Method with single-channel mixing adapter and precipitation for manufacturing nano-powder

A nano-powder and mixer technology, which is applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve the problems of difficult acid-base precipitation reaction, small diameter of microchannel, and inability to carry out the reaction. , to achieve the effect of uniform particle size, simple method and narrow distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

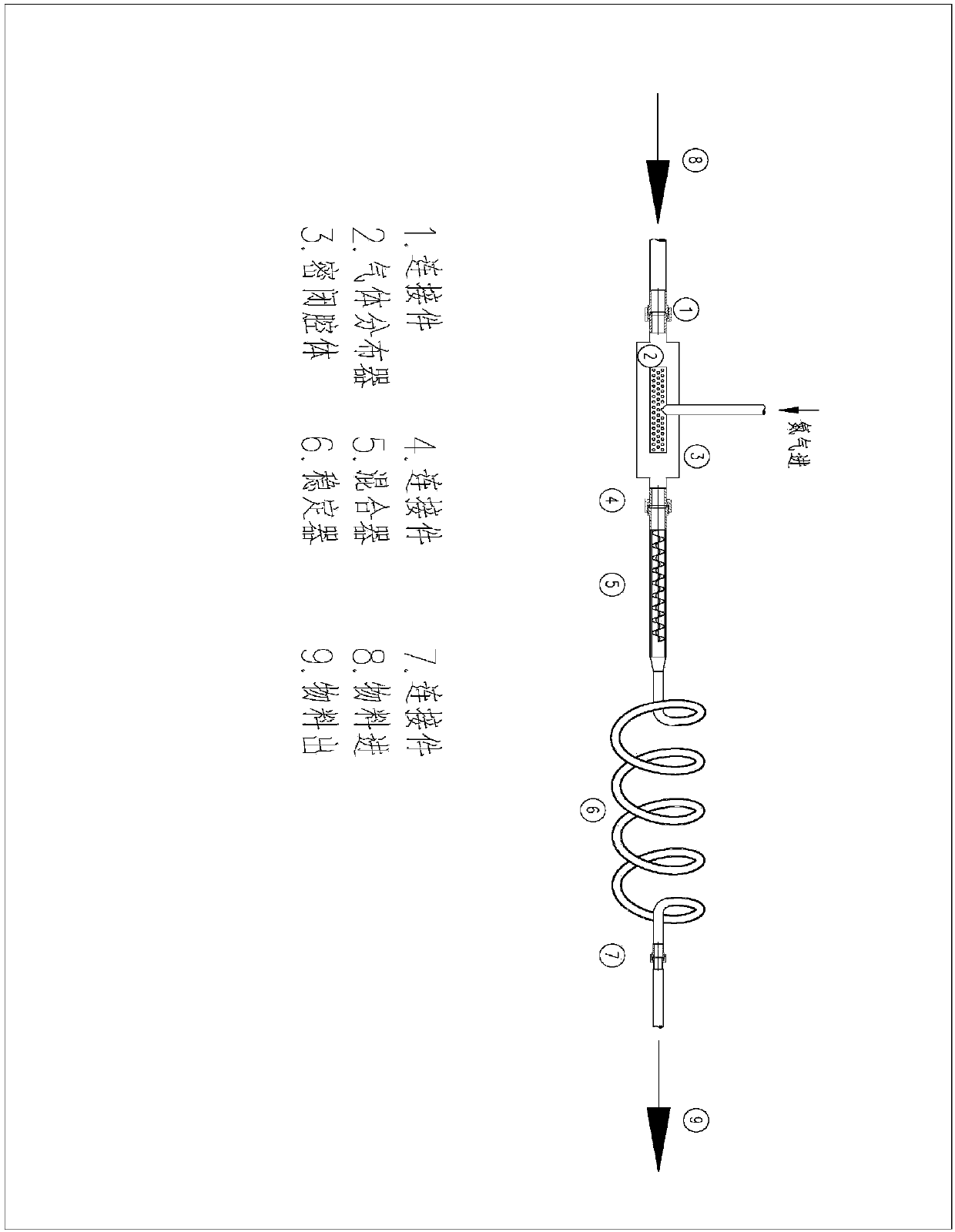

[0030] Embodiment 1 methanol synthesis catalyst CuO-ZnO-Al 2 o 3 preparation

[0031] 105 kg copper nitrate Cu(NO 3 ) 2 ·3H 2 O, 47 kg of zinc nitrate Zn (NO 3 ) 2 ·6H 2 O, 30 kg of aluminum nitrate Al(NO 3 ) 3 9H 2 O dissolved in deionized water to form 1m 3 Solution, heated to 60°C, labeled as Solution A. 132 kg anhydrous Na 2 CO 3 solution deionized water to form 1m 3 solution, labeled Solution B. Heat solution A and solution B to 60°C, keep the raw materials warm, and feed them into the single-channel mixer of the present invention at a flow rate of 40 L / min with a metering pump. The flow rate of nitrogen in the gas distributor is 4L / min, the mixer is controlled by jacket constant temperature water at 60°C, the residence time in the mixer is 12s, the residence time in the stabilizer is 40s, and the reaction precipitation liquid enters the aging stirring tank for aging for 2 hours , and then washed, dried, roasted at 350°C for 4 hours, and molded to obtain t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com