Method for no-grounding treatment and comprehensive utilization of oil-gas field downhole operation output solution

A technology for producing fluids and oil and gas fields, which is applied in earthwork drilling, wellbore/well components, production fluids, etc., and can solve problems such as ineffective separation of produced fluids, narrow scope of application, and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

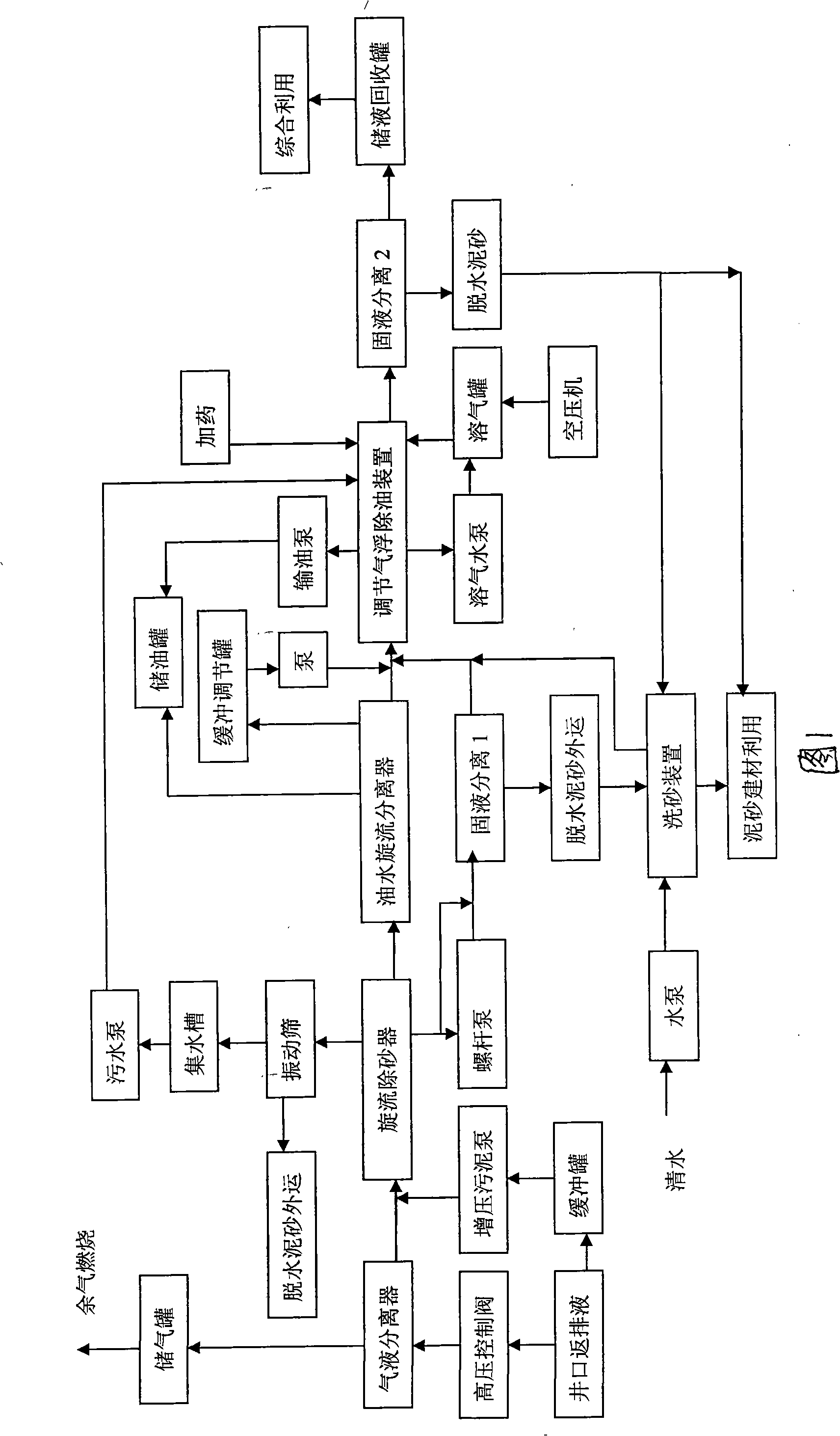

[0008] The invention can carry out non-ground treatment and comprehensive utilization of the output fluid from downhole operations such as fracturing, acidification, sand washing, well washing, blowout, etc. returned from the wellhead, and can realize the overall prying of downhole operation environmental protection equipment. The process is that when the pressure of the produced liquid returned from the wellhead is higher than 0.2Mpa, the high-pressure flowback liquid is adjusted through the high-pressure control valve, and the pressure is controlled from 0.2Mpa to 1Mpa. First, it enters the gas-liquid separator to separate the gas phase into the storage tank. When there is no recovery condition for the gas tank, the remaining combustible gas is burned with a torch, and the liquid and solid phase enters the cyclone desander and uses the centrifugal force to make the solid particles with higher density (particle size greater than 0.25mm) in the liquid be thrown away When the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com