Patents

Literature

10232 results about "Copper wire" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

F-inverted compact antenna for wireless sensor networks and manufacturing method

InactiveUS20100026605A1Effective bandwidthLow profileRadiating elements structural formsHelical antennasDielectricCopper wire

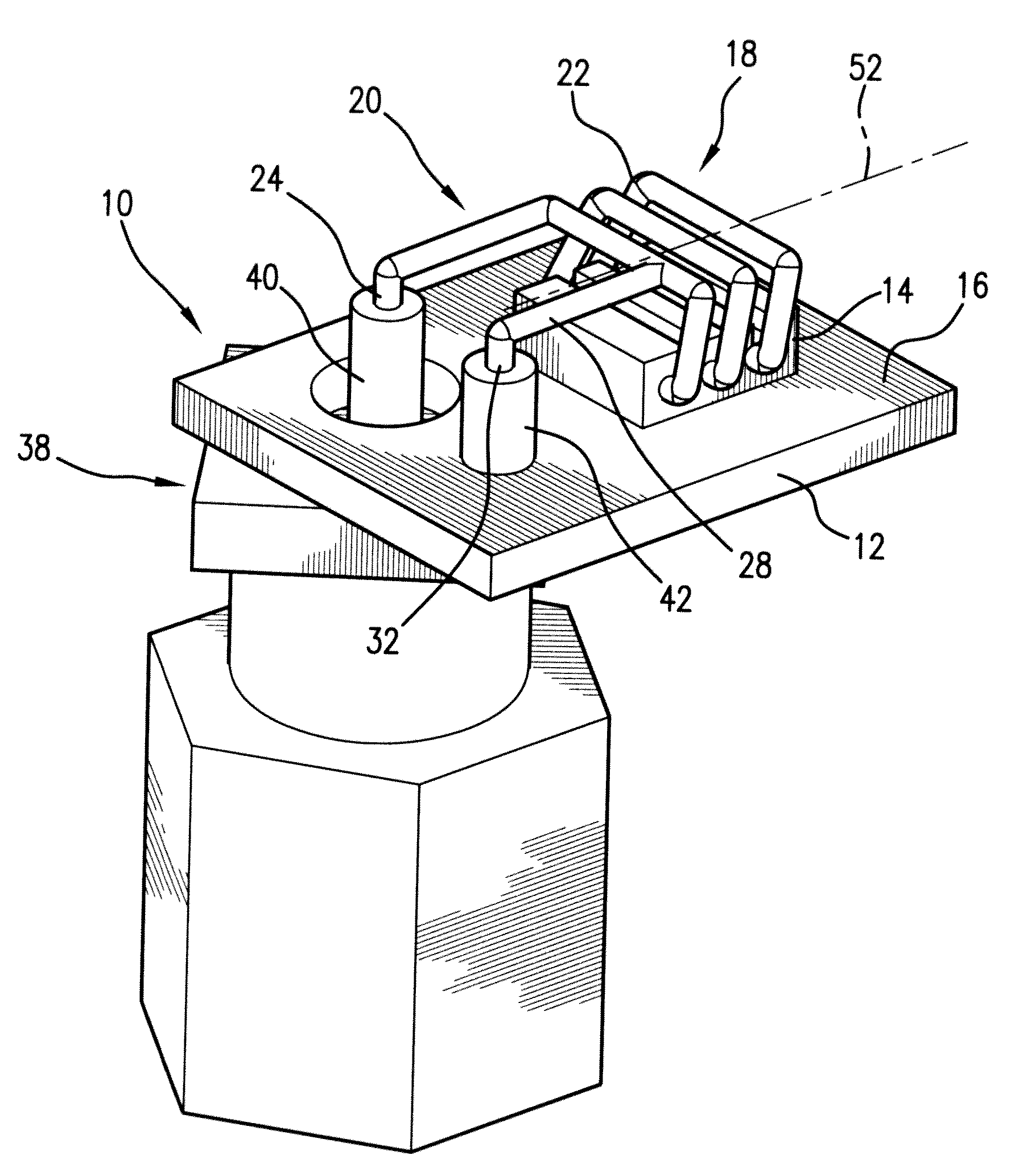

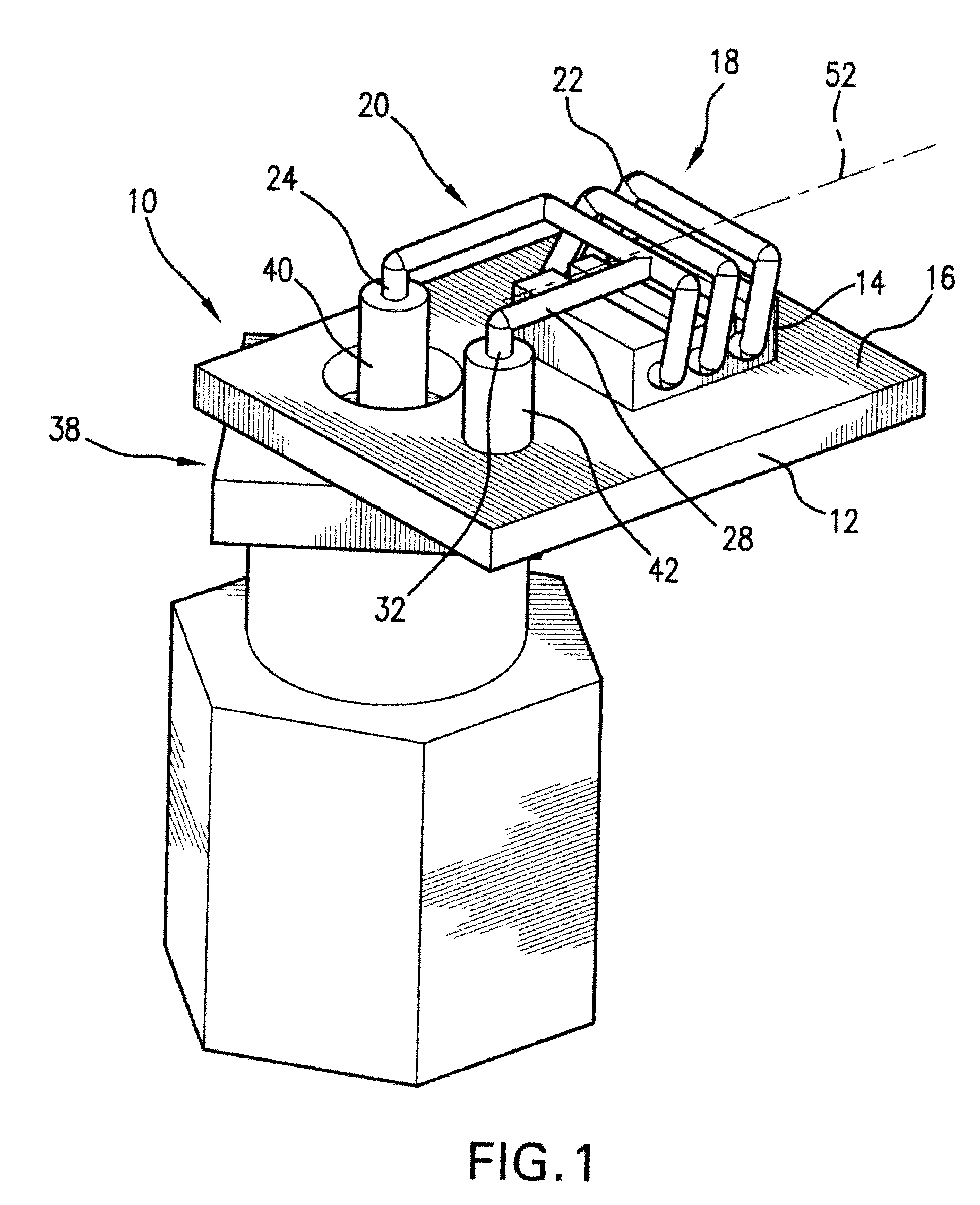

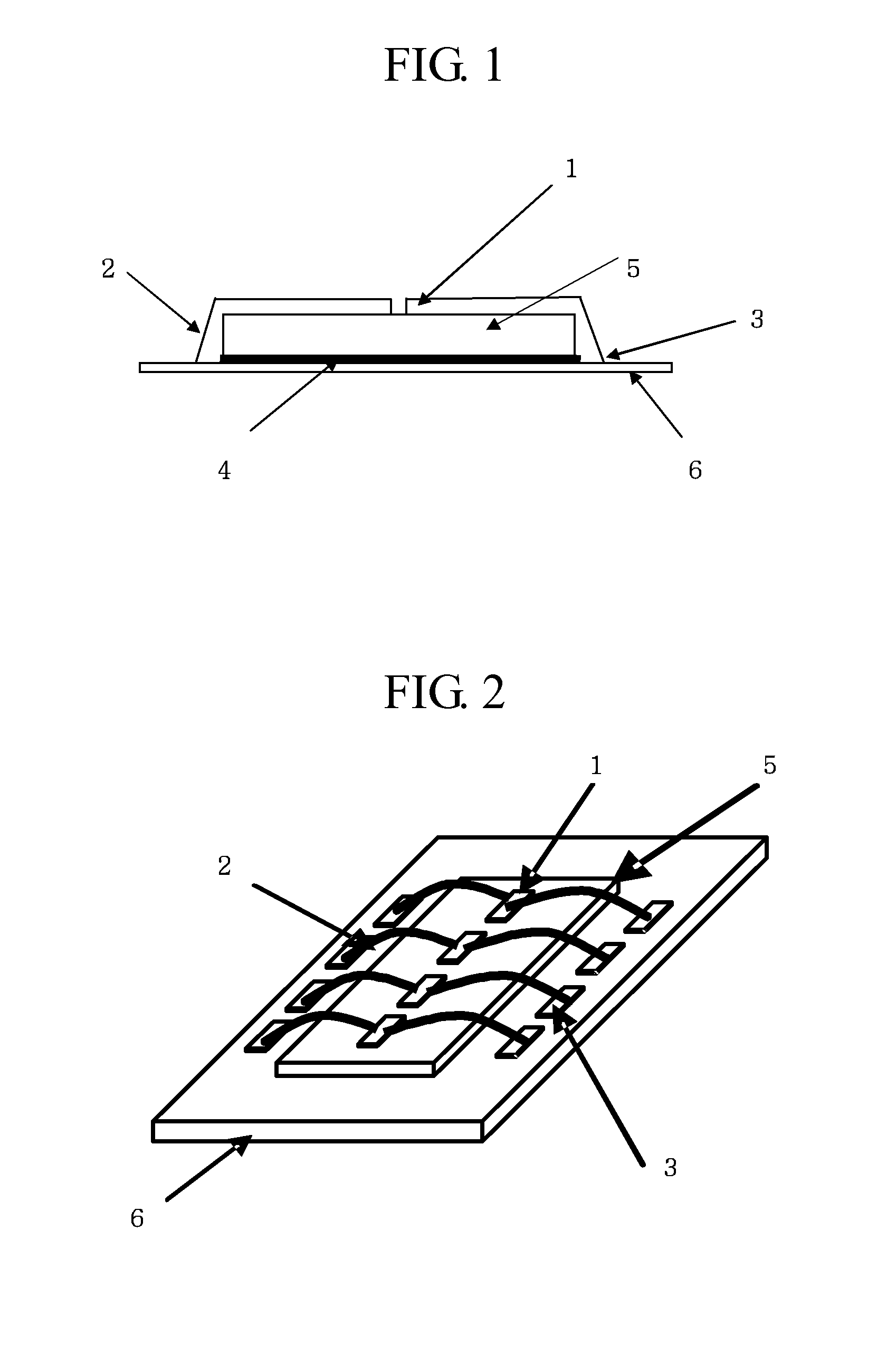

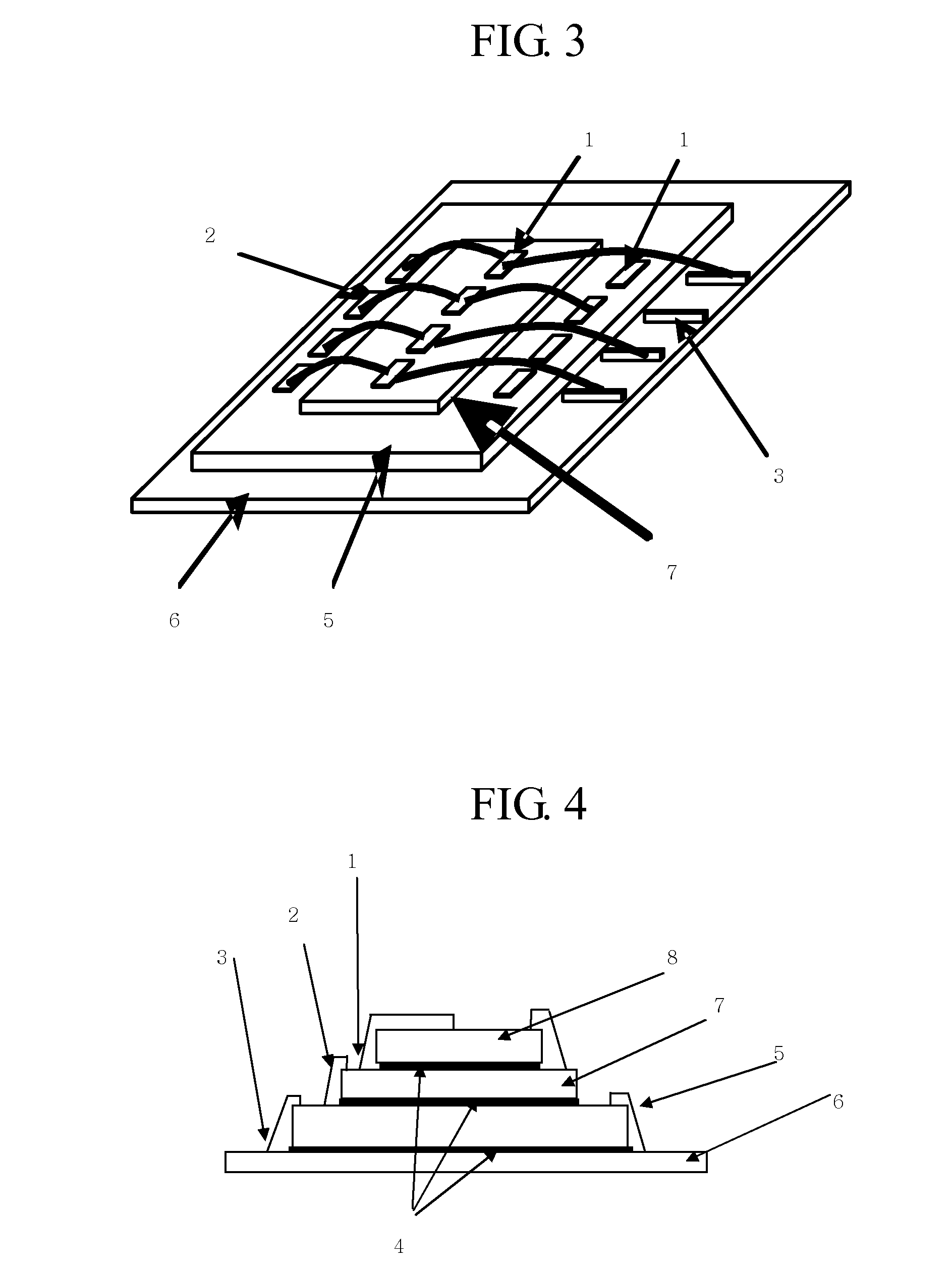

An F-inverted compact antenna for ultra-low volume Wireless Sensor Networks is developed with a volume of 0.024λ×0.06λ×0.076λ, ground plane included, where λ is a resonating frequency of the antenna. The radiation efficiency attained is 48.53% and the peak gain is −1.38 dB. The antenna is easily scaled to higher operating frequencies up to 2500 MHz bands with comparable performance. The antenna successfully transmits and receives signals with tolerable errors. It includes a standard PCB board with dielectric block thereon and helically contoured antenna wound from a copper wire attached to the dielectric block and oriented with the helix axis parallel to the PCB. The antenna demonstrates omnidirectional radiation patterns and is highly integratable with WSN, specifically in Smart Dust sensors. The antenna balances the trade offs between performance and overall size and may be manufactured with the use of milling technique and laser cutters.

Owner:UNIV OF MARYLAND

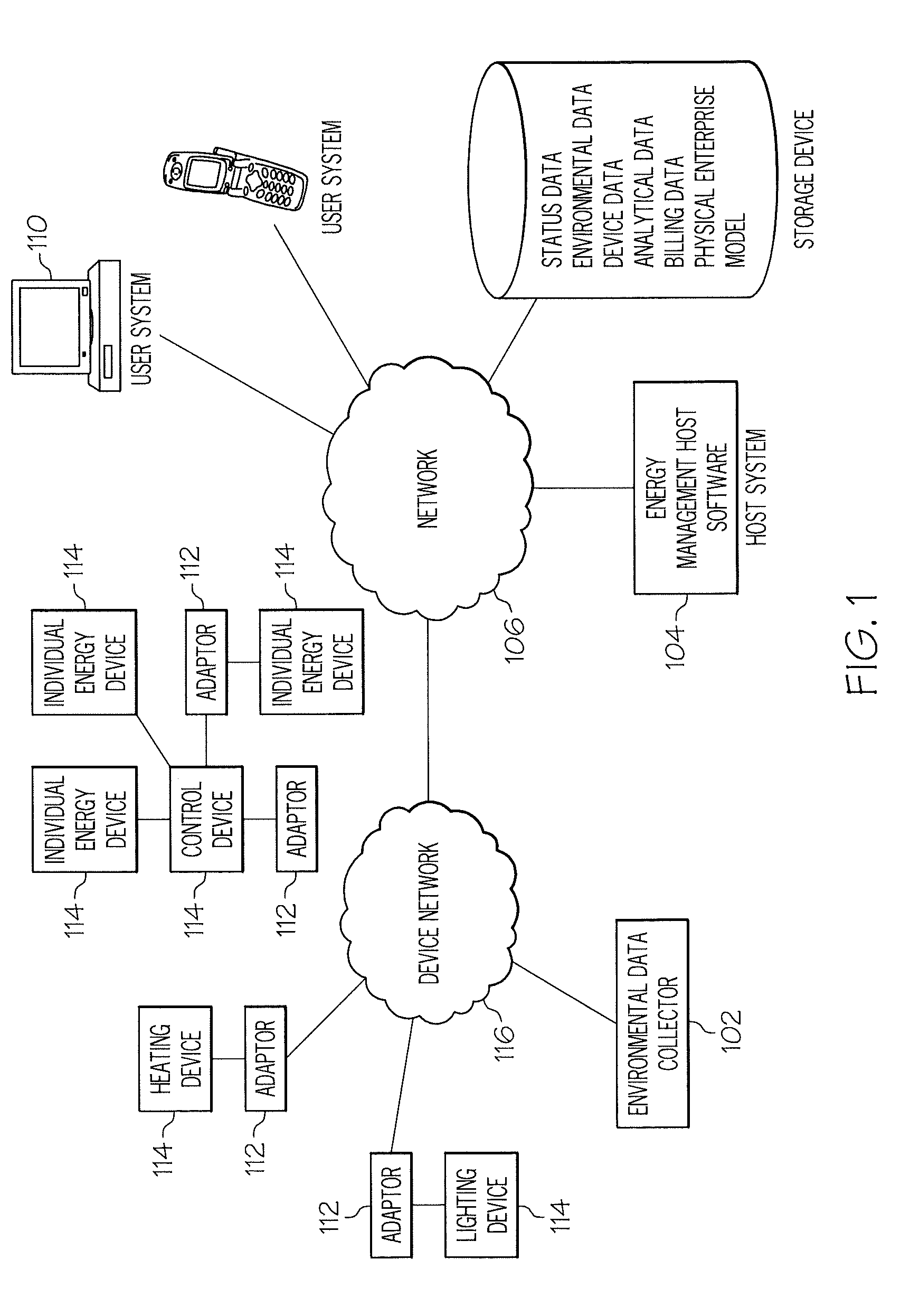

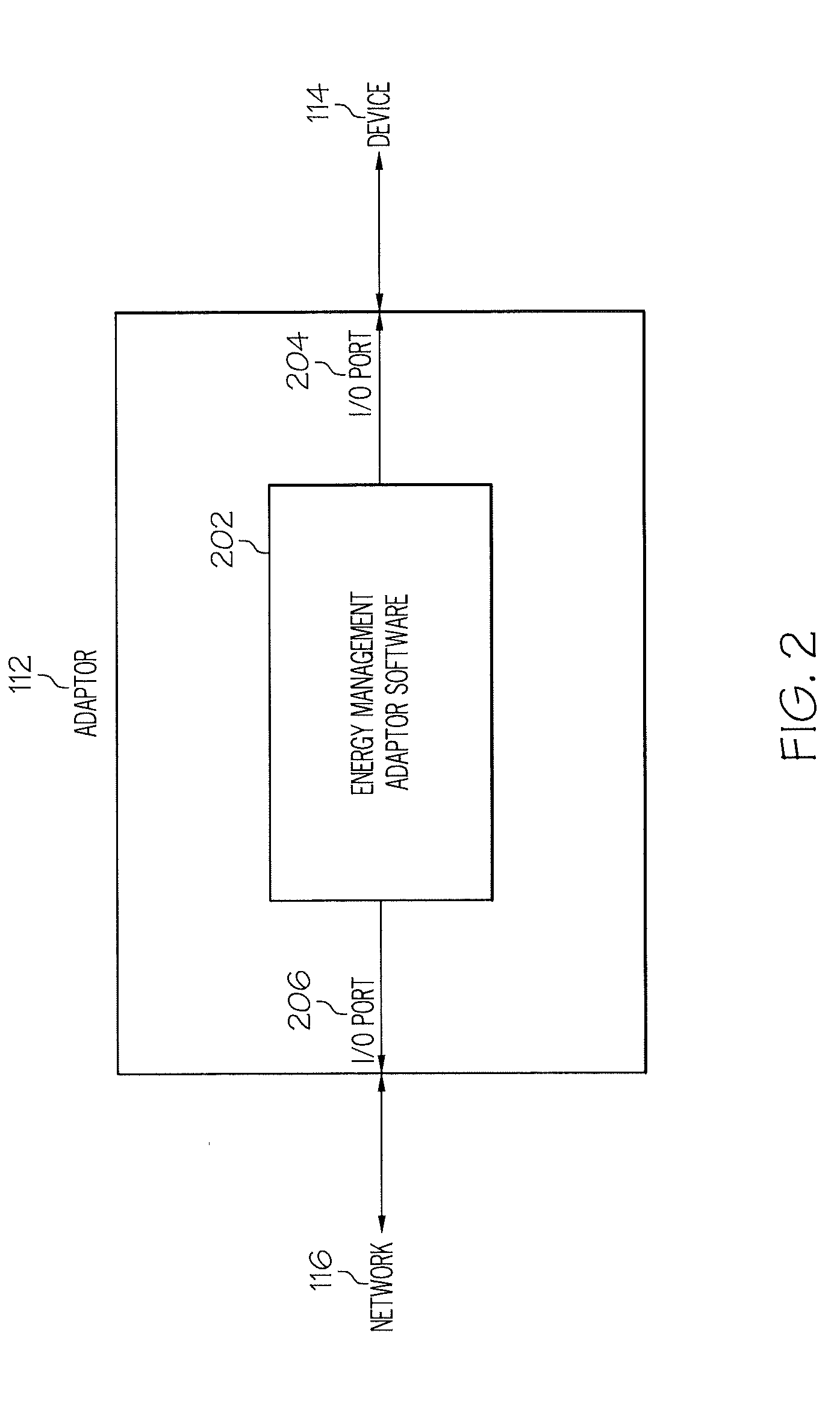

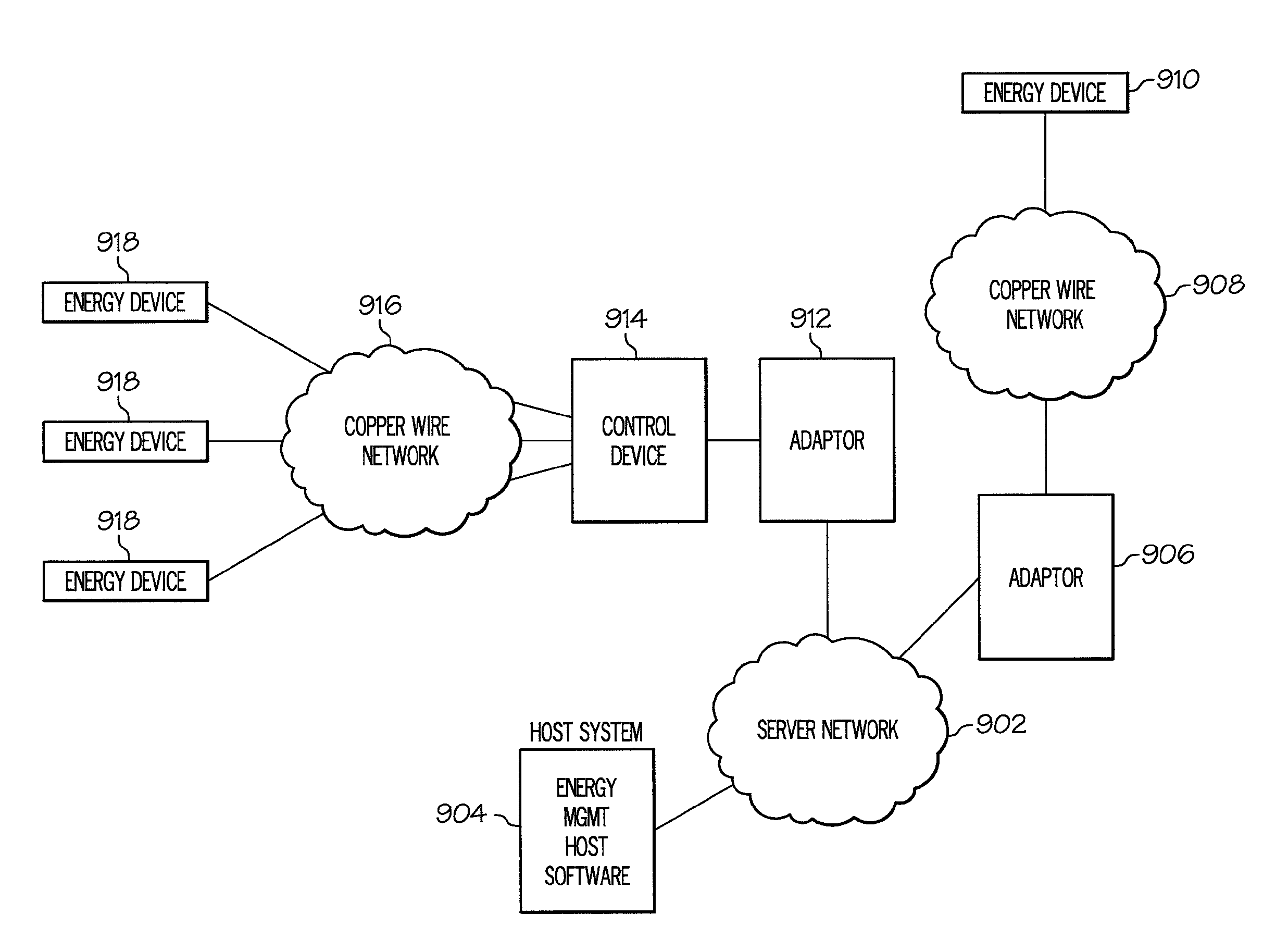

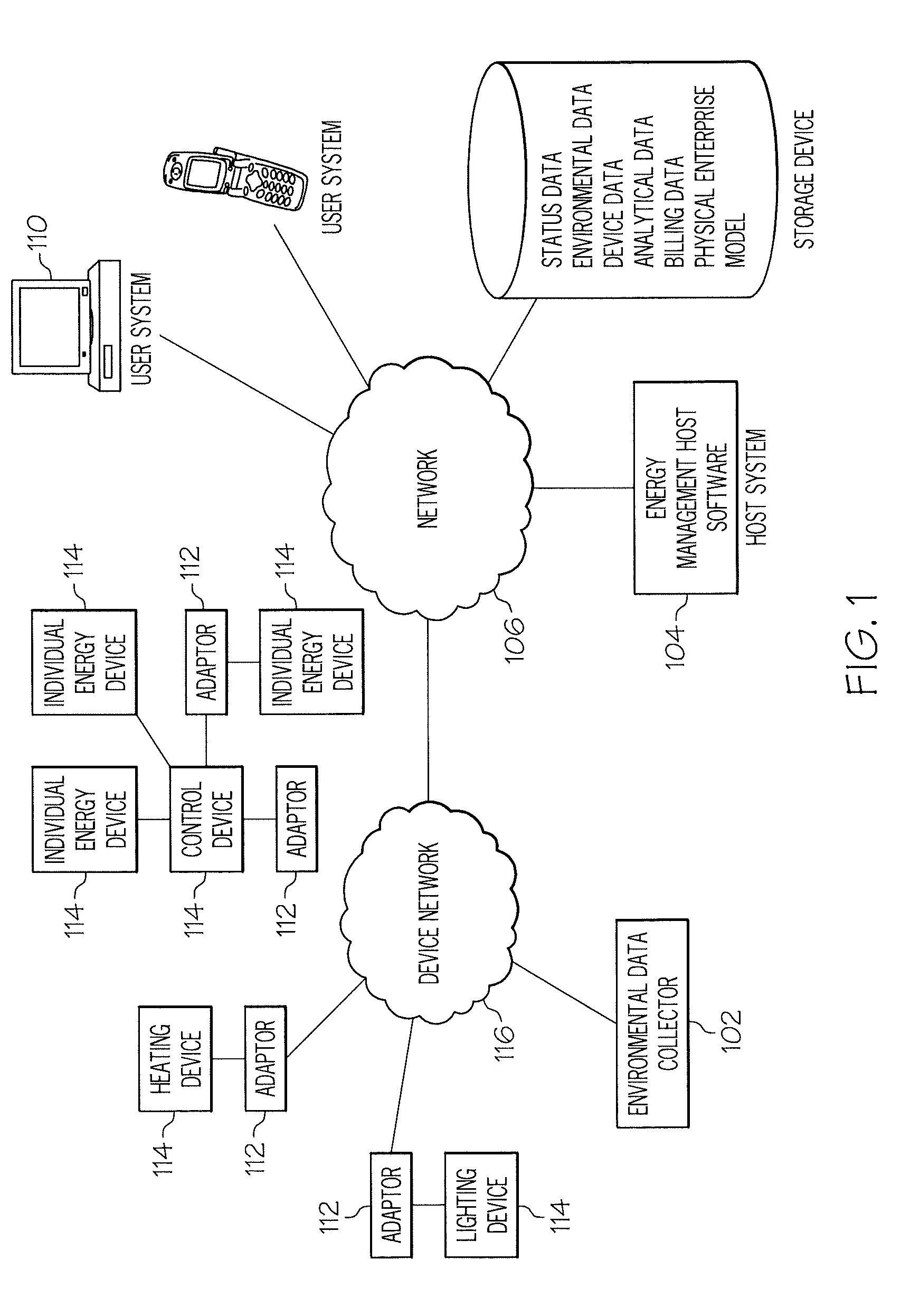

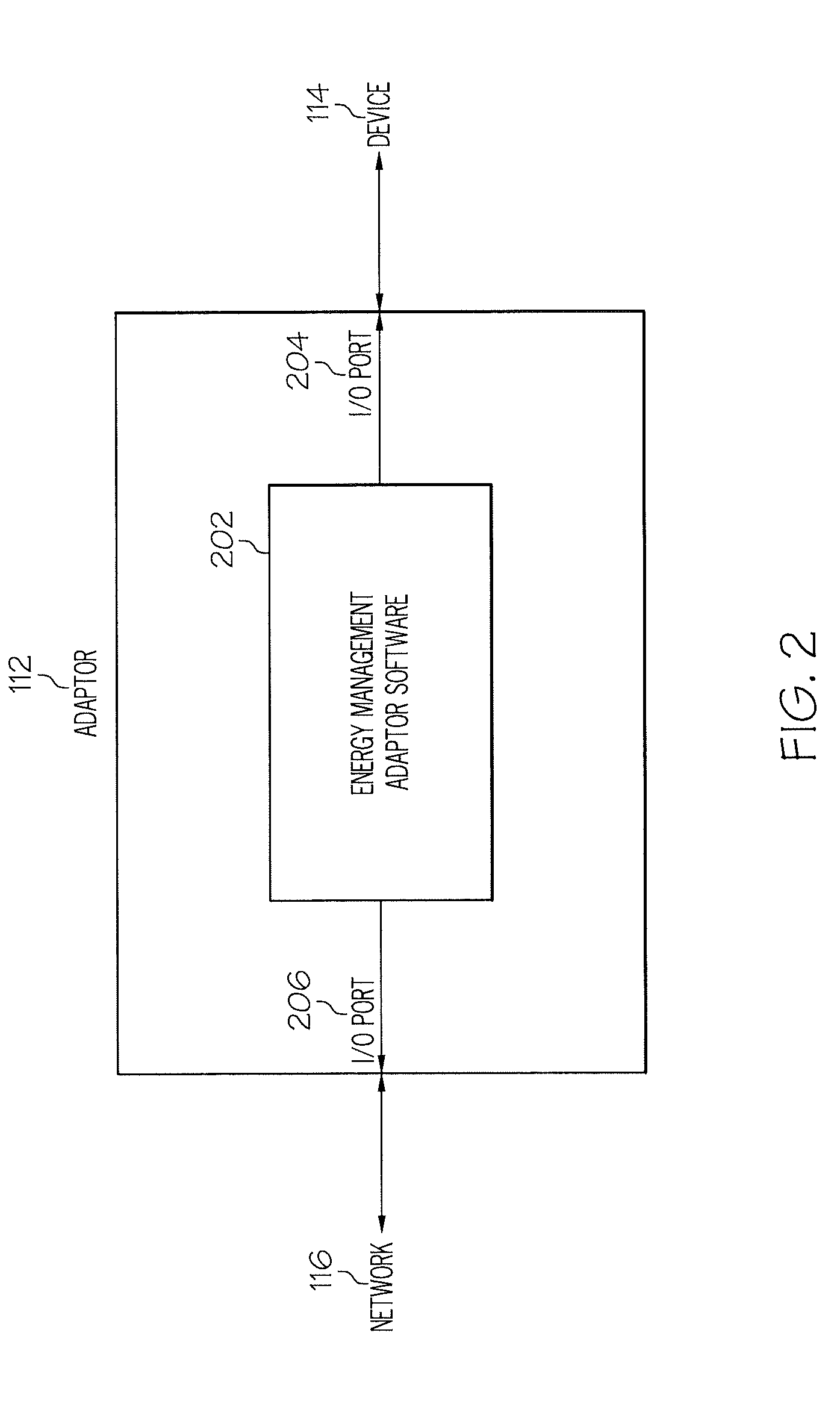

Computer based energy management

ActiveUS20090083167A1Easy to controlEasy to measureLevel controlSpecial tariff metersCopper wireEnergy management software

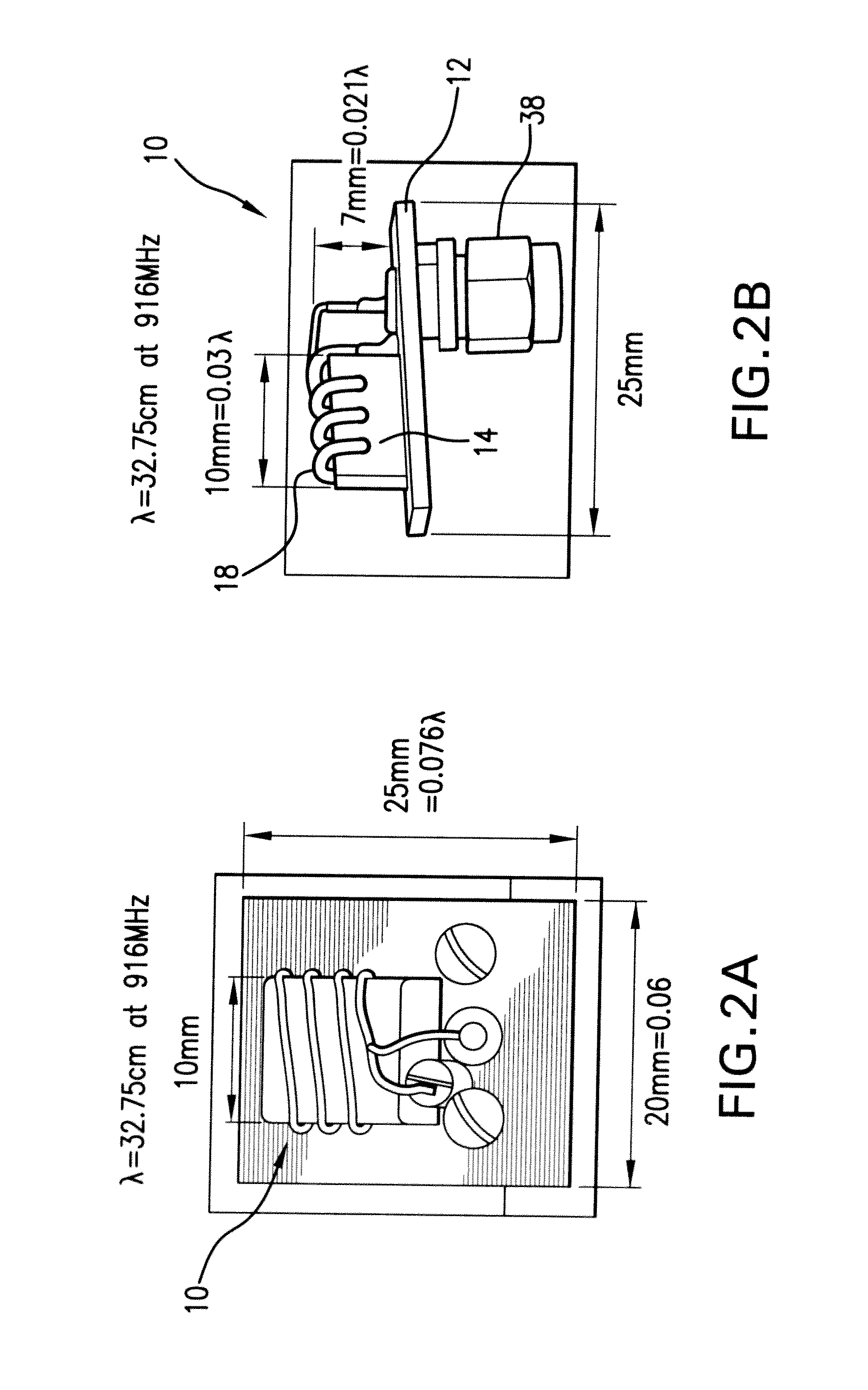

Computer based energy management including an adaptor having a server network interface and a control device interface. The server network interface receives commands from the energy management host software, the commands specify a control device and include control instructions and requests for energy usage data. The control device interface transmits the commands to the control device and receives energy usage data from the control device. The server network interface transmits the energy usage data to the energy management software in response to receiving the energy usage data from the control device. In this manner, the adaptor provides a bridge between the server network and the copper wire network to provide control and measurement of energy usage at a control device level in response to commands from a remote computer system.

Owner:BUDDERFLY INC

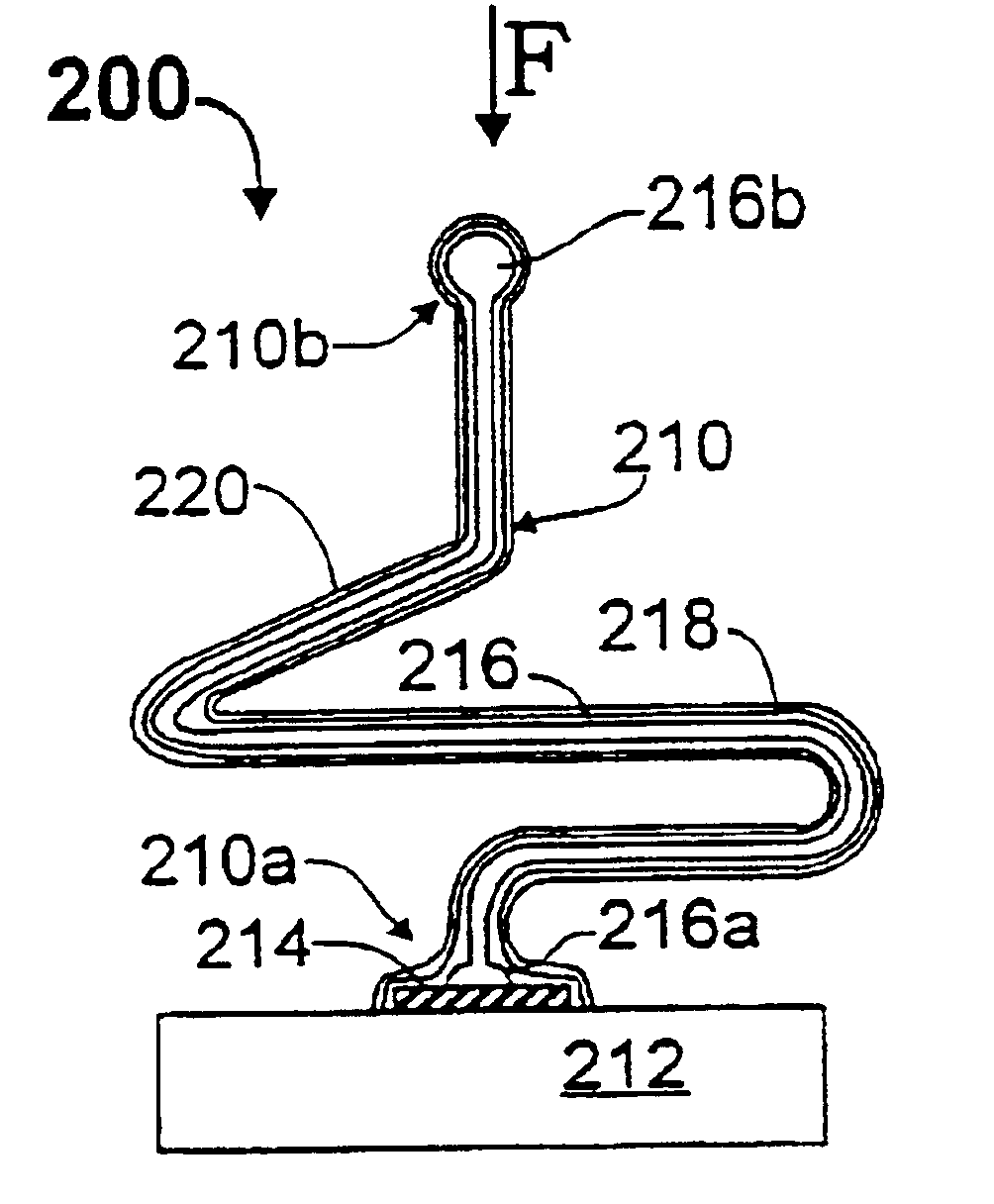

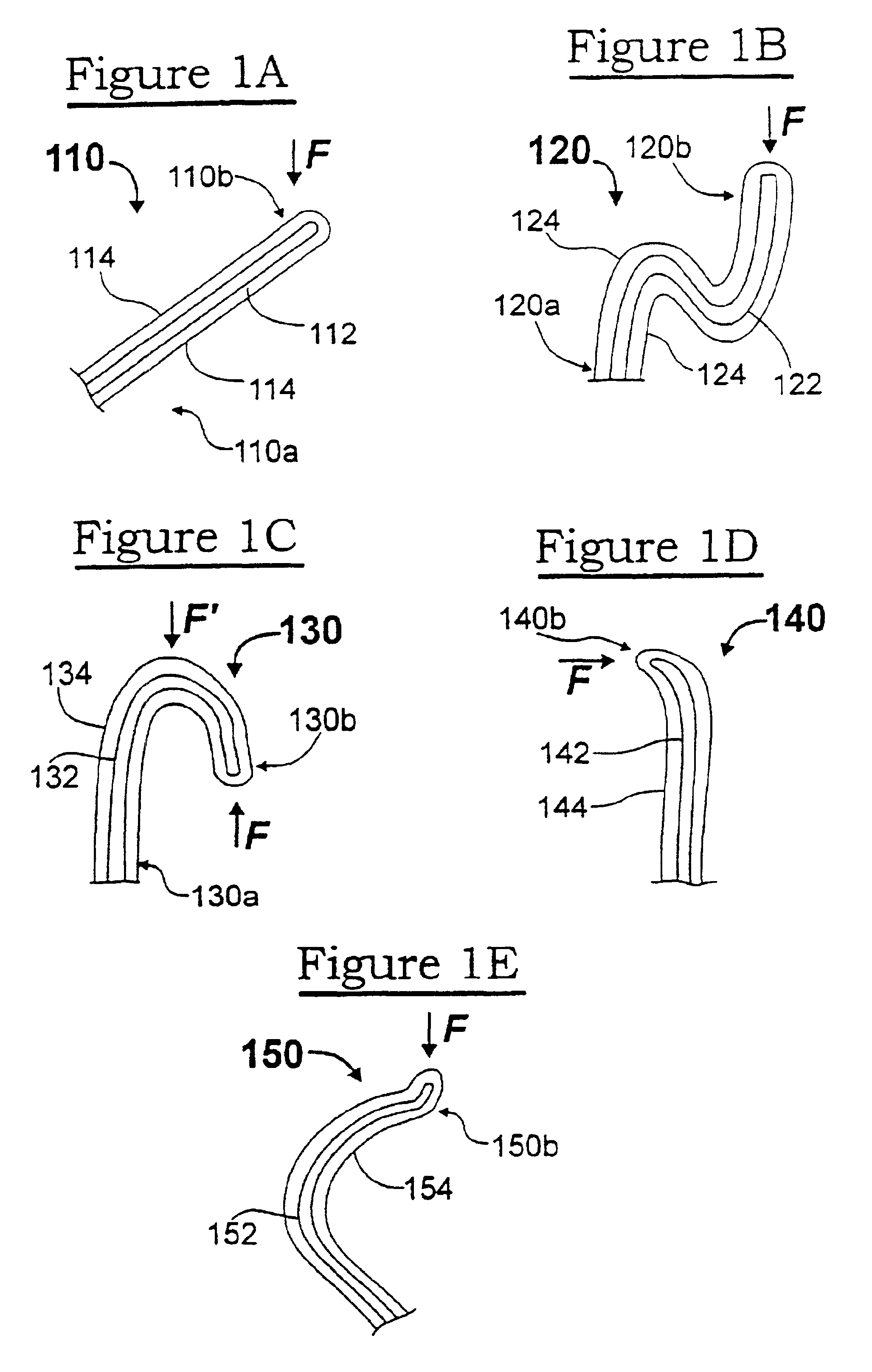

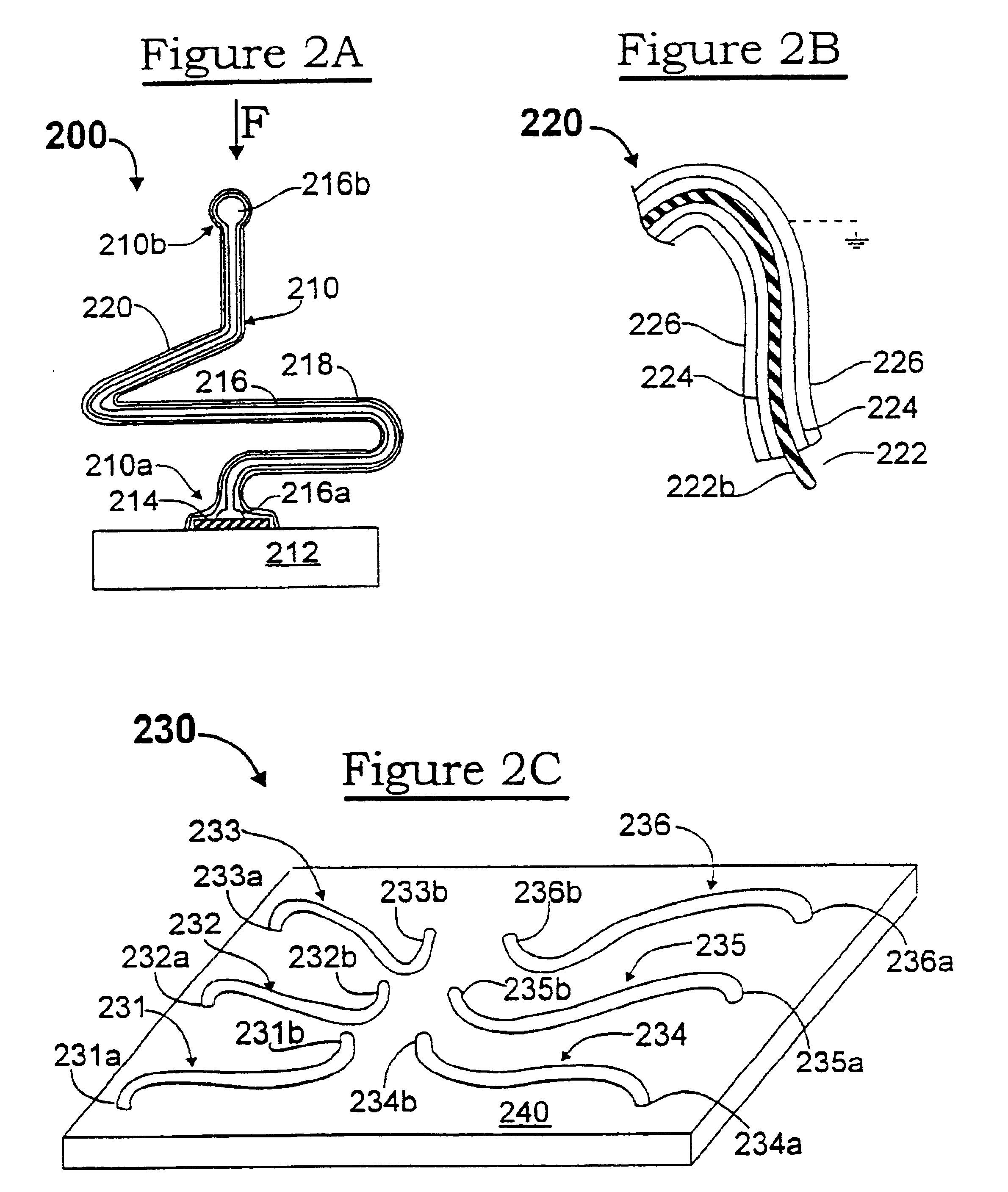

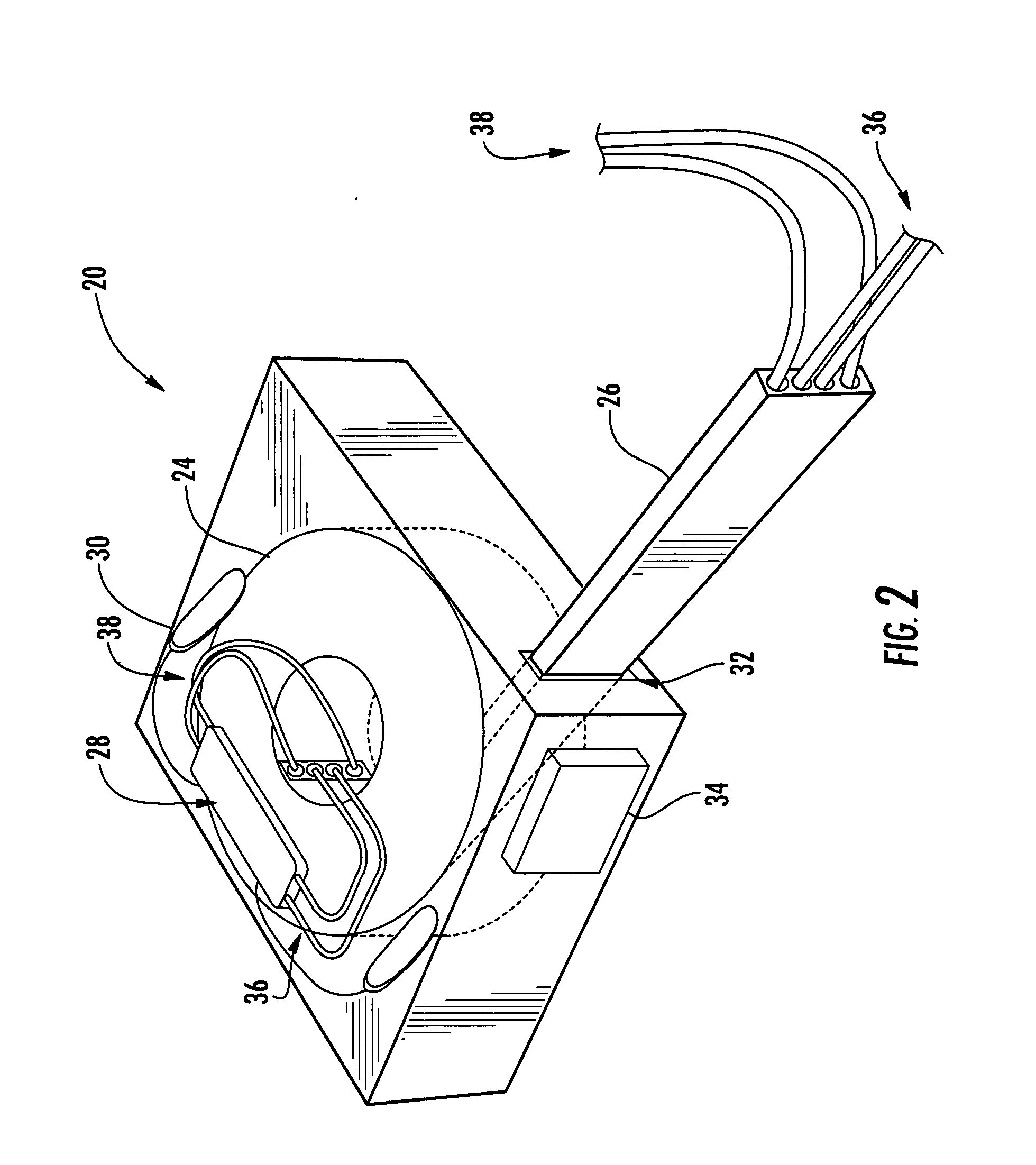

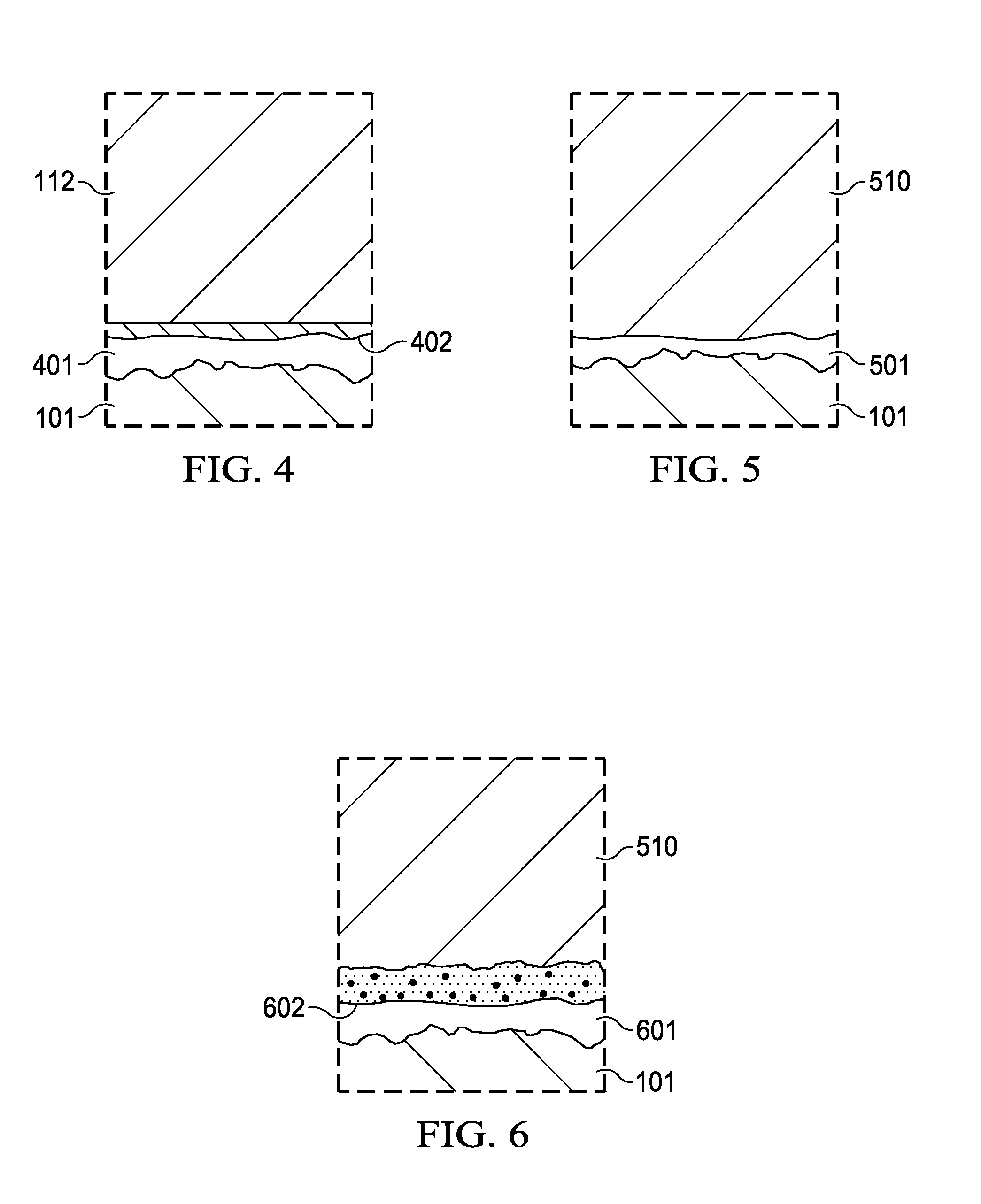

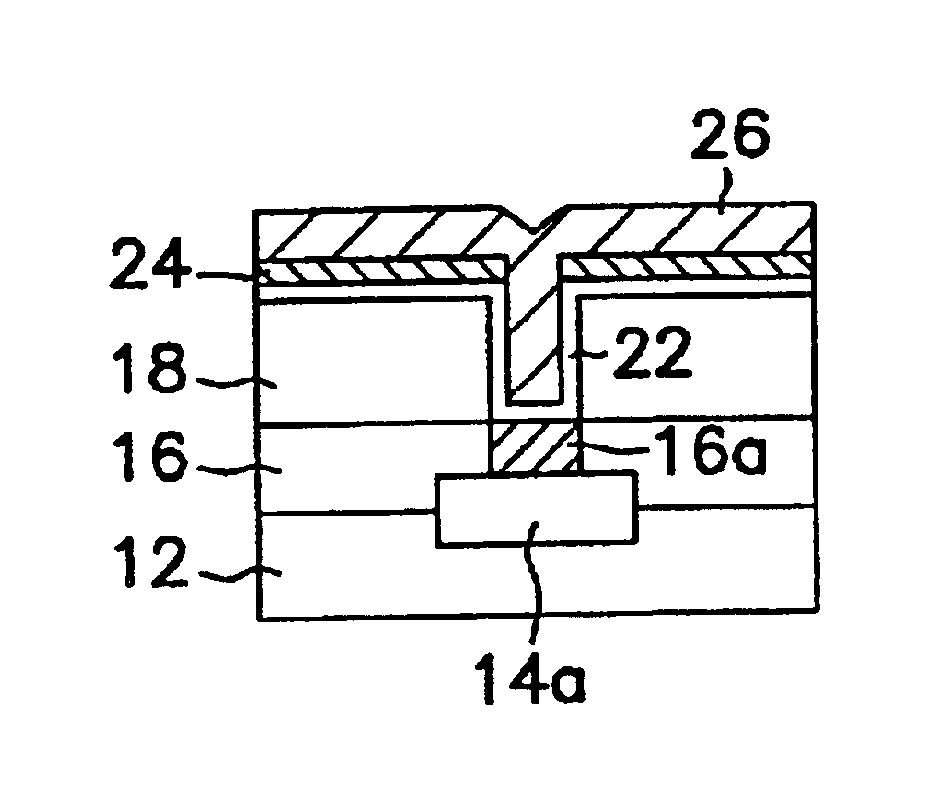

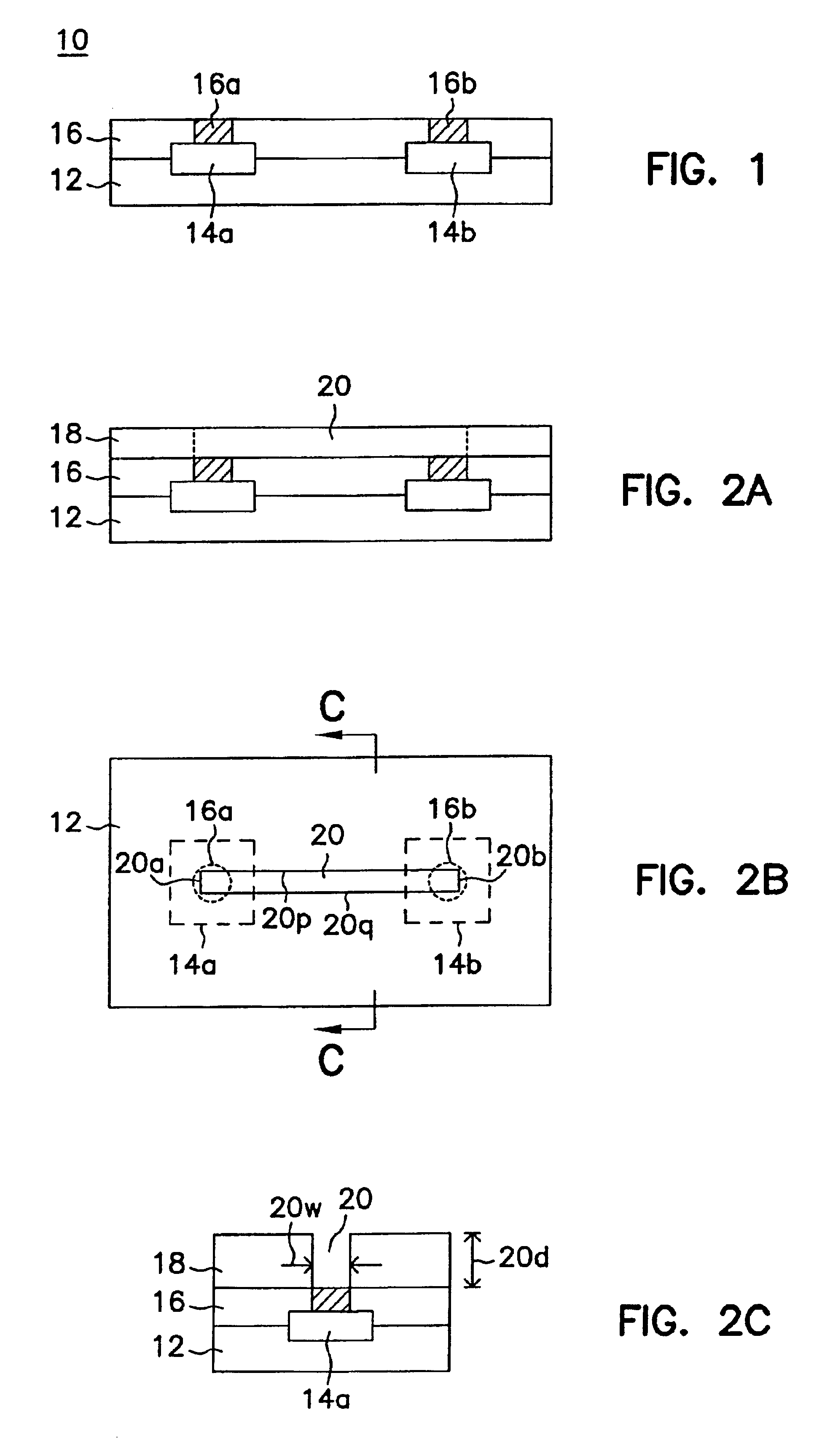

Method and apparatus for shaping spring elements

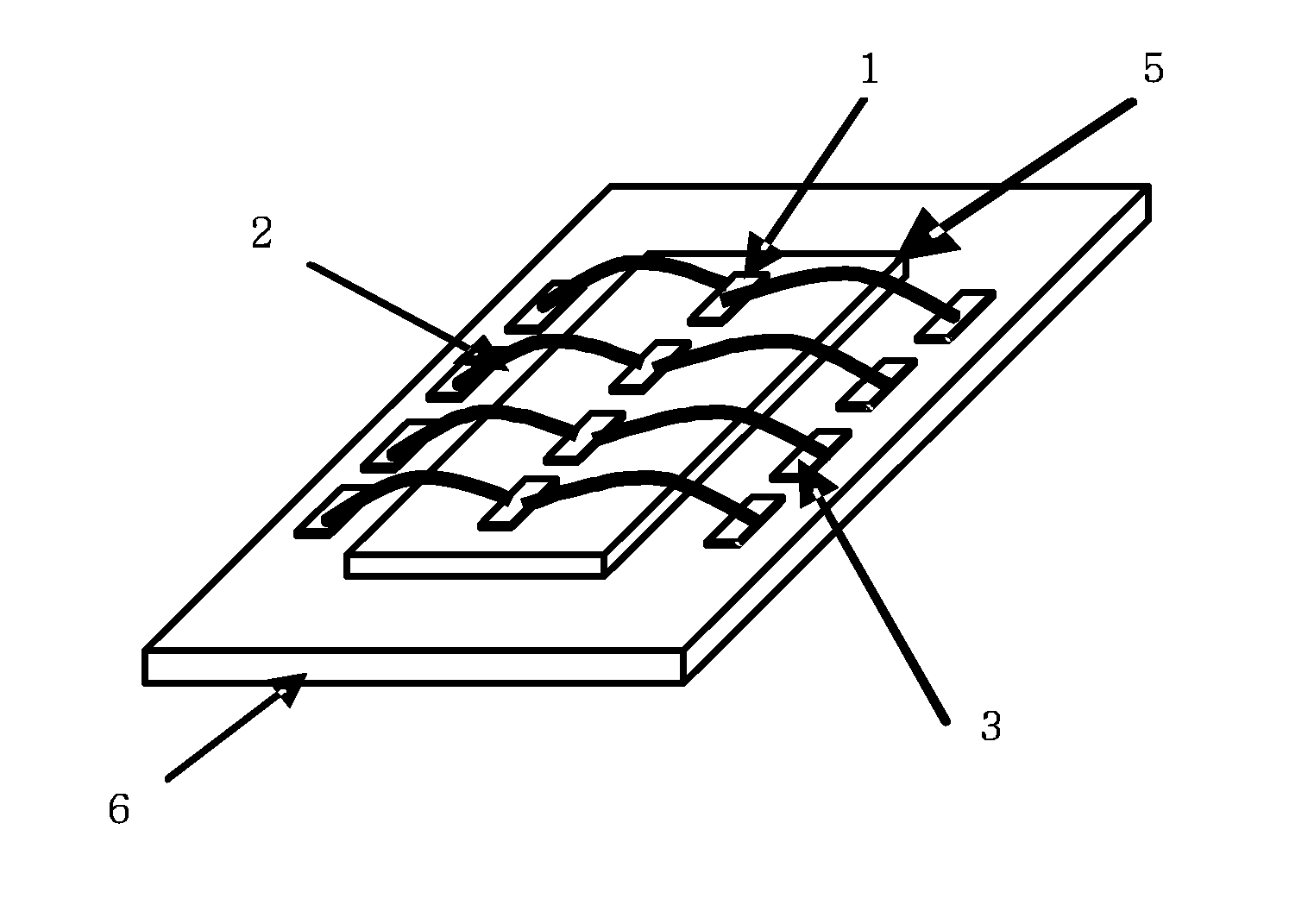

InactiveUS6836962B2Easy to disassembleEasy to manufactureElectrically conductive connectionsContact member assembly/disassemblyProbe cardCopper wire

Interconnection elements for electronic components, exhibiting desirable mechanical characteristic (such as resiliency, for making pressure contacts) are formed by using a shaping tool (512) to shape an elongate core element (502) of a soft material (such as gold or soft copper wire) to have a springable shape (including cantilever beam, S-shape, U-shape), and overcoating the shaped core element with a hard material (such as nickel and its alloys), to impart to desired spring (resilient) characteristic to the resulting composite interconnection element. A final overcoat of a material having superior electrical qualities (e.g., electrical conductivity and / or solderability) may be applied to the composite interconnection element. The resulting interconnection elements may be mounted to a variety of electronic components, including directly to semiconductor dies and wafers (in which case the overcoat material anchors the composite interconnection element to a terminal (or the like) on the electronic component), may be mounted to support substrates for use as interposers and may be mounted to substrates for use as probe cards or probe card inserts. The shaping tool may be an anvil (622) and a die (624), and may nick or sever successive shaped portions of the elongate elements, and the elongate element may be of an inherently hard (springy) material. Methods of fabricating interconnection elements on sacrificial substrates are described. Methods of fabricating tip structures (258) and contact tips at the end of interconnection elements are also described.

Owner:FORMFACTOR INC

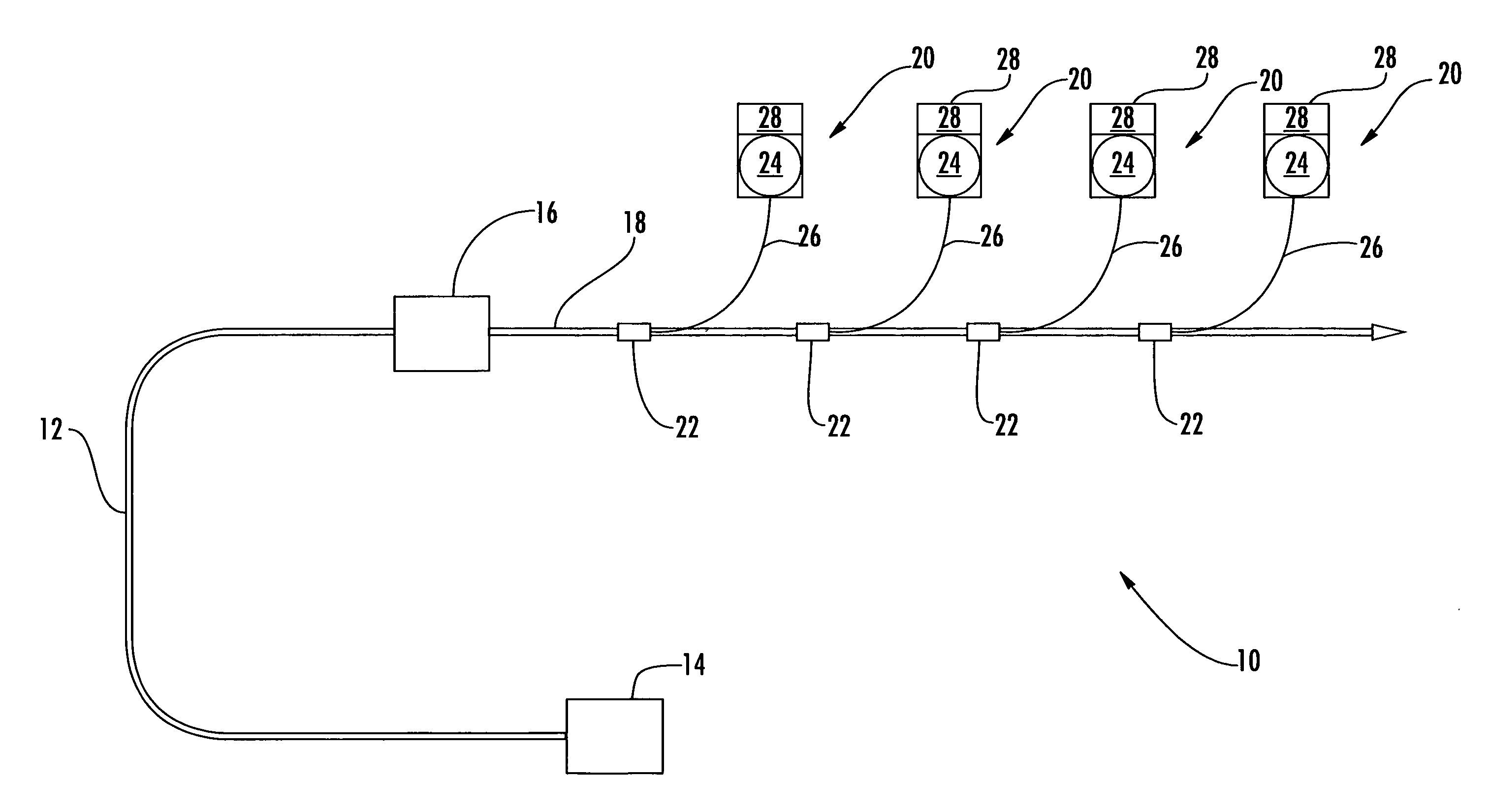

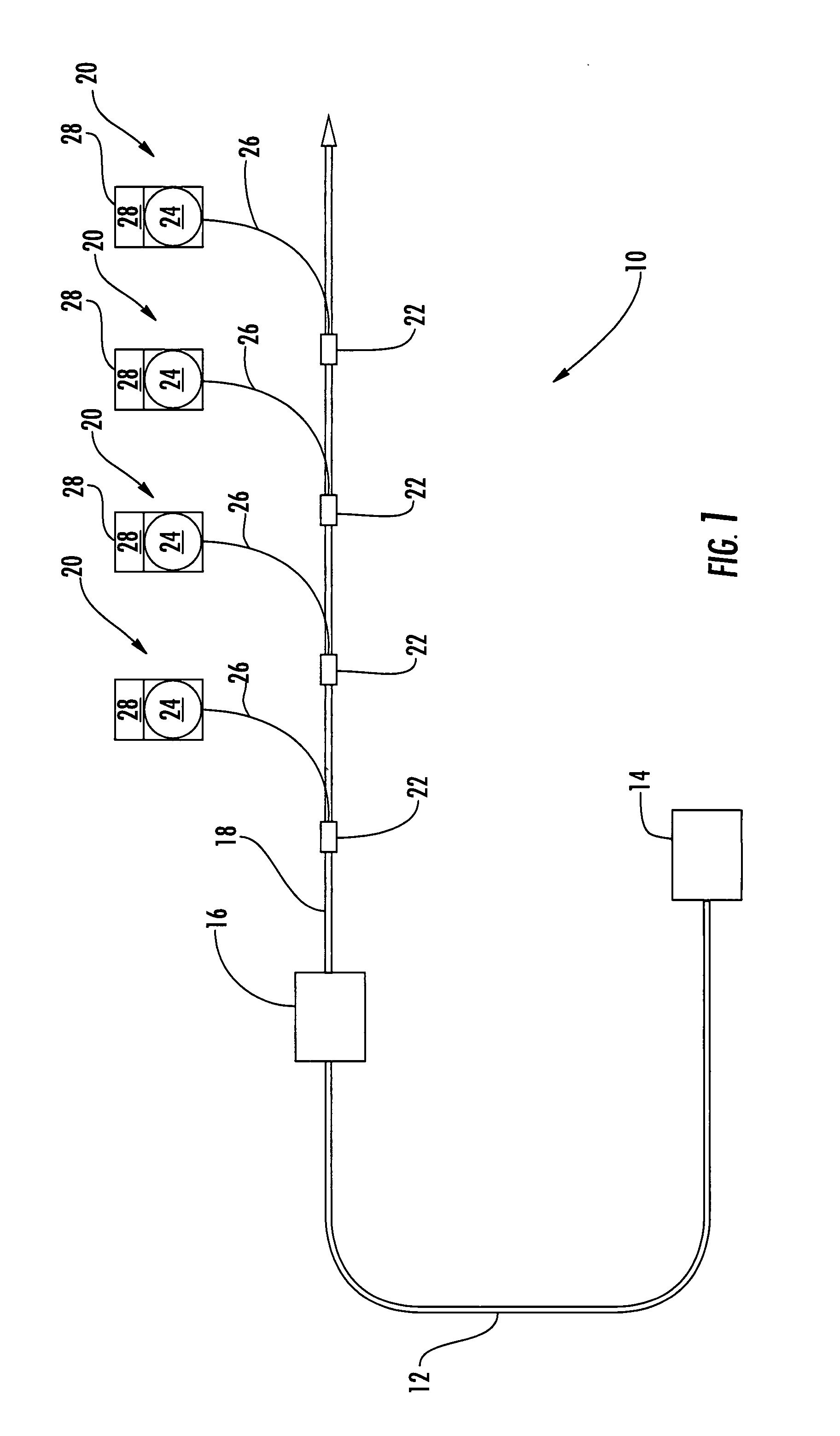

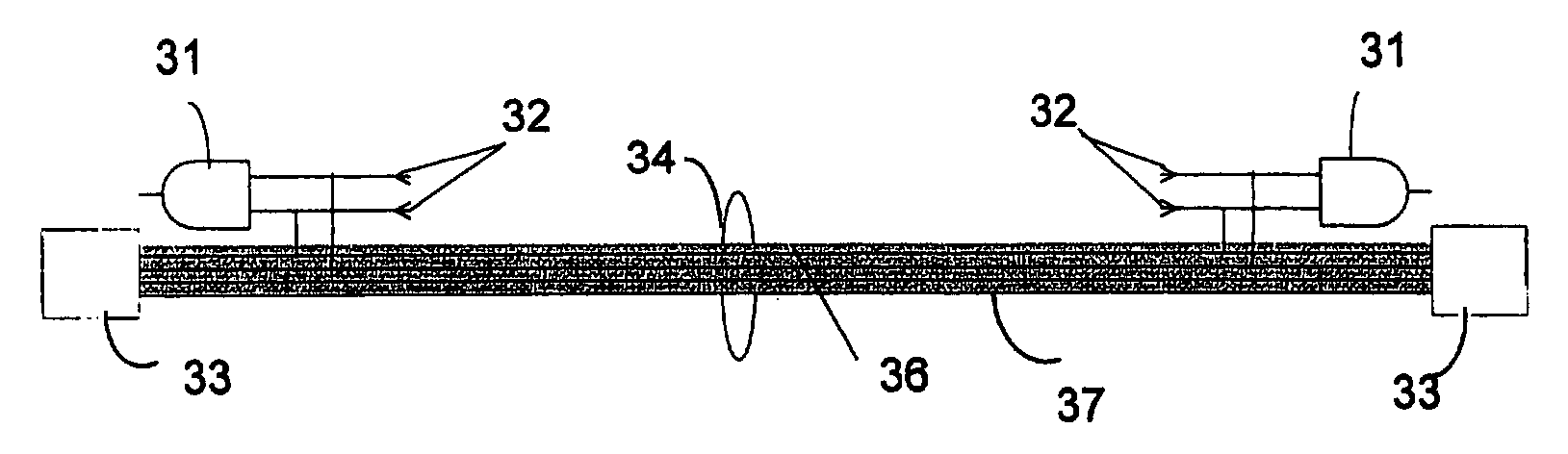

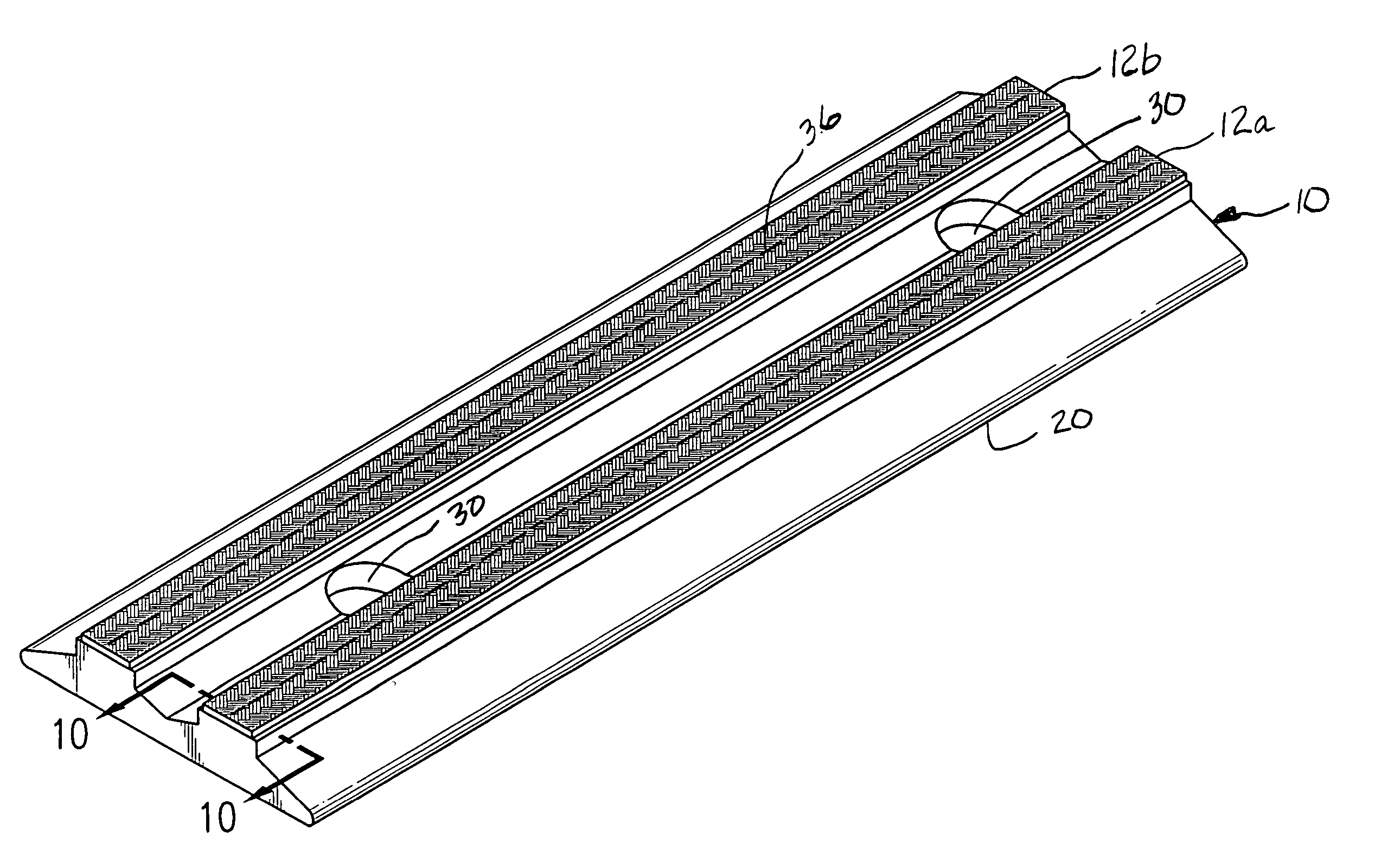

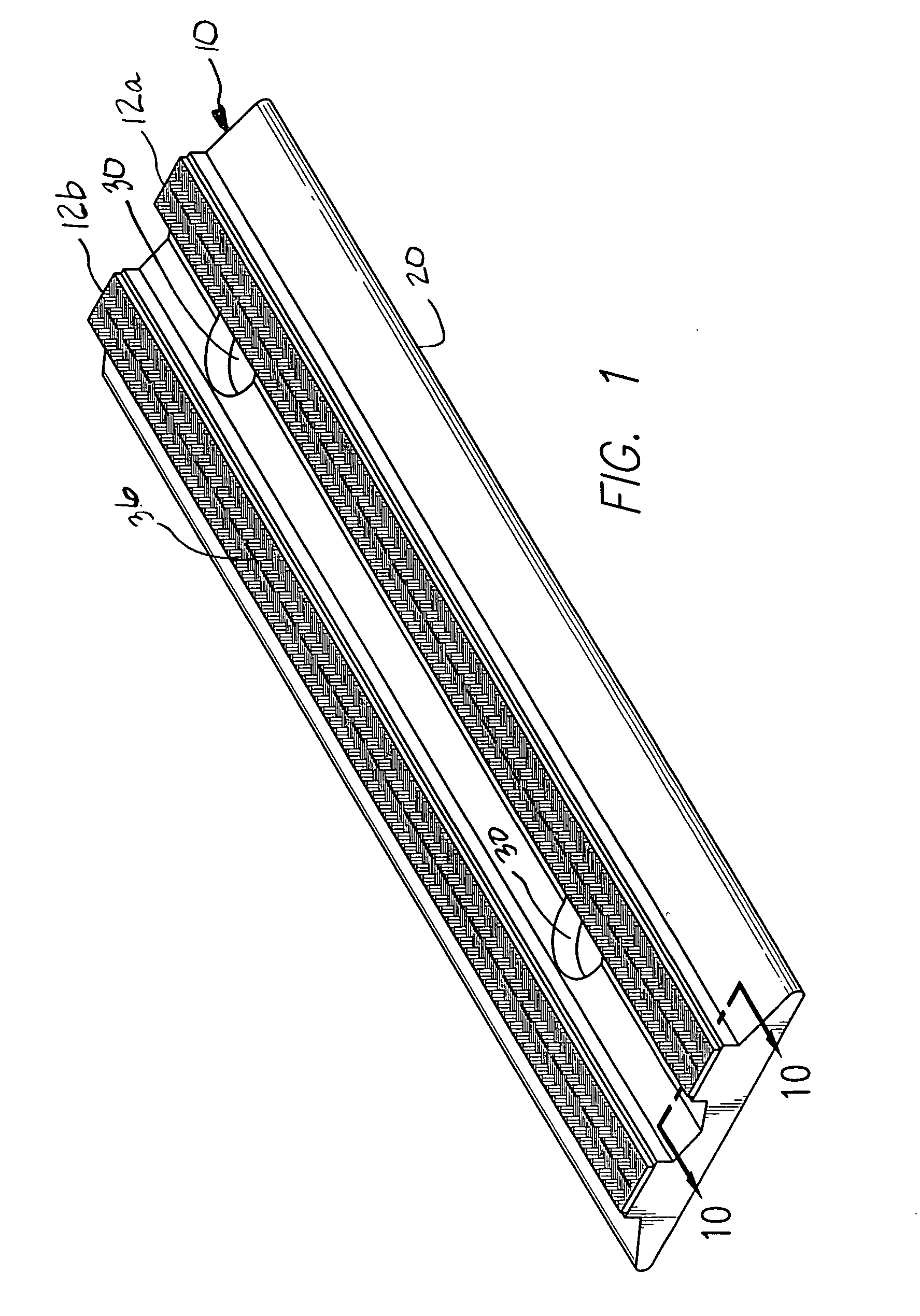

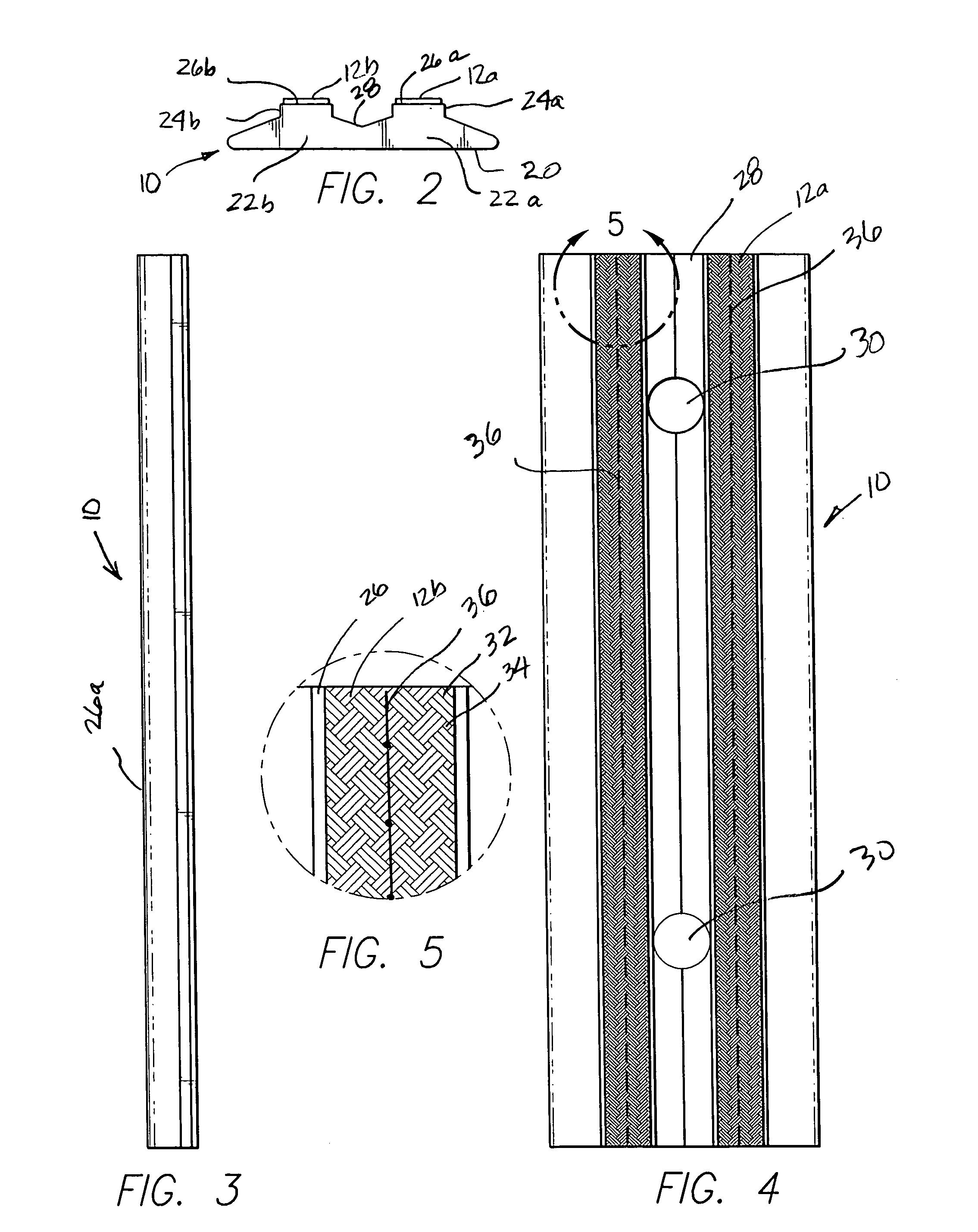

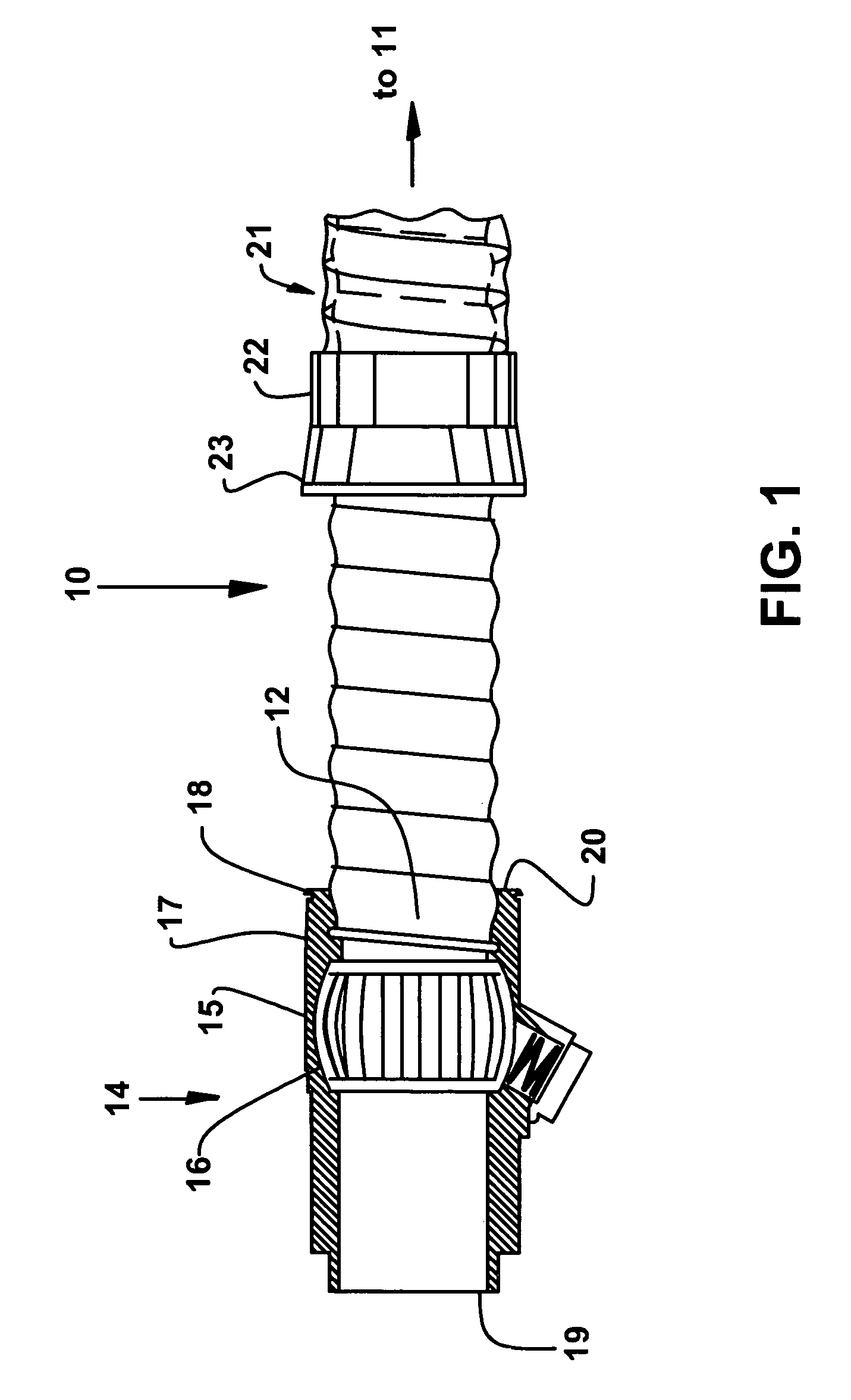

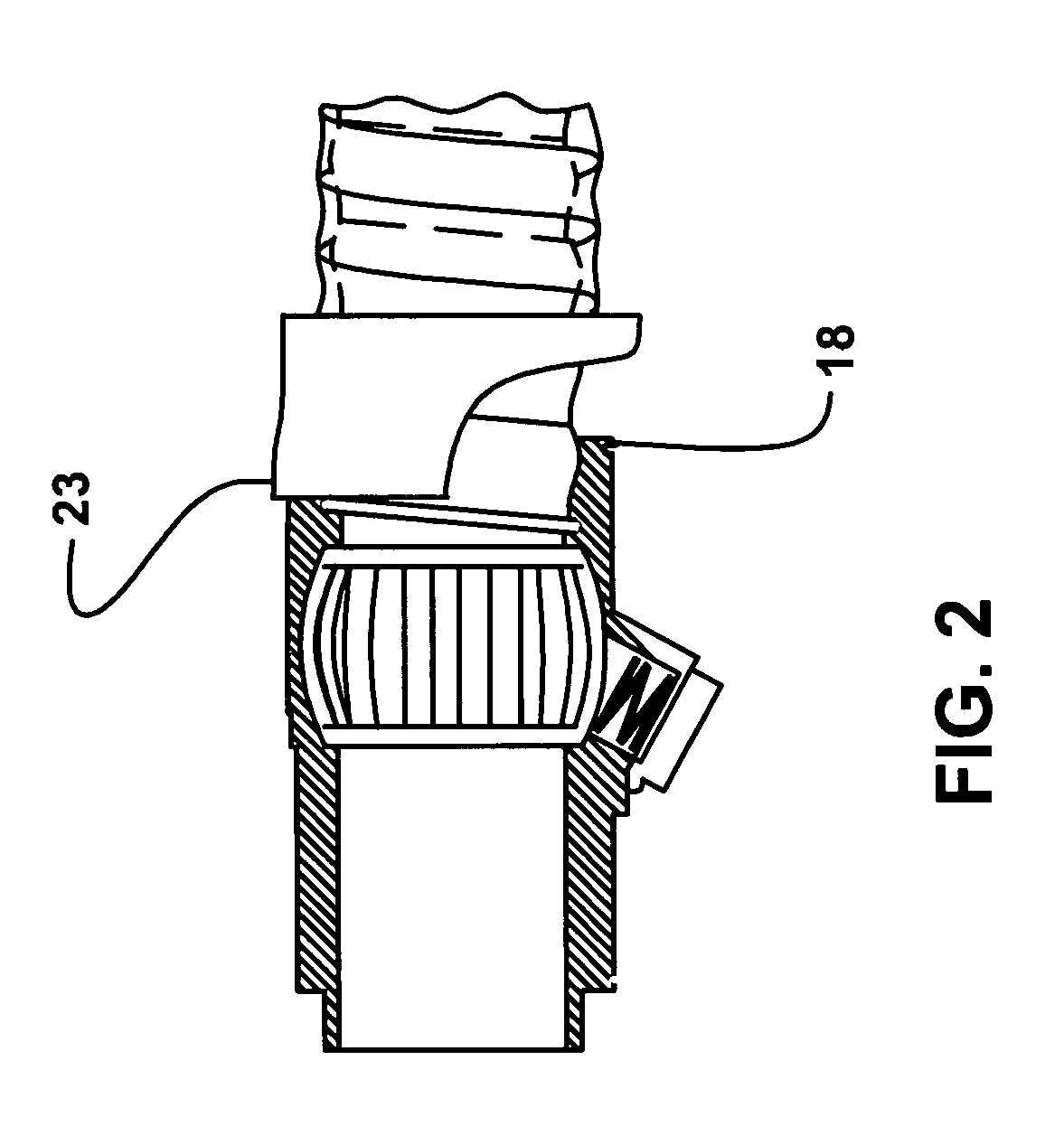

Retractable optical fiber tether assembly and associated fiber optic cable

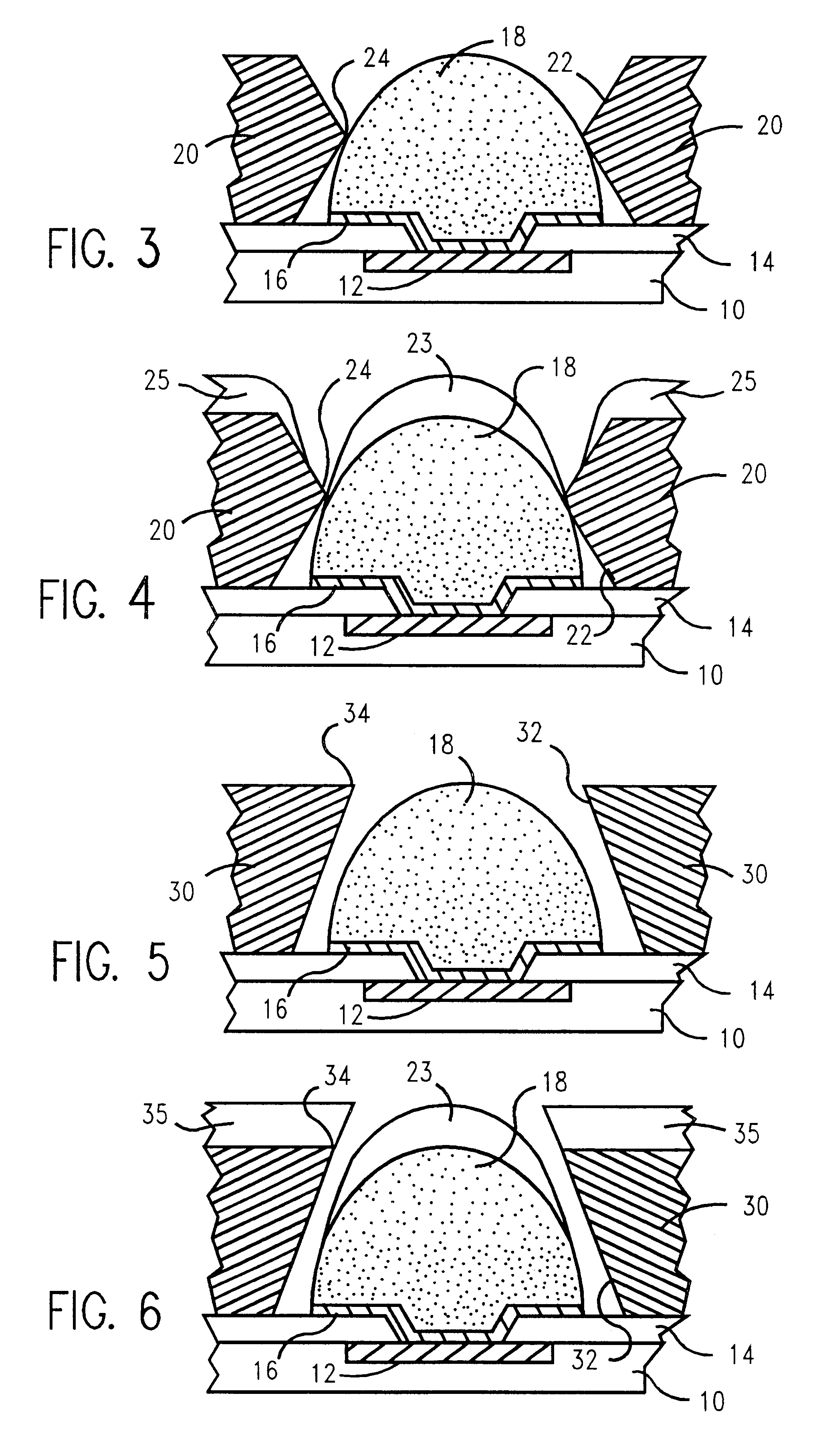

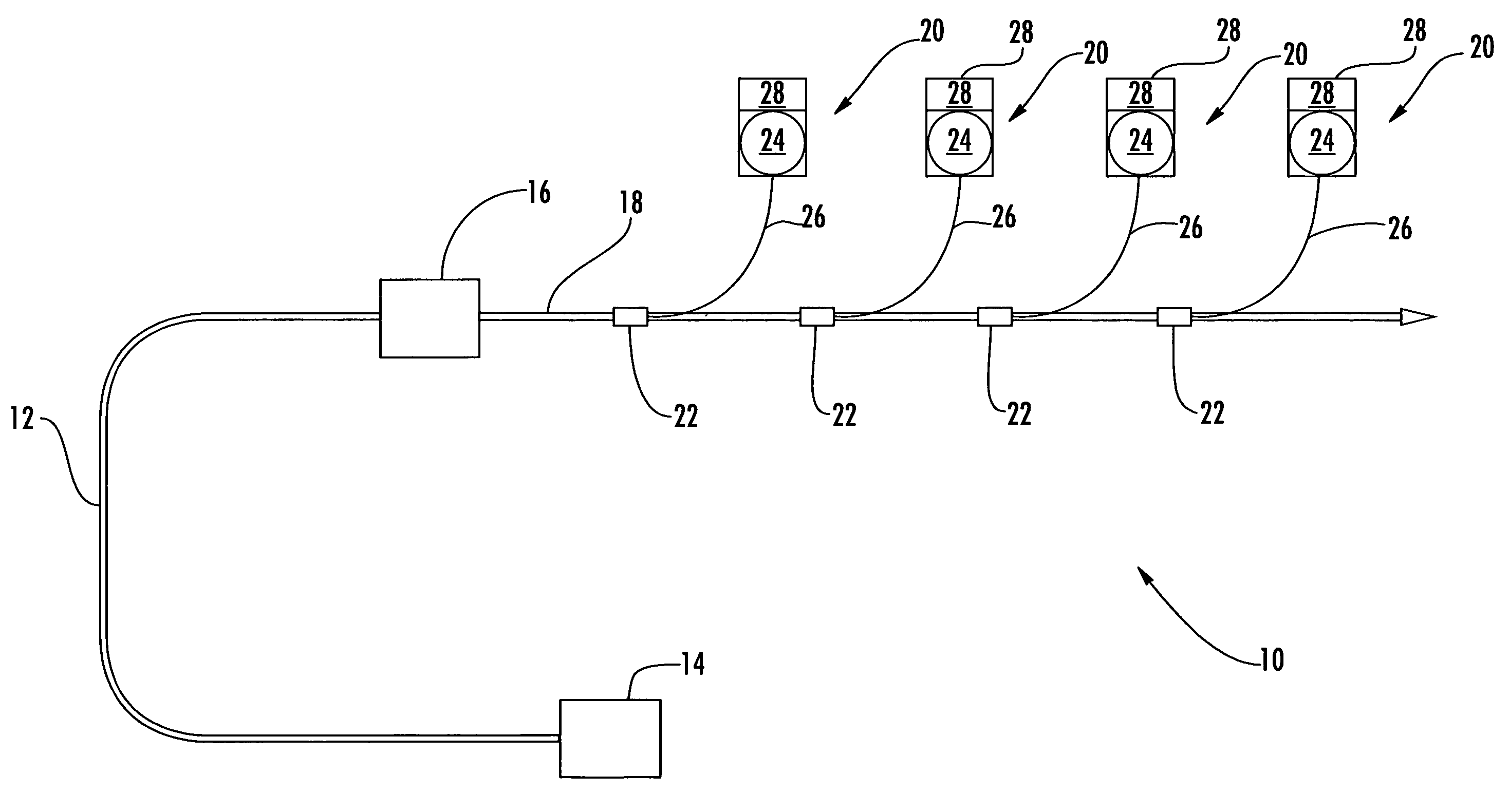

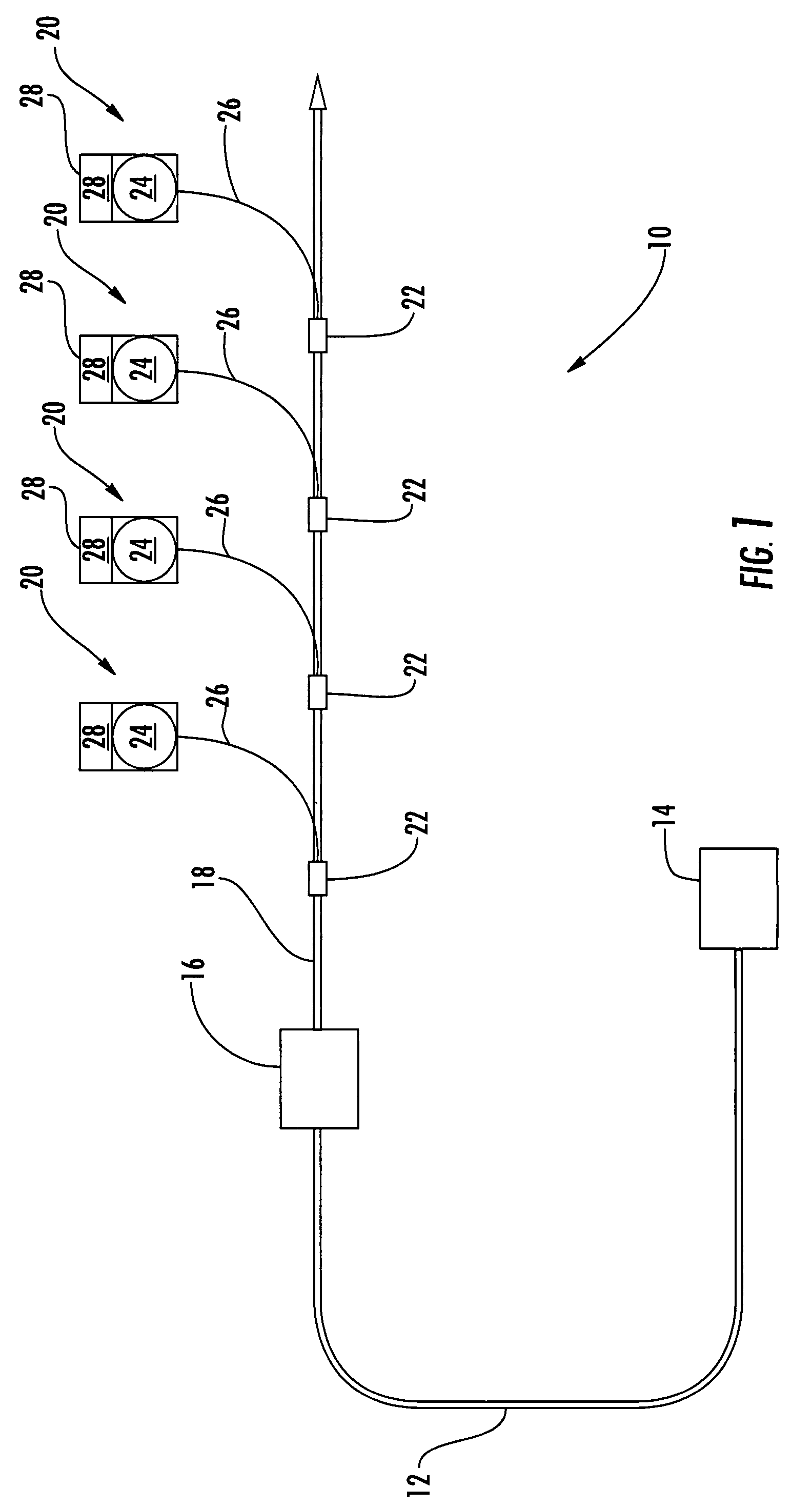

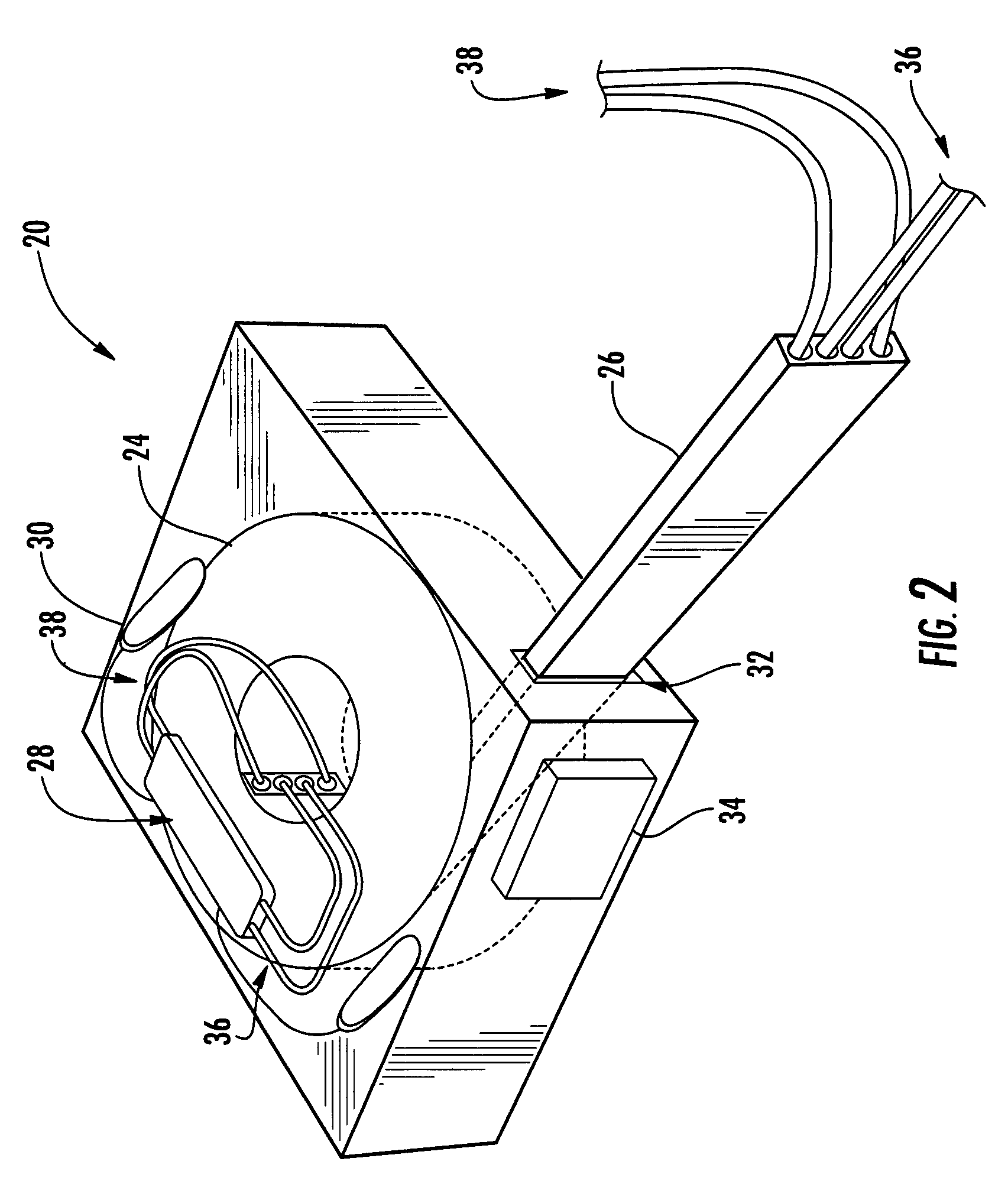

The present invention provides an optical system that allows for the flexible location of an optical device that is coupled to a patch panel in a wiring closet or other optical signal source through a series of fiber optic cables and optical connections, or the flexible location of an array of such optical devices. The optical system includes, in part, one or more retractable optical fiber tether assemblies that each allow varying lengths of tether cable to be pulled and used. The retraction device of each of the optical tether assemblies may be disposed mid-tether cable, or may terminate the respective tether cable and incorporate the given optical device. In an exemplary wireless local area network (WLAN) application, each of the retractable optical fiber tether assemblies includes an integral transceiver and associated software. Thus, each of the retractable optical fiber tether assemblies functions as an antenna. The associated fiber optic cable carries both optical fiber to provide optical continuity and copper wire to provide electrical conductivity to the antenna array.

Owner:CORNING OPTICAL COMM LLC

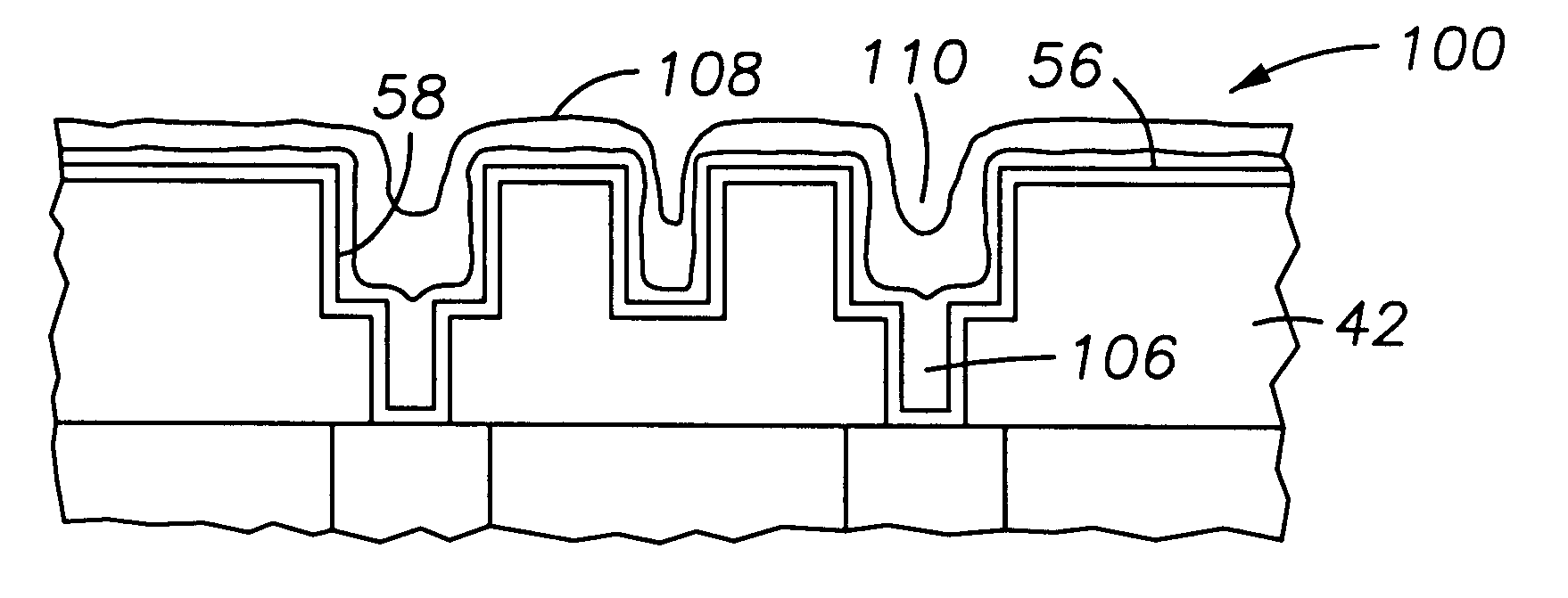

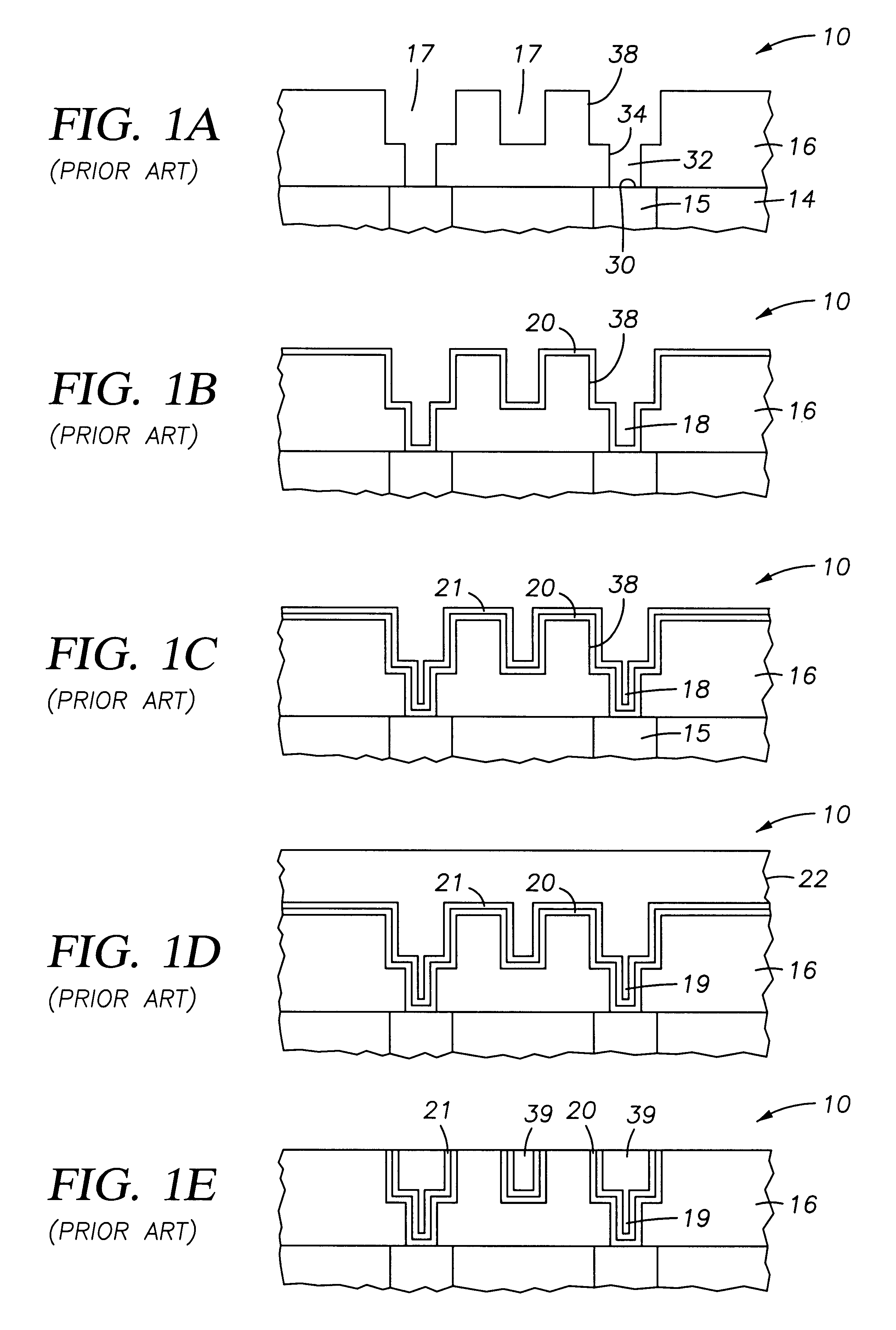

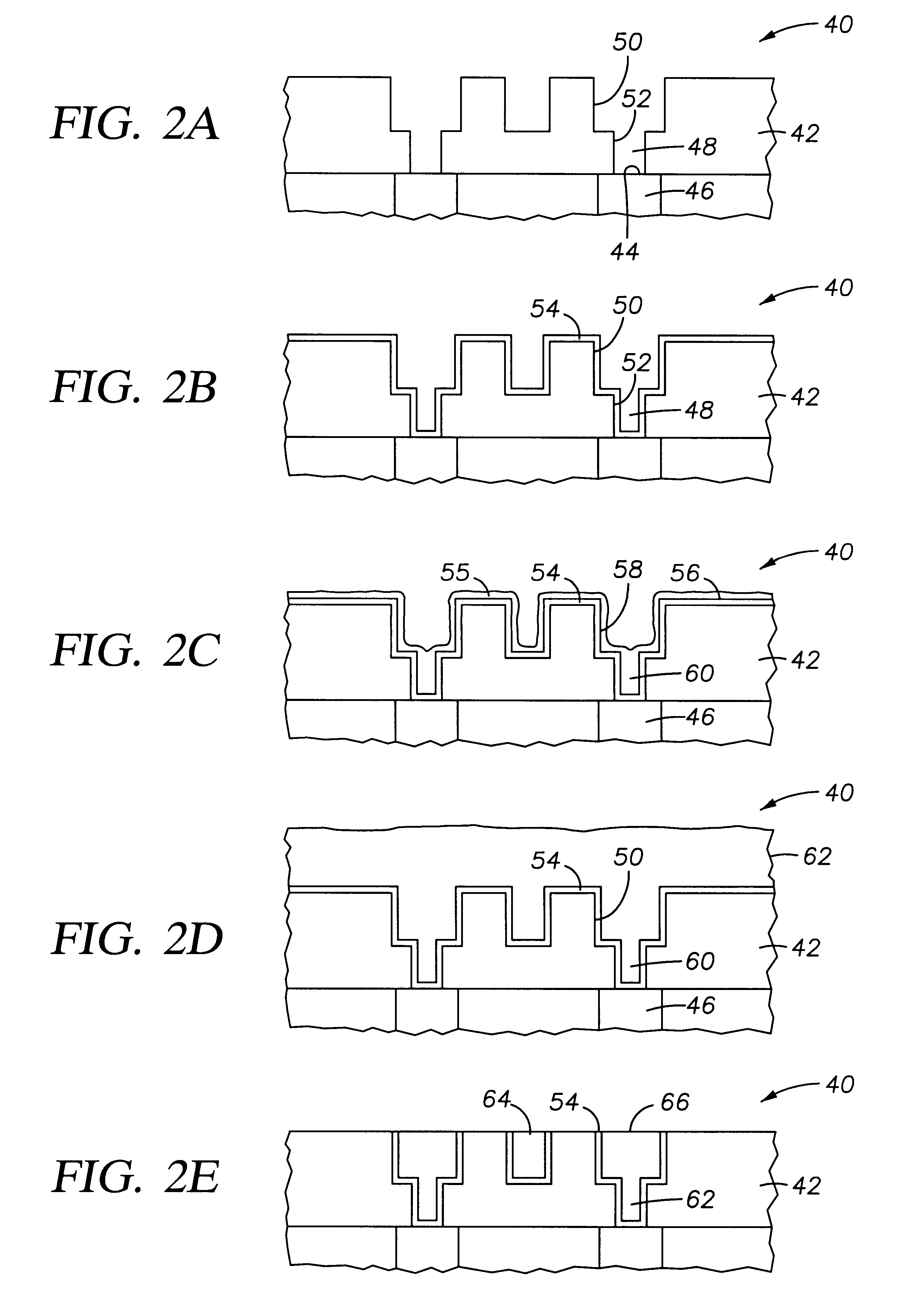

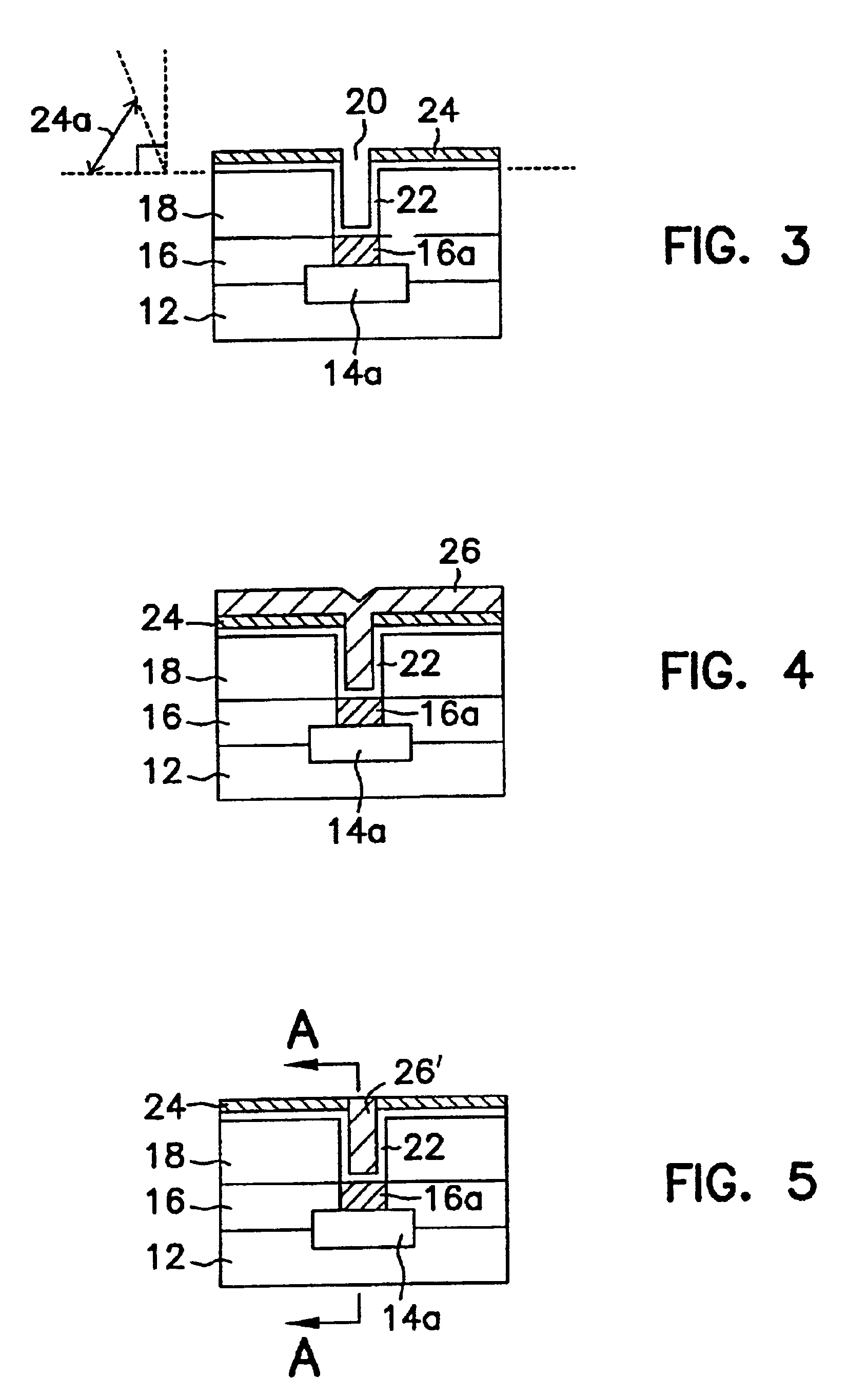

Dual damascene metallization

InactiveUS6207222B1Semiconductor/solid-state device detailsSolid-state devicesCopper wireDielectric layer

The present invention generally provides a metallization process for forming a highly integrated interconnect. More particularly, the present invention provides a dual damascene interconnect module that incorporates a barrier layer deposited on all exposed surface of a dielectric layer which contains a dual damascene via and wire definition. A conductive metal is deposited on the barrier layer using two or more deposition methods to fill the via and wire definition prior to planarization. The invention provides the advantages of having copper wires with lower resistivity (greater conductivity) and greater electromigration resistance than aluminum, a barrier layer between the copper wire and the surrounding dielectric material, void-free, sub-half micron selective CVD Al via plugs, and a reduced number of process steps to achieve such integration.

Owner:APPLIED MATERIALS INC

Computer based energy management

Owner:BUDDERFLY INC

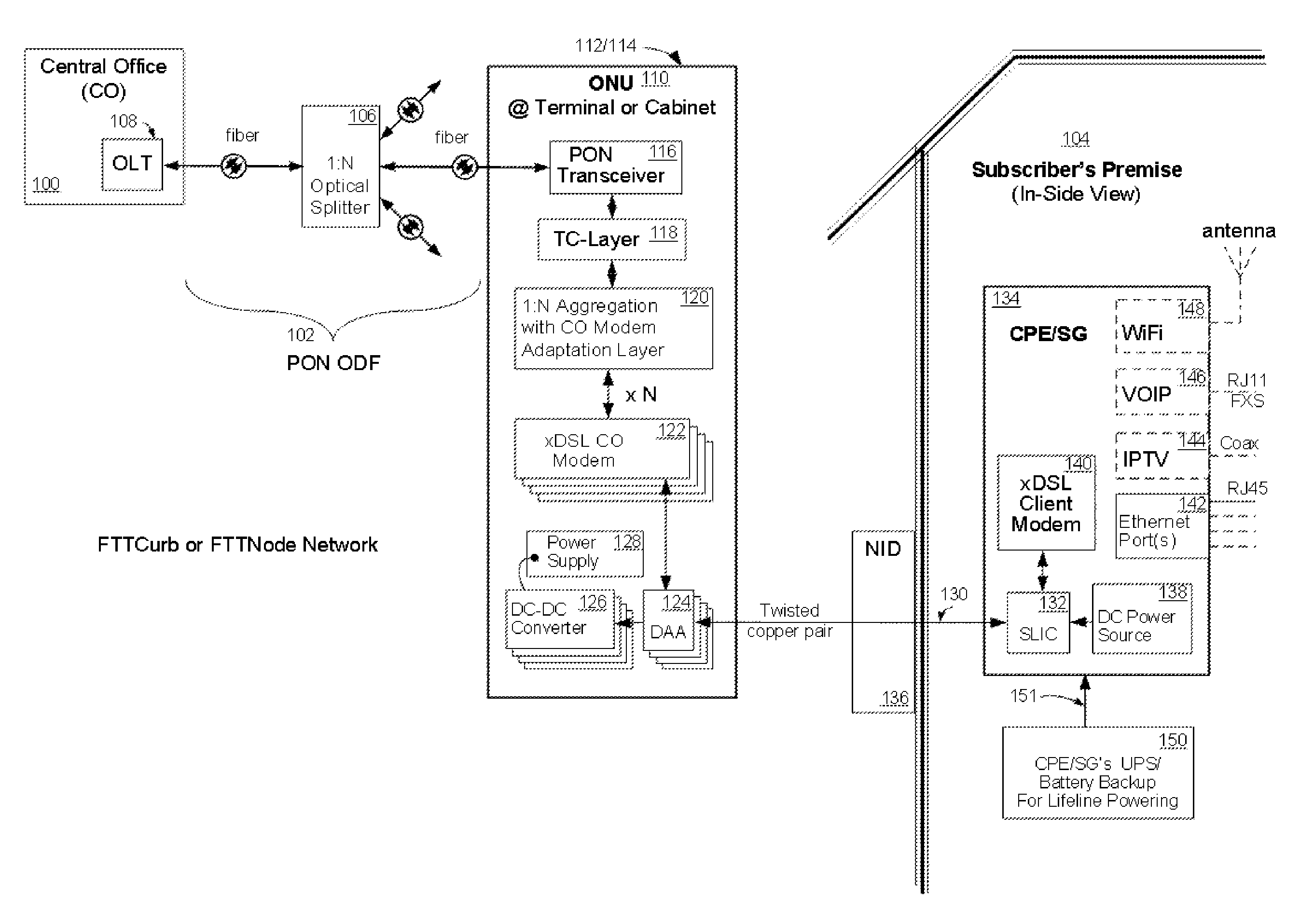

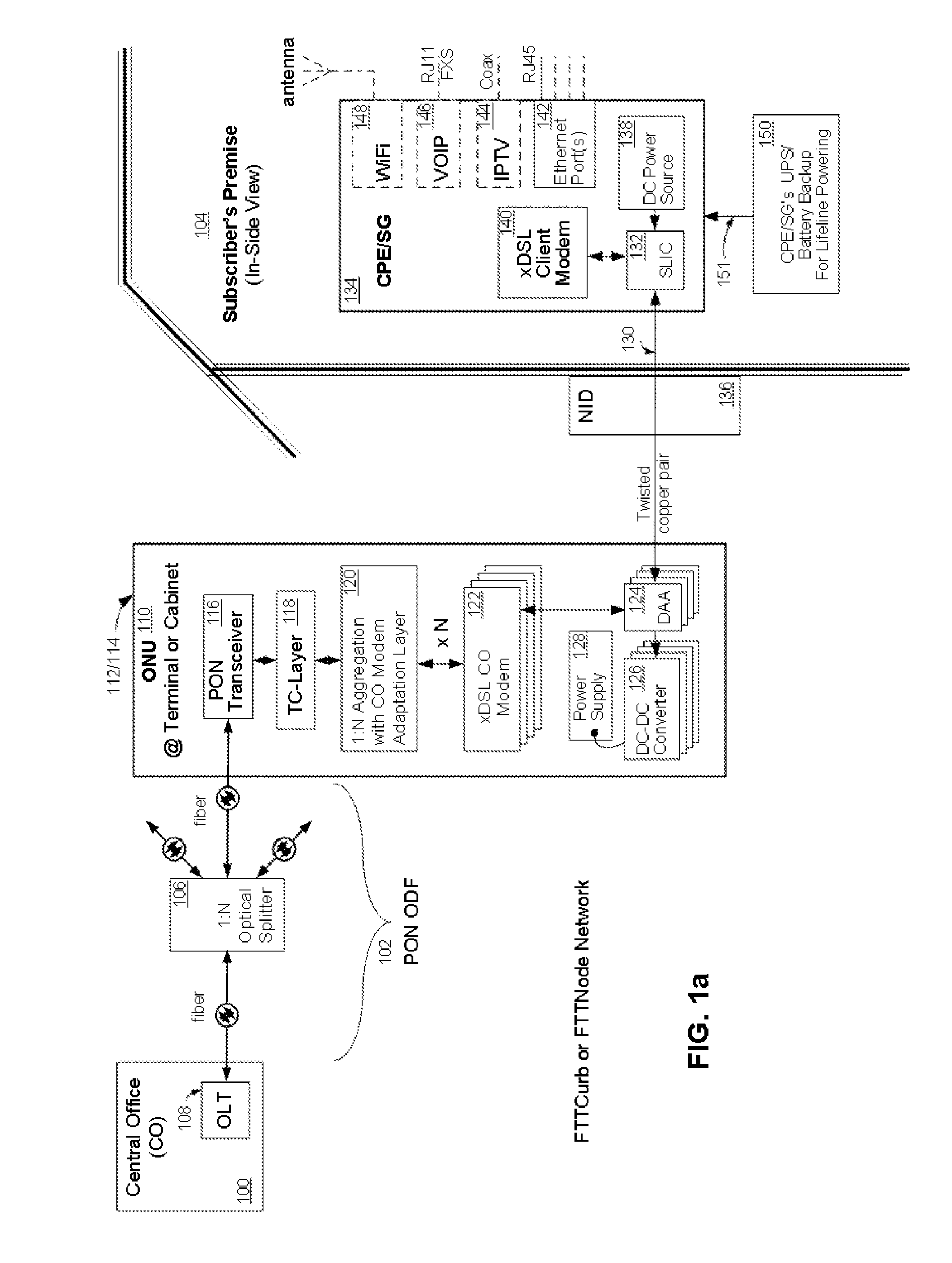

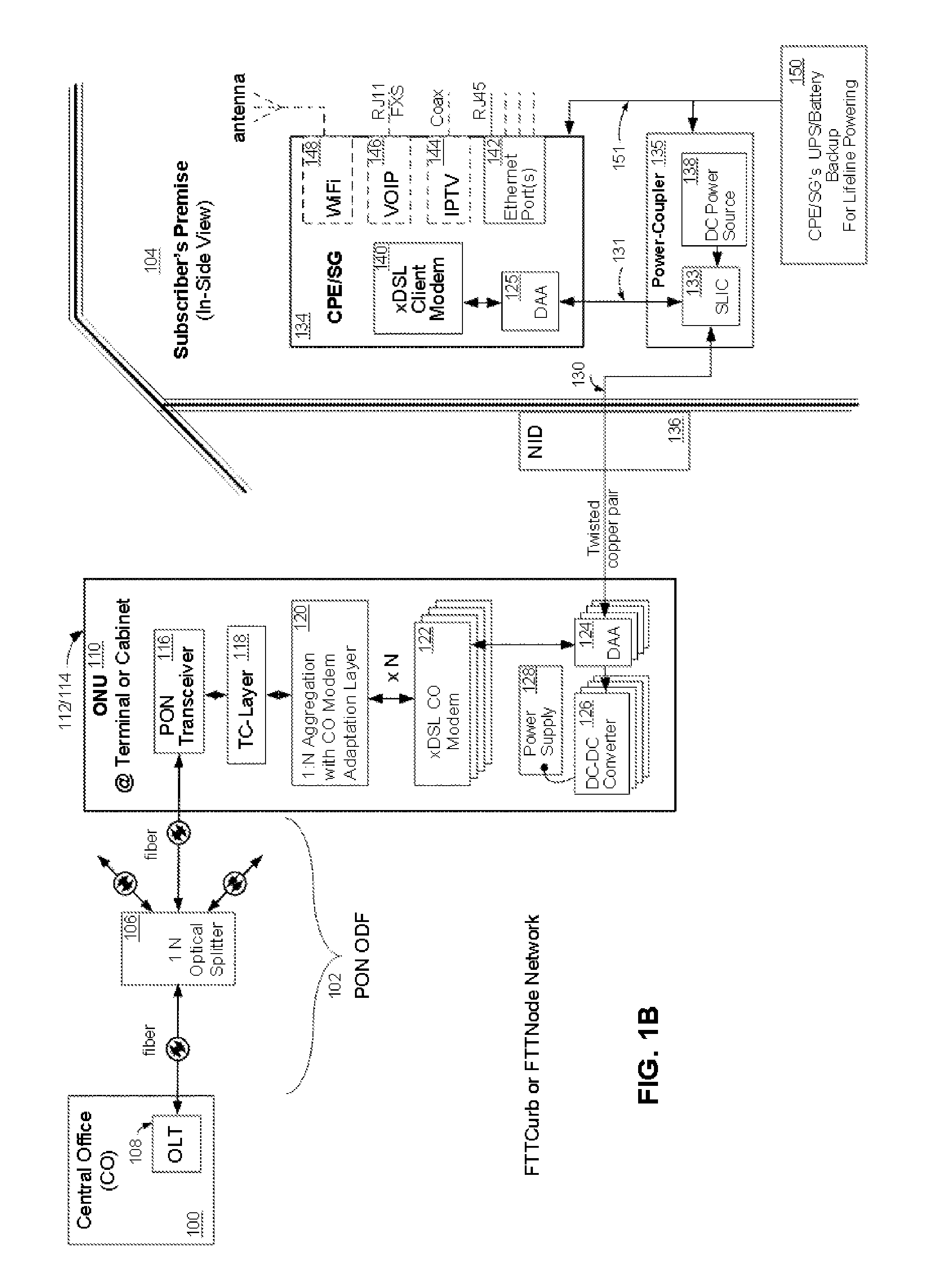

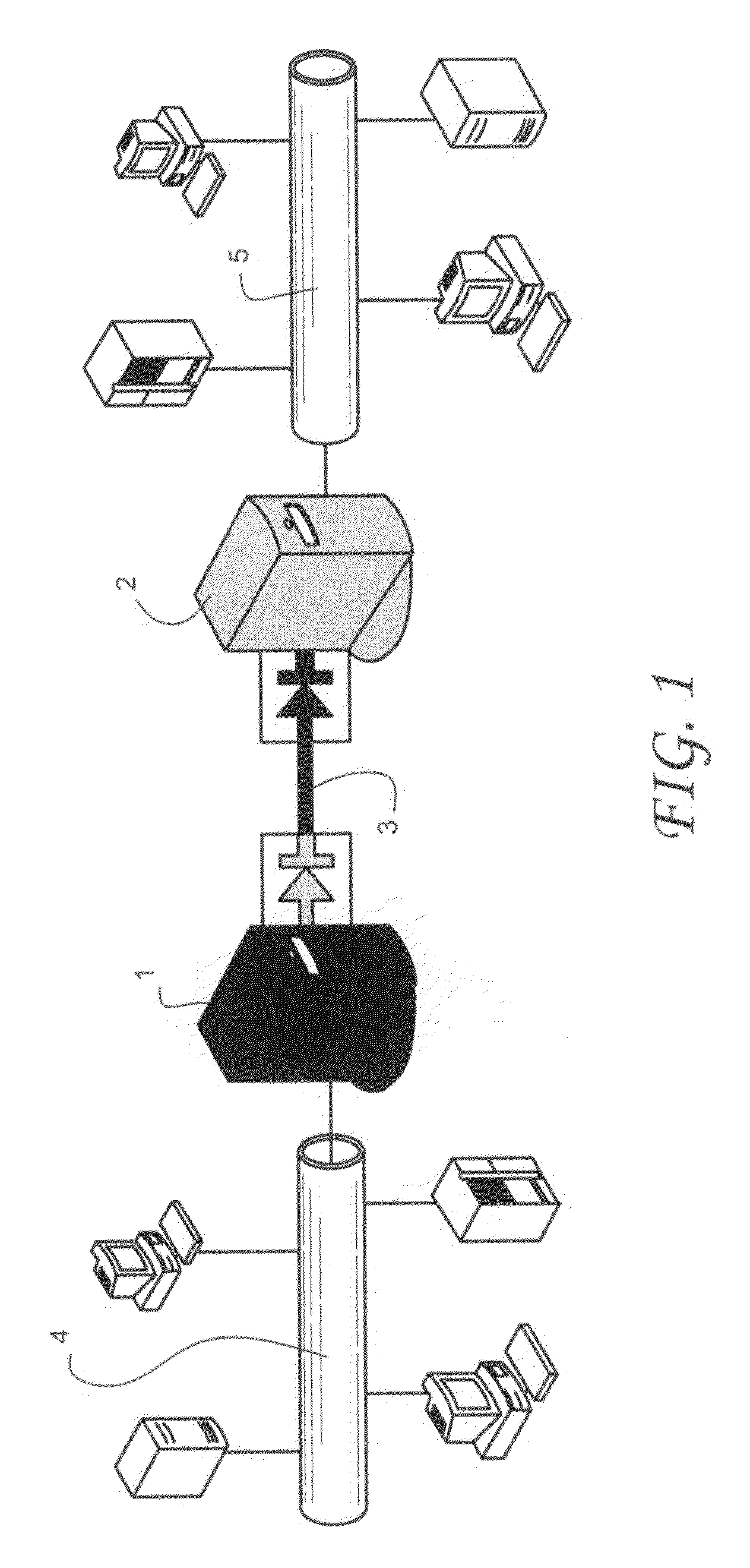

System and method for a subscriber-powered network element

A system for powering a network element of a fiber optic communication network. When communication data is transferred between a central office (CO) and a subscriber gateway using a network element to convert optical to electrical (O-E) and electrical to optical (E-O) signals between a fiber from the central office and copper wires or coax cable from the subscriber gateway, techniques related to local powering of a network element or drop site by a subscriber or customer remote device or gateway are provided. Certain advantages and / or benefits are achieved using the present invention, such as freedom from any requirement for additional meter installations or meter connection charges. Additionally the system is free of monthly meter charges and does not require a separate power network.

Owner:SOTO ALEXANDER I +1

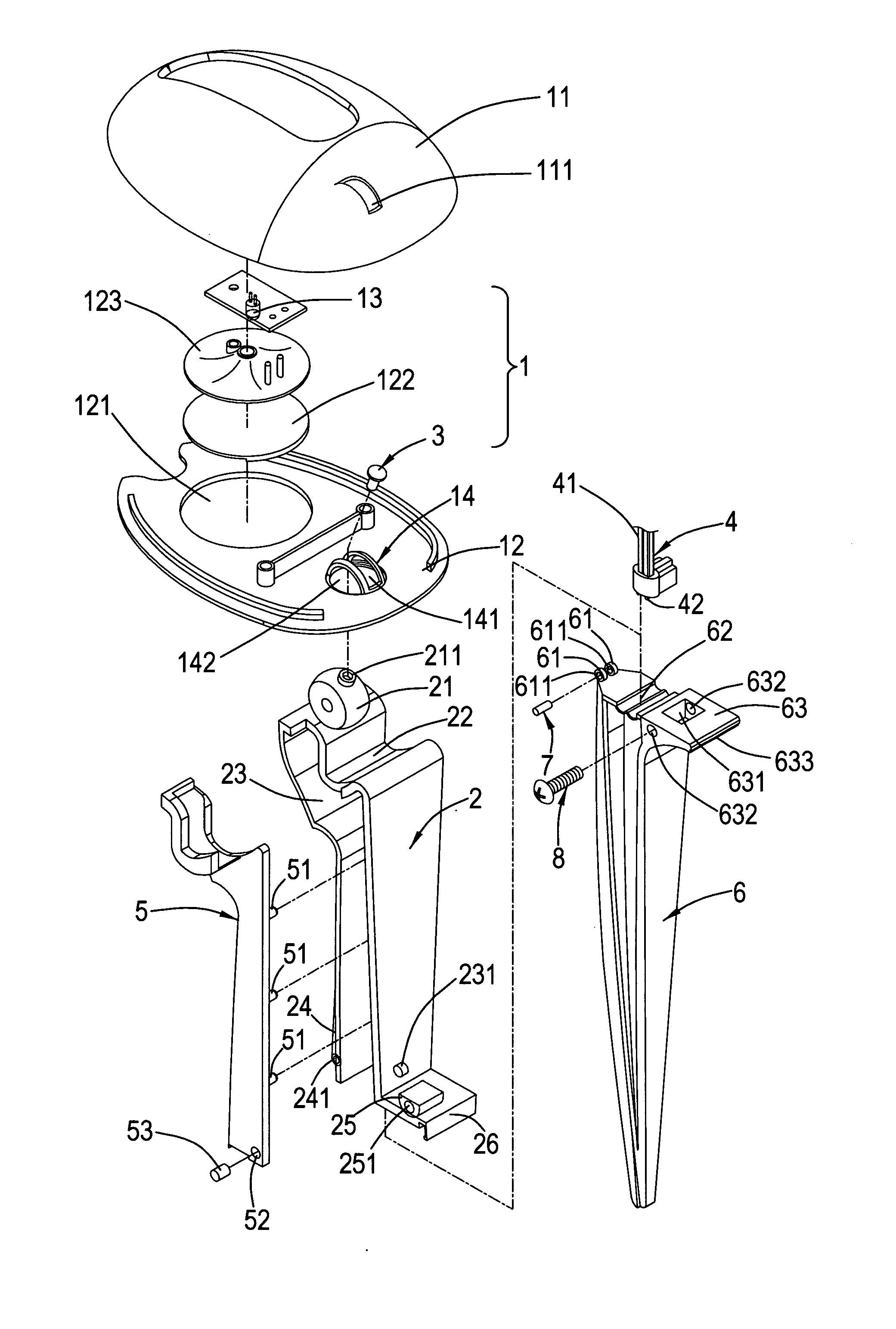

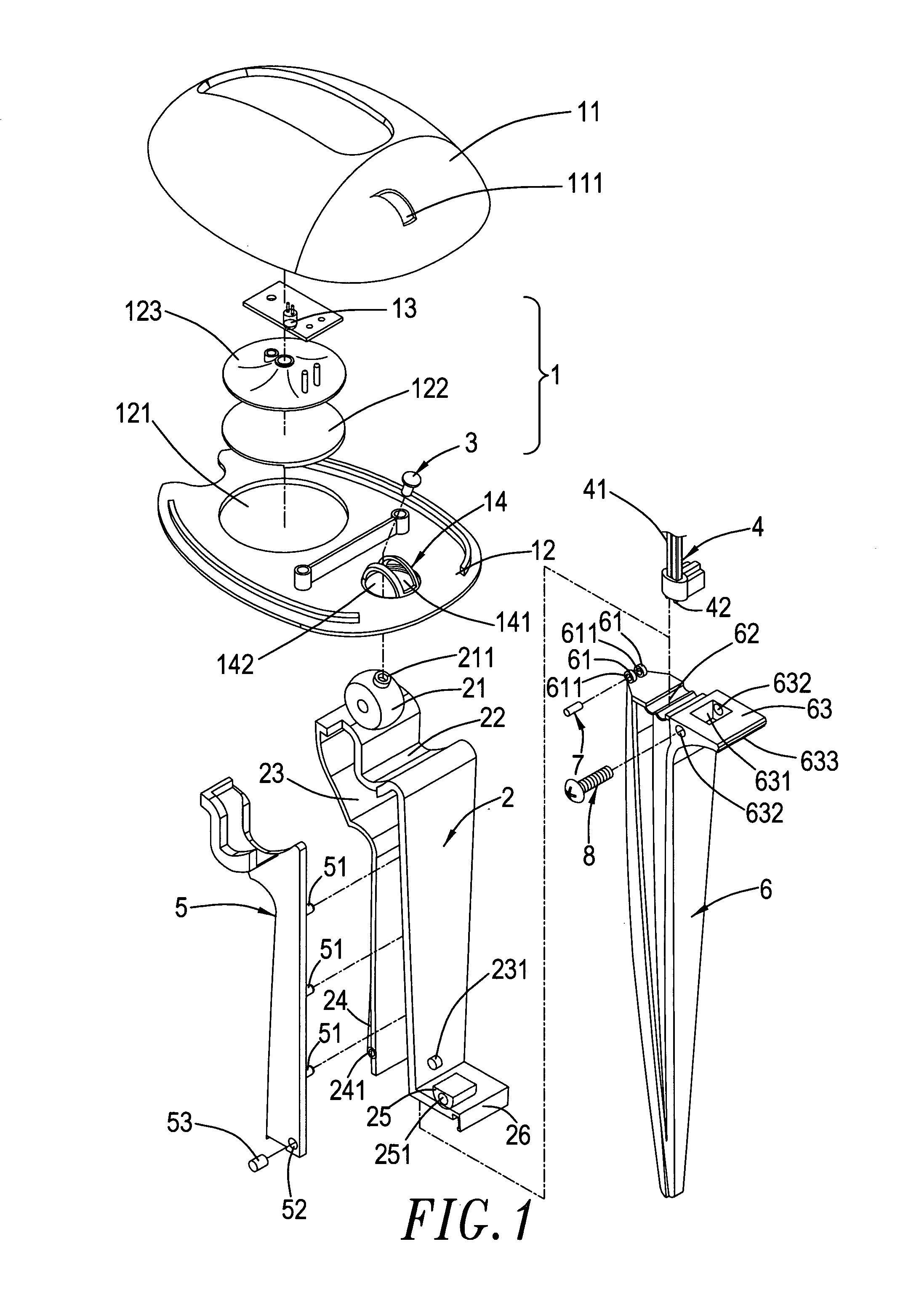

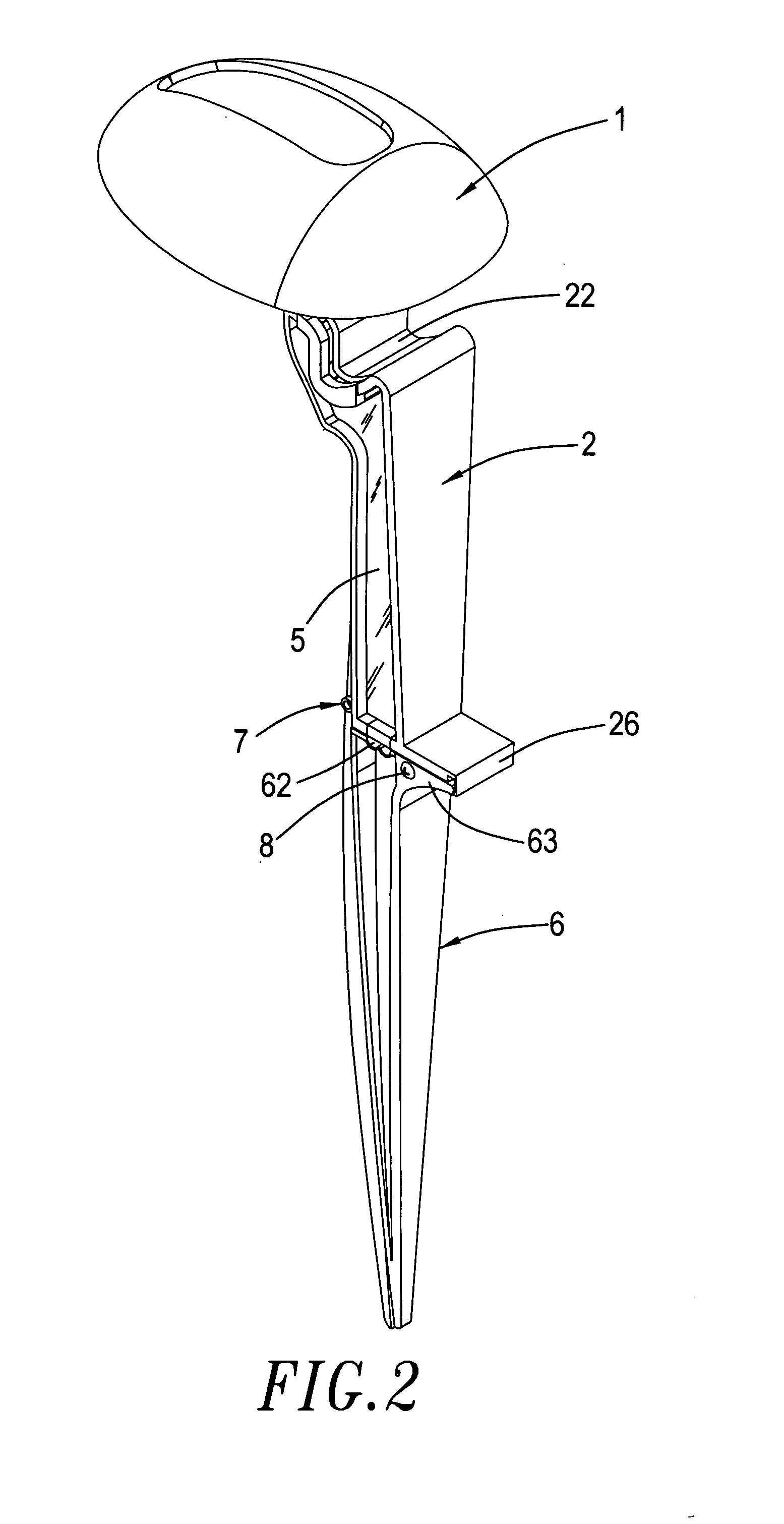

Refined illuminating lamp structure

A refined illuminating lamp structure is disclosed. A lamp case is pivotally connected to a top surface of the holder so as to reverse on the top surface of a holder. The bottom surface of the holder is connected with a taper body. The top surface of the taper body has a wire-fixing opening mounted thereon and a power conducting element is set at the connecting plane of the holder and the taper body. The power conducting element has one end which is a conducting wire and the other end exposed to have an awl conducting piece. The conducting piece is placed in the wire-fixing opening and the conducting wire connects with the illuminator inside the lamp case along the side of the holder. Several illuminating lamps are simultaneously plugged in the outdoor lawn and a long conducting wire having a power socket is placed in the power fixing opening at the top surface of the taper body. When the holder and the taper body are connected together, the conducting pieces of the power conducting element will immediately penetrate through the insulating layer of the long conducting wire and contact with the copper wire so that the illuminator inside the lamp can produce light for achieving the purpose of illuminating.

Owner:LAI LI CHUN

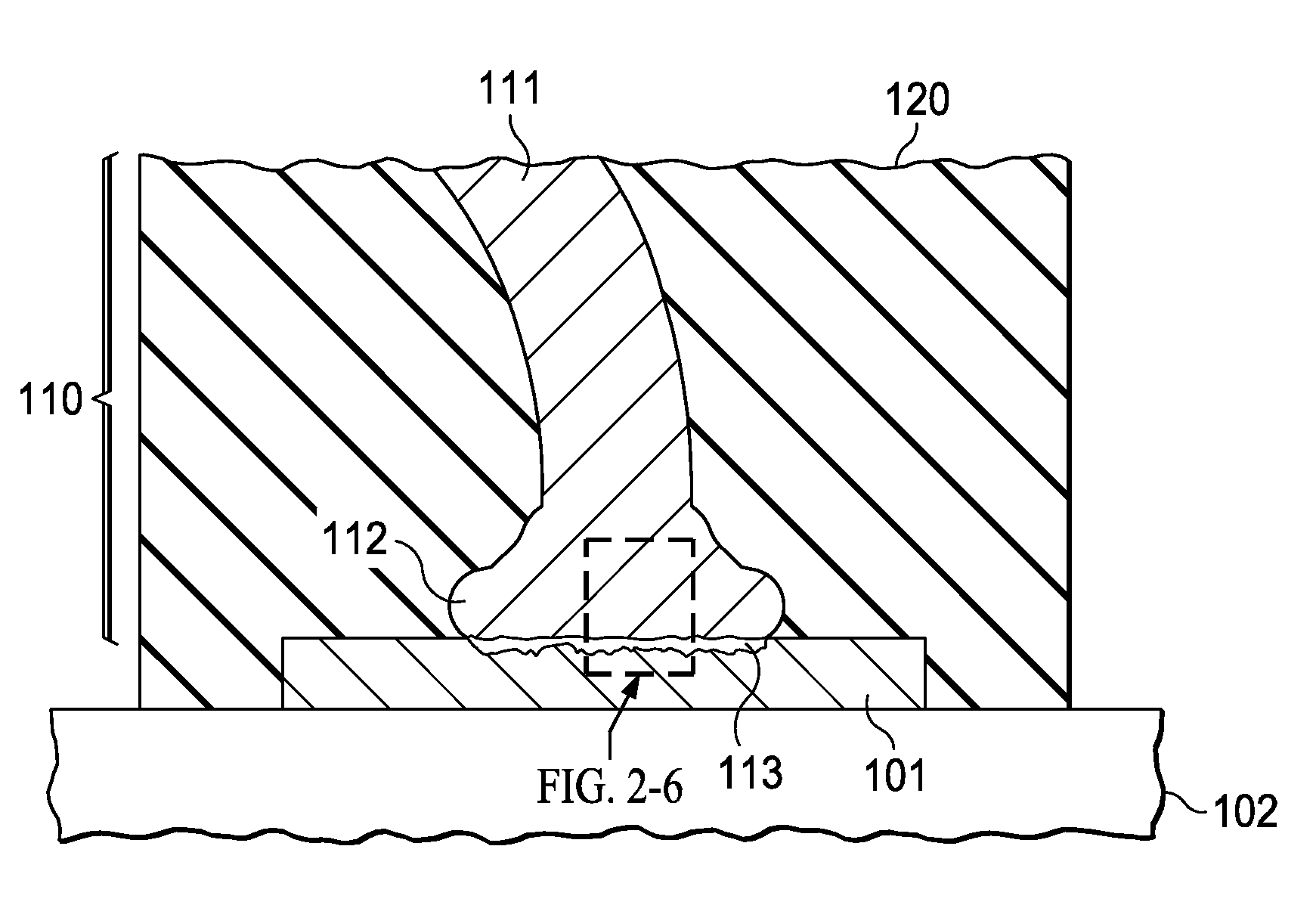

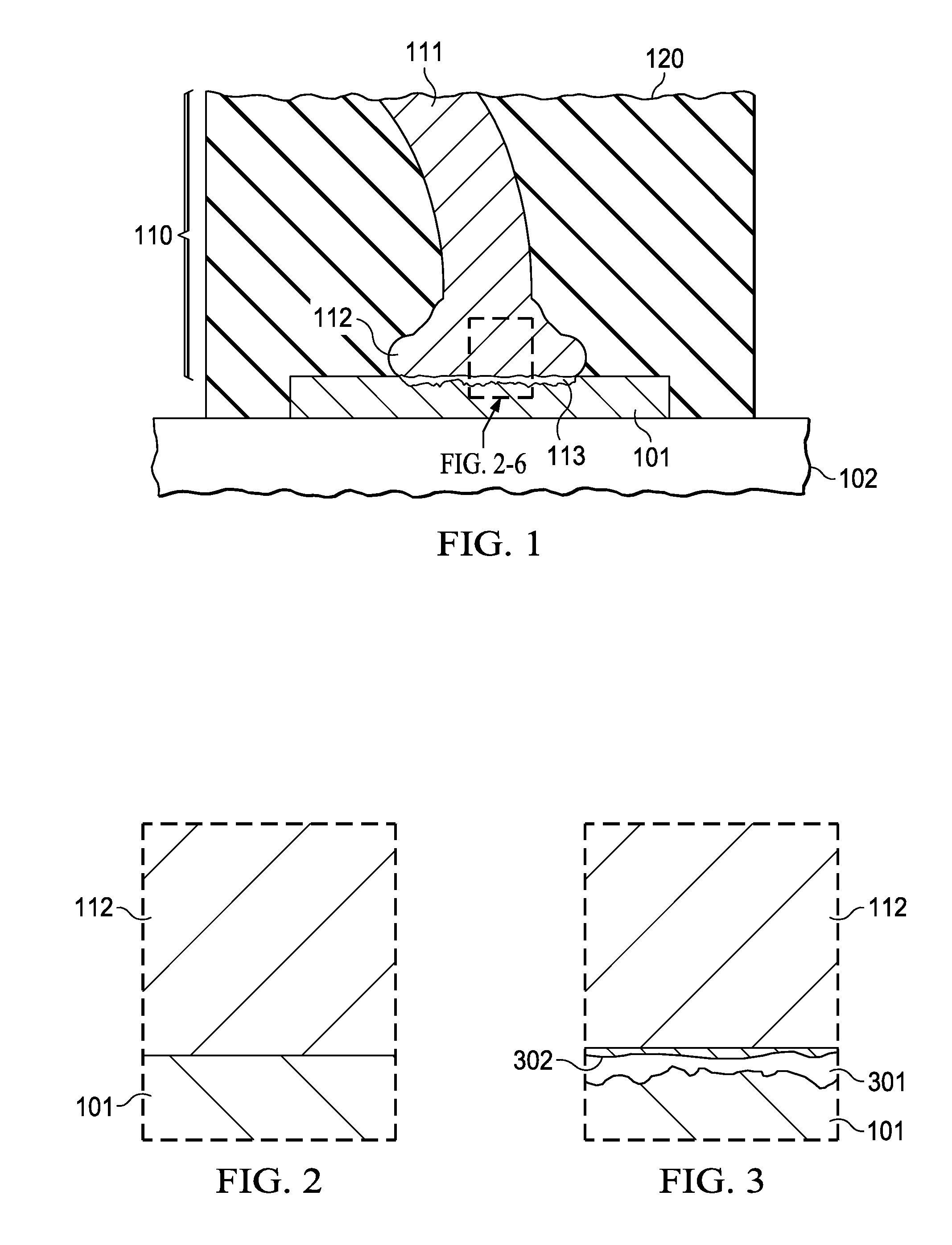

Corrosion-resistant copper-to-aluminum bonds

InactiveUS20120001336A1High electrode potentialEasy to implementSemiconductor/solid-state device detailsSolid-state devicesCopper wireSemiconductor chip

A connection formed by a copper wire (112) alloyed with a noble metal in a first concentration bonded to a terminal pad (101) of a semiconductor chip; the end of the wire being covered with a zone (302) including an alloy of copper and the noble metal in a second concentration higher than the first concentration. When the noble metal is gold, the first concentration may range from about 0.5 to 2.0 weight %, and the second concentration from about 1.0 to 5.0 weight %. The zone of the alloy of the second concentration may have a thickness from about 20 to 50 nm.

Owner:TEXAS INSTR INC

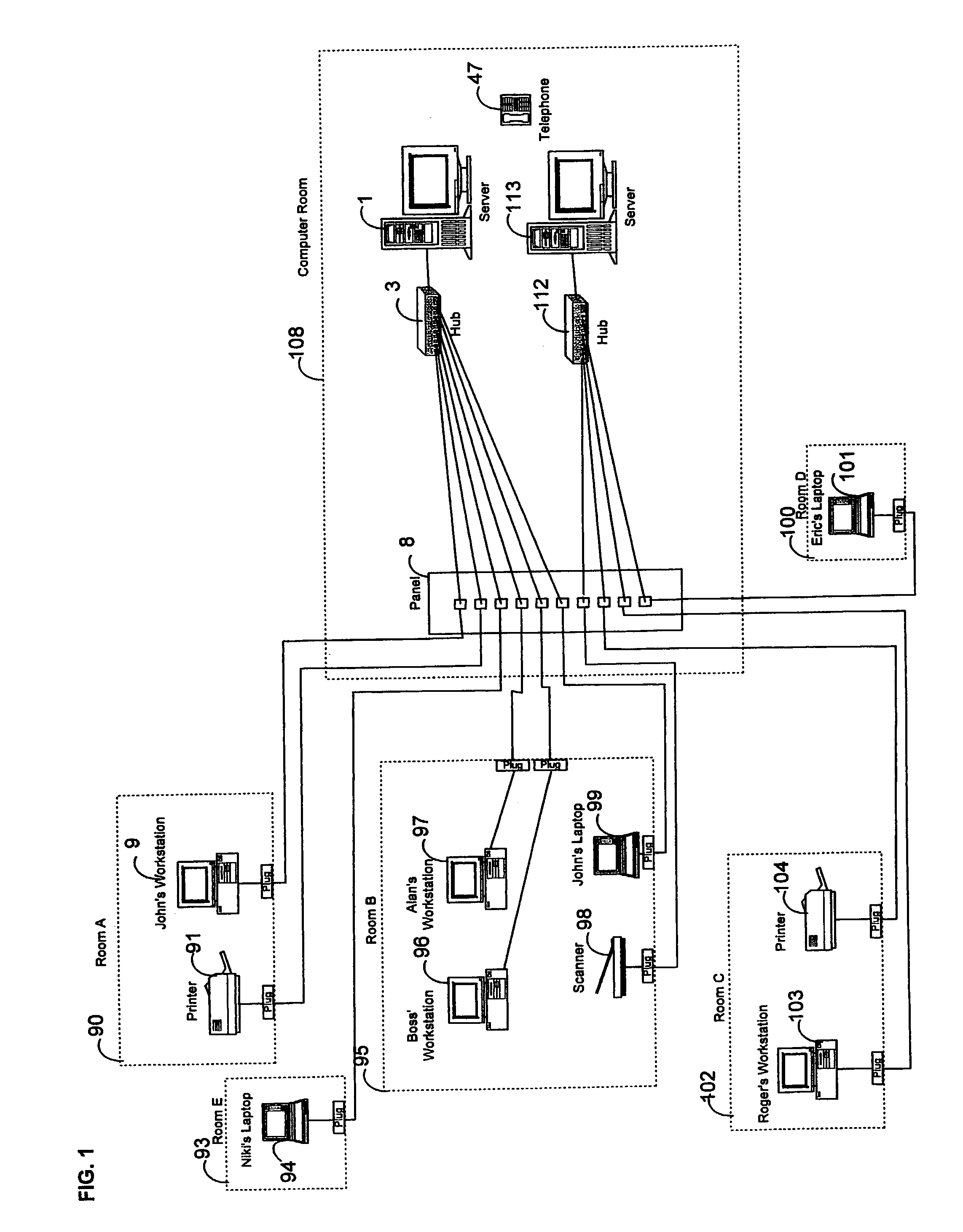

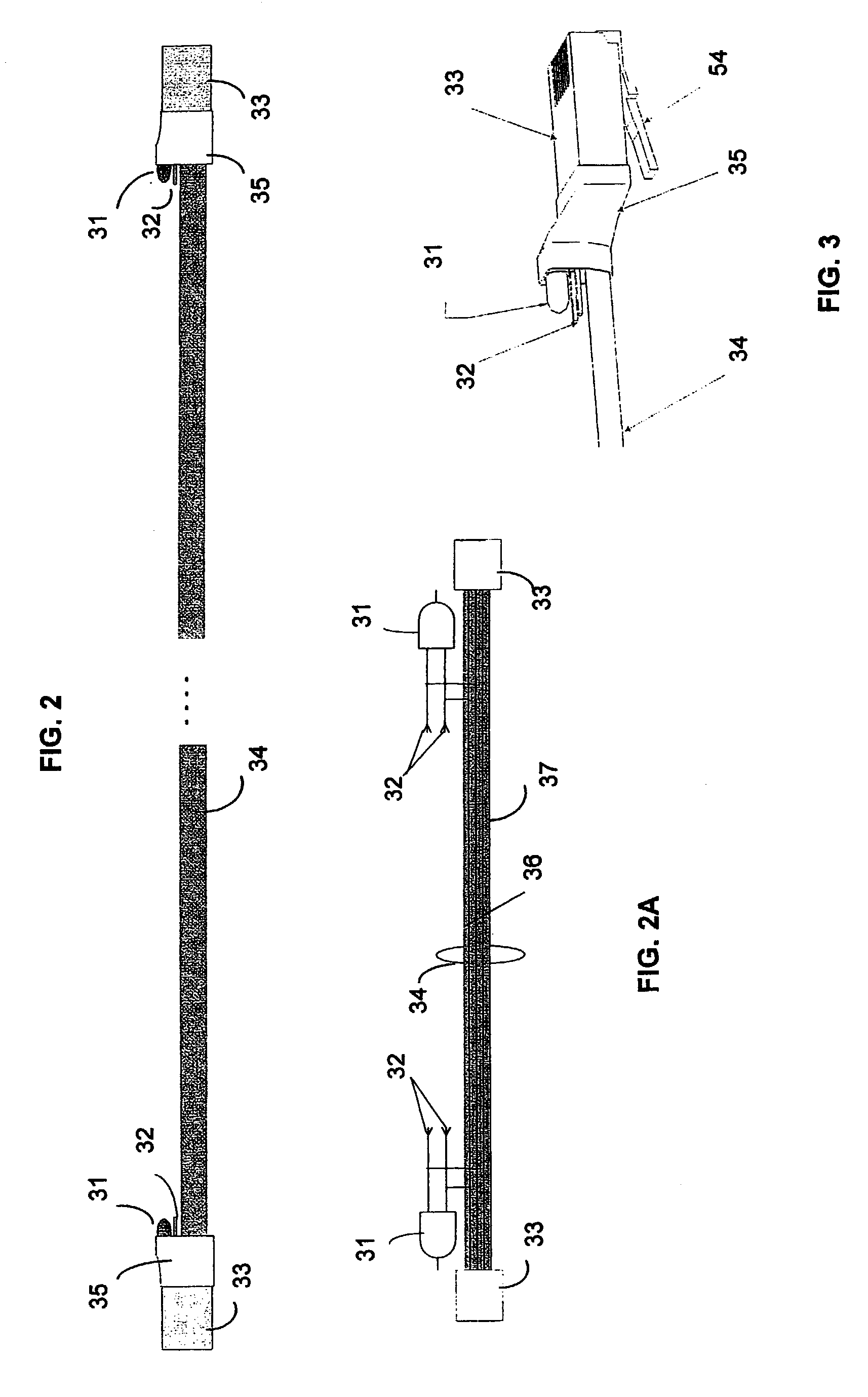

Method and apparatus for tracking remote ends of networking cables

InactiveUS6975242B2Easy to trackError preventionFrequency-division multiplex detailsElectricityService personnel

This specialized networking cable includes a plurality of twisted copper wire pairs encased in a flexible sheath for effectuating transmissive interconnections, electrically activated telltales affixed to both ends of the cable at positions adjacent to and connected to at least one of the copper wire pairs for providing an identification signal when activated; and means for selectively applying a current to the cable that activates the telltales and does not interfere with the flow of data through the cable whereby the telltales may be activated on at least one of the twisted copper pairs. An LED and an electric power connector suitable for plug-in connection of a power pack are affixed to the cable adjacent each end such that both LEDs are lighted whenever power is applied to either of the electrical connectors. The attendant illumination of the LEDs readily indicates where both ends of the networking cable are located. The networking cable also may be used for convenient telephonic communication by service personnel. One embodiment includes the cable as described above except with one end having a connector mateable with a standard Category 5 networking cable thereby providing for a standard networking cable to be converted into a specialized networking cable usable for tracing cable ends.

Owner:BROWN ALAN J

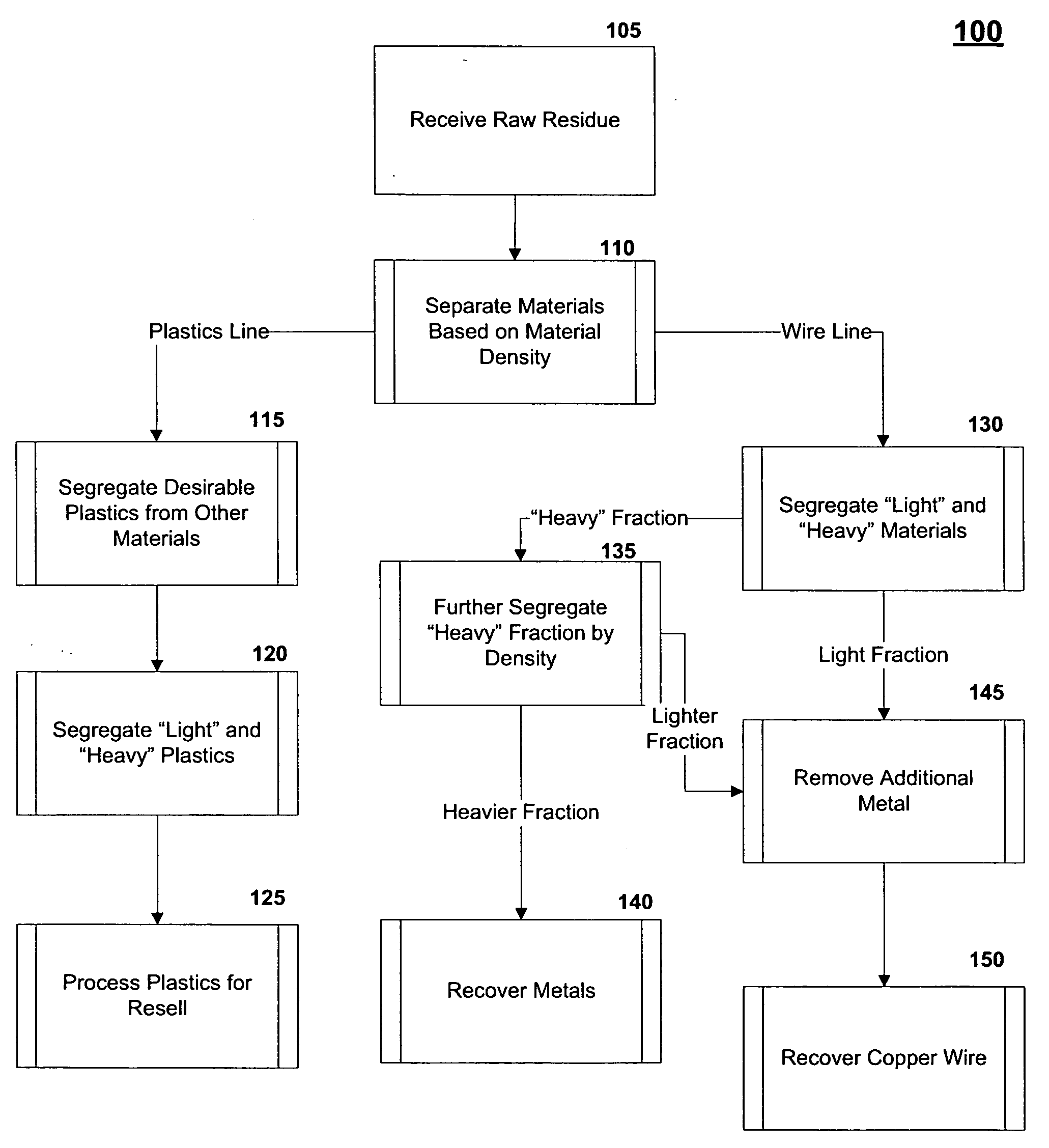

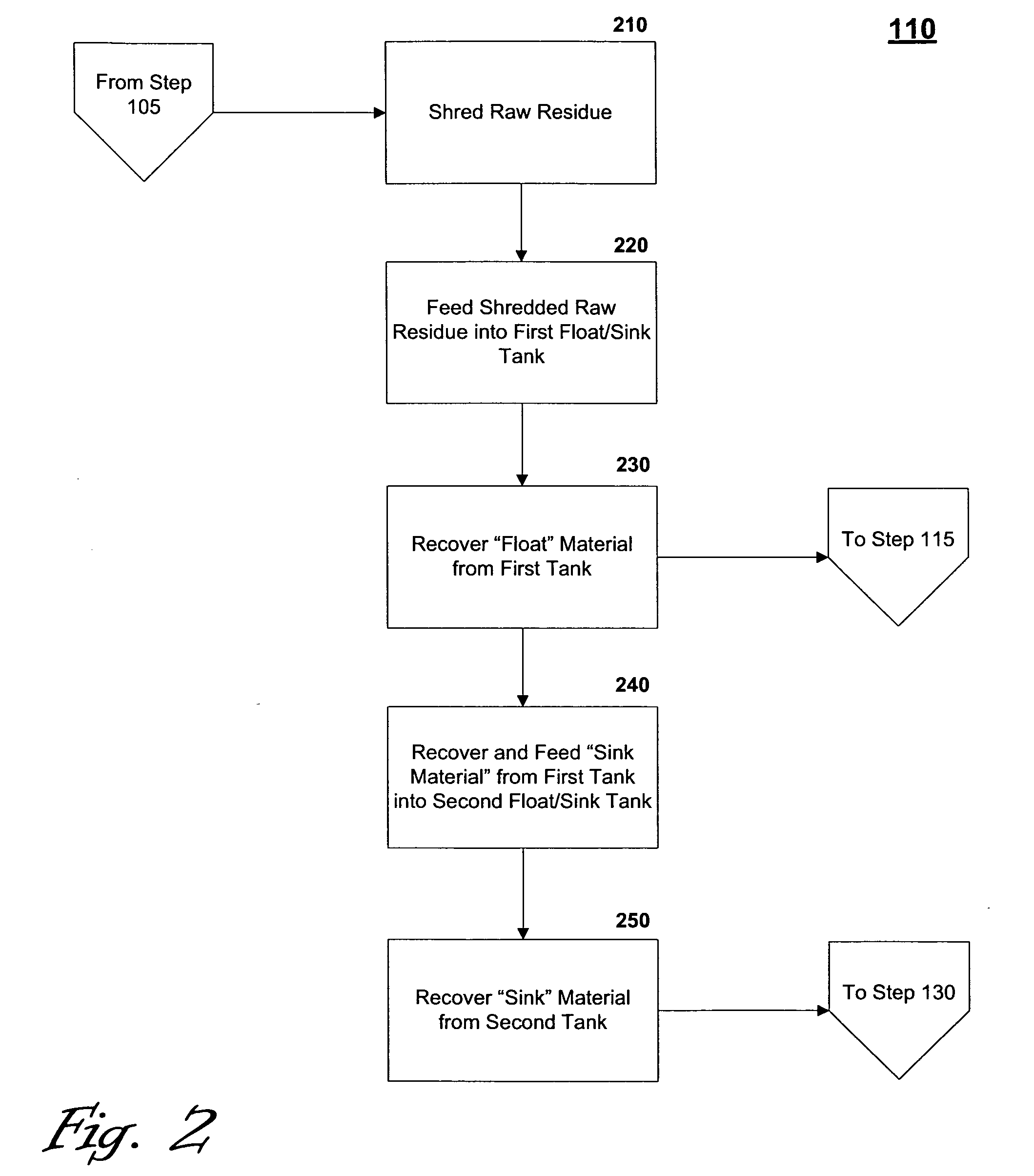

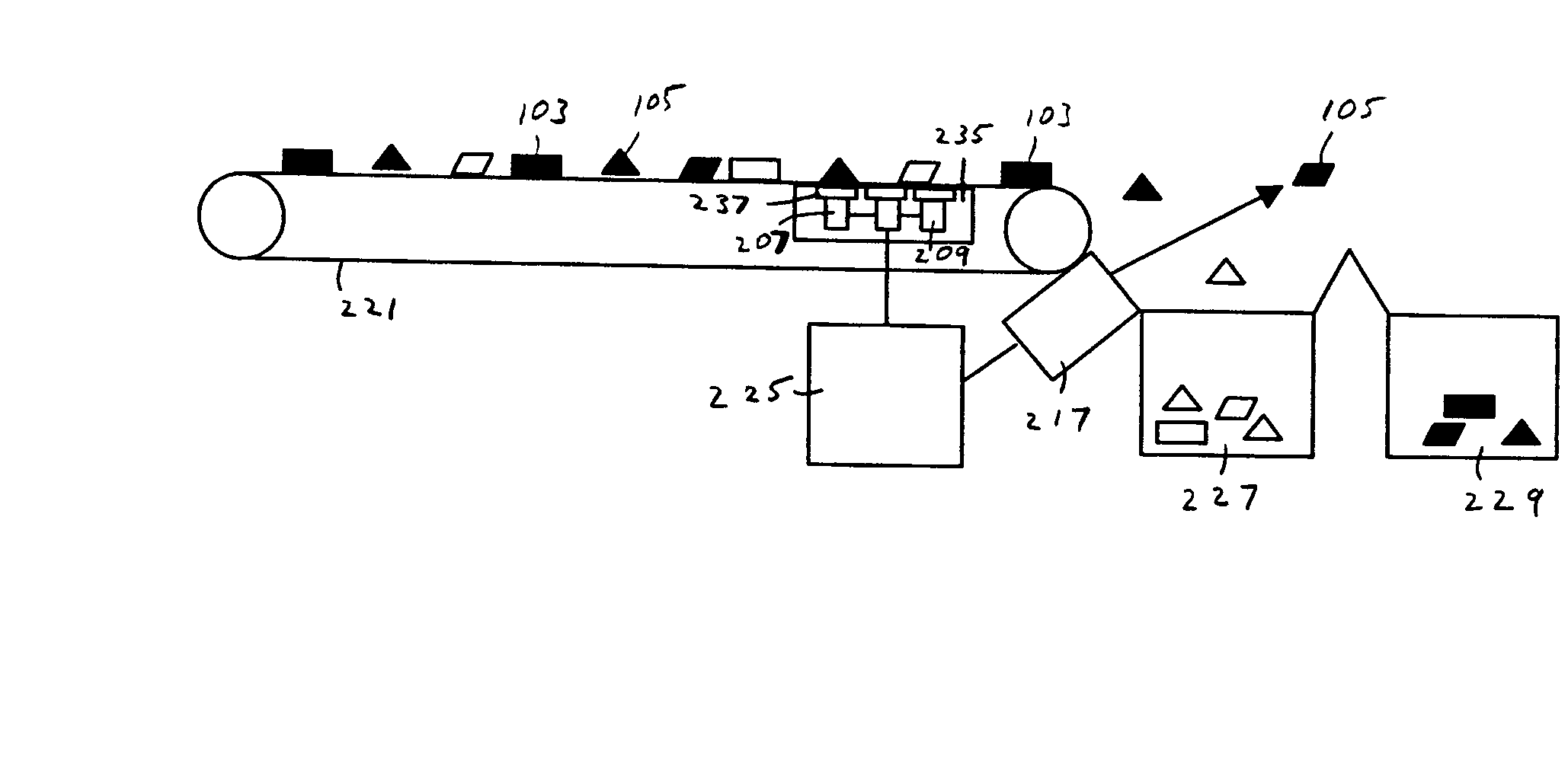

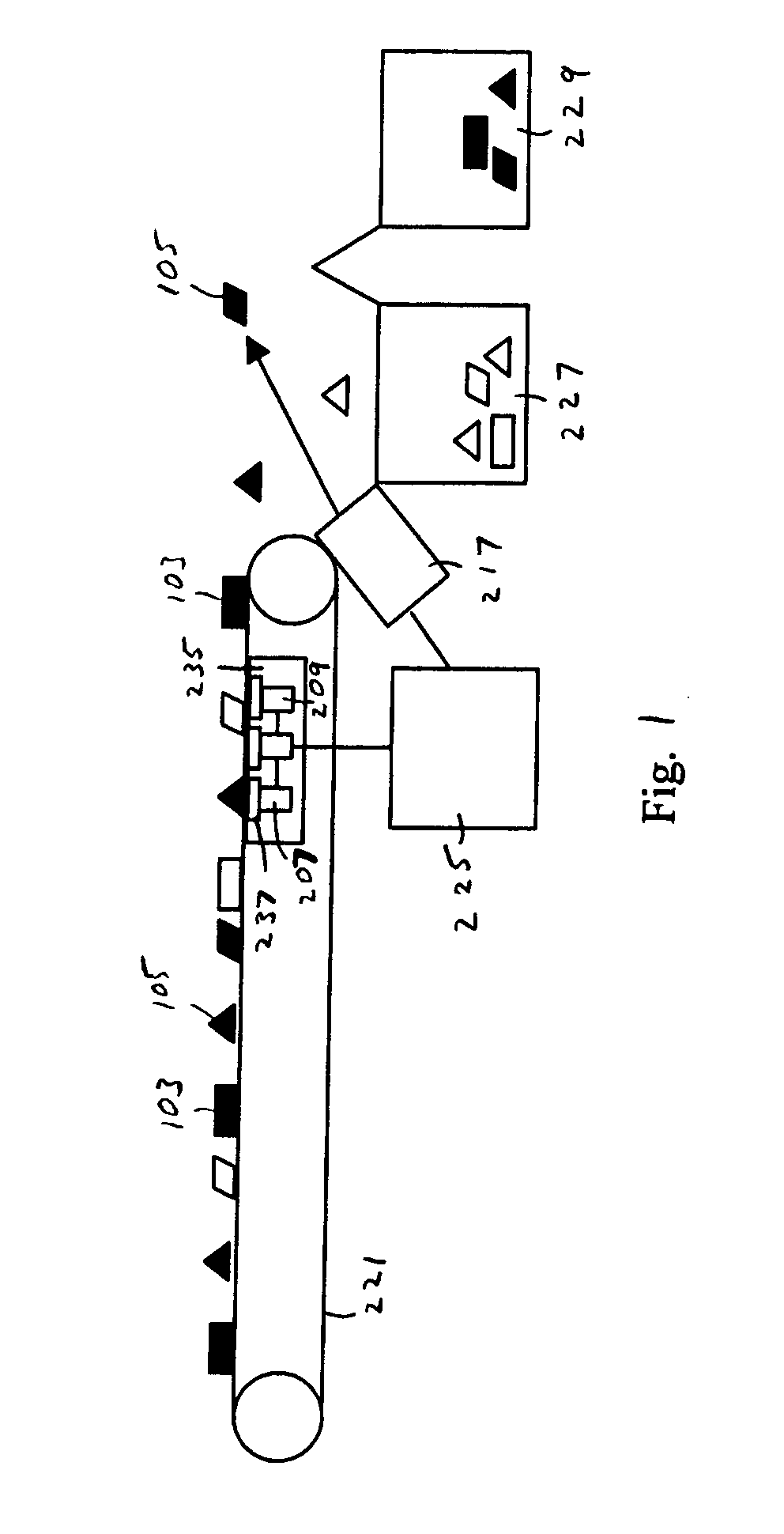

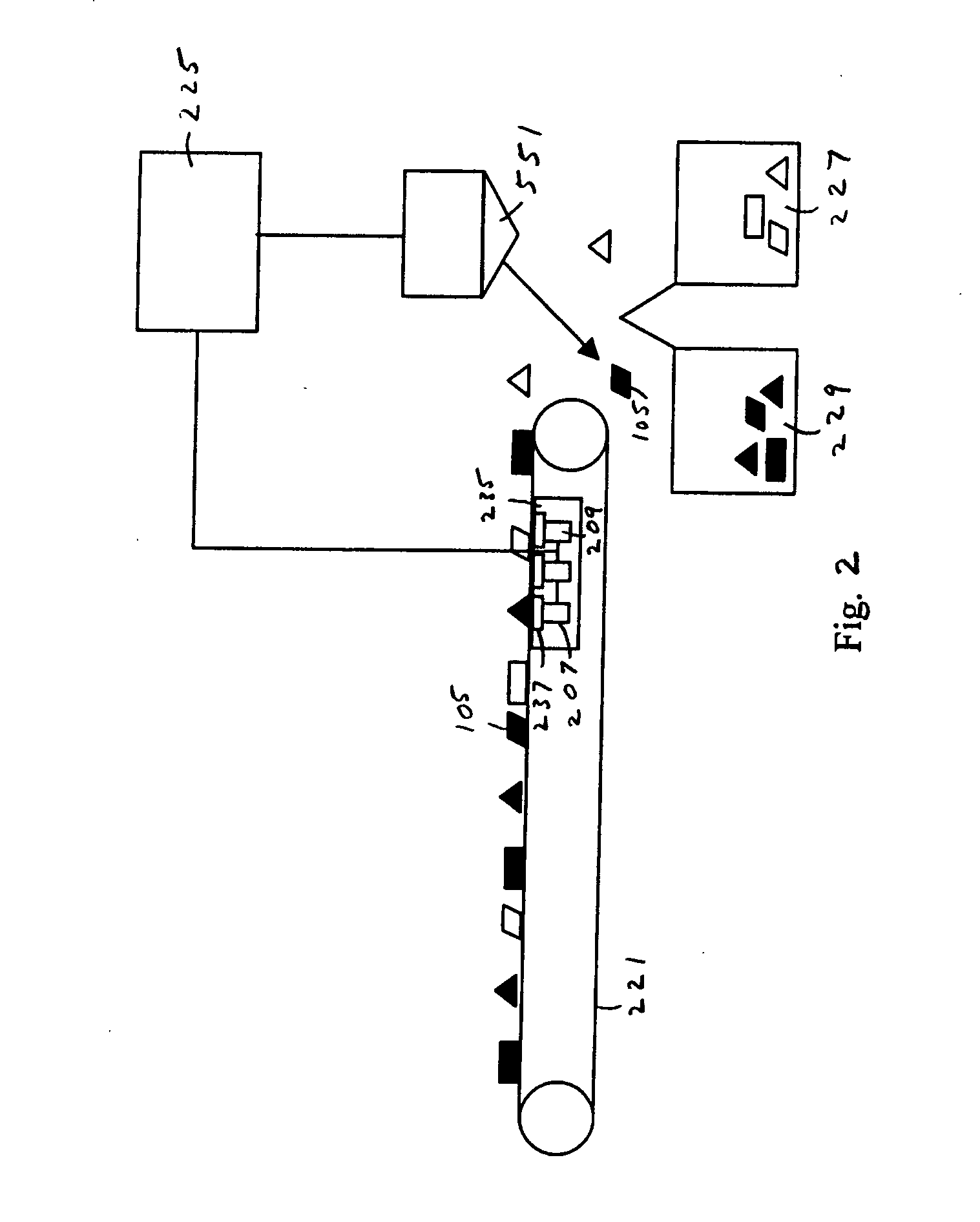

Method and system for sorting and processing recycled materials

InactiveUS20080257794A1Small sizePlastic recyclingAuxillary shaping apparatusCopper wireNonferrous metal

Processing recycled materials to recover plastics, copper wire, and other non-ferrous metals. Aspects of the invention employ density separation to separate plastic-bearing materials from copper-bearing materials. Plastic-bearing materials are further separated to separate light plastics from heavy plastics. Plastics are concentrated, extruded, and palletized. Copper and other valuable metals are recovered from copper-bearing materials using a water separation table.

Owner:VALERIO THOMAS A

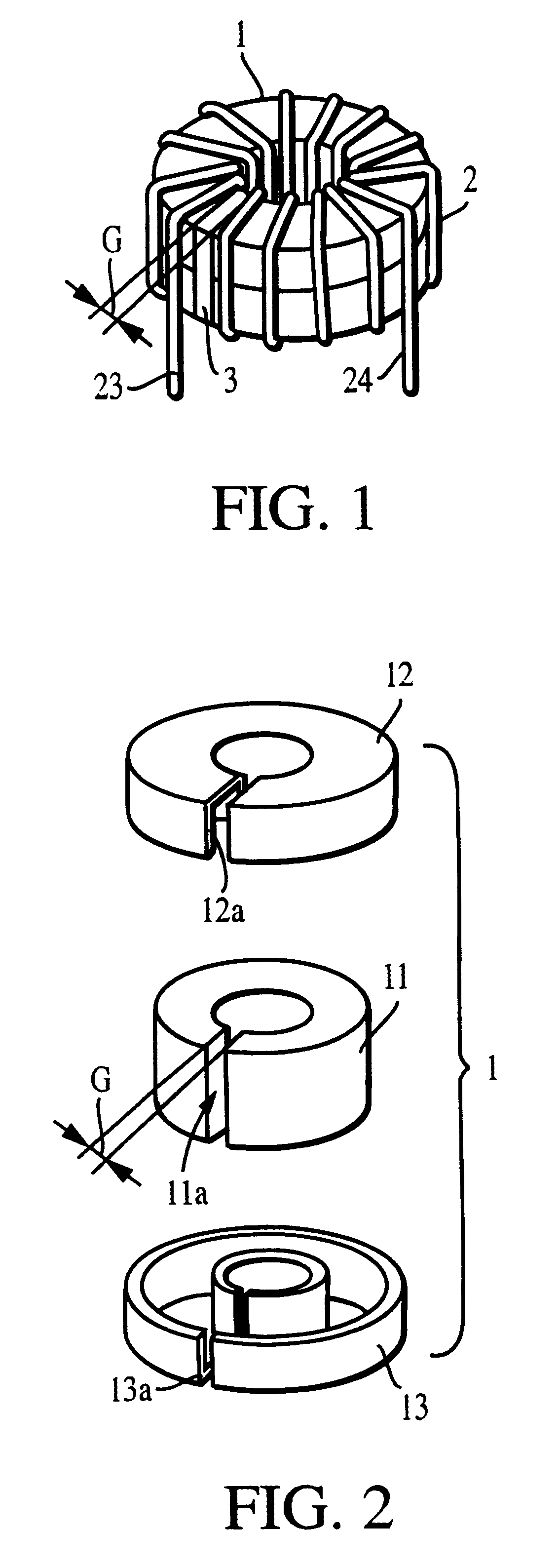

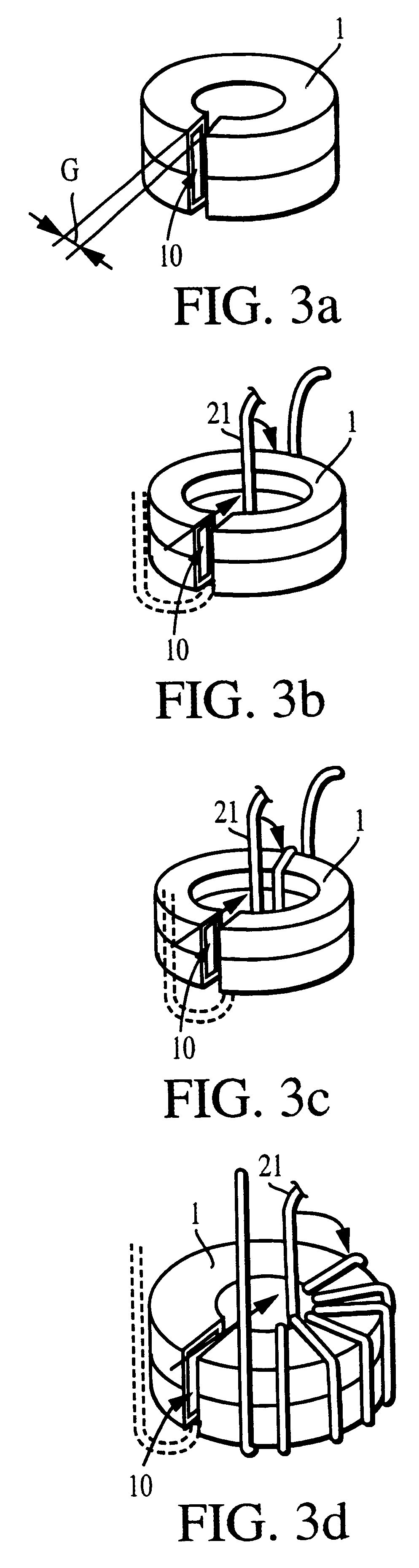

Inductor core-coil assembly and manufacturing thereof

InactiveUS6512438B1Improve magnetismImproving core-coil assembly production yieldMaterial nanotechnologyTransformers/inductances casingsCopper wireEngineering

Disclosed are a gapped magnetic core which may be coated or uncoated with an insulating layer or housed in an insulting box having a physical gap whose dimension is close to that of the gapped magnetic core and automated or semi-automated methods of applying copper wire on the gapped core or the core assembly and filling the gap with a spacer in the core or core assembly. The disclosed processes allow various combinations of core and spacer materials and gap configurations, resulting in a wide variety of core-coil assemblies which are useful as inductive components in electric and electronic circuits. Also disclosed is a core-coil assembly wherein a magnetic core with a gap directed off the conventional radial direction of a toroidally-wound core.

Owner:SHT CO LTD

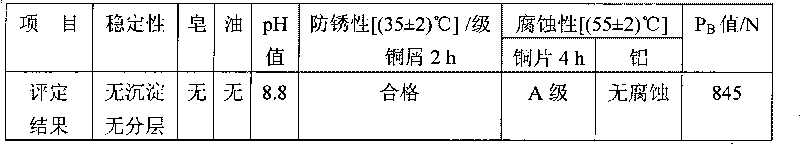

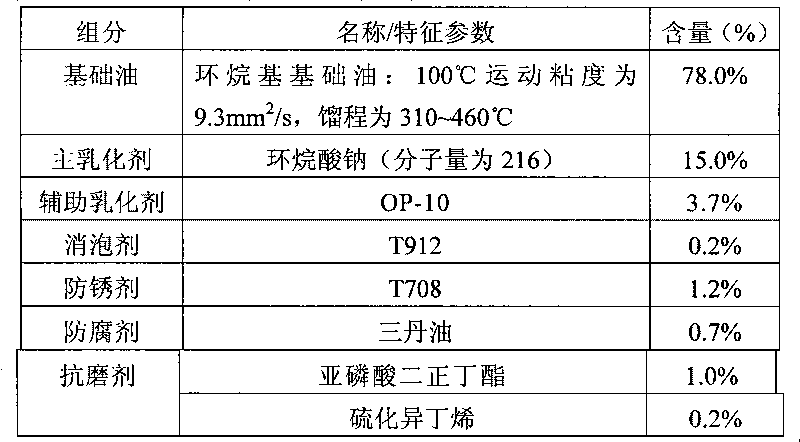

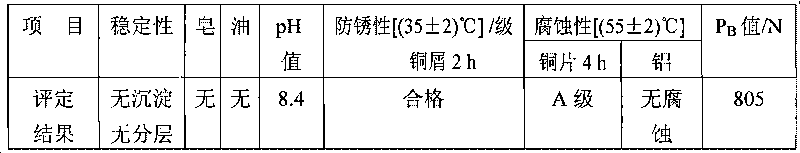

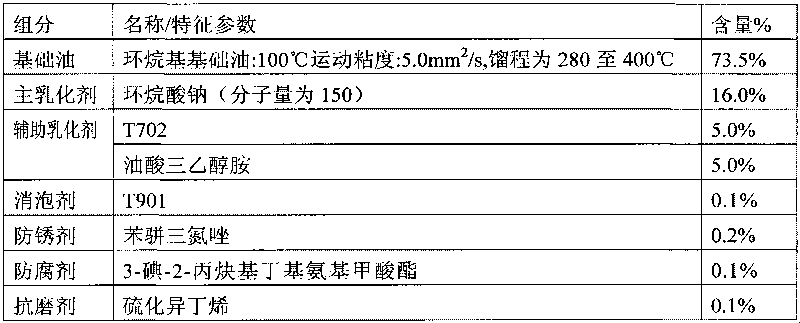

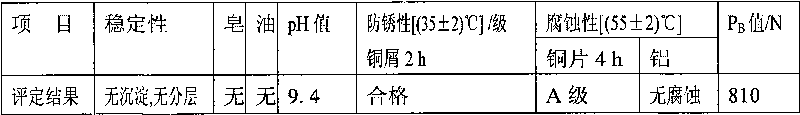

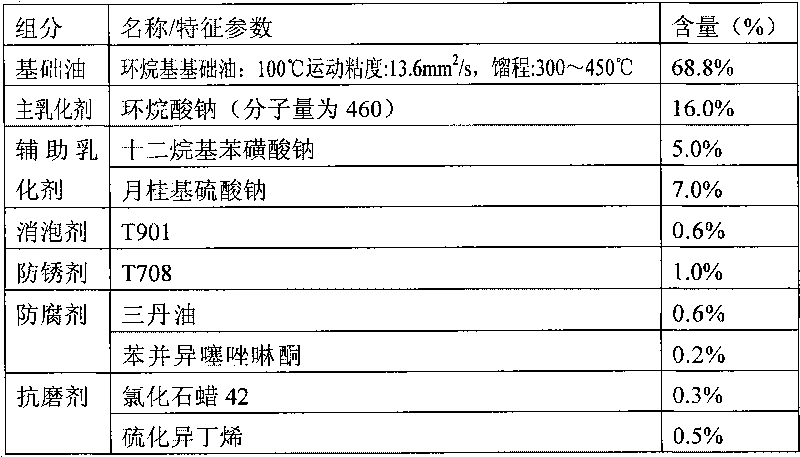

Copper and aluminum wire drawing oil and preparation method and use method thereof

The invention relates to the technical field of petroleum base lubricant composition and a preparation method thereof, which is copper and aluminum wire drawing oil and a preparation method thereof. The copper and aluminum wire drawing oil comprises base oil, an emulsifying agent, an auxiliary emulsifying agent, a defoaming agent, an antirusting agent, a preservative and an antiwear agent. The preparation method can be carried out by the following steps that: the copper and aluminum wire drawing oil is mixed into 3 percent to 45 percent of water-based emulsion according to the weight percentage. The water-based emulsion is showered into a wire drawing die cavity in the copper and aluminum wire drawing process. The product of the invention has good lubricating property, excellent light stability and storage stability, low cost, good cooling effect, fast heat-transfer speed, little temperature-rise amplitude, nonflammability and easy cleaning, thus guaranteeing safety of use environment. Copper wires and aluminum wires which are drawn by adopting the product have even line shapes, bright surfaces, and rustless property, and also have good ultraviolet and storage stability and good stability.

Owner:PETROCHINA KARAMAY PETROCHEMICAL CO LTD

Electric deterrent device

A deterrent device for delivering an electric shock to an animal, pest or bird to be deterred, having the typical components of a non-conductive base to which the electrically conductive elements are attached. Instead of the typically-used copper wire, however, the braided elements comprise smaller strands of a conductive material, such as copper, aluminum or stainless steel wire, is used and is mechanically attached to the non-conductive base. The braided elements can be mechanically attached using a simple sewing operation in which the braid is sewn to the base. Because of the mechanical attachment and the ability of the braided elements to flex in both contraction and extension, the device of this invention can be used in tight corners and other contorted locations without having the wires of the typical prior art device pull free of the base.

Owner:BIRD BARRIER AMERICA

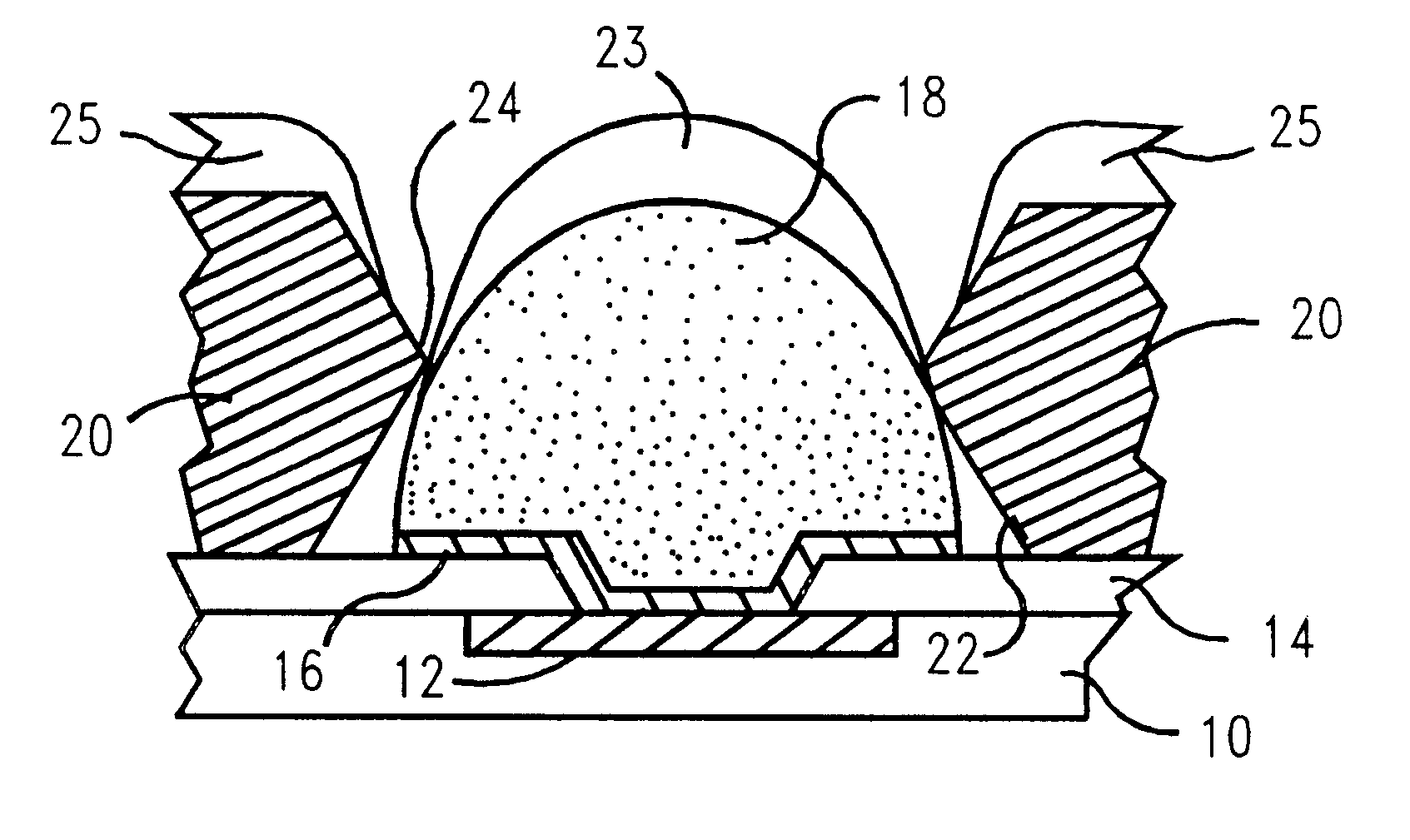

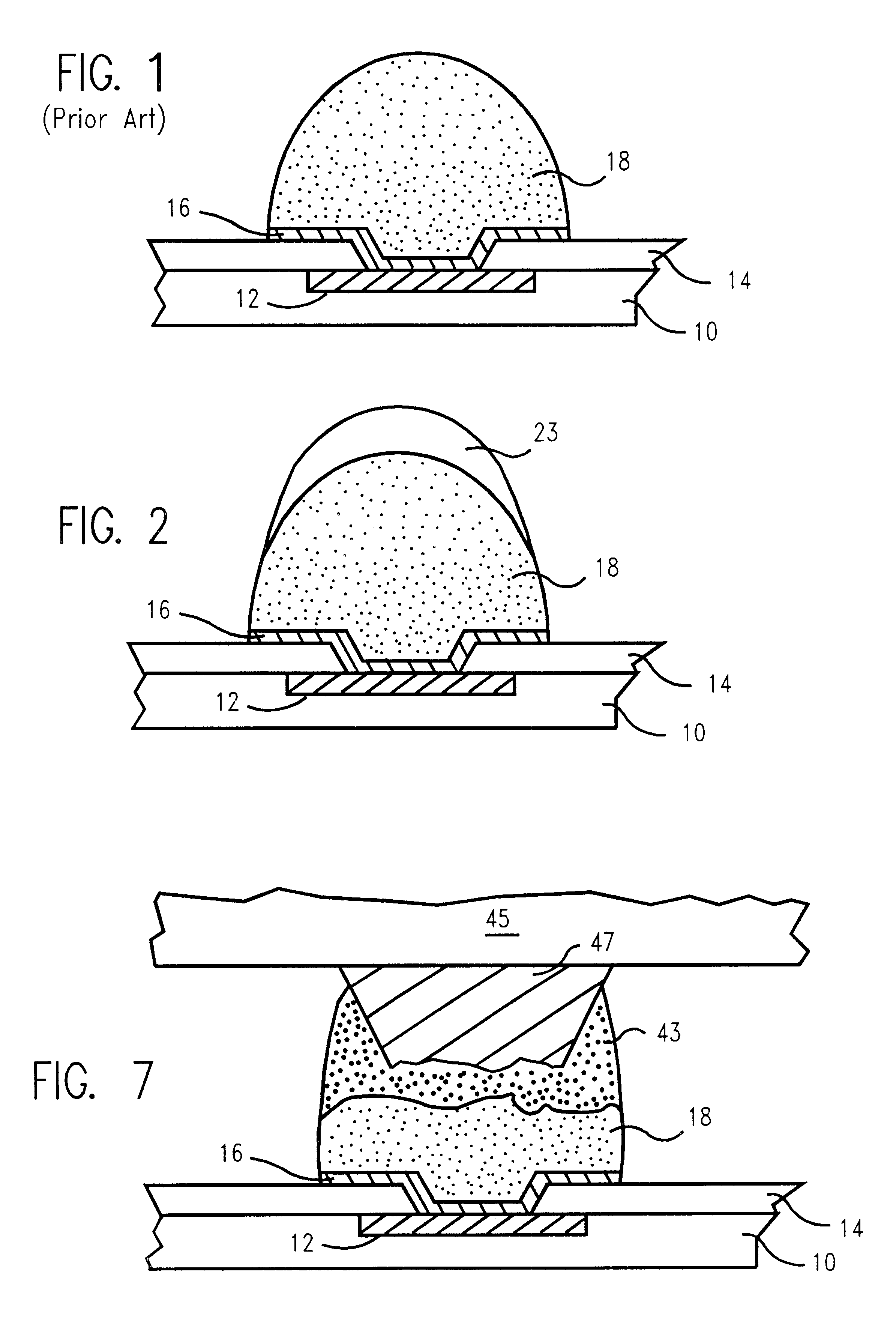

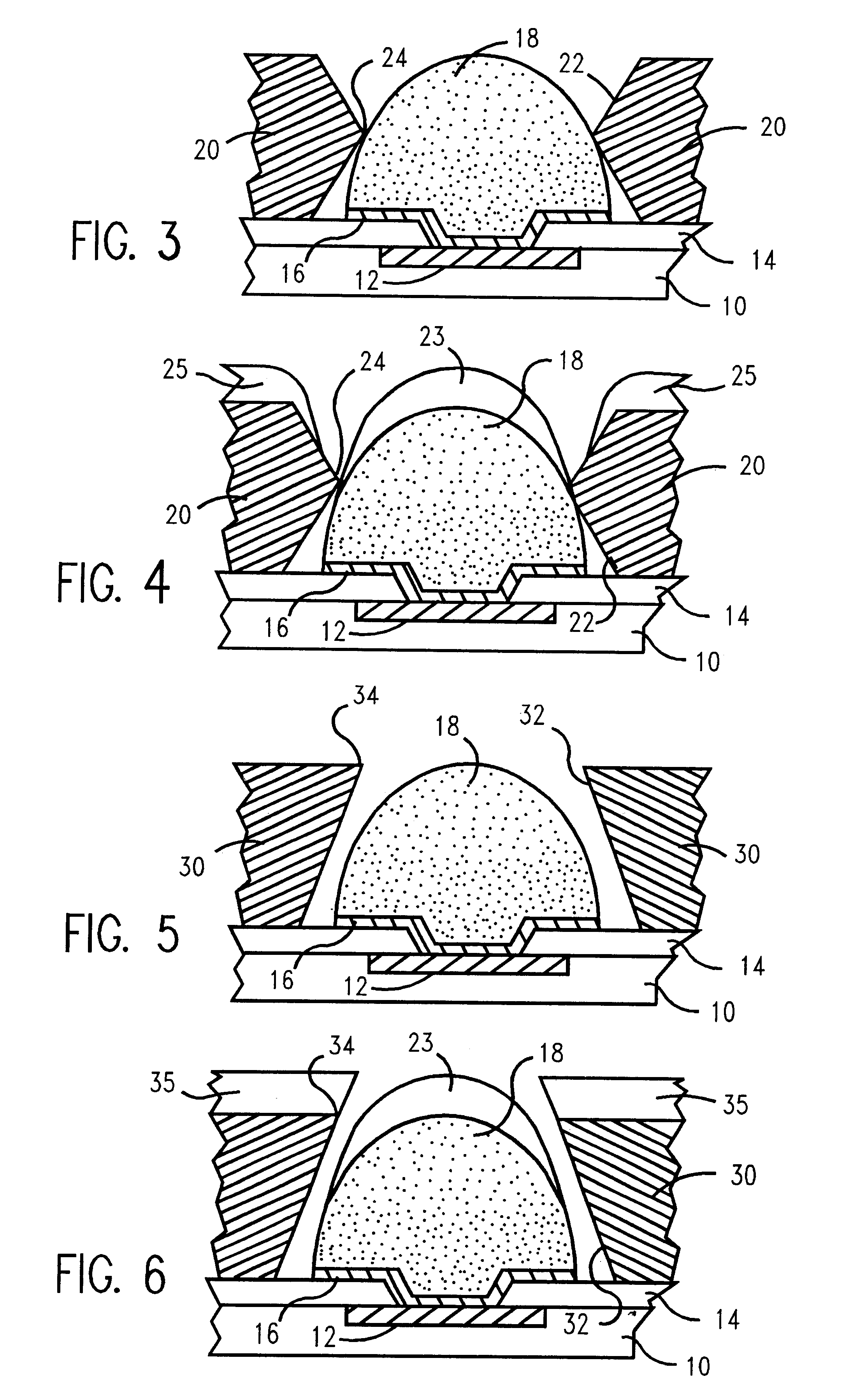

Method for forming reflowed solder ball with low melting point metal cap

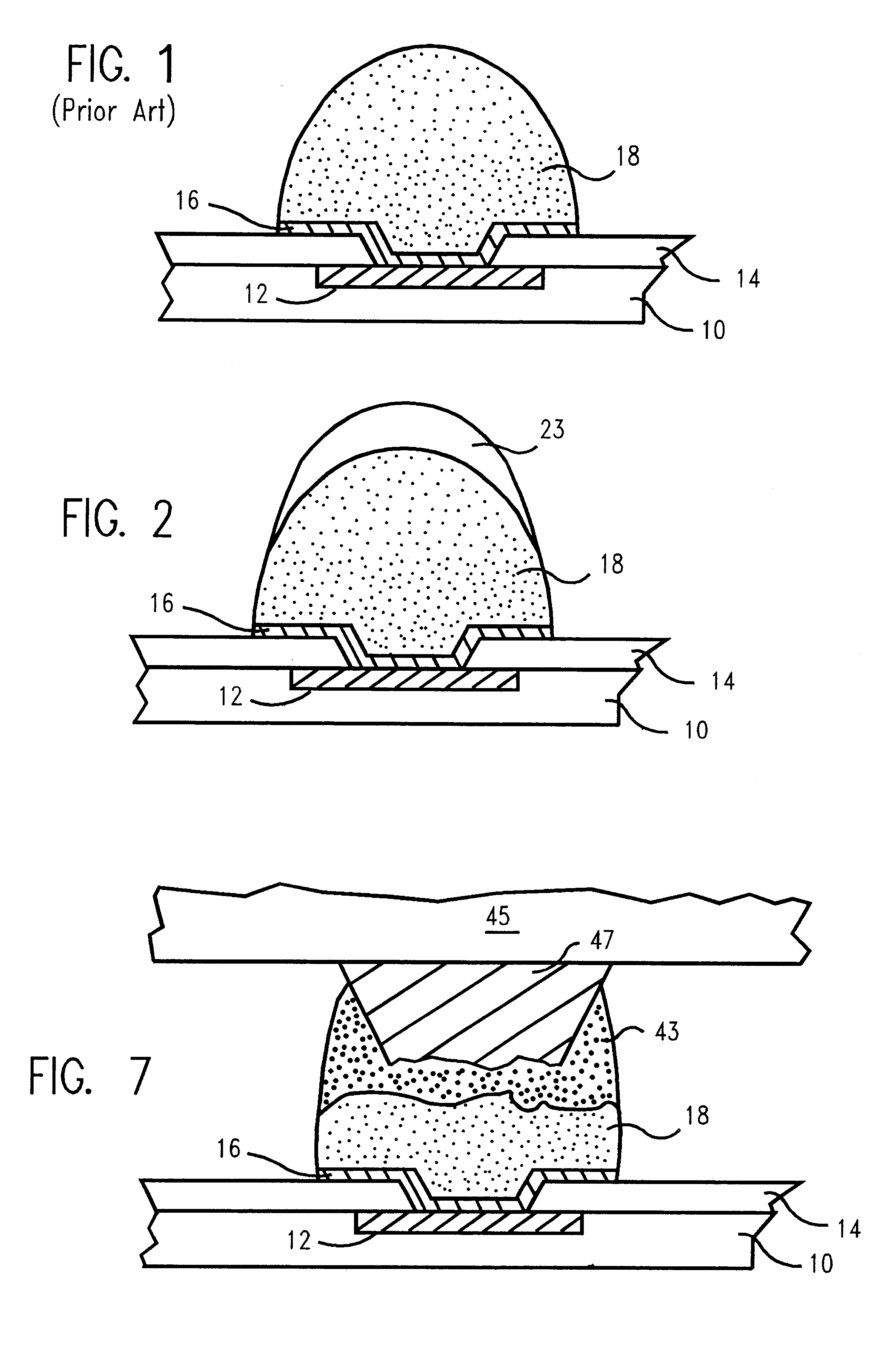

InactiveUS6344234B1Reduce the hole diameterMinimal diameterFinal product manufactureSemiconductor/solid-state device detailsTinningIndium

A method and structure for a solder interconnection, using solder balls for making a low temperature chip attachment directly to any of the higher levels of packaging substrate is disclosed. After a solder ball has been formed using standard methods it is reflowed to give the solder ball a smooth surface. A layer of low melting point metal, such as, bismuth, indium or tin, preferably, pure tin, is deposited on the top of the solder balls. This structure results in localizing of the eutectic alloy, formed upon subsequent low temperature joining cycle, to the top of the high melting solder ball even after multiple low temperature reflow cycles. This method does not need tinning of the substrate to which the chip is to be joined, which makes this method economical. It has also been noticed that whenever temperature is raised slightly above the eutectic temperature, the structure always forms a liquid fillet around the joint with copper wires. This liquid fillet formation results in substantial thermal fatigue life improvement for reduced stress at interface; and secondly, provides an easy means to remove chip for the purpose of chip burn-in, replacement or field repairs.

Owner:ULTRATECH INT INC

Retractable optical fiber tether assembly and associated fiber optic cable

The present invention provides an optical system that allows for the flexible location of an optical device that is coupled to a patch panel in a wiring closet or other optical signal source through a series of fiber optic cables and optical connections, or the flexible location of an array of such optical devices. The optical system includes, in part, one or more retractable optical fiber tether assemblies that each allow varying lengths of tether cable to be pulled and used. The retraction device of each of the optical tether assemblies may be disposed mid-tether cable, or may terminate the respective tether cable and incorporate the given optical device. In an exemplary wireless local area network (WLAN) application, each of the retractable optical fiber tether assemblies includes an integral transceiver and associated software. Thus, each of the retractable optical fiber tether assemblies functions as an antenna. The associated fiber optic cable carries both optical fiber to provide optical continuity and copper wire to provide electrical conductivity to the antenna array.

Owner:CORNING OPTICAL COMM LLC

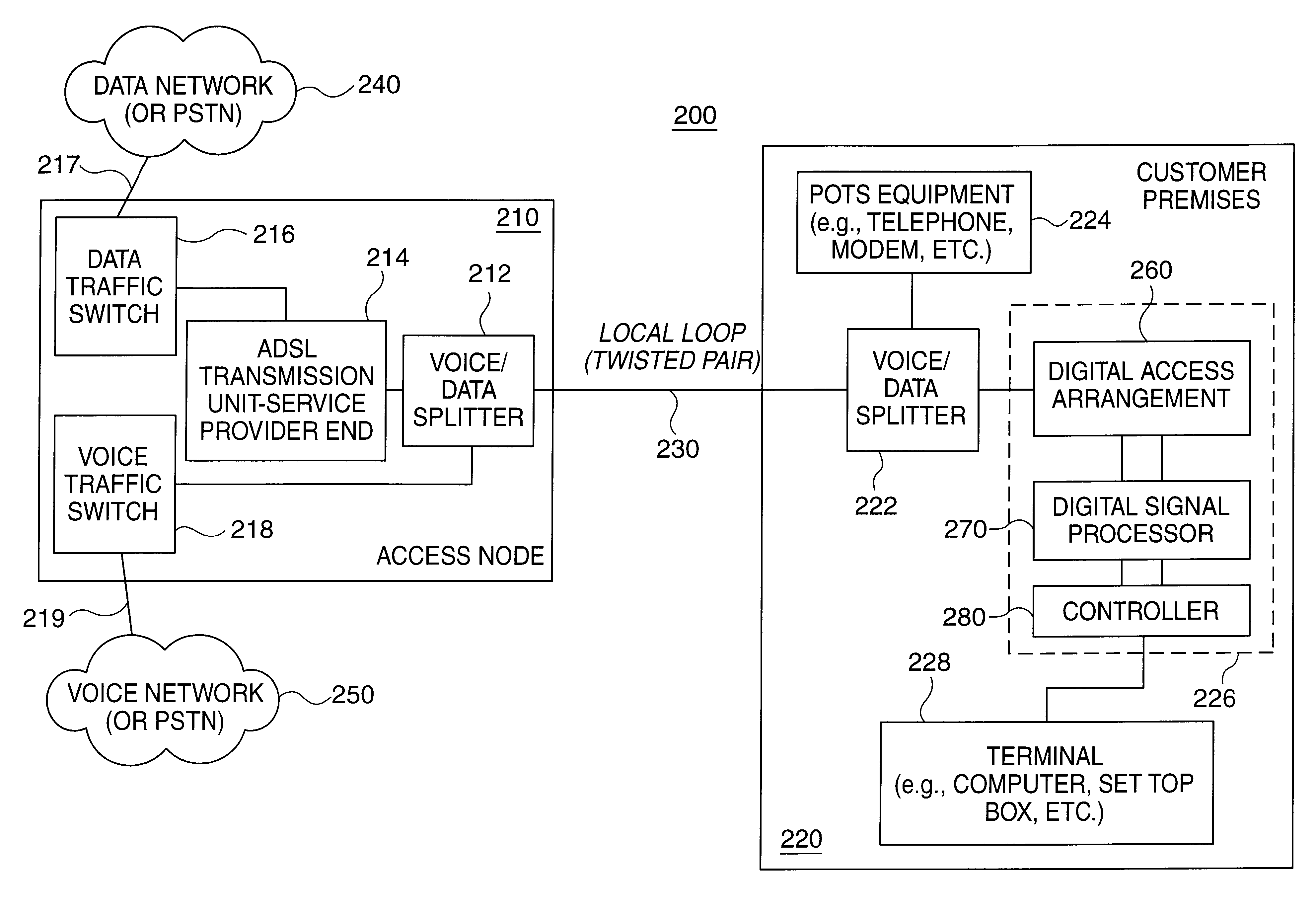

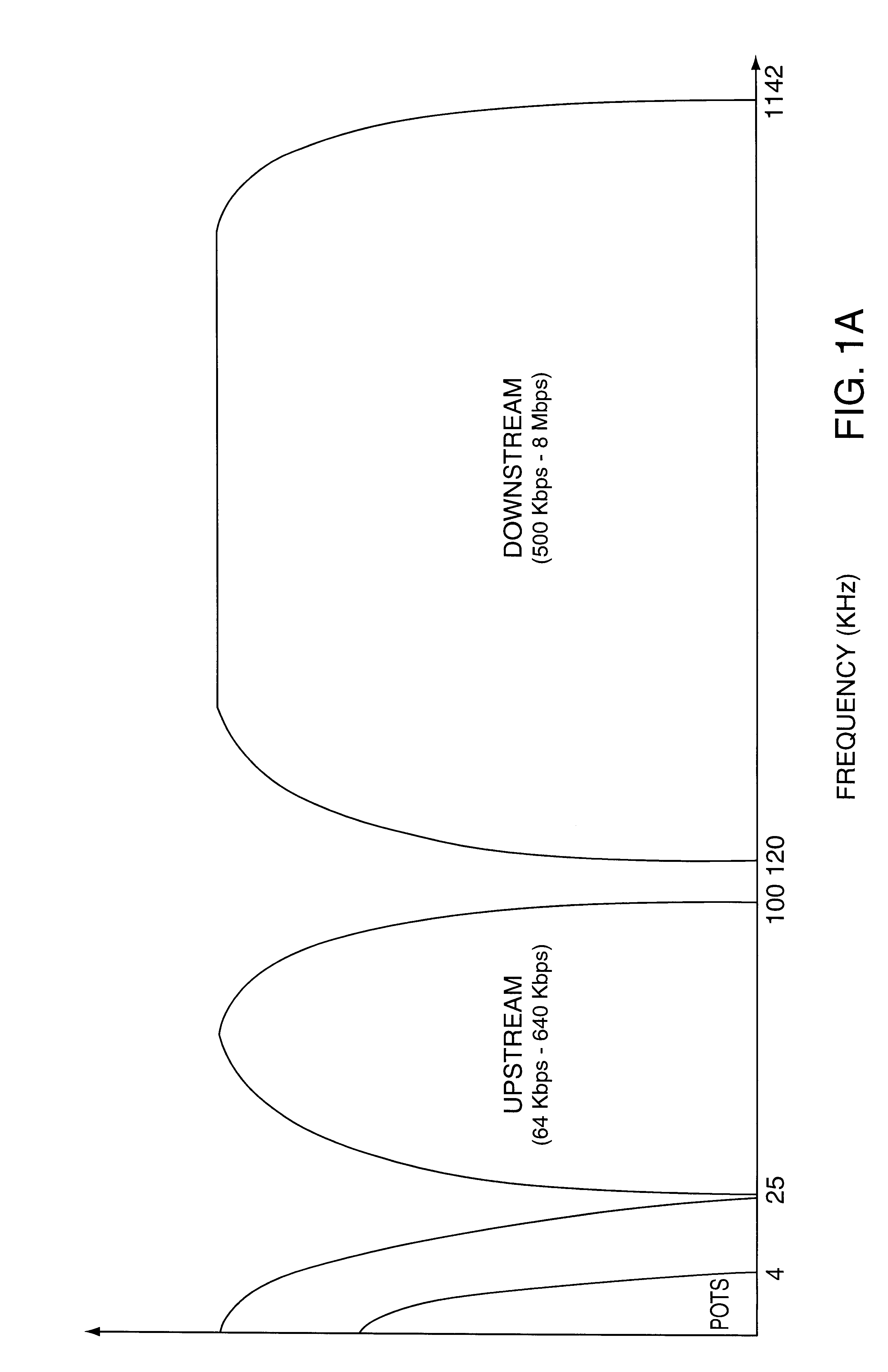

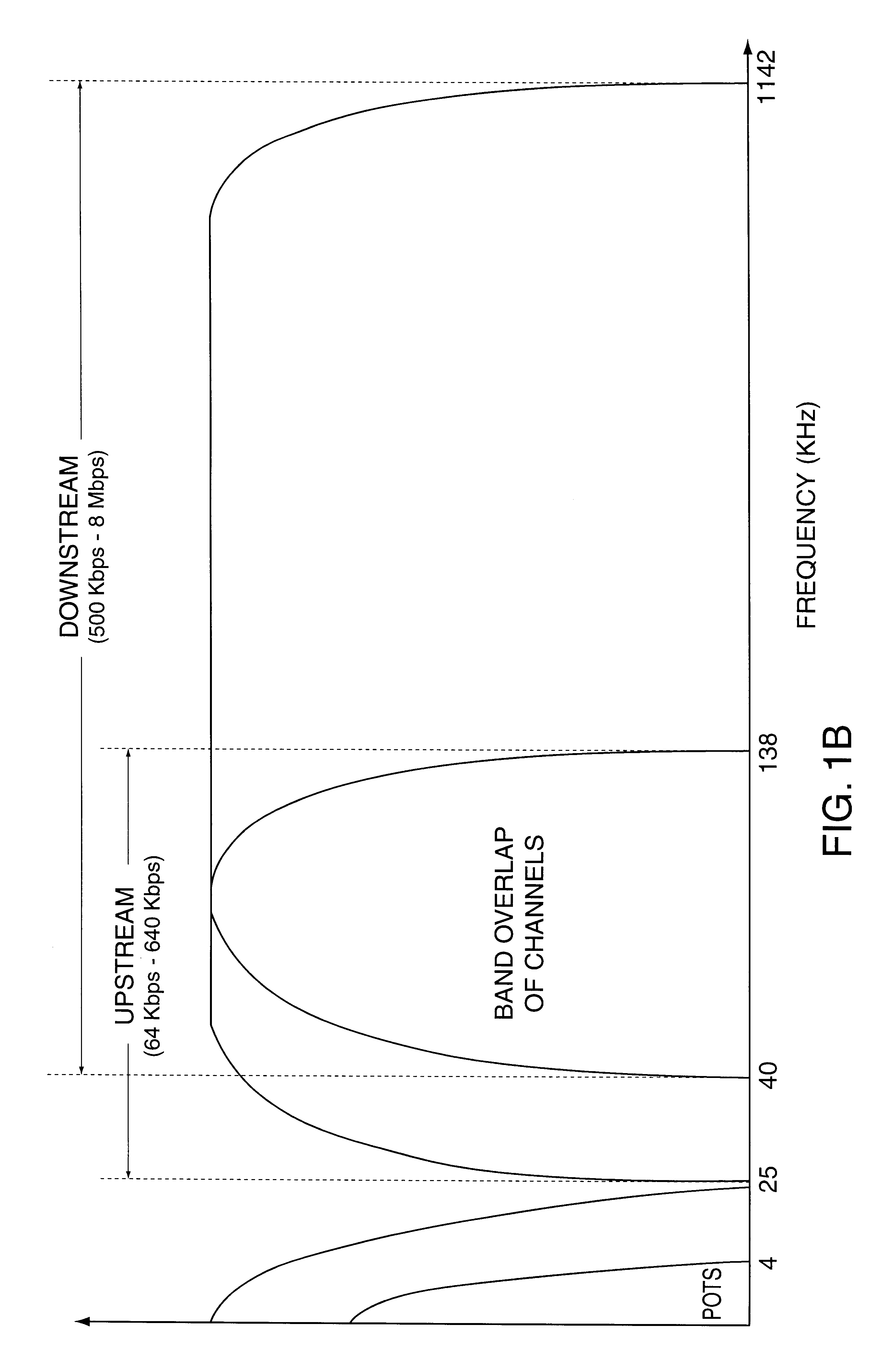

Methods and apparatus for terminating a line and supporting the asymmetric digital subscriber line protocol

InactiveUS6393110B1Two-way loud-speaking telephone systemsSubstations coupling interface circuitsNon symmetricCopper wire

A digital access arrangement for (i) isolating downstream components from twisted pair copper wire and (ii) separating upstream and downstream communications channels. The line isolation is performed with relatively small, lightweight components, such as an optical isolation unit for example, and can be operated with signals modulated at relatively high frequencies and having relatively high data rates and amplitudes.

Owner:HEWLETT PACKARD DEV CO LP

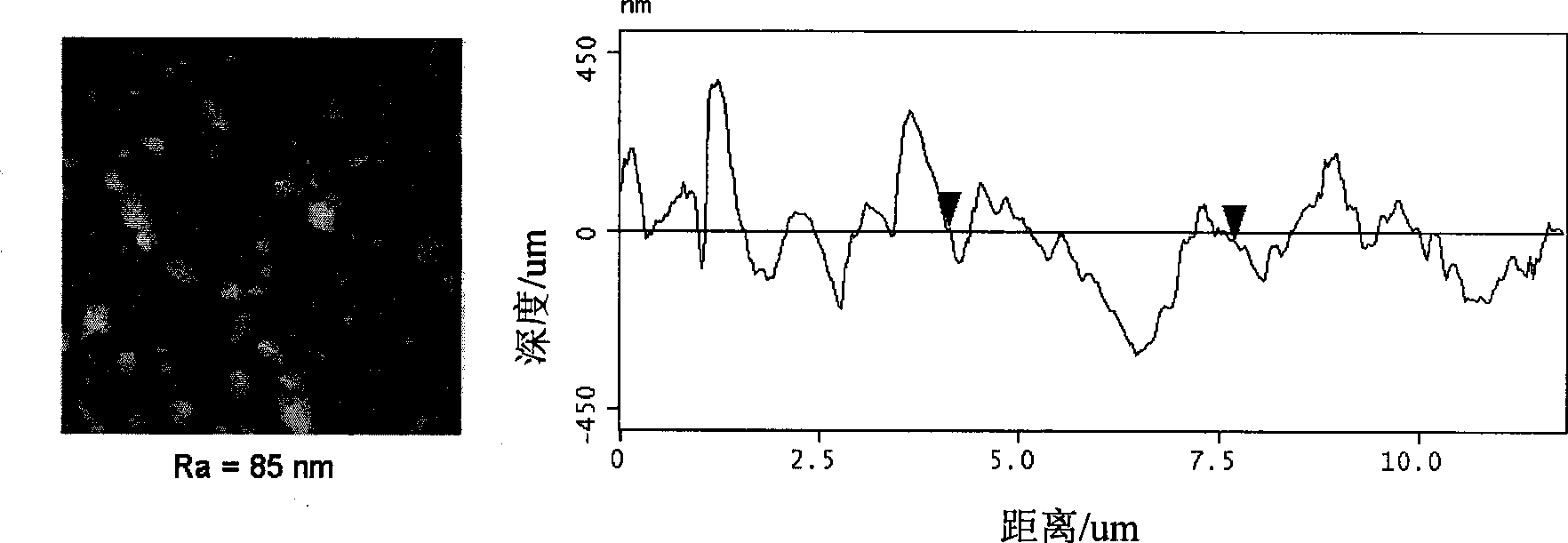

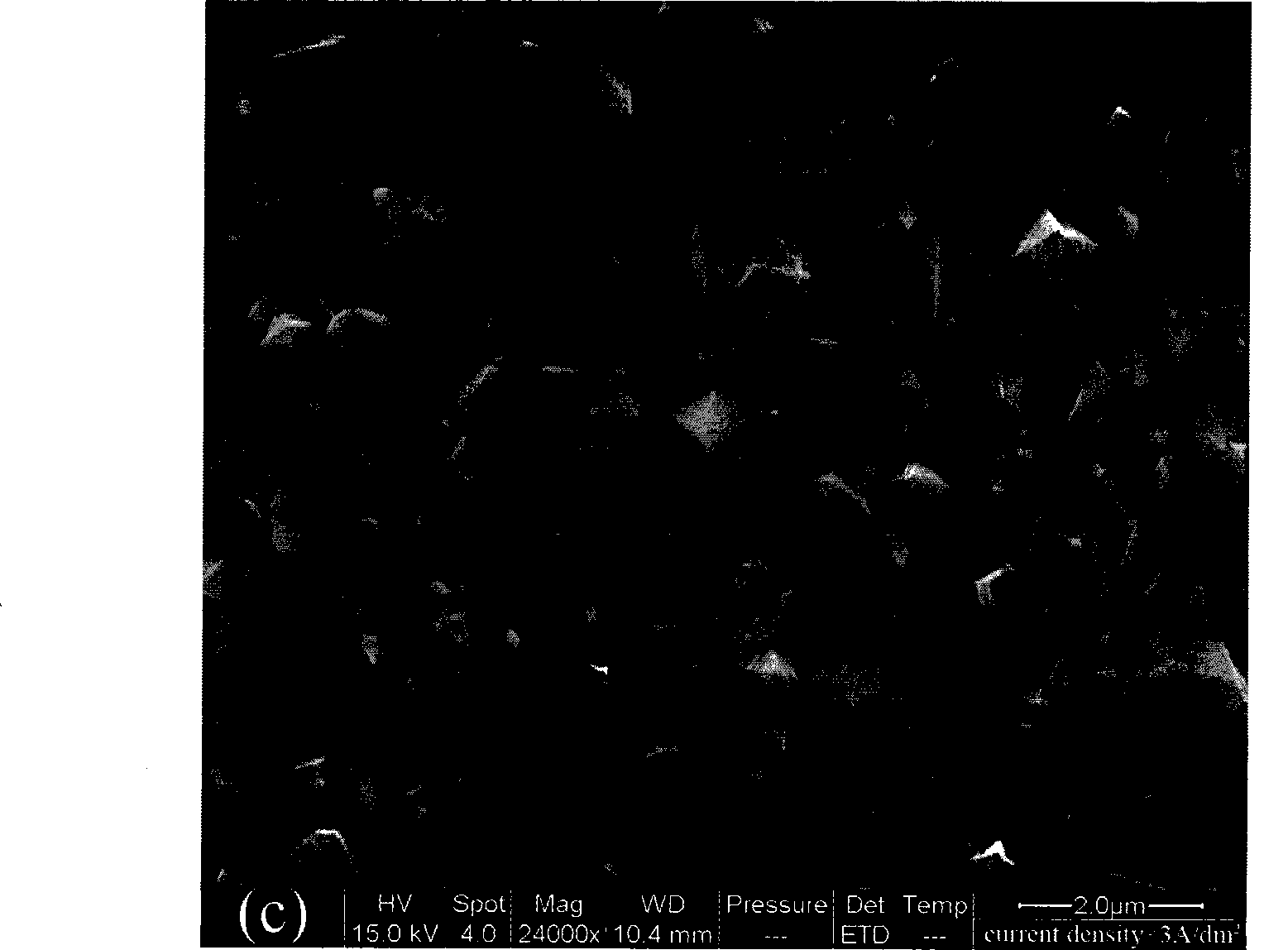

Electrolytic solution for integrated circuit copper wire laying electrodeposition

InactiveCN101481812AImprove surface topographyReduce roughnessSemiconductor/solid-state device manufacturingSemiconductor devicesCopper wirePhysical chemistry

The invention provides an electrolyte used in integrated circuit copper cabling electrodeposition, which comprises the following components and contents: 50-200g / liter of copper sulphate, 50-220g / liter of sulphuric acid, 10-150 milligram / liter of chloridion, 5-200 milligram / liter of inhibitor, 5-50 milligram / liter of accelerator, 0.5-20 milligram / liter of leveling agent and the rest of deionized water. As the electrolyte contains the chloridion, inhibitor and accelerator, the surface appearance is improved after electrodeposition and the roughness concentration is reduced. And the leveling agent can increase the adsorption of the accelerator on the surface of electrodes in the deposition process, and then increases the surface improvement effect of the accelerator; the surface roughness of the clad layer is further reduced; the orientation of the clad layer obtained by deposition Cu (111) is dominant; after deposition, the surface dendrite growth mode disappears; and the surface has no hole defects.

Owner:TSINGHUA UNIV

Electric deterrent device

Owner:BIRD BARRIER AMERICA

Water-based copper and aluminum wiredrawing oil composite and preparation method thereof

The invention relates to an oil-based lubricating composite and a preparation method thereof, in particular to a water-based copper and aluminum wiredrawing oil composite and a preparation method thereof. The water-based copper and aluminum wiredrawing oil composite comprises base oil, an emulsifier, an auxiliary emulsifier, a defoaming agent, a rust-proof agent, an antiseptic and an antiwear agent. The preparation method comprises the following steps of: configuring the water-based copper and aluminum wiredrawing oil composite into 3 percent to 45 percent water-based emulsion according to weight percentage; and spraying the water-based emulsion into a wiredrawing die cavity in the copper and aluminum wiredrawing process. The water-based copper and aluminum wiredrawing oil composite has the advantages of excellent lubricating property, great optimal light stability and storage stability, low cost, good cooling effect, fast heat transfer, little temperature increase in the using process, difficult combustion and easy cleaning and ensures the safety of the service environment; and in addition, a copper wire and an aluminum wire drawn by the method have the advantages of uniform wireshape, bright surfaces, difficult corrosion, good ultraviolet and storage stability and good stability.

Owner:PETROCHINA KARAMAY PETROCHEMICAL CO LTD

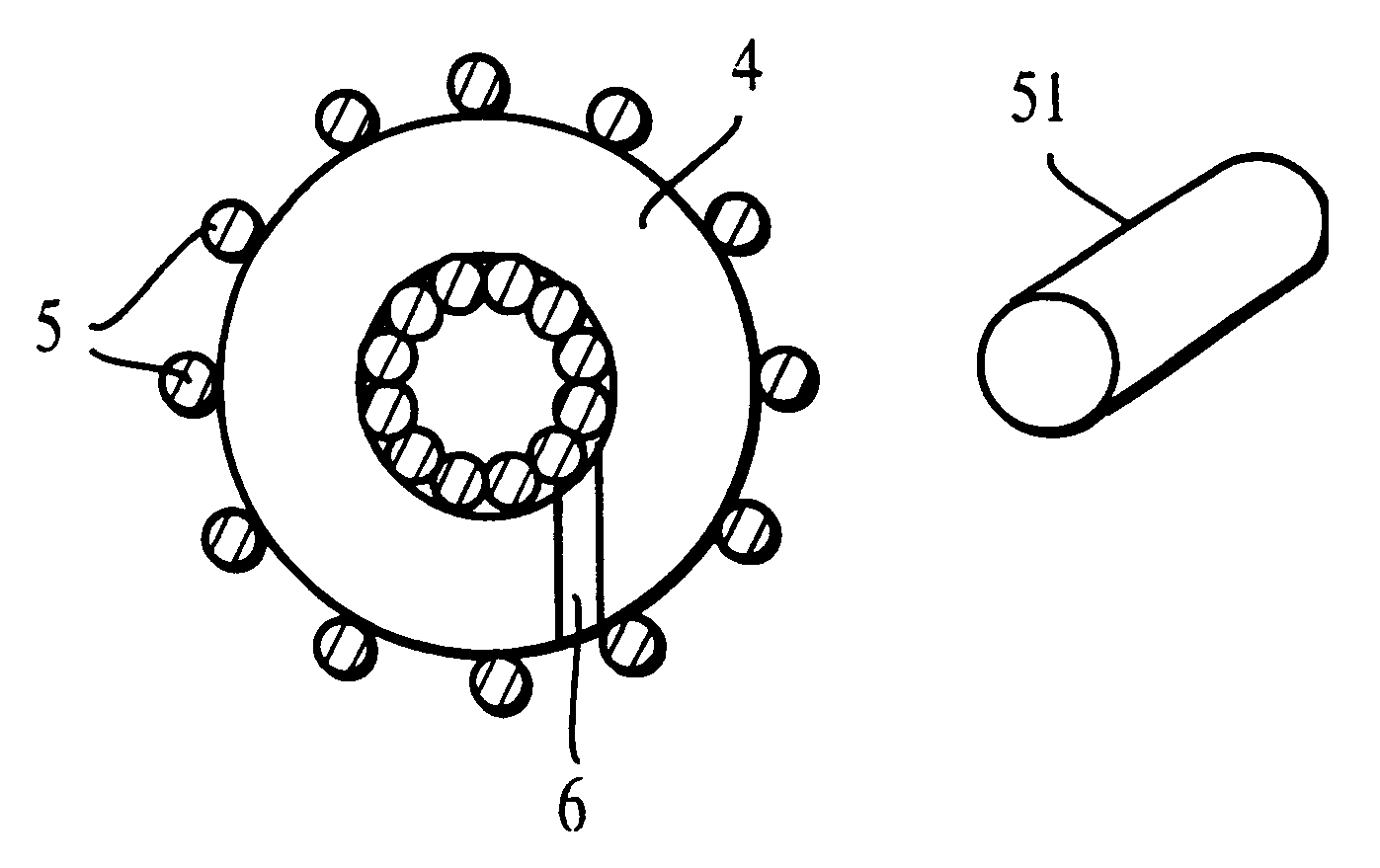

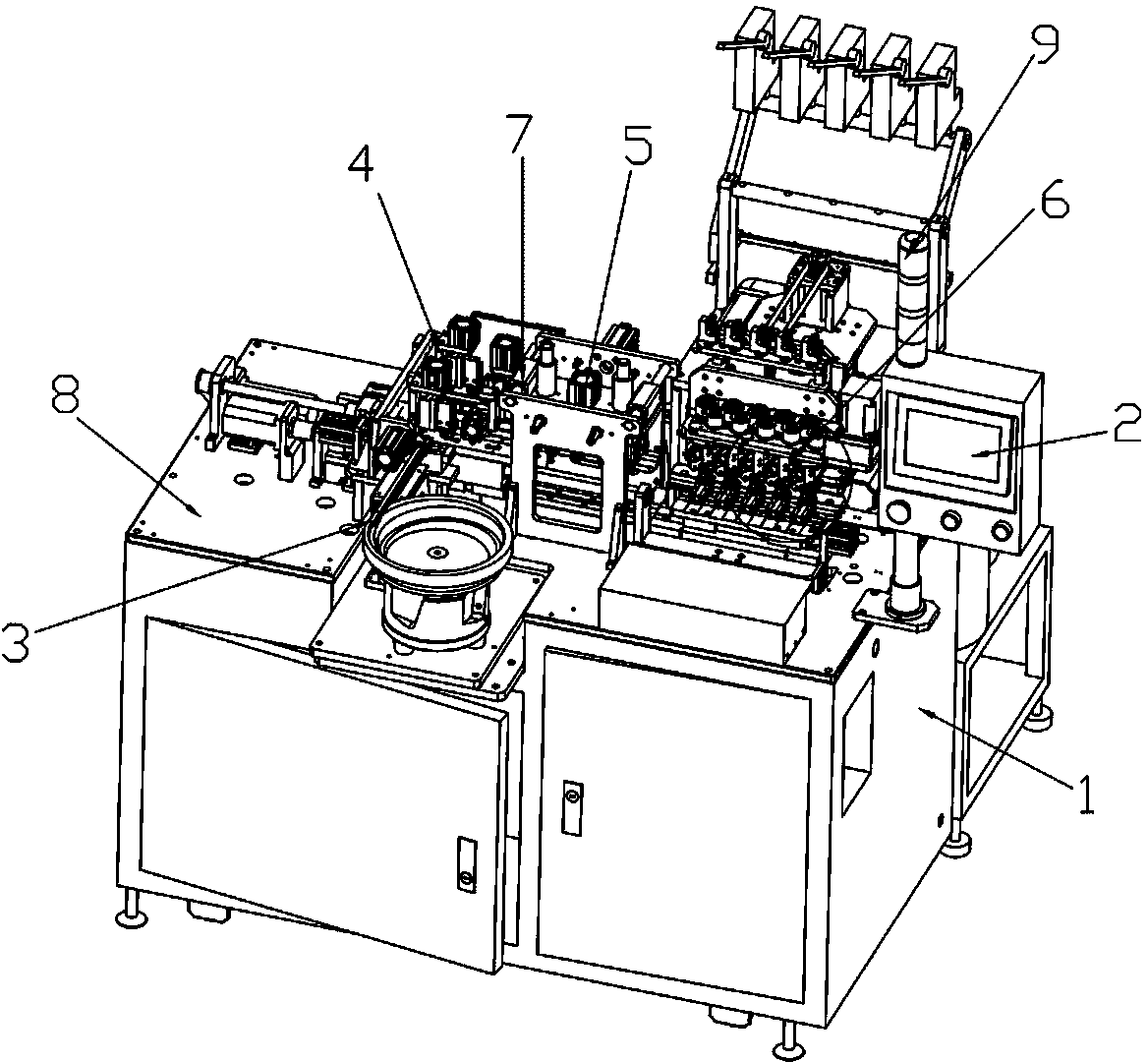

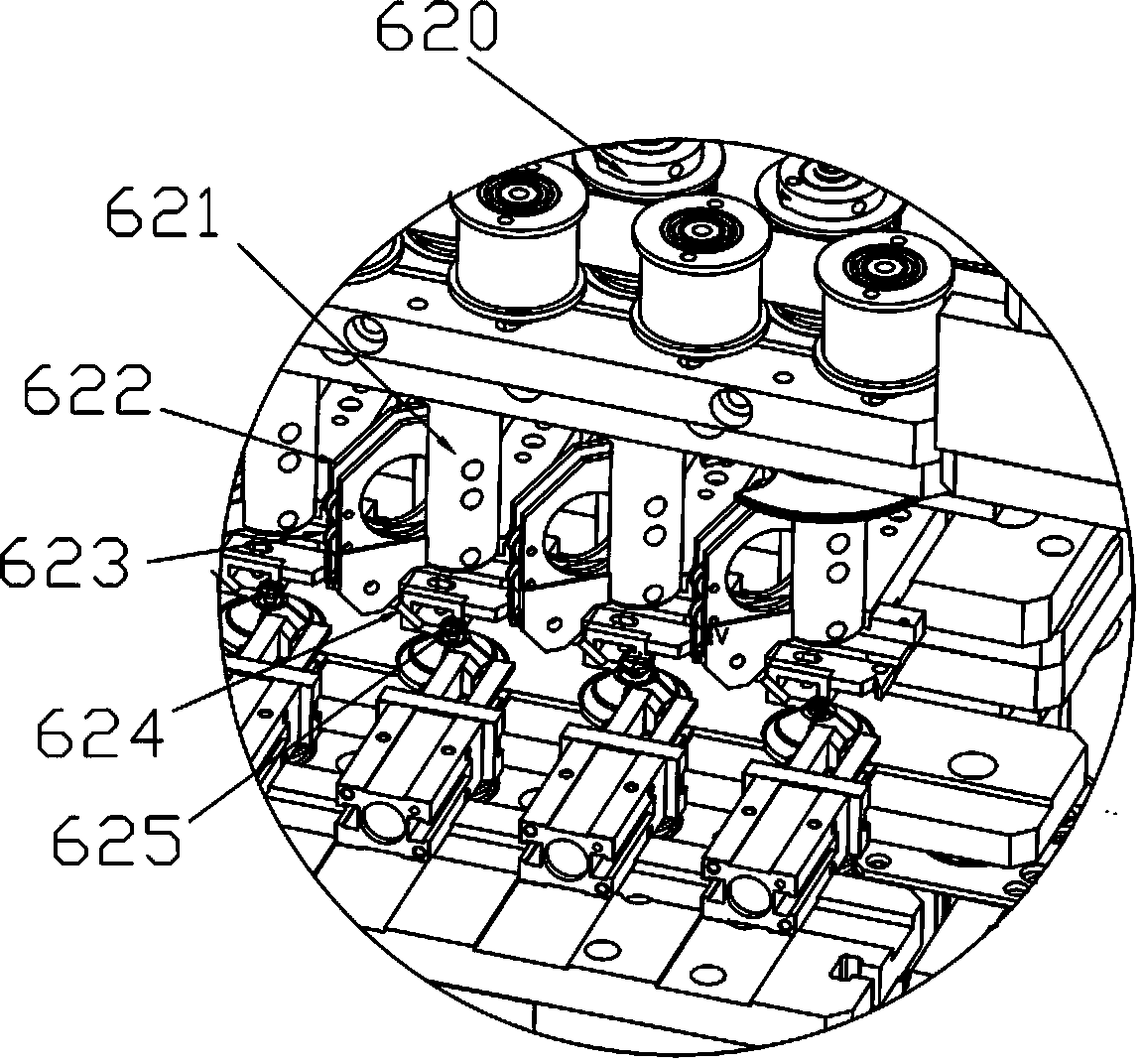

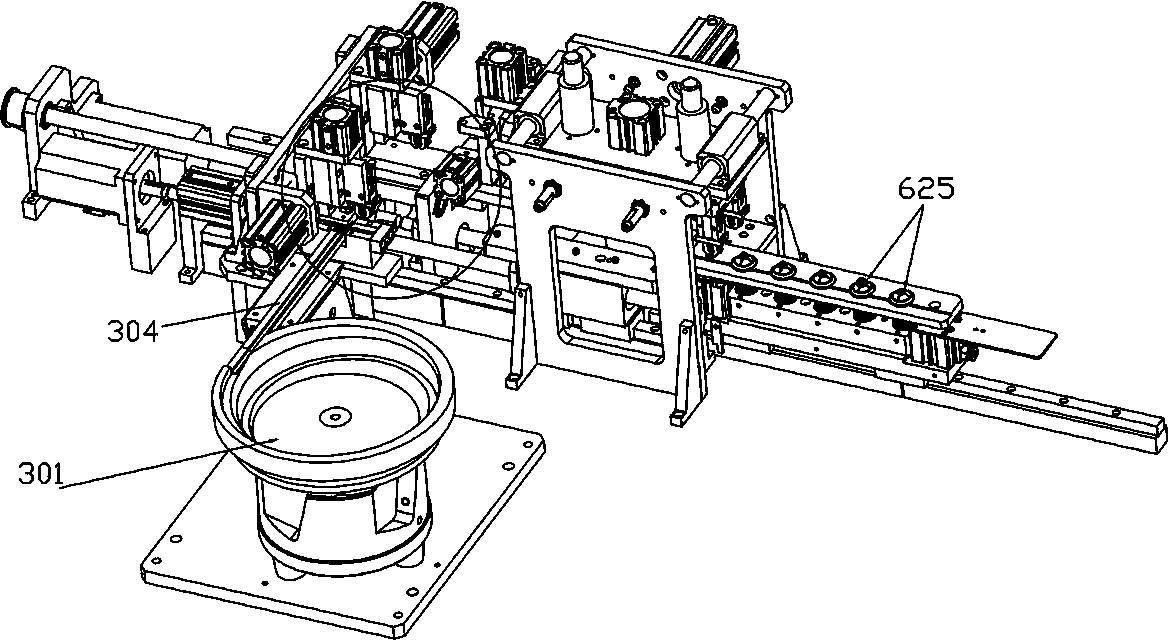

Full-automatic inductance winding machine and winding method thereof

InactiveCN103903852AImprove efficiencyImprove qualityJigging conveyorsCoils manufactureWinding machineCopper wire

The invention discloses a full-automatic inductance winding machine and a winding method of the full-automatic inductance winding machine, and belongs to the field of electronic component machining equipment. The full-automatic inductance winding machine comprises a support, a mechanical feeding mechanism, a mechanical discharging mechanism, a transfer mechanism, a winding mechanism and an operation panel and further comprises a secondary wire pressing mechanism. Compared with a traditional manual winding technology, the full-automatic winding machine has the advantages that efficiency is higher and quality is greatly improved. Compared with an existing automatic winding machine, the full-automatic inductance winding machine has the advantages that one cycle of the full-automatic inductance winding machine lasts for 7 seconds to 8 seconds, five products can be machined in one cycle, and therefore efficiency is not lower than that of a Rite winding machine; meanwhile the structure is simple, operation and maintenance are easy, manufacturing cost is 1 / 3 that of the Rite winding machine, and therefore more cost can be reduced; cut wire residues are shorter, 1 / 10 of copper wires are reduced compared with products with the same yield, it is estimated that ten thousand yuan of the copper wires can be reduced every year, the wire residues are firstly cut and then pressed, and therefore the treatment effect of the wire residues is better.

Owner:DONGGUAN KE RUI AUTOMATION TECH

Methods for making copper and other metal interconnections in integrated circuits

InactiveUS6984891B2Increase the cross-sectional areaReduce resistanceSemiconductor/solid-state device detailsSolid-state devicesMetal interconnectAcute angle

A typical integrated-circuit fabrication requires interconnecting millions of microscopic transistors and resistors with aluminum wires. Yet, aluminum wires have greater electrical resistance and are less reliable than copper wires. Unfortunately, current techniques for making copper wires are time-consuming and inefficient. Accordingly, the invention provides a method of making wires or interconnects from copper or other metals. One embodiment entails forming a first diffusion barrier inside a trench using ionized-magnetron sputtering for better conformal coating of the trench, and a second diffusion barrier outside the trench using jet-vapor deposition. The jet-vapor deposition has an acute angle of incidence which prevents deposition within the trench and thus eliminates conventional etching steps that would otherwise be required to leave the trench free of this material. After formation of the two diffusion barriers, the trench is filled with metal and annealed.

Owner:MICRON TECH INC

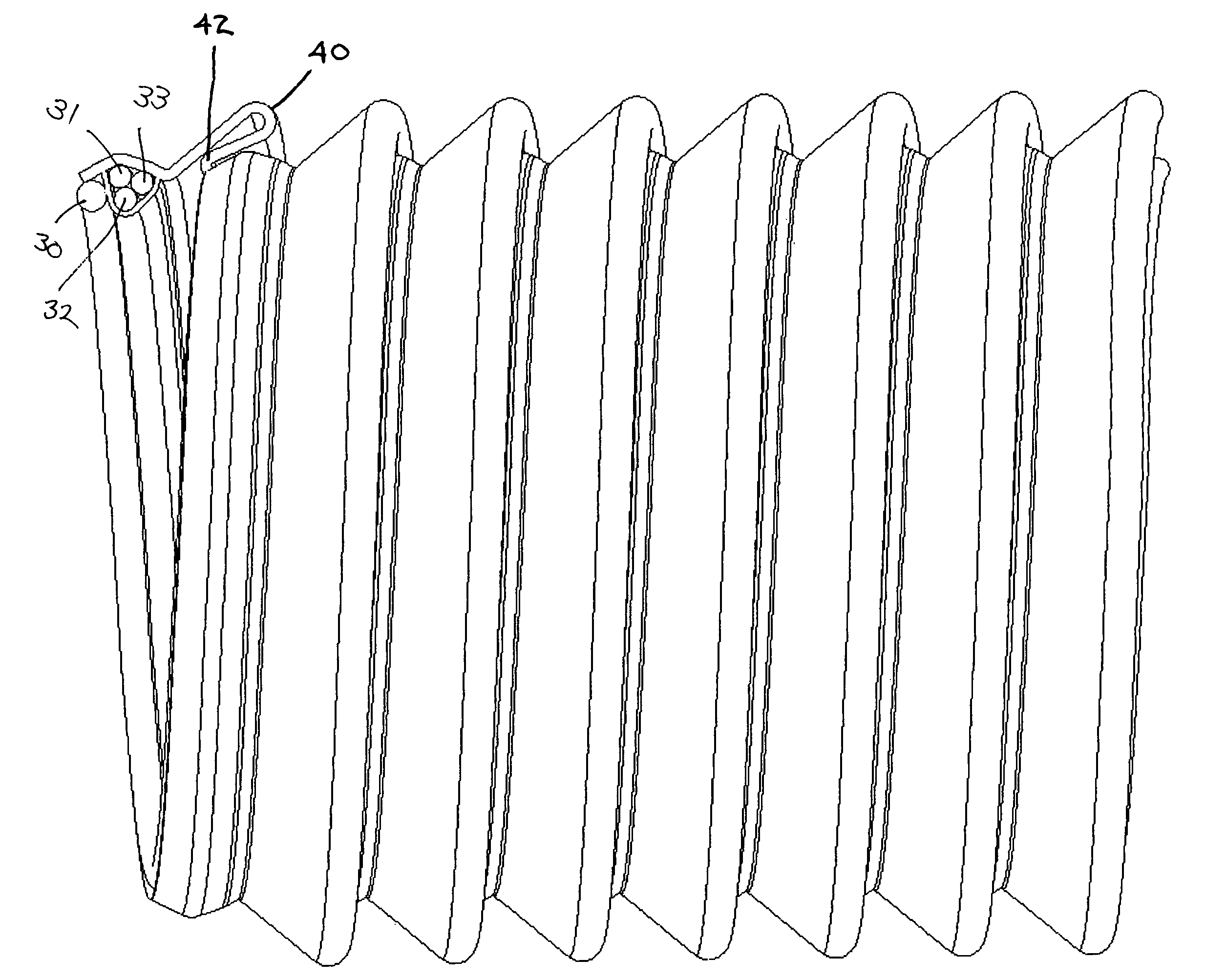

Self-extending electrical hose

InactiveUS7735523B2Maximizes inner diameterLight weightInsulated cablesPipe elementsLine tubingCopper wire

A hose construction adapted for efficiently conveying fluids while extended, but capable of neatly contracting to a fraction of its extended length for storage or transportation, while integrally incorporating lines for electrical requirements. Storage may be within an outer hose and may be triggered via closure of a valve within a nozzle so that negative pressure causes contraction of the folds of the hose. The contracted hose has a length that is a fraction of its normal extended length. The hose construction incorporates a wire reinforcing member which may bias the hose for self-extension and may also function as part of the electrical system. The electrical lines may comprise stranded copper wires to conduct power and / or serve as a remote activation circuit. The hose configuration may have a cover with external folds, which maximizes flow and provides a cushioning outer diameter to prevent damage to the hose.

Owner:FLEXIBLE TECH INC

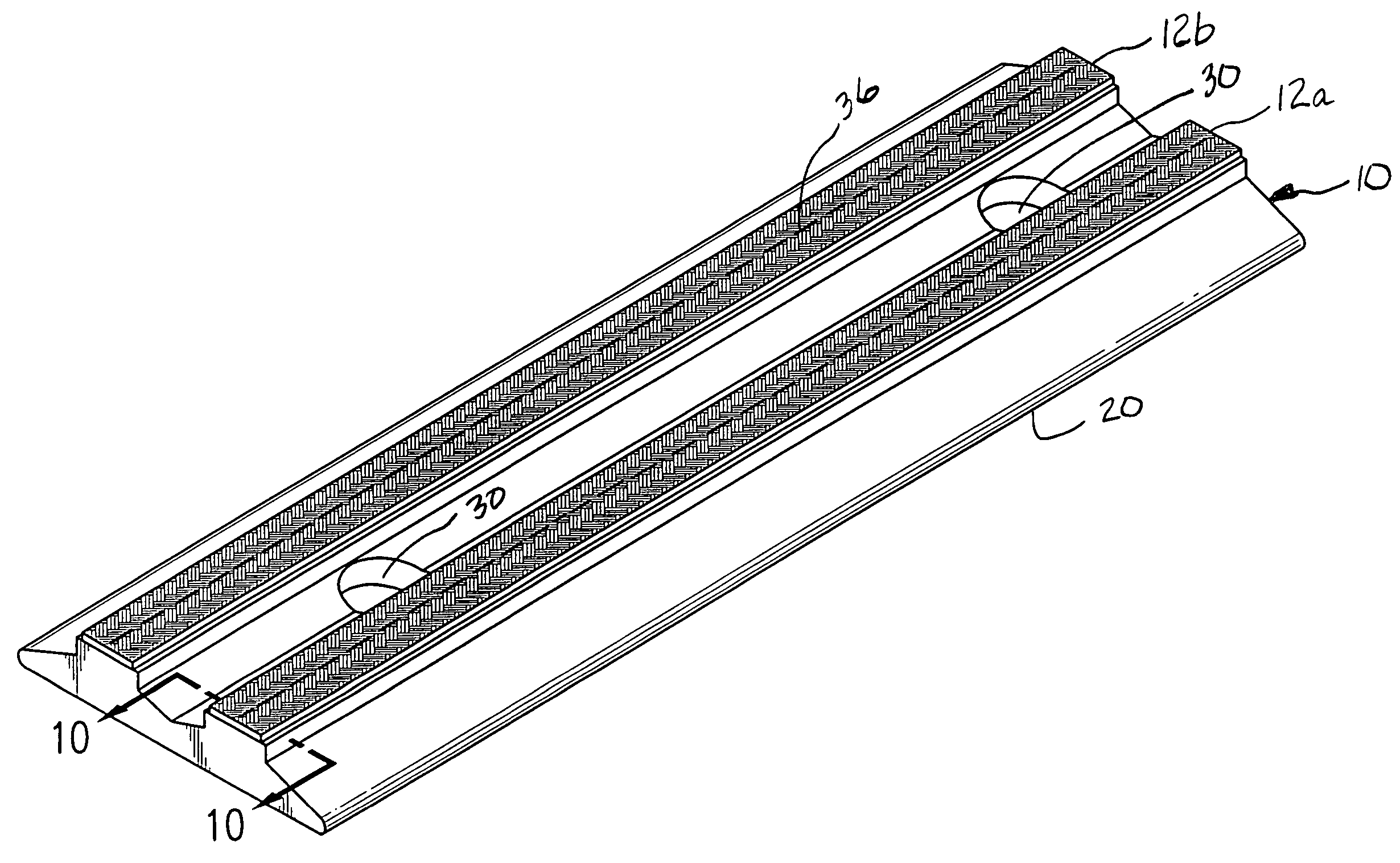

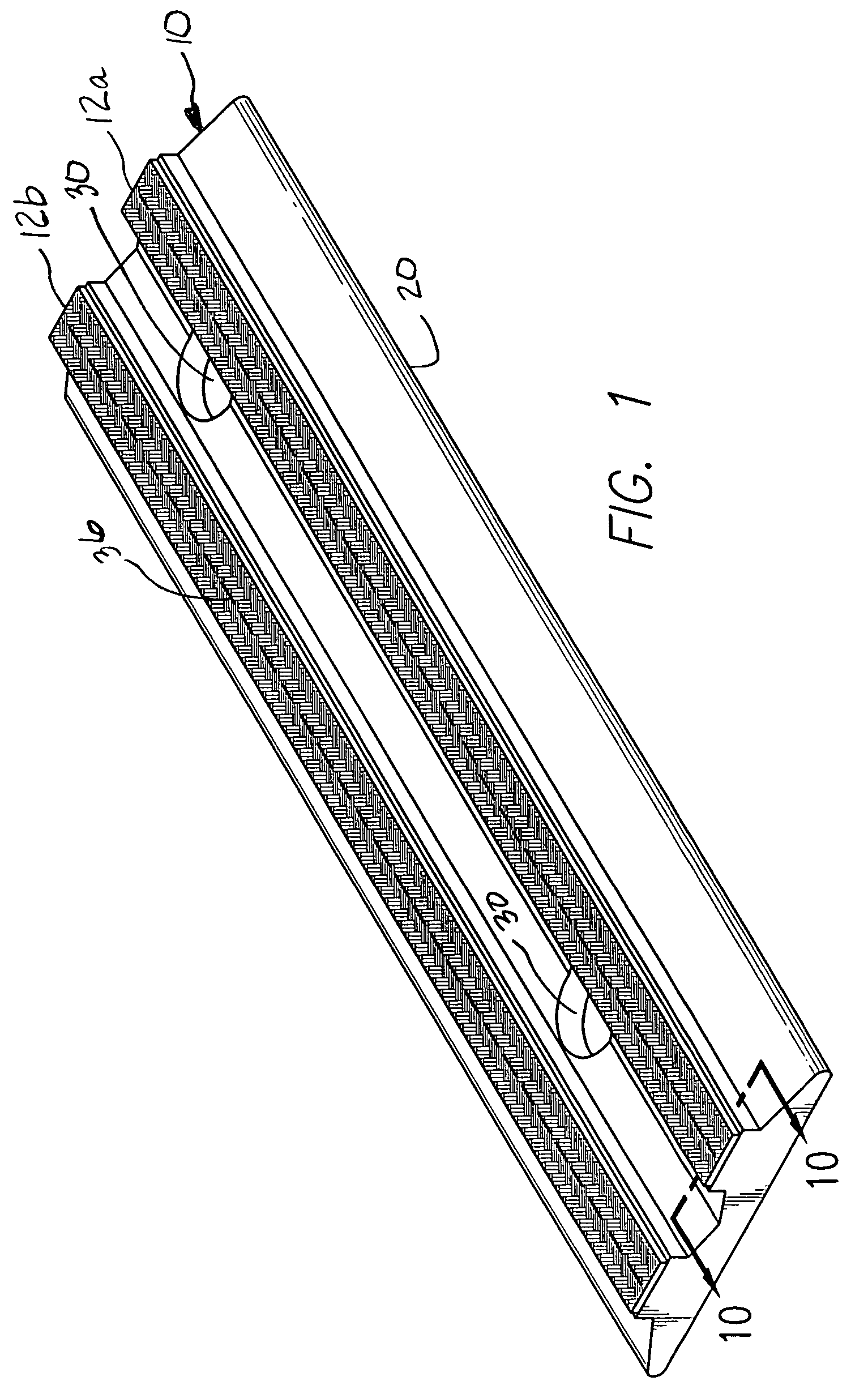

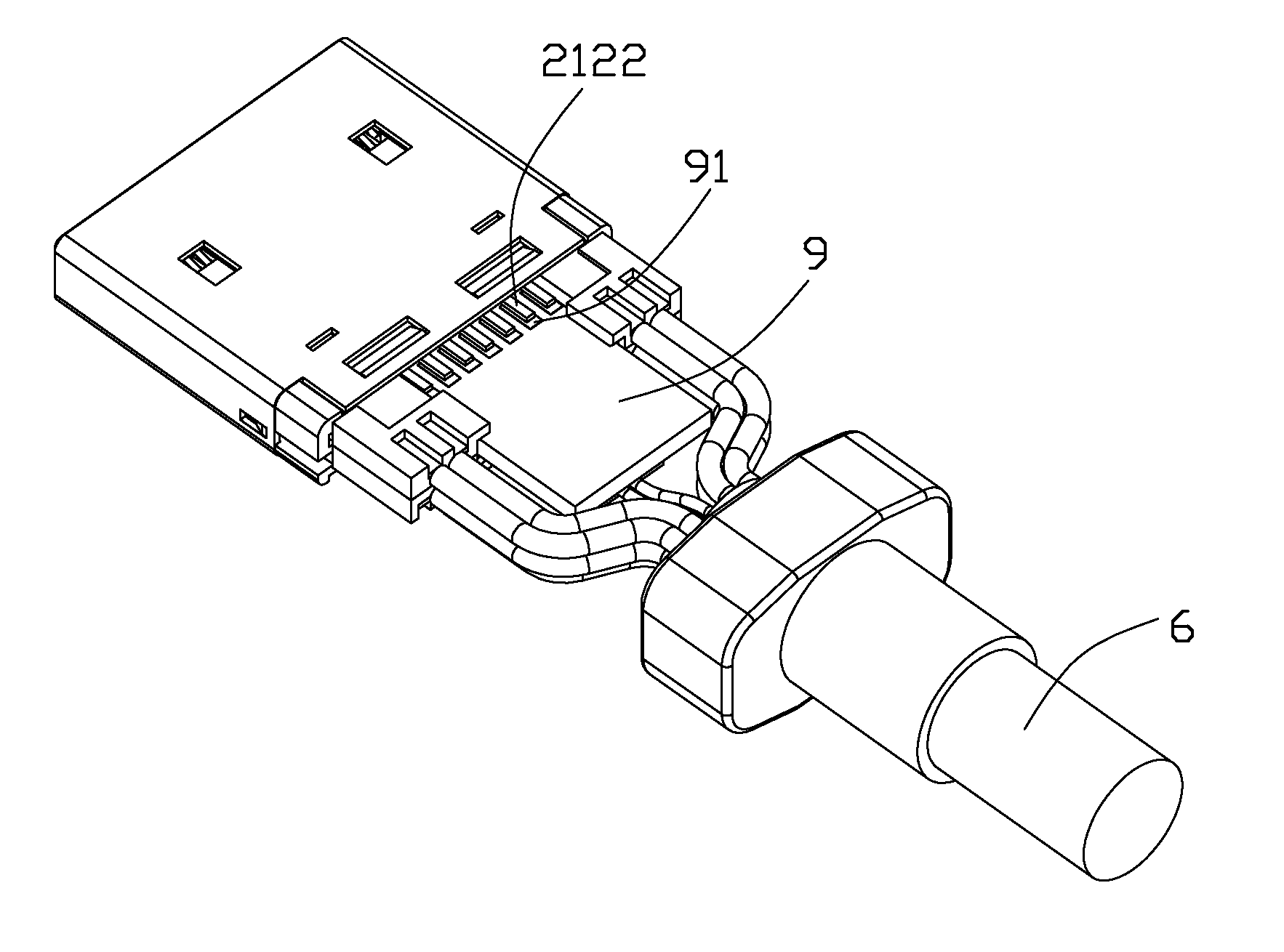

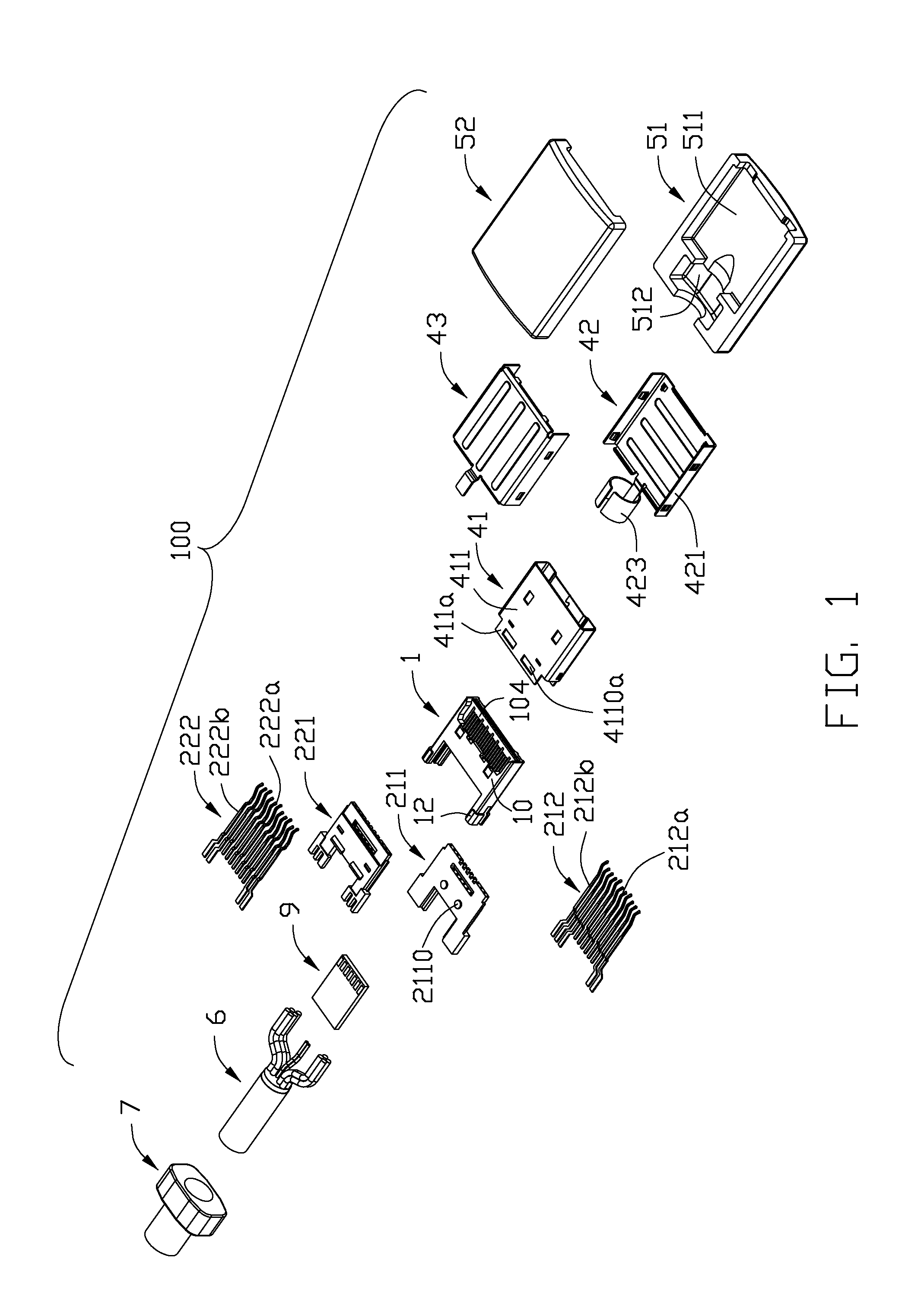

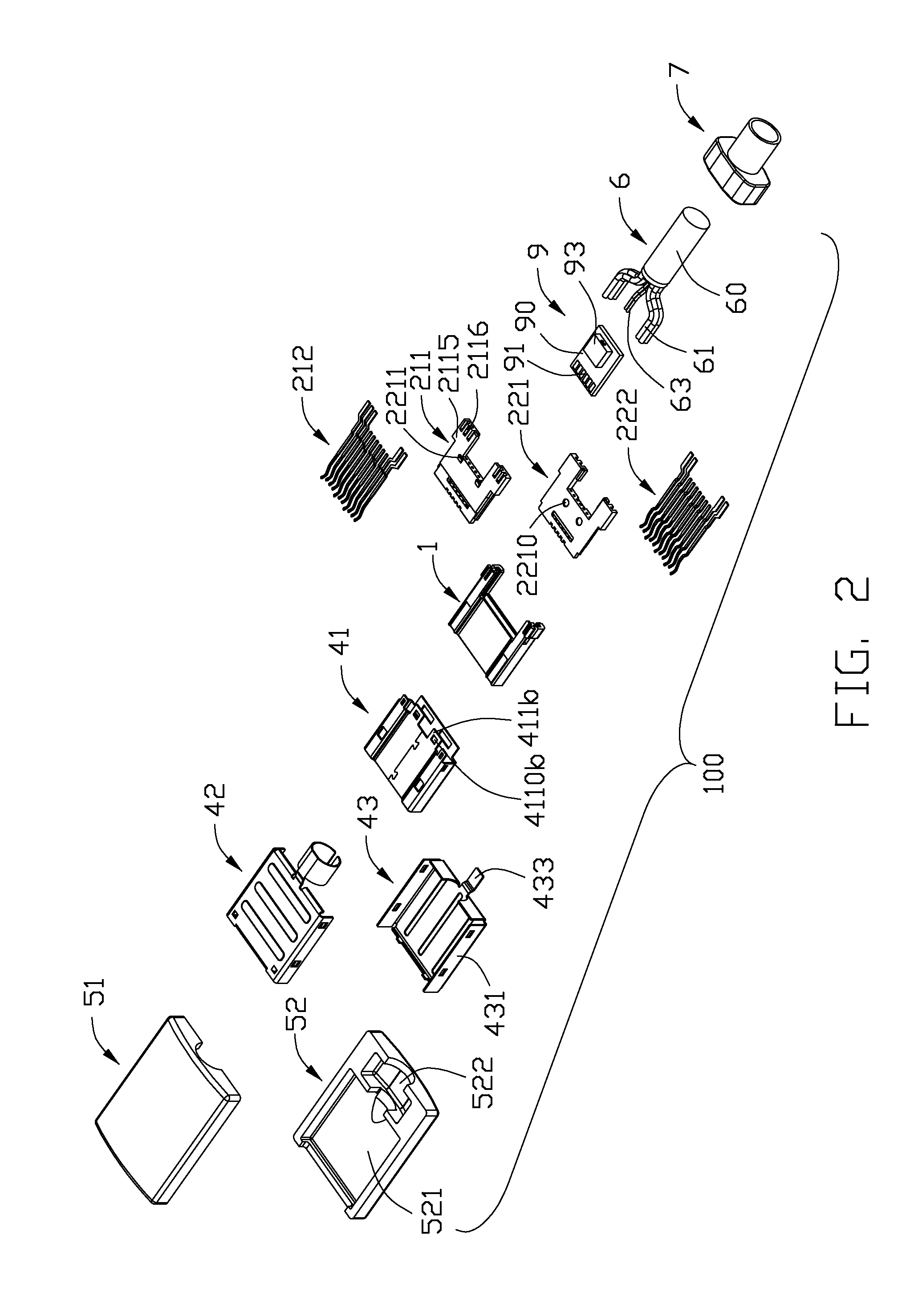

Cable assembly with elecrical and optical transmitting

An cable assembly (100) includes an insulative housing (1); a first terminal module (21) and a second terminal module (22) assembled to the insulative housing, the first terminal module (21) having first terminals (212a) and first additional terminals (212b), the second terminal module (22) having second terminals (222a) and second additional terminals (222b); a photoelectric conversion device (93) electrically connected with the first terminals and the second terminals; and a cable (6) including fiber wires (63) and copper wires (61), the fiber wires optically connected to photoelectric conversion device, the copper wires electrically connected to the first additional terminals and the second additional terminals.

Owner:HON HAI PRECISION IND CO LTD

Copper on organic solderability preservative (OSP) interconnect

InactiveUS20090008796A1Semiconductor/solid-state device detailsSolid-state devicesCopper wireSemiconductor chip

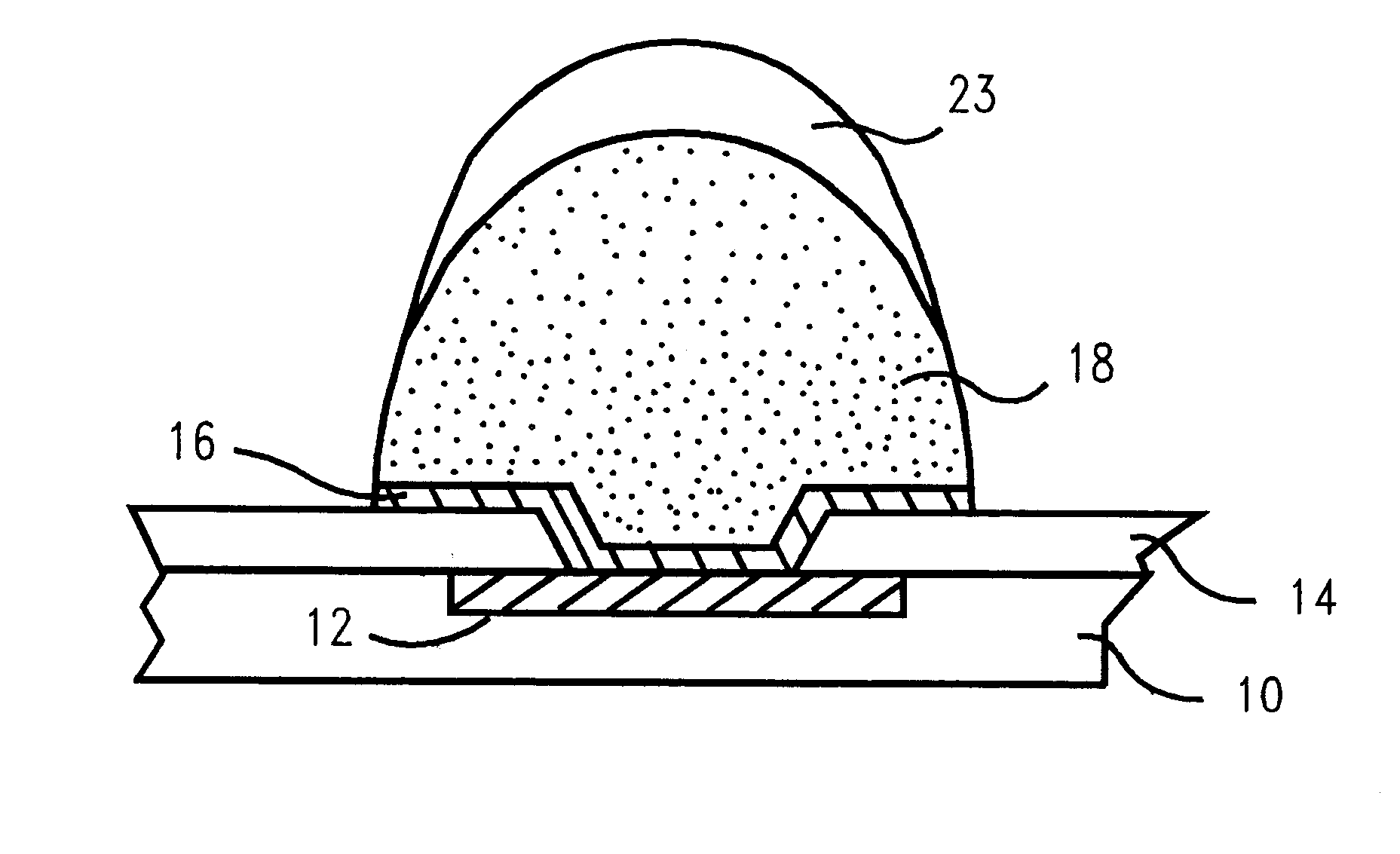

Provided is a semiconductor package, and a method for constructing the same, including a first substrate, a first semiconductor chip attached to the first substrate, and a first copper wire. At least one of the first substrate and the first semiconductor chip has an Organic Solderability Preservative (OSP) material coated on at least a portion of one surface, and the first copper wire is wire bonded through the OSP material to the first substrate and the first semiconductor chip.

Owner:UNITED TEST & ASSEMBLY CENT LTD

Reflowed solder ball with low melting point metal cap

InactiveUS6259159B1Low costEasy to buildPrinted circuit assemblingFinal product manufactureTinningIndium

A method and structure for a solder interconnection, using solder balls for making a low temperature chip attachment directly to any of the higher levels of packaging substrate is disclosed. After a solder ball has been formed using standard methods it is reflowed to give the solder ball a smooth surface. A layer of low melting point metal, such as, bismuth, indium or tin, preferably, pure tin, is deposited on the top of the solder balls. This structure results in localizing of the eutectic alloy, formed upon subsequent low temperature joining cycle, to the top of the high melting solder ball even after multiple low temperature reflow cycles. This method does not need tinning of the substrate to which the chip is to be joined, which makes this method economical. It has also been noticed that whenever temperature is raised slightly above the eutectic temperature, the structure always forms a liquid fillet around the joint with copper wires. This liquid fillet formation results in substantial thermal fatigue life improvement for reduced stress at interface; and secondly, provides an easy means to remove chip for the purpose of chip burn-in, replacement or field repairs.

Owner:IBM CORP

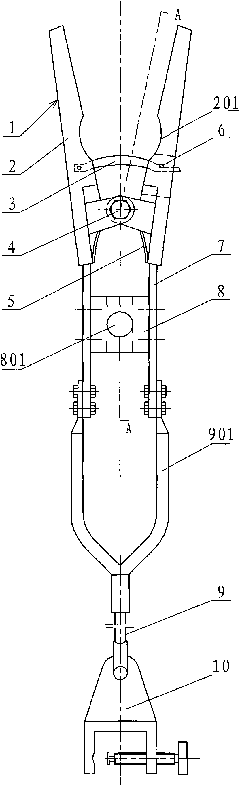

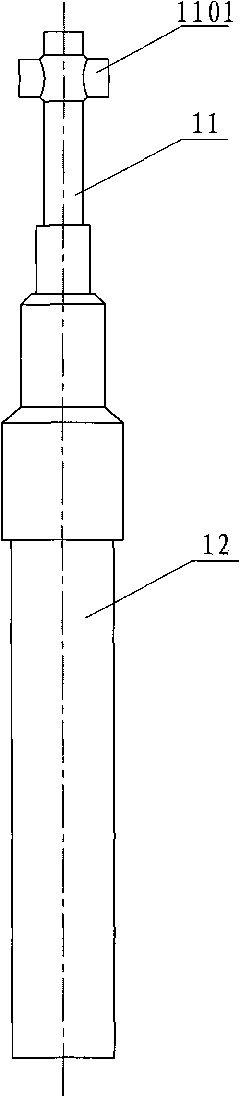

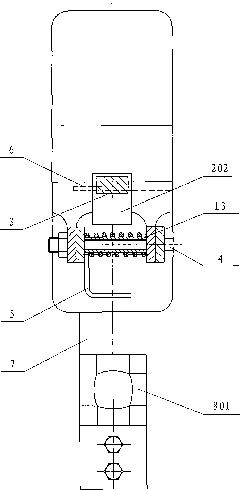

Ground line device of power transmission line tower and hitching device thereof

ActiveCN101826665ANo damageEnsure personal safetyElectric connection structural associationsConnection contact member materialCopper wireEngineering

The invention discloses a ground line device of a power transmission line tower, and the device comprises a line clamp which consists of two articulated splints and a torsion spring, a block pin is arranged between the two splints, the line clamp is connected with a grounding seat by a flexible copper wire, the tail ends of the two splints are respectively provided with symmetric connecting plates, opposite surfaces of the two connecting plates are symmetrically provided with clamping blocks which are respectively provided with cross clamping slots, and one end of the flexible copper wire which is connected with the line clamp correspondingly are divided into two connecting terminals and are respectively connected with the two connecting plates. A dedicated hitching device of the ground line device comprises an insulating bar, the front end of which is provided with a connecting shaft, and the front end of the connecting shaft is provided with a cross shaft head which is matched with the cross clamping slot of the ground line device of the power transmission line tower. The device has the advantages of simple structure, convenient use, time-saving and labor-saving operation, high safety performance, light self-weight, easy carrying and labor-saving disassembly, and the device can realize the ground line hitching on various towers at one step and is especially suitable for a tower with a large rotation angle and a terminal tower.

Owner:JINZHOU ELECTRIC POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER SUPPLY +1

Method and apparatus for sorting fine nonferrous metals and insulated wire pieces

InactiveUS20070262000A1Accurate materialsEfficient recyclingMagnetic property measurementsUsing electrical meansNonferrous metalCopper wire

A system for sorting fine nonferrous metals and insulated copper wire from a batch of mixed fine nonferrous metals and insulated wire includes an array of inductive proximity detectors, a processing computer and a sorting mechanism. The inductive proximity detectors identify the location of the fine nonferrous metals and insulated copper wire. The processing computer instructs the sorting mechanism to place the fine nonferrous metals and insulated copper wire into a separate container than the non-metallic pieces.

Owner:VALERIO THOMAS A

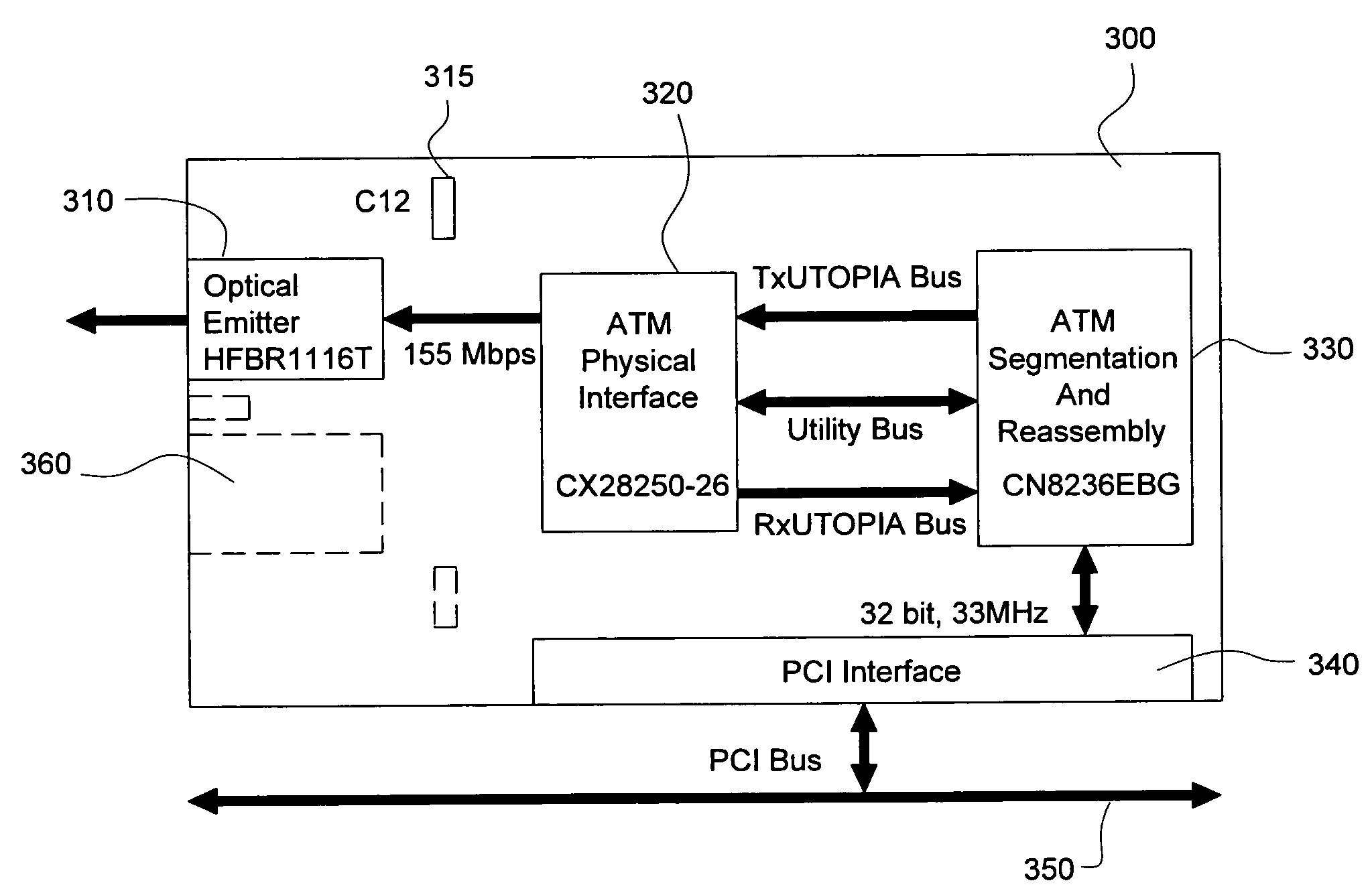

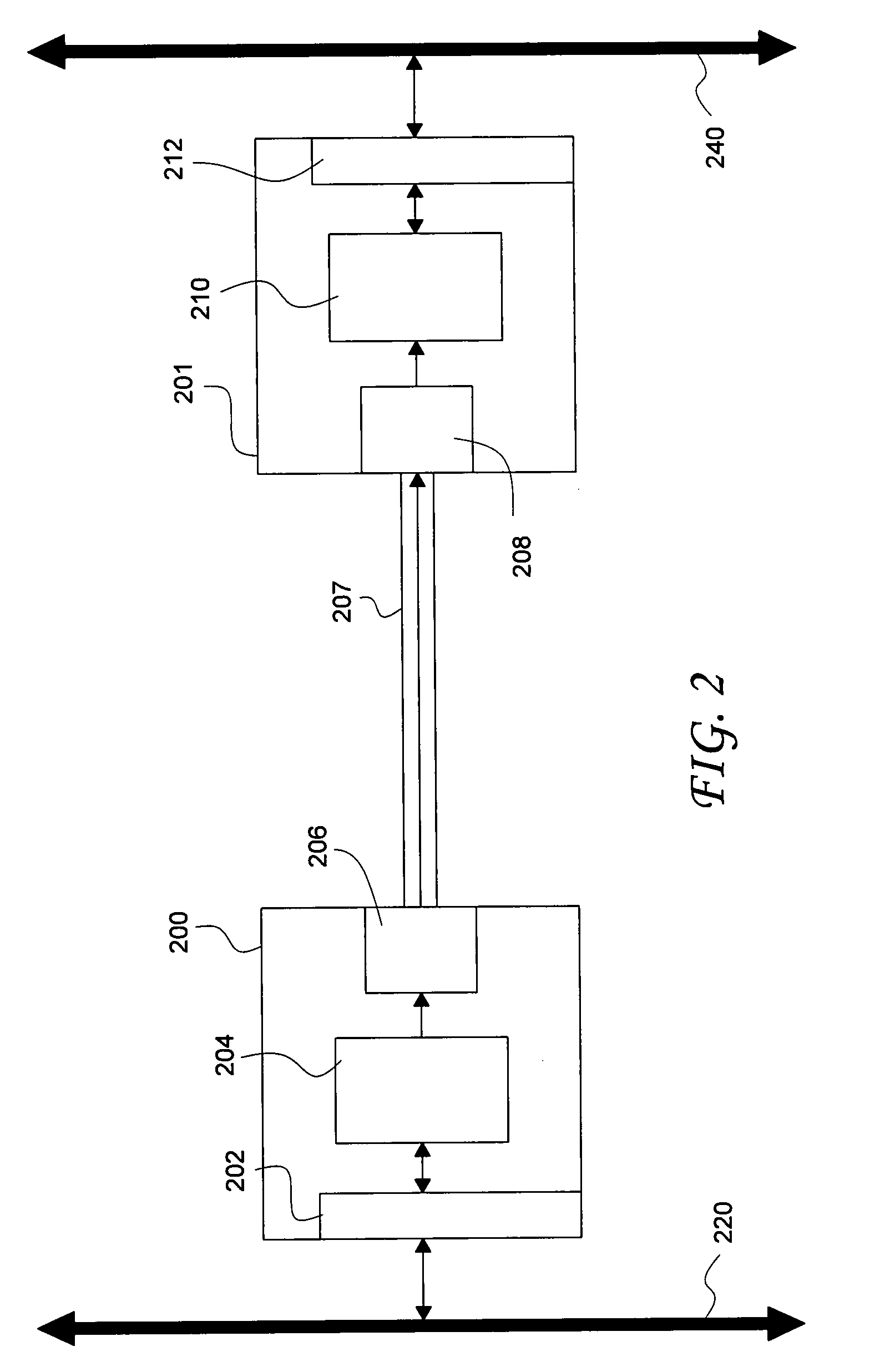

Secure one-way data transfer system using network interface circuitry

Network interface circuitry for a secure one-way data transfer from a sender's computer (“Send Node”) to a receiver's computer (“Receive Node”) over a data link, such as an optical fiber or shielded twisted pair copper wire communication cable, comprising send-only network interface circuitry for transmitting data from the Send Node to the data link, and receive-only network interface circuitry for receiving the data from the data link and transmitting the received data to the Receive Node, wherein the send-only network interface circuitry is configured not to receive any data from the data link, and the receive-only network interface circuitry is configured not to send any data to the data link. The network interface circuitry may use various interface means such as PCI interface, USB connection, FireWire connection, or serial port connection for coupling to the Send Node and the Receive Node.

Owner:OWL CYBER DEFENSE SOLUTIONS LLC

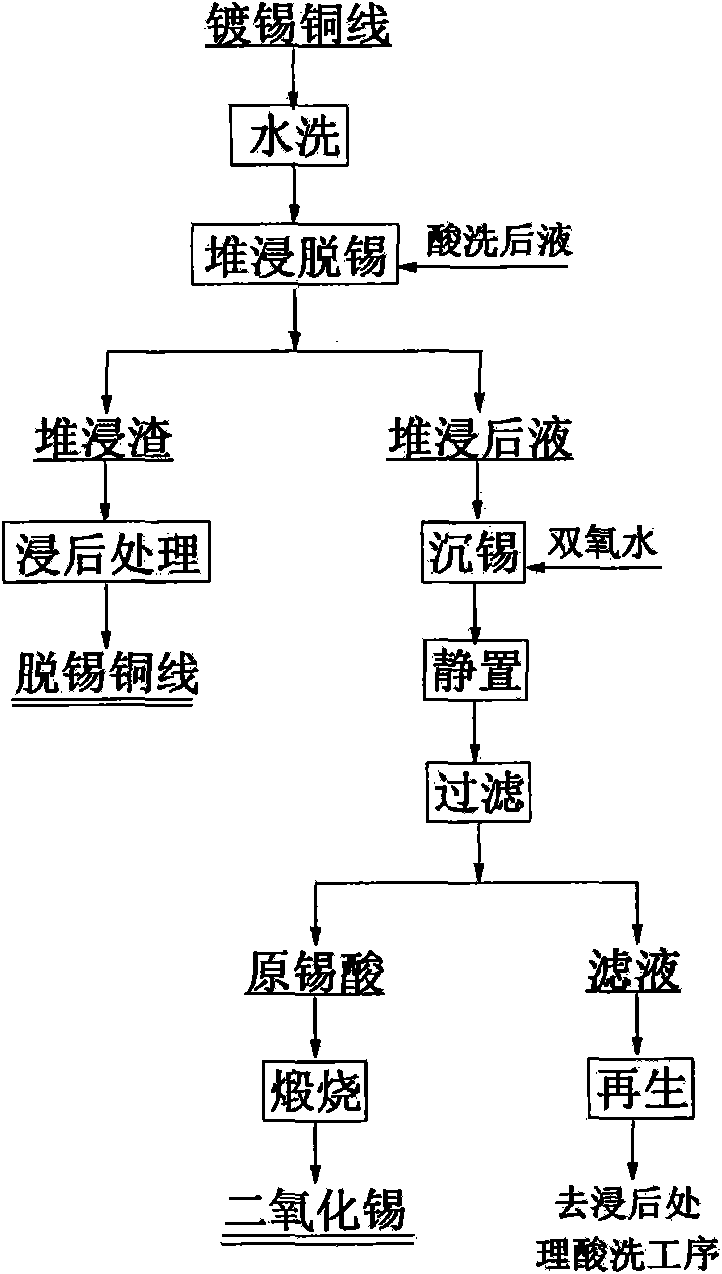

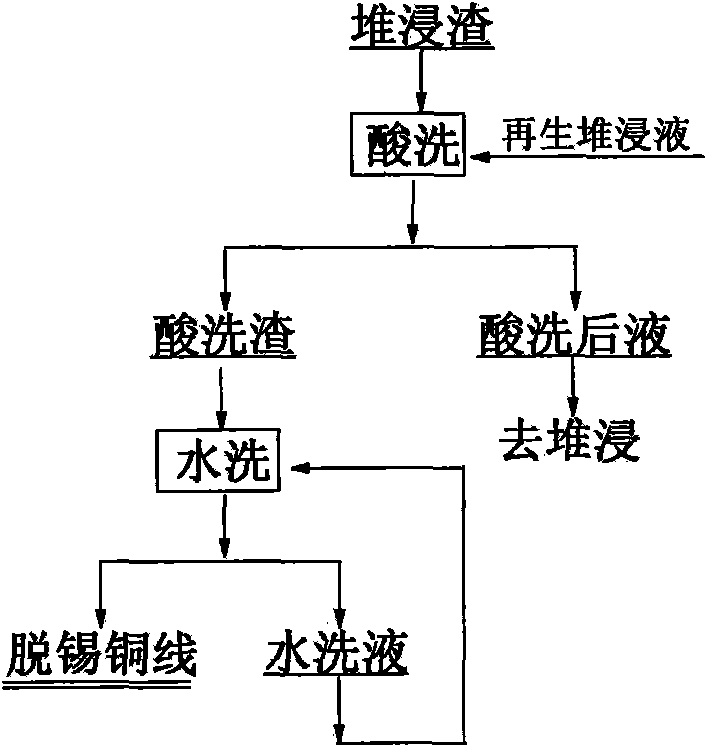

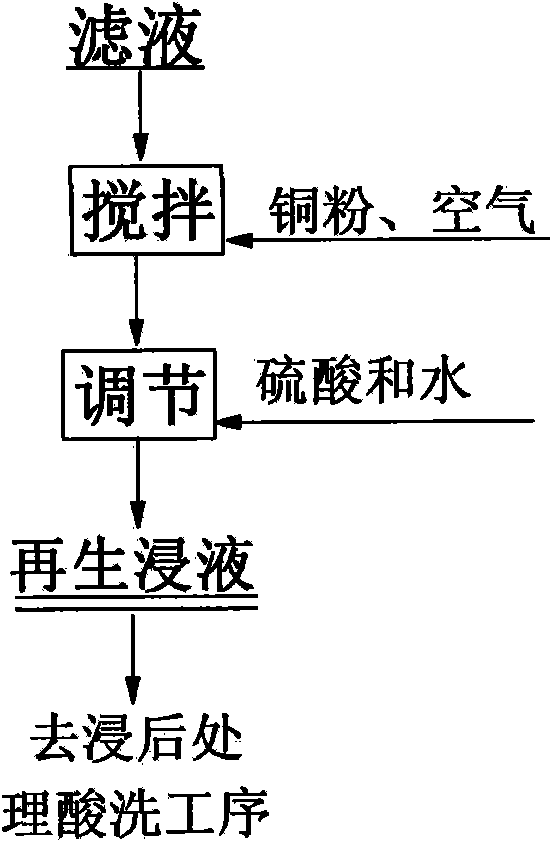

Heap-leaching method for separating copper and tin from tin-plated copper wires

ActiveCN101643852ASolve the problem of difficult mixingSimple processProcess efficiency improvementTinningHydrogen

The invention provides a heap-leaching method for separating copper and tin from tin-plated copper wires, belonging to the recovery processing of waste tin-plated copper wires. The method adopting thecopper sulfate replacement / heap-leaching method comprises the following steps: washing and stacking peeled waste tin-plated copper wires on an acid-proof and alkali-proof heap-leaching platform for heap-leaching; pickling the heap-leaching residue with recycling heap-leaching solution, and further washing the pickled heap-leaching residue to obtain detinned copper wires; adding hydrogen peroxideto the heap-leaching solution until no white precipitation is generated, heating the reaction solution until the reaction solution is boiling, standing, filtering, and drying to obtain original stannic acid, and further calcining the original stannic acid to obtain stannic oxide; adding a proper amount of copper powder and blowing air to the filtrate, wherein the addition amount of the copper power is the copper amount required by copper sulfate in the recycling heap-leaching solution; and controlling the temperature and time of the reaction and adjusting the concentrations of copper sulfate and sulfuric acid of the solution by sulfuric acid and water. The method has the advantages that the process is simple and easy-to-operate, the materials and devices are common and cheap, the tin-plated copper wires dispense with stirring in the heap-leaching process, the heap-leaching solution is recyclable and pollution-free, the removal rate of tin is higher than 95%, and the recovery rate of hydrogen peroxide immersion tin is higher than 98%.

Owner:UNIV OF SCI & TECH BEIJING +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com