Patents

Literature

3181 results about "Polyurea" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyurea is a type of elastomer that is derived from the reaction product of an isocyanate component and a synthetic resin blend component through step-growth polymerization. The isocyanate can be aromatic or aliphatic in nature. It can be monomer, polymer, or any variant reaction of isocyanates, quasi-prepolymer or a prepolymer. The prepolymer, or quasi-prepolymer, can be made of an amine-terminated polymer resin, or a hydroxyl-terminated polymer resin.

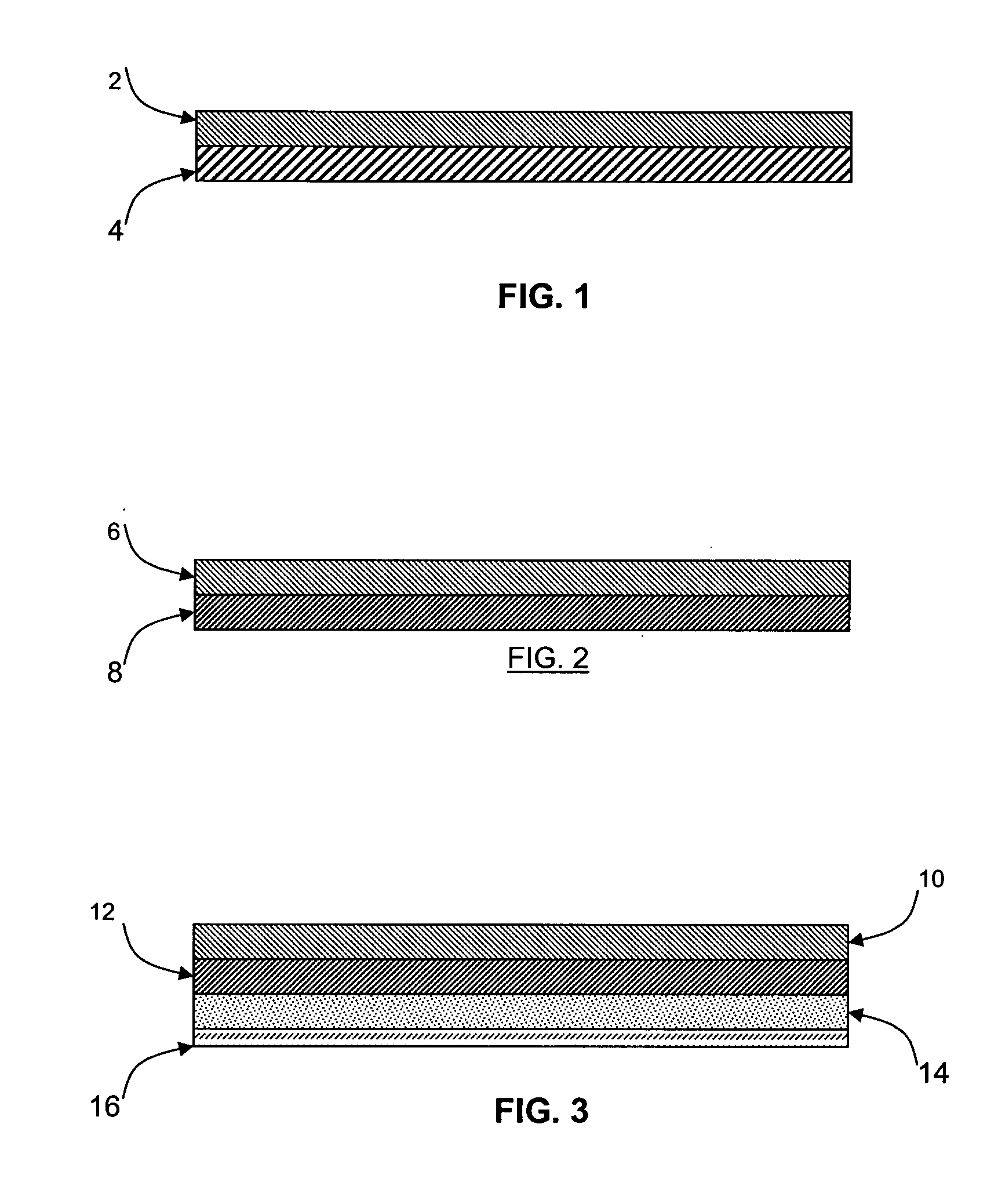

Multi-component coatings that include polyurea coating layers

ActiveUS20060046068A1Synthetic resin layered productsPolyurea/polyurethane coatingsPolymer sciencePolymer chemistry

A polyurea composition, a multi-component composite coating and articles formed therefrom, and methods of forming the same are disclosed. The coating composition is formed from a reaction mixture comprising an isocyanate-functional component and an amine-functional component. The ratio of equivalents of isocyanate groups to equivalents of amine groups is greater than 1 while the volume mixing ratio of the isocyanate-functional component to the amine-functional component is capable of being applied to a substrate at 1:1.

Owner:PPG IND OHIO INC

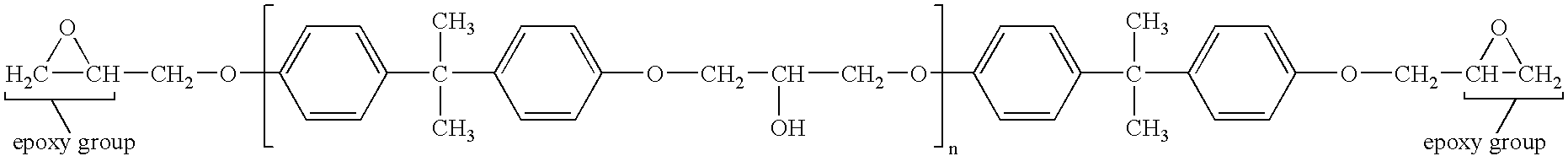

Toughened epoxy adhesive composition

ActiveUS20060276601A1Improved lap shear and impact peel strengthGood storage stabilityPolyureas/polyurethane adhesivesSynthetic resin layered productsElastomerEnd-group

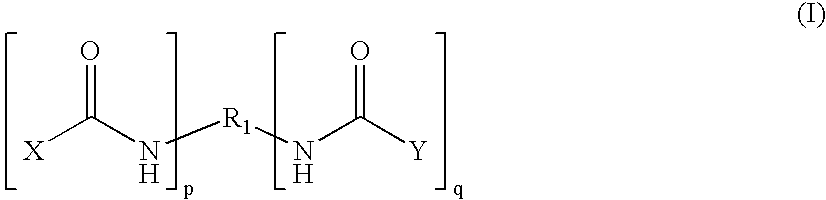

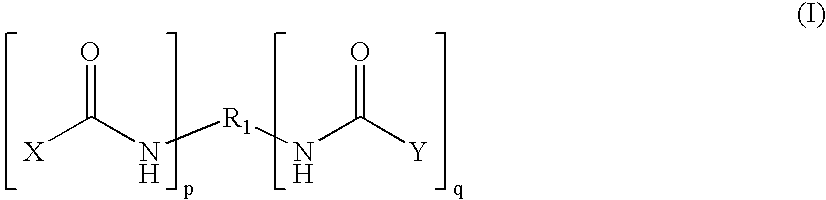

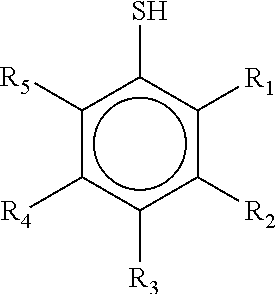

The invention is an epoxy resin based adhesive composition comprising an epoxy resin and a compound comprising an elastomeric prepolymer residue selected from the group of a polyurethane, a polyurea and a polyurea polyurethane having isocyanate end groups, the isocyanate end groups of said prepolymer residue being capped by a capping compound selected from the group consisting of a primary aliphatic, cycloaliphatic, heteroaromatic and araliphatic amine, a secondary aliphatic, cycloaliphatic, aromatic, heteroaromatic and araliphatic amine, a thiol and an alkyl amide, said capping compound being bound to the end of the polymer chain of the elastomeric prepolymer in a manner such that the end to which it is bonded no longer has a reactive group. In addition to the capping compound defined above above, a capping compound selected from the group consisting of a phenol and a polyphenol can be used for capping the isocyanate end groups of the prepolymer residue

Owner:DOW GLOBAL TECH LLC

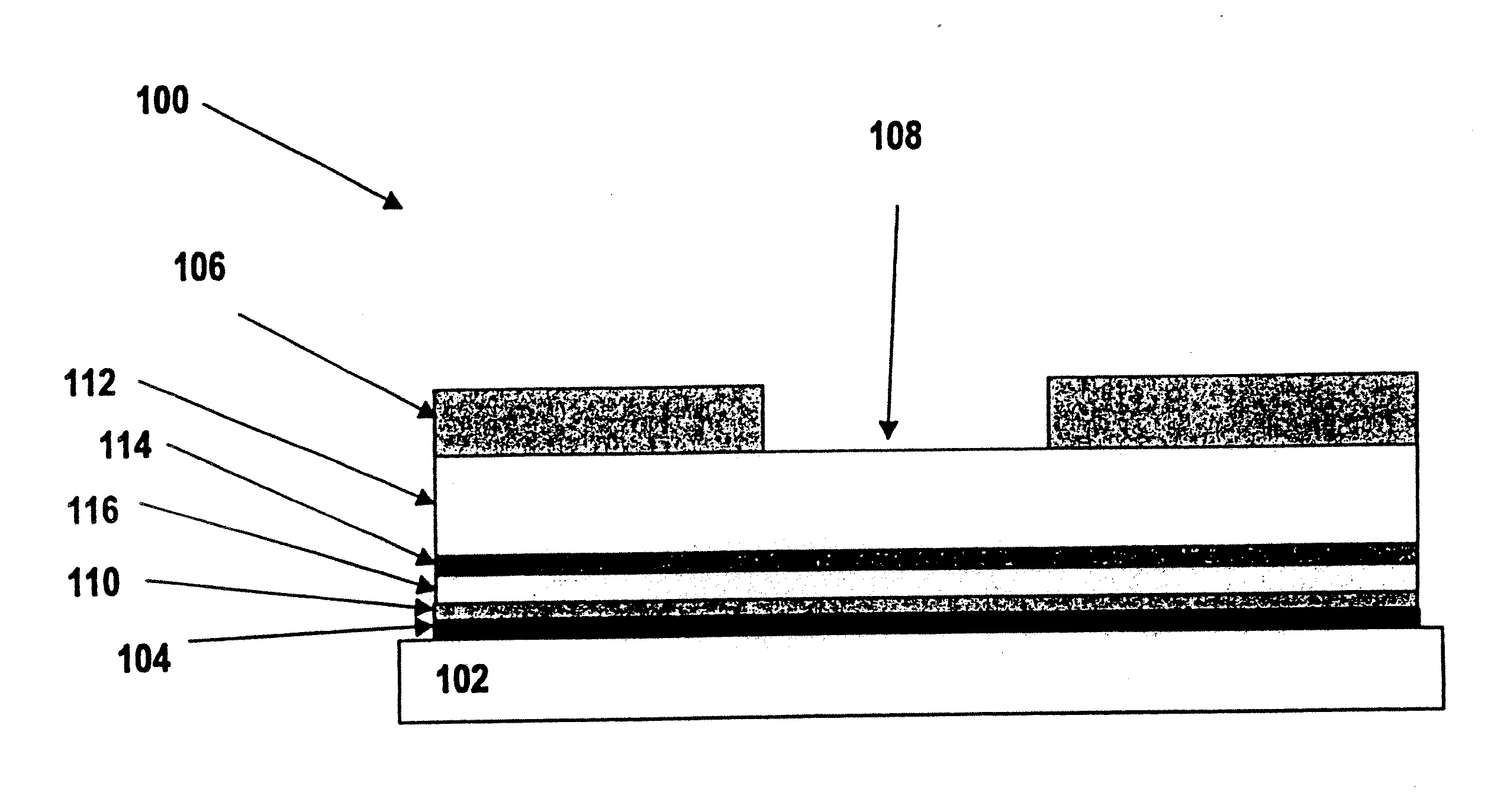

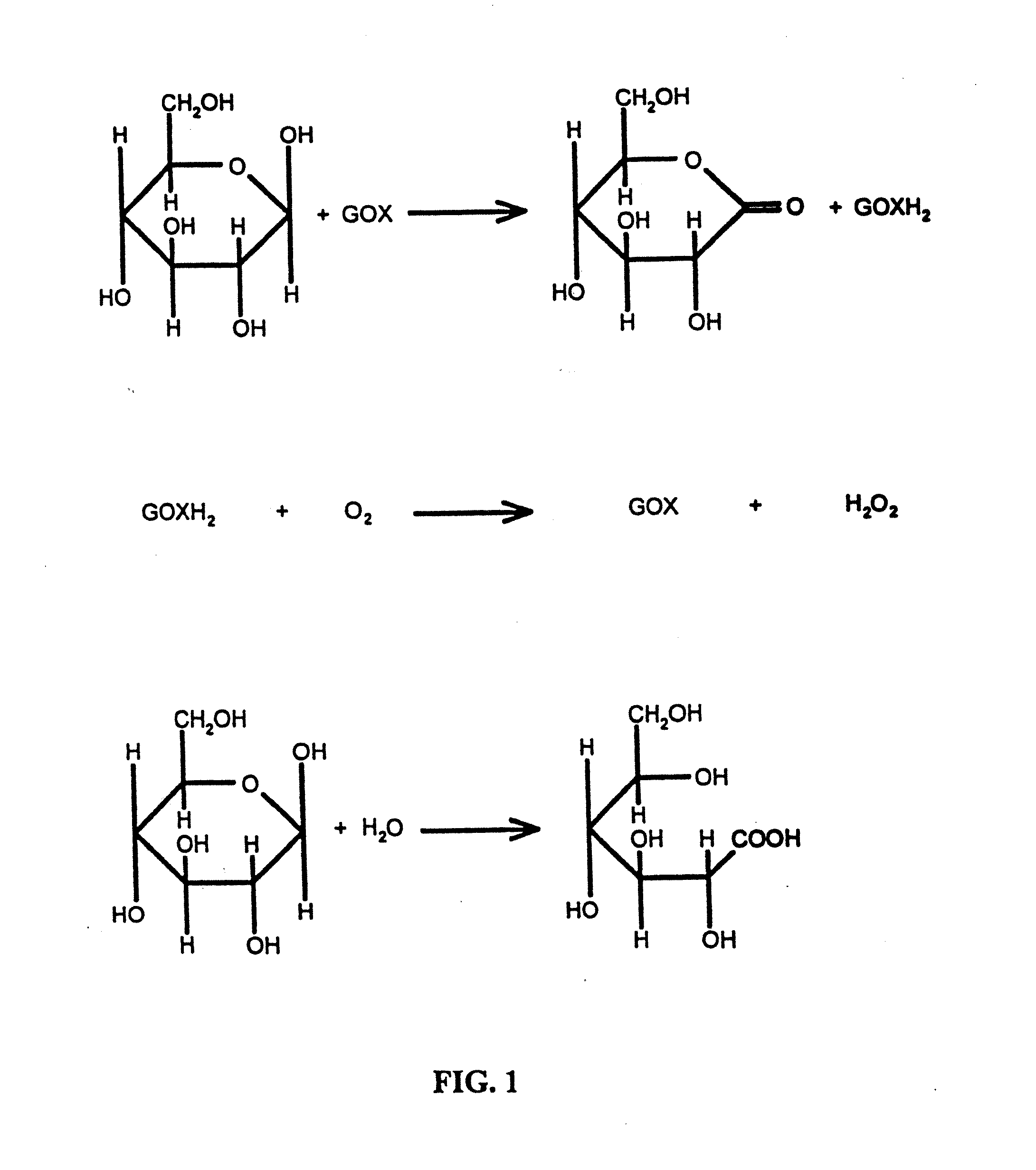

Analyte sensors comprising blended membrane compositions and methods for making and using them

ActiveUS20110152654A1Promote hydrationImprove mechanical propertiesImmobilised enzymesBioreactor/fermenter combinationsAnalyteChemical reaction

Embodiments of the invention provide analyte sensors having elements designed to modulate their chemical reactions as well as methods for making and using such sensors. In certain embodiments of the invention, the sensor includes an analyte modulating membrane that comprises a blended mixture of a linear polyurethane / polyurea polymer, and a branched acrylate polymer.

Owner:MEDTRONIC MIMIMED INC

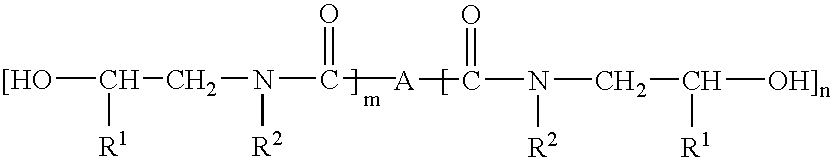

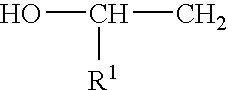

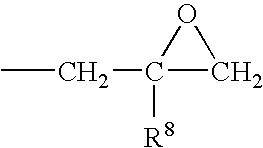

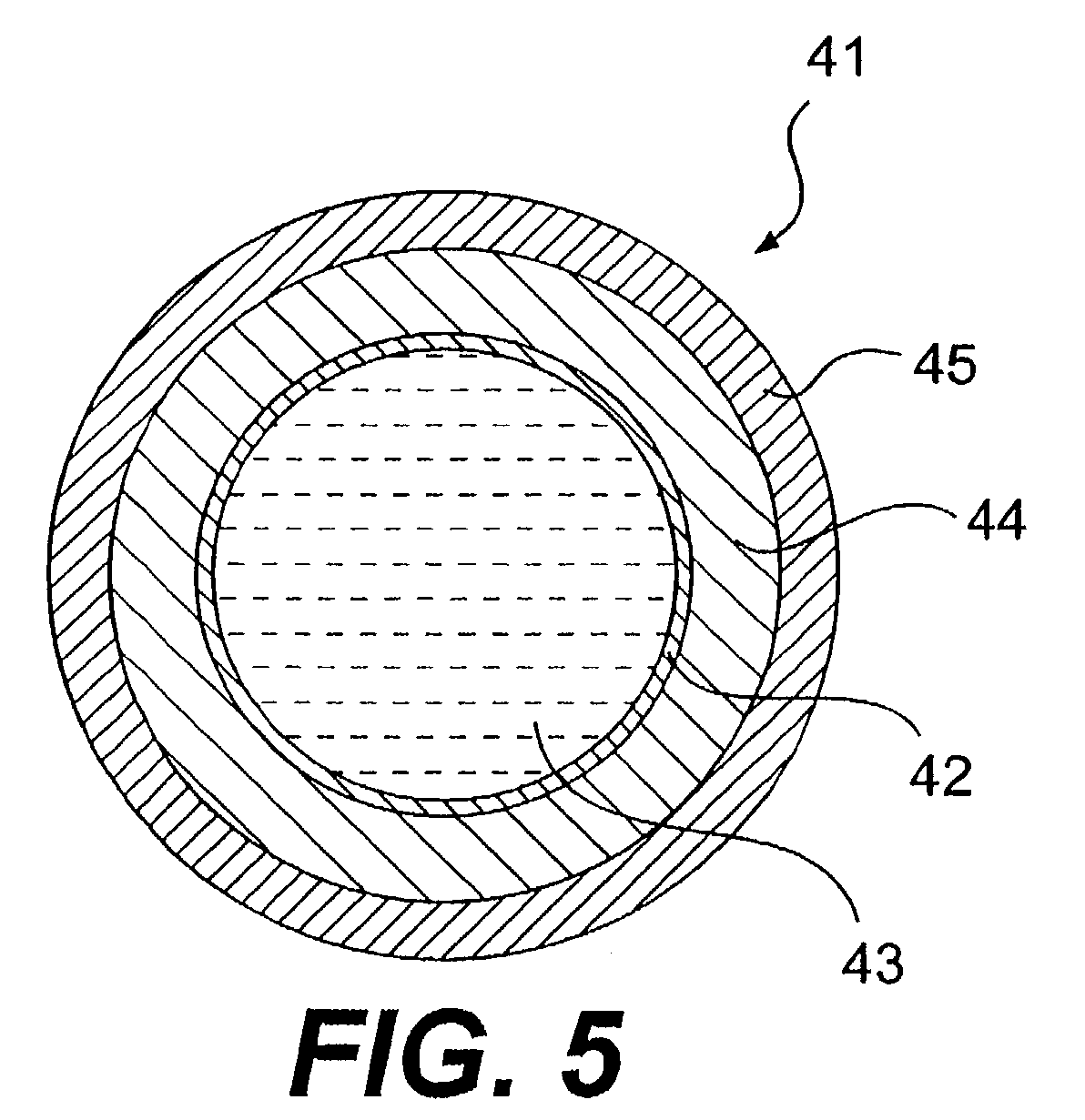

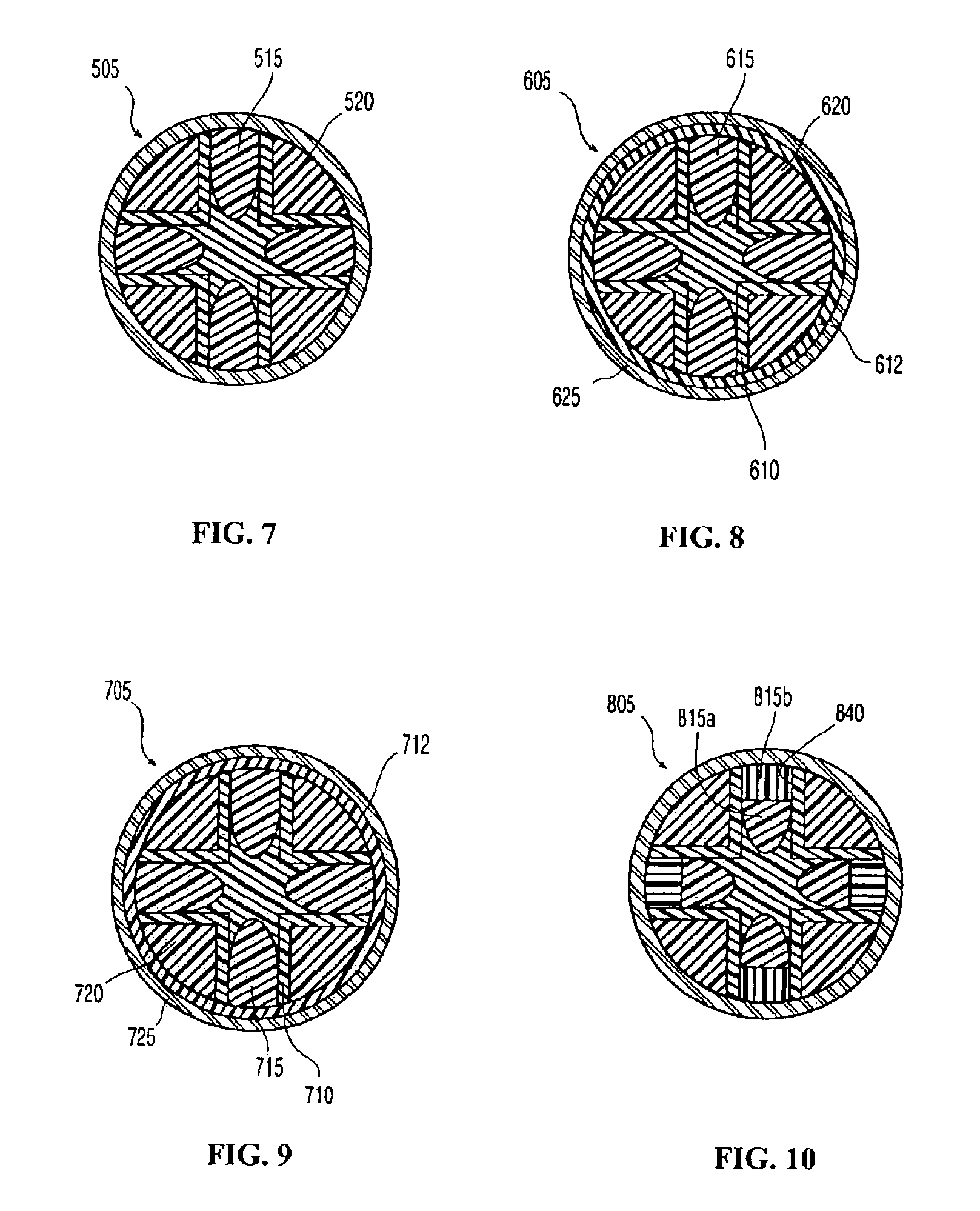

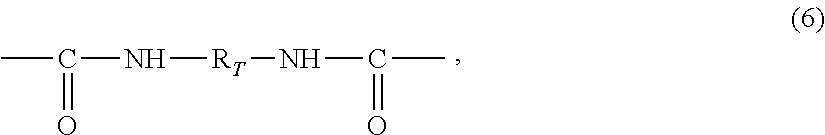

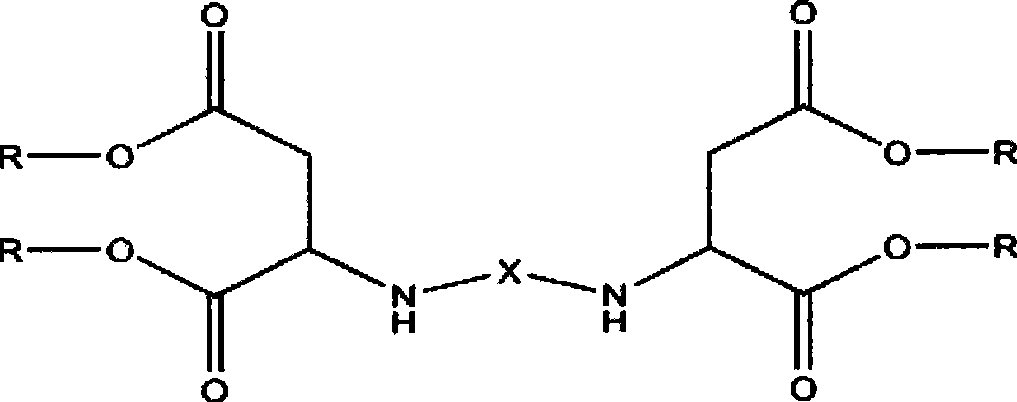

Crosslinkable polyurea prepolymers

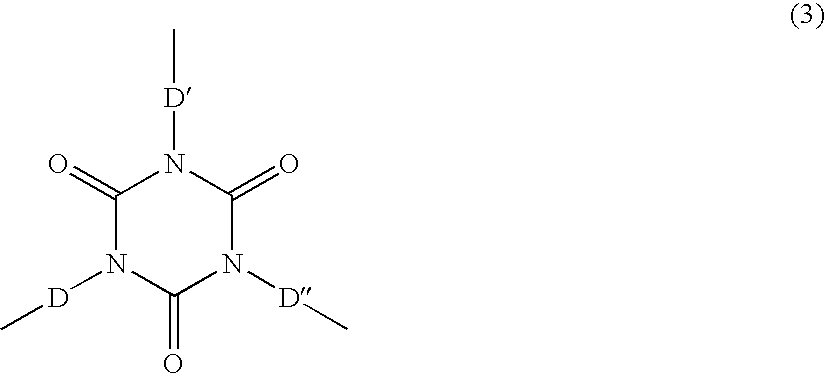

The present invention provides a water-soluble crosslinkable polyurea prepolymer. The crosslinkable polyurea prepolymer of the invention is prepared by reacting an amine- or isocyanate-capped polyurea with a multifunctional compound having at least one one ethylenically unsaturated group and a function group coreactive with the capping amine or isocyanate groups of the amine- or isocyanate-capped polyurea. The amine- or isocyanate-capped polyurea is a copolymerization production of: (a) at least one poly(oxyalkylene)diamine, (b) optionally at least one organic di- or poly-amine, (c) optionally at least one diisocyanate, and (d) at least one polyisocyanate. The crosslinkable polyurea prepolymer of the invention can find use in economically producing contact lenses which have durable, highly elastic soft contact lenses with desired physical properties. In addition, the present invention provides method for making a medical device, preferably an ophthalmic device, more preferably a contact lens.

Owner:ALCON INC

Method of preparing an aliphatic polyurea spray elastomer system

This invention concerns a method for the preparation of polyurea elastomers, comprising: (a) reacting an amine chain extender with dialkyl maleate to form an aspartic ester, wherein the chain extender has a molar amount of amine groups that is less than the moles of dialkyl maleate; (b) blending the aspartic ester with one or more polyoxyalkyleneamines to prepare a resin blend; (c) contacting the resin blend with an isocyanate under conditions effective to form a polyurea elastomer. This invention also concerns a a polyurea elastomer, comprising the reaction product of (a) a resin blend containing one or more polyoxyalkyleneamine and an aspartic ester and (b) an isocyanate, wherein the aspartic ester in the resin blend comprises a reaction product of an amine chain extender and a dialkyl maleate, wherein the mole ratio of amine functionality in the amine chain extender to dialkyl maleate or fumarate is greater than 1:1.

Owner:JPMORGAN CHASE BANK N A AS COLLATERAL AGENT +1

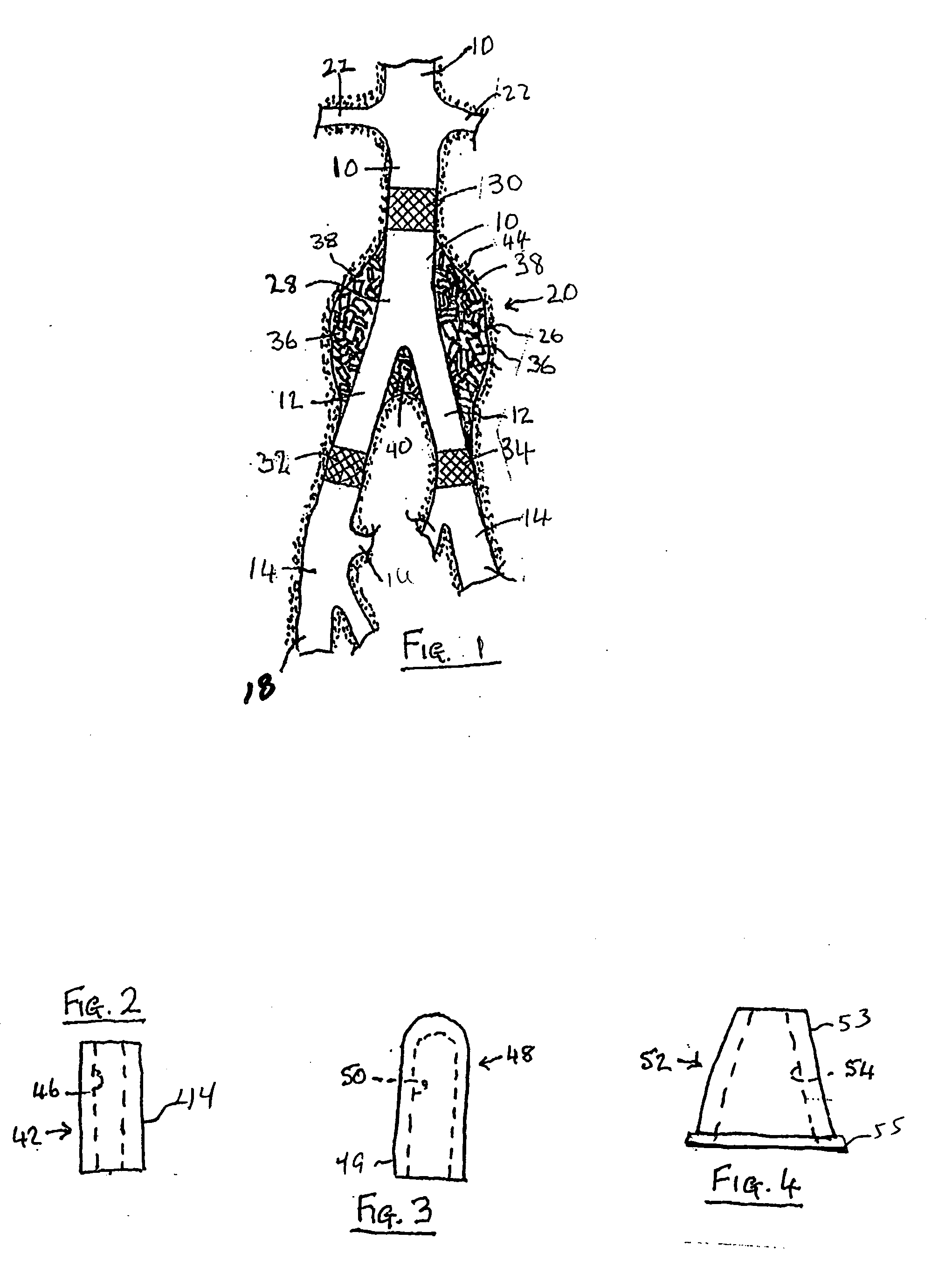

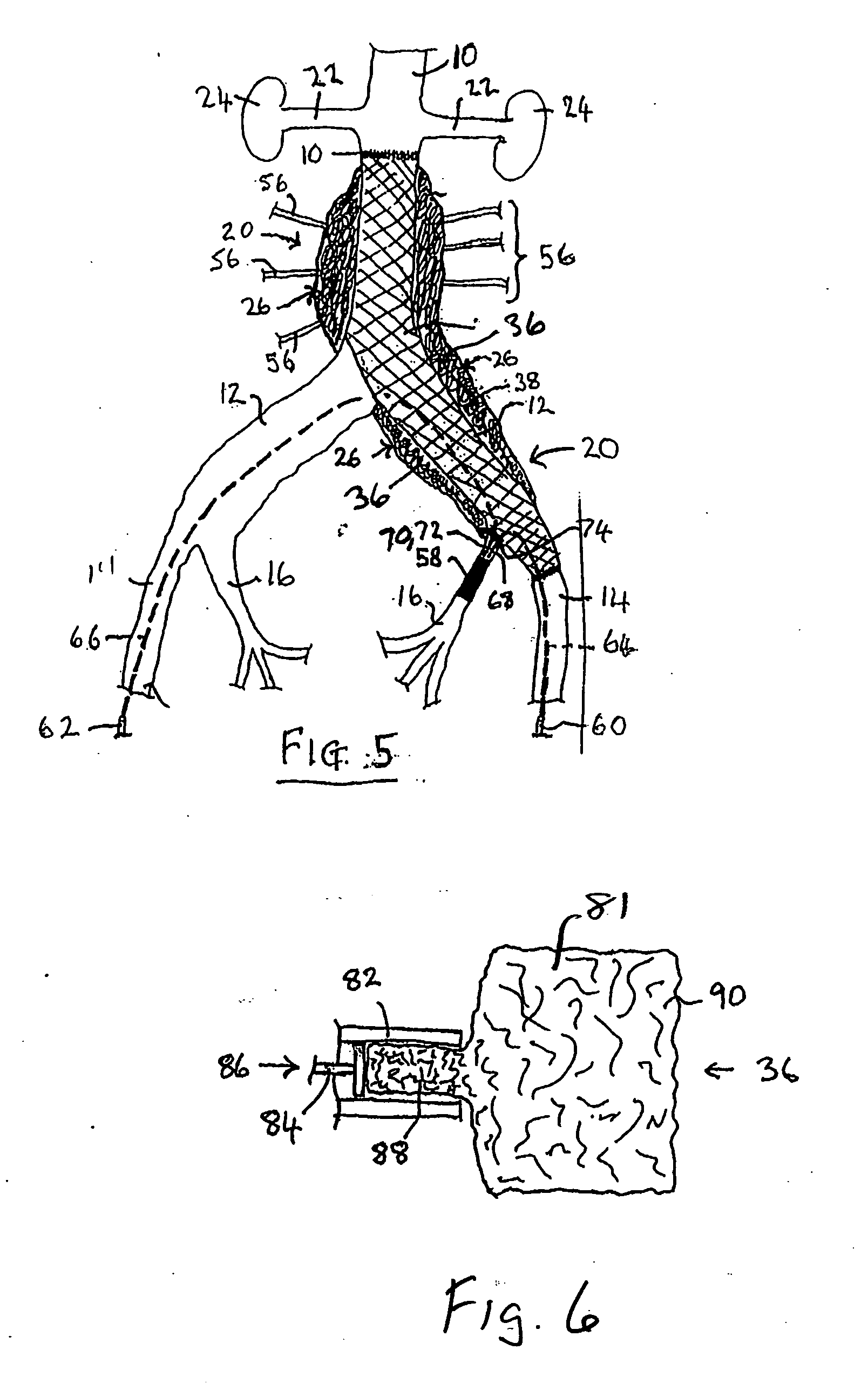

Endovascular treatment devices and methods

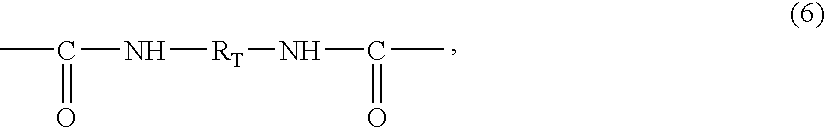

InactiveUS20050165480A1Simple and potentially effective treatmentTreating and preventing endoleakageTracheaeOcculdersEndovascular treatmentElastomer

A device for treating or preventing a vascular condition at a mammalian vascular site, comprises an implant formed from a compressible, reticulated elastomeric matrix in a shape conducive to delivery through a delivery instrument. One or more implants are delivered in a compressed state to the mammmalian vascular site where each implant recovers substantially to its uncompressed state following deployment from a delivery instrument. In a preferred embodiment the matrix comprises cross-linked polycarbonate polyurethane-urea or cross-linked polycarbonate polyurea-urethane. In another preferred embodiment the matrix comprises a cross-linked polycarbonate polyurethane. In a yet further embodiment, the matrix comprises thermoplastic polycarbonate polyurethane or thermoplastic polycarbonate polyurethane-urea.

Owner:THE BIOMERIX CORP

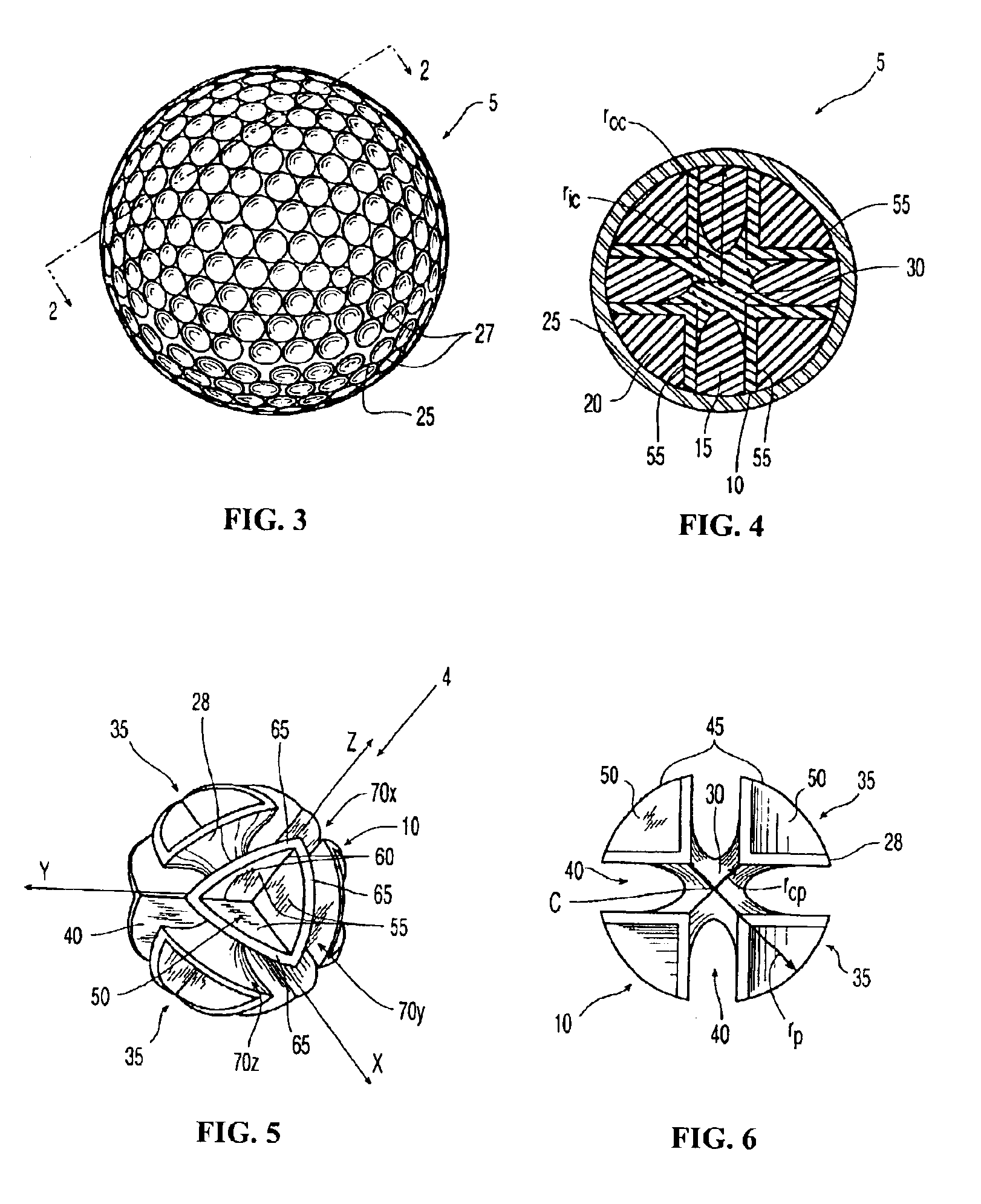

Polyurethane compositions for golf balls

Polyurethane and polyurea compositions for golf balls with improved stability of the curative blend, wherein the curative blend includes a pigment, a curing agent, and a compatible freezing point depressing agent so that the curative blend has a lower freezing point than the curing agent by itself and the blend does not lose pigment dispersion upon solidification and subsequent thawing.

Owner:ACUSHNET CO

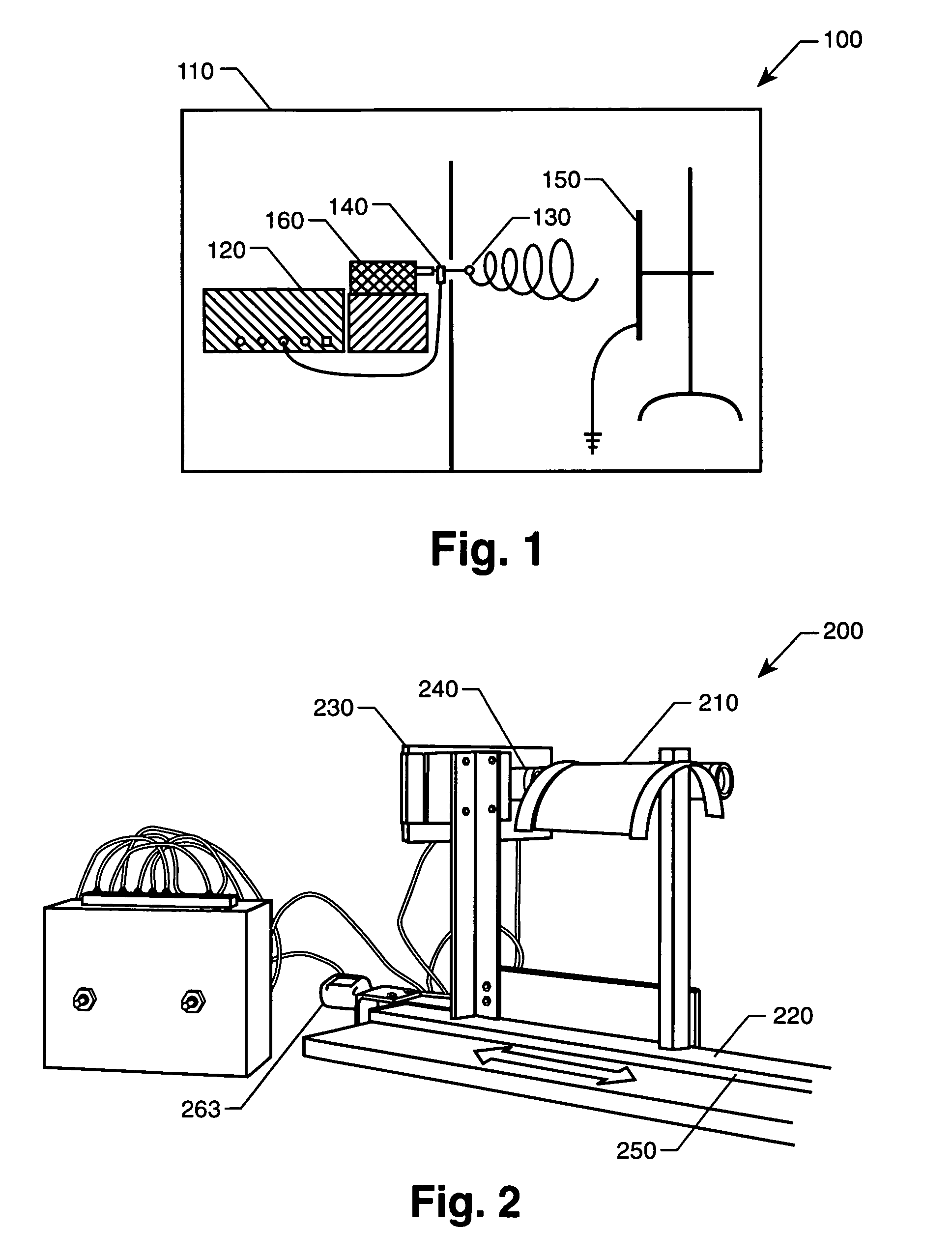

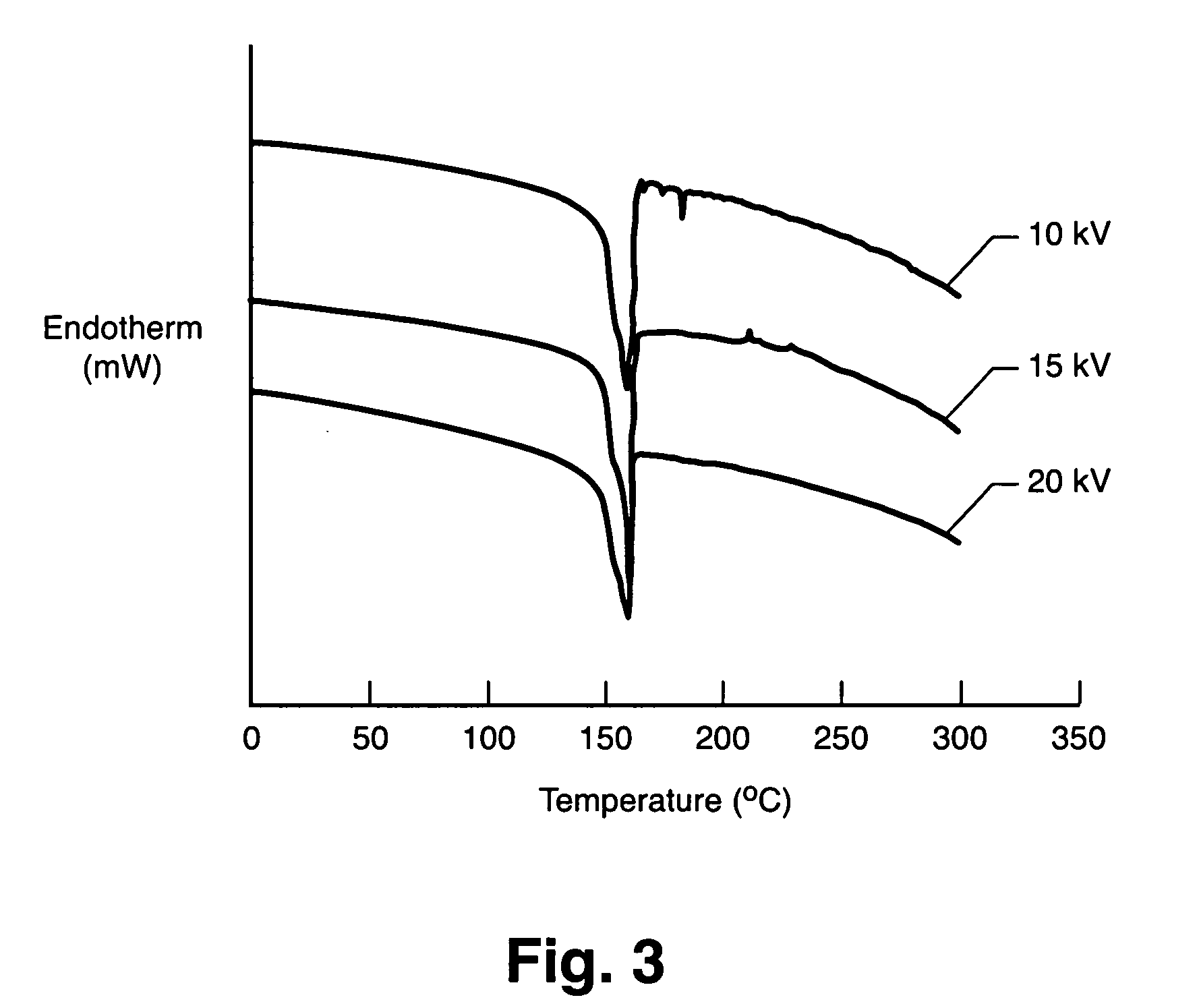

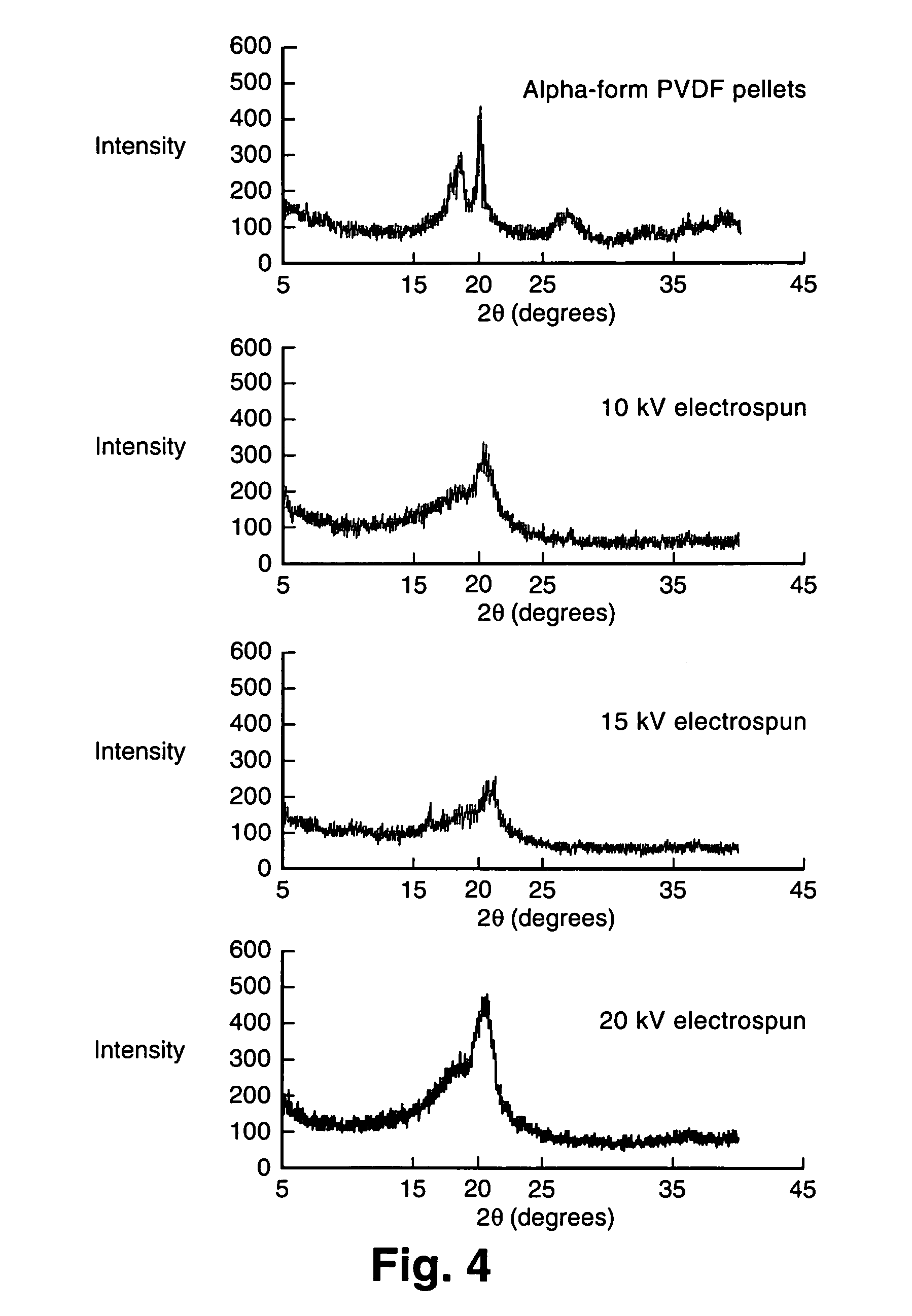

Electrospun electroactive polymers

InactiveUS20060057377A1Easy to set upFast and easy to runMaterial nanotechnologyPiezoelectric/electrostrictive device manufacture/assemblyPolyesterFiber

Electroactive polymers are produced via electrospinning. The induction of electroactivity via electrospinning can be utilized with one or more soluble polymers with polarizable moieties. Suitable polymer classes include but are not limited to polyimides, polyamides, vinyl polymers, polyurethanes, polyureas, polythioureas, polyacrylates, polyesters, and biopolymers. Any one or more solvents sufficient to dissolve the one or more polymers of interest and make a spinnable solution can be utilized. The polymer can be electrospun into fiber and fibrous nonwoven mat. The electroactive polymer can be doped with inclusions, such as nanotubes, nanofibers, and piezoceramic powders for dielectric enhancement The availability of electroactive polymer fibers and fibrous nonwoven mat will enable many new applications for electroactive polymers.

Owner:NASA +2

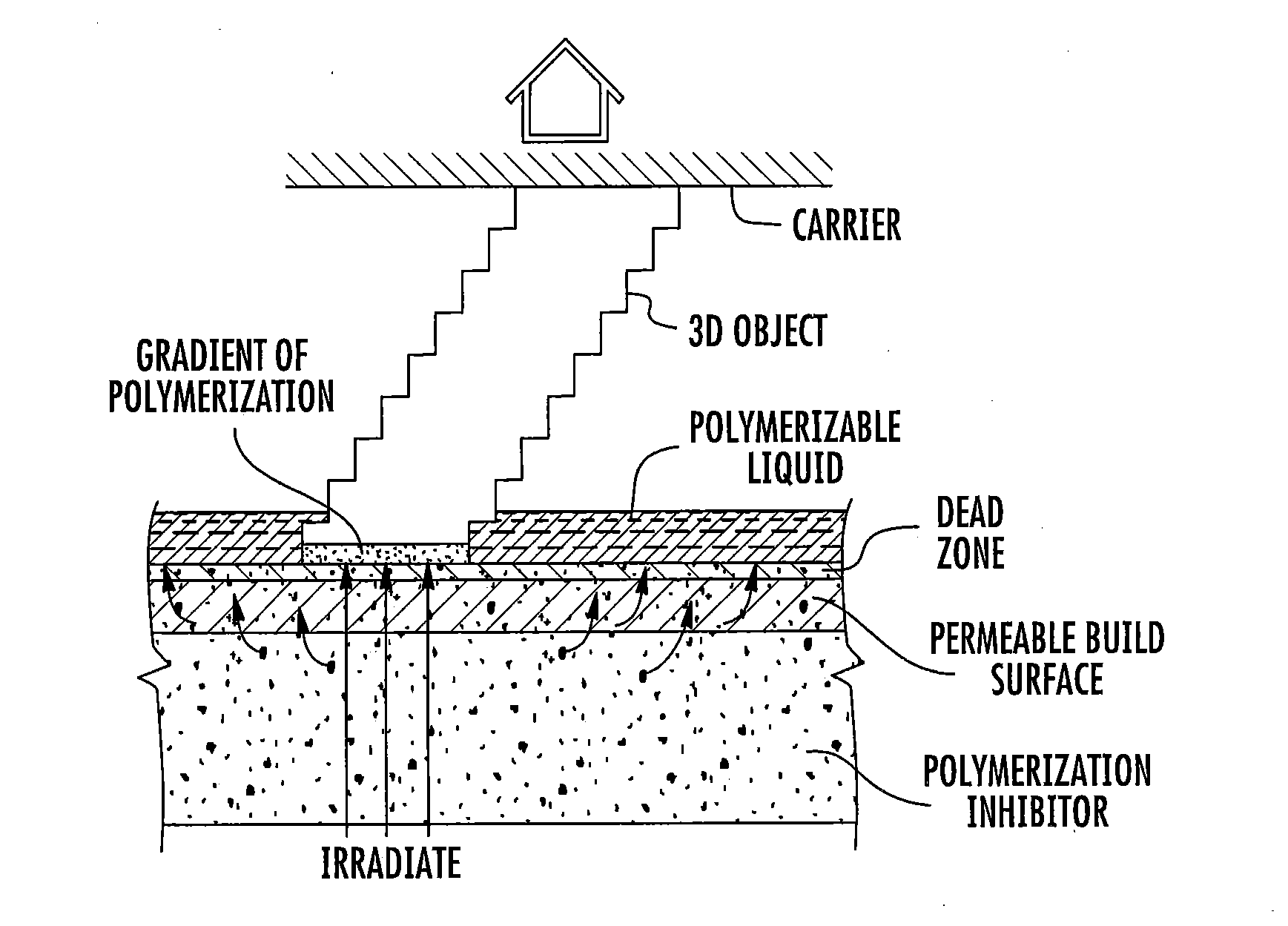

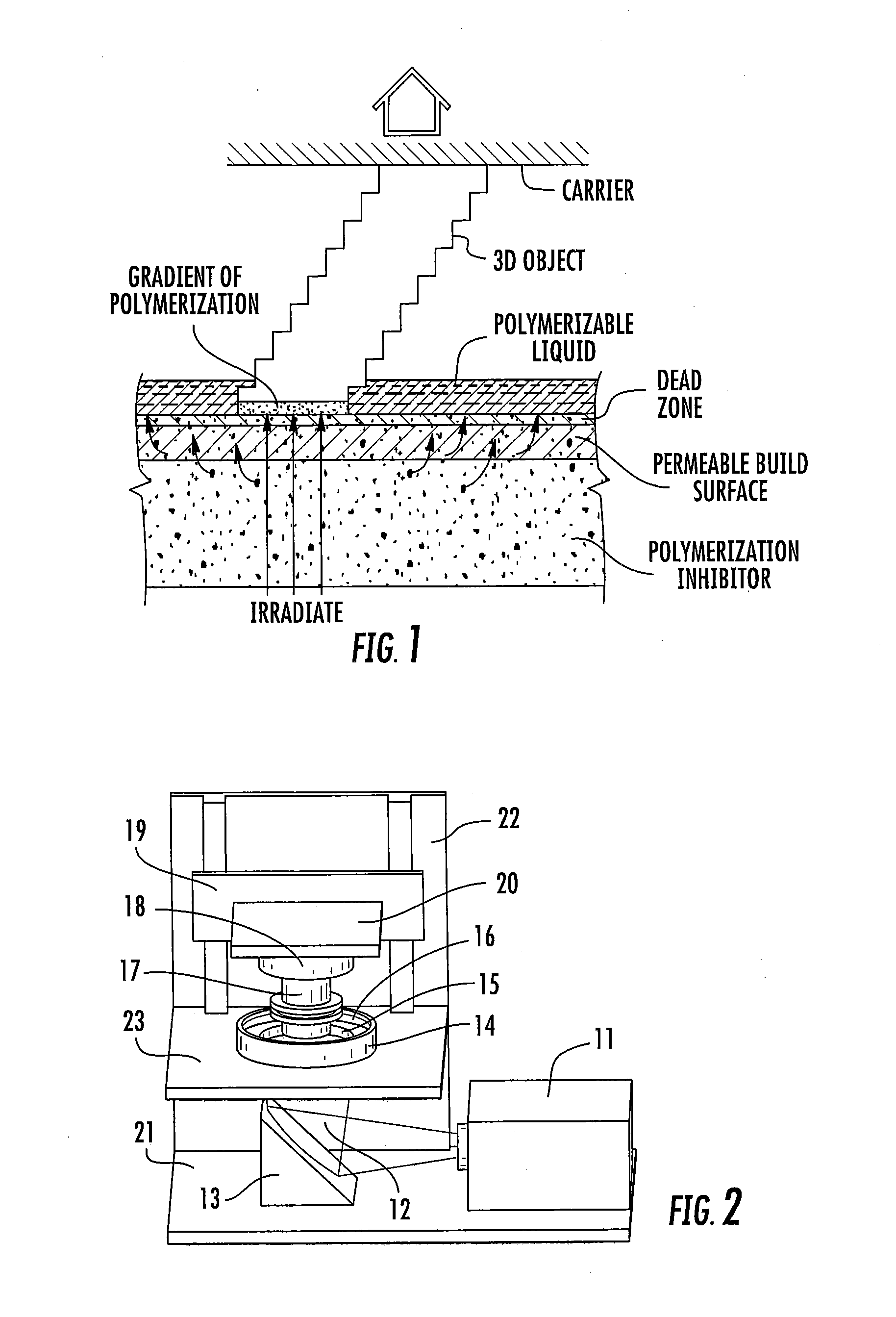

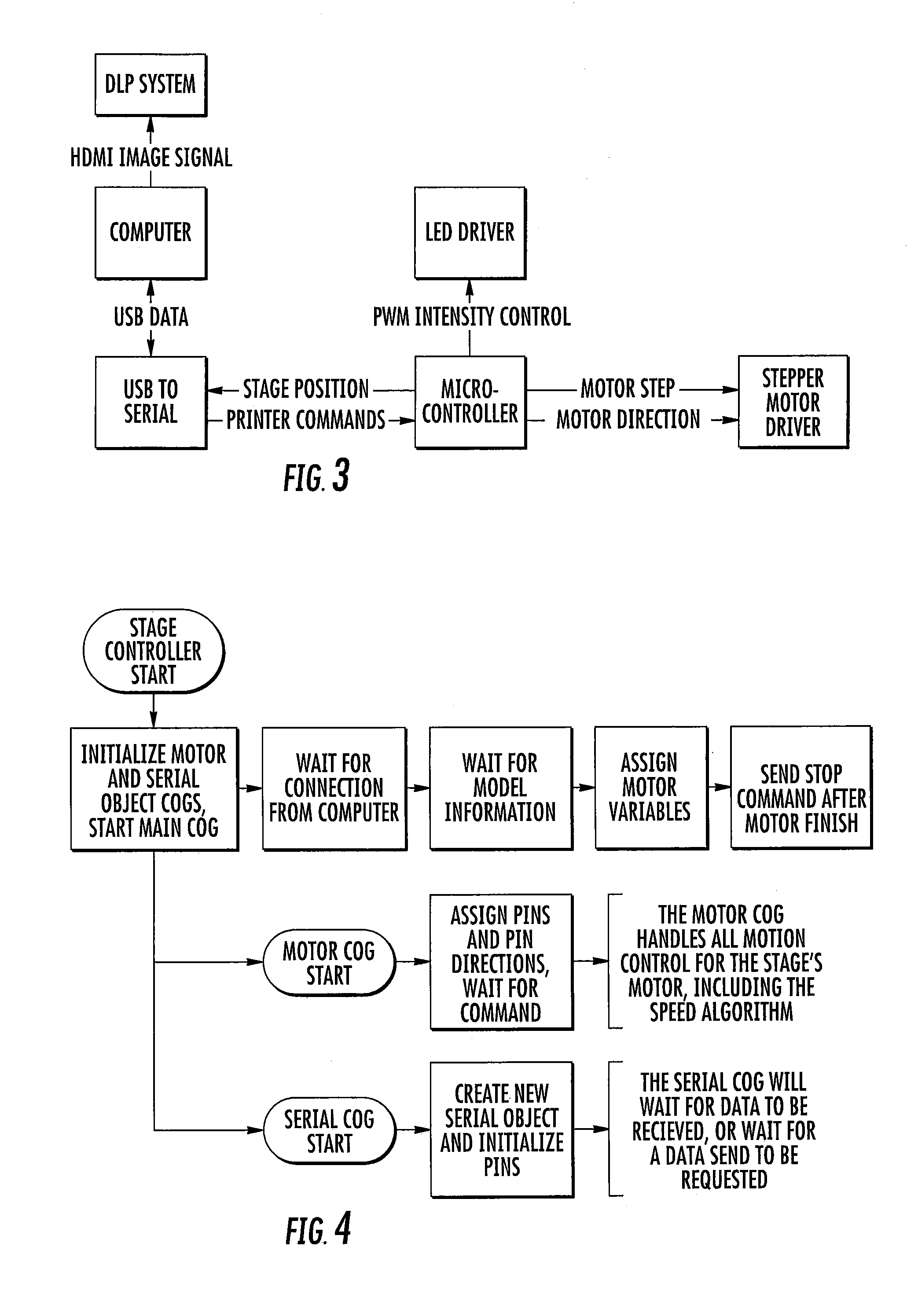

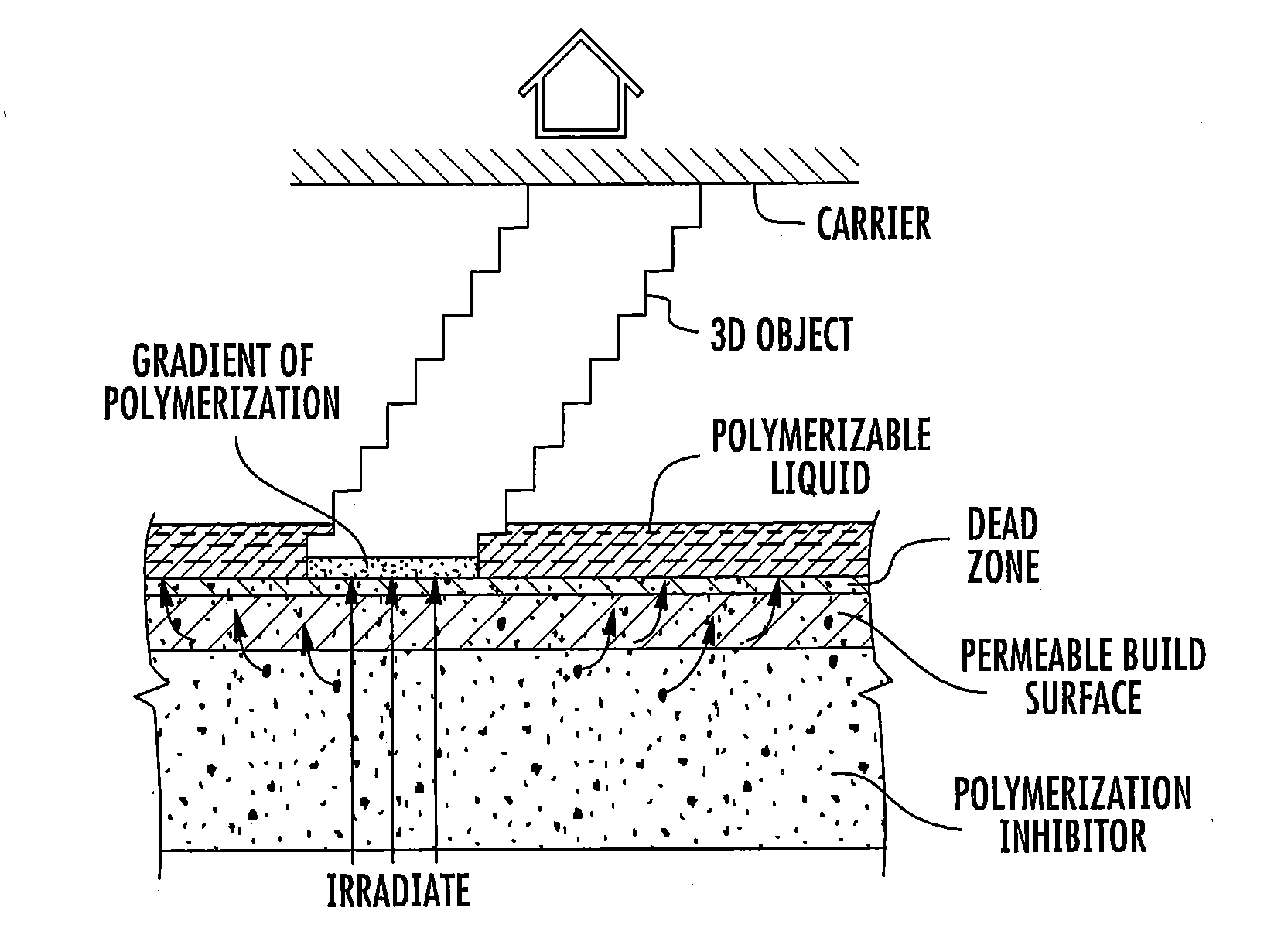

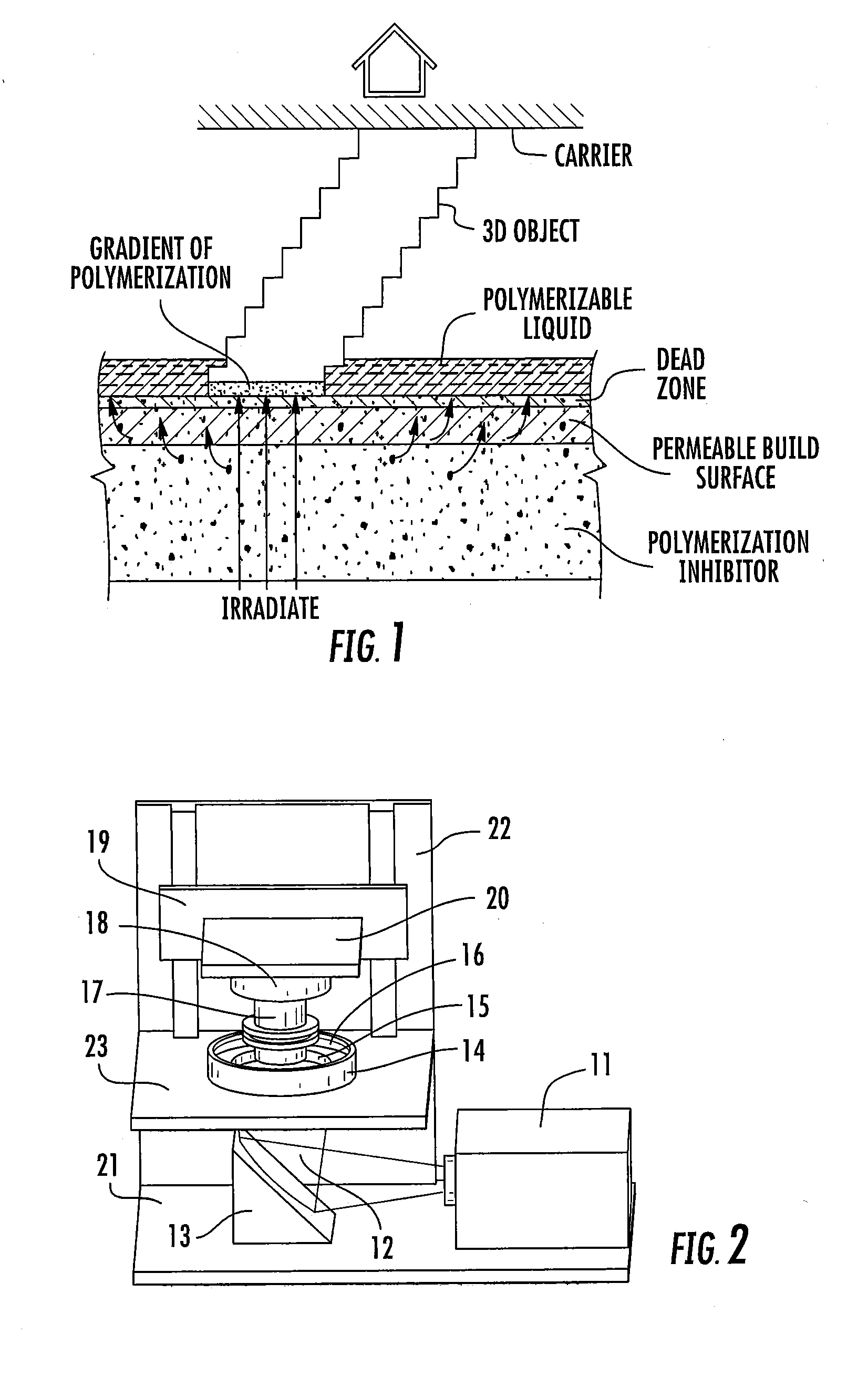

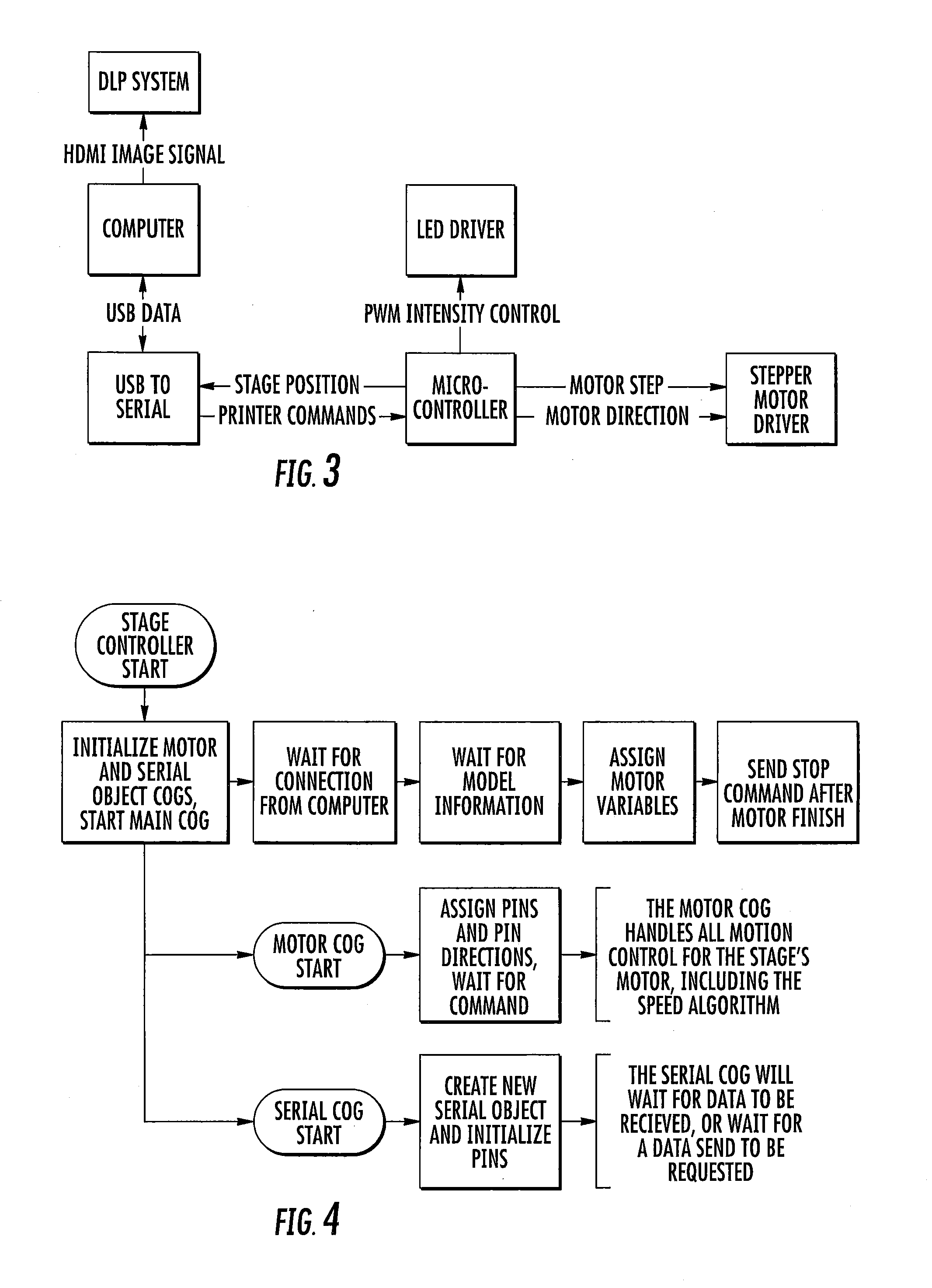

Polyurethane resins having multiple mechanisms of hardening for use in producing three-dimensional objects

ActiveUS20160137839A1Increased formationEnhance or speed the refilling of the build regionImpression capsManufacturing enclosuresEndcappingPolymer science

A polymerizable liquid, or resin, useful for the production by additive manufacturing of a three-dimensional object of polyurethane, polyurea, or a copolymer thereof, is described. The resin includes at least one of (i) a blocked or reactive blocked prepolymer, (ii) a blocked or reactive blocked diisocyanate, or (iii) a blocked or reactive blocked diisocyanate chain extender.

Owner:CARBON INC

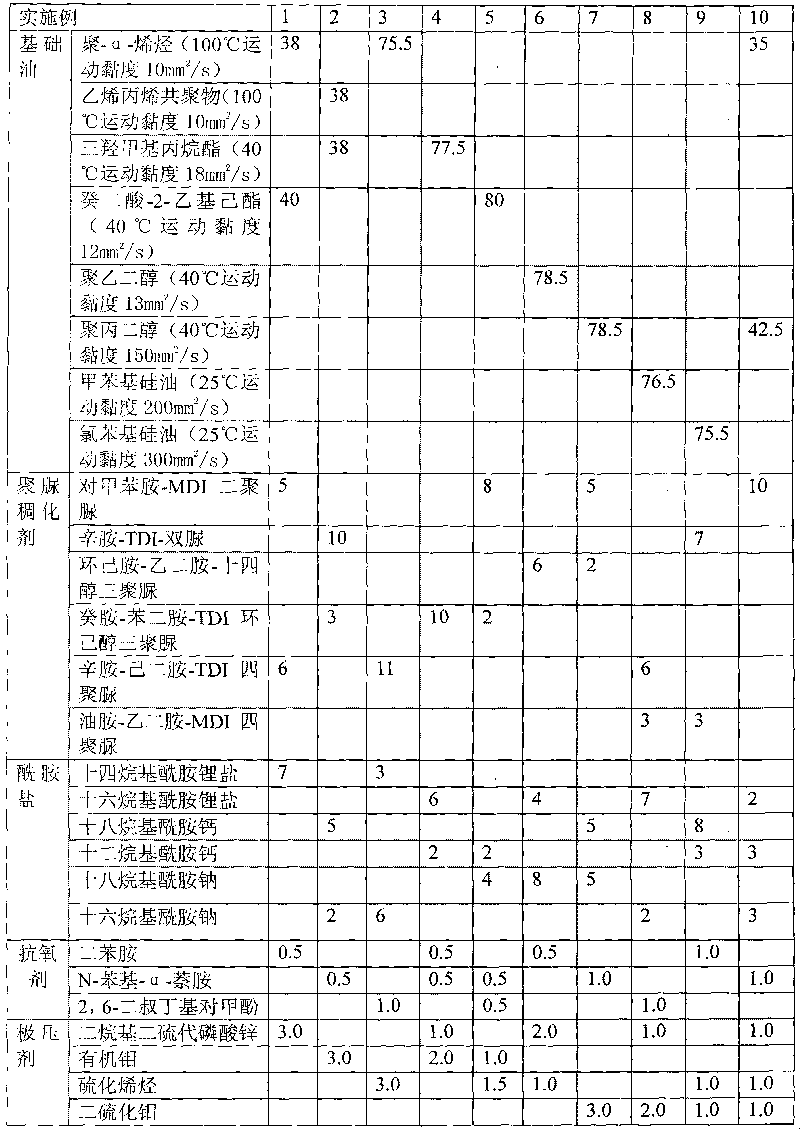

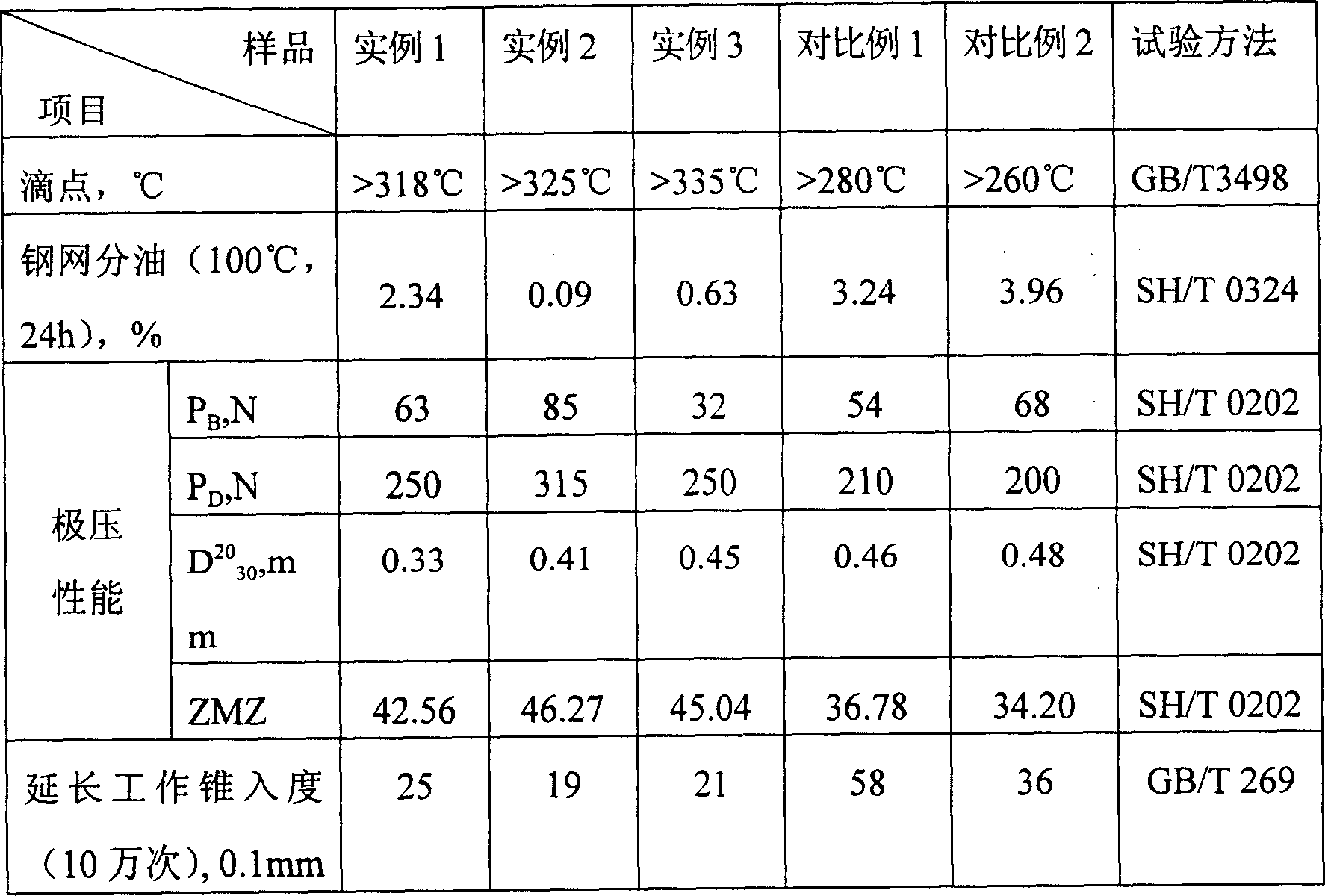

Polyurea grease composite

ActiveCN1657599AImprove extreme pressure and anti-wear performanceGood extreme pressure and anti-wear propertiesThickenersComposition BBase oil

Two lubricating polyurea-ester compositions with high stability and extreme-pressure antiwear performance contain proportionally basic oil, urea-based thickening agent, Ca-based thickening agent and extreme-pressure agent for composition A, or the composition A plus inorganic Ca salt for composition B.

Owner:CHINA PETROLEUM & CHEM CORP +1

Methods of producing polyurethane three-dimensional objects from materials having multiple mechanisms of hardening

ActiveUS20160137838A1Increased formationEnhance or speed the refilling of the build regionManufacturing enclosuresOptical articlesEndcappingPolymer science

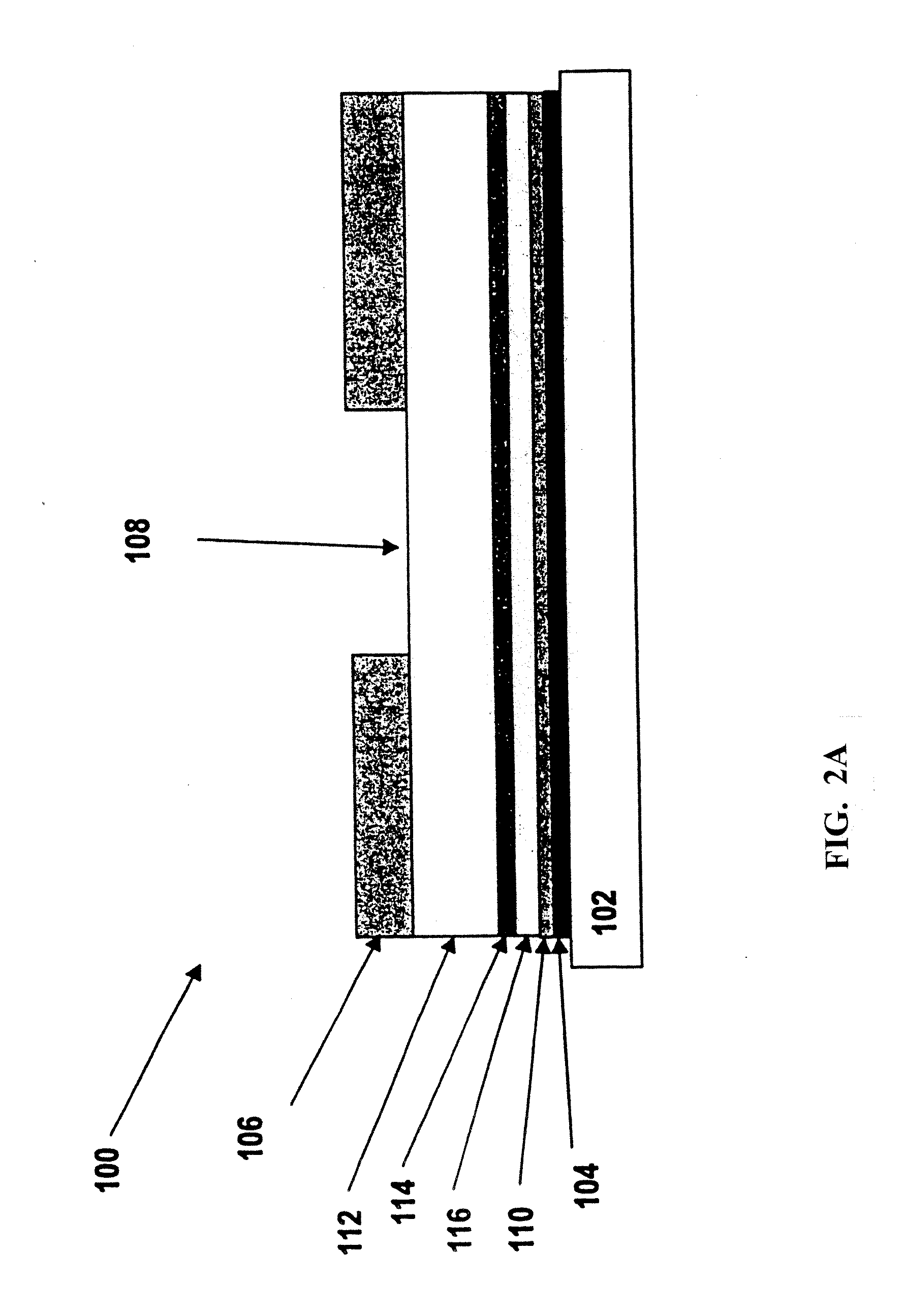

A method of forming a three-dimensional object of polyurethane, polyurea, or copolymer thereof is carried out by: (a) providing a carrier and an optically transparent member having a build surface, the carrier and the build surface defining a build region therebetween; (b) filling the build region with a polymerizable liquid, the polymerizable liquid including at least one of: (i) a blocked or reactive blocked prepolymer, (ii) a blocked or reactive blocked diisocyanate, or (iii) a blocked or reactive blocked diisocyanate chain extender; (c) irradiating the build region with light through the optically transparent member to form a solid blocked polymer scaffold and advancing the carrier away from the build surface to form a three-dimensional intermediate having the same shape as, or a shape to be imparted to, the three-dimensional object, with the intermediate containing the chain extender; and then (d) heating or microwave irradiating the three-dimensional intermediate sufficiently to form from the three-dimensional intermediate the three-dimensional object of polyurethane, polyurea, or copolymer thereof.

Owner:CARBON INC

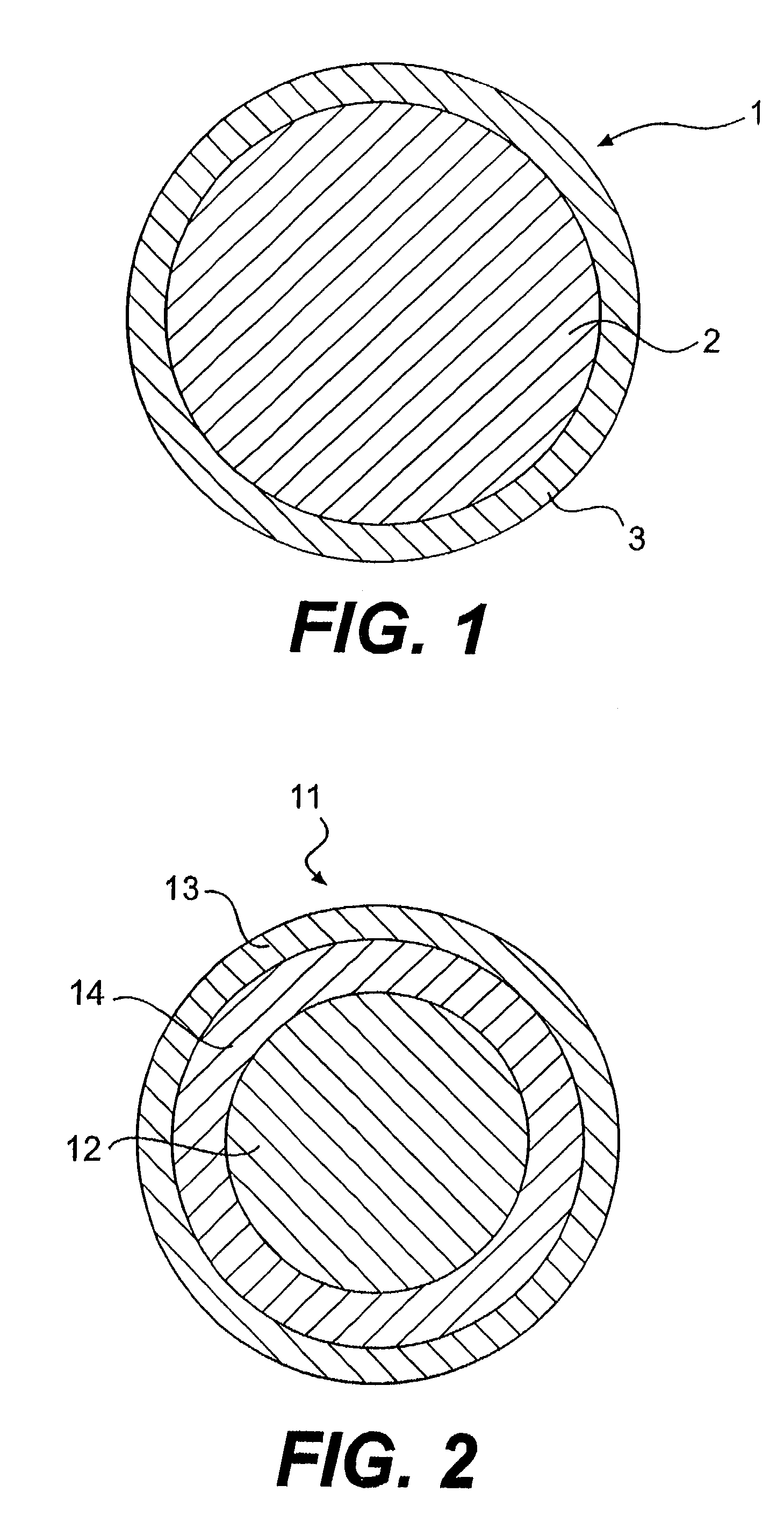

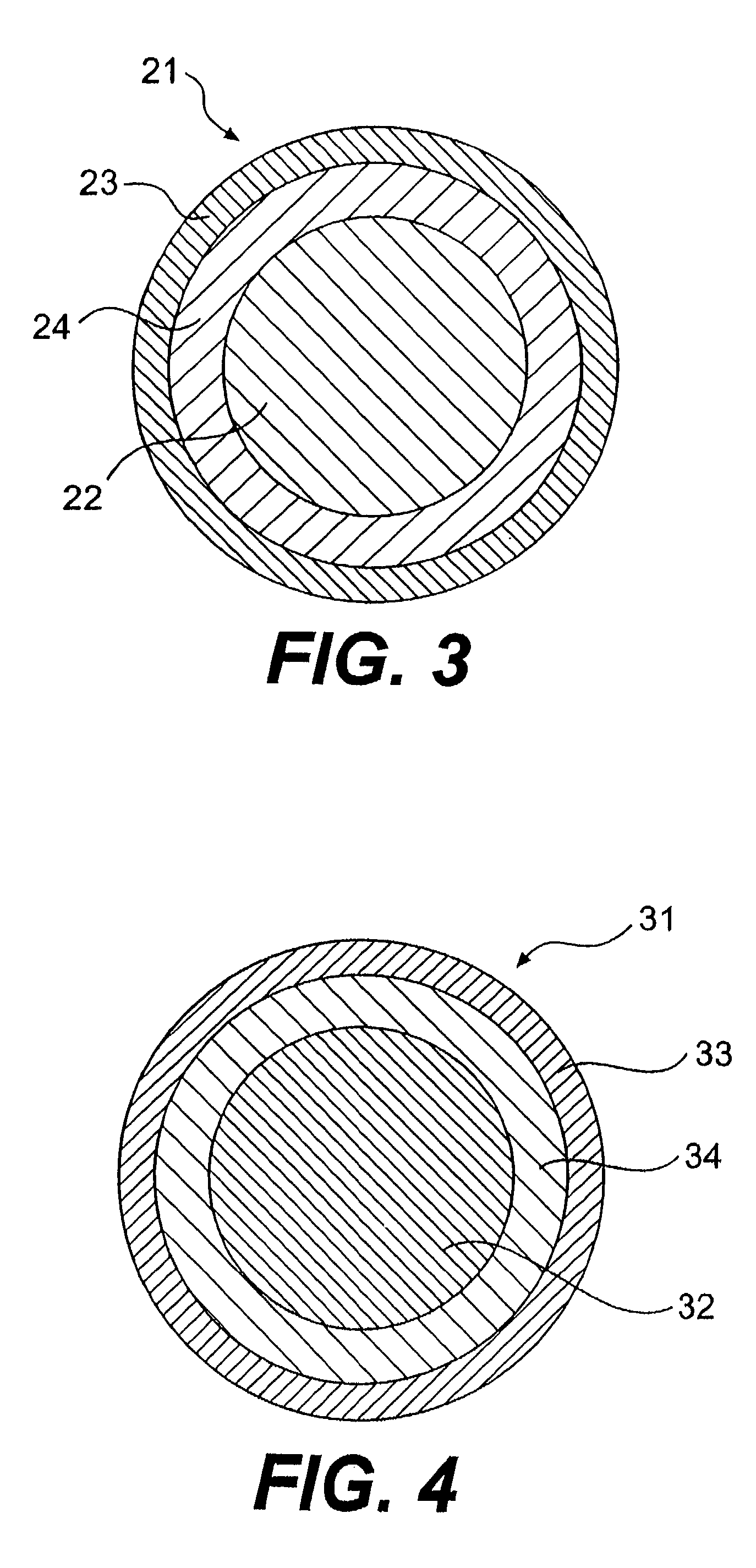

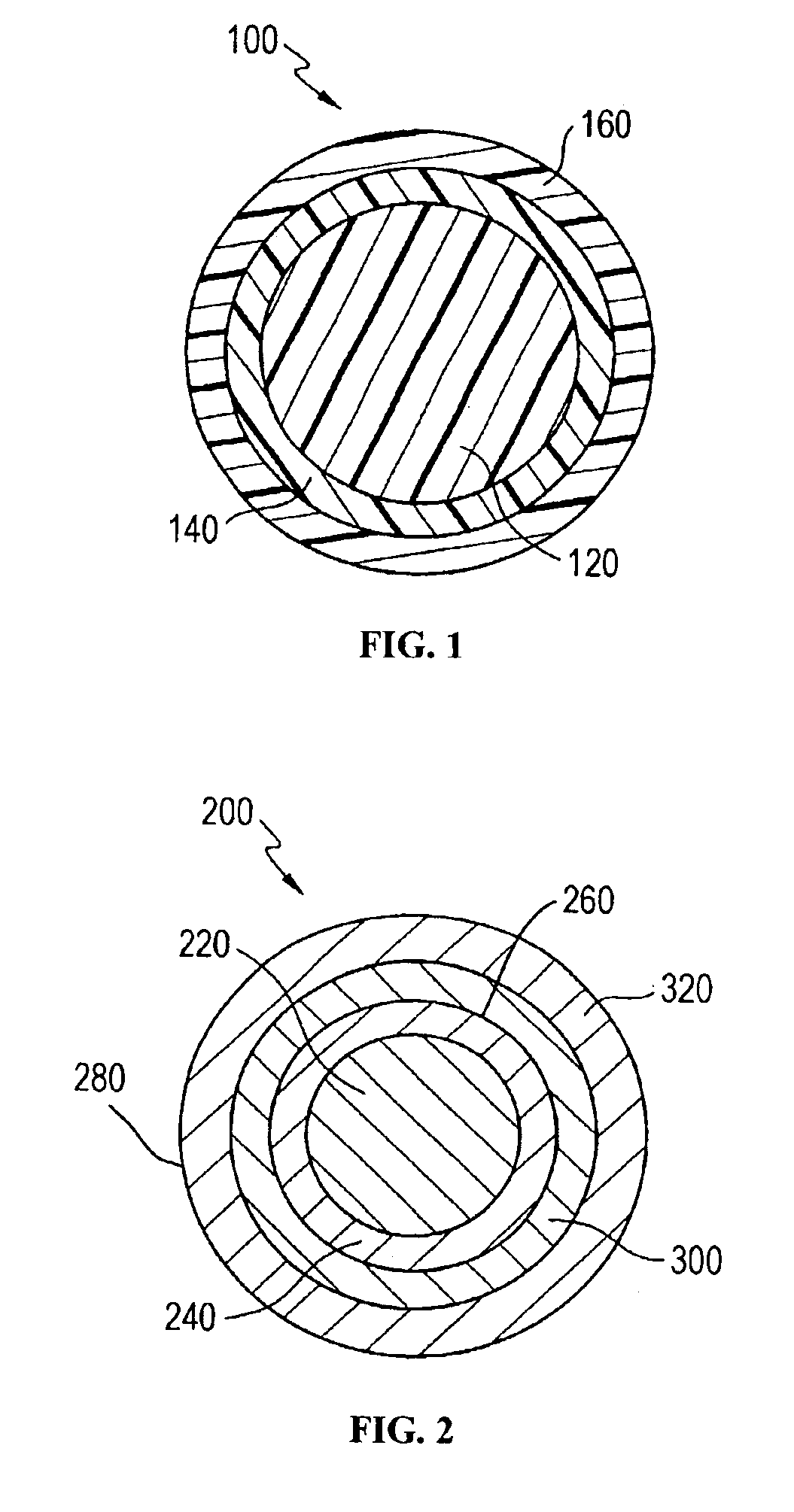

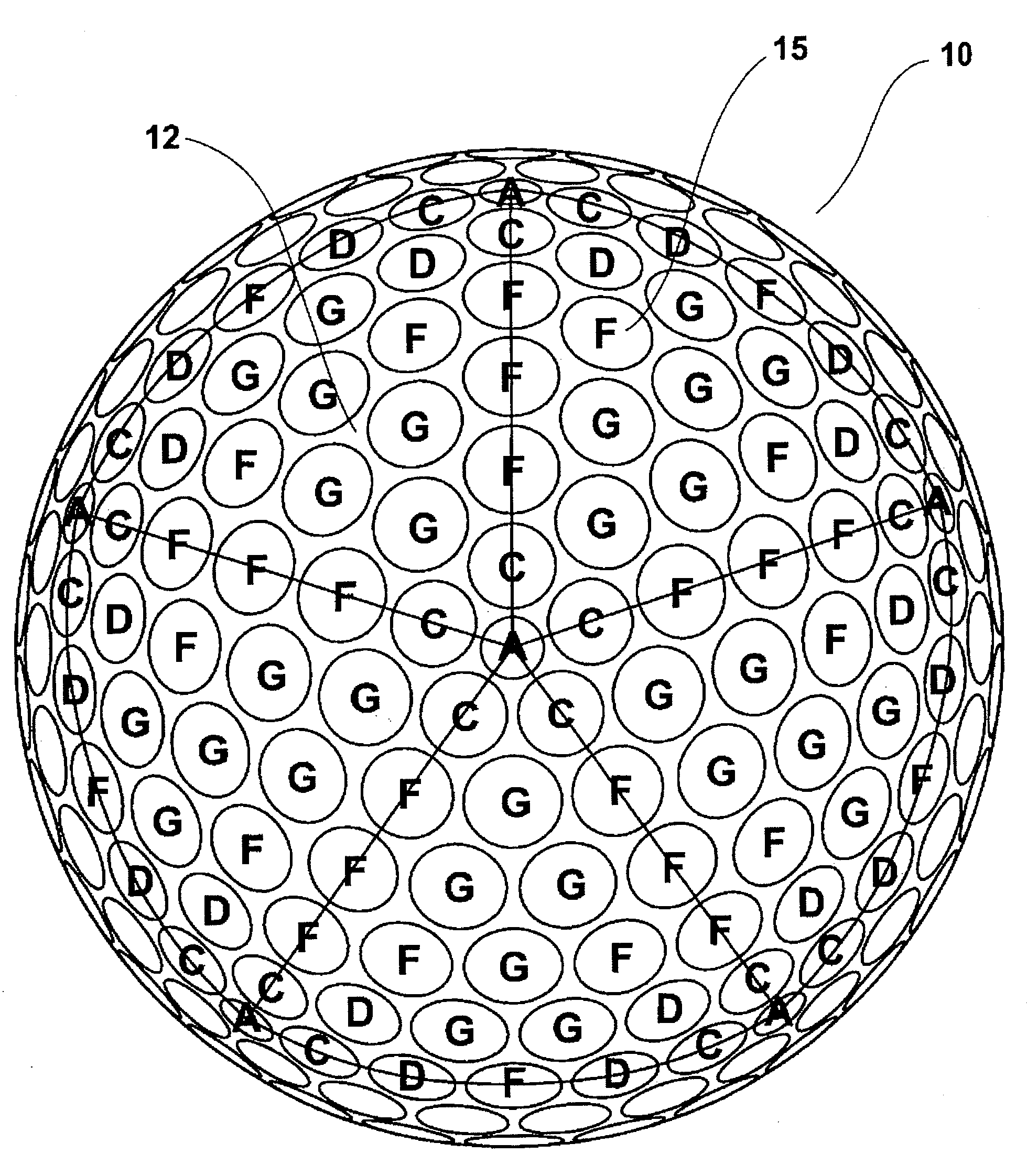

Golf balls comprising highly-neutralized acid polymers

A golf ball comprising a core included of a polymer containing an acid group fully-neutralized by an organic acid or a salt, a cation source, or a suitable base thereof, the core having a first Shore D hardness, a compression of no greater than about 90, and a diameter of between about 1.00 inches and about 1.64 inches; and a cover comprising a polyurea formed from a polyisocyanate, a polyamine, and a curing agent; wherein the ball has a compression of between about 50 and about 120.

Owner:ACUSHNET CO

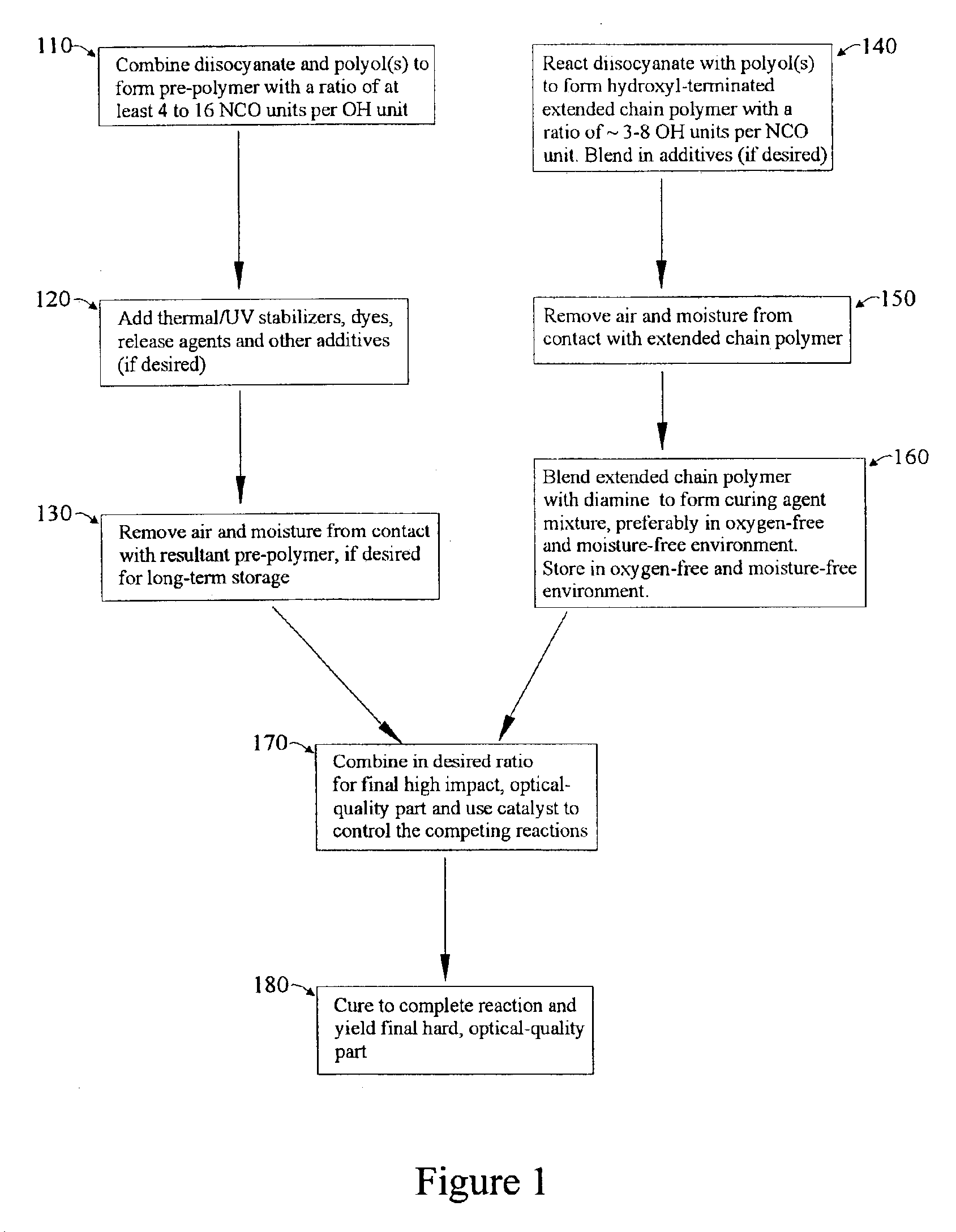

Polyurea/urethane optical material and method for making it

A polyurea / urethane material and method for making it provides for improved optical parts. The material allows for ease of manufacture of parts having good optical properties, high hardness, low density, and good impact resistance. The method provides for related manufacturing advantages.

Owner:YOUNGER MFG

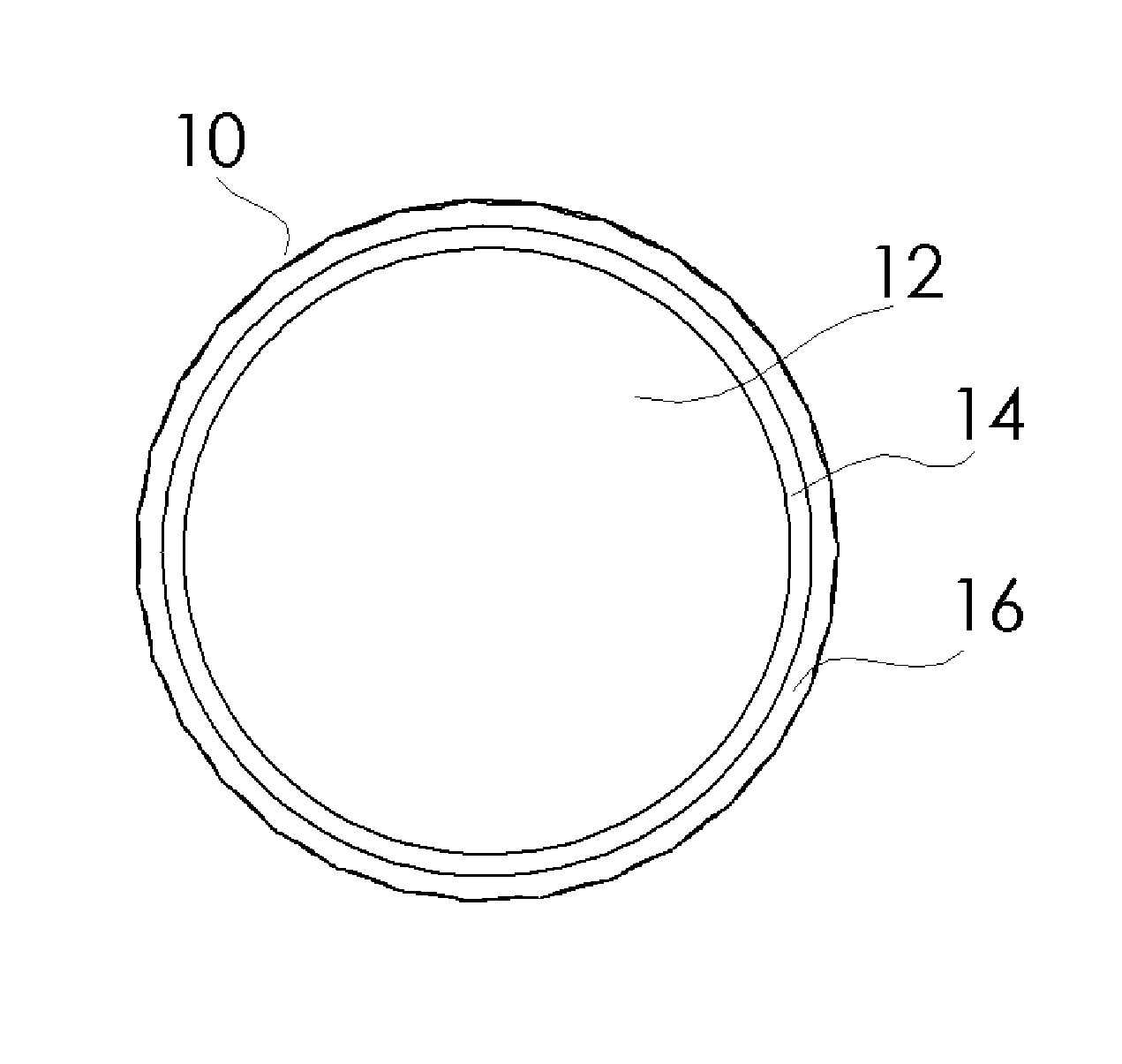

Single-surface glue water tape and making method thereof

The invention discloses a single-side glue water belt and a preparation method thereof; the water belt consists of a fiber knitting layer and a polyurea elastomer coating which is used as a lining layer which has the thickness of 0.5-1.0mm; high-strength aramids are preferably selected for the warp and woof of the knitting layer; the preparation method comprises the steps as follows: tabular knitting layer is knitted on a circular loom firstly; subsequently, isocyanate composition and resin composition are mixed and heated to 60-70DEG C and pressurized to 12-15MPa; subsequently, the mixture is sprayed at the internal side of the fiber knitting layer by a spraying gun, thus forming a polyurea elastomer coating which is then dried so as to gain the product; the water belt is used for delivering water or industrial liquids in the industries such as fire control or agriculture and industry, building and the like, has the advantages of wearability, anti-corrosion, anti-impact, long service life and the like, has simple preparation method, few equipment investment, high production efficiency and meeting the requirement of environmental protection.

Owner:5ELEM HI TECH CORP

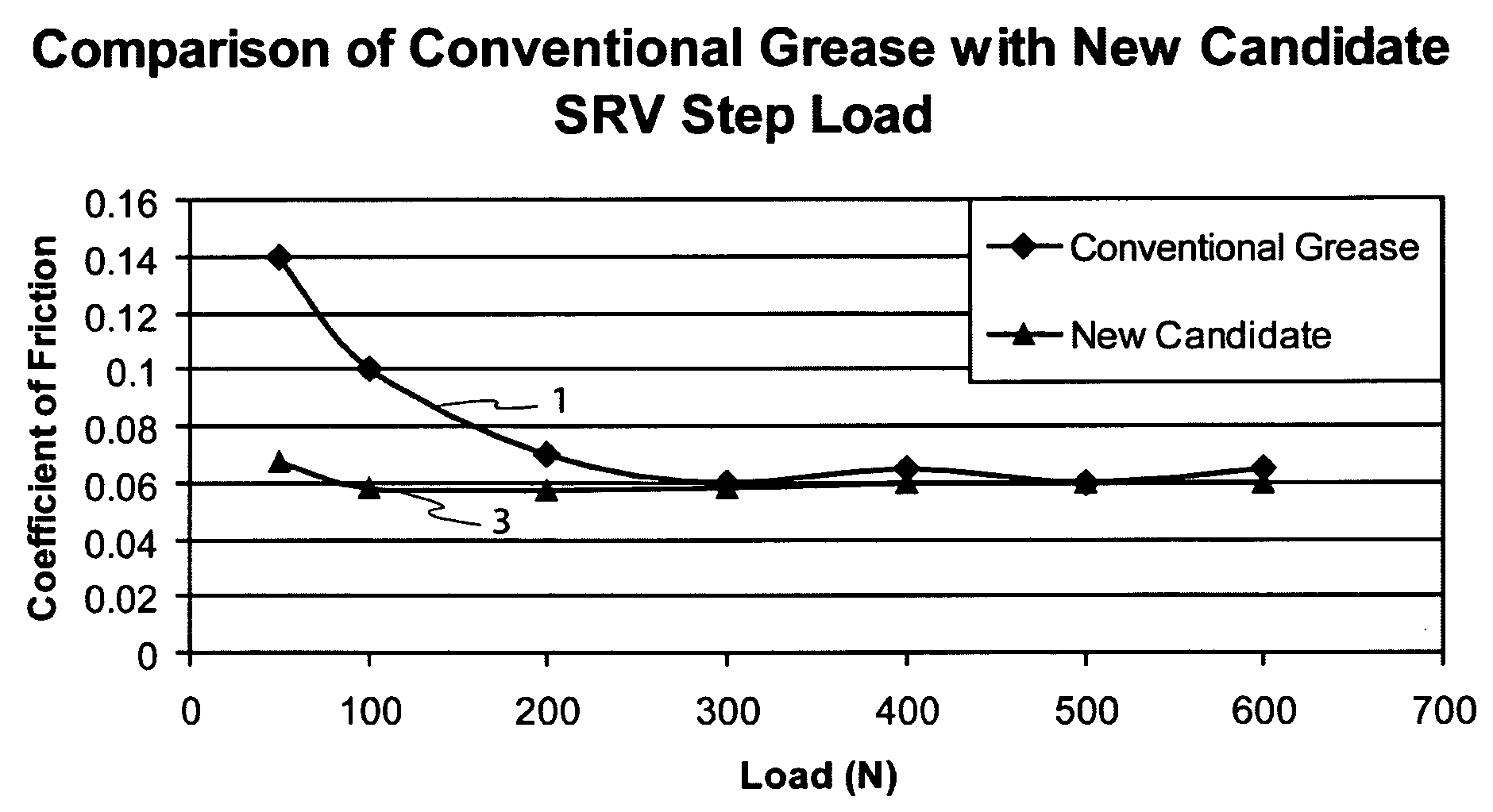

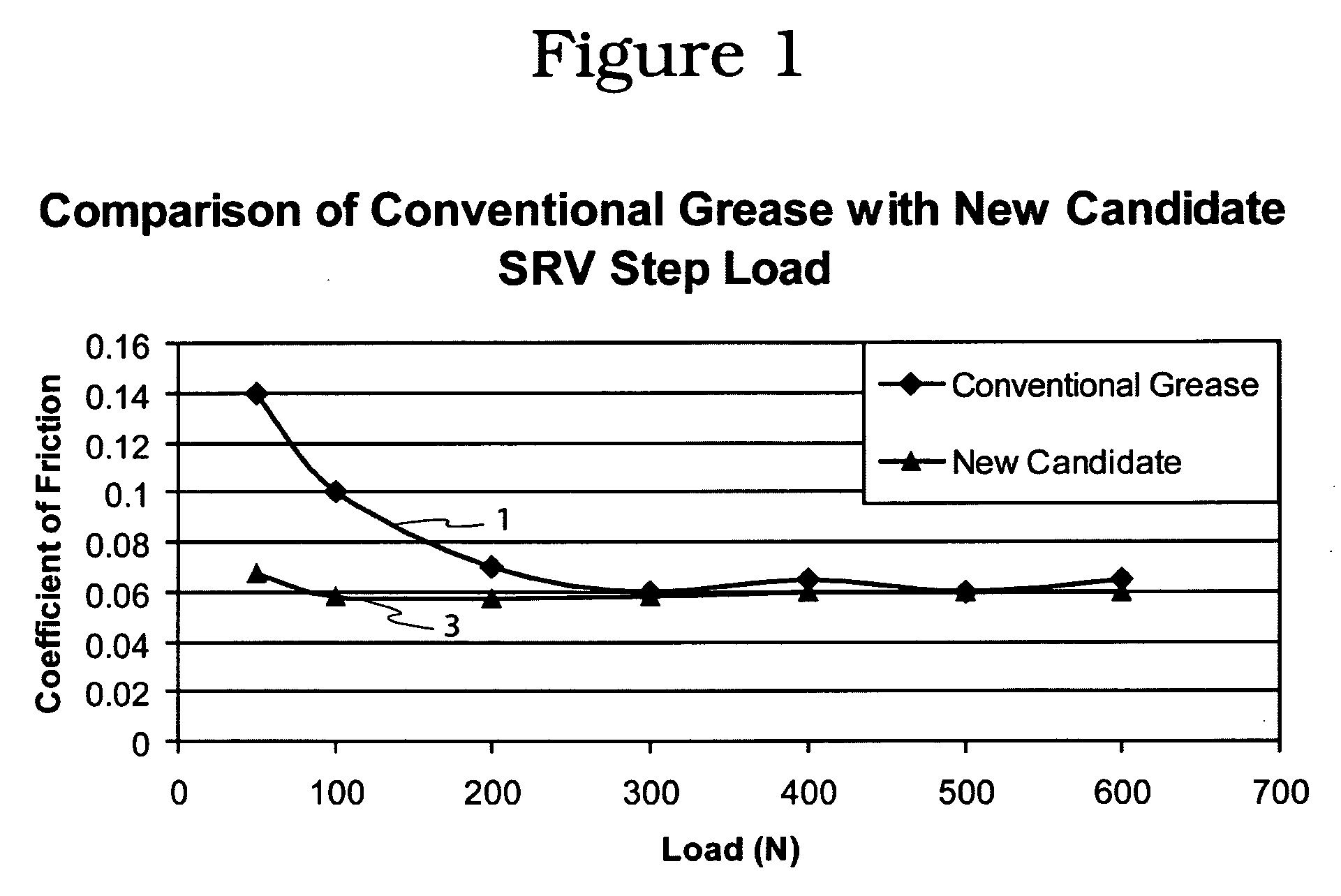

High viscosity index pao with polyurea thickeners in grease compositions

ActiveUS20090247441A1Improve friction performanceHigh indexThickenersAdditivesPolymer scienceBi modal

Owner:EXXON RES & ENG CO

Synthetic high-temperature lubricating grease and production method thereof

InactiveCN101693851AGood colloidal stabilityGood shear stabilityThickenersAdditivesAntioxidantColloid

The invention discloses a synthetic high-temperature lubricating grease and a production method thereof. The synthetic high-temperature lubricating grease is produced by taking synthetic oil as base oil and mixing the base oil with thickening agents, an extreme-pressure additive, an antioxidant and an anticorrosive agent, wherein the weight ratios of all ingredients are as follows: 47-94% of base oil, 2-20% of polyurea thickening agent, 2-20% of acylamide thickening agent, 0.5-5.0% of antioxidant, 1.0-5.0% of extreme-pressure additive and 0.5-3.0% of anticorrosive agent. In the invention, the synthetic base oil, the polyurea thickening agent and the acylamide thickening agent all have excellent high-temperature performance, and the organic combination thereof leads the lubricating grease to obtain excellent high-temperature performance; the polyurea thickening agent endows the lubricating grease with good colloid stability, and the acylamide thickening agent endows the lubricating grease with excellent anti-shear stability, therefore, the organic combination of colloid stability and anti-shear stability leads the lubricating grease to have excellent high-temperature performance and good losing resistance, does not change to thin and avoids losing at high temperature. The extreme-pressure anti-wear additive endows the lubricating grease with excellent extreme-pressure anti-wear performance, and the bearing capacity is high.

Owner:CHINA PETROLEUM & CHEM CORP

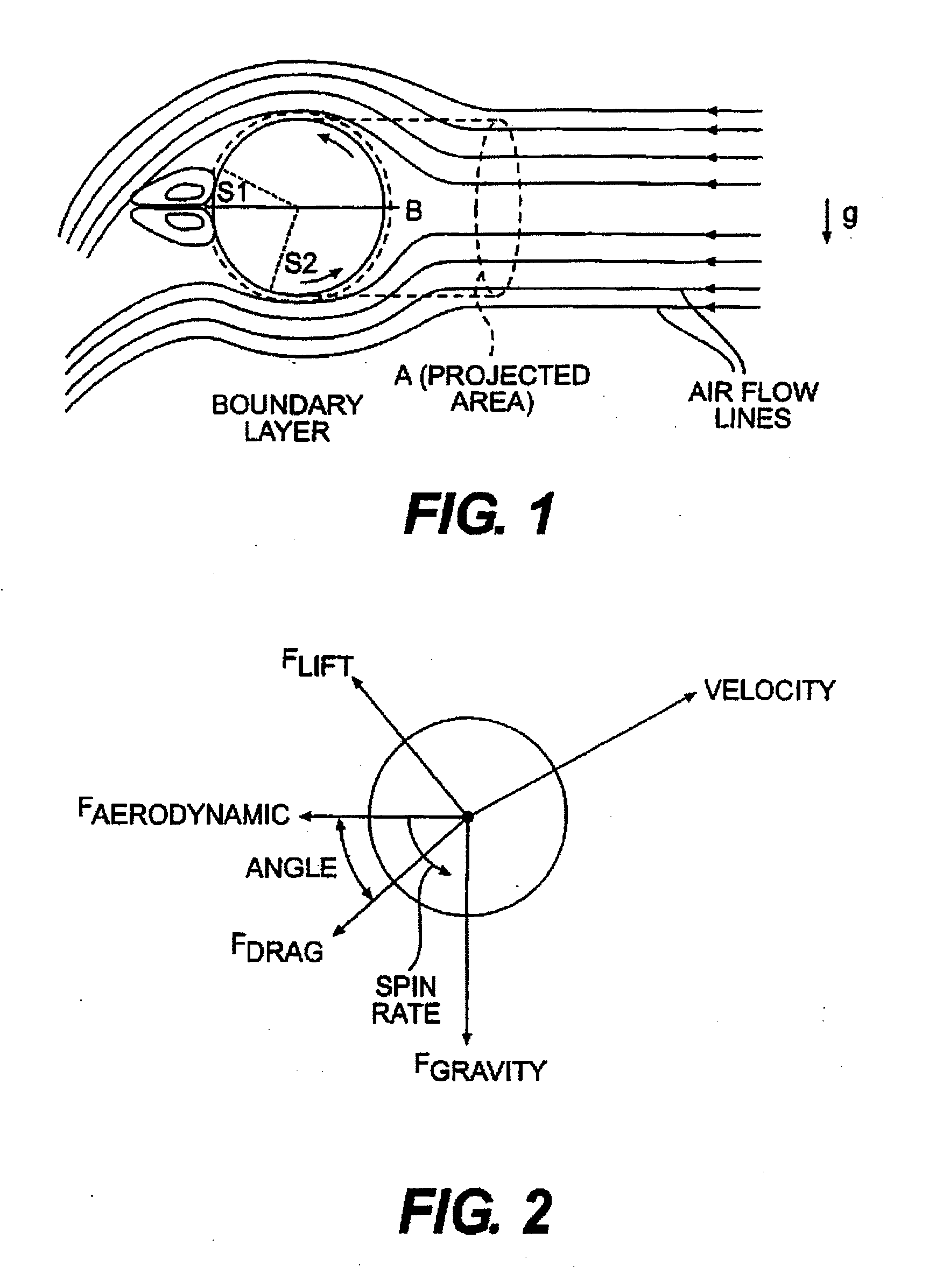

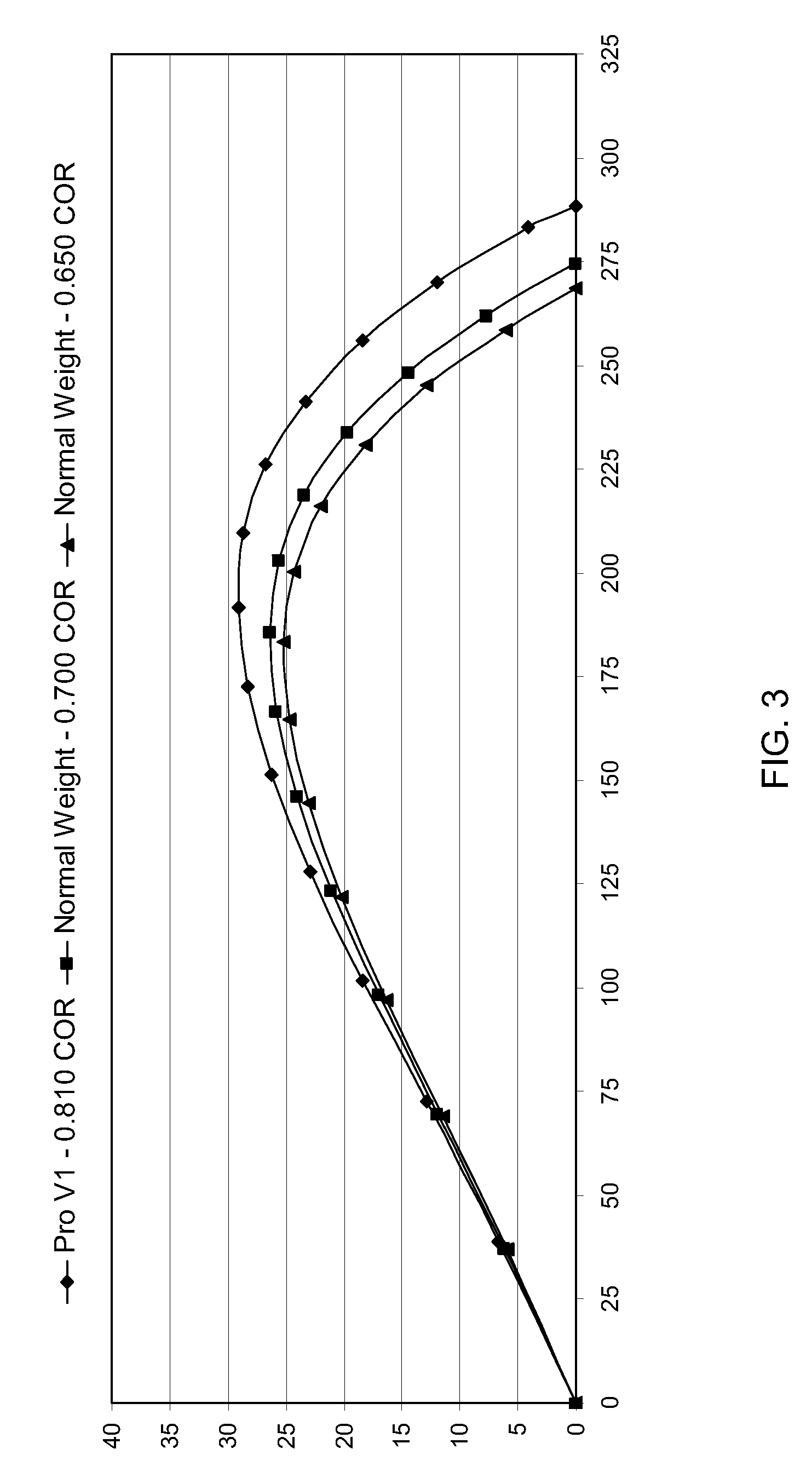

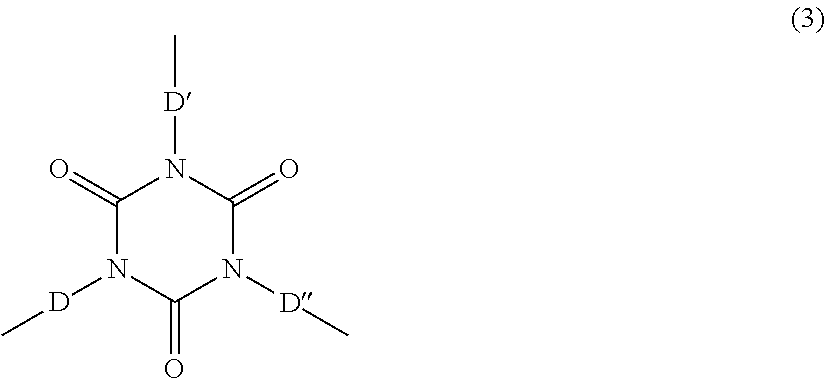

High performance golf ball having a reduced distance

InactiveUS20090247325A1Reduce distanceImprove performanceGolf ballsSolid ballsCoefficient of restitutionHardness

A golf ball comprising a core comprising from about 25 to 75 parts of butyl or halobutyl rubber and having a coefficient of restitution of 0.683 to 0.750 and a compression of less than about 60; an inner cover layer comprising an ionomer and having a Shore D hardness of at least about 60; and an outer cover layer comprising a polyurethane or polyurea having a Shore D hardness of less than about 55; wherein the golf ball has a dimple coverage of 55% to 75%, a coefficient of restitution of 0.696 to 0.775, and an Atti compression of at least about 80.

Owner:ACUSHNET CO

Crosslinkable polyurea prepolymers

The present invention provides a water-soluble crosslinkable polyurea prepolymer. The crosslinkable polyurea prepolymer of the invention is prepared by reacting an amine- or isocyanate-capped polyurea with a multifunctional compound having at least one one ethylenically unsaturated group and a function group coreactive with the capping amine or isocyanate groups of the amine- or isocyanate-capped polyurea. The amine- or isocyanate-capped polyurea is a copolymerization production of: (a) at least one poly(oxyalkylene)diamine, (b) optionally at least one organic di- or poly-amine, (c) optionally at least one diisocyanate, and (d) at least one polyisocyanate. The crosslinkable polyurea prepolymer of the invention can find use in economically producing contact lenses which have durable, highly elastic soft contact lenses with desired physical properties. In addition, the present invention provides method for making a medical device, preferably an ophthalmic device, more preferably a contact lens.

Owner:ALCON INC

Anti-Icing Composite

ActiveUS20160009971A1Zero ice adhesionMechanical robustnessOther chemical processesSynthetic resin layered productsPolymer sciencePolymer chemistry

The present invention relates to a novel anti-icing composite for preventing ice adhesion. A microphase separated, fluorinated nano / micro particles in aliphatic / fluorinated polyurethane / polyurea matrix coated on an elastic substratum results in anti-icing composite. The preparation method for novel anti-icing composite is disclosed.

Owner:WANG LIANG +1

Encapsulated essential oils

The invention provides a process for the preparation of essential oil microcapsules comprising dissolving a di- or polyisocyanate into an essential oil, emulsifying the resulting mixture in an aqueous solution containing a di- or polyamine, and / or a di or polyhydroxy compound to effect encapsulation of said essential oil through interfacial polymerization, whereby there is formed a polyurea and / or polyurethane film around the essential oil droplets which film enhances the stability of said essential oil, reduces its evaporation rate and controls its release rate when applied to a substrate.

Owner:内盖夫研发局属本古里昂大学

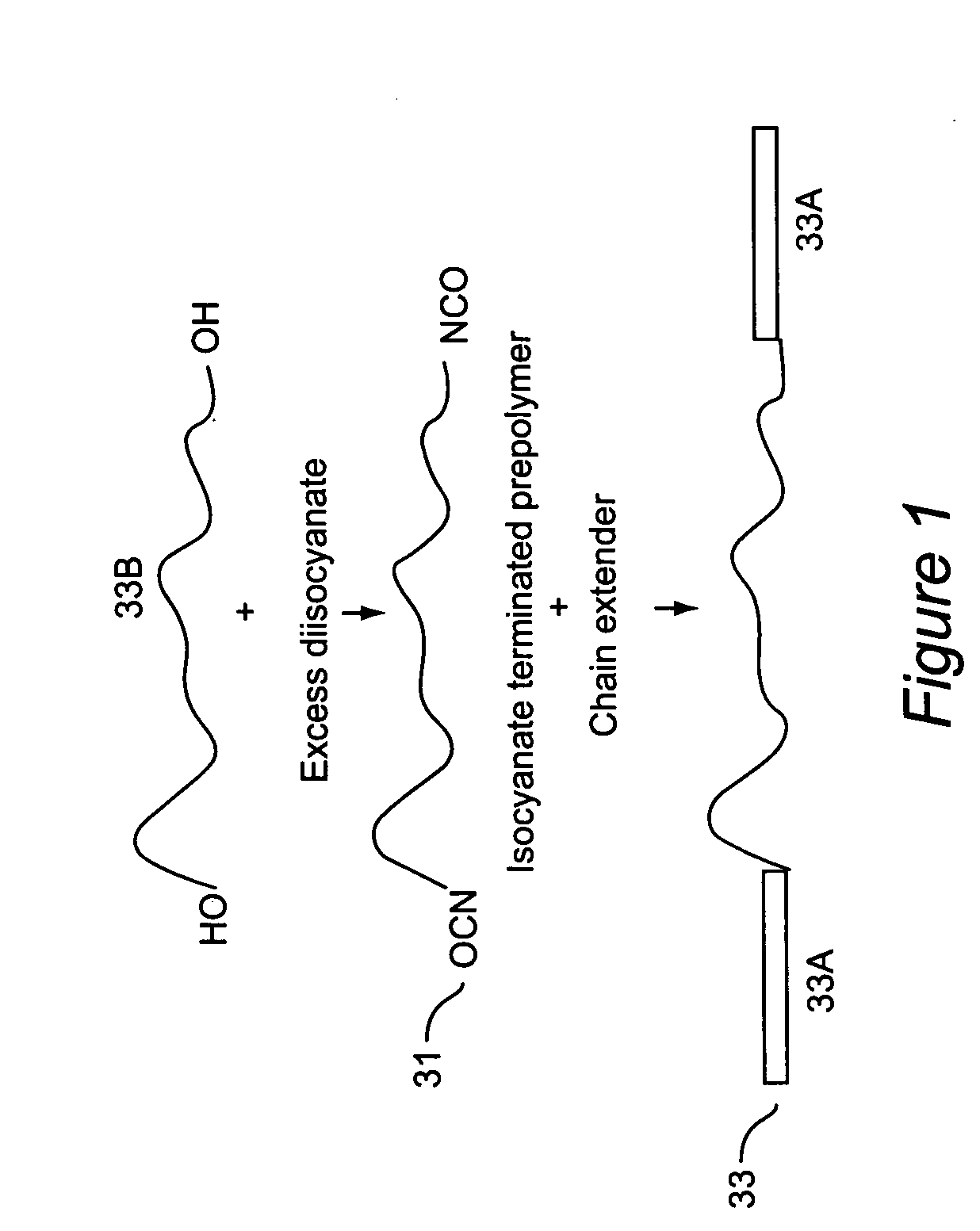

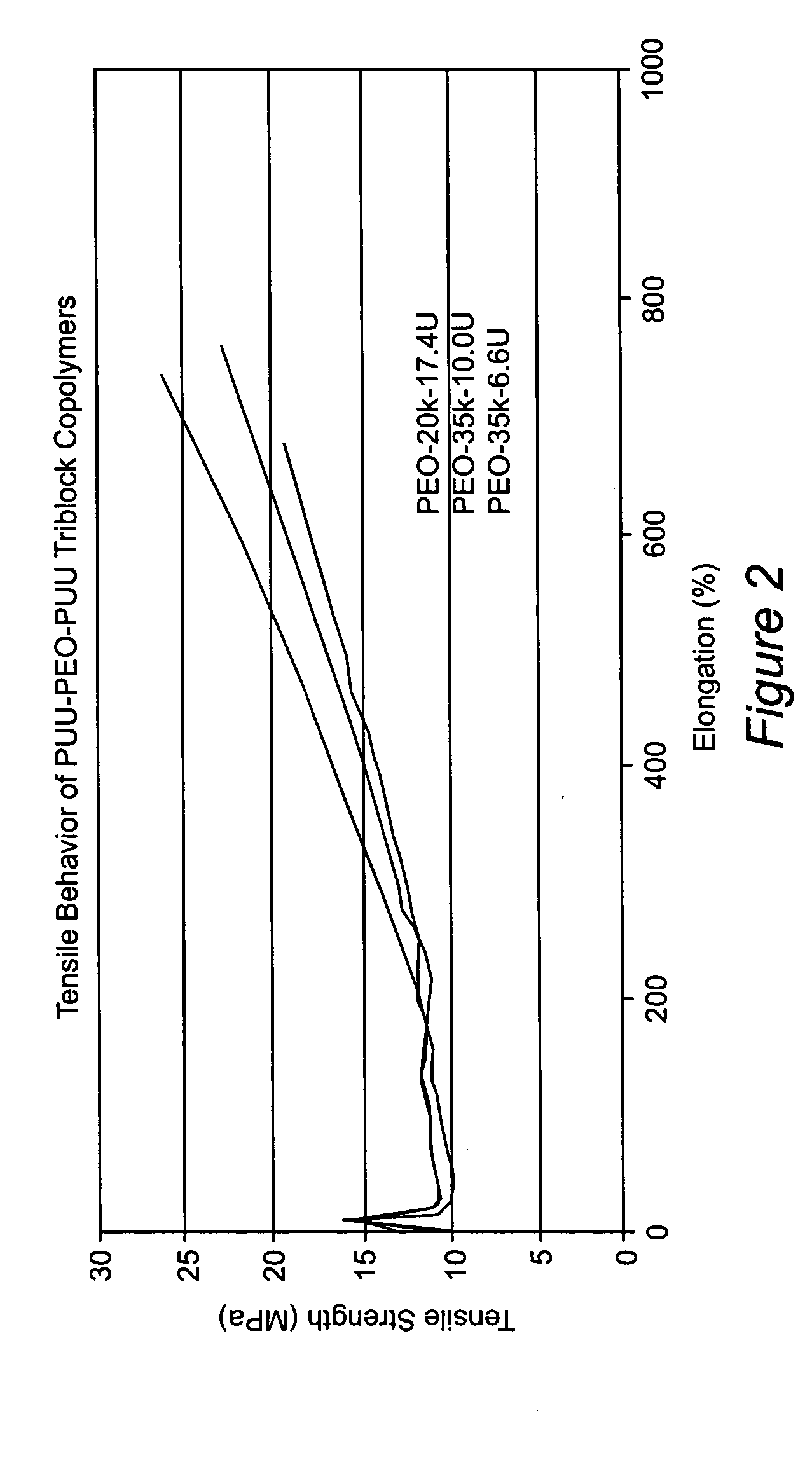

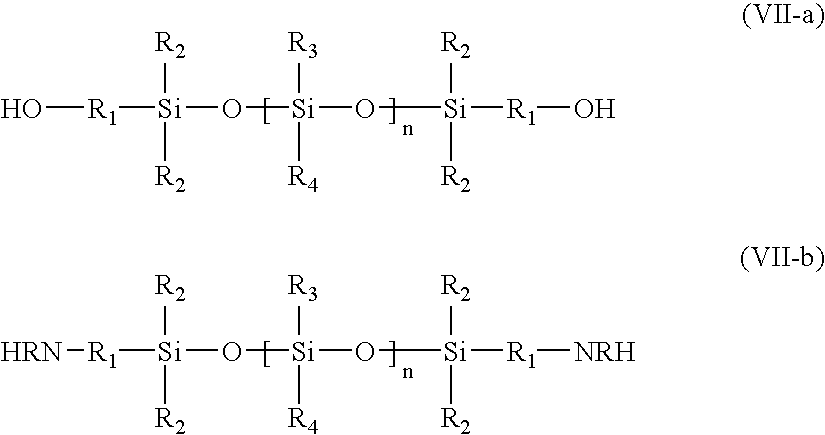

Triblock copolymers and their production methods

A new family of triblock (A-B-A type) thermoplastic, polyurethane, polyurethaneurea, polyurea and polyamide copolymers has been prepared. (A) blocks represent the hard segments, such as urethane, urea, urethaneurea or amide type segments. (B) blocks represent the soft segments, such as aliphatic polyethers, aliphatic polyesters, polydimethylsiloxanes, polyalkanes or their copolymers. These novel material display very interesting microphase morphologies, mechanical properties, solubility characteristics and melt behavior.

Owner:VIRGINIA TECH INTPROP INC

Preparation method of polyurea-composite calcium lubricating grease

InactiveCN1493673APrevent volatilizationImprove high temperature performanceAdditivesCalcium hydroxideOrganic acid

A lubricating polyureas-composite calcium grease is prepared through proportionally mixing basic oil, calcium hydroxide (oxide), water and C1-C20 organic acid together, heating to 30-100 deg.C, adding diisocyanate and organic amine, draining water, saponifying, heating to 210-230 deg.C, cooling and homogenizing. Its advantages are high refractory performance, stability and extreme-pressure antiwear nature.

Owner:CHINA PETROLEUM & CHEM CORP +1

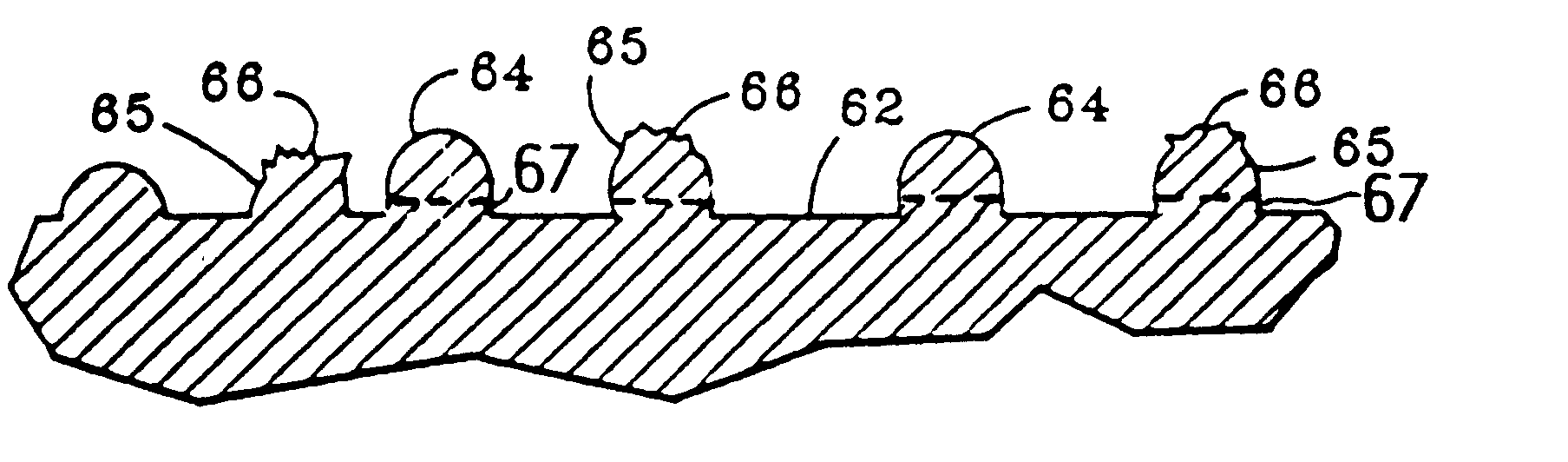

Thermoplastic products having antislip surfaces

InactiveUS6509084B2Effective antislip surface propertyGood adhesion and durability and wearabilityKitchenware cleanersCleaning machinesEngineeringVolcano

Thermoplastic products such as vehicle cargo area liners, floor mats, recreational and playground equipment, cargo pallets, and wet area walking surfaces are provided with an antislip surface treatment. The antislip surface is made up of individual non-interconnected asperities of an antislip polymer material, which do not form a continuous film over the surface of the thermoplastic product. The thermoplastic product is especially made of high density polyethylene. The antislip polymer is preferably a thermoset polymer, and most particularly is a polyurea / isocyanate polymer. The antislip polymer is preferably applied by spraying, and then the product is heat treated at a temperature in the range from 100 to 200° F., or is thermoformed at a temperature in the range from 250 to 550° F. The antislip asperities are durably bonded onto the thermoplastic base material, and provide a significantly increased coefficient of friction. The asperity size, height, and hardness can be controlled by adjusting the processing conditions. The asperities may have an increased surface relief due to a so-called "moth effect" and an increased surface roughness due to cratering as a result of a so-called "volcano effect" in the process using thermoforming.

Owner:CUSTOM PLASTICS MOLDING

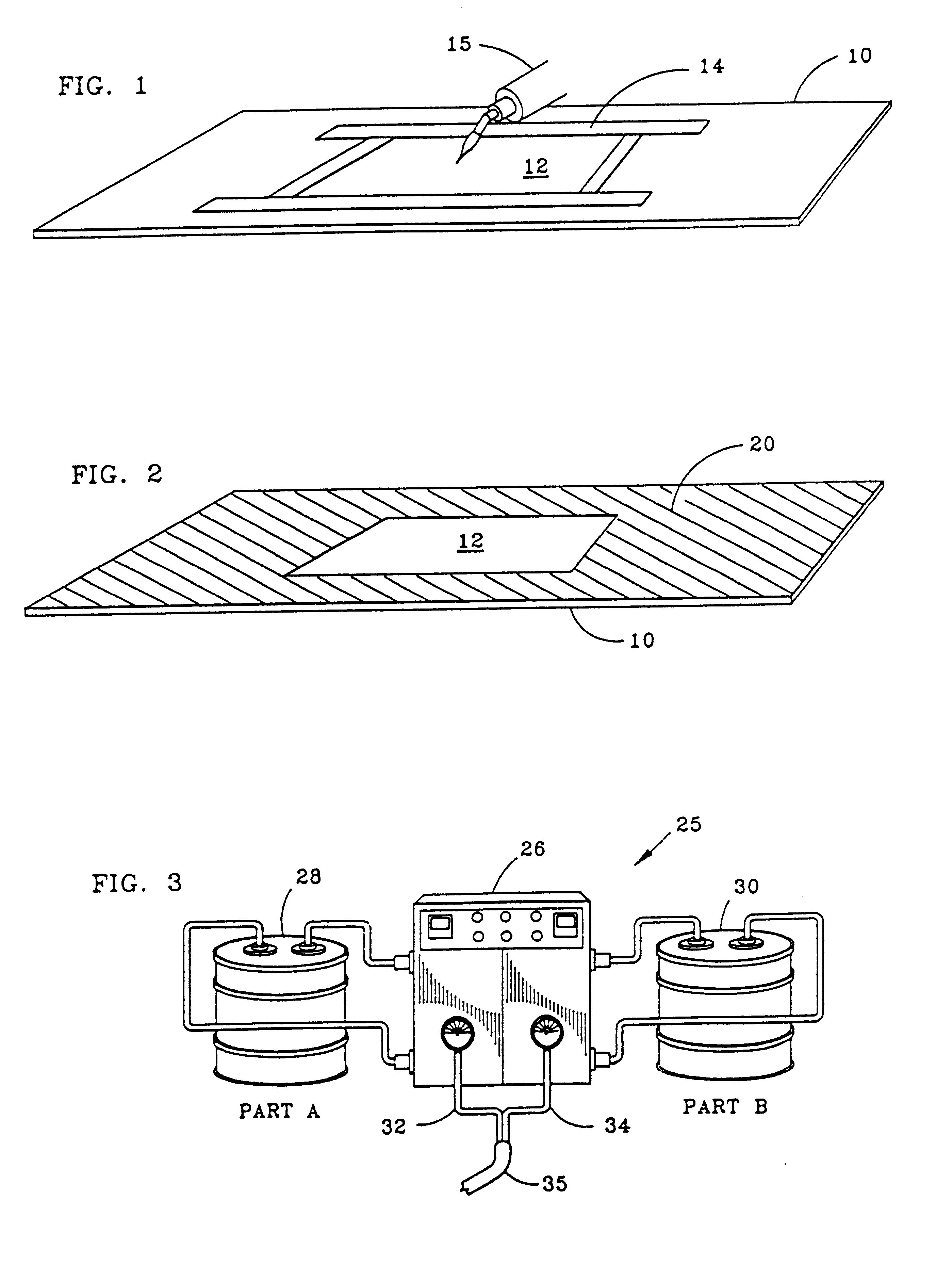

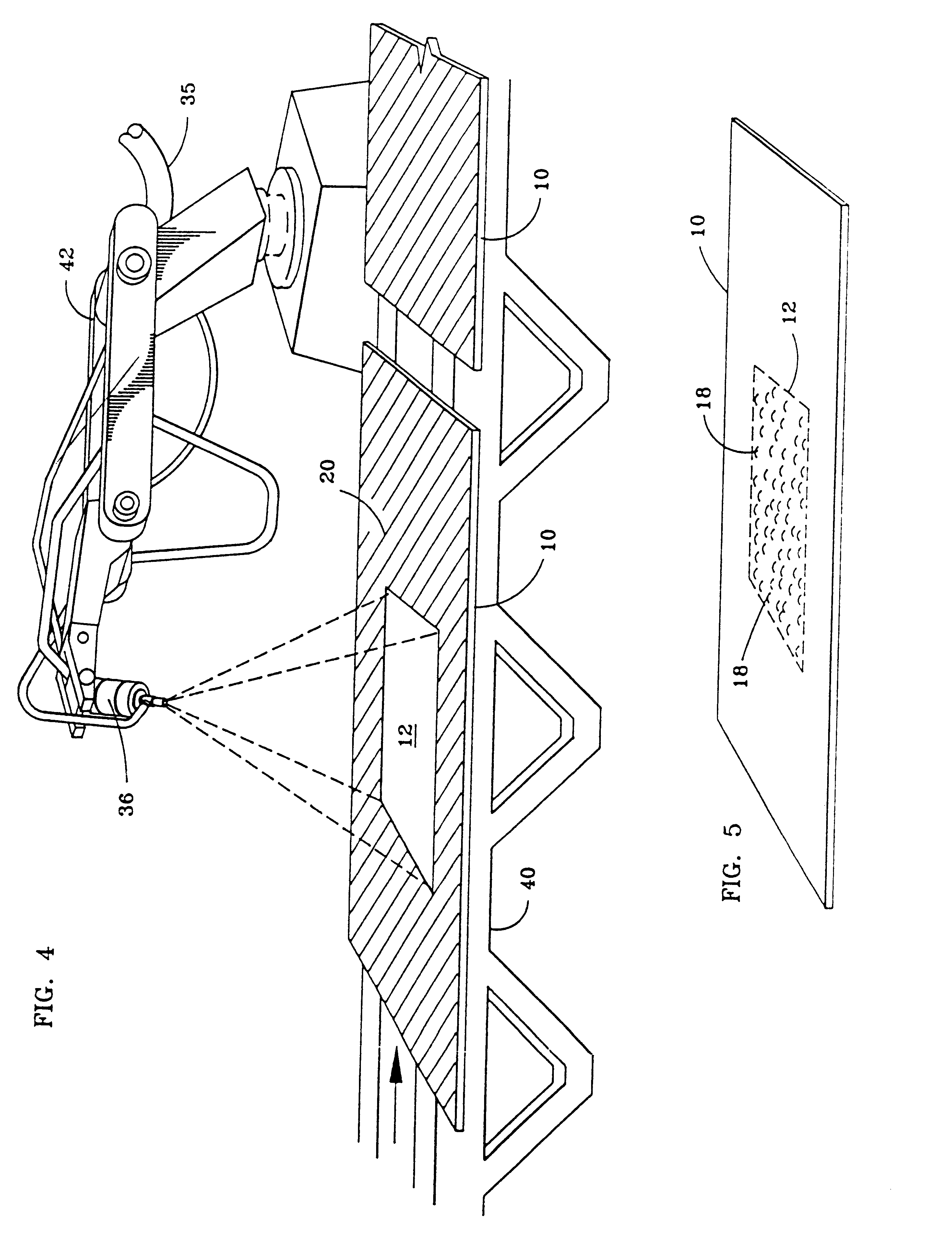

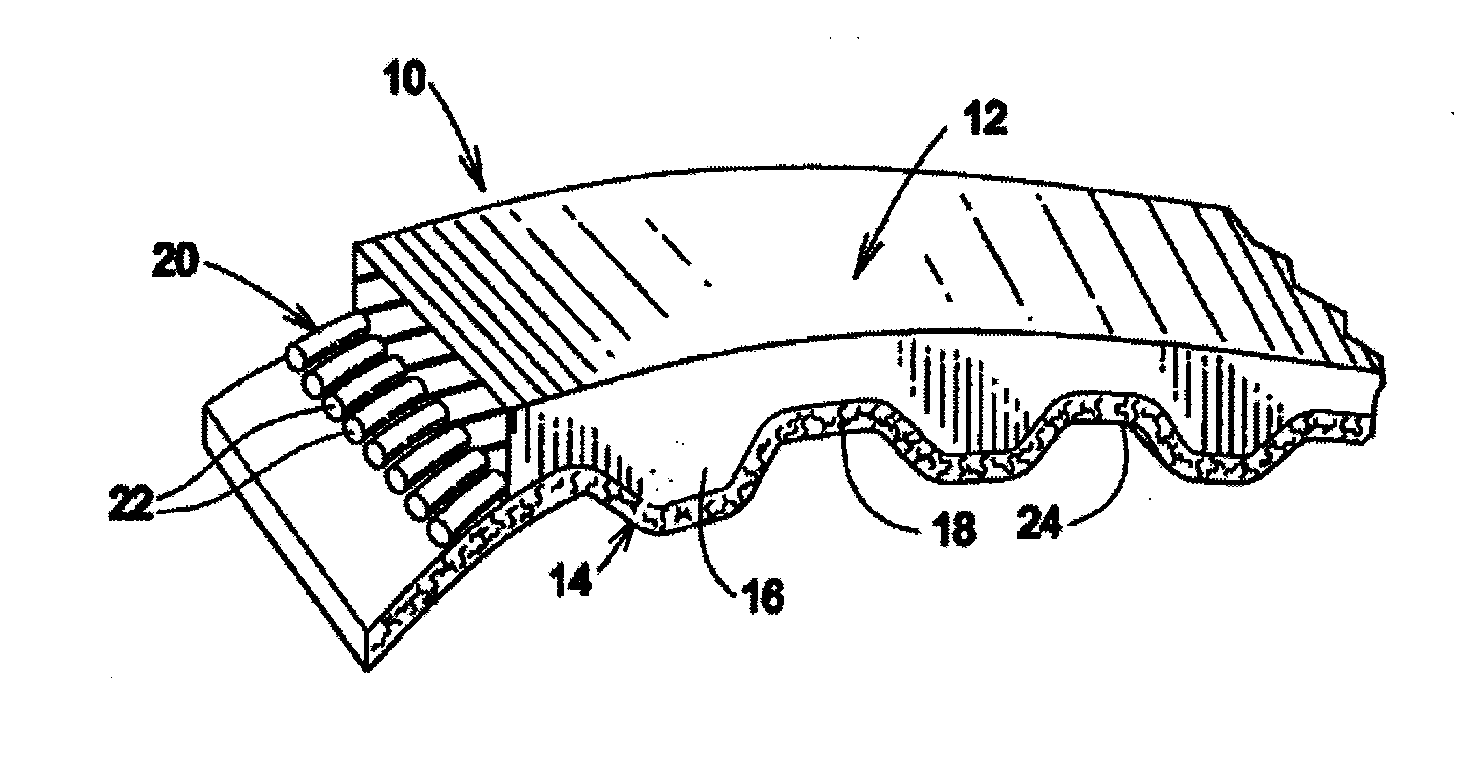

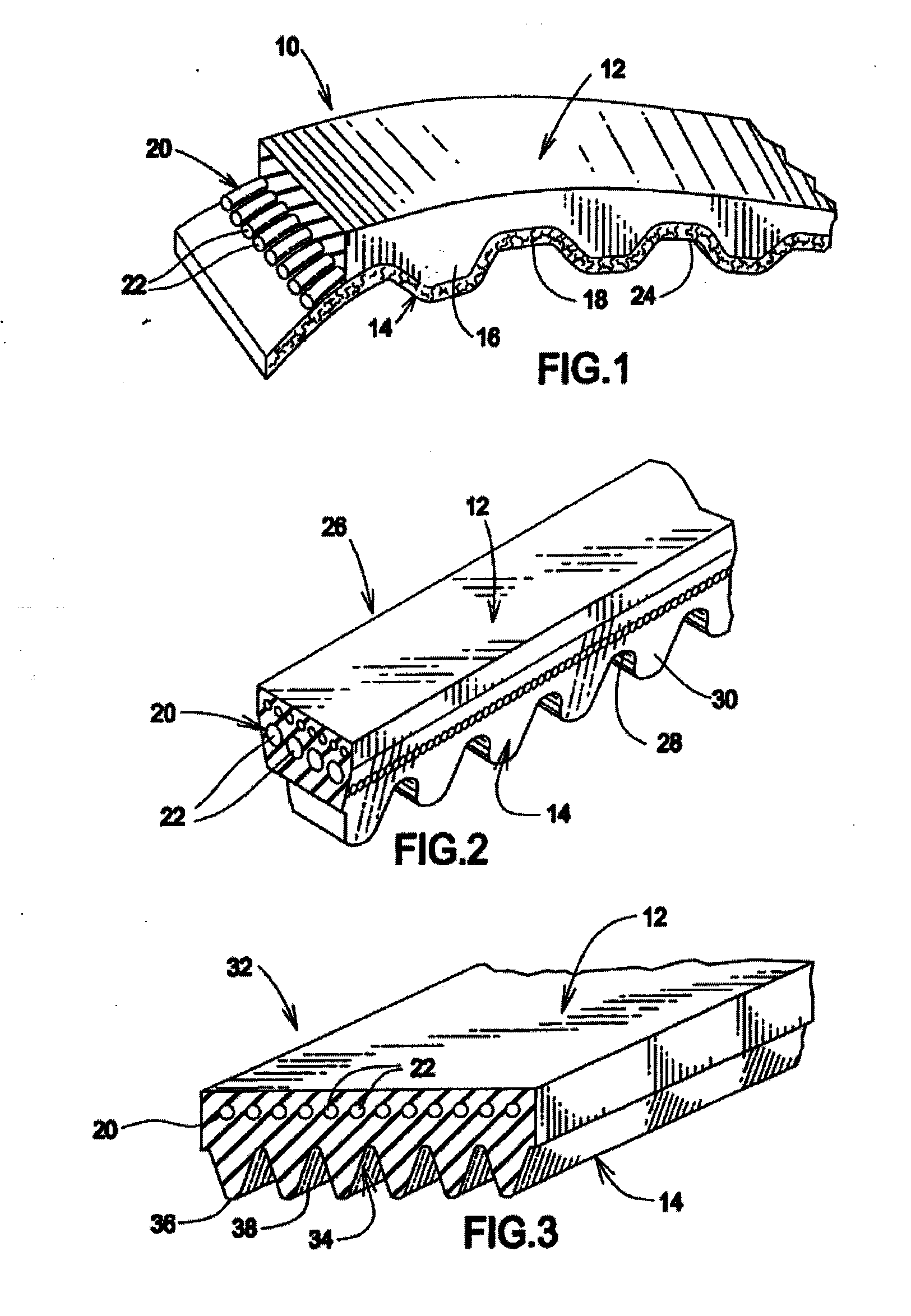

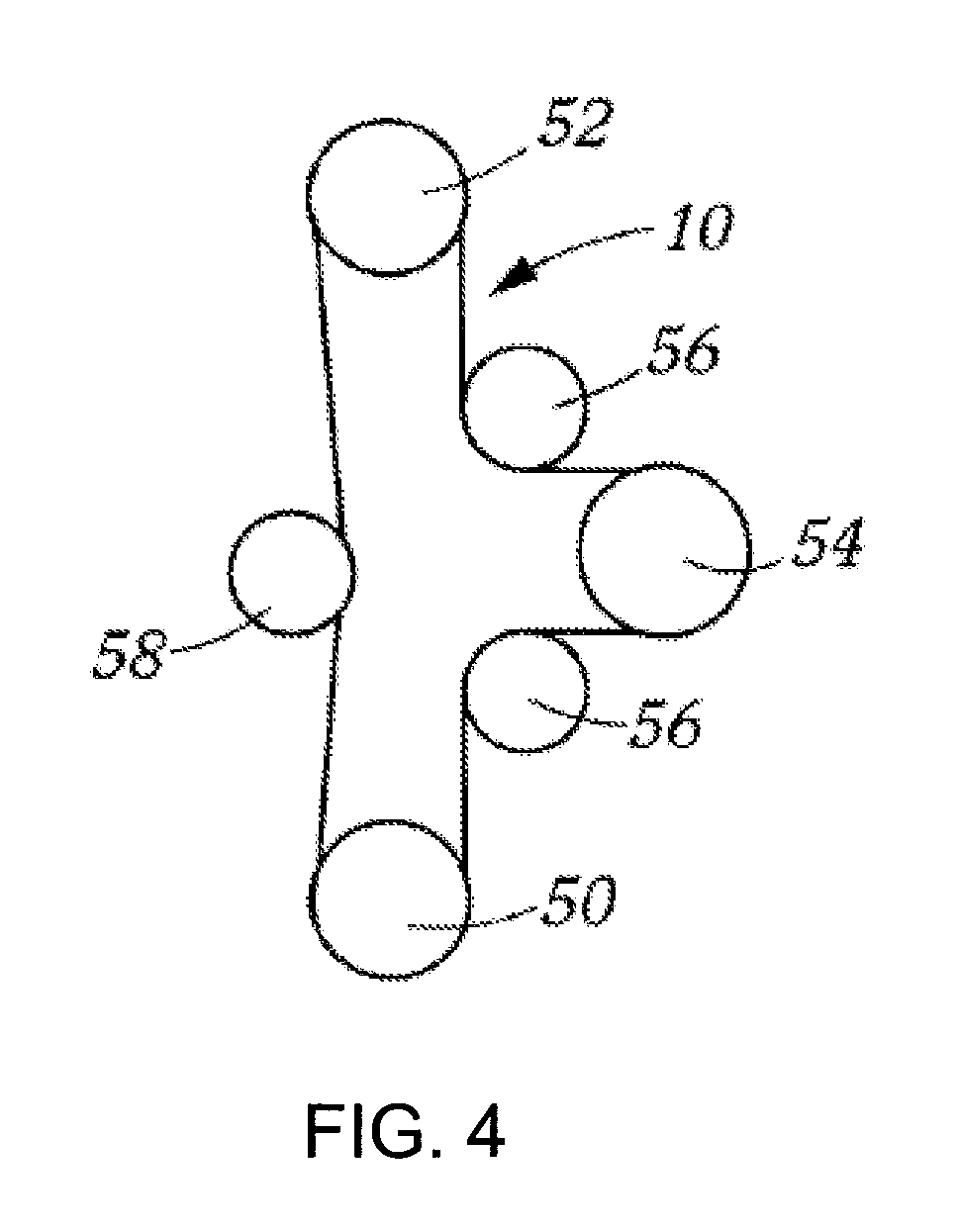

Polyurea-Urethane Cord Treatment for Power Transmission Belt and Belt

ActiveUS20110129647A1Improve adhesionGood compatibilityV-beltsPolyureas/polyurethane adhesivesPolyesterElastomer

A belt with a tensile cord embedded in an elastomeric body, having a polyurea-urethane adhesive composition impregnating the cord and coating the fibers. The composition is reaction product of a polyurethane prepolymer and a diamine curative or water. The prepolymer is a reaction product of a compact, symmetric diisocyanate and a polyester, polyether, or polycarbonate polyol. The belt body may be of cast polyurethane, vulcanized rubber, or thermoplastic elastomer. The cord may have an adhesive overcoat.

Owner:THE GATES CORP

Silicone priming compositions, articles, and methods

InactiveUS7090922B2Polyureas/polyurethane adhesivesOrganic non-macromolecular adhesiveCopolymerPolyurea

Owner:3M INNOVATIVE PROPERTIES CO

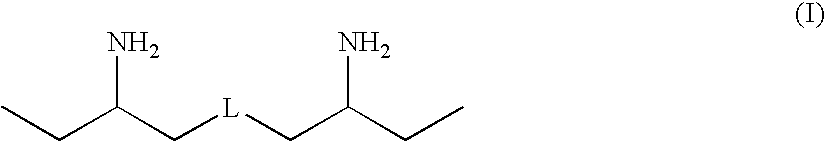

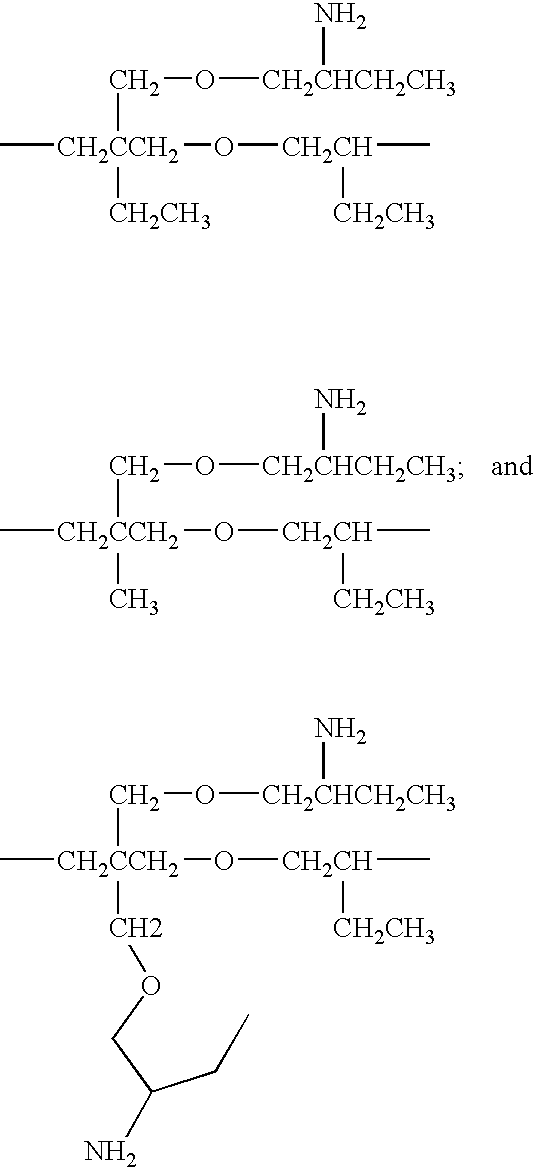

Polyether polyamine agents and mixtures therefor

Provided herein are polyamine precursors useful in the manufacture of epoxy resins. Use of a polyamine precursor according to the invention provides an epoxy resin formulation having an increased working time over prior art amines used for curing epoxies. Increased working times translate to the ability to manufacture composites which could not be made using conventional epoxy curing agents, such as composite blades for wind-driven turbines. Such polyamines are also useful in polyurea formulations for lengthening reaction time, thus allowing more flow of applied polyurea coatings prior to gellation.

Owner:HUNTSMAN PETROCHEMICAL LLC +1

Polyurethane-polyurea dispersions based on polyether-polycarbonate-polyols

The invention relates to new, hydrolysis-stable, aqueous polyurethane-polyurea dispersions based on polyether-polycarbonate-polyols, to a process for preparing them and to their use in coating materials.

Owner:BAYER MATERIALSCIENCE AG

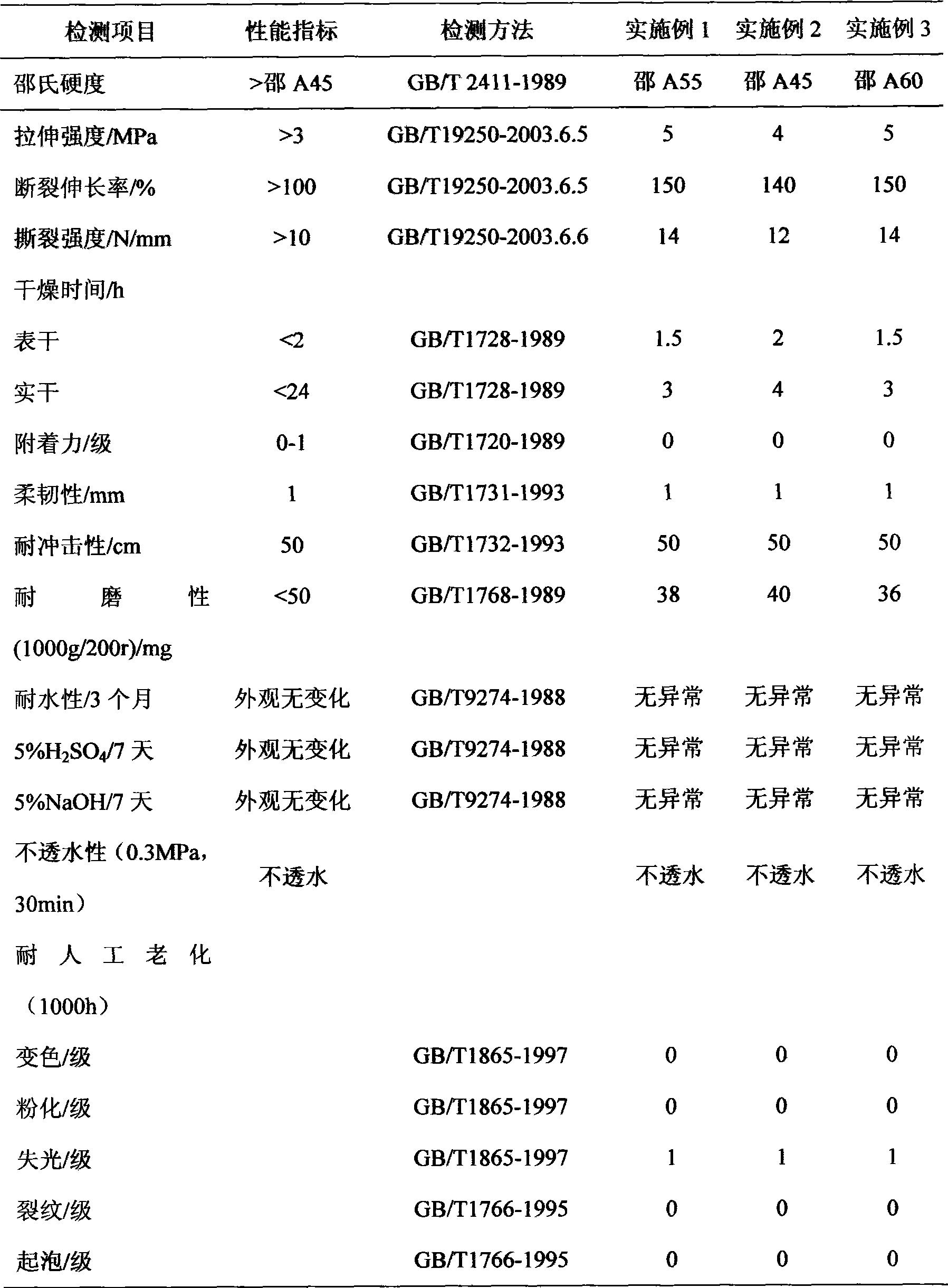

Preparation of polyaspartate polyurea waterproof coating material

InactiveCN101469246AStrong adhesionImprove toughnessAntifouling/underwater paintsPaints with biocidesAdhesion forceSpray coating

The invention discloses a method for preparing a polyaspartate polyurea waterproof coating, which is characterized in that the coating is based on polyaspartate polyurea and takes polyisocyanates as a curing agent. The coating material maintains the excellent performance of the prior polyurea coating, and also overcomes the disadvantages that the prior polyurea has overquick gelation time and needs special equipment for construction at the same time. The coating has the advantages of strong adhesion force, good toughness and wear resistance, good weather performance and so on, does not contain a solvent, is green and environment-friendly, and can reach the needed thickness through spray coating at one time.

Owner:SHANGHAI HUAYI FINE CHEM CO LTD

Multi-piece golf ball comprising low hardness gradient core

A golf ball includes a single core formed from a substantially homogenous rubber composition, an inner cover disposed about the core, and an outer cover. The inner cover includes an ionomeric material and has a hardness of about 60 Shore D or greater. The outer cover layer is disposed about the inner cover layer, is formed from a castable polyurea or polyurethane, and has a material hardness of about 60 Shore D or less. The outer surface of the core has a trans content of about 12% or less and a hardness of about 71 to 88 Shore C, the geometric center of the core has a trans content of about 10% or less and a hardness of about 70 to 80 Shore C, and the core surface hardness is greater than the geometric center hardness by about 1 to 10 Shore C to define a shallow positive hardness gradient.

Owner:ACUSHNET CO

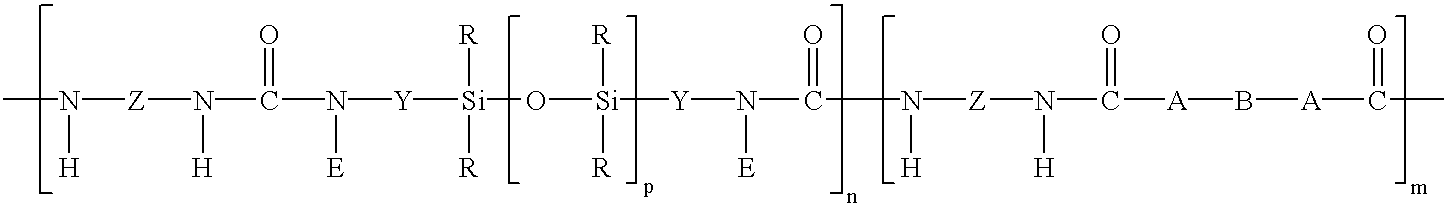

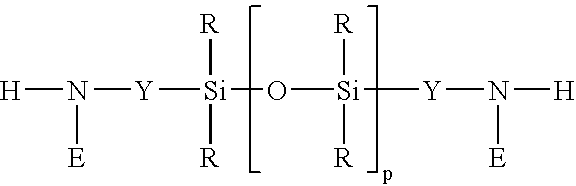

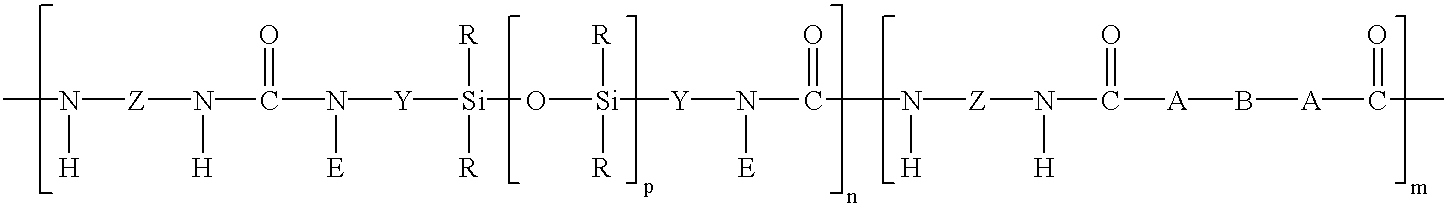

Silylated polyurethane-polyurea protective coating compositions

InactiveUS20070129527A1Improve adhesionHigh hardnessPolyurea/polyurethane coatingsPolymer scienceSilanes

A moisture-curable composition includes a silane-terminated polyurethane-polyurea polymer made by reacting a polyol, polyisocyanate, and polyamine together to provide an isocyanate-terminated polyurethane-polyurea polymer with at least two urethane linkages and at least two urea linkages in the polymer chain, and capping at least a portion of the isocyanate-terminated polymer with a silane having at least one alkoxy group to provide the moisture-curable silane-terminated polymer.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com