Patents

Literature

2787 results about "Slurry pump" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A slurry pump is a type of pump designed for pumping liquid containing solid particles. Slurry pumps changes in design and construction to adjust to multiple type of slurry which varies in concentration of solids, size of solid particles, shape of solid particles, and composition of solution. Slurry pump are more robust than liquid pumps; they have added sacrificial material and replaceable wear parts to withstand wear due to abrasion.

Methods and fluid compositions designed to cause tip screenouts

InactiveUS6837309B2Increase probabilityTreatment is limitedFluid removalDrilling compositionHigh concentrationFiber

In stimulation treatments to increase the production of hydrocarbons from subterranean formations, especially in treatments including hydraulic fracturing followed by gravel packing, desirable short wide fractures are created and filled with proppant by deliberately including in the first fluid / proppant slurry pumped a sufficiently high concentration of a bridging-promoting material, such as fibers, that reduces the mobility of the slurry when it dewaters so that screenout at or near the tip occurs.

Owner:SCHLUMBERGER TECH CORP

Trailer mounted mobile apparatus for dewatering and recovering formation sand

InactiveUS7240681B2Prevent leakageElectrostatic cleaningMultistage water/sewage treatmentDrive wheelHigh pressure water

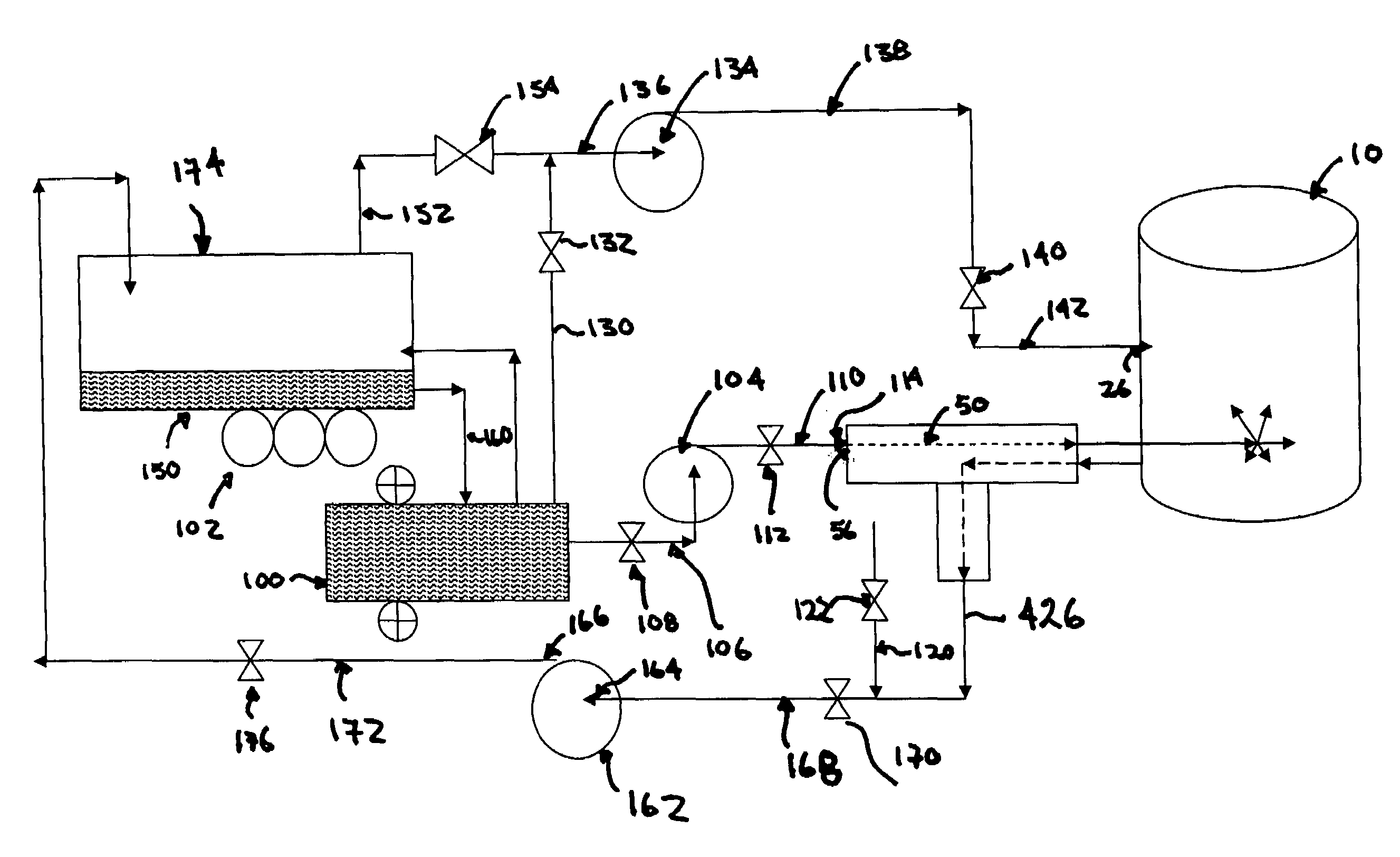

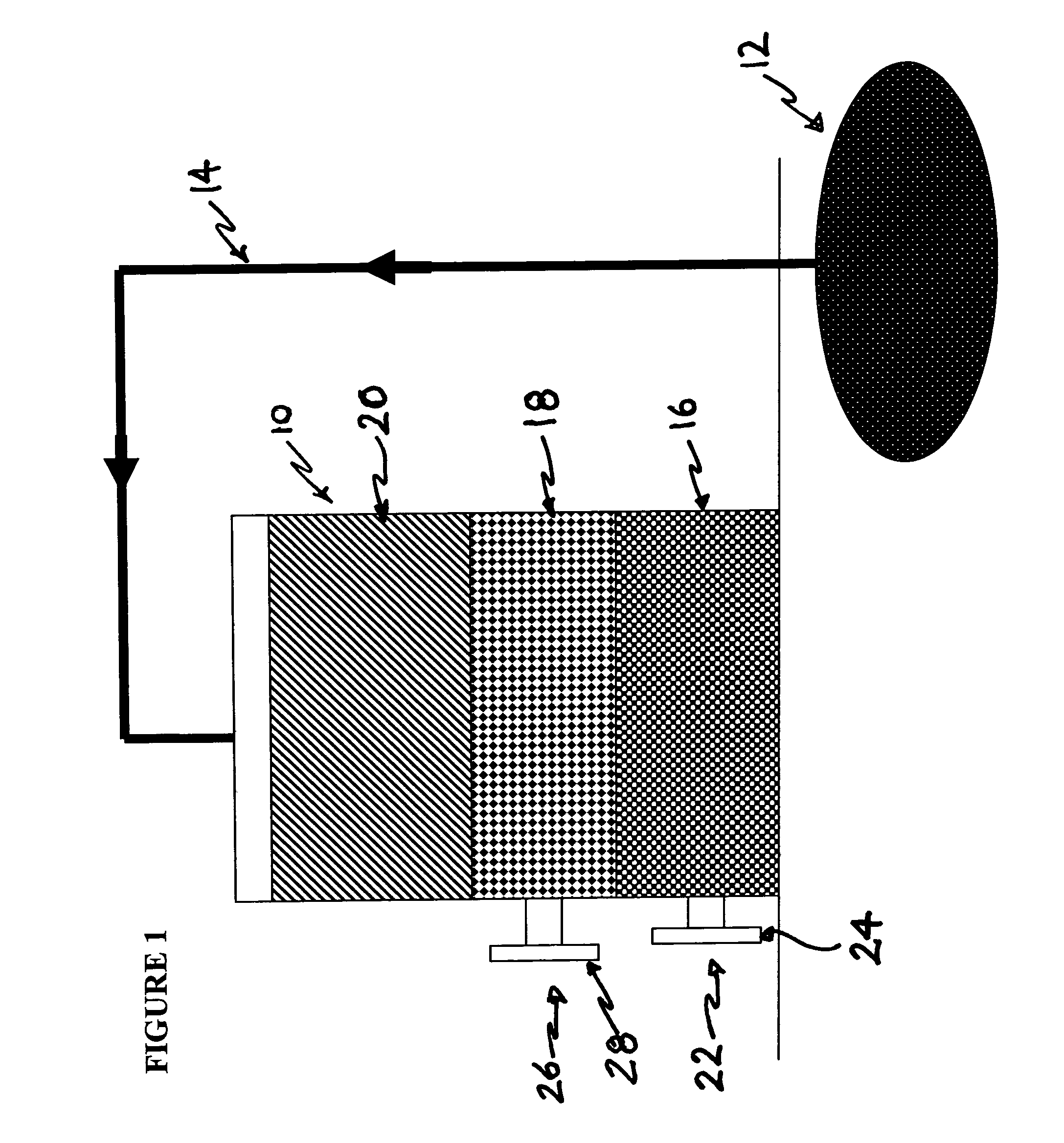

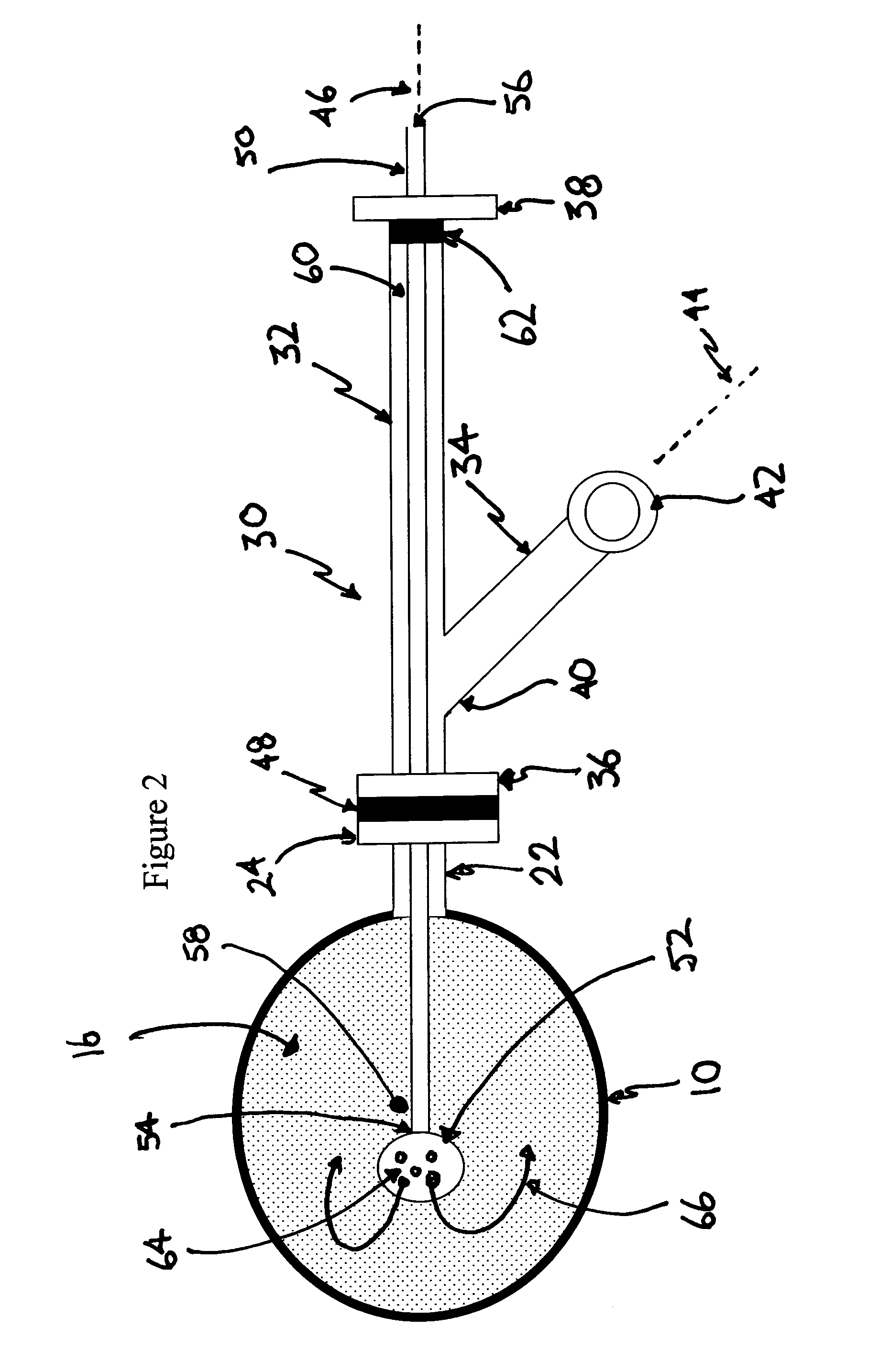

An apparatus for removing formation sand from an oil storage tank. The apparatus is mounted to a truck towable trailer so that it may be transported to remote sites. Mounted to the truck towable trailer is a container adapted to accept and dewater a sand-water slurry pumped from the oil storage tank. The slurry is formed by injecting high pressure water from a water reservoir mounted to the truck towable trailer into the approximate centre of mass of the formation sand by way of a pipe having a nozzle generating a spherical spray pattern within the slurry. The pipe is forced into the slurry by way of a two counter-rotating drive wheels in frictional contact with the pipe. Included in the apparatus is a bifurcated conduit adapted for attachment to the storage tank drain port adapted for the injection of high pressure through one branch of the conduit and withdrawal of slurry from the other branch and into the container by way of a slurry pump. The dewatering of the slurry takes place by a plurality of screen filters mounted to the bottom, side and front inside walls of the container. Oil and water extracted from the slurry is recycled back into the storage tank for later removal and treatment. All pumps and conduits are mounted to the truck towable trailer so that the apparatus is self-contained.

Owner:SAIK LARRY

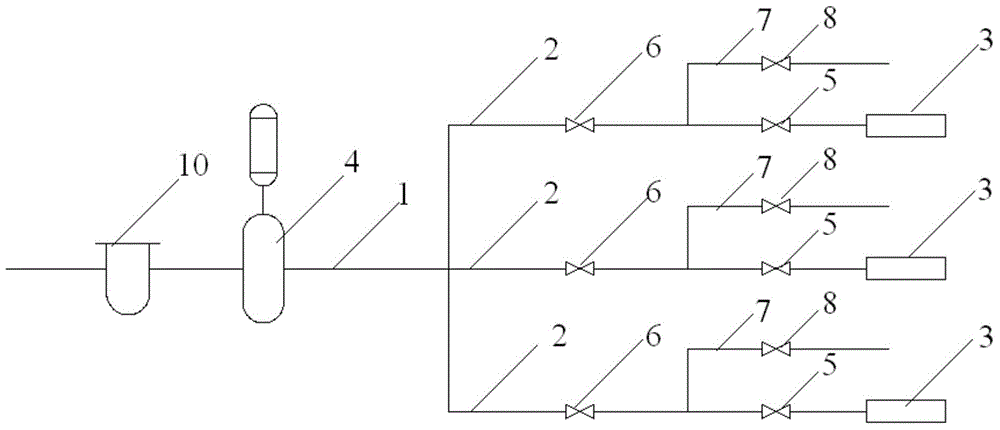

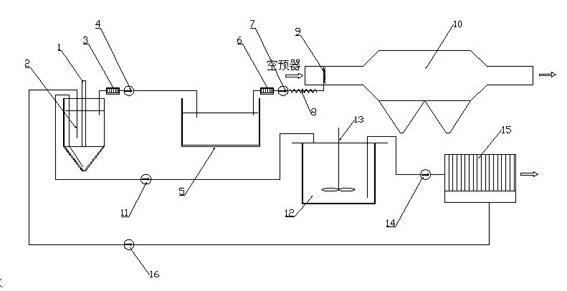

Feeding device for oil field waste treatment system and work method of feeding device

ActiveCN104803568AStrong continuity of processing operationsRealize deliverySludge treatment by pyrolysisCombustorWaste treatment

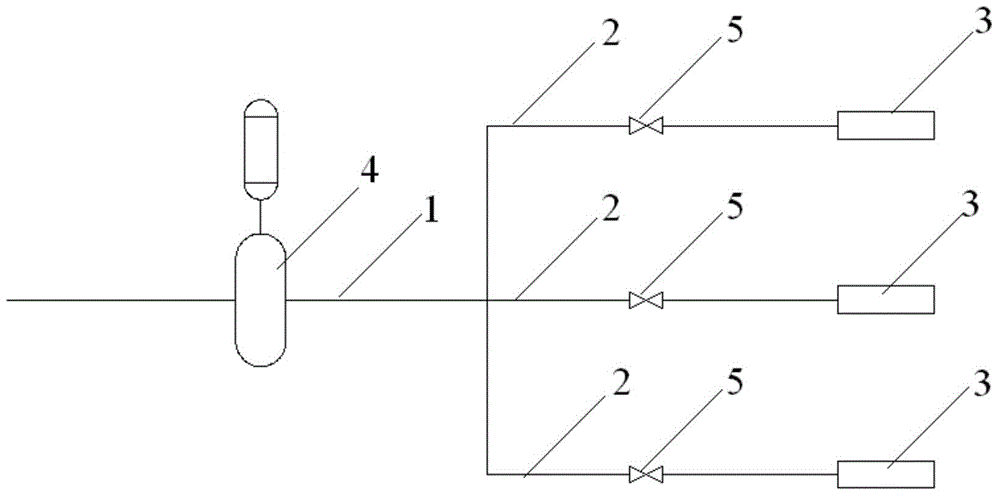

A feeding device for an oil field waste treatment system comprises a main pipe and multiple branch pipes, wherein front ends of the branch pipes are all connected with the rear end of the main pipe, and rear ends of the branch pipes are all connected with corresponding heating cavities; a main slurry pump which is a positive displacement pump is mounted on the main pipe; root valves are mounted on all of the branch pipes. The feeding device for the oil field waste treatment system adopts the positive displacement pump for pumping, materials with higher fluidity can be conveyed and distributed, and the feeding quantity can be measured, so that a proper quantity of materials are conveyed into the heating cavities, the materials are completely treated, the heat energy of a burner can be more efficiently utilized, and the treatment efficiency is improved. The materials can be constantly conveyed into the heating cavities quantitatively at a constant speed for a long time through measurement of calibration ports and regulation of branch regulation valves, the continuity of waste treatment work can be higher, and the work efficiency is further improved.

Owner:RUIJIE ENVIRONMENTAL PROTECTION TECH CO LTD

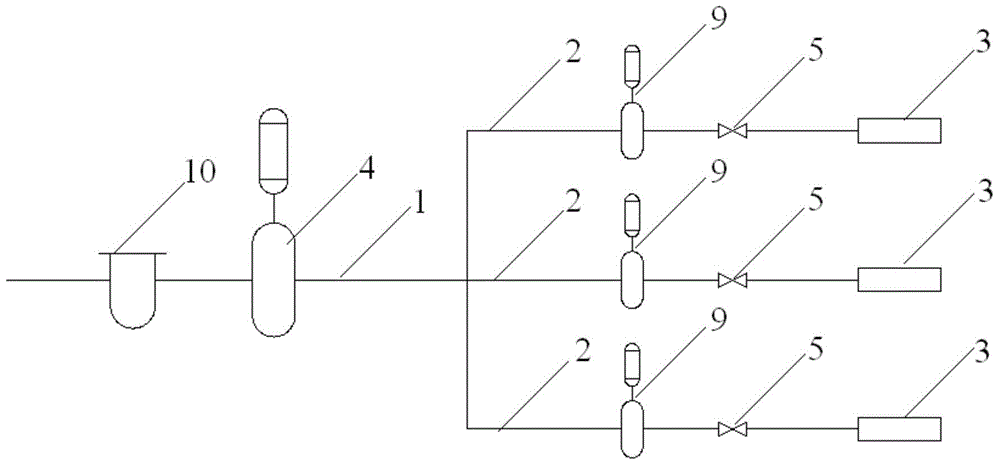

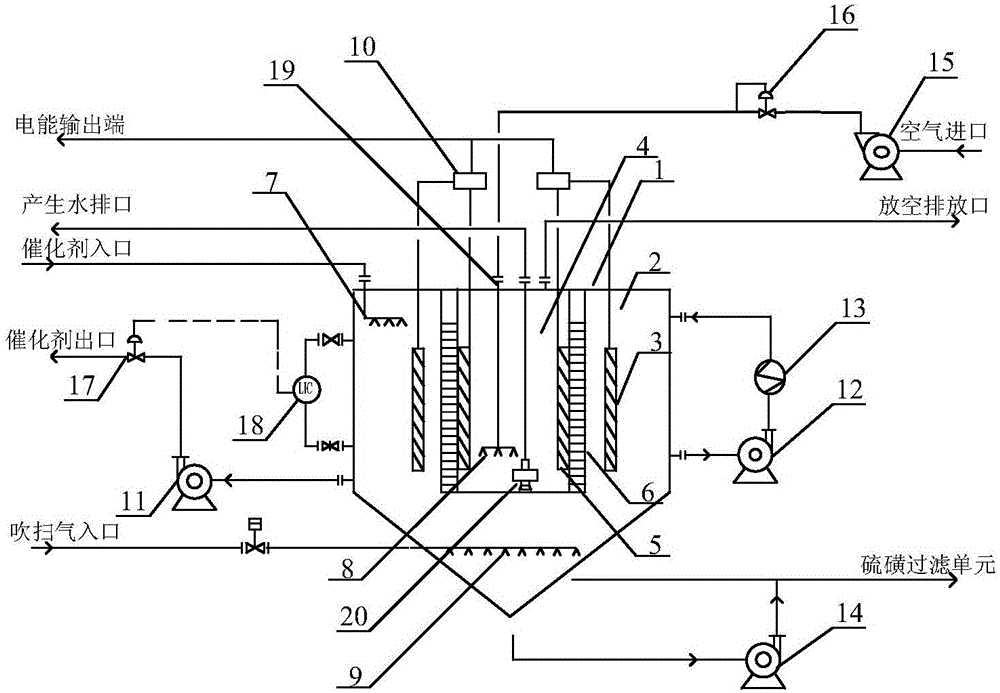

High-efficiency compound regenerative electrical energy device

InactiveCN105958098AIncreased oxidation regeneration rateReduce degradation lossRegenerative fuel cellsFuel cellsCirculator pump

The invention provides a high-efficiency compound regenerative electrical energy device. The device comprises a reactor, an anode chamber, an anode plate, a cathode chamber, a cathode plate, a proton exchange membrane module, a liquid distributor, a gas distributor, a purge distributor, a battery load, an output pump, a circulating pump, a heating / cooling device, a slurry pump, an air blower, a purge gas stop valve, a flow control valve, a magnetic flap liquidometer, a self-operated pressure-regulating valve, and an immersed pump. The gas distributor is disposed at the bottom of the cathode chamber, and the circulating pump is disposed in the middle of the reactor barrel. The air blower communicates with the gas distributor by the self-operated pressure-regulating valve, and the immersed pump is disposed at the bottom of the cathode chamber. The device uses the coupling mode of fuel cell and catalyst reactivation by means of the arrangement of air cathode fuel cell, is beneficial to improve the oxidation regeneration rate of the catalyst, and realizes the rapid regeneration of the complex catalyst.

Owner:JEREH TIANJIN PETROLEUM ENG & TECH

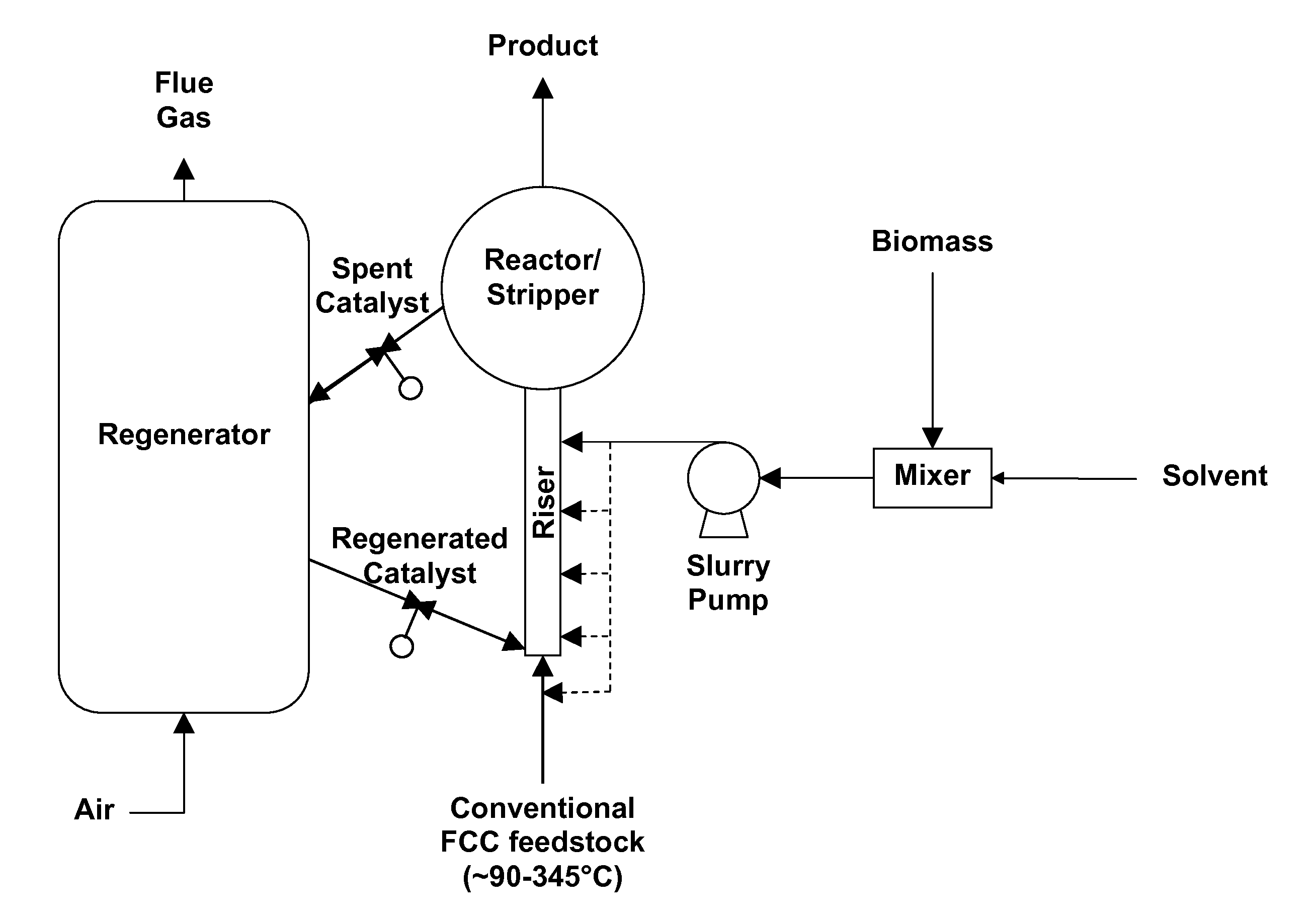

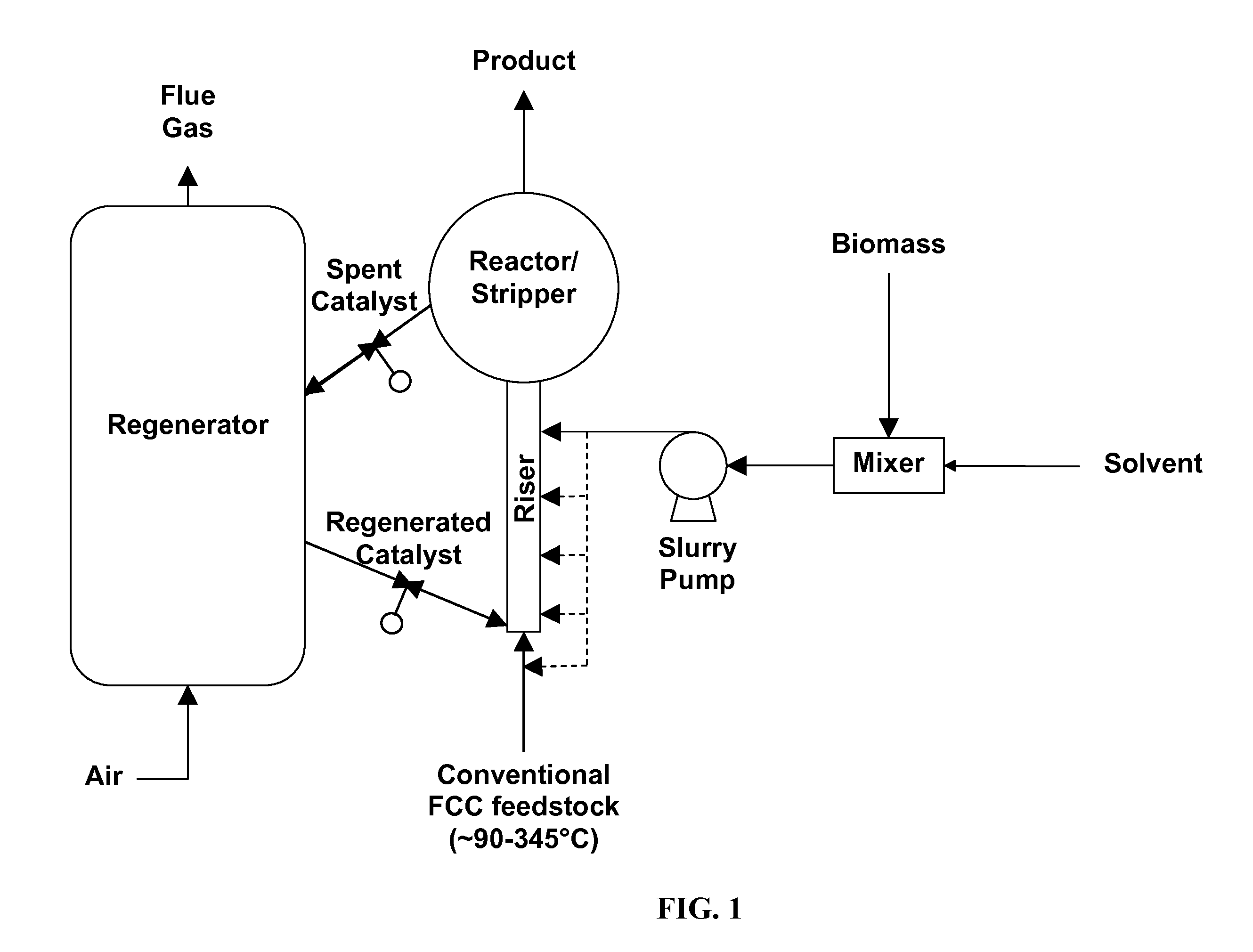

Integrated fcc biomass pyrolysis/upgrading

Owner:PHILLIPS 66 CO

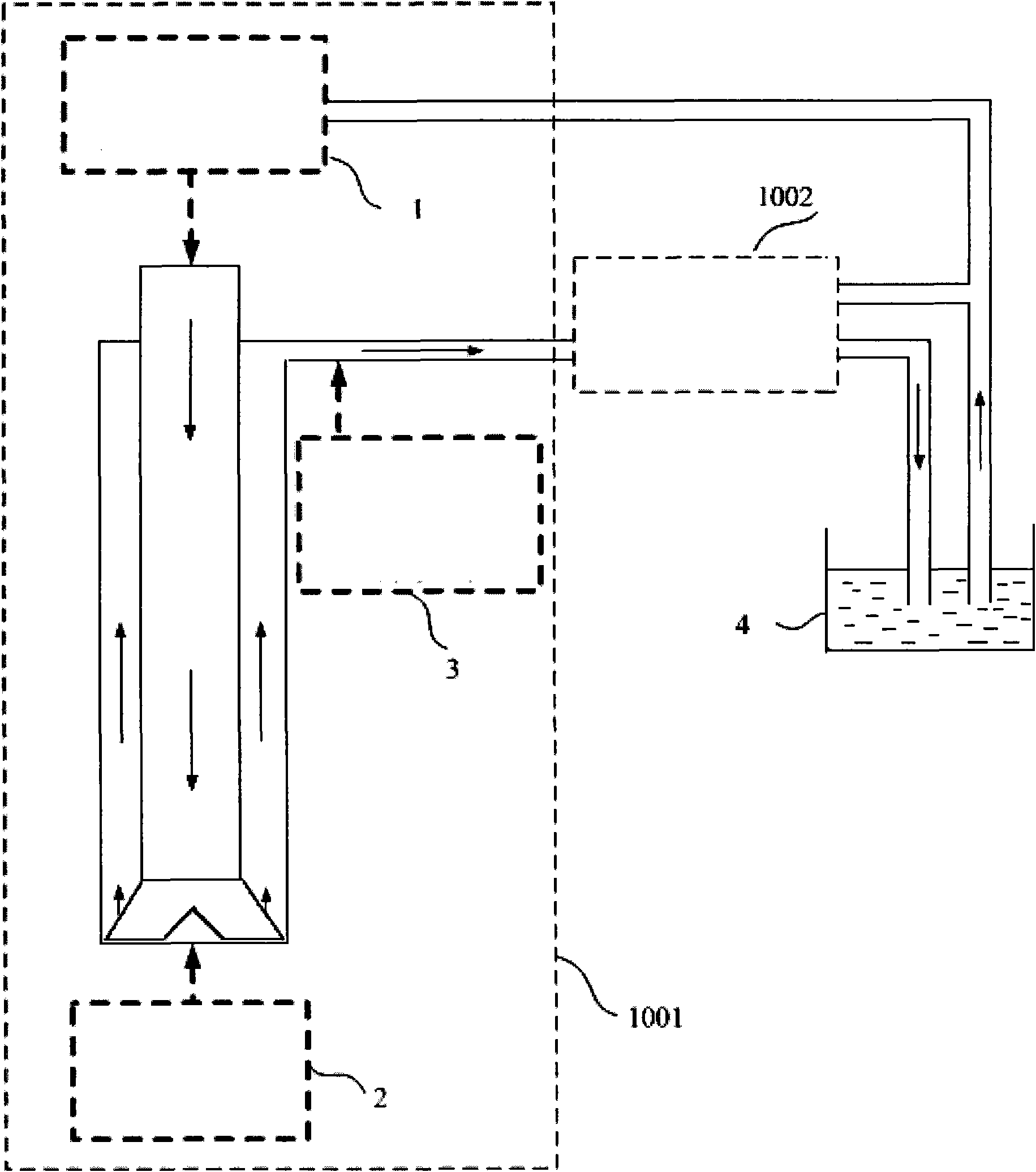

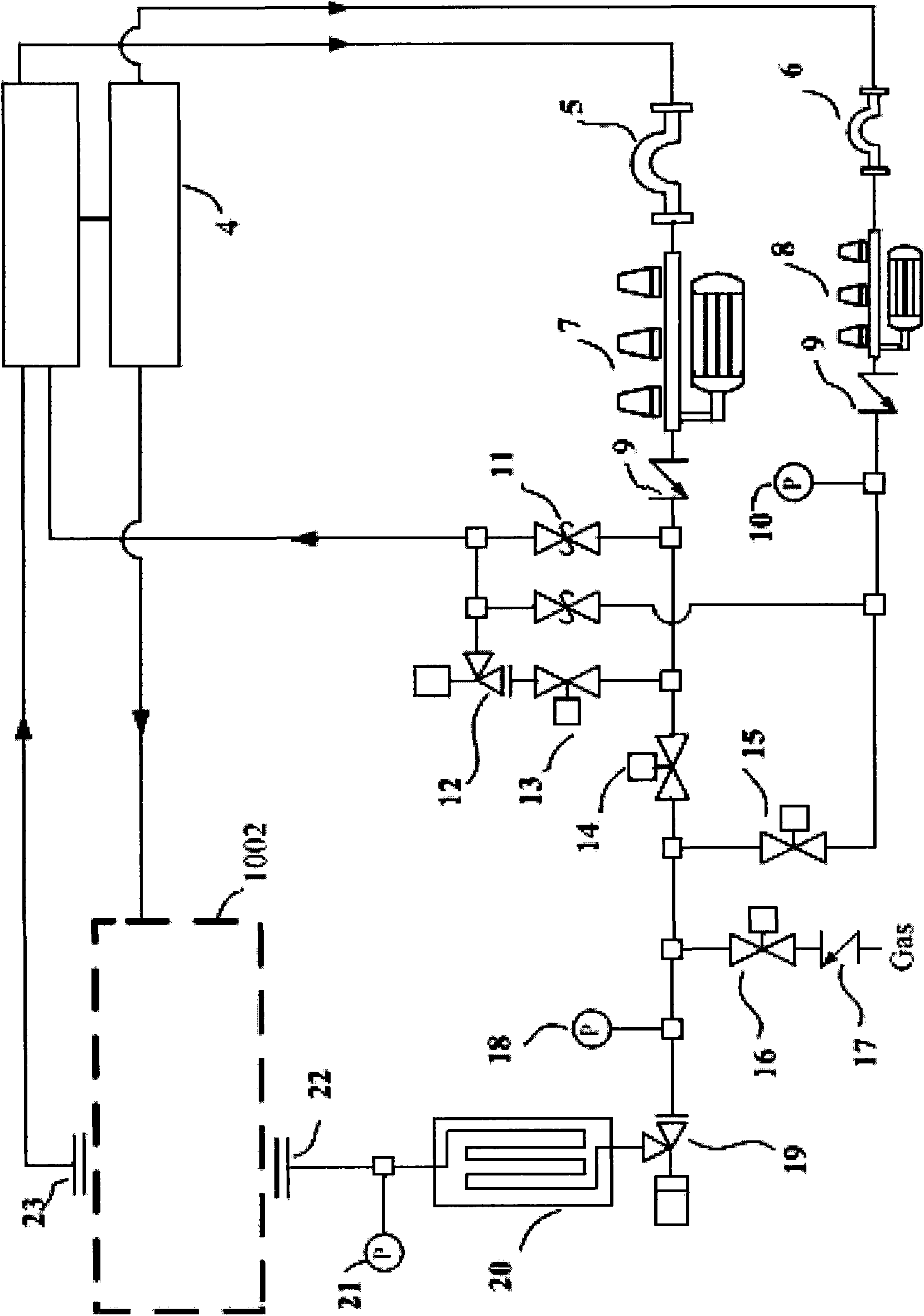

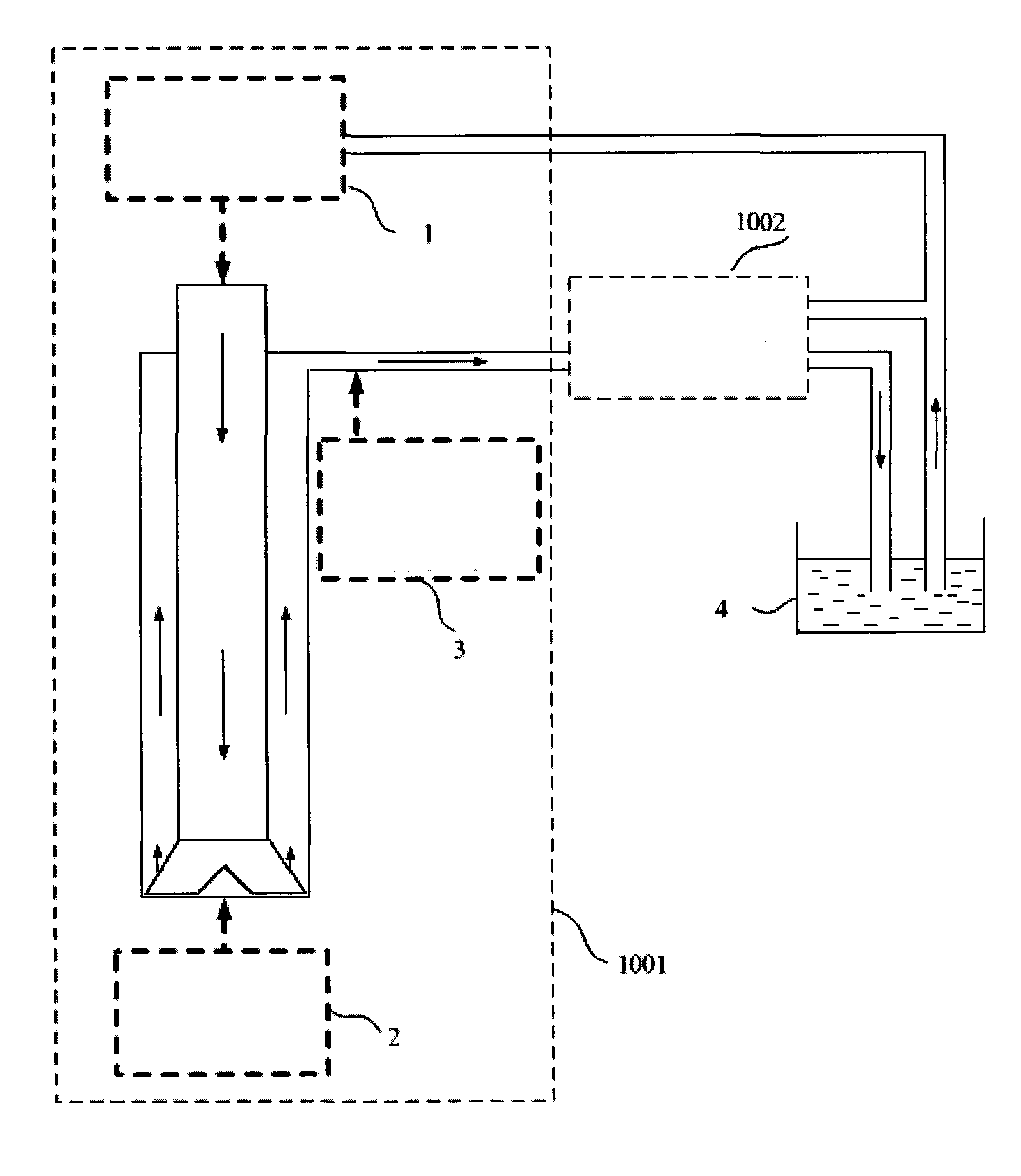

Underground working condition simulation method for controlled pressure drilling experiment and test

The invention relates to an underground working condition simulation method and a device for a controlled pressure drilling experiment and a test, wherein the underground working condition simulation device is connected with controlled pressure drilling equipment in series to perform the experiment and the test. The underground working condition simulation device simulates changes of underground working conditions, including a plurality of types of working conditions such as normal drilling, switching slurry pumping, pipe tripping, circulation loss, well kick and the like; and the controlled pressure drilling equipment automatically judges and identifies the working conditions and controls pressure changes according to the changes of the working conditions, and keeps the simulated bottom hole pressure constant to avoid abnormal conditions such as the circulation loss, the well kick and the like. The bottom hole pressure fluctuations are simulated by adjusting the opening of a throttlevalve B according to the flow and the density of a drilling fluid input by a slurry pump A; a choke manifold simulates the bore hole annular pressure loss; the opening of a throttle valve A is adjusted to simulate a circulation loss working condition; and a slurry pump B or an air source is started and the input flow is controlled to simulate a well kick working condition. By adopting the method and the device, the controlled pressure drilling parameters are precisely grasped, and the controlled pressure drilling equipment is debugged delicately.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

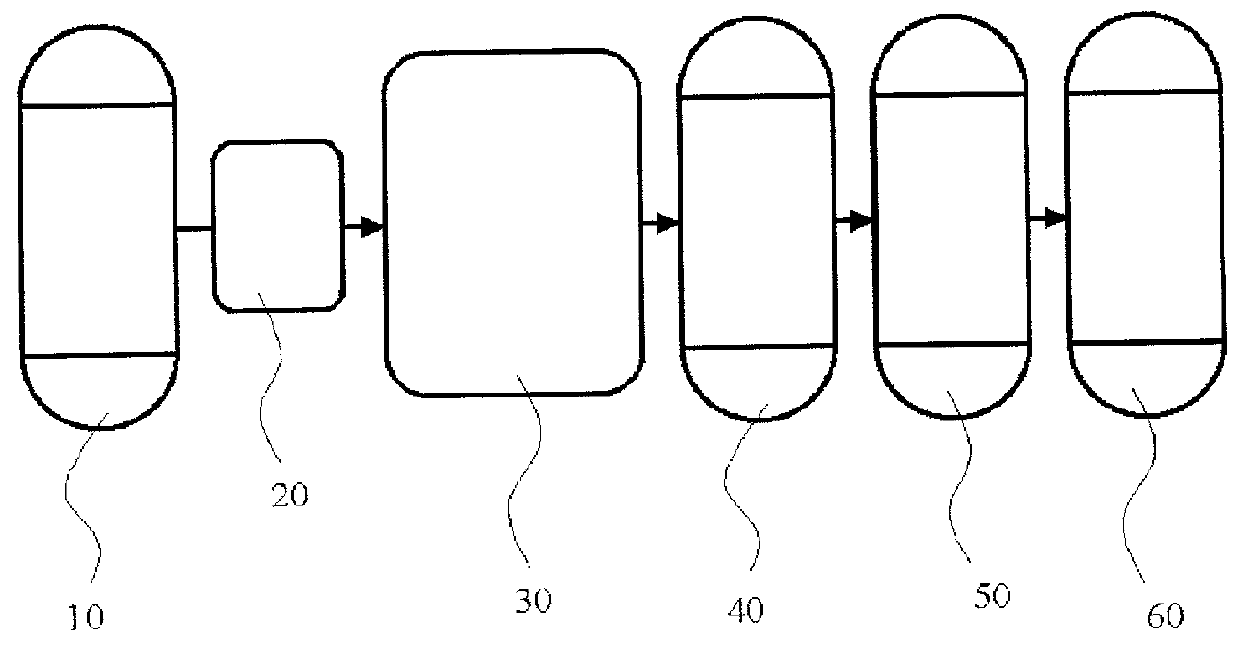

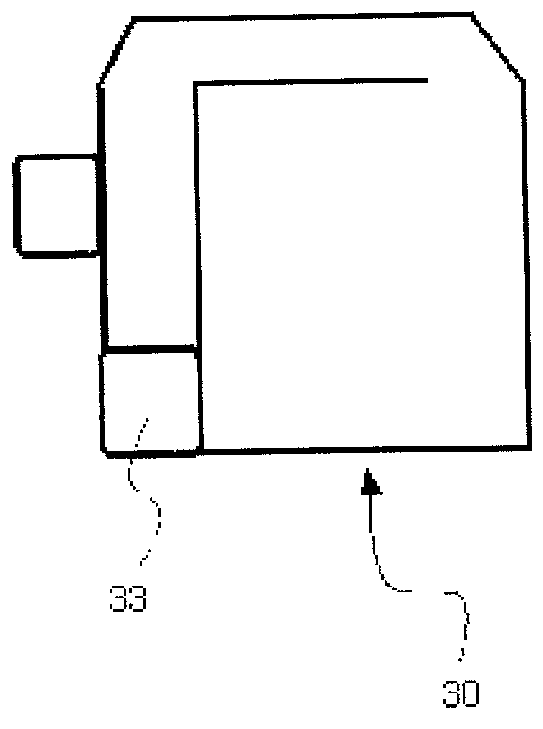

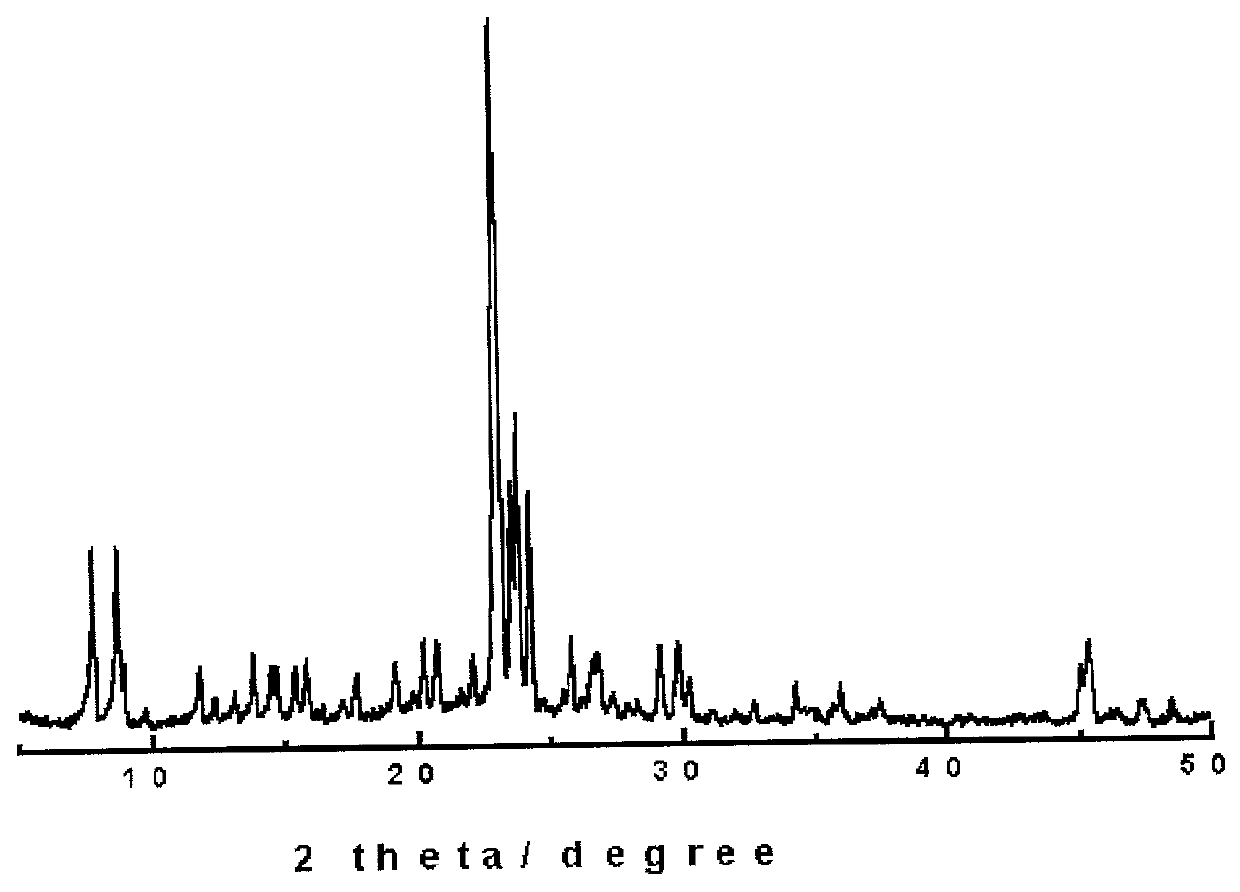

Continuous process and apparatus for preparing inorganic materials employing microwave

This invention relates to a continuous microwave synthesis process of inorganic materials and its apparatus and more particularly, to the process of synthesizing inorganic materials prepared in a manner such that after preparing a mixed solution of precursor materials for various inorganic materials such as porous molecular sieve, layered compounds and ceramics, this mixed solution is continuously added to a tube-type microwave reactor using a slurry pump for the synthesis and crystallization of inorganic materials. Thus the manufacturing process of this invention has the following advantages: (1) the reaction time is further shortened by several to tens of minutes for crystallization, compared to the conventional hydrothermal reaction requiring a prolonged time, (2) the continuous manufacturing and collection processes of this invention can give access to mass-scale production of inorganic materials with relatively small facility, compared to the conventional batch hydrothermal or microwave synthesis, and (3) less amount of organic templating agent can be required during the manufacture of porous molecular sieve.

Owner:KOREA RES INST OF CHEM TECH

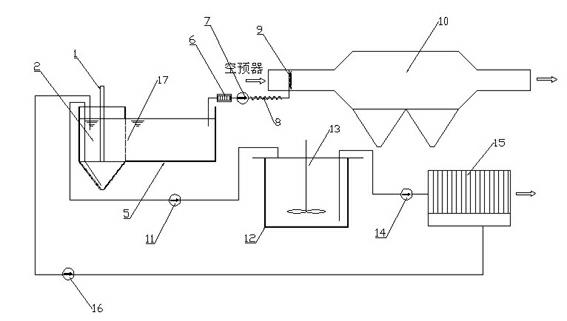

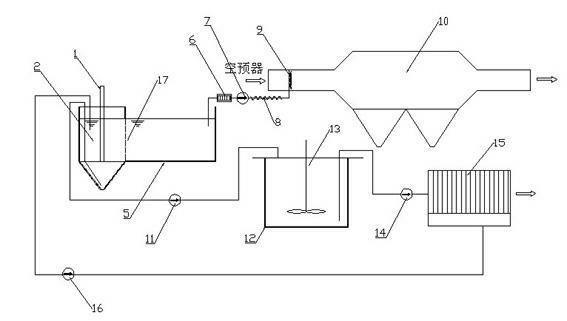

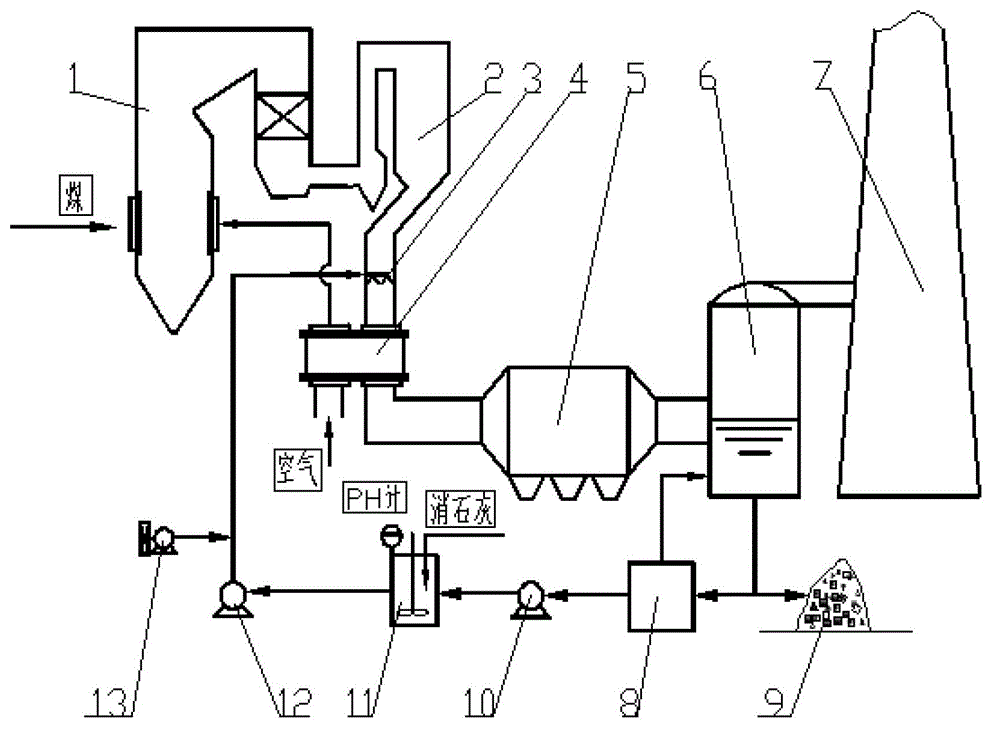

Method and system for zero emission treatment of desulfured waste water

ActiveCN102180549AConvenient zero-emission disposalSimple processWaste water treatment from gaseous effluentsMultistage water/sewage treatmentSludgeWater filter

The invention discloses a method for zero emission treatment of desulfured waste water. The method comprises the following steps: 1) discharging the desulfured waste water obtained after desulfuration in a desulfuration tower into a preliminary sedimentation tank, carrying out primary separation in the preliminary sedimentation tank, and transporting an upper clear liquid separated out to a buffer pool through a slurry pump; 2) successively passing the desulfured waste water in the buffer pool through an atomization plant and a static dust catcher; 3) transporting the waste water which is from the lower part of the preliminary sedimentation tank and has large solid content to a filter press through an another sludge pump; and 4) feeding the waste water filtered back to the preliminary sedimentation tank through the slurry pump. Simultaneously, the invention also discloses a system for zero emission treatment of desulfured waste water. The zero emission treatment is conveniently carried out on the desulfured waste water through the method, the process is simple and labor is saved; and the system has a compact structure, the method is simple to implement, energy is saved, the quality of smoke at the inlet of the dust catcher is improved, the zero emission of the desulfured waste water can be really achieved, thus the system has the advantage of popularization value.

Owner:CHENGDU SHUKE TECH

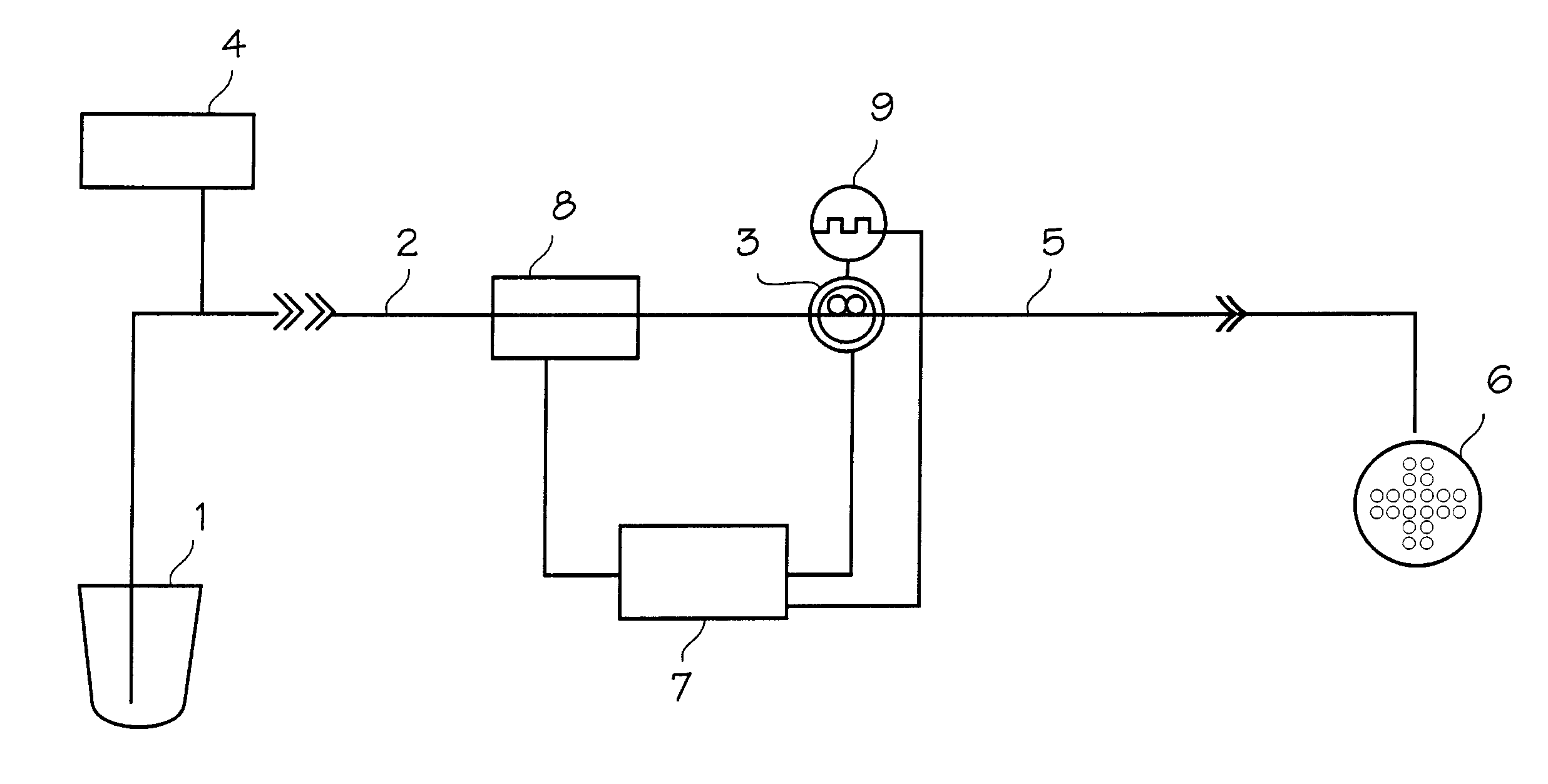

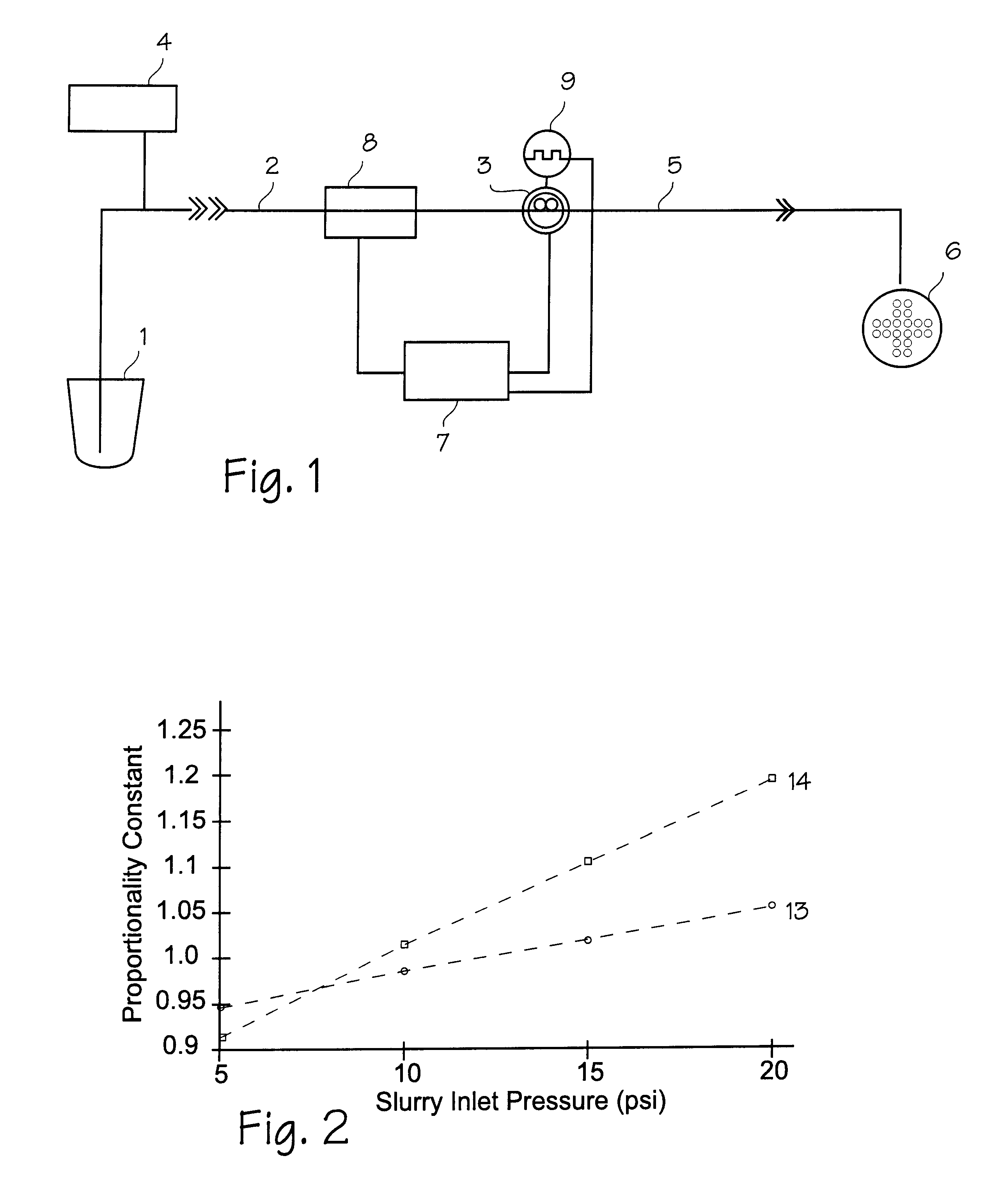

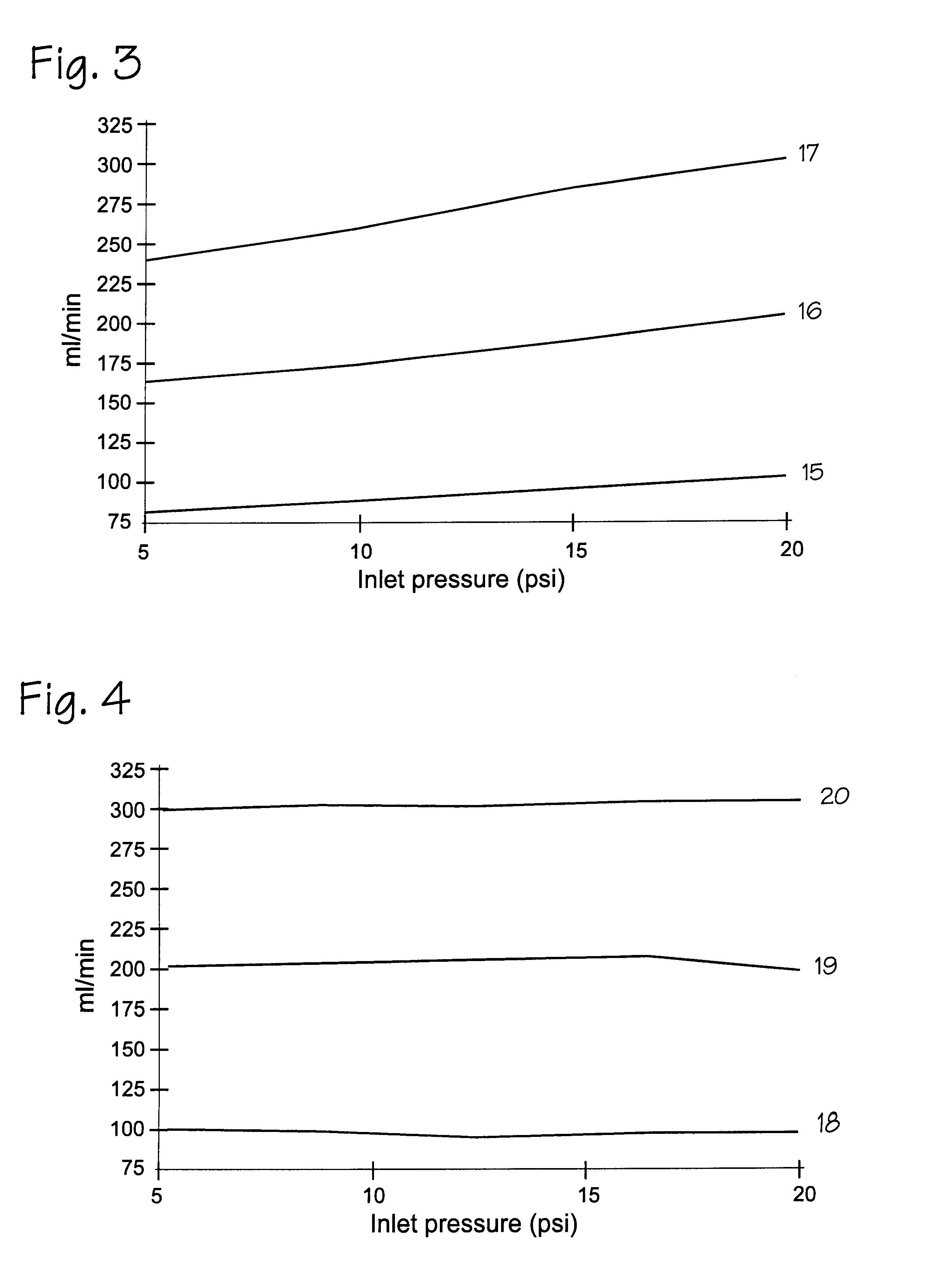

Slurry pump control system

A CMP slurry pumping system which uses the slurry pump inlet pressure as input to the pump controller, and adjusts pump speed to account for variations in inlet pressure.

Owner:REVASUM INC +1

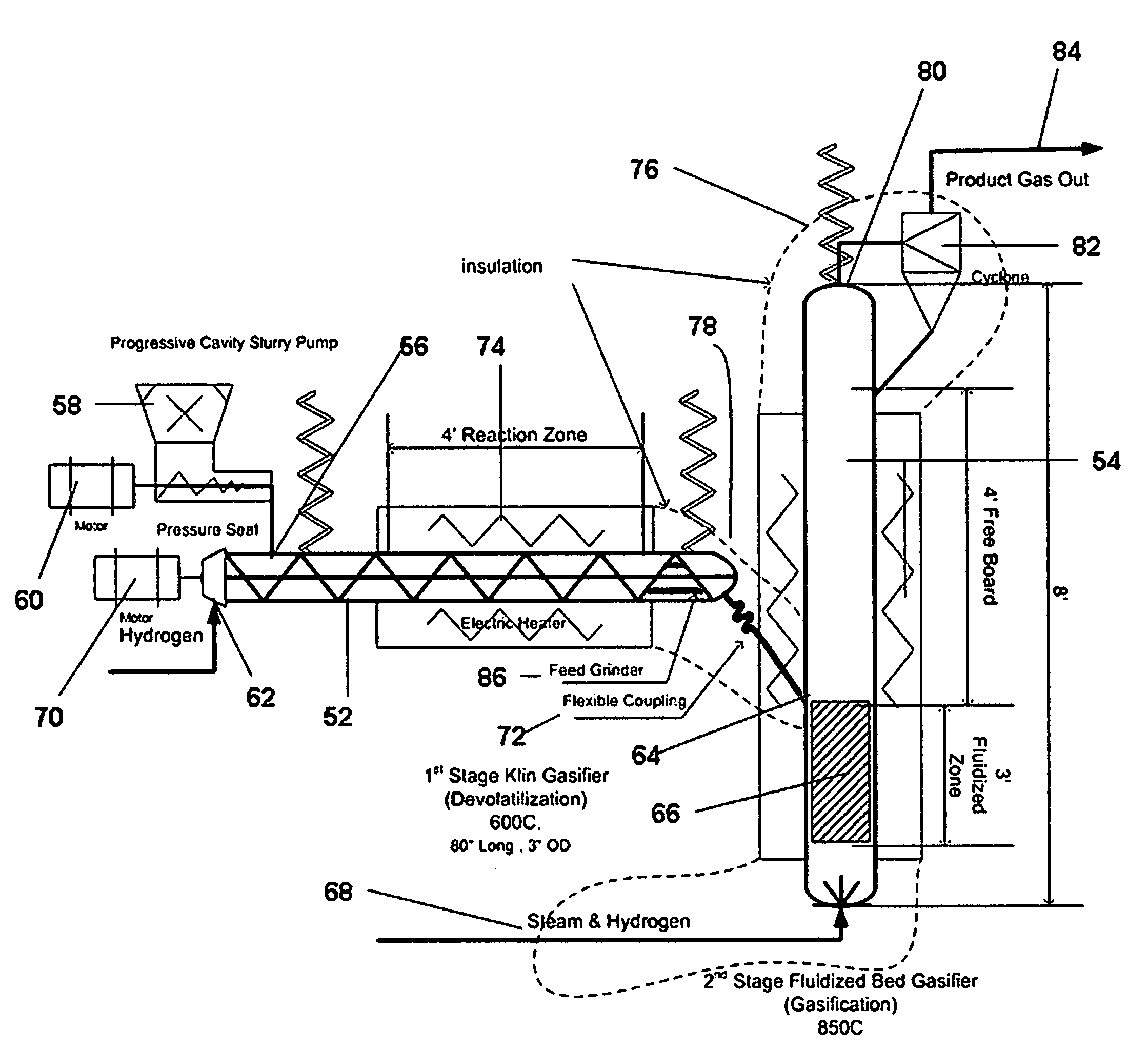

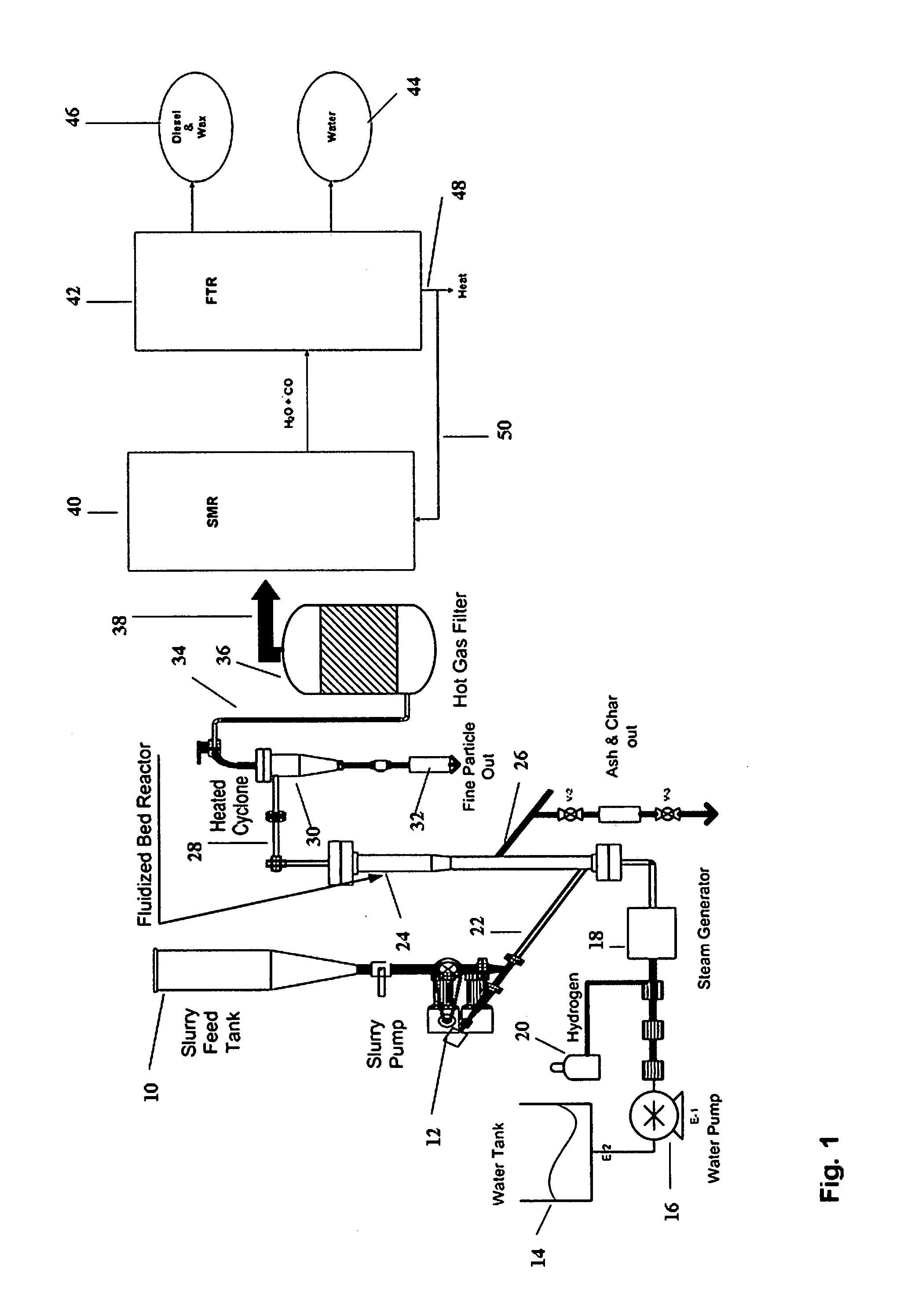

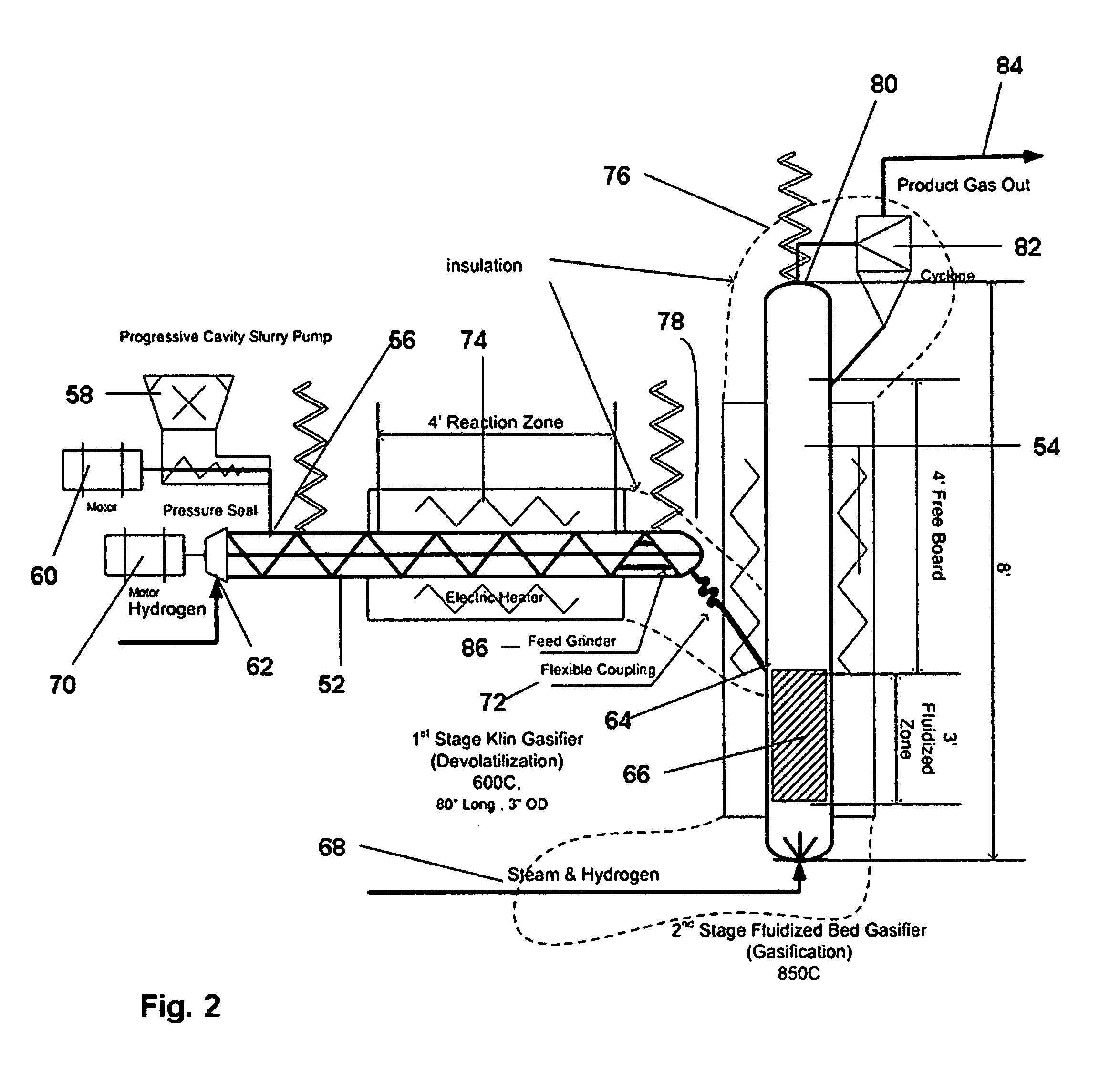

Method and apparatus for steam hydro-gasification in a fluidized bed reactor

InactiveUS20080021123A1Well mixedIncrease conversion rateCombustible gas chemical modificationHydrogenHydrogenFluidized bed

Owner:RGT UNIV OF CALIFORNIA

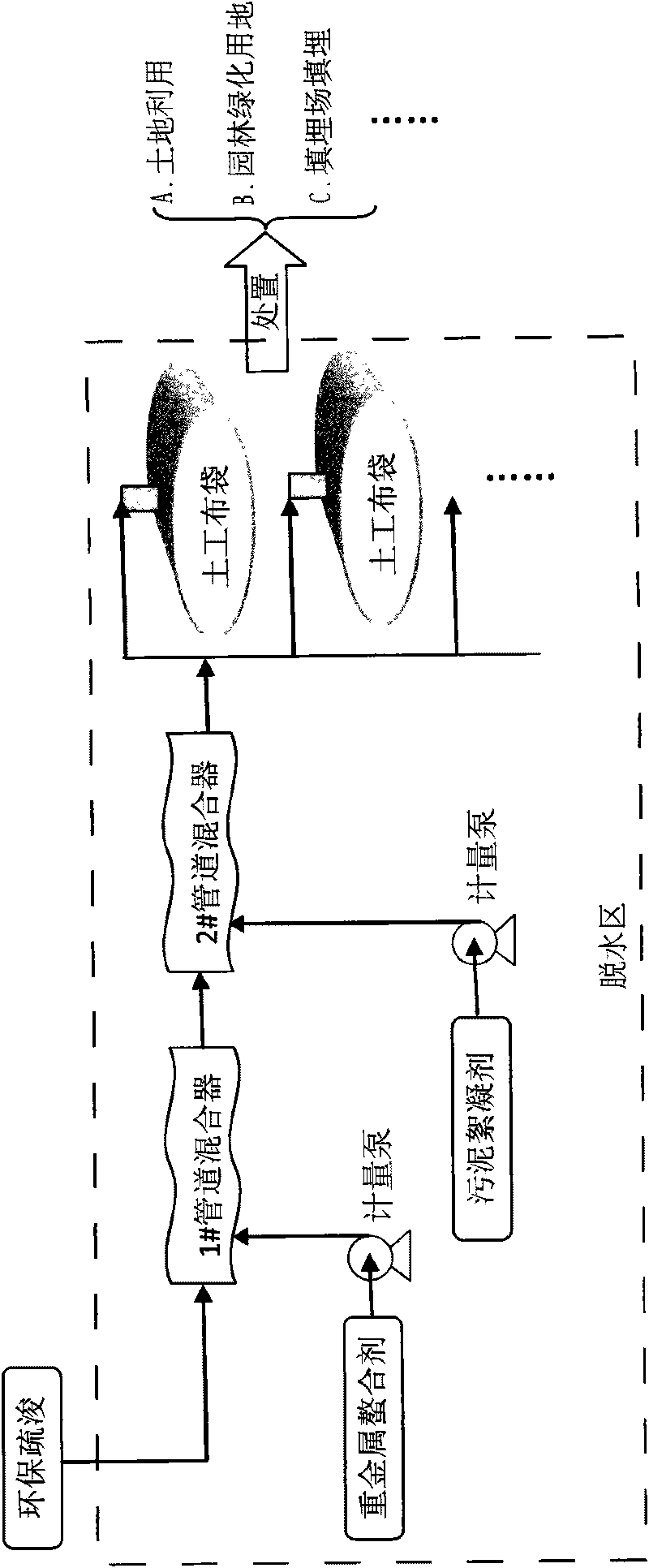

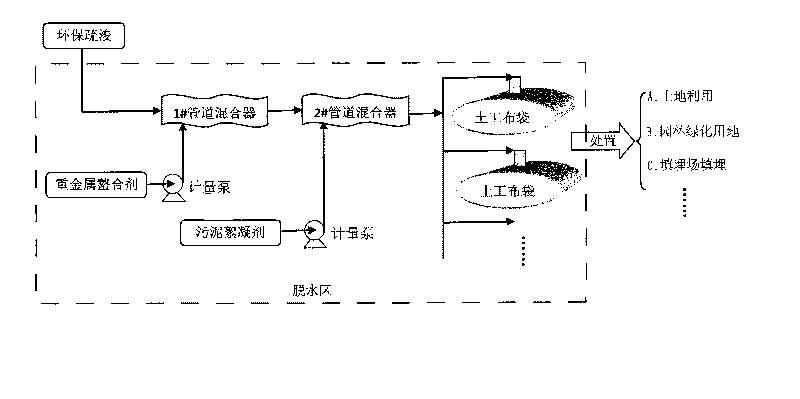

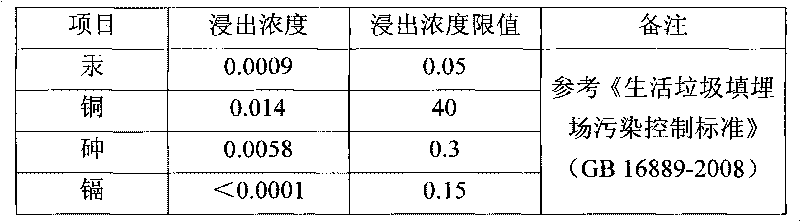

Heavy metal polluted sludge treatment method

ActiveCN101693590AWill not cause secondary pollutionAchieve dredgingSludge treatment by de-watering/drying/thickeningWater contaminantsHeavy metal chelationSludge

The invention discloses a heavy metal polluted sludge treatment method which comprises the following steps: conveying heavy metal polluted bottom sludge of rivers, lakes and reservoirs by a slurry pump of a sanddredger ashore; adding heavy metal chelate stabilizer in a first pipeline blender of dredging pipelines; and then adding flocculant in a second pipeline blender; and finally filling sludge in geotextile bags for volume reduction and dehydration; and concreting for 7-50 days after the sludge filling, wherein the sludge treated by the method can be used for land reclamation, greening or landfilling according to different water contents and heavy metal contents. Compared with the prior art, by environmental-protection dredging, transmission by closed pipelines and heavy metal stabilization, the invention completely solves the secondary solution problem of heavy metals; and the invention combines the heavy metal stabilization and a geotextile bag dehydration technology without power consumption without the input of mechanical dehydration equipment, and is suitable for heavy metal polluted sludge treatment in occasions of large treatment area, short work period, small dehydration site, less once investment, low operation cost and the like.

Owner:TIANJIN ECOLOGY CITY ENVIRONMENTAL PROTECTION

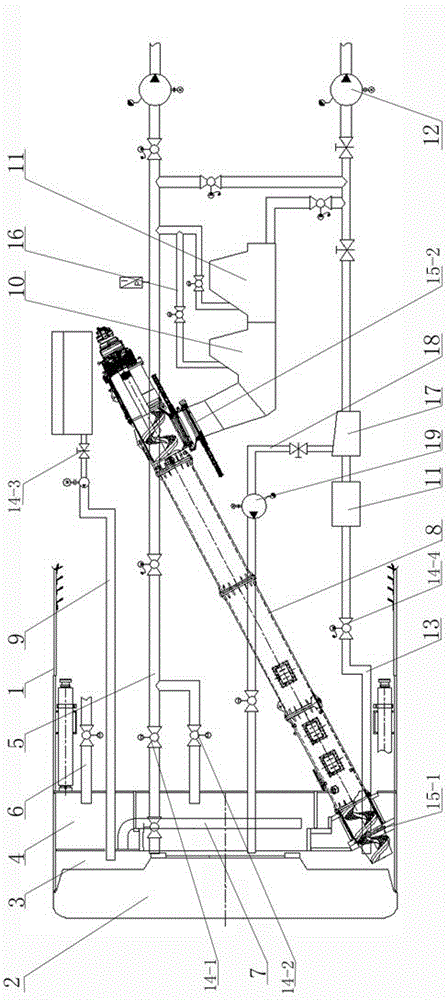

Double-mode shield tunneling machine

The invention belongs to the field of shield construction, and discloses a double-mode shield tunneling machine. The double-mode shield tunneling machine comprises a shield tunneling main engine, a cutterhead arranged on the front portion of the shield tunneling main engine, an earth bin, an air cushion bin, an earth pressure balancing system and a slurry balancing system, wherein the earth bin, the air cushion bin are sequentially formed in the rear portion of the cutterhead. When the shield tunneling machine works, the shield tunneling machine can be switched between an earth pressure balancing tunneling mode and a slurry balancing tunneling mode according to the strata of practical tunnels, so that the shield tunneling machine is adaptive to tunneling under different geological conditions, and the adaptability to complex strata and the shield construction efficiency are improved. Meanwhile, a dilution tank and a breaker are mounted on the tail of a spiral conveyer to break large rocks to the grain size which can be conveyed by a slurry pump, and the broken large rocks are then discharged through a slurry pipeline, and in this way, the situation that large rocks cannot be discharged smoothly in a slurry mode can be prevented effectively.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Construction method for super-long high-precision horizontal drilling

ActiveCN101158268AImprove stabilityImprove airtightnessDirectional drillingTunnelsConstruction planSlurry pump

The invention discloses a super-long and high-accurate horizontal boring construction plan. The plan is that a proper horizontal borer is used for driving a bit connected with a bore rod to turn to take cores and cut holes; a guiding device is used for controlling a decline rate; a slurry pump is used for pumping out the bore scraps generated in a boring process, so as to form a set-caliber super-long and high-accurate horizontal boring. The invention adopts a compound connection measure of combining a screw connection and a welding connection to connect the bore rod, guaranteeing the concentricity and sealing of the bore rod. When in a horizontal boring process, a freezing cut sealing and a freezer sealing are adopted. An area ranging from 8cm to 10cm is preserved as a safety layer in a tube-boring process on a concrete wall. And a strict deviation measuring and a deviation controlling are adopted to guarantee the construction safety. The form and improvement of the construction plan of the invention experiences many tests, researches and improvements, and a horizontal frozen boring bored through the construction plan of the invention can be provided with a high accuracy even when a construction horizontal length is too long.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

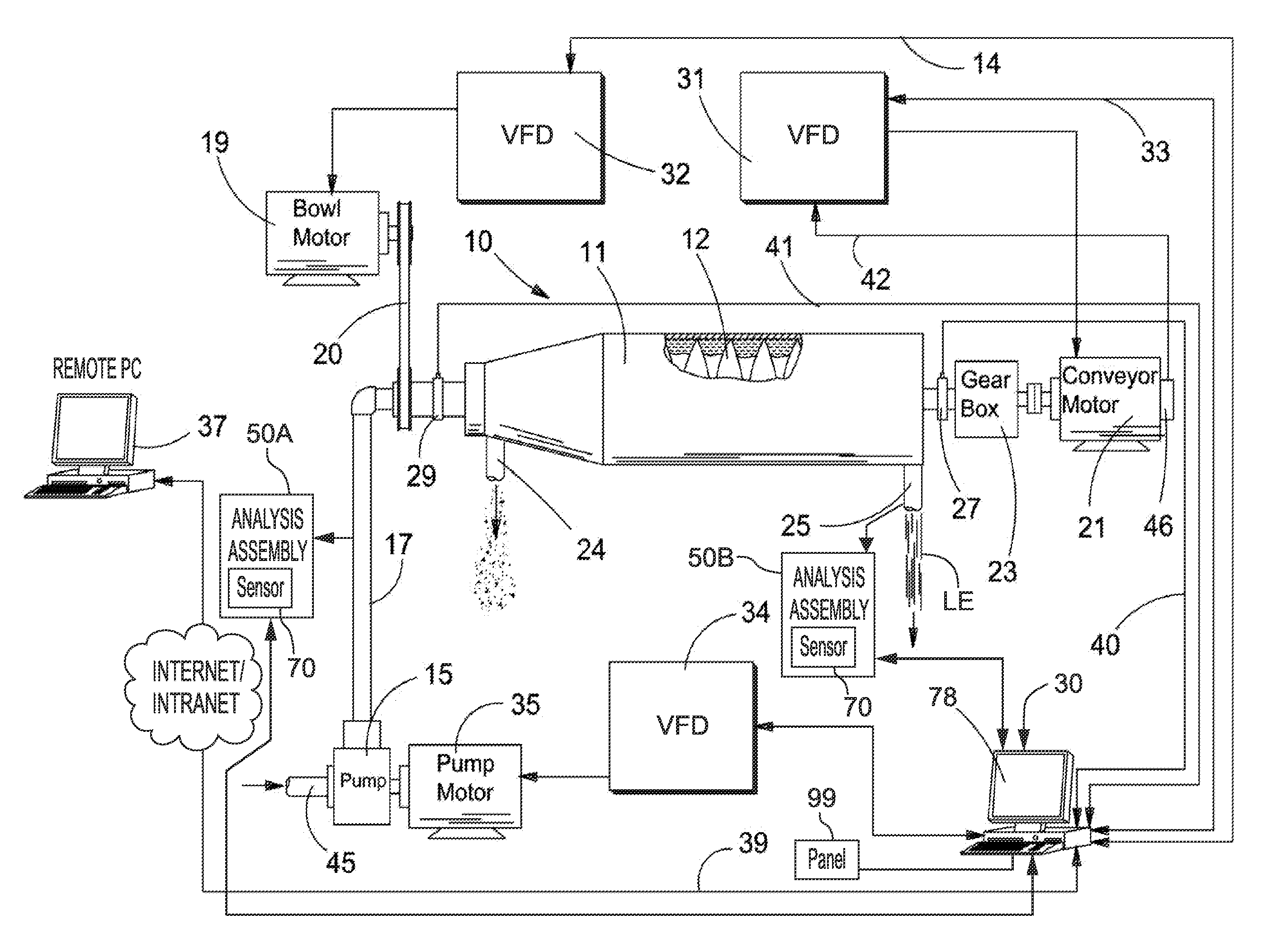

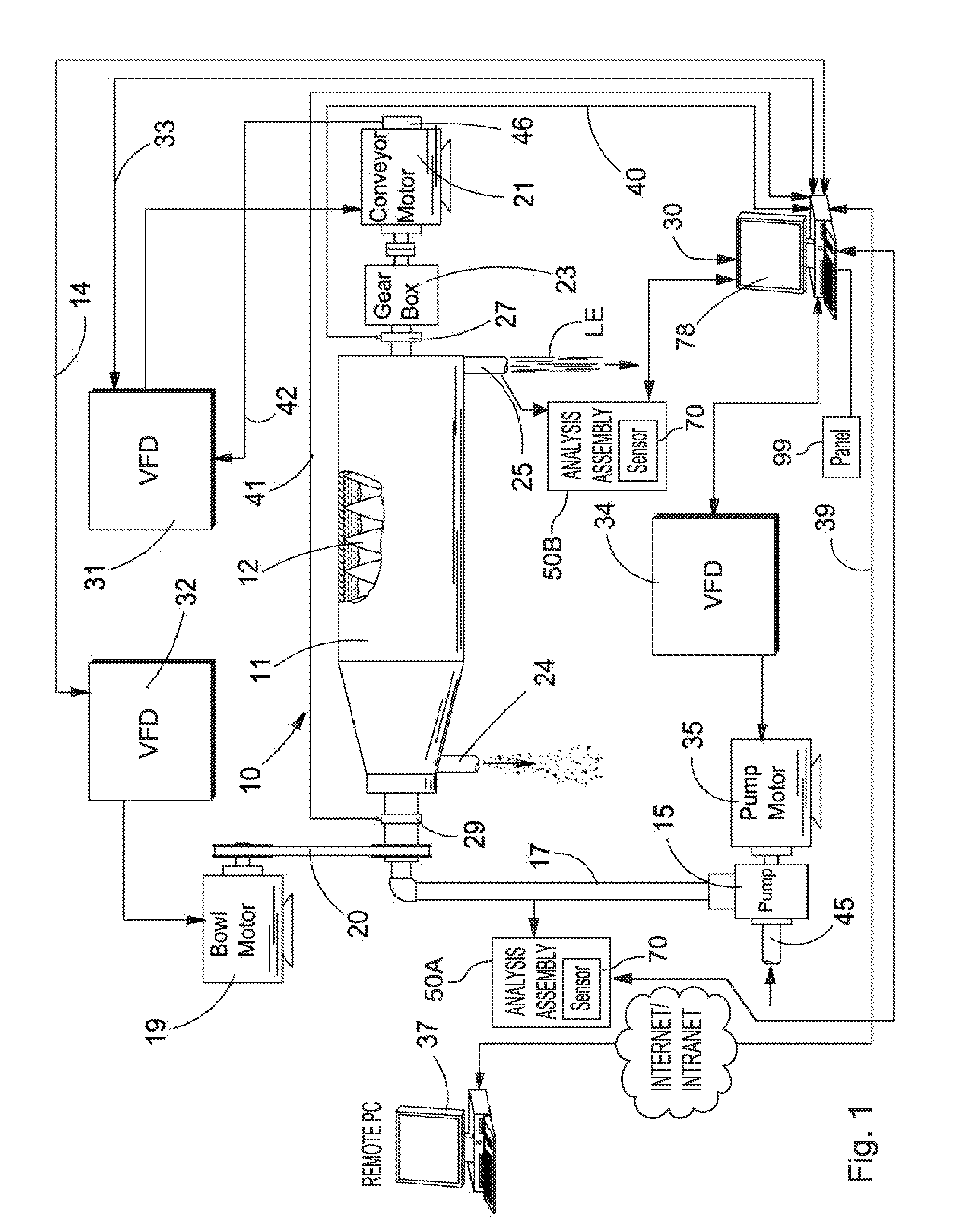

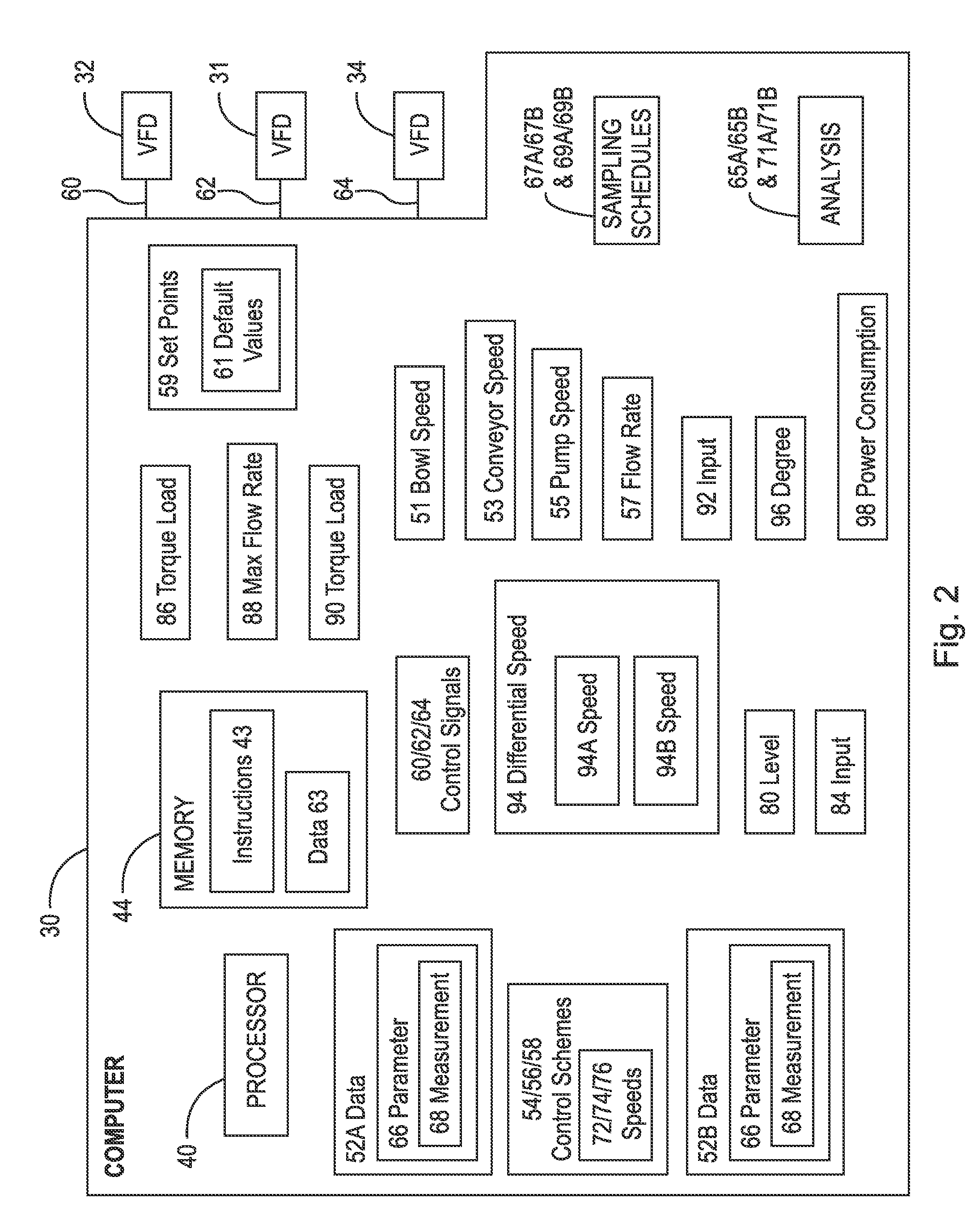

Centrifuge with automatic sampling and control and method thereof

A centrifuge including a bowl, a bowl drive motor, a screw conveyor, a screw conveyor drive motor, a pump, a pump motor, a bowl VFD to drive the bowl drive motor, a conveyor VFD to drive the screw conveyor drive motor, a pump VFD to drive the pump drive motor, an analysis assembly and a computer electrically connected to the bowl VFD, the conveyor VFD, the pump VFD, and the analysis assembly. The analysis assembly is configured to automatically sample slurry pumped into the bowl and automatically transmit data, characterizing the slurry, to the computer. The computer is configured to calculate control schemes for the bowl VFD, the conveyor VFD, and the pump VFD using the data and, transmit control signals to the bowl VFD, the conveyor VFD and the pump VFD to operate the bowl VFD, the conveyor VFD and the pump VFD according to the control schemes.

Owner:DERRICK CORP

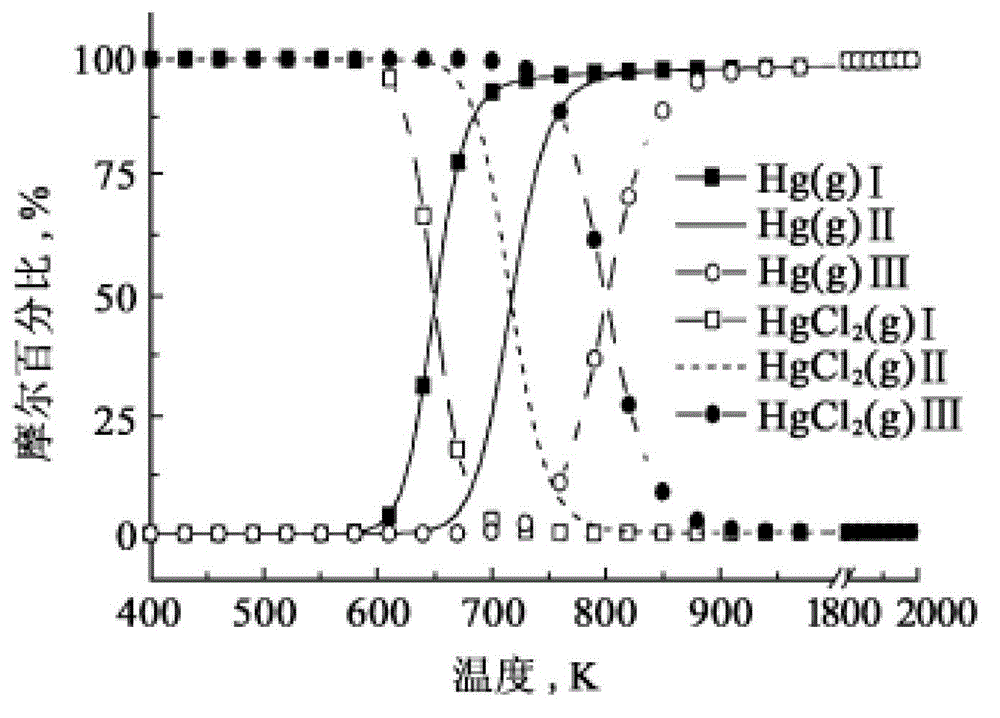

Pollutant combined removal device and method through recycling of chlorine in coal

ActiveCN103933838AAchieve recyclingIncrease the chlorine contentLighting and heating apparatusDispersed particle separationAir preheaterWastewater

The invention discloses a pollutant combined removal device and method through recycling of chlorine in coal. The pollutant combined removal device comprises a boiler, a SCR (selective catalytic reduction) denitration device, an air preheater, a dust remover, a desulfurization tower, a chimney, and a slurry pump II, wherein the boiler is connected with the SCR denitration device, the SCR denitration device is connected with the dust remover by the air preheater, the dust remover is connected with the desulfurization tower, and the desulfurization tower is connected with the chimney. The pollutant combined removal device also comprises a desulfurization?wastewater?storage box, an atomizing nozzle, a wastewater conditioning tank, and an air compressor, wherein the atomizing nozzle is arranged on a connection pipeline between the SCR denitration device and the air preheater and connected with the wastewater conditioning tank by the slurry pump II, the air compressor is connected with the atomizing nozzle, and the desulfurization?wastewater?storage box is connected with the desulfurization tower and the wastewater conditioning tank which is filled with strong base. The removal of mercury in fume is facilitated, meanwhile the PH value of the chlorine-rich desulfurization wastewater can be adjusted, so that the desulfurization?wastewater is effectively utilized and the removal efficiency of SO3 in fume is improved.

Owner:SHANDONG UNIV

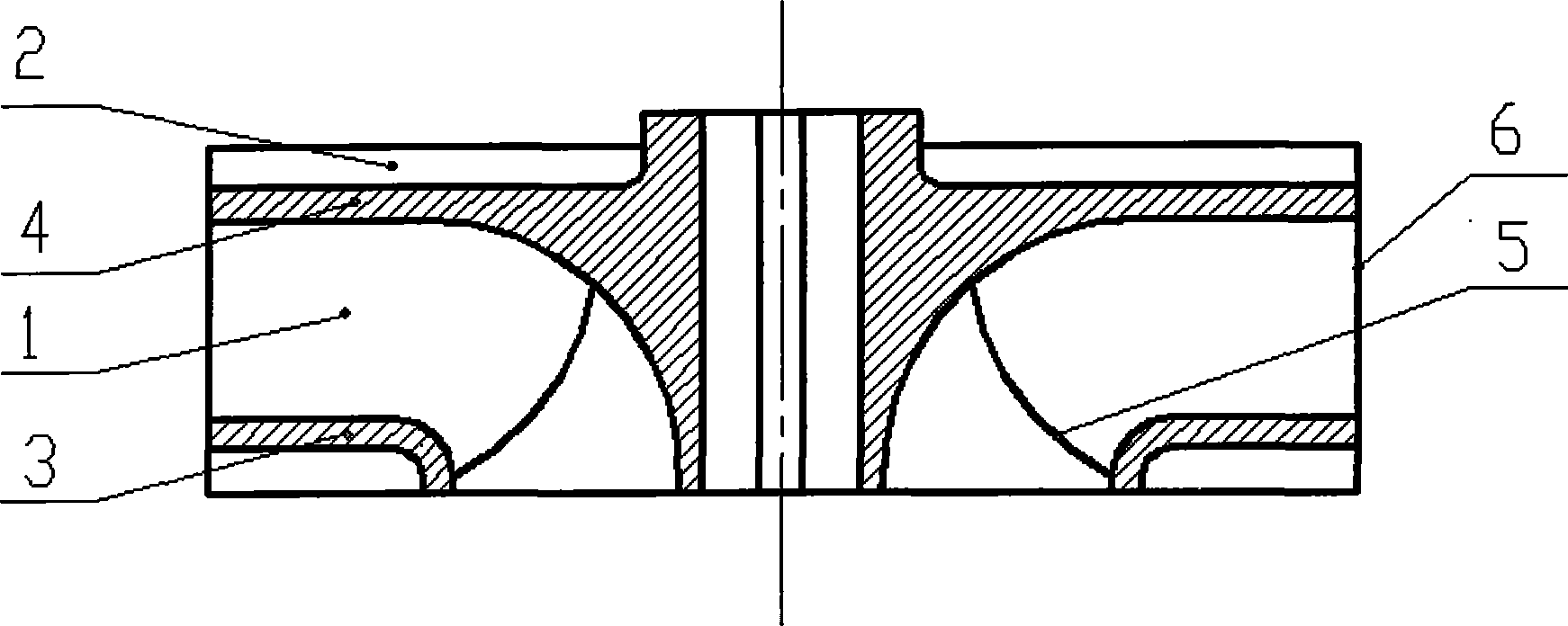

Zirconium oxide ceramic cylinder jacket material and preparation method thereof

InactiveCN101514104AImprove liquidityHigh strengthPumpsPositive-displacement liquid enginesPrice ratioYttrium

The invention provides a zirconium oxide ceramic cylinder jacket material, which comprises 65-75wt% of zirconium oxide, 3-6wt% of cerium oxide, 1-3wt% of yttrium oxide, 20-30wt% of aluminum oxide, and 0.5-2wt% of titanium dioxide. The invention also provides a preparation method for the zirconium oxide ceramic cylinder jacket material. The zirconium oxide ceramic cylinder jacket material provided by the present invention has higher strength, toughness and thermal shock resistance, and is able to resist wear, corrosion and high temperature. inner liner of slurry pumping cylinder sleeve prepared from the zirconium oxide ceramic cylinder jacket material has the following advantages that (1) service life is long, performance-price ratio is high, thereby reducing equipment cost consumption, greatly reducing frequency of shutdown to maintain cylinder jacket, reducing economical loss due to stop production and maintenance, and lightening labor intensity of workers; and (2) wearing for piston in the cylinder jacket is reduced, service life of the piston is prolonged, and piston cost is saved.

Owner:GUANGDONG ORIENT ZIRCONIC IND SCI & TECH CO LTD

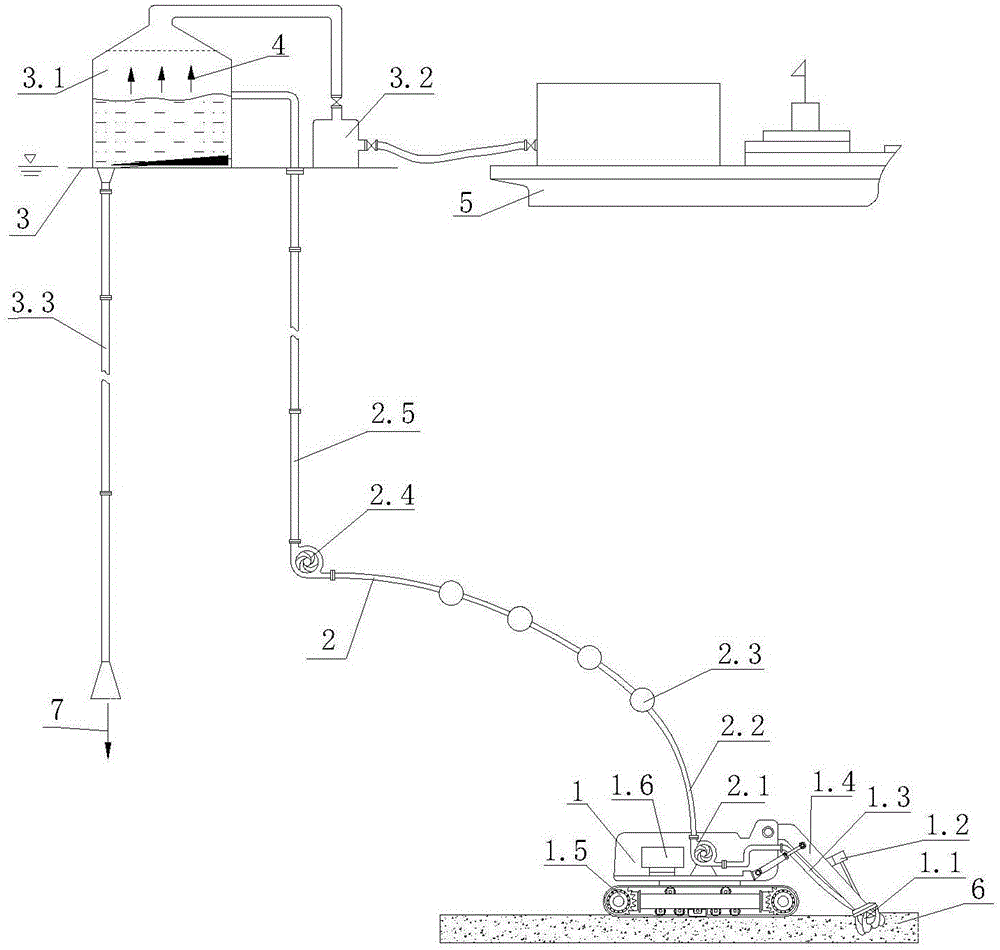

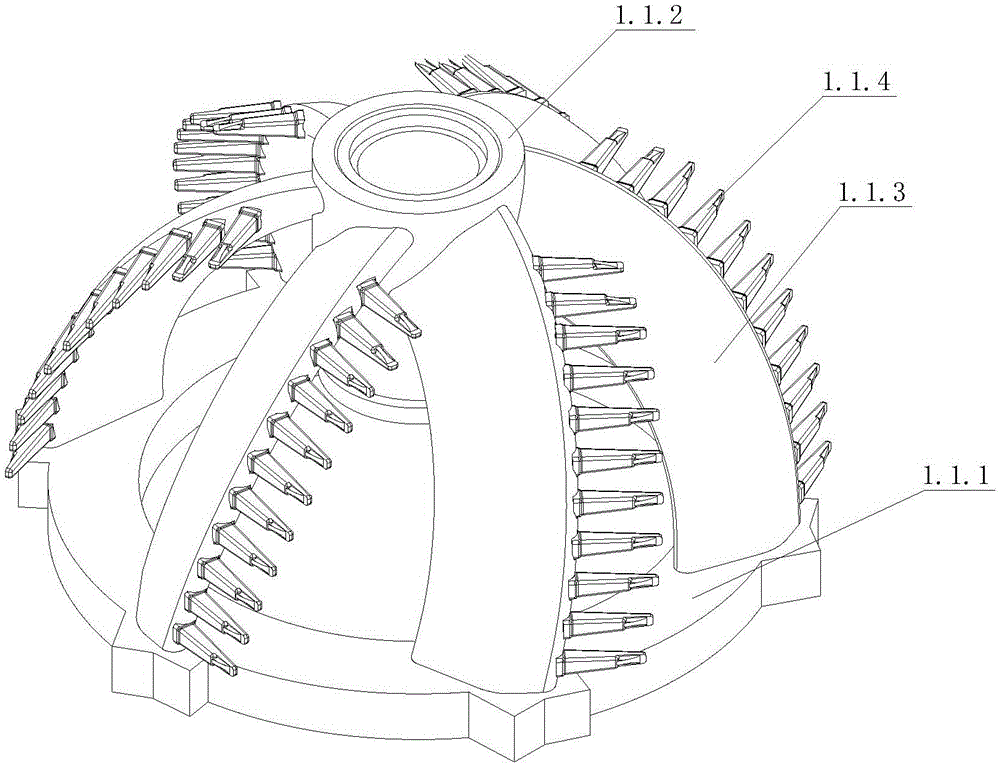

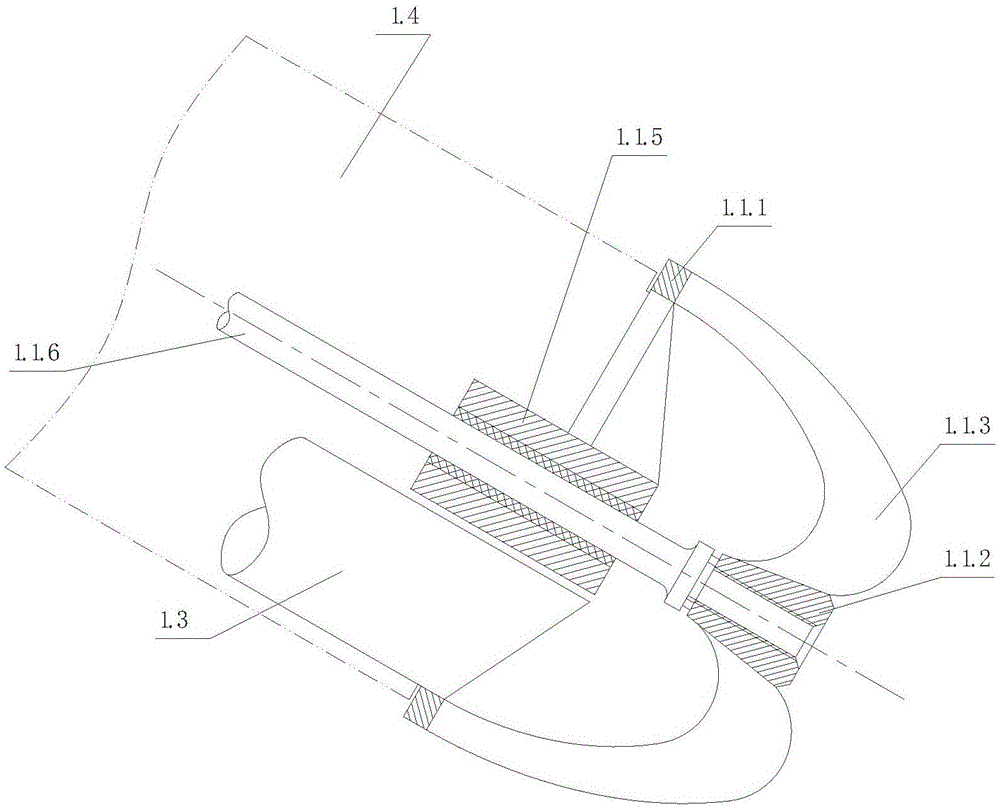

Cutter exploitation method of seabed natural gas hydrates

InactiveCN106522958ASuitable for miningWon't escapeMineral miningSlitting machinesControl systemSeabed sediment

The invention provides a cutter exploitation method of seabed natural gas hydrates. The method employs a seabed exploitation vehicle, a sea level decomposition and storage system, and a waterpower conveying system for connecting the seabed exploitation vehicle as well as the sea level decomposition and storage system. The seabed exploitation vehicle comprises a reamer, a reamer arm, a crawler type running gear as well as a power and control system, and the like, and is used for cutting and fragmenting the seabed natural gas hydrate. The waterpower conveying system comprises an auxiliary slurry pump, a conveying flexible pipe, a buoyancy ball, a main slurry pump, a conveying hard tube, and the like, and the system is used for conveying the natural gas hydrates which is fragmented by the exploitation vehicle to the sea level decomposition and storage system. The decomposition and storage system comprises a decomposer, a storage container, a mine tailing pipe, and the like, and is used for decomposing and separating the natural gas hydrates which are conveyed by the conveying system and collecting the natural gas hydrates in the storage container, and the separated seabed deposits and other refuses are discharged to the seabed. The cutter exploitation method of seabed natural gas hydrates has high production efficiency and controllable exploitation process, 'air bag' and the like are not needed to construct, and the method has good application prospects.

Owner:CENT SOUTH UNIV

Abrasion-resistant coating material for repairing abrasion of slurry pump

ActiveCN105505111ARelative density is smallLow relative density, excellent mechanical strengthPolyether coatingsEpoxy resin coatingsFiberEpoxy

The invention discloses an abrasion-resistant coating material for repairing abrasion of a slurry pump. The material comprises a primary agent and a curing agent, wherein the primary agent comprises 15-60 parts of epoxy resin, 0-5 parts of a coupling agent, 0-20 parts of flexibilizer, 0-600 parts of a grinding material, 0-60 parts of fibers, 0-80 parts of resin alloy polyphenyl ether, 0-30 parts of an antifriction material, 0-20 parts of an thixotropic agent, namely fumed silica, and 0-50 parts of pigment; the curing agent comprises 5-50 parts of organic amine substances, 3-20 parts of a coupling agent, 0.5-18 parts of accelerant, 0-300 parts of a grinding material, 0-10 parts of an thixotropic agent, namely fumed silica and 0-15 parts of pigment. In the actual application process of the coating material for repairing the slurry pump, the service life after repair is conducted can reach 1.5-2 times that of a new workpiece, for the working condition with large material particles repaired, the service life can even reach four times at times, and repeated repair can be conducted.

Owner:襄阳市百盾防护涂层材料有限公司

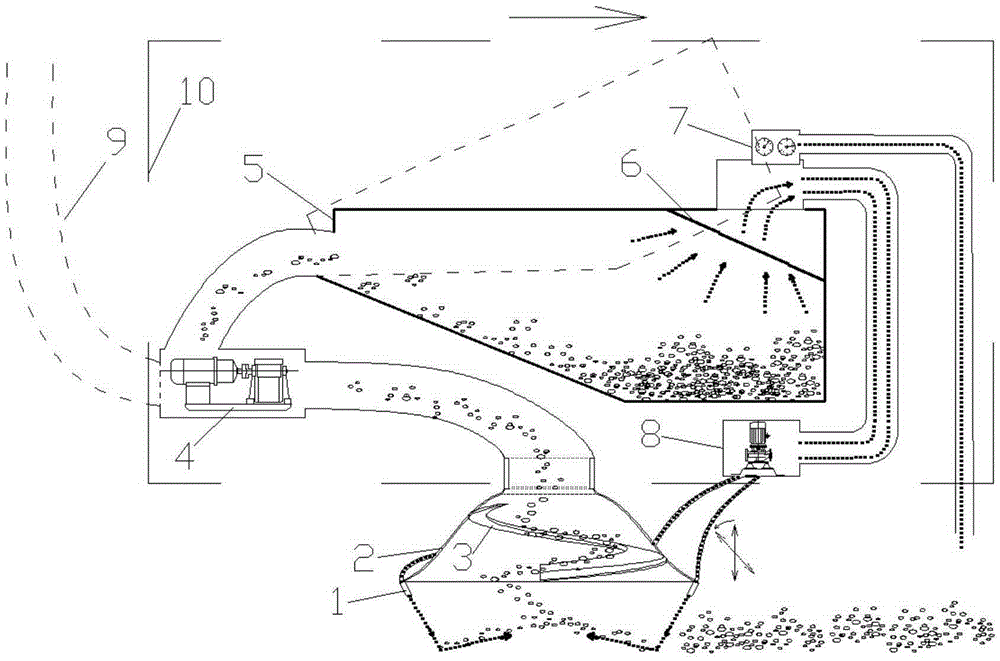

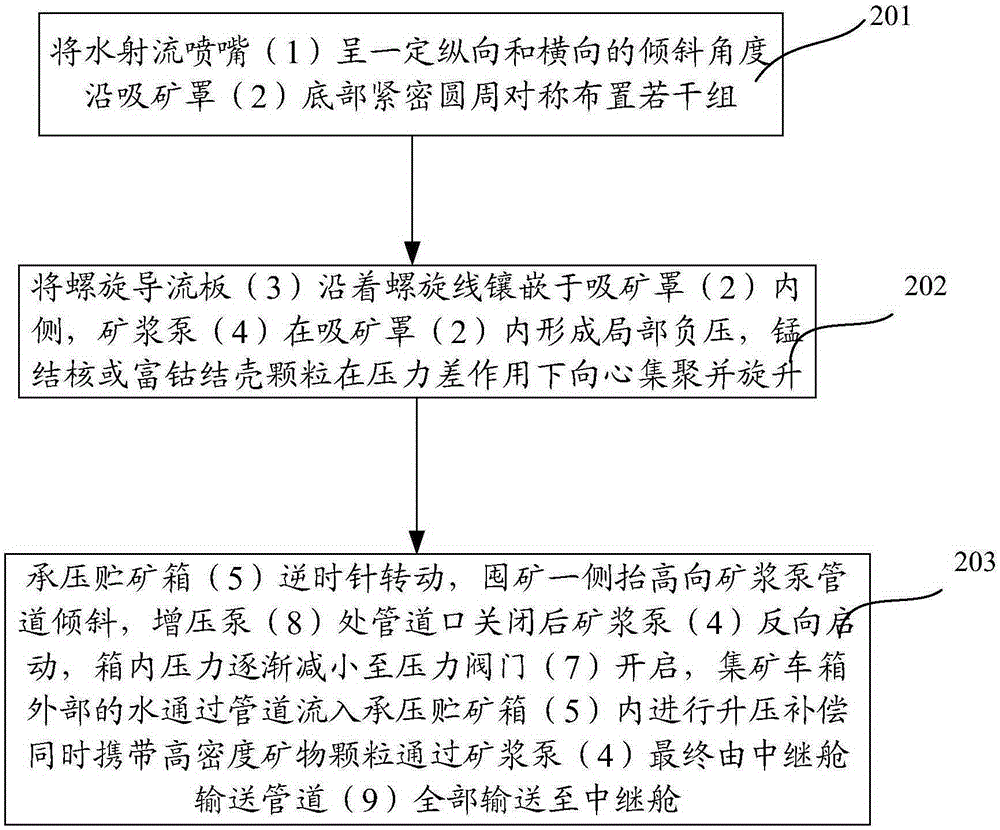

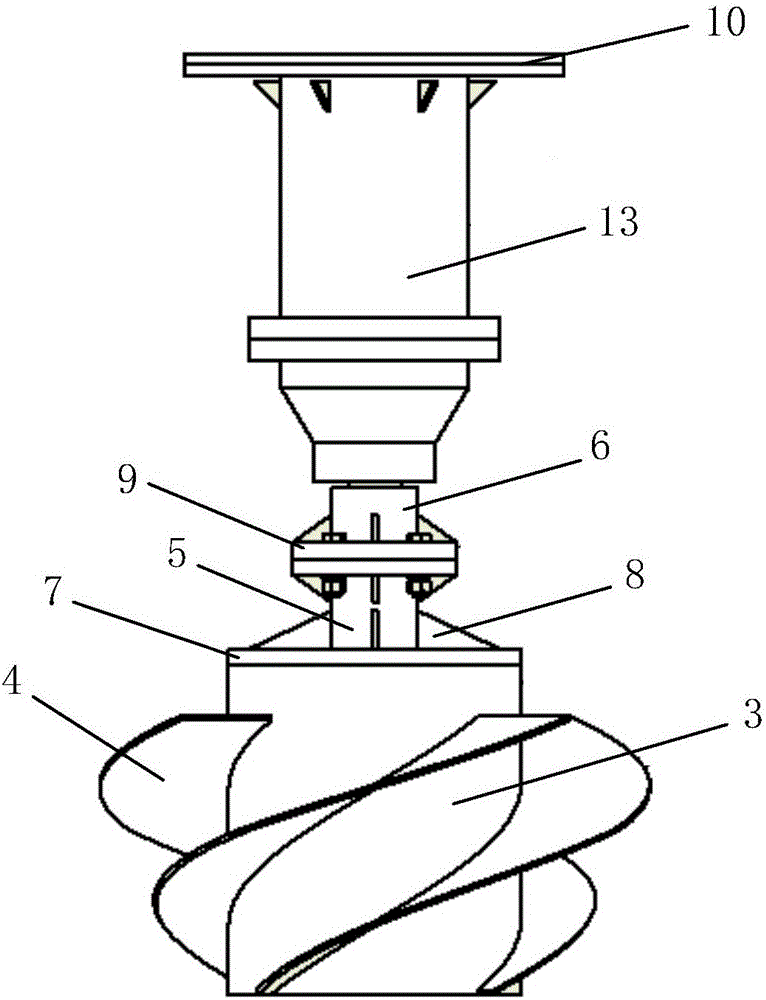

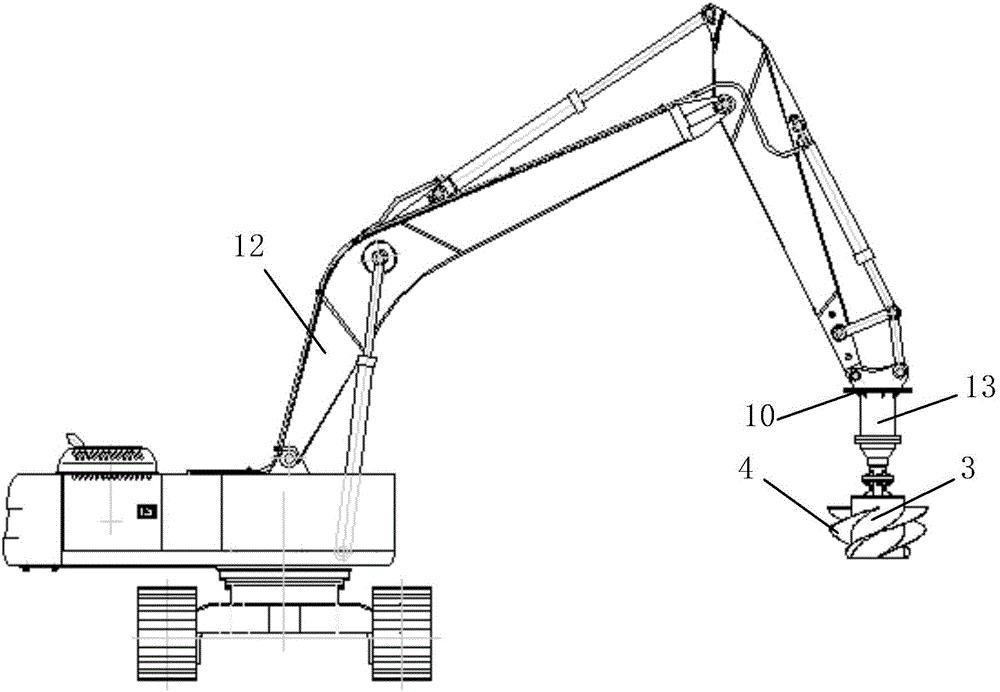

Submarine ore collecting vehicle and ore collecting method thereof

The invention discloses a submarine ore collecting vehicle and an ore collecting method thereof. The submarine ore collecting vehicle comprises water jet nozzles (1), an ore sucking hood (2), a spiral flow guiding plate (3), an ore slurry pump (4), a pressure-bearing ore storage tank (5), a relay cabin conveying pipeline (9) and an ore collecting vehicle cabin body (10), wherein the water jet nozzles (1) are closely arranged into a plurality of groups along the bottom of ore sucking hood (2) at certain vertically and transversely inclined angles; the spiral flow guiding plate (3) is embedded into the inner side of the ore sucking hood (2) along a spiral line; the ore slurry pump (4) is connected to the ore sucking hood (2) through an ore slurry pump pipeline, so that local negative pressure is formed in the ore sucking hood (2), and a vertical-axis whirlpool which flows upwards is formed under the flow guiding action of the spiral flow guiding plate (3); the ore slurry pump (4) conveys collected ores to a relay cabin through the relay cabin conveying pipeline (9), and is further connected with the pressure-bearing ore storage tank (5). The submarine ore collecting vehicle and the ore collecting method have the advantages of being environmentally friendly, efficient, lower in energy consumption, and reliable.

Owner:SHANGHAI JIAO TONG UNIV

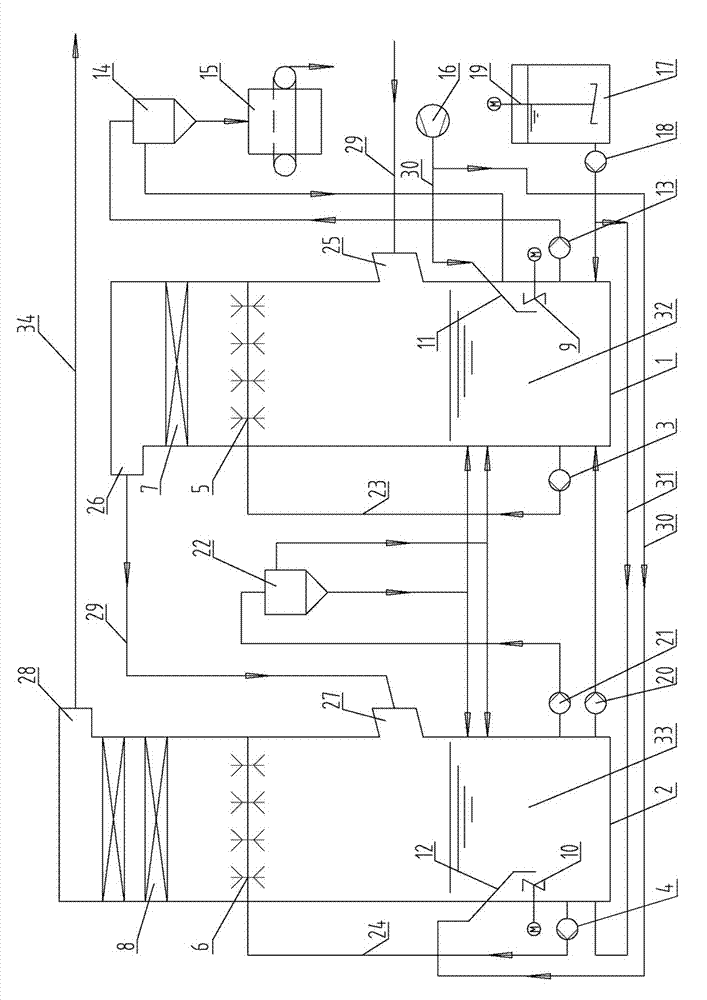

Double-tower double-circulation limestone wet method desulfurization device and method

ActiveCN102921287AImprove adaptabilityAdvanced technologyDispersed particle separationProcess engineeringTower

The invention discloses a double-tower double-circulation limestone wet-method desulfurization device and method. The double-tower double-circulation limestone wet-method desulfurization device comprises a smoke purification part, an absorbent supply part, a slurry oxidization and crystallization part and a gypsum slurry dehydration part, wherein the smoke purification part consists of a first-stage circulation absorption tower and a second-stage circulation absorption tower; the absorbent supply part consists of a gypsum slurry tank, a gypsum slurry pump and a slurry supply pipeline; the slurry oxidization and crystallization part consists of a oxidization fan, a first-stage circulation absorption tower oxidization spraying gun, a second-stage circulation absorption tower oxidization spraying gun and an oxidization air pipeline; and the gypsum slurry dehydration part consists of a first-stage circulation gypsum discharging pump, a gypsum whirlcone and a vacuum dehydration belt conveyer. The desulfurization device is extremely high in desulfurization efficiency, and the aims of reducing the sulfur dioxide and purifying air are fulfilled; and moreover, gypsum with extremely high quality can be obtained.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG

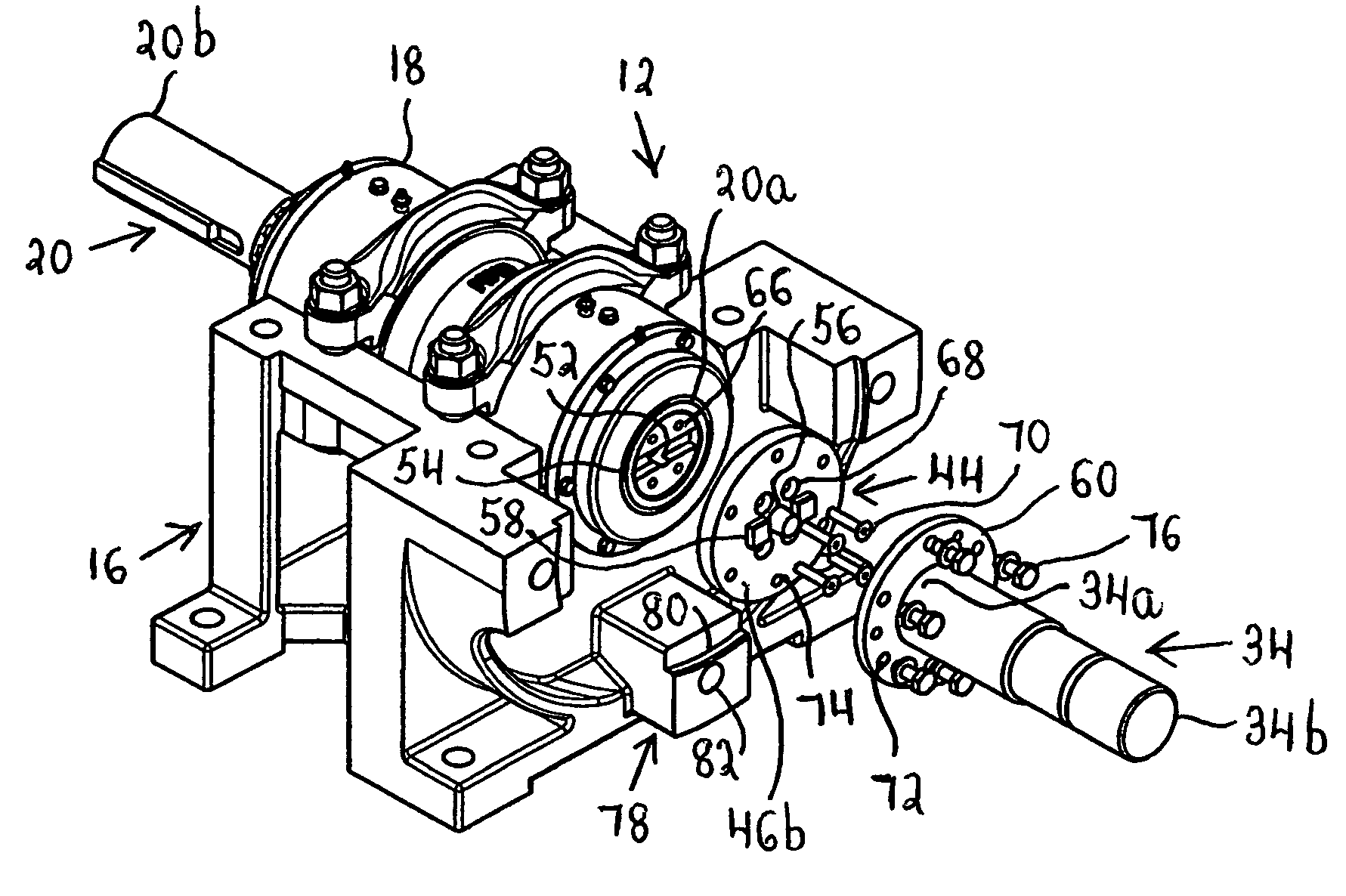

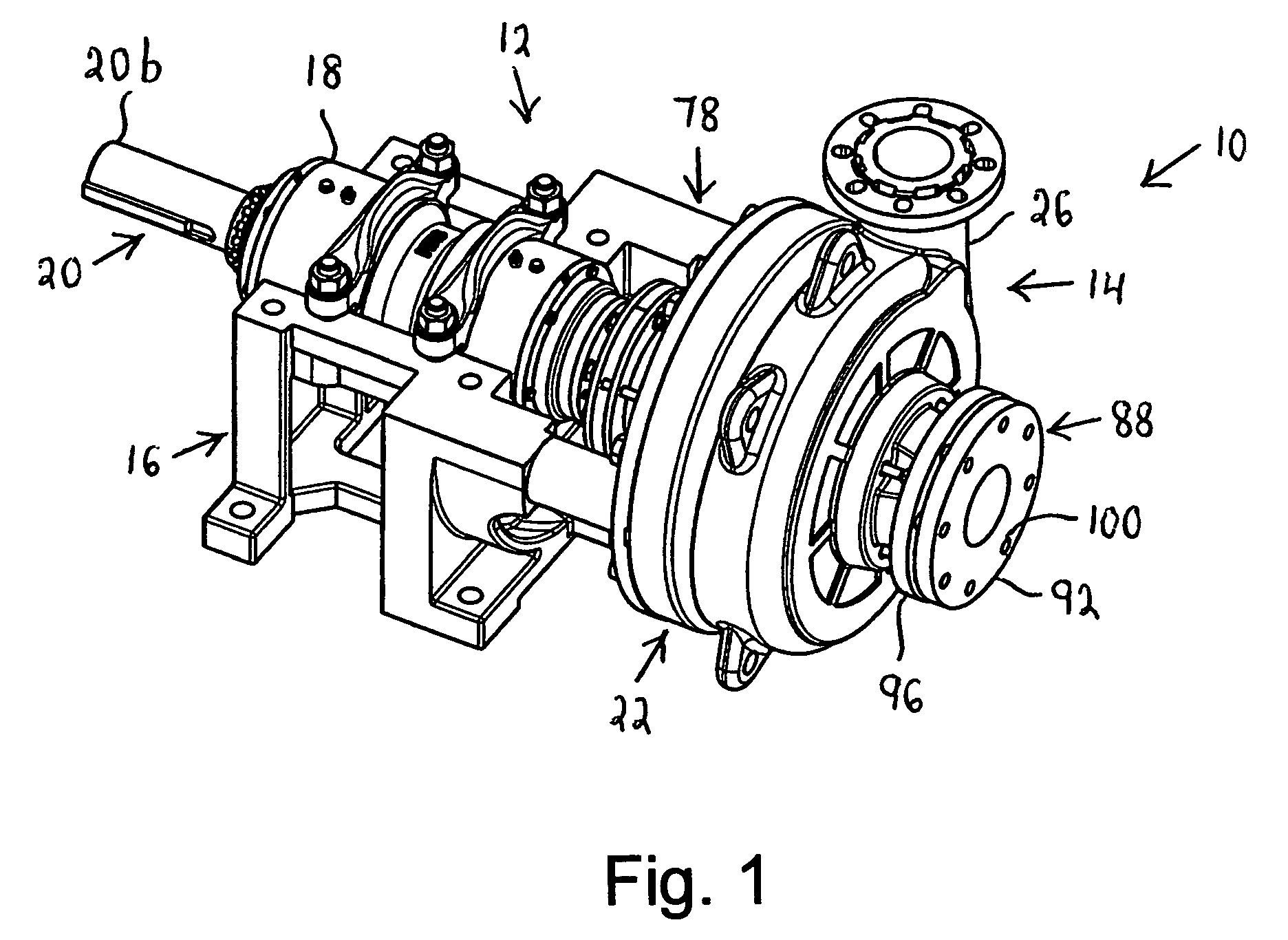

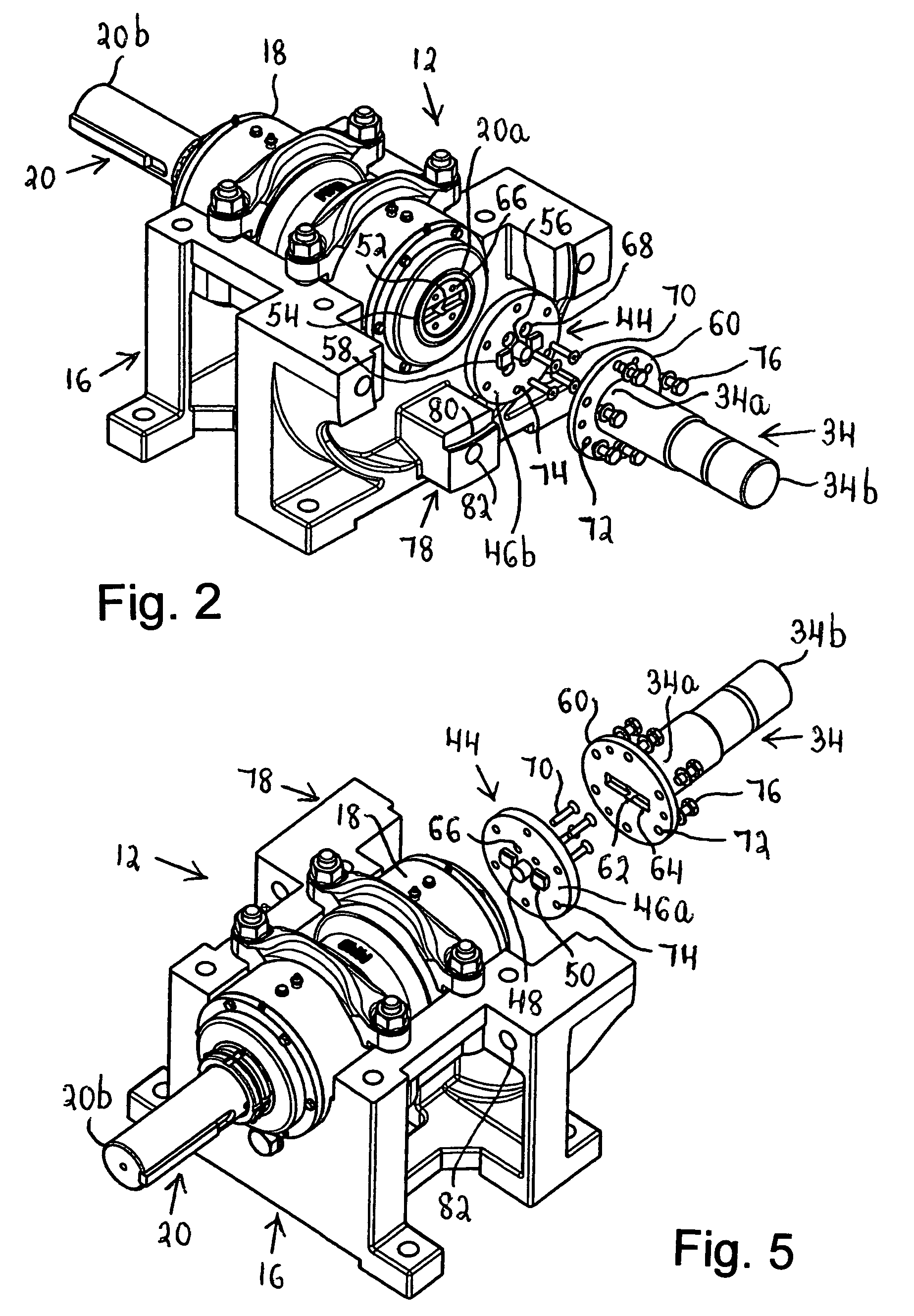

Quick-release pump module

A slurry pump includes a power frame as well as a wet end, and the wet end comprises a casing, an impeller and wear ring in the casing, a stub shaft connected to the impeller, a sleeve assembly for the stub shaft and an adapter for adjusting the wet end to the power frame. The wet end can be attached to and detached from the power frame as a module.

Owner:KREBS ENGINEERS CORP +1

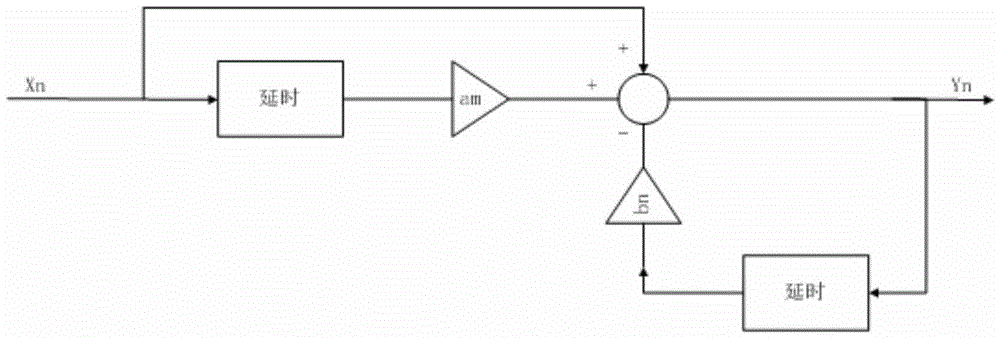

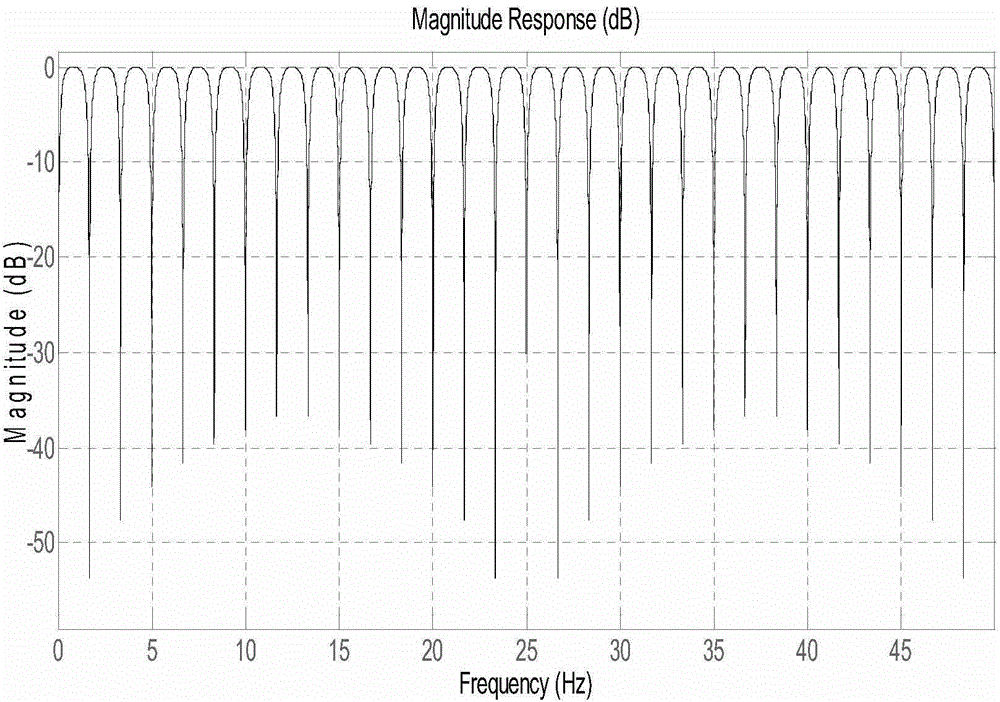

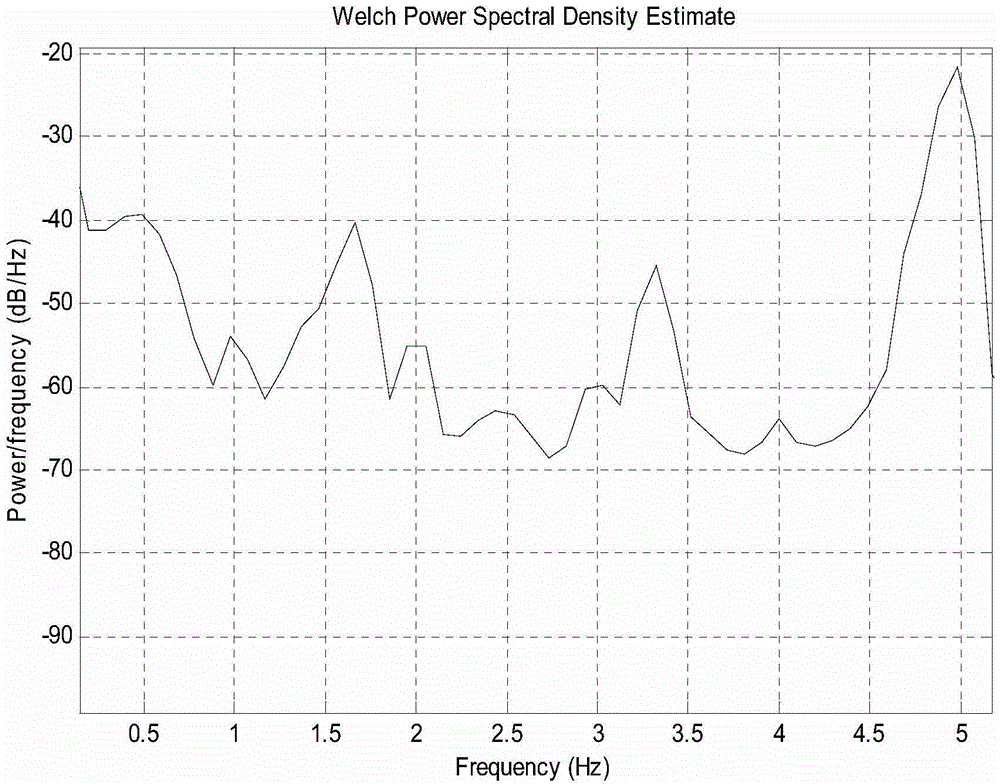

Elimination method of slurry pulse signal pump stroke noise

InactiveCN104133982AHigh precisionGood effectSurveySpecial data processing applicationsSignal-to-noise ratio (imaging)Convolution filter

The invention discloses an elimination method of slurry pulse signal pump stroke noise. The order formula (N=Fs / Fo) of a comb filter is utilized, wherein Fs is the sampling frequency of a slurry signal, and Fo is a product of the movement rate of a single slurry pump piston and the number of slurry pumps, and the order of the comb filter is determined; when the pump stroke noise is eliminated, a filtering process of a slurry pulse signal is realized by utilizing MATLAB software, and comprises the following steps: 1) collecting the slurry pulse signal on site; 2) according to the signal to noise ratio of the signal, determining the bandwidth (BW) of the comb filter, designing the required comb filter according to the BW and the determined order; 3) converting the slurry pulse signal to enable a signal value to be within an interval (-1,1), and obtaining a signal X(n); 4) loading the signal X(n) into the comb filter to carry out convolution filtering to obtain a filtered signal Y(n); and 5) plotting, and observing a signal filtering situation. The invention breaks through the restriction of a hardware circuit, the MATLAB software is utilized to effectively realize the filtering process of the slurry pulse signal, and meanwhile, the comb filter is applied to the slurry pulse signal so as to further enhance a filtering effect.

Owner:GOALTECH

Method for preparing dust suppressing covering agent

InactiveCN102558579AWide variety of sourcesReliable sourceOther chemical processesPolymer scienceCross linker

The invention relates to a method for preparing a dust suppressing covering agent, comprising the following steps: preparing raw materials including 3-10 parts of natural starch, 35-50 parts of water, 10-20 parts of acrylic acid, 30-40 parts of 30% sodium hydroxide, 1-5 parts of cross-linking agent and 5-15 parts of initiator; mixing the acrylic acid and the 30% sodium hydroxide to prepare sodium acrylate solution, and filling the sodium acrylate solution into a sodium acrylate solution storage tank for later use; fully mixing the natural starch and the water, and filling starch slurry into a starch slurry storage tank; pumping the starch slurry into a stirring reactor by using a starch slurry pump, heating for 75-80 DEG C by using a clamp sleeve of the stirring reactor, and gelatinizing for 1 hour at constant temperature; stopping heating, decreasing the temperature in the stirring reactor to 45-50 DEG C, keeping the temperature constant, and introducing nitrogen into the stirring reactor to replace the air inside the stirring reactor; adding the prepared sodium acrylate solution, the initiator and the cross-linking agent into the stirring reactor in sequence, introducing nitrogen into the stirring reactor continuously, and the stirring slowly for reaction of 3 hours at constant temperature.

Owner:NANJING TECH UNIV

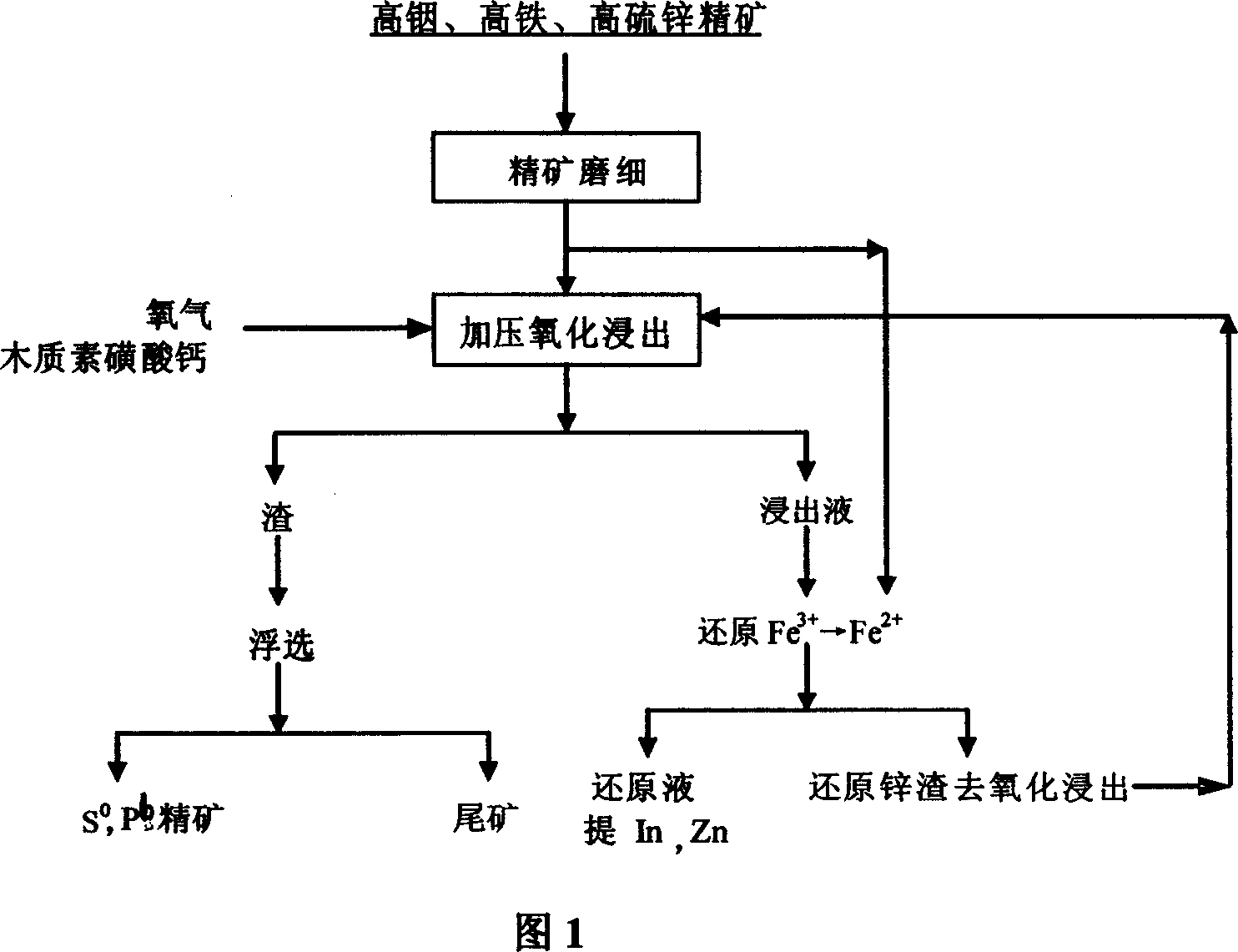

New method for soaking out enriched ores of high indium, high iron, and high sulfur zinc

This invention discloses a wet method for treating high In-Fe-S Zn concentrate by oxidative acid leaching. Compared with traditional high-pressure leaching technique, the method obviously reduces the operation temperature and pressure. Ore slurry composed of Zn concentrate, surfactant and sulfuric acid aqueous solution is operated at 95-105 deg.C under 0.2-0.4 MPa. The surfactant is sodium or calcium lignosulfonate, which can change the hydrophobicity of sulfide and sulfur, raise the leachin speed, and improve the suspension fluidity of the ore slurry. Since the operation temperature is lower than the normal pressure boiling point of the solution system, normal rubber pipe pump can be used to replace oil diaphragm high-pressure slurry pump, and Ti heat exchanger and vacuum flash evaporator are not needed. The leaching rate of Zn and In is up to 95-99%, and the yield of S is higher than 80%. The leaching solution can be treated according to normal method to recover valuable components, with total recovery rate of In up to 90-95%.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

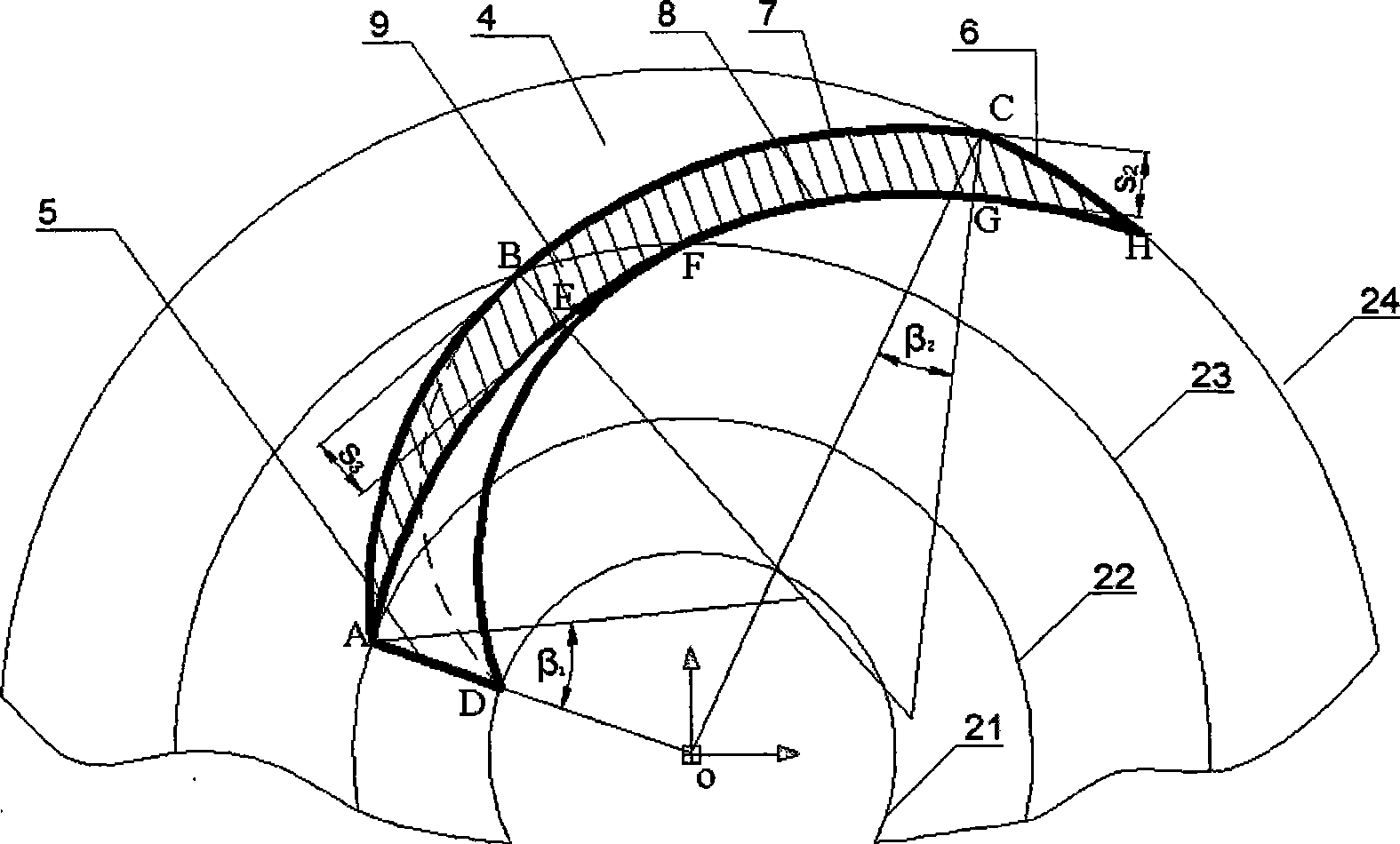

Design method of two phase flow pump impeller

InactiveCN101368574AAdhere to flow characteristicsThe angle of attack of the water flow changes evenlySpecific fluid pumpsPump componentsImpellerFriction loss

The invention discloses the design method of a two-phase flow pump; the two-phase flow pump comprises a slurry pump, a mud pump, a diving slurry pump, a diving mud pump and a diving two-phase pump; the impeller includes a main impeller and an auxiliary impeller; the main impeller mainly comprises a main vane, an auxiliary vane, a front cover plate and a back cover plate; the impeller is mainly arranged on an impeller shaft; the main vane is inclined to the front cover plate and the back cover plate through the vane inlet segment; the vane outlet segment is vertical to the front cover plate and the back cover plate to form a semi-twisted vane; the vane contour line on the impeller front cover plate has smooth transition to the vane contour line on the impeller back cover plate to form the surface of the semi-twisted vane. The auxiliary vane of the impeller and the auxiliary impeller construct a dynamic sealing device. Based on the semi-twisted vane in the invention, the water power loss and the friction loss are smaller than that of the cylindrical vane; the vibration and noise of the pump are reduced; the pump efficiency is improved; the service life of the impeller is prolonged; meanwhile, the operation of the pump become more stable.

Owner:许洪元

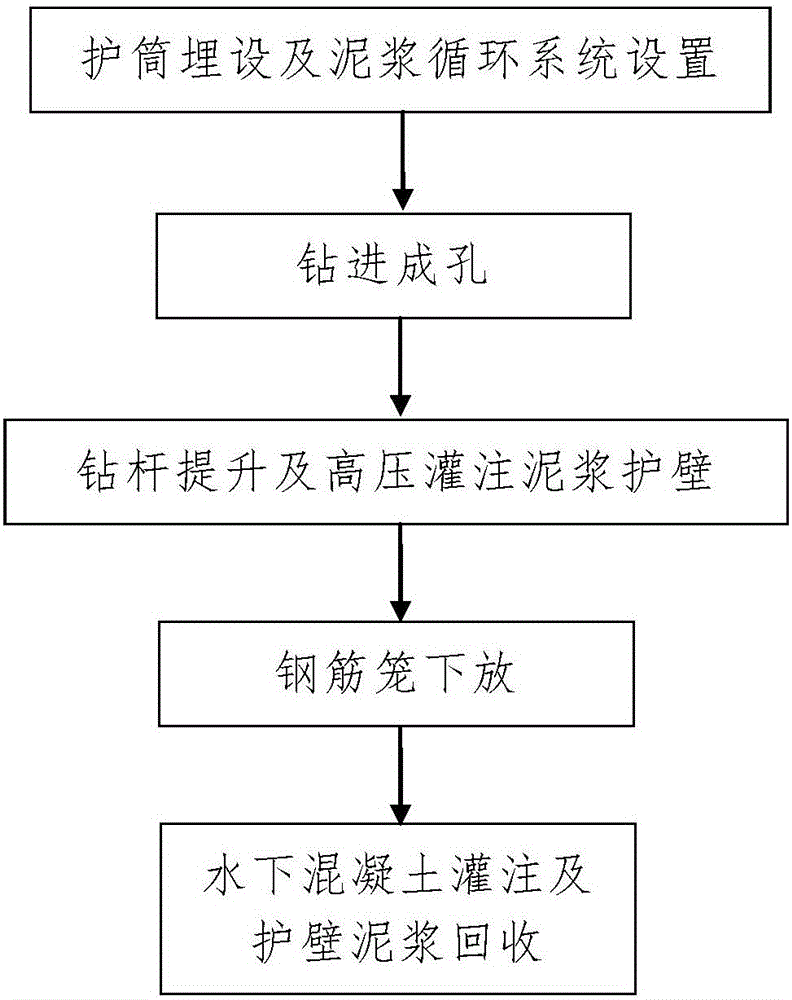

Long screw extrusion-socketed cast-in-place pile construction method based on circulating slurry breast wall

ActiveCN106284313AReasonable structural designEasy to operateBulkheads/pilesDrilling machines and methodsUnderwaterHigh pressure

The invention discloses a long screw extrusion-socketed cast-in-place pile construction method based on circulating slurry breast wall, comprising the steps of first, burying a protective barrel and setting a slurry circulating system that comprises a slurry storage tank and a slurry pumping device, with the upper portion of the protective barrel provided with an overflow hole; second, drilling to form a borehole; third, lifting a drill pipe, and casting a slurry breast wall under high pressure: lifting up the drill pipe, and continuously casting wall supporting slurry from bottom to top from the borehole bottom through the drill pipe by using the slurry pumping device; fourth, lowering a reinforcement cage; fifth, casting concrete underwater and recycling the wall supporting slurry, and recycling the wall supporting slurry discharged through the overflow hole to the slurry storage tank for backup. The method has simple steps, is easy to implement, has high hole-forming quality and good construction effect, and enables the construction of a long screw extrusion-socketed cast-in-place pile to be finished simply and quickly, and by casting the wall supporting slurry from bottom to top from the borehole bottom in a high-pressure casting manner, it is possible to effectively protect the wall and keep the borehole bottom clean with no deposit; the wall supporting slurry is reusable.

Owner:SHAANXI ZHUANGXIN CONSTR ENG +4

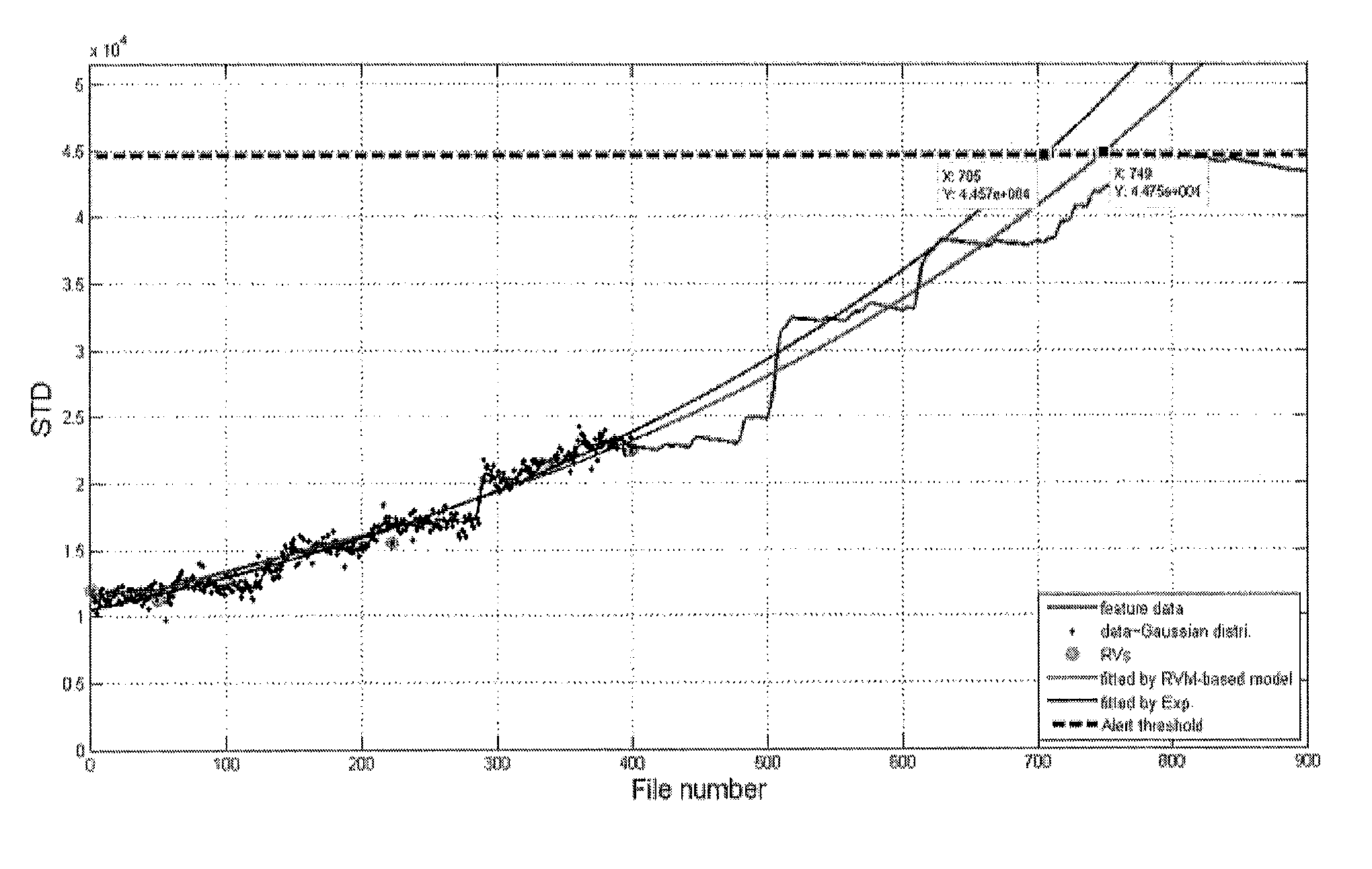

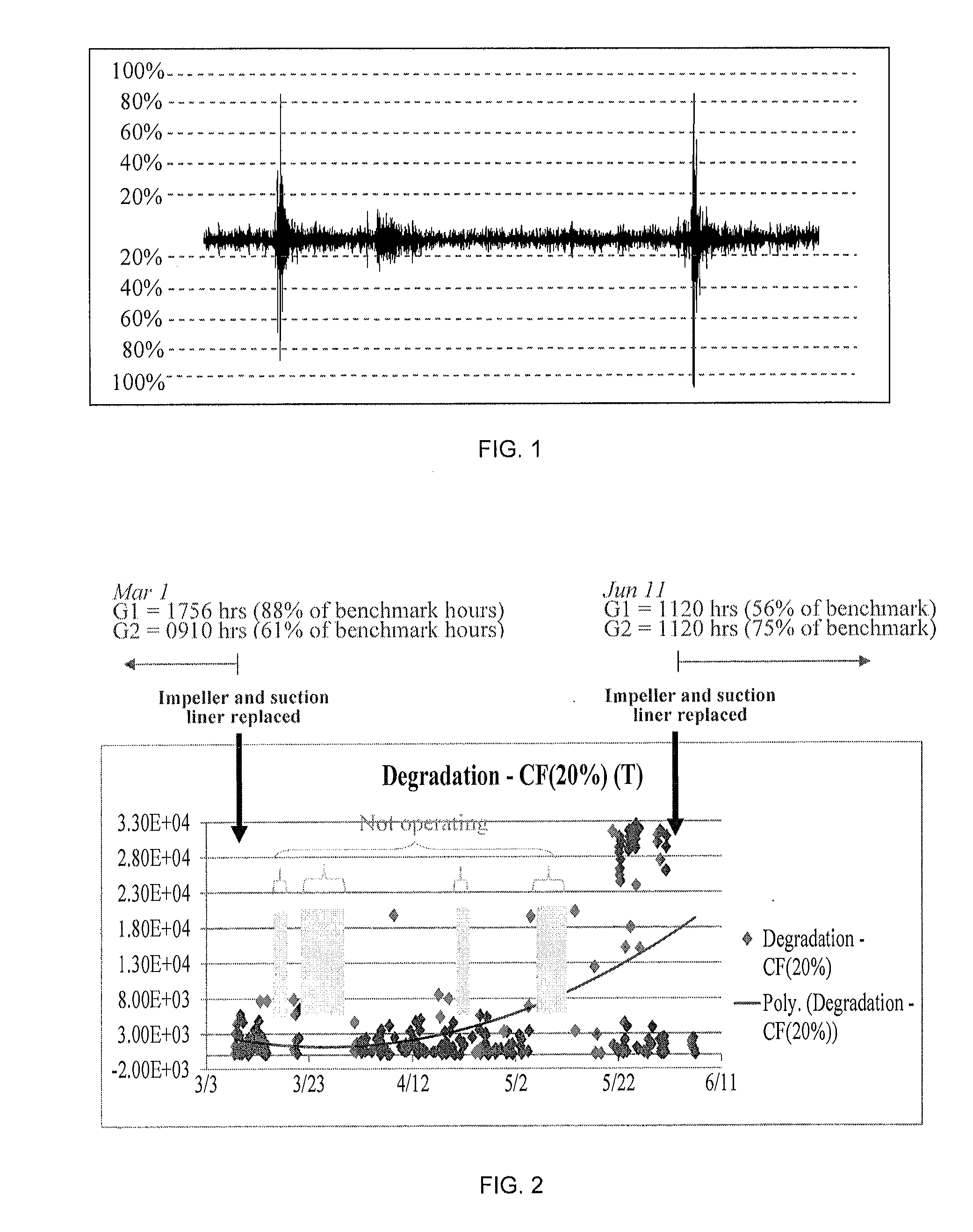

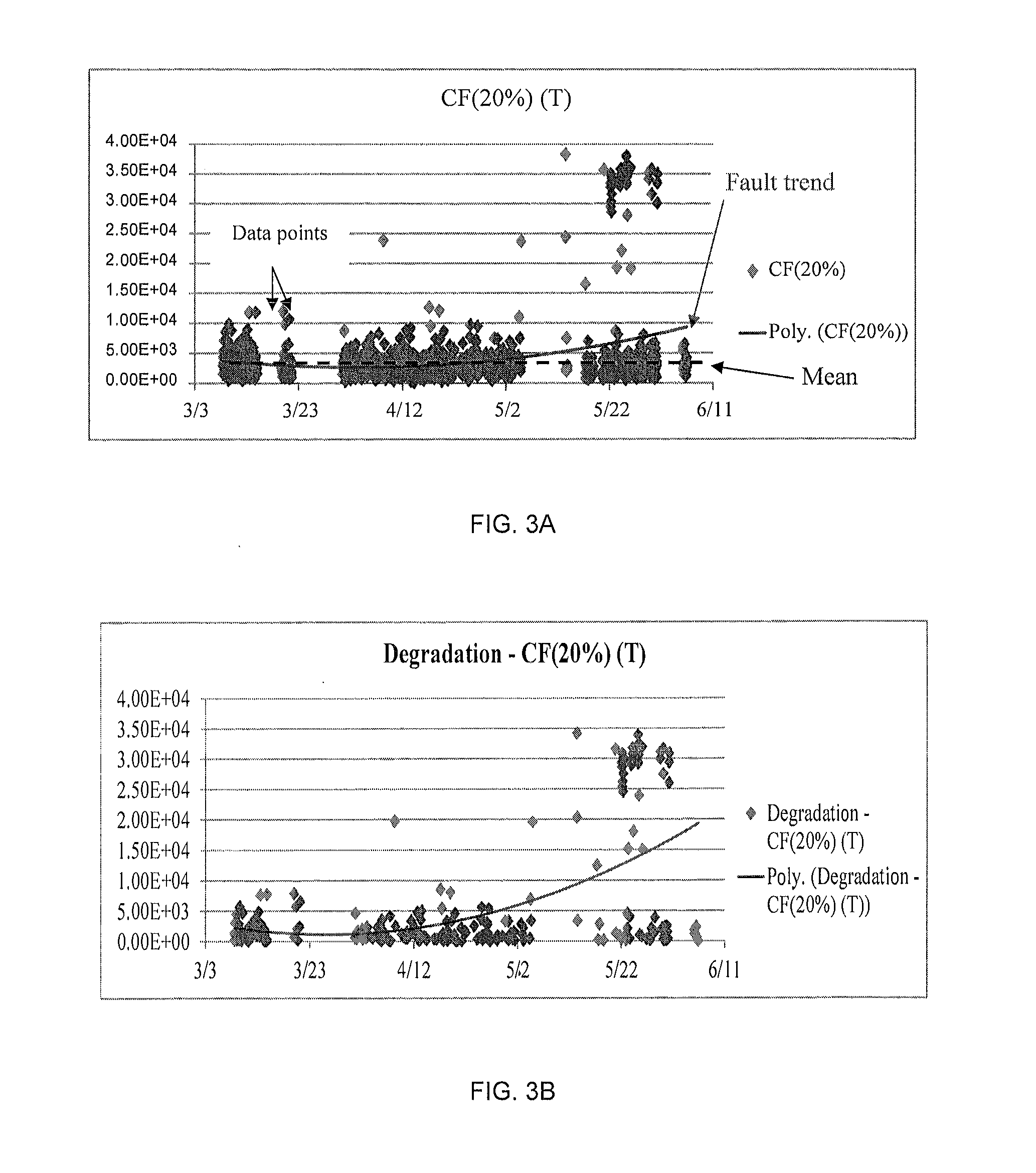

Method for diagnosing faults in slurry pump impellers

InactiveUS20150122037A1Limited abilityLow costVibration measurement in solidsMachine part testingData driven prognosticsImpeller

A method of diagnosing the condition of a slurry pump impeller is provided, comprising collecting vibration data from at least one accelerometer mounted to or proximate the pump over a specific time period; calculating indicators from the collected vibration data, the indicators comprising energy level, crest factor, square root amplitude value, and fault growth parameter; and plotting the calculated indicators against time to generate a fault trend indicative of health or deterioration of the impeller. The method further involves predicting the remaining useful life of the impeller using vibration data-driven prognostics.

Owner:SYNCRUDE CANADA LTD +1

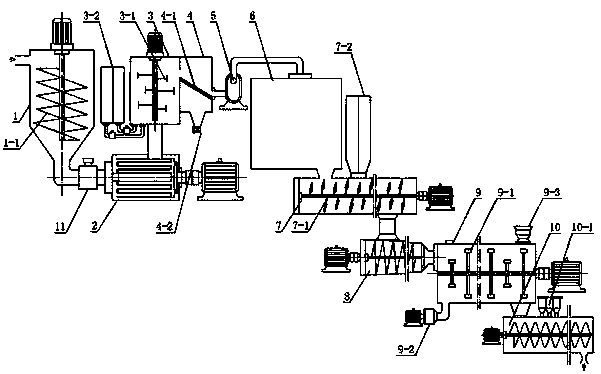

Sludge treatment method and treatment system

ActiveCN103663887AReduce consumptionCompact structureSludge treatment by de-watering/drying/thickeningFlocculationAdditive ingredient

The invention relates to a sludge treatment method and treatment system, which realize deep sludge dewatering and create technical conditions for recycling comprehensive utilization of sludge. The treatment method comprises the following steps: (1) regulating the water content of sludge; (2) cutting and crushing the sludge; (3) performing flocculation and filtration aid treatment; (4) draining and dewatering; (5) adding environmental mineral materials; (6) heating, and loosening; and (7) removing moisture. The treatment system adopts a treatment device, wherein the treatment device comprises a storage bin, a shearing dispersion machine, a treatment bin, a draining bin, a slurry pump, a filter press, an ingredient mixing machine, a heating and extruding machine, a loosening and drying machine and a discharging mechanism; the storage bin is connected with the shearing dispersion machine; the shearing dispersion machine is connected with the treatment bin; the treatment bin is connected with the draining bin; the draining bin is connected with the slurry pump; the slurry pump is connected with the filter press; the filter press is connected with the ingredient mixing machine; the ingredient mixing machine is connected with the heating and extruding machine; the heating and extruding machine is connected with the loosening and drying machine; and the loosening and drying machine is connected with the discharging machine. According to the invention, the treatment method is simple, short in process flow and low in treatment cost; and the treatment device is compact in structure, has favorable operation stability and reliability, causes no pollution in the treatment process, and is beneficial to popularization.

Owner:郑百祥

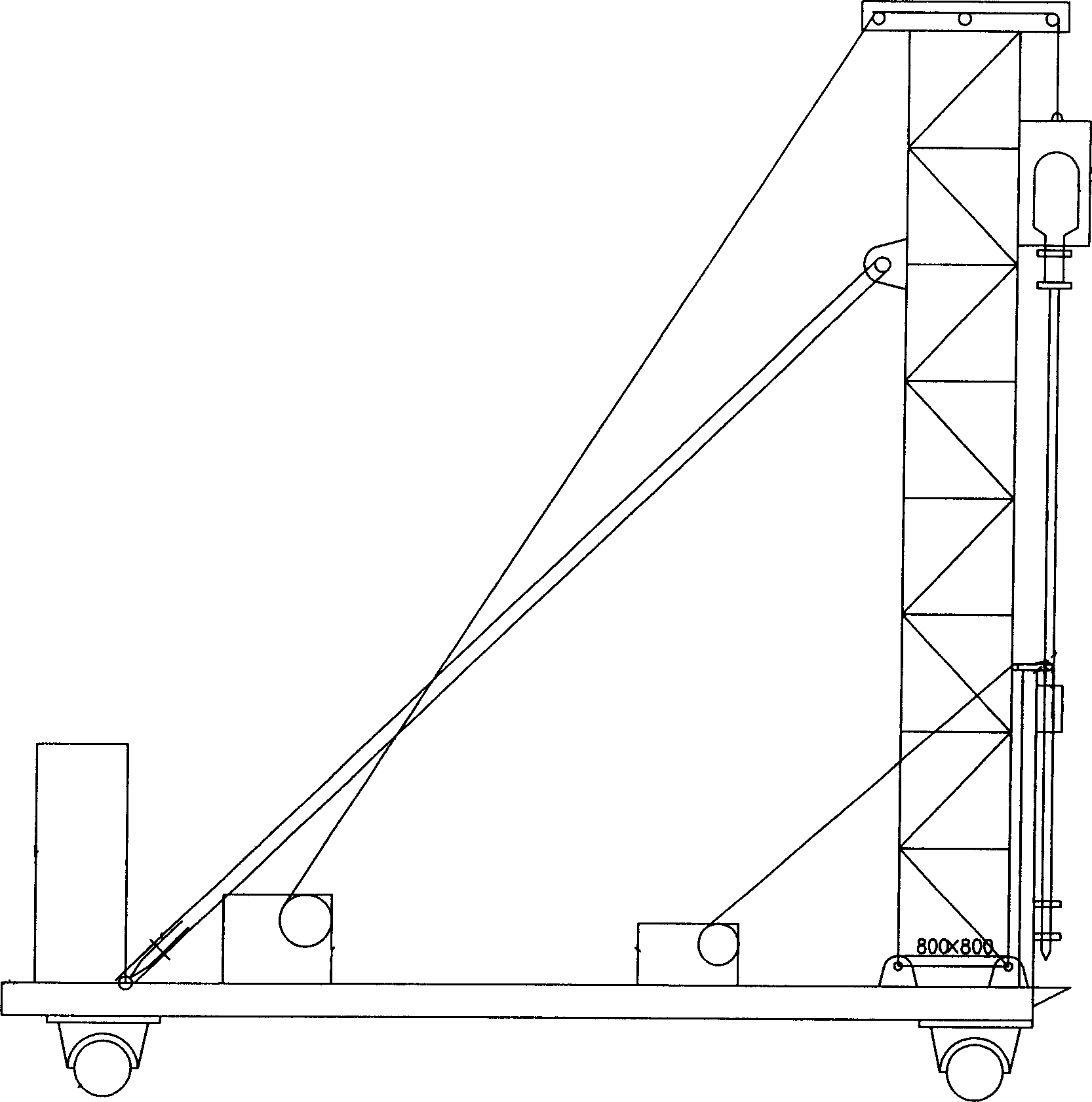

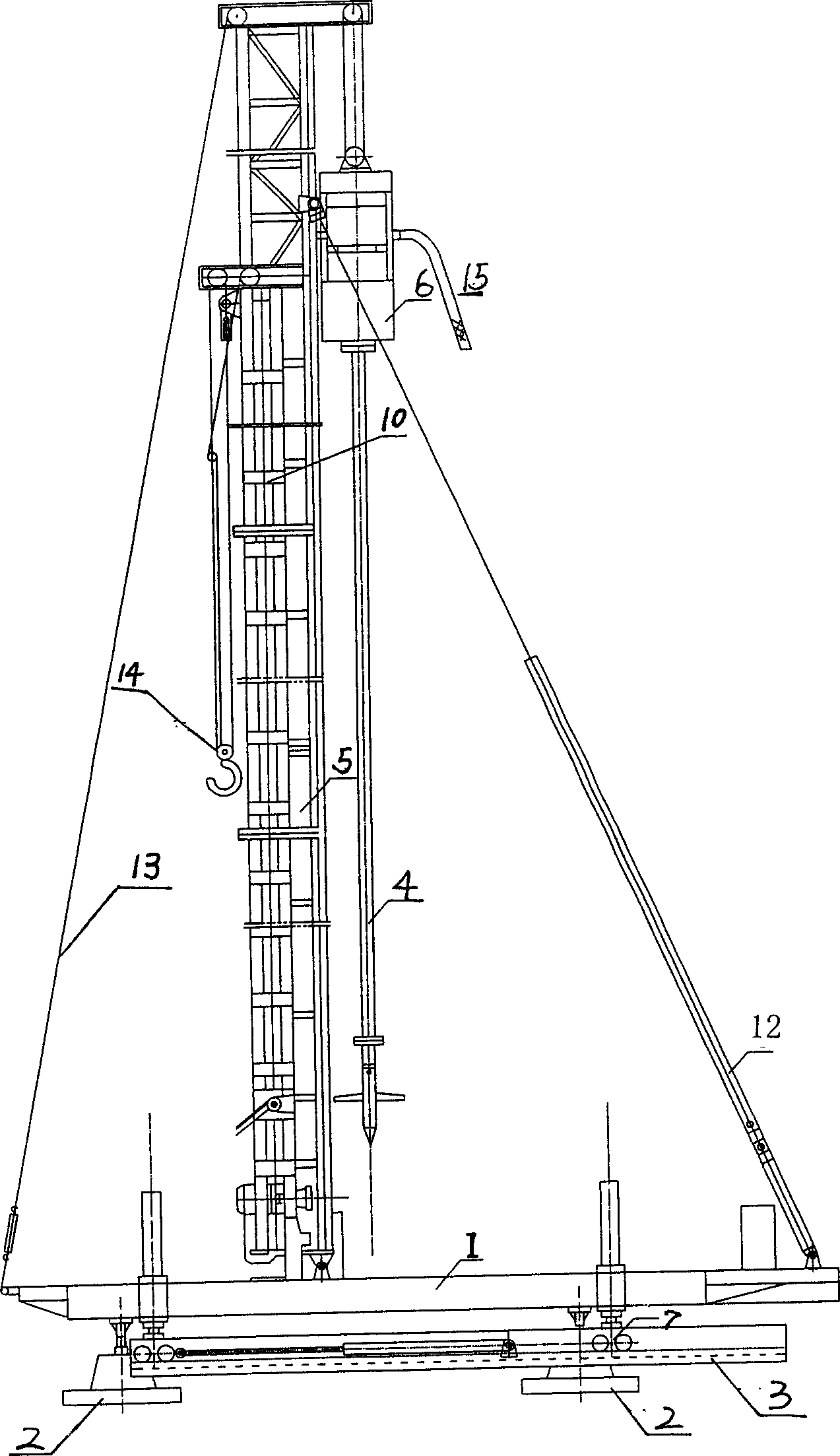

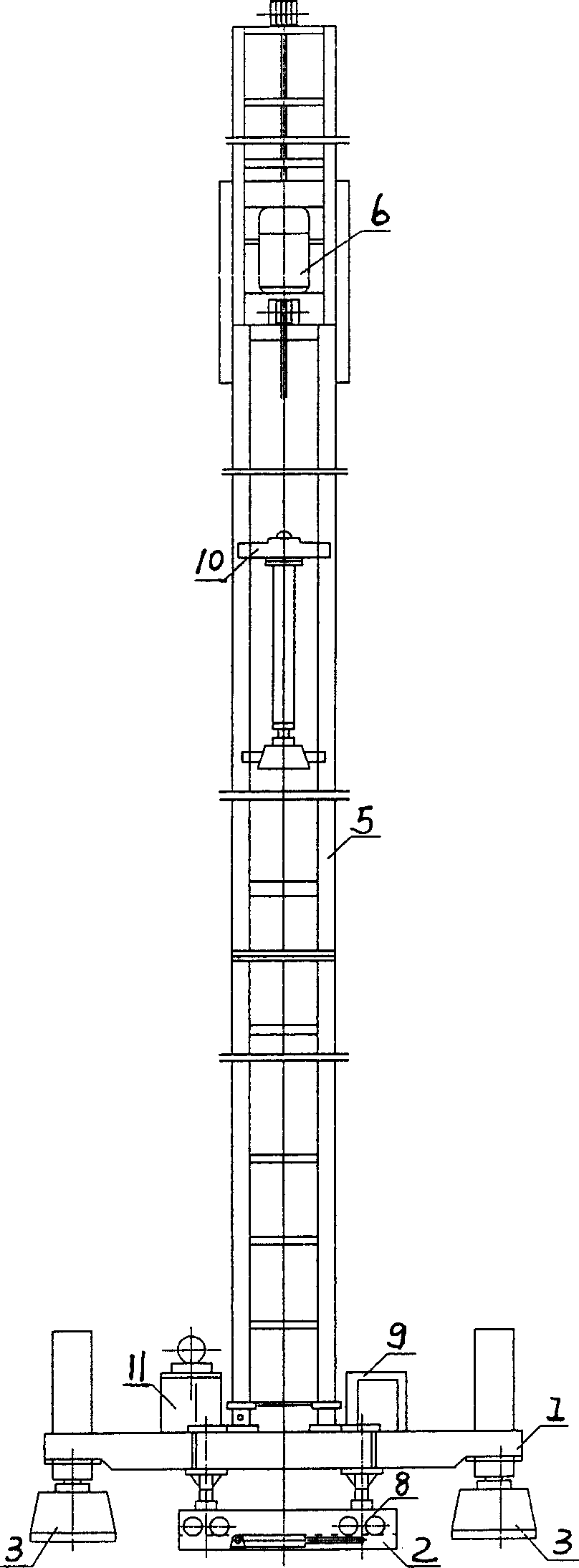

Concrete core cement soil stirring pile machine and its construction technological method

InactiveCN1718938AAvoid Weaknesses of Poor Fighting AbilityGuaranteed alignmentBulkheads/pilesHydraulic pumpArchitectural engineering

The present invention discloses a concrete core cement earth stirring pile machine and its construction process and method. The bottom portion of said pile machine is equipped with hydraulic walking system, including machine frame, base seat, hydraulic pump station, longitudinal and transverse moving beams, longitudinal and transverse roller supporting frames, guideway, deep stirring machine head, drilling machine, drill bit, slurry pump, distribution box and hydraulic pile-pressing system.

Owner:NANJING UNIV

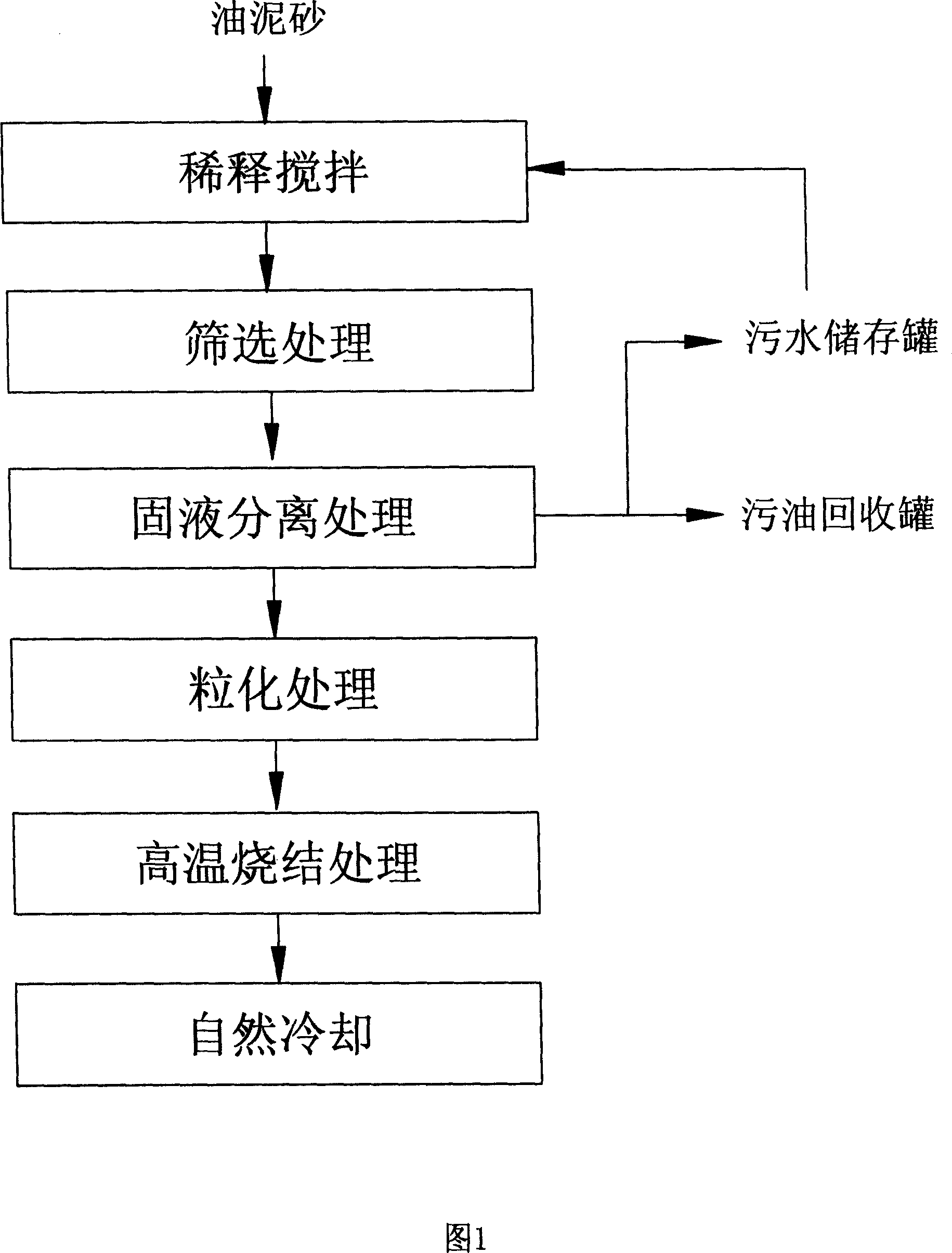

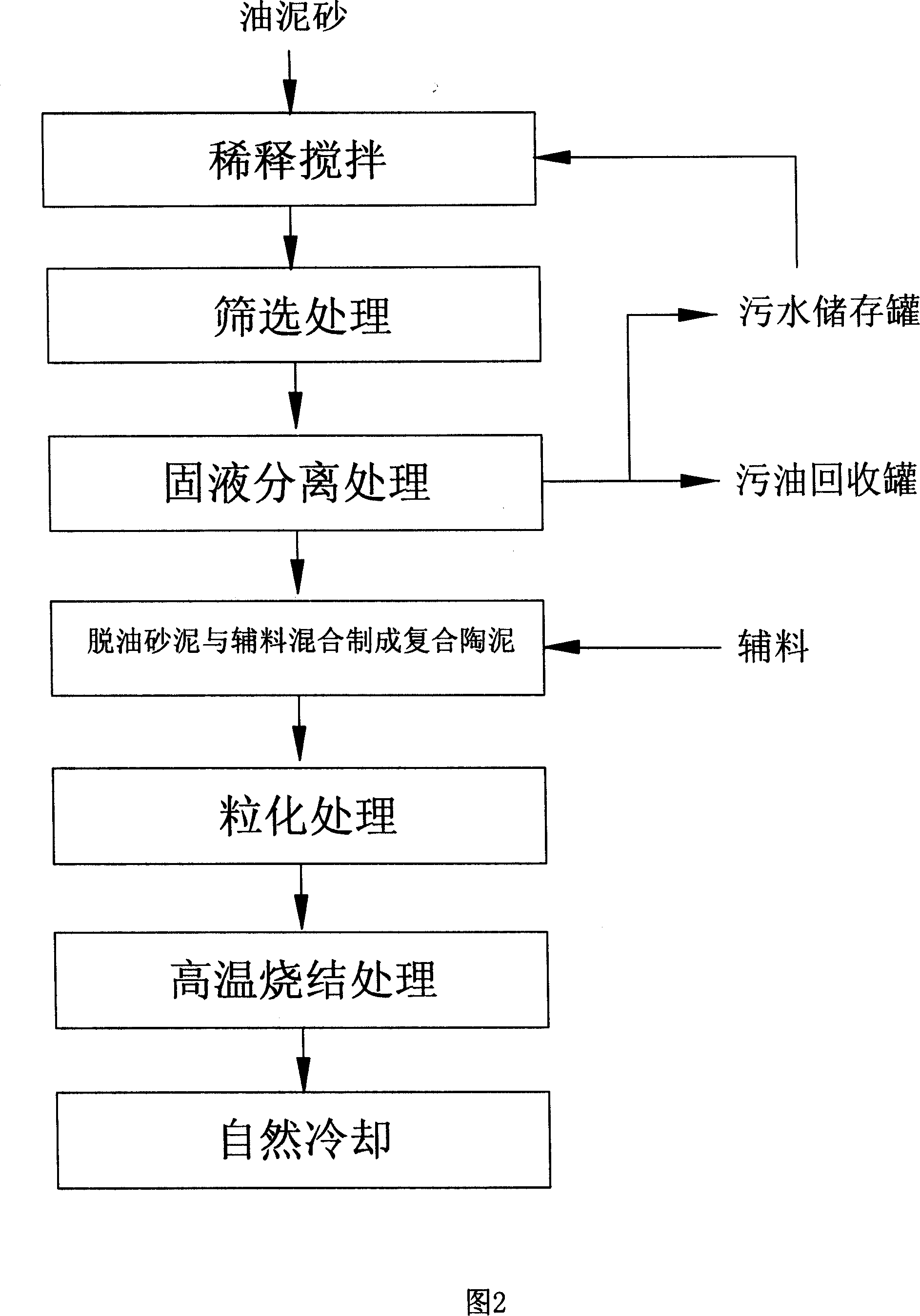

Method for producing ceramic granule from oil sludge sand

InactiveCN101100364AImprove utilizationHigh strengthCeramic materials productionClaywaresExpanded clay aggregateFree cooling

This invention relates to a method for producing ceramicite by using oily sands as raw material. The procedures are: (a), raw material oily sands are fed into a vessel with its agitator; adding water for dilution and agitating for ten minites, so the sands are treated into sand-slurry; (b), said sand-slurry is pumped, by using first sand-slurry pump, into slurry sieve to obtain fine sand slurry; (c), the fine sand slurry is pumped into a solid / liquid separator, and separated into oily dirt, waste-water and deoiled sand mud; (d), said mud is then fed into ceramicite formation machine to produce semifinished products: (e), the same is then fed into a rotary kiln and sintered under temperature of 800-1450deg.C for 50-60 minites, after natural cooling to obtain the final products with the volume-weight of 300-1500kg / m3.

Owner:桂殿宝

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com