Treatment method and device for extremely-high-concentration waste emulsion

A waste emulsion and treatment method technology, applied in chemical instruments and methods, oxidized water/sewage treatment, water/sewage treatment, etc., can solve the problem of waste oil component and property damage, waste emulsion treatment difficulty, waste oil Utilize problems such as low value to achieve full demulsification and separation, realize resource utilization, and realize the effects of separation and recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1, a kind of processing method of waste emulsion:

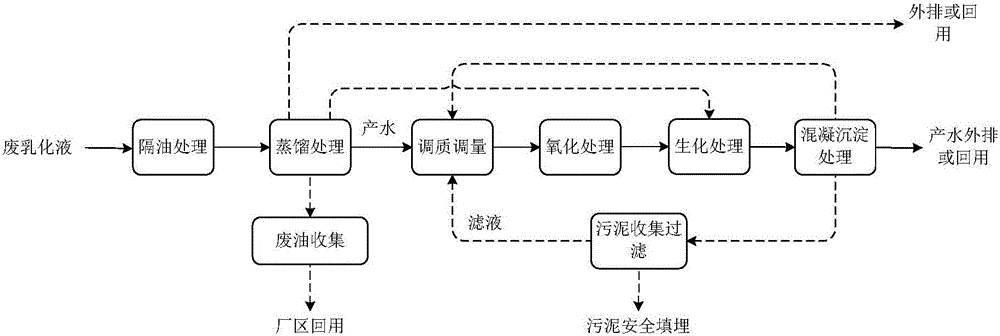

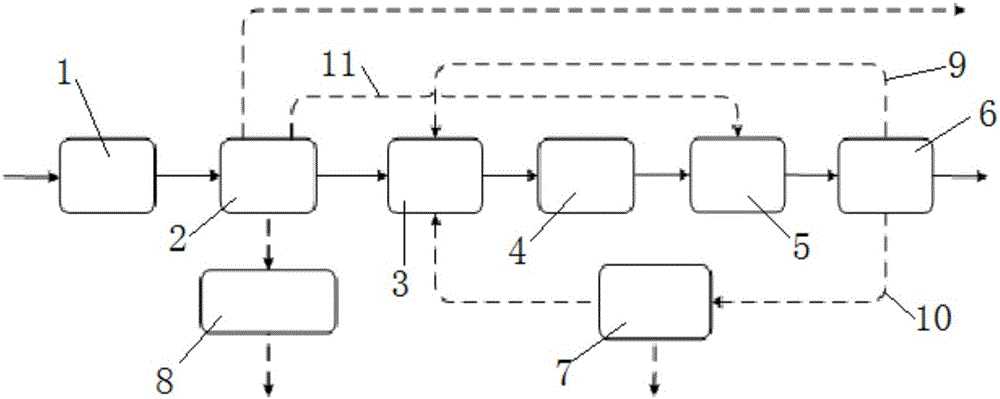

[0055] Such as figure 1 Shown, the treatment method of waste emulsion provided by the present invention comprises the steps:

[0056] 1) Carrying out oil-separation treatment to the waste emulsion, removing the oil slick on the upper layer of the waste emulsion, and obtaining the waste emulsion after the oil-separation treatment;

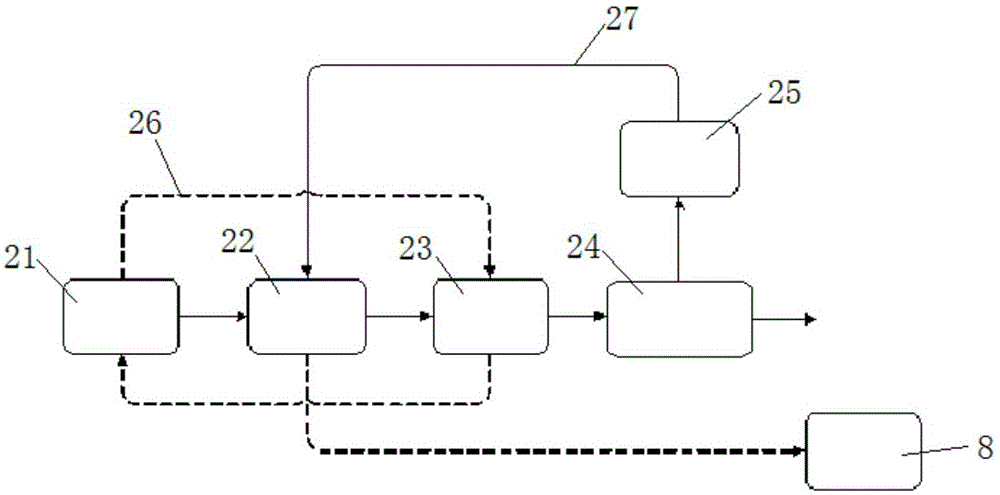

[0057] 2) The waste emulsion after the oil separation treatment is subjected to distillation pretreatment by electric heating to obtain waste oil and waste water, the waste oil obtained is collected and recycled, and the waste water obtained is subjected to next-level treatment,

[0058] Wherein, the distillation pretreatment comprises the following specific steps:

[0059] a) Preheating the waste emulsion after the oil separation treatment to obtain the preheated waste emulsion; b) Distilling the preheated waste emulsion under normal pressure to control the boiling point of the...

Embodiment 2

[0065] Embodiment 2, a kind of processing method of waste emulsion:

[0066] Such as figure 1 Shown, the treatment method of waste emulsion provided by the present invention comprises the steps:

[0067] 1) Carrying out oil-separation treatment to the waste emulsion, removing the oil slick on the upper layer of the waste emulsion, and obtaining the waste emulsion after the oil-separation treatment;

[0068] 2) The waste emulsion after the oil separation treatment is subjected to distillation pretreatment by steam heating to obtain waste oil and waste water, and the obtained waste oil is collected and recycled; the obtained waste water is subjected to next-level treatment.

[0069] Wherein, the distillation pretreatment comprises the following specific steps:

[0070] a) preheating the waste emulsion after the oil separation treatment to obtain the preheated waste emulsion; b) distilling the preheated waste emulsion under reduced pressure to control the boiling point of the d...

Embodiment 3

[0076] Embodiment 3, a kind of processing method of waste emulsion:

[0077] Such as figure 1 Shown, the treatment method of waste emulsion provided by the present invention comprises the steps:

[0078] 1) Carrying out oil-separation treatment to the waste emulsion, removing the oil slick on the upper layer of the waste emulsion, and obtaining the waste emulsion after the oil-separation treatment;

[0079] 2) The waste emulsion after the oil separation treatment is subjected to distillation pretreatment by electric heating to obtain waste oil and waste water, and the obtained waste oil is collected and recycled; the obtained waste water is subjected to next-level treatment,

[0080] Wherein, the distillation pretreatment comprises the following specific steps:

[0081]a) Preheating the waste emulsion after the oil separation treatment to obtain the preheated waste emulsion; b) Distilling the preheated waste emulsion under reduced pressure to control the boiling point of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com