Patents

Literature

108 results about "Desander" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Desanders and desilters are solid control equipment with a set of hydrocyclones that separate sand and silt from the drilling fluids in drilling rigs. Desanders are installed on top of the mud tank following the shale shaker and the degasser, but before the desilter. Desander removes the abrasive solids from the drilling fluids which cannot be removed by shakers. Normally the solids diameter for desander to be separated would be 45~74μm, and 15~44μm for desilter.

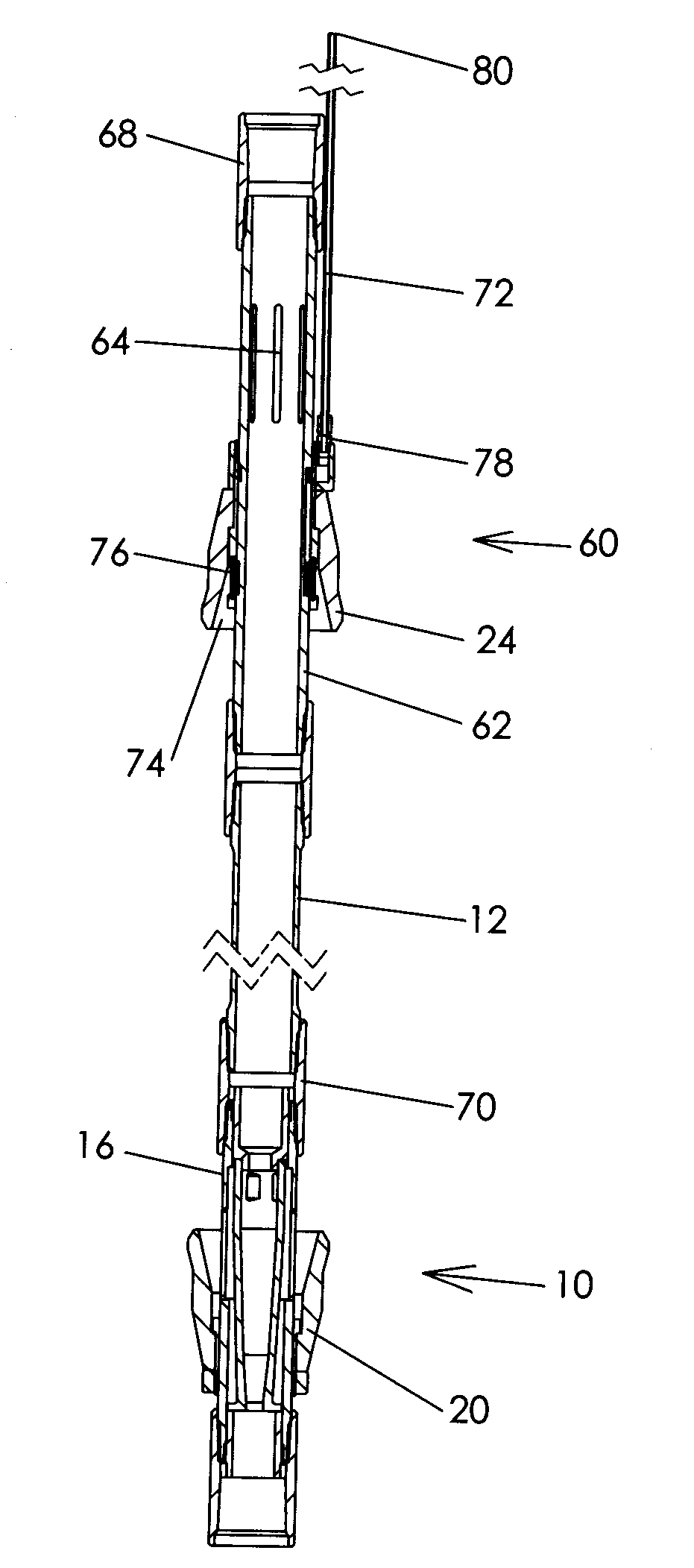

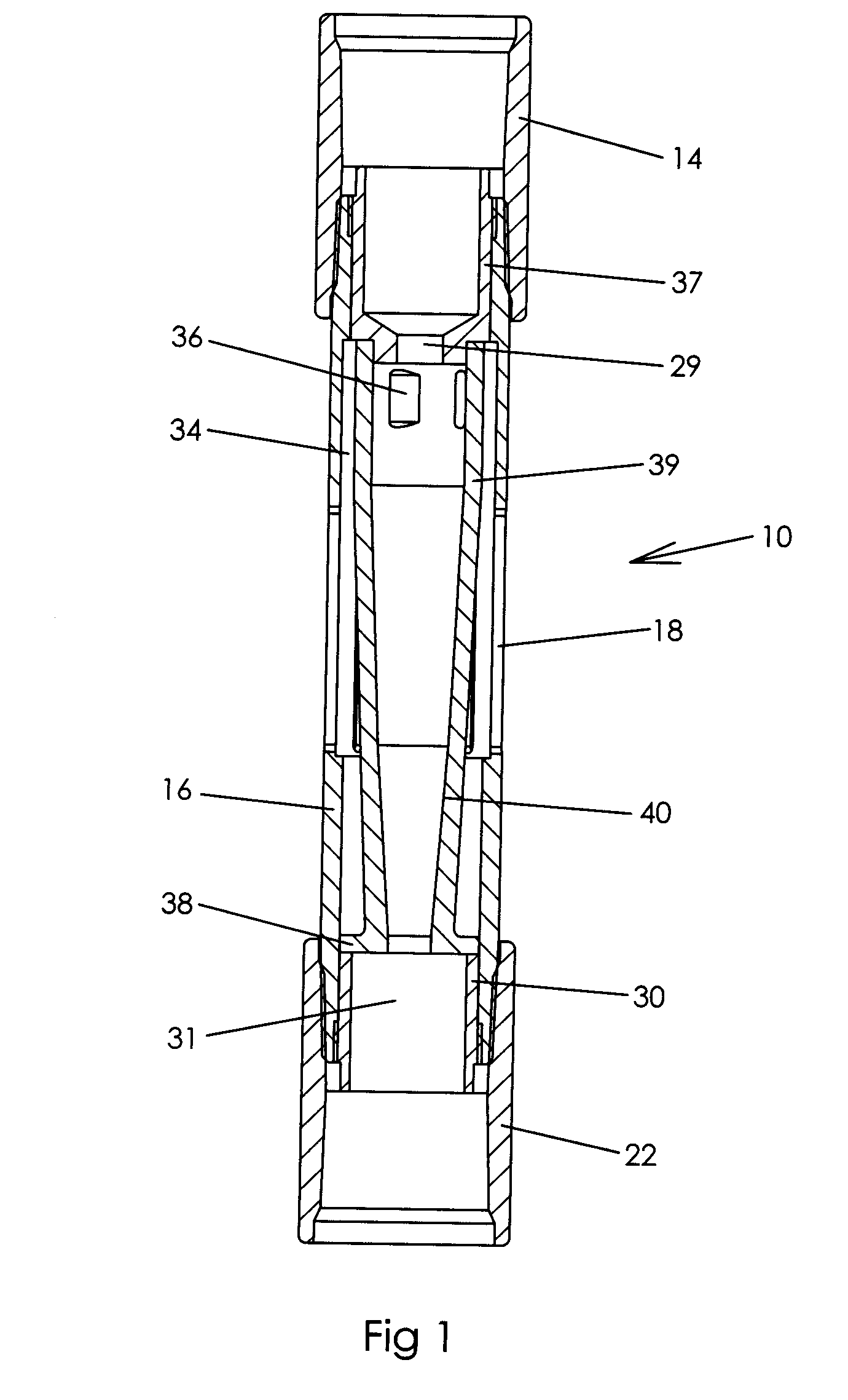

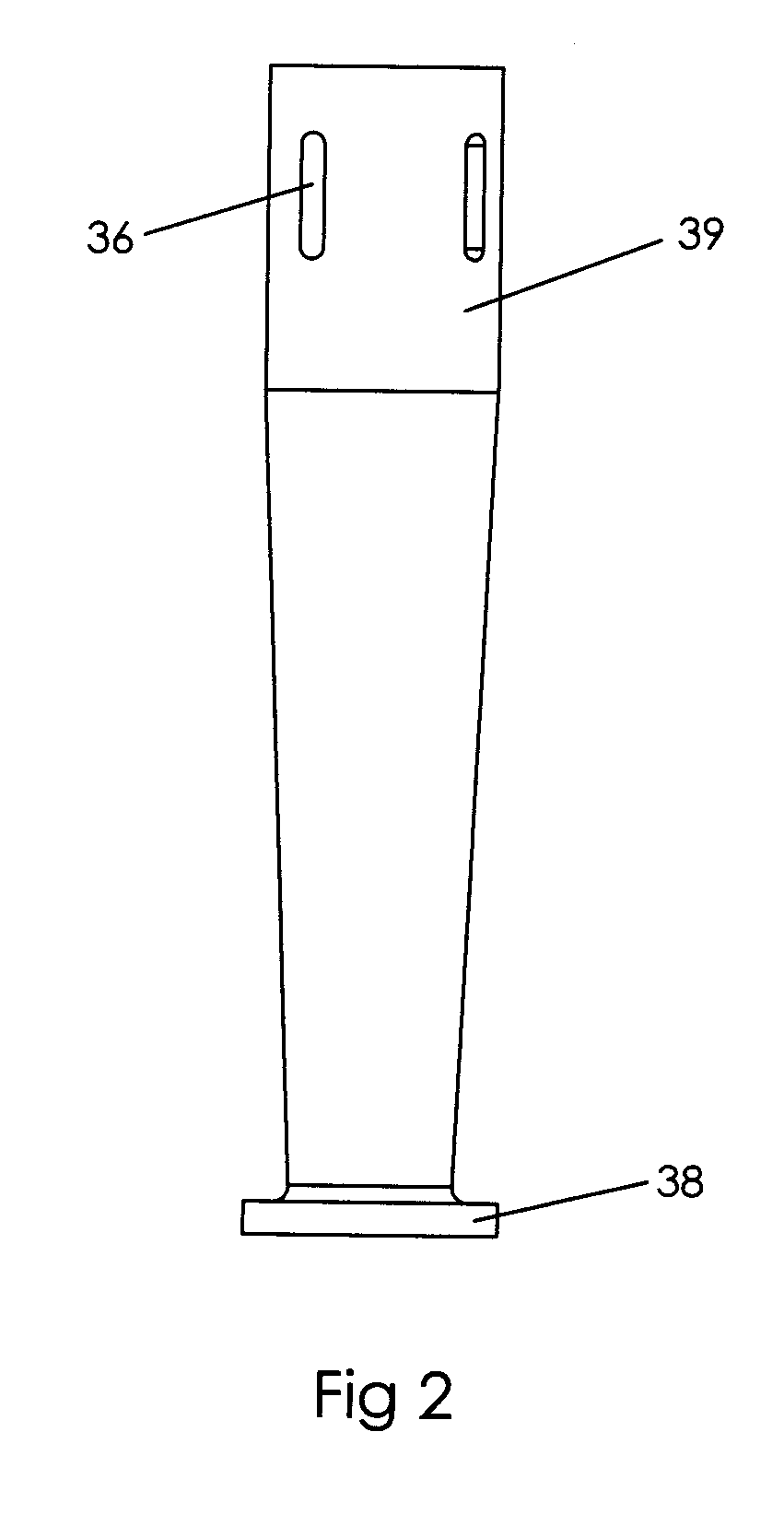

Downhole Separator

The desander (10) for positioning downhole includes a generally tubular desander body (16) and a generally sleeve-shaped vortex body (39, 94). The desander with a seal or packer may be positioned in a well below the casing perforations. The desander with an ESP may be used with gas separator (60), which may include a seal (24) for positioning above the producing formation. The separator (60) may be used independent of the desander for some applications.

Owner:COBB DELWIN E

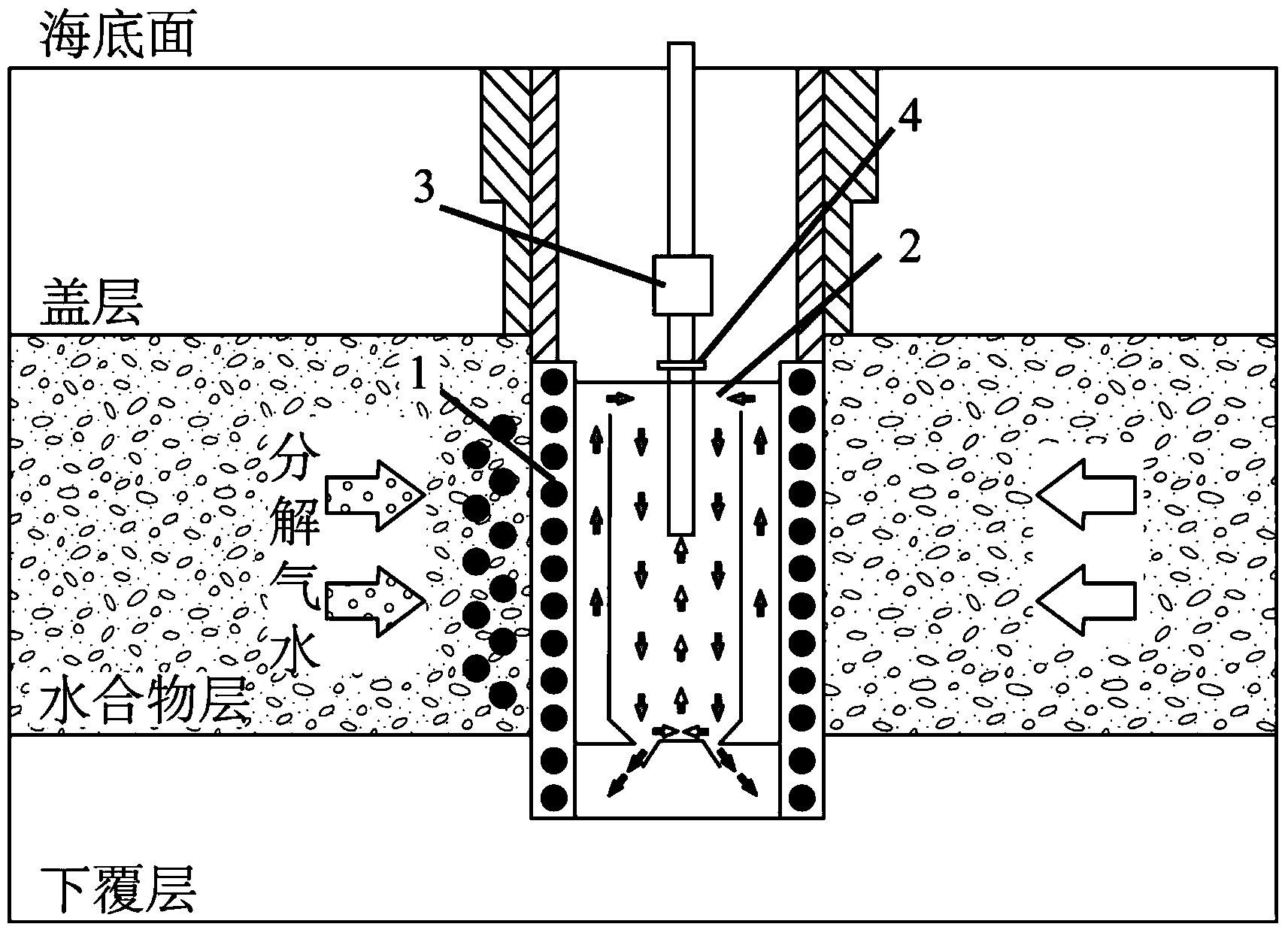

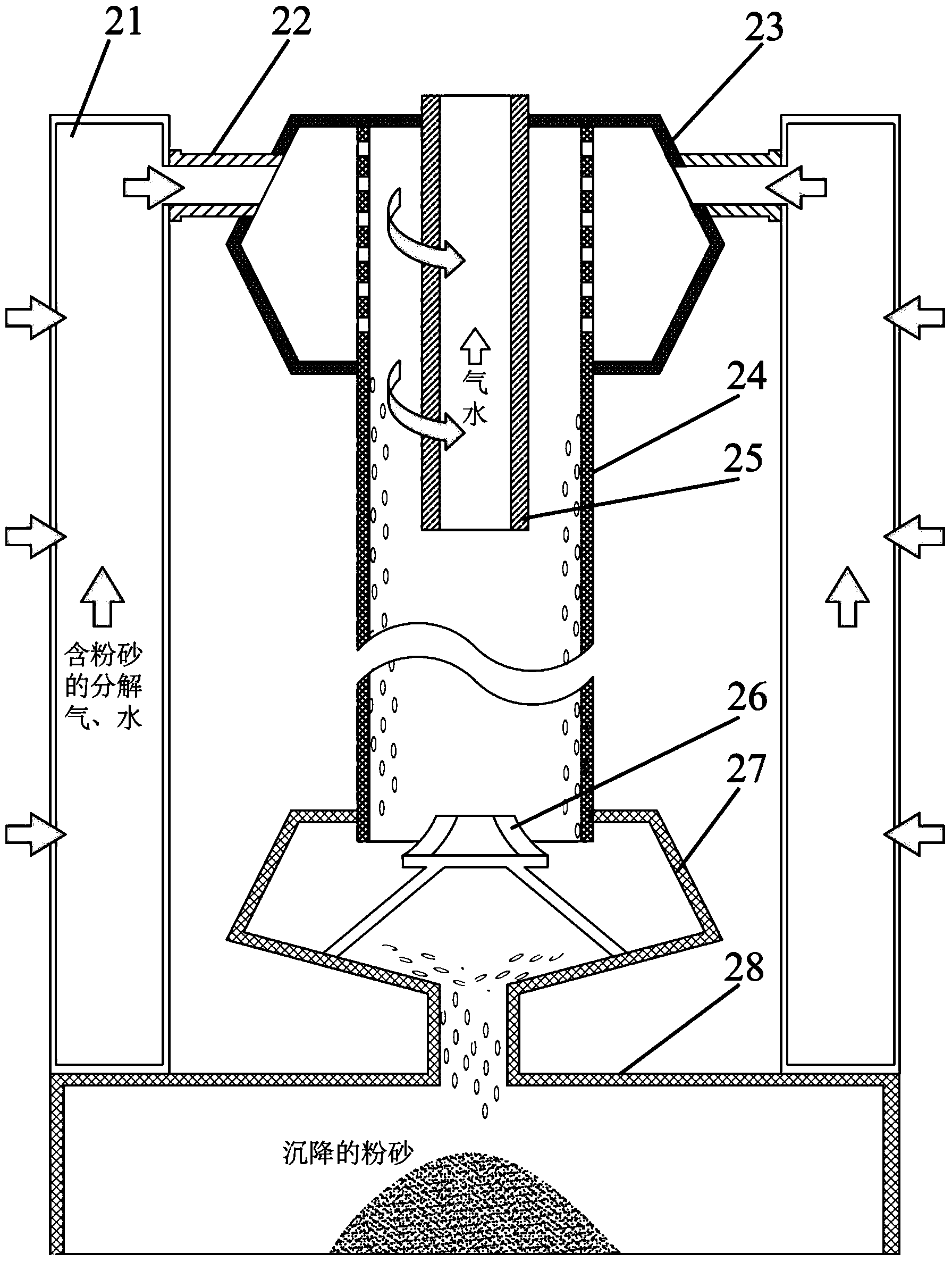

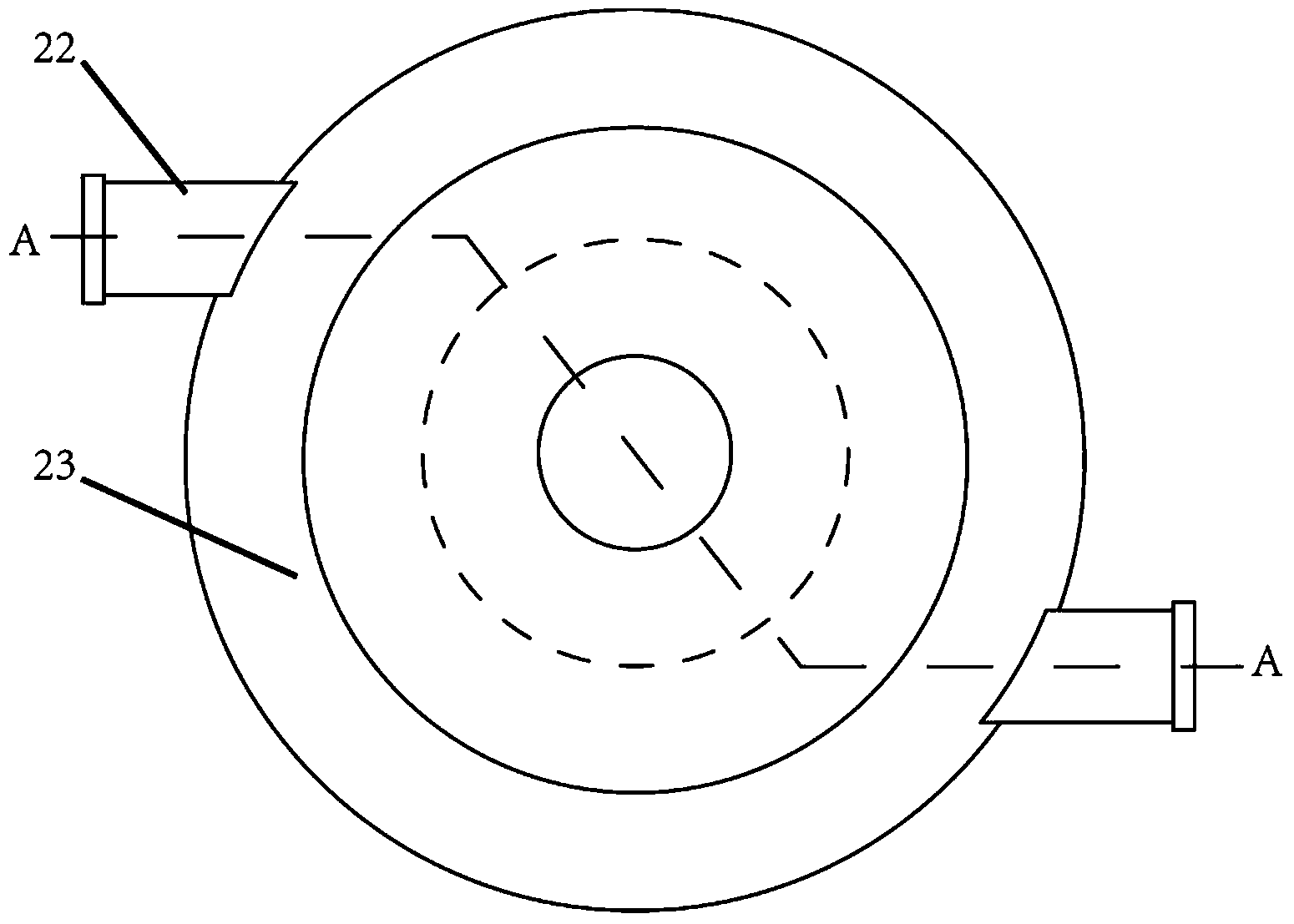

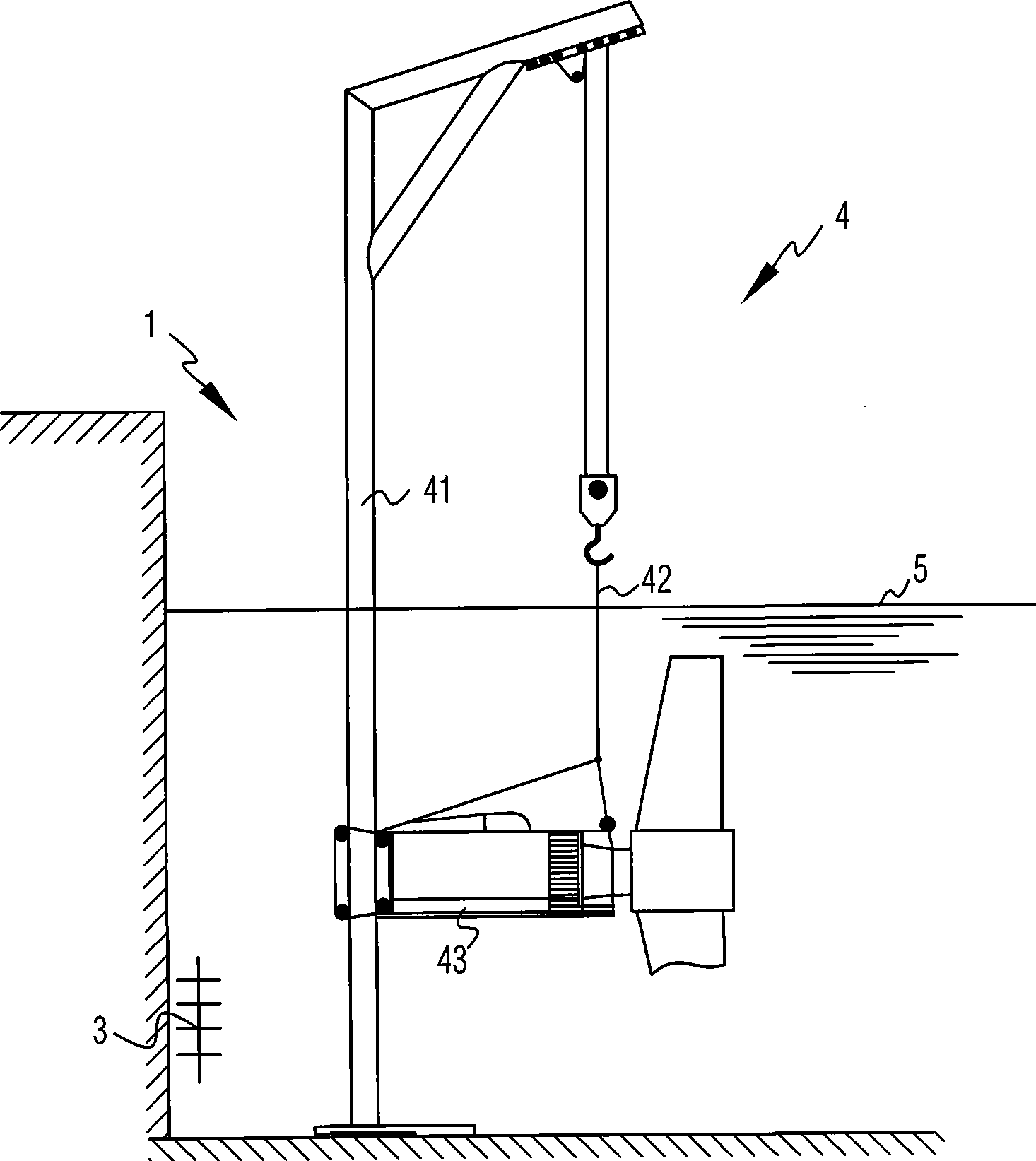

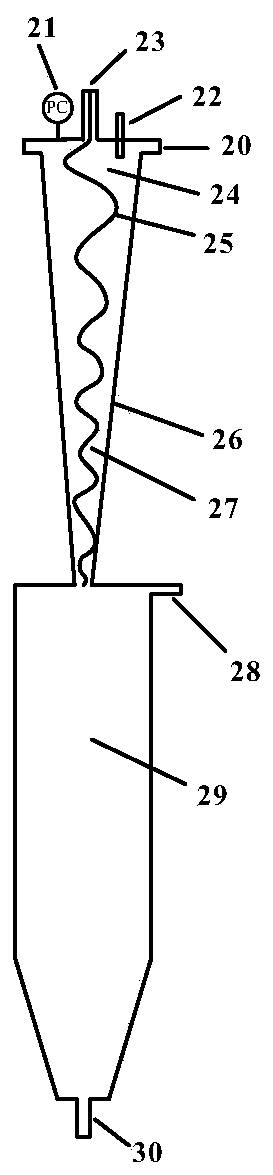

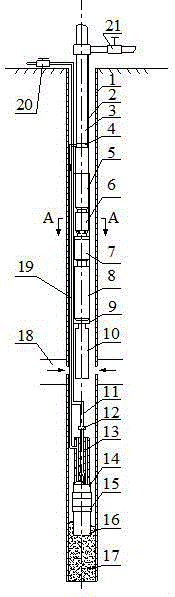

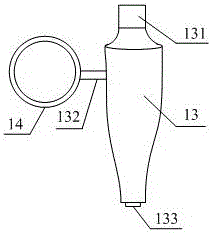

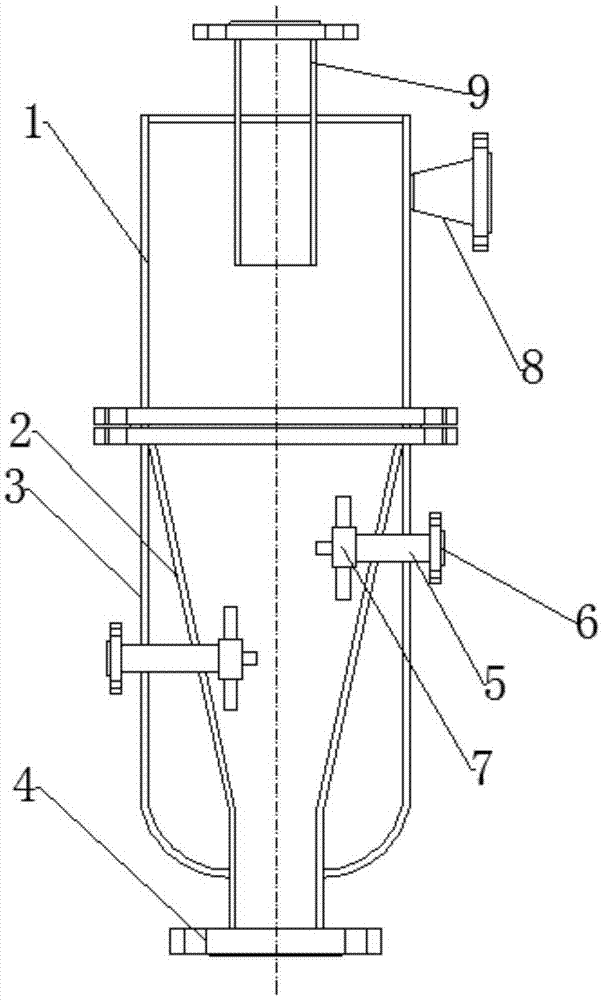

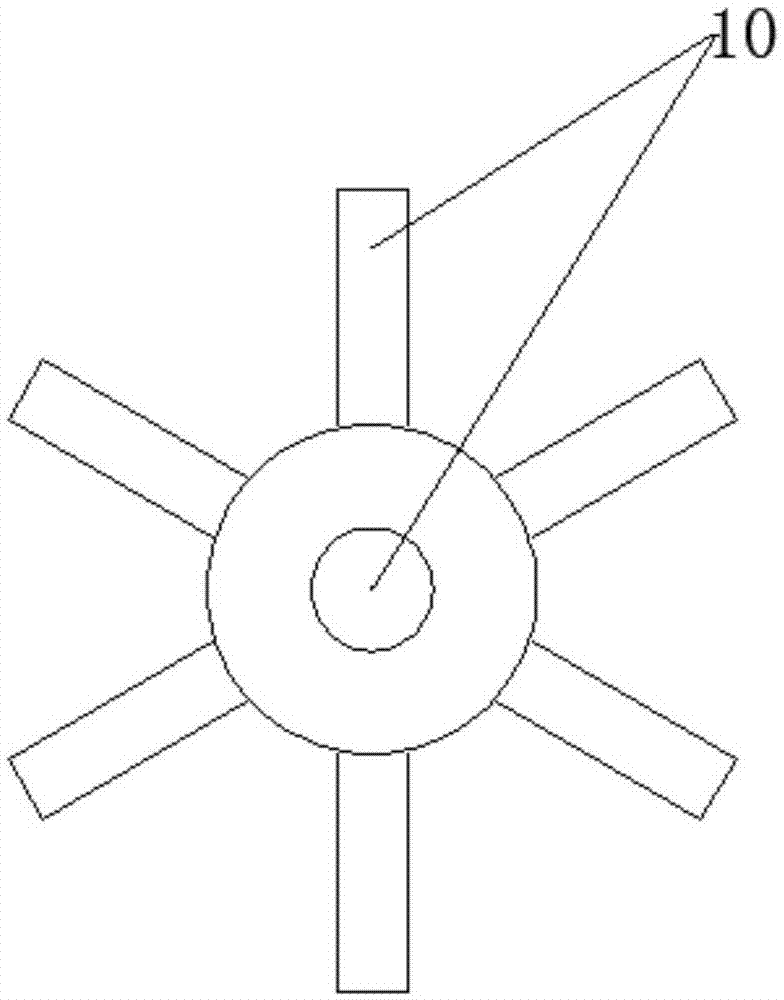

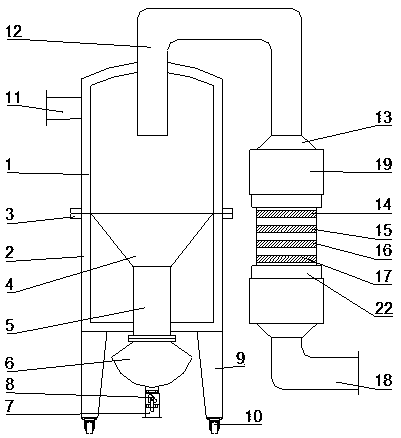

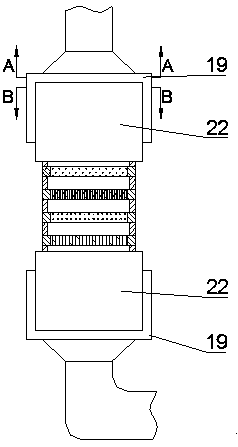

Device and method for desanding of submarine natural gas hydrate exploitation well

ActiveCN103967473ADoes not significantly affect permeabilityAvoid enteringFluid removalDesanderCentrifugal force

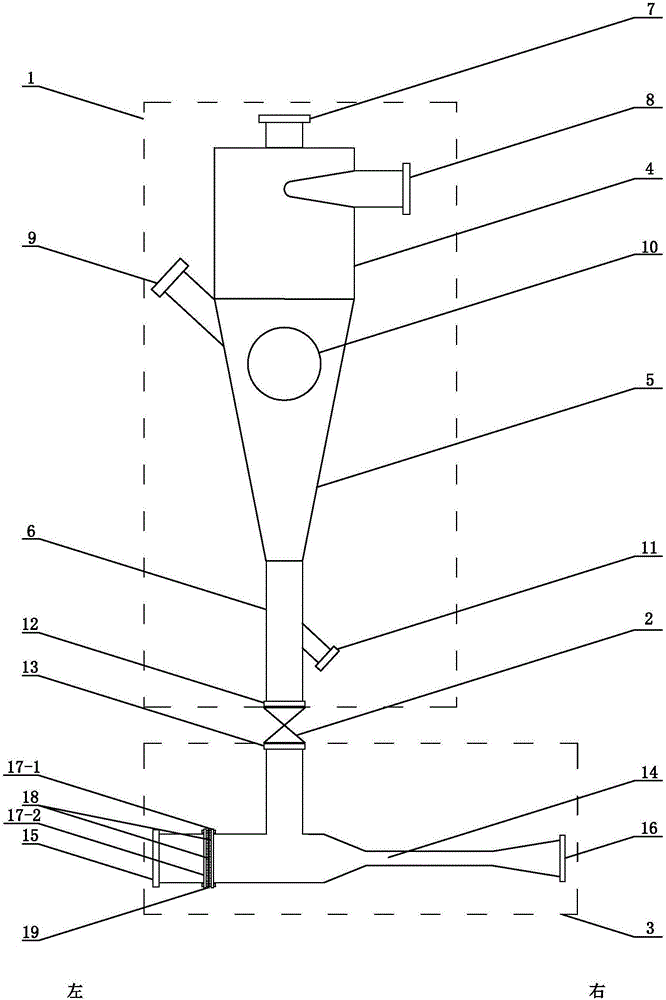

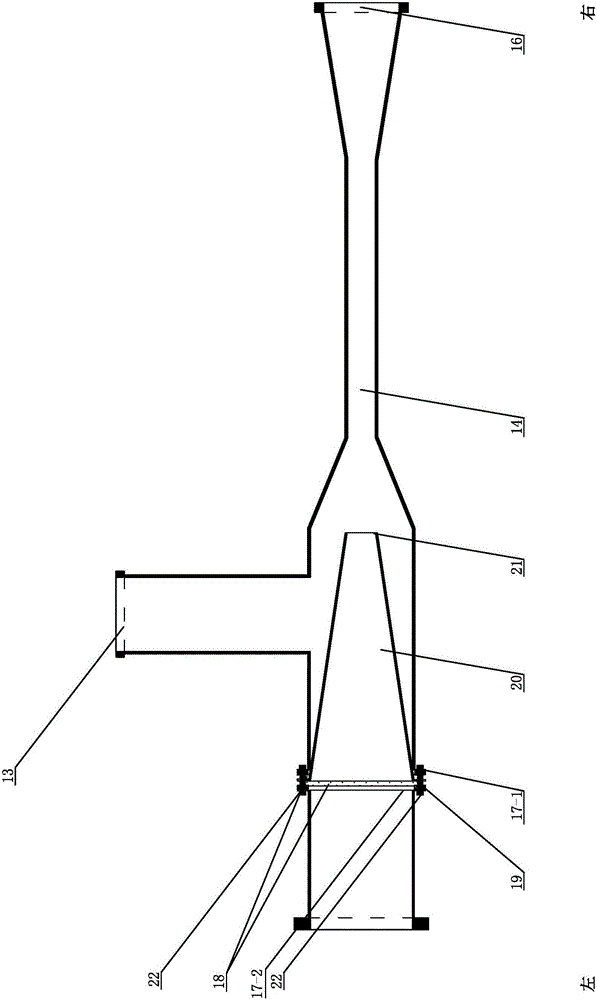

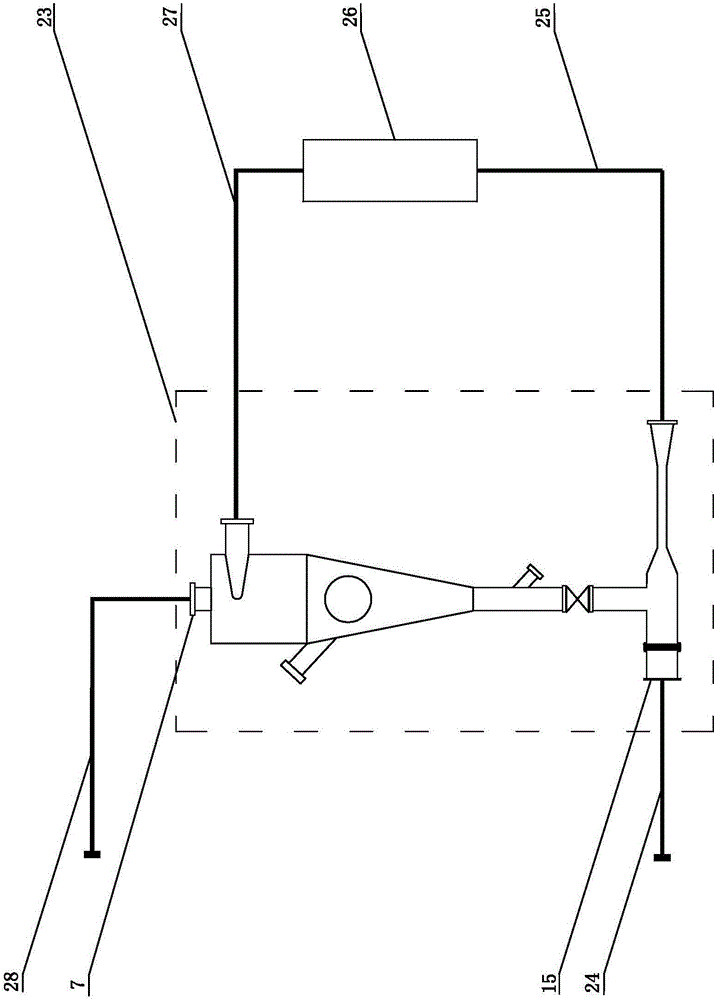

The invention provides a device and method for desanding of a submarine natural gas hydrate exploitation well. The device comprises a gravel filling set, a centrifugal desander, a submerged pump and a connecting flange. The gravel filling set is arranged at the bottom of the exploitation well, the centrifugal desander and the submerged pump are connected through the connecting flange and wholly descend to the bottom of the exploitation well, and the outer wall of a flow guide chamber is attached to the inner wall of the gravel filling set. By the adoption of the device, in the centrifugal desanding process, gas-water sand is firstly decomposed and flows to a shaft, large settled layer sand is blocked by the gravel filling set, and gas and water containing fine sand enters the shaft; gas and water containing the fine sand enter an upper collection box through the flow guide chamber and an inflow port, and cyclones are generated; under the effect of centrifugal force, the fine sand is gathered on the inner wall of a settling chamber and descends into a sand collection box. By the adoption of a secondary desanding method, desanding efficiency is improved, and permeability of a hydrate settled layer cannot be remarkably affected; by the adoption of a cyclone centrifugal mode, the fine sand and decomposed gas and water can be effectively separated, the fine sand is prevented from entering the submerged pump, and equipment wear is reduced.

Owner:DALIAN UNIV OF TECH

Feces desander and desanding method

InactiveCN101475296AImprove sand removal effectImprove efficiencySludge treatmentSoil scienceGreenhouse

The invention relates to a device for removing sand from excrement, which comprises a grit chamber. The grit chamber is separated into multistage overflow structures through a detachable gate, and the sand in the excrement is separated through gradual overflow of the grit chamber after the excrement and water are mixed. The invention also relates to a method for removing sand from excrement. The sand in the excrement is separated through a gradual overflow mode, the sand with the particle diameter lower than fine sand can be separated, and the sand content after sand removal can be lower than 3 percent. In addition, the method can adopt measures such as stirring, greenhouses, heating and the like to further improve the sand removing effect. The adopted grit chamber can be as long as about 100 meters, the width of the grit chamber is suitable for a vehicle to clean sand and stone, particularly suitable for large-scale industrialized excrement treatment, and both the sand removing effect and the efficiency are superior to a small settling or rotational flow treating process. The livestock excrement treated by sand removal can be used for generating marsh gas by fermentation or burning for power generation after drying.

Owner:内蒙古蒙牛生物质能有限公司

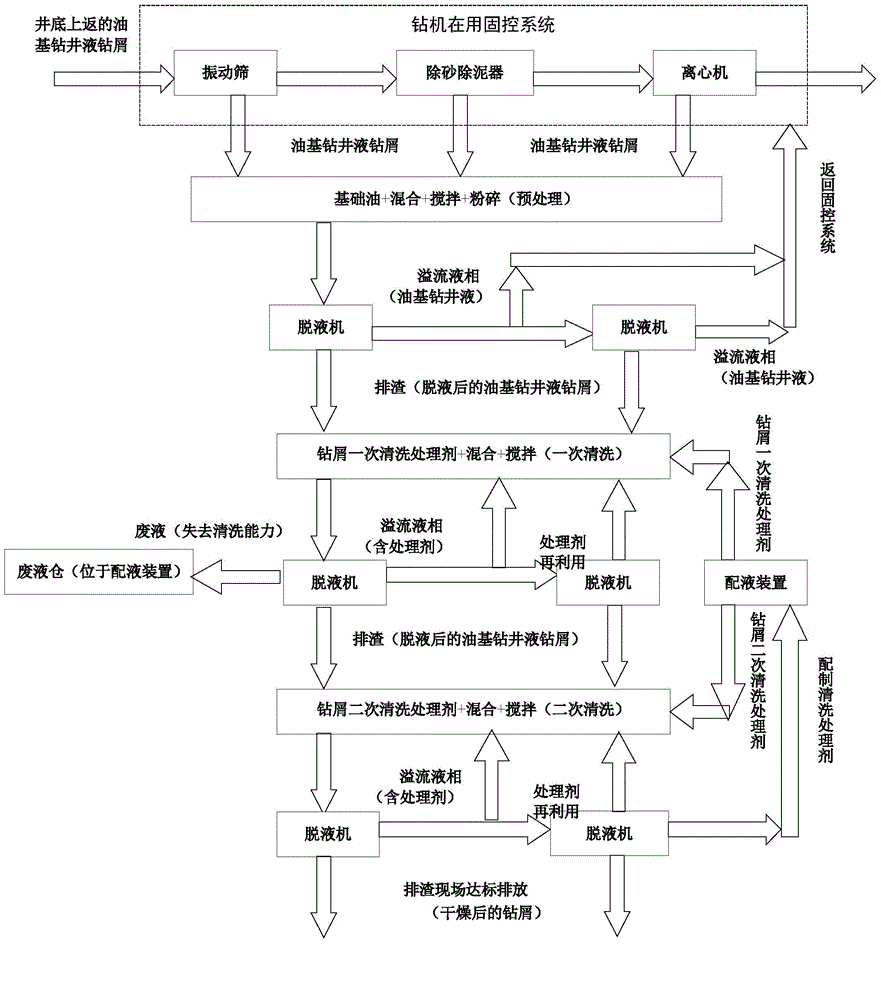

Oil-based drilling fluid drilling cutting while-drilling treatment method

The invention discloses an oil-based drilling fluid drilling cutting while-drilling treatment method. The method is used for conducting oil-based drilling fluid recycling and drilling cutting while-drilling cleaning treatment on oil-based drilling fluid drilling cuttings produced in the drilling process. The method comprises the steps that 1, the oil-based drilling fluid drilling cuttings which are high in drilling fluid content and discharged out of solid control equipment such as a vibration screen, a desander and a centrifugal machine are subjected to diluting, mixing, stirring and smashing pretreatment through base oil; and 2, the oil-based drilling fluid drilling cuttings are subjected to spin dry through oil-based drilling fluid drilling cutting removing liquid, overflowed oil-based drilling fluid can be recycled, and then the drilling cuttings are subjected to solid-liquid separation through primary and secondary cleaning treatment agents to reduce the solid content. According to the oil-based drilling fluid drilling cutting while-drilling treatment method, the oil-based drilling fluid drilling cuttings produced in the drilling crew drilling process can be subjected to site while-drilling treatment, the oil-based drilling fluid in the drilling cuttings is recycled, and the cost is reduced. The oil content of the drilling cuttings subjected to cleaning treatment meets the environmental requirements for emissions on the site.

Owner:SINOPEC SHENGLI PETROLEUM ENG CO LTD DRILLING TECH RES INST

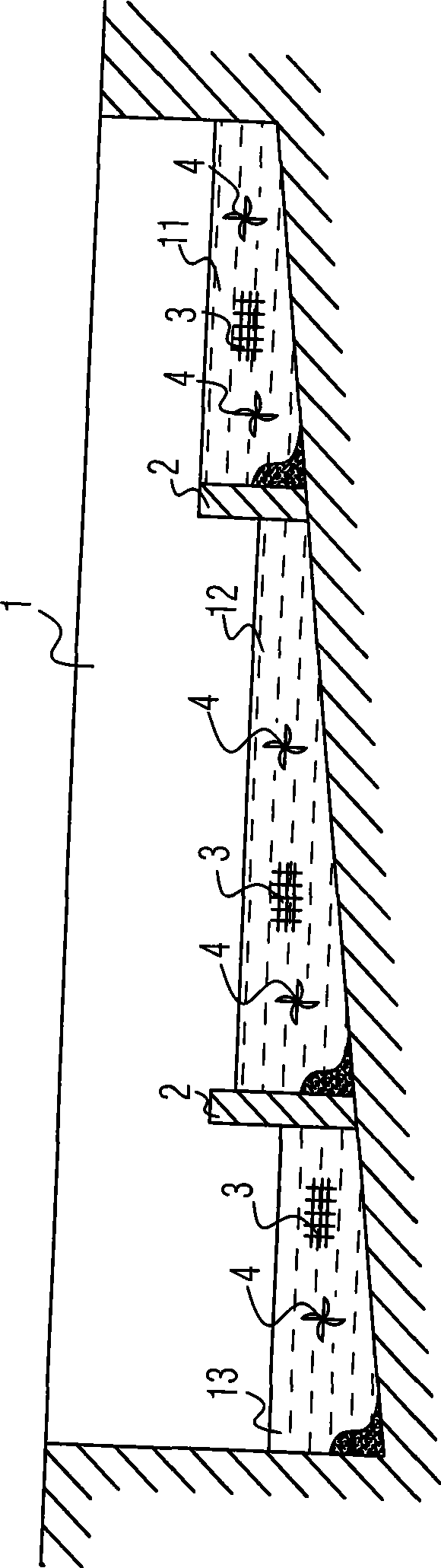

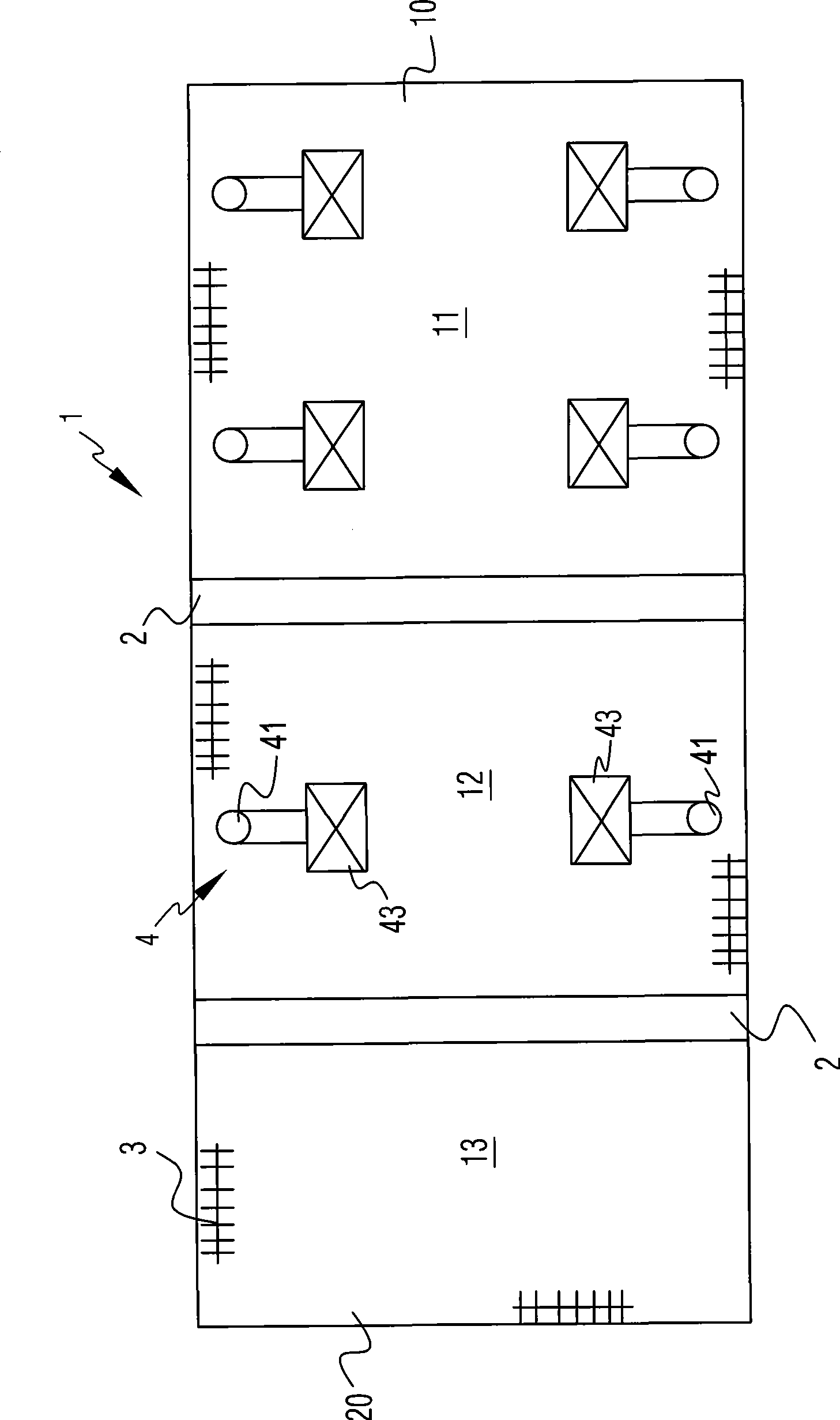

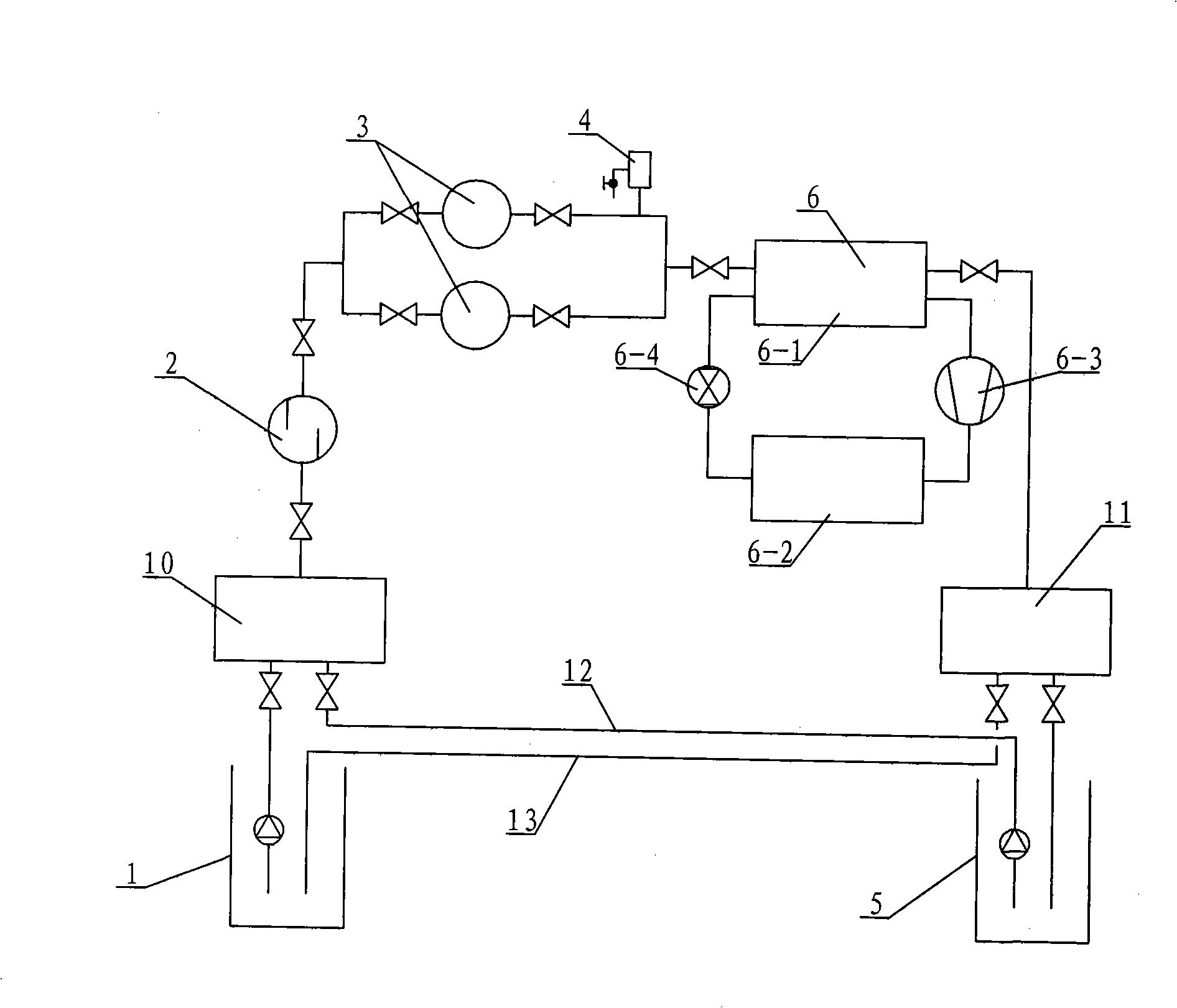

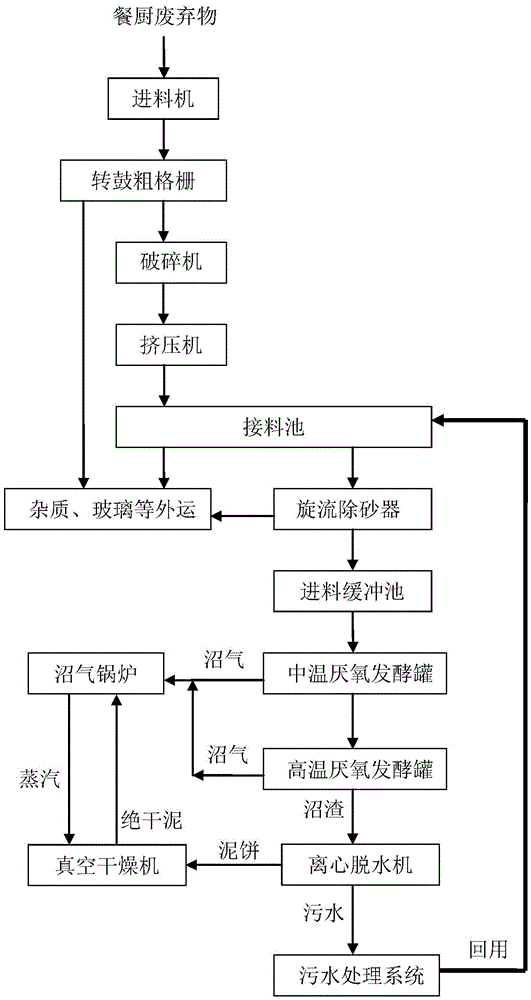

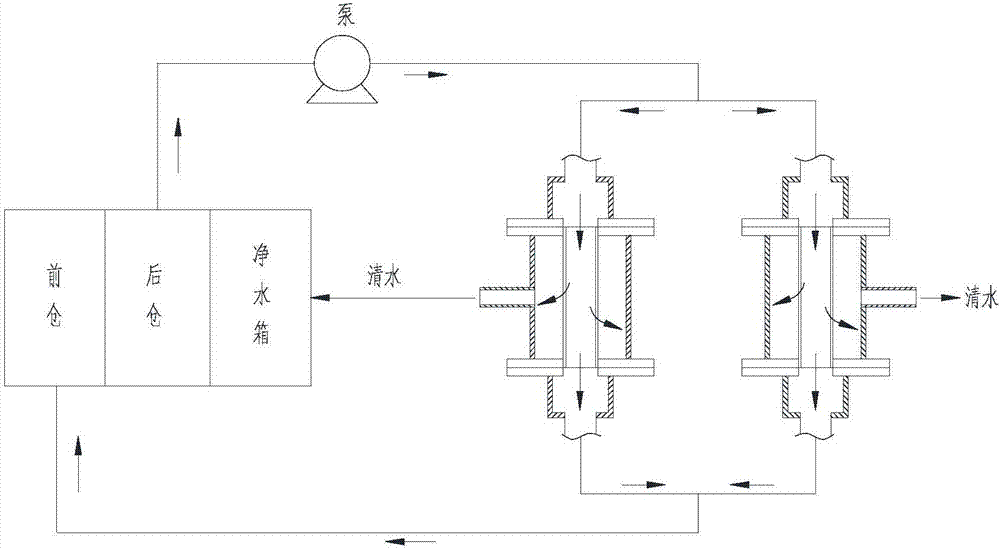

Anti-block system of ground water recharging well

InactiveCN101329113AWith non-stop backwashing functionAvoid overfillingOther heat production devicesGeothermal energy generationCycloneAnti jamming

An underground water recharge well anti-jamming system, the invention relates to an underground water recharge well device and aims at solving the problems that once the recharge well is jammed the recharged water quantity into a single well becomes less and less and the water even cannot recharged; the well pipe filtering device is arranged underground and then the cleaning and maintaining are inconvenient as these works obstruct the application of underground water-supply heat pumps. A first well (1) of the invention is connected through pipelines with a first-class cyclone desander (2), two second-class filters (3) are connected in parallel, then one end is connected through the pipeline with the first-class cyclone desander (2) and the other end is connected through pipeline with a water-supply heat pump heat-exchanging mechanism (6) which is connected with pipeline with a second well (5). With the first-class cyclone desander and the second-class filters of the invention, the suspension substances in the first well can be filtered to prevent thin sands, etc. suspension substances from jamming the second well and to avoid the problem that the recharged water quantity into the single well becomes less and less and the water even cannot recharged, so as to lead the underground water-supply heat pump to be applied well.

Owner:HARBIN INST OF TECH

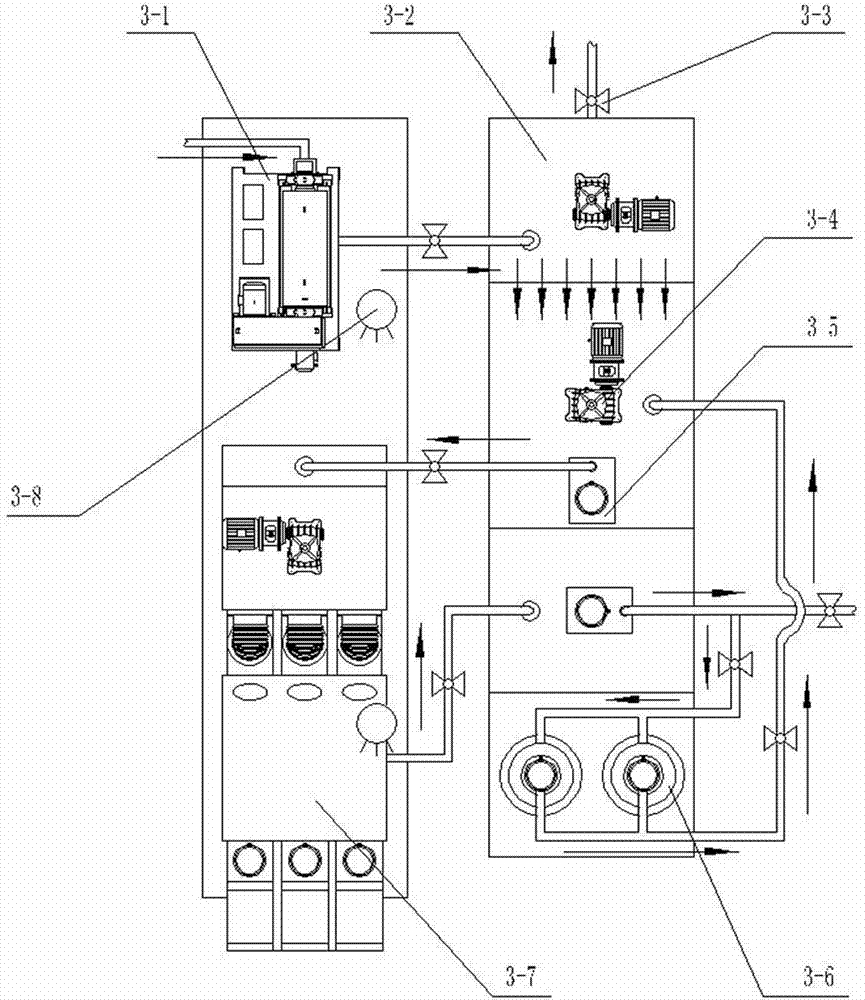

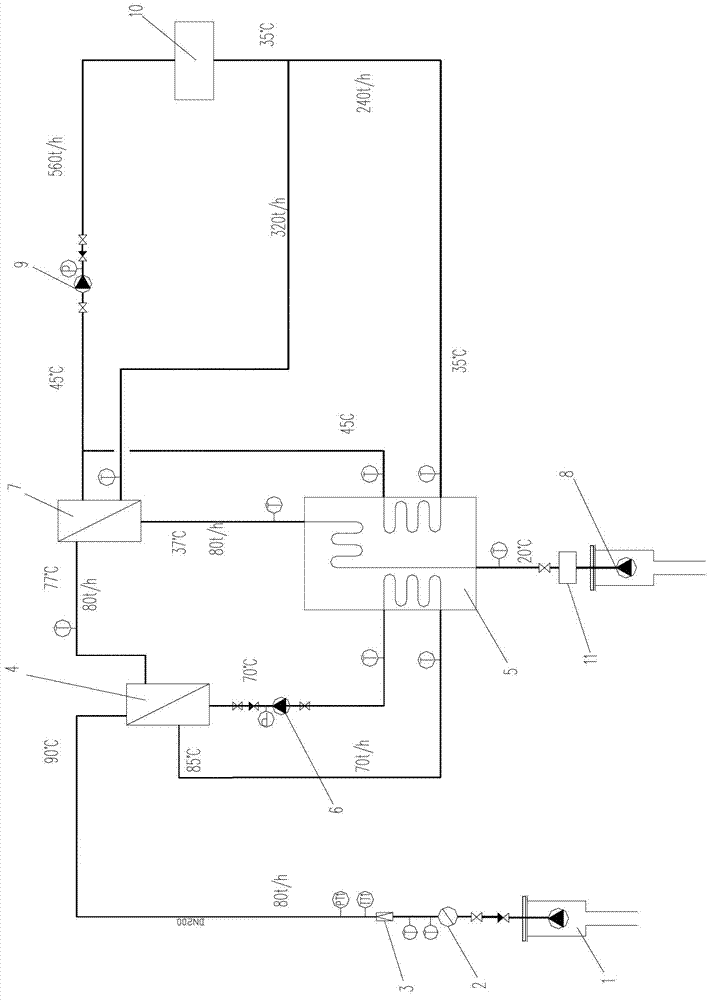

Heat storage type geothermal high-efficiency central heating system

PendingCN110145785AReduce the number of starts and stopsTake advantage ofLighting and heating apparatusEnergy efficient heating/coolingGeothermal heatingDesander

The invention belongs to the geothermal heating technology, and particularly relates to a heat storage type geothermal high-efficiency central heating system. The heating system comprises a heat collection circulating system, a heat supply circulating system and a water replenishing system, wherein the heat collection circulating system comprises a water collection well, a water collection pump, awater collector, a cyclone desander, a primary plate type heat exchanger, a secondary plate type heat exchanger, a filtering device, a recharge pressurizing pump, a water separator and a recharge well; and the heat supply circulating system comprises a heat storage device, a heat pump unit, a heat user, a heat-exchanger water pump, a heat supply circulating pump, a heat pump intermediate water circulating pump, a first heat pump bypass valve and a second heat pump bypass valve. According to the technical scheme, the heat storage technology and a geothermal energy heat supply system are combined proportionally, load shifting of the heat source heat supply load are achieved through intermittent storage in a valley heat supply load period and stable output in a peak heat supply load period.

Owner:HEBEI GREEN ENERGY GEOTHERMAL DEV CO LTD

Shale cluster well gas collection platform technological process and method

InactiveCN110700800AEasy to evaporateIncrease flow rateSurveyCleaning apparatusDesanderProcess engineering

The invention relates to a cluster well gas collection platform technological process and method. The cluster well gas collection platform technological process and method meet the standard design requirement and specifically comprise the processes of wellhead throttling, sand removing and filtering, heating throttling, gas-liquid separation and alternate metering, pipe cleaning and ball serving,pre-pressurization and the like, namely, devices such as a cyclone desander, a filtering desander, an electric throttling valve, a water jacket heating furnace, a gas-liquid two-phase horizontal separator, a conical orifice plate flowmeter, a mass flowmeter, a pipe cleaner and ball serving barrel and a reciprocating piston compressor are included, skid-mounted integration and splicing mounting areadopted, carrying and dismounting are easy, and the cyclone desander and a production separator are structurally optimized. The technological processes and devices adopted in different production periods are different, in the liquid discharging production period, the two-stage sand removing, two-stage throttling and separation process with the large processing capacity is adopted, in the high-yield period and the stable-yield period, skid-mounted equipment with the surplus load can be dismounted and then carried to other newly-built platforms to be used, the platform construction and equipment mounting period is short, and the investment cost is low.

Owner:SOUTHWEST PETROLEUM UNIV

Integrated treatment method on waste drilling mud

The invention discloses an integrated treatment method on waste drilling mud. Solid-liquid separation on the mud generated by a grit catcher, a desilter and a vibrating screen is conducted in sequence through a rock debris desizing machine, a sand removing machine and a water treatment regeneration machine existing in a drilling crew, liquid phase is collected and recycled after being possessed by the rock debris desizing machine, the sand removing machine and the water treatment regeneration machine sequentially, solid phase generated by the rock debris desizing machine, the sand removing machine, the water treatment regeneration machine and a centrifugal machine existing in the drilling crew is conveyed to a transport vehicle through a screw conveyer, and curing agent is added into the solid phase in the screw conveyer during the conveying process of the screw conveyer. According to the integrated treatment method on waste drilling mud, on the one hand, a treatment mode of classification treatment is adopted, and the use of curing agent can be reduced greatly, so that discharge of harmful solid phase is reduced fundamentally; on the other hand, solid-liquid separation is conducted without adding the curing agent during the processing process, the reuse rate of the processed liquid phase can be improved greatly, and reduction on waste drilling mud can be realized fundamentally.

Owner:天正浚源环保科技有限公司 +3

Production technique adopting electric submersible pump and jet sand-discharging pump for combined oil extraction and sand removal

InactiveCN106437569AIncrease speedDoes not affect mining volumeFlushingPump installationsCycloneElectricity

The invention discloses a production technique adopting an electric submersible pump and a jet pump for combined oil extraction and sand removal. The production technique mainly relates to the electric submersible pump, the jet pump, a cyclone desander, a well mouth extracted liquid control valve, a jet pump sand-discharging pipeline well mouth control valve and a one-way valve, wherein the electric submersible pump provides power liquid for the jet pump, and the one-way valve is used for preventing liquid extracted by the electric submersible pump from being discharged along the jet pump. Switching between the oil extraction process and the sand removing process is achieved mainly by adjusting the well mouth extracted liquid control valve and the jet pump sand-discharging pipeline well mouth control valve and adjusting a frequency converter to change the rotating speed of the electric submersible pump. According to the production technique adopting the electric submersible pump and the jet pump for combined oil extraction and sand removal, the one-way valve which can prevent the liquid extracted by the electric submersible pump from being discharged along the jet pump, the electric submersible pump which can provide high-pressure power liquid and the jet pump which has the solid-liquid mixed delivery function are ingeniously combined, the normal oil extraction procedure and the normal sand removing procedure are completed separately under the condition that the pumps are not stopped, the efficiency is improved, and the maintenance period of the electric submersible pump is prolonged. In addition, part of the high-pressure liquid extracted by the electric submersible pump is used as the power liquid, a device for providing power liquid on an offshore platform is omitted, and the space shortage of the offshore oil extraction platform is relieved.

Owner:BEIJING UNIV OF CHEM TECH

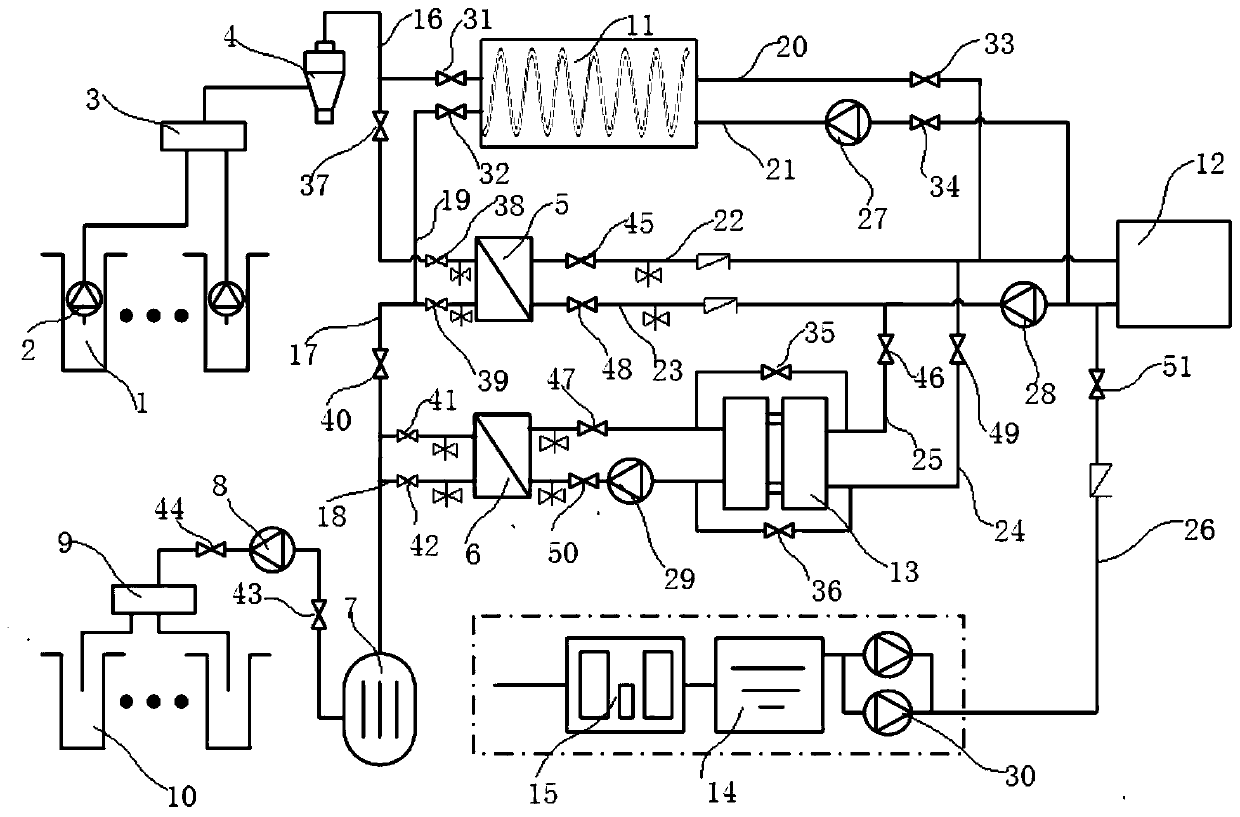

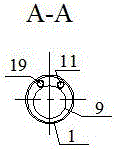

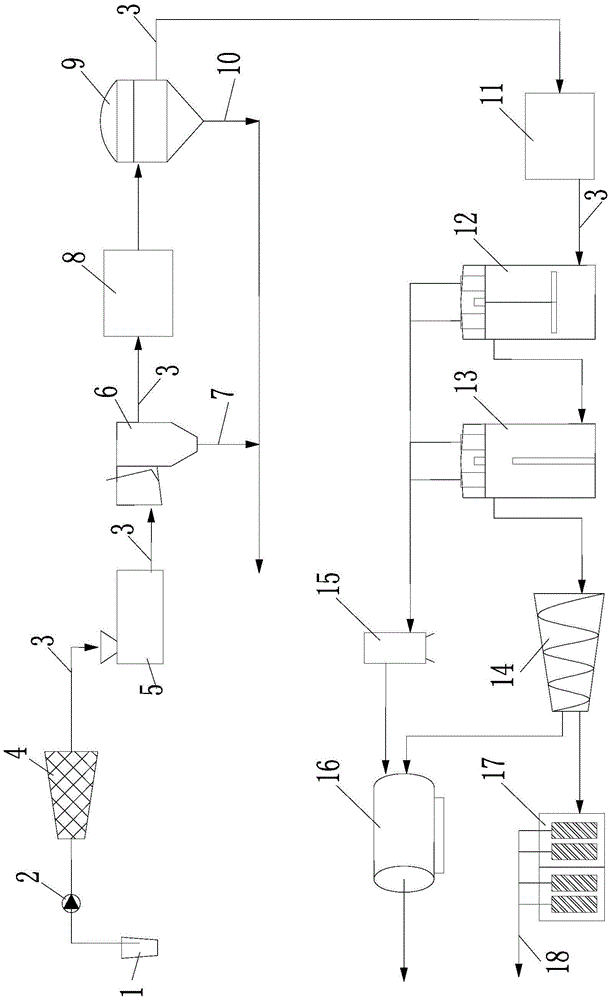

Kitchen waste medium-high-temperature combined anaerobic digestion equipment and anaerobic digestion method

ActiveCN105602844AHigh yieldZero emissionBioreactor/fermenter combinationsBiological substance pretreatmentsCycloneResource utilization

The invention discloses kitchen waste medium-high-temperature combined anaerobic digestion equipment and anaerobic digestion method. The equipment comprises a feeder, a drum coarse screen, a grinder, an extruder, a collection pool, a cyclone desander, a feeding buffer pool, a medium-temperature anaerobic fermentation tank, a high-temperature anaerobic fermentation tank, a centrifugal dehydrator, a sewage purification system, a vacuum drier and a biogas boiler, wherein the feeder, the drum coarse screen, the grinder, the extruder, the collection pool, the cyclone desander, the feeding buffer pool, the medium-temperature anaerobic fermentation tank, the high-temperature anaerobic fermentation tank, the centrifugal dehydrator and the sewage purification system are connected in sequence; the medium-temperature anaerobic fermentation tank and the high-temperature anaerobic fermentation tank are respectively connected with the biogas boiler; the contrifugal dehydrator is connected with the vacuum drier; the vacuum drier is connected with the biogas boiler; and the sewage purification system is connected with the collection pool. According to the kitchen waste medium-high-temperature combined anaerobic digestion equipment and anaerobic digestion method, the biogas yield can be improved, the system operation stability can be improved, and resource utilization is easy.

Owner:SHANGHAI ONEDEAR ENVIRONMENT TECH

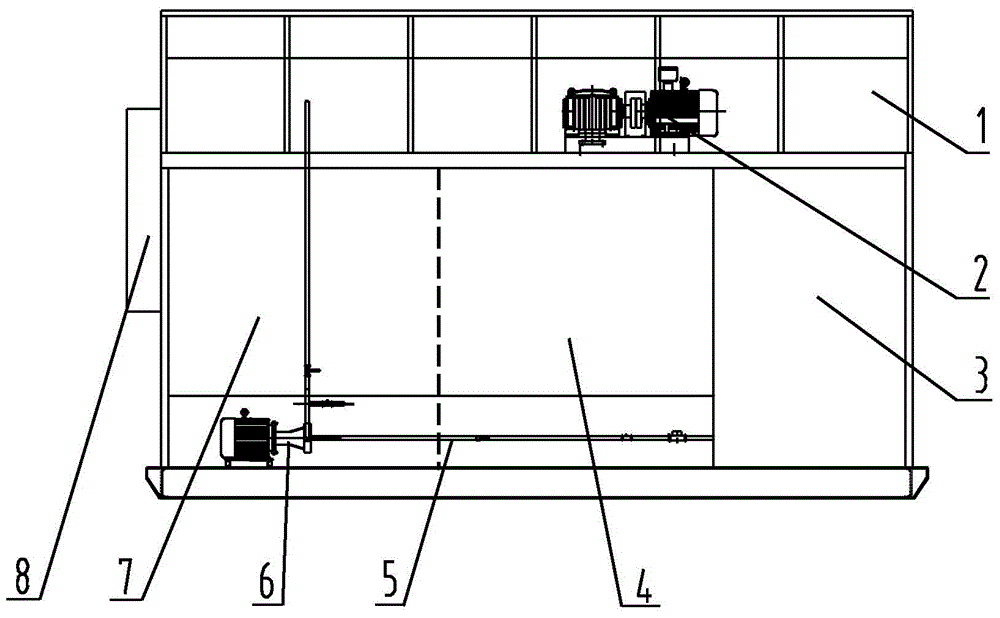

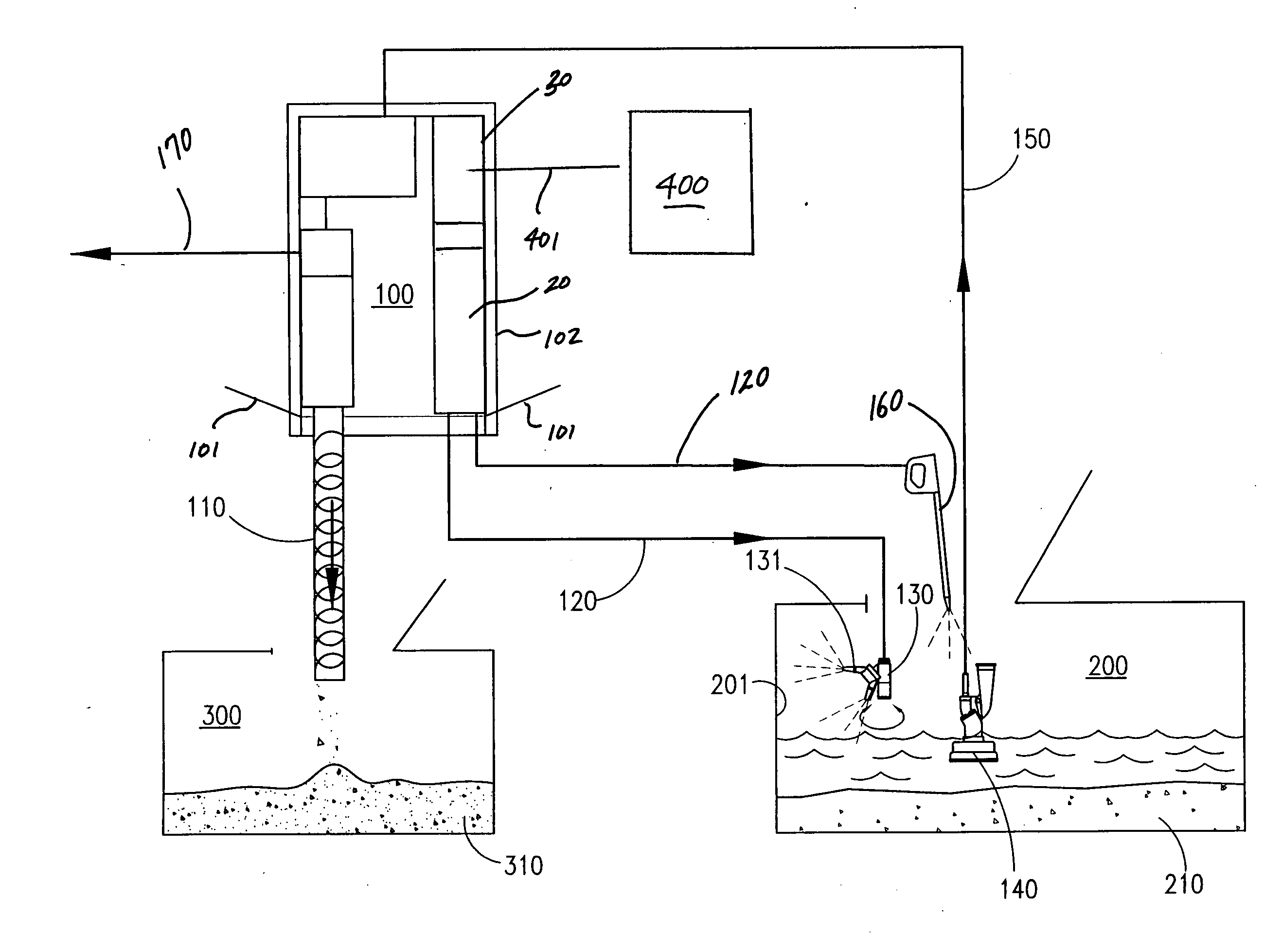

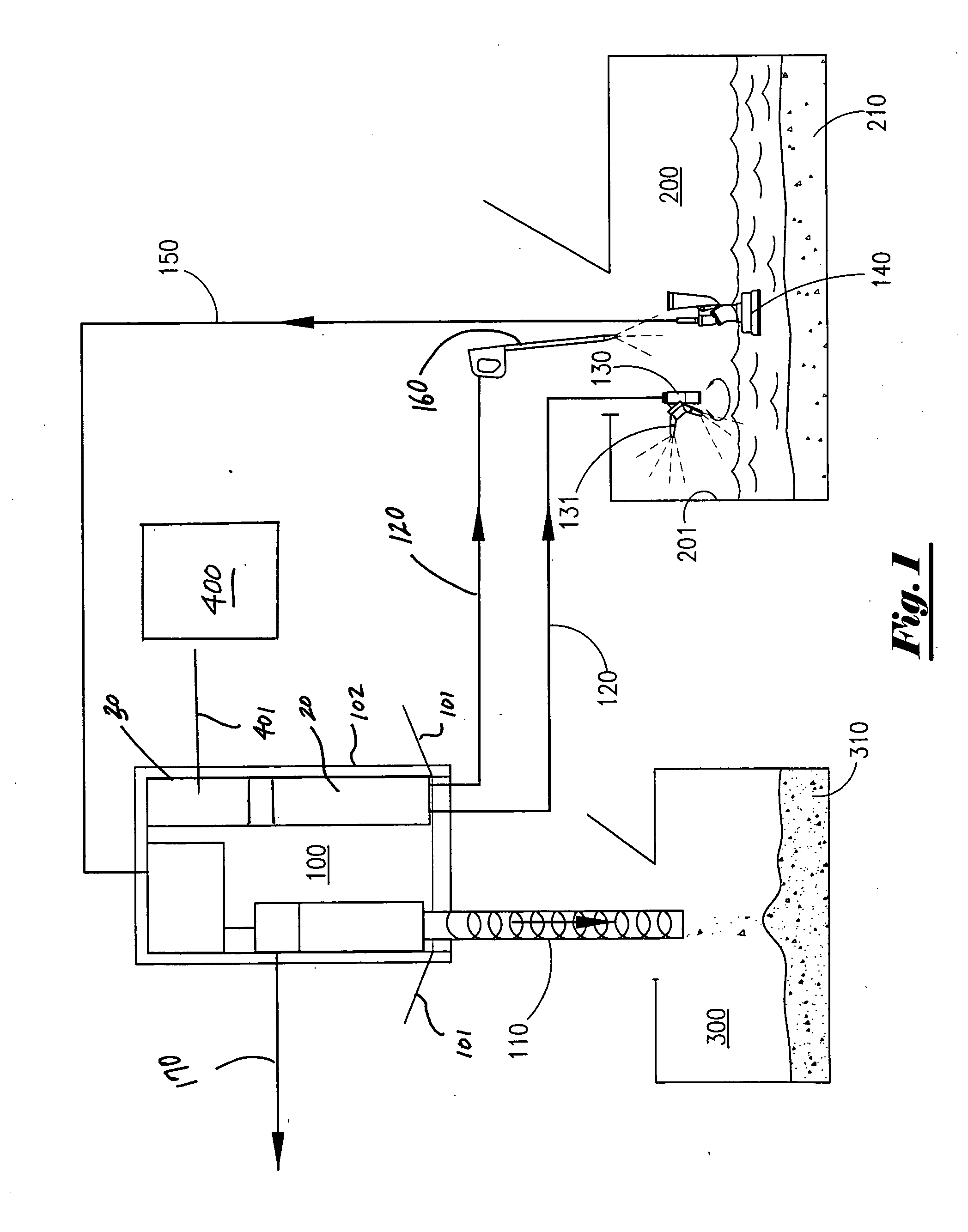

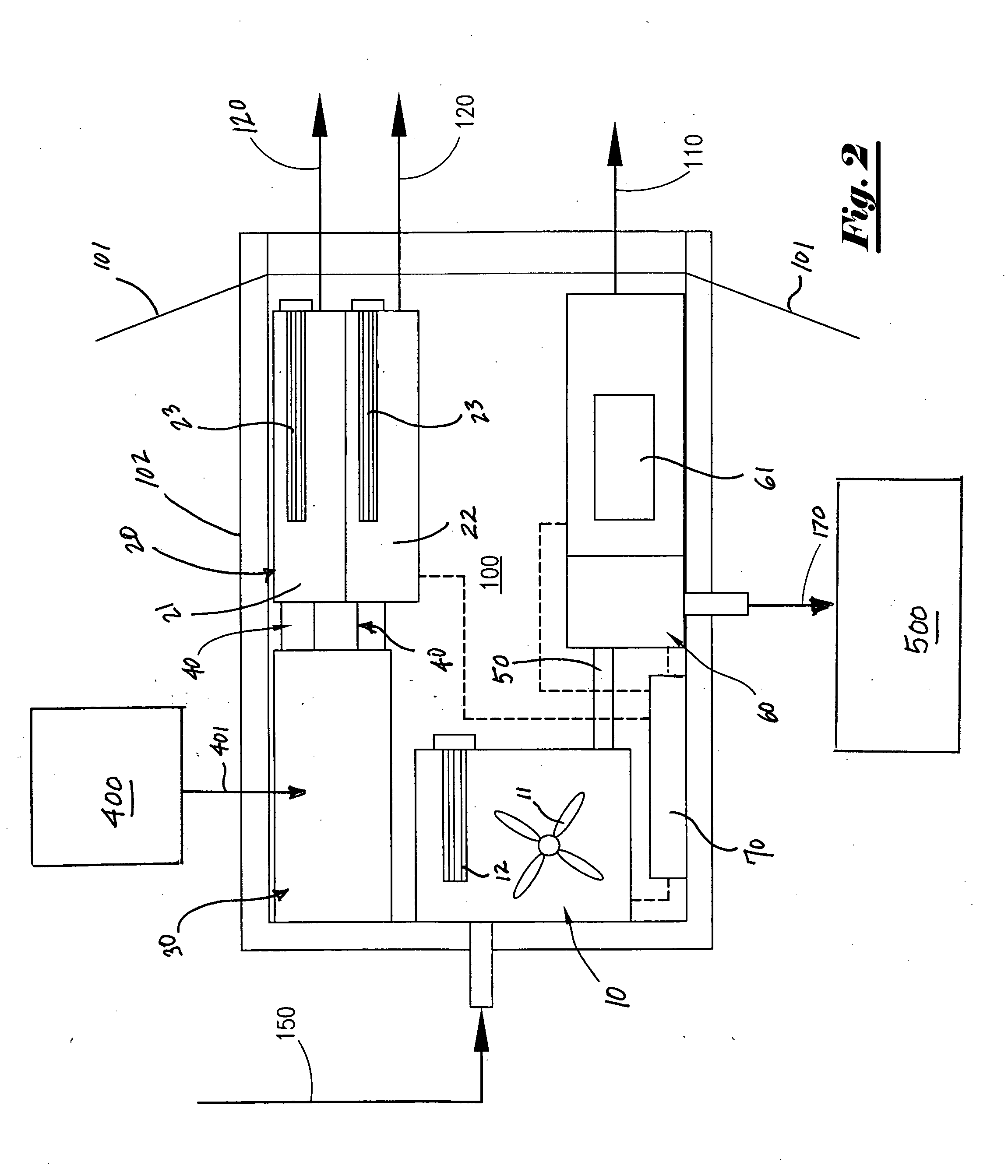

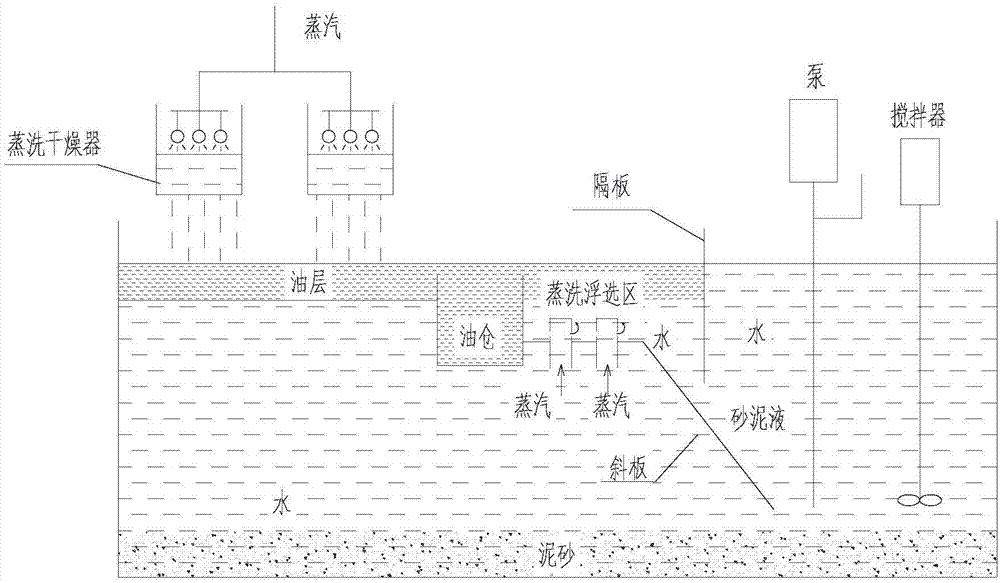

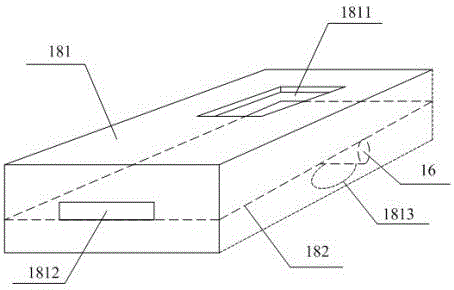

Limited space separation and cleaning system and method

ActiveUS20110315163A1Control footprintHollow article cleaningCleaning using liquidsSanderWater discharge

A cleaning and separating system is provided for cleaning tanks (such as crude oil storage tanks), and other containers or enclosures. The cleaning and separating system invention fits within a limited space having a relatively small foot-print; preferably an 8 foot tall by 8 foot wide by 10 foot deep shipping container. Although components can be interchanged or modified to fit particular applications, the cleaning and separating system can include a heated working tank having an agitator and a heating element, a centrifuge feed pump, a separation device (such as, for example, de-sander, de-silter, centrifuge, shale shaker, hydrocyclone or other similar apparatus), a liquid effluent tank, an oil and water discharge pump, an auger, a clean water tank, a high-pressure sprayer and / or a rotating nozzle.

Owner:CATES RICHARD A +1

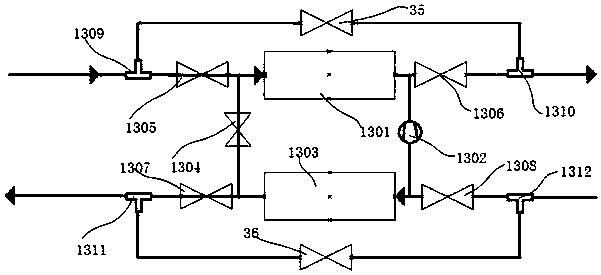

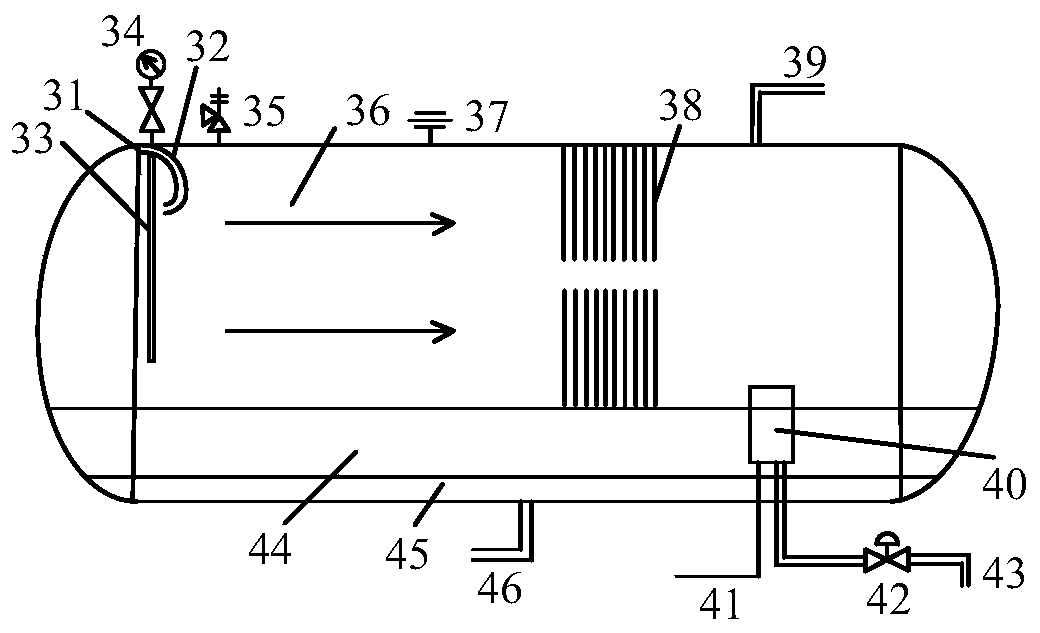

Heat transfer enhancing and scale preventing and removing device and system for sewage or surface water

InactiveCN105841544AGuaranteed cleaning effectAdjust cleaning time at any timeWater/sewage treatment by centrifugal separationHeat transfer modificationCycloneSolid particle

The invention discloses a heat transfer enhancing and scale preventing and removing device and system for sewage or surface water and belongs to the technical field of energy sources. By the adoption of the heat transfer enhancing and scale preventing and removing device and system for the sewage or surface water, heat transfer enhancement of heat exchange equipment for the sewage or surface water containing a large quantity of suspended matter and impurities is achieved, and the suspended matter and scale which are hung on the wall of the heat exchange equipment and left in the heat exchange equipment can be effectively removed. The heat transfer enhancing and scale preventing and removing device is composed of a cyclone desander, a sand regulation valve and an ejector, wherein the cyclone desander, the sand regulation valve and the ejector communicate with one another from top to bottom. The heat transfer enhancing and scale preventing and removing system is composed of the heat transfer enhancing and scale preventing and removing device, a heat exchanger and a connecting pipeline for the heat transfer enhancing and scale preventing and removing device and the heat exchanger. A water outlet of the ejector of the device communicates with the heat exchanger through a heat exchanger water inlet pipe, and the heat exchanger communicates with a water inlet of the cyclone desander of the device through a heat exchanger water outlet pipe; through repeated ejection and separation of solid particles, the solid particles are made to collide and rub the wall surface of the heat exchanger continuously in the process that the solid particles flow in the heat exchanger along with water flow, so that scale on the wall surface of the heat exchanger is removed, and meanwhile a heat exchange enhancing function is achieved. The heat transfer enhancing and scale preventing and removing device and system are used for heat exchange of the unclean water such as the sewage or the surface water.

Owner:青岛科创蓝新能源股份有限公司

Crude oil heating furnace for oil fields

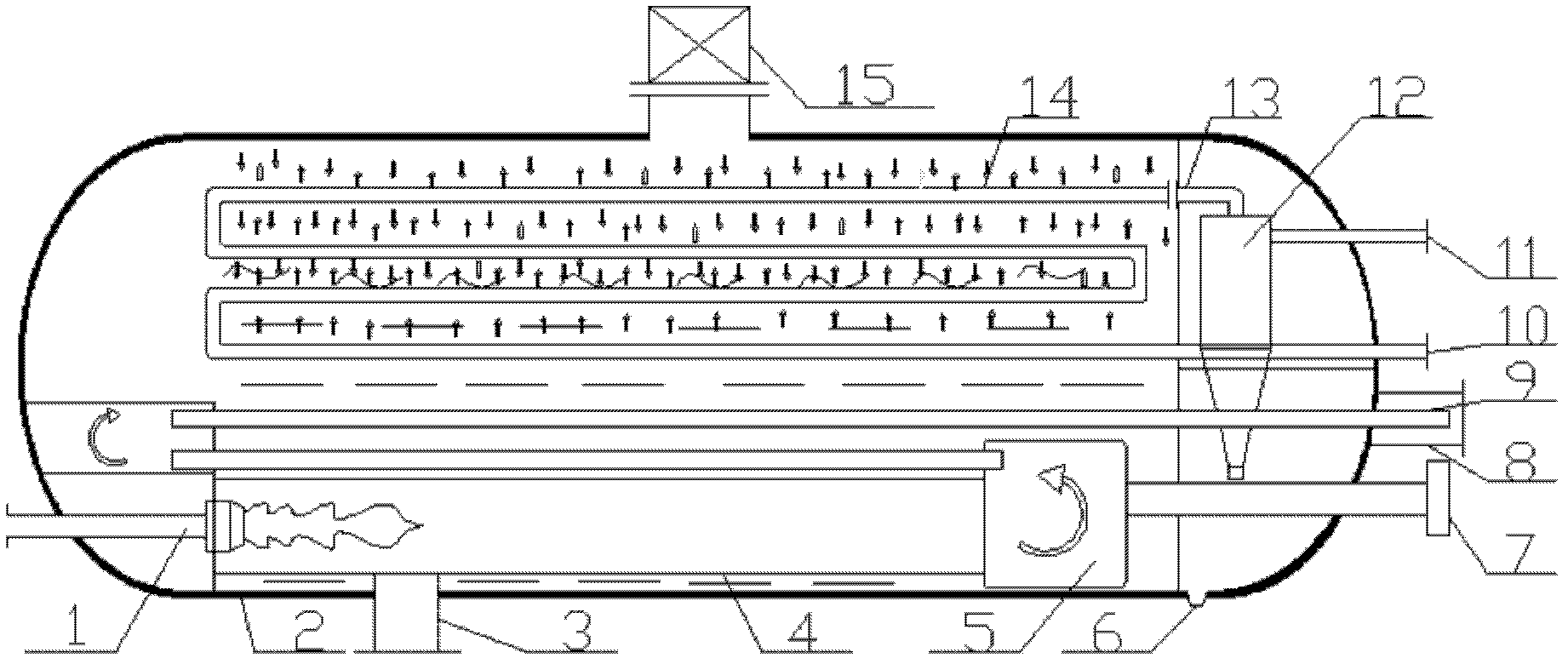

InactiveCN102840669ASimple structureImprove separation efficiencyStorage heatersCombustion chamberCombustor

The invention relates to a crude oil heating furnace for oil fields. The crude oil heating furnace is characterized in that a burner (1) is installed below the left end of a casing (2); a combustion chamber comprising a furnace pipe (4) is arranged at the lower part in the casing (2); a cyclone desander (12) is installed at the right end in the casing (2); a crude oil inlet pipe (11) is installed on one side of the cyclone desander (12); a crude oil overflow pipe (13) is installed at the top of the cyclone desander (12); an outlet of the crude oil overflow pipe (13) is connected with an inlet of a heat exchanger coil (14) in the casing (2); and after the heat exchanger coil (14) is bent and coiled in the casing (2), the outlet is connected with a crude oil outlet pipe (10). The crude oil heating furnace can firstly remove solid, such as sand grains and the like, in crude oil, and then heats the crude oil when heating the crude oil, has the characteristics of attrition prevention, blockage prevention, and thermal resistance forming prevention, improves the efficiency, saves the cost, and prolongs the service life of the heating furnace.

Owner:YANGTZE UNIVERSITY

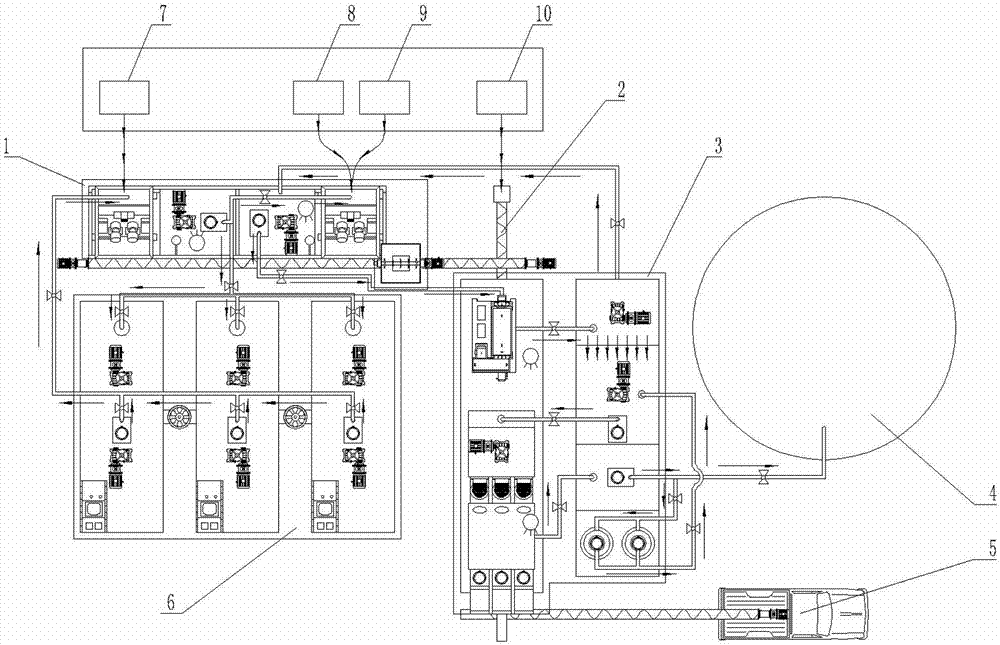

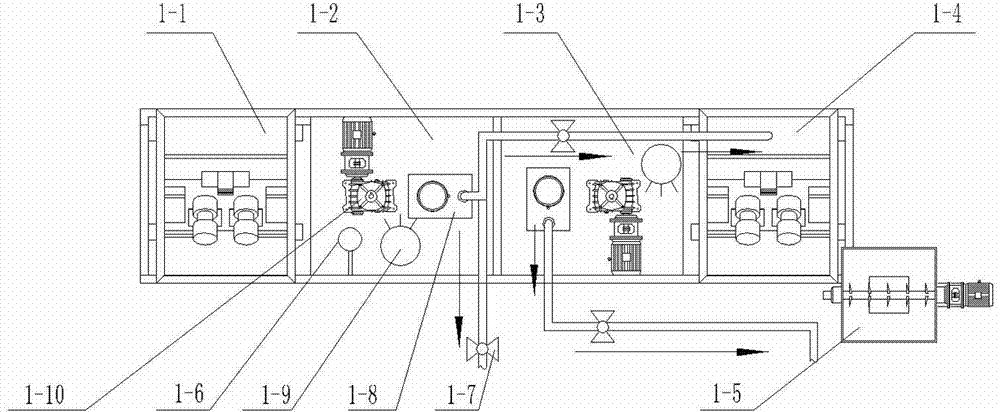

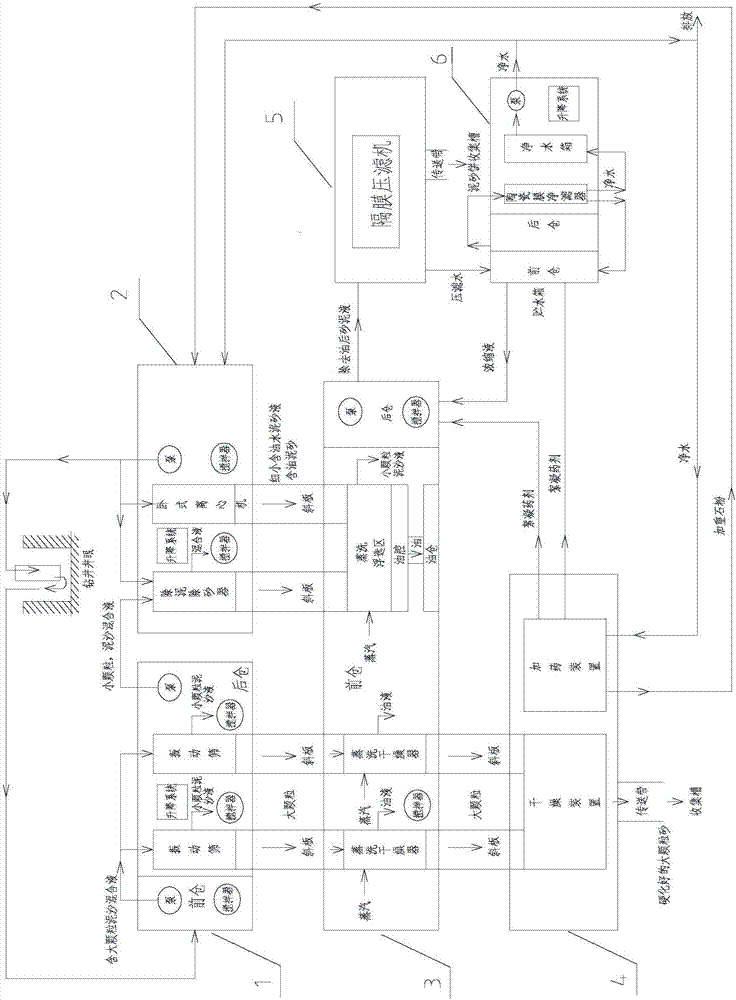

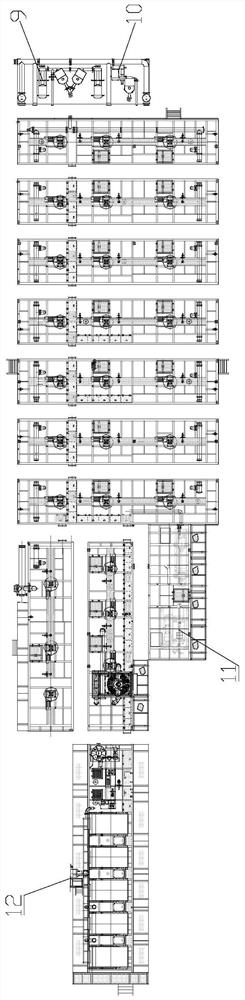

Environmental protection system for skid-mounted drilling oil base and water base slurry processing without landing and processing technology thereof

The invention relates to an environmental protection system for skid-mounted drilling oil base and water base slurry processing without landing. The environmental protection system mainly solves the problem thatexisting drilling circulating slurry is directly discharged, and water quality and soil can be polluted. The environmental protection system is characterized in that a slurry inlet pipeline is connected with a primary solid-liquid separating skid, and two vibrating screen outlets of the primary solid-liquid separating skid are connected with two corresponding steaming and washing dryer inlets in a steaming and washing oil removing skid; a rear bin slag slurry pump of the primary solid-liquid separating skid is connected with a sand remover inlet in a silt removing and sand removing device on a secondary solid-liquid separating skid; an outlet of the silt removing and sand removing device of the secondary solid-liquid separating skid and an outlet of a horizontal centrifuge are connected with an inlet of a front bin steaming and washing flotation area in the steaming and washing oil removing skid; an outlet of a steaming and washing dryer on the steaming and washing oil removing skid and an inlet of a drying device in a tail end drying multi-functional dosing skid are connected through a oblique plate groove; and an outlet of the slag slurry pump on a rear bin of the steaming and washing oil removing skid is connected with an inlet of a diaphragm pressure filter in a diaphragm pressure filter skid. The environmental protection system can achieve slurry processing without landing of different drilling stages, energy is saved, and consumption is reduced.

Owner:HEILONGJIANG WANYIDA GASOLINEEUM ENG +2

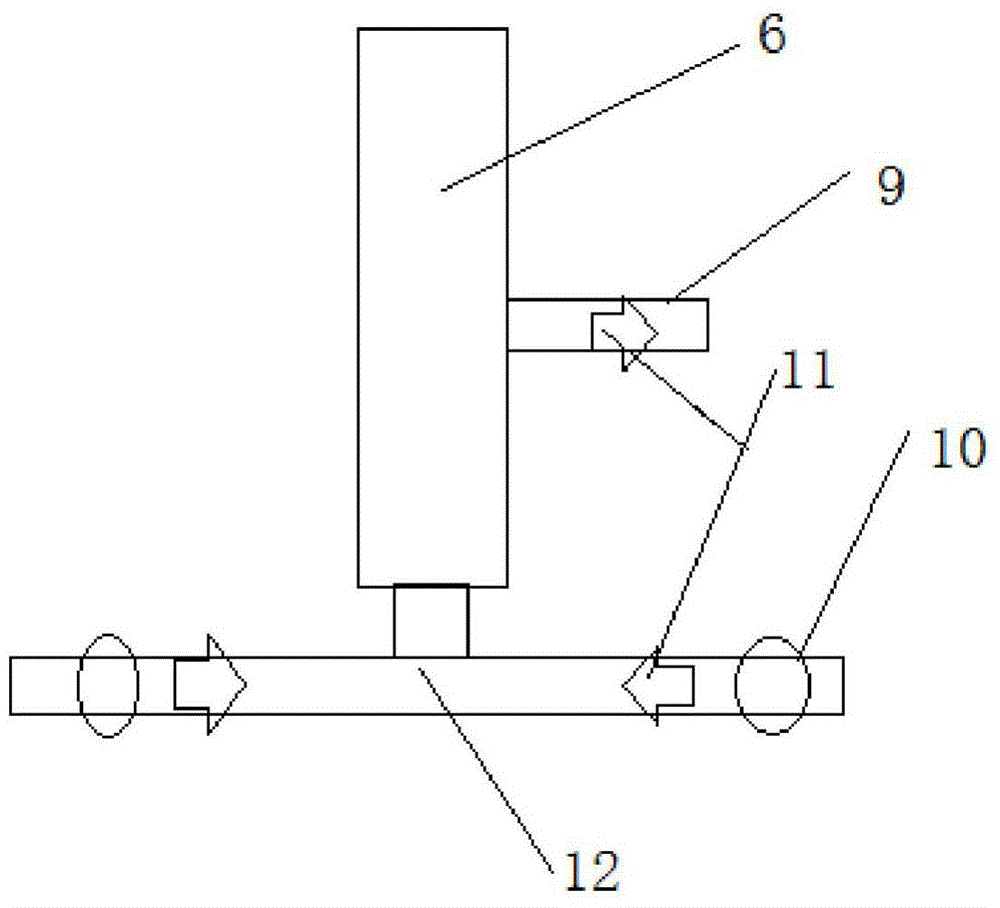

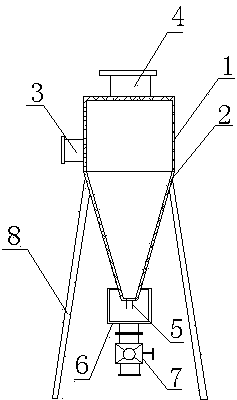

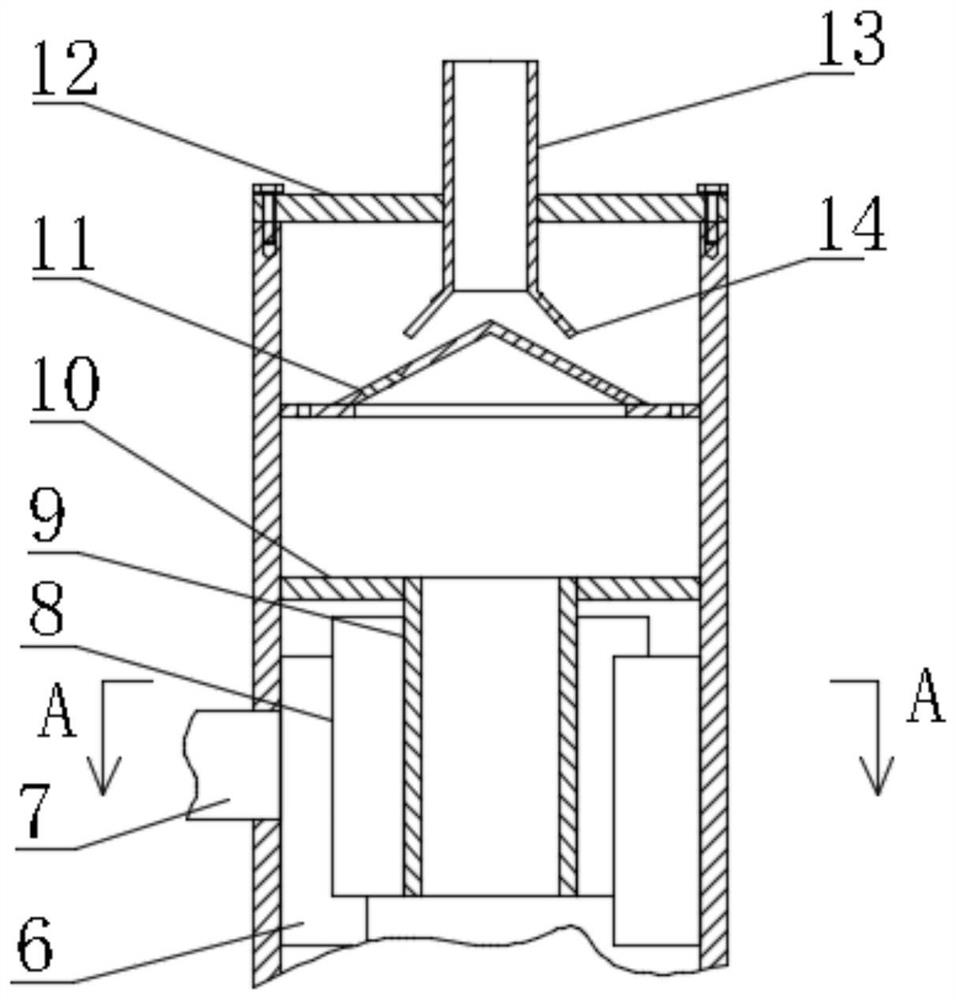

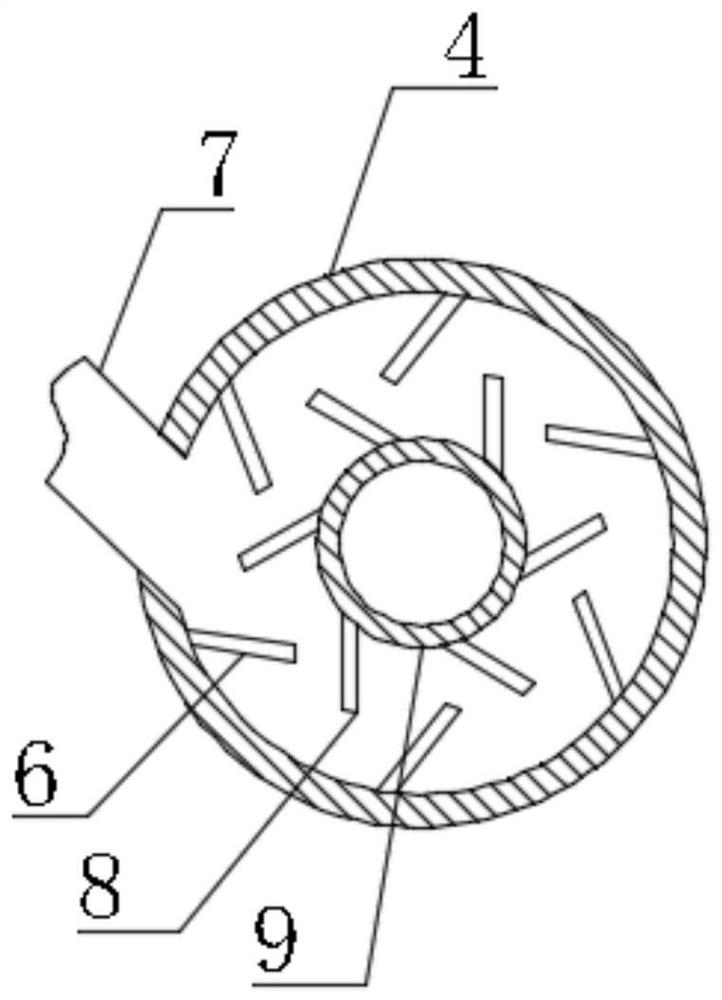

Desander

The invention discloses a cyclone desander including a cylindrical drum (1), a conical drum (2) and a bracket (8), wherein the side wall of the cylindrical drum (1) is provided with a water inlet (3), the top of the cylindrical drum (1) is provided with an overflow water outlet (4), the bottom of the conical drum (2) is provided with a sewage discharge port (5), a sewage storage tank (6) is fixedly arranged on the conical drum (2), the sewage storage tank (6) and the sewage discharge port (5) are communicated, and the sewage storage tank (6) is in fixed connection with a stop valve (7). The beneficial effects of the cyclone desander are that: the stop valve is turned on only when large particle impurities gather in the sewage storage tank (6) and need to be intensively discharged, the number of times of sand discharge can be reduced, labor intensity can be reduced, water loss can be avoided, economic losses can be reduced; in addition, the spiral structural inner wall design enables the suspension in the water to gather more easily, and at the same time also enables water to spirally flow downward, so that wear is minimized, and slag removal efficiency is improved.

Owner:成都市龙泉驿区齐盛机械厂

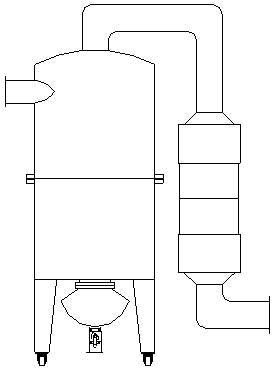

Mud and sand removal device for drilling fluid

The invention relates to a mud and sand removal device for drilling fluid, and belongs to the field of petroleum machinery. The mud and sand removal device for the drilling fluid comprises a rotational flow desilter, a beaker, a valve, a collecting pipe, a desander slurry inlet pipe, a desander overflow pipe, a desilter slurry inlet pipe, a slurry inlet pipe overflow pipe, a vertical pipe, a vertical pipe supporting column, a small screen net, a supporting pipe, a rotational flow desander, a vibrating screen, a stirring device and the like. The valve is opened, the drilling fluid in the collecting pipe flows into the beaker through the valve, and the drilling fluid after mud and sand removal is conveniently sampled to conveniently analyze a using effect of the mud and sand removal device for drilling fluid. The structure is compact, the rotational flow desander and the rotational flow desilter are arranged intensively, so that treated drilling fluid waste solid phase is discharged intensively, and the occupied area of the device is saved. The vertical pipe is arranged in the rotational flow desander, the small screen net is arranged at the lower end of the vertical pipe, mud and sand in the drilling fluid is filtered again by the small screen net, and the rotational flow desander effect of the drilling fluid is enhanced. The small screen net can overturn in the vertical pipe toshake off the mud and sand on the small screen net.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

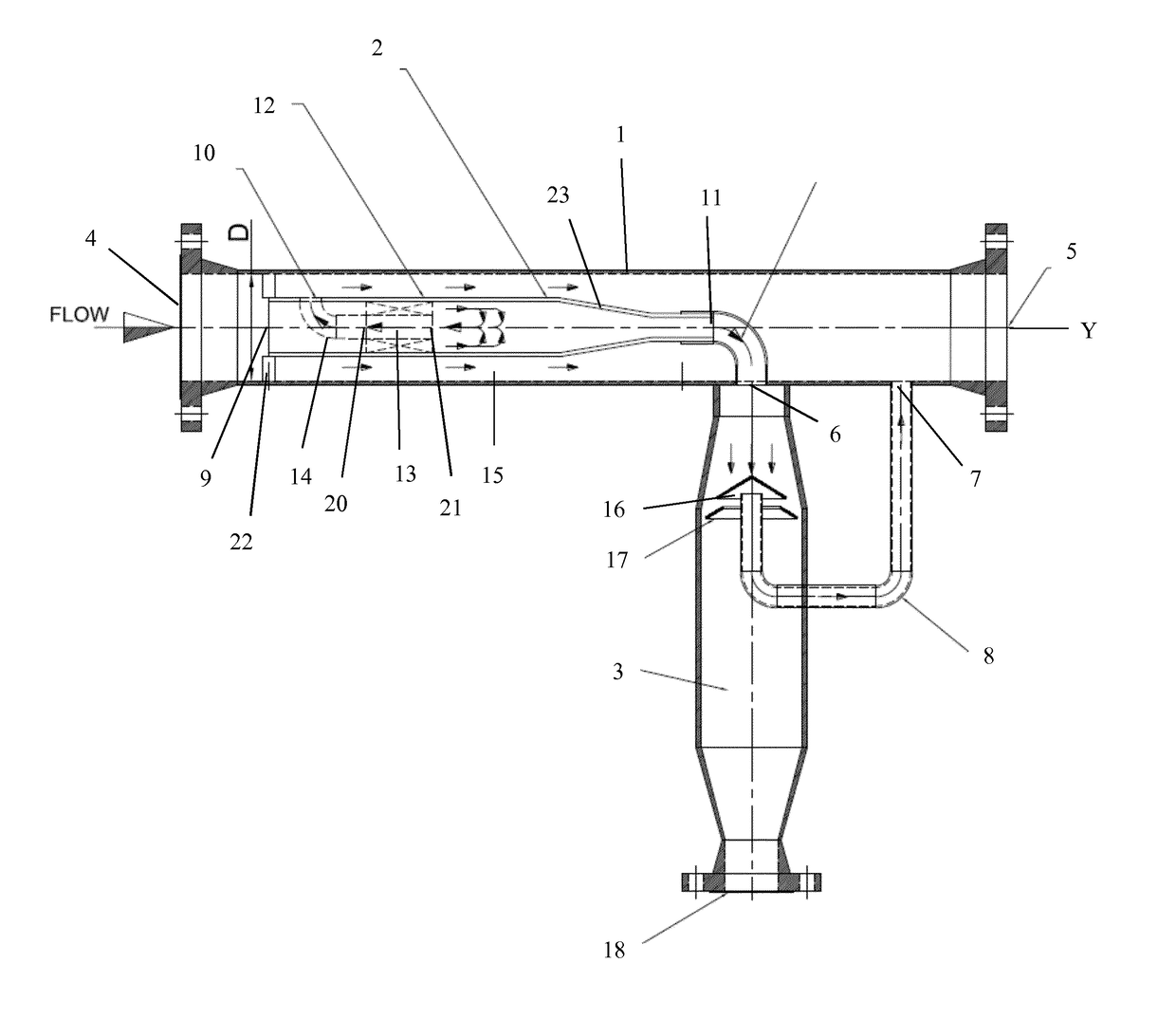

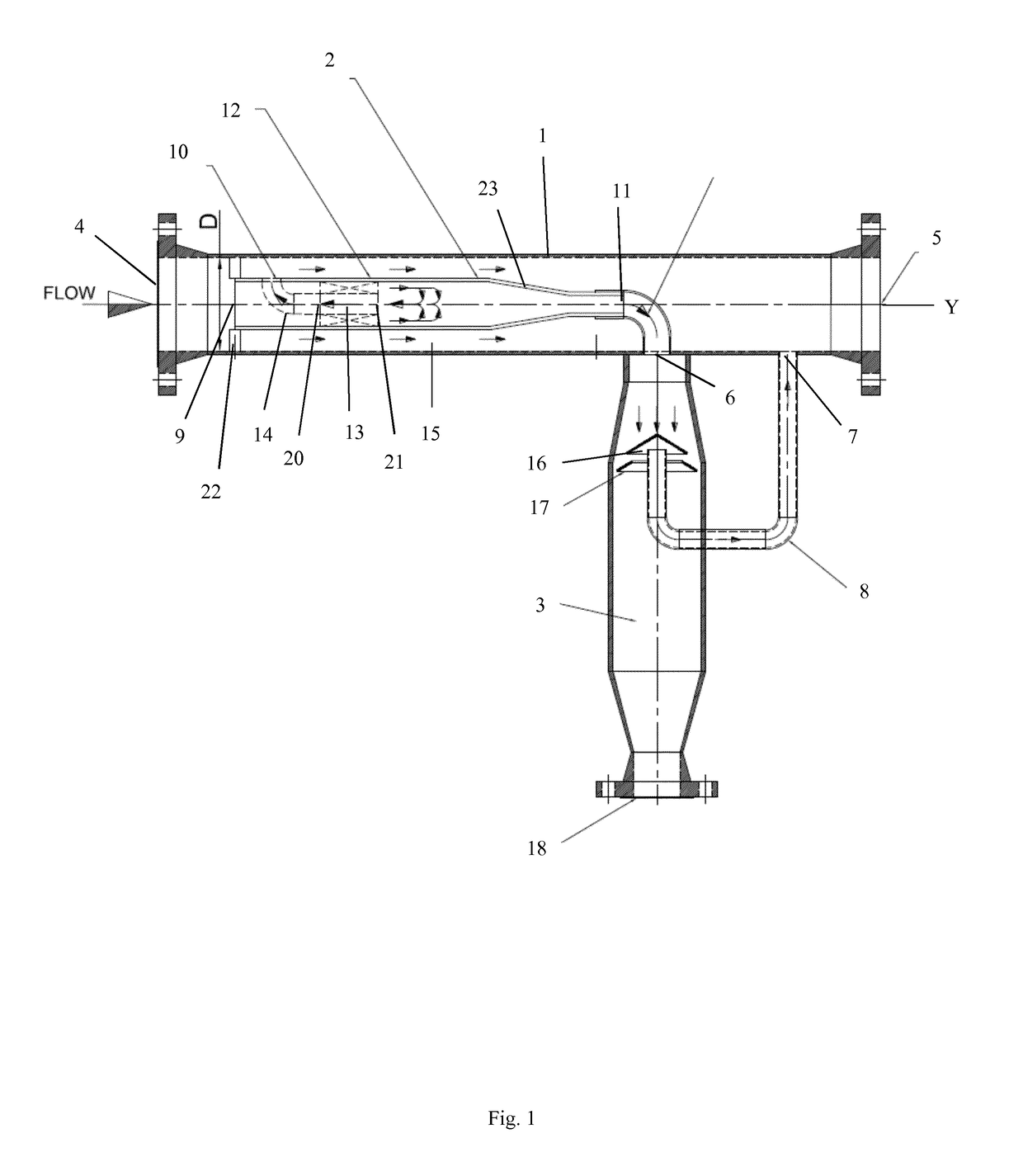

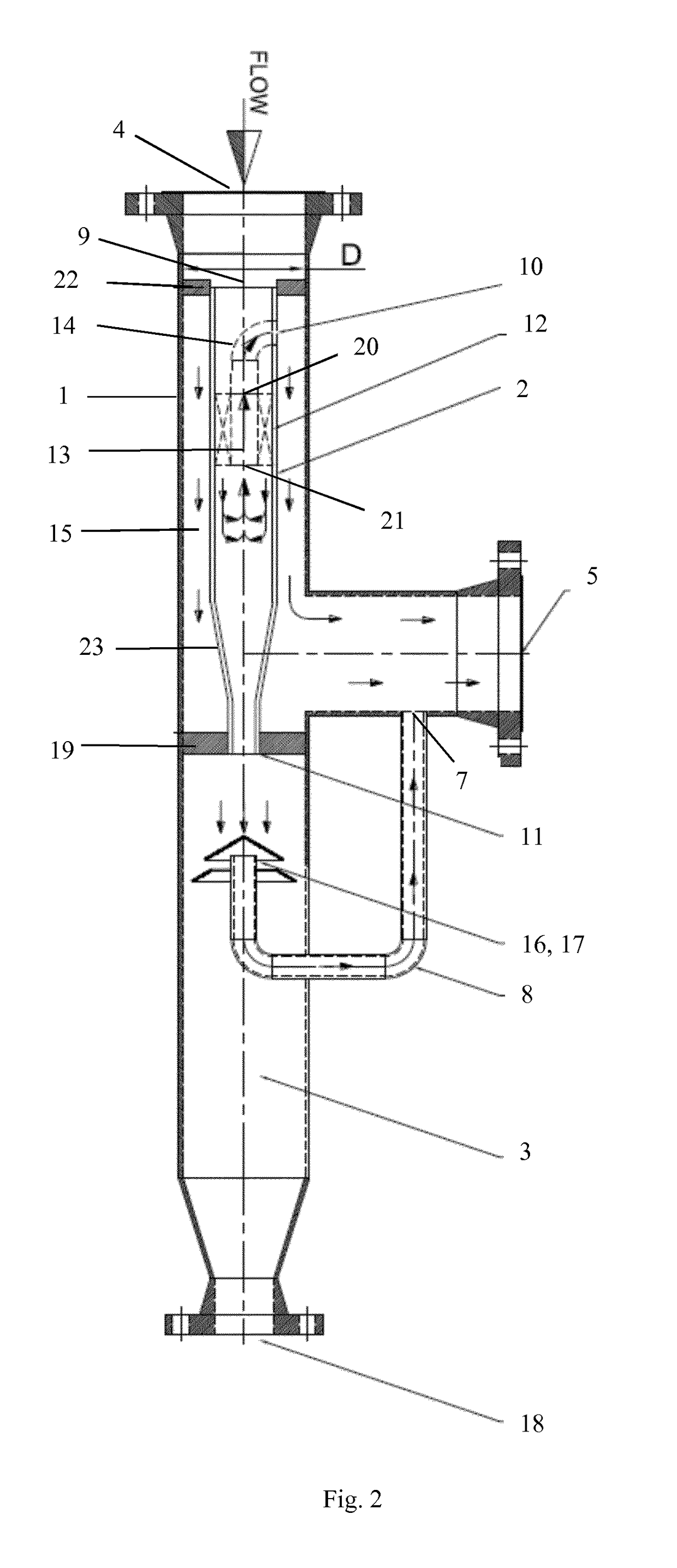

Gas desander

ActiveUS9636614B2Efficient transportReduction of inner circumferenceCombination devicesReversed direction vortexDesanderEngineering

Owner:FMC SEPARATION SYST BV

Water-retaining, peak-regulating and decoupling recharging ground water source heat pump system

InactiveCN101825375AReduced need for pumping and irrigationReduce dependenceHeat pumpsOther heat production devicesWater source heat pumpWater source

The invention discloses a water-retaining, peak-regulating and decoupling recharging ground water source heat pump system, which comprises a well side water supply main pipe (1) and a well side water return main pipe (7), wherein a heat pump host (4) is communicated between the two pipes through an evaporator branch pipe and a condenser branch pipe, and an electronic water treatment device (12), a water source side water pump (11) and a cyclone desander (10) are sequentially arranged on the water supply main pipe (1) communicated with the evaporator branch pipe and the condenser branch pipe. The ground water source heat pump system is characterized in that a water-retaining, peak-regulating and decoupling recharging device (20) is communicated between the water supply main pipe (1) and the well side water return main pipe (7) which are communicated between the two sides of the water source side water pump (11). The water-retaining and peak-regulating technology can reduce the dependence of a heat pump unit on a pumping and recharging well at a period of high load and effectively reduce the pressure of system running on the recharging of ground water under the most adverse conditions, thereby solving the outstanding problems that the recharging is difficult at the period of high load. The invention is the further optimized integration of the existing recharging technology.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

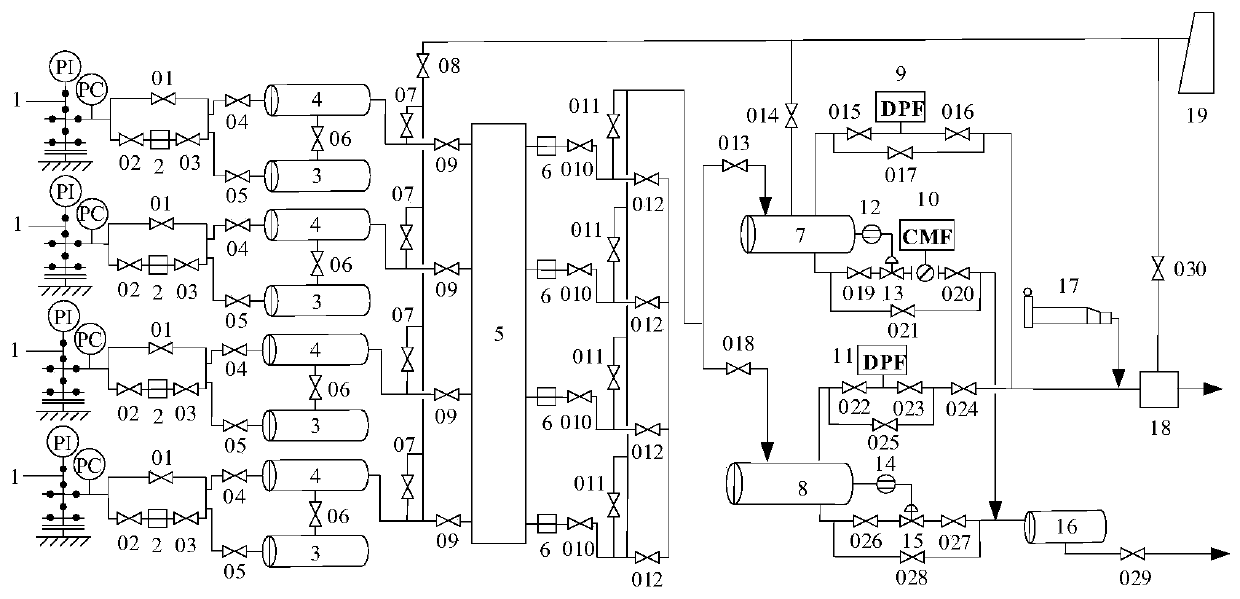

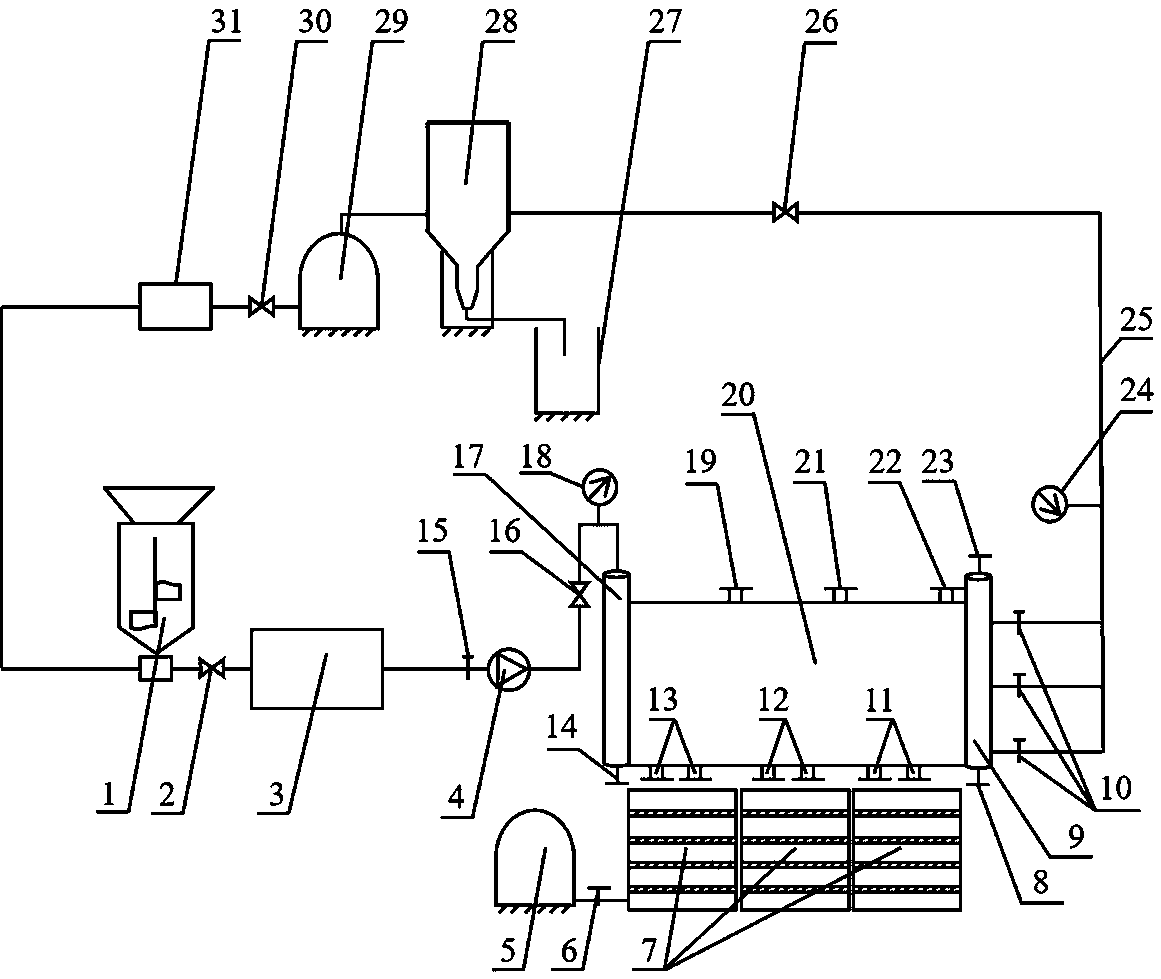

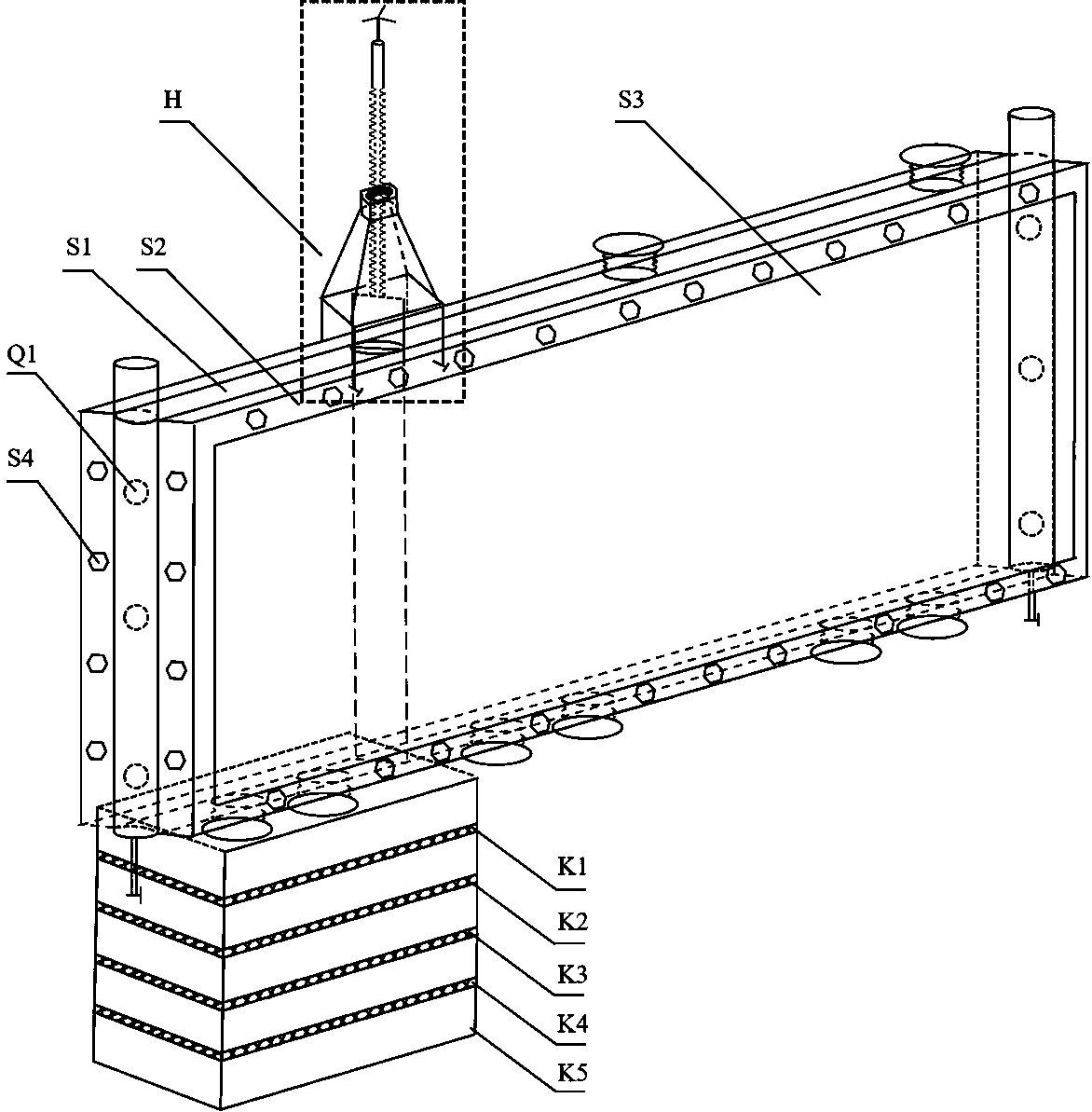

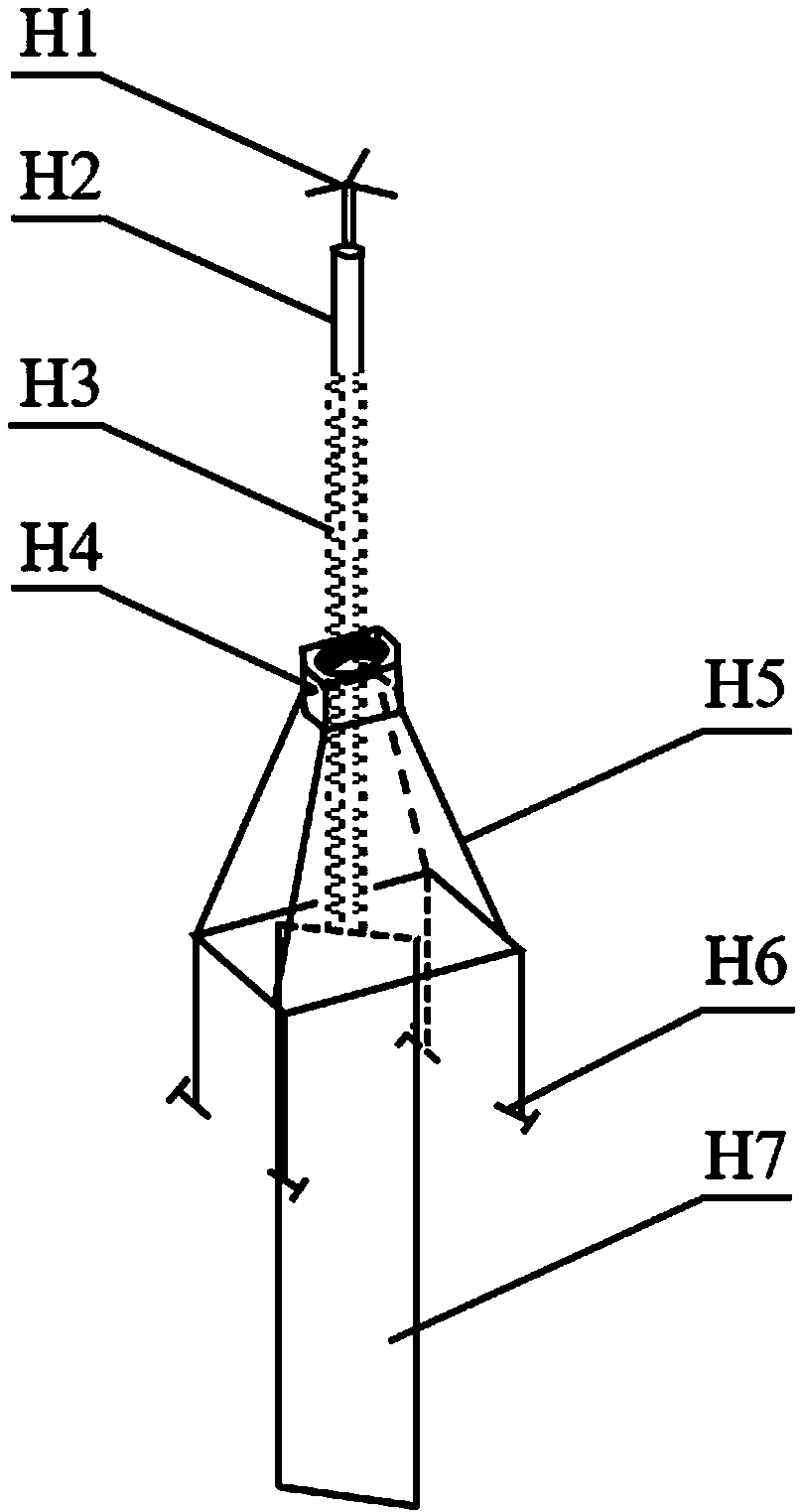

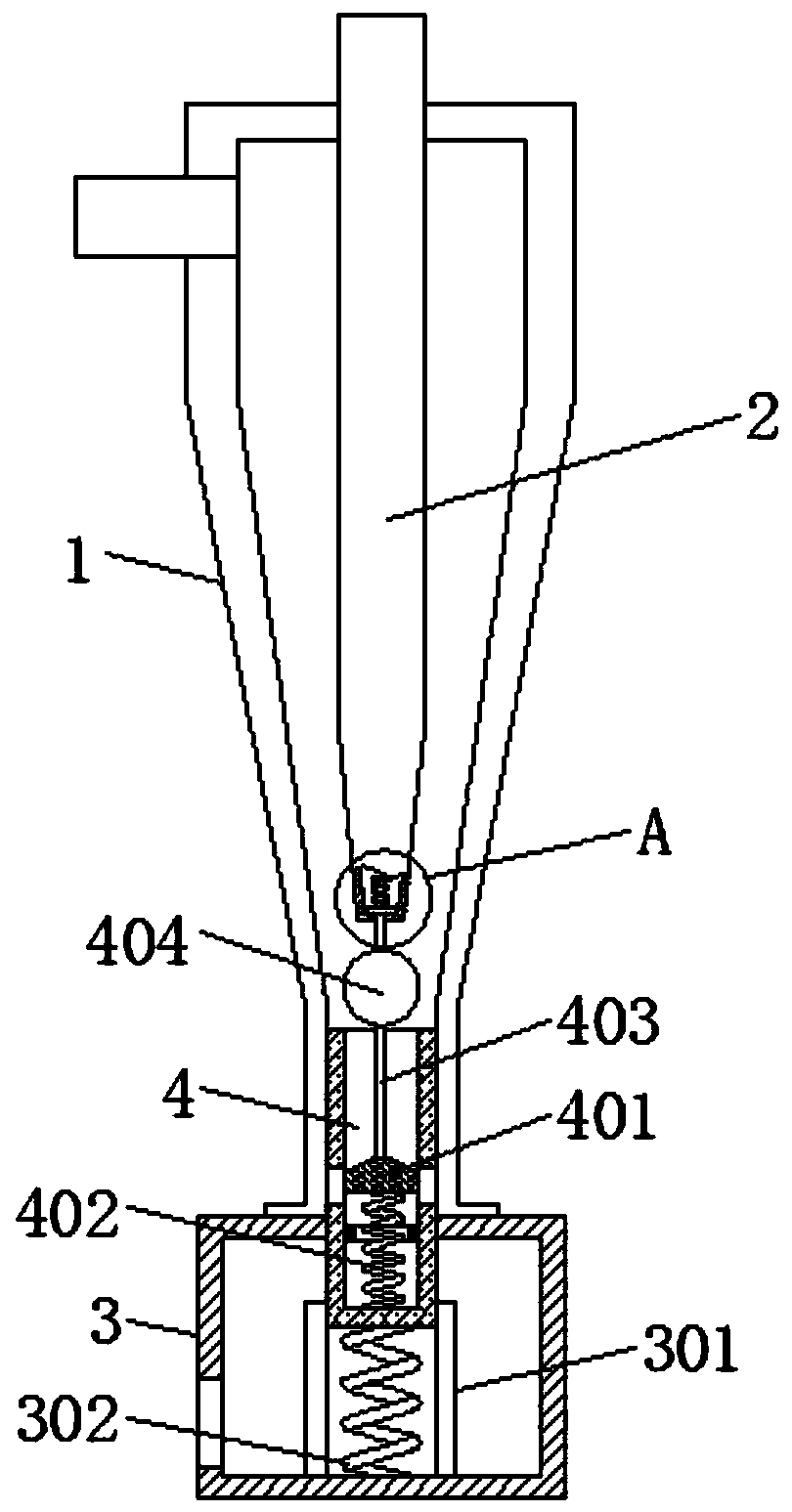

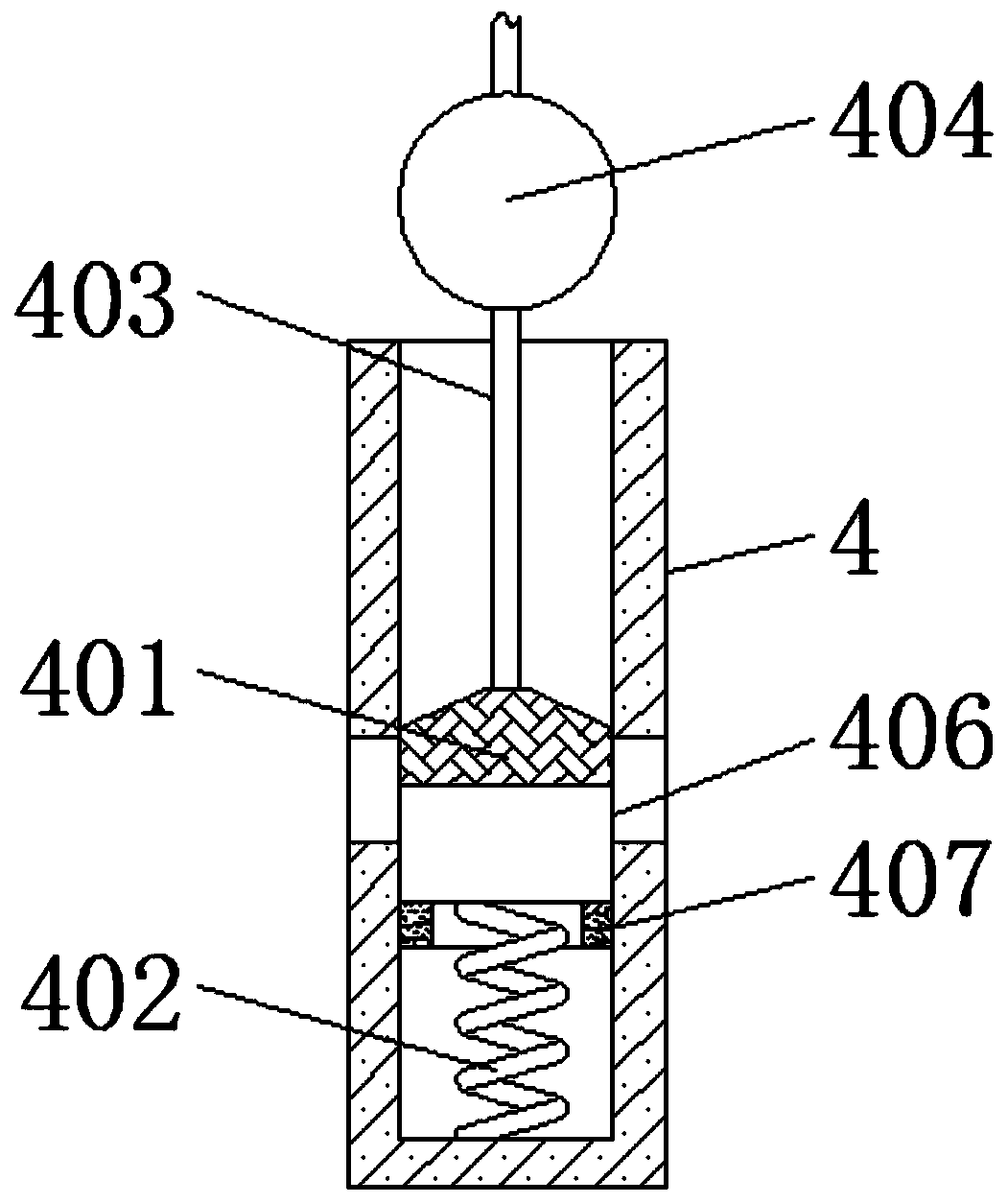

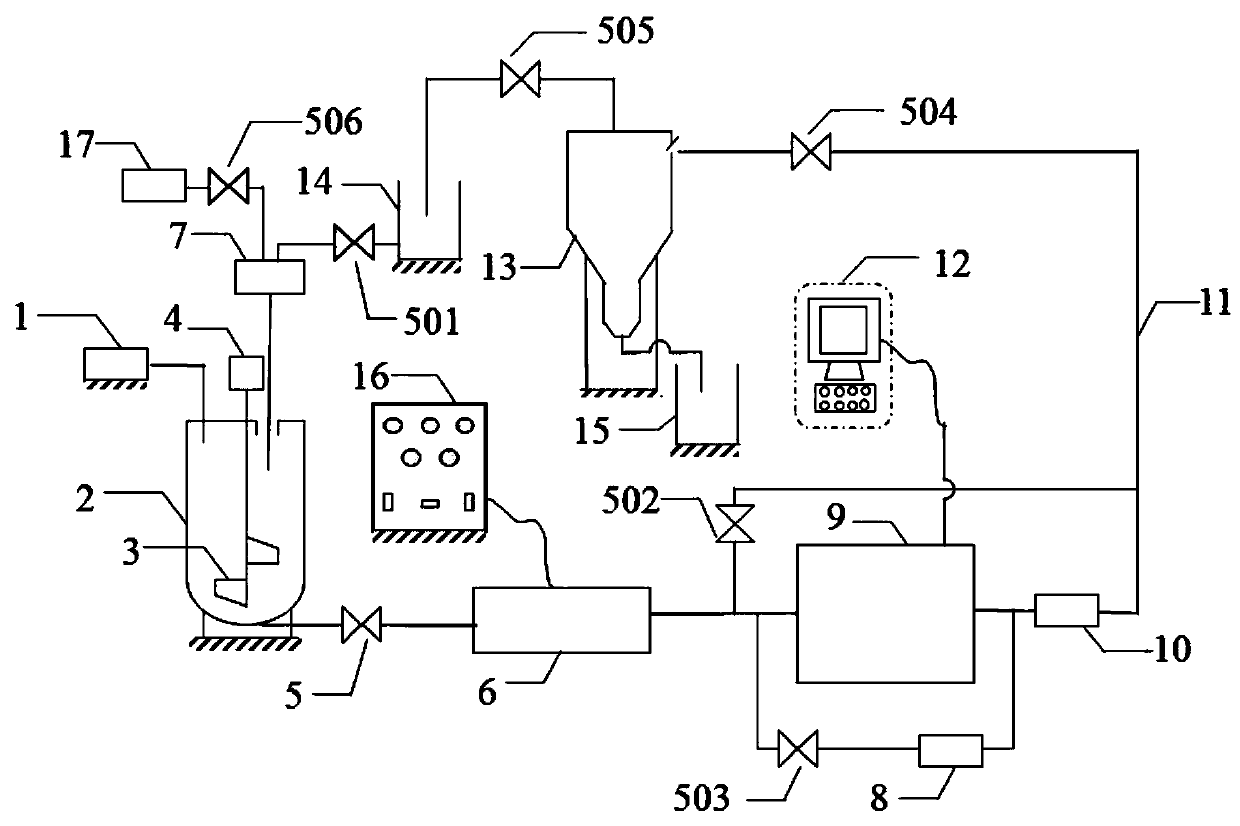

Proppant conveying experimental device and method capable of obtaining proppant particle size distribution

ActiveCN110965980ARealize visualizationOvercomes failure to achieve test proppant size distributionFluid removalParticle size analysisDesanderGeotechnical engineering

The invention relates to a proppant conveying experimental device and method capable of obtaining proppant particle size distribution. The device consists of a sand mixing tank 1, a screw pump 3, a simulated inlet shaft 17, a proppant conveying system 20, a particle size classification system 7, a mechanical segmentation system H, a simulated outlet shaft 9, a cyclone desander 28, a proppant recovery barrel 27, a liquid storage tank 29 and a liquid conveying pump 31. The method comprises the following steps of preparing a fracturing fluid, storing the fracturing fluid in the liquid storage tank, and pouring a proppant into the sand mixing tank; starting the liquid conveying pump and the sand mixing tank to uniformly mix the fracturing fluid and the proppant; enabling liquid carrying sand to enter a simulated fracture through the simulated inlet shaft, and then flow into the cyclone desander through the simulated outlet shaft and a pipeline; and opening a pore channel of a narrow plateat the upper part of the proppant conveying system, isolating the inner space of the simulated fracture by using the mechanical segmentation system, and acquiring the proppant particle size distribution information at different positions in the simulated fracture. A theoretical basis is provided for fracturing parameter design and proppant optimization, and the application prospect is wide.

Owner:SOUTHWEST PETROLEUM UNIV

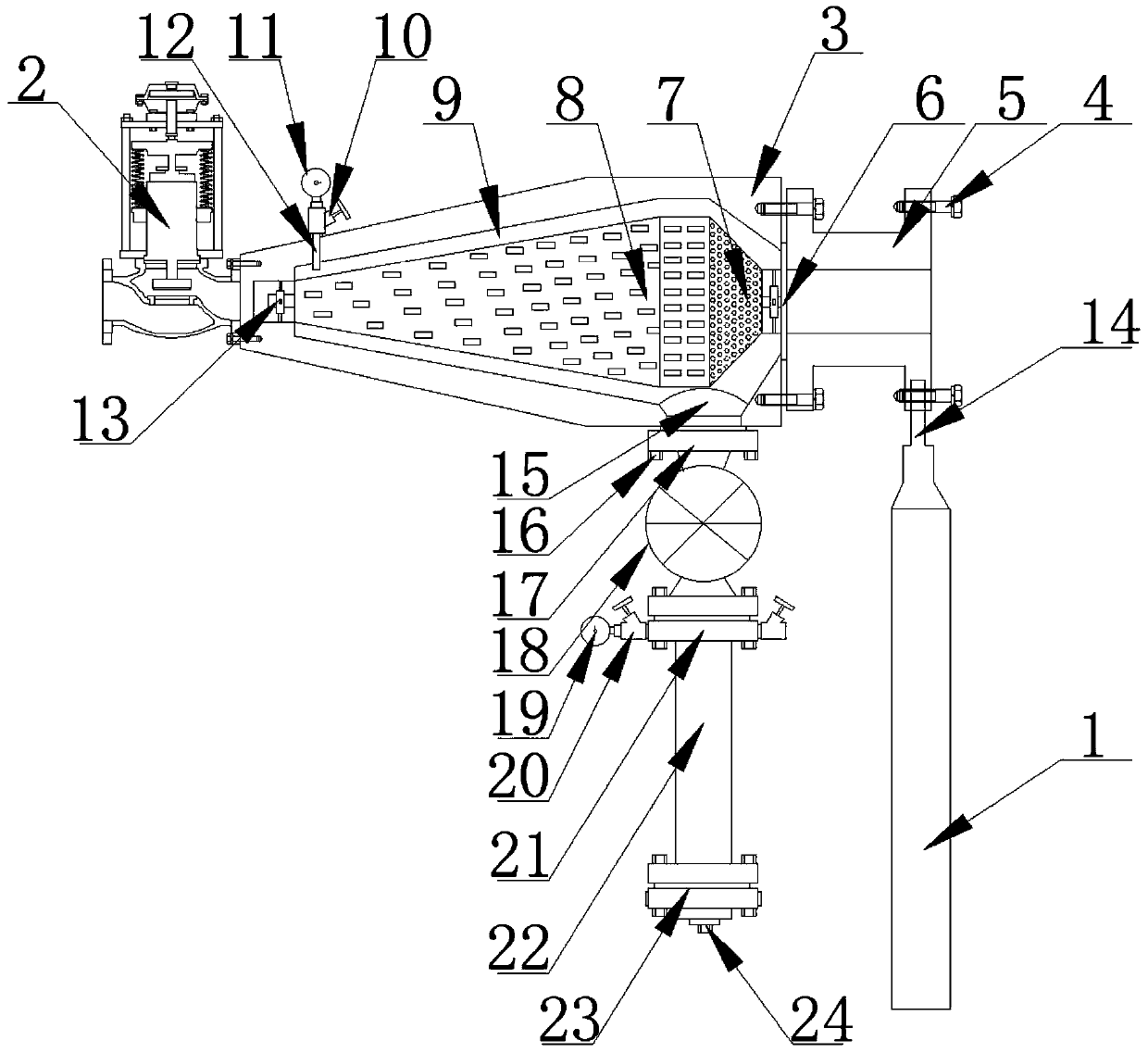

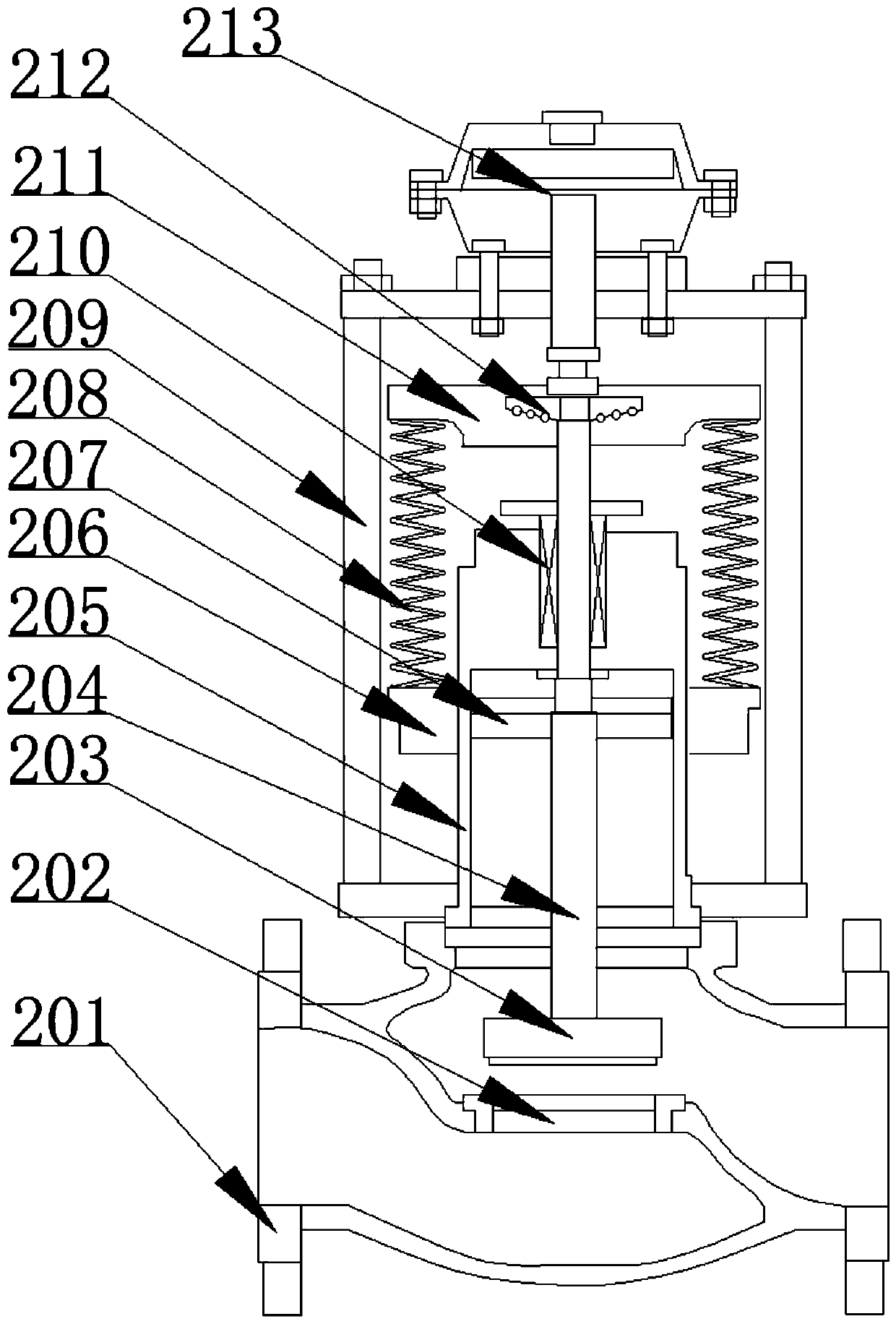

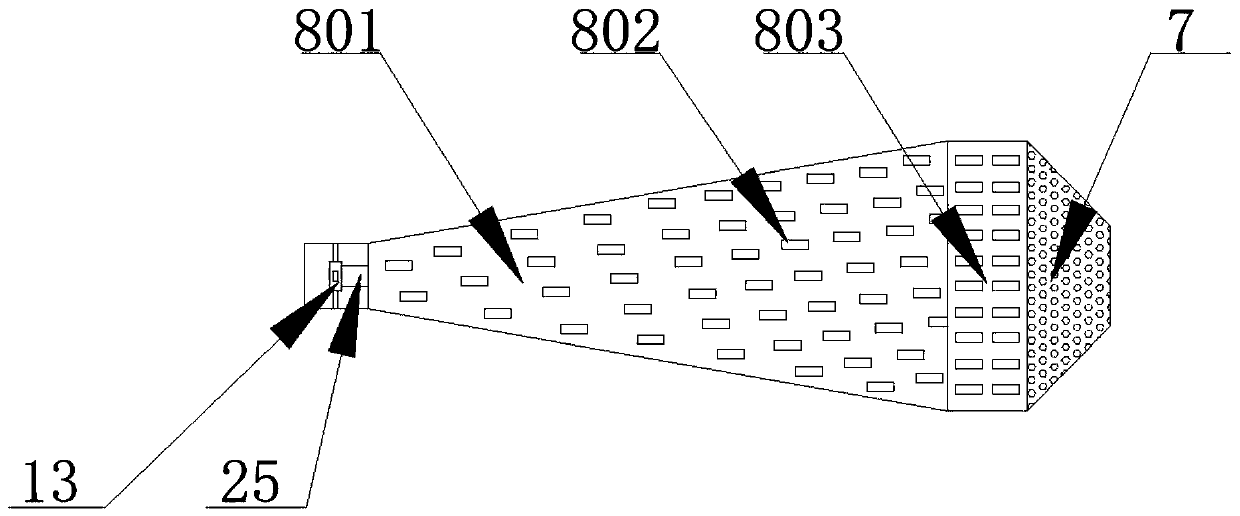

Cyclone desander for wellhead of oil field

ActiveCN110725678AImprove practicalityImprove sand removal effectSedimentation regulating devicesCentrifugal force sediment separationOil fieldDesander

The invention discloses a cyclone desander for a wellhead of an oil field, and particularly relates to the field of desanders. The cyclone desander for the wellhead of the oil field comprises a support, a pressure regulating valve, a barrel, connecting screw rods and a flange. A liquid inlet and a liquid outlet are arranged at the two ends of the barrel separately, the pressure regulating valve and the flange are mounted in the liquid inlet and the liquid outlet of the barrel respectively, a communication hole is formed in the bottom of the barrel, and a connecting flange, a valve, a desandingflange and a sand setting body are installed at the bottom of the barrel through connecting nuts. A set of independent self-operated pressure regulating valve without power supply at the liquid inletis arranged, through pressure changes of oil liquid at the liquid inlet, small pressure changes of the oil liquid at the liquid inlet are amplified by intelligent control of the valve and fed back totwo pressure chambers of the valve, the opening degree of a valve port is adjusted, the cyclone desander can achieve the purpose of adjusting the pressure of the oil liquid behind the valve without replacing the pipe diameter of an external connecting pipe or replacing desanders of other specifications, and the practicability of the cyclone desander is greatly increased.

Owner:王立臣

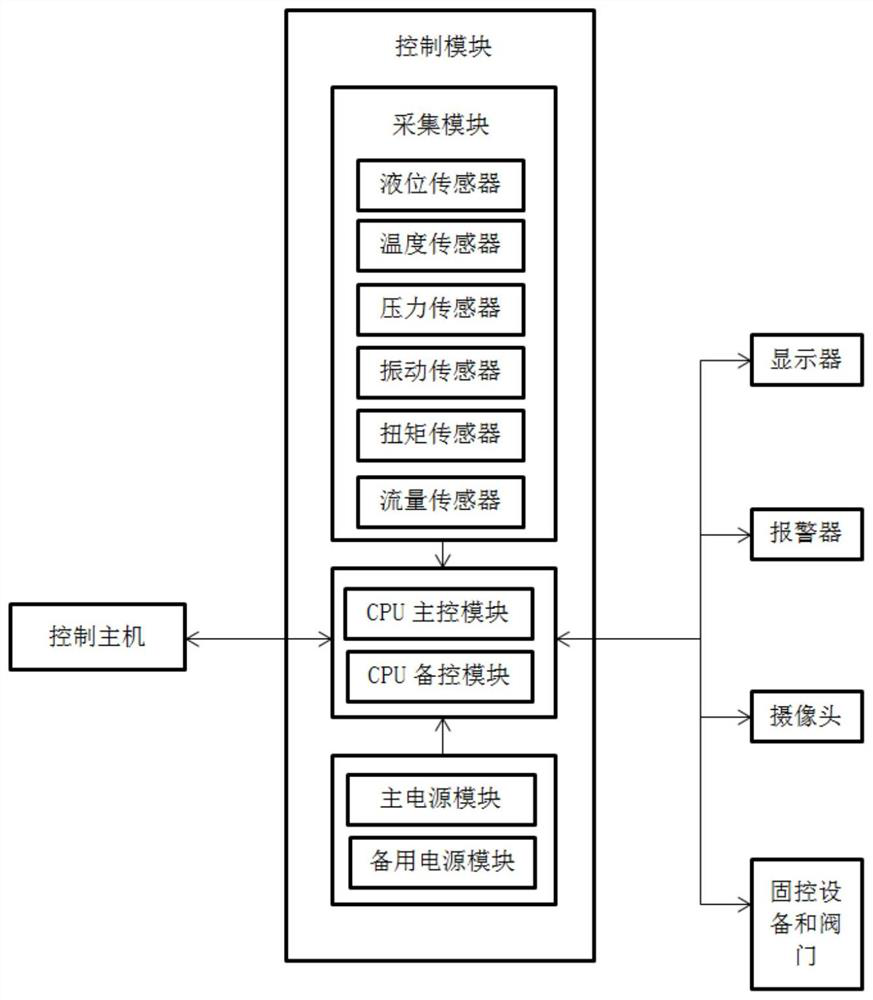

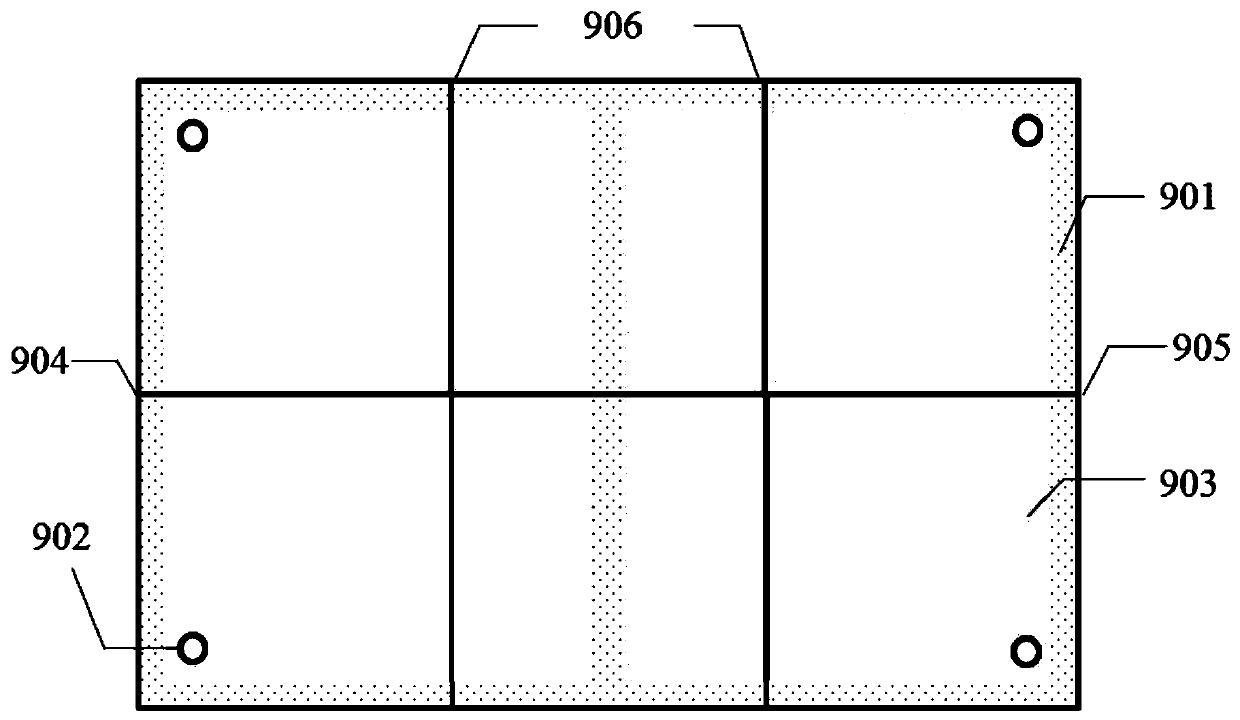

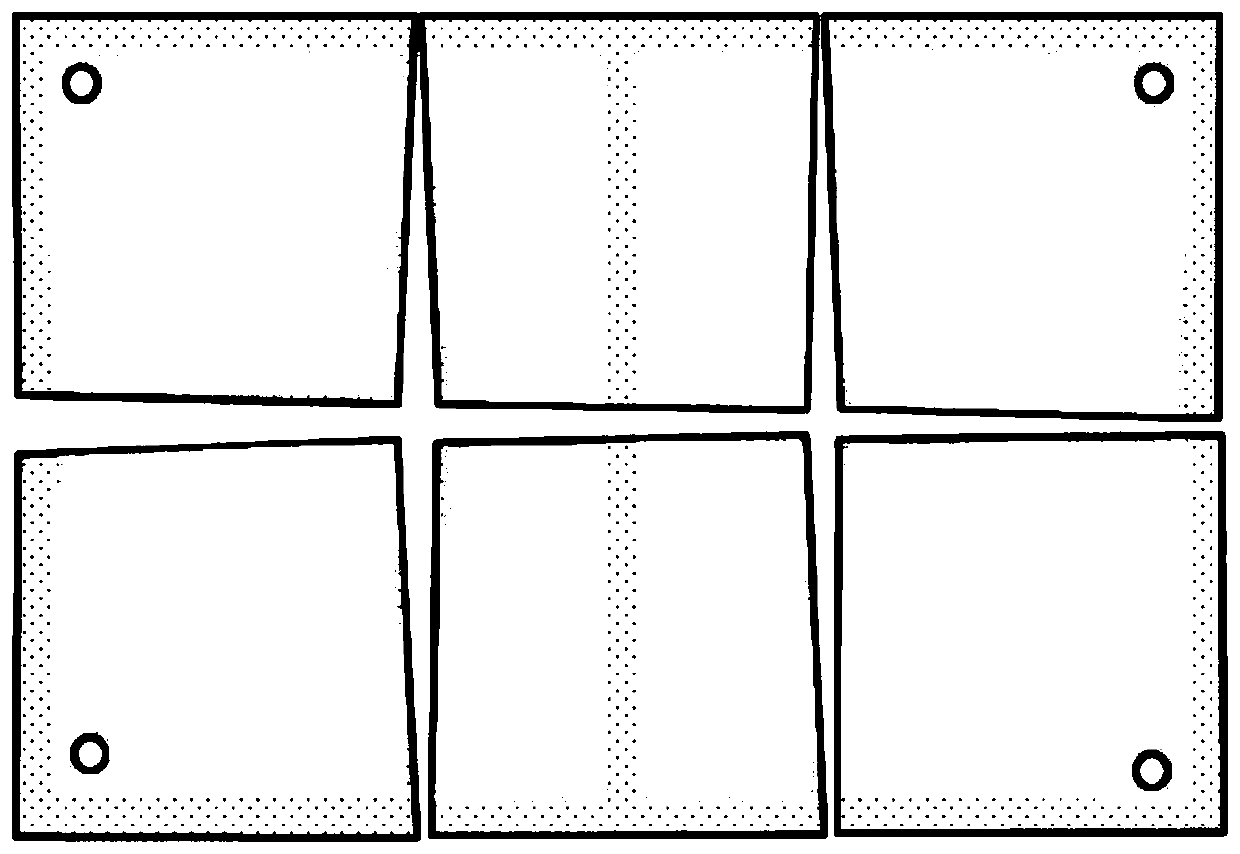

Automatic drilling fluid-solid phase control system

PendingCN111810068ARealize automatic controlReduce manual labor intensityFlushingDegasserControl system

The invention discloses an automatic drilling fluid-solid phase control system. The automatic drilling fluid-solid phase control system comprises an elevated pipe, a solid control tank, a plurality ofsolid control devices, a plurality of valves, a control host, a control module, a displayer, a camera and an alarm, wherein the plurality of solid control devices comprise a vibrating screen, a degasser, a desander, a desilter, a centrifugal machine, a stirrer, a sand pump, a weighting pump and a shearing pump. The control host can be in control connection with all the devices in the system through the control module, the operating states of all the devices in the system can be monitored in real time, centralized control over all the devices and the valves can be achieved, online monitoring is conducted according to collected data, and abnormity alarming can be conducted. The automatic drilling fluid-solid phase control system has the advantages that the structure is simple, design is reasonable, using is convenient, safety and durability are achieved, the device cost is reduced, the labor intensity of manpower is relieved, and the drilling efficiency is greatly improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

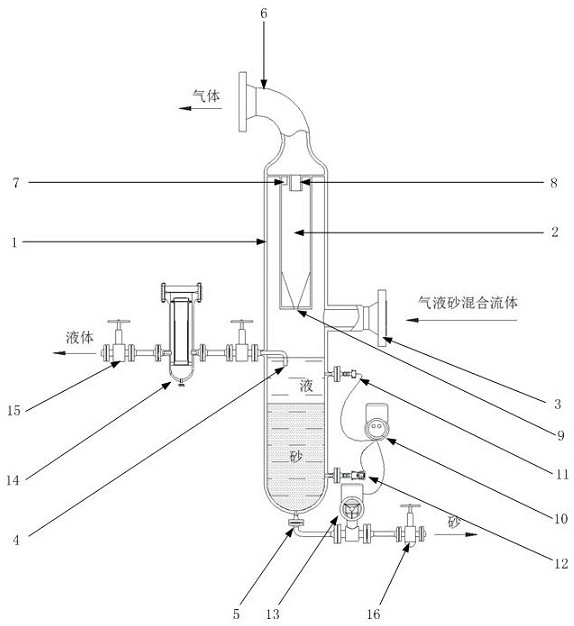

Gas-liquid-sand mixed fluid automatic desanding system for natural gas extraction

InactiveCN113209762AReduce manual operationsImprove adaptabilityCombination devicesFluid removalThermodynamicsAutomatic control

A gas-liquid-sand mixed fluid automatic desanding system for natural gas extraction comprises a shell and a desanding feeding port in the shell, a main separation cavity communicating with the desanding feeding port is formed in the shell, a first liquid discharging port and a sand discharging port are formed below the desanding feeding port, and the sand discharge port is connected with an automatic sand discharge branch; and a sand discharging system further comprises an automatic control system, the automatic control system comprises a controller, a sand level detector and a liquid level detector, the sand level detector and the liquid level detector are connected with the controller, the sand level detector is installed below the main separation cavity, the liquid level detector is installed between the installation height of the sand level detector and the installation height of the sand discharging opening, and the automatic sand discharging branch is controlled by the controller. By arranging a sensor and the control system, sand can be automatically discharged according to the stacking height in a sand remover, the whole sand discharging process is fully automatically completed, and manual operation is greatly reduced; and liquid is discharged through the liquid outlet, so that the desilting operation frequency and the subsequent sand-liquid separation work are reduced. By arranging a cyclone sand discharger, the equipment adaptability is improved, the advantages of gravity settling and cyclone separation are integrated, and the flow adaptation range is large.

Owner:成都汇川新能科技有限公司 +1

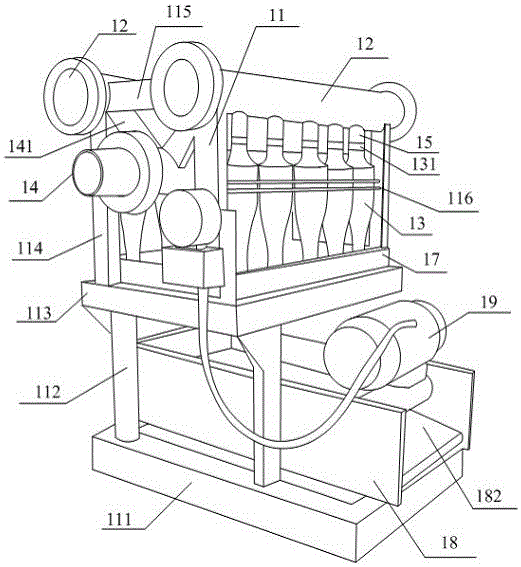

Mud-sand separator for petroleum drilling

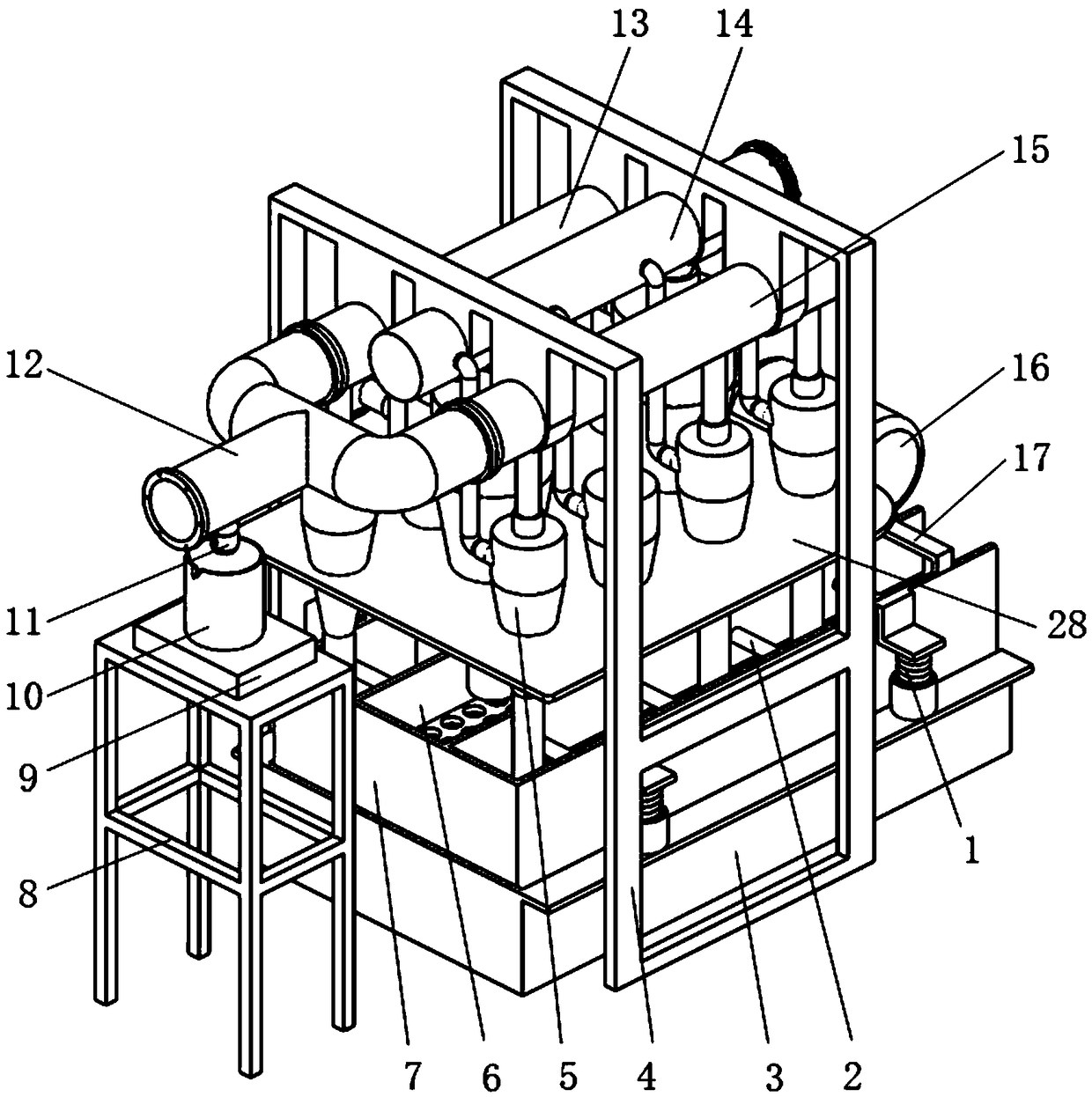

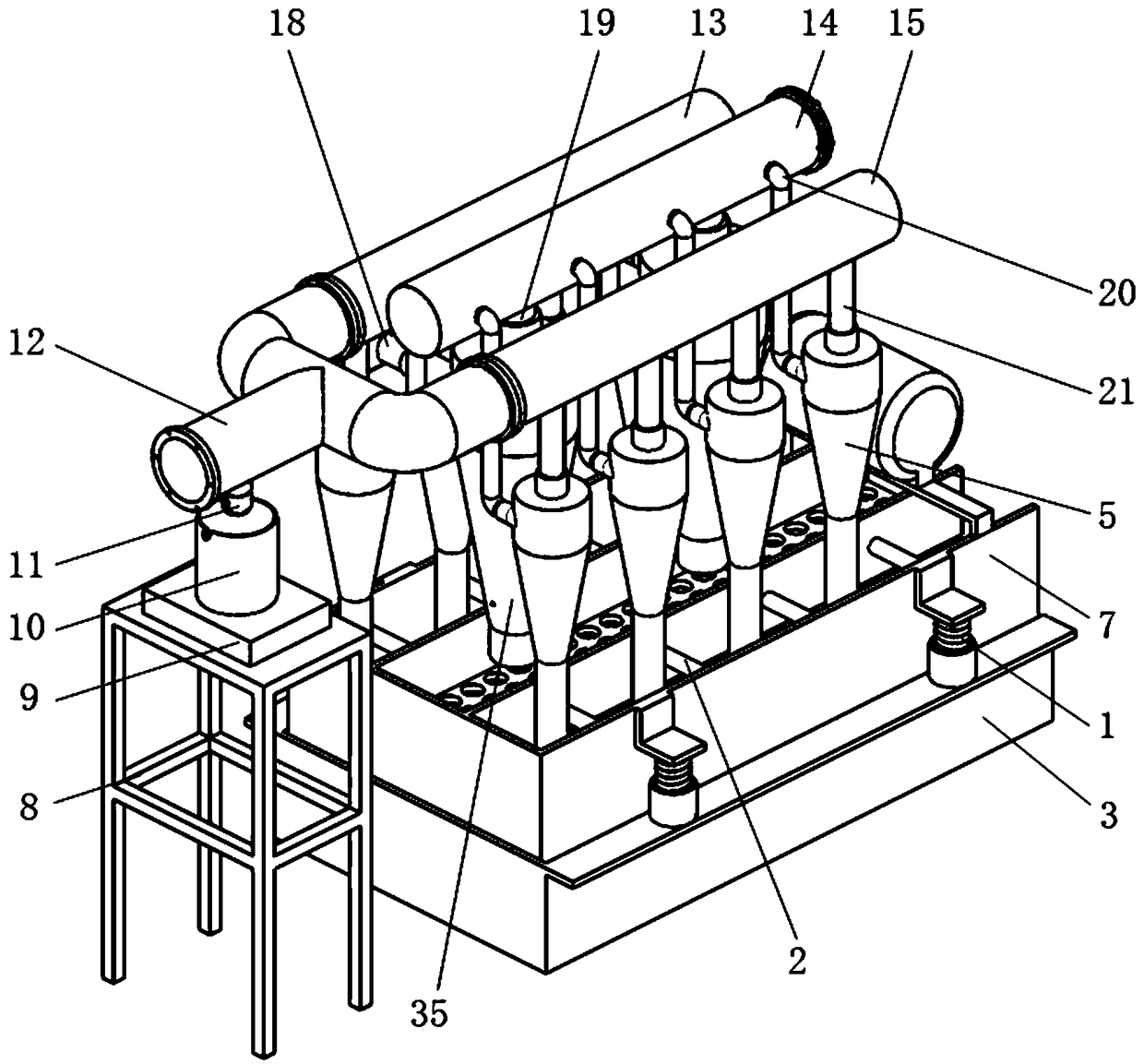

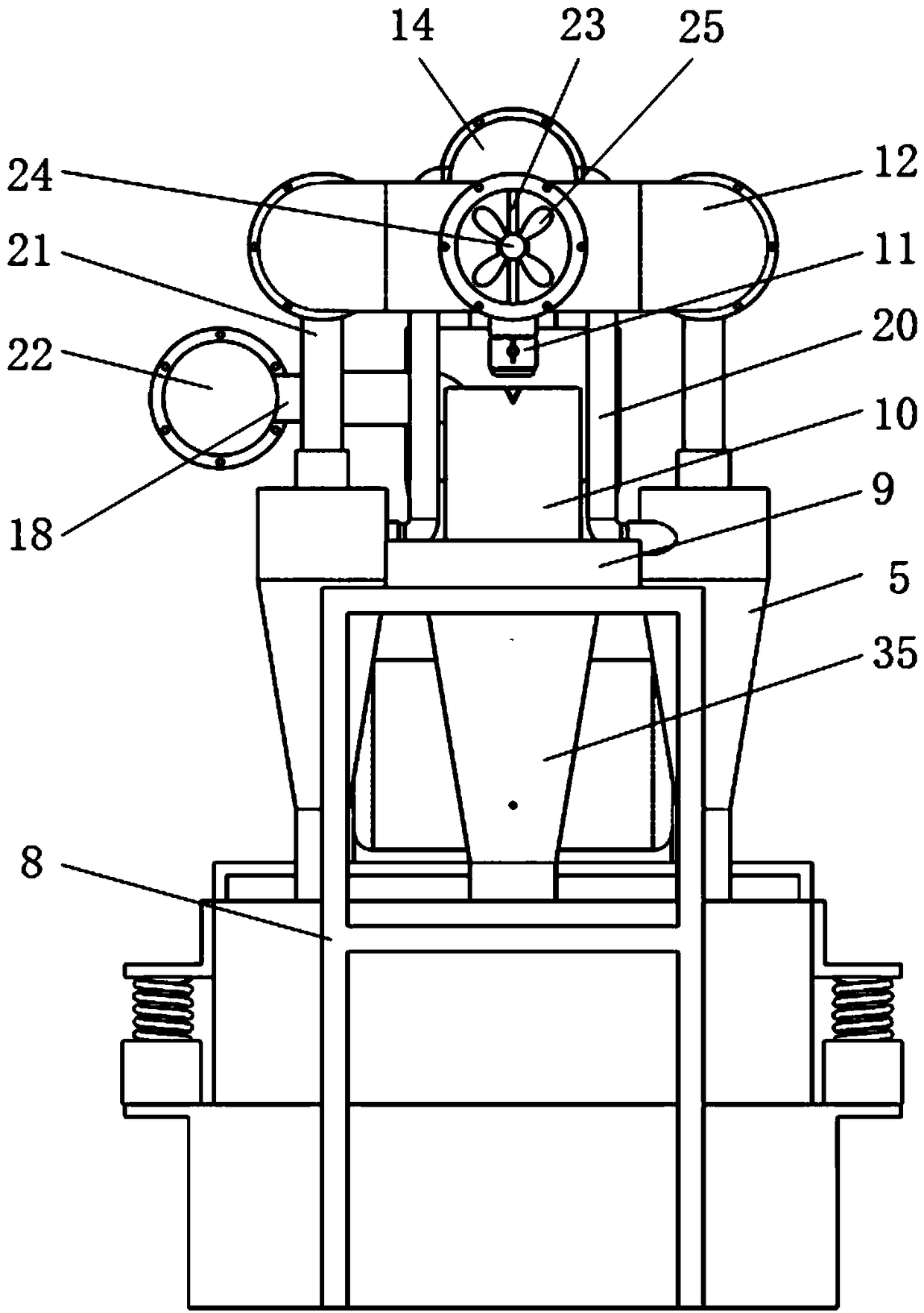

The invention discloses a mud-sand separator for petroleum drilling. The mud-sand separator comprises a machine frame, a mud temporary storage pool, two mud outlet pipes parallel to each other, a feeding pipe and a plurality of cyclone desanders, wherein the machine frame comprises a base in the shape of a rectangular frame, four first stand columns, a fixing frame and four second stand columns; a vibration sieve and the first stand columns are fixed to the base; the top ends of the four first stand columns and the lower ends of the four second stand columns are fixed to the four corners of the fixing frame; the mud temporary storage pool is welded in the fixing frame; a sewage outlet is formed in the bottom of the mud temporary storage pool; the mud outlet pipes are welded at the top ends of the second stand columns; a row of branch pipes are arranged on pipe bodies; the feeding pipe is fixed to the second stand columns, parallel to the mud outlet pipes and positioned above the mud temporary storage pool and below the mud outlet pipes; the cyclone desanders are mounted in two rows on two sides of the feeding pipe; and the top of each cyclone desander is connected with each branch pipe, the upper part of the cyclone desander is connected with the feeding pipe, and a sand outlet is formed in the bottom of the cyclone desander. According to the mud-sand separator, the cyclone desanders are adopted for mud separation simultaneously, so that the processing efficiency is high; the mud temporary storage pool is additionally arranged, so that empty opening is avoided and the energy is saved; and the mud-sand separator has the advantages of low cost and convenience for carrying.

Owner:CHENGDU DAMO PETROLEUM MACHINERY GRP

Cyclone desander capable of cleaning solids in real time

ActiveCN110227286AImprove work efficiencyReduce water flow rateSettling tanks feed/dischargeCentrifugal force sediment separationCycloneWater flow

The invention discloses a cyclone desander capable of cleaning solids in real time, belonging to the field of desanding equipment. The rotational-flow grit chamber comprises an outer cyclone tube andan inner cyclone tube, wherein the bottom of the outer cyclone tube is provided with a solid treatment case used for treating screened solid particles, and the solid treatment case is in communicationwith the inner cavity of the outer cyclone tube. According to the rotational-flow grit chamber capable of cleaning solids in real time, the separated solid particles are piled up on the bottom of theouter cyclone tube, so the flow rate of water flowing through the inner cyclone tube is reduced, a sealing piston in a movable sealing tube moves downward due to increase of downward pressure, and avalve ball seals the movable sealing tube and the inner cavity of the outer cyclone tube; at the same time, a valve core blocks the bottom port of the inner cyclone tube, and the movable sealing tubeis moved downward by pressure, so the solid particles in the movable sealing tube flow through a through groove to the treatment case, and thus, the solid particles are discharged and cleaned in realtime according to the amount of the solid particles in the outer cyclone tube without shutdown of related equipment, which enables the working efficiency of the cyclone desander to be improved.

Owner:临沂长荣环保科技有限公司

An experimental device and method for transporting sand-carrying fluid in simulated fracturing fractures

ActiveCN109812254BRealize laying simulationTraffic real-time monitoringSurveyFluid removalFracturing fluidEngineering

The invention discloses an experimental device and method for transporting sand-carrying liquid in simulated fracturing fractures, which includes a spiral proppant transport device, a mixing tank, a screw pump, a liquid transport pump, a pressure gauge, a proppant migration and distribution system, and a swirl flow Desander, waste liquid recovery barrel, proppant recovery barrel, and fracturing fluid storage tank; the spiral proppant transport device is connected to the stirring tank, and the waste liquid recovery barrel and fracturing fluid storage tank are all connected by a liquid transfer pump It is connected with the stirring tank; the bottom end of the stirring tank is connected with the proppant migration and distribution system through a screw pump. By setting up a computer to accurately control the transparent three-dimensional crack component containing the hydraulic tank, the present invention can simulate the laying of sand-carrying liquid under a certain closing pressure. In addition, the transparent three-dimensional crack component can produce slight deformation without causing damage. , in order to study the laying rules of sand-carrying liquid in the opening and expansion stages of the fracture network system composed of hydraulic fractures and natural fractures.

Owner:SOUTHWEST PETROLEUM UNIV

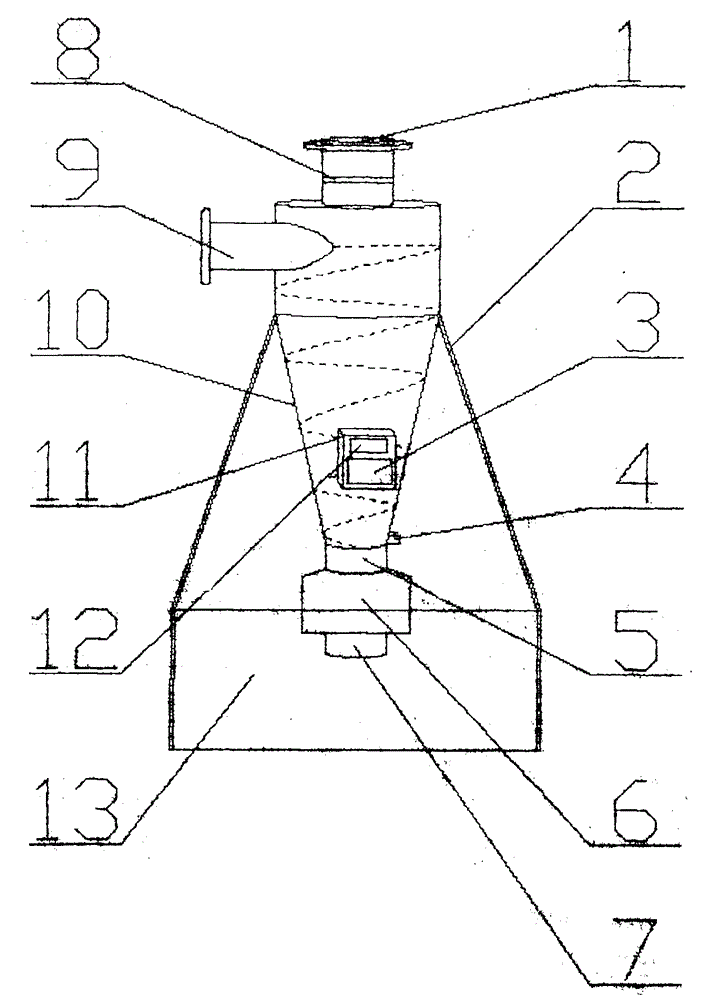

Cyclone desander device

InactiveCN106861938AEfficient removalClean up thoroughlyReversed direction vortexDesanderEngineering

The invention provides a swirl desander device, which comprises a swirl upper cylinder and a swirl lower cylinder, the swirl upper cylinder and the swirl lower cylinder are connected by bolts, and the upper part of the swirl upper cylinder is provided with a liquid outlet pipe ,The eccentric position of the upper cylinder is equipped with a liquid inlet pipe, the outer circumference of the lower cylinder is equipped with a protective cover, the two sides of the lower cylinder are respectively equipped with flushing devices, and the bottom of the lower cylinder is provided with a sand discharge port , The flushing device includes a switch valve, a spray pipe and a base, the switch valve and the base are connected by bolts and fixed on the swirling lower cylinder, and the spray pipe is arranged on the base. The problem to be solved by the present invention is to provide a cyclone desander with simple structure, small volume, safety and reliability, good sand discharge effect, and more thorough treatment of residual sand particles on the inner wall in all directions.

Owner:TIANJIN ZHENDA PUMP CO LTD

Geothermal energy-driving heat recovery system

InactiveCN102809187AReduce the temperatureIncrease profitHeat recovery systemsOther heat production devicesDesanderAbsorption heat pump

The invention provides a geothermal energy-driving heat recovery system which comprises a geothermal energy exploitation well, a desander, a flowmeter, a absorption heat pump, heating equipment, a geothermal energy recharge well and recharge treatment facilities, and further comprises a first heat exchanger, a second heat exchanger, a first circulating pump, a second circulating pump, a pressure gauge and a thermometer, wherein valves are respectively arranged at the two ends of the first circulating pump and the second circulating pump; and a temperature transmitter and a pressure transmitter are arranged at the outlet end of the geothermal energy exploitation well. The heat recovery system has the benefits that the heat of the used geothermal water with reduced temperature can be further utilized so as to greatly improve the utilization rate of the geothermal energy, and meanwhile, other energy is not consumed. Therefore, the heat recovery system has a more realistic significance for areas with abundant geothermal energy.

Owner:TIANJIN REJIAN ELECTROMECHANICAL ENG

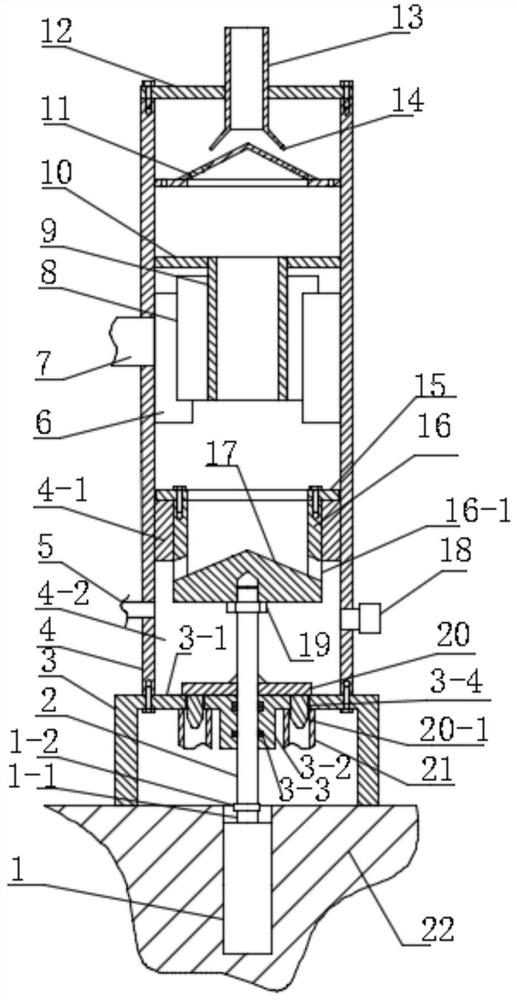

Natural gas wellhead shutdown-free desanding separation device

ActiveCN114293969AImprove sand removal efficiencyEnsure air qualityFluid removalDesanderMechanical engineering

The invention discloses a natural gas wellhead shutdown-free desanding separation device, and belongs to the technical field of natural gas extraction. Comprising a support, and a bottom plate is fixed to the upper end of the support; a cylinder body is fixed on the bottom plate; an upper cover is fixed at the upper end of the barrel, one side of the barrel is connected with an air inlet pipe, and a sand remover opposite to the air inlet pipe is mounted in the barrel; the upper cover is connected with an air outlet pipe; a pull rod penetrates through the center of the bottom plate; lifting devices are connected to the lower ends of the pull rods; the upper ends of the pull rods are connected with conical seats; the conical seat is connected with a sand gathering cylinder; the lower side of the conical seat is a sand gathering cavity; a pressurizing pipe and a pressure reducing valve which are communicated with the sand gathering cavity are mounted on the side wall of the barrel; a sand unloading hole is formed in the bottom plate, and a sand outlet pipe is connected below the sand unloading hole; a pressure plate is fixed on the pull rod; and a sealing column which is relatively matched with the sand unloading hole is fixed below the pressure plate. In the whole sand unloading process, the air inlet pipe does not stop air inlet, the whole machine continuously works, and the working efficiency is improved.

Owner:江苏华普泰克石油装备有限公司

Rotational flow type sand-removing multi-grade filtering device for agricultural irrigation

InactiveCN107823960AEasy to replacePrevent overflowWater/sewage treatment by centrifugal separationCrystallization separationCycloneWater discharge

The invention discloses a cyclone-type sand removal multi-stage filter device for agricultural irrigation, which comprises an upper tank body, a lower tank body, a conical sand settling bucket, a sand discharge device, an overflow pipe, a filter cylinder, a rotating cylinder and a moving annular cylinder ;Due to the filtering effect of sand and stone filter plates, activated carbon filter plates, light ceramsite filter plates of biological filter materials and hollow spherical magnesium oxide adsorption plates on water, the impurity content in the discharged water is less, avoiding the traditional rivers, etc. The pollution problem caused by direct irrigation of water can conveniently turn out the first filter layer, the second filter layer, the third filter layer and the fourth filter layer to facilitate the replacement of the filter plate. When the filter plate is replaced, twist Rotate the cylinder so that the directions of the magnetic south pole and the magnetic north pole of the first magnet and the second magnet adjacent up and down are opposite, and the two moving annular rings are in contact with each other, which prevents water from passing through the first filter layer, the second filter layer, and the second filter layer. The situation where a large amount of overflow occurs due to the gap at the joint between the third filter layer and the fourth filter layer.

Owner:蒋炳坤

Novel cyclone desander

InactiveCN106823485ARealize automatic sand removalImprove sand removal rateSettling tanks feed/dischargeCentrifugal force sediment separationCycloneDesander

The invention discloses a novel cyclone desander, which comprises an overflow opening, supporting columns, an operation panel, a residual sand discharging opening, a first electromagnetic valve, a sand storing bucket, a second electromagnetic valve, a filtering screen, a water inlet, a conical barrel, a control box and a sand storing tank, wherein the upper and lower ends of the sand storing bucket are provided with the first electromagnetic valve and the second electromagnetic valve respectively; the first electromagnetic valve is connected with the bottom of the conical barrel into a whole; the conical barrel is connected and provided with the control box and the residual sand discharging opening; the conical barrel is fixed right above the sand storing tank by the supporting columns; the conical barrel is connected with a cylindrical barrel into a whole; the cylindrical barrel is provided with the water inlet and the overflow opening respectively; the filtering screen is arranged in the overflow opening. Compared with the prior art, the novel cyclone desander has the beneficial effects that the novel cyclone desander can be used for realizing full-automatic sand discharge through periodically controlling the two electromagnetic valves; meanwhile, the bottom end of the conical barrel is provided with the residual sand discharging opening; the overflow opening is provided with the filtering screen; residual fine sand in the conical barrel can be removed; the desanding efficiency is further improved.

Owner:SHANDONG LIANXING ENERGY GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com