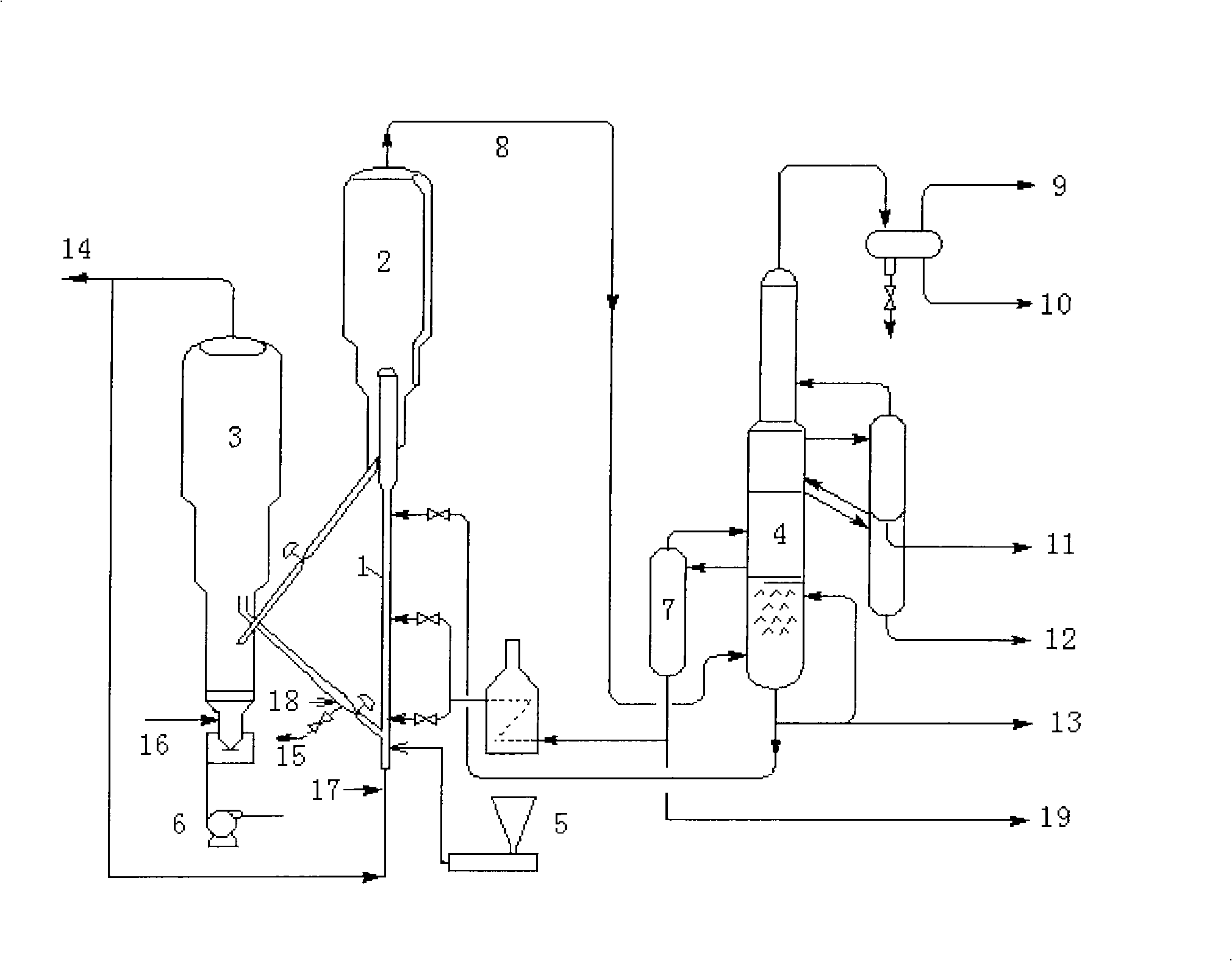

Piston type fluidized bed low temperature dry distillation technological process

A process method and fluidized bed technology, applied in special dry distillation, petroleum industry, coke oven, etc., can solve the problems of small single furnace processing capacity, high investment and operation costs, and large water consumption, so as to avoid secondary polymerization Wait for the reaction, improve the heat utilization rate, improve the effect of production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Raw materials: Maoming oil shale (the property is mass content) has a water content of 2%, an oil content of 7.15%, and an oil recovery rate of >95%. It takes about 14 tons of oil shale to produce 1 ton of oil.

[0046] The production is carried out according to the processing capacity of 6 million t / a (retort raw material processing capacity), and the riser fluidized retort-water gas production device with the above parameters and conditions is adopted. The powdered Maoming oil shale with a particle size of less than 3mm is sent to the raw material tank, and then sent to the lower end of the riser reactor through the screw propeller, and the superheated steam is used to adjust the temperature of the high-temperature water gas to 650-680°C, and 750t / h powdered Maoming The oil shale enters the riser reactor, and the reaction materials pass through the riser reactor in a plug-flow fluidized bed reaction, and the semi-coke is separated from the oil and gas in the settler; t...

Embodiment 2

[0065] Raw materials: Angolan oil sands (the nature is mass content) moisture content 95%, producing 1 ton of oil requires about 10.5 tons of oil sands, gas production 30m 3 / t.

[0066] According to the 6 million t / a oil shale processing equipment and conditions in Example 1, the Maoming oil shale was replaced with Angola oil sand.

[0067] The processing capacity of powdery Angola oil sand is 750t / h=6 million t / a

[0068] Gas heat carrier at 650-680°C: the amount required to maintain the thermal balance of the system

[0069] Available: liquid oil 570,000 t / a

[0070] Dry gas 180 million m 3 / a

[0071] Ash slag 5.29 million t / a

[0072] (Charged amount 30,000t / a)

[0073] Water gas 116.25 million m 3 / a

Embodiment 3

[0075] Raw materials: Lignite (mass content) moisture content 3 / t.

[0076] According to Example 1 in the 6 million t / a oil shale processing equipment and conditions, powdery lignite replaces Maoming oil shale.

[0077] Powdered lignite processing capacity: 750t / h=6 million t / a

[0078] Gas heat carrier at 650-680°C: the amount required to maintain the thermal balance of the system

[0079] Available: liquid oil 1.2 million t / a

[0080] Dry gas 120 million m 3 / a

[0081] Ash 930,000 t / a

[0082] (Charged amount 4.29 million t / a)

[0083] Water gas 6641.75 million m 3 / a

[0084] Using Fischer-Tropsch water gas to synthesize petroleum: 6641.75 million m of water gas 3 / a

[0085] Available: light synthetic oil 2.19 million t / a of which C 5 + 1.28 million t / a

[0086] by-product CO 2 2.19 million t / a

[0087] Hydrogen production with water gas can obtain high-purity H 2 : 300,000 t / a.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com