Method for producing ceramic granule from oil sludge sand

A technology of oil sludge sand and ceramsite, which is applied in the production and application of ceramic materials, household appliances, etc., can solve the problems of land occupation, waste of sediment resources, and cost of processing costs, and achieve reuse, save land resources, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment one: a kind of method using oil sludge sand as raw material to produce ceramsite, described method comprises the following steps:

[0036] a. Send the collected oil sludge sand to the ceramsite molding machine for granulation treatment to make granular ceramsite blanks; when the oil content in the oil sludge sand raw material is less than 3%, and the water content in the mud is less than 10%, it can be directly formed , that is, the oil sludge sand is directly sent to the ceramsite molding machine for granulation treatment without any pretreatment, and is made into a granular ceramsite blank.

[0037] Use the conveyor belt to transport the collected oil sludge sand to the ceramsite molding machine, and according to the requirements of different ceramsite products, it can form block, spherical, and oval products; this example uses a conventional ceramsite molding machine, and you can choose B18- 003 fly ash ceramsite molding machine.

[0038] b. Send the gran...

Embodiment 2

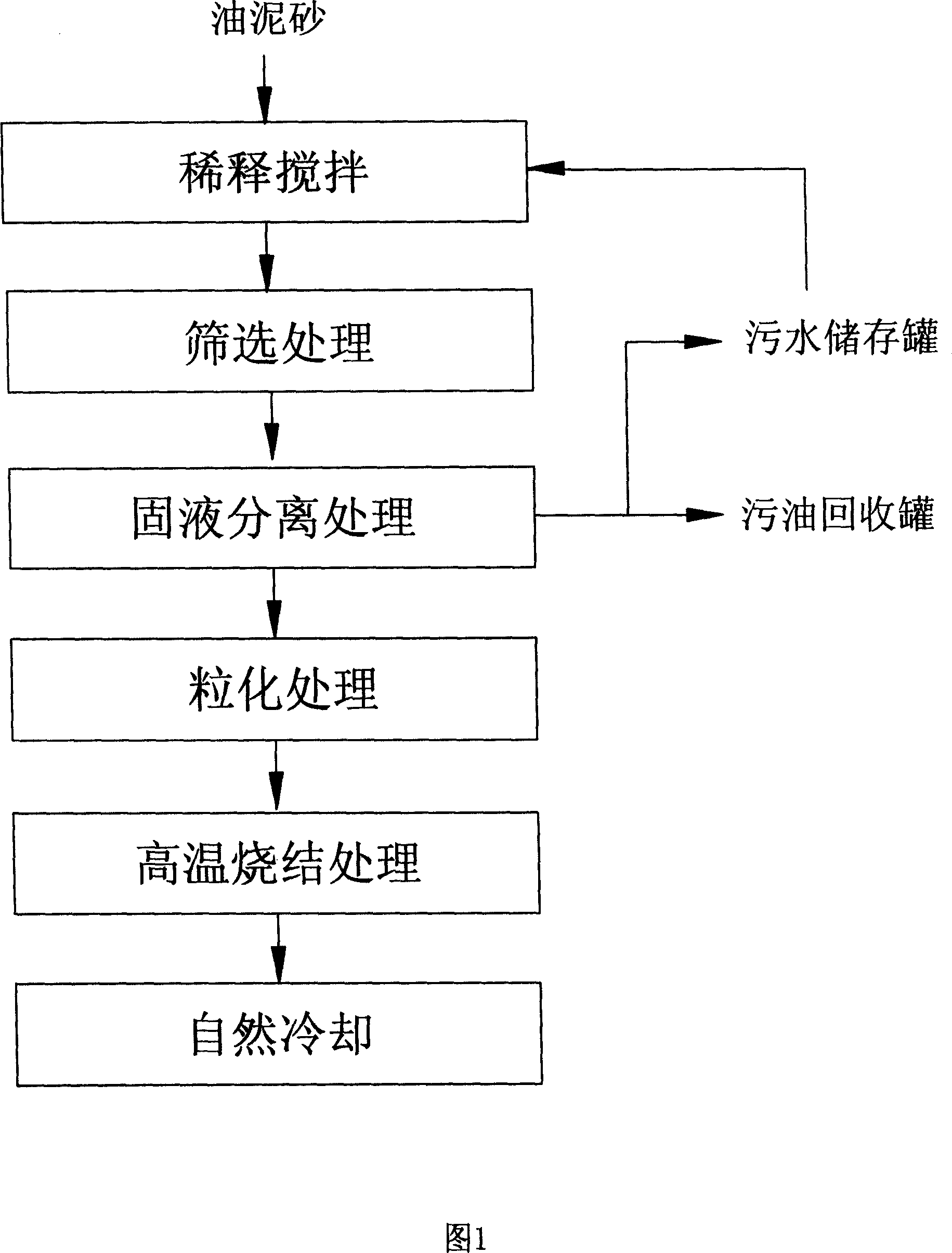

[0041] Embodiment two: referring to Fig. 1, a kind of method for producing ceramsite with oil mud sand as raw material, described method comprises the following steps:

[0042] a. Use a mixing container, put the collected oil sludge sand in the mixing container, add dilution water, start the agitator to stir for 10 minutes, and process the oil sludge sand into oil sludge mortar, the water content in the oil sludge mortar is 60-80 %;

[0043] b. The oil sludge mortar is sent to the sludge sieve through the first-stage mortar pump for screening treatment to obtain the oil sludge sand fine slurry; in this embodiment, the SYZ series vibrating screen can be used as the sludge screen, and its purpose is to screen out large pieces Foreign matter such as sand, impurities and cotton yarn;

[0044]c. Send the oil sludge sand fine slurry into the solid-liquid separator for solid-liquid separation treatment to form waste oil, sewage and deoiled sand mud respectively, and detect the deoil...

Embodiment 3

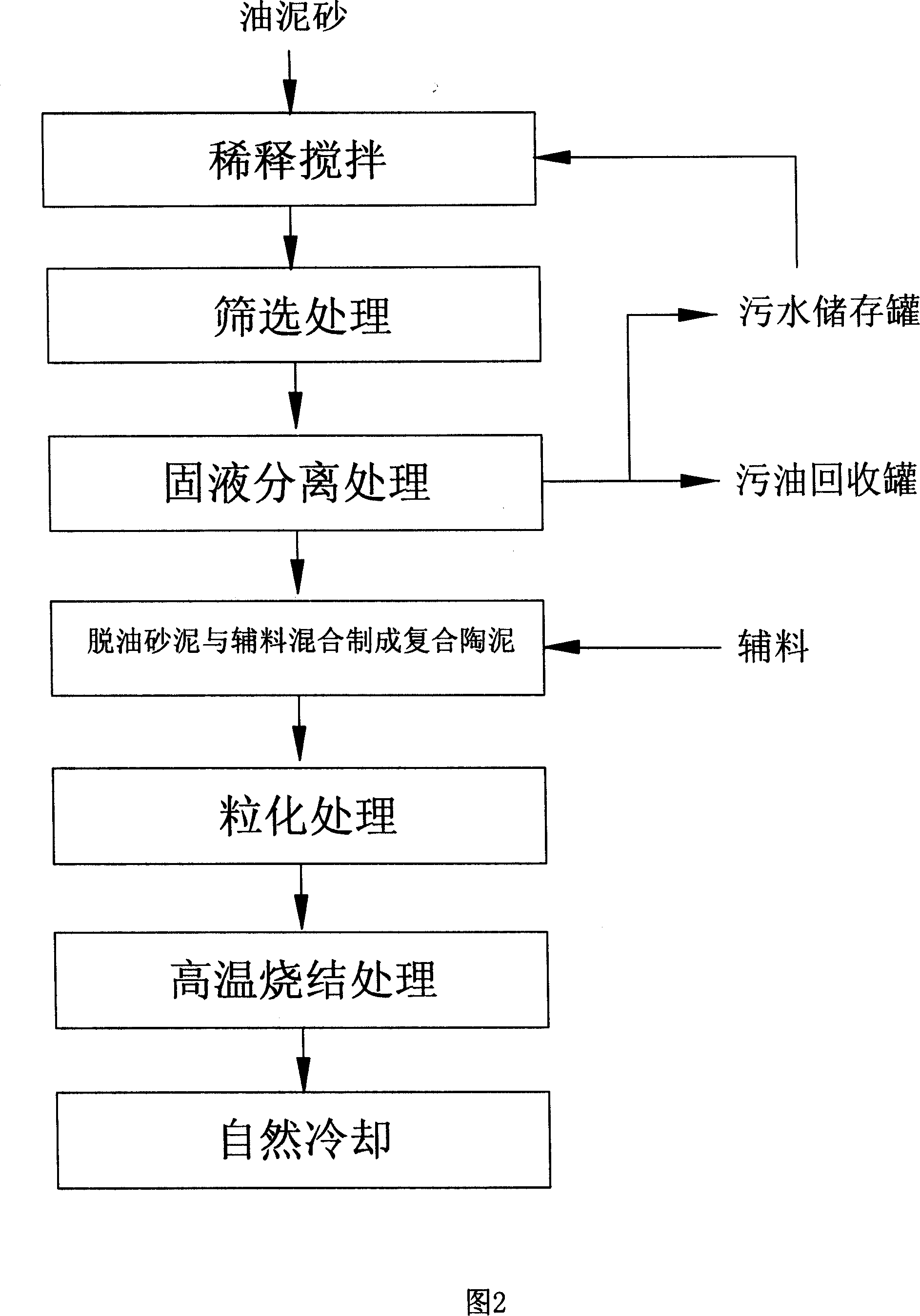

[0052] Embodiment three: referring to Fig. 2, a kind of method that uses oily mud sand as raw material to produce ceramsite, described method comprises the following steps:

[0053] a. Use a mixing container, put the collected oil sludge sand in the mixing container, add dilution water, start the agitator to stir for 10 minutes, and process the oil sludge sand into oil sludge mortar, the water content in the oil sludge mortar is 60-80% ;

[0054] b. The oil sludge mortar is sent to the sludge sieve through the first-stage mortar pump for screening treatment to obtain the oil sludge sand fine slurry; in this embodiment, the SYZ series vibrating screen can be used as the sludge screen, and its purpose is to screen out large pieces Foreign matter such as sand, impurities and cotton yarn;

[0055] c. Sending the oil sludge sand fine slurry into a solid-liquid separator for solid-liquid separation treatment to form waste oil, sewage and deoiled sand mud respectively;

[0056] In ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com