Flexible rare earth bonded magnet with roll anisotropy and manufacturing method thereof

An anisotropic, bonded magnet technology, applied in the manufacture of inductors/transformers/magnets, magnetic objects, magnetic materials, etc., can solve the cumbersome and complex production process of rare earth bonded magnets, and achieve good flexibility and high magnetic properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

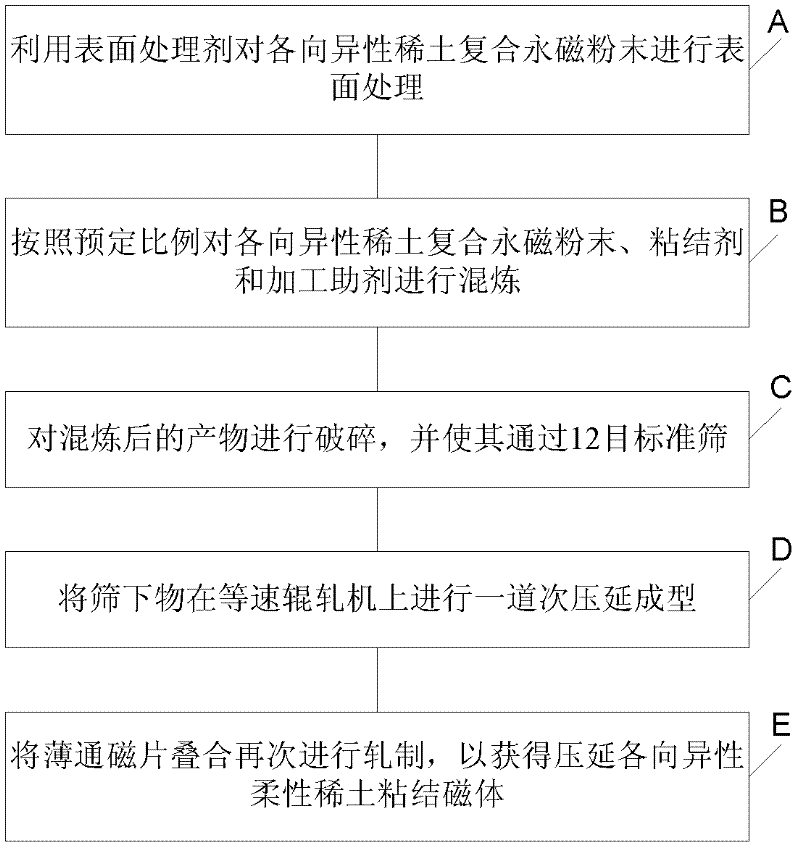

Method used

Image

Examples

Embodiment 1

[0084] In this embodiment, the surface-treated anisotropic rare earth composite permanent magnet powder used is 94 parts, the binder is 5.5 parts and the processing aid is 0.5 parts. Among them, in the anisotropic rare earth composite permanent magnet powder after surface treatment, the anisotropic NdFeN permanent magnet powder after surface treatment accounts for 10% of the total amount of anisotropic rare earth composite permanent magnet powder after surface treatment. 3 parts, surface-treated anisotropic samarium-iron-nitrogen permanent magnet powder accounted for 3 parts of the total amount of surface-treated anisotropic rare earth composite permanent magnet powder, surface-treated anisotropic ferrite powder It accounts for 5 parts of the total amount of anisotropic rare earth composite permanent magnet powder after surface treatment, and the anisotropic NdFeB permanent magnet powder after surface treatment accounts for 5 parts of the total amount of anisotropic rare earth ...

Embodiment 2

[0099] In this embodiment, the surface-treated anisotropic rare earth composite permanent magnet powder used is 95 parts, the binder is 4.5 parts and the processing aid is 0.5 parts. Among them, in the anisotropic rare earth composite permanent magnet powder after surface treatment, the anisotropic NdFeN permanent magnet powder after surface treatment accounts for 10% of the total amount of anisotropic rare earth composite permanent magnet powder after surface treatment. 3 parts, surface-treated anisotropic samarium-iron-nitrogen permanent magnet powder accounted for 3 parts of the total amount of surface-treated anisotropic rare earth composite permanent magnet powder, surface-treated anisotropic ferrite powder It accounts for 4 parts of the total amount of anisotropic rare earth composite permanent magnet powder after surface treatment, and the anisotropic NdFeB permanent magnet powder after surface treatment accounts for 4 parts of the total amount of anisotropic rare earth ...

Embodiment 3

[0108] In this embodiment, the surface-treated anisotropic rare earth composite permanent magnet powder used is 96.5 parts, the binder is 3.3 parts and the processing aid is 0.2 parts. Among them, in the anisotropic rare earth composite permanent magnet powder after surface treatment, the anisotropic NdFeN permanent magnet powder after surface treatment accounts for 10% of the total amount of anisotropic rare earth composite permanent magnet powder after surface treatment. 3 parts, surface-treated anisotropic samarium-iron-nitrogen permanent magnet powder accounted for 2 parts of the total amount of surface-treated anisotropic rare earth composite permanent magnet powder, surface-treated anisotropic ferrite powder It accounts for 4 parts of the total amount of anisotropic rare earth composite permanent magnet powder after surface treatment, and the anisotropic NdFeB permanent magnet powder after surface treatment accounts for 4 parts of the total amount of anisotropic rare eart...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com