Patents

Literature

16622results about "Plastic recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Highly filled polymer composition with improved properties

InactiveUS6362252B1Reduce manufacturing costHigh tensile strengthConductive materialPlastic recyclingPolymer sciencePlasticizer

A highly filled polymer composition with improved properties comprising: a continuous matrix material; a filler material in an amount of 10 to 80 wt. % of said composition; a polymer plasticizer dispersed in said continuous matrix material in an amount of 0.5 to 15 wt. % of said filler; a filler coating material which coats said filler particles in the form of a continuous coating layer thus forming coated filler particles; a diffusion zone around said coated filler particles where said filler coating and said continuous matrix material are mutually diffused into one another wherein said filler coating material is distributed with concentration decreasing in the direction outward from said continuous coating layer. Provided also is a method of preparing the aforementioned composition which guarantees that during extrusion or similar treatment the filler particles are coated with a continuous layer of the filler coating material and that the aforementioned diffusion zone is formed around the coated filler particles. In the manufacture of various products such as pipes, sheets, profiles, etc., the composition of the invention combines high deformation capacity with sufficient strength. Furthermore, the composition of the invention possesses high anticorrosive properties, has low shrinkage, and has high adhesion to metals, wood, plastics, etc.

Owner:NEXT GENERATIONS TECH

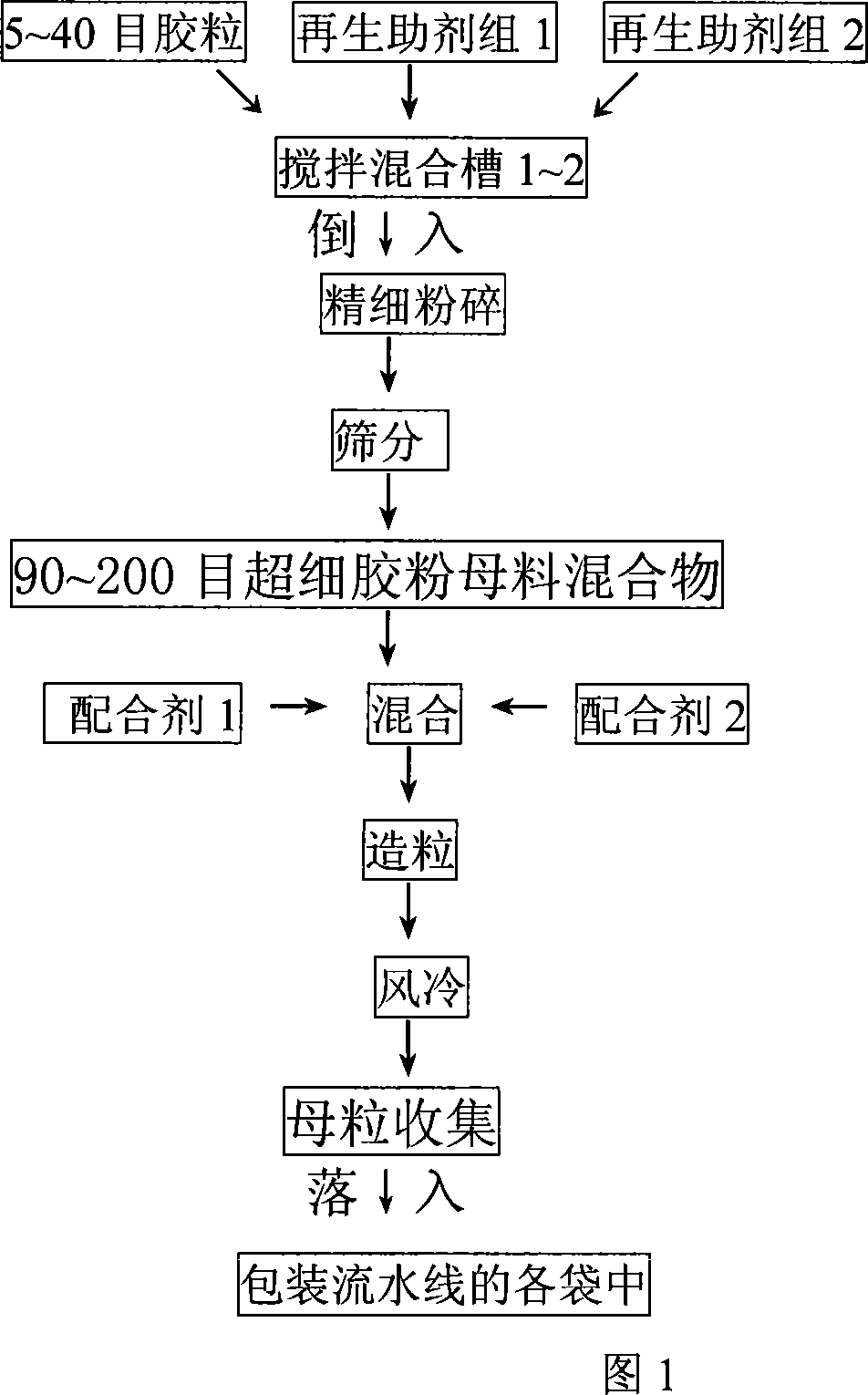

Reproduction new method for waste elastomer and plastic

InactiveCN101041725AThe ratio is roughly constantReduce or eliminate the impact of flow fluctuationsPlastic recyclingElastomerEngineering

The invention discloses a new regenerating method of waste elastics and plastic, which comprises the following steps: 1. blending waste elastics or / and plastic with grain size between 5 and 80 order and non-polluted regenerative adjuvant according to proportion; placing into the manufacturing machine; grinding; sieving; heating to desulfurize; bulking; soaping; emulsifying; kneading; pressing; graining; obtaining composite product 1 with mother material or mother particle or mother gel of plastic elastic powder; 2. weighing product 1 and non-polluted mating agent into mixing machine according to proportion; kneading; blending evenly; pressing; graining; obtaining the product 2 of mother material or mother particle or mother gel with 5-95% waste elastic or / and plastic.

Owner:陈书怡 +1

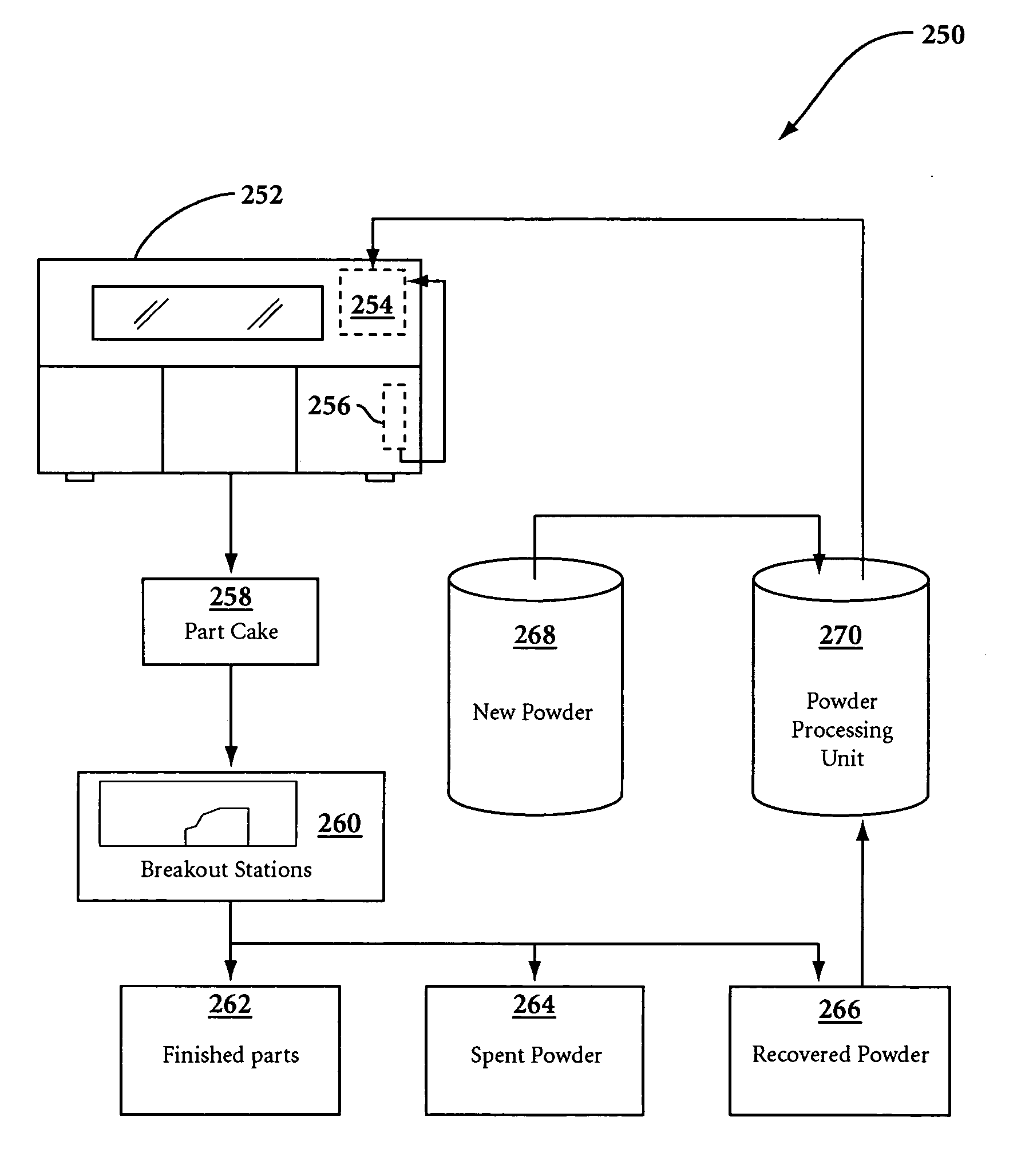

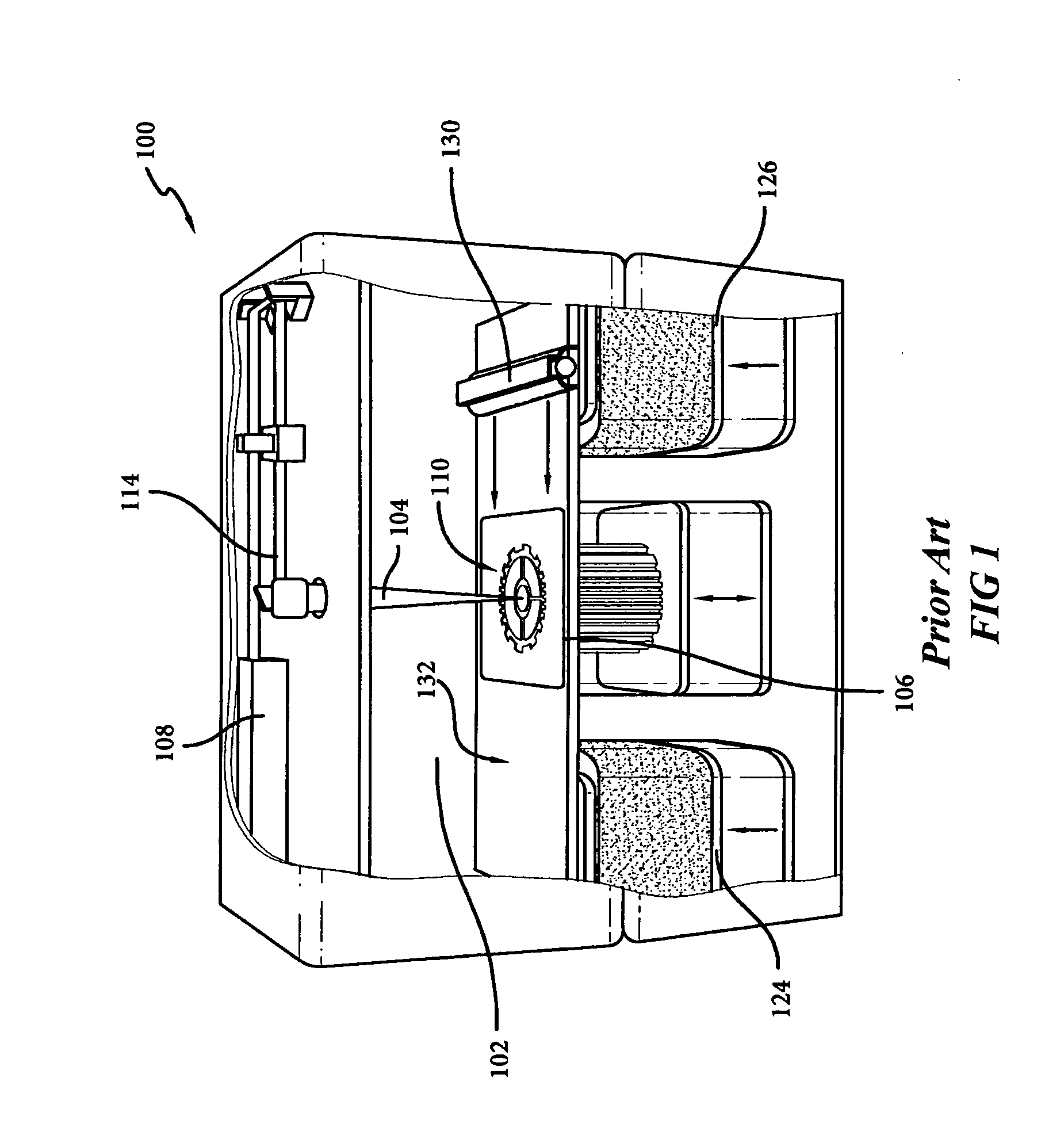

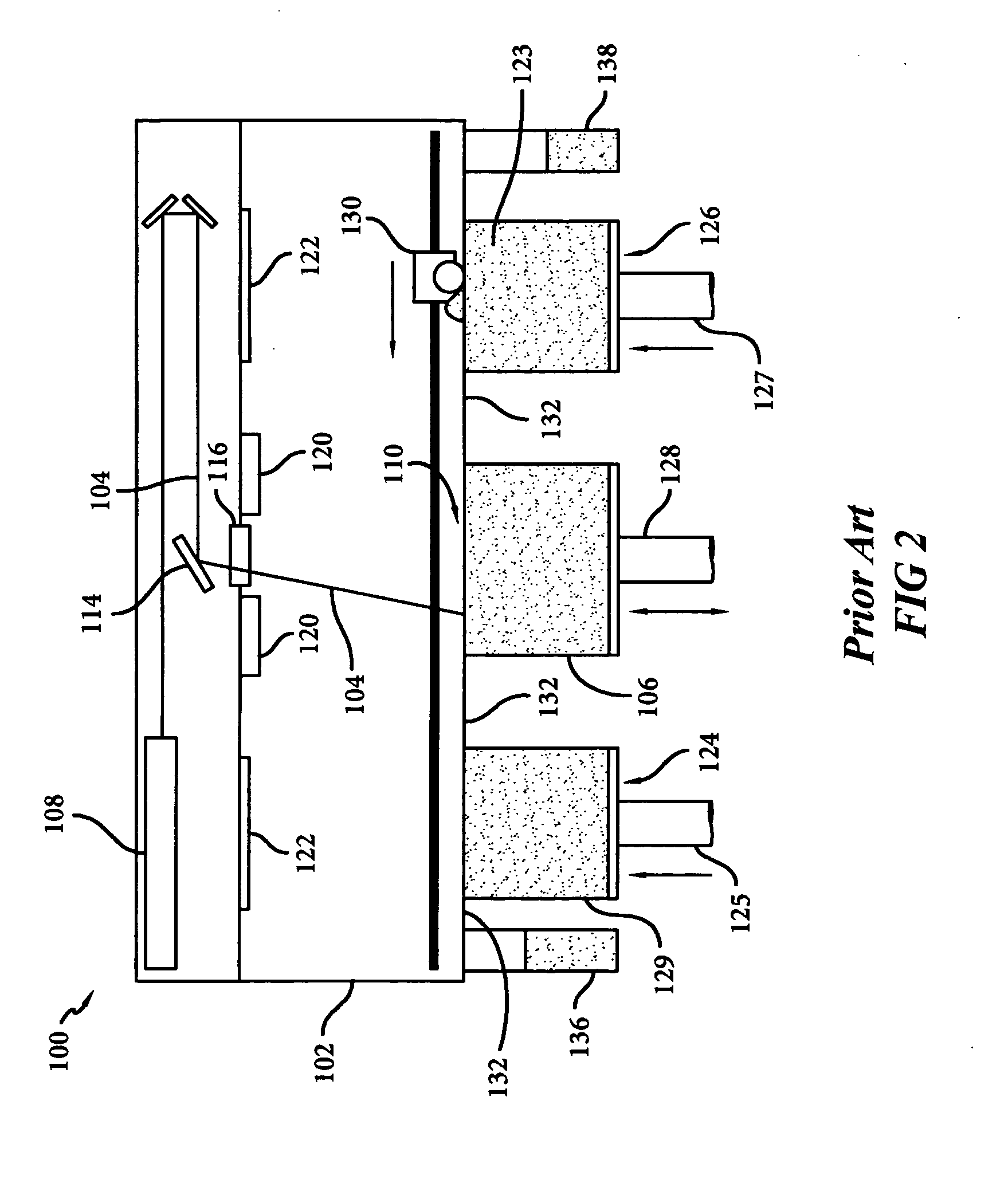

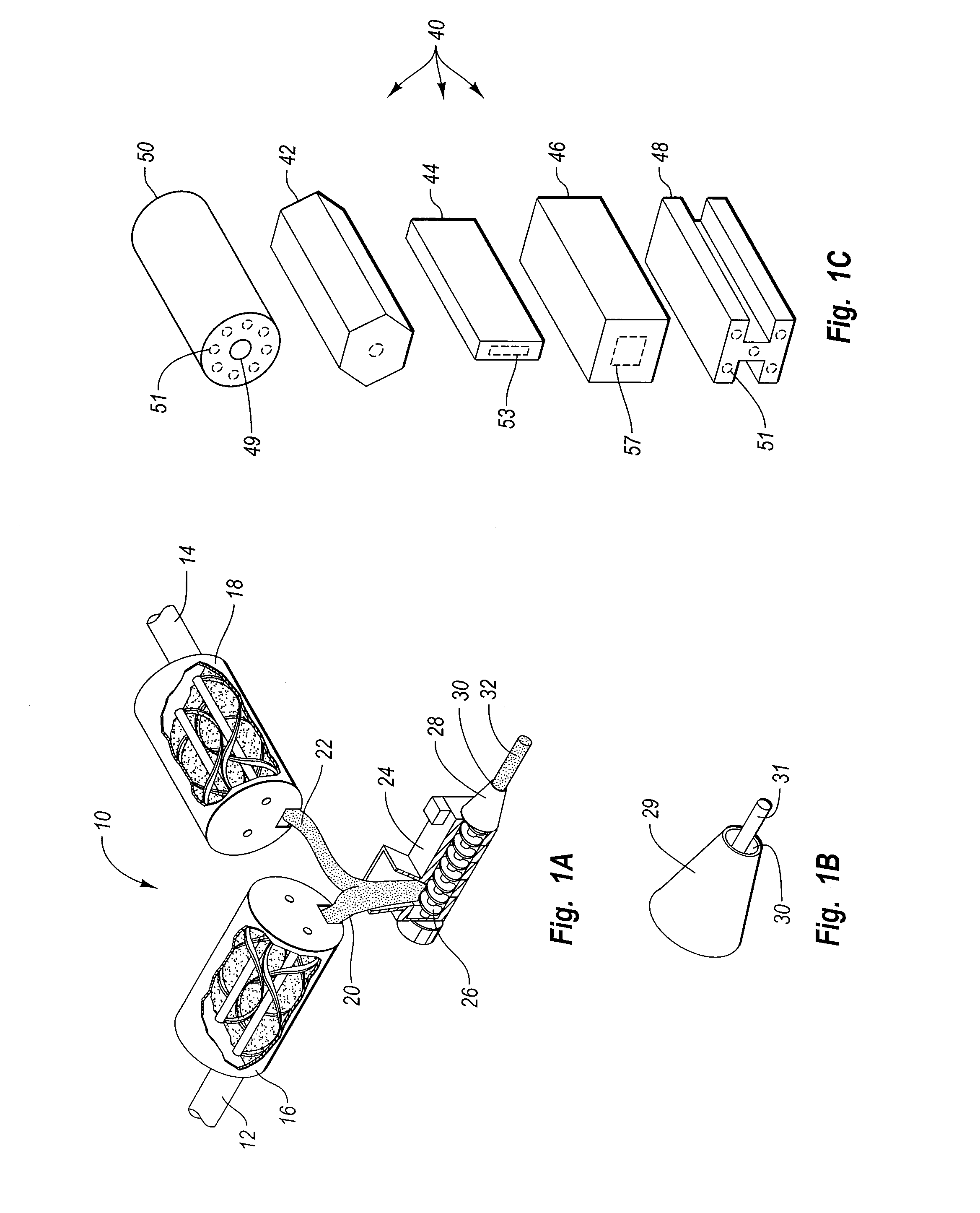

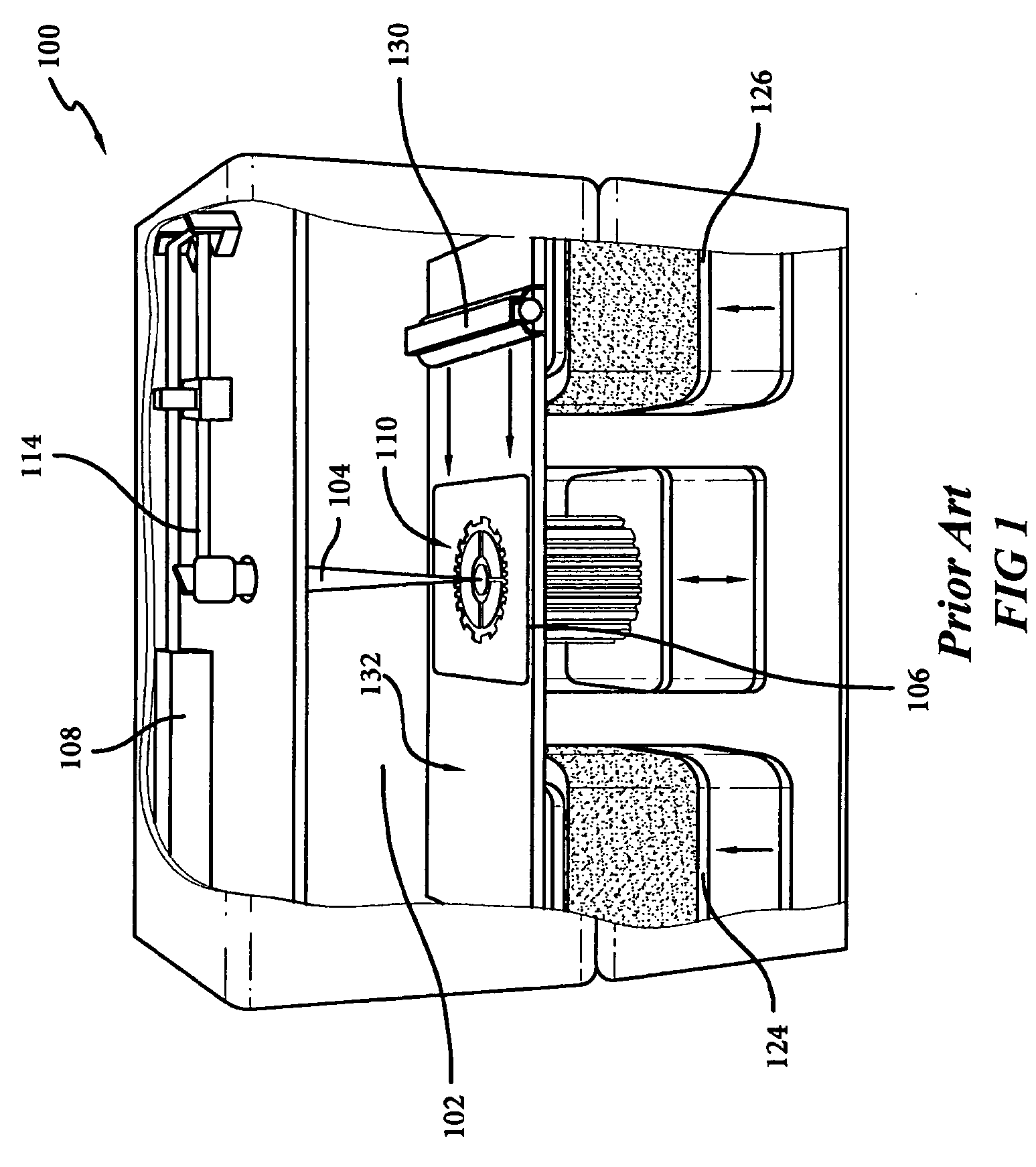

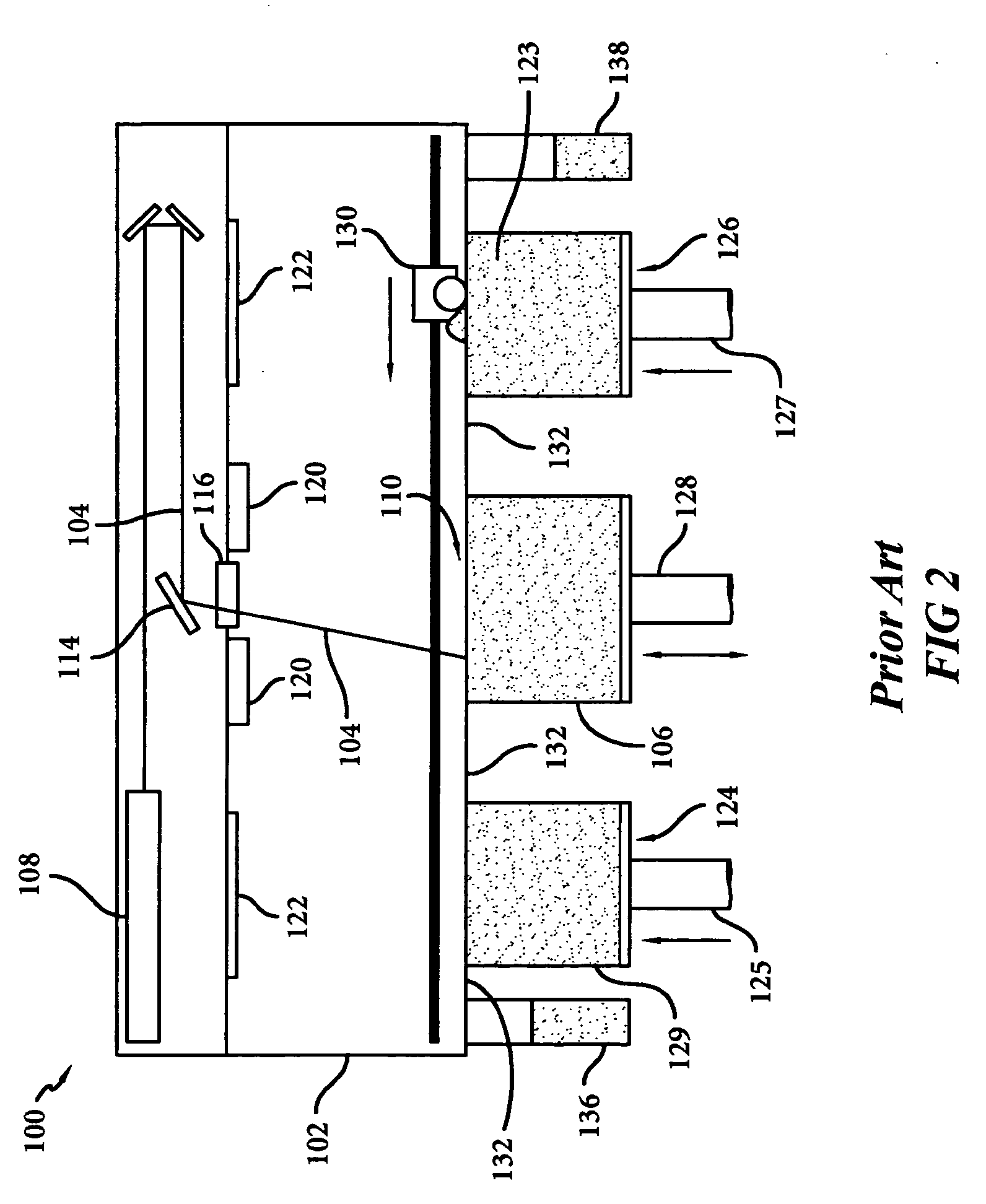

Laser sintering powder recycle system

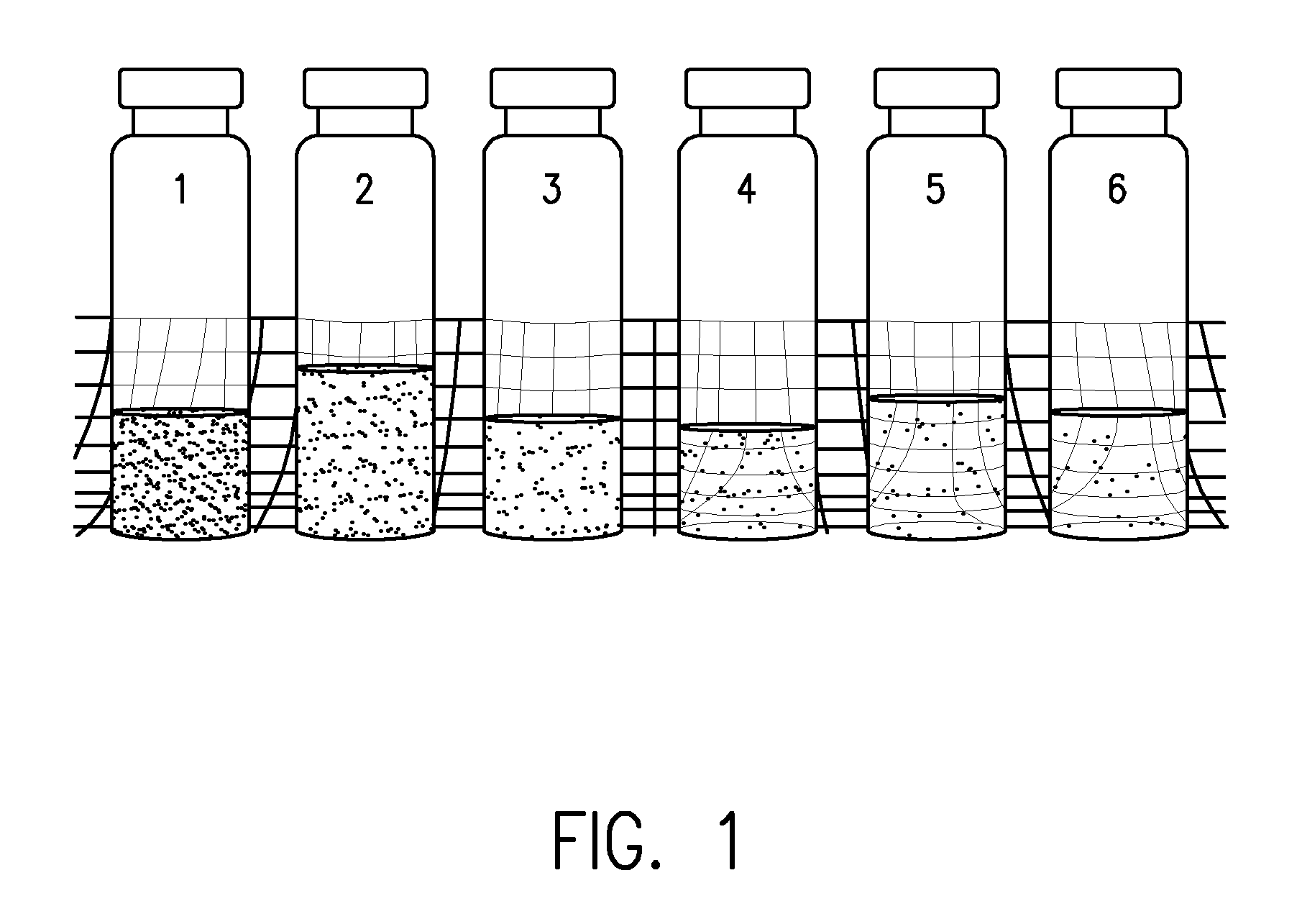

InactiveUS20060214335A1Reduce powder lossGood blendingFlow mixersTransportation and packagingMetallurgyLaser

A method and apparatus for forming three-dimensional objects by laser sintering that includes the use of dense phase pneumatic conveying to internally recycle overflow powder, and to thoroughly blend overflow, recovered and virgin powder to provide a consistent powder feed mix to a laser sintering machine. Overflow powder from the laser sintering machine is recovered and recycled back into the laser sintering machine for reuse. The approach results in a compact and reliable powder recycle system with complete blending and minimum attrition to the handled powder.

Owner:3D SYST INC

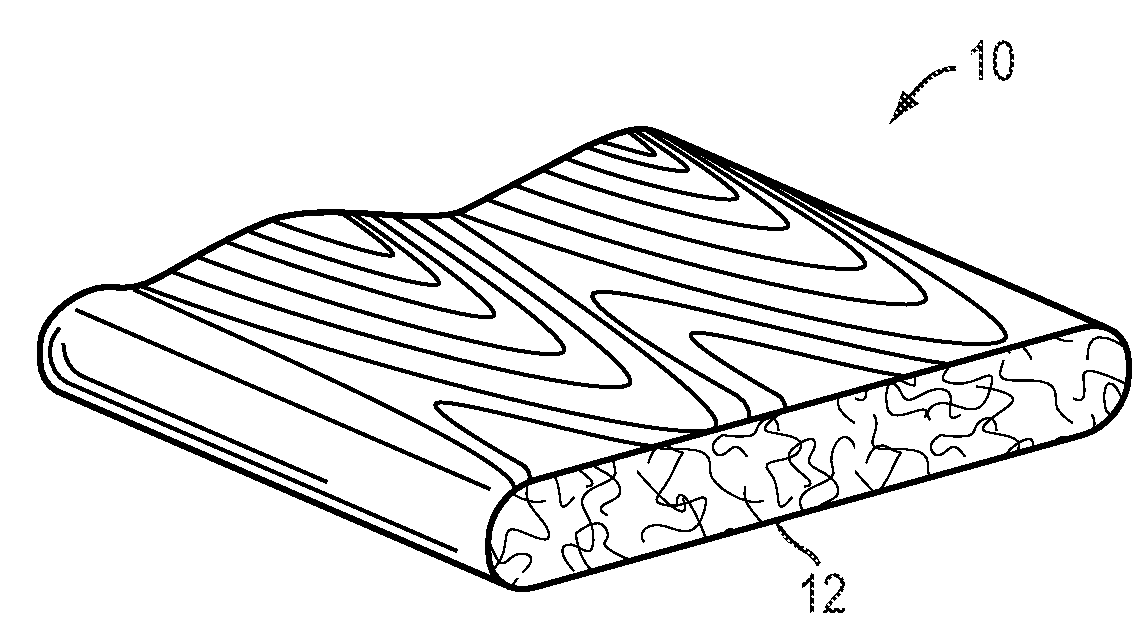

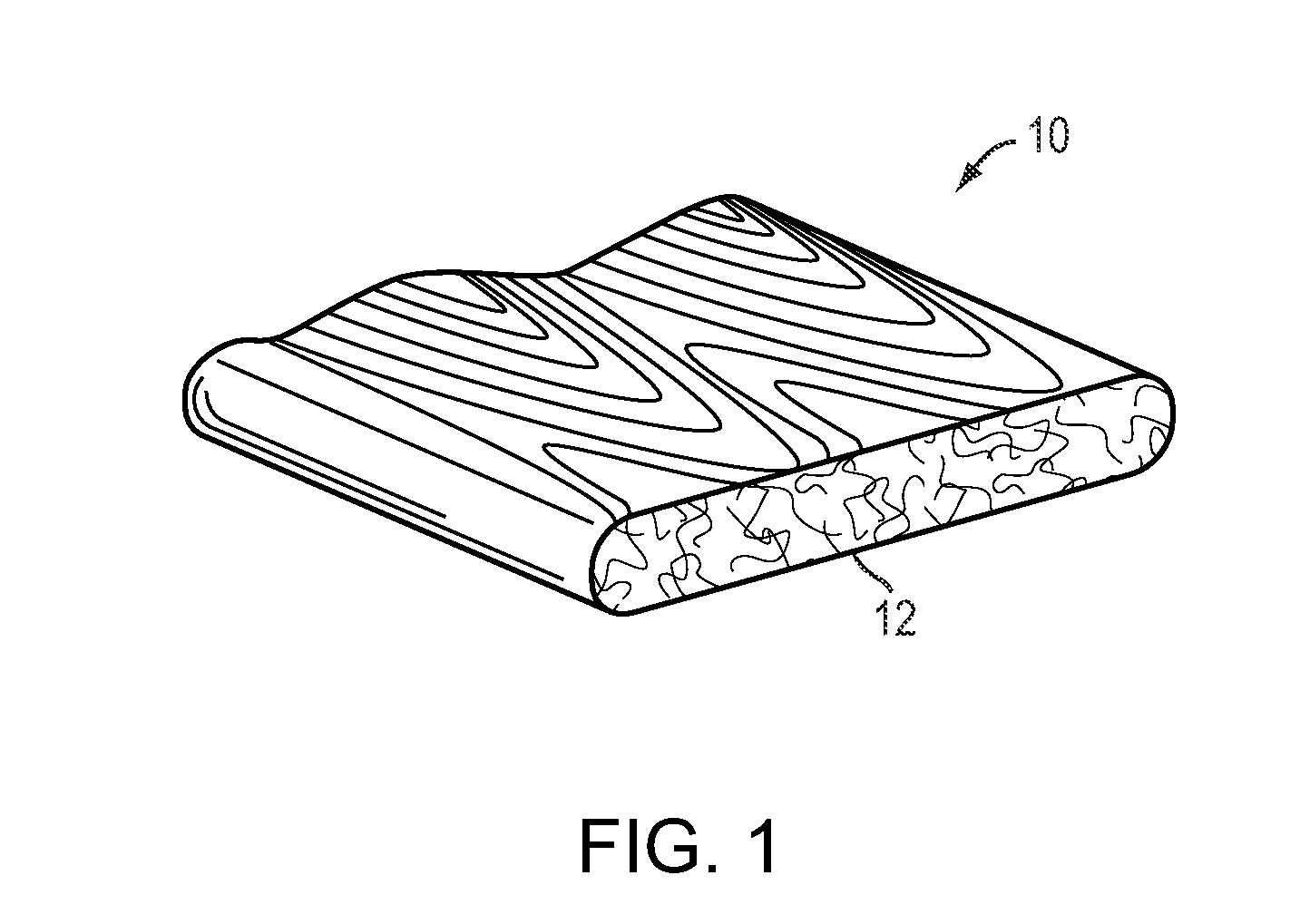

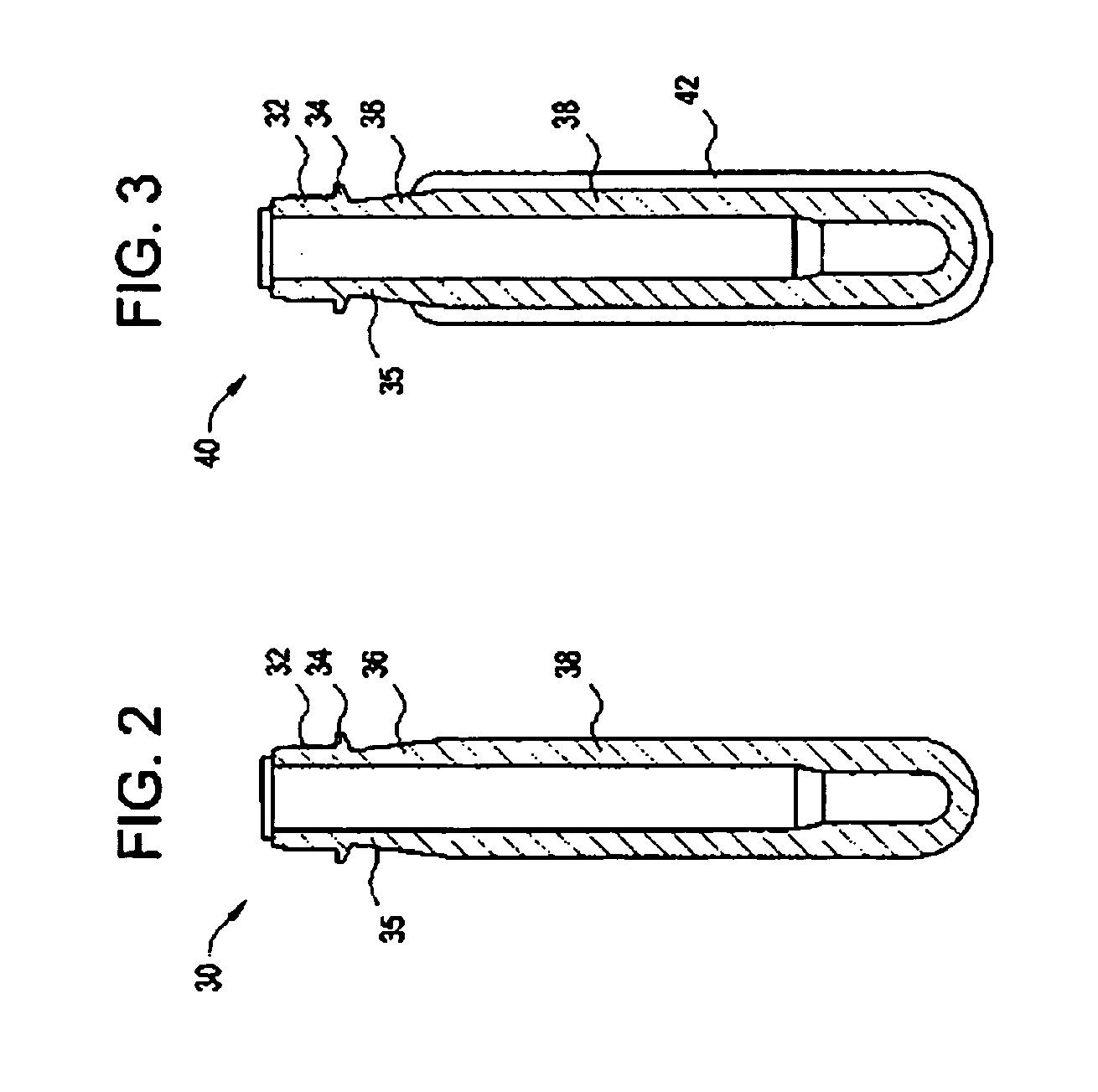

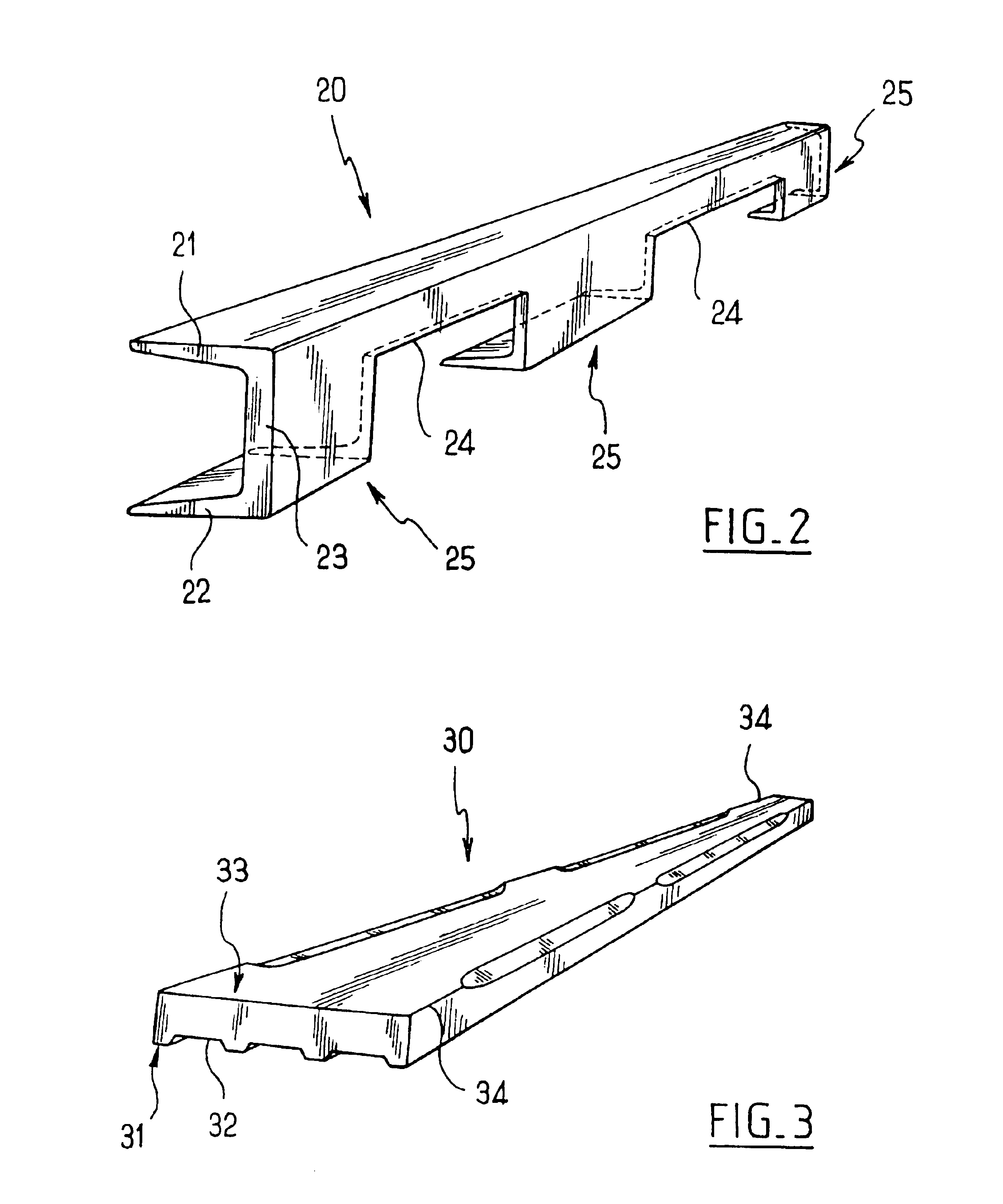

Advanced polymer wood composite

InactiveUS6015611AHigh modulusHigh compressive strengthSynthetic resin layered productsPlastic recyclingWater basedThermoplastic

A composition in the form of pellets comprising a thermoplastic and wood fiber composite material suitable for forming structural members as a replacement for wood in the manufacture of doors and windows. The composite has less than about 10 wt % water based on pellet weight and a Young's modulus of at least about 500,000. Structural members are typically formed from the composite in an extrusion or an injection molding process.

Owner:ANDERSEN CORPORATION

Compositions and composites of cellulosic and lignocellulosic materials and resins, and methods of making the same

Owner:XYLECO INC

Cementitious composites having wood-like properties and methods of manufacture

InactiveUS20080099122A1Harder to saw, nail or screwLow densityPlastic recyclingLaminationPorosityBuilding product

A method of manufacturing a cementitious composite includes: (1) forming mixing an extrudable cementitious composition by first forming a fibrous mixture comprising fibers, water and a rheology modifying agent and then adding hydraulic cement; (2) extruding the extrudable cementitious composition into a green extrudate, wherein the green extrudate is characterized by being form-stable and retaining substantially a predefined cross-sectional shape; (3) removing a portion of the water by evaporation to reduce density and increase porosity; and (4) causing or allowing the hydraulic cement to hydrate to form the cementitious composite. Such a process yields a cementitious composite that is suitable for use as a wood substitute. The wood-like building products can be sawed, nailed and screwed like ordinary wood.

Owner:E KHASHOGGI INDS

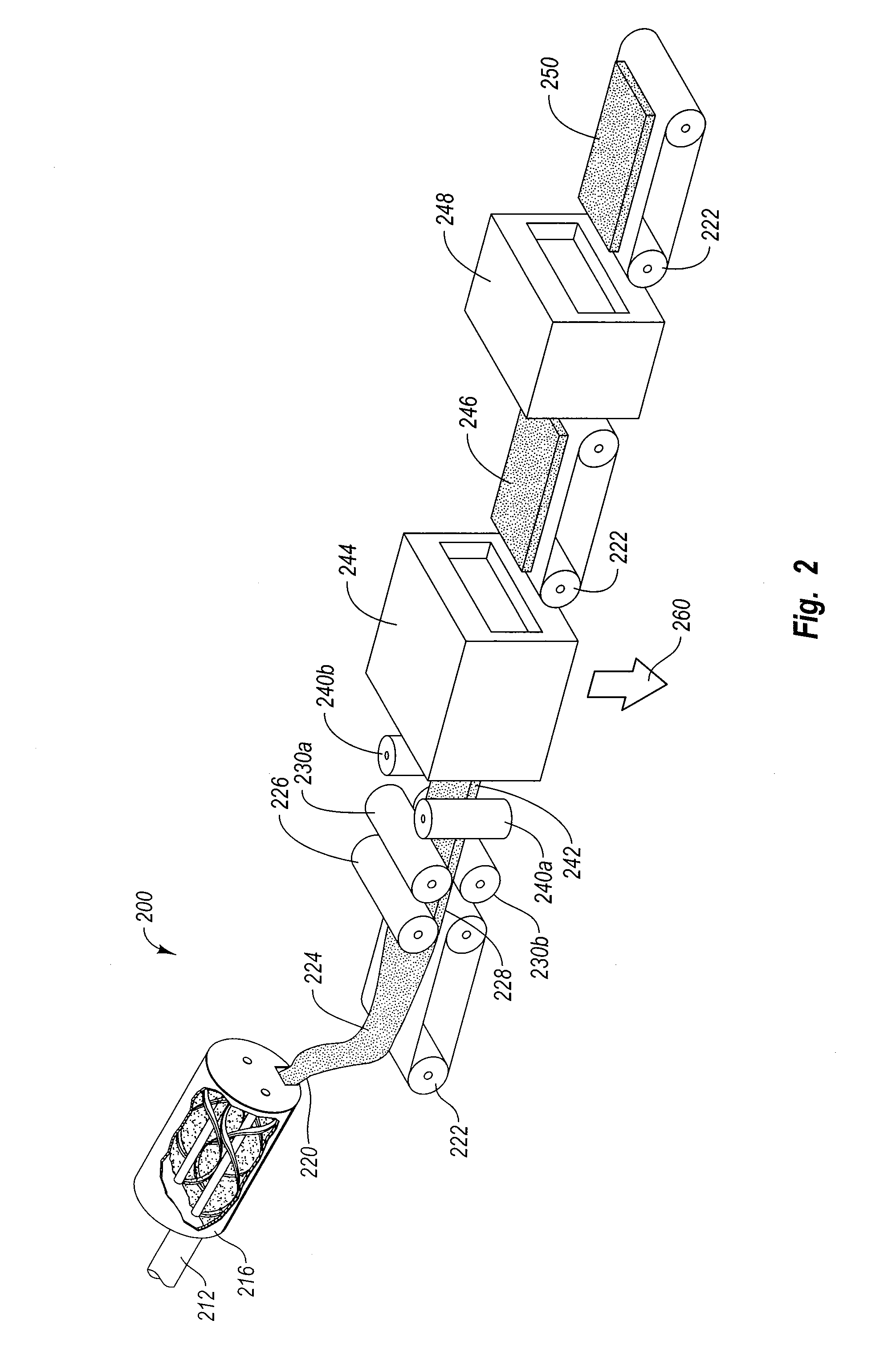

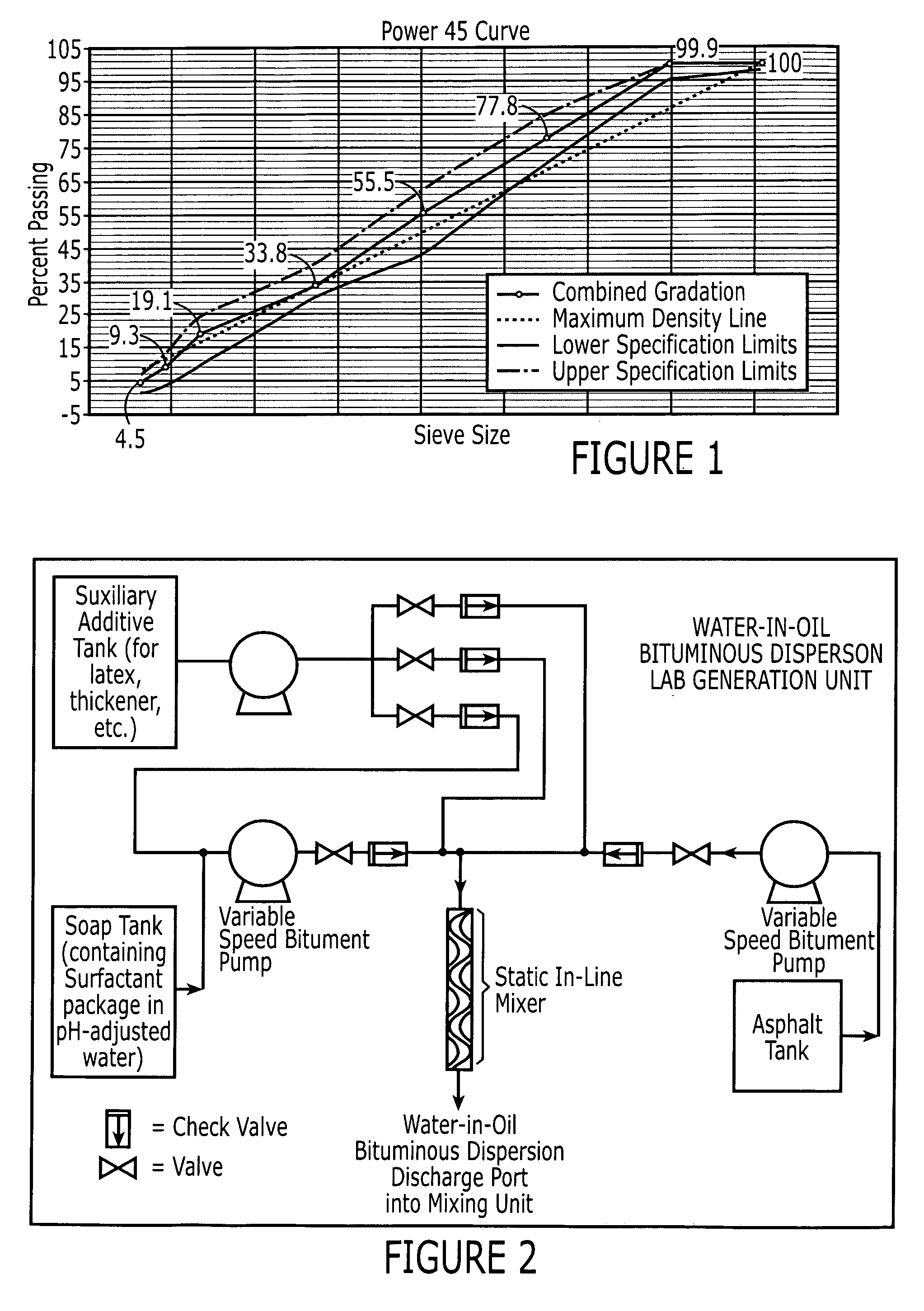

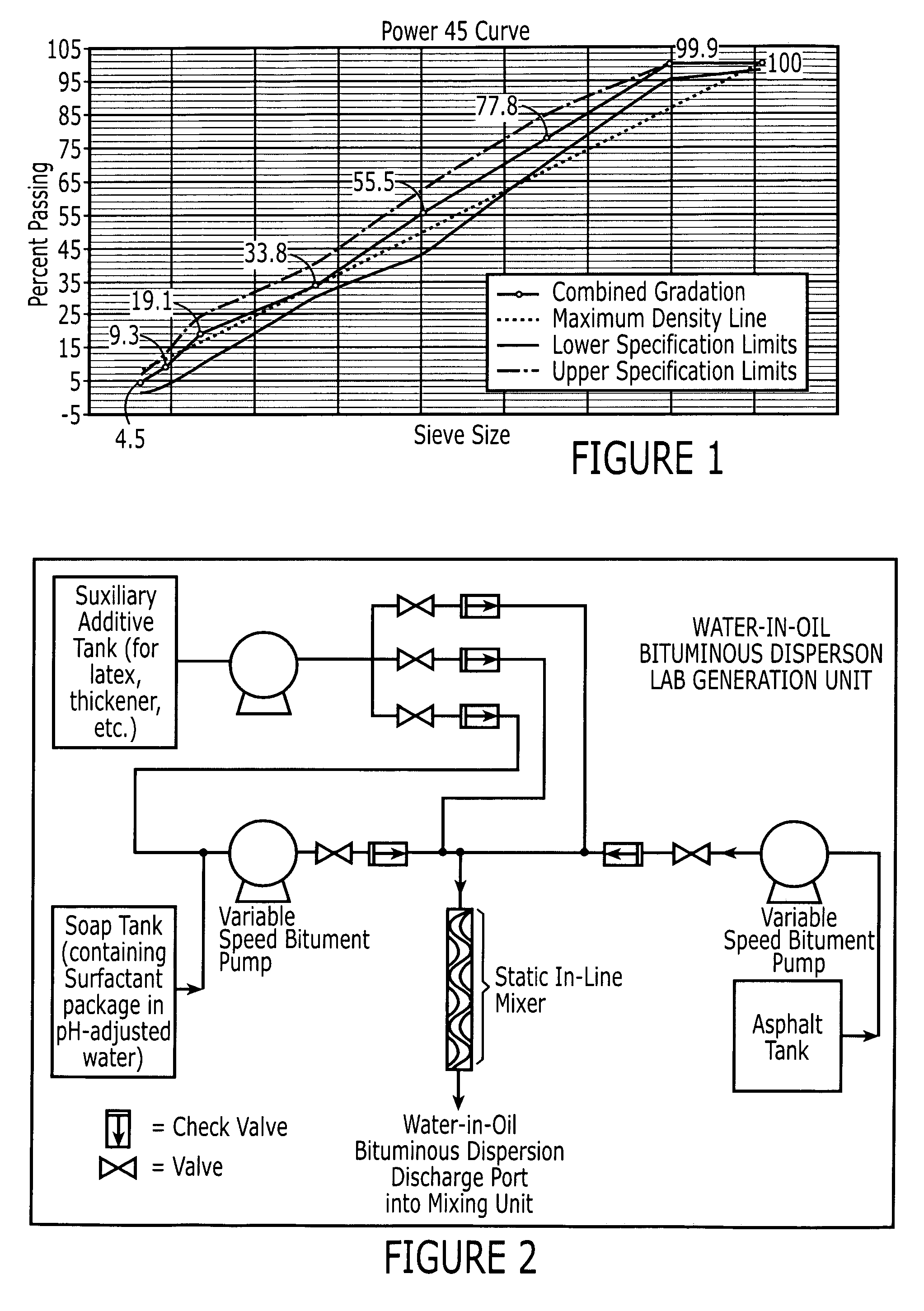

Water-in-oil bituminous dispersions and methods for producing paving compositions from the same

ActiveUS20070082983A1Low viscosityAccelerated strength developmentProductsIn situ pavingsSolvent freeSURFACTANT BLEND

There is provided a method for making bituminous compositions comprising water-in-oil bituminous dispersion and aggregate by the steps of: preparing a solvent-free, water-in-oil bituminous dispersion comprising: (1) bitumen, in an amount from about 75.0% to about 95.0% by total weight of the bitumen dispersion; (2) a surfactant in an amount from about 0.05% to about 2.0% by total weight of the bitumen dispersion; and (3) water in an amount to complete the water-in-oil bituminous dispersion, and producing the bituminous composition having a temperature from about 50° C. to about 120° C. by mixing: (1) the water-in-oil bituminous dispersion of step (A), having a temperature from about 75° C. to about 95° C., in an amount from about 2.0% to about 10.0% by total weight of the bituminous composition, and (2) aggregate, having a temperature from about 60° C. to about 140° C., in an amount from about 90.0% to about 98.0% by total weight of the bituminous composition.

Owner:INGEVITY SOUTH CAROLINA

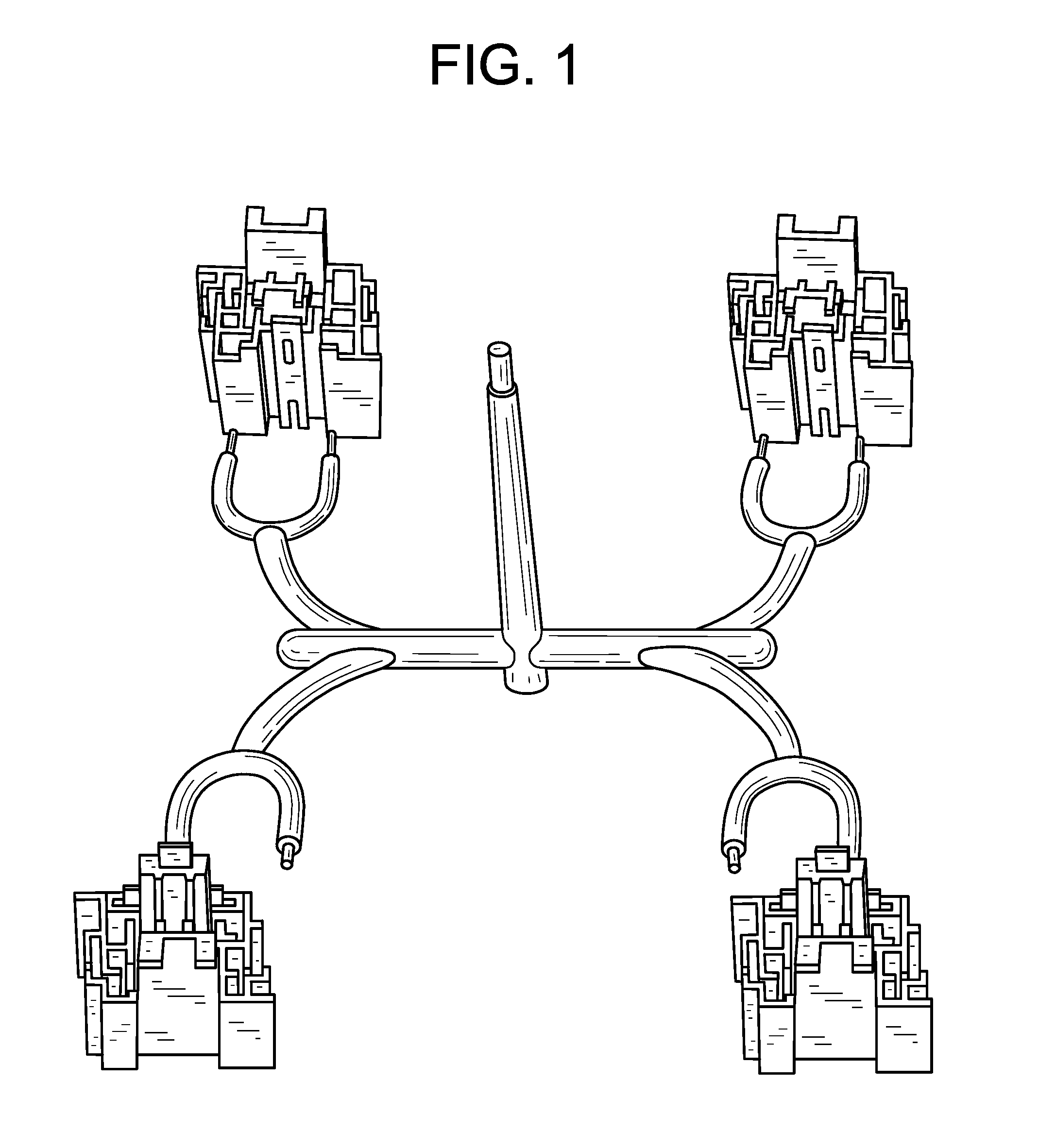

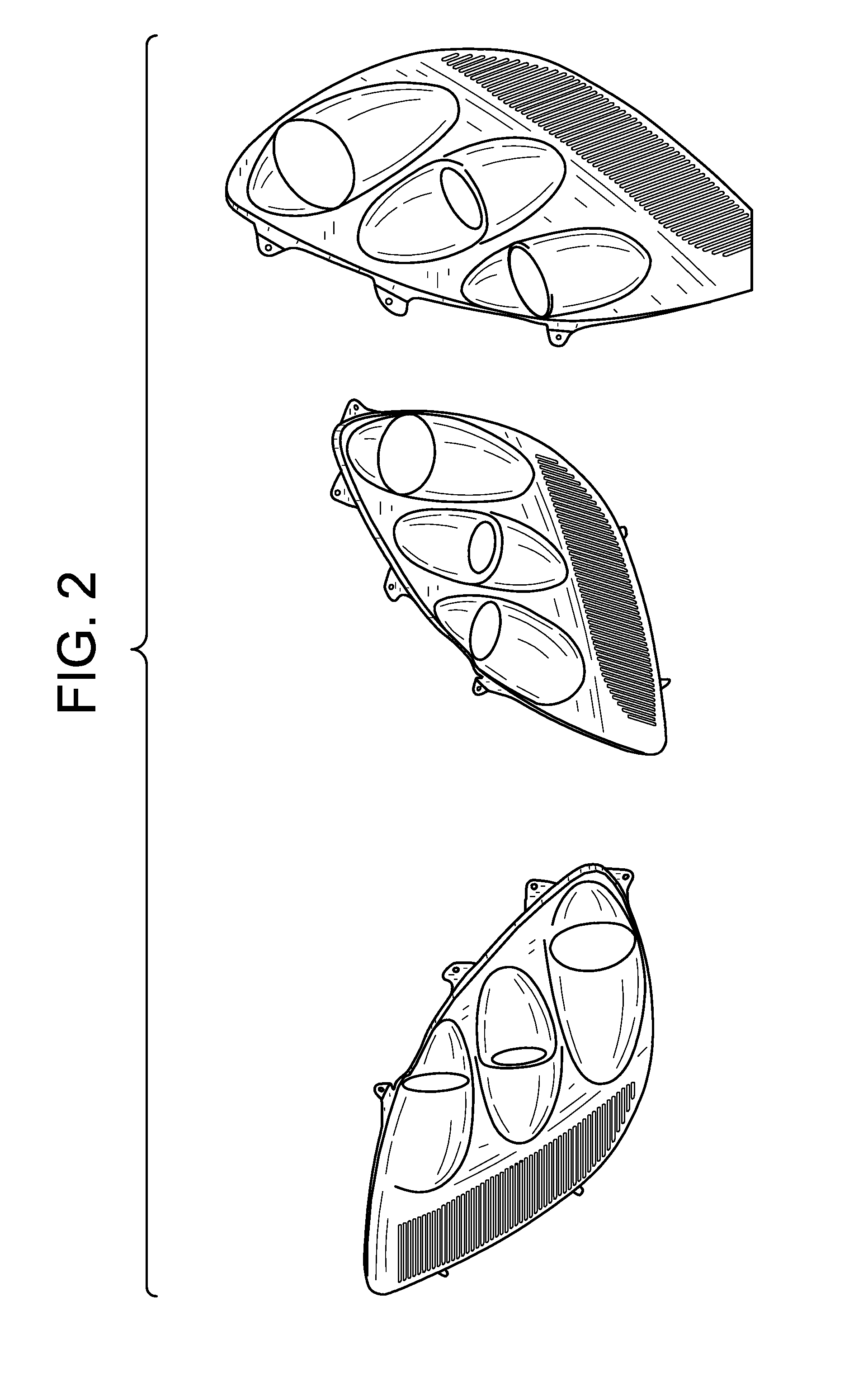

Articles derived from compositions containing modified polybutylene terephthalate (PBT) random copolymers derived from polyethylene terephthalate (PET)

ActiveUS20070275242A1Useful performance propertyPlastic recyclingSpecial tyresPolytetramethylene terephthalatePolyethylene terephthalate glycol

Compositions of matter including articles derived from (a) from 5 to 99.99 wt % of a modified polybutylene terephthalate random copolymer that (1) is derived from polyethylene terephthalate and (2) contains a at least one residue derived from polyethylene terephthalate selected from the group consisting of antimony, germanium, diethylene glycol groups, isophthalic acid groups, cis isomer of cyclohexane dimethanol, trans isomer of cyclohexane dimethanol, sodium benzoate, alkali salts, napthalane dicarboxylic acids, 1,3-propane diols, cobalt, cobalt-containing compounds, and combinations thereof, and (b) from 0.01 to 95 wt. % of a member selected from the group consisting of (1) fillers, (2) a carboxy reactive component, (3) polyethyelene terephthalate, (4) a component including a polycarbonate and an impact modifier. The articles may be derived from various conversion processes, e.g., injection molding processes, extrusion processes, thermoforming processes, melt-blown process.

Owner:SHPP GLOBAL TECH BV

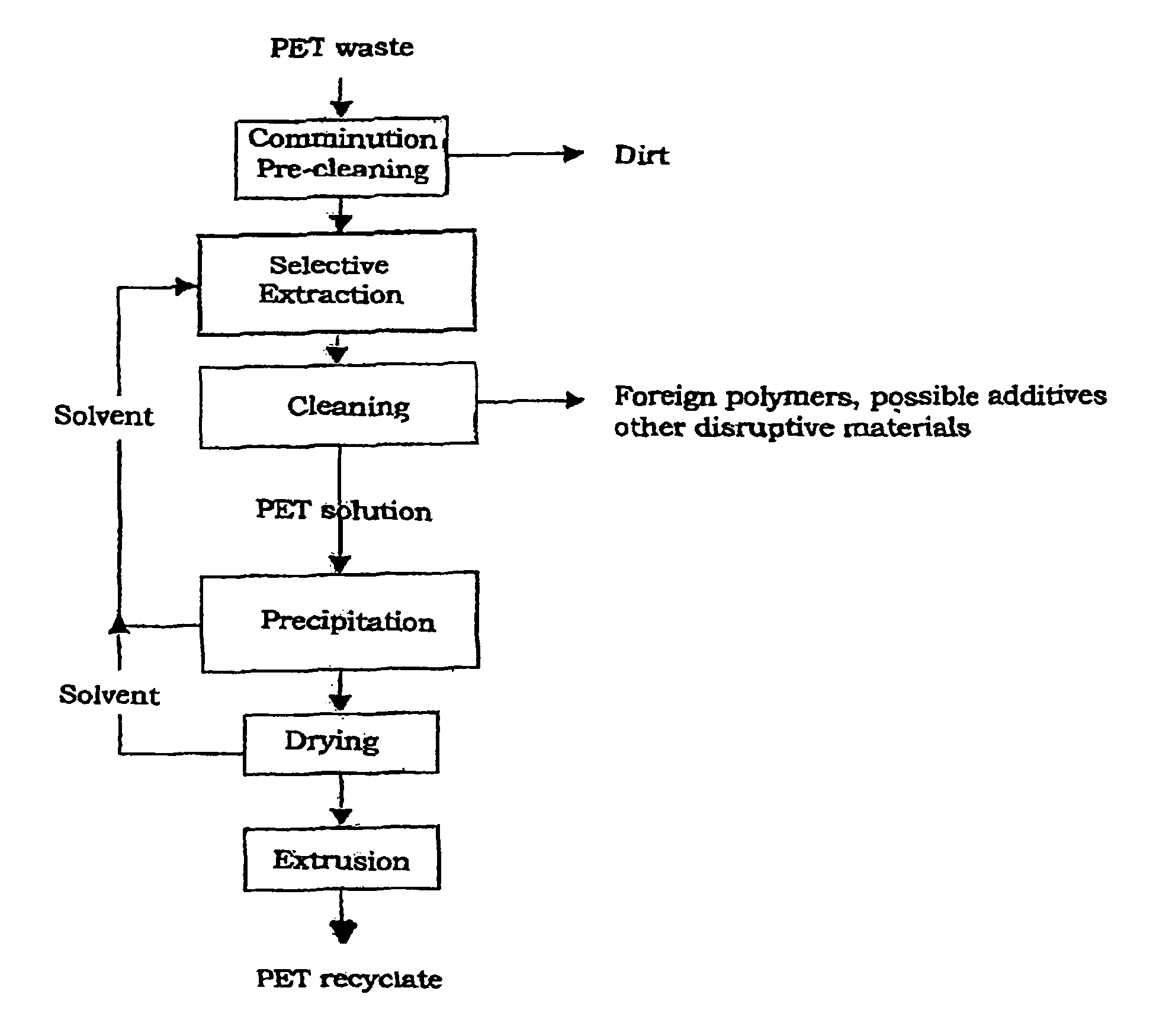

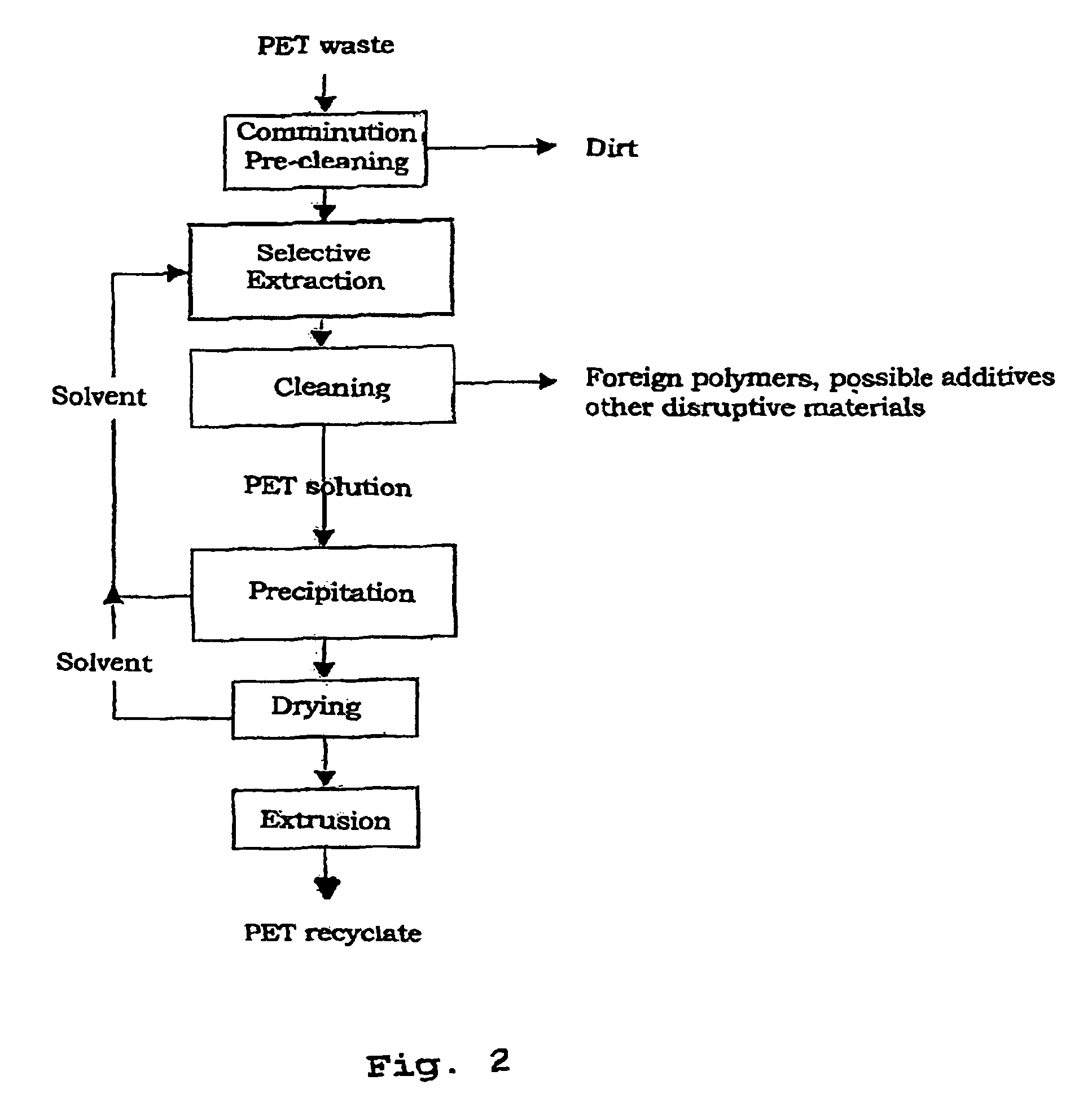

Method for recycling polyesters or polyester mixtures from polyester-containing waste

The invention relates to a method for recycling polyesters or polyester mixtures from polyester-containing waste, in which the polyester or the polyester mixture is dissolved in a solvent and subsequently free-flowing particles are precipitated herefrom with a precipitant. The precipitant is thereby chosen such that subsequent separation of precipitant and solvent is made possible in a simple manner.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

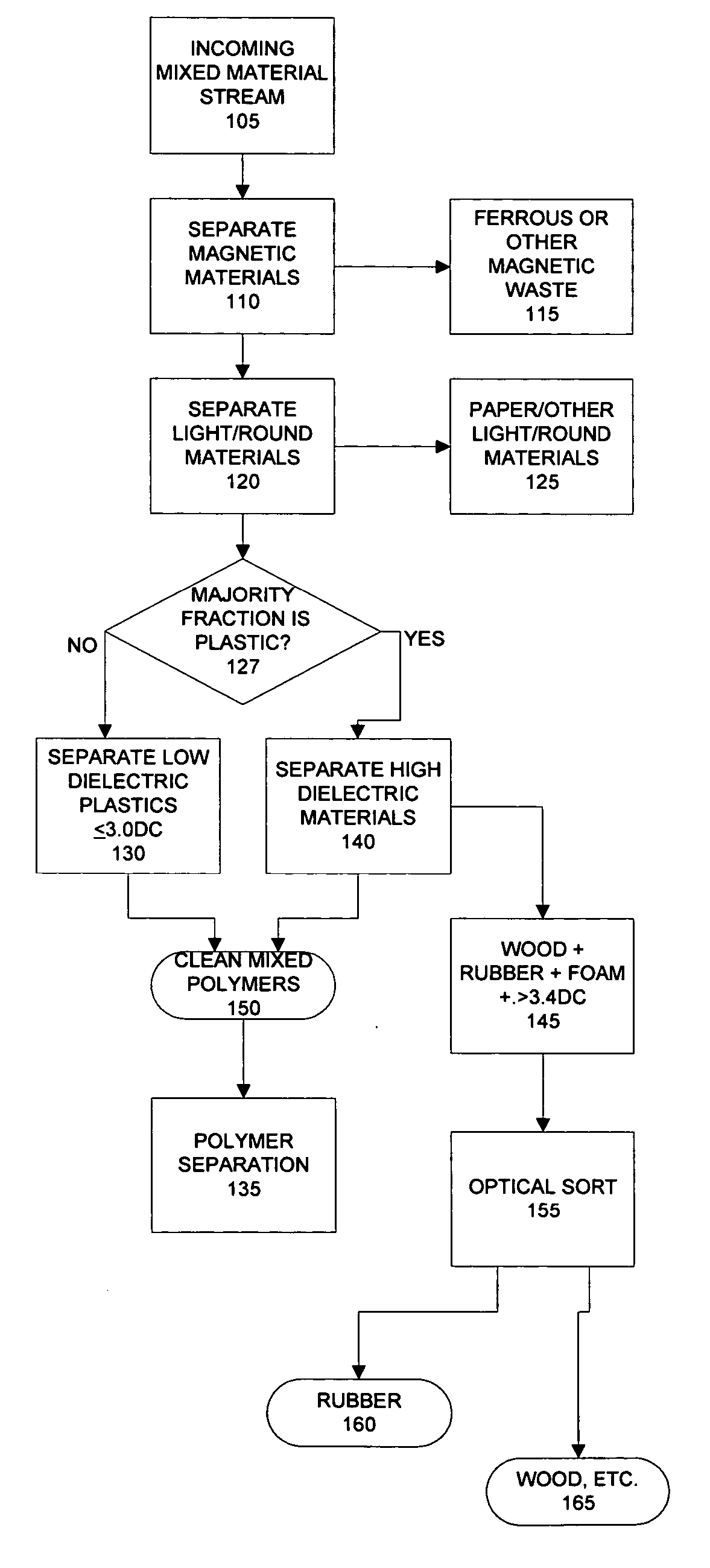

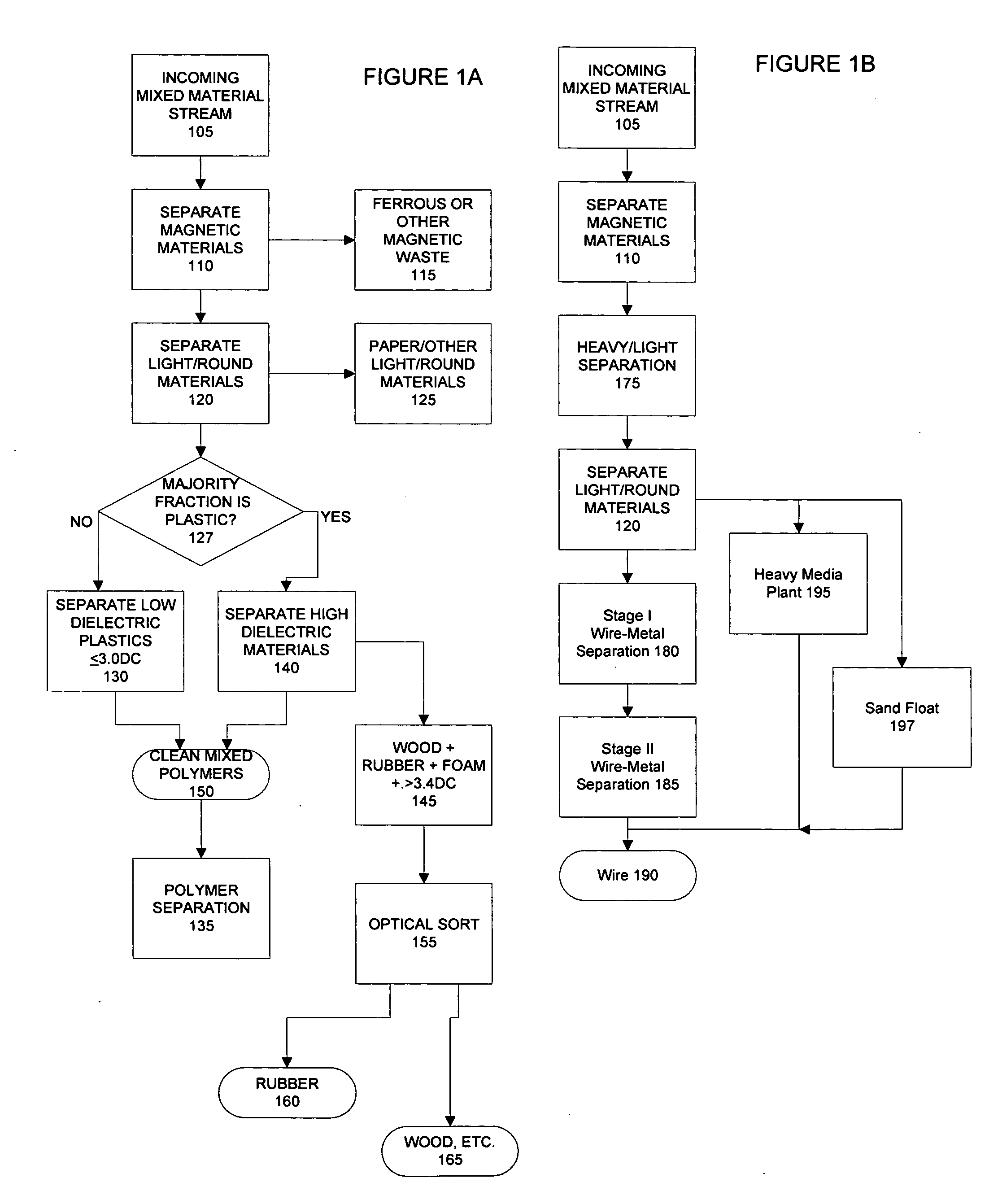

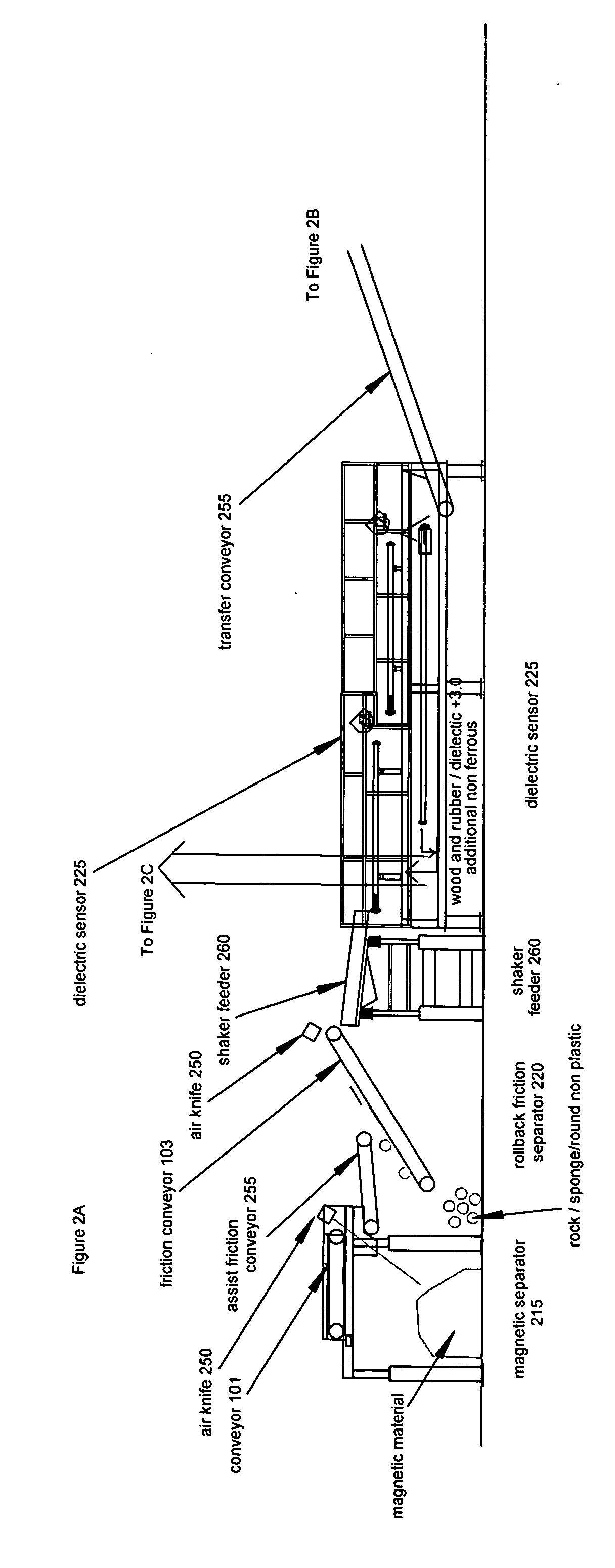

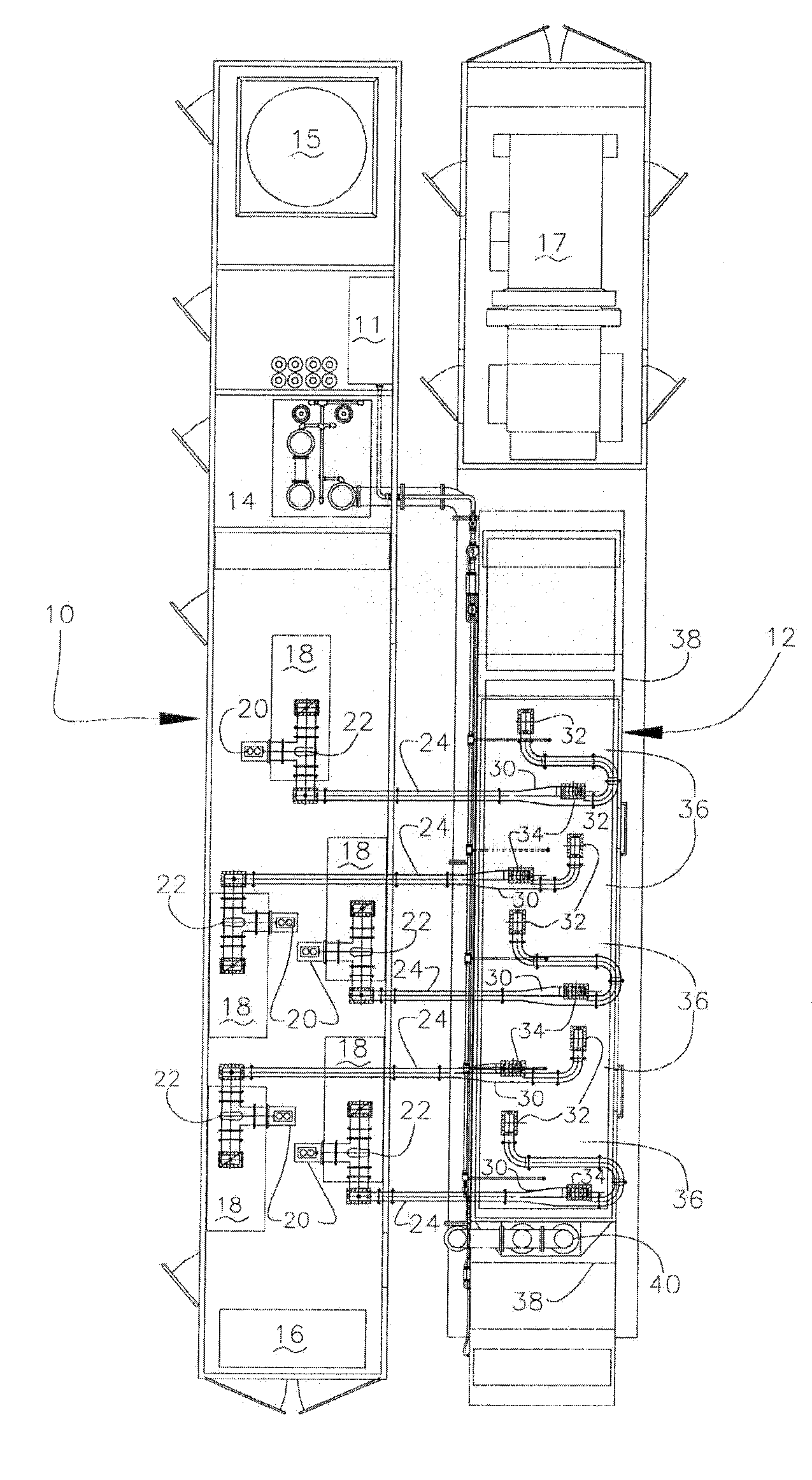

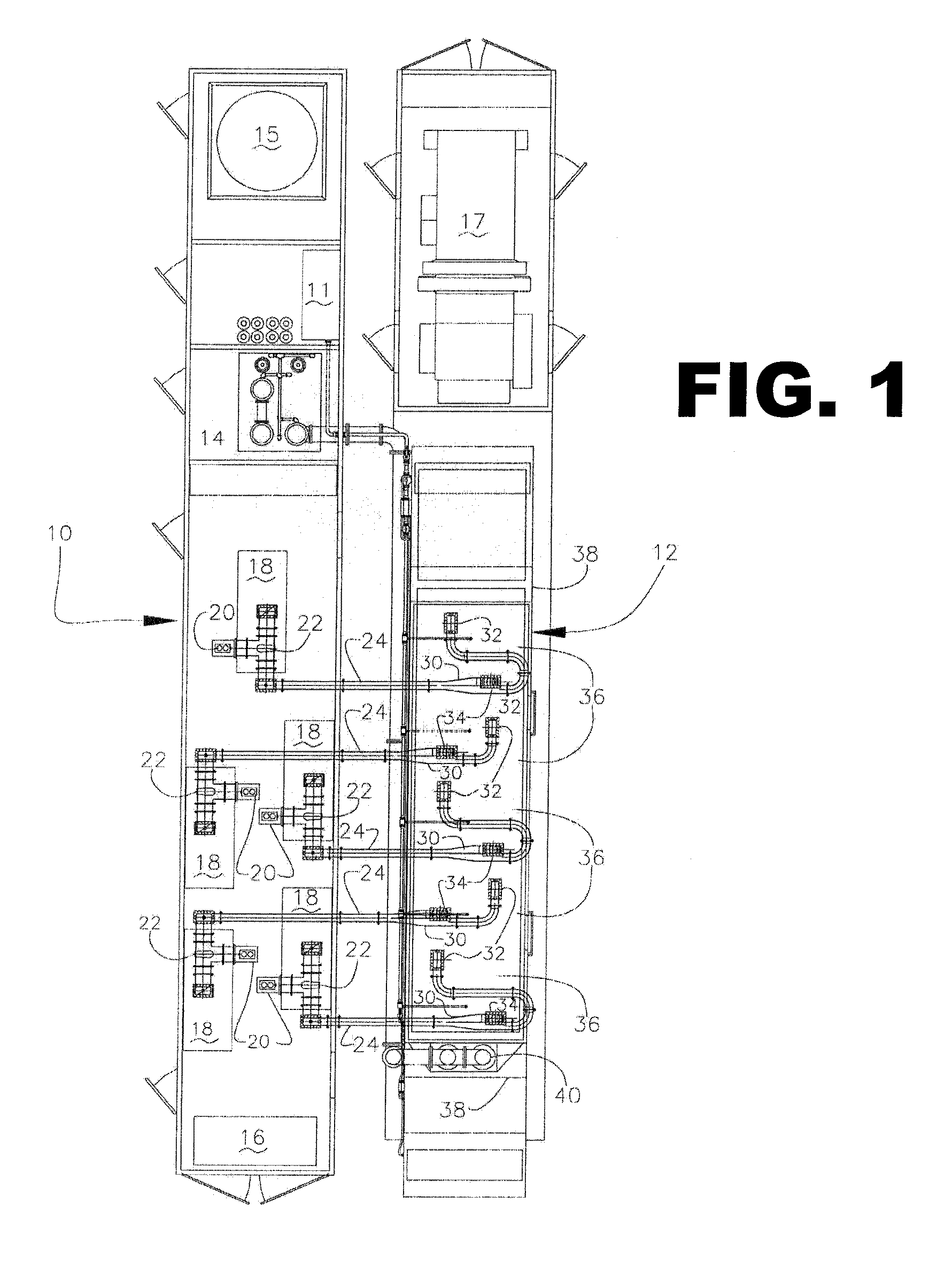

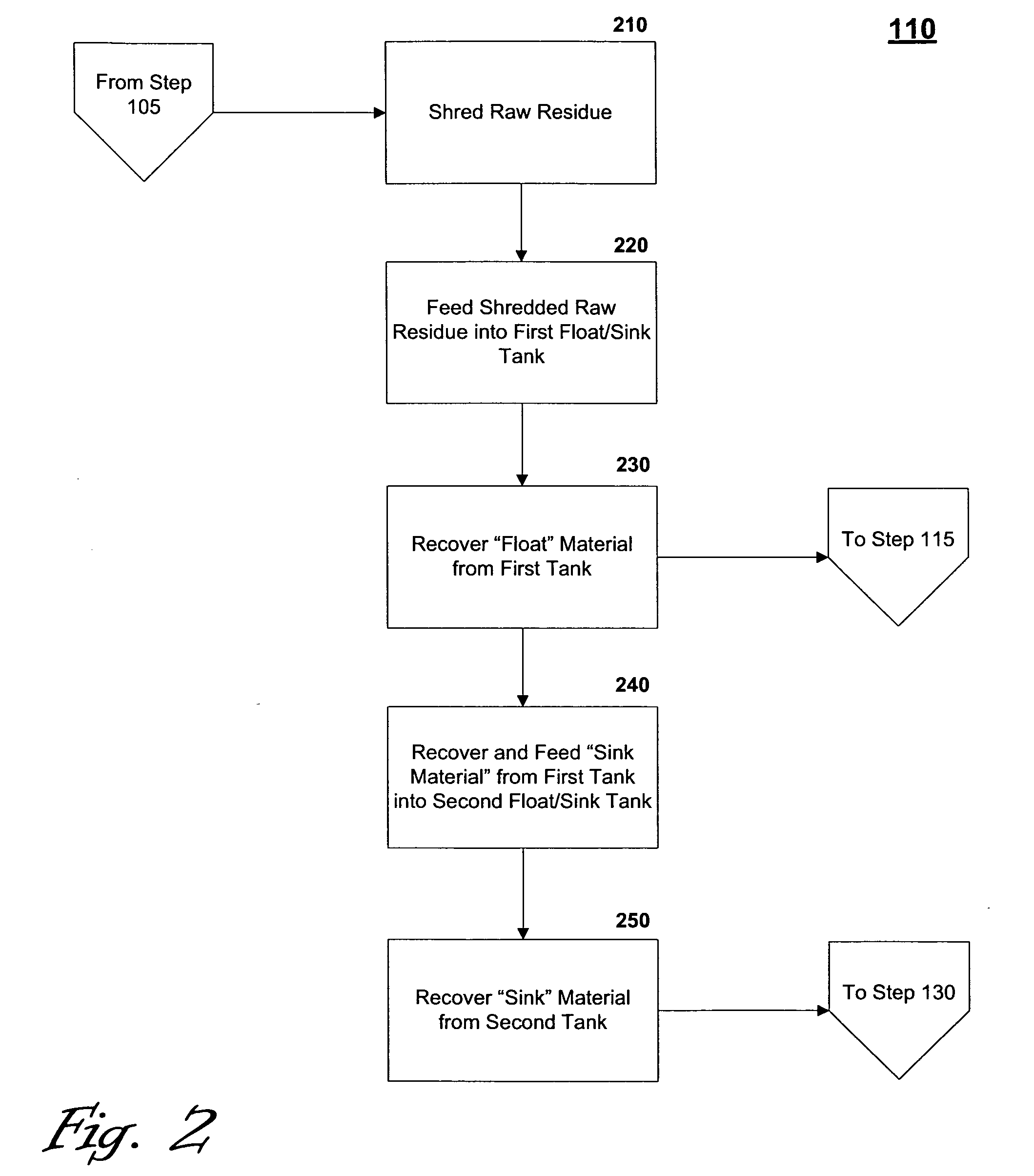

Dissimilar materials sorting process, system and apparata

InactiveUS20070187299A1Improve uniformityUnified operationGas current separationSolid waste disposalElectricityMagnetic separator

An automated system for sorting dissimilar materials, and in particular for sorting plastics from other materials and for sorting different types of plastics from one another comprises, depending upon the embodiment, combinations of a sizing mechanism, a friction separation, an air separator, a magnetic separator, a dielectric sensor sortation bed, shaker screening, a ballistic separator, an inductive sensor sortation system and a float / sink tank. The dielectric sensor sortation system may be either analog or digital, depending upon the particular implementation. One or more float / sink tanks can be used, depending upon the embodiment, each with a media of a different specific gravity. The media may be water, or water plus a compound such as calcium chloride. In addition, multiples of the same general type of module can be used for particular configurations. A heavy media system or a sand float process can be used either alternatively or additionally.

Owner:VALERIO THOMAS A

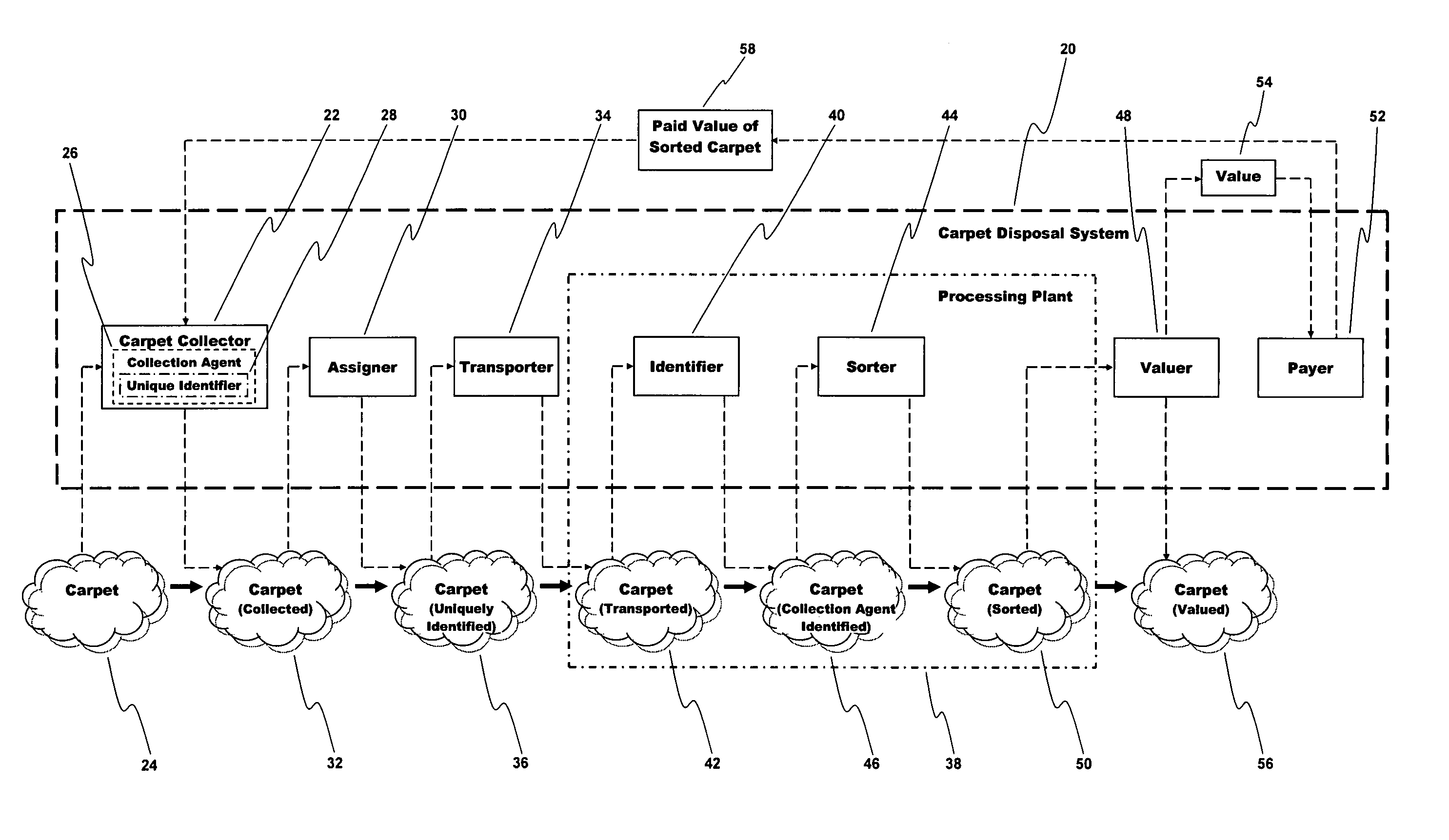

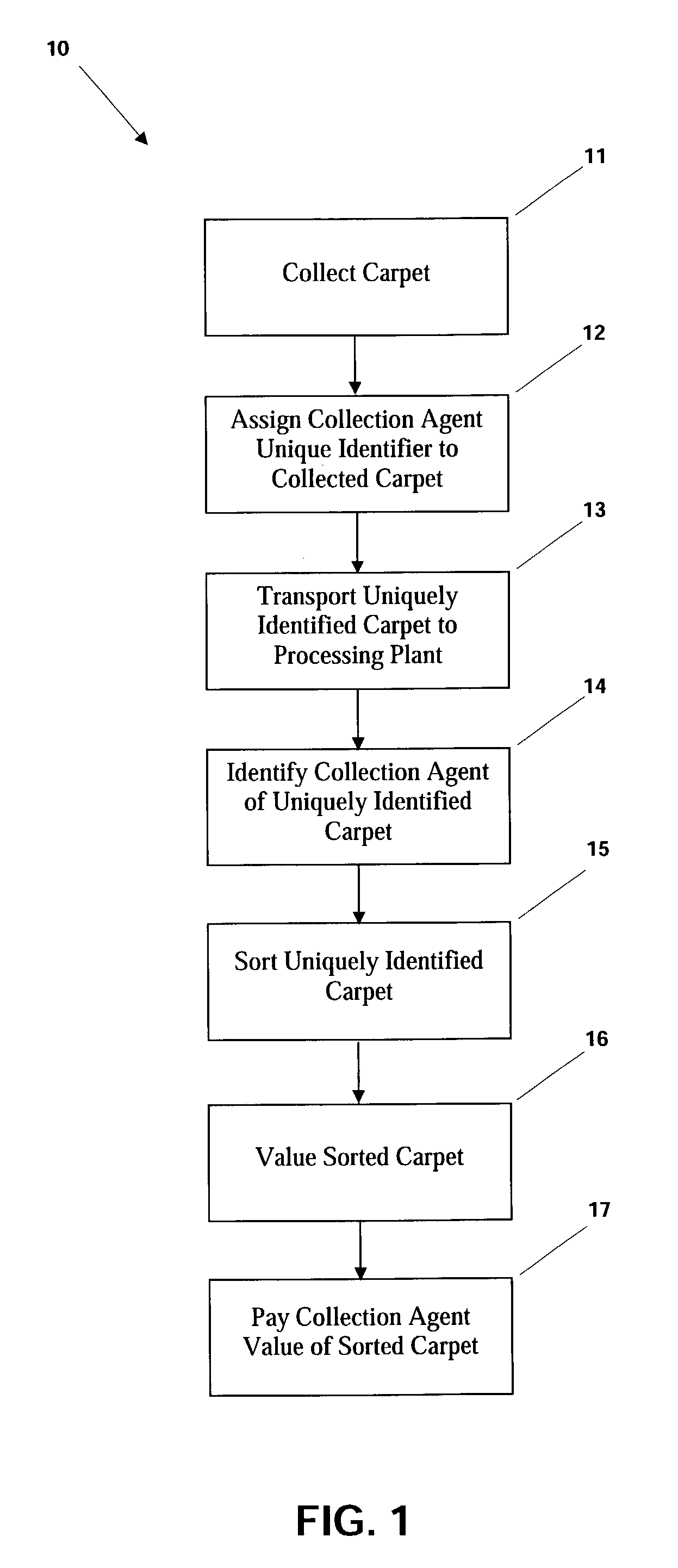

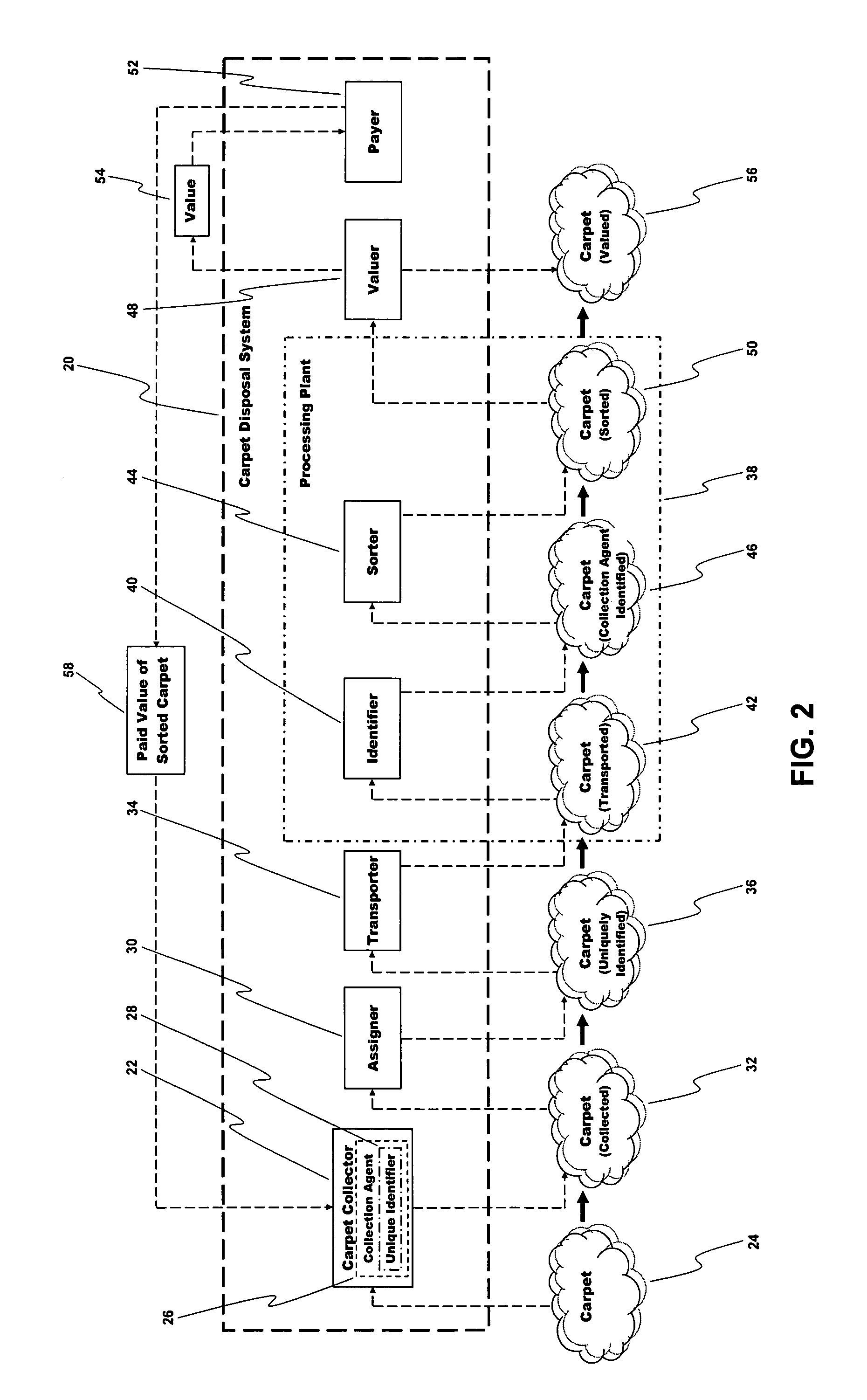

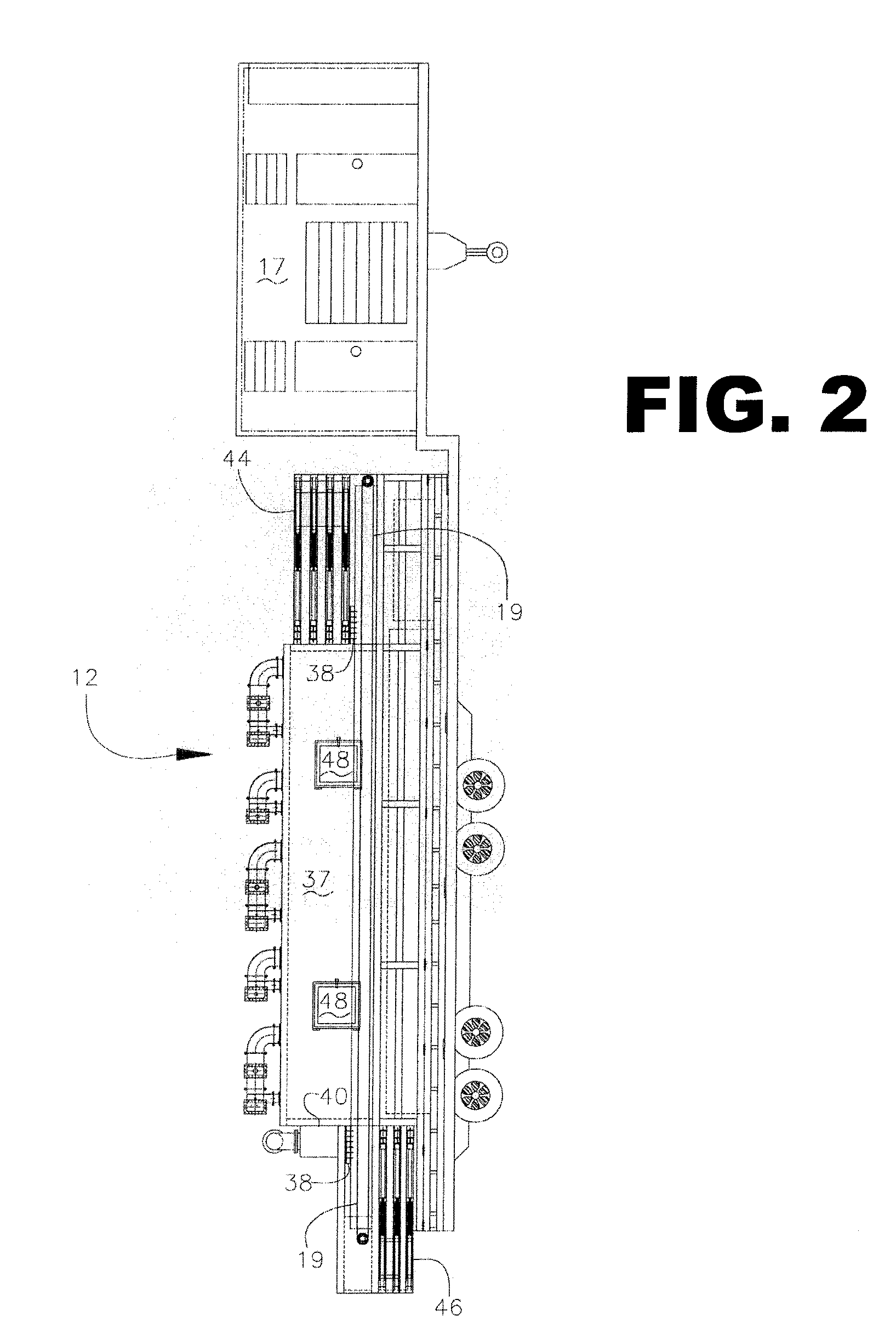

System for gathering discarded post-consumer carpet, for recycling

InactiveUS6953119B1Efficient collectionInteract smoothly and efficientlyPlastic recyclingCharacter and pattern recognitionUnique identifierHandling system

A carpet disposal method, comprising: collecting carpet, performed by a collection agent having a unique identifier; assigning the collection agent unique identifier to the collected carpet; transporting the uniquely identified carpet to a processing plant; identifying the collection agent of the uniquely identified carpet at the processing plant; sorting the uniquely identified carpet; valuing the sorted carpet; paying the identified collection agent the value of the sorted carpet; and carpet disposal system comprising: a carpet collector that collects carpet, a collection agent having a unique identifier; an assigner that assigns the collection agent unique identifier to the collected carpet; a transporter that transports the uniquely identified carpet to a processing plant; an identifier that identifies the collection agent of the uniquely identified carpet; a sorter that sorts the uniquely identified carpet; a valuer that values the sorted carpet; a payer that pays the identified collection agent the sorted carpet value.

Owner:ENVIRONX

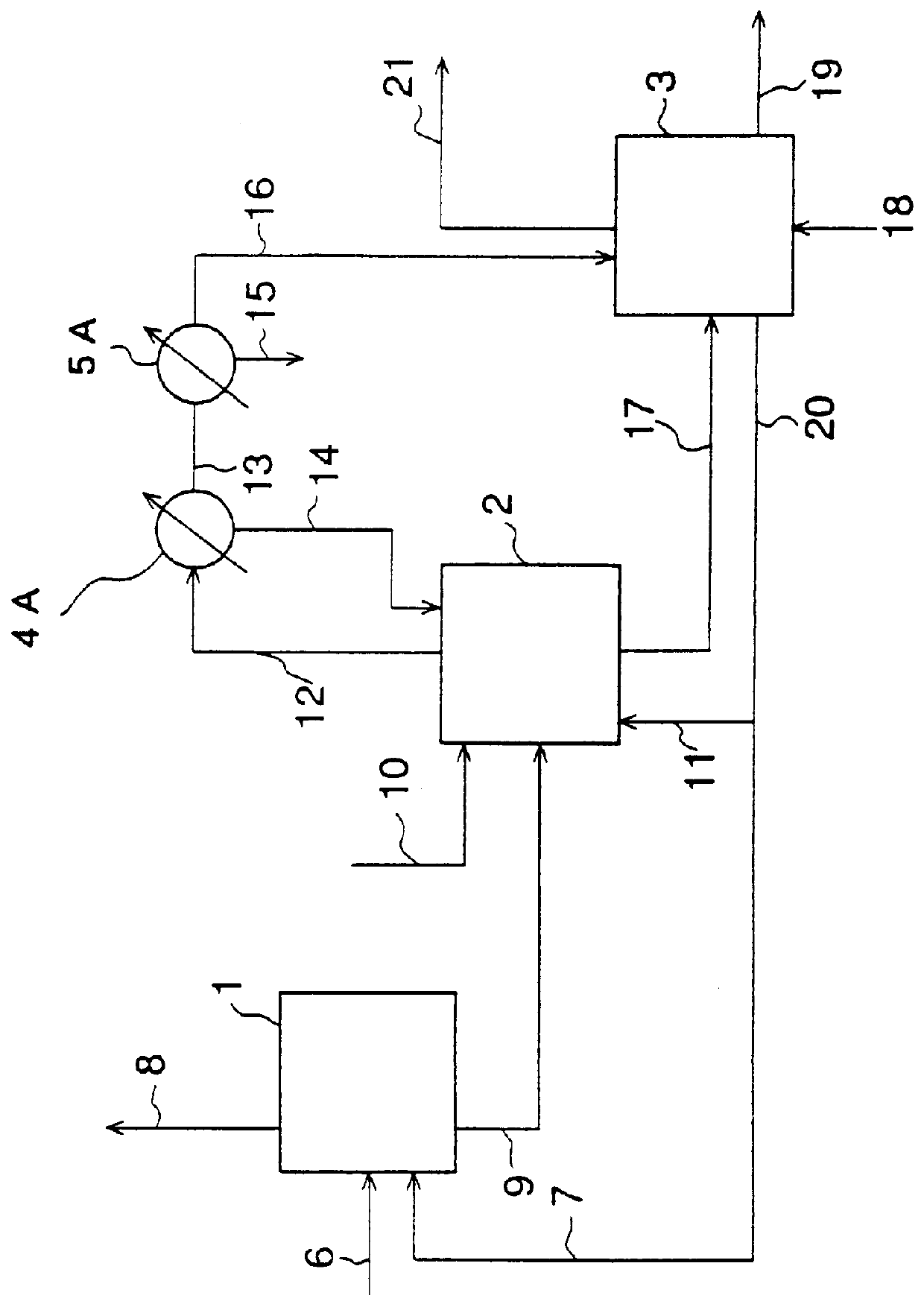

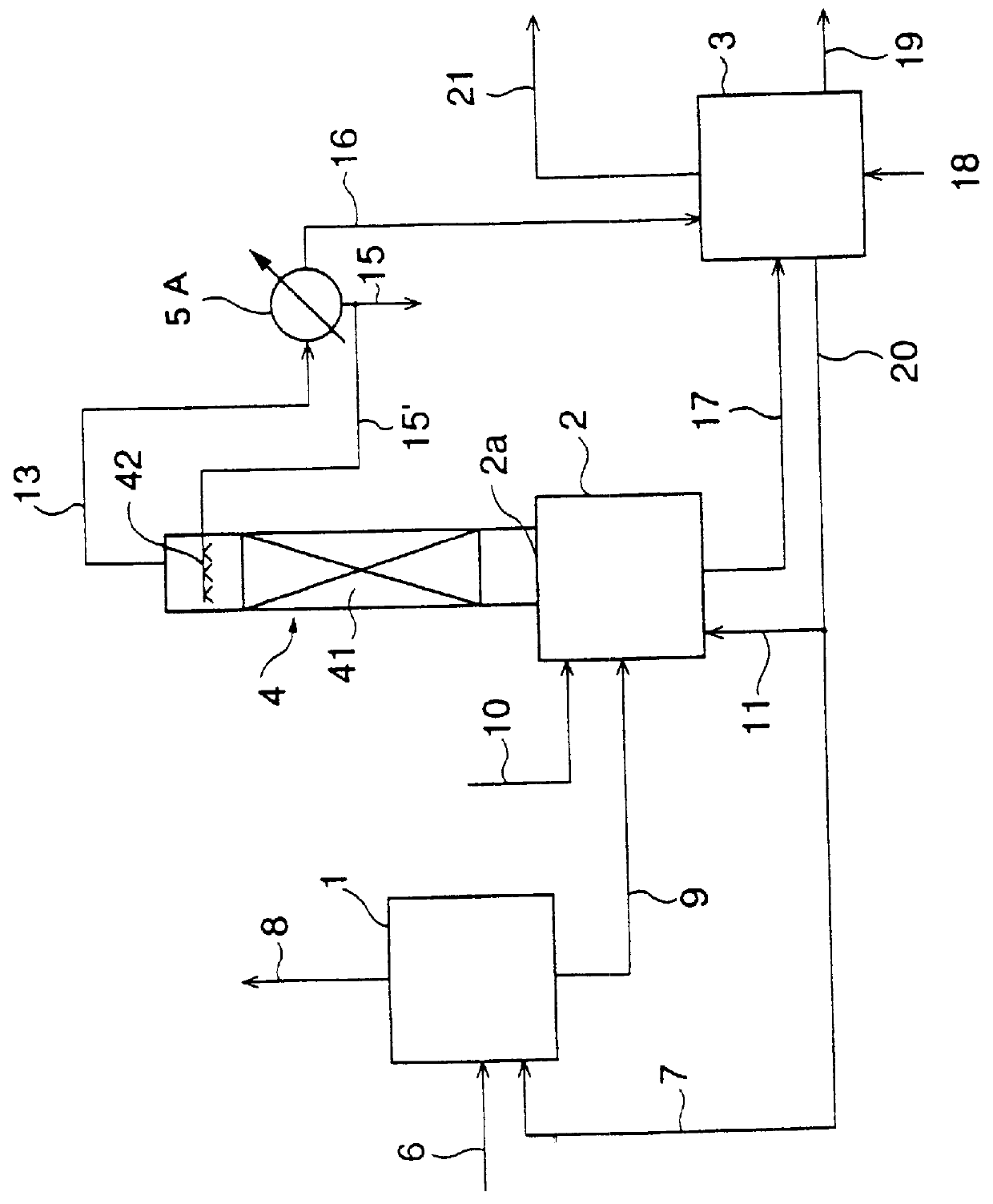

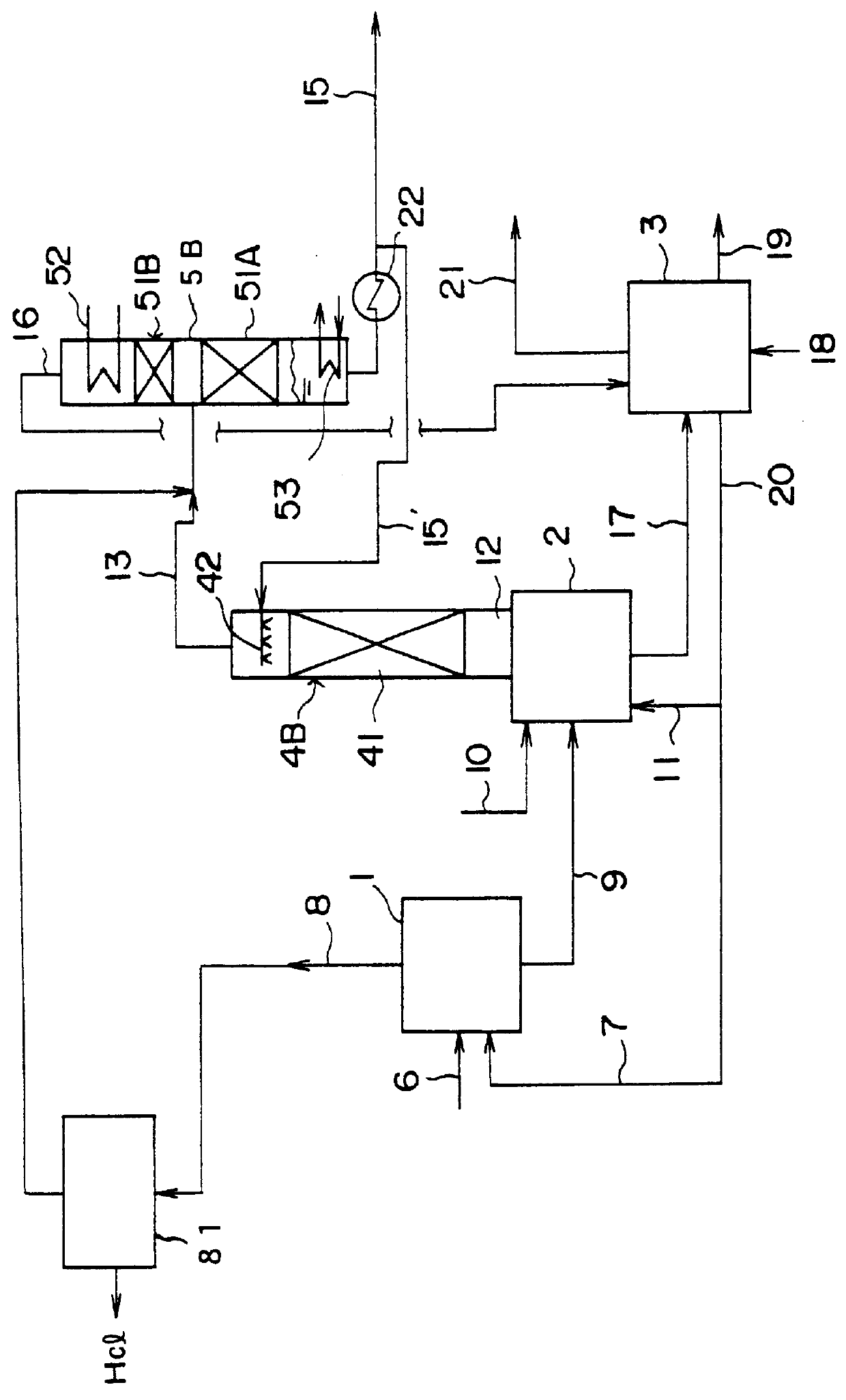

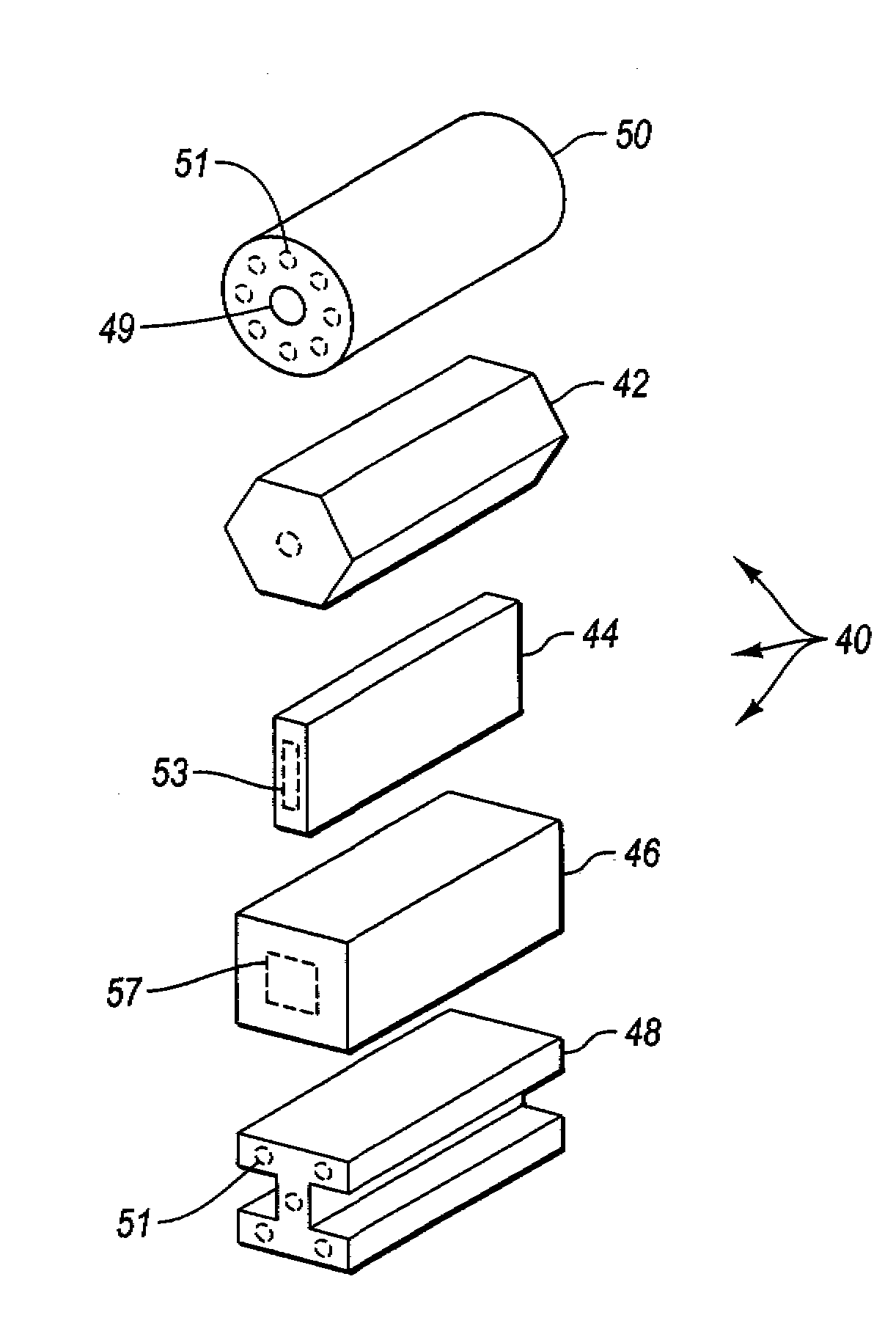

Method and apparatus for reclaiming oil from waste plastic

InactiveUS6011187AIncrease productionContinuous operationPlastic recyclingIndirect and direct heating destructive distillationForeign matterBoiling point

PCT No. PCT / JP97 / 00572 Sec. 371 Date Jan. 8, 1998 Sec. 102(e) Date Jan. 8, 1998 PCT Filed Feb. 27, 1997 PCT Pub. No. WO97 / 31990 PCT Pub. Date Sep. 4, 1997This invention provides a method for reclaiming oil from waste plastic in such a way that thermosetting resins and solid foreign matter in the plastic will not pose a problem. This method greatly reduces the burden of presorting the garbage or industrial waste. To achieve this objective when oil is to be reclaimed from a waste plastic containing chlorine compounds, such as vinyl chloride, the plastic must first be stripped of chlorine. Prior to pyrolysis, while being conveyed forward in a continuous stream, the plastic is mixed with heated sand and / or an additive agent to raise its temperature to 250-350 DEG C. This creates a product which is comprised of a mixture of sand and substantially dechlorinated plastic. The product is mixed with heated sand to heat it directly to a temperature of 350-500 DEG C. It is maintained at this temperature until pyrolysis occurs. In order to obtain high-quality oil with a low boiling point, a first gas / liquid separation process separates the product obtained from the aforesaid pyrolysis into liquid high-boiling point oil, gaseous low-boiling point oil and low molecular-weight gases, and recirculates the liquid high-boiling point oil to the pyrolysis process, and a second gas / liquid separation process separates the gaseous low-boiling point oil and low molecular-weight gases into liquid low-boiling point oil and low molecular-weight gases. The first and second gas / liquid separation process are connected in sequence.

Owner:MITSUBISHI HEAVY IND LTD

Extruded fiber reinforced cementitious products having wood-like properties and ultrahigh strength and methods for making the same

InactiveUS20100136269A1High yield stressImmediate form stabilityLayered productsPlastic recyclingPorosityFlexural strength

A method of manufacturing a cementitious composite including: (1) mixing an extrudable cementitious composition by first forming a fibrous mixture comprising fibers, water and a rheology modifying agent and then adding hydraulic cement; (2) extruding the extrudable cementitious composition into a green extrudate, wherein the green extrudate is characterized by being form-stable and retaining substantially a predefined cross-sectional shape; (3) removing a portion of the water by evaporation to reduce density and increase porosity; and (4) heating the green extrudate at a temperature from greater than 65° C. to less than 99° C. is disclosed. Such a process yields a cementitious composite that is suitable for use as a wood substitute. Particularly, by using higher curing temperatures for preparing the cementitious building products, the building products have a lower bulk density and a higher flexural strength as compared to conventional products. The wood-like building products can be sawed, nailed and screwed like ordinary wood.

Owner:E KHASHOGGI INDS

Method and Apparatus for Microwave Reduction of Organic Compounds

InactiveUS20070102279A1Maximum protectionElectrical coke oven heatingSolid waste disposalEngineeringVolumetric Mass Density

The invention described herein generally pertains to utilization of high power density microwave energy to reduce organic compounds to carbon and their constituents, primarily in a gaseous state. The process includes, but is not limited to, scrap tires, plastics, asphalt roofing shingles, computer waste, medical waste, municipal solid waste, construction waste, shale oil, and PCB / PAH / HCB-laden materials. The process includes the steps of feeding organic material into a microwave applicator and exposing the material to microwave energy fed from at least two linear polarized sources in non-parallel alignment to each other, and collecting the material. The at least two sources of microwave energy are from a bifurcated waveguide assembly, whose outputs are perpendicular to each other and fed through waveguide of proper impedance, such that the microwave sources are physically and electrically 90° out of phase to each other. The microwave frequency is between 894 and 1000 MHz, preferably approximately 915 MHz.

Owner:NOVAK JUDITH

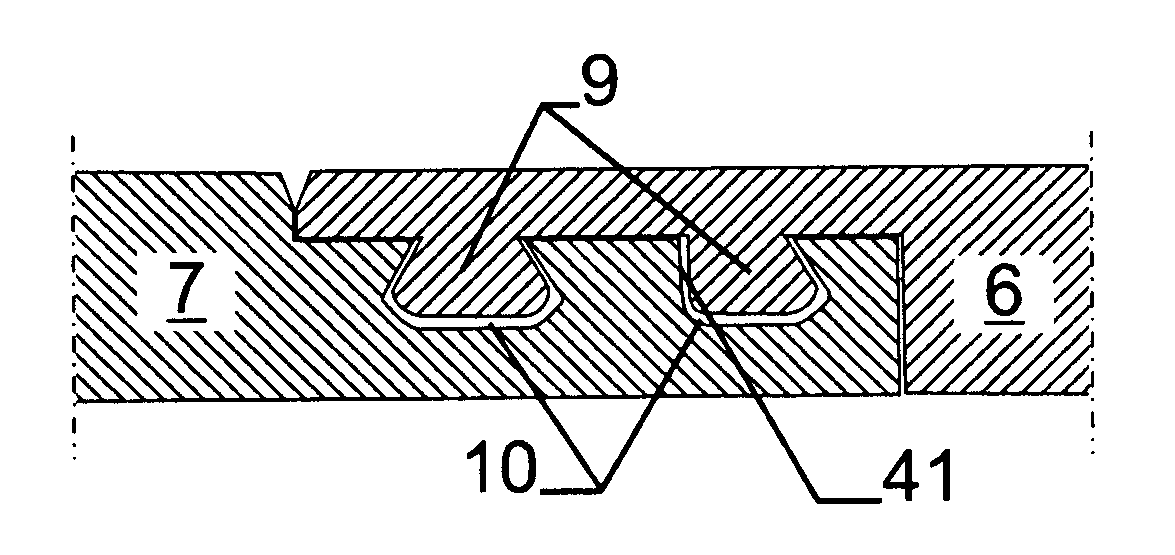

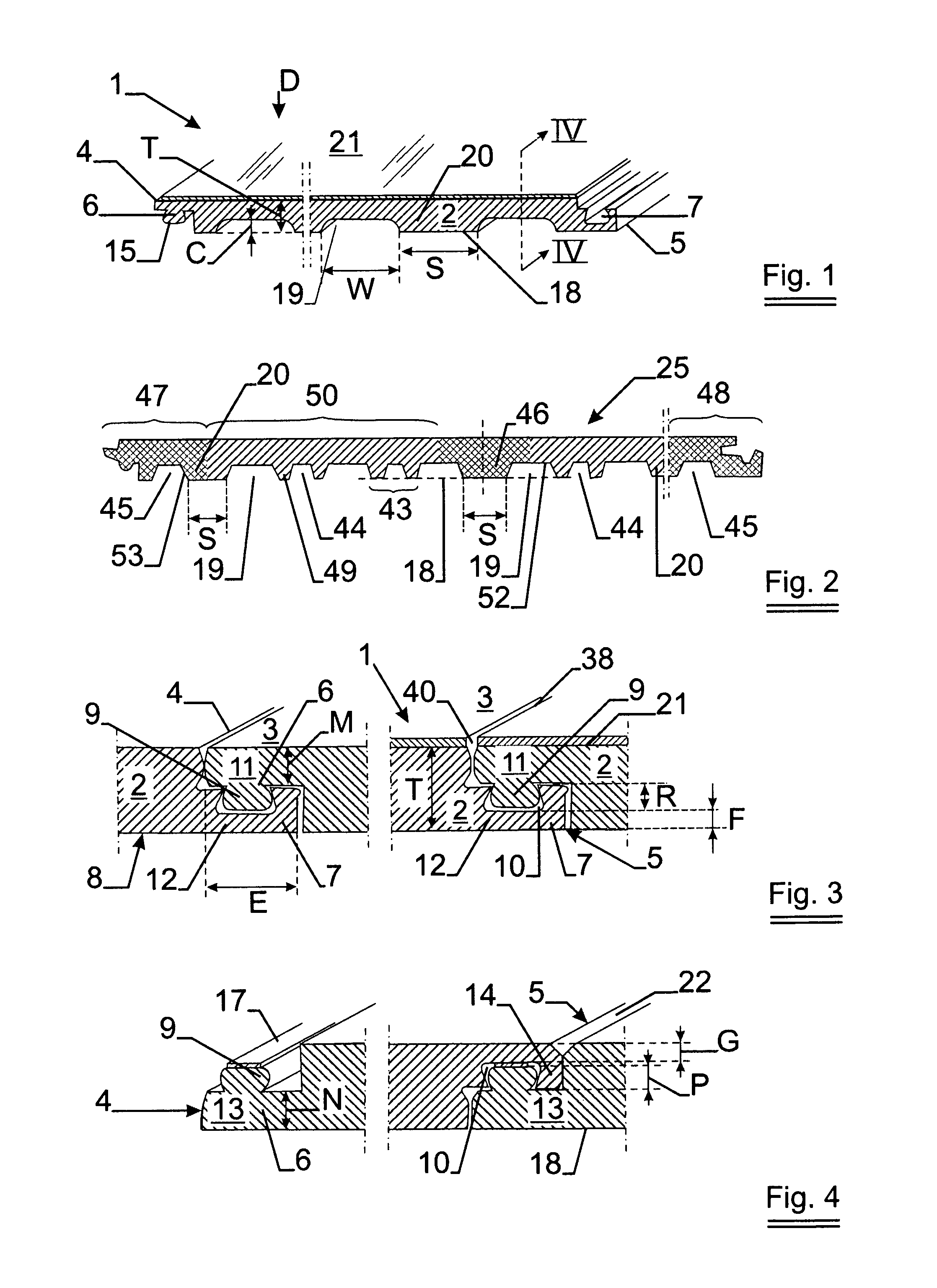

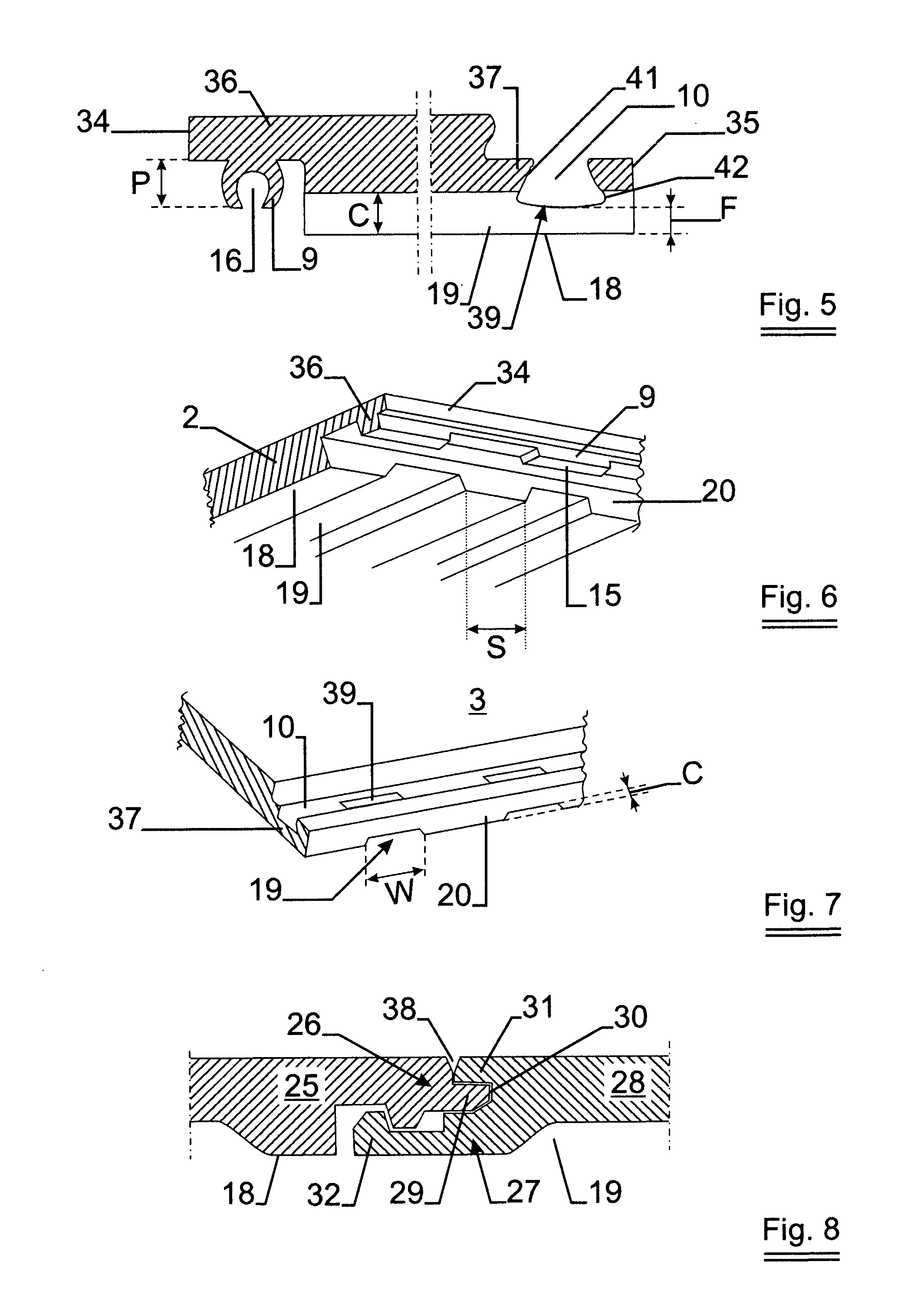

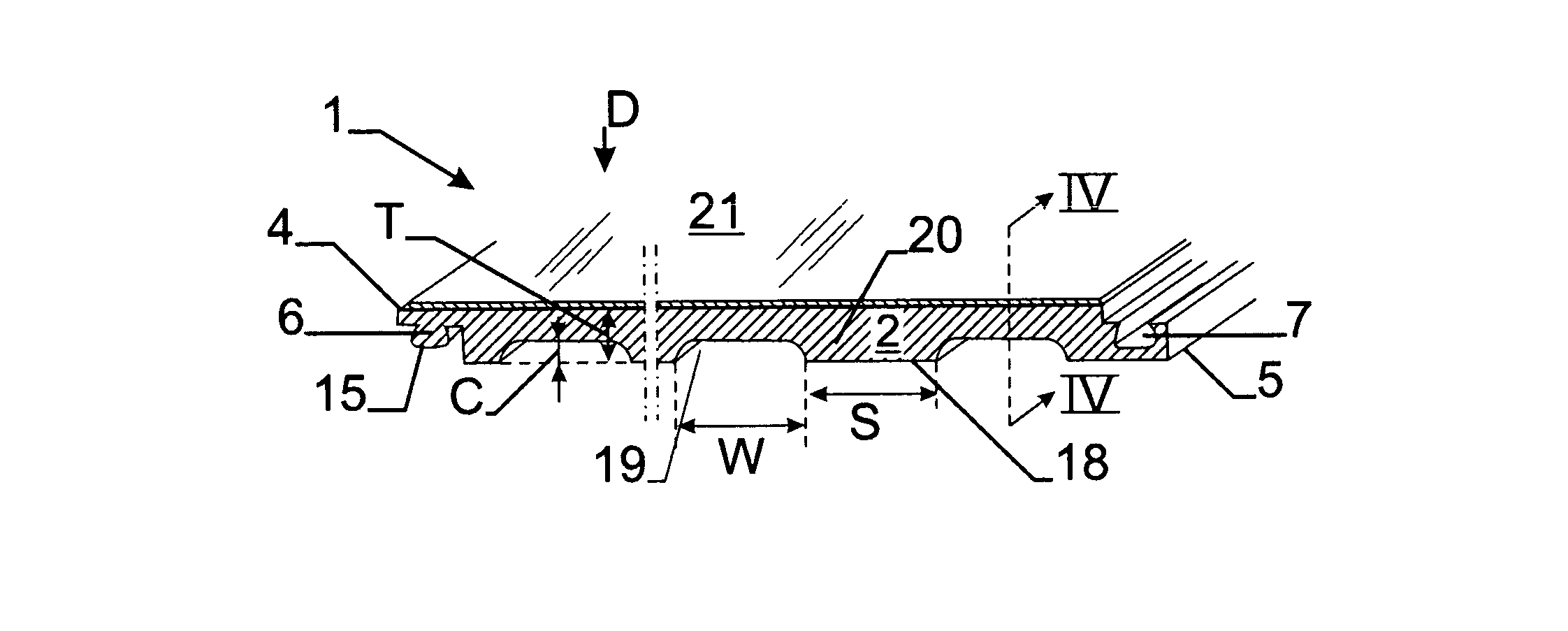

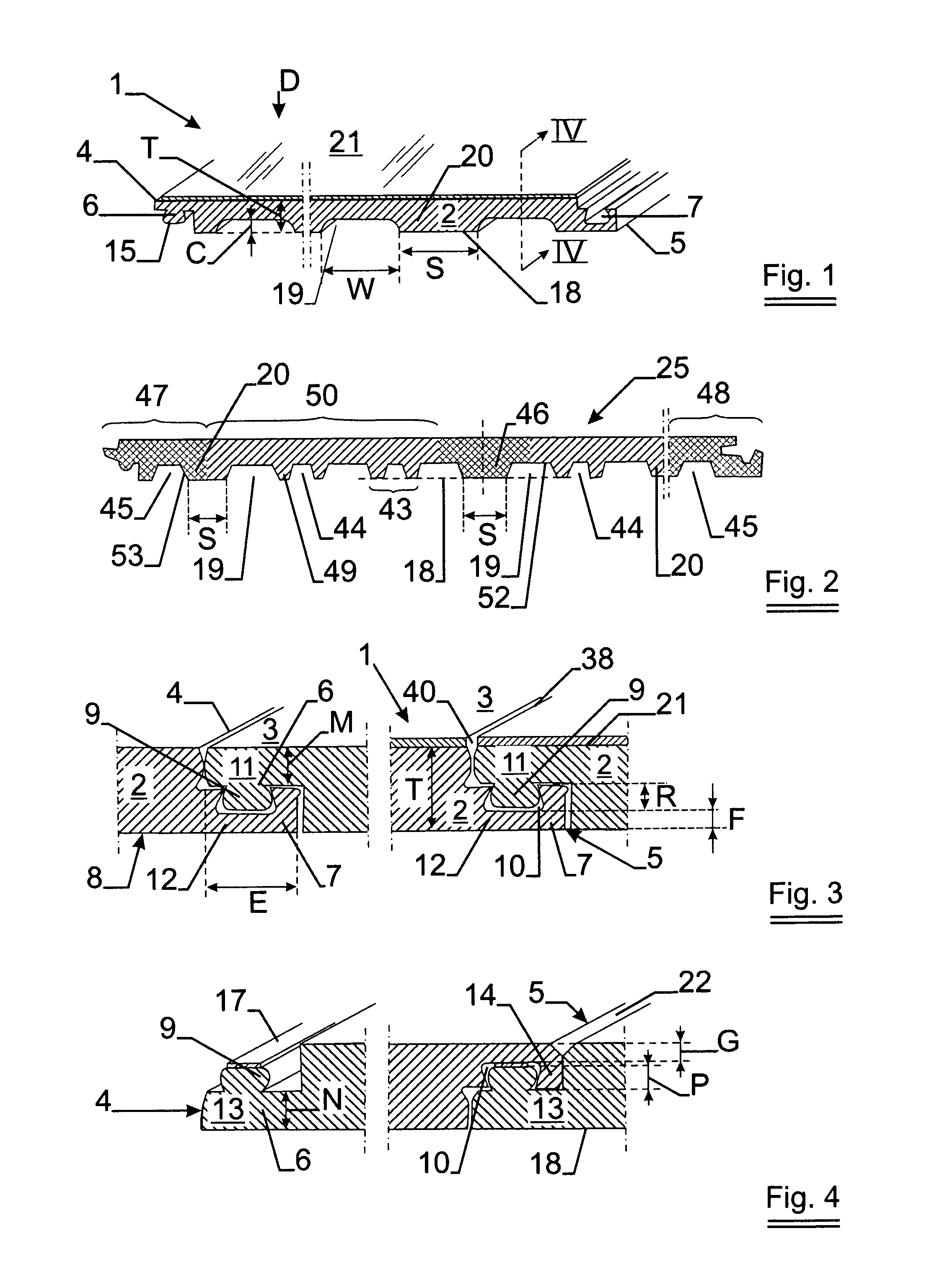

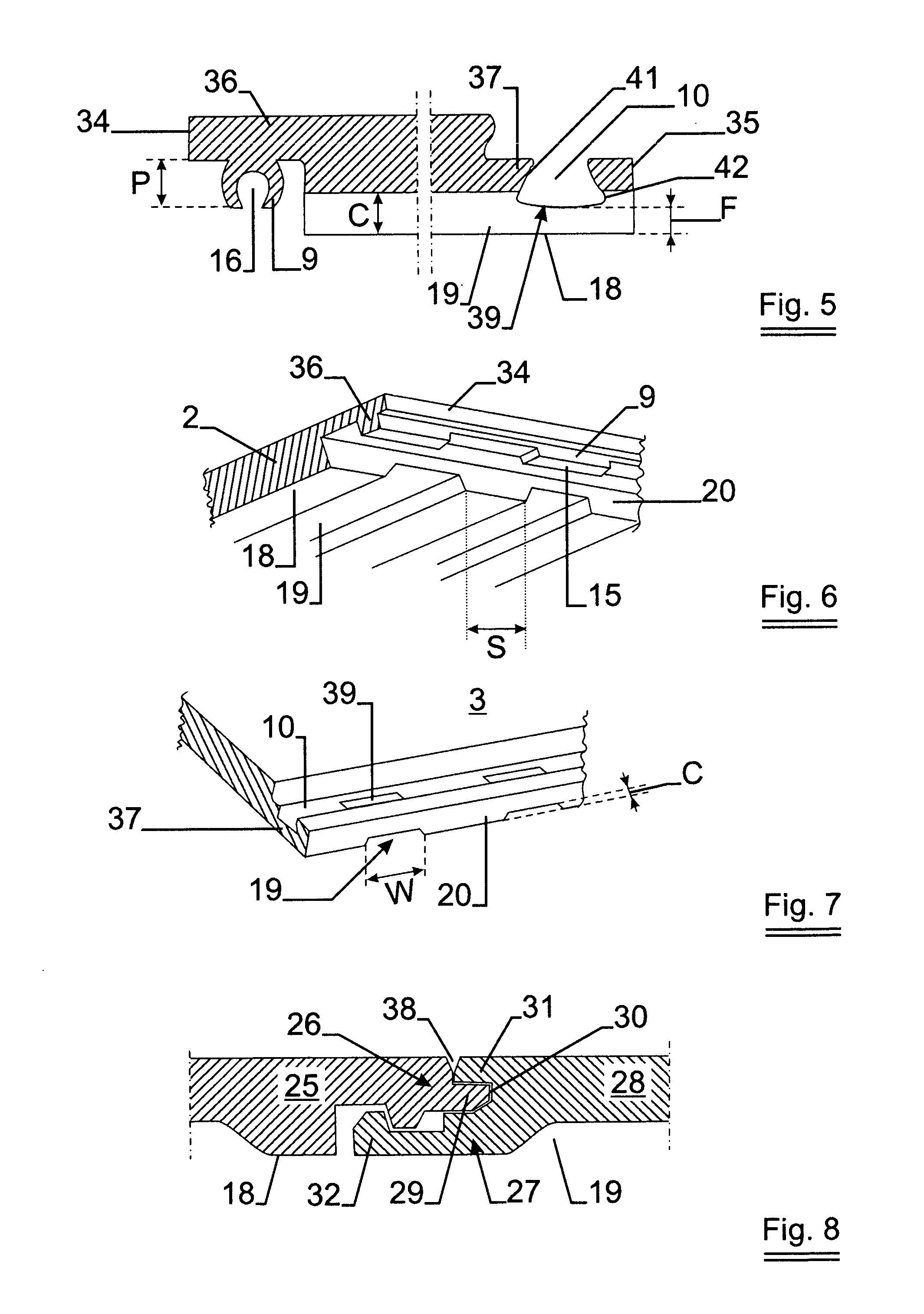

Covering panel

A covering panel has a support plate, made from synthetic plastic material, with a flat and even top surface, a bottom face and pairs of opposite sides provided with complementary profile edges in the form of a male profile edge on one side and a female profile edge on the other, where said male profiled edge can be connected to a female edge of an equal adjacent covering panel, preferably according to a direction that runs perpendicular to said top surface. In their bottom face there are strip-shaped recesses that run according to the direction of extrusion and alternate with a number of support strips, of which at least a part has a width S along that bottom face that complies with 1.5 T<S<10 T, and whereby 0.4 T<C<0.7 T applies, in which C is the average depth of these recesses. A process extrudes a synthetic plastic plate.

Owner:I4F LICENSING NV

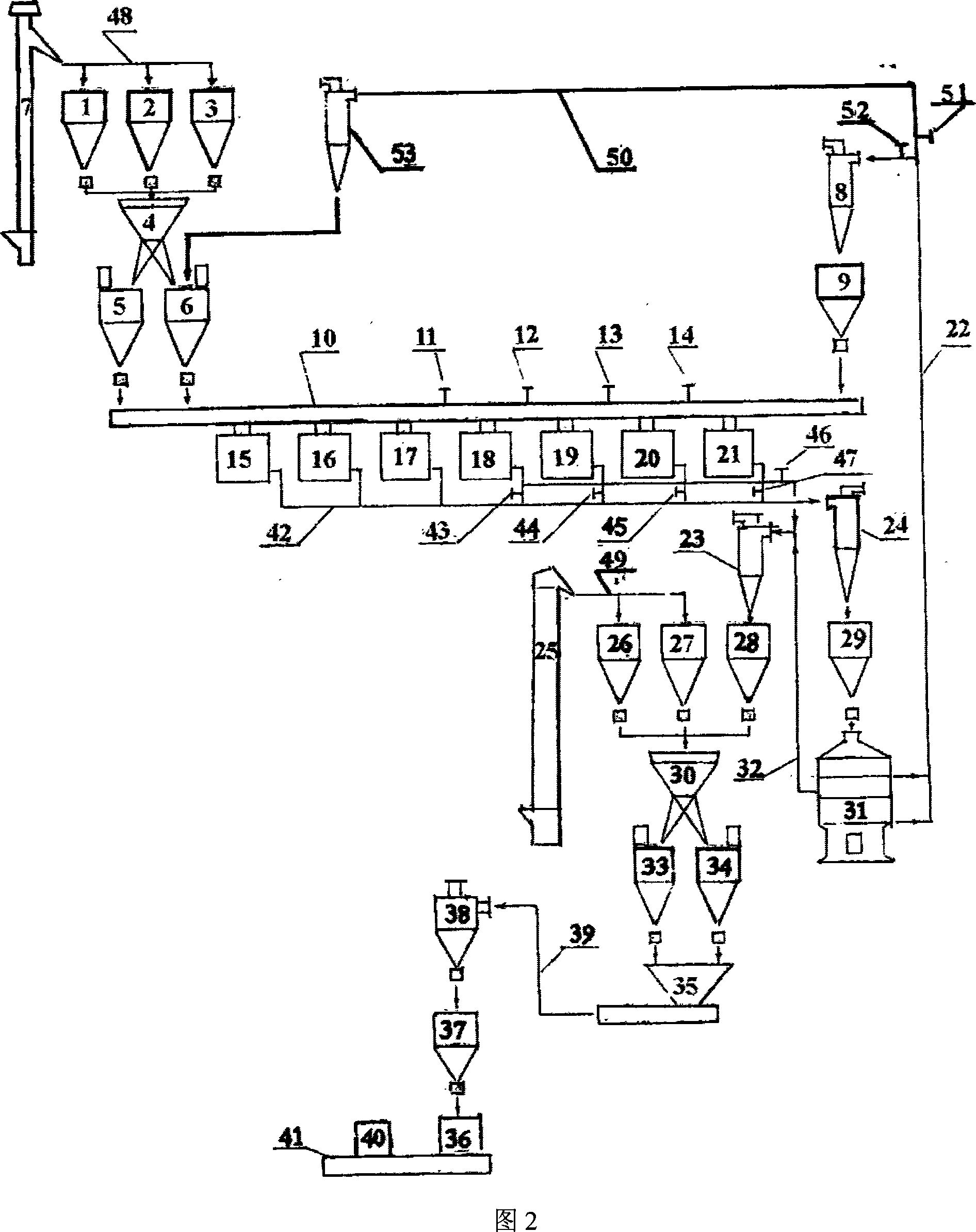

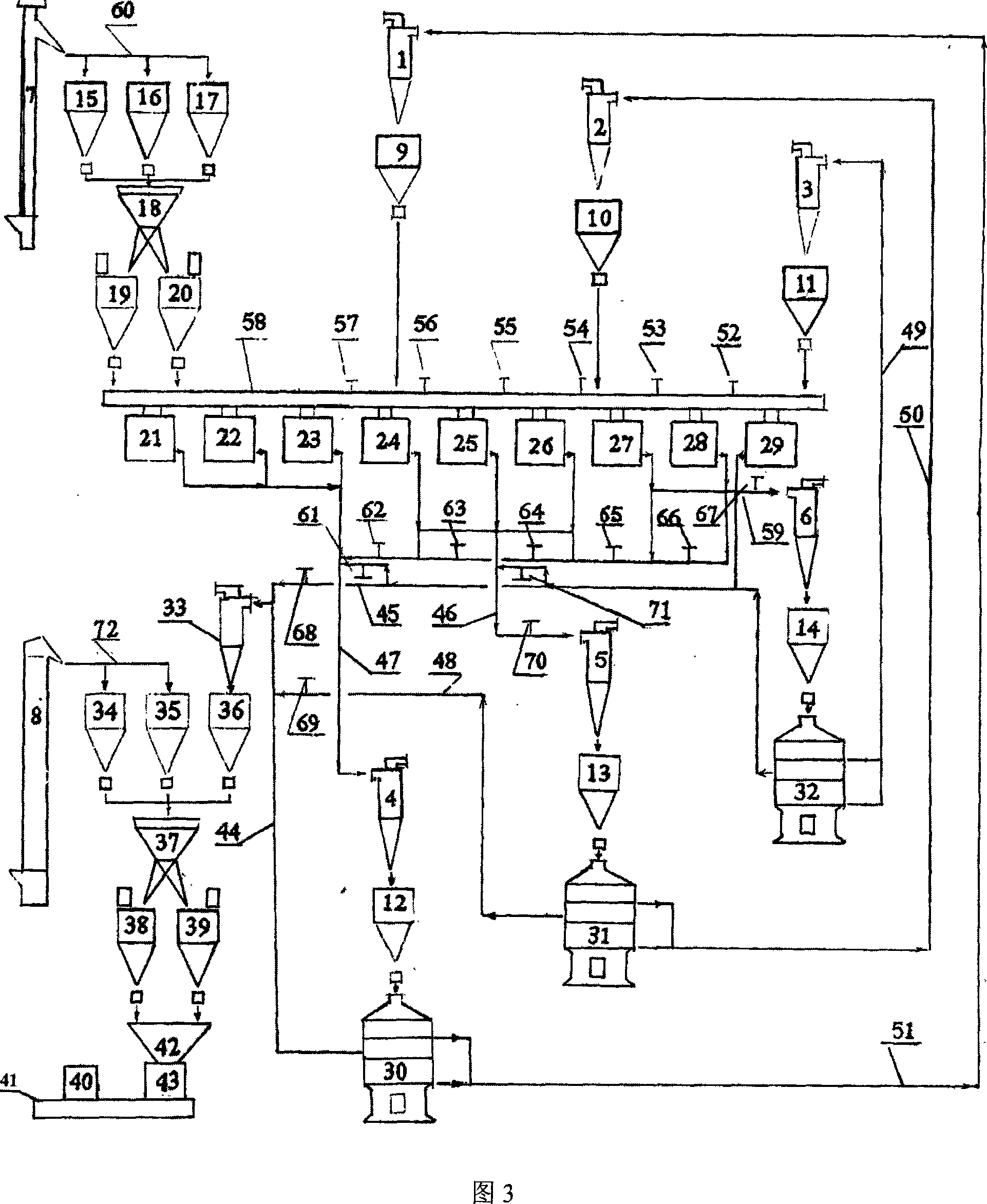

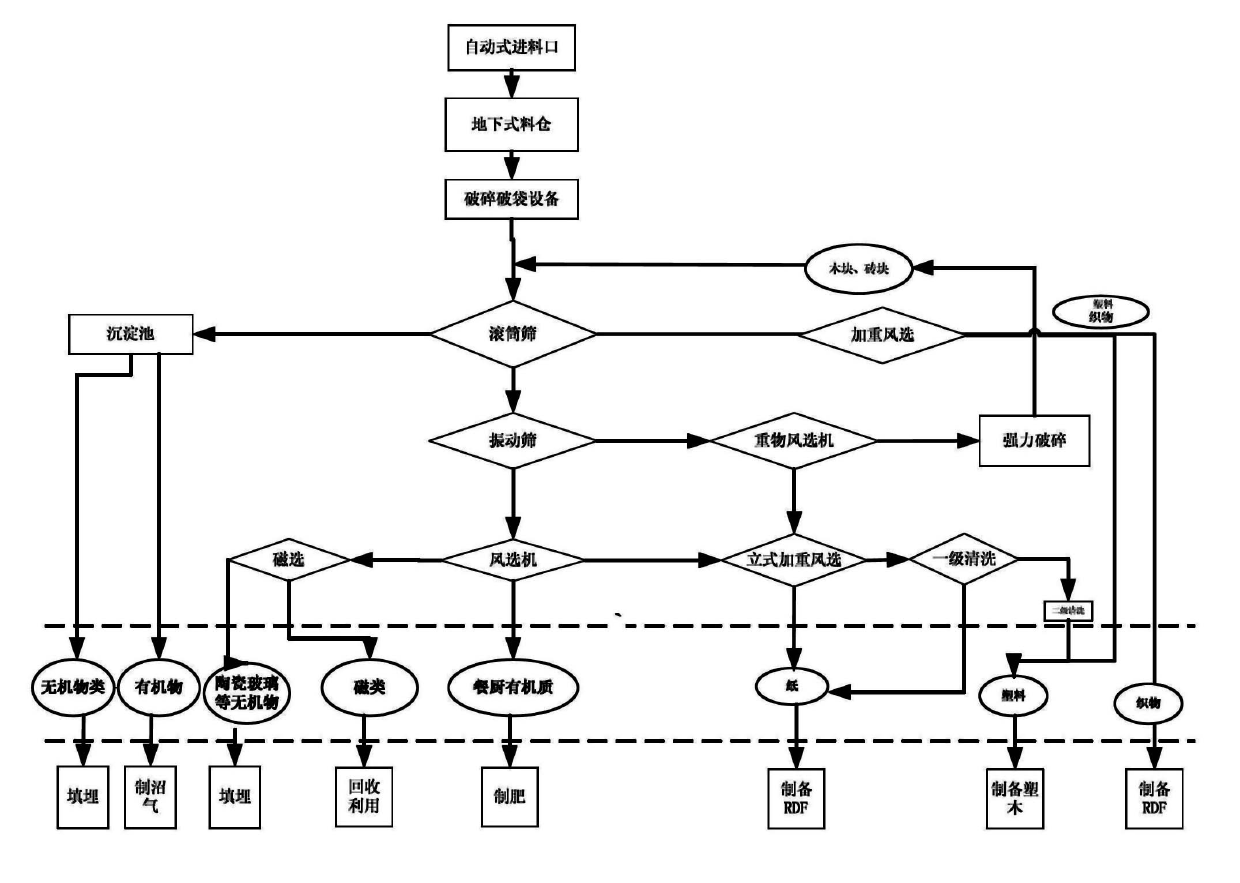

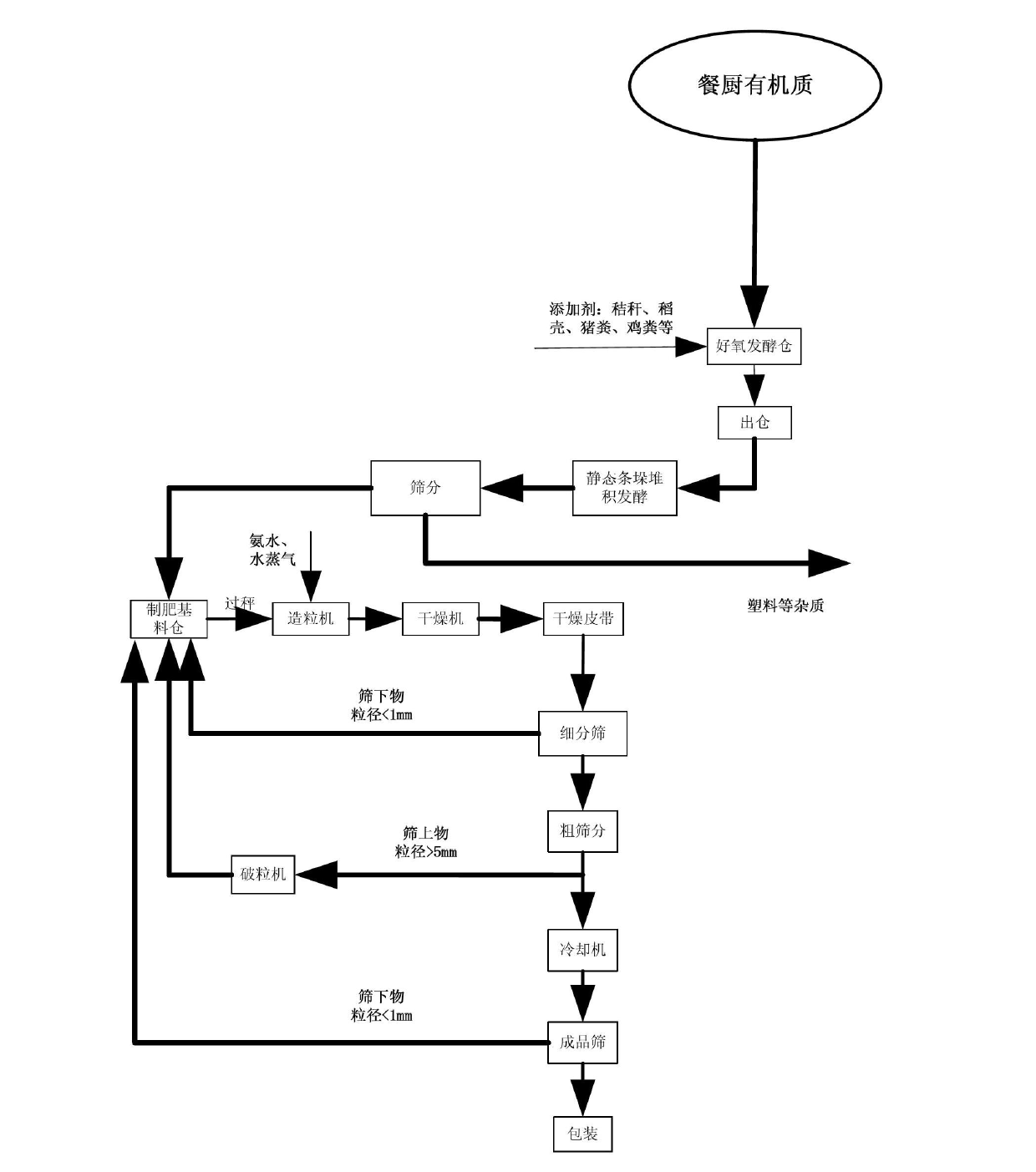

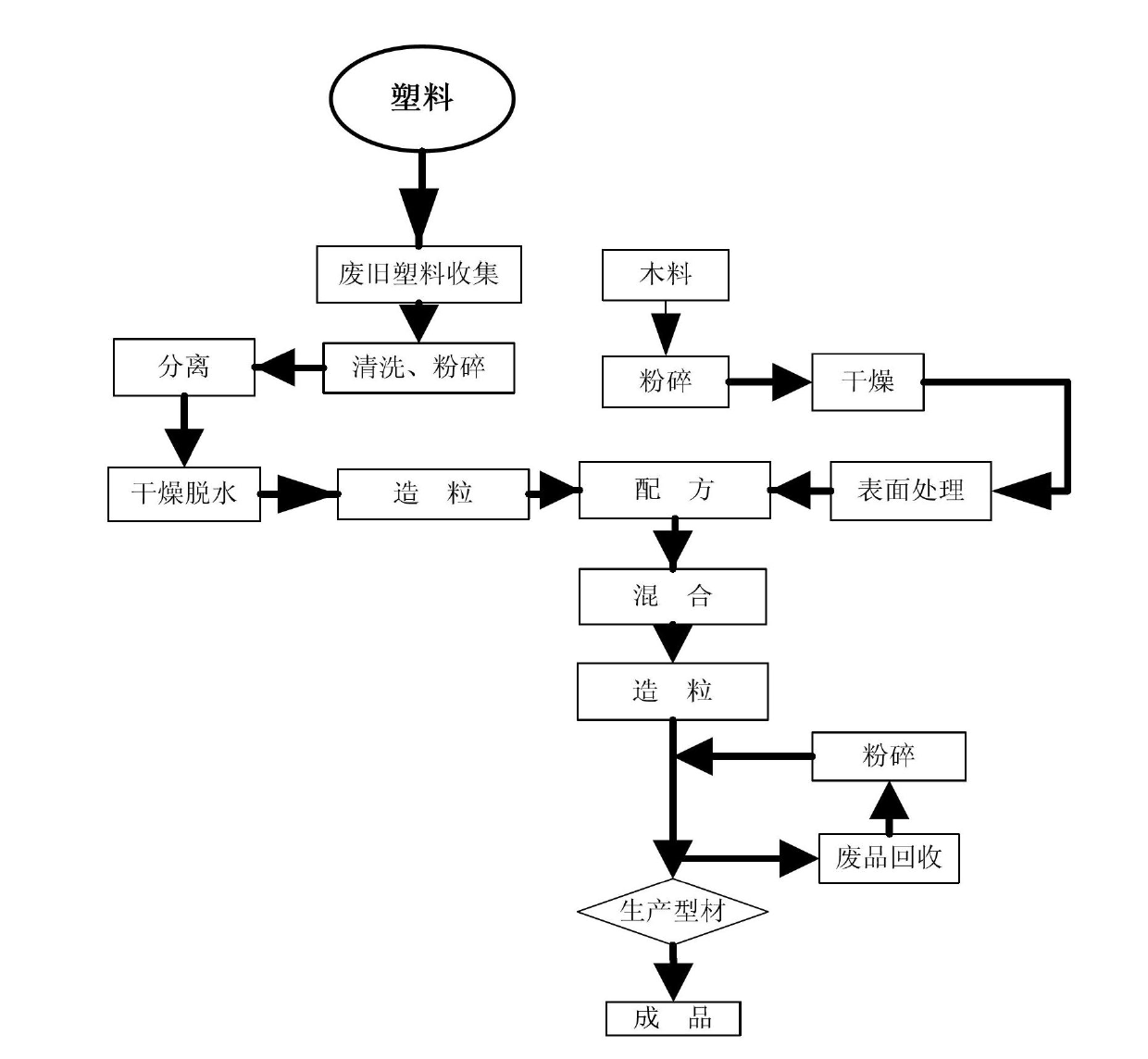

Method for sorting and comprehensively using urban mixed garbage

InactiveCN102671928AStructural innovationRealize full mechanizationBio-organic fraction processingSolid waste disposalRefuse-derived fuelPulp and paper industry

The invention discloses a method for sorting and comprehensively using urban mixed garbage. The method comprises the following steps: 1) allowing the urban mixed garbage to enter a feed bin through a feeding hole, discharging, and introducing into crushing and bag breaking equipment; 2) breaking garbage bags and crushing block garbage by using the crushing and bag breaking equipment; 3) feeding the garbage subjected to crushing and bag breaking into a two-stage rotary screen, screening out dust of which the grain size is less than 3mm, and picking out strip substances; and 4) feeding the mixed garbage into a vibration screen, separating inorganic cakes, large-sheet plastics and paper from an oversize material by using a heavy winnowing machine, and winnowing heavy substances, light substances and intermediate substances from an undersized material in a double-wind chamber multifunctional winnowing machine. Sorting equipment is effectively combined, so that the mixed garbage is efficiently sorted and recycled; and the sorted paper and textiles, plastics and kitchen organics are respectively used for preparing garbage derived fuel, plastic wood and fertilizers.

Owner:SICHUAN CRUN ENVIRONMENTAL PROTECTION ENERGY TECH CO LTD +1

Process for the preparation of transparent shaped articles

ActiveUS20060197246A1Improve claritySuitable for preparationEnvelopes/bags making machineryFilament/thread formingPolyesterPolymer science

Disclosed is a process for the preparation of shaped articles such as, for example, sheeting, films, tubes, bottles, preforms and profiles, having high transparency and low haze comprising immiscible blends of one or more thermoplastic polymers selected from polyesters, polycarbonates, and polyarylates, and a copolyamide or a transamidized, homogeneous blend of a least two polyamides. The components of the immiscible blend which have refractive indices which differ by about 0.006 to about −0.0006. The small difference in the refractive indices enable the incorporation of regrind into the polymer composition to produce transparent shaped articles. These articles may have one or more layers and can exhibit improved excellent barrier properties and good melt processability while retaining excellent mechanical properties. Metal catalysts can be incorporated into the compositions to produce shaped articles having oxygen-scavenging properties.

Owner:EASTMAN CHEM CO

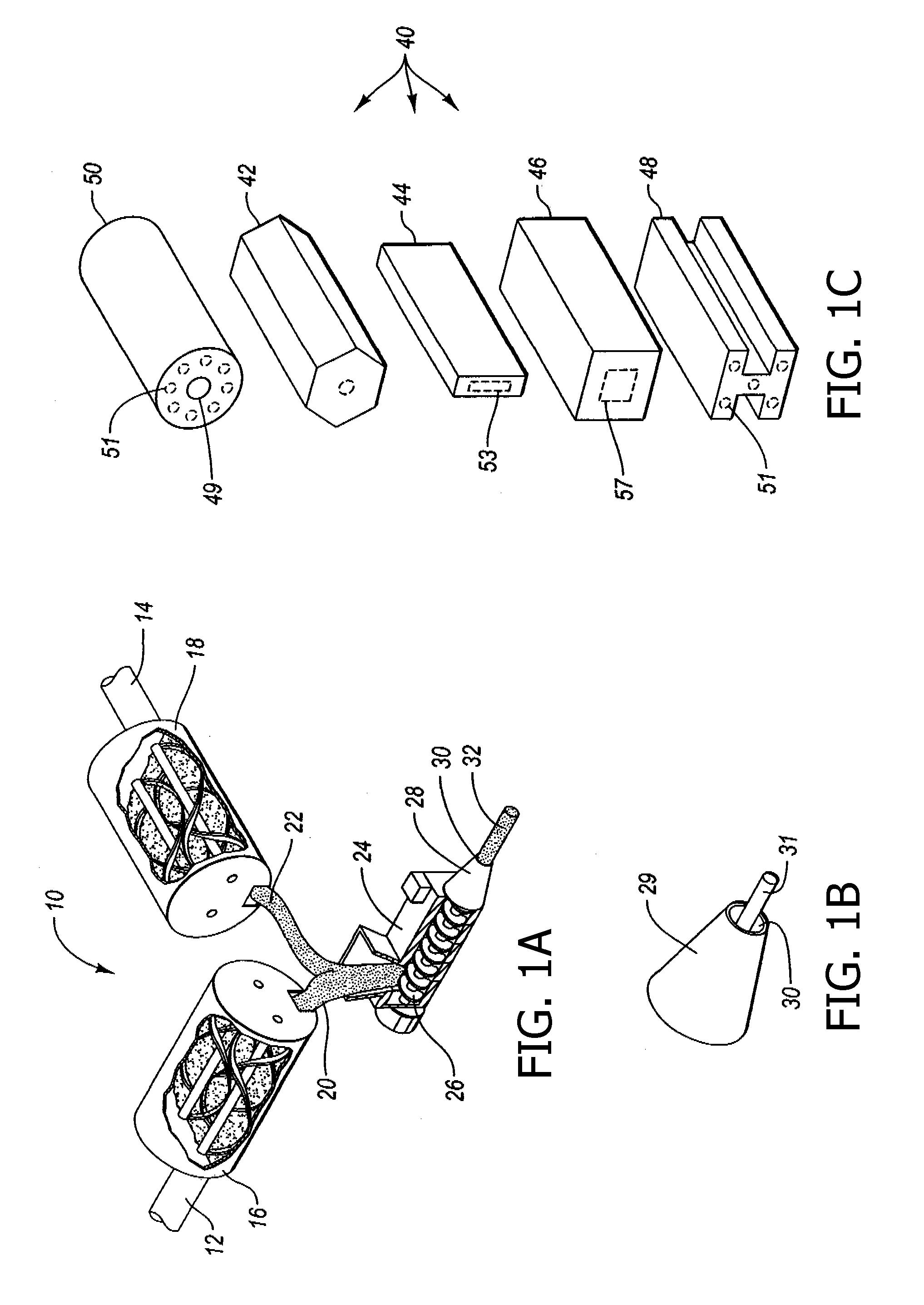

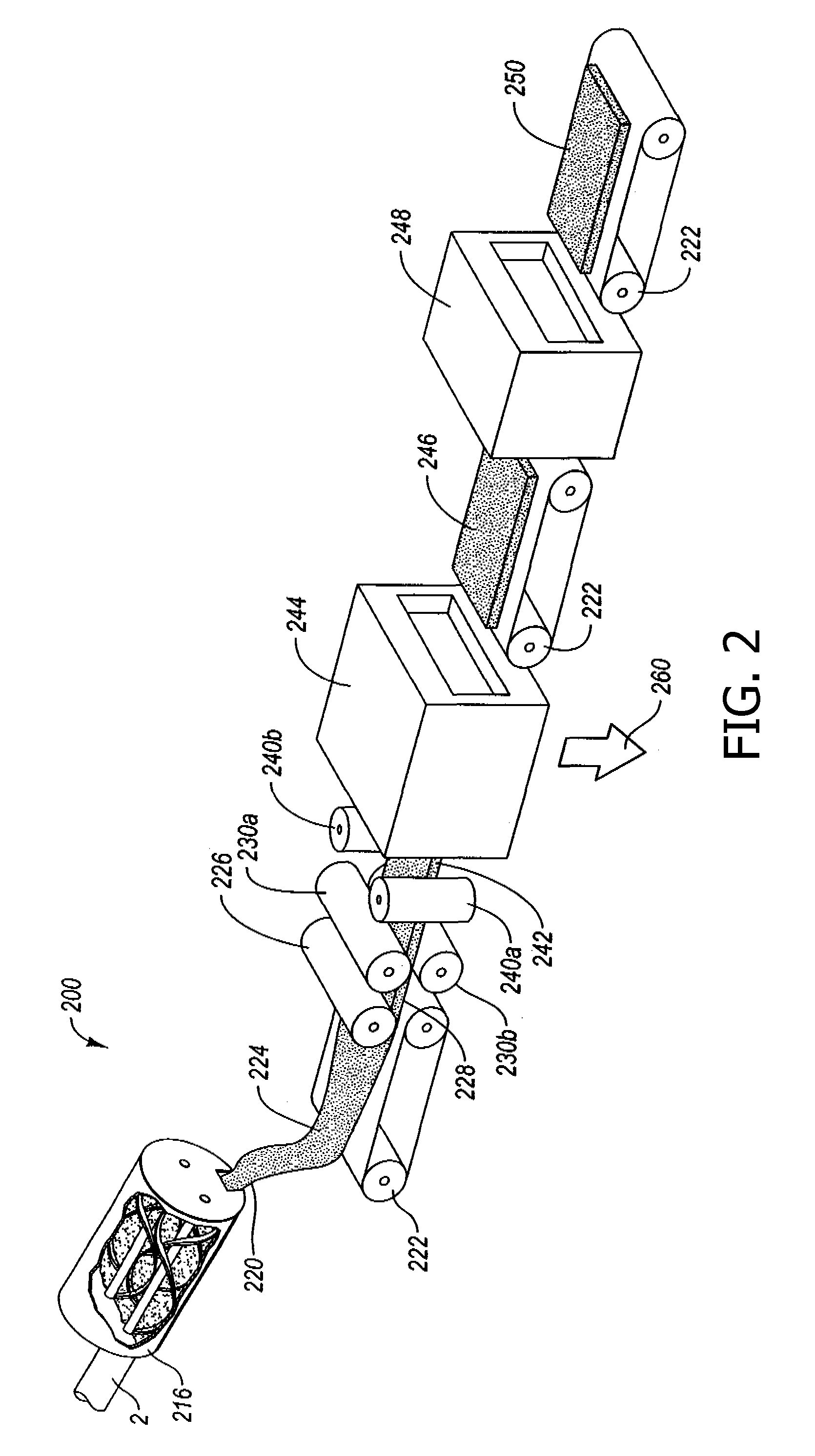

Wood-Plastic Composites Using Recycled Carpet Waste and Systems and Methods of Manufacturing

InactiveUS20080128933A1Reduce material costsPlastic recyclingBuilding constructionsFoaming agentVolumetric Mass Density

An extruded composite utilized as a building material includes a base polymer, unseparated processed recycled carpet waste, and a filler material, which may be a wood filler or other natural fiber. The recycled carpet waste may be used to decrease the amount of both base polymer and wood filler to achieve an equivalent product at lower cost. The extruded composite may also utilize chemical foaming agents to reduce density. Both foamed and non-foamed composites may be capstocked.

Owner:MATERIAL INNOVATIONS LLC

Regeneration method of waste elastic body

A process for regenerating the used or rejected elastomer features that the non-odor softening agent prepared from the kernel of plant fruit, oil-containing decolored mud and / or frequently used softener, non-odor activating agent, anti-oxidizing-antiageing agent, adsorbent, industrial refuse, the powder of bone, shell, or straw, and / or reinforcing filler are used to treat said used or rejected elastomer to obtain fine (80 meshes) powder, which can be used as the filler of rubber or plastics.

Owner:陈民铎

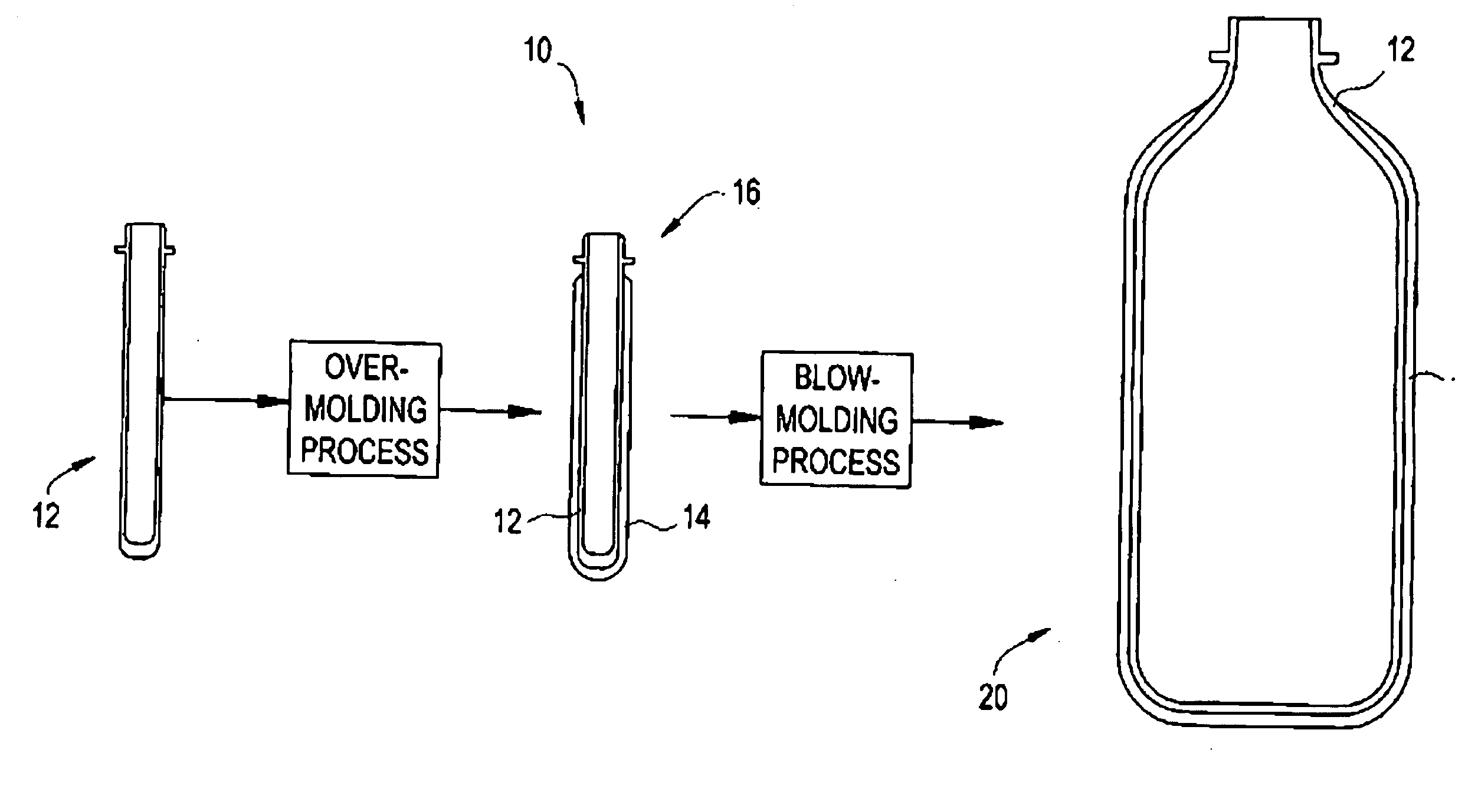

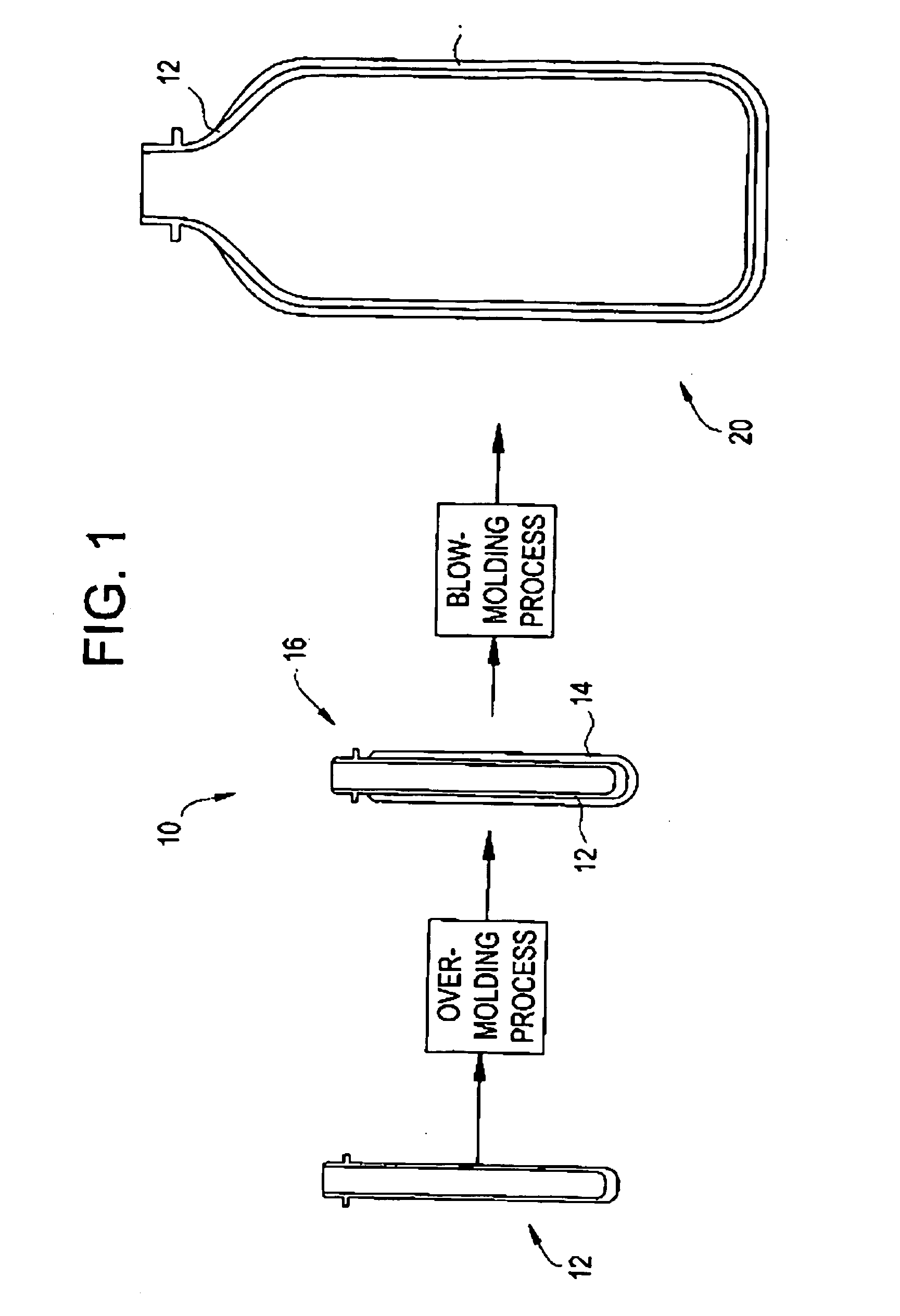

Overmolded containers and methods of manufacture and use thereof

ActiveUS20060210746A1Enhanced visualEnhanced tactile characteristicBottlesPlastic recyclingBlow moldingThermal insulation

Overmolded containers and methods of manufacture thereof are disclosed, which may provide enhanced visual and tactile characteristics, enabling innovative packaging designs, improved grippability and thermal insulation. The containers can be made cost effectively manner, with minimal impact on polymer recycling streams. The methods of making the container include the steps of providing a container preform which comprises a thermoplastic polymer, such as a PET copolymer; overmolding an elastomeric material over at least a portion of the preform to form an overmolded preform; and blow-molding the overmolded preform to form an overmolded container. In one embodiment, the overmolded container is a beverage container.

Owner:THE COCA-COLA CO +1

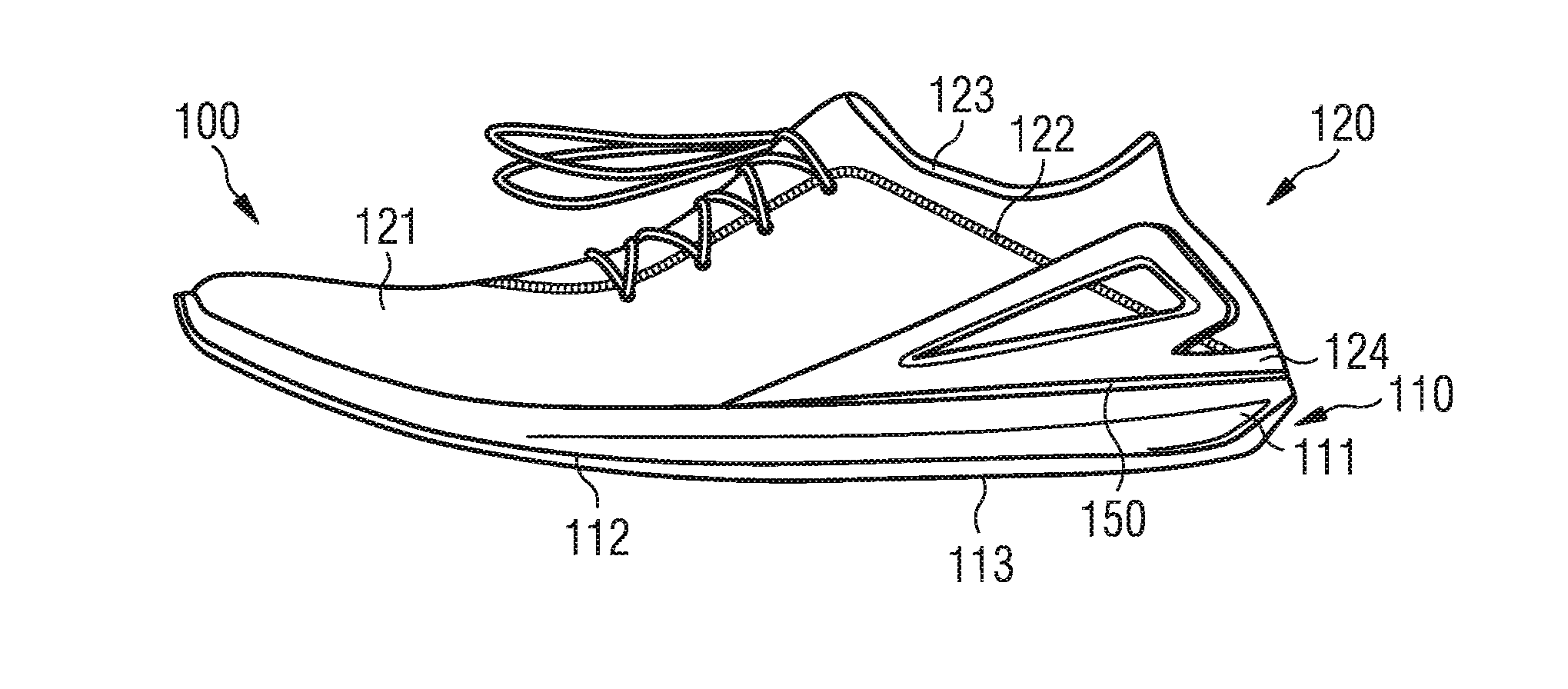

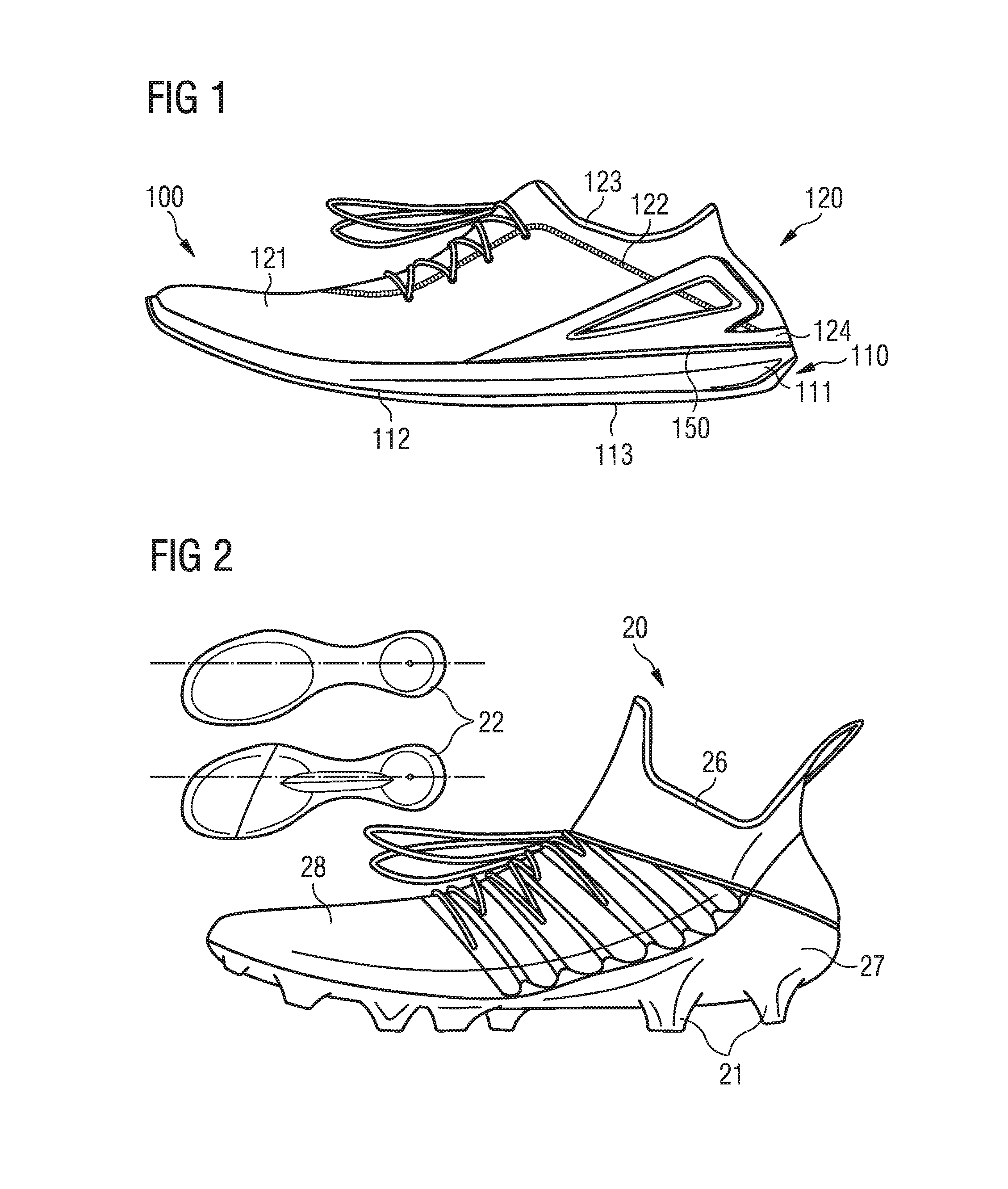

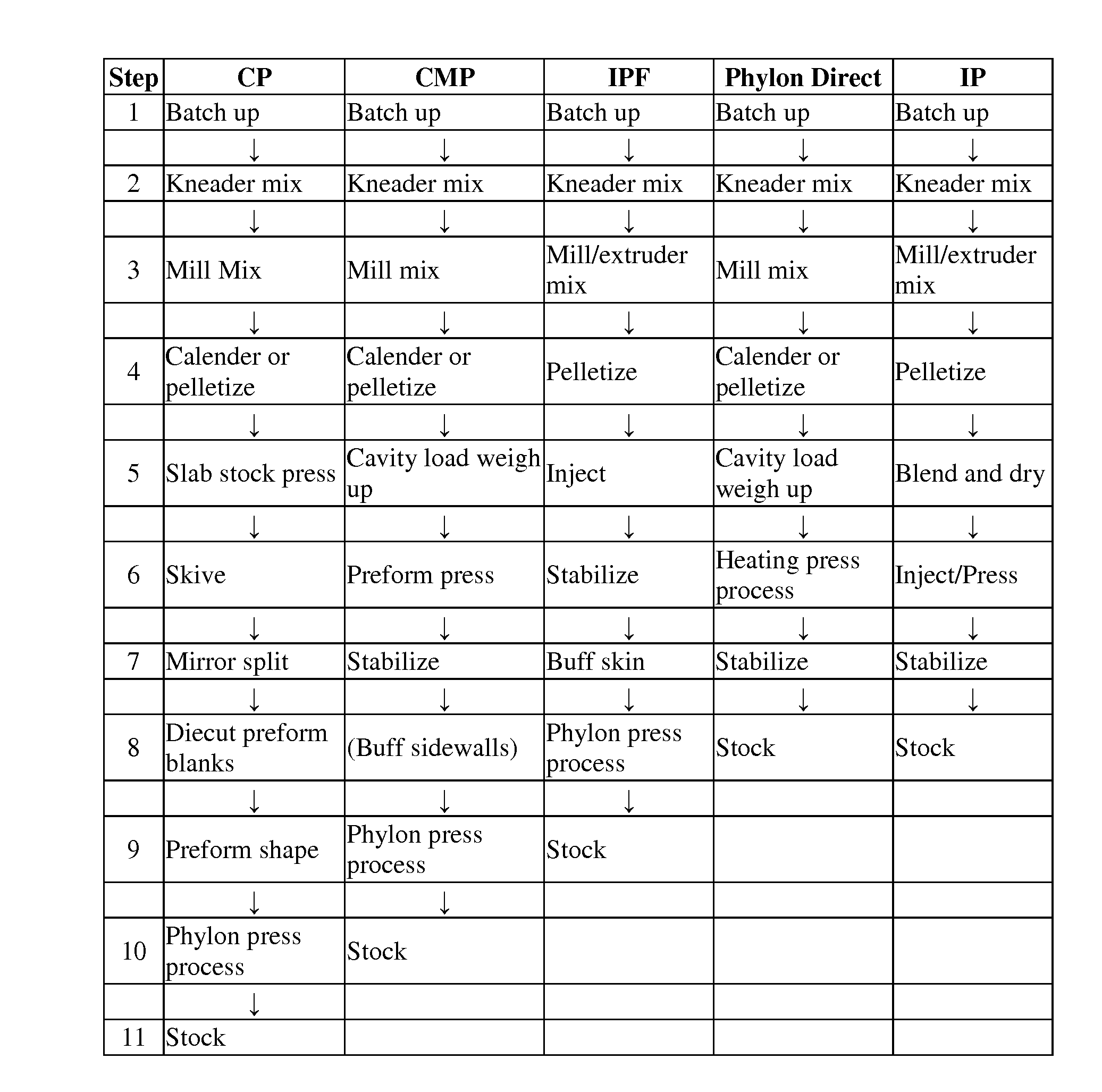

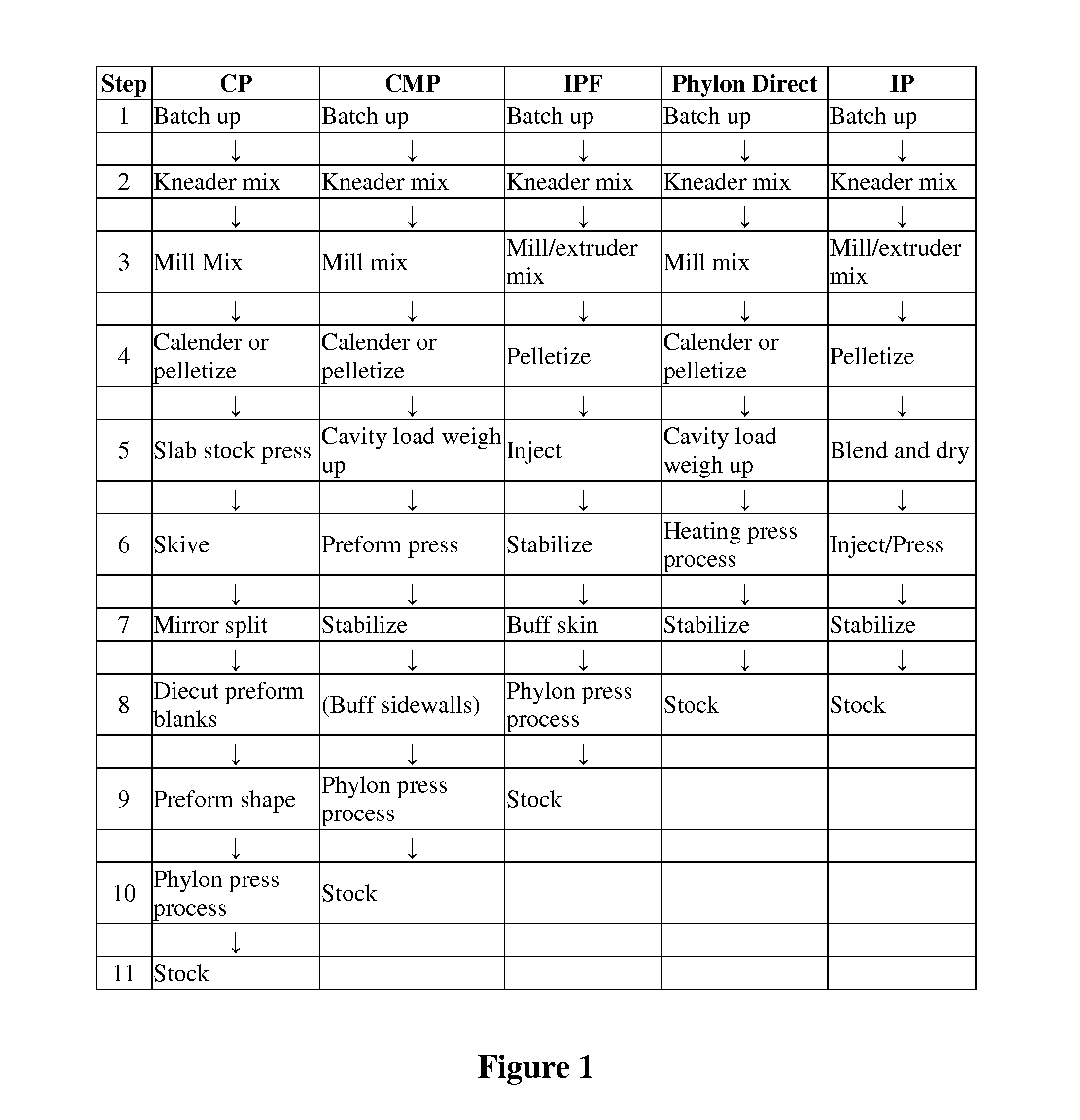

Sports Shoes and Methods for Manufacturing and Recycling of Sports Shoes

InactiveUS20160302508A1Easy to identifySolesInsolesPolyethylene terephthalatePolyethylene terephthalate glycol

A sports shoe includes an upper wherein a majority by weight of the upper is made from a thermoplastic base material and a sole wherein a majority by weight of the sole is made from the same thermoplastic base material. The sole and the upper are individually fabricated and joined to each other. The thermoplastic base material includes at least one of the following materials: thermoplastic polyurethane TPU, polyamide PA, polyethylene terephthalate PET, or polybutylene terephthalate PBT.

Owner:ADIDAS

Covering panel

Owner:I4F LICENSING NV

Method for releasing adhered article

It is an object of the invention to provide a separation method of an adherend capable of easily and reliably separating an adherend stuck using an adhesive, a method for recovering an electronic part from an electronic part laminate, and a separation method of laminate glass. The invention provides a separation method of an adherend, which is a method of separating an adherend stuck by using an adhesive, and comprises the steps of: air-tightly sealing the adherend together with a fluid being a gas at a normal temperature and normal pressure in a pressure resistant container, making the inside of the pressure resistant container in a high pressure state, and releasing the pressure of the inside of the pressure resistant container.

Owner:SEKISUI CHEM CO LTD

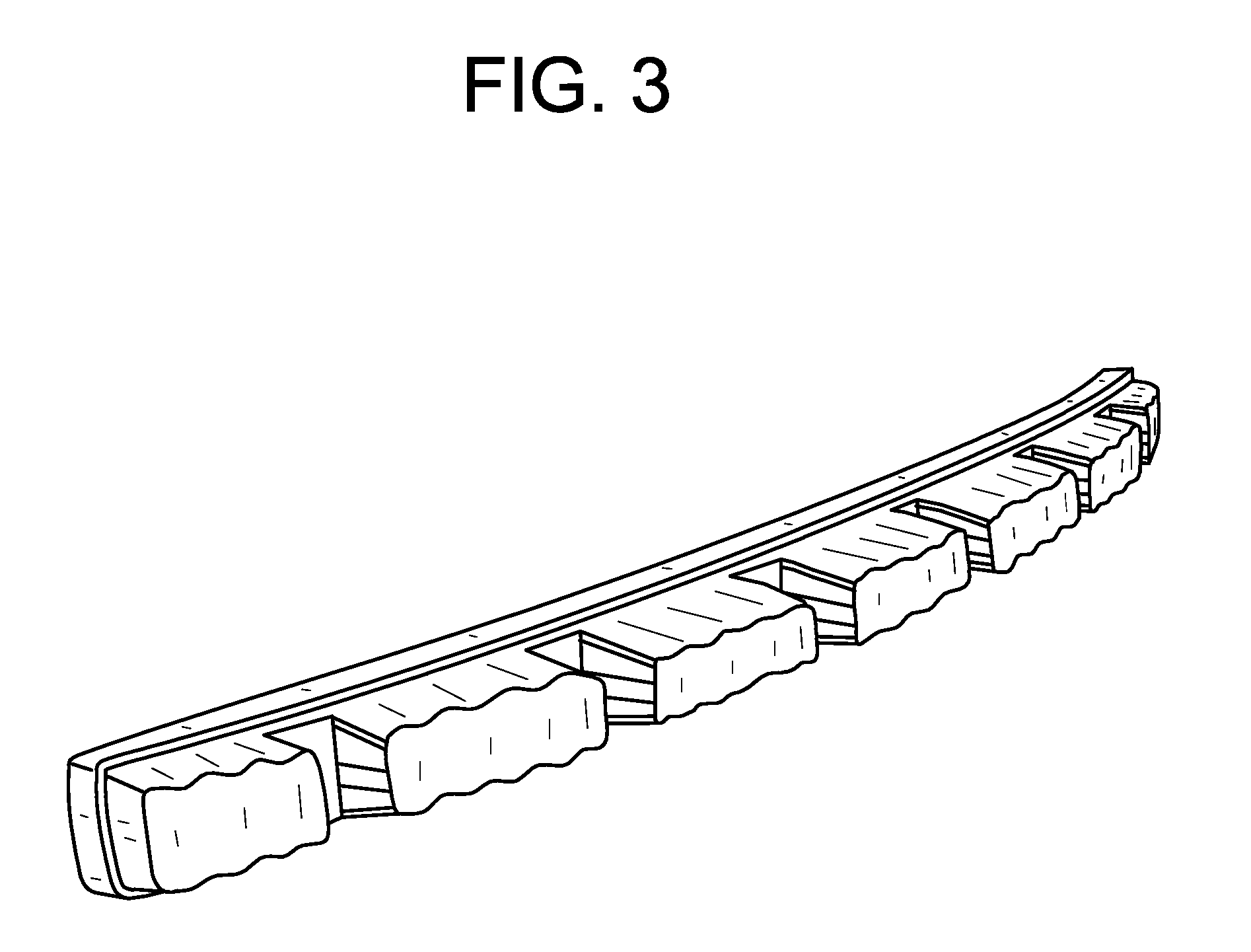

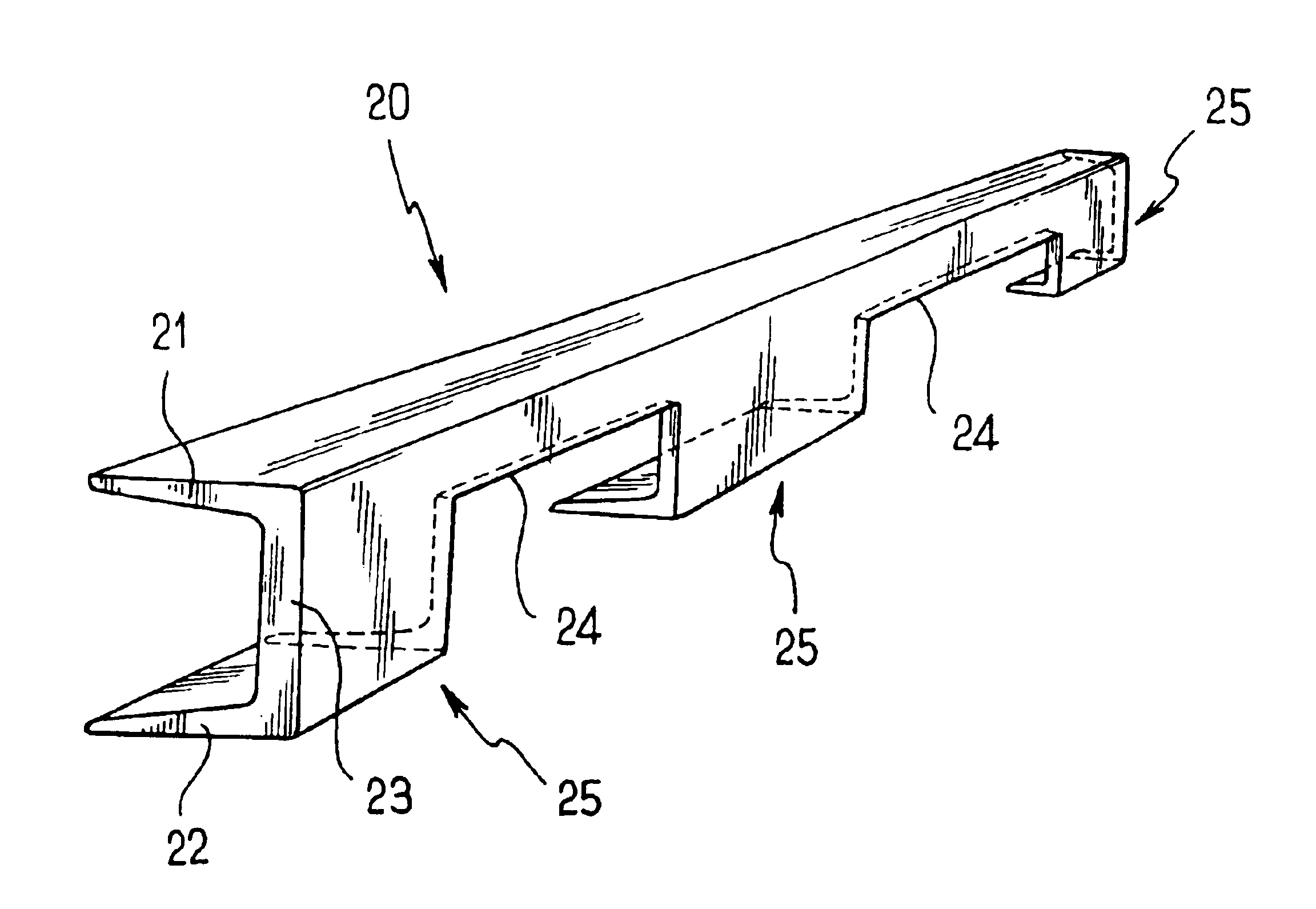

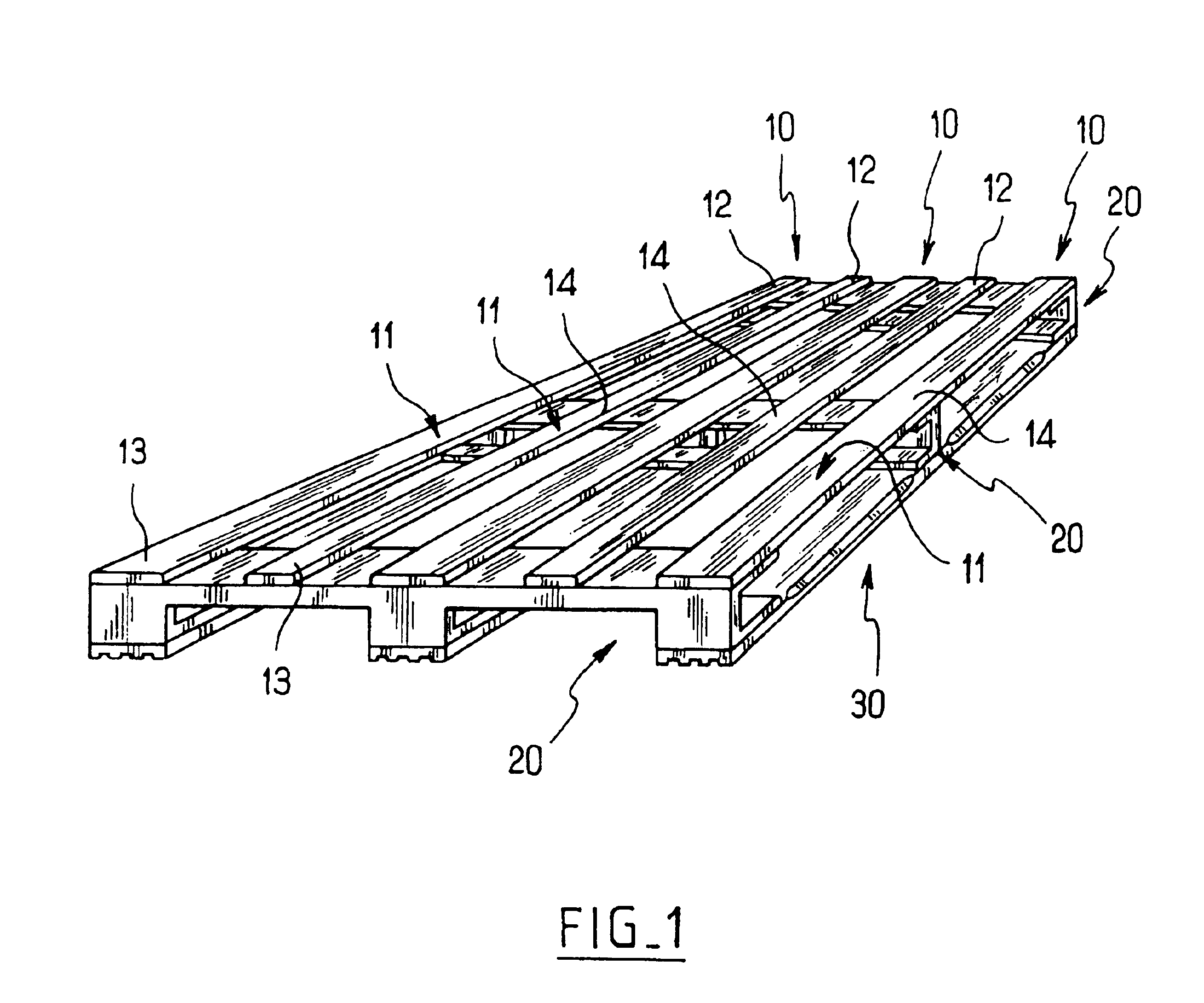

Part made of recycled thermoplastic material, a corresponding method of manufacture, and a pallet comprising at least one bar of this type

InactiveUS6780500B2Improve featuresSatisfactory characteristicSynthetic resin layered productsPlastic recyclingPolyethylene terephthalateEngineering

Owner:DUMOUCHEL CATHERINE +1

Eva recycling method

ActiveUS20140066530A1Good physical propertiesMore rubberySolesPlastic recyclingFoaming agentPetroleum resin

A method of recycling scrap ethylene-vinyl acetate (EVA) foam involves foaming and crosslinking a blend containing virgin EVA resin and scrap EVA foam, as well as a crosslinking agent and blowing agent for the EVA resin. The blend further contains a compatibilizer, which is a hydrogenated petroleum resin.

Owner:NIKE INTERNATIONAL LTD

Water-in-oil bituminous dispersions and methods for producing paving compositions from the same

ActiveUS7297204B2Low viscosityHighly preventive effectProductsIn situ pavingsSolvent freeSURFACTANT BLEND

Owner:INGEVITY SOUTH CAROLINA

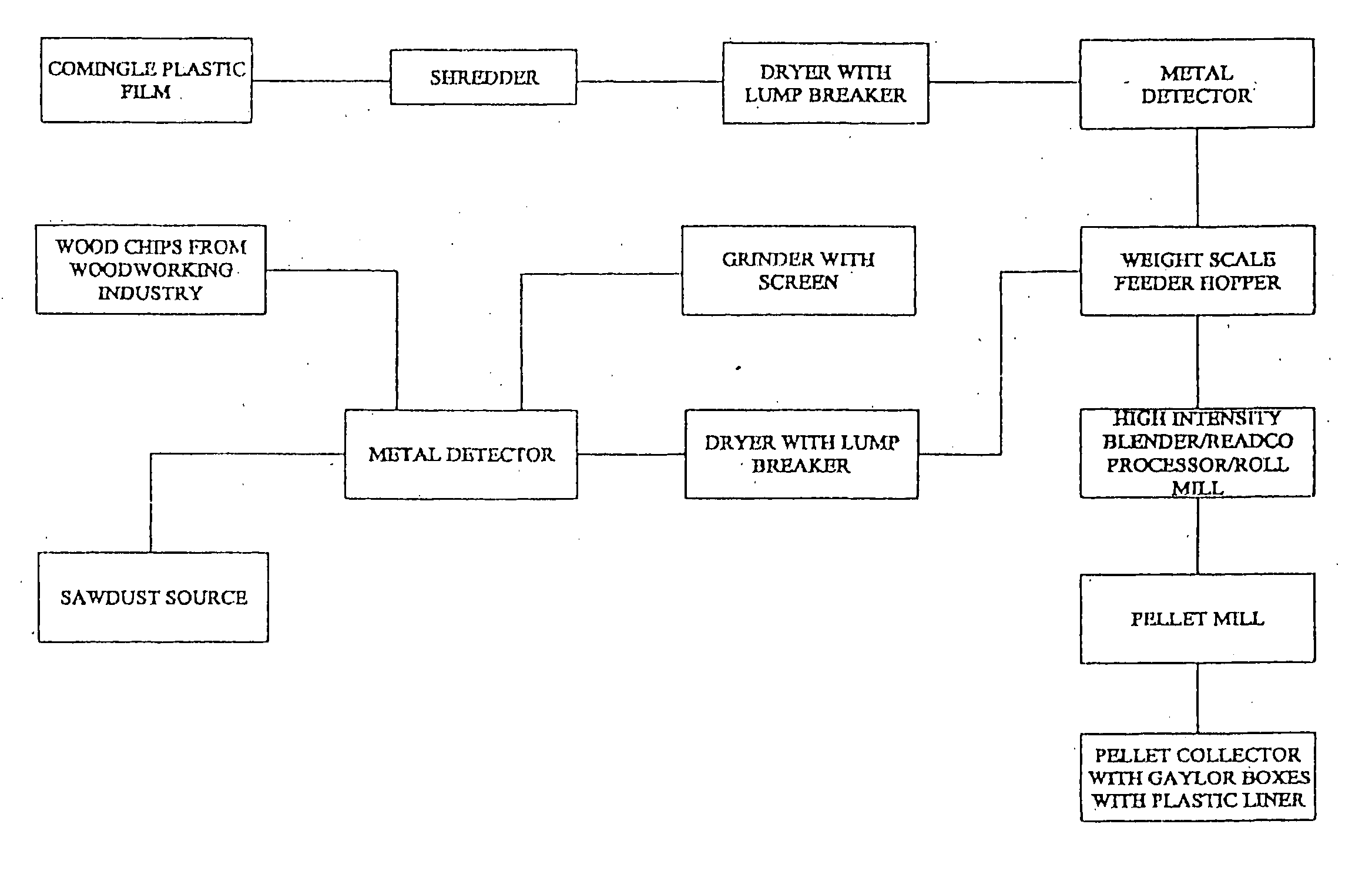

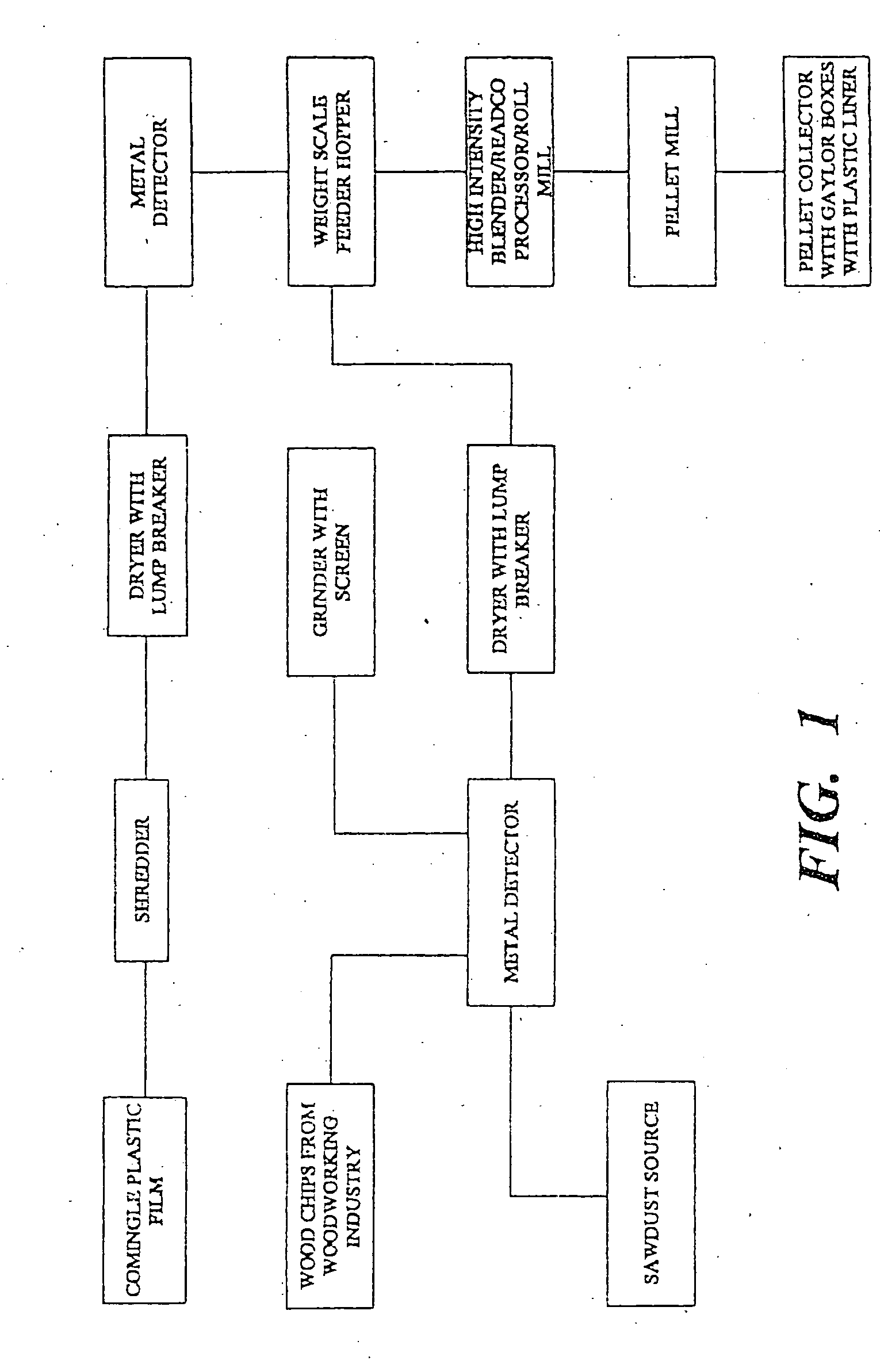

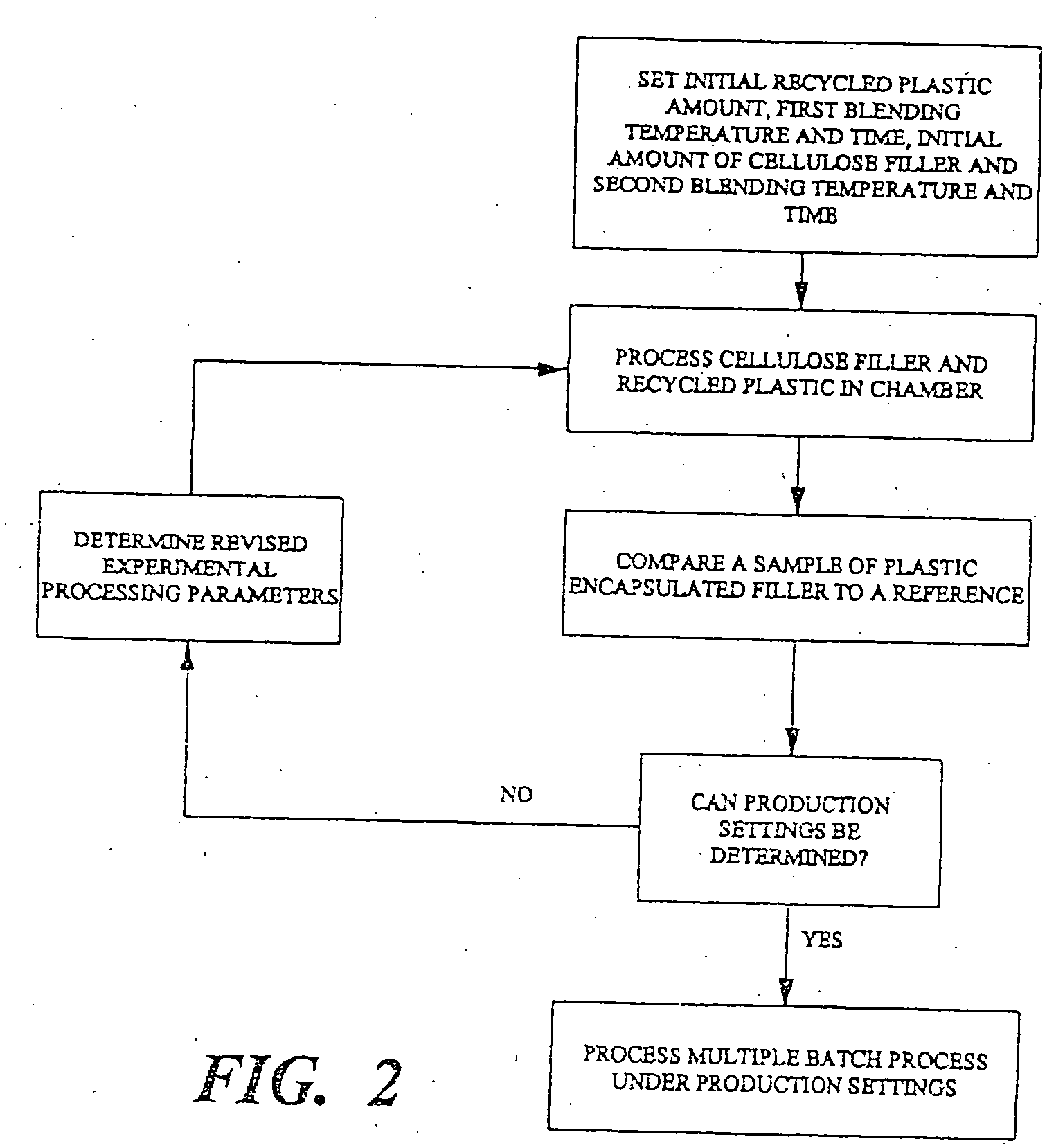

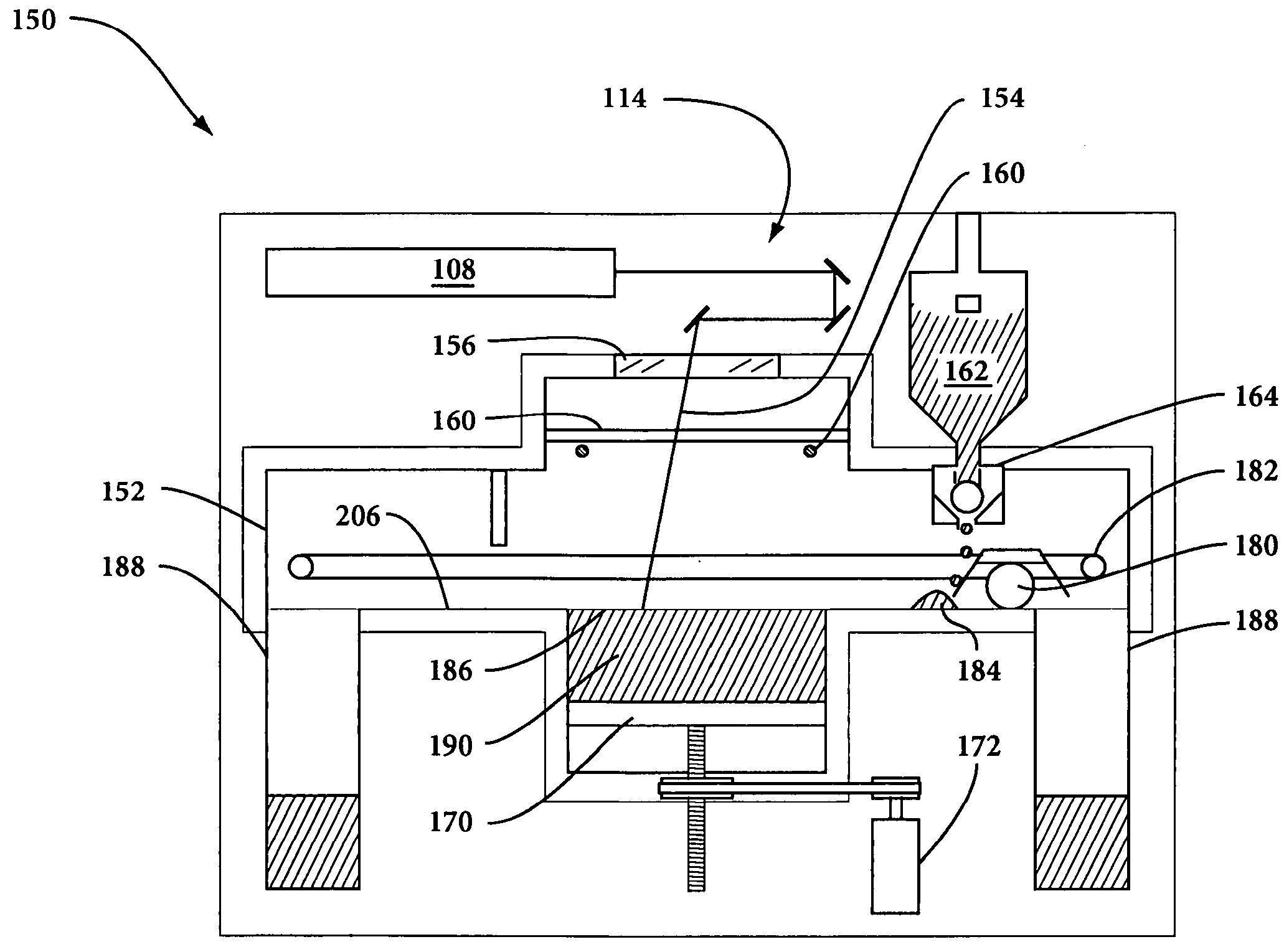

Process for making modified cellulosic filler from recycled plastic waste and forming wood substitute articles

InactiveUS20060006564A1Reduce the possibilityLower melting and softening temperaturePlastic recyclingWood working apparatusThermoplasticPolyvinyl chloride

A low cost process of making modified cellulosic materials by melt blending with at least 30% recycled and commingled plastic waste stream at higher temperature and pressure where at least 70% of plastics melts and encapsulate the filler. The plastic encapsulated filler can be used as a feed stock for continuous or discontinuous process of compression, extrusion, coextrusion and injection molded structural (e.g. profiles, stake, panel) and non-structural (e.g. sheet, thin-board) articles by mixing with a thermoplastic (e.g. polyethylene, polypropylene, polyvinyl chloride, polystyrene) or a hybrid mixture of said thermoplastics, bonding agents, plastic processing additives, impact modifiers, colorant and with / without a lightner.

Owner:MALDAS DEBESH +1

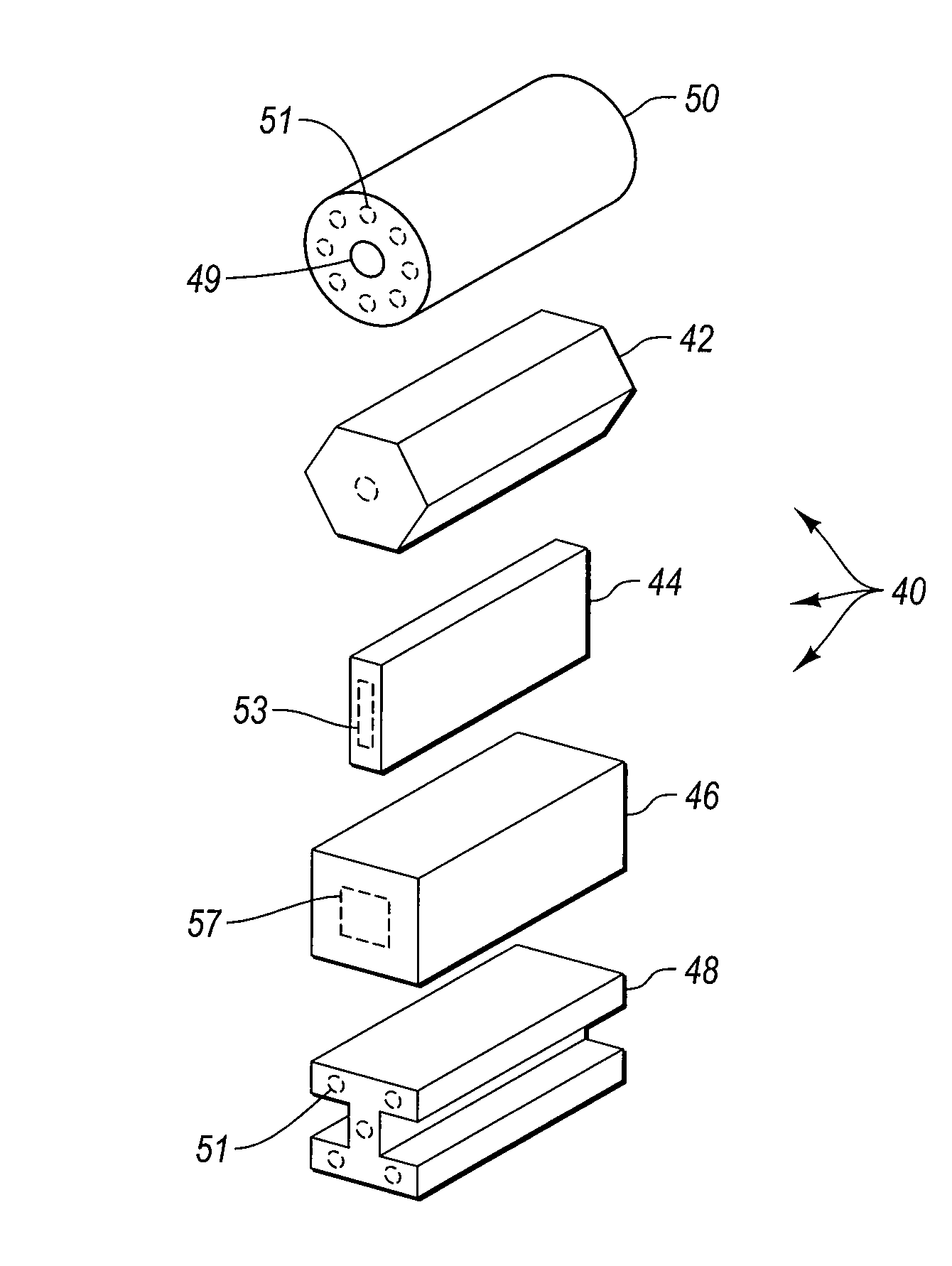

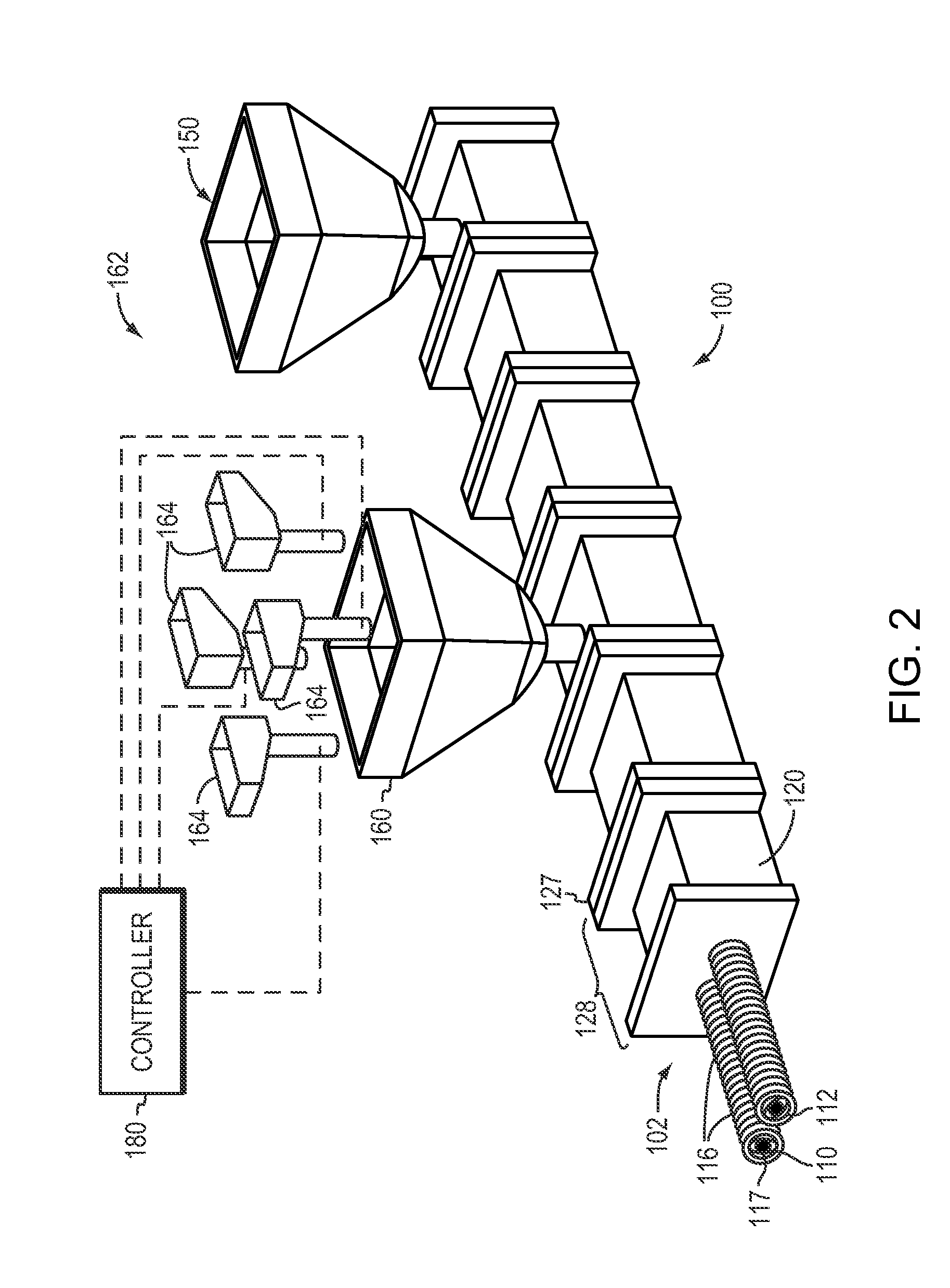

Selective Laser Sintering Powder Recycle System

ActiveUS20090169664A1Good blendingReduce powder lossFlow mixersTransportation and packagingSelective laser sinteringMetallurgy

A method and apparatus for forming three-dimensional objects by laser sintering that includes the use of dense phase pneumatic conveying to internally recycle overflow powder, and to thoroughly blend overflow, recovered and virgin powder to provide a consistent powder feed mix to a laser sintering machine. Overflow powder from the laser sintering machine is recovered and recycled back into the laser sintering machine for reuse. The approach results in a compact and reliable powder recycle system with complete blending and minimum attrition to the handled powder.

Owner:3D SYST INC

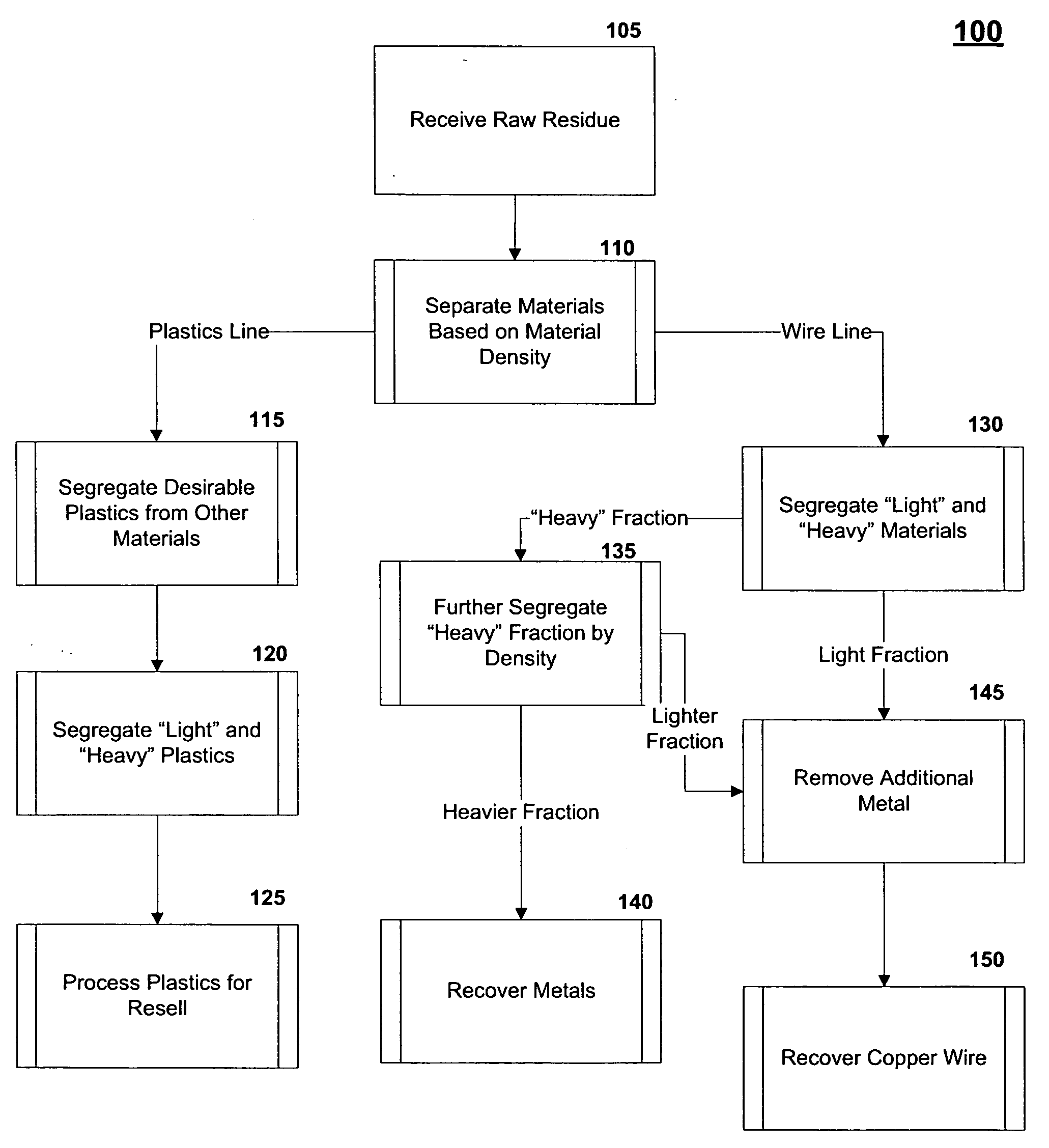

Method and system for sorting and processing recycled materials

InactiveUS20080257794A1Small sizePlastic recyclingAuxillary shaping apparatusCopper wireNonferrous metal

Processing recycled materials to recover plastics, copper wire, and other non-ferrous metals. Aspects of the invention employ density separation to separate plastic-bearing materials from copper-bearing materials. Plastic-bearing materials are further separated to separate light plastics from heavy plastics. Plastics are concentrated, extruded, and palletized. Copper and other valuable metals are recovered from copper-bearing materials using a water separation table.

Owner:VALERIO THOMAS A

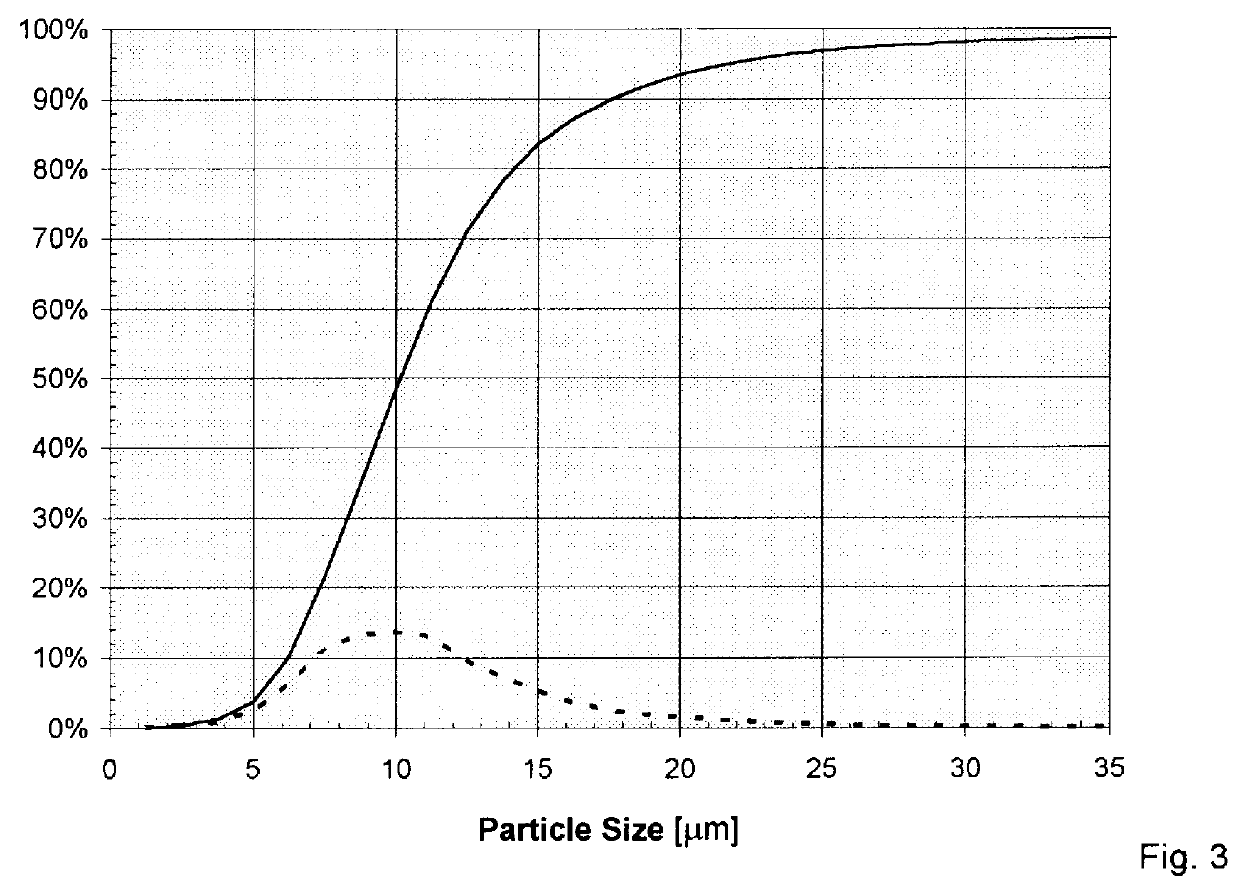

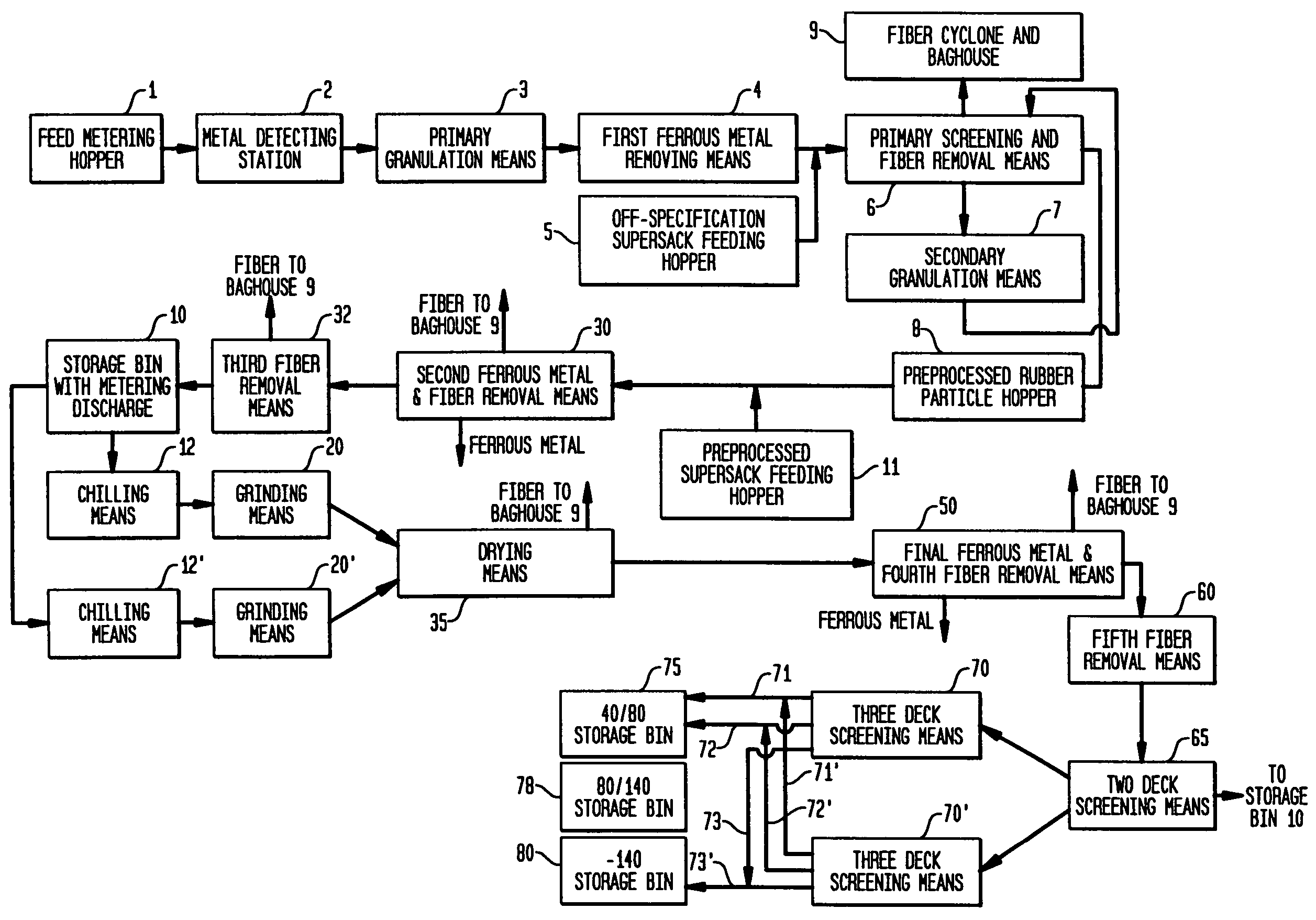

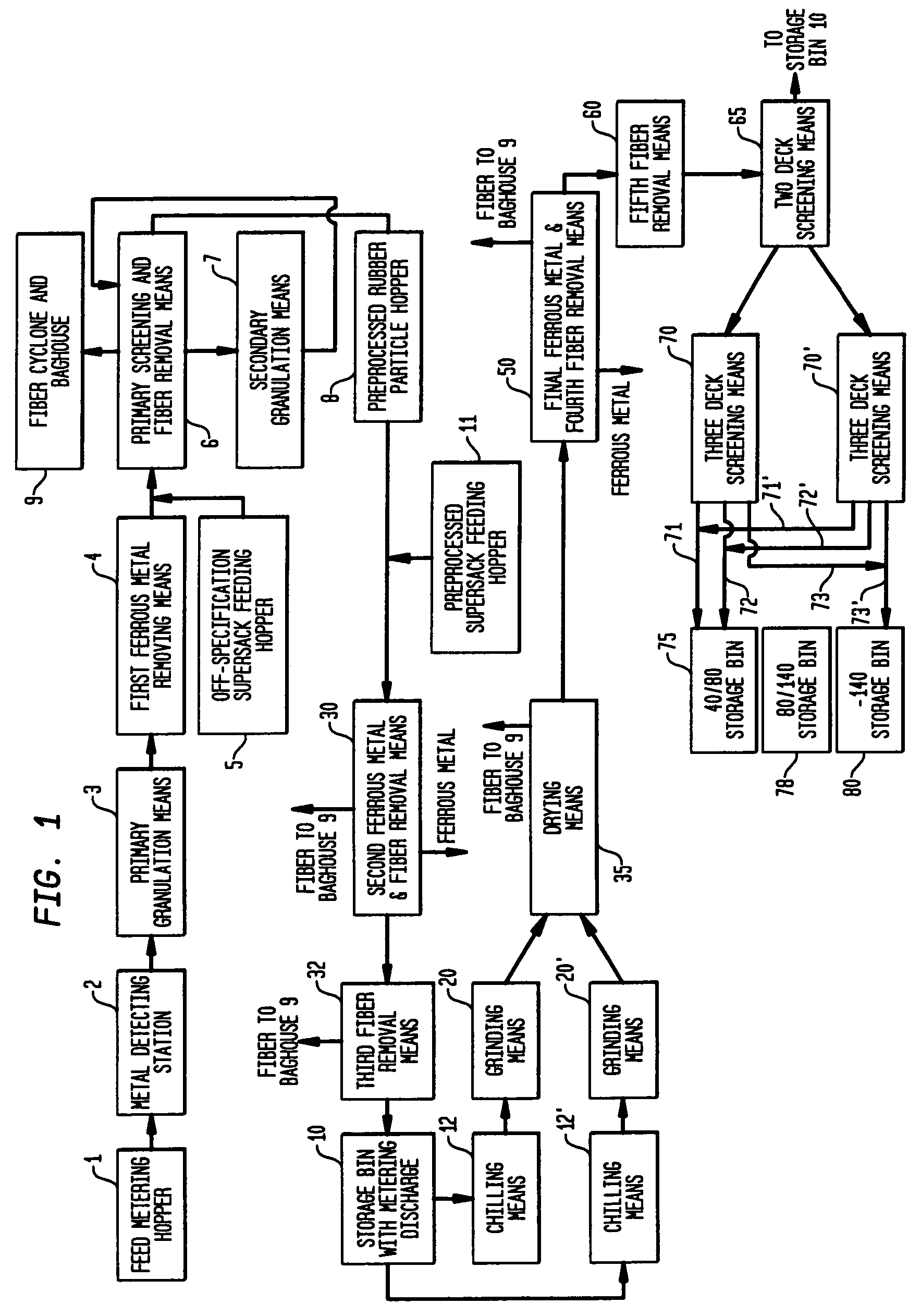

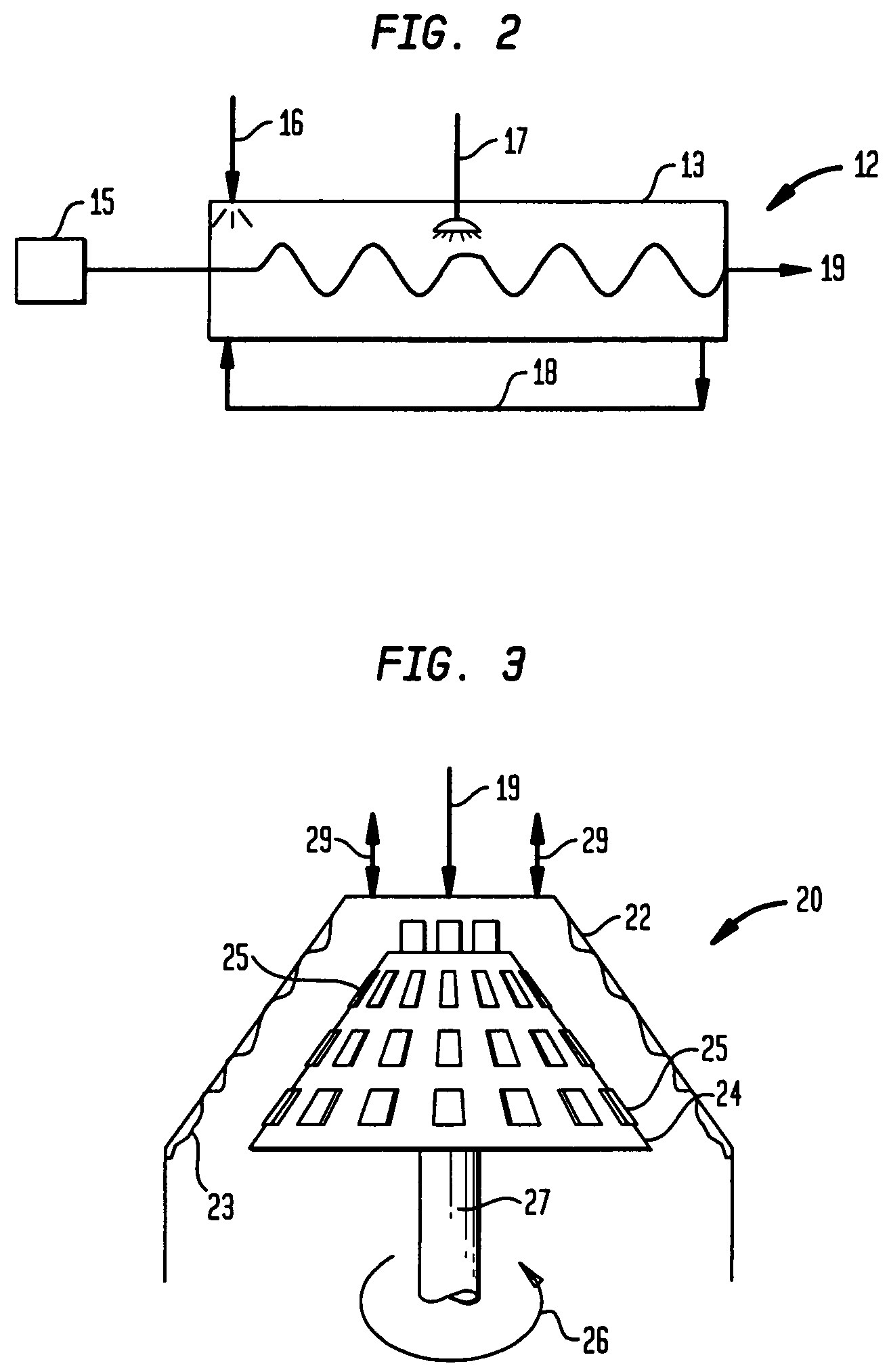

Process and apparatus for manufacturing crumb and powder rubber

A process and apparatus for manufacturing crumb and powder rubber. The process and apparatus include a cooling step, effectuated by cooling means, wherein the temperature of cryogenically cooled preprocessed rubber particles is controlled. The process and apparatus also include a grinding step, effectuated by grinding means, in which the degree of grinding, and thus the product particle size range, is controlled.

Owner:LEHIGH TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com