Patents

Literature

350 results about "Manufactured Object" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A physical object created by hand or machine.

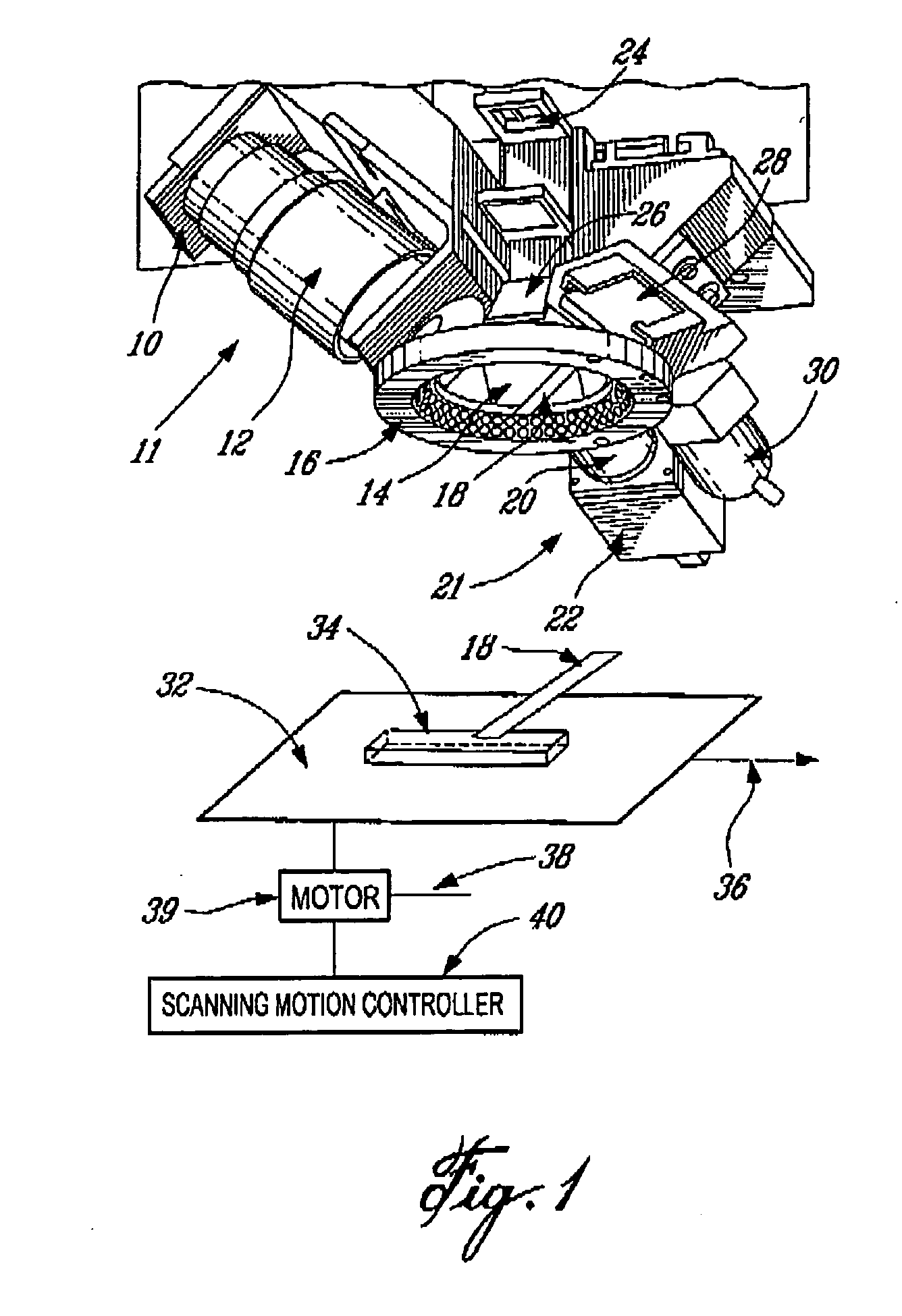

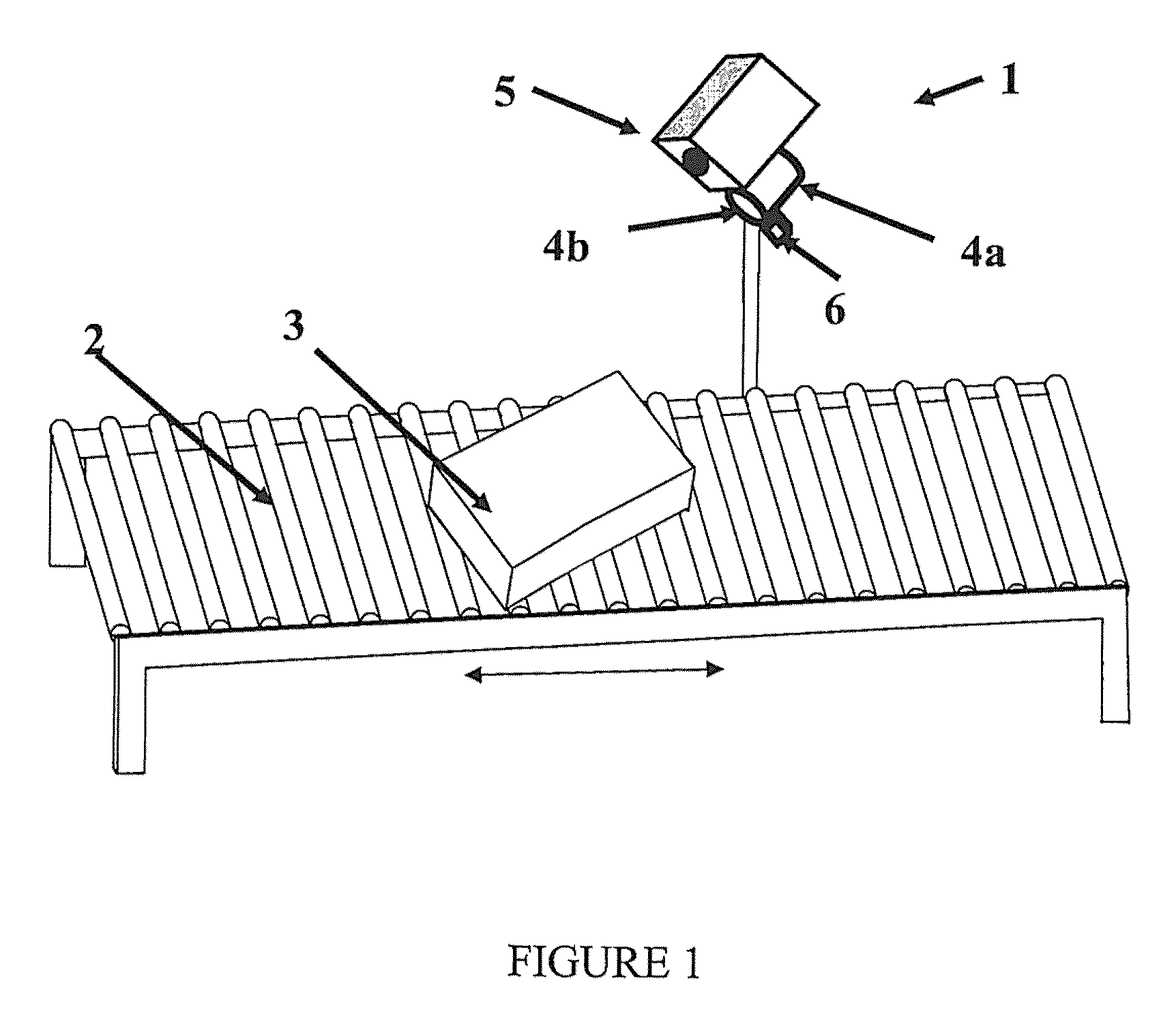

Dimensioning system

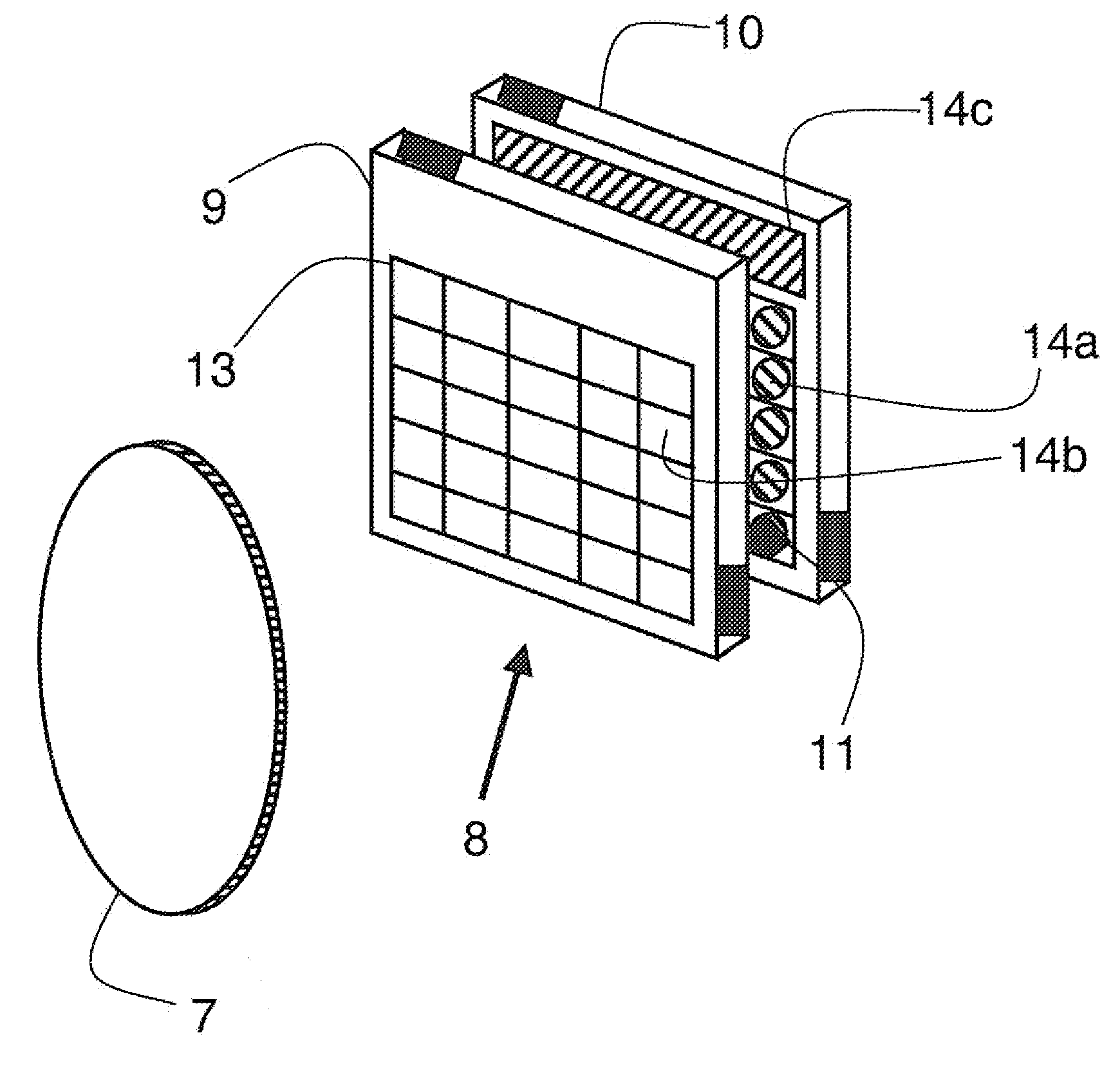

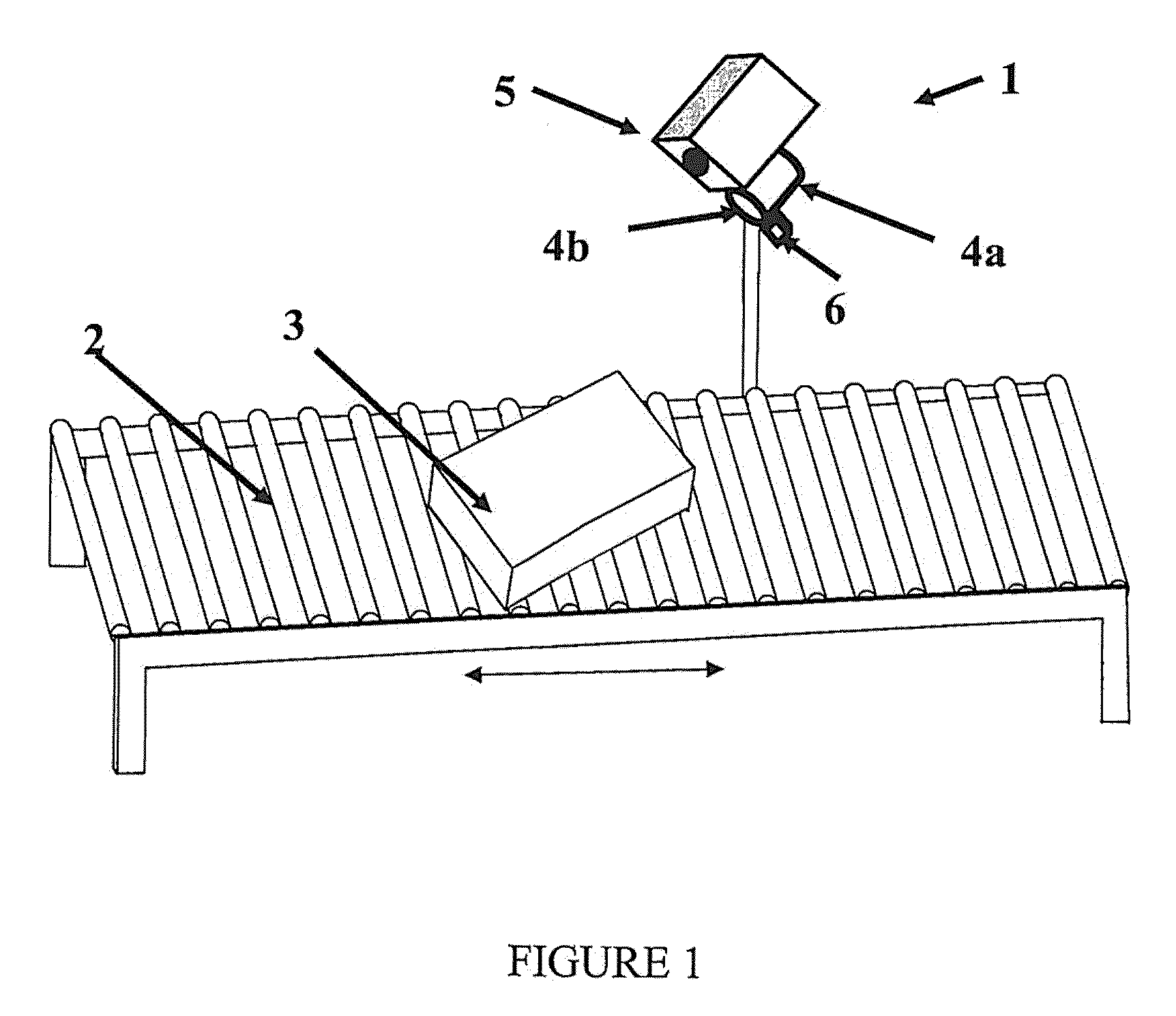

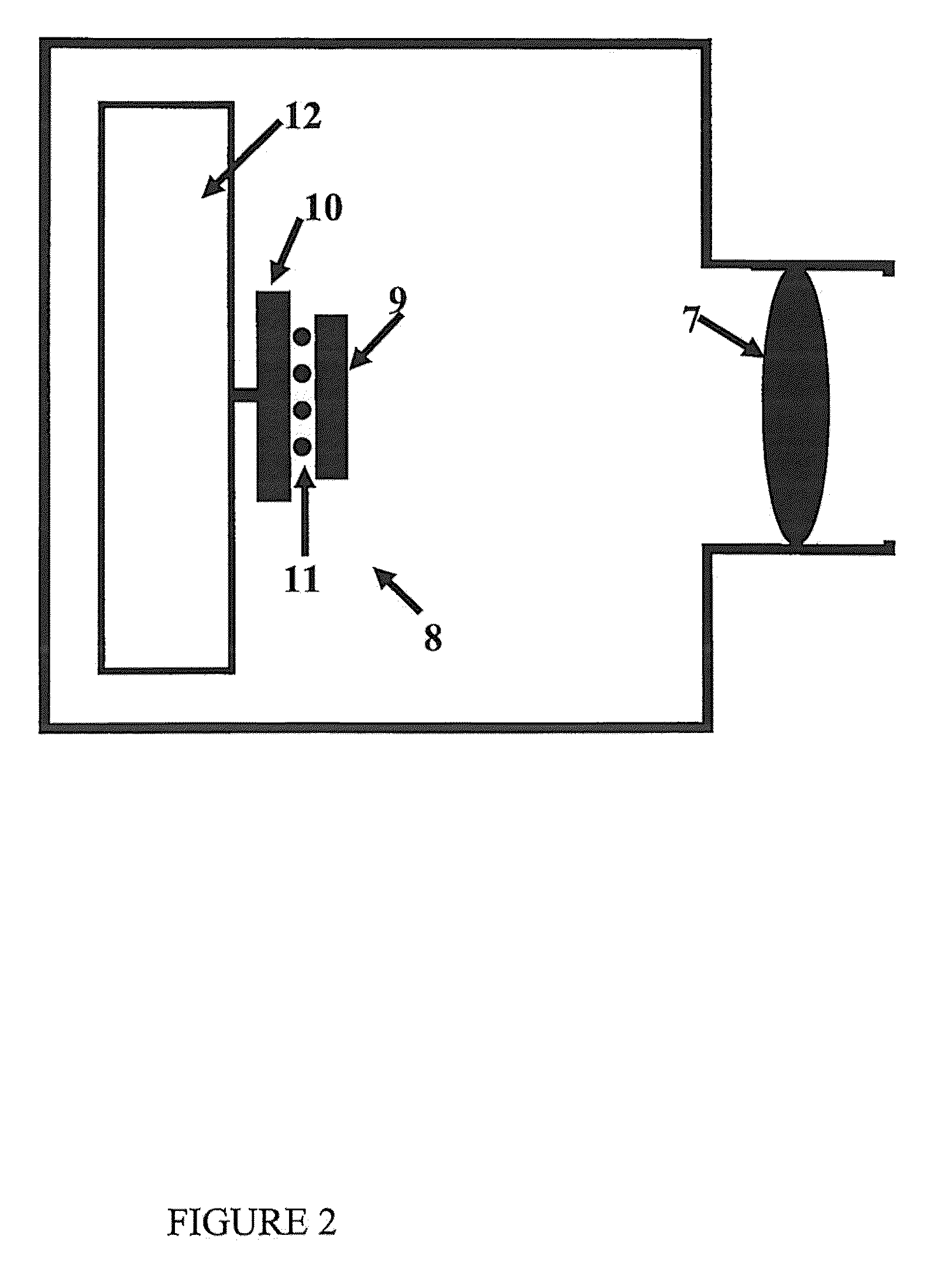

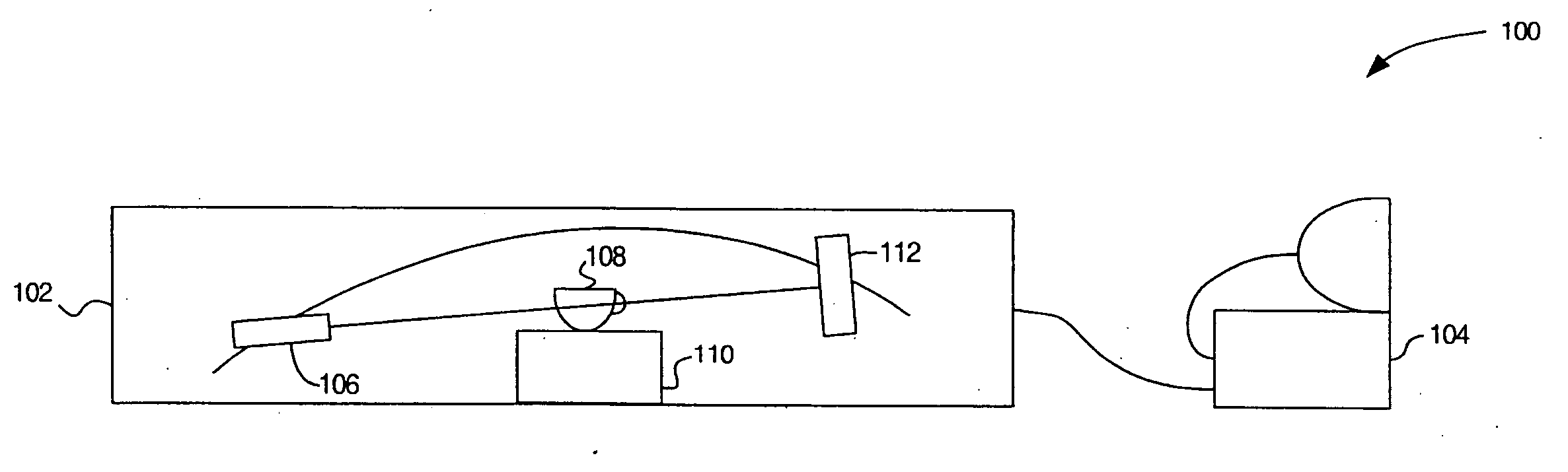

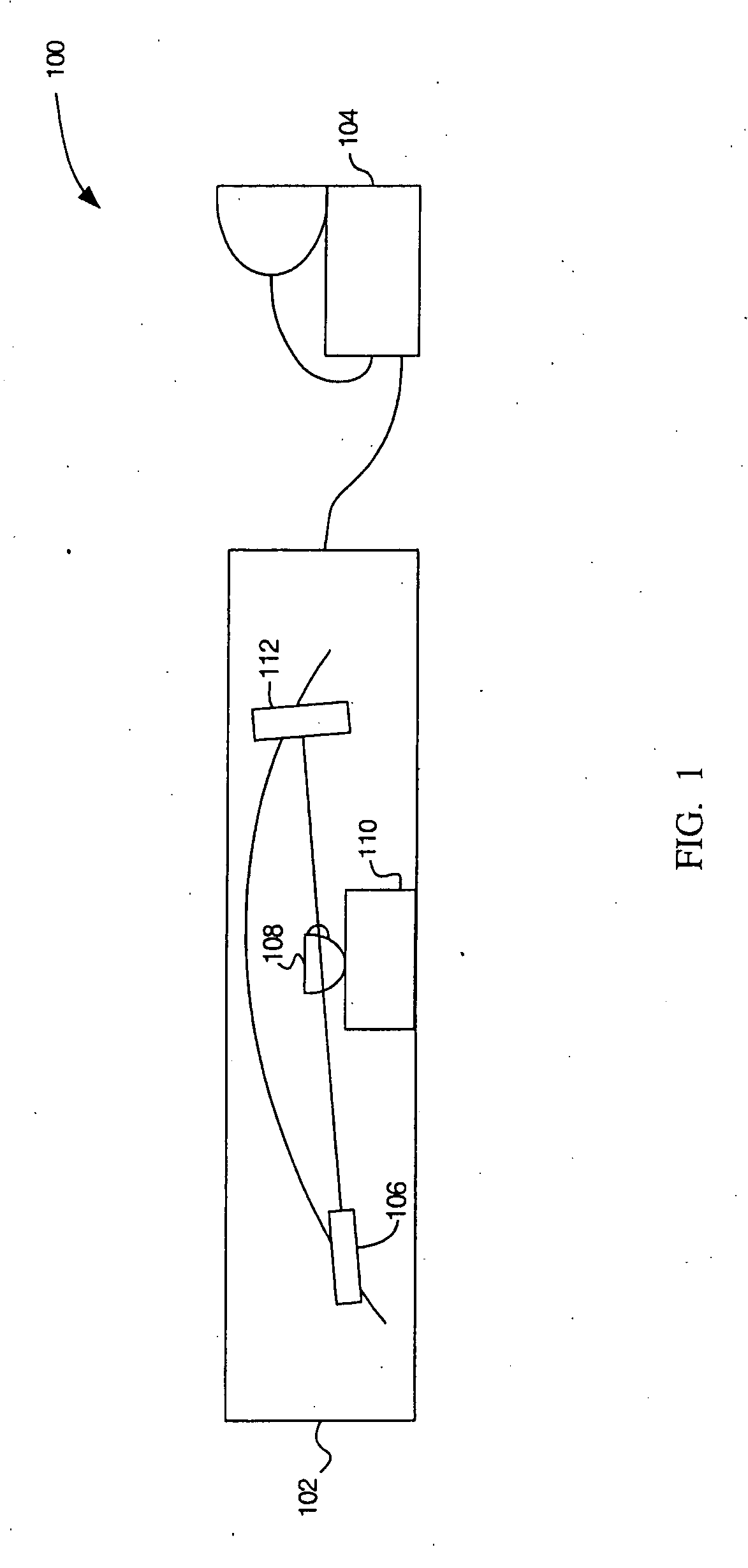

ActiveUS20100208039A1Enhanced third dimension accuracyMechanically simpleUsing optical meansRobotQuality controlLaser pulse shaping

The present invention determines the dimensions and volume of an object by using a novel 3-D camera that measures the distance to every reflective point in its field of view with a single pulse of light. The distance is computed by the time of flight of the pulse to each camera pixel. The accuracy of the measurement is augmented by capture of the laser pulse shape in each camera pixel. The camera can be used on an assembly line to develop quality control data for manufactured objects or on a moving or stationary system that weighs as well as dimensions the objects. The device can also ascertain the minimum size of a box required to enclose an object.

Owner:CONTINENTAL AUTONOMOUS MOBILITY US LLC

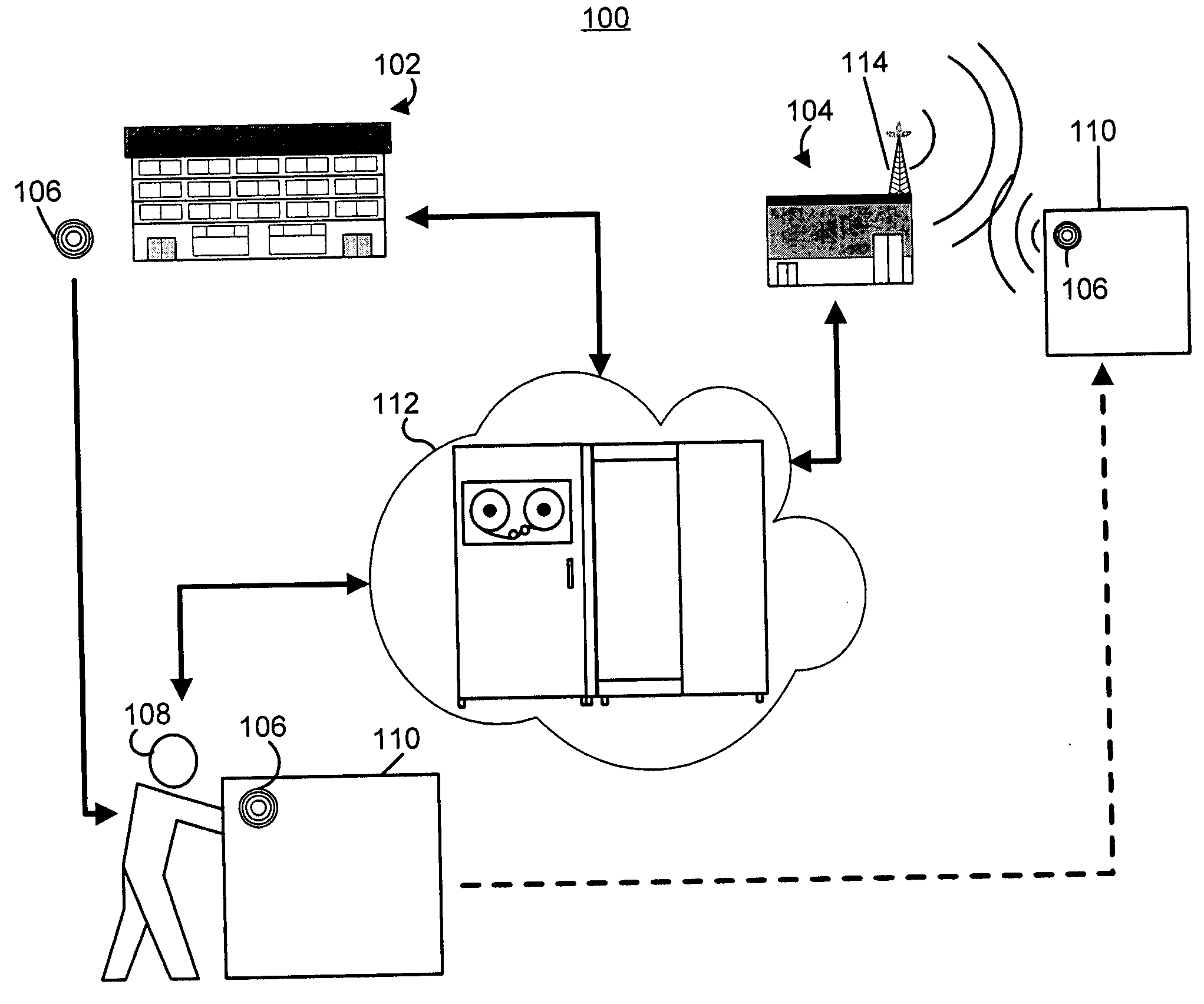

Manufactured article recovery system

ActiveUS20050035860A1Easy to identifyData processing applicationsMemory record carrier reading problemsNetwork connectionDatabase

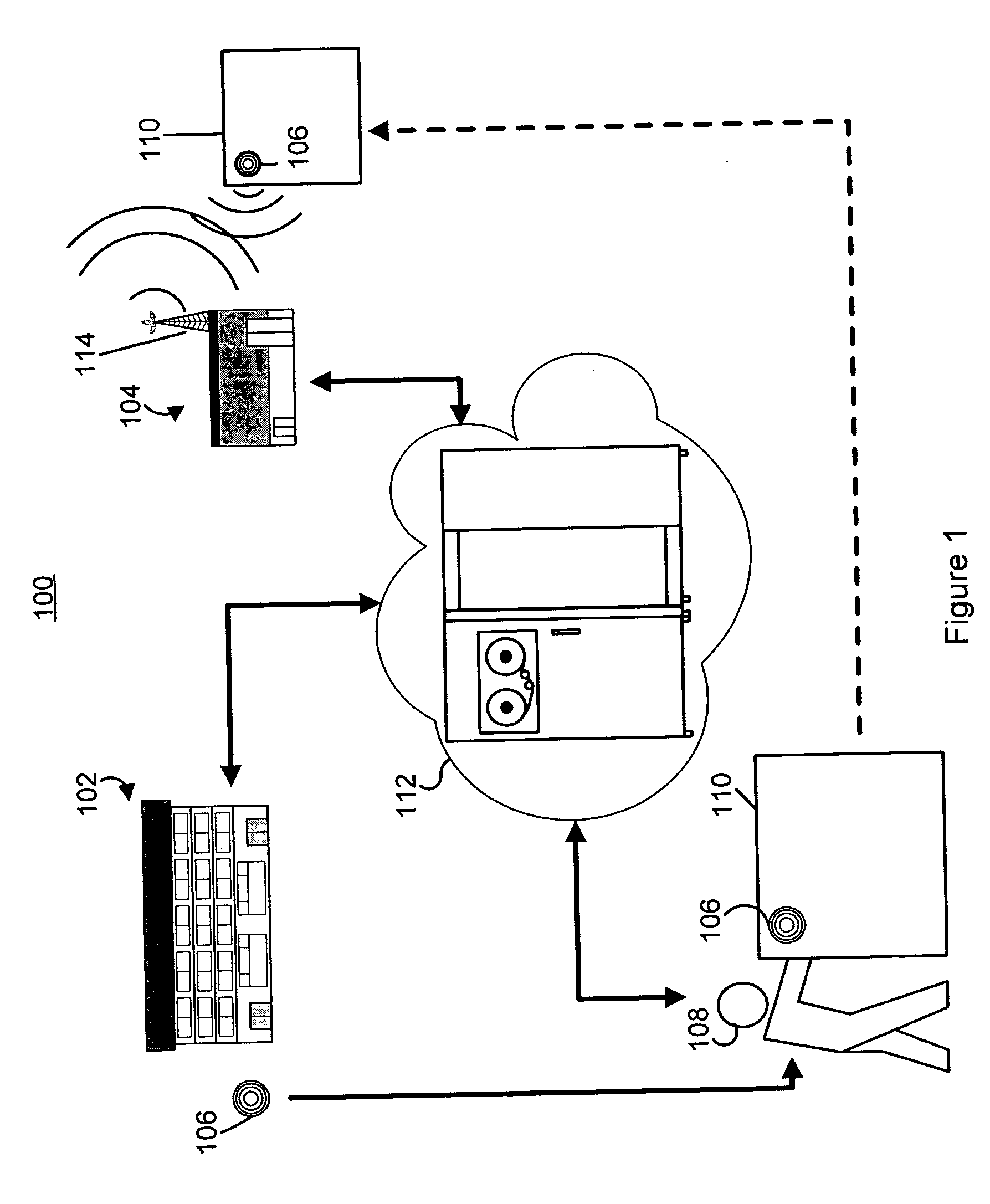

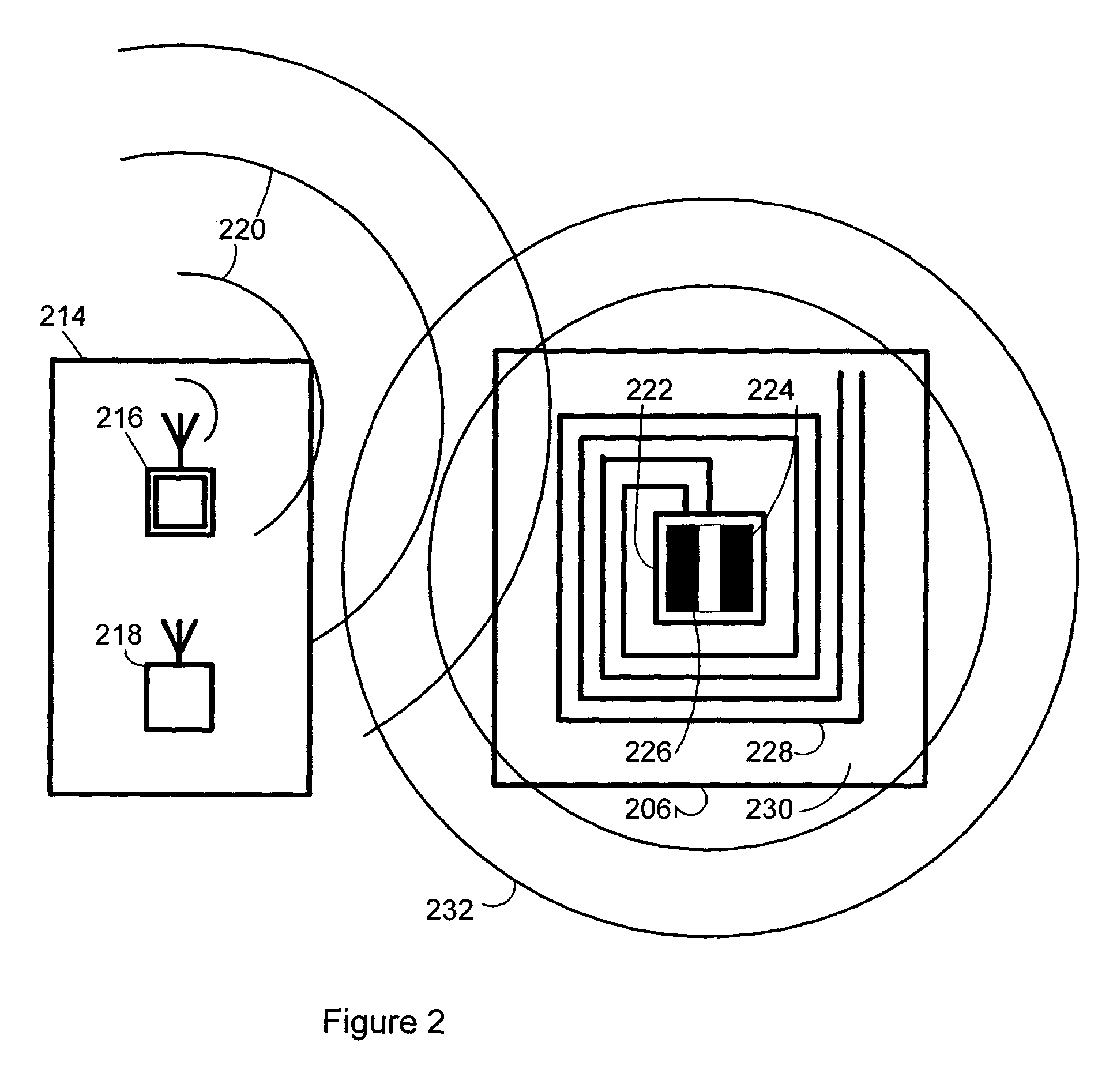

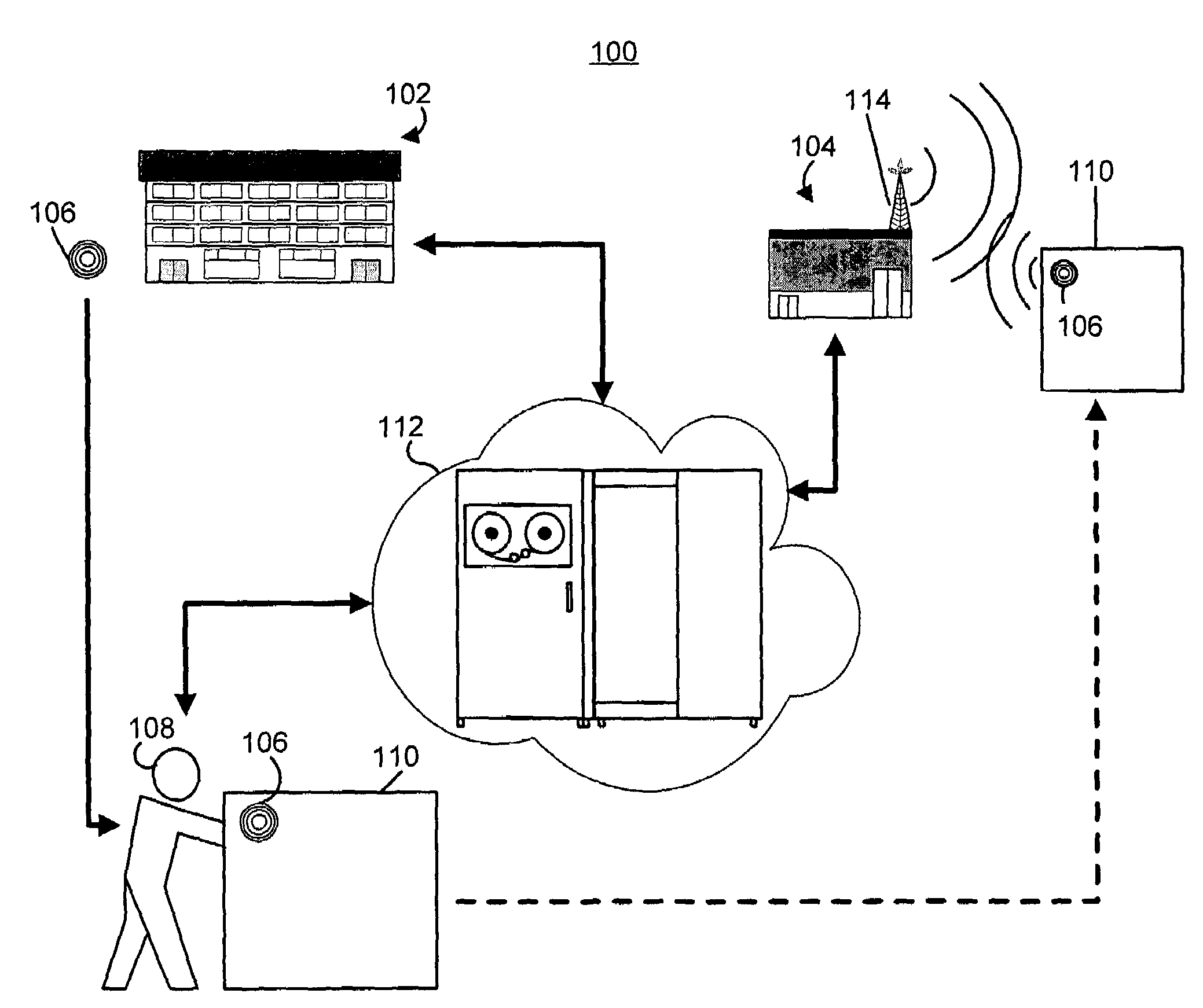

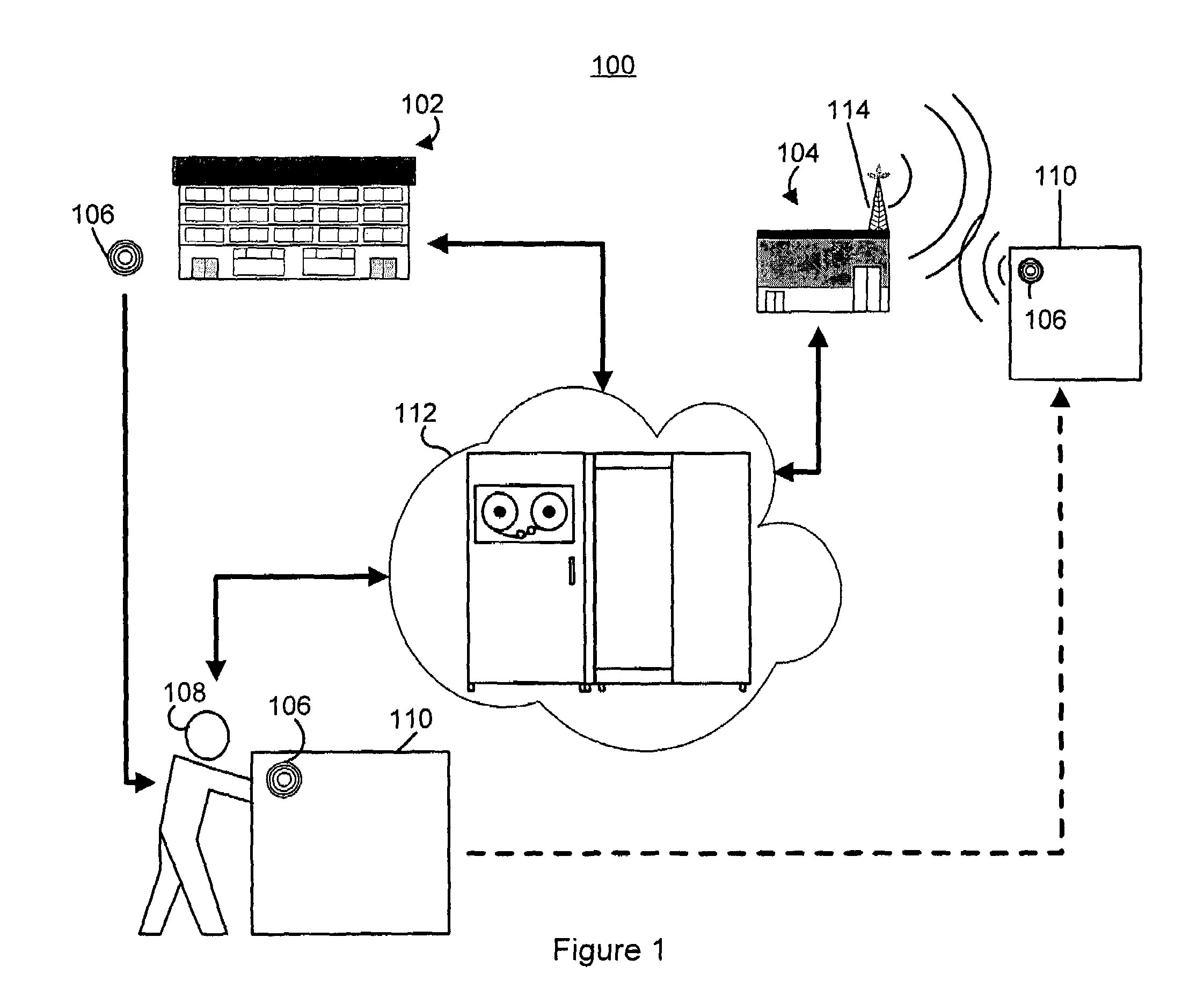

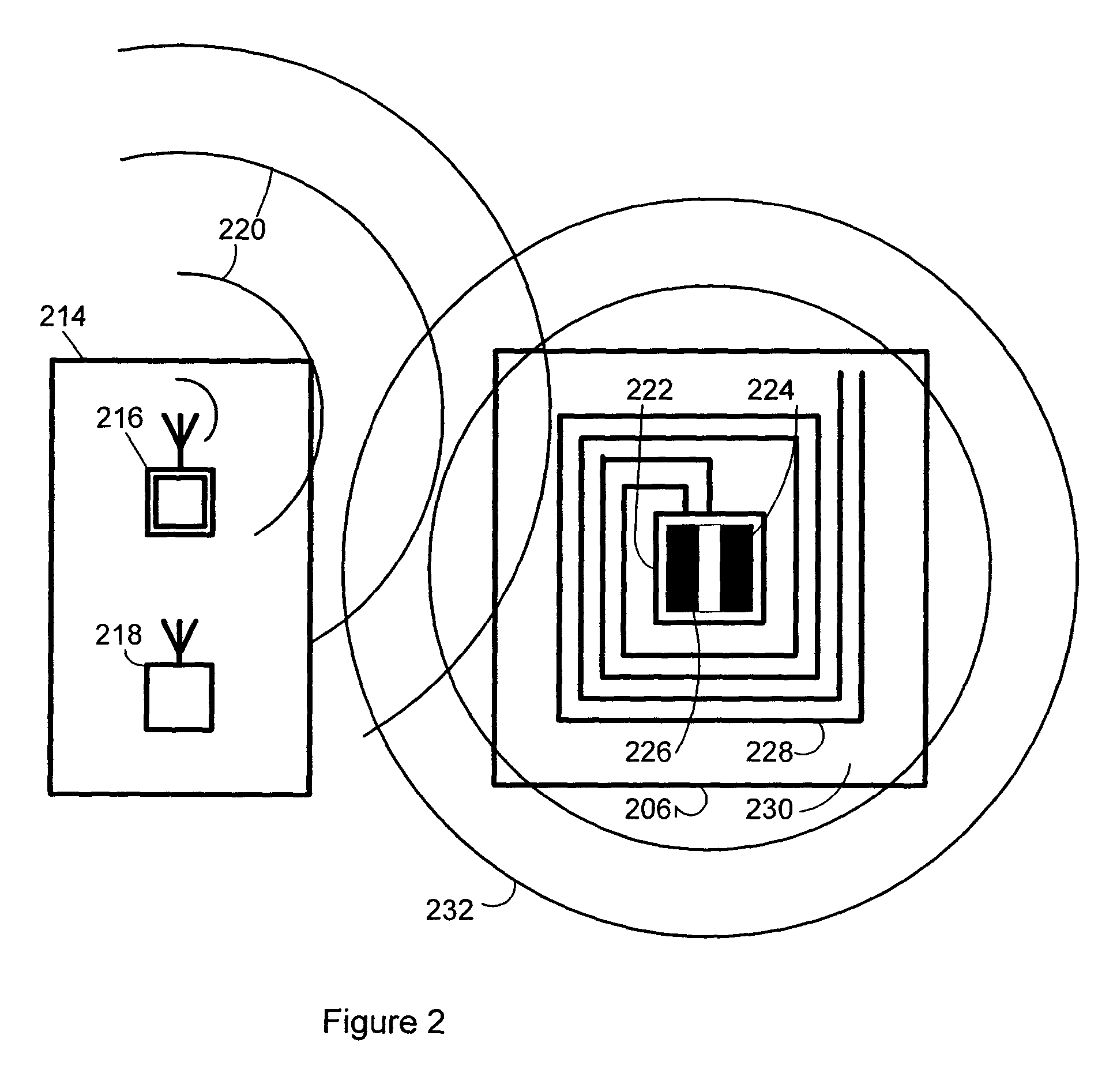

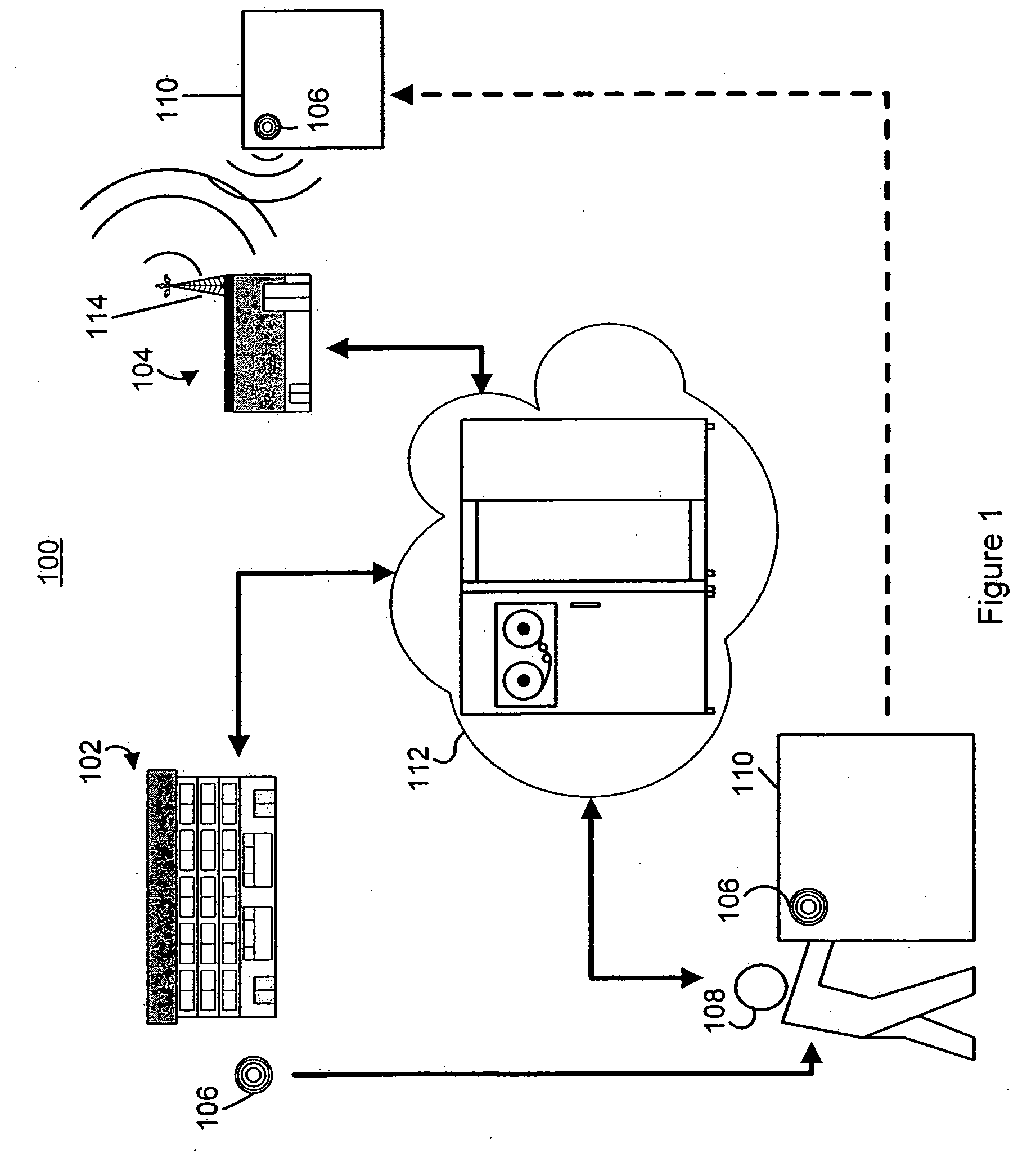

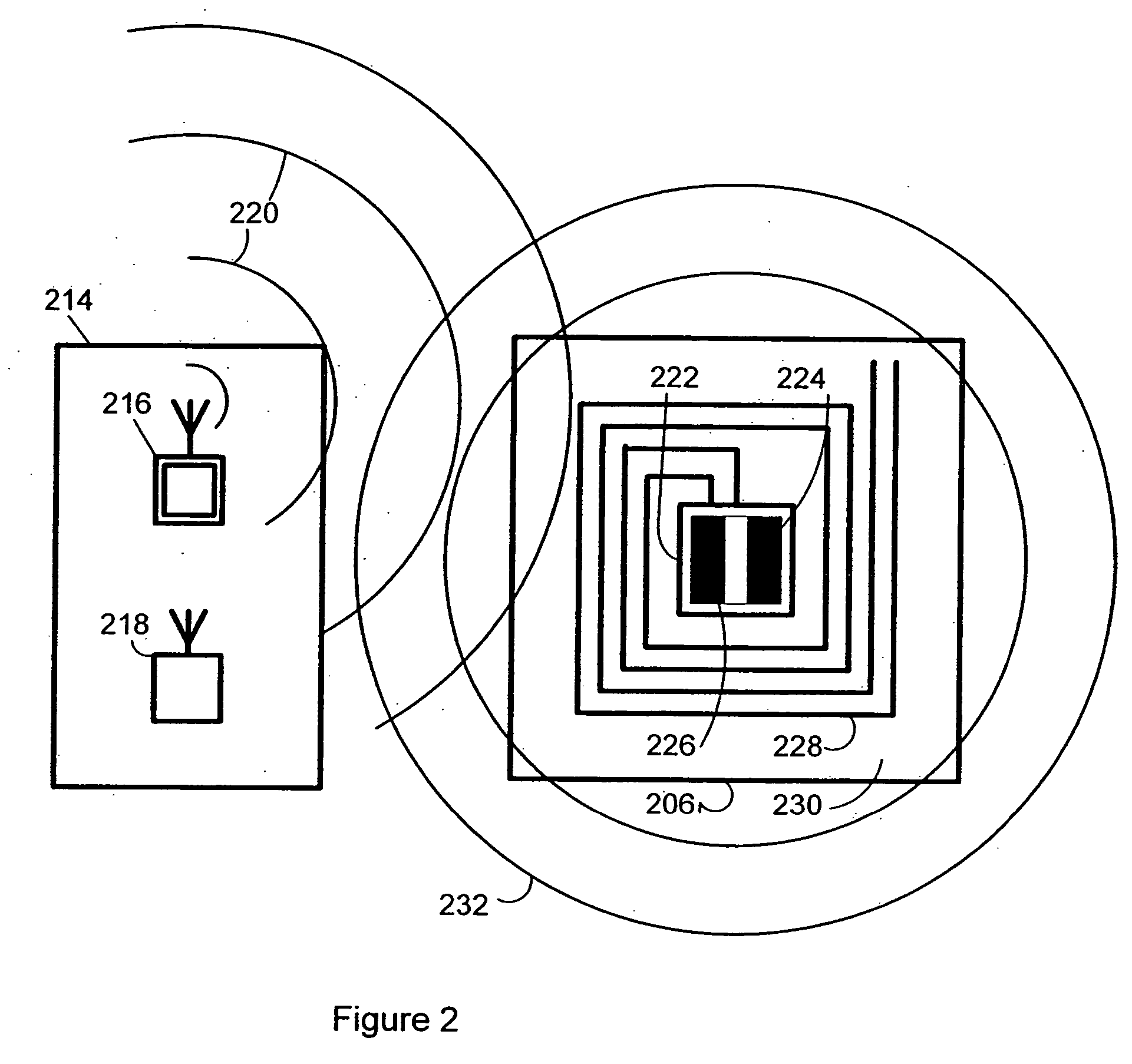

A system for recovering a manufactured article is disclosed. The system includes an electronic reader that reads a unique code associated with the manufactured article when that article is within range of the reader. The unique code may be based on a radio-frequency identification (RFID) tag positioned with the manufactured article. The reader may be positioned with a facility associated with retrieval of misplaced or reposed consumer items, or within a community. A database may store records of unique codes and information related to owners of manufactured articles. The database may be downloaded to a local cache. The database also may be queried based on the unique code. The owner of the item may be determined based on a match of a unique code read by the reader to a record in the database. The database may be accessed through an open-network connection to a computerized network.

Owner:ACCENTURE GLOBAL SERVICES LTD

Manufactured article recovery system

InactiveUS6967577B2Easy to identifyData processing applicationsMemory record carrier reading problemsNetwork connectionRadio frequency

Owner:ACCENTURE GLOBAL SERVICES LTD

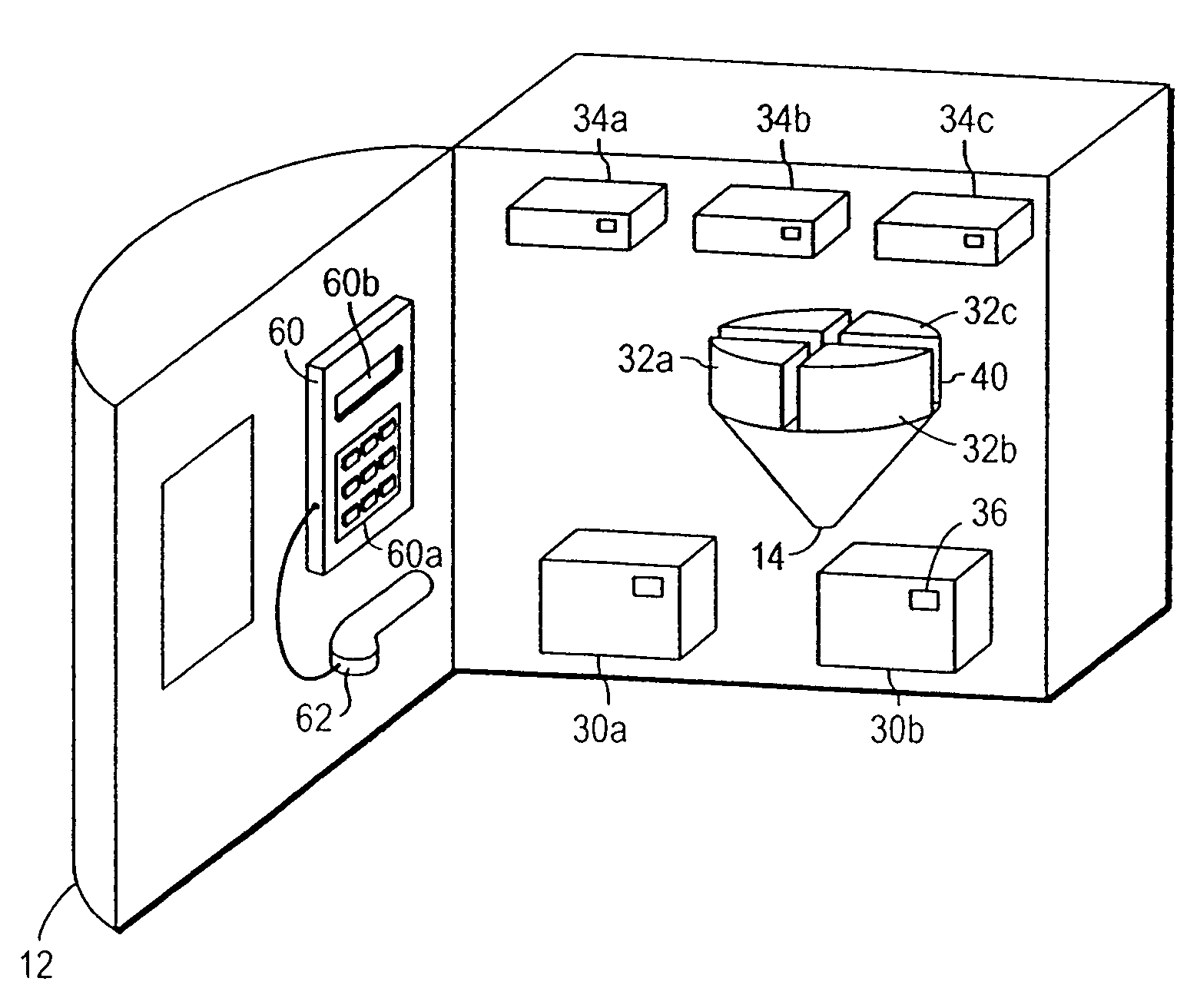

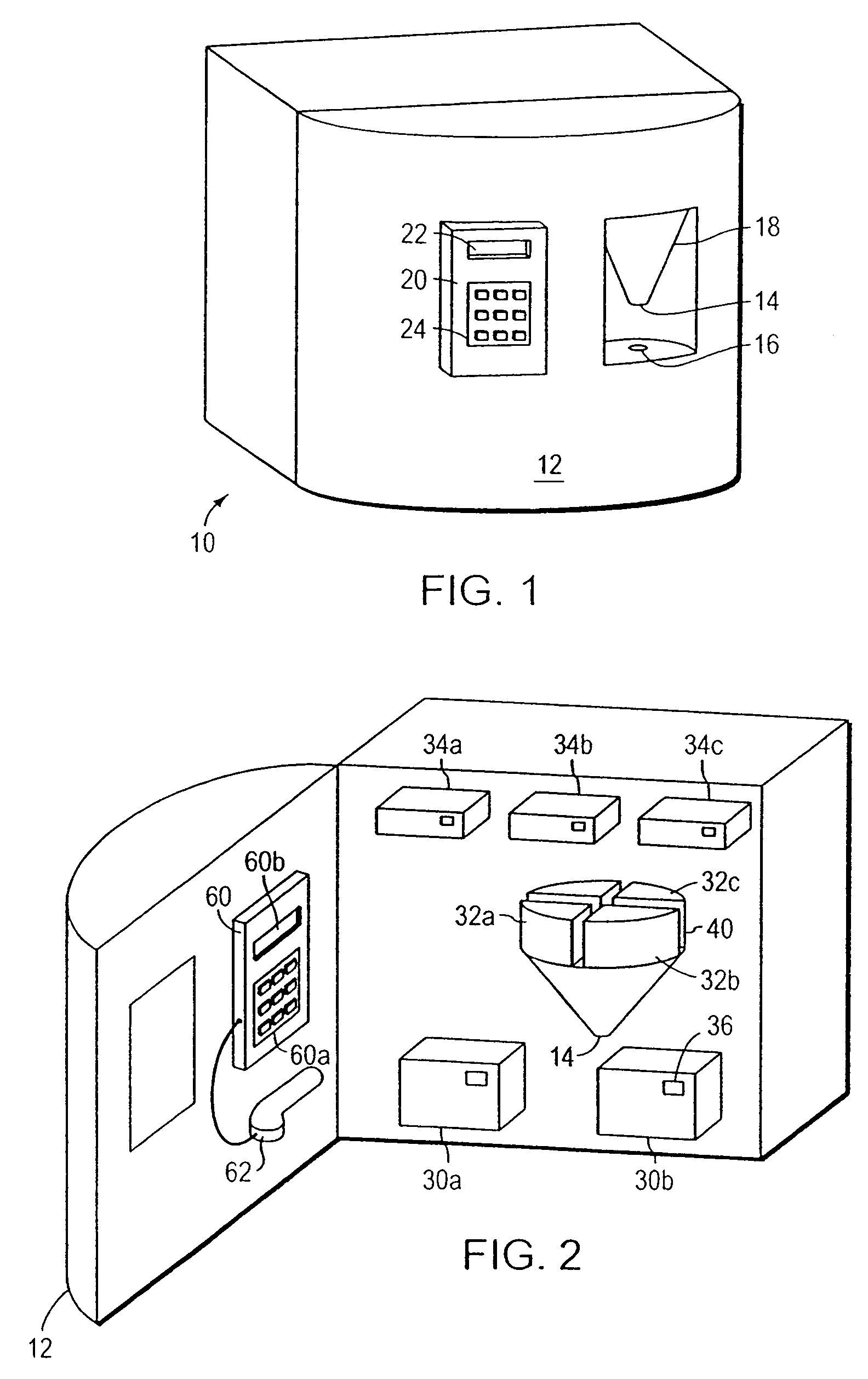

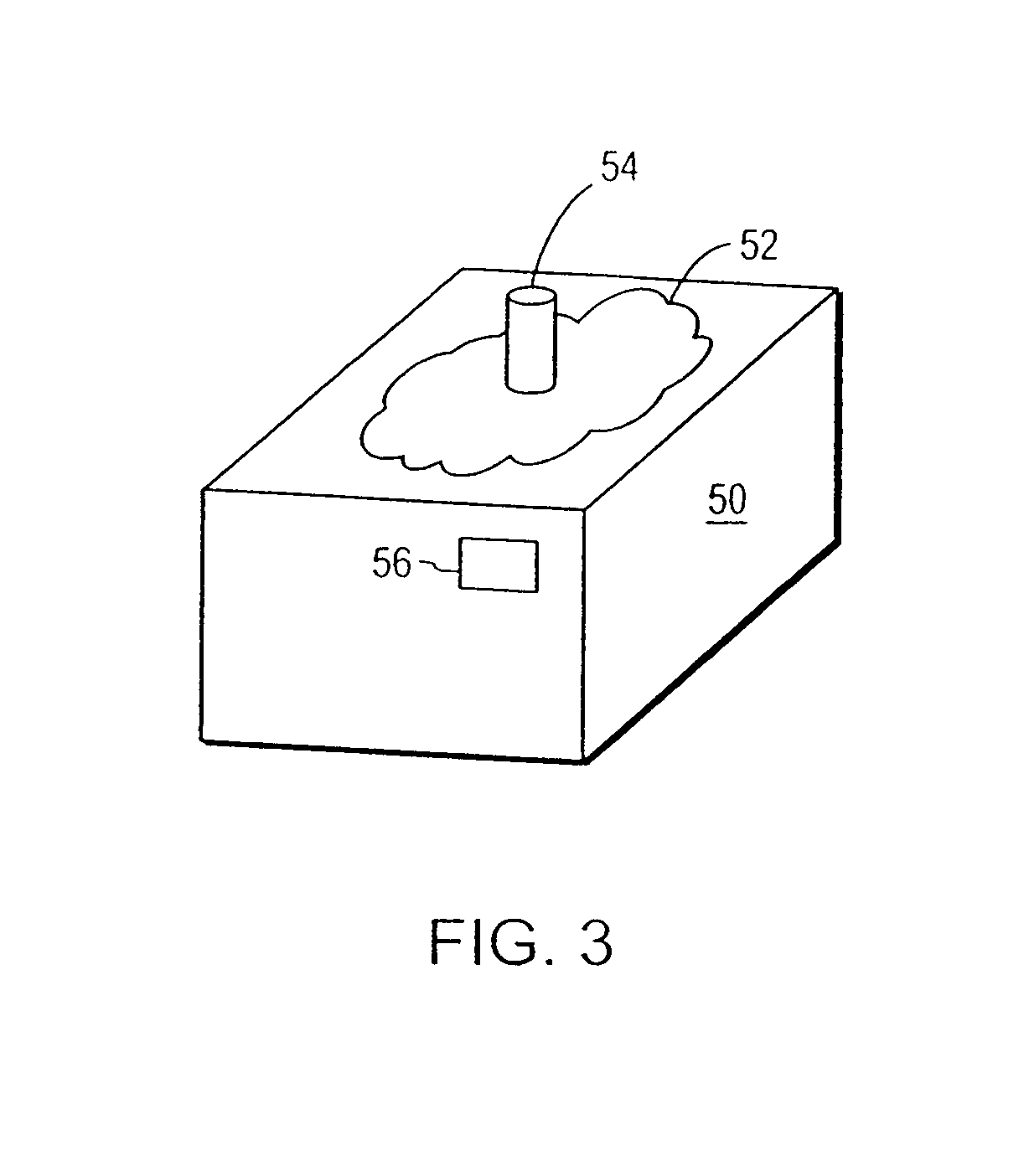

Dynamic process control

A method and apparatus for defining the processing of an ingredient of a manufactured product, particularly one that is manufactured “one-the-spot” to a consumer's specification, such as ice cream, among other products. A tag encoded on a container for the product carries indicia that, directly or indirectly, define one or more formulations for the product. Apparatus into which the ingredient is loaded sets the processing of ingredients in accordance with the formulations so specified. By connecting the apparatus which is to process the ingredients to a control station, the formulations may be changed at will.

Owner:MOOBELLA ACQUISITION +1

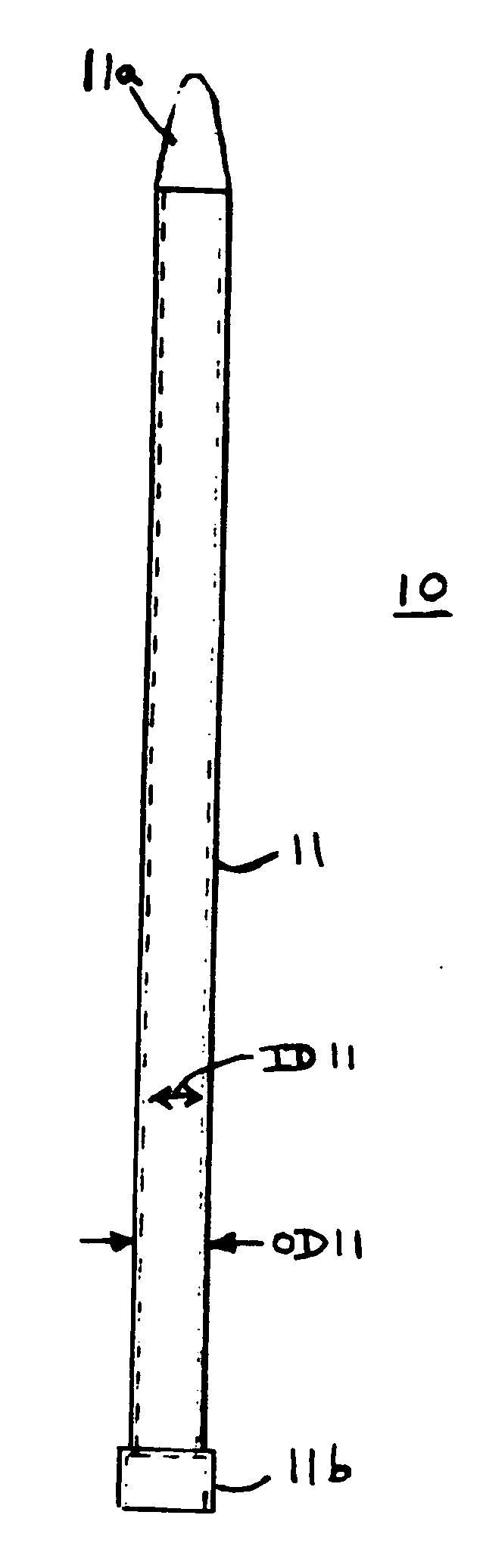

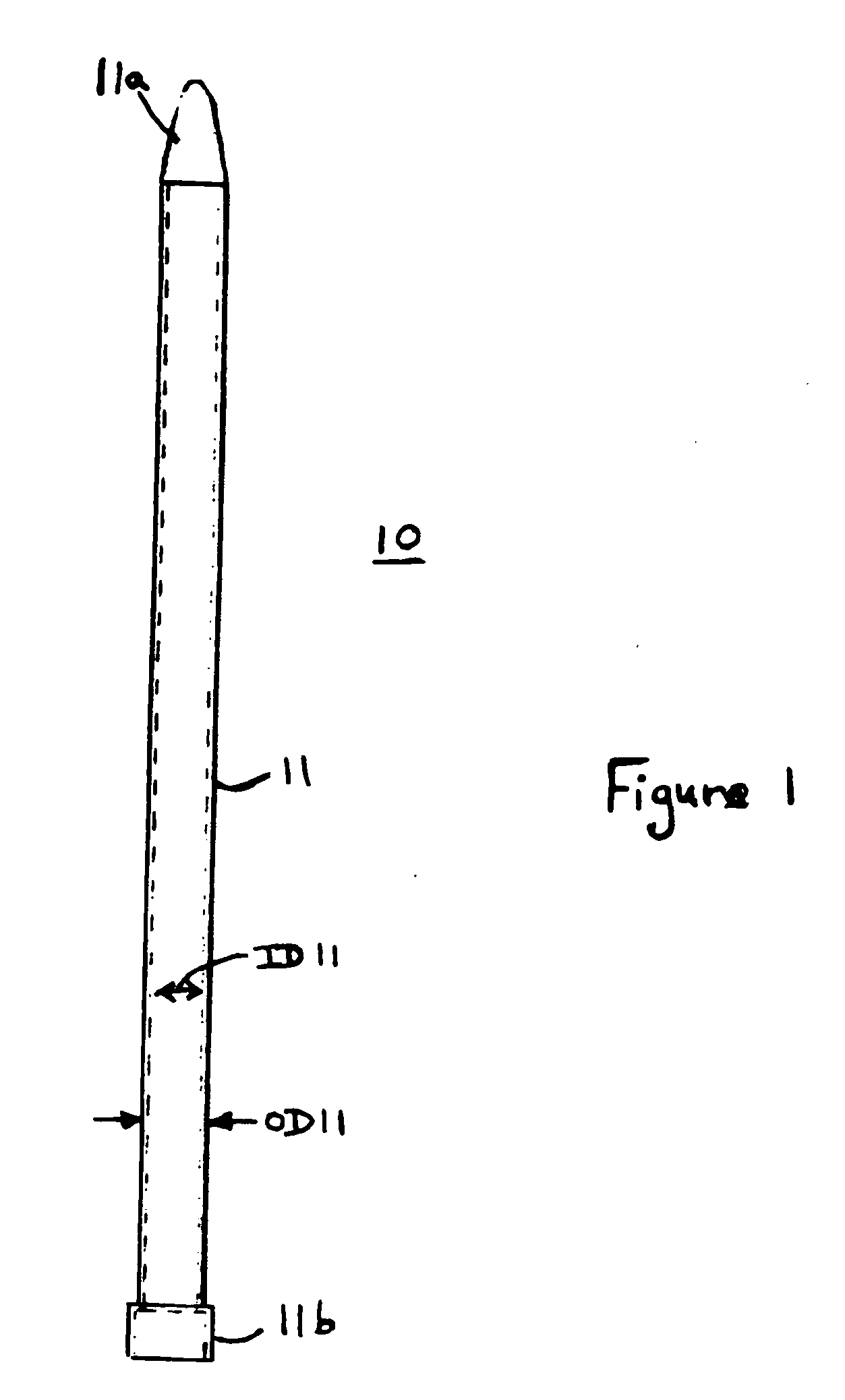

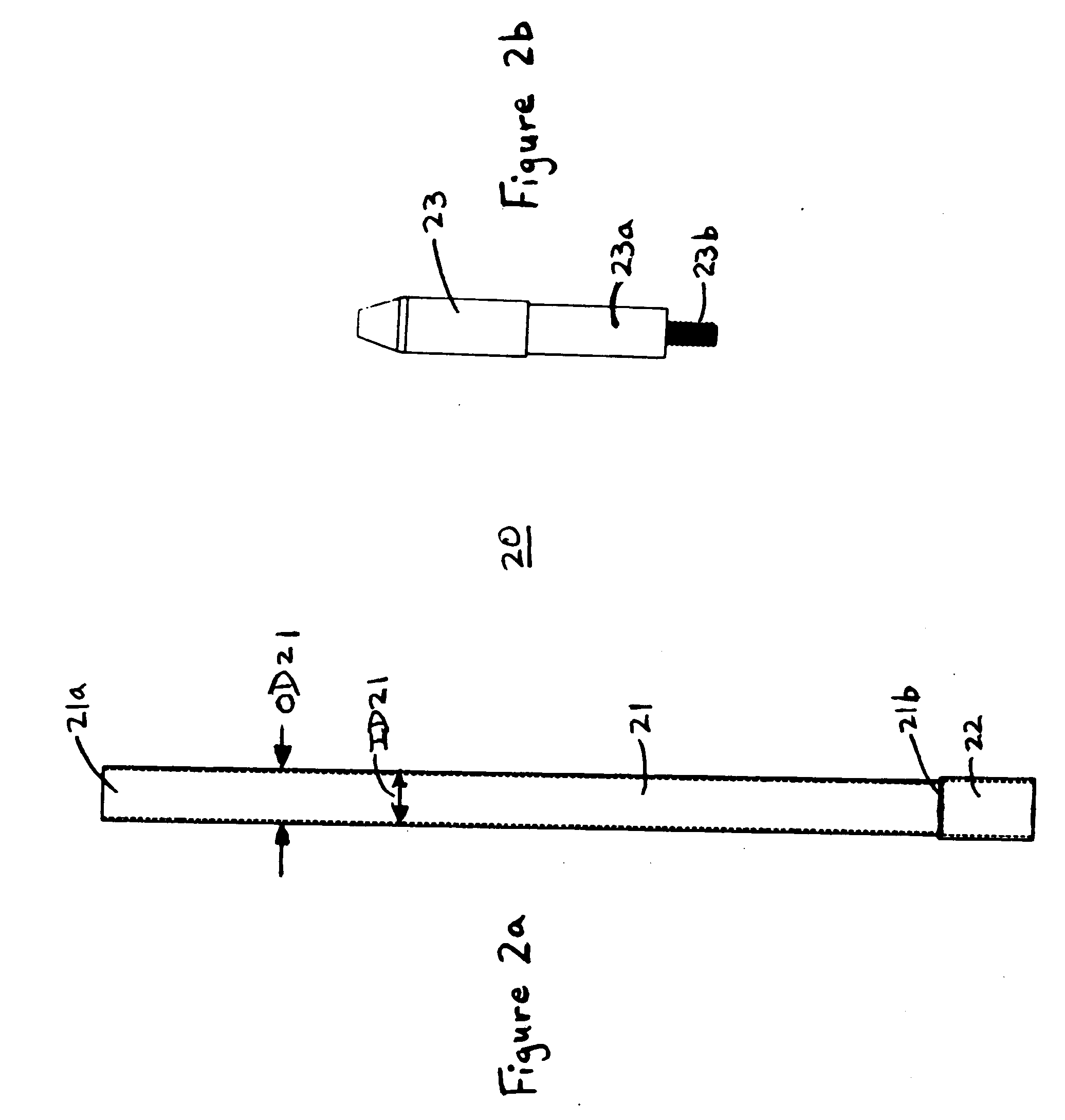

Spindle sleeve

InactiveUS20070090006A1Light-weight and durableRecord information storageOther accessoriesEngineeringManufactured Object

A spindle sleeve configured to be placed over a spindle for holding a plurality of manufactured articles is provided. The spindle sleeve includes a hollow cylindrical body having a top end and an open bottom end and configured to slip over the spindle. An inner diameter of the cylindrical body is greater than an outer diameter of the spindle. The spindle sleeve may be used for stacking and transporting a plurality of optical discs. In such an instance, an outer diameter of the cylindrical body is smaller than a diameter of a center hole of the optical disc.

Owner:CINRAM GRP

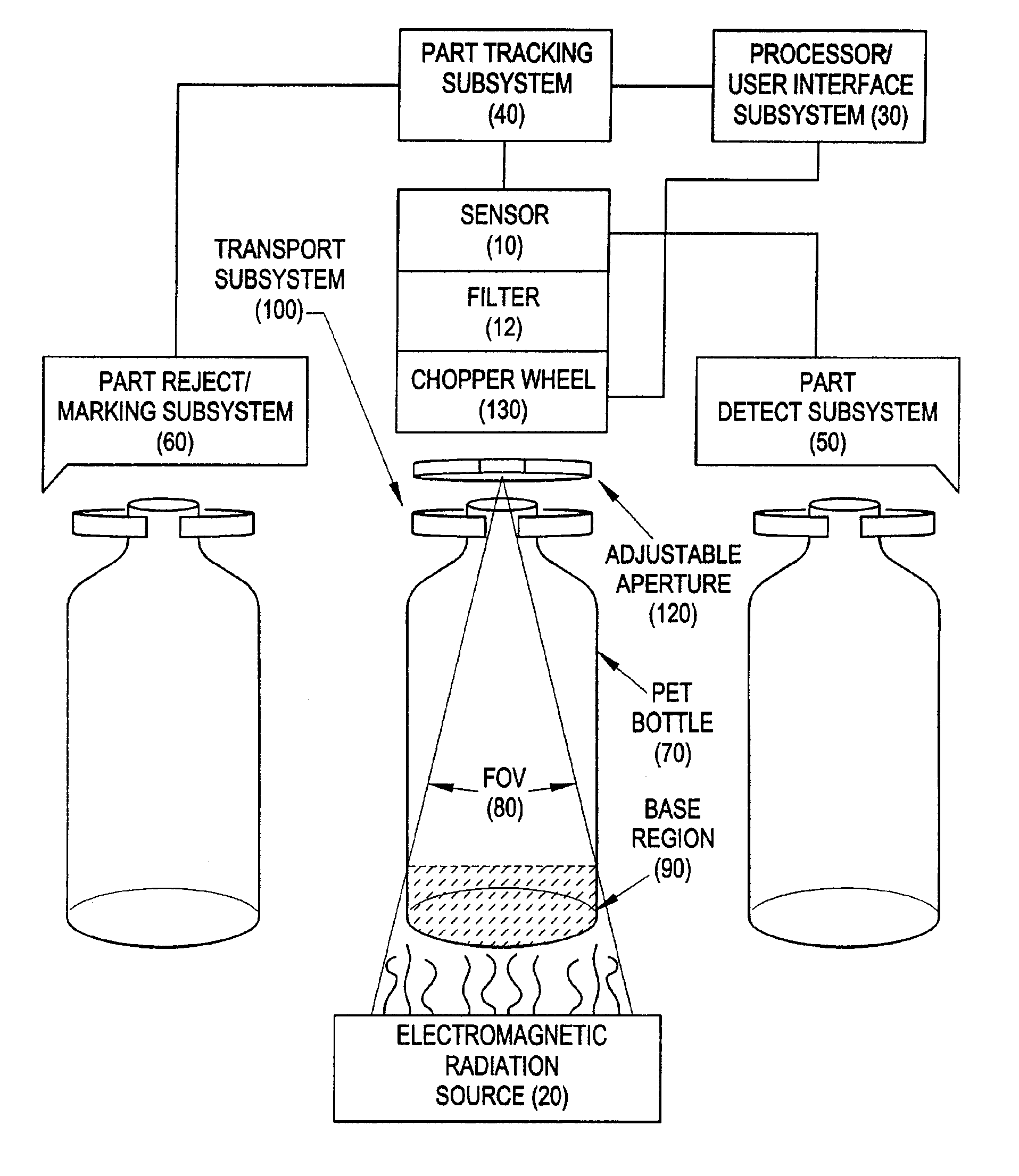

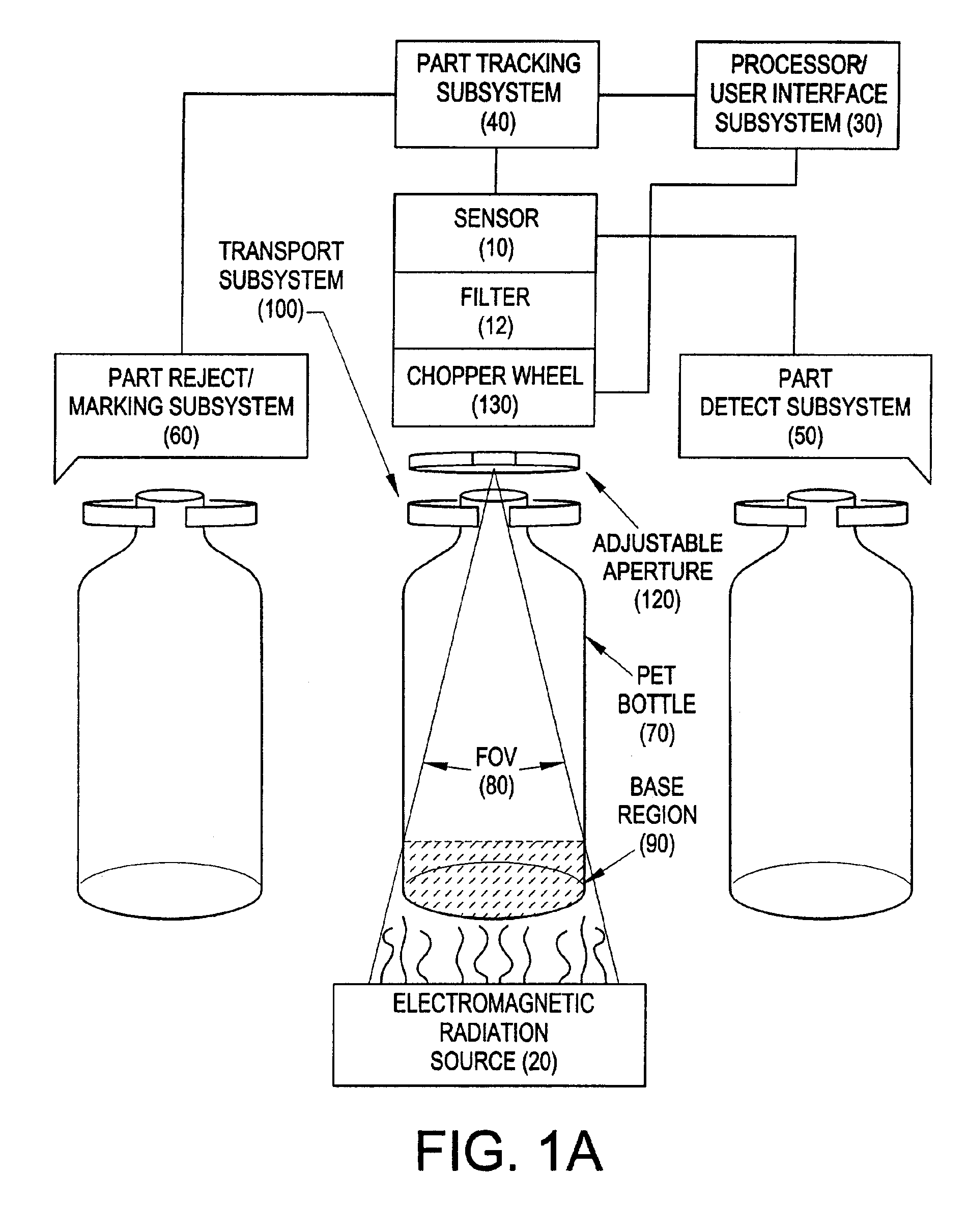

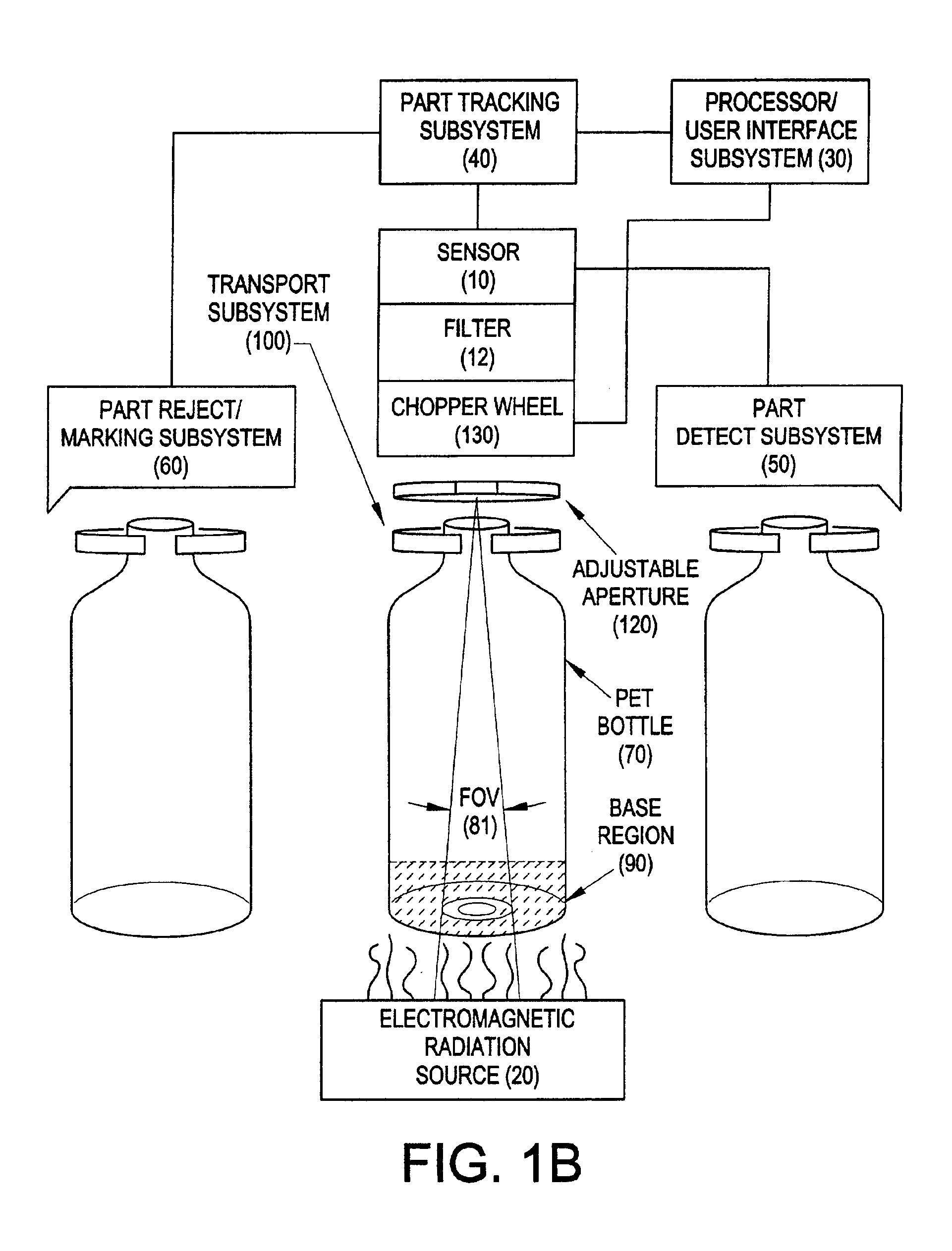

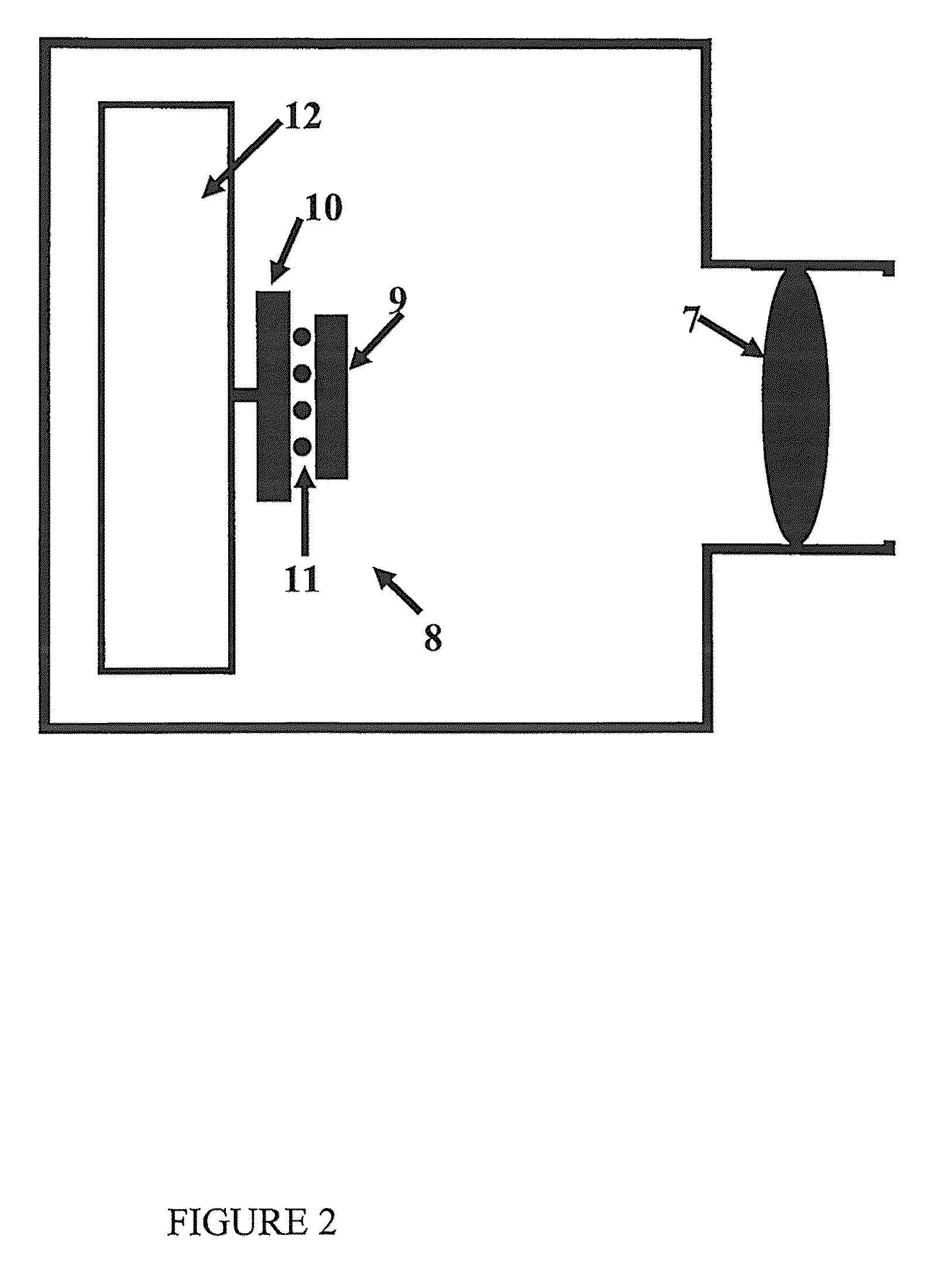

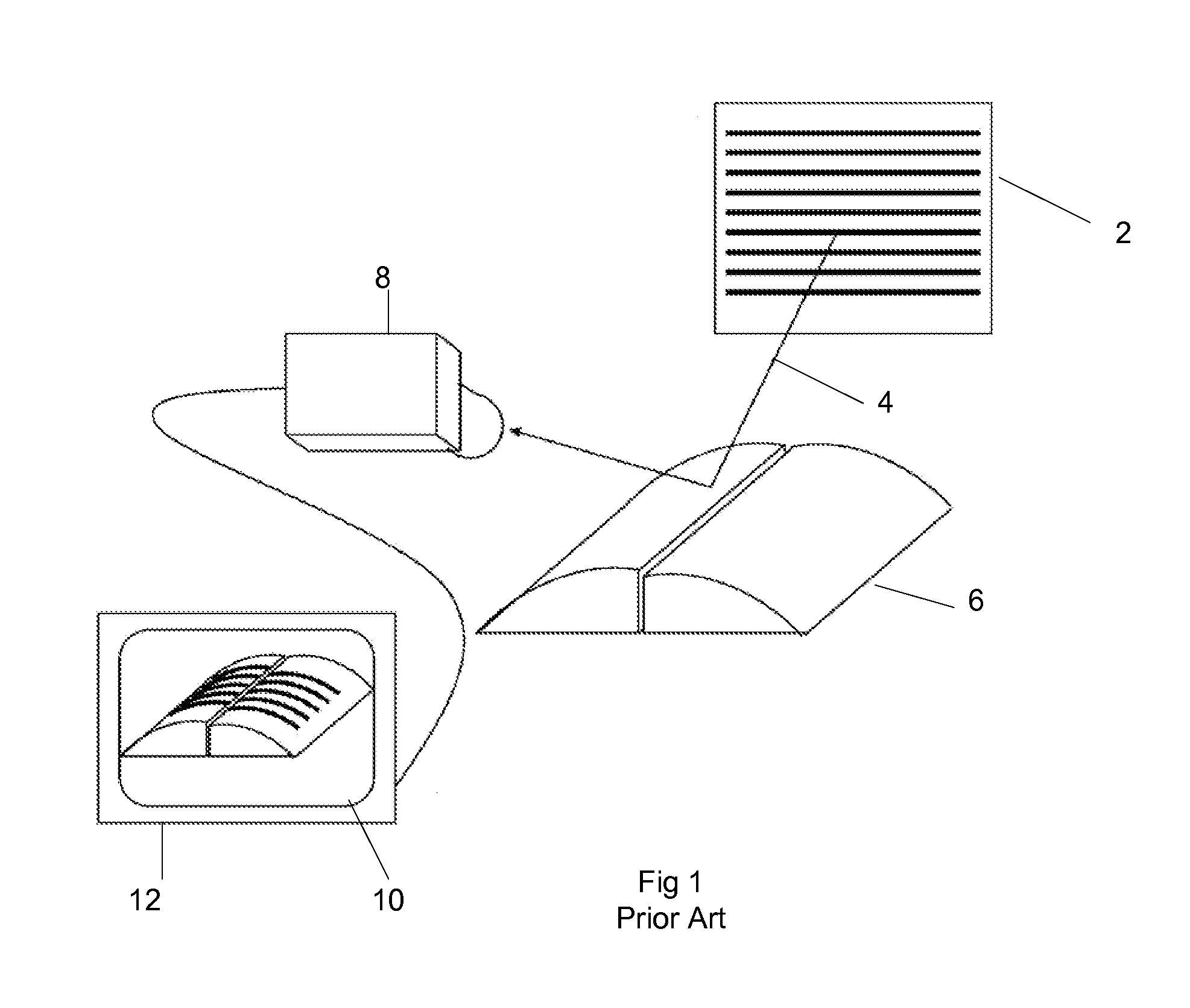

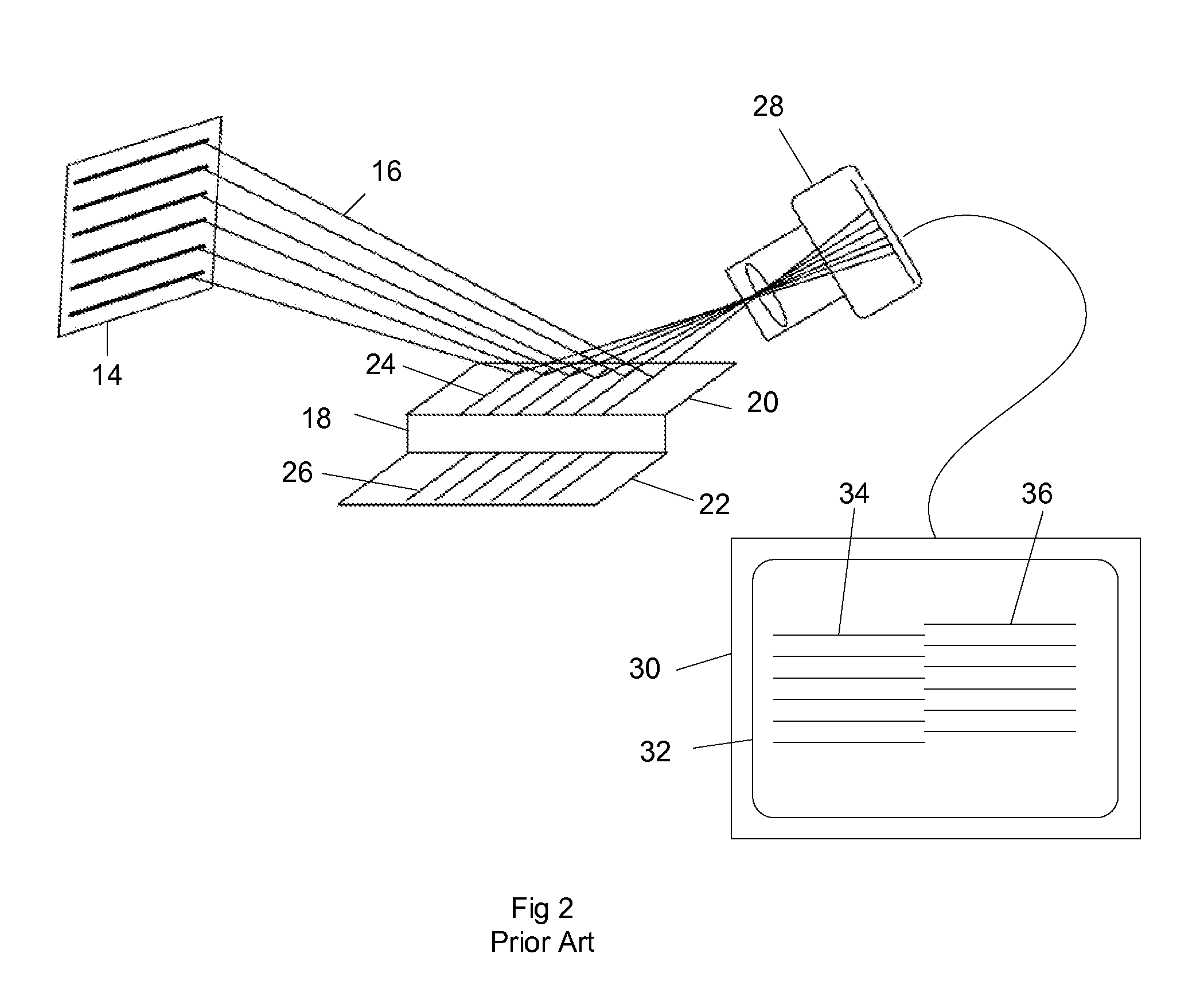

Apparatus and method for providing spatially-selective on-line mass or volume measurements of manufactured articles

InactiveUS6872895B2Material analysis by optical meansMaterial check-weighingVolume measurementsQuality control

This invention relates to a method and apparatus for mass and / or volume measurements of manufactured articles. More particularly, this invention relates to a method and apparatus for mass and / or volume measurements that can be performed on-line in a part manufacturing process. On-line measurement of the mass or volume of material contained in a specific region of interest of the manufactured items is performed 100% on-line. Real-time process control information is based on real-time measurement of the mass or volume of material contained in a specific region of interest of a manufactured item. Automated quality control inspection for manufactured articles is based on real-time measurement of the mass or volume of material contained in a specific region of interest of manufactured items. A manufacturing closed-loop process is directly corrected to keep it within control limits based on real-time measurement of the mass or volume of material contained in a specific region of interest of manufactured items soon after these items are manufactured.

Owner:PRESSCO TECH INC

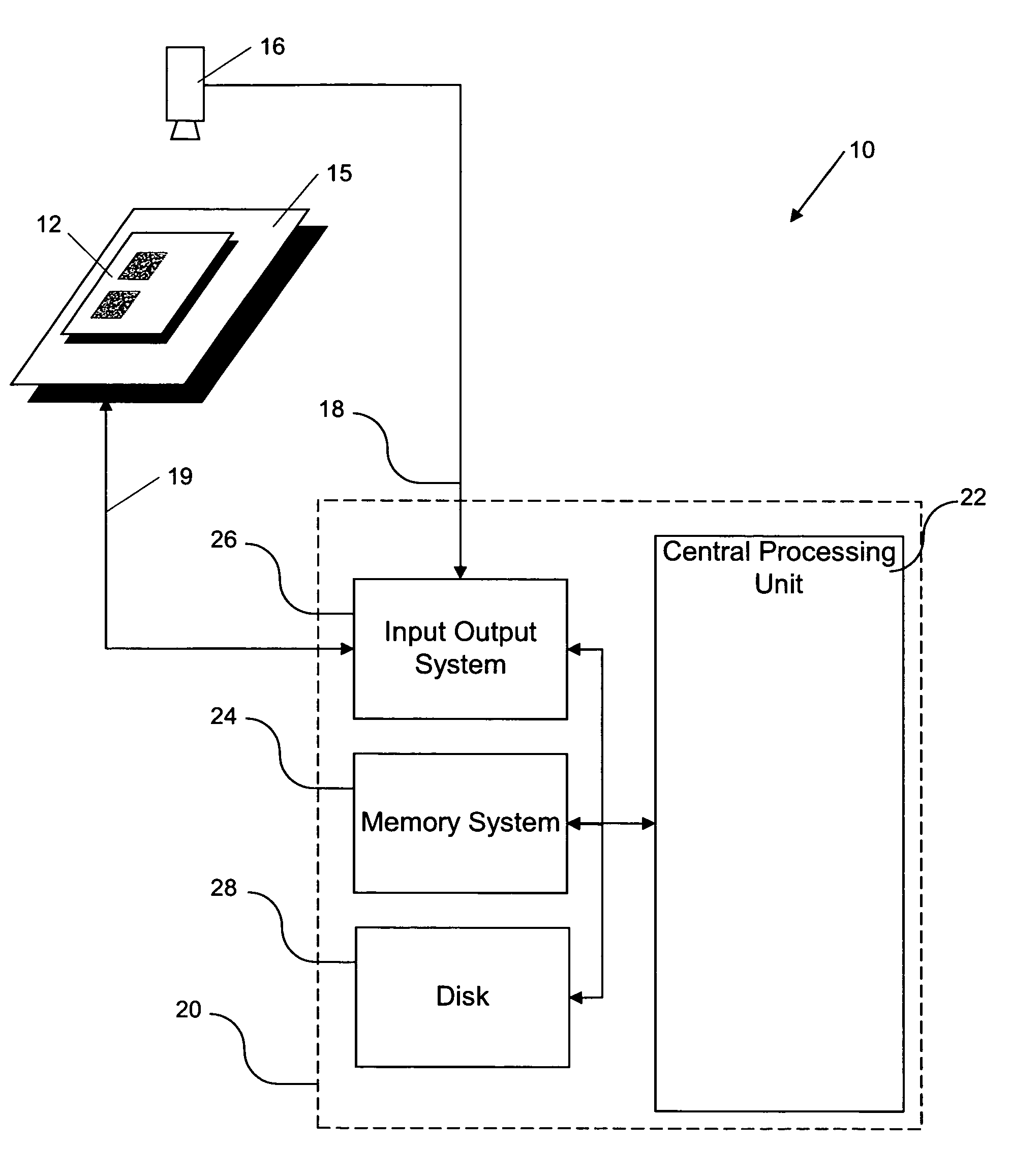

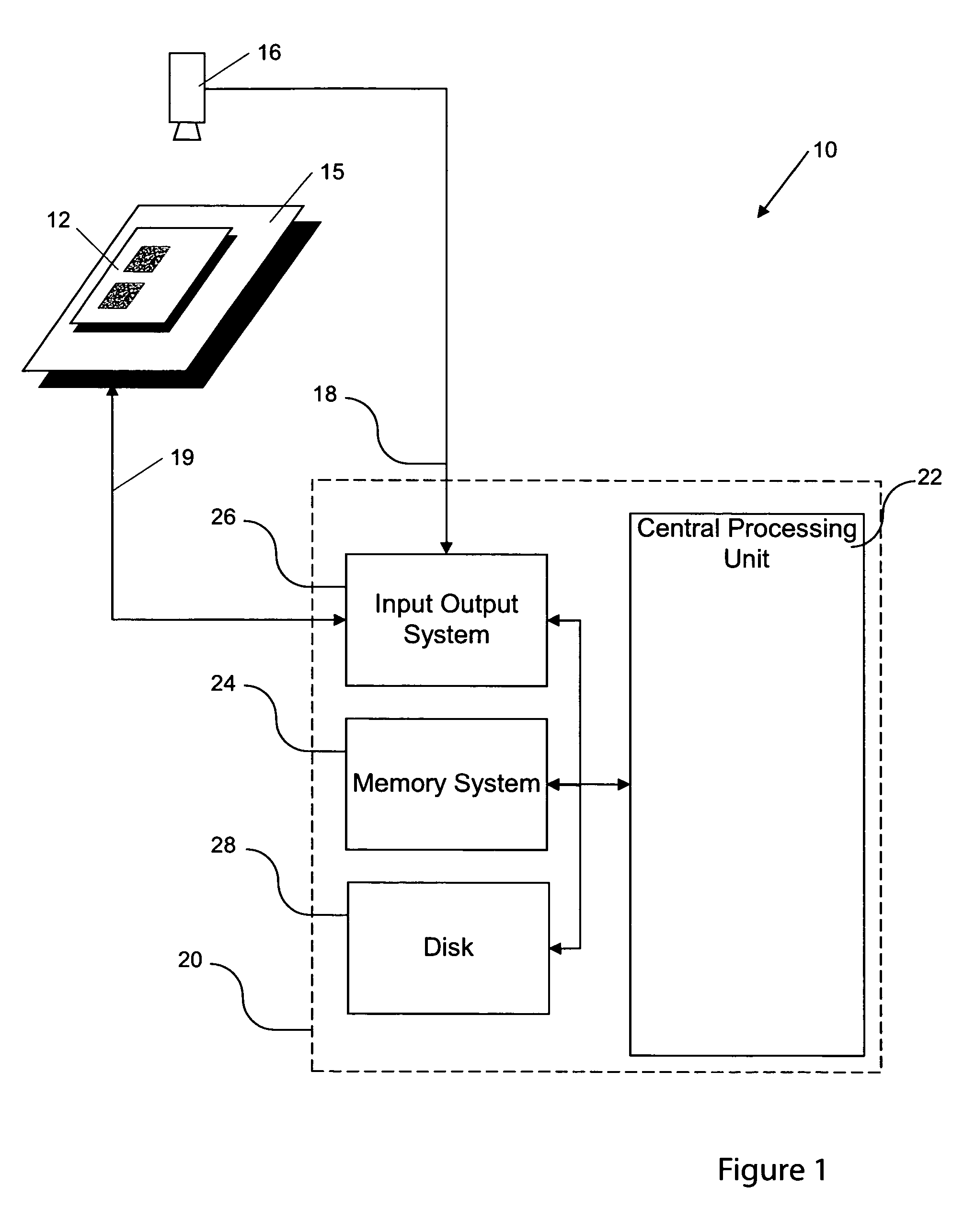

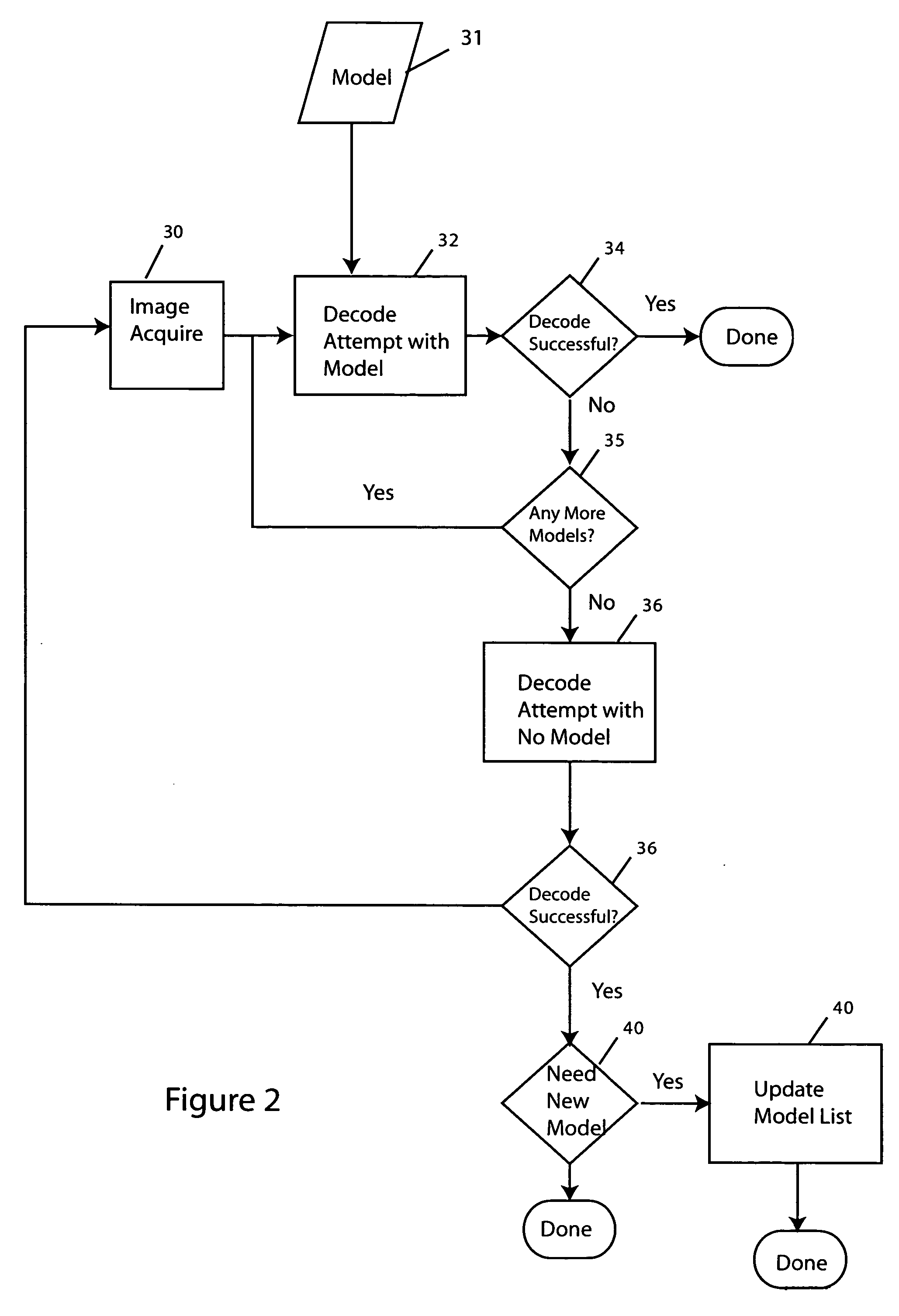

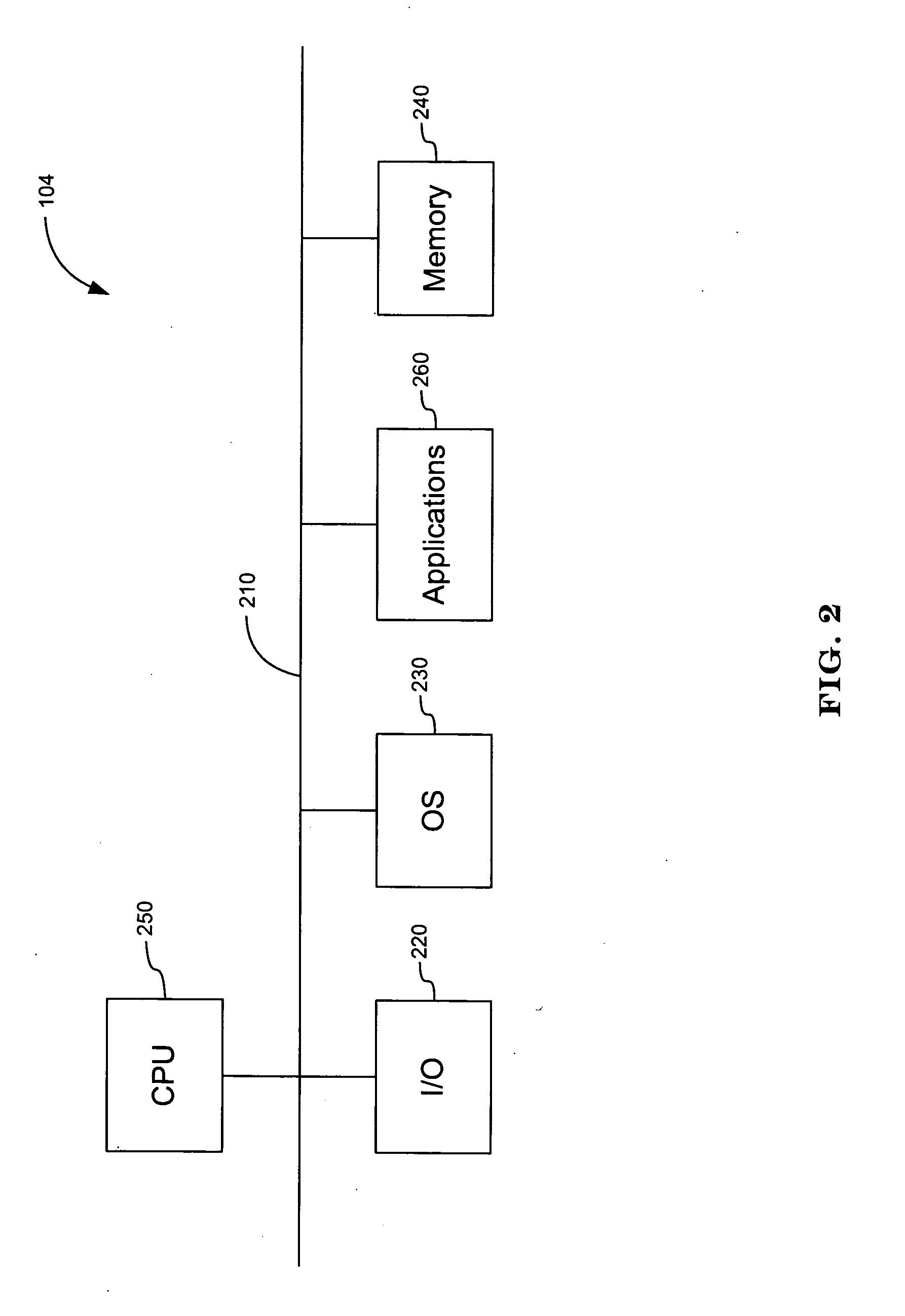

Methods and apparatus for reading bar code identifications

InactiveUS20060043186A1Easy to readSpeed bar code readingCharacter and pattern recognitionSensing by electromagnetic radiationDigital dataJet aeroplane

The invention provides methods and appartaus for analysis of images of two-dimensional (2D) bar codes in which a model that has proven successful in decoding of a prior 2D image of a 2D bar code is utilized to speed analysis of images of subsequent 2D bar codes. In its various aspects, the invention can be used in analyzing conventional 2D bar codes, e.g., those complying with Maxicode and DataMatrix standards, as well as stacked linear bar codes, e.g., those utilizing the Codablock symbology. Bar code readers, digital data processing apparatus and other devices according to the invention be used, by way of non-limiting example, to decode bar codes on damaged labels, as well as those screened, etched, peened or otherwise formed on manufactured articles (e.g., from semiconductors to airplane wings). In addition to making bar code reading possible under those conditions, devices utilizing such methods can speed bar code analysis in applications where multiple bar codes of like type are read in succession and / or are read under like circumstances—e.g., on the factory floor, at point-of-sale locations, in parcel deliver and so forth. Such devices can also speed and / or make possible bar code analysis where in applications where multiple bar codes read from a single article—e.g., as in the case of a multiply-encoded airplane propellor or other milled parts. The invention also provides methods and apparatus for optical character recognition and other image-based analysis paralleling the above.

Owner:COGNEX TECH & INVESTMENT

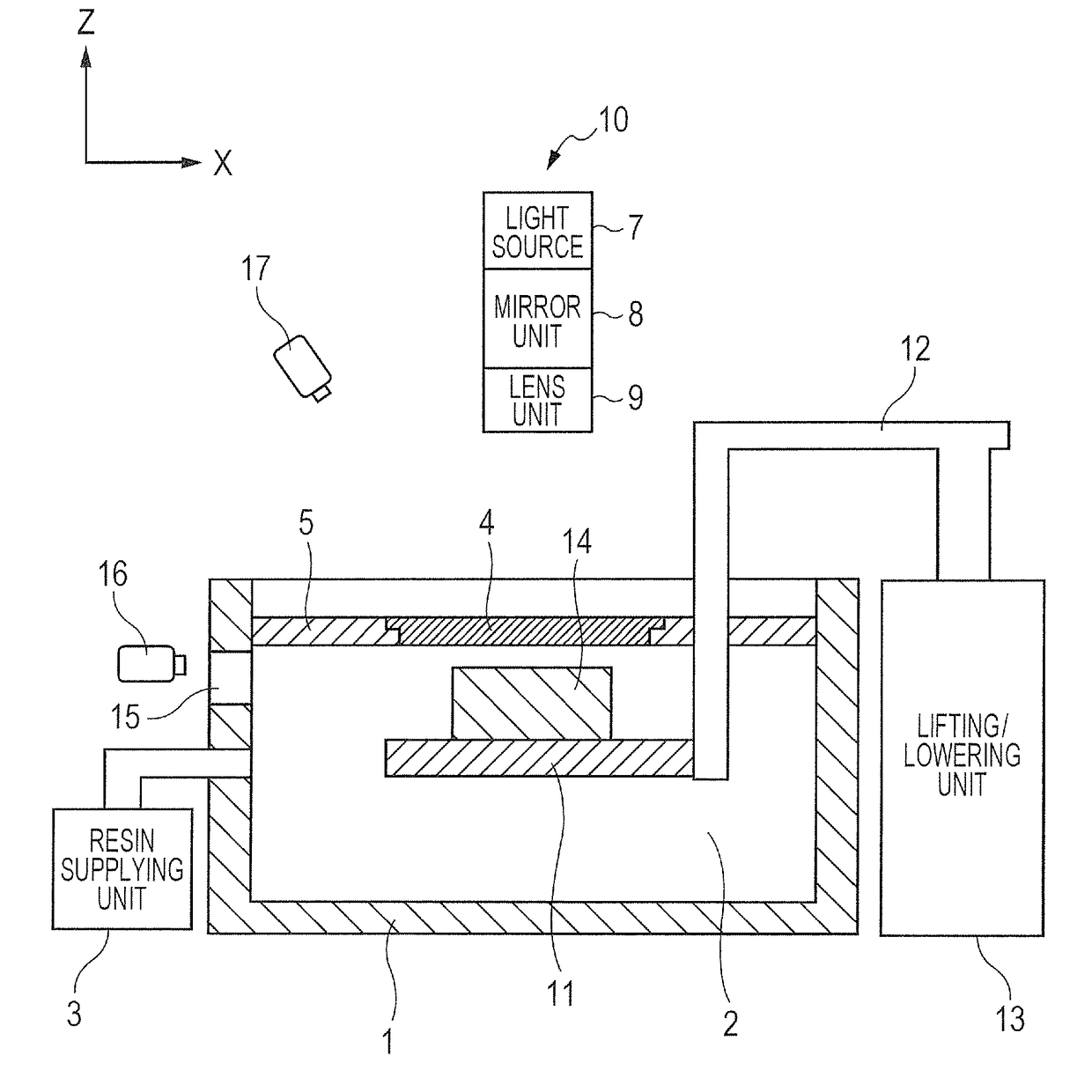

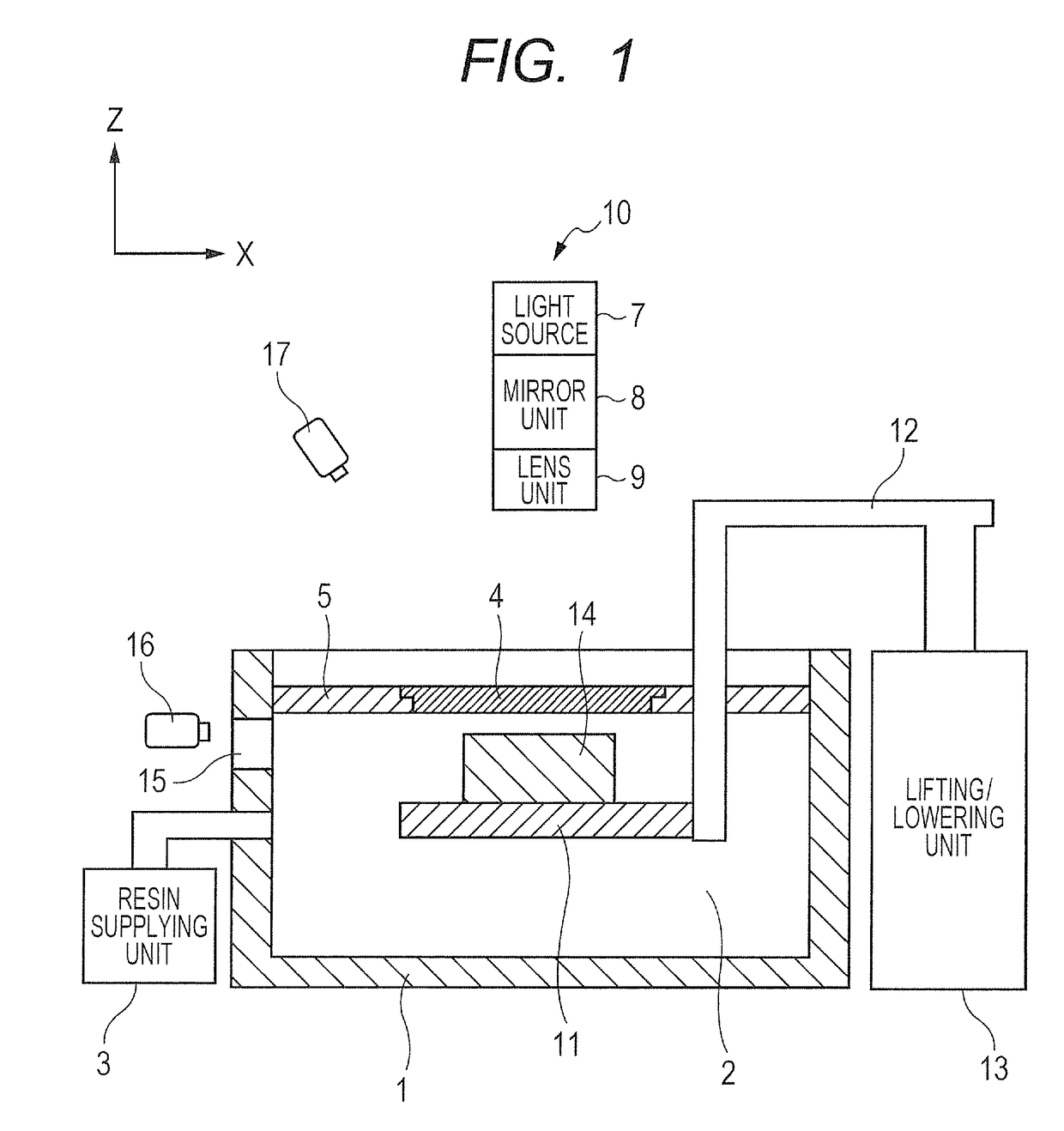

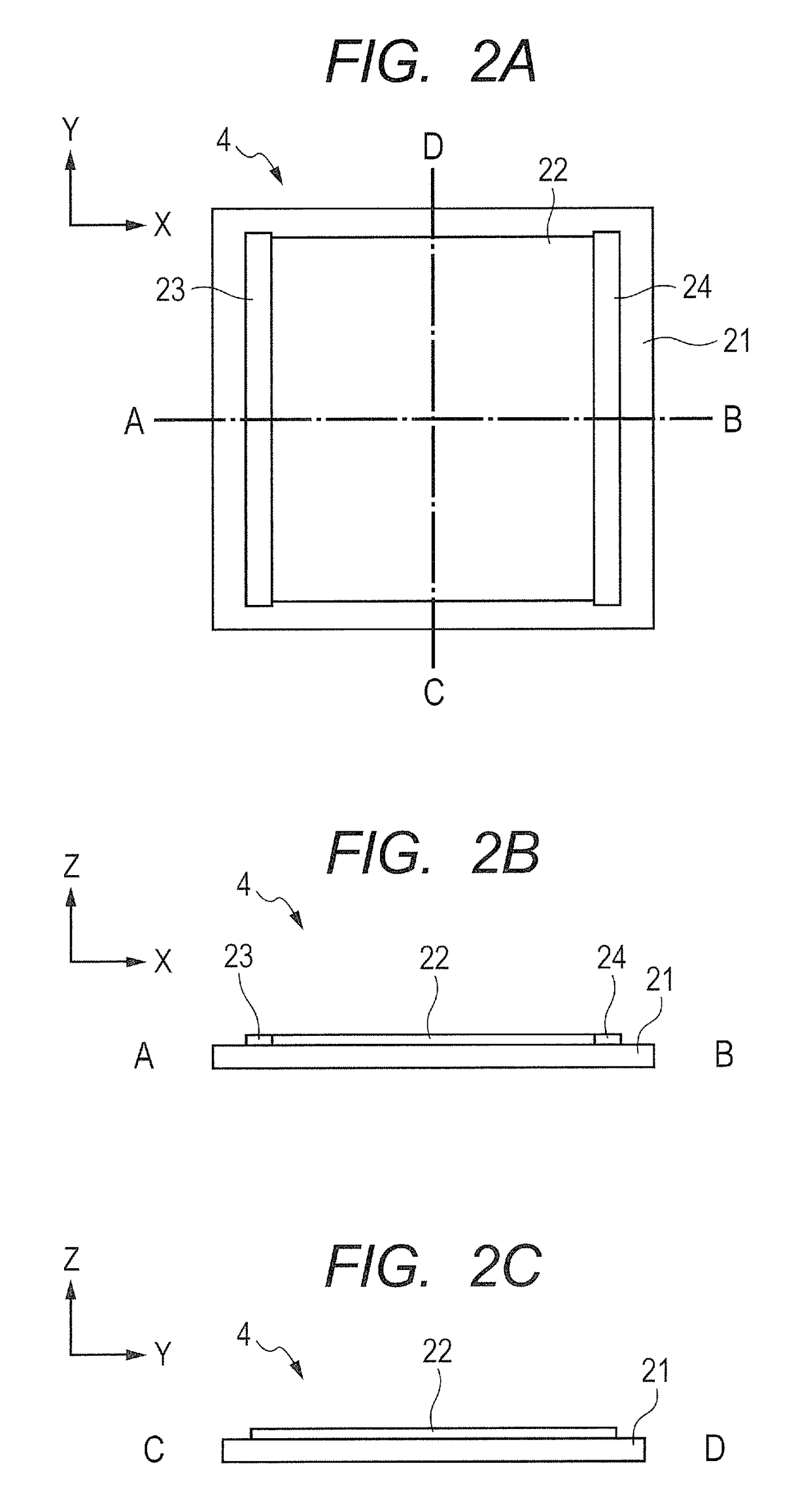

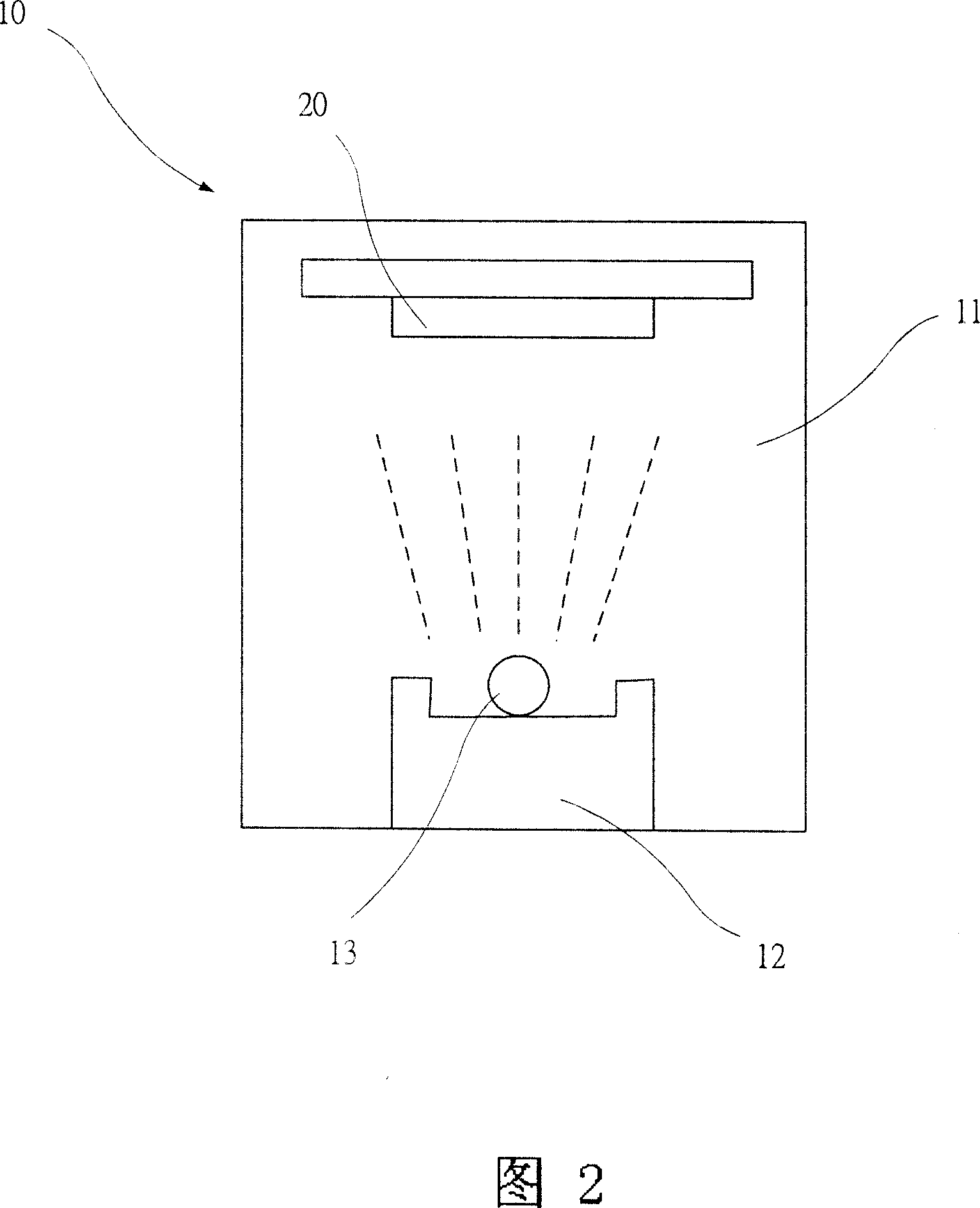

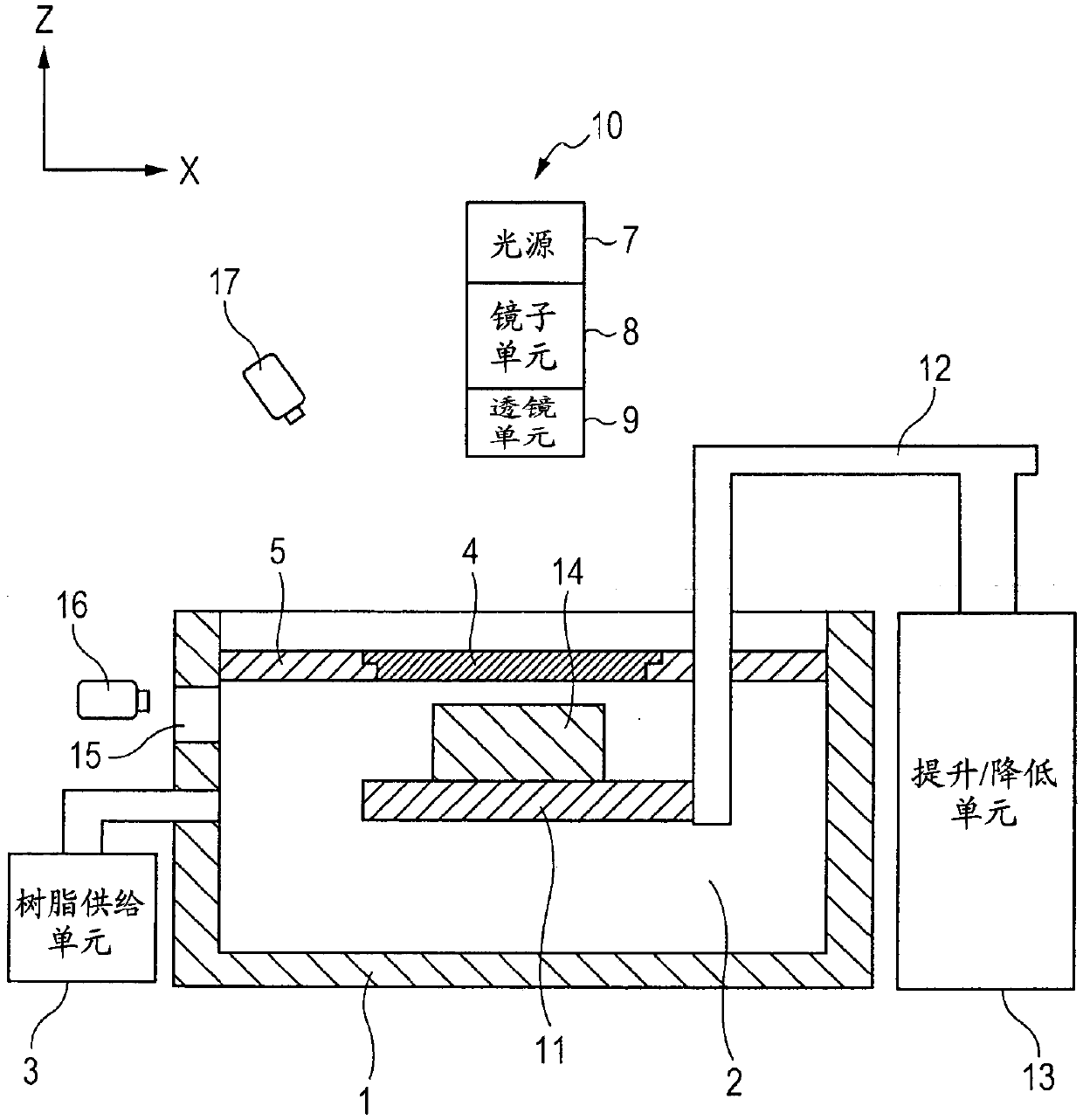

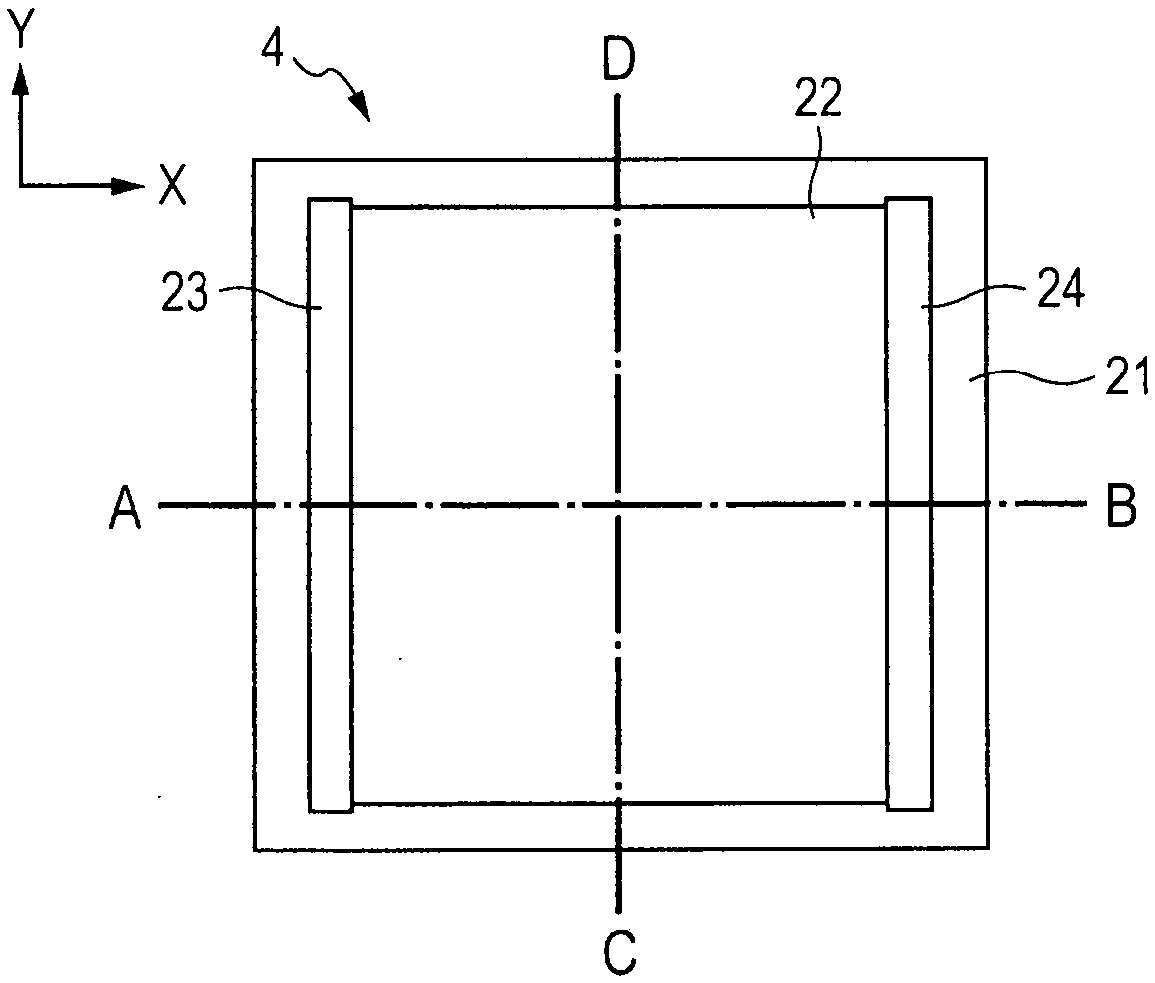

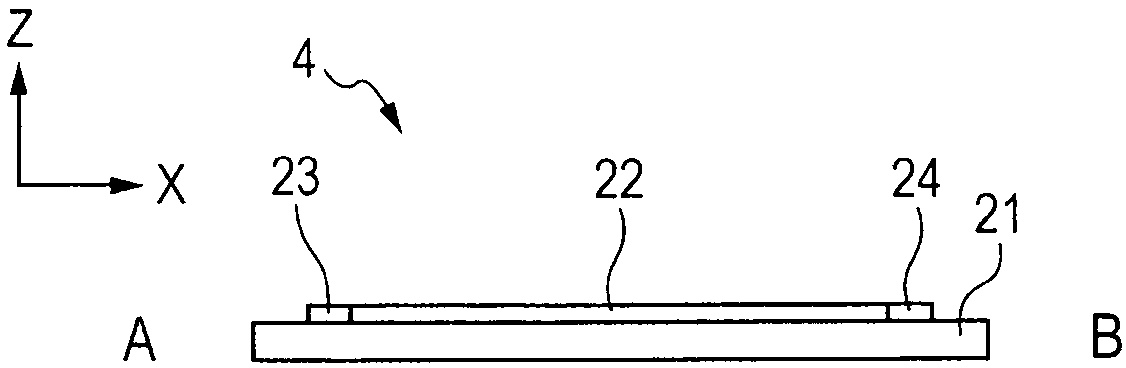

Three-dimensional manufacturing apparatus, three-dimensional manufactured object producing method, and container for three-dimensional manufacturing apparatus

ActiveUS20180065302A1Easy to moveManufacturing platforms/substratesManufacturing enclosuresEngineeringManufactured Object

There is provided a three-dimensional manufacturing apparatus which is characterized by comprising: a container configured to hold a liquid photocurable resin; a base configured to support a solid manufactured object obtained by curing the liquid photocurable resin; a moving unit configured to move the base; and a light source unit configured to irradiate light for curing the liquid photocurable resin. The container comprises a light transmission portion which is provided between the light source unit and the base, and is in contact with the liquid photocurable resin. The three-dimensional manufacturing apparatus further comprises a flow facilitating unit configured to facilitate a flow of the photocurable resin which is in contact with the light transmission portion, the flow being attended by the movement of the base.

Owner:CANON KK

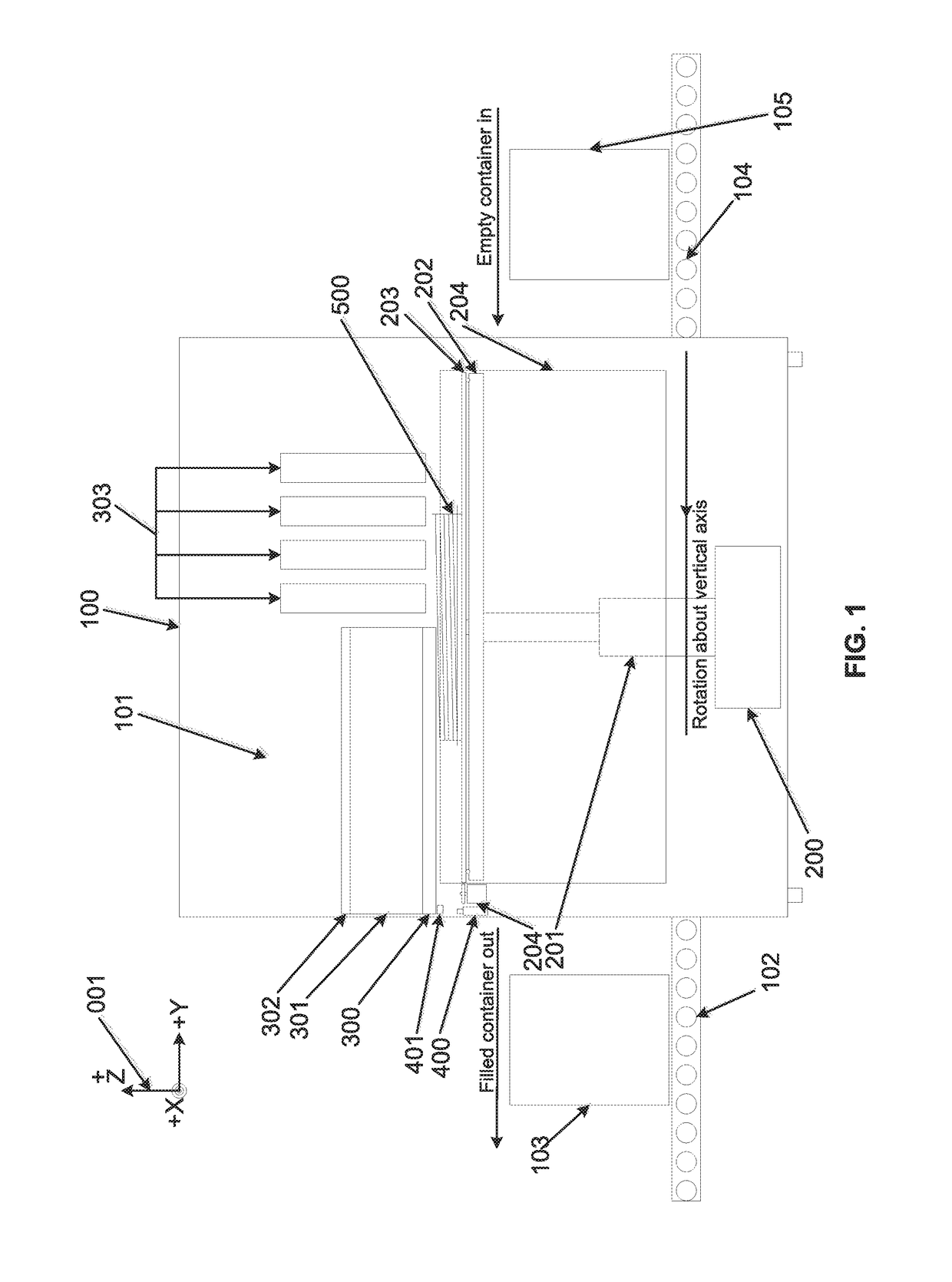

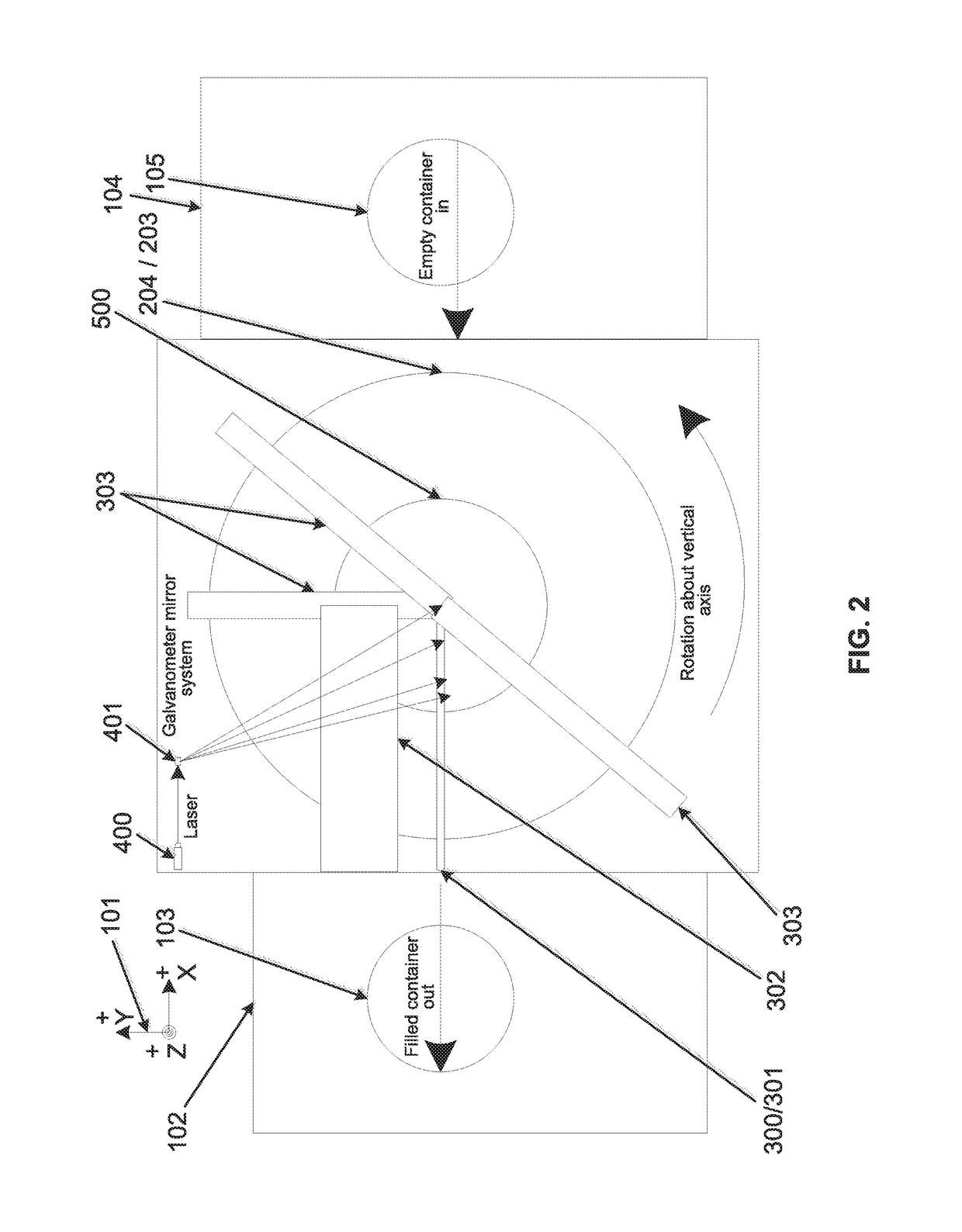

3D manufacturing using multiple material deposition and/or fusion sources simultaneously with single or multi-flute helical build surfaces

A method and apparatus to improve the speed of the free-form manufacture of complex systems uses the helical build process to 3D print or manufacture objects by using multiple material fusion sources simultaneously with single- or multi-flute helical build surfaces. As a result of the stationary material deposition line in a helical build machine, the speed of the fusion process can be improved by simultaneously using multiple fusion in sources in parallel on each fusion line. The geometry of the fixed location of the fusion line allows for changes in the optics of laser based machines which may lead to improvements in speed of over 100× compared to the speed of a single flute machines. Speed improvements are possible for all types additive manufacturing processes that use the helical build approach.

Owner:NEW YORK UNIV IN ABU DHABI CORP

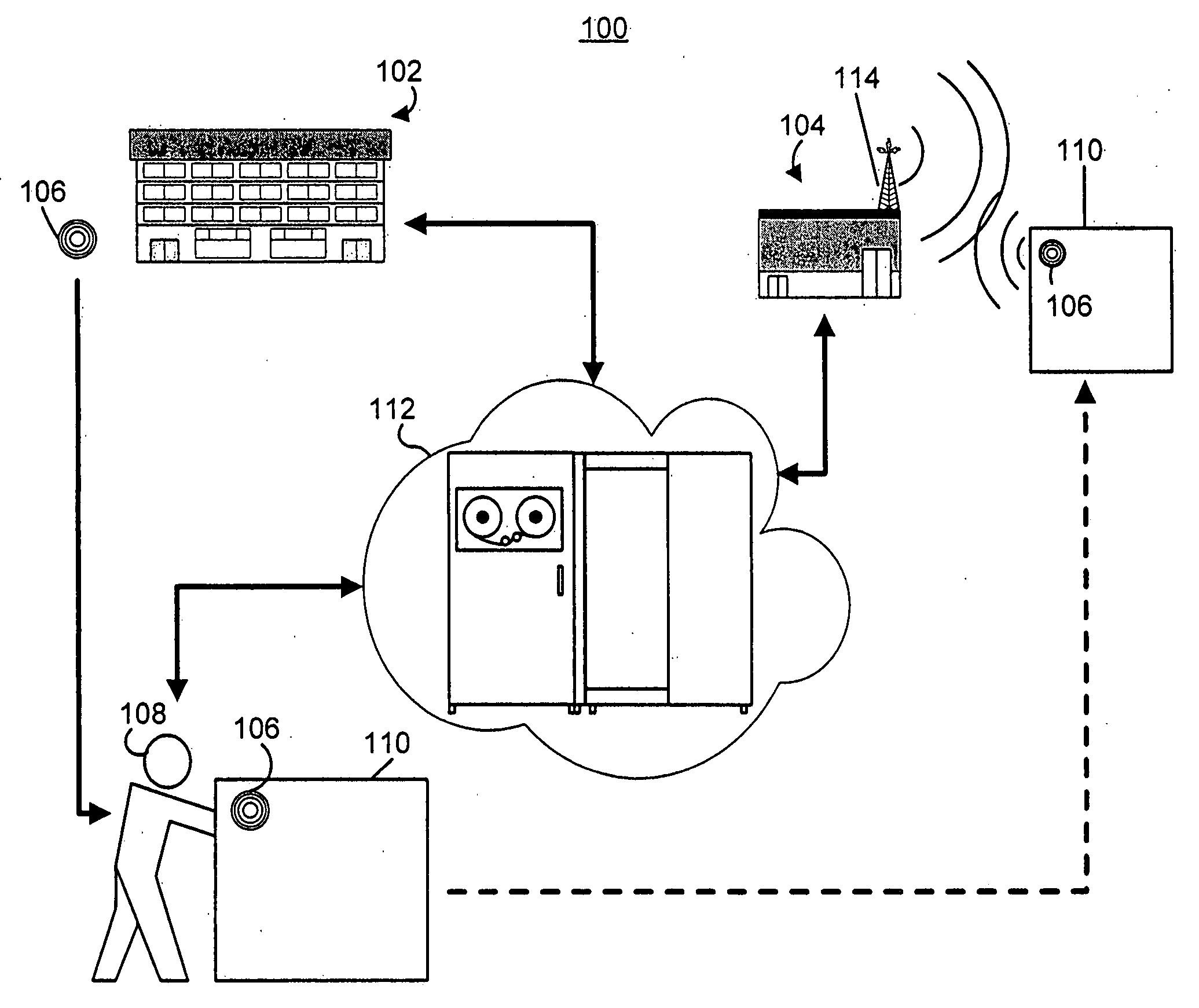

Manufactured article recovery system

InactiveUS20060028343A1Easy to identifyData processing applicationsMemory record carrier reading problemsNetwork connectionDatabase

A system for recovering a manufactured article is disclosed. The system includes an electronic reader that reads a unique code associated with the manufactured article when that article is within range of the reader. The unique code may be based on a radio-frequency identification (RFID) tag positioned with the manufactured article. The reader may be positioned with a facility associated with retrieval of misplaced or reposed consumer items, or within a community. A database may store records of unique codes and information related to owners of manufactured articles. The database may be downloaded to a local cache. The database also -may be queried based on the unique code. The owner of the item may be determined based on a match of a unique code read by the reader to a record in the database. The database may be accessed through an open-network connection to a computerized network.

Owner:ACCENTURE GLOBAL SERVICES LTD

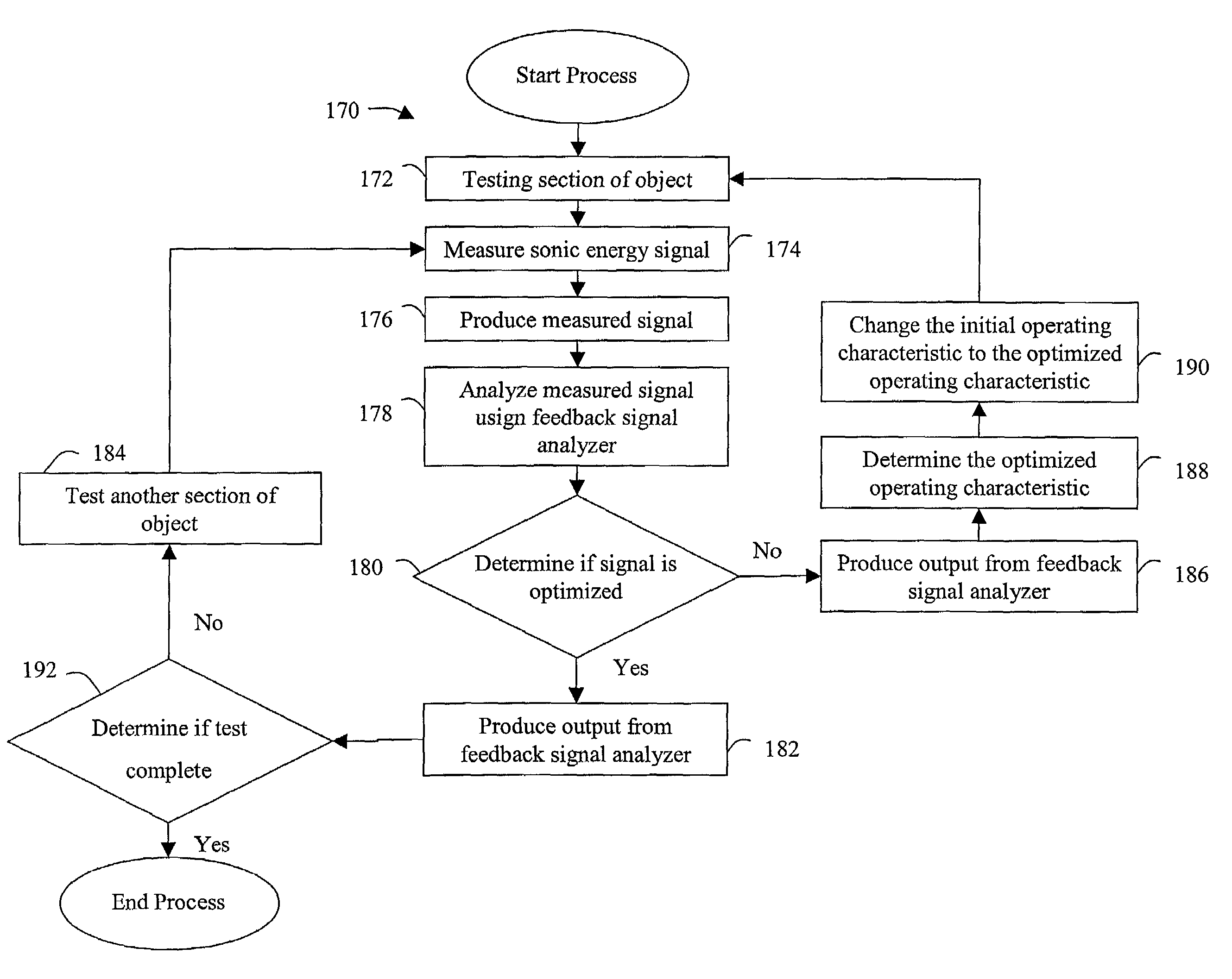

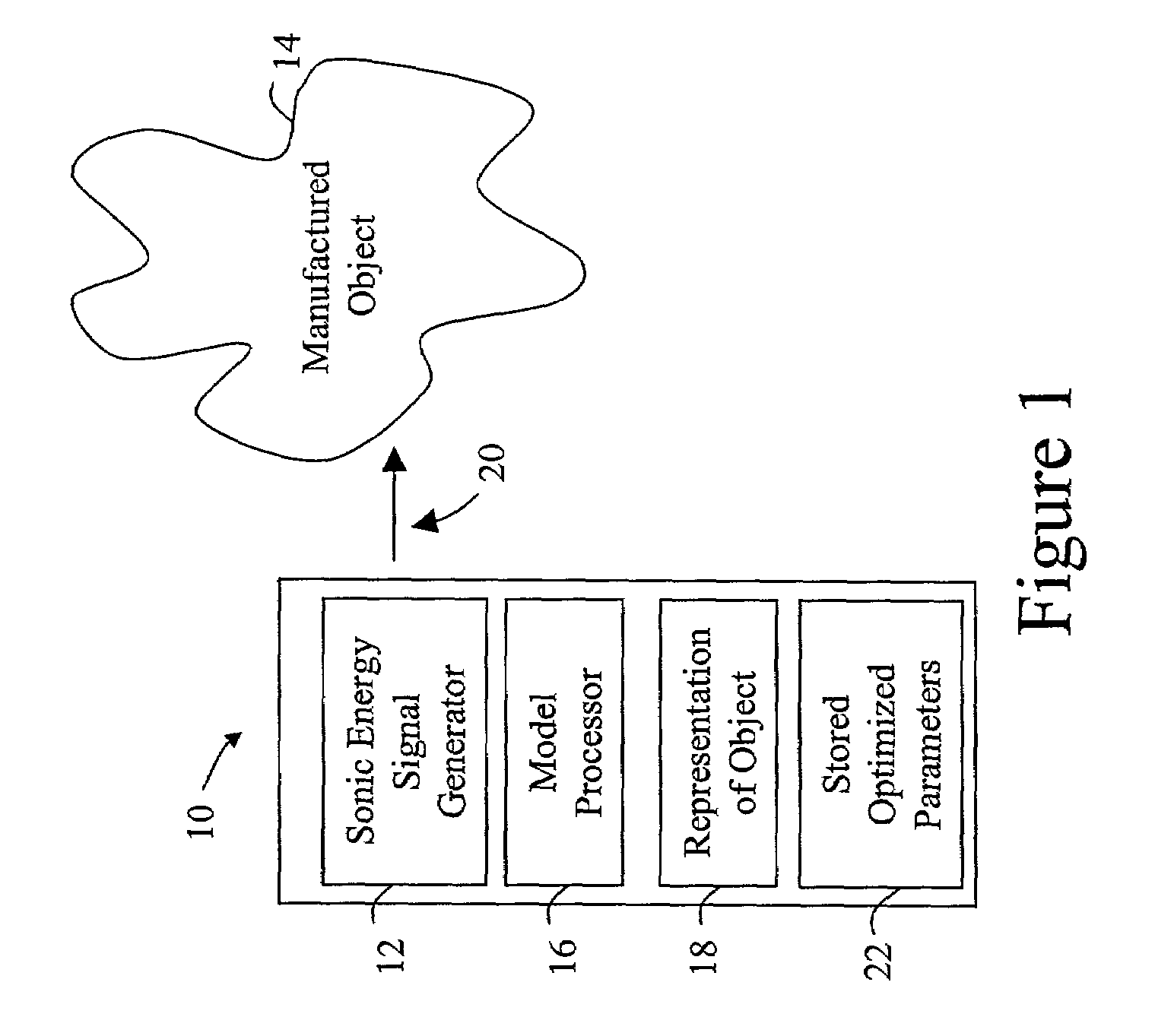

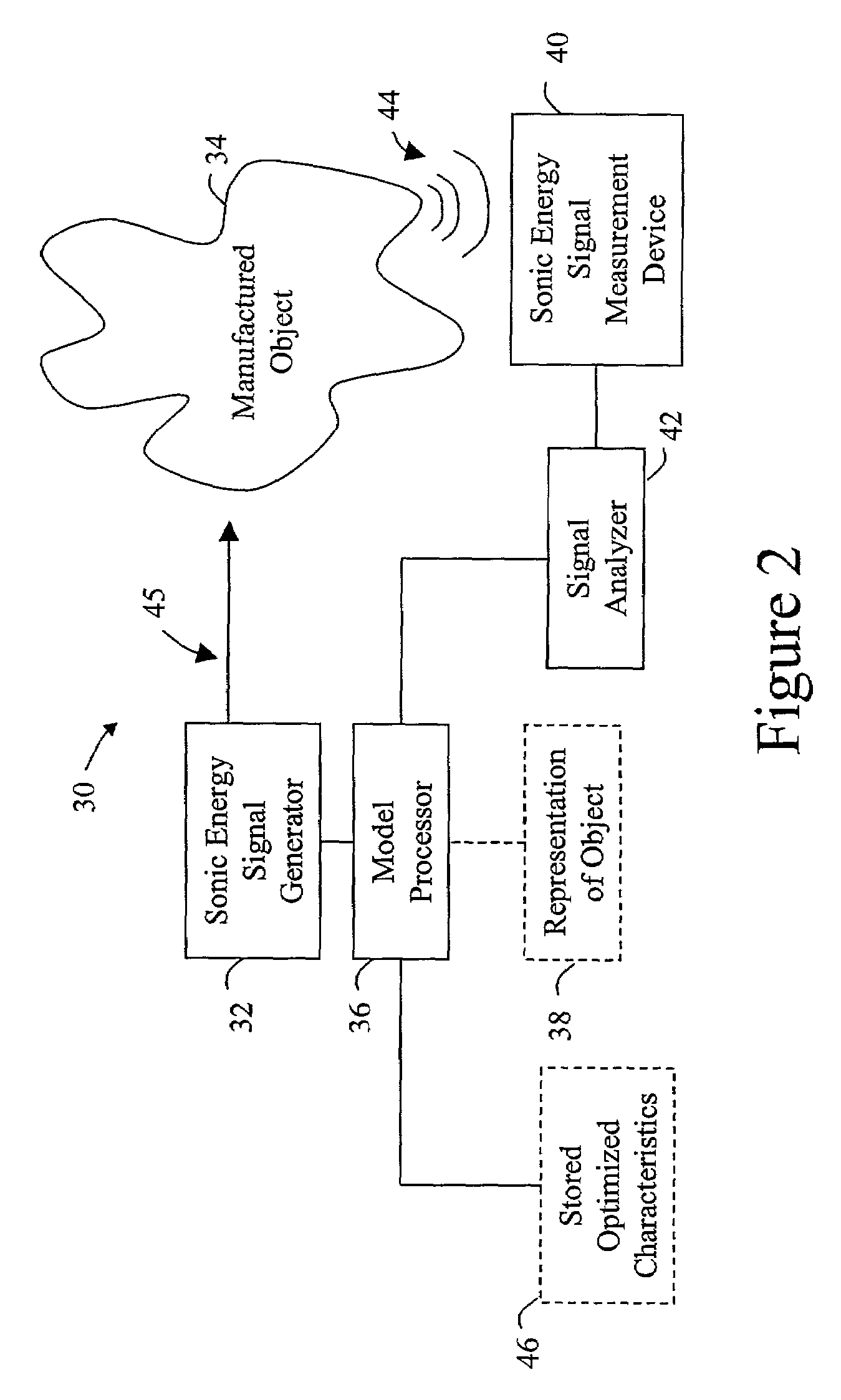

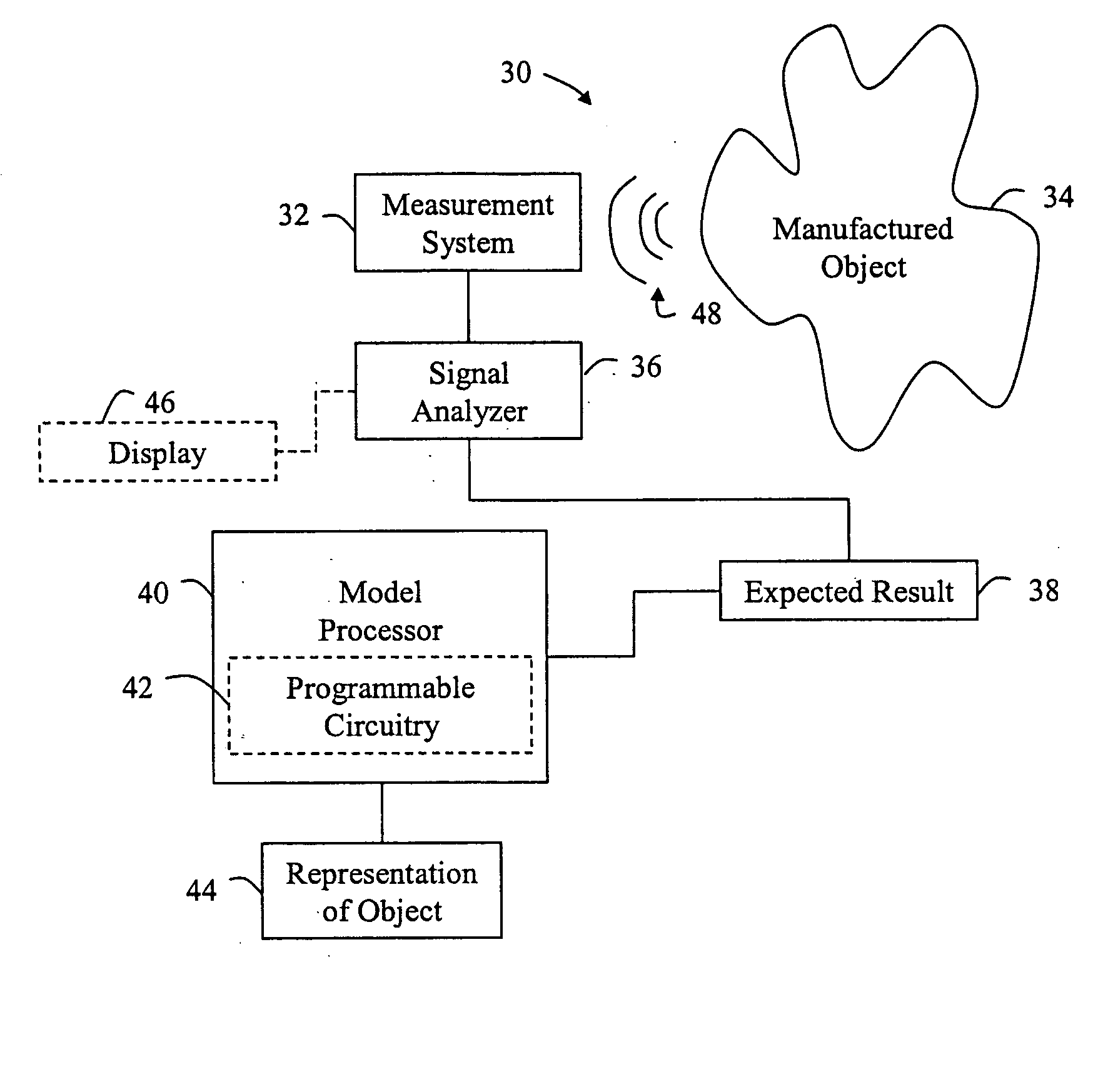

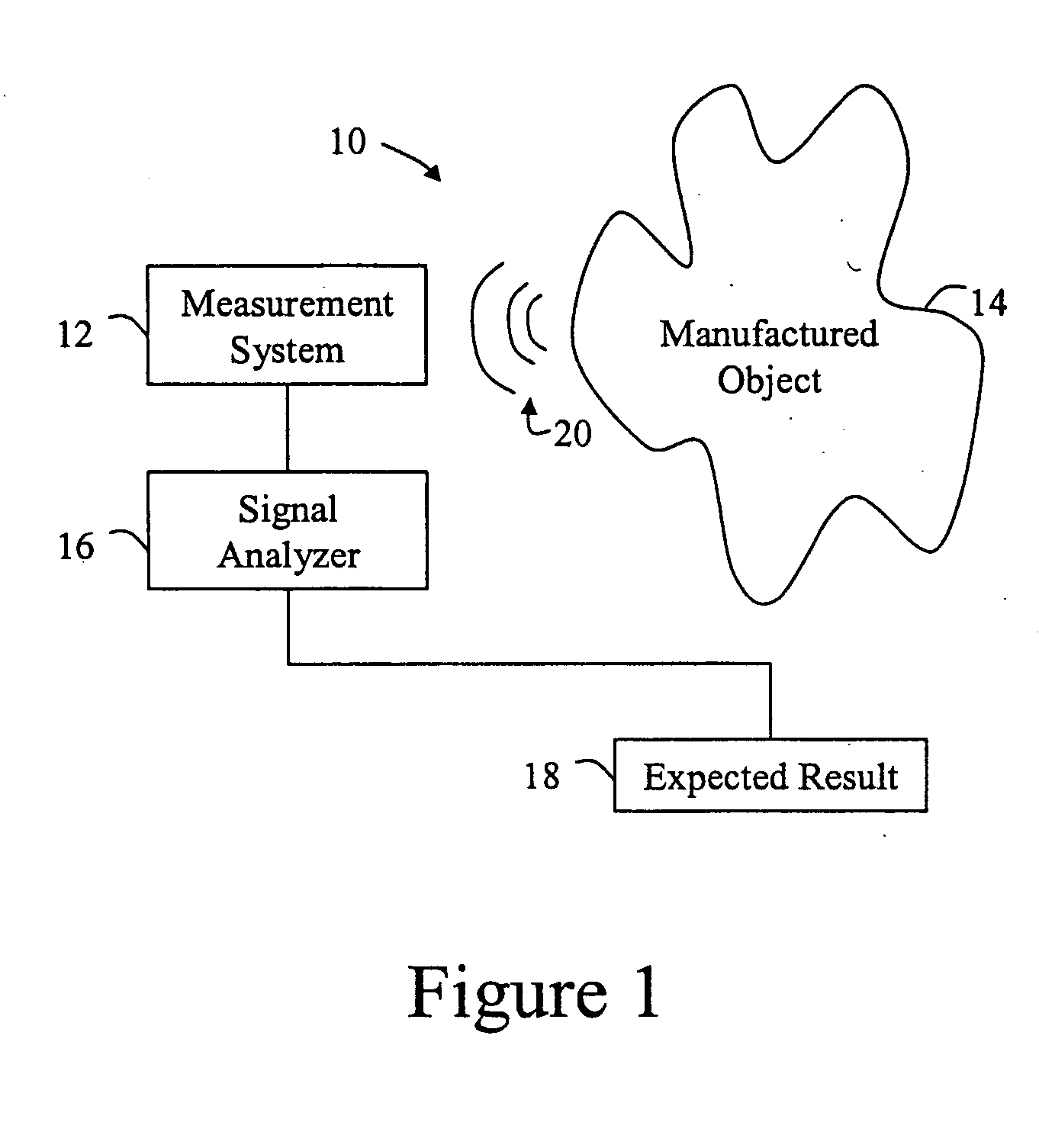

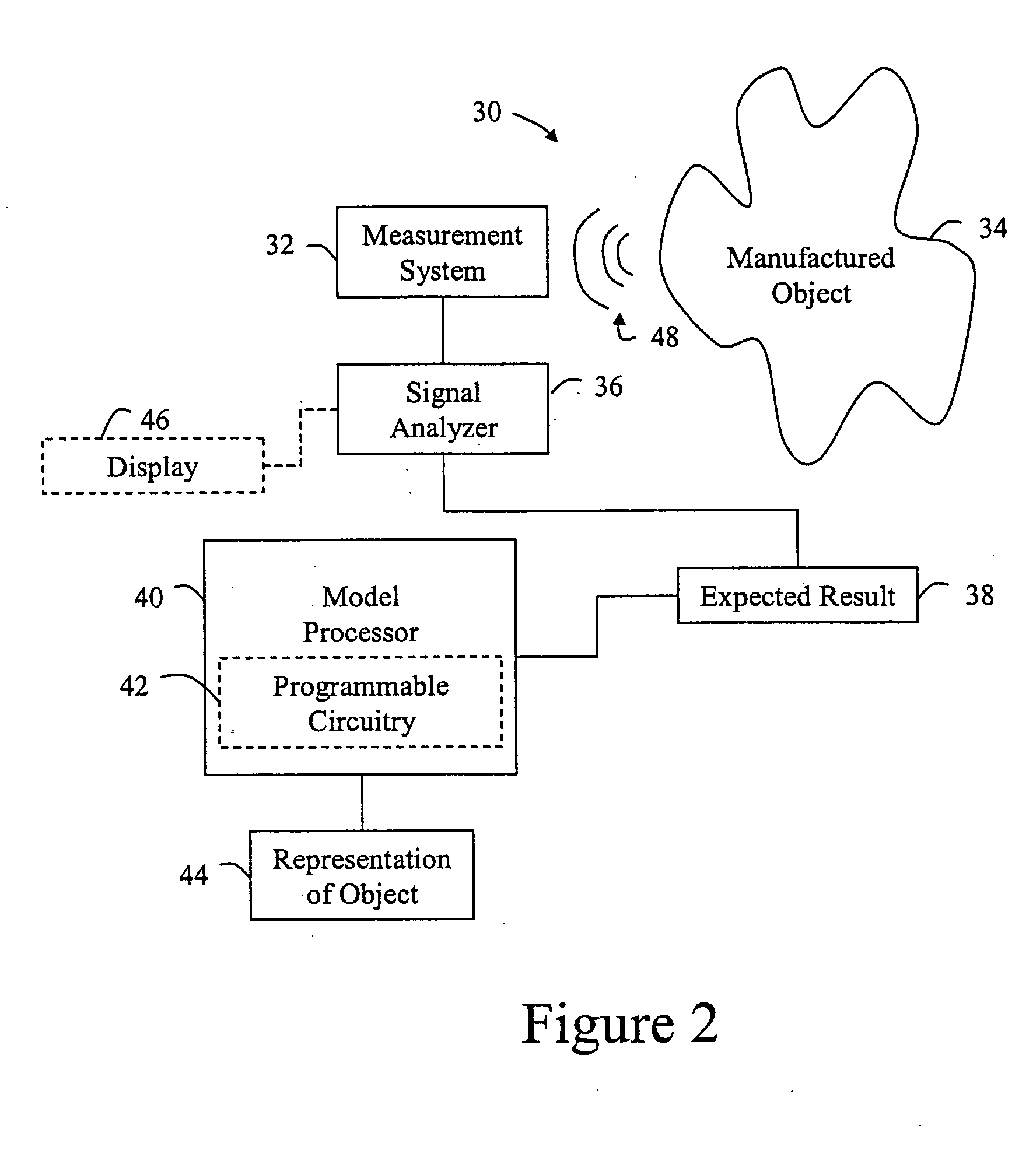

Method to optimize generation of ultrasound using mathematical modeling for laser ultrasound inspection

ActiveUS7117134B2Improved sonic responseImprove operating characteristicsSimulator controlProcessing detected response signalMeasurement deviceSonification

The invention is directed to a laser ultrasound testing system with adaptive generation of sonic energy signals. The system may detect or test features of the manufactured object such as defects and layer properties. A laser generator initiates a sonic energy signal in a manufactured object. A measuring device measures the sonic energy signal. Then, a signal analyzer and / or a model processor determine if the signal is optimized. If the signal is not optimized, optimized operating characteristics of the laser generator are calculated. These optimized operating characteristics may include wavelength, beam dimension, temporal profile and power. Next, the laser generator initiates an improved sonic energy signal by utilizing the optimized operating characteristics. In this manner, more accurate testing and detection is achieved.

Owner:LOCKHEED MARTIN CORP

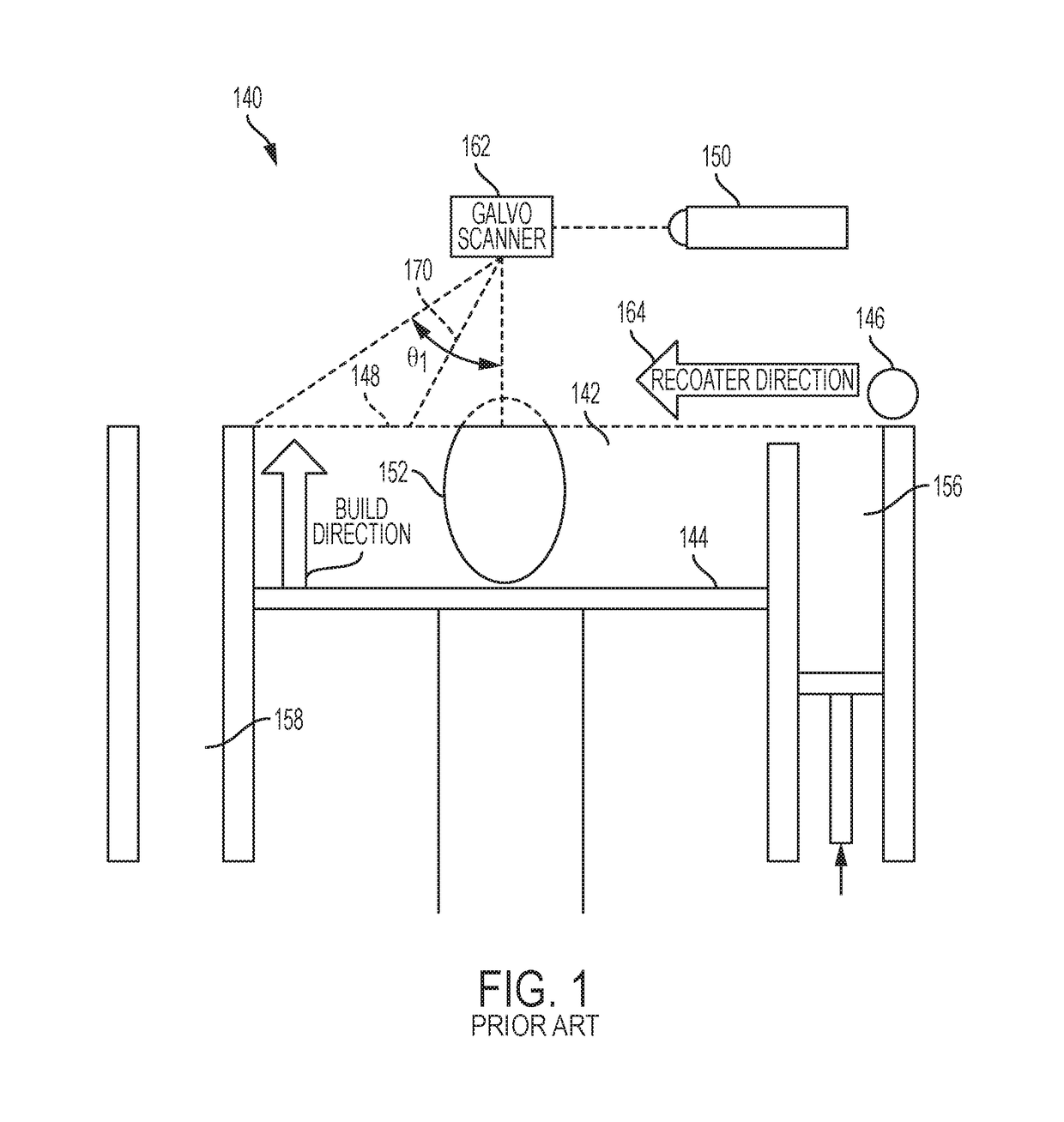

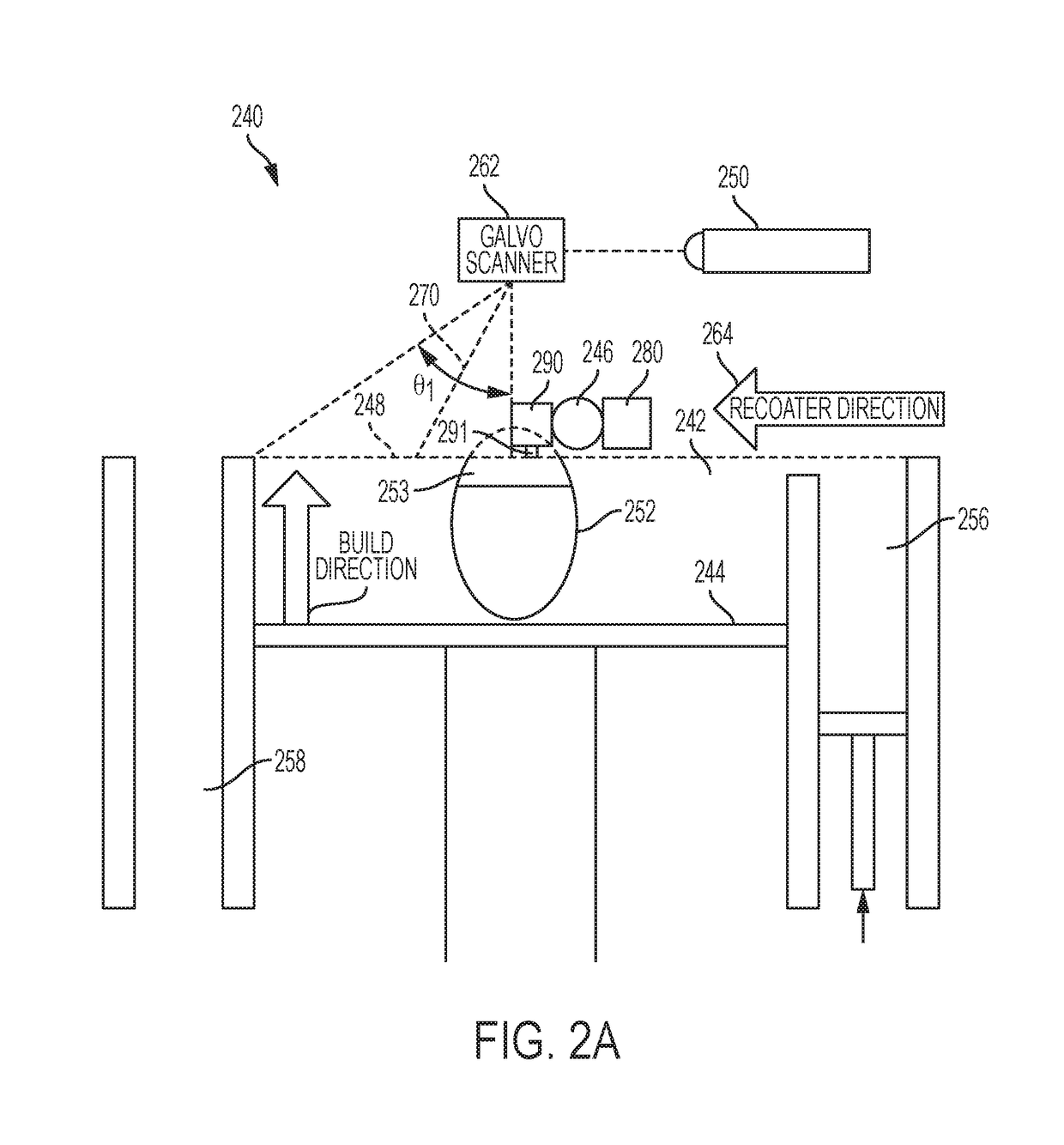

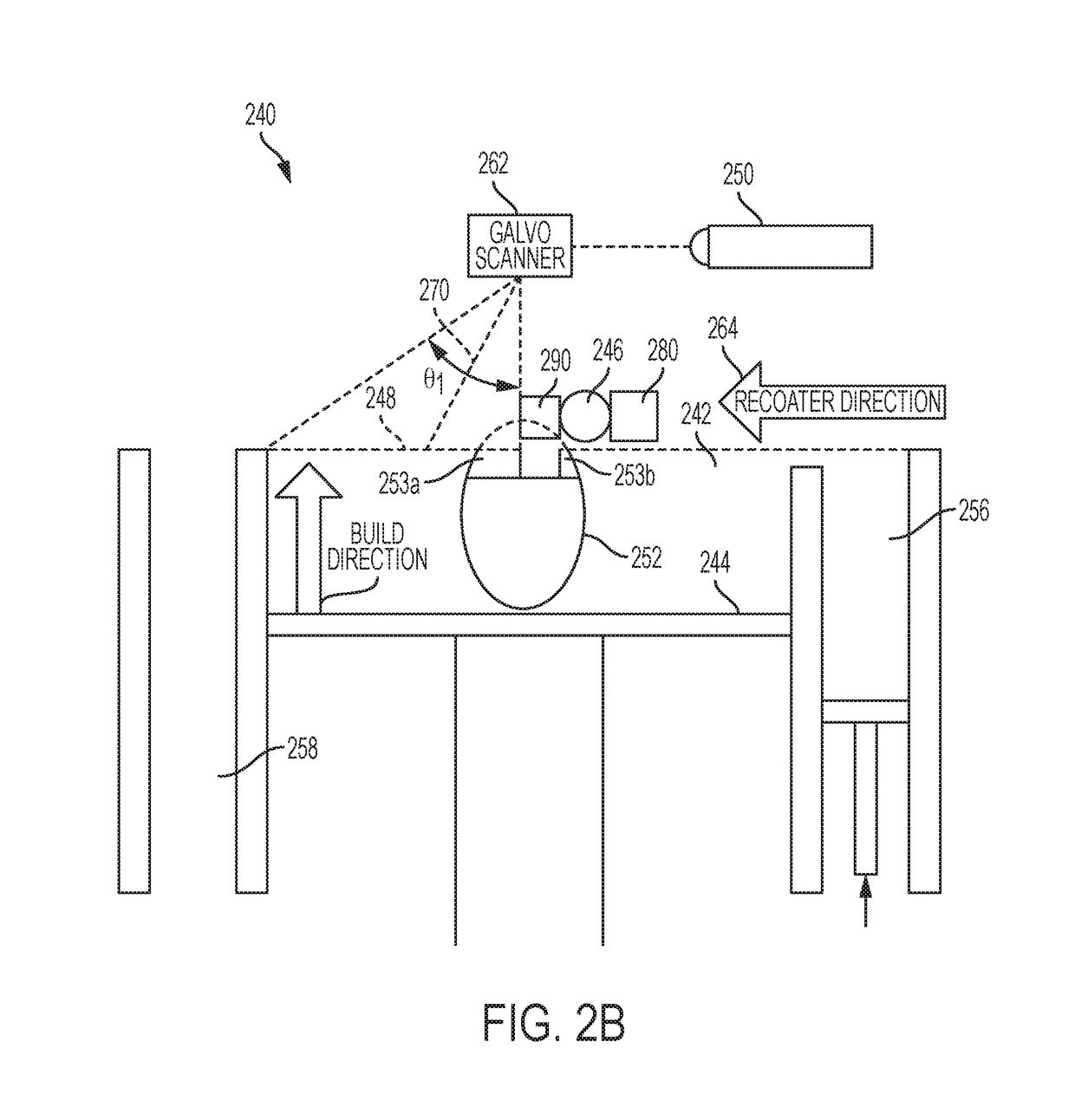

Selective powder processing during powder bed additive manufacturing

ActiveUS20180370213A1Additive manufacturing apparatusIncreasing energy efficiencyMulti materialMetallurgy

Owner:GENERAL ELECTRIC CO

Method to characterize material using mathematical propagation models and ultrasonic signal

InactiveUS20050102109A1Analysing fluids using sonic/ultrasonic/infrasonic wavesAcceleration measurement using interia forcesSonificationSignal analyzer

The invention is directed to a system and method for detecting defects in a manufactured object. These defects may include flaws, delaminations, voids, fractures, fissures, or cracks, among others. The system utilizes an ultrasound measurement system, a signal analyzer and an expected result. The signal analyzer compares the signal from the measurement system to the expected result. The analysis may detect a defect or measure an attribute of the manufactured object. Further, the analysis may be displayed or represented. In addition, the expected result may be generated from a model such as a wave propagation model. One embodiment of the invention is a laser ultrasound detection system in which a laser is used to generate an ultrasonic signal. The signal analyzer compares the measured ultrasonic signal to an expected result. This expected result is generated from a wave propagation model. The analysis is then displayed on a monitor.

Owner:LOCKHEED MARTIN CORP

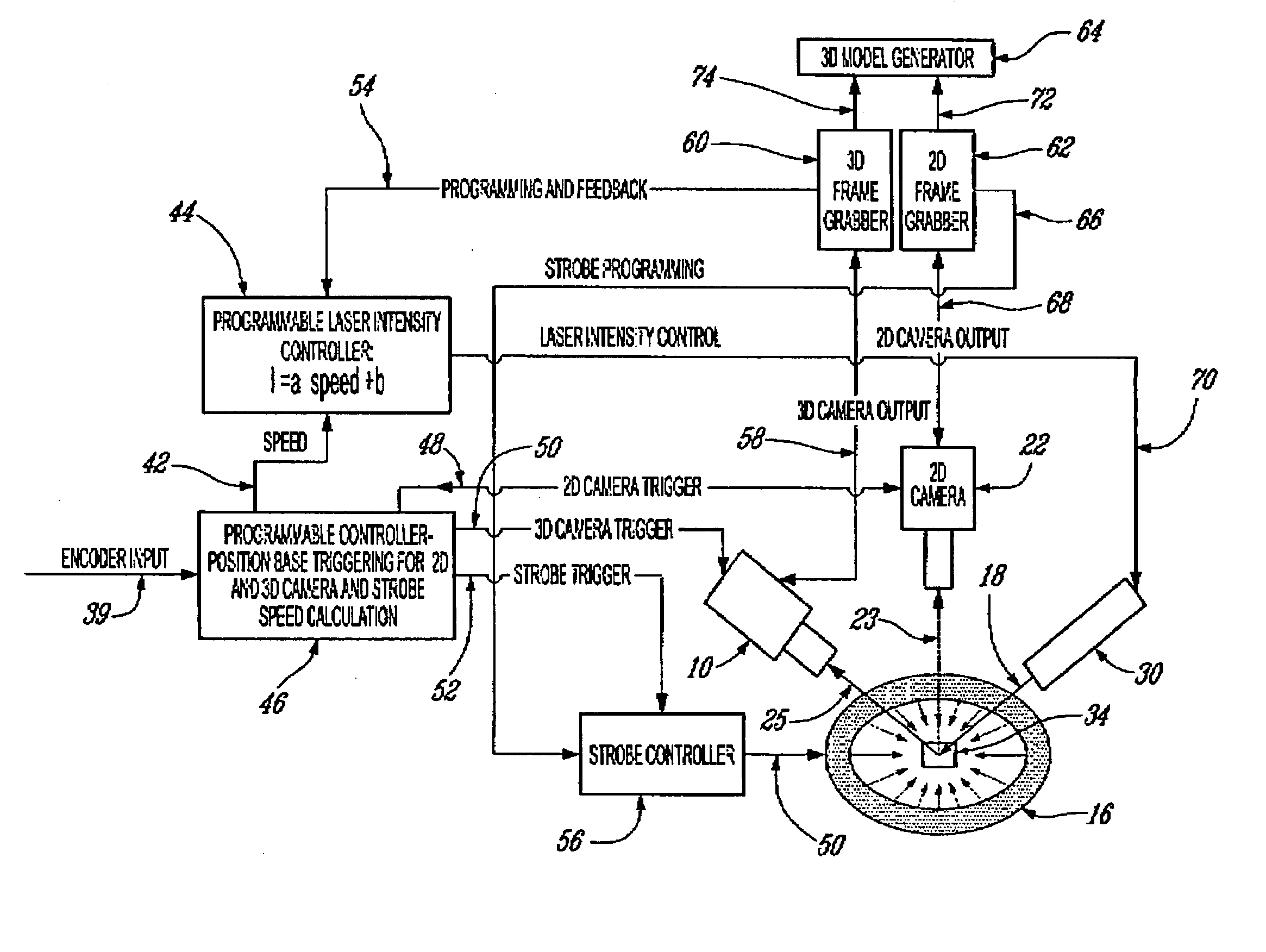

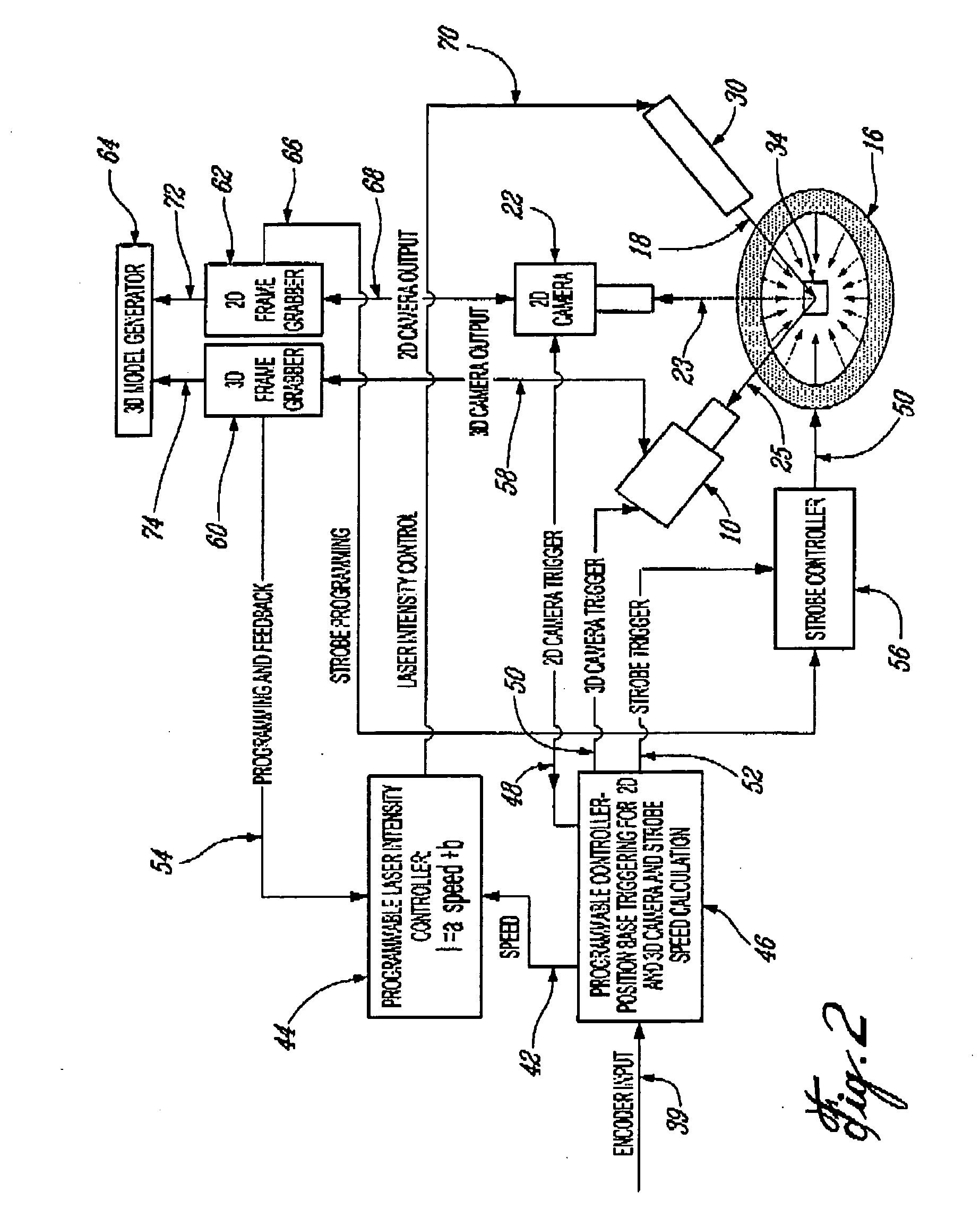

Method and an apparatus for simultaneous 2D and 3D optical inspection and acquisition of optical inspection data of an object

ActiveUS20070103675A1Improve image qualityReduce processing timeMaterial analysis by optical meansUsing optical meansEngineeringField of view

The present invention relates to optical inspection of manufactured products, such as integrated circuits wafer bumps. There are provided methods and apparatus for acquisition of optical inspection data of said object, as well as for optical inspection and manufacturing of said object. The invention comprises a 2D optical scanning system and a 3D optical scanning system that can have common image trigger control and / or operate simultaneously without interference to have the same field of view.

Owner:NIDEC-READ CORPORATION

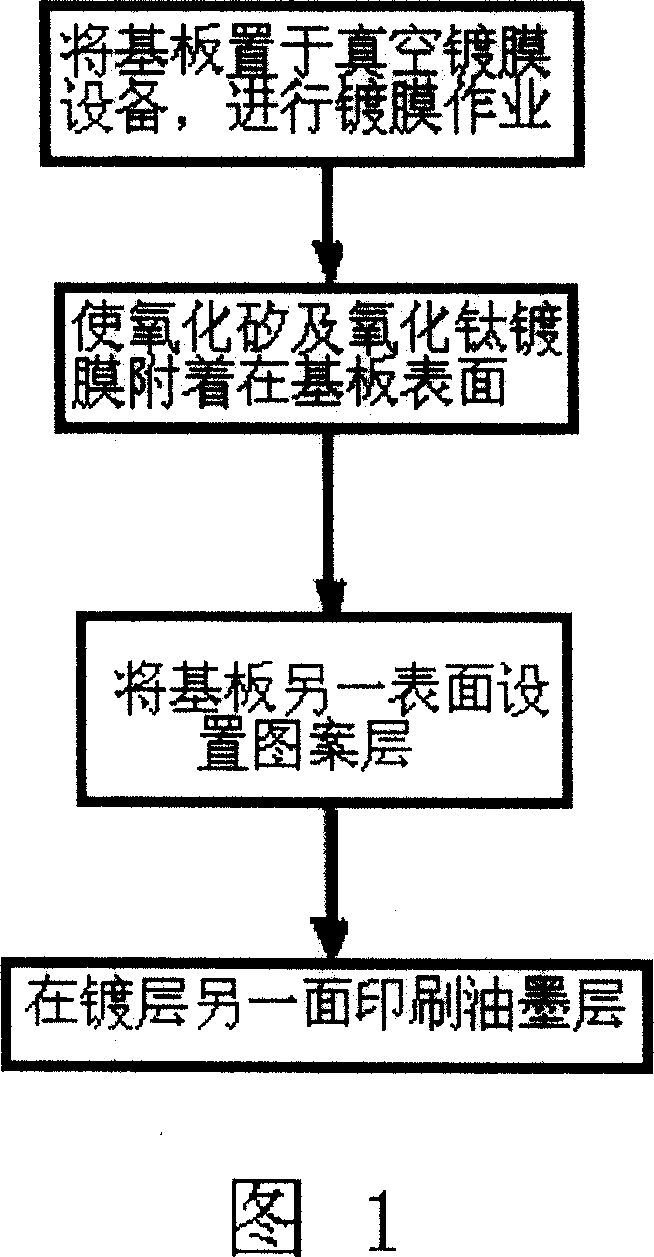

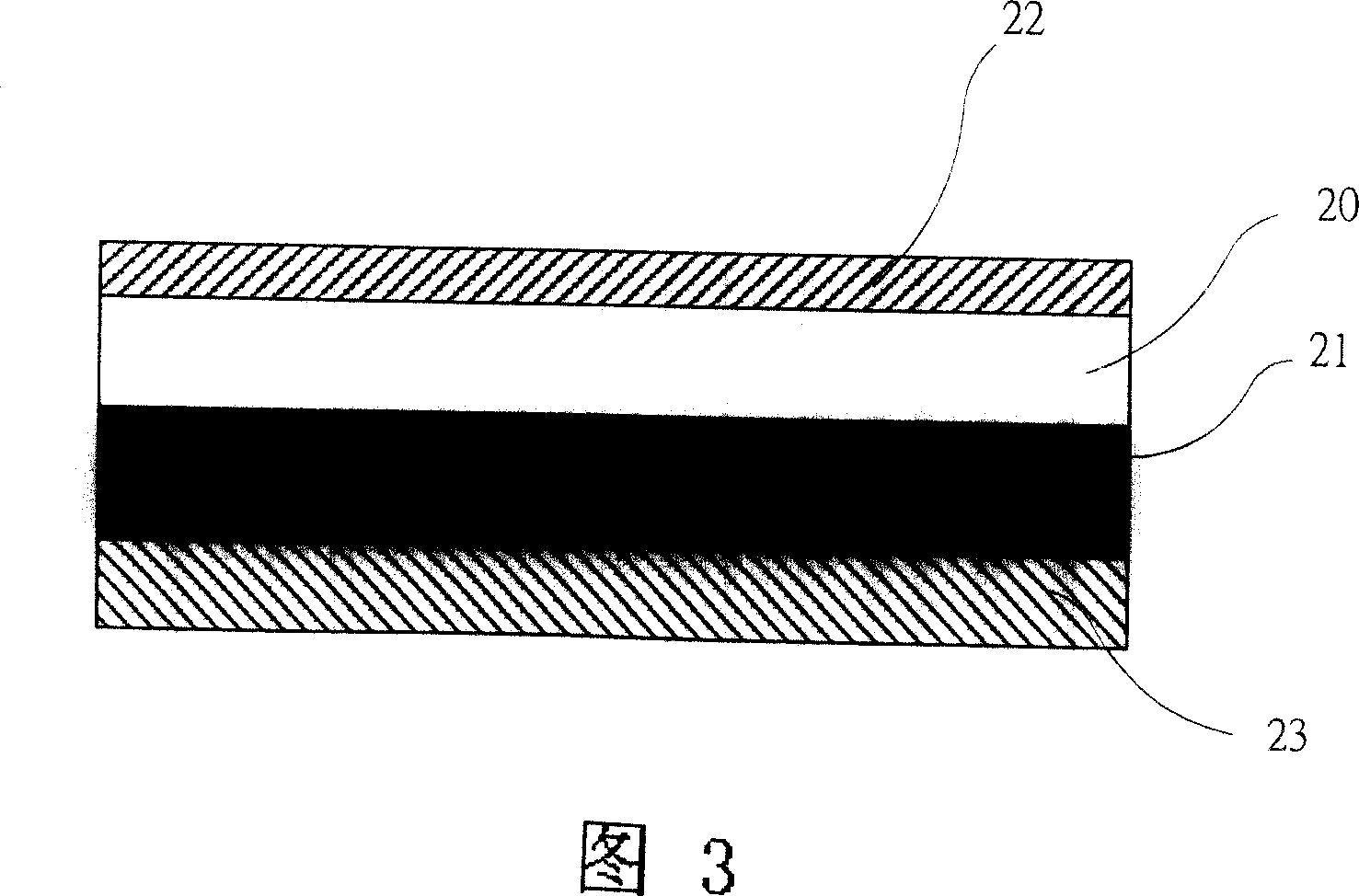

Vacuum coating apparatus, method and product with laser pattern formed on substrate surface

InactiveCN1974235ADifferent color variationsDifferent visualLayered productsDecorative surface effectsPolymer substrateLaser patterning

The present invention is vacuum coating apparatus, method and product for forming laser pattern on the surface of substrate. Carbonate polymer substrate or acryl substrate is set inside vacuum coating apparatus to vaporize silica and titania coating on the substrate surface. On the coated substrate, one pattern layer is printed in the other surface and one color layer is set on the coating layer. When the product is illuminated with light, the coating layer will refract light to exhibit color change and image refracting visual effect.

Owner:HUAI JIE ENTERPRISE

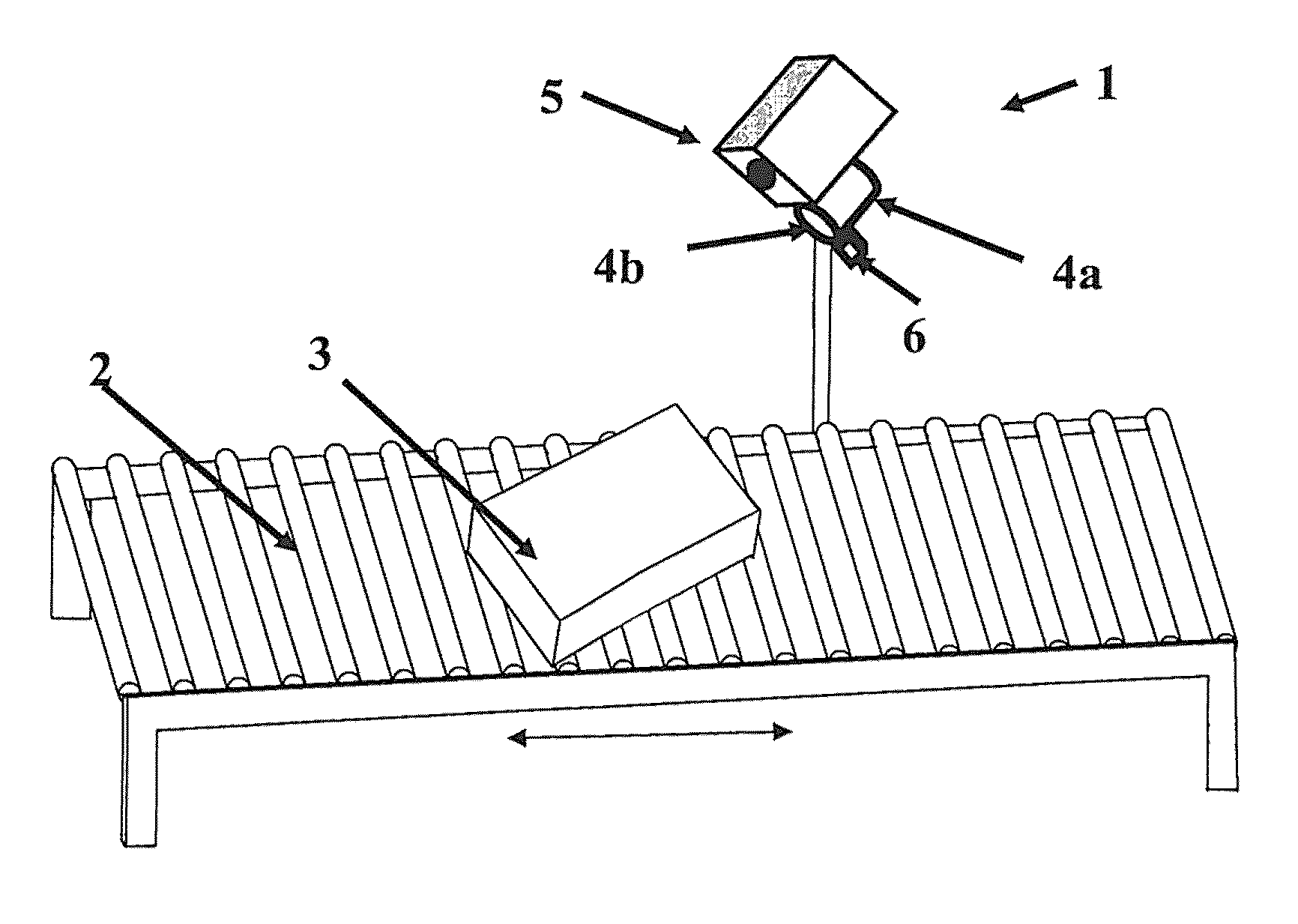

Dimensioning system

ActiveUS8294809B2Enhanced third dimension accuracyMechanically simpleTelevision system detailsOptical rangefindersQuality controlLaser pulse shaping

The present invention determines the dimensions and volume of an object by using a novel 3-D camera that measures the distance to every reflective point in its field of view with a single pulse of light. The distance is computed by the time of flight of the pulse to each camera pixel. The accuracy of the measurement is augmented by capture of the laser pulse shape in each camera pixel. The camera can be used on an assembly line to develop quality control data for manufactured objects or on a moving or stationary system that weighs as well as dimensions the objects. The device can also ascertain the minimum size of a box required to enclose an object.

Owner:CONTINENTAL AUTONOMOUS MOBILITY US LLC

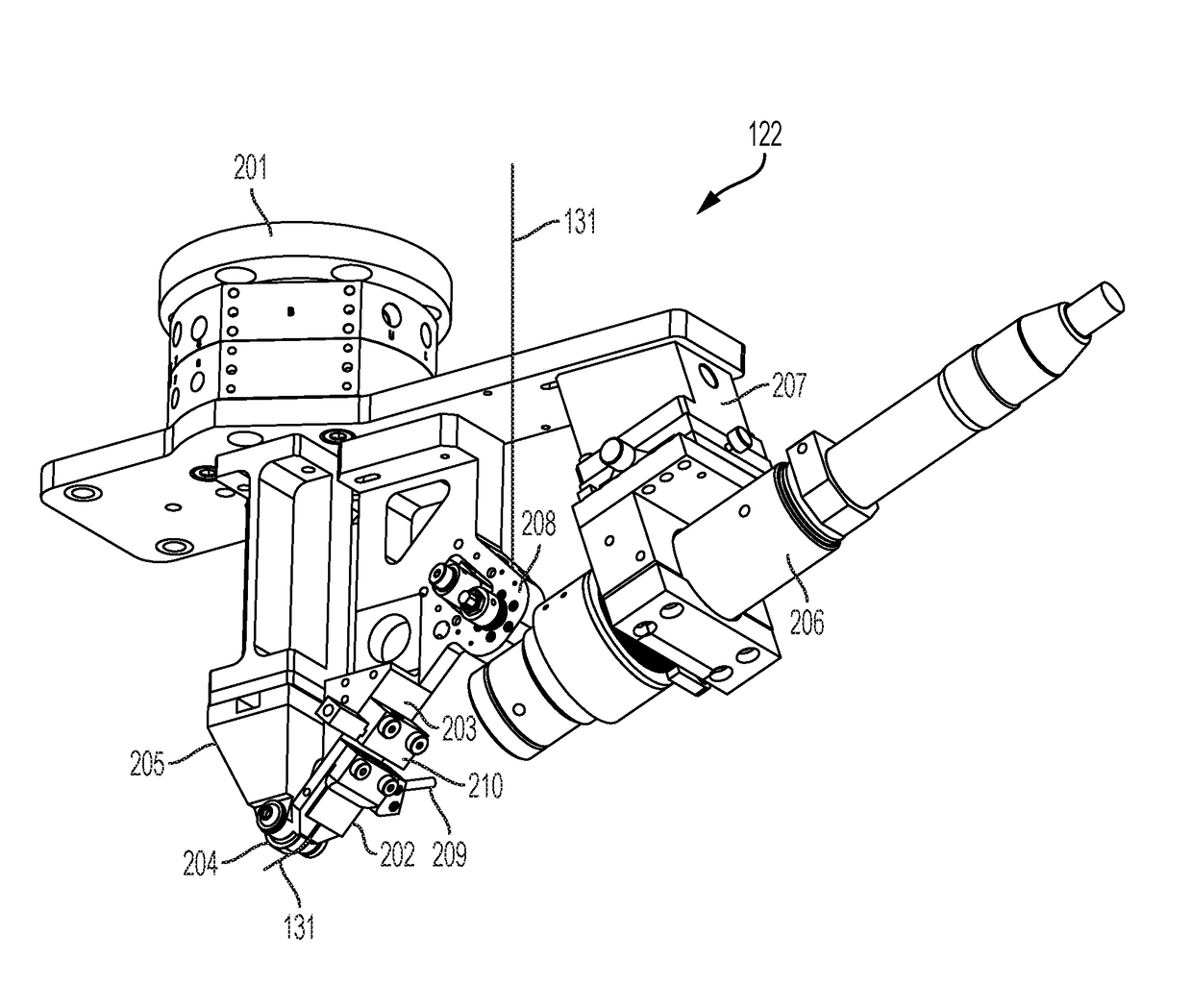

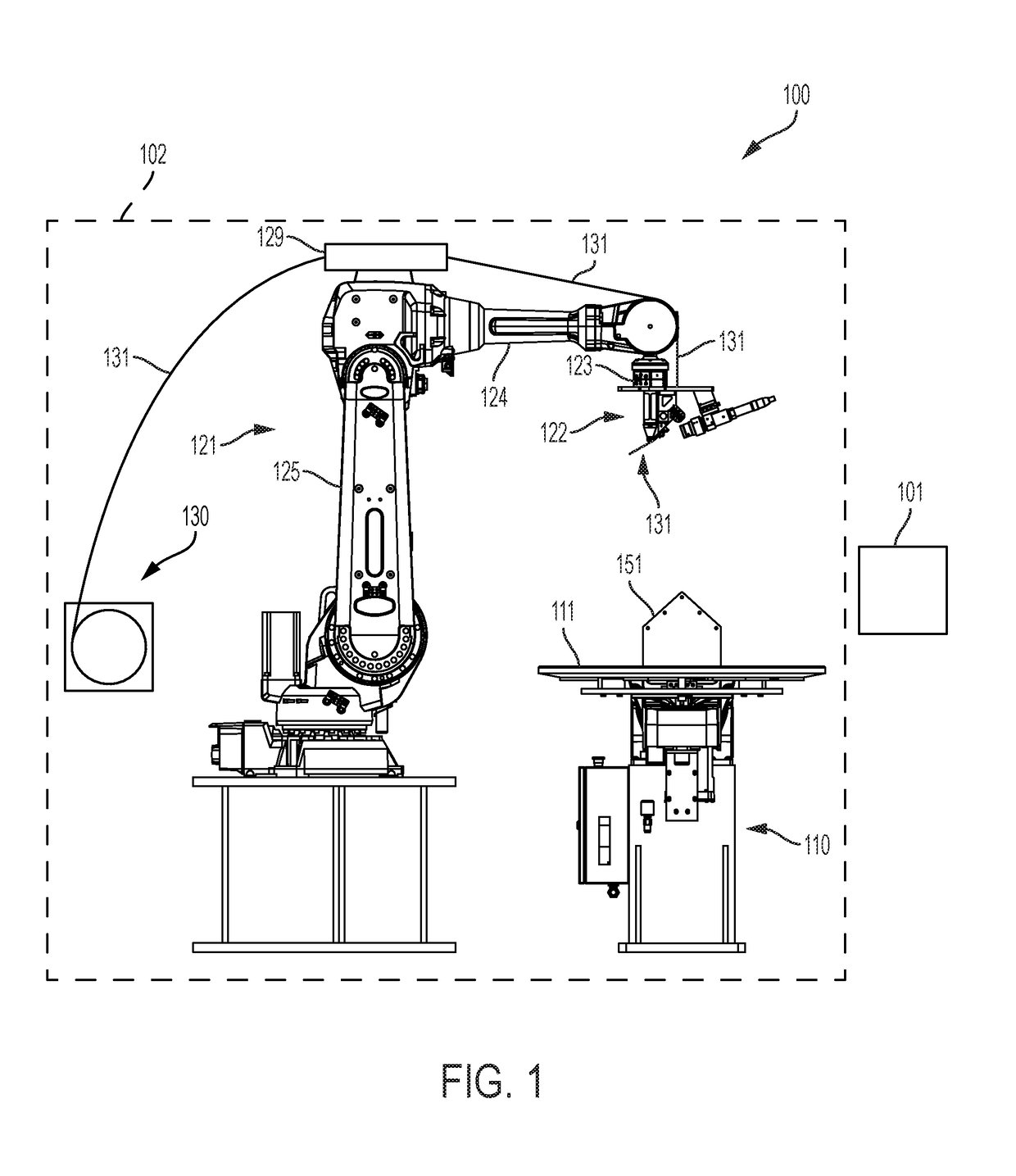

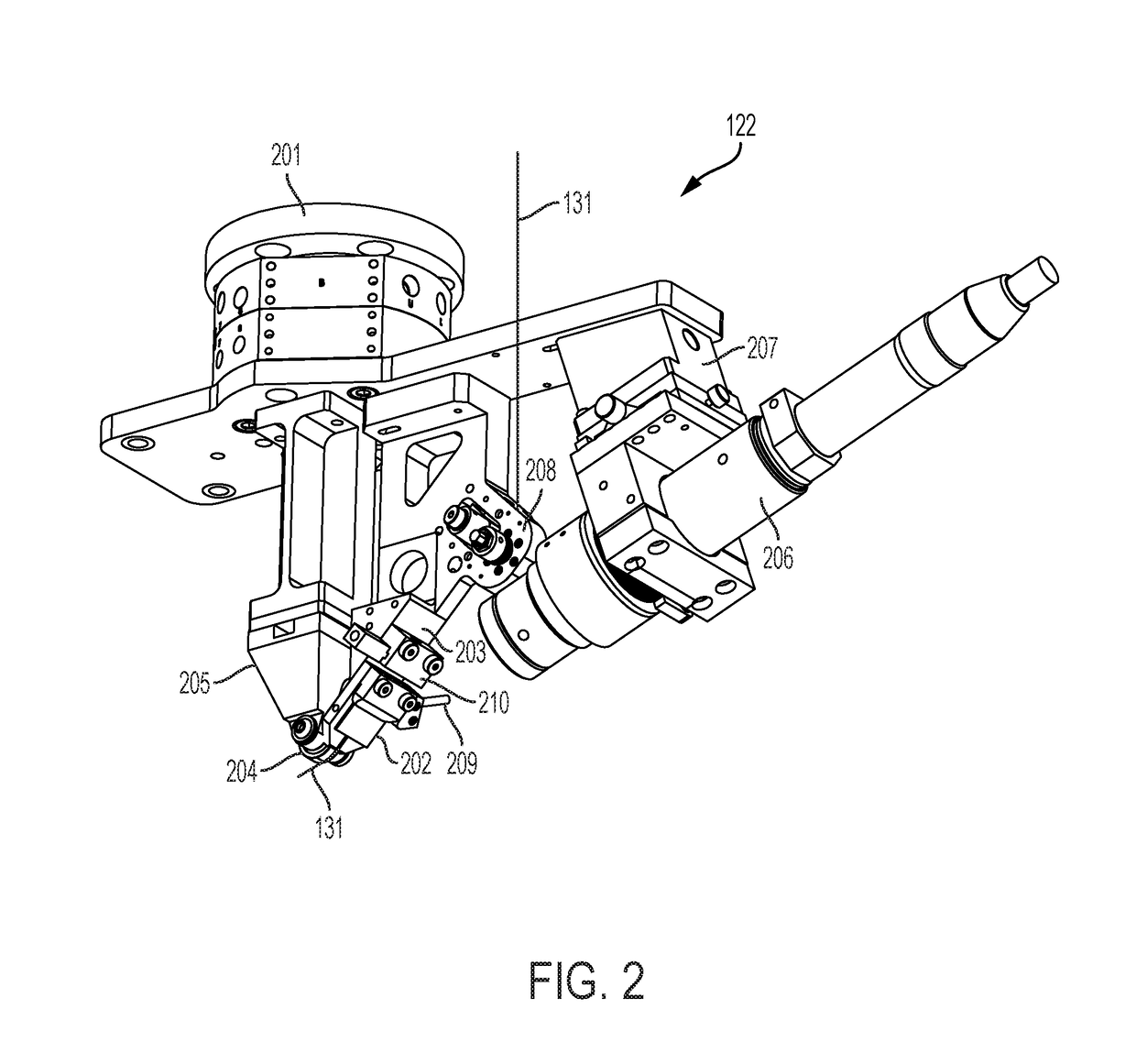

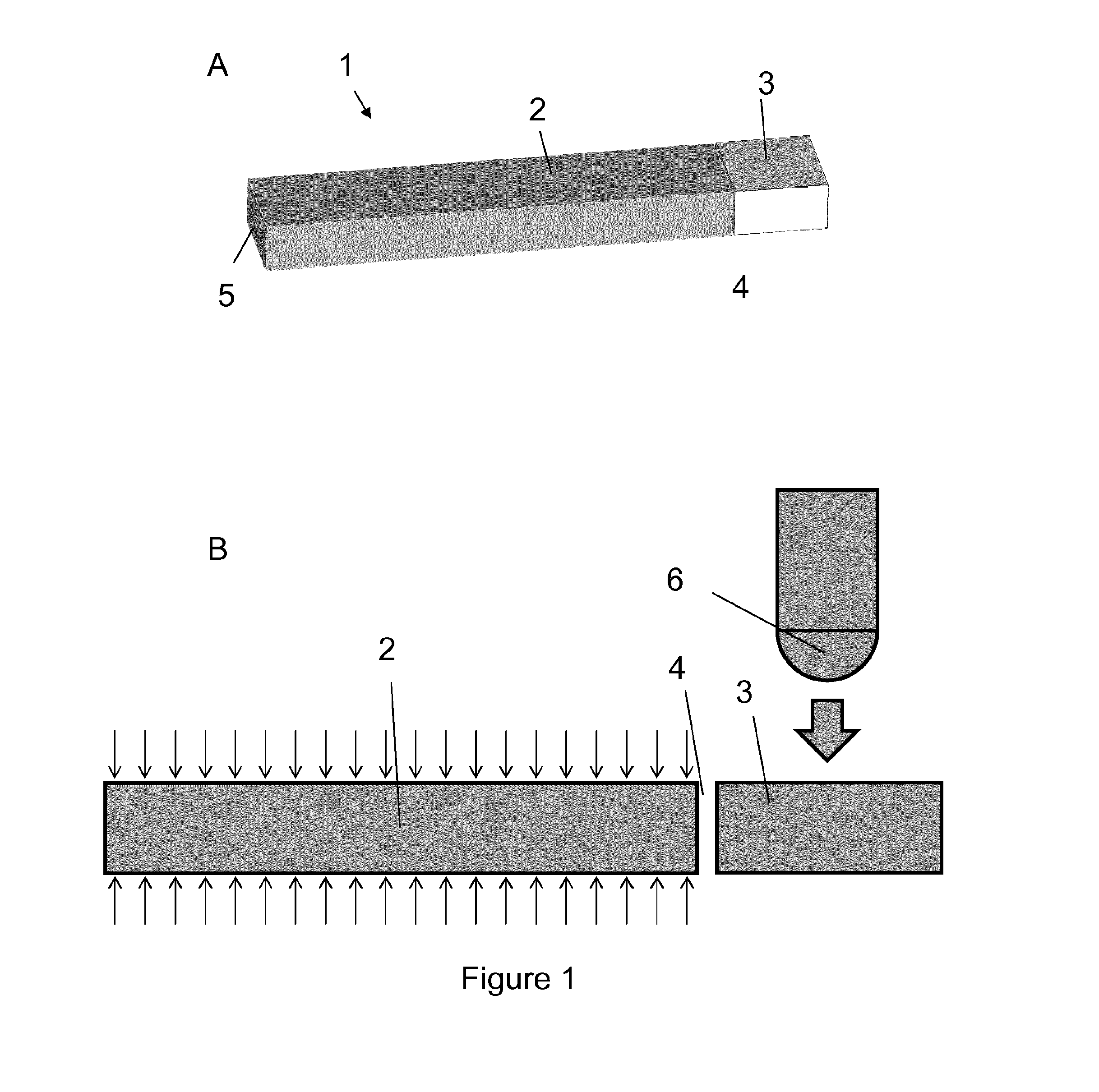

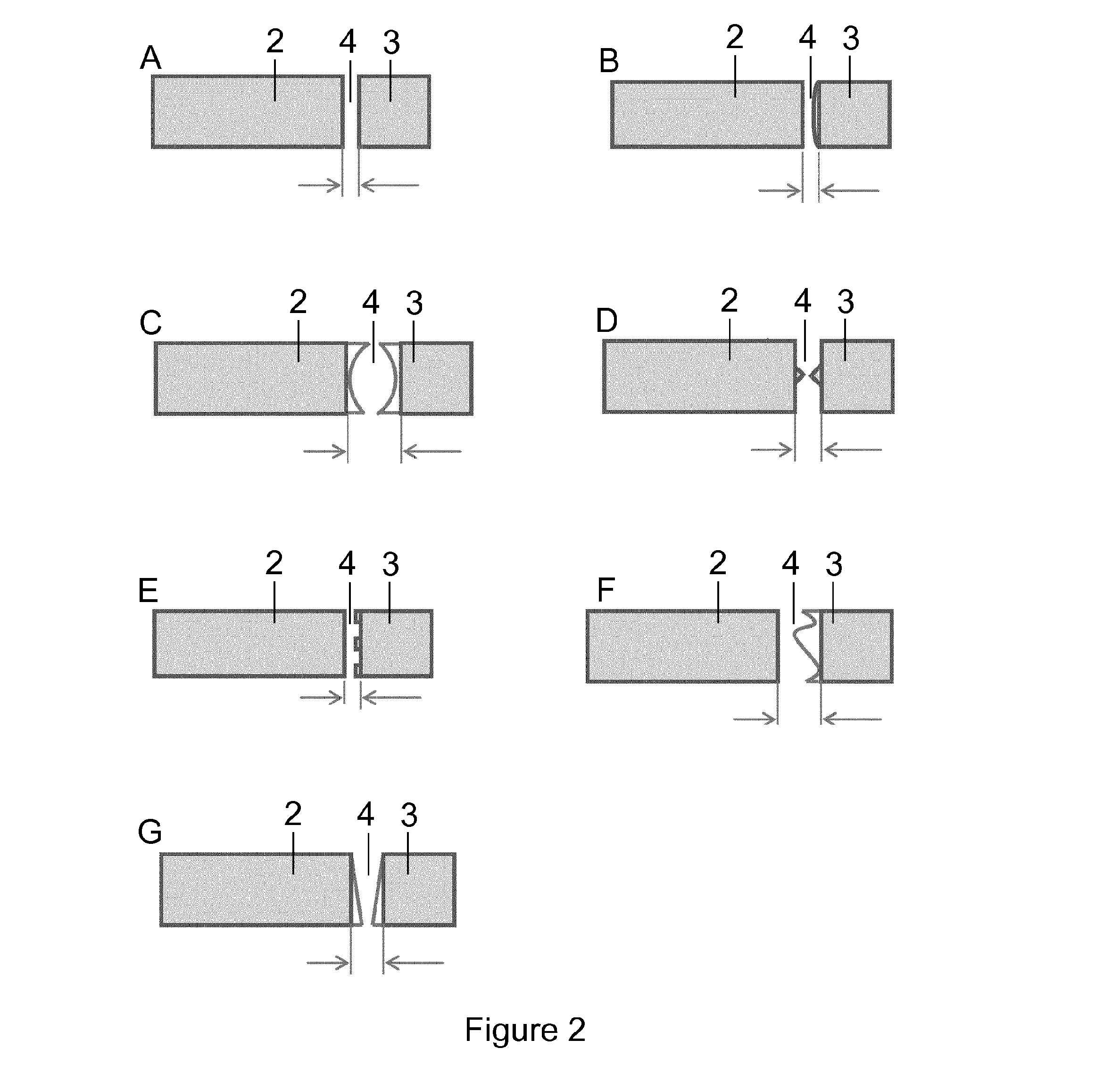

Alleviating torsional forces on fiber-reinforced thermoplastic filament

ActiveUS10046511B1Large forceEliminate torqueAdditive manufacturing apparatus3D object support structuresFiberThermoplastic

An apparatus and method for managing bending and other applied forces that are exerted on a filament of thermoplastic with reinforcing fibers in a 3D printing system during the deposition process that is associated with the manufacturing of an object. The quality of the manufactured object is enhanced through a process that comprises i) applying torque to certain portions of the solid filament in a manner that is commensurate with the expected motions of the deposition head while depositing those portions, but only after ii) heating each portion to a sufficient temperature. A heating device and a twisting device act on the filament while it is moving toward the deposition point and while under the control of a controller that is operating according to a computer model of the object being manufactured.

Owner:AREVO INC

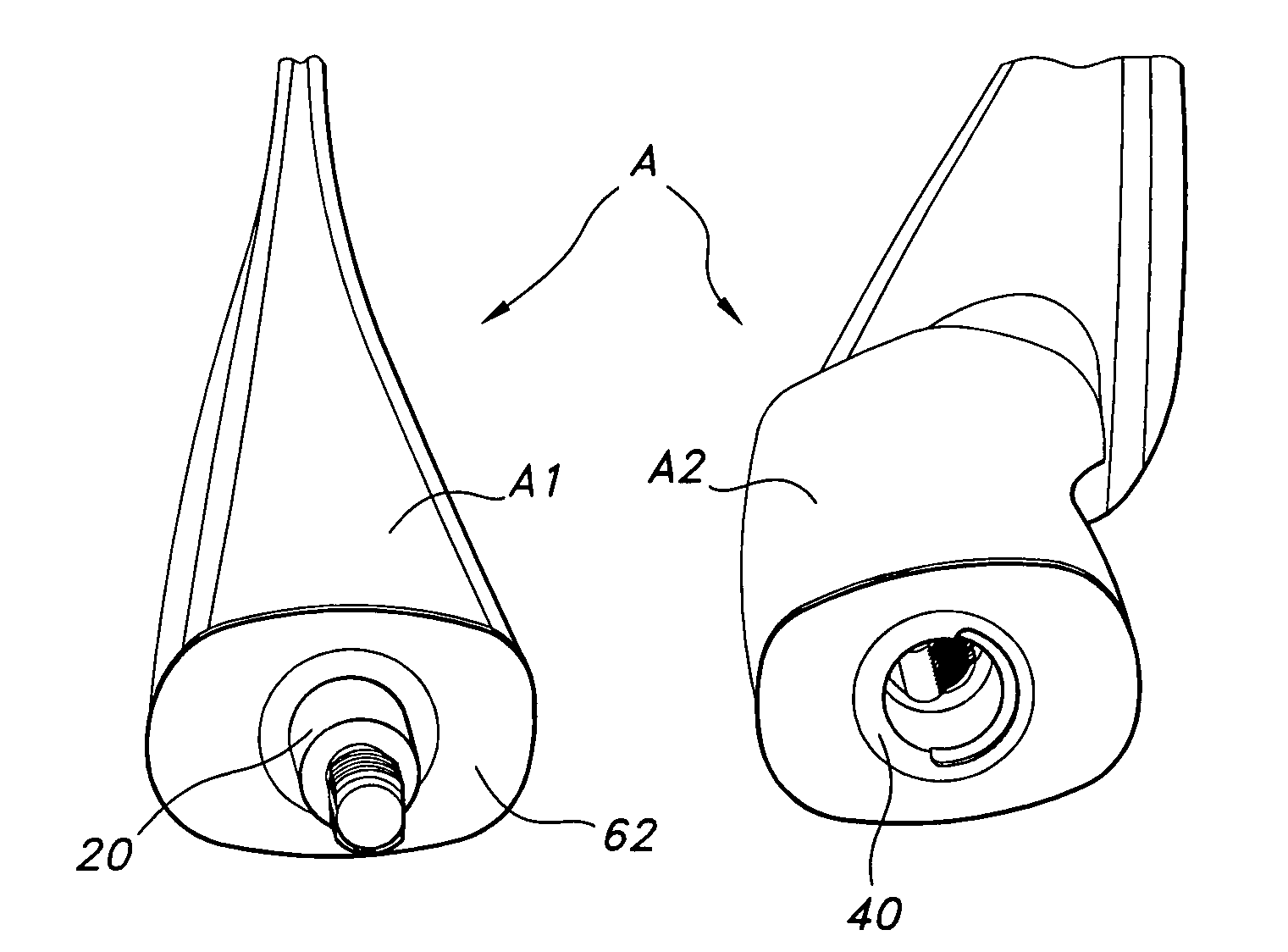

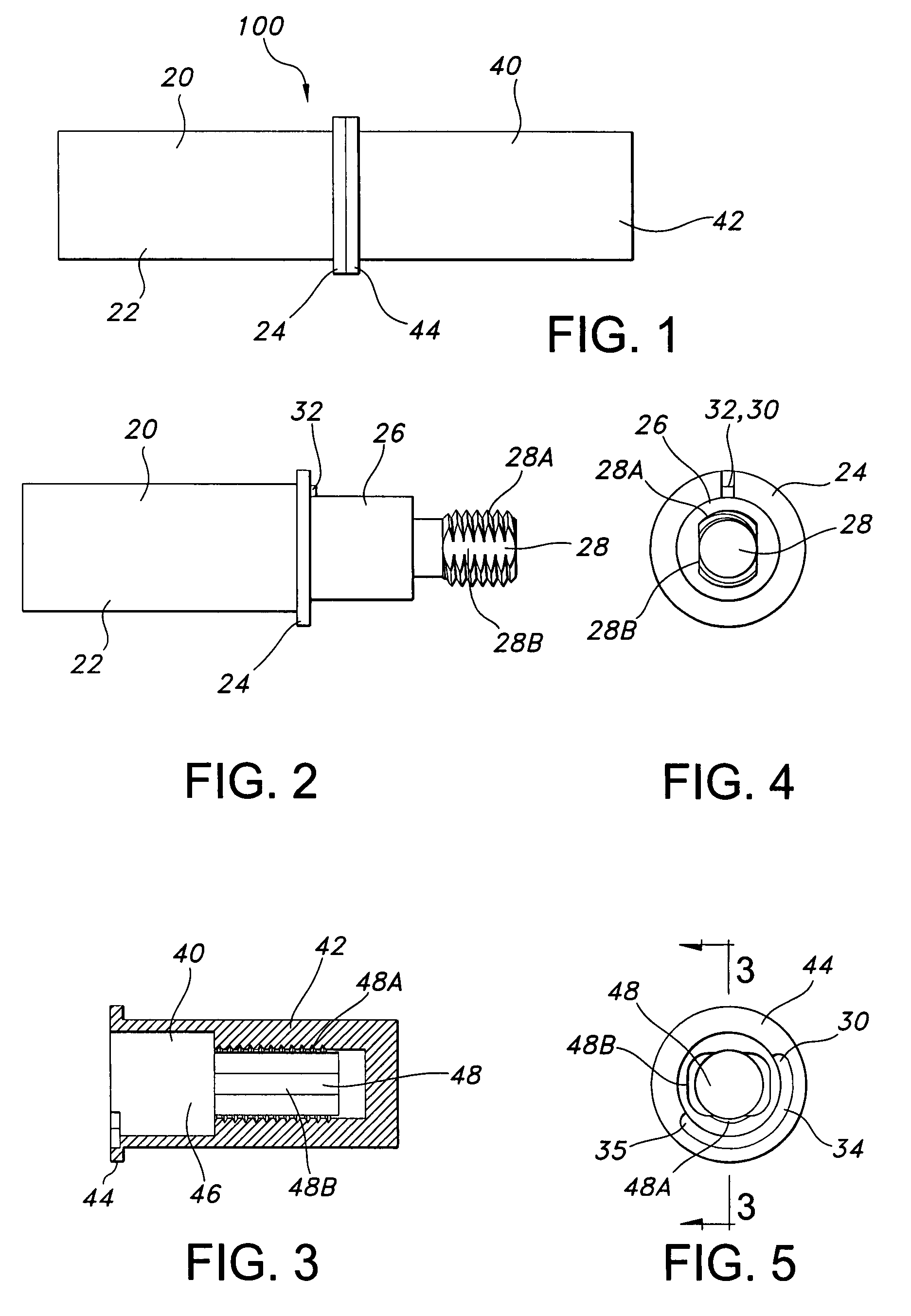

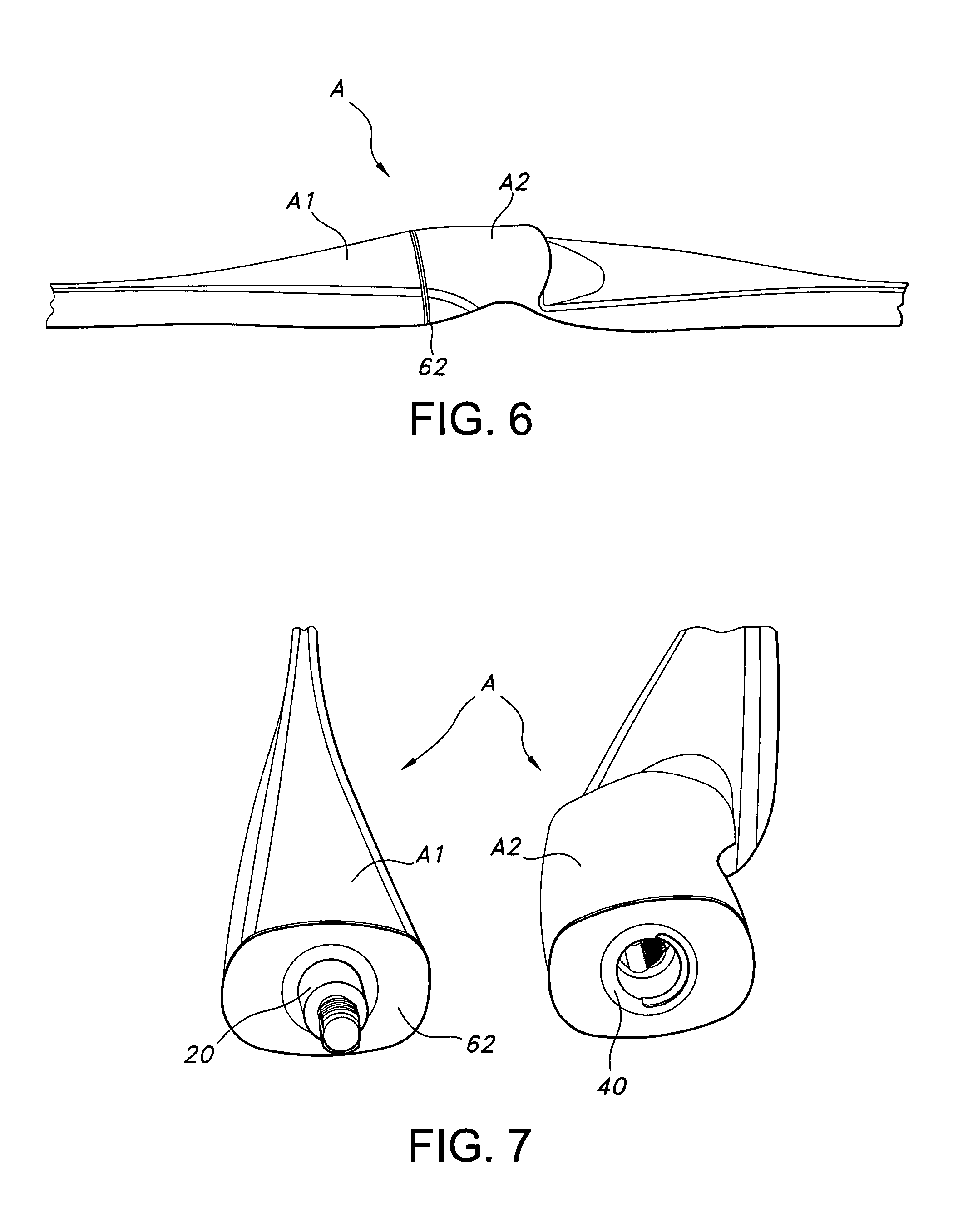

Precision aligning fastener

Precision aligning fastener for releasably joining two halves of a manufactured article. The precision aligning fastener has a male body that threads into a female body. The threads on the male and female threads, bodies are provided in an interrupted-thread pattern, allowing the male body to be completely inserted into the female body before twisting and engaging the threads. A stop means is provided, to assist in aligning and to prevent overtightening of the fastener. The fastener is particularly well-suited to releasably join long, slender articles that must be precisely aligned to function properly, such as a hunter's longbow, billiard cues, furniture, etc.

Owner:WARREN CRAIG A

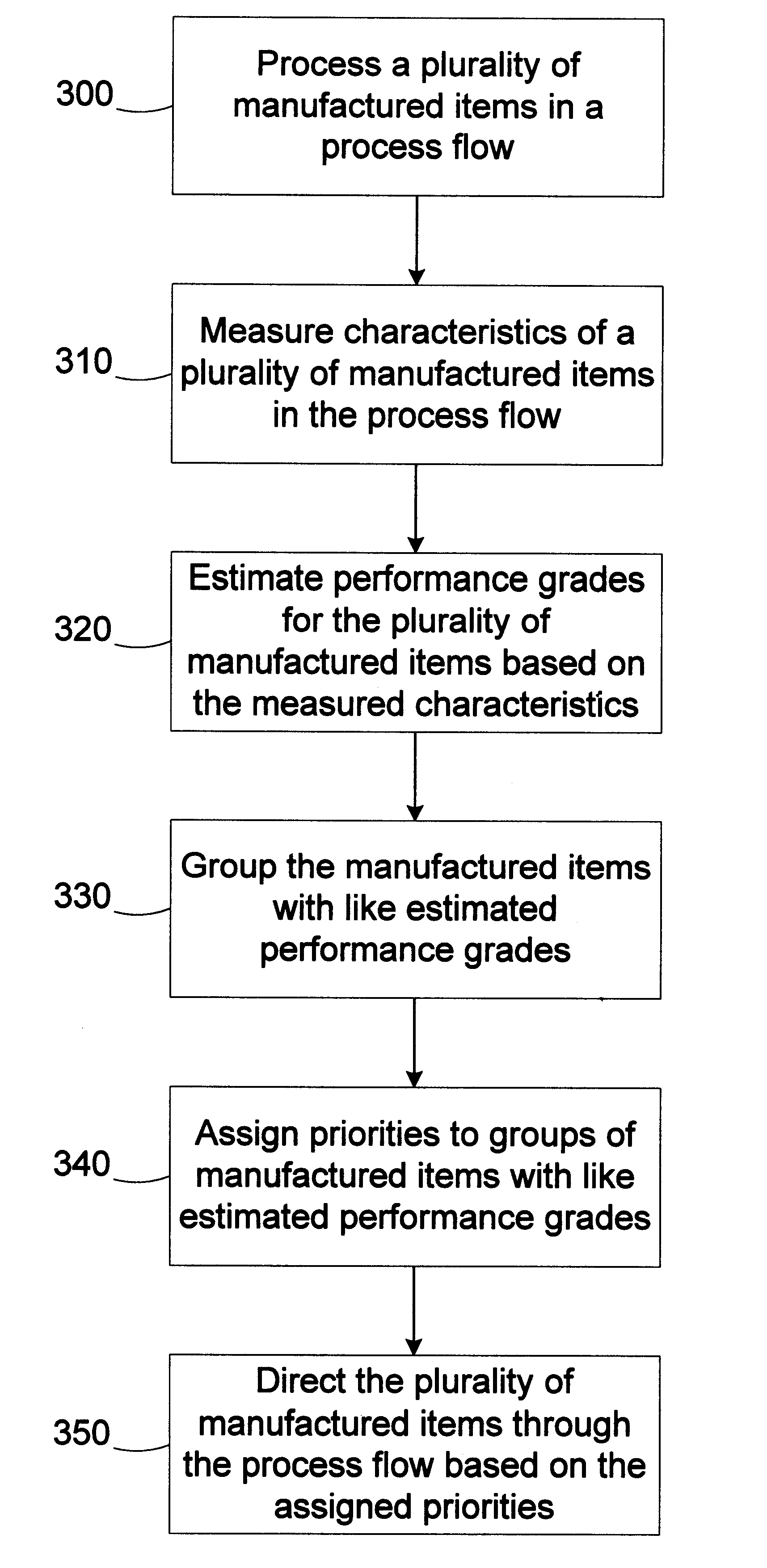

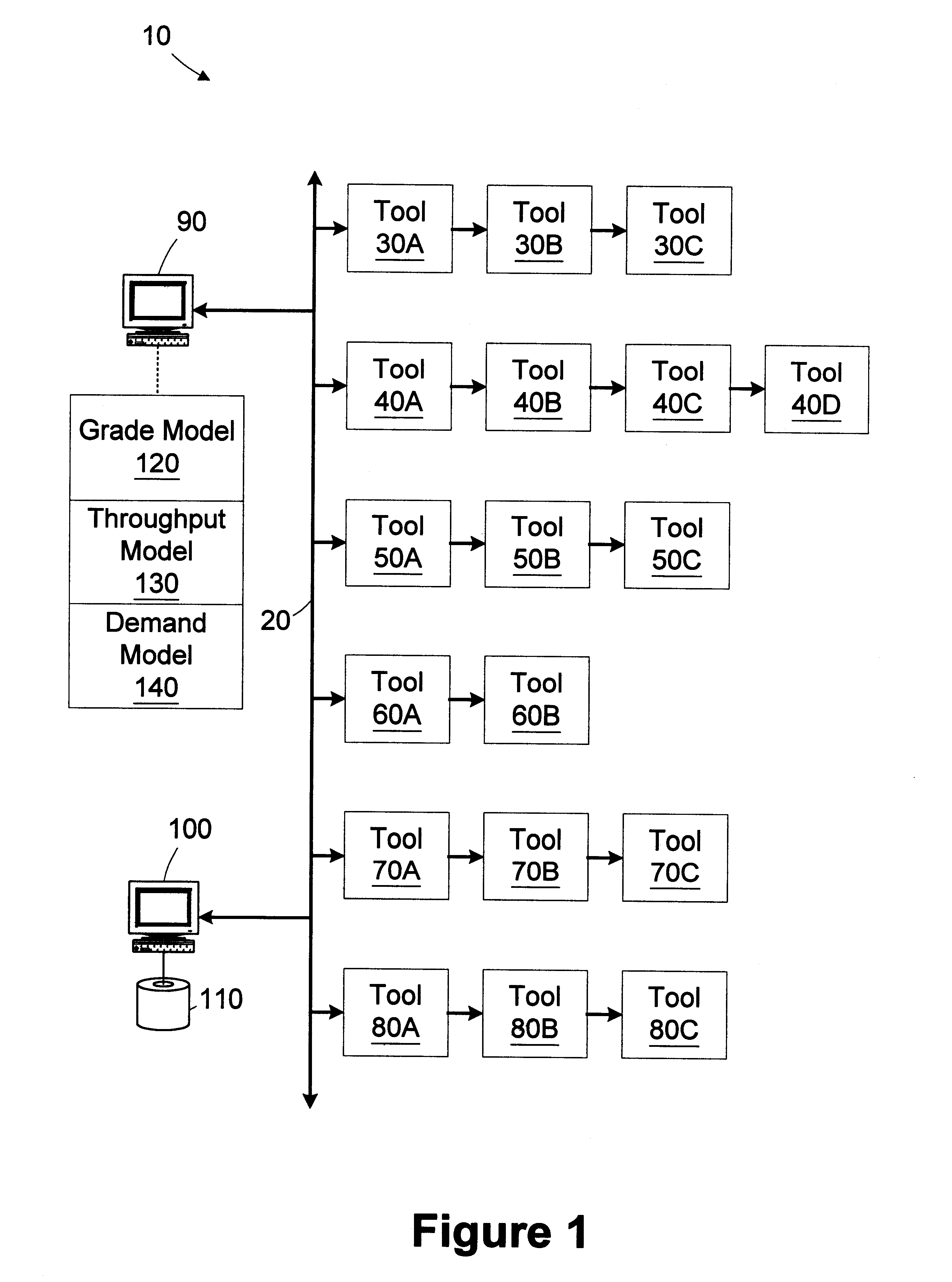

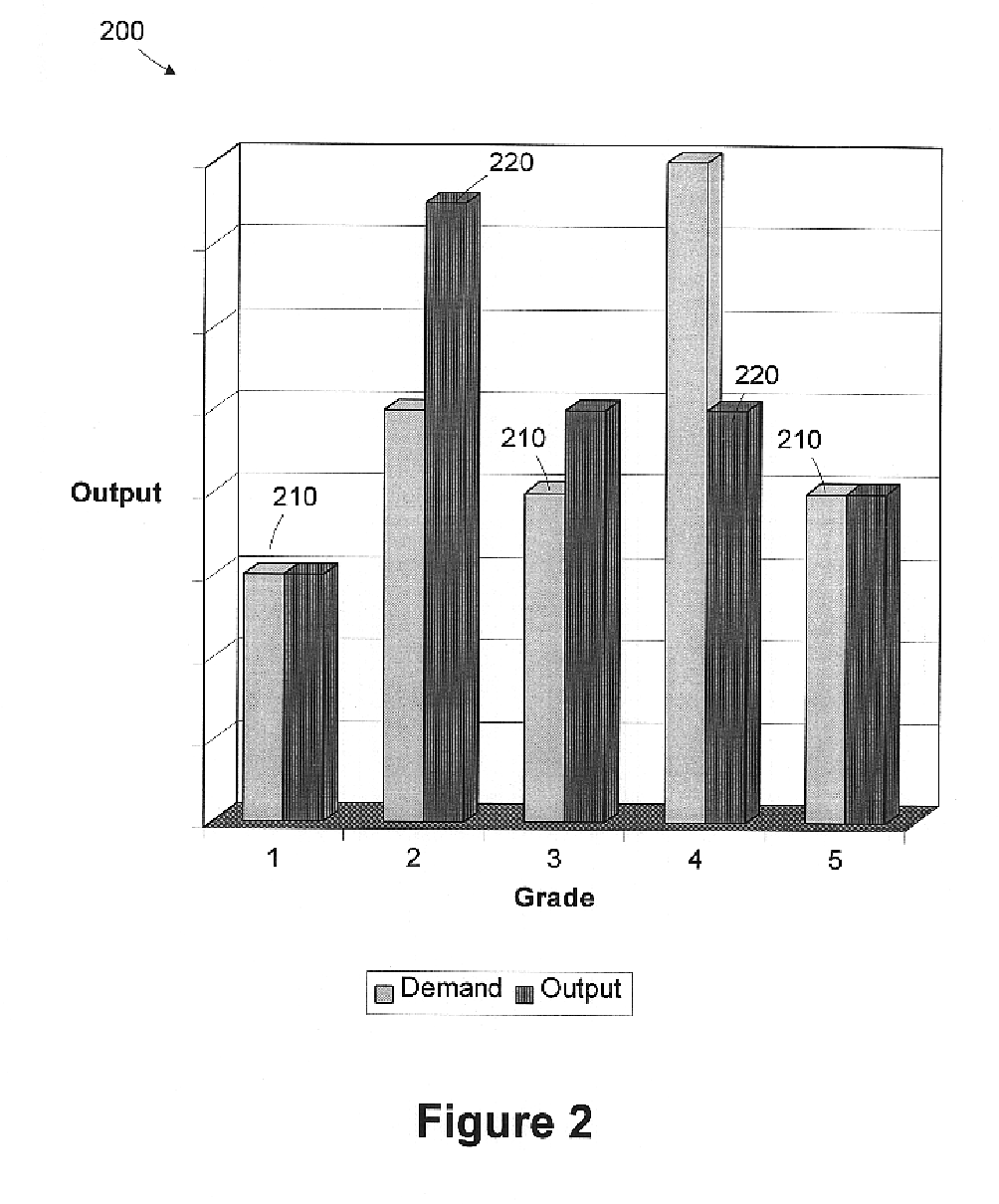

Method for prioritizing production lots based on grade estimates and output requirements

InactiveUS6699727B1Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingMetrologyPerformance grade

A method for prioritizing production flow includes processing a plurality of manufactured items in a process flow; measuring characteristics of a plurality of manufactured items in the process flow; estimating performance grades for the plurality of manufactured items based on the measured characteristics; grouping the manufactured items with like estimated performance grades; assigning priorities to groups of manufactured items with like estimated performance grades; and directing the plurality of manufactured items through the process flow based on the assigned priorities. A manufacturing system includes a plurality of processing tools adapted to process a plurality of manufactured items in a process flow, a metrology tool, and a process control server. The metrology tool is adapted to measure characteristics of a plurality of manufactured items in the process flow. The process control server is adapted to estimate performance grades for the plurality of manufactured items based on the measured characteristics, group the manufactured items with like estimated performance grades, assign priorities to groups of manufactured items with like estimated performance grades, and direct the plurality of manufactured items through the process flow based on the assigned priorities.

Owner:GLOBALFOUNDRIES US INC

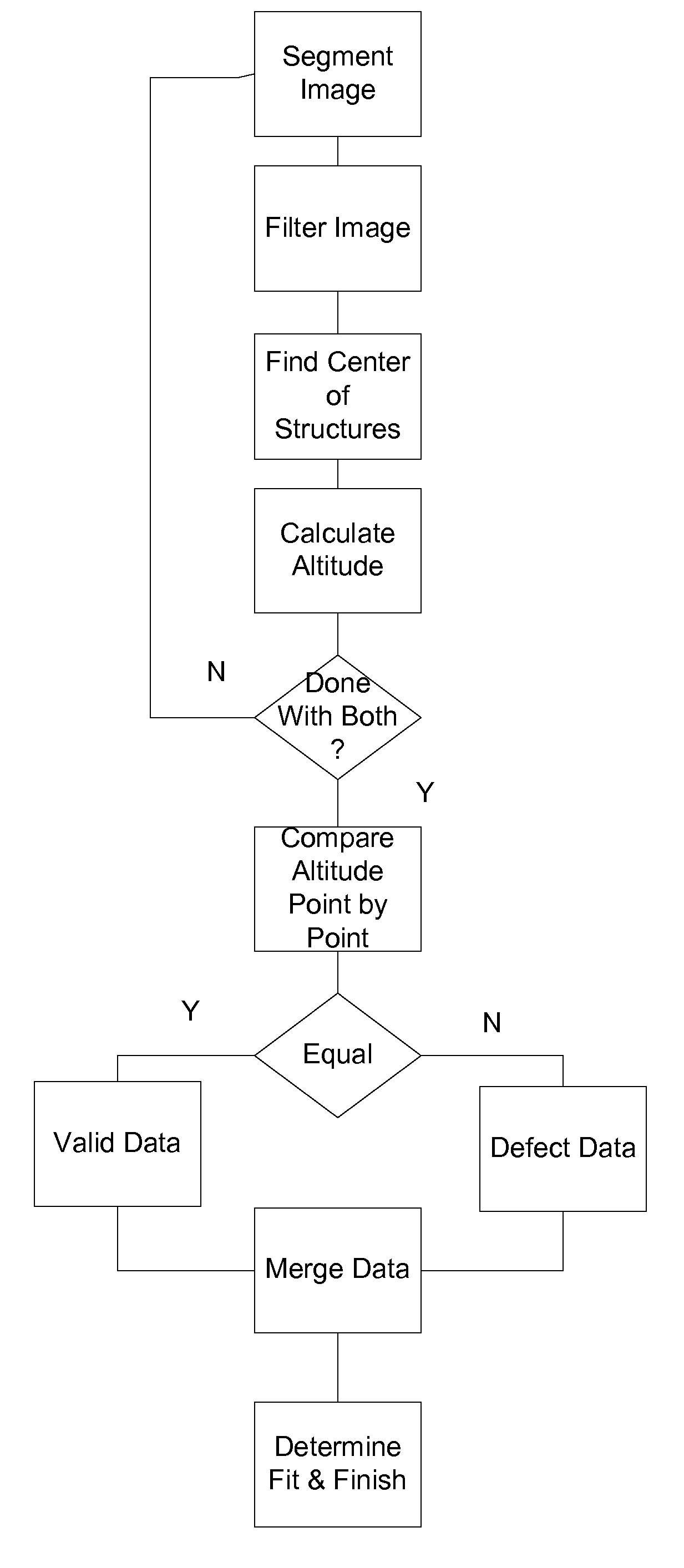

Method and apparatus for detecting defects using structured light

InactiveUS20090245614A1Simple calculationImage enhancementImage analysisImproved methodManufactured Object

An improved method and apparatus for detecting problems with fit and finish of manufactured articles is presented which uses structured light. Two or more structured light images acquired from opposing directions is used to measure the fit of mating surfaces while avoiding false positives caused by small defects near the seam.

Owner:ELECTRO SCI IND INC

Metal ceramic reinforced body

The invention discloses a metal ceramic reinforced body which is formed by zirconia alumina, Cr-Fe powder and an organic binding agent after being sintered. A plurality of through holes are uniformly arranged on a sintered and moulded block body; the through holes are arranged on the upper end face and the lower end face, and through grooves are arranged on four side faces. According to the metal ceramic reinforced body, grooves at edge portions of two adjacent reinforced bodies form an intact through hole after different reinforced bodies are spliced together, and metal liquid is poured into the through holes, so that metallic phase can infiltrate among ceramic particles and uniformly wrap ceramic phase. Not only toughness and abrasive resistance of product ceramic are enhanced, but also heat-vibration resistance is improved.

Owner:洛阳鹏飞耐磨材料股份有限公司

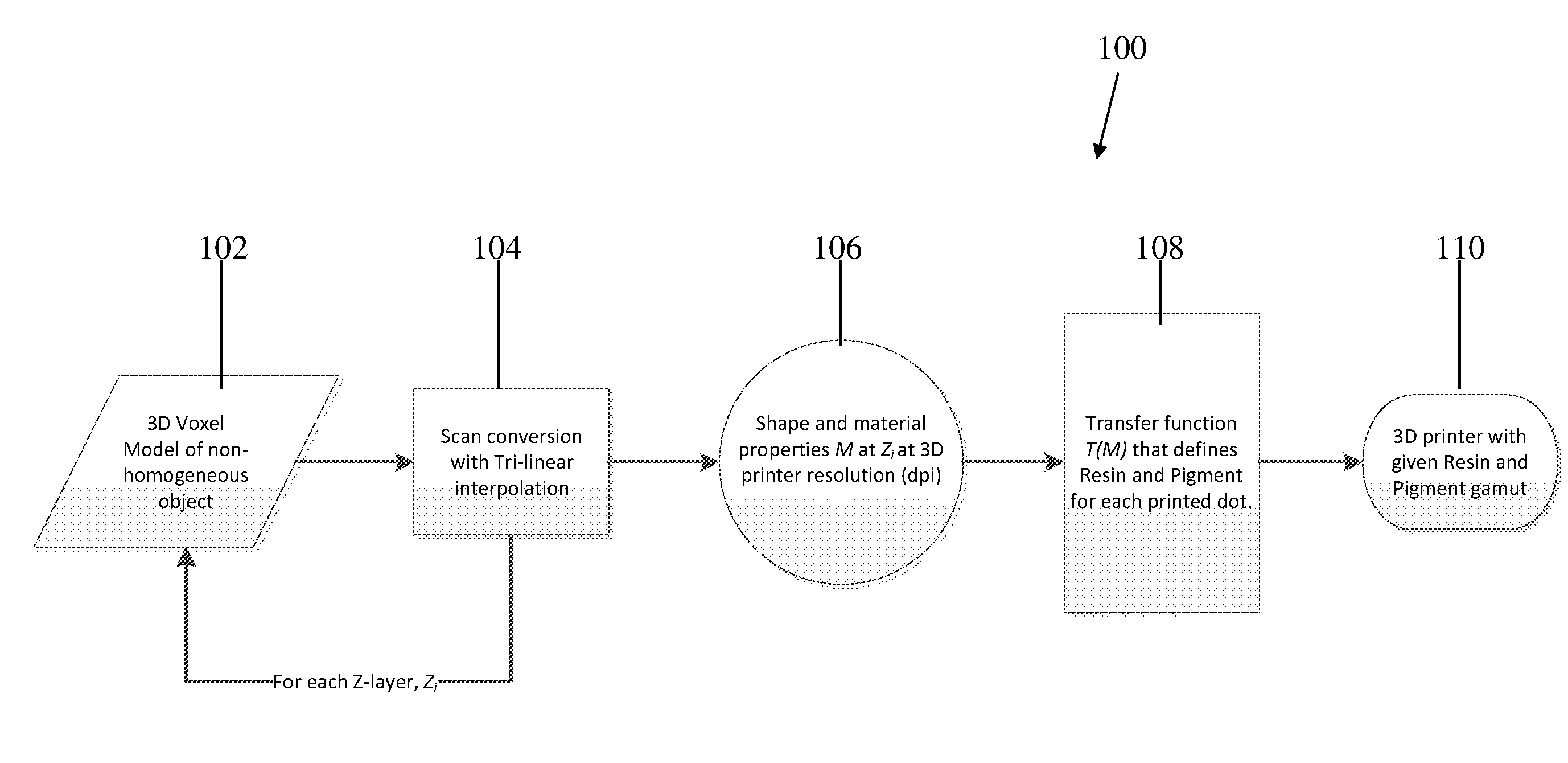

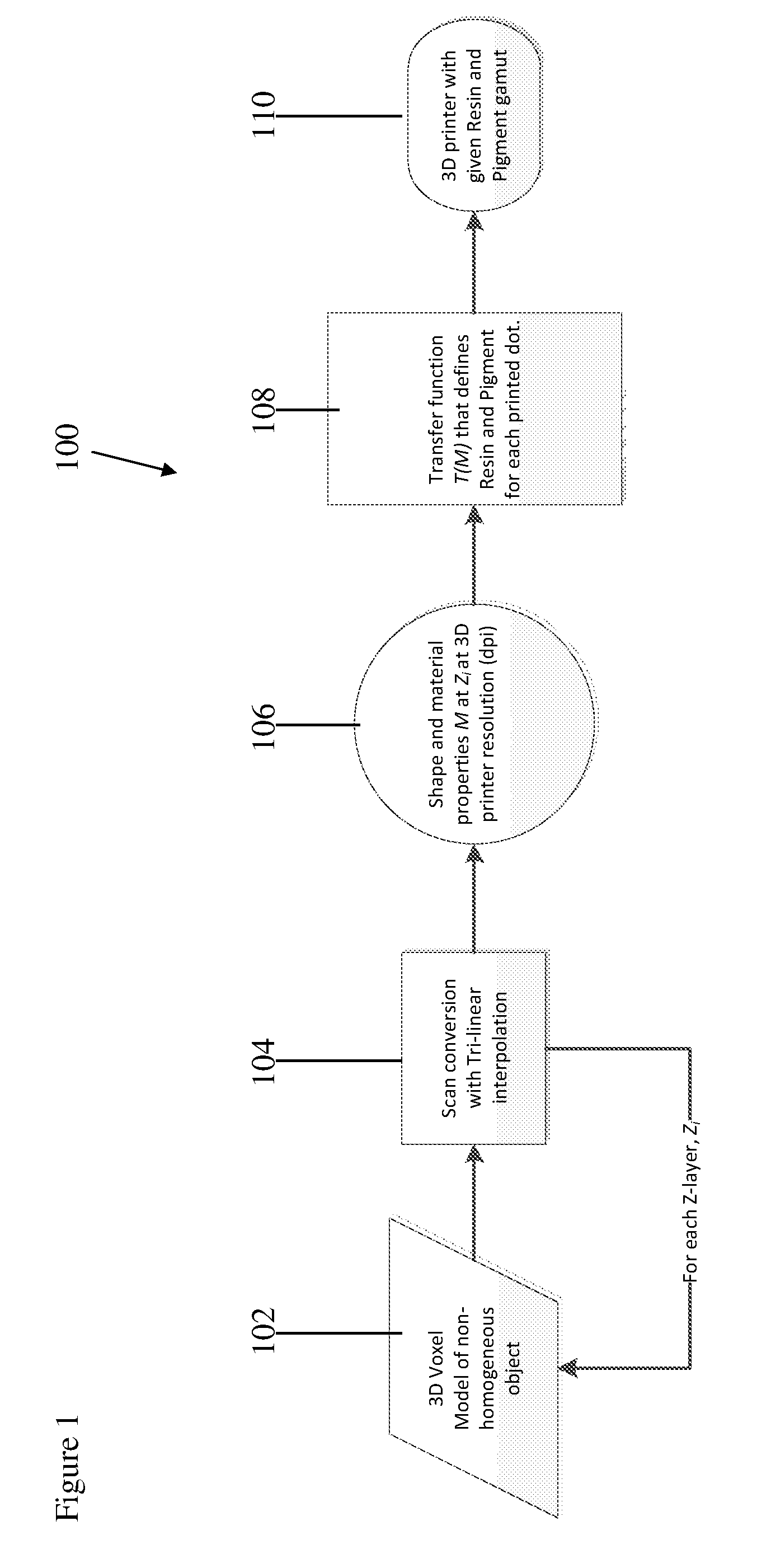

Fabrication of Non-Homogeneous Articles Via Additive Manufacturing Using Three-Dimensional Voxel-Based Models

The invention provides systems and methods for manufacture of a non-homogeneous article using a 3D voxel-based model of the article and a rapid prototyping device. Use of a voxel-based model provides processing advantages and offers improved realism of the manufactured object with regard to non-homogeneous (i) color, (ii) translucency, and / or (iii) hardness, for example.

Owner:3D SYST INC

Method and apparatus for automated tomography inspection

A method for rapid automated inspection of manufactured objects uses tomography to acquire projections of an object and then compares those projections to similar projections obtained from a standard. Variance projections of the variations between the object and standard projections for particular perspectives are generated. Variant portions of the variance projections are identified and used to generate a 3D reconstruction of just the variations between the object and the standard. The 3D reconstruction can then be evaluated to qualify the object. An apparatus of the invention comprises an imaging system in communication with a computer system configured to perform the method.

Owner:MICRO TOMO

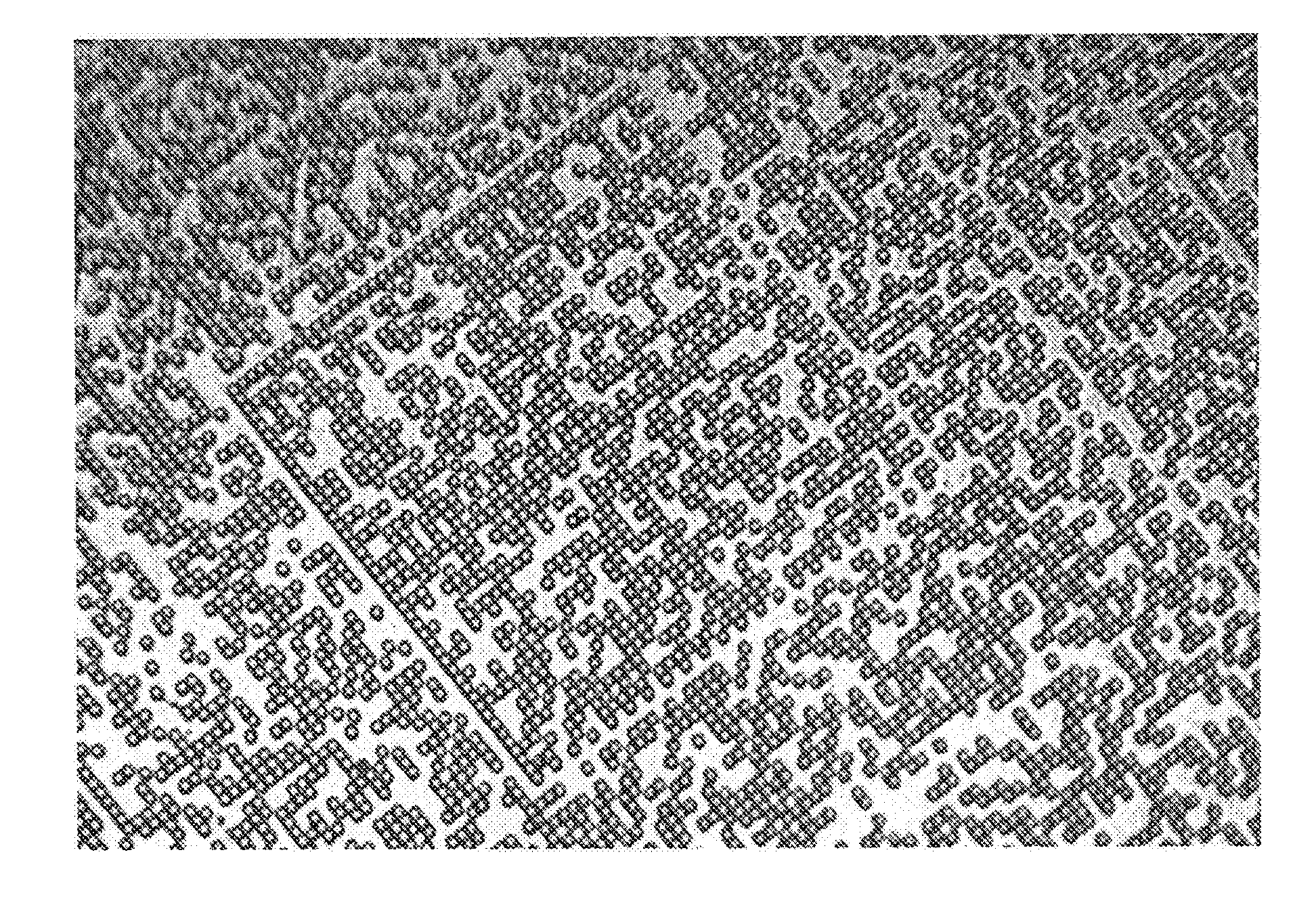

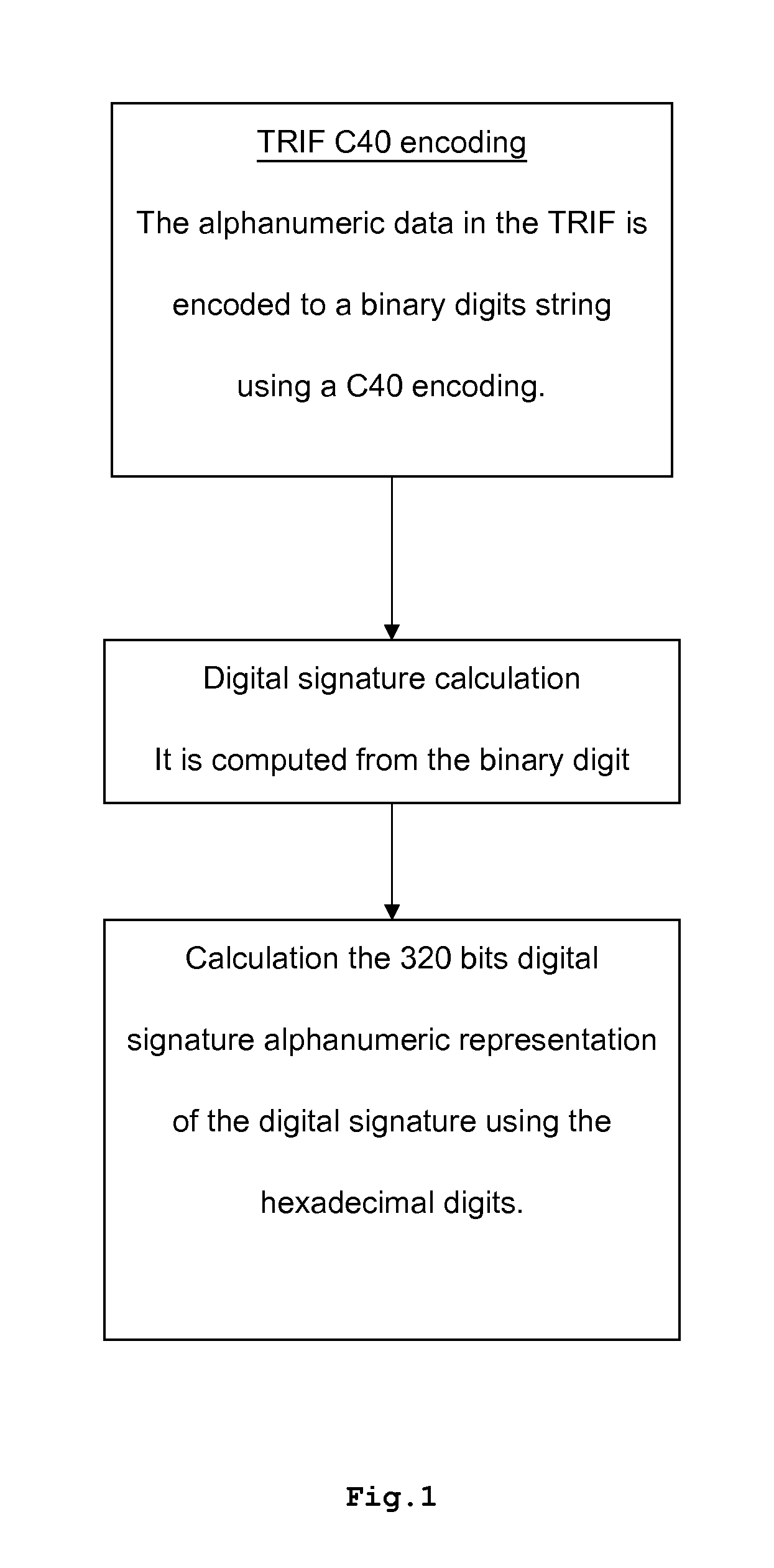

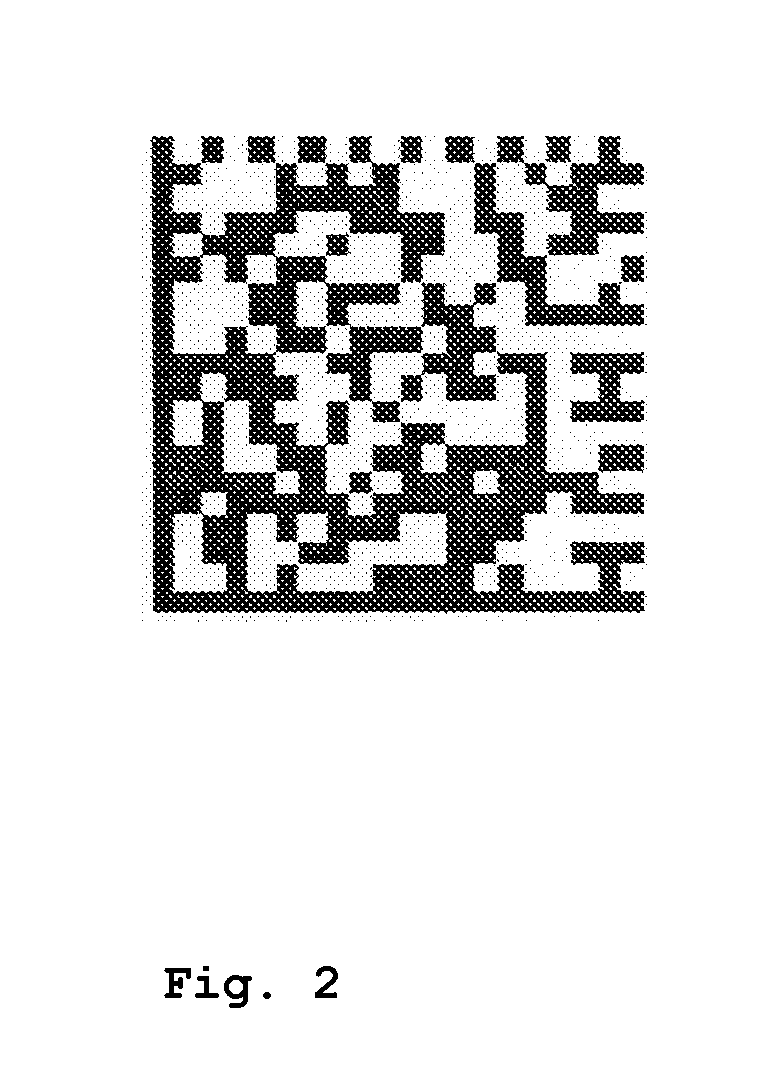

Authentication method and device for protecting manufactured goods

InactiveUS20110240739A1High pixel entropyConfectioneryCeramic shaping apparatusAuthenticationRandom pattern

The present invention is related to a method for the authentication of an article comprising the steps of generating identification data about an article, geometrical coding the identification data to form one geometric coding, incorporating the geometrical coding into a random pattern to forman authentication pattern, and embedding physically the authentication pattern onto the surface of the article to create a specific roughness.

Owner:UNIVERSITY OF MONS

Method for producing concrete brick by using residual slurry of tubular pile

InactiveCN101875211AReduce processing costsAvoid pollutionCeramic shaping apparatusMaterials preparationBrick

The invention discloses a method for producing a concrete brick by using residual slurry of a tubular pile, and belongs to the manufacturing field of building materials. The method comprises the steps of material preparation, raw material stirring, brick pressing, indoor standing, water-holding curing and product formation. The invention discloses a method for simply determining a matching ratio by simply evaluating effective ingredients of the residual slurry of the tubular pile. Compared with the prior art, the method is simple and practical; the residual slurry of the tubular pile, originally serving as waste, is used as the raw material, and the concrete brick meets various standards related with national buildings, so the treatment expense of a tubular pile production enterprise on the residual slurry of the tubular pile is saved, and the pollution of the residual slurry of the tubular pile to the environment is avoided; and on the other hand, the residual slurry of the tubular pile substitutes cement and is used as a cementing material for making bricks, so the production cost of a concrete brick production enterprise is reduced.

Owner:宁波市镇海宏佳建材有限公司

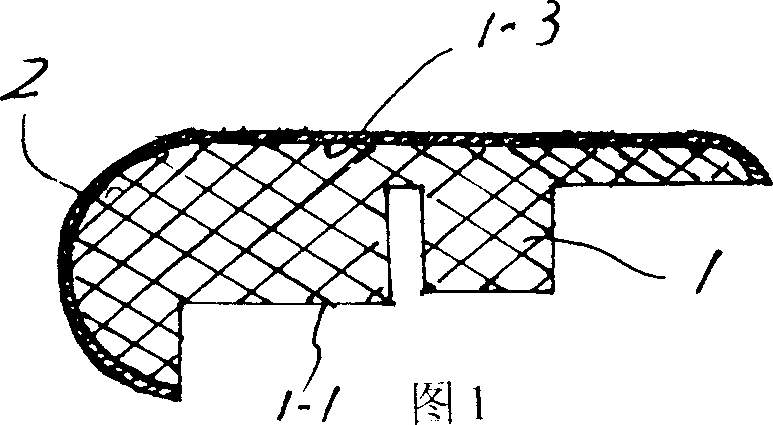

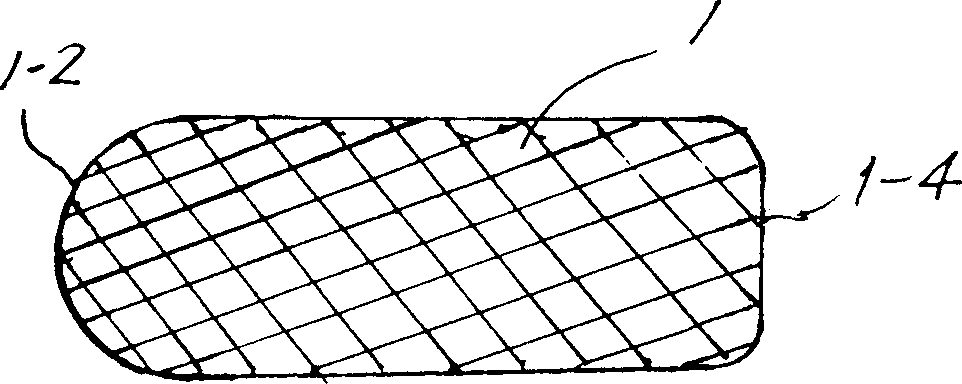

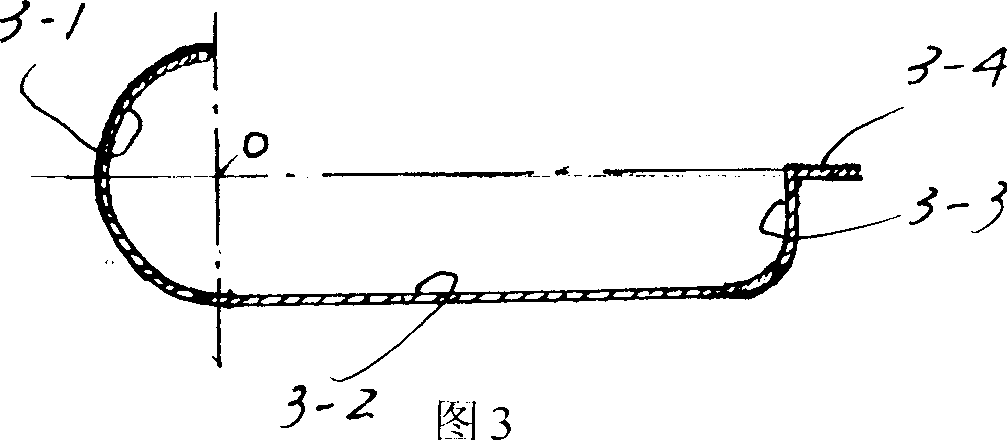

Method for manufacturing composite plate with lateral round end arc wrap angle ranged from 90 degrees to 180 degrees and products thereof

InactiveCN1730252AFlat surfaceNo raised streaksWood veneer joiningDomestic articlesEngineeringComposite plate

The invention disclosed a product and method of manufacture of clad plate whose wrap angle of side round-head and circular arc is between 90 deg and 180 deg. The method of manufacture, mainly characterized by base plate preform body bundling paster and filling it in cover die and then imbedding it into molded die and hot pressing it to modeling, have other characteristics of simple technology, producing convenience, and the surface of manufactured products being no relief design. Said clad plate comprises base plate and paster on circular arc of base plate, which is mainly characterized by flattening and coherence, and have other characteristics of surface-burnishing, perfect appearance and unnecessary of restoring and dealing. The invention solves the critical technology that is the surface of round-head of round-head clad plate, whose wrap angle of side round-head and circular arc is more than 90 deg, exist relief design.

Owner:常州法司特木线条厂

Additive manufacturing of tiled objects

ActiveUS20140217647A1Increase flexibilityEasy to disassembleAdditive manufacturing apparatusIncreasing energy efficiencyBrickCasting mold

Objects and methods for the manufacture of objects are provided such that the manufactured objects comprise a plurality of tile pieces and seams between the tile pieces, the seams allowing for controlled breaking of the objects. In some embodiments, the objects comprise casting molds or mold parts comprising a tile structure.

Owner:MATERIALISE NV

Three-dimensional manufacturing apparatus, three-dimensional manufactured object producing method, and container for three-dimensional manufacturing apparatus

ActiveCN107791512AManufacturing platforms/substratesManufacturing enclosuresManufactured ObjectLight transmission

The invention discloses a three-dimensional manufacturing apparatus, a three-dimensional manufactured object producing method, and a container for the three-dimensional manufacturing apparatus. Thereis provided a three-dimensional manufacturing apparatus which is characterized by comprising: a container configured to hold a liquid photocurable resin; a base configured to support a solid manufactured object obtained by curing the liquid photocurable resin; a moving unit configured to move the base; and a light source unit configured to irradiate light for curing the liquid photocurable resin.The container comprises a light transmission portion which is provided between the light source unit and the base, and is in contact with the liquid photocurable resin. The three-dimensional manufacturing apparatus further comprises a flow facilitating unit configured to facilitate a flow of the photocurable resin which is in contact with the light transmission portion, the flow being attended bythe movement of the base.

Owner:CANON KK

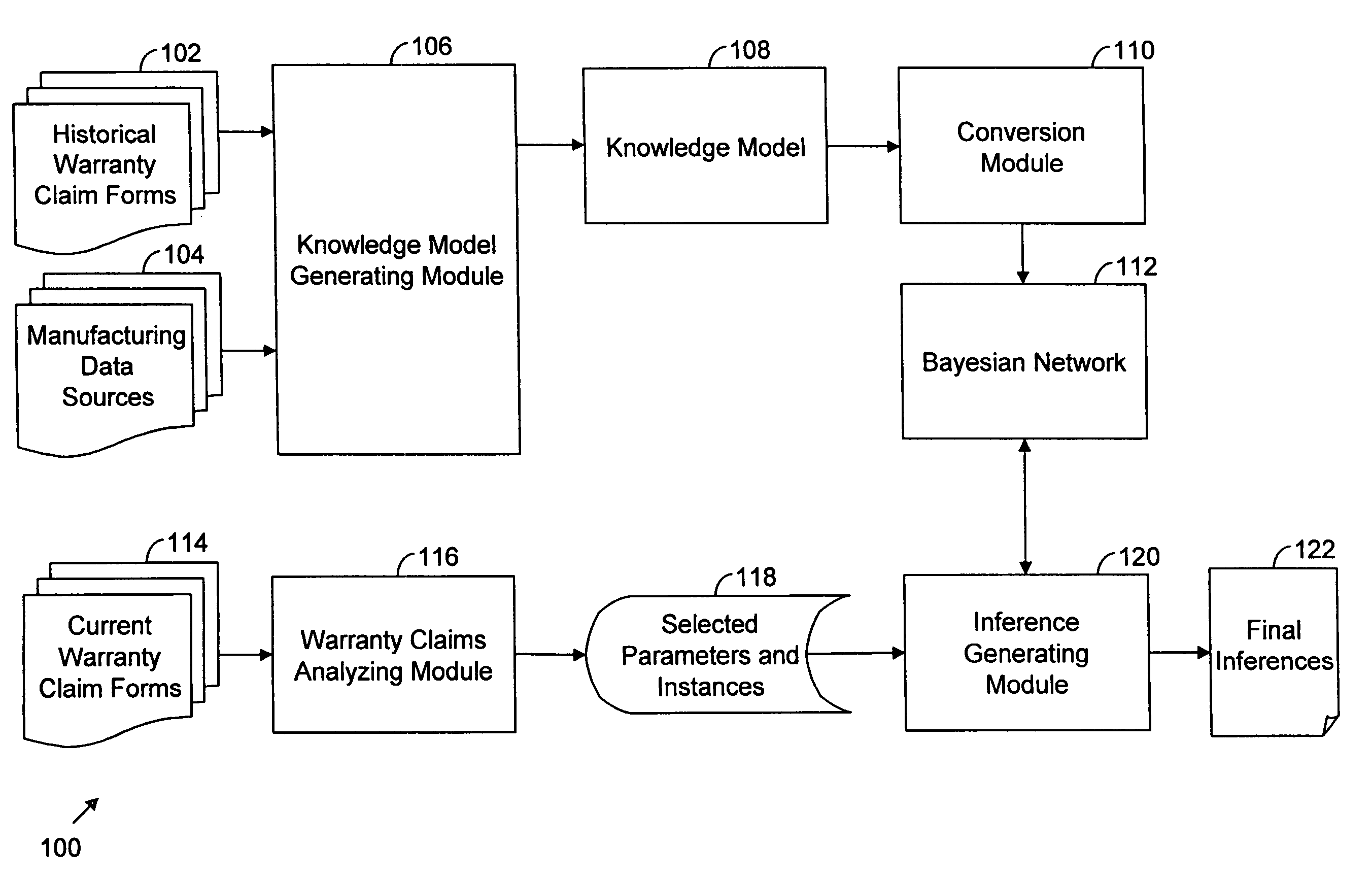

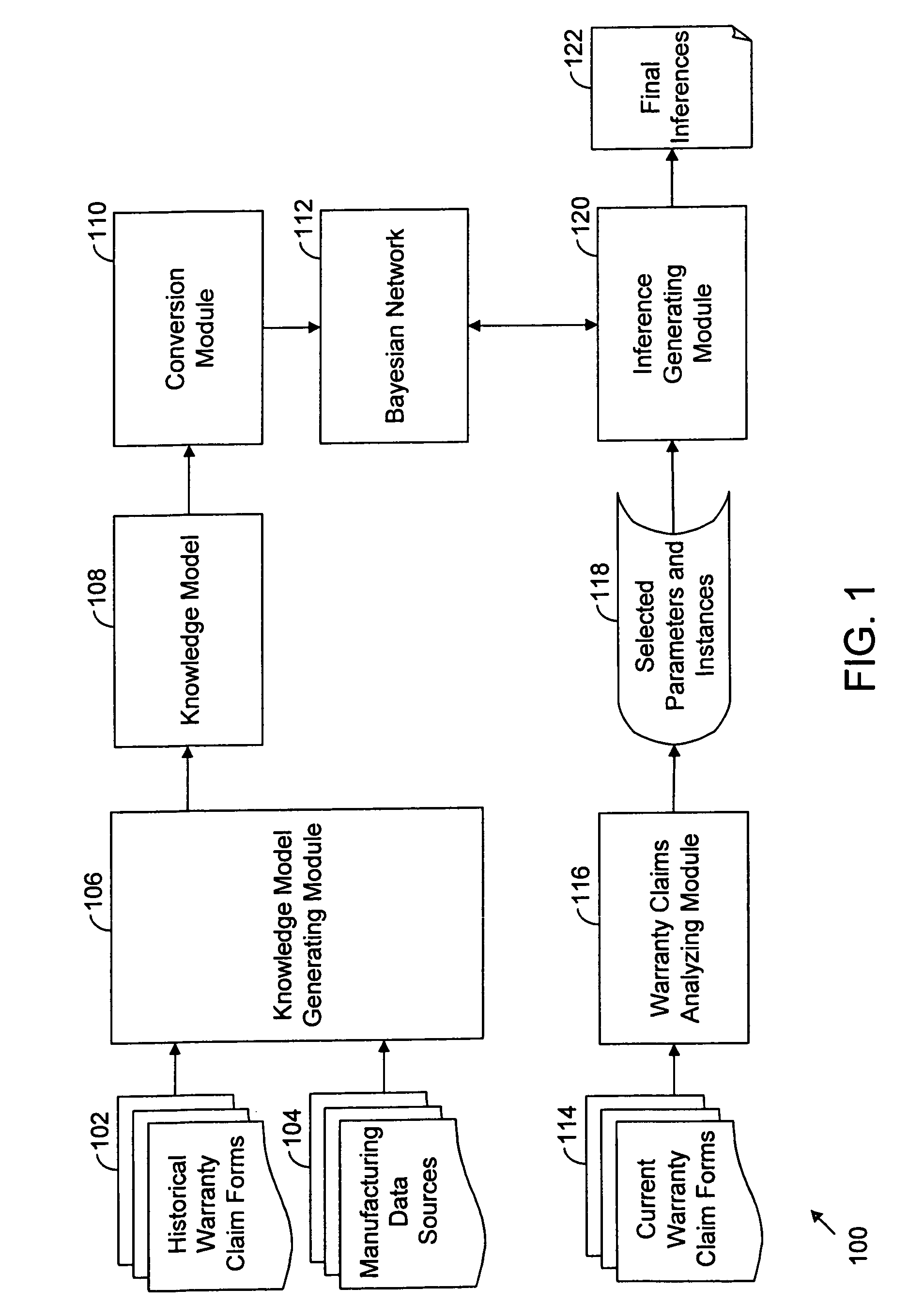

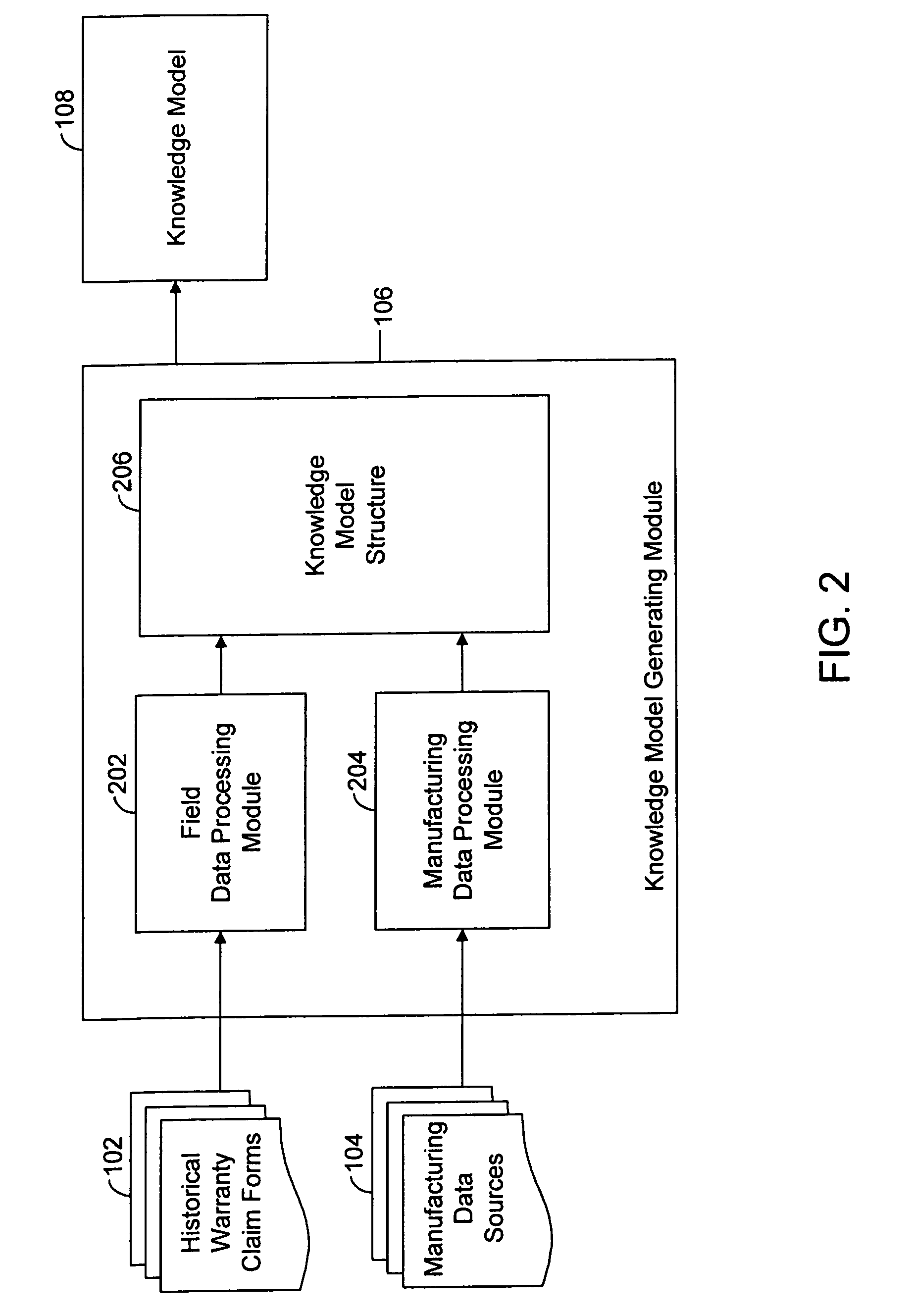

System and method for root cause analysis of the failure of a manufactured product

ActiveUS8489530B2Simple technologyEliminate dependenciesError detection/correctionComputation using non-denominational number representationFree formUser interface

A system, method and computer program product for the root cause analysis of the failure of a manufactured product is disclosed. The present invention includes the development of a knowledge model, based on information obtained from historical warranty claim forms and various manufacturing data sources. The invention also includes processing text information in a free-form text that is obtained from warranty claim forms by using text-tagging and annotation techniques. Thereafter, the knowledge model is converted to a Bayesian network. The present invention provides a user interface to select parameters and corresponding instances from current warranty claim forms. The selected parameters and corresponding instances are used as input evidence for the Bayesian network. The present invention facilitates the process of drawing inferences for root cause analysis of the failure of manufactured products and corresponding probabilities.

Owner:INFOSYS LTD

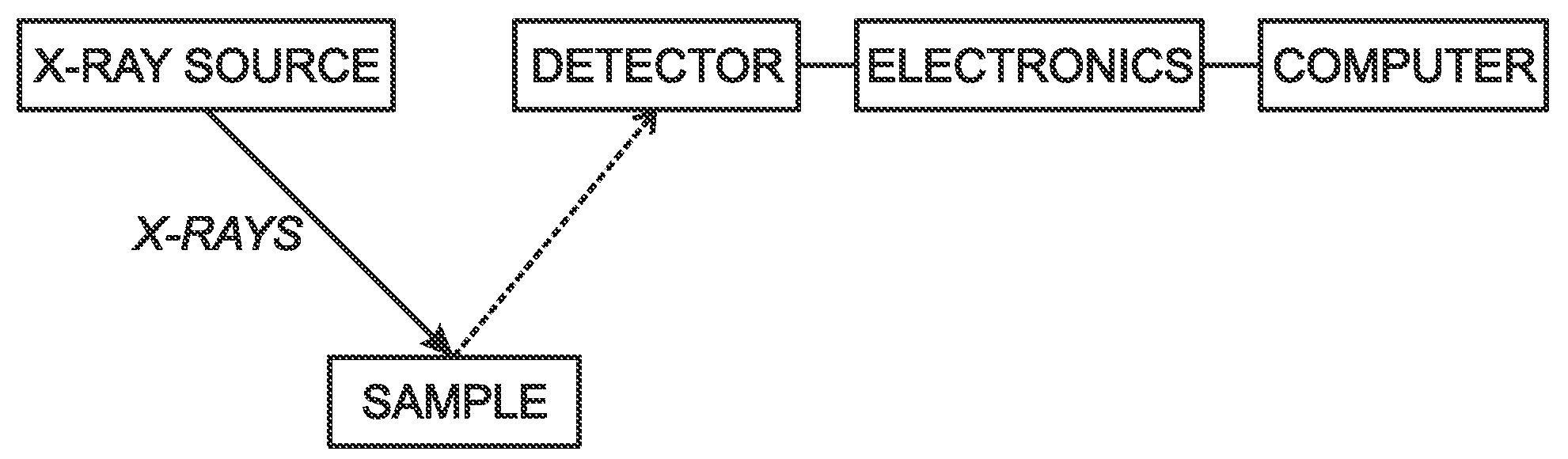

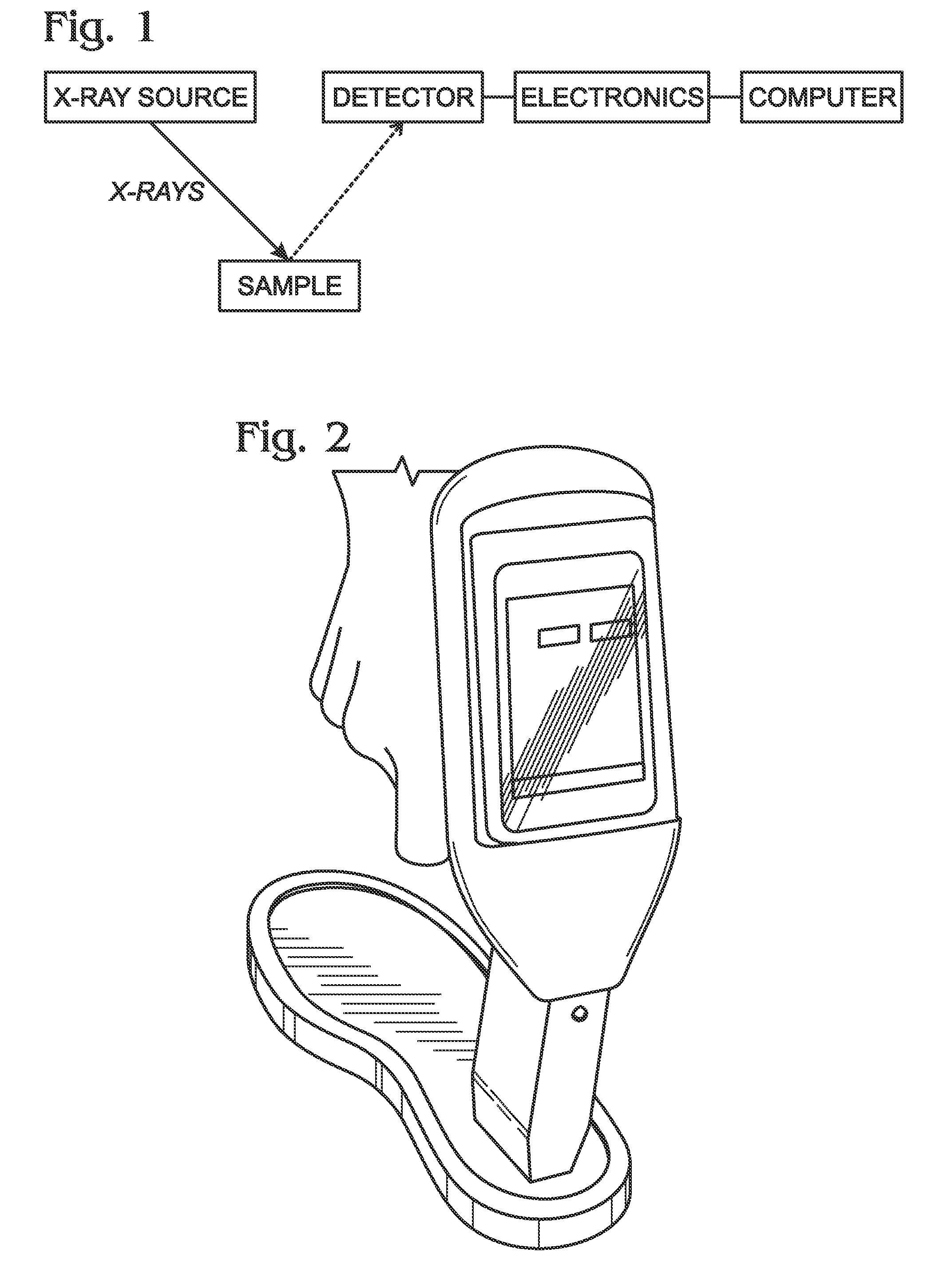

In situ indicator detection and quantitation to correlate with an additive

InactiveUS20090129541A1X-ray spectral distribution measurementMaterial analysis using wave/particle radiationX-rayManufactured Object

An additive formulation includes a carrier material, a first additive present in the carrier material at a first additive concentration, and a tracer present in the carrier material at a first tracer concentration. The tracer is a metal amenable to detection by X-ray fluorescence analysis. Further embodiments include a manufactured article having incorporated therein the additive formulation. A method is also disclosed for detecting an additive in a manufactured article, the method involving application of X-ray fluorescence analysis of the tracer element.

Owner:MICROBAN PROD CO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com