Patents

Literature

1966results about How to "Improve magnetism" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

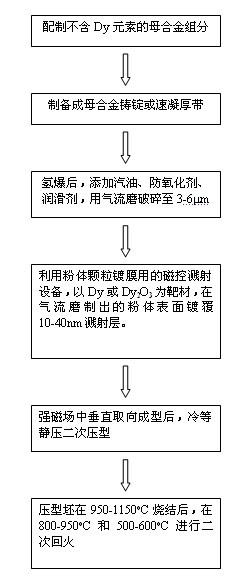

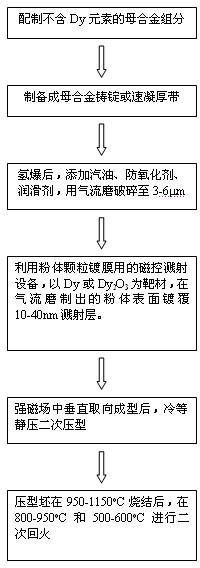

A preparation method of high-performance sintered NdFeB with low dysprosium content

The invention discloses a method for preparing sintered NdFeB with low dysprosium (Dy) content and high performance; the method comprises the following steps of: sputtering and plating the Dy element on the surface of jet mill powder by using the powder plate technology based on magnetron sputtering on the basis of preparing NdFeB powder, and then sufficiently dispersing the Dy element to micron-sized NdFeB crystal particles by dispersing the Dy element at high temperature in the sintering and tempering process, thereby achieving the effect of improving magnetic performance of the sintered NdFeB. Compared with the introduction of the Dy element in the proportioning process of the prior art, the method disclosed by the invention has the advantages: the low dysprosium content and high performance is limited in the nano-size by adopting the physical gas-phase deposition, the consumption quantity of the Dy element during the production process is controlled effectively and the preparationof sintered NdFeB with low dysprosium content and high performance is realized. Compared with the sintered NdFeB of the same components prepared by the traditional casting and powder metallurgy process, both the intrinsic coercivity and the maximum magnetic energy product of the sintered NdFeB rare-earth permanent magnetic material obtained according to the invention are improved obviously; compared with the sintered NdFeB with the same performance prepared by the traditional casting and powder metallurgy process, the dosage of the dysprosium element is reduced remarkably. The method can be widely applicable to producing and manufacturing sintered NdFeB with high performance.

Owner:NANJING UNIV OF SCI & TECH +1

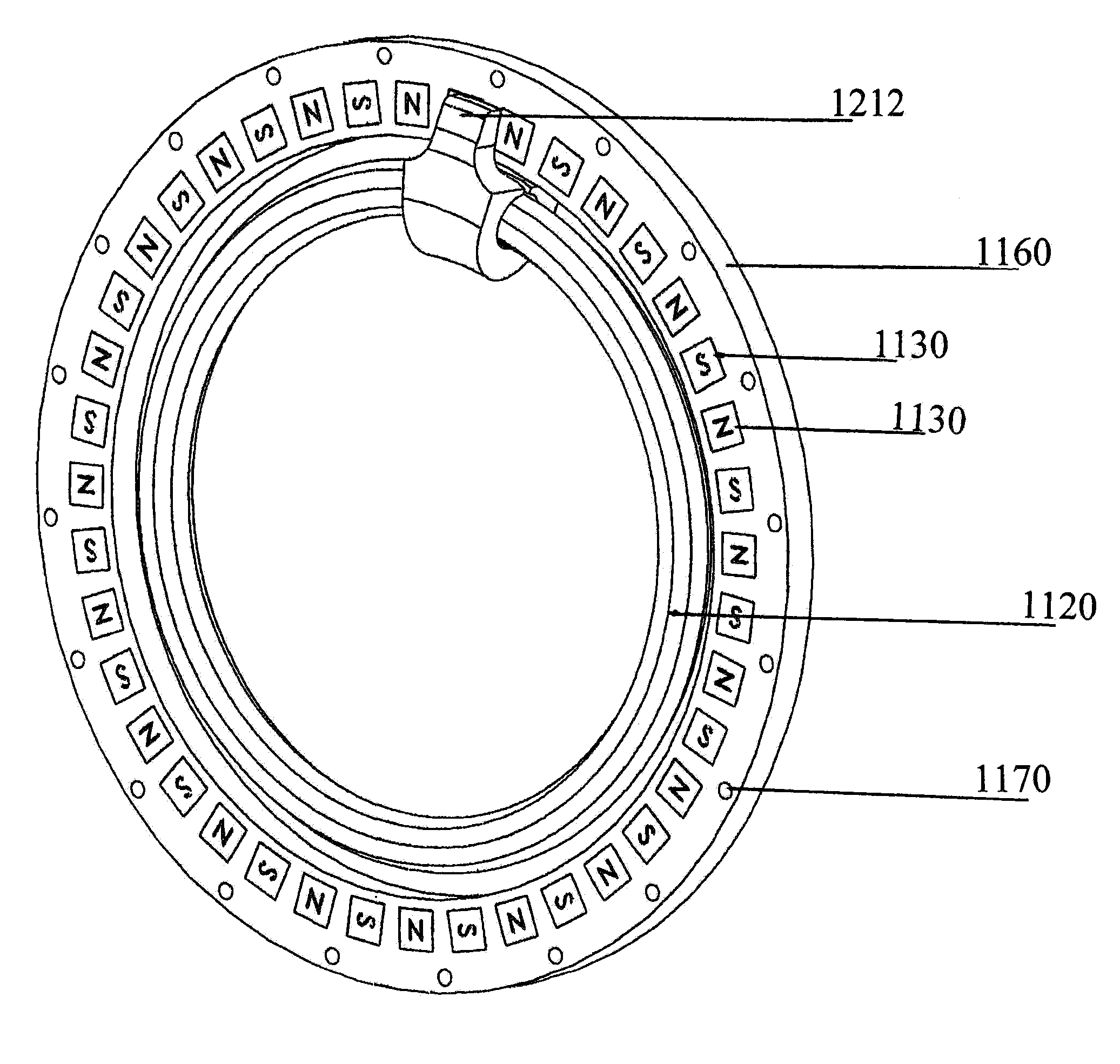

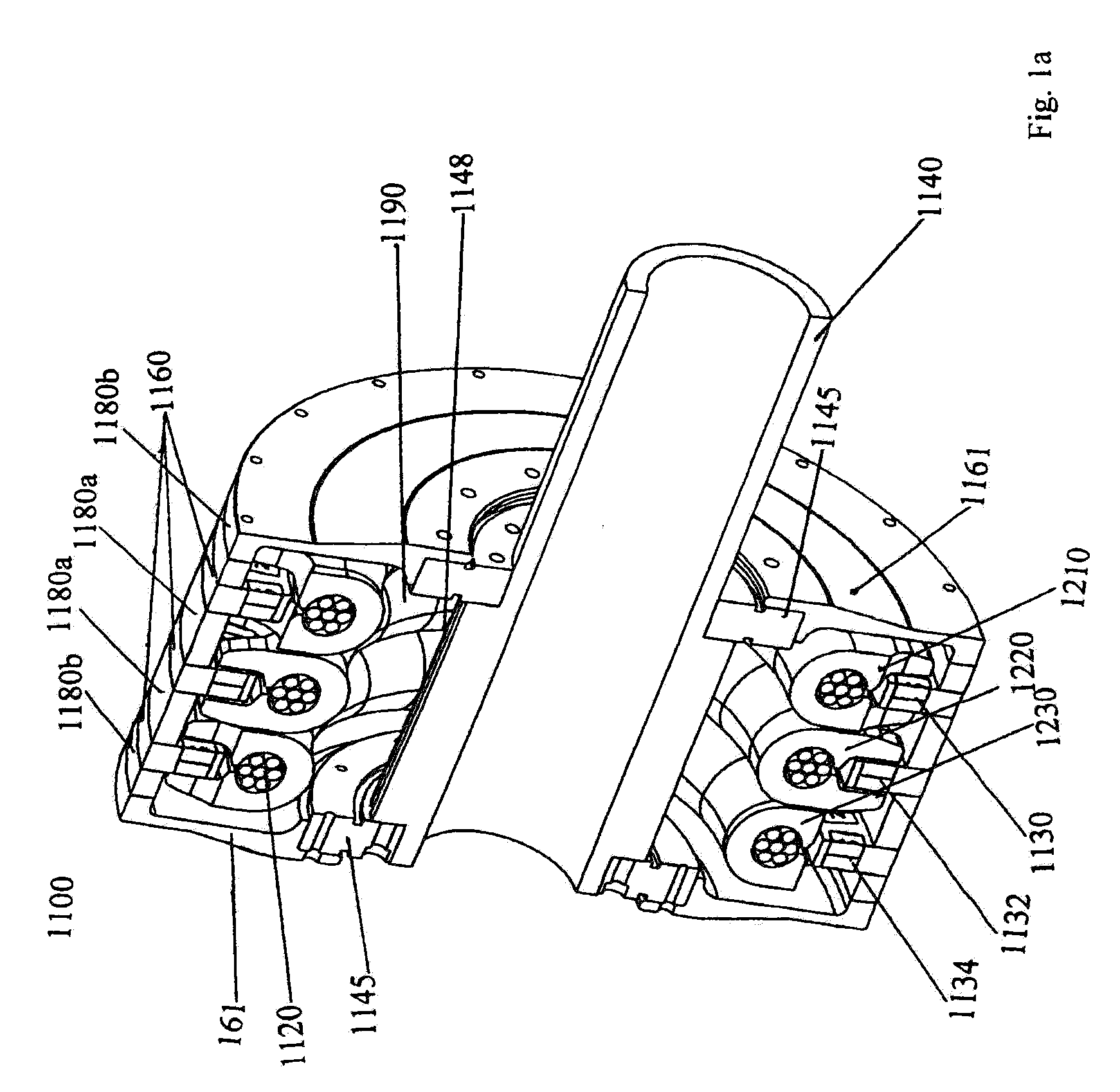

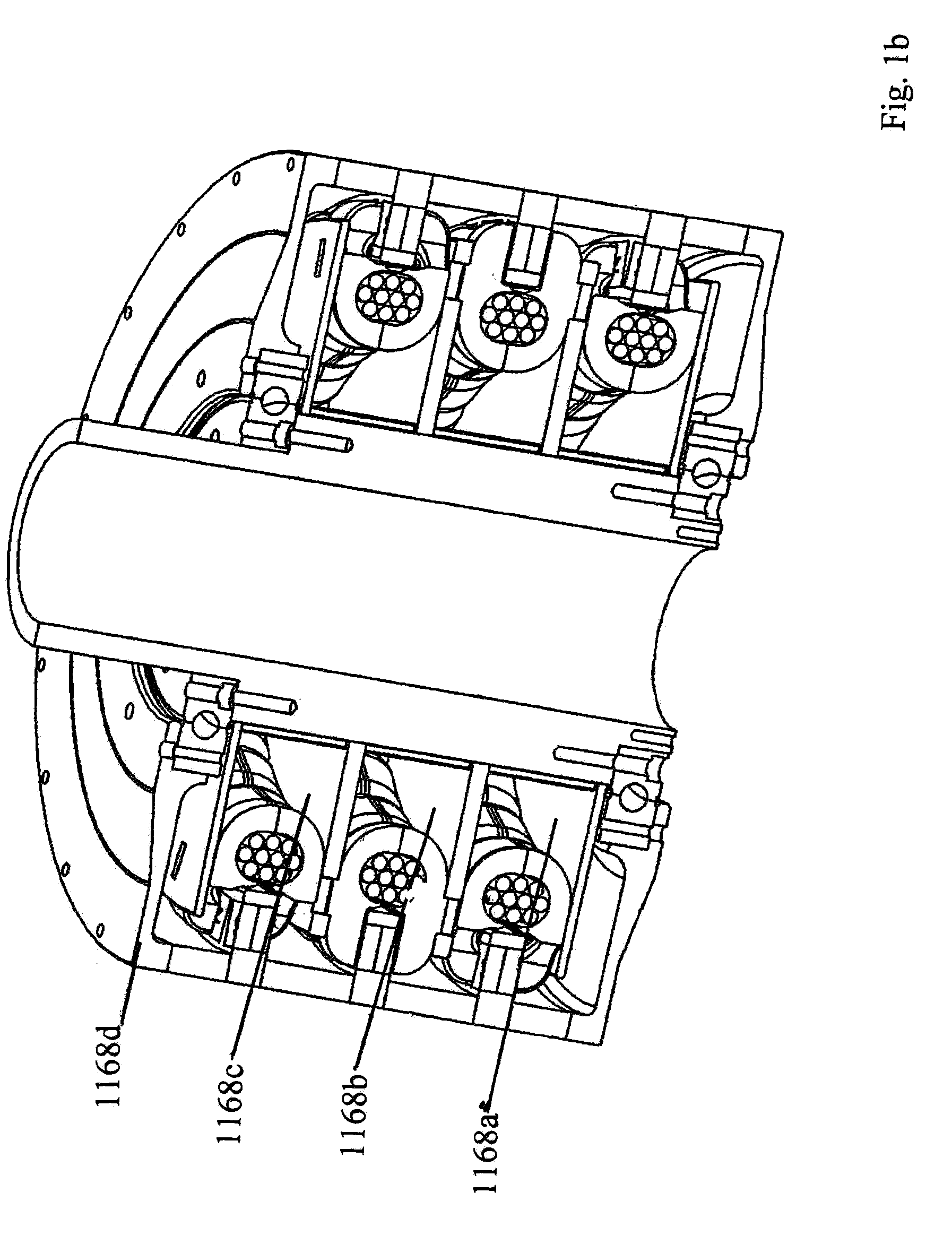

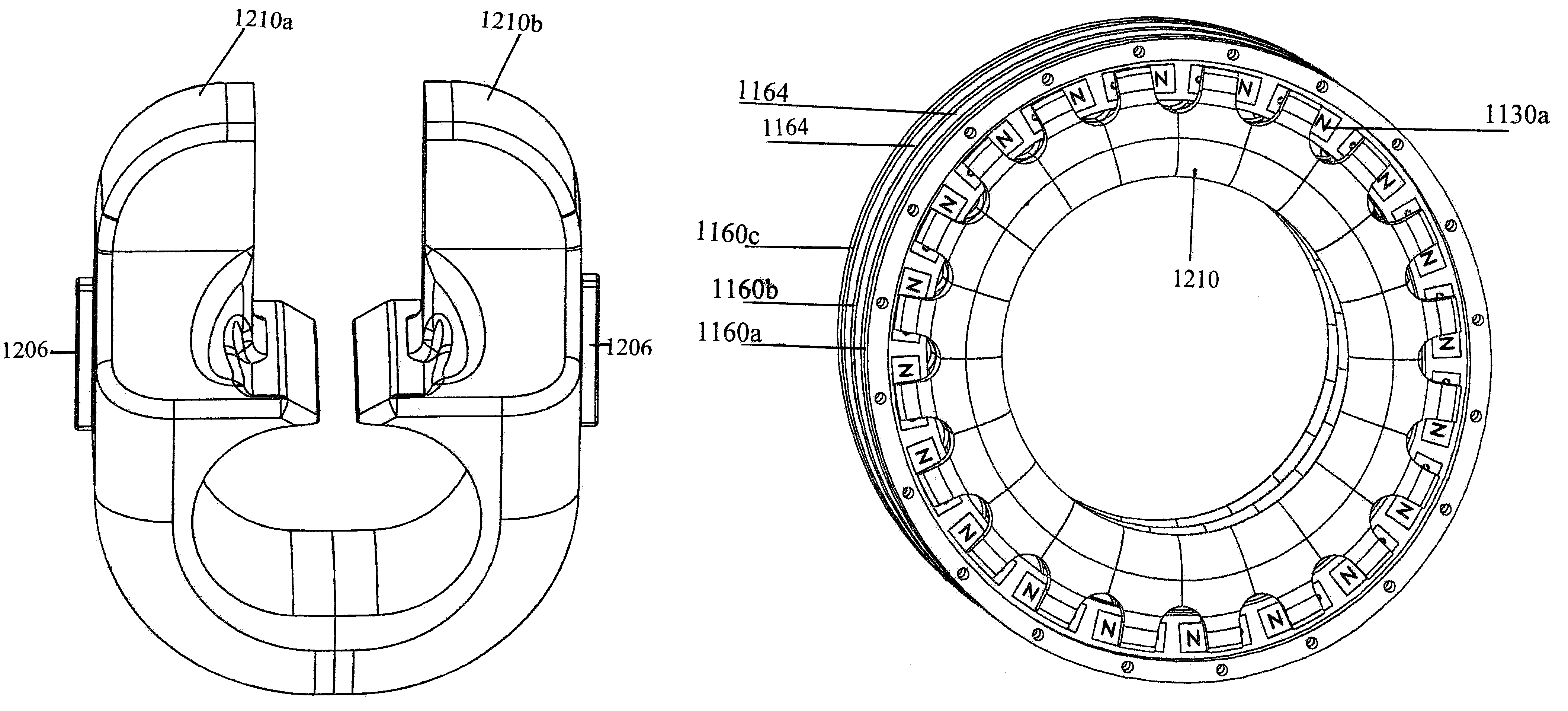

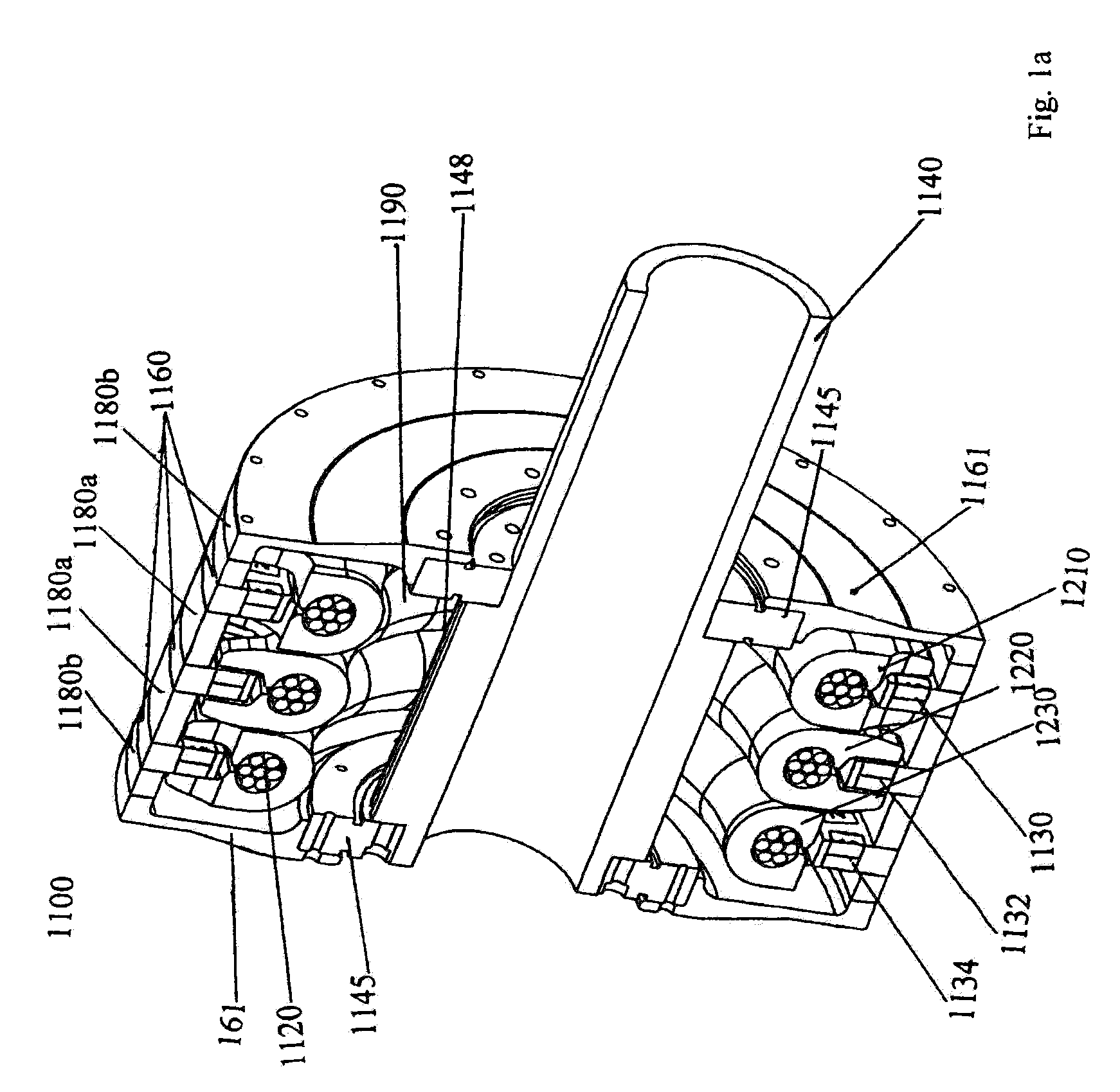

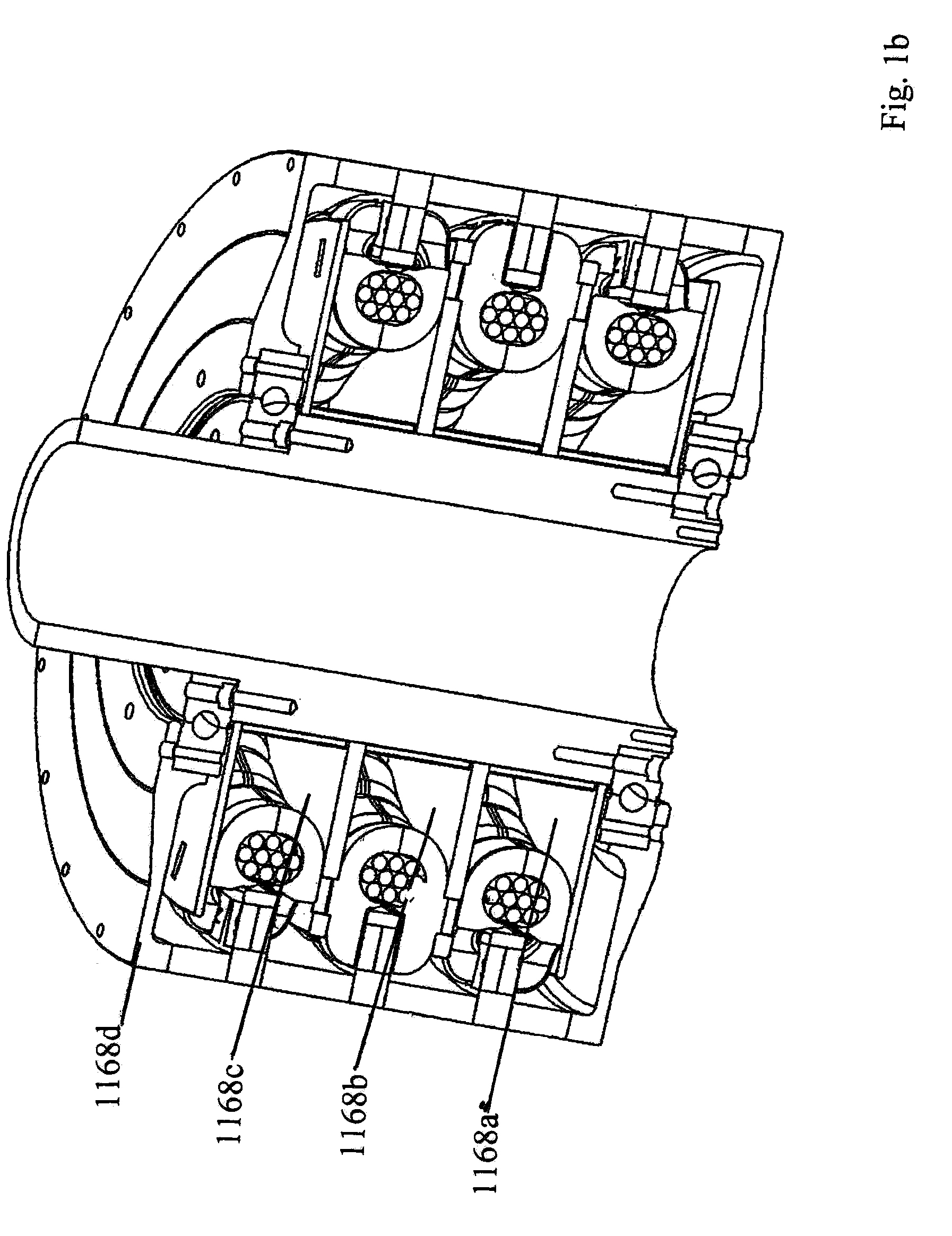

High-Efficiency Wheel-Motor Utilizing Molded Magnetic Flux Channels with Transverse-Flux Stator

InactiveUS20090322165A1Reducing hysteresis lossIncrease torqueMotor/generator/converter stoppersMotor control for very low speedsTransverse fluxEngineering

A motor including an outside rotor having a rotor disc with plural magnets alternating polarities flush mounted in the disc, an inside stator assembly with a ring of pole pieces forming a channel to house a transversely wound stator windings, and a controller coupled with feedback electronics for monitoring a timing, speed and direction and coupling a signal to a processing unit for adjusting the drive electronics driving the phase windings. A u-shaped gap above the channel to receive the rotor disc and focus the captured magnetic flux in the pole pieces toward the magnets. In an embodiment the molded magnetic flux channel pole pieces of the inside stator are sets of molded magnetic flux channel pole pieces, each set forming a channel and corresponding to one phase of the motor; and a section of each one of the transverse windings passing through one channel, the remaining section folding back outside the set in close proximity to the outer base of the set of molded magnetic flux channel pole pieces.

Owner:RITTENHOUSE NORMAN P

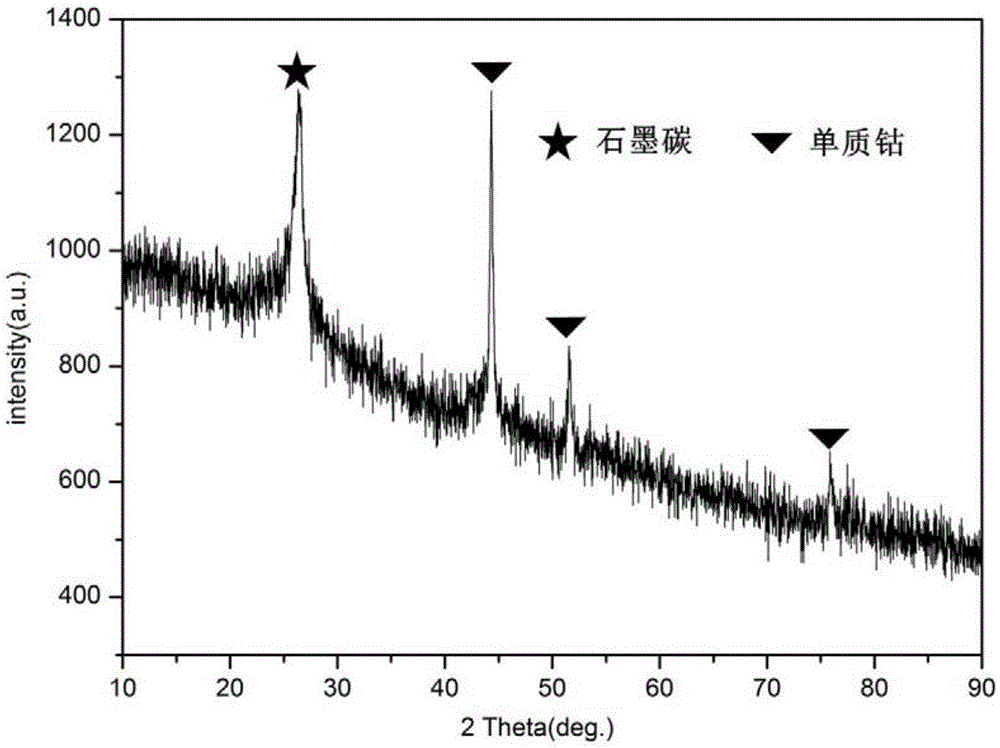

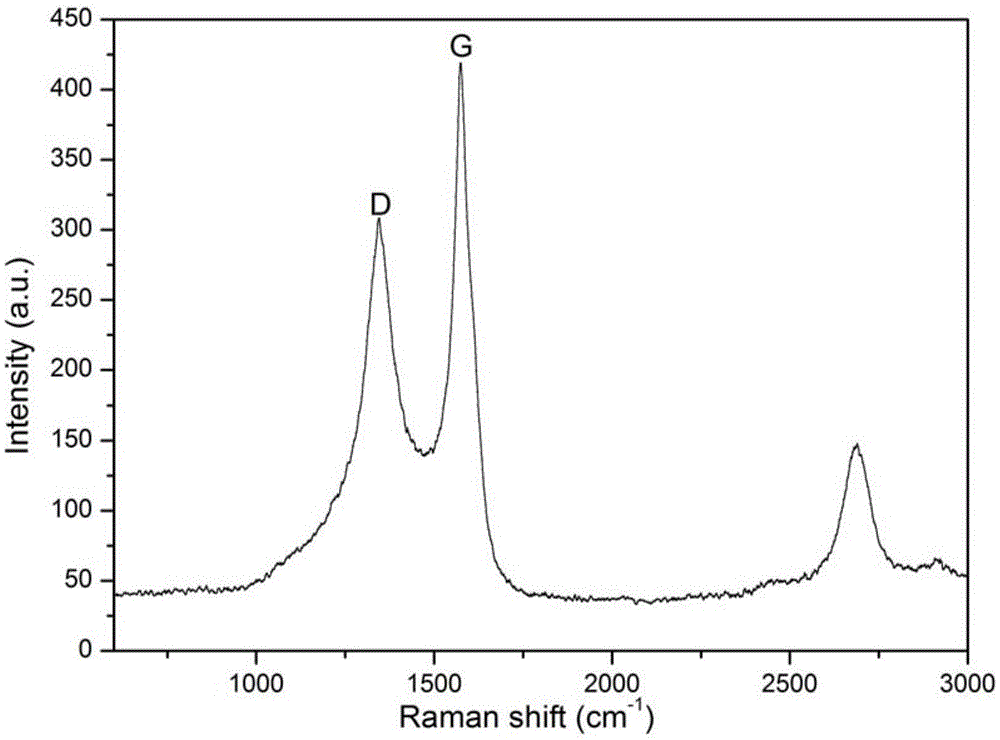

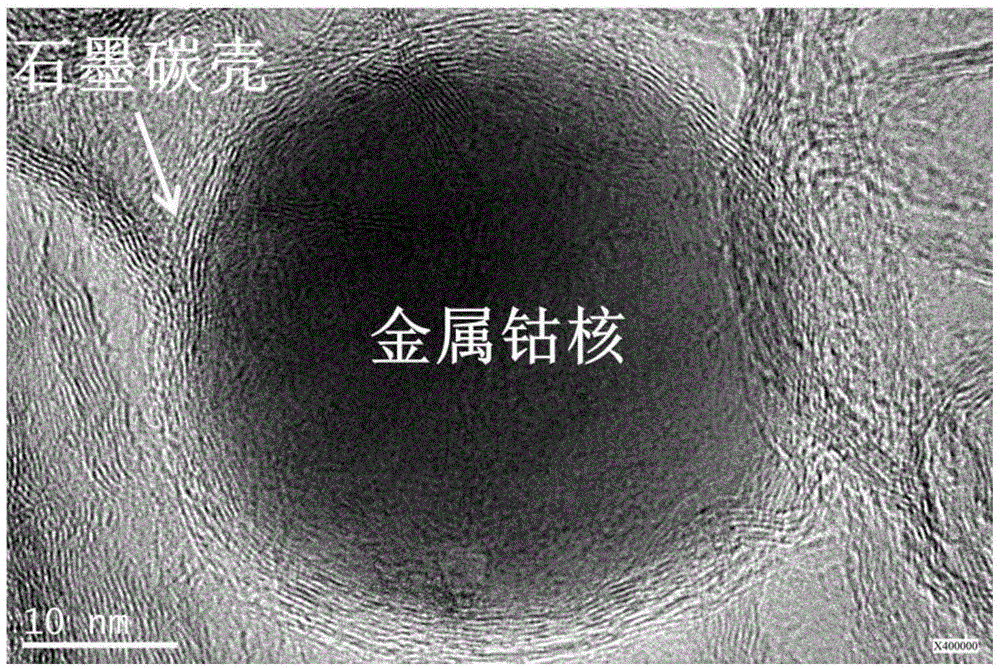

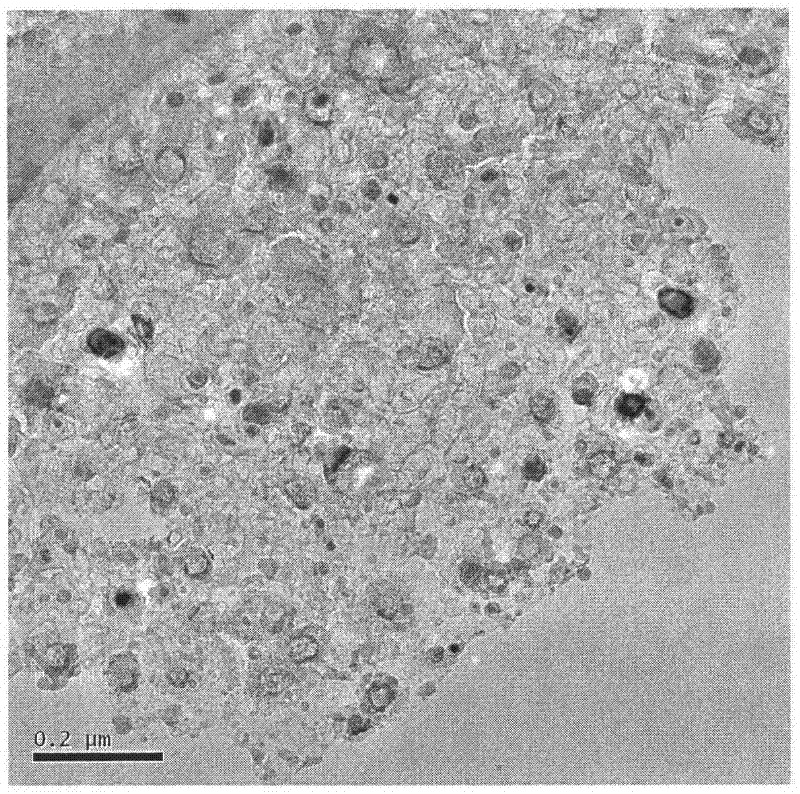

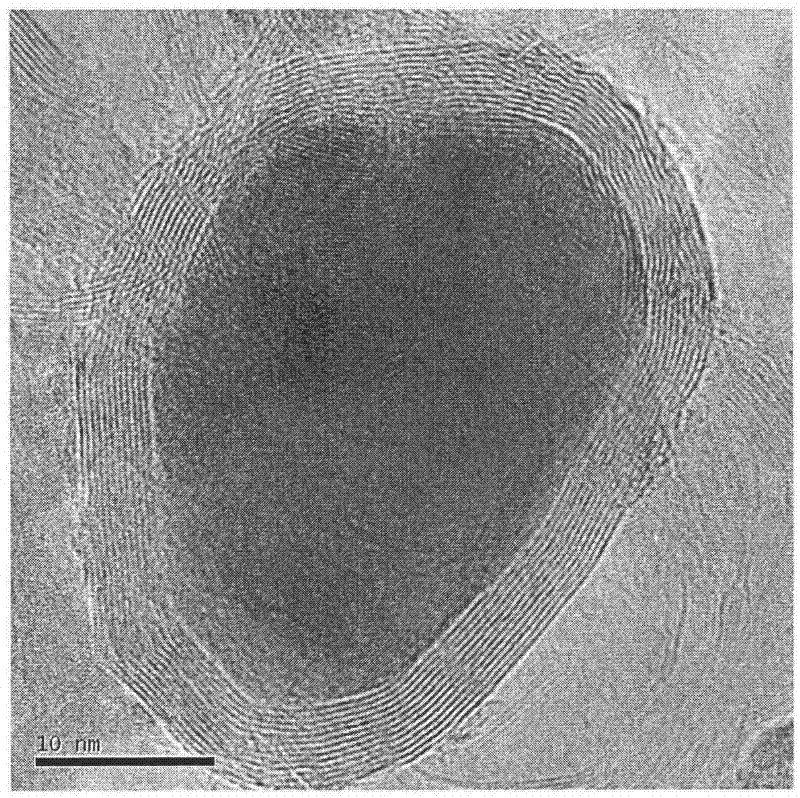

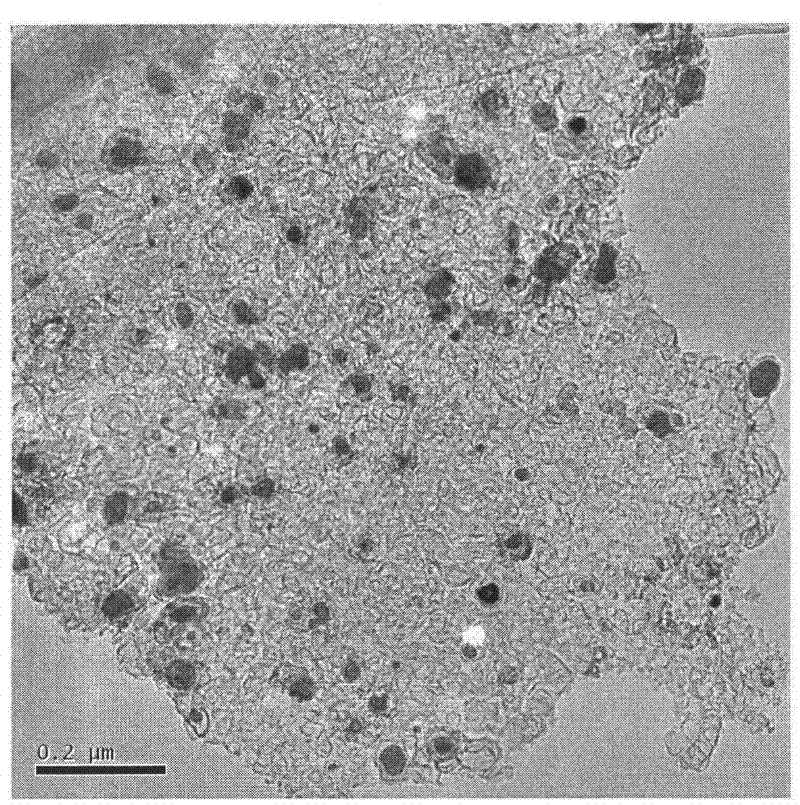

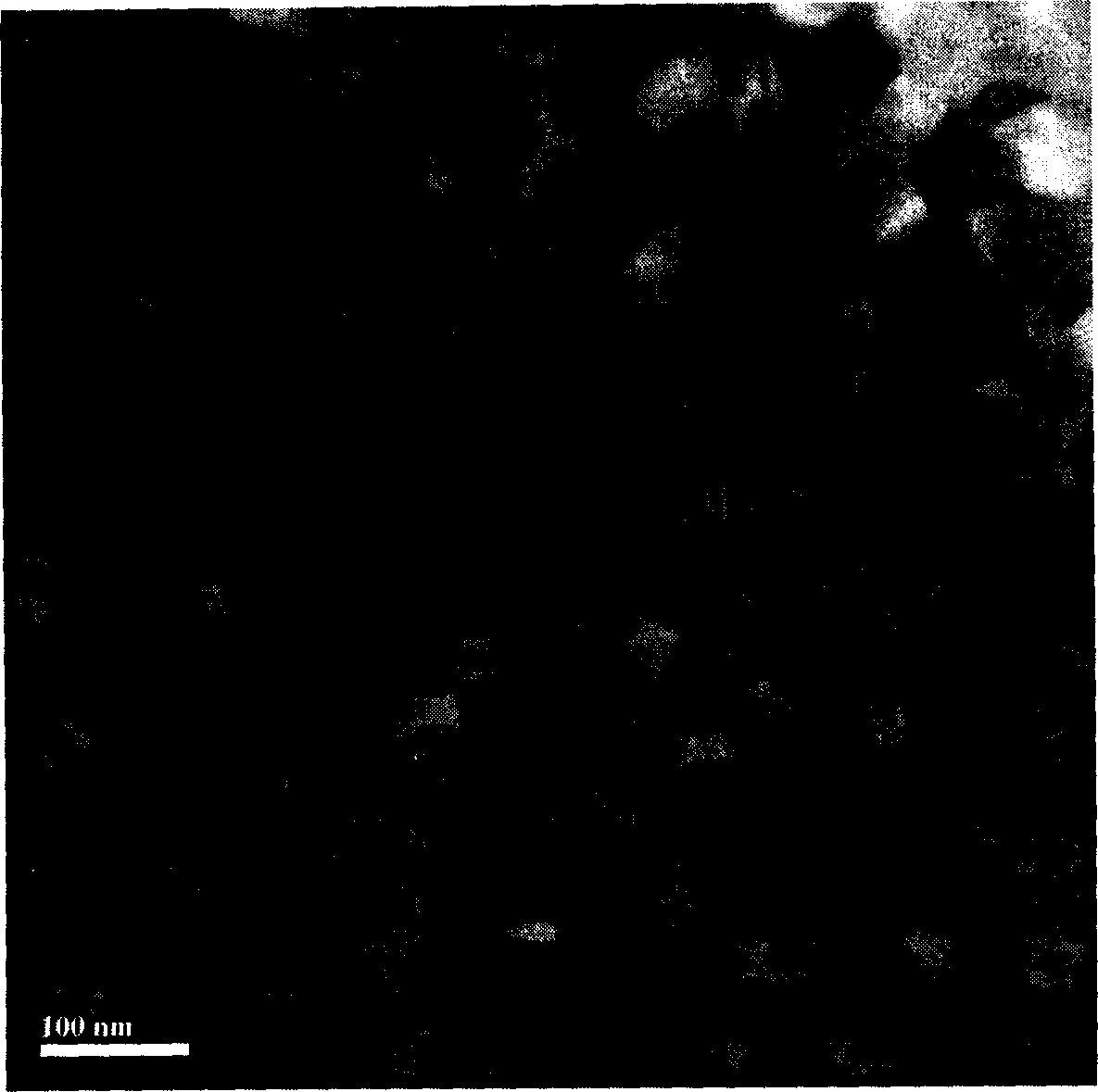

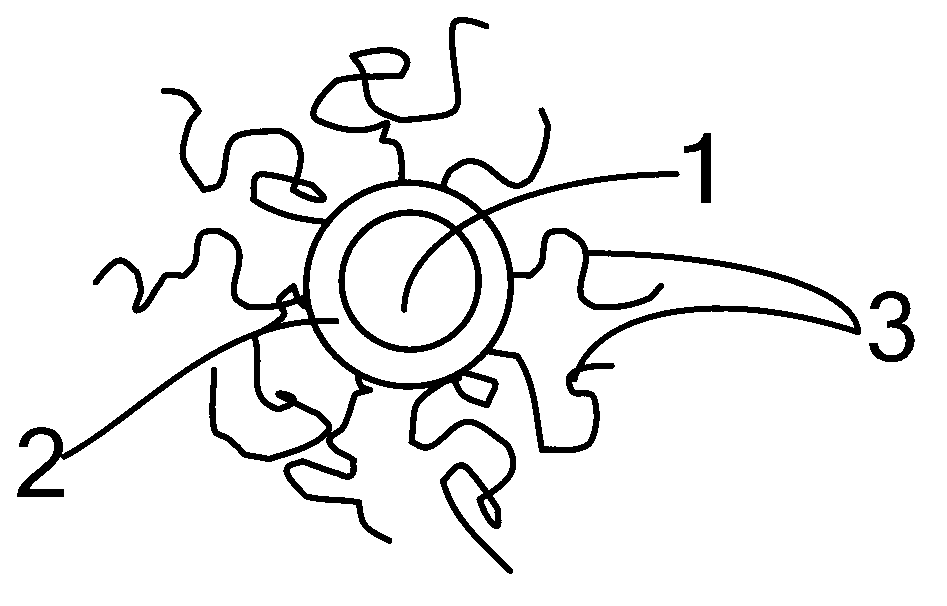

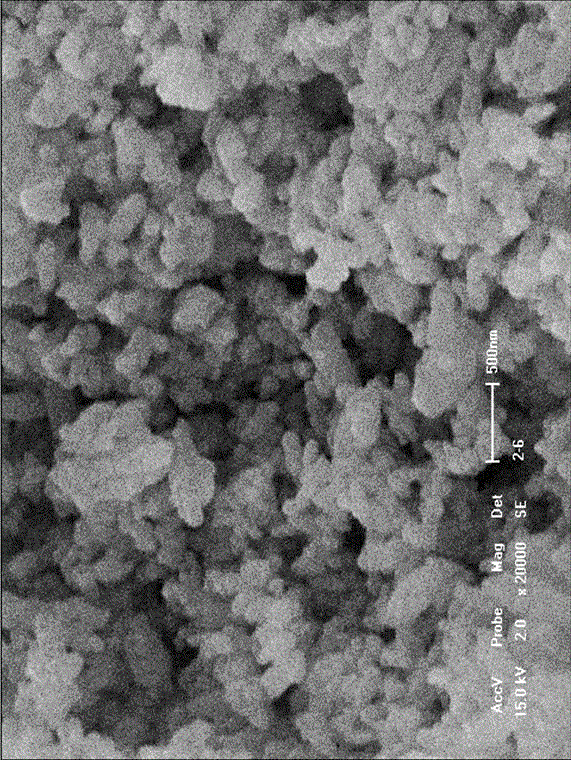

Method for preparing non-metallic element doped carbon coated metal nanoparticle magnetic composite

ActiveCN105478755AGood dispersionHigh purityTransportation and packagingMetal-working apparatusDispersityCyanamide compound

The invention discloses a method for preparing a non-metallic element doped carbon coated metal nanoparticle magnetic composite. The method comprises the steps that water-soluble metal divalent salt, a cyanamide compound and a nitrogen or boron or sulfur containing non-metallic compound are added into a methanol solution to be mixed, dissolved, dried and ground, and obtained homogeneous-phase powder is subjected to roasting pyrolysis under the protection of inert gas; and a pyrolysis product is subjected to acid pickling, washing, drying and grinding, and a target product is obtained. According to the whole preparing process of the method, metal ion reduction, metal nanoparticle coating and doping of nitrogen / boron / sulfur and other non-metallic elements are achieved in one step. The composite prepared through the method is high in degree of graphitization, good in dispersity between particles and high in purity, and the preparing method has the advantages that the cost is low, the process is simple, and large-quantity synthesis can be easily achieved.

Owner:合肥庐阳科技创新集团有限公司

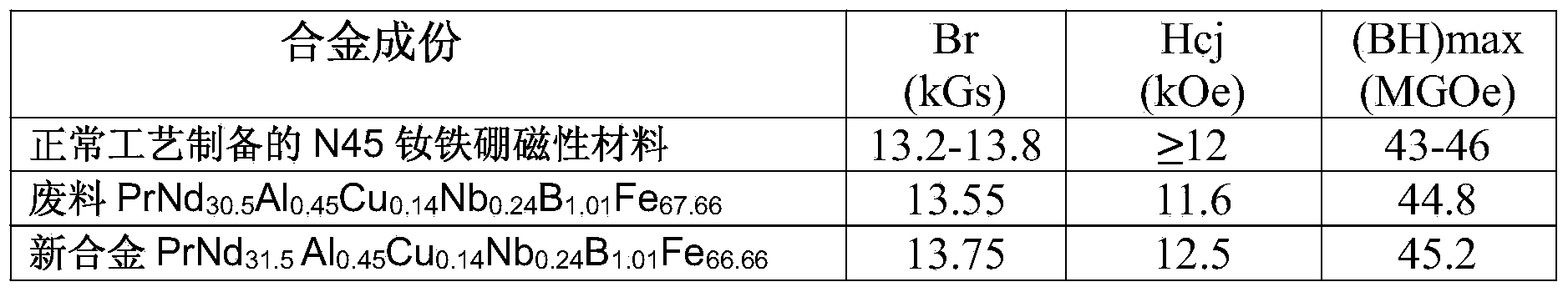

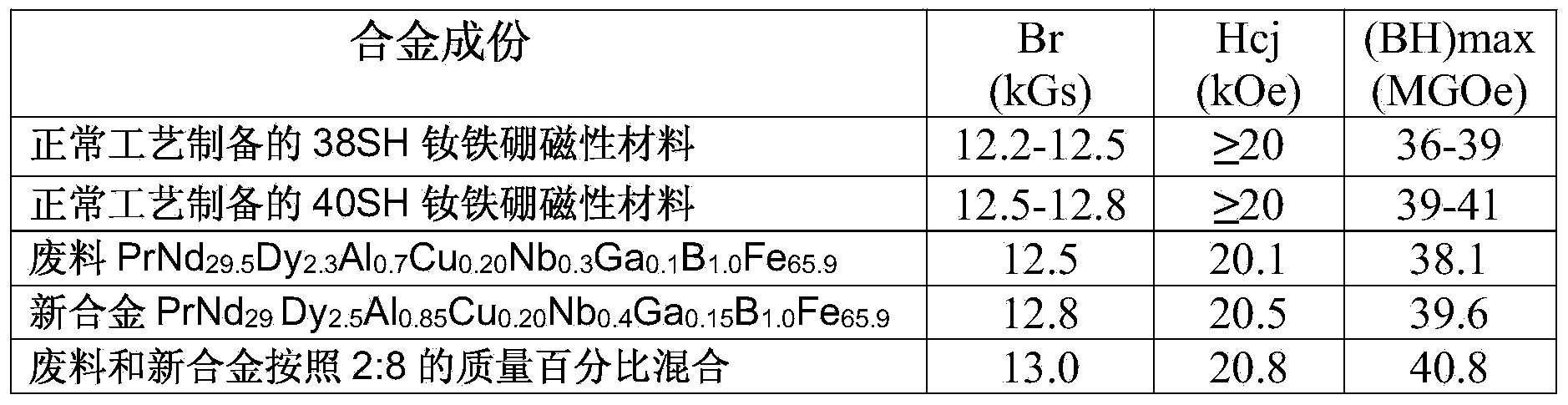

Method for preparing neodymium iron boron through regenerating waste material containing neodymium, iron and boron

ActiveCN103866127AFully absorb hydrogenImprove recycling ratesMagnetic materialsProcess efficiency improvementMetallurgyEconomic benefits

The invention provides a method for preparing neodymium iron boron through regenerating a waste material containing neodymium, iron and boron. The method comprises steps of (1) preprocessing the waste material; (2) correcting the components of the waste material; (3) crushing by hydrogen; (4) preparing into powder; (5) molding under a magnetic field; and (6) vacuum sintering. The method fully uses the waste material recycled in a production process, has high recovery rate of the waste material, can produce high performance product, has a simple and controllable flow, has high operability, uses no strong acid and strong base polluting the environment, is environment-friendly and energy-saving, and has high social and economic benefits.

Owner:CHINALCO JINYUAN RARE EARTH

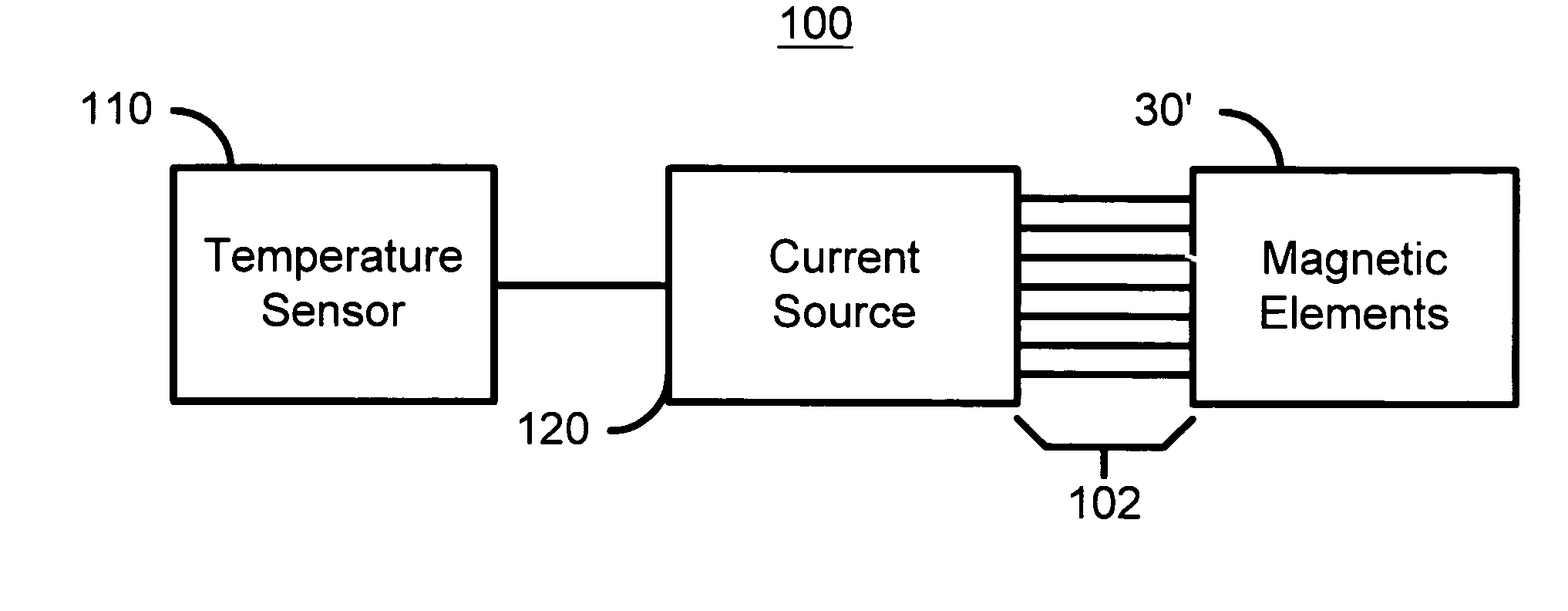

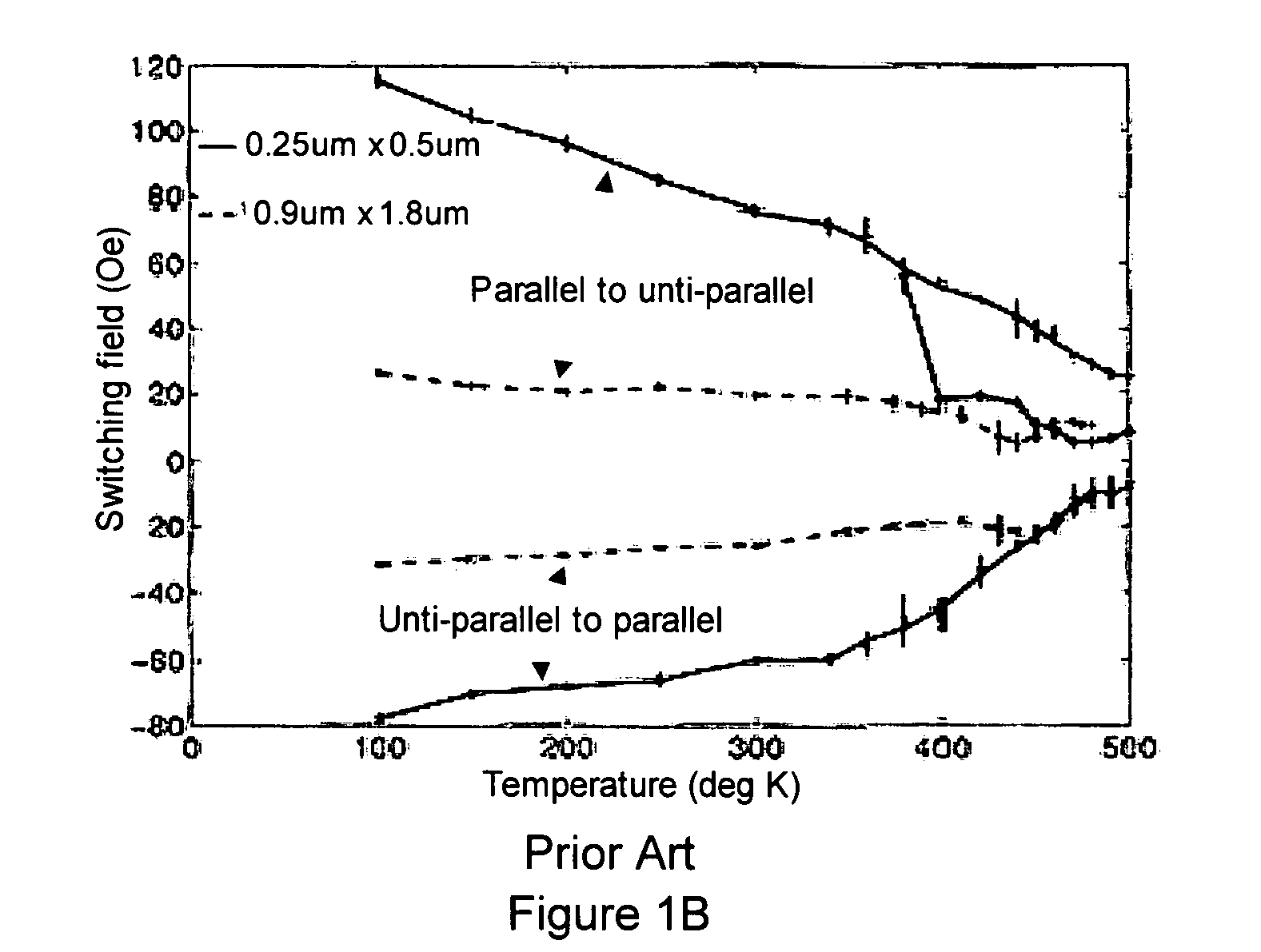

Method and system for providing temperature dependent programming for magnetic memories

InactiveUS6982916B2Improve magnetismImprove performanceDigital storageMagnetic memoryElectrical current

Owner:APPLIED SPINE TECH

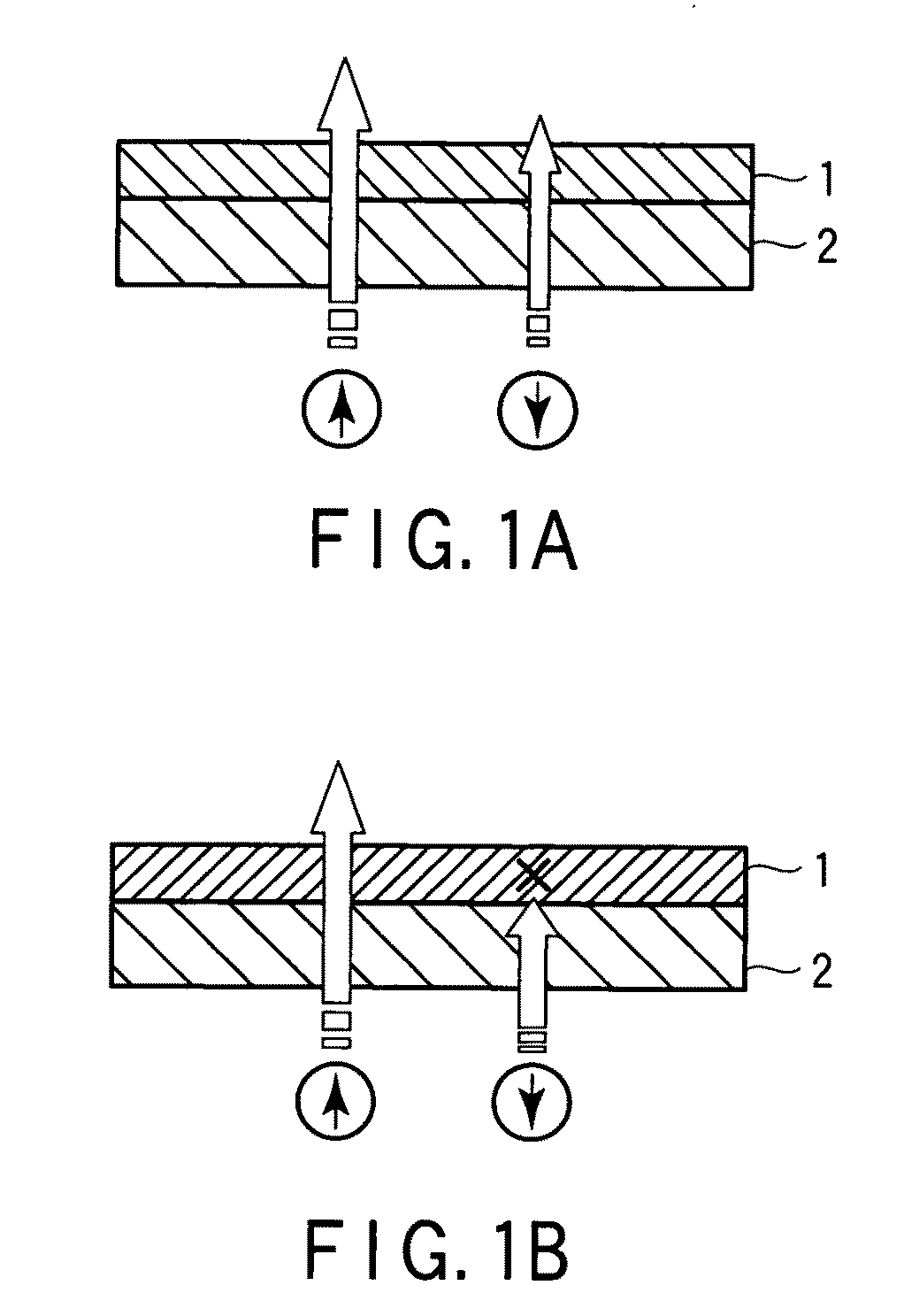

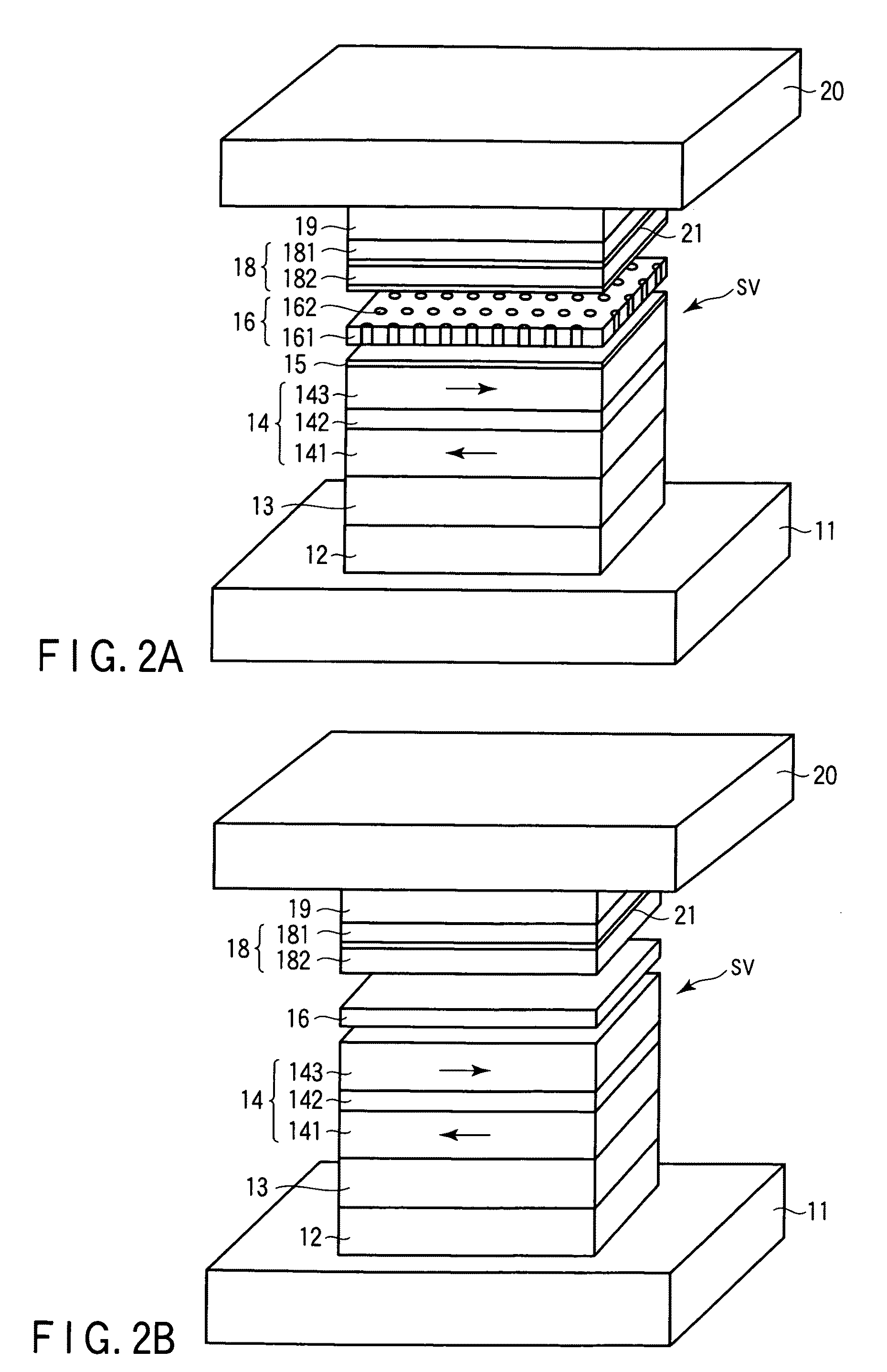

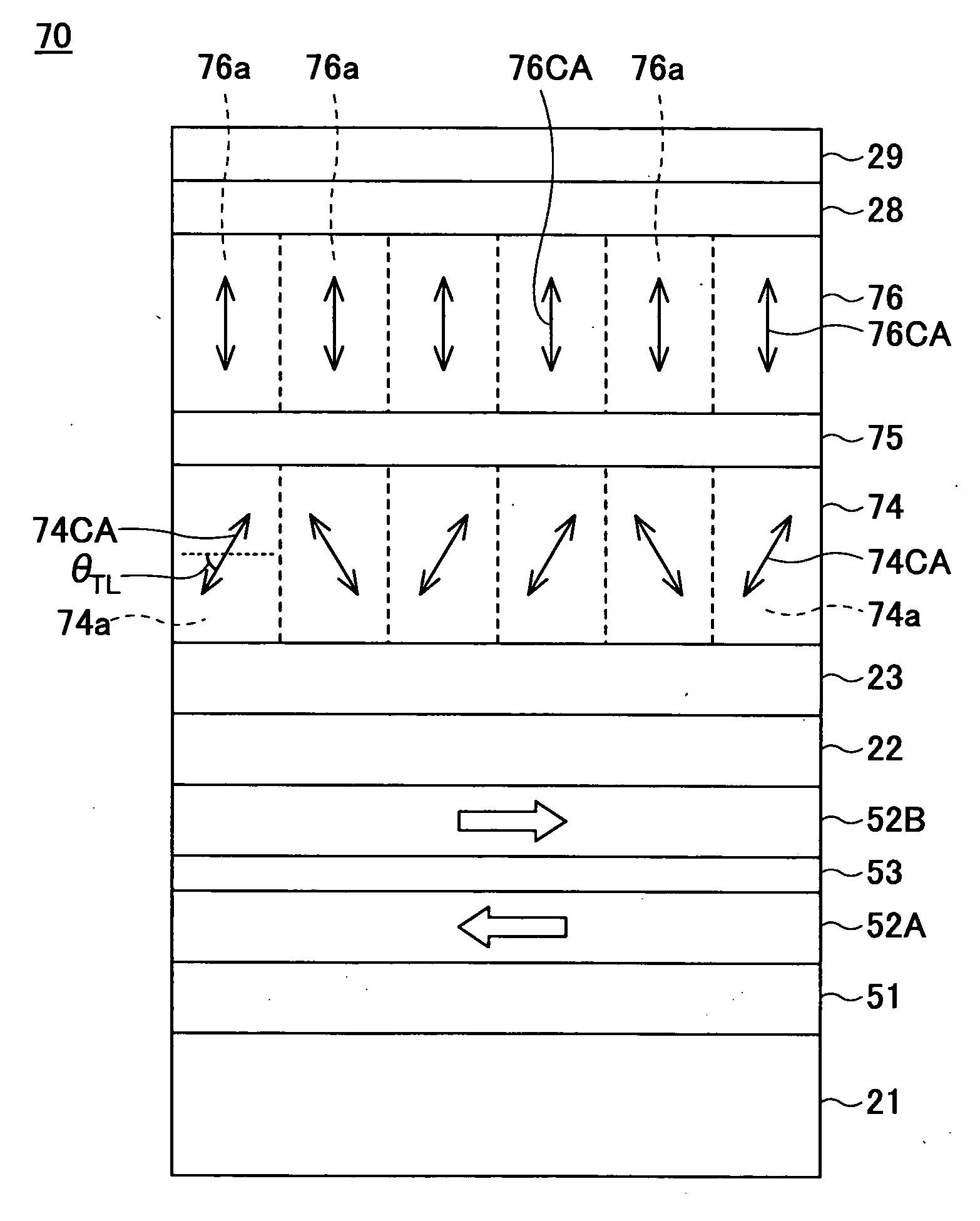

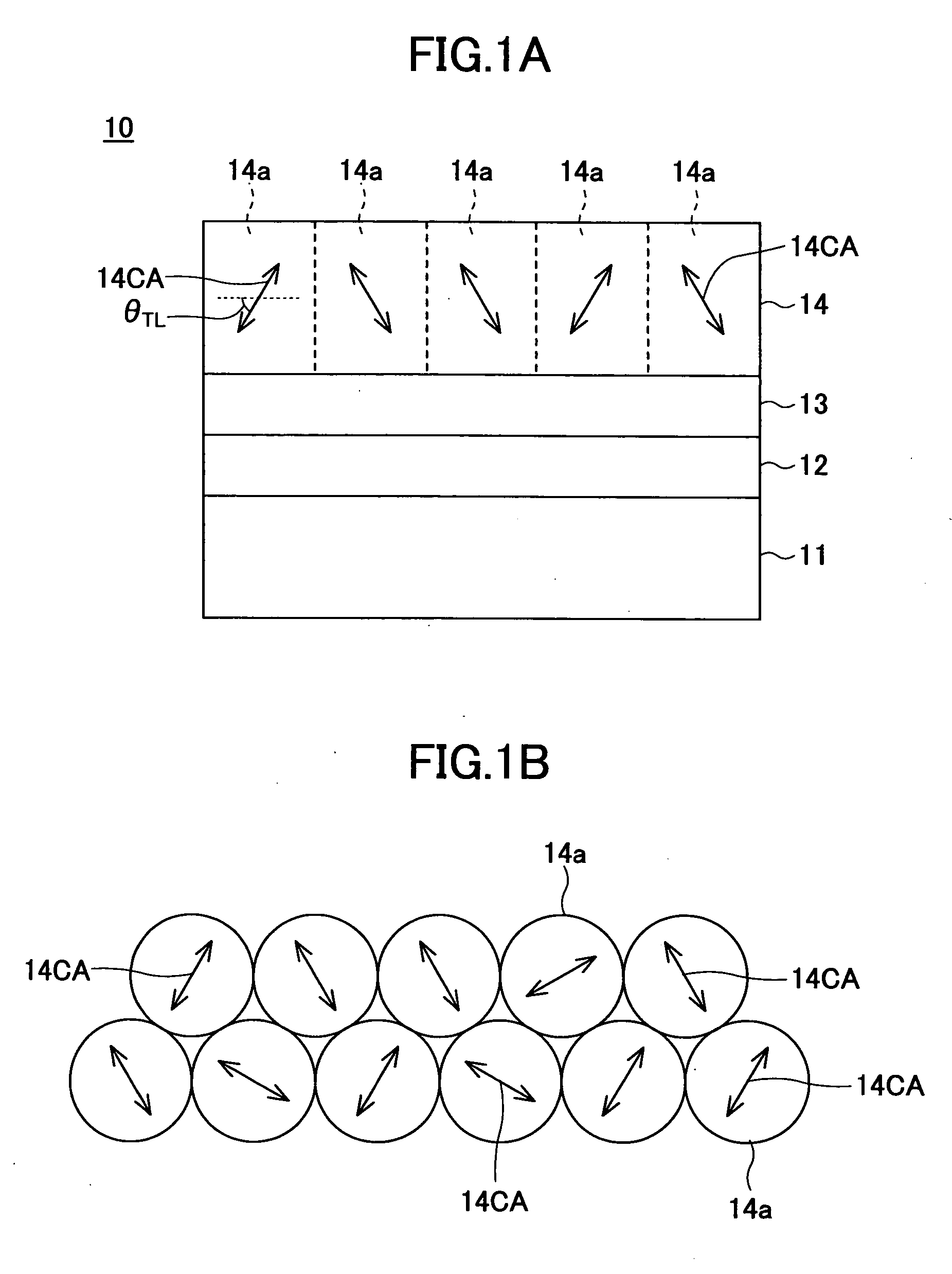

Magnetoresistive element and method of manufacturing the same

ActiveUS20090190262A1Improve magnetismMarked technical improvement in the field of magnetic devicesNanomagnetismMagnetic measurementsMagnetic reluctanceNitrogen

A magnetoresistive element includes a magnetoresistive film including a magnetization pinned layer, a magnetization free layer, an intermediate layer arranged between the magnetization pinned layer and the magnetization free layer, a cap layer arranged on the magnetization pinned layer or on the magnetization free layer, and a functional layer formed of an oxygen- or nitrogen-containing material and arranged in the magnetization pinned layer, or in the magnetization free layer, and a pair of electrodes which pass a current perpendicularly to a plane of the magnetoresistive film, in which a crystalline orientation plane of the functional layer is different from a crystalline orientation plane of its upper or lower adjacent layer.

Owner:KK TOSHIBA

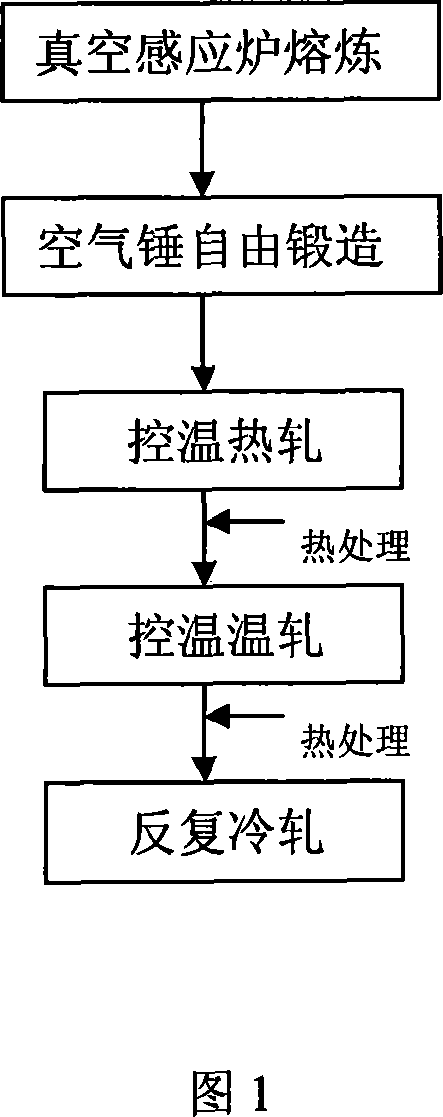

Preparation method for cold rolling sheet of duriron

InactiveCN101049669AWide applicabilityLow purityRoll force/gap control deviceTemperature control deviceAlloyThin sheet

A cold rolling method for preparing high-Si steel sheet containing Fe (85-96 Wt%) and Si (4-15) includes such steps as providing raw material containing Si, B and Fe, smelting, casting, forging, hot rolling, warm rolling, heat treating and cold rolling.

Owner:UNIV OF SCI & TECH BEIJING

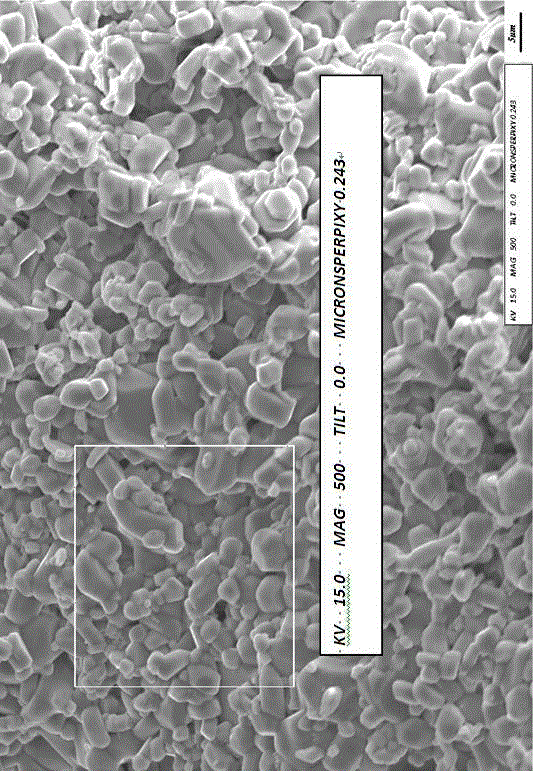

Method for preparing heavy rare earth hydride nano-particle doped sintered NdFeB permanent magnet

ActiveCN101521069AImprove coercive forceNot easily oxidizedInorganic material magnetismRare-earth elementDehydrogenation

The invention discloses a method for preparing a heavy rare earth hydride nano-particle doped sintered NdFeB permanent magnet, which belongs to the technical field of magnetic materials. The prior preparation method improves the coercive force and the temperature stability of magnets by adding heavy rare earth elements, namely terbium or dysprosium into master alloy, but the method can cause the residual magnetism of the magnets, the reduction of magnetic energy product and the increase of manufacturing cost. The method adopts heavy rare earth terbium hydride and dysprosium hydride nano-powder doping technology to prepare the sintered NdFeB permanent magnet with high coercive force and excellent magnetic property. The method comprises the following steps: preparing NdFeB powder by a rapidly solidified flake process and a hydrogen decrepitation process; preparing the terbium hydride or the dysprosium hydride nano-powder by physical vapor deposition technology; mixing the two powders, and performing magnetic field orientation and press forming; and performing dehydrogenation treatment, sintering and heat treatment on a green compact at different temperatures, and obtaining the sintered magnet. The coercive force of the magnet prepared by the method is higher than that of the prior sintered magnet with the same ingredients; and compared with the sintered magnet with the equivalent coercive force, the proportion of the terbium and dysprosium needed by the magnet prepared by the method is remarkably reduced.

Owner:BEIJING UNIV OF TECH

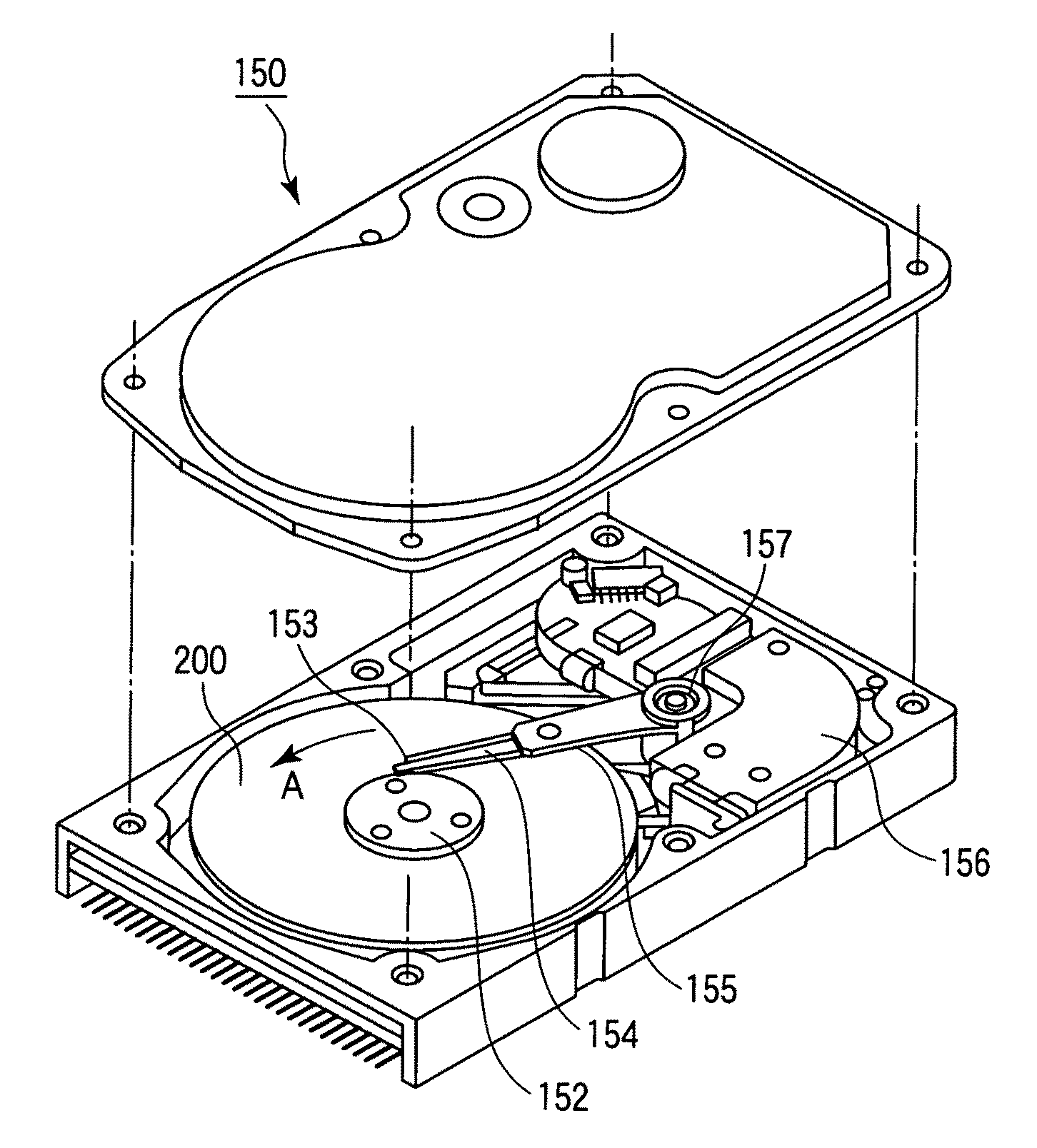

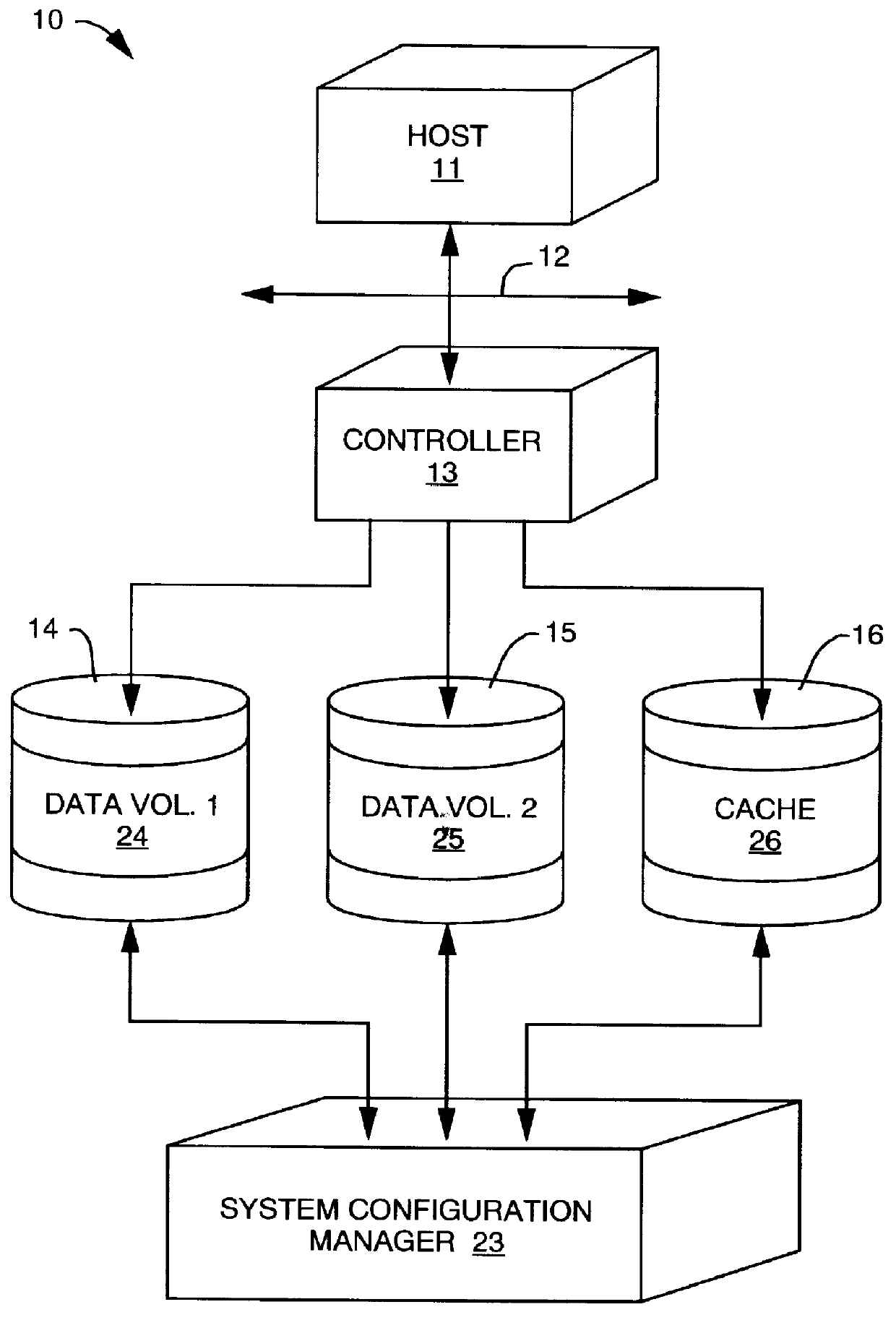

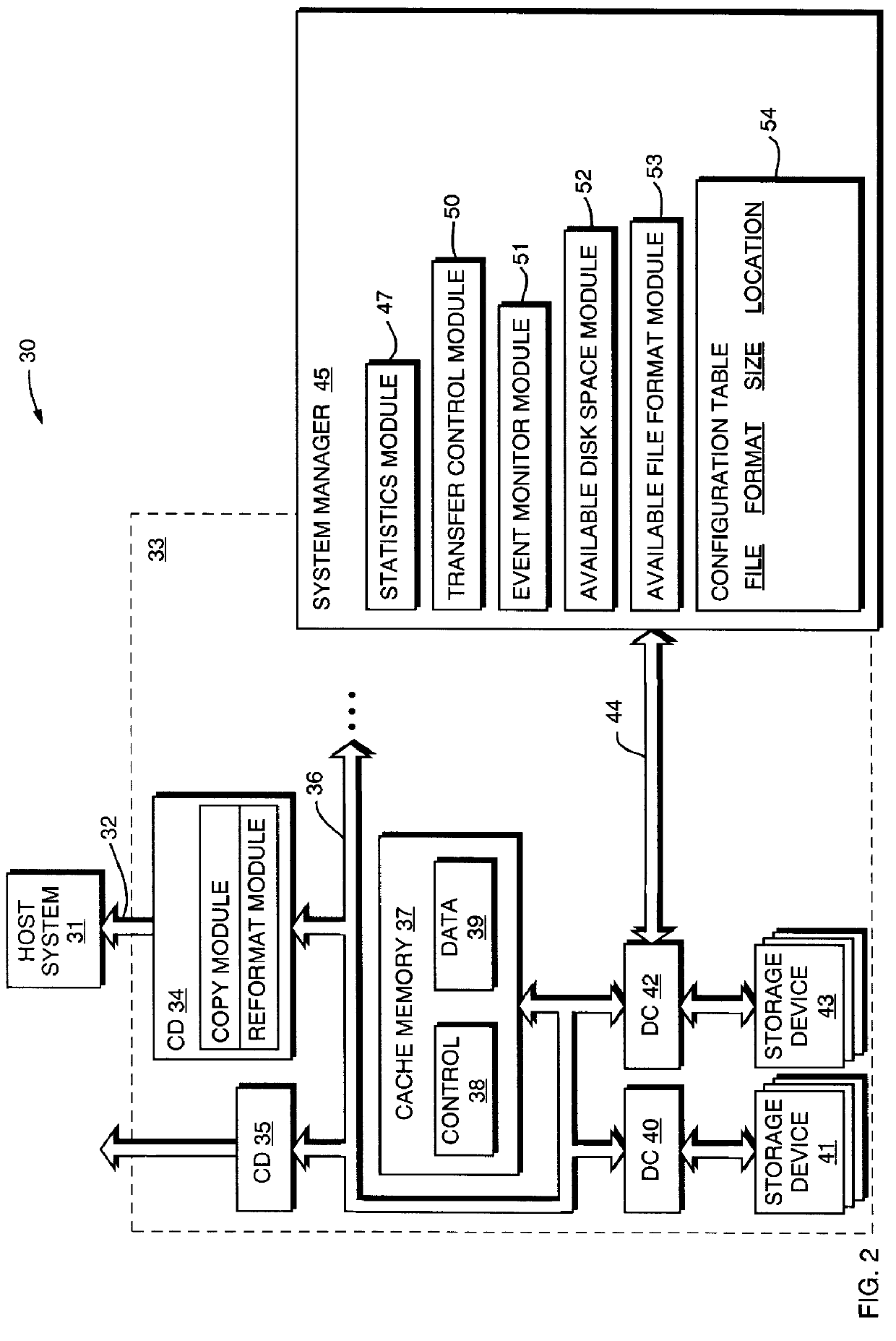

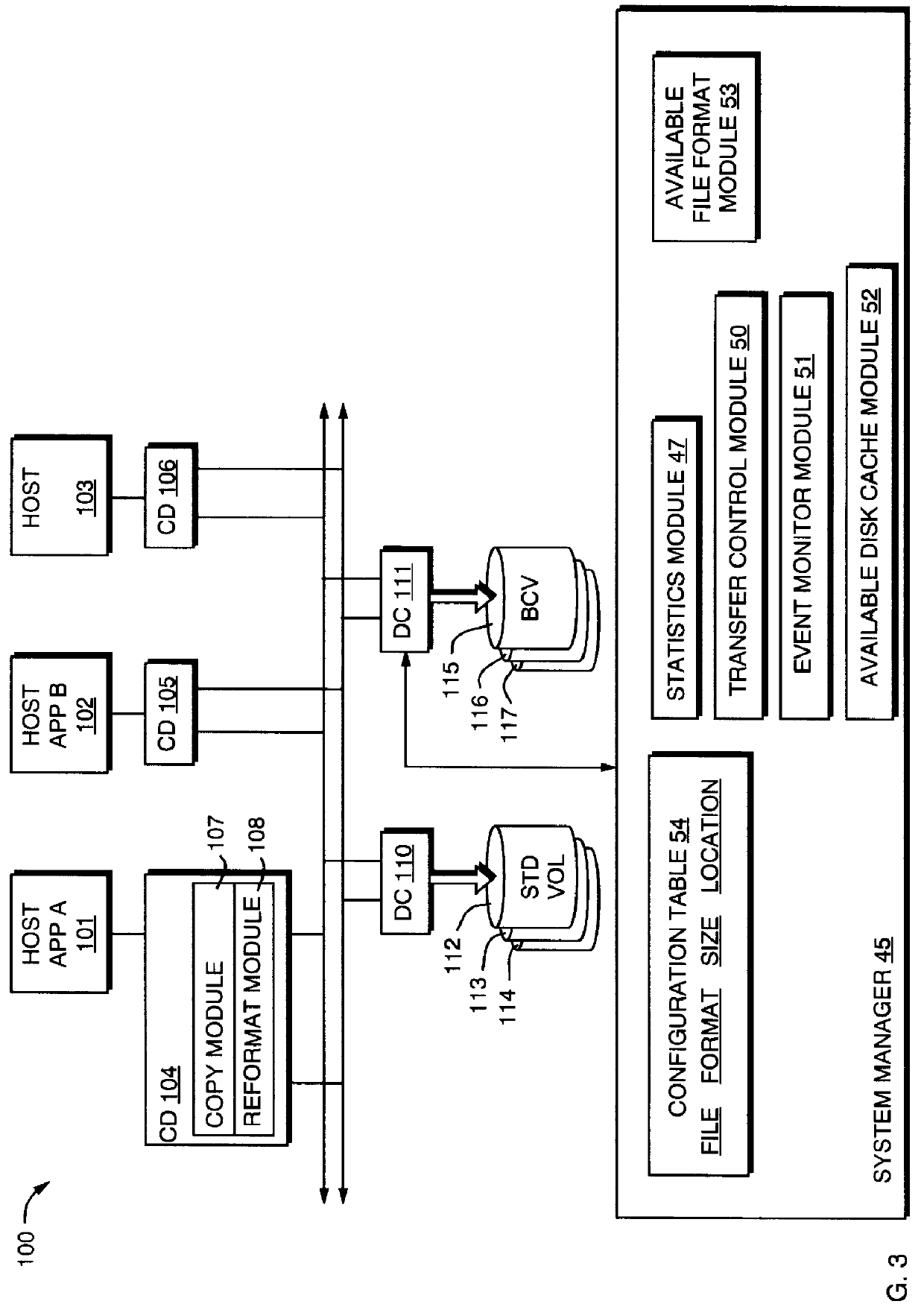

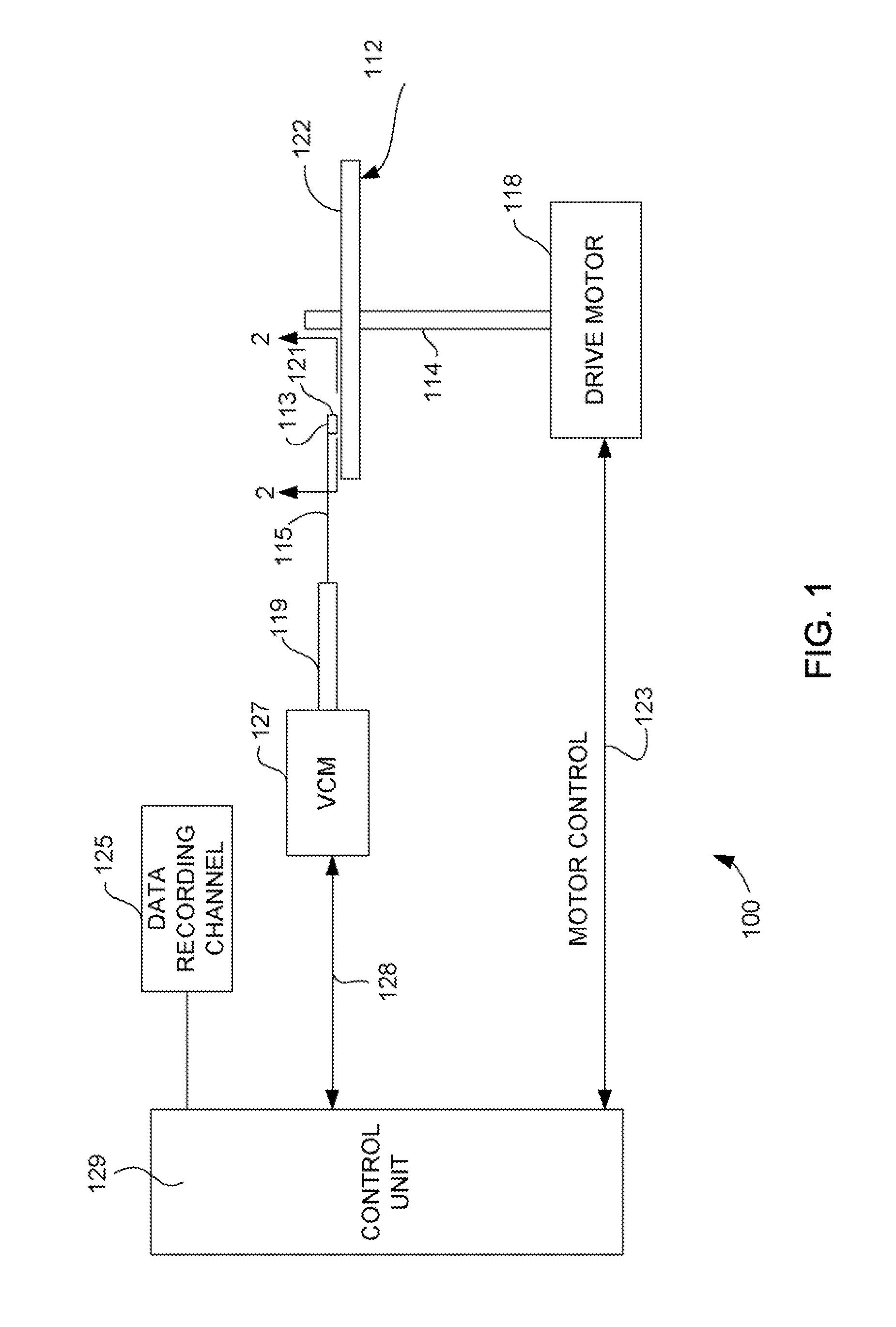

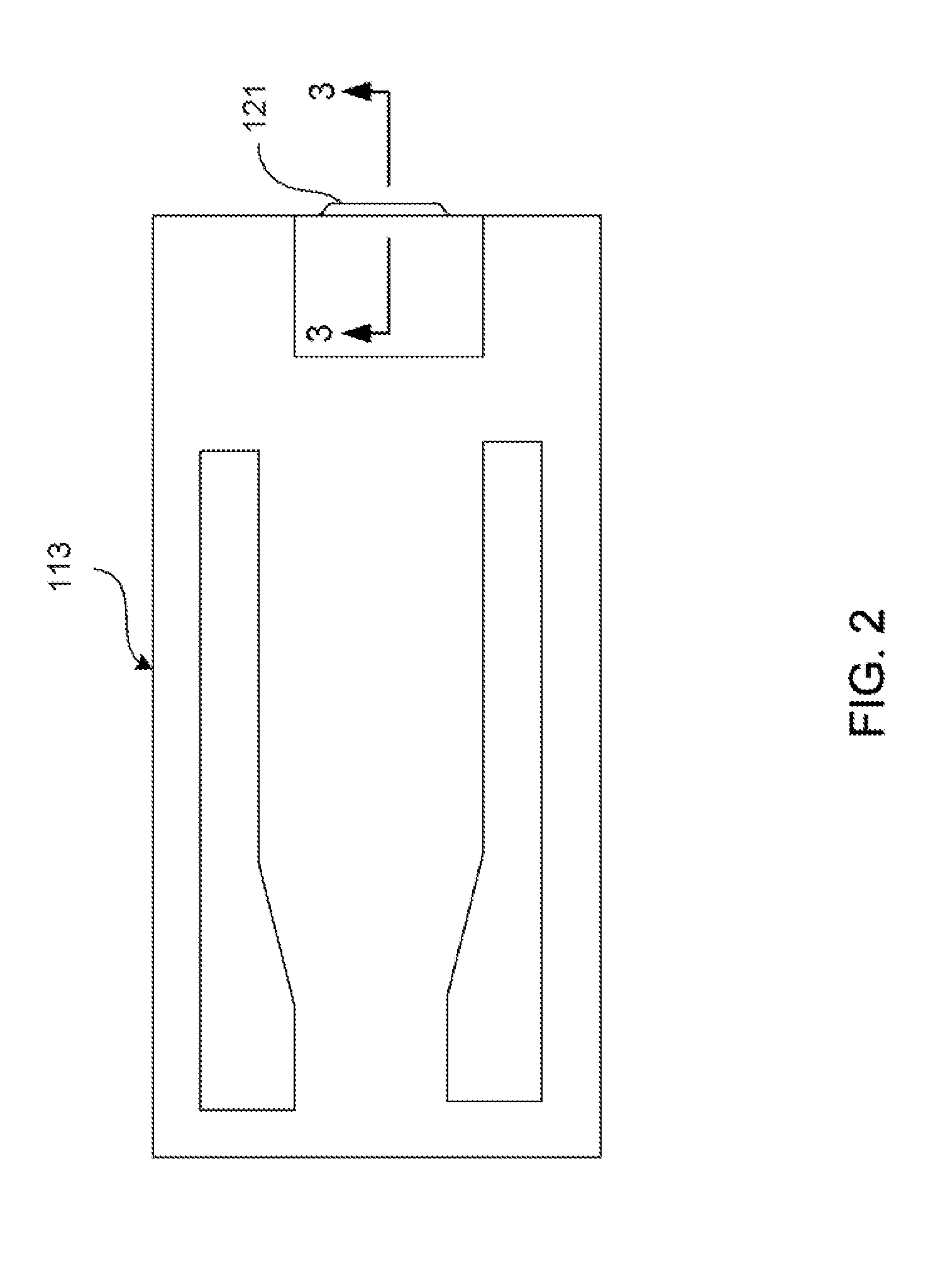

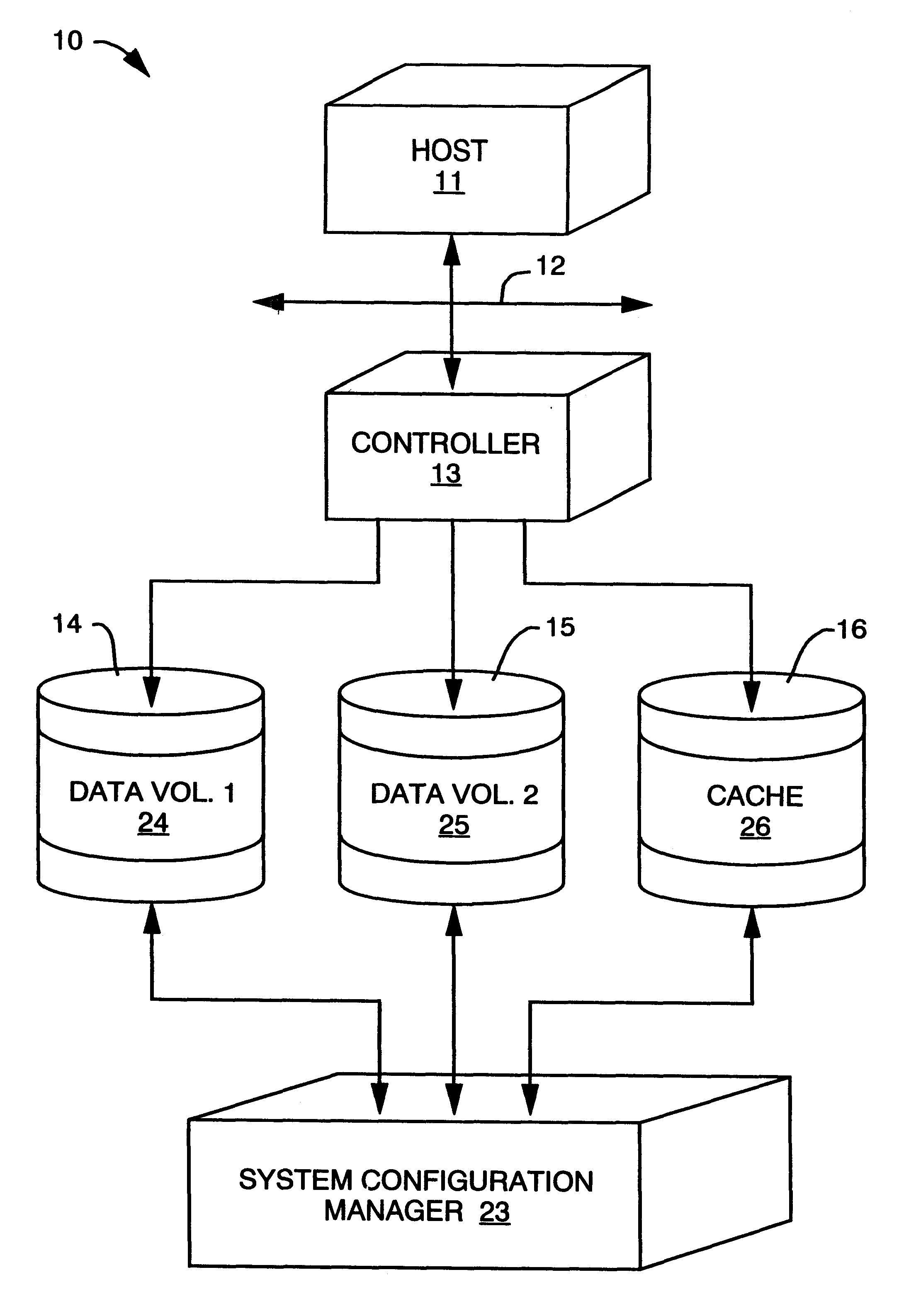

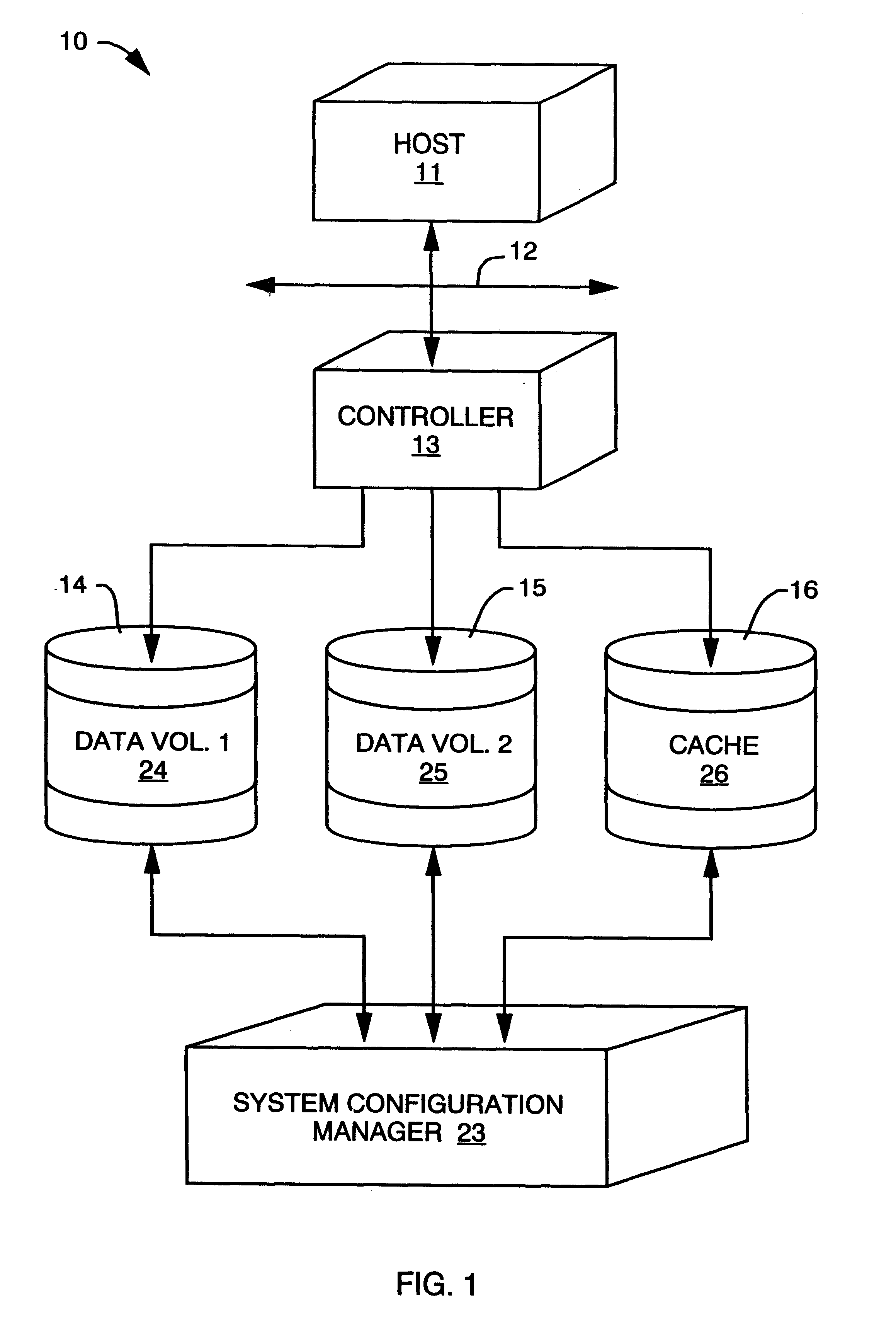

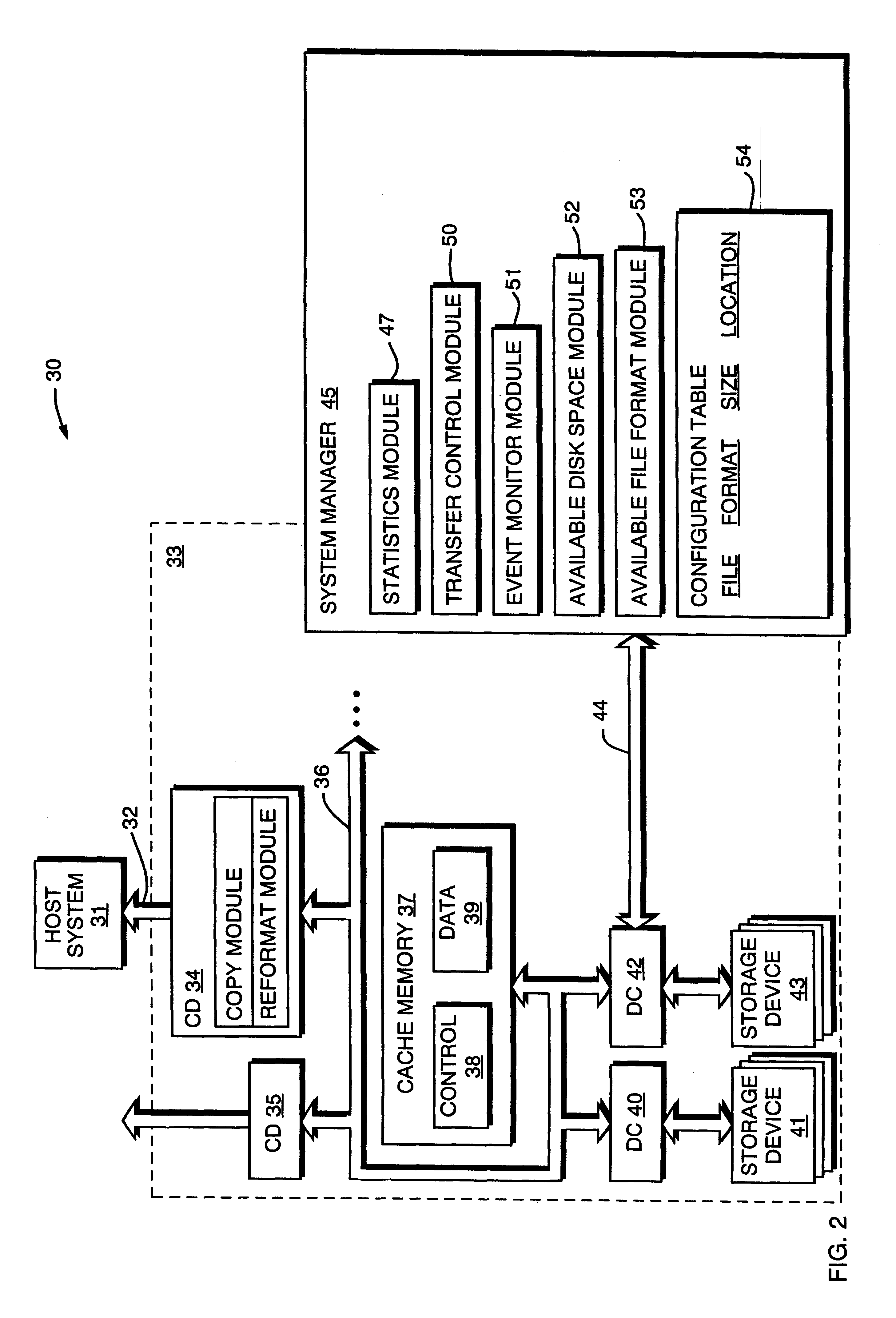

System and method for improving the performance of a disk storage device by reconfiguring a logical volume of data in response to the type of operations being performed

InactiveUS6122685AImprove magnetismImprove performanceMemory architecture accessing/allocationInput/output to record carriersMagnetic disksDisk storage

A method and apparatus for reconfiguring a file or logical volume stored on a magnetic disk storage system for optimal performance. The magnetic disk storage system contains a cache volume constituted as free storage. When appropriate, a file can be copied from its normal storage location to the cache volume with a different format to optimize the file for subsequent operations. After such operations are complete, the file can be transferred from the cache volume back to the normal storage location in the original format.

Owner:EMC IP HLDG CO LLC

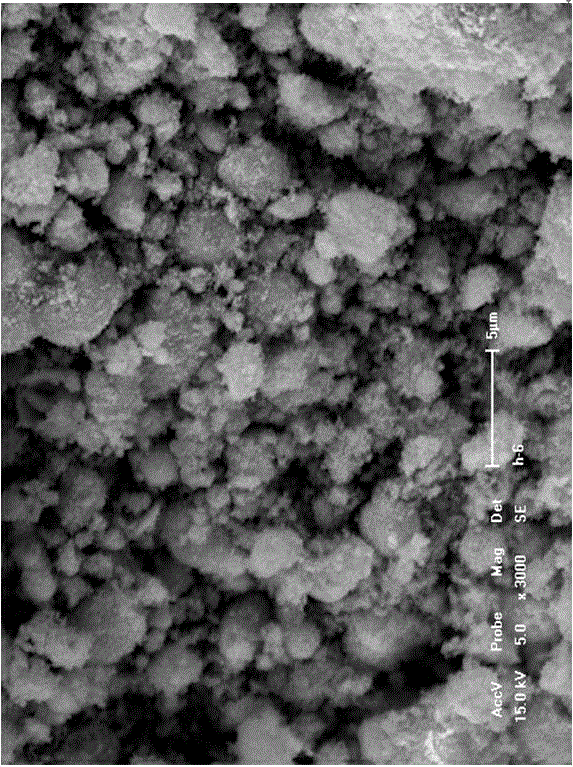

Preparation method of carbon-coated metallic nano-particles

InactiveCN102500295AEasy to operateHigh degree of graphitizationMicroballoon preparationMicrocapsule preparationTube furnaceCarbon coated

The invention discloses a preparation method of carbon-coated metallic nano-particles, which comprises the steps that: NaCl serves as dispersant and a carrier, and is fully mixed with a metal source and a solid carbon source; the mixed solution is dried under a vacuum condition, and mixture is obtained; the mixture is put into a tubular furnace and calcinated in the inertial / reduction atmosphere, and a calcinated product is obtained; and the calcinated product is washed and ground, and the carbon-coated metallic nano-particles are obtained. The method is safe, non-toxic, environmental-friendly and simple to operate, so that the grain sizes of the prepared carbon-coated nano-particles are controlled to be 0nm to 100nm, the graphitization degree of a carbon layer is high, the dispersion of the particles is good, and the yield is high. The carbon-coated metallic nano-particles which are prepared through the preparation method have better magnetism and larger specific surface areas, can be used for electronic and magnetic materials, and can be used for magnetic resonance imaging, targeted drug transportation and other fields through functionalization treatment and other steps.

Owner:TIANJIN UNIV

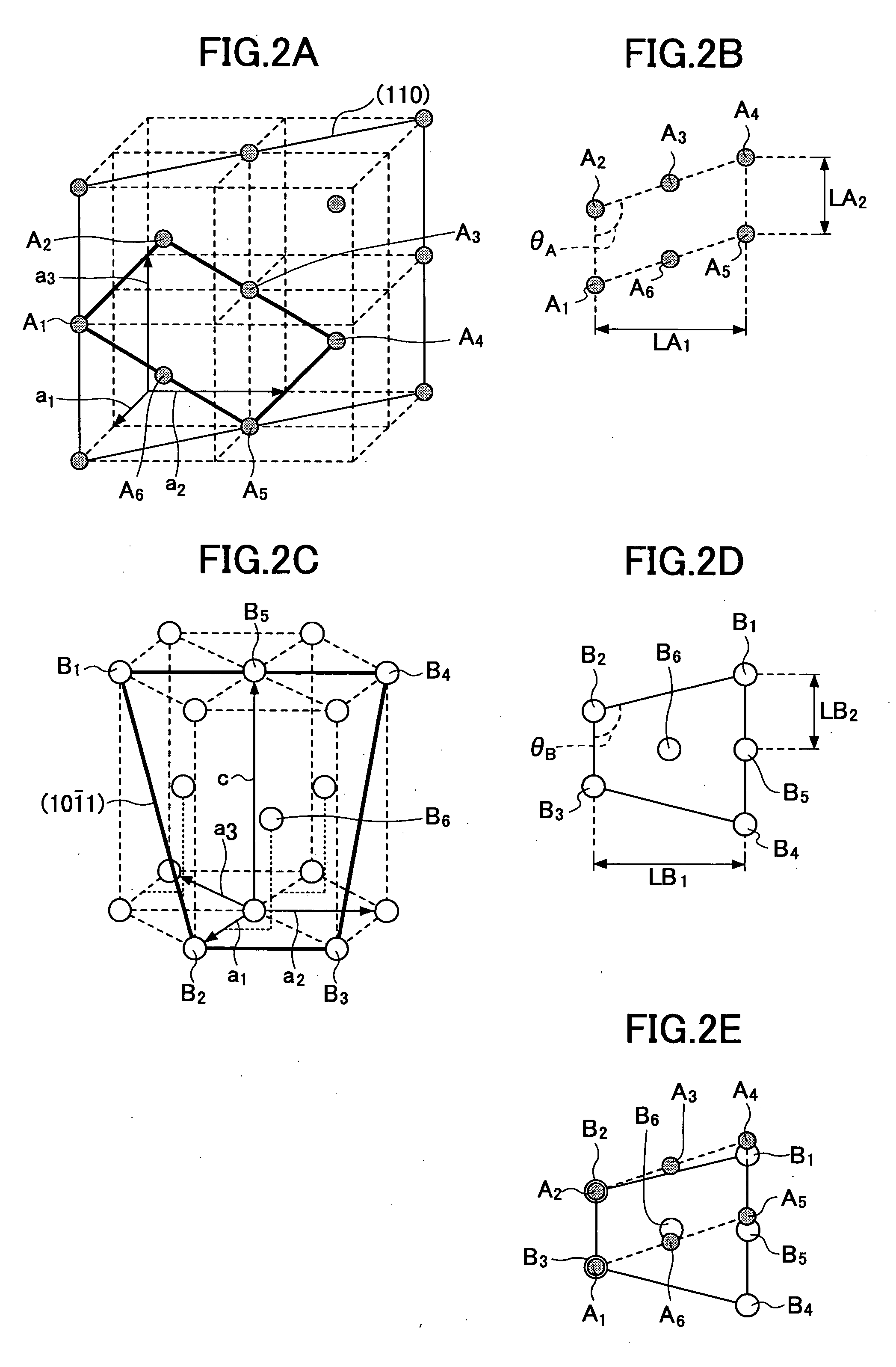

Magnetic recording medium, method of producing the same, and magnetic storage apparatus

InactiveUS20060177702A1Satisfactory recording performanceImprove thermal stabilityRecord information storageDisk carriersMagnetic storageCrystal structure

A magnetic recording medium is provided with an orientation control layer and an underlayer disposed above the substrate, an underlayer disposed above the orientation control layer, and a recording layer having an hcp crystal structure and disposed on a surface of the underlayer. A part of the recording layer is epitaxially grown on the surface of the underlayer and has c-axes that are inclined with respect to a surface of the substrate.

Owner:SHOWA DENKO KK

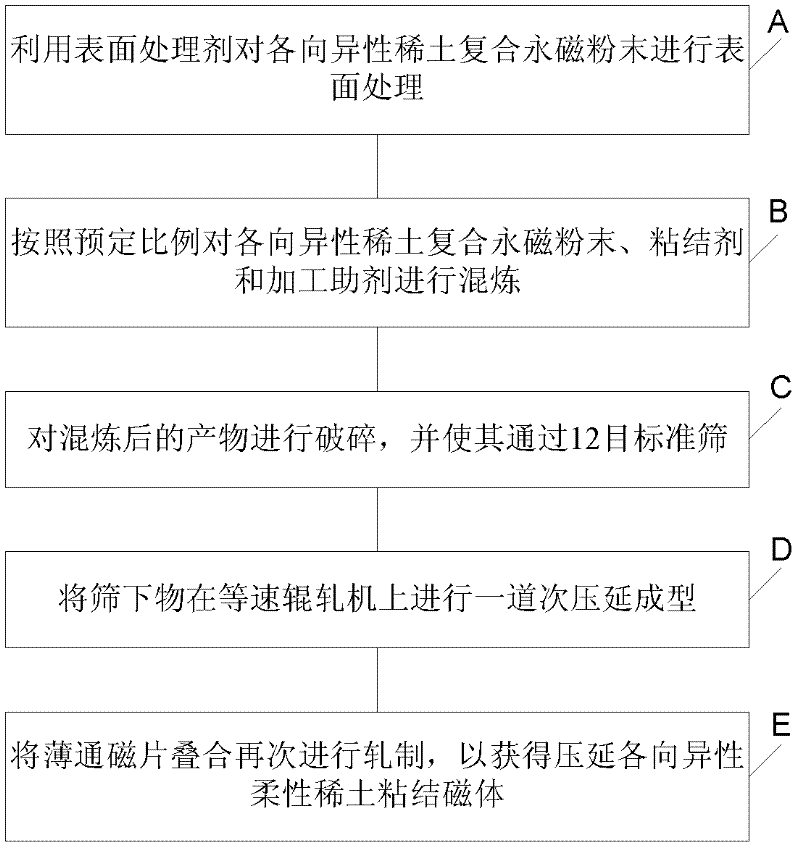

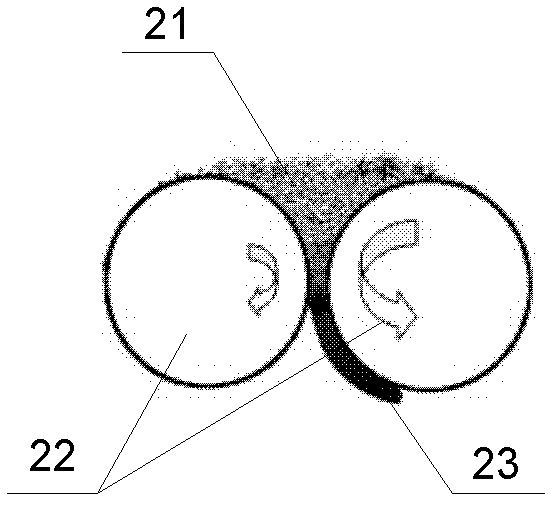

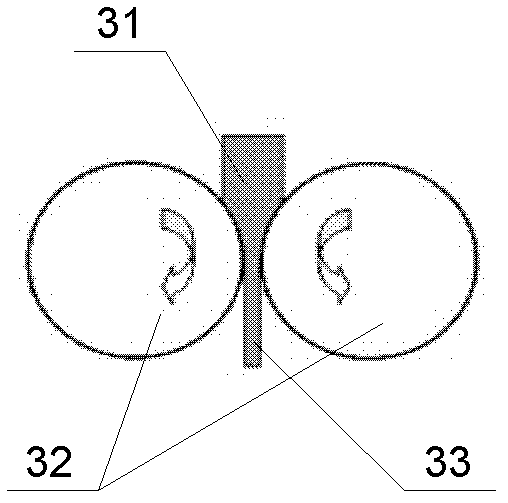

Preparation method of flexible anisotropy bonding rare earth permanent magnet material

InactiveCN101800106AAbundant resourcesReduce manufacturing costInorganic material magnetismInductances/transformers/magnets manufactureMagnetizationRare earth

The invention discloses a preparation method of flexible anisotropy bonding rare earth permanent magnet material, belonging to the field of magnetic materials. The material is prepared by combining the two-step approach accompanying temperature magnetic field orientation technology of which the calendaring process and the accompanying temperature magnetic field orientation process are separated. A certain quantity of anisotropy magnetic powder which is performed with surface treatment by the processing agent in advance, binder and processing agent are evenly mixed; the mixed material is calendered into flaky flexible bonding magnetic body by the calendaring technology; then, the flaky flexible bonding magnetic body is cut into parts which are heated at certain temperature under the condition of heat preservation for certain time, after that, the obtained product is put into an orientation magnetic field for accompanying temperature magnetic field orientation; and the direction of the orientation magnetic field is parallel to the plane normal direction of the flaky flexible bonding magnetic body. In the preparation technology, magnetic powder can overcome the constraint of a bonding system and rotates under the action of magnetic field force to ensure that the direction of easy magnetization of the magnetic powder generally points to the orientation direction, and the magnetic property of prepared flexible anisotropy bonding rare earth permanent magnet material can be greatly improved.

Owner:UNIV OF SCI & TECH BEIJING

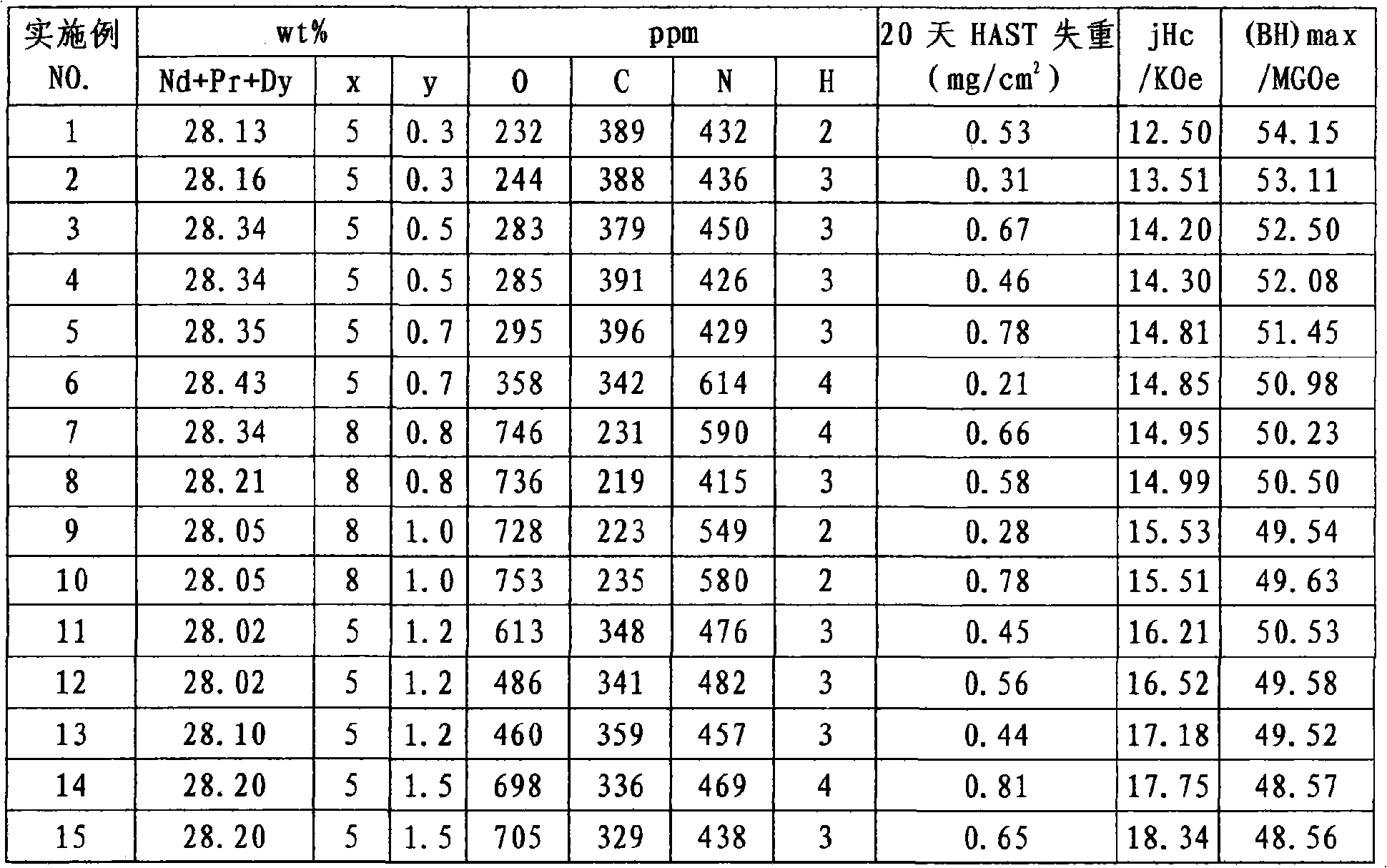

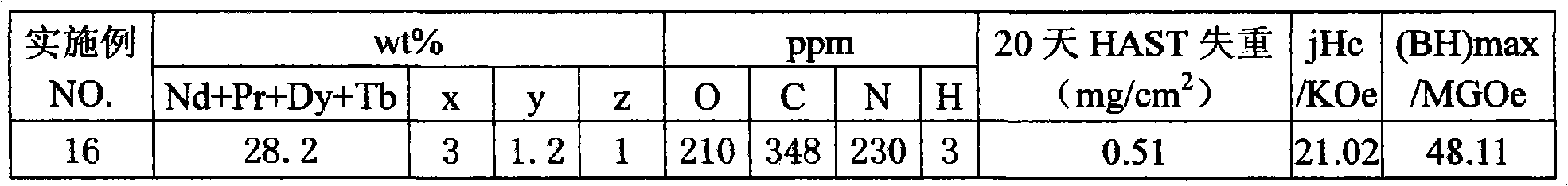

High ant-erosion and high performance R-Fe-B agglomeration magnetic body and its making method

InactiveCN101266856AImprove corrosion resistanceImprove magnetismInorganic material magnetismWeightlessnessVolumetric Mass Density

The invention discloses a magnet and a manufacturing method thereof, more particularly a sintering magnet with outstanding corrosion resistance and high performance R-(Fe, TM)-Cu-B-X system and a manufacturing method thereof; condition of the magnet is HAST experiment of 130 DEG C, 95% rRH, 2,7bar air pressure, magnet weightlessness in 20 days is less than 2mg / cm<2>, sum of [(BH)max]+[jHc] reaches 64-75, density of the magnet reaches 7.56-7.8g / cm<2>; in the process of manufacturing, an oxygen-free procedure technology using inertia gases or N<2> gas for protection controls contents of oxygen, carbon, nitrogen and hydrogen in the magnet, adjusts cooling speed of a continuous casting furnace with blanks, and controls thickness of an alloy sheet, granularity of powders and pressed compact density within a special range in order to obtain the sintering magnet with outstanding corrosion resistance and high performance R-Fe-B system, greatly saving the strategic metal Co and reducing the cost.

Owner:YANTAI ZHENGHAI MAGNETIC MATERIAL CO LTD

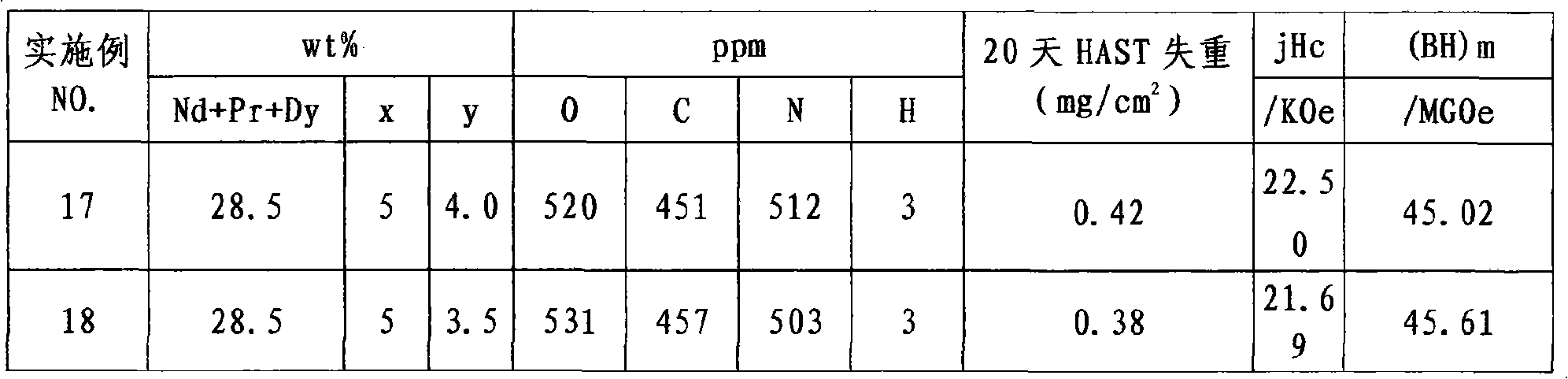

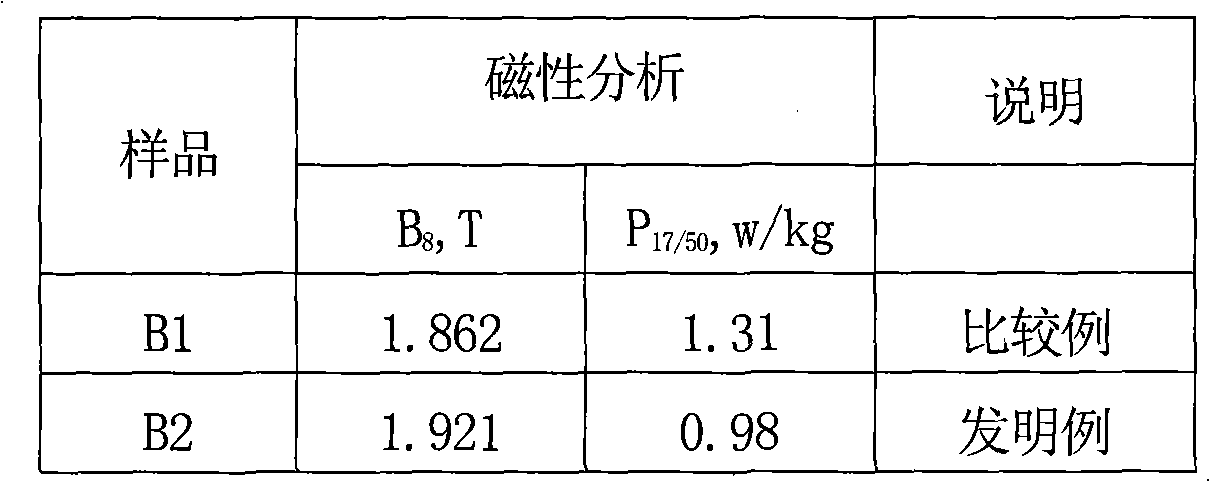

High magnetic induction grain-oriented silicon steel and production method thereof

ActiveCN101353760AReduce contentInhibition formationRoll mill control devicesMetal rolling arrangementsChemical compositionSilicon

The invention discloses a high magnetic induction oriented silicon steel and a production method thereof. The silicon steel comprises the following chemical composition: 0.055wt percent to 0.080wt percent of C, 2.9wt percent to 3.5wt percent of Si, 0.01wt percent to 0.02wt percent of Mn, 0.005wt percent to 0.010wt percent of Als, 0.0050wt percent to 0.0090wt percent of N, 0.25wt percent to 0.55wt percent of Sn, 0.010wt percent to 0.030wt percent of P, 0.10wt percent to 0.20wt percent of Cu, and the rest are Fe and unavoidable impurities. The production method comprises the following steps of: smelting, continuous casting, hot rolling, reeling, cold rolling, decarburizing annealing and high-temperature annealing. The production method effectively overcomes the shortcoming of poor producibility of the prior art and improves the production efficiency as well as the magnetism of the silicon steel.

Owner:BAOSHAN IRON & STEEL CO LTD

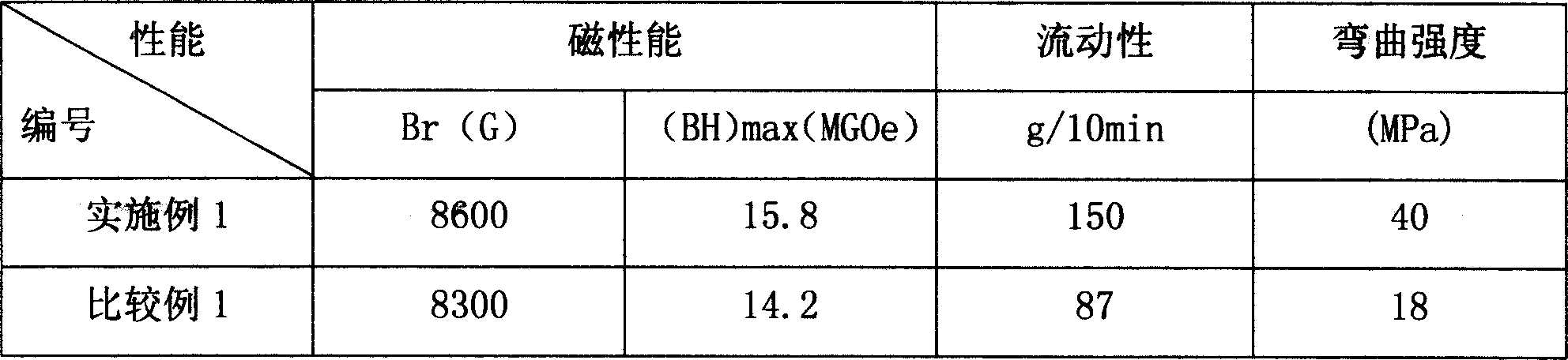

Formula of compoiste adhering magnet

ActiveCN1645525AImprove liquidityLow molding temperatureInorganic material magnetismMetallurgyAdditive ingredient

The invention is related to a permanent magnet consisting of more than two kinds of permanent magnetic powder, special binder, organic or inorganic lubricant, and other additives. The invention has following features: 1) the organic or inorganic lubricant makes the ingredient have good fluidity, low forming temperature, and high loading level of magnetic powder; 2) the production cost is low and the application of magnetic property is wide.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Method for preparing rare-earth iron series biphase nanocrystalline composite permanent-magnet material

InactiveCN1737955AHigh densityImprove magnetismInorganic material magnetismRare earthInduction furnace

The invention belongs to the field of magnetic material. At present much of the permanent magnet material is thin belt or powder, and since the custom sintering process for preparing block material will make the crystal grow, the magnetic property drops significantly. The steps of said invention comprises: the alloy whose component is RxFeyBz, in which R stands for rare-earth Nd or Pr element and the content of x is 4-10, y is 78-88, z is 6-18, is smelted for mother alloy in induction furnace in vacuum; Then preparing the quenched alloy in amorphous, nanometer crystalline state or amorphous-nanometer mixed state by smelting quick-quench method; the linear speed of smelting quick-quench is arranged between 10-50 m / s; under the protection of inertance gas, abrading the alloy into powder whose coarseness is lower than 80 items; encasing the powder into module to precompression and shaping, while range of pressure is 10-1000MPa; carrying the process of discharging plasma sintering, while the sintering temperature is 550Deg C.-700Deg C., the pressure is 30-1000MPa, the elevated temperature speed is 50-500Deg C. / min, the time of heat preservation is 0-10 min, the elevated temperature speed is 50-200Deg C. / min, Said invention can realize high magnetic property material with high degree of compactness, whose crystal grain is smaller than 100 nanometers, and it can be used in high temperature.

Owner:BEIJING UNIV OF TECH

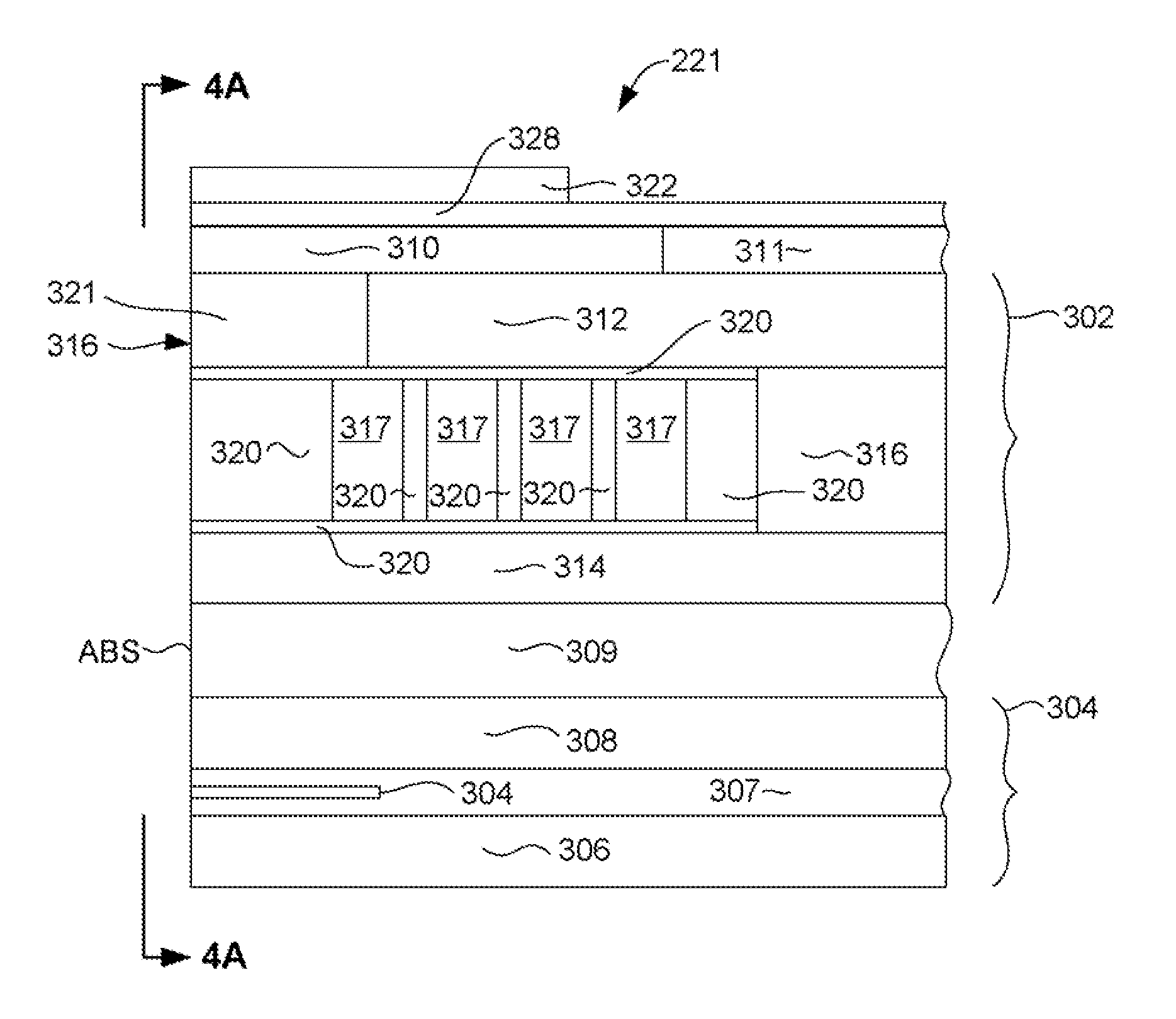

Perpendicular magnetic write head having a conformal, wrap-around, trailing magnetic shield for reduced adjacent track interference

InactiveUS20070211384A1Improve magnetic performanceImprove magnetismRecord information storageHeads for perpendicular magnetisationsAir bearing surfaceEngineering

A perpendicular magnetic write head having a conformal wrap around trailing shield. The write head includes a write pole that can be configured with a trapezoidal shape as viewed from the Air Bearing Surface (ABS) and which includes a wrap around trailing magnetic shield. The magnetic shield has a trailing portion that is separated from the leading edge of the writ pole by a non-magnetic trailing gap, and has side shield portions that are separated from first and second side portions of the write pole by first and second non-magnetic side gaps. The magnetic shield can be configured with notches at either side of the trailing portion of magnetic shield. These notches can extend in the trailing direction by a distance that is preferably ¼ to 1 times the trailing gap thickness. The width of the straight, trailing portion of the shield is preferable ½ to 1 times of the main pole width.

Owner:WESTERN DIGITAL TECH INC

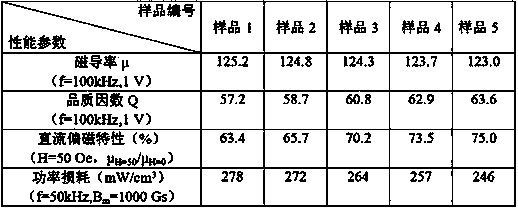

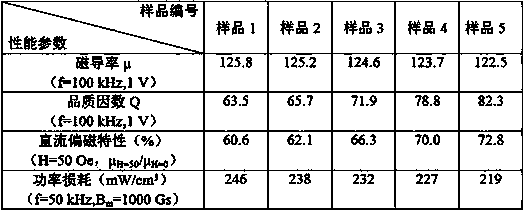

Preparing method of metal magnetic powder core

InactiveCN104036902AImprove processing performanceShorten milling timeInorganic material magnetismAlloy elementQuenching

The invention discloses a preparing method of a metal magnetic powder core. The preparing method includes the following steps that (1) master alloy is melt through a vacuum induction furnace, and an alloy thin belt is obtained through a quick quenching device; (2) ball milling is conducted on the thin belt; (3) annealing is conducted on powder; (4) particle size distribution is conducted on the annealed powder; (5) passivant is added into the distributed powder to conduct passivating on the powder, and then a binding agent and an insulating agent are added into the powder to conduct insulating bonding and wrapping on the powder; (6) a lubricating release agent is then added, the mixture is mixed, and compression moulding is conducted; (7) annealing is conducted on a sample obtained through compression moulding, and the sample is cooled along with the furnace, and spraying and coating are conducted to obtain the target product. According to the preparing method, the master alloy contains an appropriate number of alloy elements, so that the alloy processing performance is improved; the alloy powder and an insulating medium are mixed and pressed to be the magnetic powder core, so that eddy-current loss under a high frequency can be greatly reduced; meanwhile, the problem that alloy materials are limited in use due to single shapes is solved through shape diversity of the magnetic powder core.

Owner:ZHEJIANG MINGHE STEEL PIPE CO LTD +1

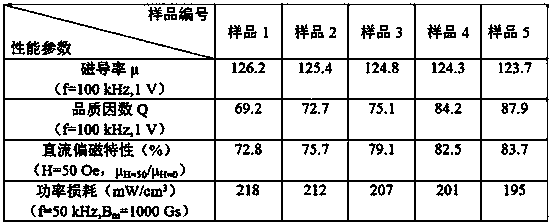

Fe-Si-Al magnetic core preparation method and inorganic composite insulation coating material for magnetic core

ActiveCN105304308AEasy to processGood temperature characteristicsInductances/transformers/magnets manufactureMagnetic materialsHeat treatingSurface coating

The invention discloses a Fe-Si-Al magnetic core preparation method and an inorganic composite insulation coating material for a magnetic core, belonging to the field of Fe-Si-Al magnetic material and used for solving the high eddy-current loss problem of existing magnetic cores and such problems caused by the fact that the existing magnetic cores usually use organic coating materials as stress is difficult to eliminate in a forming process, the insulation property of the material is poor, and the volatilization quantity of organics is large in heating processes such as heat treatment. The Fe-Si-Al magnetic core preparation method disclosed by the invention comprises the following steps: cast ingot smelting, powder making, surface phosphorization, insulation coating, compression moulding, annealing treatment and surface coating; the prepared Fe-Si-Al magnetic core has the advantages of low eddy-current loss, small magnetic conductivity temperature coefficient, good temperature stability, high direct current superposition characteristic, high saturation flux density and good high-frequency characteristic and meets the requirements for high frequency, small size, high power and electromagnetic interference resistance of electronic devices.

Owner:临沂银凤新材料技术服务有限公司

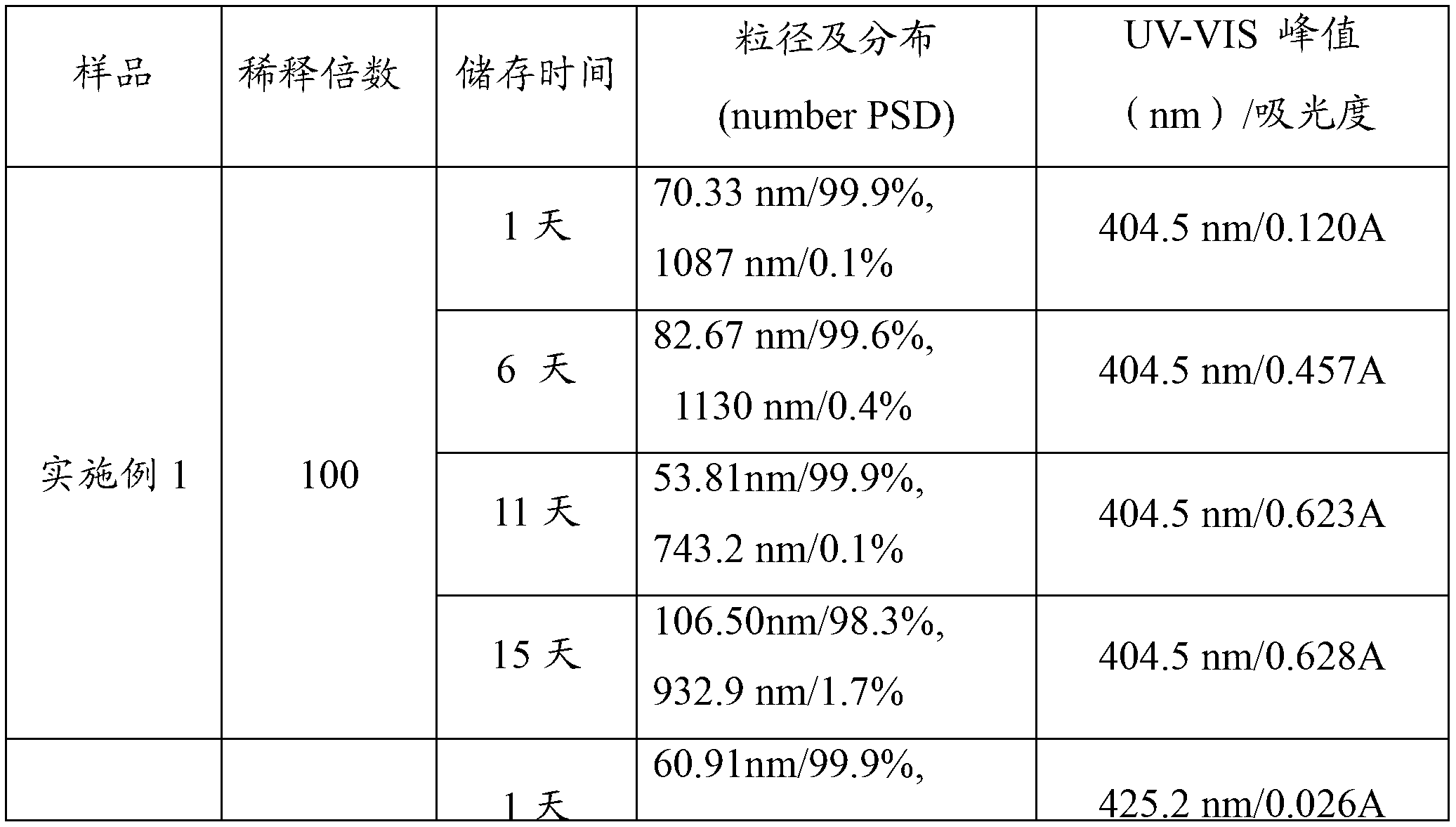

Nano-silver dispersion liquid and preparation method of nano-silver dispersion liquid as well as preparation method of nano-silver antibacterial coating

ActiveCN103212720AControl particle sizeControl shapeLiquid/solution decomposition chemical coatingChemical LinkageRoom temperature

The embodiment of the invention discloses a preparation method of nano-silver dispersion liquid. The preparation method comprises the following steps that thickening agents and dispersing agents are added into pure water or deionized water, then, soluble silver salt is dissolved in solution, and the silver salt solution is obtained; and under the stirring effect, silver complexing agents are firstly added into the silver salt solution, then, reducing agents are added, or silver complexing reduction agents are directly added, the reaction is carried out for at least 12 hours under the condition of room temperature to 90 DEG C, silver ions in the silver salt solution are reduced into metal silver, the nano-silver dispersion liquid is obtained, the silver complexing agents and the silver complexing reduction agents can form the chemical bonding with the nano-silver particle surface, and in addition, functional groups with the cross linking effect are reserved. The invention correspondingly provides the nano-silver dispersion liquid prepared by the method. The process of the preparation method is simple, the stability of the prepared nano-silver dispersion liquid is good, nano-silver particles are uniform, the application is convenient, and the bonding force of the nano-silver and substrates is high. In addition, the invention also provides a preparation method of a nano-silver antibacterial coating.

Owner:ENVIROCHEM TECH

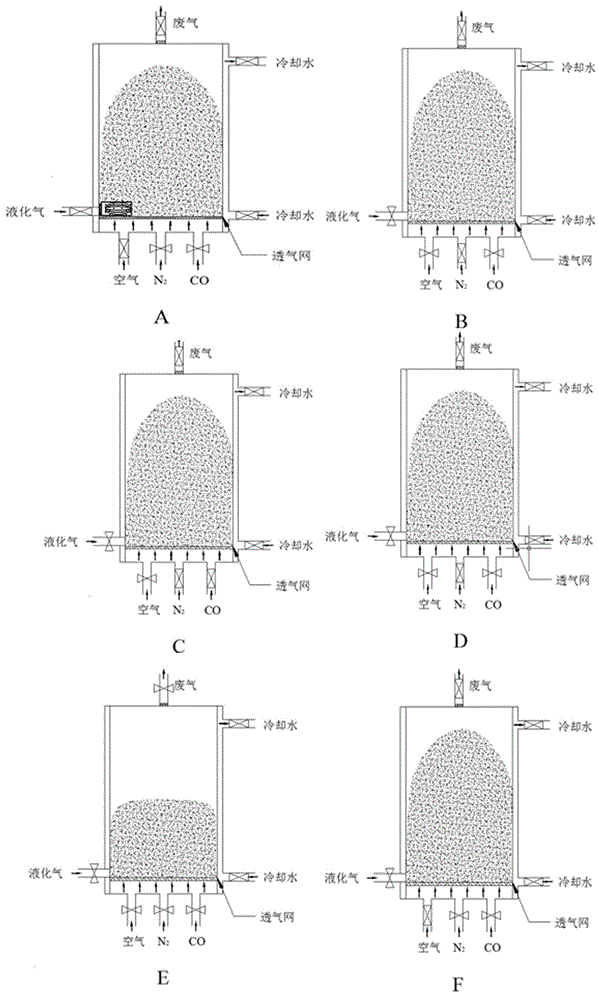

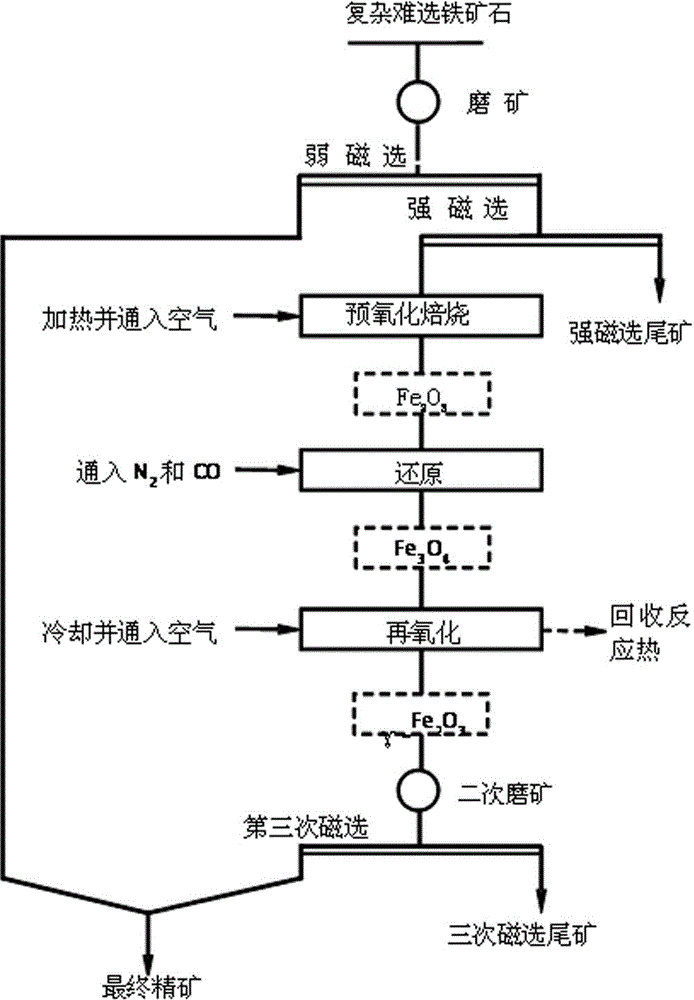

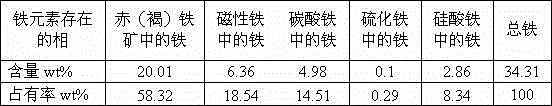

Preenrichment-three segment suspension roasting-magnetic separation treatment method of complex refractory iron ores

The invention discloses a preenrichment-three segment suspension roasting-magnetic separation treatment method of complex refractory iron ores, and belongs to the technical field of mineral processing. The method comprises the following steps: 1, levigating the complex refractory iron ores, carrying out weak magnetic separation, and carrying out strong magnetic separation on mine tailings; 2, putting concentrate obtained after strong magnetic separation in a suspension roasting furnace, and heating to 450-800DEG C in a suspension state in order to carry out pre-oxidation roasting; 3, introducing nitrogen to displace air, and introducing a reducing gas to carry out reduction in a suspension loose state; 4, introducing air when the temperature decreases to 250-400DEG C in order to oxidize, taking out the obtained material when the temperature decreases to below 100DEG C, and carrying out ore milling; and 5, carrying out third segment magnetic separation, and mixing concentrate obtained after three segment magnetic separation with concrete obtained after the weak magnetic separation to obtain finial concentrate. The method has the advantages of simple process, improvement of the recovery rate of the complex refractory iron ores, strong adaptability, safe and reliable process, uniform and stable product quality, energy saving and consumption reduction.

Owner:上海逢石科技有限公司

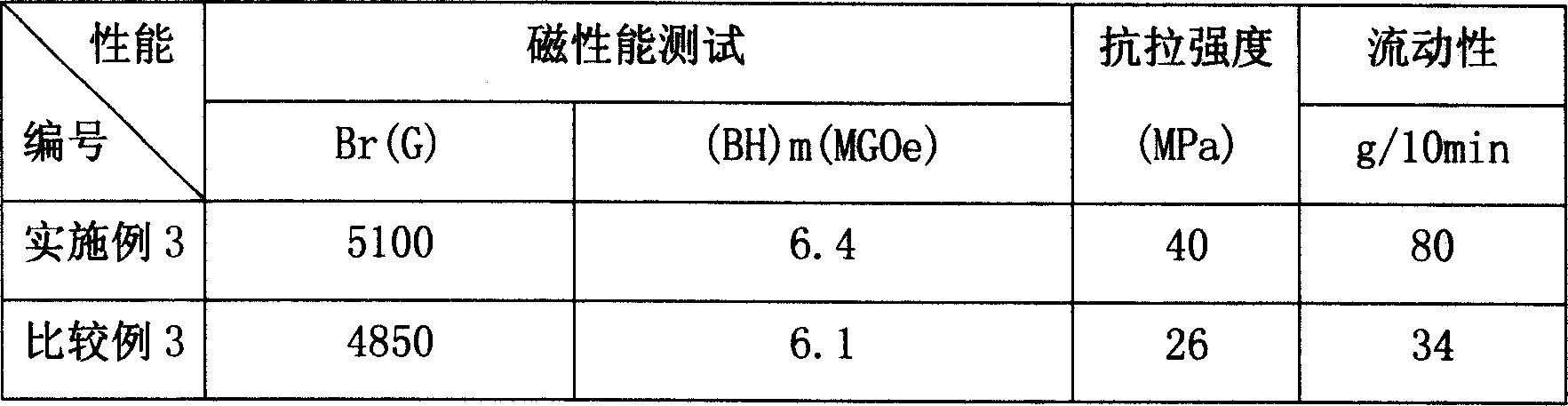

Flexible rare earth bonded magnet with roll anisotropy and manufacturing method thereof

ActiveCN102360653AGood flexibilityImprove magnetic propertiesPermanent magnetsInorganic material magnetismSurface finishingProcessing aid

The invention discloses a flexible rare earth bonded magnet with roll anisotropy and a manufacturing method thereof. The magnet comprises the following components in part by mass: 94 to 97 parts of anisotropic rare earth composite permanent magnet powder, 2.8 to 5.5 parts of binder and 0.2 to 0.5 part of processing aid, wherein the anisotropic rare earth composite permanent magnet powder comprises anisotropic ferrite permanent magnet powder, anisotropic samarium-iron-nitrogen permanent magnet powder, anisotropic neodymium-iron-nitrogen permanent magnet powder and neodymium-iron-boron permanent magnet powder with roll anisotropy. The anisotropic rare earth composite permanent magnet powder is subjected to surface treatment by using a surface treatment agent. A permanent magnet product with the thickness of 0.35 to 8mm and the maximum width of 1,000mm can be manufactured by processing the components by a calendering method; the disadvantages of various conventional permanent magnet materials are overcome; and a magnetic material which has a thin wall, large length-diameter ratio, high flexibility and higher magnetic performance can be manufactured under the condition that an oriented magnetic field is not required to be applied.

Owner:BEIKUANG MAGNETS FUYANG CO LTD

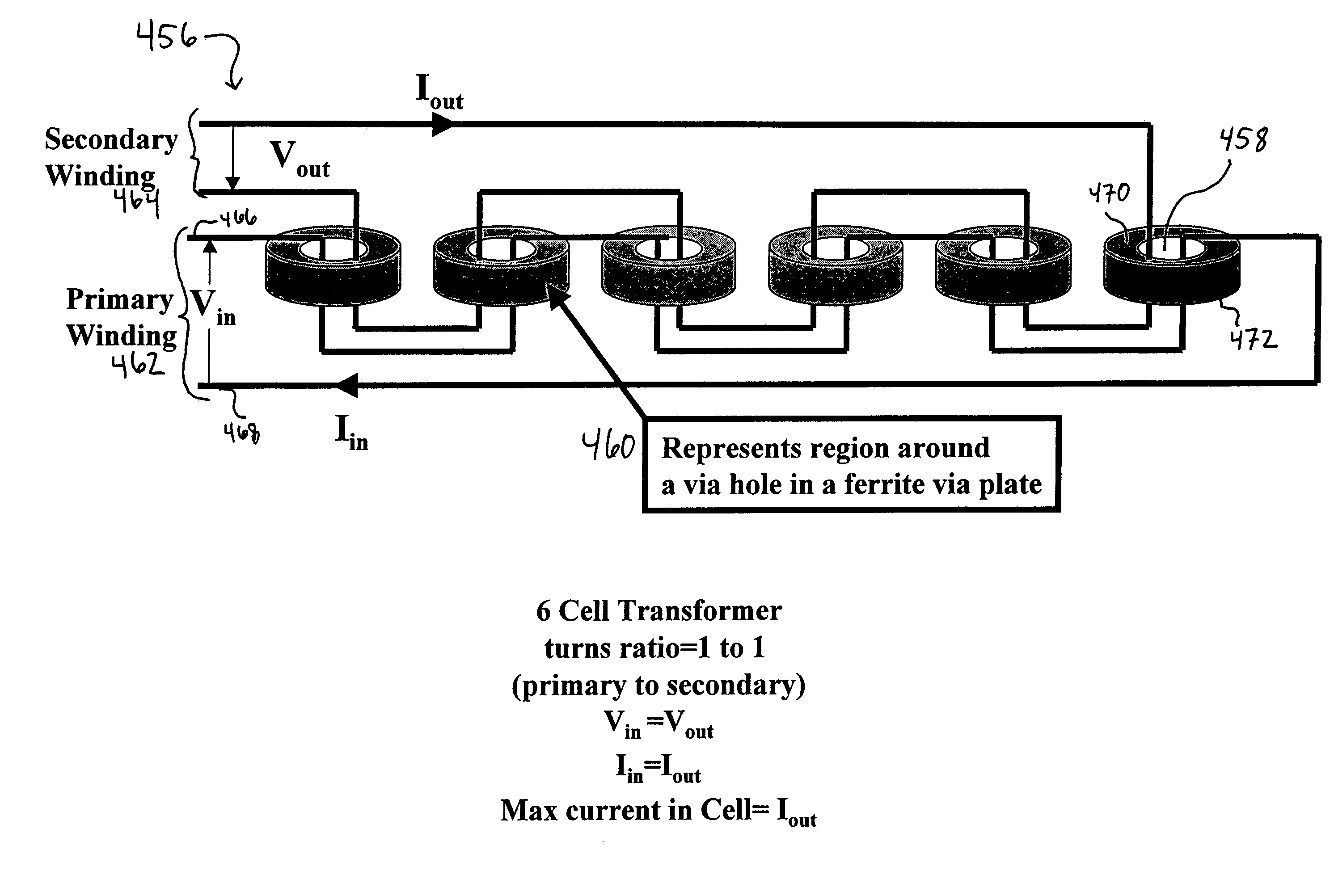

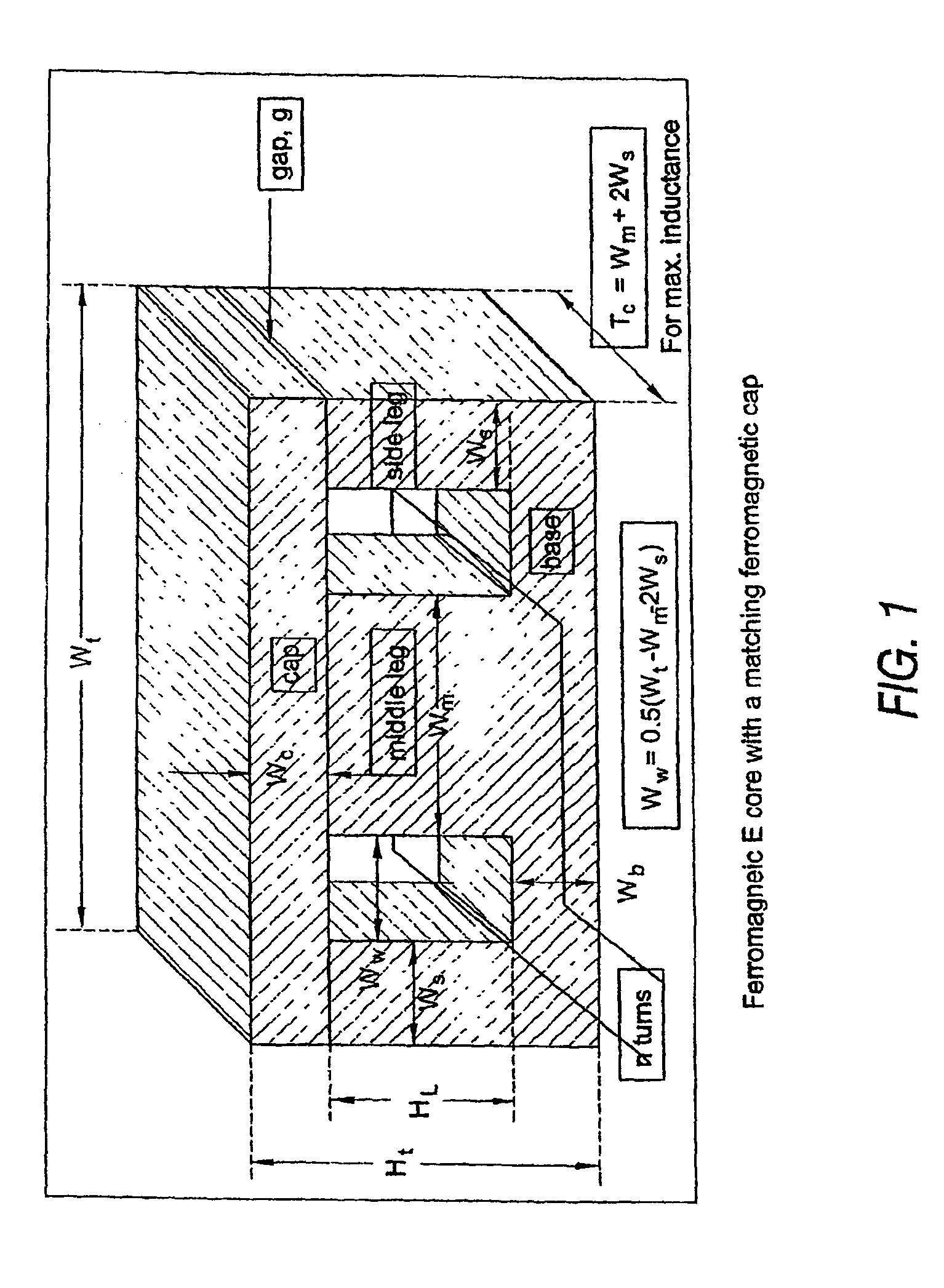

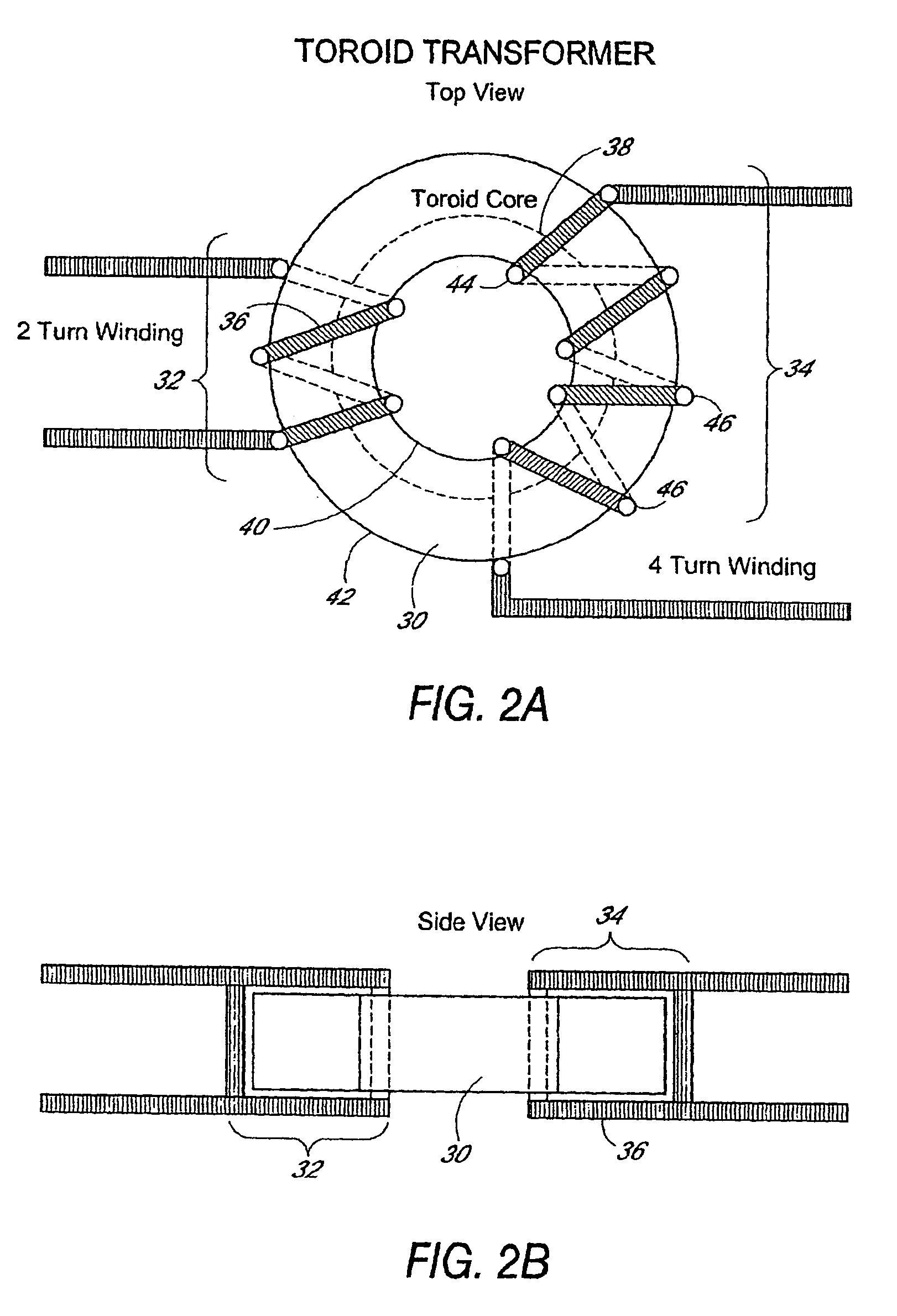

Electronic transformer/inductor devices and methods for making same

InactiveUS7135952B2Improve cooling effectSimplifies electrical connectionsTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresCombustionElectrical conductor

The present invention relates to transformer 1 inductor devices and to the methods of construction for inductive components such as inductors, chokes, and transformers. Plural via holes are formed through a ferromagnetic substrate. Primary and secondary conductors are placed through common vias to form a plurality of cell transformers have a 1:1 turns ratio. Circuits connect these primary and secondary winding in parallel and serial combustion to provide a transformer having the desired turns ratio.

Owner:MULTI FINELINE ELECTRONIX INC

System for improving the performance of a disk storage device by reconfiguring a logical volume of data in response to the type of operations being performed

InactiveUS6272571B1Improve magnetismImprove performanceMemory architecture accessing/allocationInput/output to record carriersMagnetic disksDisk storage

A method and apparatus for reconfiguring a file or logical volume stored on a magnetic disk storage system for optimal performance. The magnetic disk storage system contains a cache volume constituted as free storage. When appropriate, a file can be copied from its normal storage location to the cache volume with a different format to optimize the file for subsequent operations. After such operations are complete, the file can be transferred from the cache volume back to the normal storage location in the original format.

Owner:EMC CORP

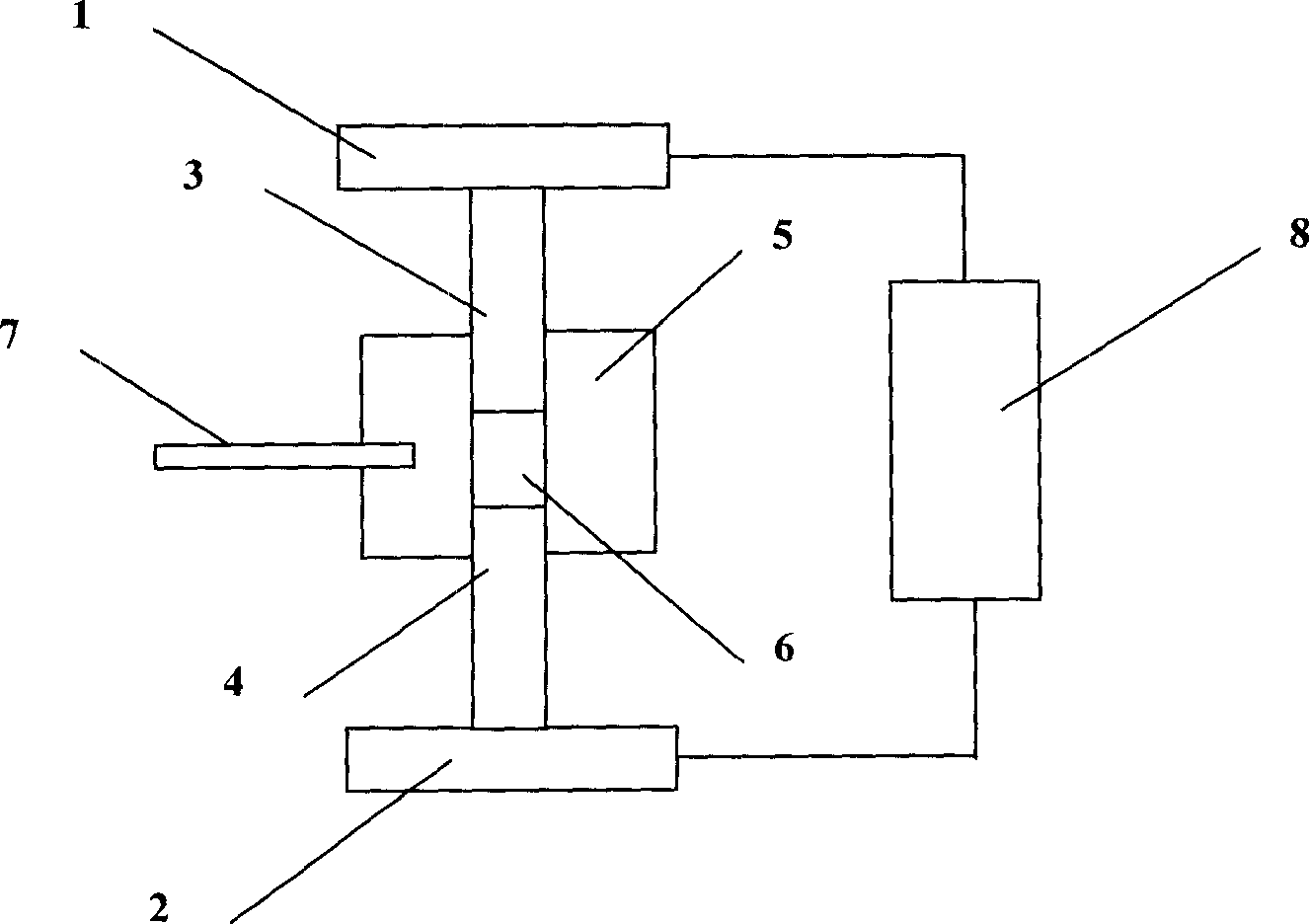

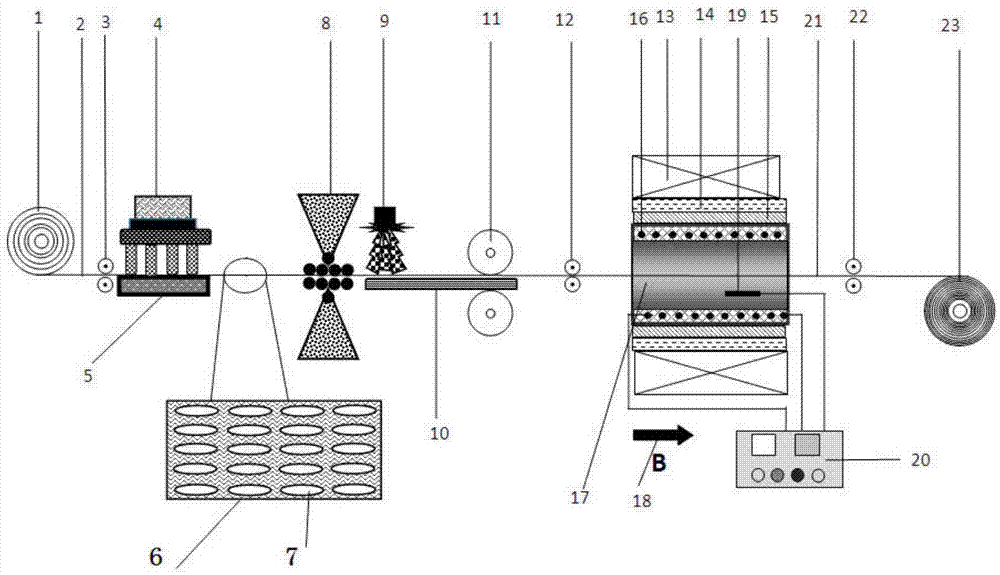

Method and device for preparing high-silicon silicon steel thin strip under magnetic field through powder diffusion method

PendingCN107282928AAvoid processing difficultiesEnhanced diffusionContinuous operationNear net shape

The invention discloses a method and a device for preparing a high-silicon silicon steel thin strip under a magnetic field through a powder diffusion method. According to the method, holes are formed in a low-silicon steel strip to be machined, then surface reinforcing treatment is carried out on the low-silicon steel strip to be machined, the holes are filled with an iron-silicon alloy powder and rolling forming is carried out on the powder, and then heat treatment is carried out on the powder in a magnetic field environment to obtain the high-silicon silicon steel thin strip with certain orientation, a silicon content of 6.5wt%Si and excellent magnetic performance. According to the method and the device, long-size and continuous operation can be realized; and moreover, a near-net-shape thin strip can be prepared, and therefore, a preparation cost can be remarkably lowered.

Owner:GUIZHOU INST OF TECH

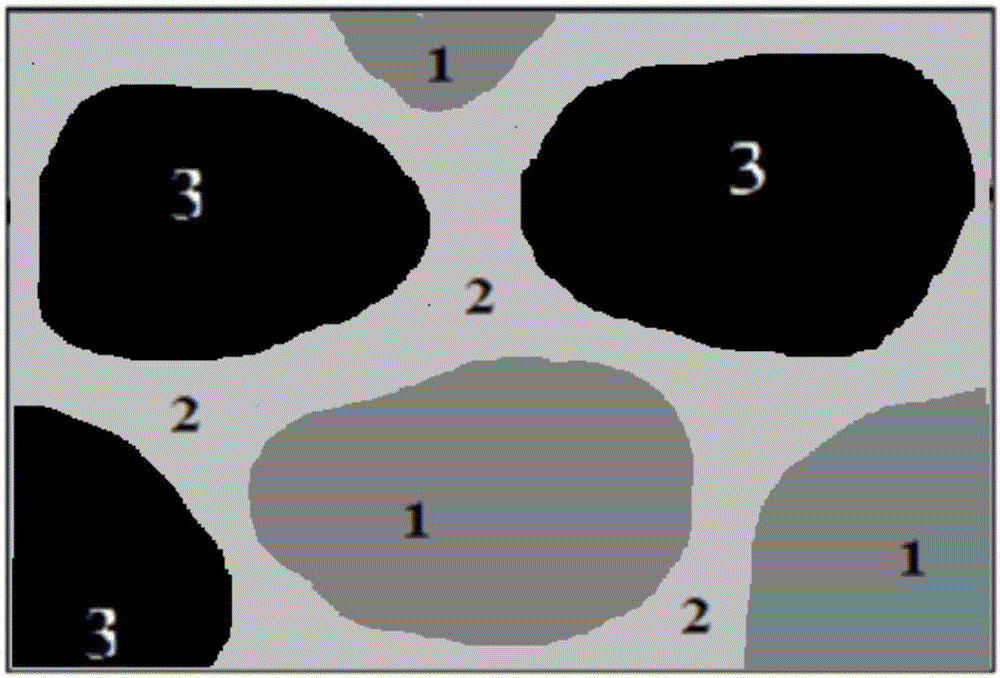

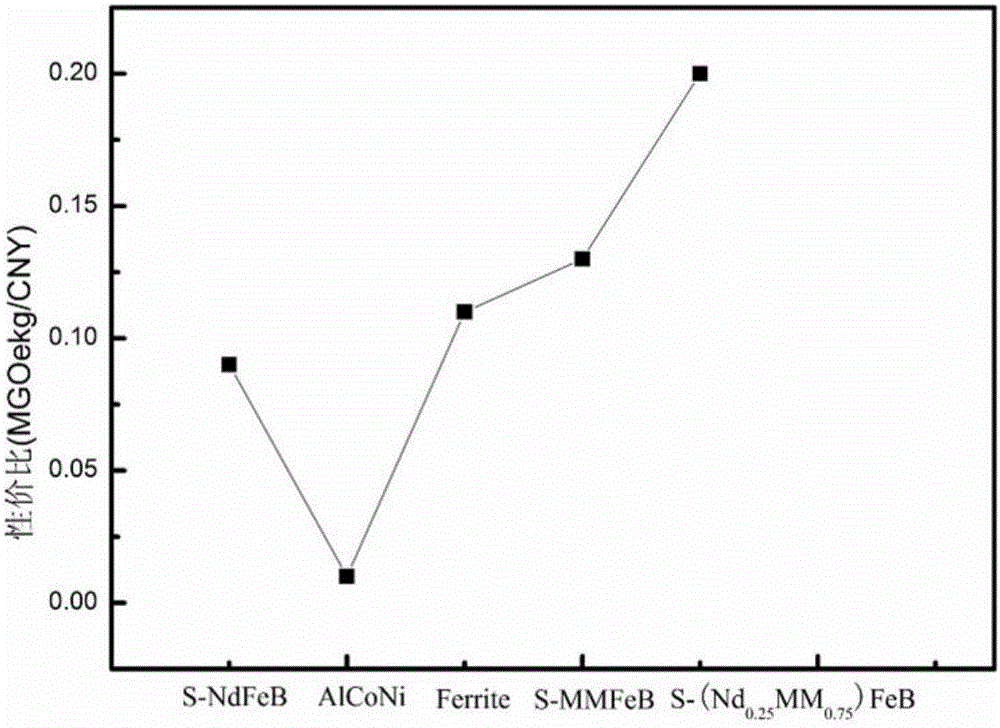

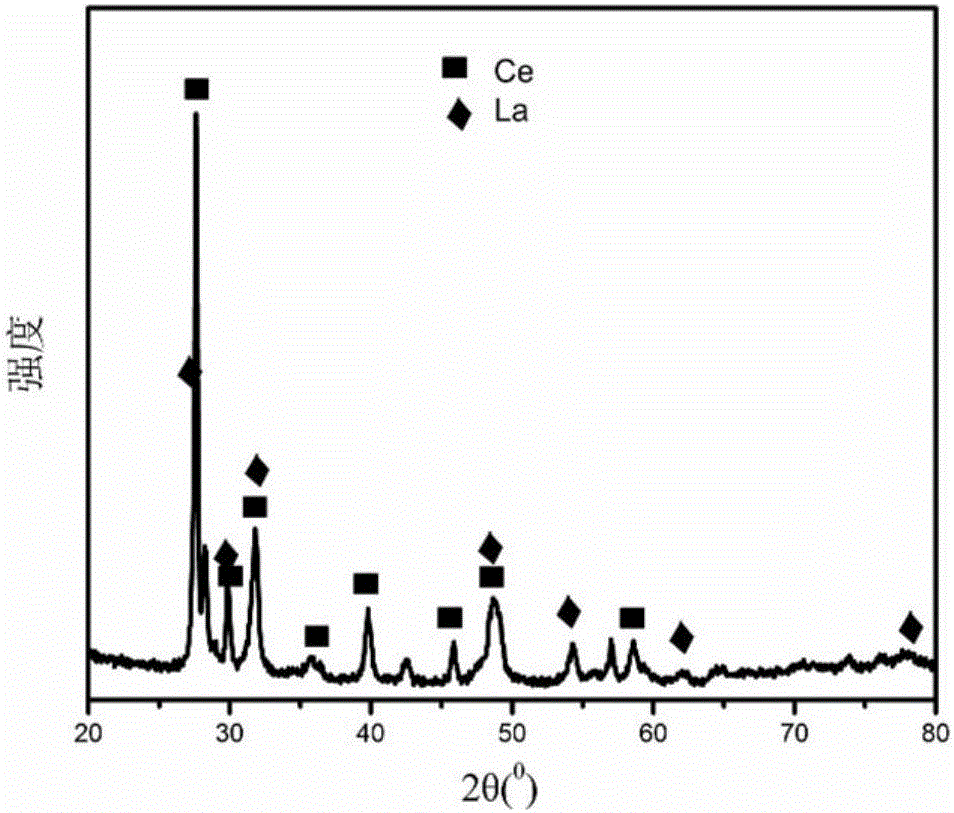

Double-hard magnetic main phase mixed rare-earth permanent magnet and preparation method thereof

ActiveCN106128674ANo wasteNo pollution in the processInductances/transformers/magnets manufactureMagnetic materialsChemical compositionCerium

The invention relates to a double-hard magnetic main phase mixed rare-earth permanent magnet and a preparation method thereof. The permanent magnet comprises double hard magnetic main phases and a rear-earth-rich phase, wherein the double hard magnetic main phases are MM<2>Fe<14>B and (PrNd)<2>Fe<14>B respectively; the permanent magnet is prepared from the following chemical component in percentage by mass: [MM<x1>(PrNd)<1-x1>]<x>Fe<100-x-y-z>B<y>TM<z>; x is smaller than or equal to 31 and greater than or equal to 27; x1 is smaller than or equal to 1 and greater than or equal to 0; y is smaller than or equal to 1 and greater than or equal to 0.9; z is smaller than or equal to 1.5 and greater than 0; TM is a composition of more of the elements Al, Cu, Co, Nb, Ga, Tb and Zr; and MM is a mixed rare-earth alloy which is directly separated from raw ore and contains La, Ce, Pr and Nd. The anisotropic sintered mixed rare-earth permanent magnet with high cost performance within a range of 10-48MGOe can be prepared by adjusting the content of PrNd. A basic rare-earth raw material used by the permanent magnet is cheap mixed rare earth, so that a separation and purification technology for the rare earth can be reduced, efficient utilization of lanthanum-cerium rare earth is achieved and the double-hard magnetic main phase mixed rare-earth permanent magnet meets the requirements of low carbon economy on green production technology innovation of a rare-earth permanent magnet product.

Owner:CENT IRON & STEEL RES INST

Nano toughening NdFeB magnetic material and preparation method thereof

InactiveCN102751064AEasy to processImprove coercive forceInorganic material magnetismRare-earth elementGrain boundary

The invention discloses a nano toughening NdFeB magnetic material and a preparation method of the nano toughening NdFeB magnetic material. The main mechanism is that a nano composite crystal boundary phase is formed on an NdFeB main phase crystal boundary, an H-grade rare earth permanent magnetic material with high coercive force M is prepared without doping any heavy rare earth, and then, a SH-grade rare earth permanent magnetic material is prepared by adding a little heavy rare earth. The nano material is prepared by a plasma arc method, has a grain size of 5-80nm and mainly contains metallic elements, such as Al, Cu, Cr, Co, Fe, Zn and the like, and all kinds of rare earth elements. A NdFeB main phase having a rare earth content of Pr-Nd is prepared by a SC-HD process; after smelting and hydrogen breaking, the product grain size is milled to be about 3.5 microns by an air-current mill, and in the argon protection atmosphere, a nano additive is added in a manner of jetting composite, so the nano additive is uniformly attached to the NdFeB main phase. In the sintering process, the nano powder and the main phase form the crystal boundary, the coercive force of NdFeB is greatly increased, and since the product has uniform crystal components, the machining property is also elevated well, the NdFeB magnetic material can be applied to the wider field. At the same time, the technical process is simple, low-cost and suitable for the batch production.

Owner:辽宁恒德磁业有限公司

Non-oriented high-silicon electrical steel ribbon and its making method

InactiveCN103060701ASolve the characteristics of poor processing performanceImprove magnetismElectrical steelUltimate tensile strength

The invention relates to a non-oriented high-silicon electrical steel ribbon and its making method, and belongs to the fields of the metallurgical technology and the material science. The chemical components of the ribbon comprise 4.5-7.0wt% of Si, 2.0-5.0wt% of Cr, 0.06-1.0wt% of Al, 0.3-0.8wt% of Mn, 0.005wt% or less of N, 0.004wt% or less of S, 0.02wt% or less of P, 0.003wt% or less of O, 0.005wt% or less of C, and the balance Fe, and the thickness of the ribbon is 0.35-0.5mm. The making method comprises the following steps: smelting non-oriented high-silicon steel in a vacuum smelting furnace; carrying out double-roller ribbon roll-casting at a casting temperature of 1420-1460DEG C to the ribbon thickness of 1.0-1.5mm; carrying out hot rolling of the ribbon at 800-1100DEG C to the hot rolled ribbon thickness of 0.8-1.0mm; pickling, and preheating the ribbon, and carrying out warm rolling at 400-700DEG C; and annealing. The addition of the Cr element in the high-silicon electrical steel ribbon obviously improves the processing performance of the high-silicon steel ribbon, the iron loss value is same to the iron losses of present high-silicon steel products, and the magnetic induction intensity is above 0.03T higher than that of the present products. The making method has the advantages of simple technology, low energy consumption, high yield, and excellent product magnetic property.

Owner:NORTHEASTERN UNIV

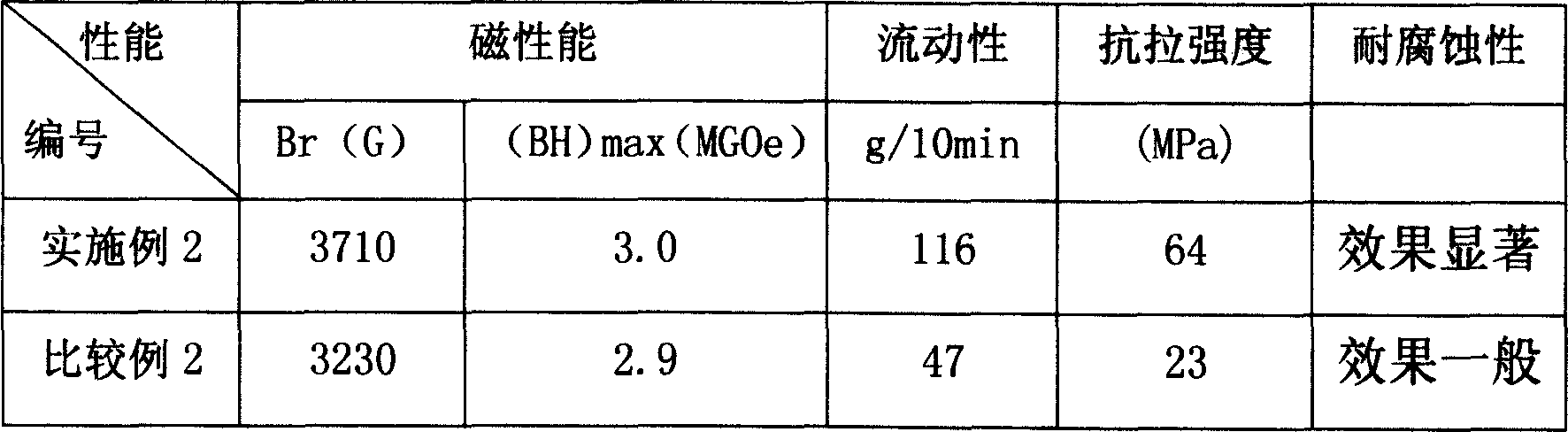

Ferrite injection molding granule and preparation method thereof

ActiveCN102408230AImprove liquidityImprove magnetismInorganic material magnetismPelletizingPolyamide

The invention belongs to the field of magnetic material and specifically relates to a ferrite injection molding granule, which contains the following constituents in percentage by weight: 85-92% of ferrite magnetic powder, 0.3-0.5% of coupling agent, 7-14% of bonder and 0.1-0.5% of lubricant, wherein the bonder is mixture of PPS (polyphenylene sulfite) and PA (polyamide). The invention also provides a preparation method of the ferrite injection molding granule, which comprises a step of modifying magnetic powder surface, a step of mixing glue with magnetic powder, a step of lubricating and a step of mixing and pelletizing, wherein the step of lubricating is an individual step, namely, lubricant is added after the glue mixing process is finished and the magnetic powder has formed uniform mixture along with the bonder. The ferrite granule prepared by the invention has the characteristics of ferrite / PPS granule and ferrite / PA granule, and has good high temperature resistance and better mechanical property.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

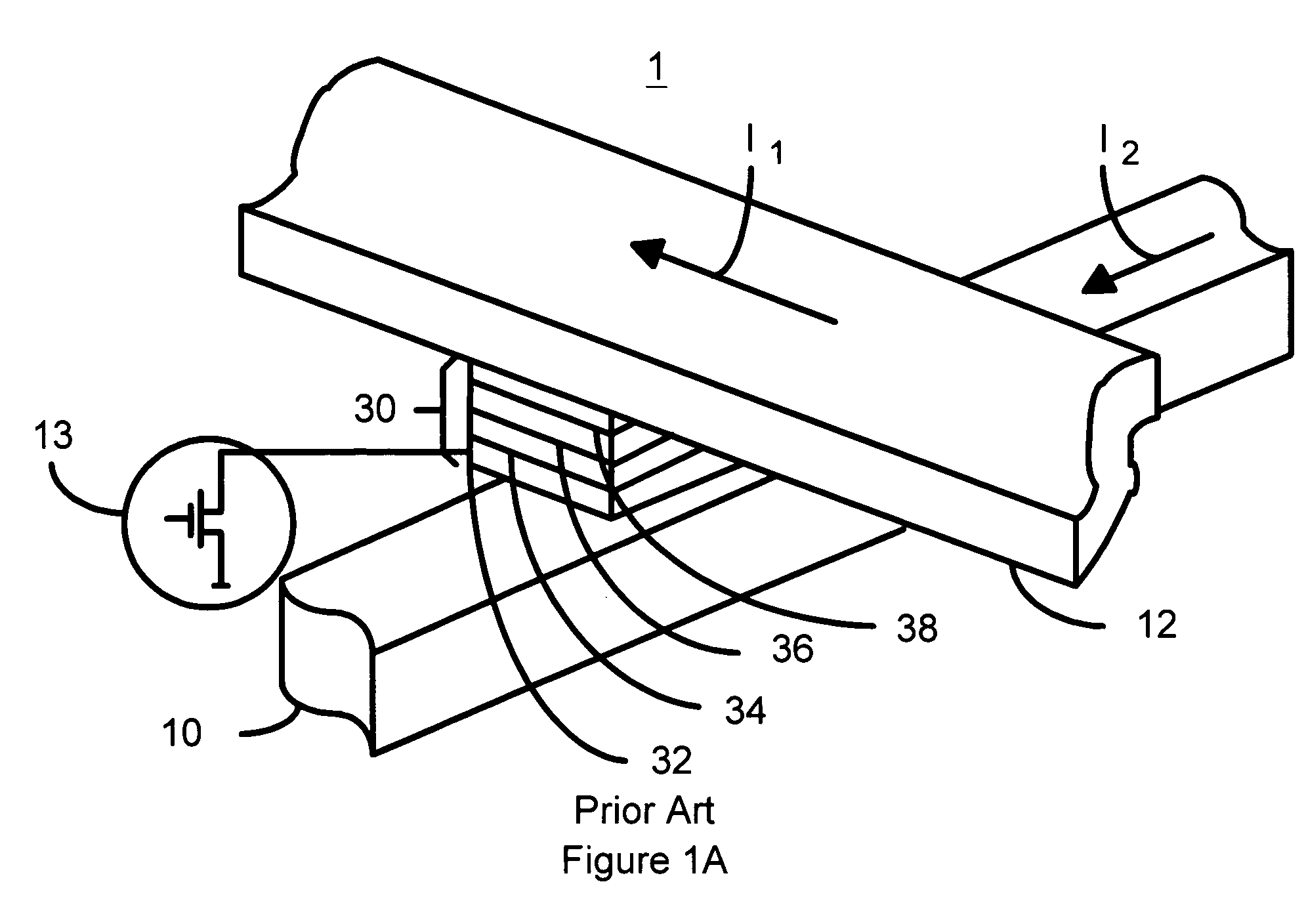

High-efficiency wheel-motor utilizing molded magnetic flux channels with transverse-flux stator

InactiveUS7868510B2Improve efficiencyImprove magnetismMotor control for very low speedsMagnetic circuit rotating partsTransverse fluxElectric machine

A motor including an outside rotor having a rotor disc with plural magnets alternating polarities flush mounted in the disc, an inside stator assembly with a ring of pole pieces forming a channel to house a transversely wound stator windings, and a controller coupled with feedback electronics for monitoring a timing, speed and direction and coupling a signal to a processing unit for adjusting the drive electronics driving the phase windings. A u-shaped gap above the channel to receive the rotor disc and focus the captured magnetic flux in the pole pieces toward the magnets. In an embodiment the molded magnetic flux channel pole pieces of the inside stator are sets of molded magnetic flux channel pole pieces, each set forming a channel and corresponding to one phase of the motor; and a section of each one of the transverse windings passing through one channel, the remaining section folding back outside the set in close proximity to the outer base of the set of molded magnetic flux channel pole pieces.

Owner:RITTENHOUSE NORMAN P

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com