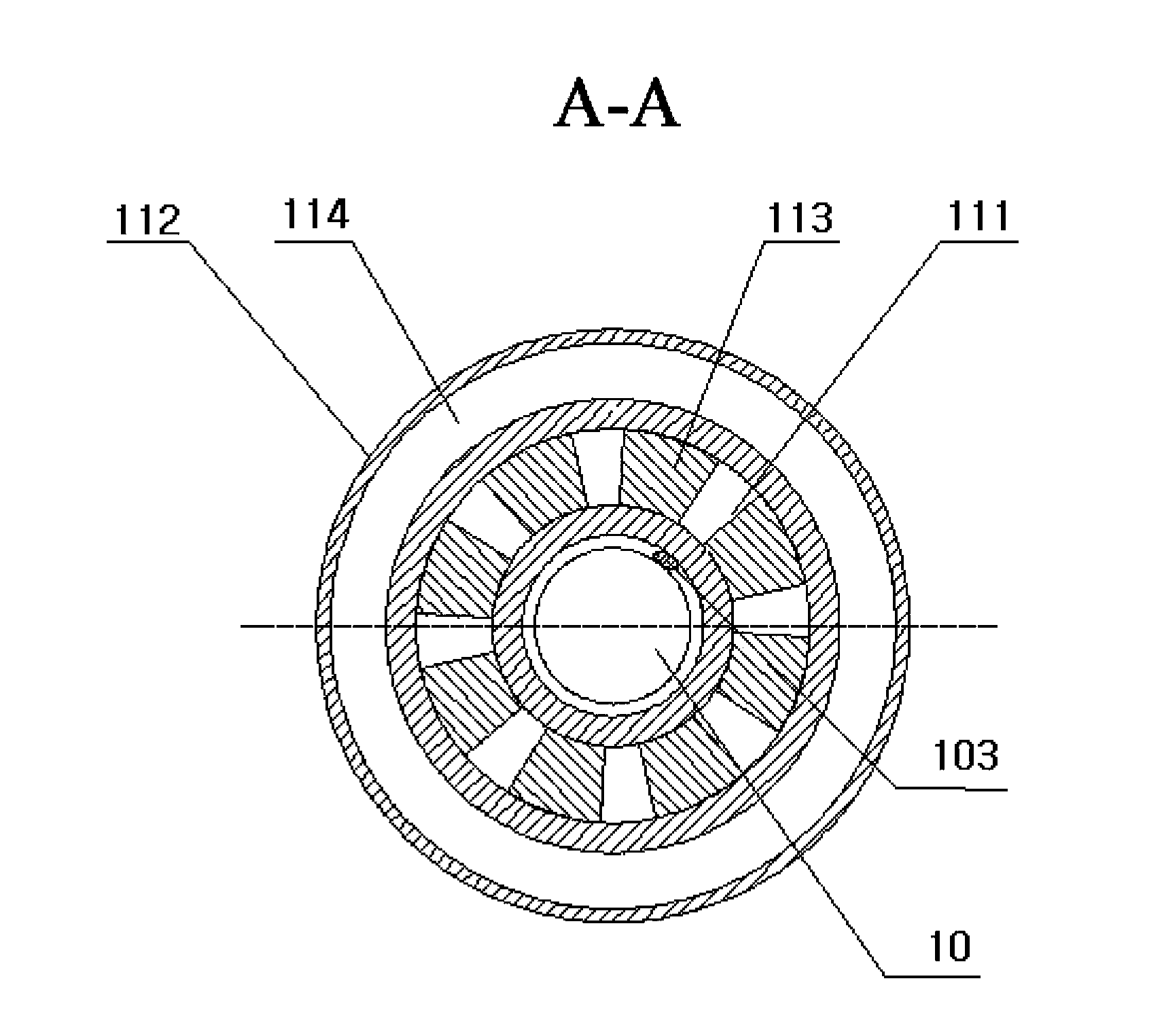

Wearing type five-finger recovery manipulator

ActiveCN103767856AControl range of motionGymnastic exercisingChiropractic devicesPull forceIndex finger

Owner:XI AN JIAOTONG UNIV

System for recovery of regenerative braking energy of vehicle and method thereof

ActiveCN101823438AFully recycleAvoid security issuesElectrodynamic brake systemsElectricityCarrying capacity

The invention discloses a system for recovery of regenerative braking energy of a vehicle and a method thereof. The vehicle comprises an on-board battery. The system comprises an energy recovery ratio adjusting device, a speed sensor, a battery management system and a whole vehicle controller, wherein the energy recovery ratio adjusting device is used for setting an energy recovery ratio; the speed sensor is used for detecting the current speed of a vehicle; the battery management system is used for determining the current carrying capacity of the onboard battery; and the whole vehicle controller is electrically connected with the energy recovery ratio adjusting device, the speed sensor and the battery management system, and is used for calculating the expected regenerative braking generation power according to the energy recovery ratio, the current speed and the current carrying capacity, and adjusting a motor according to the expected regenerative braking generation power, so that the difference between the actual regenerative braking generation power generated by the motor and the expected regenerative braking generation power is within a preset range. The invention can provide multiple choices for the driver, so that the driver can select different energy recovery ratios according to the driving habits, thereby not only ensuring the full recovery of energy, but also avoiding the loss of vehicle safety.

Owner:BEIQI FOTON MOTOR CO LTD

System and method for a consistency check of a database backup

InactiveUS7277905B2Data processing applicationsDigital data information retrievalDatabase backupFull recovery

Owner:MICROSOFT TECH LICENSING LLC

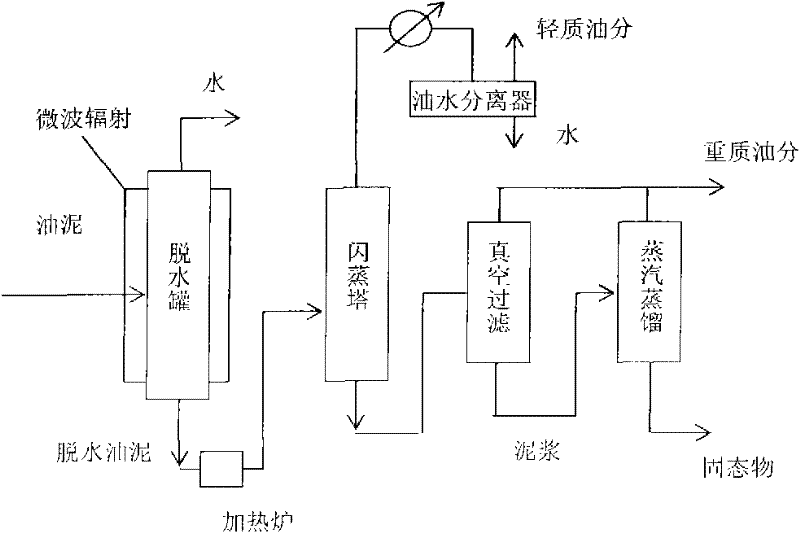

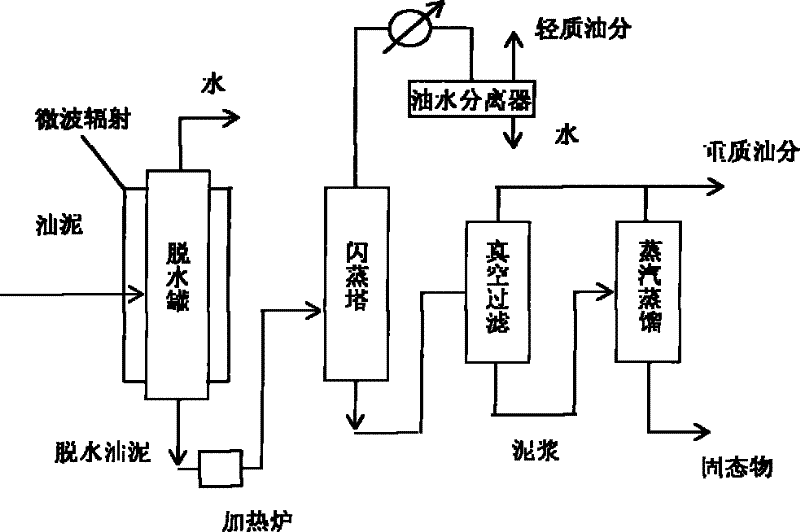

Method for treating oil sludge

ActiveCN102452776AImprove processing efficiencySmall scaleSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningFull recoveryOil sludge

The invention discloses a method for treating oil sludge. The method realizes oil sludge integrated treatment by utilization of microwave demulsification dehydration, heat treatment flash evaporation and steam distillation. Concretely, the method comprises the following steps of 1, carrying out a microwave pretreatment demulsification dehydration process on oil sludge to reduce water content of the oil sludge, 2, heating the oil sludge subjected to the microwave pretreatment demulsification dehydration process to a temperature of 100 to 300 DEG C in an oxygen-free environment, feeding the heated oil sludge into a separating column, carrying out a heat treatment flash evaporation process, through condensation, recovering a light oil component and water separated by the heat treatment flashevaporation, and taking out sludge comprising a heavy oil component and solids from the separating column, and 3, carrying out solid-liquid separation of the sludge in the bottom of the separating column, recovering the heavy oil component as a coking or catalytic cracking raw material, and carrying out a steam distillation process on the solids to further recover an oil component from the solids. The method can realize full recovery of various valuable components of oil sludge and has good industrial application economical efficiency.

Owner:CHINA PETROLEUM & CHEM CORP +1

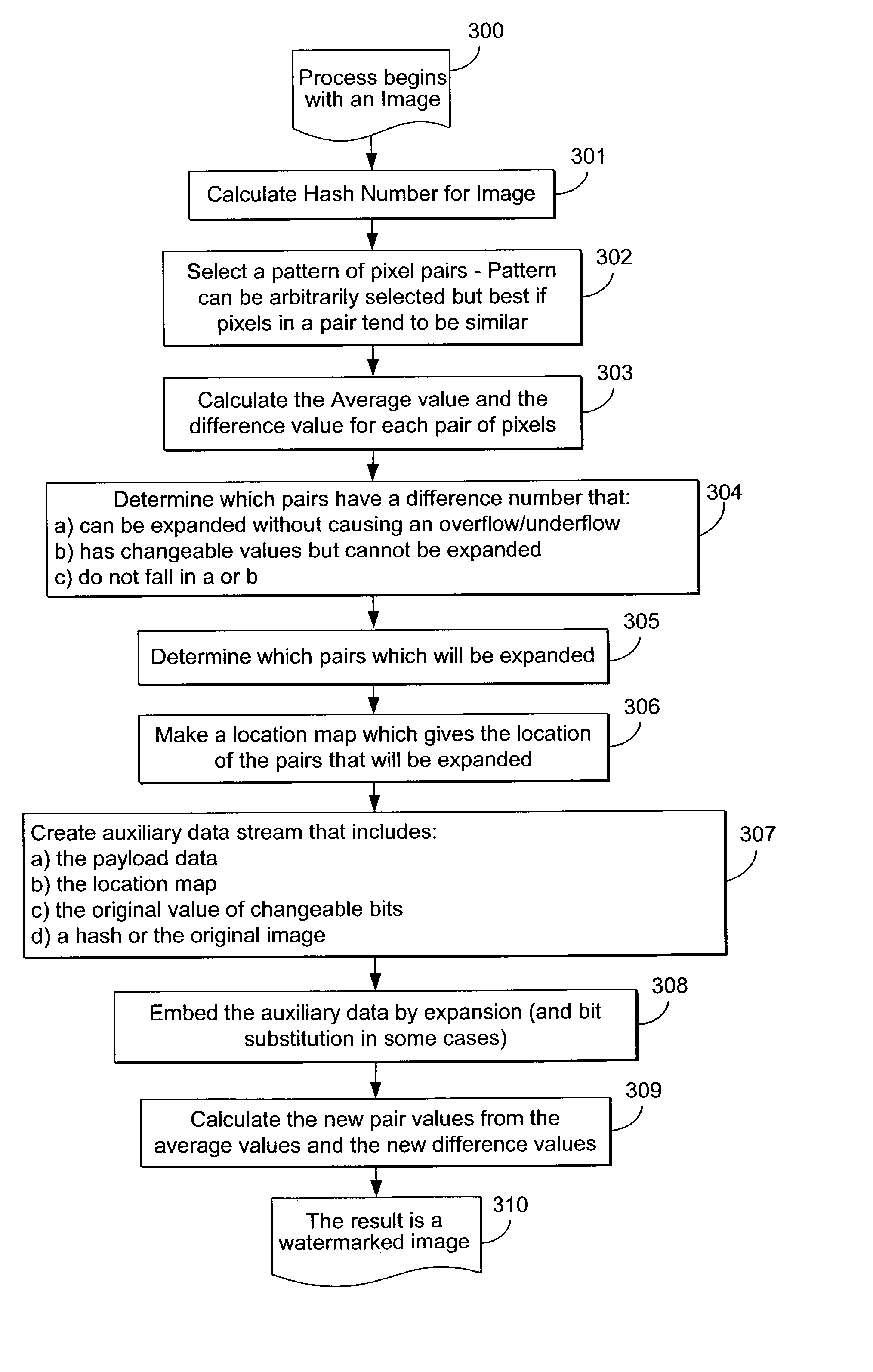

Reversible watermarking

A reversible watermarking method embeds auxiliary data into a data set, such as an image, audio, video or other data, in a manner that enables full recovery of the original, un-modified data set. This method may be used to determine whether the data set has been tampered. To improve embedding capacity without the need for compression of the auxiliary data, the method uses an expansion technique. One particular approach exploits the correlation or redundancy within the data set to convert the data to a set of small, expandable values, such as difference values. These small values are then expanded by inserting auxiliary data as one or more additional bits, increasing the number of bits without causing an underflow or overflow. This approach also uses a property of the data set that is invariant to the embedding operation to identify embedding locations, obviating the need for separate data to identify where data is embedded in a data set.

Owner:DIGIMARC CORP

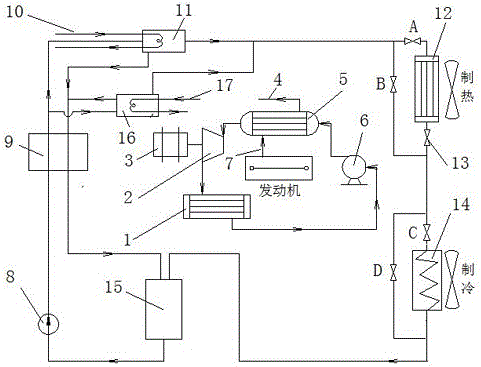

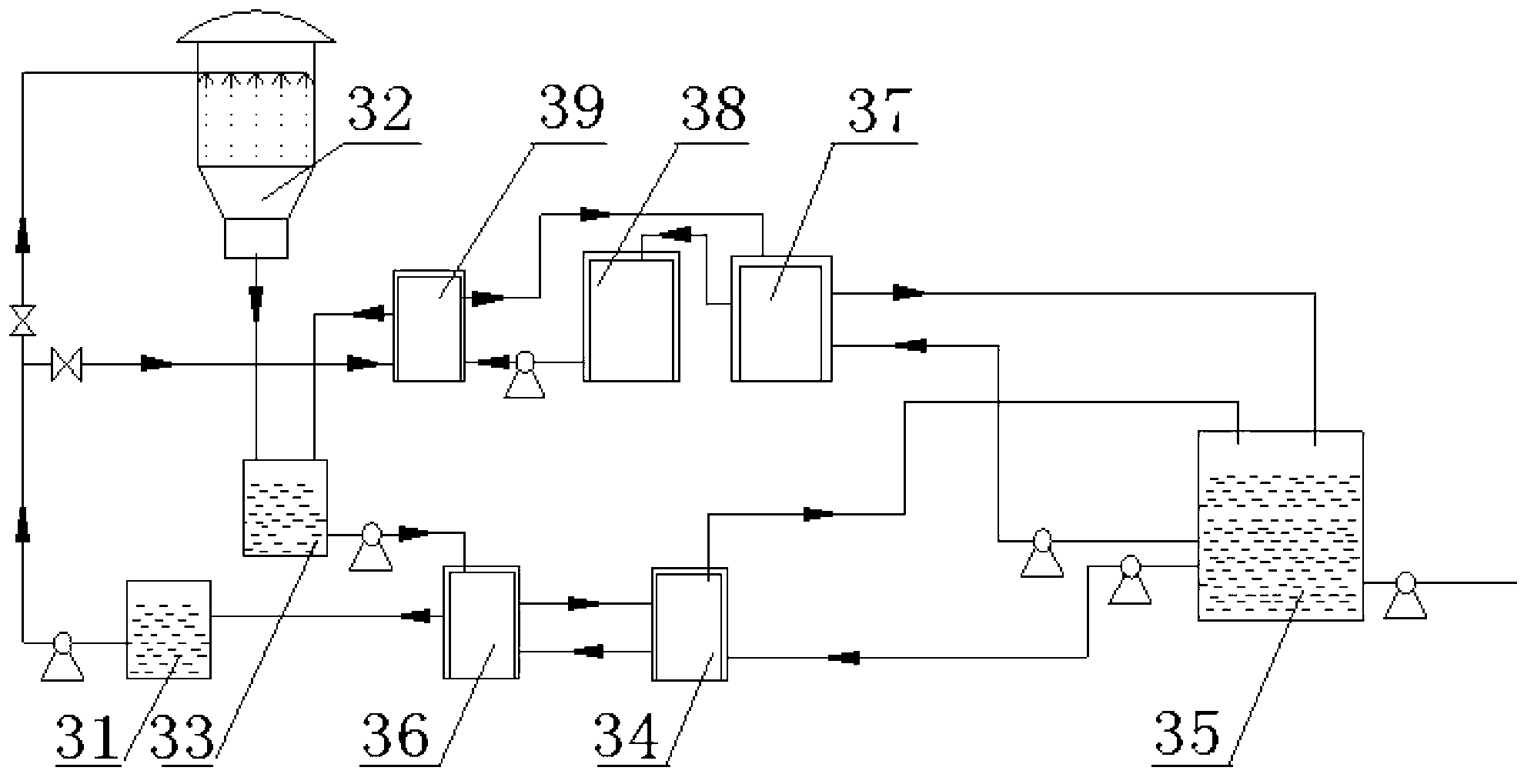

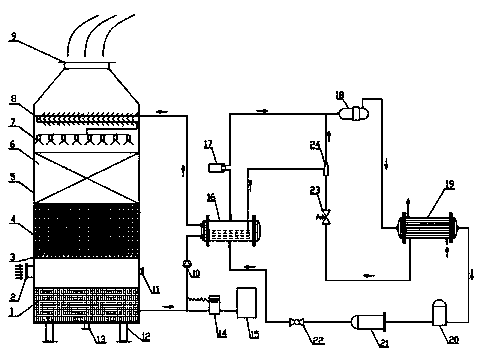

Engine waste heat comprehensive recovery system

ActiveCN106246268AImprove integrityEasy to operateAir-treating devicesVehicle heating/cooling devicesFull recoveryLithium bromide

The invention relates to an engine waste heat comprehensive recovery system. The engine waste heat comprehensive recovery system comprises a condenser I, a single-screw expander, a power generator, an engine tail gas exhaust gas exhaust pipe, an evaporative heat exchanger, a working medium pump, an engine tail gas exhaust pipe, a solution pump, a solution heat exchanger, an engine connected cooling water pipe, a first generator, a condenser II, a throttle valve, an evaporator, an absorber, a second generator, an engine connected tail gas exhaust gas exhaust pipe and stop valves A, B, C and D. The engine waste heat comprehensive recovery system has the advantages that the engine high-grade energy recovery system is used for recovering tail gas with high-grade energy, treated tail gas exhaust gas and low-grade energy engine cooling water jointly serve as a heat source to drive a lithium bromide absorption refrigerator for full recovery of tail gas heat, designed valve group-condenser-evaporator units are used in the engine heat recovery system, the function integrity of the system is improved, and the purposes of convenient and rapid operation and easy control are achieved.

Owner:HARBIN INST OF TECH AT WEIHAI

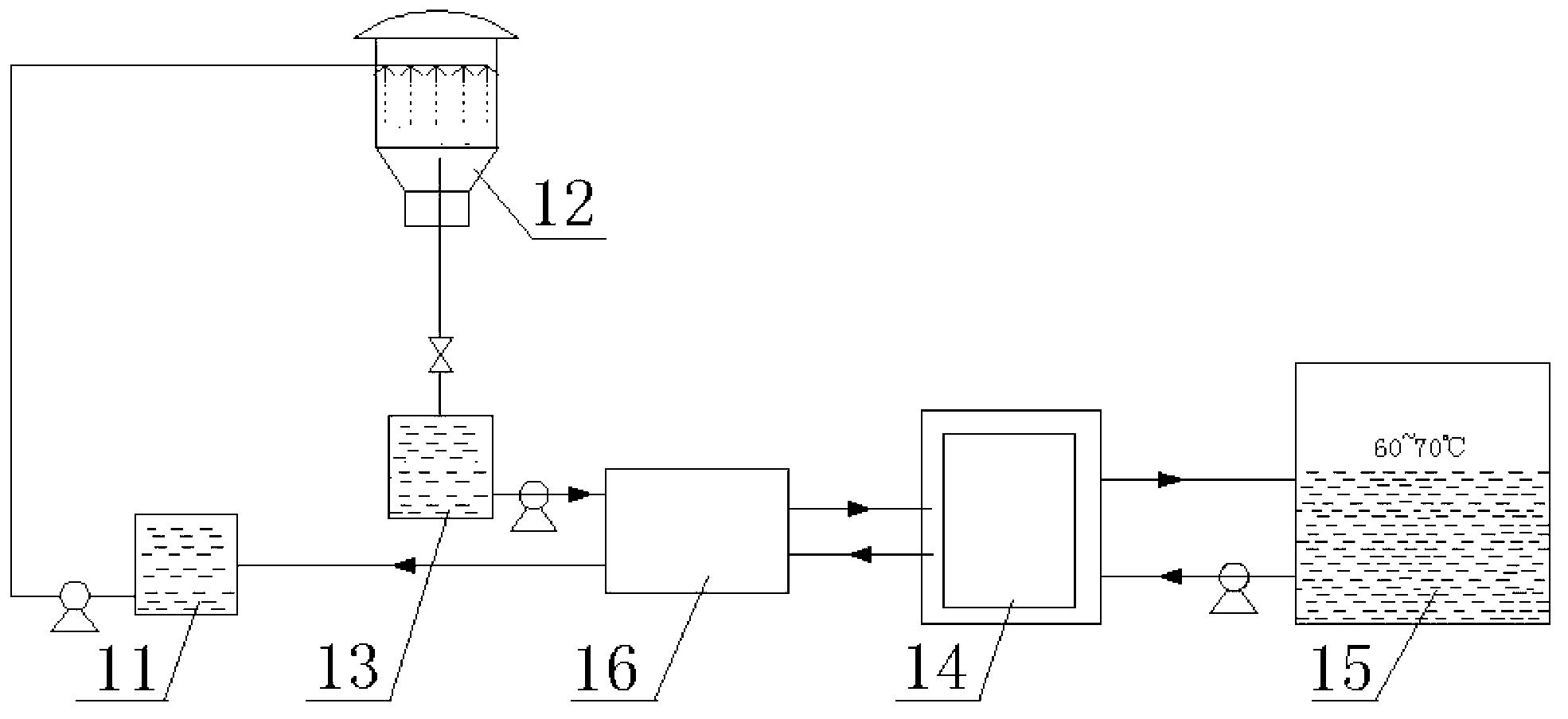

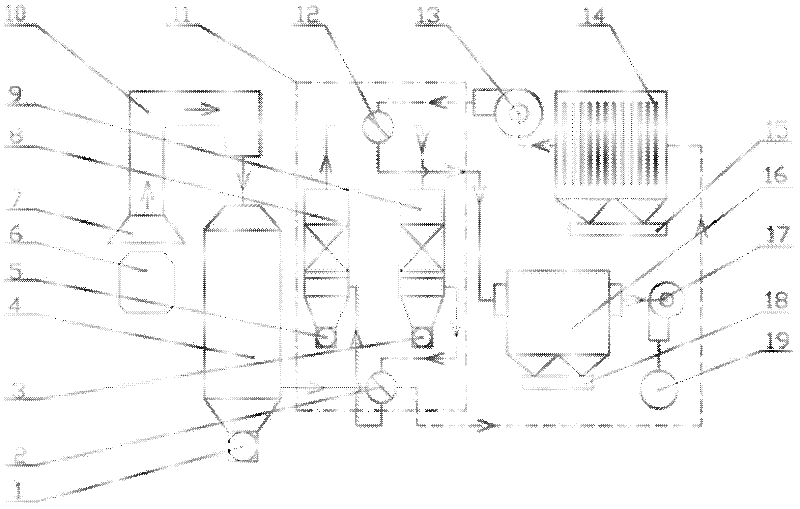

Air compressor residual-heat utilization system and method

InactiveCN102797661AReduce the temperatureImprove efficiencyPositive displacement pump componentsPositive-displacement liquid enginesComputer control systemFull recovery

The invention provides an air compressor residual-heat utilization system and method. The air compressor residual-heat utilization system comprises a water storage tank, a computer control system, and a first heat exchanging system and a second heat exchanging system which conduct heat exchange with the air compressor respectively, wherein the first heat exchanging system comprises a hot water tank, a cold water tank, a heat exchanger, an internal circulation water tank and a heat pump unit; and the second heat exchanging system comprises an air compressor residual-heat recycling device. The invention also discloses an air compressor residual-heat utilization method. The air compressor residual-heat utilization system and method overcomes a plurality of defects in the prior art, and realizes full recovery of the air compressor residual heat, and the residual-heat utilization ratio approximates 100 percent.

Owner:CRRC QIQIHAR ROLLING CO LTD

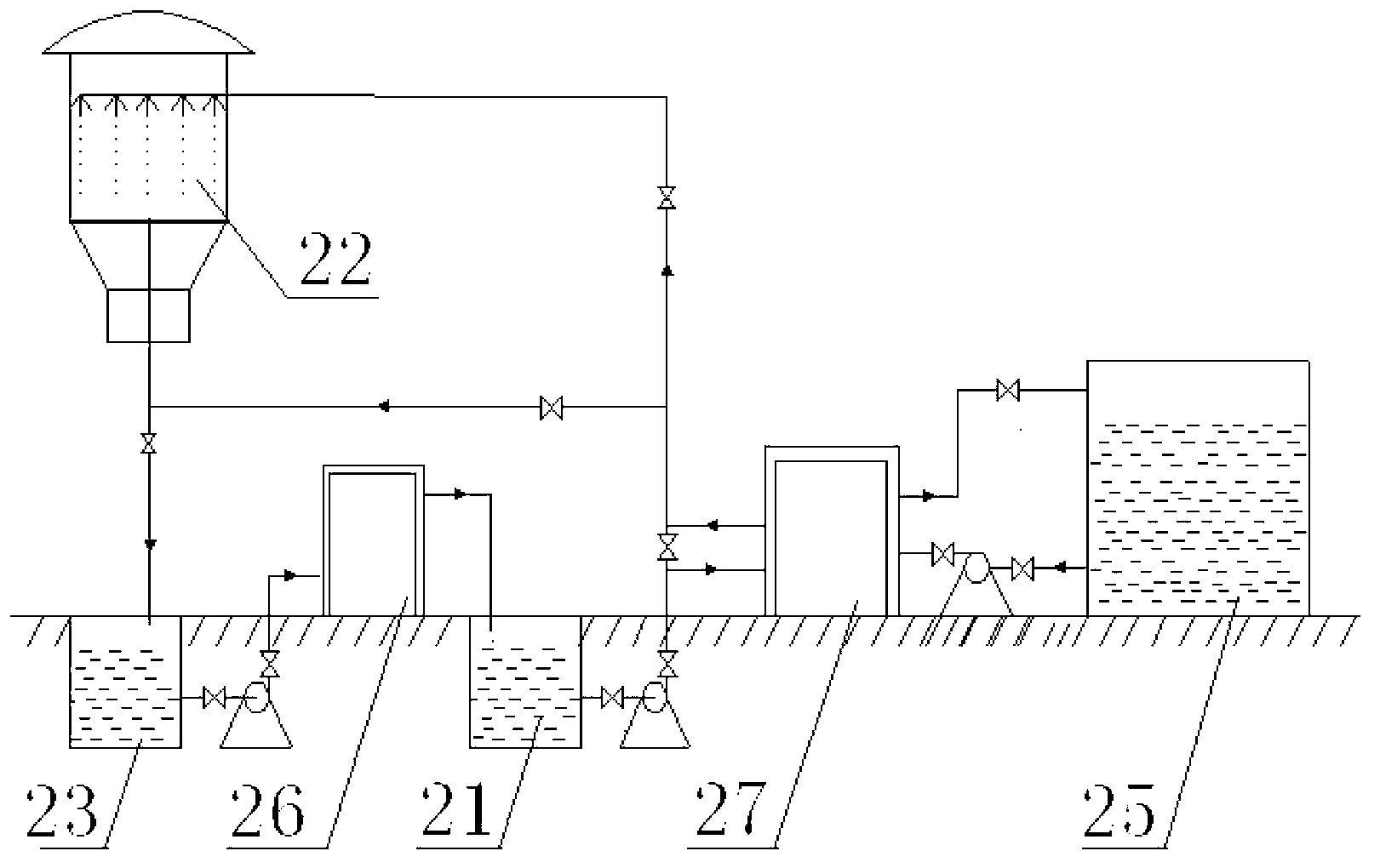

Process and device for recycling flue gas afterheat of electric furnace

ActiveCN102243025AHuge heat exchange area per unit volumeIncrease heat exchange intensityIncreasing energy efficiencyWaste heat treatmentElectric arc furnaceFull recovery

The invention provides a process for recycling flue gas afterheat of an electric furnace. The process comprises the following steps: firstly passing high-temperature flue gas generated by the electric furnace through a flue gas hood and an evaporative cooling flue so as to enter into a burning settling chamber, introducing the discharged flue gas into a heat accumulating type rapid cooling device, changing the working conditions of two heat accumulating units (A and B) of the heat accumulating type rapid cooling device periodically, introducing the flue gas into a bag-type dust collector for dedusting, and then discharging the processed flue gas into the atmosphere through a draft fan and a chimney. The invention provides a device for recycling flue gas afterheat of the electric furnace. The device mainly comprises the hood, a flue, the burning settling chamber, a flue gas inlet, a flue gas outlet, a circulating inlet, a circulating air outlet, a circulating fan, a convection type afterheat boiler, the bag-type dust collector, the draft fan and the chimney, and is characterized in that the heat accumulating type rapid cooling device is installed on the back of the burning settling chamber, mainly consists of a heat transfer unit A and a heat transfer unit B which are provided with honeycomb ceramic heat accumulators, and has two operating modes. The process and device for recycling the flue gas afterheat of the electric furnace have the advantages of realizing full recovery of low-temperature flue gas afterheat, simultaneously avoiding the new synthesis of dioxin, and realizing the standard flue gas emission.

Owner:北京中冶设备研究设计总院有限公司

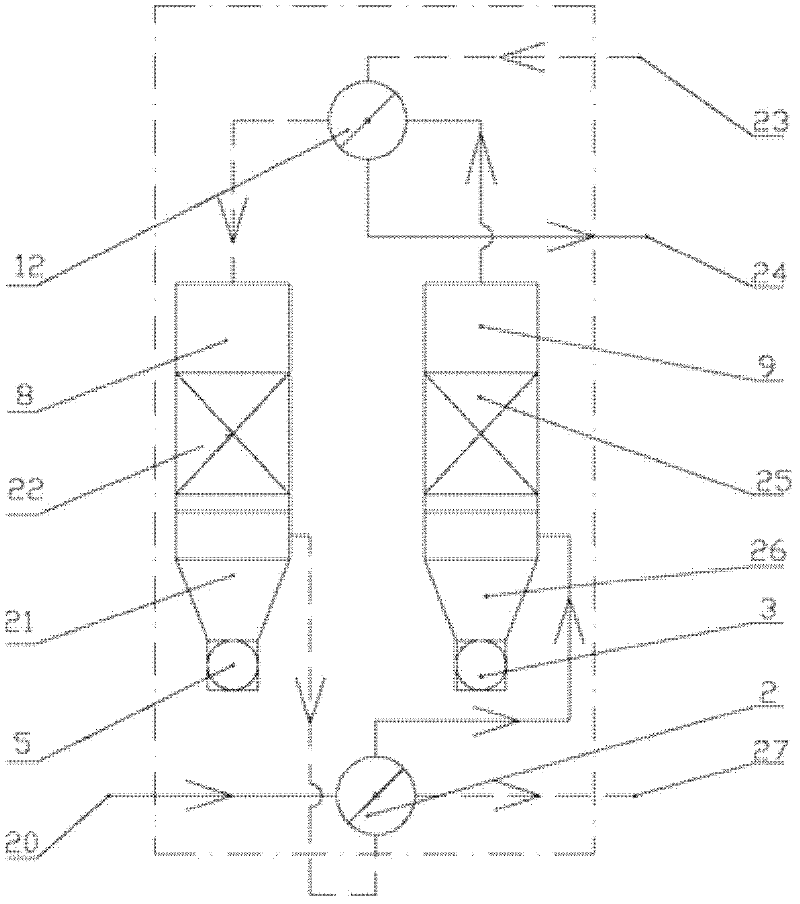

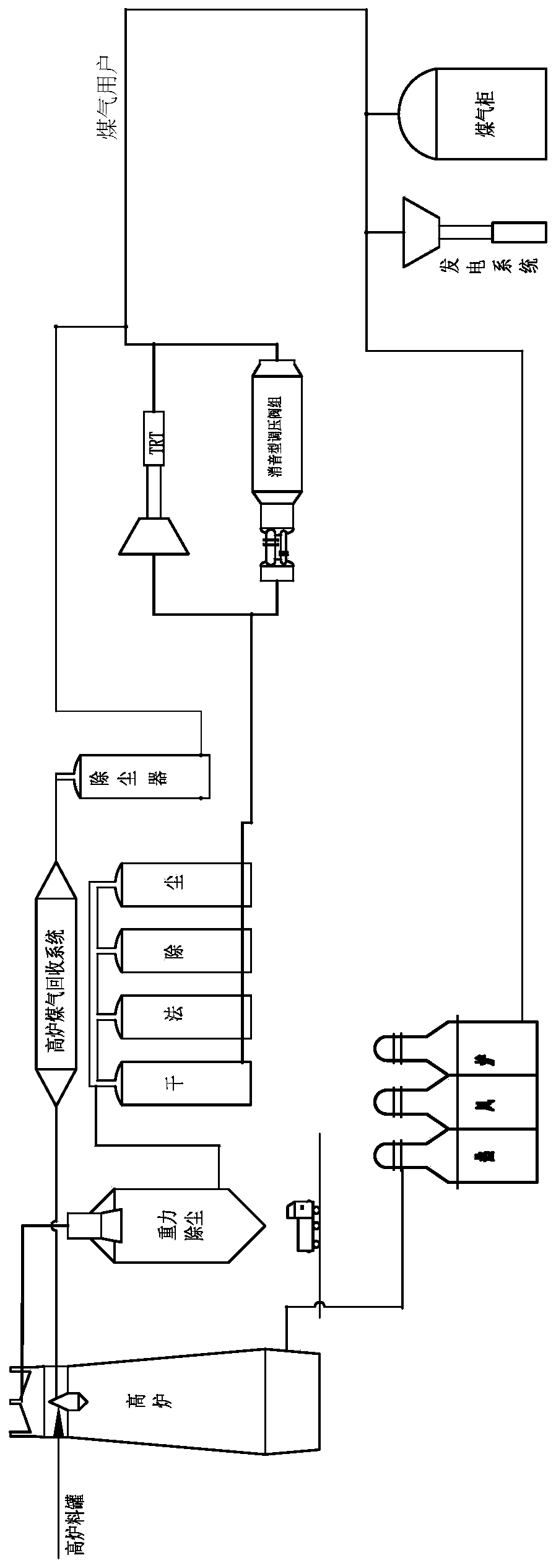

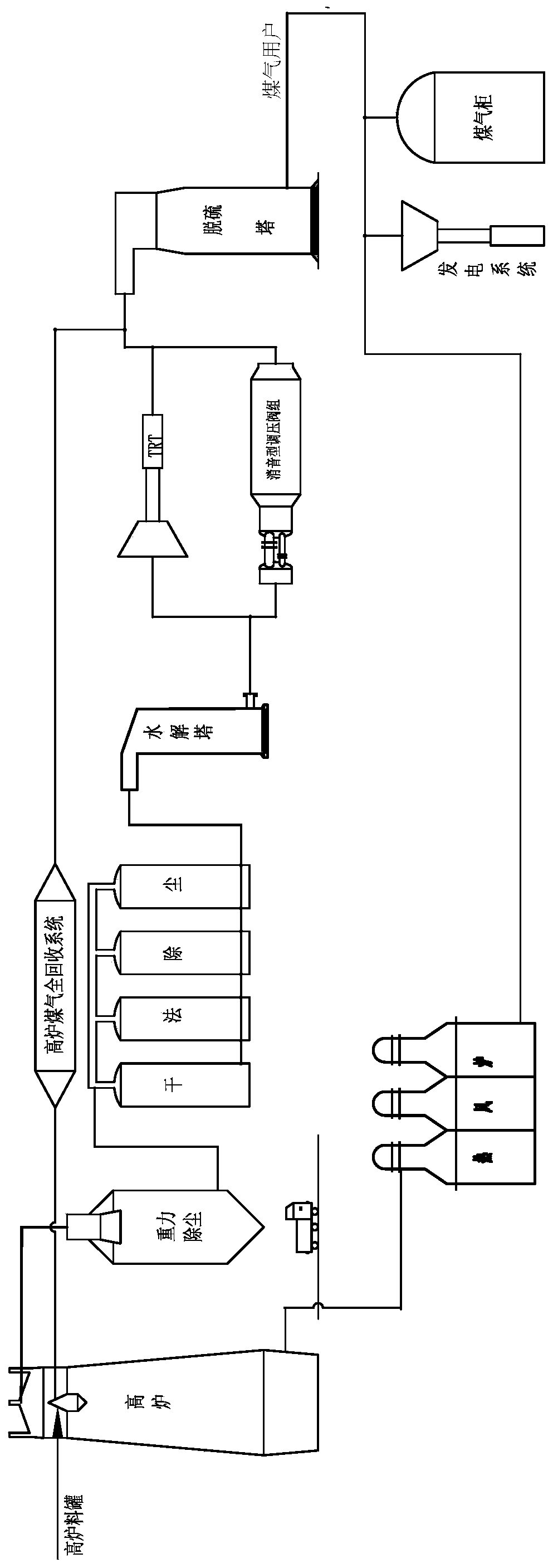

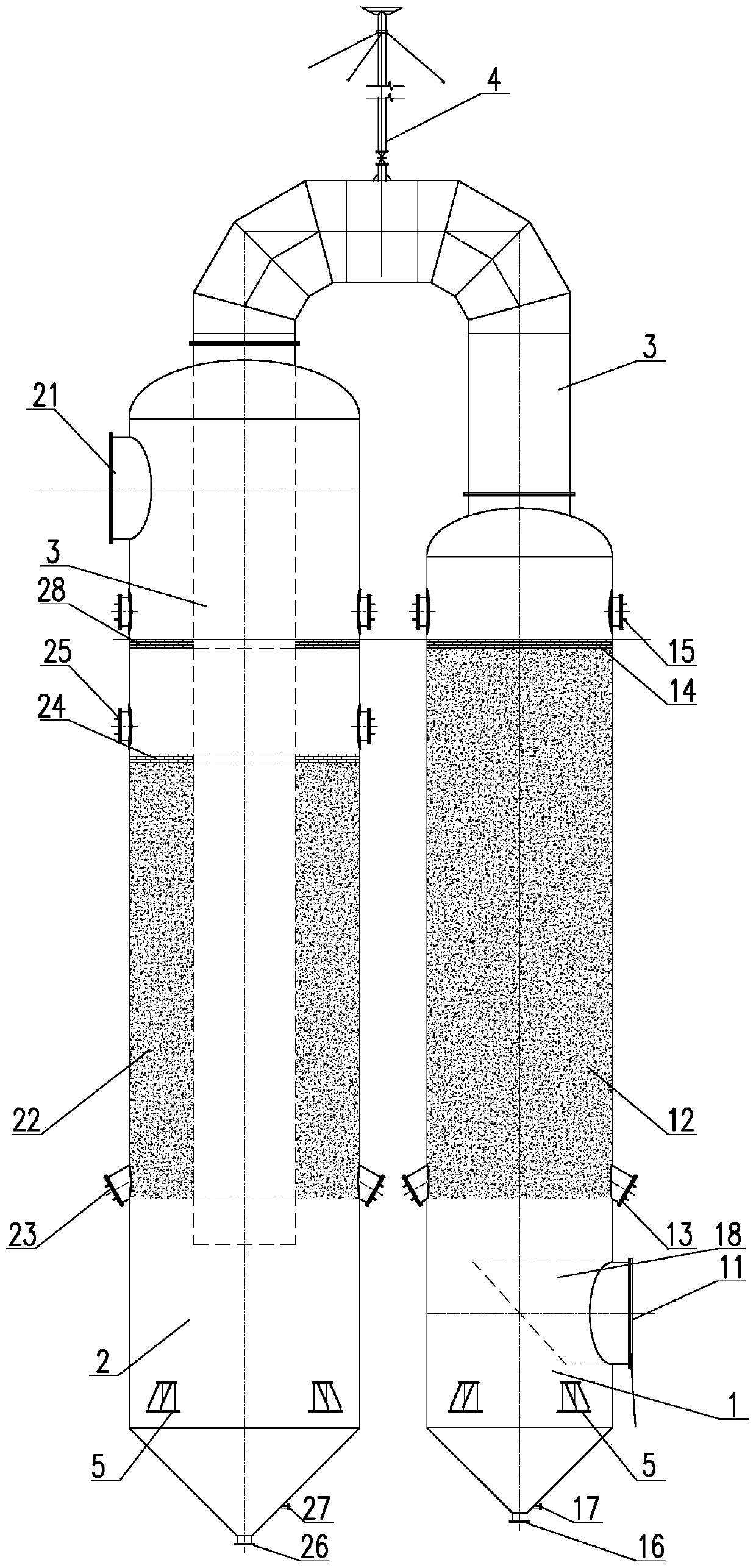

System and technology for environmentally-friendly comprehensive treatment of iron making blast furnace gas

PendingCN110452744AEfficient removalGroundbreakingBlast furnace detailsDust arrestersFull recoveryMetallurgy

The invention provides a system and a technology for environmentally-friendly comprehensive treatment of iron making blast furnace gas. The system comprises a blast furnace top uniform pressure gas full-recovery system, a gravity deduster and a dry bag filter, and further comprises a blast furnace gas hydrolysis tower and a blast furnace gas desulfurization tower. The blast furnace gas goes through the gravity deduster and the dry bag filter, and then is conveyed into the blast furnace gas hydrolysis tower, COS in the blast furnace gas is hydrolyzed by the blast furnace gas hydrolysis tower toform H2S; the treated blast furnace gas goes through a TRT / or pressure regulating valve group, and then is conveyed into the blast furnace gas desulfurization tower, and the blast furnace gas desulfurization tower desulfurizes and dechlorinates H2S and Cl<-> in the blast furnace gas; and the treated blast furnace gas is conveyed into a blast furnace gas user or is stored in a gas cabinet througha gas pipe network. The integral treatment technology which integrates blast furnace gas desulfurization, dechlorination and blast furnace top uniform pressure gas recovery has a high integration degree, and can run stably and reliably.

Owner:LOFON CONTROL EQUIP BEIJING

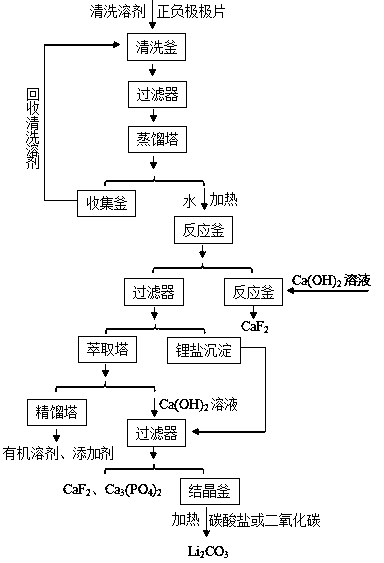

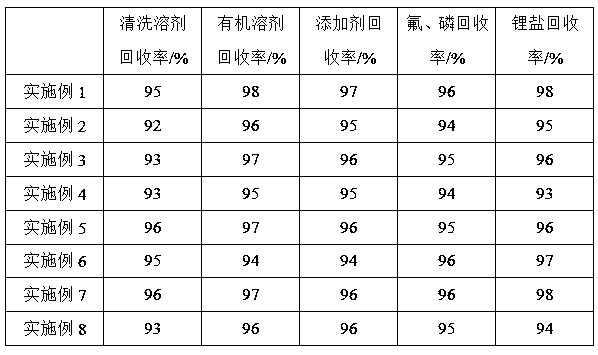

Full recovery method of waste lithium ion battery electrolyte

ActiveCN110203949ASimple processHigh feasibilityCalcium/strontium/barium fluoridesWaste accumulators reclaimingRecovery methodOrganic solvent

The invention provides a full recovery method of waste lithium ion battery electrolyte, aiming at recovering valuable lithium salts, organic solvents and additives in the waste electrolyte, and recovering harmful impurities such as fluorine, phosphorus and the like after harmless treatment. According to the invention, after cleaning, cleaning solvent recovery, organic solvent and additive recovery, fluorine and phosphorus recovery and lithium salt recovery processes, lithium salt is finally recovered in the form of lithium carbonate, organic solvent and additive are separated, purified and recycled, and fluorine and phosphorus are recovered in the form of precipitation. The process is simple and feasible. Waste electrolyte is fully recycled and has no pollution to the environment. The recovery rate of components of waste electrolyte is over 95%, which is suitable for large-scale industrial application.

Owner:中科行发医疗科技有限公司

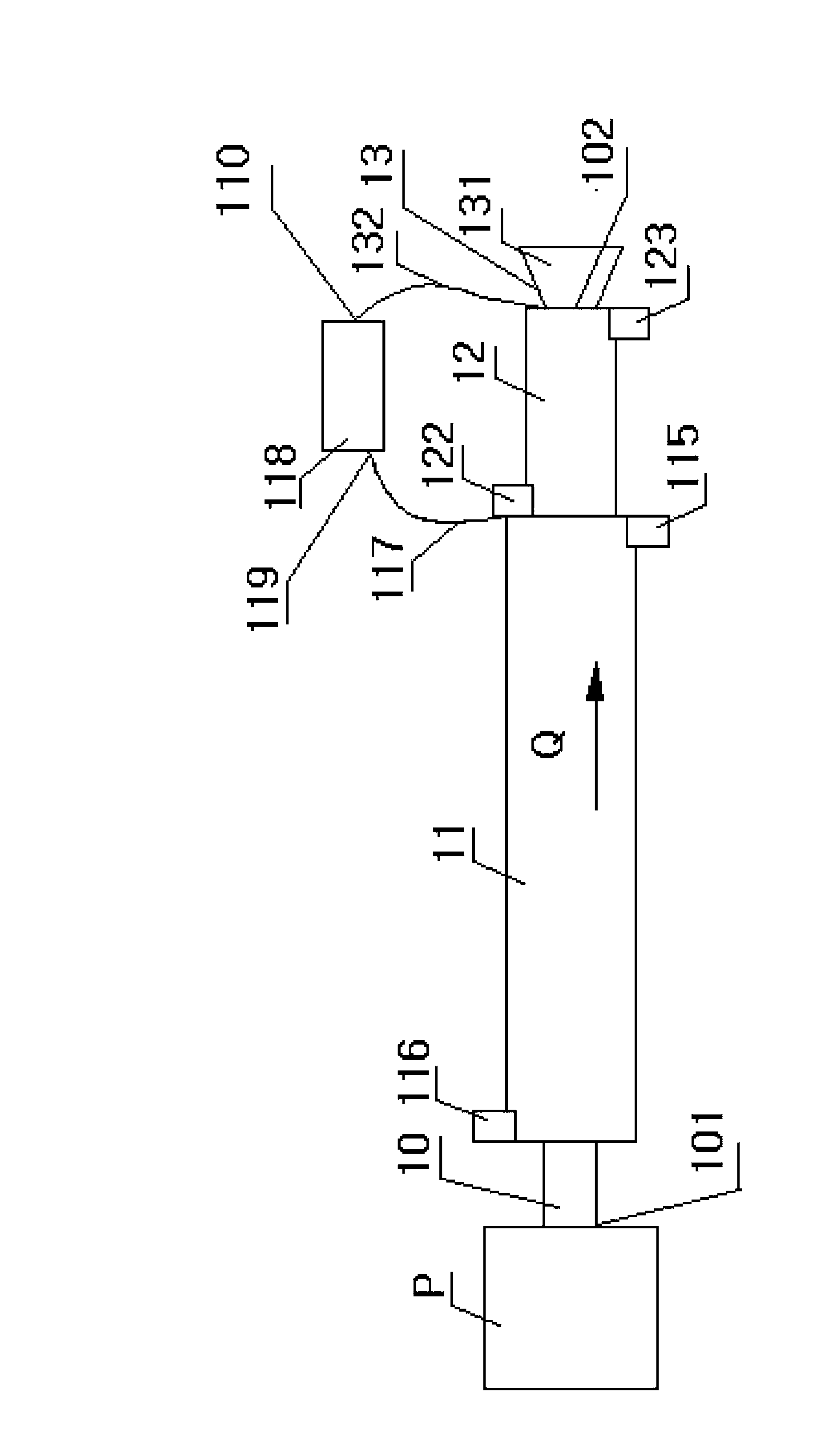

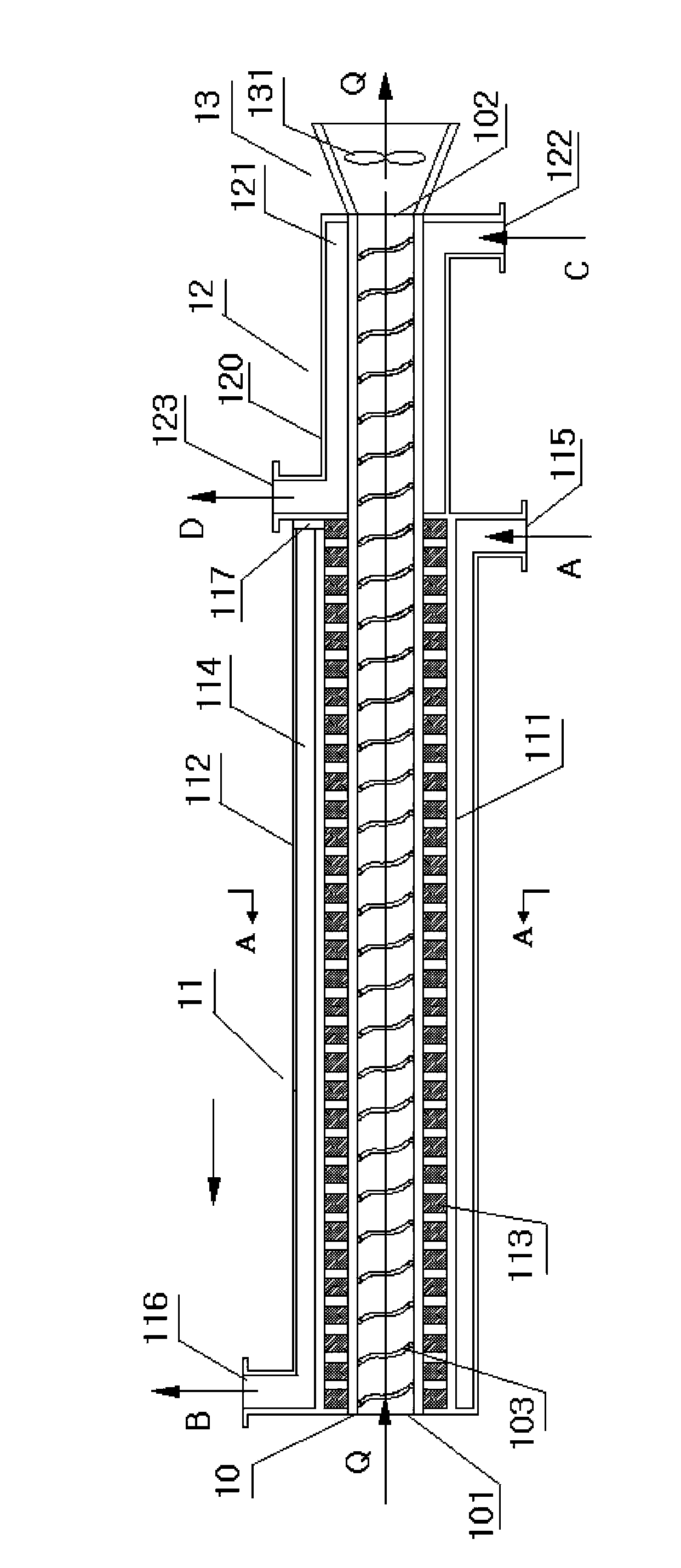

Flue gas waste heat thermoelectric recovery device

ActiveCN104167956AOvercome the situation of direct radiation without recovery of heatSmooth dischargeStationary tubular conduit assembliesGenerators/motorsFull recoveryFlue gas

The invention discloses a flue gas waste heat thermoelectric recovery device which is arranged on a flue gas pipeline. The inner wall of the flue gas pipeline is provided with fins arranged along the overall length of the flue gas pipeline in the axial direction. The device comprises a temperature difference power generation section and a hot water section which are sequentially arranged in the flowing direction of the flue gas, wherein the temperature difference power generation section comprises a first pipe body which sleeves the flue gas pipeline. The first pipe body has a cold end of the temperature difference power generation section and a hot end of the temperature difference power generation section; and power generation modules are arranged between the first pipe body and the flue gas pipeline, wherein each power generation module closely attaches to the inner wall of the pipe body and the outer wall of the flue gas pipeline. The temperature difference power generation section also comprises a second pipe body which sleeves the first pipe body to form a cooling water annular pipeline, wherein the cooling water annular pipeline has a cooling water outlet and a cooling water inlet. The hot water section comprises a third pipe body which sleeves the flue gas pipeline to form a hot water annular pipeline, wherein the hot water annular pipeline has a hot water outlet and a hot water inlet, so that full recovery of the flue gas waste heat is realized.

Owner:BAOSHAN IRON & STEEL CO LTD +1

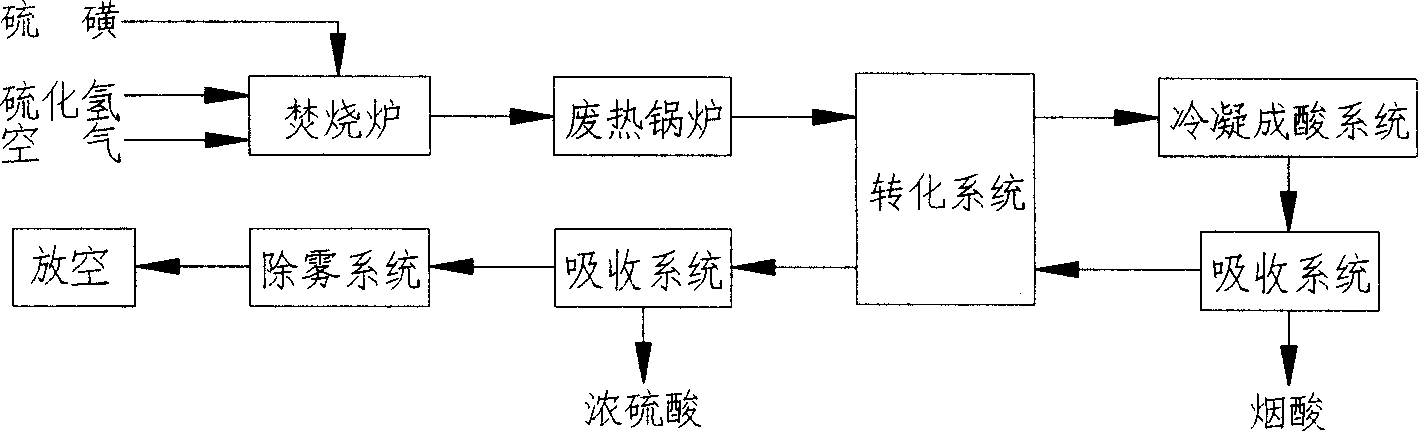

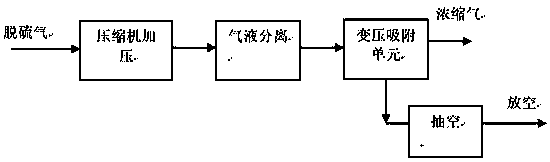

Combined dry and wet process of preparing high concentration sulfuric acid with hydrogen sulfide

InactiveCN1636866AThorough responseFlexible operationSulfur-trioxide/sulfuric-acidHigh concentrationThermal energy

The combined dry and wet process of preparing high concentration sulfuric acid with hydrogen sulfide is suitable for treating tail gas containing acid hydrogen sulfide gas. Acid hydrogen sulfide gas, sulfur and air are mixed to burn to prepare SO2 gas, SO2 gas is converted in the combined dry and wet conversion process into SO3 gas, and SO3 gas is produced into high concentration sulfuric acid fuming sulfuric acid via combined direct condensation and adsorption process. The present invention has complete reaction of hydrogen sulfide, full recovery of reaction heat, advanced technological process, simple operation, low running cost, and high safety and reliability.

Owner:HUNAN BAILI ENGINEERING SCIENCE AND TECHNOLOGY CO LTD

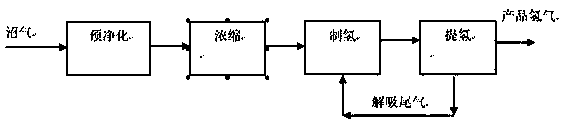

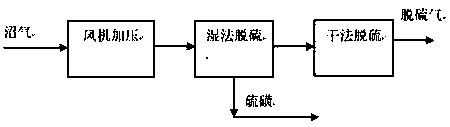

Method for producing hydrogen from biogas biomass

Owner:SICHUAN TECHAIRS

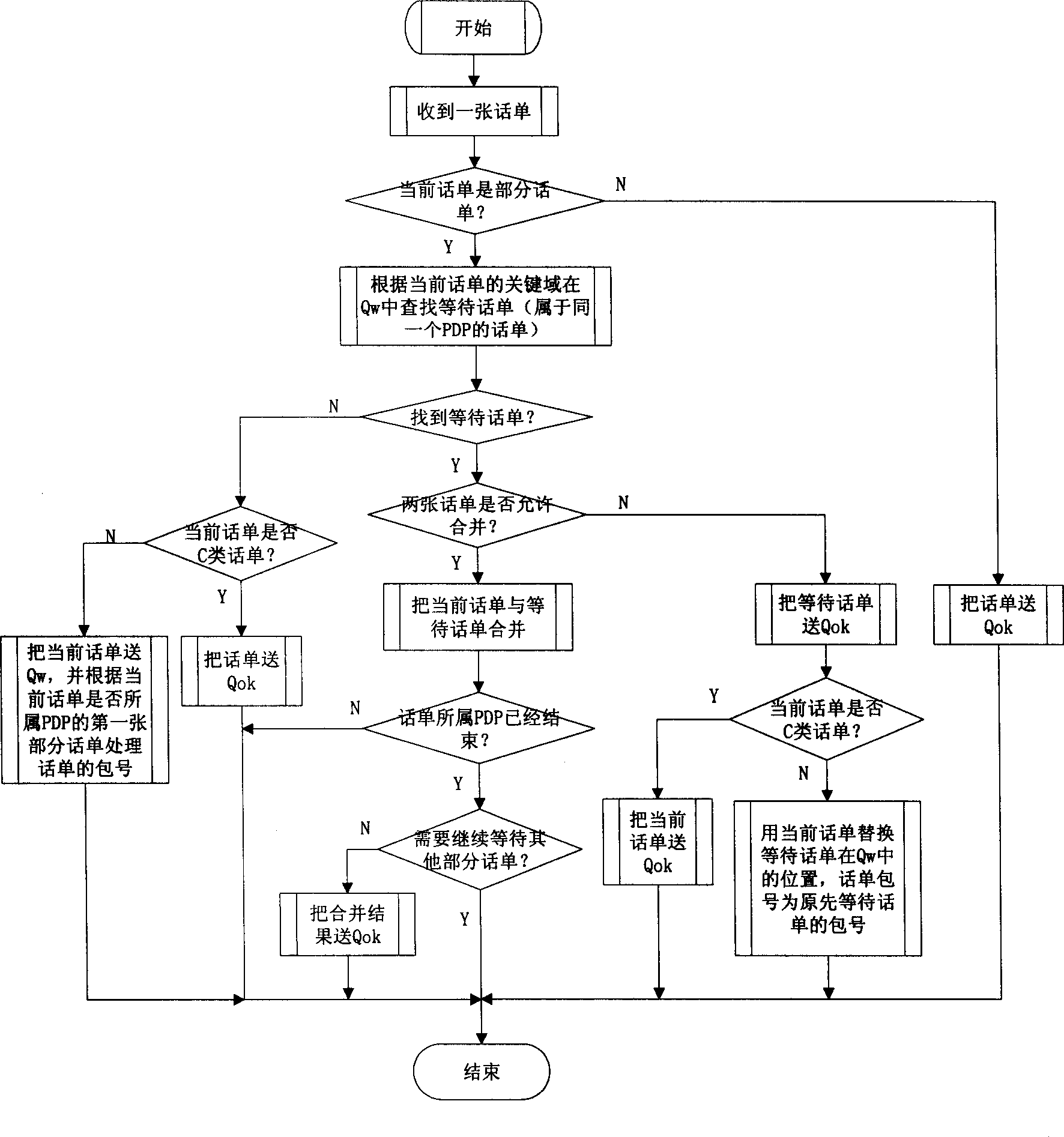

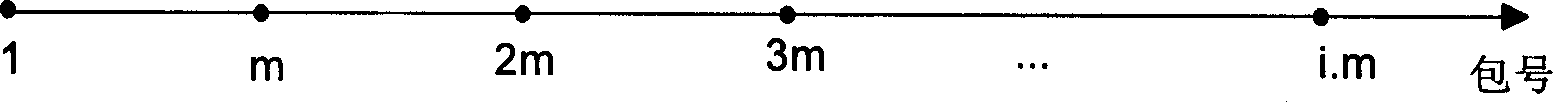

Telephone bill combining process method

InactiveCN1479485AReduce congestionEasy to controlMetering/charging/biilling arrangementsStore-and-forward switching systemsFull recoveryIntermediate state

A method for merging and processing call tucket, Controlling time and number of waiting call ticket makes merging procedure easy to control, reducing possibility of data congestion happened in merging procedure processed by host in network. Black call ticket concept is introduced in the invention and real time detecting is carried out for merging procedure regularly. forcibly interrupting the merging procedure for the call tickets taking up network resources for long time as well as using buffer mechanism makes merging procedure smooth. In events of abnormity or power down occurred in mergingprocedure, information in intermediate state is saved. Based on the said saved intermediate state, relevant waiting queue of Qw lists are recovered effectively, full recovery of data is guaranteed inprinciple. The invention can processes call tickets created by host in GPRS, WCDMA network as well as solve the issue of losing or repeating call tickets.

Owner:HUAWEI TECH CO LTD

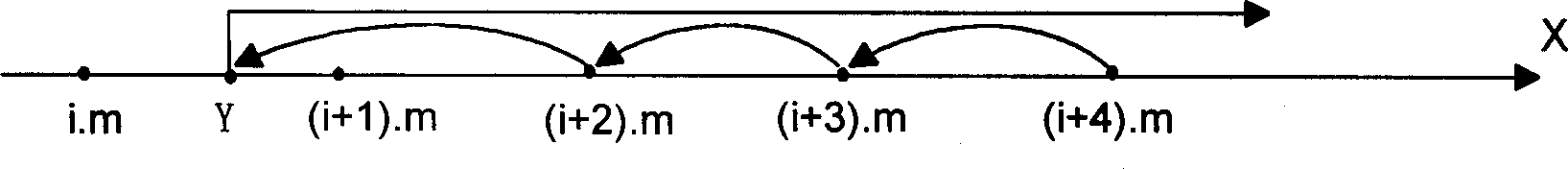

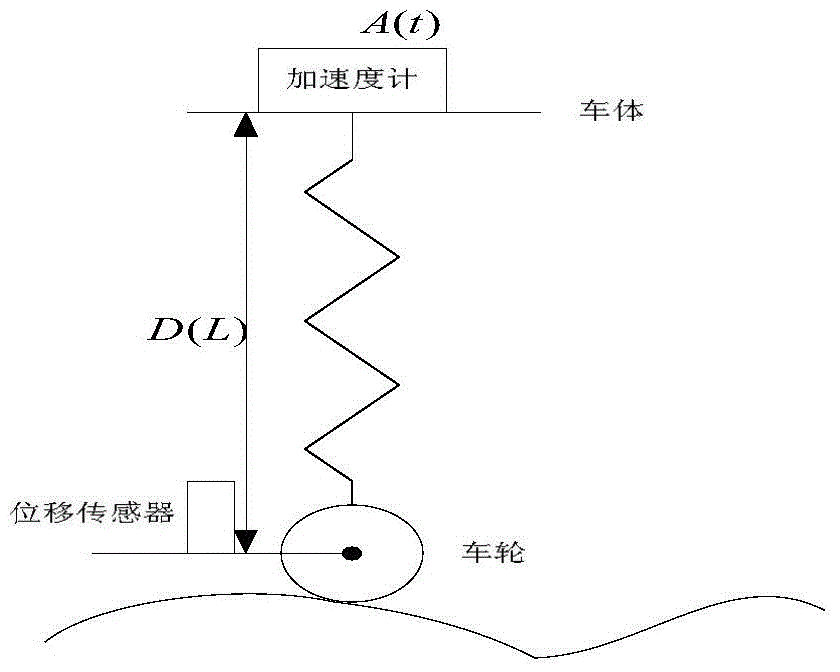

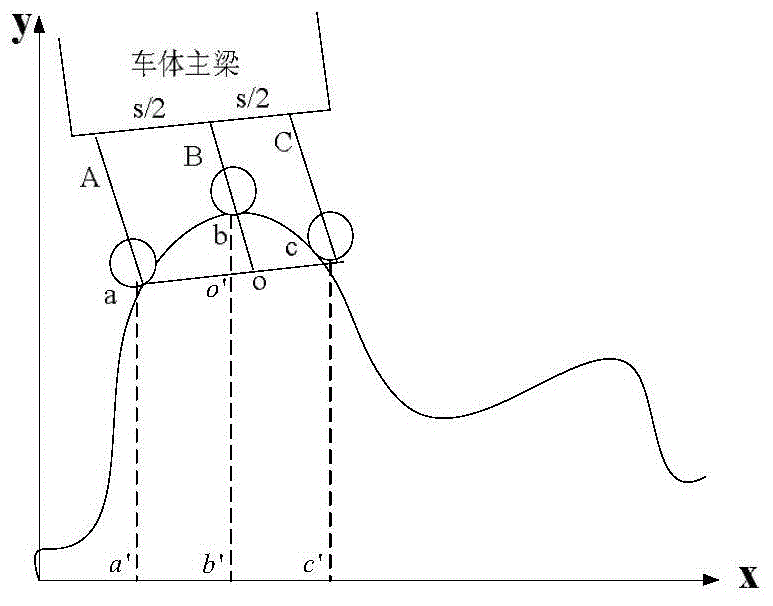

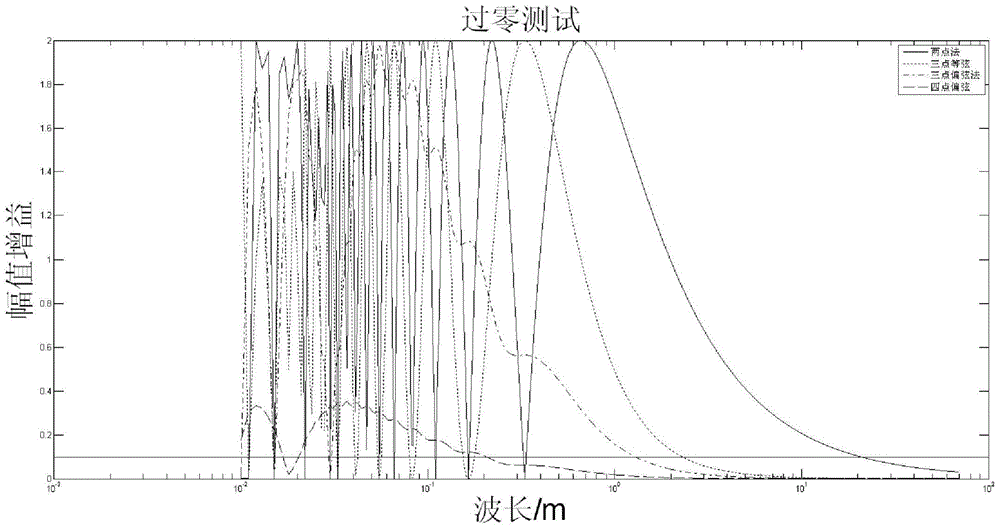

Combined chord measurement method for longitudinal irregularity of steel rail

The invention discloses a combined chord measurement method for longitudinal irregularity of a steel rail. Under the premise of no increase in the system cost, through comparison and selection of a particular chord length of 1m and combination of a cord length dividing ratio of 3:97, an optimal FIR inverse filter design method and flexible combination (three one-dimensional sensors simultaneously use a three-point deflected chord, and only 1# and 3# sensors use a two-point chord) of three sensors in the same group are combined, the short wavelength detection and the long wavelength detection are integrated, and actual irregular waveforms of the rail in a full recovery band can be accurately restored.

Owner:HUNAN UNIV

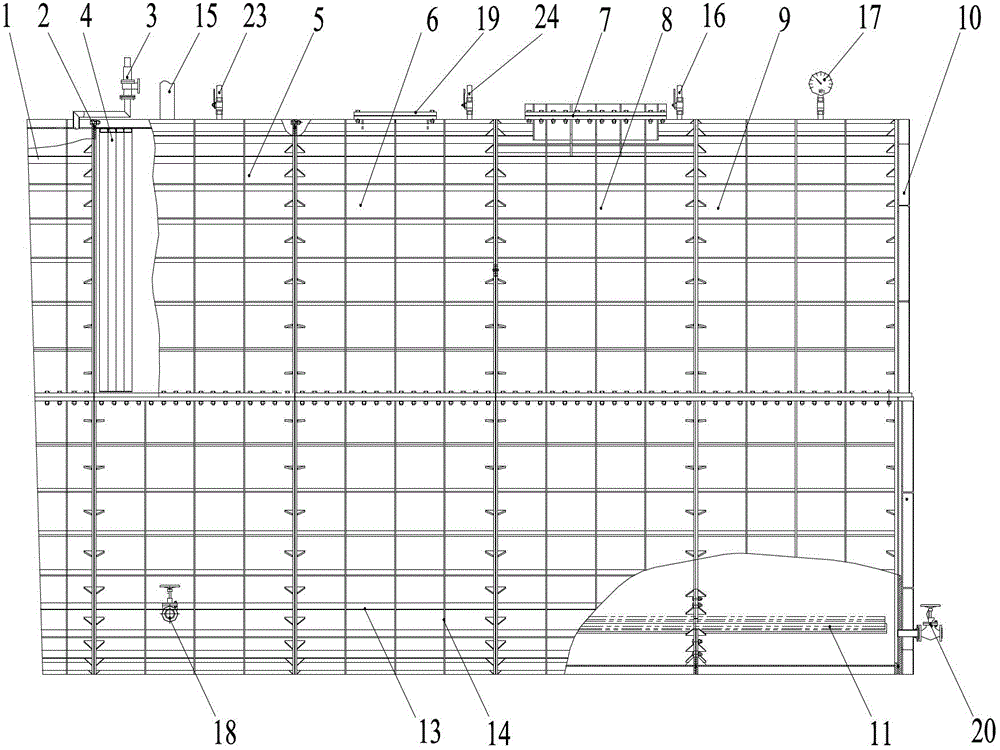

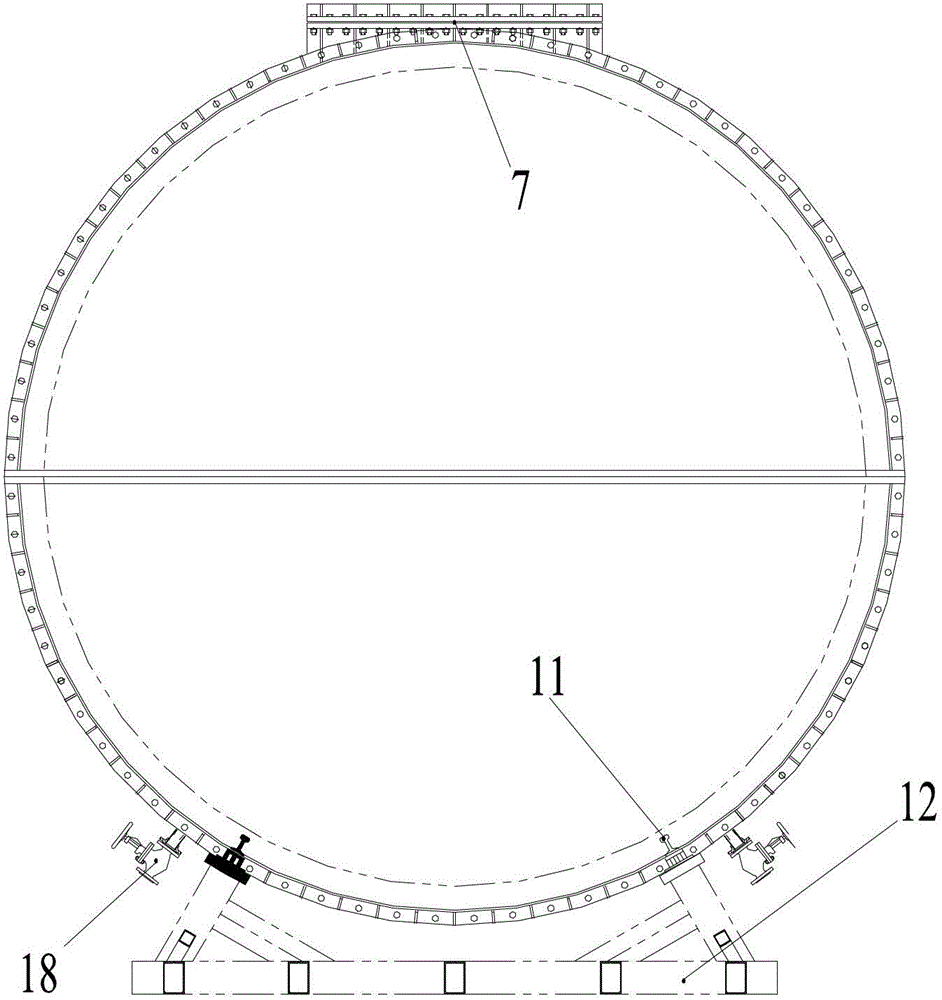

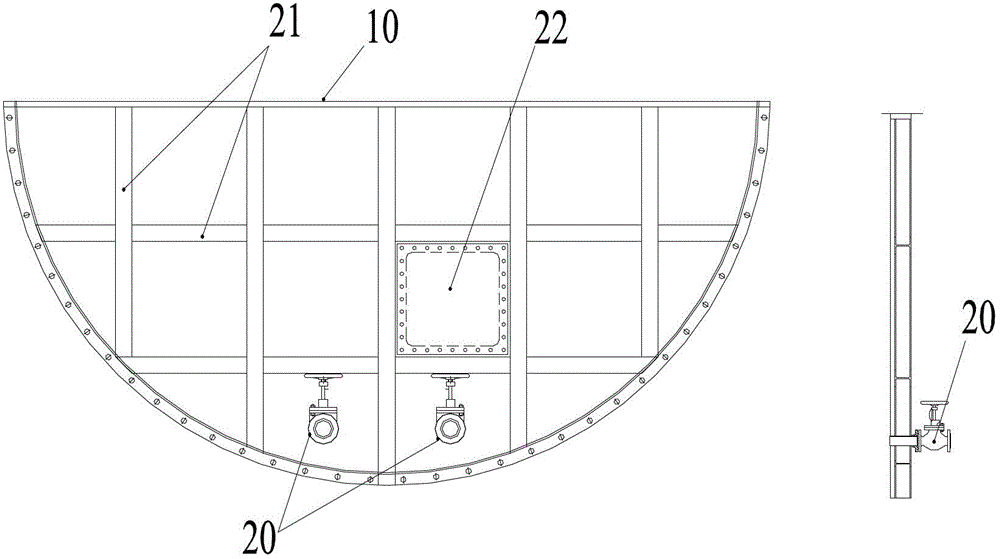

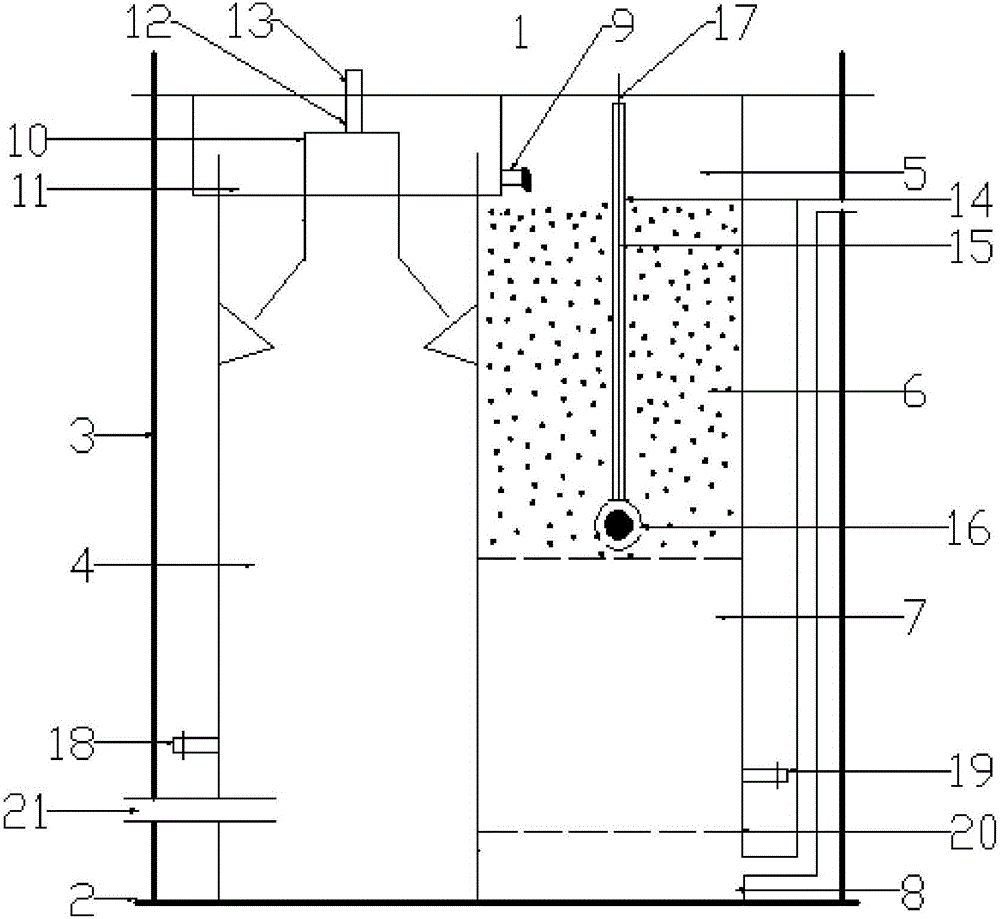

Full-recovery shield tunnel enter and exit water stop device

InactiveCN102748038AIncrease profitImprove construction efficiencyUnderground chambersTunnel liningFull recoveryEngineering

The invention relates to a full-recovery shield tunnel enter and exit water stop device which is a horizontally lain steel sleeve of which an inner cavity is filled with water. The full-recovery shield tunnel enter and exit water stop device is formed by sequentially connecting a transition barrel, a standard barrel group and an end cover in a sealed mode, wherein the transition barrel is connected with a hole circle of a tunnel portal; one end of the standard barrel group is connected with the transition barrel; the other end of the standard barrel group is connected with the end cover; the standard barrel group consists of a standard barrel or a plurality of standard barrels which are connected end to end in a sealed mode; a freezing pipe for filling a refrigerant medium is arranged in an inner cavity of the standard barrel group; the bottom of the inner cavity is provided with a guide rail for bearing a shield; the top of the standard barrel group is provided with a prepared hole, a water injection hole, an air vent, a discharge hole, a vent hole, a lifting hole and a pressure gauge; the bottom of the standard barrel group is provided with a base; the transition barrel is provided with an overflow valve; and the end cover is provided with a stop valve for draining water. The full-recovery shield tunnel enter and exit water stop device has two hole enter and exit water stop functions, has a simple structure and is convenient to assemble and disassemble; the shield can be totally recycled so as to save the construction cost; and the construction that the shield safely and rapidly enters and exits from a tunnel can be implemented.

Owner:上海盾构设计试验研究中心有限公司 +1

Method for preparing hydroxylapatite coating by cold spraying

InactiveCN101591777AHigh bonding strengthGood biological stabilityPressure inorganic powder coatingFull recoveryApatite

The invention discloses a method for preparing a hydroxylapatite coating by cold spraying, which belongs to the field of implant processing and preparation in biomedical material engineering. The method adopts cold spraying equipment to spray dried hydroxylapatite powder onto a matrix of a biomedical implant metal material with the surface subjected to sand blasting treatment, thereby obtaining the hydroxylapatite coating with high crystallinity and good biological stability. The method can effectively avoid the thermal decomposition of sprayed powder, namely hydroxylapatite during the processing, can reduce the non-crystallization and hydroxyl loss, has small influence on an organization structure of the material, retains a structure of the originally spayed HA powder, and does not generate impurity phases. The hydroxylapatite powder used by the sprayed powder can realize the full recovery, which saves the powder for spraying in a large quantity. The method can prepare the hydroxylapatite coating on the surfaces of implant metal materials to ensure that the surfaces of biologically inert metal matrixes have biological activity, and can prepare medical implant devices such as dental roots, artificial joints and the like.

Owner:BEIJING UNIV OF TECH

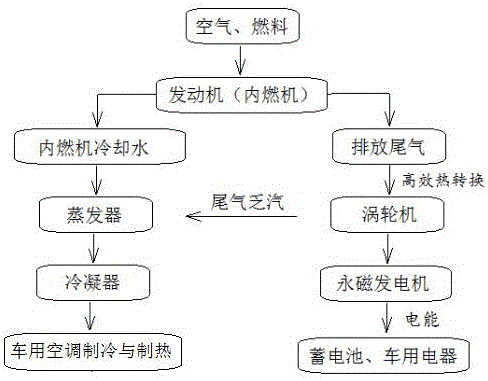

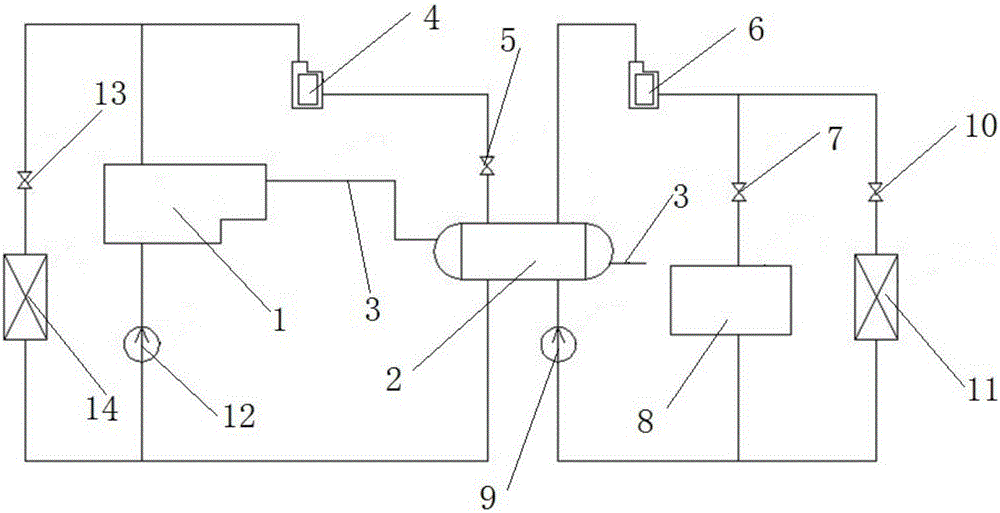

Engine waste heat recovery type vehicle-mounted air conditioner system

PendingCN106627034AFull recoveryRealize heatingAir-treating devicesVehicle heating/cooling devicesThermal energyWaste heat recovery unit

The invention provides an engine waste heat recovery type vehicle-mounted air conditioner system. Firstly, waste heat generated by an engine is collected and stored through a waste heat recovery and storage tank installed on the engine, and the stored waste heat is used for a vehicle-mounted air conditioner, so that heating or refrigeration can still be achieved when the engine does not work during winter heating or summer refrigeration; and meanwhile, the stored heat can be used for preheating during vehicle start-up in winter, no oil is consumed, and more energy is saved. Compared with existing novel engine waste heat recovery systems, the engine waste heat recovery type vehicle-mounted air conditioner system is advantageous in that the heat is directly stored rather than being converted into electric energy, full recovery of the heat is achieved, and energy conservation and environment friendliness are achieved.

Owner:CHANGAN UNIV

System and technology for cleaning flue gas

ActiveCN102847430AAvoid secondary pollutionInnovative designDispersed particle separationAir quality improvementChemical industrySystems design

The invention relates to a technology for cleaning flue gas. The system comprises a raw flue gas input pipe, an absorption tower and a clean flue gas discharge device, wherein the raw flue gas input pipe, the absorption tower and the clean flue gas discharge device are connected. The system also comprises an oxidation device connected to the raw flue gas input pipe, an absorbent feeding device and an absorption liquid regenerating and recovery device, wherein the absorbent feeding device and the absorption liquid regenerating are connected to the absorption tower. A slurry tank, an absorbent spraying layer and a demister layer are arranged in the absorption tower from bottom to top. The technology adopts a sodium-based absorbent to realize removal of nitrogen and sulphur pollutants in flue gas at a low temperature or a normal temperature. The system has a novel design and the technology has simple and environmentally friendly processes, realizes recycling integrated purification treatment on flue gas, realizes synchronous efficient desulfuration and denitration by the same process route, avoids secondary pollution on the environment in full recovery and treatment on later-stage products, is conducive to reduction of an economic cost, and is suitable for purification treatment on flue gas or industrial tail gas produced by a metallurgical chemical industry and a coal-fired power generation industry mainly discharging sulfur and nitrogen oxides as pollutants.

Owner:BEIJING ZHONGNENG NUOTAI ENERGY SAVING & ENVIRONMENTAL PROTECTION CO LTD

Method for extraction of pyridine compounds from coal tar

ActiveCN104893750AAchieve full recoveryImprove the level of comprehensive utilizationOrganic chemistryOrganic compound preparationFull recoverySolvent

The present invention provides a method for extraction of pyridine compounds from coal tar, the method includes the units of fractional distillation of coal tar into narrow fractions, extraction of phenolic compounds from the narrow fractions, extraction of pyridine compounds from the phenolic compounds by use of solvent I, extraction of pyridine compounds from dephenolized oil by use of pyridine compound salt-base 1, neutralization of pyridine compound salt-base 2 s by use of solvent II, and refining of crude pyridine compounds. By the method, the pyridine compounds in the phenolic compounds and the pyridine compounds in the dephenolized oil are extracted, the goal of full recovery of the pyridine compounds can be achieved, and the entire process is free of pollutants.

Owner:SHAANXI COAL & CHEM IND GRP SHENMU TIANYUAN CHEM IND +1

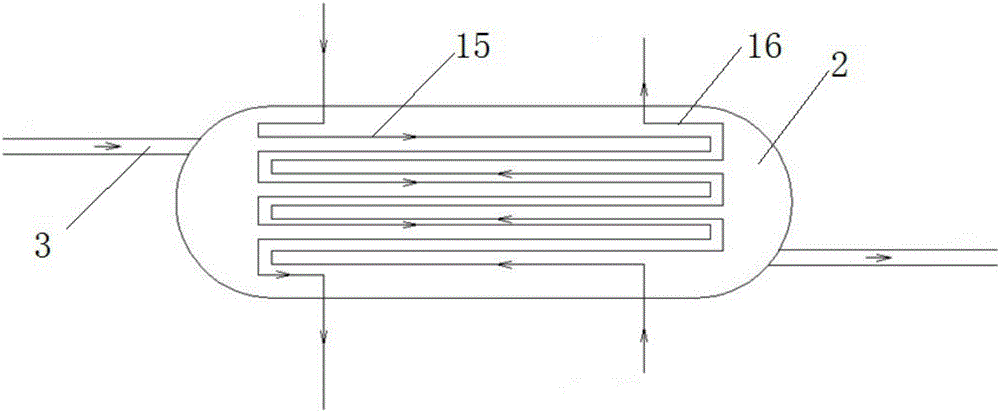

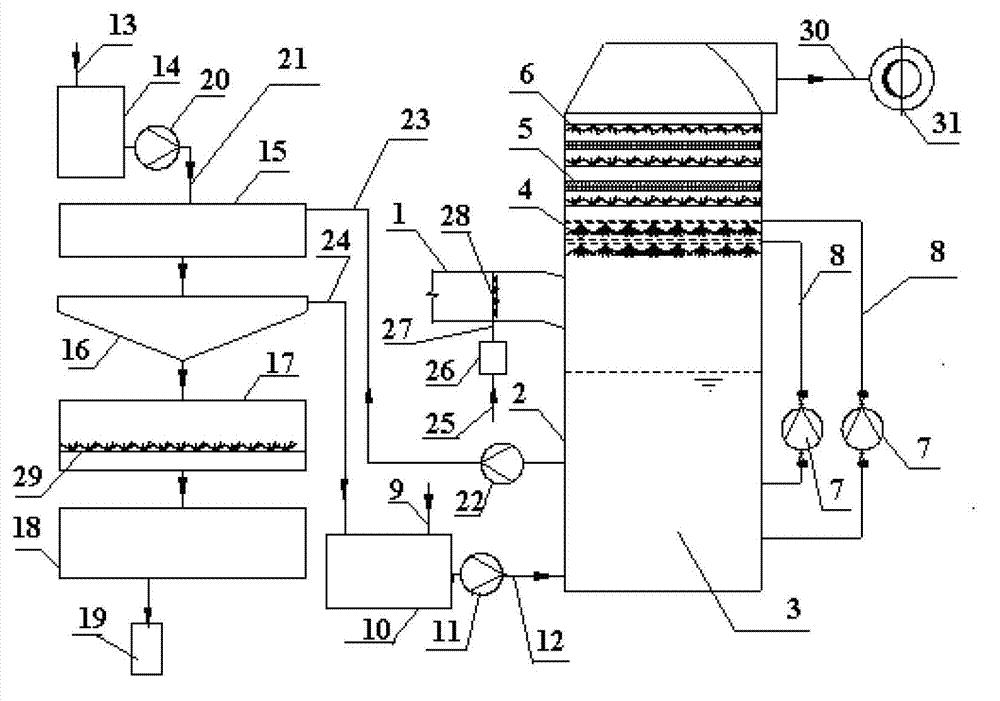

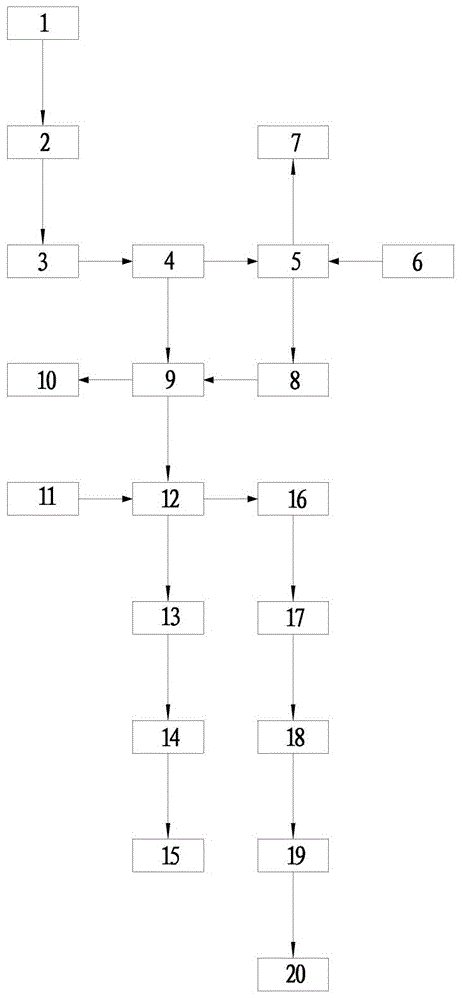

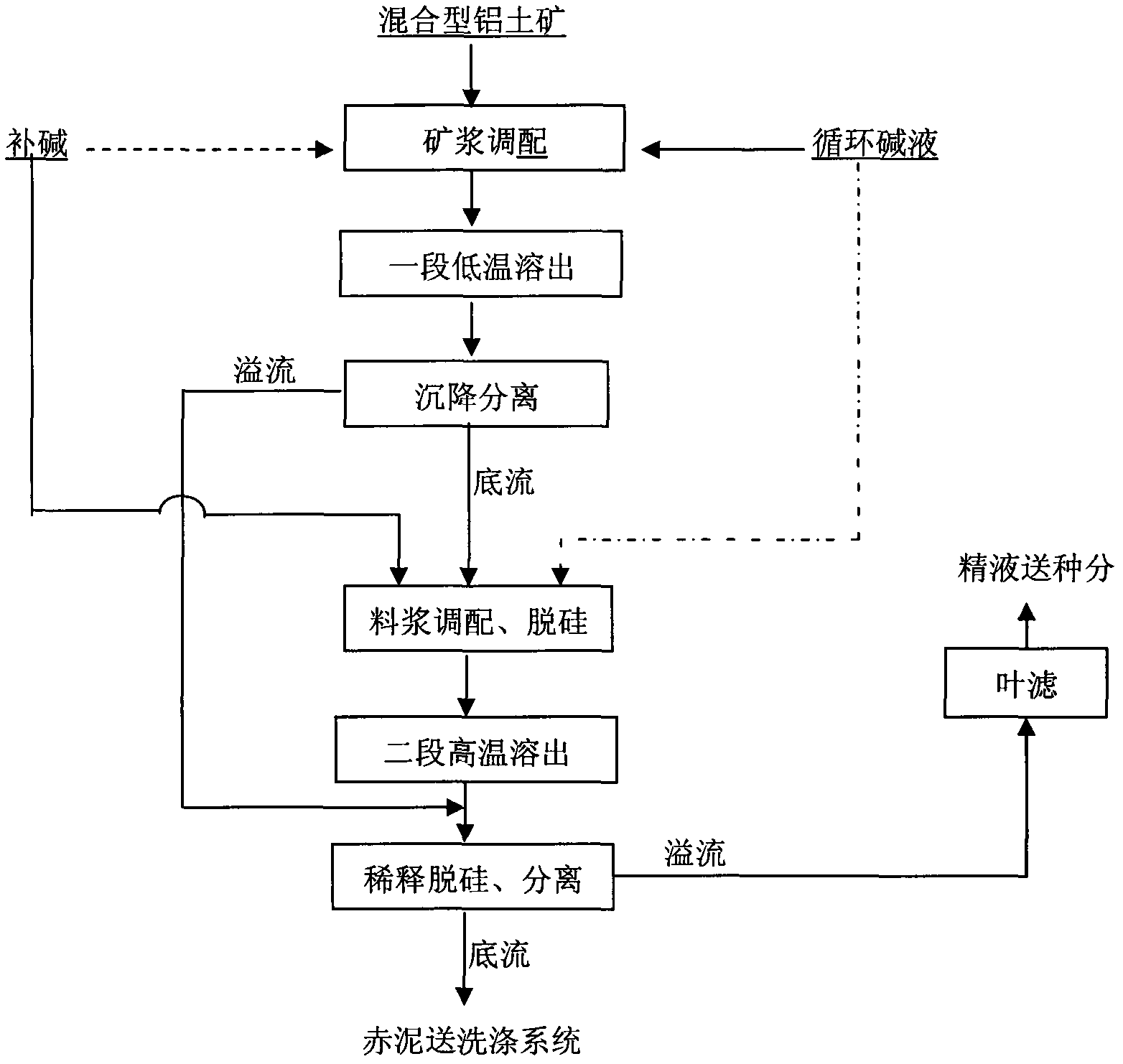

Two-stage digestion process of boehmite-gibbsite hybrid bauxite

InactiveCN102826577AOptimize process systemReduce material flowAluminium oxides/hydroxidesRed mudFull recovery

The invention relates to a two-stage digestion process of boehmite-gibbsite hybrid bauxite. The process is characterized in that soluble gibbsite of the boehmite-gibbsite hybrid bauxite is dissolved under a normal pressure and in short time without adding lime during the digestion process; and that insoluble boehmite is treated by a high temperature. The method can not only ensure full recovery of alumina but also reduce energy consumption of the digestion greatly. By performing predesilicification of ore pulp under a condition of high solid content after a first bottom flow is added to a systemized supplement with alkali, heating surface scar of a second high-temperature digestion slows down; and pulp liquid volume of predesilicification can be reduced. Loss of alumina and red mud amount can be reduced because no lime is added in the digestion process. With the two-stage digestion process of the boehmite-gibbsite hybrid bauxite, problems of low alumina recovery rate or large investment, high energy consumption and the like existing in a process of Bayer digestion process of the boehmite-gibbsite hybrid bauxite can be solved; and objects of economically producing alumina with the two-stage digestion process by employing the boehmite-gibbsite hybrid bauxite as raw materials are realized.

Owner:长沙瑞德新材料科技发展有限公司 +1

Integrated carbon and nitrogen removal bioreactor

InactiveCN105936546AAchieve removalRealize denitrificationSpecific water treatment objectivesWater contaminantsWater sourceFull recovery

An integrated carbon and nitrogen removal bioreactor comprises a reactor body, a pedestal, a support arranged in the periphery of the reactor body, a main water inlet tube, and a main water outlet tube connected with an outside water source, the inner chamber of the reactor body is divided into a first chamber and a second chamber which are independent through a vertical separator plate, and the first chamber is connected with the second chamber through a second water inlet tube; the first chamber is an anaerobic digestion unit used for filling anaerobic granular sludge; the second chamber is sequentially divided into a water inlet area provided with an aeration device, a short-cut nitrification unit used for filling a lightweight biological carrier, an anaerobic ammoxidation unit used for filling a suspension filler, and a water outlet area from top to bottom; the bottom of the anaerobic ammoxidation unit is provided with a second mud discharge port provided with a control valve; and the water outlet area is provided with a water outlet connected with the main water outlet tube. The integrated carbon and nitrogen removal bioreactor has the advantages of full recovery and utilization of energy contained in organic matters in wastewater, low nitrogen removal cost, and realization of comprehensive productivity in the wastewater treatment process.

Owner:HANGZHOU NORMAL UNIVERSITY

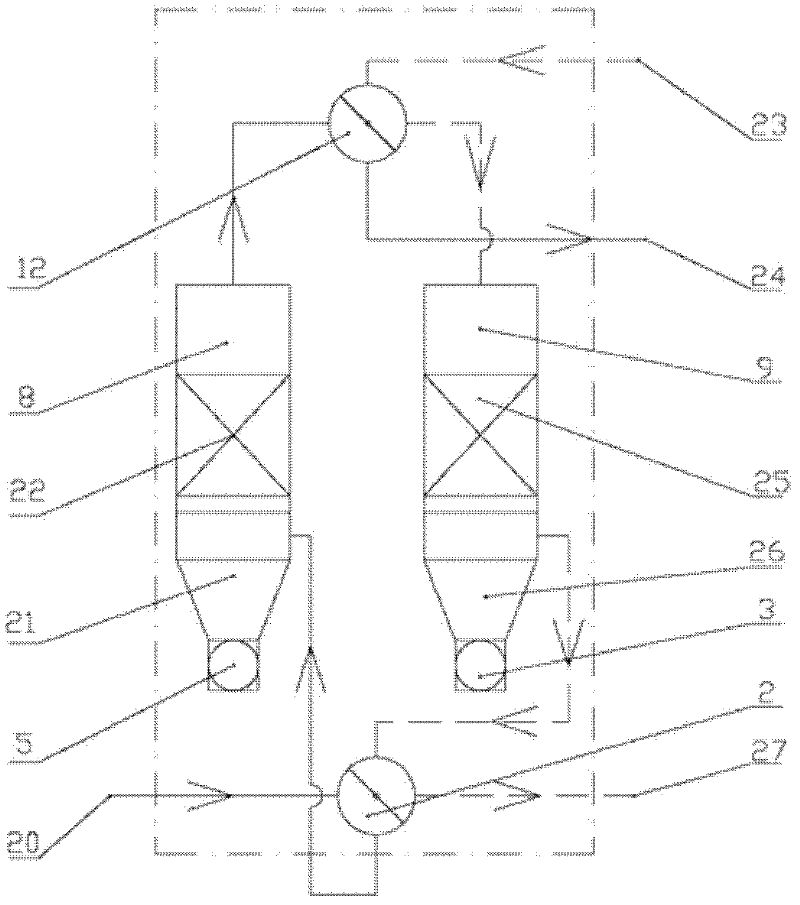

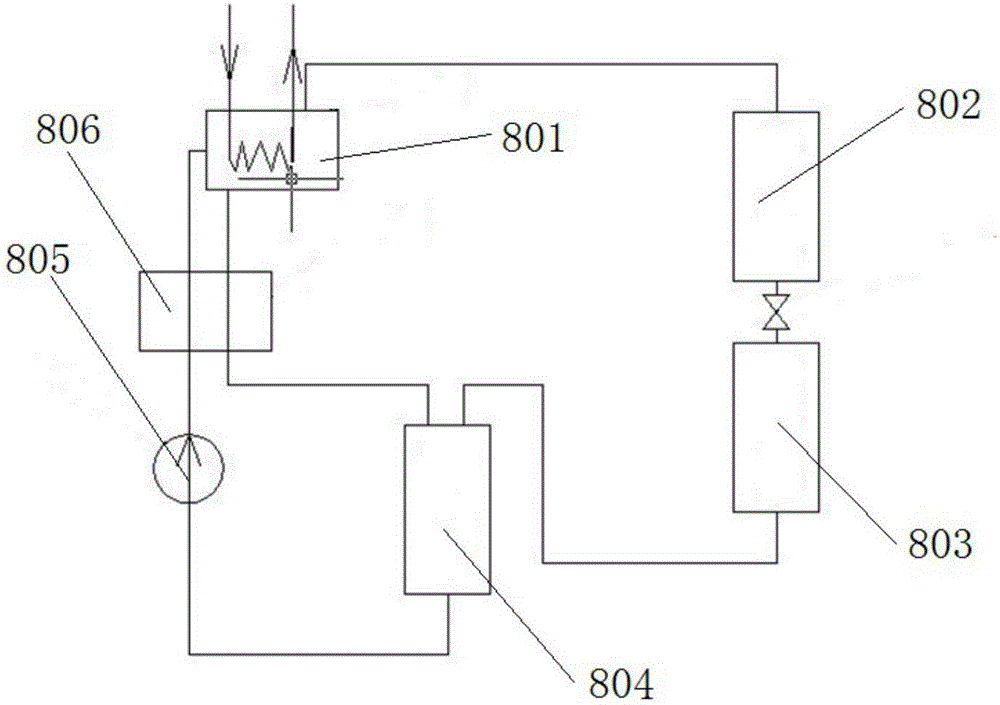

Heat pump system with smoke waste heat full-recovery function and method for preparing high-temperature hot water

InactiveCN104279794ALow flow resistanceIncrease heat exchange spaceFluid heatersHeat pumpsWater source heat pumpWater source

The invention discloses a heat pump system with a smoke waste heat full-recovery function and a method for preparing high-temperature hot water. The heat pump system comprises a waste heat recovery device and a water source heat pump device. The waste heat recovery device comprises a spraying type waste heat recoverer, a circulating water pump and a circulating water pipeline. The water source heat pump device comprises a flooded evaporator and a petal pore plate type condenser. The circulating water pipeline of the waste heat recovery device is connected with the flooded evaporator of the water source heat pump device to enable the waste heat recovery device and the water source heat pump device to form the heat pump system. An automatic monitoring and controlling system is applied to operation of the heat pump system. The method for preparing the high-temperature hot water includes fully recovering sensible heat and latent heat of smoke by the spraying type waste heat recoverer, transmitting the recovered heat to the flooded evaporator through the circulating water pipeline, increasing the grade of the recovered heat by the water source heat pump device, and transmitting the high-grade heat to tap water by the petal pore plate type condenser to produce the high-temperature hot water. The heat pump system can fully recover smoke waste heat, and has a smoke purification function.

Owner:ZHENGZHOU UNIV +1

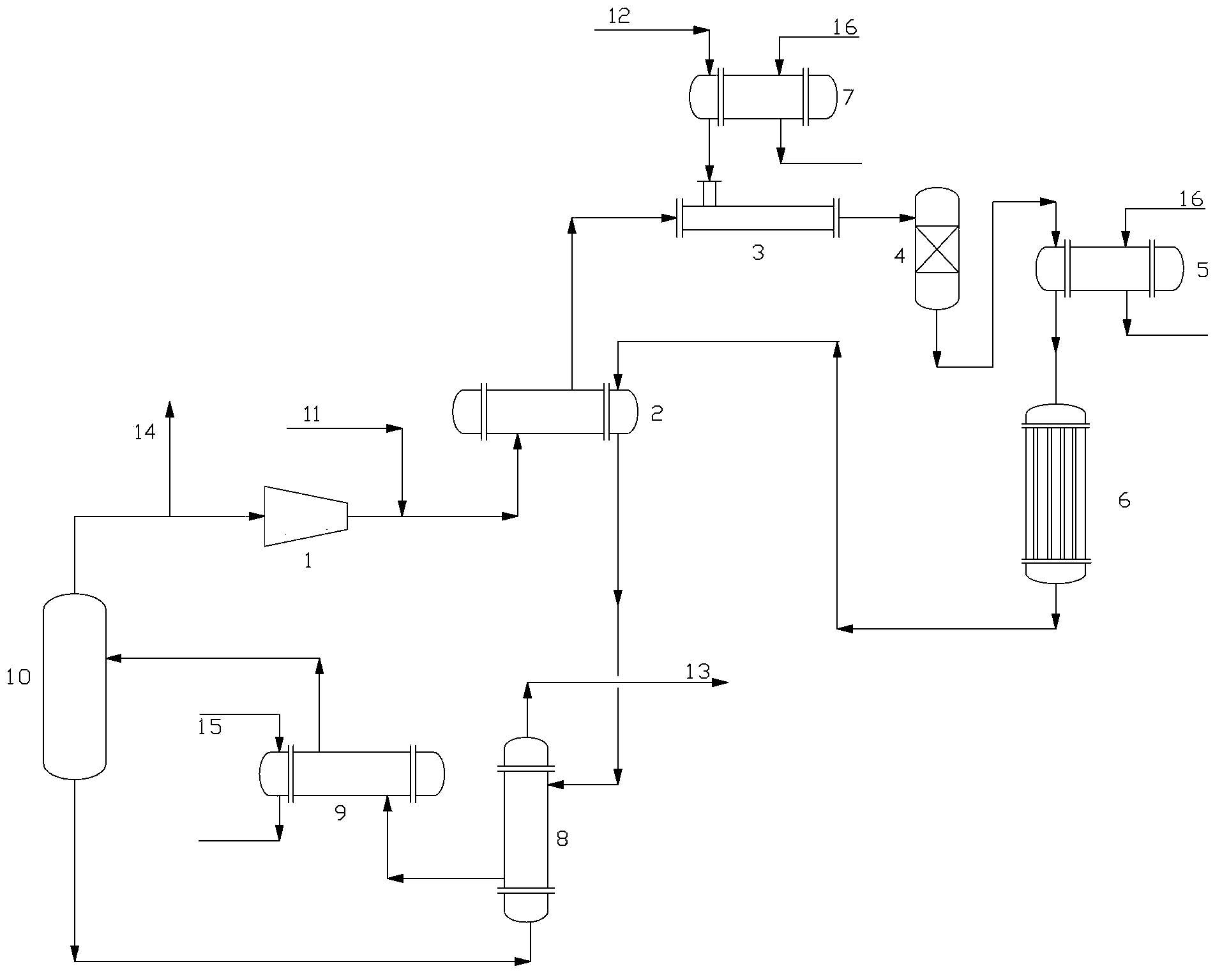

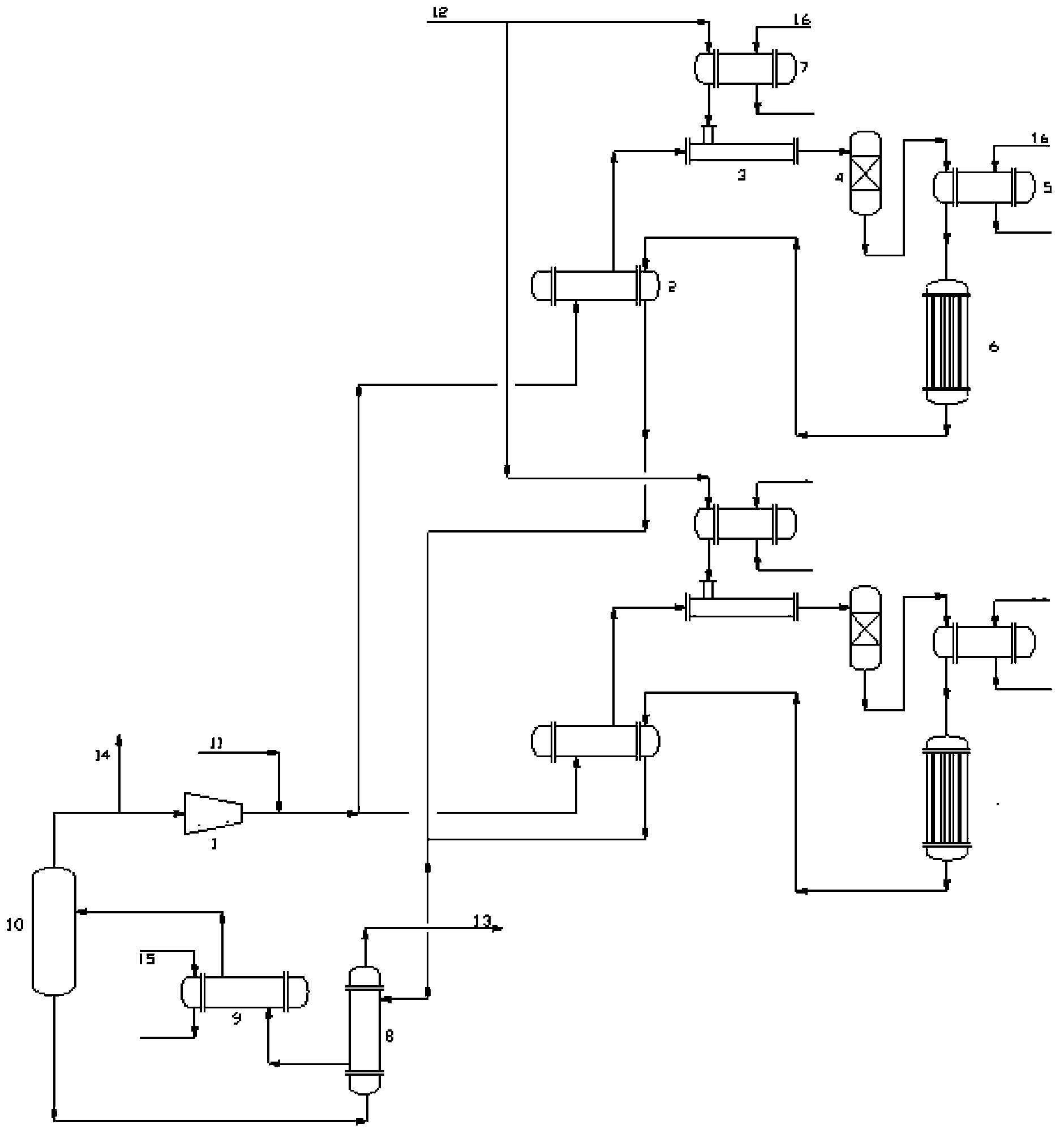

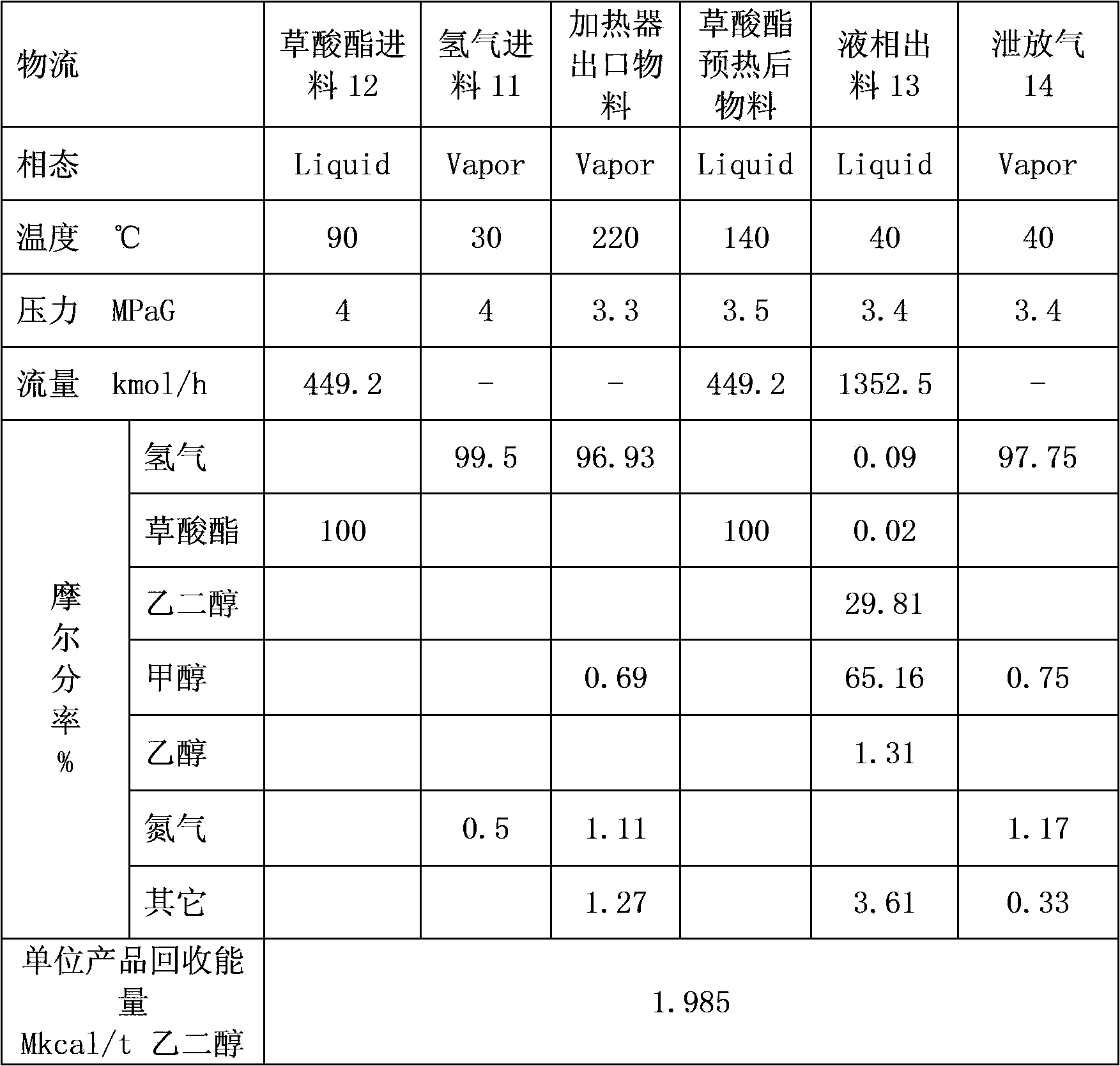

System and method used for preparing glycol via hydrogenation of oxalic ester

ActiveCN103804142AEasy to operateAvoid heat exchangeOrganic compound preparationChemical industryFull recoveryEvaporation

The invention discloses a system and a method used for preparing glycol via hydrogenation of oxalic ester. The system comprises a recycle hydrogen compressor, a charging and discharging heat exchanger, a mixer, a charging protection bed, a recycle hydrogen heater, a hydrogenation reactor, a raw material preheater, a reaction product intermediate heat exchanger, a reaction discharging cooler, and a gas-liquid separation tank; the charging and discharging heat exchanger is connected with the mixer, the charging protection bed, and the recycle hydrogen heater successively; the raw material preheater is connected with the mixer; an outlet of the recycle hydrogen heater is connected with an inlet of the hydrogenation reactor; an outlet of the hydrogenation reactor is connected with the charging and discharging heat exchanger, the reaction product intermediate heat exchanger, the reaction discharging cooler, and the gas-liquid separation tank successively. The method comprises following steps: hydrogen and oxalic ester are heated, and are mixed so as to realize complete evaporation; and obtained mixture is delivered into the hydrogenation reactor so as to obtain glycol via reaction. The system and the method are capable of ensuring needed reaction conditions effectively, controlling reactor bed layer temperature rise stably, realizing full recovery of energy, reducing energy consumption, and ensuring conversion rate of oxalic ester and selectivity of product glycol.

Owner:CHINA PETROCHEMICAL CORP +1

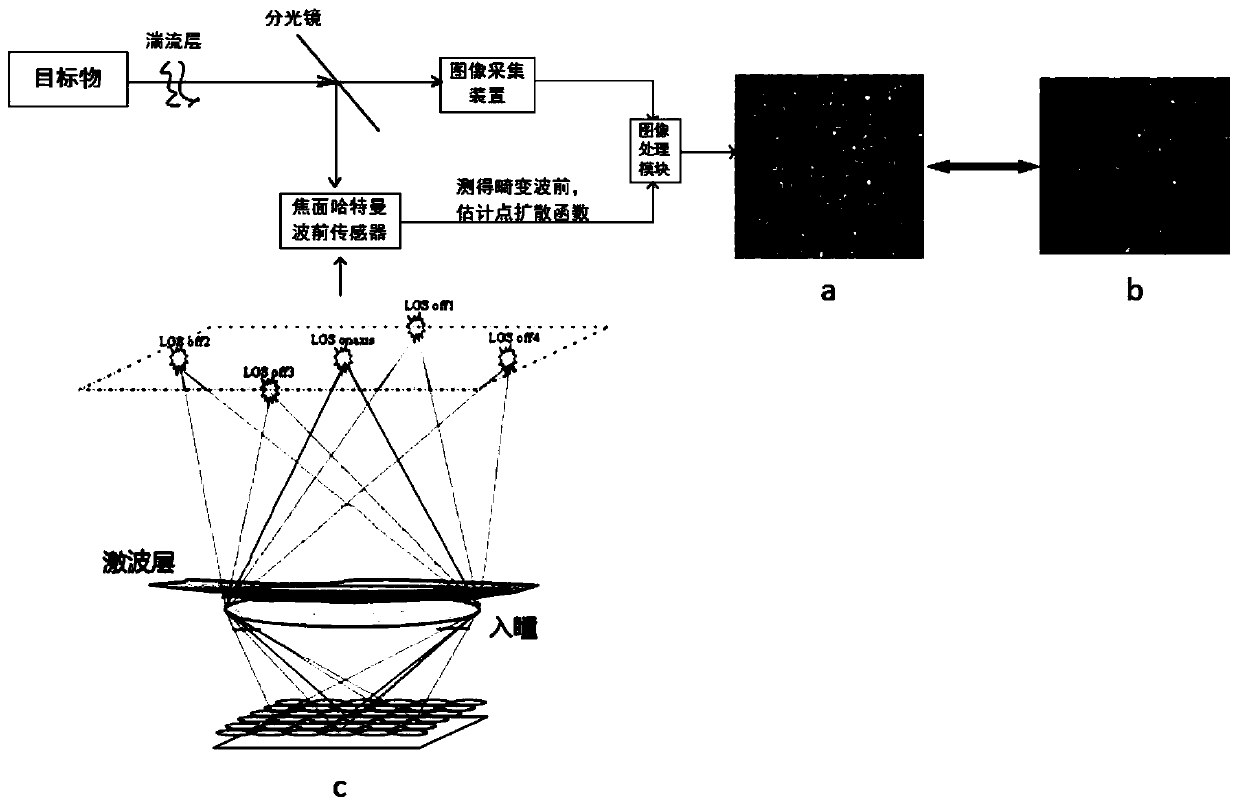

Large field of view image sharpening device and method based on focal plane Hartmann wavefront sensor

ActiveCN110146180AIncrease restore areaGood field of view divisionOptical measurementsWavefront sensorFull recovery

Owner:重庆连芯光电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com