Porcelain formula and production technology

A production process and formula technology, applied in the field of ceramics, can solve problems such as unsatisfactory yield and complex production process, and achieve the effects of improving quality, improving glaze gloss, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

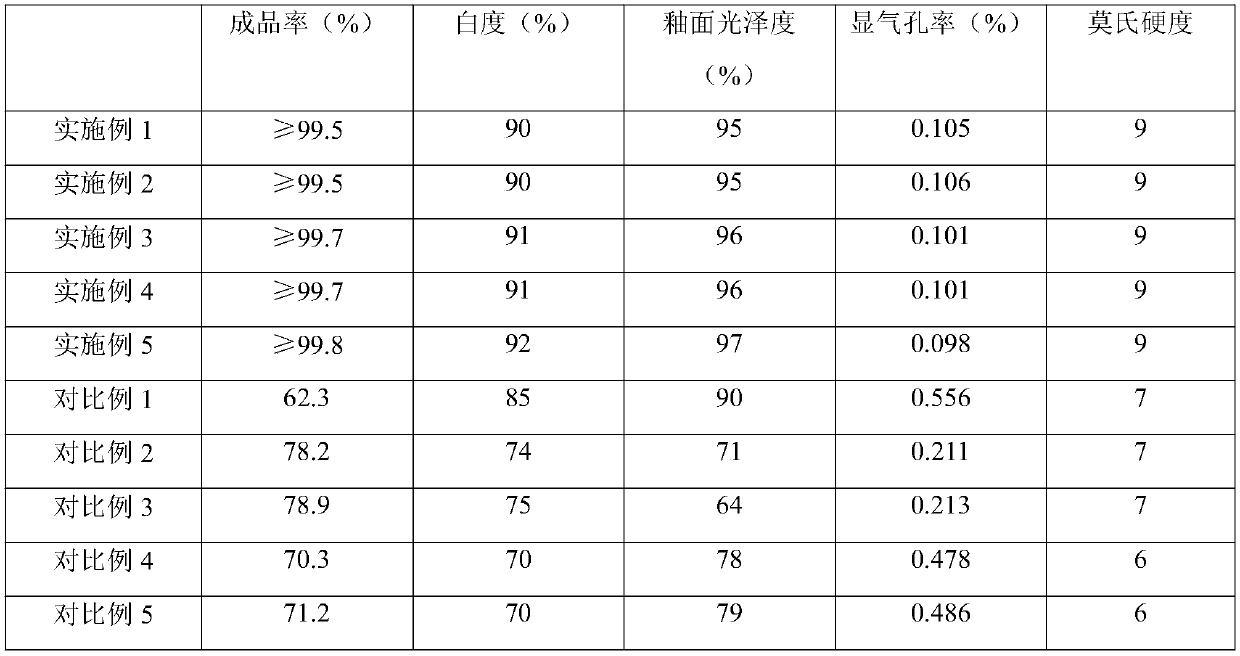

Examples

Embodiment 1

[0033] A porcelain formula, including two parts of a base material and a glaze, in parts by weight, the base material is made of the following raw materials: 50 parts of sepiolite, 22 parts of xuanshi, 21 parts of albite, and 15 parts of soft kaolin 13 parts of diatomite, 11 parts of coke gem, 18 parts of talc, 10 parts of calcite, 5 parts of wax stone, 5 parts of andalusite, 6 parts of serpentine, 1 part of large ball clay, 1 part of bone carbon; glaze Made from the following raw materials: SiO 2 50 parts, Si 3 N 4 20 parts, SiC 20 parts, ZrO 2 31 copies, K 2 ZrF 6 18 parts, CaCO 3 22 parts, α-Al 2 o 3 5 copies, B 2 o 3 3 parts, ZnO 5 parts, BaO 3 parts, Y 2 o 3 4 parts, MgO 4 parts.

[0034] Among them, the plain tire is fired by using the tire material, and the glaze layer is formed on the surface of the plain tire, and the thickness of the glaze layer is 0.2mm.

[0035] The production technology of above-mentioned a kind of porcelain formula, concrete ...

Embodiment 2

[0044] A porcelain formula, including two parts of a base material and a glaze, in parts by weight, the base material is made of the following raw materials: 50 parts of sepiolite, 28 parts of xuanshi, 25 parts of albite, and 20 parts of soft kaolin 17 parts of diatomite, 15 parts of coke gem, 25 parts of talc, 15 parts of calcite, 8 parts of wax stone, 8 parts of andalusite, 8 parts of serpentine, 2 parts of large ball mud, 2 parts of bone carbon; glaze Made from the following raw materials: SiO 2 50 parts, Si 3 N 4 25 parts, SiC 25 parts, ZrO 2 35 copies, K 2 ZrF 6 22 parts, CaCO 3 30 parts, α-Al 2 o 3 10 copies, B 2 o 3 11 parts, ZnO 8 parts, BaO 8 parts, Y 2 o 3 9 parts, MgO 8 parts.

[0045] Among them, the plain tire is fired by using the tire material, and the glaze layer is formed on the surface of the plain tire, and the thickness of the glaze layer is 0.4mm.

[0046] The production technology of above-mentioned a kind of porcelain formula, concre...

Embodiment 3

[0055] A kind of porcelain formula, including two parts of base material and glaze, in parts by weight, the base material is made of the following raw materials: 50 parts of sepiolite, 22 parts of xuanshi, 25 parts of albite, 15 parts of soft kaolin 17 parts of diatomite, 11 parts of coke gem, 25 parts of talc, 10 parts of calcite, 8 parts of wax stone, 5 parts of andalusite, 8 parts of serpentine, 1 part of large ball clay, 2 parts of bone carbon; glaze Made from the following raw materials: SiO 2 50 parts, Si 3 N 4 20 parts, SiC 25 parts, ZrO 2 31 copies, K 2 ZrF 6 22 parts, CaCO 3 22 parts, α-Al 2 o 3 10 copies, B 2 o 3 3 parts, ZnO 8 parts, BaO 8 parts, Y 2 o 3 9 parts, MgO 8 parts.

[0056] Among them, the plain tire is fired by using the tire material, and the glaze layer is formed on the surface of the plain tire, and the thickness of the glaze layer is 0.2mm.

[0057] The production technology of above-mentioned a kind of porcelain formula, concret...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com