Patents

Literature

49results about How to "No backmixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

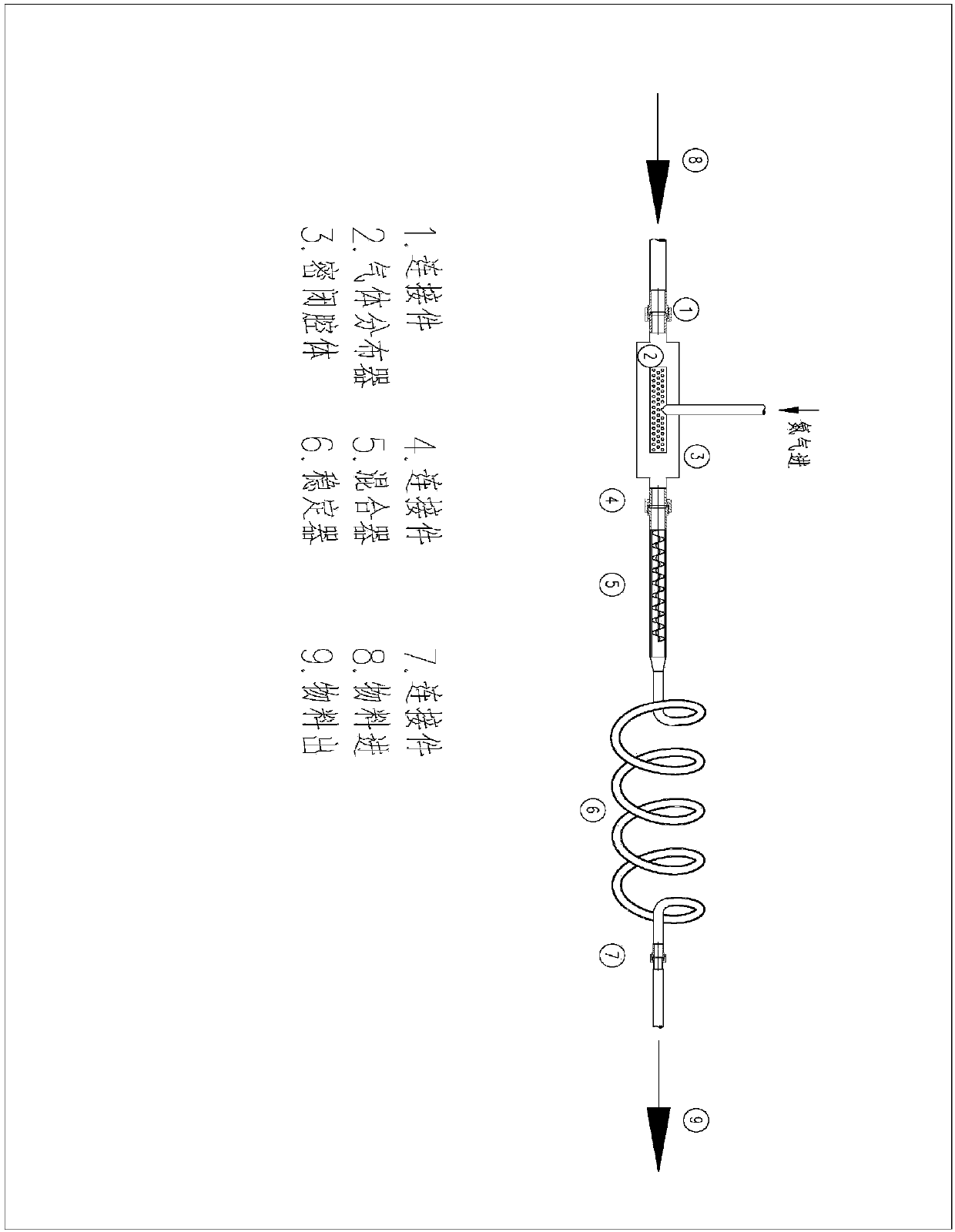

Process and device for continuous ultrasound desulfurization of scrapped lead paste

InactiveCN101518711AReduce the number of settingsSmall footprintDispersed particle separationIonSodium carbonate

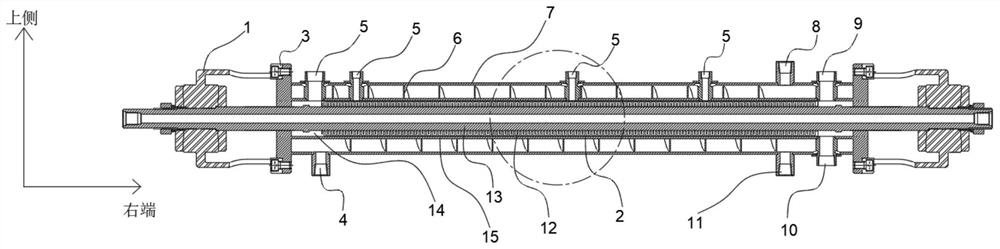

The invention relates to a process and a device for continuous ultrasound desulfurization of scrapped lead paste. The process for continuous ultrasound desulfurization of scrapped lead paste comprises the following steps: (1) sodium carbonate or ammonium carbonate is selected as desulfurizing agent, and the desulfurizing agent and the scrapped lead paste are taken according to the mole ratio (1.2 to 2.2:1) of the Na iron or the (NH4)2 iron in the desulfurizing agent to the S iron in the scrapped lead paste; (2) the scrapped lead paste, the desulfurizing agent and water are prepared into flowing pulp with solid-liquid (S / L) weight ratio being equal to 3 / 5 to 4 / 5 in a pulping tank; (3) under the condition of ultrasonic wave, the flowing pulp enters a first reaction chamber for heating and stirring from the lower end part in the first reaction chamber, is discharged out from an overflow opening at the upper end of the first reaction chamber, then enters a second reaction chamber for heating and stirring from the lower end part of the second reaction chamber and finally, and is discharged out from a discharging opening at the upper end of an nth (ranging from 3 to 12) reaction chamber after sequent flow for reaction and discharge. The process has the advantages of low cost, small occupied area, continuous production and high efficiency.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Method for preparing hydroxypivalaldehyde through micro-channel reactor

InactiveCN105693491AShort residence time at high temperatureImprove conversion rateOrganic compound preparationCarbonyl compound preparationProduct selectionReaction temperature

The invention relates to a method for preparing hydroxypivalaldehyde through a micro-channel reactor. The problems that in the prior art, reaction time is long, product selectivity is poor, and the raw material conversion rate is low are mainly solved. By means of the method for preparing hydroxypivalaldehyde through the micro-channel reactor, isobutyraldehyde, formaldehyde raw materials and a catalyst are mixed completely through a pre-mixer of the micro-channel reactor and then enter a constant-temperature reactor of the micro-channel reactor to react, and the product containing hydroxypivalaldehyde is obtained; the mass ratio of formaldehyde to isobutyraldehyde in the raw materials is (1-1.4) : 1; the using quantity of the catalyst is 0.5-5% of the total mass of a reaction solution; reaction temperature in the micro-channelconstant-temperature reactor is 100-140 DEG C, the pressure of a reaction meter is 0.5-1.5 MPa, and the reaction staying time of the reaction solution in the micro-channel reactor is 30-300 s; the technical scheme that after reaction, the conversation rate of the raw material isobutyraldehyde in the reaction solution after reaction is larger than 95%, the selectivity of the product hydroxypivalaldehyde is larger than 95% well solves the problems, and the method can be used for preparing hydroxypivalaldehyde.

Owner:SHANGHAI HUAYI GRP CO

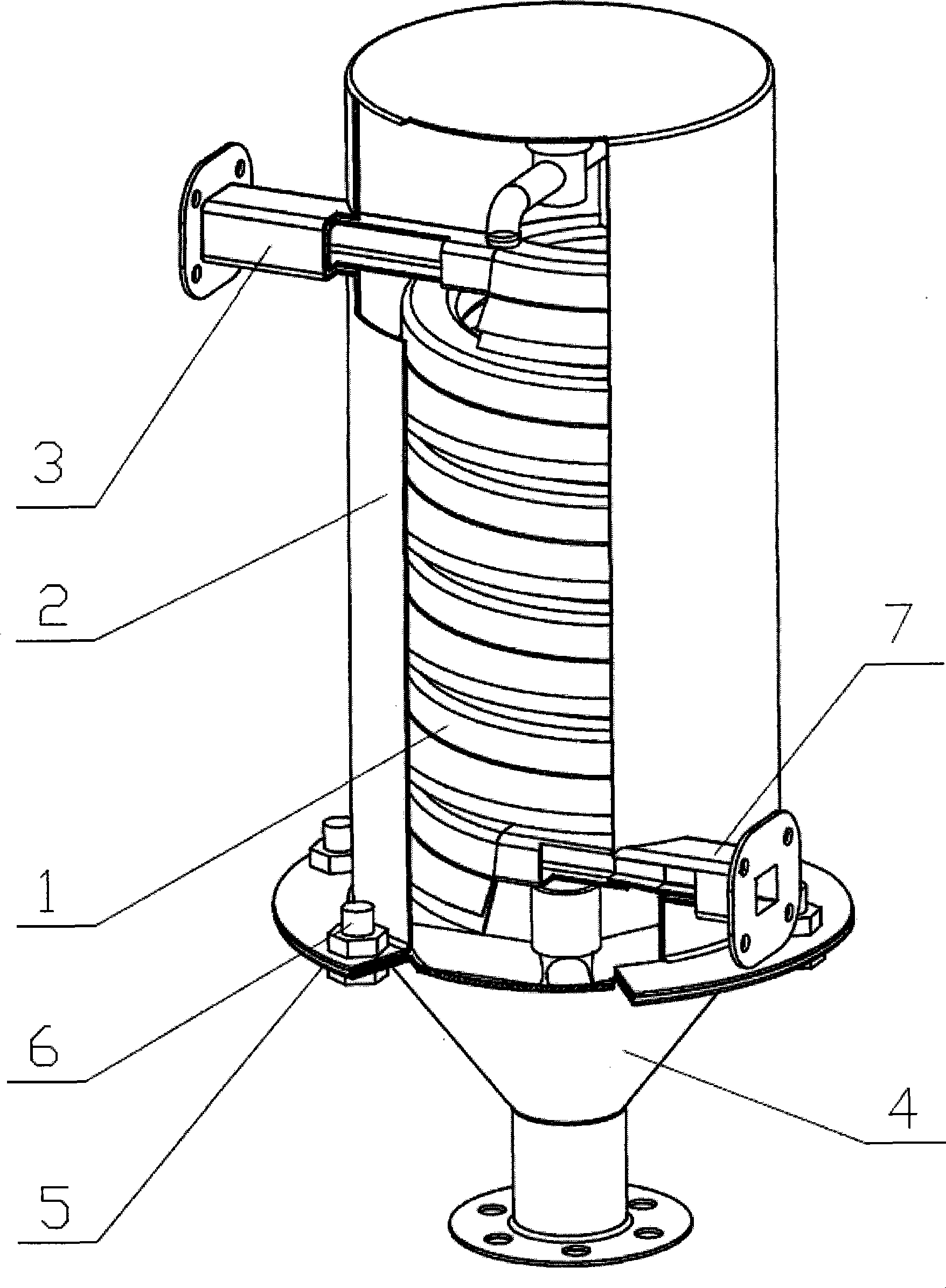

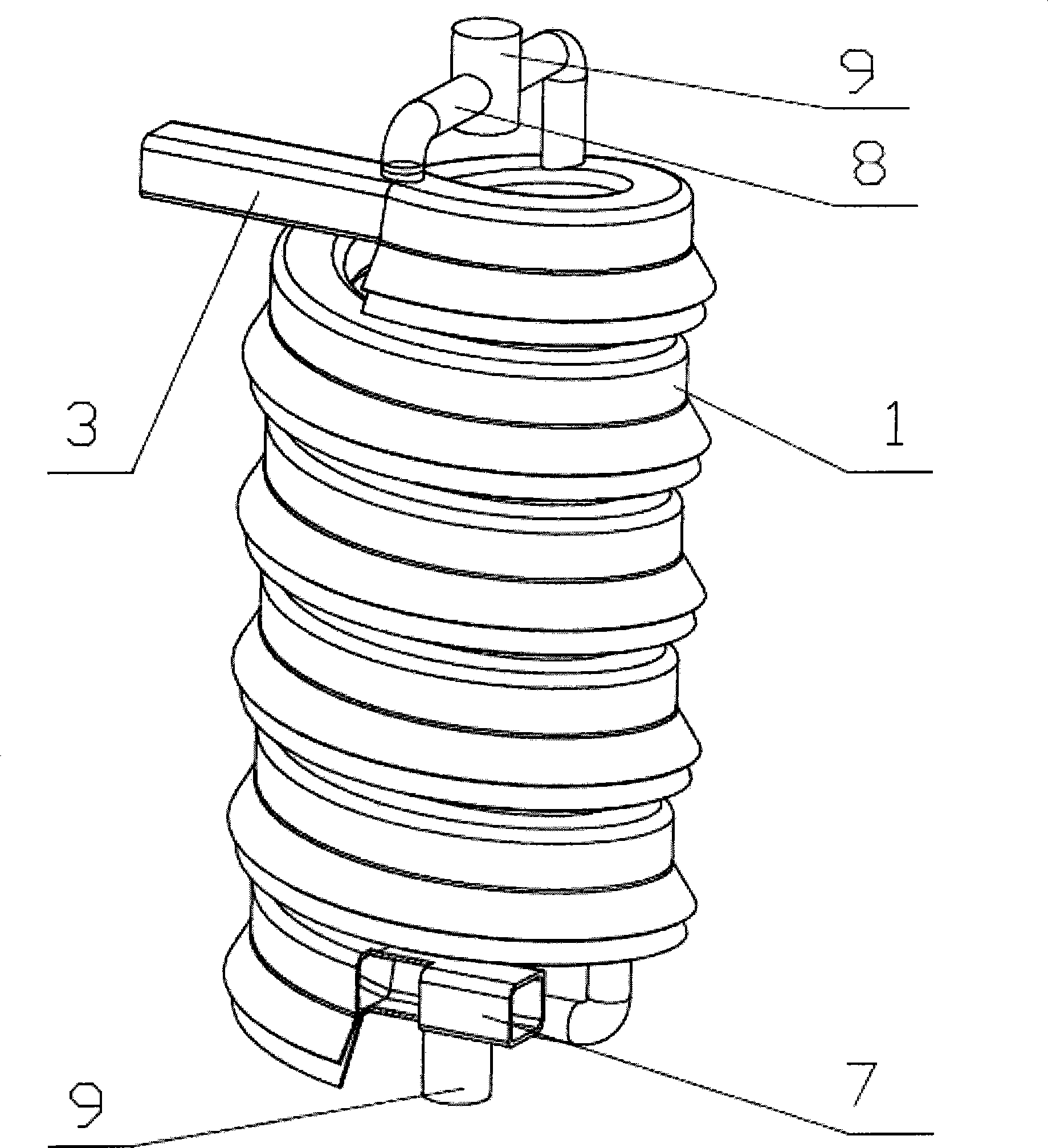

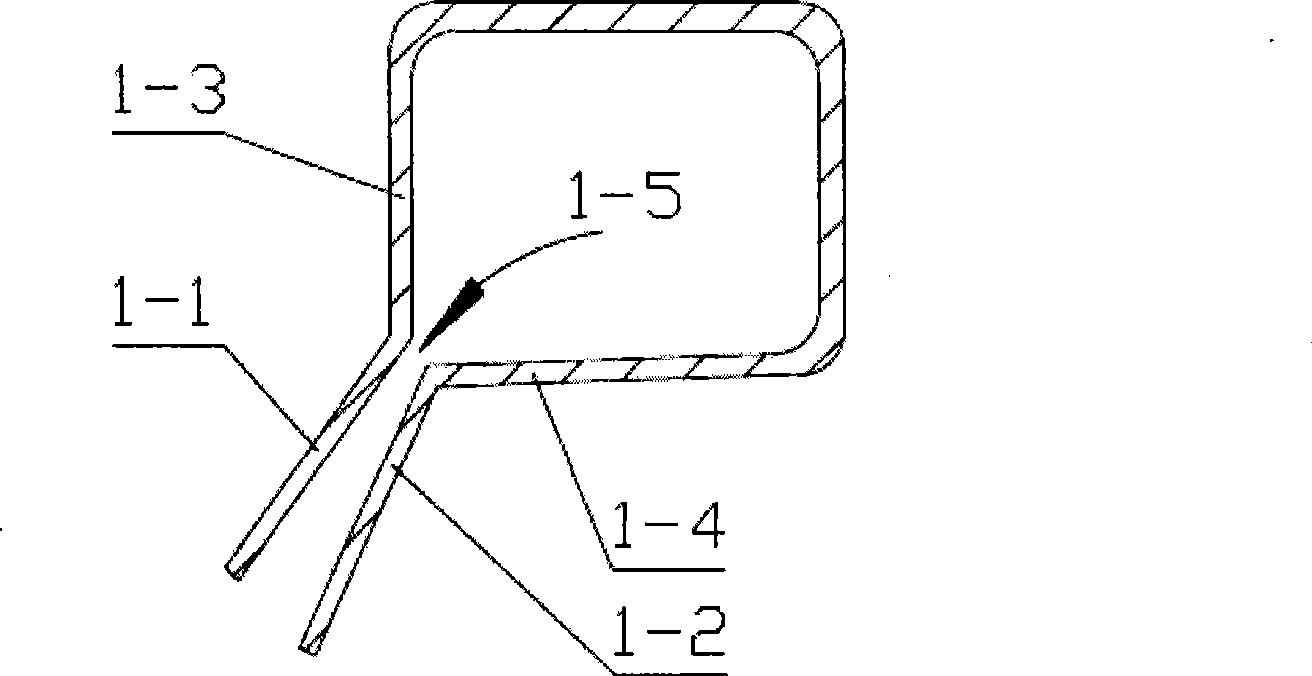

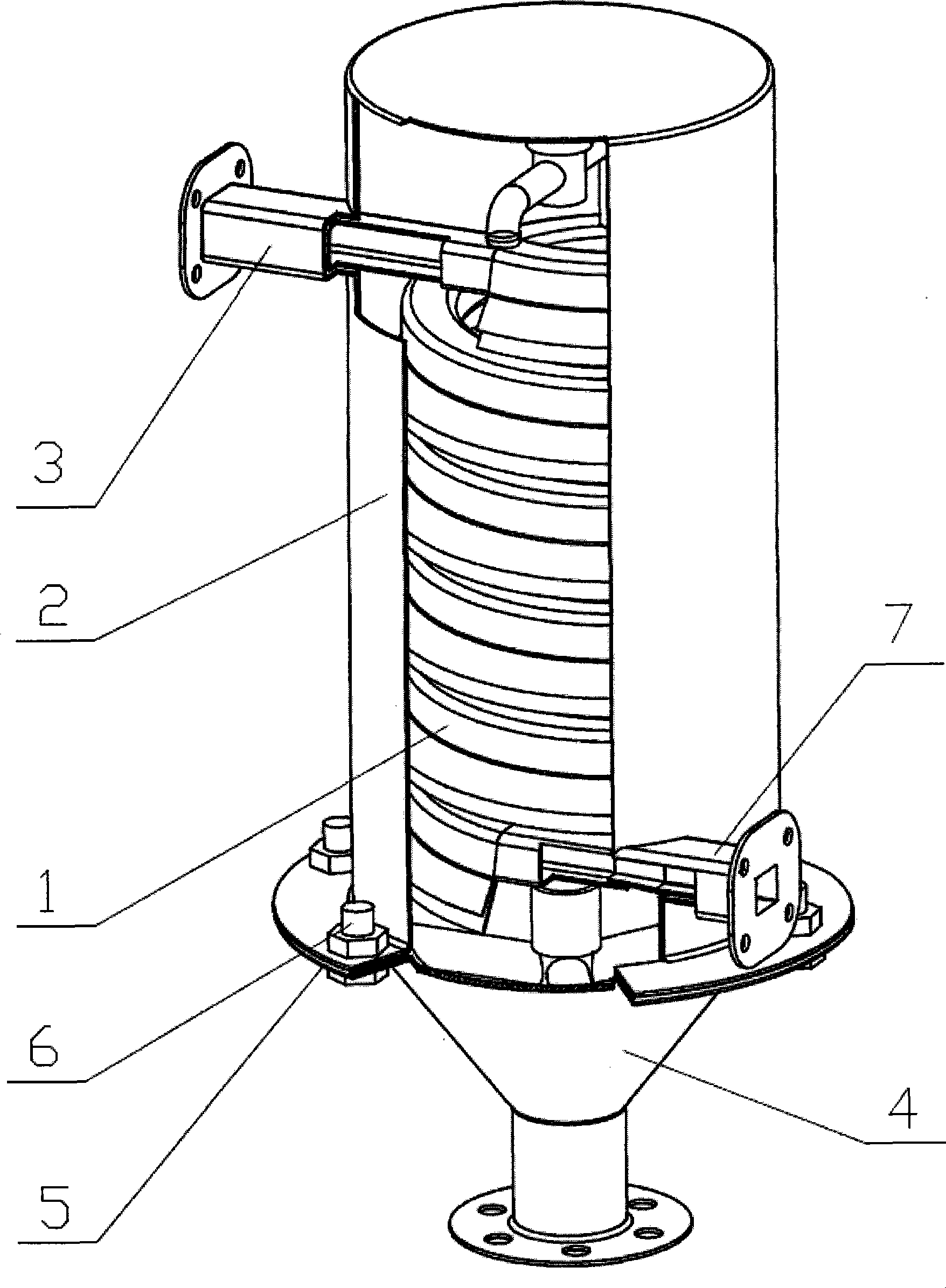

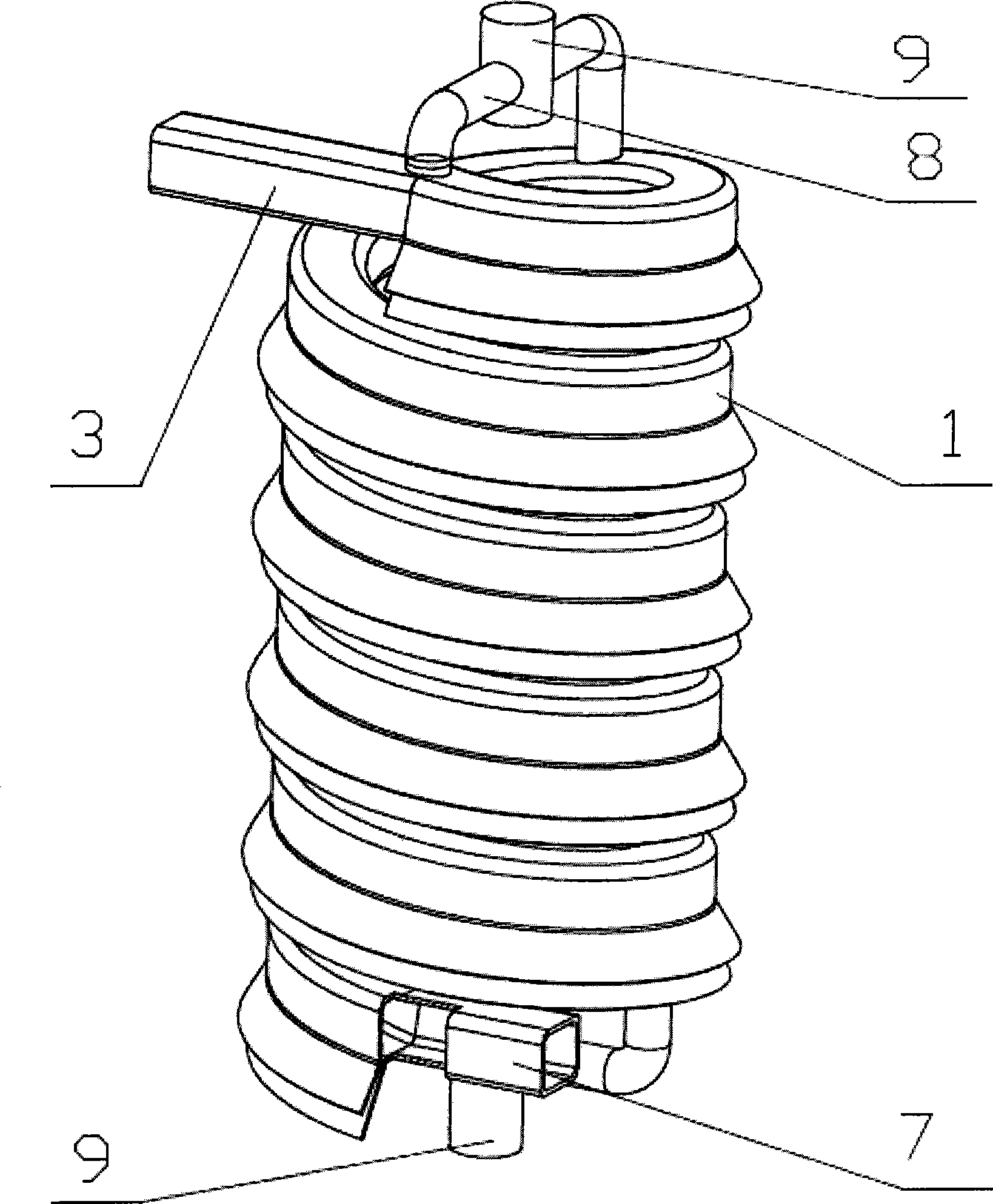

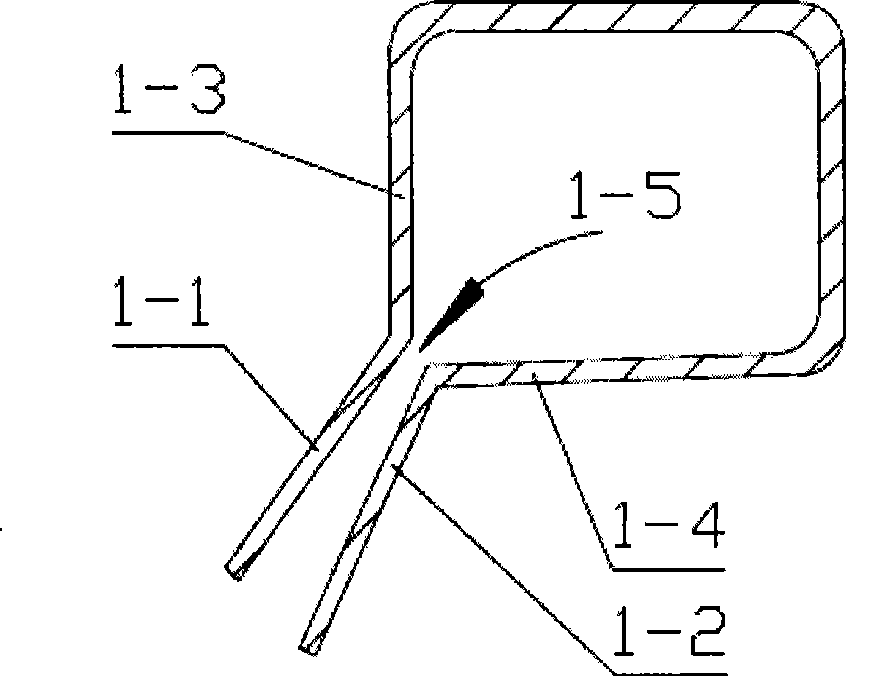

Spiral type gas-solid separation device

InactiveCN101391165ANo airflow interferenceSmall pressure lossDispersed particle separationGas solidLower upper

The invention discloses a spiral gas-solid separation device, which comprises a conical dust collector (4), and is characterized in that a cylindrical seal cover (2) is arranged on a horn mouth of the conical dust collector (4), a spiral air current channel (1) is disposed in the cover coaxially, and an air current inlet (7) and an air current outlet (3) of the channel respectively extend out from side walls of the lower part and the upper part of the cylindrical seal cover (2); and a gap (1-5) is arranged at the junction of the outer wall (1-3) and the lower wall (1-4) of the spiral air current channel (1) for dust settling after centrifugal separation. The device has the advantages of rather complete gas-solid separation, non interference of air current flow up and down and low pressure loss.

Owner:GUANGZHOU UNIVERSITY

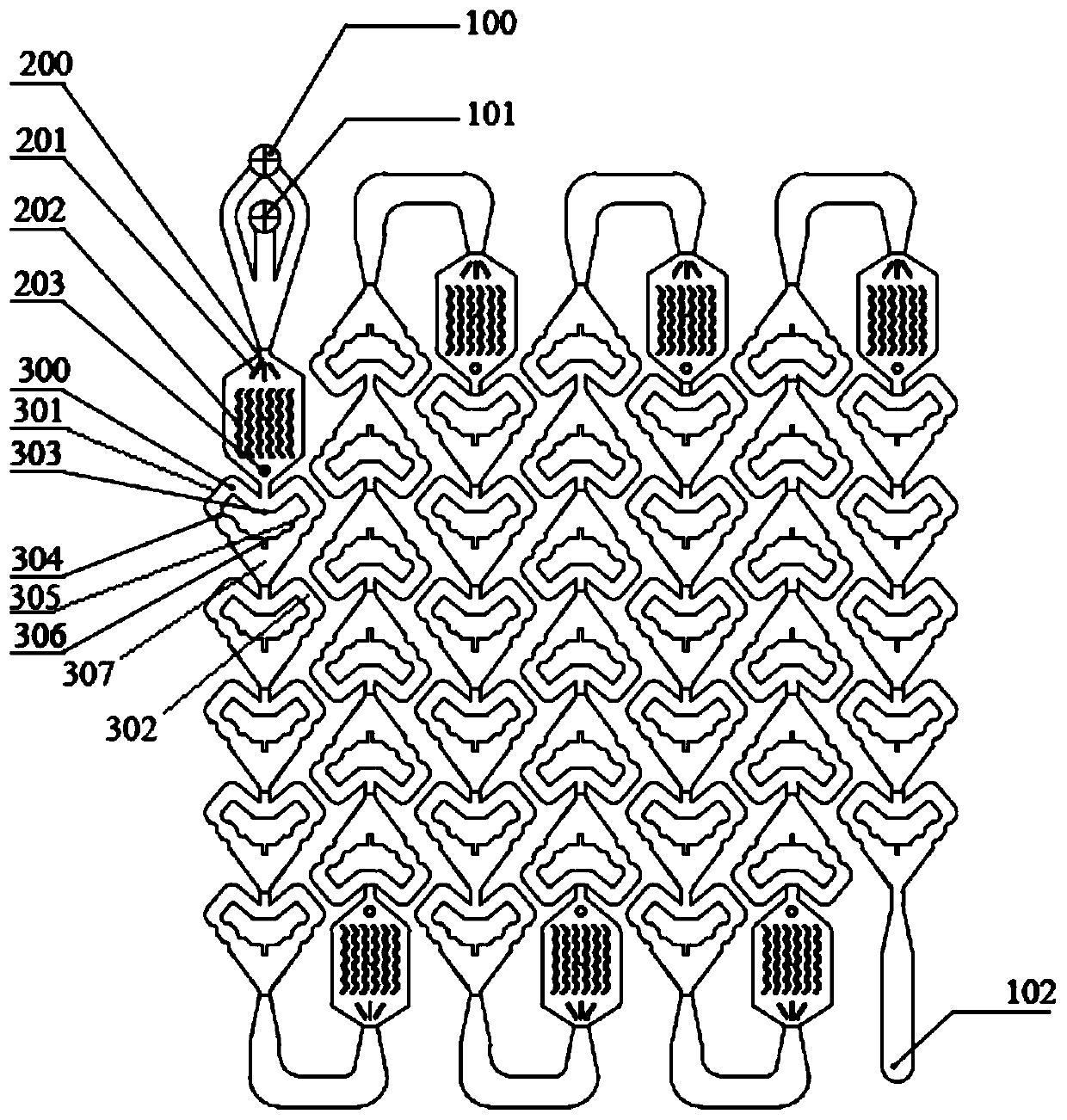

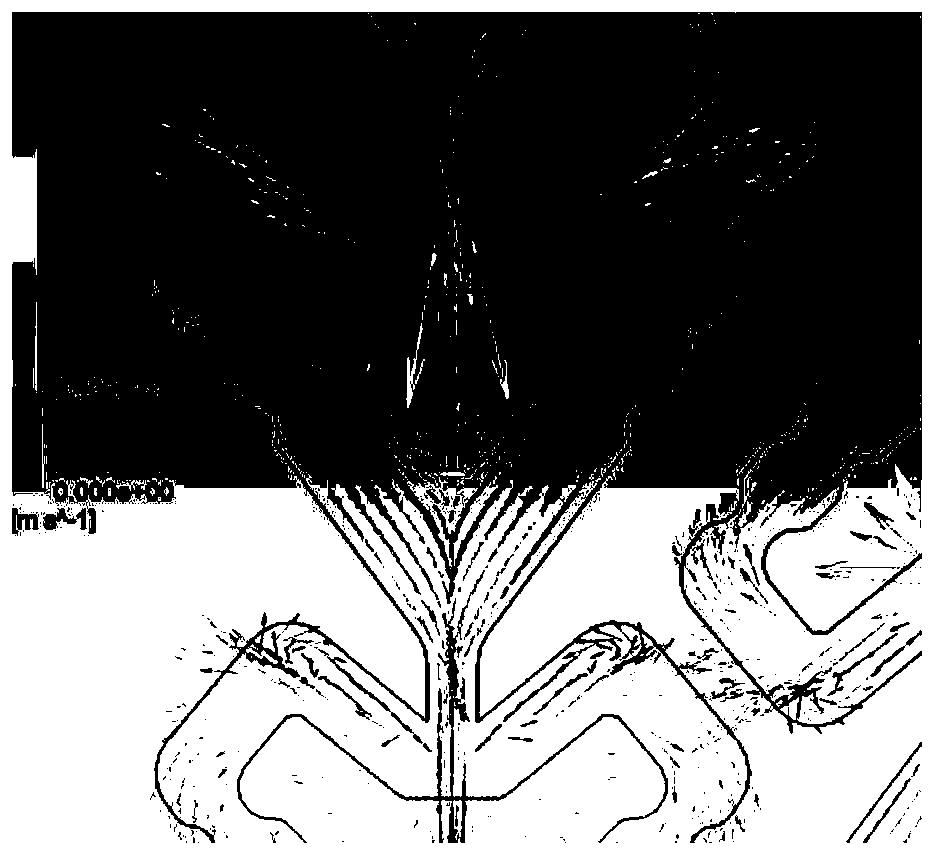

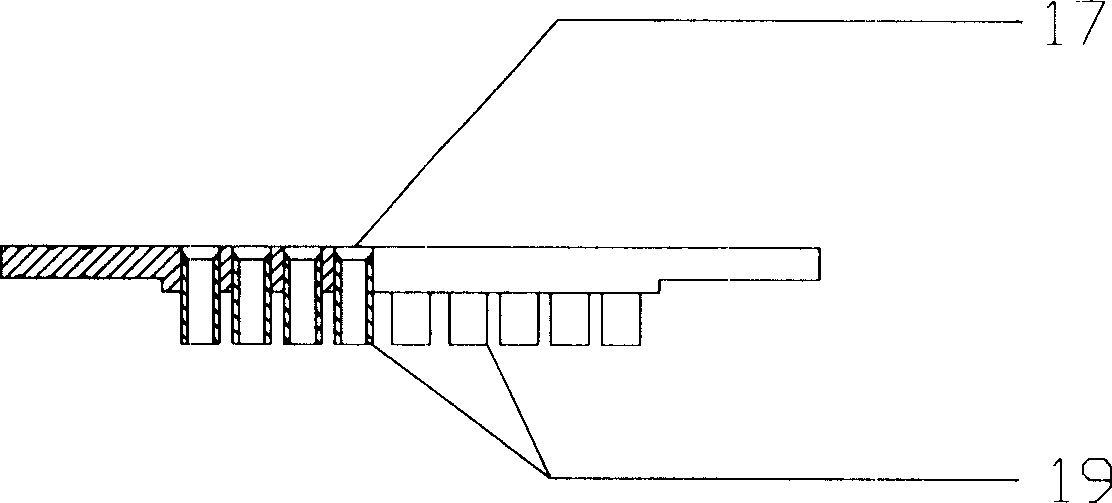

Microreactor

PendingCN110090607ALarge specific surface areaNo swirlChemical/physical/physico-chemical microreactorsMicroreactorEngineering

The invention discloses microreaction channel and relates to the field of chemical equipment. The microreaction channel comprises a reinforced mixing cavity which is left and right symmetrical along acentral symmetry axis, wherein the outlet part of the reinforced mixing cavity is provided with a confluent mixing region. A partition body is arranged in the reinforced mixing cavity. The partitionbody and the inner wall of the reinforced mixing cavity form a symmetrical first subchannel and a symmetrical second subchannel. And the first subchannel and the second subchannel extend outwards relative to the central symmetry axis to cross the inlet part of the reinforced mixing cavity and then are connected with the confluent mixing region. The microreaction channel has the advantages of a high specific surface area up to 10000-50000 m<2> / m<3>. A fluid in the channel belongs to a horizontal thrust flow, has no vortex and back mixing, and can effectively avoid the bad and uneven mixing effect in the channel caused by the pulse of a feed pump; the microreaction channel has a low pressure drop and good mixing effect. Under a same substrate area, a large channel area the can be arranged, and no area is wasted, so the liquid holdup is large and the residence time is long.

Owner:山东微井化工科技有限公司

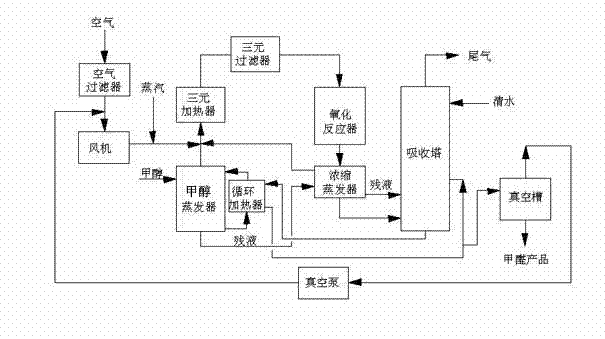

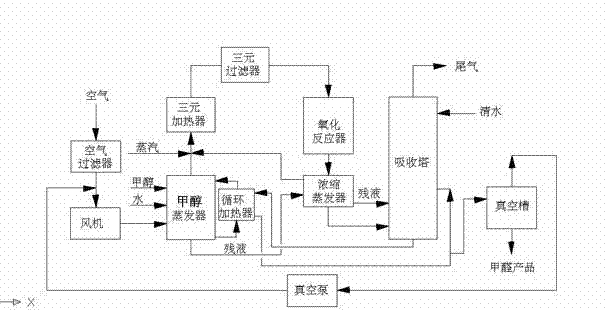

Method and device for reducing methanol content in formaldehyde process by silver method

ActiveCN103086854ANo backmixingReduce loadOrganic compound preparationChemical industryEnvironmental resistanceFormox process

The invention relates to a method and a device for reducing methanol content in a formaldehyde process by a silver method, and belongs to the technical field of chemical production. The technical scheme is that the method comprises the following steps of: after thermally recovering and cooling a formaldehyde liquid at the bottom of an absorption tower in the formaldehyde process by the silver method, extracting and feeding part of the formaldehyde liquid to a vacuum groove; conveying gas analyzed at the top of the vacuum groove to an inlet of an air fan; arranging a concentration evaporator between the outlet of an oxidation reactor and the inlet of the absorption tower; evaporating and condensing residual liquid of the evaporator by reaction waste heat at 90-110 DEG C; evaporating methanol in the residual liquid with water; recovering mixed gas of vapor and methanol steam to material gas; and recovering methanol which is less than 0.5% in percentage by weight in the condensed residual liquid to the absorption tower. According to the invention, the inlet temperature of the absorption tower is reduced, while the heat recovery efficiency of the system is improved. The load of a water cooler of the absorption tower is reduced, and the consumption of cooling water is reduced, so that the residual liquid is recovered in grades by 100%, and methanol recovered is free from backmixing, therefore, the energy-saving, consumption reducing and environmental protecting purposes are realized.

Owner:HEBEI KAIYUE CHEM GROUP

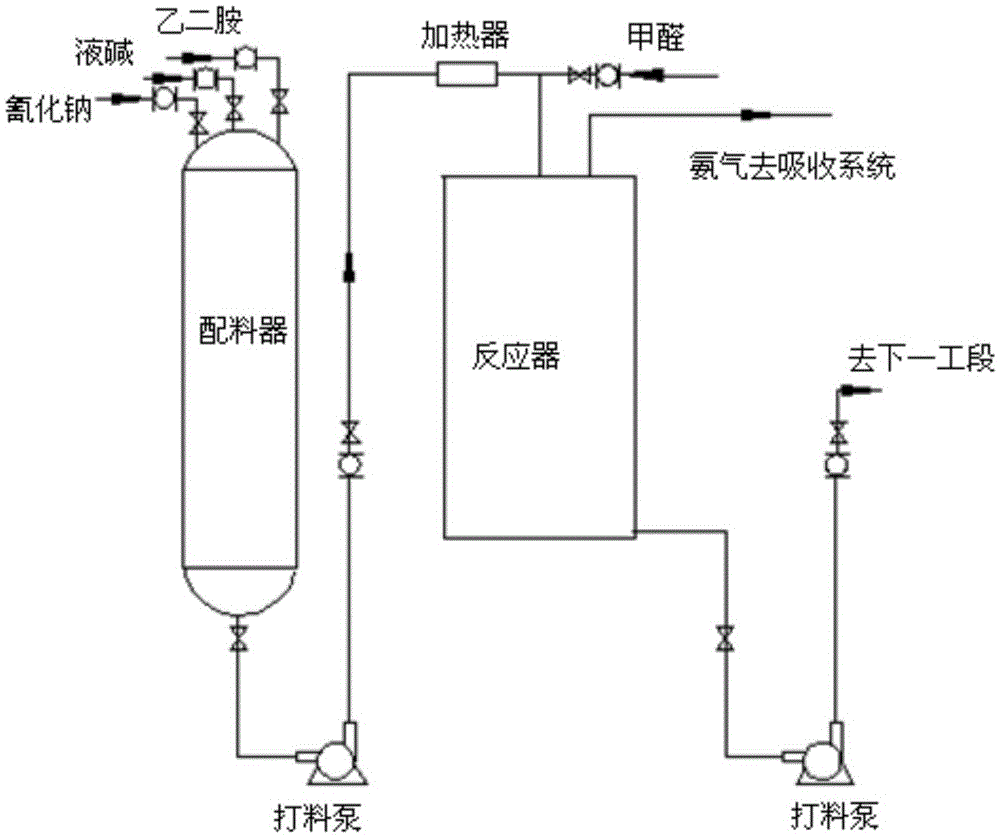

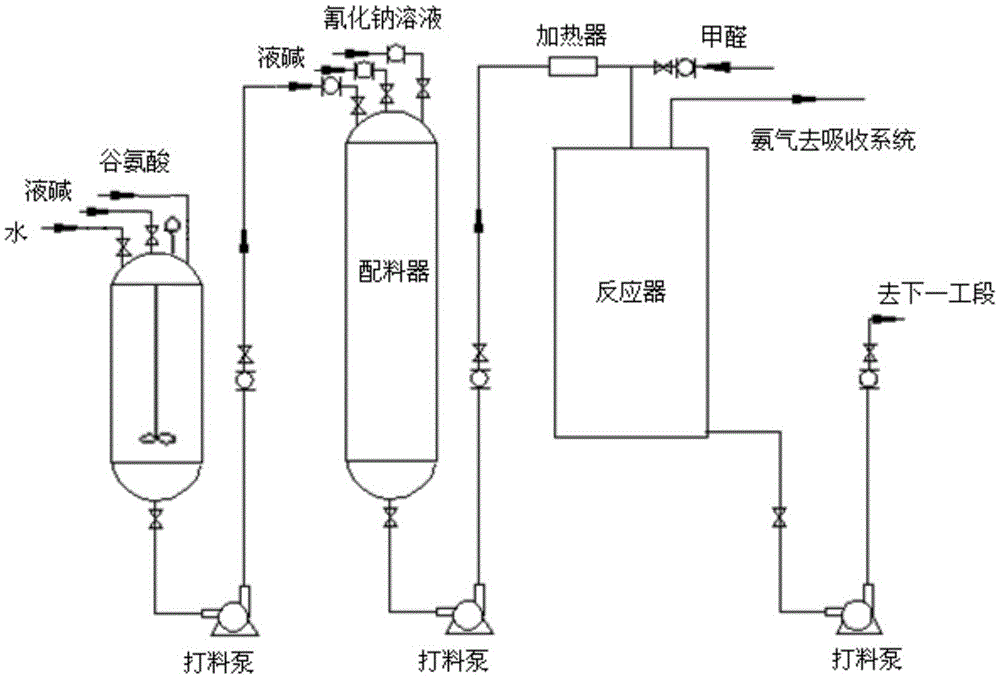

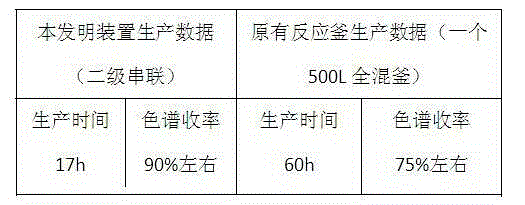

Novel continuous automated reaction process for preparing aminopolycarboxylic acids chelating agent

ActiveCN105646254AImprove qualityHigh yieldOrganic compound preparationAmino-carboxyl compound preparationContinuous reactorAfter treatment

The invention discloses a novel continuous automated reaction process for preparing an aminopolycarboxylic acids chelating agent and belongs to the technical field of aminopolycarboxylic acids chelating agents. Production is conducted through a flow reactor, a whole reaction system is under DCS automation control, and the process comprises the following steps: 1, material blending and mixing, wherein raw materials are continuously and stably pumped into a batcher for mixing, so that a liquid mixture is obtained; 2, preheating treatment, wherein the liquid mixture is pumped out of the batcher through a material delivering pump, and the liquid mixture which is pump out is subjected to heating treatment through a heater; 3, reaction and generation, wherein heated liquid materials and formaldehyde or heated liquid materials and a glycolonitrile solution are added into the reactor for a reaction, ammonia gas generated through the reaction is discharged through the top of the reactor and collected, and a reaction solution is drained through the bottom of the reactor and delivered to the acidification procedure for after-treatment through the material delivering pump, so that the aminopolycarboxylic acids chelating agent is obtained. By means of the process, the aminopolycarboxylic acids chelating agent can be produced in a continuous and automated mode, and stability of the reaction process is improved.

Owner:石家庄杰克化工有限公司

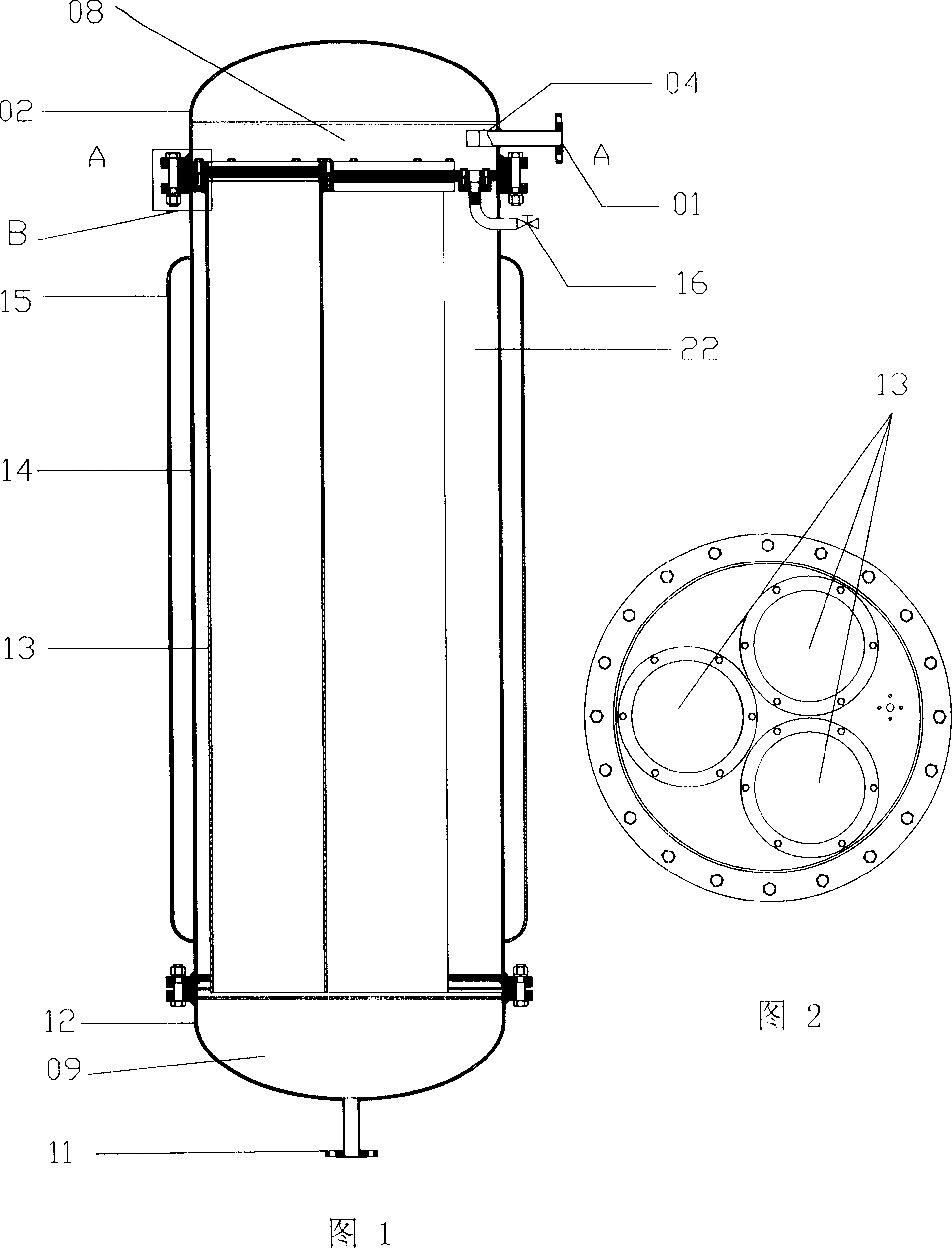

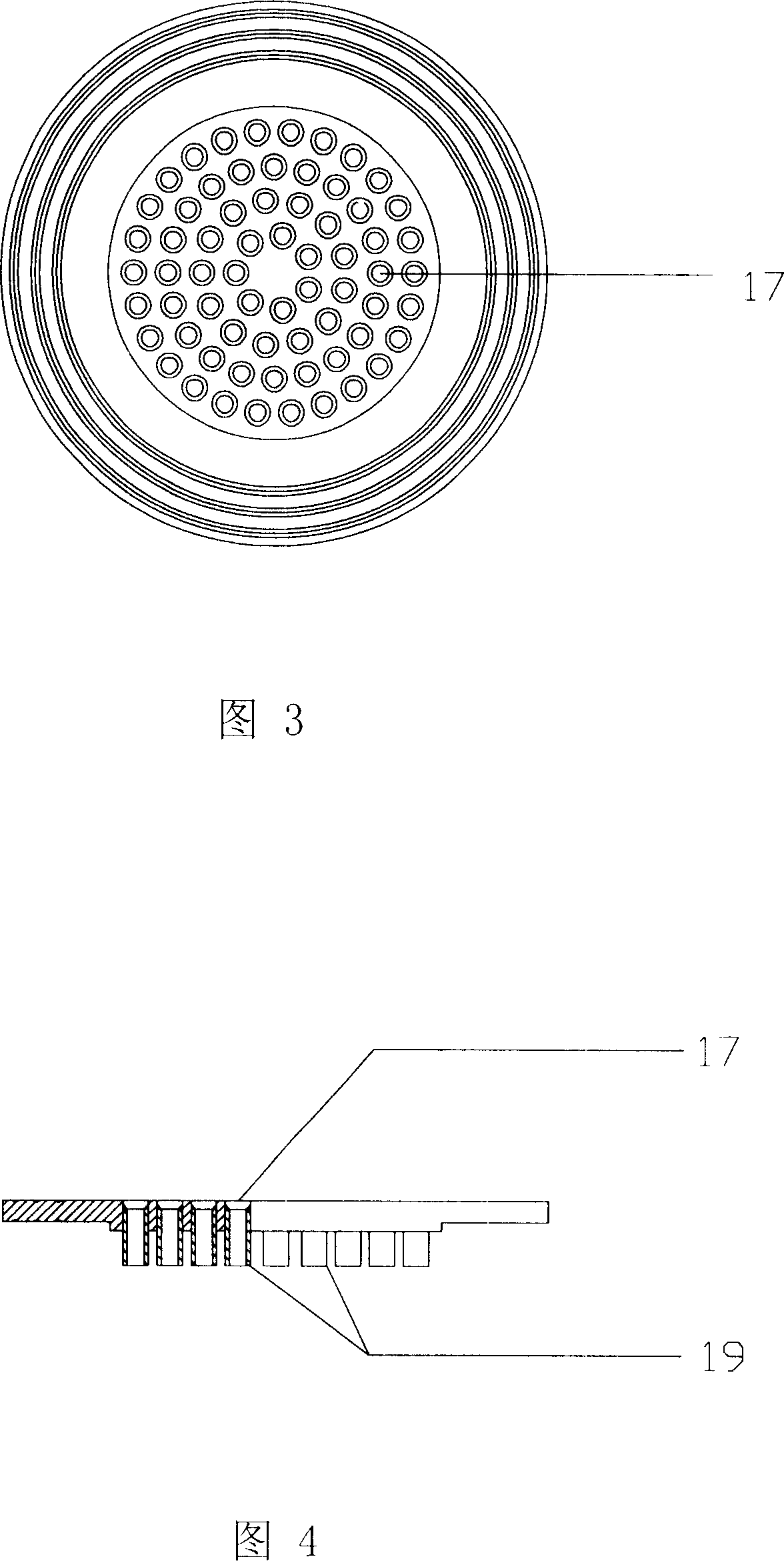

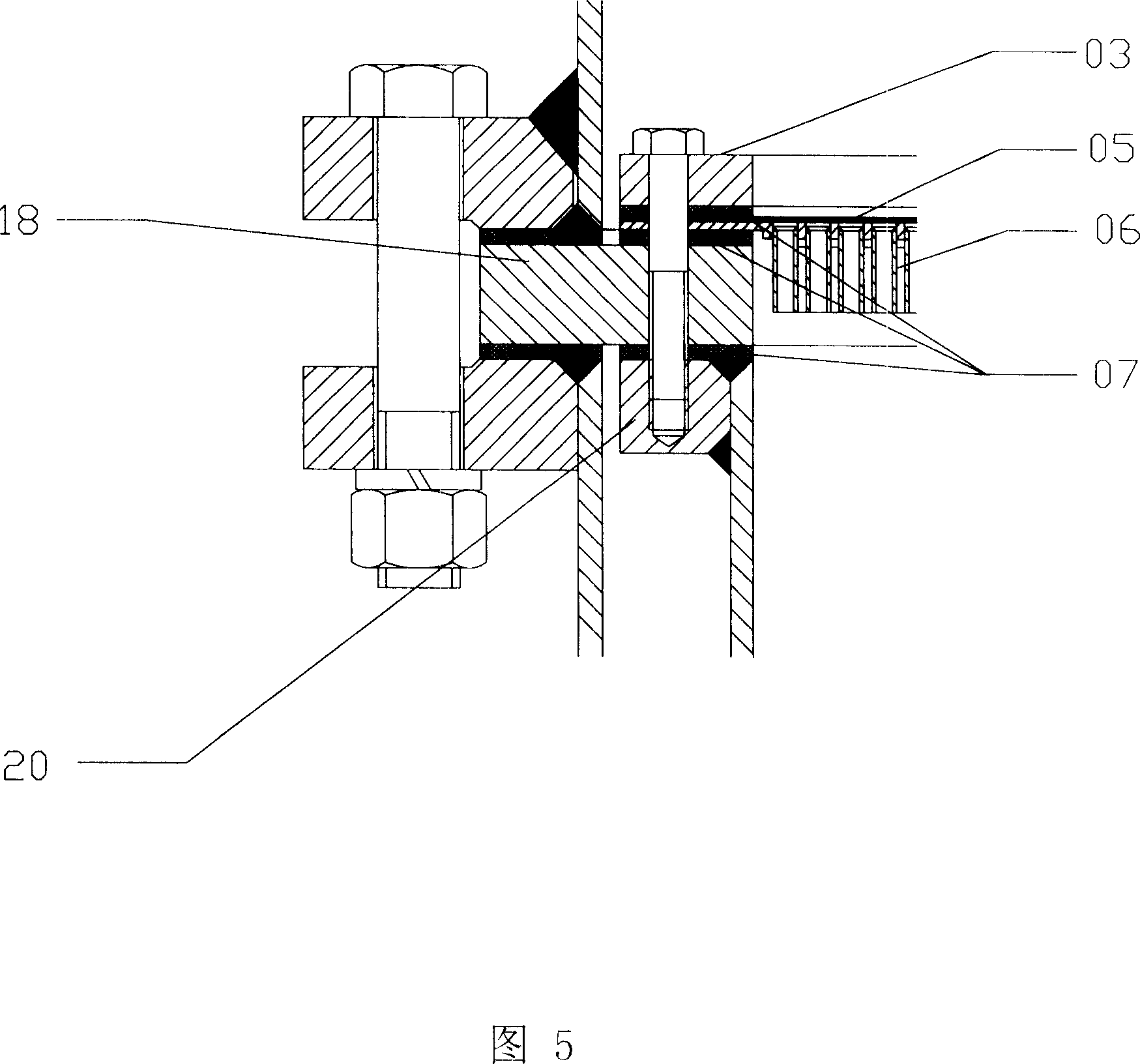

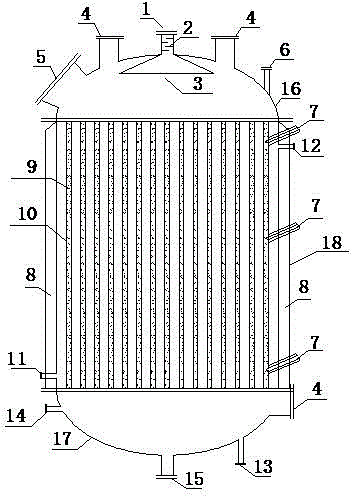

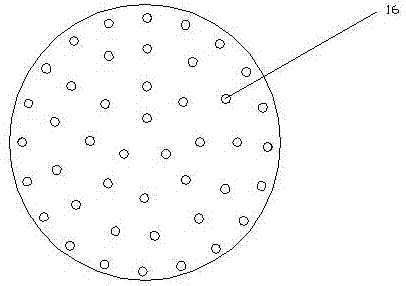

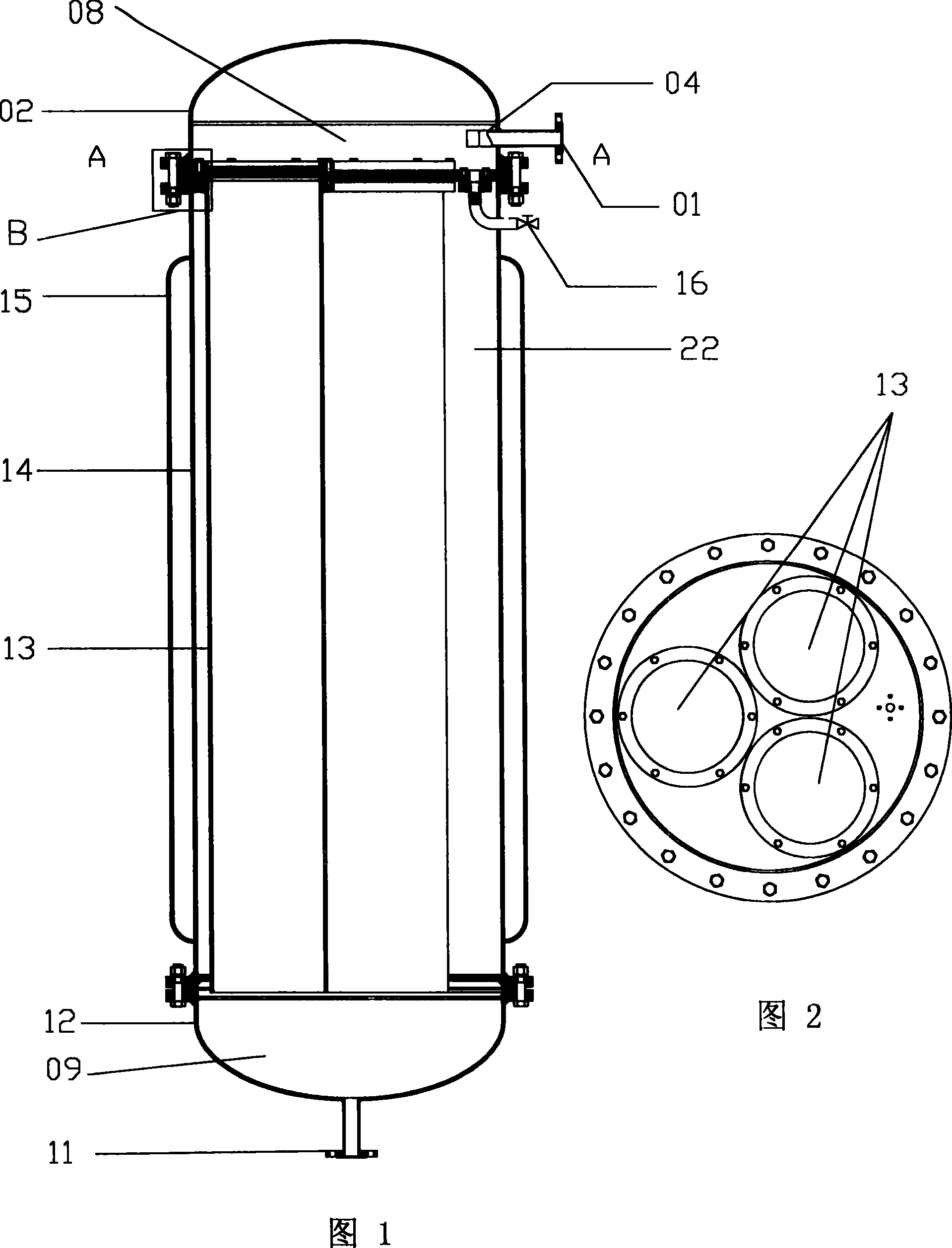

Shell-and-tube fixed bioreactor

InactiveCN101020891ANo backmixingShorten the timeBioreactor/fermenter combinationsBiological substance pretreatmentsResource utilizationFixed bed bioreactor

The shell-and-tube fixed bed bioreactor includes one upper end sealing body with liquid inlet; one reaction cavity with stuffing pipes filled with solid stuffing; one lower end sealing body; and one distributor in the upper end of the stuffing pipes with homogeneously distributed through holes for the liquid from the upper end sealing body to be sprayed homogeneously to inside the stuffing pipes. The shell-and-tube fixed bed bioreactor has simple structure, easy operation, high yield and high resource utilizing rate.

Owner:领先生物农业股份有限公司

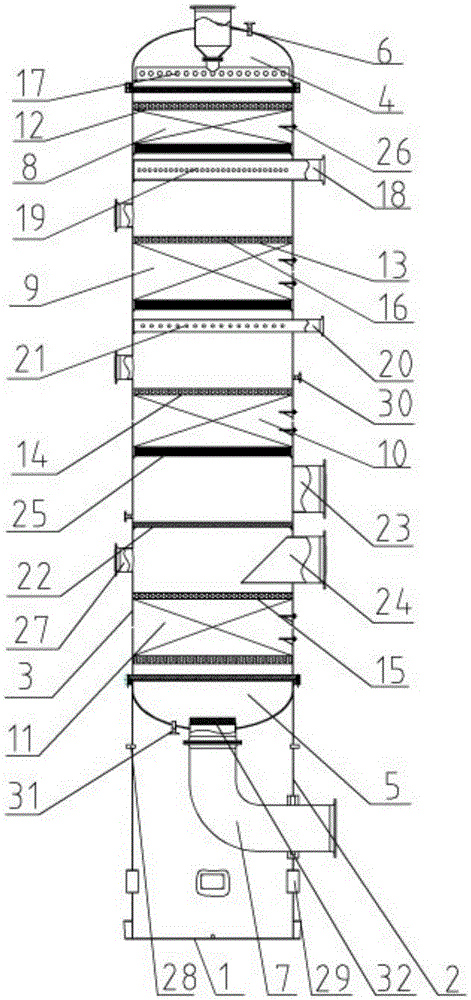

Multi-section type heat insulation fixed bed reactor for PX production

InactiveCN105413591AReduce lossFully contactedChemical/physical processesFixed bedProcess engineering

The invention discloses a multi-section type heat insulation fixed bed reactor for PX production. The multi-section type heat insulation fixed bed reactor comprises a basic component, a skirt support and a reactor body, wherein a first reaction region, a second reaction region, a third reaction region and a fourth reaction region are arranged in the reactor body in sequence from top to bottom; a fixed bed layer filled with a catalyst is arranged above each reaction region; a sieve pipe distributor is arranged below each reaction region; a first cold material inlet is formed in the side wall between the first reaction region and the second reaction region; a second cold material inlet is formed in the side wall between the second reaction region and the third reaction region; a heat exchange pipe outlet and a heat exchange pipe inlet are formed between the third reaction region and the fourth reaction region. The multi-section type heat insulation fixed bed reactor for PX production solves the problems that the existing fixed bed reactor is poor in heat dissipation effect, easily causes inactivation of catalysts and high loss of the catalysts and affects the reaction efficiency; meanwhile, by the adoption of material feeding from the side wall, heat in the reactor can be effectively used, and the heat supply cost is reduced.

Owner:CHONGQING TIANYI HENGHUA TECH CO LTD

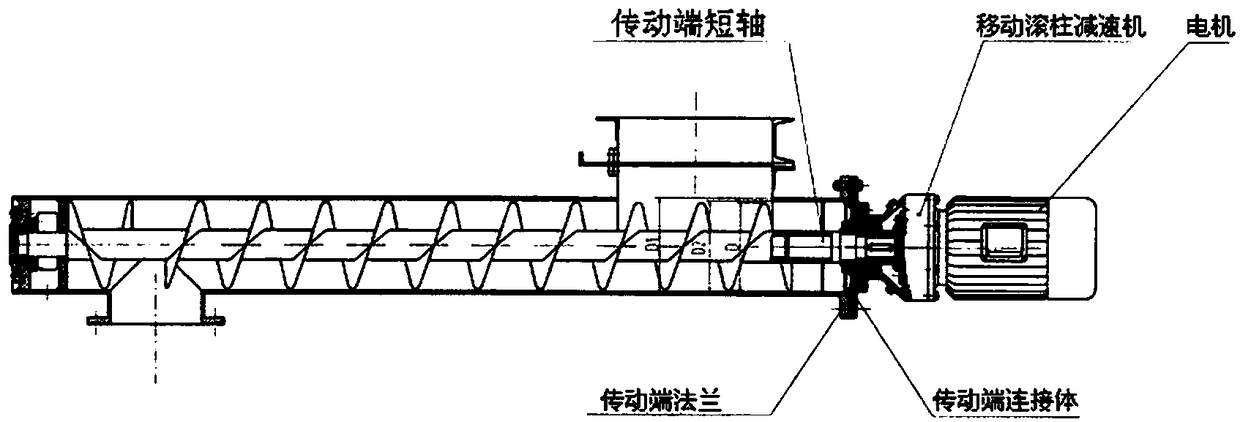

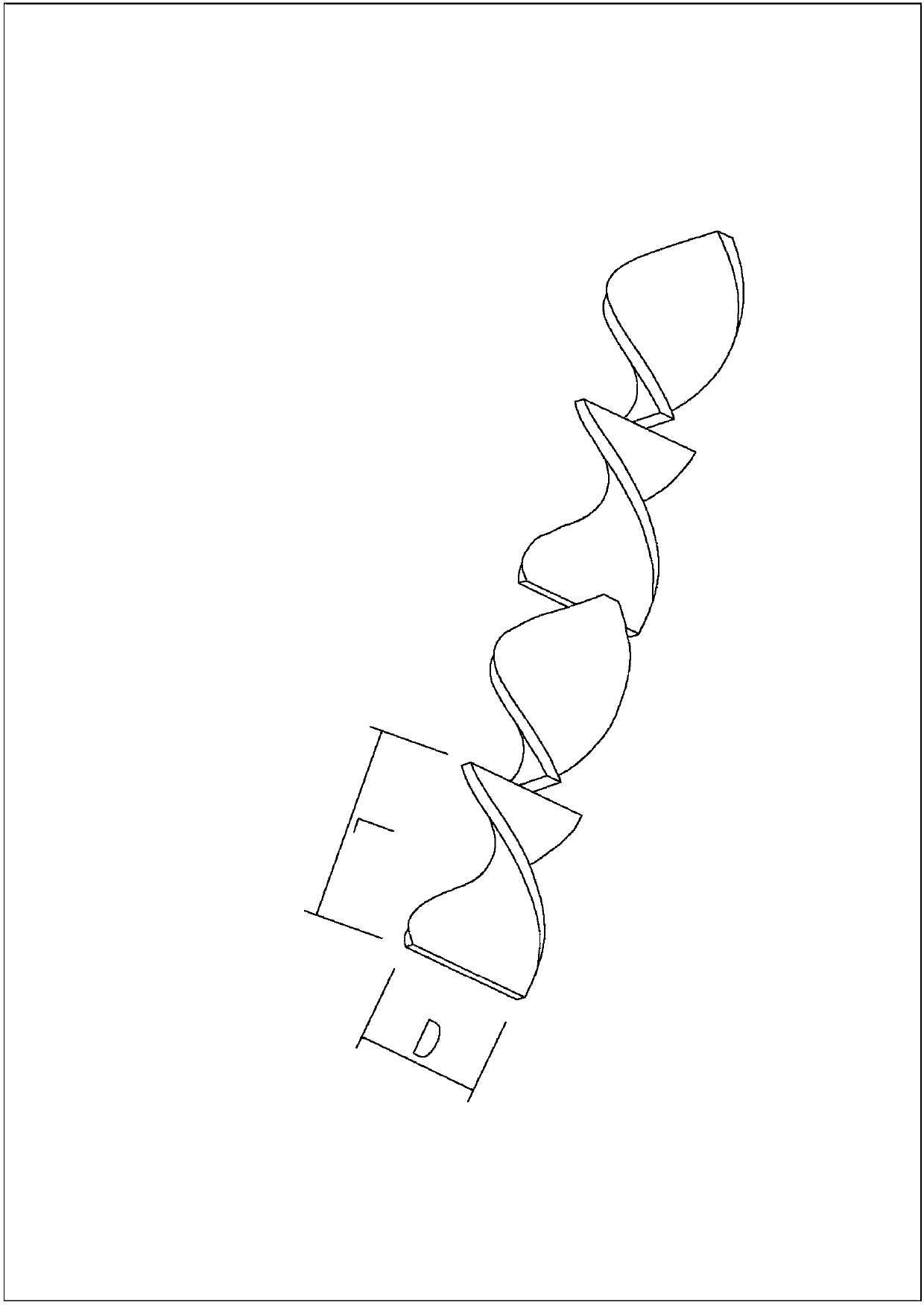

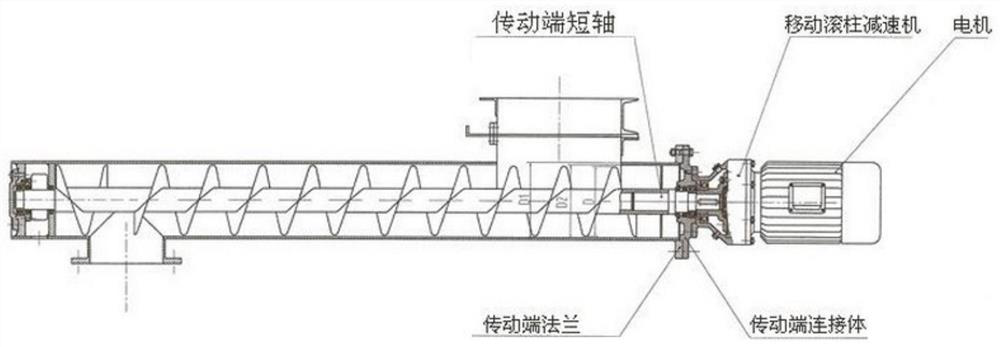

Method for large-scale continuous preparation of nanometer zero-valent metal materials

ActiveCN108247079AImprove utilization efficiencyImproves dispersibility and reducing activityNanotechnologyIonBiomass

The invention relates to preparation of nanometer materials and specifically discloses a method for large-scale continuous preparation of nanometer zero-valent metal materials. The method includes thefollowing steps that (1) biomass adsorption particles and a metal salt ion solution make contact in a soaking mode according to the solid-to-liquid ratio of 1:1-50 g / ml, and after filtering, separation and washing, water is added for size mixing to form a suspension state according to the solid-to-liquid ratio of 1:1-50 g / ml, and a material A is obtained; (2) a sodium borohydride aqueous solutionwith the concentration being 0.1-1 mol / L is prepared to serve as a material B; and (3) the material A and the material B are added into an auger type spiral mixer in a mixed mode according to the volume-flow rate ratio of 1:1-5, mixing and reinforcing contact are carried out in the auger type spiral mixer, a reduction reaction is completed, residual reagents are removed by rapidly washing outputmaterials, and the nanometer zero-valent metal loaded composite materials are obtained. By means of the method, the technical problems that nanometer zero-valent metal is prone to air oxidation and solid-liquid separation and washing are difficult in large-scale preparation are solved, and a highly engineered technological approach for large-scale preparation of the nanometer zero-valent metal materials is provided.

Owner:北京科大科技园有限公司

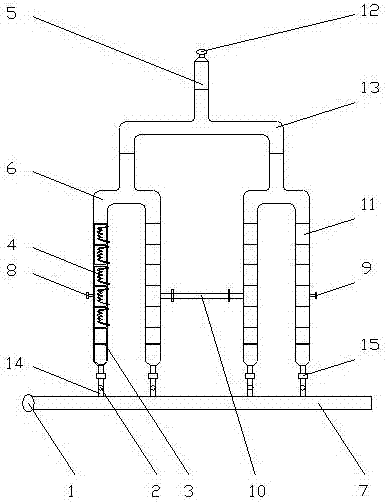

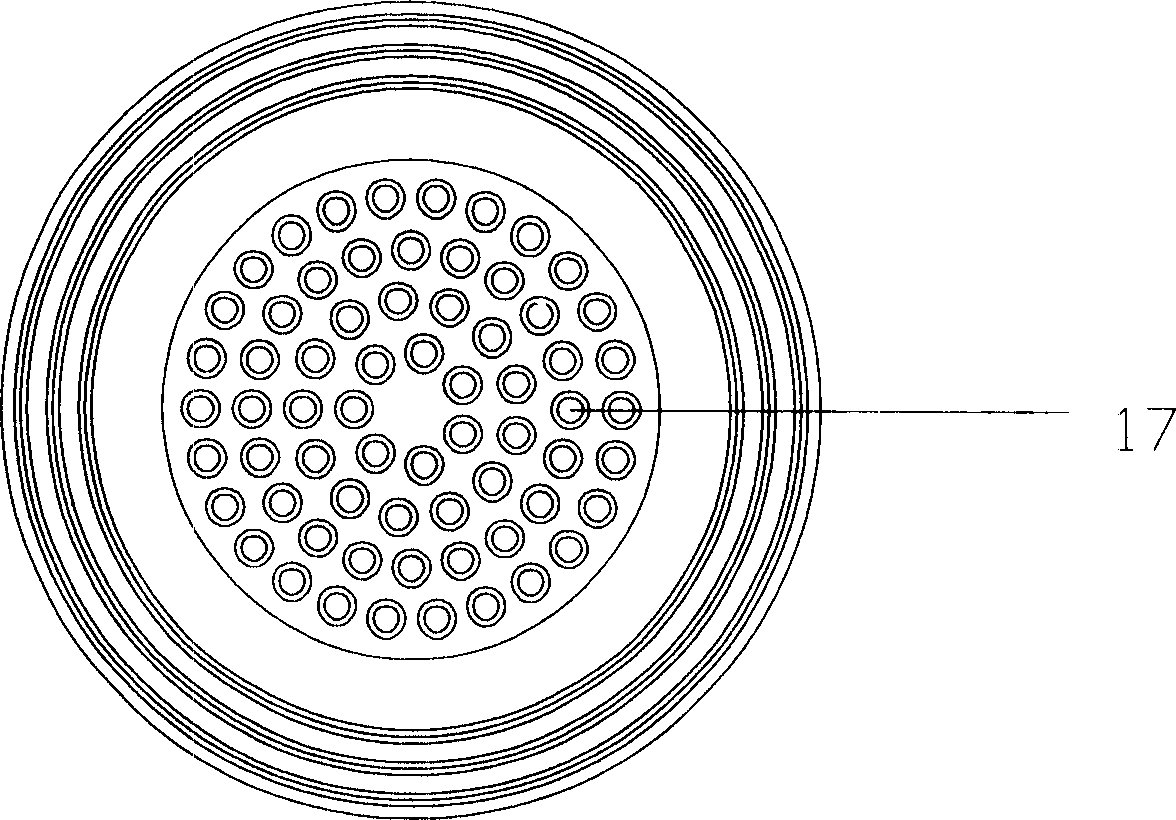

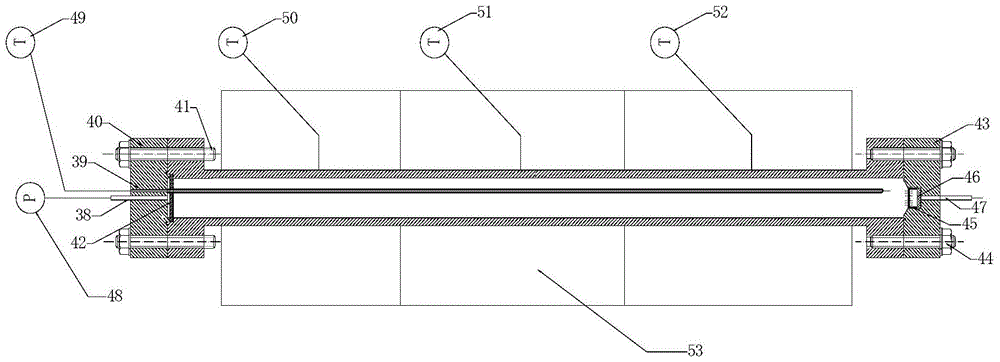

Continuous ultralow temperature reaction device

ActiveCN104162388AHigh heat transfer efficiencyLow energy consumptionChemical/physical processesSide reactionContinuous production

The invention discloses a novel continuous ultralow temperature reaction device and belongs to the field of chemical equipment. The reaction device comprises an upper seal head, a lower seal head and a kettle body, and is characterized in that a manhole orifice, a sight glass orifice, an inert gas protection pipeline and a feeding hole are formed in the upper seal head; a static tower plate is arranged in a pipeline of the feeding hole; the tail end of the pipeline of the feeding hole is connected with a distributor; the kettle body consists of tubes, an outer jacket and a thermo detector; the tubes are vertically arranged in parallel and have the same length as the kettle body; the upper orifice of each tube is correspondingly connected with round holes distributed on a bottom plate of the upper seal head, and the lower orifice of each tube is correspondingly connected with round holes distributed on a bottom plate of the lower seal head; solid catalysts or solid reaction raw materials or solid inert fillers are filled in the tubes, and a filtering net is arranged at the bottom of the tubes; liquid nitrogen is filled among the tubes; the thermo detector is positioned on one side outside the kettle body, and one end of the thermo detector is connected with the tubes; a vacuum jacket layer is arranged outside the kettle body; the sight glass orifice, a pressure gage, an inert gas outlet and a discharge opening are formed in the lower seal head. The continuous ultralow temperature reaction device can realize continuous production and avoid intensified side reactions, is low in energy consumption, high in reaction yield and stable in quality and is particularly suitable for industrial popularization and application of ultralow temperature reactions of organophosphorus, boric acid and the like.

Owner:HENAN ACADEMY OF SCI CHEM RES INST CO LTD +1

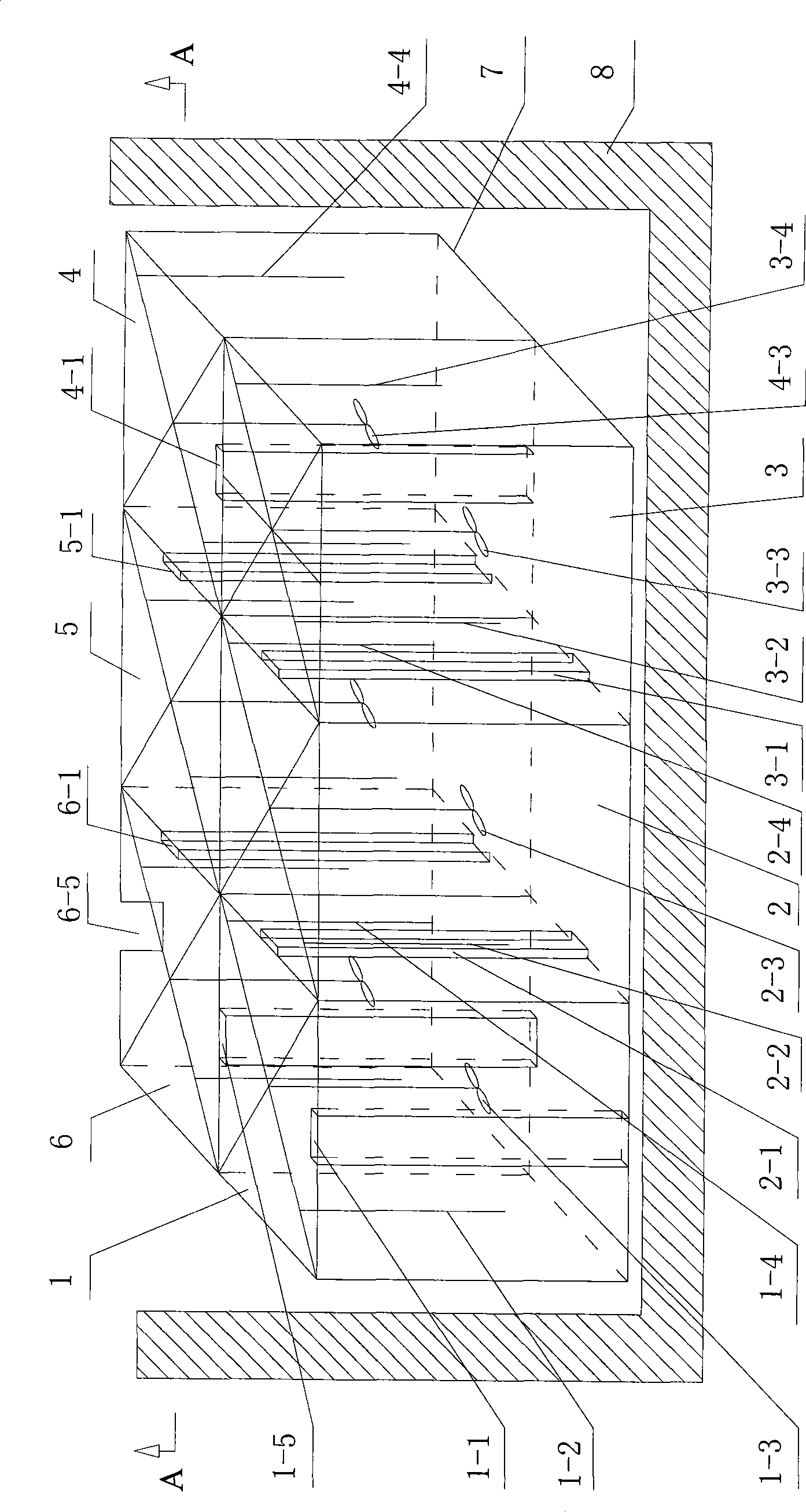

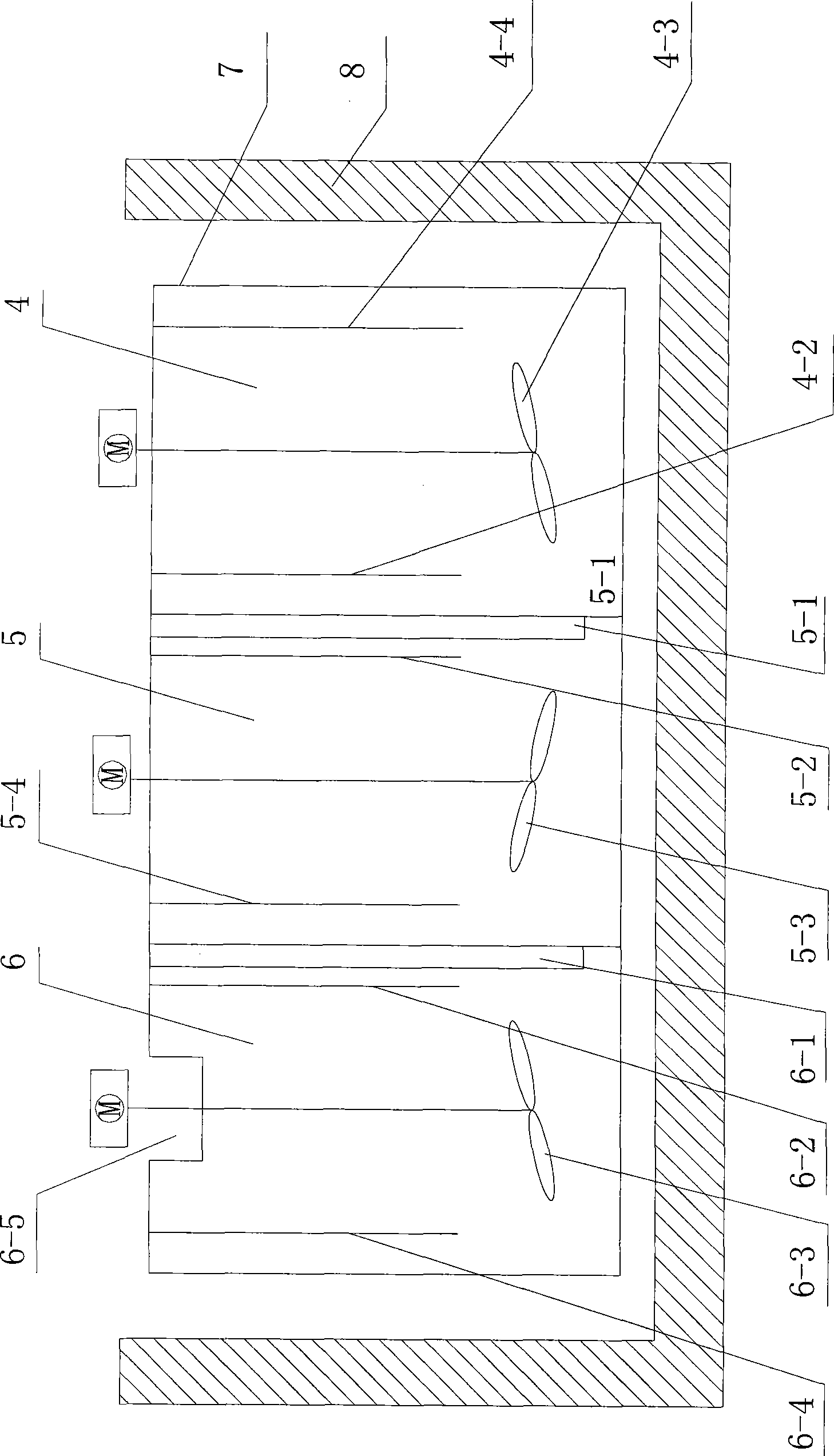

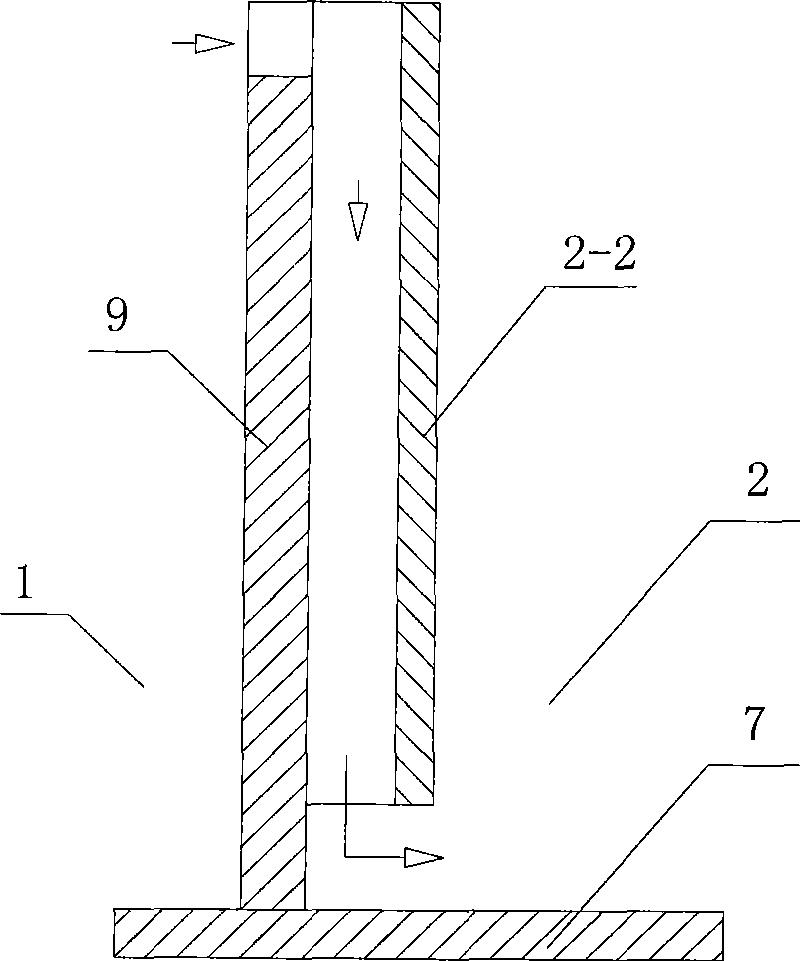

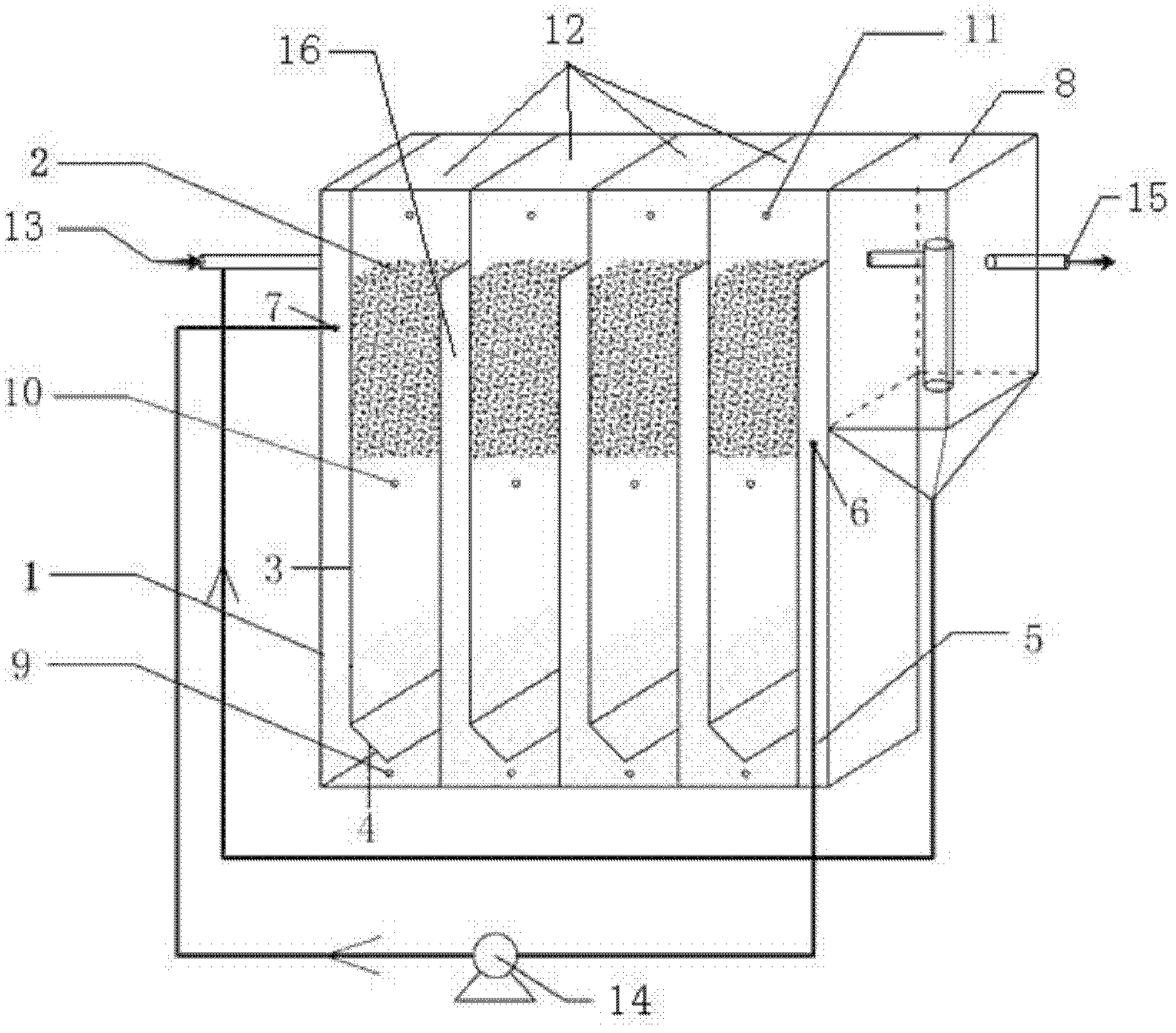

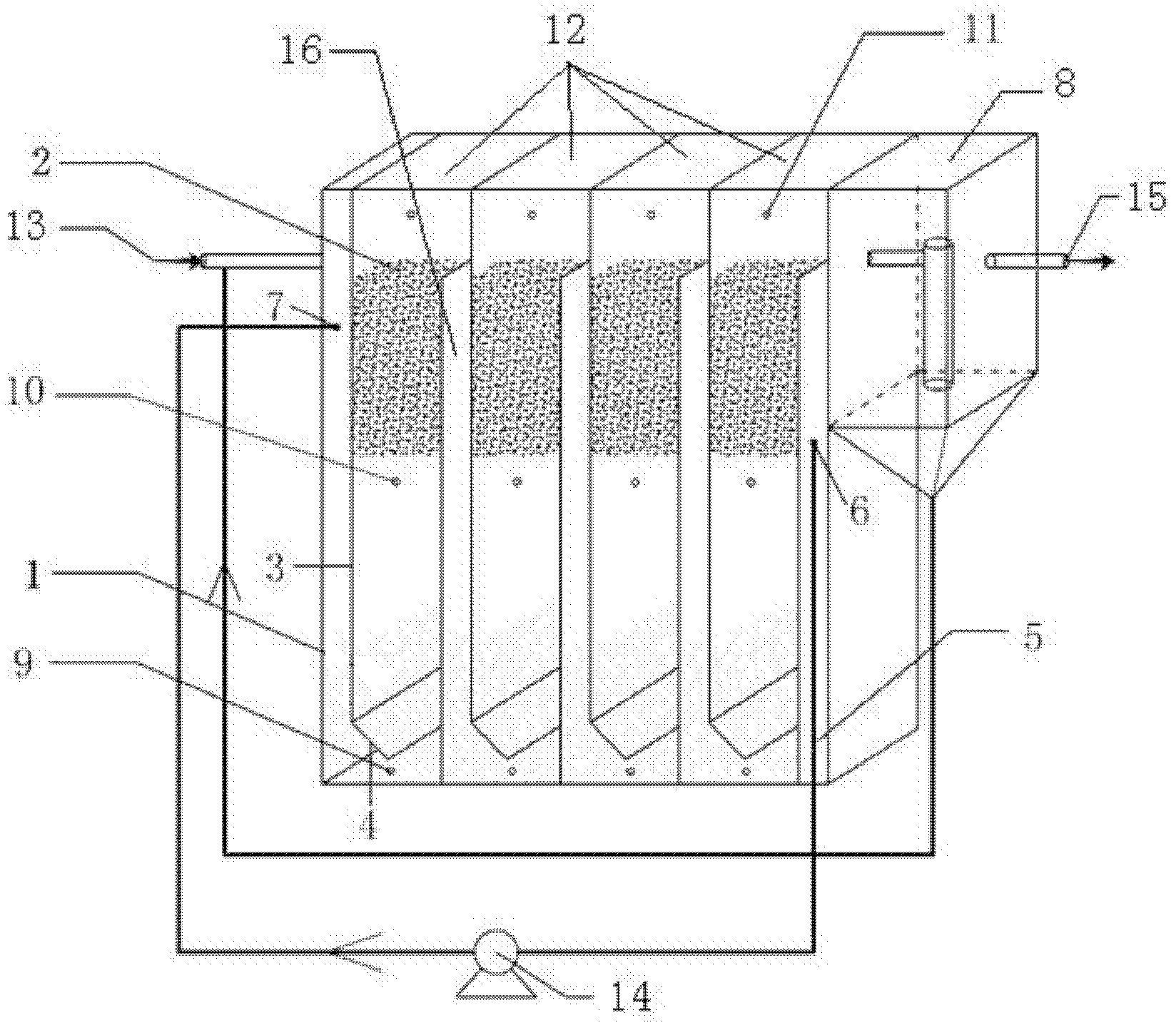

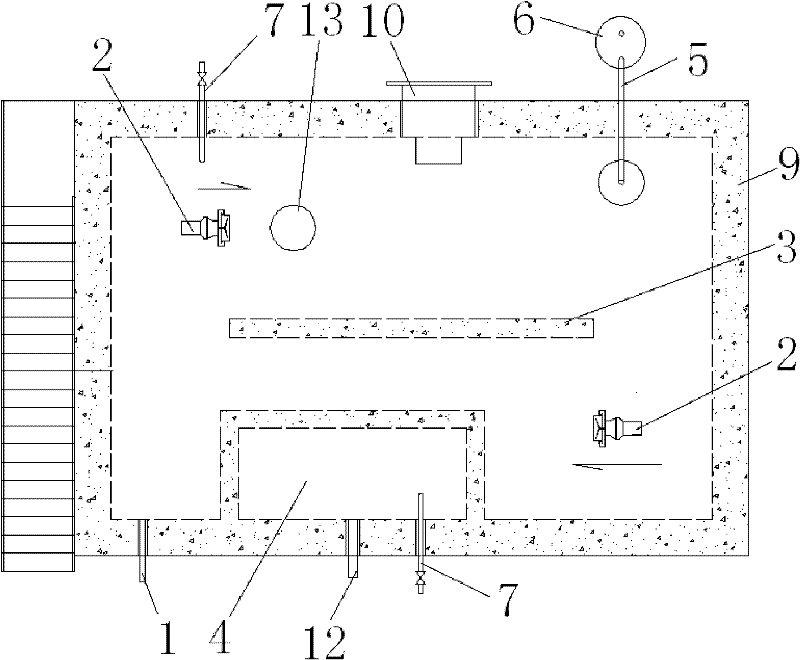

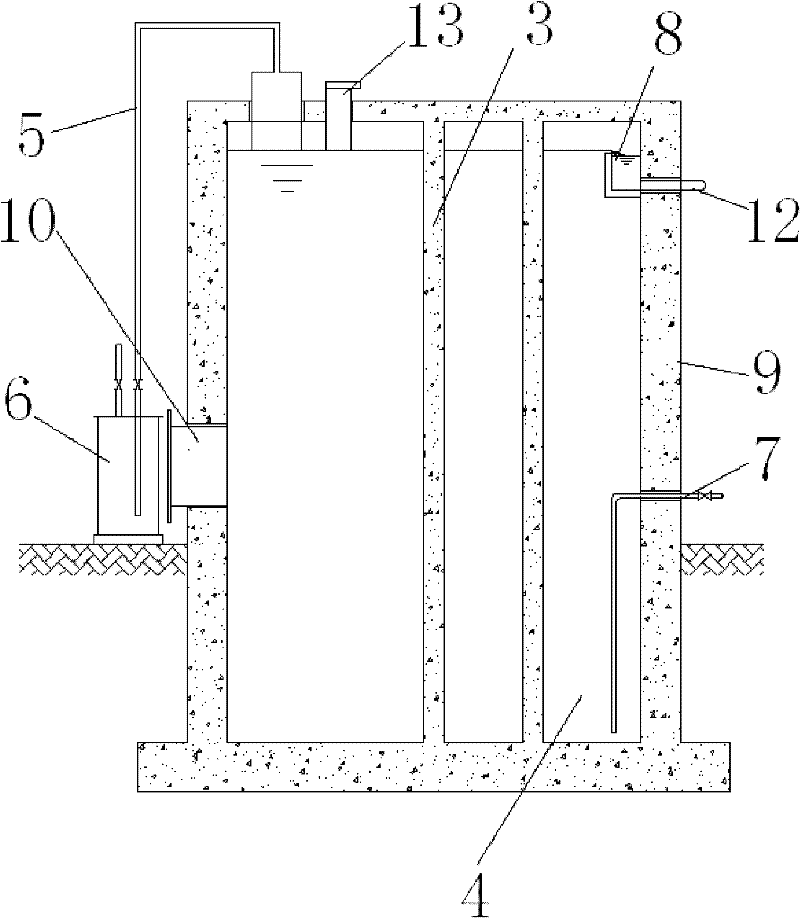

Anaerobic baffled reactor suitable for dyeing and finishing wastewater treatment

InactiveCN102557251AHas a push-flow natureImprove processing efficiencyWaste based fuelTreatment with anaerobic digestion processesLoad resistanceSludge

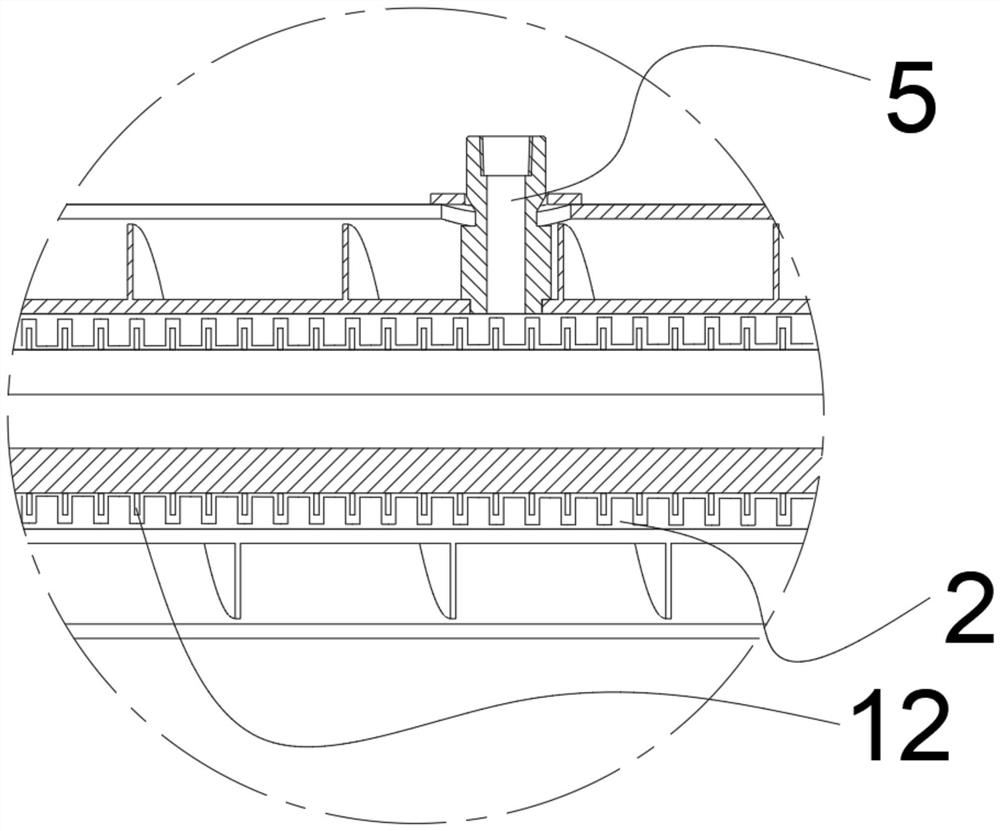

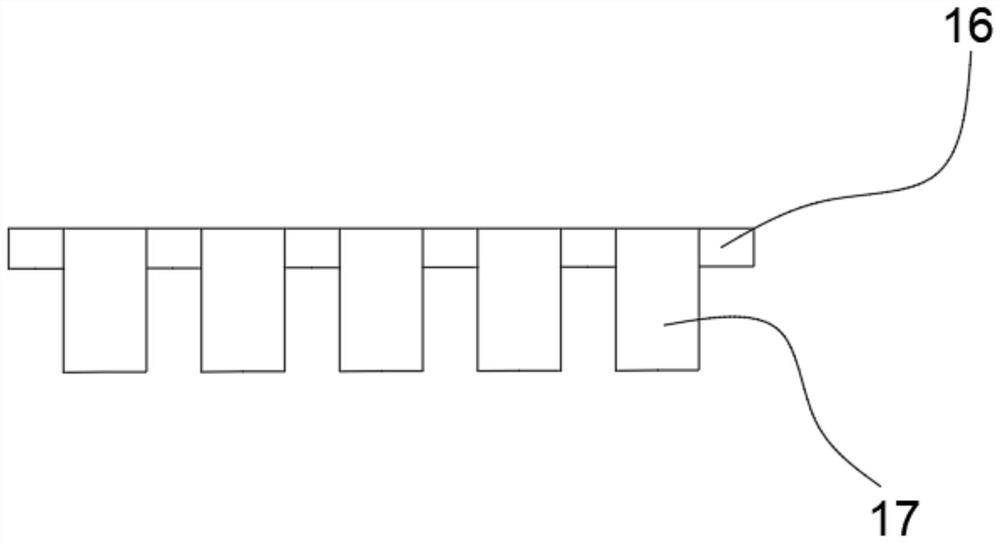

The invention relates to an anaerobic baffled reactor suitable for dyeing and finishing wastewater treatment. The anaerobic baffled reactor comprises a box body (1), middle water baffles (3), baffling chambers (12) and a sedimentation tank (8), wherein a plurality of clapboards (16) are arranged in the box body (1) vertically and uniformly, so that the box body (1) is divided into a plurality of baffling chambers (12); the middle water baffles (3) are arranged in the baffling chambers (12) vertically; baffling boards (4) are connected to lower ends of the middle water baffles (3); filling layers are arranged between the upper ends of the clapboards (16) and the middle water baffles (3); an anaerobic granular sludge layer is paved at the bottom of each baffling chamber (12); a backflow chamber (5) is arranged at the right end of the box body (1); a water inlet pipe (13) is arranged on the left side of the box body (1); and the sedimentation tank (8) which is communicated with the water inlet pipe (13) is connected to the upper end of the right side of the box body (1). The anaerobic baffled reactor has a simple structure, has excellent sludge interception performance and high impact load resistance, and has unique advantage in the treatment of printing and dyeing wastewater with high chromaticity.

Owner:DONGHUA UNIV

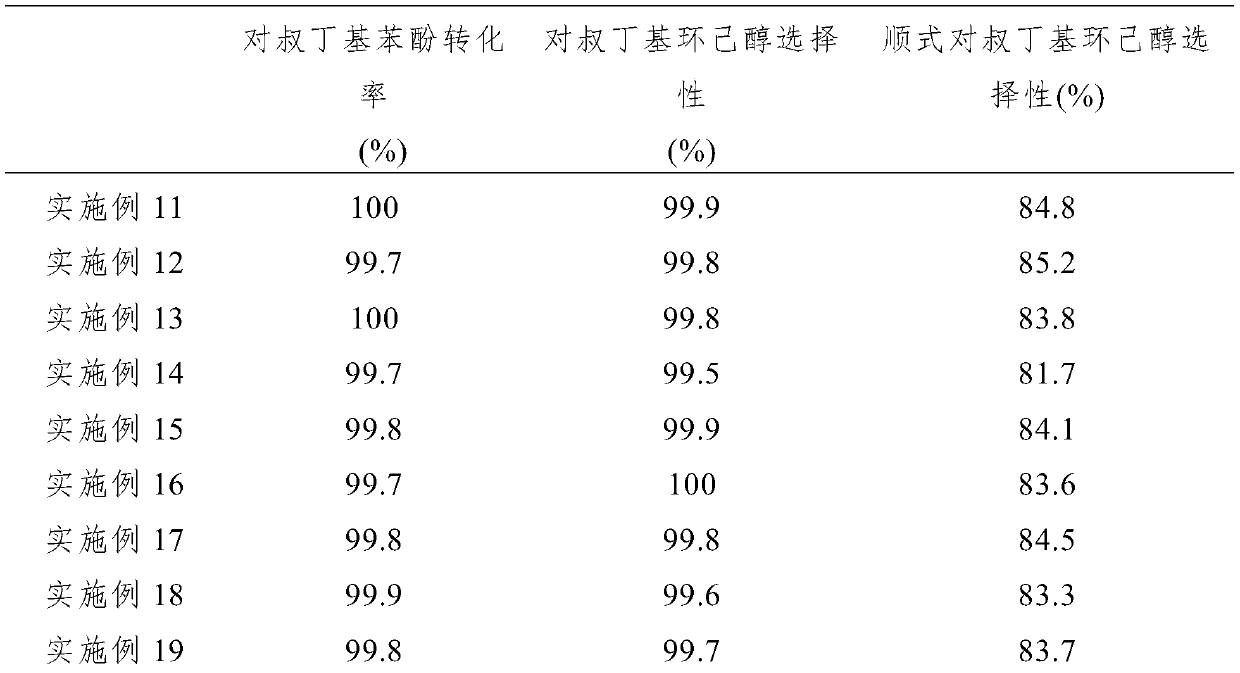

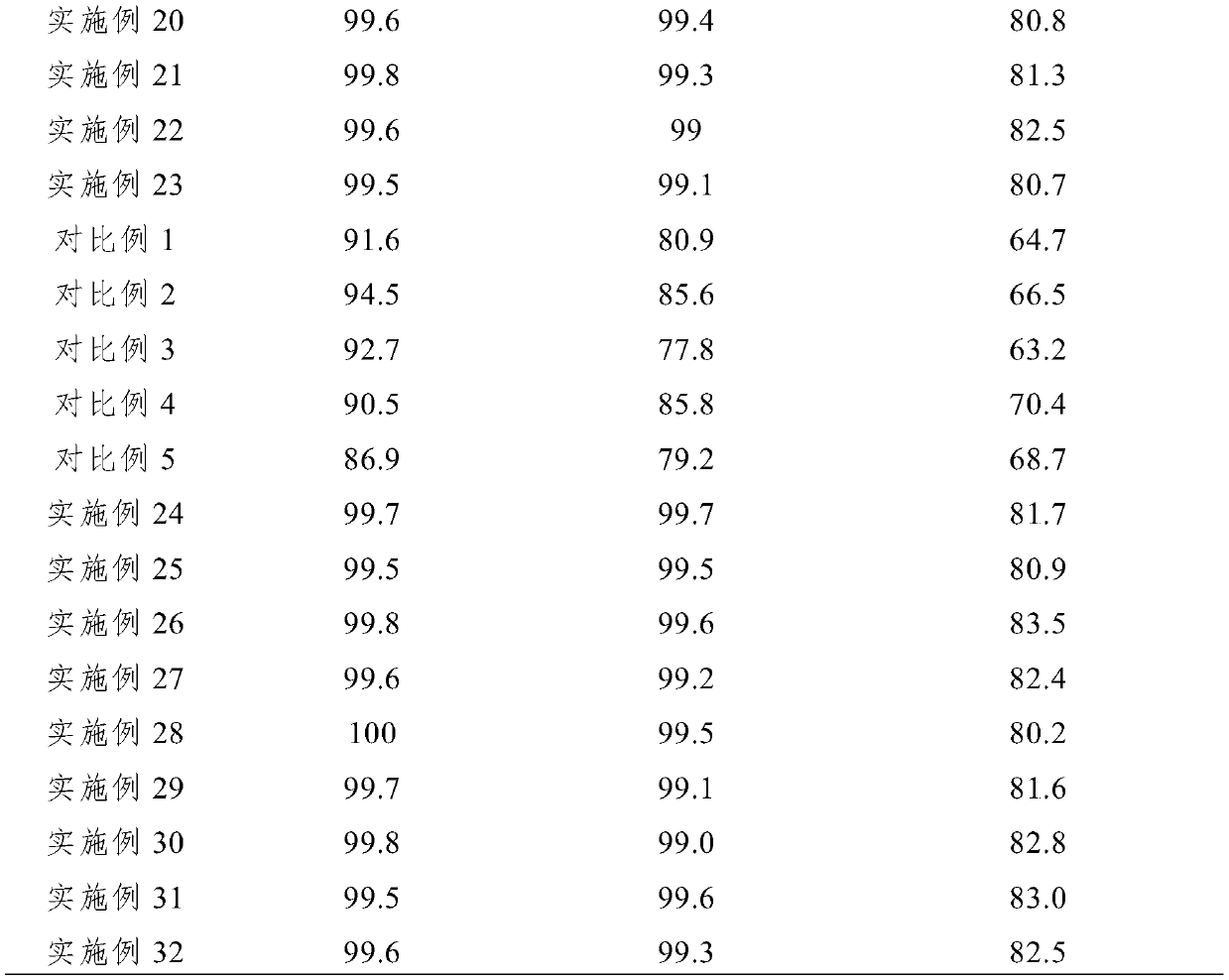

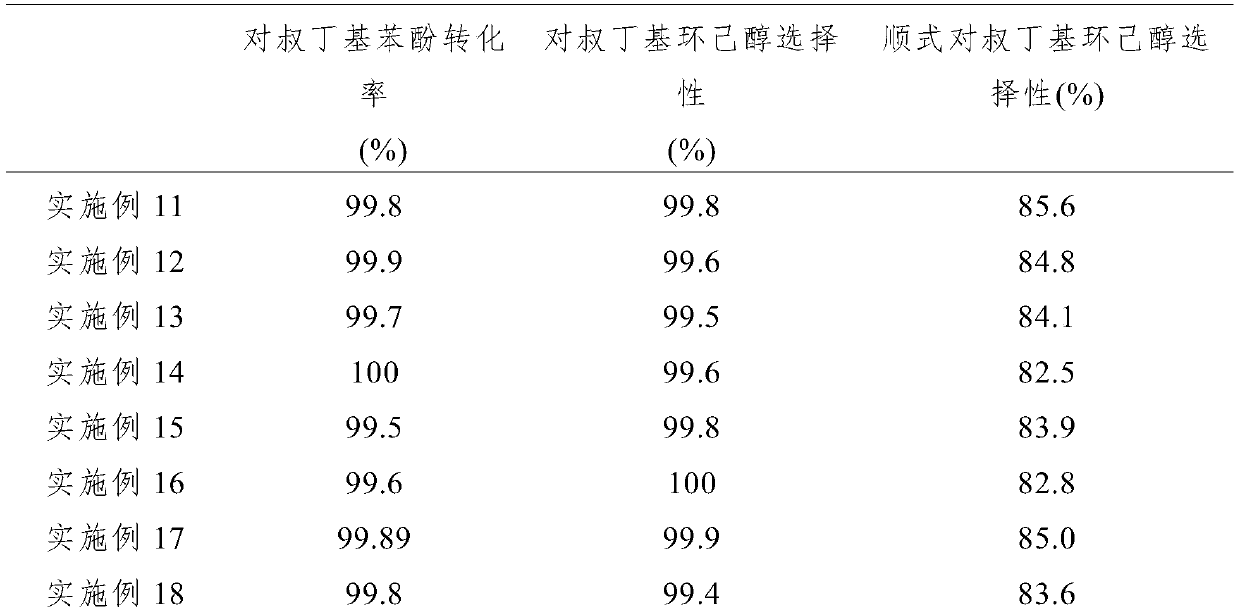

Catalyst for continuously preparing cis-p-tert-butylcyclohexanol, and preparation method and application

ActiveCN110743546AEnhanced Surface AcidityImprove stabilityMolecular sieve catalystsOrganic chemistry methodsPtru catalystP-tert-Butylphenol

The invention discloses a catalyst for continuously preparing cis-p-tert-butylcyclohexanol. The catalyst comprises a porous material carrier, Pd, Ru, a non-metal auxiliary agent component, and a metalauxiliary agent component, wherein a mass percentage of Pd is 0.05%-1%, a mass percentage of Ru is 0.2%-3%, a mass percentage of the non-metal auxiliary agent component is 0.01%-0.5%, a mass percentage of the metal auxiliary agent component is 0.05%-0.8%, the non-metal auxiliary agent component is one or more of P, F and B, and the metal auxiliary agent component is one or more of Mn, Zr, Wu, V,Nb and Ti. In addition, the invention also provides a preparation method and application of the catalyst. The catalyst can significantly improve the selectivity of continuously preparing cis-p-tert-butylcyclohexanol, a molar conversion rate of p-tert-butylphenol exceeds 99.5%, the selectivity of p-tert-butylcyclohexanol exceeds 99%, and the selectivity of cis-p-tert-butylcyclohexanol exceeds 80%.

Owner:XIAN CATALYST NEW MATERIALS CO LTD

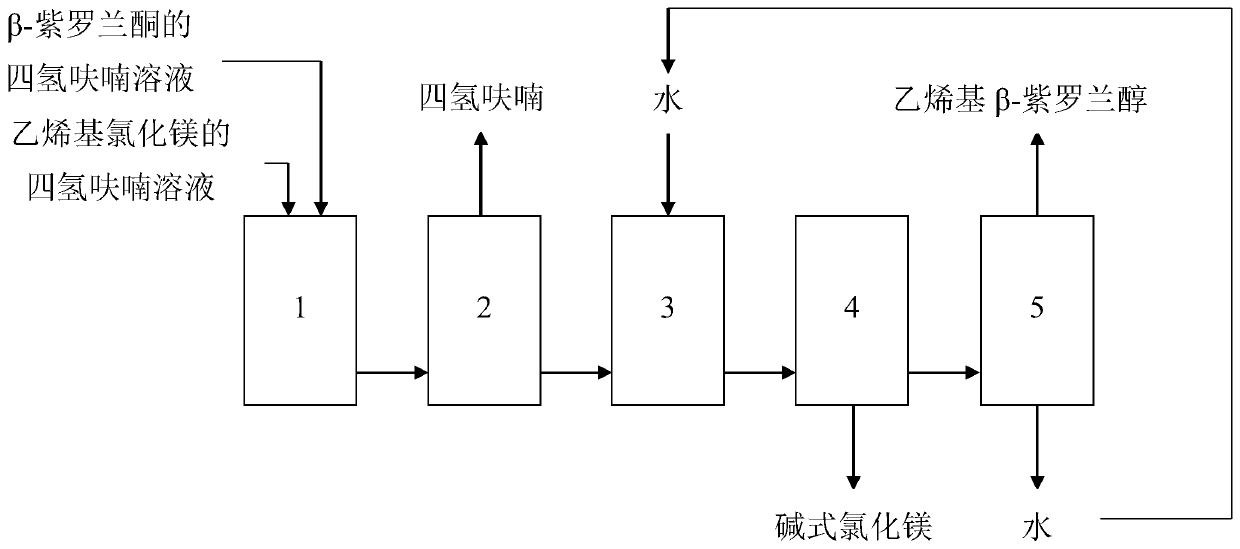

Green process for producing vinyl beta-ionol

ActiveCN110304990AStrong mass transfer abilityHigh selectivityOrganic compound preparationHydroxy compound preparationGrignard reactionSolvent

The invention discloses a green process for producing vinyl beta-ionol. The green process includes: pumping a solvent into a microchannel reactor, discharging air in channels, and continuously pumpinga beta-ionone solution and a vinyl magnesium chloride solution into the microchannel reactor to perform Grignard reaction to obtain reaction liquid; subjecting the obtained reaction liquid to normal-temperature reduced pressure distillation to recycle the solvent, and allowing the solvent to return to the microchannel reactor used in the previous step; adding residues after the normal-temperaturereduced pressure distillation into water, stirring to perform hydrolysis reaction, and filtering to remove basic magnesium chloride solid to obtain filtrate; standing the filtrate for layering, and separating upper-layer oil phase to obtain the vinyl beta-ionol, wherein the lower-layer water phase returns to the hydrolysis reaction of the previous step. The green process is simple in process flow, low in cost and energy consumption, safe, environmentally friendly and capable of continuously producing the vinyl beta-ionol.

Owner:南京瑞鼎生物医药有限公司

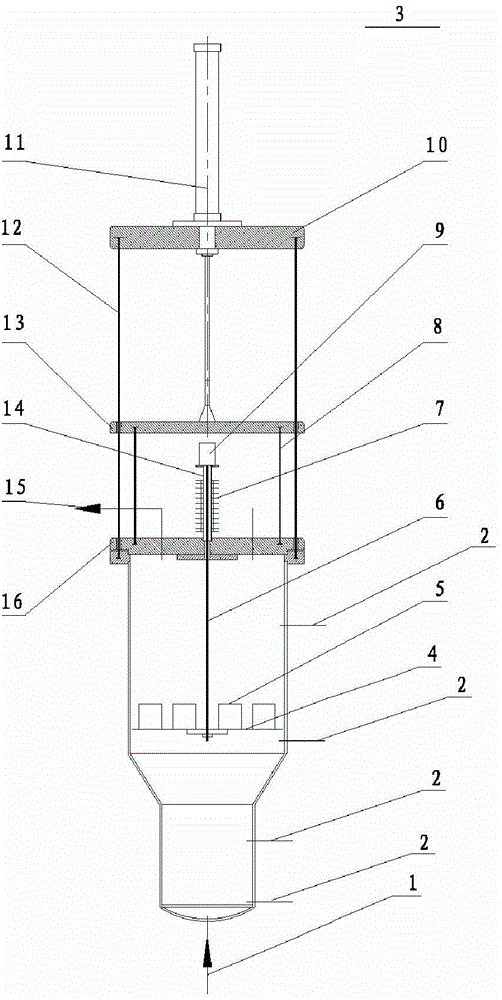

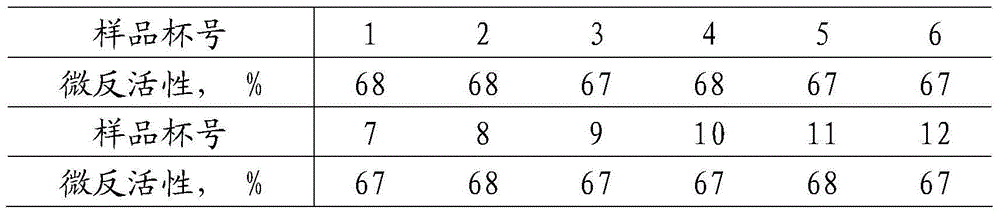

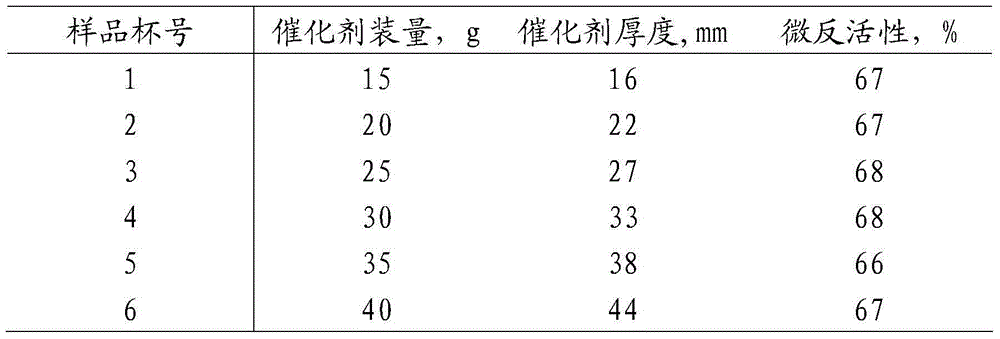

Suspended rotary catalyst ageing oven

InactiveCN104007004AWidely used valueGood repeatability of spin agingPreparing sample for investigationEngineeringFlange

The invention relates to a suspended rotary catalyst ageing oven, comprising a feeding pipe, temperature measuring pipes, an ageing oven, a sample cup bracket, a sample cup, a rotating shaft, a radiator, supporting rods, a motor, a cylinder fixing plate, a lifting cylinder, lifting guide rails, a connecting plate, a motor support frame, a steam outlet pipe and a flange, wherein the upper end of the rotating shaft is connected with the motor and then passes through the center of the flange, the lower end of the rotating shaft is connected with the center of the sample cup bracket, the sample cup is arranged on the sample cup bracket, the motor is supported and fixed by the motor support frame which is fixed on the flange, the flange is fixed on the connecting plate through the two supporting rods, the lifting cylinder is fixed on the cylinder fixing plate, the upper ends of the lifting guide rails are fixed on the cylinder fixing plate, the lower ends of the lifting guide rails are fixed on the flange, the feeding pipe is located at the bottom end of the aging oven, the steam outlet pipe in located between the connecting plate and the flange, the radiator is arranged on the rotating shaft, and the temperature measuring pipes are arranged between the bottom end of the aging oven and the flange.

Owner:KYMSON LUOYANG PETROCHEM EQUIP

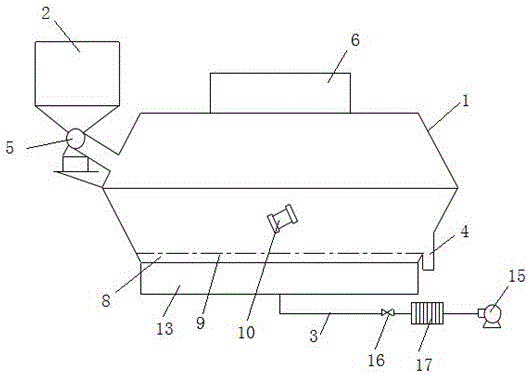

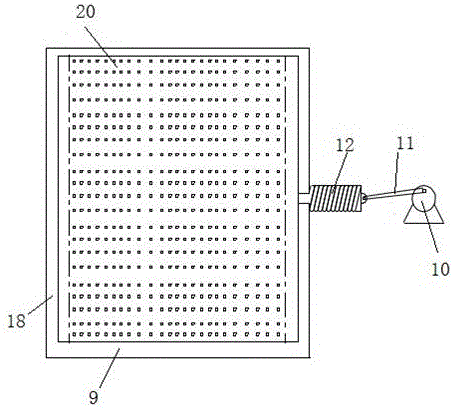

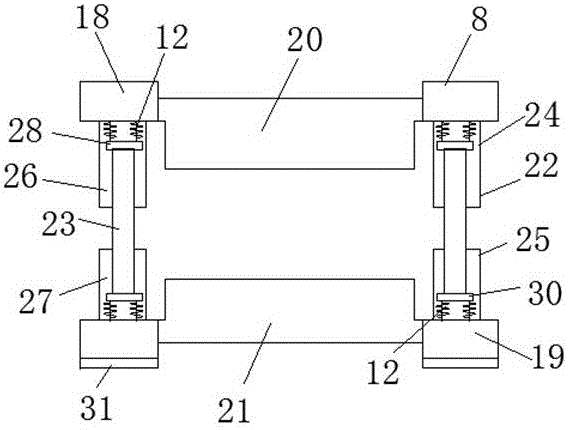

Automatic fluidized bed suspension material bin cleaning device

InactiveCN106643001ACheap savingsCheap agglomeration phenomenonDrying solid materials with heatHearth type furnacesFluidized bedWind field

The invention relates to an automatic fluidized bed suspension material bin cleaning device which comprises a housing, a hopper, an air intake device and a discharge port; a feed port is formed in the left end of the housing, and is connected with the hopper; a material distributing device is arranged at the lower end of the hopper; an air outlet is formed in the upper end of the housing; a discharge port is formed in the lower end of the housing; a cleaning mechanism is arranged in the housing, and comprises a suspension plate, a vibration motor, a link mechanism and a spring; the vibration motor is connected with the link mechanism; the link mechanism is connected with the suspension plate through the spring; an air distributing chamber is formed below the cleaning mechanism, and is connected with the air intake device; the air intake device comprises a blower, an air valve and a heater; the blower is connected with the air distributing chamber through the heater; and the air valve is arranged between the heater and the air distributing chamber. The suspension plate is driven to vibrate through the vibration motor, so that the problem of dust accumulation and agglomeration in a wind field is effectively solved, accumulated and agglomerated dust automatically falls off through vibration, the outage cleaning time is saved effectively and the production efficiency is improved.

Owner:江苏迈达新材料股份有限公司

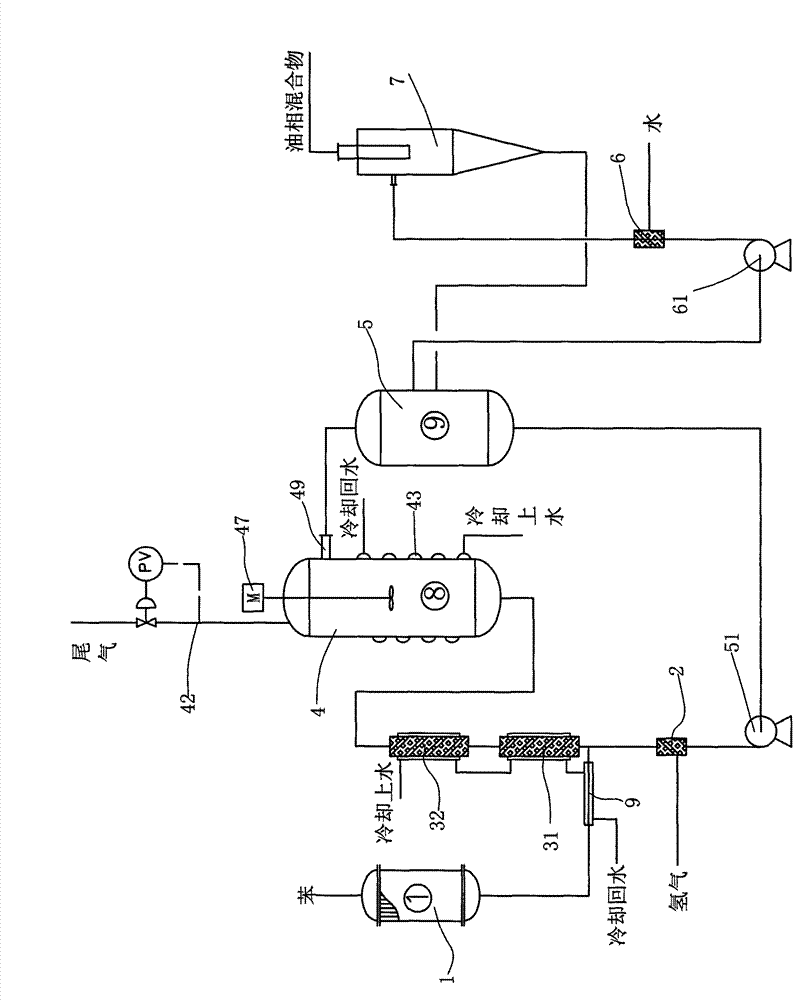

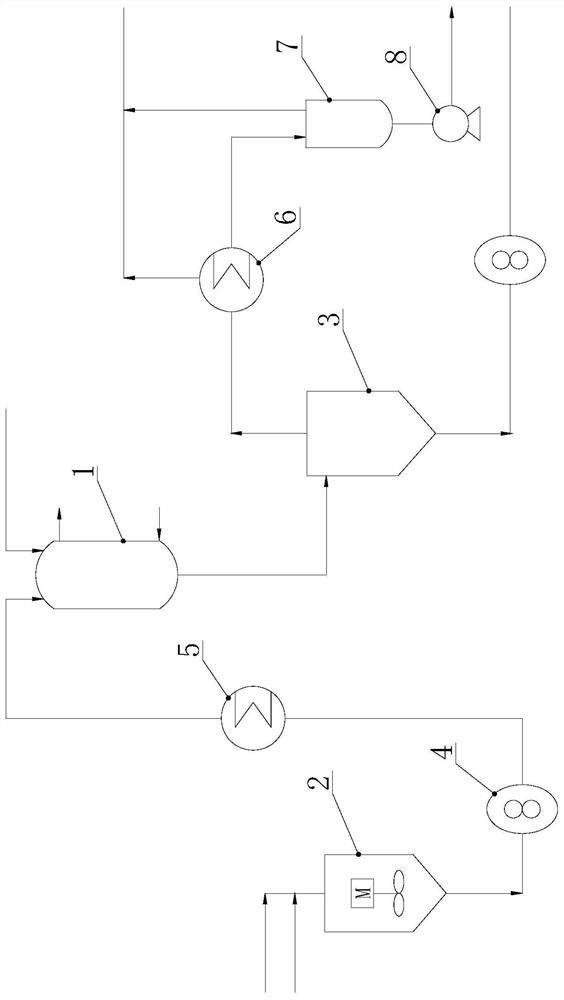

Reaction device and process for preparing cyclohexene by selectively hydrogenating benzene

The invention relates to a reaction device and process for preparing cyclohexene by selectively hydrogenating benzene. The reaction device comprises a benzene refiner, a gas-liquid mixer, a static mixed reactor and a separation tank, wherein the benzene refiner is used for refining raw material benzene; the gas-liquid mixer is used for mixing hydrogen with catalyst slurry; the static mixed reactor is taken as a main place of selective hydrogenation; and the separation tank is used for separating a reaction product from a catalyst, wherein the reaction product and the catalyst are conveyed by using the static mixer reactor. A process method for finishing a reaction comprises the following steps of: feeding the raw material benzene into the benzene refiner for refining, and exchanging heat to 100-130 DEG C; feeding the catalyst slurry and the hydrogen into the gas-liquid mixer with a certain pressure according to a certain proportion simultaneously for fully mixing; feeding the refined benzene and the catalyst slurry obtained by mixing into the static mixed reactor; controlling certain reaction temperature, reaction pressure and liquid flow rate; making the materials react in the static mixed reactor to obtain a cyclohexene-containing mixture; and feeding the cyclohexene-containing mixture into the separation tank for separating. Compared with the prior art, the process has the advantages of stable and easily-controlled reaction and high benzene transformation rate and cyclohexene selectivity.

Owner:SEDIN NINGBO ENG +1

Device for preparing styrene through dehydrating phenethyl alcohol as well as method

ActiveCN110724025AReduce volumeShort stayChemical industryHydrocarbon from oxygen organic compoundsPtru catalystReboiler

The invention belongs to the field of styrene and discloses a device for preparing styrene through dehydrating phenethyl alcohol. The device comprises a dehydrating tower, a dehydrating tower condenser, a dehydrating tower reflux tank, a dehydrating tower reactor circulating pump and a dehydrating tower reboiler, wherein a catalyst feeding pipeline is connected with a dehydrating tower reactor, and a crude phenethyl alcohol feeding pipeline is connected with an inlet of the dehydrating tower reactor and / or the dehydrating tower reboiler; the top of the dehydrating tower is sequentially connected with the dehydrating tower condenser and the dehydrating tower reflux tank; the dehydrating tower reflux tank is connected with the dehydrating tower; the bottom of the dehydrating tower is sequentially connected with the dehydrating tower reactor circulating pump and the dehydrating tower reboiler; an outlet of the dehydrating tower reboiler is connected with the dehydrating tower; and the dehydrating tower reboiler is a shell-and-tube heat exchanger. According to the device and the method, the dehydrating tower reboiler is used as a reactor, phenethyl alcohol and a catalyst can be uniformly mixed and react immediately after entering the dehydrating tower reboiler, so that the residence time of the phenethyl alcohol is shortened, thus, the size of the reactor is reduced, and the equipment investment is reduced.

Owner:SINOPEC ENG +2

Method with single-channel mixing adapter and precipitation for manufacturing nano-powder

PendingCN107855091AUniform particle sizeGood dispersionOrganic compound preparationHeterogenous catalyst chemical elementsDispersityPrill

The invention discloses a method with single-channel mixing adapter and precipitation for manufacturing nano-powder. The single-channel mixing adapter includes mixing adapters and stabilizers with mixing mechanisms inside, which connect with each other in succession. A gas distributor is installed on the pipeline connecting with liquid at the liquid entry end of the mixing adapter. The liquid, firstly, passes through the mixing adapter, in which the liquid, after being mixed uniformly, becomes sediments. Then, the sediments enter into the stabilizer to grow stably, after which products flows out through a material guiding pipe. Then, the products, after being matured, separated, dried or drily roasted, become nano-powders. By adopting the method with single-channel mixing adapter and precipitation to produce nano-powder, the liquid can be mixed uniformly in the mixing adapter. At the same time, the produced sediments can grow stably in the stabilizer. Also, by adopting the method withsingle-channel mixing adapter and precipitation to produce nana-powder, the nucleation process and the growing process of the sediments in precipitation reaction can be separated. The diameter of theproduced particles can be adjusted. The dispersity of the particles is good. The distribution of the particles is narrow. The differences of the features of the particles are small. The method with single-channel mixing adapter and precipitation for manufacturing nano-powder is simple and is convenient for industrial manufacturing.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Preparation method of electronic grade propylene glycol monomethyl ether and product obtained by preparation method

ActiveCN111807934AAvoid contact opportunitiesReduce generationEther separation/purificationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystMonomethyl ether

The invention discloses a preparation method of electronic grade propylene glycol monomethyl ether and a product obtained by the preparation method, and belongs to the technical field of preparation of fine chemicals. The method comprises the following steps of: 1) mixing methanol, propylene oxide and a basic ionic liquid catalyst, and carrying out reaction in a micro-channel reactor to obtain a reaction solution; 2) removing light components from the reaction solution to obtain a light component removed reaction solution; and 3) evaporating the light component removed reaction solution obtained in step 2), and performing negative pressure rectification on the obtained steam to obtain the electronic grade propylene glycol monomethyl ether. The preparation method of the electronic grade propylene glycol monomethyl ether provided by the invention are mild in reaction conditions, the purity of the prepared product is high, the yield is high, and the activity and selectivity of the catalyst are high.

Owner:HAIKE GRP RES INST OF INNOVATION & TECH

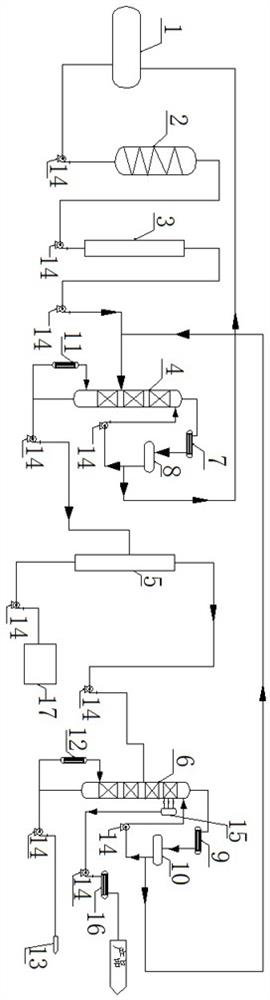

Cumene hydroperoxide normal-pressure tubular reactor and production technology

InactiveCN106905211ASimple structureLow costOrganic compound preparationChemical/physical/physico-chemical processesPlate heat exchangerNuclear engineering

A cumene hydroperoxide normal-pressure tubular reactor and production technology belong to the technical fields of an organic peroxide oxidation apparatus and production technology. The reactor comprises reactor bodies, spiral tube heat exchangers, a condenser and connection pipelines. The reactor is characterized by comprising no less than two reactor bodies (11), which are connected through flanges to form no less than four reactor sets. A tube wall of the first reactor set which is counted from the left is provided with a feed inlet, and a tube wall of the first reactor set which is counted from the right is provided with a feed outlet. One end of the connected reactor set is connected to a condenser through a reactor connection pipe and a condenser connection pipe, and a tube wall located at the other end is internally equipped with an air distributor, which is connected to an air inlet pipe connecting pipe through an air inlet pipe connecting pipe flange, the air inlet pipe connecting pipe is connected to an air inlet pipe, the air inlet pipe is connected to an air compressor, and the reactor bodies are internally provided with the spiral tube heat exchangers. The reactor is simple in structure, low in cost, convenient to use, and high in production efficiency, the product purity can reach about 95%, and the safety of the reactor is obviously improved.

Owner:辽宁抚清助剂有限公司

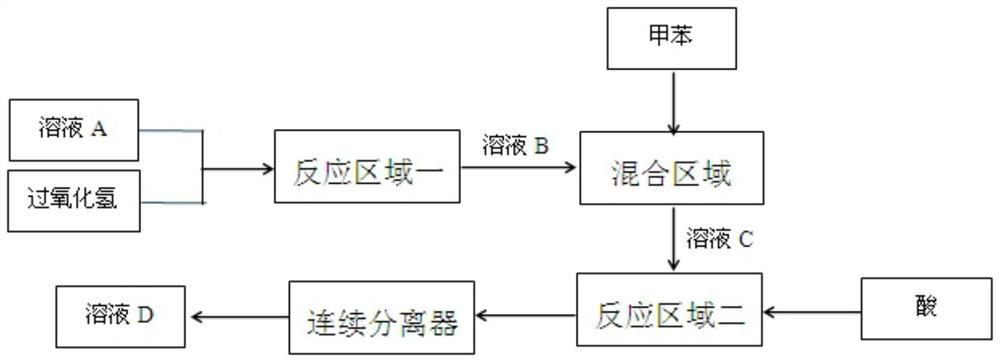

Method for preparing 2, 2 '-dihydroxy-3, 3', 5, 5 '-tetra-tert-butylbiphenyl by using microchannel reactor

PendingCN114539030AShorten the high temperature reaction timeLower unit liquid holdupOrganic chemistryOrganic compound preparationTert butyl phenolPhysical chemistry

The invention relates to a method for preparing 2, 4-difluorobenzene by using a The invention discloses a method for preparing 2, 2 '-dihydroxy-3, 3', 5, 5 '-tetra-tert-butylbiphenyl, which comprises the following steps: preparing a mixed solution from 2, 4-di-tert-butylphenol and alkali liquor according to a certain proportion, respectively pumping the mixed solution and a hydrogen peroxide solution into a micro-channel reactor, fully mixing, reacting the mixed material in a first reaction area module of the micro-channel reactor, mixing with toluene in a mixing area module, and reacting at the temperature of 80-90 DEG C to obtain the 2, 2'-dihydroxy-3, 3 ', 5, 5'-tetra-tert- The method comprises the following steps: adding a toluene solution into a first reaction area module, carrying out a neutralization reaction on the toluene solution and an acid solution in a second reaction area module, carrying out continuous phase separation on the obtained product solution to obtain a toluene solution D containing 2, 2 '-dihydroxy-3, 3', 5, 5 '-tetra-tert-butylbiphenyl, and carrying out concentration, crystallization and washing to obtain the target product 2, 2'-dihydroxy-3, 3 ', 5, 5'-tetra-tert-butylbiphenyl. By utilizing the method, the reaction efficiency can be obviously improved, the reaction time is greatly shortened, the possible explosion risk is avoided, the production process is more convenient to control, the production cost is reduced, and the defects of high labor intensity, long production period, low product quality and the like in the traditional production are overcome.

Owner:SHANGHAI CHEM REAGENT RES INST

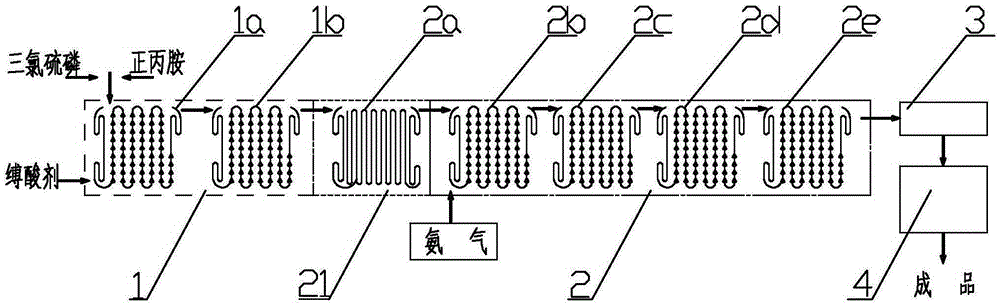

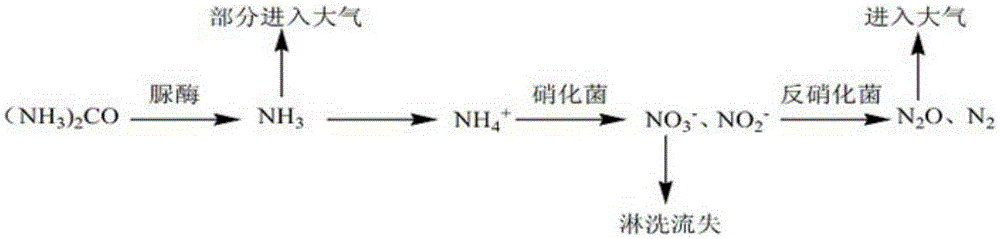

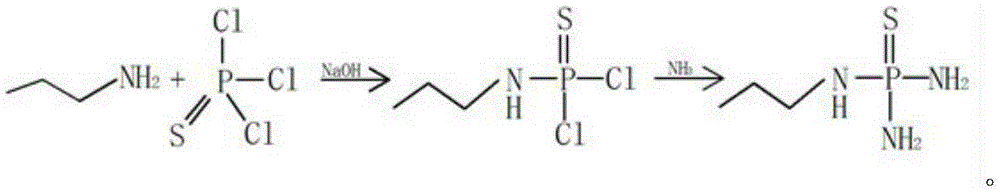

Synthesis method for urease inhibitor and application of urease inhibitor

InactiveCN105254664AShort processing flowRealize continuous productionGroup 5/15 element organic compoundsChemical industryEnzyme Inhibitor AgentUrease enzyme

The invention relates to a synthesis method for urease inhibitor and application of the urease inhibitor and belongs to the technical field of fertilizer synergists. The synthesis method includes the steps that n-propylamine / n-butylamine and phosphorus oxychloride serve as initial raw materials and are mixed with a solvent respectively to form two mixtures; an acid-binding agent is added to the two mixtures, the first temperature process temperature is adjusted to 10-50 DEG C, pressure is controlled to 0-0.5 MPa, after a first temperature process reaction, the temperature is reduced to 0-30 DEG C, and ammonia gas is introduced for a second temperature process reaction; a crude product is obtained after the second temperature process reaction is completed, and the finished product is obtained after the crude product is layered and then treated. The synthesis method is applied to preparation of the urease inhibitor and special urea and has the advantages of being short in processing flow, fewer in product impurities, high in utilization rate and good in heat stability, achieving continuous production and the like.

Owner:ZHEJIANG AOFUTUO CHEM

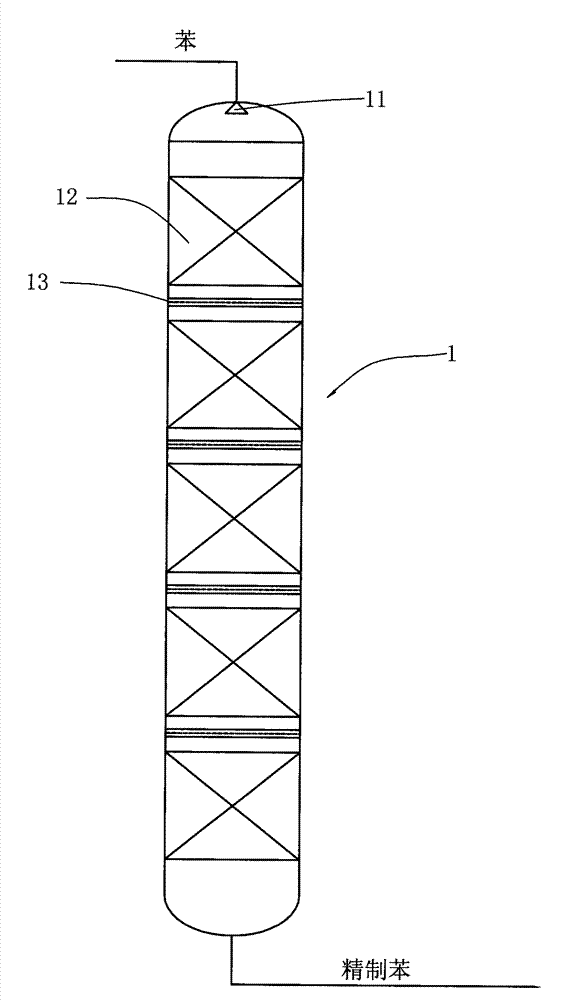

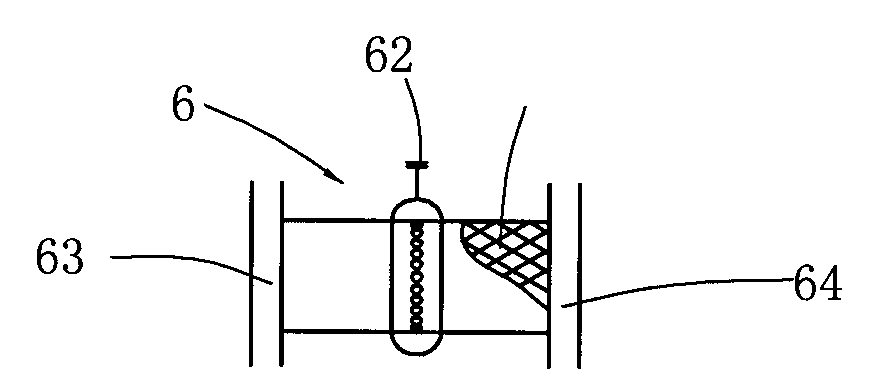

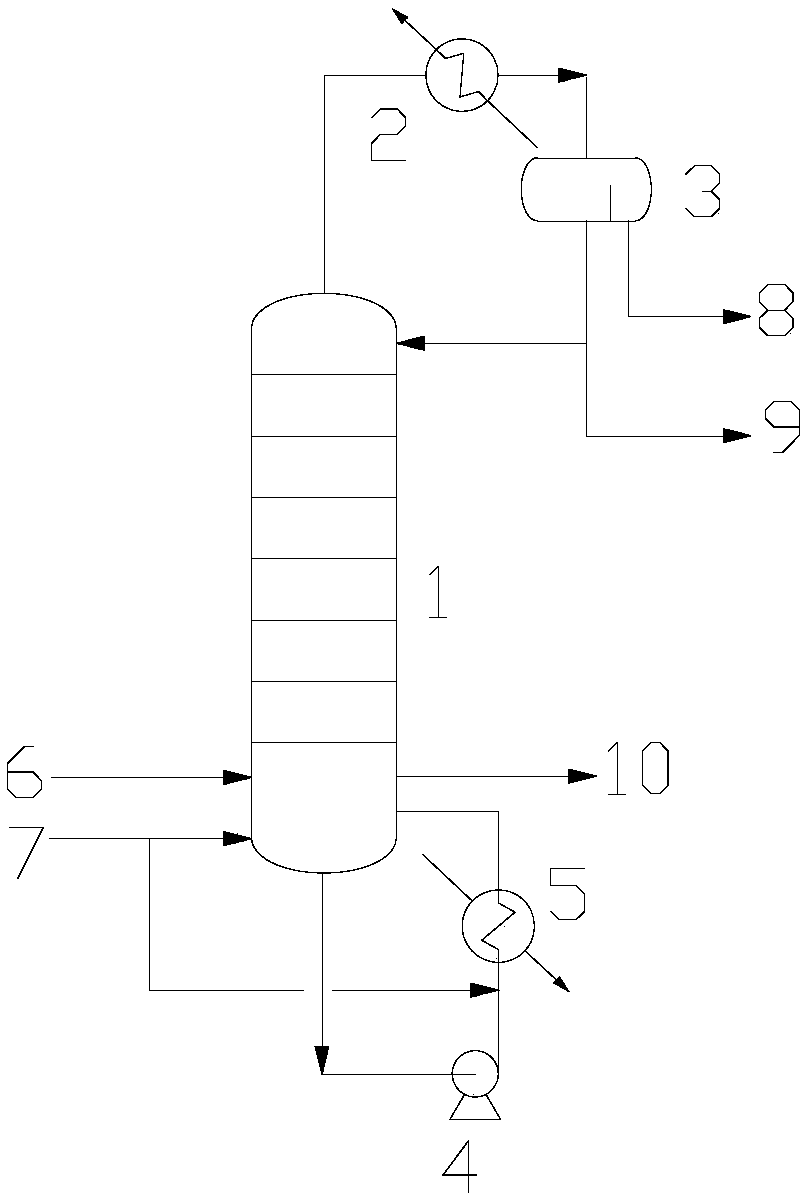

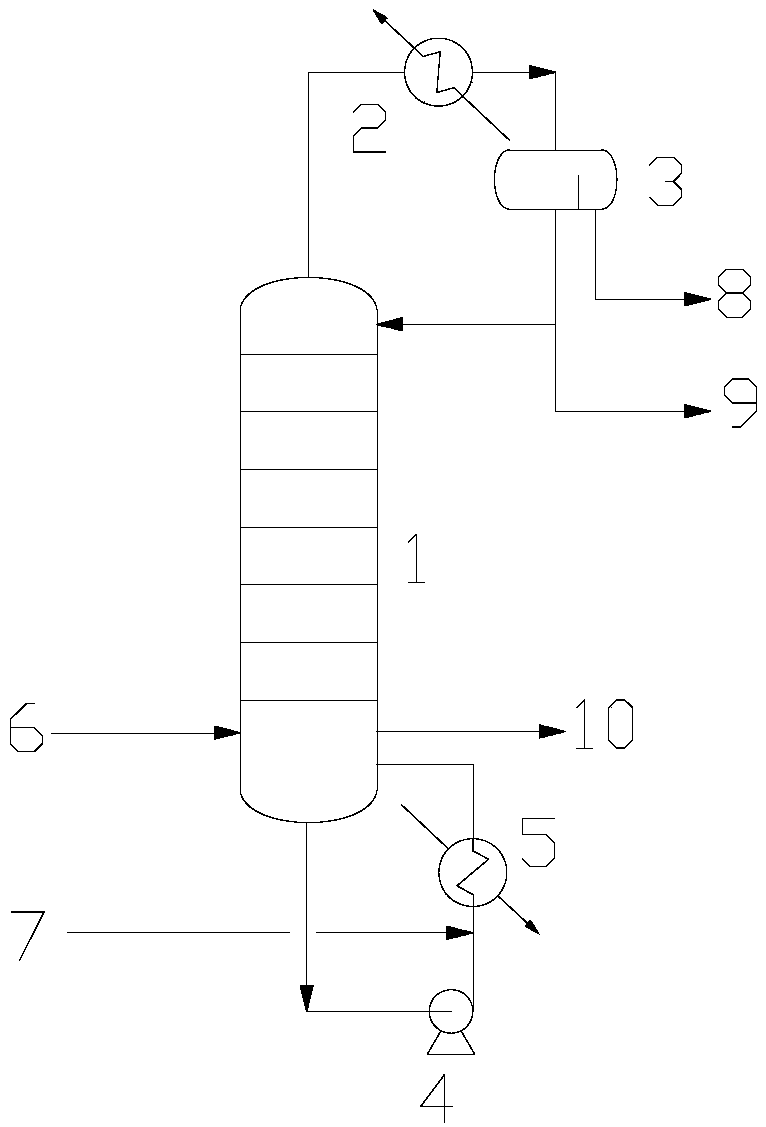

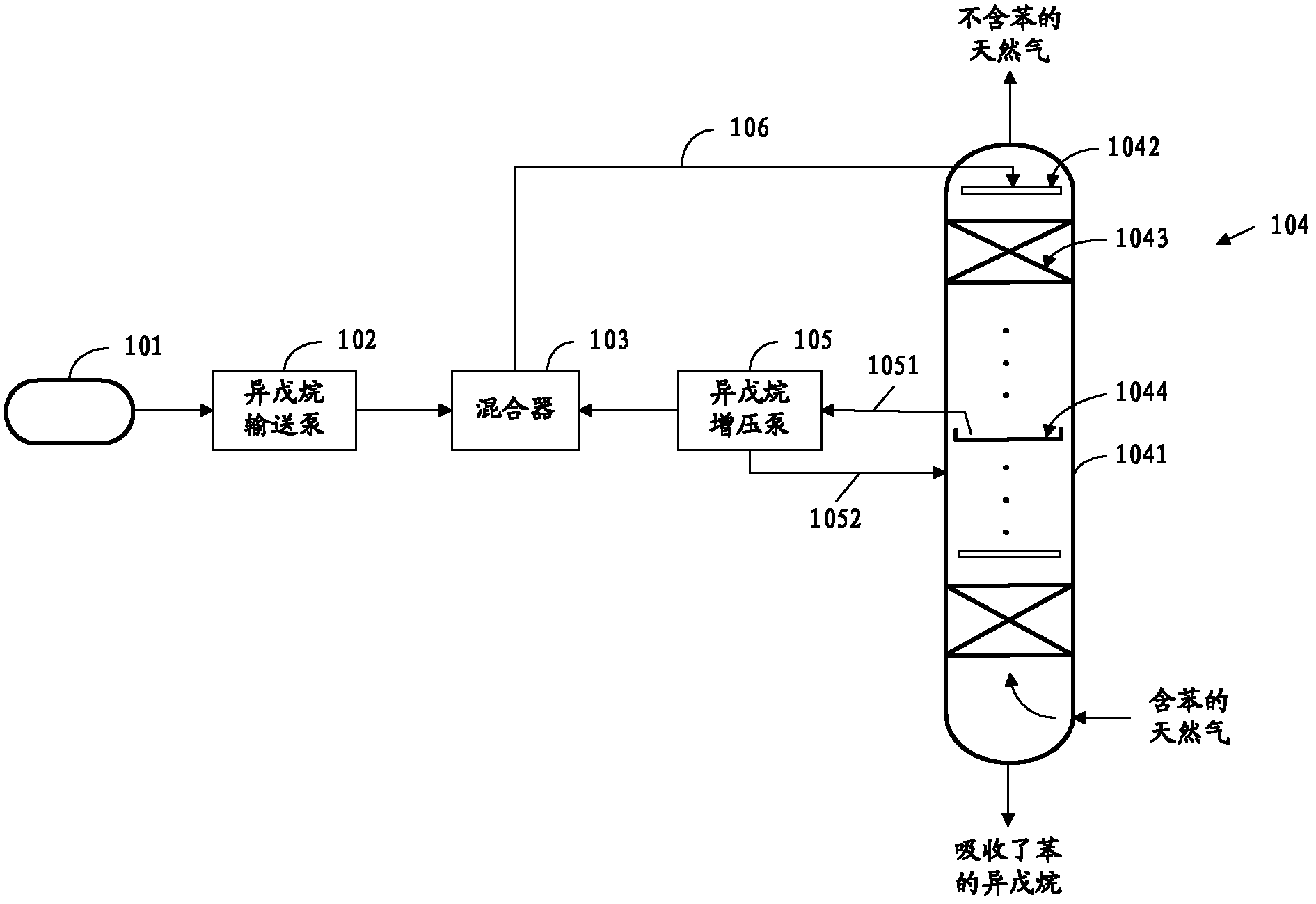

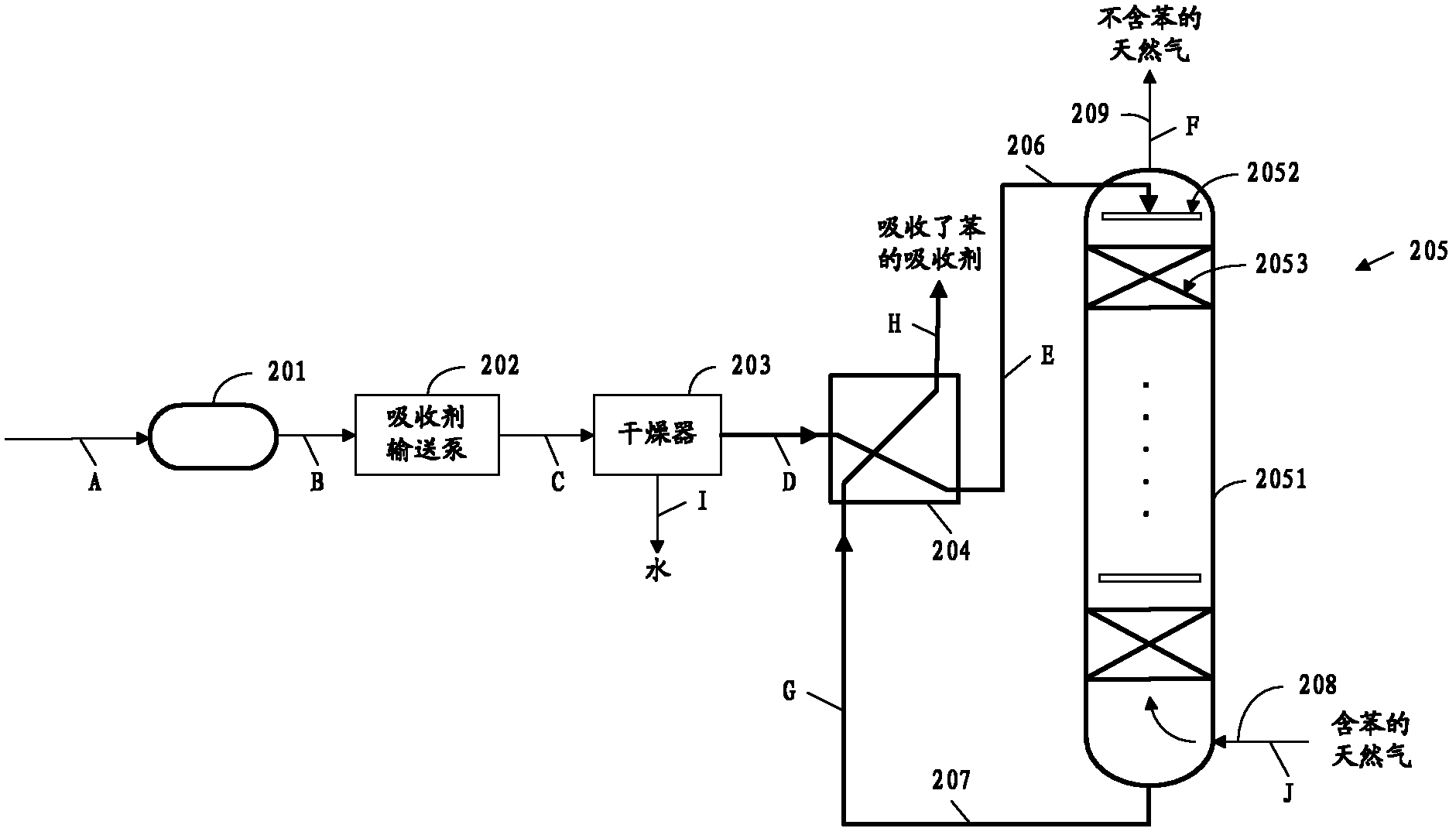

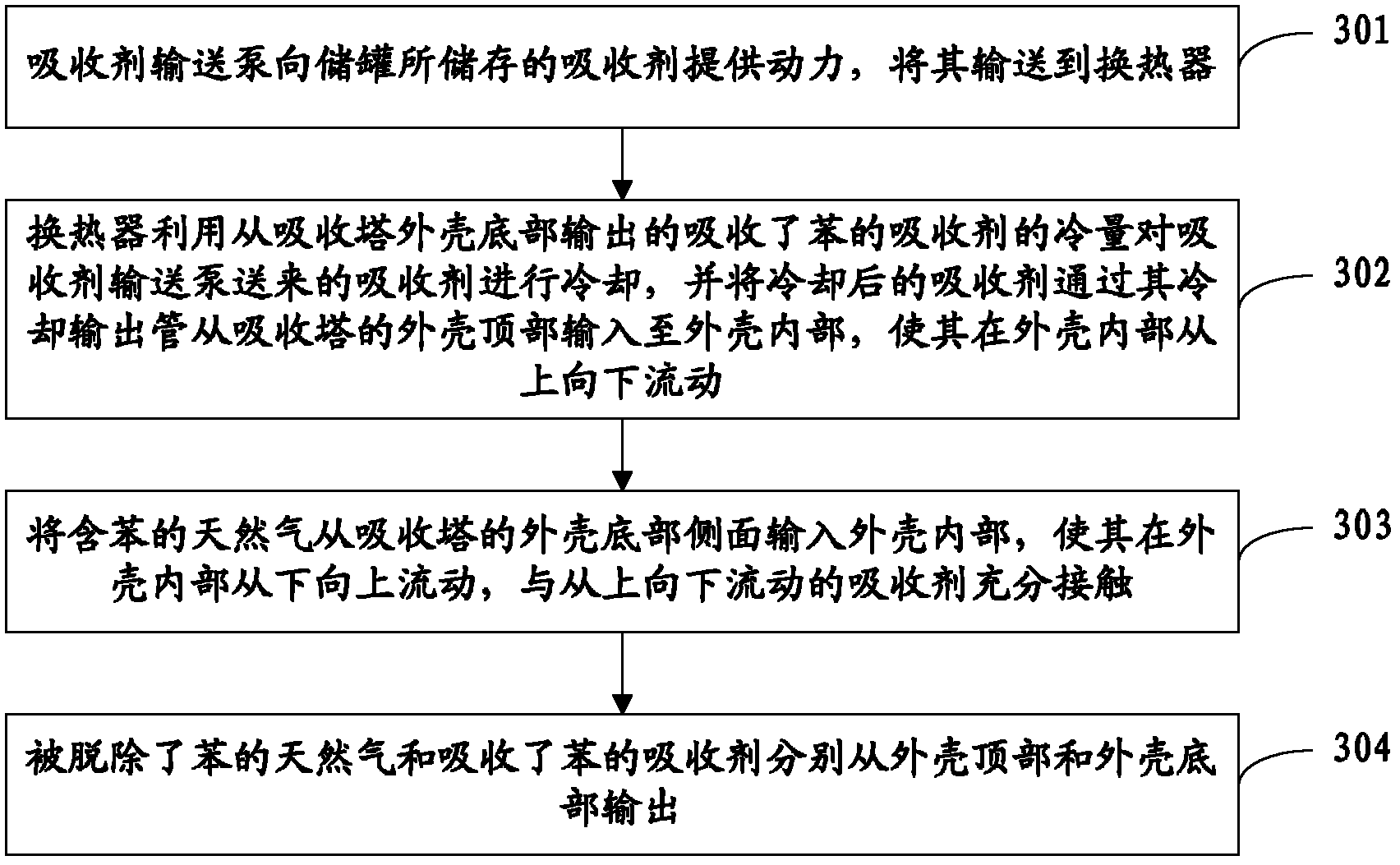

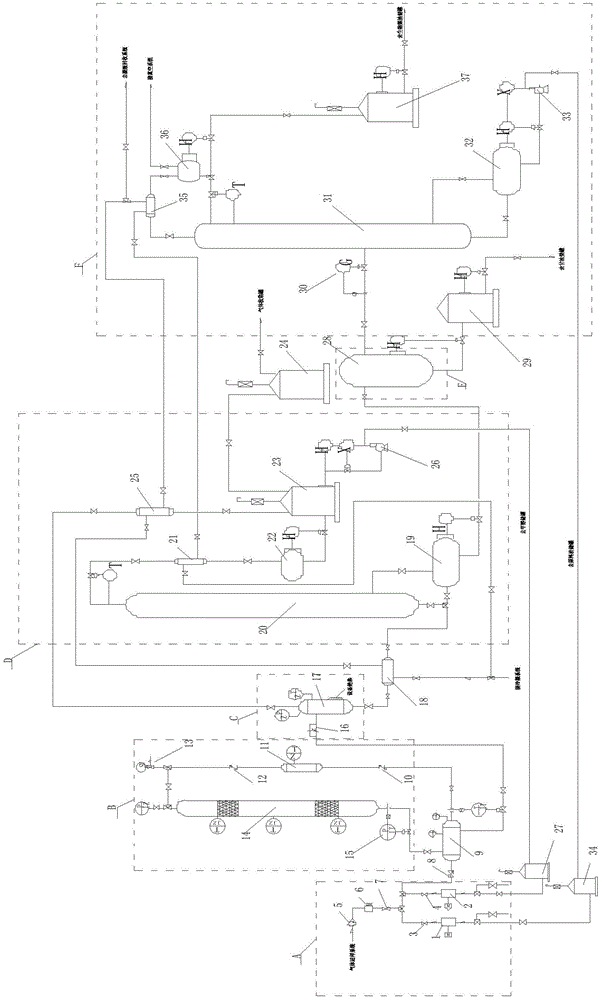

System and method for removing benzene in natural gas

The invention relates to a system and a method for removing benzene in natural gas. The system comprises a storage tank for storing an absorbent, an absorbent delivery pump for providing powder to the absorbent, an absorption tower, a natural gas input pipe for inputting the natural gas containing benzene into the inside of a shell, a natural gas output pipe for outputting the natural gas without benzene, a heat exchanger for precooling the absorbent and an absorbent outputting pipe for outputting the benzene-absorbing absorbent, wherein the absorption tower includes a liquid distributor and a packing layer; the heat exchanger is respectively connected with the absorbent delivery pump and the absorbent outputting pipe so that the absorbent is cooled by utilizing the cold amount of the benzene-absorbing absorbent delivered by the absorbent outputting pipe, and the cooled absorbent is output through the cooling outputting pipe of the heat exchanger; and the cooling outputting pipe enters into the inside of the shell from the shell top of the absorption tower so as to connect the liquid distributor, so that the cooled absorbent flows from up to down inside the shell. By the system and method provided by the invention, the removal efficiency of benzene in the natural gas can be improved, and the equipment investment of the system can be reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Dynamic tangential flow tubular reactor

PendingCN112354498AAvoid wastingAvoid cleaning difficultiesChemical/physical/physico-chemical stationary reactorsPhysicsEngineering

The invention relates to the field of biological medicine reaction devices, and discloses a dynamic tangential flow tubular reactor which comprises a reactor shell, a rotating shaft arranged in the reactor shell, a rotating fixing device used for connecting the rotating shaft with the reactor shell, and a feeding and discharging port assembly arranged on the outer wall surface of the reactor shell, a plurality of stirring columns are vertically arranged on the outer wall surface of the rotating shaft; a reaction cavity is formed between the inner wall surface of the reactor shell and the outerwall surface of the rotating shaft; the reactor further comprises a scraper assembly arranged on the inner wall surface of the reactor shell. The dynamic tangential flow tubular reactor is used for solving the problems of failure shutdown, material waste and difficulty in cleaning of the reactor caused by easy adhesion of materials on the rotating shaft of the reactor.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

Spiral type gas-solid separation device

InactiveCN101391165BNo airflow interferenceSmall pressure lossDispersed particle separationGas solidLower upper

The invention discloses a spiral gas-solid separation device, which comprises a conical dust collector (4), and is characterized in that a cylindrical seal cover (2) is arranged on a horn mouth of the conical dust collector (4), a spiral air current channel (1) is disposed in the cover coaxially, and an air current inlet (7) and an air current outlet (3) of the channel respectively extend out from side walls of the lower part and the upper part of the cylindrical seal cover (2); and a gap (1-5) is arranged at the junction of the outer wall (1-3) and the lower wall (1-4) of the spiral air current channel (1) for dust settling after centrifugal separation. The device has the advantages of rather complete gas-solid separation, non interference of air current flow up and down and low pressureloss.

Owner:GUANGZHOU UNIVERSITY

Shell-and-tube fixed bioreactor

InactiveCN101020891BNo backmixingShorten the timeBioreactor/fermenter combinationsBiological substance pretreatmentsResource utilizationEngineering

The shell-and-tube fixed bed bioreactor includes one upper end sealing body with liquid inlet; one reaction cavity with stuffing pipes filled with solid stuffing; one lower end sealing body; and one distributor in the upper end of the stuffing pipes with homogeneously distributed through holes for the liquid from the upper end sealing body to be sprayed homogeneously to inside the stuffing pipes.The shell-and-tube fixed bed bioreactor has simple structure, easy operation, high yield and high resource utilizing rate.

Owner:领先生物农业股份有限公司

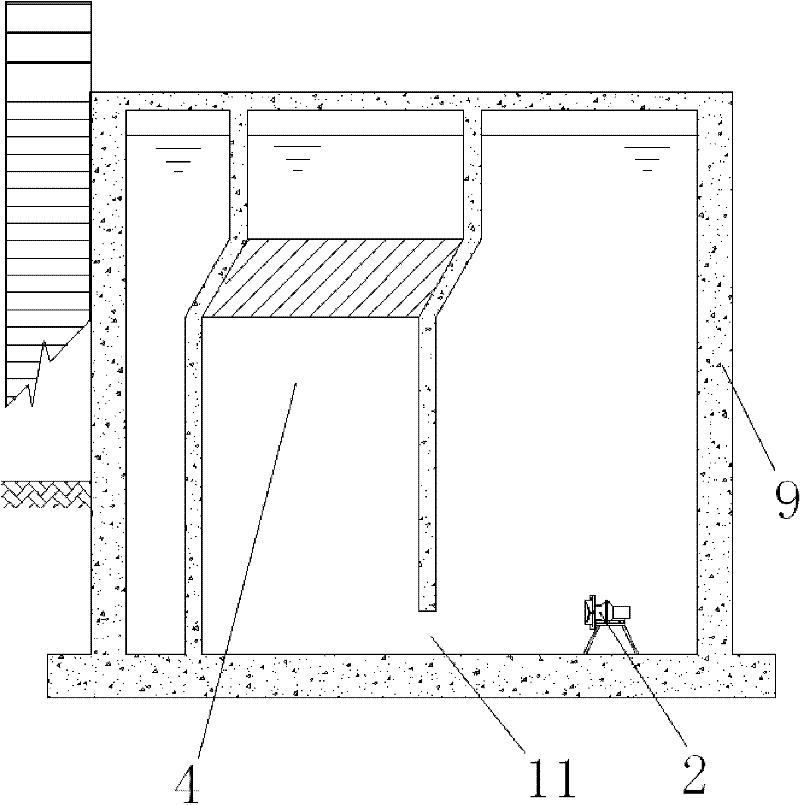

Internal circulation anaerobic reactor

InactiveCN102153197BRealize the water cycleReduce churnBioreactor/fermenter combinationsBiological substance pretreatmentsBiochemical engineeringPropeller

The invention discloses an internal circulation anaerobic reactor. The anaerobic reactor comprises a tank body, a biogas collection pipe internally communicated with the tank body and a water-sealed tank and also comprises a water inlet pipe and an inclined plate setting tank, wherein the middle of the tank body is provided with an isolation wall; two inner opposite corners of the tank body are separately provided with submerged propellers which are used to push the mixed water body in the tank to flow along the isolation wall; the inclined plate setting tank is arranged on one side of the inside of the tank; and the lower end of the inclined plate setting tank is provided with an opening communicated with the inclined plate setting tank and the tank body. By adopting the structure, the internal circulation anaerobic reactor has the following advantages: 1) water circulation can be realized in the tank body, the flow rate is stable on each section which is perpendicular to the flowingdirection in a steady state; 2) on each section of the reactor, the concentration of material can not change with time, the loss of sludge can be reduced; 3) fluid particles can not be mixed in the flowing direction of fluid, the backmixing phenomenon does not exist, all the fluid particles have the same residence time; 4) mud and water can be fully mixed; and 5) the impact resistance can be increased.

Owner:芜湖慧安水处理科技有限公司

Esterification device and method for AA and BDO in PBAT production process

PendingCN113499596ANo backmixingReduce circulationVacuum distillation separationChemical/physical/physico-chemical stationary reactorsEngineeringProcess engineering

An esterification device for AA and BDO in the PBAT production process comprises a micro-interface wound tube type reactor, a stock bin and a vacuum flash tank. A feeding port of the stock bin is used for being connected with an AA source and a BDO source, a discharging port of the stock bin is connected with a material channel inlet of the reactor through a feeding pump and a heater, and a material channel outlet of the reactor is connected with the vacuum flash tank. A micro-interface generator is arranged at an inlet of the material channel, a liquid outlet in the bottom of the vacuum flash tank is used for discharging BSA, a steam outlet in the top of the vacuum flash tank is connected with a vacuum separator through a condenser, and non-condensable gas outlets of the condenser and the vacuum separator are both connected with a negative pressure source. The device is simple in structure and convenient to operate, the operation efficiency is greatly improved, the production requirement of large-scale production of PBAT can be met at low cost, the esterification reaction can be carried out in the forward direction without adopting an excessive BDO mode, the esterification rate of AA and BDO can be effectively improved and reaches 98.5% or above, material backmixing can be effectively avoided, the circulation amount of BDO is reduced by 95%, and energy consumption is greatly reduced.

Owner:华峰集团上海工程有限公司

A method for large-scale continuous preparation of nanometer zero-valent metal materials

ActiveCN108247079BImprove utilization efficiencyAvoid reunionNanotechnologyMetallic materialsAqueous solution

The invention relates to preparation of nanometer materials and specifically discloses a method for large-scale continuous preparation of nanometer zero-valent metal materials. The method includes thefollowing steps that (1) biomass adsorption particles and a metal salt ion solution make contact in a soaking mode according to the solid-to-liquid ratio of 1:1-50 g / ml, and after filtering, separation and washing, water is added for size mixing to form a suspension state according to the solid-to-liquid ratio of 1:1-50 g / ml, and a material A is obtained; (2) a sodium borohydride aqueous solutionwith the concentration being 0.1-1 mol / L is prepared to serve as a material B; and (3) the material A and the material B are added into an auger type spiral mixer in a mixed mode according to the volume-flow rate ratio of 1:1-5, mixing and reinforcing contact are carried out in the auger type spiral mixer, a reduction reaction is completed, residual reagents are removed by rapidly washing outputmaterials, and the nanometer zero-valent metal loaded composite materials are obtained. By means of the method, the technical problems that nanometer zero-valent metal is prone to air oxidation and solid-liquid separation and washing are difficult in large-scale preparation are solved, and a highly engineered technological approach for large-scale preparation of the nanometer zero-valent metal materials is provided.

Owner:北京科大科技园有限公司

Catalyst and preparation method for preparing biodiesel and preparation process of biodiesel

ActiveCN103877958BImprove solubilityIncrease productivityPhysical/chemical process catalystsFatty acid esterificationBiodieselCleaner production

The invention discloses a catalyst for preparing biodiesel and a preparation method of the catalyst as well as a novel process applied to preparation of the biodiesel. The catalyst comprises the following components by weight percent: 85.38%-91.42% of ZrO2, 6.75%-9.72% of Al2O3 and 2.68%-4.16% of TiO2. The solid catalyst is used for catalyzing an ester exchange reaction to produce the biodiesel, the reaction time is short, the conversion rate is high, various raw materials can be widely used, the ester exchange reaction can be carried out in a methanol subcritical state to produce the biodiesel, the catalyst is automatically separated from a product after the reaction is finished, and the rinsing operation is not required, thus the clean production of the biodiesel is realized and the production cost of the biodiesel is remarkably reduced.

Owner:KUSN INNOVATION INST OF NANJING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com