Fast baking process of environment protecting water and air permeable brick in roller kiln

A water-permeable, air-permeable, production process technology, applied in the production process field of using roller kiln to quickly fire environmentally friendly water-permeable and air-permeable bricks, can solve problems such as refractory material corrosion, and achieve the effects of preventing irradiation, maintaining stability, and increasing humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with embodiment:

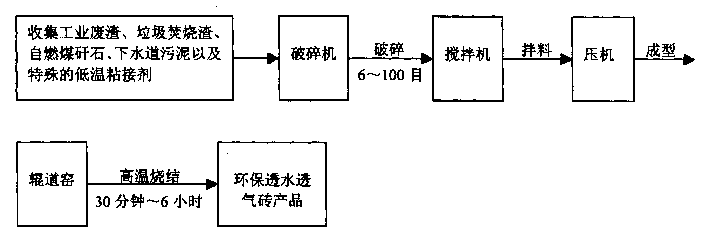

[0032] The production process of using roller kiln to quickly fire environmentally friendly permeable and breathable bricks includes:

[0033] (1) It is made of waste ceramics, refractory materials, clay, slag and other industrial waste residues, spontaneous combustion coal gangue, garbage incineration residue, urban sewer sludge, waste plastics, wood chips, bamboo chips and the following raw materials with the following weight ratios. Low Temperature Adhesives:

[0034] Modified starch 5~30 Modified dextrin 5~30 Wood chips (bamboo chips) 10~40

[0035] Hydroxymethylcellulose 10~50 PE 5~10 PVC 6~20 Polyvinyl alcohol 5~10

[0036] Or make a special low-temperature adhesive by mixing the raw materials in the following weight ratio

[0037] Water glass 2~30 Sodium glass 5~30 Soda ash 2~15

[0038] Feldspar 5~60 Pegmatite Granite 5~60 Iron Slag 5~50

[0039] The low-temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com