Patents

Literature

5106results about How to "Realize resource utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

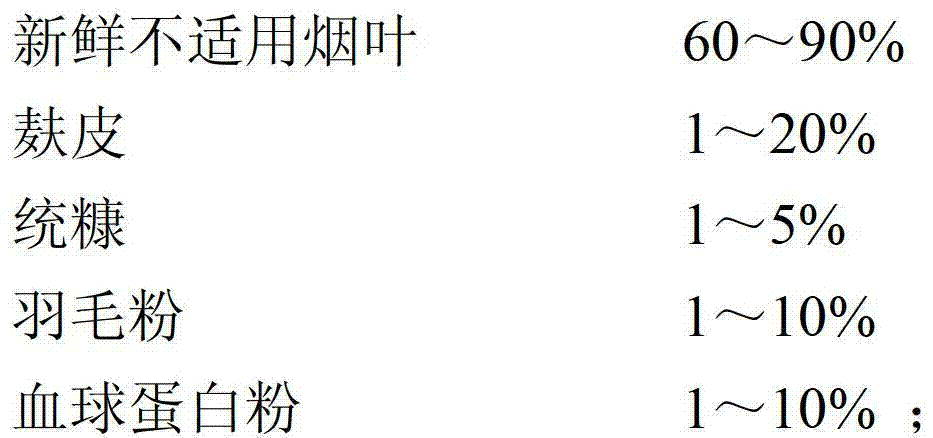

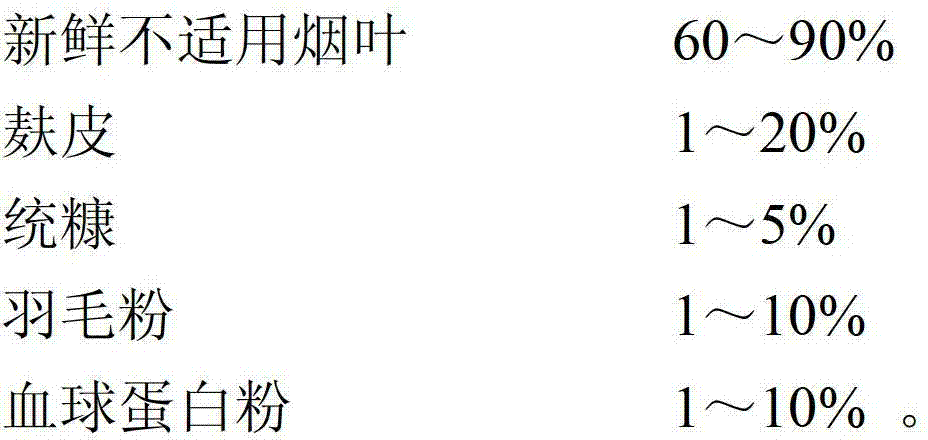

Method for processing inapplicable tobacco leaves by musca domestica larva to prepare biological protein feed

ActiveCN103109972ARealize resource utilizationIncrease profitAnimal feeding stuffAnimal scienceResource utilization

The invention discloses a method for processing inapplicable tobacco leaves by musca domestica larvae to prepare a biological protein feed, and belongs to the technical field of environmental protection. The method for processing the inapplicable tobacco leaves by the musca domestica larvae to prepare the biological protein feed comprises the steps of: crushing fresh inapplicable tobacco leaves until the grain size of the crushed leaves is 1-5mm; adding bran, mixture of rice chaff and husk, feather meal and spray-dried animal blood cells to prepare compost; and inoculating housefly eggs at the surface of the compost, cultivating the housefly eggs for 5 days at 25-35 DEG C, collecting the compost containing the musca domestica larvae, drying and preparing the biological protein feed. The method disclosed by the invention is strong in handling capacity, small in floor area, and low in energy consumption in the processing process, achieves the resource utilization of the inapplicable tobacco leaves, changes waste into precious resources, improves the environmental health, simultaneously produces the biologic protein feed, and has a good application prospect.

Owner:胡新军 +2

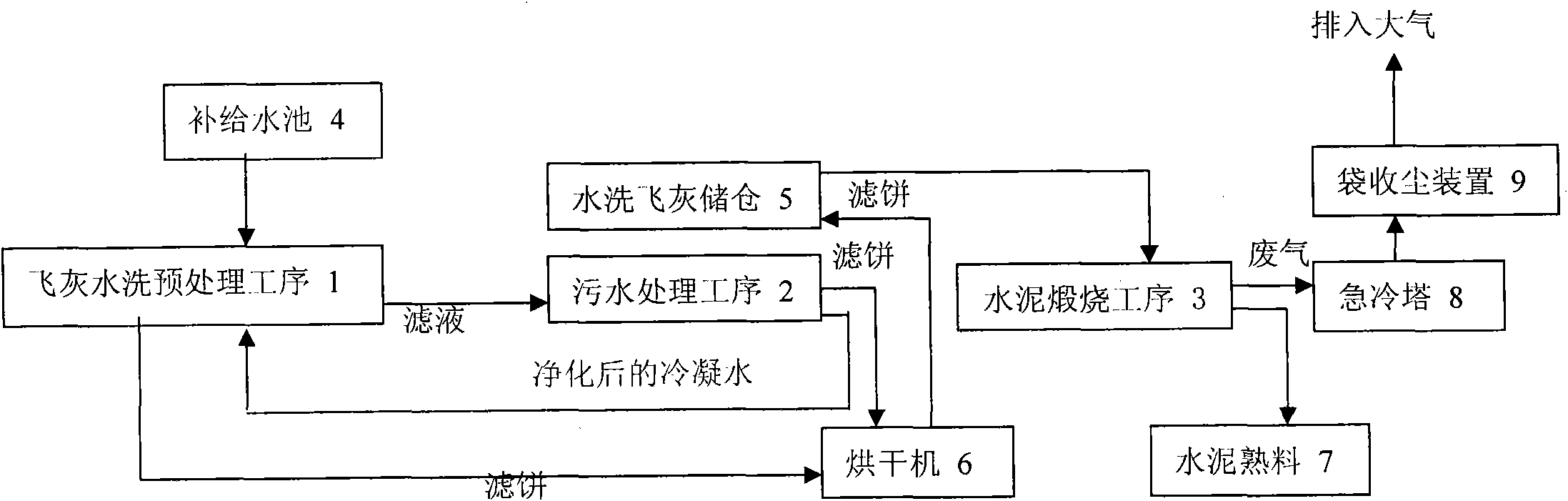

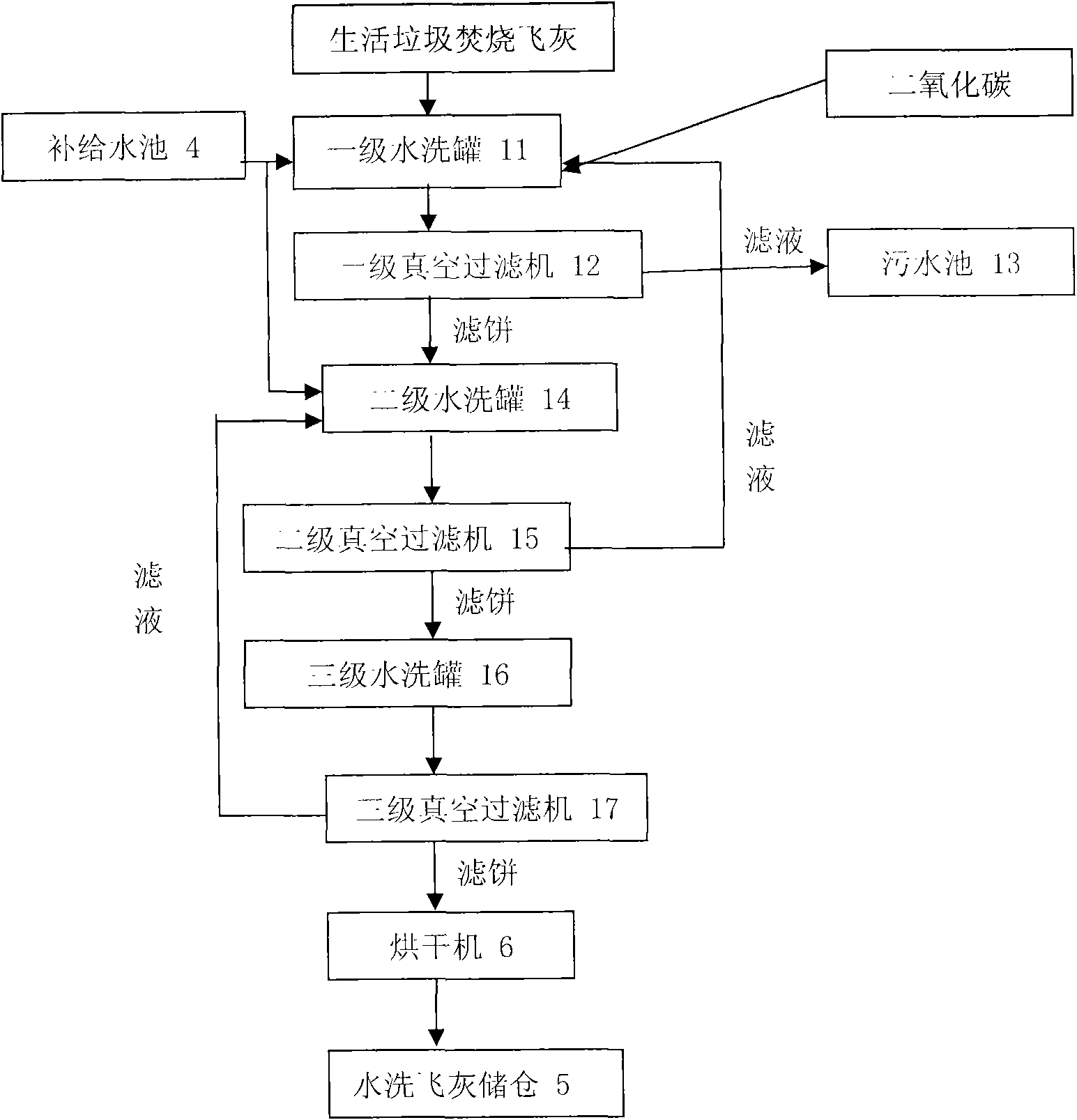

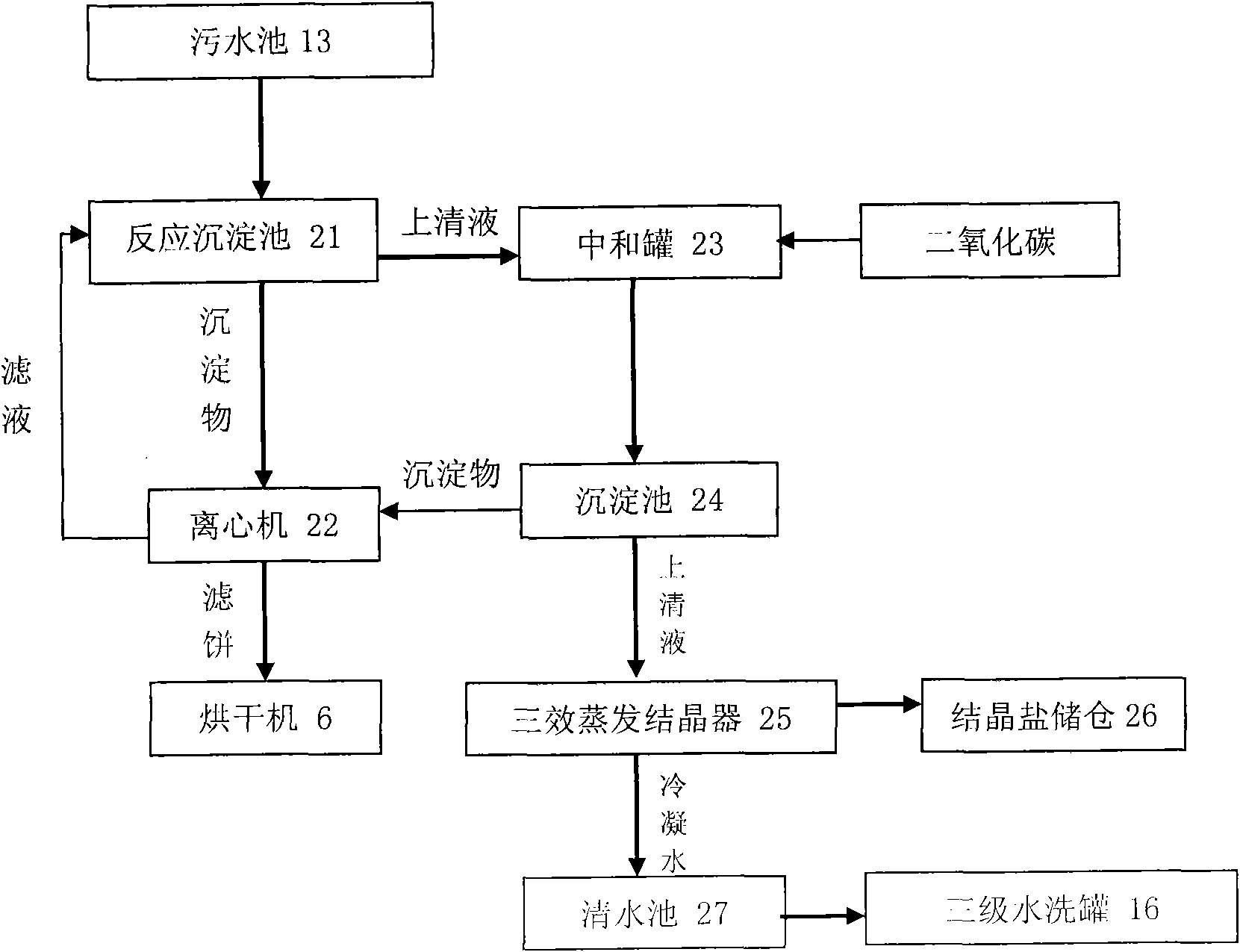

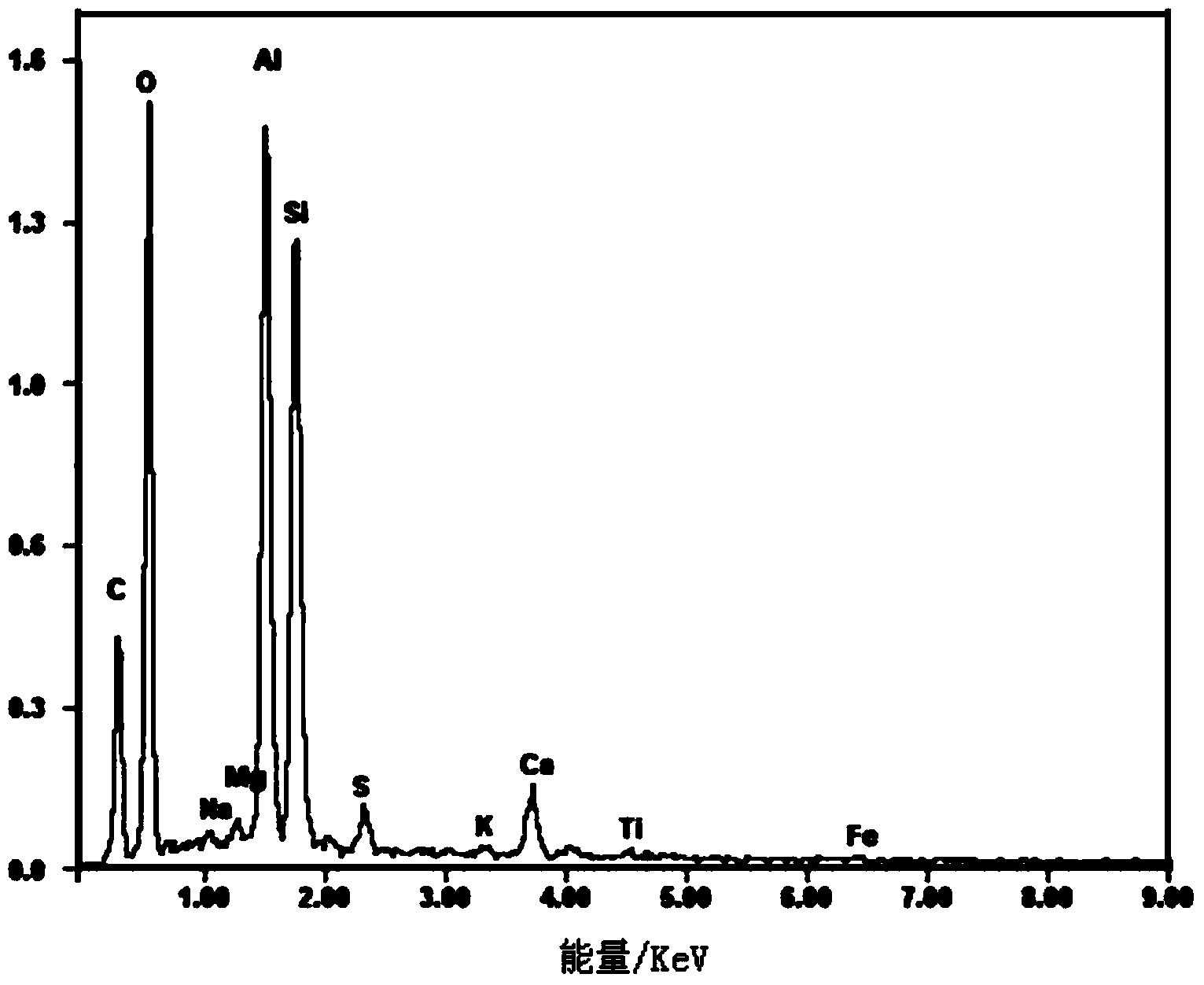

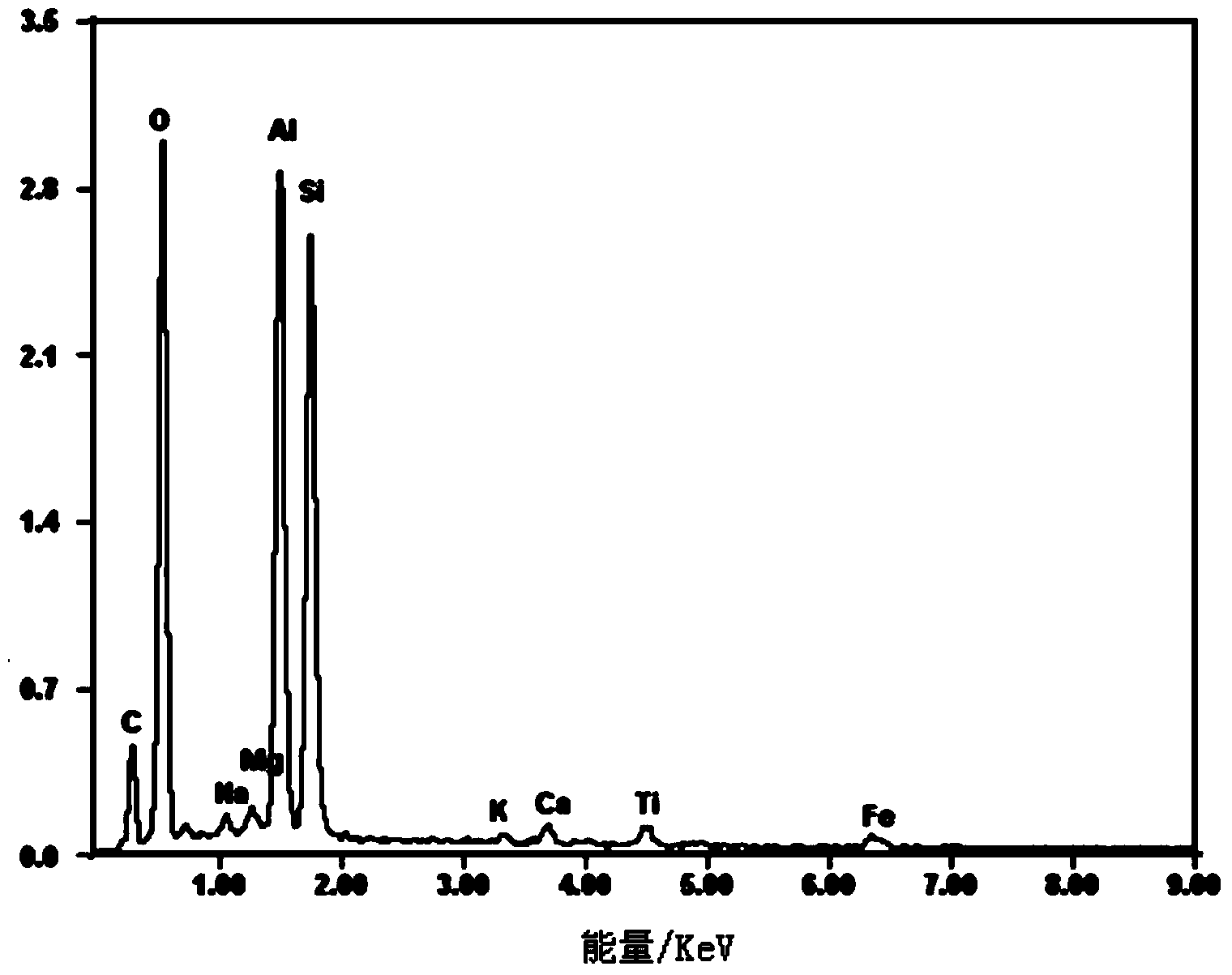

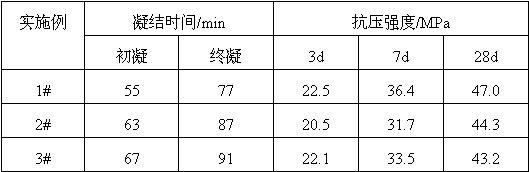

Method for treating incinerated fly ash of domestic garbage with cooperation of cement kiln

ActiveCN101817650AEasy to handleRealize resource utilizationMultistage water/sewage treatmentIonHeavy metals

The invention discloses a method for treating incinerated fly ash of domestic garbage with cooperation of a cement kiln, which comprises the following steps of: 1) washing and pre-treating the fly ash, 2) treating sewage, and 3) calcining cement clinker, wherein the process of washing and pre-treating the fly ash in the step 1) comprises a step of washing the fly ash by using a three-stage washing treatment device consisting of a washing tank and a vacuum filter, and the water and the fly ash are mixed in a weight ratio of 2:1-3:1; the process of treating the sewage in the step 2) comprises steps of desalting supernate and returning the purified condensate water to the step 1) to perform repeated washing so as to realize water recycle; and when the cement clinker is calcined in the step 3), the calcining temperature in the cement kiln can reach 1,750 DEG C. Therefore, the method can ensure that heavy metal ions in the treated fly ash are effectively fixed in crystal lattices of the cement clinker and dioxin is totally decomposed, and realizes hazard-free and reclamation treatment of the fly ash; and the calcined cement can reach the physical and mechanical properties of P.O42.5 cement.

Owner:BEIJING LIULIHE CEMENT

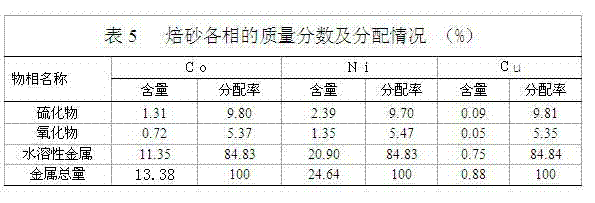

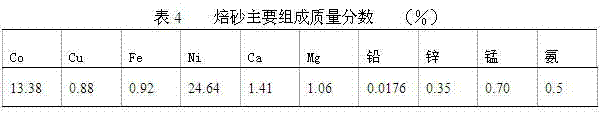

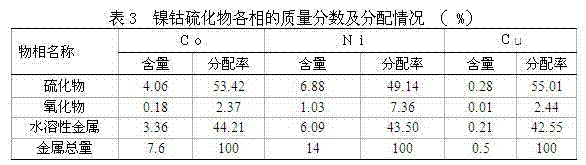

Treatment method of nickel-cobalt material

The invention provides a treatment method of a cobalt-containing material, belonging to the technical field of non-ferrous metal smelting. In the treatment method, through six steps such as peroxidation roasting, sulfuric acid leaching, N902 extraction of copper, chemical iron calcium magnesium removal, P204 extraction and impurity removal, P507 extraction and separation of nickel-cobalt, nickel,cobalt and copper in the nickel-cobalt material are extracted in high recovery, and impurities such as iron, zinc, manganese, calcium, magnesium and the like in the nickel-cobalt material are removed, thereby achieving nickel-cobalt-copper separation and resource comprehensive utilization. According to the treatment method provided by the invention, the process is simple and production cost is relatively low; the adaptability of the method on raw materials is strong and can be used for treating the nickel-cobalt material with complicated components and high copper-zinc-magnesium contents.

Owner:JINCHUAN GROUP LIMITED

Environmental-friendly waterproof polymer mortar

InactiveCN101560084AImprove adhesionStrong bondSolid waste managementSilicate CementConstruction aggregate

The invention relates to environmental-friendly waterproof polymer mortar, which comprises the following components in portion by weight: 50 to 230 portions of low-clinker silicate cement, 200 to 450 portions of quartz sand, 80 to 120 portions of fly ash, 1 to 18 portions of re-dispersible polyethylene vinyl acetate latex powder, 1 to 10 portions of dispersible polyvinyl acetate vinyl versatate latex powder, 0.2 to 0.6 portion of water reducing agent, 0.05 to 0.3 portion of antifoaming agent, and 0.25 to 2.25 portions of polypropylene fibers. A gel material prepared from steel slag, tailings and the fly ash replaces silicate cement and partial aggregate in the prior mortar; the modified waterproof polymer mortar has the advantages of excellent impermeability, good mechanical property and construction property, simple production technology, and easy manufacture, greatly consumes industrial and mining wastes, controls the ecological environment, and lowers the cost; and the product has reliable quality and wide market; and the environmental-friendly waterproof polymer mortar can be popularized and applied in large area.

Owner:黑龙江省学府环艺雕塑有限公司

CaSO* crystal whisker with desulfurized gypsum as raw material and preparing method

InactiveCN101550602AReduce pollutionShort processPolycrystalline material growthFrom solid stateWhiskersCalcium sulphate crystals

The present invention relates to a CaSO4 crystal whisker with desulfurized gypsum as raw material and a preparing method. A technical scheme includes: mixing desulfurized gypsum, water and habit modifier fully for forming suspension; wherein, mass concentration of desulfurized gypsum is 1-8%, mass concentration of habit modifier is 5-20%; or stirring the above suspension 1-3 hours under conditions of normal pressure, 100-128 deg c and 120-210 r / min stirring speed, adding calcium sulphate crystal whisker by weight of 0.5-1% as inoculating crystal, reacting 1-3 hours, adding modifying agent, or stirring the above suspension 3-8 hours, adding the modifying agent directly; or stirring the above suspension 3-8 hours, and adding the modifying agent directly, the amount of the modifying agent is 0.4-1% of the suspension weight, stirring 0.5-1 hours; then pump filtering, washing and three-section drying for obtaining three various type calcium sulphate crystal whisker. The method uses a normal pressure salt solution crystallization method for preparing CaSO4 crystal whisker which has short process flow, geniality condition and low cost, and is an efficient purpose for realizing resource utilizing.

Owner:WUHAN UNIV OF SCI & TECH

Granular filtering material for adsorbing and removing heavy metals in water and preparation method thereof

ActiveCN104289185AWide variety of sourcesRealize resource utilizationOther chemical processesWater contaminantsIndustrial waste waterSorbent

The invention discloses a granular filtering material for adsorbing and removing heavy metals in water and a preparation method thereof. The granular material consists of the following components in part by mass: 80-120 parts of an adsorbent, 7-14 pats of an additive and 0.5-3 parts of a binding agent, wherein the adsorbent consists of the following components in part by mass: 50-70 parts of coal ash and 30-50 parts of zeolite powder or sea-foam stone powder; the additive consists of the following components in part by mass: 5-7 parts of Mg-Al hydrotalcite, 2-6 parts of biochar and 0.5-1 part of magnesium Lignosulfonate; the binding agent is bentonite. The granular filtering material is prepared through the steps of adsorbent acid modification, biochar preparation, granulation and heat treatment process. According to the invention, the prepared granular filtering material is 3-6 mm in granule size, is large in adsorption capacity and excellent in adsorption effect and can effectively remove heavy metals in water, and no secondary pollutants are dissolved out, so that the granular filtering material can be applied to the treatment on heavy metal micro-polluted water and industrial waste water containing heavy metals, and has good economic and social benefits.

Owner:BEIJING FORESTRY UNIVERSITY

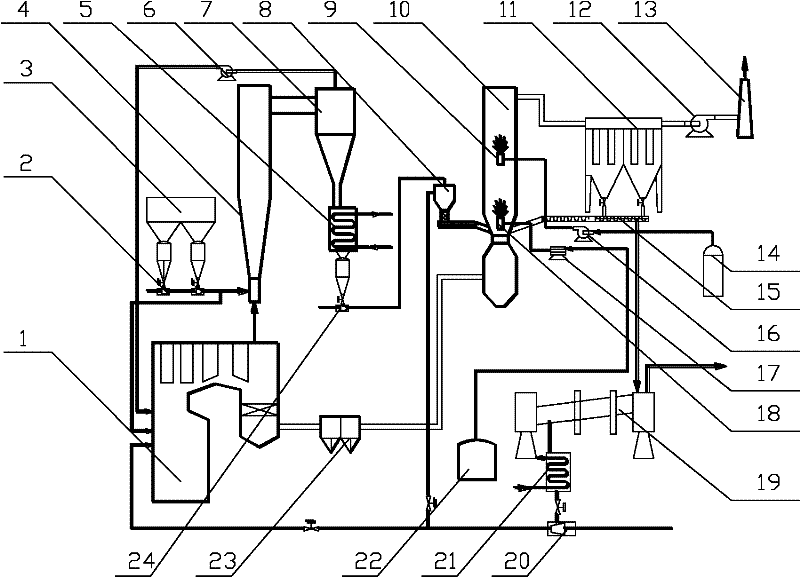

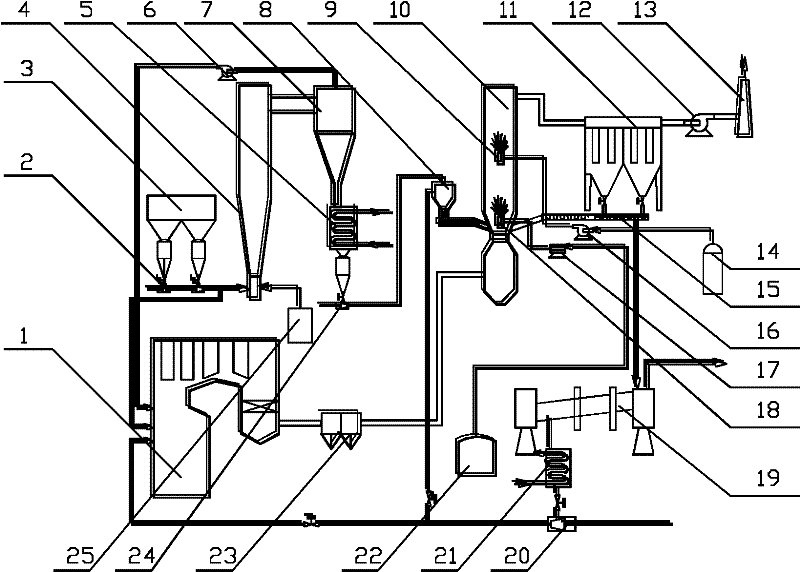

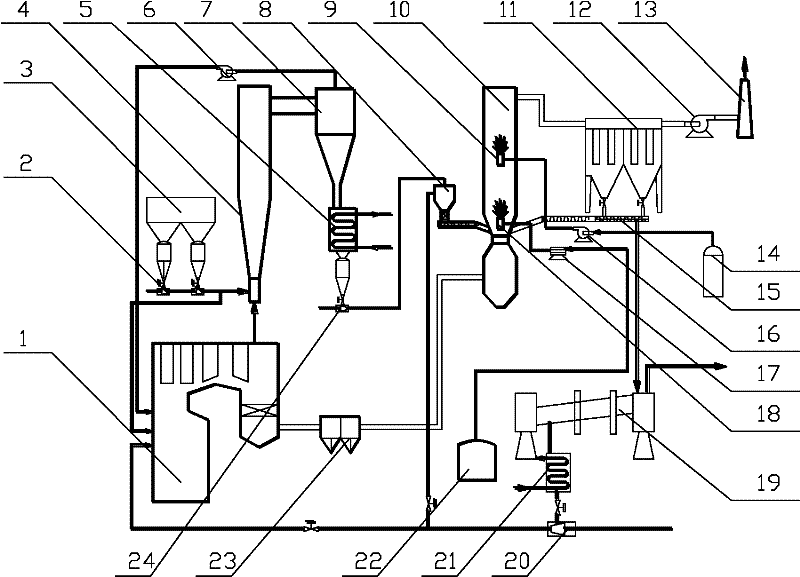

Coal-fired power plant coal dust prepared activated coke flue gas comprehensive purification system and technology

InactiveCN102350214ARealize reburning and denitrificationFull joint removalDispersed particle separationResource utilizationCoal dust

The invention relates to a coal-fired power plant coal dust prepared activated coke flue gas comprehensive purification system and a technology. The technology provided by the invention comprises the following steps of: using coal dust in a coal-fired power plant as a raw material, simultaneously carrying out carbonization and activation on coal dust in an activated coke preparation reactor to obtain powdered activated coke, using pyrolysis gas obtained during the preparation process as reburning fuel and sending it into a boiler so as to remove part of NOx; sending the powdered activated coke into a flue gas adsorption tower, adsorbing pollutants such as sulfur dioxide, mercury and the like at an appropriate temperature, injecting ammonia gas and nitrogen oxide to perform a catalytic reduction reaction so as to remove nitrogen oxide; reusing the adsorbed activated coke after regeneration; sending the activated coke into the boiler for combustion after multiple adsorption / regeneration; regenerating the activated coke after adsorbing sulfur dioxide to obtain high-density sulfur dioxide gas to realize resource utilization. By the utilization of coal resources in a coal-fired power plant, the comprehensive purification of flue gas and the resource utilization of sulfur dioxide are realized without discharge of waste water, exhaust gas and solid waste.

Owner:SHANDONG UNIV

Exterior wall composite insulation heat-proof plastering material

InactiveCN101229970ARealize resource utilizationImprove protectionSolid waste managementFiberResource utilization

The invention relates to compound thermal insulation plastering material for external wall, which consists of a compound cementing material and a lightweight aggregate. The compound cementing material consists of cement, active admixture, lime powder, promoter, surfactant, anti-crack and waterproof agent, water retaining agent, flame retardant, re-dispersible emulsion powder, alkali-resistance fiber and coal flying ash cenosphere; the lightweight aggregate consists of EPS grain and expanded perlite. The invention has the advantages of low density, thermal performance, high strength, good impact resistance, bond strength and low shrinkage. The compound cementing material adopts a plurality of polymeric cementing materials, allows the insulation material to have good bond performance and simultaneously ensures falling and slipping resistance performance. The invention has good water resistance and high softening coefficient. By using cement-based cementing material as main material and organic reinforced material and waterproof component as auxiliary materials, the invention has a hydrophobic rate more than 98 percent and a softening coefficient more than 0.7. The invention can save energy and protect environment. A great deal of industrial waste residue is used in the materials, which can save a great number of energy, realize resource utilization of the waste residue and is in favor of environmental protection.

Owner:SHANGHAI TONGBIAO INSULATION TECH

Heavy metal-contaminated soil solidifying agent and application method thereof

ActiveCN103833274AHigh strengthReduce risk of leachingSolid waste managementOrganic fertilisersDry weightChemical reaction

The invention discloses a heavy metal-contaminated soil solidifying agent and an application method thereof. The solidifying agent comprises the following components by mass: on the basis of the dry weight of heavy metal-contaminated soil, 10 to 15% of a binding material, 5% of biochar, 10% of vegetable fiber and 1% of a stabilizing agent. The components are added according a sequence of the stabilizing agent-the biochar-the vegetable fiber-the binding material. Addition of the chemical stabilizing agent and the biochar in the process of stabilization enables heavy metals to be absorbed and passivated and to lose mobility; preparation of heavy metal-contaminated soil slurry provides conditions for a later chemical reaction; the whole processing process is free of dust pollution and discharging of unwanted sewage. Addition of the vegetable fiber enables cracking of heavy metal-contaminated soil solidified by using a conventional solidifying agent to be effectively prevented and endurance of a solidified body to be improved. The method provided by the invention has the advantages of strong operability, low cost, extensive applicability, a high resource utilization rate, low environmental risk and easy large-scale popularization.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

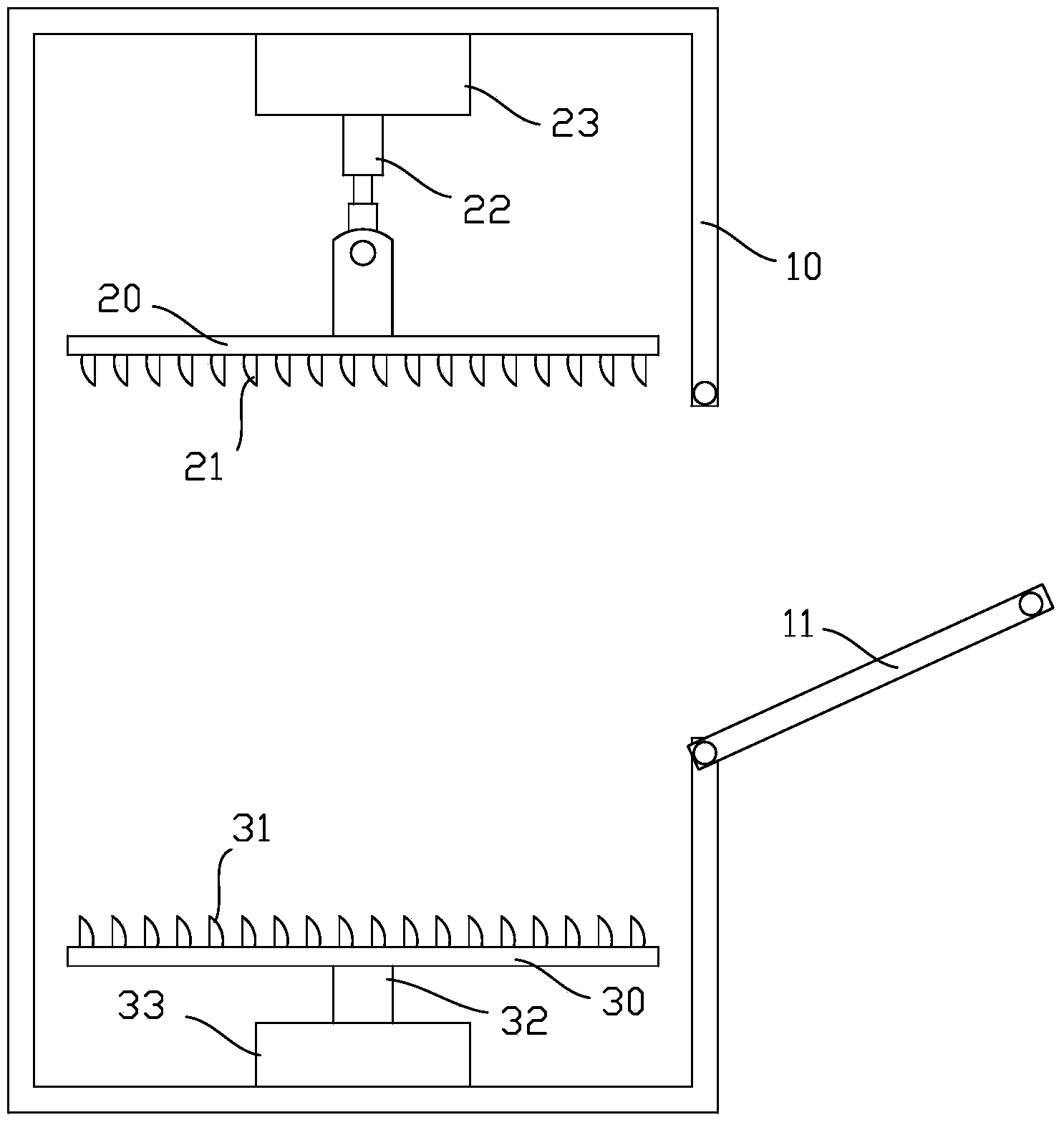

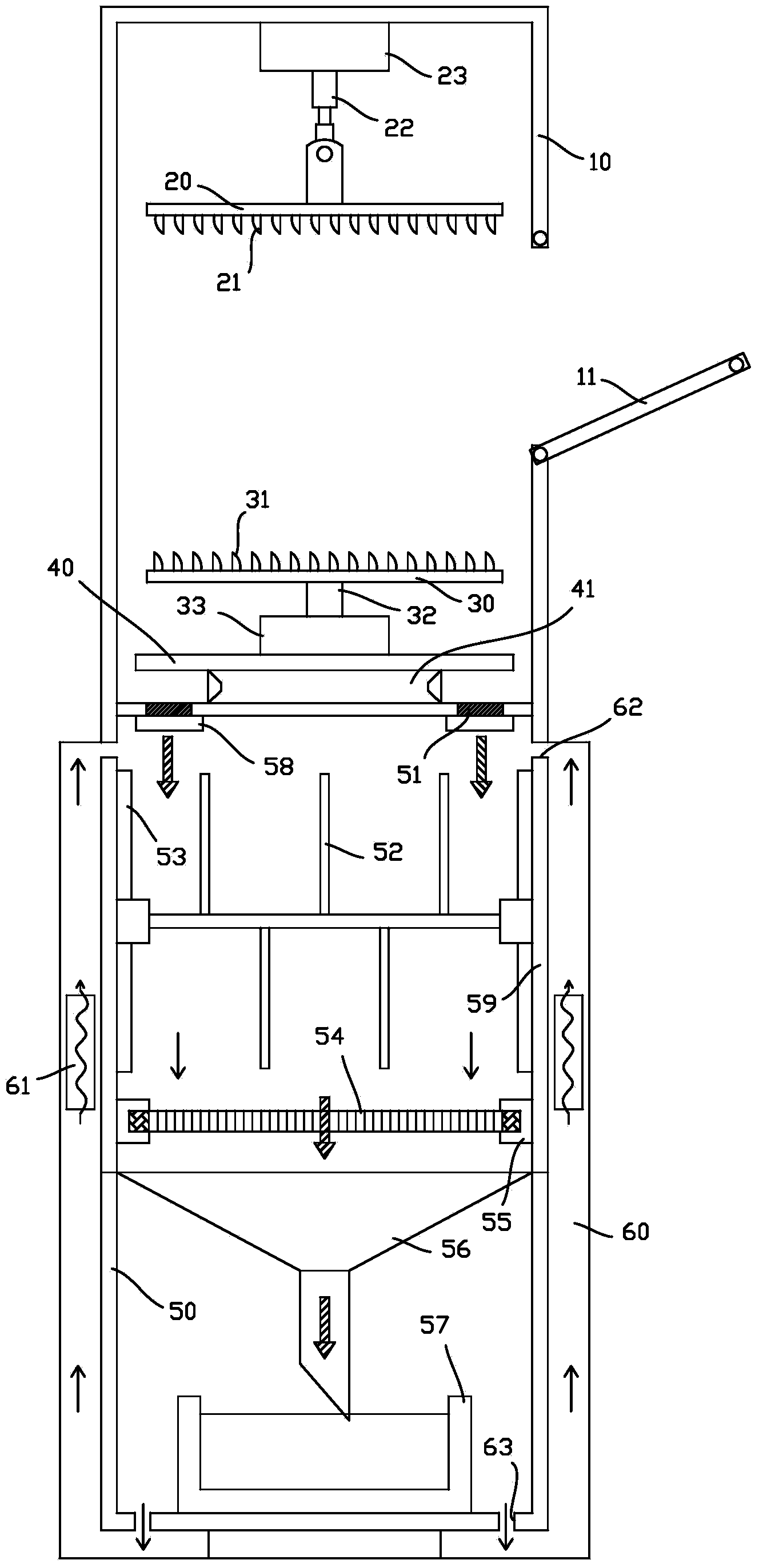

Waste and old mixed plastic recovery and separation device and method

ActiveCN103934923AEffective classificationRealize resource utilizationPlastic recyclingMechanical material recoveryPlastic forming machineMolten state

The invention discloses a waste and old mixed plastic recovery and separation device and method, and belongs to the field of resource recycling of waste and old mixed plastic. The waste and old mixed plastic recovery and separation device comprises a crushing device and a melting, sorting and recovering device, wherein a material feeding mechanism, a crushing mechanism and a material discharging mechanism are arranged in a crushing box body of the crushing device; a heating device, a screening mechanism and a plastic molding mechanism are arranged in a melting box body of the melting, sorting and recovering device; the heating mechanism is used for heating crushed granular materials to a molten state in a staged way; the screening mechanism is used for separating the materials in the molten state and un-melted granular materials; the plastic molding mechanism is placed on the bottom of the melting box body and recycling the separated materials in the molten state. The recovery and separation device can effectively classify the waste and old plastic generated in daily life and industrial production; different plastics are separated and are made into a single plastic which is relatively pure, so that the resource utilization of the waste and old plastic is realized; the post-processing process is omitted; energy resources are saved; the operation is simple; the automation degree is high; the sorting degree is high; the sorting range is wide.

Owner:ANHUI UNIV OF SCI & TECH

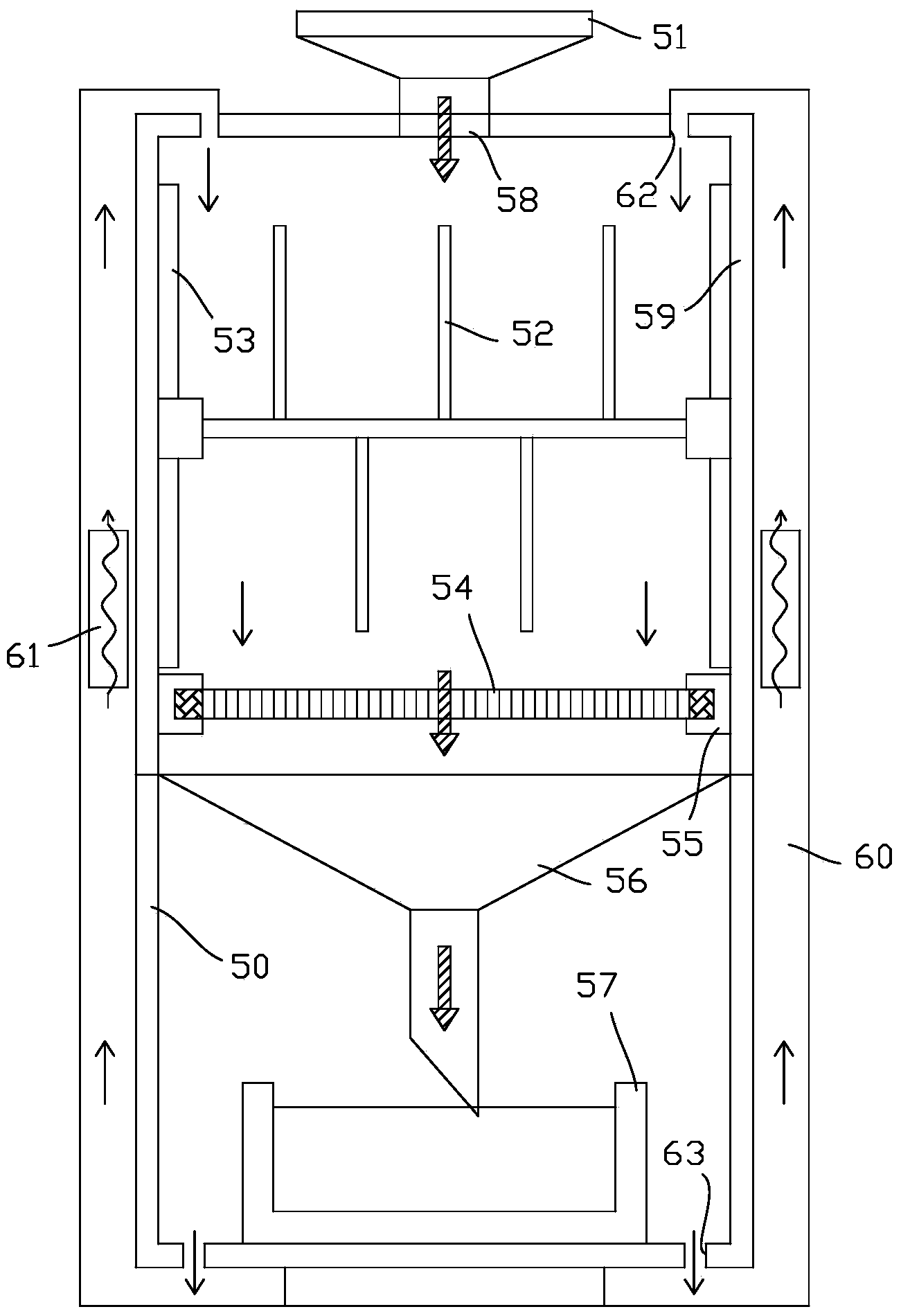

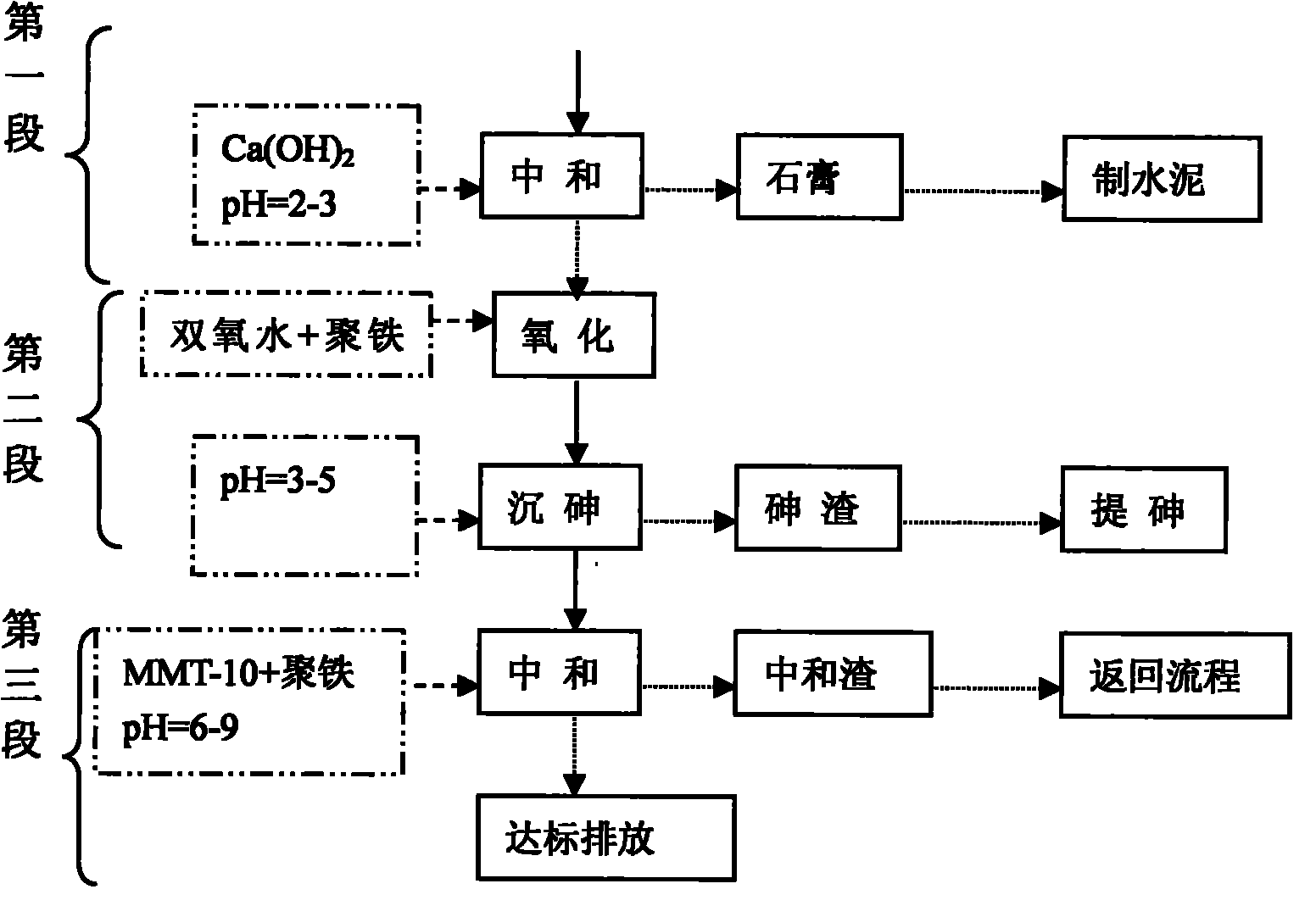

Method for treating waste acid by gypsum sedimentation, arsenic oxidizing sedimentation and iron salt neutralization and co-precipitation

ActiveCN101830583AAchieving zero emissionsRealize resource utilizationWater contaminantsMultistage water/sewage treatmentIron saltsSlag

The invention discloses a method for treating waste acid by gypsum sedimentation, arsenic oxidizing sedimentation and iron salt neutralization and co-precipitation. The method comprises the following steps of: the first section: gypsum sedimentation, namely putting lime cream into the waste acid, and removing most sulfuric acid from the waste acid through neutralization reaction to generate CaSO4sediment and gypsum; the second section: arsenic oxidizing sedimentation, namely performing solid-liquid separation after the gypsum reaction, adding polymeric iron into supernate, adding hydrogen peroxide oxidant into the supernate to oxidize Fe2+ into Fe3+ and oxidize As3+ into As6+ under the condition of low pH, and removing most arsenic from the waste acid through oxidizing sedimentation reaction so as to enrich the arsenic in the waste acid and produce arsenic slag; and the third section: iron salt neutralization and co-precipitation, namely performing solid-liquid separation after the arsenic reaction, adding polymeric iron and heavy metal ion hunting agent into the supernate, and removing residual arsenic and heavy metal ions from the waste acid to generate neutralized slag and water meeting the national discharge standard. The method has the advantages of short flow, simplicity, practicability, good pollution control effect and good gypsum byproduct, and the removal rate of arsenic is up to 99.999 percent.

Owner:YUNNAN COPPER CO LTD

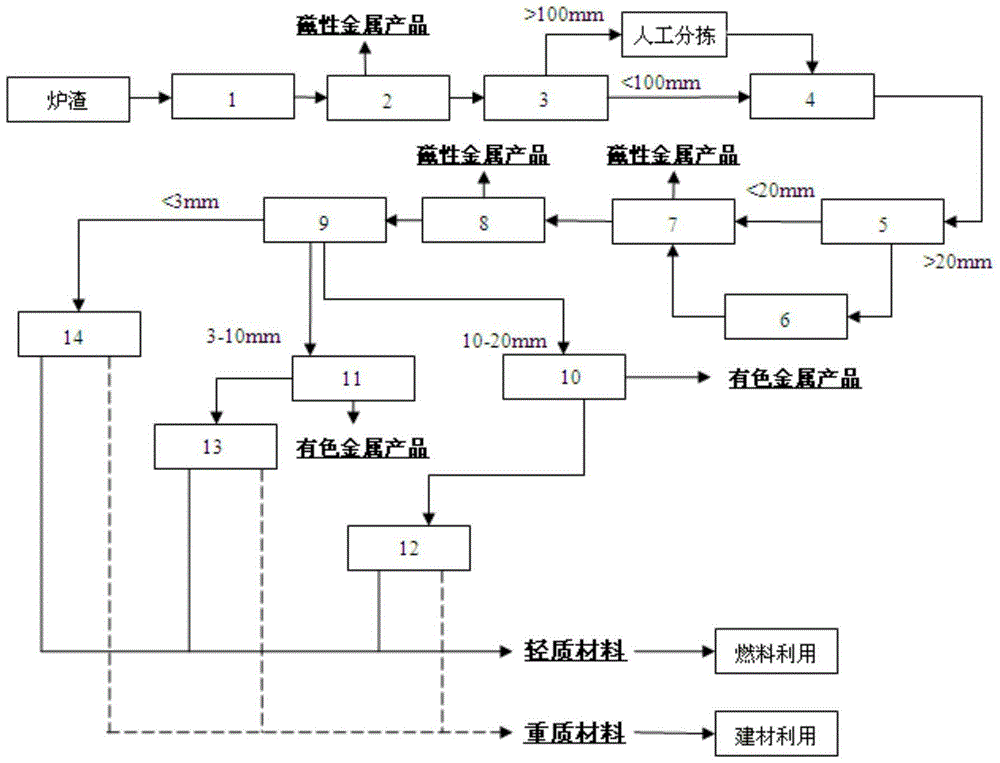

Method for recycling metal and combustibles from domestic waste incineration slag

The invention relates to a method for recycling metal and combustibles from domestic waste incineration slag, and belongs to the field of the solid waste harmless and recycling technology. By means of multi-stage gradient magnetic separation, separation of magnetic metal in the slag is achieved. By means of two-stage eddy current, nonferrous metal in the slag is separated and recycled. According to the grain size distribution and chemical morphological characteristics of the metal in the slag, the metal is crushed and screened in multiple steps so that separated slag particles can be uniform, the recycling rate of magnetic separation and eddy current separation is effectively increased, and finally, according to the density difference of materials, air separation is used for recycling the combustibles in the slag. Finally, the magnetic separation recycling rate of iron in the technological process is 60-80%, the recycling rate of the nonferrous metal aluminum is 60-70%, the recycling rate of the nonferrous metal copper is 40-50%, and separation of the metal in the slag and slag particles can be effectively achieved. The separated metal products can be directly sold or sold after refining, the combustibles can serve as waste incinerator fuel, and the remaining slag can be used as building materials.

Owner:TONGJI UNIV

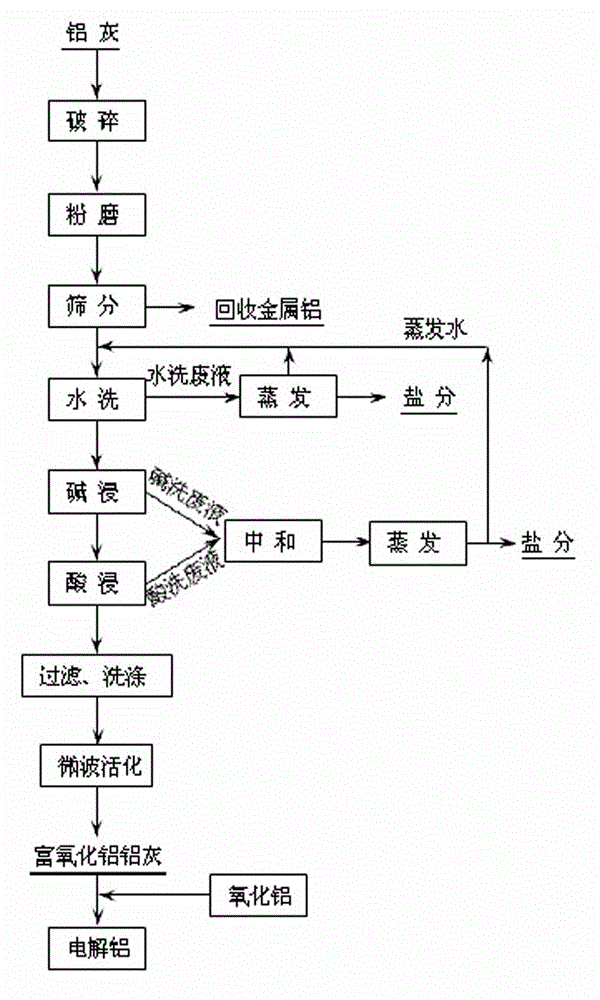

Resource utilization method of aluminum ash

ActiveCN103555955AEfficient recyclingComprehensive recyclingProcess efficiency improvementLiquid wasteMicrowave

The invention discloses a resource utilization method of aluminum ash. The method comprises the following steps: by taking primary slag and flammable dross generated in a smelting process of electrolytic aluminum, and aluminum ash such as salt slag and scum generated in a coarse aluminum refining and processing process as raw materials, recovering aluminum through process steps of crushing, grinding and vibrating screening; and then, respectively carrying out technologies such as washing, pressurized alkaline leaching and normal pressure acid leaching to obtain aluminum oxide-rich aluminum ash. The aluminum ash dried and activated by microwaves returns to an aluminum cell. After the acid-washing liquid waste and alkali-washing waste are effectively neutralized, the acid-washing liquid waste and alkali-washing waste are concentrated and evaporated to recover effective salt. The process provided by the invention can realize resource utilization of aluminum ash on the spot, and is simple and easy to operate and low in production cost, so that the environmental pollution and resource waste caused by aluminum ash are avoided.

Owner:KUNMING METALLURGY INST

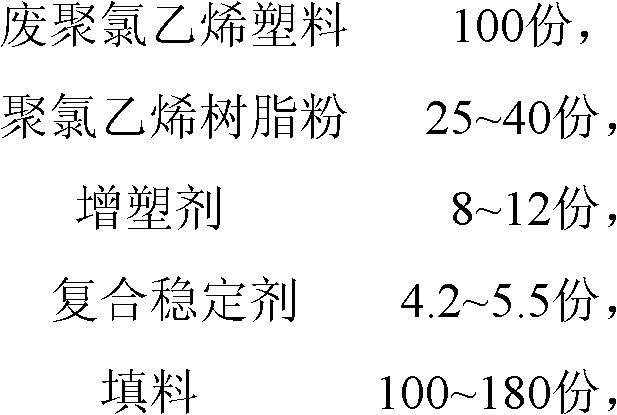

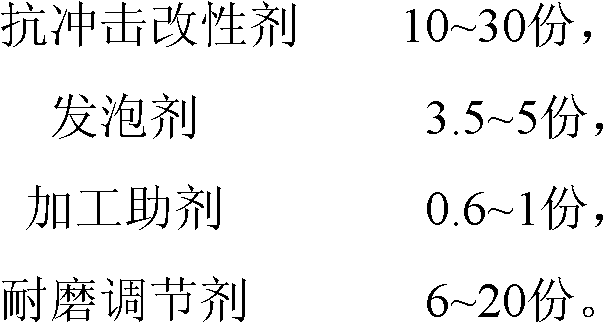

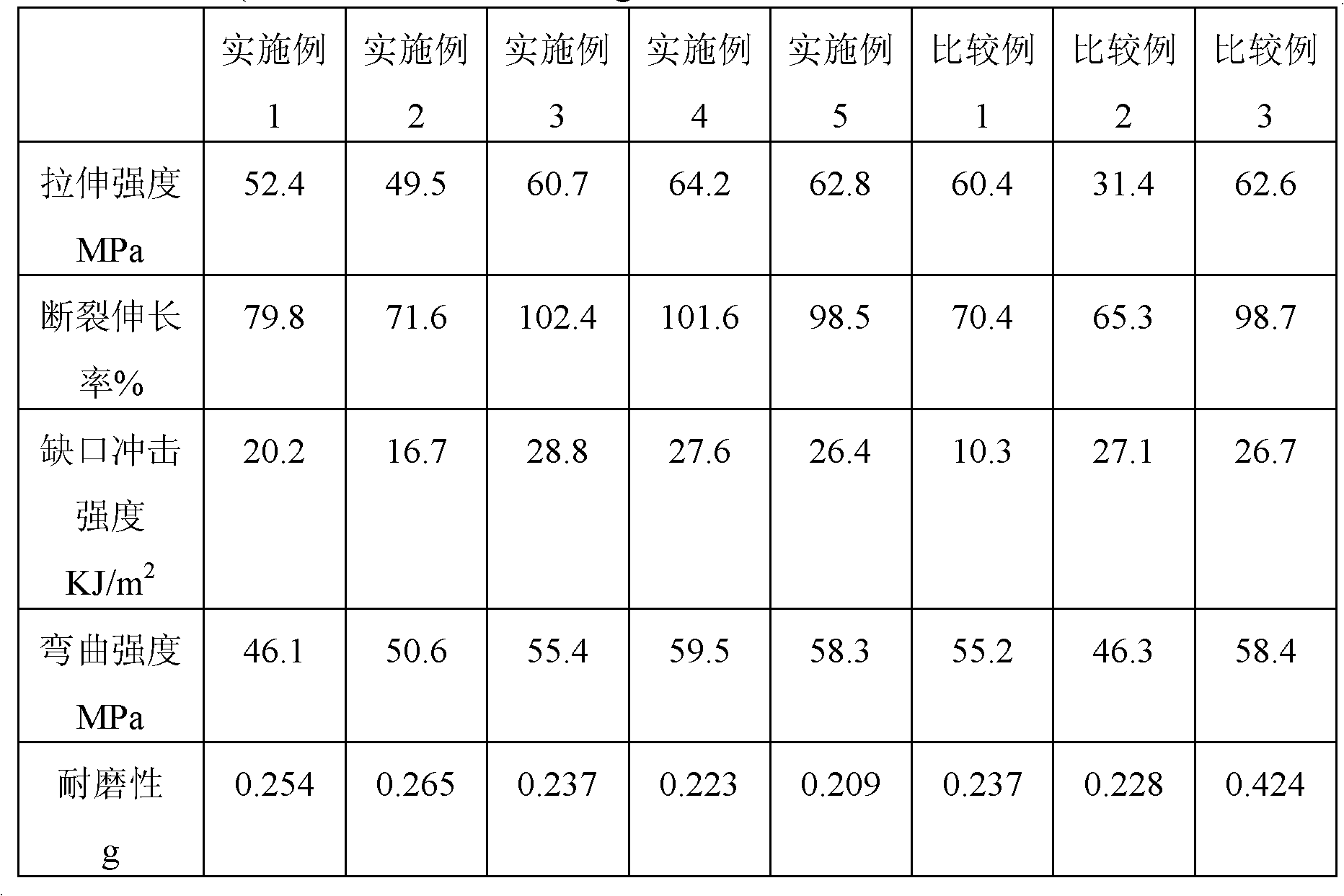

Modified plastic, and preparation method and application thereof

ActiveCN103146094AHigh strengthImprove toughnessPlastic recyclingFlooringPolymer scienceFoaming agent

The invention relates to the field of recycling modification and processing technology of polymer materials, and relates to a modified plastic, and a preparation method and an application thereof. The modified plastic is prepared by the following components of, by weight, 100 parts of waste polyvinyl chloride (PVC) plastics, 25-40 parts of polyvinyl chloride (PVC) resin powder, 8-12 parts of a plasticizer, 4.2-5.5 parts of a compound stabilizer, 100-180 parts of a filler, 10-30 parts of an impact modifier, 3. 5-5 parts of a foaming agent, 0.6-1 part of a processing agent, 6-20 parts of a wear-resistant regulator. The modified plastic provided by the invention can be used for producing wear-resistant floor blocks by using recycled waste polyvinyl chloride (PVC) plastics. The product has the advantages of high strength, good toughness, impact resistance, fire retardance, easy processing, weather resistance, wear resistance and low cost. The method is simple and practical, has the biggest advantage of recycling and processing the waste plastics, saves material resources, lowers production cost, and is environment-friendly.

Owner:滁州格美特科技有限公司

Light glazed ceramic tile with anion function and low water absorption and production method thereof

The invention discloses a light glazed ceramic tile with anion function and low water absorption and a production method thereof. The formula of the glazed ceramic tile is as follows: fancy glaze containing 0.1-90 portions of stamp powder, 0.0-190 portions of pigments, 100-200 portions of stamp-pad ink and 0.01-15 portions of anion material; a green body containing 10-45 portions of ceramic shraff, 15-20 portions of clay, 10-20 portions of feldspar, 30-50 portions of sandstone, 30-50 portions of water, 0.0-0.3 portion of lignin, and 0.0-1.0 portion of sodium tripolyphosphate; and conventionalcover glaze. The production method comprises the following steps: stirring and screening the fancy glaze materials to obtain the fancy glaze; conducting ball-milling, screening and pelleting after materials of the green body are mixed, and then conducting compression moulding and drying, glazing, embossing, and sintering for 50-55 minutes at the temperature of 1195-1205 DEG C, thus obtaining the product. The ceramic tile has the characteristics of being light, low in water absorption, high in mechanical strength, small in coefficient of thermal conductivity, strong in antifouling capability and the like, can continuously release anions with the number of more than 500 / cm3 in space, and can be widely applied to decoration of building outer walls and home furnishing spaces.

Owner:GUANGDONG KITO CERAMICS GROUP CO LTD +2

Alga microorganism fertilizer agent and preparation method thereof

ActiveCN102924134AStable structureWide range of functionsOrganic fertilisersMonosodium glutamateBiology

The invention relates to an alga microorganism fertilizer agent and a preparation method thereof and belongs to the technical field of aquiculture and the like. The alga microorganism fertilizer agent is fermented in such a way that monosodium glutamate waste liquid, alga paste, photosynthetic bacteria, actinomycetes, azotobacters and bacillus subtilis are compounded, and meanwhile, chitosan, chitosan oligosaccharide, microelements and molasses are added according to appropriate parts. The alga microorganism fertilizer agent is formed in such a way that the monosodium glutamate waste liquid is adopted for fermentation, and the raw materials preparation is simple; high-content compound bacteria are contained (the content of the bacillus subtilis is larger than three hundred million / mL, and the total content of the photosynthetic bacteria, the actinomycetes and the azotobacters is larger than one hundred million / mL) and the fertilizing effect is obvious; and the alga microorganism fertilizer agent also has a function of purifying water body, has a wide application range, and is suitable for sea-water and fresh-water cultivation.

Owner:日照巴斯德生物科技有限公司

Method for water plugging and profile controlling of underground polymerization of oil exploitation sludge

The invention relates to a method for water plugging and profile controlling of underground polymerization of oil exploitation sludge, comprising the following steps of: adding 2-7% of crylic acid, 0-3% of acrylamide, 0.2-0.6% of cross linking agent and 0.01-0.05% of initiator into 15-25% of oil exploitation sludge, injecting the mixture together with the oil field water or tap water in the ground; and subsequently generating plugging substances of solid mesh structure wrapping sludge owning to the polymerization reaction under the action of oil pool temperature, thus playing an effect of sealing the underground seams, wherein the oil exploitation sludge is a tank bottom sludge generated during the oil exploitation process of the oil field or the sludge in the sludge pool; the sludge is athin oil sludge; the cross linking agent is a polyol, a glycerin, an N, N-methylene bisacrylamide or N, N-dimethybisacrylamide; and the initiator is the alkali metal salt or the ammonium salt of a persulphuric acid. The method changes the aboveground polymerization process of the oil exploitation sludge grain profile control agent into the underground polymerization process, saves corresponding procedures and the equipment and devices, and generates the water-plugging profile control agent with high intensity and long-term effect by adjusting the concentration of the monomer.

Owner:PETROCHINA CO LTD

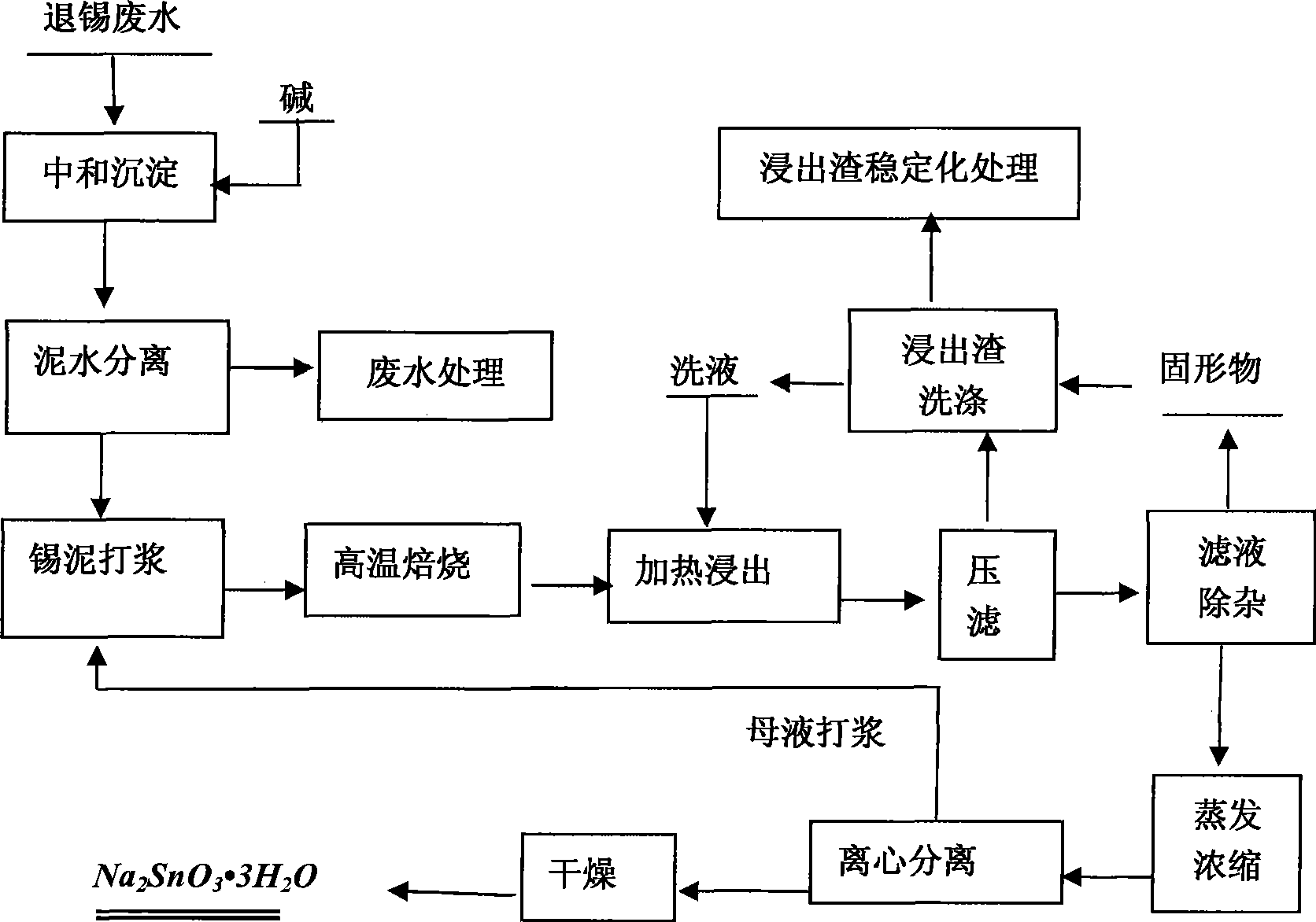

Method for preparing sodium stannate using circuit board tin-stripping wastewater

ActiveCN101497458AReduce manufacturing costRaise the gradeTin compoundsMultistage water/sewage treatmentResource utilizationSludge

The invention relates to a method for preparing sodium stannate by utilizing tin-stripping wastewater of a circuit board. Collected tin-stripping wastewater is neutralized and precipitated by adding alkali to obtain tin sludge with higher tin content; the tin sludge is beat by adding the alkali, and is subjected to high-temperature roasting and countercurrent leaching; then a leachate is subjected to filter pressing; a filtrate is subjected to evaporation, concentration and centrifugal separation after impurity removal; and 10 to 15 percent sodium hydroxide solution is used to wash the obtained product, and thus a crude sodium stannate product can be obtained and then is vacuum dried at a temperature of between 100 and 110 DEG C for 2 to 3.0 hours to obtain a sodium stannate product. The method ensures that the separation rate of tin in the tin-stripping wastewater can reach more than 99 percent, finds a novel treatment way for the tin-stripping wastewater which is produced by printed circuit board industry and is extremely difficult to treat, gives a reasonable fate for all pollutants in the tin-stripping wastewater, and realizes the resource utilization of useful components of the tin-stripping wastewater to the utmost extent when realizing the innoxious treatment of the tin-stripping wastewater.

Owner:江西东江环保技术有限公司

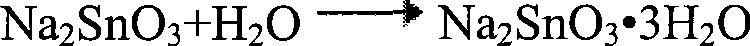

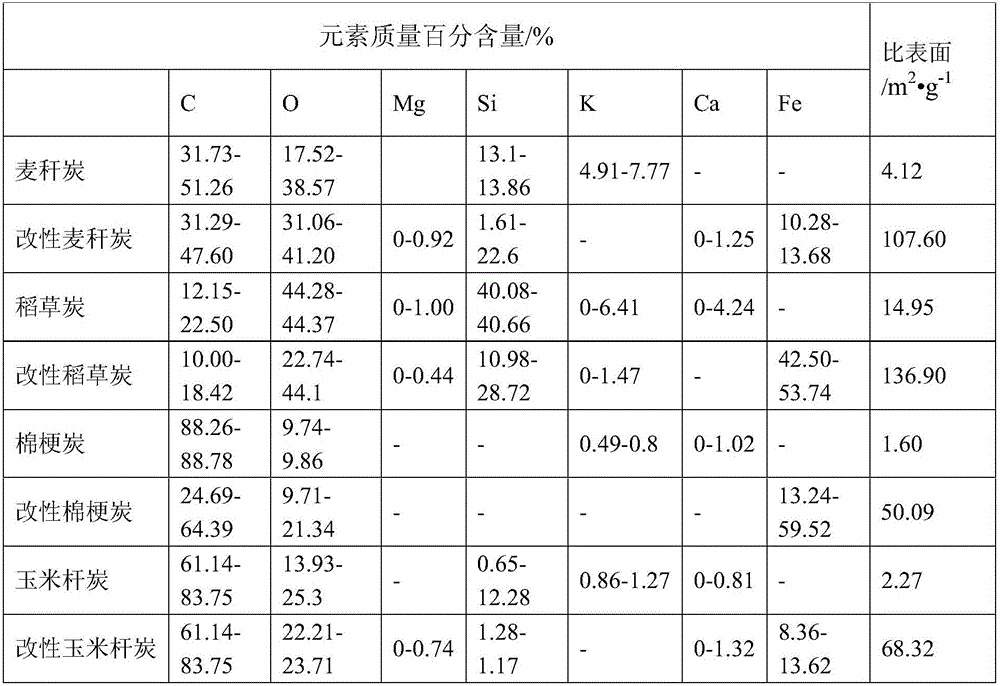

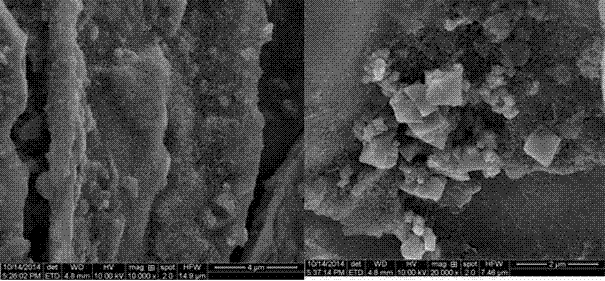

Modified biomass charcoal for treating arsenic pollution as well as preparation method and application of modified biomass charcoal

InactiveCN105944668AImprove stabilityLow carbonization temperatureOther chemical processesWater contaminantsArsenic pollutionFood safety

The invention provides modified biomass charcoal for treating arsenic pollution as well as a preparation method and an application of the modified biomass charcoal. The preparation method of the modified biomass charcoal comprises steps as follows: (1) biomass raw materials are charred, and the biomass charcoal is obtained; (2) the biomass charcoal is subjected to a reaction with a hydrochloric acid solution, solid-liquid separation is performed, a solid substance is obtained, is washed till the pH is neutral and then is dried, and the pretreated biomass charcoal is obtained; (3) the pretreated biomass charcoal and a FeCl3 solution are subjected to a reaction under the condition that the solution pH is neutral, solid-liquid separation is performed after the reaction, and mud cake is obtained; (4) the mud cake is dried and then washed till the pH is neutral, solid-liquid separation is performed, an obtained solid is dried for a second time, and the modified biomass charcoal is obtained. The modified biomass charcoal has large specific surface area and high iron content; the preparation method is simple and easy to operate; the modified biomass charcoal can be applied to treatment of arsenic waste and passivation of arsenic in farmland soil, and food safety is guaranteed.

Owner:INST OF ENVIRONMENT & SUSTAINABLE DEV IN AGRI CHINESE ACADEMY OF AGRI SCI

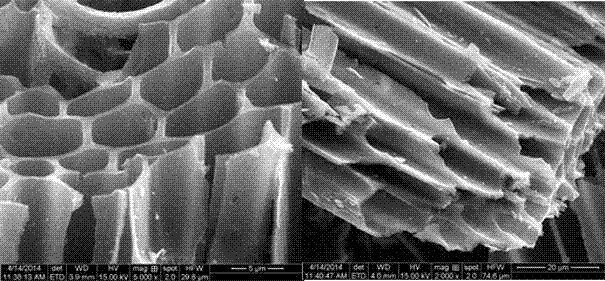

Modified magnetic biochar adsorbing material and application thereof

ActiveCN104258823AStable structureAvoid easy cloggingOther chemical processesAlkali metal oxides/hydroxidesCarbonizationBiochar

The invention discloses a modified magnetic biochar adsorbing material and application thereof. The adsorbing material is prepared through the following steps: taking agricultural waste corn stalks as a raw material, magnetizing and carbonizing the raw material, and adhering chitosan coating to the surface of the raw material. The adsorbing material is wide in raw material source, stable in structure, low in possibility of blocking, high in efficiency of effectively removing typical heavy metal pollutants namely cadmium ions and copper ions in water, convenient to separate, recycle and reuse and free of secondary pollution, achieves resource utilization, and has good environmental benefits and economic benefits.

Owner:UNIV OF JINAN

Copper mine tailing slag porous ceramic material and preparation method thereof

A copper mine tailing slag porous ceramic material comprises copper mine tailing slag, a pore-foaming agent, an adhesion agent and a fluxing agent. A preparation method comprises the steps of using the copper mine tailing slag as aggregate, adding the pore-foaming agent, the adhesion agent, the fluxing agent and water to be stirred evenly, using a mold to perform compression molding to obtain a blank, controlling the temperature and sintering through a high-temperature procedure after drying, and obtaining porous ceramics. Raw materials used by the copper mine tailing slag porous ceramic material are cheap and easy to obtain, the compression strength of the porous ceramic material can be remarkably improved and can reach to 5-25 MPa only by adding the copper mine tailing slag and a small amount of additives, and the apparent porosity can reach to 40%-65%. A large amount of beneficiation tailing slag can be utilized effectively, the environmental pollution is reduced, wastes are turned into wealth, and the prepared porous ceramic material can be used as an excellent adsorbing material and a filter material. The technical process is simple, the utilization amount of the copper mine tailing slag is large, secondary pollution is not caused, the porous ceramic material is high in compression strength and porosity, and the resource utilization of the copper mine tailing slag is achieved. The copper mine tailing slag porous ceramic material is suitable for industrial production.

Owner:CENT SOUTH UNIV

Ceramsite prepared by using smelting wastes, and preparation method thereof

ActiveCN103922698AHarmlessAchieve reductionCeramic materials productionClaywaresSocial benefitsSludge

The invention relates to the technical field of harmlessness treatment of smelting wastes, and especially relates to a ceramsite prepared by using smelting wastes, and a preparation method thereof. The ceramsite comprises 10-90% of smelting waste powder, 5-40% of municipal sludge, 4-20% of fly ash, 0-20% of gangue and 0.1-10% of a curing agent. The preparation method of the ceramsite comprises the following steps: 1, crushing the smelting wastes by using a crusher to prepare the smelting waste powder; 2, weighing the smelting waste powder, the municipal sludge, the fly ash, gangue and the curing agent, mixing, and uniformly stirring to prepare ceramsite powder; 3, conveying the ceramsite powder to a ball forming granulation machine, and carrying out granulation molding to prepare ceramsite balls; 4, drying the ceramsite balls; and 5, calcining he dried ceramsite balls to prepare the finished ceramsite. The ceramsite prepared in the invention has the advantages of light weight, environmental protection and wide uses; and the preparation method recycles the smelting wastes, and has good economic and social benefits.

Owner:DONGGUAN YICHENG ENVIRONMENTAL TECH

Manganese residue compound fertilizer and preparation method thereof

ActiveCN102674965ARealize resource utilizationImprove void structureFertilizer mixturesSulfateManganese

The invention relates to a manganese residue compound fertilizer and a preparation method thereof. Manganese ore leached residue is used as the main raw material, a carbonate-containing fertilizer is added to convert calcium sulfate in the manganese residue into calcium carbonate, and the manganese residue compound fertilizer is prepared from the manganese residue containing the calcium carbonate, the lignin-containing additive, and one or more of nitrogen fertilizer, phosphate fertilizer and potash fertilizer. The carbonate-containing fertilizer and the lignin-containing additive can effectively prevent soil from packing together, keep the acid-base balance in soil, and enhance the fertilizer efficiency. The invention can effectively utilize abundant manganese residue generated in electrolytic manganese industry, and provides an effective way for recycling manganese residue.

Owner:CENT SOUTH UNIV

Method for producing sulphate aluminum cement

The invention relates to a method for producing sulphate aluminum cement. The method comprises the following steps: preparing cement raw meal by proportioning limestone, phosphogypsum, low grade alumina and coke; uniformly grinding and calcining at high temperature; in the calcining process, promoting phosphogypsum to be decomposed as much as possible; replacing partial limestone by calcium oxide generated by decomposition; collecting sulfur dioxide to prepare sulfuric acid; and adding natural dihydrate gypsum in the cement clinker and grinding to prepare a cement product. Compared with the existing conventional production methods, according to the method, the utilization of phosphogypsum can be greatly improved, the utilization concentration of sulfur dioxide discharged by decomposition of little gypsum in the production process can be guaranteed to be reached, the use level of limestone is further reduced and emission of carbon dioxide is reduced. Cement calcined is wide in adaptability, can be widely applied to production of sulphate aluminum cement by phosphogypsum, and further can be suitable for producing high early strength cement, expansive cement and the like.

Owner:CHONGQING UNIV

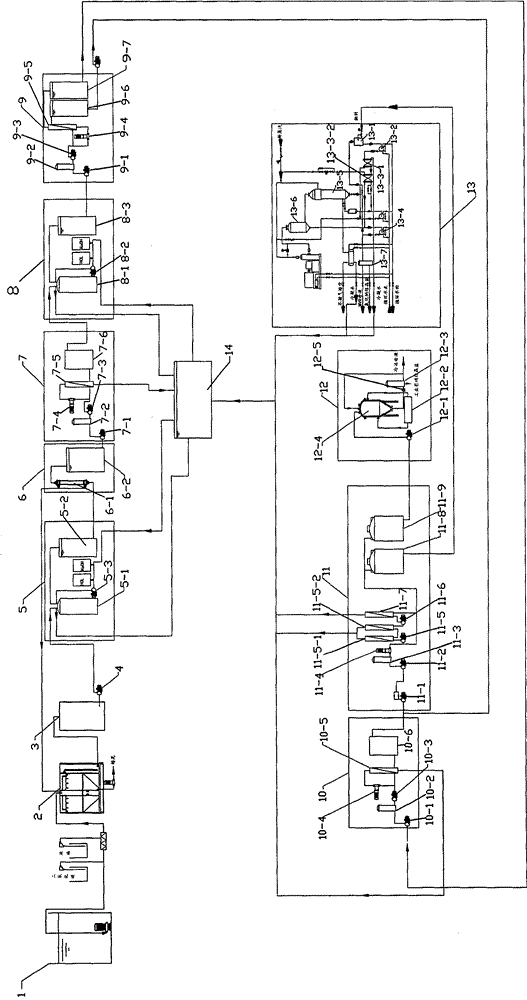

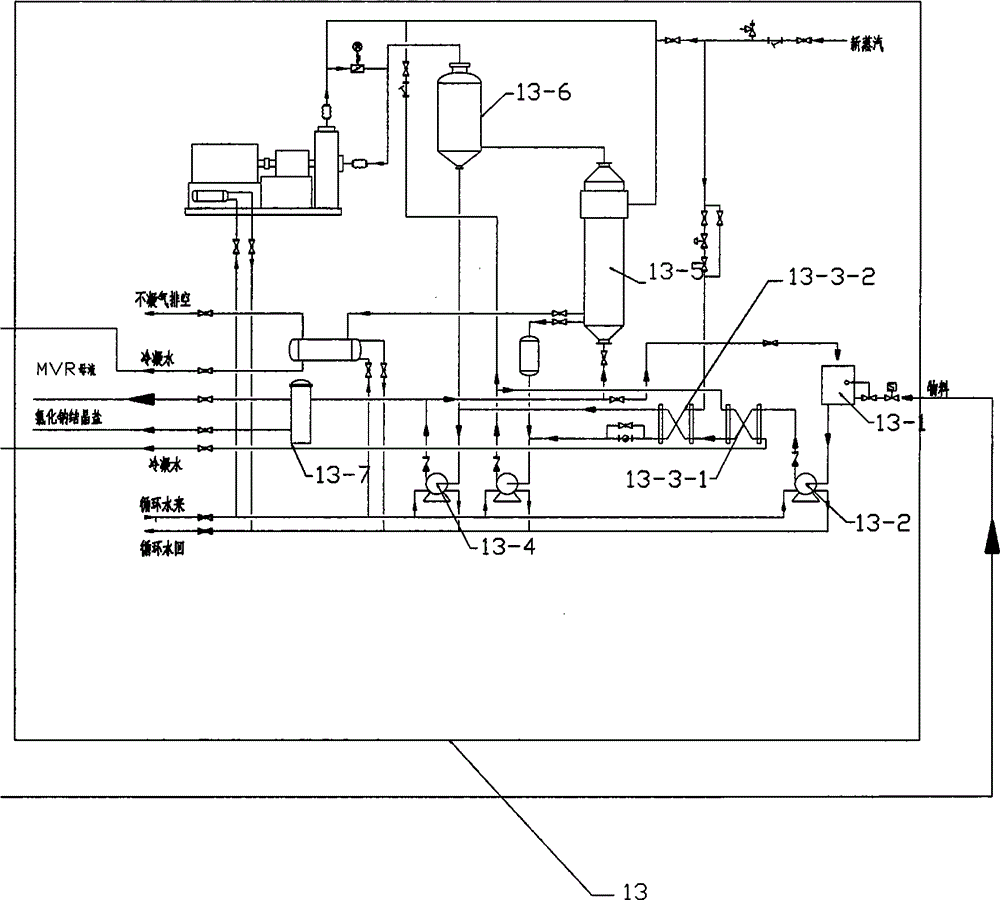

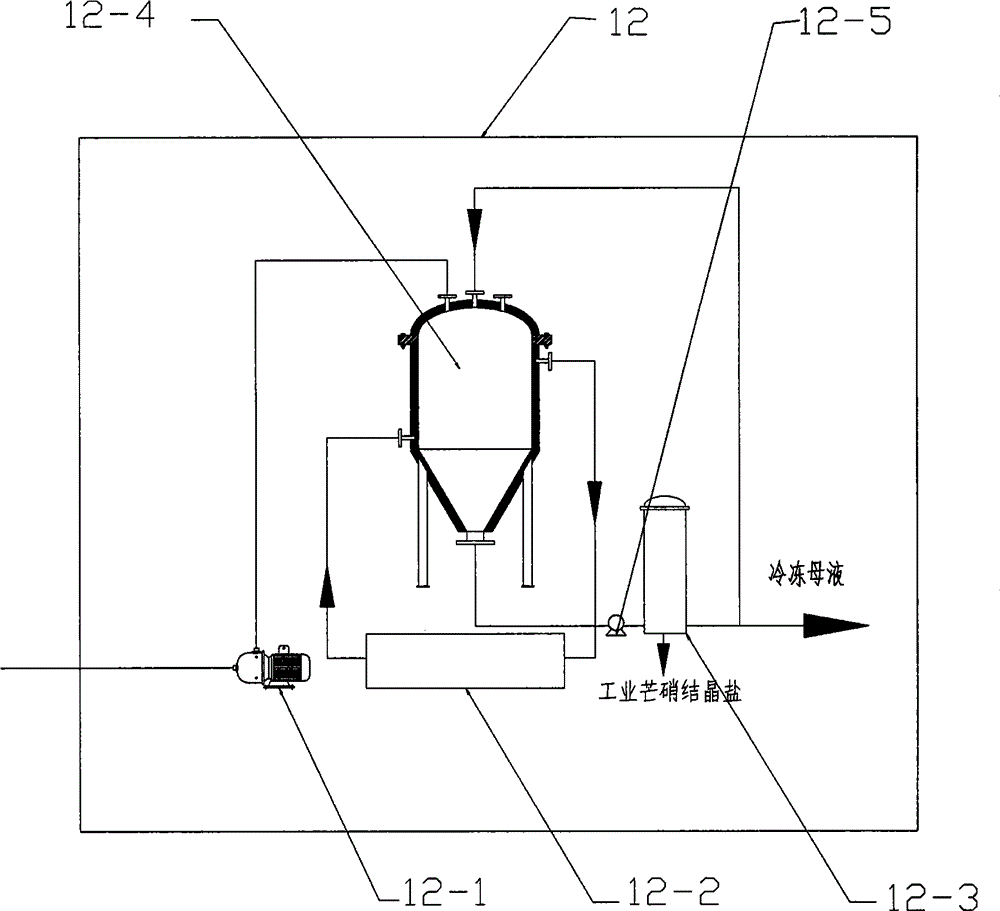

A treatment system for high-salt waste water

InactiveCN104787951ARealize resource utilizationEfficient separationMultistage water/sewage treatmentSalt-wastingSmall footprint

The invention relates to a treatment system for high-salt waste water, and belongs to water treatment techniques. The treatment system comprises an adjusting tank, a high-density sedimentation tank, a V-type filter tank, a first-section ion exchange resin system, an ultrafiltration system, a first-section reverse osmosis system, a second-section ion exchange resin system, a high-pressure nanofiltration system, a second-section reverse osmosis system, a high-pressure flat sheet membrane system and an MVR system in order. The high-pressure nanofiltration system, the high-pressure flat sheet membrane system and a freezing crystallization system are connected in order. The ultrafiltration system is connected to the high-density sedimentation tank. The treatment system reasonably coupling ultrafiltration, nanofiltration, reverse osmosis and a high-pressure flat sheet membrane method and combining MVR crystallization and freezing crystallization techniques is adopted to treatment of the high-salt waste water, and is low in cost, low in running cost, free of secondary pollution, safe, compact in structure, small in occupied space and high in economic value.

Owner:INNER MONGOLIA JIUKE KANGRUI ENVIRONMENTAL TECH

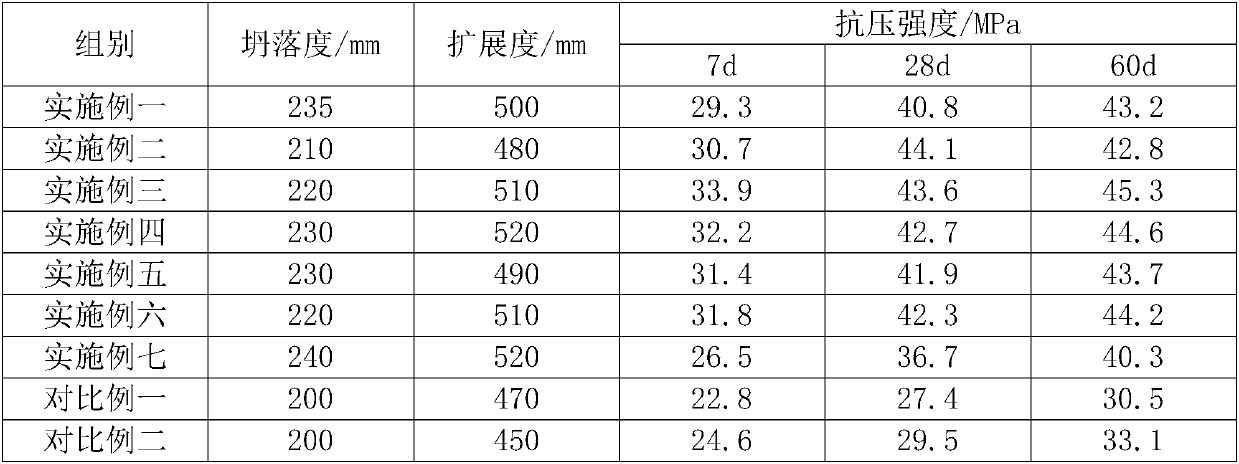

Recycled concrete and preparation method thereof

InactiveCN109574565ASave natural resourcesReduce land occupation and damage to the environmentBuilding materialWork performance

The invention relates to recycled concrete and a preparation method thereof, and belongs to the technical field of building material concrete. The recycled concrete is prepared from, by weight, 140-150 parts of cement, 580-590 parts of recycled coarse aggregates, 260-270 parts of recycled fine aggregates, 95-105 parts of machine-made sand, 35-45 parts of river sand, 70-80 parts of mineral additives, 15-32 parts of hybrid fibers, 4.2-4.6 parts of concrete additives and 80-90 parts of water. The preparation method includes the steps: firstly, weighing various raw materials according to formula ratio, and mixing the coarse aggregates, the recycled fine aggregates, the machine-made sand and the river sand; secondly, adding the cement, the mineral additives and the hybrid fibers, uniformly stirring mixture, adding the concrete additives and the water, and uniformly stirring mixture to obtain the recycled concrete. The recycled concrete has the advantages that natural materials are saved, and environmental protection is achieved. The prepared recycled concrete is excellent in working performance and mechanical property, stable in quality and low in cost.

Owner:武汉中阳明建材有限公司

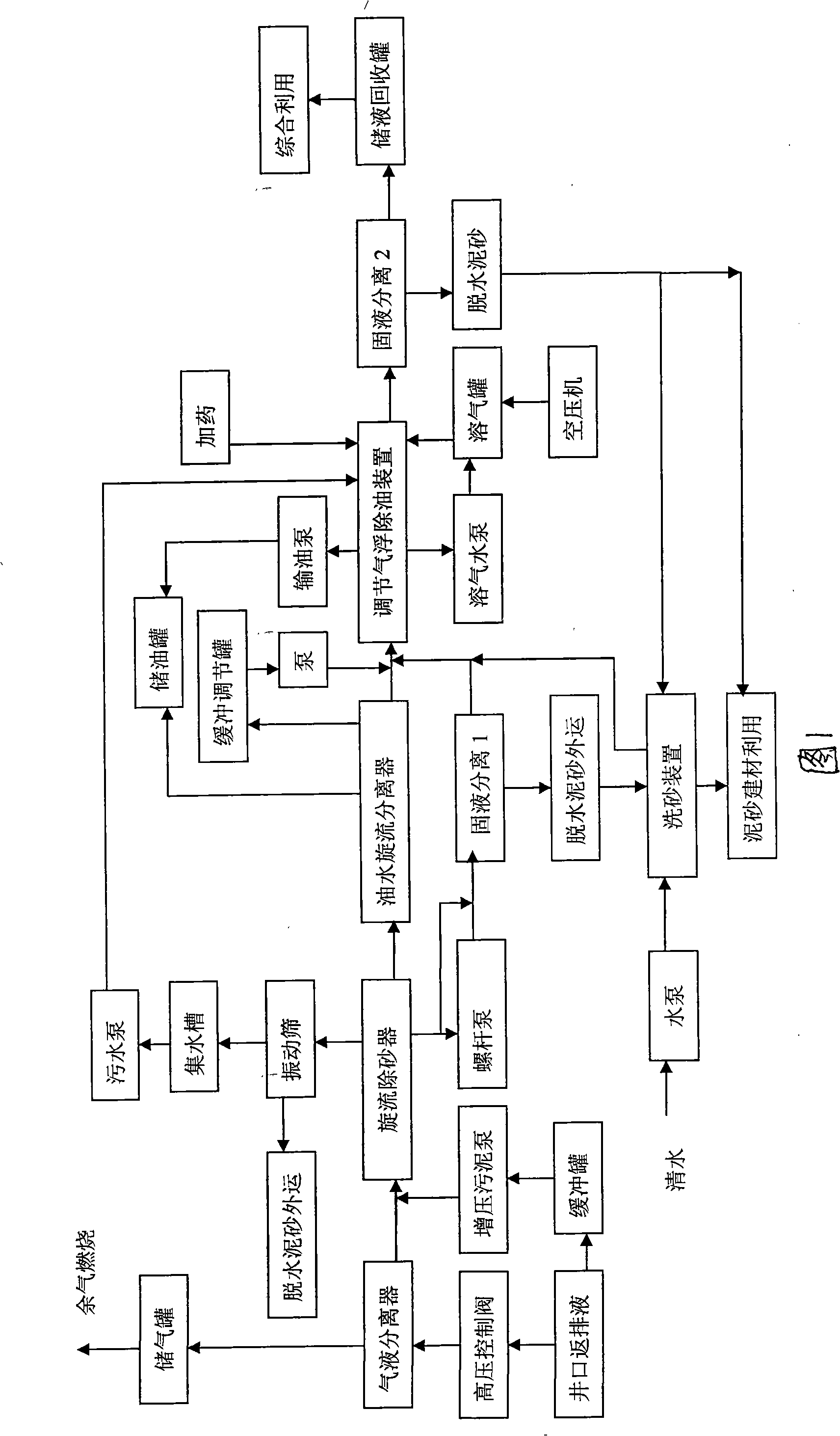

Method for no-grounding treatment and comprehensive utilization of oil-gas field downhole operation output solution

The invention relates to a treatment and integrated utilization method for preventing the liquid output from the oil field and gas field underground operation from dropping on the ground, so that the liquid output from the oil field and gas field underground operation is received and enters into the process of the method to be treated through a sealing process when returning at the well head; after the oil, the gas, the sand and the mud contained in the output liquid are classified, refined and separated through the processes of gas-liquid separation, whirling sand removal, oil-water separation, regulating addition emulsion breaking air floating, and solid-liquid separation, the oil-gas overflows and is utilized; quite large water containing sand particles are cleaned with clean water and then used as building material after the solid-liquid separation process, and the mud with small grain size is made into cake shapes through pressure filtration for brick manufacturing, so that the output liquid can be recycled after being regulated and purified, so as to thoroughly solve the problems of preventing the liquid output from underground operation from dropping on the ground and the resource utilization, and does not bring any potential pollution.

Owner:PUYANG TIANDIREN ENVIRONMENTAL PROTECTION TECH CO LTD

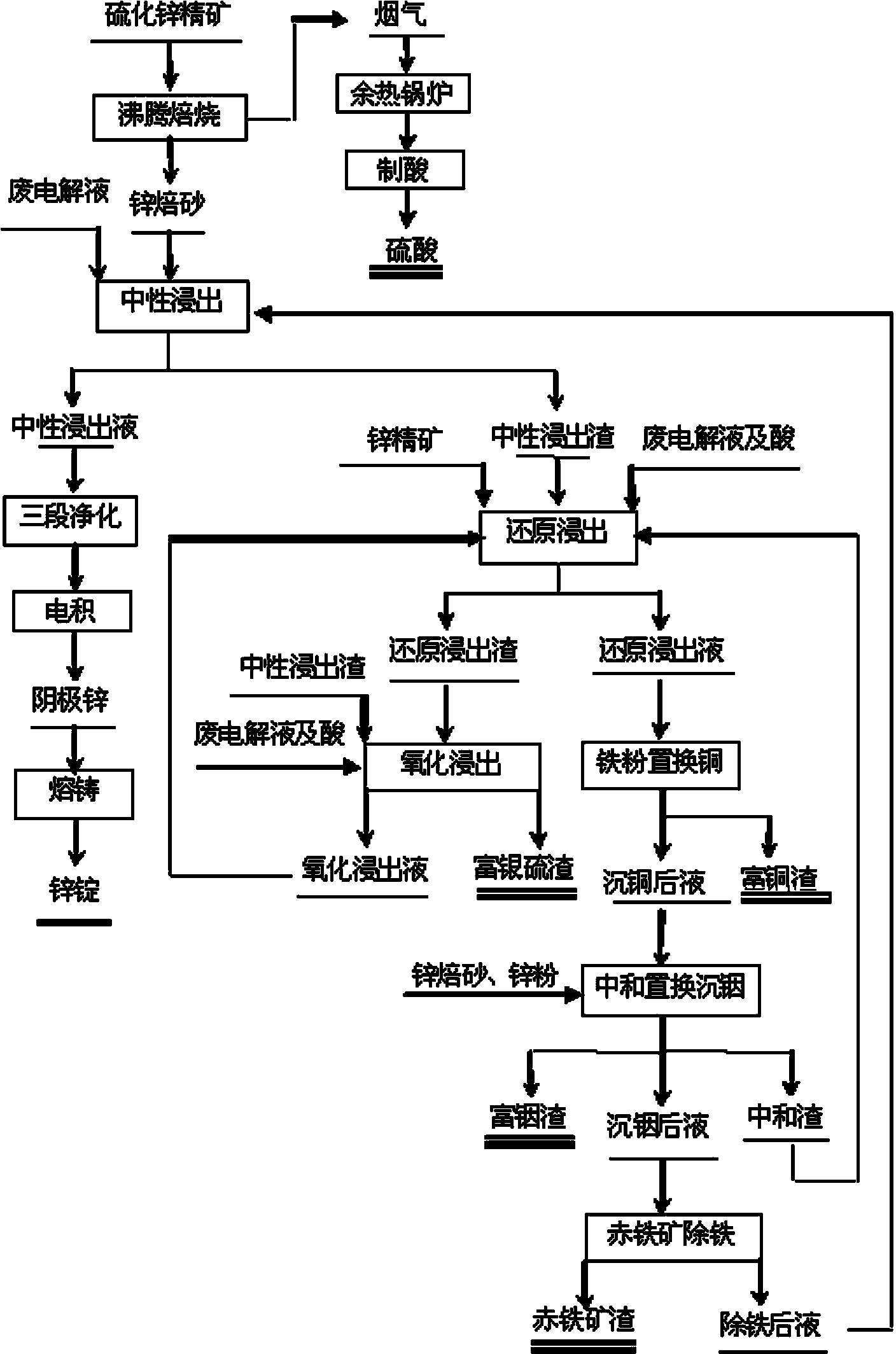

Method for individually processing high-iron zinc sulfide concentrate

ActiveCN103409622AThe process is highly targetedHigh enrichment ratioProcess efficiency improvementIndiumHydrometallurgy

The invention belongs to the technical field of hydrometallurgy, and particularly relates to a method for individually processing high-iron zinc sulfide concentrate. The method comprises a step of subjecting the high-iron zinc sulfide concentrate to calcination in a fluidized bed combustion boiler to obtain zinc calcine; a step of subjecting the zinc calcine to neutral leaching to produce neutral leaching solution and neutral leaching residue; a step of, after the neutral leaching residue and the high-iron zinc sulfide concentrate are mixed, successively performing reduction leaching and oxidation leaching, and circulating oxidation leaching solution to the reduction leaching to produce reduction leaching solution and silver-rich sulfur residue; a step of replacing the reduction leaching solution by using iron powder to precipitate copper and to produce copper-rich slag and solution after copper precipitation; a step of subjecting the solution after copper precipitation to pre-neutralization by using the zinc calcine, and then replacing by using zinc powder to precipitate indium and to produce indium-rich slag and solution after indium precipitation; and a step of bubbling oxygen into the solution after indium precipitation, heating and removing iron to obtain iron removal solution and hematite slag. The hematite slag can be utilized as a raw material for ironmaking. The method has strong pertinence, short technological process and high metal recovery yield, and the method is clean, efficient, energy-saving and environmental friendly. Separation and comprehensive utilization of zinc, indium, copper and iron are achieved.

Owner:KUNMING UNIV OF SCI & TECH TECH IND SALES MANAGEMENT

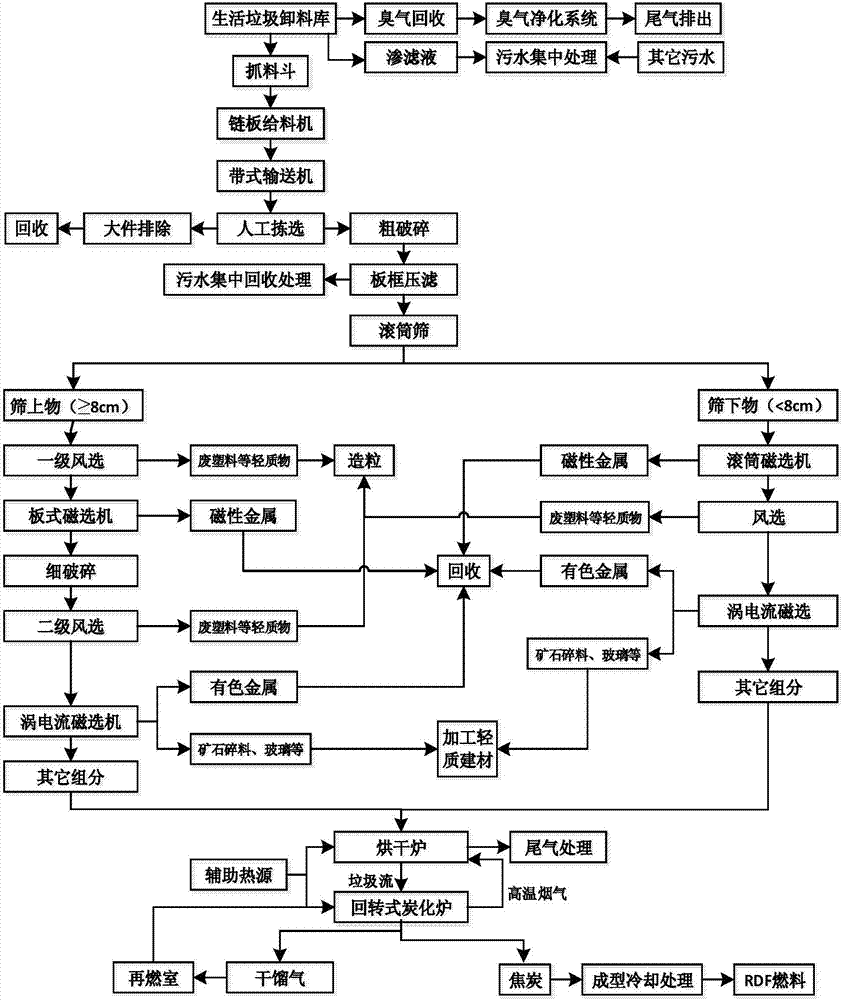

Urban household garbage sorting and charring comprehensive treatment resource recovery method

InactiveCN107497831AHigh degree of automationImprove sorting efficiencyTransportation and packagingSolid waste disposalSolid carbonResource recovery

A urban household garbage sorting and charring comprehensive treatment resource recovery method comprises the first step of garbage sorting treatment, wherein original household garbage is subjected to uniform feeding, manual large garbage sorting, coarse crushing, plate-frame pressure filtering, rolling cylinder screening, full-closed mechanical selecting by winnowing, plate-type magnetic separator treating, eddy current magnetic separator treating and fine crushing process treatment; the second step of garbage drying treatment; the third step of garbage charring treatment, wherein a rotary charring furnace is adopted, and garbage charring is carried out in a normal-pressure low-temperature and low-oxygen atmosphere so that solid carbon can be prepared; the fourth step of coke forming and cooling treatment; the fifth step of bad smell purifying treatment, wherein bad smell generated in a household garbage discharging warehouse and bad smell generated in all treatment process links are collected to a bad smell purifying system through a negative pressure induced draught system; and the sixth step of waste water purifying treatment. The urban household garbage sorting and charring comprehensive treatment resource recovery method is relatively high in automation degree, sorting efficiency and recovery utilization rate and has more sorting functions.

Owner:李新方

Garden waste biomass charcoal-based compound fertilizer and preparation method thereof

InactiveCN104817383AReduce pollutionReduce manufacturing costFertilizer mixturesMoistureNutrients substances

The invention relates to the technical field of compound fertilizer, in particular to garden waste biomass charcoal-based compound fertilizer and a preparation method thereof. The preparation method includes steps that cracking garden waste under a high temperature to obtain garden waste biomass charcoal and combustible gas; mixing raw material of the compound fertilizer with 8-12% of garden waste biomass charcoal according to the total raw material weight of the compound fertilizer, melting, granulating and gathering granules; cooling the gathered granules under negative pressure, and sieving; enveloping the sieved granules, packaging and delivering to obtain the garden waste biomass charcoal-based compound fertilizer. The garden waste biomass charcoal-based compound fertilizer is rich in nutrient substance, coordinating and durable in nutrient element release, high in fertilizer nutrient use efficiency, capable of effectively improving and fertilizing the soil, improving the fertilizer utilization rate, increasing the organic substance content of the soil, lowering the volume weight of the soil, improving the moisture and fertility preserving ability of the soil and accelerating the crop growth, and also capable of obviously improving the crop output and improving the crop quality.

Owner:GUANGDONG DAZHONG AGRI SCI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com