Patents

Literature

14231 results about "Kiln" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A kiln (/kɪln/ or /kɪl/) is a thermally insulated chamber, a type of oven, that produces temperatures sufficient to complete some process, such as hardening, drying, or chemical changes. Kilns have been used for millennia to turn objects made from clay into pottery, tiles and bricks. Various industries use rotary kilns for pyroprocessing—to calcinate ores, to calcinate limestone to lime for cement, and to transform many other materials.

Process and system for converting carbonaceous feedstocks into energy without greenhouse gas emissions

InactiveUS7220502B2Improve efficiencyHigh hydrogen contentFuel cell auxillariesWaste based fuelPetroleum cokeToxic industrial waste

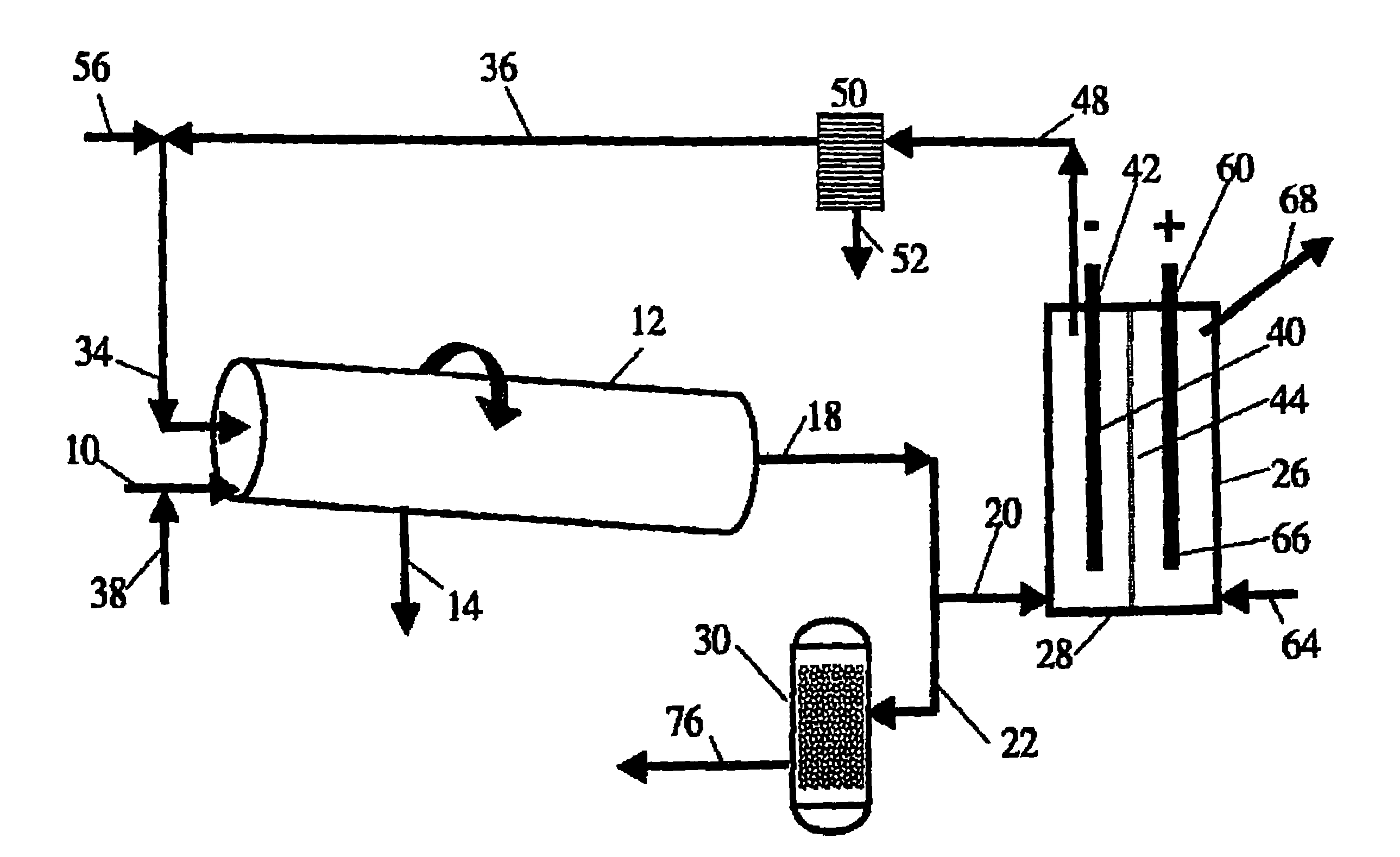

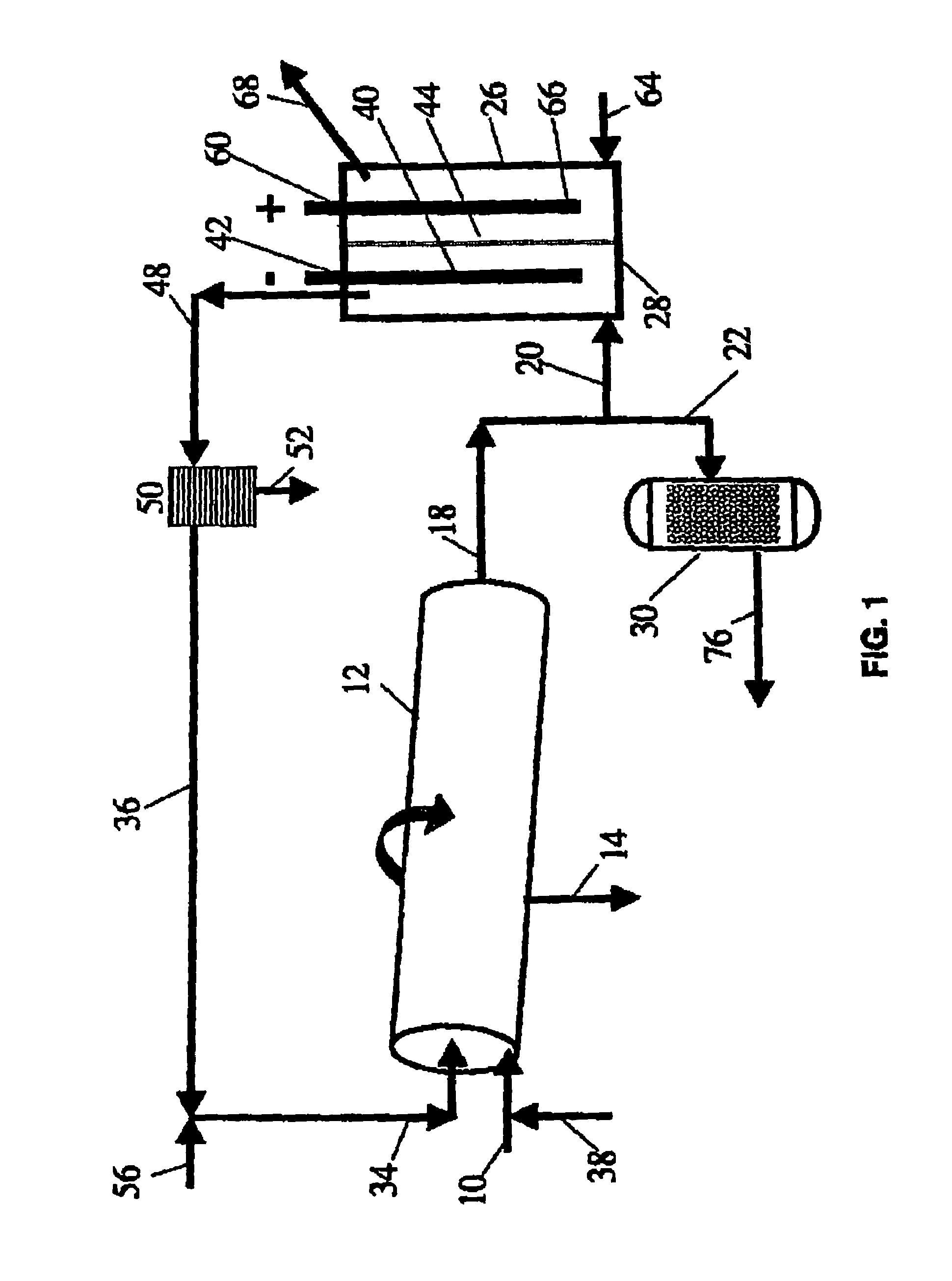

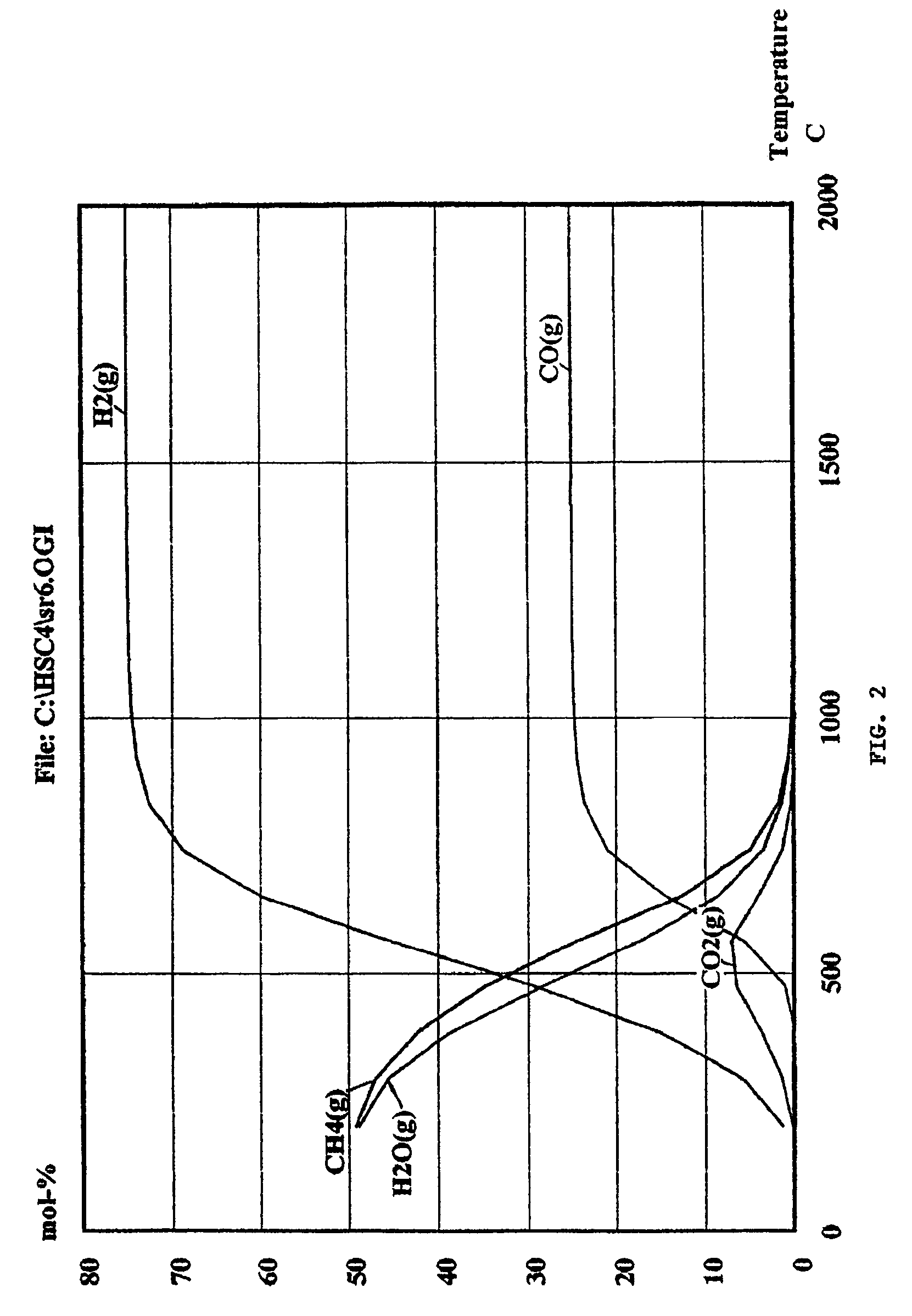

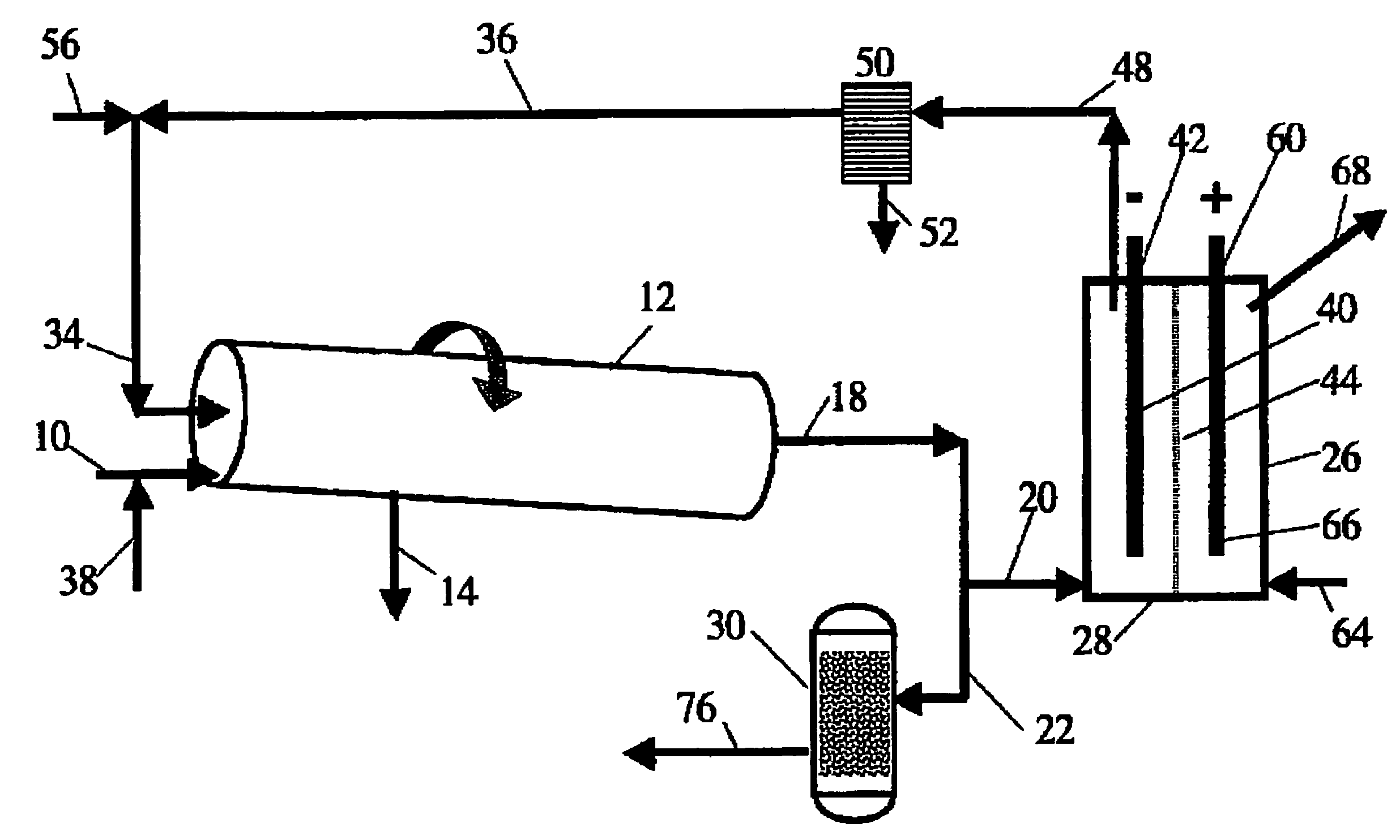

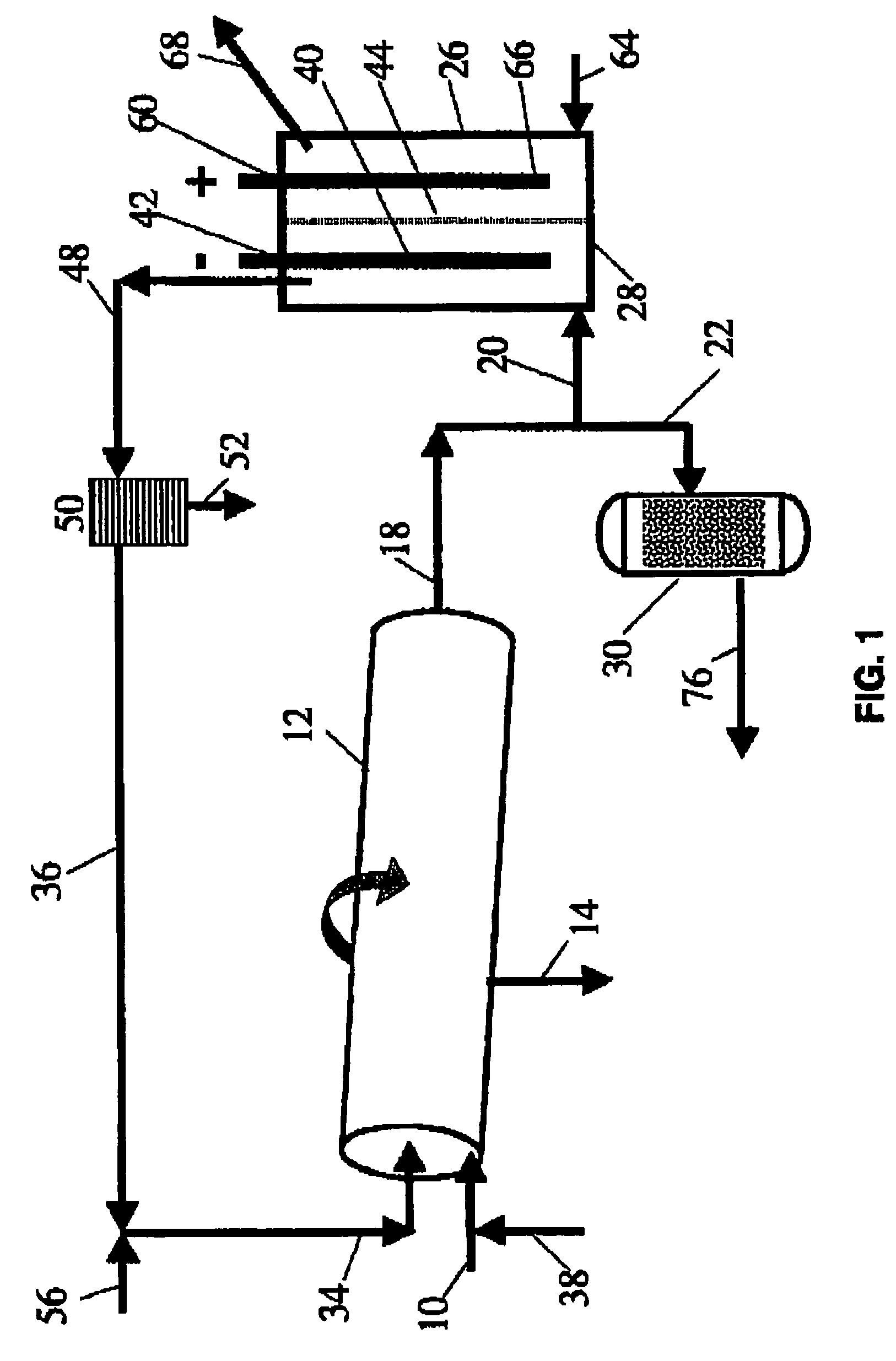

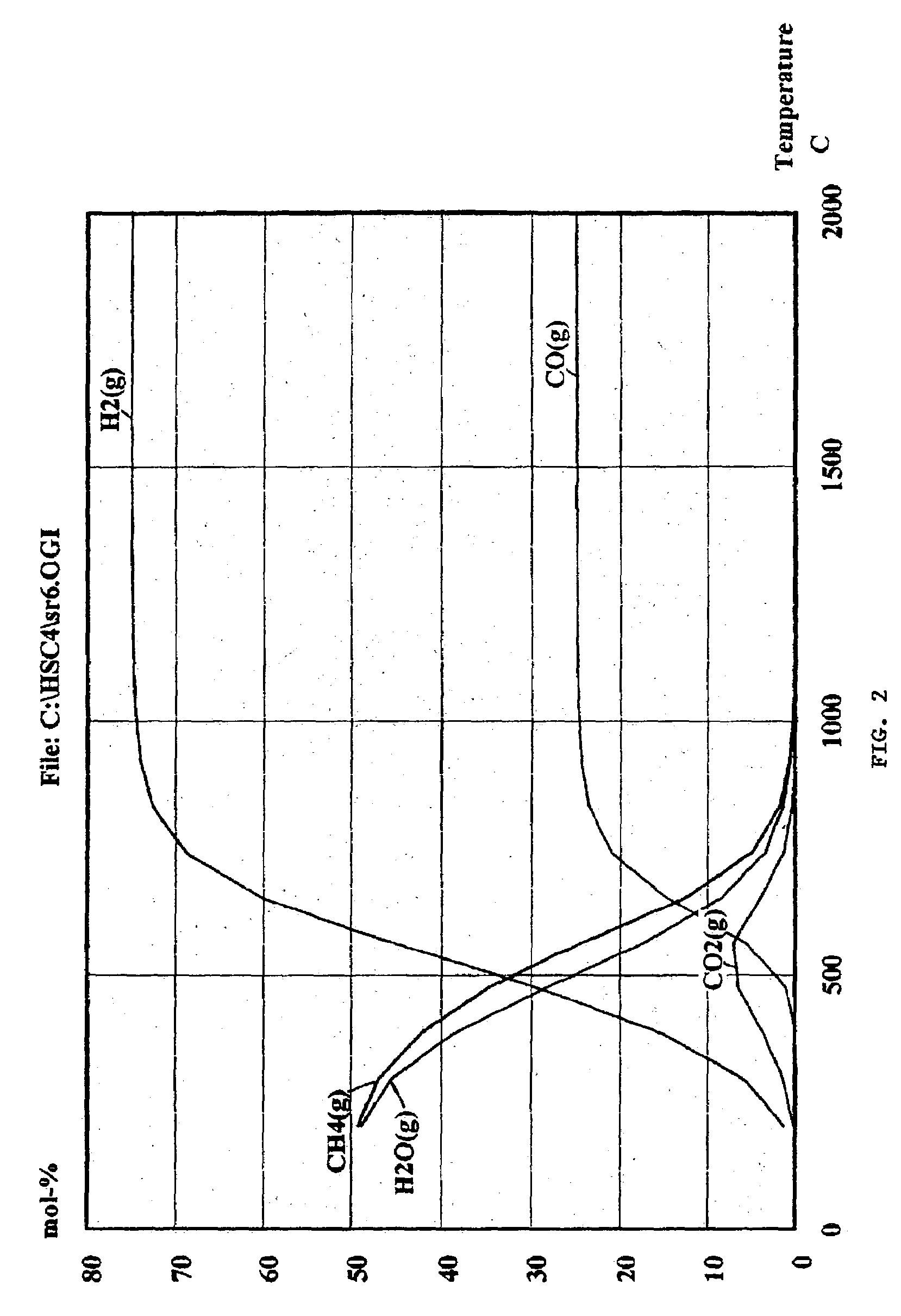

The process and system of the invention converts carbonaceous feedstock such as coal, hydrocarbon oil, natural gas, petroleum coke, oil shale, carbonaceous-containing waste oil, carbonaceous-containing medical waste, carbonaceous-containing military waste, carbonaceous-containing industrial waste, carbonaceous-containing medical waste, carbonaceous-containing sewage sludge and municipal solid waste, carbonaceous-containing agricultural waste, carbonaceous-containing biomass, biological and biochemical waste, and mixtures thereof into electrical energy without the production of unwanted greenhouse emissions. The process and system uses a combination of a gasifier, e.g., a kiln, operating in the exit range of at least 700° to about 1600° C. (1300-2900° F.) to convert the carbonaceous feedstock and a greenhouse gas stream into a synthesis gas comprising mostly carbon monoxide and hydrogen without the need for expensive catalysts and or high pressure operations. One portion of the synthesis gas from the gasifier becomes electrochemically oxidized in an electricity-producing fuel cell into an exit gas comprising carbon dioxide and water. The latter is recycled back to the gasifier after a portion of water is condensed out. The second portion of the synthesis gas from the gasifier is converted into useful hydrocarbon products.

Owner:RAVEN SR INC

Method for producing health ceramic brick capable of releasing negative ion

The production process of health ceramic brick capable of releasing negative ion includes introducing nanometer negative ion powder comprising tourmaline 20-40 wt%, dravite 10-20 wt%, nanometer TiO2 20-40 wt% and composite RE salt 5-12 wt%, making the nanometer negative ion powder combined well with ceramic base and sintering at 1080-1200 deg.c inside roller hearth kiln. The health ceramic brick has stable negative ion releasing function in health level and radiation performance index meeting relevant requirement.

Owner:GUANGDONG TIDIY CERAMICS

Process and system for converting carbonaceous feedstocks into energy without greenhouse gas emissions

ActiveUS7132183B2Improve efficiencyHigh hydrogen contentFuel cell auxillariesGasification processes detailsWaste oilHigh pressure

The process and system of the invention converts carbonaceous feedstock such as coal, hydrocarbon oil, natural gas, petroleum coke, oil shale, carbonaceous-containing waste oil, carbonaceous-containing medical waste, carbonaceous-containing hazardous waste, carbonaceous-containing medical waste, and mixtures thereof into electrical energy without the production of unwanted greenhouse emissions. The process and system uses a combination of a gasifier, e.g., a kiln, operating in the exit range of at least 700° to about 1600° C. (1300–2900° F.) to convert the carbonaceous feedstock and a greenhouse gas stream into a synthesis gas comprising mostly carbon monoxide and hydrogen without the need for expensive catalysts and or high pressure operations. One portion of the synthesis gas from the gasifier becomes electrochemically oxidized in an electricity-producing fuel cell into an exit gas comprising carbon dioxide and water. The latter is recycled back to the gasifier after a portion of water is condensed out. The second portion of the synthesis gas from the gasifier is converted into useful hydrocarbon products.

Owner:RAVEN SR INC

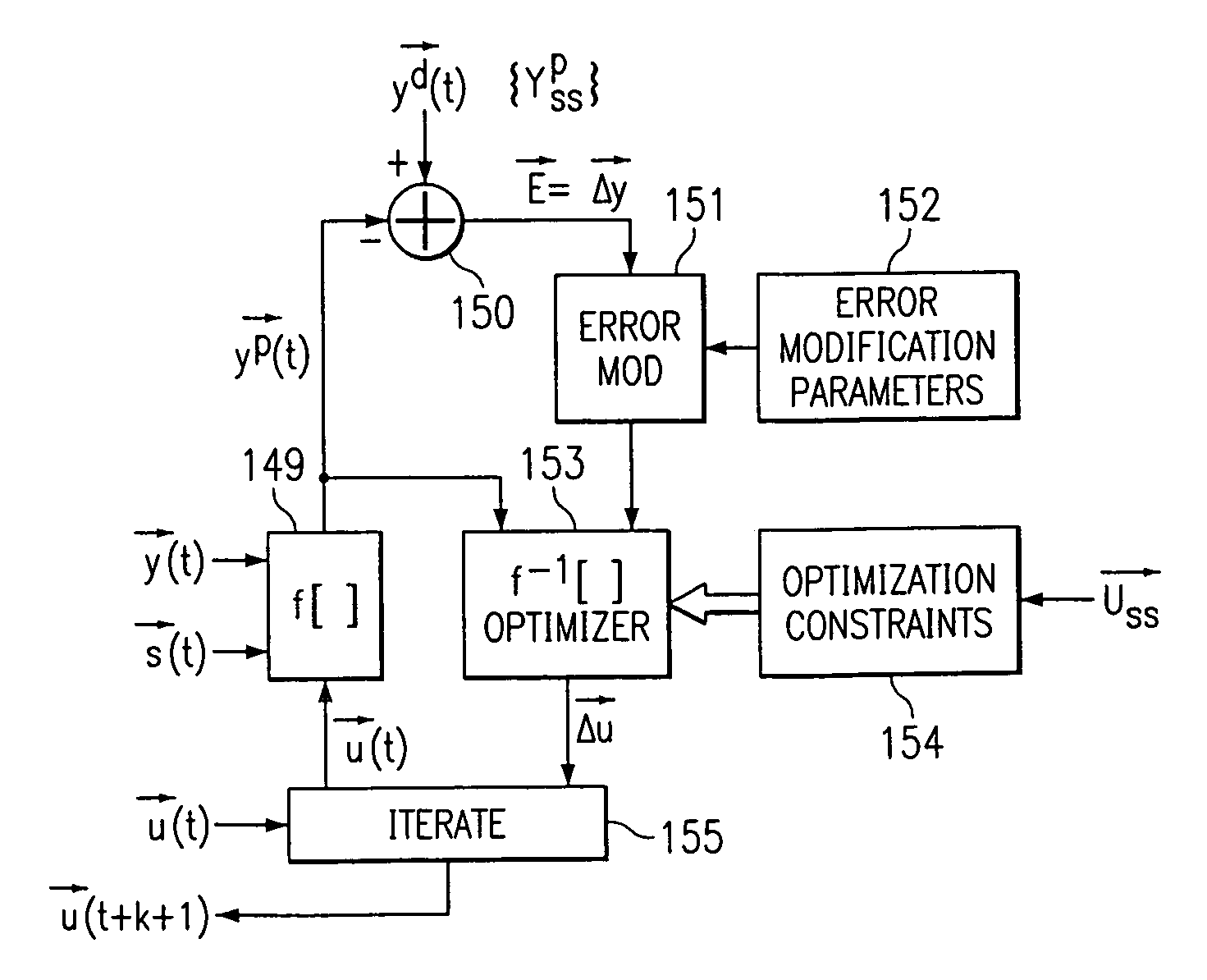

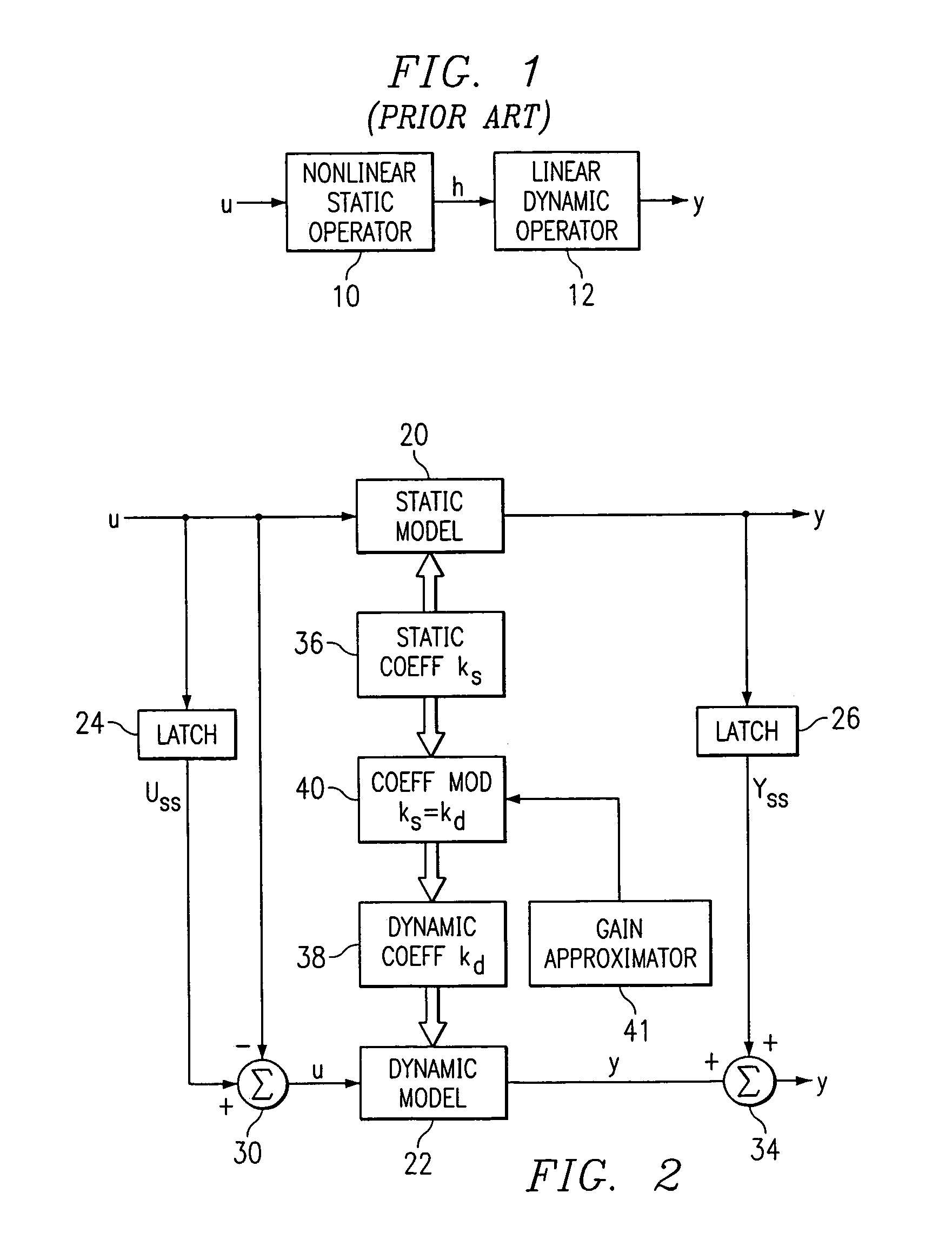

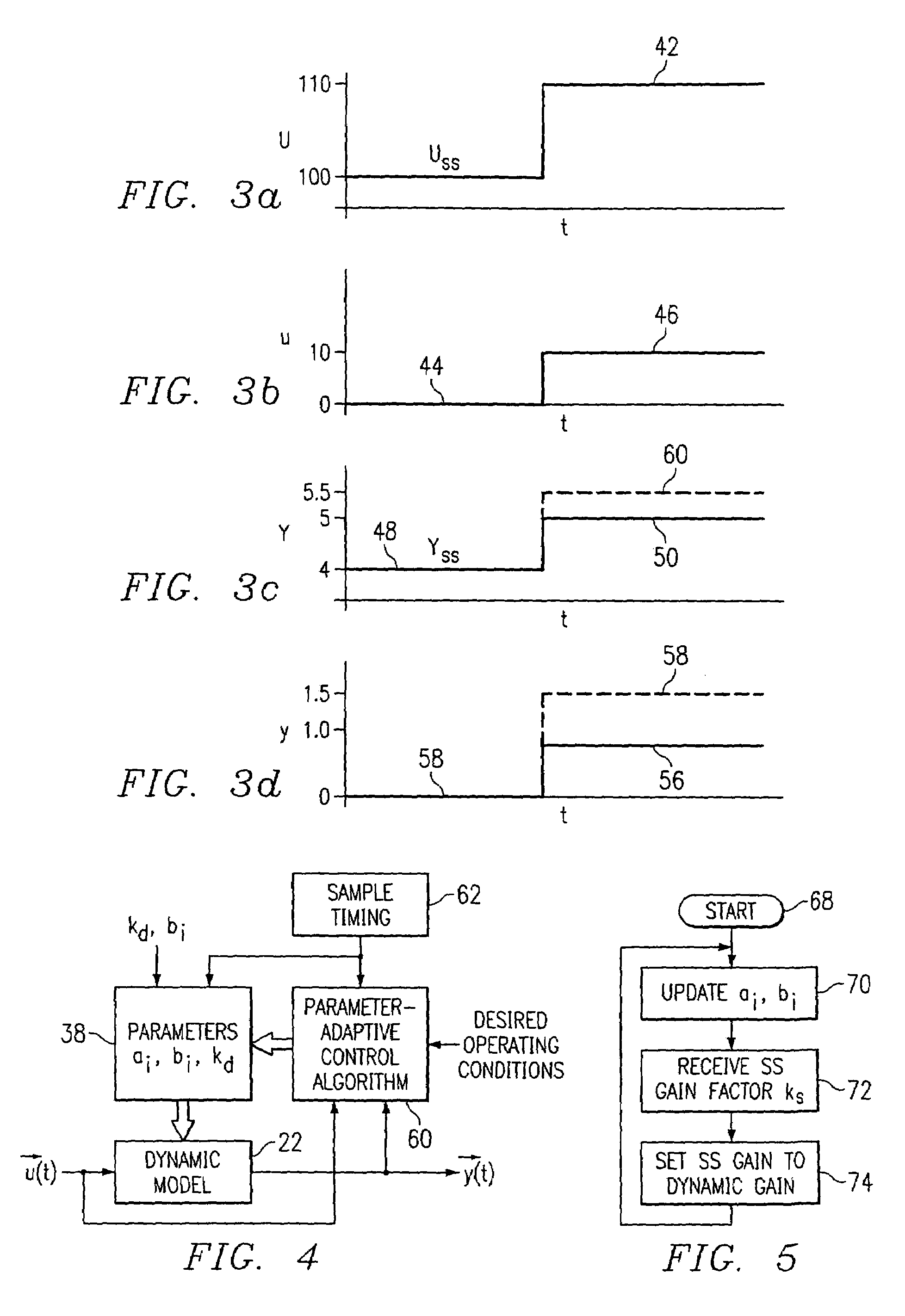

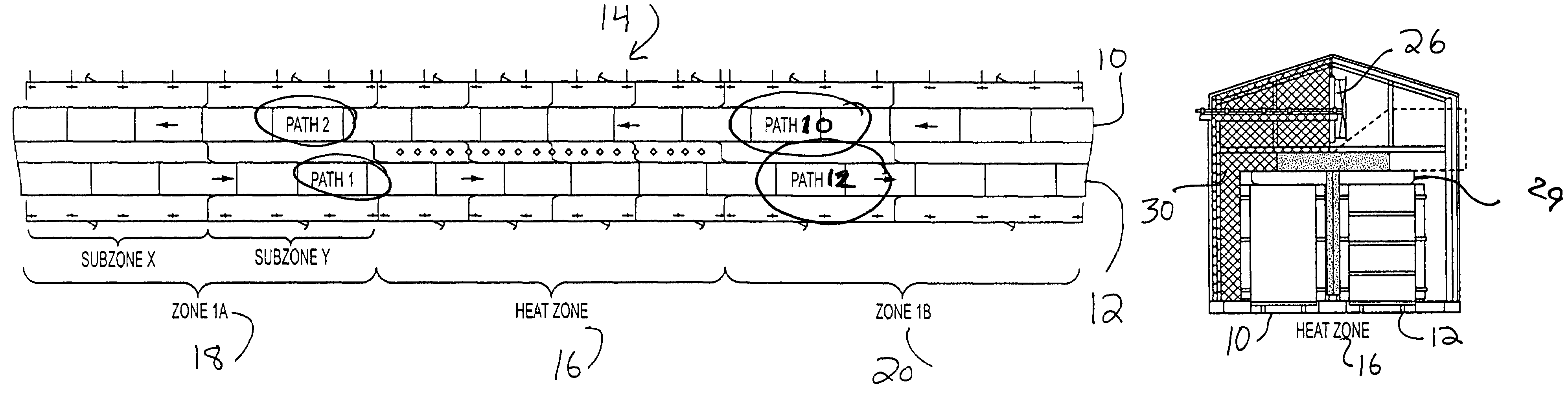

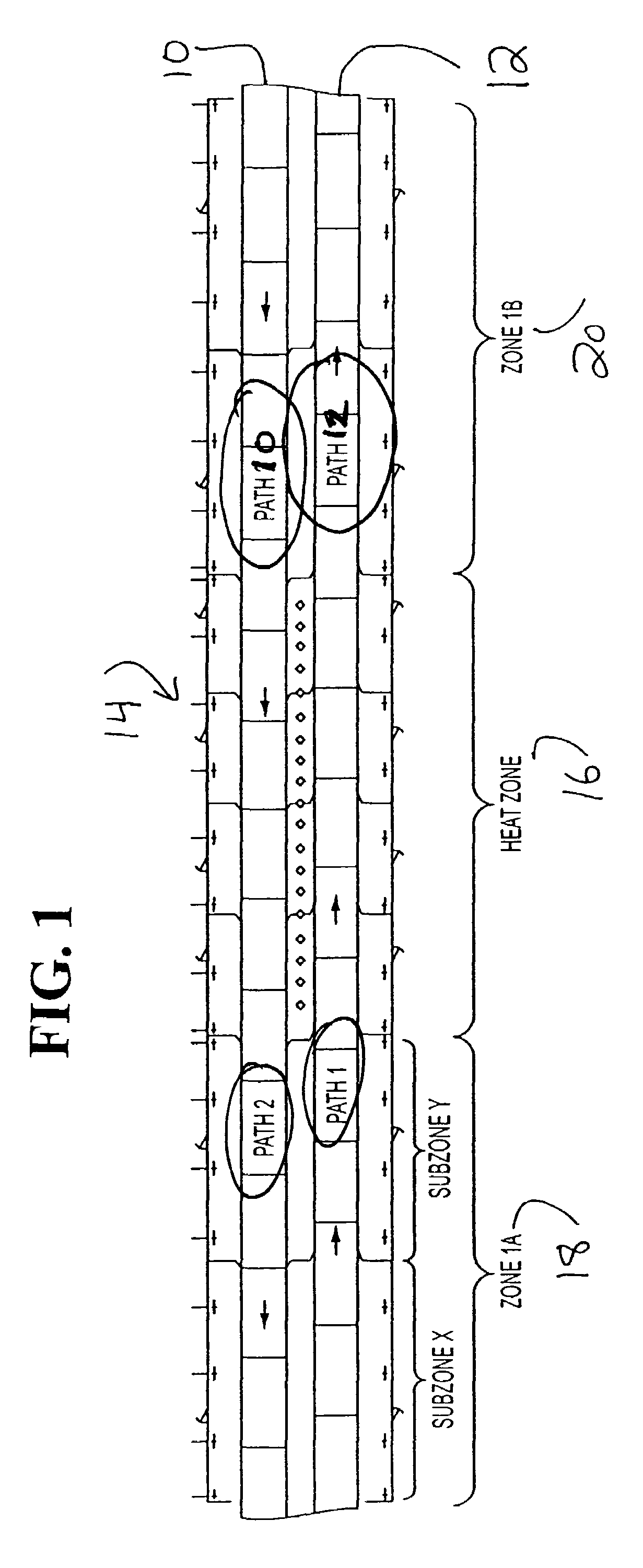

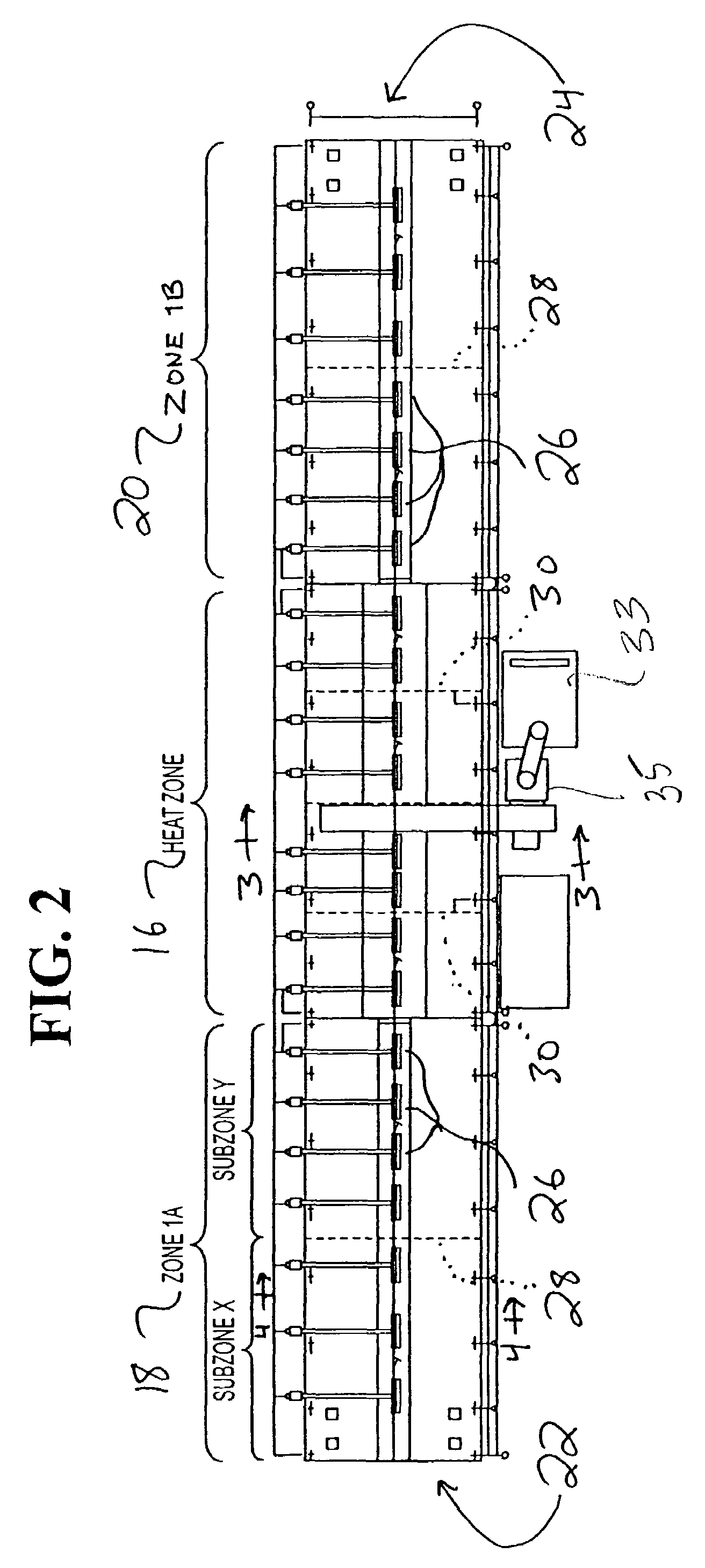

Kiln control and upset recovery using a model predictive control in series with forward chaining

InactiveUS7149590B2Simulator controlComputation using non-denominational number representationPredictive controllerControl theory

A method for controlling a non-linear process includes the steps of first providing a controller that is operable to receive inputs representing measured variables of the process and predicting on an output of the controller predicted control values for manipulatible variables that control the process. An expert system is provided that models the actions of an operator of the process over an operating region of the process that represents a set of rules for actions to be taken by an operator upon the occurrence of predetermined conditions in the operation of the process. The operation of the controller is modified with the expert system when one of the predetermined conditions exists.

Owner:ROCKWELL AUTOMATION TECH

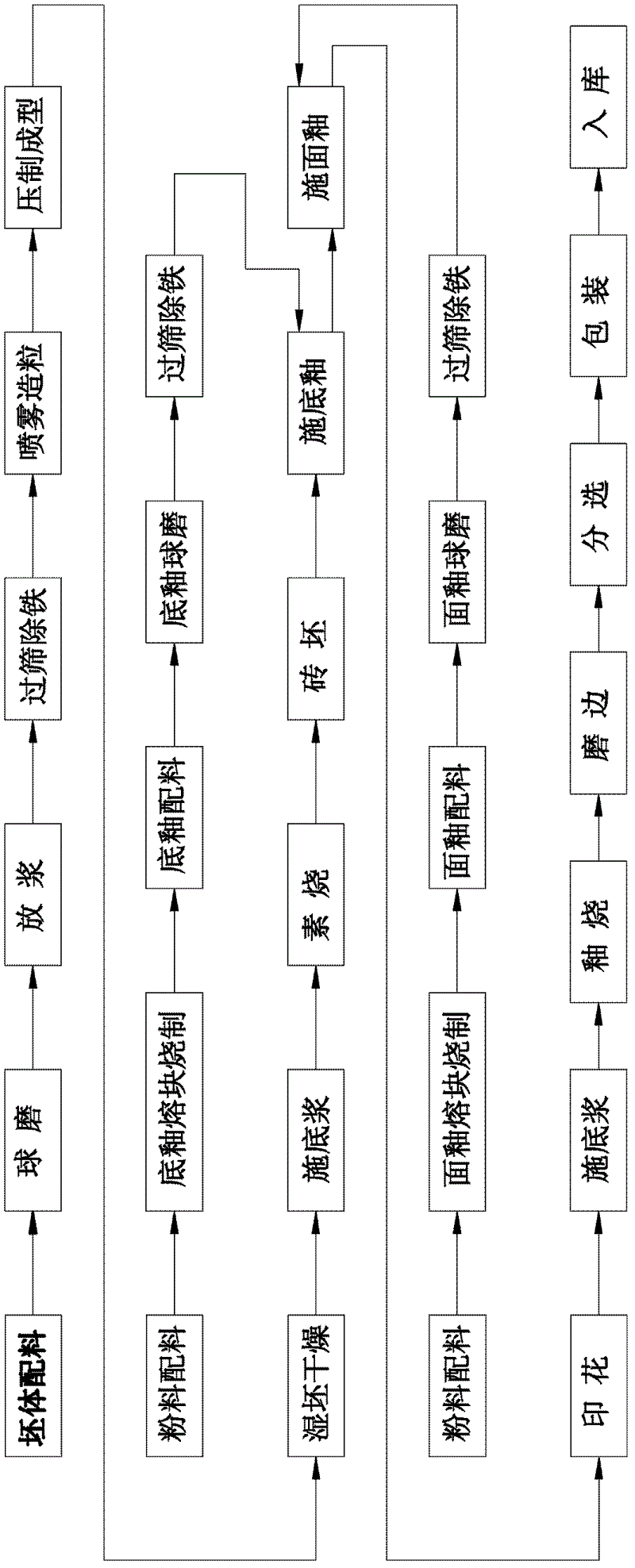

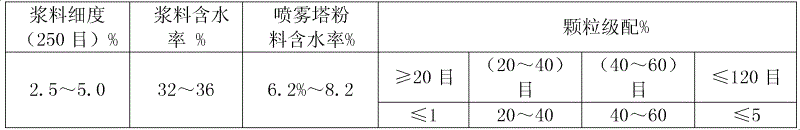

Formula and method for manufacturing ceramic tile blank bodies and glazed tiles by utilizing polished waste residues

The invention discloses a formula and a method for manufacturing ceramic tile blank bodies by utilizing polished waste residues. The formula adopts ingredients by weight portions: porcelain clays account for 18 to 40 parts, clays account for 20 to 30 parts, limestone grains account for 1 to 10 parts, wollastonite grains account for 3 to 15 parts, glazed tile sludge residues account for 3 to 10 parts, ceramic polished waste residues account for 15 to 45 parts, soluble glass accounts for 1 to 2 parts, thinners account for 0.15 to 0.4 parts, sodium tripolyphosphate accounts for 0.05 to 0.2 parts, and a proper amount of water is adopted. A manufacturing method of the ceramic tile blank bodies comprises the steps as follows: a. raw materials are put in a ball grinder for ball milling after being blended so as to form sizing agents with proper fineness and screen tailings through milling, and the sizing agents are processed through deferrization, sieving and spray drying so as to form powders; and b. the powders are put in a die cavity of a press forming machine to form waterish blanks through pressing, the waterish blanks are dried in a drying kiln, the dried waterish blanks are applied with base pulp and then enter a biscuit firing kiln, biscuit firing is carried out under the temperature ranging from 1080 to 1160 DEG C, heat preservation is carried out in an area with the temperature ranging from 1040 to 1060 DEG C, the sintering time of the area is prolonged, and the sintering process for oxidizing atmosphere can be enhanced at the same time so as to obtain the ceramic tile blank bodies.

Owner:GUANGDONG WINTO CERAMICS +1

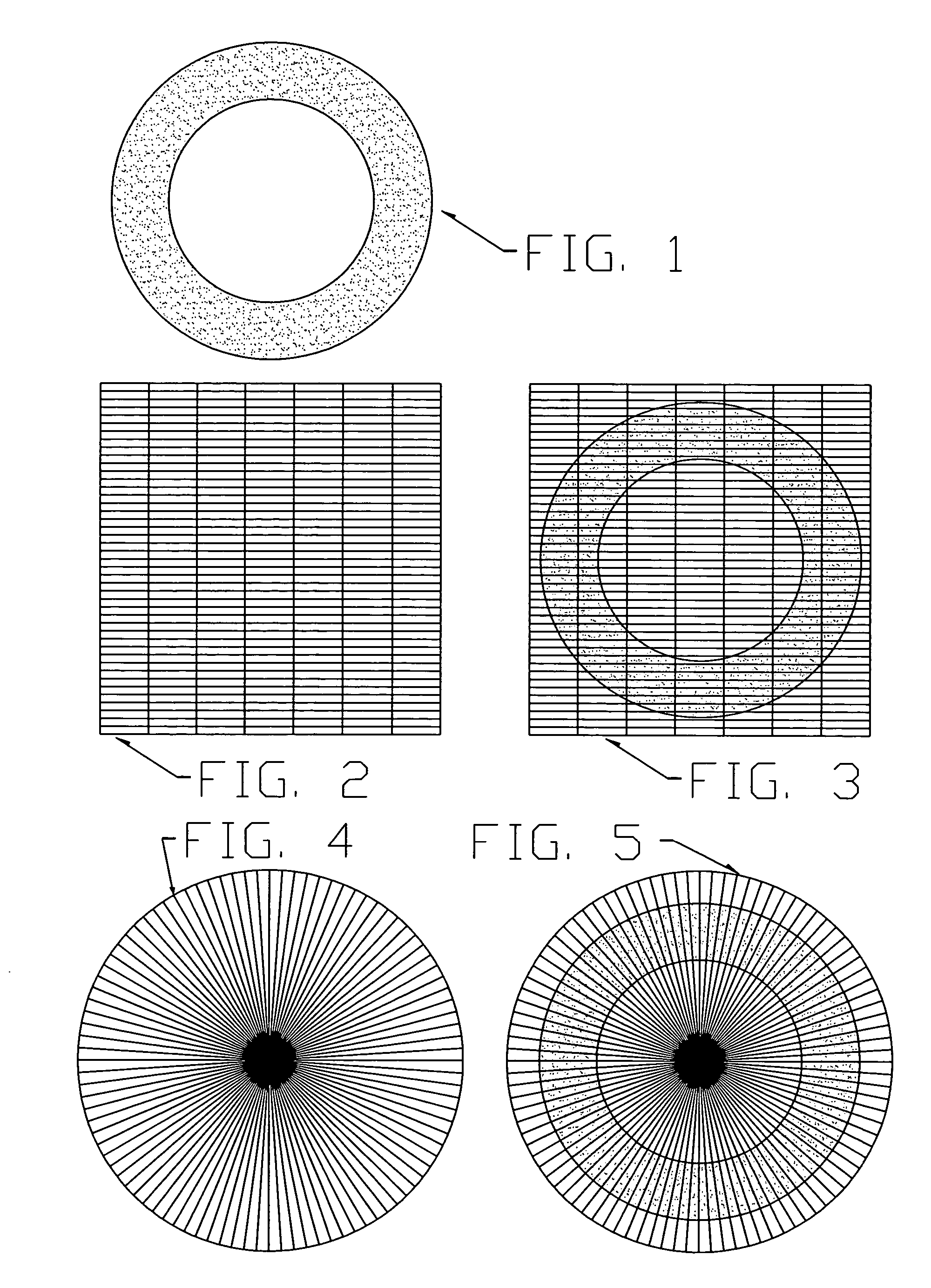

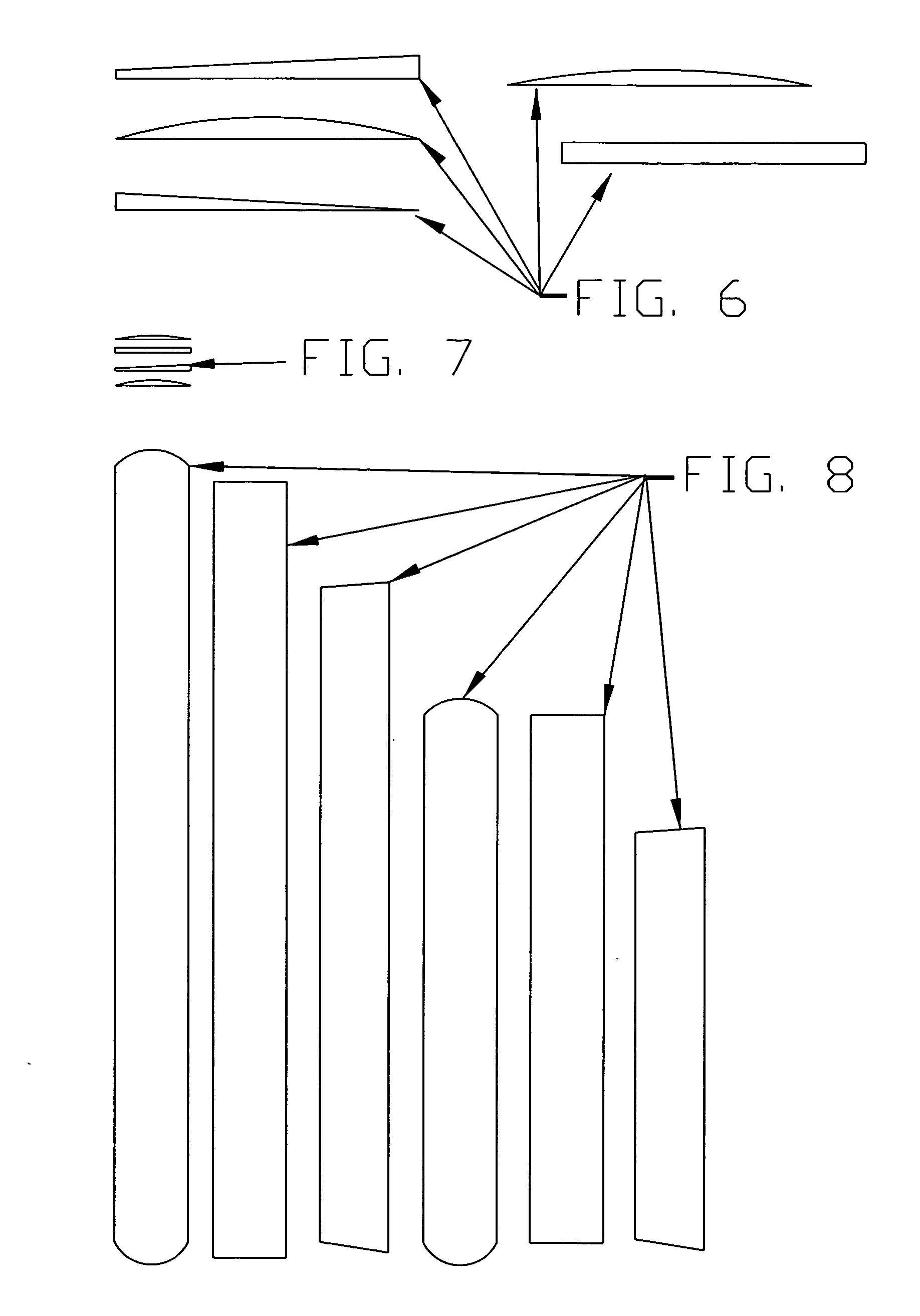

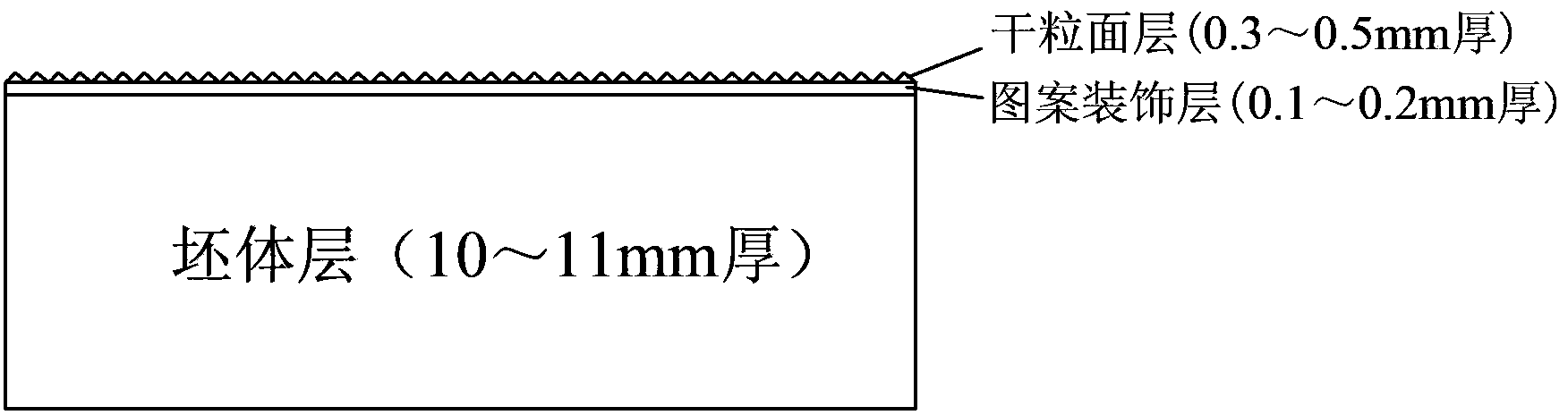

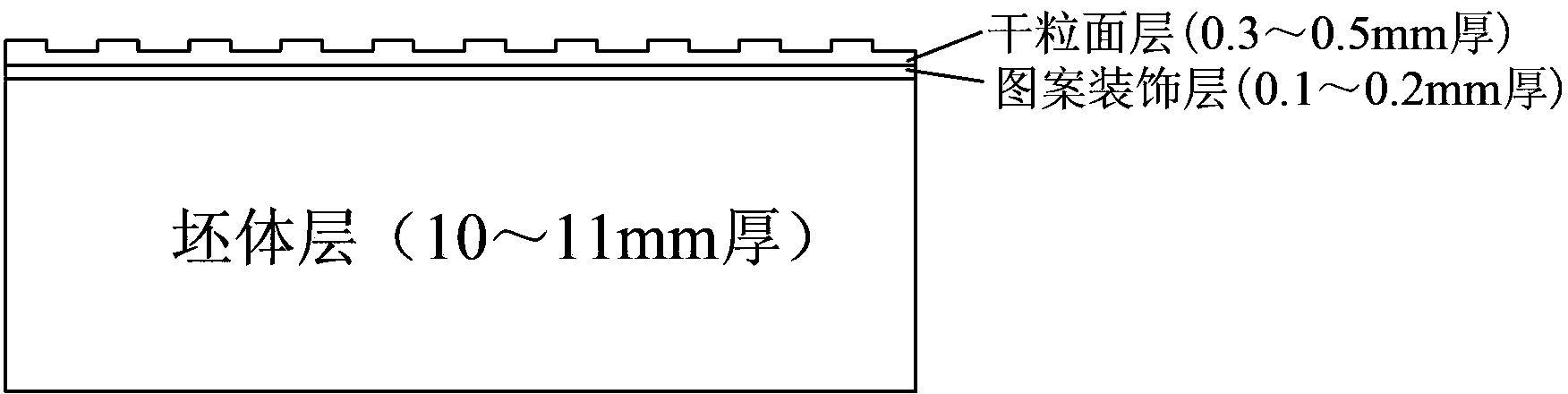

Ceramic tile with dry particle glaze-decorated surface and manufacturing method thereof

The invention relates to a ceramic tile with a dry particle glaze-decorated surface. The structure of the ceramic tile comprises a blank layer, a base glaze layer, a cover glaze layer, a printing layer and a dry particle layer from bottom to top, wherein the dry particle layer comprises the same kind of dry particles or the combination of more than two different kinds of dry particles; the different kinds of dry particles are different in particle size and refractoriness; and the particle size of the middle dry particles in the dry particle layer is (-60)-(-120) meshes. The invention also provides a preparation method of the ceramic tile with a dry particle glaze-decorated surface, which sequentially comprises the following steps: (a) producing a blank by using a press; (b) drying the blank by using a drying kiln; (c) applying the base glaze; (d) applying the cover glaze; (e) printing; (f) applying the dry particle glaze; (g) firing; (h) polishing; and (i) edging. The ceramic tile shows unique third dimension of light in the change of different lights and different heights so that the decorative pattern of the ceramic tile has a perfect texture; and moreover, the ceramic tile has good effects in slip resistance, wear resistance, dirt prevention and the like. The preparation method is easy to operate, the cost is low, and the product has a good effect.

Owner:GUANGDONG KITO CERAMICS GROUP CO LTD +2

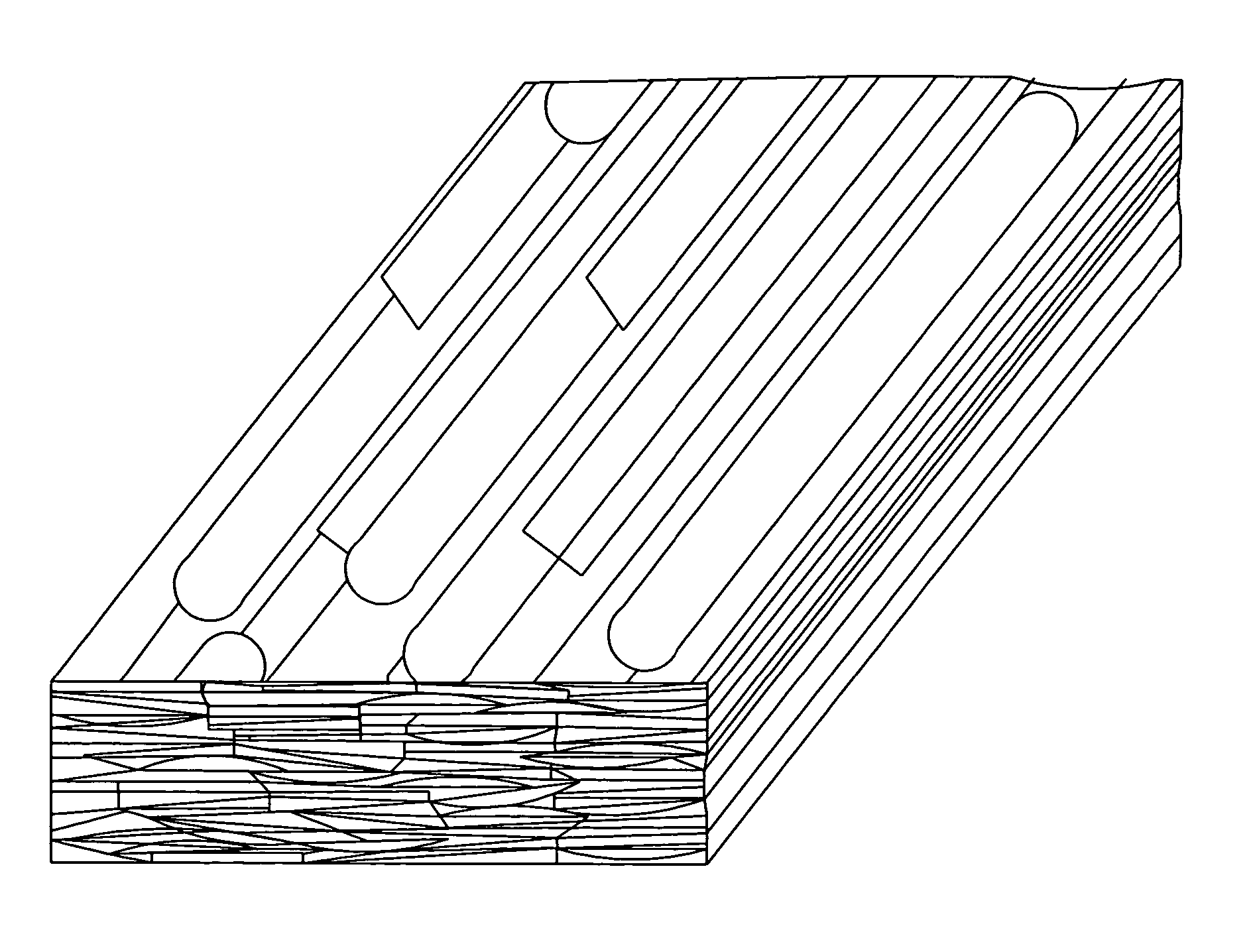

Bamboo chip treatment and products

InactiveUS20050161852A1Equally distributedVoid space is smallWood working apparatusAbsorbent padsEngineeringUltimate tensile strength

Thin elongated bamboo chips are produced and then are softened and dried. The softening of the chips reduces void spaces which uses less glue and produces stronger members. The chips are then joined together with glue under pressure to form a bamboo board. By varying the depth and length of the chip form, the member produced can form a board, chipboard, beams, or columns of any size. Additional boards may be produced and glued together to form a larger board, beam, or column. Several chipboard layers fabricated in large sheets and glued together will form ‘multi-ply bamboo’, a bamboo substitute for plywood. Once cured, the member is kiln dried and sealed for moisture. The resulting bamboo member's strength and geometrical form is stable and consistent enough to be used as a structural grade member for frames, homes, buildings, and furniture.

Owner:DECKER EMIL GUY +1

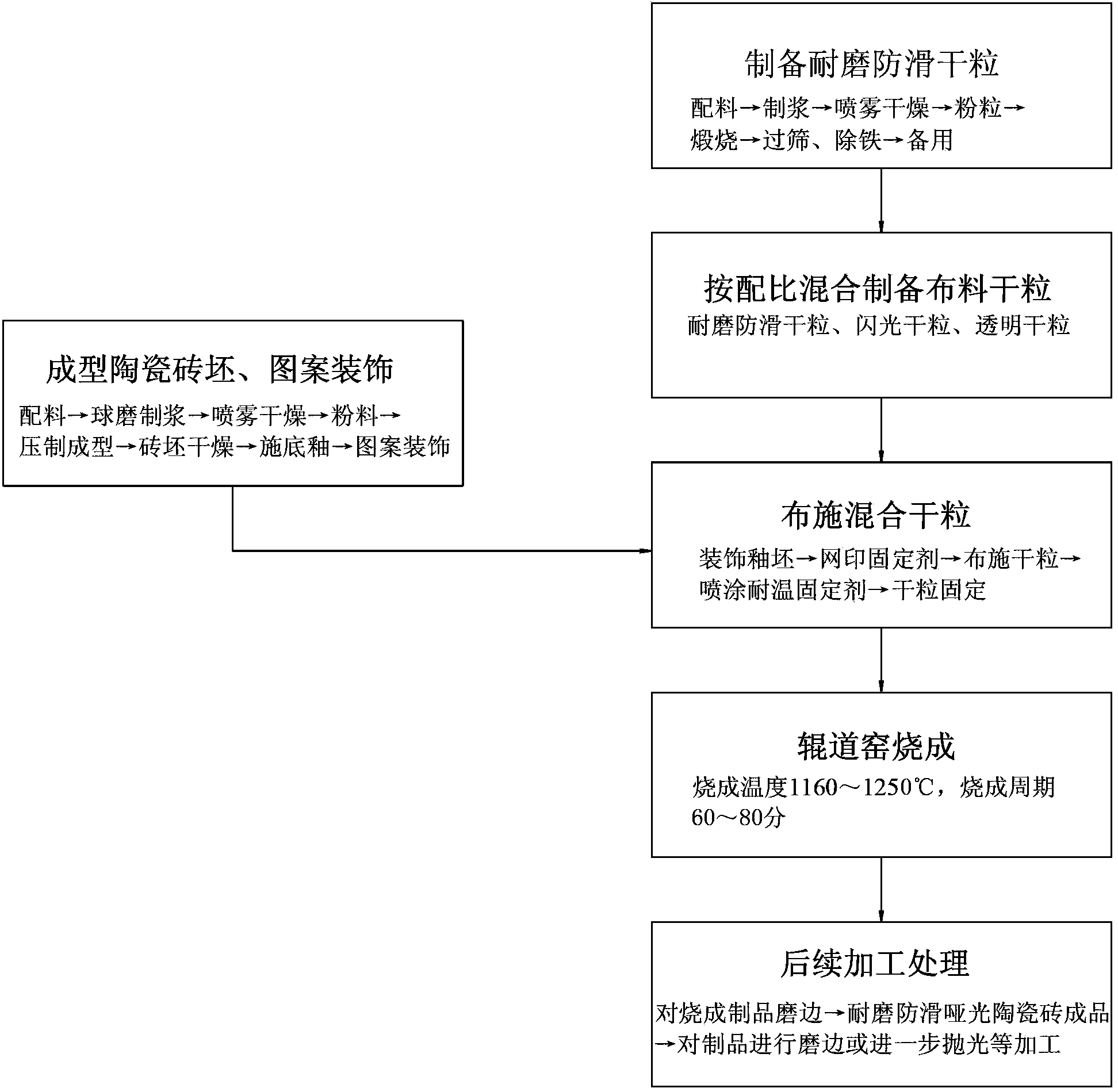

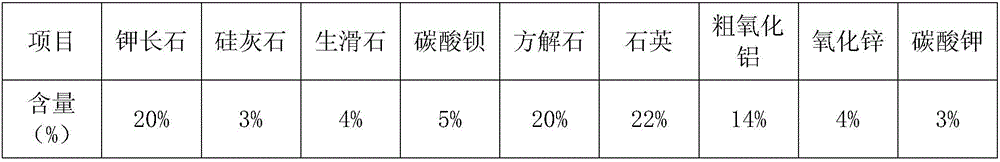

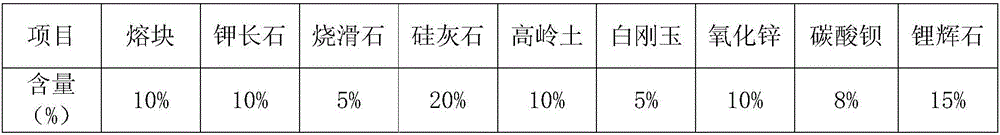

Method for manufacturing wear-resistant antiskid dry-particle ceramic tile

The invention relates to a method for manufacturing a wear-resistant antiskid dry-particle ceramic tile, which comprises the following steps: (1) forming a ceramic tile plane matrix and carrying out pattern decoration; (2) preparing dry particles with wear-resistant and antiskid properties; (3) mixing the wear-resistant antiskid dry particles, flashing dry particles and transparent dry particles according to a certain proportion for distribution; (4) applying the mixed dry particles to the surface of a decorative glazed body and spraying a temperature-resistant fixing agent; (5) conveying the obtained product to a roller kiln for firing and preparing the finished product of the ceramic tile through subsequent processes. According to the method for manufacturing the wear-resistant antiskid dry particle ceramic tile, the dry particles with good wear resistance are mixed with the transparent dry particles and the flashing dry particles, a dry powder distribution mode is adopted and the wear-resistant antiskid dry particles are bulged due to different melting performance of various dry particles in the firing process, so that the problems of wear resistance of the surface and thickness of a wear-resistant layer are solved; by distributing the transparent dry particles, a decorative pattern has a stereoscopic decorating effect under the covering of a glass layer, so that unification of wear-resistant and antiskid properties and decoration of the ceramic tile is achieved.

Owner:JIANGXI HEMEI CERAMICS

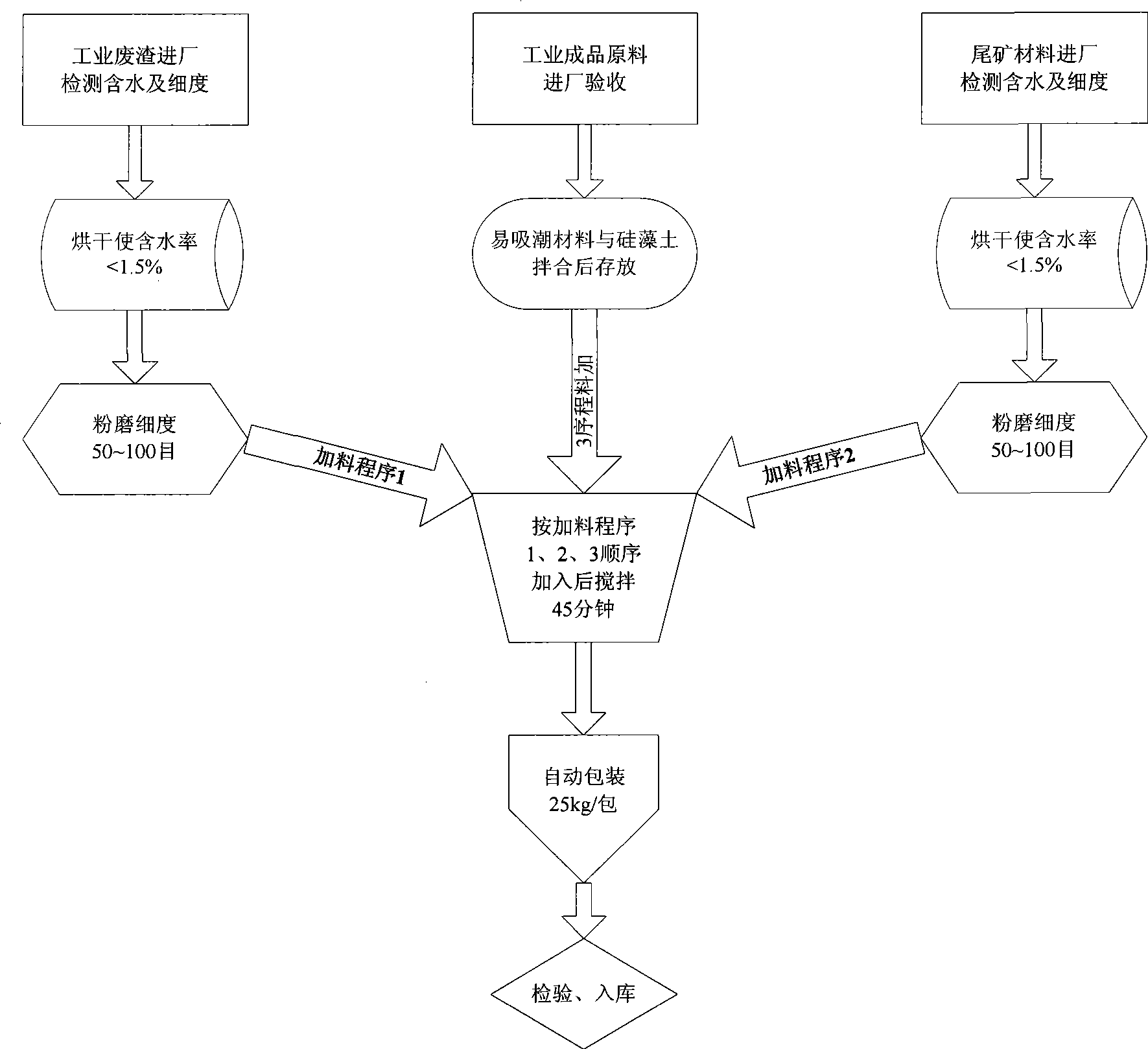

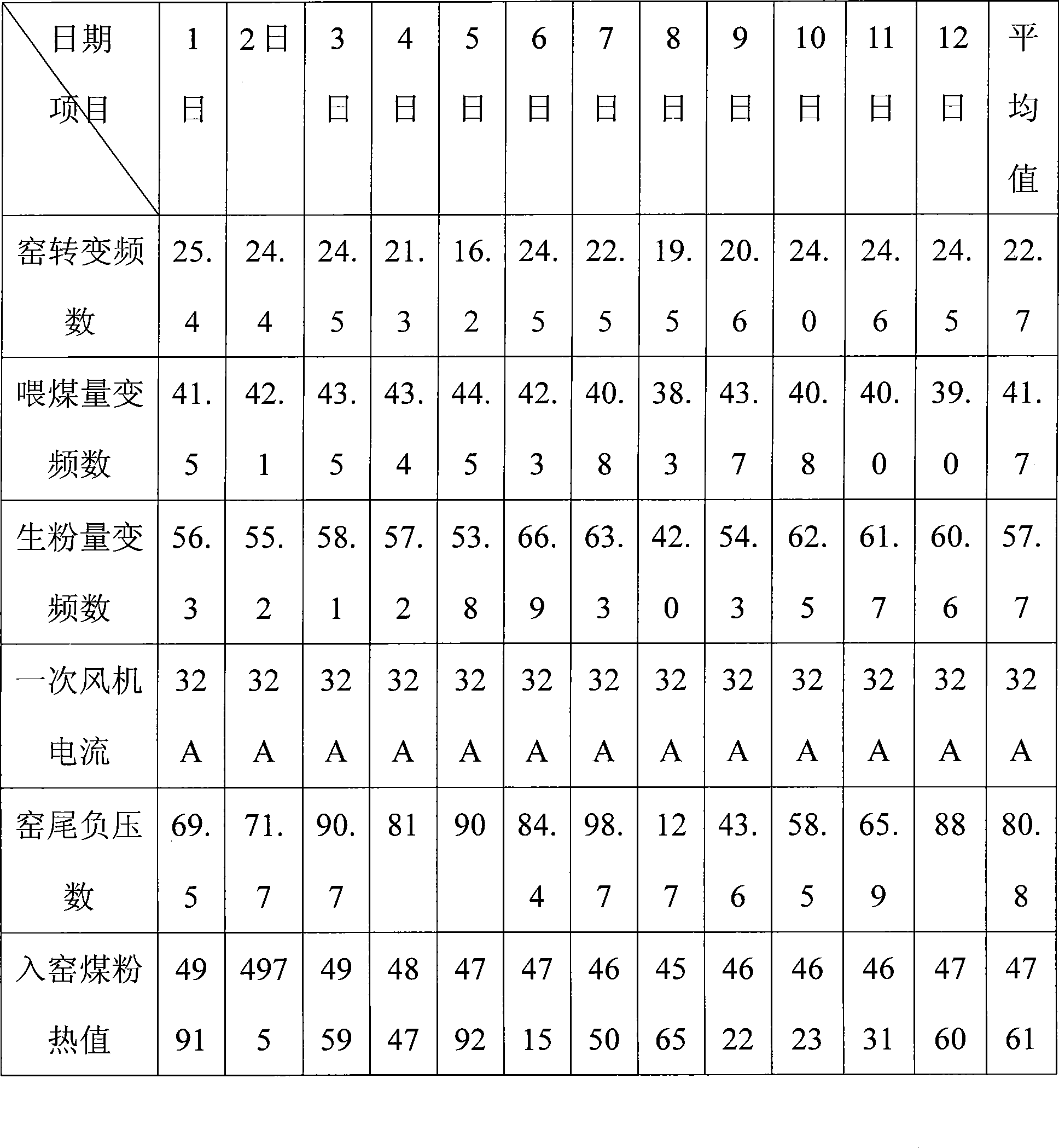

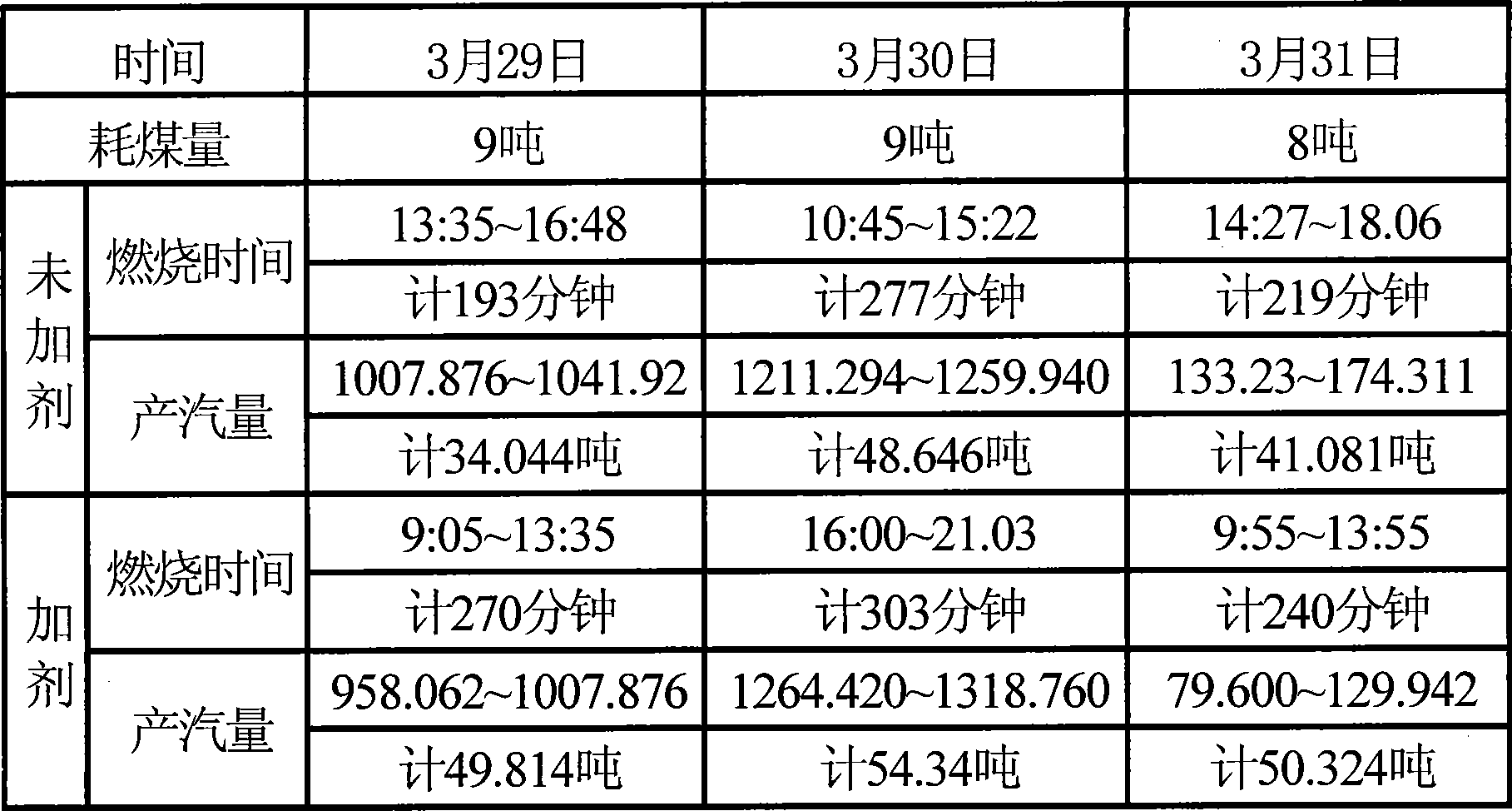

Non-sodium chloride environment-friendly type coal-saving combustion adjuvant special for cement

InactiveCN101475864AReduce contentReduce consumptionSolid fuelsClinker productionChromium CompoundsAdjuvant

The invention discloses a sodium chloride-free environment-friendly coal-saving combustion improver special for cement, which aims to solve the technical problem of eliminating the damage of sodium chloride to furnaces, kiln bodies and the atmosphere. The combustion improver consists of an industrial grade finished product raw material, industrial residue, and a tailing material, and contains a barium compound, boride, carbonate, a chromium compound, fluoride, a magnesium compound, a manganese compound, nitride, a molybdenum compound II, a zirconium compound, industrial residue or tailings of rare earth, oxide and dicyclopentadienyl iron. Compared with the prior art, the combustion improver completely cancels the sodium chloride, furthest reduces the content of Cl<-> in ingredients, eliminates the damage of the sodium chloride to the furnaces, the kiln bodies and the atmosphere, reduces the damage of causing acid rain to the atmosphere, increases a plurality of metal acids, oxygen compounds and rare earth minerals, contains waste residue, ensures that the combustion is controllably performed, improves combustion environment, improves the combustion efficiency of fire coal, reduces energy consumption, prolongs the service life of equipment, and protects the environment.

Owner:深圳市伯益科技有限公司

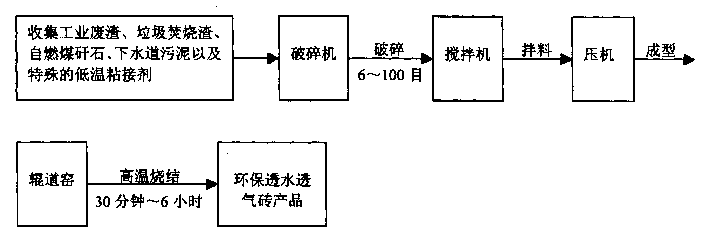

Fast baking process of environment protecting water and air permeable brick in roller kiln

InactiveCN1436750AReduce the temperatureStable water tableSolid waste managementSolid waste disposalEnvironmental resistanceCooking & baking

Owner:广东唯美新技术实业有限公司

Method for preparing core-shell silicon dioxide coated nano calcium carbonate

InactiveCN101225245AImprove acid resistanceImprove qualityInorganic pigment treatmentCarbonizationHydrolysis

The invention provides a preparation method for core-shell type silicon dioxide-coated nanometer calcium carbonate, which comprises following steps: adding silicate in calcium carbonate suspension pulp; stirring and mixing using emulsion pump; introducing kiln gas with CO2 for carbonization until the pH is 6.5 to 7.0; heating to 60 to 90 DEG C; adding coating agent for coating treatment; the product is obtained after the coated pulp is filtered and the filter cake is dried. The preparation method for core-shell type silicon dioxide-coated nanometer calcium carbonate has the advantages of improving the acid resistance of nanometer calcium carbonate since silica sol precipitated through hydrolysis is coated on the surface of nanometer calcium carbonate, improving dispersion of the product in polymer due to surface treatment using coupling agent and organic acid, good acid resistance and dispersion, greatly improving physical and chemical properties, and felicitating industrial production with simple operation.

Owner:上海卓越纳米新材料股份有限公司

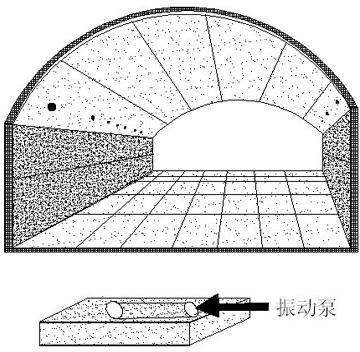

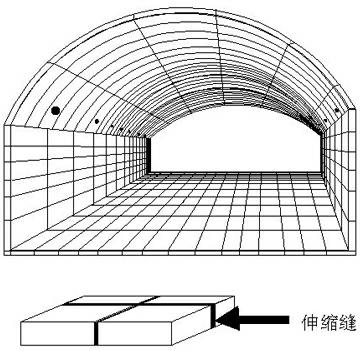

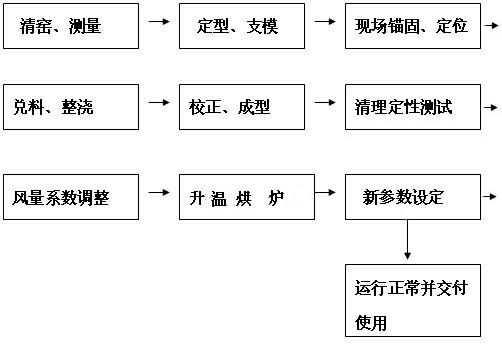

Composite fire-proof material with high refractoriness under load for coke ovens as well as furnace-building process and products thereof

InactiveCN102584294AImprove bindingWaste heat can be recovered for power generationCoke oven brickworkEnergy inputAdhesiveRefractory

The invention discloses a composite fire-proof material with high refractoriness under load for coke ovens. The preparation method of the material comprises the following steps of: evenly mixing and crushing 40%-60% of Al2O3, 15%-30% of SiC micro powder, less than 2% of Fe2O3, 5%-10% of Si micro powder and 1%-3% of cement as an additive; adding 3%-5% of Al(H2PO4)3 as an adhesive and stirring and mixing evenly; and pouring the mixture to a working region in 20-30 minutes. The furnace-building process comprises the following steps of: cleaning a kiln, measuring, molding, positioning and supporting a mould, adding materials, pouring and correcting, cleaning, starting for warming up and testing. The coke ovens newly built by pouring is characterized in that the top of the chamber of the furnace is fan-shaped, the chamber of the furnace is built by on-site seamless overall vibration pouring according to the process above with the furnace-building materials above, afterheat of the furnace can be recycled for power generation and no chemical residues exist. The furnace is short in charring time and higher in coke recovery and can be started and used at any time between the normal temperature and 1550 DEG C.

Owner:GUIYANG DONGJIBOYU REFRACTORY MATERIALS

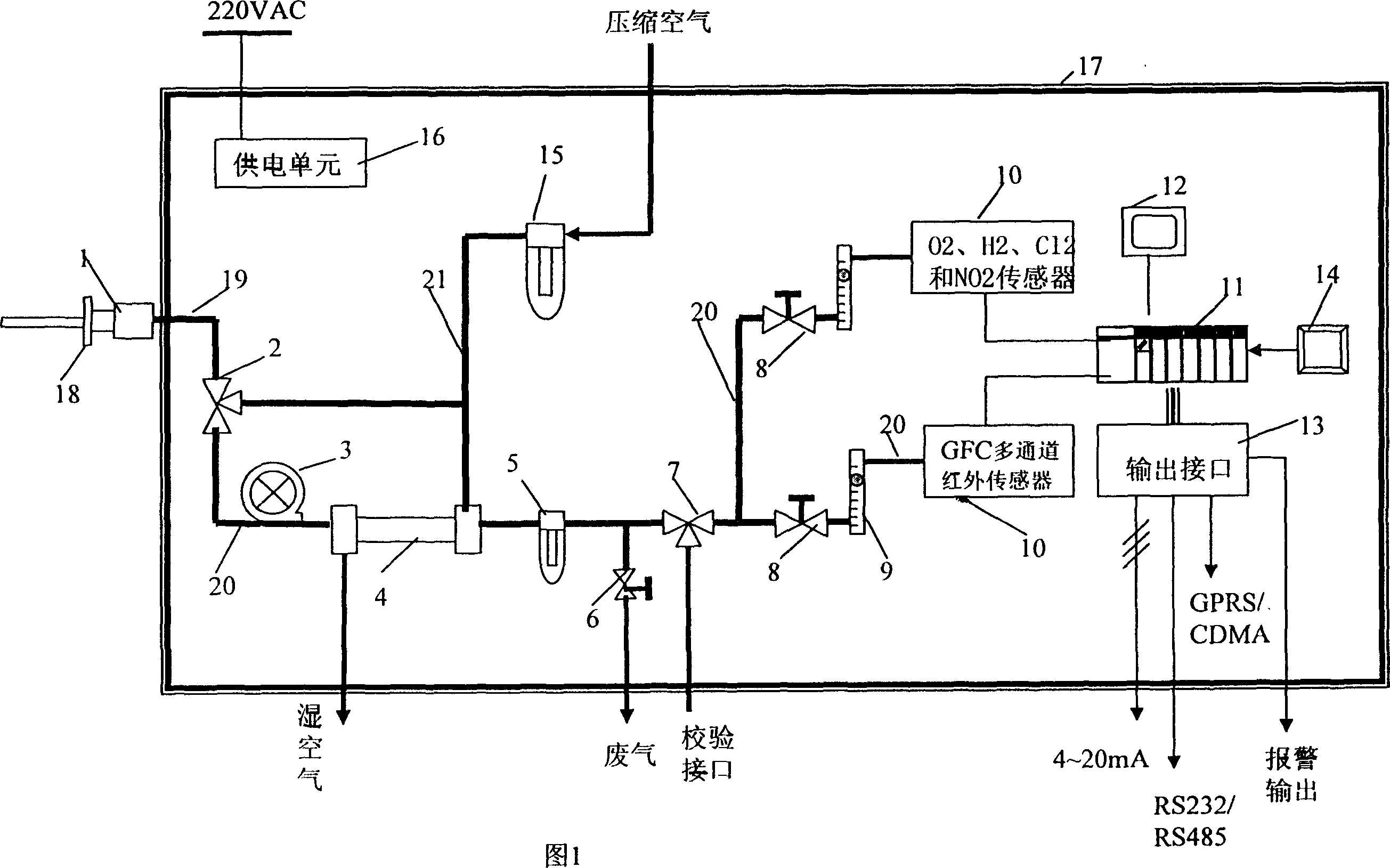

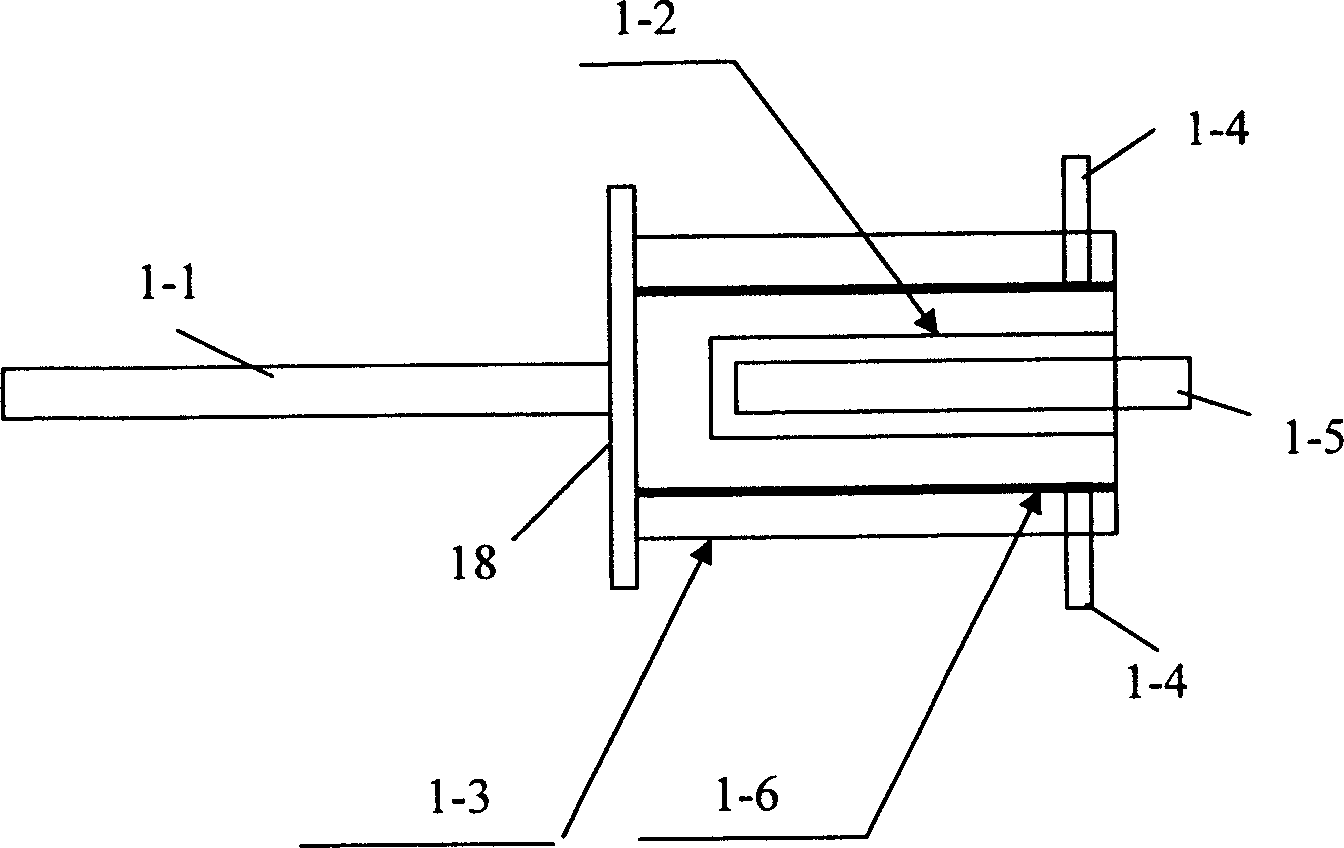

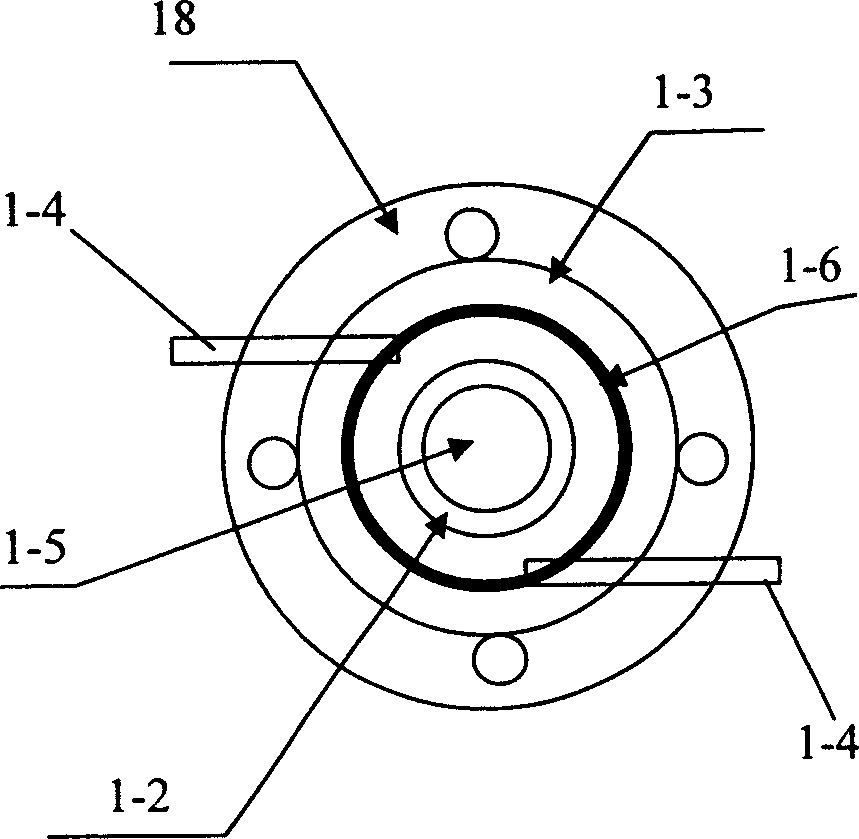

Integrated gas online detector

InactiveCN1866027ARealize simultaneous measurementAvoid long distance transportPreparing sample for investigationMaterial analysis by electric/magnetic meansGas analysisGas composition

The related integrated on-line gas detector can continual detect the content of CO, CO2, SO2, NO, NO2, N2O, CH4, HCl, H2S, HF, O2, H2 and Cl2 in smoke gas, kiln gas and furnace gas, which comprises: a sampling probe, a back-blow valve, a pump, a dehydrator, a fine filter, a bypass valve, a check valve, a stable valve, a flowmeter, a gas analysis sensor, a controller, a signal display, a signal output interface, an operation button, a drier, a power, an outdoor case, a sampling pipe, a sample-gas pipe, and a back-blow pipe. This invention has wide application.

Owner:南京卓成自动化设备有限公司

Composition and method for oxidizing mercury in combustion processes

InactiveUS7413719B2Emission reductionExcessive emissionUsing liquid separation agentEmission preventionCombustion chamberCombustor

The invention can be summarized as follows. There is provided a method for oxidizing elemental mercury in a combustion process comprising, adding a composition comprising an aluminum silicate to a combustion chamber, boiler or kiln downstream from the burner region combustion zone. There is further provided a method for reducing the emission of one or more heavy metals in a combustion process by adding a composition comprising an aluminum silicate to a combustion chamber downstream from the burner region combustion zone. There is also provided a composition comprising an aluminum silicate that may be employed to oxidize elemental mercury generated in a combustion process. The composition also may be employed to reduce the emission of one or more heavy metals generated in a combustion process.

Owner:DIGDON WILLIAM TROY

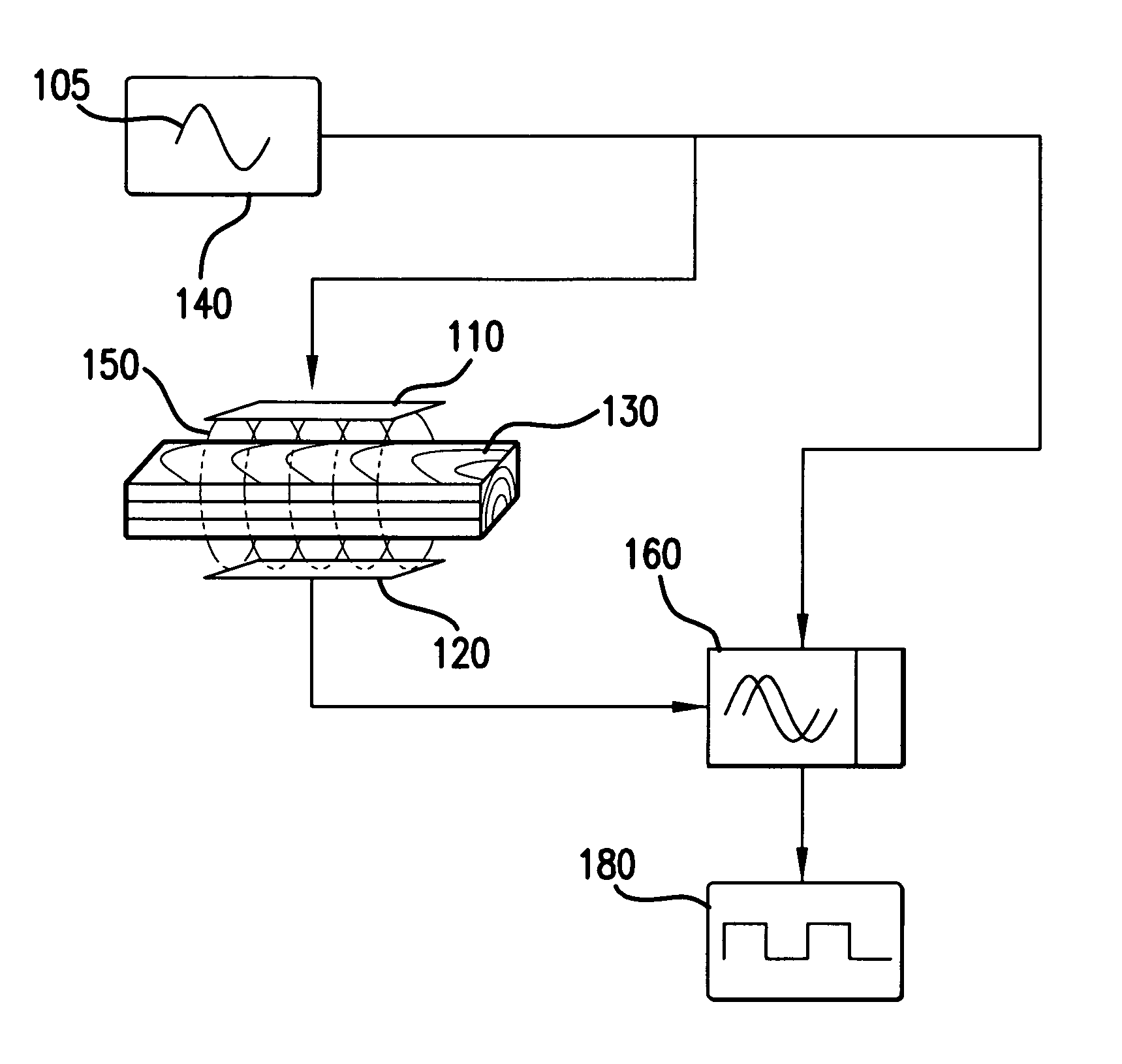

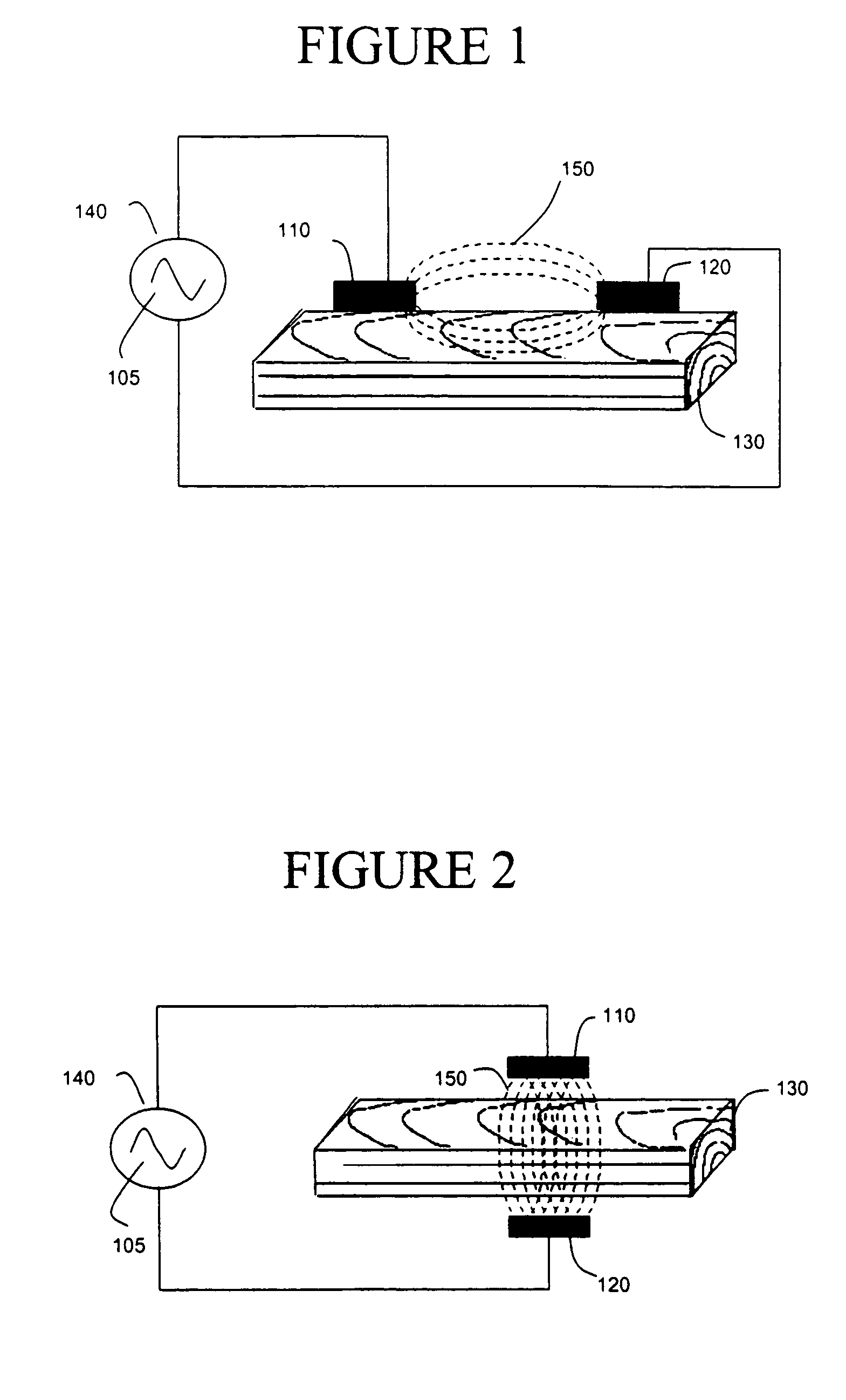

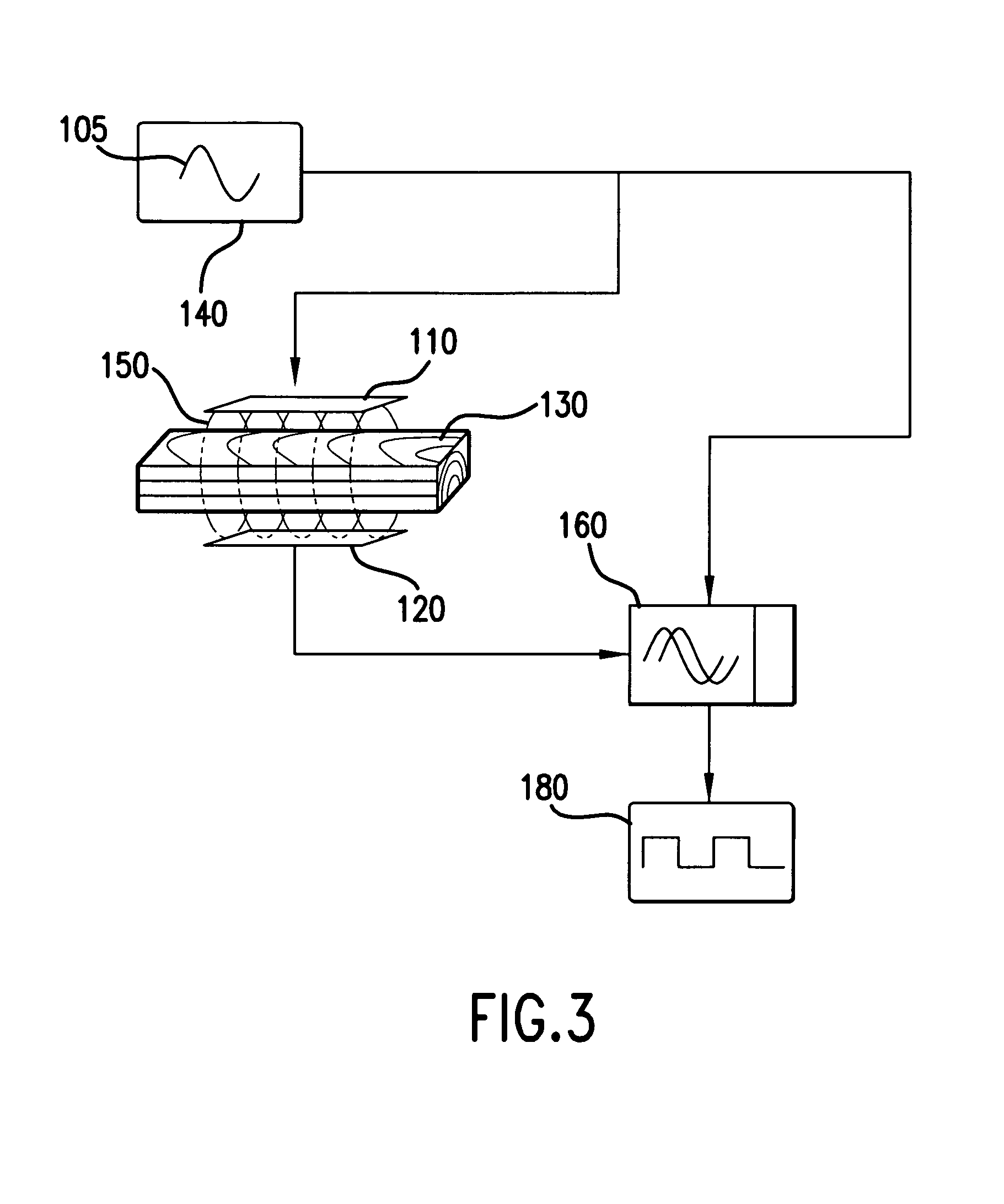

Moisture and density detector (MDD)

InactiveUS7068050B2Positive identificationPhase shift decreasesResistance/reactance/impedenceMoisture content investigation using microwavesCapacitancePhase shifted

A Moisture and Density Detector (MDD) provides a method and apparatus to determine the moisture content and / or density, as well as presence and location of anomalies, and / or wood type of any dielectric material for various purposes. This device is very useful in detecting the moisture content of wood and wood-based materials, such as that of lumber in a dry kiln prior to, during and / or following drying. The MDD passes a radio frequency signal and / or any other signal between opposed or adjacent capacitance electrodes and measures the signal strength and phase shift of the signal. The addition of phase shift and multiple frequencies improves the accuracy of the results.

Owner:MISSISSIPPI STATE UNIVERSITY

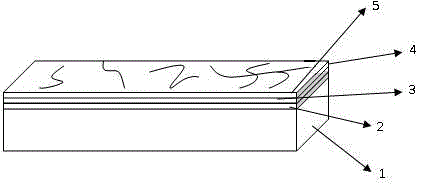

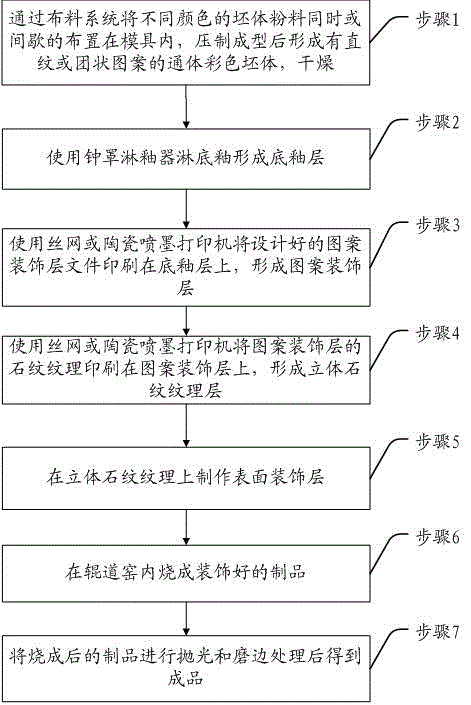

Whole-body polished porcelain tile having three-dimensional stone texture and production method of tile

The invention discloses a whole-body polished porcelain tile having three-dimensional stone texture and a production method of the tile. The tile comprises a whole-body colored blank layer, a ground coat layer, a pattern decoration layer, a three-dimensional stone texture layer and a surface decoration layer. The production method comprises steps as follows: 1) a whole-body colored blank is prepared; 2) the ground coat layer on the blank surface is formed; 3) the pattern decoration layer is formed; 4) ink or glaze having a dent effect is applied to the pattern decoration layer, a pattern corresponds to pattern texture of the decoration layer, and the three-dimensional stone texture layer is formed; 5) the surface decoration layer is formed; 6) a roller kiln is formed through sintering; 7) a finished product is obtained through polishing, edging and packaging. The surface color of the product produced with the scheme is integrated with the color of the blank, the stone texture changes naturally with the pattern texture of the product, the texture layer is protected by the surface decoration layer, and the tile has the decoration effect of natural stone. Properties of the product are superior to those of the natural stone, mining of the natural stone can be effectively reduced, and the natural environment is protected.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +1

Porous ceramic material and preparation method thereof

The invention discloses a porous ceramic material and a preparation method thereof. The invention comprises 5-50 portions of ceramic polishing waste, 20-50 portions of ceramic waste, 0-20 portions of ceramic clay, 0-15 portions of high temperature sand, 0-15 portions of low temperature sand by weight; the raw materials are mixed and water of 10-60 percent of the total weight of the raw materials is added, then 0-3 portions of grinding aids and 0-3 portions of binders are added and wet ball-milling is carried out; the mixture is pressed into a ceramic brick body and the invention can be obtained after the ceramic brick body is put into a ceramic roller kiln to be burned. The invention makes full of the ceramic waste and self foaming mechanism of the polishing brick waste, needs no foaming agent and can produce the porous ceramic material with light weight, low thermal conductivity and high strength. The invention has simple technique, the operation is easy to be controlled and the product has the functions of insulation, heat insulation, sound proof and fire proof, etc.

Owner:SOUTH CHINA UNIV OF TECH

Use of organic waste/mineral by-product mixtures in cement manufacturing processes

InactiveUS20050066860A1Reduce nitrogen oxide (NOx) emissionNitrogen compoundsDispersed particle separationNitrogen oxidesCement manufacturing

The use of organic waste / mineral by-product mixtures as raw materials in the manufacture of cement clinker; as alternative or supplemental fuel sources for heating a kiln used in a cement clinker manufacturing process; and, to reduce nitrogen oxide (NOx) emissions generated during cement manufacturing processes are disclosed.

Owner:N VIRO INT

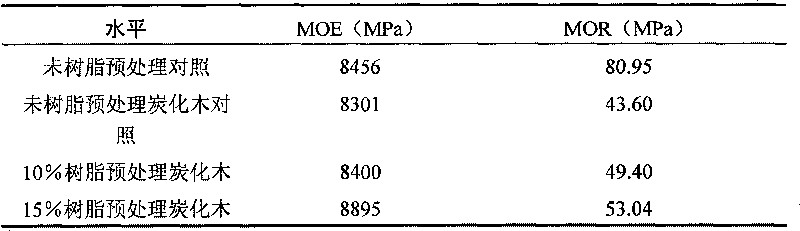

Method for producing rubber tree carbonized wood by resin pretreatment

ActiveCN101716790AHigh strengthIncrease added valuePressure impregnationWood impregnation detailsPulp and paper industryAdditional values

The invention belongs to the technical field of wood modification, in particular relating to a method for producing rubber tree carbonized wood by resin pretreatment. The method comprises the following steps: putting the rubber saw wood of which the water content is less than 15% in a vacuum treatment tank for impregnating; then, stacking and airing the wood, putting the wood in a kiln, routinely drying the wood in the kiln until the water content is less than 12%, and then, taking the wood out of the kiln; and putting the obtained wood in heat treatment equipment for high-temperature heat treatment, and taking the wood out of the kiln to obtain the rubber tree carbonized wood, wherein the water content of the wood is 4-6%. The invention has simple processes, high heating rate in the heat treatment process and high production efficiency, can increase the strength of the rubber tree carbonized wood by vacuum pressurization and impregnation of resin, and can effectively prevent the wood from deforming and cracking in the heat treatment process. The obtained rubber tree carbonized wood has the advantages of little loss of strength of the wood, elegant color, more excellent dimensional stability and durability and the like, and can be widely used for indoor and outdoor floors, landscapes, decorative materials and the like, thereby widening the application field of the rubber tree wood and increasing the additional value of the rubber tree wood.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI +1

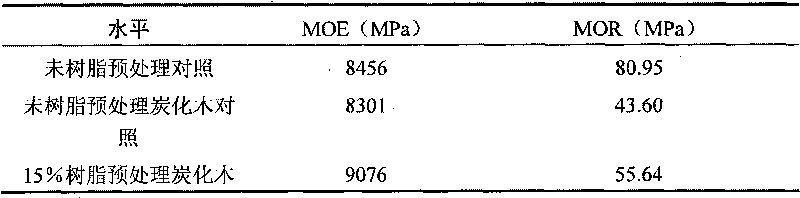

Tourmaline monolithic honeycomb ceramic and preparation method thereof

ActiveCN102285816AImprove adsorption capacityEnhance the efficacy of toxic and harmful substances in liquidsCeramicwareMicrowaveHoneycomb

The invention discloses a tourmaline integral honeycomb ceramic and the ceramic mainly comprises the following components by weight percent: 10-75% of tourmaline, 2-20% of clay, 2-40% of fluxing agent and 1-30% of auxiliary material. The preparation method of the tourmaline integral honeycomb ceramic comprises the following steps: adding tourmaline, clay, the fluxing agent, the auxiliary materialand a dry powder forming agent in a medium mill in proportion to grind and mix so as to obtain a mixture, then adding a appropriate amount of water and a liquid forming agent in the mixture to knead and obtain mud, granulating the mud, aging, extruding to obtain mud sections, moulding the mud sections, performing microwave forming, drying to prepare a semi-finished product, and placing the semi-finished product in a kiln at 500-850 DEG C to fire. Compared with the existing tourmaline products, the characteristics of the existing honeycomb ceramics, namely large specific surface area and porescan be ensured, the effect of tourmaline can be extremely exerted, the amount of tourmaline can be greatly reduced and the ceramic has good energy-saving effect. The energy consumption of the tourmaline integral honeycomb ceramic is one tenth of the energy consumption of the tourmaline ball fired at the same temperature.

Owner:曹南萍

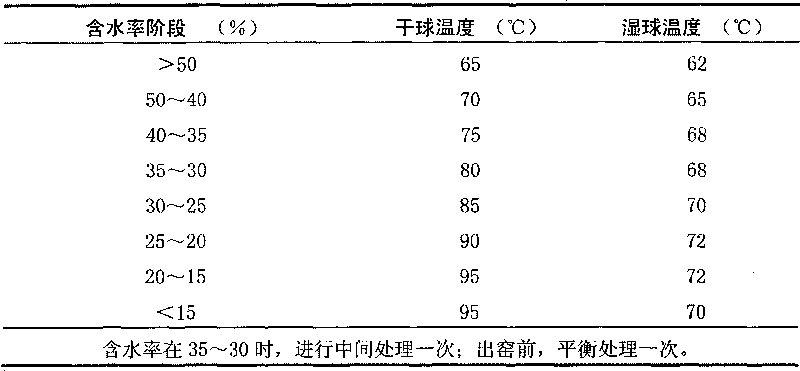

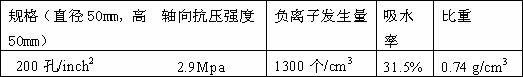

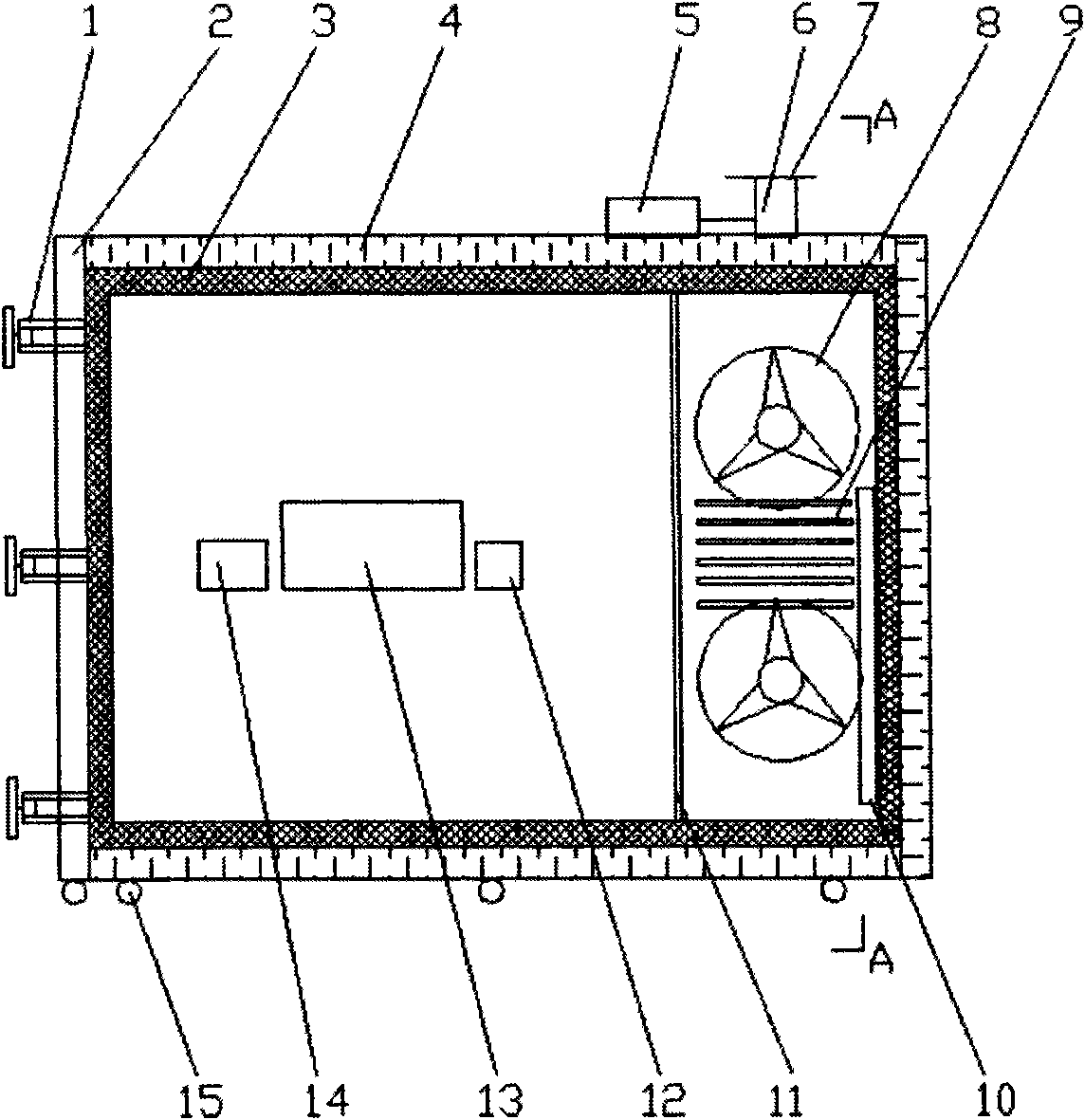

Method and system for drying wood

InactiveCN101561216ANo pollutionEfficient use ofDrying solid materials with heatDrying gas arrangementsControl systemProcess engineering

The invention discloses a system for drying wood, which comprises a drying kiln, a humidity generator, a heat energy recoverer, a filter and a control system, wherein the drying kiln is provided with a gas inlet and a gas outlet; high-temperature waste gas discharged out of the gas outlet of the drying kiln is filtered by the filter, then is input to the heat energy recoverer, and is discharged out after performing heat exchange with low temperature gas from the humidity generator in the heat energy recoverer, and the heated low temperature gas output by the heat energy recoverer is sent into the gas inlet of the drying kiln through a pipeline; and the control system controls the work of the drying kiln, and controls the humidity of the low temperature gas output by the humidity generator according to the temperature, the humidity and the moisture content of the wood to be controlled in the drying kiln so as to control the humidity of the gas input in the drying kiln. By setting the humidity generator and the heat energy recoverer, the system optimizes the drying quality of the wood and minimizes the energy consumption; and simultaneously, because the working gas is used circularly, the waste gas is prevented from being discharged to the atmosphere to pollute the environment.

Owner:周玉成

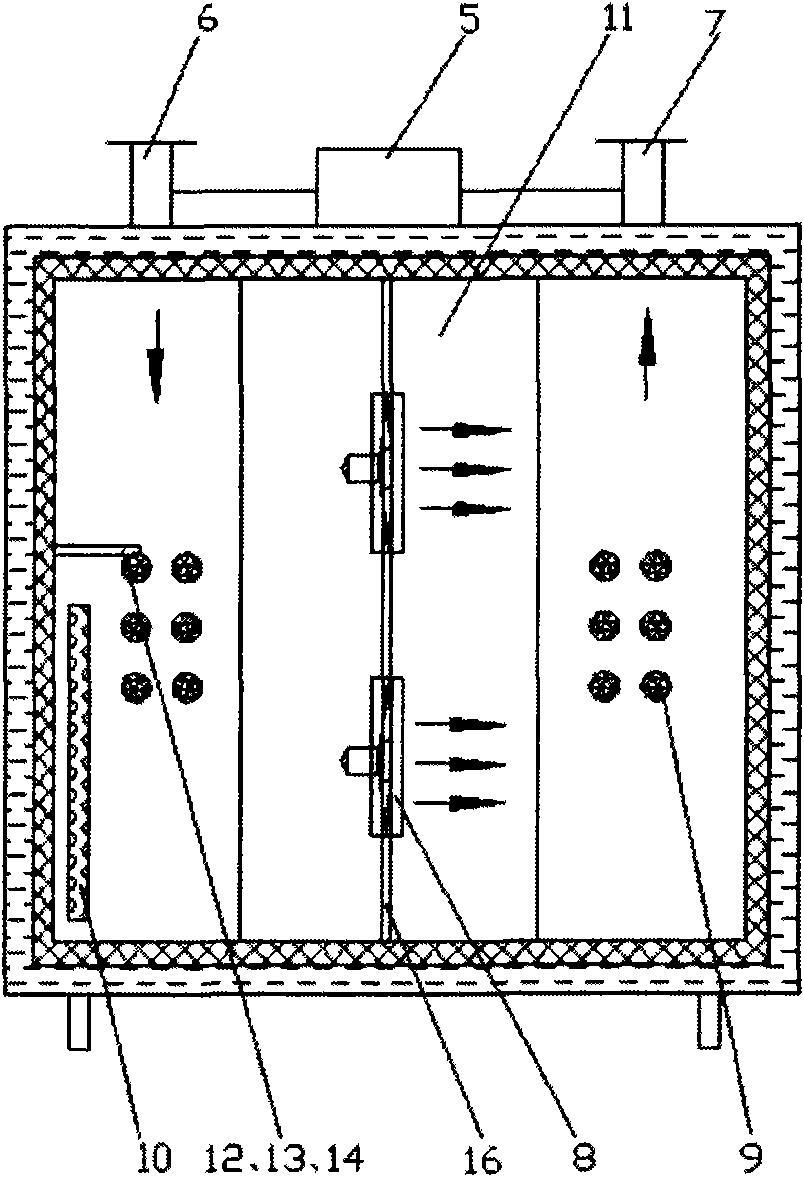

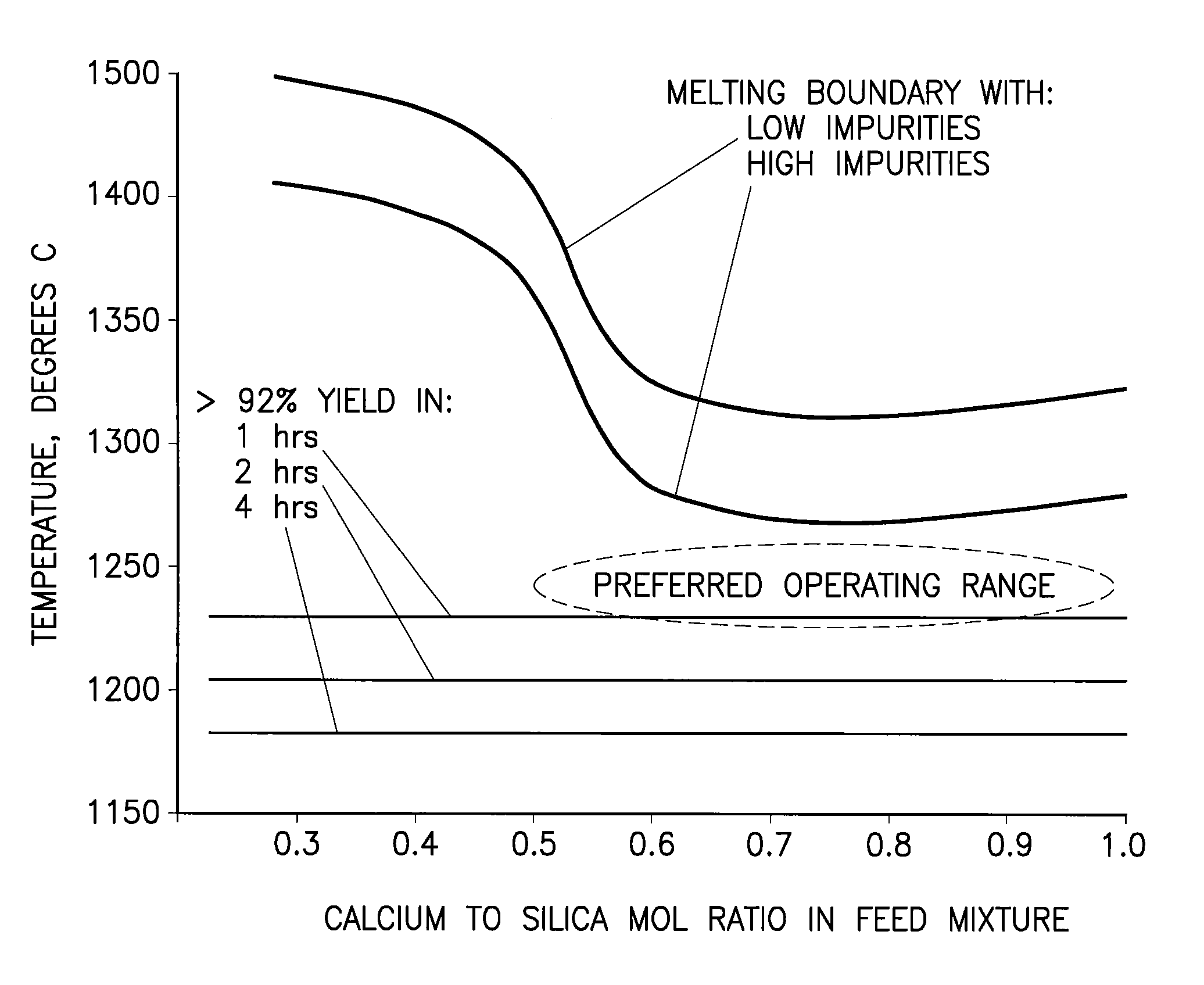

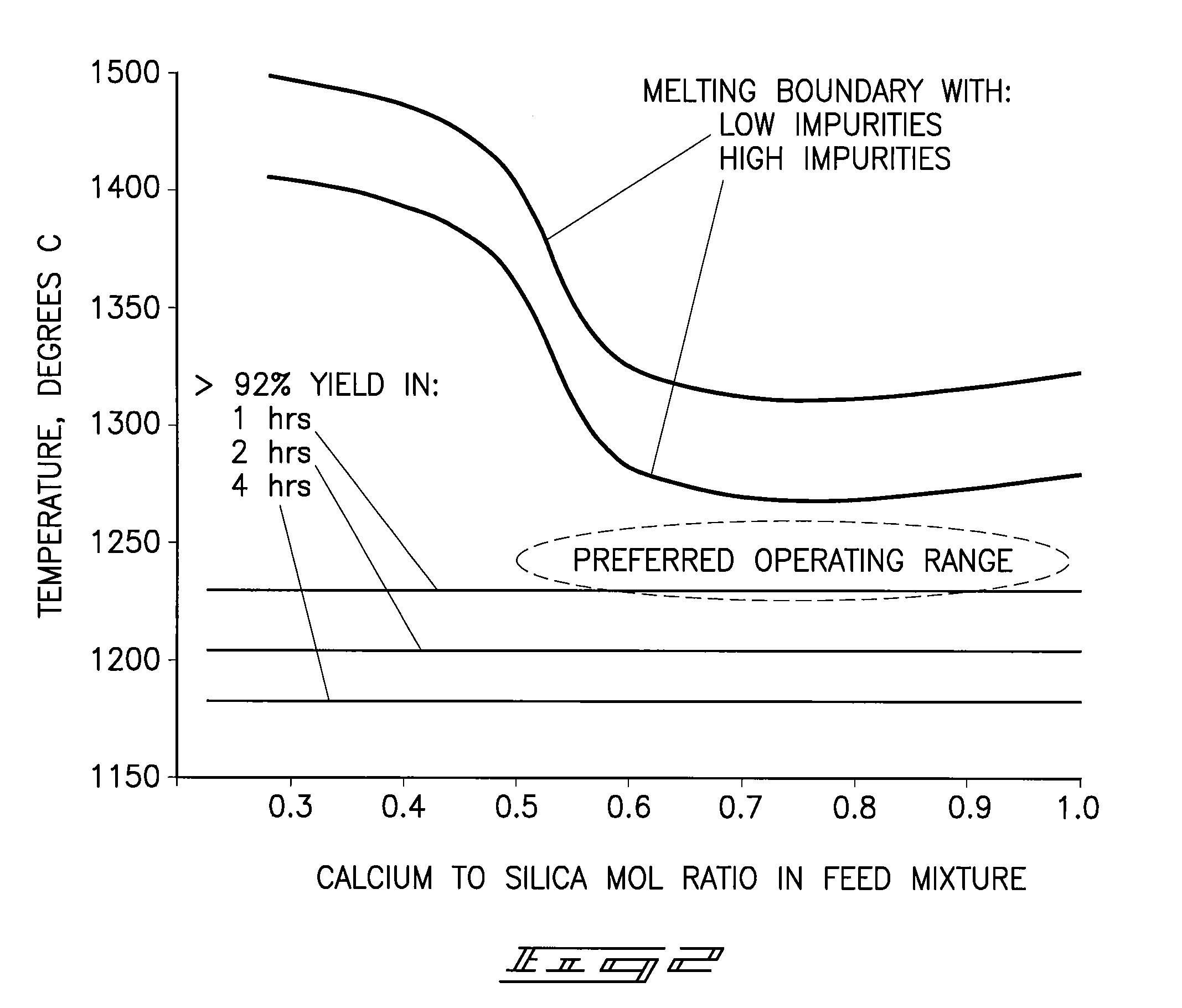

Phosphorous pentoxide producing methods

A phosphorous pentoxide producing method includes forming a kiln bed using feed agglomerates with a calcium-to-silica mole ratio of from 0.5 to 1.0 and maintaining a bed temperature at or above 1260° C. along a portion of the bed length without exceeding 1380° C. along the entire bed length. Less than 10% of the agglomerates' phosphate input to the kiln remains in the kiln residue as phosphate. Another method includes maintaining a bed temperature at or above 1180° C. along a portion of the bed length and establishing a bed surface-to-volume ratio multiplied by a time for bed heat up to 1180° C. of less than 50 minutes-ft2 / ft3.

Owner:NOVAPHOS INC

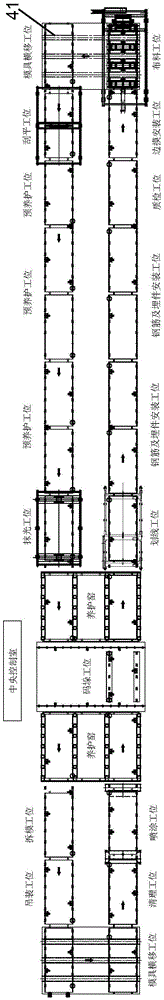

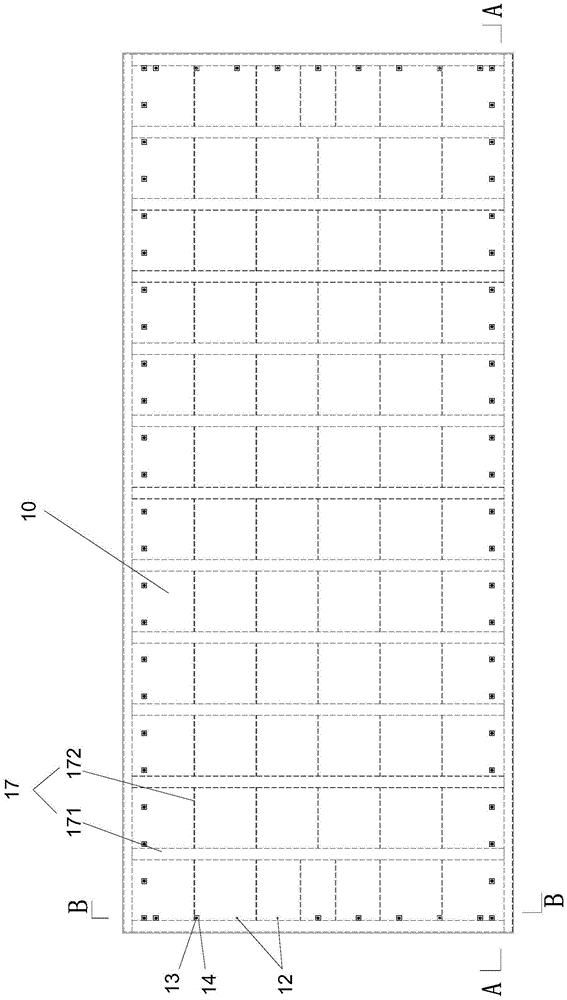

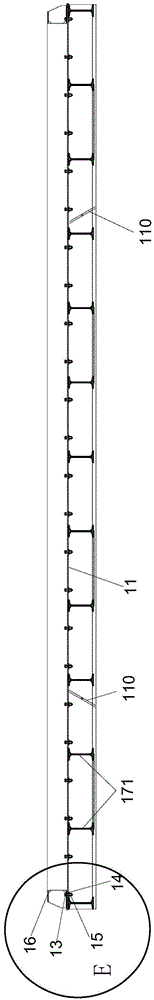

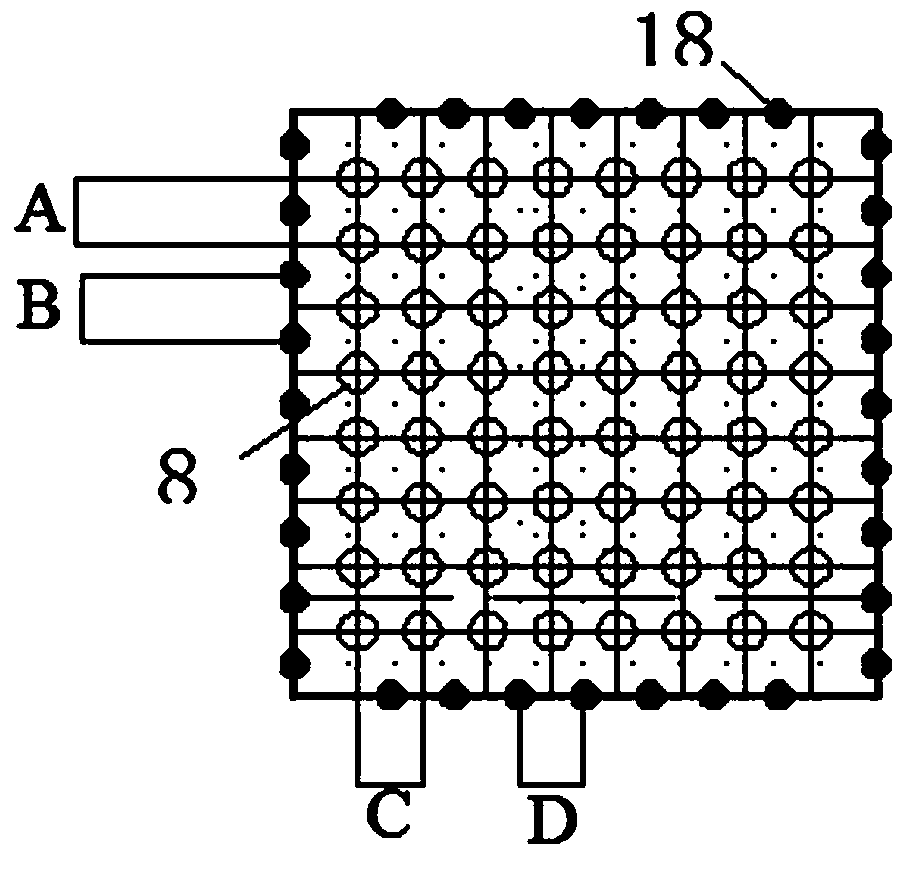

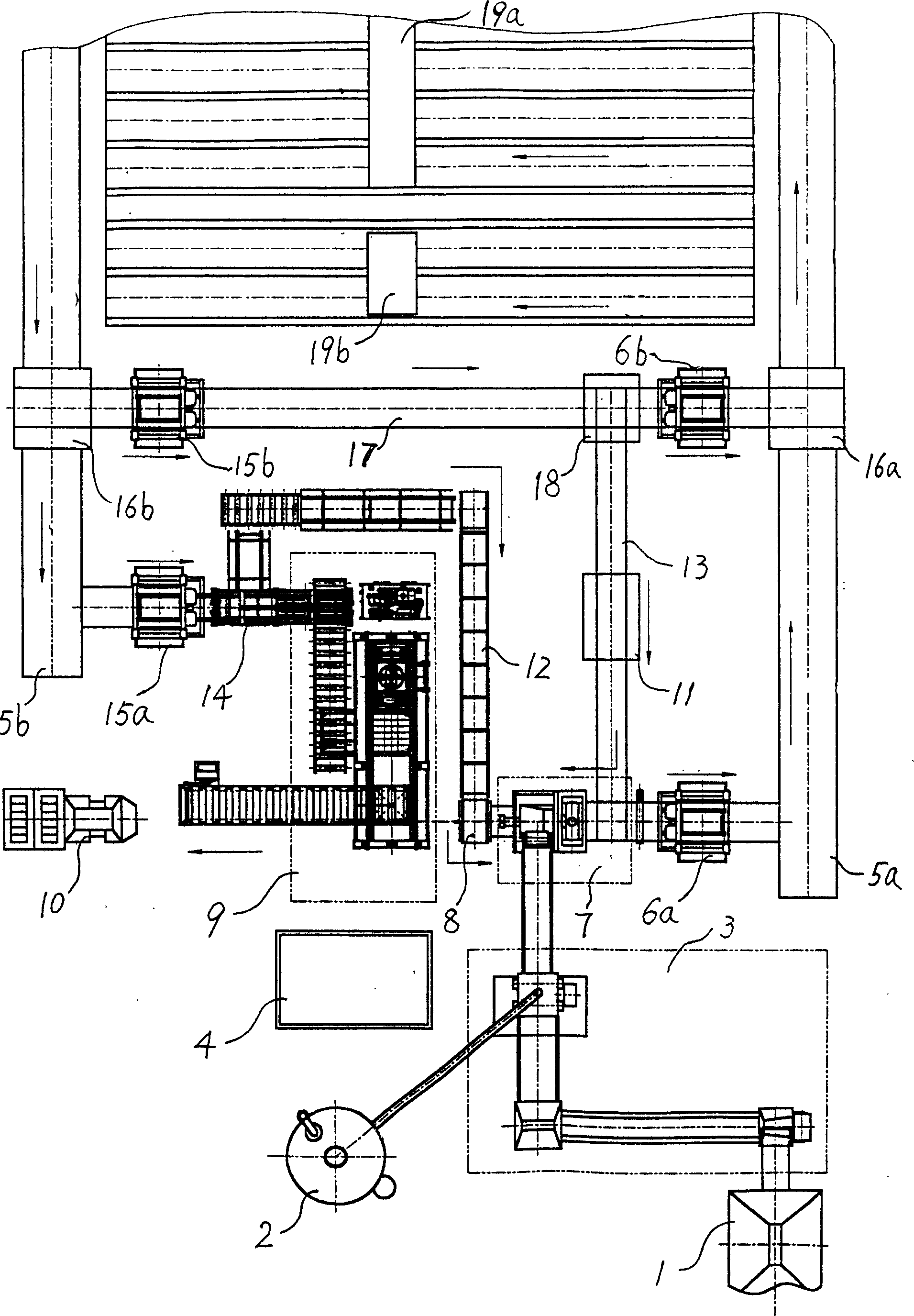

PC component production line

ActiveCN105459258AReduce wasteReduce manufacturing costCeramic shaping plantsFeeding arrangmentsProduction lineMaterial resources

The invention provides a PC component production line. The PC component production line comprises a clearing work station, a spraying work station, a scribing work station, a reinforcing steel bar and embedded part mounting work station, a quality inspection work station, a side die mounting work station, a laying work station, a die transverse movement work station, a leveling work station, a pre-curing work station, a smoothing work station, a curing kiln, a stacking work station, a die removing work station, a lifting work station and the like, which are connected by a conveying rail. A die component moves with the conveying rail in the order of the work stations and is processed by the procedures of all the work stations. Various models and sizes of PC components can be produced and manufactured. The layout of the production line is reasonable. Various PC components can be cyclically produced on one production line, so that various sizes of fixing dies do not need to be manufactured. The waste of material resources is greatly reduced, the production cost is reduced, and the production efficiency is improved.

Owner:HEBEI YUGOU BUILDING MATERIALS CO LTD

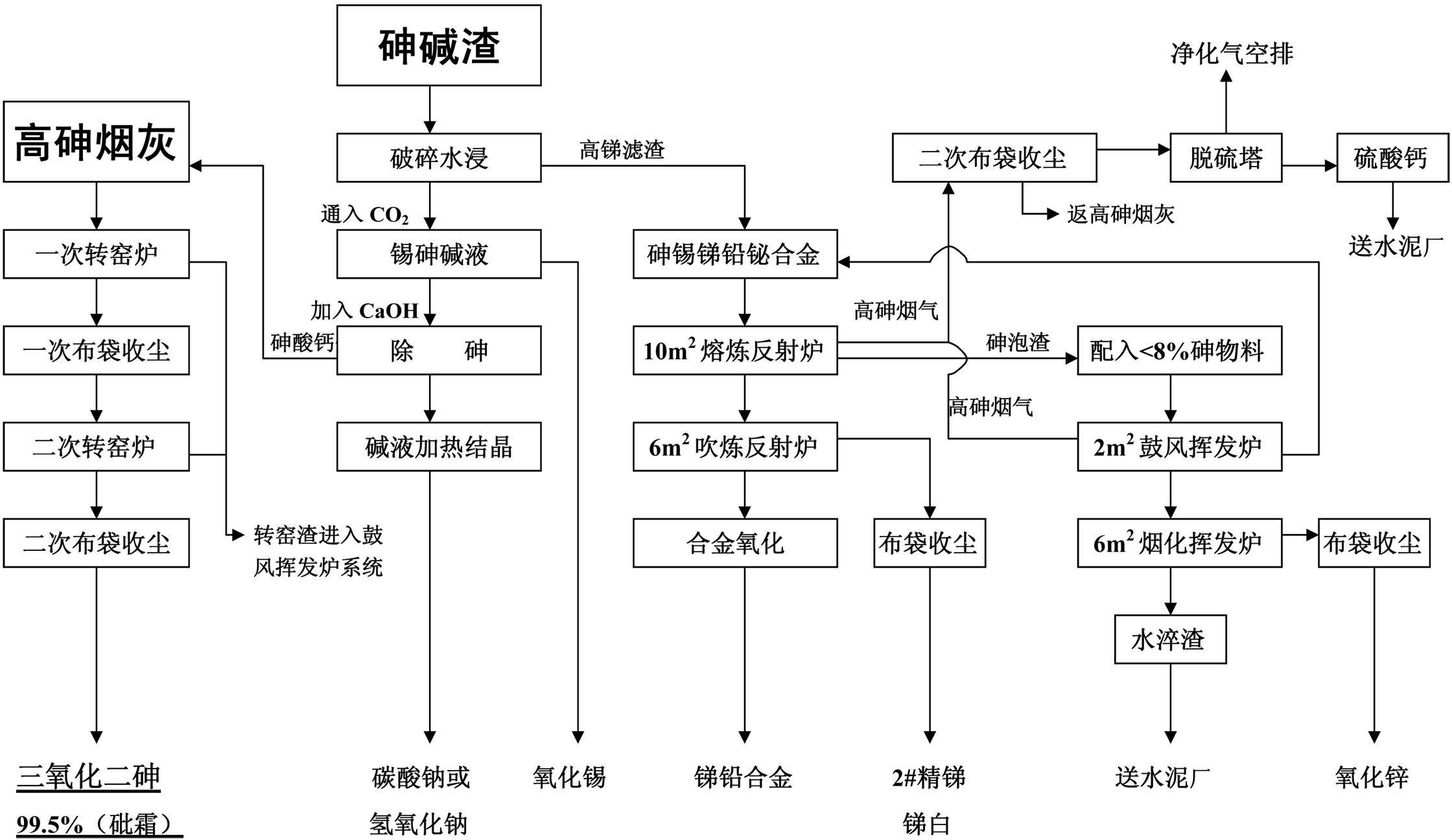

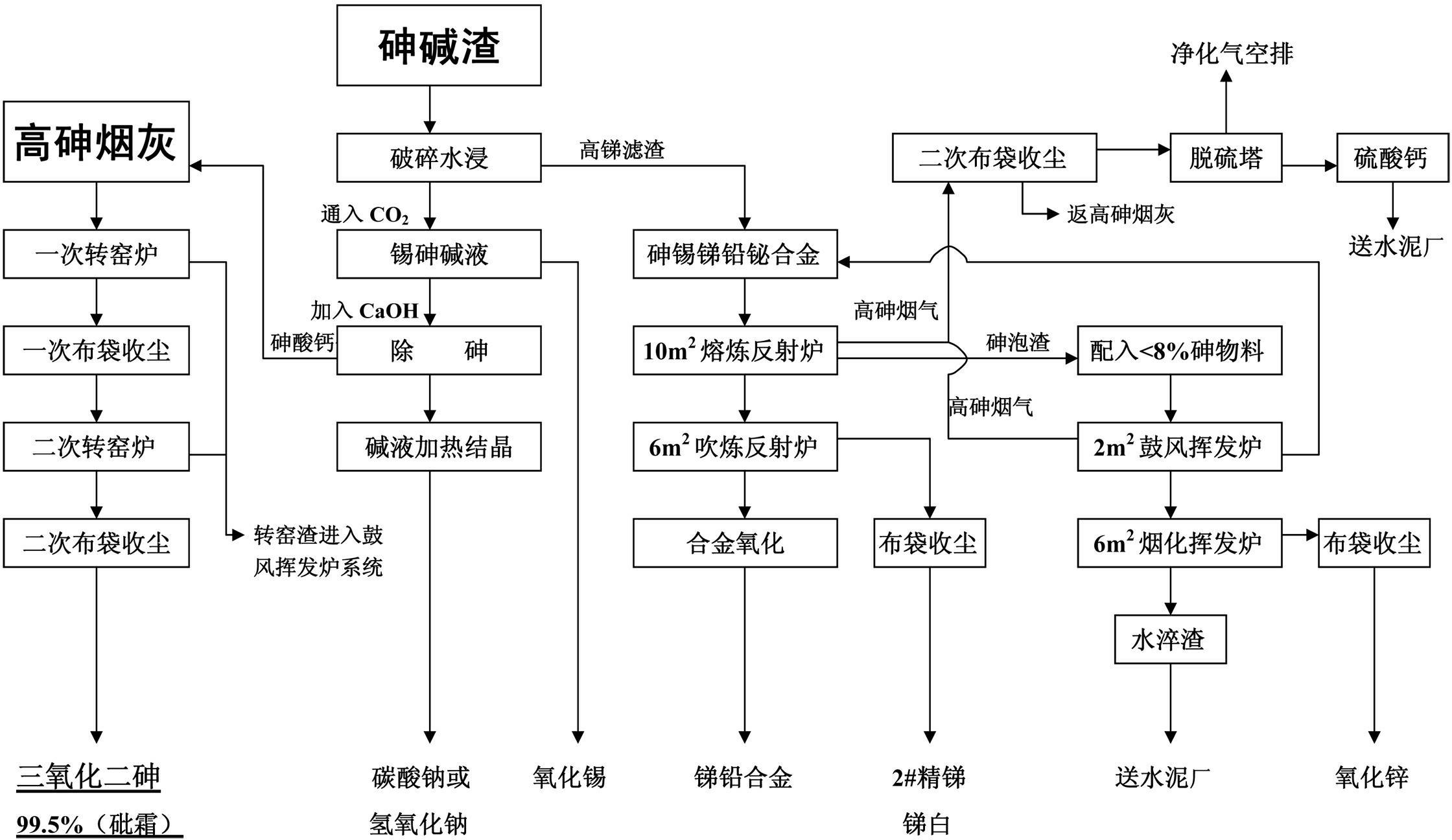

A comprehensive recovery method for complex arsenic-containing and valuable metal slag dust materials

ActiveCN102286665ANo pollutionCement productionProcess efficiency improvementRecovery methodTin dioxide

Disclosed is a comprehensive recovery method for a complex material containing arsenic and valuable metal slags, comprising passing the materials containing arsenic through a primary rotating kiln to volatilize the arsenic, and through a secondary rotating kiln to purify the arsenic, so that an arsenic product containing 99.5% As 2 O 3 is produced; reduction smelting slags from the primary and secondary rotating kilns in a blowing volatilization furnace, with the resultant highly arsenious dust being returned to the primary rotating kiln for treatment, and the slags being used as a raw material in a cement manufactory and a raw material for zinc after undergoing strongly reductive dearsenization and volatilization of zinc in a fuming furnace; the resultant alloy containing arsenic being subjected to basic oxidizing refinement, and the oxidized / refined alloy after dearsenizations containing Pb > 72%, Sb > 12%, As 2 O 3 <0.02%, being sold as a lead-antimony alloy; the basic slags from the refinement, containing As 2 O 3 10%-20%, being subjected to crushing, dissolution in base, and filtration, with the slags thereof being returned to a blowing volatilization furnace for treatment; precipitating tin from the basic solution containing tin and arsenic by blowing in CO 2 , with the filtered tin oxide being sold as a raw material for tin; adding Ca(OH) 2 into the basic filtrate containing arsenic to precipitate arsenic, returning the filtered slags of calcium arsenate to the primary rotating kiln for treatment, and evaporating the remaining basic solution to concentrate and recover the base.

Owner:LEIYANG YANXIN NON FERROUS METALS

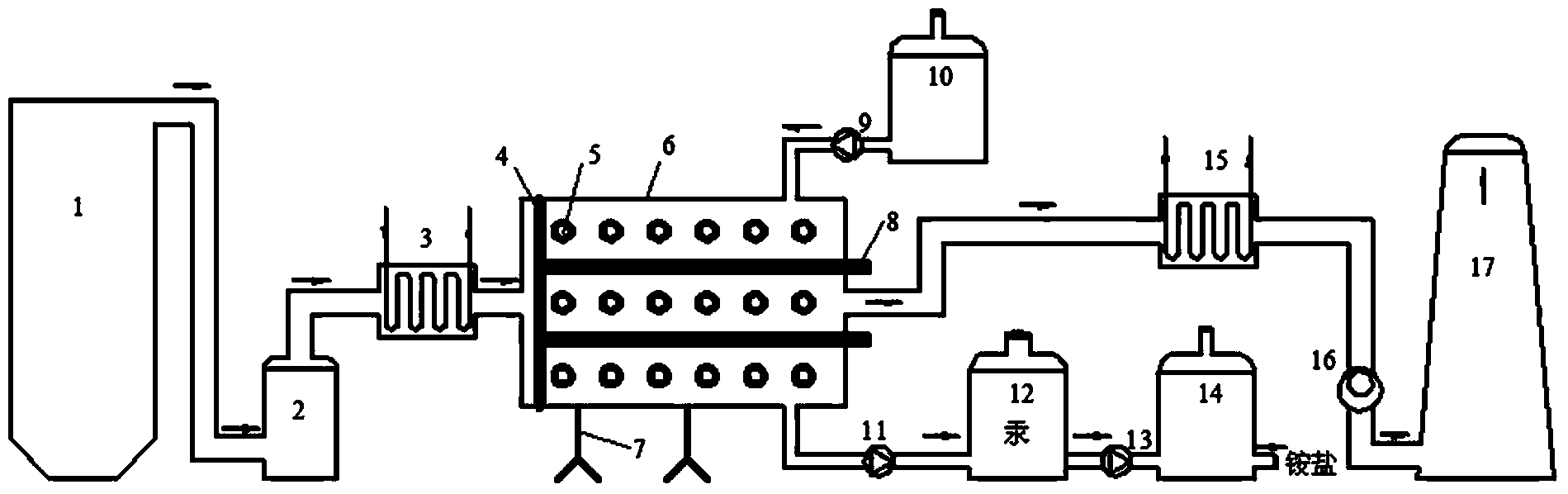

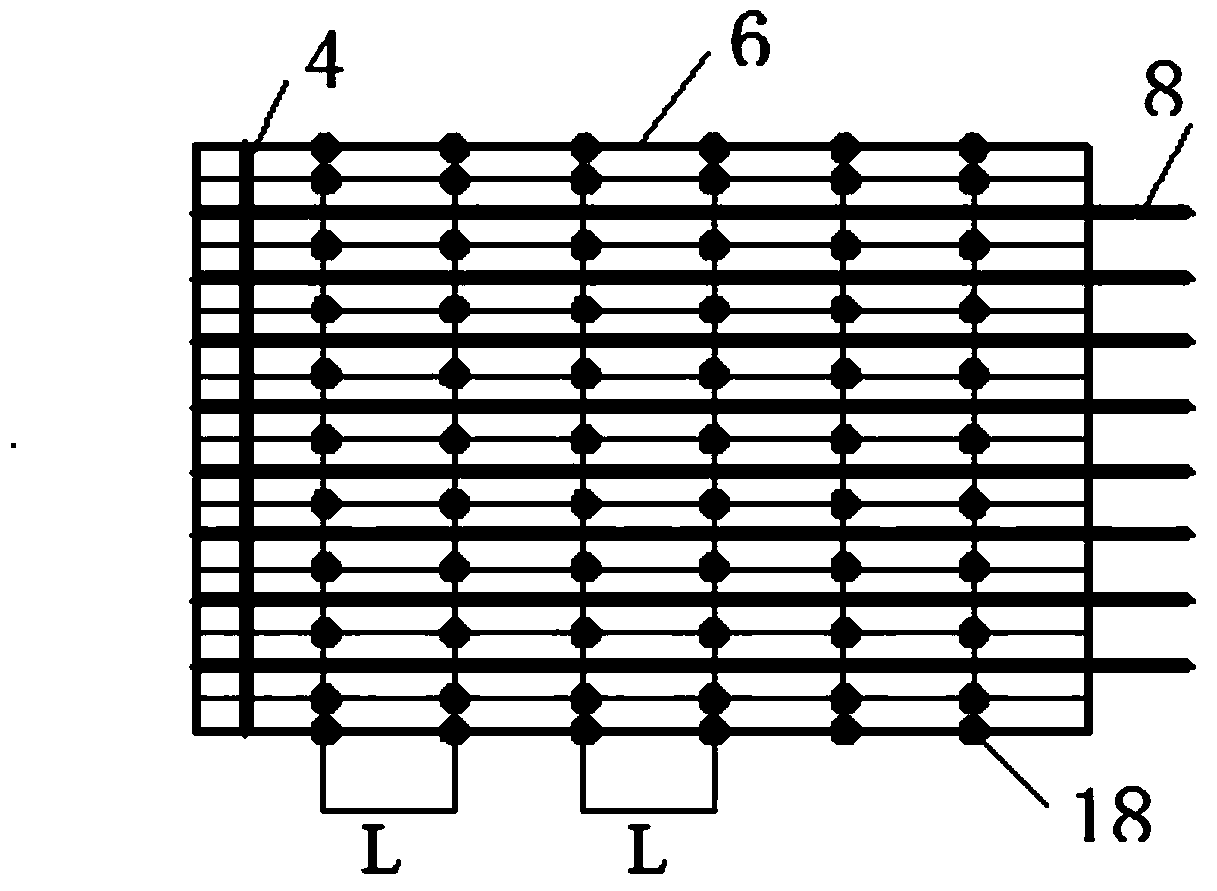

System and method for desulfurizing, denitrifying and removing mercury based on photoactivation ammonium persulfate

ActiveCN103638796ALow investment costLow running costDispersed particle separationAir quality improvementSulfate radicalsResource utilization

The invention discloses a system and a method for desulfurizing, denitrifying and removing mercury based on photoactivation ammonium persulfate. The system is mainly provided with a boiler or kiln, a deduster, a flue gas temperature regulator, a photochemistry reactor, a liquid spraying system as well as a byproduct post-processing system. Flue gas discharged from the boiler or kiln enters the photochemistry reactor arranged on a flue channel after being subjected to dedusting and temperature regulation, and an ammonium persulfate solution from the liquid spraying system is sprayed into the photochemistry reactor in a mist form; an UV (ultraviolet) lamp in the photochemistry reactor emits UV light to perform catalytic decomposition on ammonium persulfate, releases sulfate radical free radicals with high oxidizing property (SO4-.), and meanwhile oxidizes and removes SO2, NOx and mercury in the flue gas. Oxidized products are subjected to resource utilization after being processed by the byproduct post-processing system. The method has the prominent advantages that the method can be used for removing multiple pollutants in coal burned flue gas synchronously, has no secondary pollution during removing, and can be used for transforming aging units and the like, and the system is a novel flue gas purifying system with a wide application prospect.

Owner:JIANGSU UNIV

Fully automatic jproduction line for building block of heat retaining building mould for polyphenylene concrete

ActiveCN1695912AReasonable layoutOptimize layoutDischarging arrangementProduction lineControl system

A full-automatic production line for the insulating building blocks made of polyphenylene concrete is composed of raw materials proportioning stirrer, shaping machine, pallet supplying unit, two program-controlled kiln cars, curing kilm consisting of precuring kiln for the moulds of building block and curing kiln for building blocks, demoulding unit, mould pushing unit, pallet-building block separator, stacking system, two pallet-raising unit, two pallet-lowering unit and control system.

Owner:XIAN SILVER HORSE IND DEV CO LTDRIAL DEV CO LTD

Production method of imitated natural marble polished glazed brick

The invention provides a production method of an imitated natural marble polished glazed brick. The method comprises the following steps: 1, mixing a widely-known rough body raw material with a pigment, and granulating the obtained mixture to obtain granular colored powder; 2, mixing and distributing the colored powder and the widely-known rough body powder, and carrying out stamping forming to make a green ceramic brick wholly having finishing texture; 3, applying a transparent glaze to the green brick obtained in step 2; and 4, adding the glazed green brick to a kiln, sintering the glazed green brick, and polishing the sintered brick to obtain the imitated natural marble polished glazed brick. The production method of the imitated natural marble polished glazed brick allows the green brick with a whole texture effect to be formed through mixing the widely-known green body raw material with the pigment to prepare slurry, granulating the slurry to obtain the granular colored powder, and mixing and distributing the colored powder and the rough body raw material, and allows the texture of the cross section of the produced polished glazed brick to be same to that of natural stones.

Owner:FOSHAN DONGPENG CERAMIC +3

Thermal-shock-resistant corundum-spinel refractory castable and preparation method thereof

The invention discloses thermal-shock-resistant corundum-spinel refractory castable which comprises the following raw materials in percentage by weight: 65-80% of corundum particles and fine powder, 3-10% of aluminum oxide fine powder, 2-8% of materials containing Zr, 10-15% of magnesium-aluminum spinel fine powder, 3-8% of bonding agent, 0.05-0.1% of organic fiber (additional) and 0.2-0.6% of water reducing agent (additional). The preparation method of the corundum-spinel refractory castable comprises the following process steps of burdening, mixing, molding, maintaining, drying, storage and transportation, using and the like. Compared with the prior art, the thermal-shock-resistant corundum-spinel refractory castable provided by the invention has high thermal-shock-resistant property, and favorable high-temperature resistance and anti-erosion capability, and is suitable for steel ladles, intermediate ladles, RH (relative humidity) immersion tubes, cement high-temperature kilns and the like.

Owner:LUOYANG LIER REFRACTORY MATERIAL +2

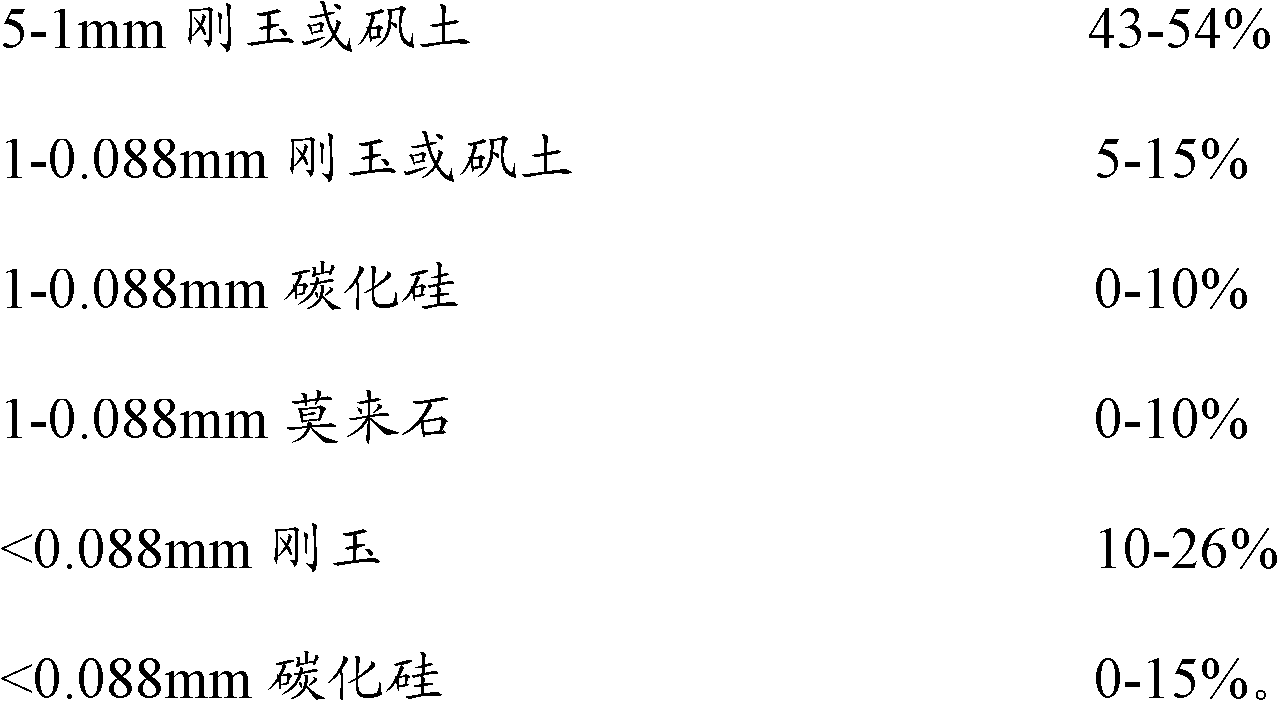

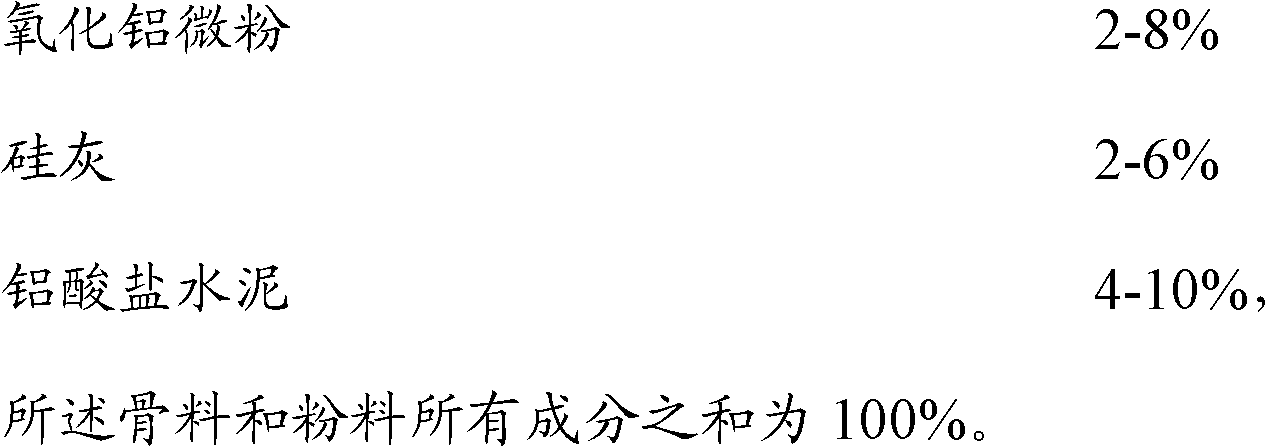

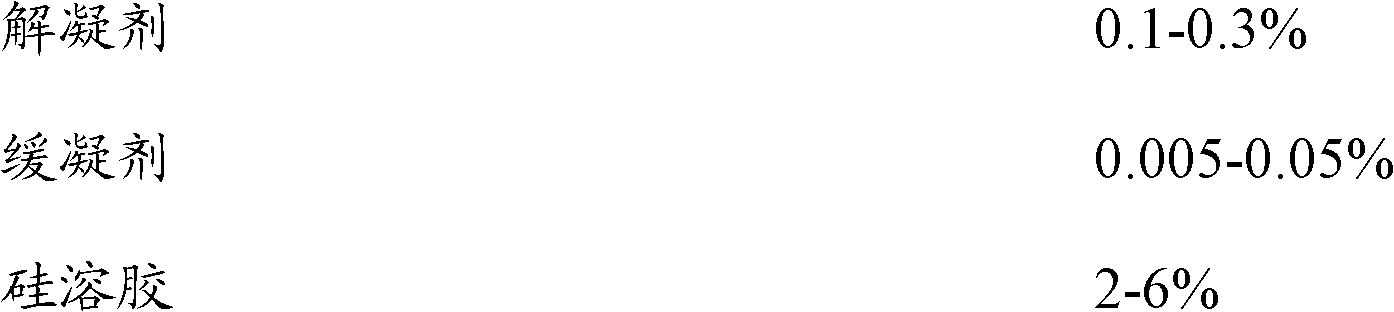

Composite bonding low-temperature constructional castable refractory

The invention relates to a composite bonding low-temperature constructional castable refractory, which can be used for high-temperature kiln engineering. According to the castable refractory, corundum, alumina, mullite and silicon carbide are used as an aggregate, silica sol is used as a bonding agent, aluminate cement is used as a curing agent and a bonding aid, and alumina micro powder, wollastonite, a deflocculant, a retarder, water and the like are added. The composite bonding low-temperature constructional castable refractory has high low-temperature constructional performance, high performance of high-temperature resistance, erosion resistance, thermal shock resistance and high mechanical performance, and meets the requirements of overhauling in winter on the premise that the service life of the castable refractory is not influenced.

Owner:ANHUI RUITAI NEW MATERIALS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com