Patents

Literature

50 results about "Pegmatite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A pegmatite is an igneous rock, formed underground, with interlocking crystals usually larger than 2.5 cm in size (1 in). Most pegmatites are found in sheets of rock (dikes and veins) near large masses of igneous rocks called batholiths.

Selective flotation collector for spodumene and application thereof

ActiveCN102921559AGood water solubilityImprove diffusivityDifferential sedimentationSolubilityHydroxylamine Hydrochloride

The invention discloses a selective flotation collector for spodumene and an application thereof. The collector is formed by performing saponification reaction on industrial fatty acid, hydroxylamine compounds and inorganic base in a mass ratio of (65-85%): (5-15%): (10-20%). The collector is suitable for being used at an ore pulp temperature of 10-25 DEG C, the dosage of the collector ranges from 100 to 600 g / t according to the change of the mineral content of spodumene in ores (or the difference of the contents of LiO2 in ores), and the collector is suitable for selectively floating and recovering spodumene from pegmatite ore. The principle that the collector plays a role of selective flotation on spodumene lies in that the oxy-oximido groups of the hydroxylamine compounds in the collector play a role of selective chelation on the active sites of aluminium, lithium and the like which are exposed on the surface of spodumene, thus enhancing the selective collection of the fatty acid components for spodumene ores. Via the saponification reaction, the water-solubility of the collector and the dispersivity of the collector in ore pulps are enhanced, so that the acting effect of the collector is improved.

Owner:CENT SOUTH UNIV

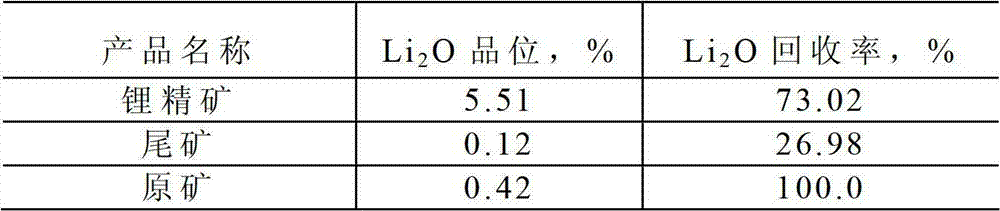

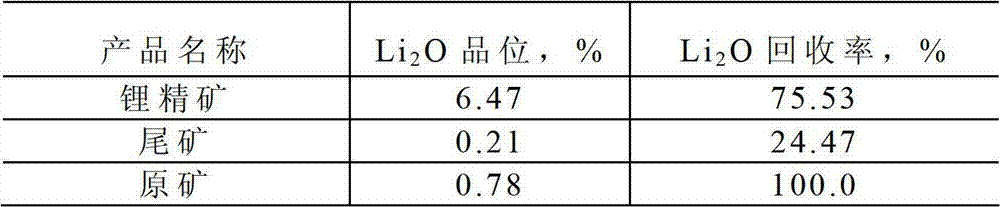

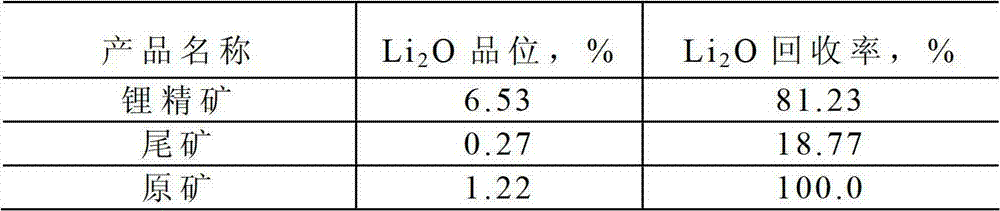

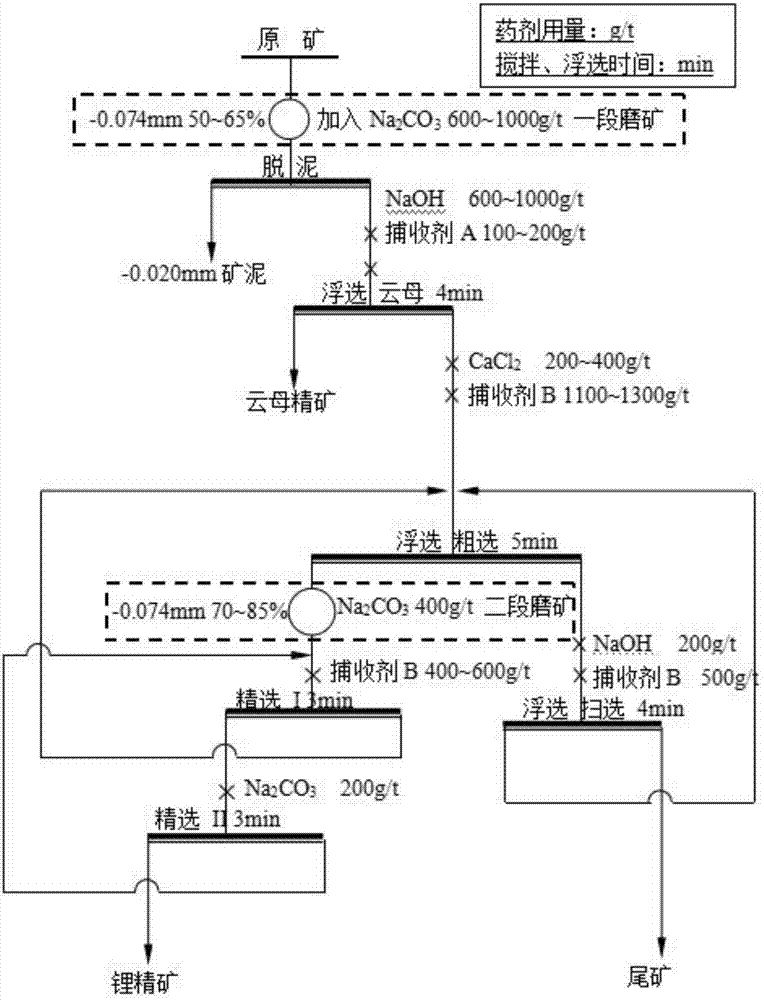

Efficient flotation method for pegmatite type spodumene

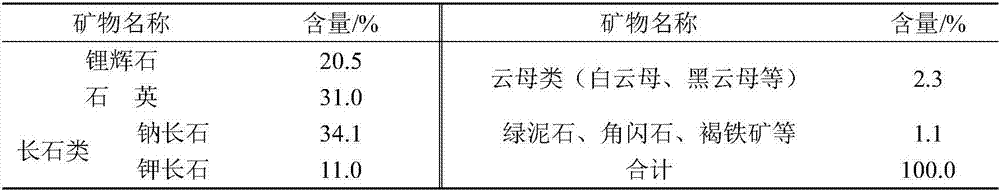

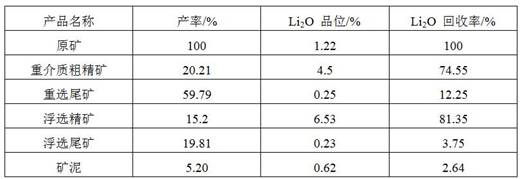

The invention provides an efficient flotation method for pegmatite type spodumene and belongs to the technical field of beneficiation engineering. A two-stage ore grinding flotation method is adopted; after the first stage of ore grinding is conducted, desliming, mica flotation and spodumene roughing work are conducted; and in the second stage of ore grinding, rough concentrates obtained after spodumene roughing is ground again, the regrinding amount is small, and ore grinding electric consumption and cost are greatly saved. On the base, a collecting agent adopted during mica flotation is a mixed collecting agent composed of lauryl amine and naphthenic soap, and a collecting agent adopted during lithium coarse ore flotation is a mixed collecting agent composed of lauryl amine and oxidized paraffin soap. The grade of Li2O obtained through the method can reach 6.20%, and the recovery rate can reach 87.34%. By means of the method, high-grade lithium concentrates can be obtained, in addition, the good recovery rate is achieved, meanwhile, the dosage of a flotation reagent is small, the regrinding amount is small, only two times of selection operation are needed, and good technical effects and economic benefits are achieved.

Owner:SOUTHWEAT UNIV OF SCI & TECH

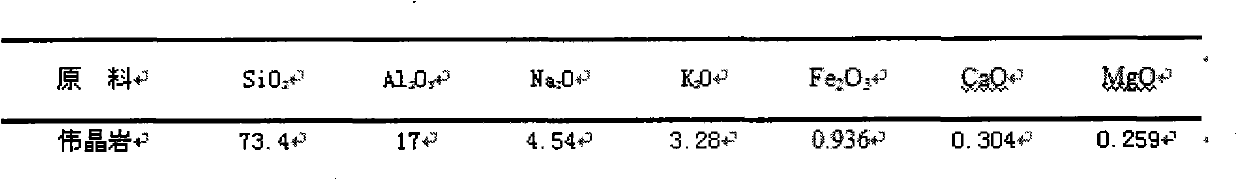

Process for burning porcelain by utilizing large ball clay as raw material

The invention provides a process for burning porcelain by utilizing large ball clay as a raw material. The large ball clay is also called halloysite, is efflorescence residue of plagioclase granite pegmatite and is original kaolin, and the chemical components of the large ball clay are close to theoretical values of kaolin. The process provided by the invention comprises the steps of making a briquette, biscuiting, glazing and burning. According to the process provided by the invention, certain properties of the large ball clay (also called halloysite clay) are utilized, the raw materials of the porcelain are selected, and the burning process is improved to further improve the whiteness and glossiness of the porcelain and reduce the chromatic aberration, a porcelain finished product made by the process provided by the invention is high in whiteness, good in glossiness, strong in transparency, smooth and tender in glaze, and green is doped in a white bottom, so that the porcelain can meet the aesthetic requirements of the modern on high grade porcelain.

Owner:湖南大球泥瓷艺集团有限公司

Anti-staining ceramic permeable floor tile for city roads

The invention discloses an anti-staining ceramic permeable floor tile for city roads. The anti-staining ceramic permeable floor tile is prepared from the following raw materials in parts by weight: 40-43 parts of sludge from a sewage plant, 6-7 parts of rice hulls, 4-5 parts of feldspar powder, 10-12 parts of fly ash, 10-12 parts of water glass, 18-20 parts of pegmatite, 6-7 parts of quartz sand, 8-9 parts of silicon nitride, 3-4 parts of titanium dioxide, 5-6 parts of zirconium oxide, 4-5 parts of aluminum dihydrogen phosphate and 2-3 parts of pregelatinized starch. The floor tile disclosed by the invention is prepared by adding the components such as pegmatite, titanium dioxide and zirconium dioxide through a series of sintering processes, the compactness and porosity of the product are improved, and the product has high strength, bright and clean surface, high anti-staining property and good permeability and is suitable for gardens, playgrounds and city roads.

Owner:HEFEI ZHENGTUO DECORATION MATERIALS CO LTD

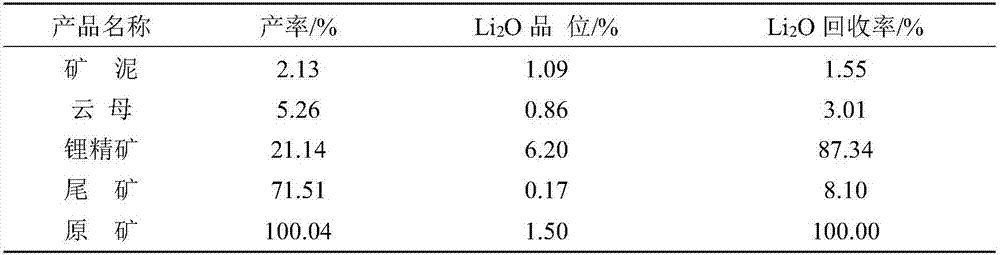

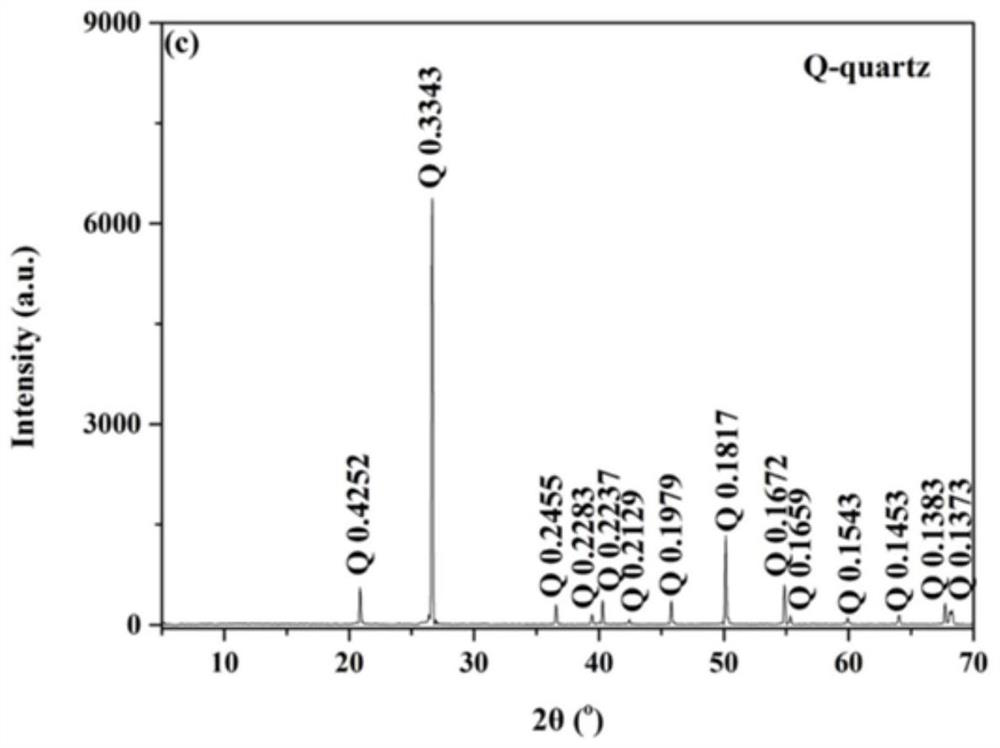

Method for preparing 4N high-purity quartz sand by taking pegmatite quartz as raw material

ActiveCN111874914AHigh purityImprove adsorption capacitySilicaFlotationHydrofluoric acidPregnant leach solution

The invention discloses a method for preparing 4N high-purity quartz sand by using pegmatite quartz as a raw material, and the method comprises the following steps: (1) crushing, grinding and screening pegmatite quartz raw ore to obtain pegmatite quartz powder; (2) adjusting the pegmatite quartz powder into ore pulp, adjusting the pH value of the ore pulp to 2-3, adding an anionic collecting agentinto the ore pulp, performing stirring, and then adding a cationic collecting agent for flotation treatment; (3) roasting the pegmatite quartz concentrate at 850-1,000 DEG C for 3-7 hours, and carrying out water quenching treatment on the pegmatite quartz concentrate after roasting is finished; (4) mixing the pegmatite quartz concentrate obtained after roasting and water quenching treatment withleachate, and performing hot-pressing leaching treatment, wherein the hot-pressing leaching temperature ranges from 220 DEG C to 250 DEG C, the hot-pressing leaching time ranges from 4 h to 8 h, and the leachate is a mixed solution of a sulfuric acid solution and a hydrofluoric acid solution. According to the method disclosed by the invention, the quartz sand with higher purity can be obtained, and the preparation process flow is simple.

Owner:WUHAN UNIV OF TECH

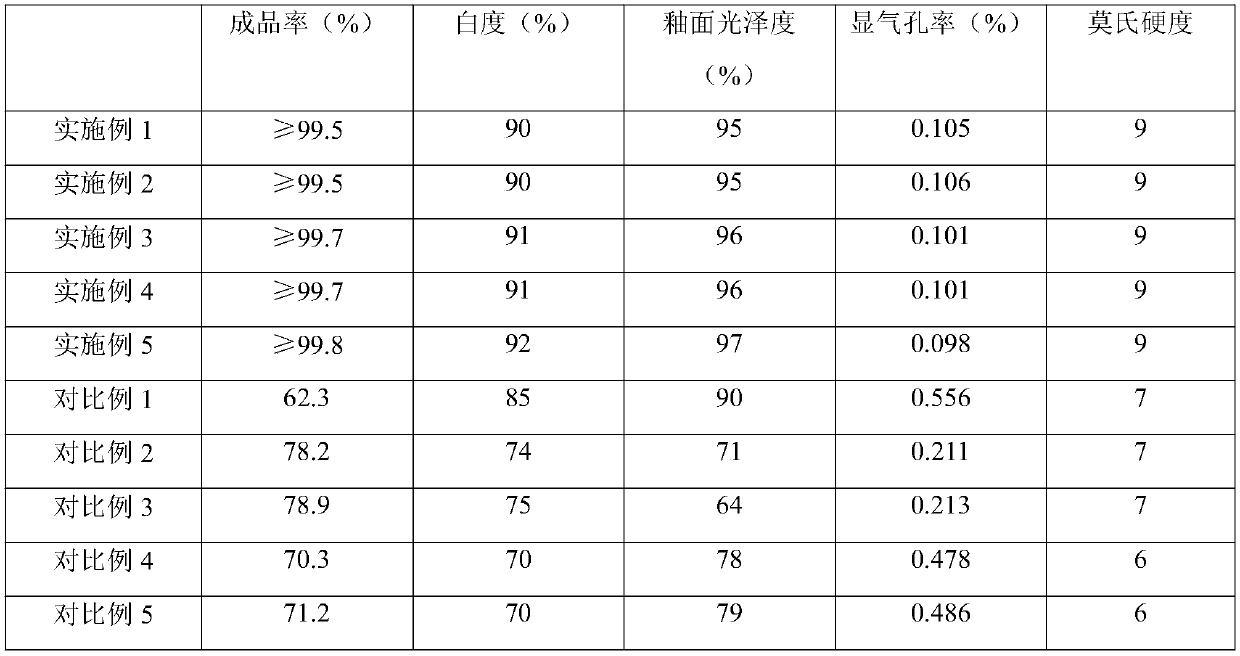

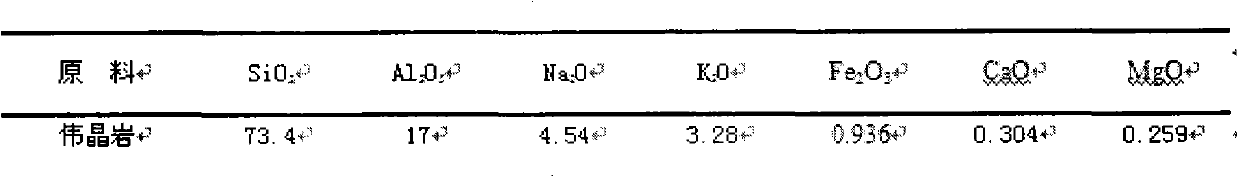

Porcelain formula and production technology

The invention provides a porcelain formula and a production technology. The porcelain formula comprises two parts including a blank material and a glaze material; the blank material is prepared from the following raw materials in parts by weight: 50 parts of sepiolite, 22 to 28 parts of Xuancheng stones, 21 to 25 parts of albite, 15 to 20 parts of soft kaolin, 13 to 17 parts of diatomite, 11 to 15parts of flint clay, 18 to 25 parts of talcum, 10 to 15 parts of calcite, 5 to 8 parts of agalmatolite, 5 to 8 parts of andalusite, 6 to 8 parts of ophiolite, 1 to 2 parts of pegmatite and 1 to 2 parts of bone charcoal; the glaze material is prepared from the following raw materials in parts by weight: 50 parts of SiO2, 20 to 25 parts of Si3N4, 20 to 25 parts of SiC, 31 to 35 parts of ZrO2, 18 to22 parts of K2ZrF6, 22 to 30 parts of CaCO3, 5 to 10 parts of alpha-Al2O3, 3 to 11 parts of B2O3, 5 to 8 parts of ZnO, 3 to 8 parts of BaO, 4 to 9 parts of Y2O3 and 4 to 8 parts of MgO. The porcelainformula provided by the invention has a high rate of finished products; obtained porcelain has the advantages of high whiteness, high glaze surface glossiness, low apparent porosity and high Mohs hardness.

Owner:潮州市雄美陶瓷实业有限公司

Porcelain material and production method thereof

A porcelain material is prepared from raw materials in percentage by mass as follows: 46%-60% of a pegmatite weathered material of Xuefeng Mountain, 5%-15% of high-quality kaolin I, 4%-10% of high-quality kaolin II, 25%-35% of high-quality potassium feldspar, 15%-25% of high-quality quartz, 3%-8% of high-quality talc and 2%-3% of a special-grade plasticizer. The production method of the porcelain material comprises steps as follows: the raw materials in percentage by mass are put in a ball grinding mill and ground until the fineness is 320 meshes and screen residues are 0.2%-0.3%; the raw materials are subjected to vacuum pugging, molding, fettling of a finished green body, biscuiting, polishing, glazing, biscuiting, internal glazing, color painting, glaze spraying, encastage and one-step firing for 16 h, then fire is stopped, a product is cooled to the room temperature, and porcelain is produced. A porcelain formula is improved, so that whiteness and glossiness of the porcelain are further improved, and aesthetic requirements of modern people for high-grade porcelain are met; the whiteness of a finished porcelain product is 90 degrees or higher, the glossiness is 85% or higher, the water absorption rate is lower than 0.1%, heat stability of the product is good, and defects of glaze cracking, bursting and the like during heat and cold exchange at the temperature from 180 DEG C to 20 DEG C are avoided.

Owner:张帅

Flotation collector solvent for recovering tantalum-niobium from granitic pegmatite tantalum-niobium ore and application thereof

The invention discloses a flotation collector solvent for recovering tantalum-niobium from granite pegmatite tantalum-niobium ore and application thereof. The flotation collector solvent comprises a main collector solvent hydroxamic acid compound and an auxiliary collector solvent TB, The mass ratio of the main collector solvent hydroxamic acid compound (in terms of the mass of the hydroxamic acid) to the auxiliary collector solvent TB (in terms of the mass of the fatty acid) is 1: (0.2-2). In the flotation collector solvent, the hydroxamic acid compound formed by the hydroxamic acid and the inorganic metal ion compound is used for replacing the traditional form of activating the inorganic metal ion and then adding the hydroxamic acid collector solvent, and the selectivity of the hydroxamic acid compound is better than that of the traditional form of activating the inorganic metal ion; the auxiliary collecting solvent TB which can generate synergistic action with the hydroxamic acid compound is added auxiliary, so that the flotation collector solvent can greatly improve the collecting capacity of the medicament and improve the flotation recovery rate of tantalum-niobium; Meanwhile,the auxiliary collector solvent TB with lower cost is added, so that the dosage of the hydroxamic acid can be greatly reduced, and the cost of the flotation reagent for recovering the tantalum -niobium from the granitic pegmatite tantalum -niobium ore is greatly reduced.

Owner:淄博特斯博新材料科技有限公司

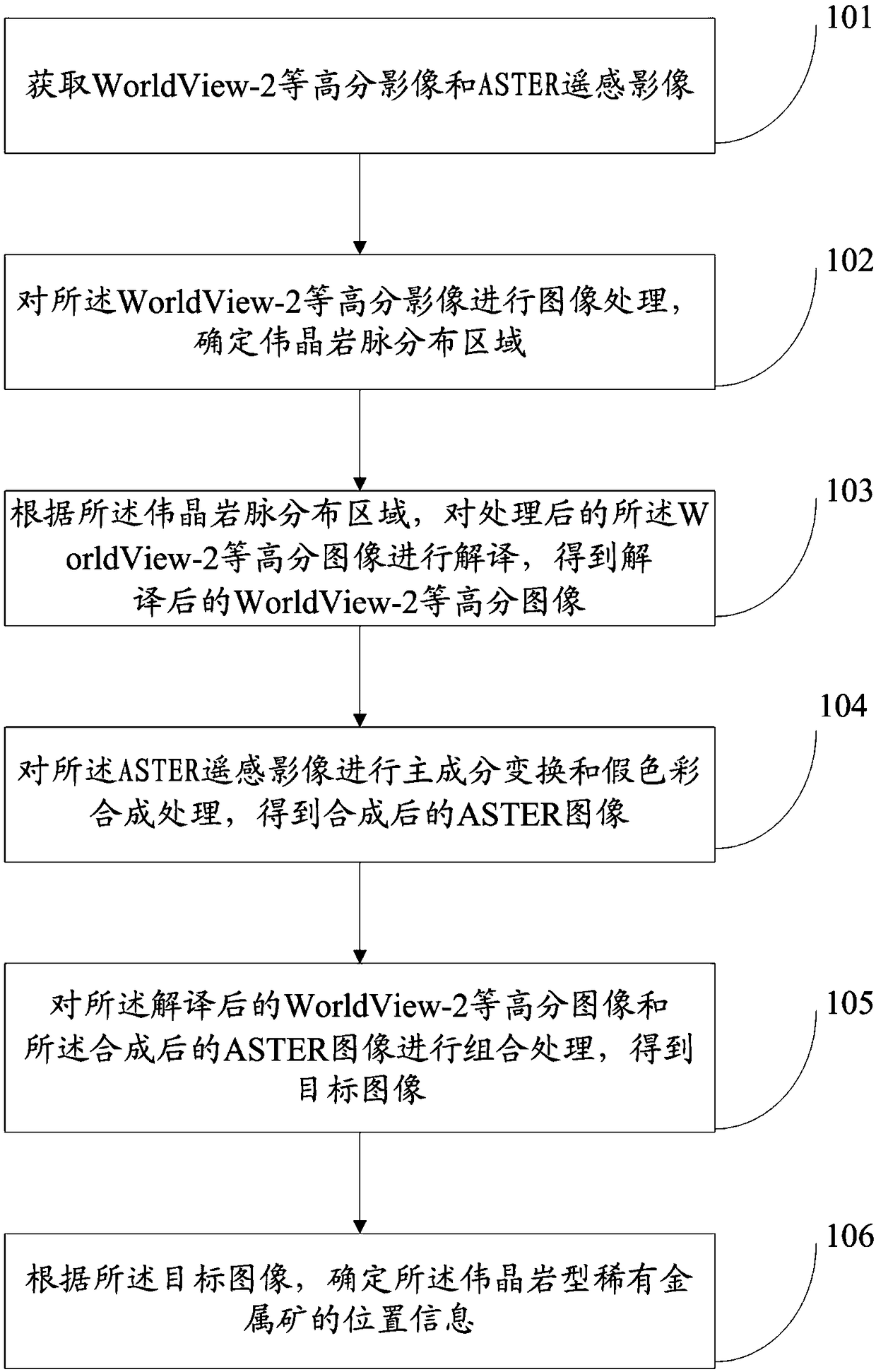

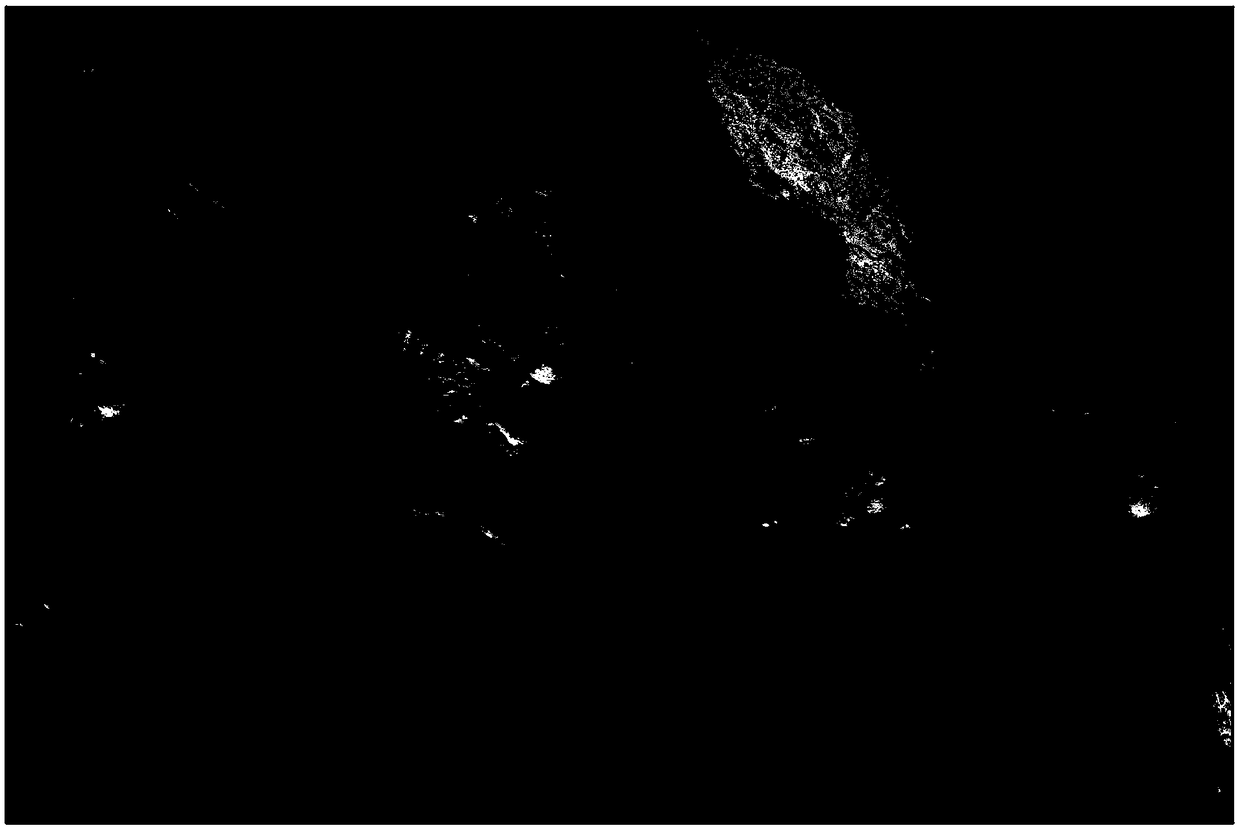

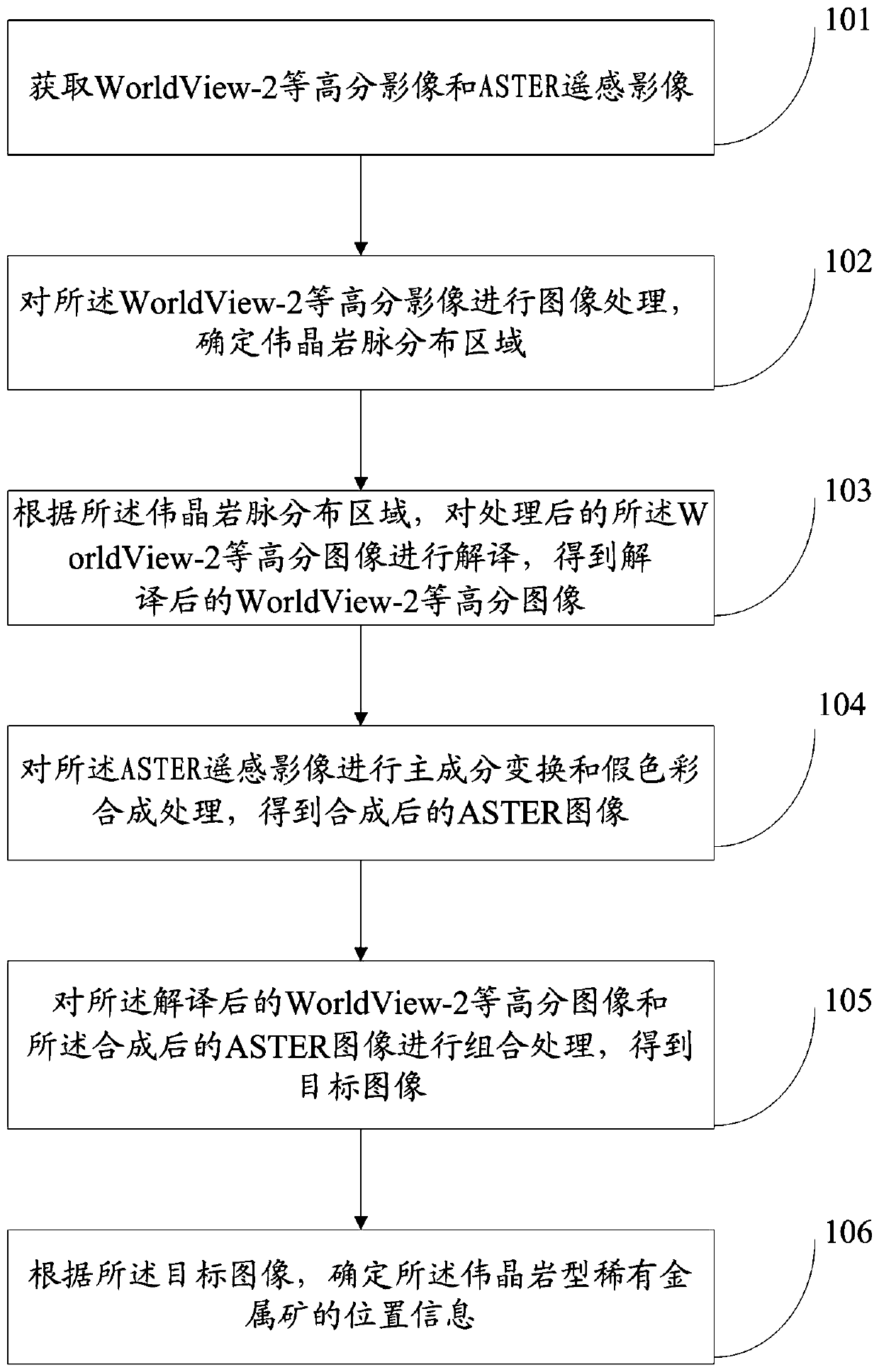

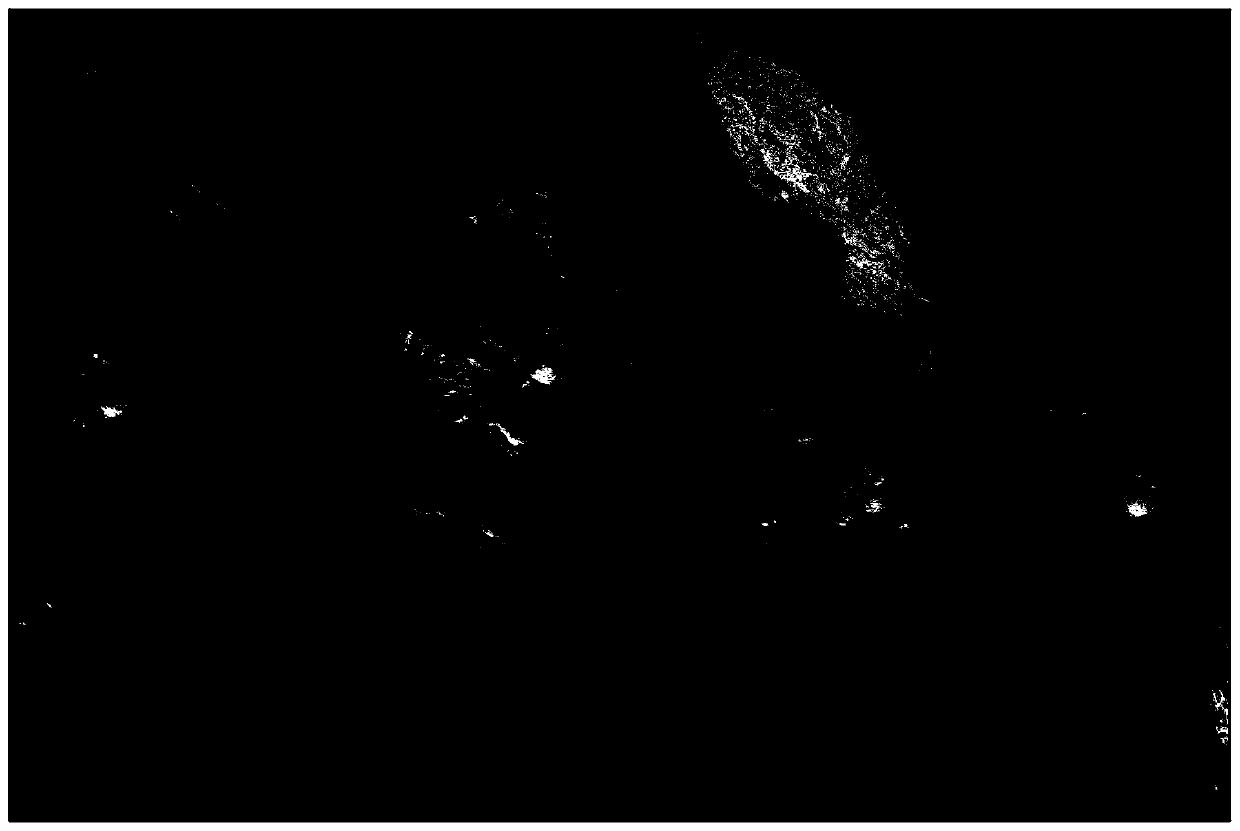

Identification method and system for pegmatite type rare metal ore

ActiveCN108181664AEfficient determinationQuick fixOptical prospectingScene recognitionImaging processingDark color

The invention discloses an identification method and system for pegmatite type rare metal ore. The method comprises: image processing is carried out on an obtained WorldView-2 equal-high-resolution image, a pegmatite vein distribution area is determined, and the processed WorldView-2 equal-high-resolution image is interpreted based on the pegmatite vein distribution area to obtain an interpreted WorldView-2 equal-high-resolution image; principal component transformation and fake color synthesis processing are carried out on an obtained ASTER remote sensing image to obtain a synthesized ASTER image, wherein the dark color area of the synthesized ASTER image is a distribution area of the pegmatite type rare metal ore; and the interpreted WorldView-2 equal-high-resolution image and the synthesized ASTER image are combined to determine location information of the pegmatite type rare metal ore. According to the identification method and system, the distribution area of the pegmatite is determined based on the WorldView-2 equal-high-resolution image; and the location information of the pegmatite type rare metal ore is determined efficiently, quickly, and accurately within short time by combining the ASTER remote sensing image for extraction of the ore-included area of the pegmatite rare-metallic ore.

Owner:XIAN CENT OF GEOLOGICAL SURVEY CGS

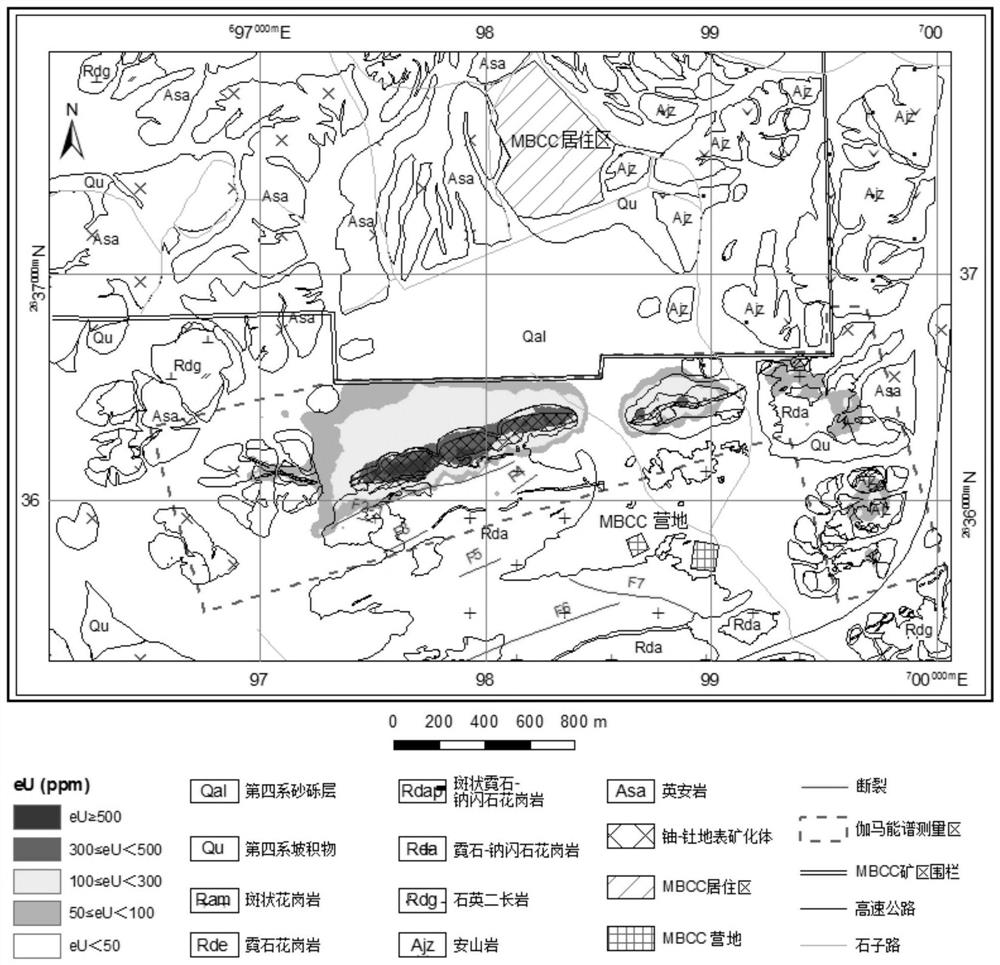

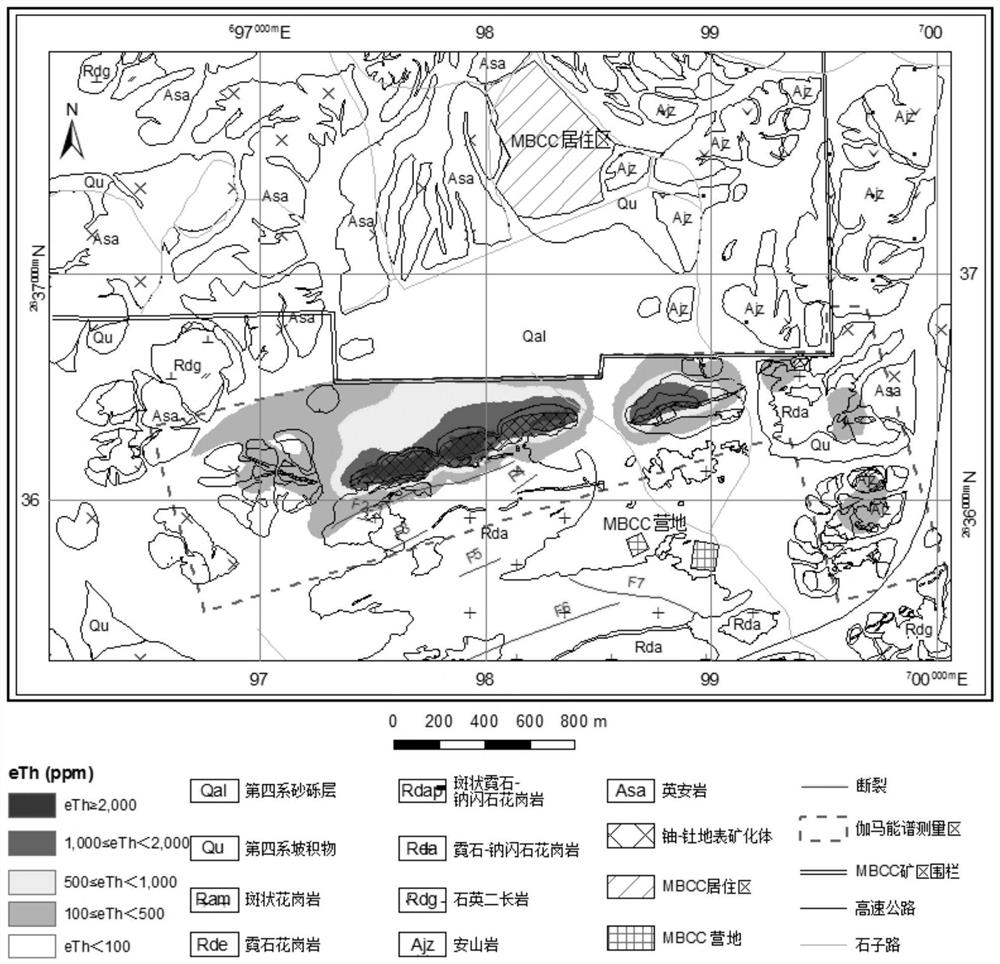

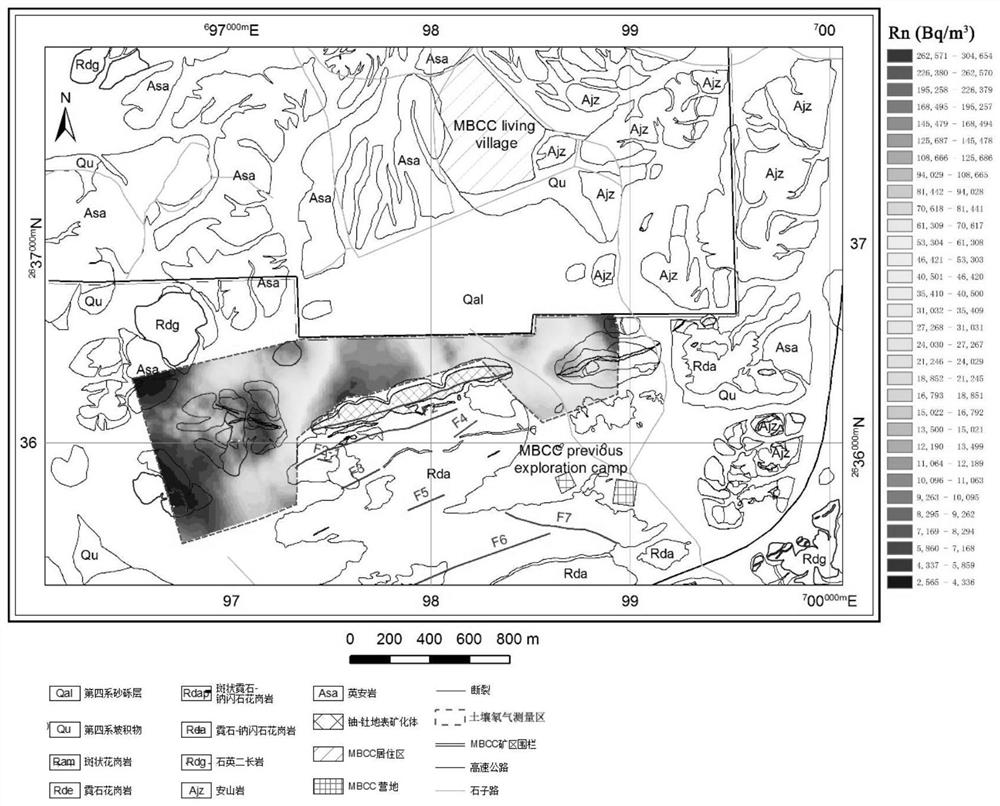

Method for predicting pegmatite type uranium and thorium resources related to alkaline magma

PendingCN114384605ASimplify the exploration processImprove the drilling rateGeological measurementsMagmaRadon gas

The invention belongs to the technical field of uranium and thorium mineral product prediction and evaluation, and particularly relates to a method for predicting pegmatite type uranium and thorium resources related to alkaline magma, which comprises the following steps: step (1), carrying out geological survey, and clarifying mineral control element characteristics; (2) carrying out surface energy spectrum measurement, and evaluating a surface mineralization distribution range; (3) soil radon gas measurement is carried out, and the deep mineralization abnormal range is evaluated; step (4), carrying out audio magnetotelluric profile measurement, and delineating an ore control structure range; and (5) multi-information superposition is carried out, and the deep uranium and thorium ore body is predicted and evaluated. According to the method, exploration is carried out on the basis of analysis of multivariate information such as geological ore control elements, the concealed ore body can be predicted more accurately, effectively and quickly, the prospecting efficiency is improved, and the exploration cost is reduced.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

Method for preparing flaky ground calcium carbonate powder

InactiveCN101514028AReduce manufacturing costImprove grinding effectCalcium/strontium/barium carbonatesCalciteBall mill

The invention relates to a method for preparing flaky ground calcium carbonate powder by dry process, which takes pegmatite calcite as raw material and comprises the following steps: (1) the raw material is crushed to be 5-10mm; (2) dry process grinding: the crushed raw material is ground by a horizontal ball mill, the grinding medium is a zirconium oxide rod which has the diameter of 30-50mm and the length of 60-100mm, and the grinding time is 40-60min; finally, the flaky ground calcium carbonate powder is obtained. The flaky ground calcium carbonate powder prepared by the invention has 92-96% of content with the grain diameter being smaller than 8mum, and the radius-thickness ratio of the flaky ground calcium carbonate powder is more than 4:1. The flaky ground calcium carbonate powder prepared by dry process can be obtained without drying, and the production cost is lower.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

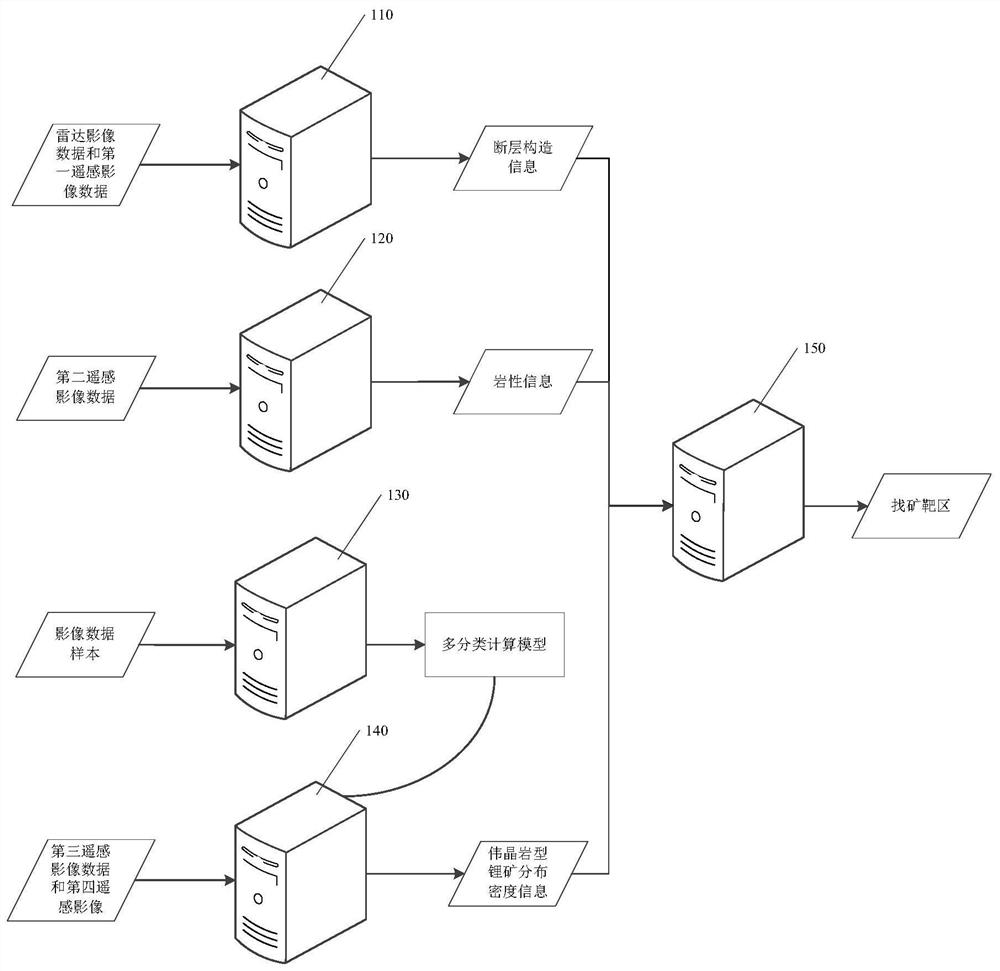

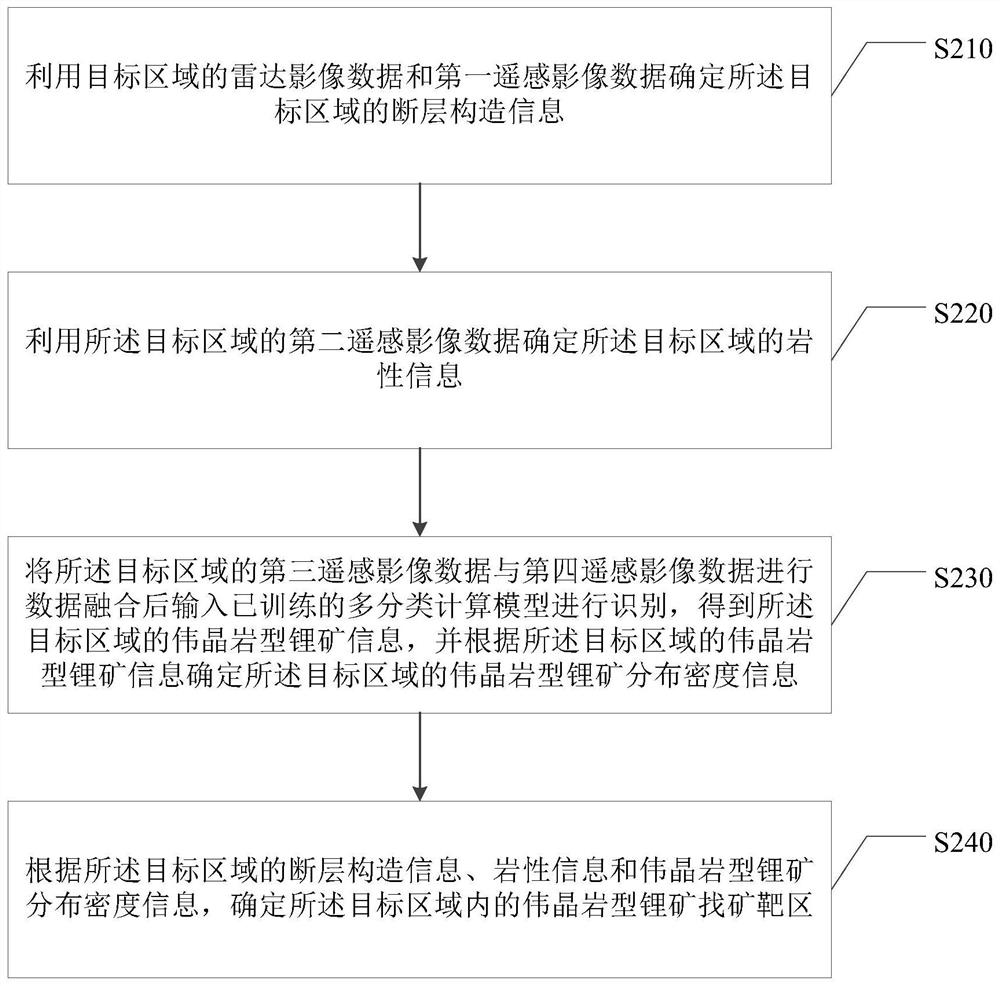

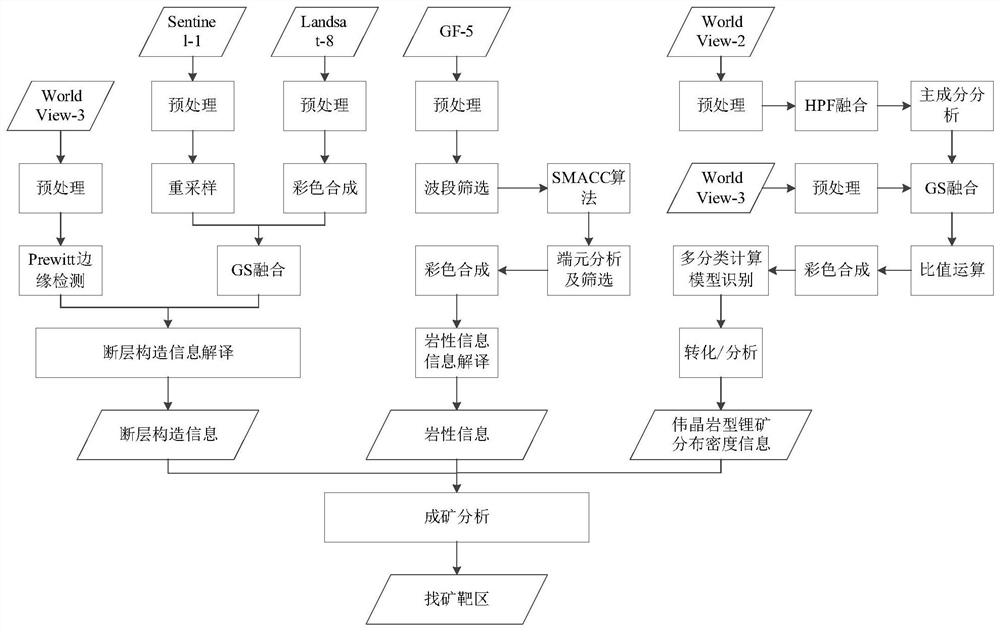

Prospecting method and device for pegmatite type lithium ore, computer equipment and medium

ActiveCN113625363AExact searchOvercome the difficulty of extracting and interpreting pegmatite turning stone informationCharacter and pattern recognitionGeological measurementsLithologyEngineering

The embodiment of the invention discloses a prospecting method and device for pegmatite type lithium ore, computer equipment and a medium. A specific embodiment of the method comprises the following steps: determining fault structure information of a target area by using radar image data and first remote sensing image data of the target area; determining lithology information of the target area by using the second remote sensing image data of the target area; the third remote sensing image data and the fourth remote sensing image data of the target area being subjected to data fusion and then input into a trained multi-classification calculation model for recognition, obtaining pegmatite type lithium ore information of the target area, and determining pegmatite type lithium ore distribution density information of the target area according to the pegmatite type lithium ore information of the target area; and according to the fault structure information, the lithology information and the pegmatite type lithium ore distribution density information of the target area, determining a pegmatite type lithium ore prospecting target area in the target area. According to the implementation mode, a powerful scientific basis can be provided for finding pegmatite type lithium ore more accurately and prospecting in the field.

Owner:INST OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

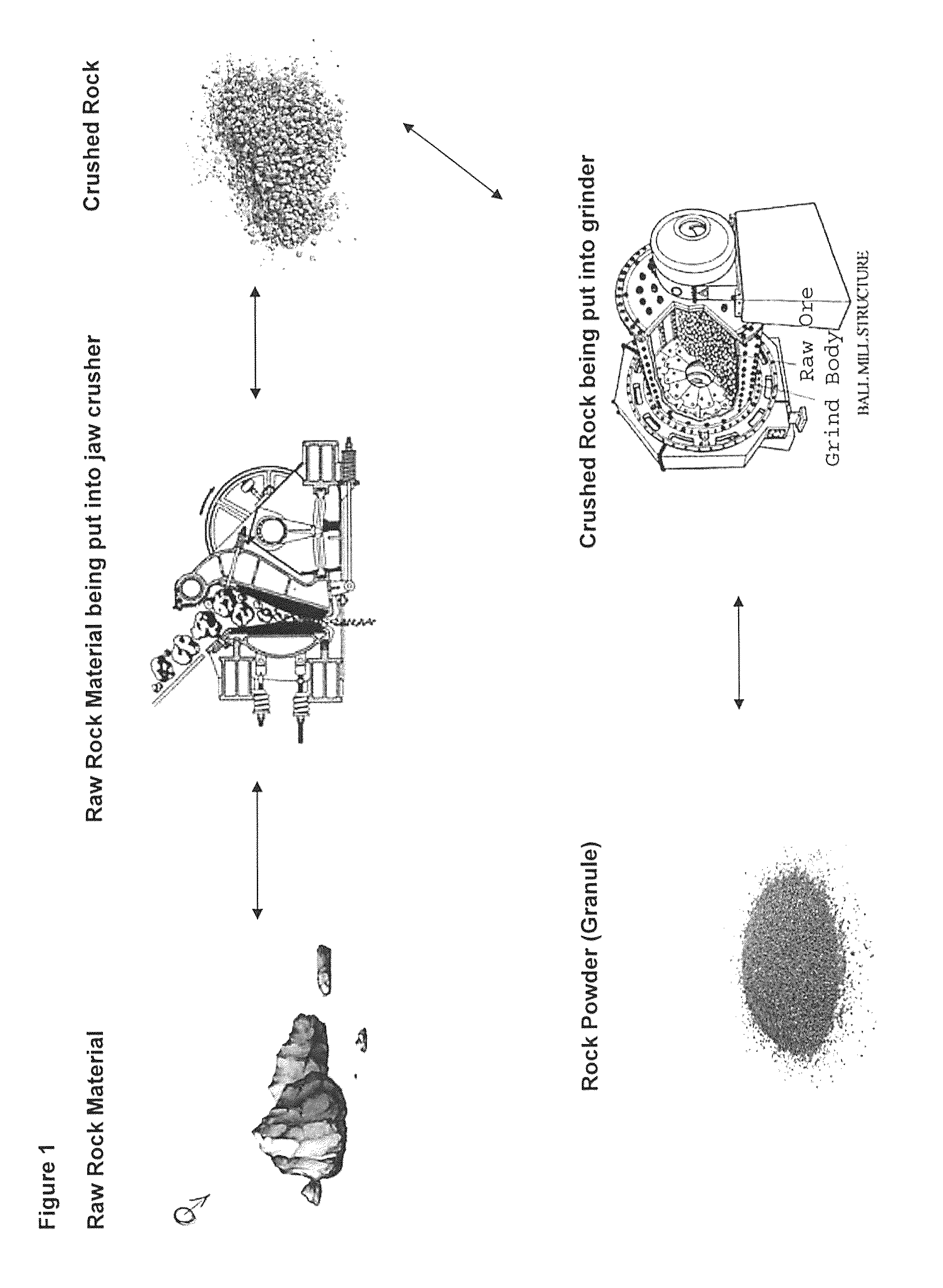

Mineral paper

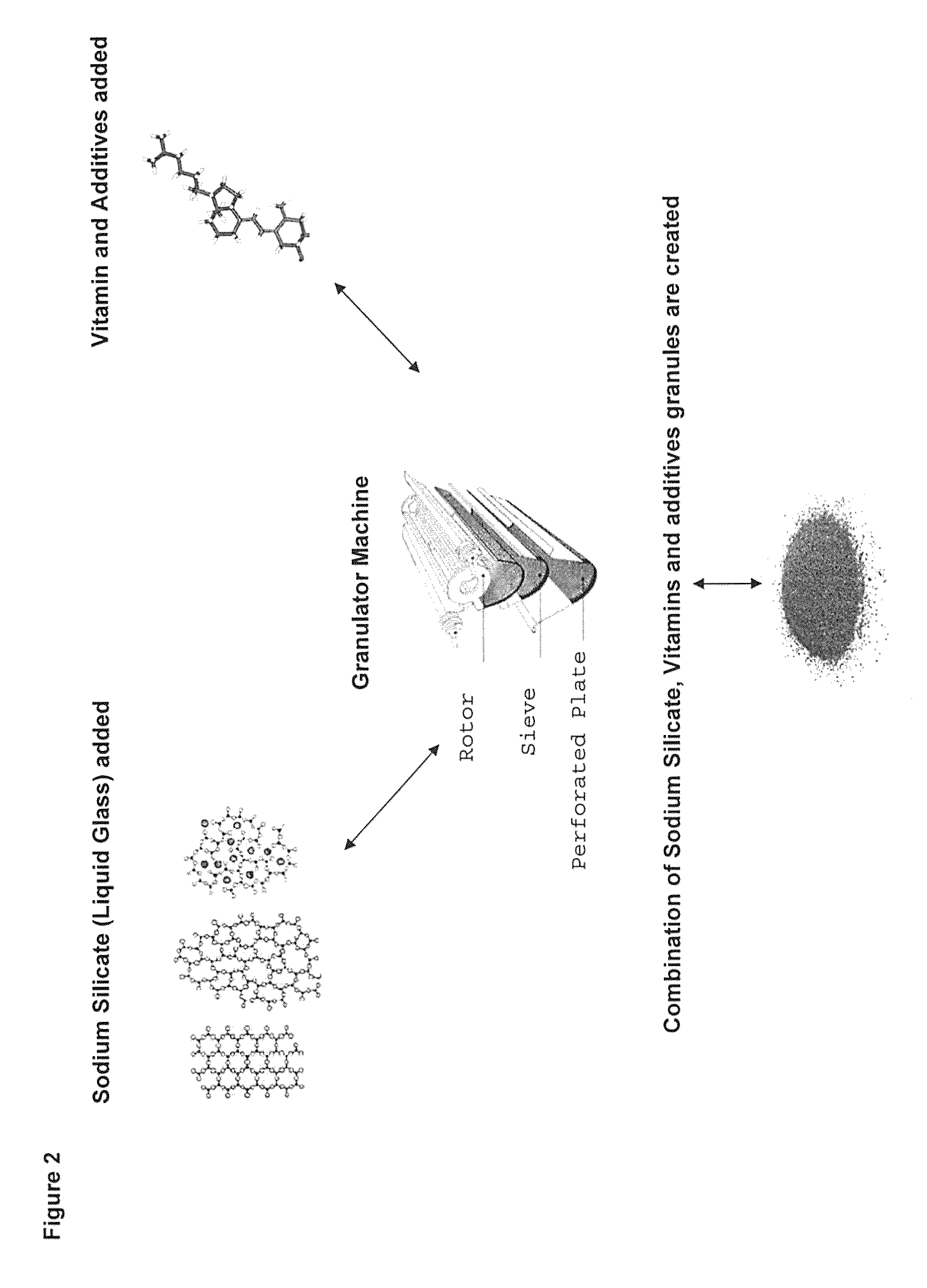

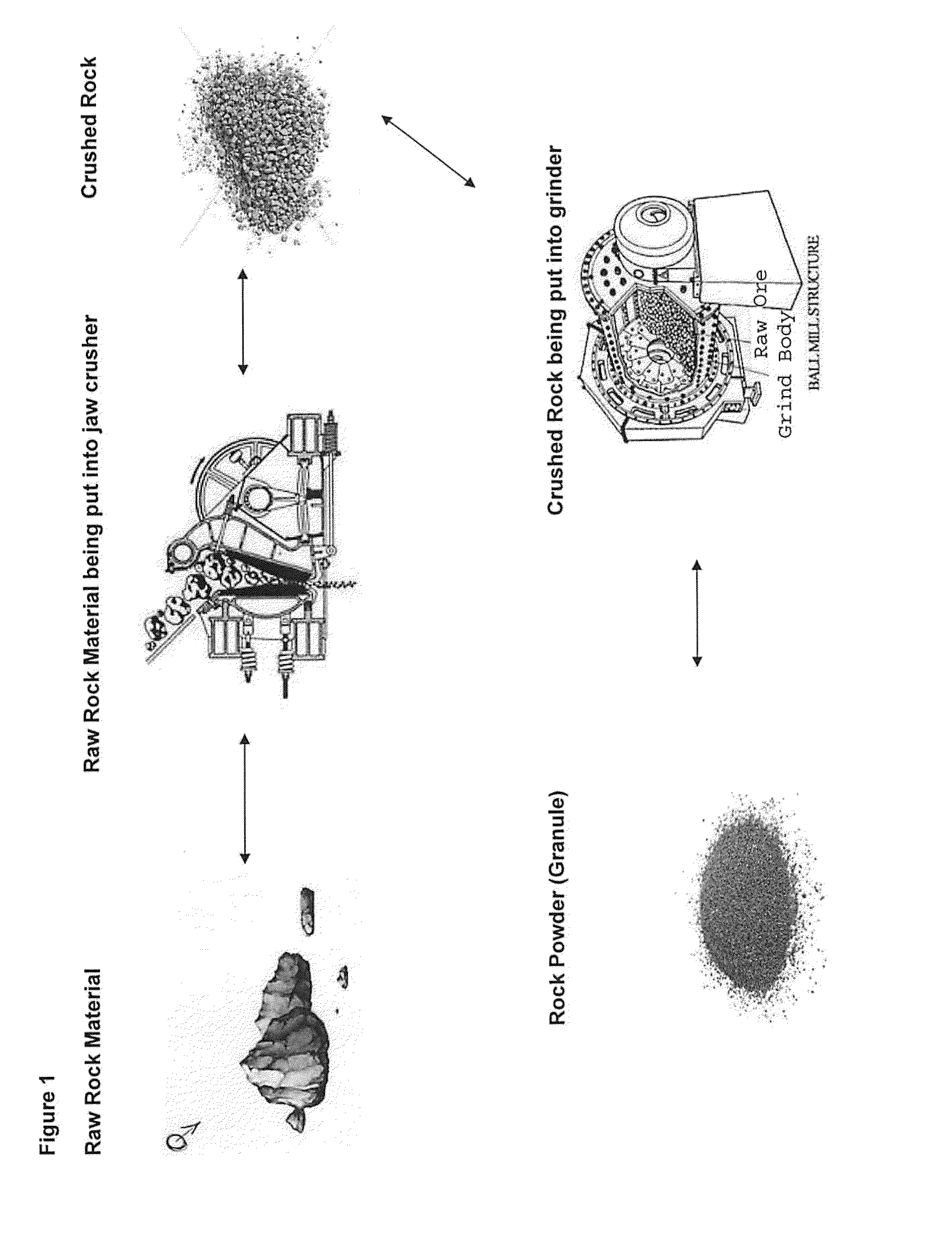

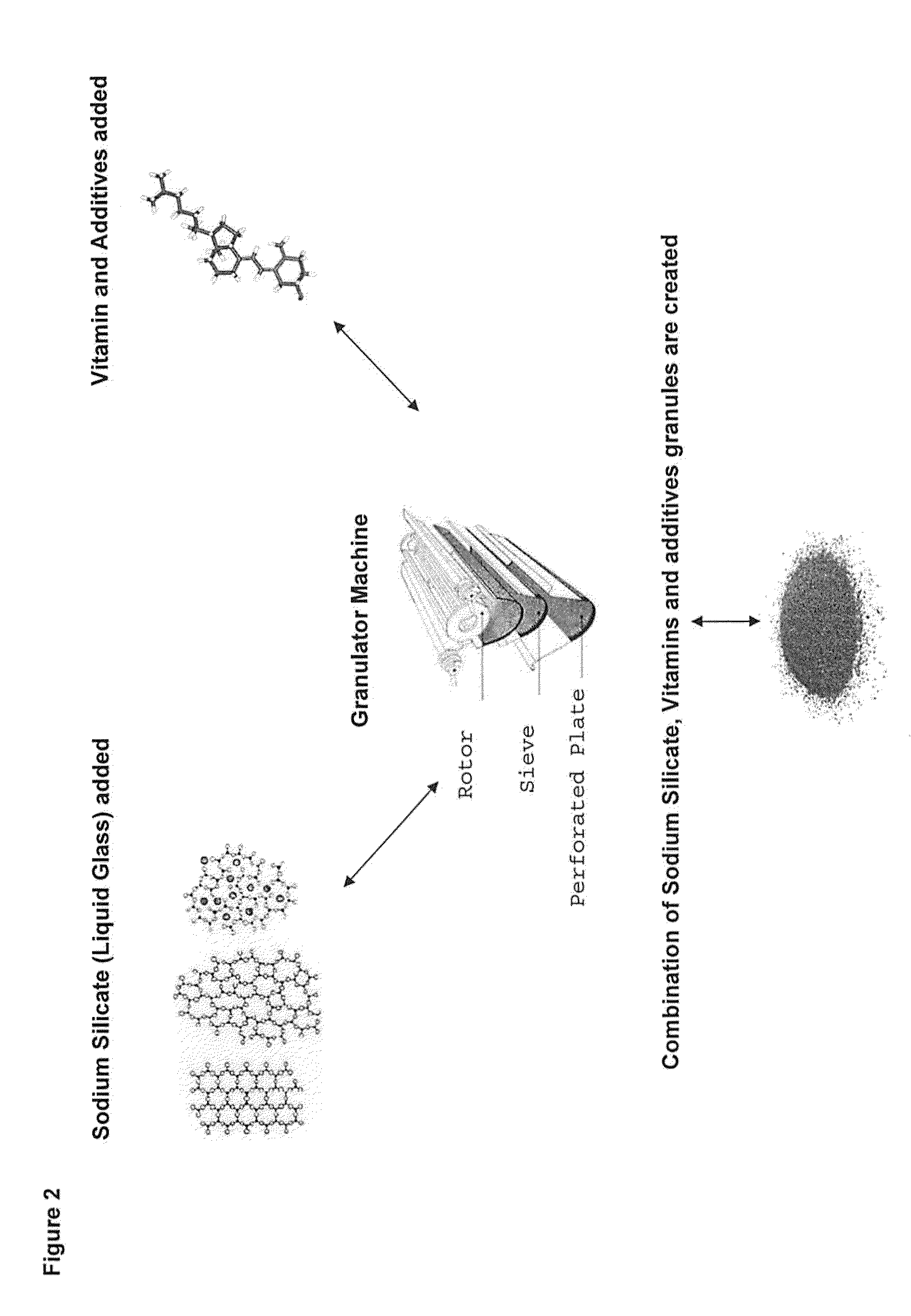

A process to manufacture a paper derived from minerals includes the steps of preparing a mineral preparation that includes 50% to 70% of total dry weight of rocks that have been crushed and ground into a powdery substance; combining the mineral preparation with a sodium silicate solution of total dry weight of 30% to 50%; and adding additives having a weight of 2% to 5% of a total dry weight. The powdery substance may have granules of about 0.05 mm to 0.08 mm in diameter and can be mixed with vitamin powder. The igneous rocks can be selected from the set of: dolostone, basalt, granite, gabbro, andesite, diorite, obsidian, pegmatite, peridotite, pumice, rylolite, and scoria. Sedimentary rocks can be selected from the set of: limestone, sandstone, conglomerate, shale, siltstone, brecca, gypsum, chert, travertine, flint, iron ore, rock salt, and oil shale.

Owner:NEW MILLENIUM

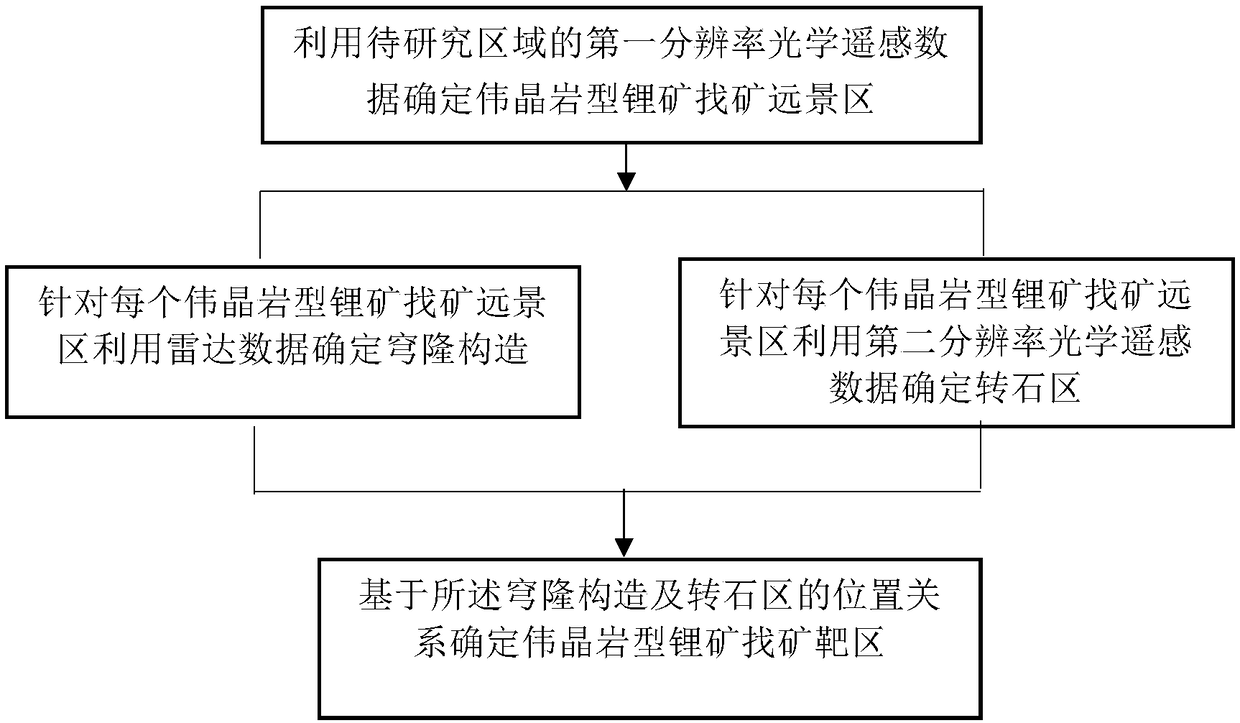

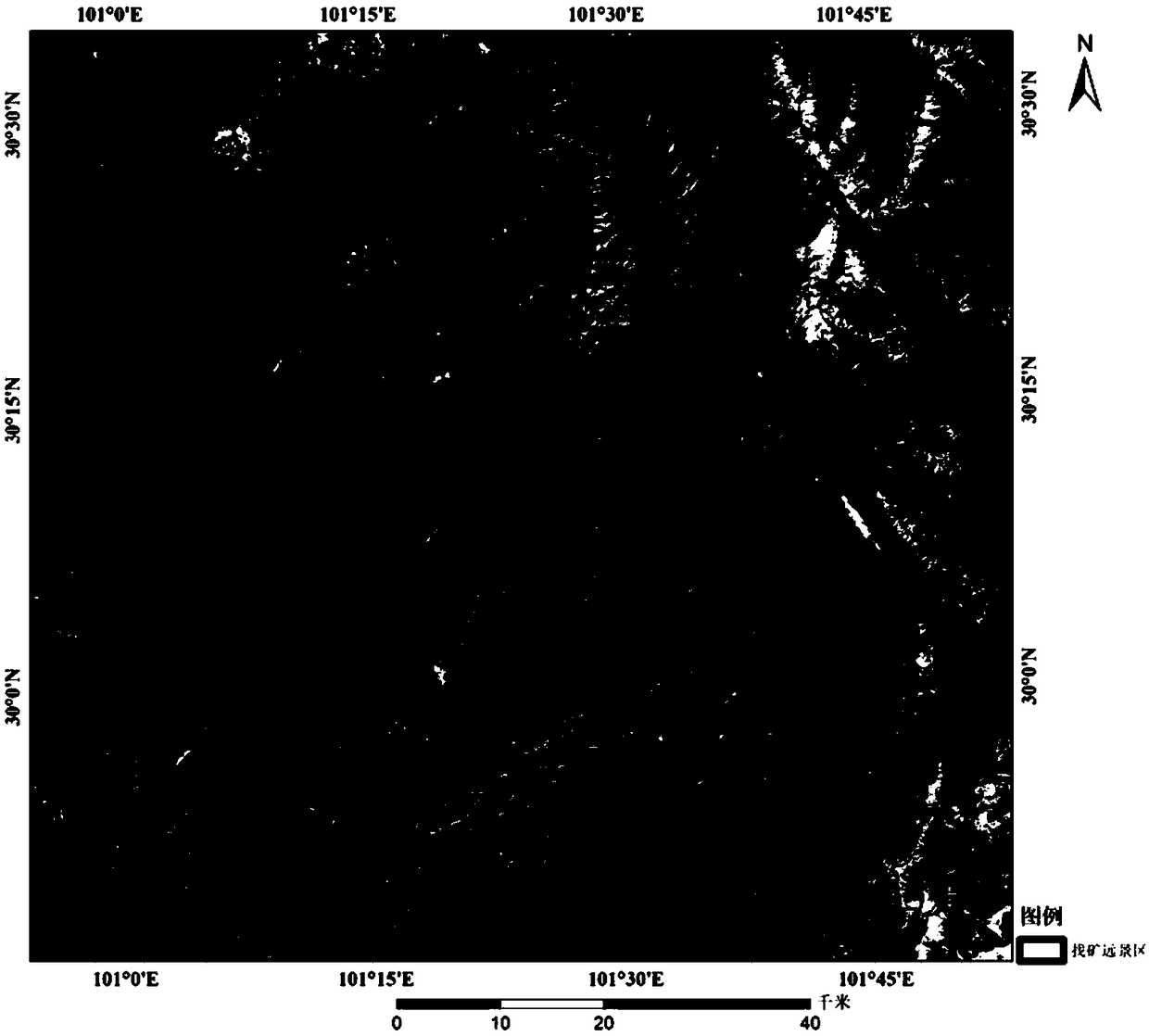

A pegmatite-type lithium ore prospecting method based on multi-source remote sensing data

ActiveCN109359621AFind faster and more accuratelyOvercoming difficulty in extracting and interpreting pegmatite turning stone informationScene recognitionSensing dataLithium

The invention discloses a pegmatite-type lithium ore prospecting method based on multi-source remote sensing data, which comprises the following steps: determining a prospecting prospect area of the pegmatite-type lithium ore by using the first resolution optical remote sensing data of an area to be studied; For each prospecting prospect area of pegmatite lithium deposit, the dome structure is determined by radar data and the rotating rock area is determined by optical remote sensing data with second resolution, and the second resolution is higher than the first resolution. The prospecting target area of pegmatite lithium deposit is determined based on the dome structure and the positional relationship of the rotating stone area. The invention utilizes relatively low-resolution first-resolution optical remote sensing data to determine a prospecting prospect area, The dome structure of each prospecting prospect area is then determined using radar data and the rotating rock area of eachprospecting prospect area is determined using relatively high resolution second resolution optical remote sensing data, Finally, the dome structure and the rotating rock area are taken as the key field prospecting clues, and the prospecting target area is determined through the position relationship between them, which provides scientific basis for field prospecting.

Owner:INST OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

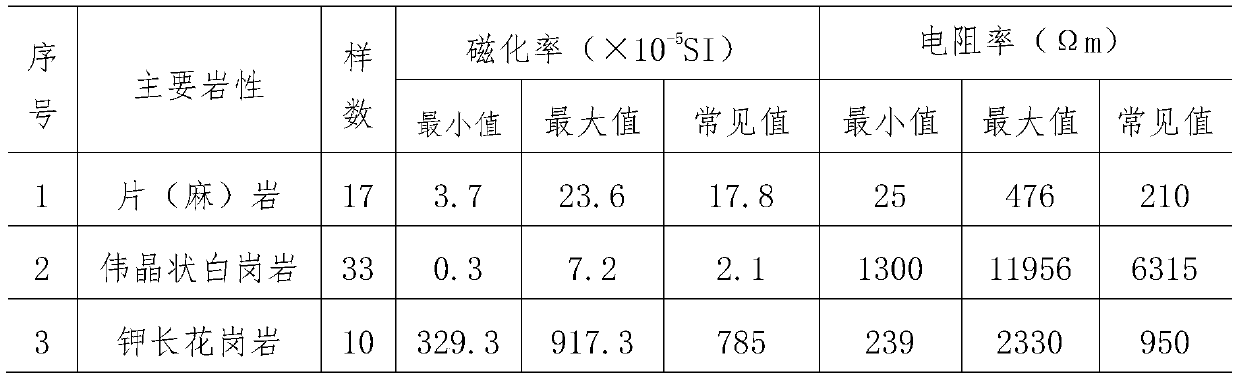

Exploration method of concealed pegmatite-like alaskite type uranium ore

InactiveCN111045087AEasy to identifyQuick identificationMaterial resistanceElectric/magnetic detectionLithologyMagnetic susceptibility

The invention belongs to the technical field of uranium mine exploration, and relates to an exploration method of a concealed pegmatite-like alaskite type uranium ore. The exploration method comprisesthe following steps of: step 1, deploying a measuring net and a measuring line in a measurement region, and determining a measurement position; step 2, measuring magnetic susceptibility and resistivity parameters of the measurement position determined in the step 1, acquiring typical rock samples with different lithologies, and testing the magnetic susceptibility and resistivity parameters thereof; step 3, counting and analyzing the magnetic susceptibility and resistivity parameters of different types of rocks in the measurement region; and step 4, carrying out preprocessing and later inversion calculation on the acquired data, mapping by using software, and finally delineating a concealed pegmatite-like alaskite mass. The exploration method can accelerate the prospecting speed, improve the prospecting hit rate, greatly reduce the drilling workload, shorten the exploration period and reduce the exploration cost.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

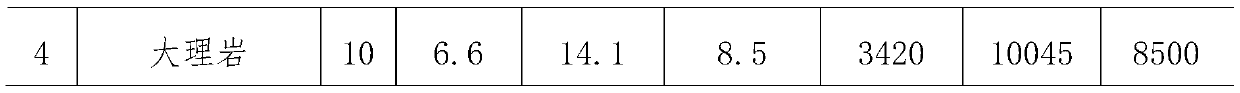

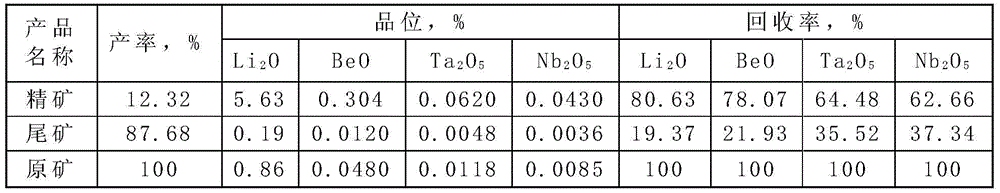

Composite collecting agent for recycling LiBeTaNb from granite pegmatite ore

The invention discloses a composite collecting agent for recycling LiBeTaNb from granite pegmatite ore. The composite collecting agent for recycling LiBeTaNb from granite pegmatite ore is a faint yellow cream which is obtained by mixing, by weight percentage, 80%-90% of industrial fatty acid, 5%-10% of primary amine chemical compounds and 5%-10% of alkyl amino-propionic acid, and then adding sodium hydroxide into the mixture at ordinary pressure and 30-40 DEG C for reaction for 40 minutes. The collecting agent for recycling LiBeTaNb from granite pegmatite ore can effectively achieve selective collection of minerals such as spodumene, aquamarine and Nb-Ta-Fe ore. The action principle of the collecting agent is that relatively strong electrostatic absorption, relatively strong hydrogen bond bonding and relatively strong absorption can be generated between the composite collecting agent and the positive ion active particles such as Li, Be, Ta and Nb exposed on the surfaces of different minerals; due to the fact that the surfaces of gangue minerals such as quartz and feldspar do not contain any active positive ion particles, the collecting agent can generate weak absorption force on the surfaces of the gangue minerals, further good selectivity and relatively good separation effects during a flotation process can be obtained.

Owner:CENT SOUTH UNIV

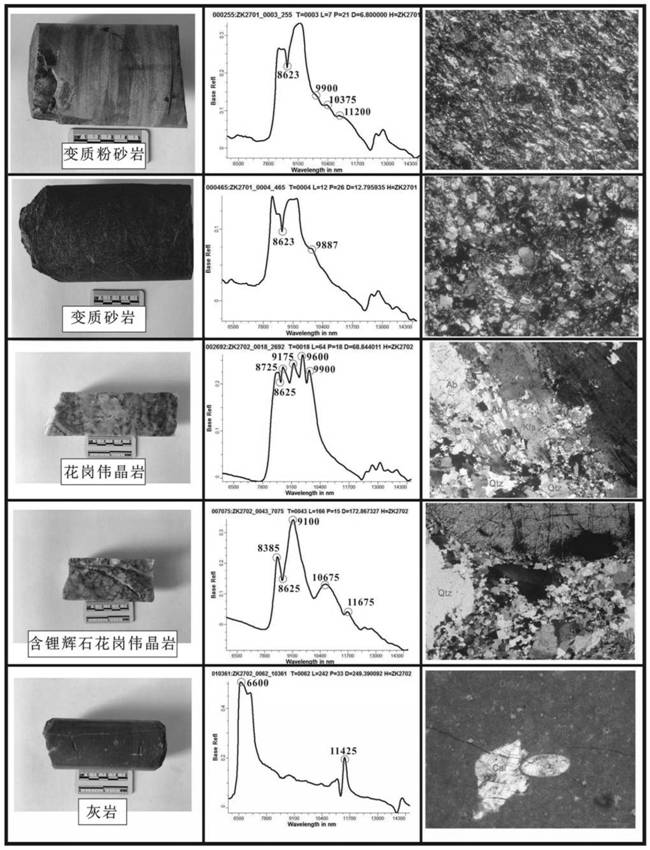

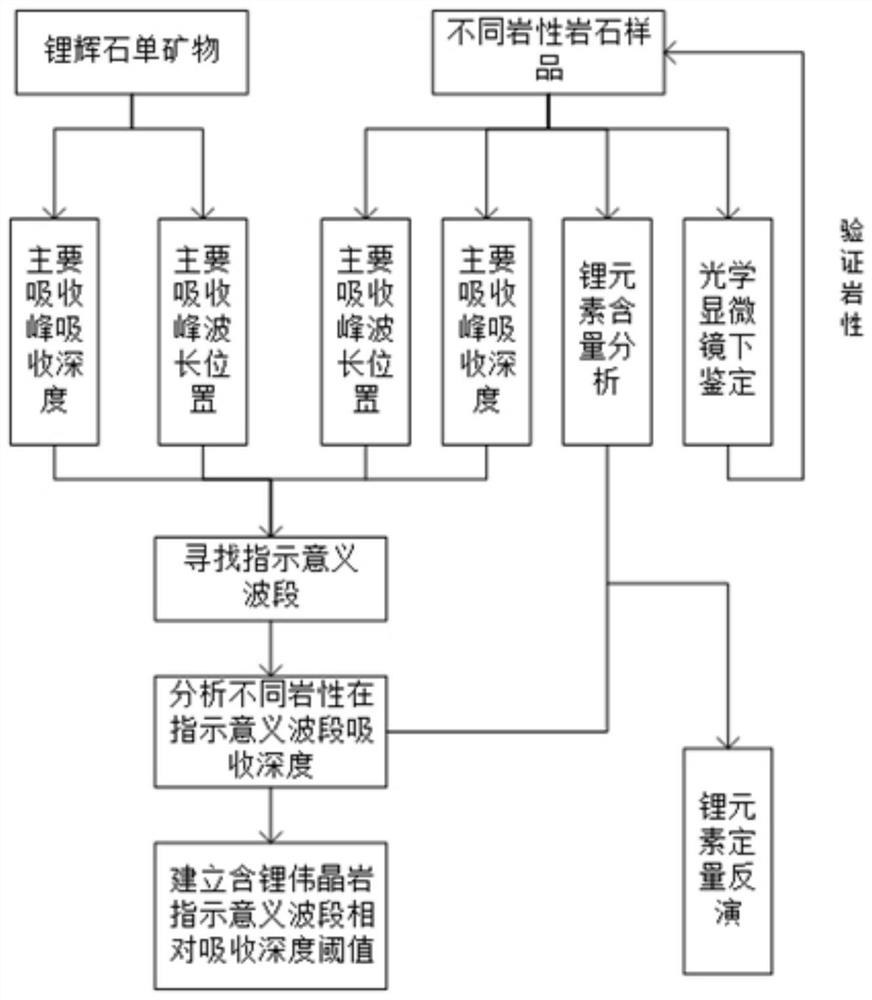

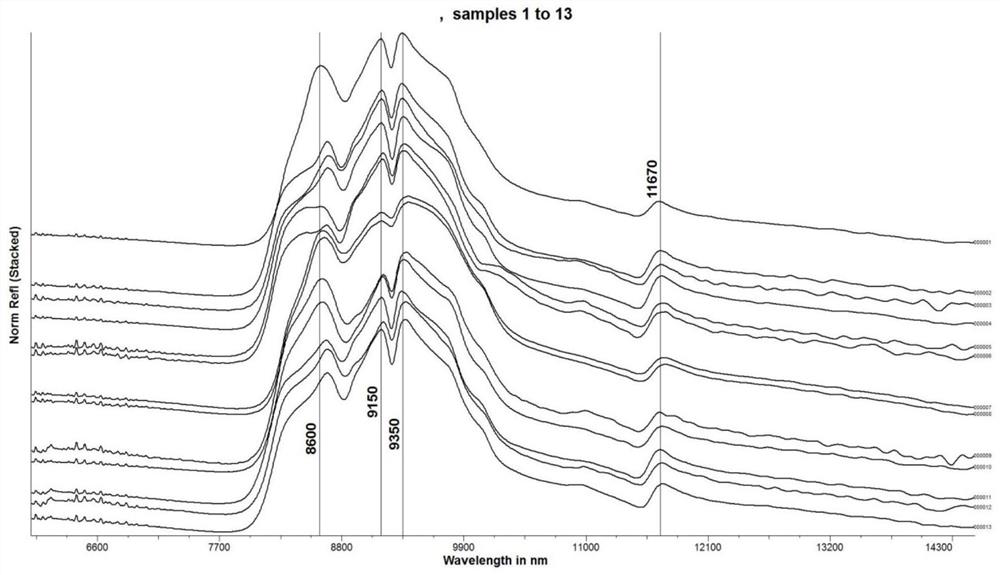

Method for identifying spodumene-containing pegmatite through thermal infrared spectrum and application of thermal infrared spectrum

The invention discloses a method for identifying spodumene-containing pegmatite through a thermal infrared spectrum and application of the thermal infrared spectrum and belongs to the technical fieldof thermal infrared spectrum data interpretation and application. The method comprises the step of performing thermal infrared band spectrum data acquisition on a mineral sample by adopting a thermalinfrared spectrometer in the process of identifying spodumene-containing pegmatite; and the thermal infrared band is 6000-14500nm. According to the method disclosed by the invention, the difference ofspectral characteristics of spodumene-containing pegmatite, spodumene-free pegmatite and surrounding rock in a thermal infrared band is distinguished, and the content of the lithium element is estimated according to the absorption depth of a specific absorption peak of the spodumene-containing pegmatite, so that pegmatite type spodumene ore bodies can be rapidly identified and grade estimation iscarried out.

Owner:自然资源实物地质资料中心

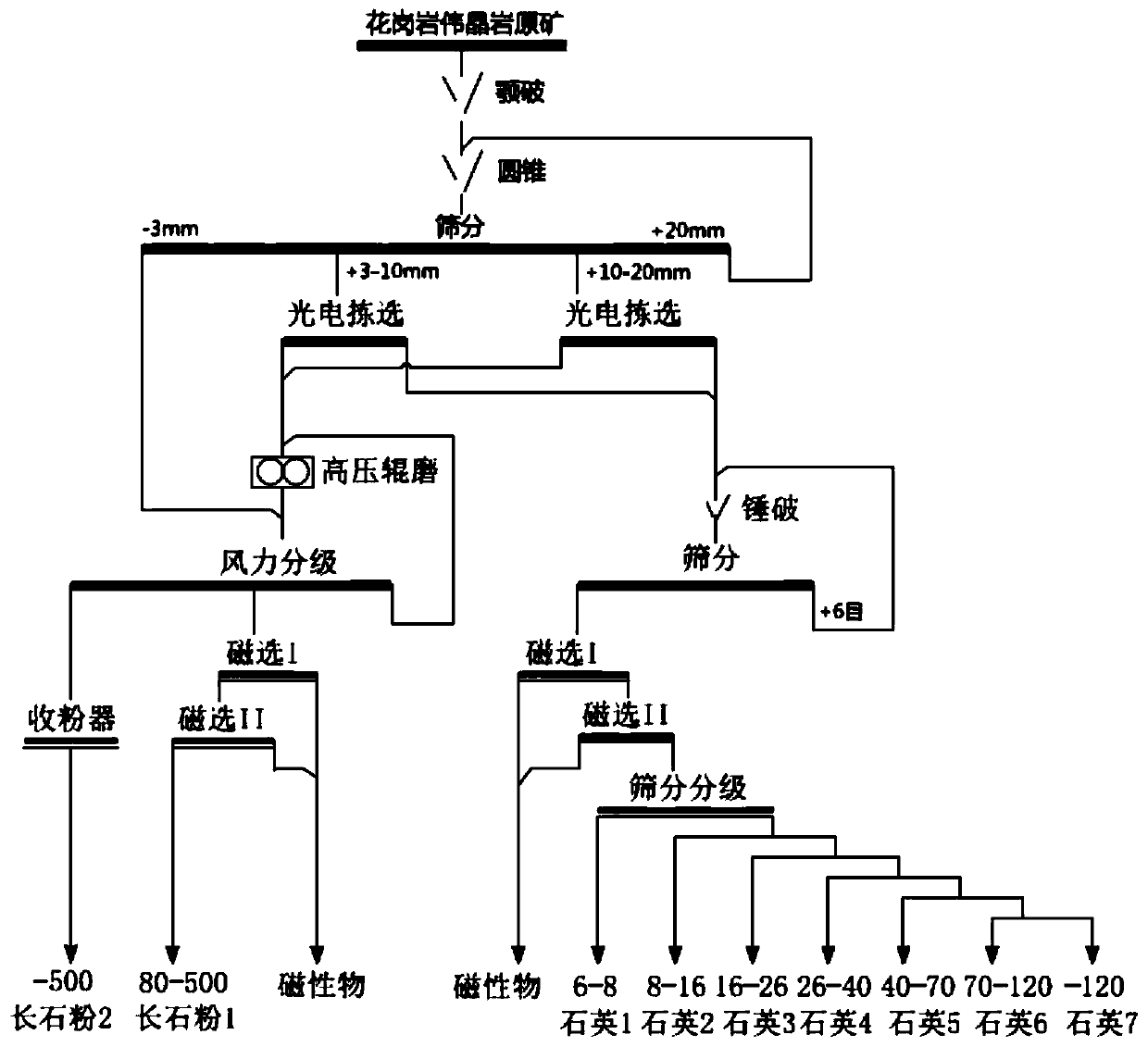

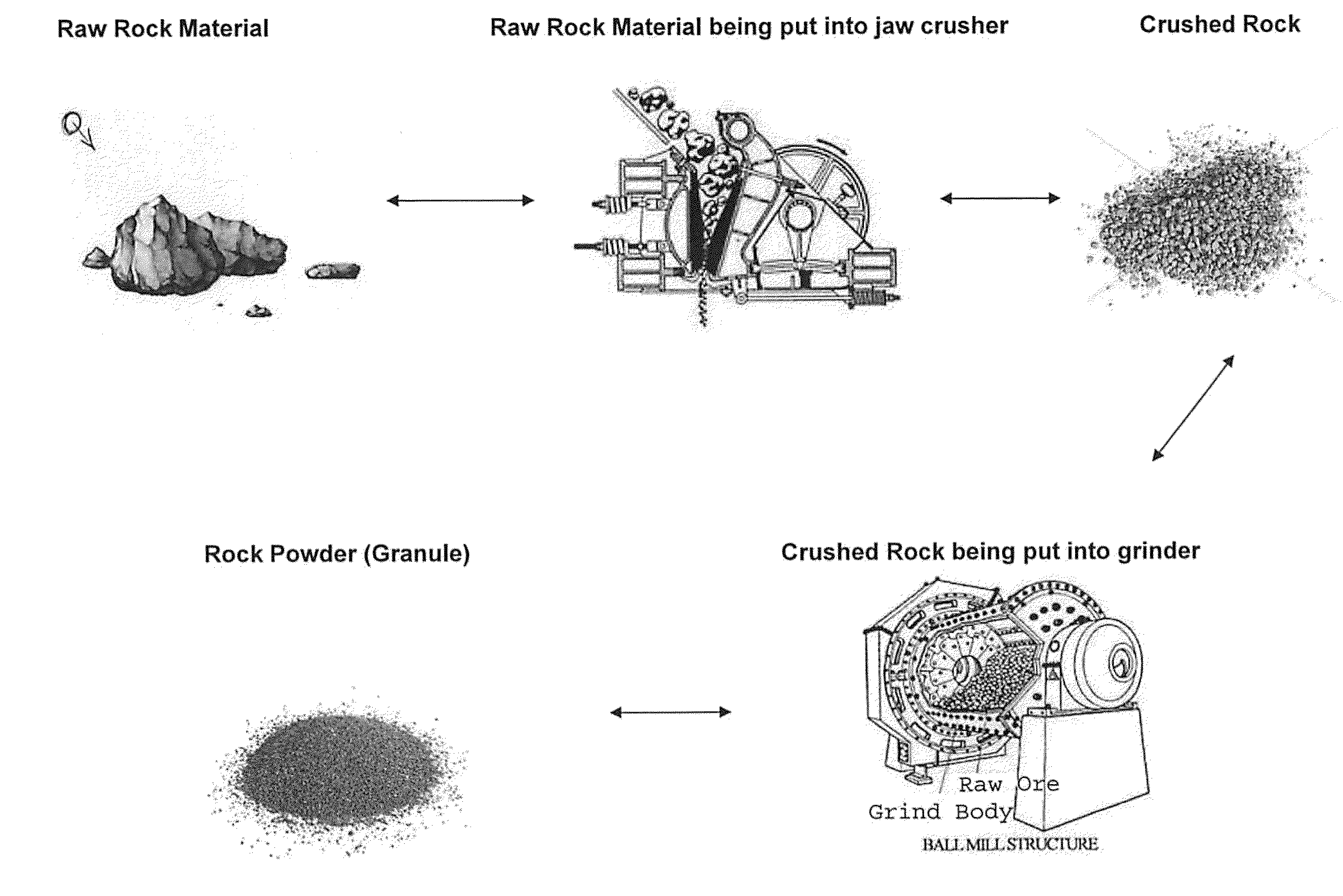

Method for coarse grain separation and dry-type powdering of granite pegmatite

InactiveCN110639692ALarge amount of processingShort processSolid separationMineral particlesMaterials science

The invention provides a method for coarse grain separation and dry-type powdering of granite pegmatite. The preparation method comprises the steps that (1) crude ores of granite pegmatite are crushedand graded, so mineral particles 1 with a particle size of 3mm-20mm and mineral particles 2 with a particle size of -3mm are obtained, the mineral particles 1 are processed with photoelectric sorting, and quartz particle concentrate ores and feldspar particle concentrate ores are obtained; (2) the mineral particles 2 and the feldspar particle concentrate ores are processed by a high-pressure rollgrinding-air classification closed-cycle powdering system, so fine grain materials and a gas material mixture are obtained, feldspar powder 1 is obtained after magnetic sorting and purification of the fine grain materials, the gas material mixture is processed by a powder collector for gas-material separation, and feldspar powder 2 is obtained; and (3) the quartz particle concentrate ores are treated by hammer crushing, screening, magnetic sorting and purification, and a quartz product is obtained finally through screening and grading. The method provided by the invention has the beneficial effects of short processes, the small quantity of devices, a large processing amount, a small particle size of the product and the like; energy consumption cost is reduced; and the method can be applied to industrial and large-scape production.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

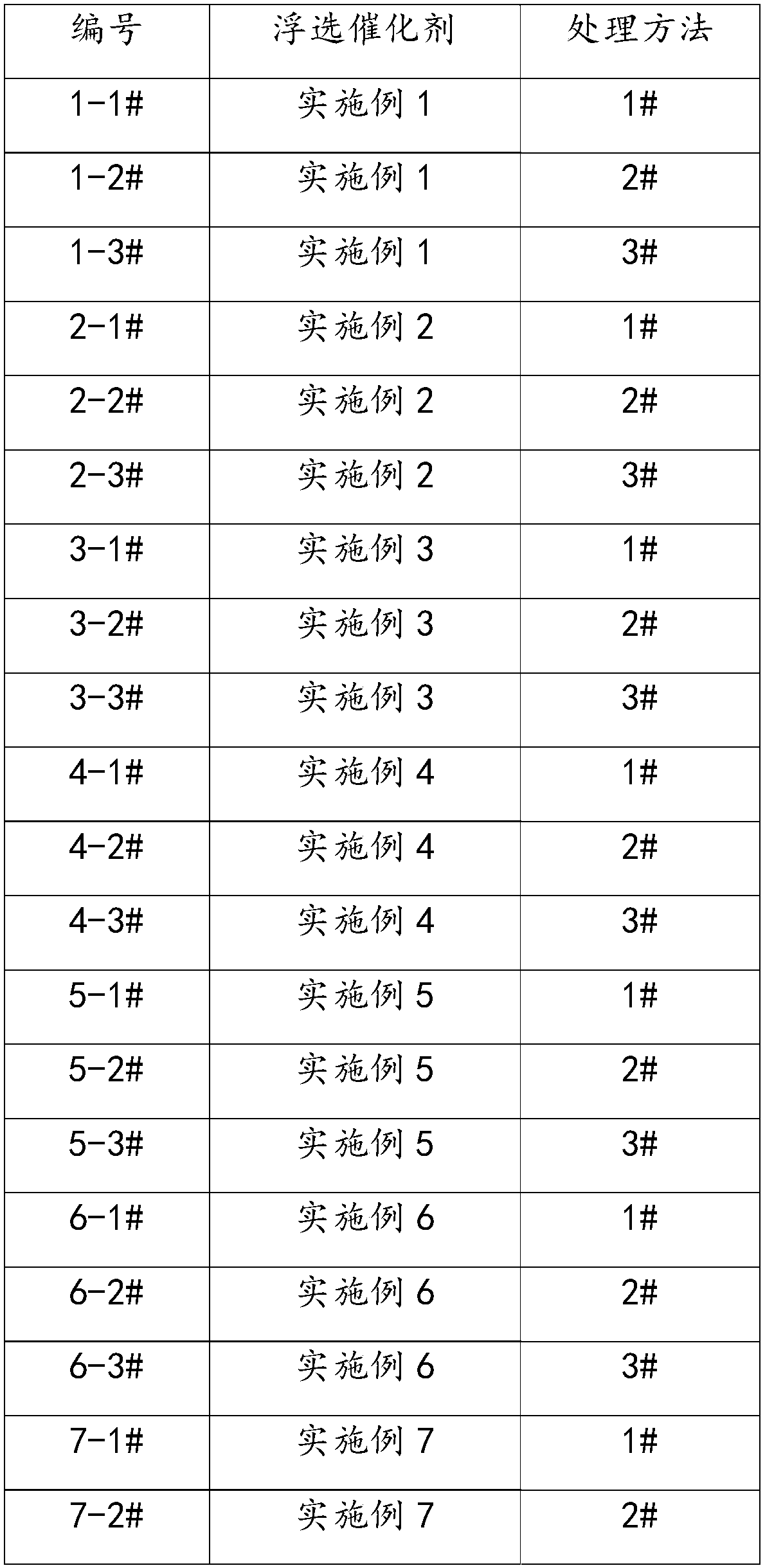

Pegmatite-type spodumene flotation collecting agent and preparation method and application thereof

ActiveCN109225648AStrong mud resistanceStrong ability to resist calcium and magnesium ionsFlotationHigh resistanceWater quality

The invention relates to the technical field of beneficiation engineering, in particular to a pegmatite-type spodumene flotation collecting agent and a preparation method and application thereof. Thepegmatite-type spodumene flotation collecting agent is mainly prepared from, by weight, 50-75 parts of petroleum sulfonate, 15-45 parts of a surfactant and 5-10 parts of an emulsifier. The preparationmethod comprises the steps that the emulsifier is dissolved in water and uniformly mixed with petroleum sulfonate and the surfactant. The flotation collecting agent is prepared by mixing and compounding the components above, the collecting capability and the selectivity under low-temperature conditions are both high, increase of the grade and recovery rate of spodumene concentrates is facilitated, and fluctuation of flotation indexes caused by temperature changes is reduced; the collector has high resistance to mud and calcium and magnesium ions, high applicability in mineral water and high adaptability to various kinds of pegmatite-type spodumene at different altitudes and areas, the usage of an adjusting agent can be decreased, and production technical indexes of a beneficiation factoryare stabilized.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

Refractory brick with low coefficient of linear expansion and preparation method thereof

InactiveCN106518102AImprove fire resistanceImprove performanceCeramic materials productionClaywaresSlagPetroleum coke

Owner:MAANSHAN BAOLONG NEW BUILDING MATERIALS

High-filterability composite cordierite ceramic filter element

InactiveCN104138686AImprove adsorption capacityImprove thermal stabilityOther chemical processesFiltration separationFiberPyrophyllite

The invention discloses a high-filterability composite cordierite ceramic filter element. The high-filterability composite cordierite ceramic filter element is characterized by comprising, by weight, 25-40 parts of cordierite, 20-40 parts of normal hexane, 35-70 parts of granite pegmatite, 10-40 parts of quartz sand, 5-17 parts of white cement, 35-47 parts of ordinary Portland cement, 20-50 parts of pyrophyllite, 11-38 parts of fiber brucite, 1-9 parts of silica, 11-35 parts of methylcellulose, 10-17 parts of pitch, 4-9 parts of zirconium oxide, 1.5-3.6 parts of boron nitride, 12.5-37.9 parts of bud naw powder and 15-60 parts of zirconium oxide. The high-filterability composite cordierite ceramic filter element is high in adsorptive property, high in thermostability, stable in chemical property and high in mechanical strength; furthermore, the filter element is good in toughness and has porous performance, and therefore filtration and adsorption performance is improved; the filter element is porous, high in adsorptive property and strength, easy to regenerate, economical and durable; besides, the filter element is long in service life and resistant to corrosion and can be used for air adsorption filtration.

Owner:QINGDAO XIANGHAI ELECTRONICS

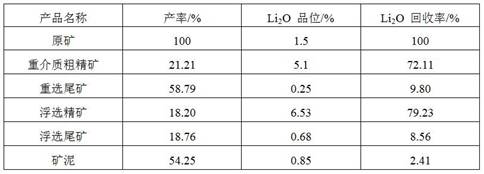

Beneficiation method for pegmatite type spodumene

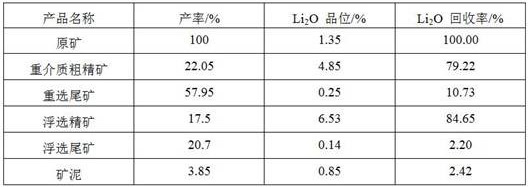

ActiveCN112024110AReduce the amount of raw oreReduce energy costsFlotationWet separationMining engineeringMaceral

The invention relates to a beneficiation method for pegmatite type spodumene, and belongs to the technical field of mineral processing. The method comprises the following steps of crushing and screening spodumene ore, classifying the spodumene ore into a coarse fraction and a fine fraction, carrying out ore washing and desliming operation on coarse fraction materials, carrying out dense medium separation operationon deslimed products, and separating out dense medium rough concentrates and dense medium tailings; carrying out medium removal on the dense medium tailings, and dehydrating the tailings; carrying out grading operation slime generated in the desliming operation on fine-fraction minerals, and removing the part of superfine slime; and carrying out ore grinding and flotation on the underflow of dense medium rough concentrates subjected to medium removal operation and desliming operation, and finally obtaining spodumene concentrates. The beneficiation method for pegmatite type spodumene has a good separation effect. With the method, minerals such as quartz and feldspar with large disseminated grain sizes can be removed by adopting a dense medium, minerals such as mica, quartzand feldspar with small disseminated particle sizes can be removed by adopting a flotation process. The method has the characteristics of low ore grinding energy consumption, low mineral processing cost, remarkable economic effect and the like.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

Industrial waste residue reuse type glass ceramic

The invention discloses industrial waste residue reuse type glass ceramic. The glass ceramic is characterized by comprising, by weight, 10-80 parts of steel slag, 35-70 parts of rock ballast, 1.8-6.4 parts of magnesium, 15-36 parts of polyvinyl alcohol, 1-29 parts of hydroxylapatite, 1.8-13.8 parts of sodium fluorosilicate, 3-11 parts of pegmatite, 11.5-27 parts of ferric oxide, 50.9-67.9 parts of silicon,11.73-15.73 parts of aluminum, 1-7.5 parts of hydrophobic modification nanoscale silicon oxide, 11-40 parts of pyrophyllite and 0-37 parts of kaolinite. The glass ceramic has the advantages of being good in intensity and texture, capable of being well applied to producing building and ornament materials, industrial wear-resistant corrosion-resistant materials and craft products, reliable in product quality and broad in market prospect.

Owner:QINGDAO XIANGHAI ELECTRONICS

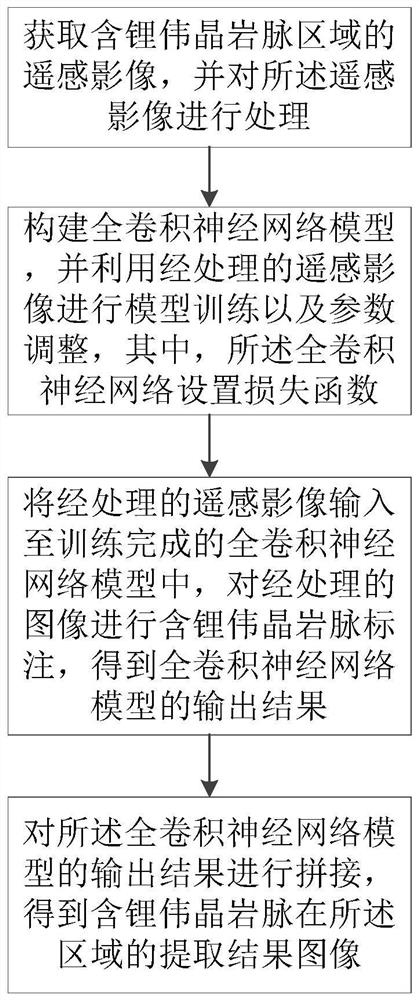

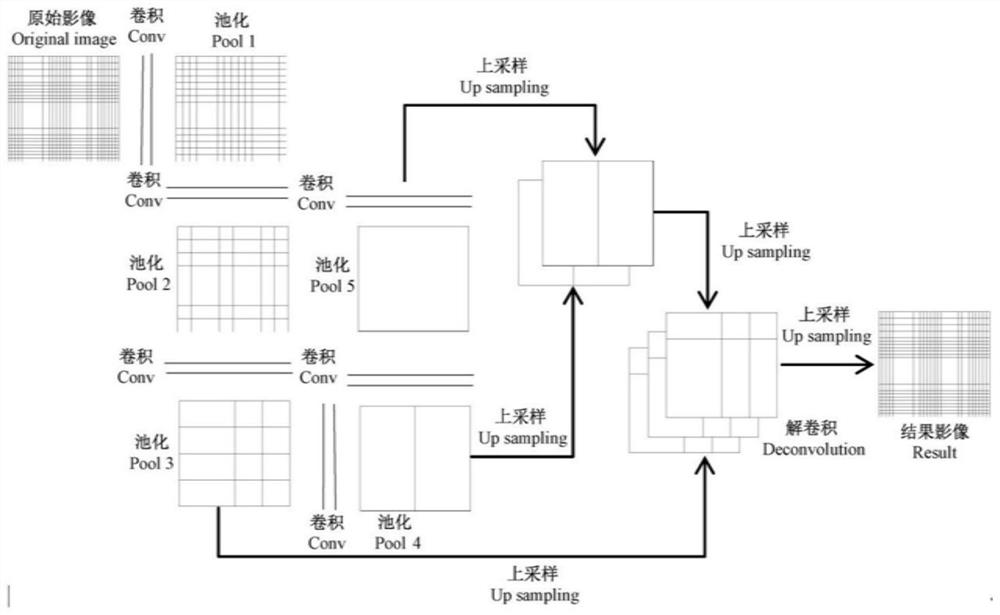

Lithium-containing pegmatite vein extraction method based on full convolutional neural network

InactiveCN112784806AImprove accuracyRealize automatic extractionGeometric image transformationScene recognitionEngineeringComputer vision

The embodiment of the invention discloses a lithium-containing pegmatite vein extraction method based on a full convolutional neural network, and the method comprises the steps: obtaining a remote sensing image of a lithium-containing pegmatite vein region, and carrying out the processing of the remote sensing image; constructing a full convolutional neural network model, using the processed remote sensing image for model training and parameter adjustment, wherein the full convolutional neural network is provided with a loss function, inputting the processed remote sensing image into the trained full convolutional neural network model, carrying out lithium-containing pegmatite vein marking on the processed image to obtain an output result of the full convolutional neural network model; and splicing output results of the full convolutional neural network model to obtain an extraction result image of the lithium-containing rock vein in the region.

Owner:INST OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

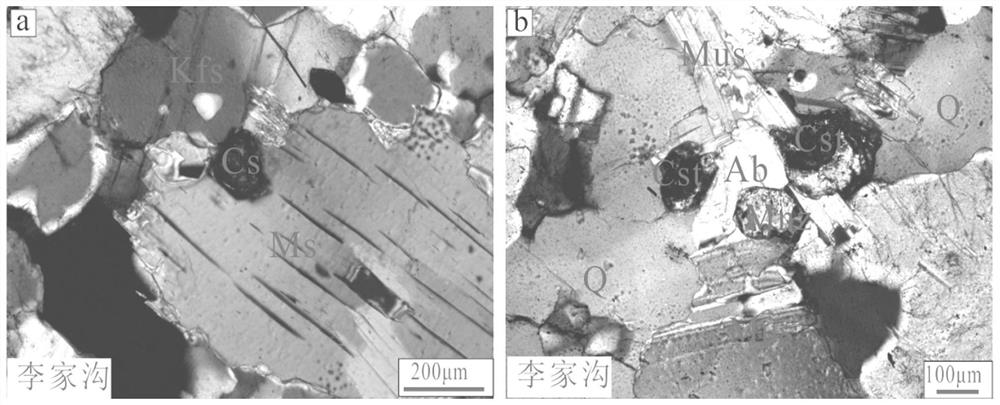

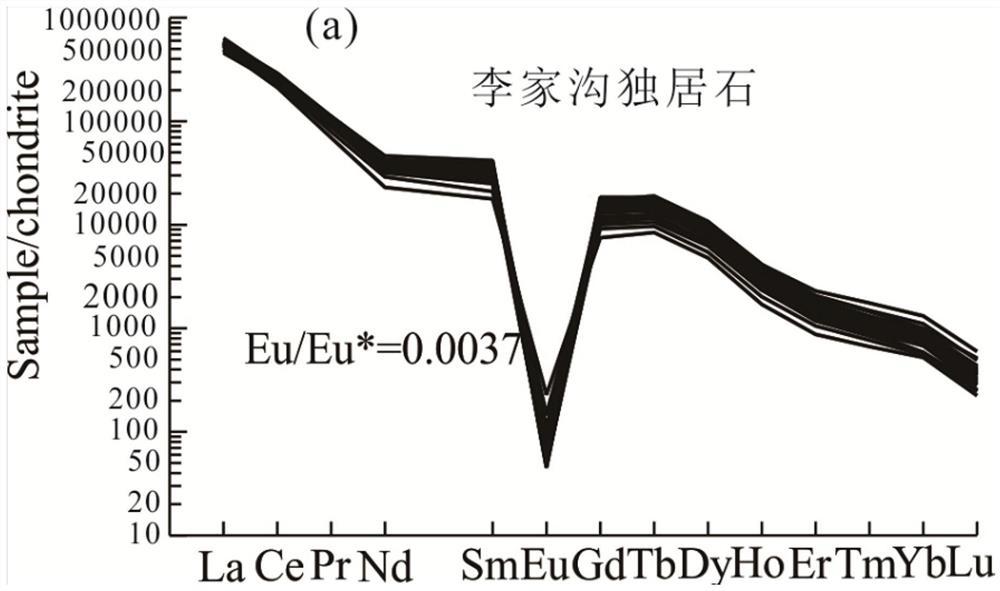

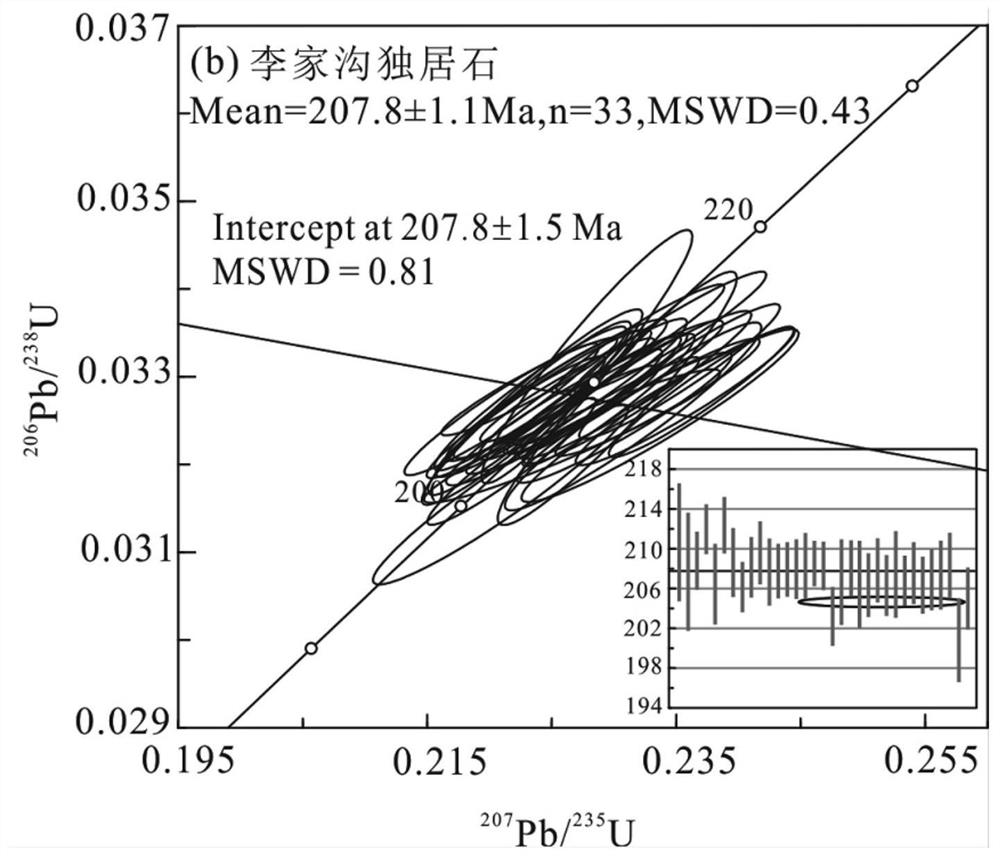

Method for determining metallogenic age of rare metal pegmatite

ActiveCN113092569AAddresses limitations that cannot be used for direct dating of all rare metal pegmatitesFast and accurate mineralization agePreparing sample for investigationMaterial analysis by electric/magnetic meansMetallogenyTrace element

The invention discloses a method for determining metallogenic age of rare metal pegmatite, which belongs to the technical field of chronology and mainly comprises the following steps: (1), collecting rare metal pegmatite samples in the field; (2) cutting the sample in the step (1) into polished thin slices, and observing monazite rare metal minerals in the sample under a mirror; (3) pre-treating a sample, sticking a target to prepare the target, and taking a picture; (4) observing the rare metal minerals in the target sample obtained in the step (3) again; (5) performing component analysis on rare earth and trace elements of monazite rare metal minerals on the target sample which is not subjected to hydrothermal alteration and obtained in the step (3) through adoption of an LA-ICP-MS method; and (6) carrying out U-Pb dating on the monazite caused by magma on the target sample. According to the method, new rare metal minerals suitable for U-Pb dating in rare metal pegmatite are developed, the mineralization age can be rapidly obtained, and the accuracy is high.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Preparation method of pegmatite porous glass ceramics

InactiveCN103373814AImprove flexural strengthWith thermal shock resistancePolyvinyl alcoholFlexural strength

The invention belongs to the technical field of novel materials and in particular provides porous glass ceramics, mainly nano-pore glass ceramics prepared with pegmatite as a raw material. The nano-pore glass ceramics are prepared by adopting the method of adding a pore forming agent stearic acid and a binder polyvinyl alcohol and carrying out second sintering. The nano-pore glass ceramics also take silica, calcite, borax, zinc oxide, sodium nitrate and sodium carbonate as additives. Compared with common heat insulating materials, the nano-pore glass ceramics have the advantages of high compressive and flexural strength, heat shock resistance, low heat capacities and good heat insulating properties, are the best materials for external wall insulation, are low in preparation costs and are suitable for popularization and application in related technical fields.

Owner:杨梅

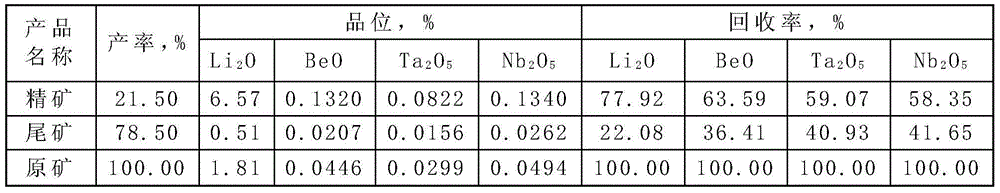

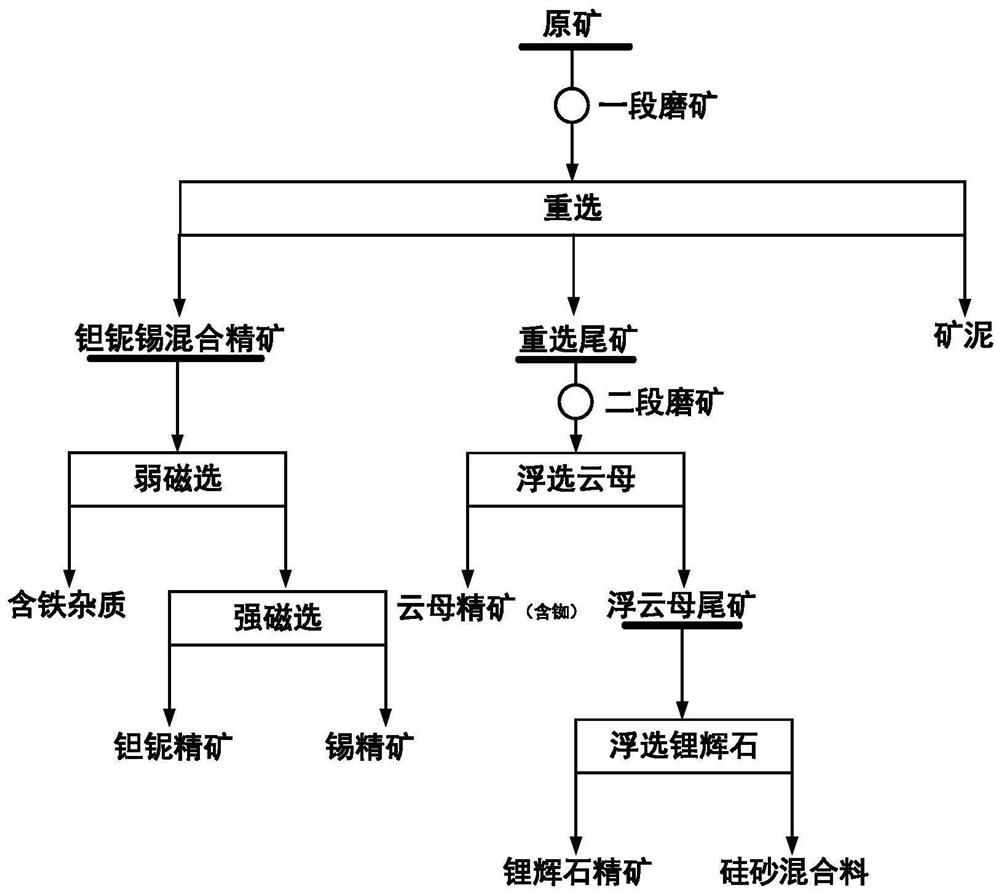

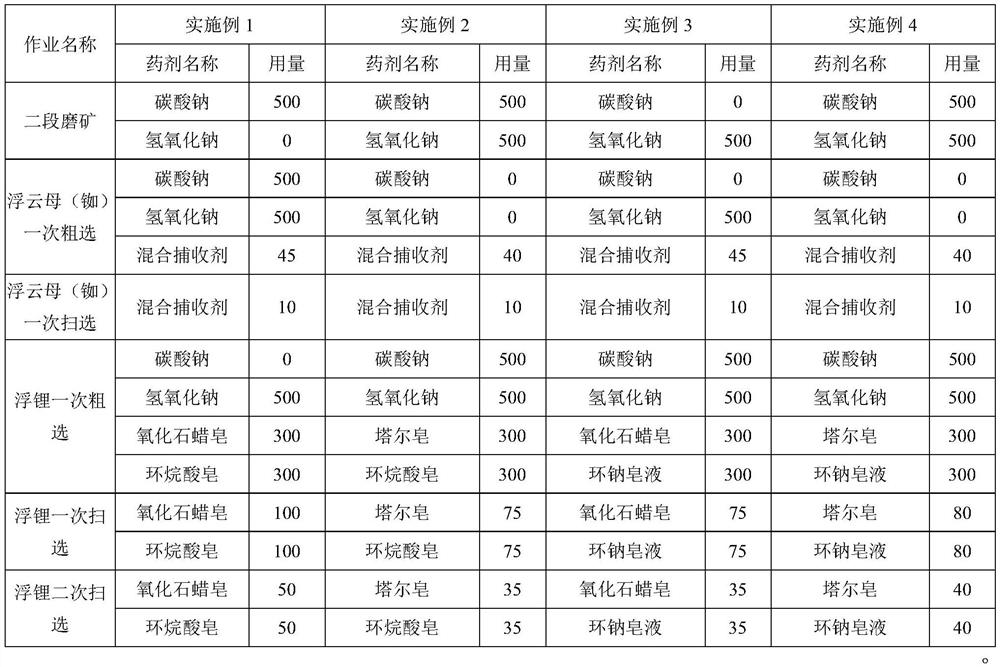

Beneficiation method for pegmatite type lithium polymetallic ore

ActiveCN112958273AAchieve high enrichmentAchieve recyclingSolid separationMechanical material recoveryNiobiumSeparation technology

The invention relates to a beneficiation method for pegmatite type lithium polymetallic ore. The beneficiation method comprises the steps of first-stage ore grinding, screening, reselection, magnetic separation, second-stage ore grinding, size mixing, flotation of rubidium-containing mica, flotation of spodumene and the like. The tantalum-niobium concentrate, the tin concentrate, the mica concentrate, the spodumene concentrate and the silica sand mixture are obtained through the gravity-magnetism-flotation combined technology, comprehensive recovery of tantalum, niobium, tin, rubidium, lithium, silicon, aluminum and other elements is sequentially achieved, and the method has the advantages of being simple and convenient in separation technology, good in separation effect, high in resource utilization rate and the like.

Owner:INST OF RESOURCES COMPREHENSIVE UTILIZATION GUANGDONG ACAD OF SCI

Mineral Paper

A process to manufacture a paper derived from minerals includes the steps of preparing a mineral preparation that includes 50% to 70% of total dry weight of rocks that have been crushed and ground into a powdery substance; combining the mineral preparation with a sodium silicate solution of total dry weight of 30% to 50%; and adding additives having a weight of 2% to 5% of a total dry weight. The powdery substance may have granules of about 0.05 mm to 0.08 mm in diameter and can be mixed with vitamin powder. The igneous rocks can be selected from the set of: dolostone, basalt, granite, gabbro, andesite, diorite, obsidian, pegmatite, peridotite, pumice, rylolite, and scoria. Sedimentary rocks can be selected from the set of: limestone, sandstone, conglomerate, shale, siltstone, brecca, gypsum, chert, travertine, flint, iron ore, rock salt, and oil shale.

Owner:NEW MILLENIUM

High-performance cordierite composite ceramic filter element

InactiveCN104446407AImprove adsorption capacityImprove thermal stabilityOther chemical processesDispersed particle filtrationPyrophylliteFiltration

The invention discloses a high-performance cordierite composite ceramic filter element, which is prepared from the following components in parts by weight: 17-31 parts of cordierite, 12-34 parts of pegmatite, 20-56 parts of pyrophyllite, 3-11 parts of silochrom, 10-19 parts of montmorillonite, 3-8 parts of calcium sulfate, 1-8 parts of sodium citrate, 1-4 parts of sorbitan monooleate, 0.5-3.2 parts of hydrophobic modified nano silicon oxide, 1-2 parts of cadmium sulfate, 3-7 parts of kieselguhr, 0-4 parts of calcium alkylbenzene sulfonate, 11-28 parts of zirconia, 4-15 parts of silica gel, 1-7 parts sodium alginate and 25-67 parts of Razor clam kink shell powder. The high-performance cordierite composite ceramic filter element provided by the invention has high adsorption property, good thermal stability, stable chemical property, and higher mechanical strength; the filter element has good toughness; meanwhile, the filter element has porous property; the filter adsorption property is improved; the filter element has developed gaps, good adsorption property, high strength, easy regeneration, economy and durability, long service life and corrosion resistance; the filter element can be used for air adsorption filtration.

Owner:QINGDAO JINXIU SHUIYUAN COMMERCE & TRADE

A method and system for identifying pegmatite-type rare metal deposits

ActiveCN108181664BEfficient determinationQuick fixOptical prospectingScene recognitionImaging processingComputer science

The invention discloses a method and a system for identifying pegmatite type rare metal ore. The method includes: image processing of acquired WorldView‑2 and other high-resolution images, determining the distribution area of pegmatite veins, and determining the distribution area of pegmatite veins according to the Die distribution area, interpret the processed WorldView‑2 and other high-score images to obtain the decoded WorldView‑2 and other high-score images; perform principal component transformation and false color synthesis on the acquired ASTER remote sensing images to obtain The synthesized ASTER image; the dark area of the synthesized ASTER image is the distribution area of pegmatite-type rare metal ores; the decoded WorldView‑2 and other high-score images and the synthesized ASTER image are combined to determine Location information of pegmatite-type rare metal ore. Therefore, the present invention determines the distribution area of pegmatite based on high-resolution images such as WorldView‑2, and combines the ASTER remote sensing image that can extract the ore-bearing area of pegmatite rare metal minerals, thereby efficiently and effectively in a short time. Quickly and accurately determine the location information of pegmatite-type rare metal deposits.

Owner:XIAN CENT OF GEOLOGICAL SURVEY CGS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com