Environmental protection system for skid-mounted drilling oil base and water base slurry processing without landing and processing technology thereof

A drilling and mud technology, applied in the field of skid-mounted drilling oil-based, water-based mud non-ground treatment environmental protection system and its treatment process, can solve the problems affecting the growth of animals and plants, pollute water quality and soil, etc., to save manpower and improve efficiency , cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing:

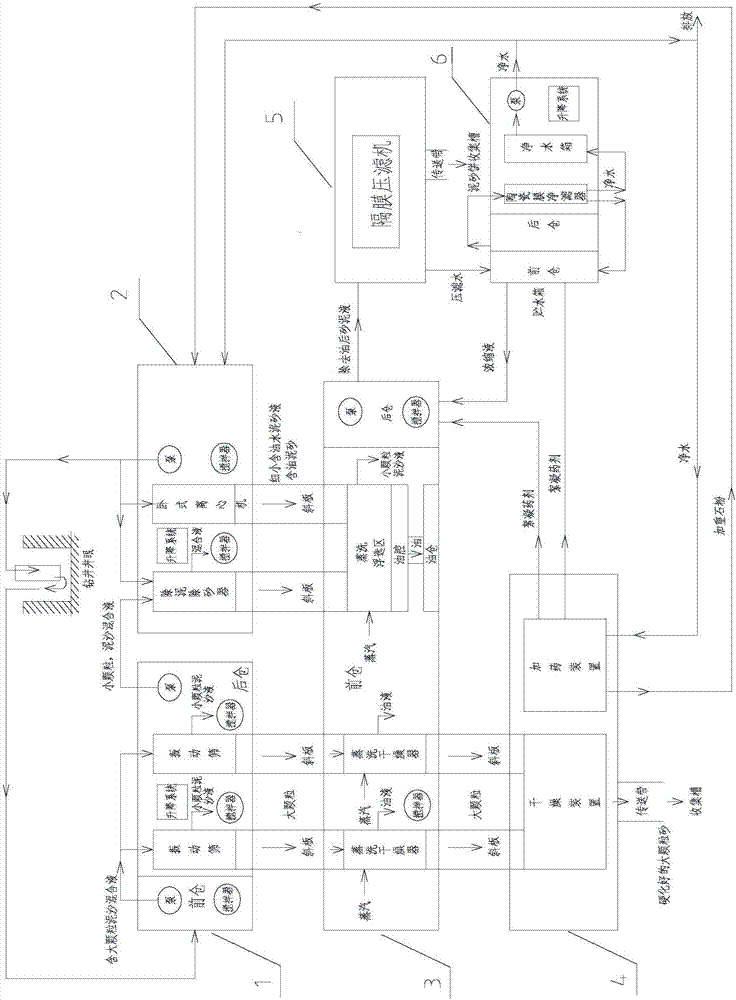

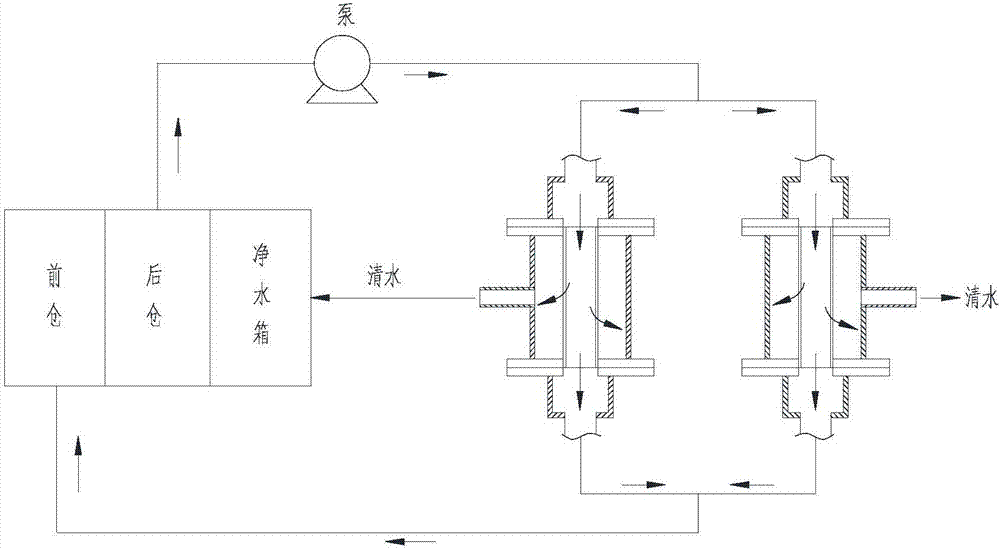

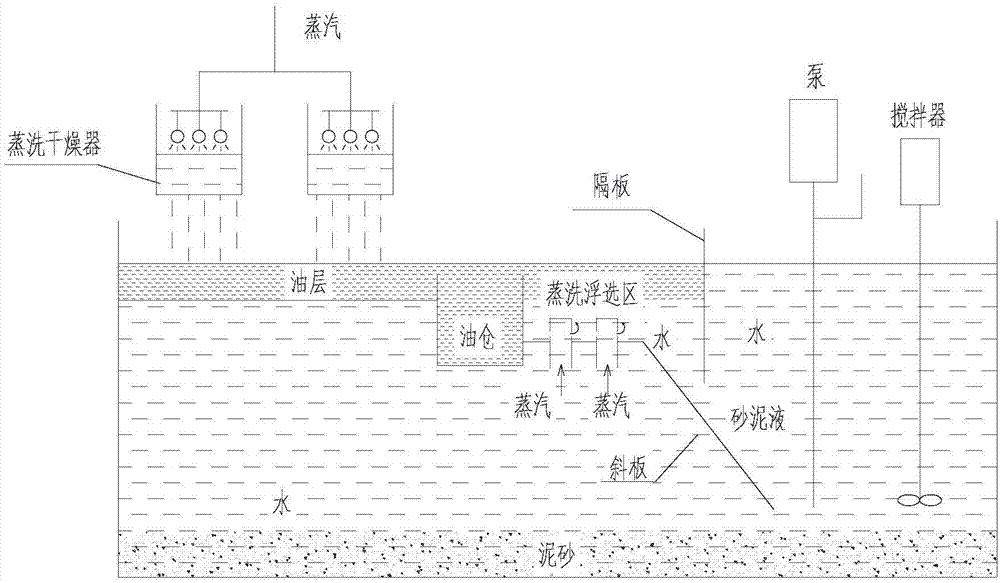

[0026] as attached figure 1 As shown, the skid-mounted drilling oil-based and water-based mud treatment environmental protection system includes mud inlet pipeline and 6 skids, which are primary solid-liquid separation skid 1, secondary solid-liquid separation skid 2, steam washing and oil removal Skid 3, terminal drying multi-functional drug dosing skid 4, diaphragm filter press skid 5, porcelain membrane net filter set water tank skid 6. The primary solid-liquid separation skid 1, the secondary solid-liquid separation skid 2, the steam-washing and degreasing skid 3, and the ceramic membrane net filter set water tank skid 6 are all storage tank-type skids. The end drying multifunctional dosing skid 4 and the membrane filter press skid 5 are heat preservation board room skids.

[0027] The primary solid-liquid separation skid 1 is divided into a front warehouse and a rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com