High-impact water-supply pipe granular material and preparation method thereof

A technology of water supply pipe fittings and high impact resistance, applied in the direction of pipes/pipe joints/fittings, hoses, pipes, etc., can solve the problem of unrecorded composition, structure, preparation method and source of silica gel coupling agent, and increase the difficulty of injection molding , Destroying the fluidity of PVC melt, etc., to achieve the effect of facilitating fluidity, easy injection molding processing, and improving gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

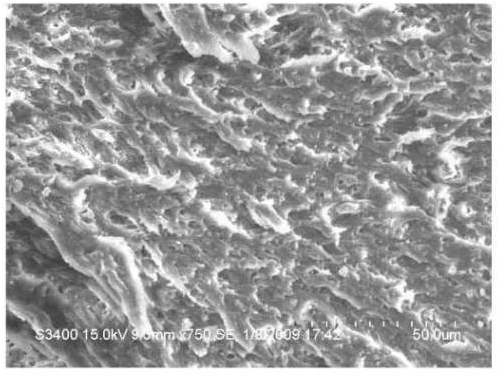

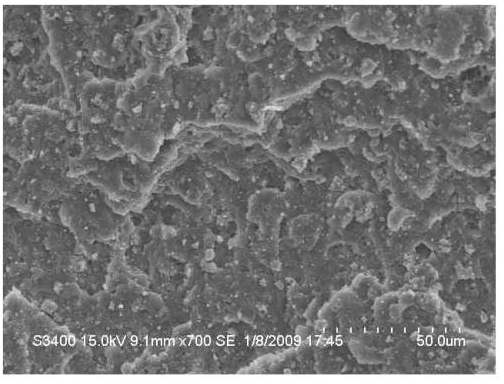

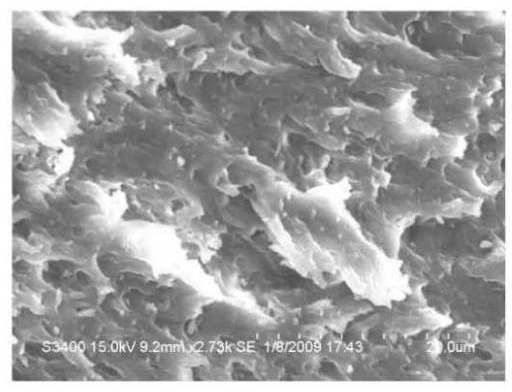

Image

Examples

Embodiment 1)

[0031]The pellets for high-shock water supply pipe fittings in this embodiment are a blend system composed of PVC resin and additives blended in the PVC resin. The additives include tougheners, stabilizers, lubricants, fillers, processing aids and titanium dioxide. There are two kinds of stabilizers, the first one is organotin stabilizer, the second one is epoxidized soybean oil, and the two stabilizers form a composite stabilizer system in the blending system. In 124.8 kg of high-shock water supply pipe fitting pellets, the above-mentioned components and their contents are as follows:

[0032] PVC resin 100kg, toughening agent methyl methacrylate-butadiene-styrene copolymer 7.5kg, organotin stabilizer 2.7kg, stabilizer epoxy soybean oil 0.7kg, lubricant polyethylene wax 2.8kg, processing aid Agent ACR resin 5.6kg, titanium dioxide 0.4kg, filler modified micron calcium carbonate 5.1kg.

[0033] The organotin stabilizer is an organotin heat stabilizer, which is derived from a...

Embodiment 2)

[0049] The rest of this embodiment is the same as that of Embodiment 1, except that: in the 121.54 kg high-scourability water supply pipe fitting pellets, each component and corresponding content are as follows:

[0050] PVC resin 100kg, toughening agent chlorinated polyethylene 8.8kg, organotin stabilizer methyl mercaptide tin 2.7kg, stabilizer epoxy soybean oil 0.8kg, lubricant stearic acid 2.7kg, processing aid ACR resin 2kg, Titanium dioxide 0.5kg, filler modified micron grade calcium carbonate 4.04kg.

[0051] The weight ratio of the micron grade calcium carbonate to the silane coupling agent in the filler is 100:1.

[0052] The above-mentioned tin methyl mercaptide is derived from tin methyl mercaptide heat stabilizer produced by Shanghai Zhiqiang Plastic Additives Co., Ltd. with the commodity code SS-218.

[0053] Correspondingly, when preparing the above-mentioned high-shock water supply pipe fitting pellets, in step ①, when preparing modified micron-sized calcium car...

Embodiment 3)

[0057] The rest of this embodiment is the same as that of Embodiment 1, except that: in the 124.88 kg high-scourability water supply pipe fitting pellets, each component and corresponding content are as follows:

[0058] PVC resin 100kg, toughening agent methyl methacrylate-butadiene-styrene copolymer 9.2kg, organotin stabilizer methyl mercaptide tin 2.8kg, stabilizer epoxy soybean oil 0.7kg, lubricant polyethylene wax 2.7kg, processing aid ACR resin 2.8kg, titanium dioxide 0.5kg, filler modified micron calcium carbonate 6.18kg.

[0059] In the above-mentioned filler, the weight ratio of the micron calcium carbonate to the silane coupling agent is 100:3.

[0060] The above-mentioned tin methyl mercaptide is derived from tin methyl mercaptide heat stabilizer produced by Shanghai Zhiqiang Plastic Additives Co., Ltd. with the commodity code SS-218.

[0061] Correspondingly, when preparing the above-mentioned high-shock water supply pipe fitting pellets, in step ①, when preparing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com