Patents

Literature

140results about How to "Possible to obtain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

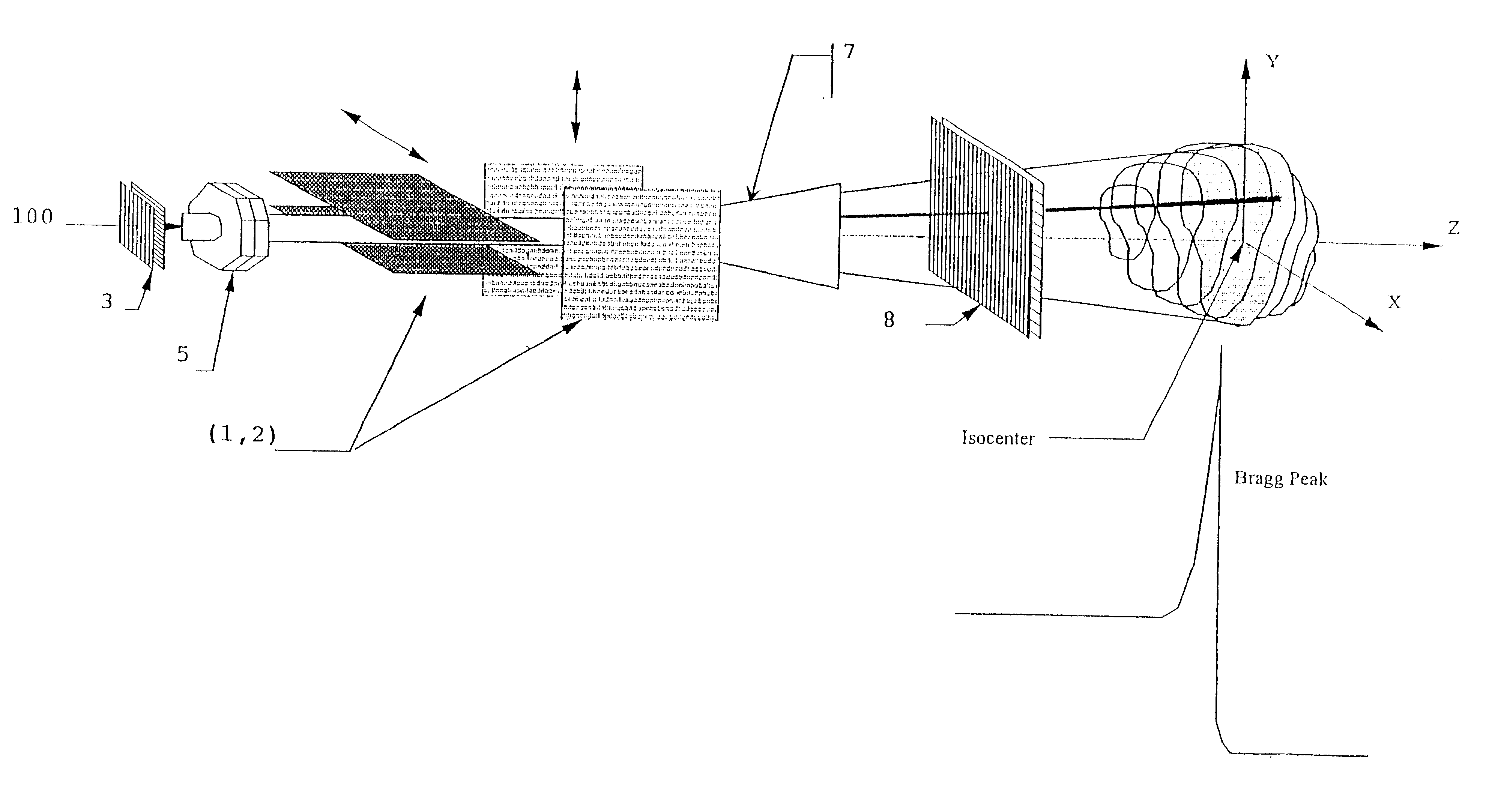

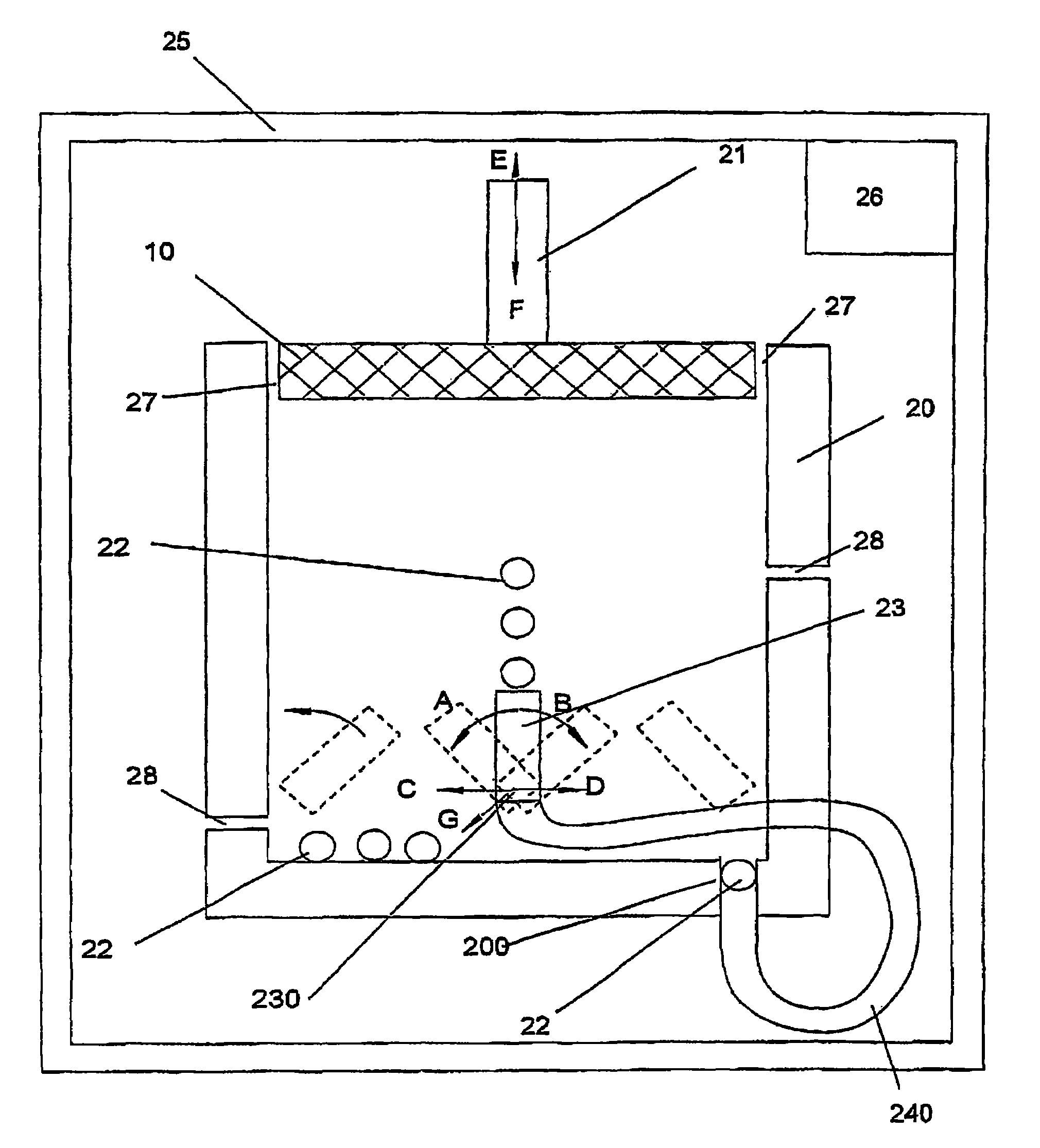

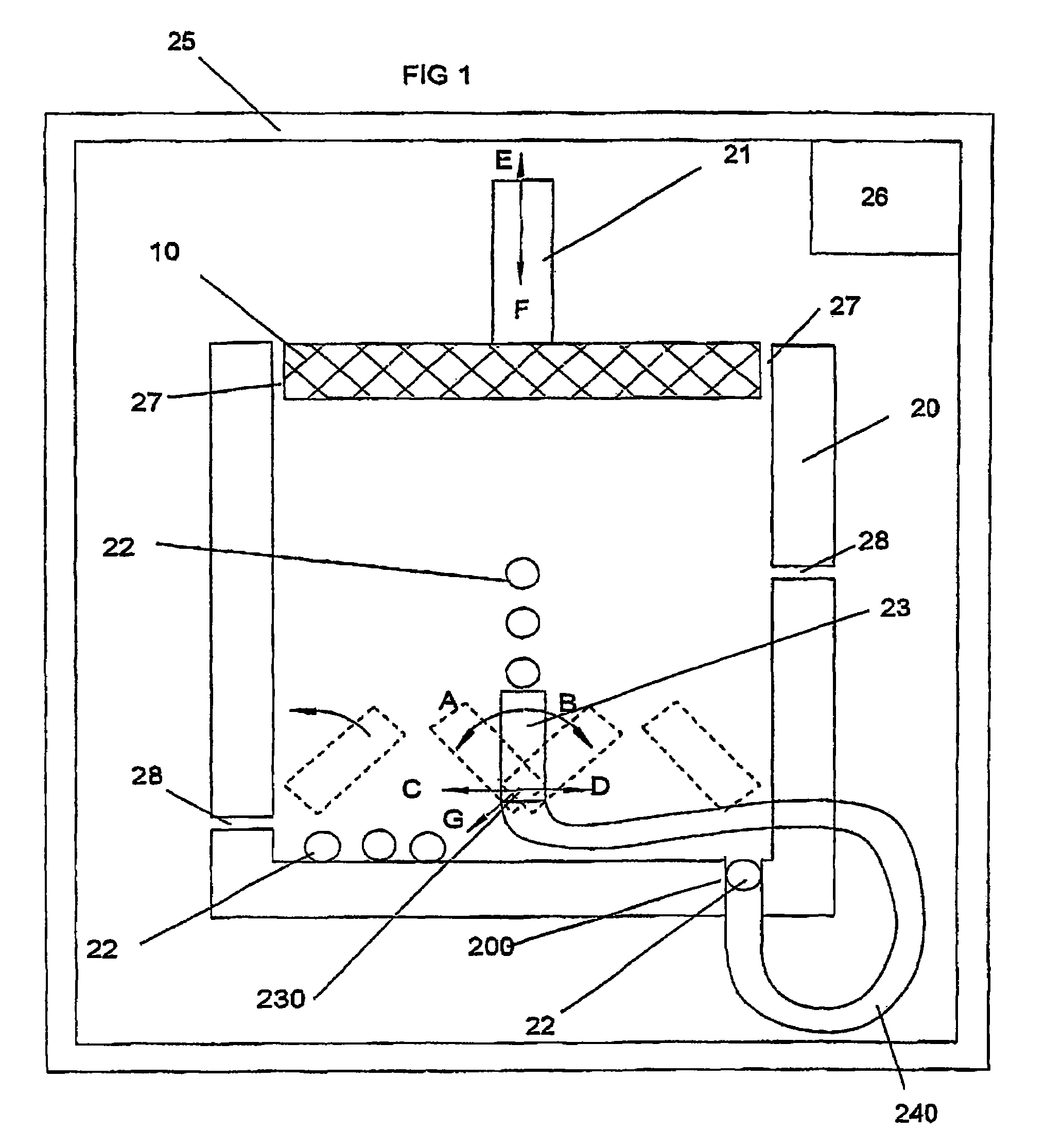

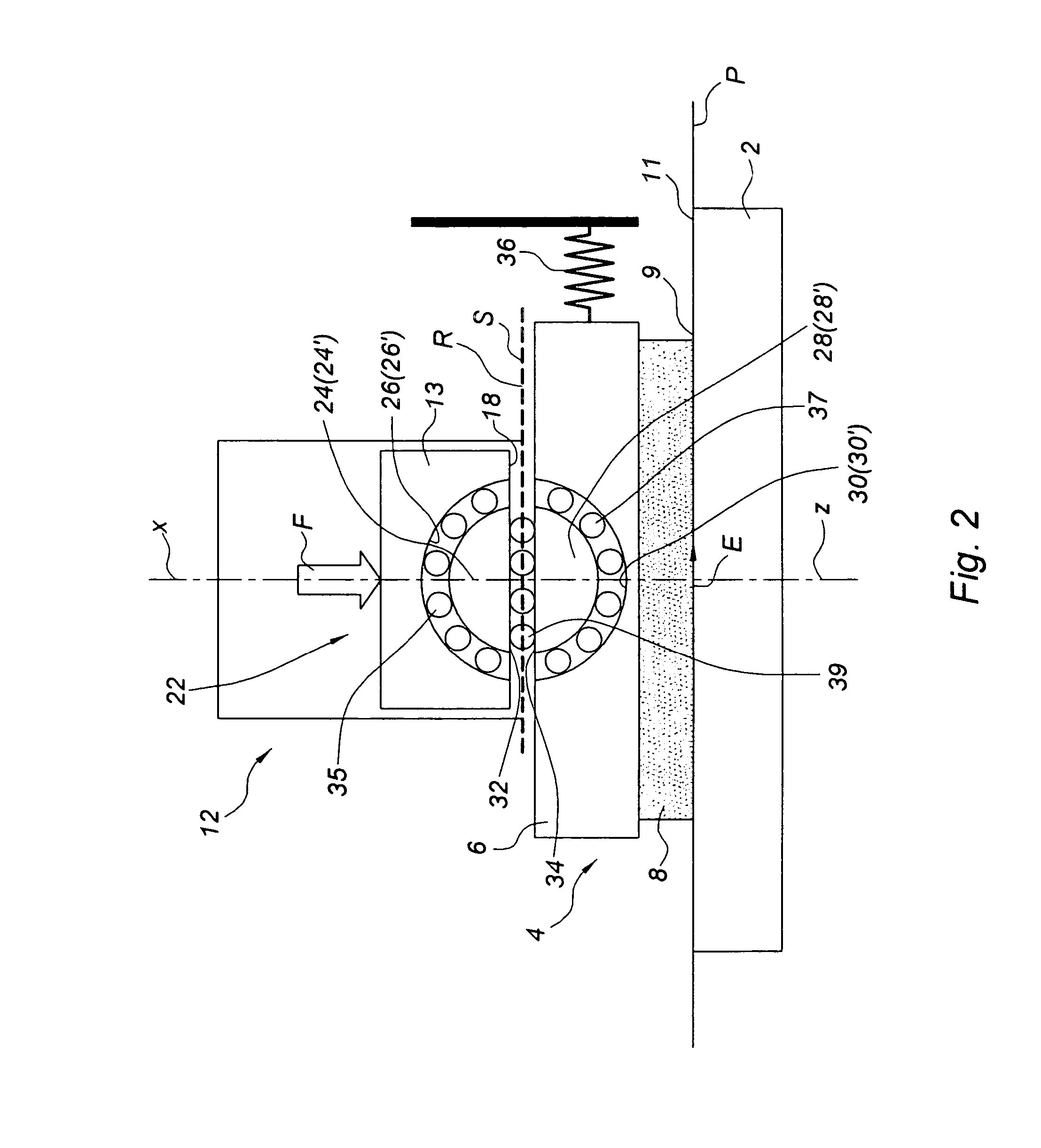

Method for treating a target volume with a particle beam and device implementing same

InactiveUS6717162B1Good flexibilityPossible to obtainRadiation/particle handlingElectrode and associated part arrangementsParticle beamParticle physics

The invention concerns a method for treating a target volume with a particle beam, in particular a proton beam, which consists in generating said particle beam using an accelerator and in producing from said beam a narrow spot directed towards the target volume, characterized in that said spot sweeping speed and the particle beam intensity are simultaneously varied.

Owner:ION BEAM APPL

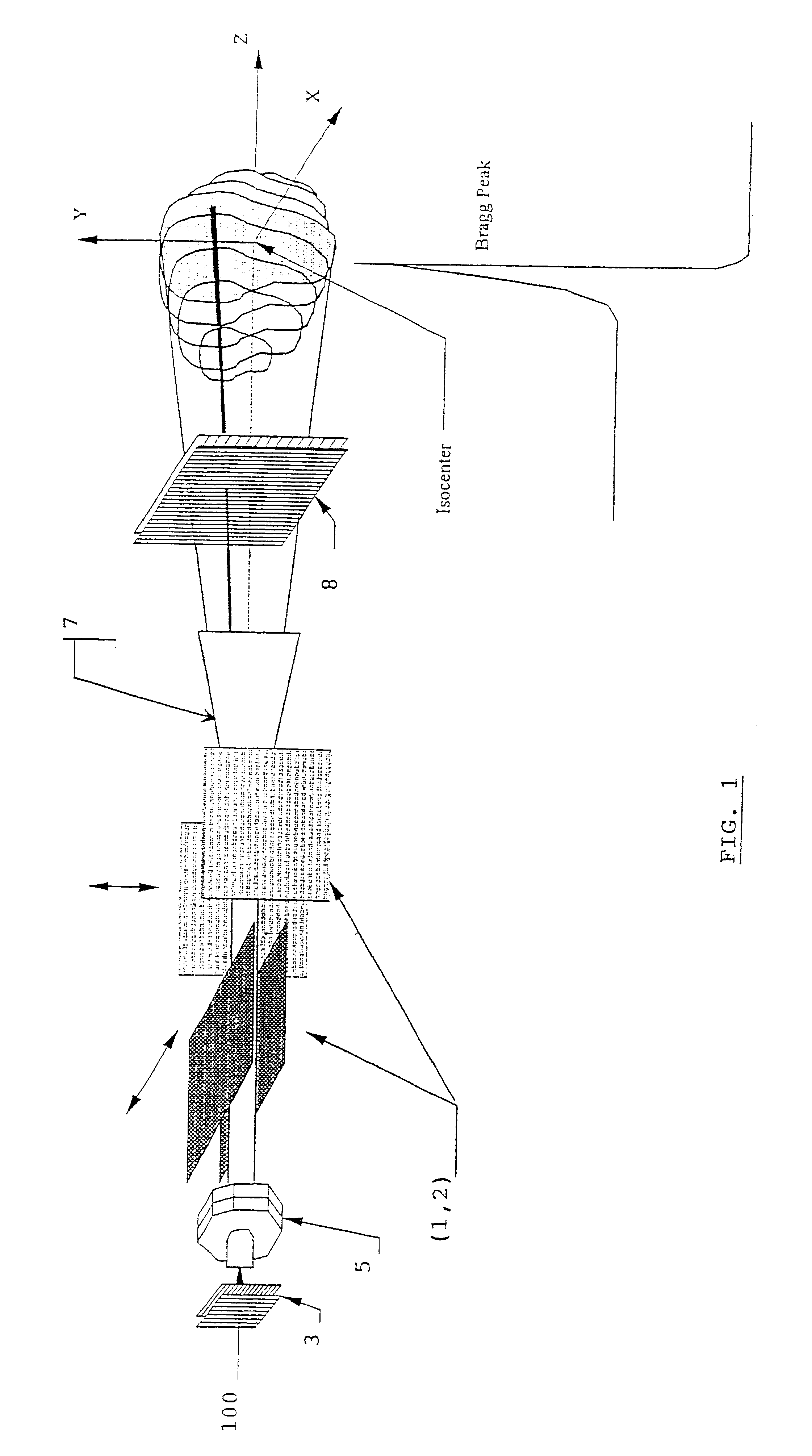

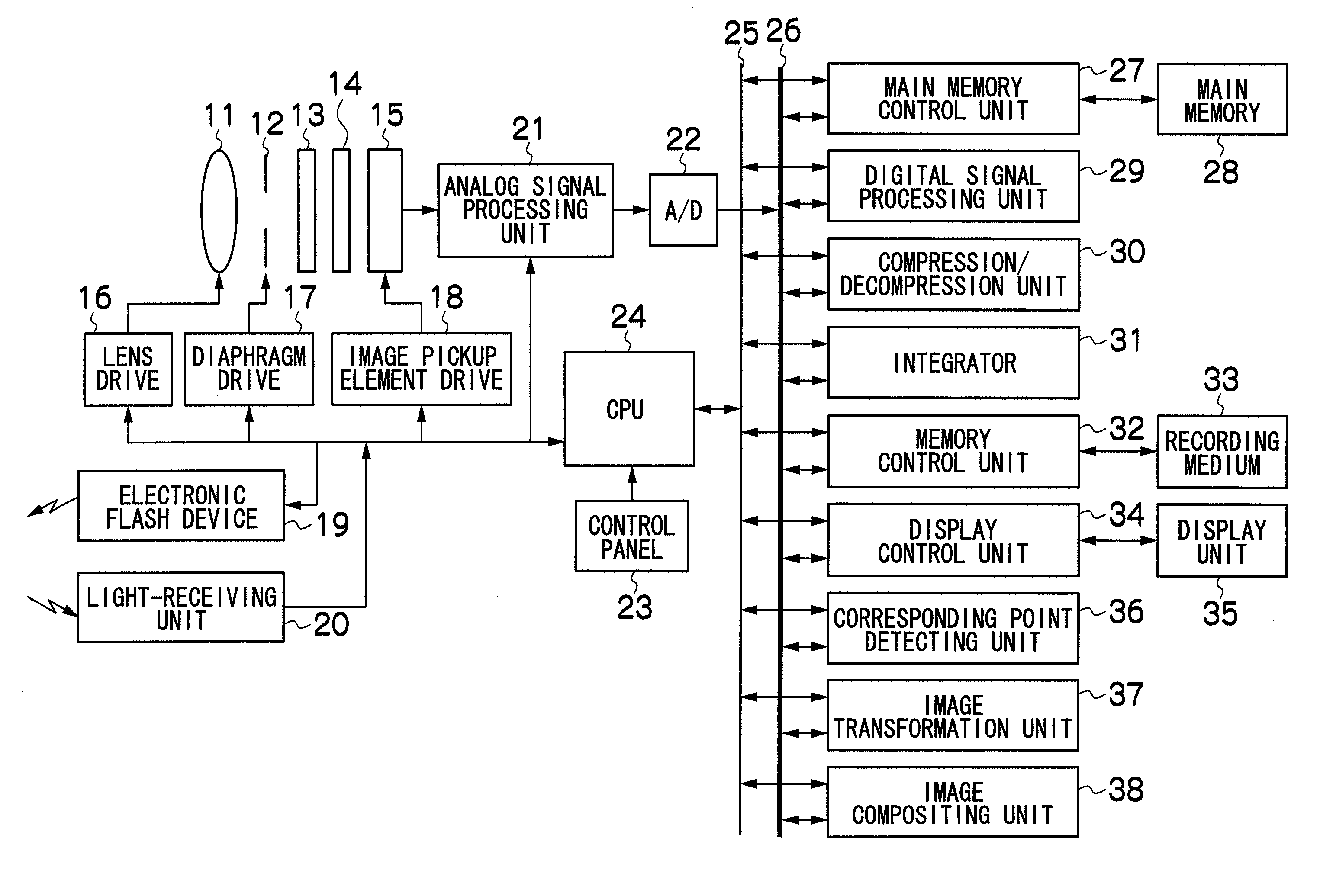

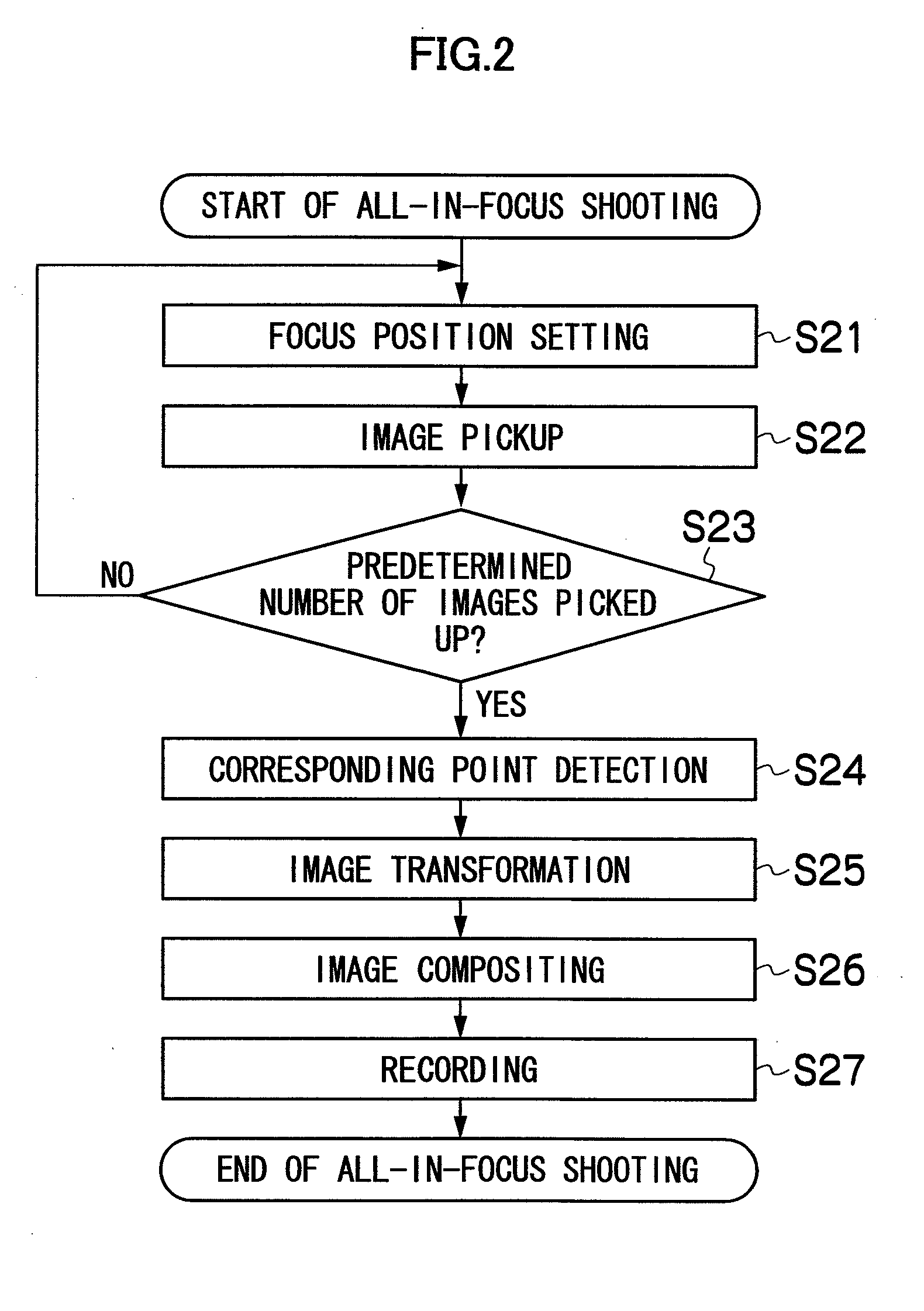

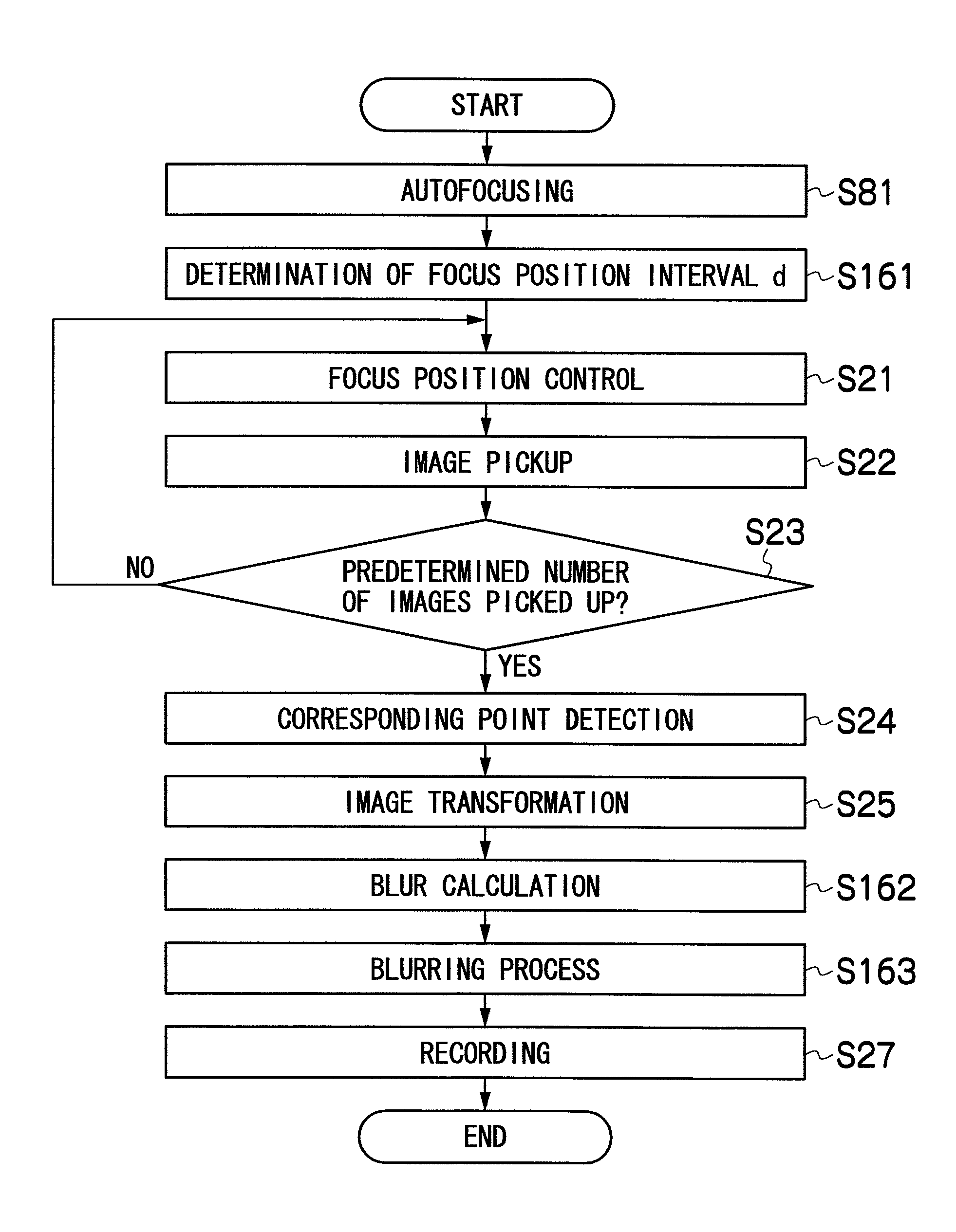

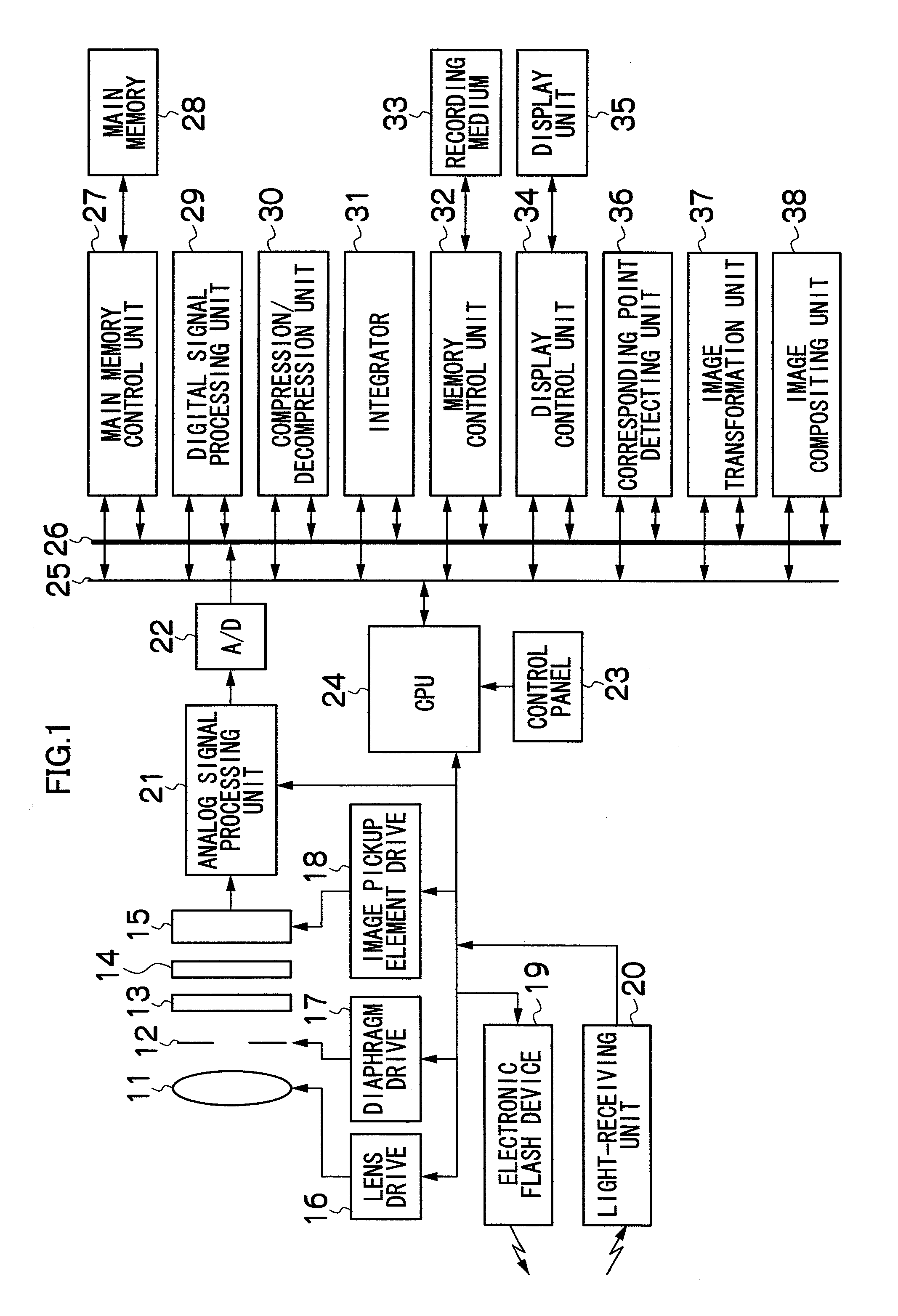

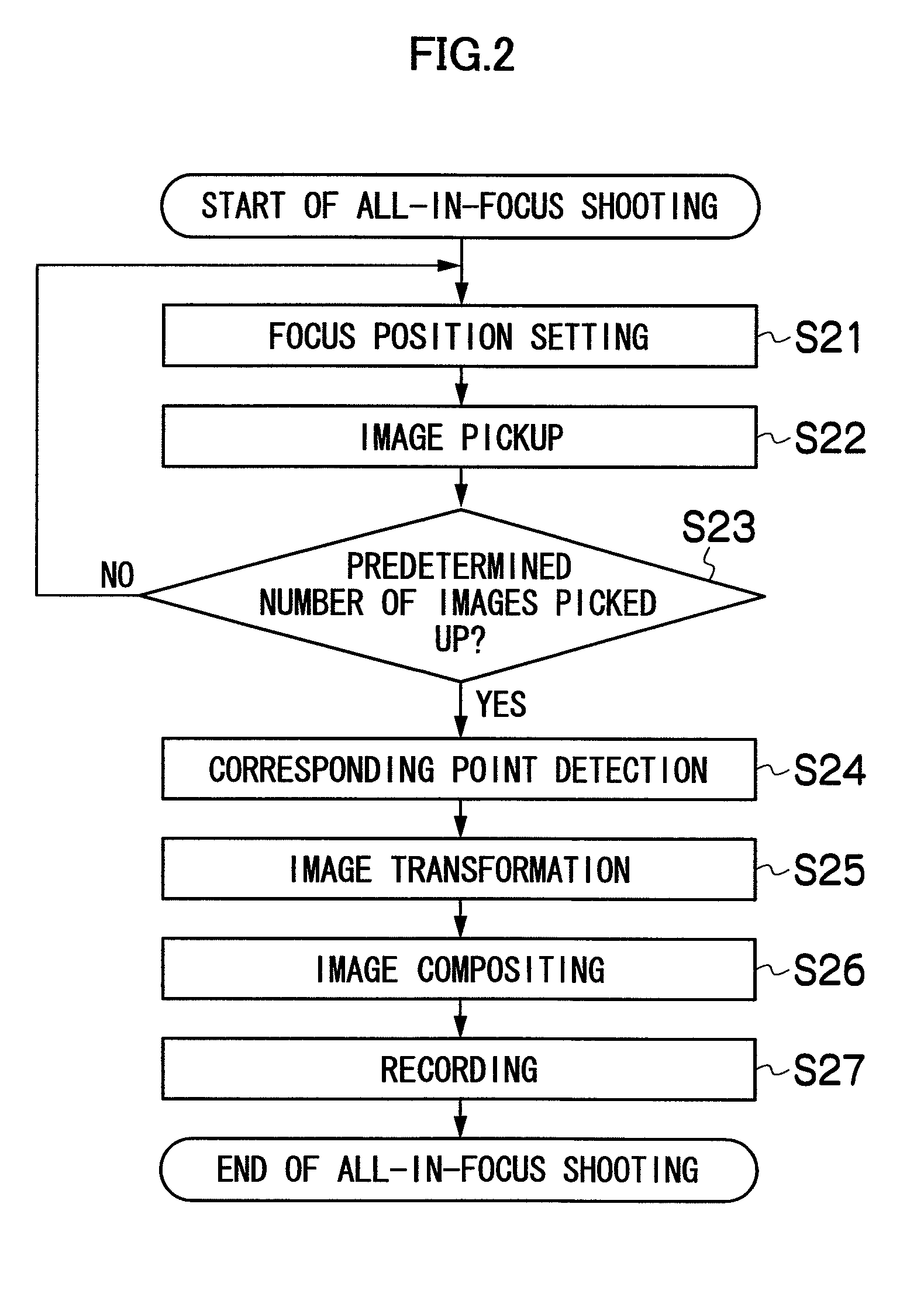

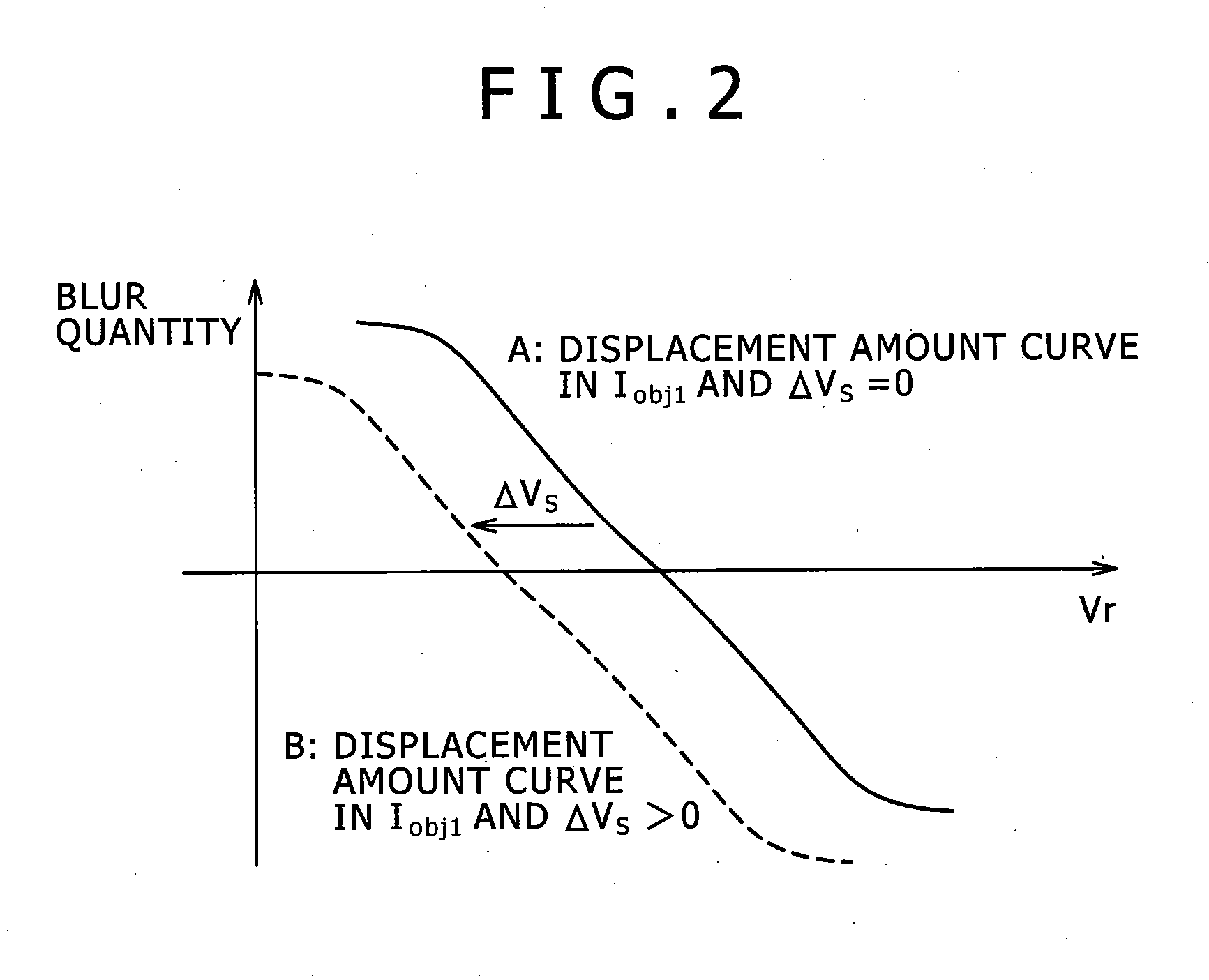

Image pickup apparatus, image processing apparatus, image pickup method, and image processing method

ActiveUS20080259176A1Minimize timePossible to obtainTelevision system detailsProjector focusing arrangementImaging processingPoint match

The present invention, which transforms multiple images so that positions of corresponding points will coincide between the images and composites the images with the corresponding points matched, provides an image pickup apparatus, image processing apparatus, image pickup method, and image processing method which make it possible to obtain an intended all-in-focus image or blur-emphasized image even if there is camera shake or subject movement.

Owner:FUJIFILM CORP

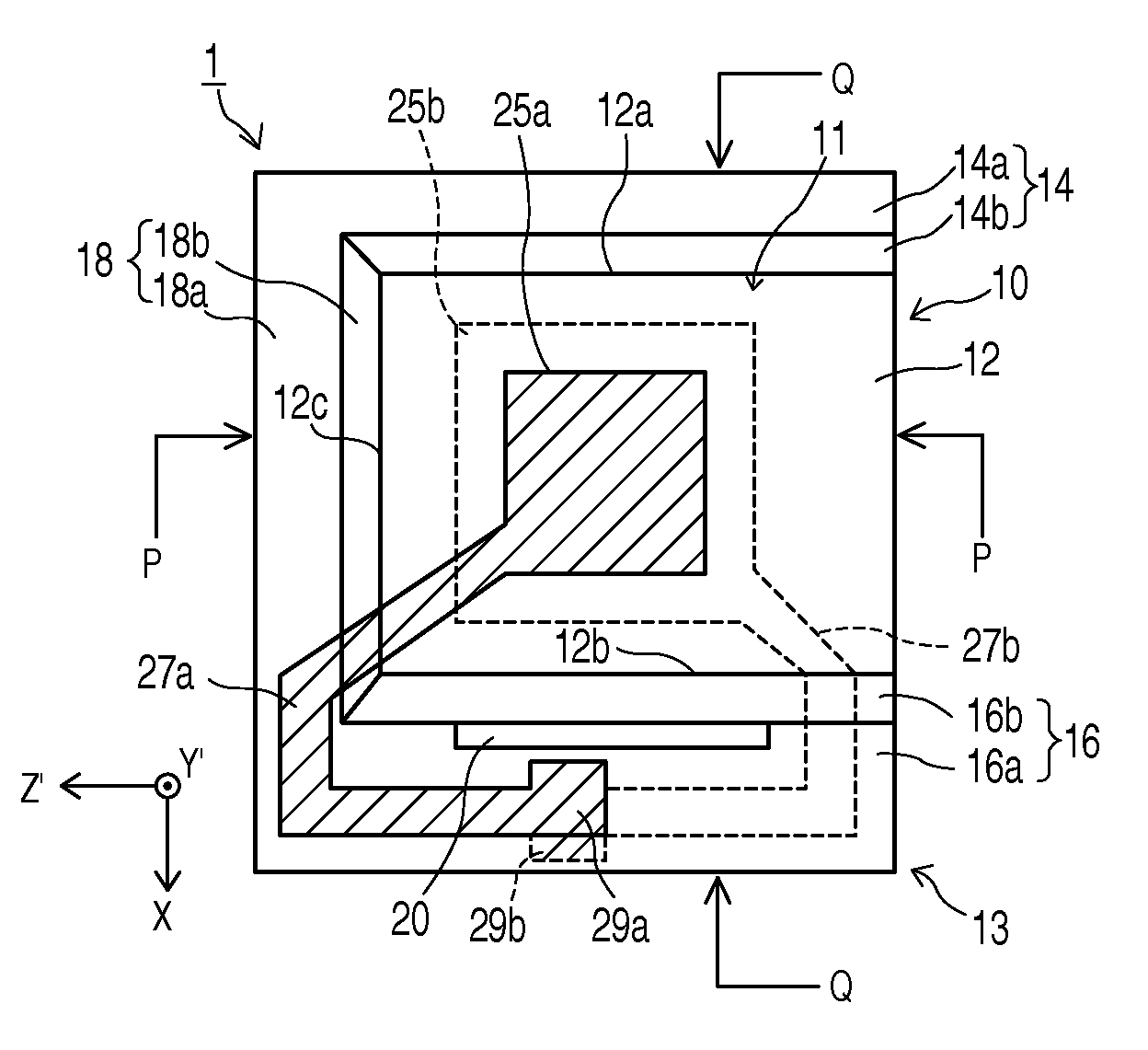

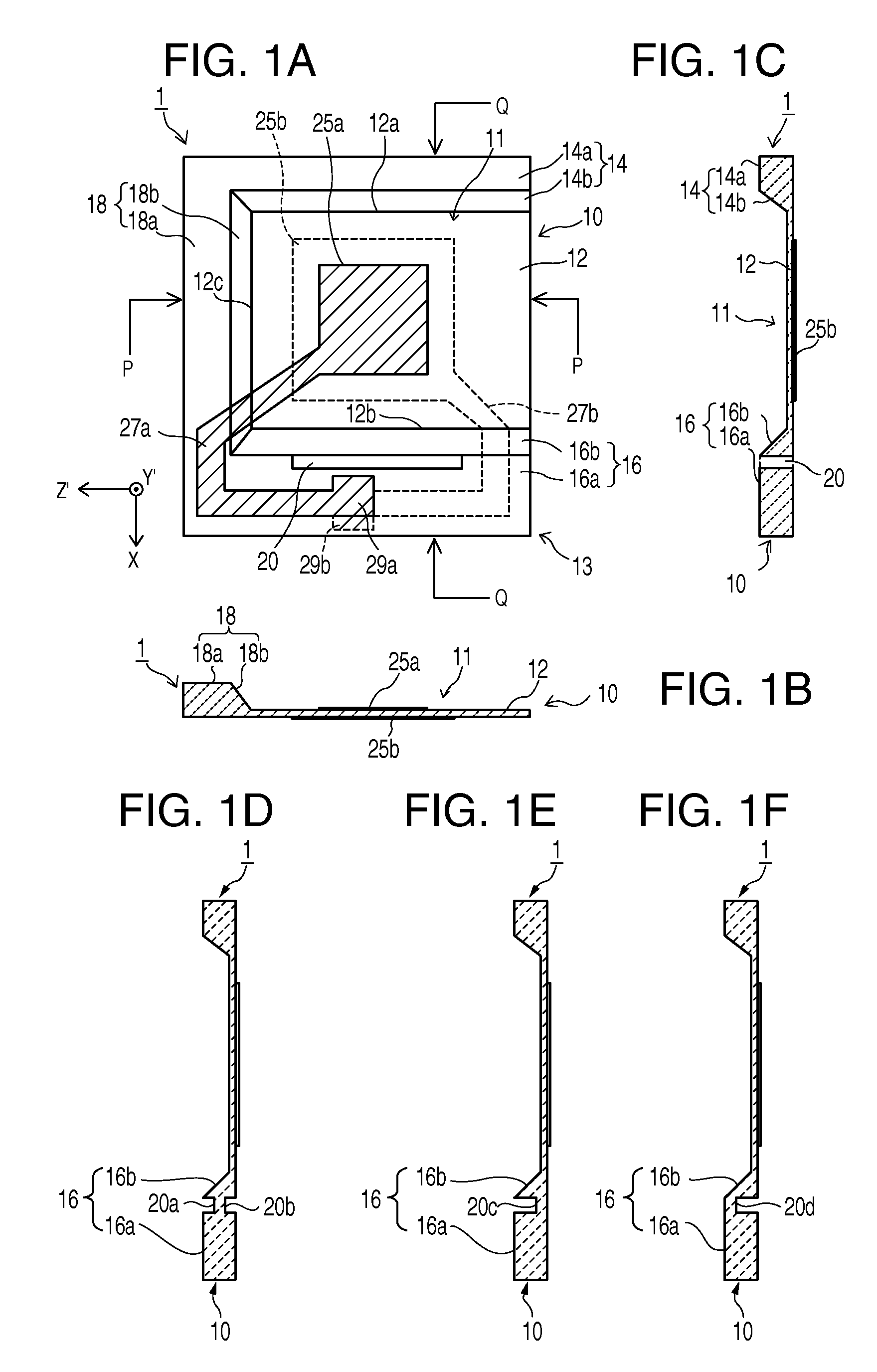

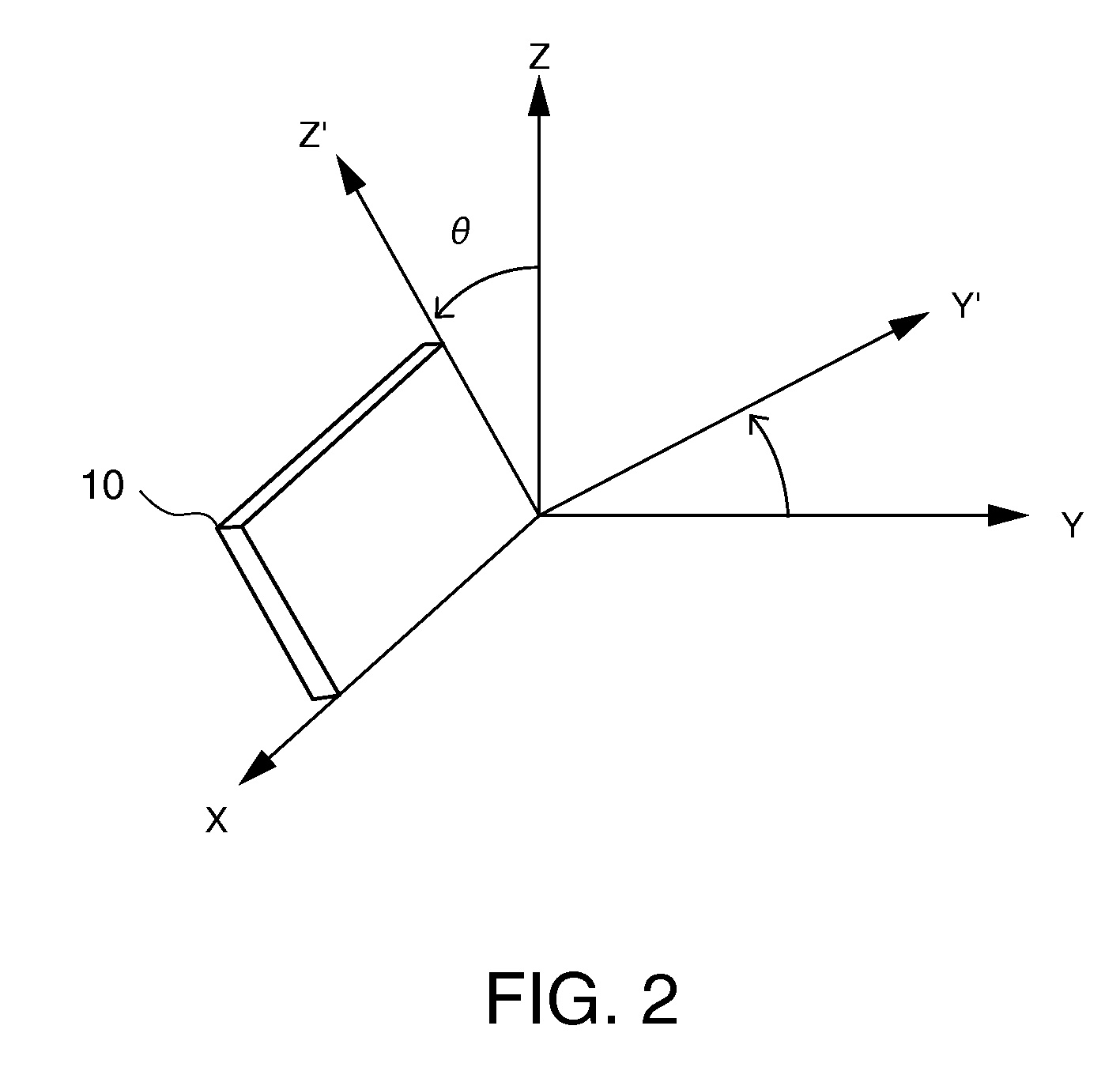

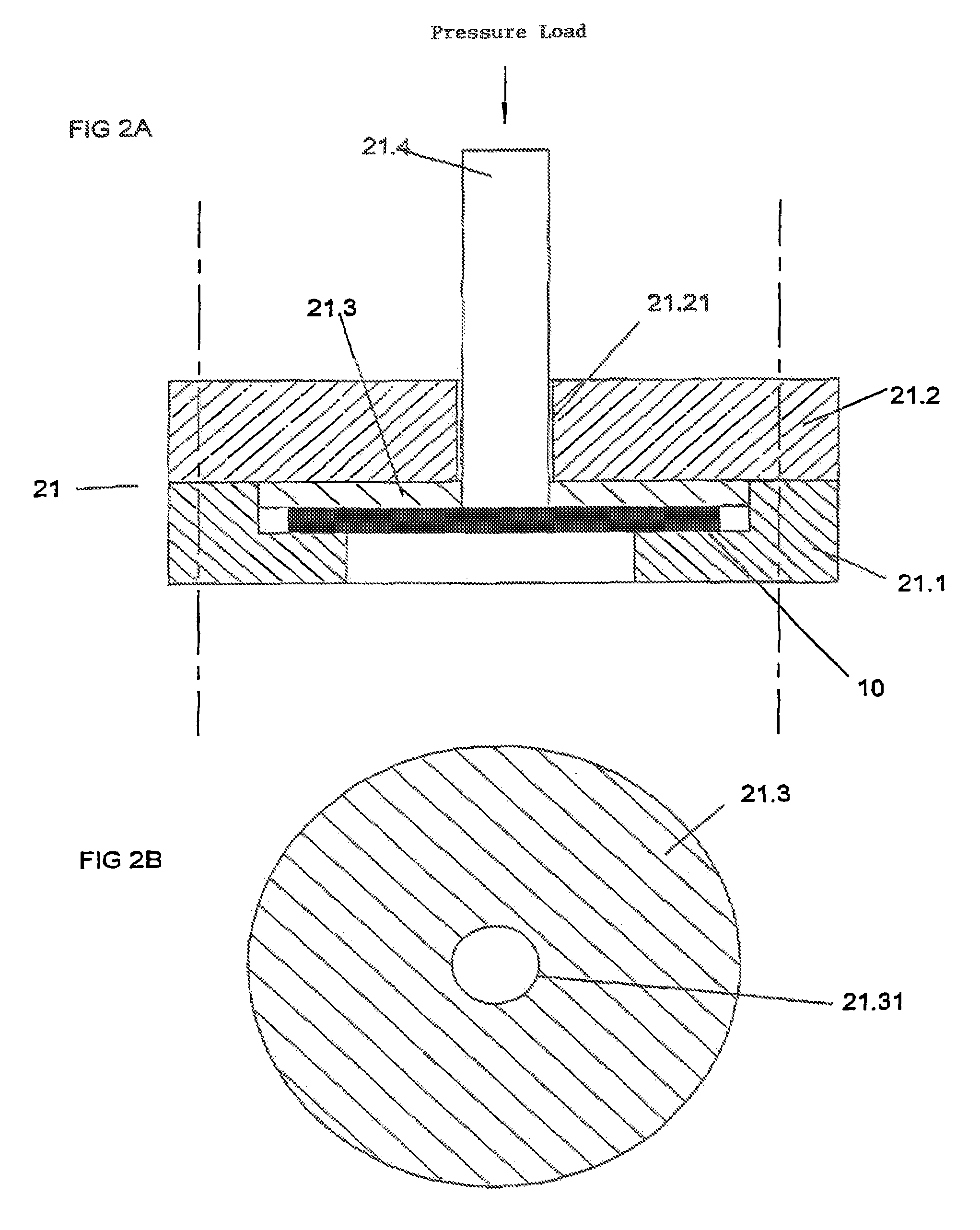

Piezoelectric vibration element, manufacturing method for piezoelectric vibration element, piezoelectric resonator, electronic device, and electronic apparatus

ActiveUS20120306321A1Spread of stress due to bonding and fixing can be suppressedAvoid smallPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksStress relaxationLead electrode

A piezoelectric vibration element includes a piezoelectric substrate including a thin vibration region and a thick section integrated along three sides excluding one side of the vibration region, excitation electrodes respectively arranged on the front and rear surfaces of the vibration region, and lead electrodes. The thick section includes a first thick section and a second thick section arranged to be opposed to each other across the vibration region and a third thick section connected between proximal ends of the first and second thick sections. The second thick section includes an inclined section connected to the one side of the vibration region, a second thick section main body connected to the other side of the inclined section, and at least one slit for stress relaxation.

Owner:SEIKO EPSON CORP

Image pickup apparatus, image processing apparatus, image pickup method, and image processing method

ActiveUS8023000B2Minimize timePossible to obtainTelevision system detailsProjector focusing arrangementImaging processingPoint match

The present invention, which transforms multiple images so that positions of corresponding points will coincide between the images and composites the images with the corresponding points matched, provides an image pickup apparatus, image processing apparatus, image pickup method, and image processing method which make it possible to obtain an intended all-in-focus image or blur-emphasized image even if there is camera shake or subject movement.

Owner:FUJIFILM CORP

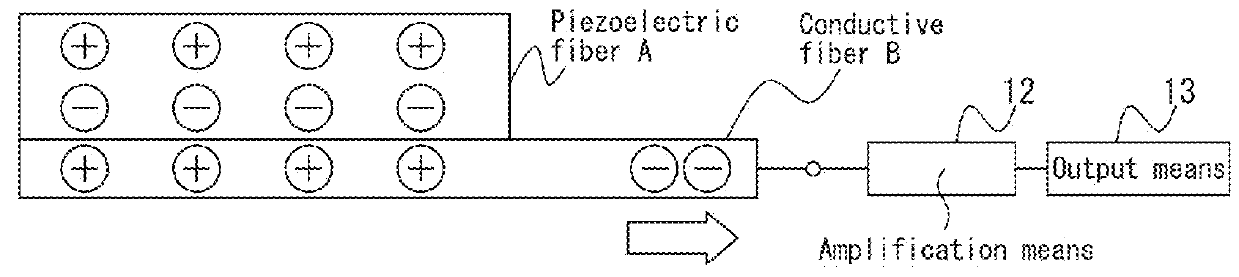

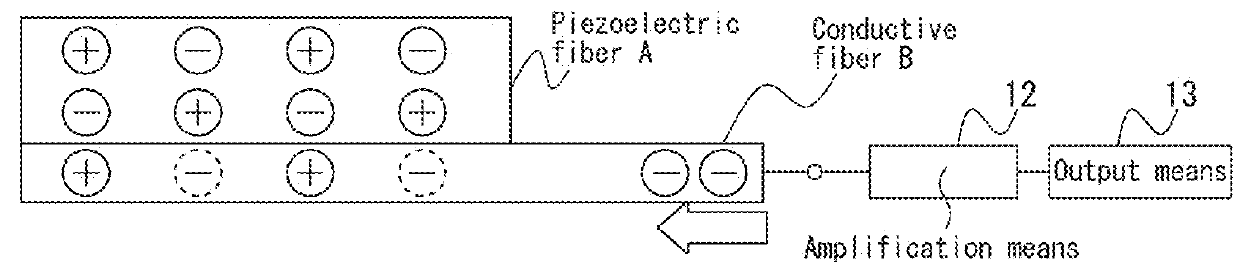

Piezoelectric element and device using same

ActiveUS20180108826A1Large electrical signalSuppress noise signalPiezoelectric/electrostrictive device manufacture/assemblyForce measurement using piezo-electric devicesFiberEngineering

The purpose of the present invention is to provide a fibrous piezoelectric element which enables a large electric signal to be drawn out by stress produced by relatively small deformation. A piezoelectric element includes a braid composed of a conductive fiber and a piezoelectric fiber. In the braid, the conductive fiber is a core, and the piezoelectric fiber is a covering fiber that covers the periphery of the conductive fiber.

Owner:TEIJIN LTD +1

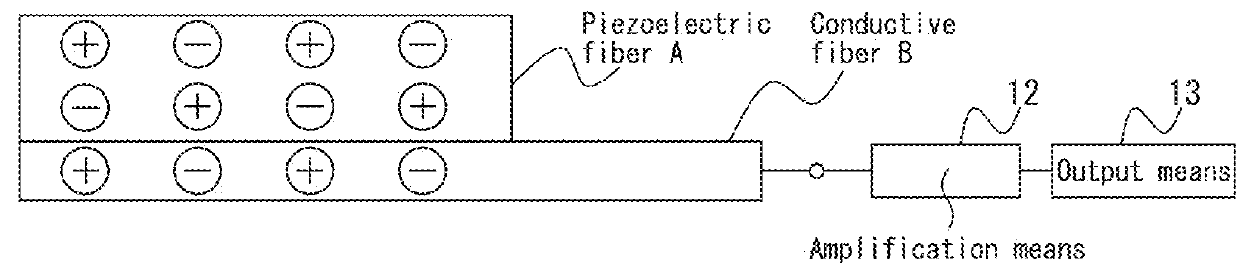

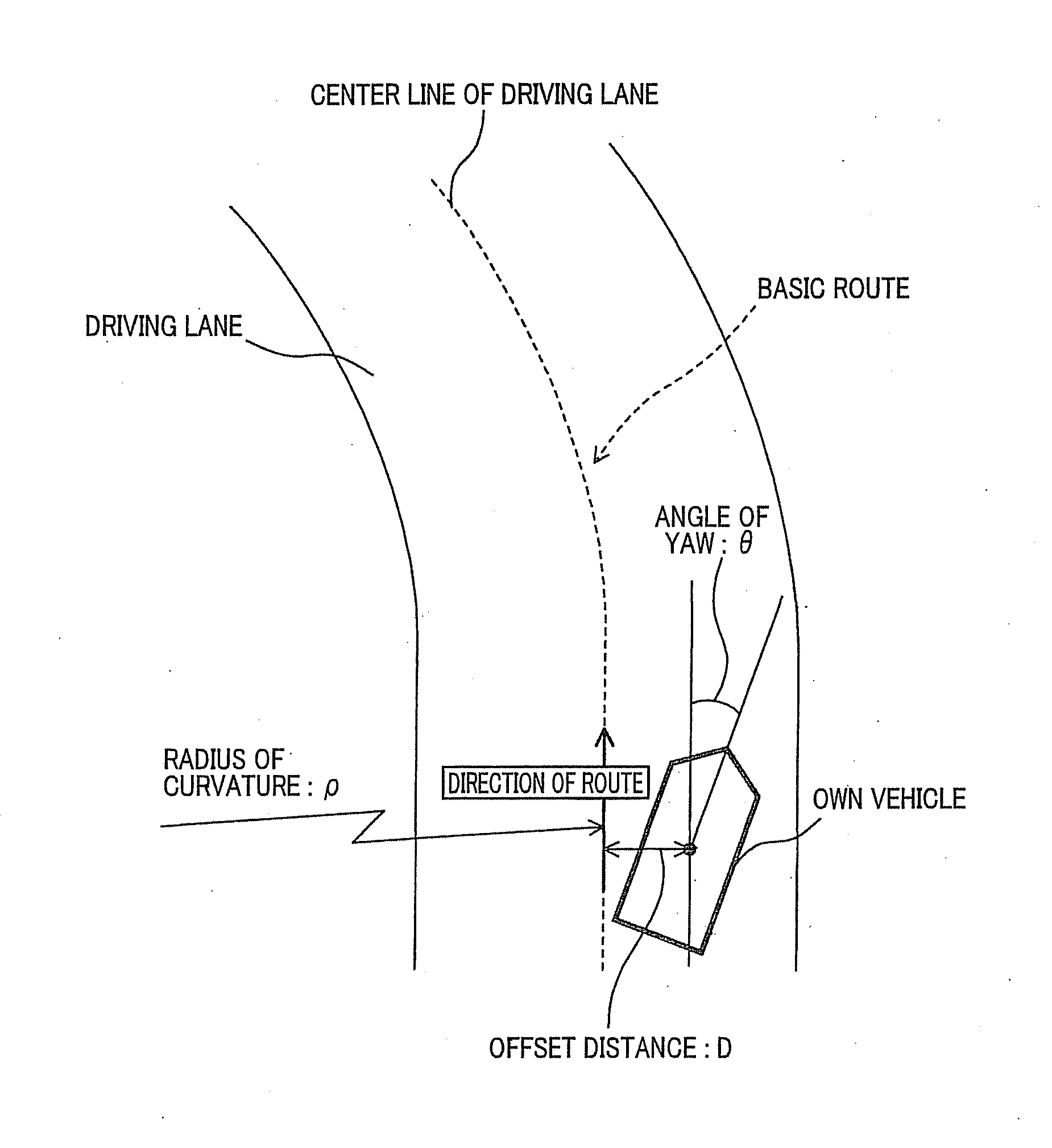

Vehicle control device

InactiveUS20140180543A1Possible to obtainEasy to adaptSteering initiationsDigital data processing detailsOffset distanceEngineering

In a vehicle control device, a basic steering amount calculation section calculates a basic steering amount to drive an own vehicle on a basic route along a driving lave. A posture detection section detects a vehicle posture state indicated by a lateral position and an angle of yaw. An offset distance detection section detects an offset distance between the basis route and the lateral position. A correction steering amount calculation section calculates a correction steering amount as a steering control amount to drive the own vehicle along a virtual correction route. The posture of the own vehicle is alien with a predetermined target posture at a predetermined virtual target point by using the virtual correction route. An instruction steering amount calculation section calculates an instruction steering amount on the basis of the basic steering amount and the correction steering amount.

Owner:DENSO CORP

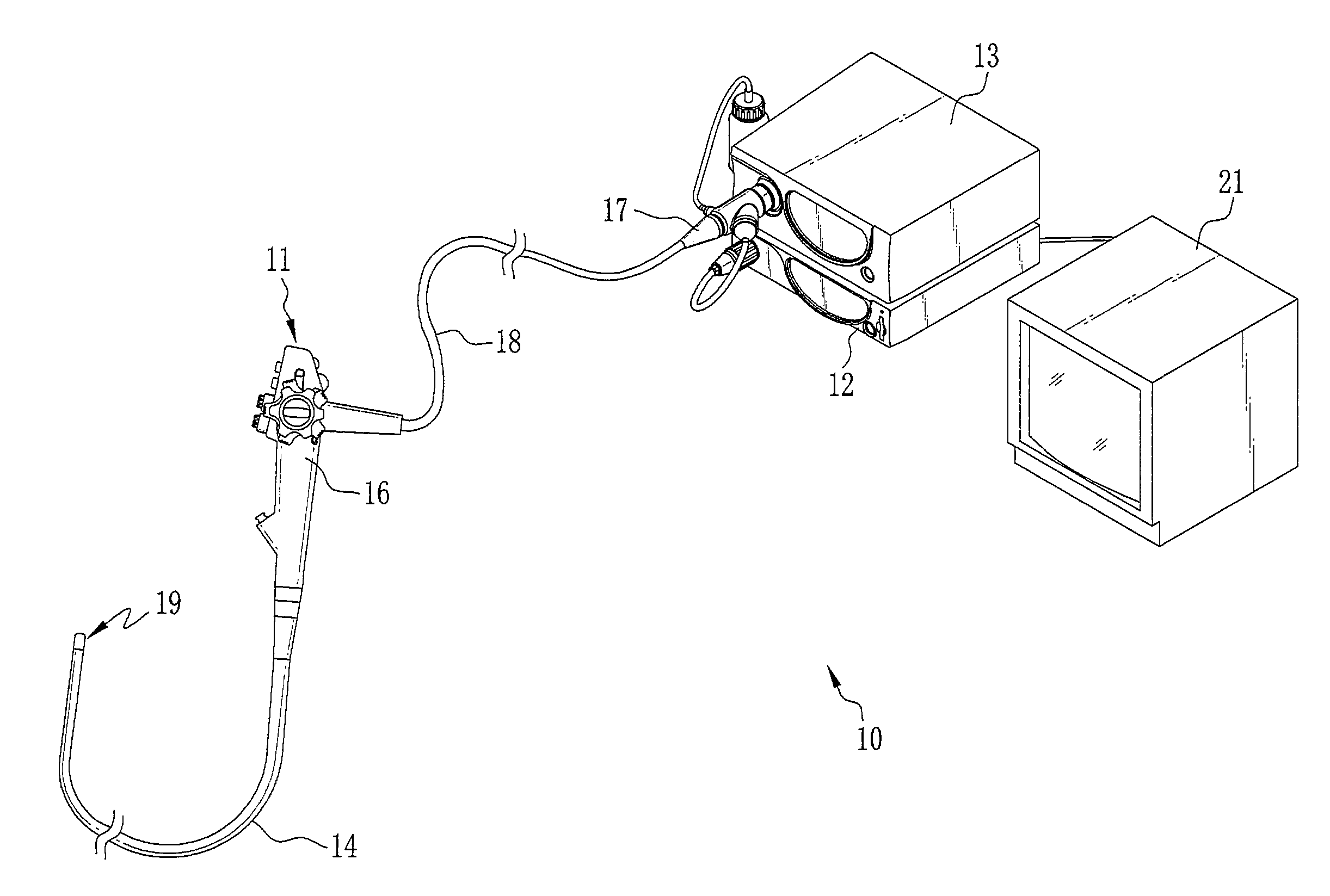

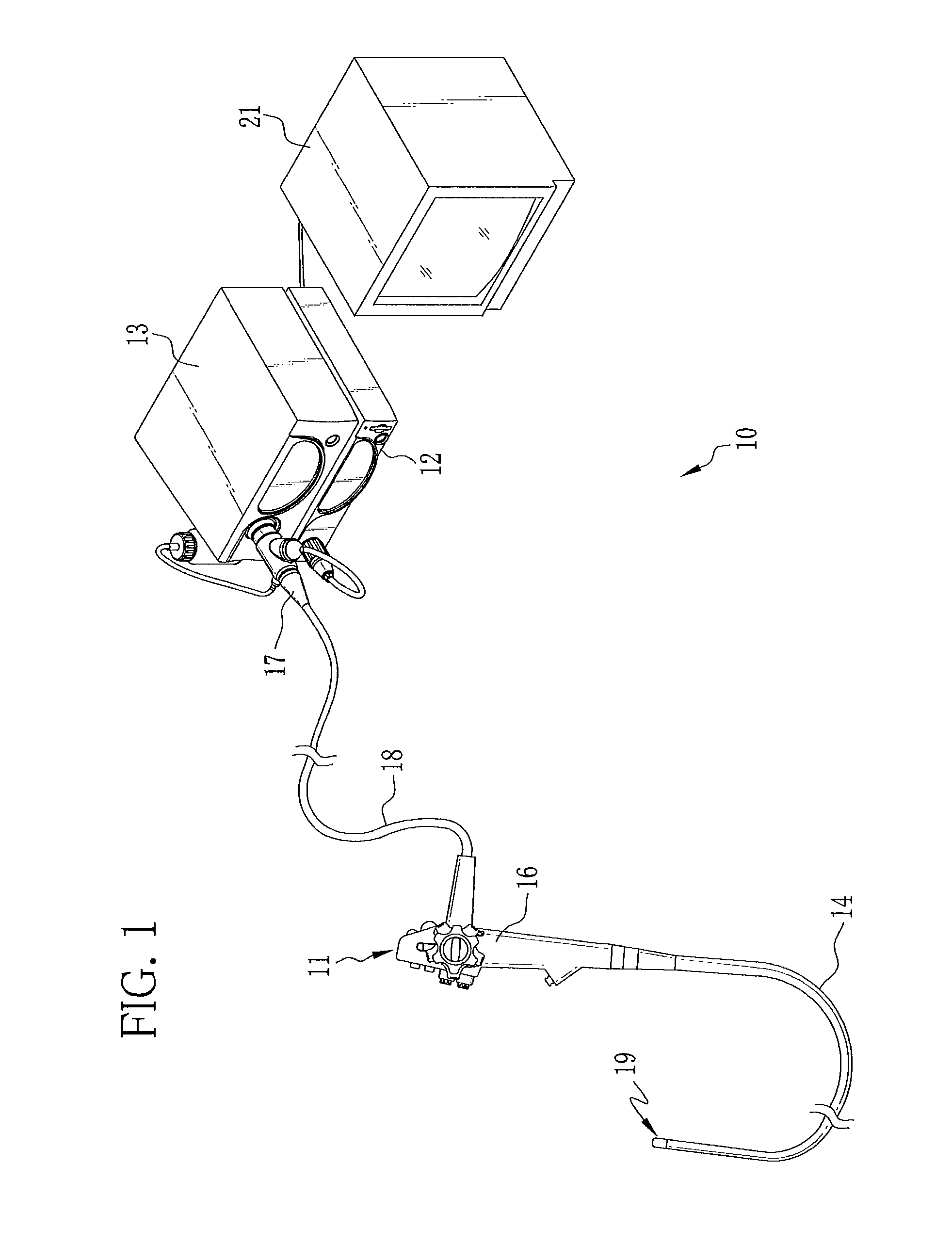

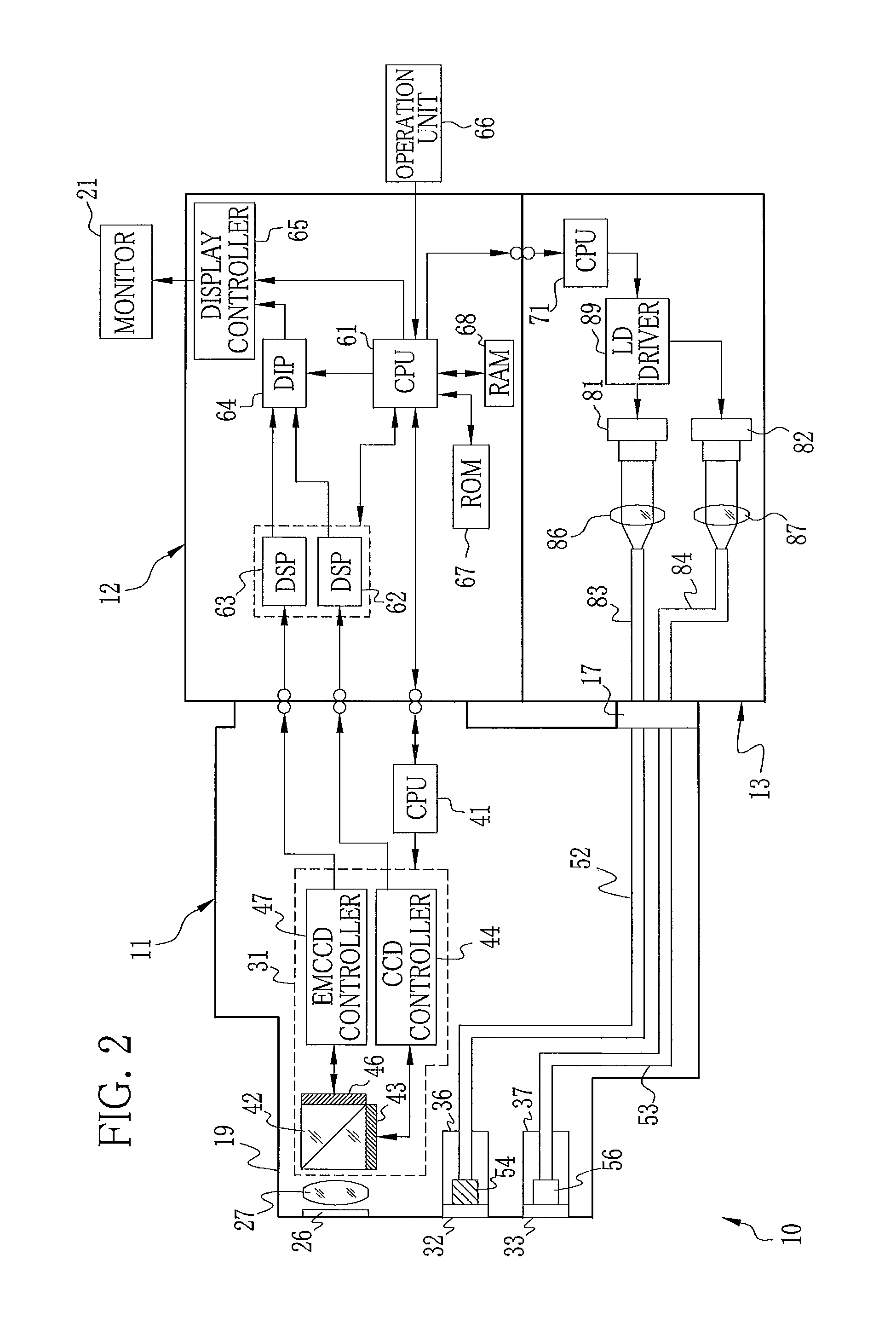

Electronic endoscope system

InactiveUS20120197080A1Possible to obtainQuality improvementSurgeryEndoscopesWhite lightBeam splitter

In an electronic endoscope, an insert section has a beam splitter, a CCD, and an EMCCD at its distal end portion. When white light being normal light is applied to an internal body portion, the reflected white light is incident on the CCD through the beam splitter, and a normal image is produced. When the internal body portion is irradiated with special light being excitation light, weak autofluorescence is emitted from specific tissue of the internal body portion. The weak autofluorescence is incident on the EMCCD through the beam splitter. The EMCCD uses an avalanche multiplication effect in its electron multiplier. The EMCCD multiplies signal charge produced from the weak autofluorescence by the electron multiplier, and outputs a high level signal.

Owner:FUJIFILM CORP

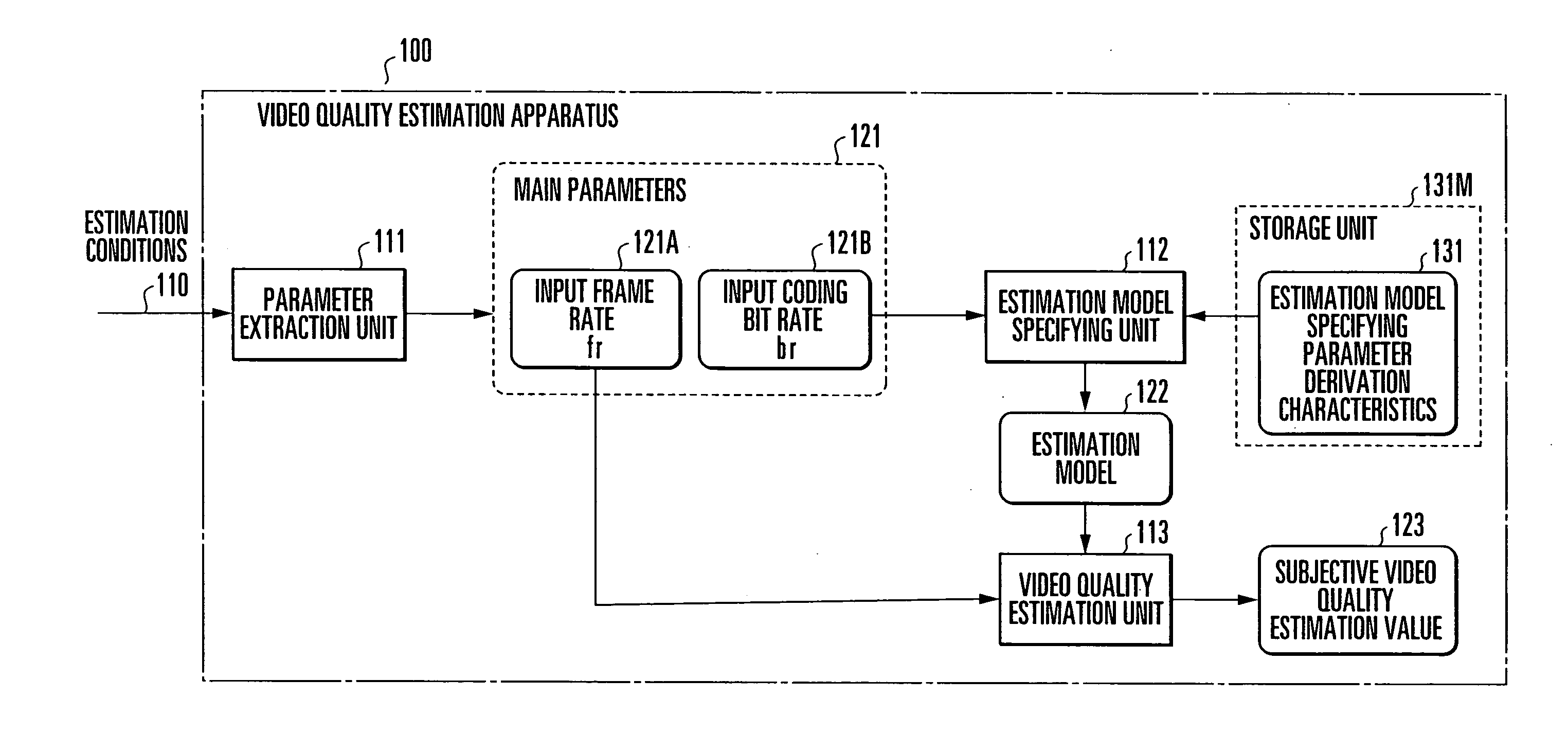

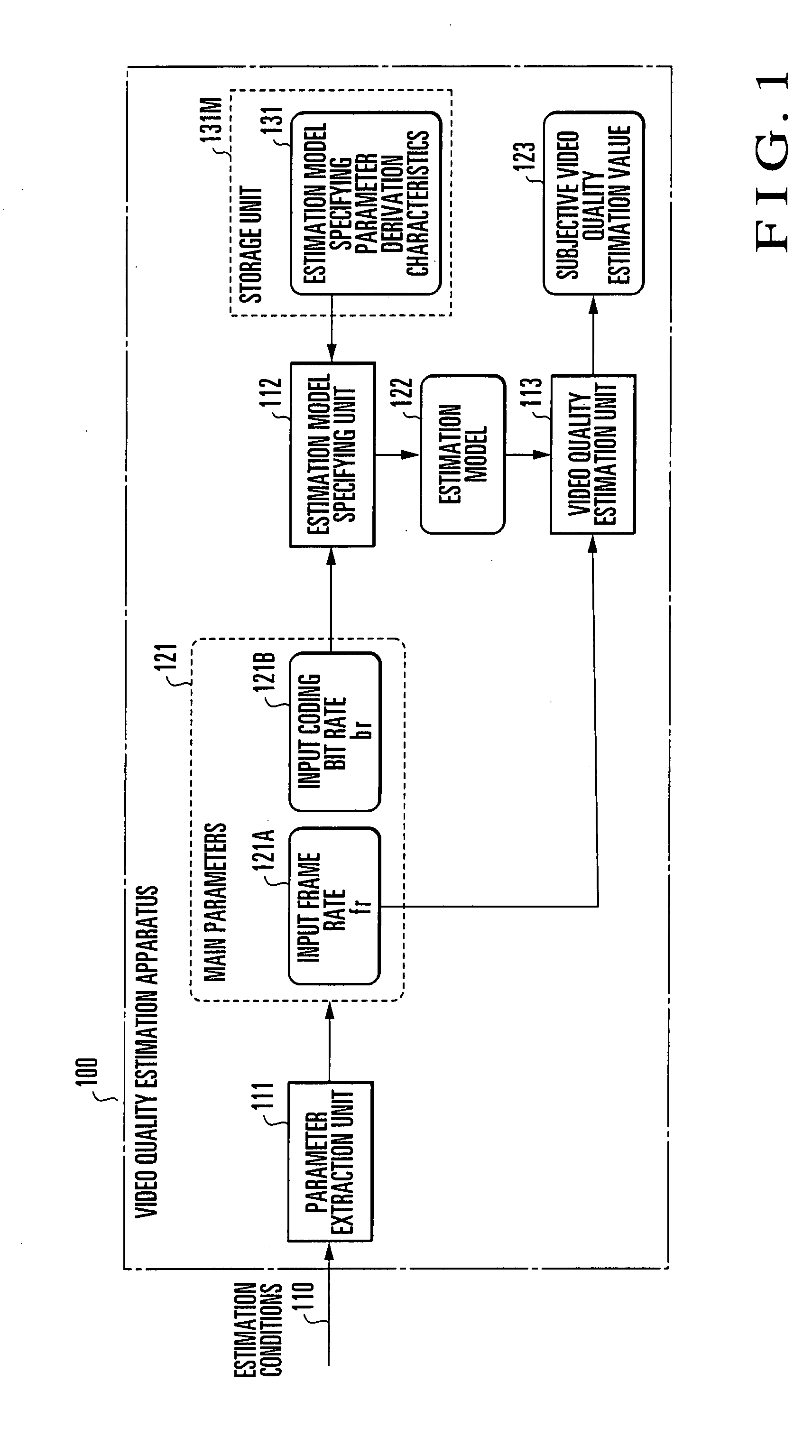

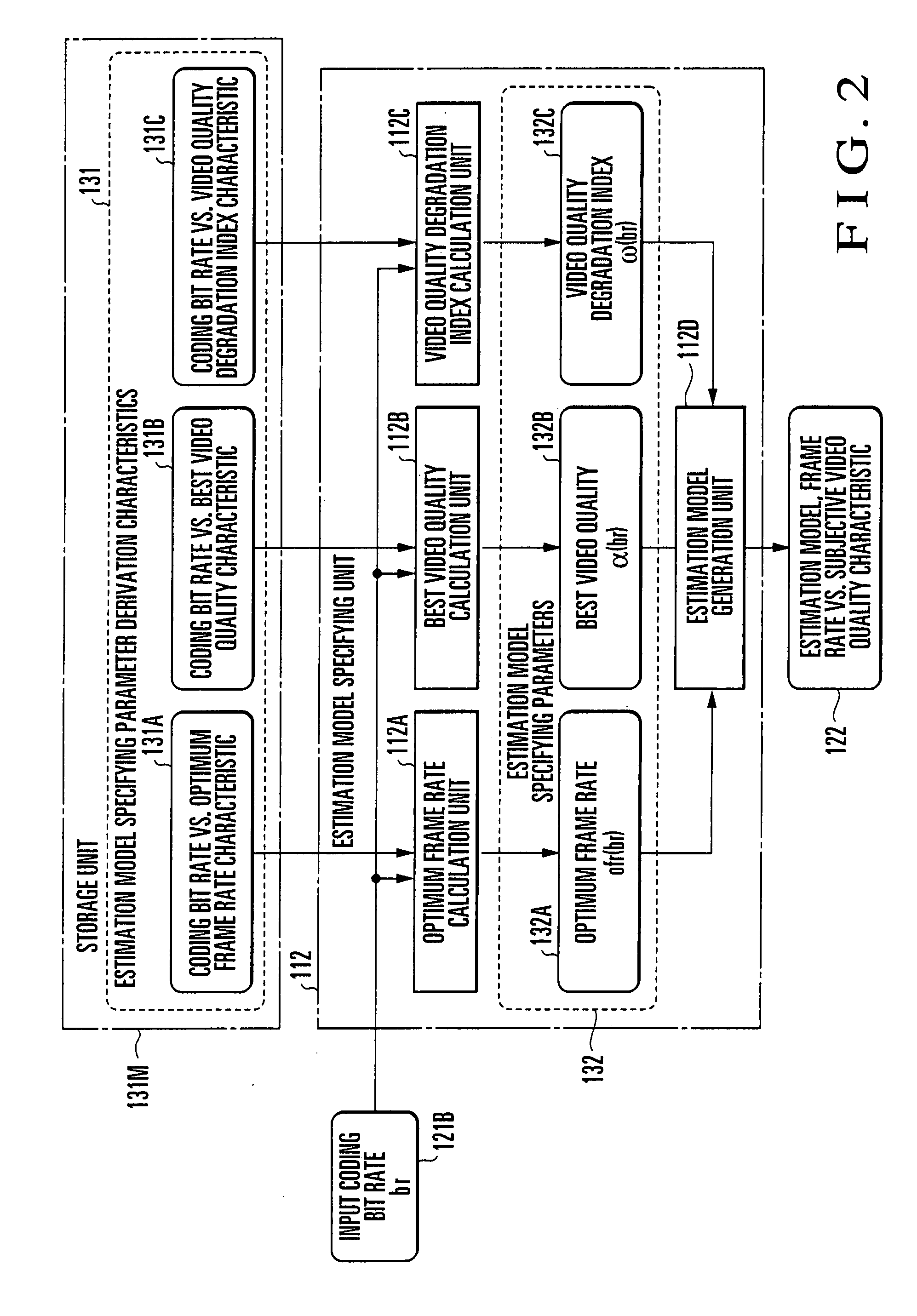

Video Quality Estimation Apparatus, Method, and Program

ActiveUS20090262198A1Possible to obtainRoad vehicles traffic controlTelevision systemsSubjective video qualityFrame rate

In estimating subjective video quality corresponding to main parameters (121 / 221) which are input as an input coding bit rate (121B / 221B) representing the number of coding bit rates per unit time and an input frame rate (121A / 221A) representing the number of frames per unit time of an audiovisual medium, an estimation model specifying unit specifies, on the basis of the input coding bit rate (121B / input frame rate (221A)), an estimation model (122 / 222) representing the relationship between subjective video quality and the frame rate ( / coding bit rate) of the audiovisual medium. Subjective video quality corresponding to the input frame rate (121A / input coding bit rate 221B) is estimated by using the specified estimation model (122 / 222) and output as an estimation value (123 / 223).

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

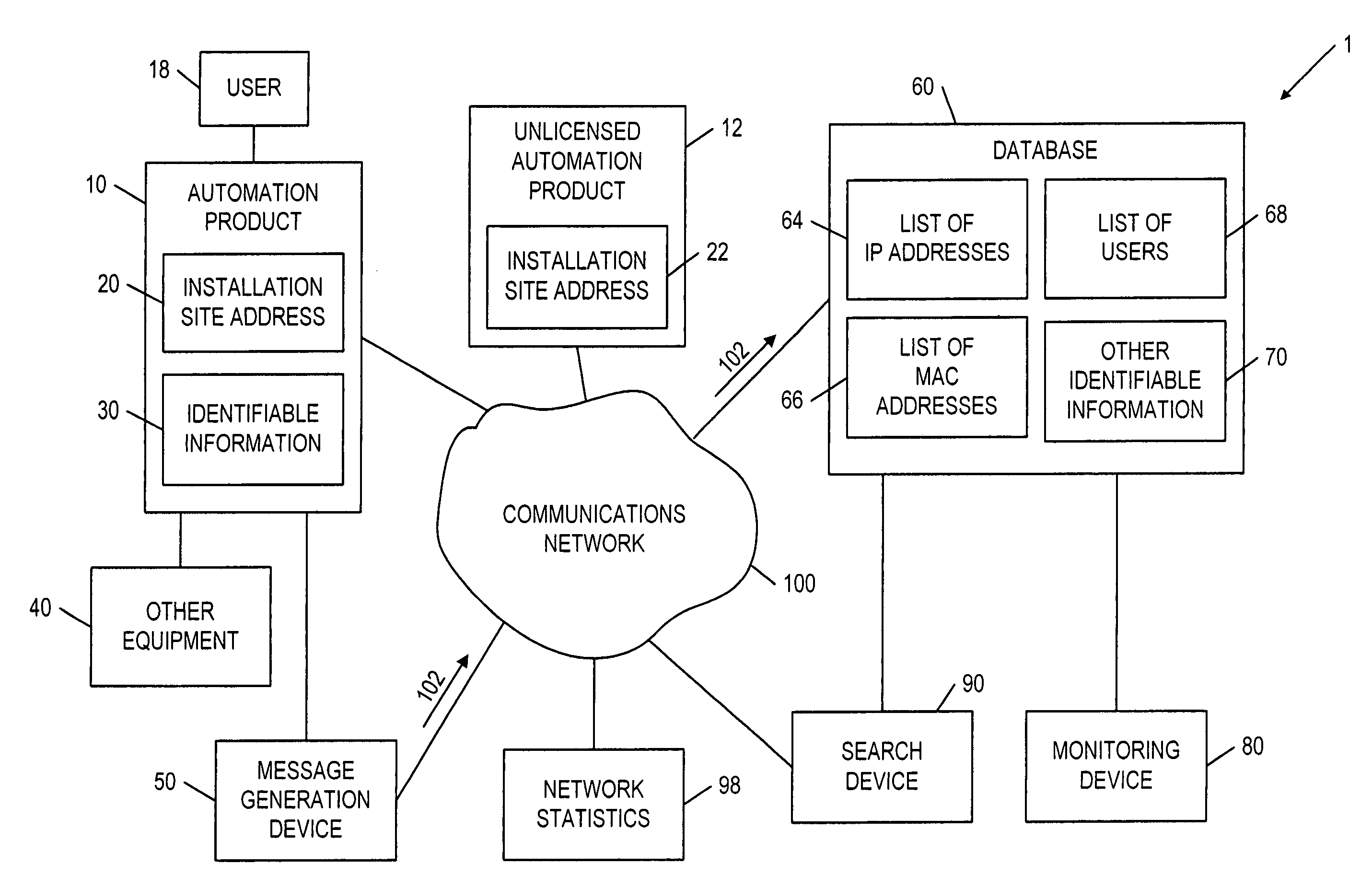

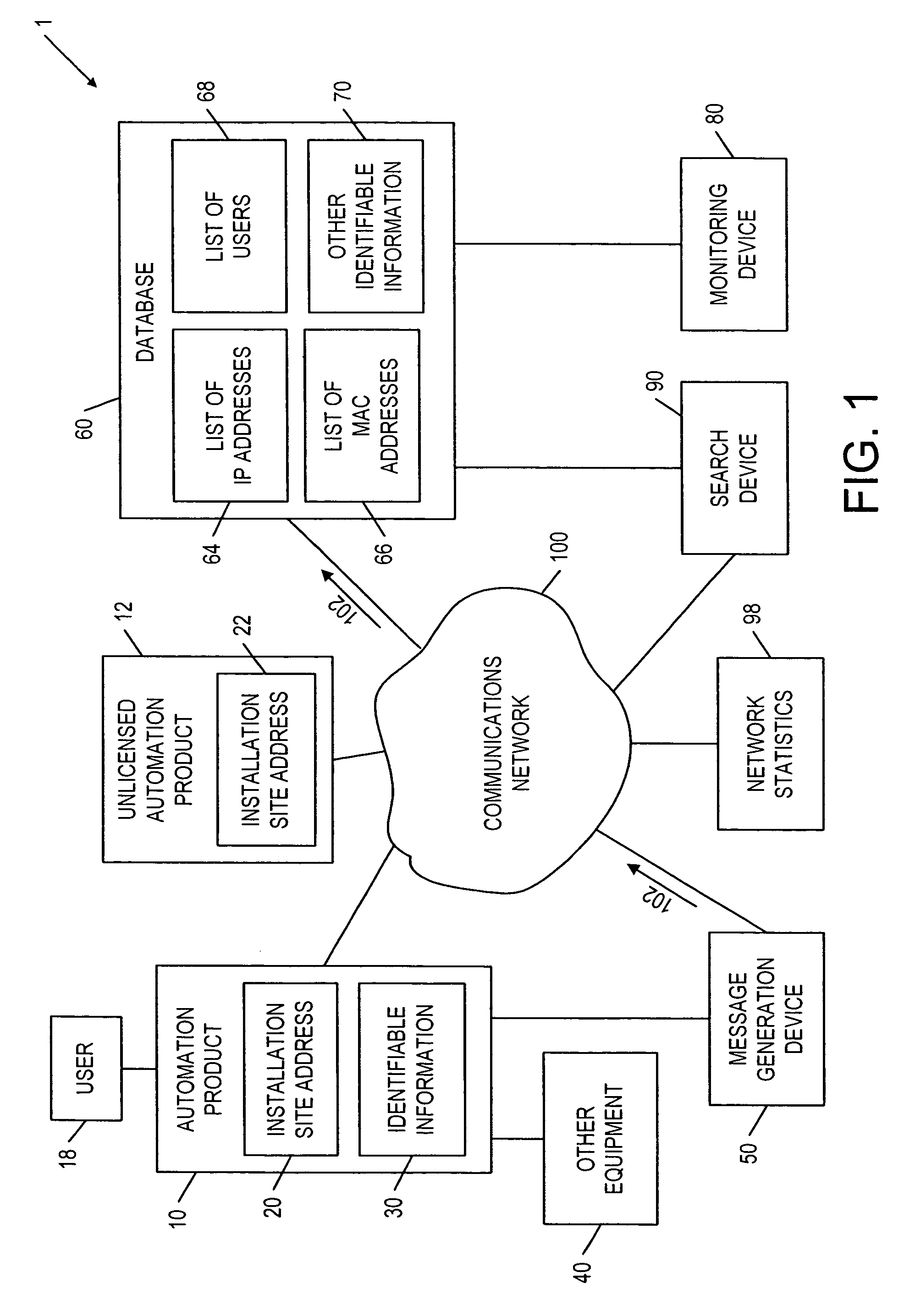

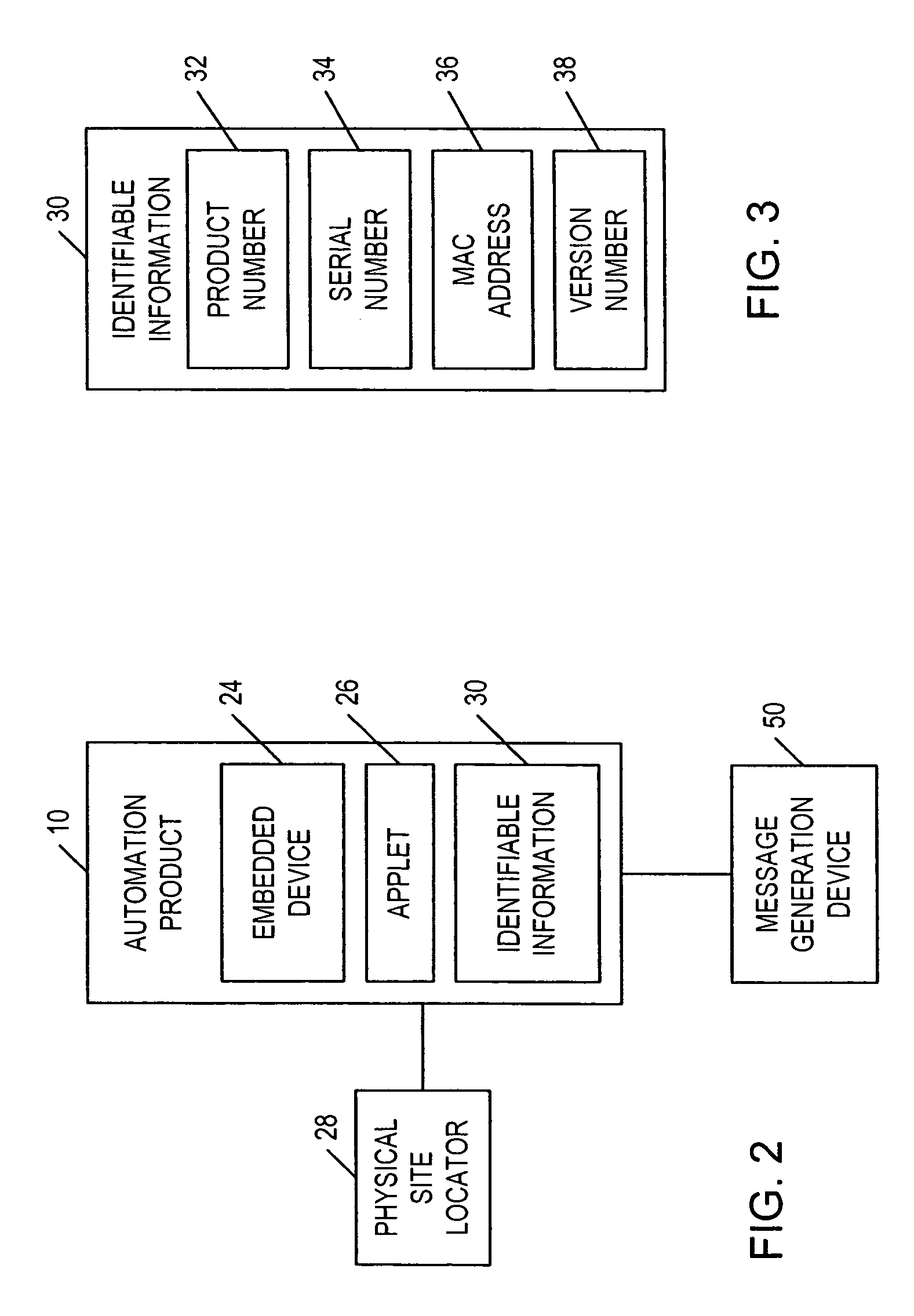

Remote monitoring of factory automation users

InactiveUS6961633B1Possible to obtainComputer controlSimulator controlManufacturing engineeringNetwork monitoring

A method and system for monitoring a factory automation product via a communications network. The factory automation product is installed at an installation site having an installation site address and includes identifiable information such as a product number, a version number, a serial number and a MAC address. By obtaining the installation site address and the identifiable information, it is possible to associate the installation site address to the factory automation product based on the identifiable information. Based on the installation site address, it is possible to determine whether the factory automation product is used in violation of licenses.

Owner:SCHNEIDER AUTOMATION INC

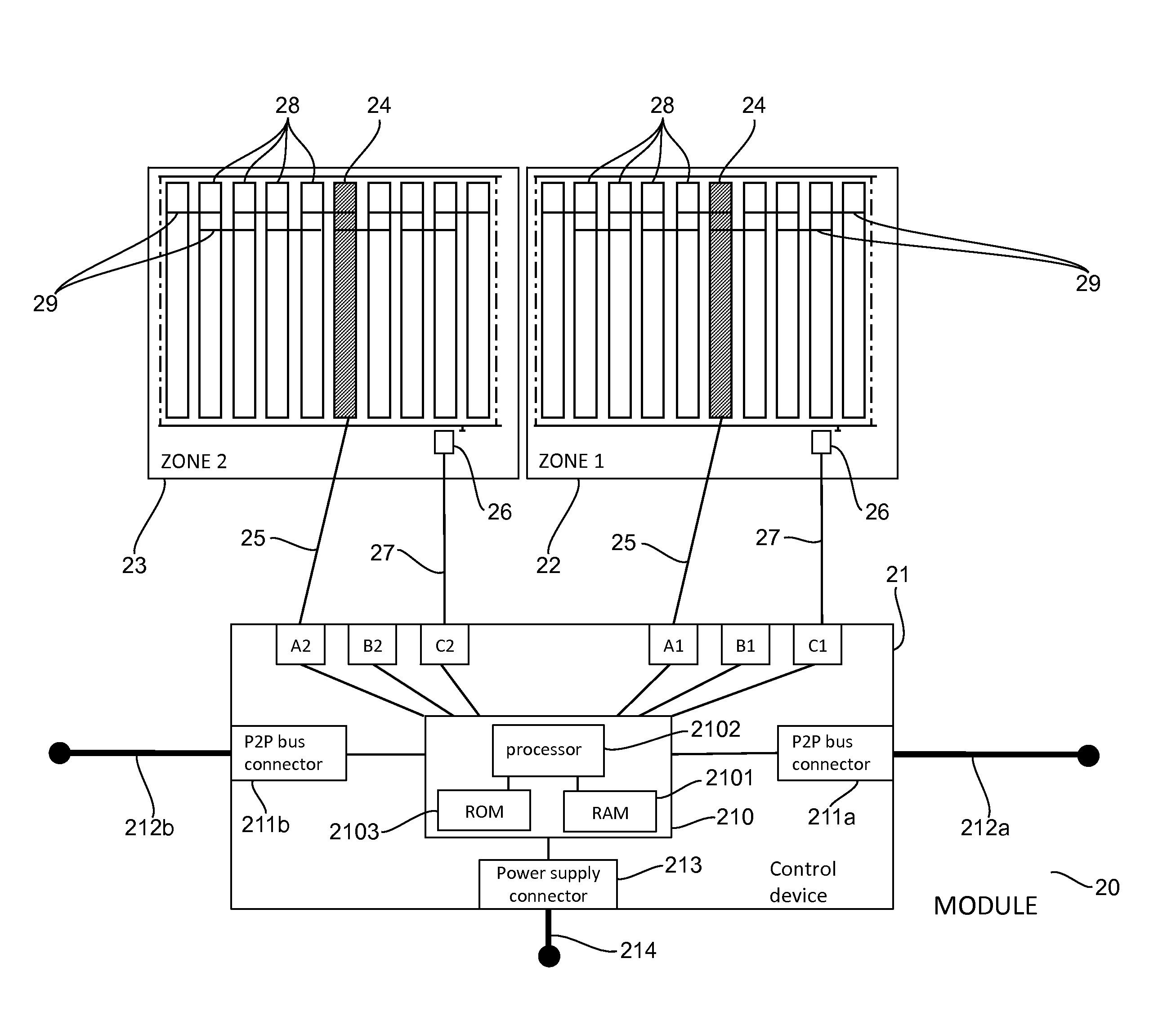

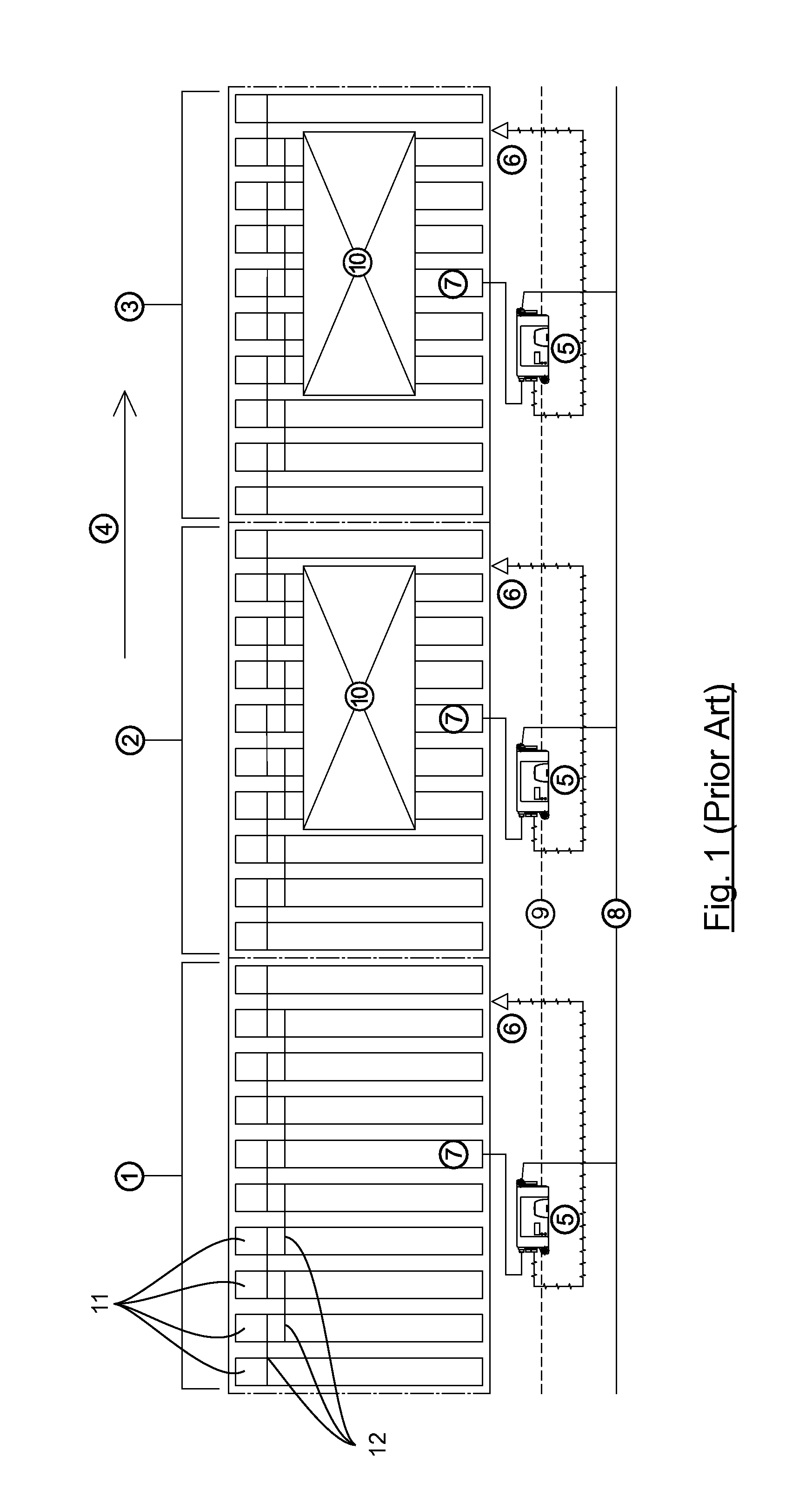

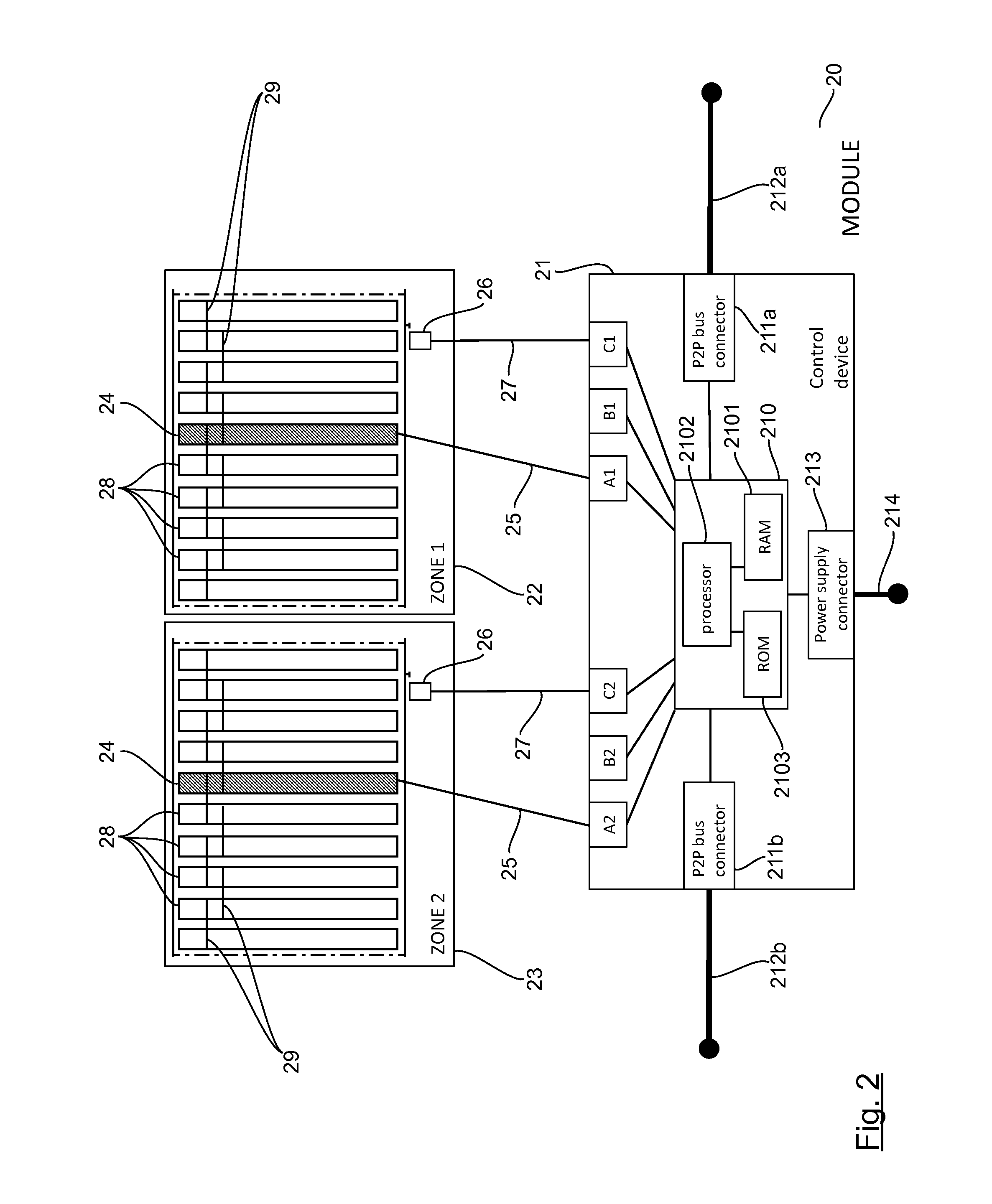

Modular conveyor system and corresponding method

ActiveUS20150151921A1Promote migrationReduce in quantityComputer controlDigital data processing detailsEngineeringCommunication device

A conveyor system includes successive modules forming a conveyor segment, each module includes a control device associated with, and controlling, at least one zone. Each control device includes a communication device for communicating with the control devices included in the adjacent modules. The control devices execute a mechanism for propagation and enrichment of quantitative segment information, from the two end zones of the conveyor segment, thereby providing for each zone: a first quantitative segment information item (propagated and enriched from upstream to downstream and relating to all of the zones in an upstream sub-segment located upstream from the zone) and / or a second quantitative segment information item (propagated and enriched from downstream to upstream and relating to all of the zones in a downstream sub-segment located downstream from the zone). Each control device dynamically adapts the behaviour of each zone it controls, according to the available quantitative segment information.

Owner:SAVOYE

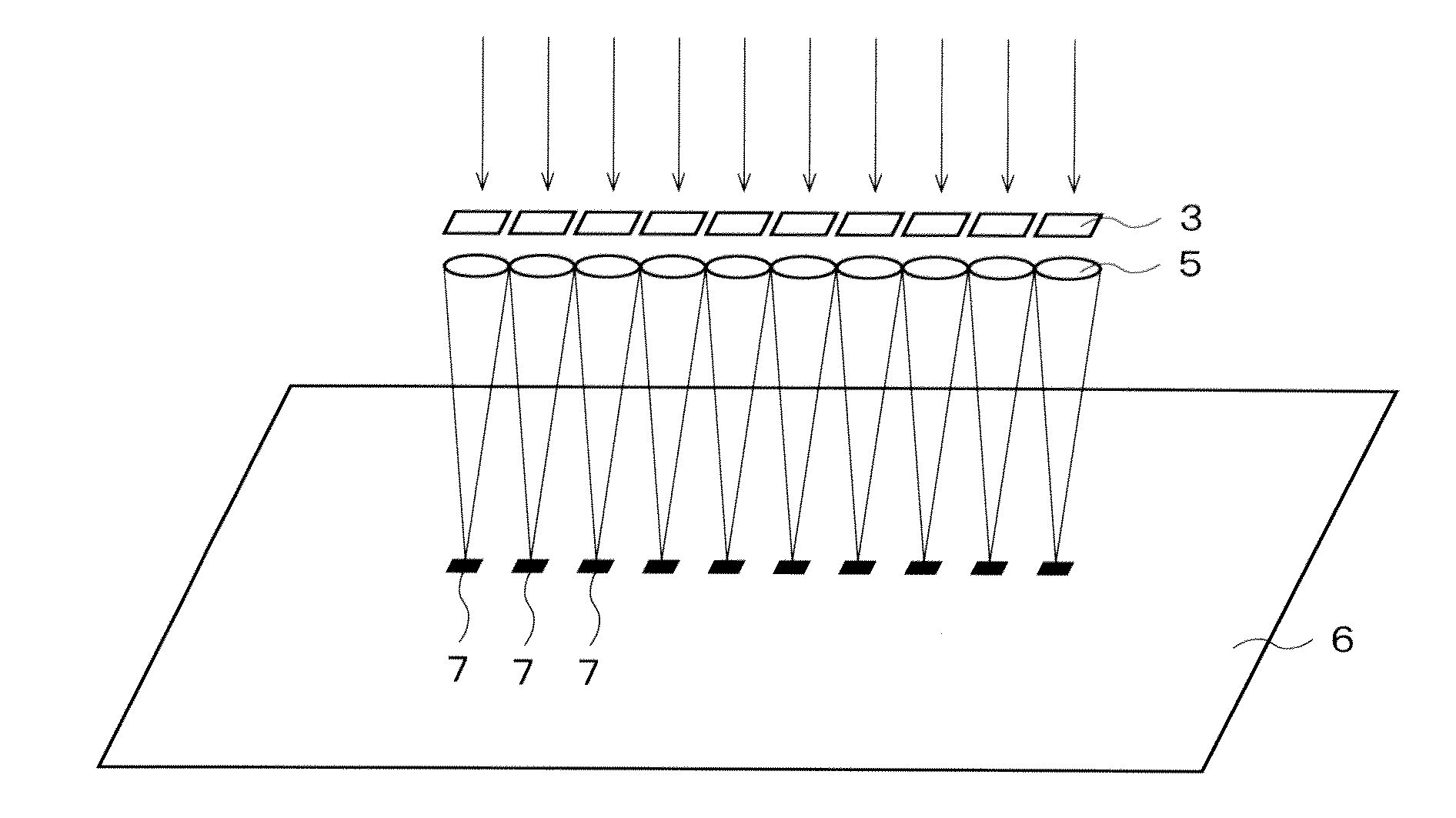

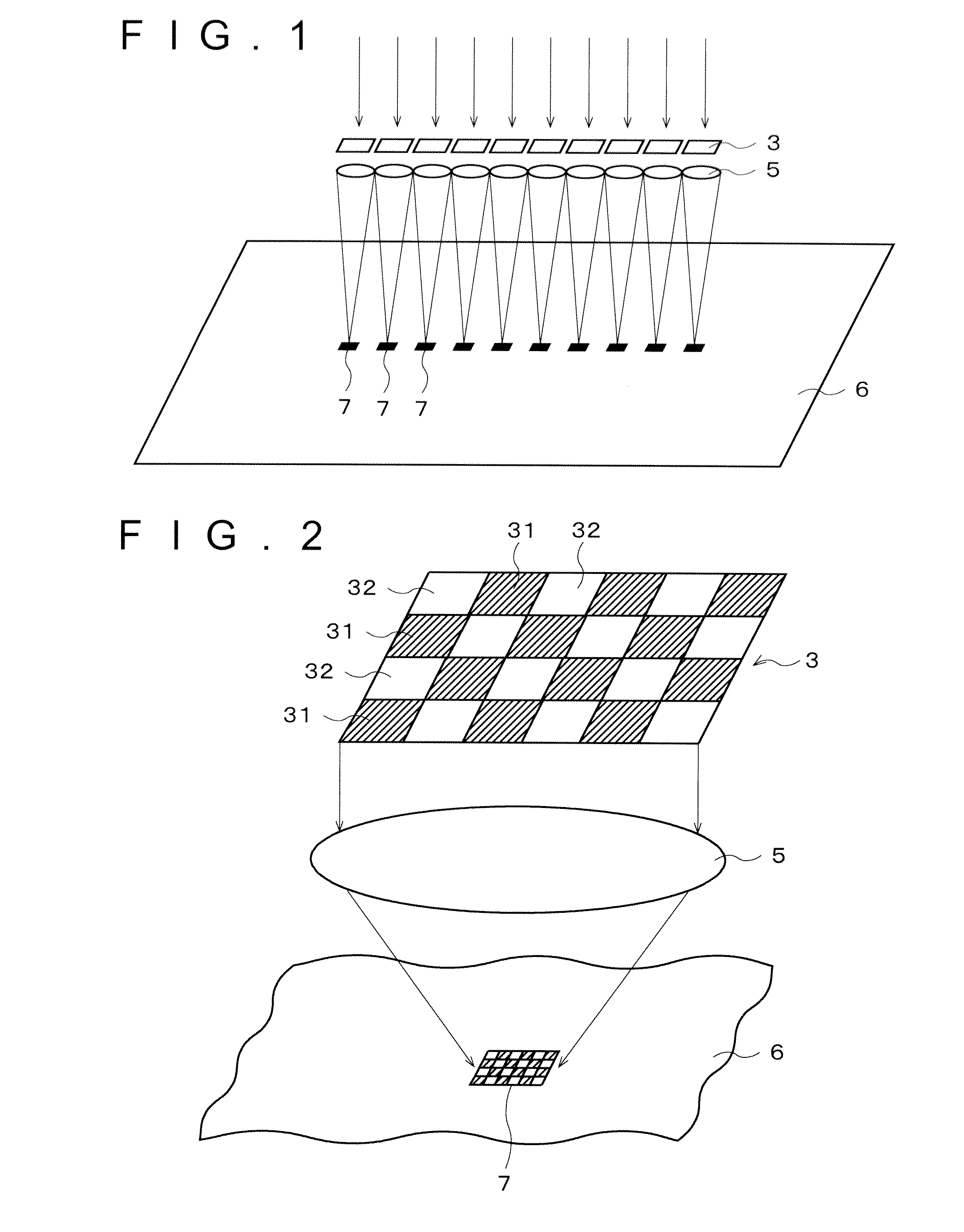

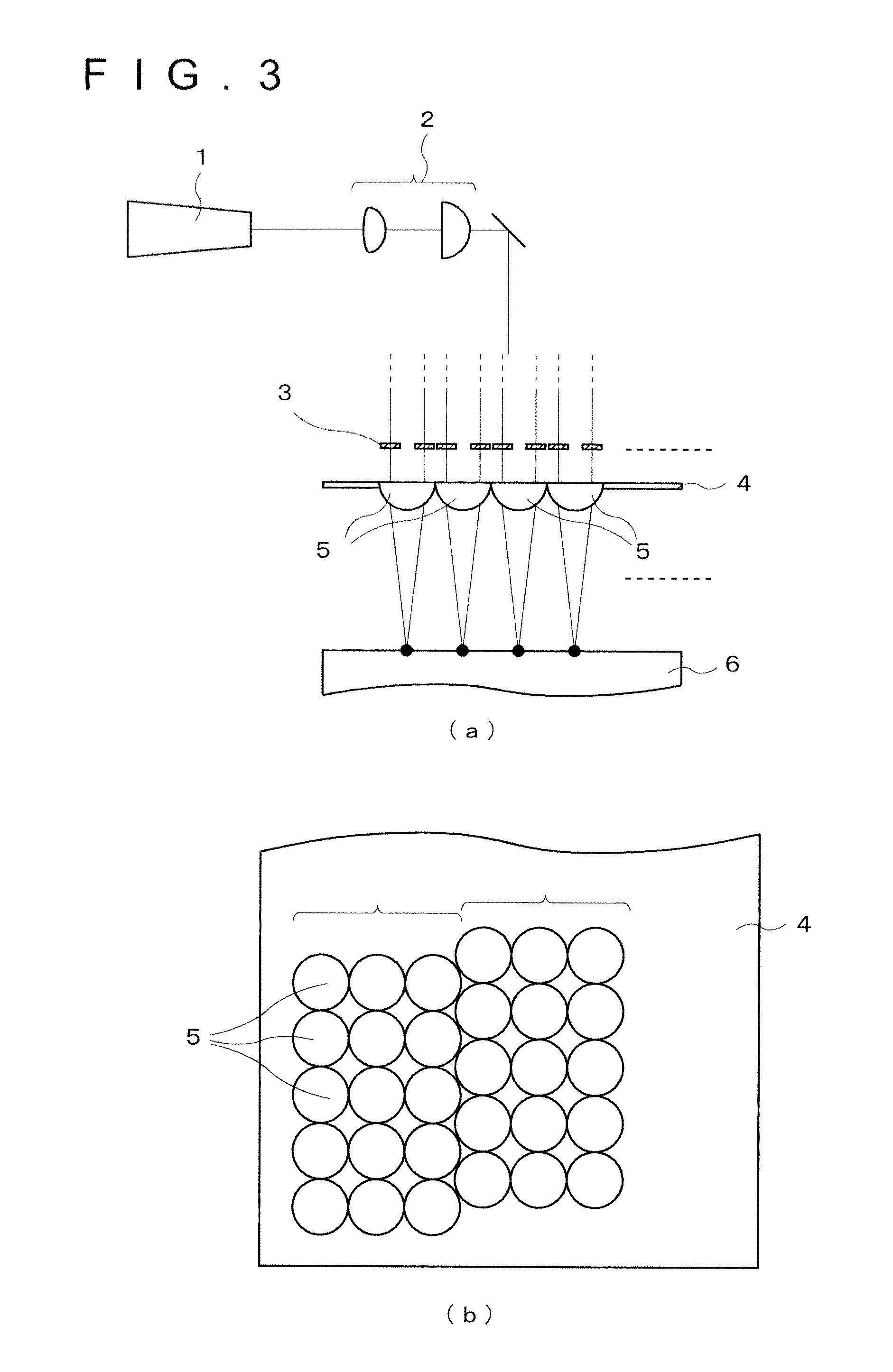

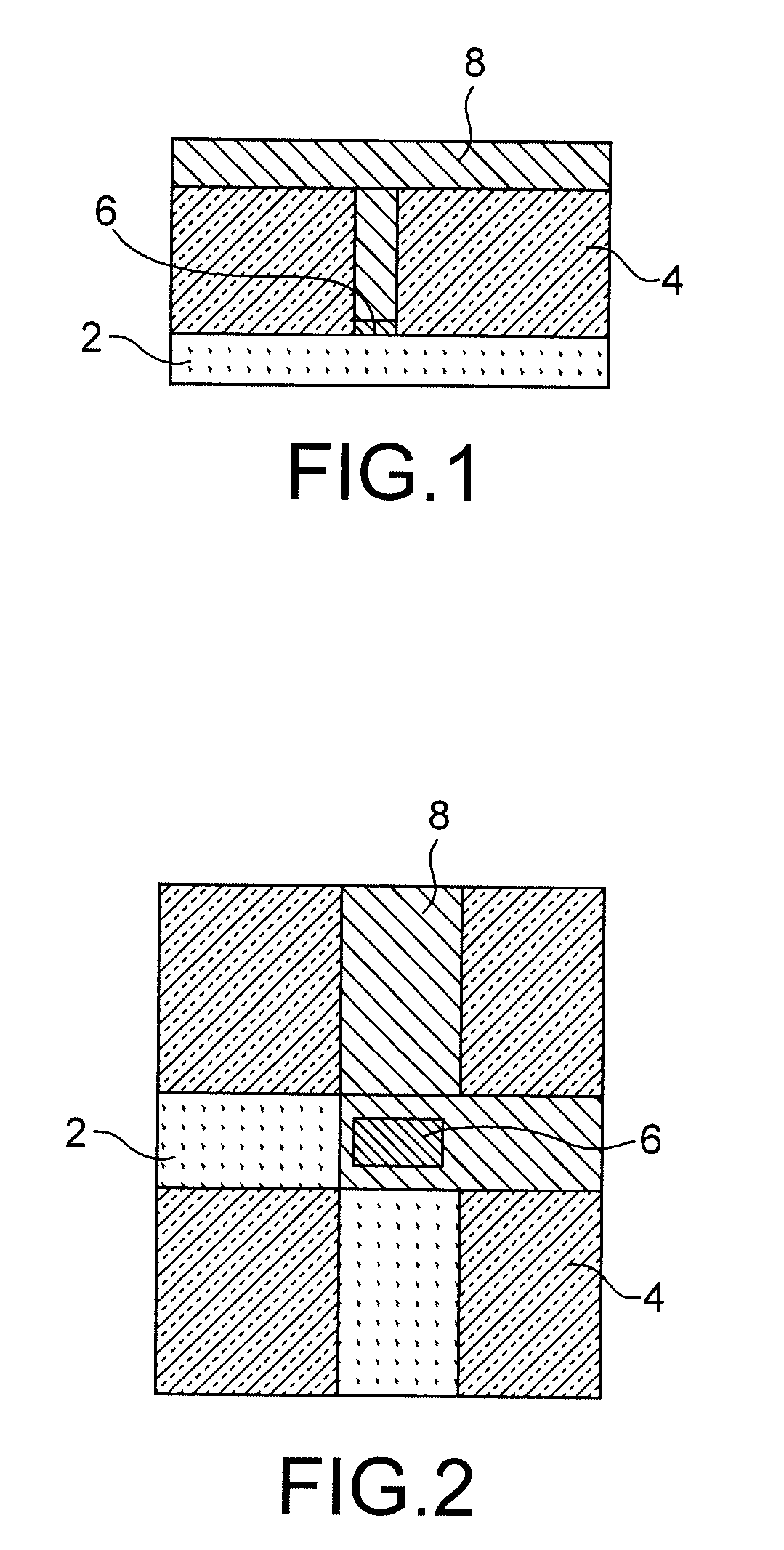

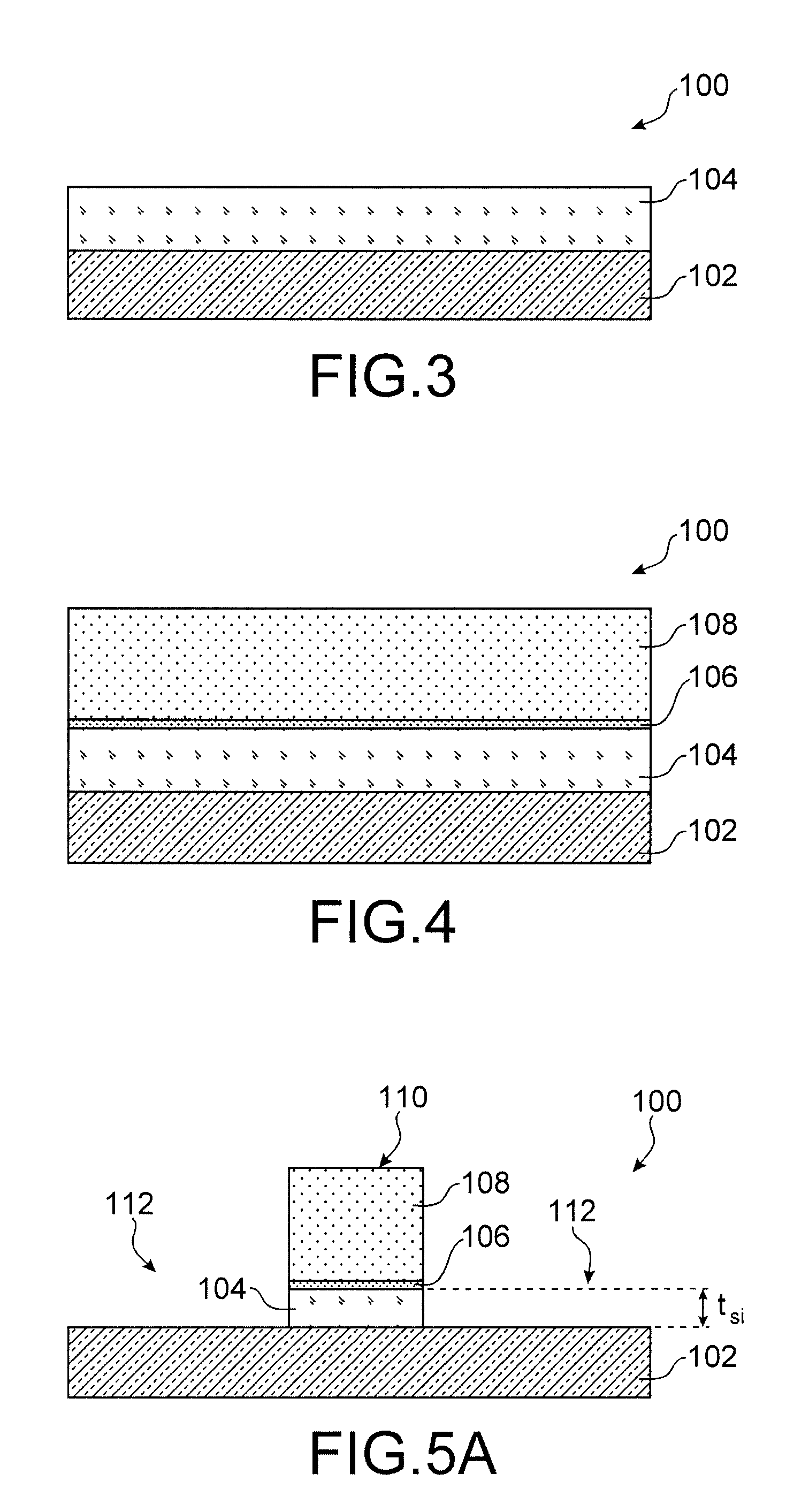

Device and method for forming low-temperature polysilicon film

InactiveUS20120220140A1Increase in sizePossible to obtainTransistorPolycrystalline material growthOptoelectronicsLaser light

Provided is a forming device and method making it possible to obtain a low-temperature polysilicon film in which the size of crystal grains fluctuates minimally, and is uniform. A mask has laser-light-blocking areas and laser-light-transmission areas arranged in the form of a grid such that the light-blocking areas and transmission areas are not adjacent to one another. Laser light is directed by the microlenses through the masks to planned channel-area-formation areas. The laser light transmitted by the transmission areas is directed onto an a-Si:H film, annealing and polycrystallzing the irradiated parts thereof. The mask is then removed, and when the entire planned channel-area-formation area is irradiated with laser light, the already-polycrystallized area, having a higher melting point, does not melt, while the area in an amorphous state melts and solidifies, leading to polycrystallization. The grain size of the polysilicon film obtained is regulated by the light-blocking areas and transmission areas and is thus controlled to a predetermined range.

Owner:V TECH CO LTD

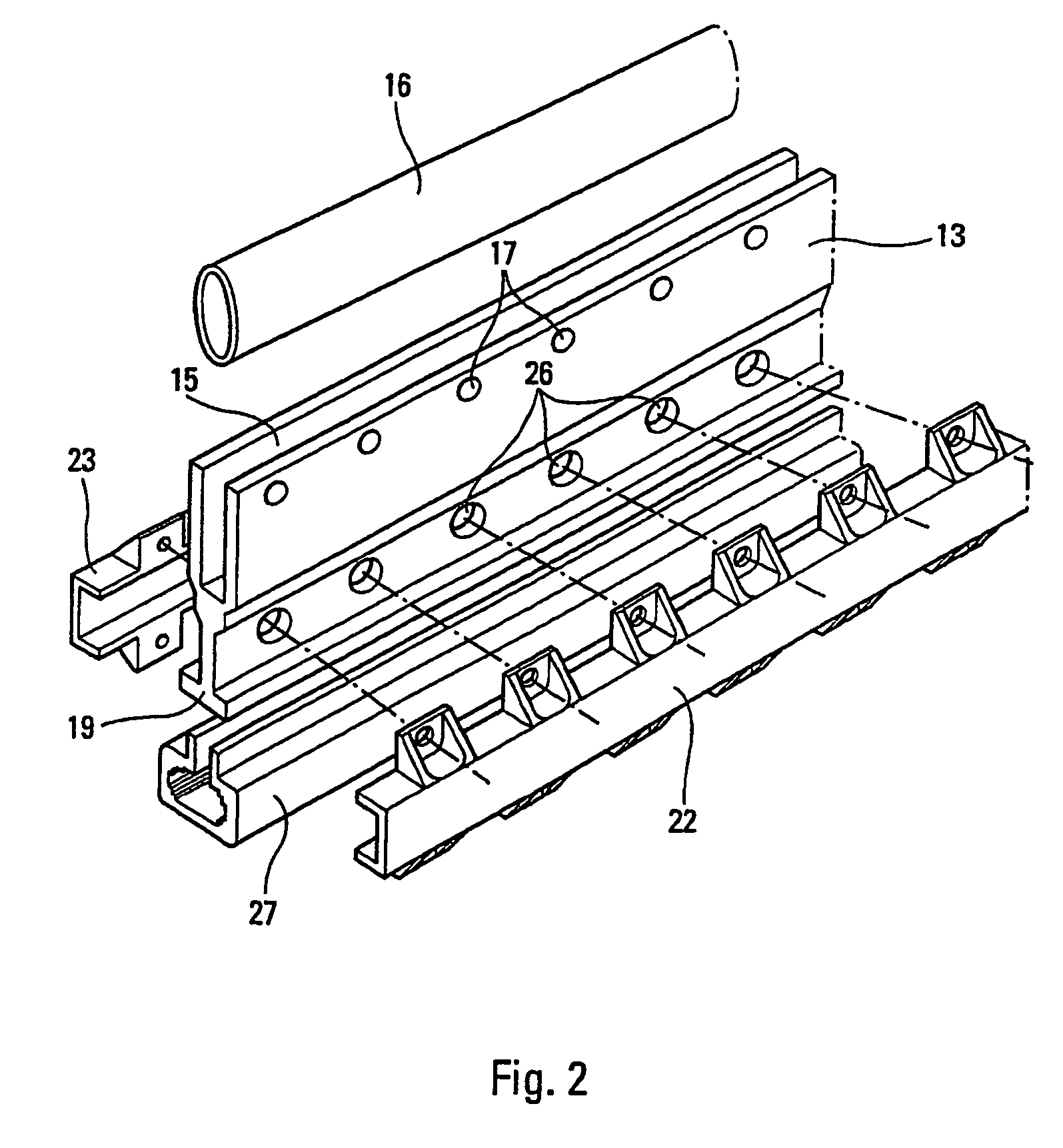

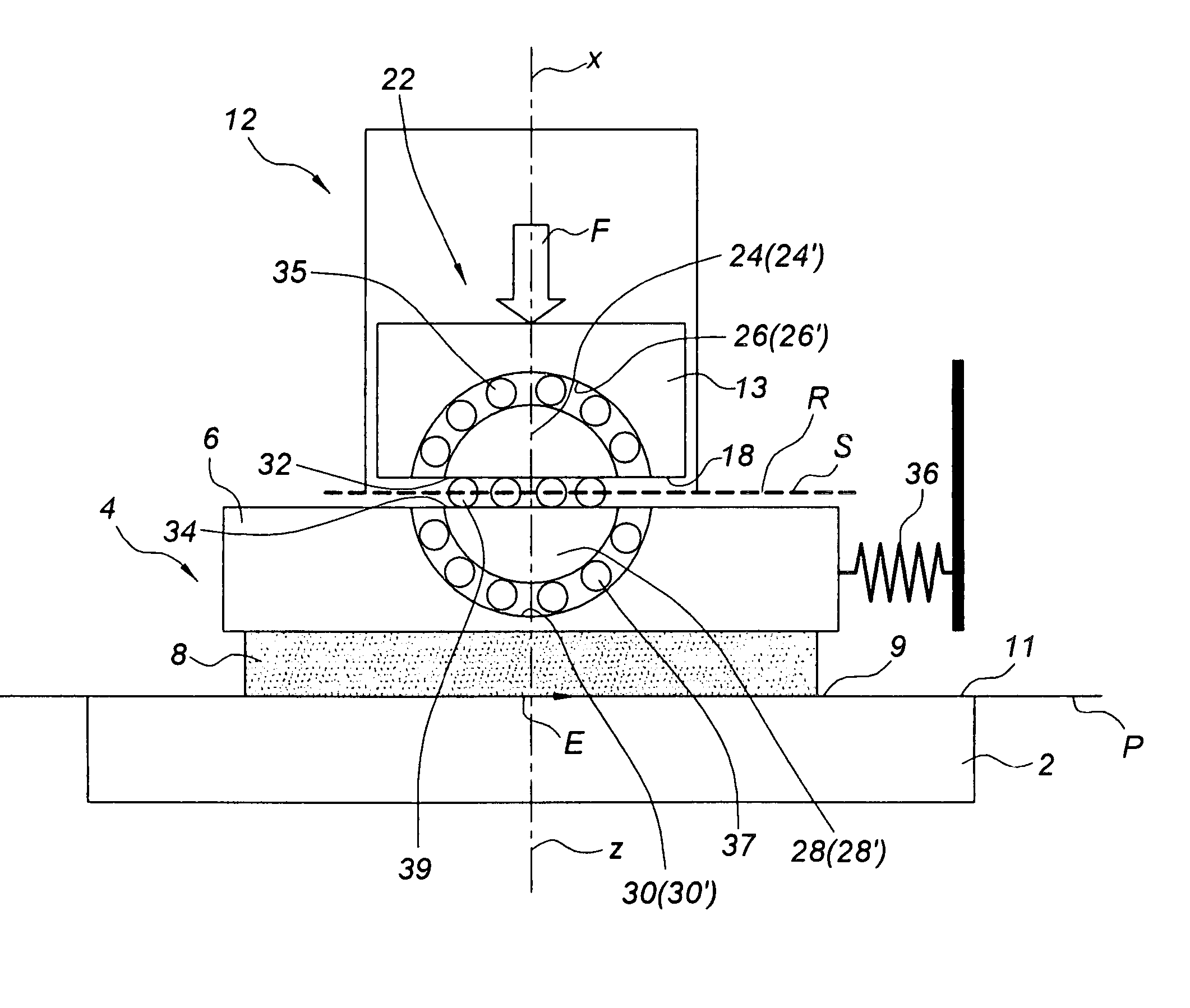

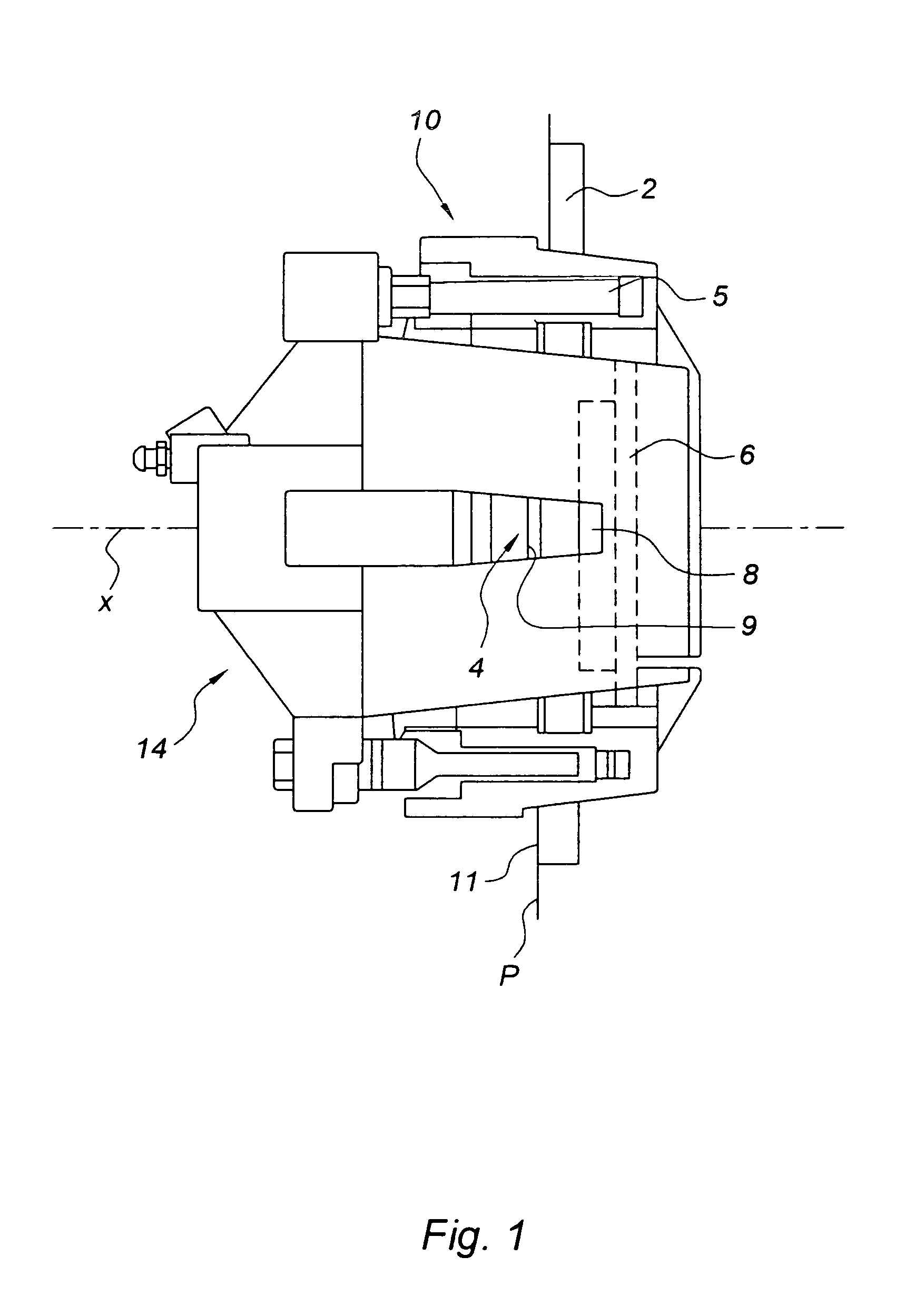

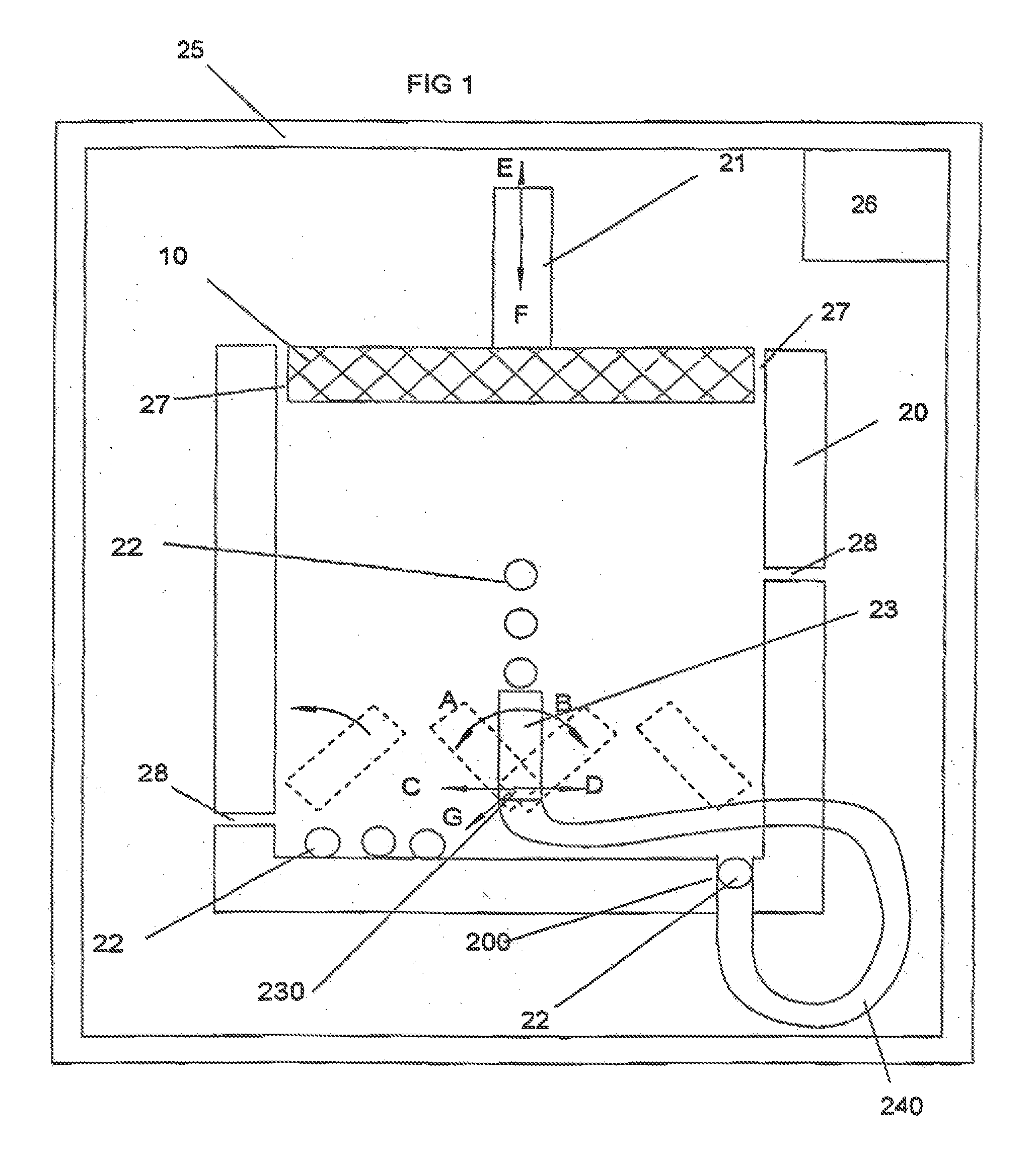

Device for generating nanostructures

InactiveUS7300622B2Drawback can be obviatedPossible to obtainSolid state diffusion coatingBurnishing machinesDiffusionChemical compound

The present invention concerns a method for generating nanostructures in order to obtain in an area on the surface of a metal piece (10) a nanostructured layer of defined thickness, characterized in that it comprises: a step for projecting onto an impact point in the area of the surface of the piece (10) to be treated, for a given duration, at a given speed and at variable incidences at the same impact point, a given quantity of perfectly spherical balls (22) of given dimensions, reused continuously during the projection; repetition of the preceding step with a shift of the impact point so that the impact points as a group cover the entire surface of the piece to be treated; a step for treatment by diffusion of chemical compounds into the nanostructured layer generated during the step for implementing the method for generating nanostructures.

Owner:UNIVERSITY OF TECHNOLOGY OF TROYES +1

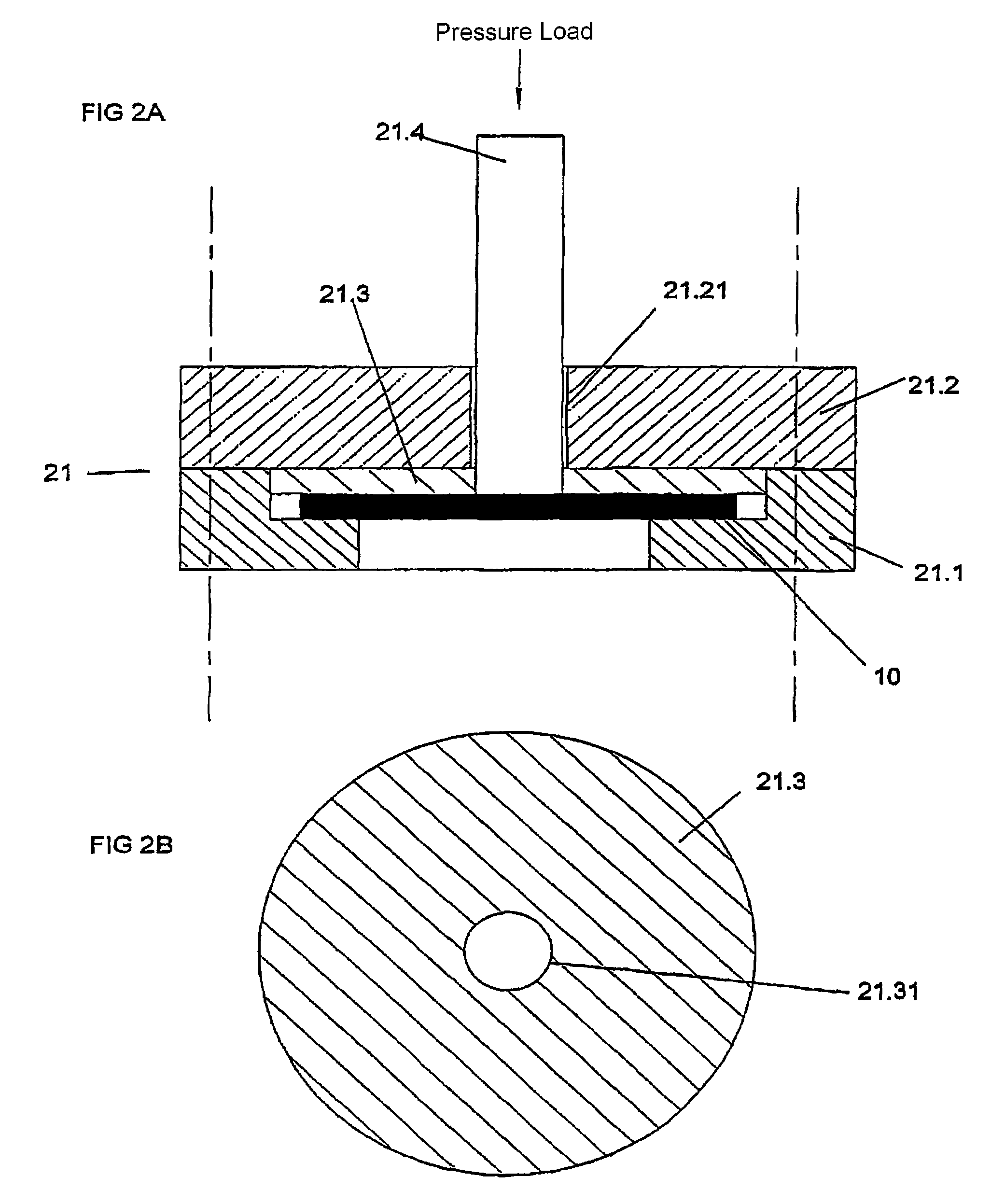

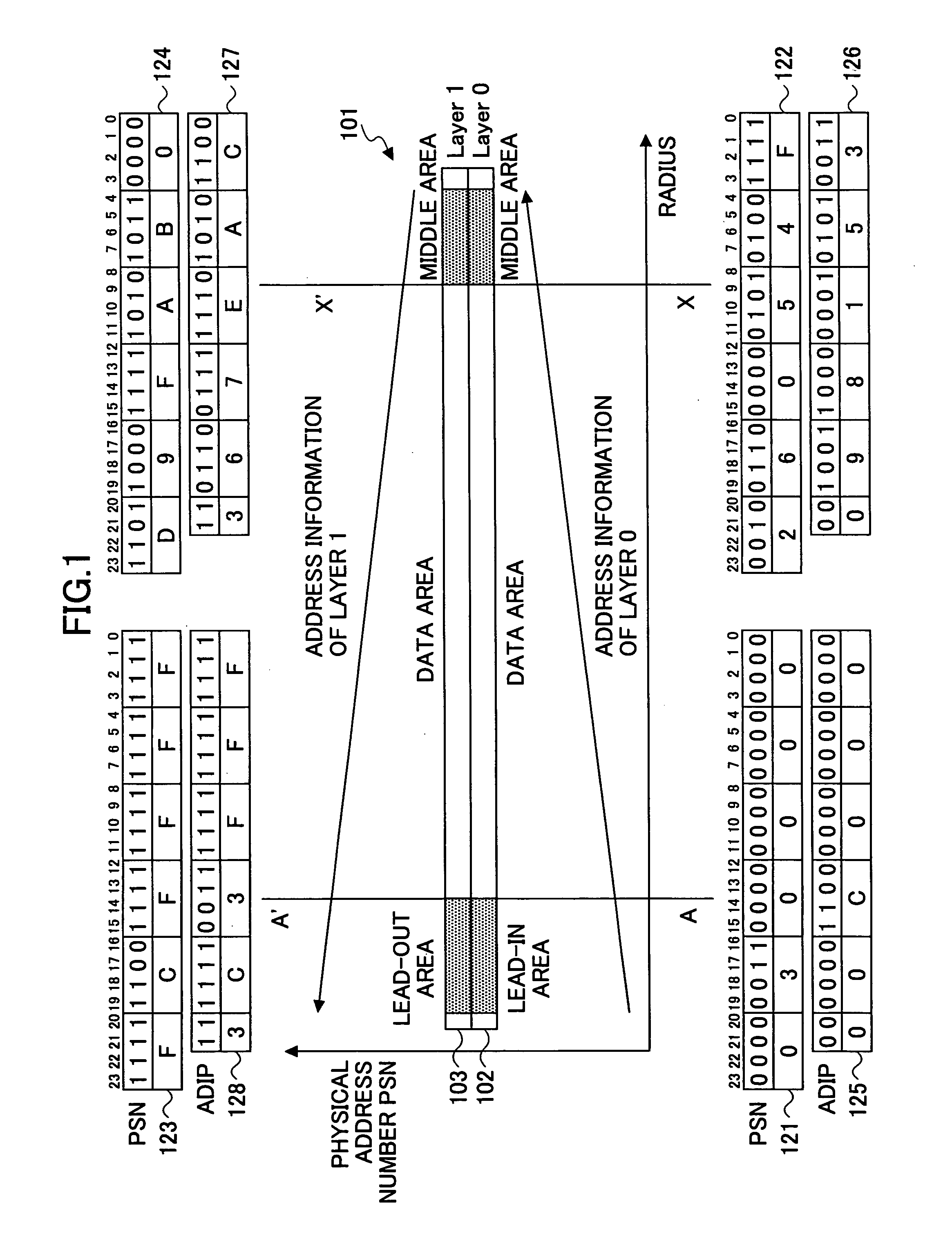

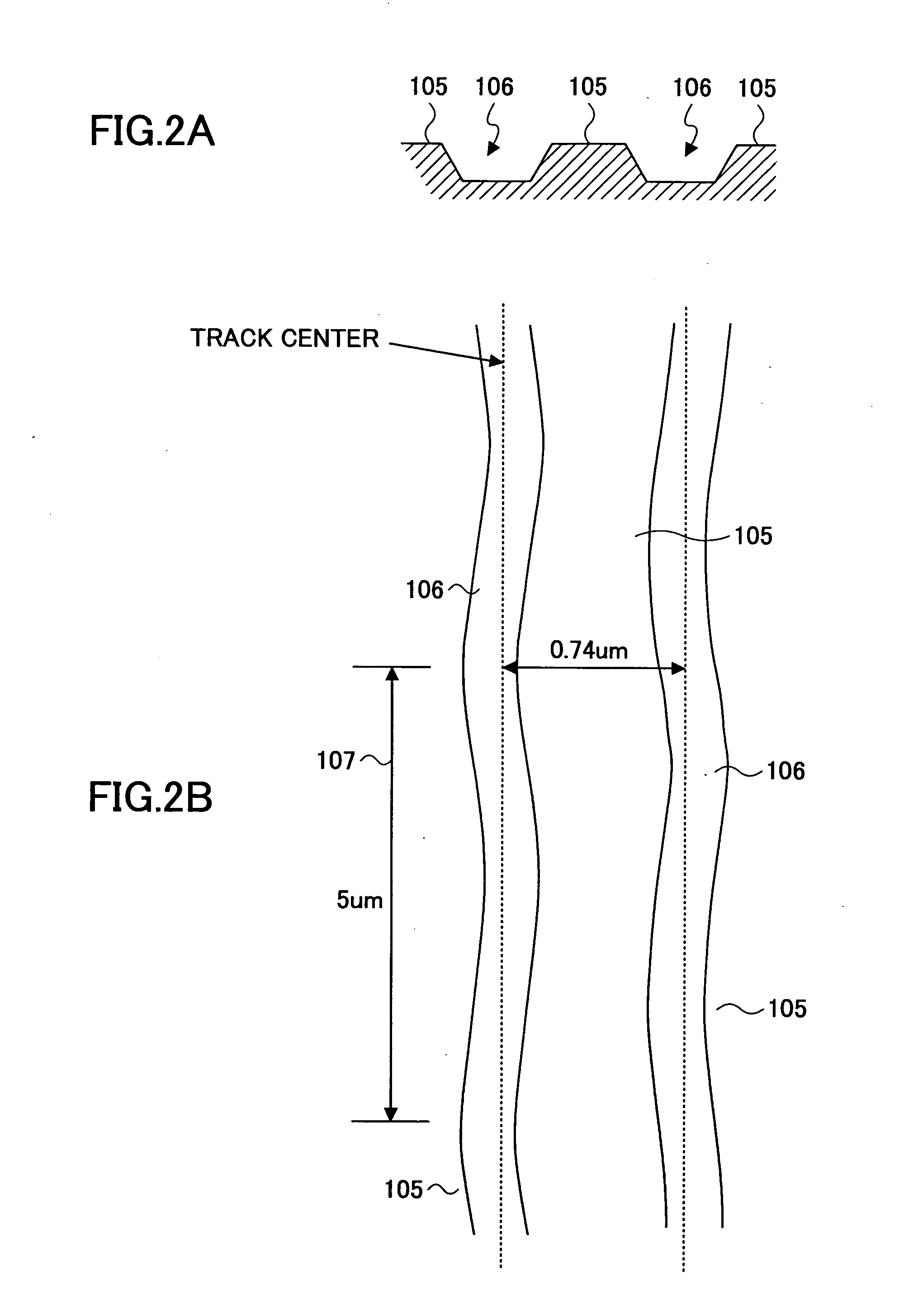

Optical information recording medium, optical information recording apparatus, information processing apparatus, optical information recording method, program and recording medium

ActiveUS20050041546A1Possible to obtainEasy to getFilamentary/web record carriersRecord information storageComputer hardwareInformation processing

An optical disk 101 includes a plurality of recording layers 102 and 103 and allows recording of information on each of the recording layers 102 and 103. A spiral guide groove having wobbles meandering in radial directions of the optical disk 101 is formed on each of the recording layers 102 and 103. Recording data can be recorded on or between the guide grooves. ADIP, which is address information embedded by wobble modulation of the guide groove, is recorded. The address information indicates positional information with respect to a radial direction of the recording layer 102 or 103 of the optical disk 101 on which the wobbles of the guide groove are formed.

Owner:RICOH KK

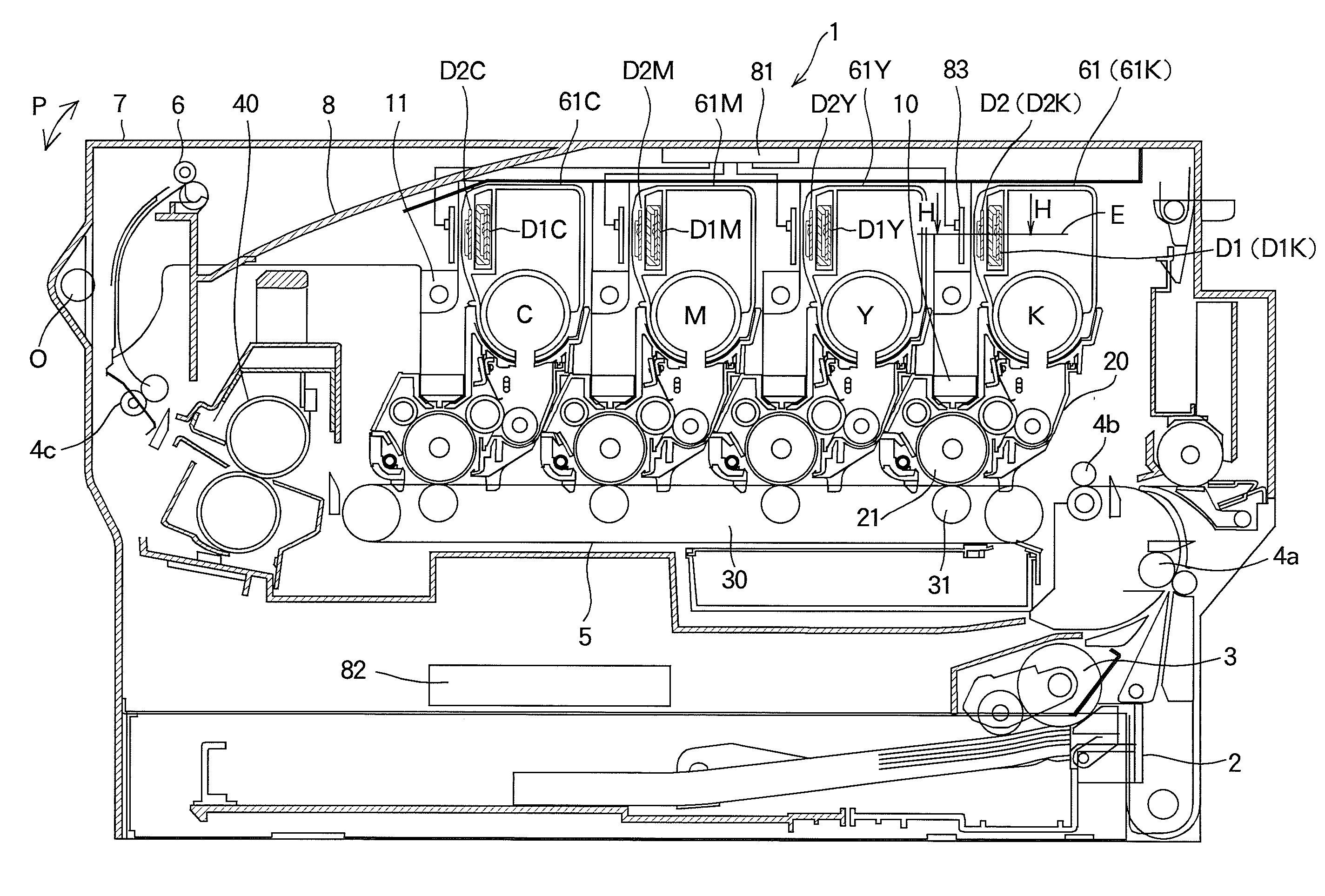

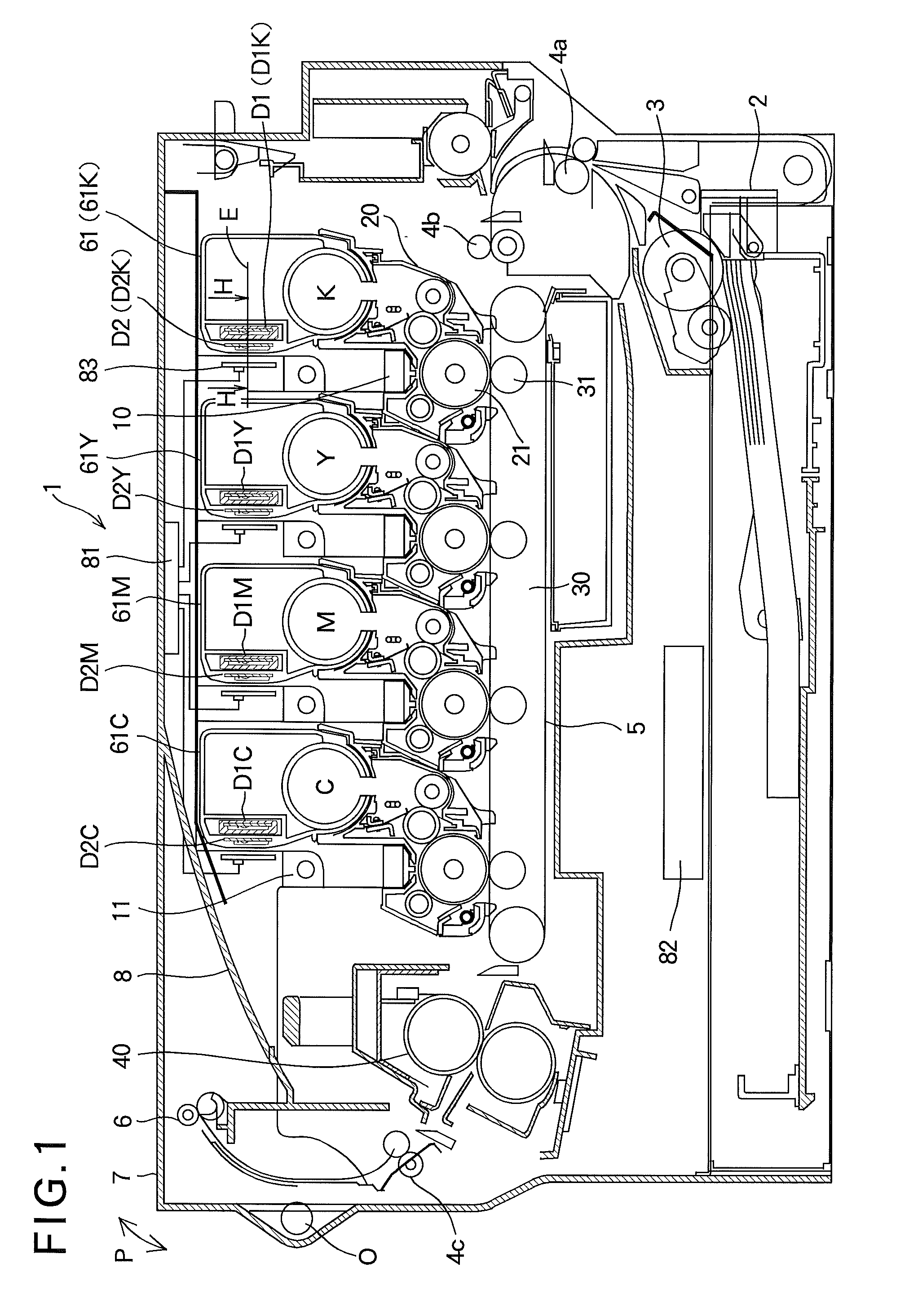

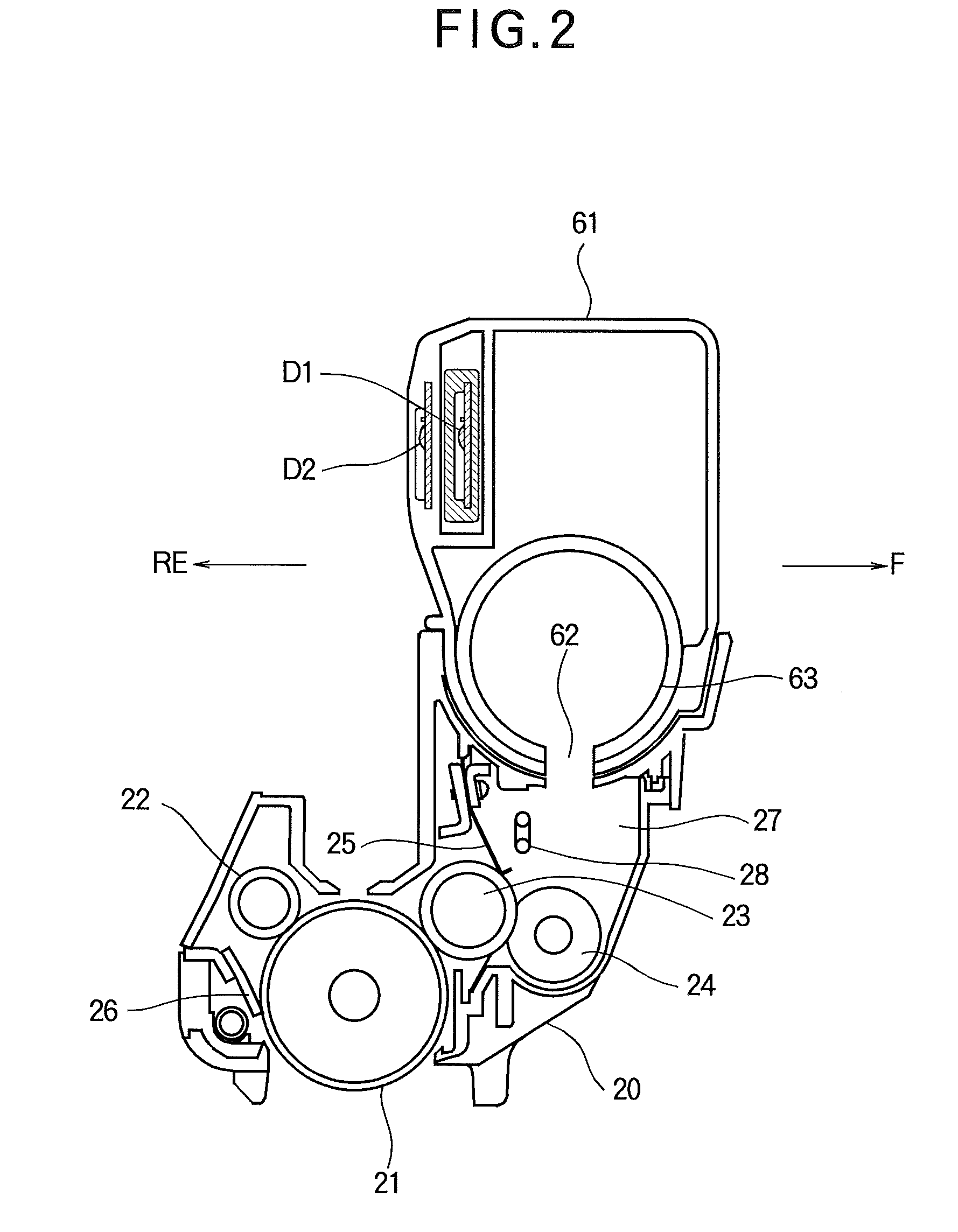

Information processing apparatus and image forming apparatus

ActiveUS20120274992A1Possible to obtainElectrography/magnetographyPictoral communicationInformation processingComputer hardware

An information processing apparatus includes a first storage unit that stores first information regarding a first unit, a second storage unit that stores second information regarding a second unit, and a reading unit disposed so as to face the first unit and the second unit. The reading unit reads the first information stored in the first storage unit and the second information stored in the second storage unit.

Owner:OKI ELECTRIC IND CO LTD

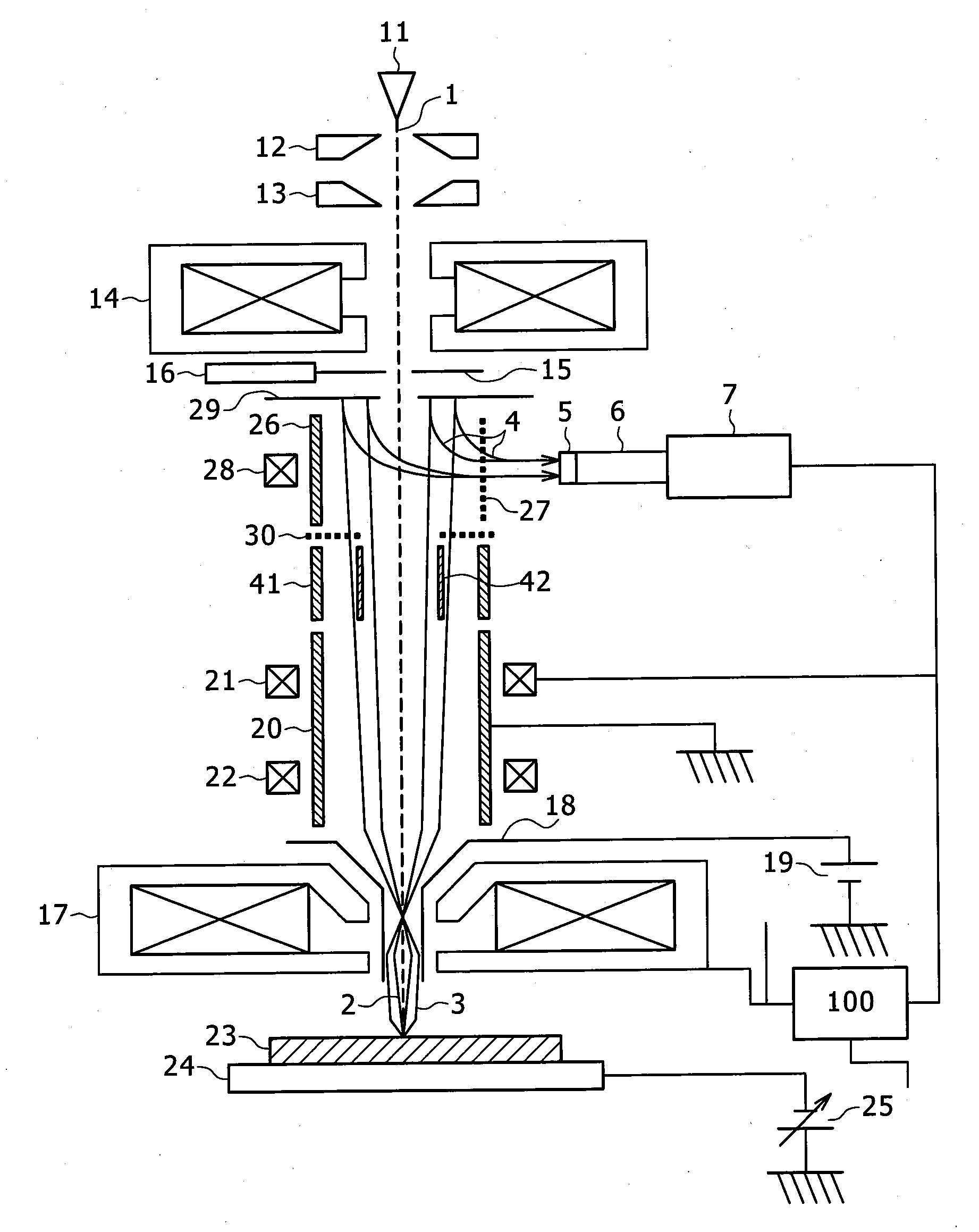

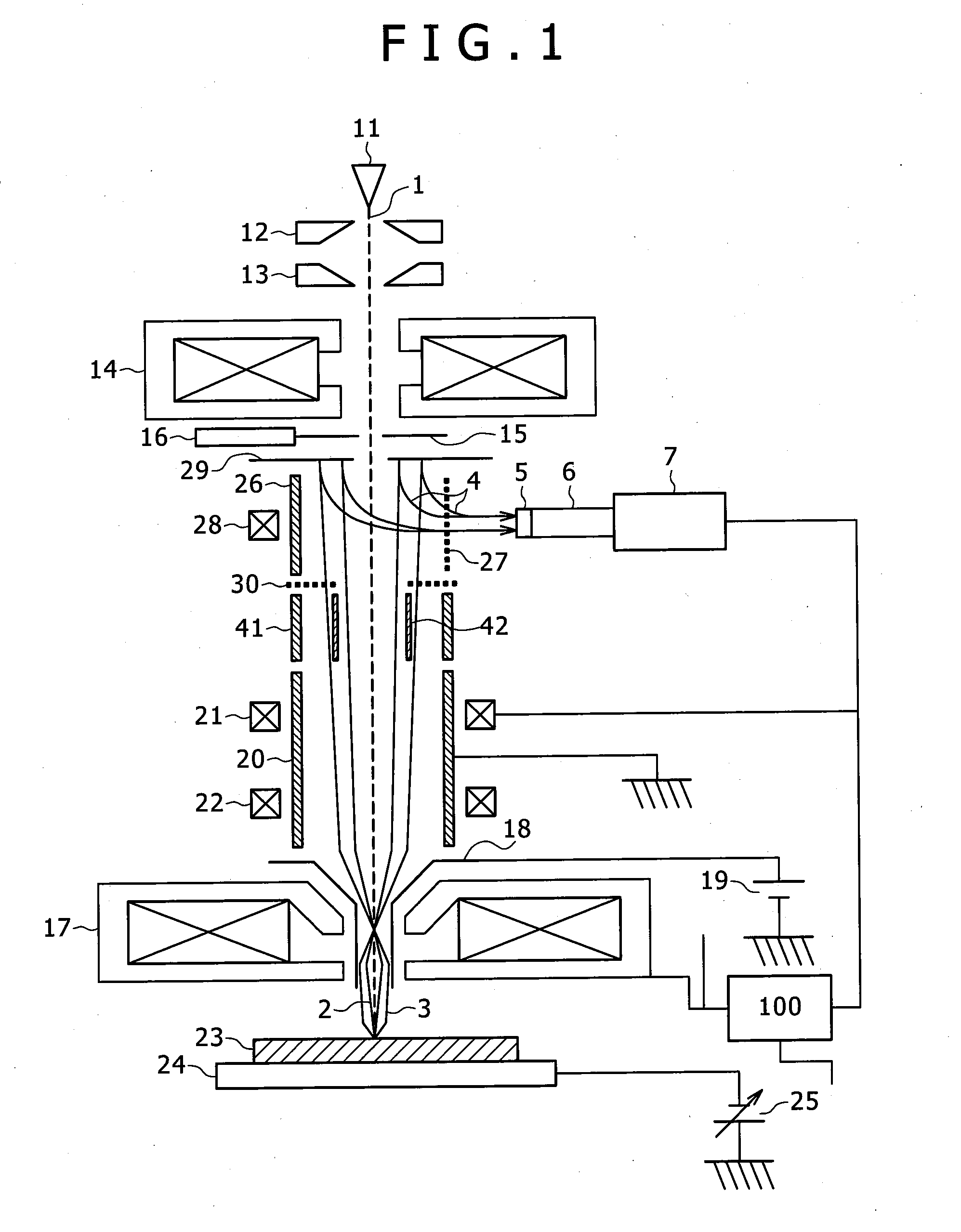

Electron microscope

InactiveUS20090039264A1Improve spatial resolutionEliminate potential gradientMaterial analysis using wave/particle radiationElectric discharge tubesScanning electron microscopeElectron microscope

Disclosed herein are a method for applying, while a charged particle beam is in a state being irradiated toward the sample, a voltage to the sample so that the charged particle beam does not reach the sample (hereafter such state may be referred to as a mirror state) and detecting information on a potential of a sample using a signal obtained then, and a device for automatically adjusting conditions of the device based on the result of measuring.

Owner:HITACHI HIGH-TECH CORP

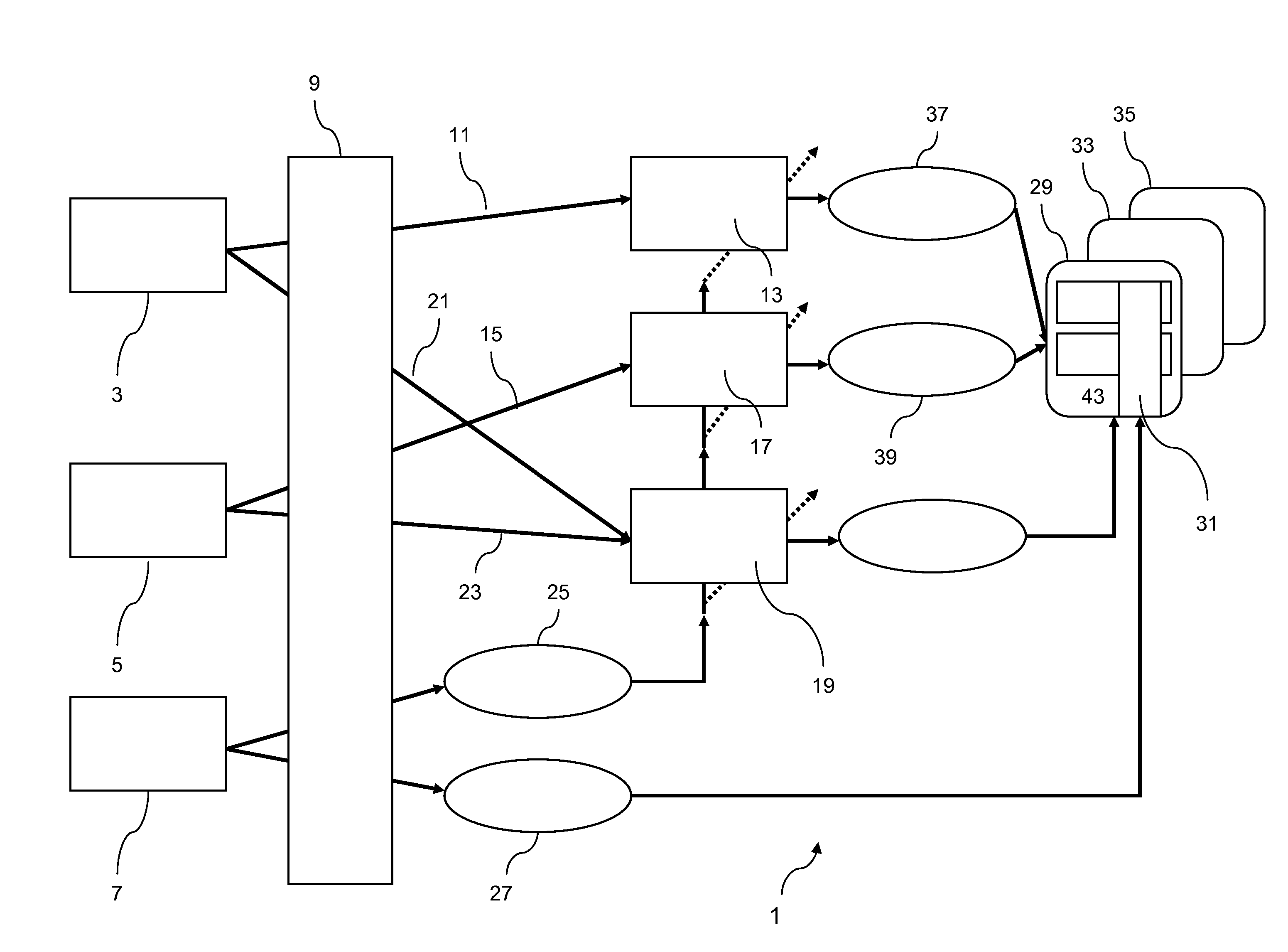

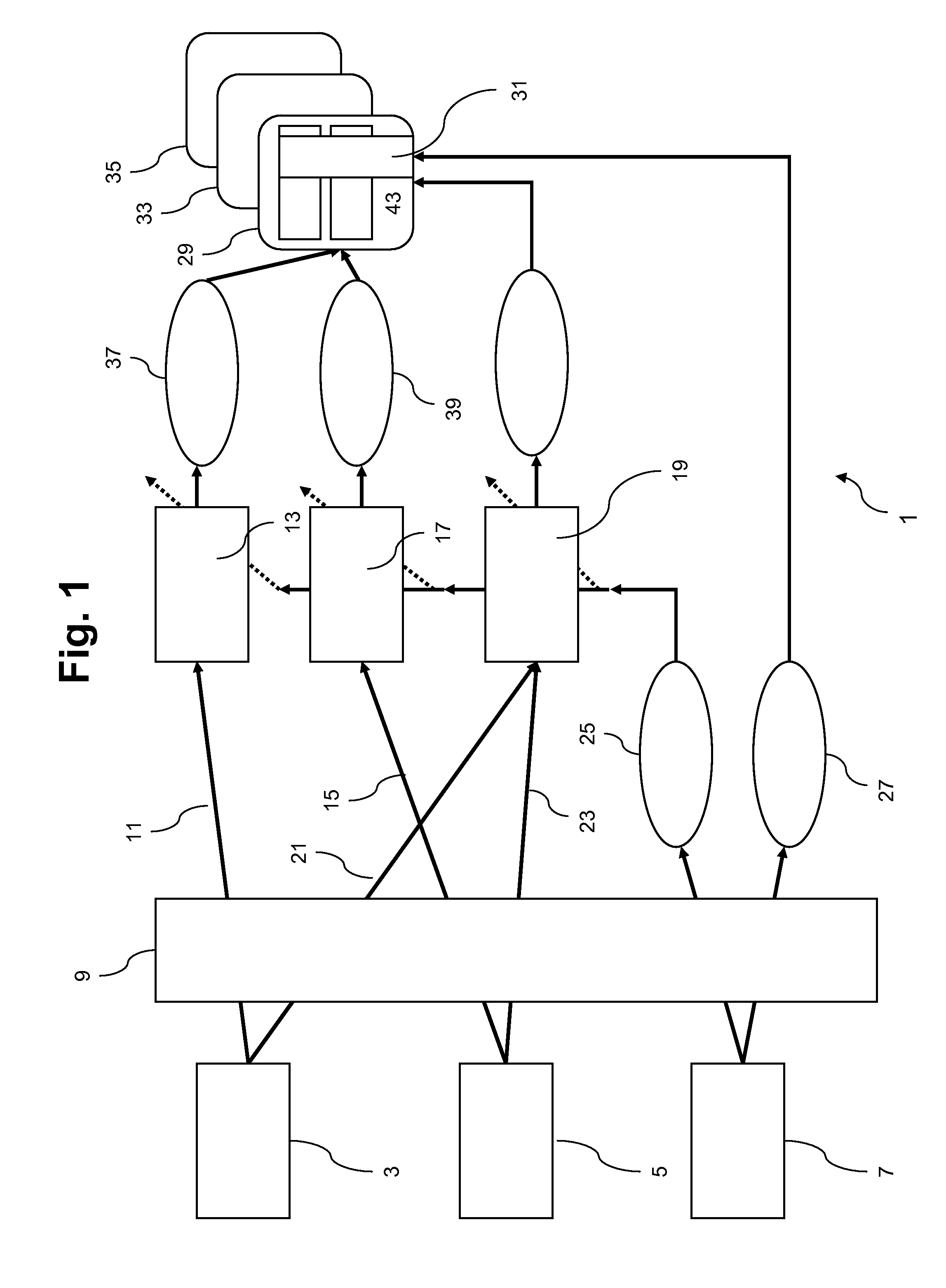

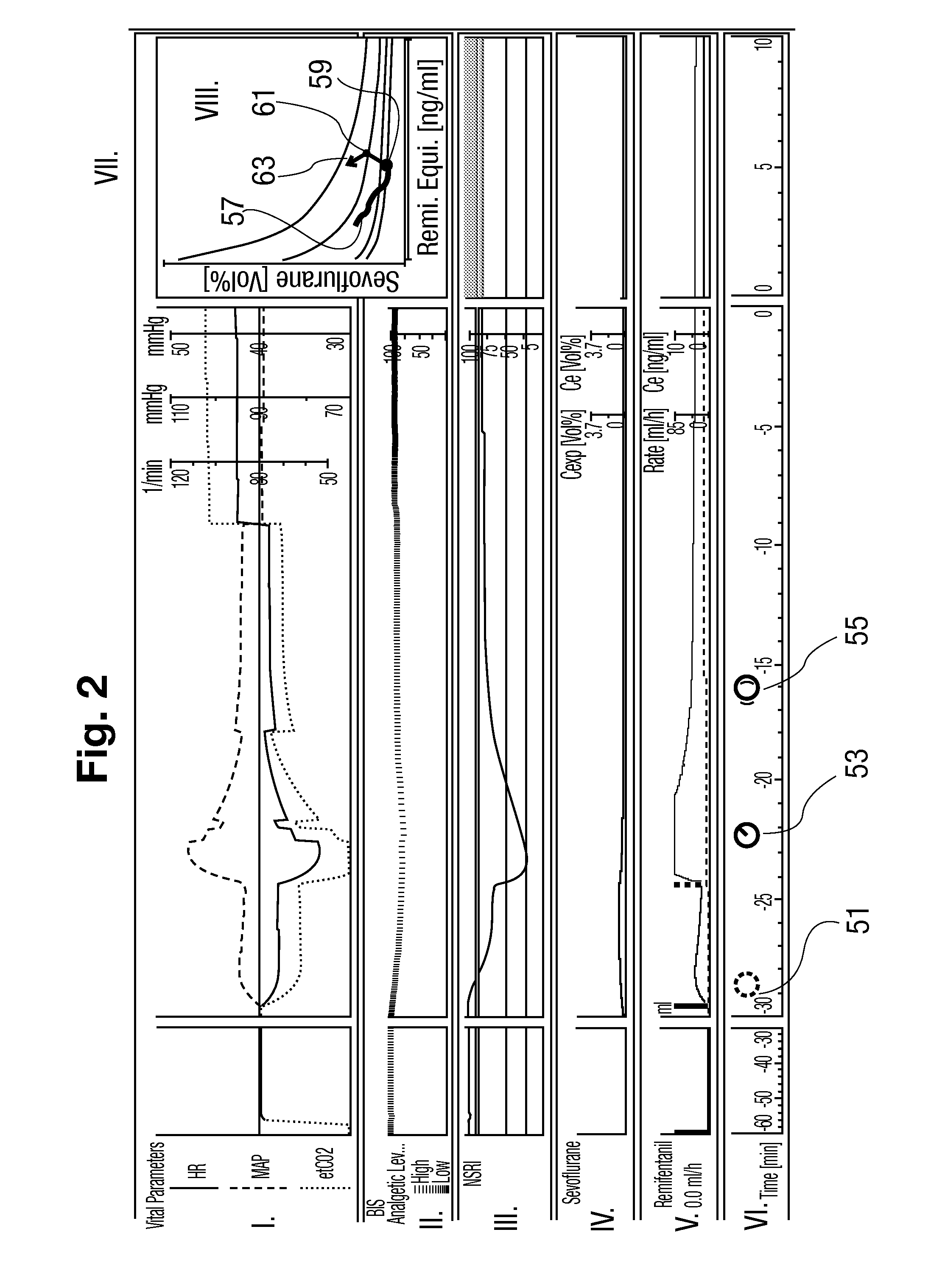

Process and device for monitoring a patient during anesthesia and for determining the combined effect of a plurality of anesthetics

ActiveUS20090005655A1Easy to take care ofDispense the anesthetics more adequatelyRespiratorsElectrocardiographyAnestheticBiology

Owner:DRAGERWERK AG +1

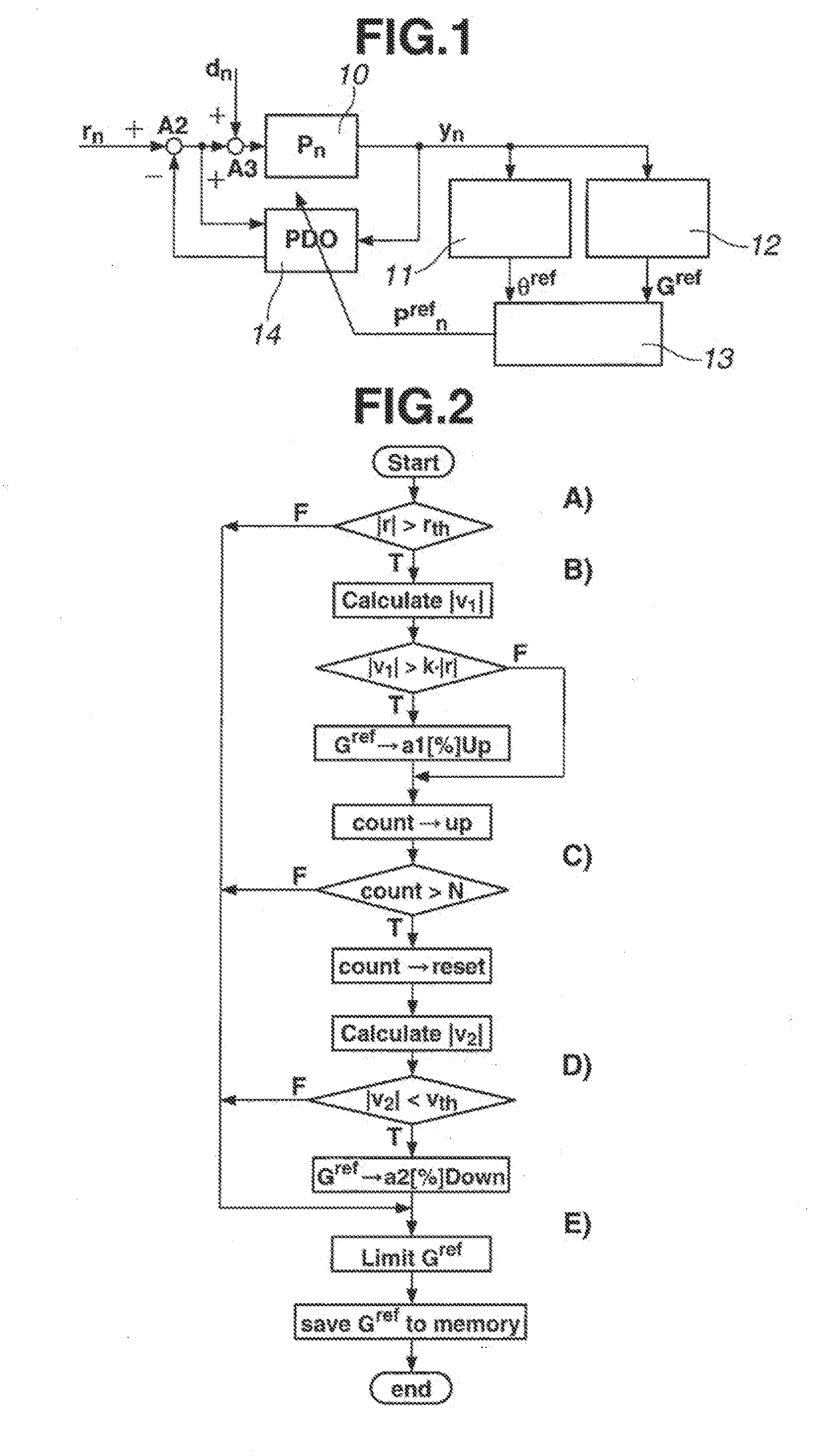

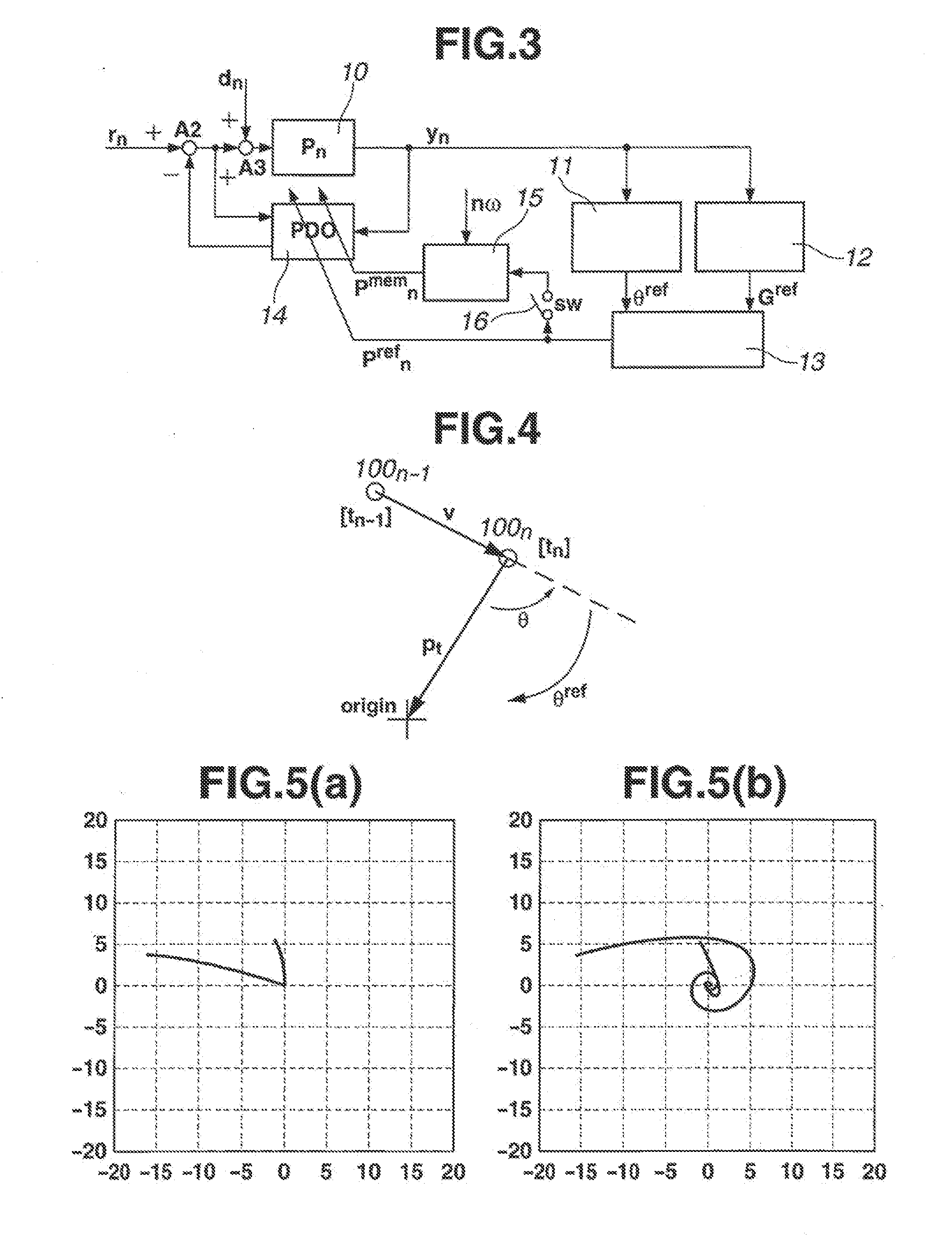

Periodicity disturbance suppression device and periodicity disturbance suppression method

InactiveUS20140039694A1Improve robustnessCorrection errorSampled-variable control systemsMechanical oscillations controlPhase correctionErrors and residuals

In a torque ripple suppression control effected by a periodicity disturbance observer, it is necessary to consider plant fluctuation and fluctuation of plant characteristics caused by over time usage. Thus, improvement for robustness to an identification model error has been required. For fulfilling this requirement, there is provided a system that includes a phase correction amount calculation portion 11 that derives a phase correction amount by calculating a phase of a vector trajectory drawn by a frequency component of the periodicity disturbance, a gain correction amount calculation portion 12 that derives a gain correction amount by calculating a progress speed of the vector trajectory drawn by the frequency component of the periodicity disturbance and comparing the calculated progress speed with a threshold value and a rotation vector calculation portion 13 that derives a system identification model correction value by multiplying the phase correction amount by the gain correction amount and corrects the system identification model of a periodicity disturbance observer portion 14 based on the system identification model correction value.

Owner:MEIDENSHA ELECTRIC MFG CO LTD

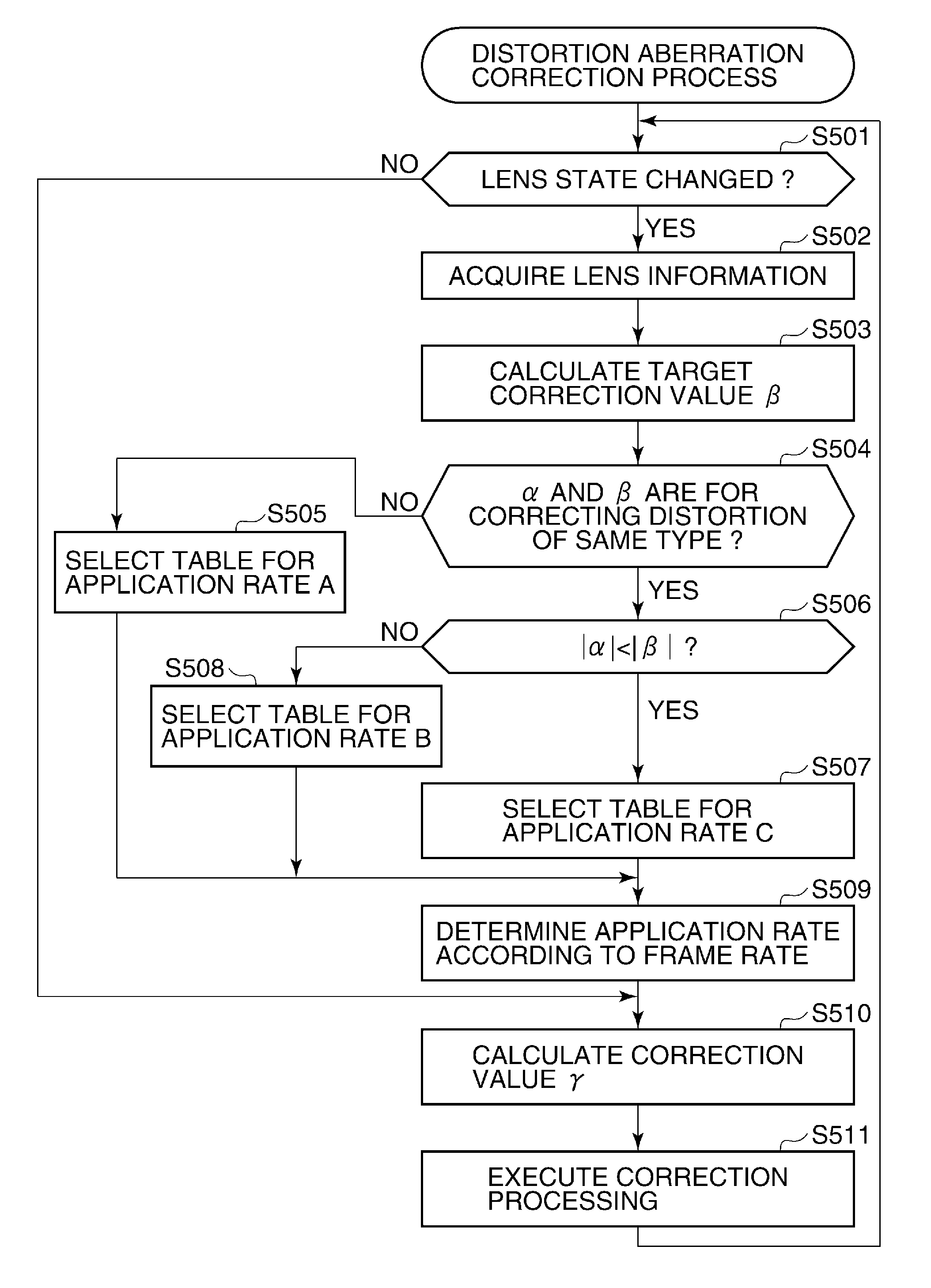

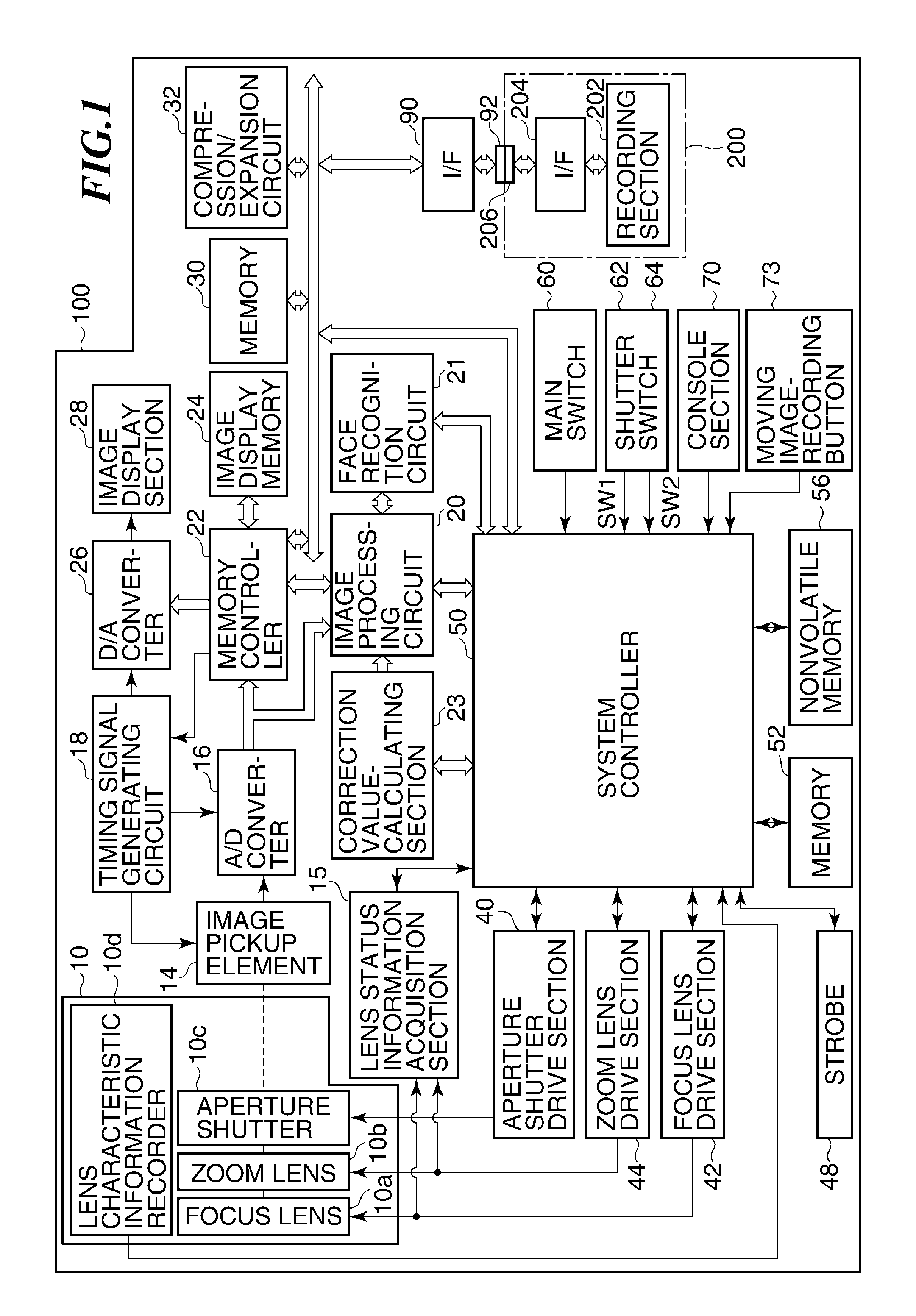

Image pickup apparatus capable of correcting image quality degradation due to optical member, method of controlling image pickup apparatus, and nonvolatile storage medium

ActiveUS8355058B2Possible to obtainNot easily be givenTelevision system detailsColor signal processing circuitsSystem controllerComputer science

An image pickup apparatus capable of forming a corrected image which does not give a feeling of wrongness to a user. In the apparatus, an image pickup element photoelectrically converts an optical image to output the same as image data. A target correction value is calculated for correcting image quality degradation due to a lens unit, based on lens characteristic information and a status of the lens unit. A system controller sets a rate of change to stepwise make the current correction value closer to the target correction value, and repeatedly calculates the correction value according to the target correction value and the rate of change. The image data is corrected based on the repeatedly calculated correction value. The rate of change is changed depending on the relationship between a preceding value of the correction value calculated in the past and the target correction value.

Owner:CANON KK

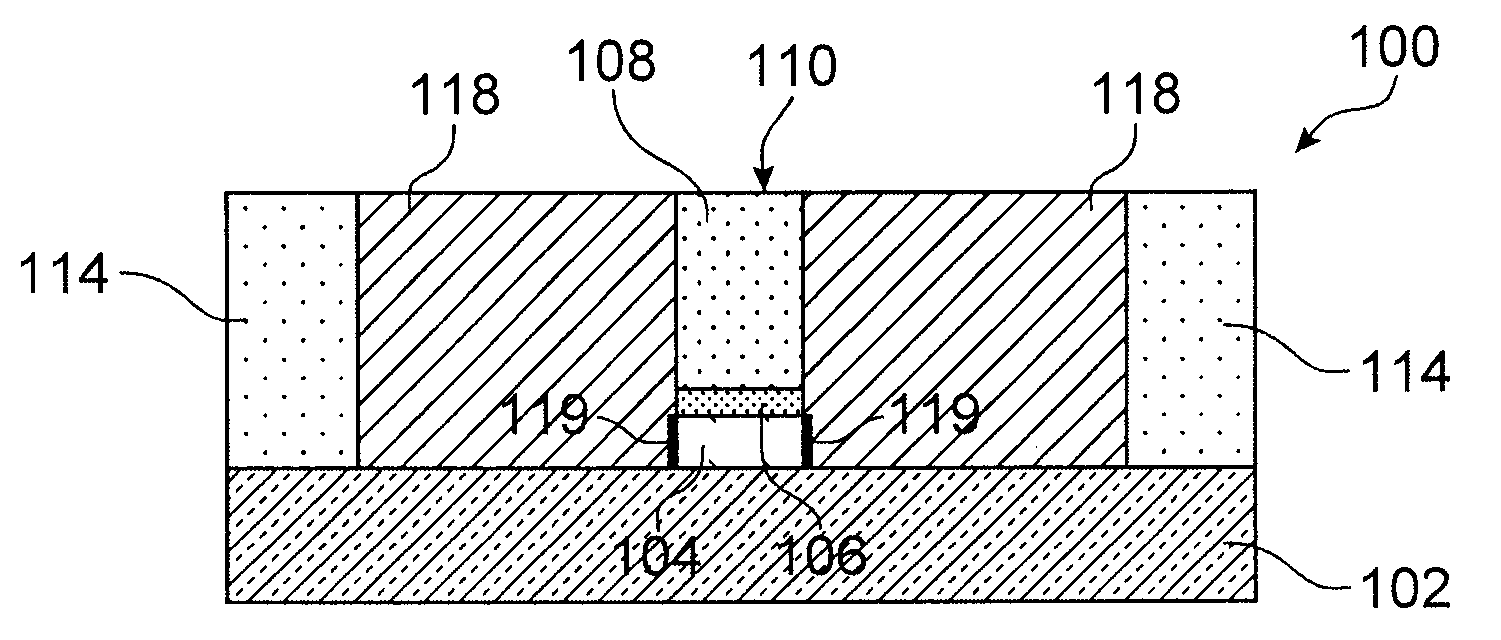

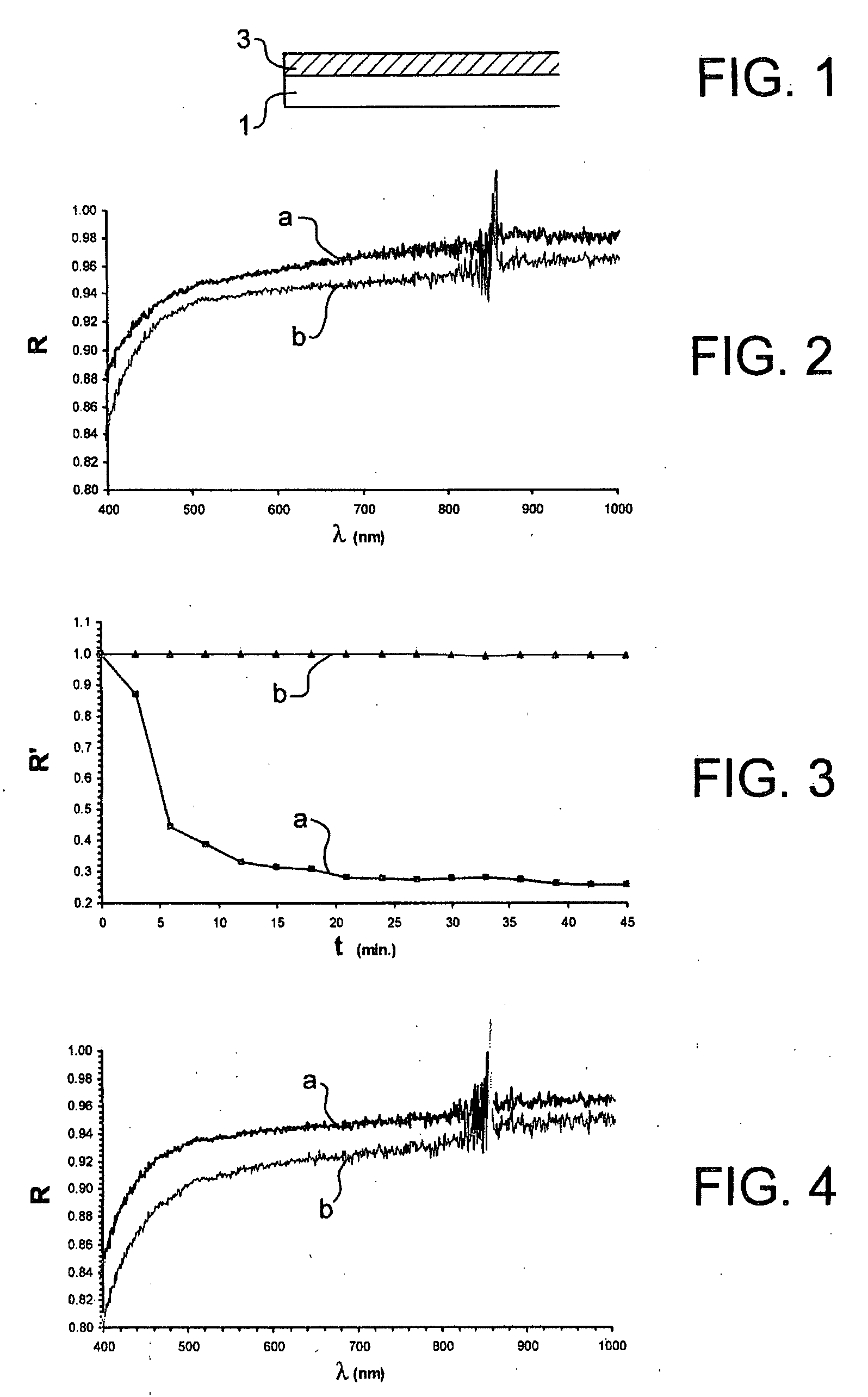

Device for measuring metal/semiconductor contact resistivity

InactiveUS20080297180A1Possible to obtainSemiconductor/solid-state device testing/measurementResistance/reactance/impedenceSemiconductorMaterials science

A device for measuring the resistivity ρc of an interface between a semiconductor and a metal, comprising at least:one dielectric layer,at least one semiconductor-based element of a substantially rectangular shape, which is arranged on the dielectric layer, having a lengthwise L and widthwise W face in contact with the dielectric layer and having a thickness t,at least two interface portions containing the metal or an alloy of said semiconductor and said metal,each of the two opposing faces of the semiconductor element, having a surface equal to t×W and being perpendicular to the face in contact with the dielectric layer, being completely covered by one of the interface portions.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

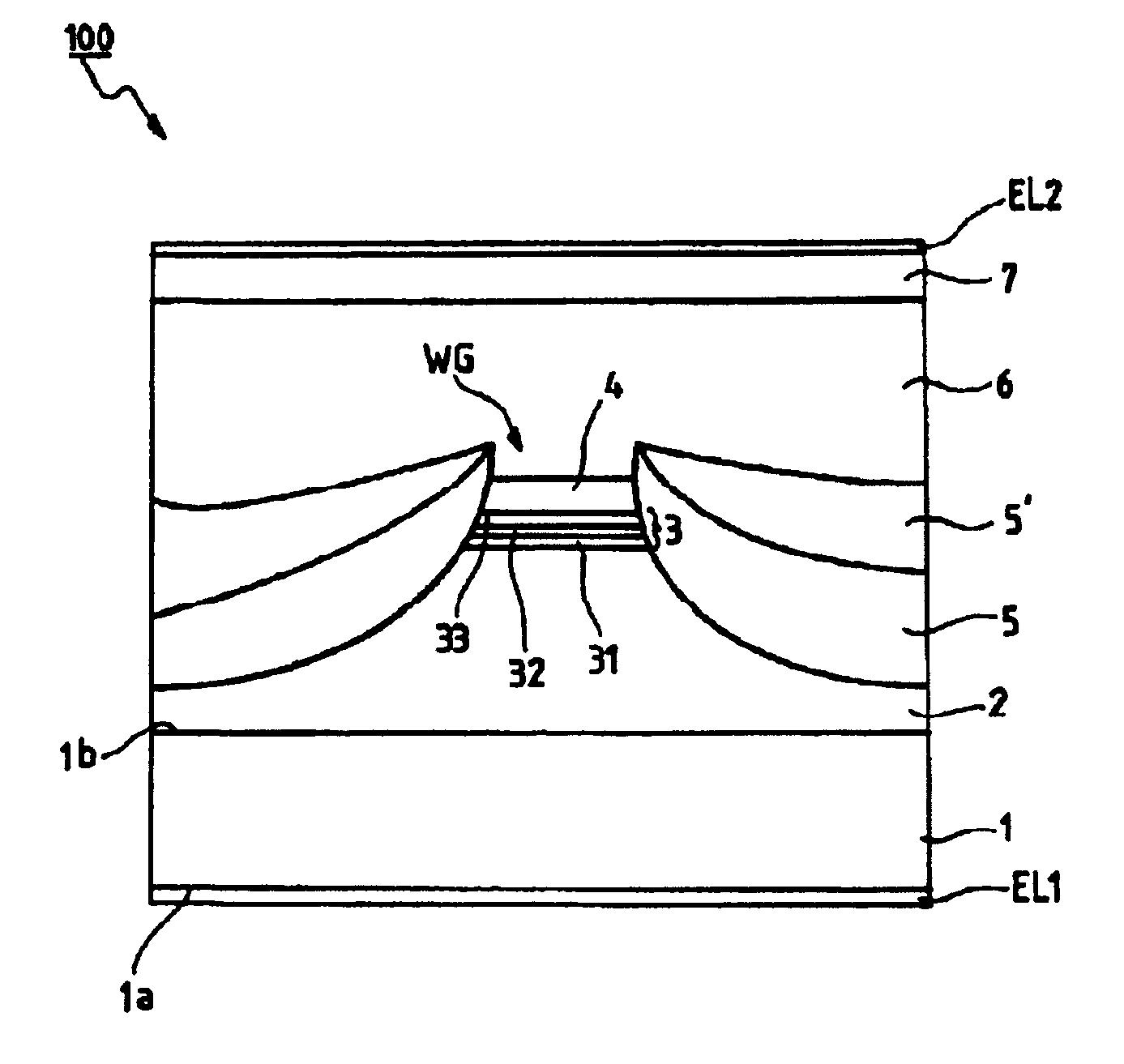

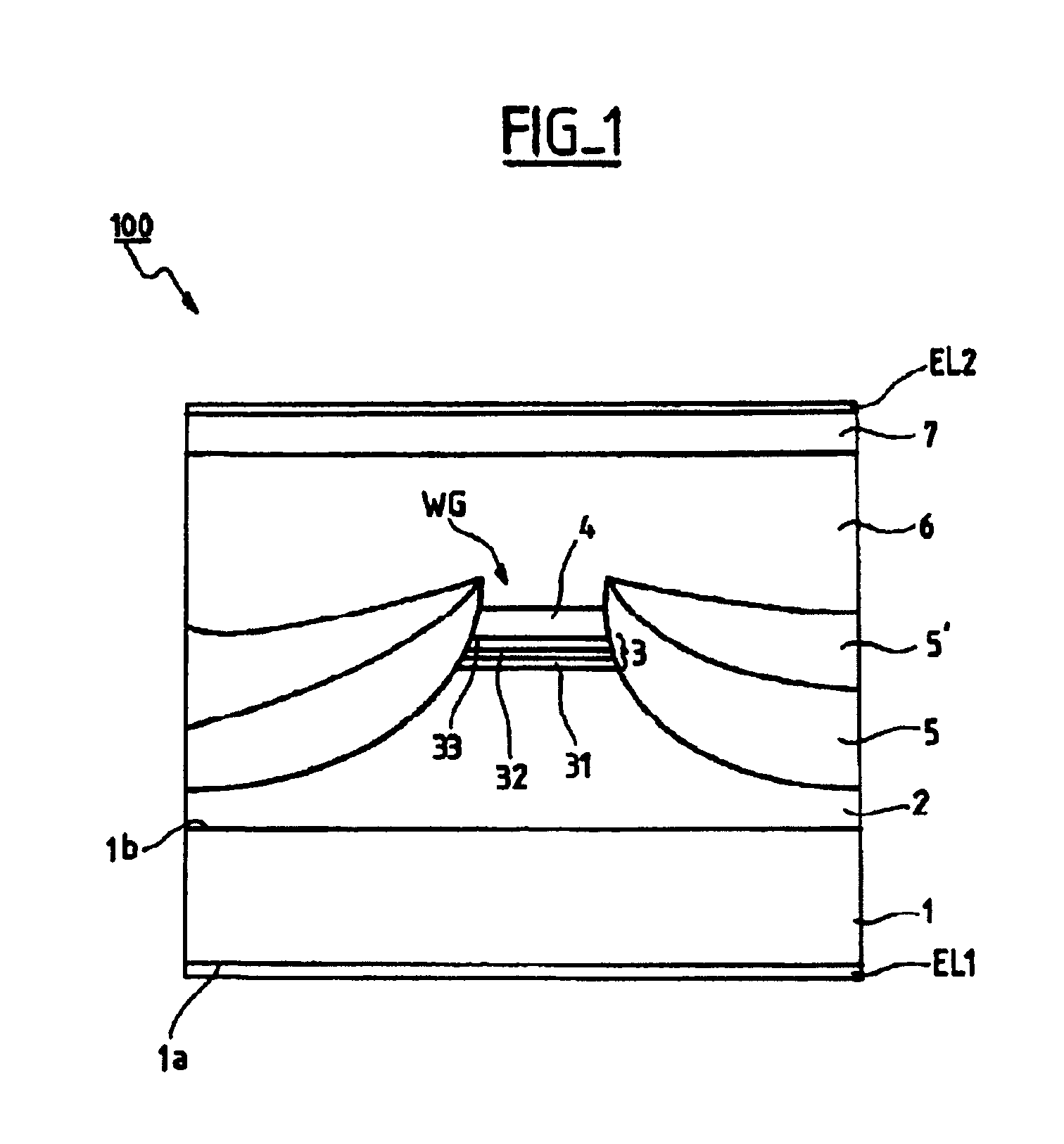

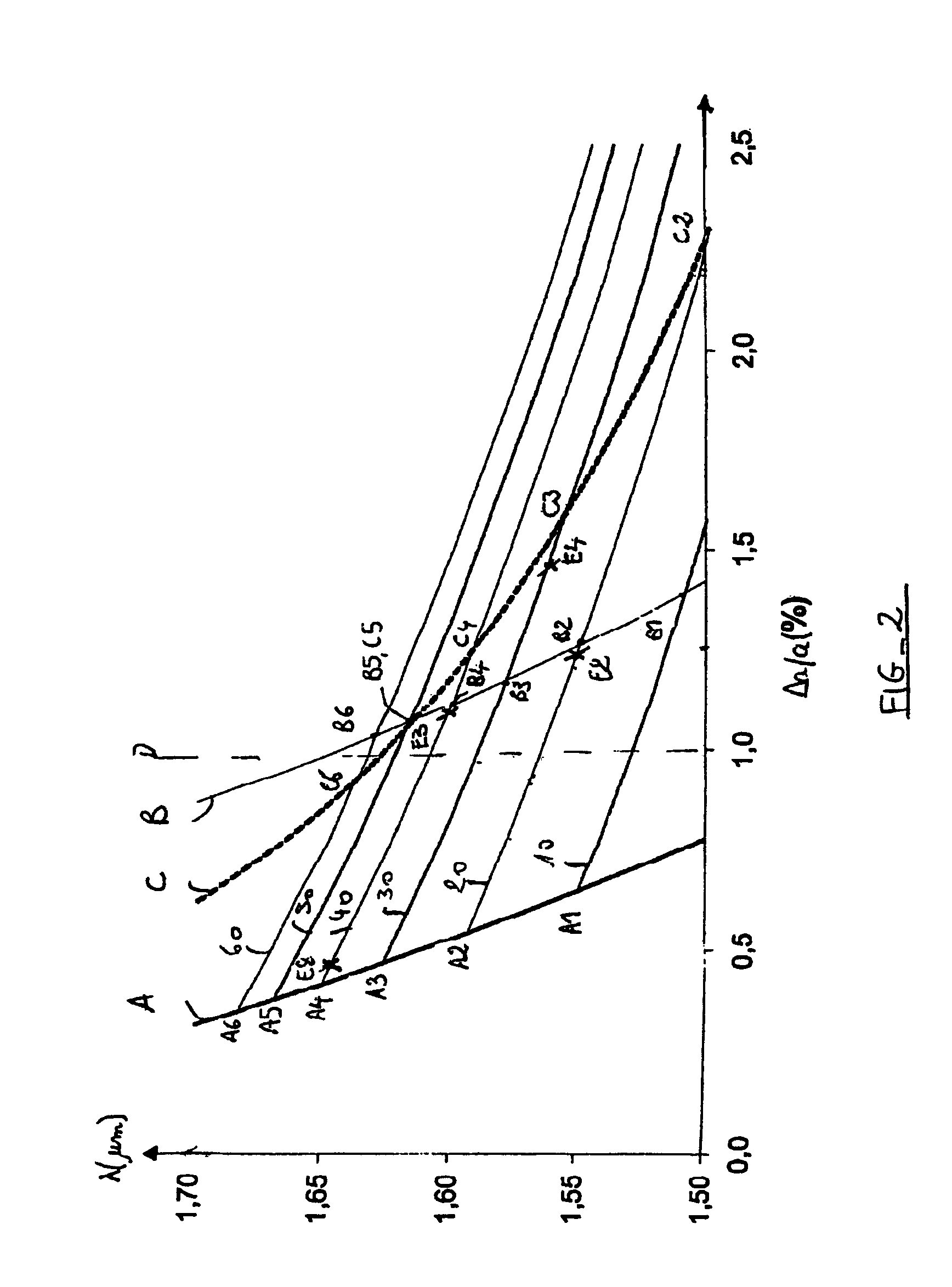

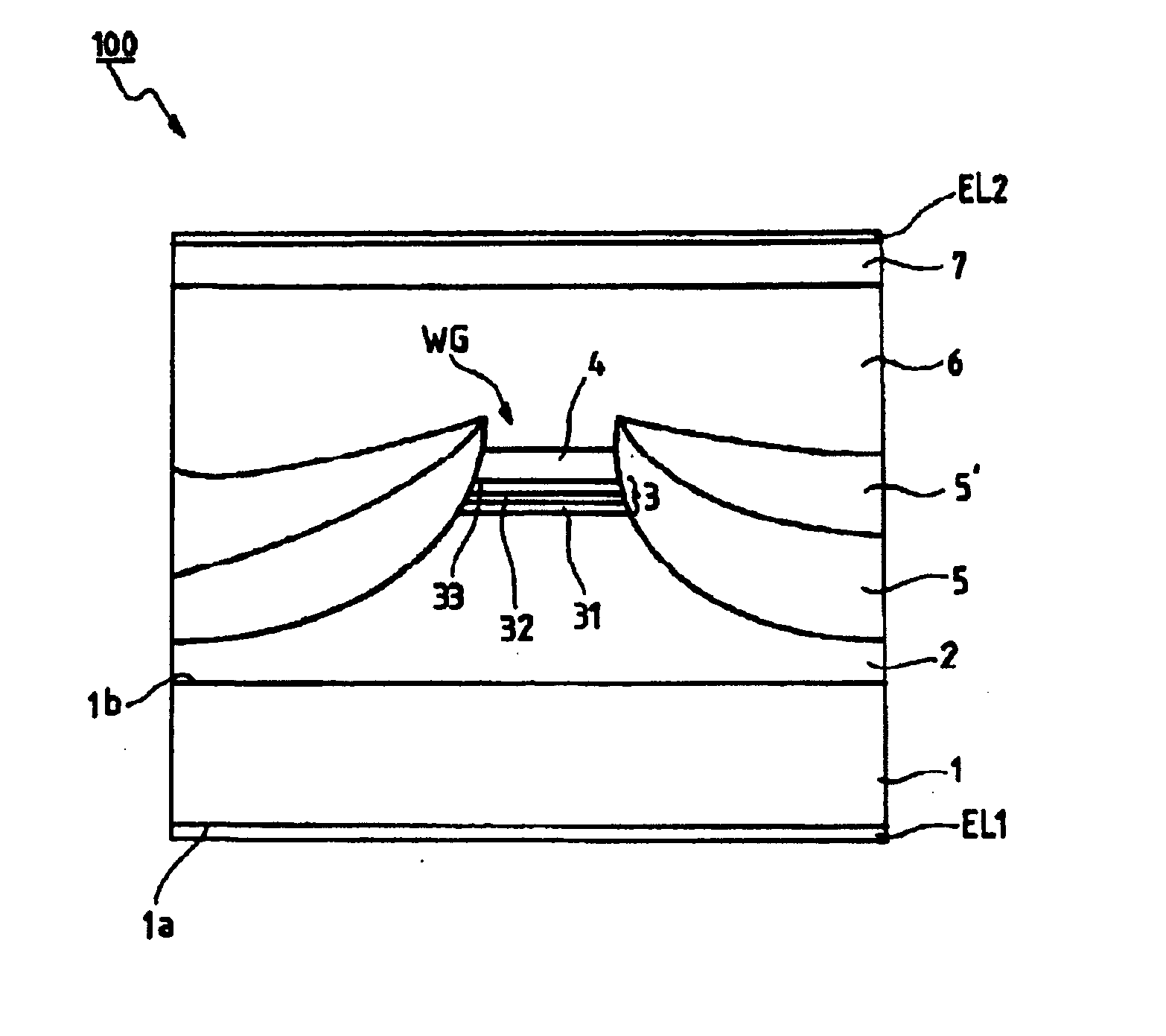

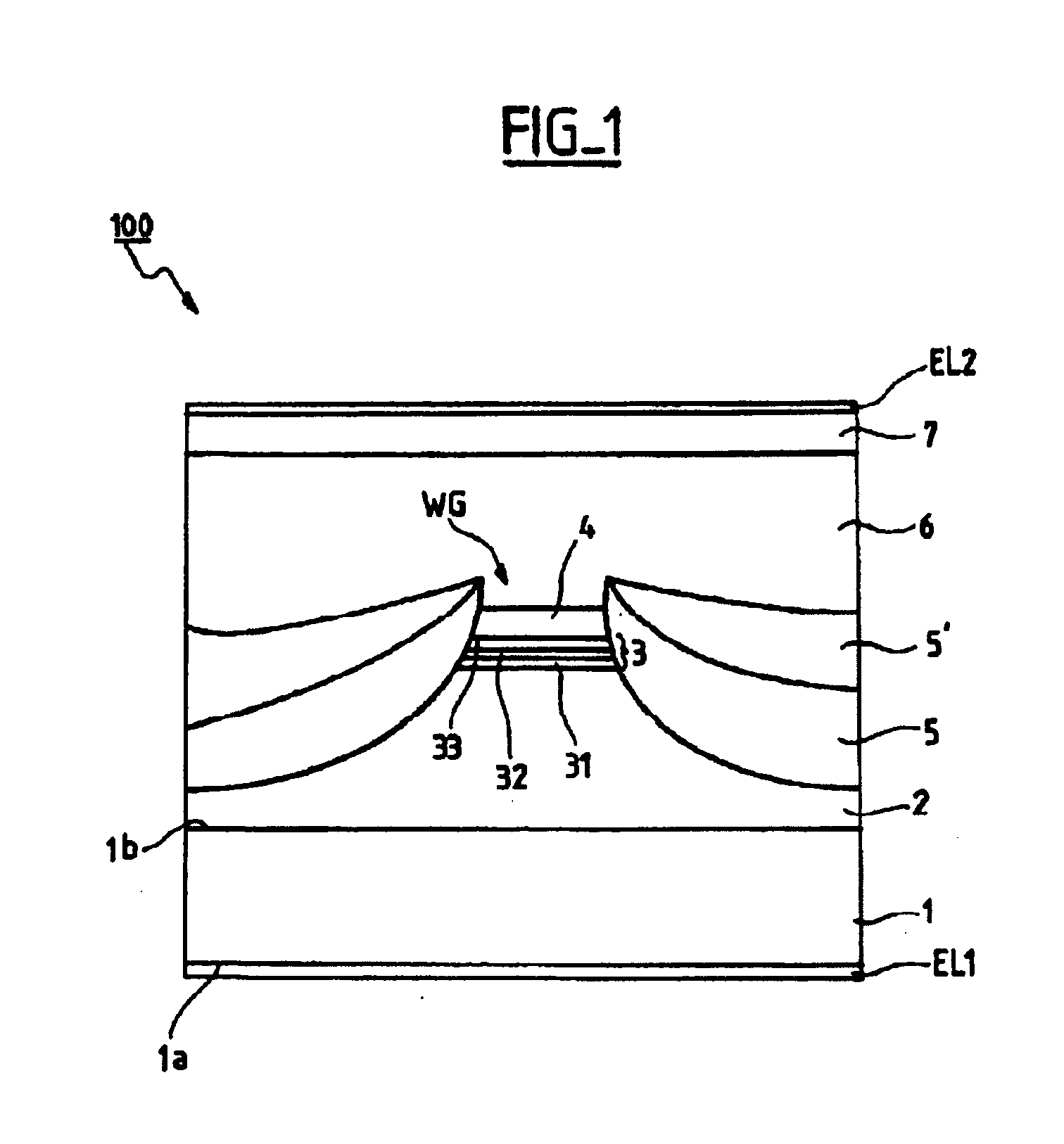

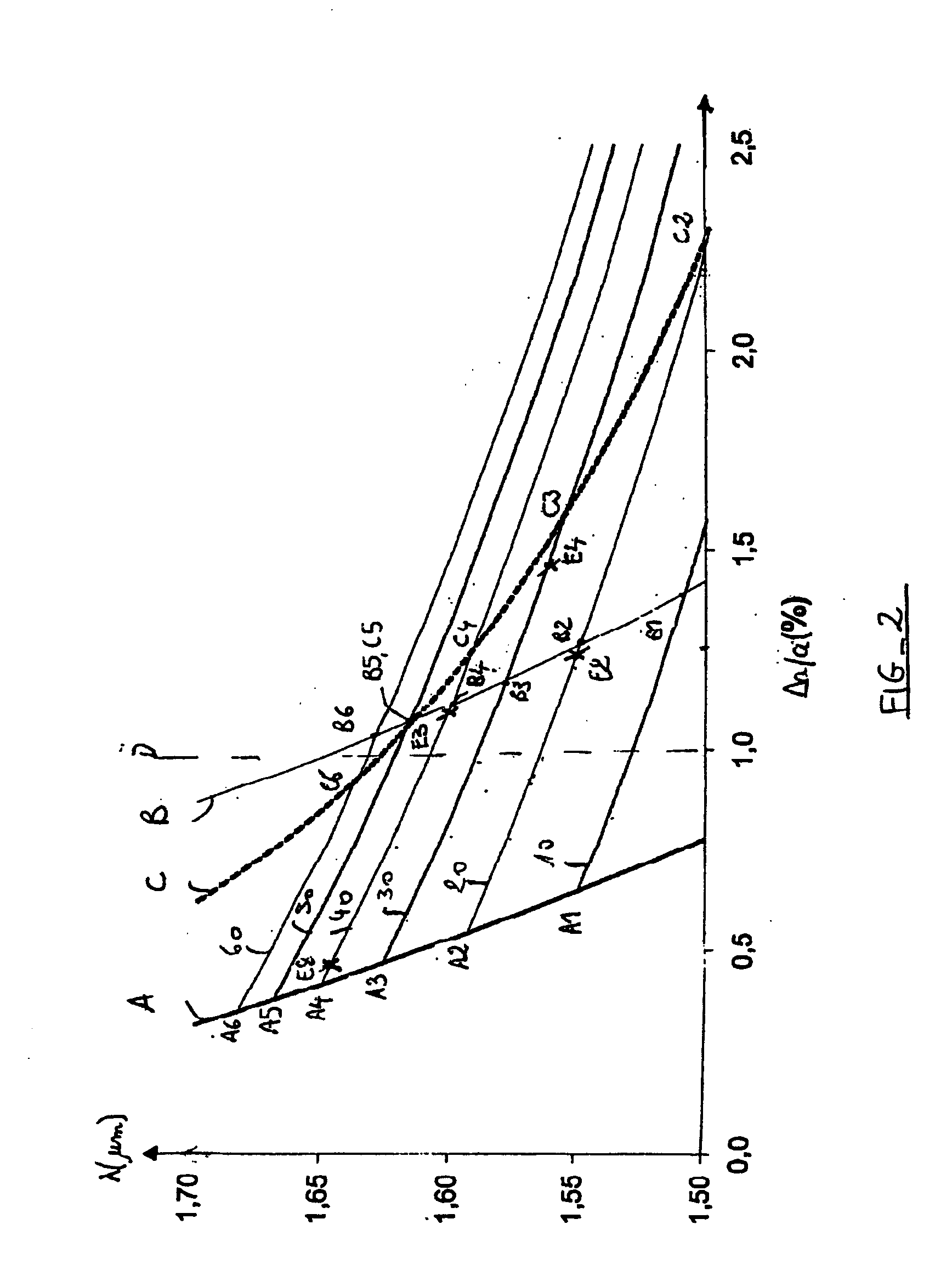

Semiconductor optical device on an indium phosphide substrate for long operating wavelengths

ActiveUS7109526B2Weaken energyPossible to obtainLaser detailsLaser active region structureQuantum wellSemiconductor alloys

A semiconductor optical device such as a laser or semiconductor optical amplifier (SOA) based on an indium phosphide substrate or equivalent buffer layer. The active layer of the device is based on conventional InGaAs(P) alloy, but additionally includes N in order to increase the operating wavelength to greater than 1.5 μm, preferably to a wavelength lying in the C- or L-band. The active layer composition may thus be denoted In1-xGaxAsyNzPp with x≧0.48, y≦1−z−p, z≦0.05, p≧0. The active layer may include a quantum well or multi-quantum wells in which case its thickness is preferably less than the critical thickness for lattice relaxation. In other embodiments the active layer is a “massive” layer with quasi-bulk properties. The active layer may advantageously be under tensile stress, preferably roughly between 1% and 2.2%, to manipulate the light and heavy hole bands. The active layer is typically bounded by barrier layers made of a suitable semiconductor alloy, such as AlInAs or InGaAs(P).

Owner:OCLARO NORTH AMERICA

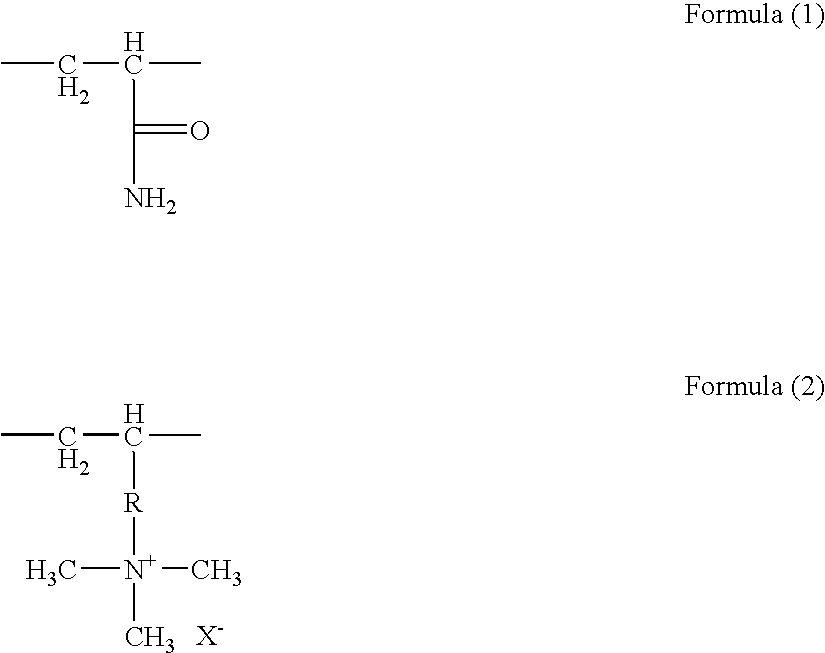

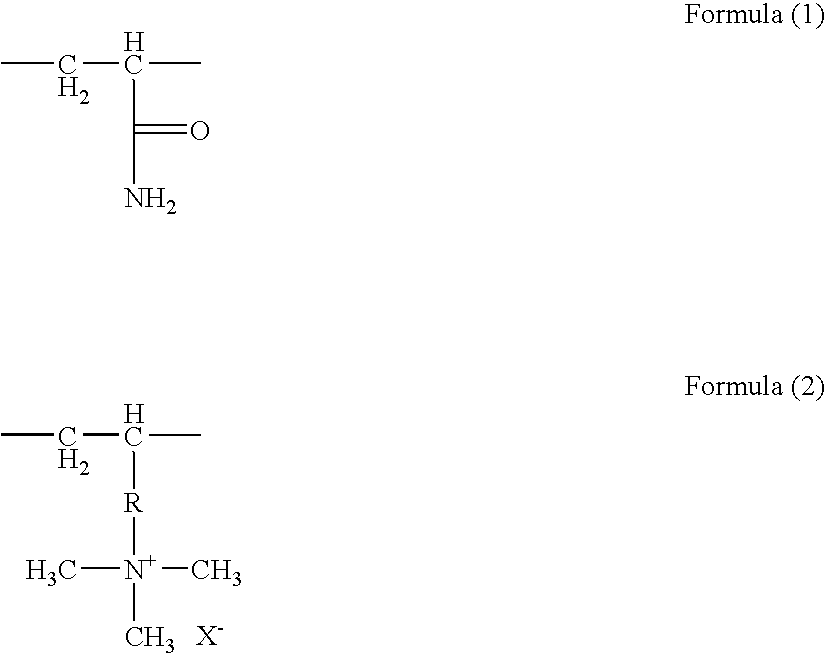

Microporous coating based on polyurethane polyurea

InactiveUS20070249746A1Possible to obtainPolyurea/polyurethane coatingsPolyurethane dispersionPolyurea

The invention relates to novel microporous coatings and to a process for the production of microporous coatings. A composition comprising an aqueous, anionically hydrophilised polyurethane dispersion (I) and a cationic coagulant (II) is foamed and dried to provide the microporous coating.

Owner:BAYER MATERIALSCIENCE AG

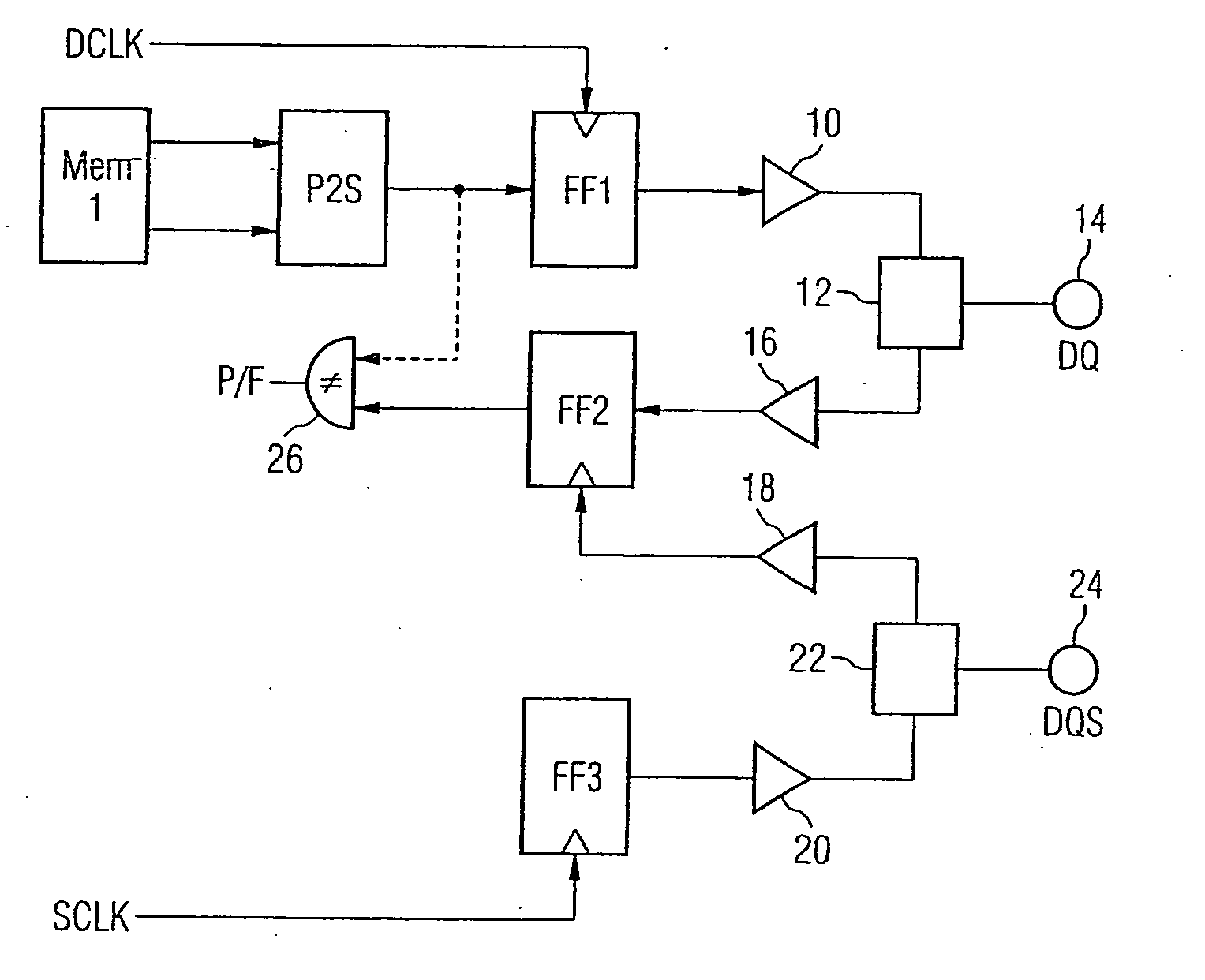

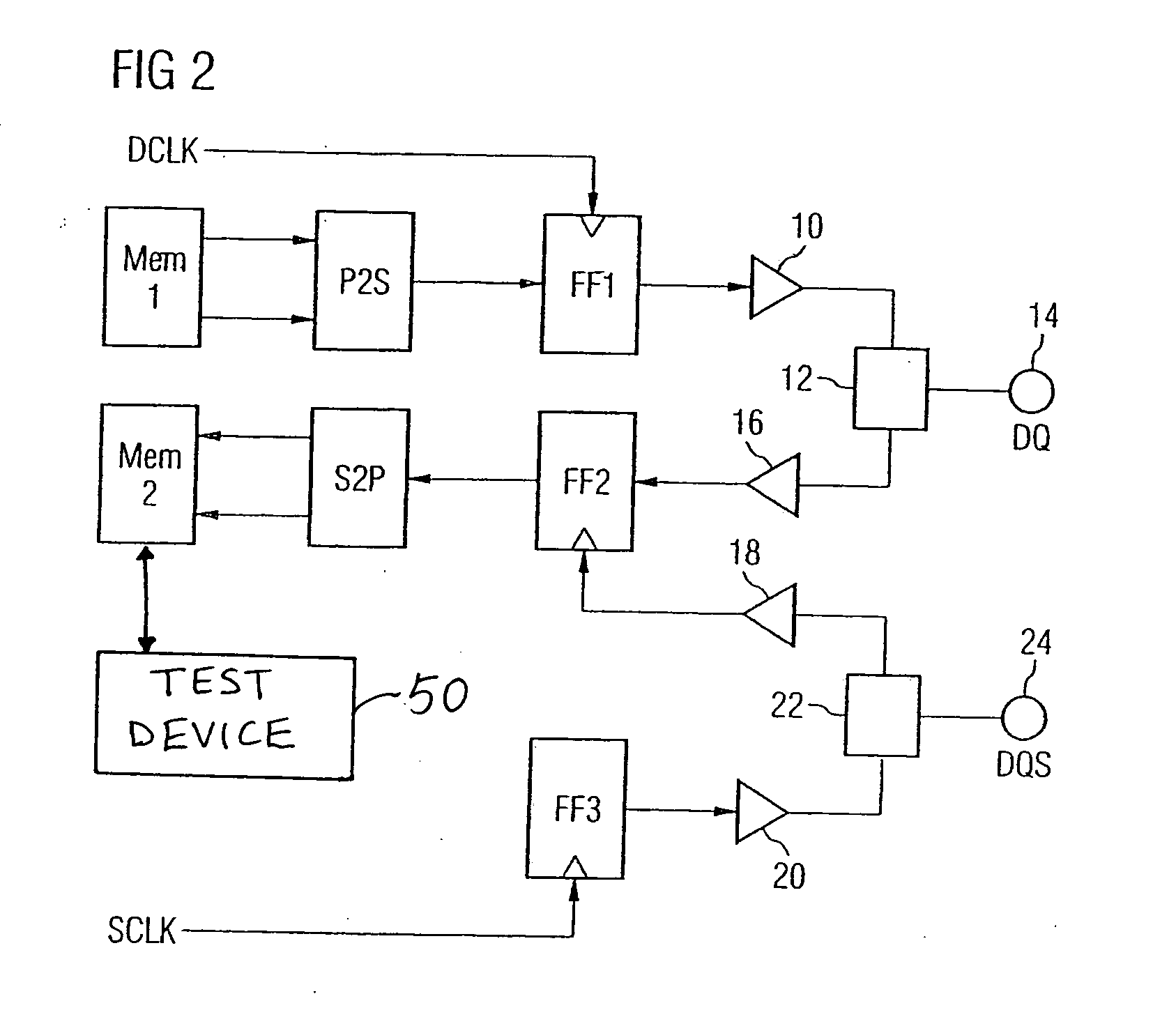

Loop-back method for measuring the interface timing of semiconductor memory devices using the normal mode memory

The invention relates to a method for testing a semiconductor memory device, the semiconductor memory device being able to be operated in a normal operating mode and a test mode. The method for testing includes communicating test input data to be used for a test to the semiconductor memory device; storing the test input data in memory cells of a memory area of the semiconductor memory device; and reading out the stored test input data from the memory cells for carrying out a test in order to obtain test output data, the memory area in which the test input data are stored in the test mode being used for storing data in the normal operating mode. In addition, the invention relates to a semiconductor memory device and a system for testing a semiconductor memory device.

Owner:INFINEON TECH AG

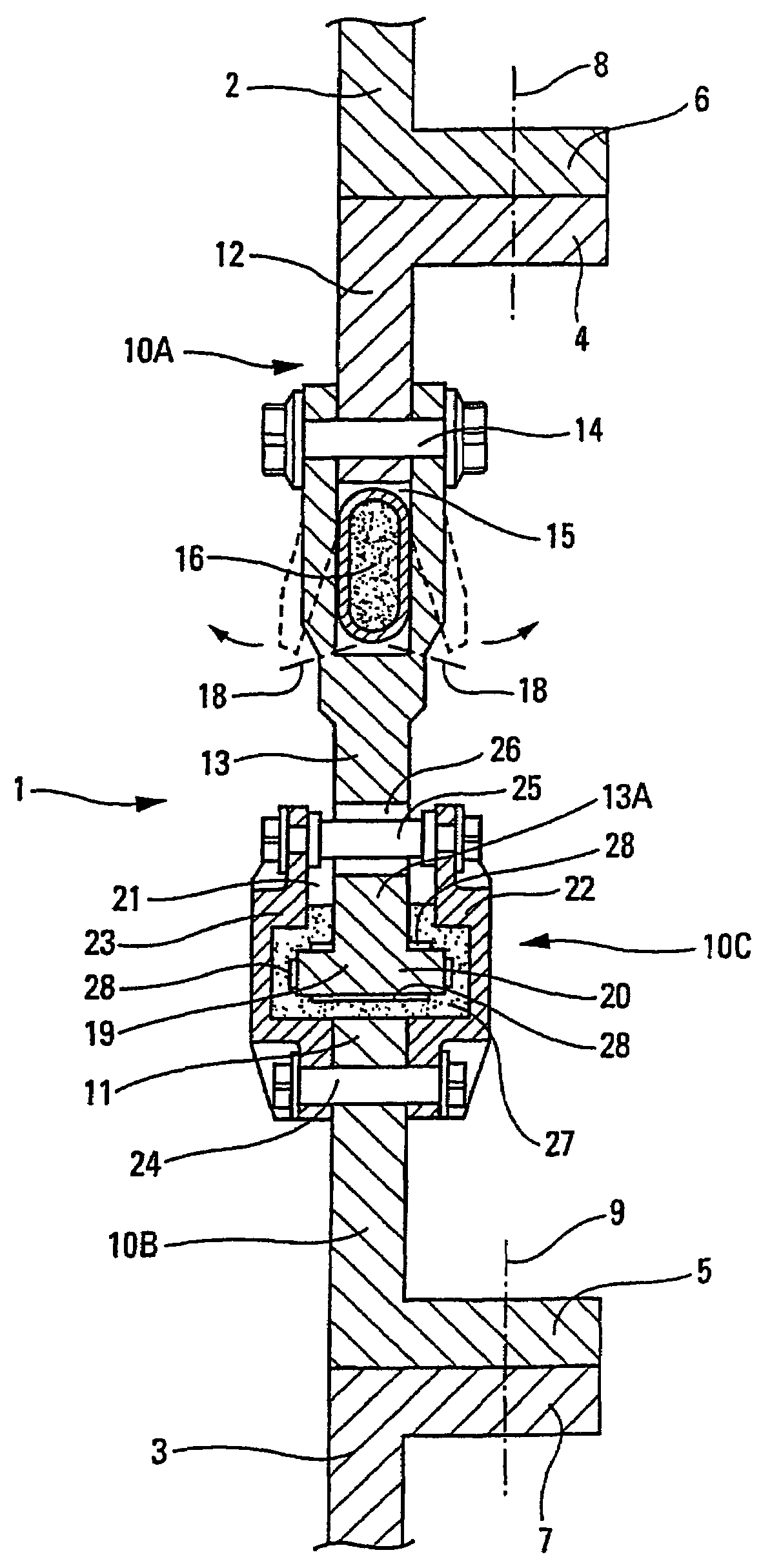

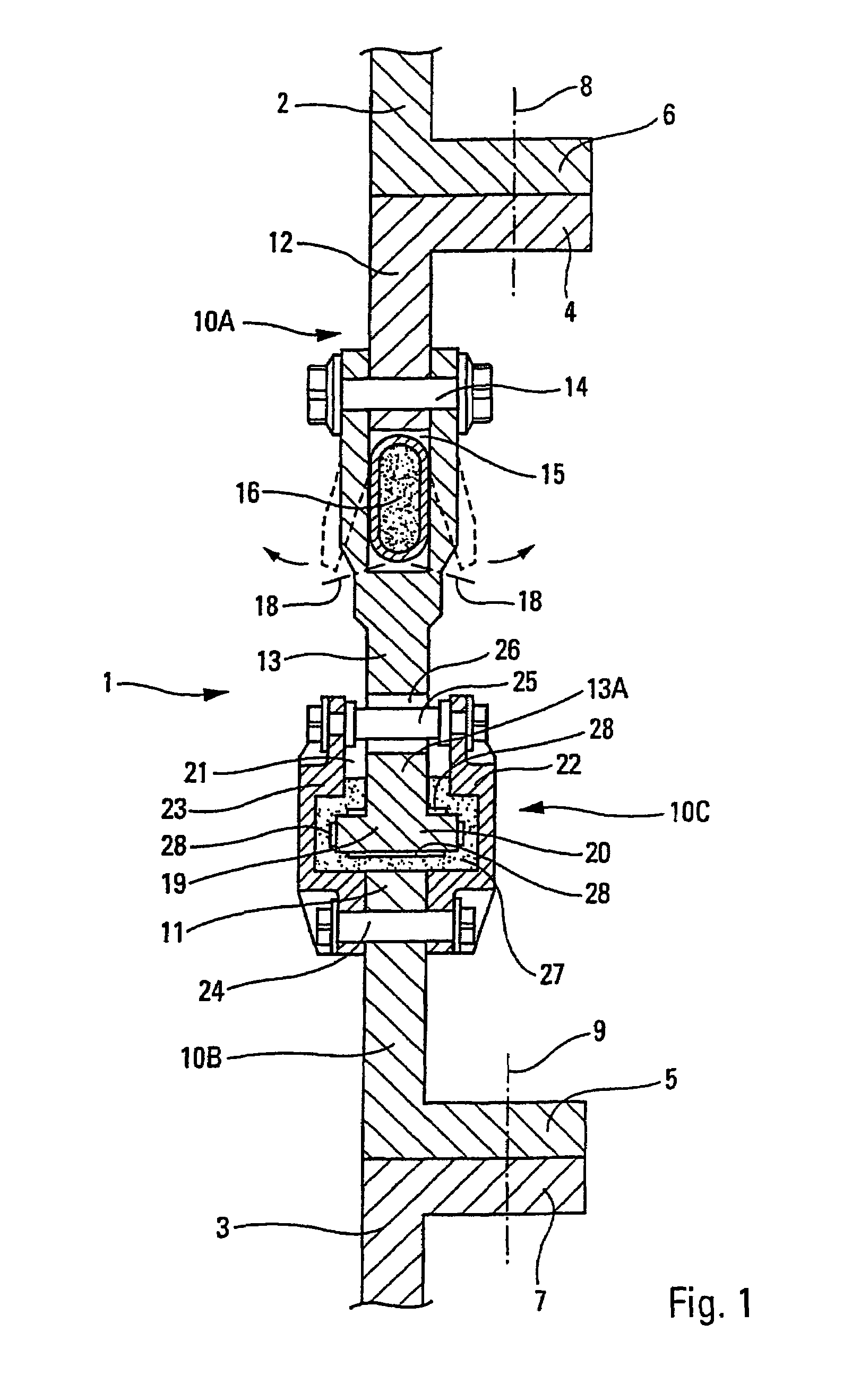

Composite structural part comprising pyrotechnic detonating rupture means

InactiveUS7513184B2Effectiveness of damping is highImprove efficiencyAircraft componentsCosmonautic vehiclesDetonationEngineering

A pyrotechnically-ruptureable composite structural component, intended to transmit forces between first and second structural elements, has an elongate pyrotechnic detonation separation component incorporated in the structural component for breaking the structural component and separating the first and second elements. The structural component has a first part in which the pyrotechnic separation component is incorporated and which is able to be connected to the first element, and a second part that connects to the second element. The first and second parts are rigidly assembled via their free ends, which are the opposite ends to the first and second elements respectively. The rigid assembly has a damper arranged between the free ends of the first and second elements so as to damp a detonation shock propagating to the free end of the first part when the pyrotechnic separation component is detonated.

Owner:EADS SPACE TRANSPORTATION

Process for Preparing a Sol-Gel Solution and Use of this Solution to Form a Coating to Protect a Substrate Having a Metal Surface

InactiveUS20080193746A1Improve stabilitySame protective propertySolar heating energySolar heat devicesSilane compoundsOrganic solvent

The invention relates to a process for preparing a stable sol-gel solution comprising, in succession, the following steps:a) preparing a sol-gel solution by bringing one or more molecular metal and / or metalloid precursors into contact with a medium comprising an organic solvent;b) adding at least one mercaptoorganosilane compound to the solution obtained in a);c) hydrolyzing the solution obtained in b); andd) adding, to the solution obtained in c), one or more complexing agents chosen from carboxylic acids, β-diketone compounds and hydroxamate compounds.Use of this solution for forming coating materials for metallic substrates, in particular for a silver-based substrate, such as mirrors

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Disc brake comprising at least one inclinable brake pad

InactiveUS20050126864A1Safe and effectivePossible to obtainFluid actuated brakesMechanically actuated brakesEngineeringBearing surface

The present invention mainly relates to a brake device for a motor vehicle, the brake device including a friction first element suitable for having a first face pressed against a first face of a second element which is secured to a wheel of the motor vehicle in order to slow said vehicle down, and an application third element for applying a braking force bearing via a first end against a second face of the friction first element that is opposite from the first face of the friction first element and suitable for pressing the friction first element against the second element, said brake device also including amplifier means for modifying the inclination of a tiltable plane containing the bearing surface between the friction first element and the application third element relative to a plane containing the first face of the second element.

Owner:ROBERT BOSCH GMBH

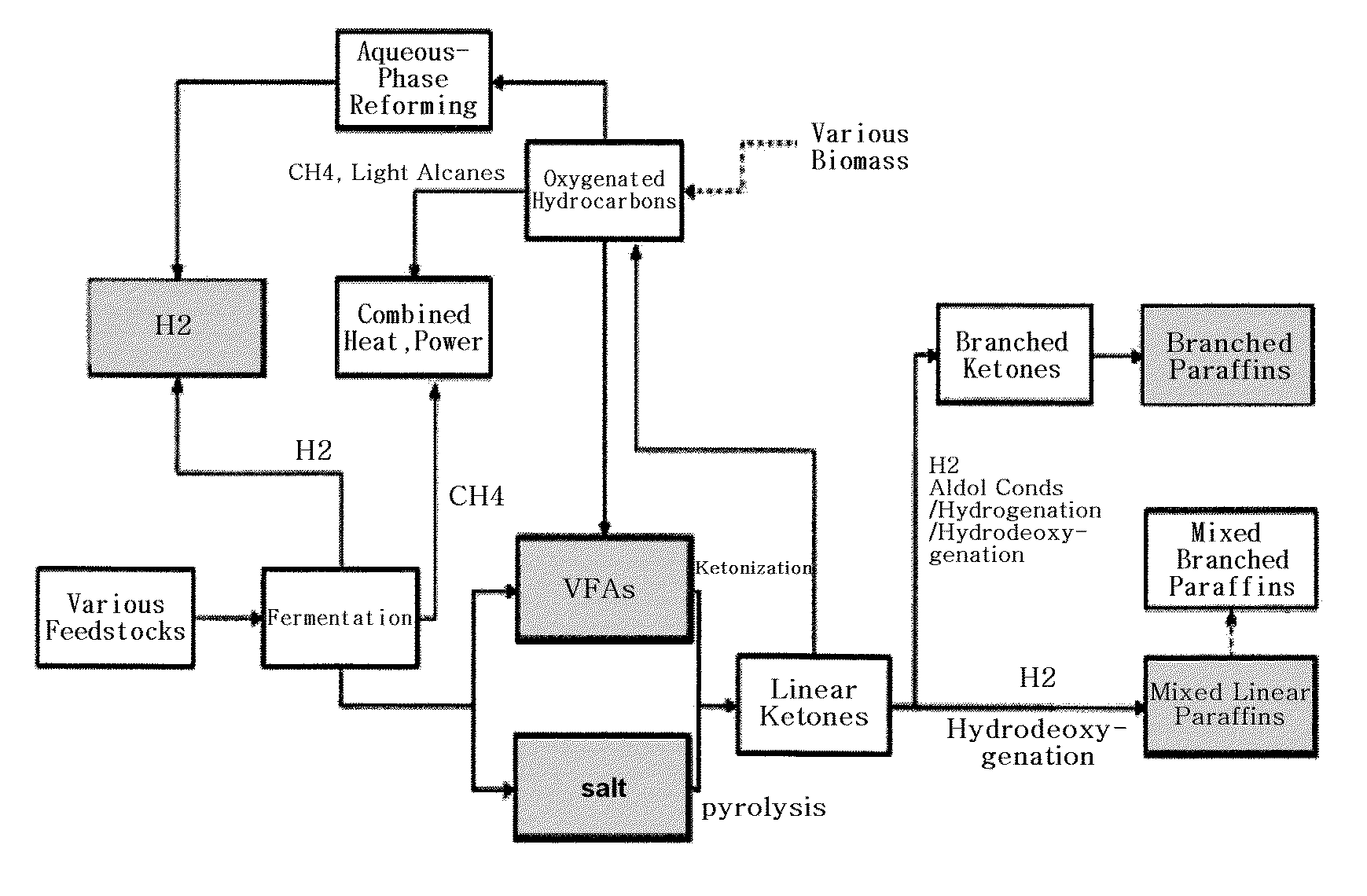

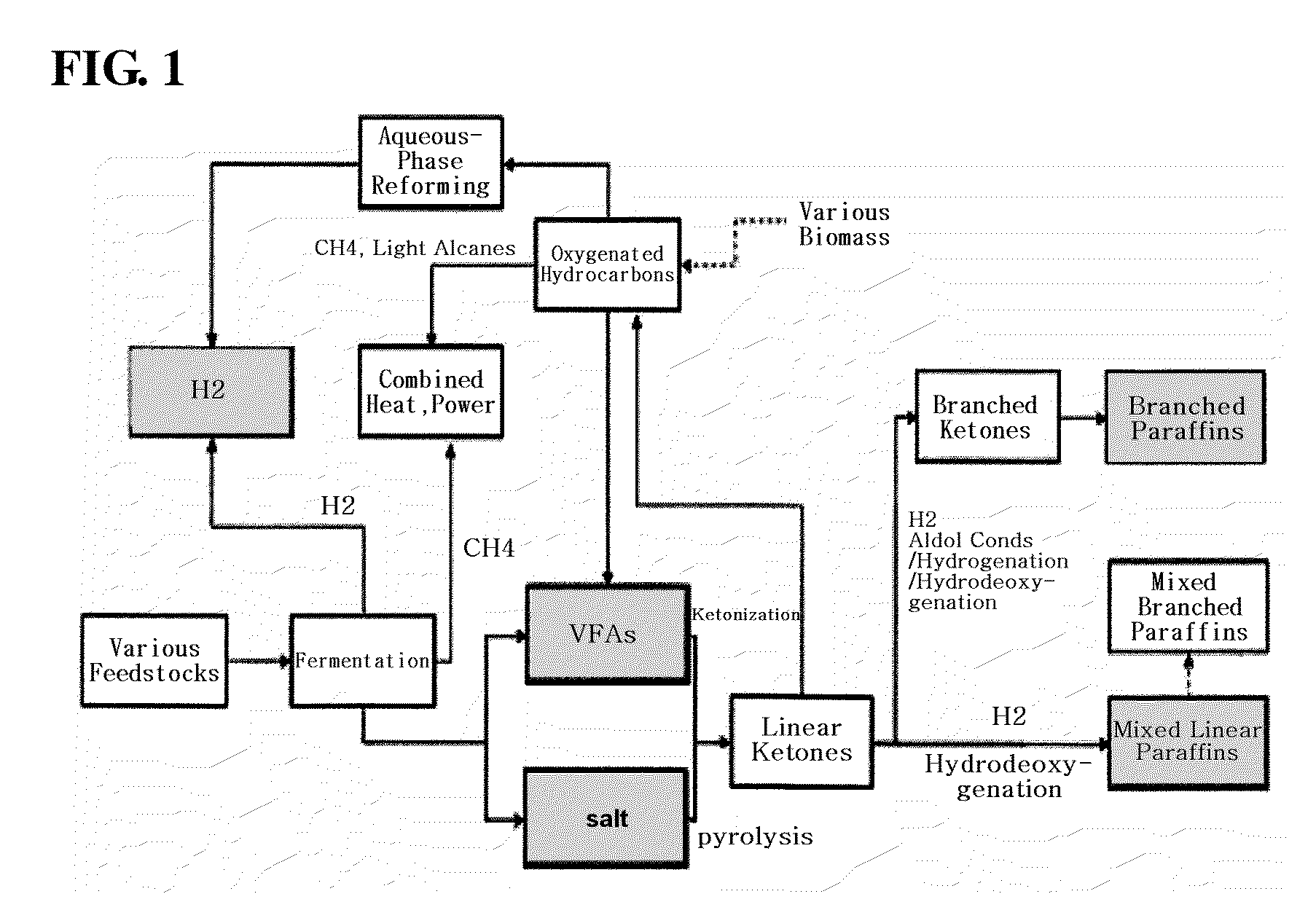

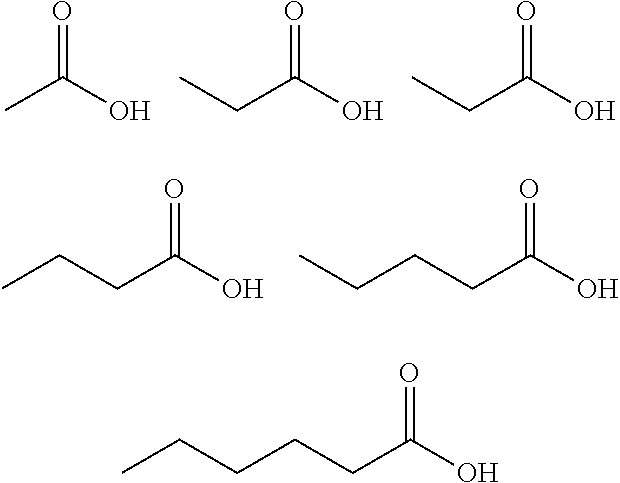

Preparation method of transportation fuel or lubricating base oil using biomass

ActiveUS20130017590A1Possible to obtainEconomic efficiency be increaseHeterogenous catalyst chemical elementsCatalyst activation/preparationParaffin waxBiomass

The present invention relates to a method of economically preparing paraffin compounds corresponding to gasoline fuel or lubricating base oil using volatile fatty acids (VFAs) derived from biomass.

Owner:SK INNOVATION CO LTD

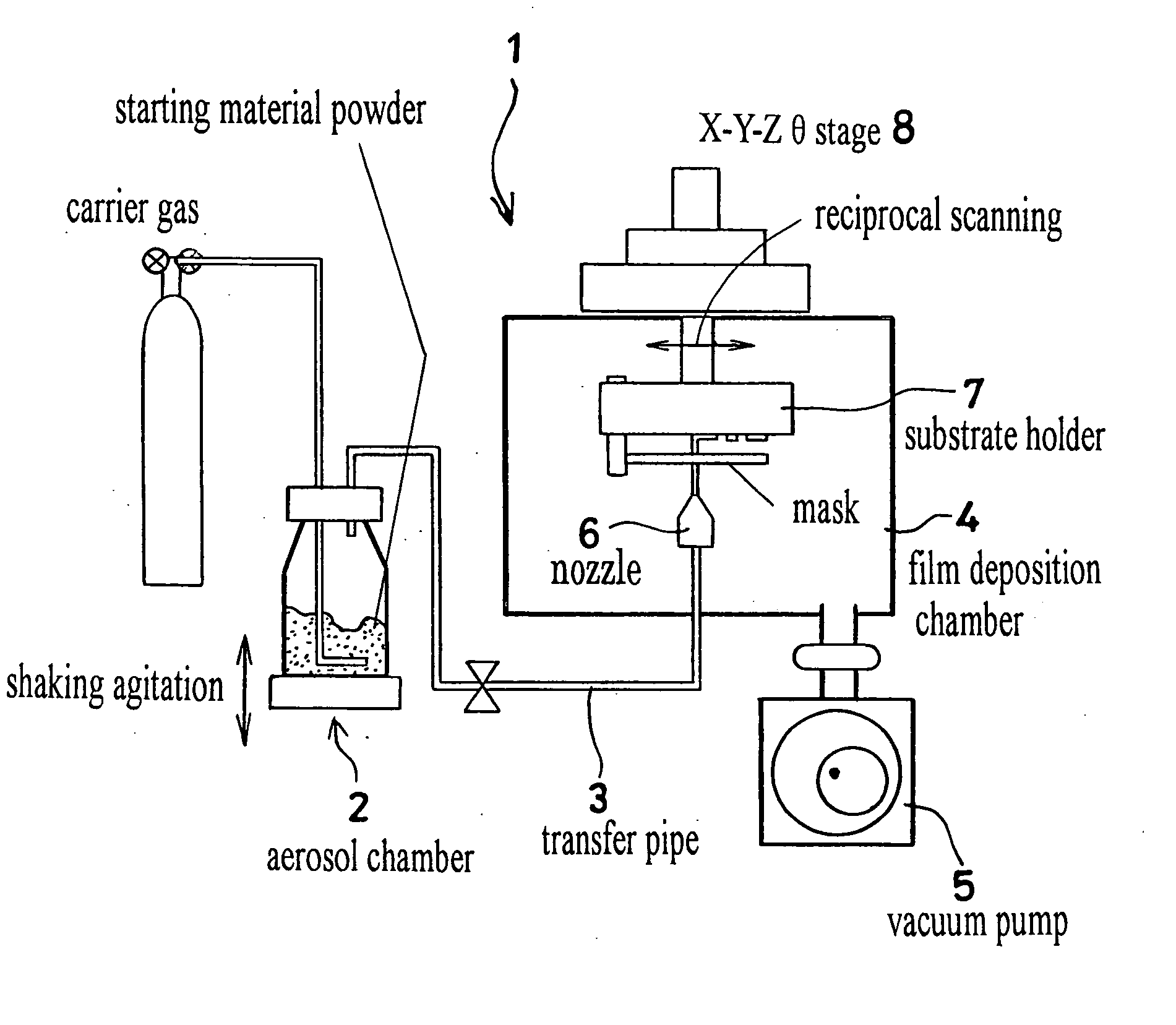

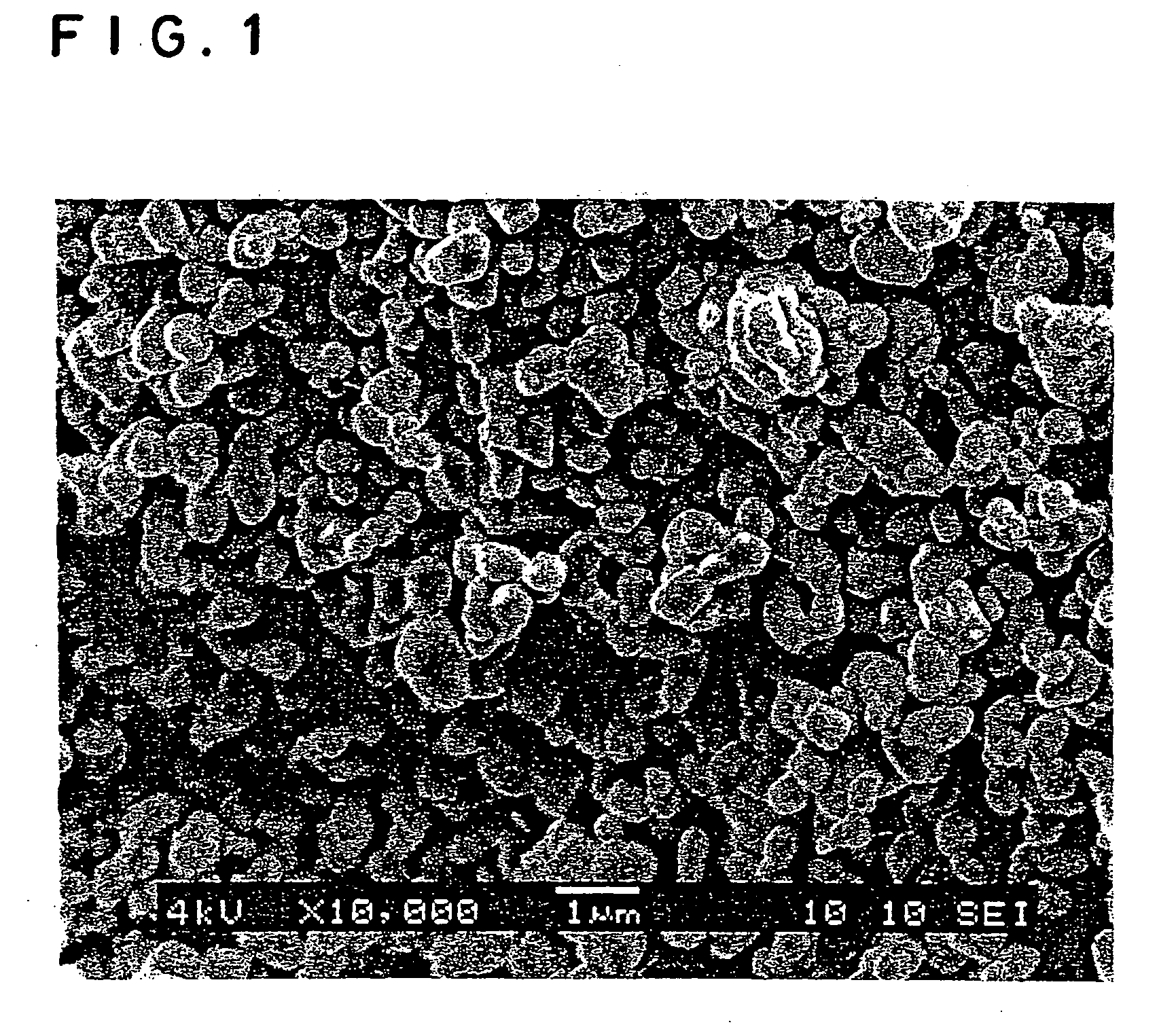

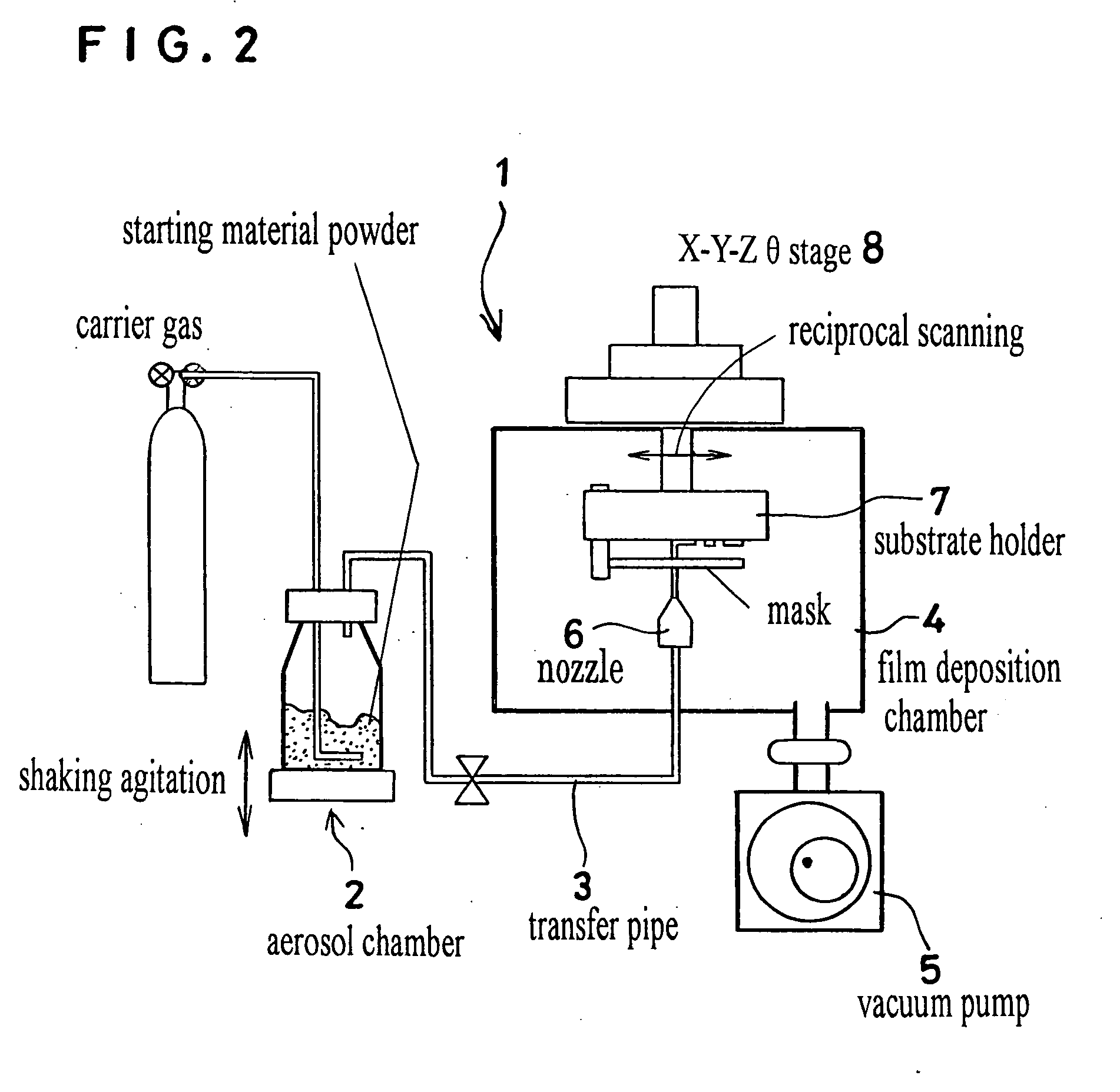

Method of altering crystal structure of group 13 element nitride, group 13 element nitride and structure material containing cubic nitride

InactiveUS20070160872A1Possible to obtainPolycrystalline material growthAfter-treatment detailsCubic crystal systemCrystal structure

An aerosol of a powder composed of helium carrier gas and particles of a hexagonal aluminum nitride is charged through a transfer pipe 3 into a film deposition chamber 4 whose interior is depressurized by gas evacuation using a vacuum pump 5 to maintain a degree of vacuum of 200-8000 Pa during supply of the carrier gas and the aerosol is blown from a nozzle 6 provided on the end of the transfer pipe 3 inside the film deposition chamber 4 to impinge on a substrate fastened to a substrate holder 7 to make the impact force of the particles at collision with the substrate 4 GPa or greater, thereby transforming the crystal structure of the aluminum nitride from hexagonal to cubic to deposit cubic aluminum nitride on the substrate. As a result, a method of transforming the crystal structure of a Group XIII nitride is provided that enables transformation of a Group XIII nitride to cubic crystal structure using a system of simpler configuration than that used for transforming the crystal structure of a Group XIII nitride by a static pressure application process.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Method for generating nanostructures and device for generating nanostructures

InactiveUS7691211B2Drawback can be obviatedPossible to obtainSolid state diffusion coatingBurnishing machinesChemical compoundConfocal

Owner:UNIVERSITY OF TECHNOLOGY OF TROYES +1

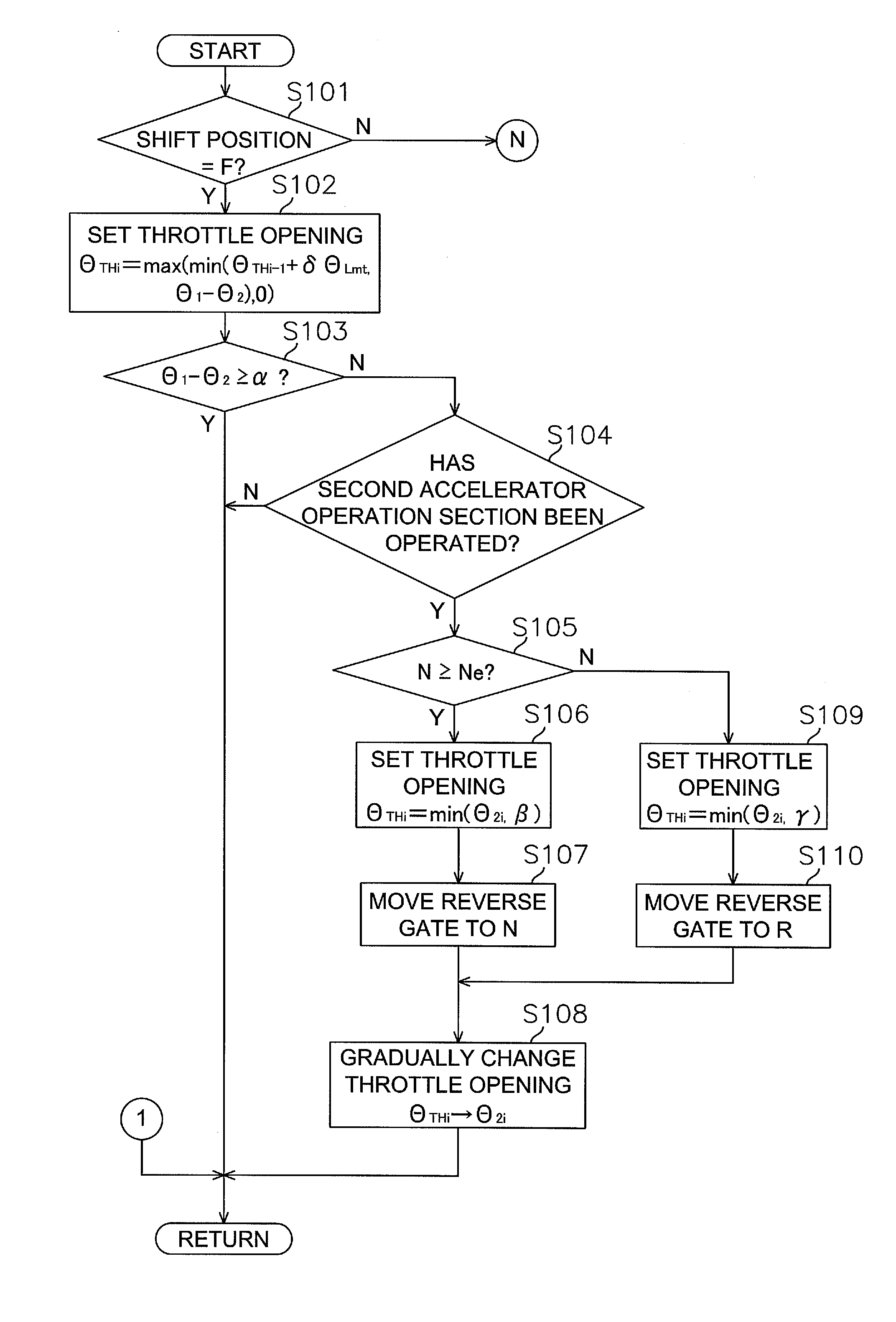

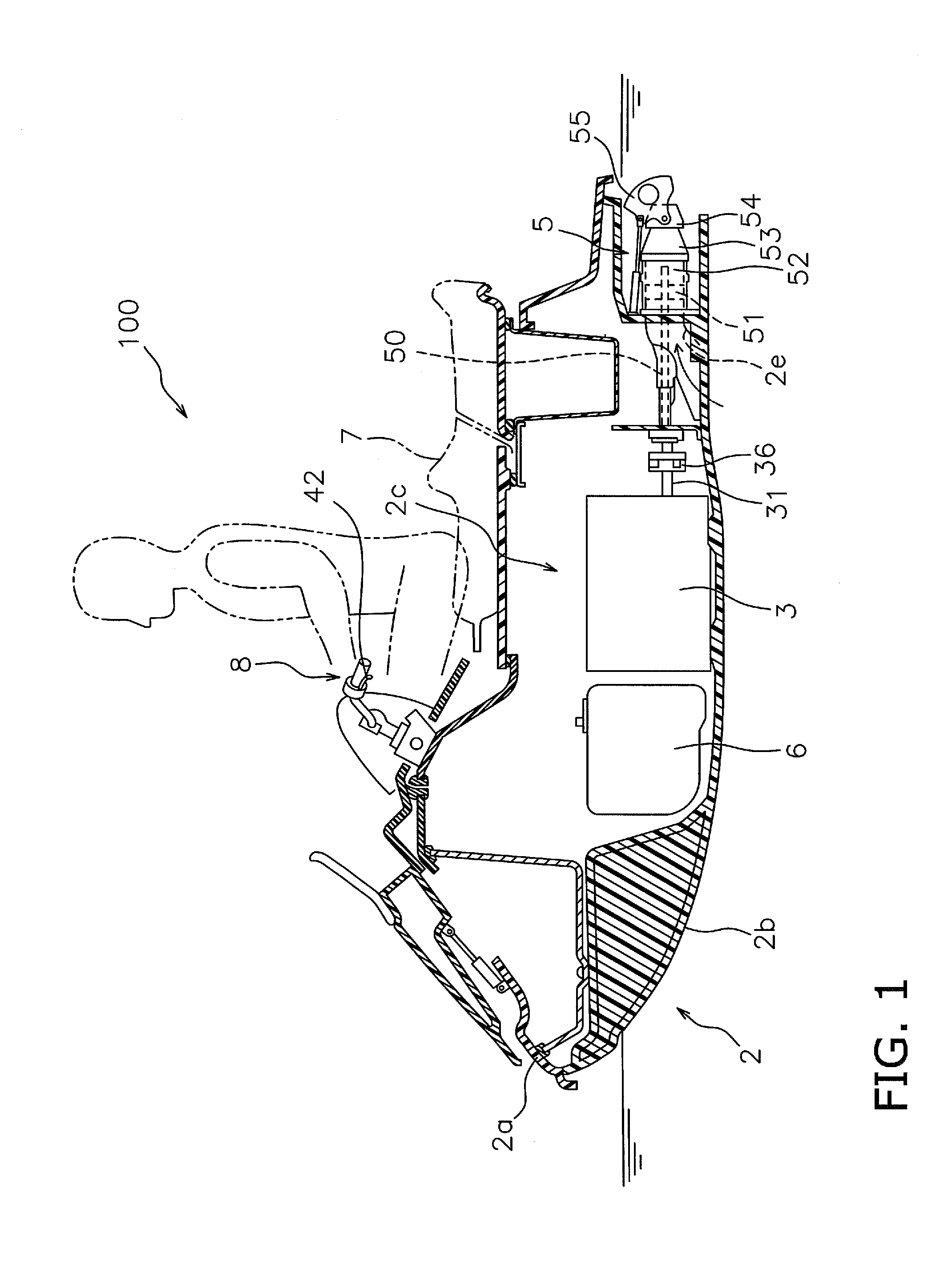

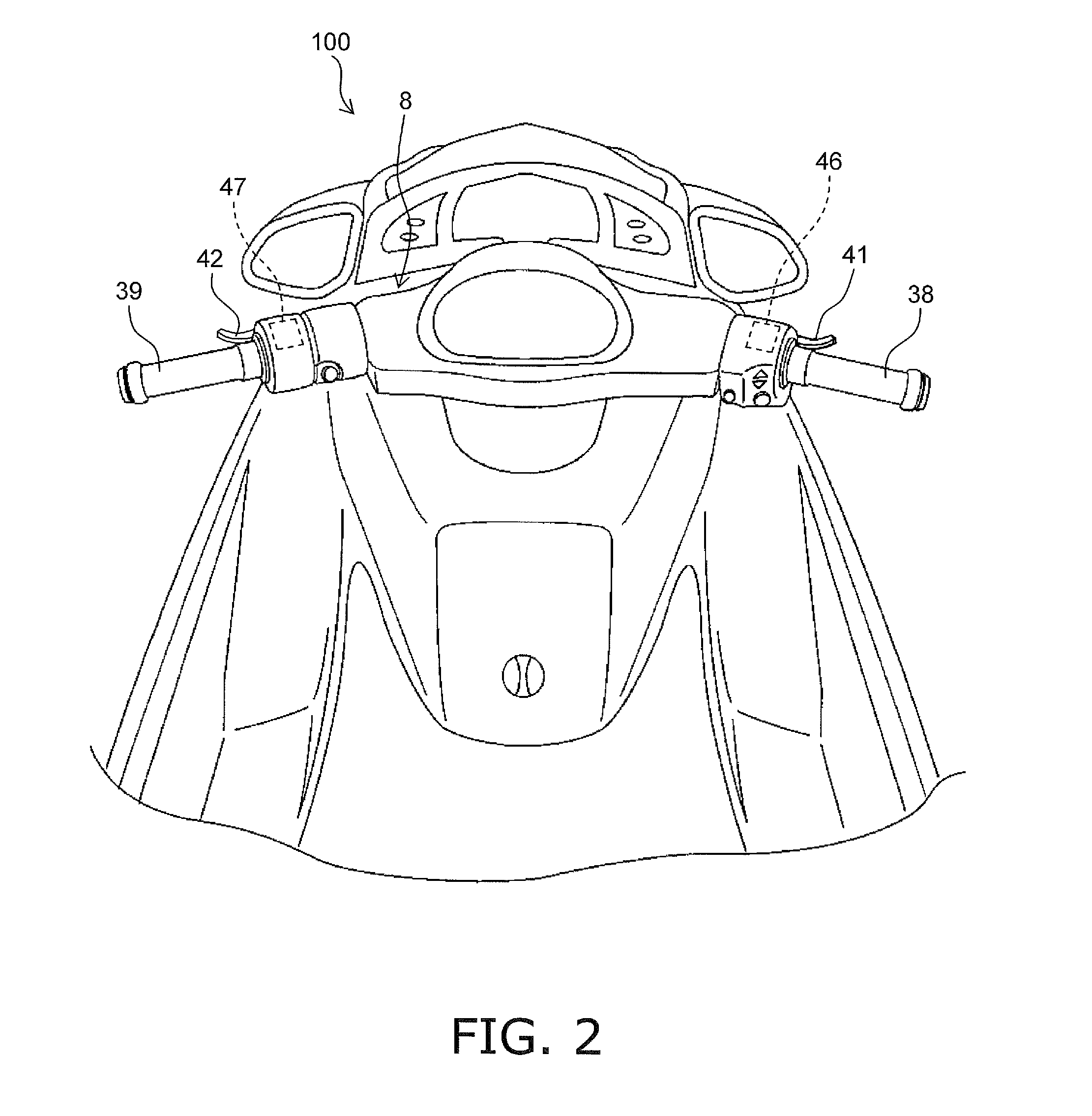

Water jet propulsion boat

ActiveUS20130344754A1Lower performance requirementsPossible to obtainElectrical controlPropulsion power plantsJet propulsionThrottle opening

A water jet propulsion boat includes a boat body, an engine, a jet propulsion mechanism, a first accelerator operation section, a second accelerator operation section, a reverse gate, and a control section. The engine is accommodated in the boat body. The jet propulsion mechanism generates a propulsion power using a drive power from the engine. The reverse gate is arranged to move to a first position and to a second position. The boat body advances when the reverse gate is in the first position. The reverse gate reduces the propulsion power which advances the boat body when the reverse gate is in the second position. The control section is programmed to set the position of the reverse gate and a throttle opening of the engine based on an operation amount of the first accelerator operation section and an operation amount of the second accelerator operation section.

Owner:YAMAHA MOTOR CO LTD

Semiconductor optical device on an indium phosphide substrate for long operating wavelengths

ActiveUS20050056868A1Improve thermal efficiencyWeaken energyLaser detailsLaser active region structureQuantum wellSemiconductor alloys

A semiconductor optical device such as a laser or semiconductor optical amplifier (SOA) based on an indium phosphide substrate or equivalent buffer layer. The active layer of the device is based on conventional InGaAs(P) alloy, but additionally includes N in order to increase the operating wavelength to greater than 1.5 μm, preferably to a wavelength lying in the C- or L-band. The active layer composition may thus be denoted In1-xGaxAsyNzPp with x≧0.48, y≦1-z-p, z≦0.05, p≧0. The active layer may include a quantum well or multi-quantum wells in which case its thickness is preferably less than the critical thickness for lattice relaxation. In other embodiments the active layer is a “massive” layer with quasi-bulk properties. The active layer may advantageously be under tensile stress, preferably roughly between 1% and 2.2%, to manipulate the light and heavy hole bands. The active layer is typically bounded by barrier layers made of a suitable semiconductor alloy, such as AlInAs or InGaAs(P).

Owner:OCLARO NORTH AMERICA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com