Metal ceramic reinforced body

A technology of cermets and reinforcements, applied in the field of wear-resistant ceramics, can solve the problem of uneven distribution of metal phases and ceramic phases, increase wear resistance, improve interface bonding strength and improve overall performance, toughness and thermal shock resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

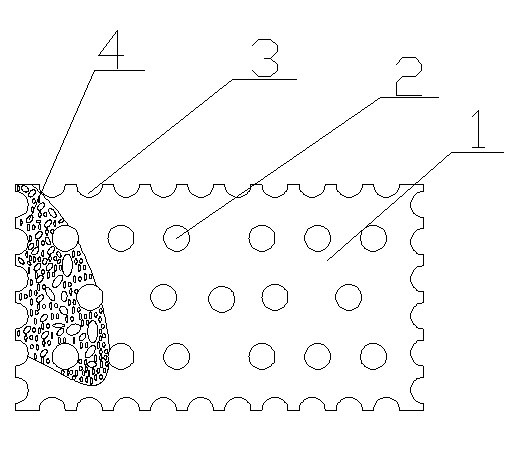

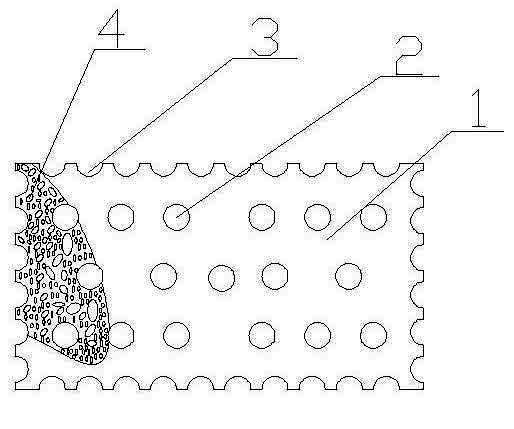

Image

Examples

Embodiment 1

[0027] A metal-ceramic reinforcement, the preparation steps of which are as follows:

[0028] Step 1. According to the weight ratio, take 70 parts of zirconium corundum with a particle size of 2-5mm, and 30 parts of ferrochrome powder with a particle size of 150-500um, put them into a container, mix them evenly, and make a mixture;

[0029] Step 2, in the mixture that step 1 is made, add 10 parts of epoxy resins, mix evenly, obtain the mixture that contains organic binder;

[0030] Step 3, putting the mixture containing the organic binder into the mold prepared in advance, extruding and demoulding, and making a blank with multiple through holes;

[0031] Step 4. Send the billet into the drying room and let it dry naturally;

[0032] Step 5. Send the dried blank into a sintering kiln for sintering. The sintering temperature is 1200-1250°C and the sintering time is 5-8 hours.

Embodiment 2

[0034] A metal-ceramic reinforcement, the preparation steps of which are as follows:

[0035] Step 1. According to the weight ratio, take 95 parts of zirconium corundum with a particle size of 2-5mm, and 5 parts of ferrochrome powder with a particle size of 150-500um, put them into a container, mix them evenly, and make a mixture;

[0036] Step 2, in the mixture made in step 1, add 3 parts of polyvinyl chloride, mix evenly, obtain the mixture containing organic binder;

[0037] Step 3, putting the mixture containing the organic binder into the mold prepared in advance, extruding and demoulding, and making a blank with multiple through holes;

[0038] Step 4, sending the billet into the drying chamber and drying;

[0039] Step 5. Send the dried blank into a sintering kiln for sintering. The sintering temperature is 1200-1250°C and the sintering time is 5-8 hours.

Embodiment 3

[0041] A metal-ceramic reinforcement, the preparation steps of which are as follows:

[0042] Step 1. According to the weight ratio, take 83 parts of zirconium corundum with a particle size of 2-5mm and 17 parts of ferrochrome powder with a particle size of 150-500um, put them into a container, mix them evenly, and make a mixture;

[0043] Step 2, in the mixture made in step 1, add 7 parts of phenolic liquid resin, mix evenly, obtain the mixture containing organic binder;

[0044] Step 3, putting the mixture containing the organic binder into the mold prepared in advance, extruding and demoulding, and making a blank with multiple through holes;

[0045] Step 4. Send the billet into the drying room, and let it air dry or dry naturally;

[0046] Step 5. Send the dried blank into a sintering kiln for sintering. The sintering temperature is 1200-1250°C and the sintering time is 5-8 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com