Process for recovering polyethylene glycol and silicon carbide in waste mortar from silicon wafer wire cutting

A technology of polyethylene glycol and recovery method, applied in chemical instruments and methods, plastic recycling, separation methods, etc., can solve the problems of waste polyethylene glycol, large investment, low recovery rate of polyethylene glycol, etc., and achieve convenient Filtration treatment, the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

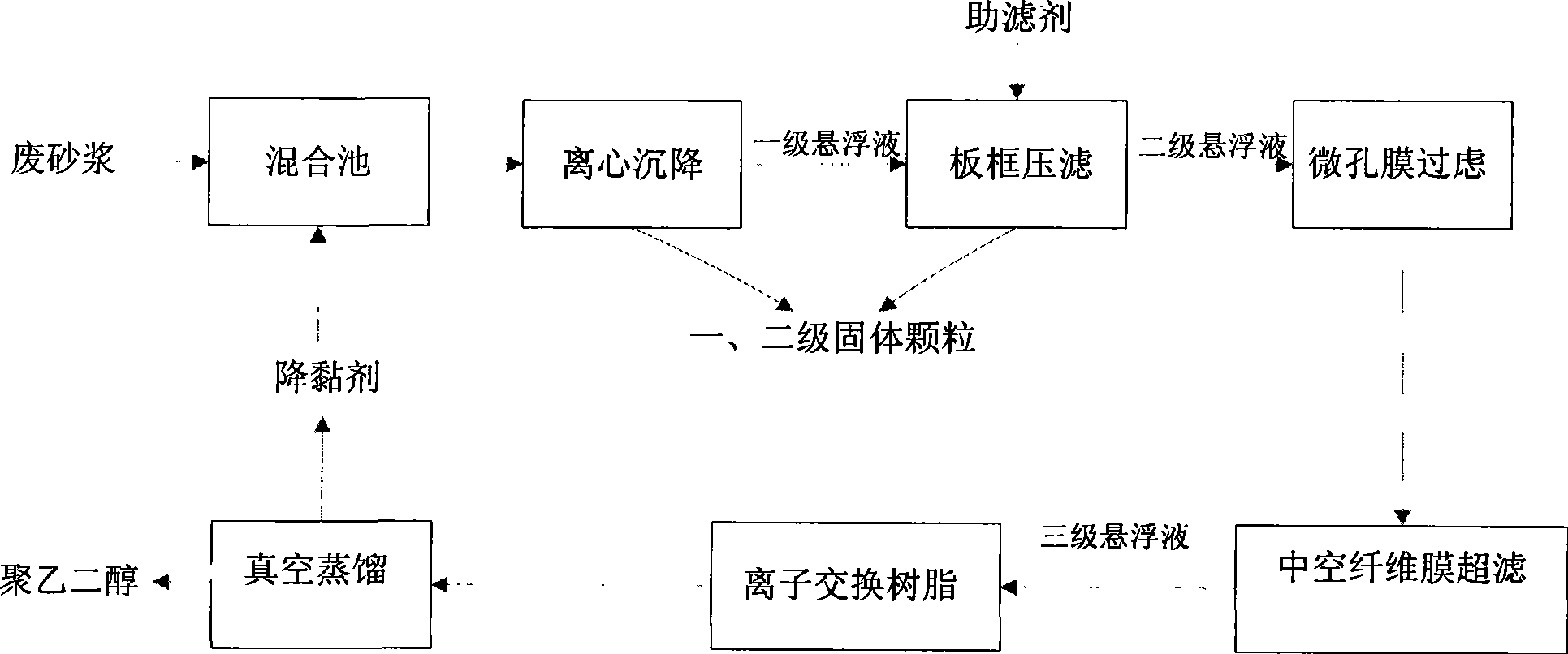

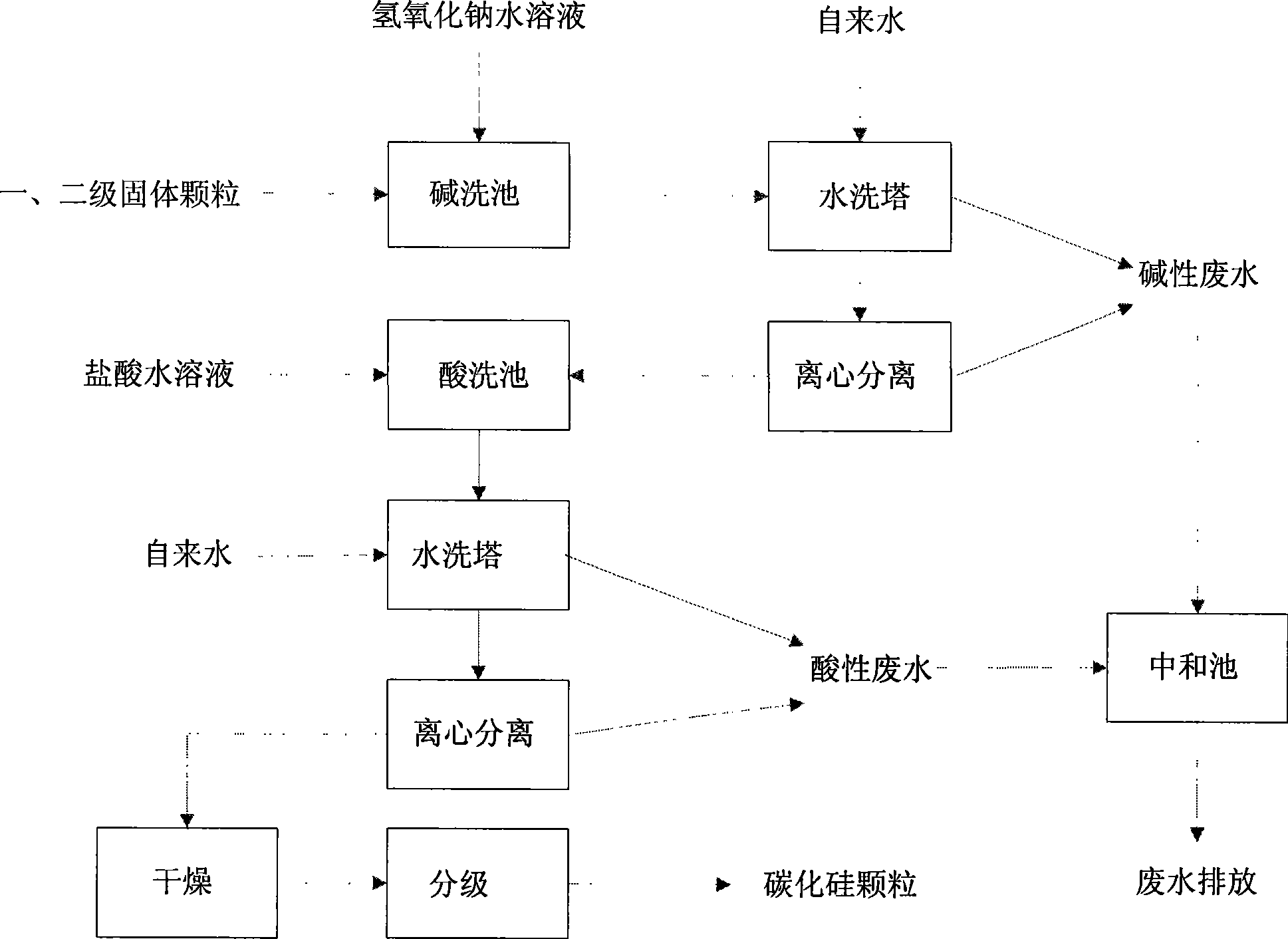

[0037] Utilize the present invention to process the waste mortar after the single and polysilicon slicing process is processed by the multi-wire saw cutting fluid, wherein the mass ratio of silicon carbide and polyethylene glycol suspension is about 1:1, and the specific steps are as follows:

[0038] Step 1, stir the waste mortar, add viscosity reducer - methanol, wherein the volume ratio of viscosity reducer and waste mortar is 3.5:1, and then enter the filter centrifuge for primary solid-liquid separation to obtain primary suspension and primary Grade solid particles;

[0039] Step 2, stirring the primary suspension, adding polyacrylamide, a filter aid with a mass fraction of 2 / 10,000 of the primary suspension, and then passing through a plate and frame filter to obtain secondary suspension and secondary solid particles;

[0040] Step 3, the secondary suspension is sequentially filtered through a microporous membrane with a pore size of 0.18 microns, and a polyethersulfone ...

Embodiment 2

[0043] Utilize the present invention to process the waste mortar after the single and polysilicon slicing process is processed by the multi-wire saw cutting fluid, wherein the mass ratio of silicon carbide and polyethylene glycol suspension is about 1:1, and the specific steps are as follows:

[0044] Step 1, stir the waste mortar, add viscosity reducer - ethanol, wherein the volume ratio of viscosity reducer and waste mortar is 4:1, and then enter the decanter centrifuge for primary solid-liquid separation to obtain primary suspension and primary Grade solid particles;

[0045] Step 2, stirring the primary suspension, adding polyamine, a filter aid with a mass fraction of 2 / 10,000 of the primary suspension, and then passing through a plate and frame filter press to obtain a secondary suspension and secondary solid particles;

[0046] Step 3, the secondary suspension is sequentially filtered through a microporous membrane with a pore size of 0.22 microns, and a polyethersulfon...

Embodiment 3

[0049] Utilize the present invention to process the waste mortar after the single and polysilicon slicing process is processed by the multi-wire saw cutting fluid, wherein the mass ratio of silicon carbide and polyethylene glycol suspension is about 1:1, and the specific steps are as follows:

[0050] Step 1, stir the waste mortar, add viscosity reducer—water, wherein the volume ratio of viscosity reducer to waste mortar is 4.5:1, and then enter the filter centrifuge for primary solid-liquid separation to obtain primary suspension and primary Grade solid particles;

[0051] Step 2, stirring the primary suspension, adding polyvinyl alcohol, a filter aid with a mass fraction of 2 / 10,000 of the primary suspension, and then passing through a vacuum filter to obtain a secondary suspension and secondary solid particles;

[0052] Step 3, the secondary suspension is filtered sequentially through a microporous membrane with a pore size of 0.26 microns, and a polyethersulfone hollow fib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com