Engine waste heat recovery type vehicle-mounted air conditioner system

A technology for waste heat recovery and on-board air conditioning, applied in vehicle components, air handling equipment, heating/cooling equipment, etc., can solve the problems of low thermal power conversion rate of engine waste heat energy, high fuel consumption of on-board air conditioning, resource waste, etc., to reduce Thermal pollution, lower discharge temperature, good heat storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

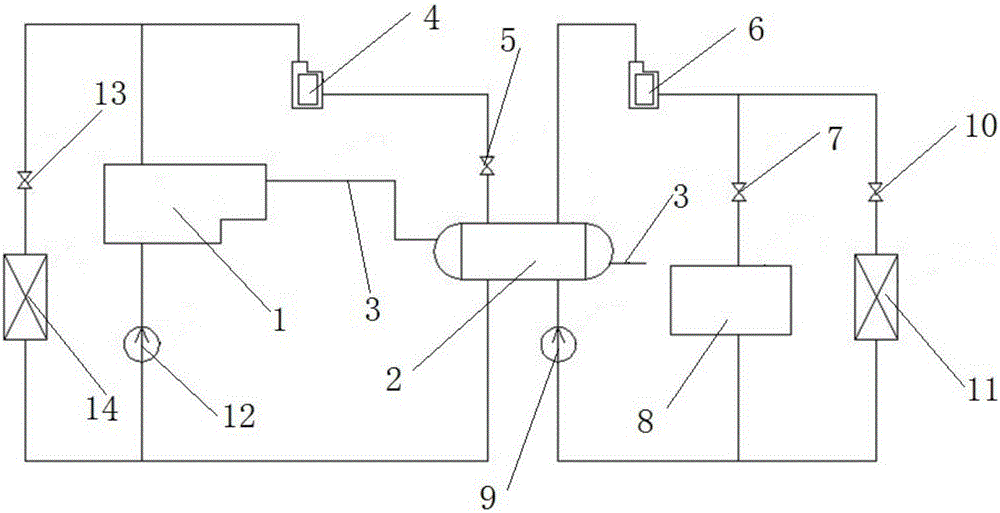

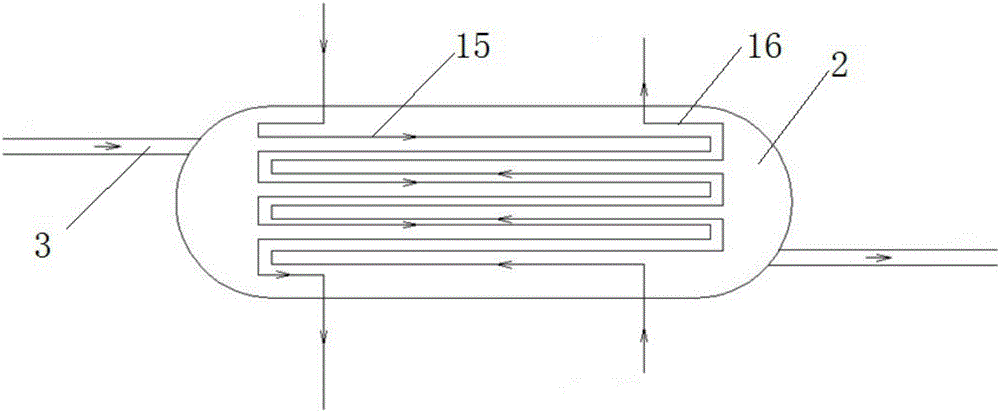

[0028] Such as figure 1 As shown, the engine waste heat recovery vehicle-mounted air conditioning system provided by the present invention includes an engine waste heat recovery system, an engine cooling system, and a vehicle air conditioning and heating system. Wherein, the cooling circuit of the engine includes the heat transfer outlet of the internal circulation coolant of the engine 1, and the heat transfer outlet successively conducts heat transfer with the cooling valve 13, the second radiator 14, the coolant pump 12, and the internal circulation coolant of the engine 1. The inlet is connected to form a cooling loop.

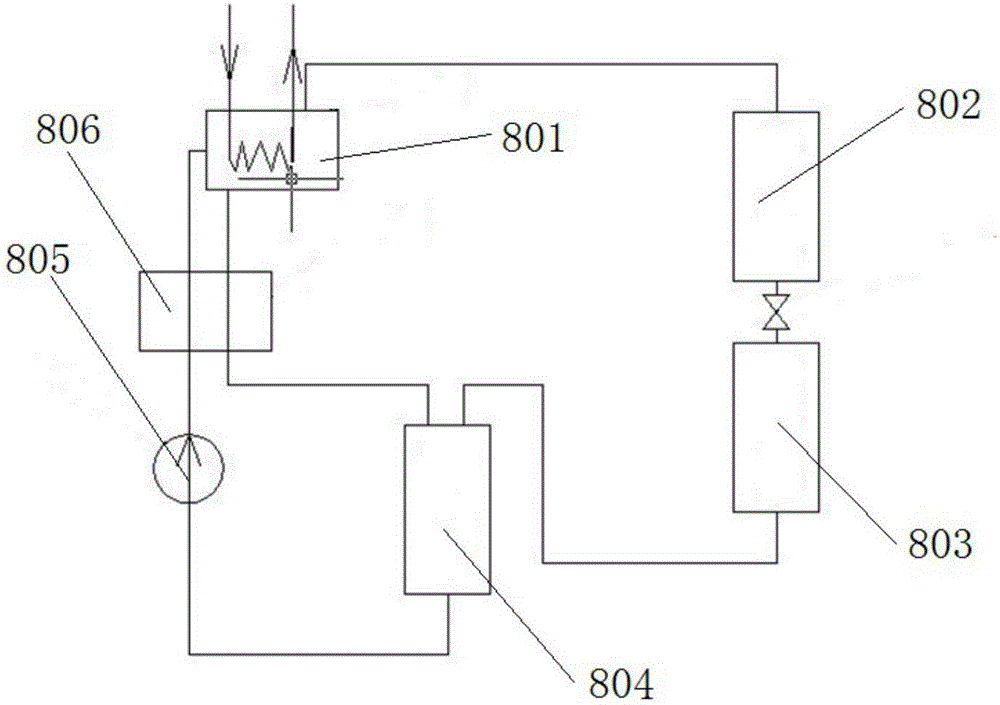

[0029] The engine waste heat recovery circuit includes the heat transfer outlet of the internal circulation coolant of the engine 1, and the heat transfer outlet is sequentially connected with the coolant storage tank 4, the coolant valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com