Patents

Literature

1022results about "Manufacturing enclosures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methods of producing three-dimensional objects from materials having multiple mechanisms of hardening

ActiveUS20160136889A1Increased formationEnhance or speed the refilling of the build regionManufacturing enclosuresOptical articlesPolymer scaffoldChemistry

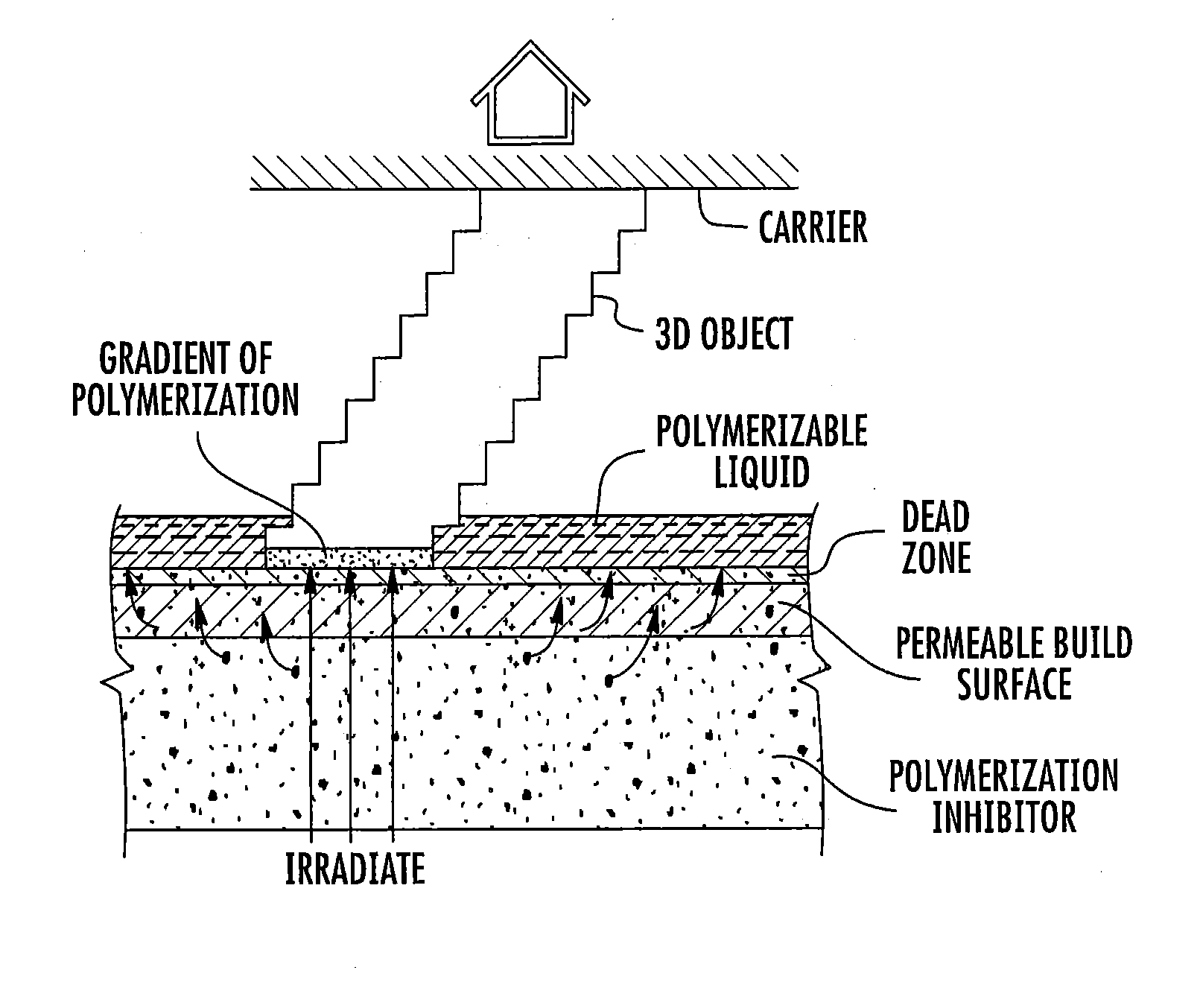

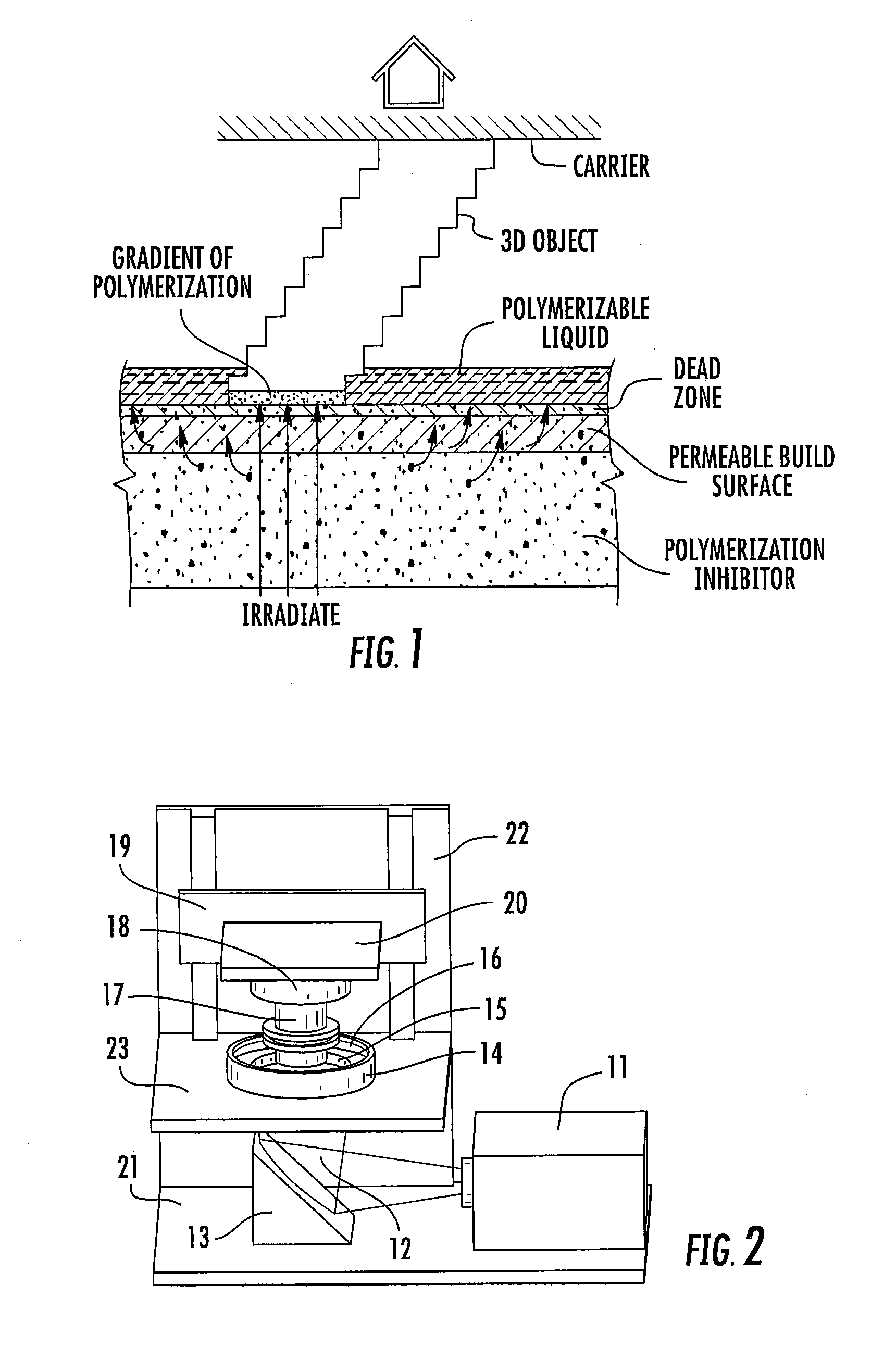

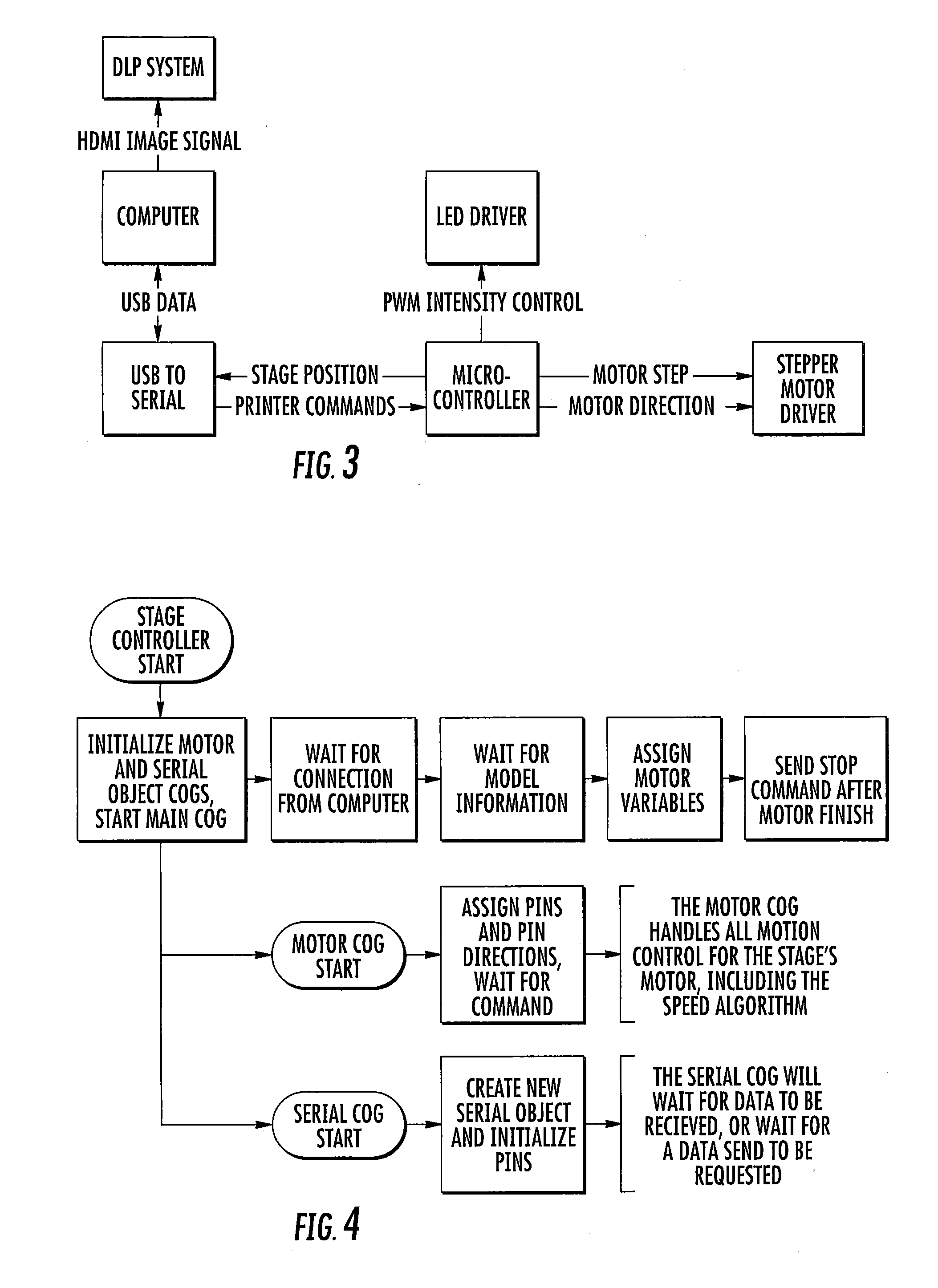

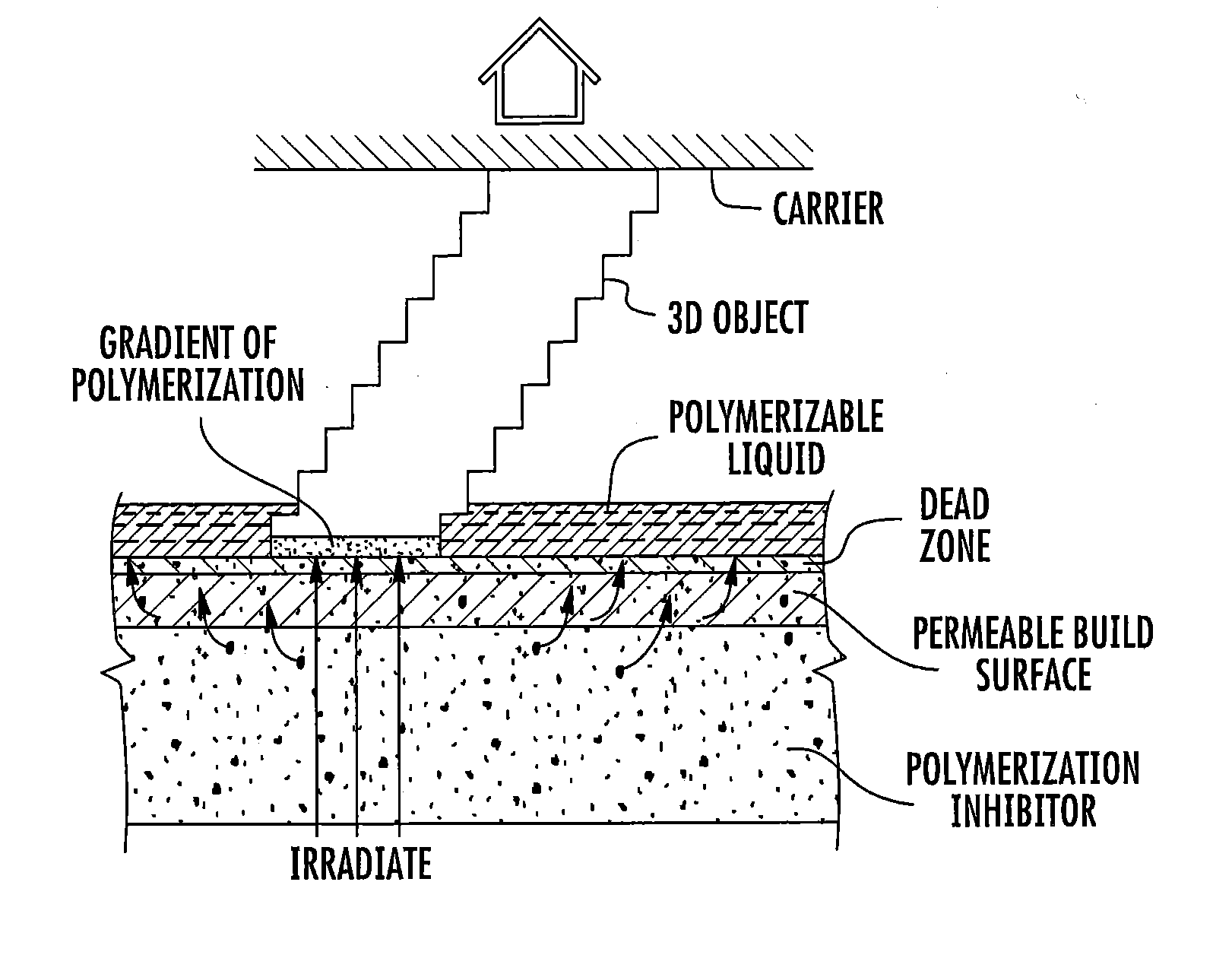

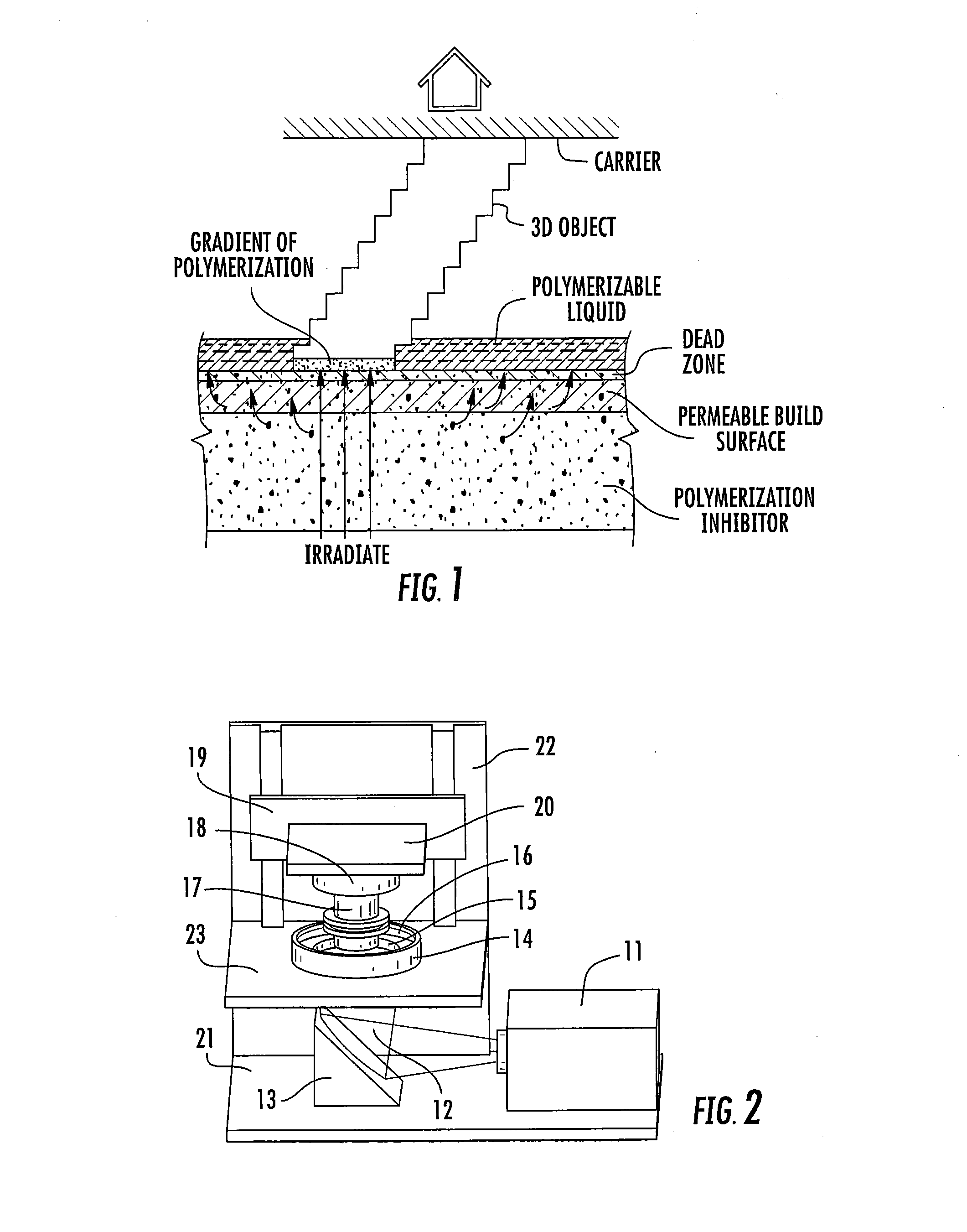

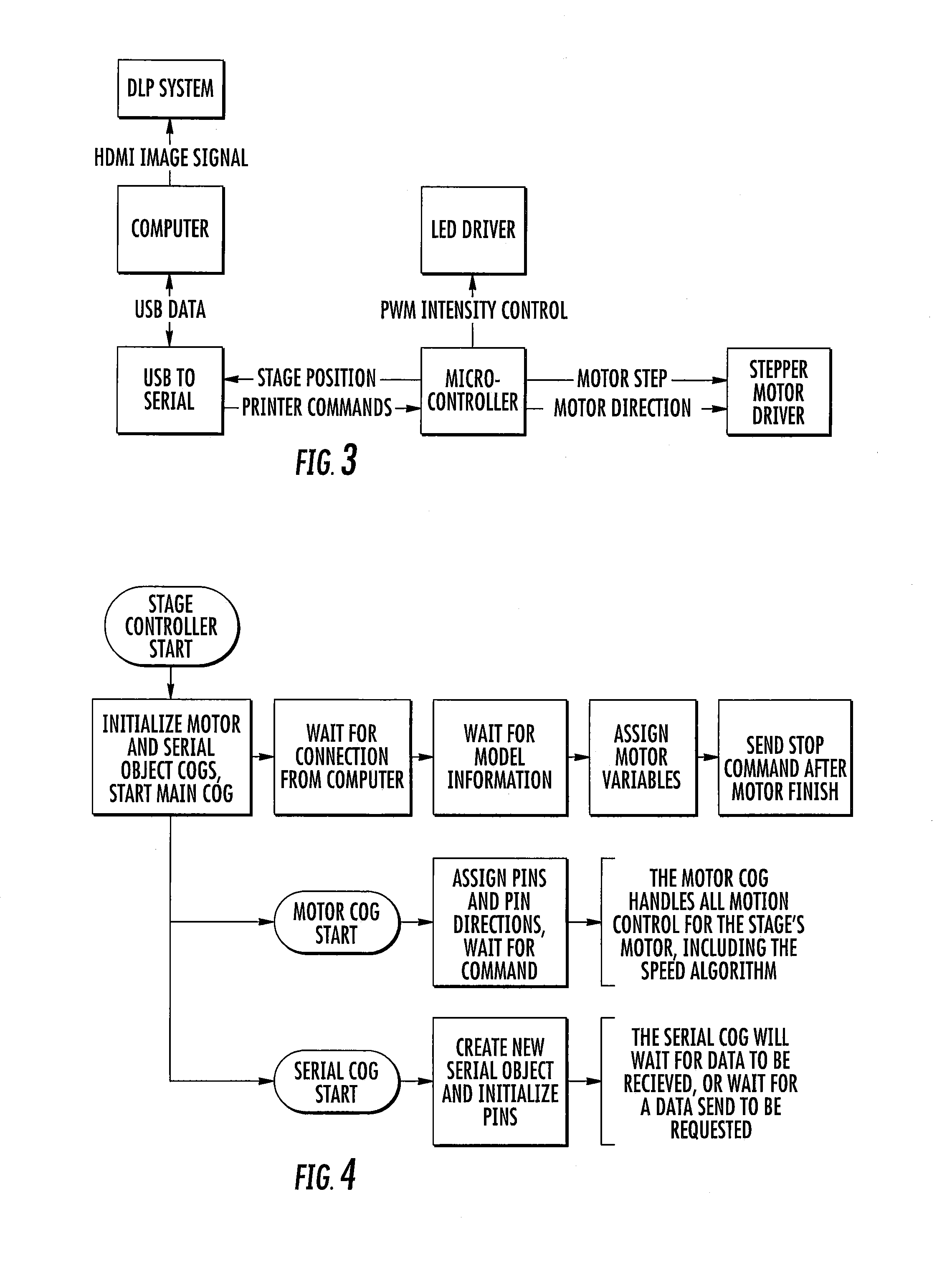

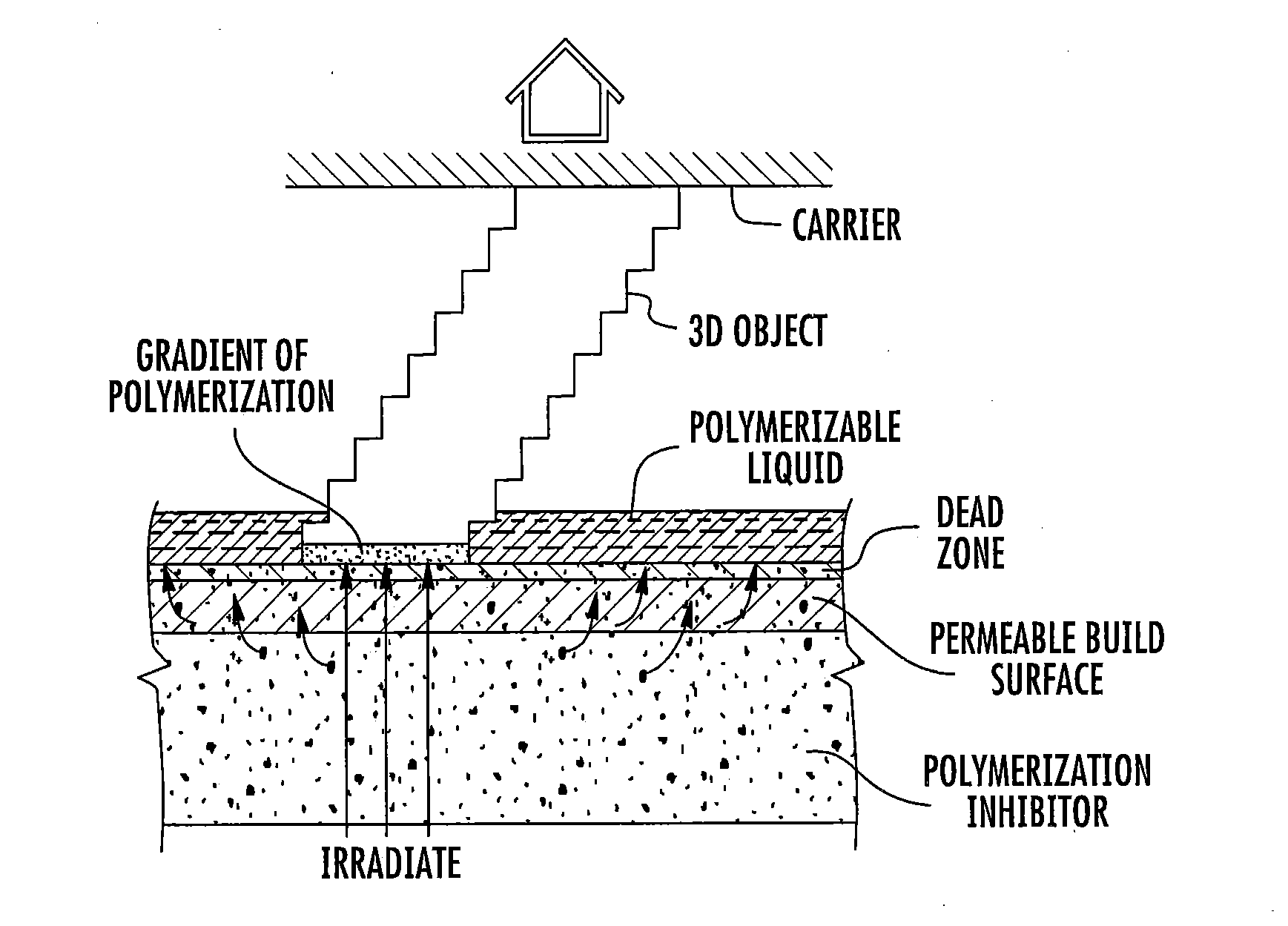

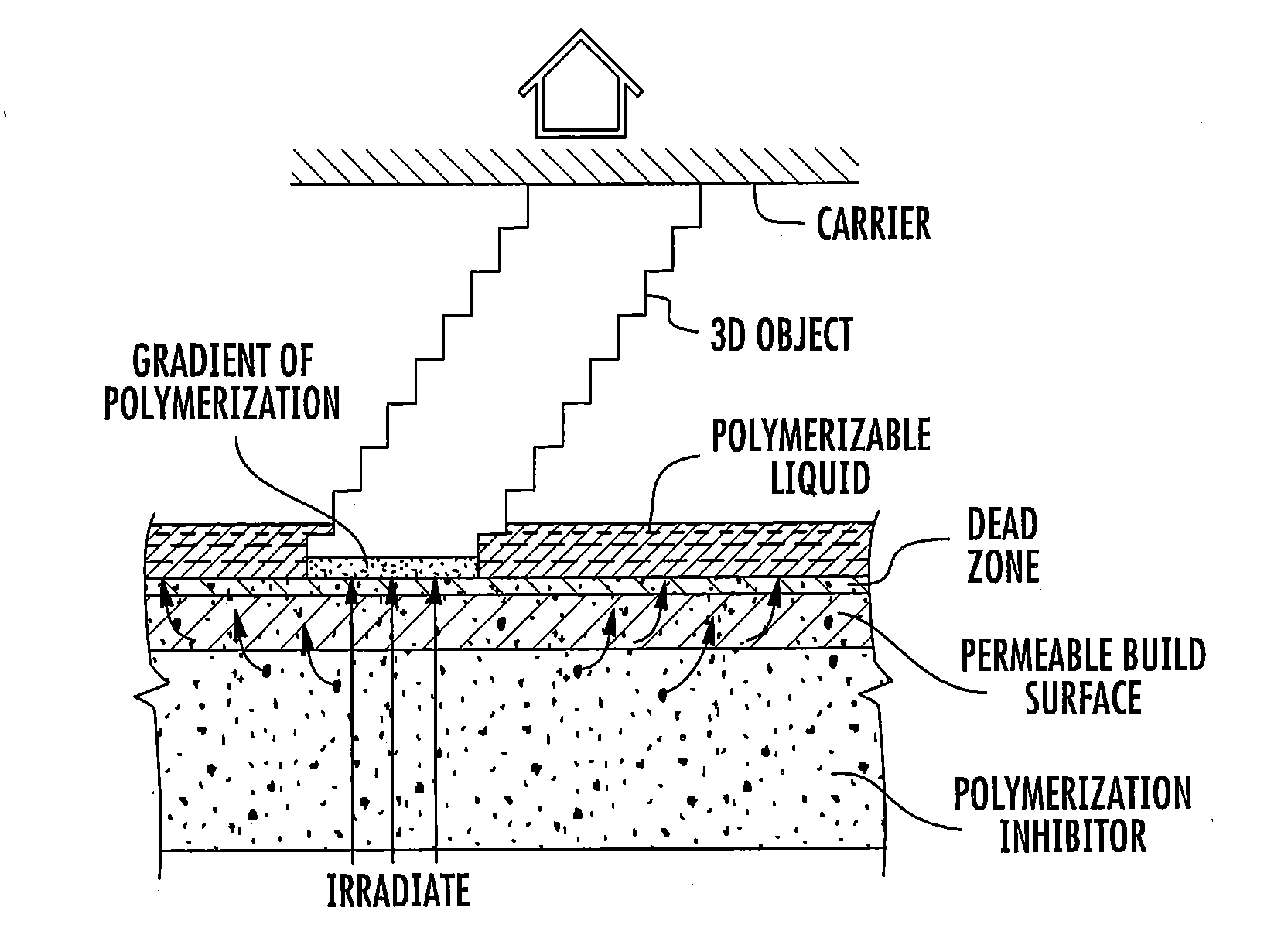

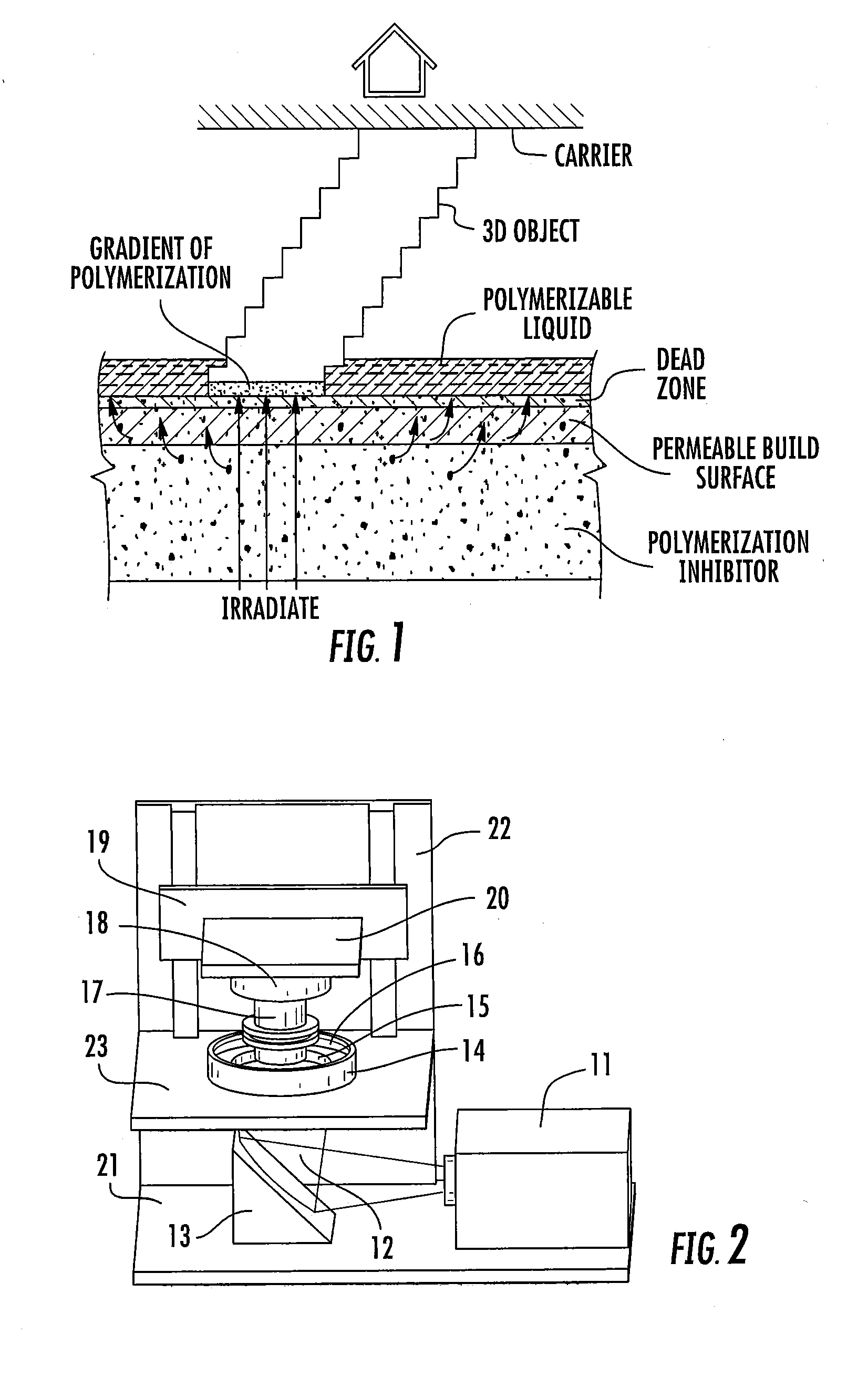

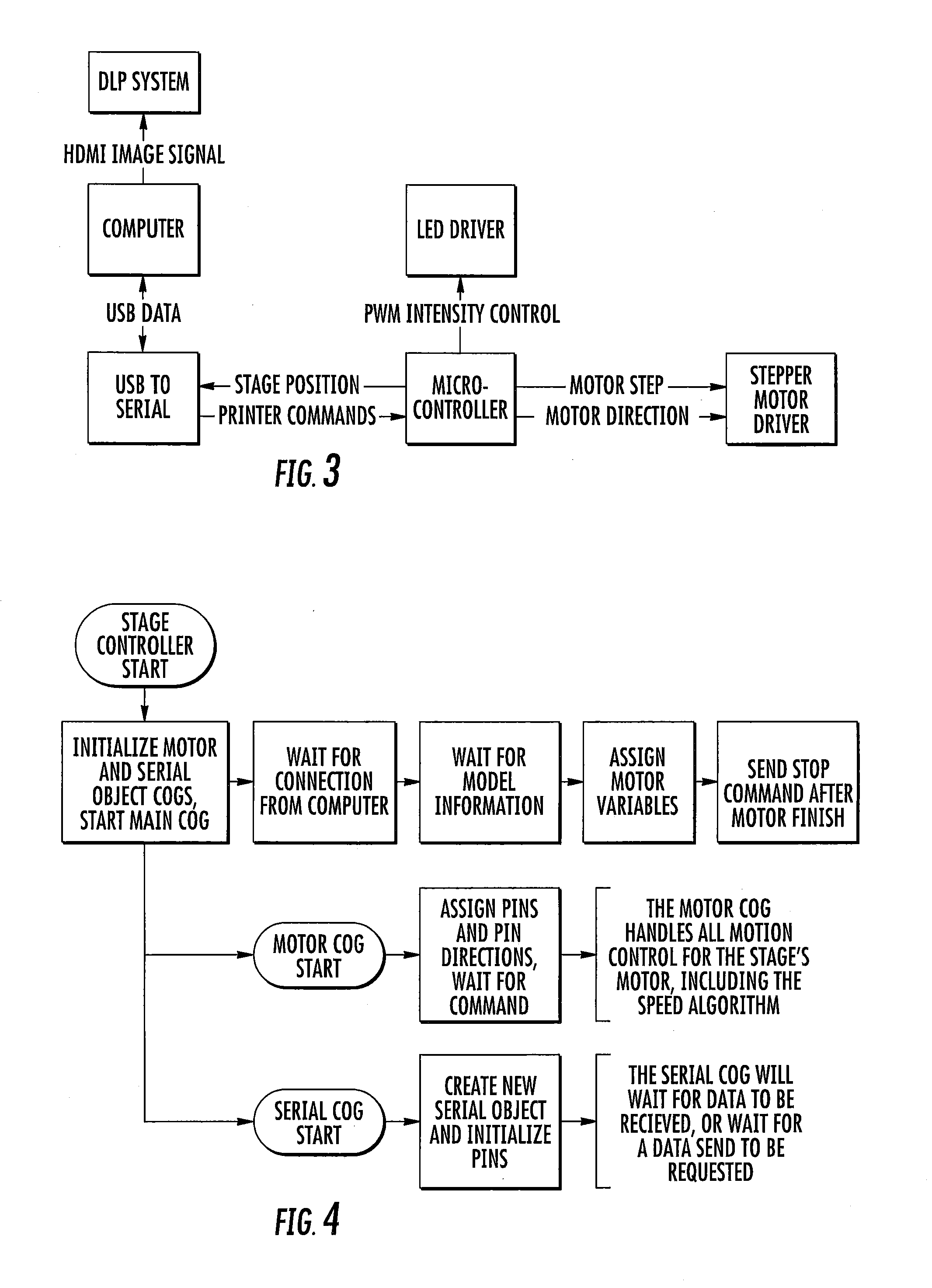

A method of forming a three-dimensional object is carried out by: (a) providing a carrier and an optically transparent member having a build surface, the carrier and the build surface defining a build region therebetween; (b) filling the build region with a polymerizable liquid, the polymerizable liquid including a mixture of (i) a light polymerizable liquid first component, and (ii) a second solidifiable component that is different from the first component; (c) irradiating the build region with light through the optically transparent member to form a solid polymer scaffold from the first component and also advancing the carrier away from the build surface to form a three-dimensional intermediate having the same shape as, or a shape to be imparted to, the three-dimensional object, and containing the second solidifiable component carried in the scaffold in unsolidified and / or uncured form; and (d) concurrently with or subsequent to the irradiating step, solidifying and / or curing the second solidifiable component in the three-dimensional intermediate to form the three-dimensional object.

Owner:CARBON INC

Three-dimensional objects produced from materials having multiple mechanisms of hardening

InactiveUS20160160077A1Enhance or speed the refilling of the build regionIncreased formationManufacturing enclosuresLayered productsPolymer scienceCationic polymerization

A three dimensional object includes (a) a light polymerized first component; and (b) a second solidified component different from the first component. The object is preferably of a polymer blend formed from the first component and the second component, with the polymer blend as an interpenetrating polymer network, a semi-interpenetrating polymer network, or a sequential interpenetrating polymer network. In some preferred embodiments, the second component does not contain a cationic polymerization photoinitiator. In some preferred embodiments, the three dimensional object is produced by the process of continuous liquid interface production.

Owner:CARBON INC

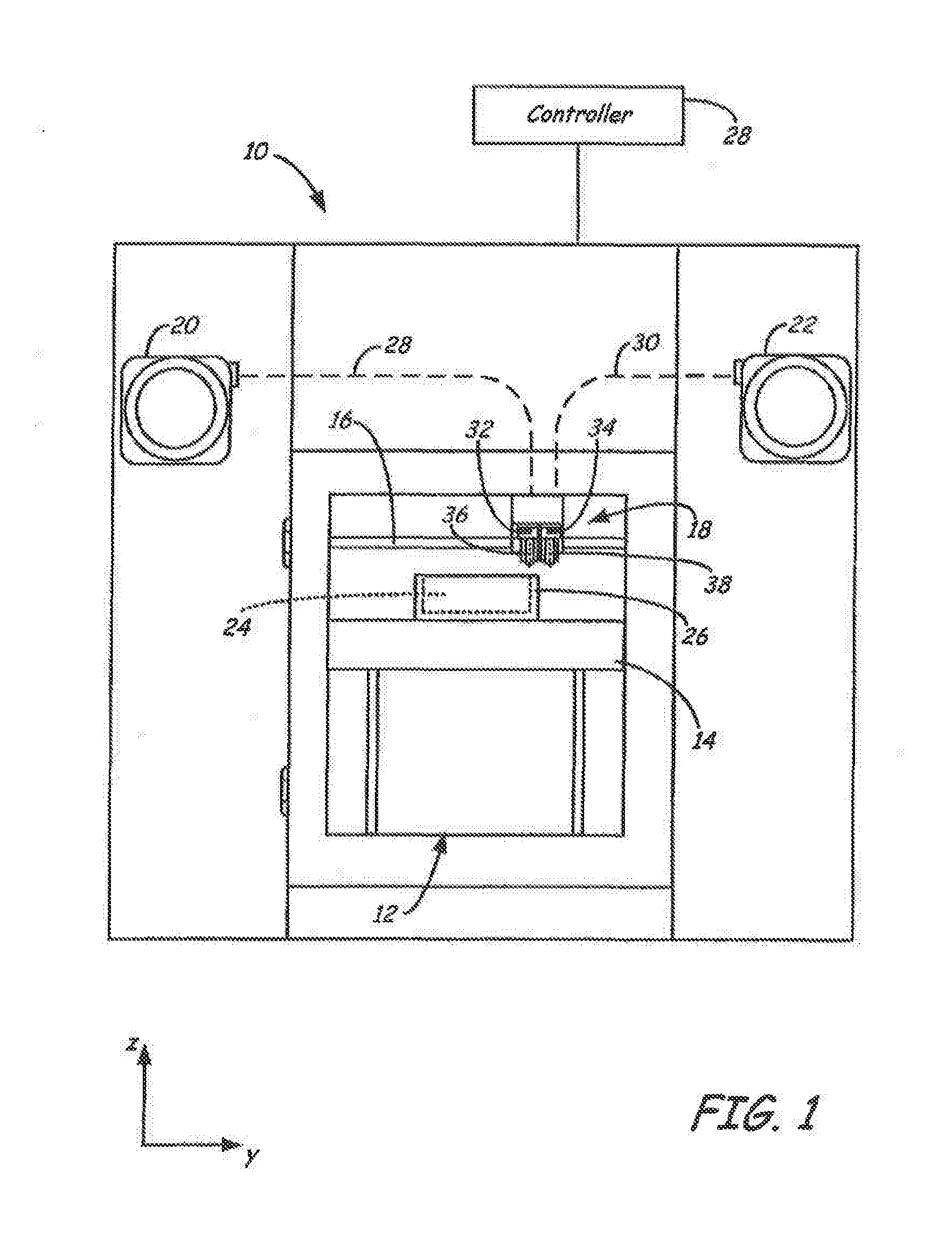

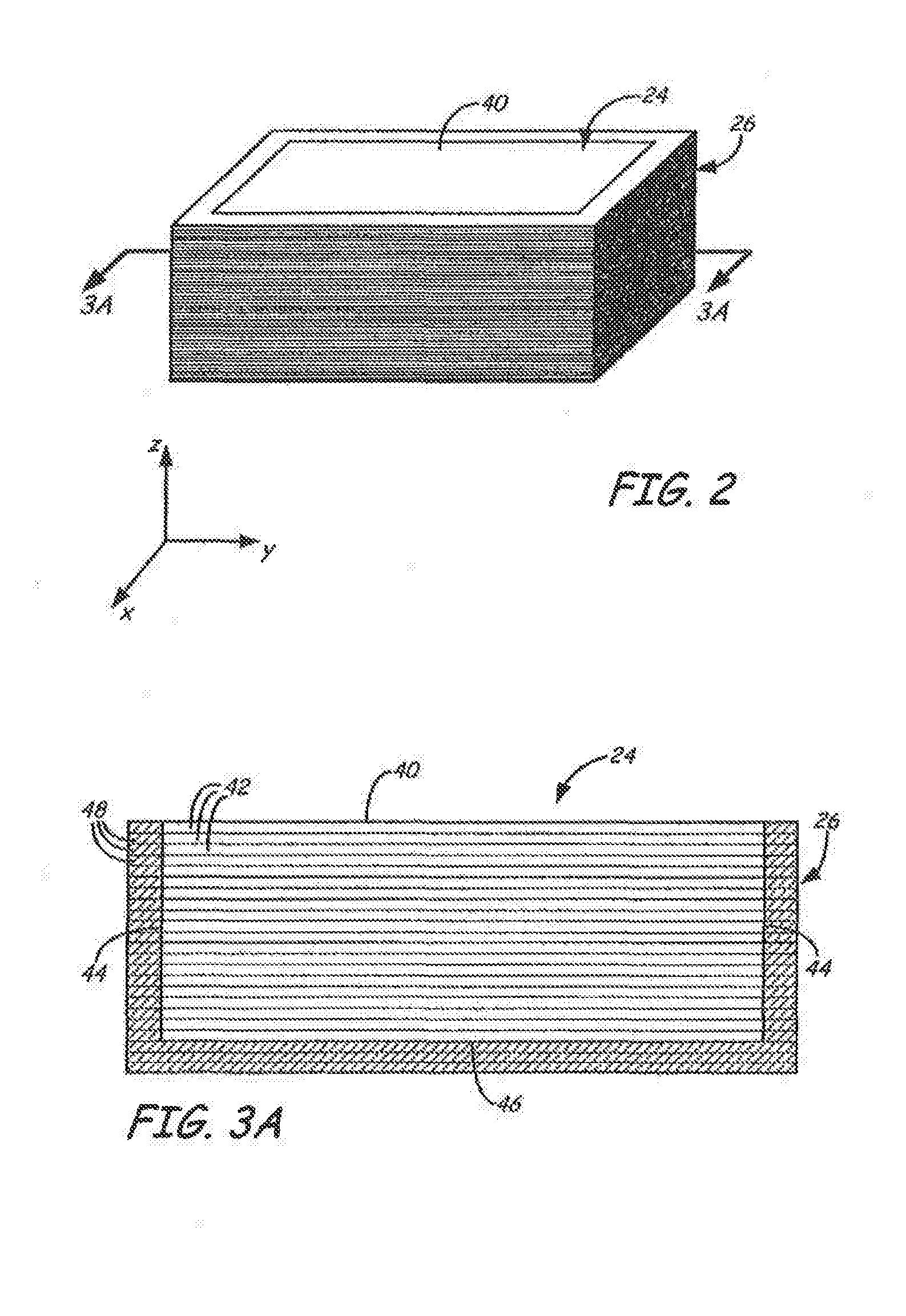

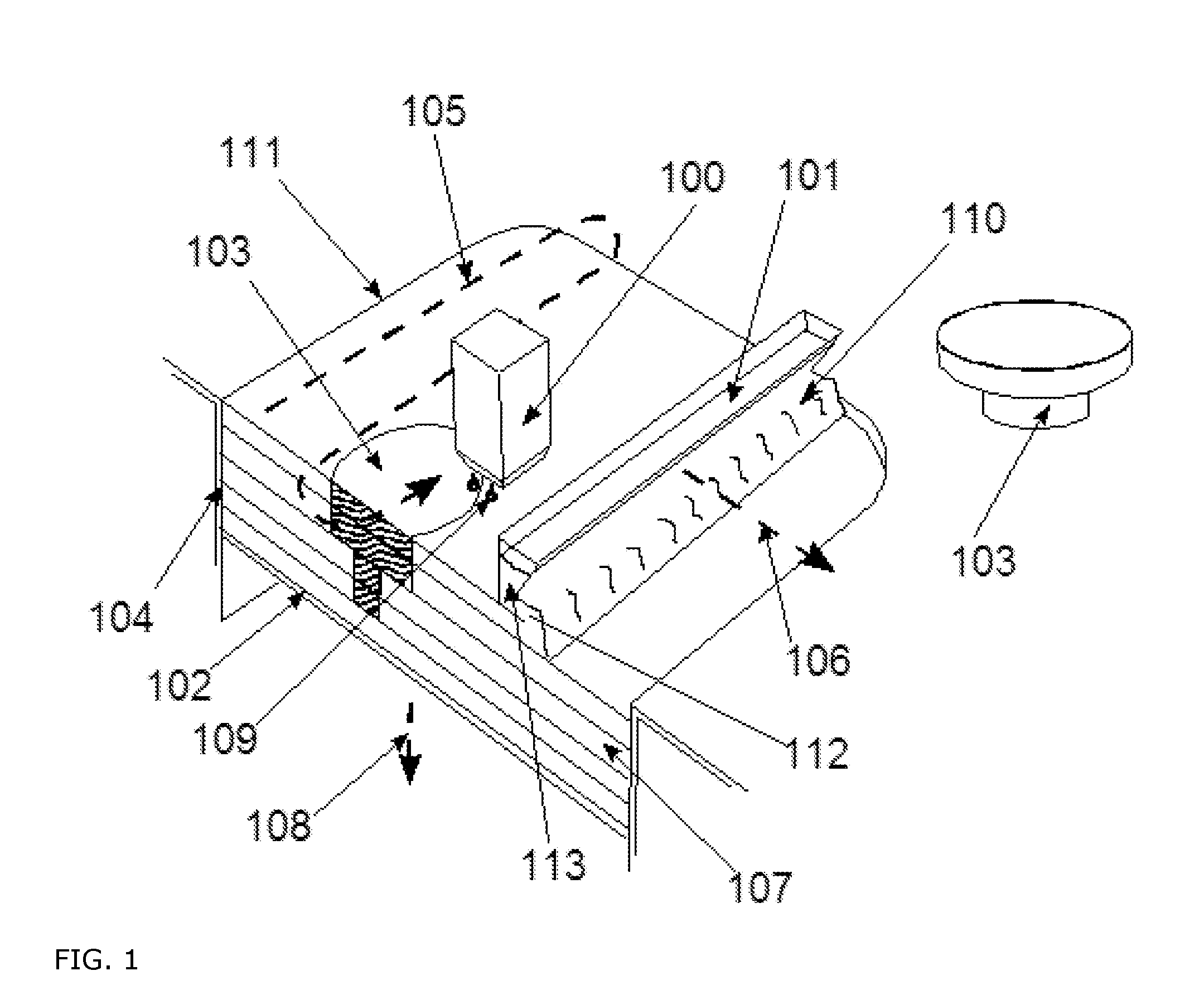

Manufacturing within a single-use container

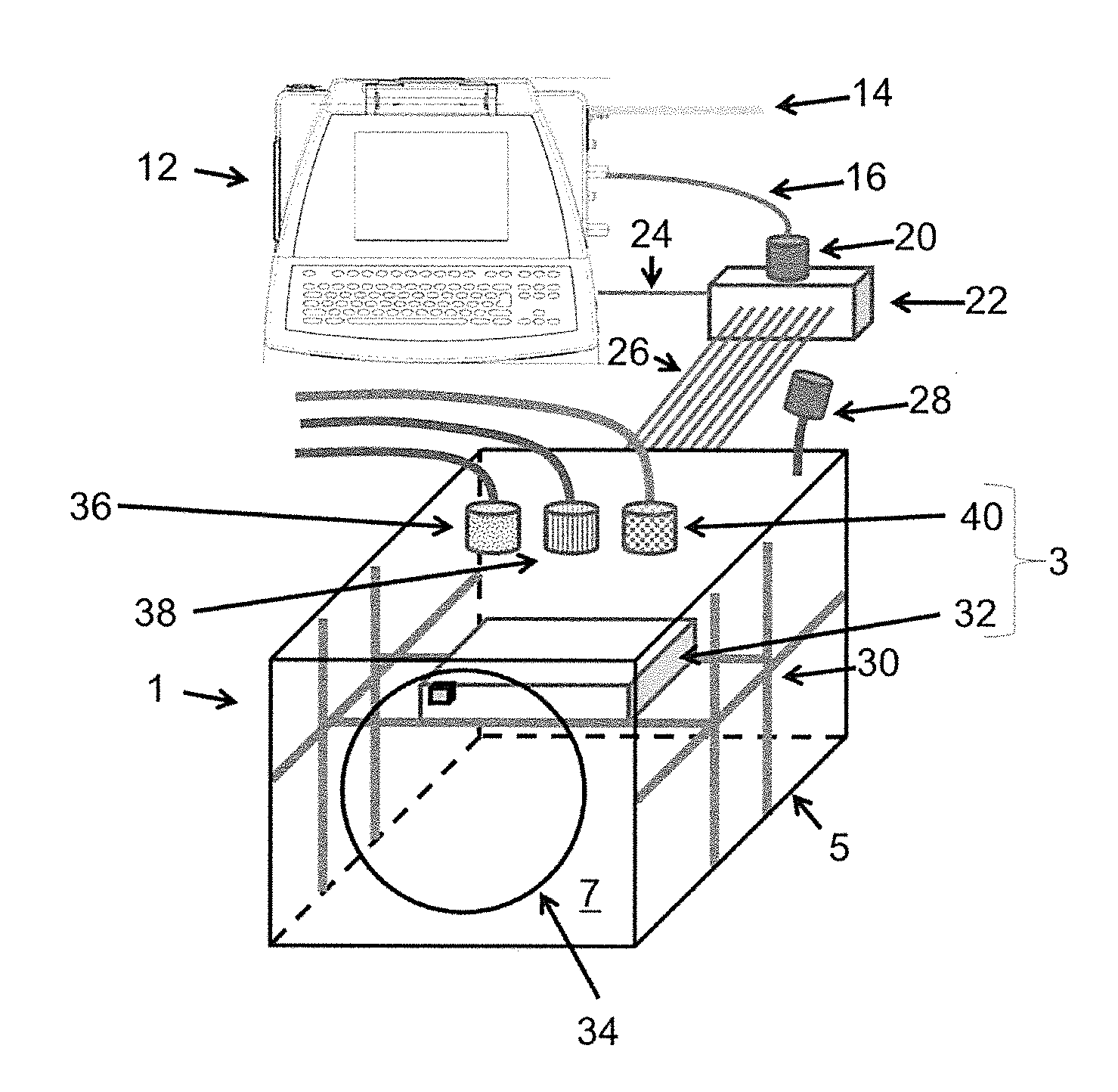

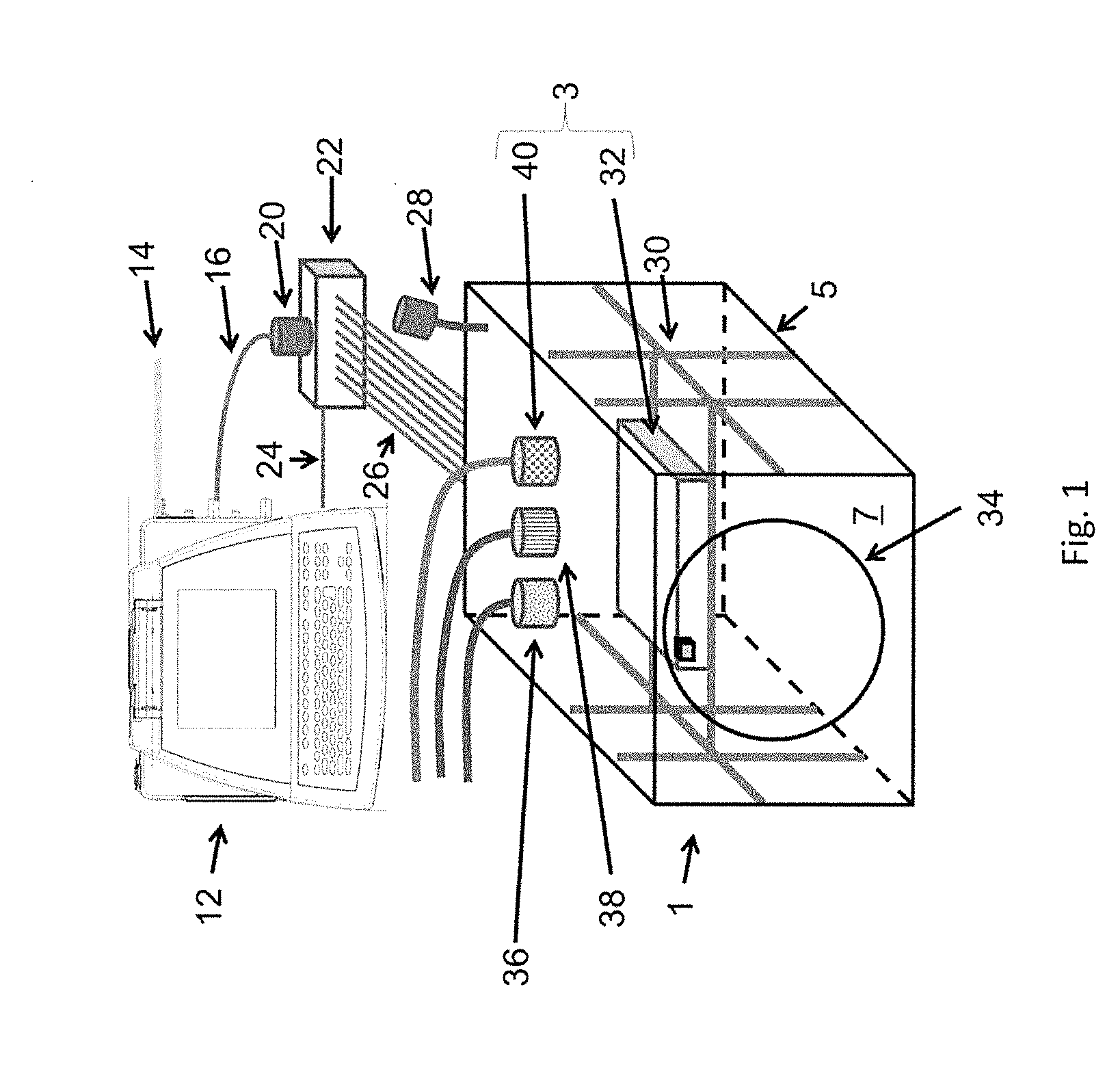

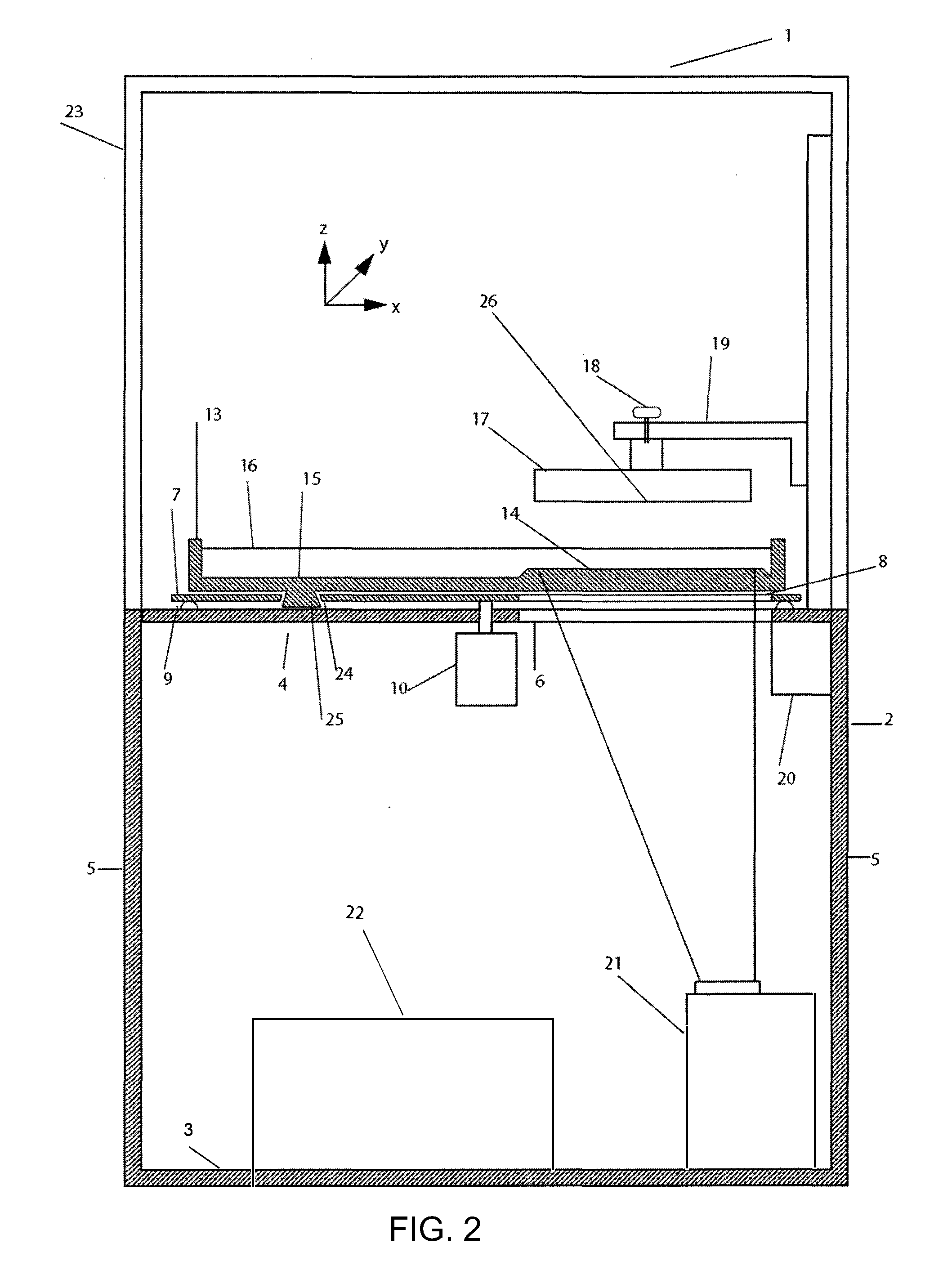

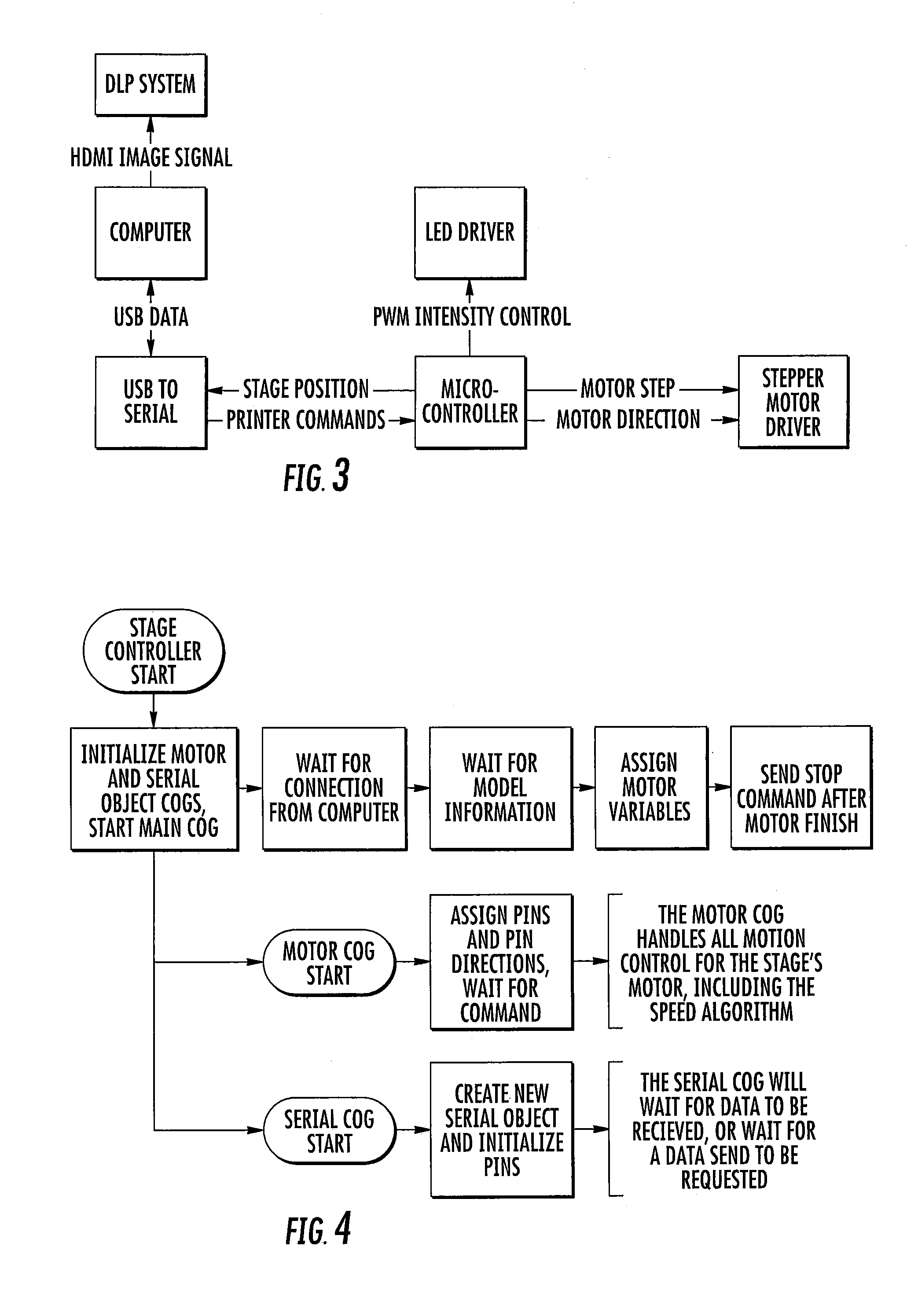

ActiveUS20160068793A1Function increaseProgramme-controlled manipulatorBioreactor/fermenter combinationsNumerical controlThree degrees of freedom

A manufacturing assembly has at least a sterilizable chamber containing at least one of a three-dimensional printing device (additive manufacturing), a Computer Numerical Controlled (CNC) finishing head (subtractive manufacturing), a vacuum-forming unit, an injection-molding unit, a laser-cutting unit, a ultrasonic-welding unit, a robotic arman analysis device, a sampling device or a combination thereof. A plurality of individual sterilizable chambers may be aseptically connected into a network of sterilizable chambers that provides additional functionality for the manufacturing assembly. A sterilizable printer assembly may include at least one printing head, a printing platform, and a driving mechanism adapted to perform a movement of the at least one printing head relative to the printing platform along three degrees of freedom; a printer housing enclosing the printer assembly in a sterile manner, at least one aseptic connector fluidly connected to a corresponding one of the at least one printing head.

Owner:SARTORIUS STEDIM BIOTECH GMBH

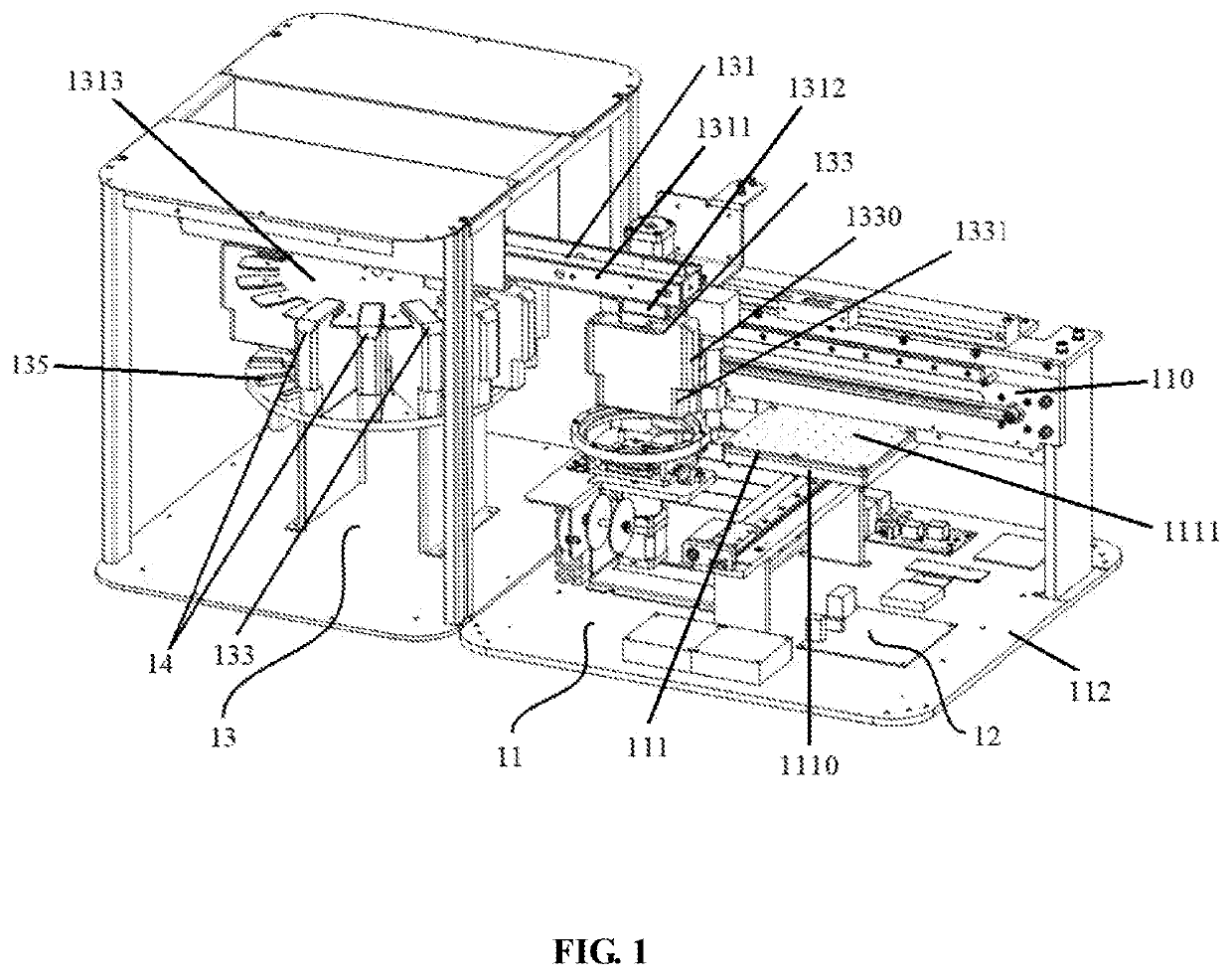

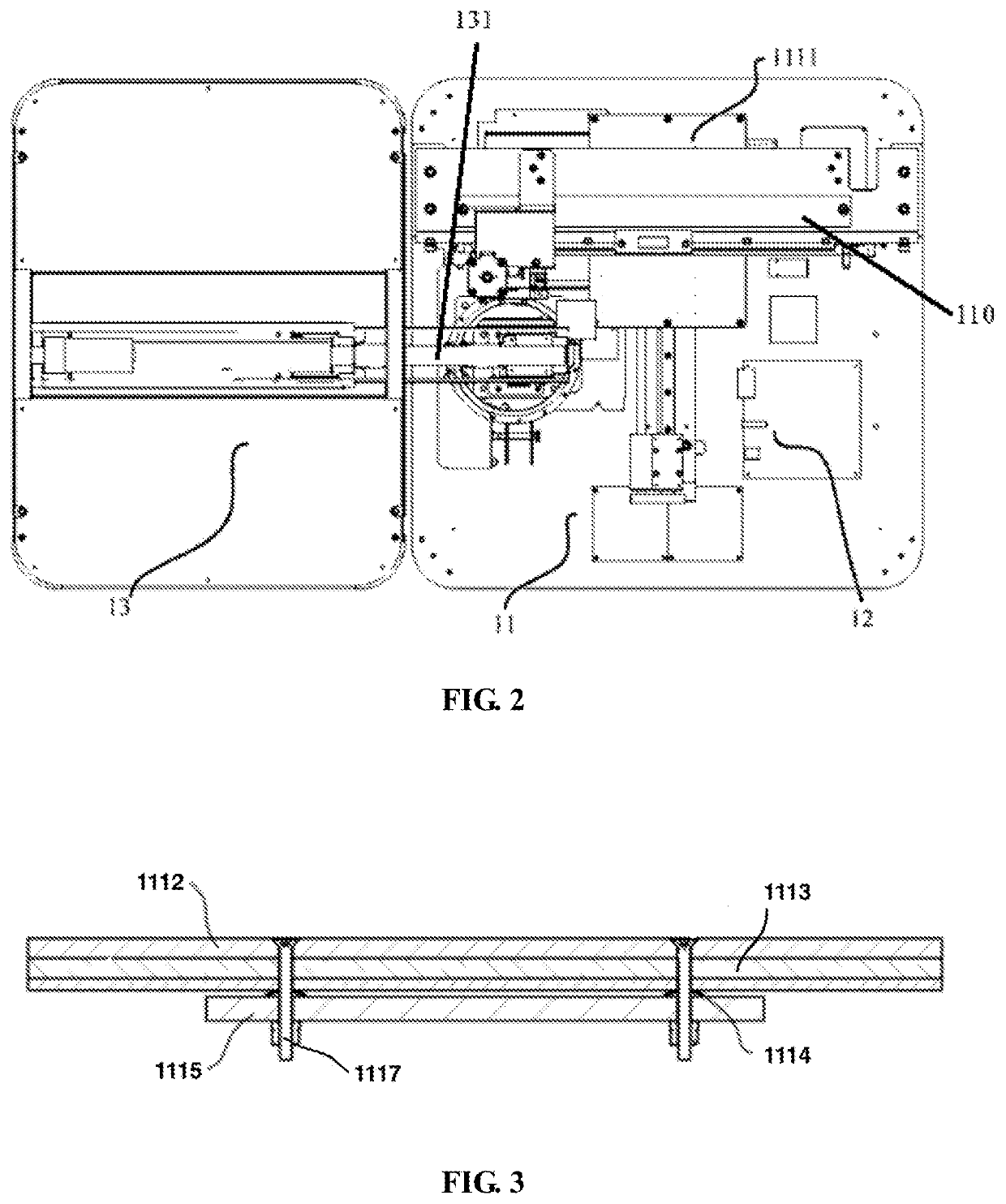

Stereolithography apparatus

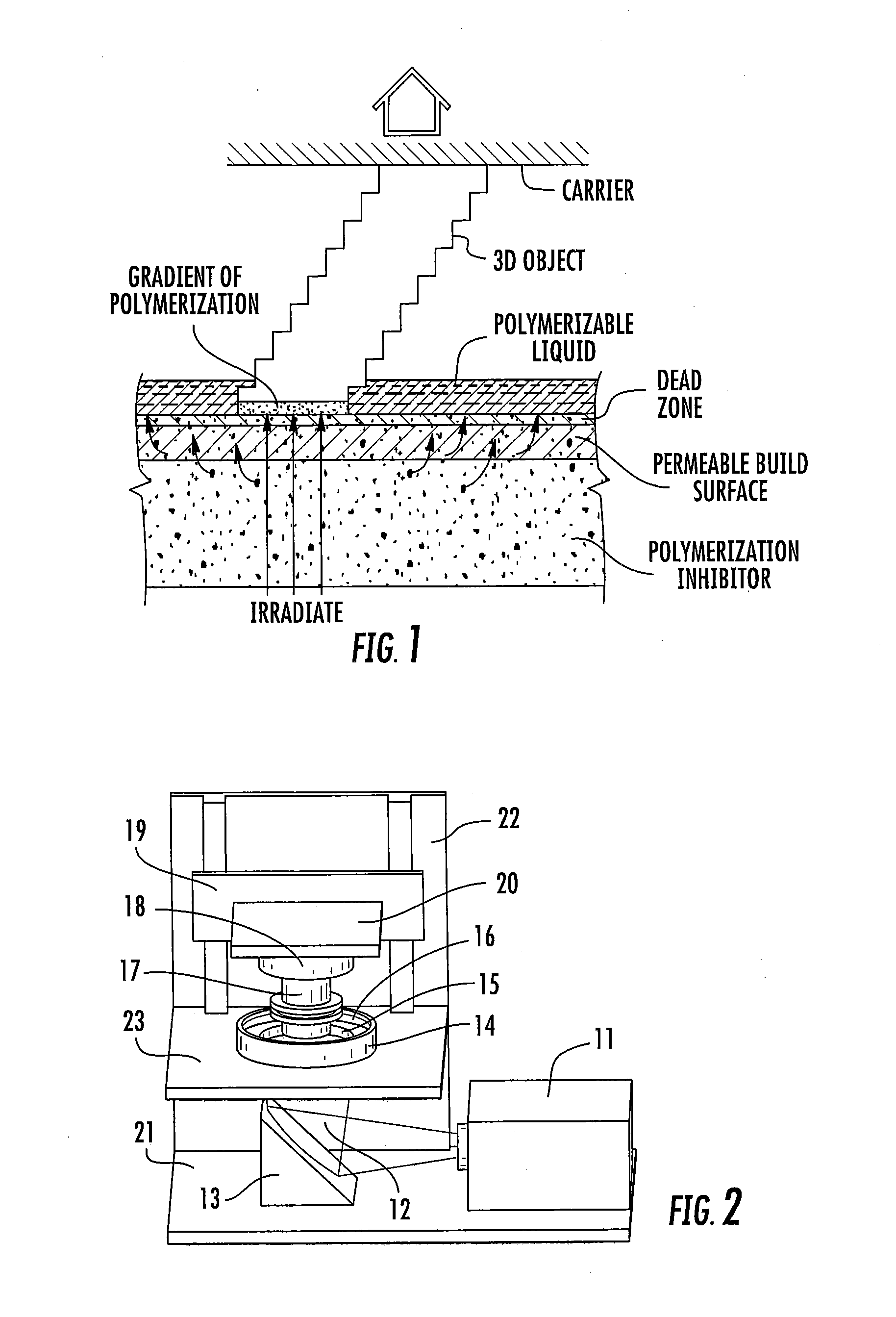

ActiveUS20150064298A1Improve printing qualityIncrease speedManufacturing platforms/substratesManufacturing enclosuresEngineeringStereolithography

A stereolithography apparatus includes a supporting frame assembly, a tank supported on the supporting frame assembly, a vertically moving module, and a build platform. The tank has an anchored portion anchored to the supporting frame assembly. The build platform is vertically moved relative to the tank by the vertically moving module. After a resin layer is solidified and adhered to the bottom of the tank and the build platform, the tank is peeled away from the resin layer starting from a portion of the resin layer adjacent to the anchored portion and partially moves upward relative to the supporting frame assembly around the anchored portion when the build platform leaves the supporting frame assembly. To further reduce the separation force between the cured resin layer and the tank, the bottom of the tank is covered with materials that are transparent, chemically resistant, impact resistant or / and elastic.

Owner:SYAO KAO CHIH

Powder pre-processing for additive manufacturing

ActiveUS20150290710A1Shorten the timeRemove moistureManufacturing enclosuresTransportation and packagingMetallurgyPre treatment

The present invention relates to a method for removing moisture from powder to be used in an additive manufacturing process for forming a three-dimensional article through successive fusion of parts of at least one layer of a powder bed provided on a work table, which parts corresponds to successive cross sections of the three-dimensional article, characterized in that said method comprising the steps of: providing at least a first powder tank and at least at least a second powder tank, providing a predetermined amount of powder on a movable table inside said first powder tank, heating the top surface of the powder in said first powder tank to a predetermined temperature interval for removing moisture from said powder, raising said movable table a predetermined distance, moving a predetermined thickness of the powder material from said first powder tank to said second powder tank.

Owner:ARCAM AB

Polymeric Material for Three-Dimensional Printing

A polymeric material that is capable of being employed as a build material and / or support material in a three-dimensional printer system is provided. The polymeric material is formed from a thermoplastic composition containing a continuous phase that includes a matrix polymer. A microinclusion additive and nanoinclusion additive are dispersed within the continuous phase in the form of discrete domains.

Owner:KIMBERLY-CLARK WORLDWIDE INC

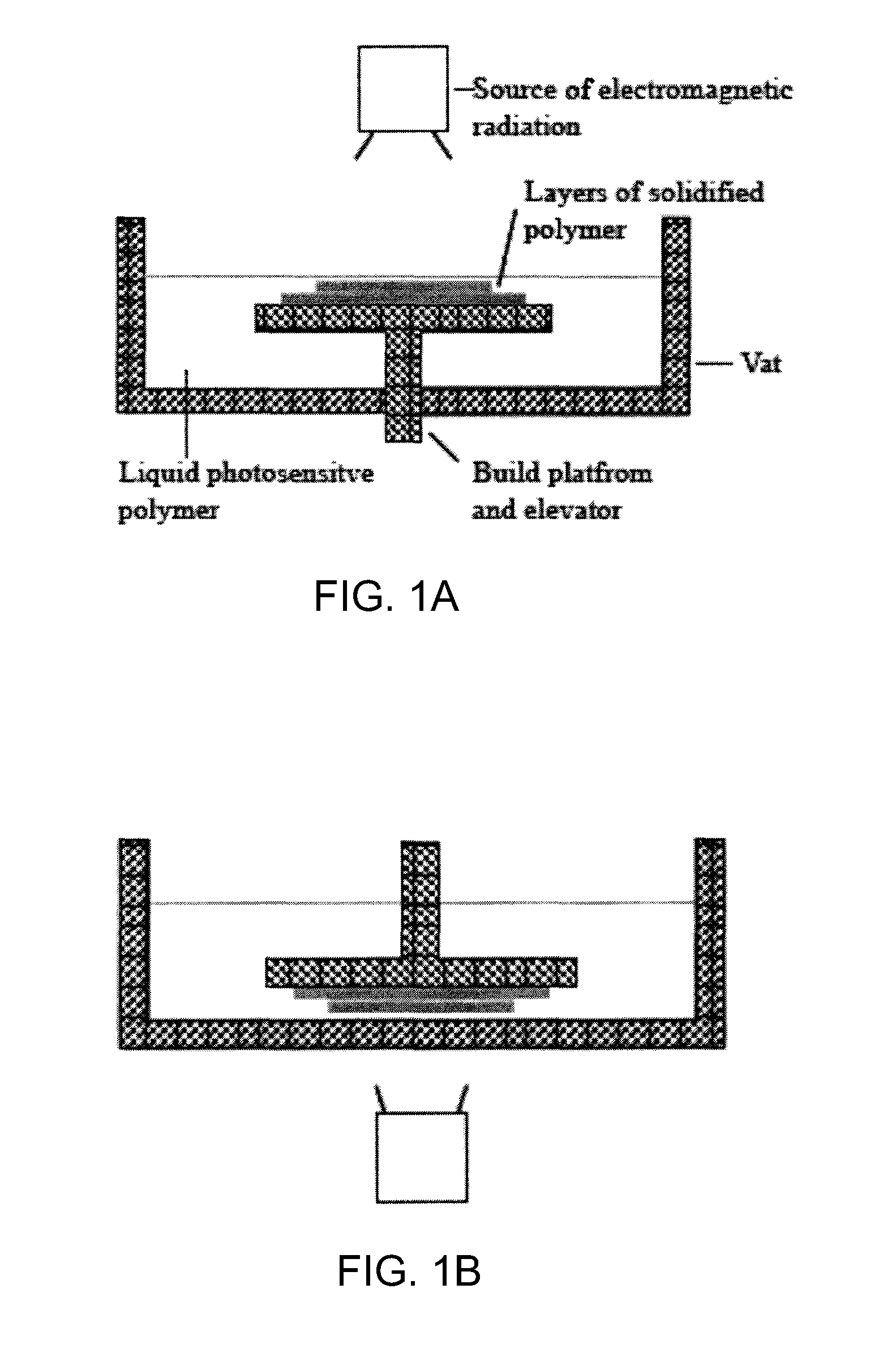

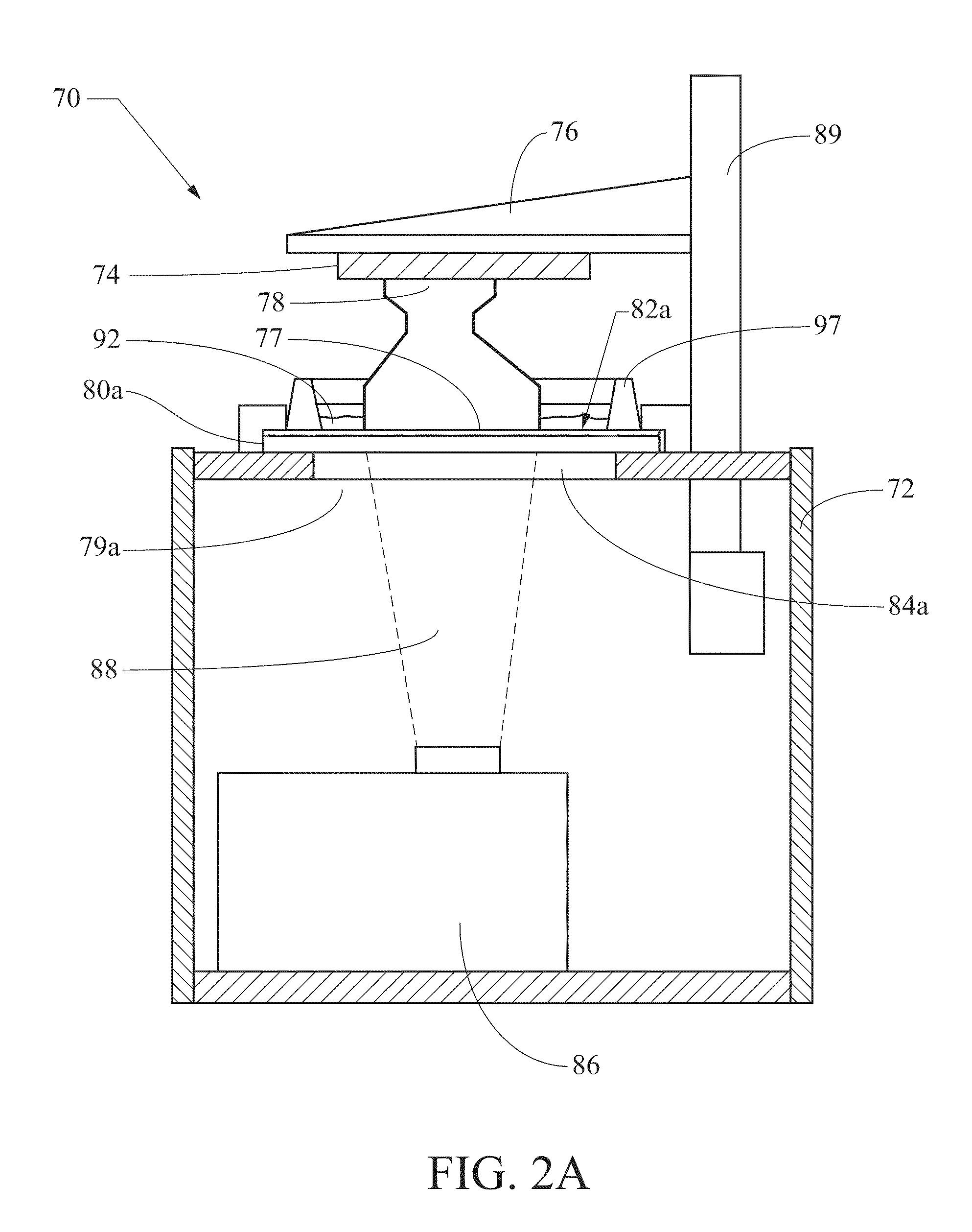

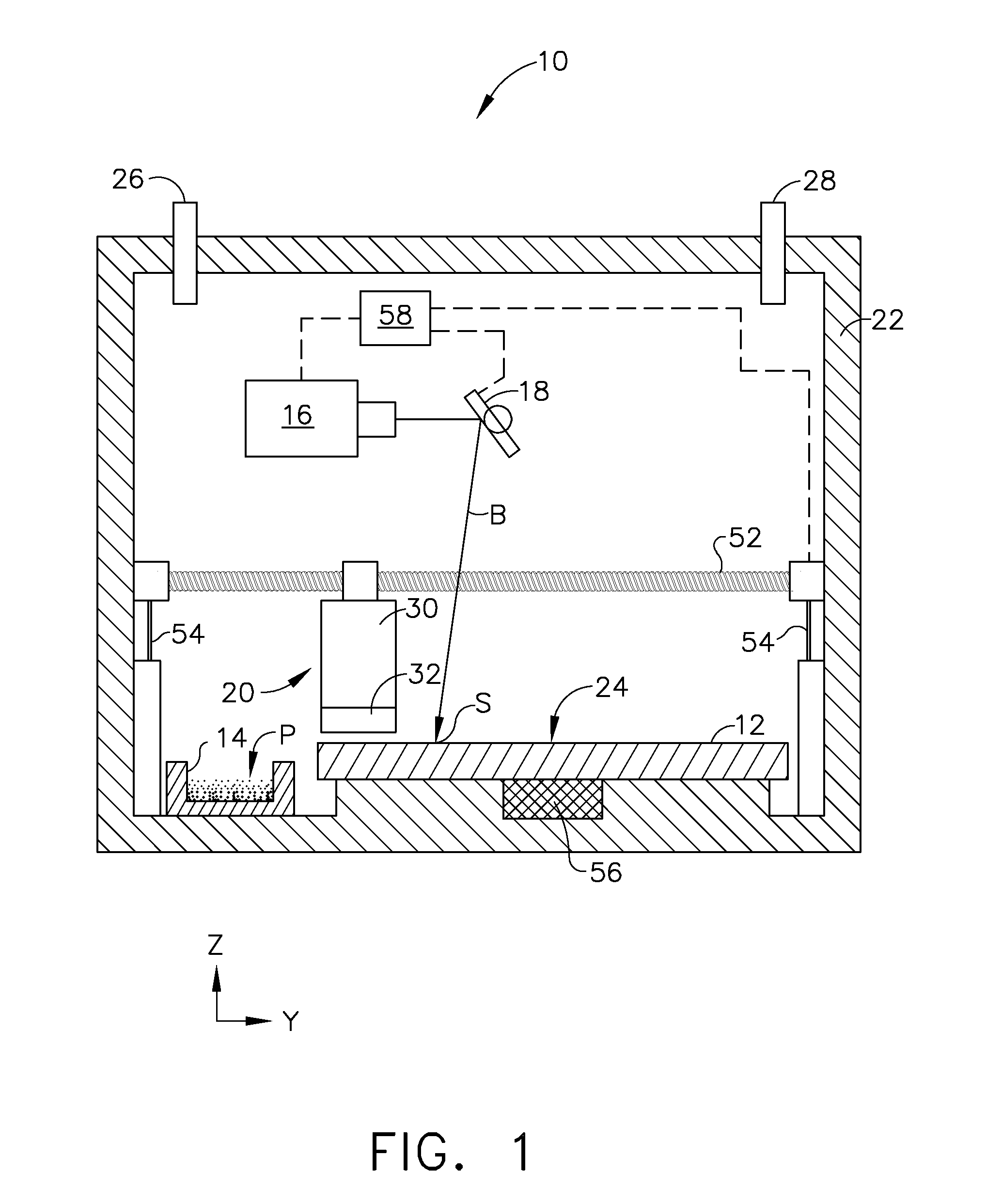

Apparatus for fabrication of three dimensional objects

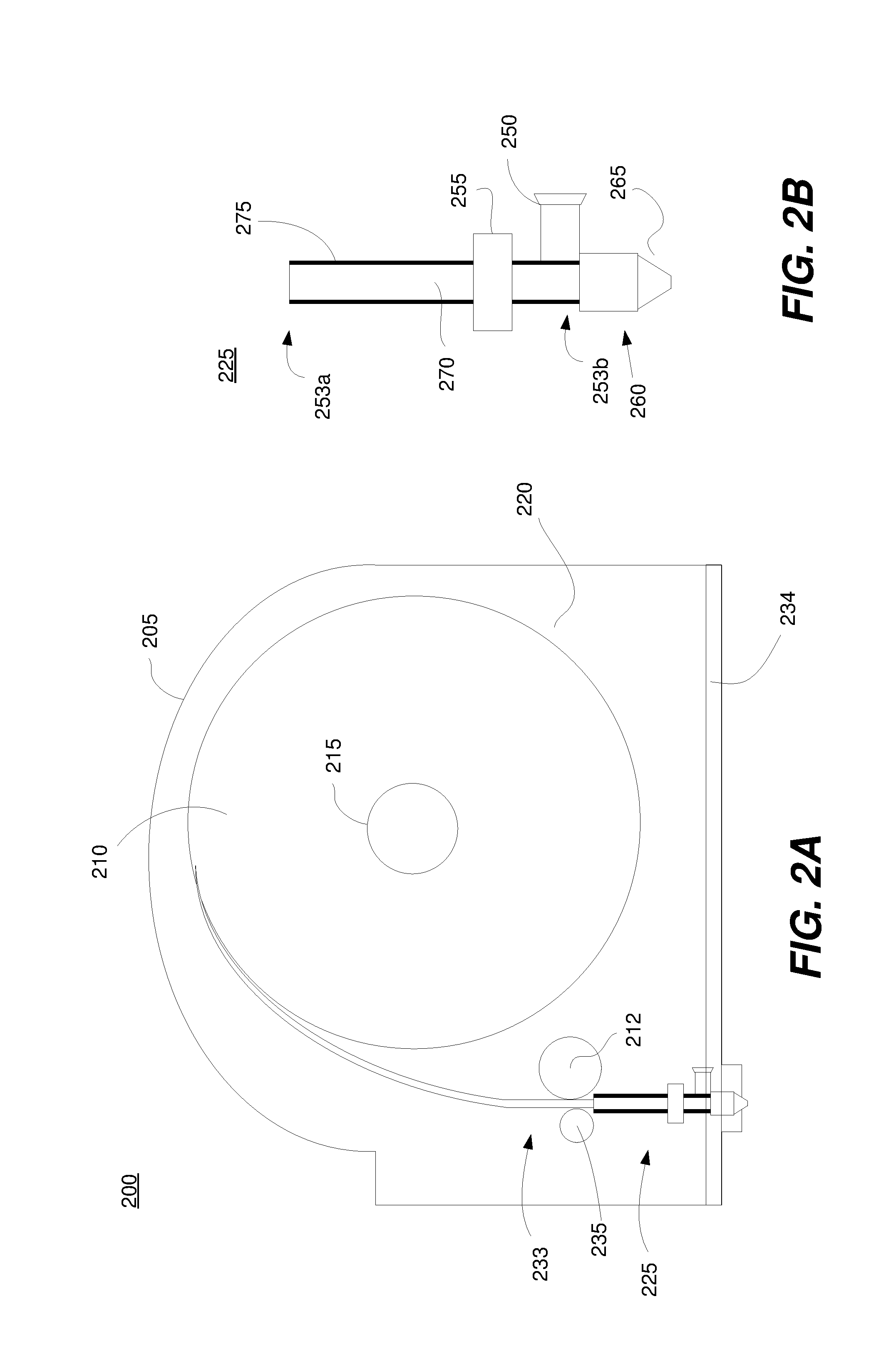

ActiveUS20140339741A1Reduce power outputIncrease exposure timeManufacturing driving meansManufacturing enclosuresPhotosensitive polymerEngineering

An apparatus for bottom-up fabrication of three dimensional objects, the apparatus comprising: a vat for a photosensitive polymer, the floor of the vat including a working surface arranged such that, in use, light incident on the working surface interacts with the photosensitive polymer at the working surface to fabricate a portion of the three dimensional object; a build platform capable of being inserted into the vat, the build platform having a planar surface; an elevator mechanism capable of adjusting the separation between the working surface of the vat and the planar surface of the build platform; and a rotation mechanism capable of varying the relative rotational position of the vat relative to the build platform, the relative rotation being about an axis which is normal to the working surface of the vat.

Owner:HOLO INC

Polyurethane resins having multiple mechanisms of hardening for use in producing three-dimensional objects

ActiveUS20160137839A1Increased formationEnhance or speed the refilling of the build regionImpression capsManufacturing enclosuresEndcappingPolymer science

A polymerizable liquid, or resin, useful for the production by additive manufacturing of a three-dimensional object of polyurethane, polyurea, or a copolymer thereof, is described. The resin includes at least one of (i) a blocked or reactive blocked prepolymer, (ii) a blocked or reactive blocked diisocyanate, or (iii) a blocked or reactive blocked diisocyanate chain extender.

Owner:CARBON INC

Methods of producing polyurethane three-dimensional objects from materials having multiple mechanisms of hardening

ActiveUS20160137838A1Increased formationEnhance or speed the refilling of the build regionManufacturing enclosuresOptical articlesEndcappingPolymer science

A method of forming a three-dimensional object of polyurethane, polyurea, or copolymer thereof is carried out by: (a) providing a carrier and an optically transparent member having a build surface, the carrier and the build surface defining a build region therebetween; (b) filling the build region with a polymerizable liquid, the polymerizable liquid including at least one of: (i) a blocked or reactive blocked prepolymer, (ii) a blocked or reactive blocked diisocyanate, or (iii) a blocked or reactive blocked diisocyanate chain extender; (c) irradiating the build region with light through the optically transparent member to form a solid blocked polymer scaffold and advancing the carrier away from the build surface to form a three-dimensional intermediate having the same shape as, or a shape to be imparted to, the three-dimensional object, with the intermediate containing the chain extender; and then (d) heating or microwave irradiating the three-dimensional intermediate sufficiently to form from the three-dimensional intermediate the three-dimensional object of polyurethane, polyurea, or copolymer thereof.

Owner:CARBON INC

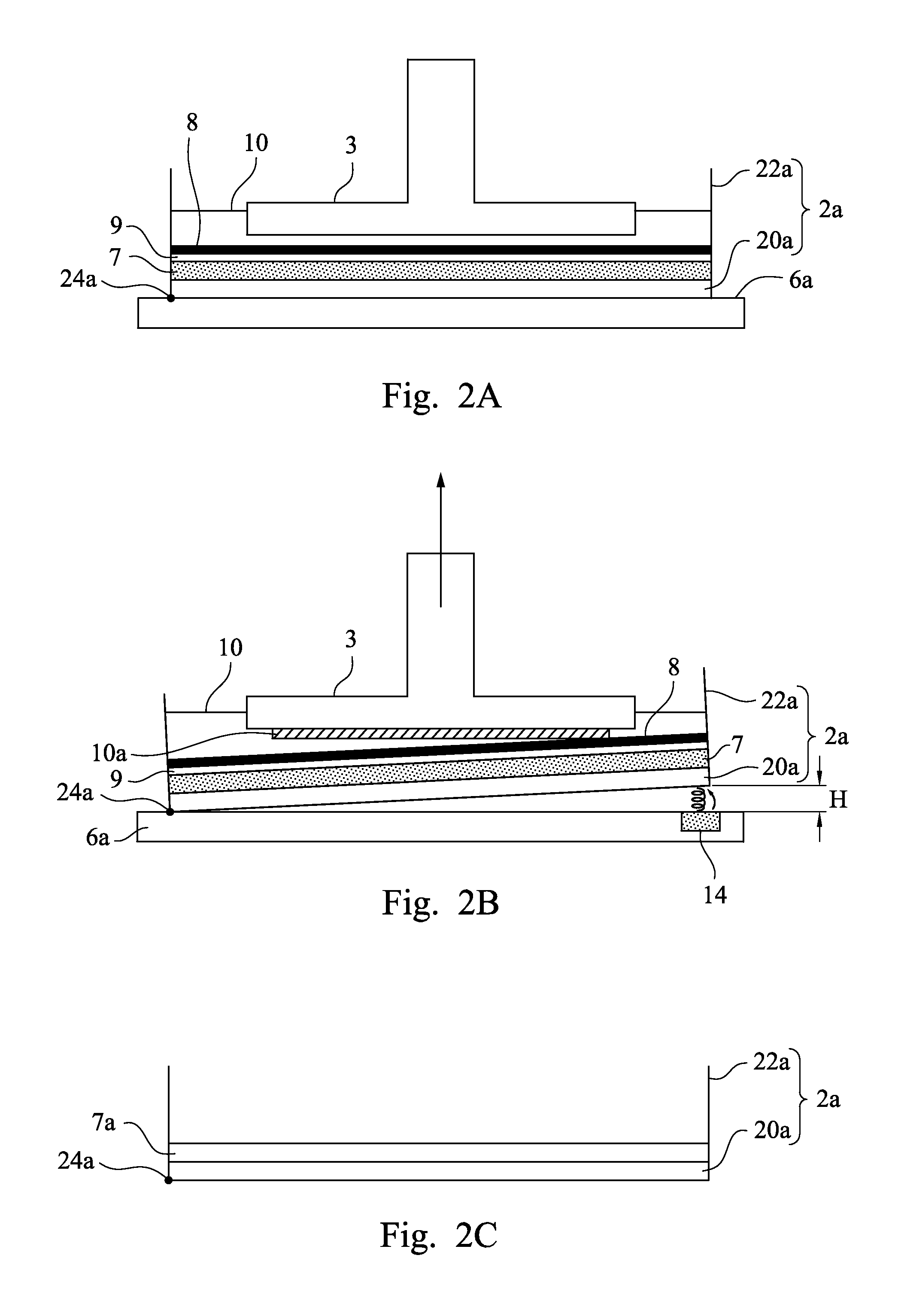

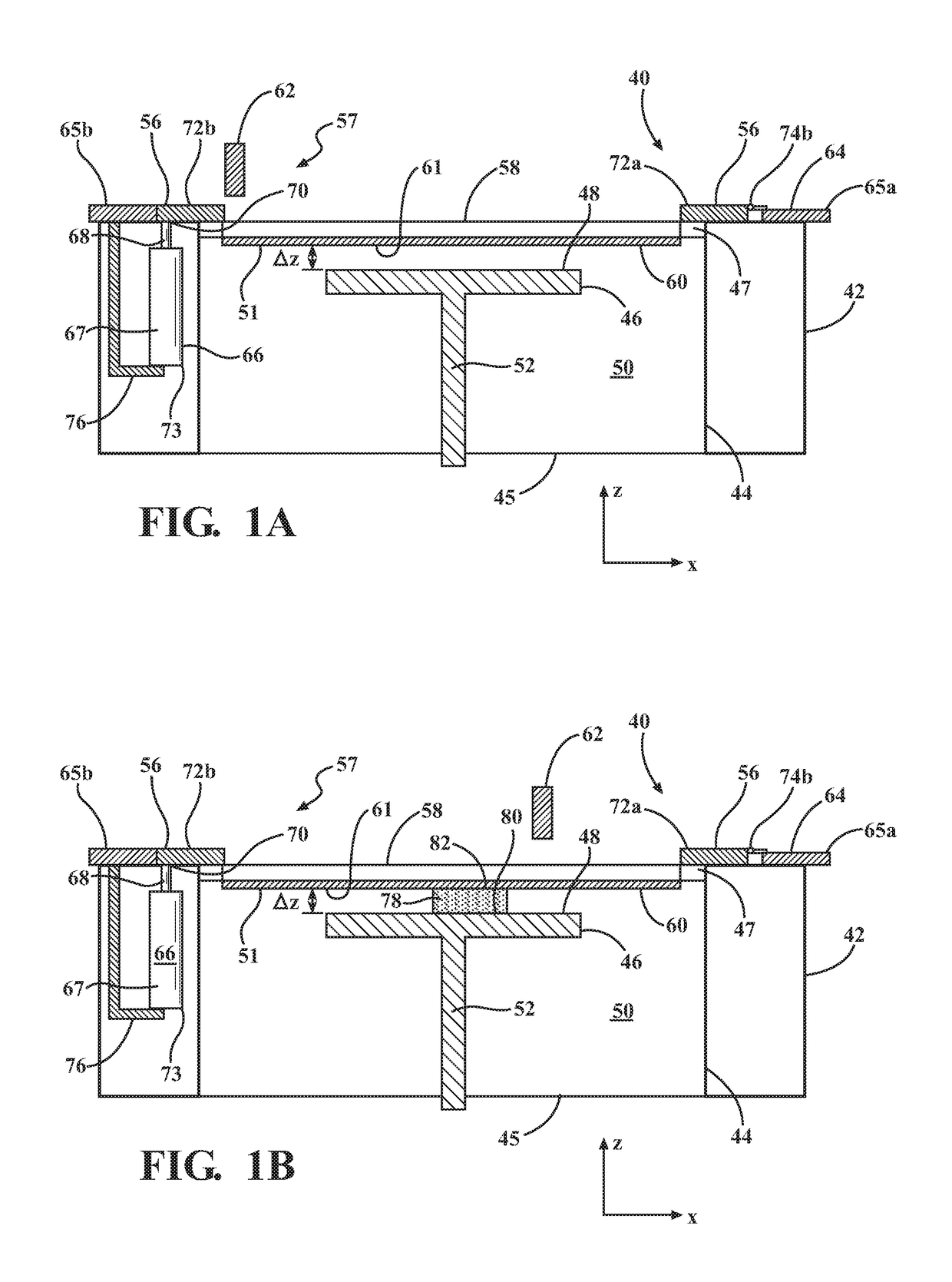

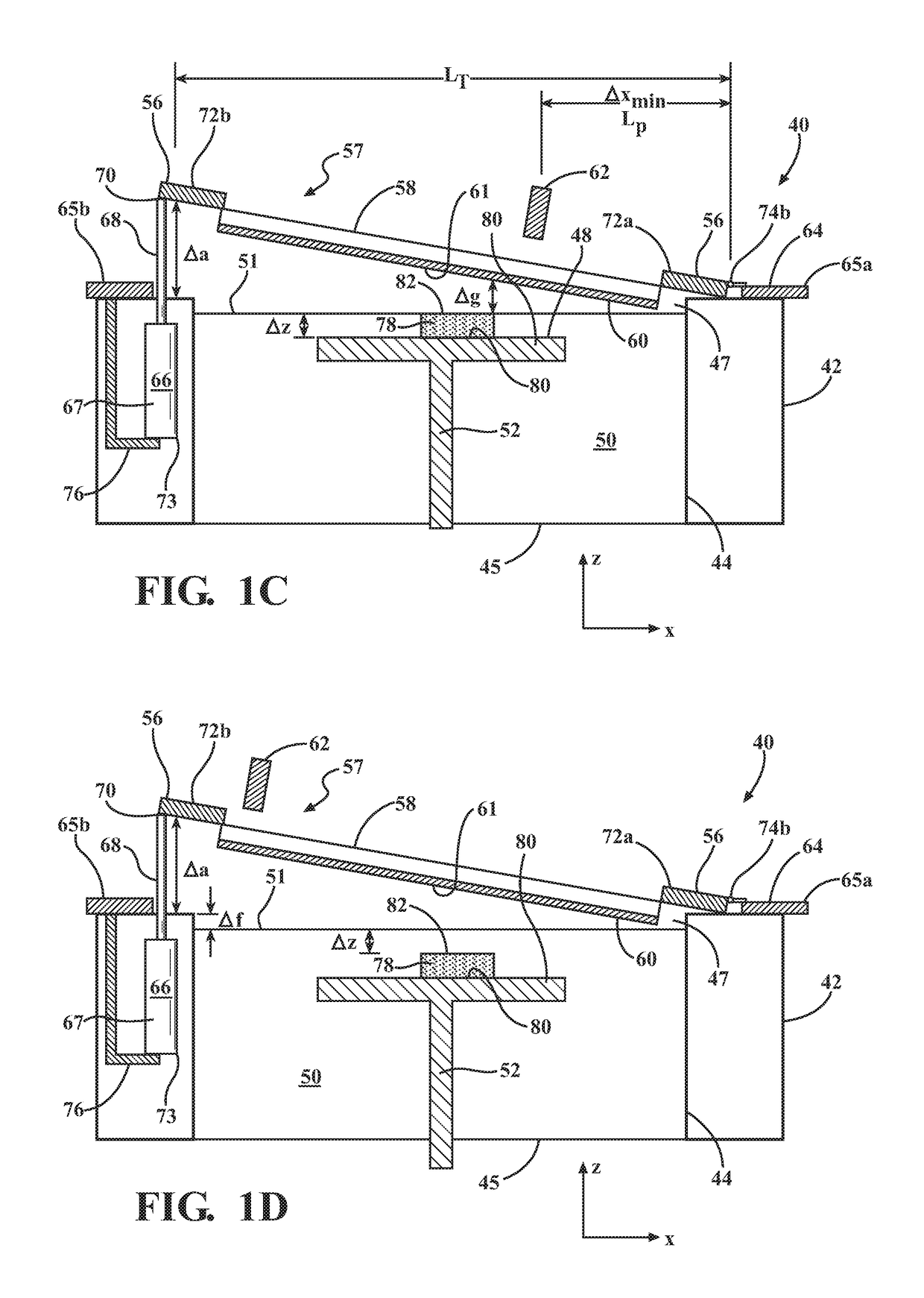

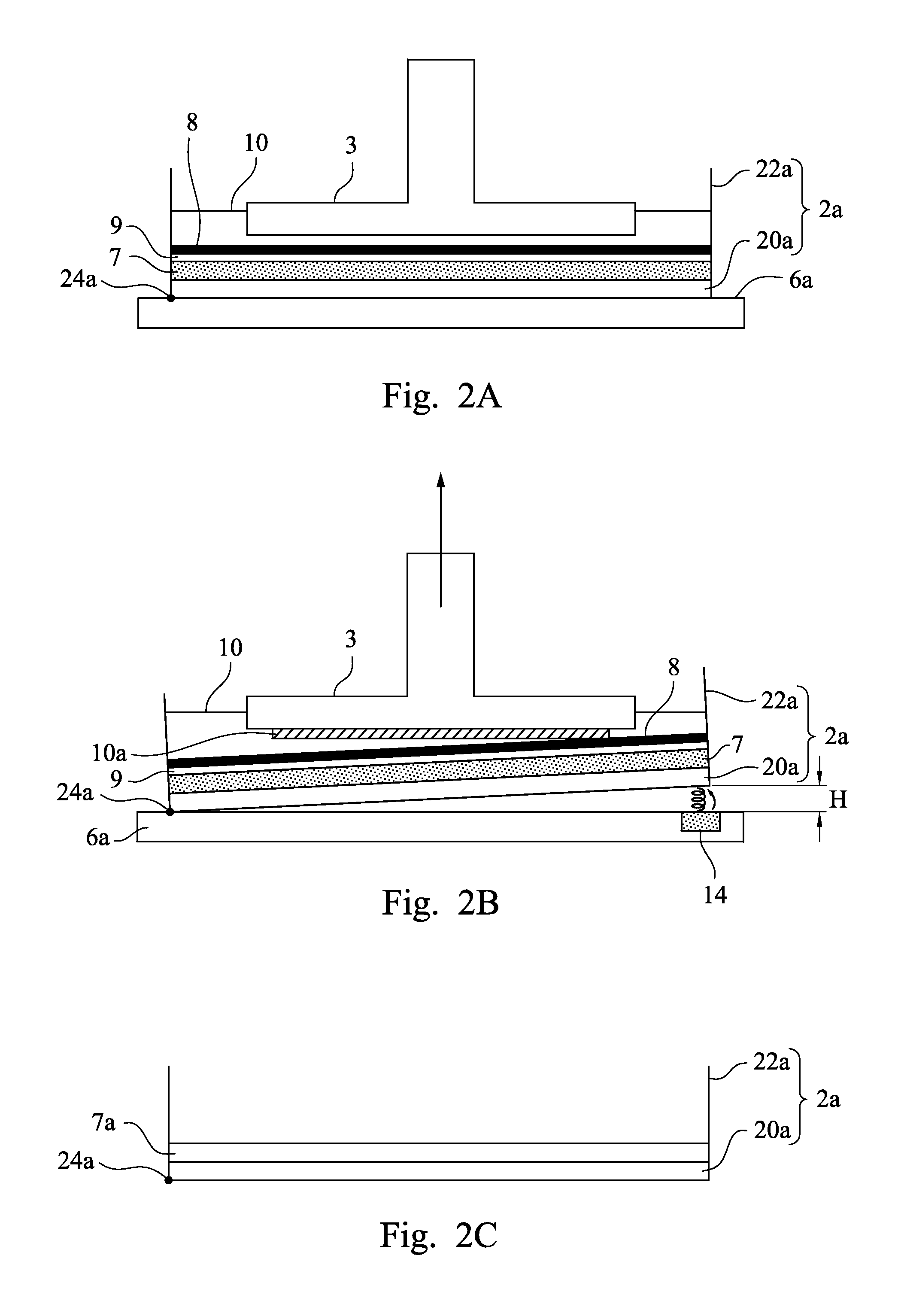

Resin solidification substrate and assembly

ActiveUS8372330B2Manufacturing platforms/substratesManufacturing enclosuresEngineeringMechanical engineering

A solidification substrate assembly for making a three-dimensional object from a solidifiable material includes a solidification substrate assembly. In certain examples, the solidifiable material solidifies in contact with the solidification substrate, and the tilting of the substrate and / or or the use of a peeling member facilitates separation of the substrate from the solidified material. In other examples, the solidification substrate assembly includes a film that is adjacent to a rigid or semi-rigid layer. The solidifiable material solidifies in contact with the film, and a peeling member peels the film away from the solidified material. Intelligent solidification substrate assemblies are also described in which a force sensor determines when to expose the solidifiable material to solidification energy and / or whether to use a peeling member to separate the solidification substrate from a solidified objection section.

Owner:GLOBAL FILTRATION SYST

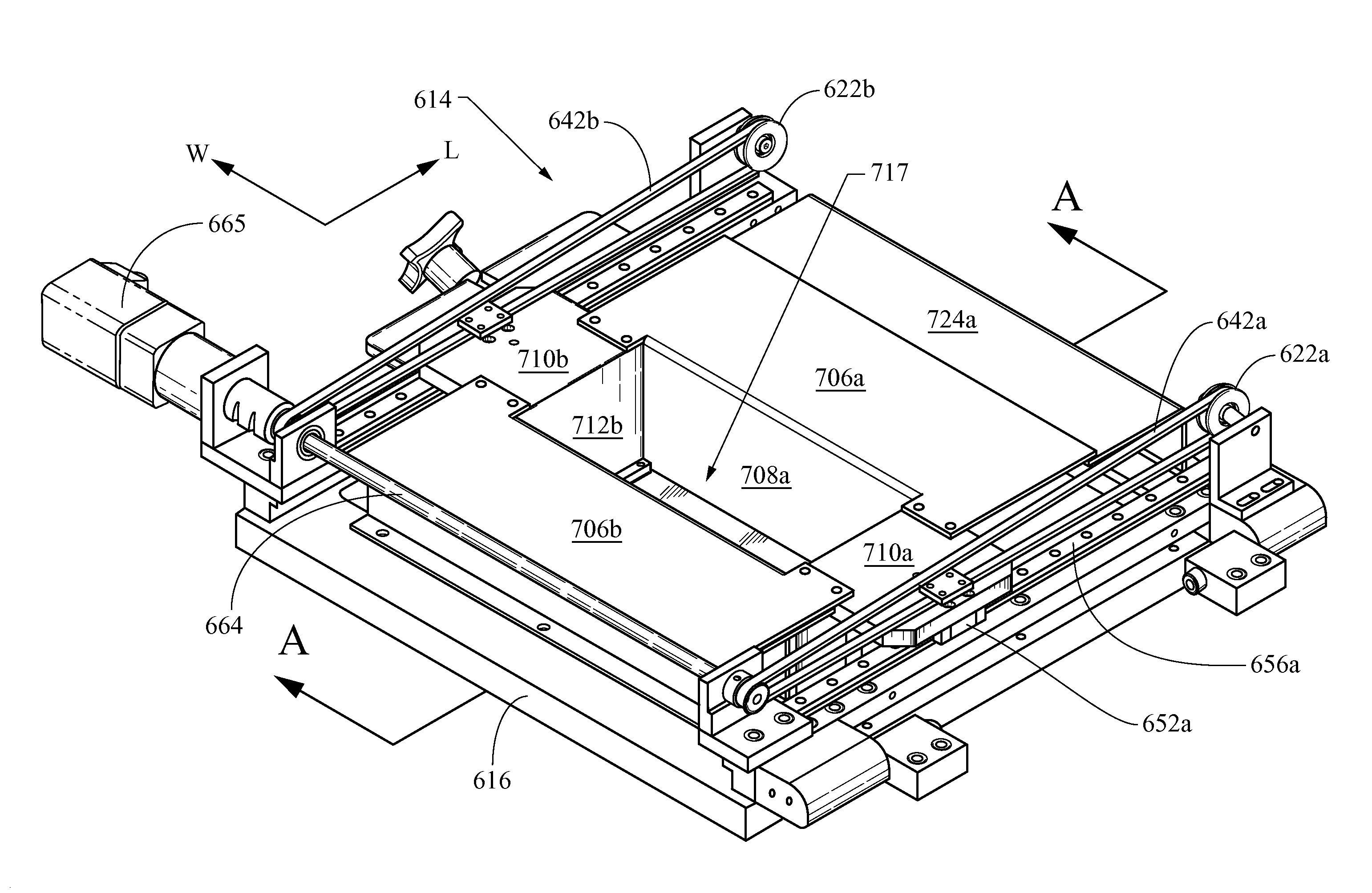

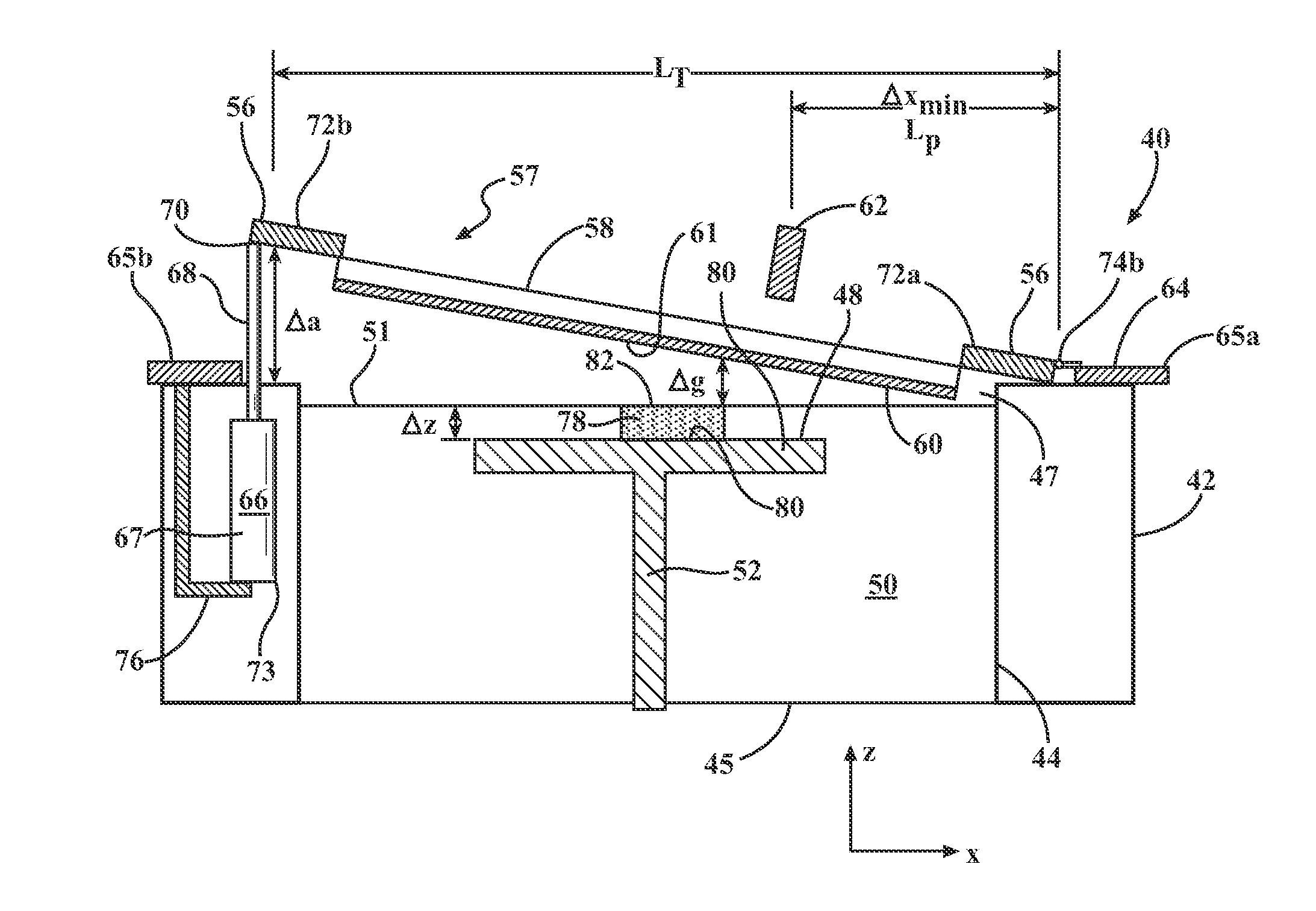

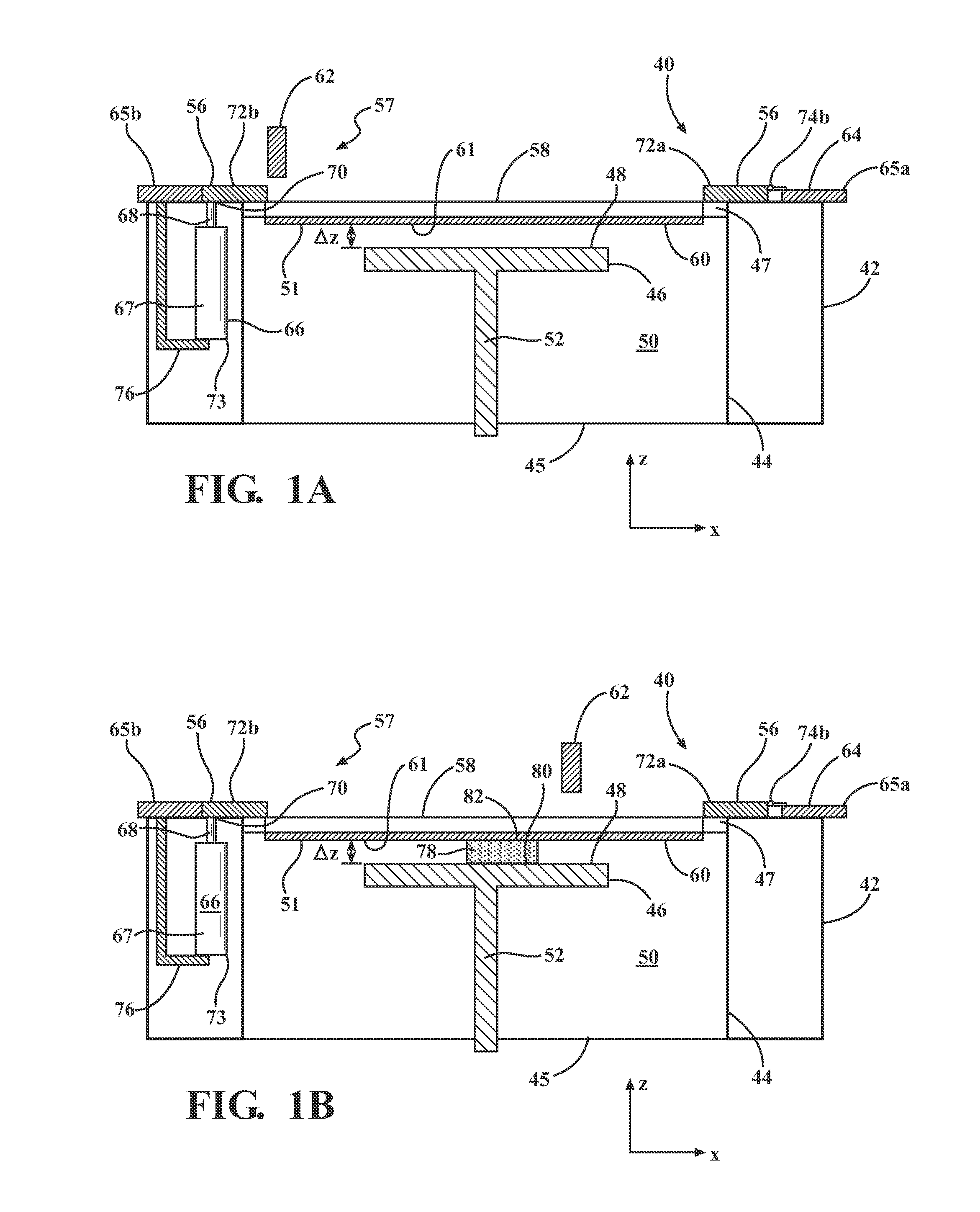

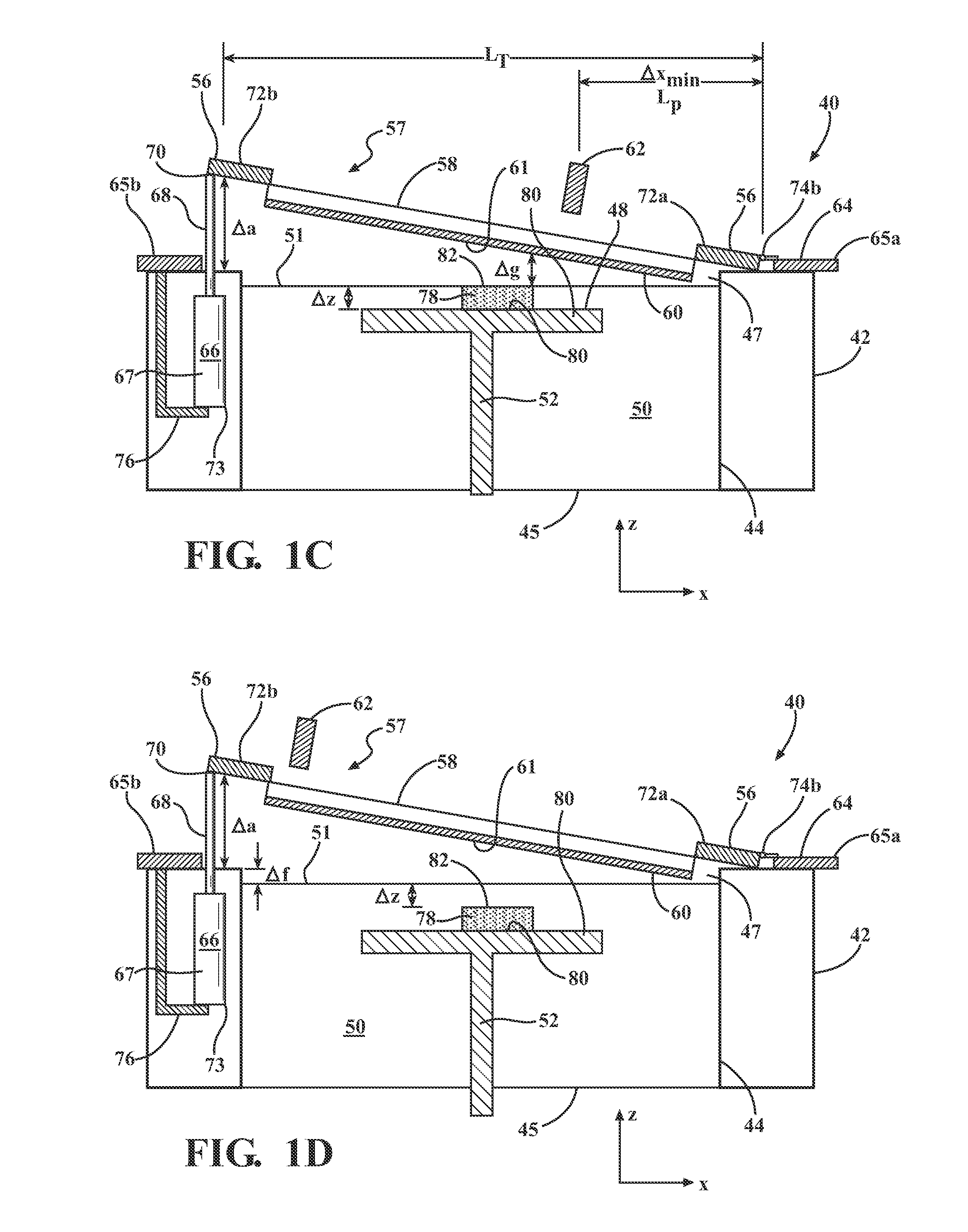

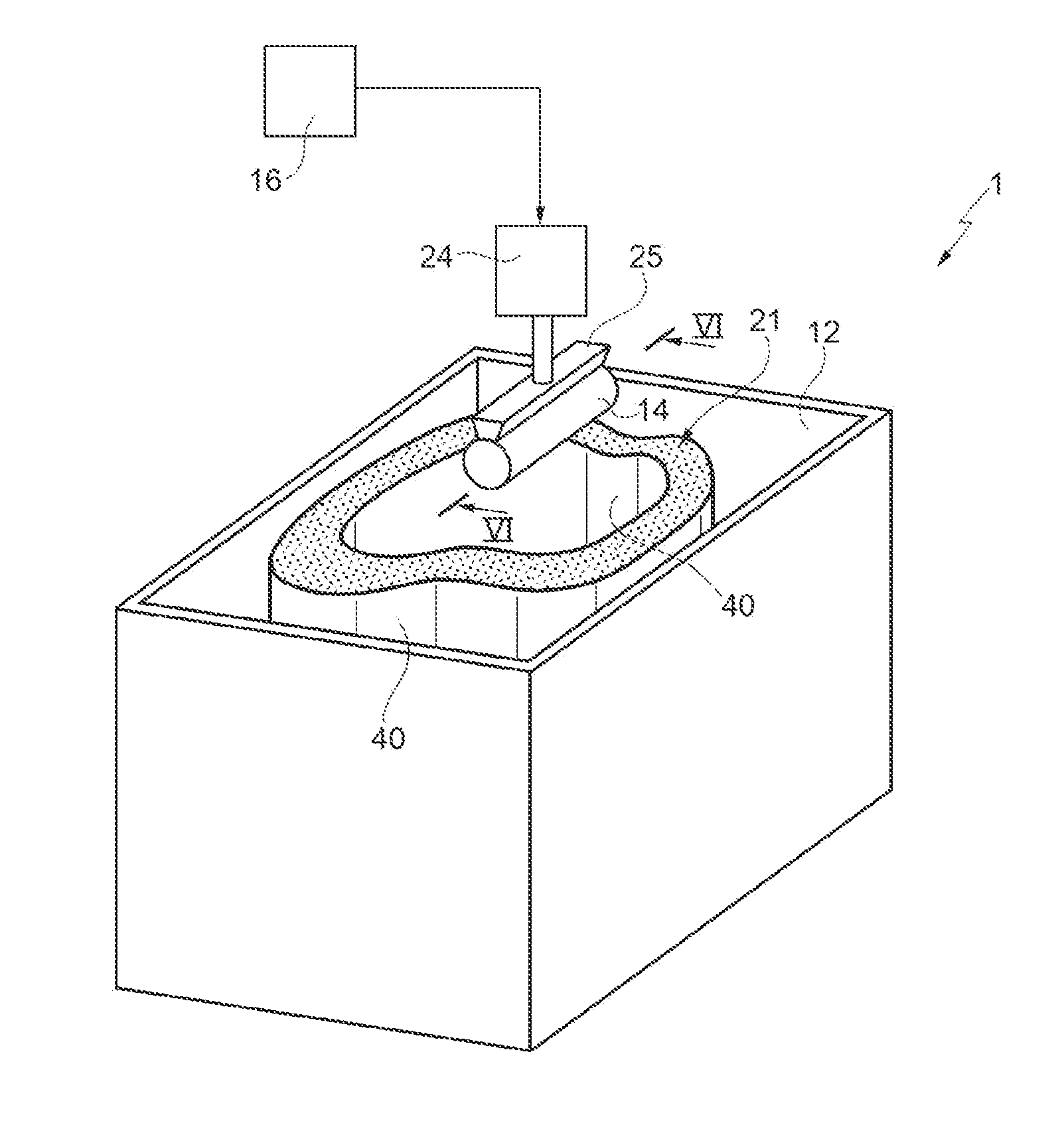

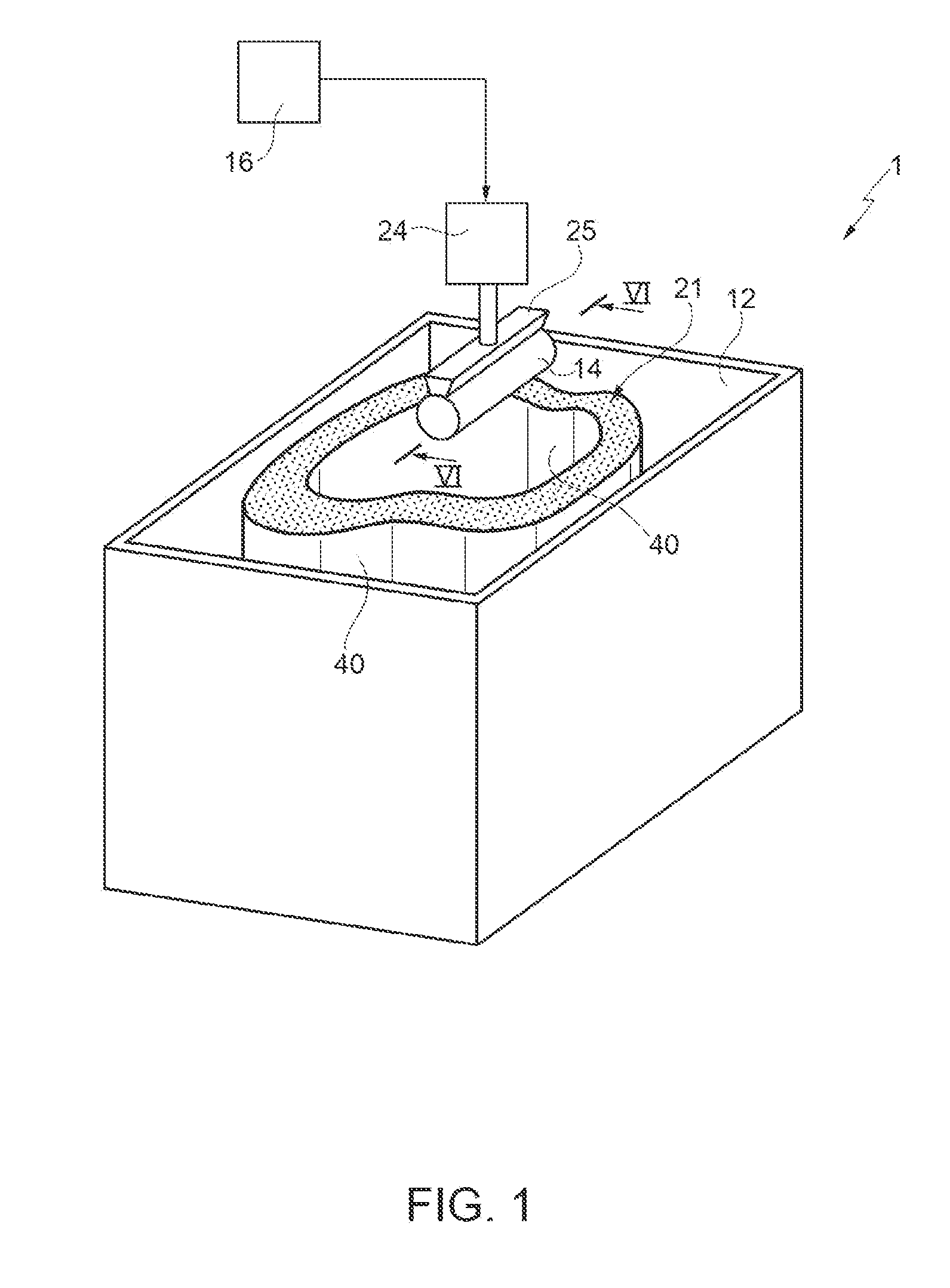

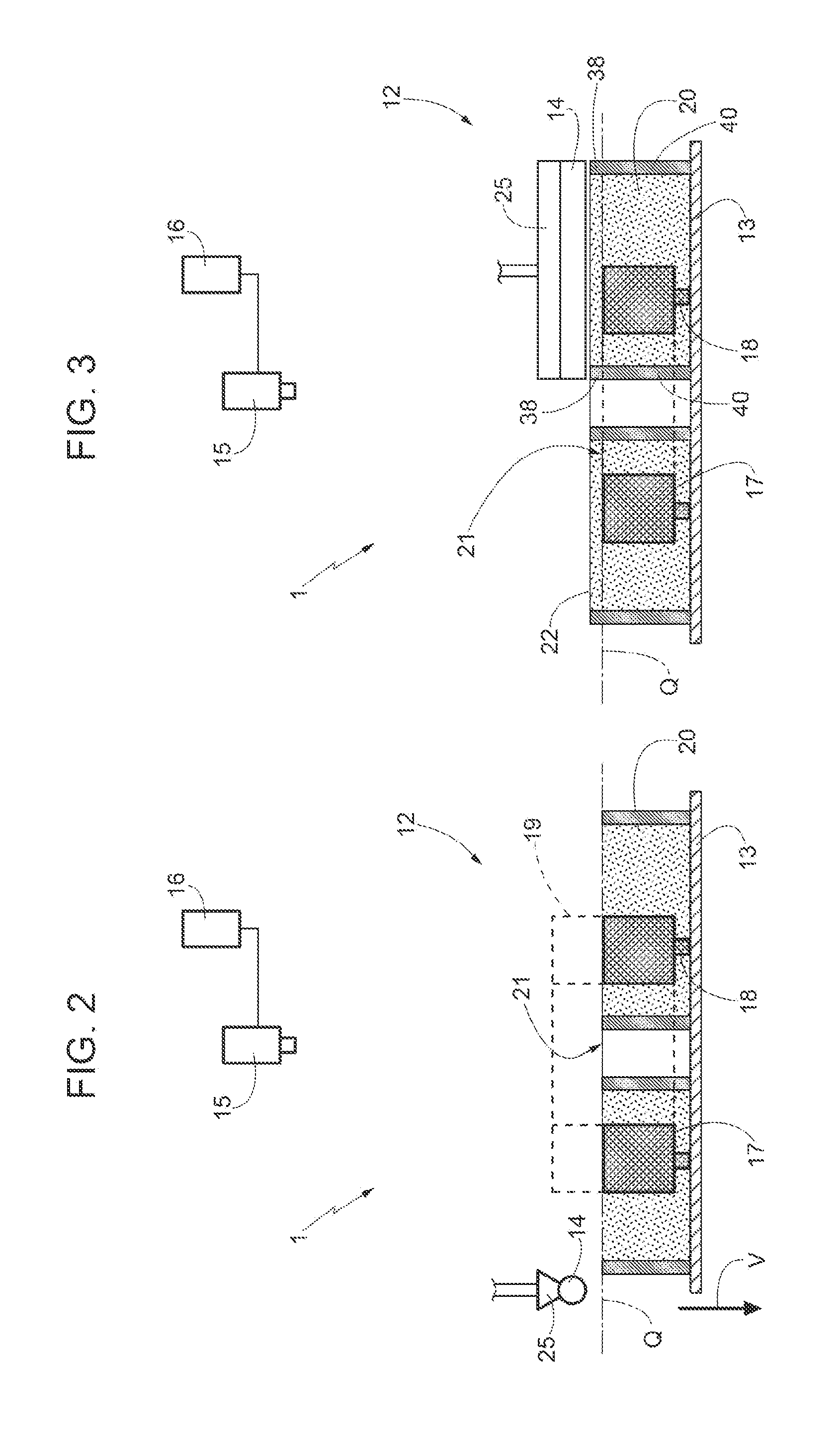

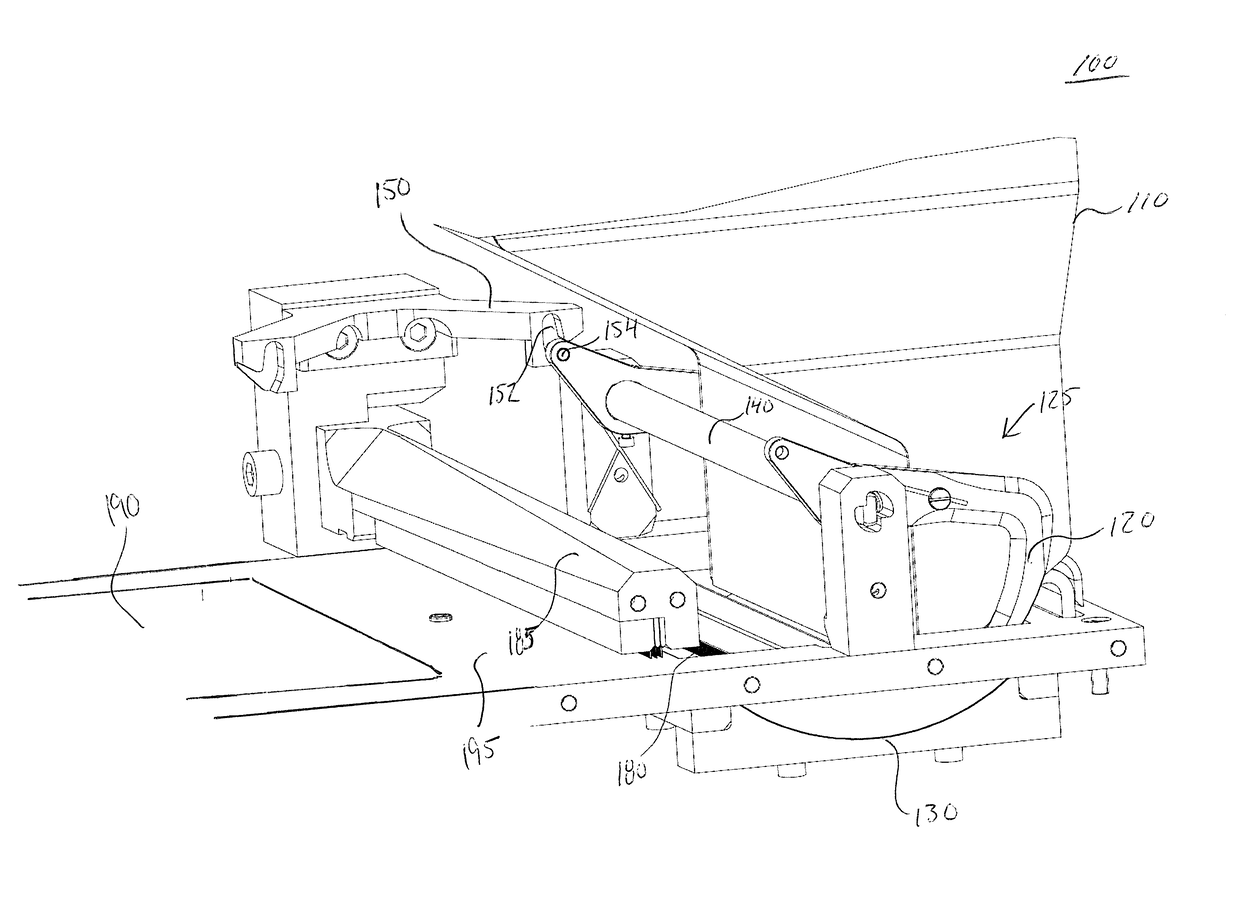

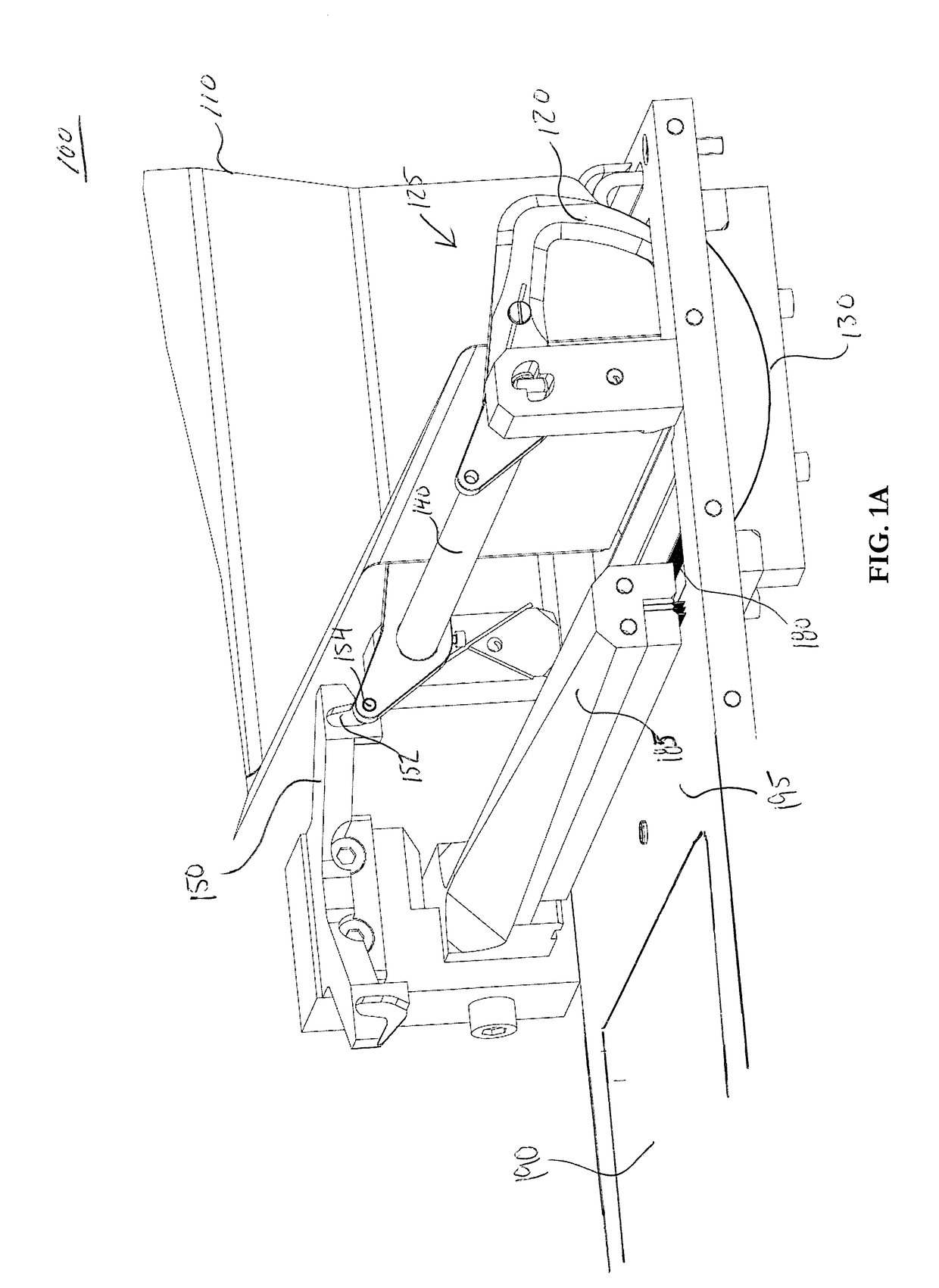

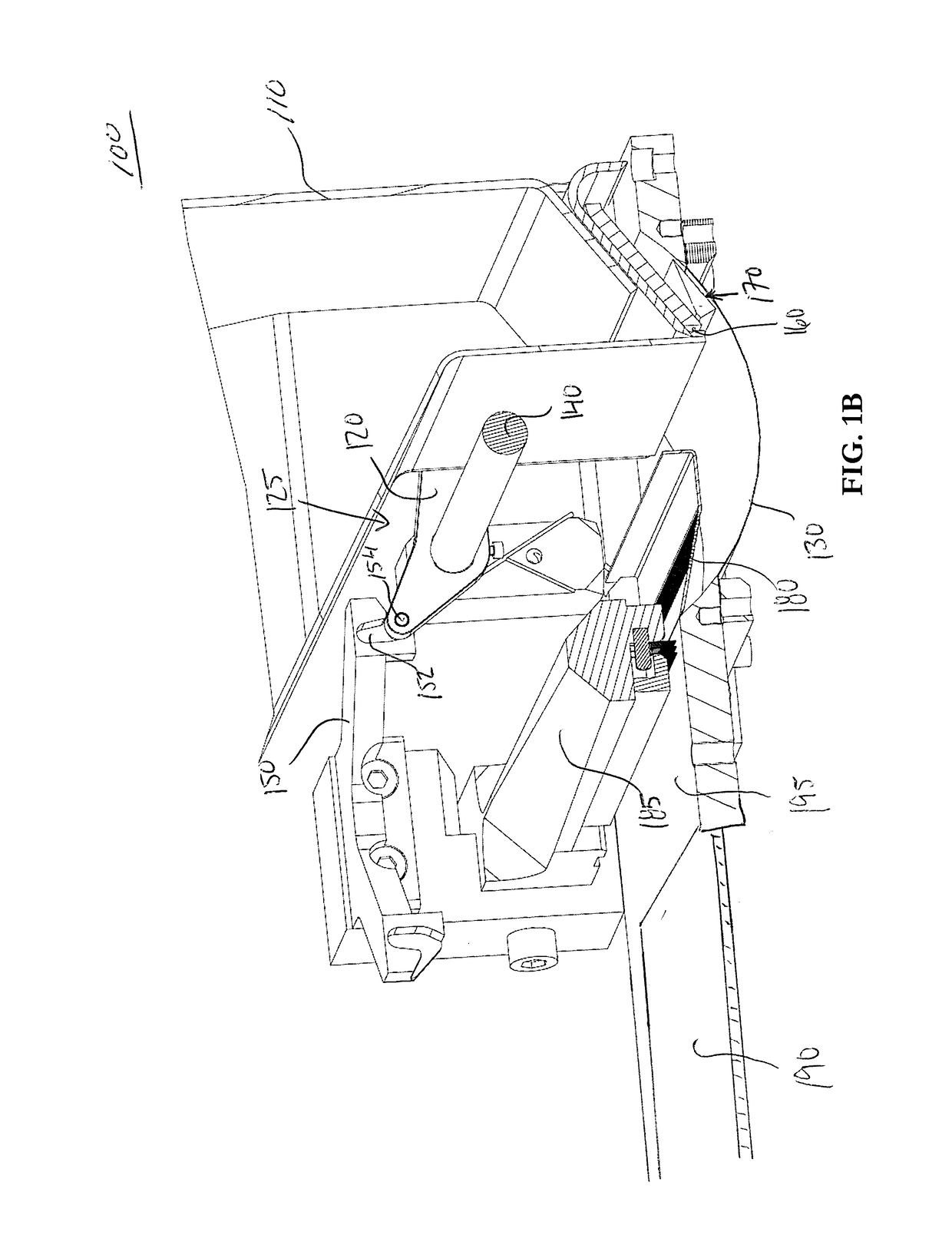

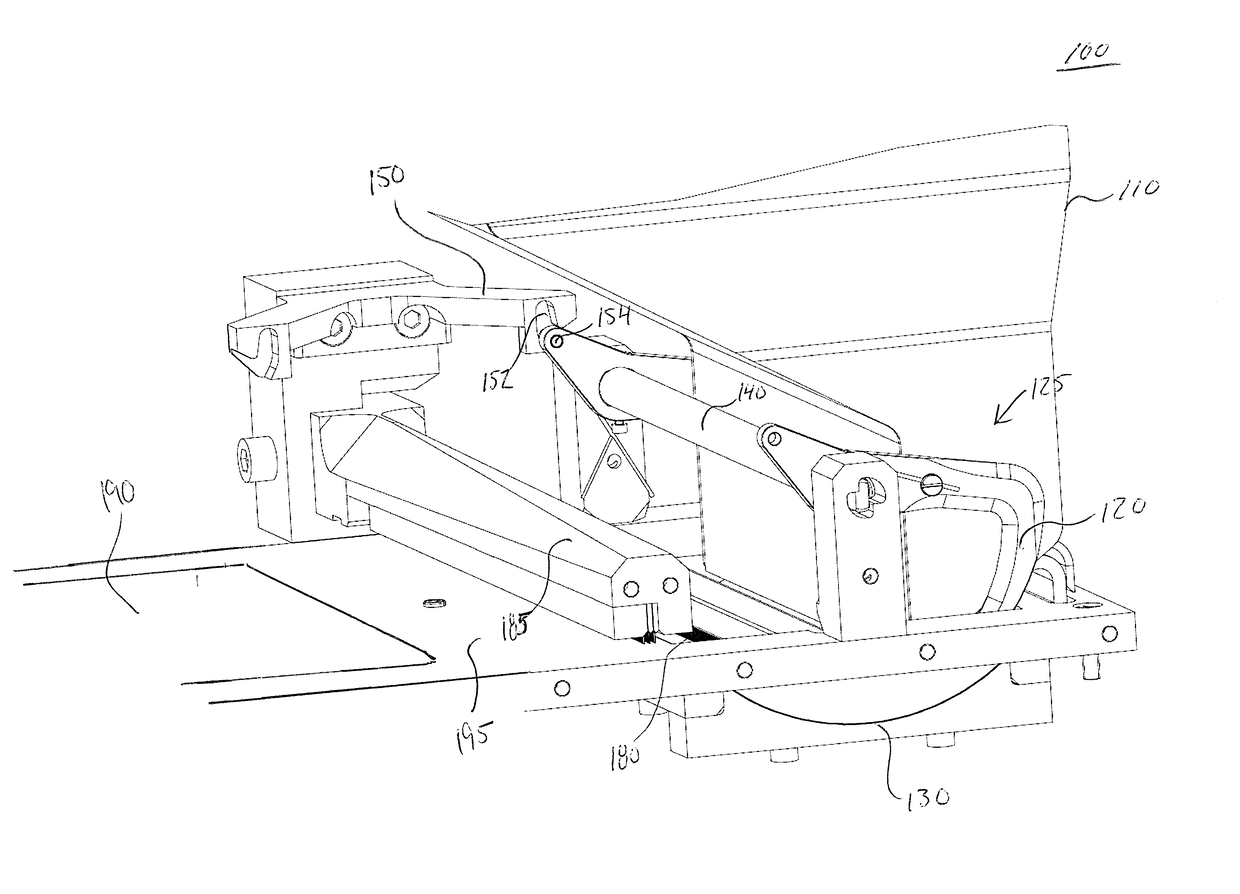

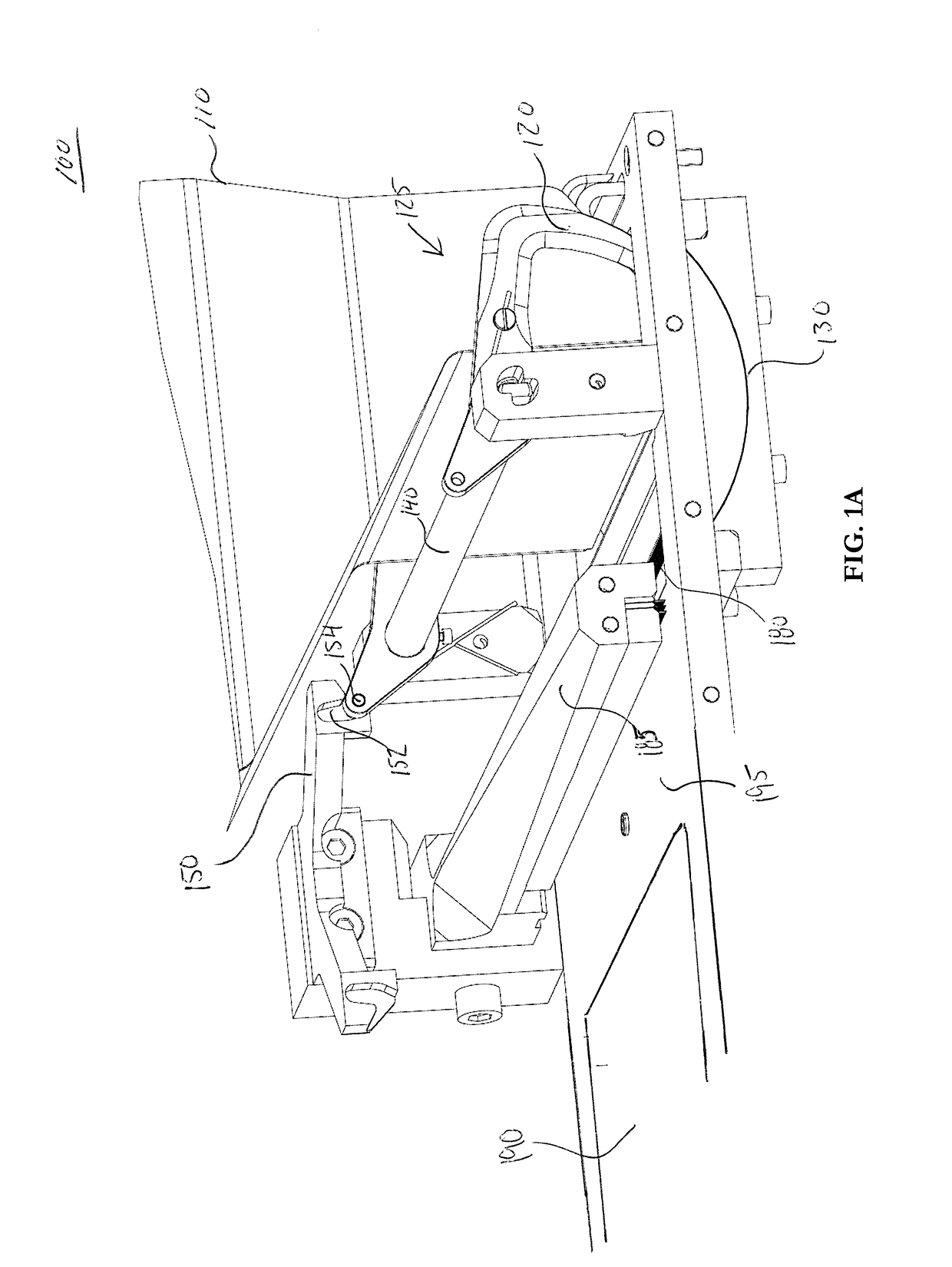

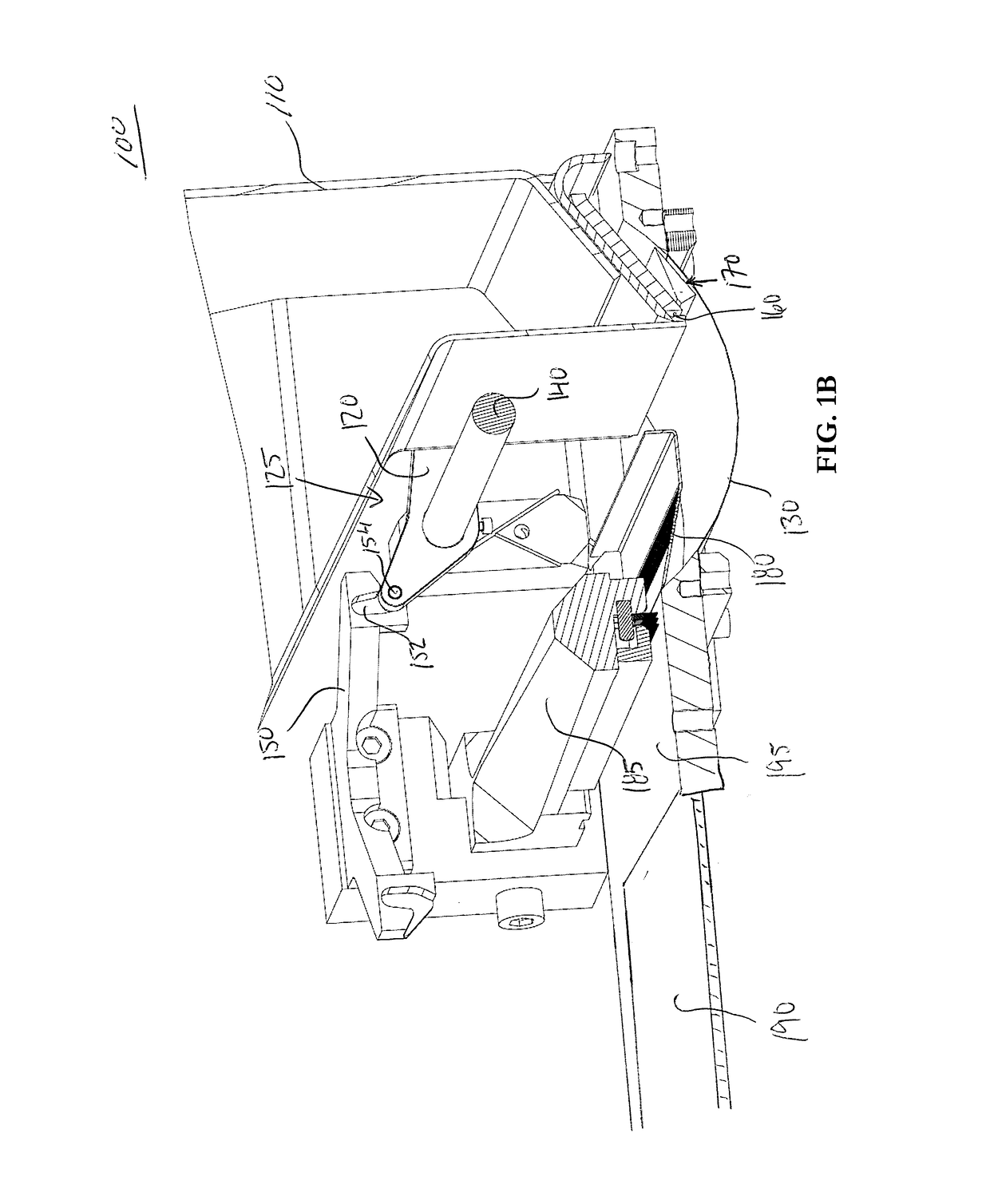

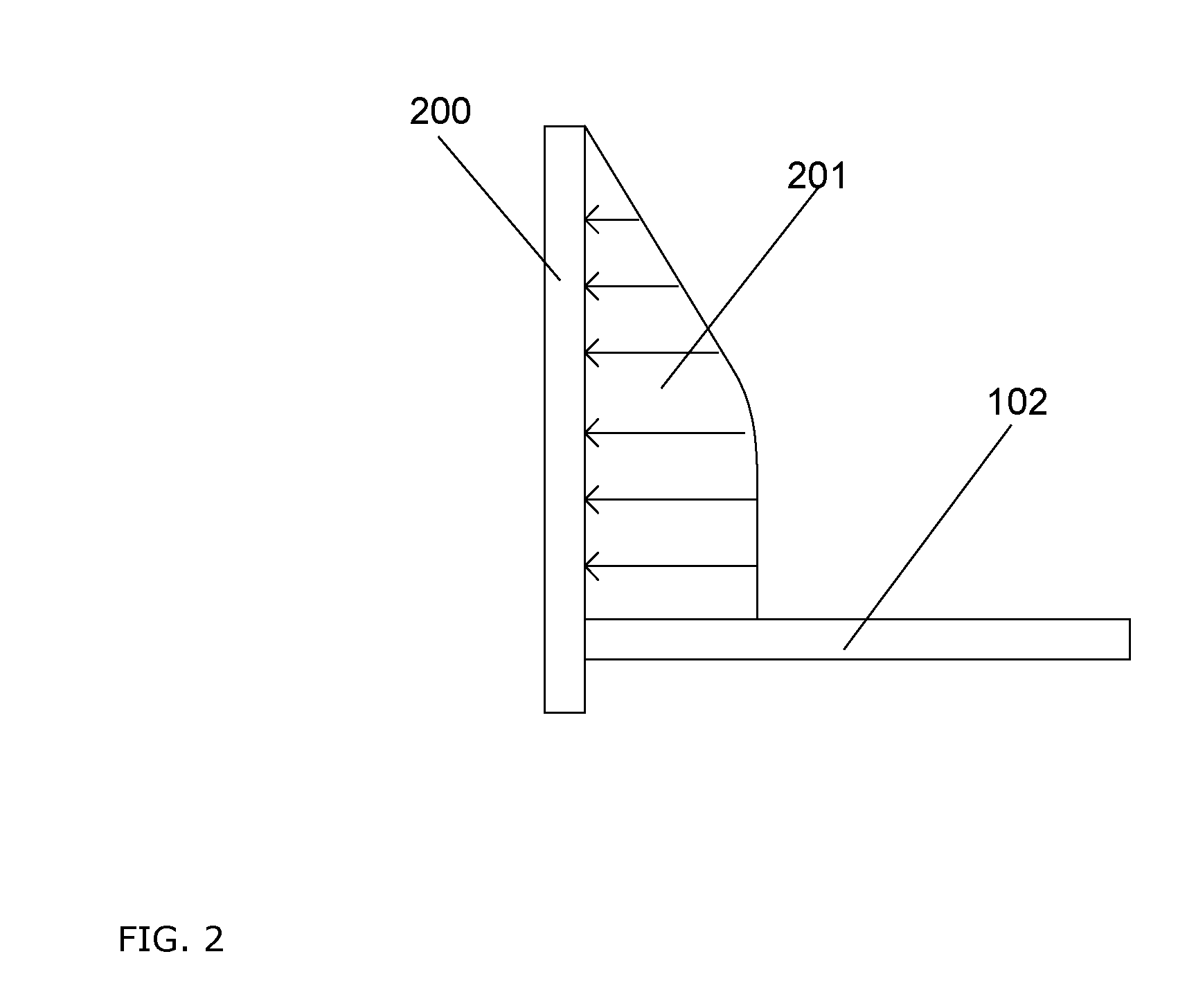

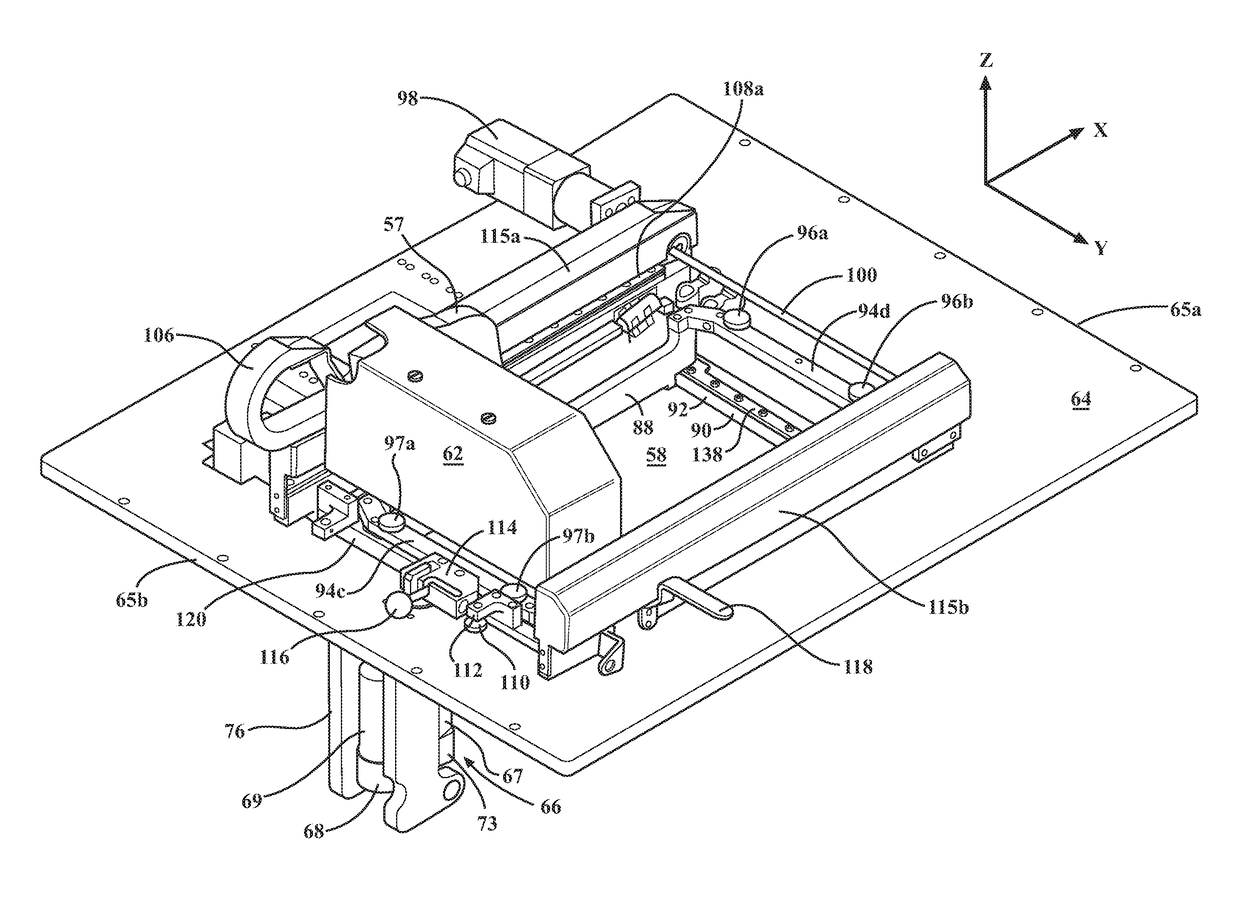

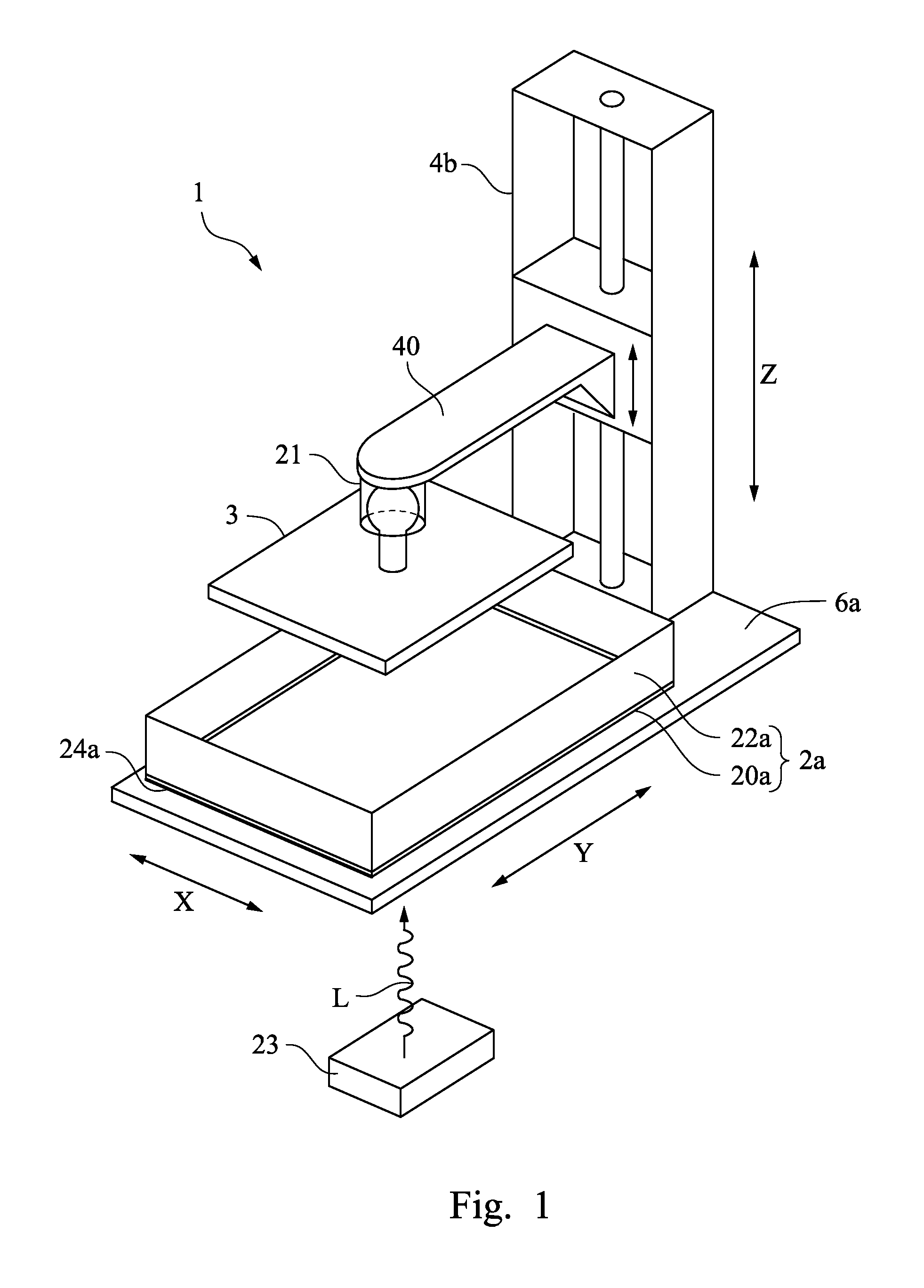

Apparatus and method for forming three-dimensional objects using a tilting solidification substrate

An apparatus and method for making a three-dimensional object from a solidifiable material using a linear solidification device is shown and described. The apparatus includes a solidification substrate that is tiltable relative to a film about a tilting axis. Layers of the solidifiable material solidify in contact with a film located between the most recently solidified object layer and a solidification substrate that comprises the solidification substrate assembly. The tilting of the solidification substrate relative to the film allows the substrate to be used to squeeze excess solidifiable material from between the film and the most recently solidified object surface while minimizing or eliminating the formation of bubbles in the solidifiable material which can prolong object build times. In addition, tilting the solidification substrate before separating an adhered object surface from the film breaks any vacuum formed between the substrate and the film which reduces the forces involved in separating the object form the film.

Owner:GLOBAL FILTRATION SYST

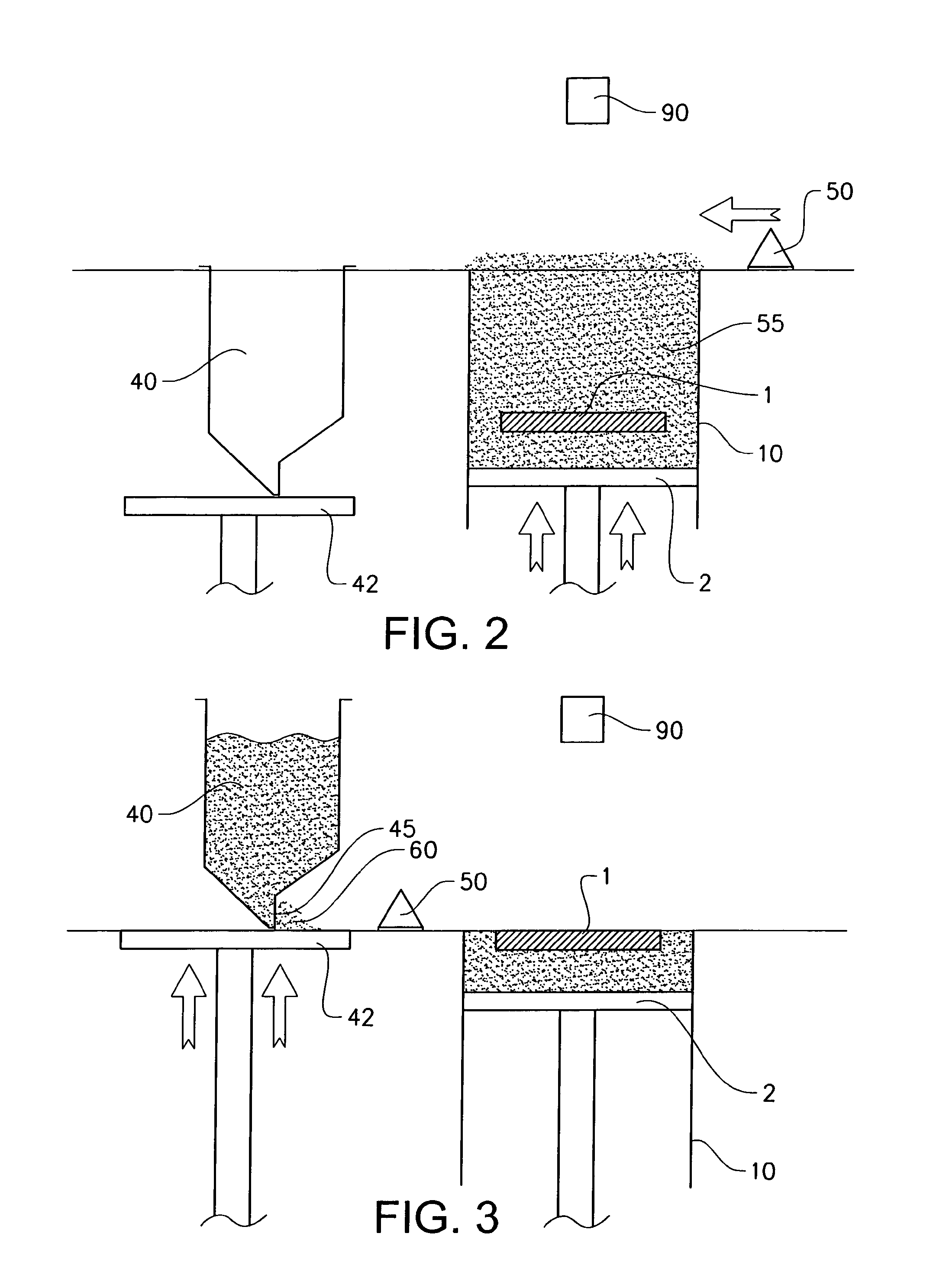

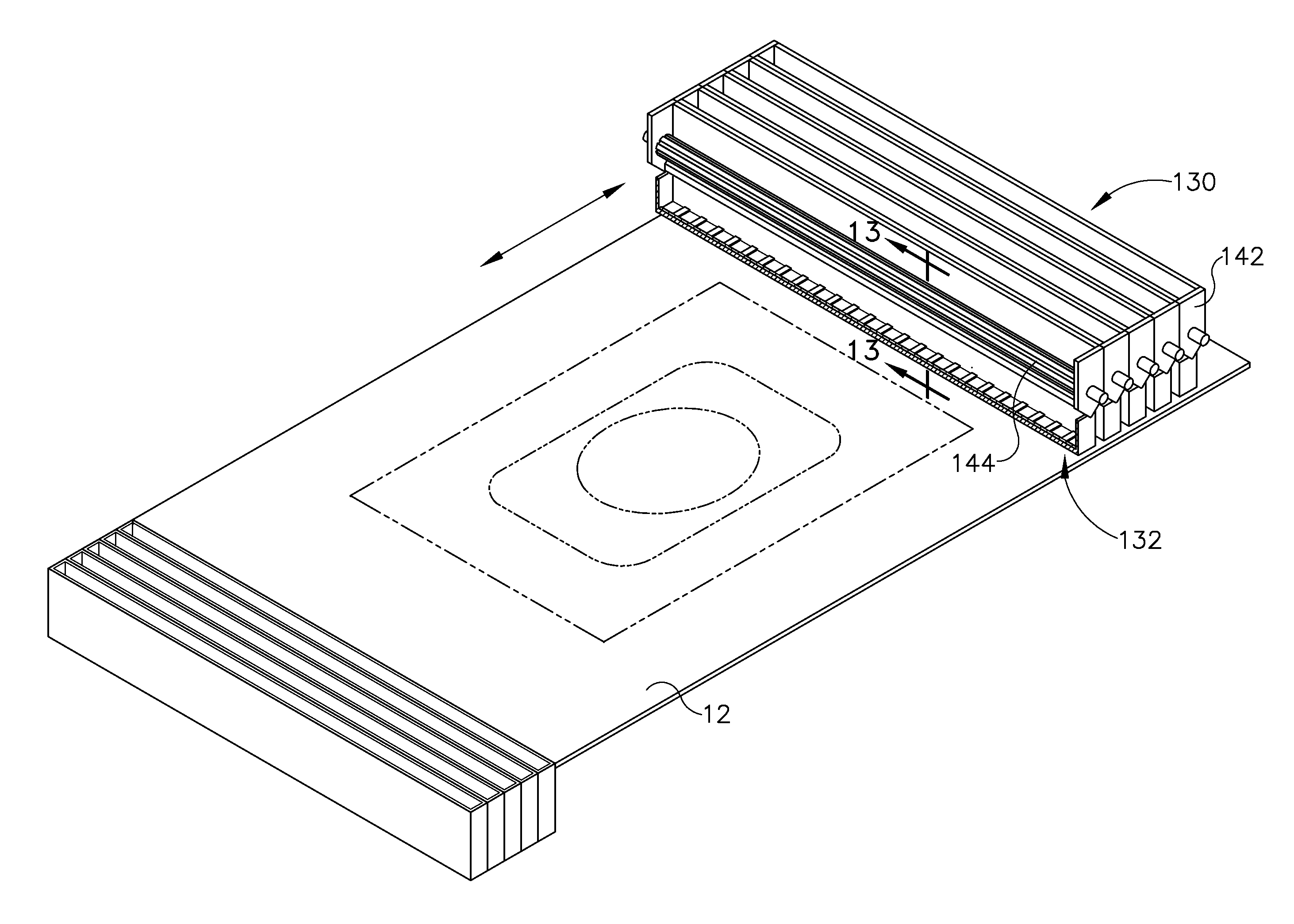

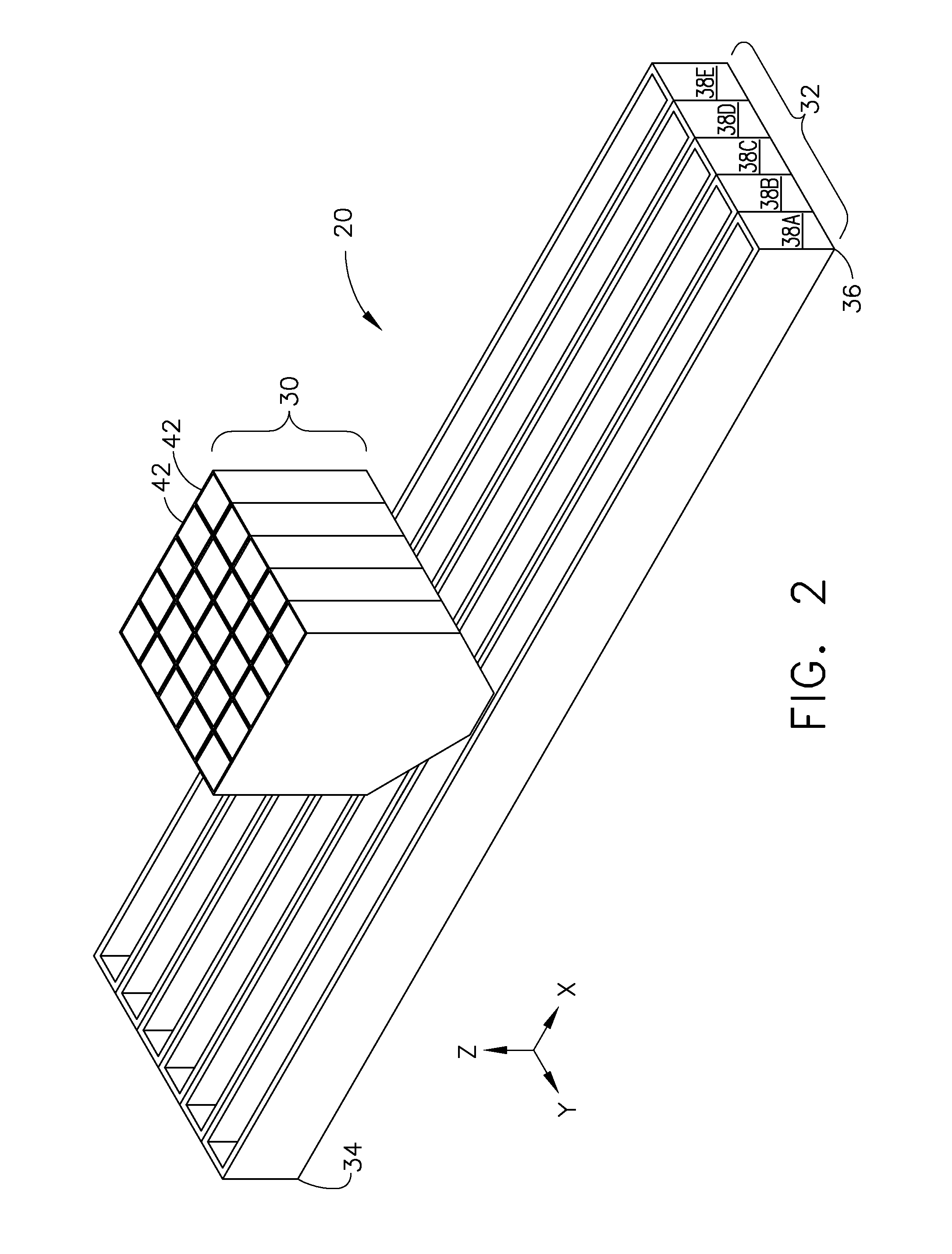

Powder dispenser for making a component by additive manufacturing

ActiveUS20160129502A1Simple and cost-effectiveManufacturing enclosuresIncreasing energy efficiencyHorizontal axisVertical channel

A powder dispenser (14) has a vertical channel (55), which, at the top, is adapted to communicate with a tank for receiving the powder and inferiorly ends at an opening (26), which is elongated along a horizontal direction and comprises an outlet portion (51) for letting the powder fall; the dispenser further has a shutter device (50) for varying the length of the outlet portion (51) with respect to the total length of the opening (26) along its horizontal axis (36).

Owner:SBC KNOWLEDGE VENTURES LP +1

Three-dimensional printer

ActiveUS20170348771A1Form evenlyLong automationManufacturing enclosuresManufacturing material handlingMaterial supplyRetaining wall

A three-dimensional printer (1) includes a material supply device (3) that supplies material powder to a table which is movable vertically, a powder retaining wall (26) that surrounds the table and retains the material powder, a material-recovery bucket (30) that accommodates excess material powder and impurities discharged from the powder retaining wall, an impurity removing device (43) that removes the impurities from the material powder, and a material drying device (47) that dries the material powder. The material powder from which the impurities have been removed and which has been dried is returned and recycled to the material supply device.

Owner:SODICK CO LTD

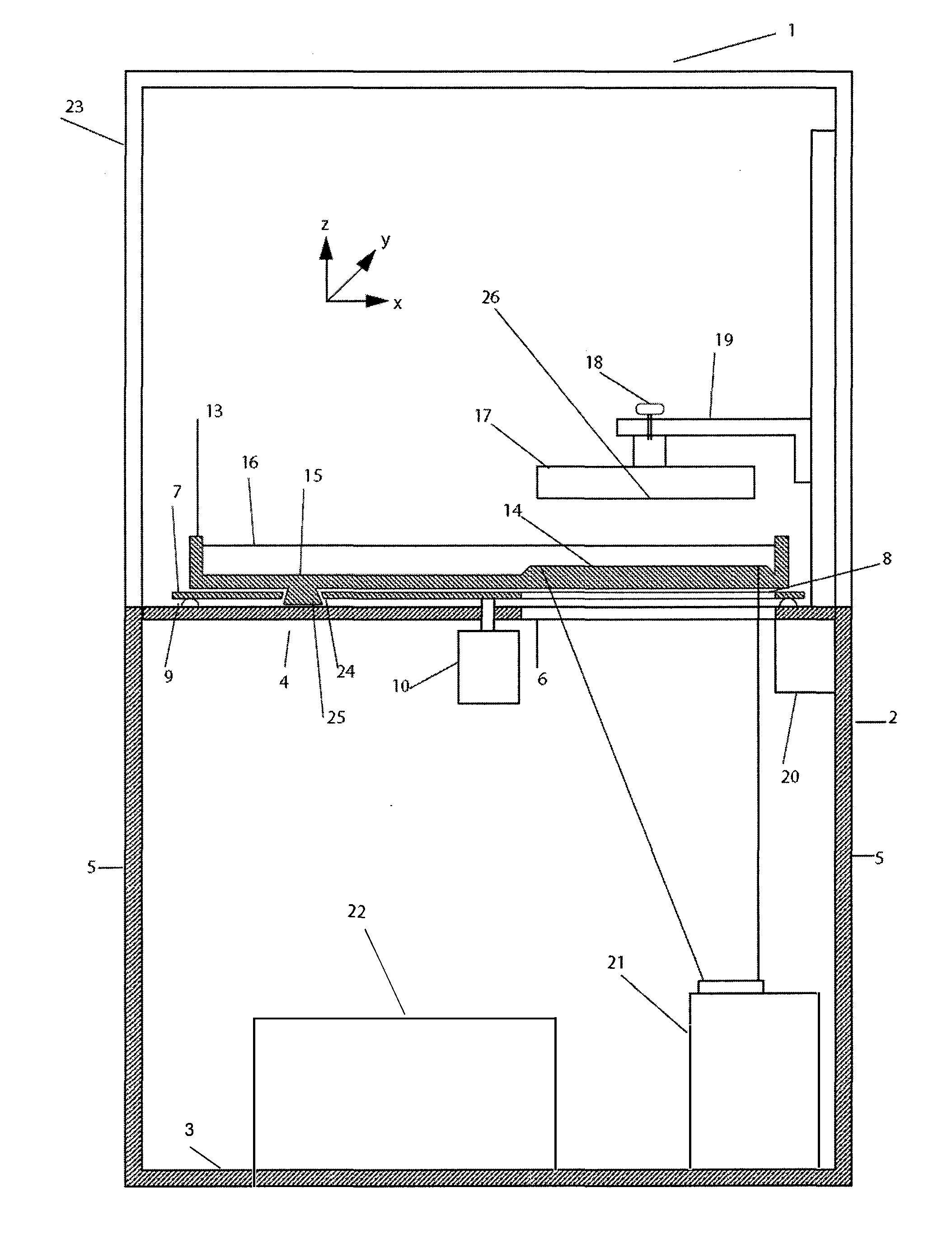

Method and apparatus for producing a three-dimensional article

ActiveUS20170106443A1Easy to solveImprove accuracyManufacturing enclosuresIncreasing energy efficiencyMaterials scienceComputer program

Apparatus for producing a three-dimensional object layer by layer using a powdery material which can be solidified by irradiating it with an energy beam, said apparatus comprising: a working area onto which layers of powdery material are to be placed; a powder storage unit, where said base surface is supporting a supply of powder in said powder storage unit; a powder distribution member, a pivoted powder pushing device for bringing a portion of powder from said base surface to a position between said distribution member and said working area, said distribution member further being arranged to be moveable towards and across the working area so as to distribute the portion of powder onto the working area, wherein a first portion of said pivoted powder pushing device is movable under said distribution member. An associated method and computer program product are also provided.

Owner:ARCAM AB

Method and apparatus for producing a three-dimensional article

ActiveUS20170106570A1Easy to solveImprove accuracyManufacturing enclosuresIncreasing energy efficiencyEngineeringMechanical engineering

A pivoted powder pushing device is provided, comprising a first portion and a contact member, wherein: the contact member is configured to operatively engage a grip arm of the distribution member when the distribution member is positioned at least in part above the base surface, and the first portion is moved via the engagement of the grip arm and the contact member in a first direction opposite a direction of travel of the distribution member, such that the first portion of said pivoted powder pushing devicepasses under said distribution member. An associated apparatus, method, and computer program product are also provided.

Owner:ARCAM AB

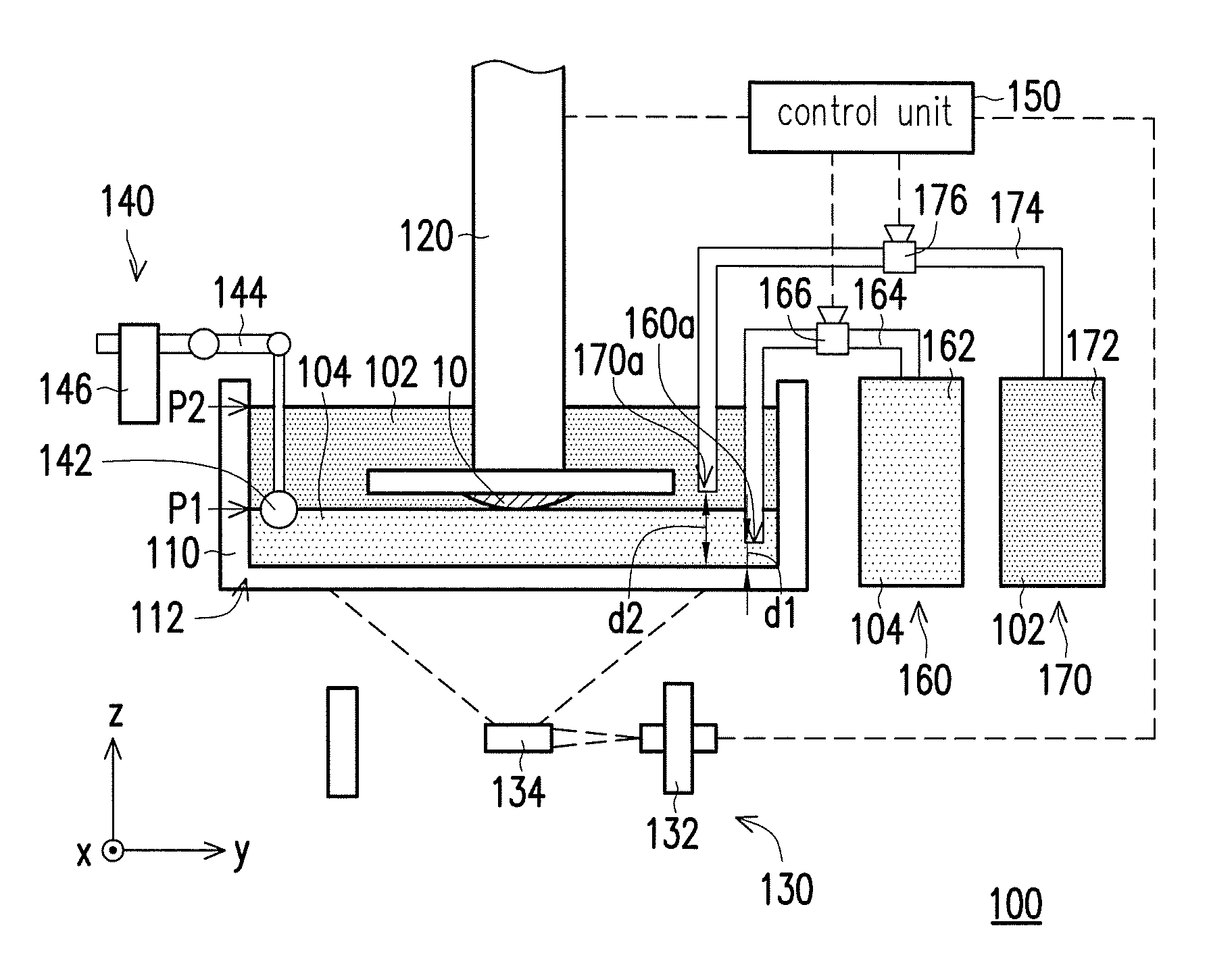

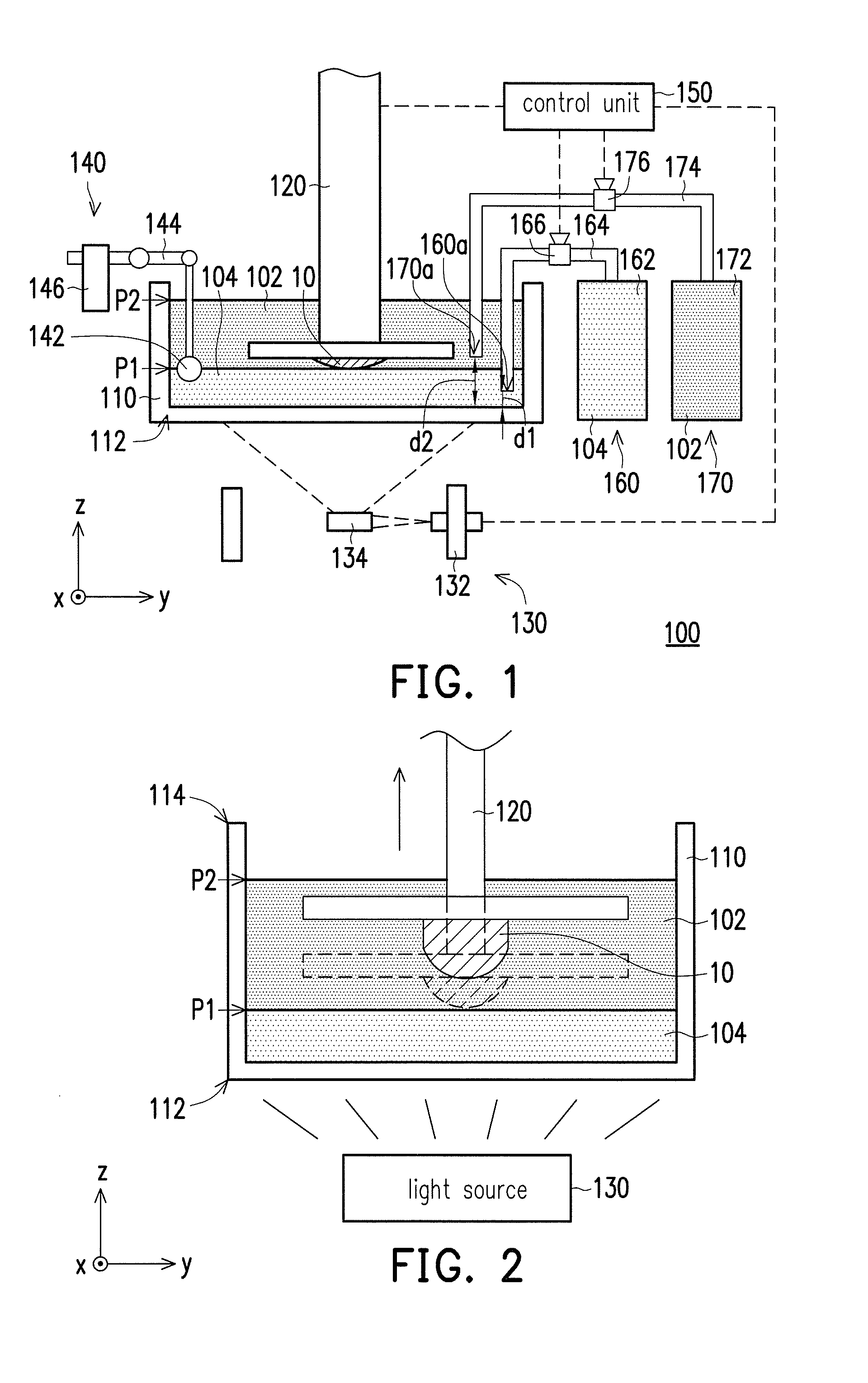

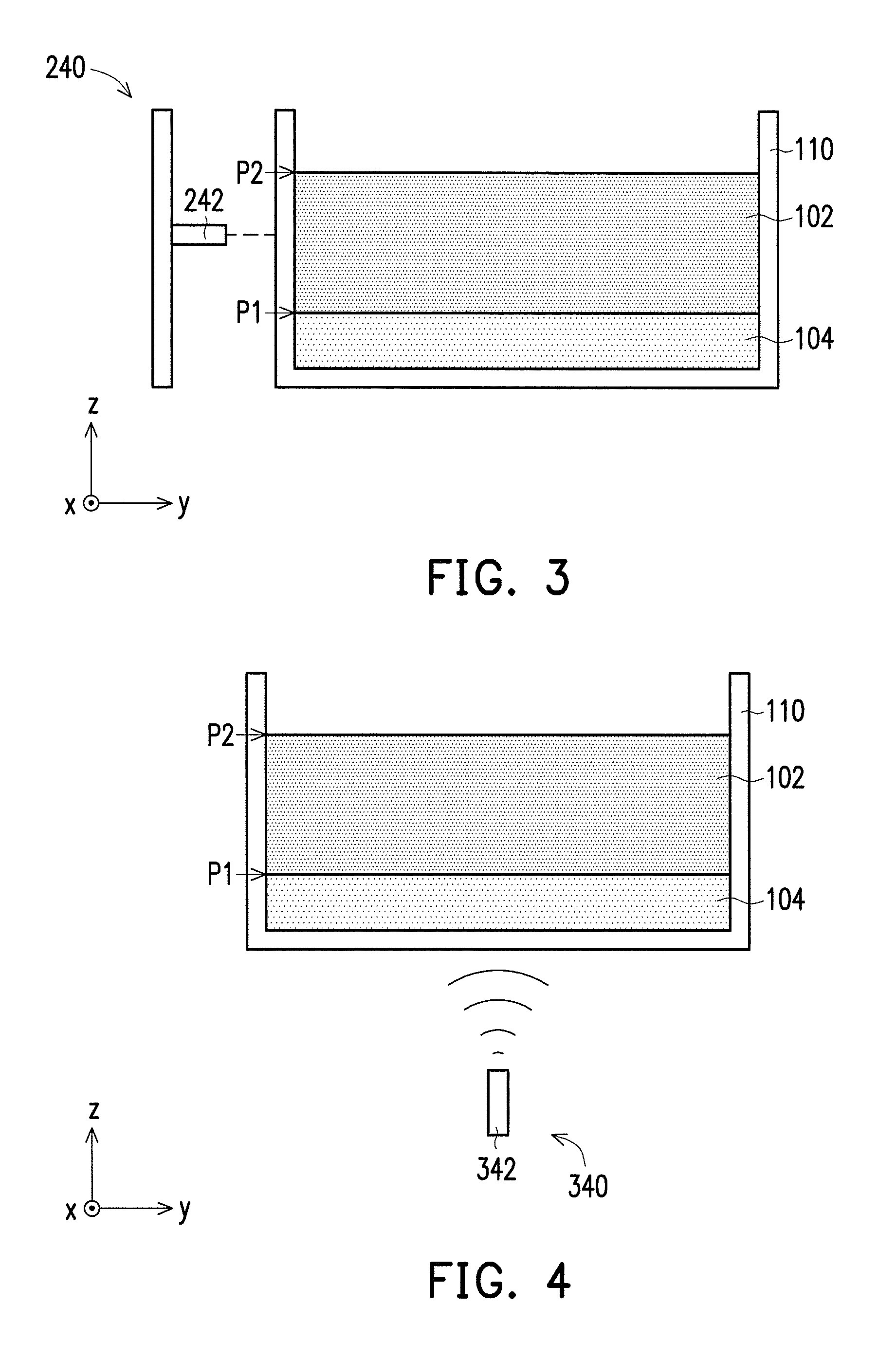

Three dimensional printing apparatus

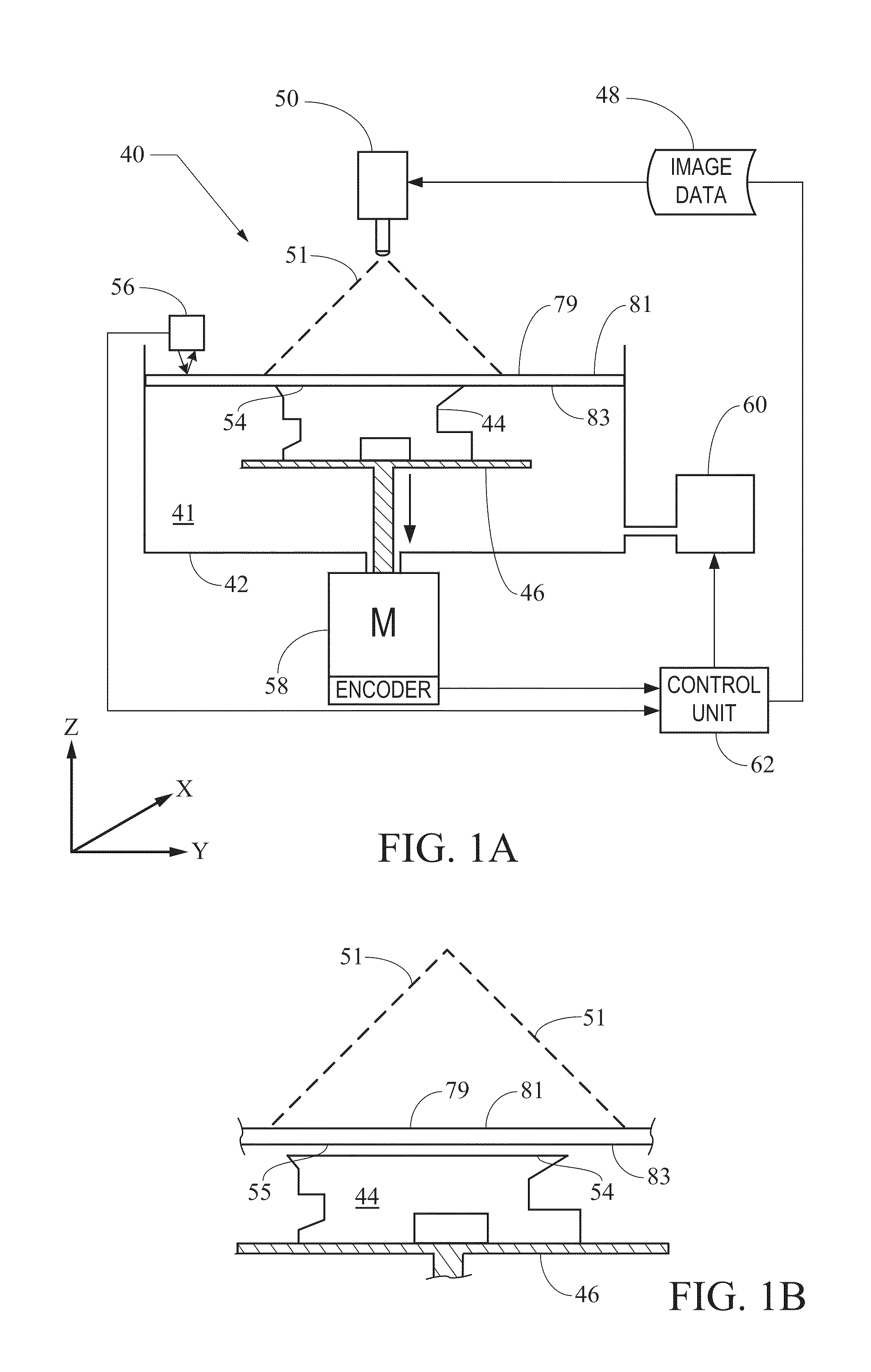

ActiveUS20150165678A1Improve printing qualityAvoid stickingManufacturing platforms/substratesManufacturing enclosuresEngineeringControl unit

A three-dimensional printing apparatus including a tank, a moving platform, a light source disposed below the tank, a detecting unit and a control unit is provided. The tank is filled with a liquid forming material and a separating liquid, wherein the specific density of the separating liquid is larger than the specific density of the liquid forming material, so that the separating liquid sinks between the tank and the liquid forming material. The control unit controls an initial depth at which the moving platform immerses into the liquid forming material, so as to form a three-dimensional object. A three-dimensional printing apparatus is also provided, wherein the light source thereof is disposed above the tank, and the specific density of the liquid forming material is larger than the specific density of the separating liquid, so that the liquid forming material sinks between the tank and the separating liquid.

Owner:XYZPRINTING +2

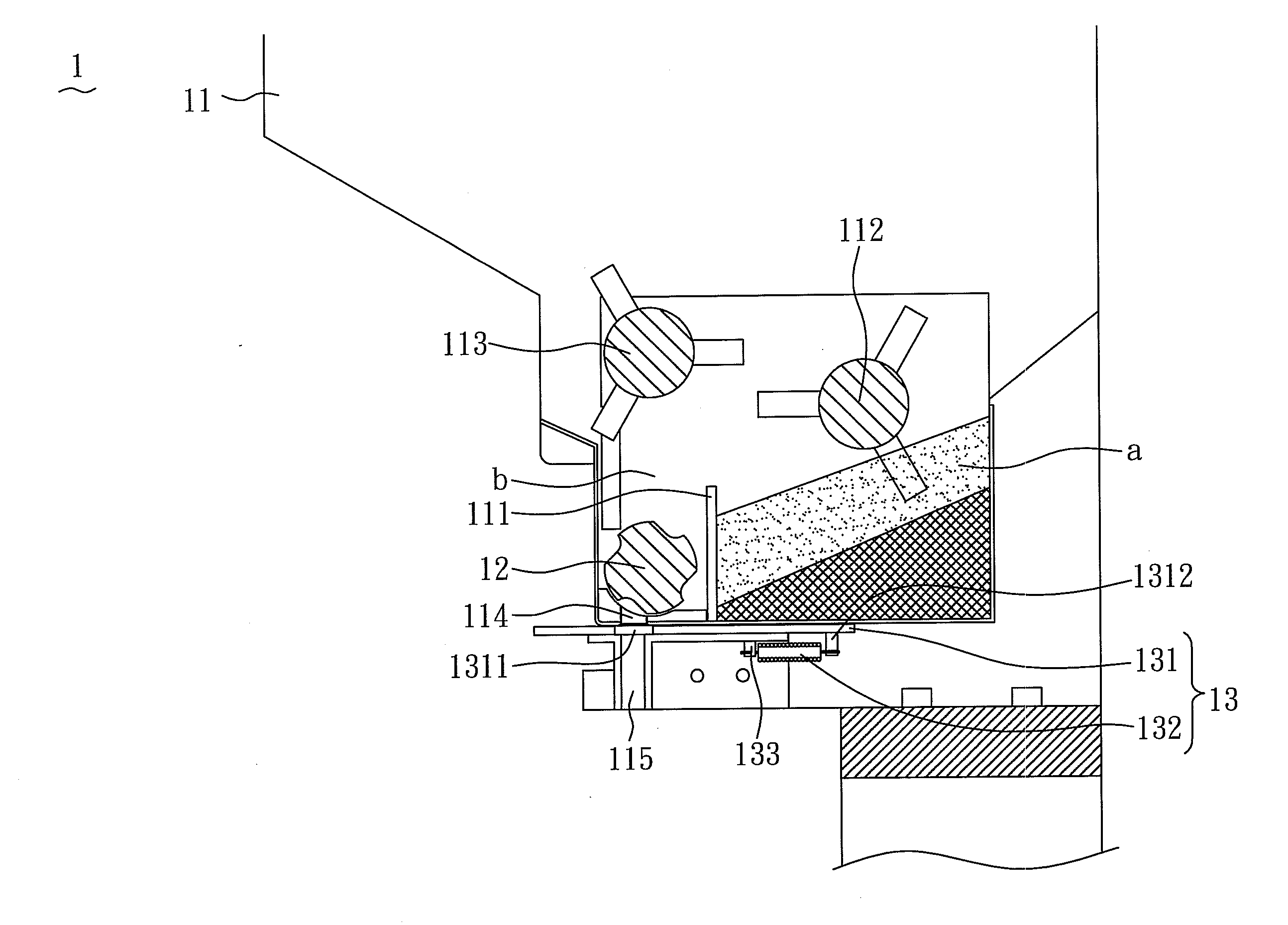

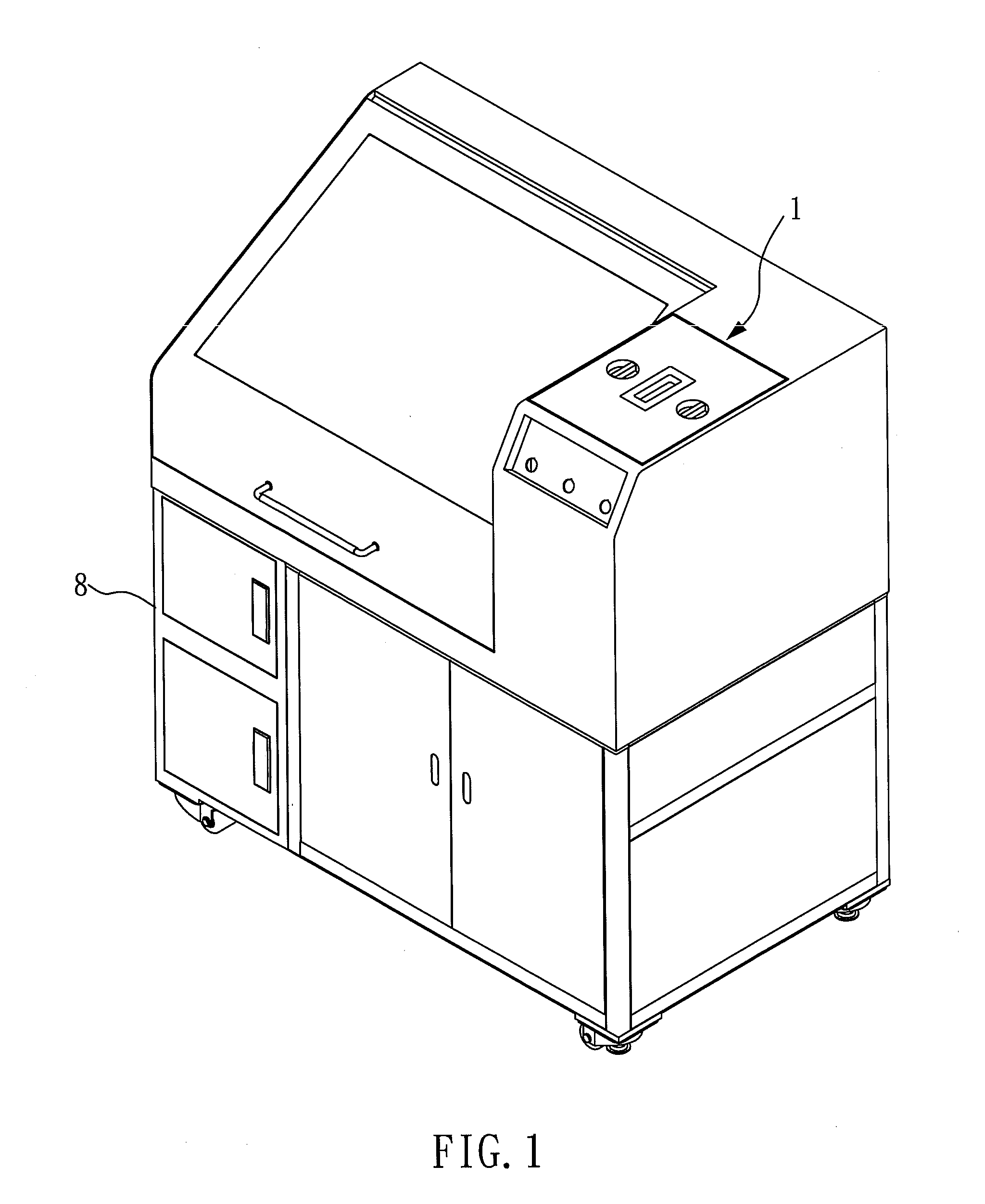

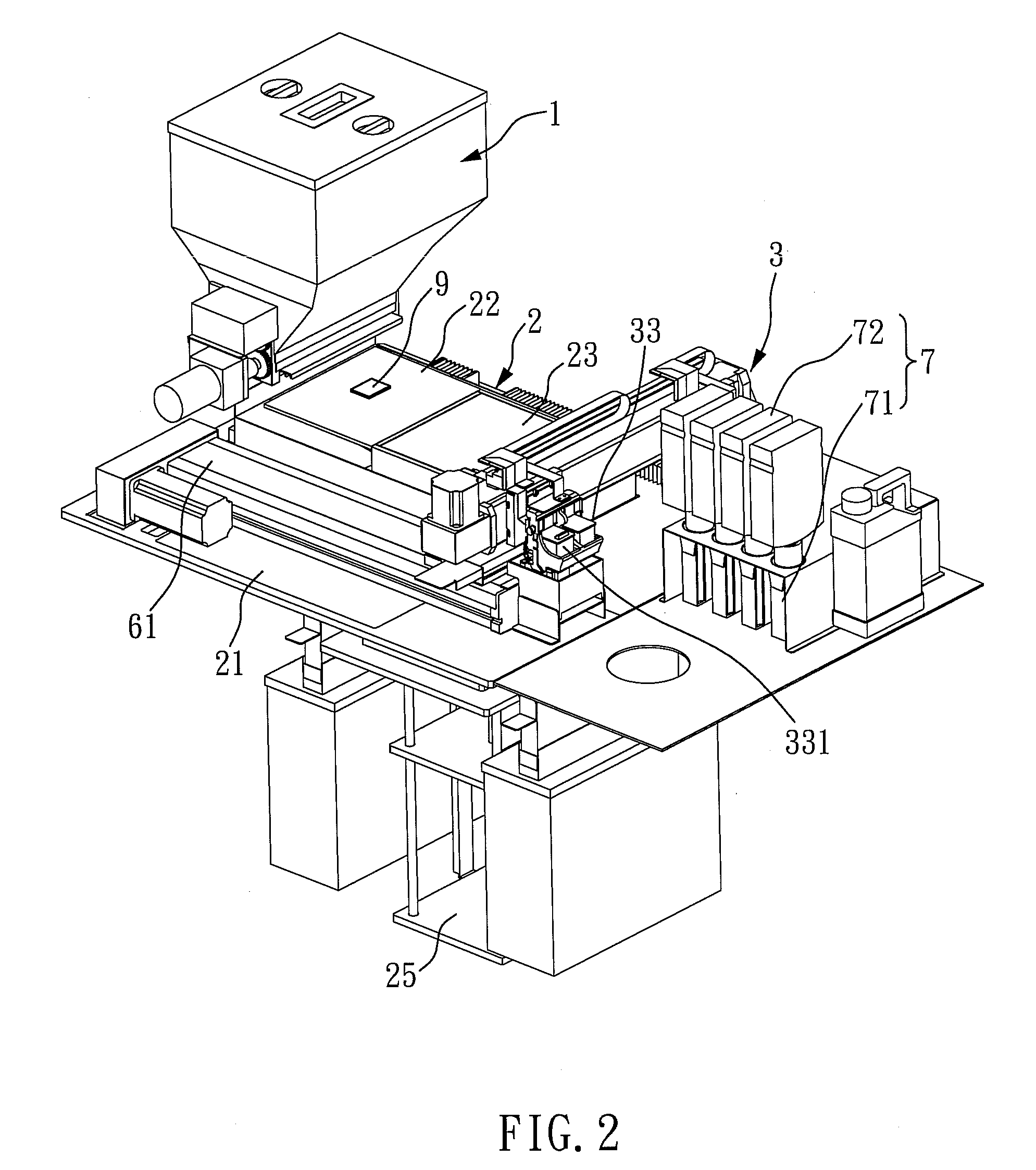

Three-dimensional object-forming apparatus

ActiveUS20110300248A1Avoid wastingLow production costManufacturing enclosuresConfectioneryEngineeringHeating system

A three-dimensional object-forming apparatus is disclosed, which includes an in-batches powder-rationing tank system, a construction tank system, a printing powder-applying system, a rapid drying heating system, a printing maintenance device, a dust-proof device, a successive liquid-supplying device, a powder auto-filtrating and recycling device, and a print quality detection device.

Owner:MICROJET TECH

Interchangeable container wiht moveable side walls

ActiveUS20170050378A1Reduce frictionQuality improvementManufacturing platforms/substratesManufacturing enclosuresEngineeringMechanical engineering

Owner:VOXELJET AG

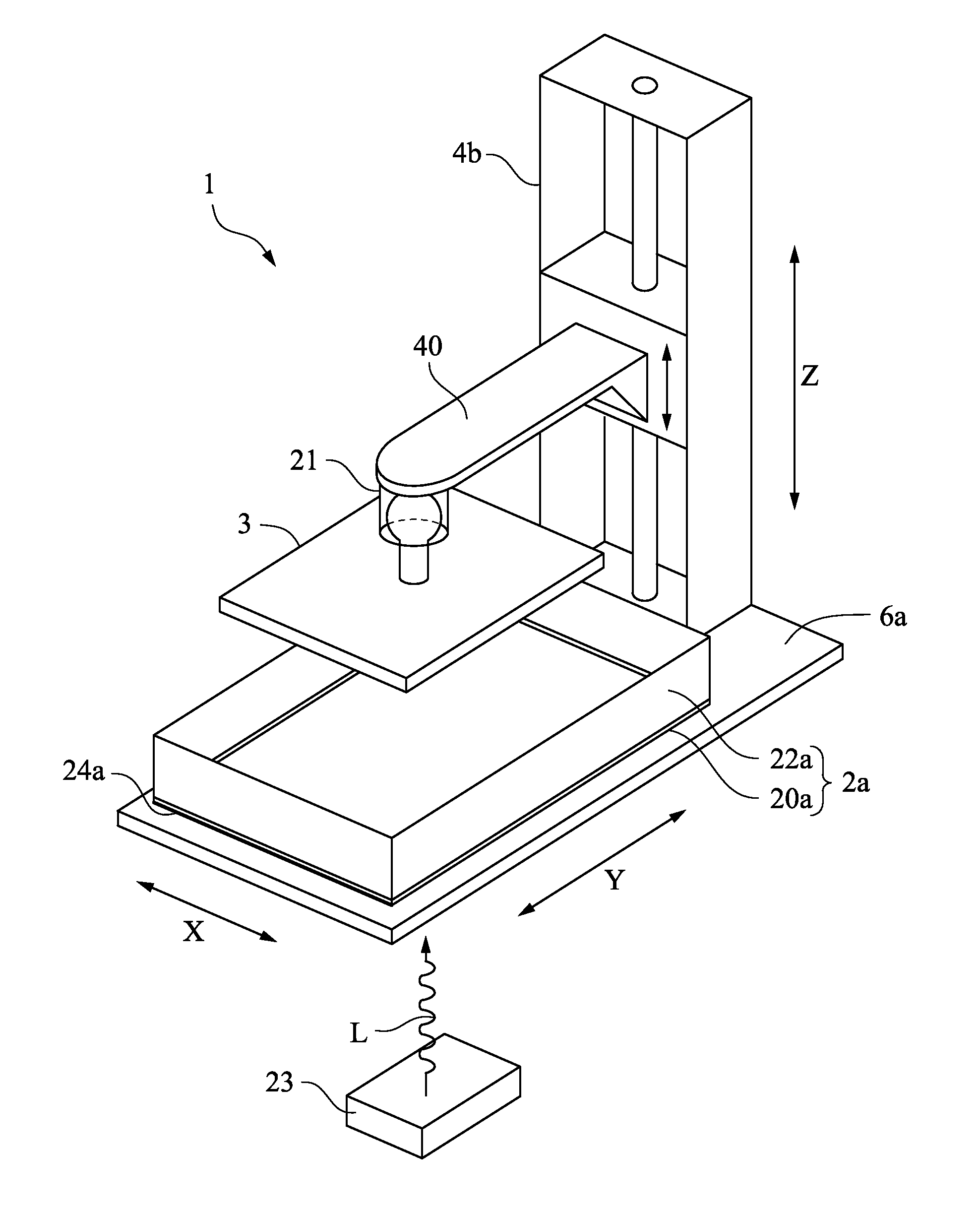

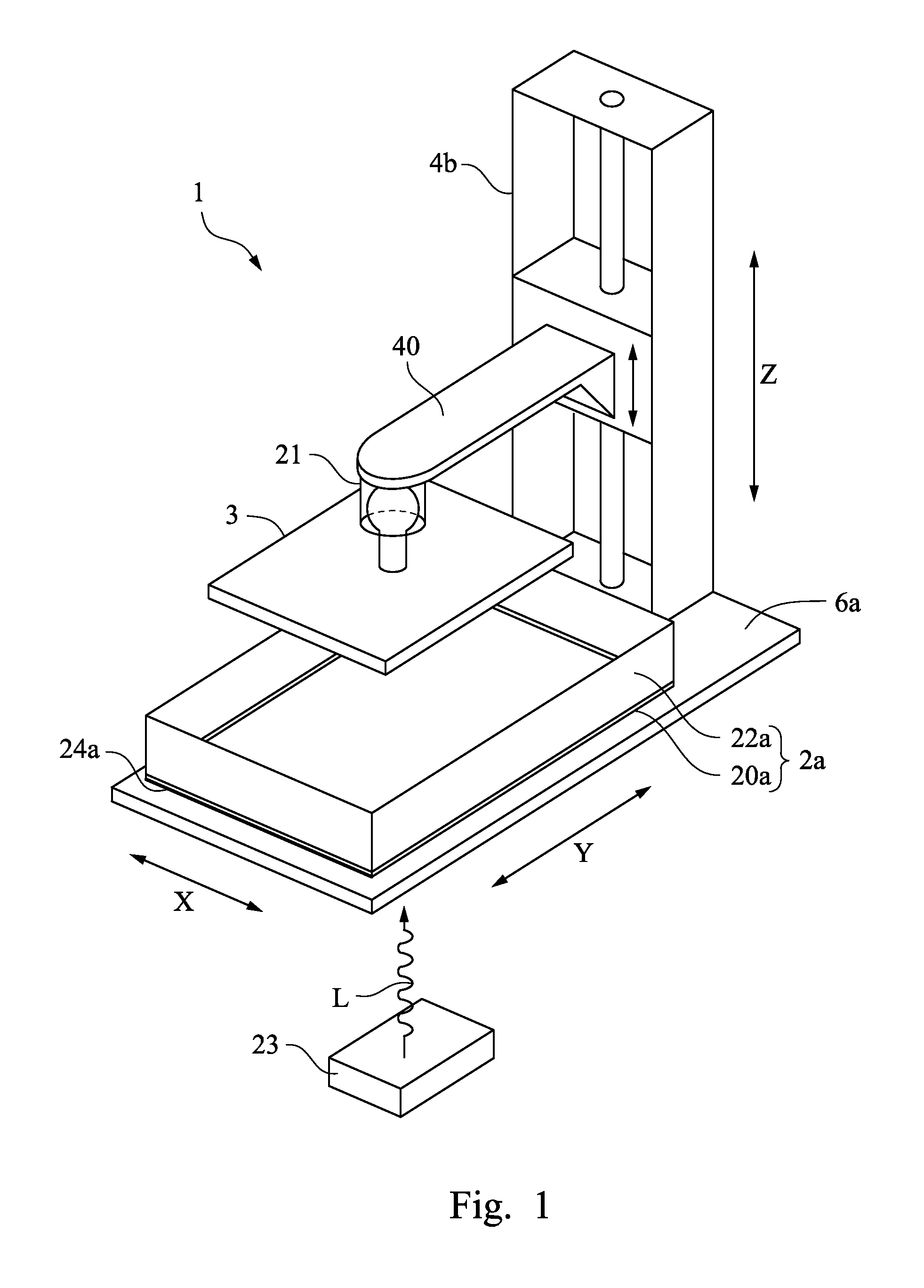

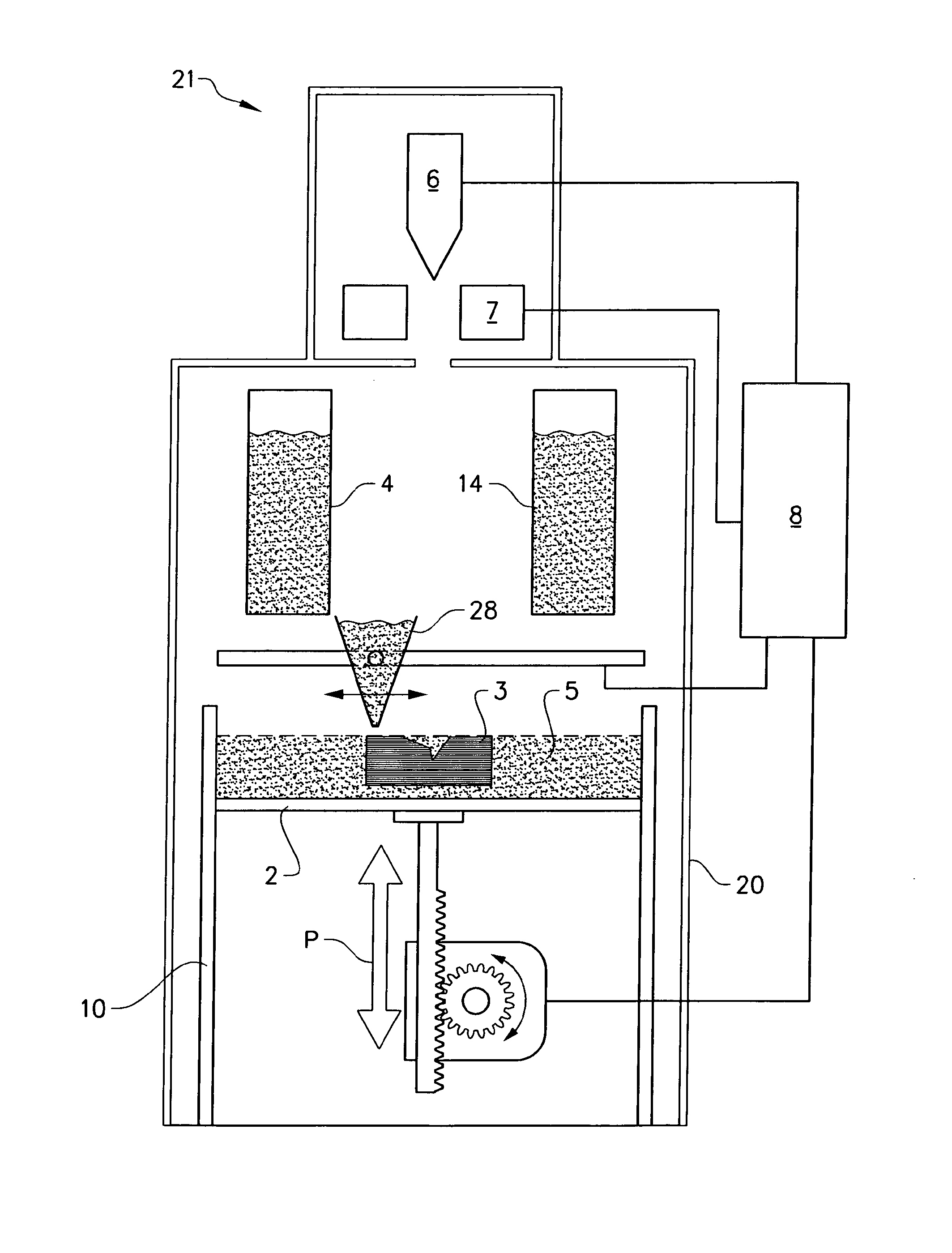

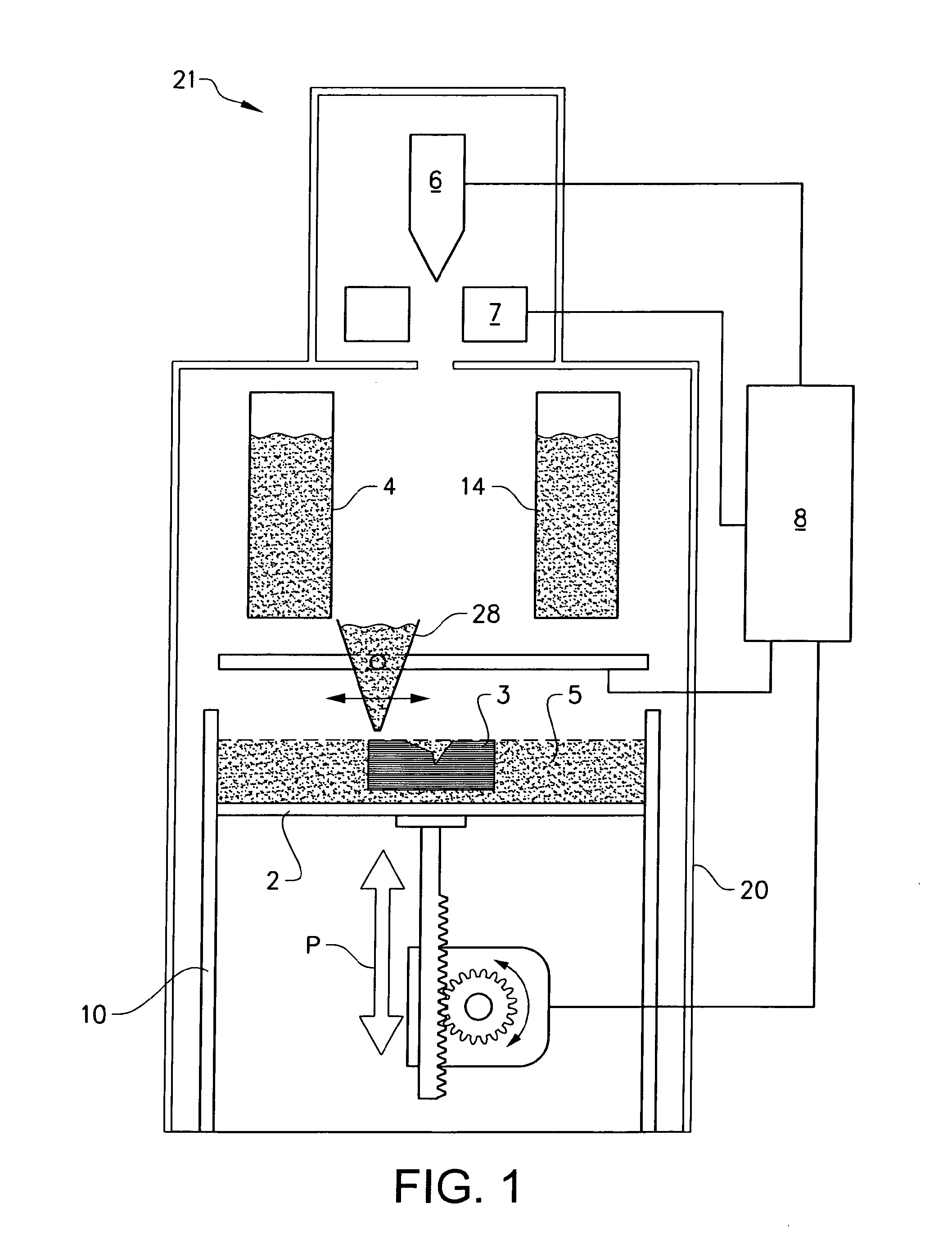

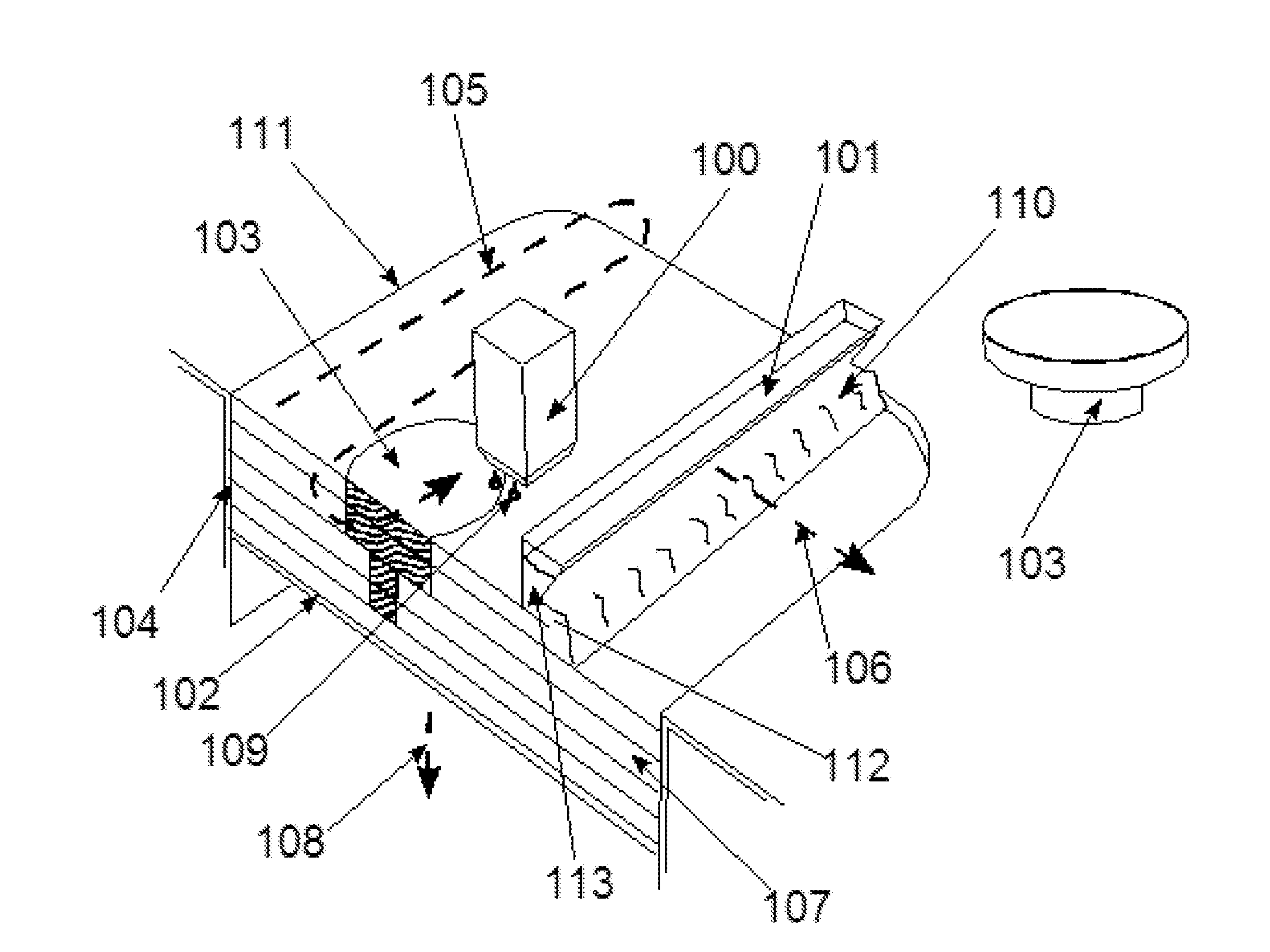

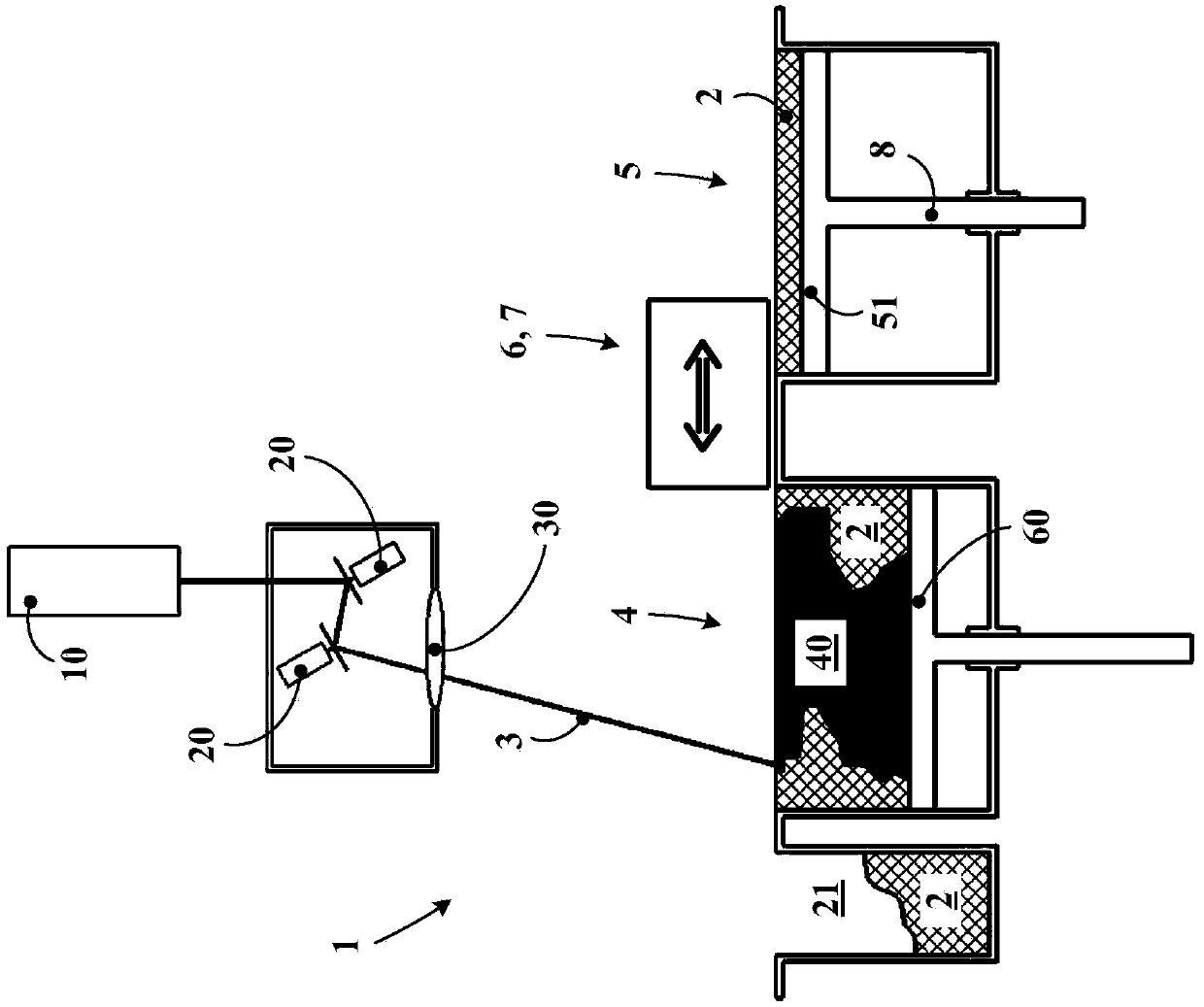

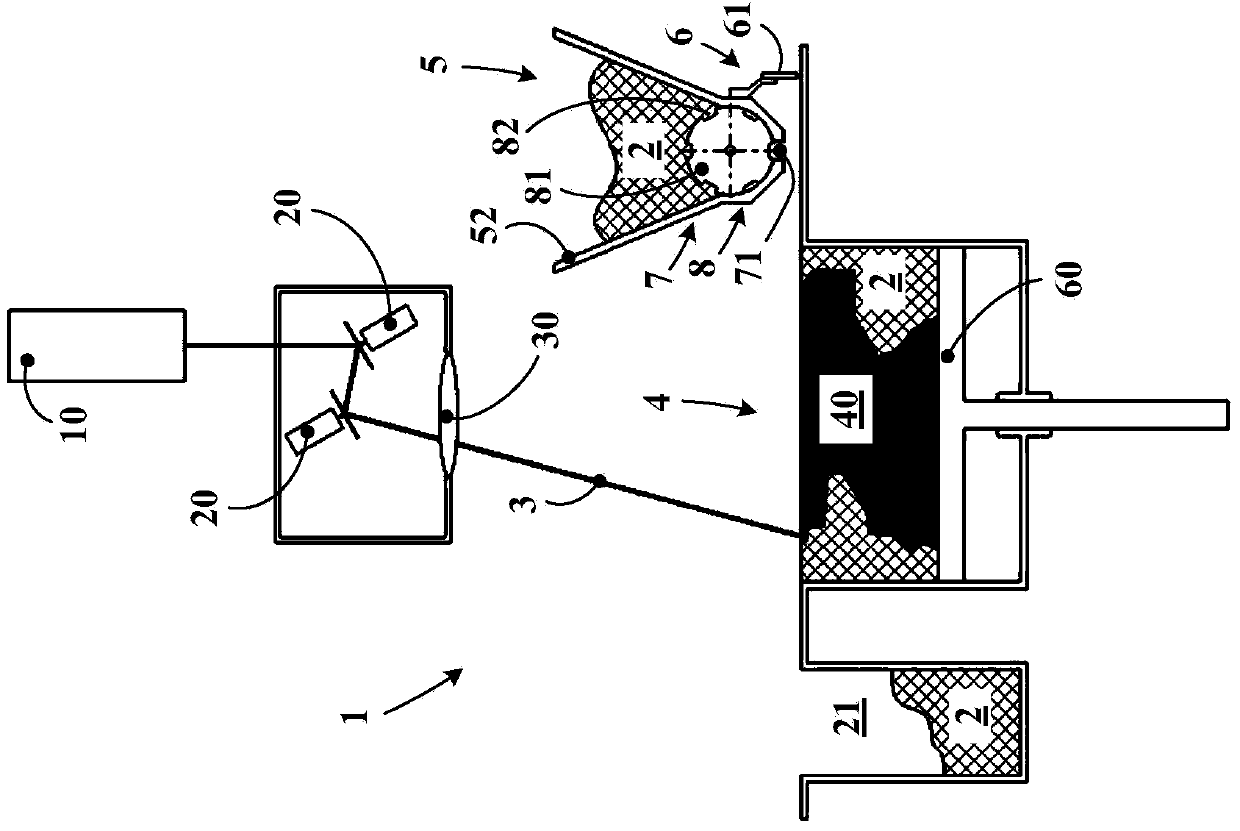

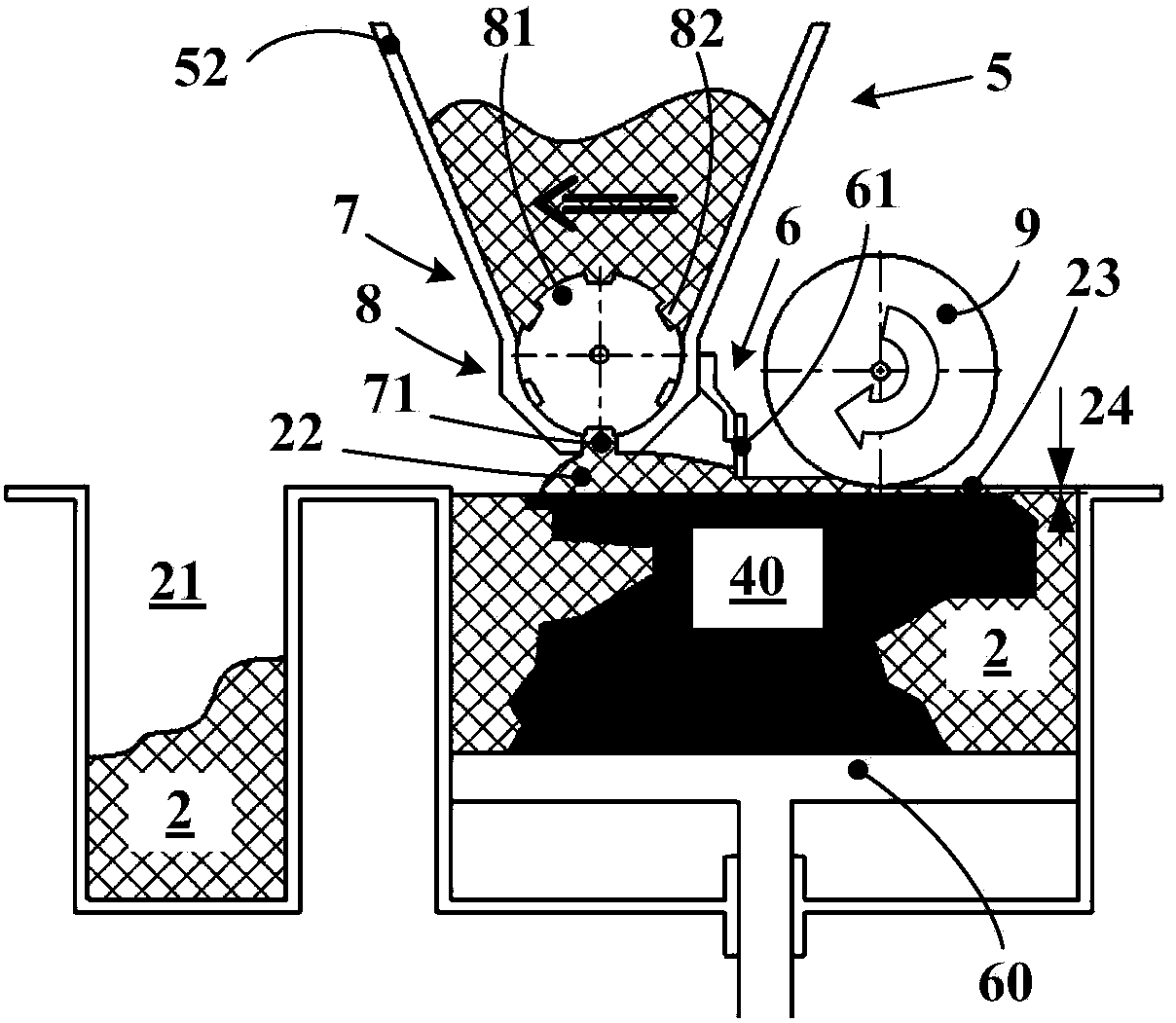

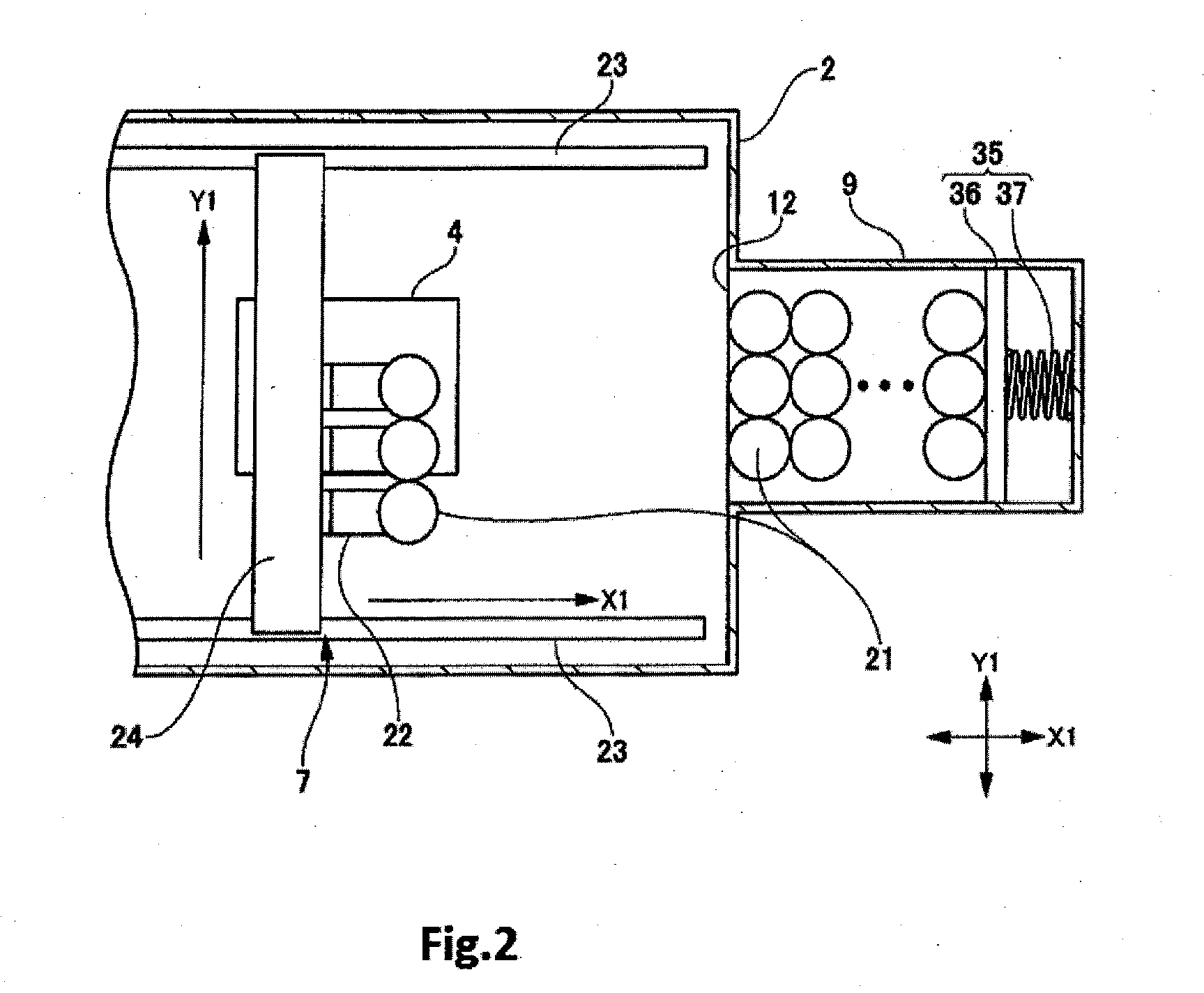

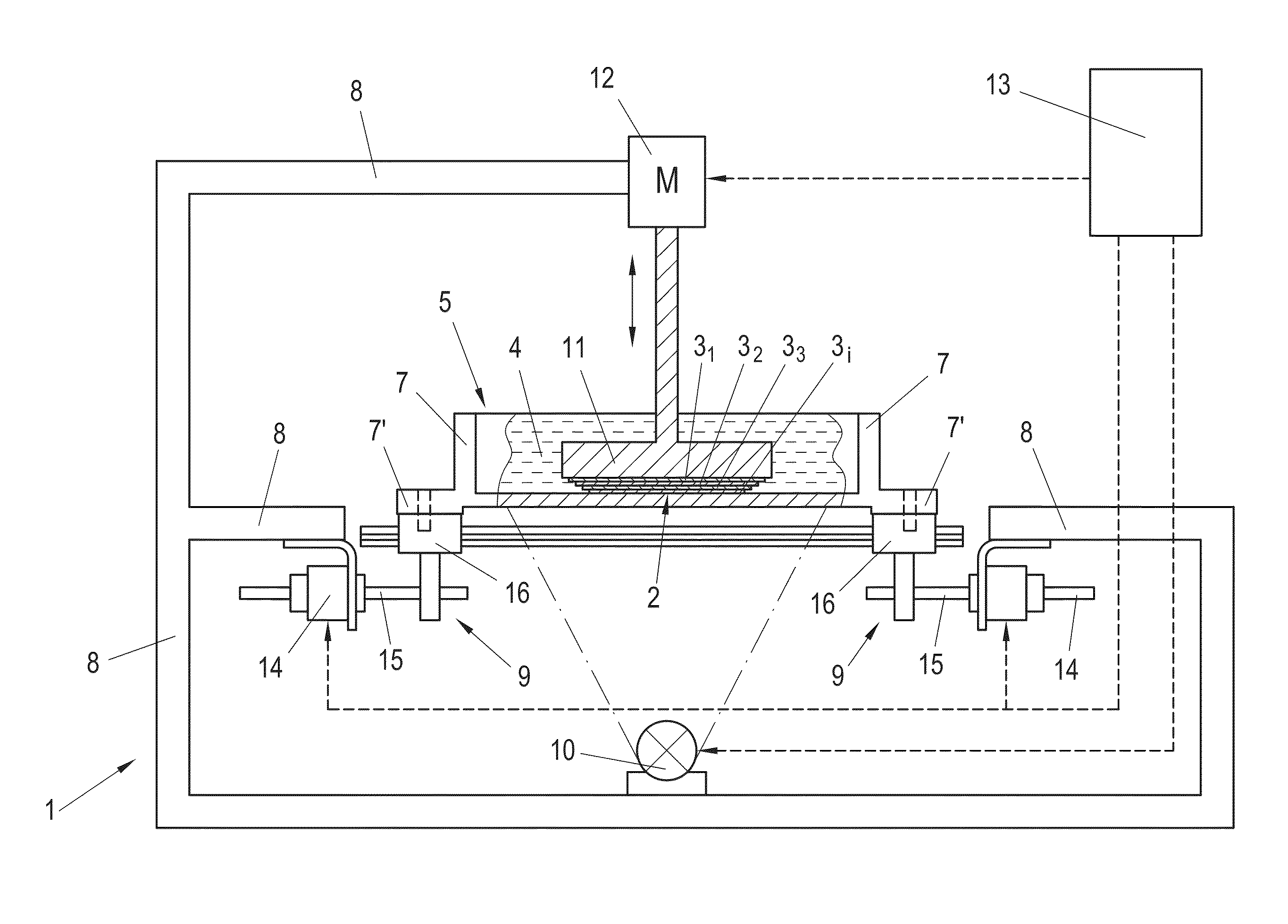

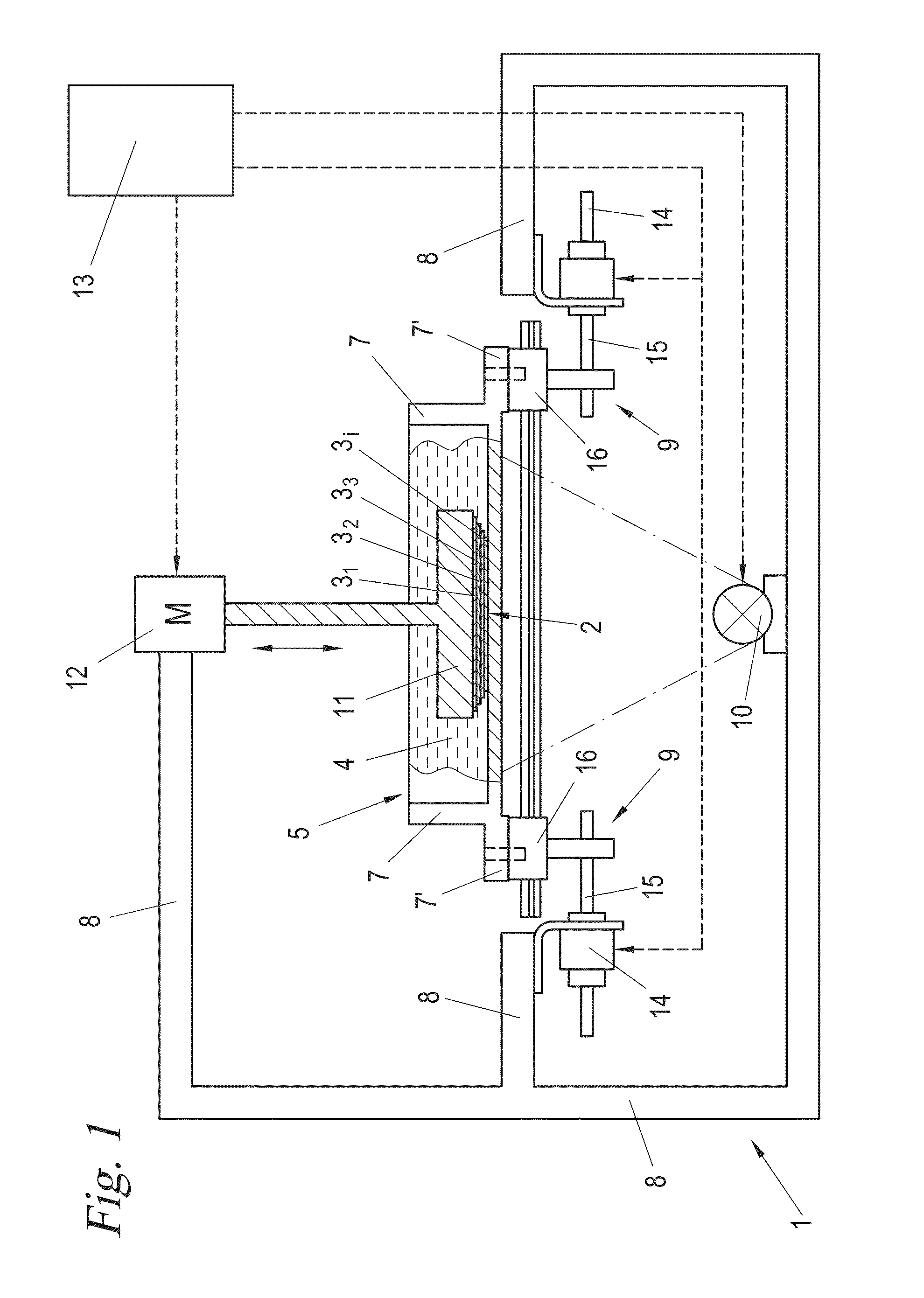

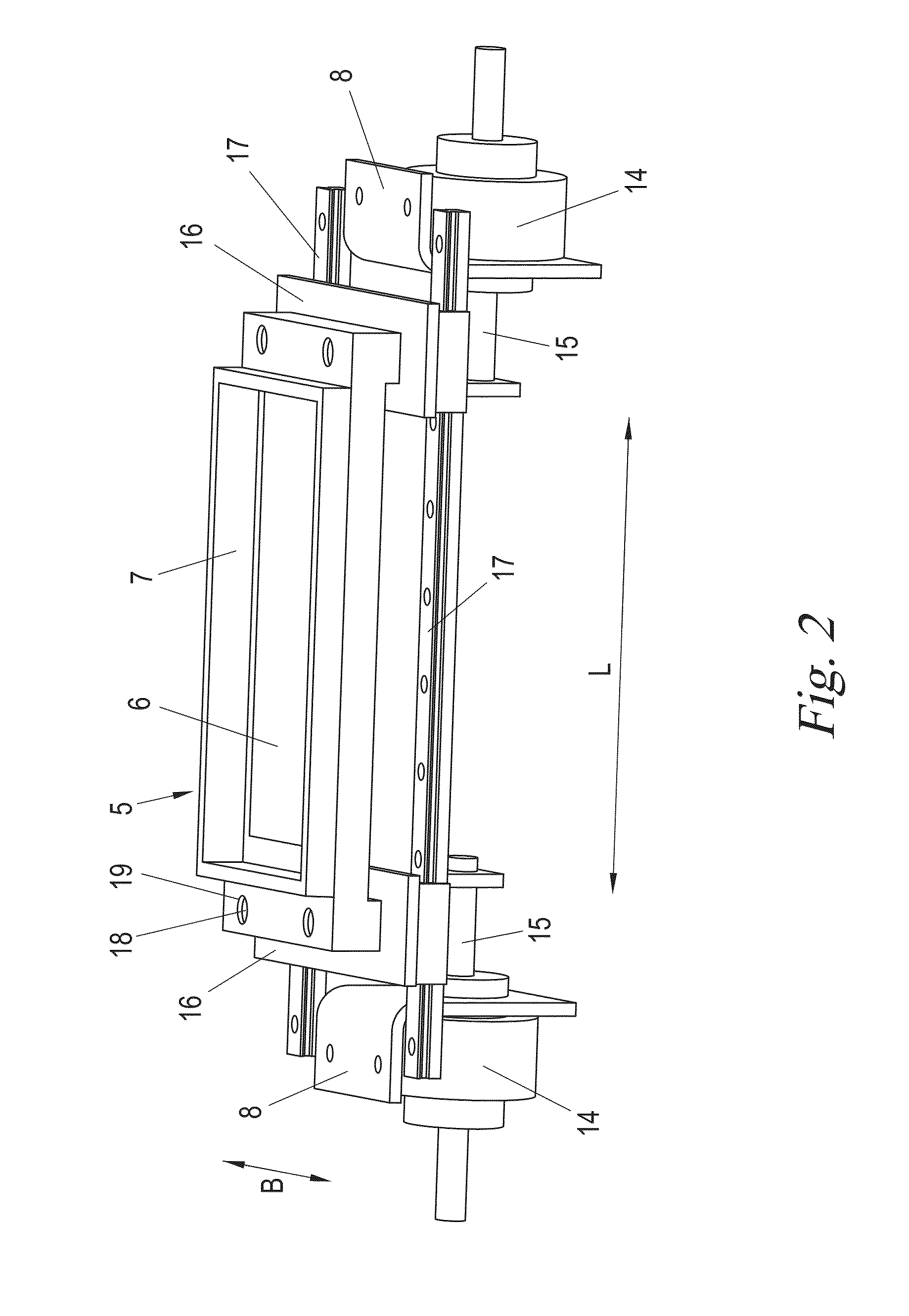

Machine and process for powder-based additive manufacturing

ActiveCN104010750AImprove uniformityManufacturing enclosuresPretreated surfacesProcess engineeringMechanical engineering

The invention in particular relates to a machine (1) for additive manufacturing that frits or melts powder (2) using an energy beam (3) acting on a powder layer (23) in a working zone (4), said machine comprising a device for producing a layer of said powder, said device comprising: means (5) of storing the powder; means (6) for distributing the powder, which means is able to travel over the working zone in order to distribute the powder in a layer (23) having a final thickness (24) tailored to the additive manufacturing; feeding means (7) able to transfer the powder from the storage means (5) to the distributing means (6); and dosing means (8) able to control the amount of powder transferred from the storage means (5) to the distributing means (6), said machine being characterised in that: the storing means (5) are located above the working zone (4); the feeding means (7) are gravitational feeding means; and the feeding means (7) and the dosing means (8) are able to move with the distributing means (6).

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Apparatus and method for forming three-dimensional objects using a tilting solidification substrate

An apparatus and method for making a three-dimensional object from a solidifiable material using a linear solidification device is shown and described. The apparatus includes a solidification substrate that is tiltable relative to a film about a tilting axis. Layers of the solidifiable material solidify in contact with a film located between the most recently solidified object layer and a solidification substrate that comprises the solidification substrate assembly. The tilting of the solidification substrate relative to the film allows the substrate to be used to squeeze excess solidifiable material from between the film and the most recently solidified object surface while minimizing or eliminating the formation of bubbles in the solidifiable material which can prolong object build times. In addition, tilting the solidification substrate before separating an adhered object surface from the film breaks any vacuum formed between the substrate and the film which reduces the forces involved in separating the object form the film.

Owner:GLOBAL FILTRATION SYST

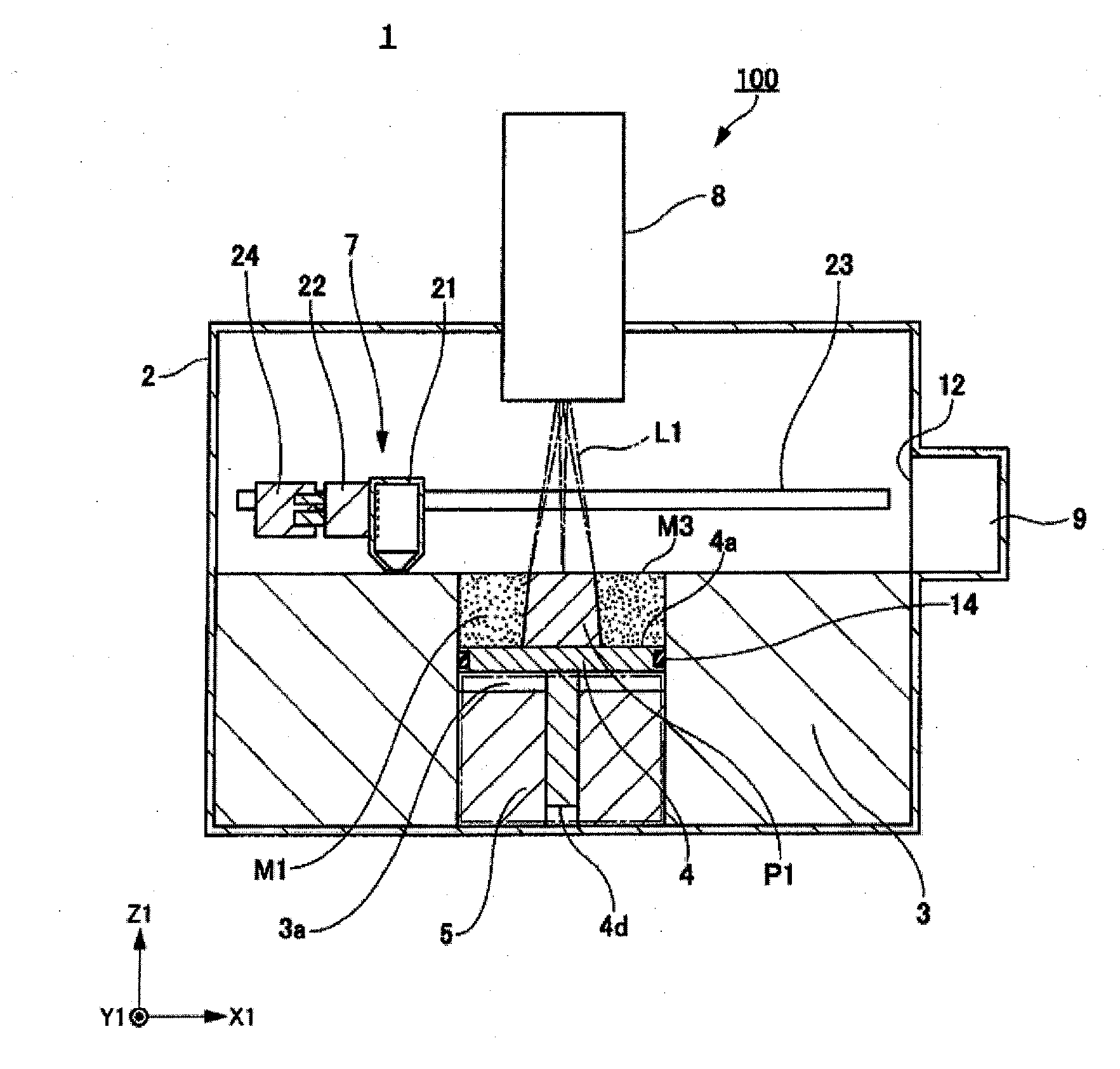

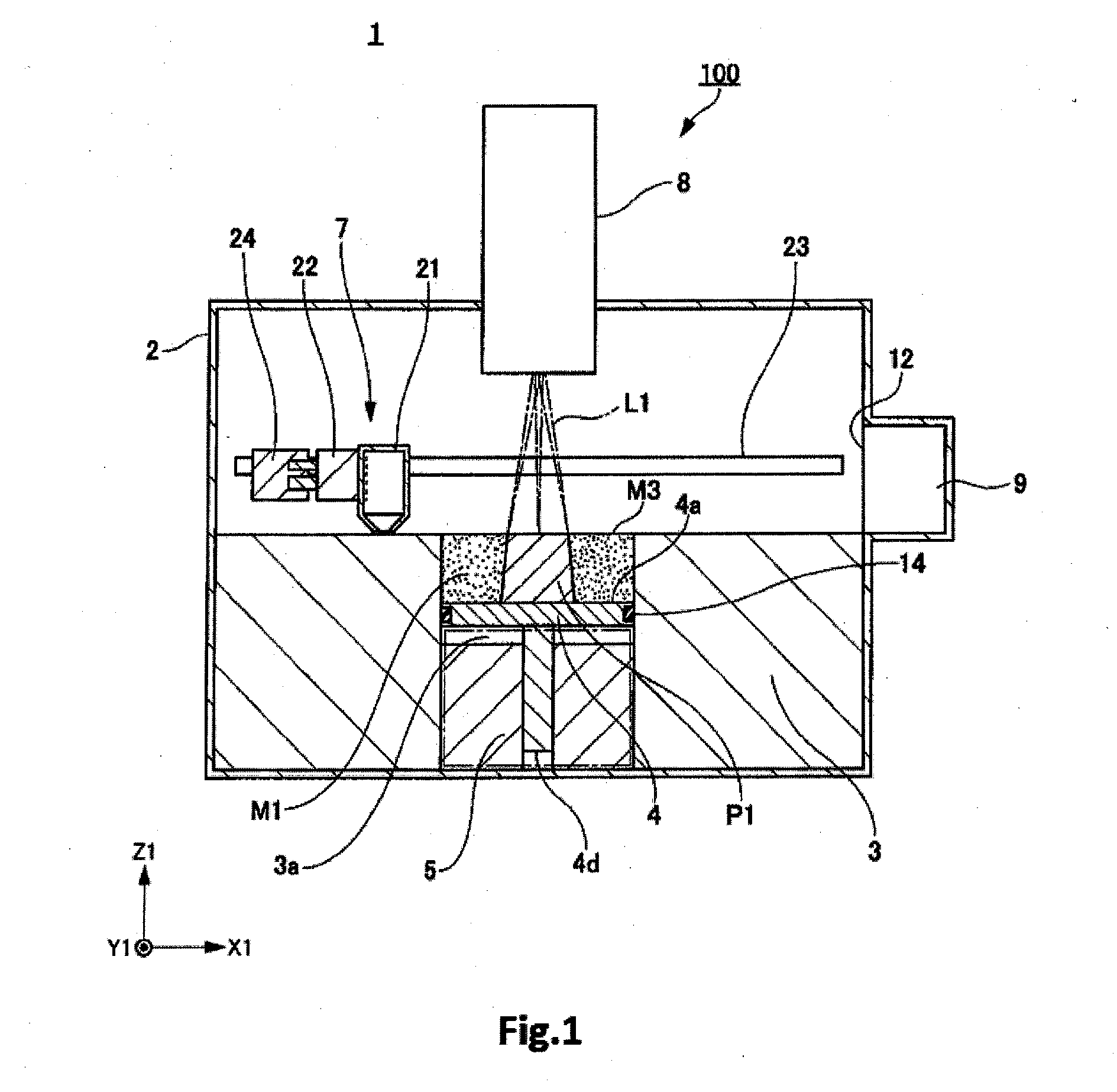

Additive Manufacturing Machine

InactiveUS20150306666A1Suppression problemAvoid wastingManufacturing enclosuresIncreasing energy efficiencyEngineeringMechanical engineering

An additive manufacturing machine is offered which can stably supply a powdered material onto a support stage and can suppress contamination of the interior of a processing chamber with the powdered material. The additive manufacturing machine (1) has the support stage (4) and a powder supply unit (7). The supply unit (7) has powder cartridges (21) and holding mechanisms (22) by which the cartridges (21) are detachably held. Each cartridge (21) has a cartridge body (26) for receiving an amount of powdered material (M1) to be spread tightly as one or plural layers on the stage (4) and an exhaust port (26a) through which the powdered material (M1) received in the cartridge body (26) is discharged.

Owner:JEOL LTD

Coater apparatus and method for additive manufacturing

ActiveUS20170057013A1Manufacturing enclosuresIncreasing energy efficiencyAdditive layer manufacturingManufacturing engineering

Owner:GENERAL ELECTRIC CO

3D printer

ActiveUS20200282659A1Avoid cloggingRealize switchingManufacturing platforms/substratesManufacturing driving meansComputer hardwareMachine vision

Full-automatic microelectronic printer comprising a printing platform, a control component, a feeding component, a camera component, a machine vision device, an ink droplet observation device, and a CAD / CAM system. The printing platform comprises a four-axis linkage system, a printing worktable, a base, a protective housing, an automatic ink cartridge turning device, and an automatic cleaning device; the feeding component comprises a switching control device, an ink cartridge, and an auxiliary processing component; the control component comprises a core control integrated circuit board, a plurality of drive control circuit boards, and a control module interface. The feeding component switches the ink cartridges and the auxiliary processing components to the printing platform in response to the control component which drives the ink cartridges and auxiliary processing components to print, and the protective housing removes fine particles and gas odors. CAD / CAM system assists in designing, generating, and sending instruction to the control component, printing platform, and feeding component to operate and realize full-automatic multi-layer printing.

Owner:SHANGHAI MI FANG ELECTRONICS LTD

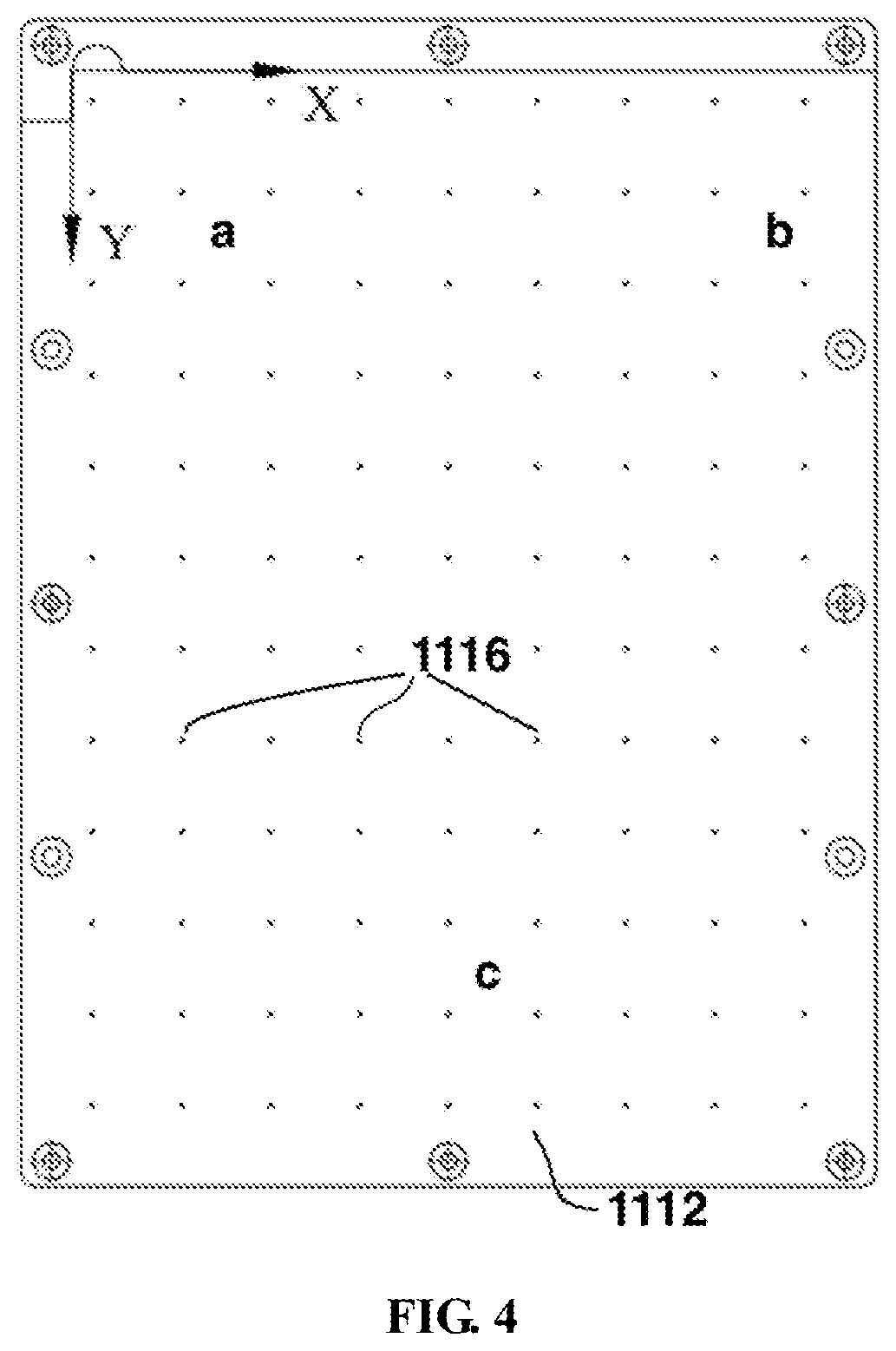

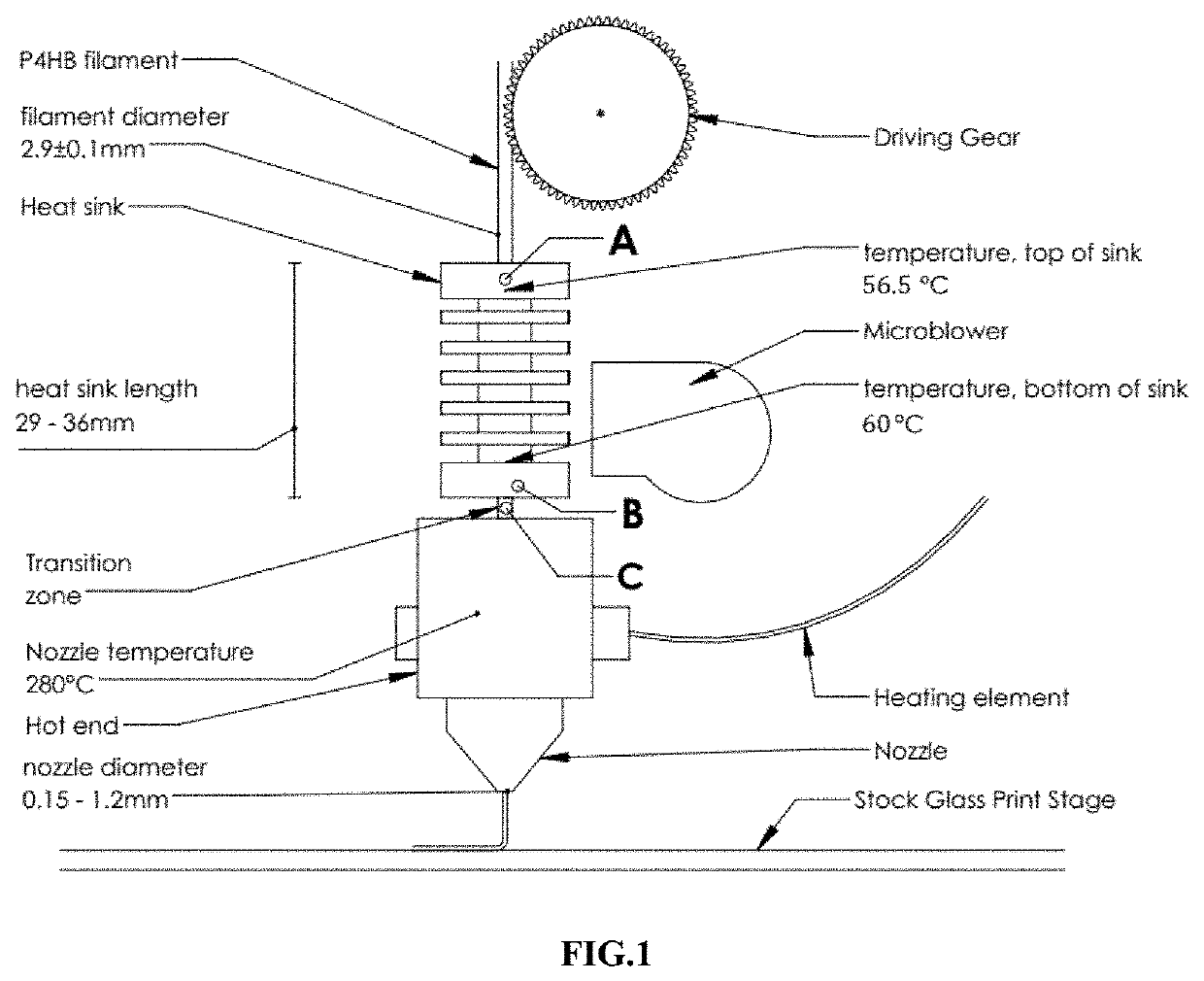

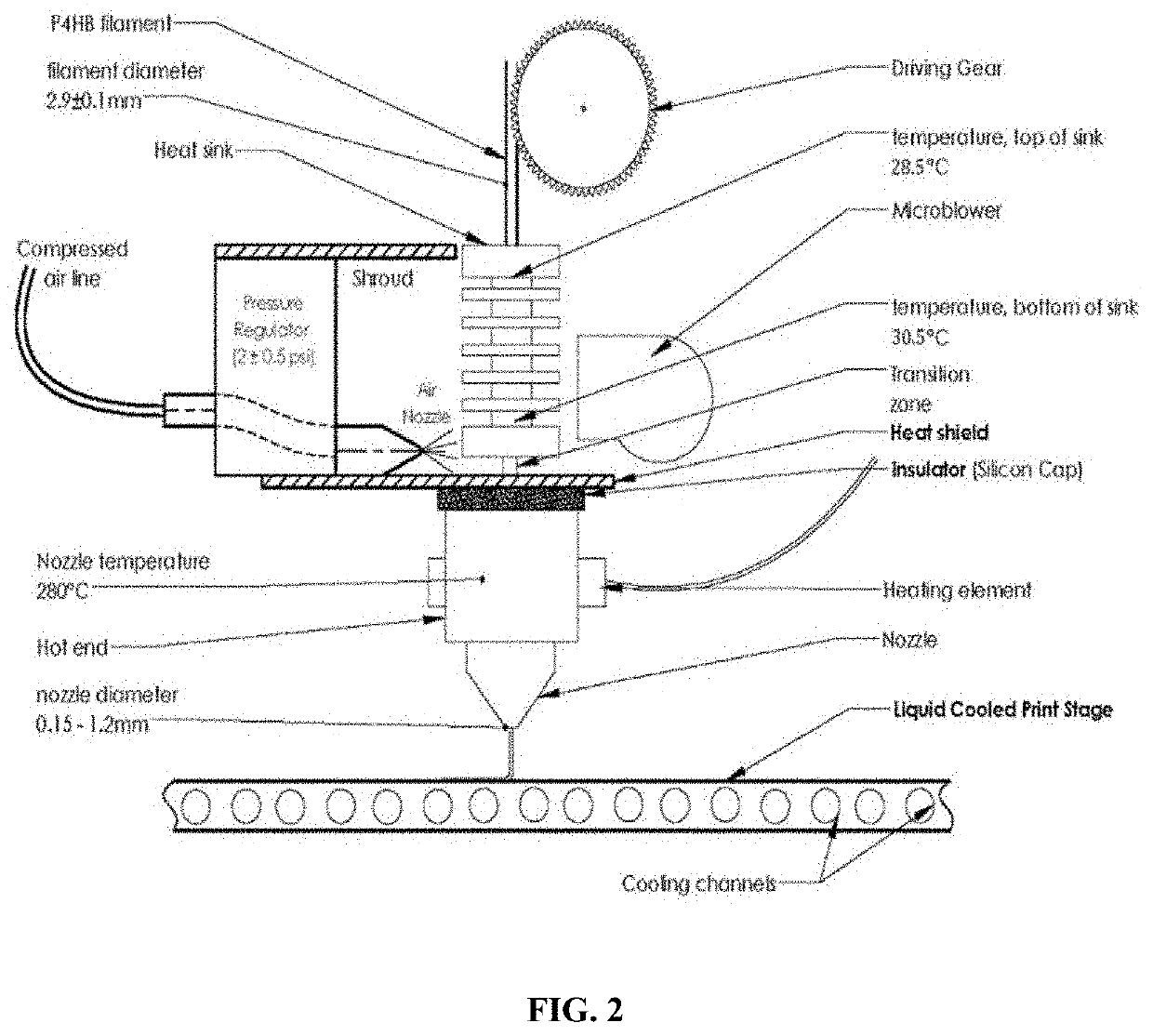

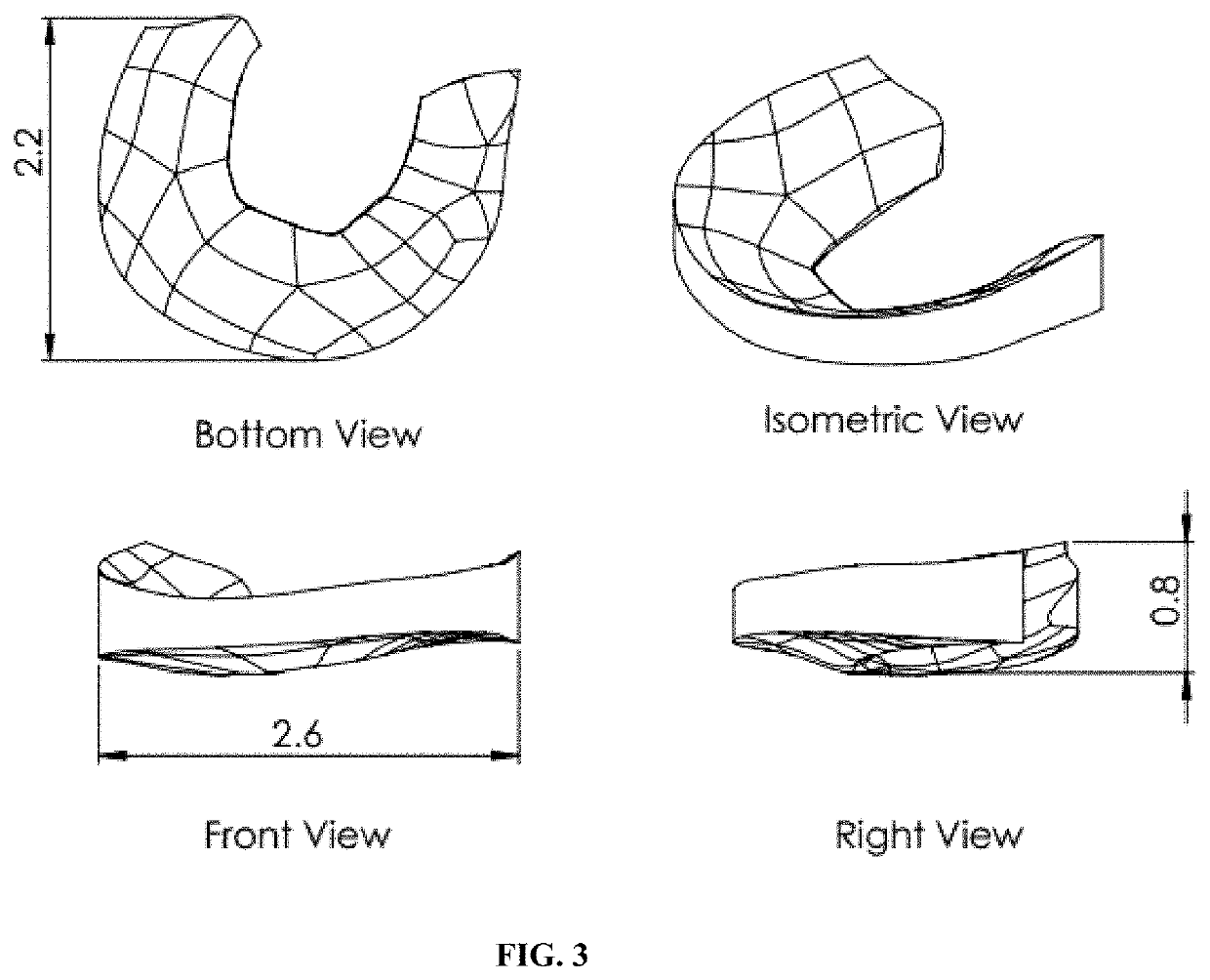

Methods for 3D printing of poly-4-hydroxybutyrate and copolymers

ActiveUS20190375149A1Reduce molecular weightImprove printing qualityManufacturing driving meansManufacturing enclosuresSelective laser meltingFused filament fabrication

Methods to fabricate objects by 3D printing of poly-4-hydroxybutyrate (P4HB) and copolymers thereof have been developed. In one method, these objects are produced by continuous fused filament fabrication using an apparatus and conditions that overcome the problems of poor feeding of the filament resulting from the low softening temperature of the filament and heat creep along the fed filament. Methods using an apparatus including a heat sink, a melt tube, a heating block and nozzle, and a transition zone between the heat sink and heating block, with the melt tube extending through the heat sink, transition zone, and heat block to the nozzle are disclosed. 3D objects are also printed by fused pellet deposition (FPD), melt extrusion deposition (MED), selective laser melting (SLM), printing of slurries and solutions using a coagulation bath, and printing using a binding solution and polymer granules.

Owner:TEPHA INC

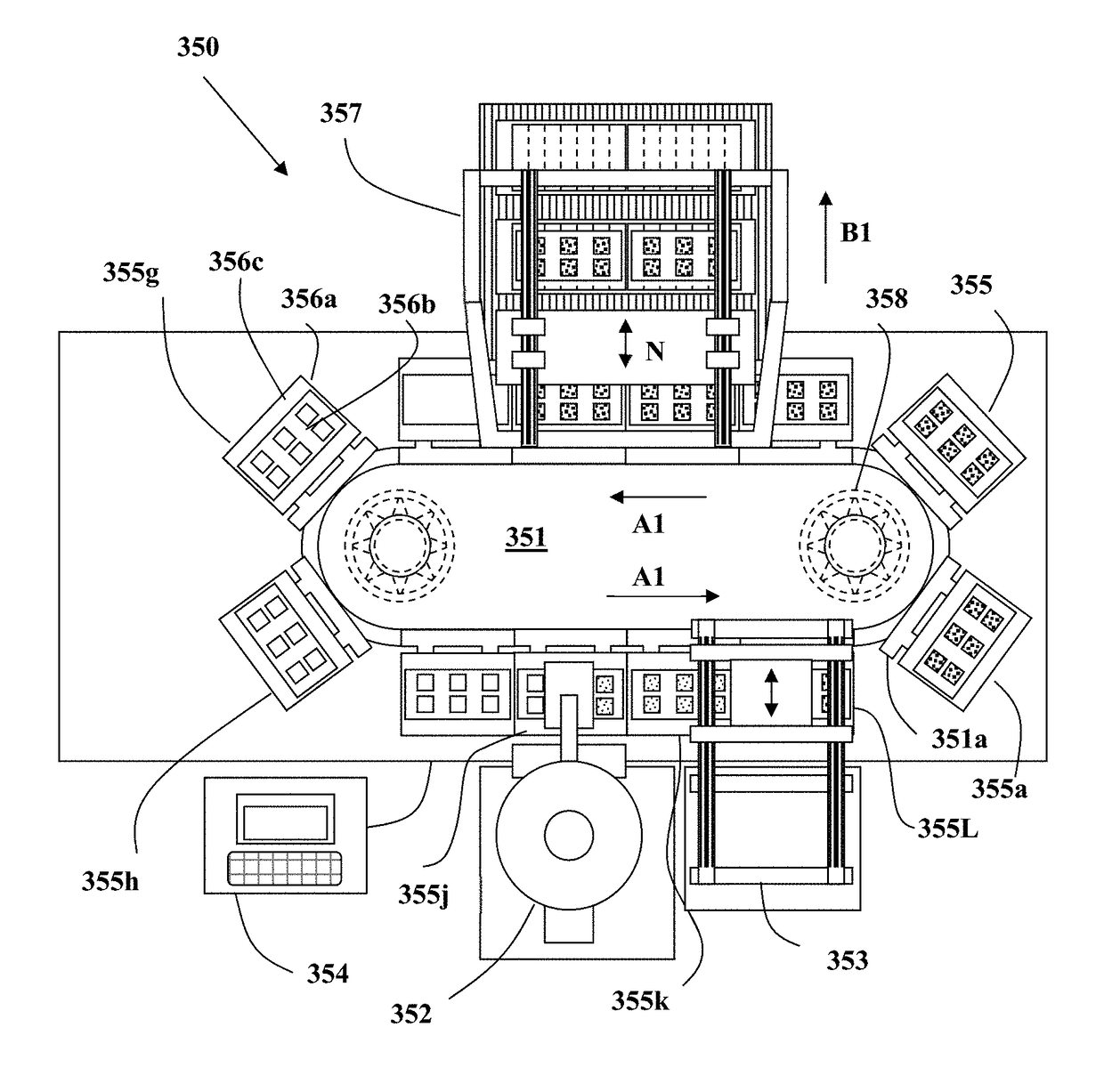

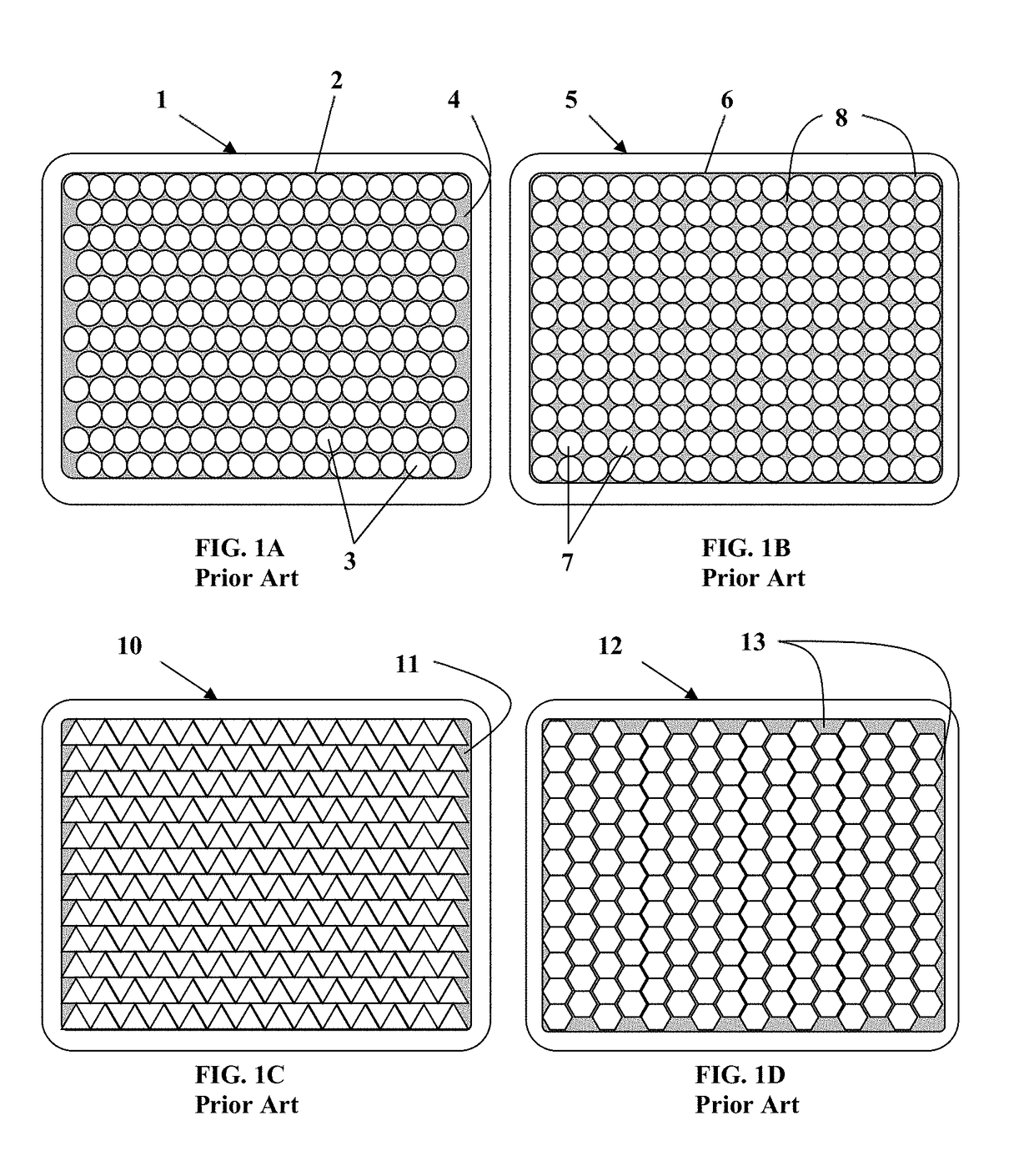

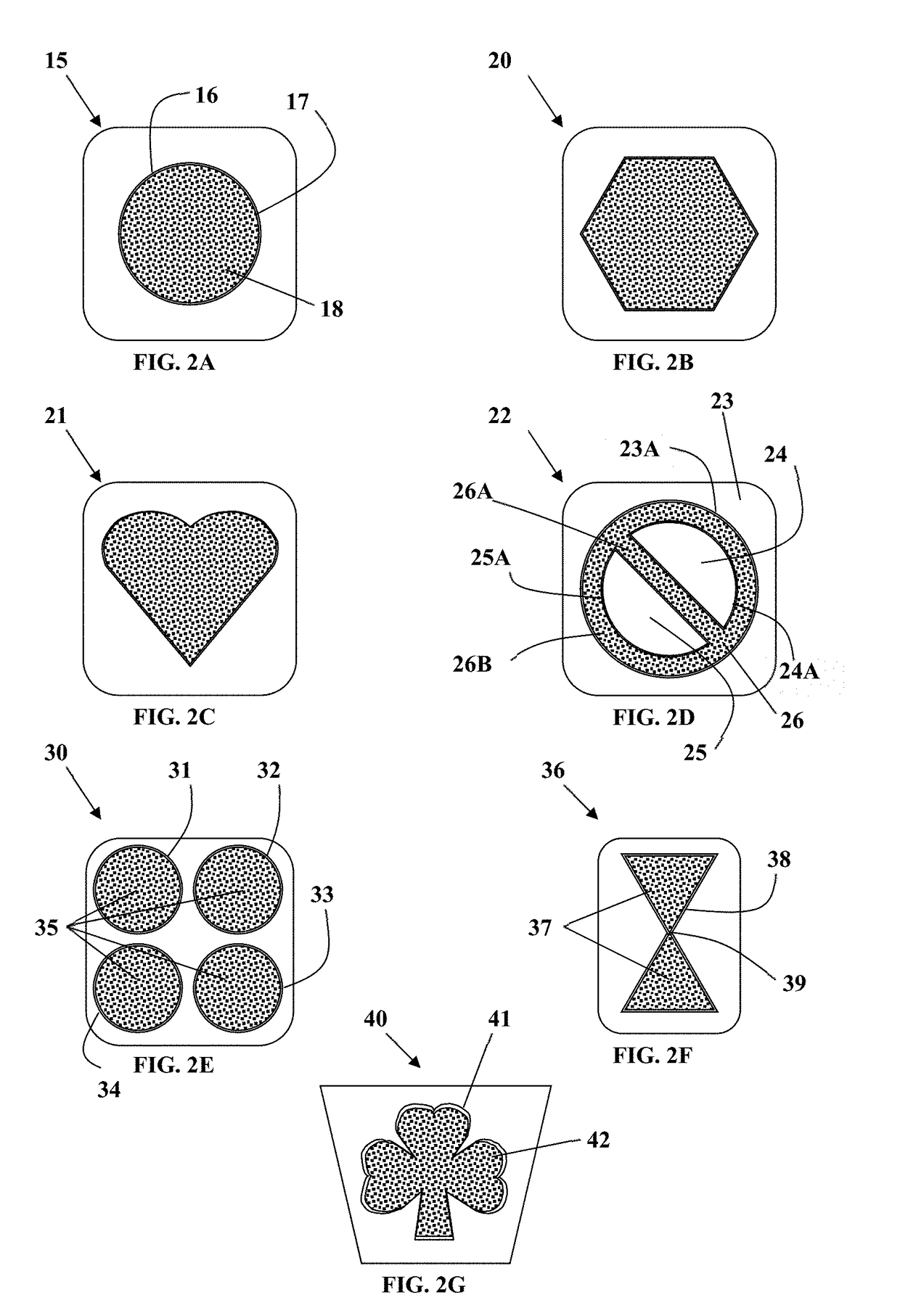

Three-dimensional Printing System and Equipment Assembly

ActiveUS20180141275A1Minimal product lossImprove efficiencyManufacturing platforms/substratesPowder deliveryPharmaceutical drugAppliance component

A three-dimensional printing system and equipment assembly for the manufacture of three-dimensionally printed articles is provided. The equipment assembly includes a three-dimensional printing build system, an optional liquid removal system and an optional harvester system. The build system includes a conveyor, plural build modules and at least one build station having a powder-layering system and a printing system. The equipment assembly can be used to manufacture pharmaceutical, medical, and non-pharmaceutical / non-medical objects. It can be used to prepare single or multiple articles.

Owner:APRECIA PHARMA LLC

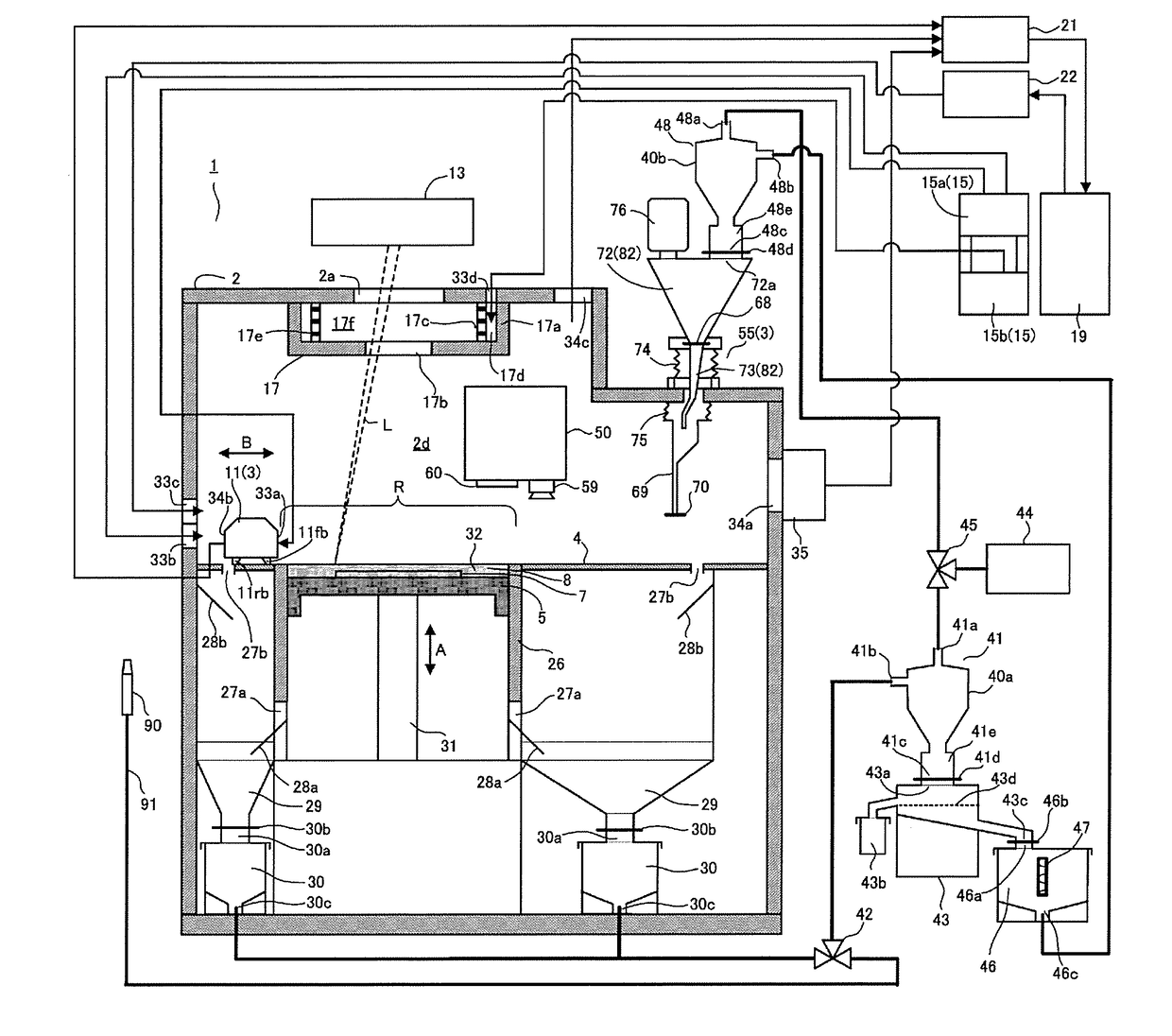

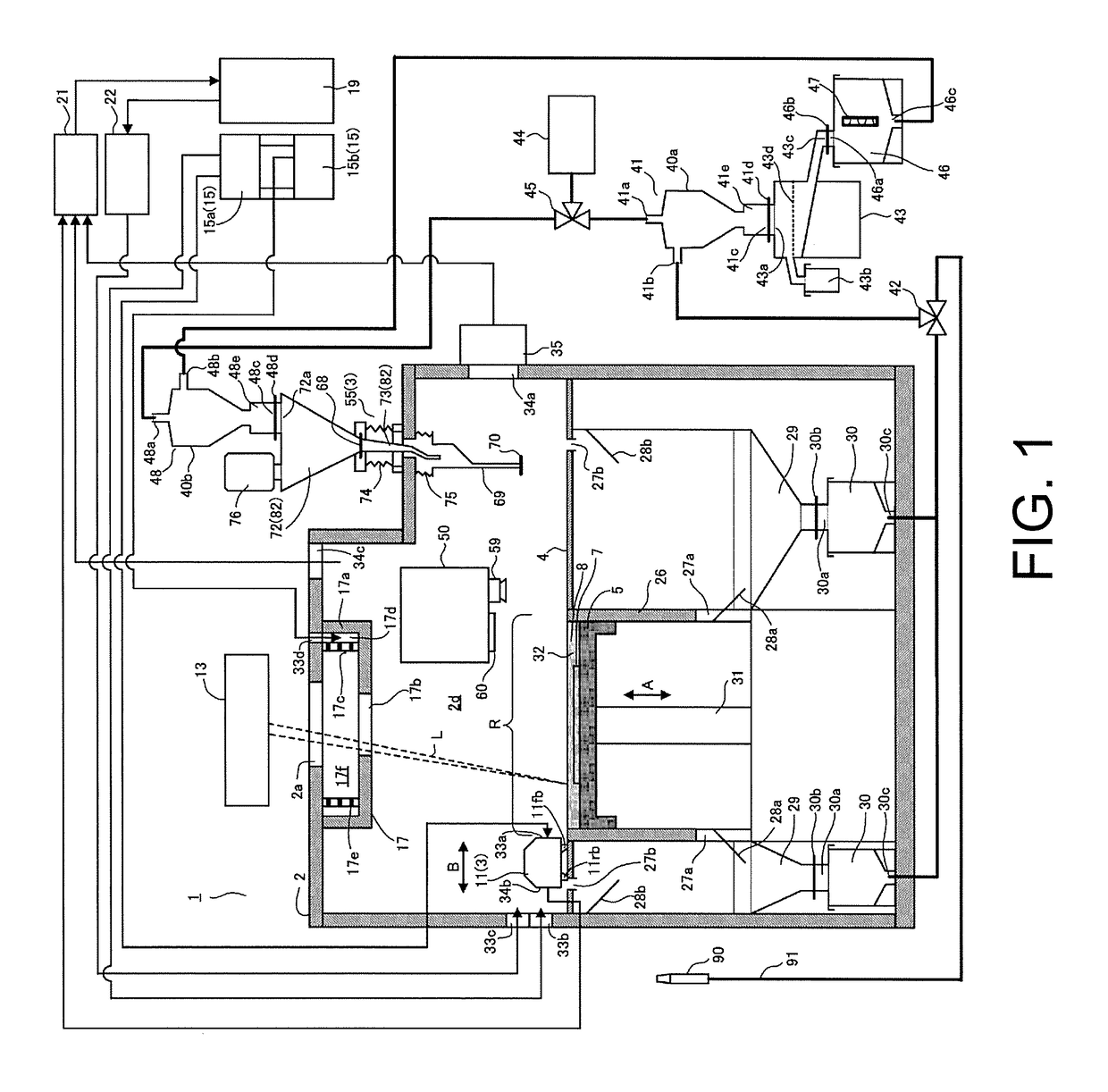

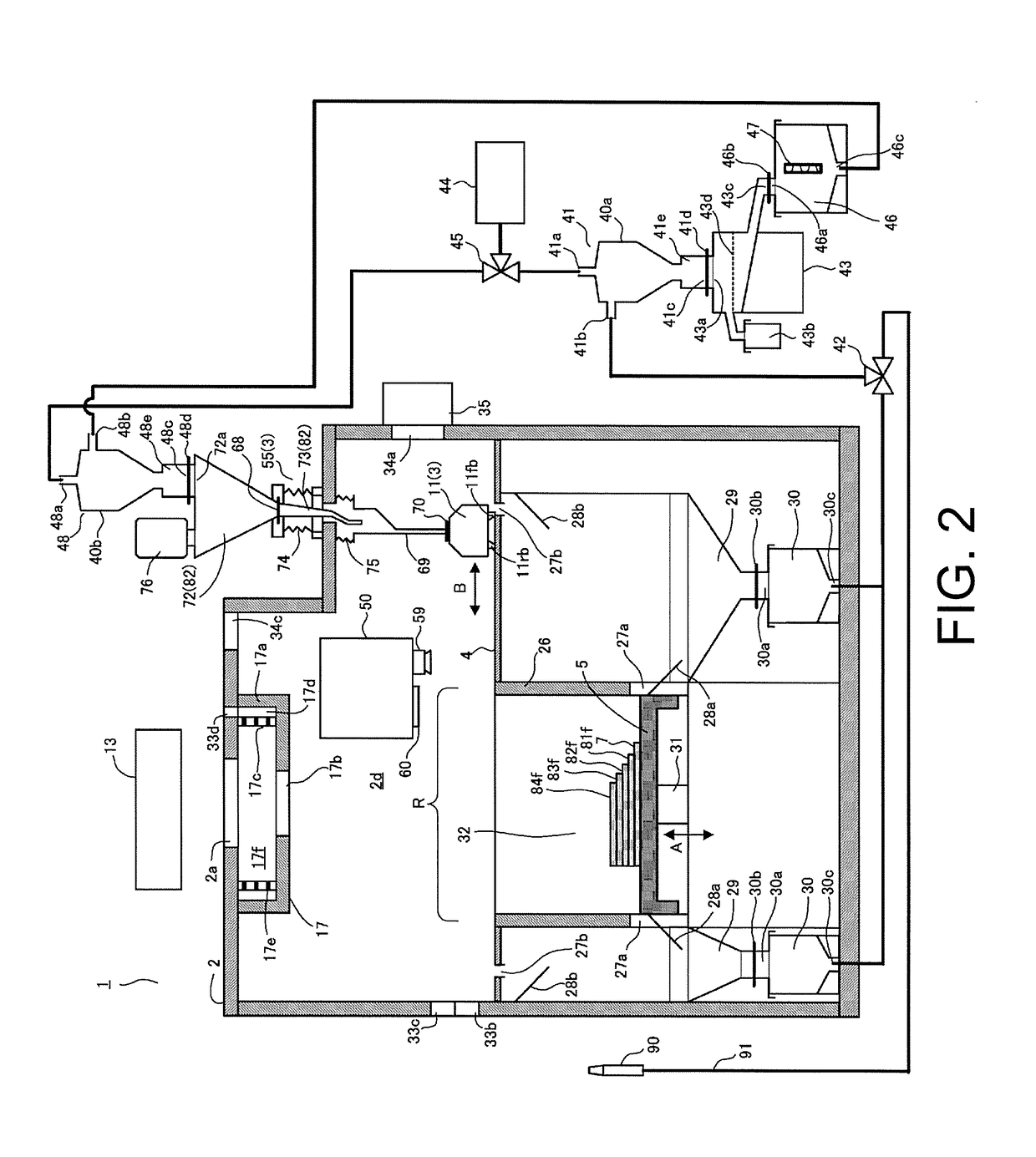

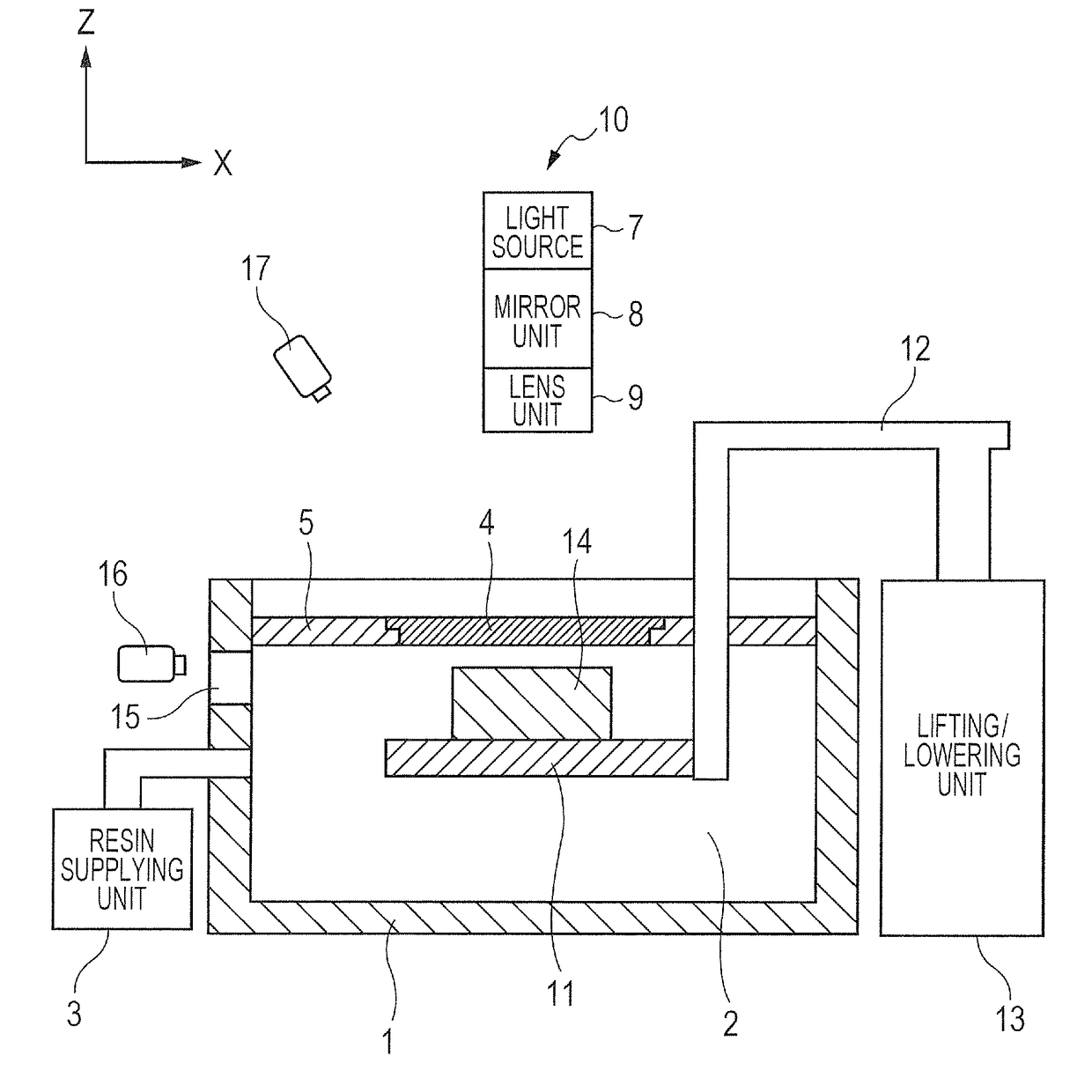

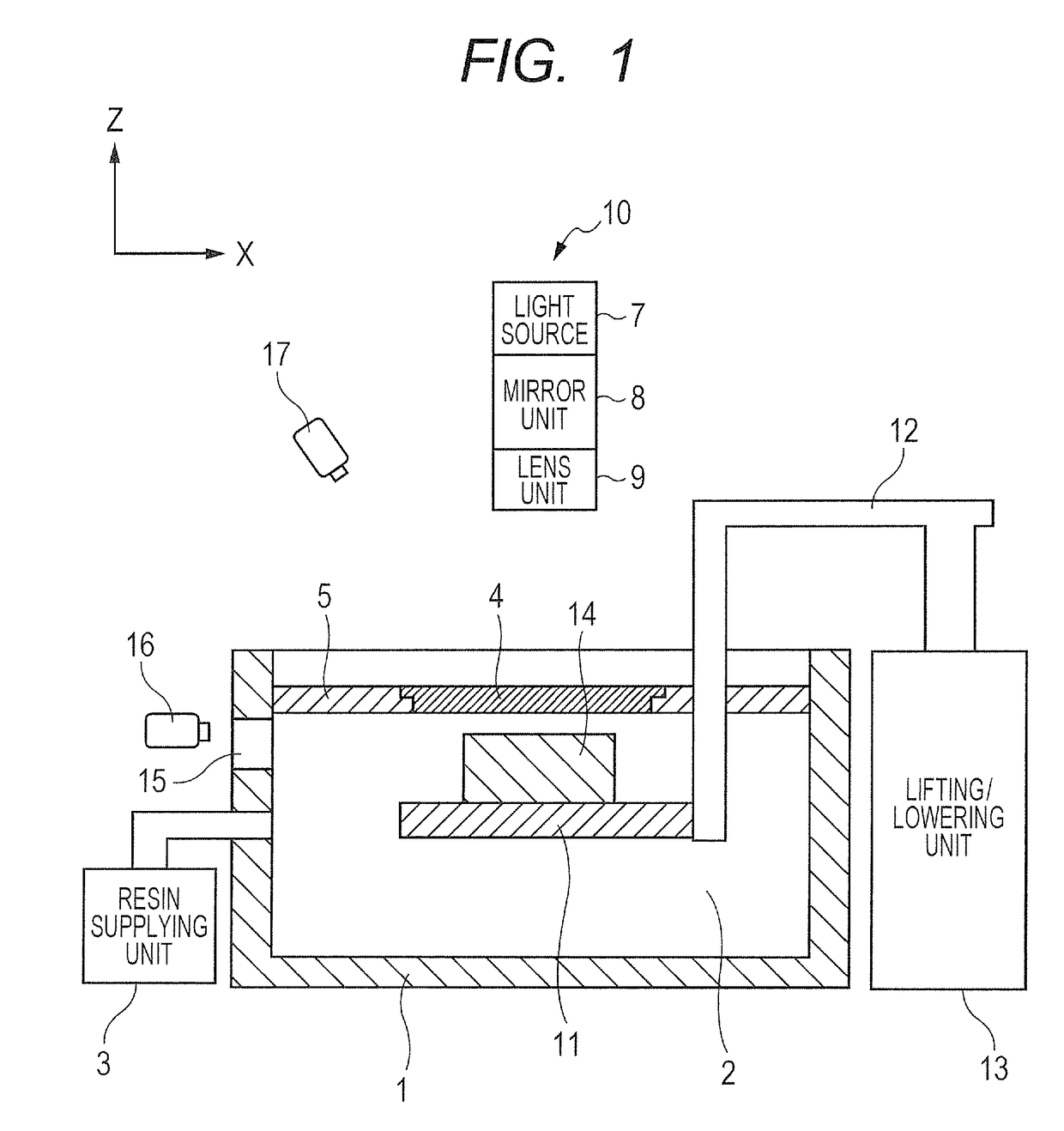

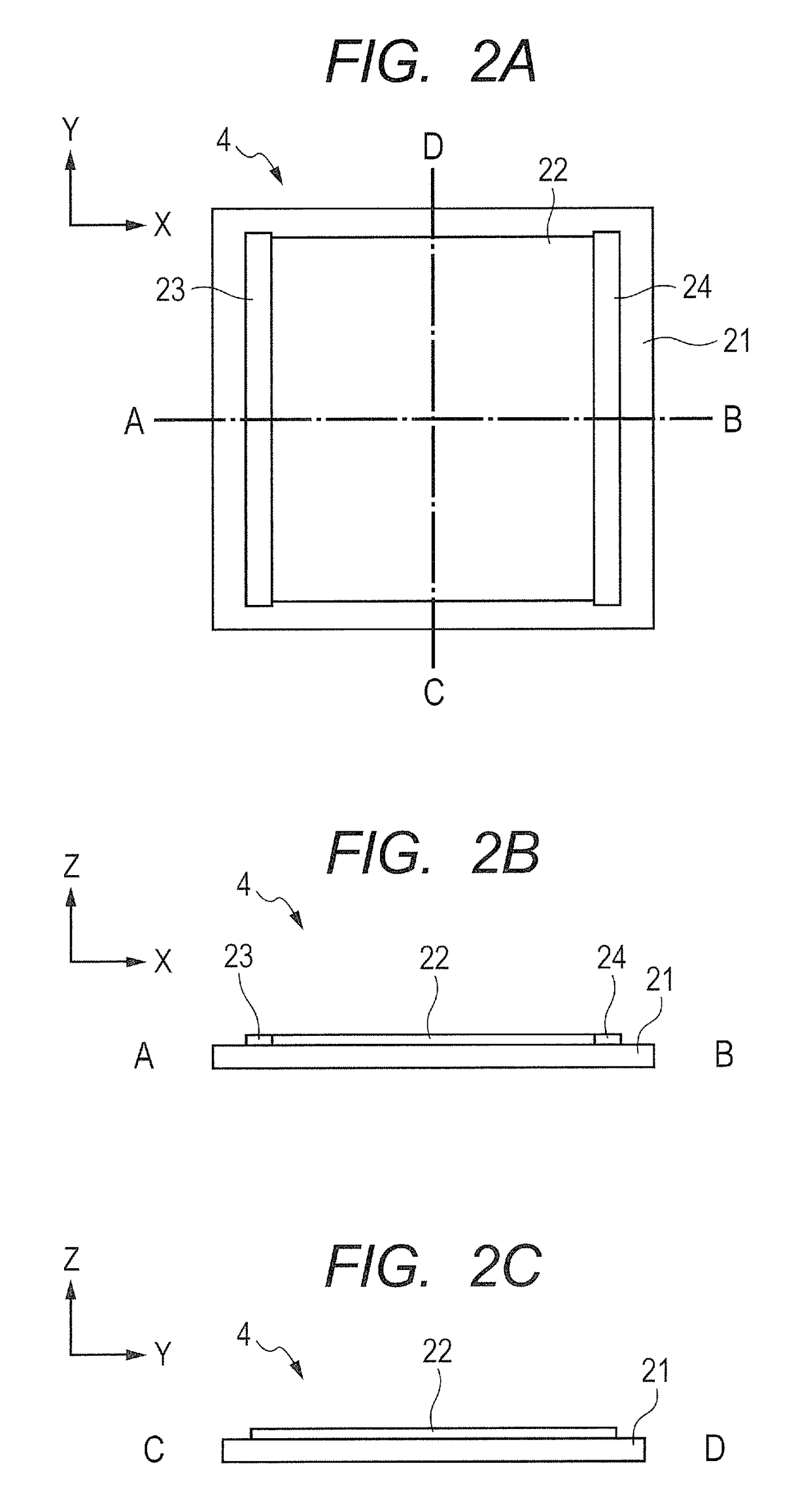

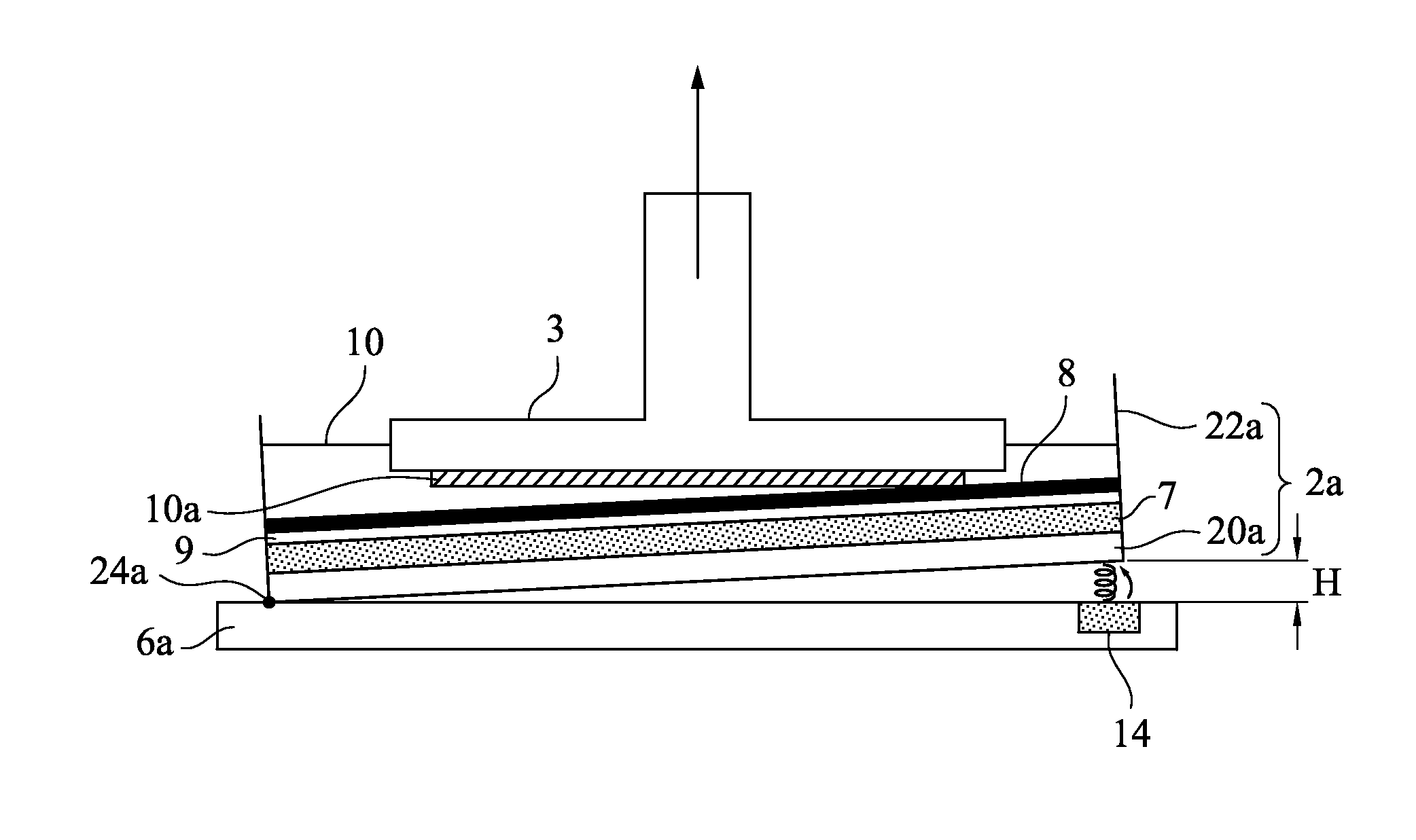

Three-dimensional manufacturing apparatus, three-dimensional manufactured object producing method, and container for three-dimensional manufacturing apparatus

ActiveUS20180065302A1Easy to moveManufacturing platforms/substratesManufacturing enclosuresEngineeringManufactured Object

There is provided a three-dimensional manufacturing apparatus which is characterized by comprising: a container configured to hold a liquid photocurable resin; a base configured to support a solid manufactured object obtained by curing the liquid photocurable resin; a moving unit configured to move the base; and a light source unit configured to irradiate light for curing the liquid photocurable resin. The container comprises a light transmission portion which is provided between the light source unit and the base, and is in contact with the liquid photocurable resin. The three-dimensional manufacturing apparatus further comprises a flow facilitating unit configured to facilitate a flow of the photocurable resin which is in contact with the light transmission portion, the flow being attended by the movement of the base.

Owner:CANON KK

Stereolithography apparatus

ActiveUS9452567B2Overcome problemsSmall distanceManufacturing platforms/substratesManufacturing enclosuresBraced frameFuel tank

A stereolithography apparatus includes a supporting frame assembly, a tank supported on the supporting frame assembly, a vertically moving module, and a build platform. The tank has an anchored portion anchored to the supporting frame assembly. The build platform is vertically moved relative to the tank by the vertically moving module. After a resin layer is solidified and adhered to the bottom of the tank and the build platform, the tank is peeled away from the resin layer starting from a portion of the resin layer adjacent to the anchored portion and partially moves upward relative to the supporting frame assembly around the anchored portion when the build platform leaves the supporting frame assembly. To further reduce the separation force between the cured resin layer and the tank, the bottom of the tank is covered with materials that are transparent, chemically resistant, impact resistant or / and elastic.

Owner:SYAO KAO CHIH

System for layered construction of a body and pan therefor

ActiveUS20160136902A1Easy to wearThin wallManufacturing platforms/substratesManufacturing enclosuresRegioselectivityEngineering

A system is described for layered construction of a body made of a light-curable substance. The system comprises a tray made of resilient material for receiving the substance in a liquid or pasty state, a light source for regionally selective curing of the layer of the substance lying on the tray base, a construction platform arranged above the tray base and capable of being lowered and raised relative thereto for adhering to and lifting the cured substance layer, a tensioning means configured to exert tension or compression onto the tray, and a control means controlling the tensioning means and the construction platform accordingly. A tray is also described for use in a system of this type.

Owner:WAY TO PRODION

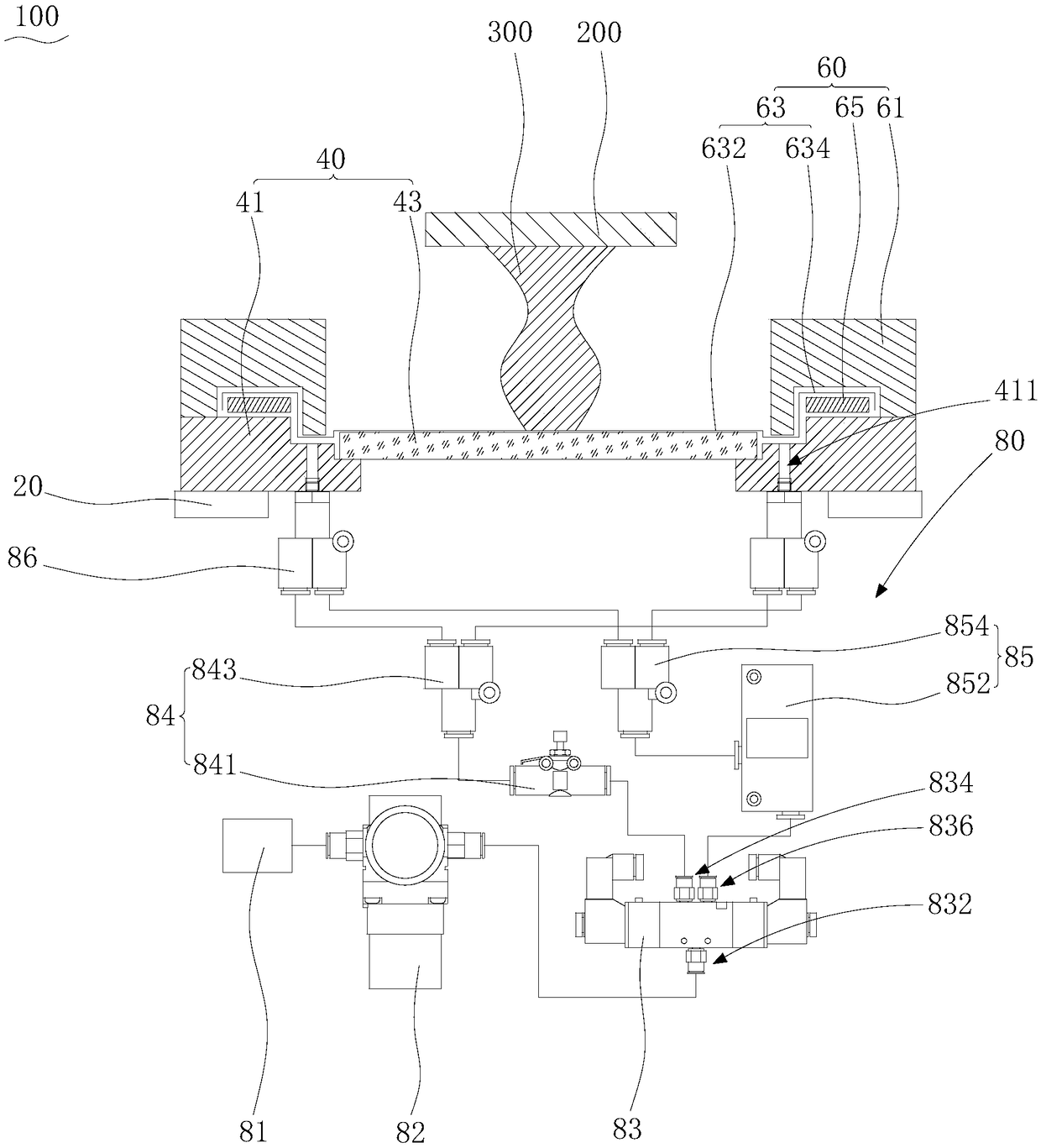

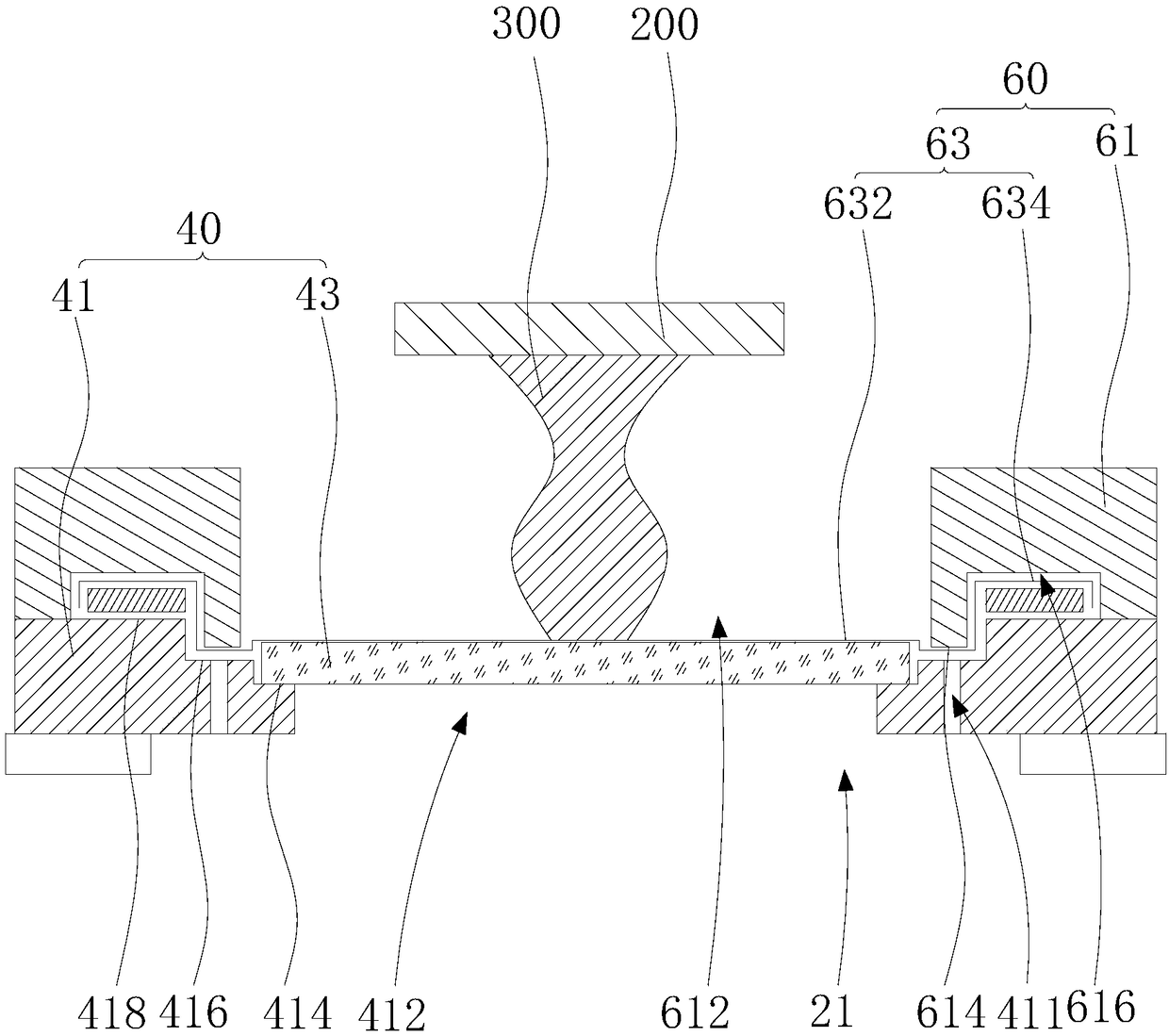

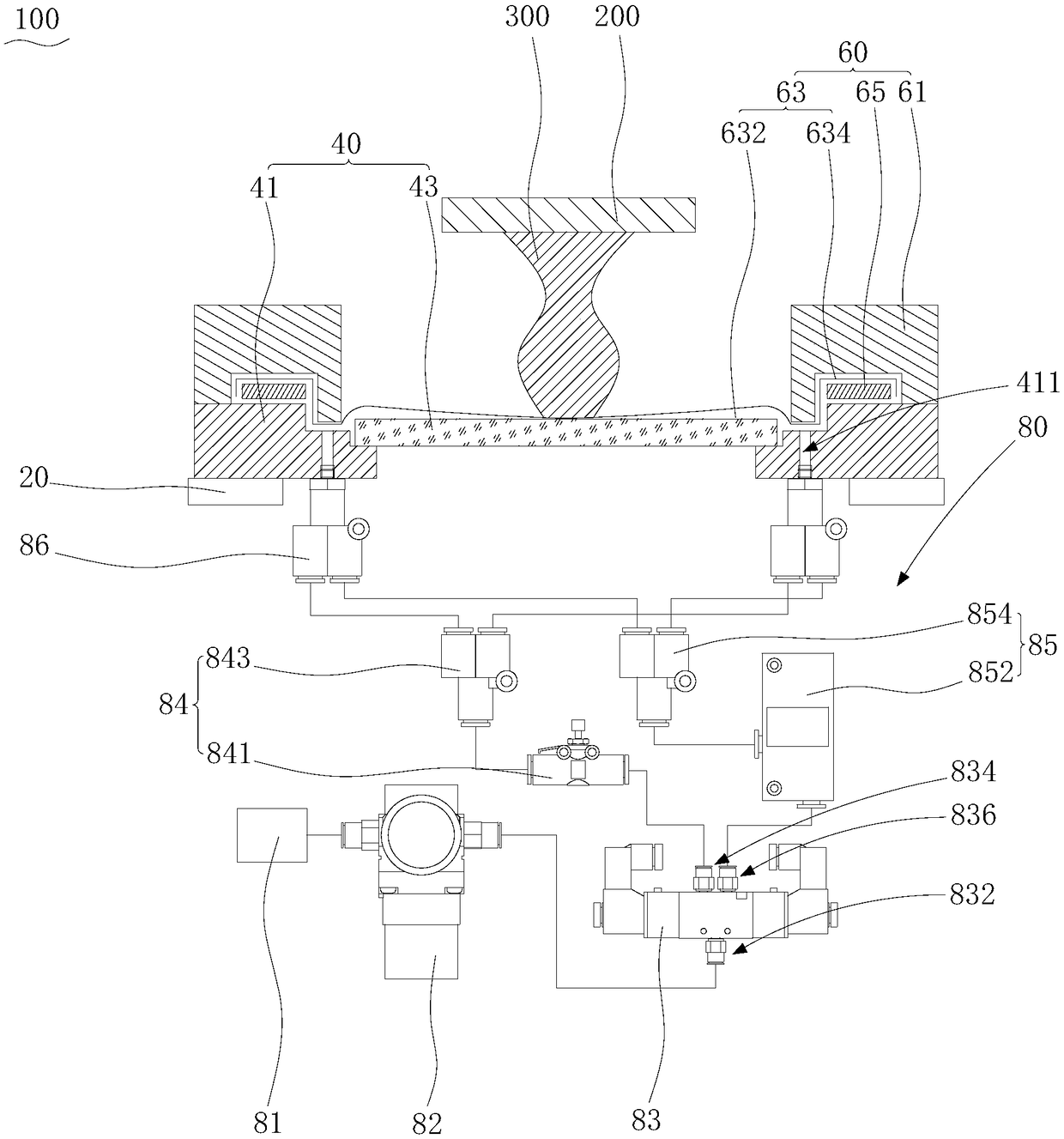

Liquid tank device, three-dimensional printing device provided therewith and printing model separating method

The invention relates to a liquid tank device, a three-dimensional printing device provided therewith and a printing model separating method. The liquid tank device comprises a fixed platform; a supporting structure comprising a pallet and a light-transmitting plate; a liquid tank structure comprising a liquid tank body and a separation membrane; and a pneumatic separation mechanism for introducing a gas between the separation membrane and the light-transmitting plate, or extracting a gas between the separation membrane and a support structure out; wherein the separation membrane and the support structure together form a venting gap. The pneumatic separation mechanism can supply the gas into the venting gap between the separation membrane and the support structure to deform the separationmembrane so as to separate the separation membrane from the light-transmitting plate to break vacuum environment between the separation membrane and the light-transmitting plate. Therefore, the separation membrane can be deformed following a printing layer due to the ductility of the separation membrane, and the printing layer can be finally separated from the separation membrane easily. When thepneumatic separation mechanism evacuates the gas in the venting gap between the separation membrane and the support structure, the separation membrane can be reattached to the light-transmitting plateto prepare for next printing.

Owner:HANS LASER TECH IND GRP CO LTD

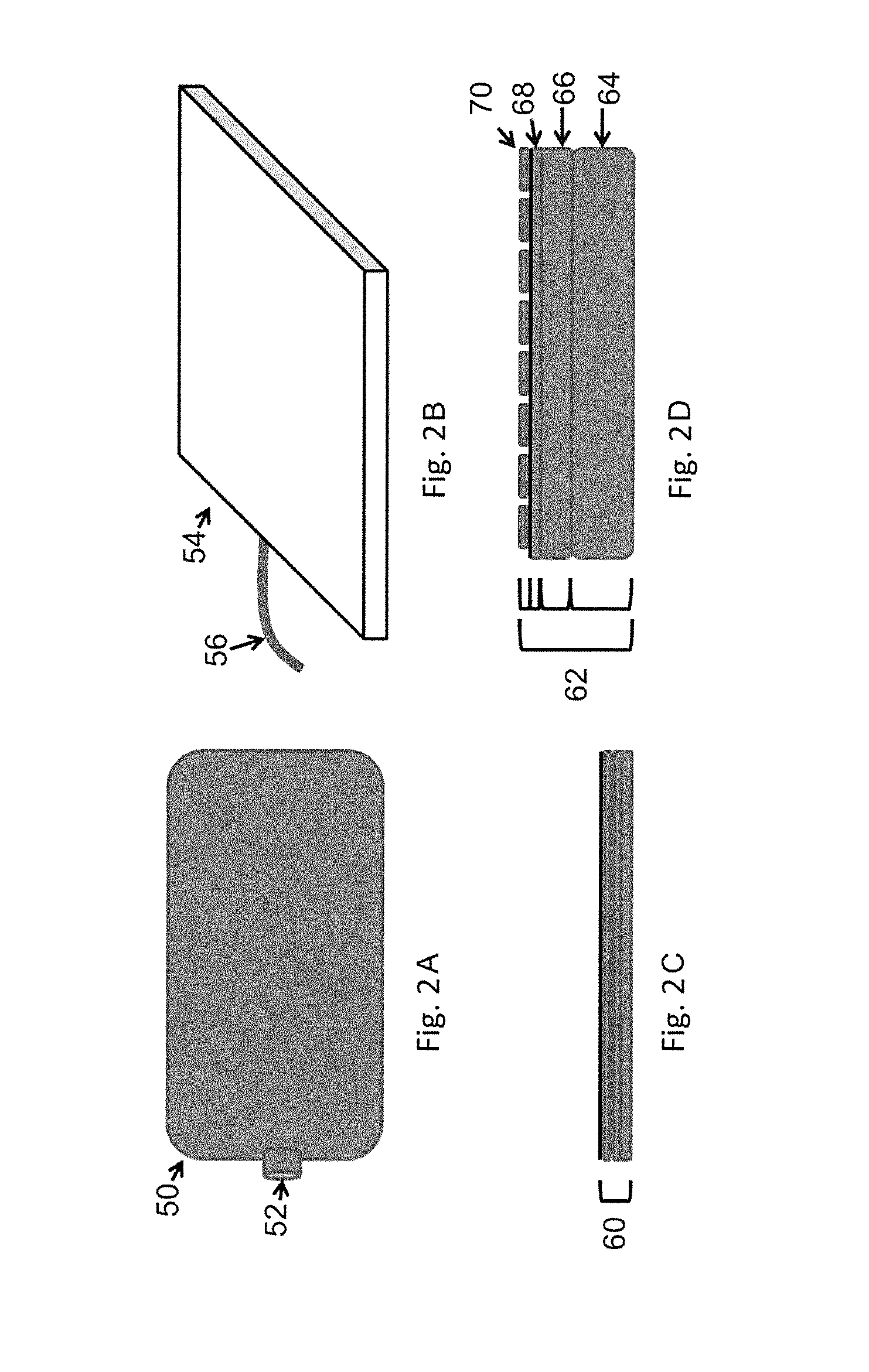

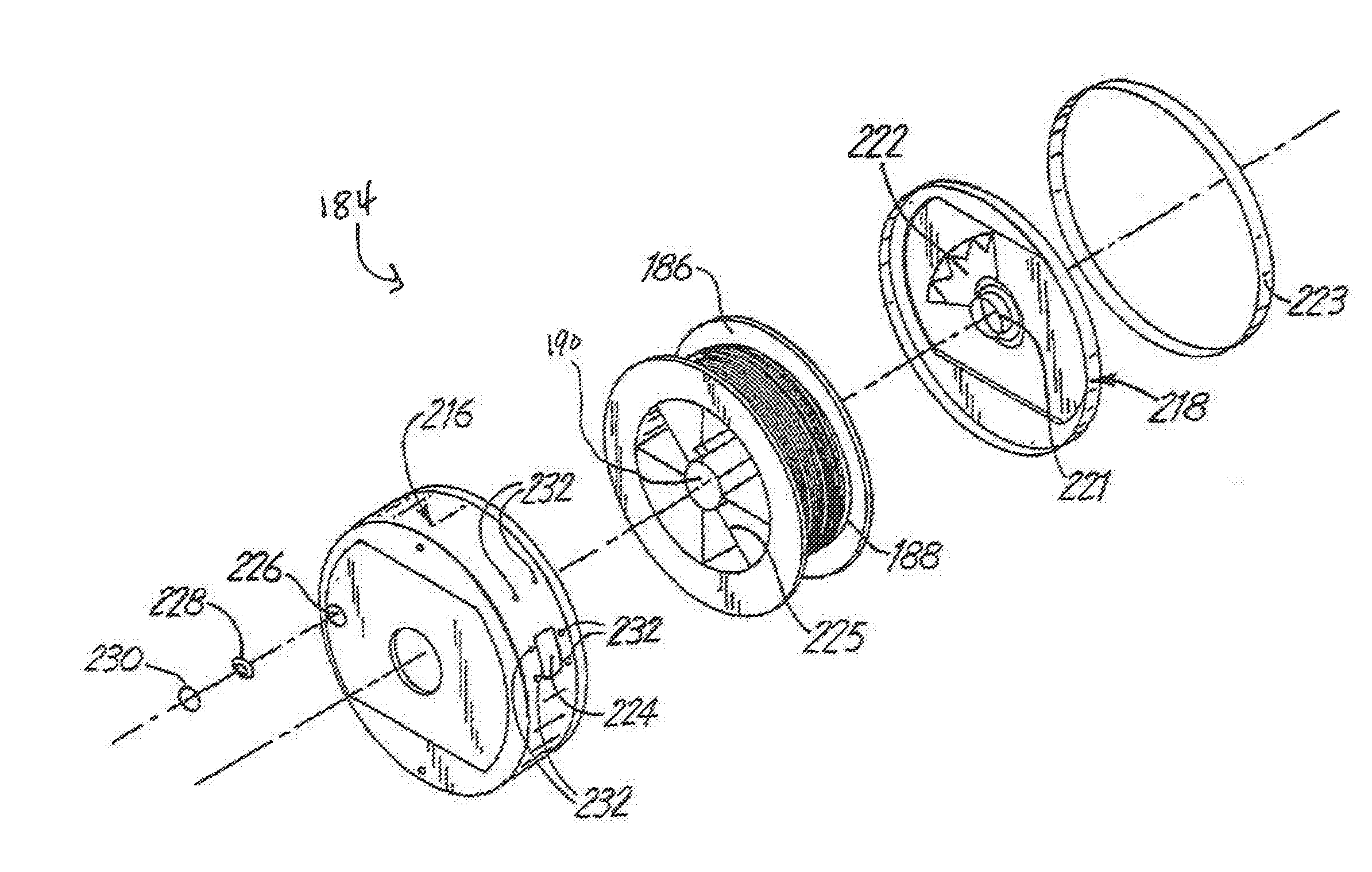

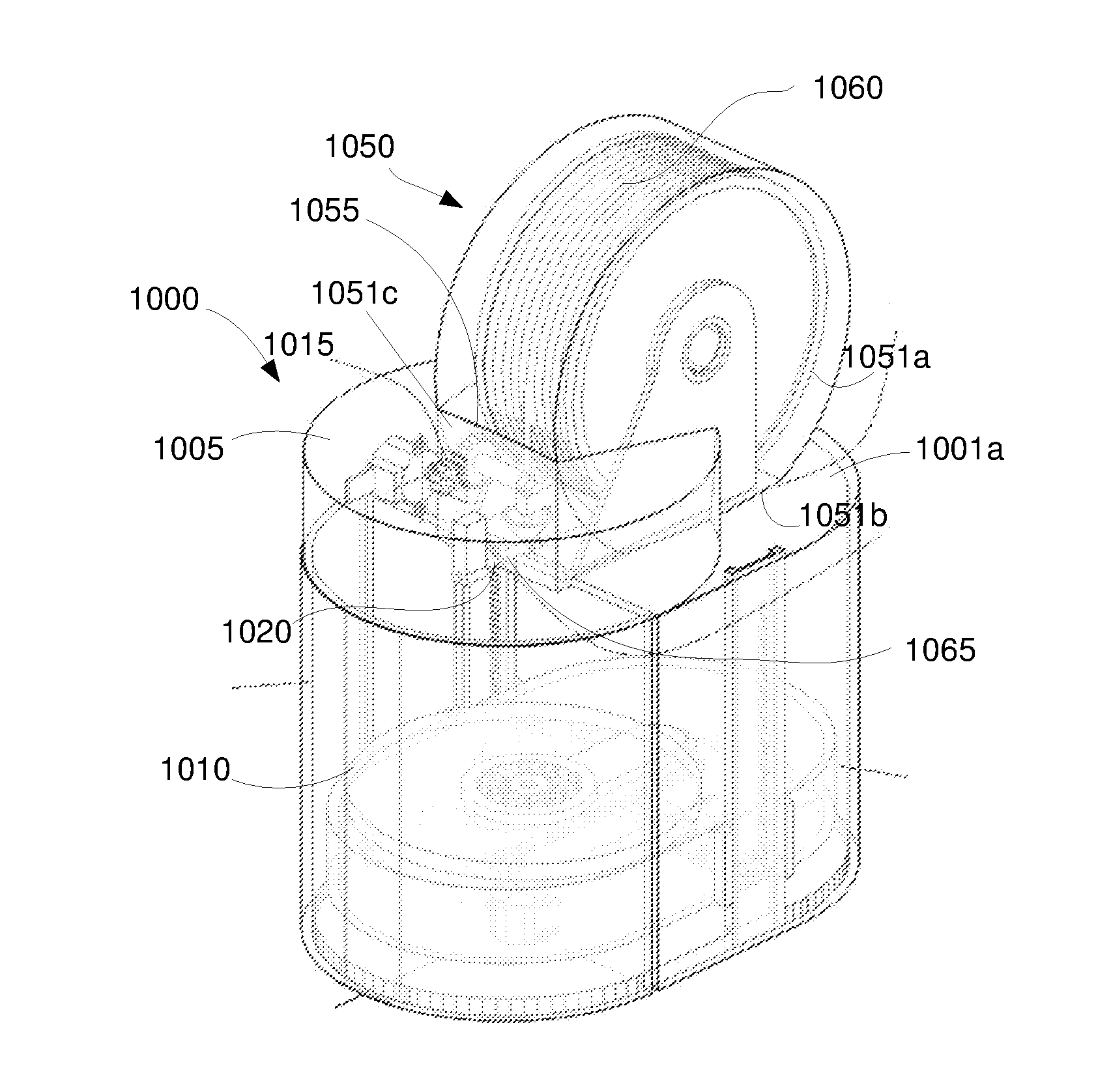

Three dimensional printer and cartridge

ActiveUS20160257068A1Manufacturing platforms/substratesManufacturing driving meansEngineeringSoftware

In one aspect of the present invention, a cartridge for use in a three dimensional (3-D) printer is described. Another aspect of the invention relates to a 3-D printer that is arranged to engage the cartridge. Various embodiments relate to devices, methods, software and systems related to the above cartridge and / or printer.

Owner:FUNFARE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com