Patents

Literature

1062 results about "Oil sands" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oil sands, tar sands, crude bitumen, or more technically bituminous sands, are a type of unconventional petroleum deposit. Oil sands are either loose sands or partially consolidated sandstone containing a naturally occurring mixture of sand, clay, and water, saturated with a dense and extremely viscous form of petroleum technically referred to as bitumen (or colloquially as tar due to its superficially similar appearance). The oil sands have long been referred to as tar sands; however, industry groups dispute this name due to its negative environmental associations.

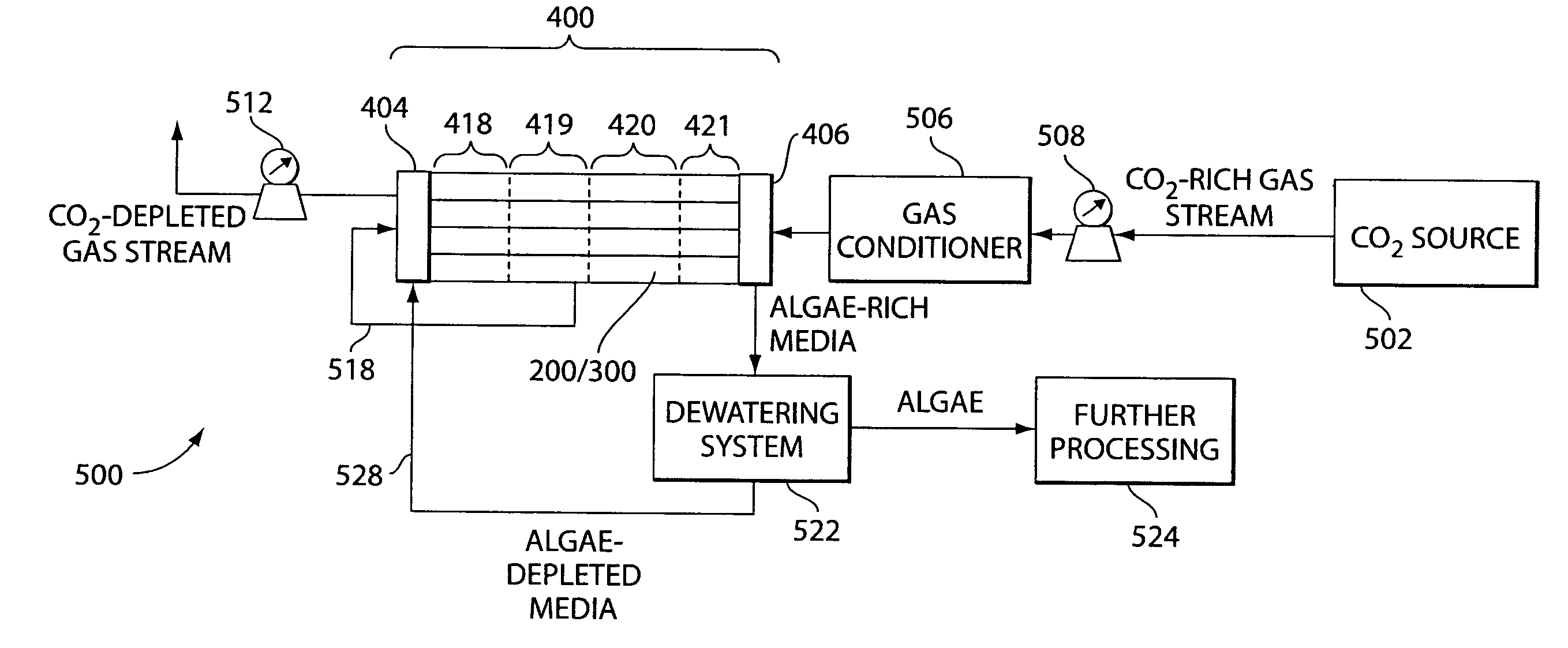

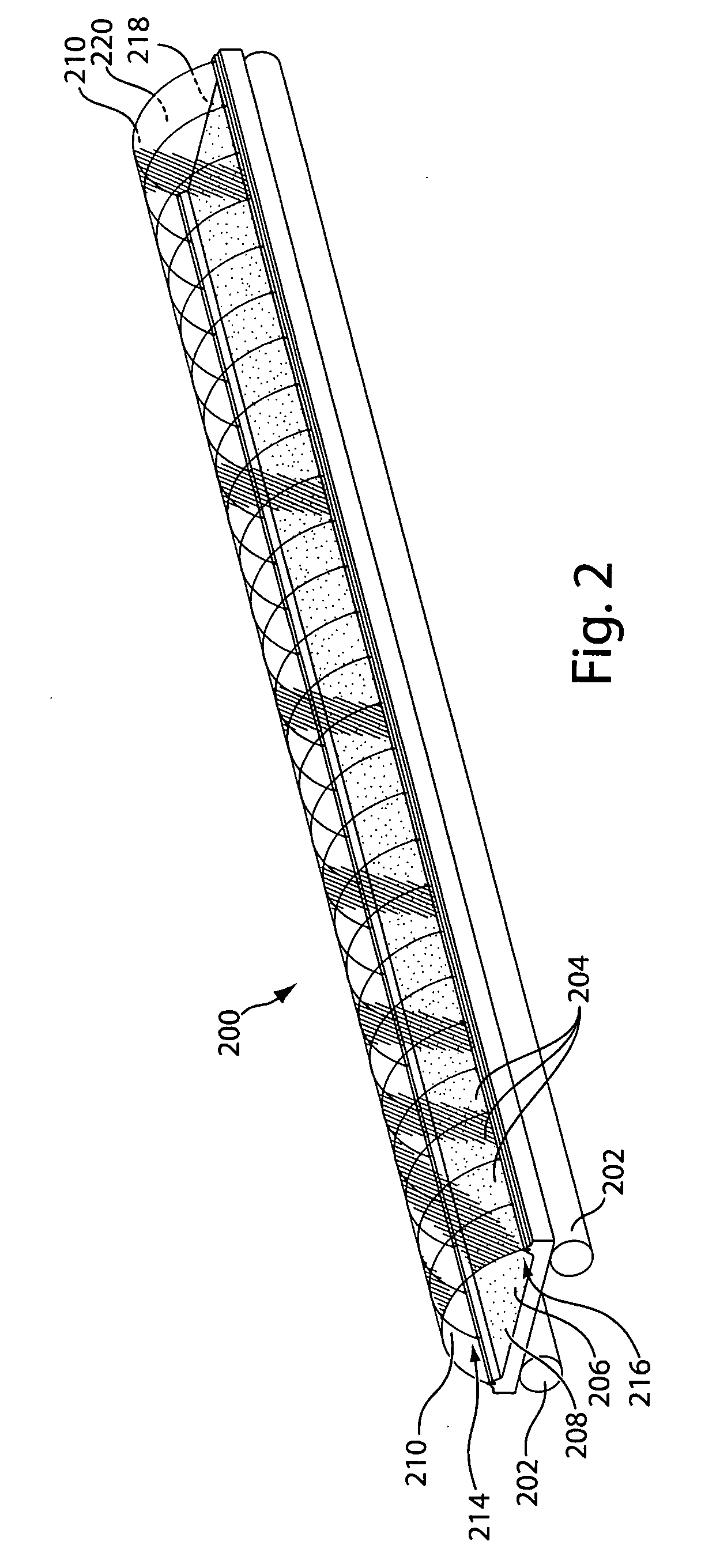

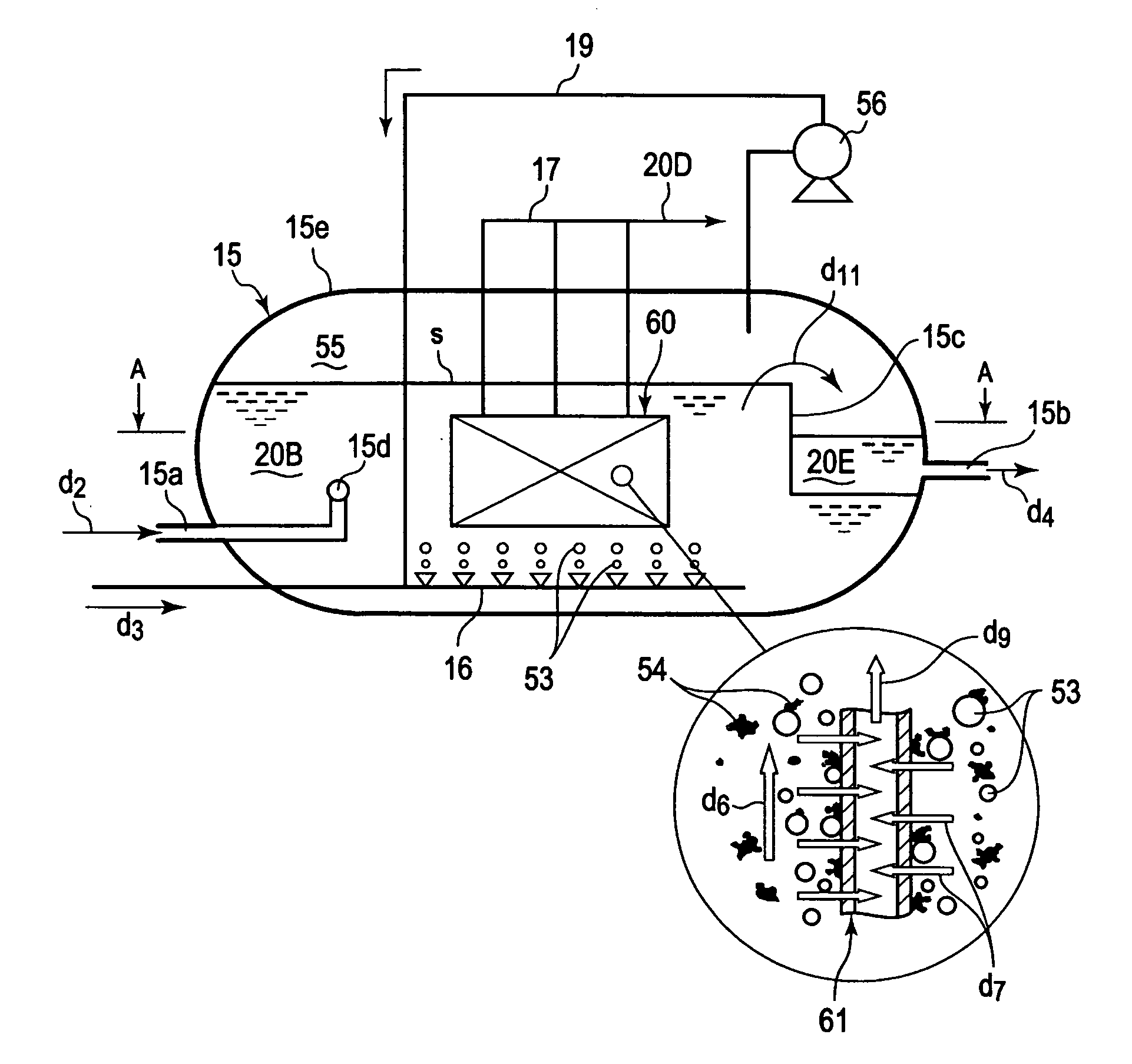

Integrated photobioreactor-based pollution mitigation and oil extraction processes and systems

InactiveUS20080009055A1Bioreactor/fermenter combinationsBiological substance pretreatmentsBiodieselLiquid medium

Integrated systems including a photobioreactor system designed to contain a liquid medium comprising at least one species of phototrophic organism therein, and a facility associated with extracting and / or processing oil extracted from mixtures of oil and solid material, such as an oil sands facility, are described. Processes for using a photobioreactor system as part of a gas-treatment process and system able to at least partially remove certain undesirable pollutants from a byproduct gas stream produced by an oil sands facility are also described. Examples of such pollutants that may be removed include compounds contained within combustion gases, e.g., CO2 and / or NOx. These pollutants processed with the photobioreactor system, and, in some embodiments, biomass produced with the photobioreactor system may be utilized to produce a fuel source (e.g., biodiesel) and cutting stock for further operation of or use in the oil sands facility. Such uses of certain embodiments can provide an efficient means for recycling carbon, thereby reducing CO2 emissions, fuel, and / or cutting stock requirements for a given quantum of energy produced. In addition, in some cases the photobioreactor can be integrated with a holding pond and waste heat from the oil extraction process can be used to maintain the photobioreactor temperature and / or provide energy for other processes. Accordingly, embodiments described herein can improve the overall environmental and economic profile of the oil sands facility.

Owner:GREENFUEL TECHNOLOGIES CORPORATION

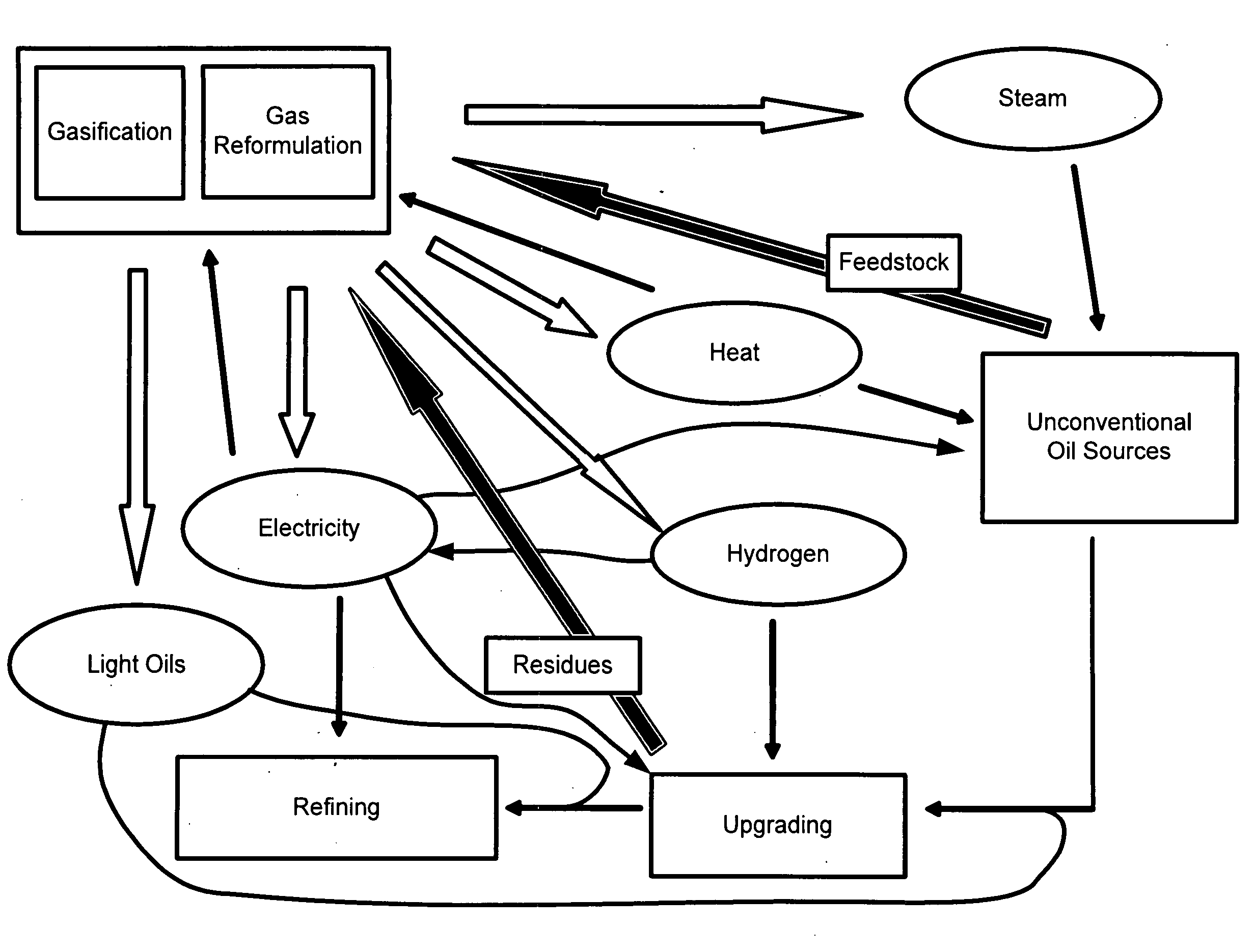

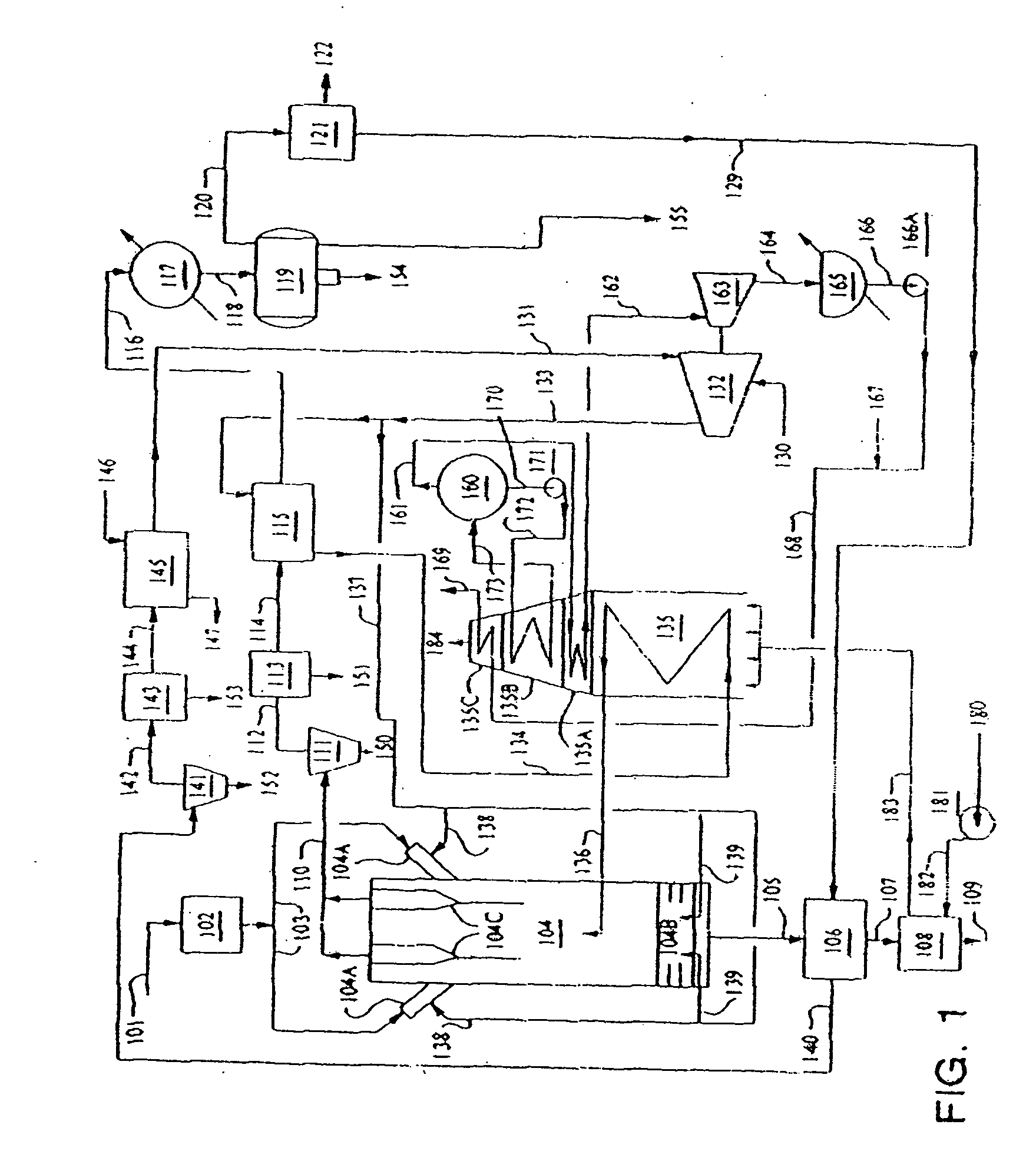

System comprising the gasification of fossil fuels to process unconventional oil sources

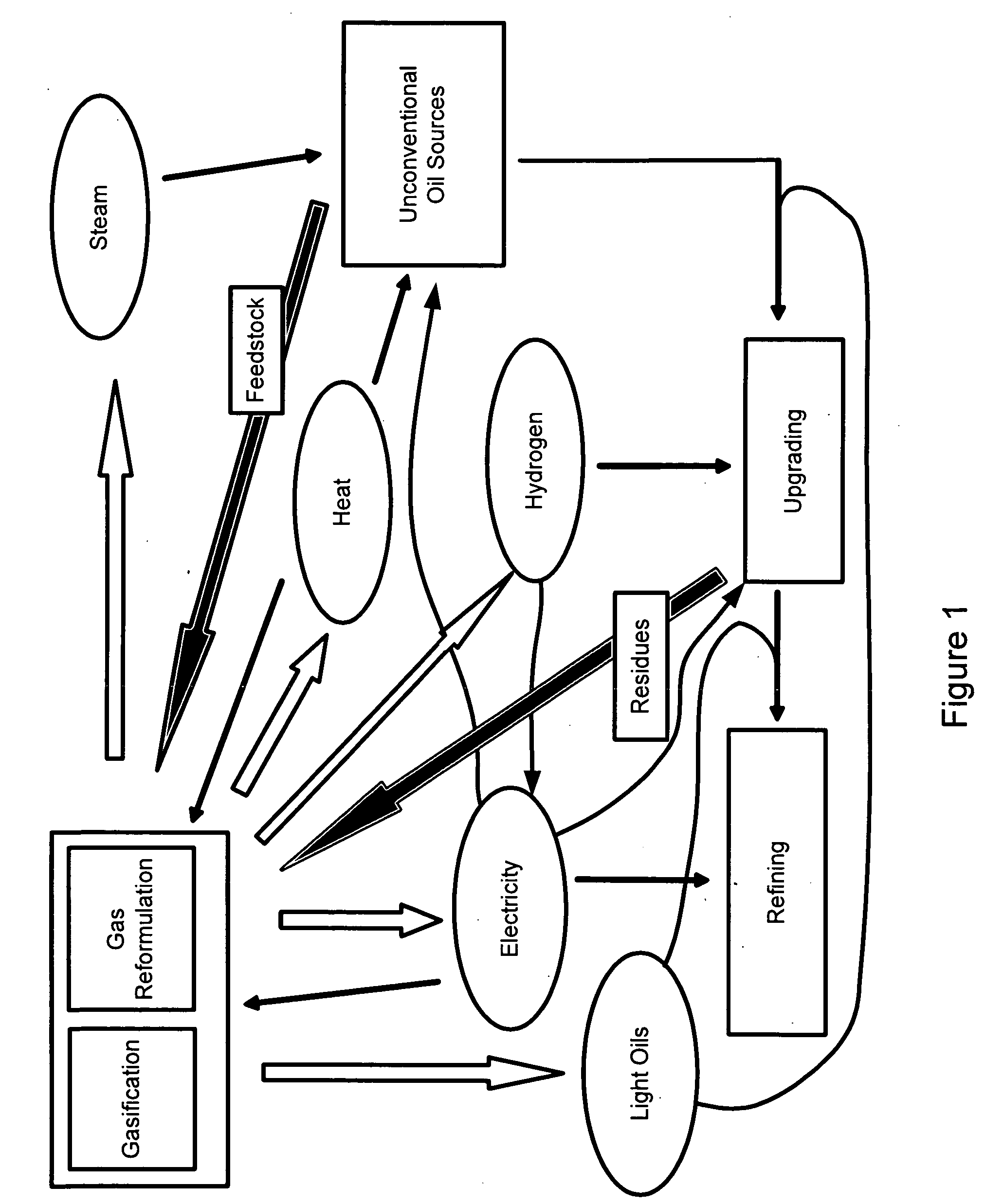

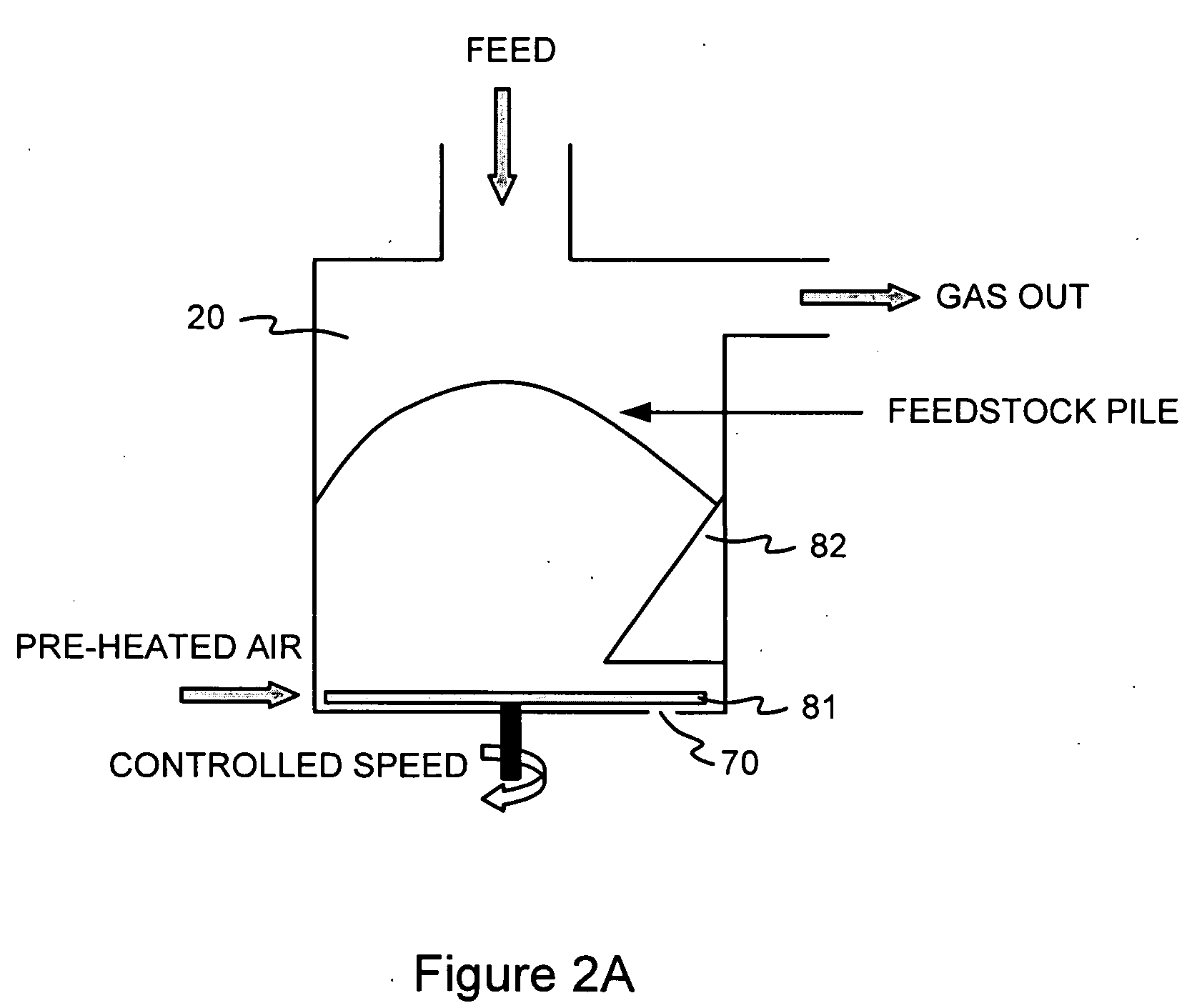

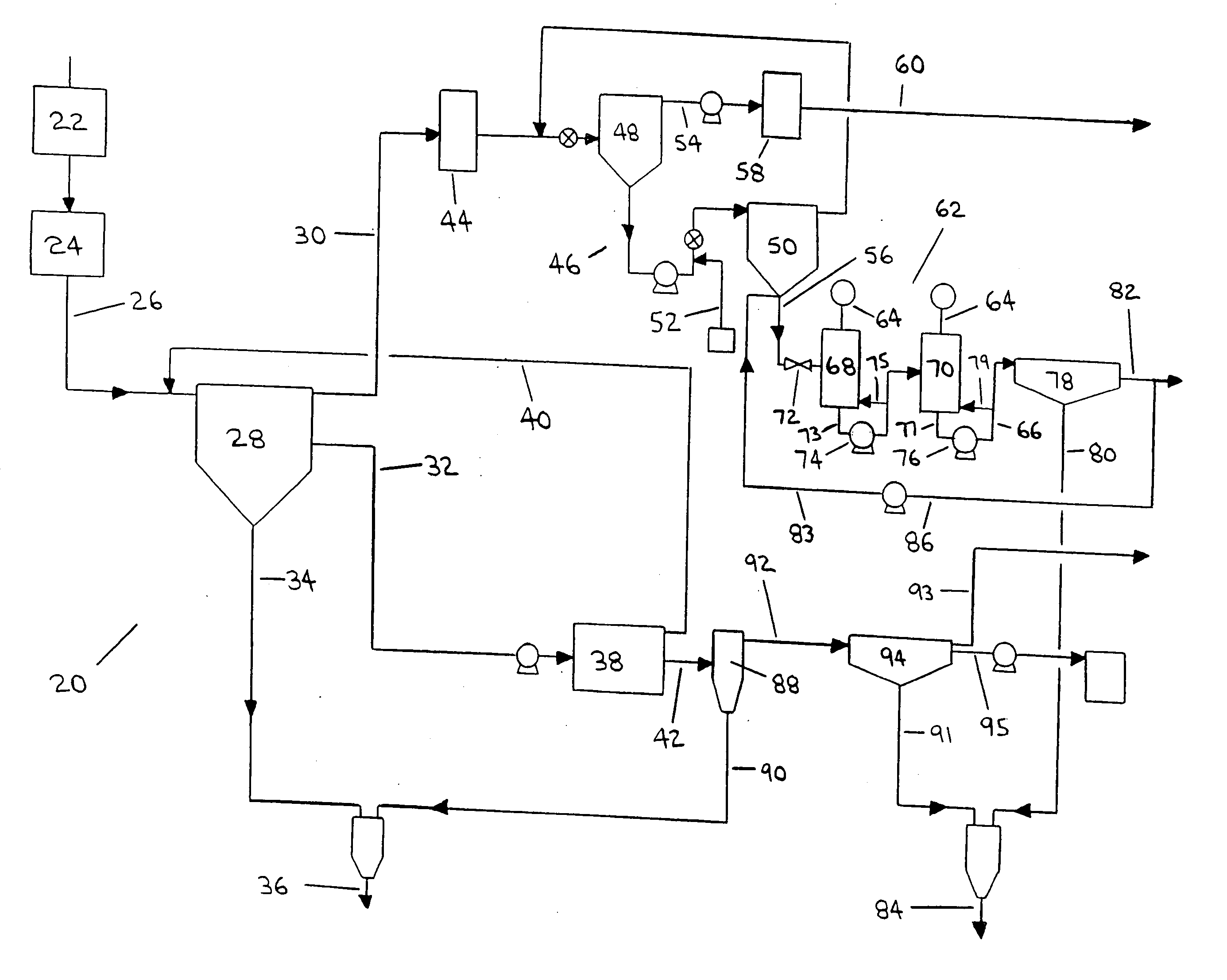

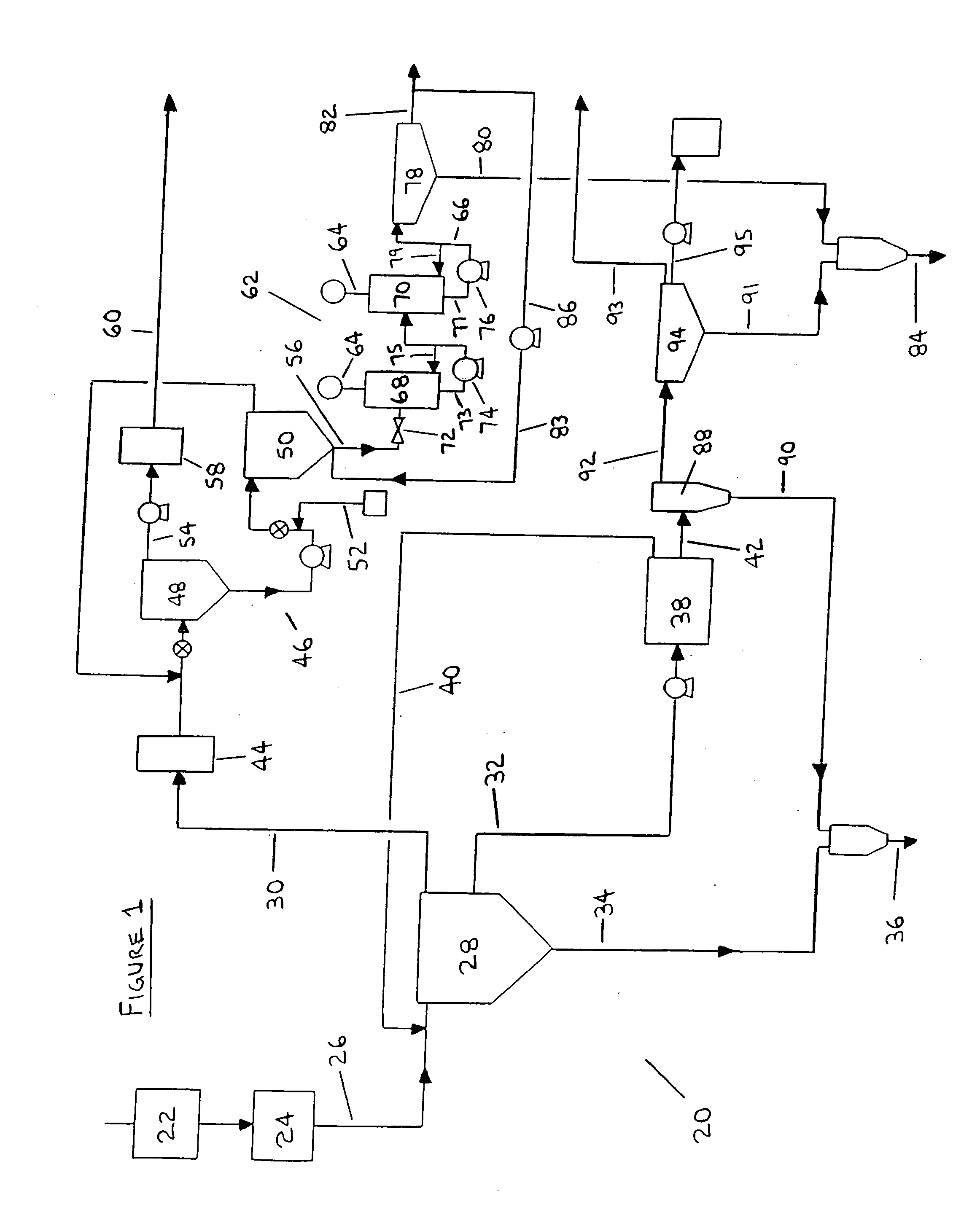

A facility comprising integrated systems for the extraction, and optionally upgrading and / or refinement, of unconventional oil sources, using fossil fuels as a primary source of energy. In particular, this facility provides a means to gasify one or more fossil fuels in an efficient manner, converting it into intermediate products such as heat, steam and electricity, which are then used by the system to obtain useful fuel products from unconventional oil sources such as tar sands and oil shale. The design of the components of this facility is optimized such that the overall costs are competitive with an equivalent unconventional oil source processing facility that uses natural gas as a source of processing energy. The facility can be used on its own, may use supplemental natural gas energy sources, or may be used in conjunction with an existing facility that uses natural gas as an energy source in order to improve the overall cost effectiveness of the processing and / or reduce the requirement for other energy sources, such as natural gas.

Owner:PLASCO ENERGY GROUP INC

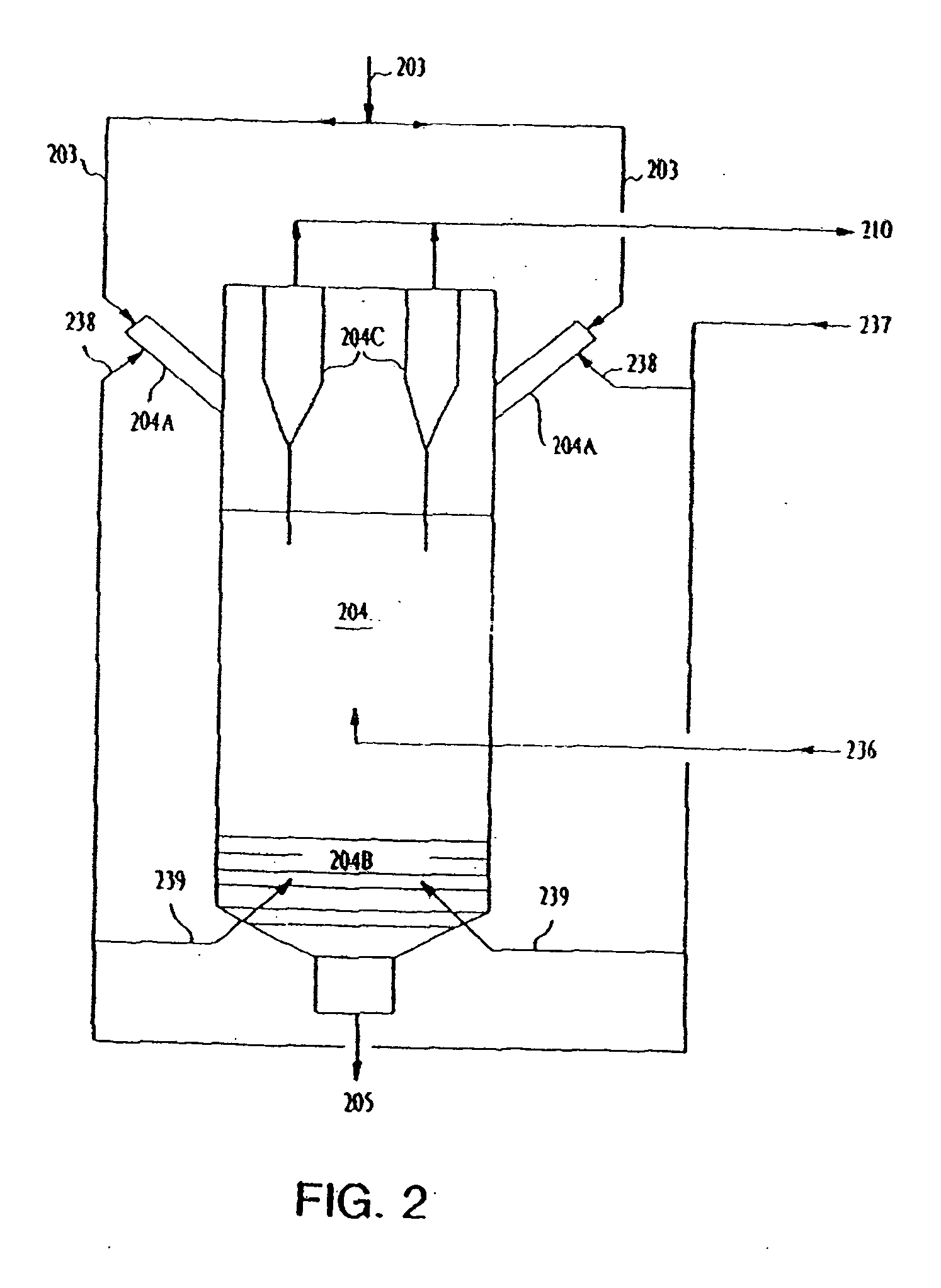

Process and apparatus for treating tailings

ActiveUS20050150844A1Easy to separateMaximize efficiencyWorking-up pitch/asphalt/bitumen by selective extractionSolid separationSolventOil sands

Processes and apparatus for the treatment of product streams from mineral processing operations, including the treatment of tailings which result from oil sand processing operations. The processes and apparatus relate to the recovery of a diluent solvent from bitumen froth tailings and to the thickening of tailings from a bitumen froth stream and a middlings stream resulting from an oil sand extraction process. In one aspect the processes and apparatus relate particularly to the recycling of product streams to maximize process efficiencies. In a second aspect the processes and apparatus relate particularly to the thickening of tailings to produce an underflow component, a clarified overflow component and an unclarified overflow component.

Owner:TRUENORTH ENERGY CORP

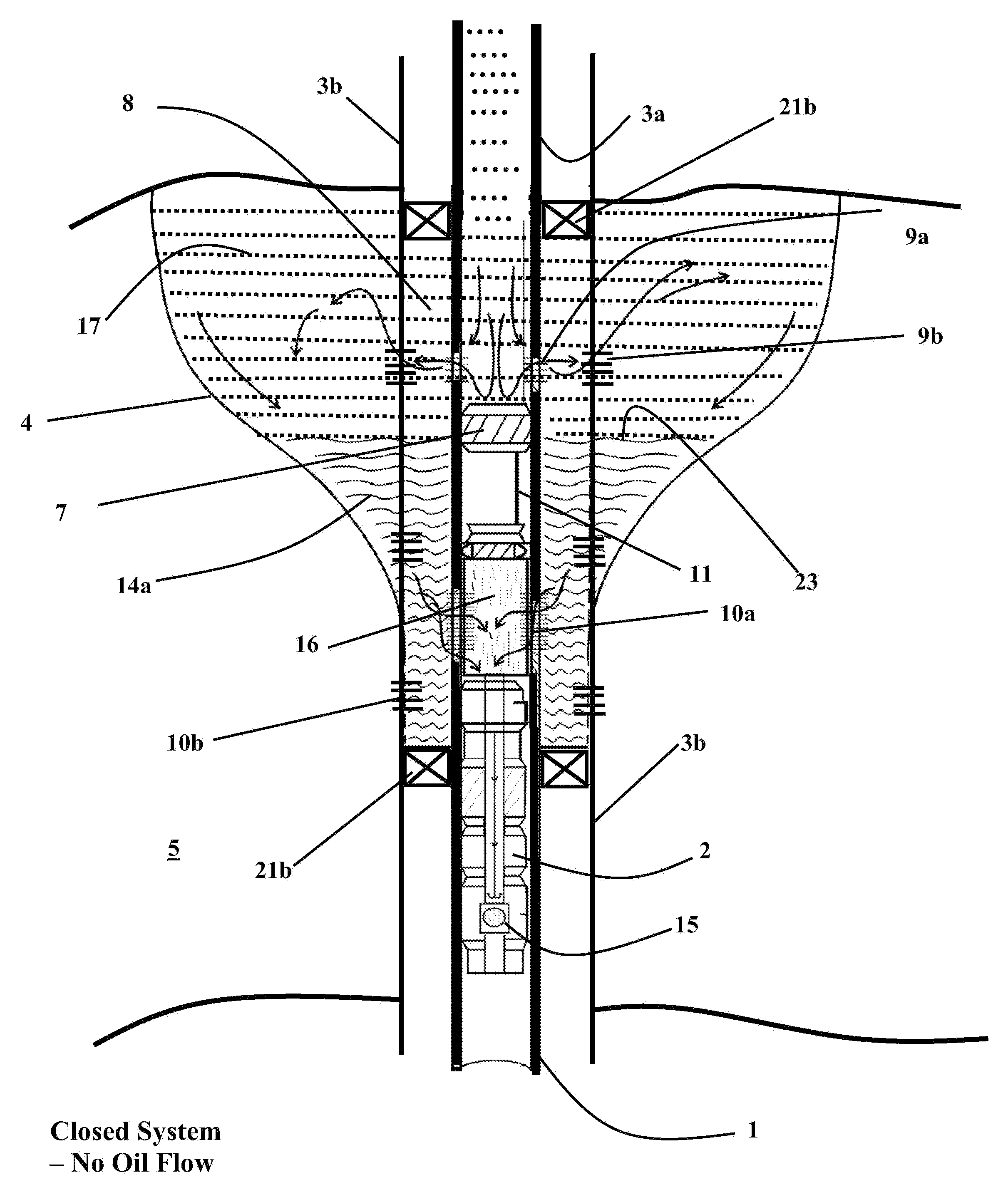

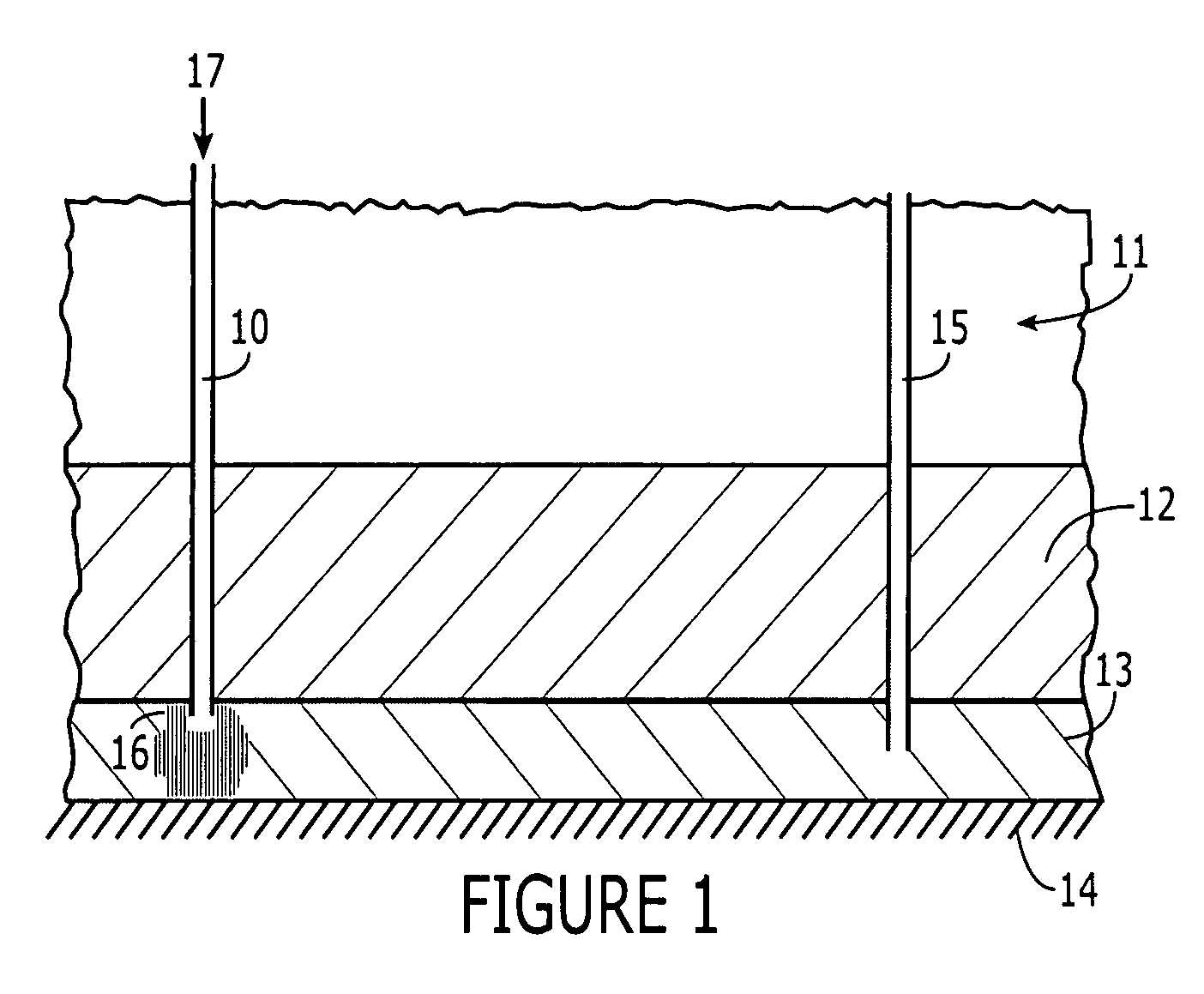

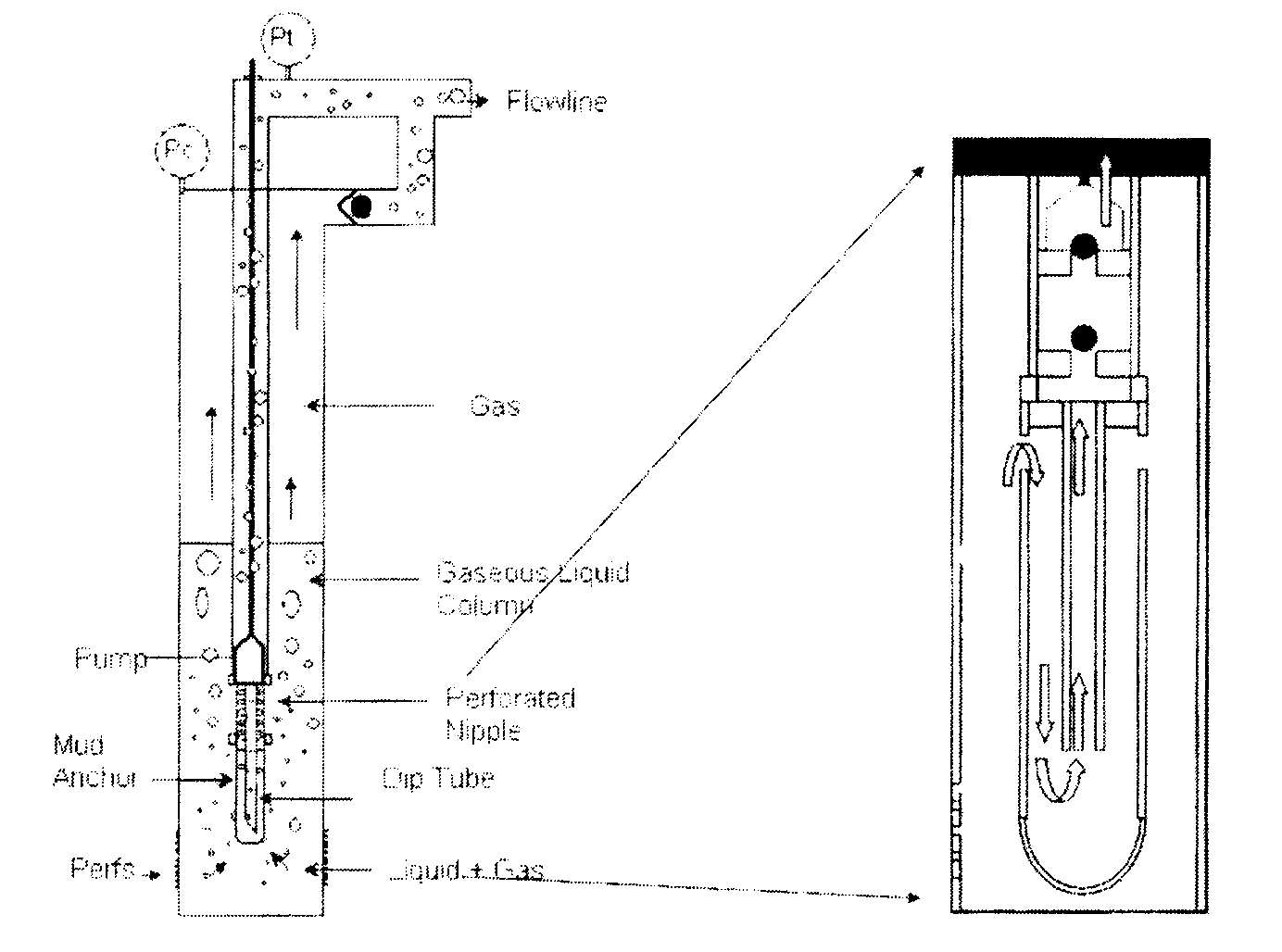

Heavy Oil Recovery and Apparatus

A thermal in-situ method and apparatus are provided for recovering hydrocarbons from subterranean hydrocarbon-containing formations such as oil sands, oil shale and other heavy oil systems. Recovery of viscous hydrocarbon by hot fluid injection into subterranean formations is assisted by using a specially designed wellbore with an active hydraulic seal, with a axial communication zone with multiple injection perforations separated from the production perforations by a moveable packer. In addition, a novel downhole thermal sensing apparatus is used to monitor and control oil production. A producing mechanism including pumping equipment lifts the produced oil from the central cavity to the surface.

Owner:CRICHLOW HENRY B

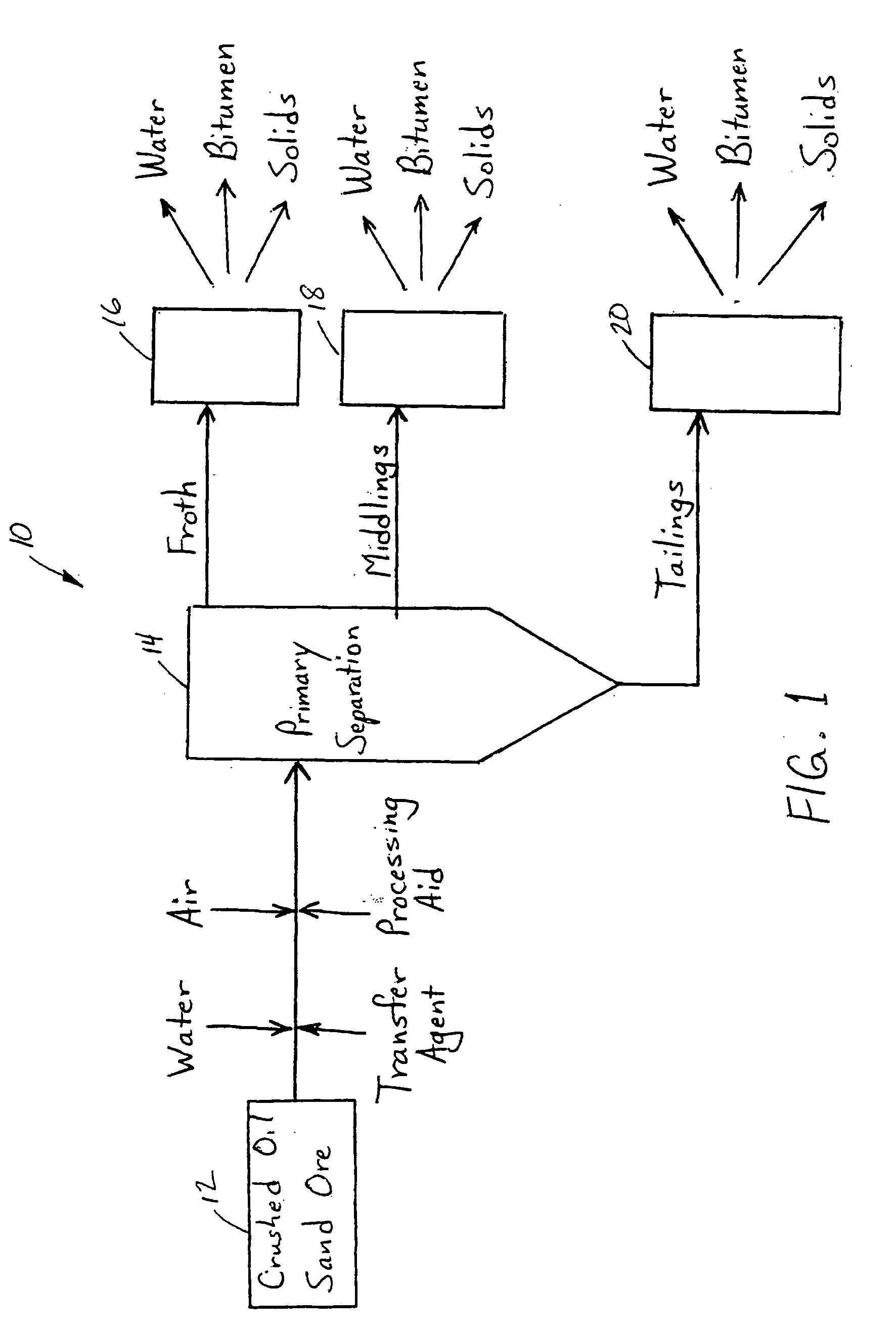

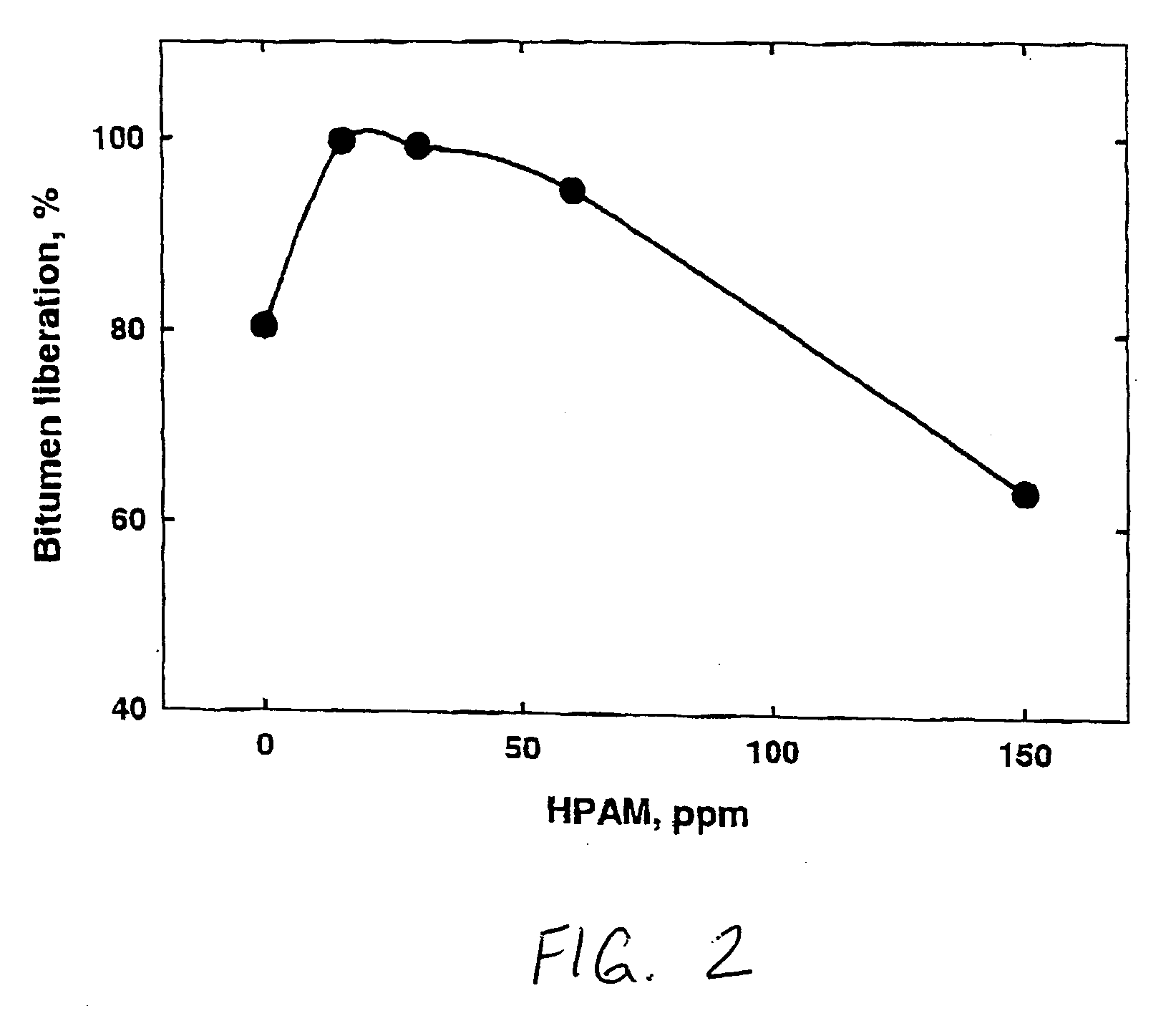

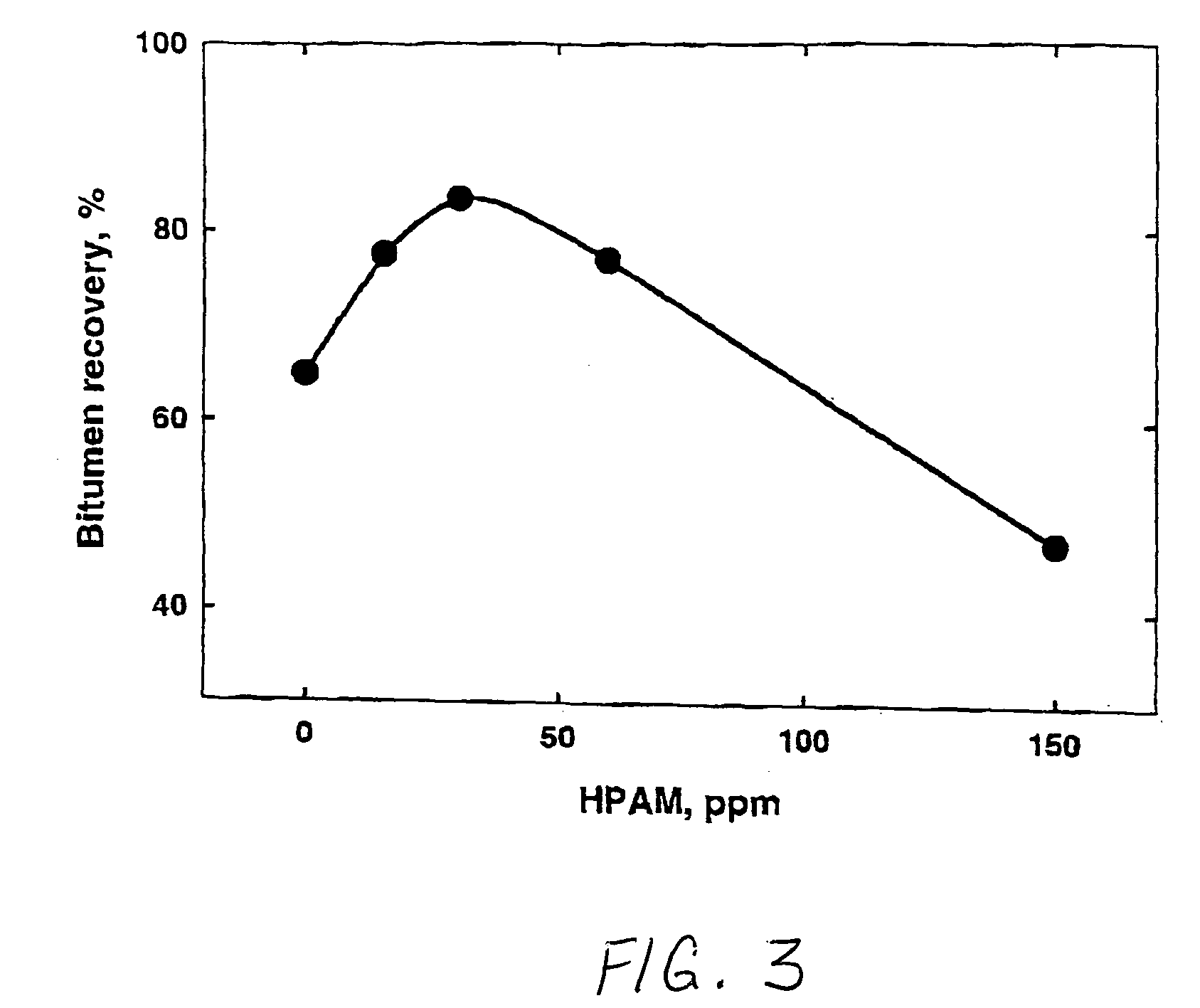

Processing aids for enhanced hydrocarbon recovery from oil sands, oil shale and other petroleum residues

InactiveUS20050194292A1Liberation of additionalPromote recoveryDewatering/demulsification with chemical meansLiquid hydrocarbon mixture productionHydrocotyle bowlesioidesSlurry

A method of improving hydrocarbon recovery from oil sands, oil shale, and petroleum residues includes adding a polymeric or nonpolymeric processing aid capable of sequestering cations, such as the multivalent calcium, magnesium and iron cations. The hydrocarbons are preferably contacted with the processing aid before a primary separation of the hydrocarbons in order to increase bitumen recovery. A processing aid is provided in an effective amount to increase the liberation of the hydrocarbons from inorganic solids, particularly when the source is a poor processing ore. Preferred processing aids include citric acid or a polymeric acid selected from polyacrylic acid, polymethacrylic acid, salts of these acids, partial salts of these acids, and combinations thereof. The processing aids significantly increase the hydrocarbon recovery typically with concentrations less than 50 ppm and the polymeric processing aids can also provide beneficial flocculation of solids in tailings slurry.

Owner:THE GOVERNORS OF THE UNIV OF ALBERTA

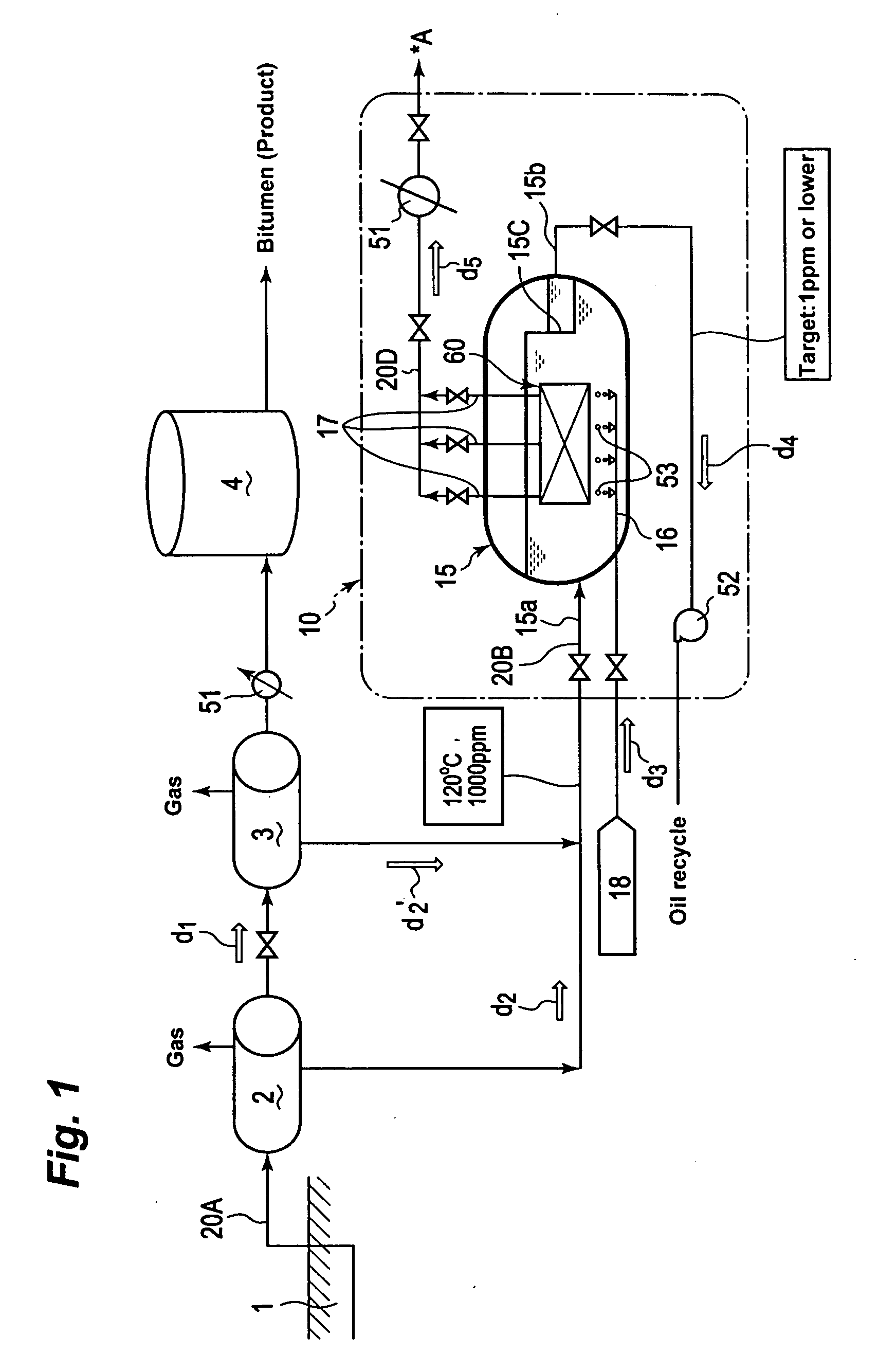

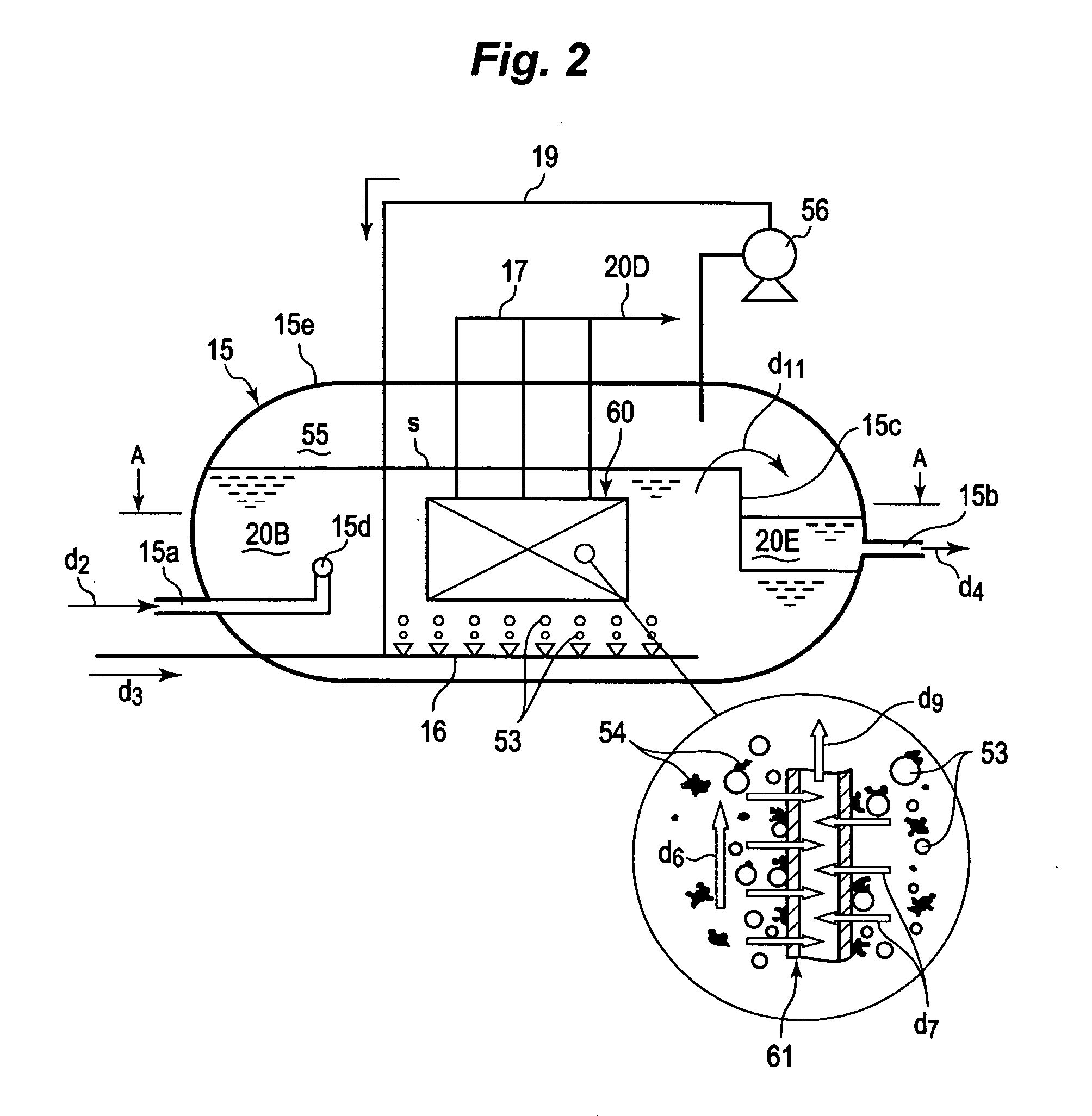

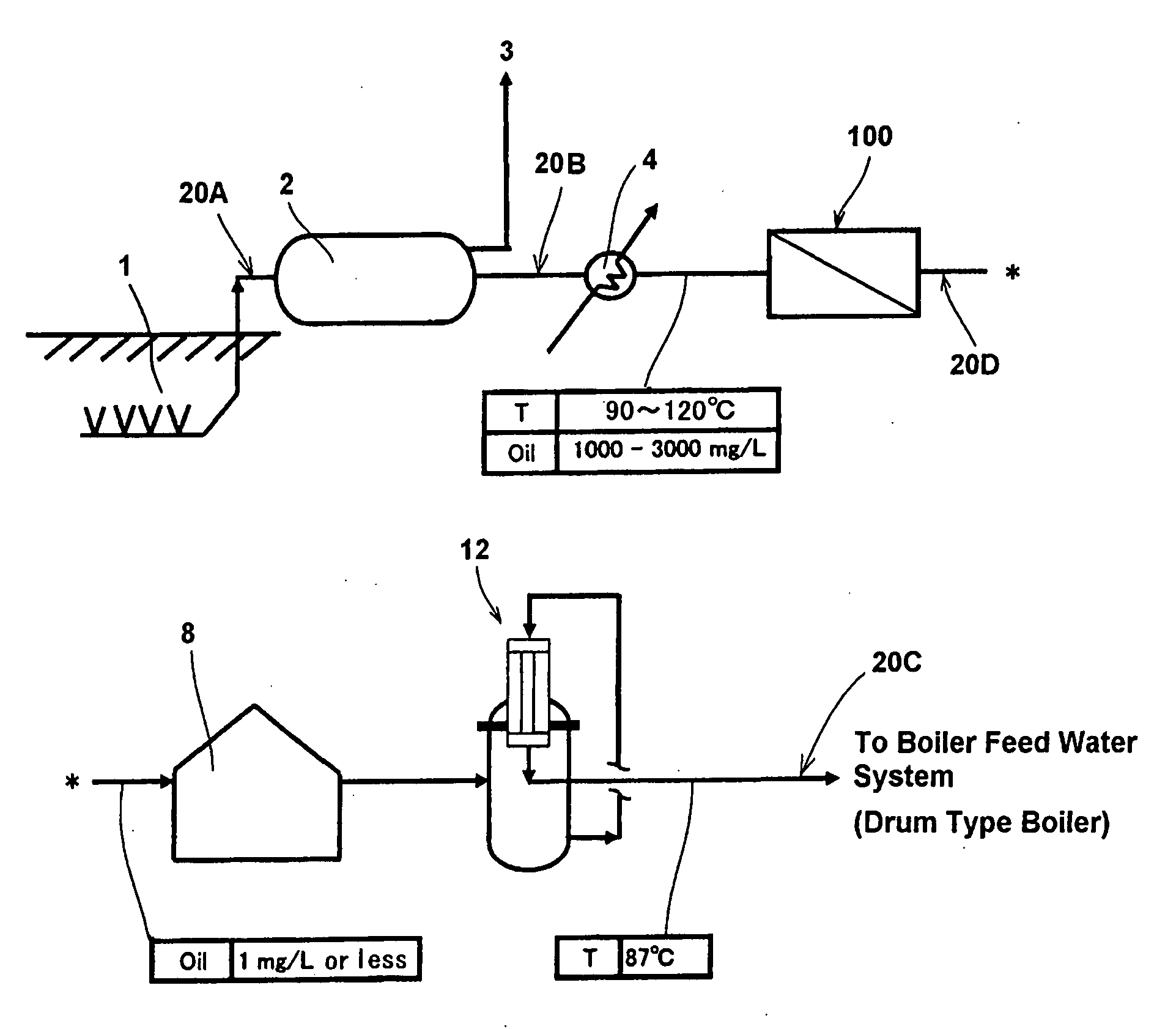

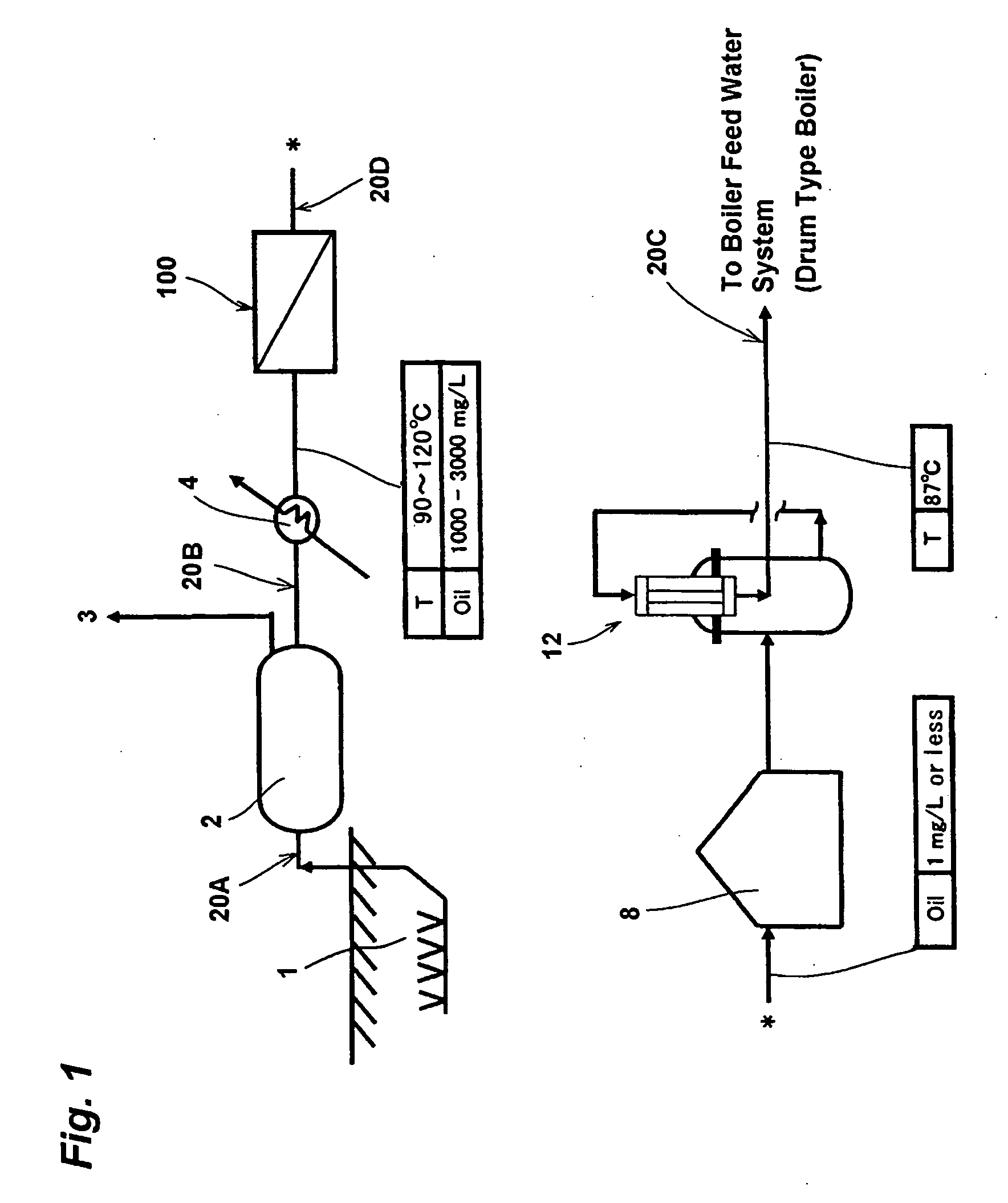

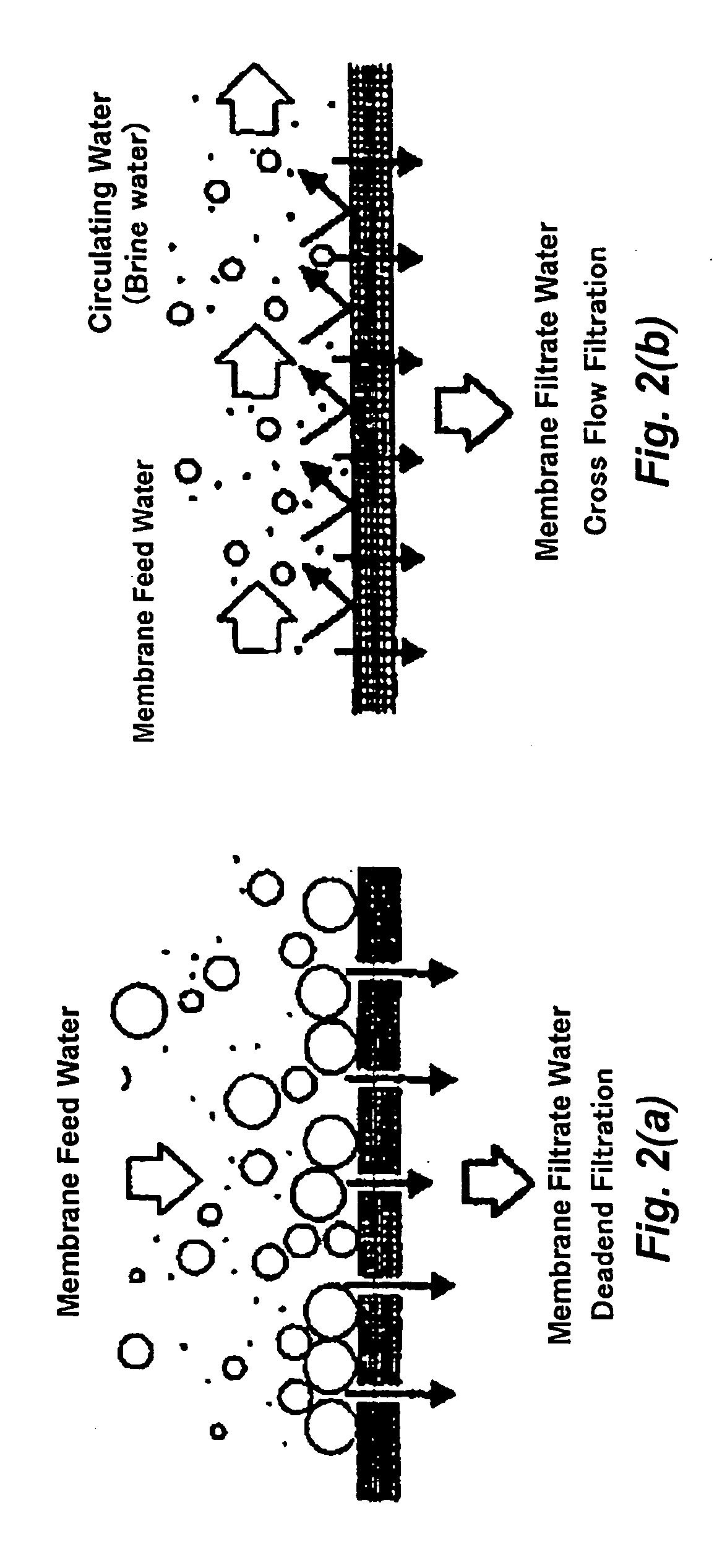

Apparatus of produced water treatment, system and method of using the apparatus, and method of water reuse by using the same

An apparatus of produced water treatment, to be adopted in an in-situ recovery method of producing bitumen from oil sand, the apparatus capable of removing the oil from produced water, the produced water of being left by separating the bitumen from bitumen-mixed fluid having been recovered from the oil sand, the apparatus having: a vessel for receiving the produced water; a submerge type filtration membrane module, installed in the vessel, for filtering the produced water in the condition of the membrane being submerged in the produced water; and a bubble generator for generating bubbles to be forwarded toward the submerged filtration membrane in the produced water.

Owner:TOYO ENG CORP +1

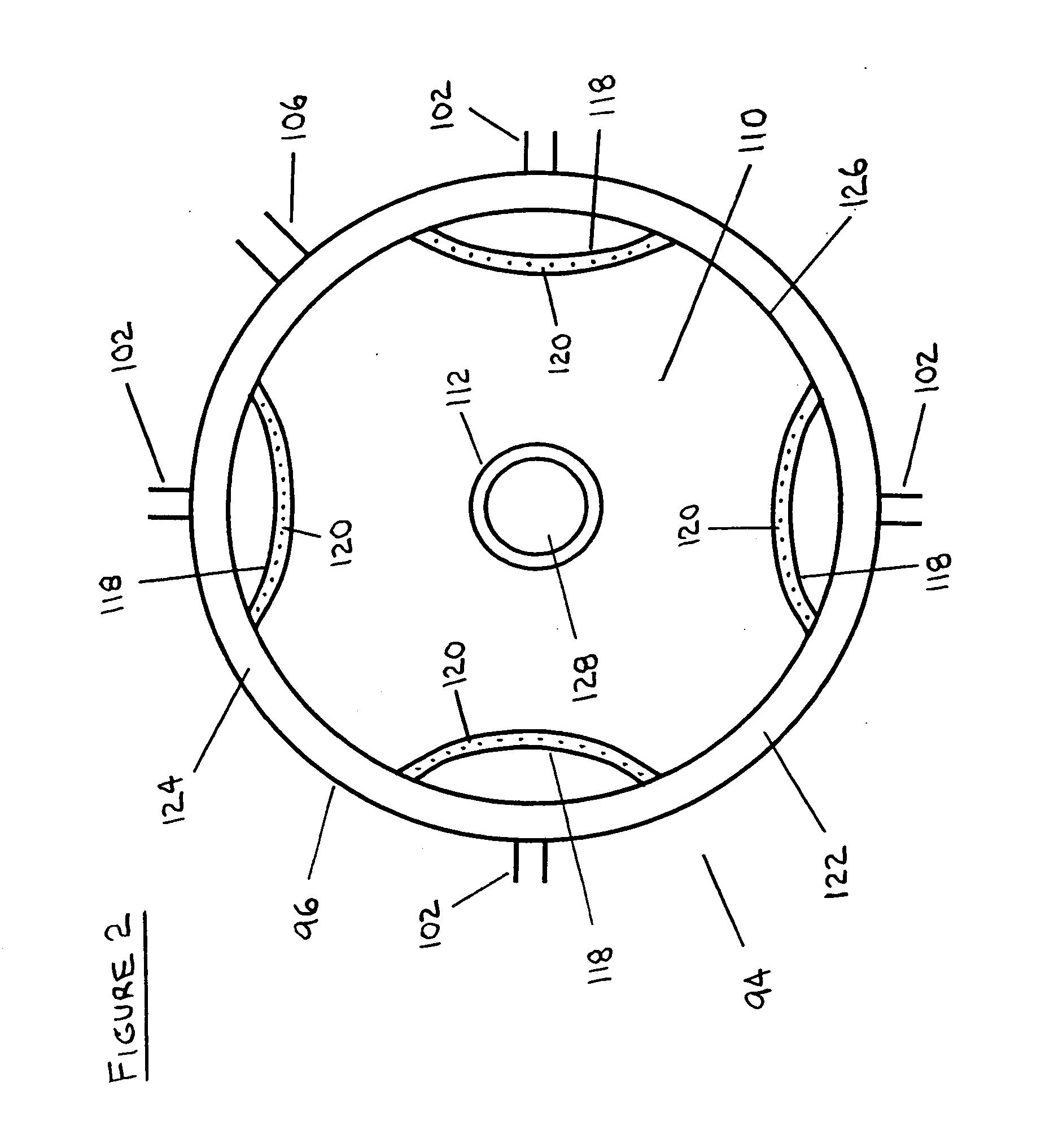

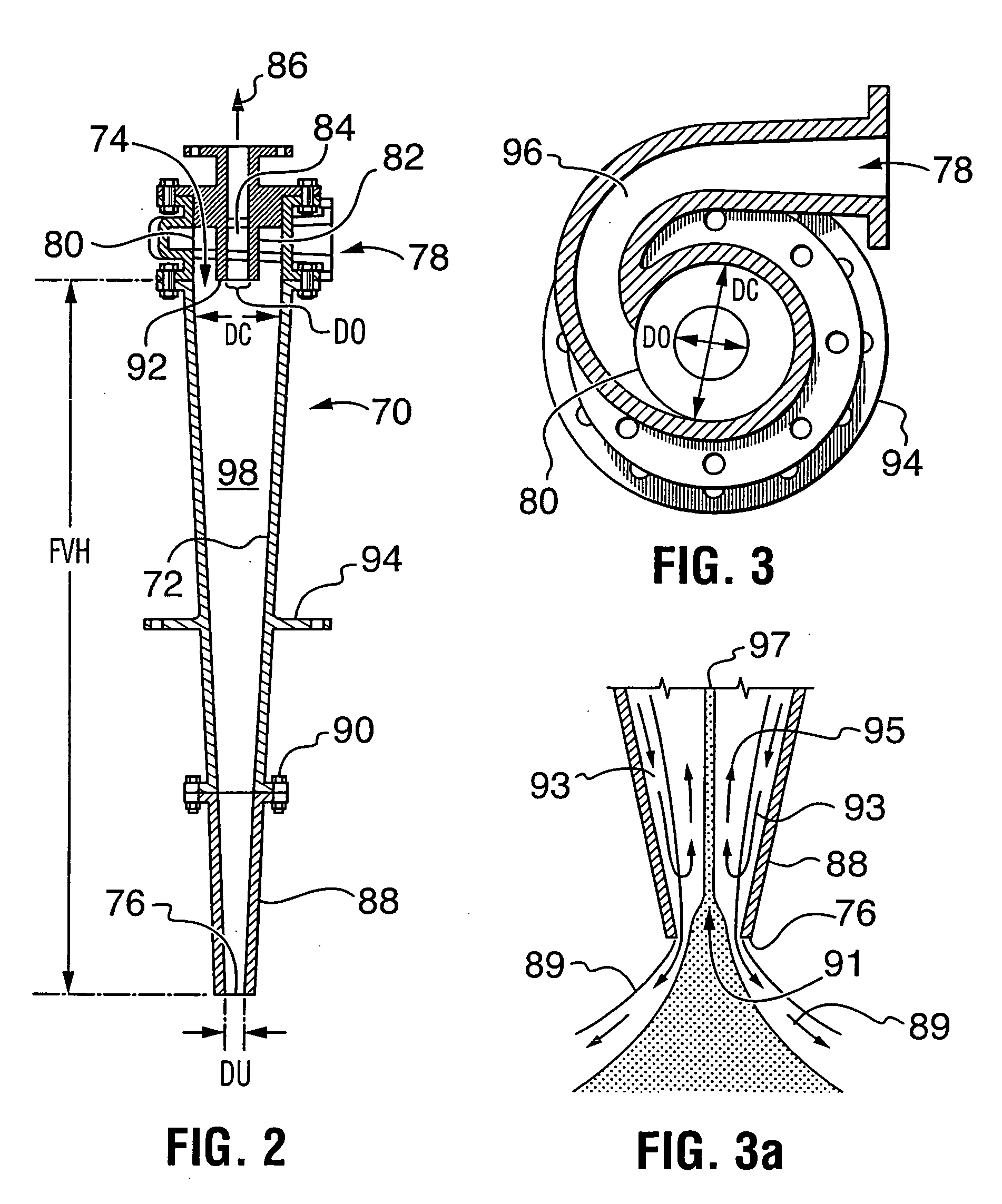

Bituminous froth hydrocarbon cyclone

InactiveUS20060138055A1Poor separationEasy to separateReversed direction vortexCentrifugal force sediment separationCycloneHydrocotyle bowlesioides

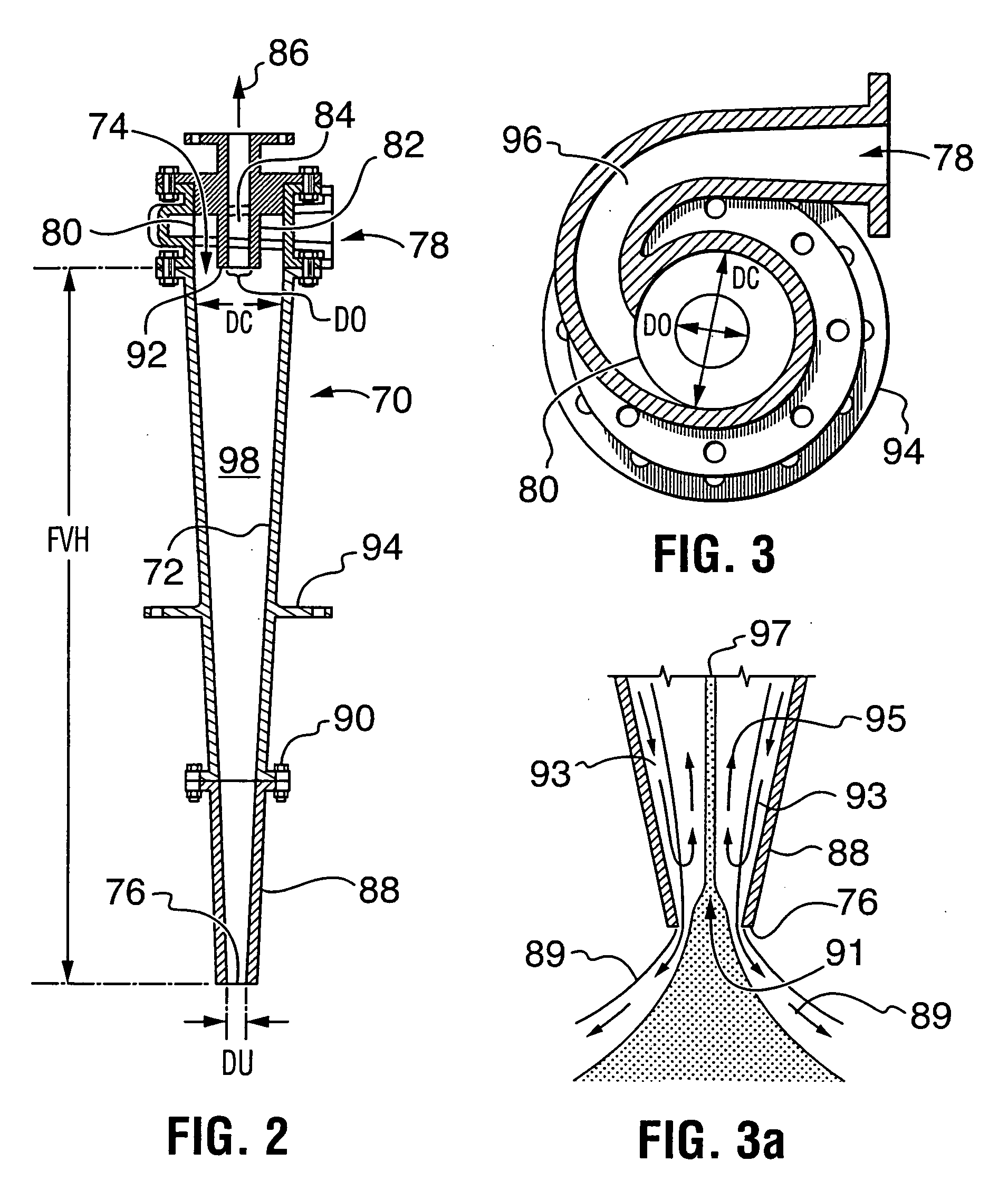

An apparatus to perform a process to remove water and minerals from a bitumen froth output of a oil sands hot water extraction process comprises: (i) a cyclone body having an elongated conical inner surface defining a cyclone cavity extending from an upper inlet region with a diameter DC to a lower apex outlet with a diameter DU; (ii) an inlet means forming an inlet channel extending into the upper inlet region of the cyclone cavity; and (iii) a vortex finder forming an overflow outlet of a diameter (DO) extending into the upper inlet region of the cyclone cavity toward the lower apex outlet and having a lower end extending an excursion distance below the inlet channel; wherein a fluid composition entering the inlet channel into the cyclone cavity is urged by force of gravity and velocity pressure downward toward the lower apex and variations in density of the constituent components of the fluid composition cause the lighter component materials to be directed toward the overflow outlet of the vortex finder.

Owner:GARNER WILLIAM NICHOLAS +2

Oxidative desulfurization and denitrogenation of petroleum oils

InactiveUS20070102323A1Reduce the temperatureShort stayOrganic chemistryRefining with oxygen compoundsHydrocotyle bowlesioidesSolvent

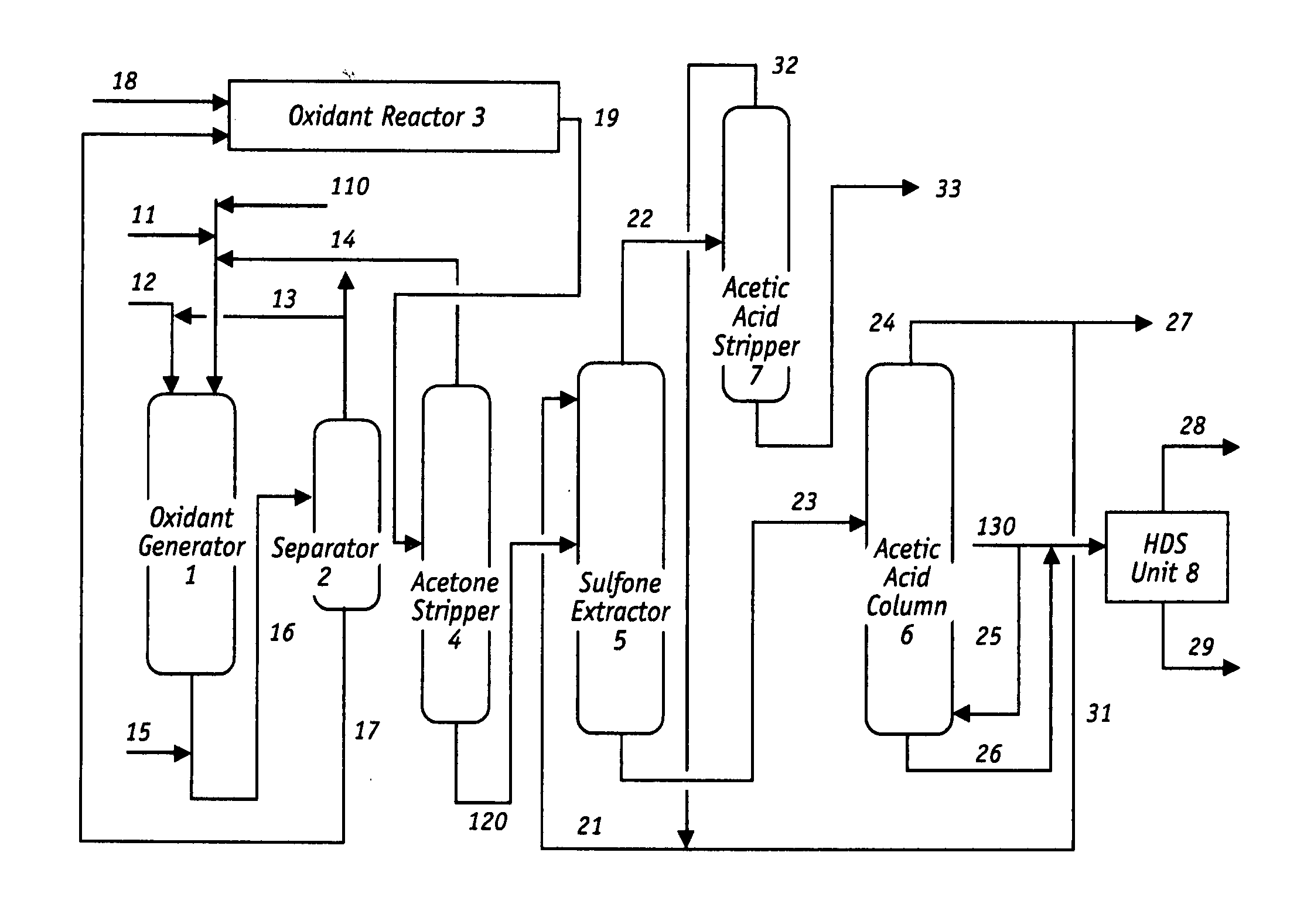

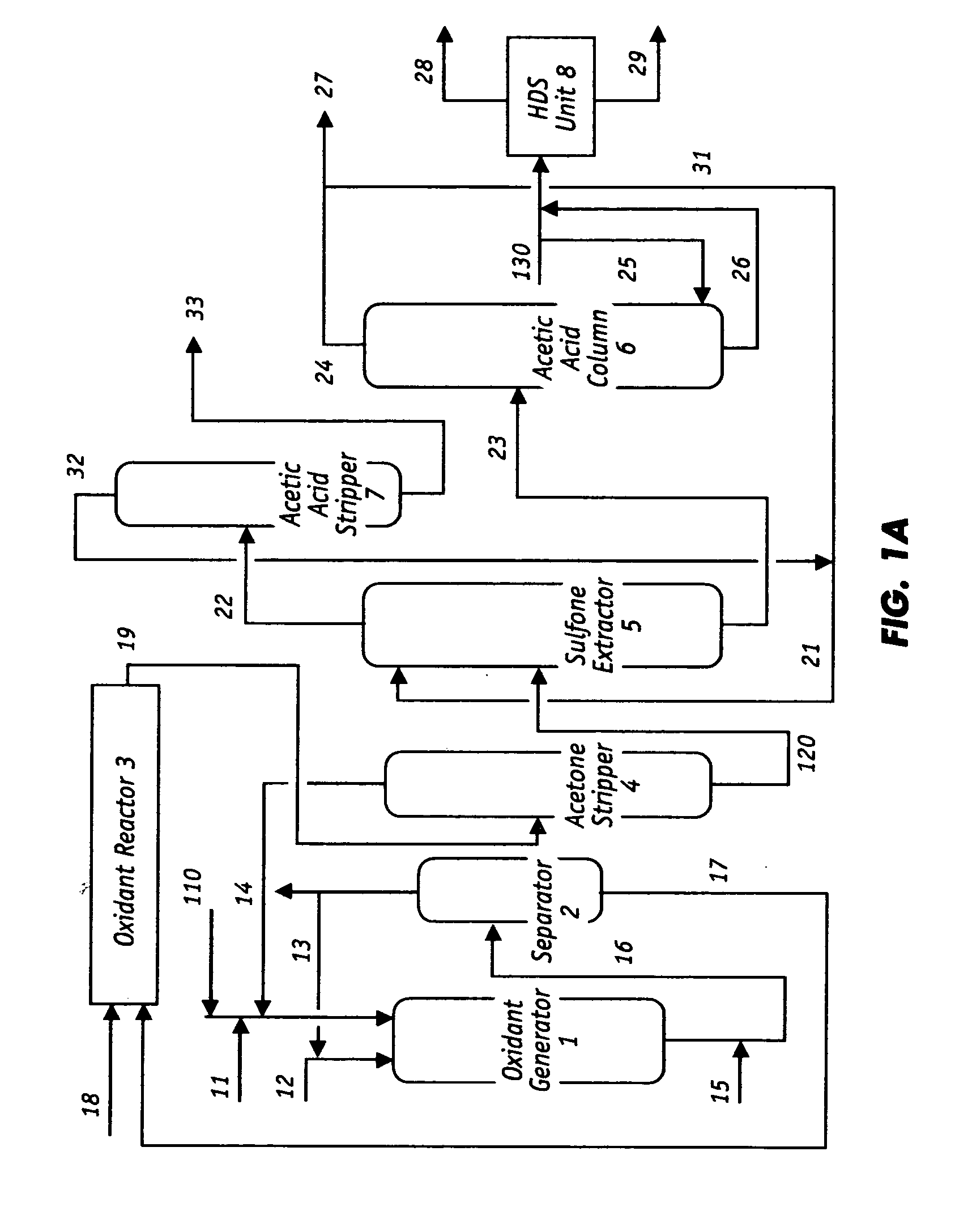

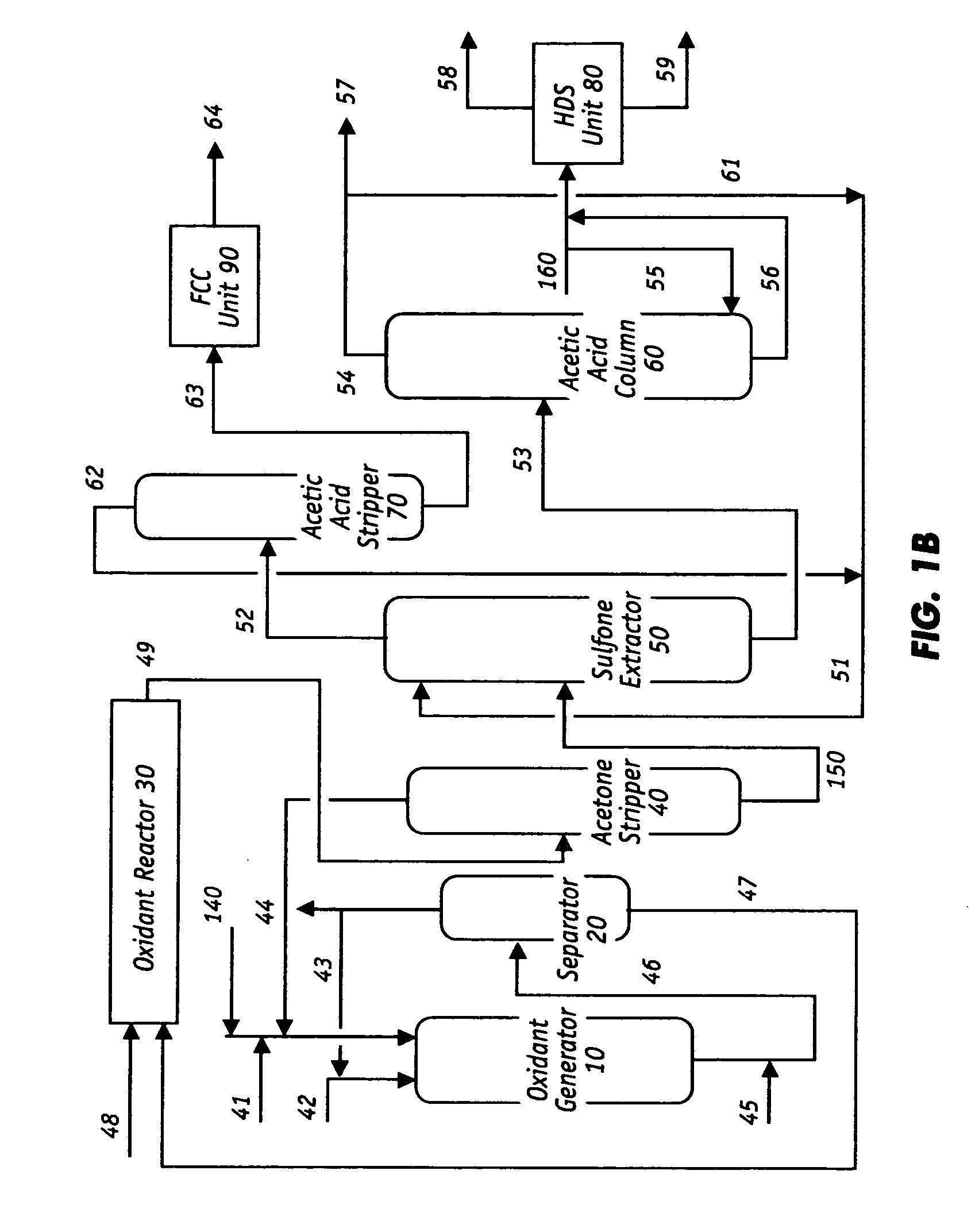

An improved oxidative process that employ a robust, non-aqueous, and oil-soluble organic peroxide oxidant for effective desulfurization and denitrogenation of hydrocarbons including petroleum fuels, hydrotreated vacuum gas oil (VGO), non-hydrotreated VGO, petroleum crude oil, synthetic crude oil from oil sand, and residual oil. Even at low concentrations and without the assistance of catalysts, the non-aqueous organic peroxide oxidant is extremely active and fast in oxidizing the sulfur and nitrogen compounds in the hydrocarbon feedstocks. Furthermore, the process generates a valuable organic acid by-product that is also used internally as the extractive solvent for effective removal of the oxidized sulfur and nitrogen from the hydrocarbons without the need of a final adsorption step. Novel process steps are also disclosed to substantially prevent yield loss in the oxidative process.

Owner:CPC CORPORATION

Sand consolidation and water plugging profile control agent made by oil sand

InactiveCN101451061ATo achieve the goal of emission reductionEnhanced overall recoveryDrilling compositionSealing/packingSlagGranularity

The invention relates to a sand-consolidating and water-blocking profile modifying agent for oil sludge sand. The profile modifying agent is prepared by mixing the following raw materials: oil sludge sand, 10 to 90 portions of consolidation agent or adding modifier, a consolidation accelerant or a consolidation retardant; the oil sludge sand is subjected to ball milling through a ball mill; part of large crude oil is separated off so as to reach the requirement of granularity of the profile control agent; therefore, the oil sludge sand with granularity of less than 200 meshes is less than 70 percent of the total mass of the oil sludge sand; and the consolidation agent is selected from one or a mixture of one or more of cement or cement clinker, steel slag, slag, pulverized coal ash, gypsum, lime and magnesia. In application, the profile control agent is prepared to a 1 to 20 percent suspension solution; and the suspension solution is injected into a deep part of stratum of an oilfield through profile modification equipment. The profile modifying agent fully utilizes mass oil sludge sand produced in the production process of various oilfields, realizes the aim of emission reduction; and the oil sludge sand is recycled and is used as the sand-consolidating and water-blocking profile modifying agent, thereby achieving the aim of consolidating sand, blocking water and improving extraction yield.

Owner:SHANDONG UNIV

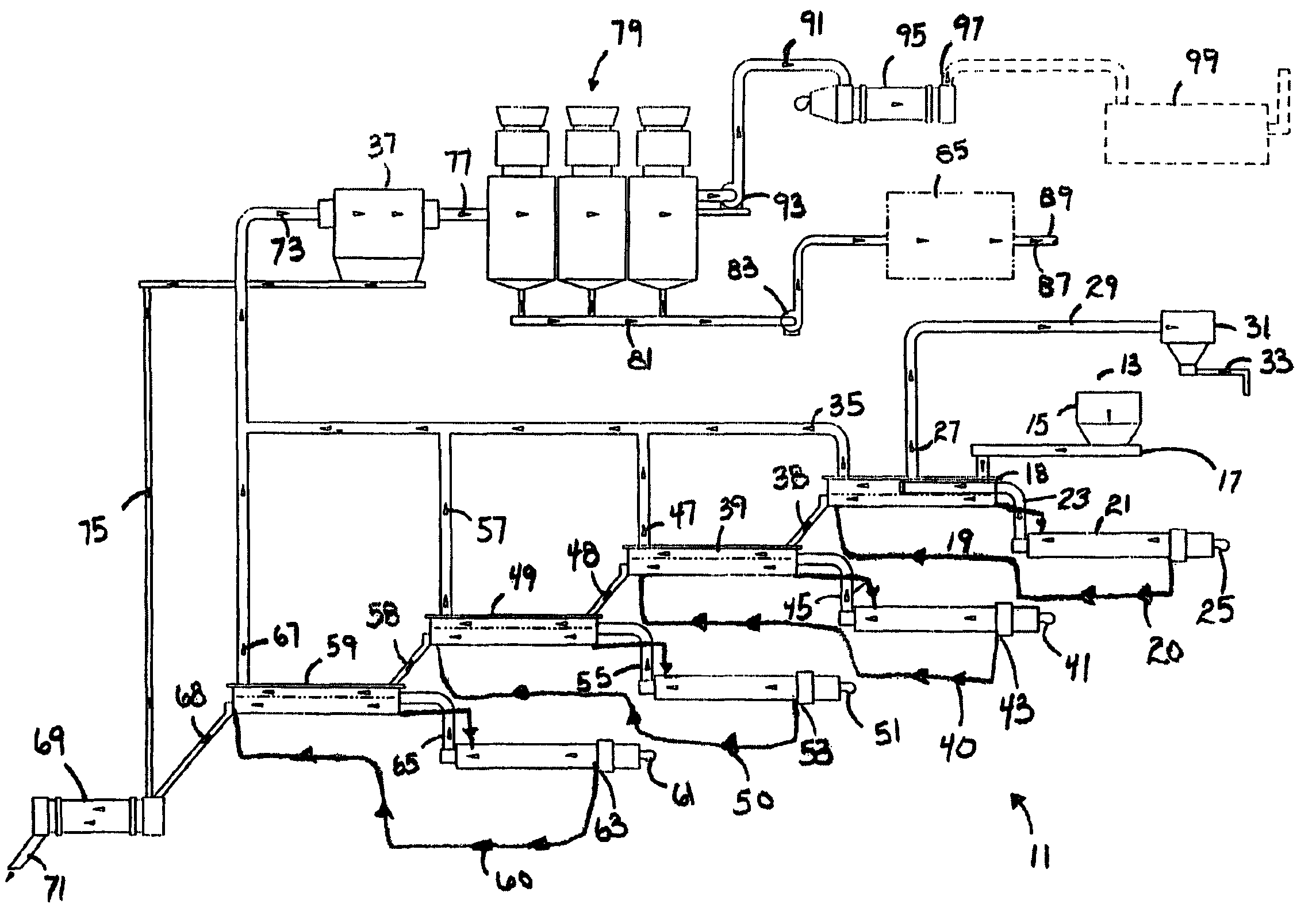

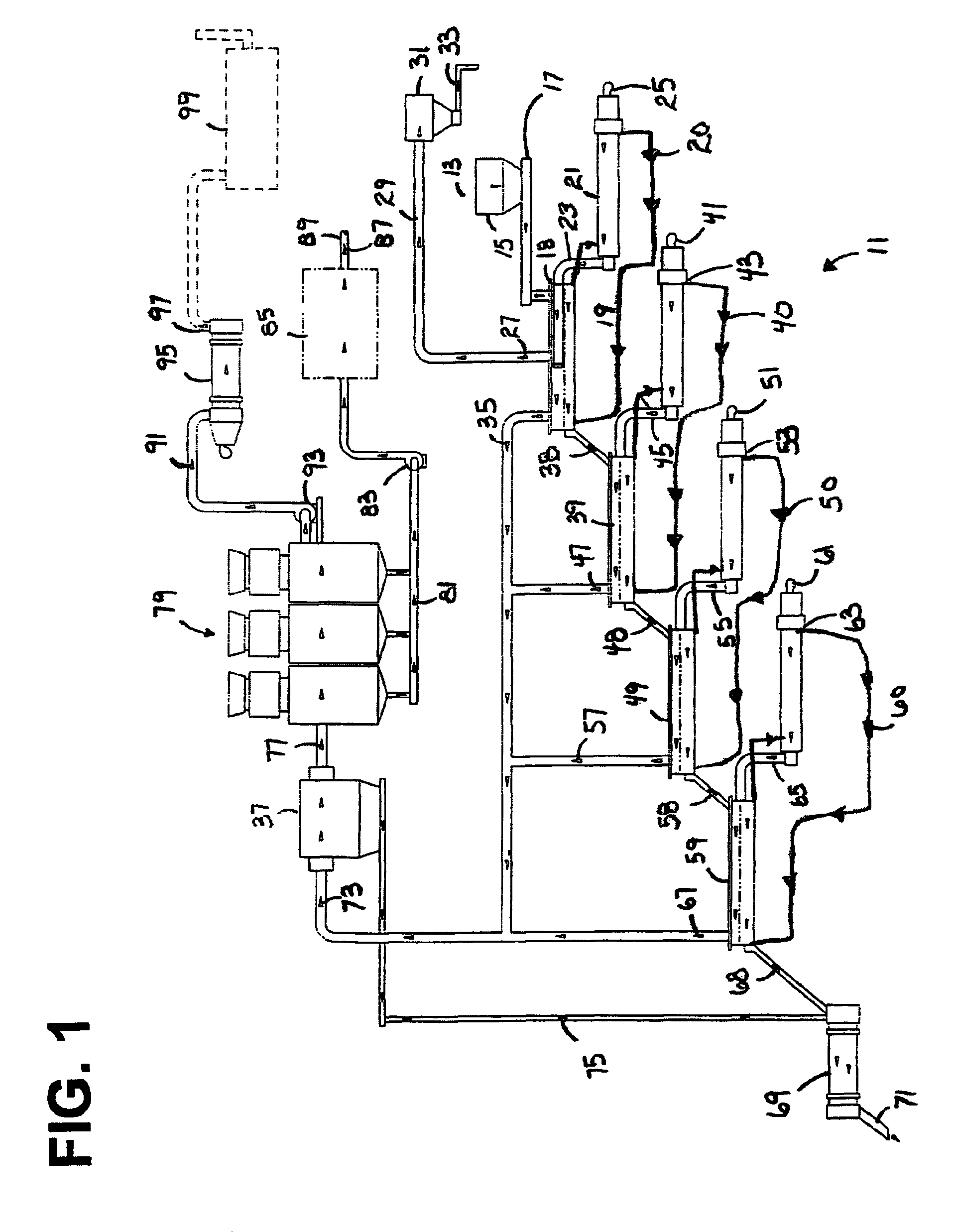

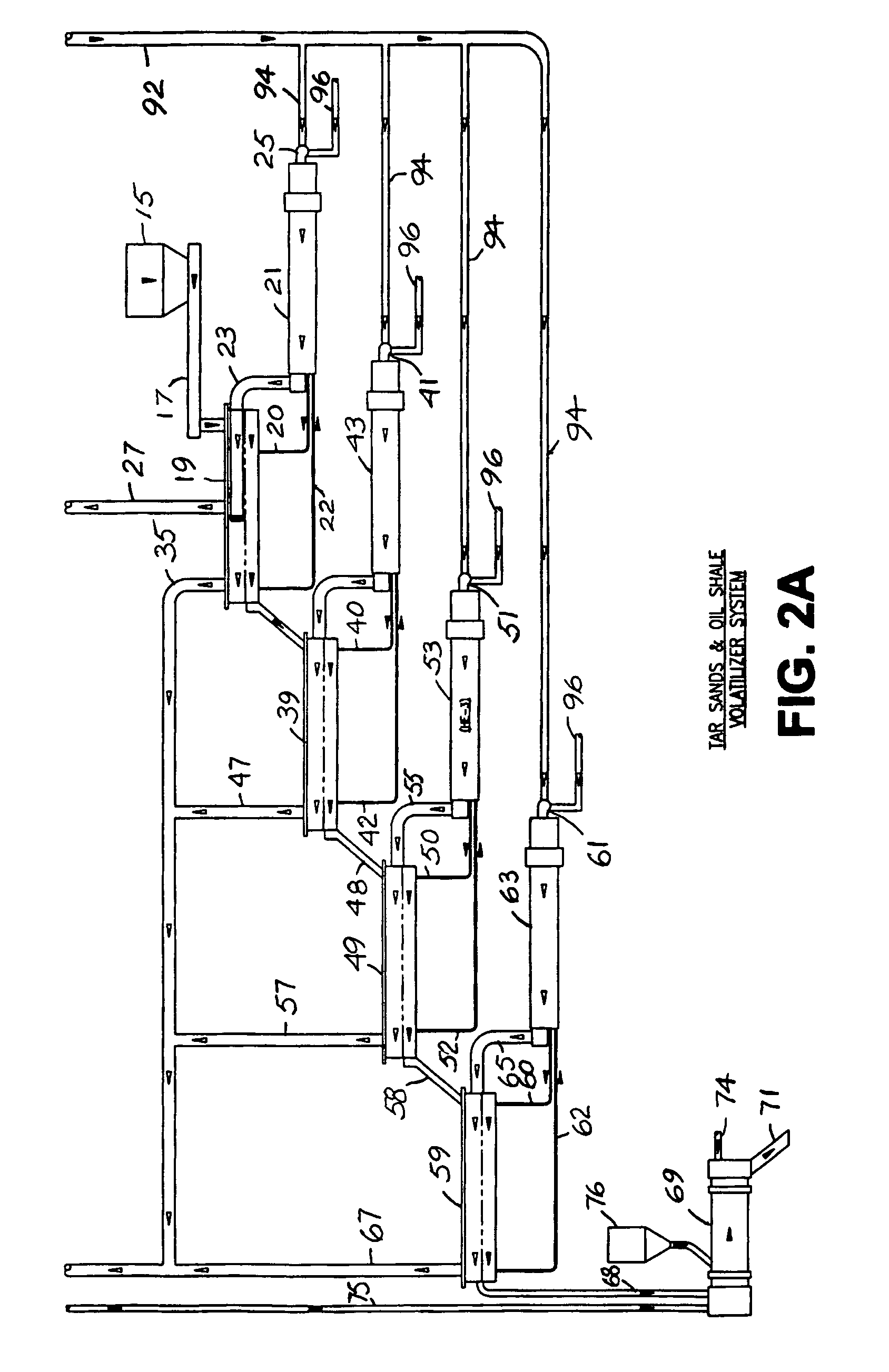

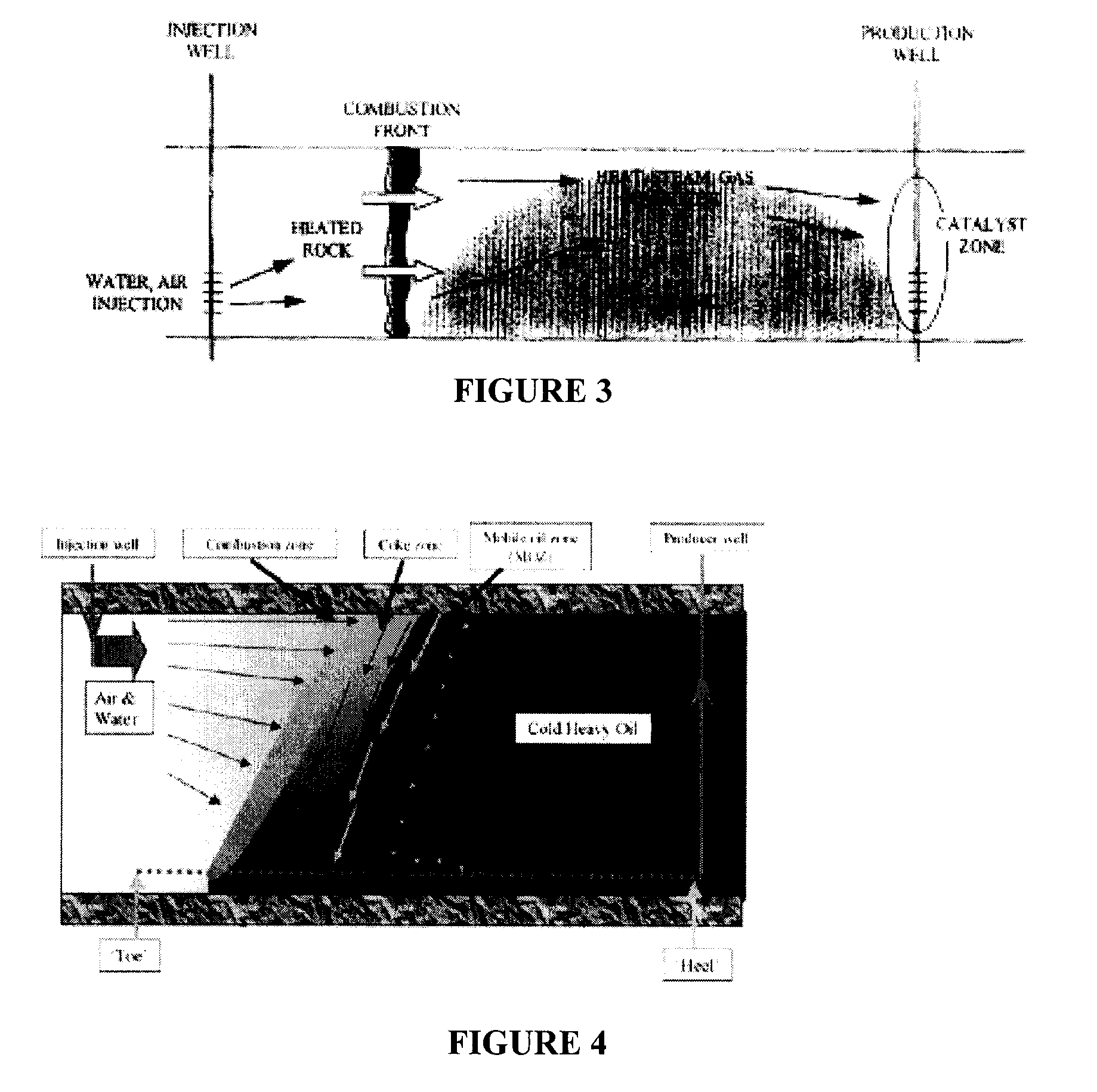

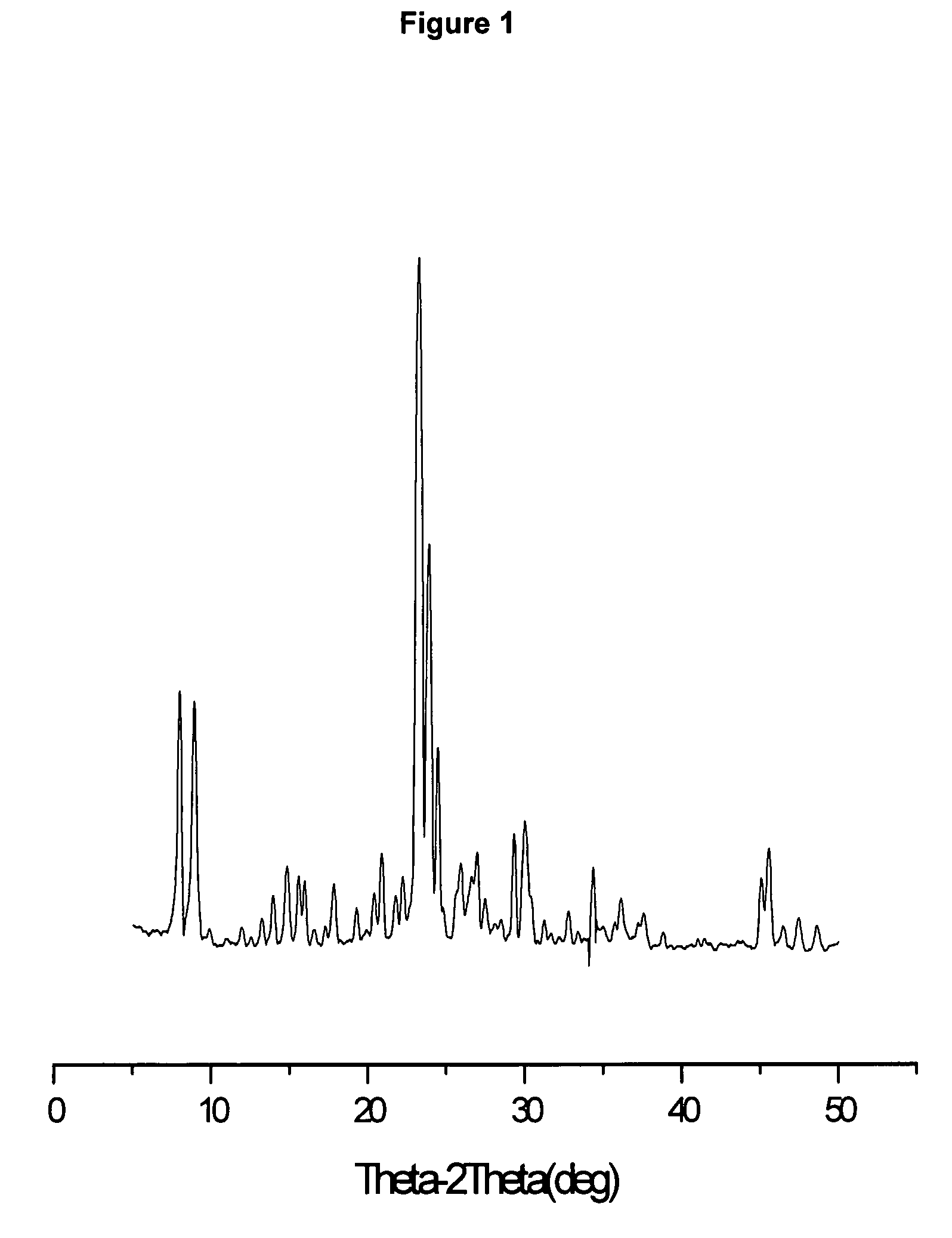

Thermal recovery of petroleum crude oil from tar sands and oil shale deposits

InactiveUS7807048B2Rule out the possibilityEliminate needHydrocarbon oil cracking processIndirect heating destructive distillationParticulatesFuel oil

A tar sand volatilizer system thermally removes petroleum crude oil from tar sands or shale oil. A series of heated augers or thermal screws are used to elevate material temperature gradually using conductive heat transfer. The thermal screws blades and auger case receive a heated fluid. The screws are driven by variable speed drive systems. The unit is sized for any throughput rate desired. Hot clean material discharges into a rotary cooler and re-hydrator unit. The exhaust gases are pulled through a high temperature filter collector for particulate removal. The particulate free petroleum vapor laden hot gas exits the filter house into a multi stage condenser system with water chillers where the vapor temperature is gradually cooled. A microwave upgrader system processes crude oil using catalyst injected microwave technology to produce a diesel like fuel oil in a continuous process stream.

Owner:COLLETTE JERRY R

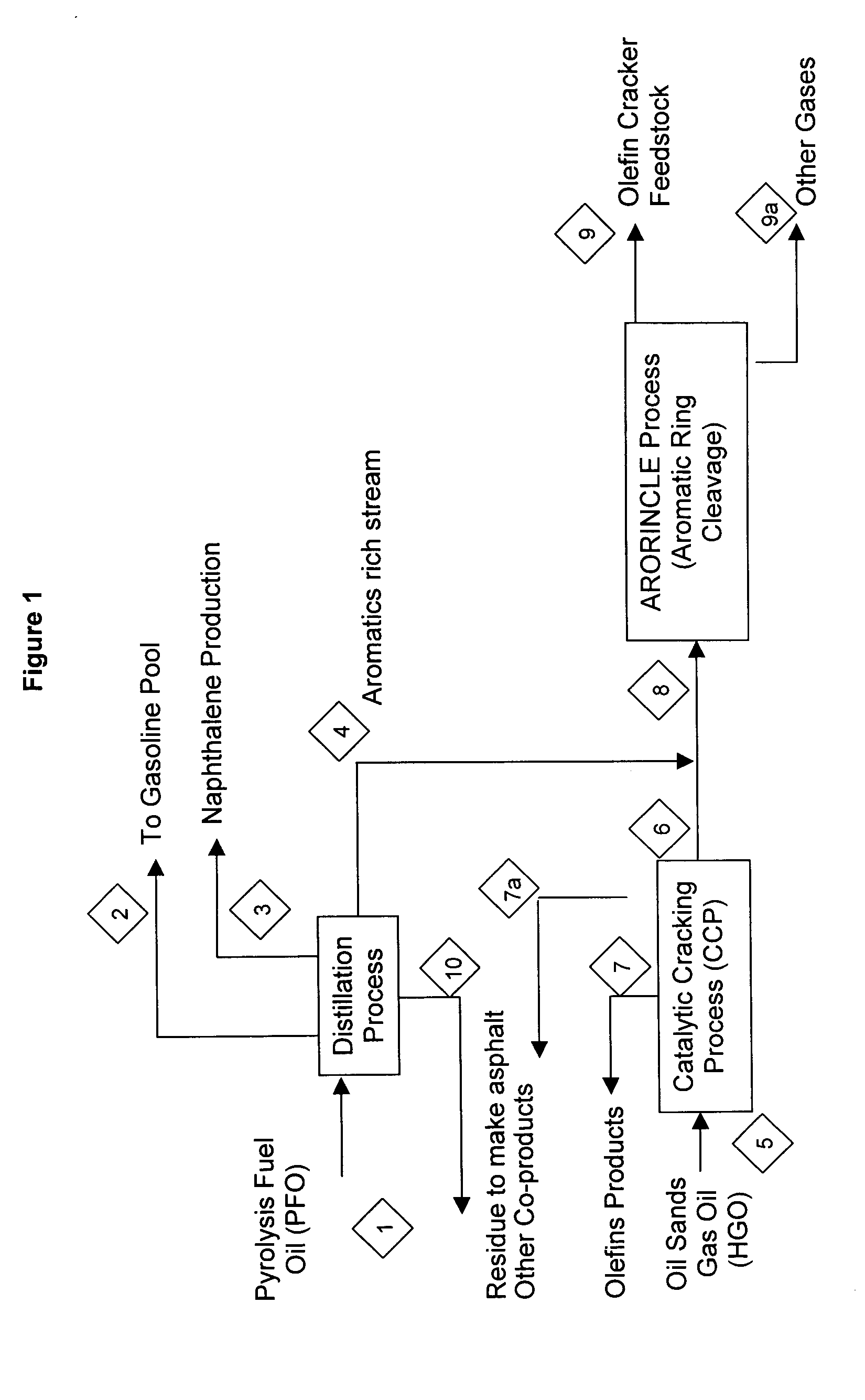

Integrated process to convert heavy oils from oil sands to petrochemical feedstock

ActiveUS20050258073A1Thermal non-catalytic crackingTreatment with plural serial cracking stages onlyAlkaneFuel oil

An aromatics / naphthalene rich stream obtained by processing heavy gas oil derived from tar sands and cycle oils derived from cracking heavy gas oil may optionally be blended and subjected to a hydrogenation process and a ring opening reaction typically in the presence of a zeolite, alumina, or silica alumina based catalyst which may contain noble metals and or copper or molybdenum to produce paraffinic feedstocks for further chemical processing.

Owner:NOVA CHEM (INT) SA

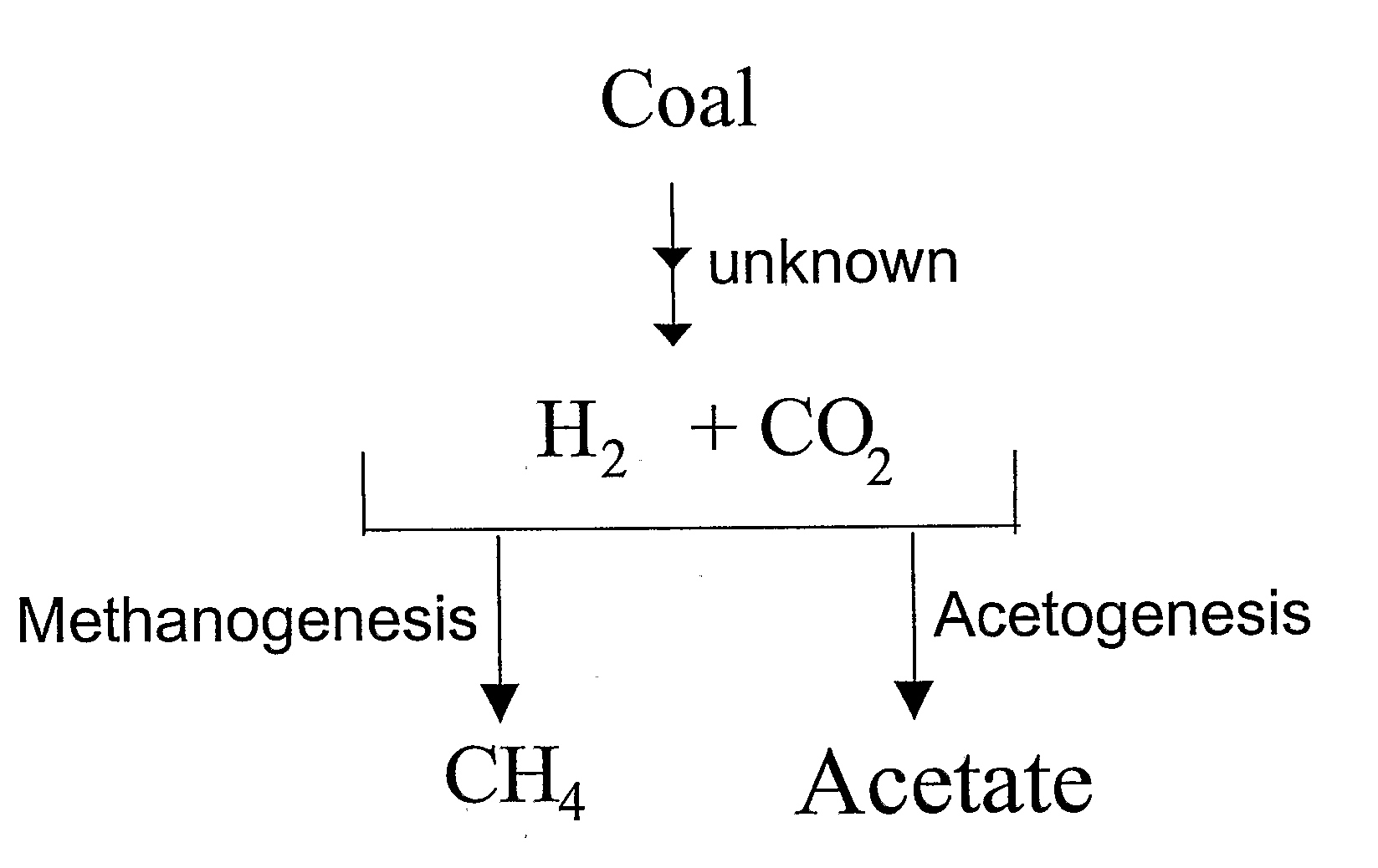

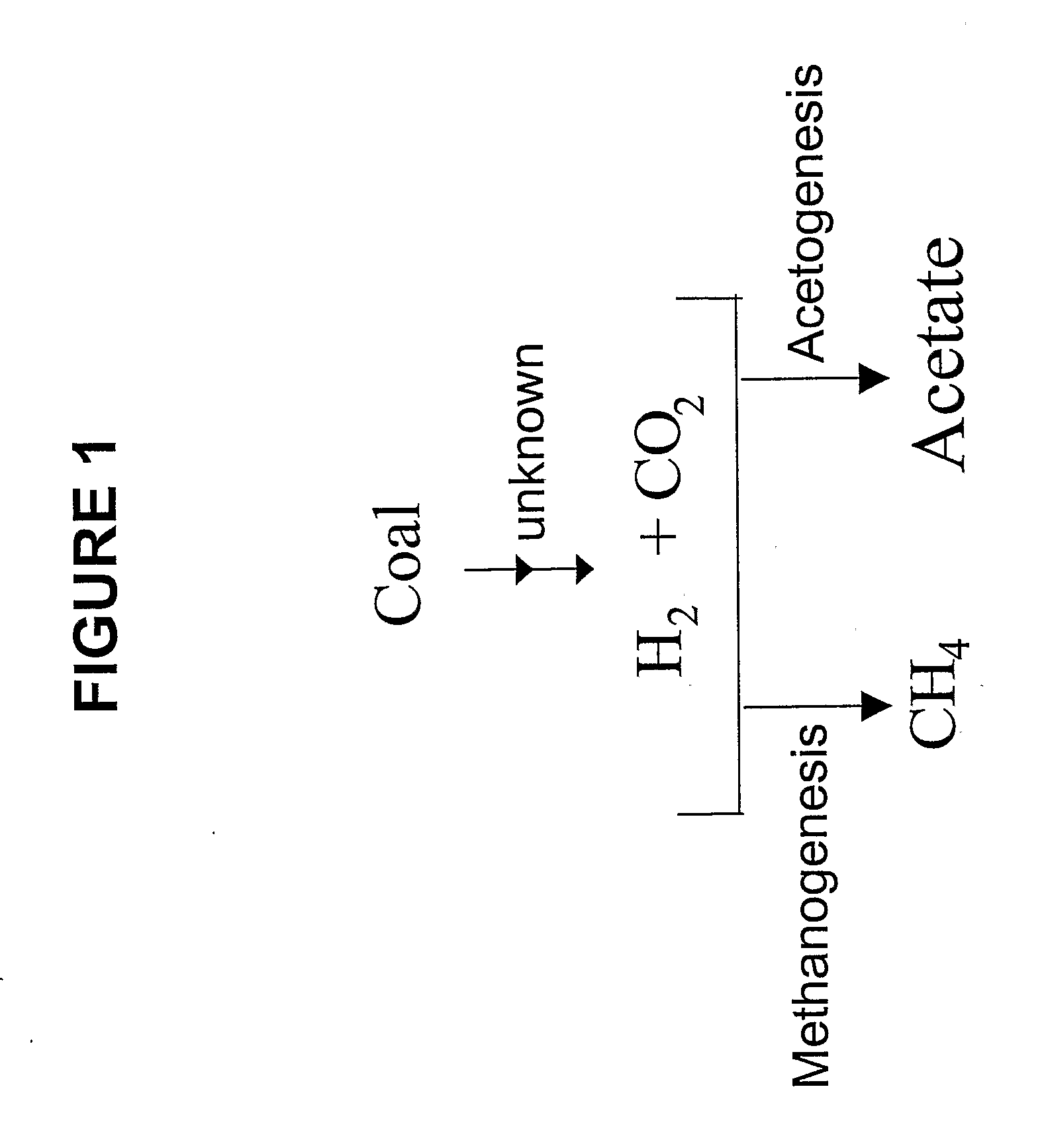

Generation of Hydrogen from Hydrocarbon Bearing Materials

ActiveUS20070248531A1Enhanced methanogenesisIncreased hydrogen productionHydrogenWaste based fuelHydrocotyle bowlesioidesSand granules

Disclosed are strategies for the economical microbial generation of hydrogen, useful as an alternative energy source, from hydrocarbon-rich deposits such as coal, oil and / or gas formations, oil shale, bitumen, tar sands, carbonaceous shale, peat deposits and sediments rich in organic matter through the management of the metabolism of microbial consortia.

Owner:TRANSWORLD TECH

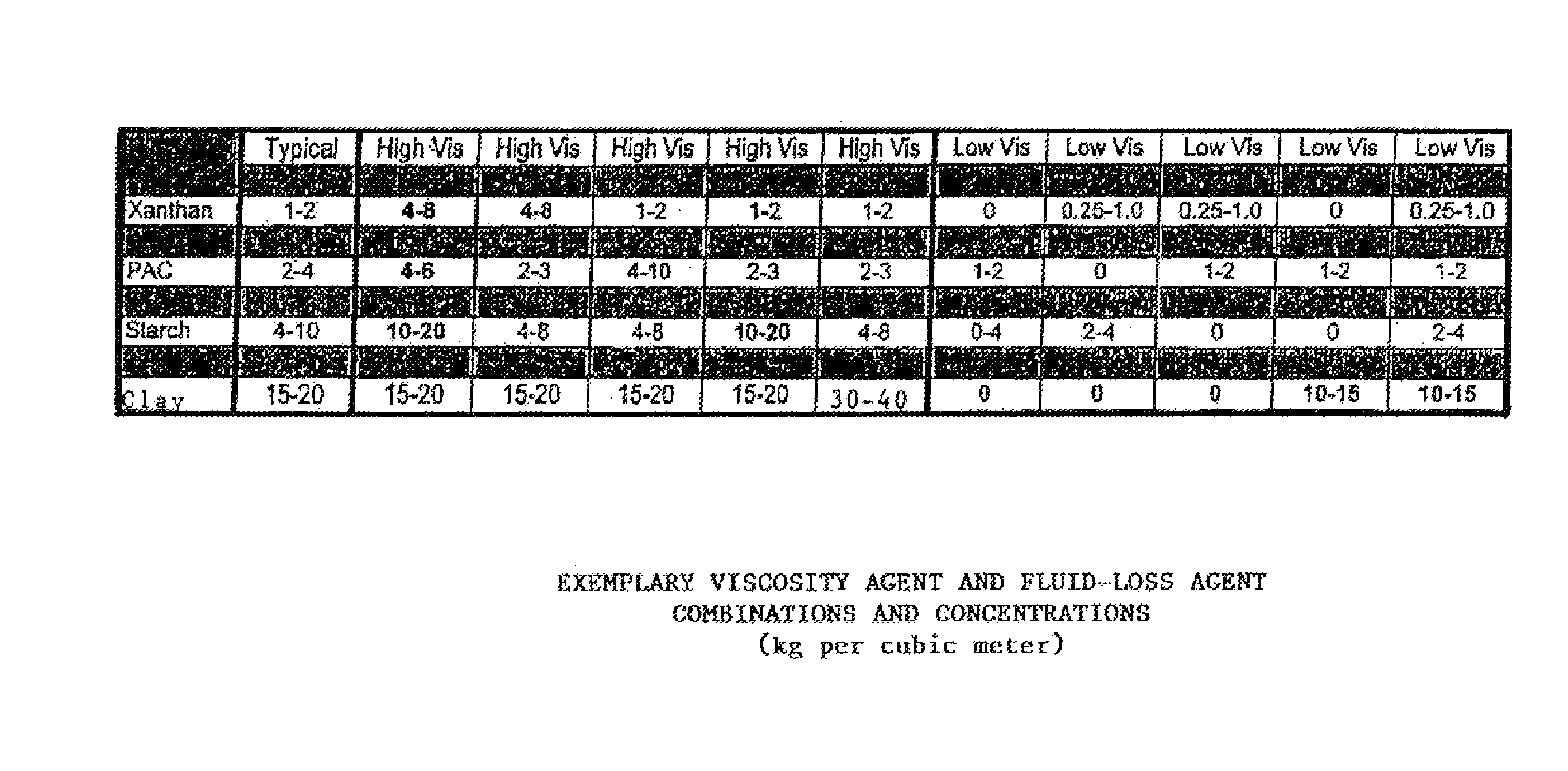

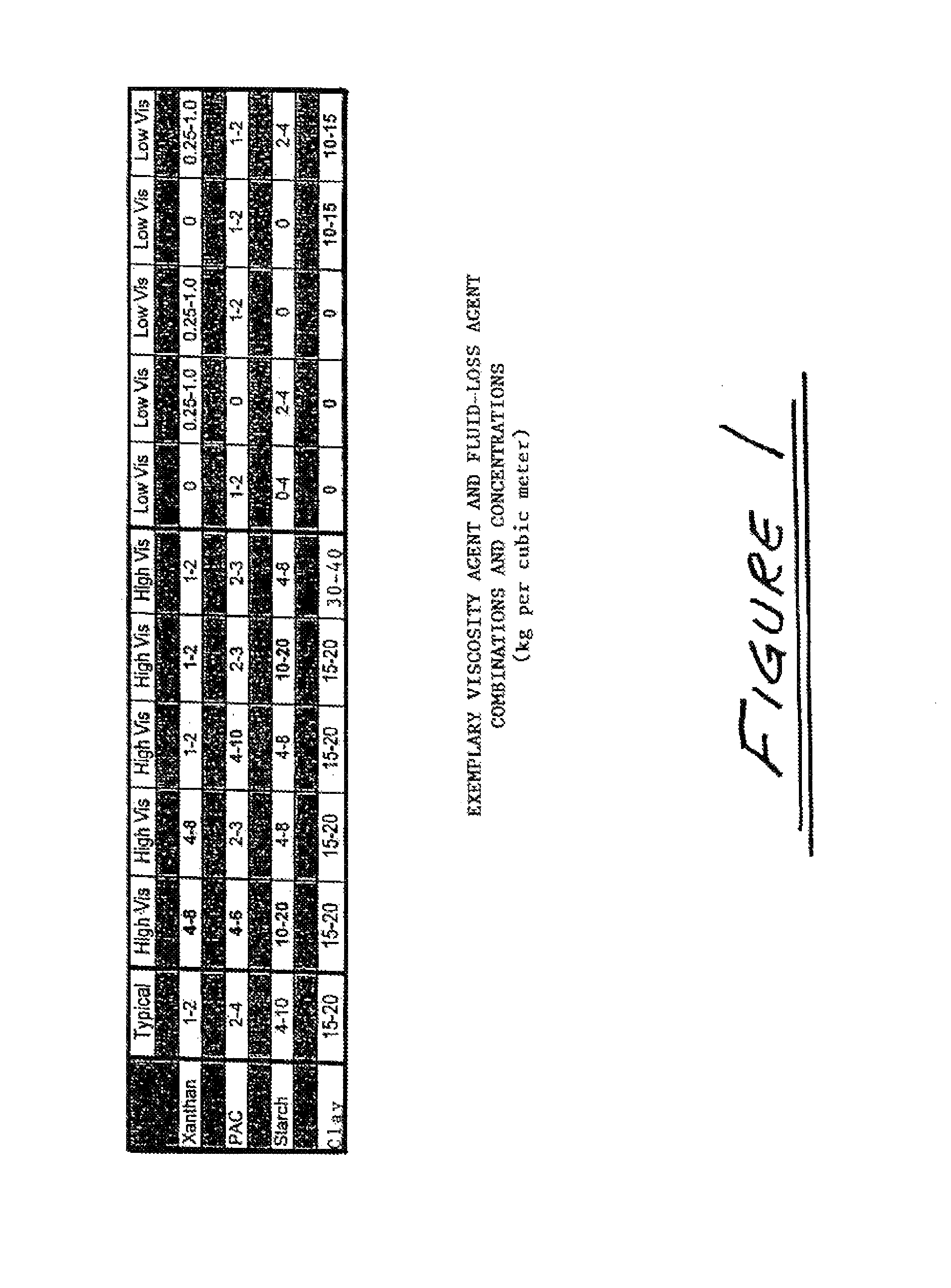

Drilling fluid composition comprising hydrophobically associating polymers and methods of use thereof

ActiveUS20090011960A1Avoid distractionExcellent bitumenLiquid hydrocarbon mixture productionFlushingFluid compositionPolymer

The present disclosure relates to drilling fluids for use in bitumen recovery from oil sands. In particular, the disclosure relates to a drilling fluid composition containing hydrophobically associating polymers which encapsulate the bitumen, and a method and use of the composition.

Owner:MUD ENG

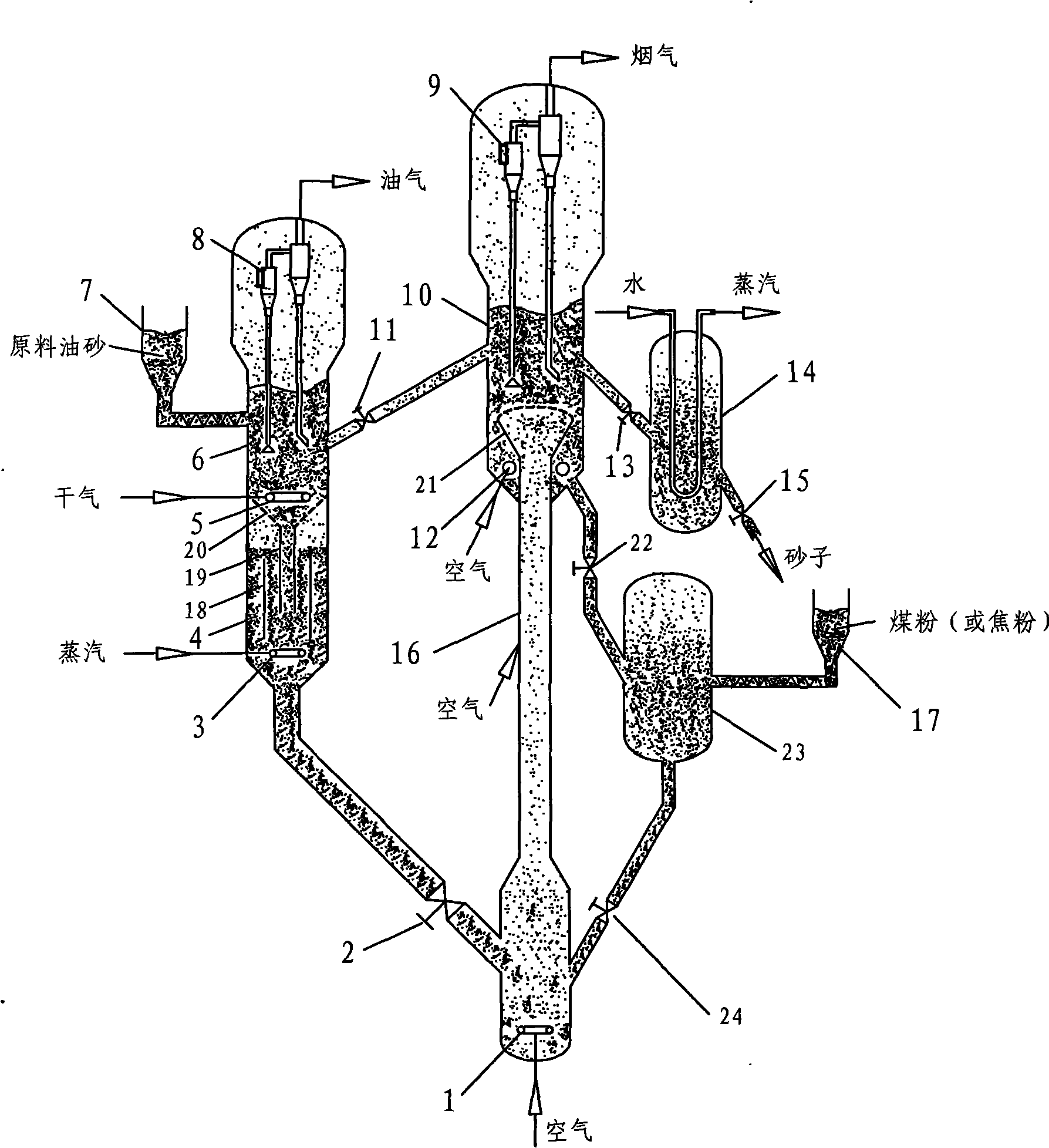

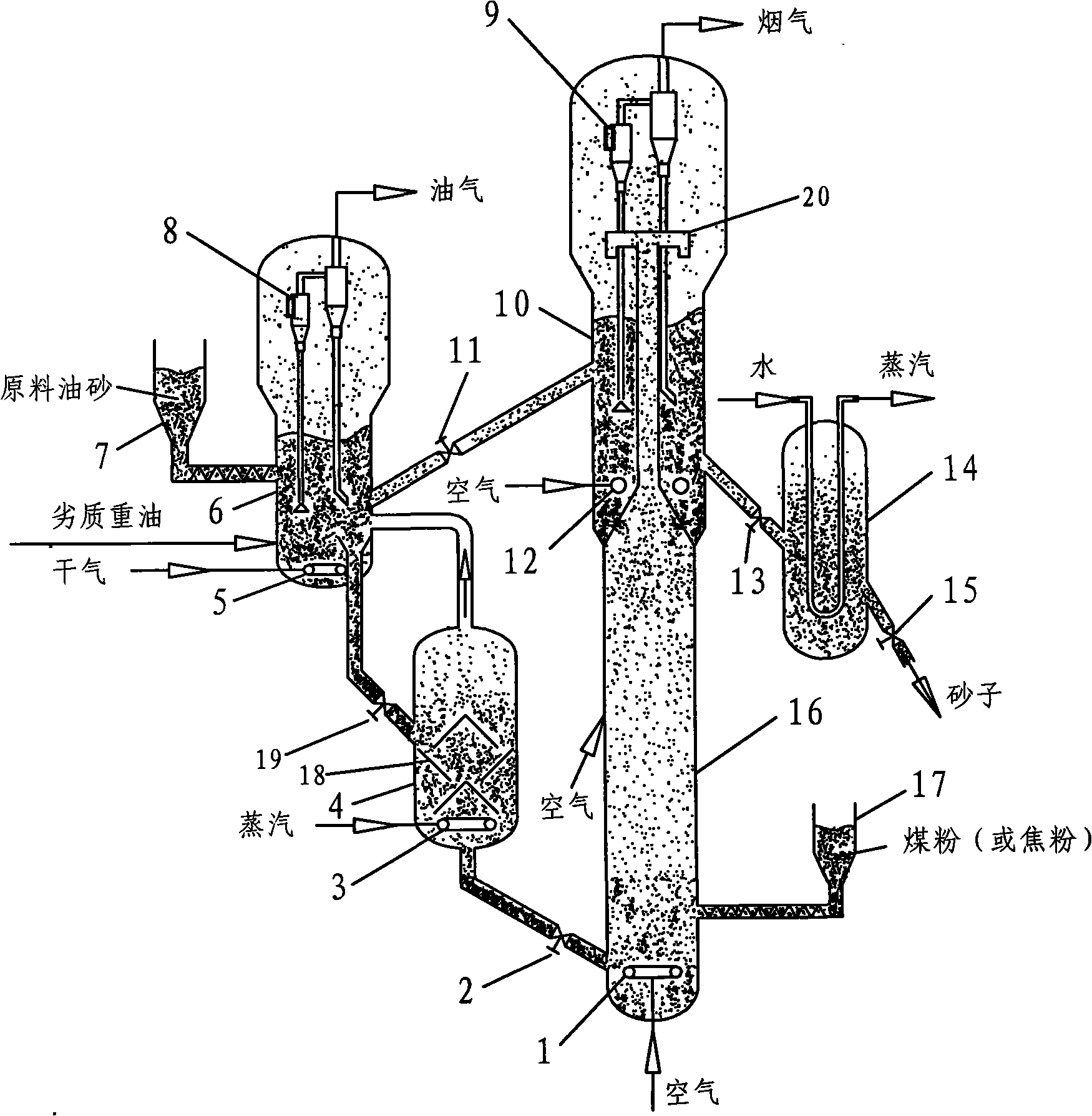

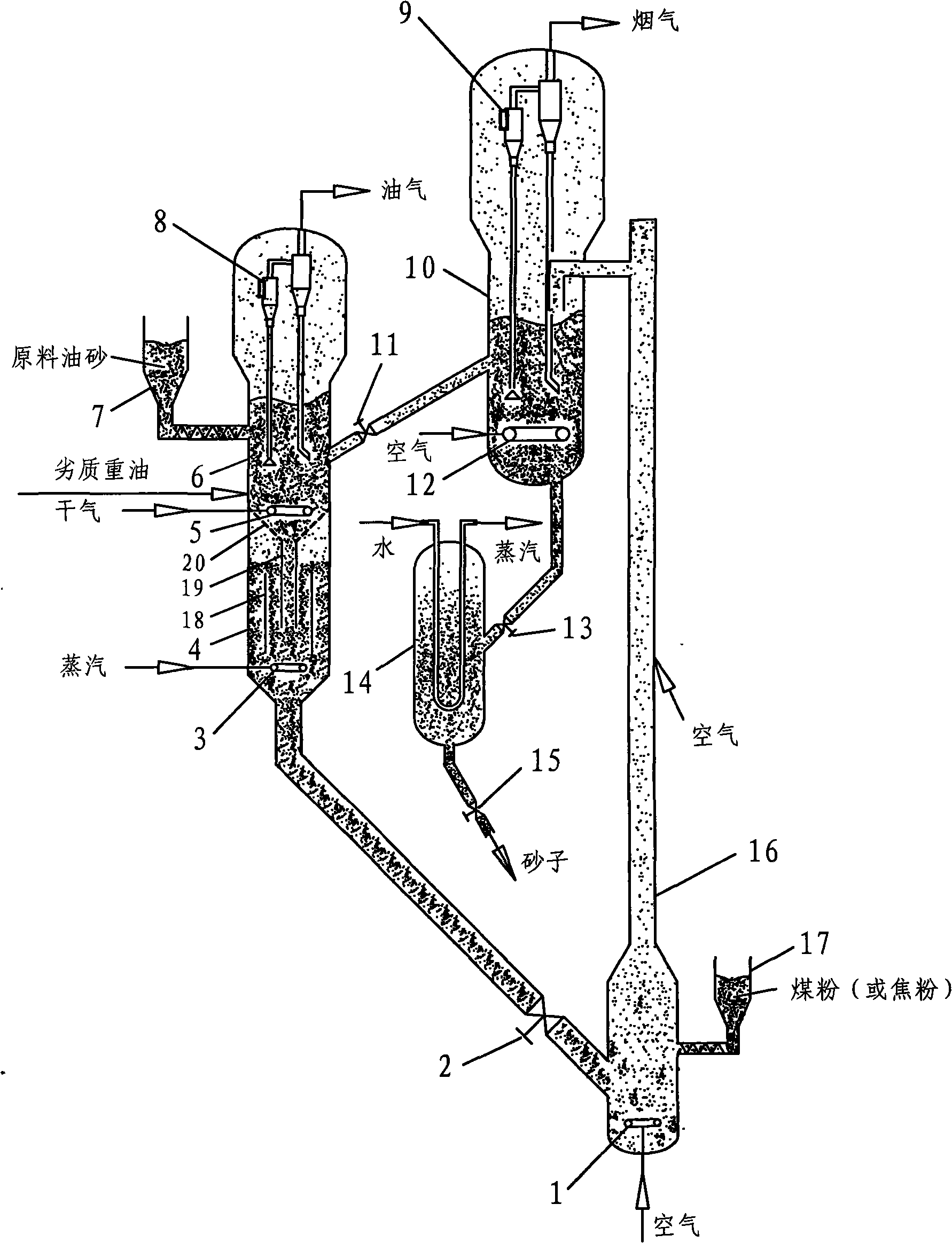

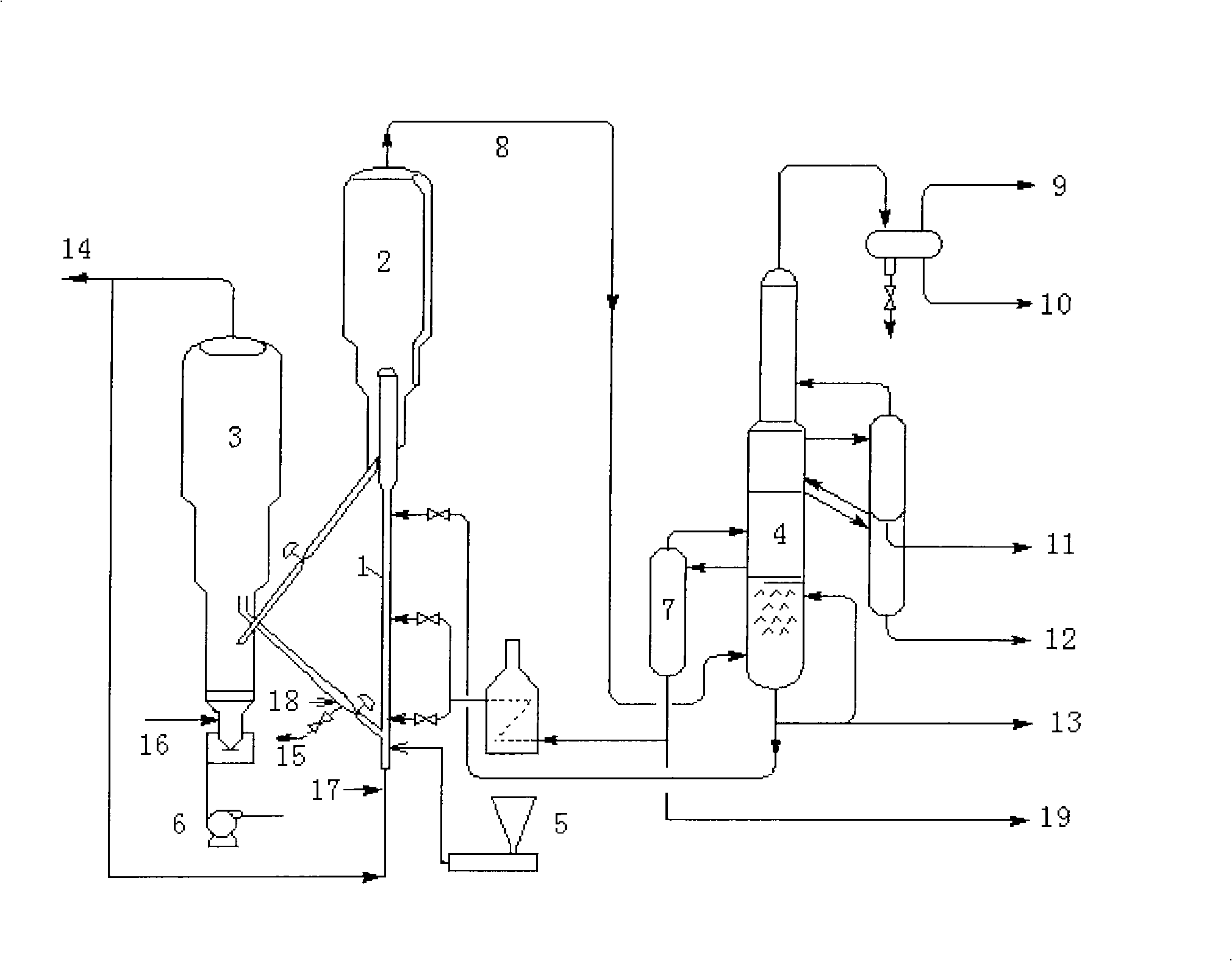

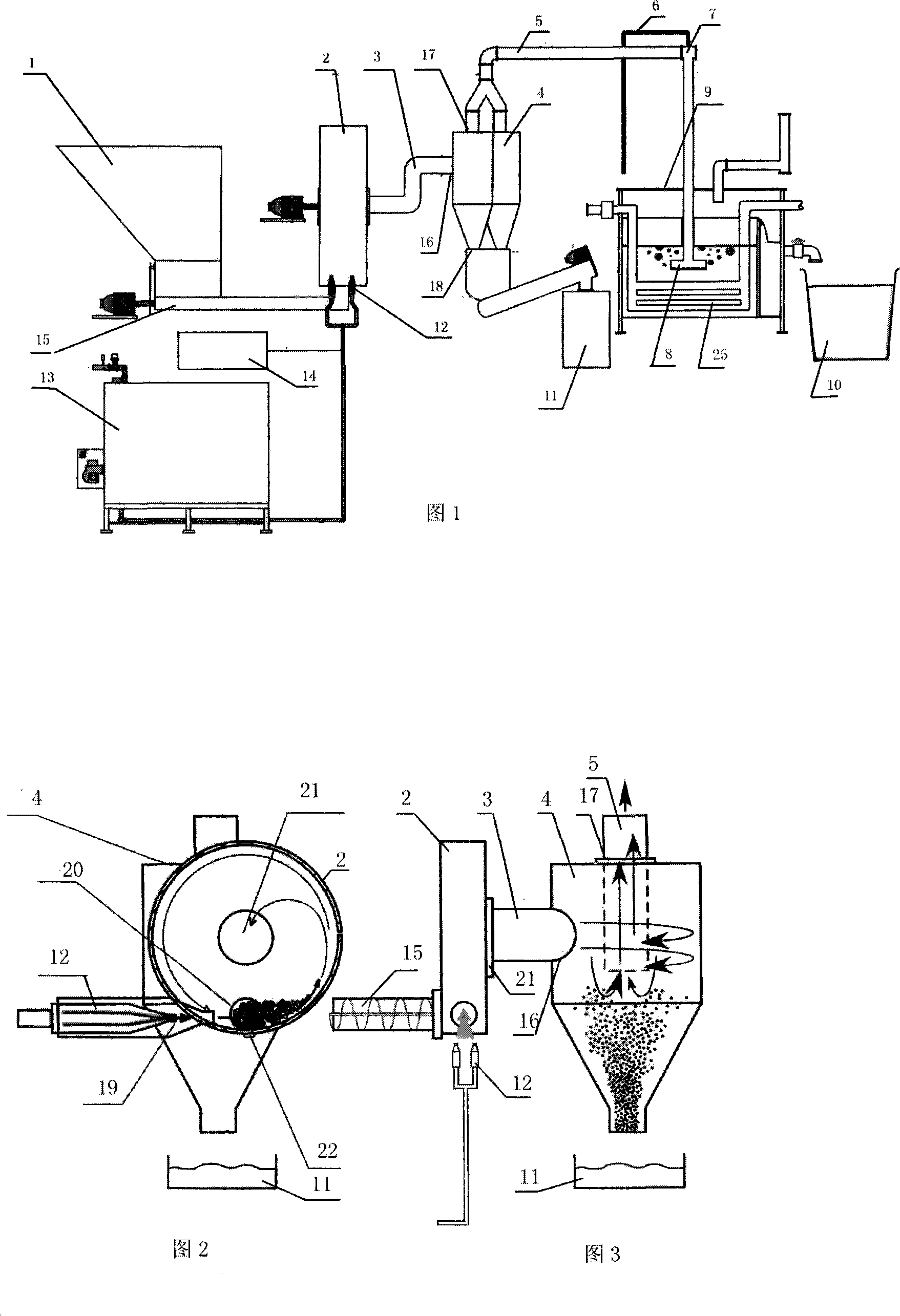

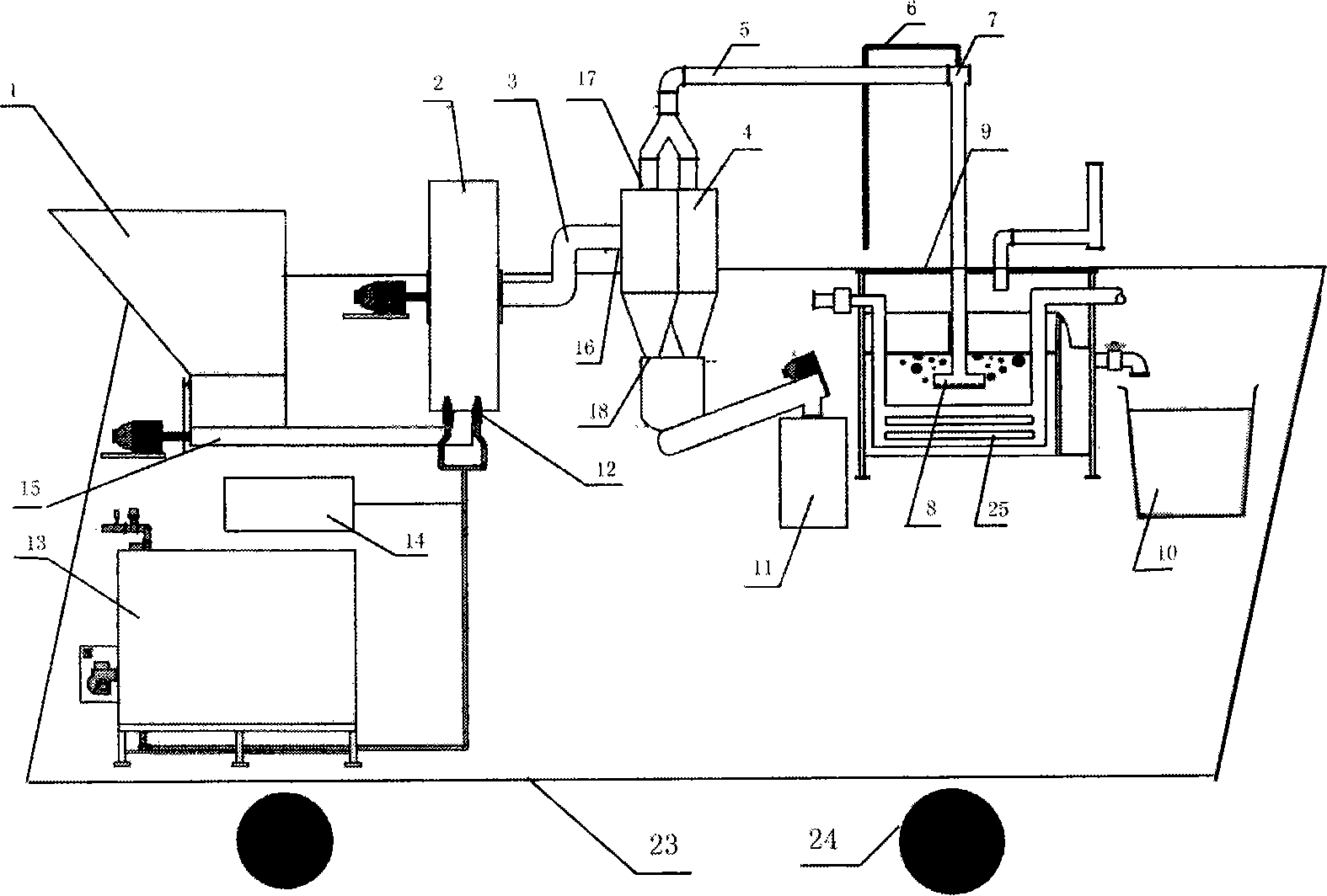

Method for directly fluid coking oil sand and apparatus

ActiveCN101358136ANo pollution in the processContinuous processingLiquid hydrocarbon mixture productionHeat carrierFluidized bed

The present invention provides a method and a device which are used for the direct coking of oil sand on a fluidized bed. The method is as follows: after being mixed with and exchanging heat with the high-temperature sand from a dense-phase coking-burning reactor, the oil sand material in a coking reactor undergoes coking reaction; the dedusted oil gas enters into a fractionation and absorption stabilization system; after being stripped by a stripper, tar sand is led into a dilute-phase coking-burning riser to be burnt in the dilute-phase coking-burning riser and the dense-phase coking-burning reactor above the dilute-phase coking-burning riser; and one flow of the burnt hot sand serving as a heat carrier is led into the coking reactor, and the other flow is led into an external heat collector for heat exchange. If the coke yield is low and the coke-burning heat is insufficient, burning oil, coal dust or coke powder can be added into the coking-burning riser in order to maintain the heat balance of the system. The device at least comprises a material feeder, the coking reactor, the stripper, the dilute-phase coking-burning riser, the dense-phase coking-burning reactor, the external heat collector and a cyclone separator. The device, which is characterized by strong continuous operability and high flexibility, can directly process unconventional petroleum resources such as oil sand and oil shales and does not pollute the environment, and the comprehensive energy utilization rate of the system is high.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method of produced water treatment, method of water reuse, and systems for these methods

ActiveUS20100264068A1Fatty/oily/floating substances removal devicesDewatering/demulsification with mechanical meansRecovery methodMicrofiltration membrane

A method of produced water treatment in an in-situ recovery method of producing bitumen from oil sand, the method has the steps of: separating bitumen from bitumen-mixed fluid so as to leave produced water, the bitumen-mixed fluid having been recovered from the oil sand wells; and filtering the produced water via a microfiltration membrane made of polytetrafluoroethylene.

Owner:SUMITOMO ELECTRIC IND LTD +1

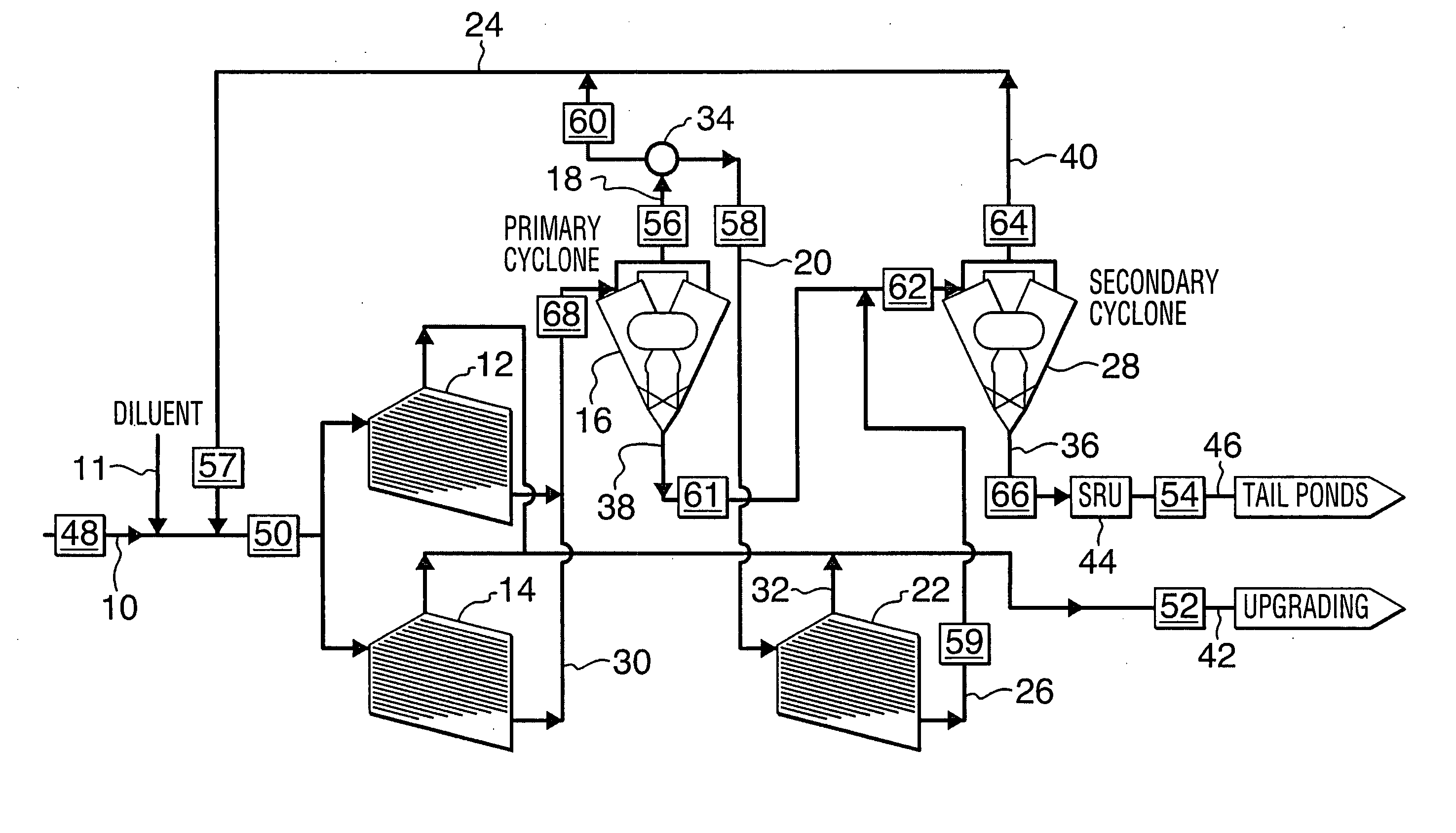

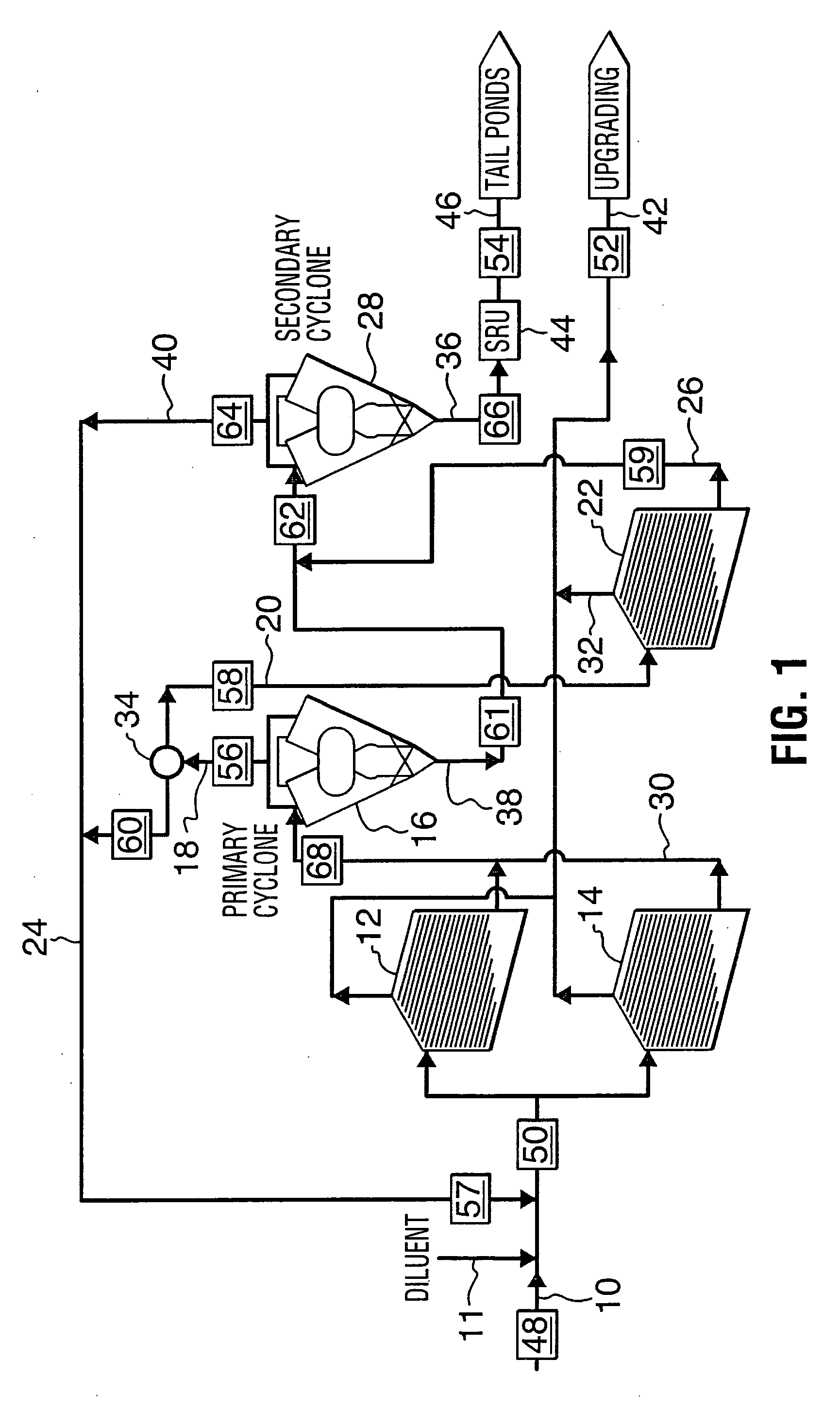

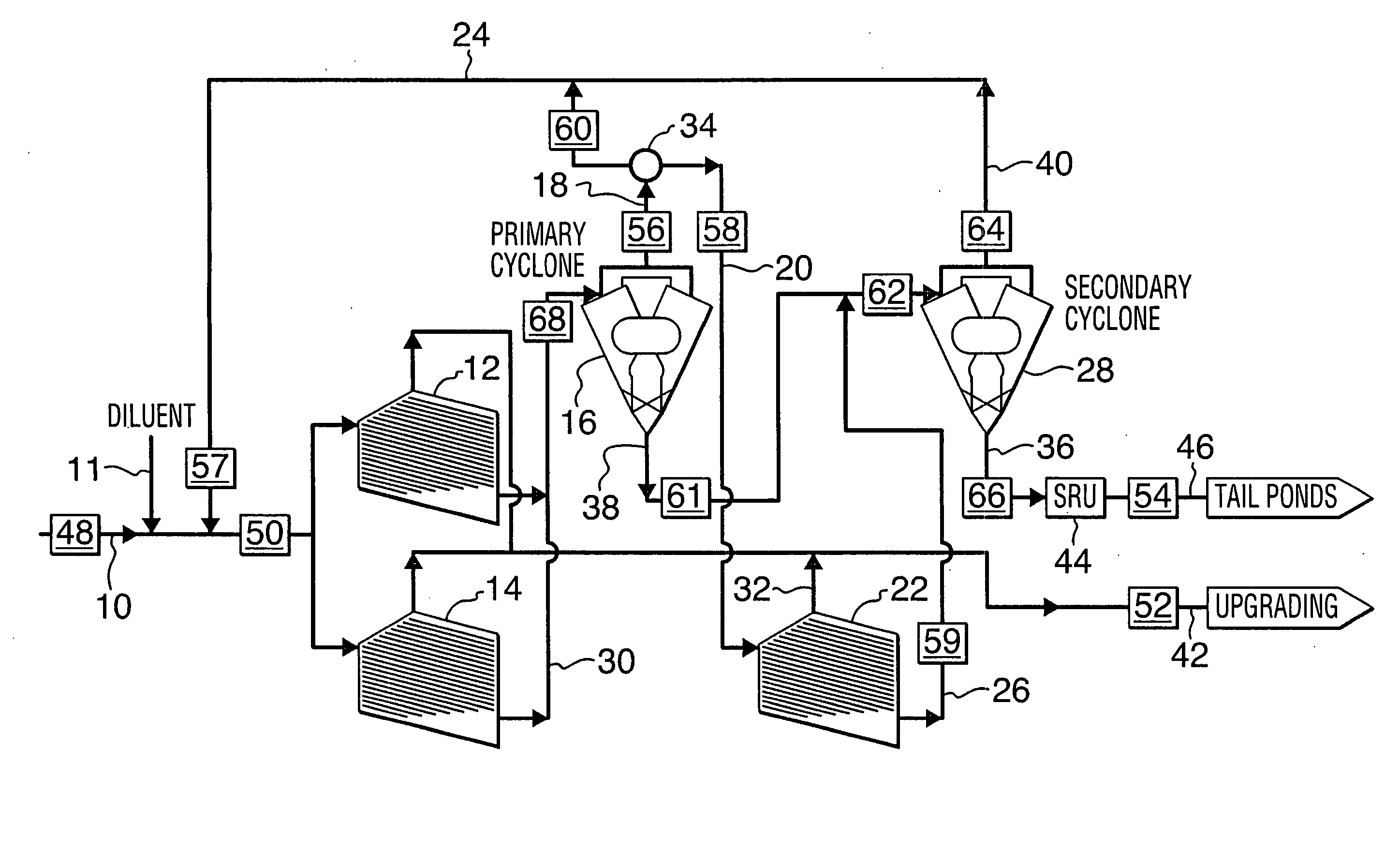

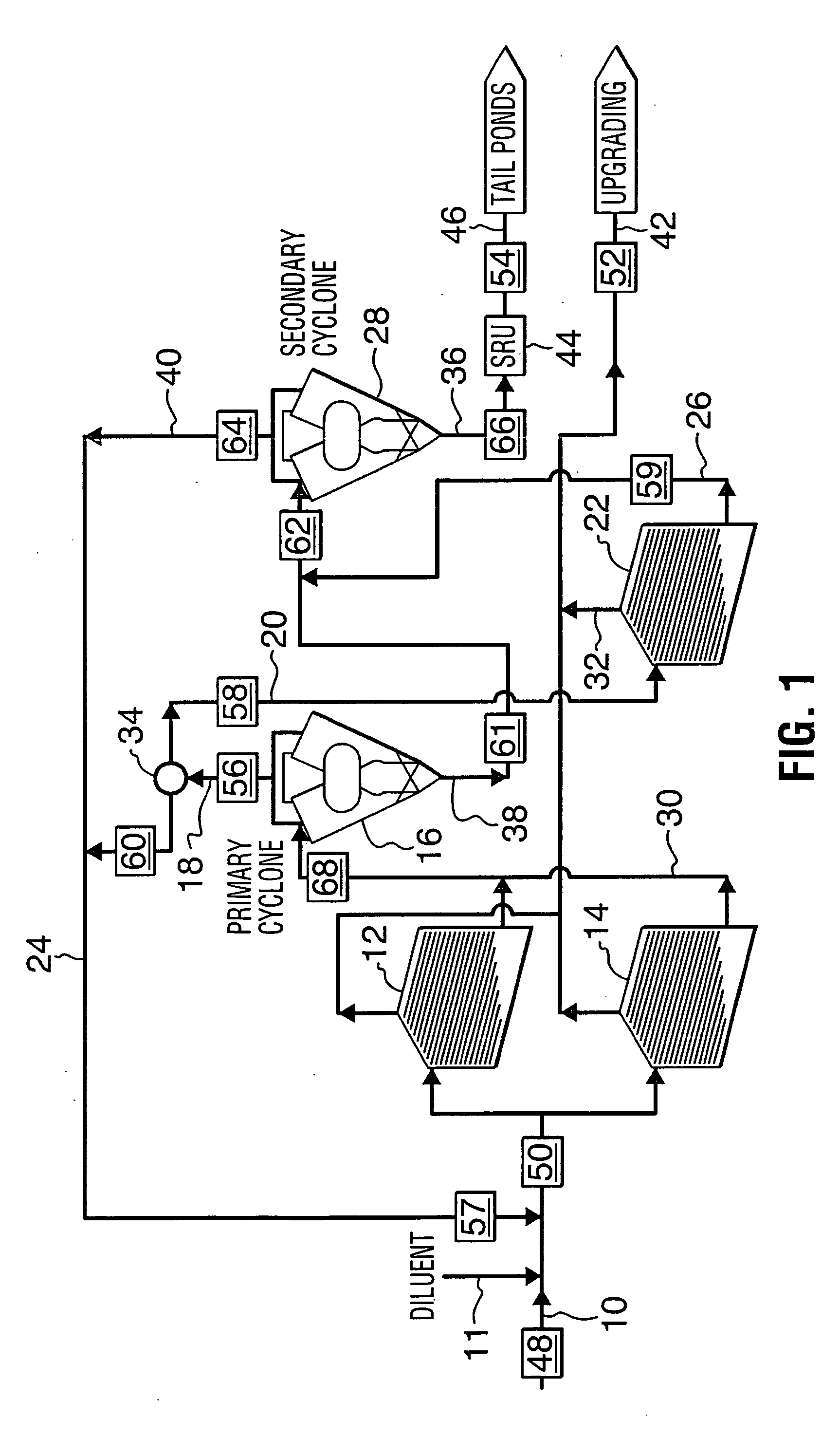

Bituminous froth inclined plate separator and hydrocarbon cyclone treatment process

InactiveUS20060138036A1Easy to separateStrong currentReversed direction vortexOther chemical processesCycloneEngineering

An apparatus for separating bitumen from a bitumen froth output of a oil sands hot water extraction process comprises an inclined plate separator (IPS) for providing a first bitumen separation stage and a cyclone for providing a second bitumen separation stage. The cyclone overflow is recycled to the IPS inlet.

Owner:SUNCOR ENERGY INC

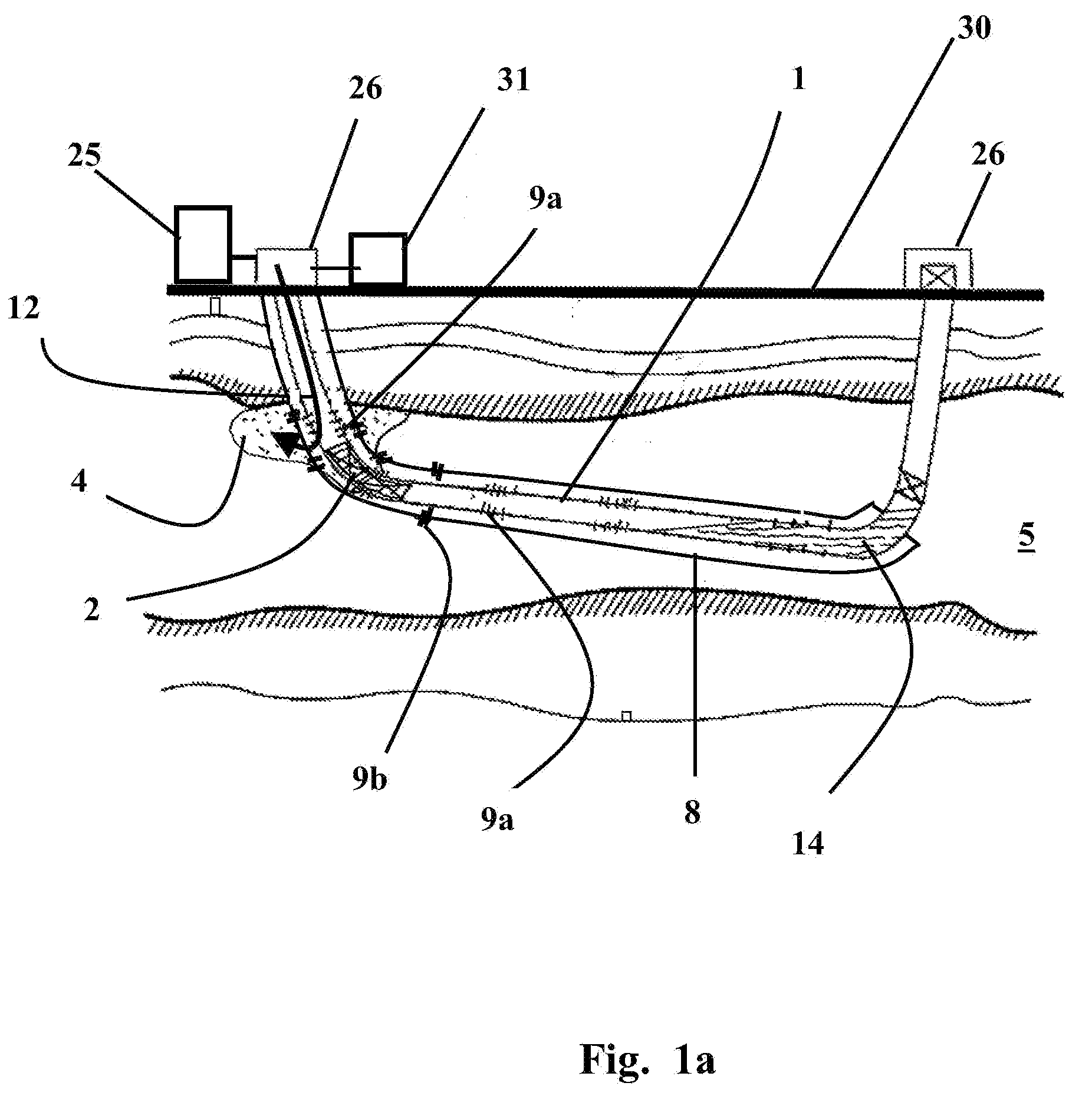

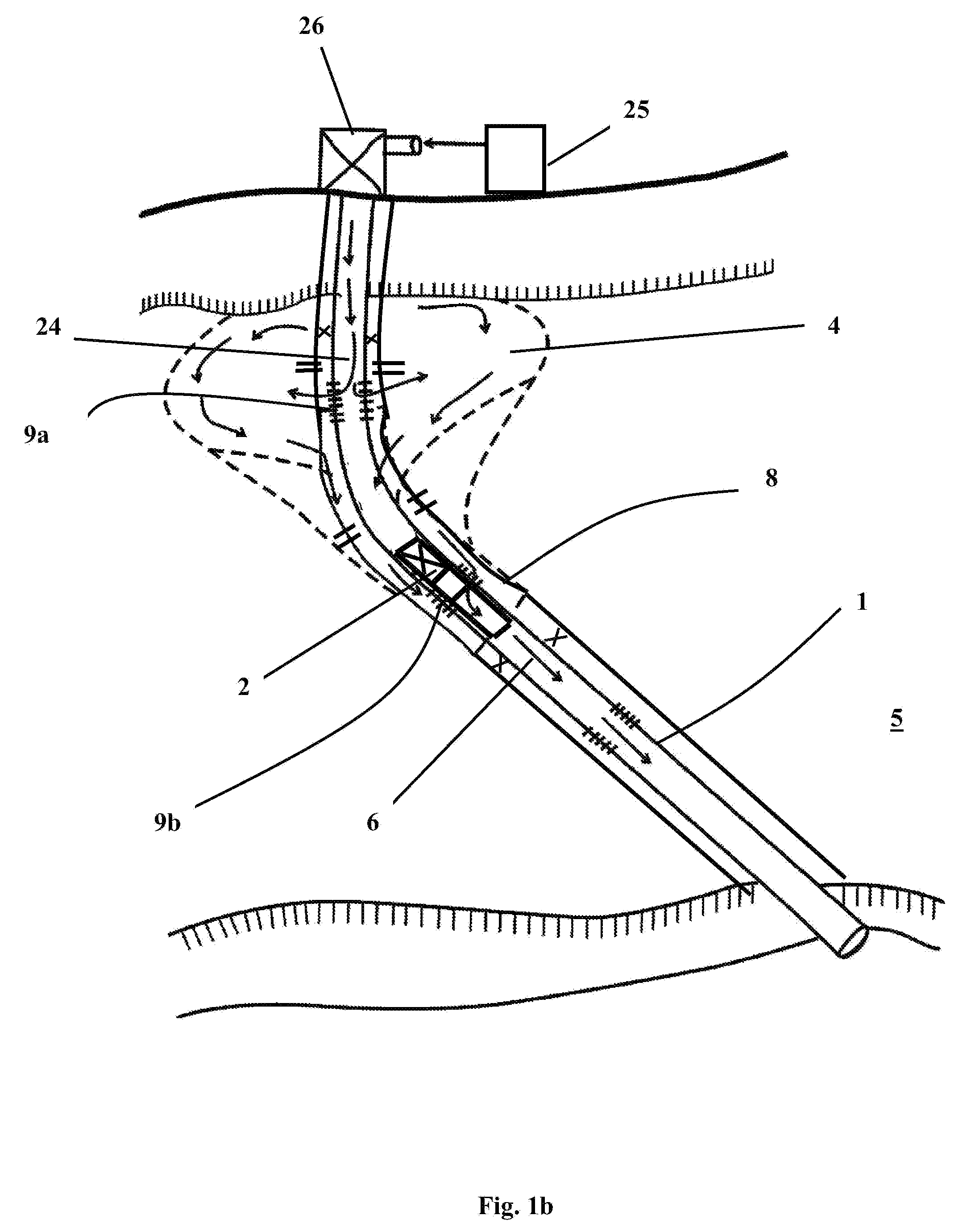

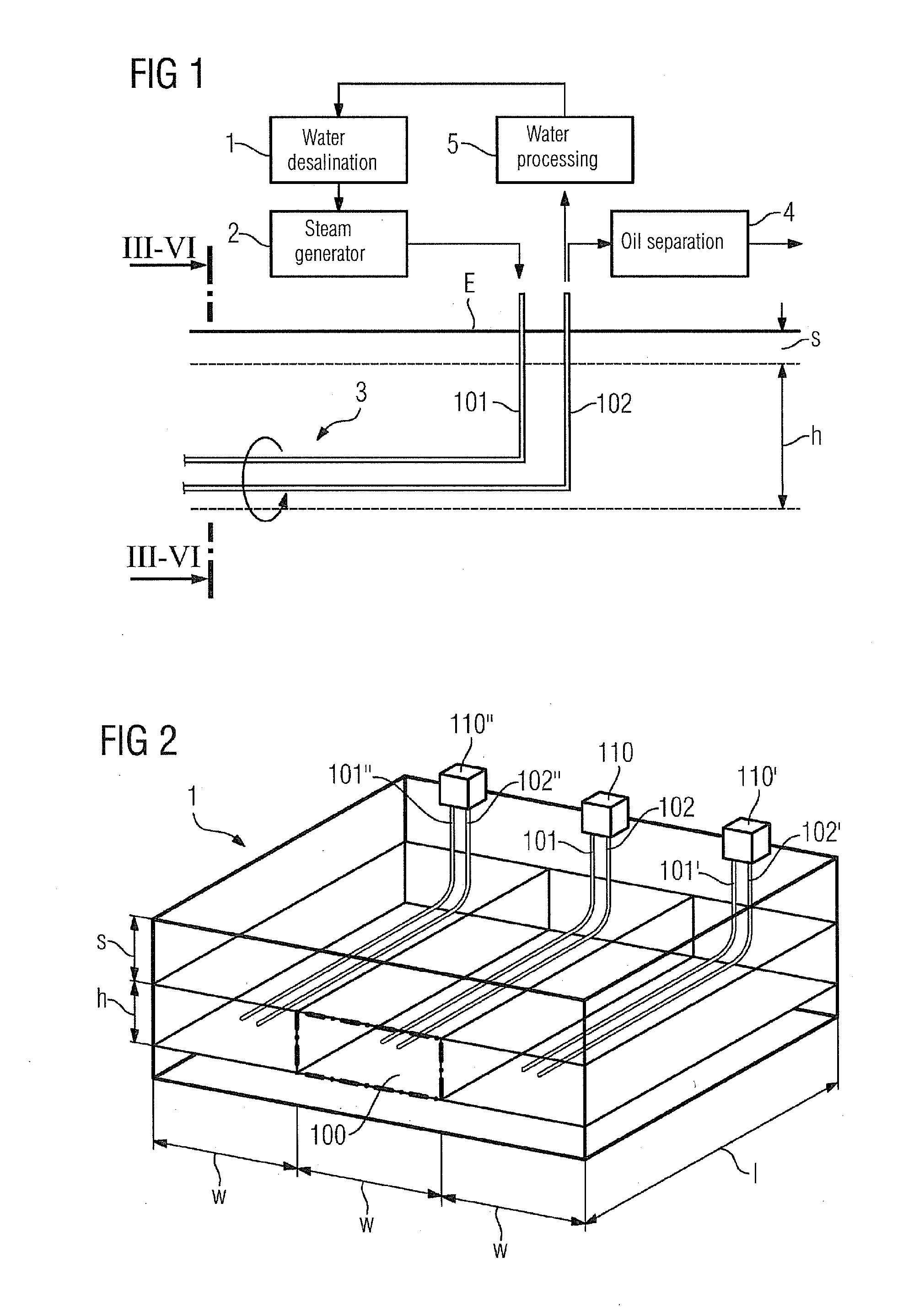

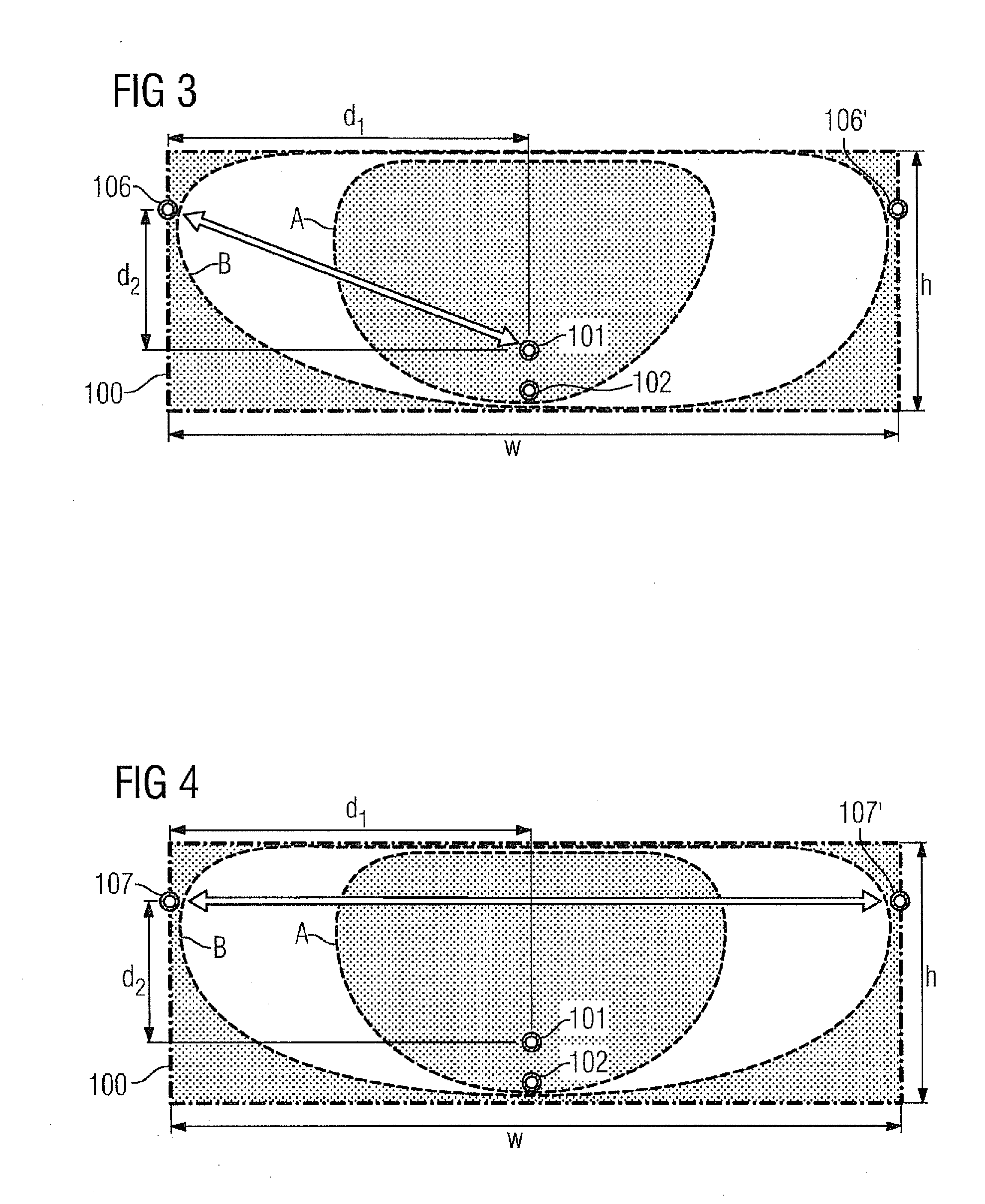

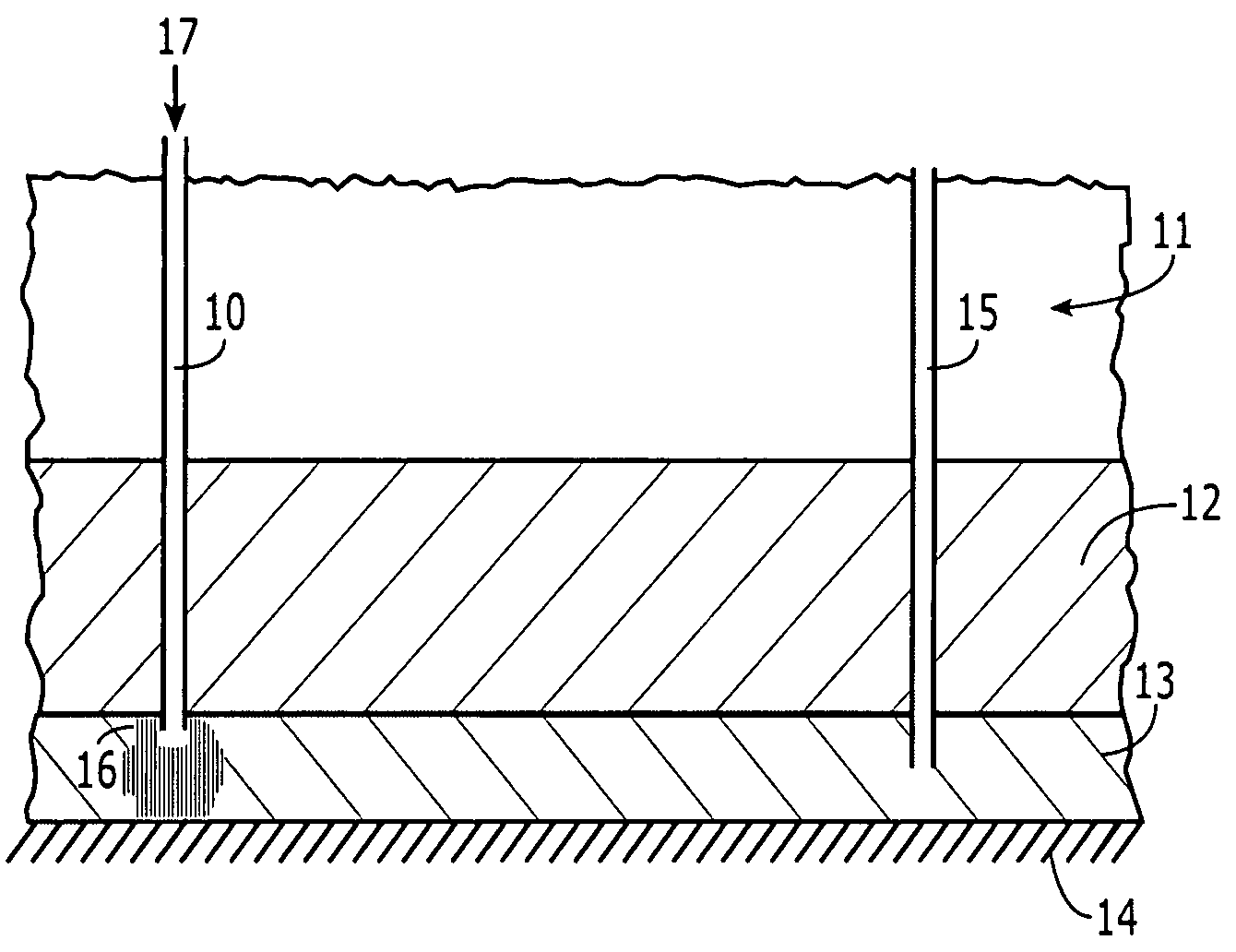

Method and Apparatus for In Situ Extraction of Bitumen or Very Heavy Oil

A method to extract bitumen or very heavy oil in situ from oil sand seams close to the Earth's surface is provided. Energy is introduced via at least two pipes at a given, repeatable distance from the seam, a predefined geometry is maintained in relation to the well pair. The associated apparatus includes at least one additional pipe which is alternatively designed as an electrode or also for feeding vapor and is placed above the injection pipe.

Owner:SIEMENS AG

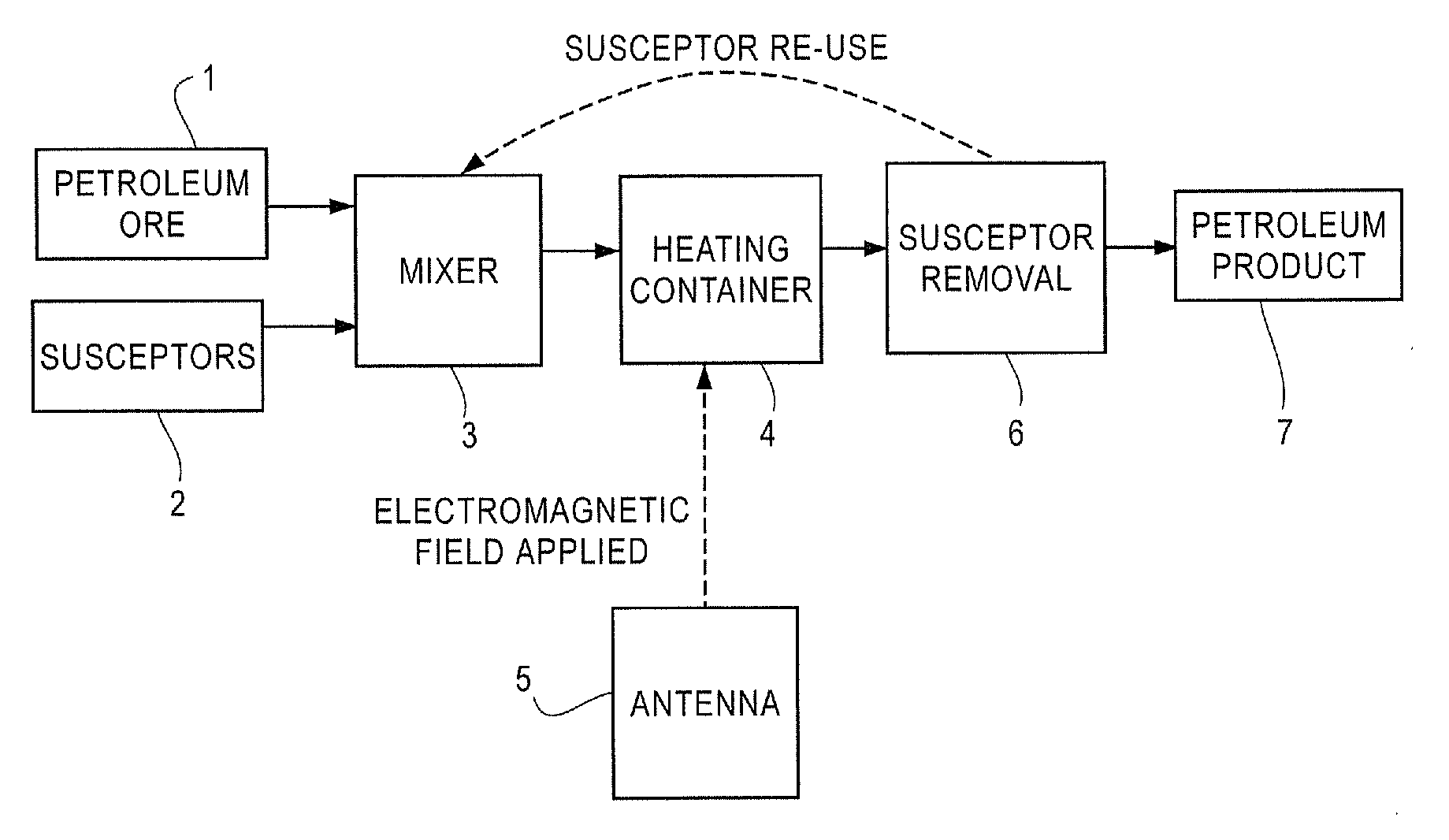

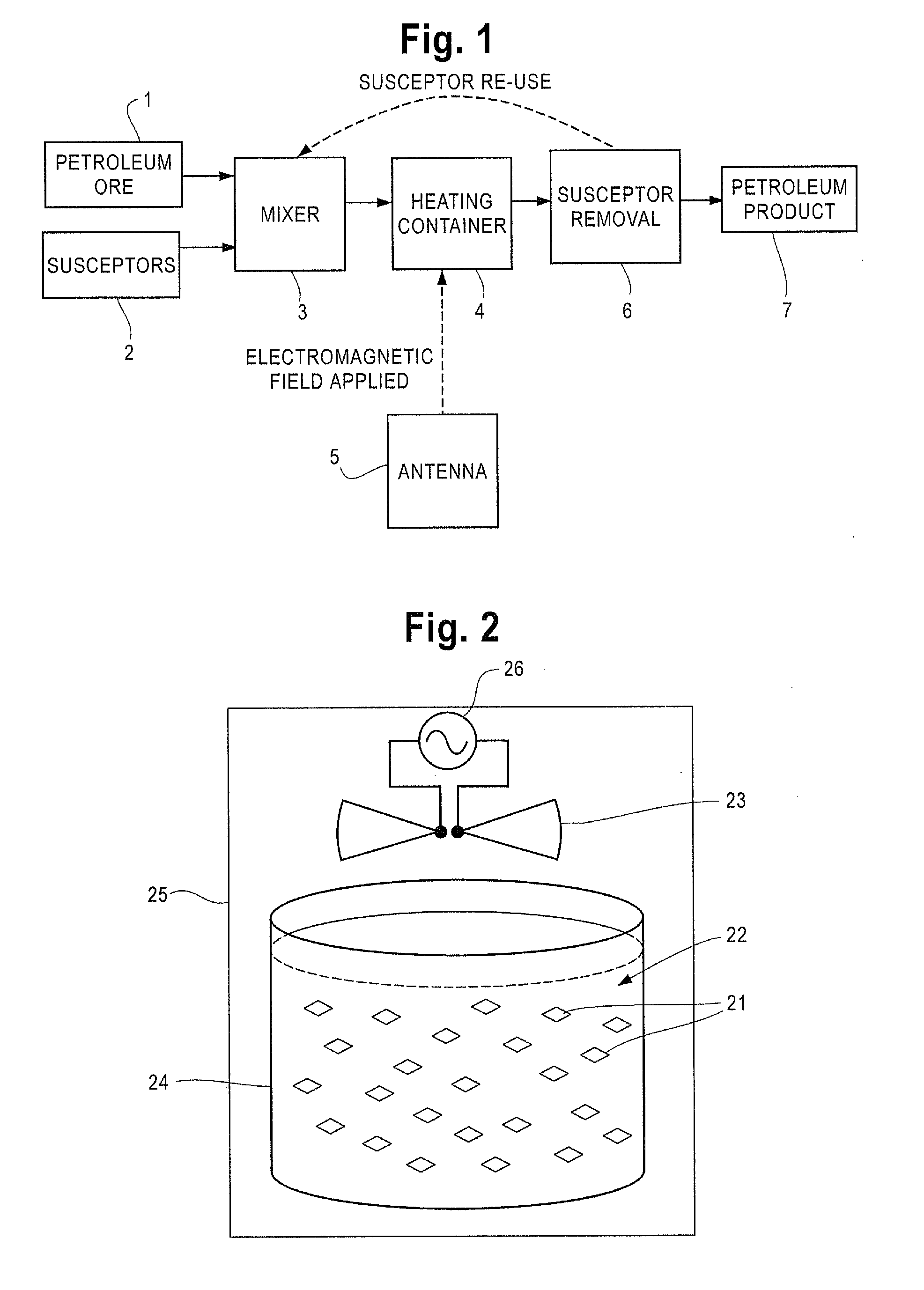

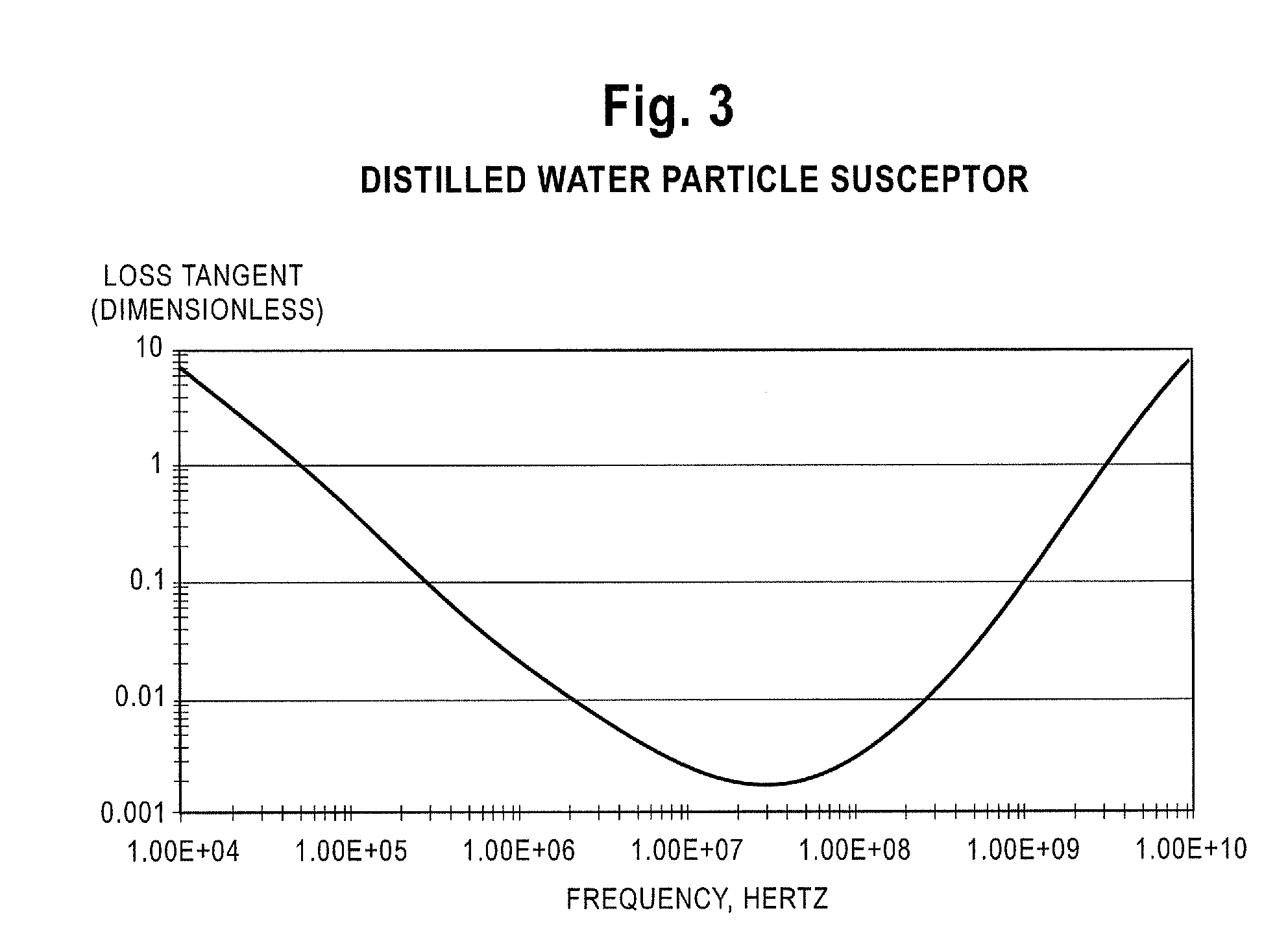

Radio frequency heating of petroleum ore by particle susceptors

ActiveUS20100219107A1Increase temperatureThermal non-catalytic crackingMagnetic paintsSusceptorDistillation

A method for heating materials by application of radio frequency (“RF”) energy is disclosed. For example, the disclosure concerns a method for RF heating of petroleum ore, such as bitumen, oil sands, oil shale, tar sands, or heavy oil. Petroleum ore is mixed with a substance comprising susceptor particles that absorb RF energy. A source is provided which applies RF energy to the mixture of a power and frequency sufficient to heat the susceptor particles. The RF energy is applied for a sufficient time to allow the susceptor particles to heat the mixture to an average temperature greater than about 212° F. (100° C.). Optionally, the susceptor particles can be removed from the mixture after the desired average temperature has been achieved. The susceptor particles may provide for anhydrous processing, and temperatures sufficient for cracking, distillation, or pyrolysis.

Owner:HARRIS CORP

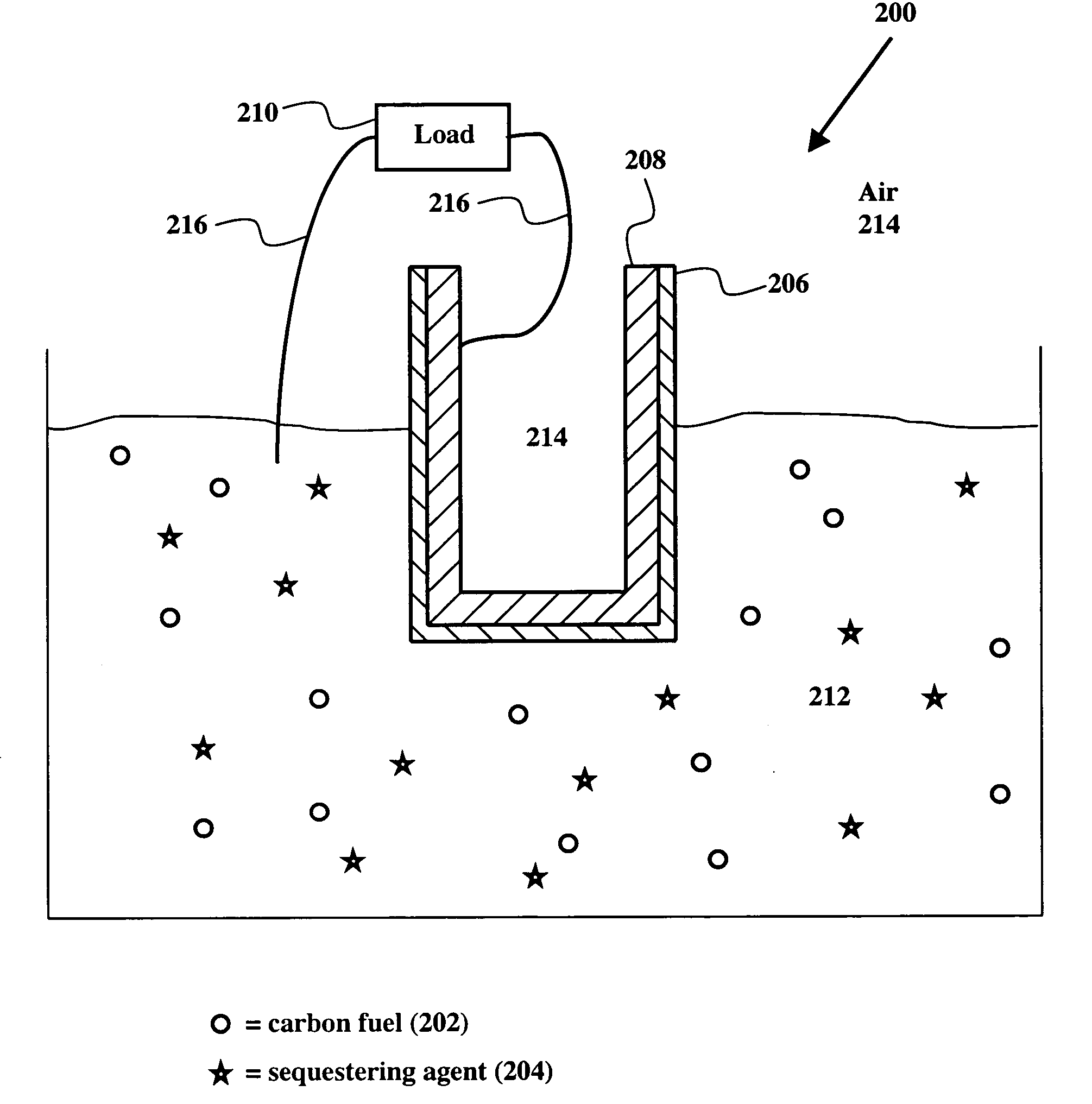

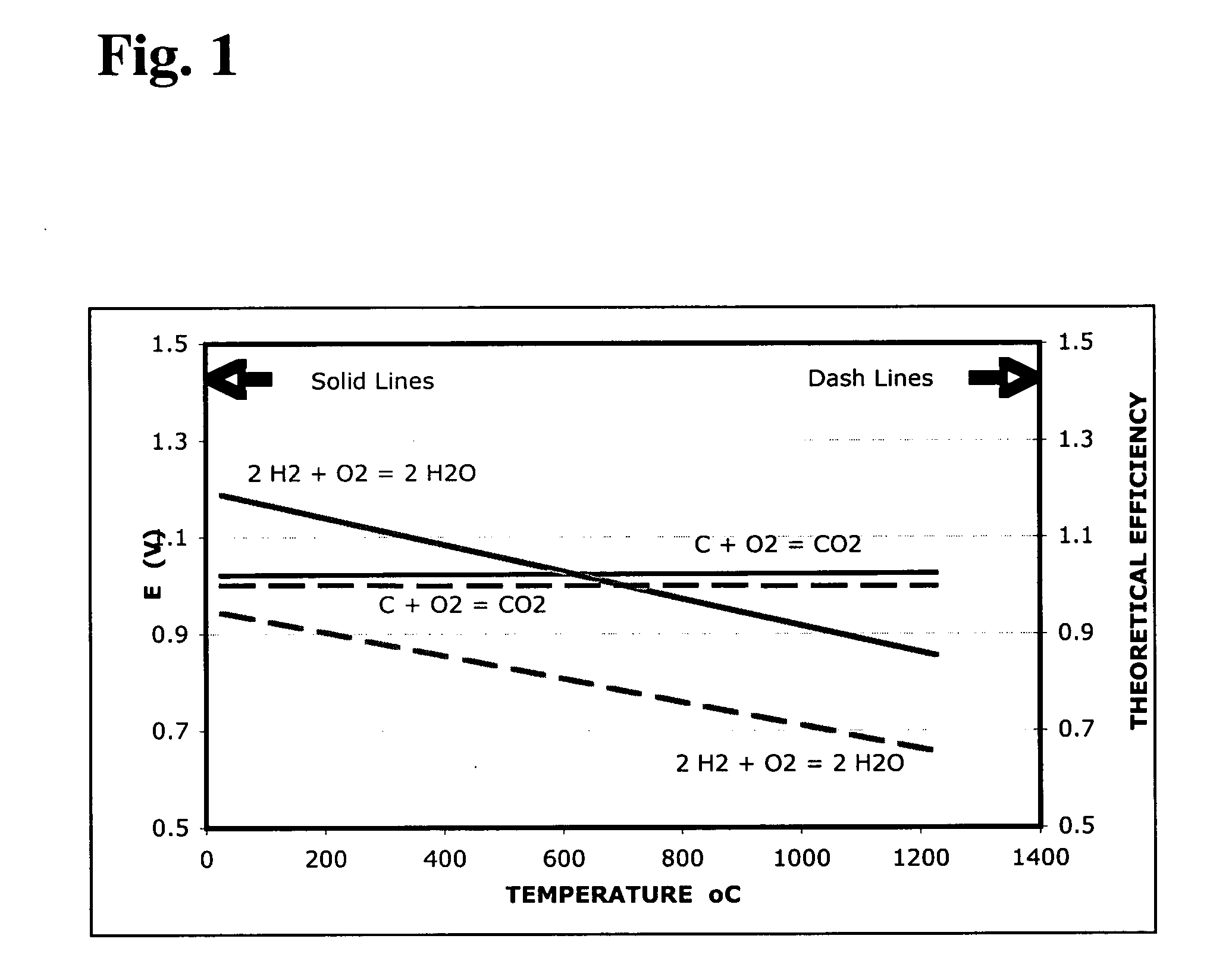

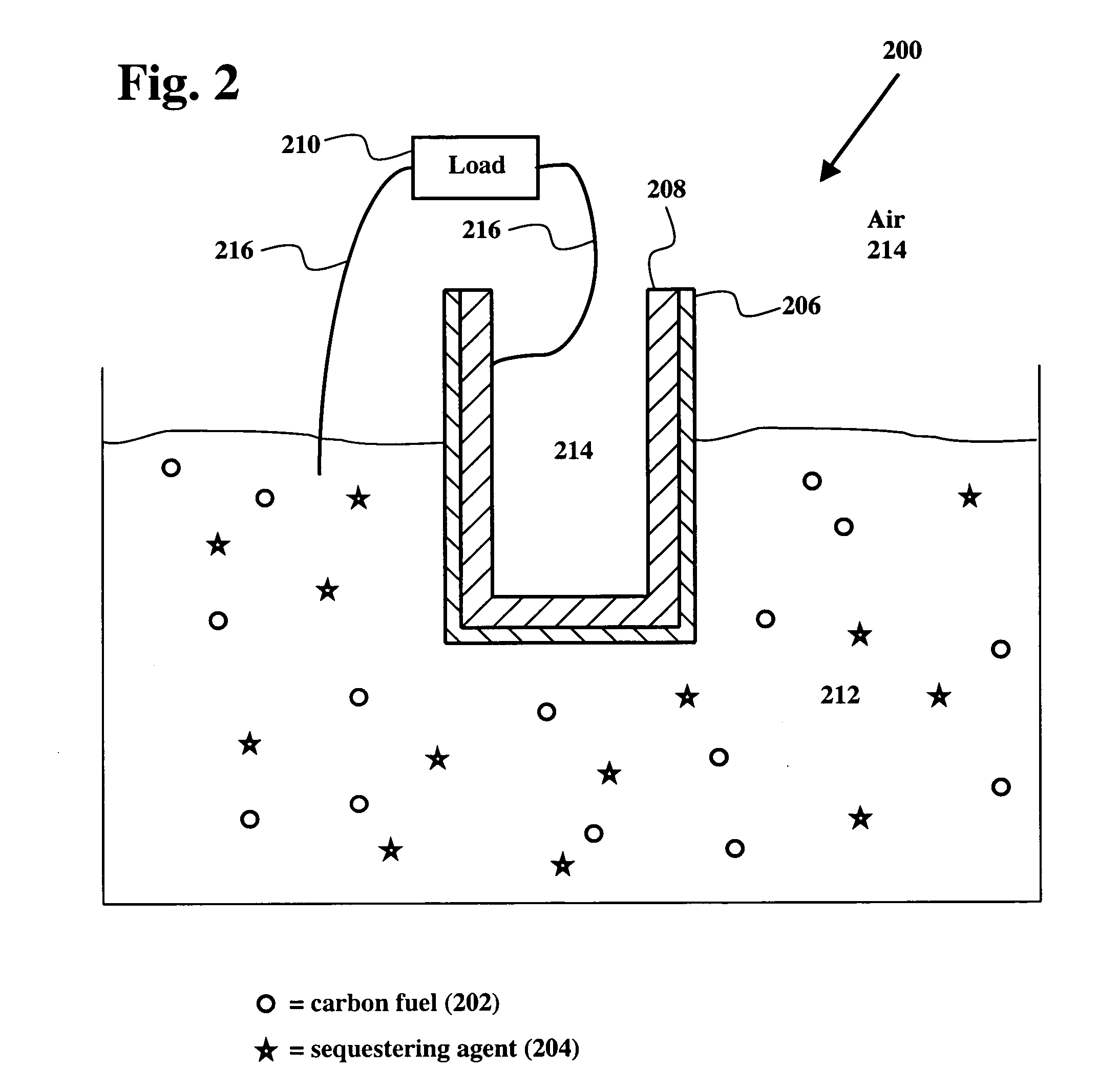

Direct carbon fuel cell with molten anode

This invention discloses a method of converting carbon-containing materials directly to electrical energy without the need for intermediate processing steps. An embodiment comprises the use of a conductive molten medium with dispersed particles of carbon material as the anode in a fuel cell with a solid oxide electrolyte which enables conversion of carbon-containing materials (such as pulverized coal, charcoal, peat, coke, char, petroleum coke, oil sand, tar sand, waste plastics, biomass, and carbon produced by pyrolysis of carbonaceous substance) directly into electrical energy in a single step process. The anode optionally may have a dispersed second solid phase that getters CO2 and SO2 gases that are produced during the anodic reaction. Hence, this invention facilitates near-zero emissions and dramatically reduces the release of environmentally harmful emissions. More importantly, this direct route to electrical energy eliminates Carnot cycle constraints and offers high thermodynamic efficiency.

Owner:DIRECT CARBON TECH

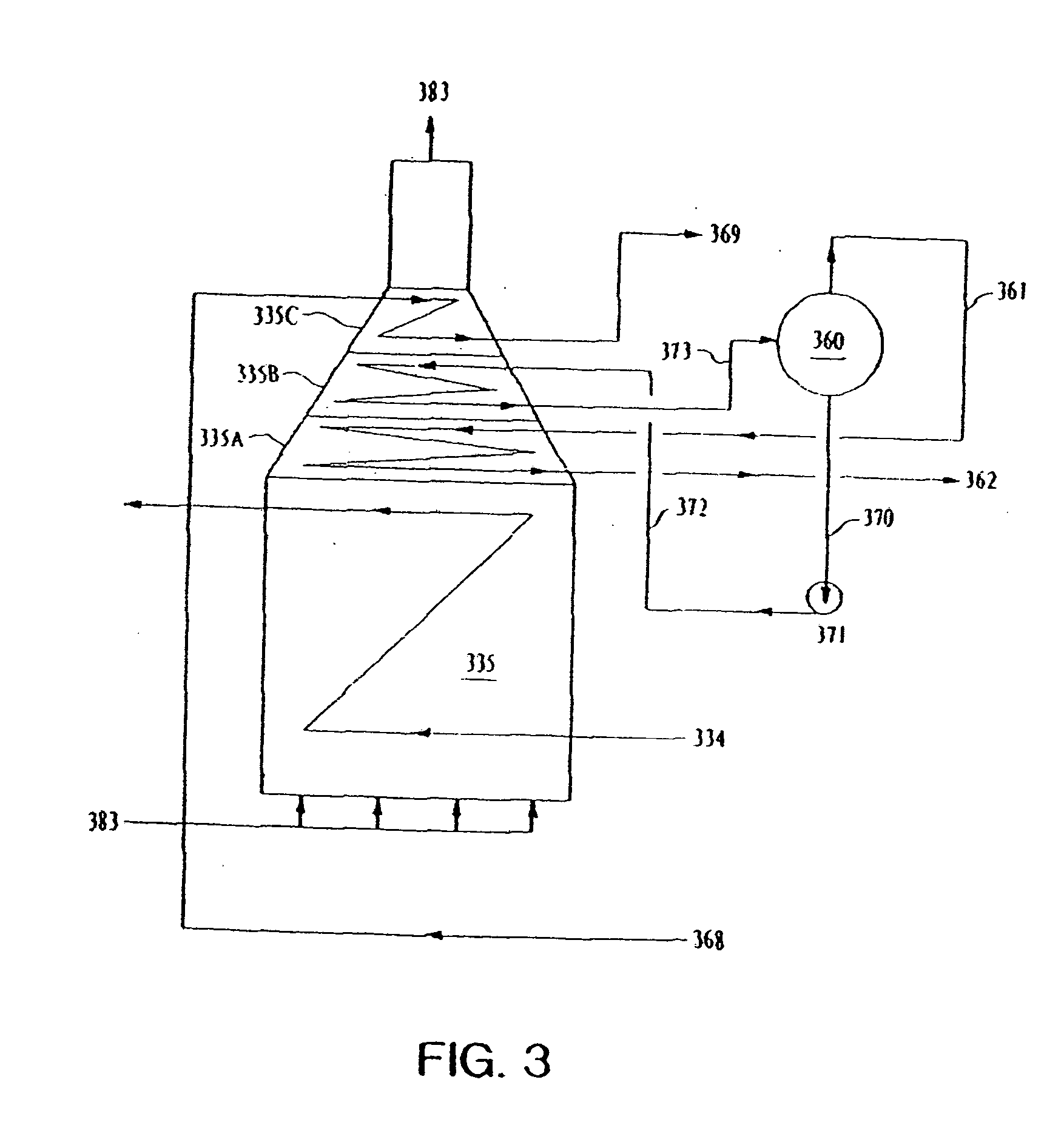

Process and apparatus for converting oil shale or oil sand (tar sand) to oil

InactiveUS20050252833A1Flexibility in processingLiquid hydrocarbon mixture productionHydrocarbon oil crackingOil shale gasPetroleum

Three new embodiments to the Chattanooga Process that convert or upgrade oil bitumen, a combination of oil sands and bitumen, a combination of sand and bitumen, and oil shale to high grade low sulfur (about 0.1 to 0.5 wt. % sulfur, or less) crude oil. The invention relates to a continuous process for producing synthetic crude oil (SCO) from oil sand bitumen which has been extracted from under ground via in situ processes, or strip mined and extracted via hot water extraction processes before upgrading. It can also apply to kerogen extracted in situ from shale underground. The process involves treating the hot bitumen with sand from an extraction process or the hot oil from kerogen with ground shale containing kerogen in a fluid bed reactor where the reactant and fluidizing medium is only hydrogen. The invention also relates to a continuous process for producing synthetic crude oil (SCO) from oil shale kerogen. The invention relates to a continuous process for producing synthetic crude oil from oil bearing material, e.g., oil shale or oil sand (tar sand), through continuous process for producing synthetic crude oil from bituminous oil sand (tar sand) or shale. The process includes treating the oil sand (tar sand) or shale to produce a fluidizable feed, feeding the fluidizable feed to a fluidized bed reactor, and fluidizing and reacting the fluidizable feed in the fluidized bed reactor with a feed of hydrogen provided by a feed stream having a stream containing hydrogen in a concentration greater than 90 vol % (90 vol %-100 vol % H2). In one embodiment, the invention relates to a continuous process which can recover methane and ethane from a recycle hydrogen stream. In one embodiment, the process can recover PSA tail gas as feed to a hydrogen plant. In one embodiment, the process can be operated to reduce or eliminate the requirement for externally provided methane feed to the hydrogen plant.

Owner:DOYLE JAMES A +1

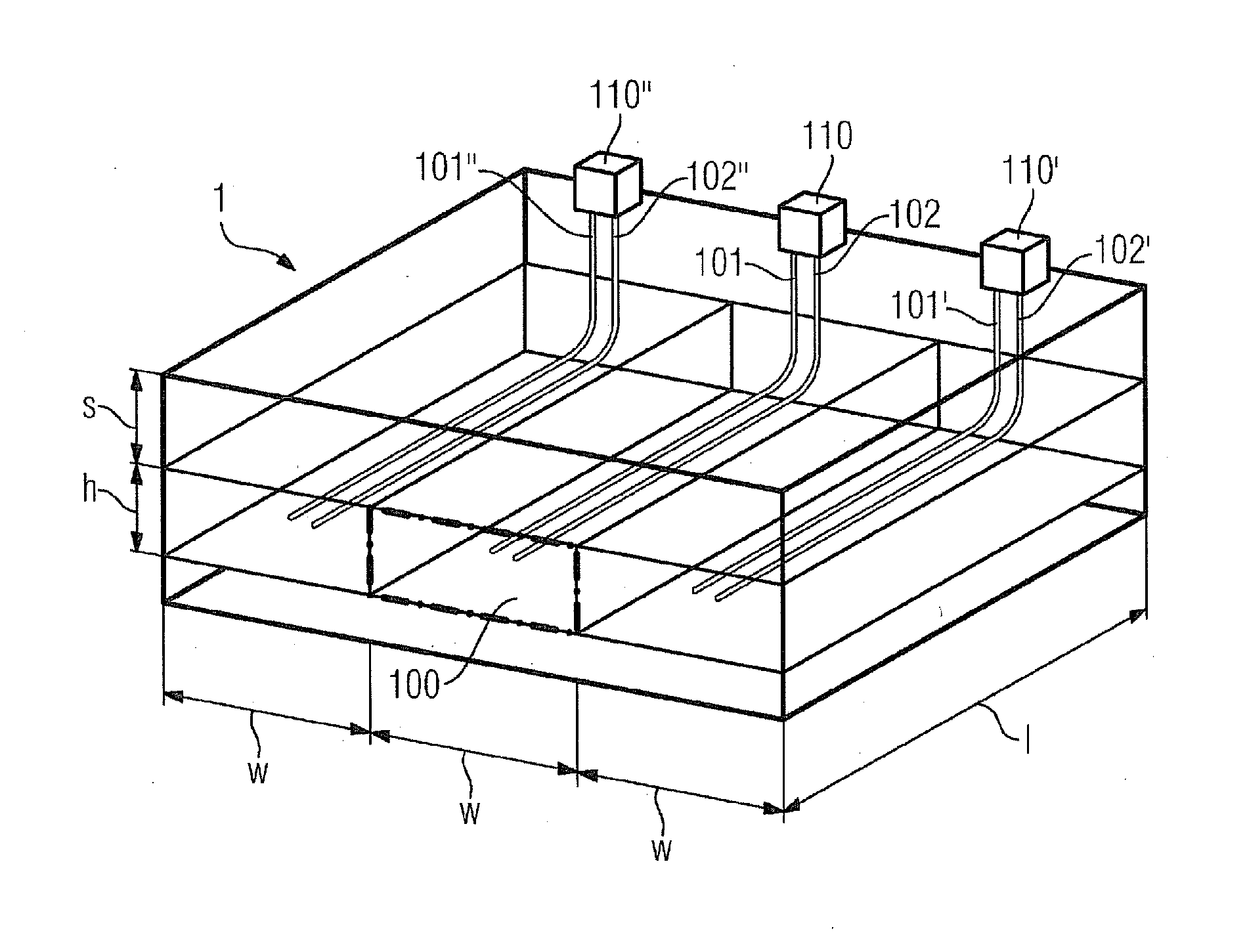

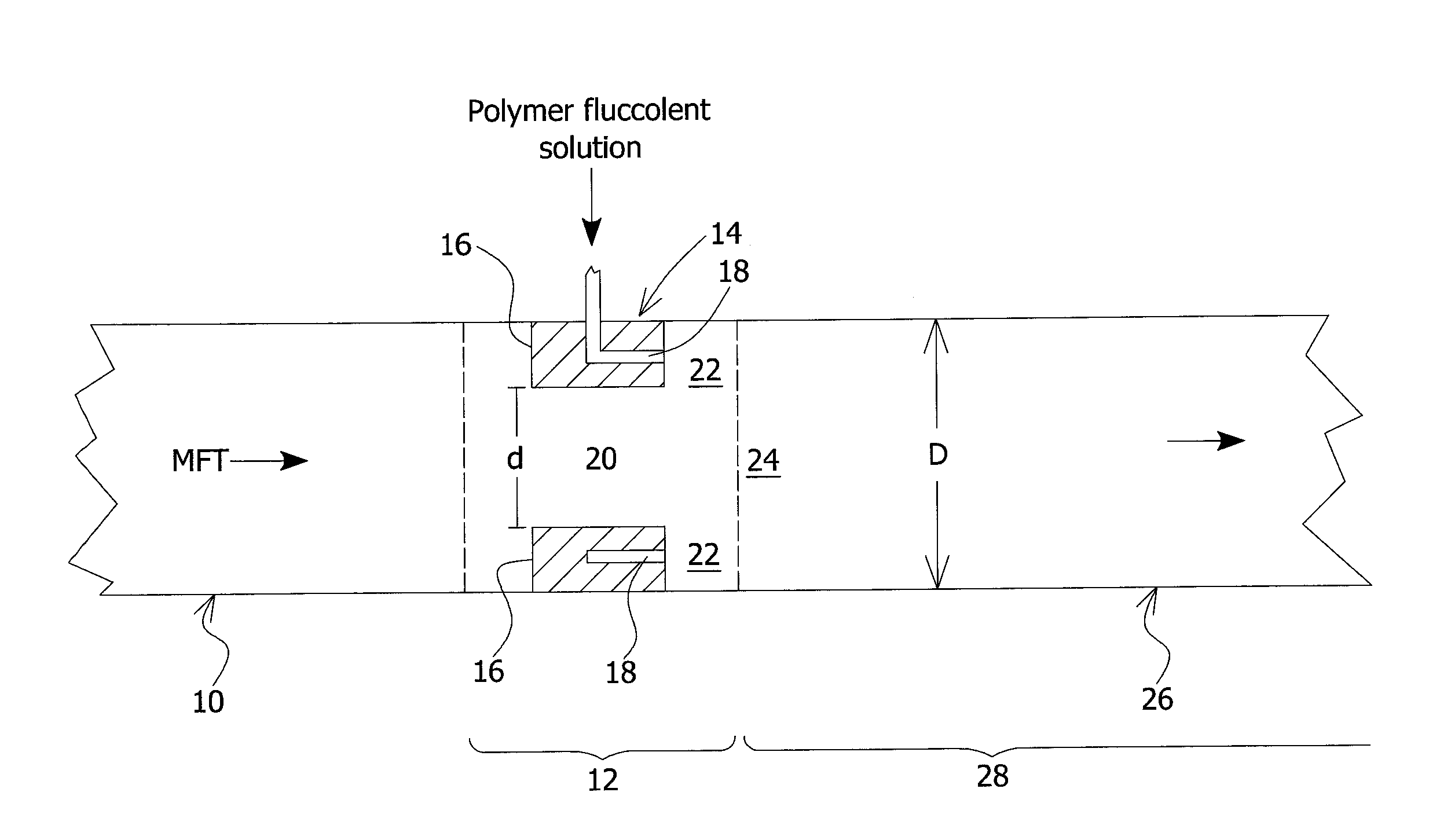

Process for Flocculating and Dewatering Oil Sand Mature Fine Tailings

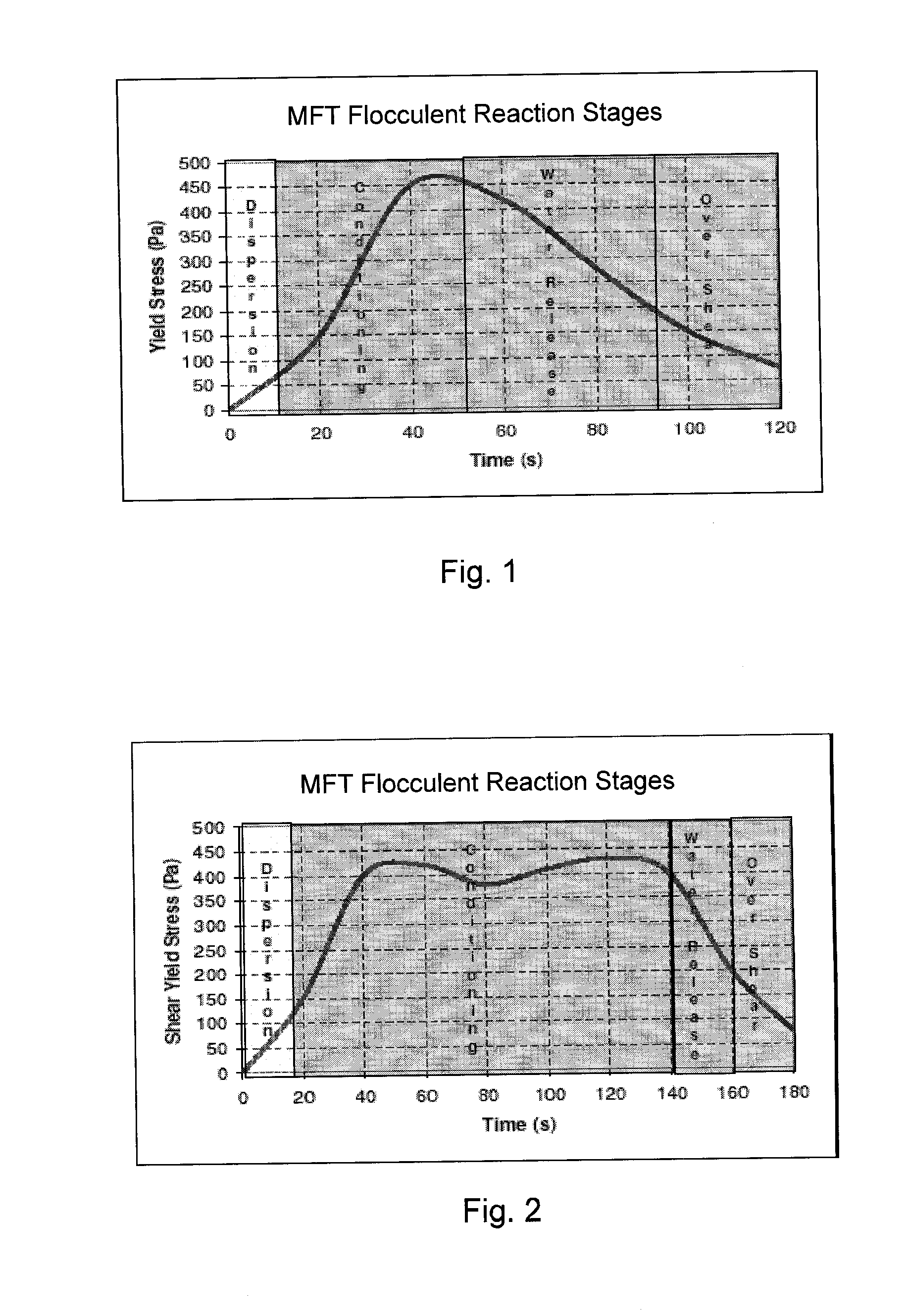

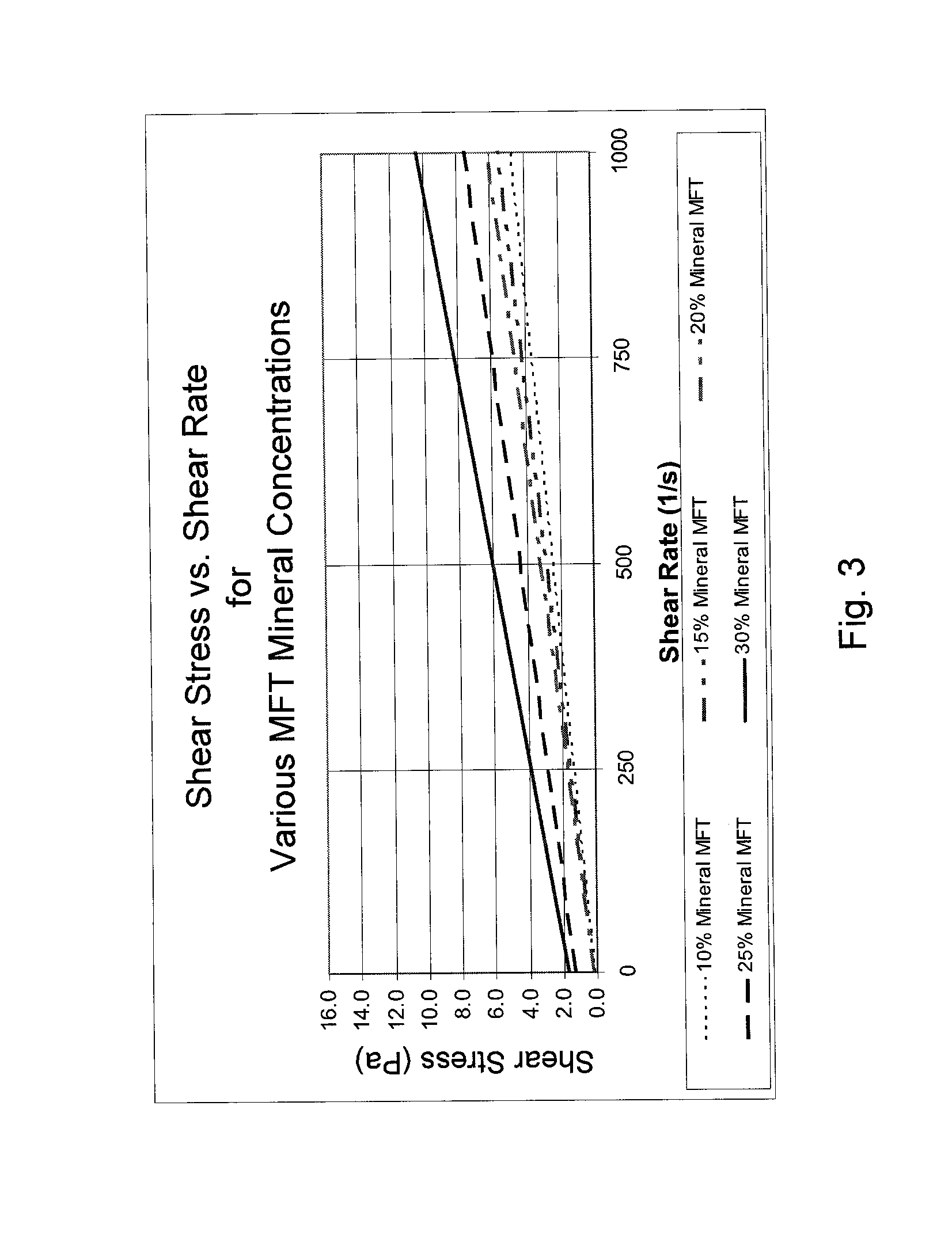

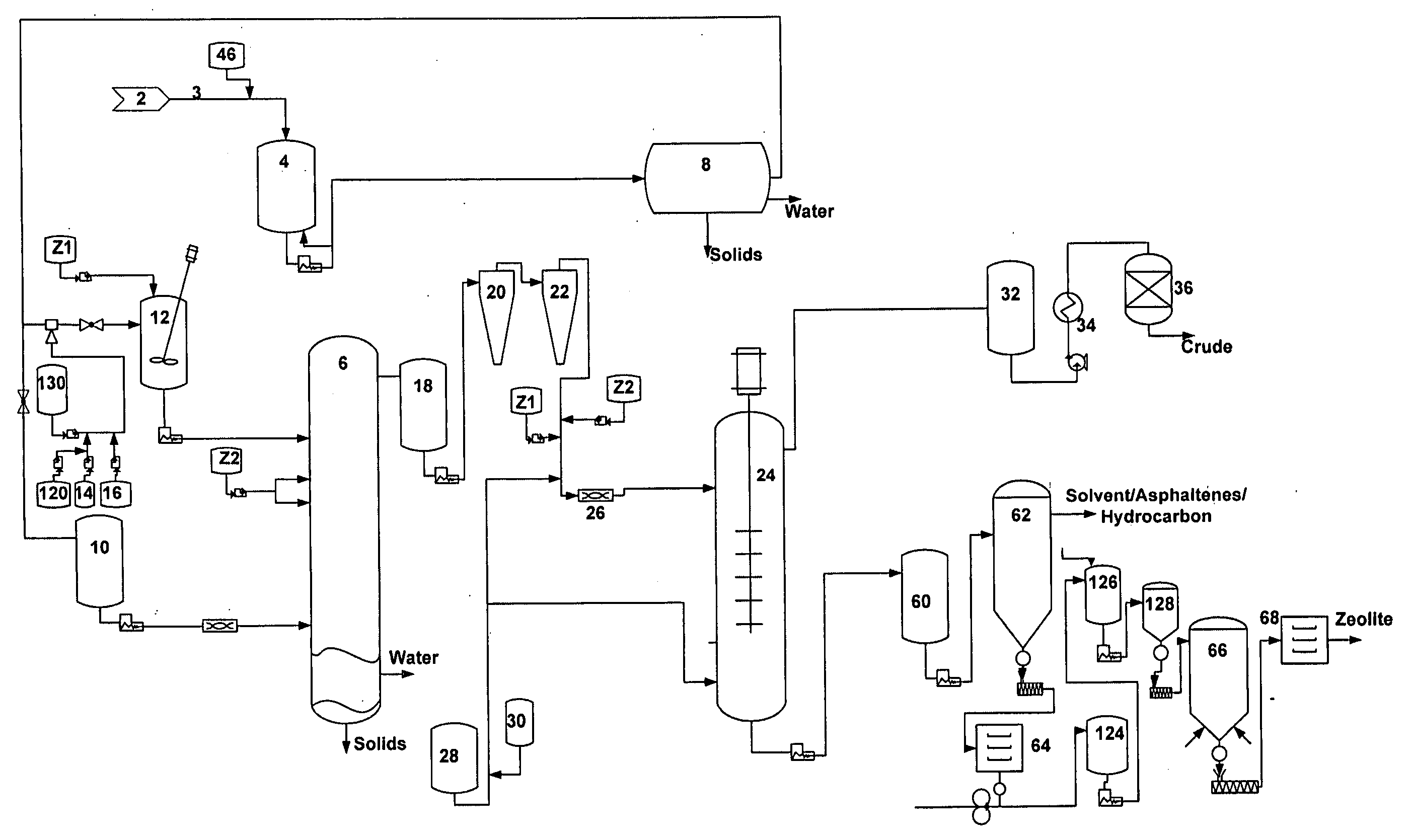

ActiveUS20120175315A1Increasing yield shear stressWaste water treatment from quariesDewatering/demulsification with chemical meansFlocculationShear stress

A process for dewatering oil sand fine tailings is provided and comprises a dispersion and floc build-up stage comprising in-line addition of a flocculent solution comprising an effective amount of flocculation reagent into a flow of the oil sand fine tailings; a gel stage wherein flocculated oil sand fine tailings is transported in-line and subjected to shear conditioning; a floc breakdown and water release stage wherein the flocculated oil sand fine tailings releases water and decreases in yield shear stress, while avoiding an oversheared zone; depositing the flocculated oil sand fine tailings onto a deposition area to form a deposit and to enable the release water to flow away from the deposit, preferably done in a pipeline reactor and managing shear according to yield stress and CST information and achieves enhanced dewatering.

Owner:SUNCOR ENERGY INC +1

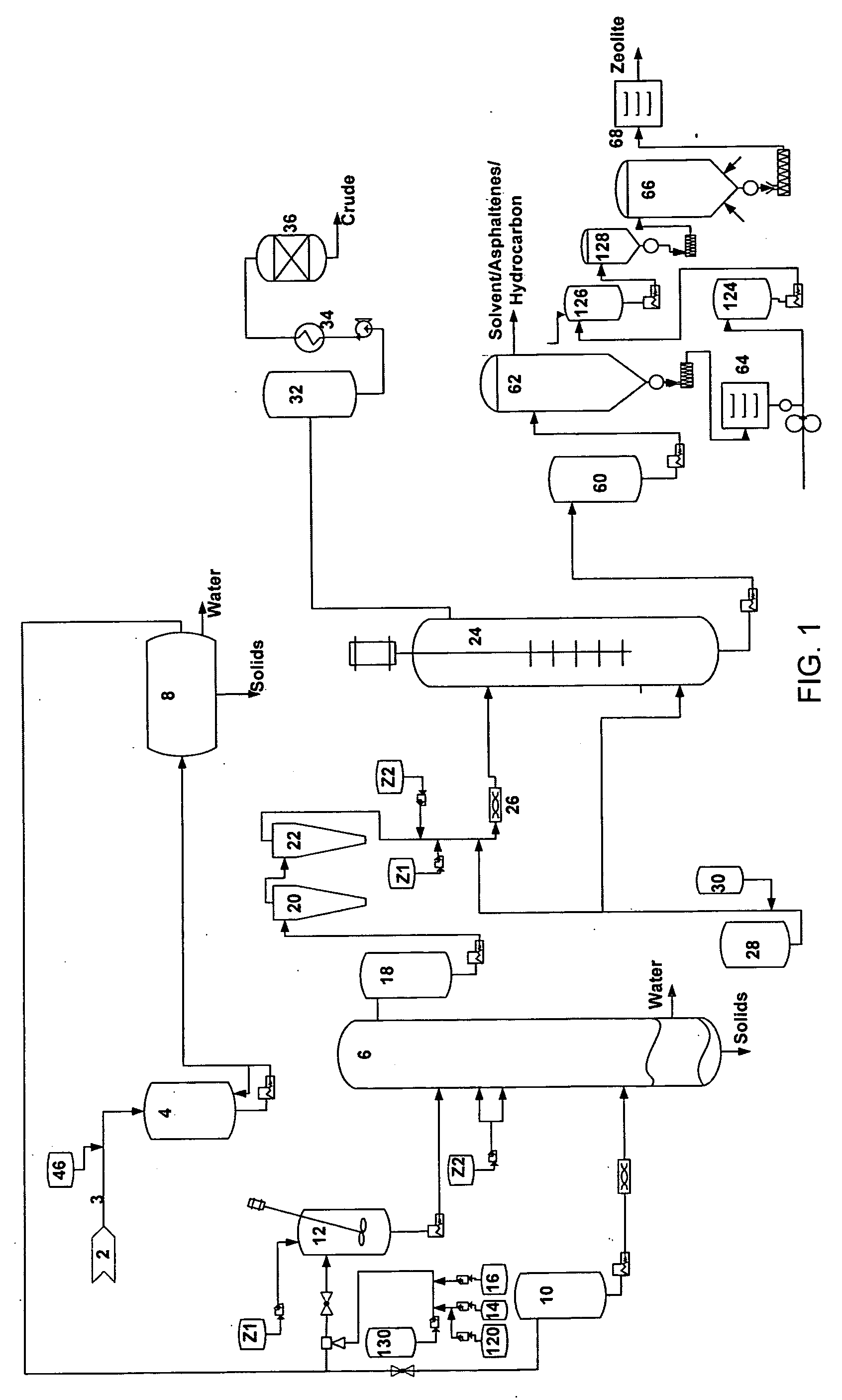

Processing unconventional and opportunity crude oils using zeolites

InactiveUS20060272983A1Hydrocarbon oil dewatering/demulsificationHydrocarbon oils refiningImpurityOil sands

The disclosed process removes or reduces impurities such as asphaltenes, solids (especially solid fines), sulfur, metals, chlorides, water, salts, and acids from bitumen, oil sands, and crude oils with a wide range of gravities. A crude source composition is contacted with one or more zeolite materials to remove asphaltenes, solids, sulfur, NSO, metals, chlorides, water, salts, and / or acids from the composition. The crude source is typically diluted with a hydrocarbon solvent such as naphtha before contacting the zeolite(s). The disclosed processes represent an improvement over prior and presently available processes because the disclosed processes are capable of processing emulsions.

Owner:DROUGHTON CHARLOTTE R +1

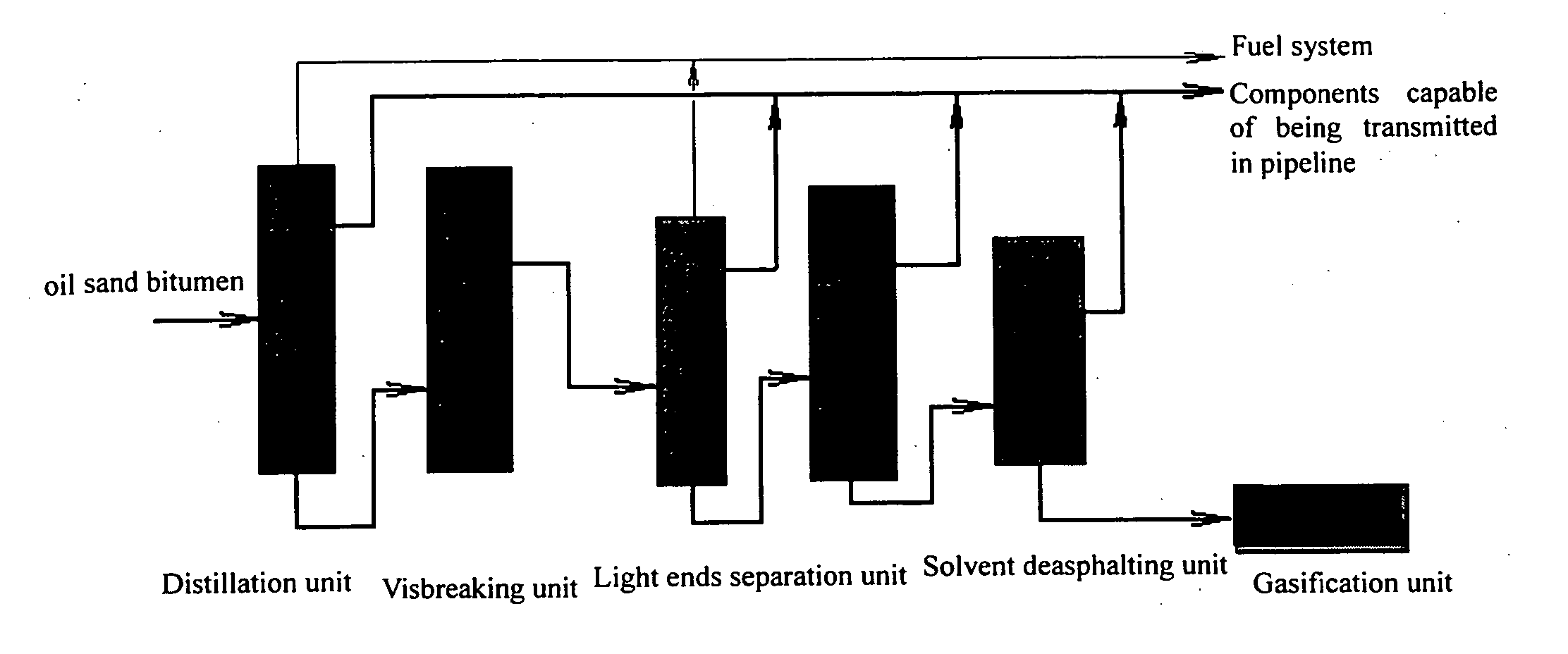

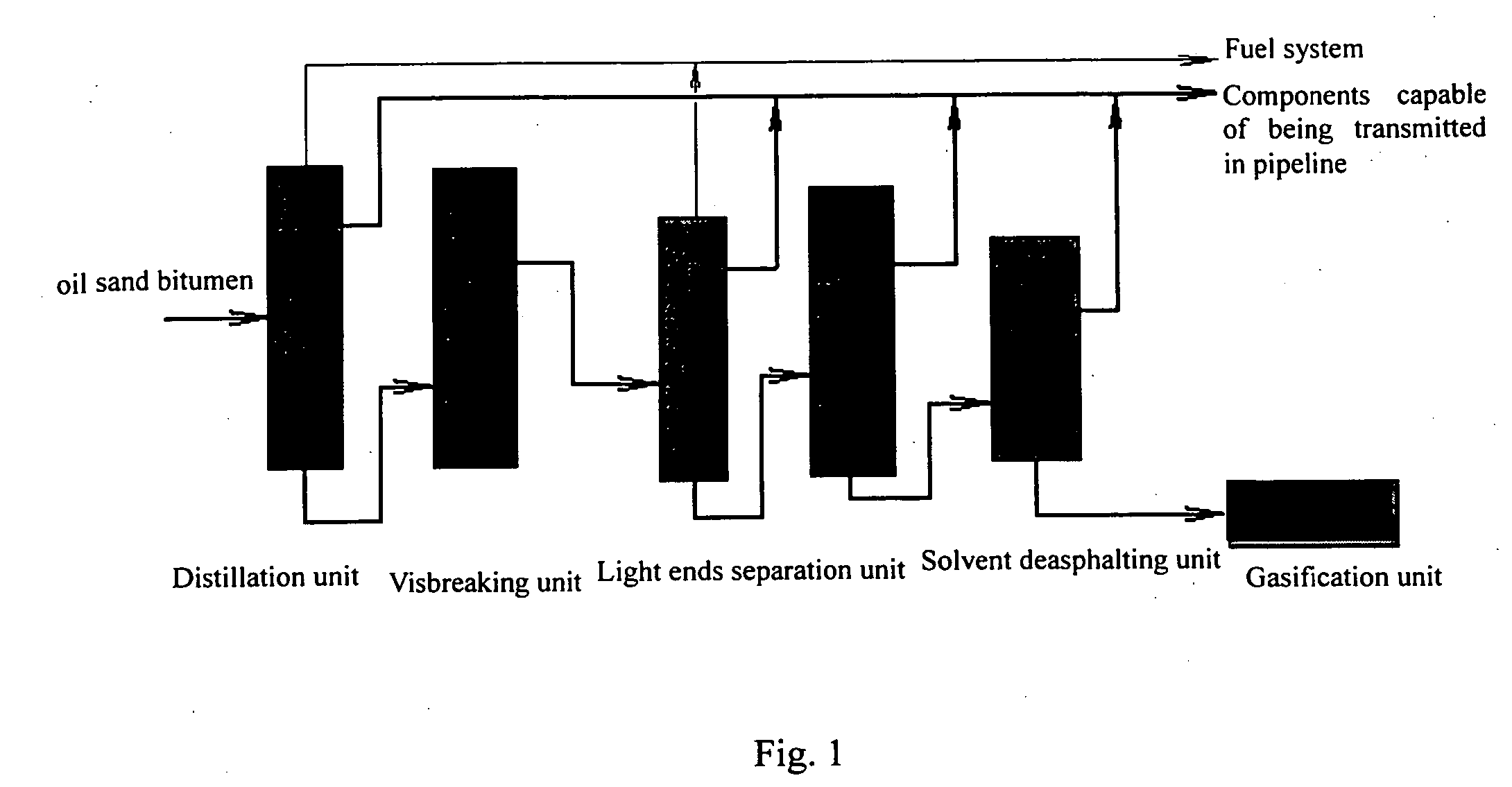

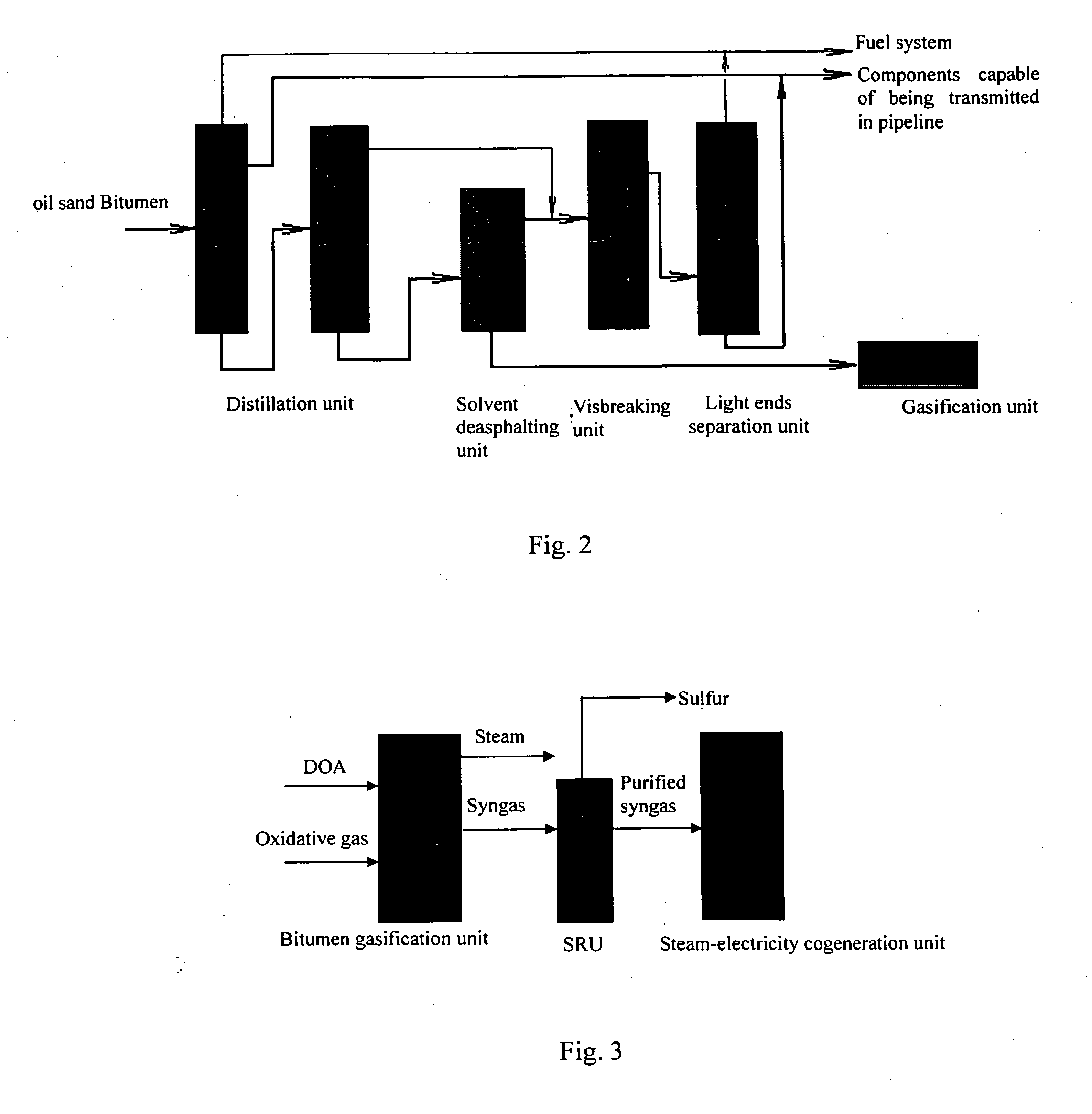

Method for processing oil sand bitumen

InactiveUS20070125686A1Low costLow viscosityTreatment with plural serial stages onlyLiquid hydrocarbon mixture productionEmission standardPollutant emissions

This invention relates to a method for processing oil sand bitumen including solvent deasphalting and visbreaking oil sand bitumen to yield de-oiled asphalt (DOA) and components capable of being transmitted in pipeline. The method for processing oil sand bitumen provided by this invention can effectively transmit oil sand bitumen in pipeline with the advantages of simple operation low equipment cost and significantly reduced operating cost. This method not only can solve the problems arising from enormous working capital required for purchasing diluting agent needed by the traditional unit for processing oil sand bitumen and complications in looking for users, but also can drastically reduce the high investment and high processing cost of such main upgrading avenues as coking and converting heavy oils to light distillates. This invention can enhance the effective products yield and increase the sales income. This method for processing oil sand bitumen can make the recovery of sulfur contained therein by means of the downstream processes easier to significantly reduce the sulfur recovery cost and ensure compliance with the pollutants emission standard.

Owner:CHINA NAT OFFSHORE OIL CORP

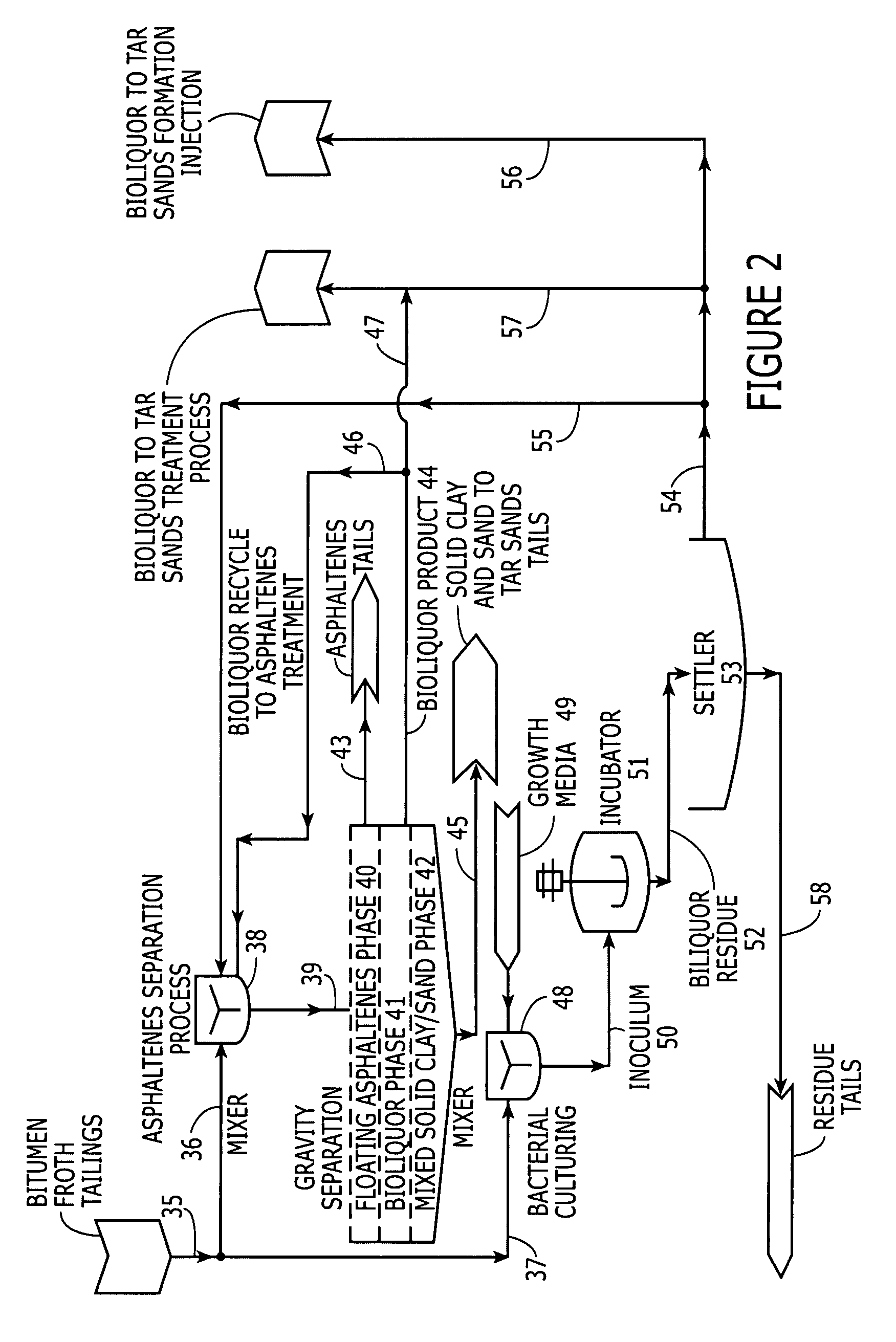

Biological enhancement of hydrocarbon extraction

ActiveUS7472747B1Reduce processing costsEnhanced overall recoveryFluid removalLiquid hydrocarbon mixture productionMicrobial enhanced oil recoverySURFACTANT BLEND

A method of microbial enhanced oil recovery for recovering oil from an oil-bearing rock formation is provided. The methodology uses a consortium of bacteria including a mixture of surfactant producing bacteria and non-surfactant enzyme producing bacteria which may release hydrocarbons from bitumen containing sands. The described bioprocess can work with existing petroleum recovery protocols. The consortium microorganisms are also useful for treatment of above oil sands, ground waste tailings, subsurface oil recovery, and similar materials to enhance remediation and / or recovery of additional hydrocarbons from the materials.

Owner:BATTELLE SAVANNAH RIVER ALLIANCE LLC

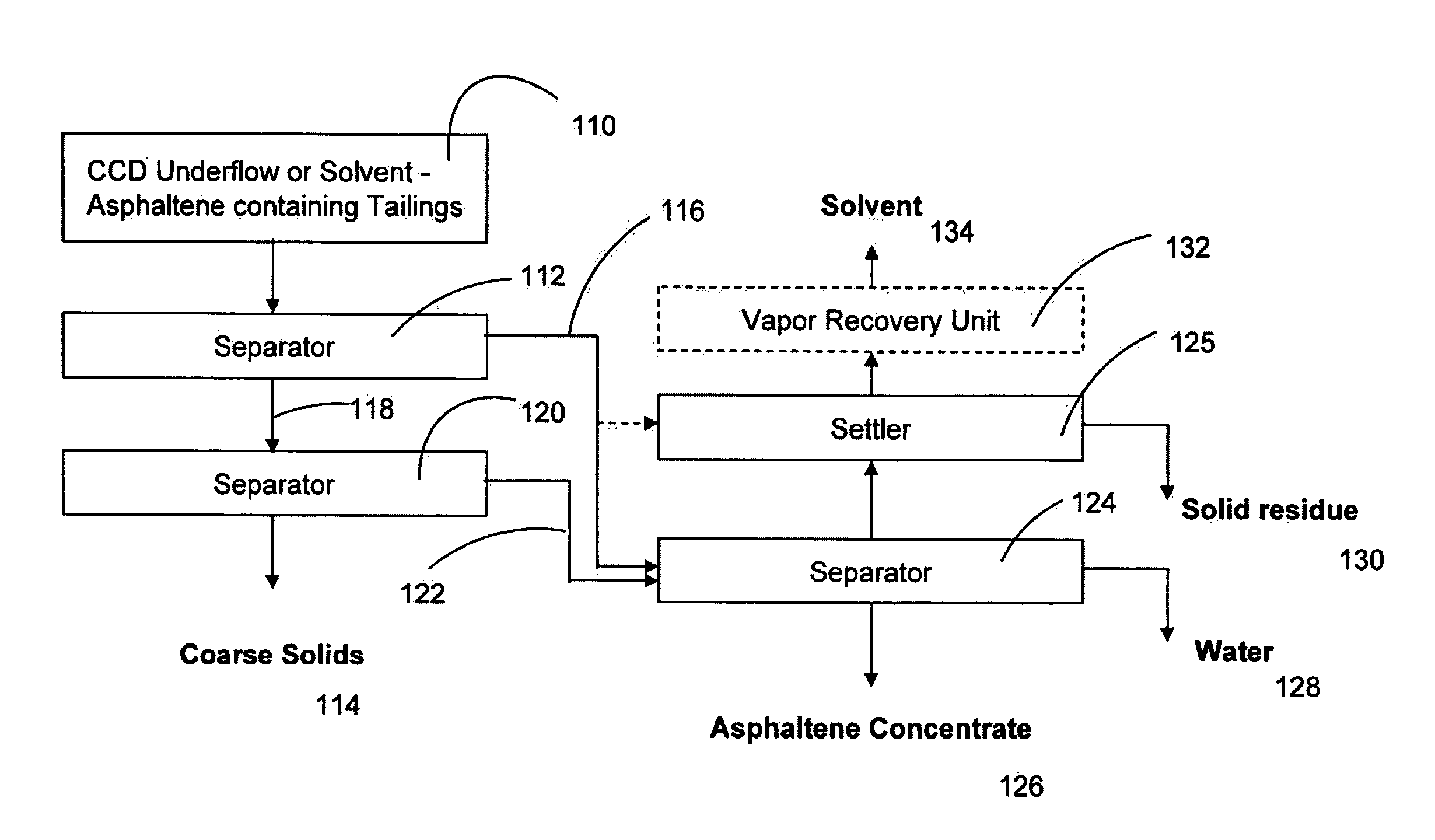

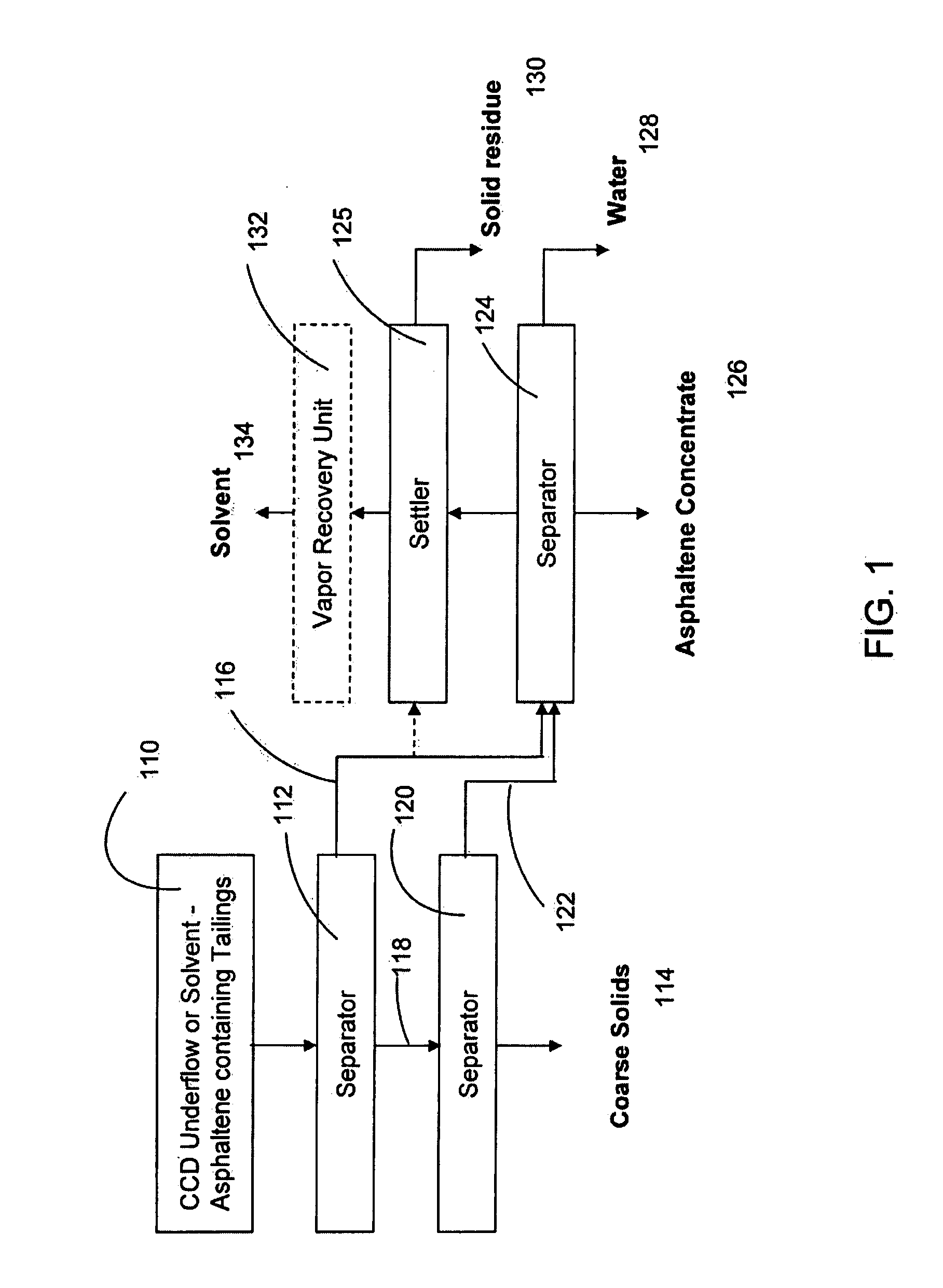

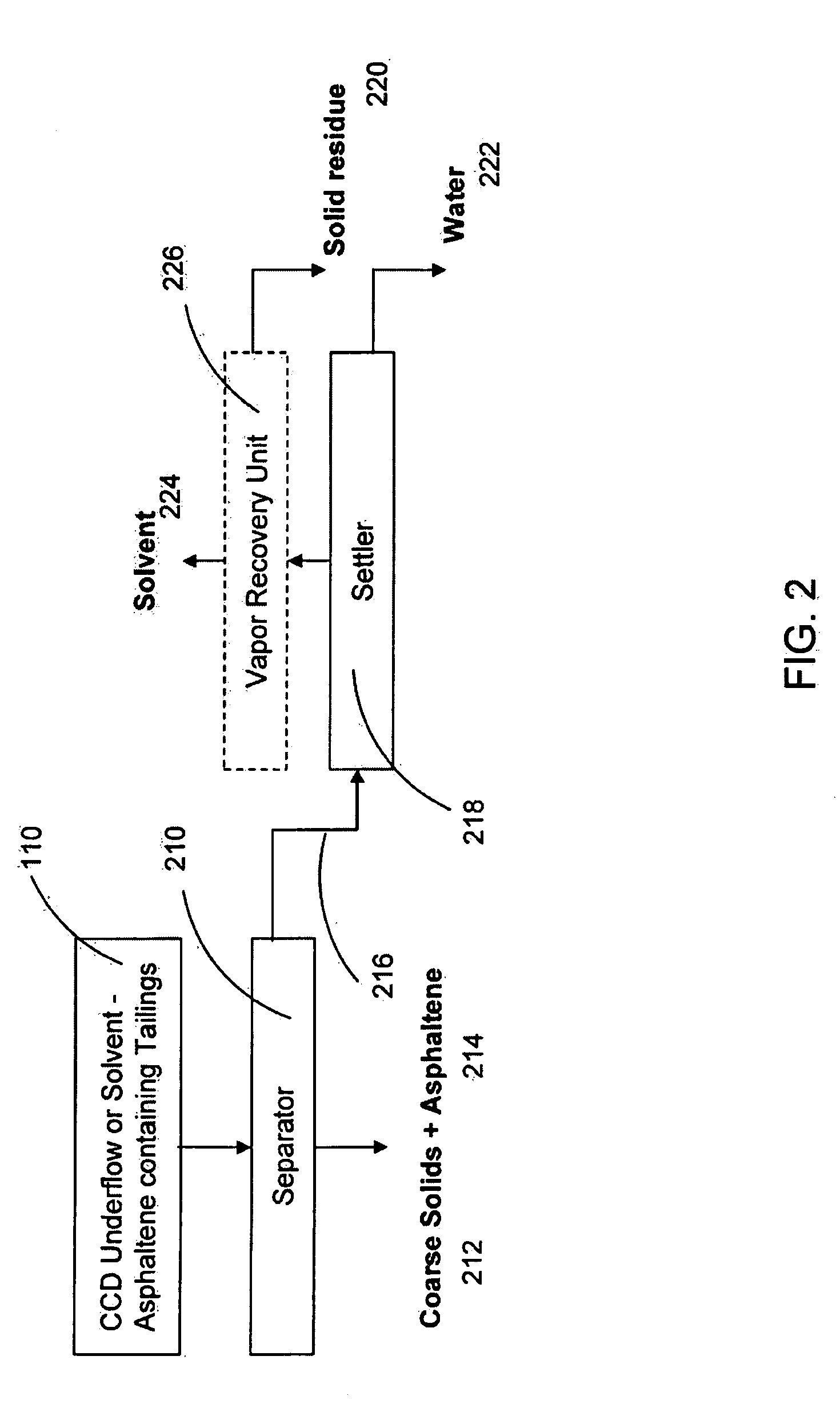

Separation of tailings that include asphaltenes

ActiveUS20080156702A1Easy and less energy intensiveSeparation easy and lessWorking-up pitch/asphalt/bitumenLiquid hydrocarbon mixture productionHydrocarbon solventsCyclonic separation

Various systems and methods are described that can be used as part of a process to separate bitumen from oil sands. The process may include adding a hydrocarbon solvent to a bitumen containing extract. The tailings from this process may contain a significant amount of solvent. The solvent may be recovered from the tailings with a tailings solvent recovery unit that utilizes negative pressure to significantly reduce the cost of the process in comparison to a conventional steam stripping unit. In one embodiment, the tailings may also separated prior to entering the tailings solvent recovery unit with a gravity separation apparatus or a cyclonic separation apparatus, such as a hydrocyclone.

Owner:CANADIAN NATURAL UPGRADING LTD +1

Piston type fluidized bed low temperature dry distillation technological process

InactiveCN101328415AReduce lossesIncrease profitSpecial form destructive distillationHeat carrierOxygen

The invention relates to a process method for low temperature carbonization on a fluidized bed. The process method uses the principle of a lift pipe fluid catalytic cracker, uses a lift pipe reactor of the lift pipe fluid catalytic cracker as a carbonization reactor, uses a catalyst regenerator of the lift pipe fluid catalytic cracker as a high-temperature water gas generator, and uses high-temperature water gas as a fluidizing medium and a heat carrier of a carbonization raw material. The carbonization method comprises the following steps that: a carbonizing raw material is conveyed to the lift pipe fluidized bed reactor for a carbonization reaction of the raw material; the reacted oil and gas are separated to produce a carbonized product; carbonized carbocoal enters the water gas regenerator; carbon in the carbonized carbocoal, oxygen and water vapour in air are subjected to oxidation reaction and water gas reaction; the water gas obtained in the reaction is used as the fluidizing medium and the heat carrier during the carbonization process; and solid clinkers produced after the carbonized carbocoal is subjected to the water gas reaction are discharged. Compared with the prior art, the method has the advantages of simple process, high production capacity, less equipment and so on, and can be used in oil shale, oil sand, coal and other substances to produce liquid petroleum products.

Owner:ZHUHAI TOP ENERGY TECH

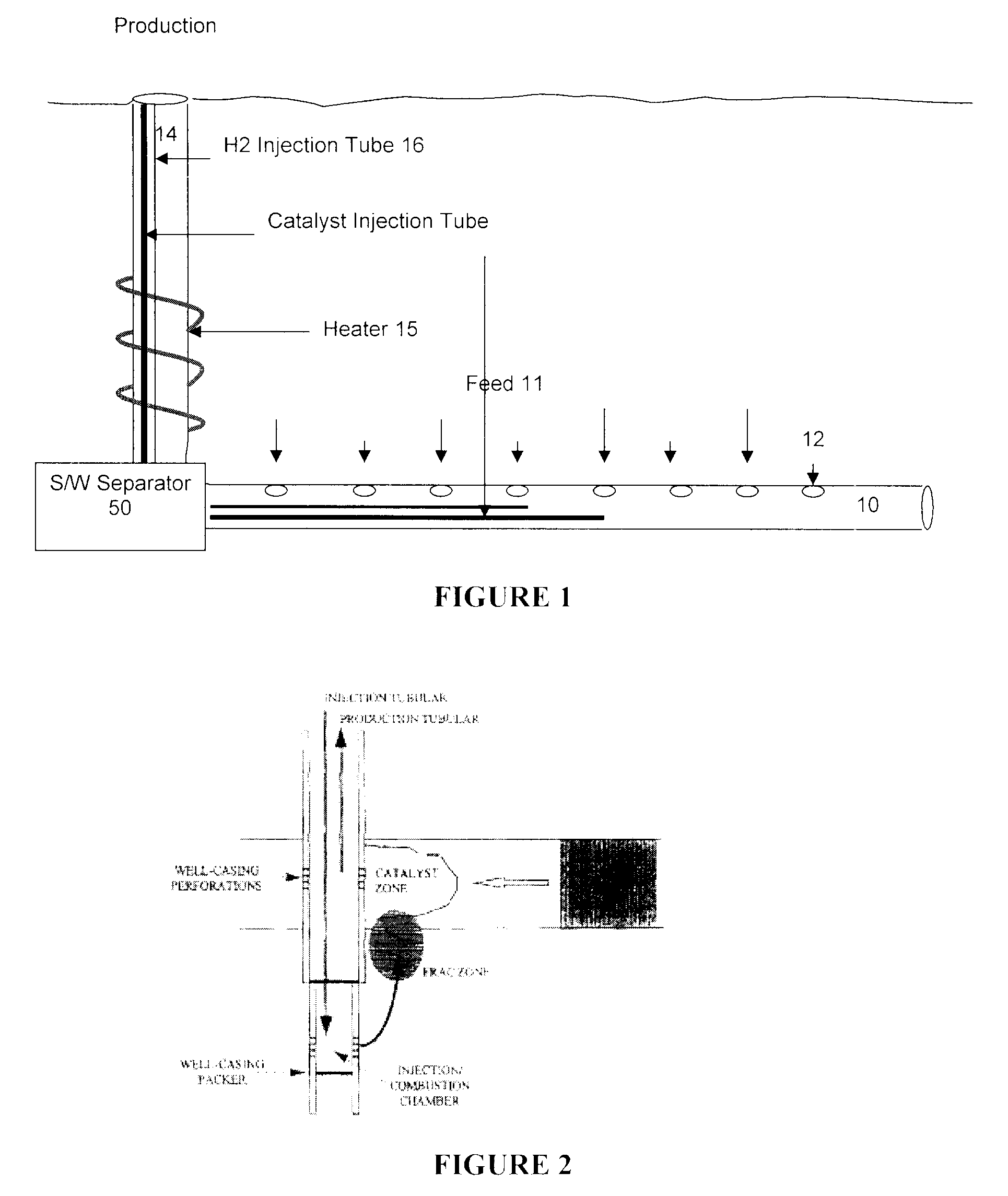

Catalytic down-hole upgrading of heavy oil and oil sand bitumens

InactiveUS20100212893A1Physical/chemical process catalystsFluid removalHydrogenHydrocotyle bowlesioides

The invention relates to systems and methods for catalytic down-hole upgrading of heavy oil and oil sand bitumens. The method enables upgrading heavy oil in a production well within a hydroprocessing zone including the steps of: introducing a controlled amount of heat to the hydroprocessing zone; introducing a selected quantity of hydrogen to the hydroprocessing zone to promote a desired hydrocarbon upgrading reaction; and, recovering upgraded hydrocarbons at the surface. The invention further includes the hardware capable of performing the method.

Owner:THE UNIV OF CALGARY

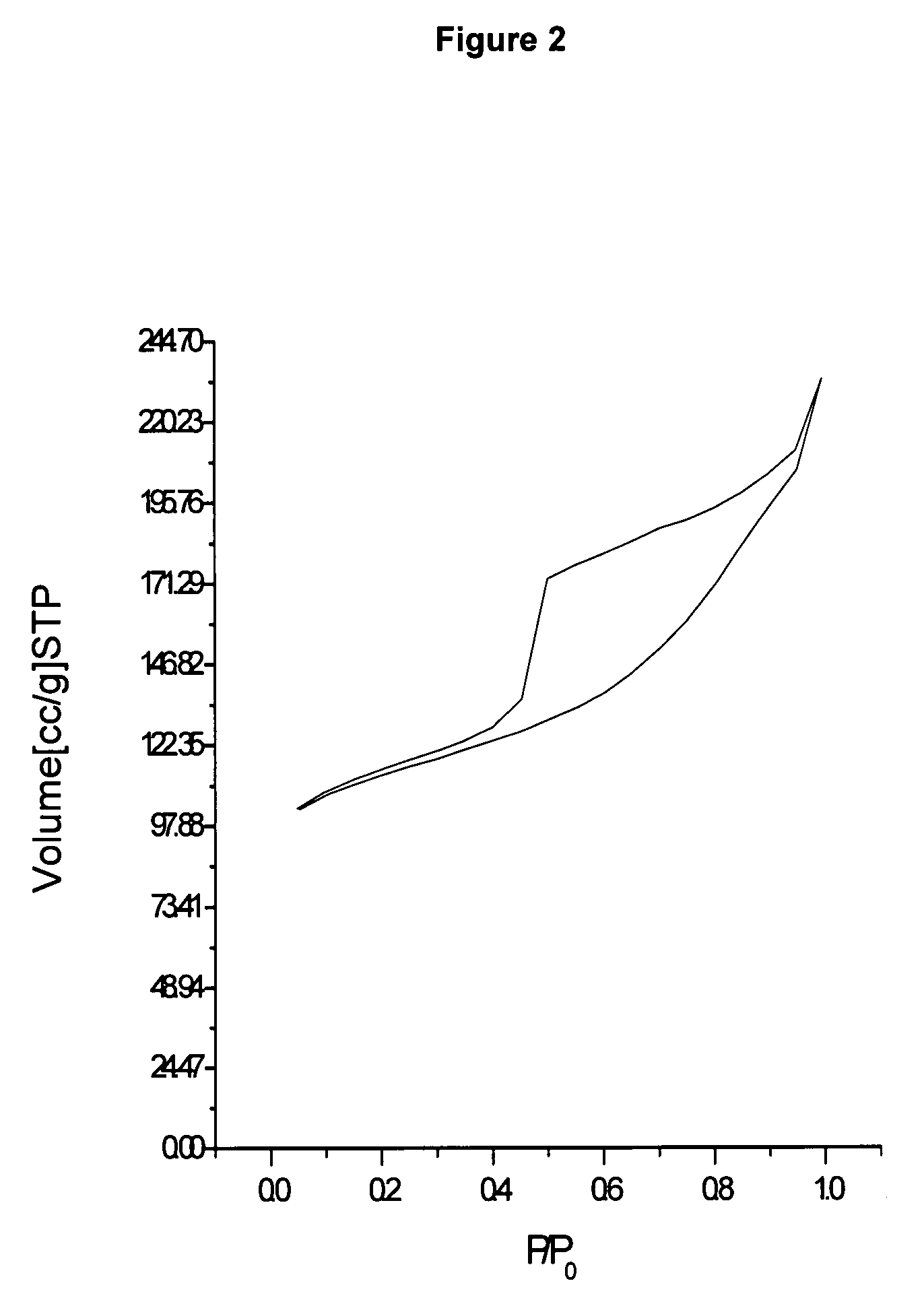

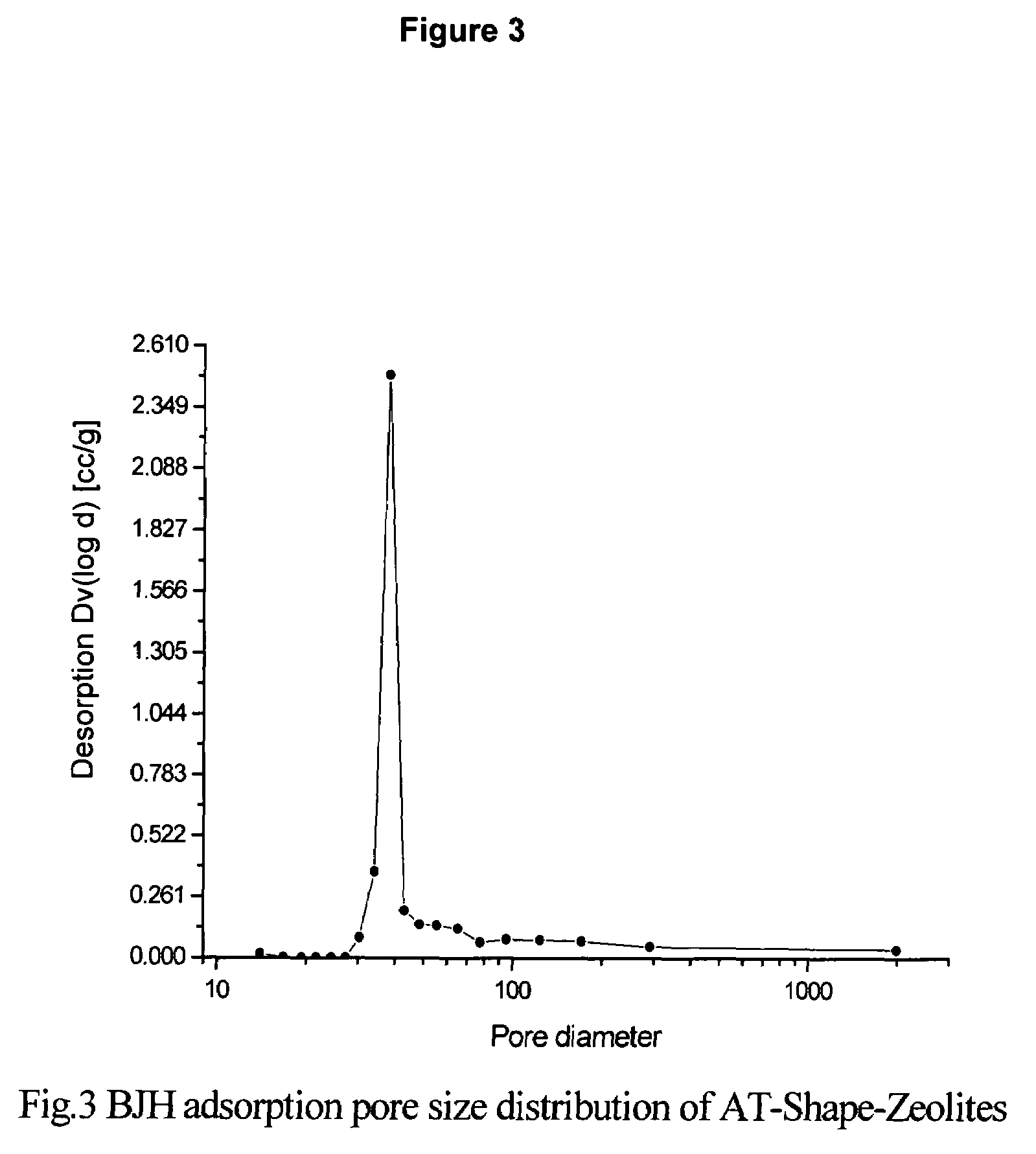

Catalyst composition for treating heavy feedstocks

The present invention provides a catalyst and a process for its preparation and its use in cracking heavy feedstocks. The catalyst comprises one or more zeolites having a controlled silica to alumina ratio and preferably treated with alkali in the presence of a matrix component selected from the group consisting of clays, synthetic matrix other than pillared clay, and mixtures thereof. The catalyst are particularly useful in treating heavy feedstock such as residues from oil sands processing.

Owner:STATE KEY LAB OF HEAVY OIL PROCESSING

Dirty oil mud separating method and device

InactiveCN101239770ANo secondary pollutionEasy to handleSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningWater vaporOil sludge

The present invention relates to a petroleum processing method and equipment, especially to an oil-bearing sludge separating method and equipment, provides a simple, economical, practical, environment-protecting and pollution-free oil-bearing sludge processing method and equipment, and the method comprises the following procedures: heating the water vapor to the superheated steam with temperature above 500 DEG C with a superheated steam boiler; injecting the superheated steam to the oil-bearing sludge with a speed of 2 mach, the oil-bearing sludge is crushed to small particles after instant colliding; separating the water component and the oil component which are evaporated and sublimed instantly with a cyclone separator; dropping the temperature and fluidifying through water spraying; and extracting the oil product up to standard by the separating of the oil-water separating pot, above 95% oil component in the oil-bearing sludge can be recovered and the oil content of the residue is lower than 5%, the petroleum processing method has the advantages of guaranteeing the quality of the recovered oil product, simple operation and maintenance, broad application that can be applied to varies types of oil-bearing sludge and oil-bearing sand, excellent economic benefit and low cost, the equipment is used for processing the oil-bearing sludge that is generated in the crude oil exploration and exploitation, crude oil transportation and the petroleum refinery wastewater treatment.

Owner:张贺新

Emulsified polymer drilling fluid and methods of preparation

A water-based polymer drilling fluid, containing effective quantities of surfactants having HLB numbers equal to or greater than approximately 7, emulsifies oil and bitumen contained in oil sand cuttings, resulting in the oil and bitumen being dispersed into the mud as an emulsion. This eliminates or significantly reduces the ability of the oil, bitumen, and cuttings to clog the well or stick to drill string components when drilling a well through oil-bearing sands, particularly sands containing highly viscous oil or bitumen. The emulsification process separates the sand particles from the oil and bitumen, such that the sand particles can be removed when the mud is run through a conventional shale shaker or other suitable apparatus.

Owner:SECURE ENERGY DRILLING SERVICES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com