Patents

Literature

1559results about How to "No cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aqueous organic-inorganic composite coating and preparation method thereof

The invention discloses an aqueous organic-inorganic composite coating, comprising the base materials of water-soluble film-forming material, pigment, filler, additive and water. The aqueous organic-inorganic composite coating is specifically composed of the following component, by weight: 15-25 parts of potassium silicate, 10-20 parts of styrene-acrylic emulsion, 0.2-0.5 part of stabilizer, 0.2-0.5 part of dispersing agent, 0.3-0.6 part of defoaming agent, 0.2-0.5 part of film-forming additive, 0.2-0.5 part of antifreeze, 0.1-0.3 part of thickening agent, 14-20 parts of titanium dioxide, 15-25 parts of heavy calcium, 5-10 parts of talcum powder and 20-25 parts of water. The invention has the following advantages: high film hardness, no cracking, excellent weather fastness, lasting replenished film, no addition of preservatives, excellent environmental protection performance, long recoating period of film and resource saving. In addition, the product has minimal construction resistance, and is easy for painting, promotion and application. The aqueous organic-inorganic composite coating has wide application range, and can be applied to coating of basement, underground parking, inner wall and outer wall.

Owner:广东嘉宝莉科技材料有限公司

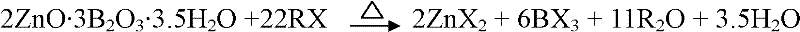

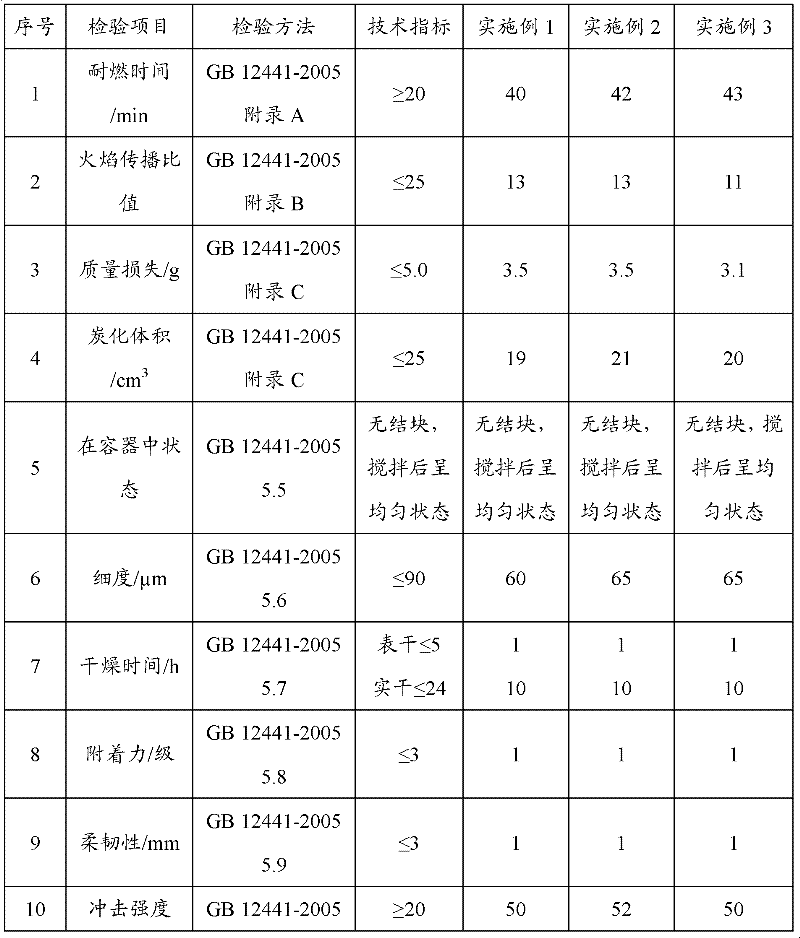

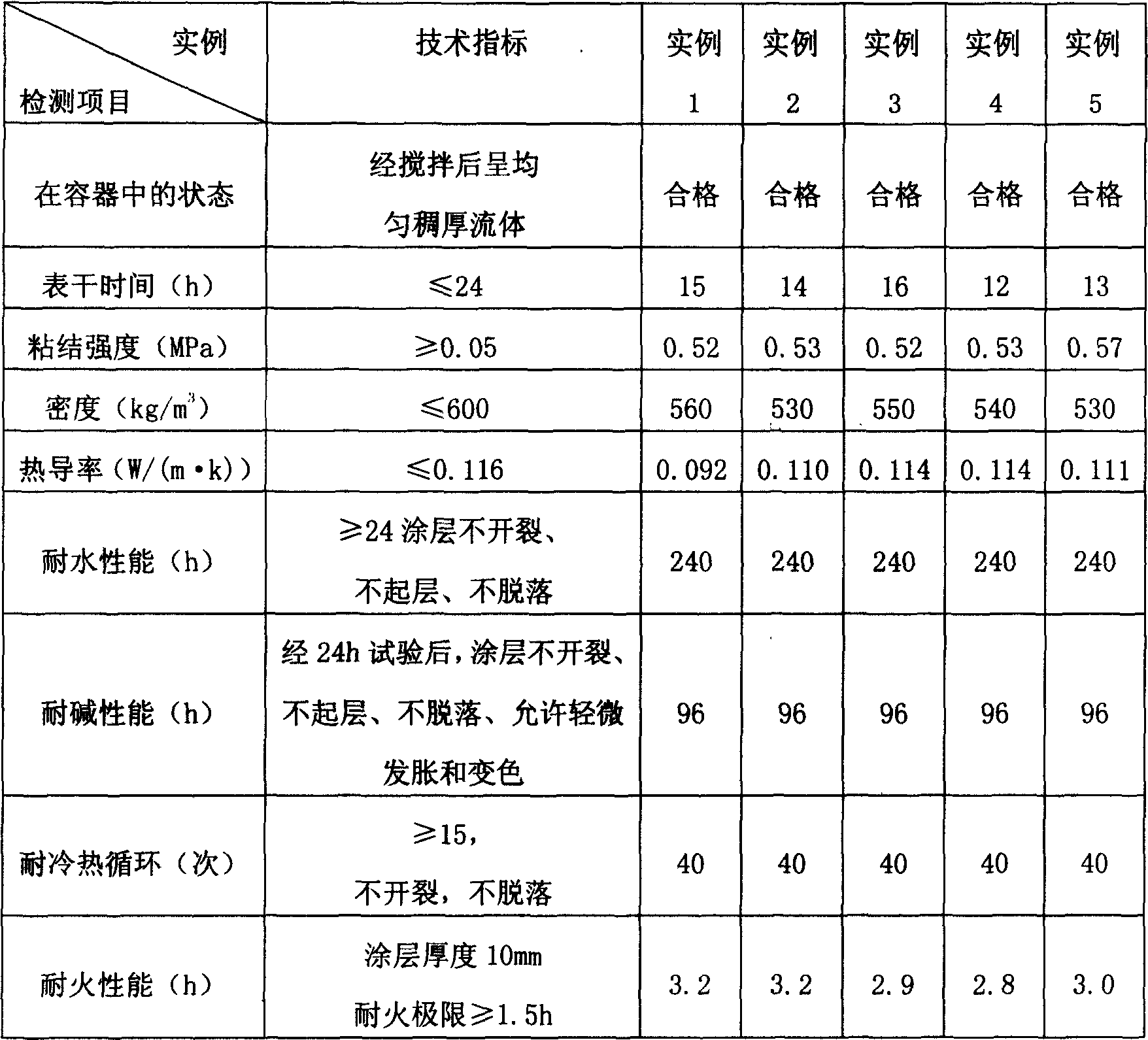

Expanded type aqueous facing fireproof coating and preparation method thereof

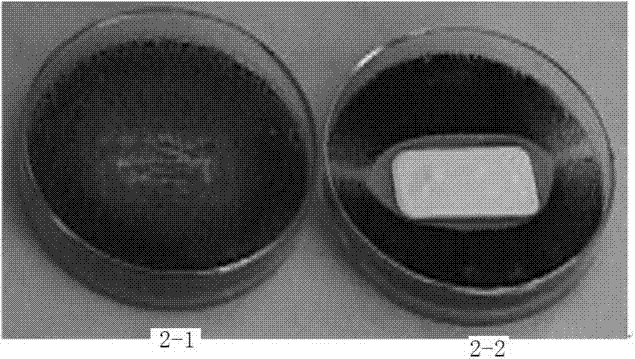

ActiveCN102675992AImprove fire resistanceImprove water resistanceFireproof paintsCelluloseChlorinated paraffins

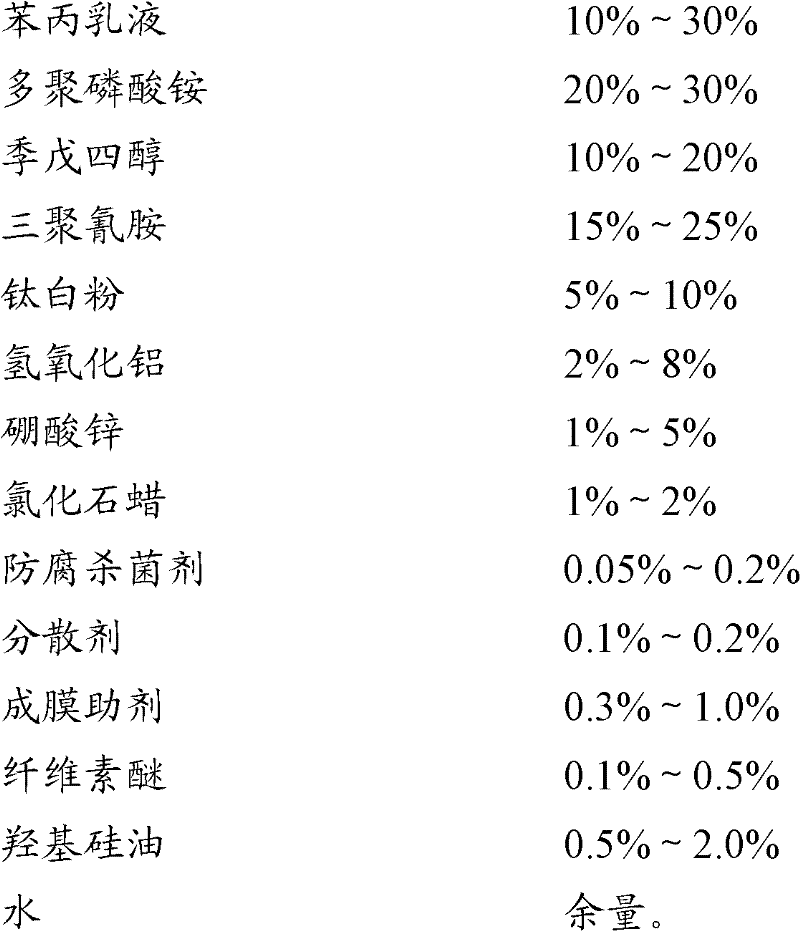

The invention provides an expanded type aqueous facing fireproof coating, which comprises the following components by weight: 10% to 30% of styrene-acrylic emulsion, 20% to 30% of ammonium polyphosphate, 10% to 20% of pentaerythritol, 15% to 25% of melamine, 5% to 10% of titanium dioxide, 2% to 8% of aluminum hydroxide, 1% to 5% of zinc borate, 1% to 2% of chlorinated paraffin, 0.05% to 0.2% of antiseptic, 0.1% to 0.2% of dispersing agent, 0.3% to 1.0% of film-forming auxiliary, 0.1% to 0.5% of cellulose ether, 0.5% to 2.0% of hydroxy silicone oil and the balance of water. The expanded type aqueous facing fireproof coating, provided by the invention, has the advantages of excellent water resistance and salt mist resistance, excellent adhesion and flexibility, good storage stability, no layering, no fineness change and no packing phenomenon, excellent waterproof resistance, smooth and fine coating film, no toxicity and pollution, and environment-friendliness.

Owner:CARPOLY CHEM GRP

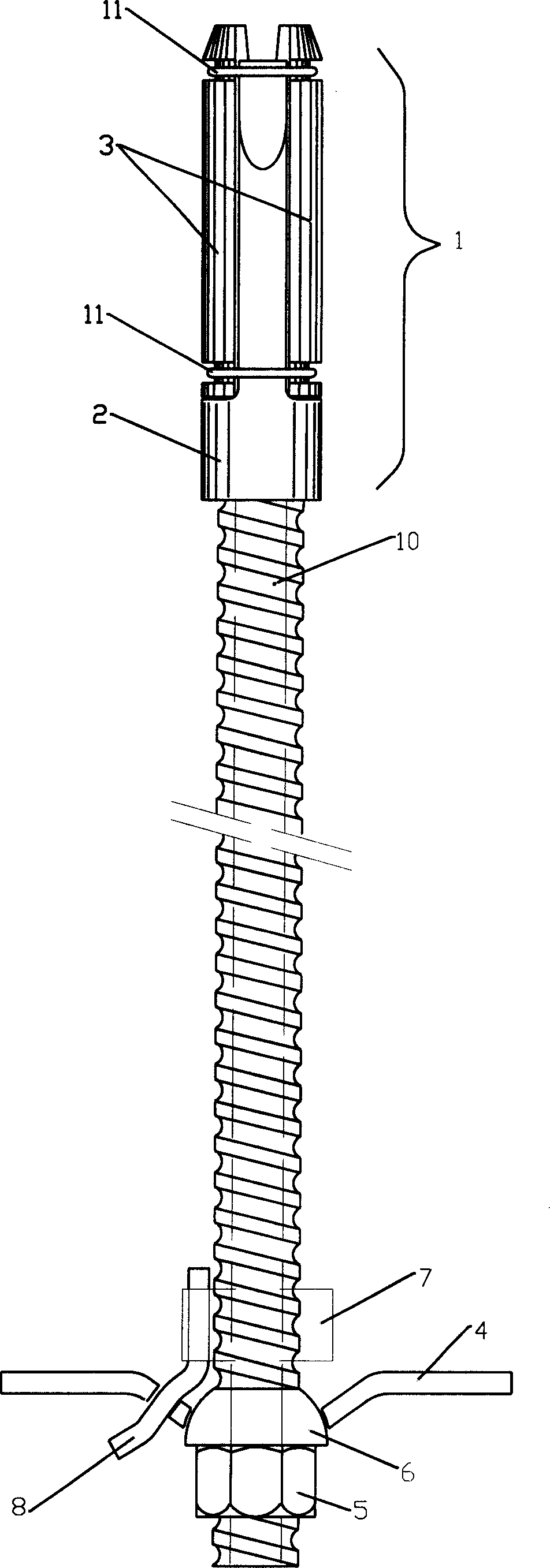

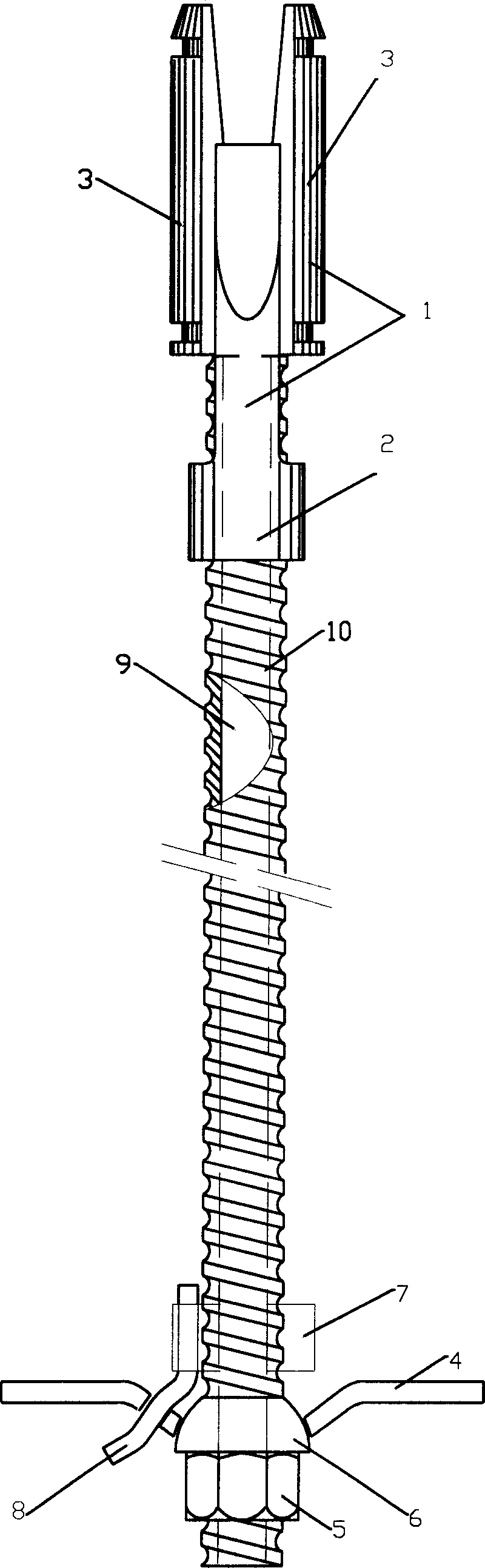

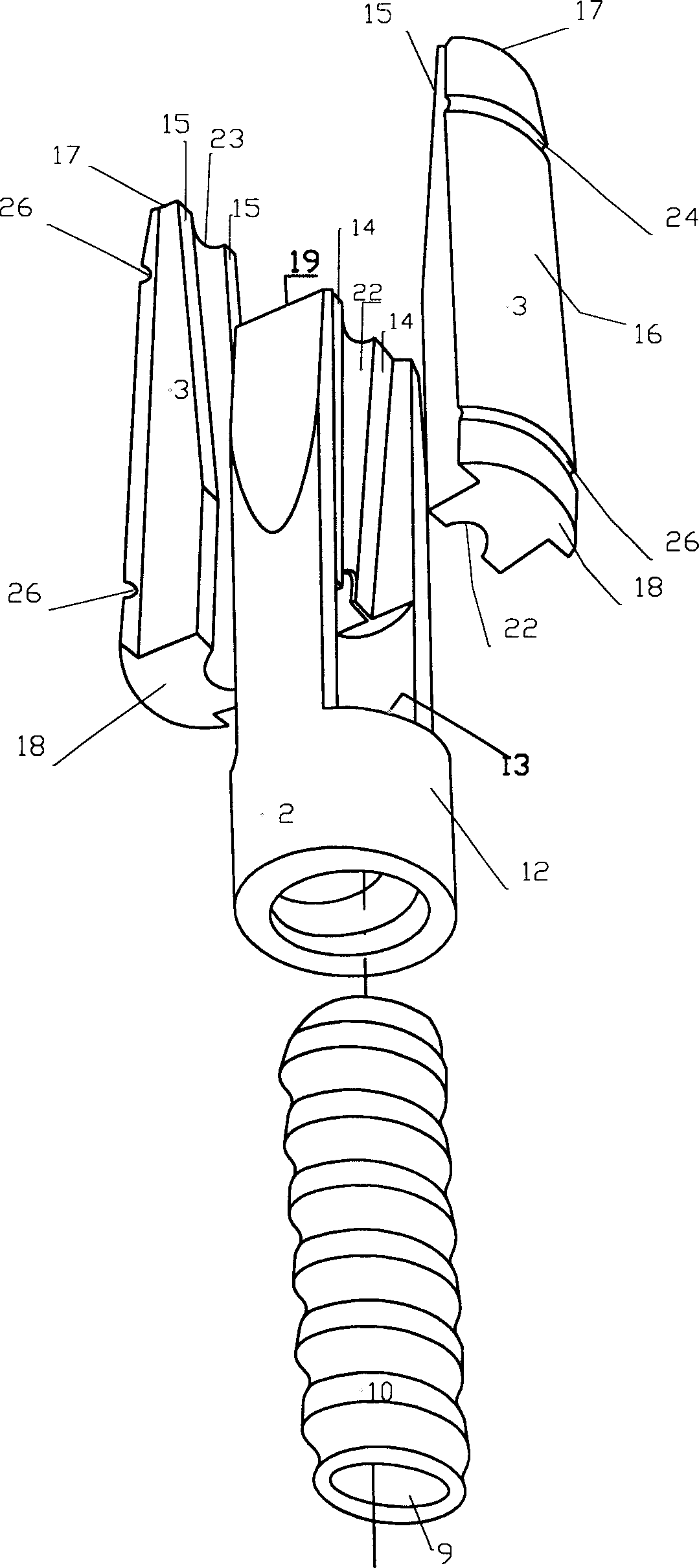

Shell expansion type rock bolt

ActiveCN1544798ASimple construction processGrouting is reliableBulkheads/pilesAnchoring boltsRock boltWedge shape

The invention is a case expanding anchor shank, composed of case expanding anchoring head, anchor shank body, supporting backing plate, fastening nut, washer, and connecting pipeline, where the anchoring head is composed of inner wedge and two clamp pieces, the clamp pieces are fixed in the open slots on two sides of the inner wedge, the lower part of the inner wedge is connected with the anchor shank body, two sides of the top of the inner wedge have the open slots with inclined wedges in the middle of the top, forming double-face wedge sliding slots; the insides of the clamp pieces have inclines to cooperate with the inclined wedges, respectively. The anchor shank is installed and can rapidly form shoring anchoring force, to control rock mass deformation, both acting as permanent both temporary shoring and can be applied to shoring on most conditions of lithoid surrounding rock.

Owner:项小珍 +4

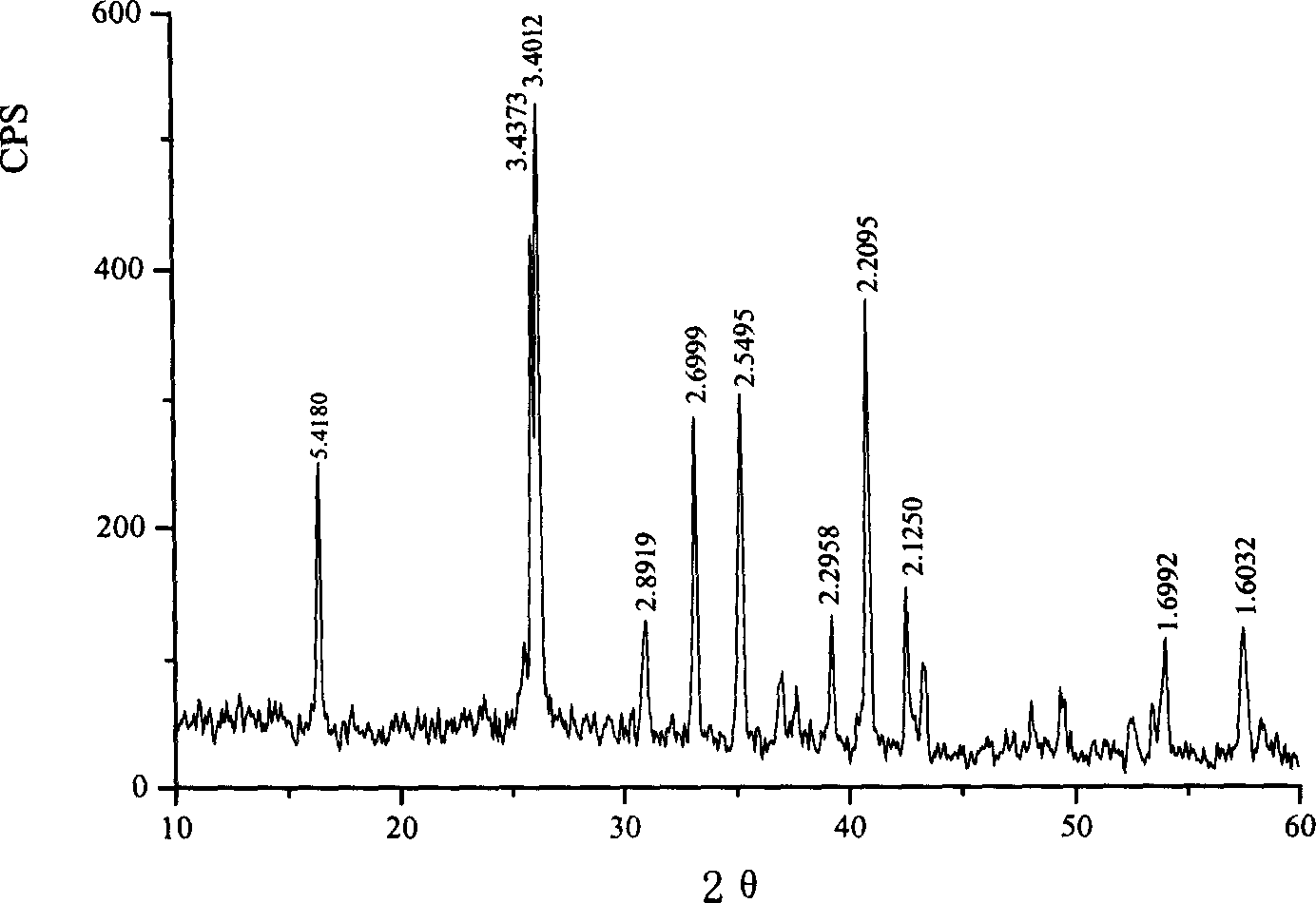

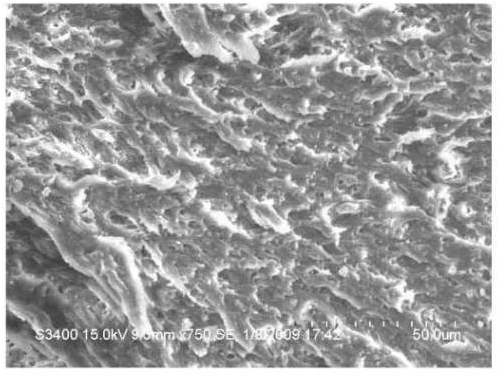

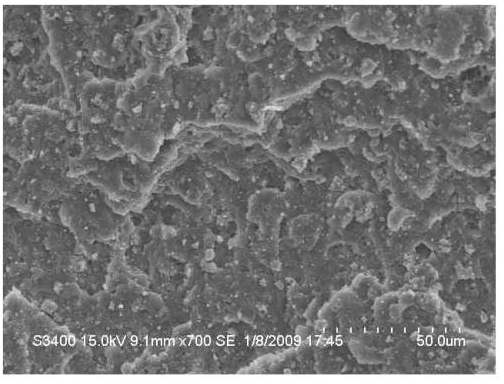

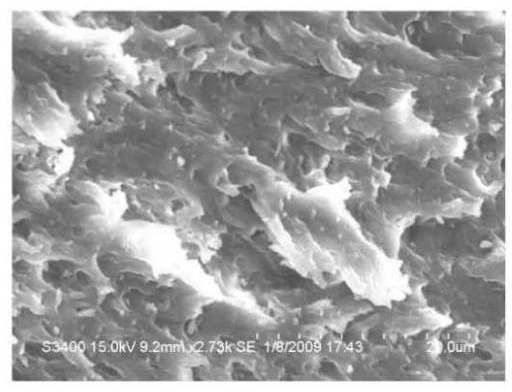

Method for preparing silicon carbide coating on graphite surface

The invention discloses a method for preparing a silicon carbide coating on a graphite surface. The method includes, firstly, placing a graphite crucible containing solid silicone materials in a high temperature graphitizing furnace and placing a graphite base body on a graphite support in the graphite crucible to generate a silicon carbide coating by means of direct reaction of silicon steam and carbon on the surface of the graphite base body; and secondly, placing the graphite base body which generates the silicon carbide coating on the surface in a chemical vapor deposition (CVD) furnace to be pyrolyzed on the surface of the silicon carbide coating which is located on the surface of the graphite base body to generate a CVD silicon carbide coating. According to the method for preparing the silicon carbide coating on the graphite surface, by means of the direct reaction of the silicon steam formed by heating the solid silicone materials and the carbon on the surface of the graphite base body, an in-situ formed chemical vapor reaction (CVR) silicon carbide coating is firmly combined on the graphite base body so that combination intensity is improved; and then a CVD process is used for pyrolyzing the CVR silicon carbide coating at high temperatures on the CVD silicon carbide coating so that pore space of the CVR silicon carbide coating is effectively filled, and combination strength is improved.

Owner:XIAN CHAOMA SCI TECH

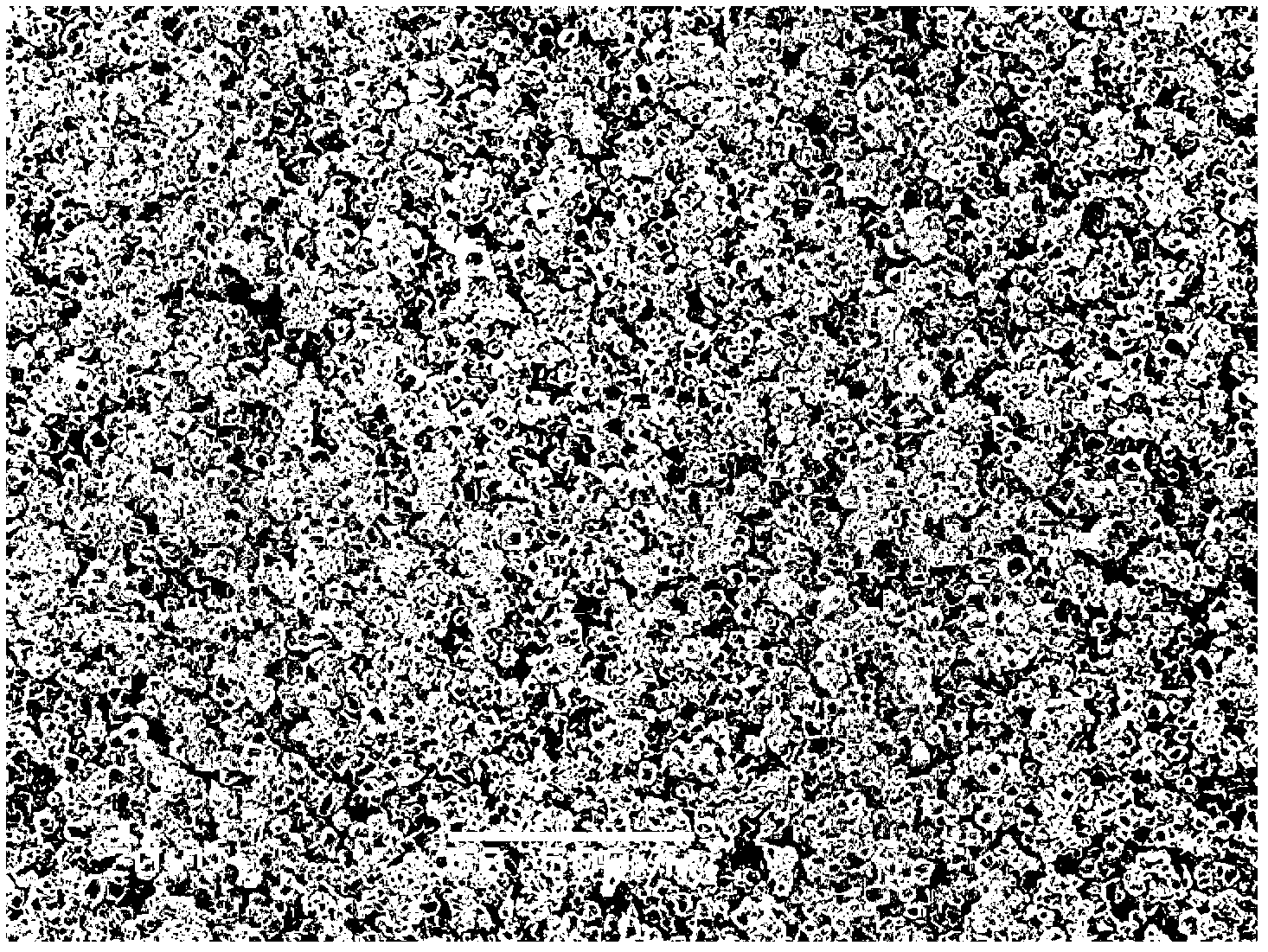

High-tap density micro aluminum powder and method for producing the same

The invention discloses minute silver powder with high tap density and a method for producing the same. The silver powder has the following properties: the average particle diameter of the silver powder is between 0.3 and 1.5 mu m; the tap density of the silver powder is not less than 4.5g / cm<3>; and the contraction rate of the silver powder is less than or equal to 19 percent after the silver powder is sintered at the temperature of less than or equal to 900 DEG C. The production method comprises: (1) preparing a solution containing silver ions for standby; (2) preparing a reducer aqueous solution containing a dispersant for standby; (3) preparing a treatment solution containing a treating agent for standby; (4) mixing and reacting the solution containing the silver ions and the reducer solution containing the dispersant for reducing the silver ions to silver particles; (5) filtering out a reaction solution, and cleaning the silver particles by deionized water; (6) pumping and leaching the cleaned silver powder, putting the cleaned silver powder into the treatment solution for treatment; and subsequently, filtering out the treatment solution; and (7) drying the silver powder in a vacuum oven; and pulverizing the dried silver powder to obtain the minute silver powder with high tap density. Silver slurry prepared from the silver powder is printed on a magnet body or a substrate, is sintered at temperature of less than or equal to 900 DEG C and has good matching property with the magnet body or the substrate. The minute silver powder is suitable for a manufacturer for producing an electronic element.

Owner:贵阳晶华电子材料有限公司

Mullite whisker-mullite composite coating and preparation process thereof

InactiveCN1793017AModerate thicknessOvercome the problem of being thin, dry and easy to crackMulliteOxidation resistant

The invention relates to mullite crystal whisker mullite compounding coating layer that the manufacture method includes the following steps: coating the mixture slime of silica sol, aluminum sol and mullite slime in vacuum of the basal material, or coating orderly, under the catalyzing effect of metal fluoride mineralizer, sintering by high temperature. The invention is simple structure, low cost of raw material, acid proof, alkali proof, etc. it could improve the intension of the material and prolong the use life.

Owner:WUHAN UNIV OF TECH

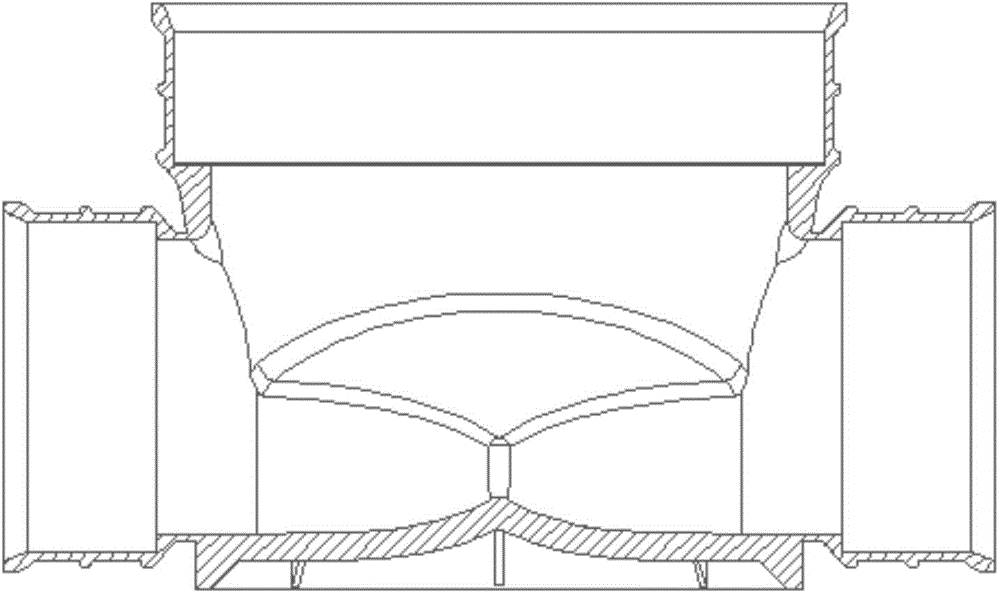

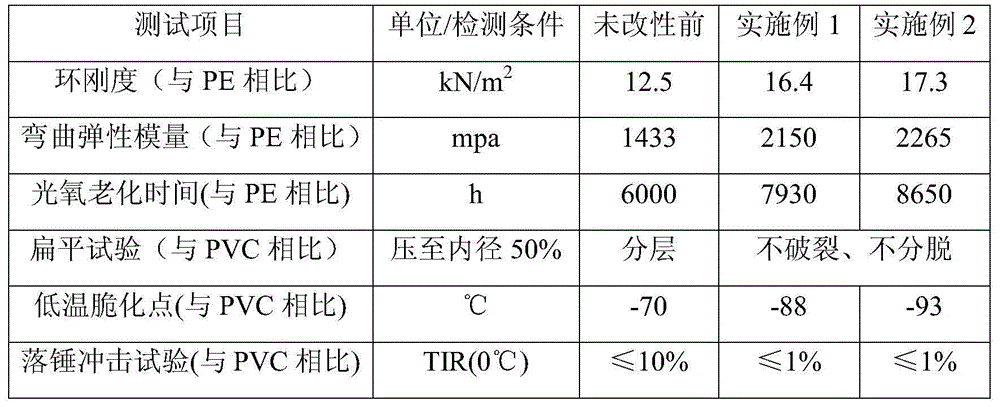

Polyethylene and polyvinyl chloride modified environment-friendly plastic check well and preparation method thereof

InactiveCN104356484AImprove impact resistanceIncreased ring stiffnessEnvironmental resistanceAntioxidant

The invention belongs to the field of a plastic check well and a preparation method thereof, and particularly relates to a polyethylene and polyvinyl chloride modified environment-friendly plastic check well and a preparation method thereof, aiming at solving the technical problem that the existing plastic check well is poor in impact strength, sensitive to temperature and bad for ring stiffness. According to the scheme for solving the technical problems, the invention provides the polyethylene and polyvinyl chloride modified environment-friendly plastic check well, which comprises the following compositions in parts by weight: 50-150 parts of polyethylene resin, 50-150 parts of polyvinyl chloride resin, 10-30 parts of nano materials, 0.5-5 parts of pigments, 2-20 parts of a lead-free stabilizer, 1-20 parts of processing aids, 1-5 parts of a lubricant, 0.5-5 parts of an antioxidant, 0.5-2 parts of a light stabilizer, 1-25 parts of a compatilizer, 1-15 parts of an impact modifier, 1-15 parts of an enhancer, and 0.5-10 parts of a coupling agent. The environment-friendly plastic check well is good in ring stiffness, high in impact strength, low in cost and long in service life.

Owner:KANGTAI PLASTIC SCI & TECH GRP

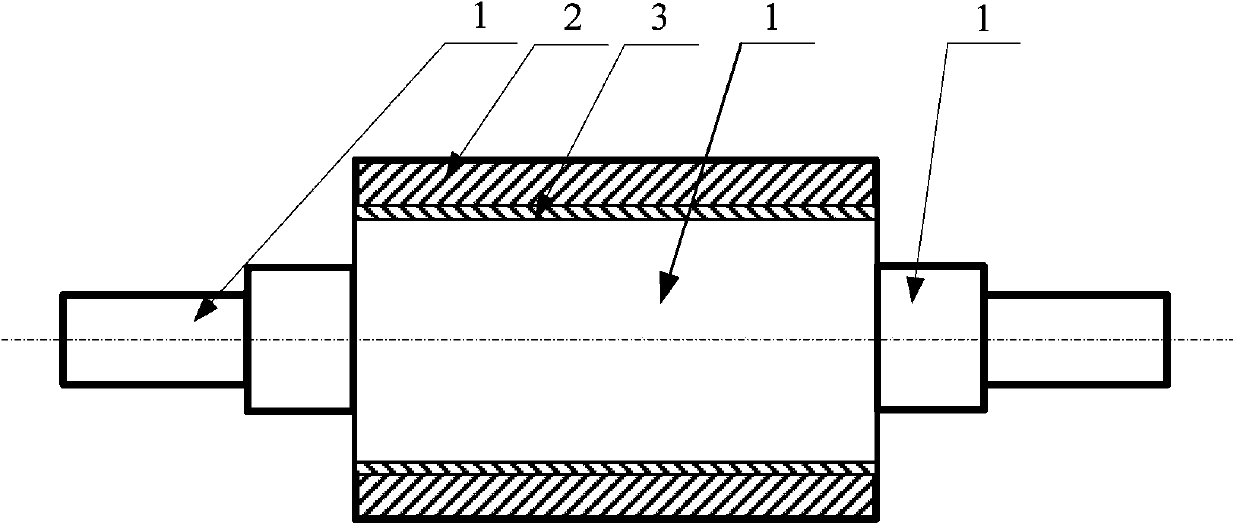

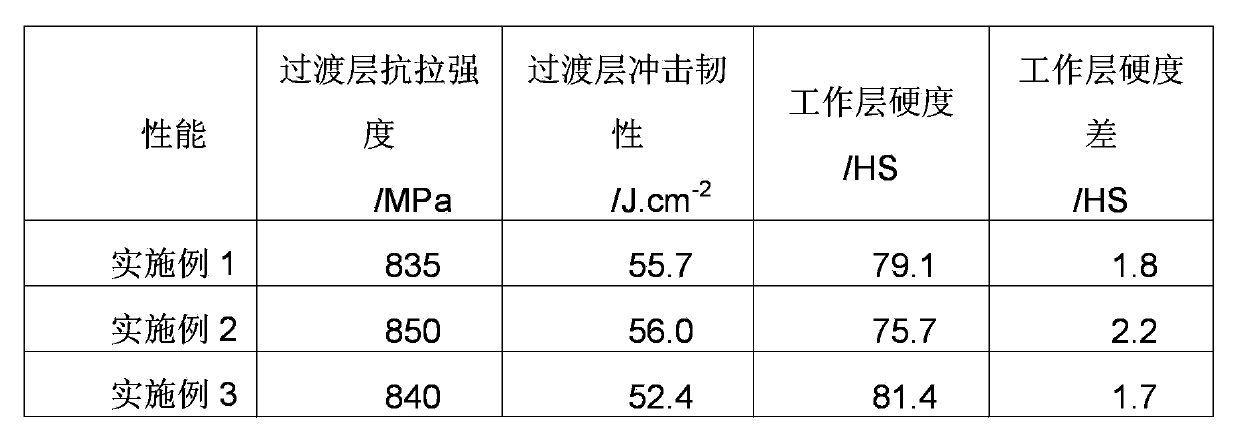

Overlaying repair method for worn roller

InactiveCN103418923AUniform hardnessHigh hardnessWelding/cutting media/materialsSoldering mediaWear resistantToughness

The invention discloses an overlaying repair method for a worn roller. The method is characterized by comprising the following process steps of turning the worn surface of the worn roller; overlaying a high-toughness transition layer on the turned surface; overlaying a wear-resistant working layer on the transition layer; performing heat treatment on the roller subjected to overlaying repair; and performing finish machining on the roller to enable the roller to reach the specified dimension and precision. Compared with the past production and manufacture process and production method, the production and manufacture cost is relatively low, the production and manufacture period is relatively short, and the roller subjected to overlaying repair is long in service life.

Owner:BEIJING UNIV OF TECH

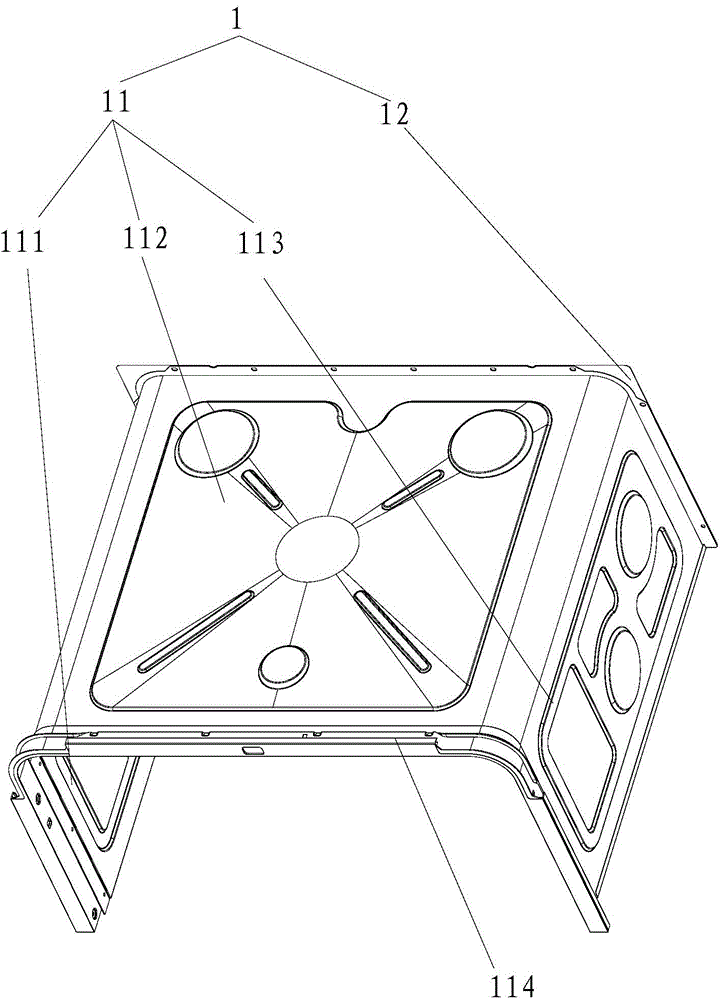

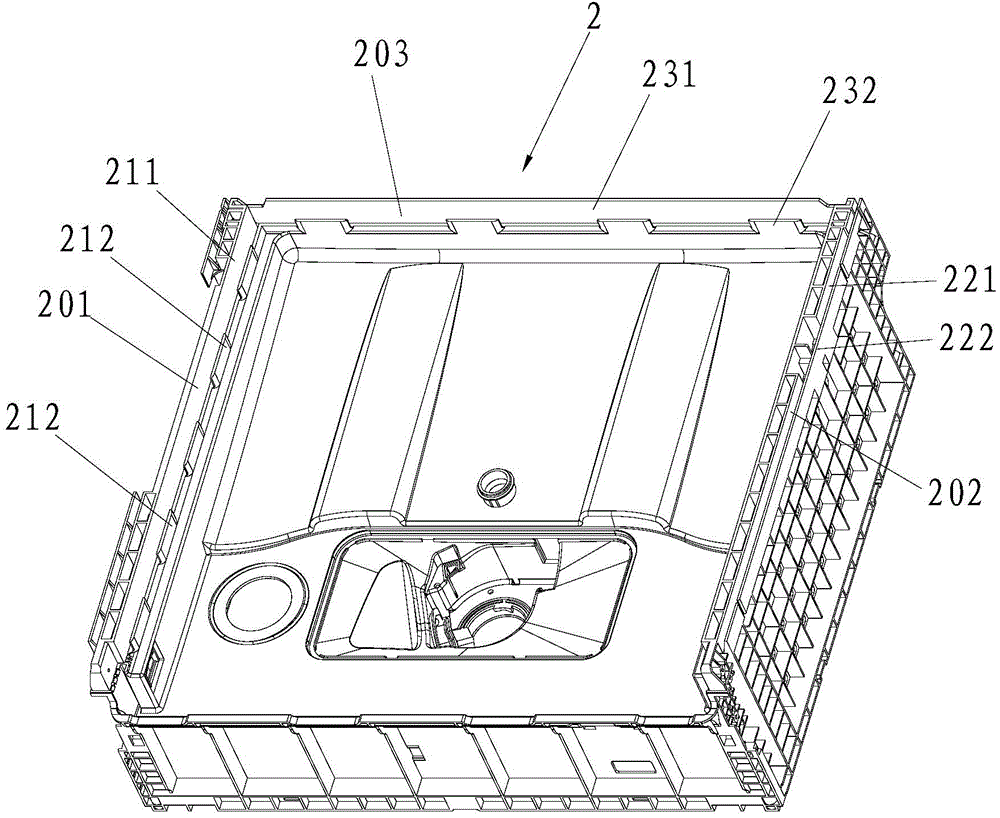

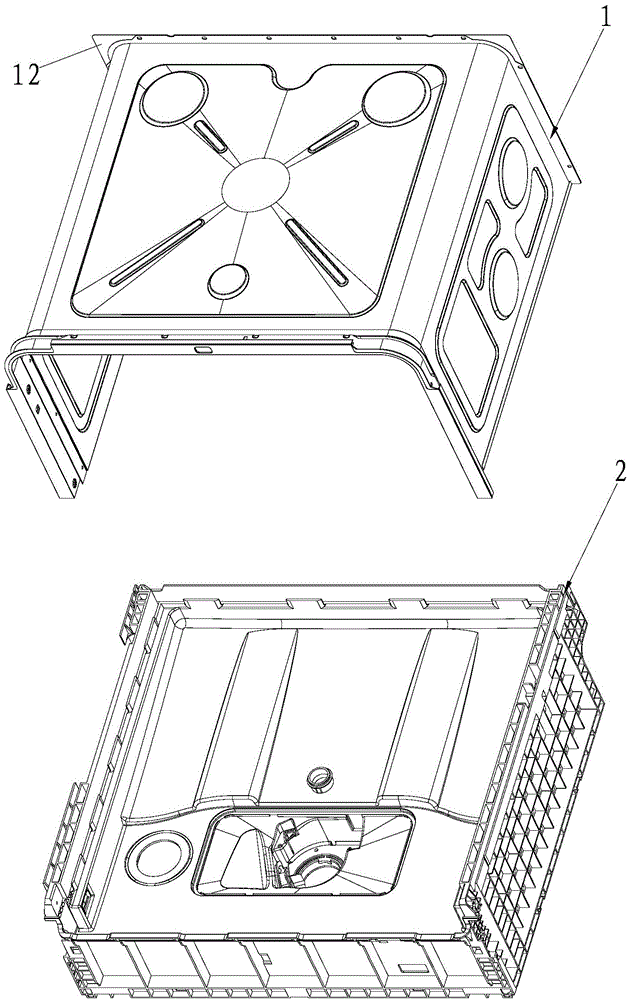

Dish washer liner pedestal component and assembling equipment and method thereof

ActiveCN104586335APrevent leakageSimple structureTableware washing/rinsing machine detailsMechanical engineeringEngineering

The invention is applied in the technical field of dish washers and discloses a dish washer liner pedestal component, assembling equipment of the dish washer liner pedestal component and an assembling method of the dish washer liner pedestal component. The dish washer liner pedestal component comprises a liner and a pedestal, wherein the pedestal is provided with a clamping groove; the edge of the liner is clamped into the clamping groove; the liner comprises an opened frame body and a rear plate connected to the opened frame body; the opened frame body comprises a top plate, a left side plate integrally molded on one side of the top plate and a right side plate integrally molded on the other side of the top plate; the left side plate and the right side plate are oppositely arranged; the rear plate is fixedly connected to or integrally molded on the opened frame body. The assembling equipment is used for manufacturing the dish washer liner pedestal component. According to the assembling method of the dish washer liner pedestal component, the assembling equipment of the dish washer liner pedestal component is adopted. According to the dish washer liner pedestal component, the assembling equipment of the dish washer liner pedestal component and the assembling method of the dish washer liner pedestal component, which are provided by the invention, the dish washer liner pedestal component is low in production cost, short in production period and high in product reliability and is conveniently used by a user.

Owner:WUHU MIDEA SMART KITCHEN APPLIANCE MFG CO LTD

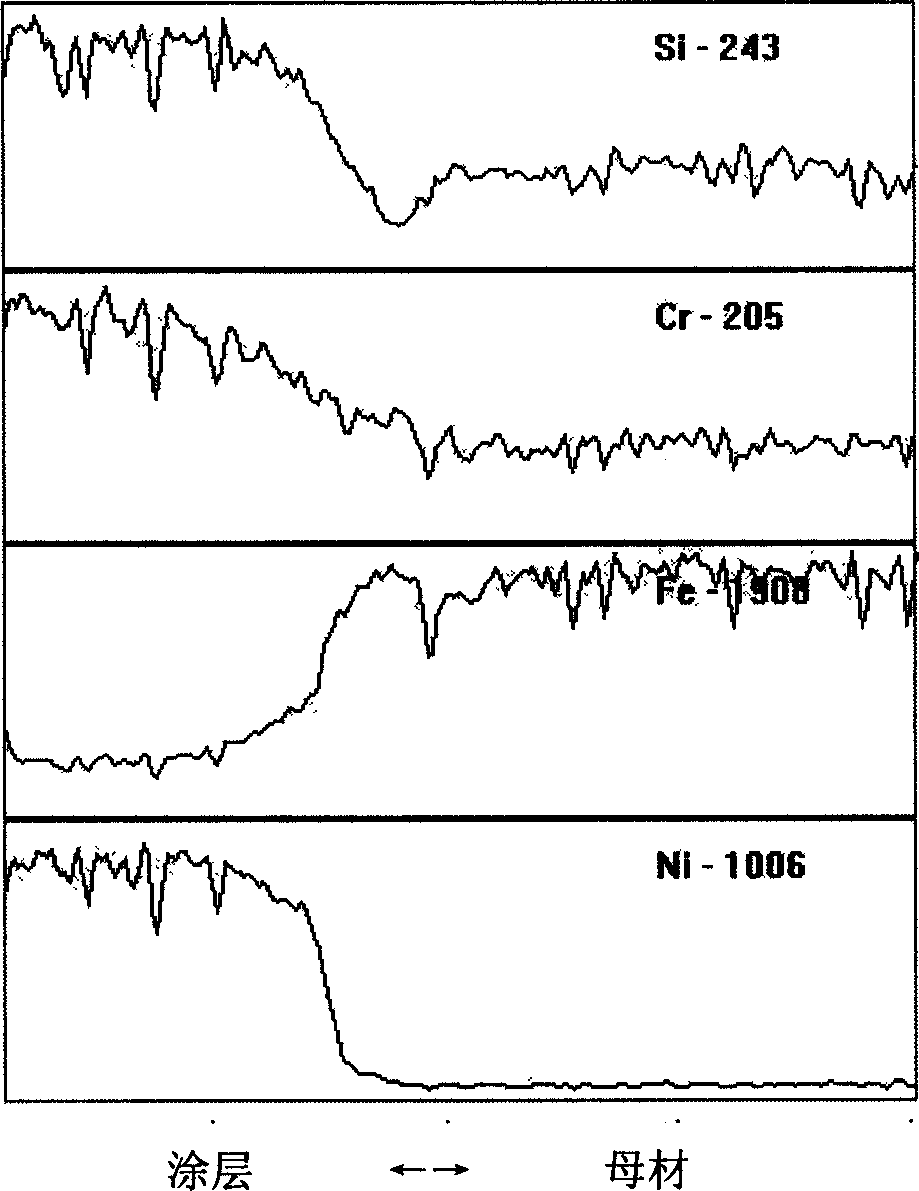

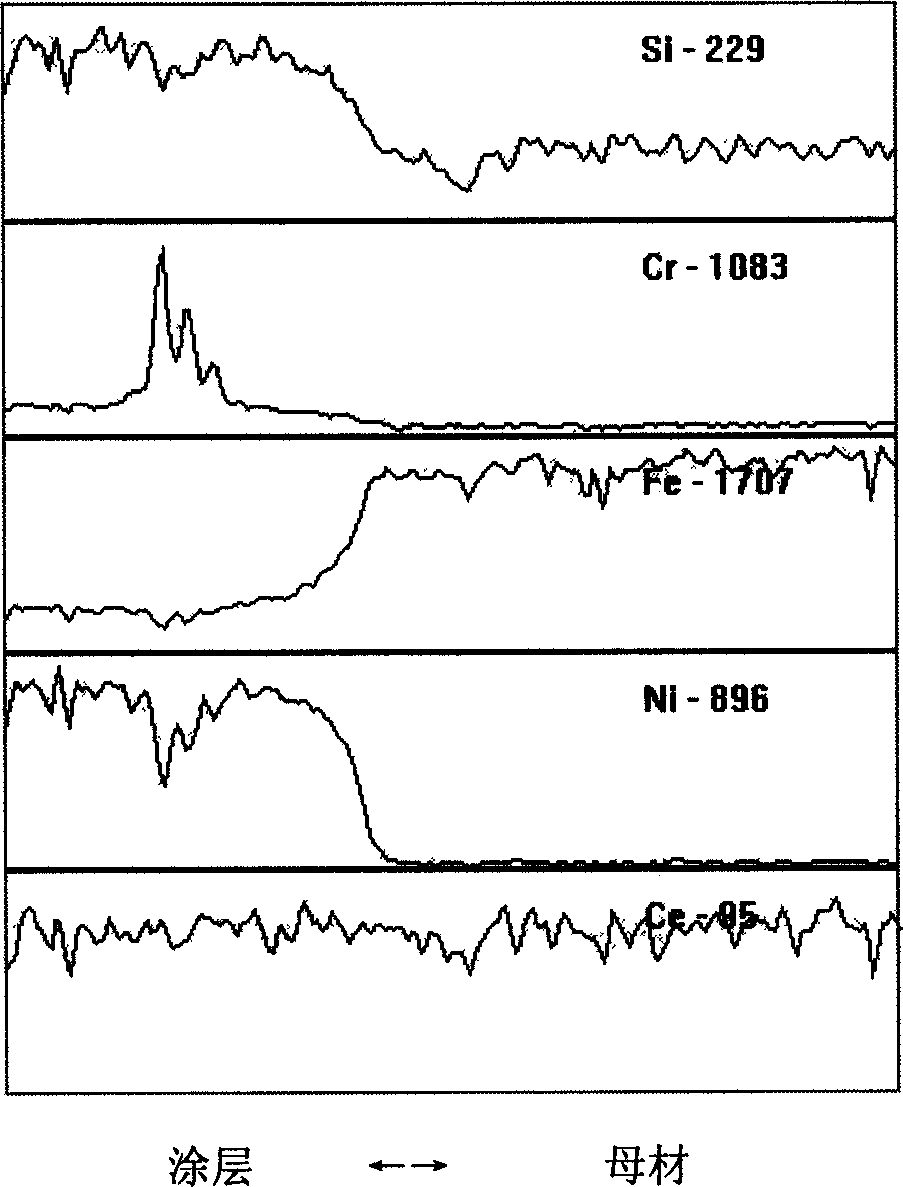

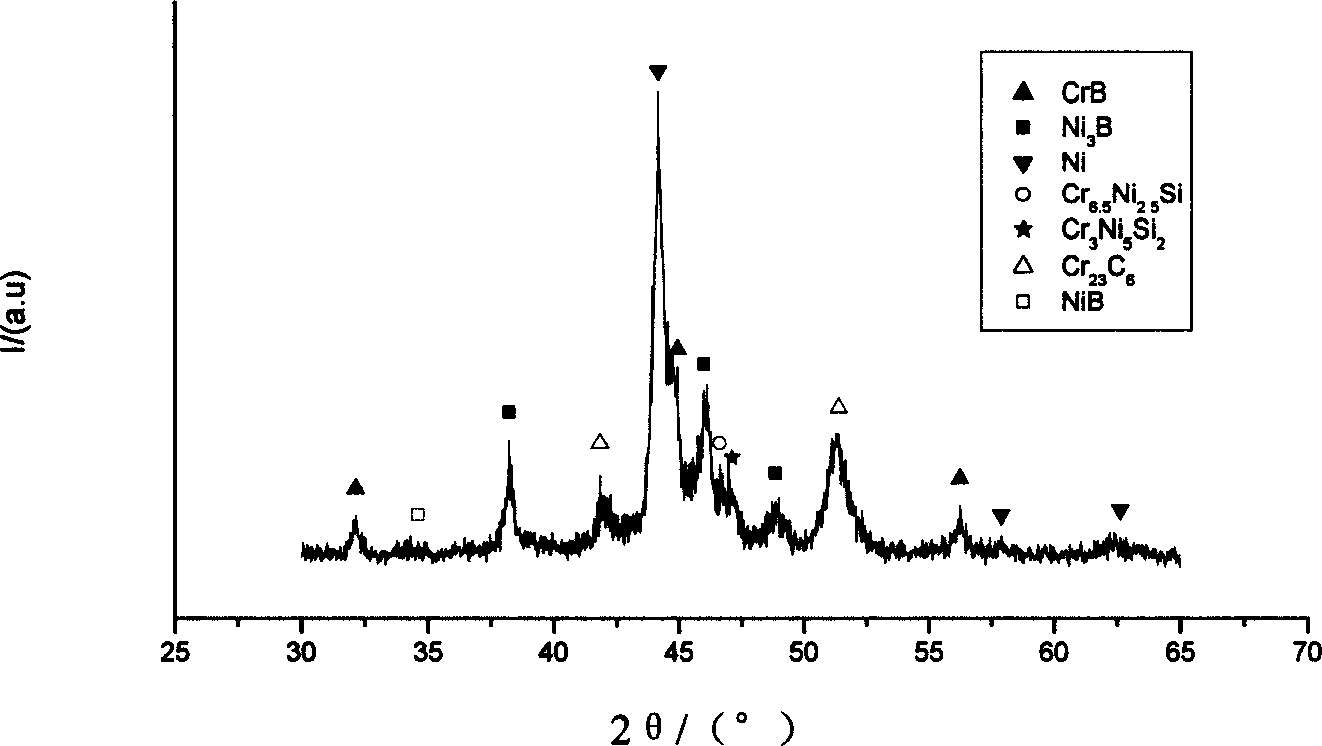

Nickel base self-fusible alloy-rare earth composite coating material and its preparing method

InactiveCN1580324AEasy to modifyImprove performanceMetallic material coating processesParticulatesSilanes

The invention is a nano-particulate demulsifying agent used in demulsification of trinary oil recovery produced fluid. The application of new technique of trinary oil recovery enhances the crude oil recovery, where the polymer injection oil-recovery technique increases the oil, obviously, but also causes the difficulty in demulsifying the produced fluid at the same time. Its character lies in that: the nano-particulate demulsifying agent is composed of particle nucleating material which processes the surface of nano silicon oxide material by silane coupler and fluorine compound and reacting solvent containing arenes as dimethylbenzene, as well as polyether demulsifying agent as multicomponent polyether, amine polyether and resin polyether. It effectively solve the problem about the demulsification of trinary oil recovery polymer injection produced fluid, field used quantity little, demulsifying speed rapid, dehydrating efficiency high and oil-water interface regular.

Owner:HEFEI UNIV OF TECH +1

Novel acrylic acid modified alkyd resin and method for preparing same

ActiveCN102993424AImprove drynessGood weather resistancePolyester coatingsLiquid mediumAging resistance

The invention aims to provide an acrylic acid modified alkyd resin which is improved in hardness, dryness, abrasion resistance and aging resistance and also maintains particular flexibility, pigment wettability and the like. Simultaneously, the acrylic acid modified alkyd resin provided by the invention solves the problem that the common acrylic acid modified alkyd resin in the market is poor in acid and alkali resistance. The acrylic acid modified alkyd resin provided by the invention is characterized that a paint film is free of bubbling, rusting, crazing and falling in 48 hours when being measured through a liquid medium resistance experiment according to GB / T 9274-1988; and the acrylic acid modified alkyd resin is obviously superior to the traditional soybean oil alkyd resin and the common acrylic acid modified alkyd resin.

Owner:SHANGHAI ZHENHUA HEAVY IND CHANGZHOU COATINGS CO LTD

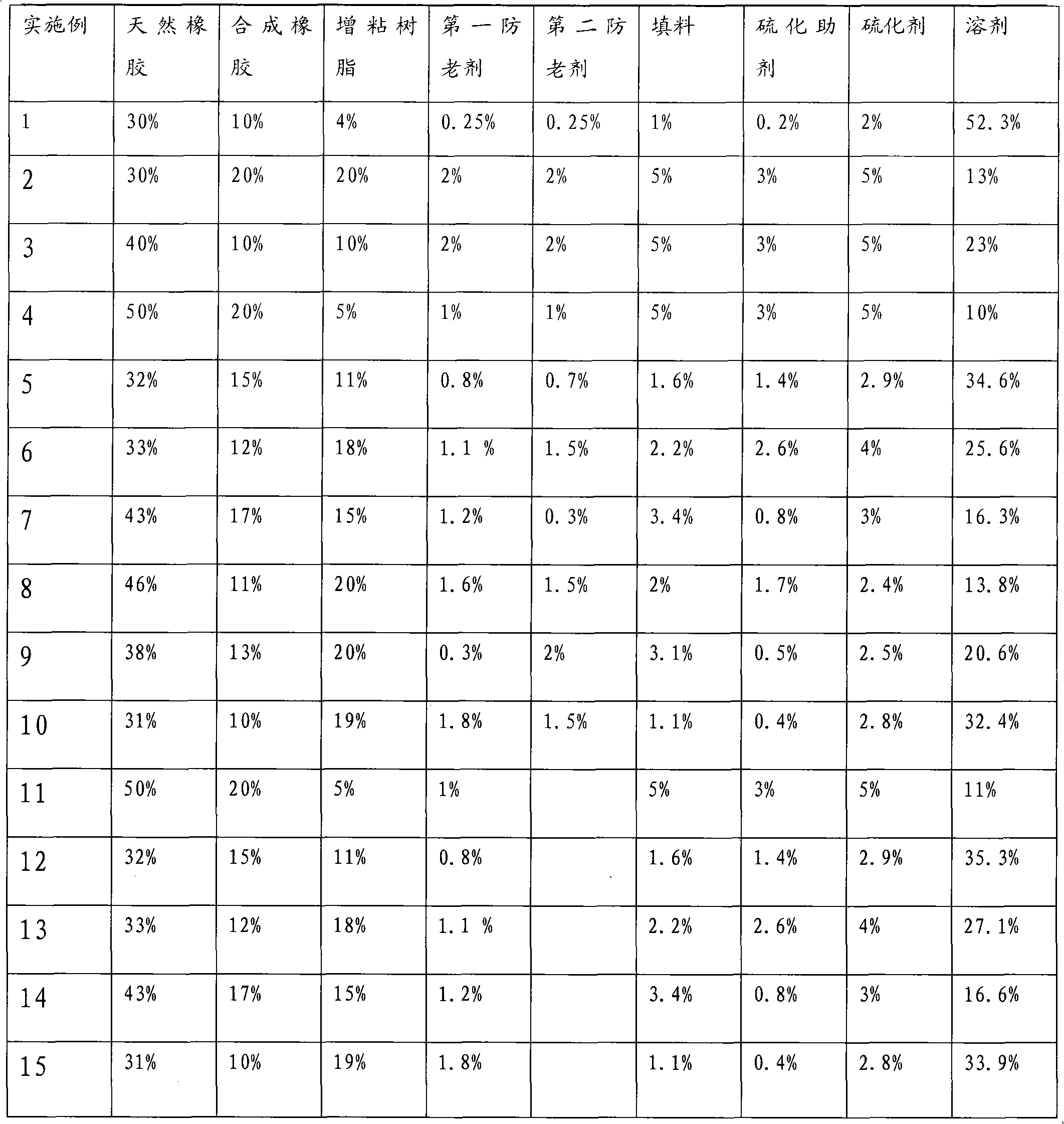

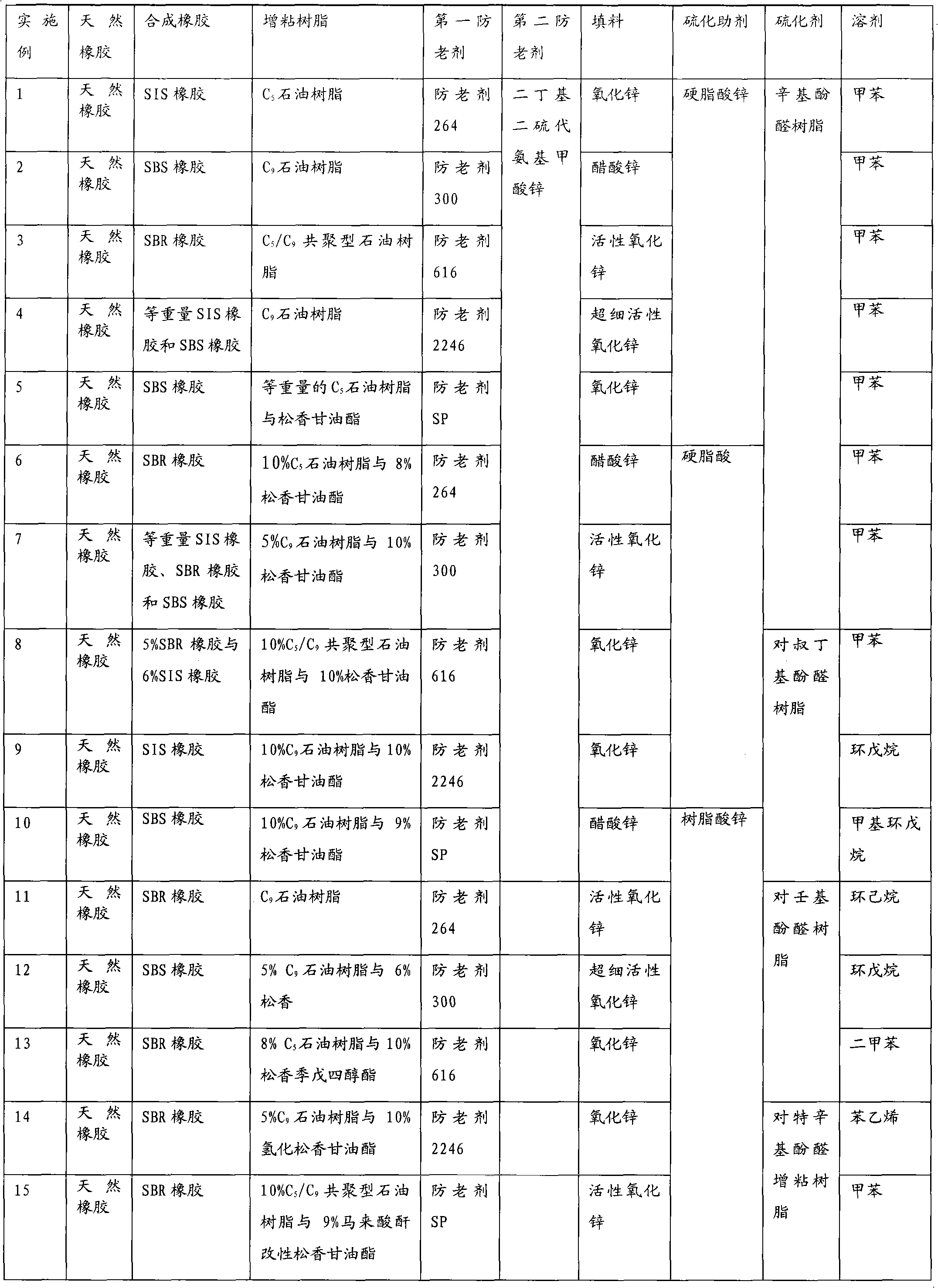

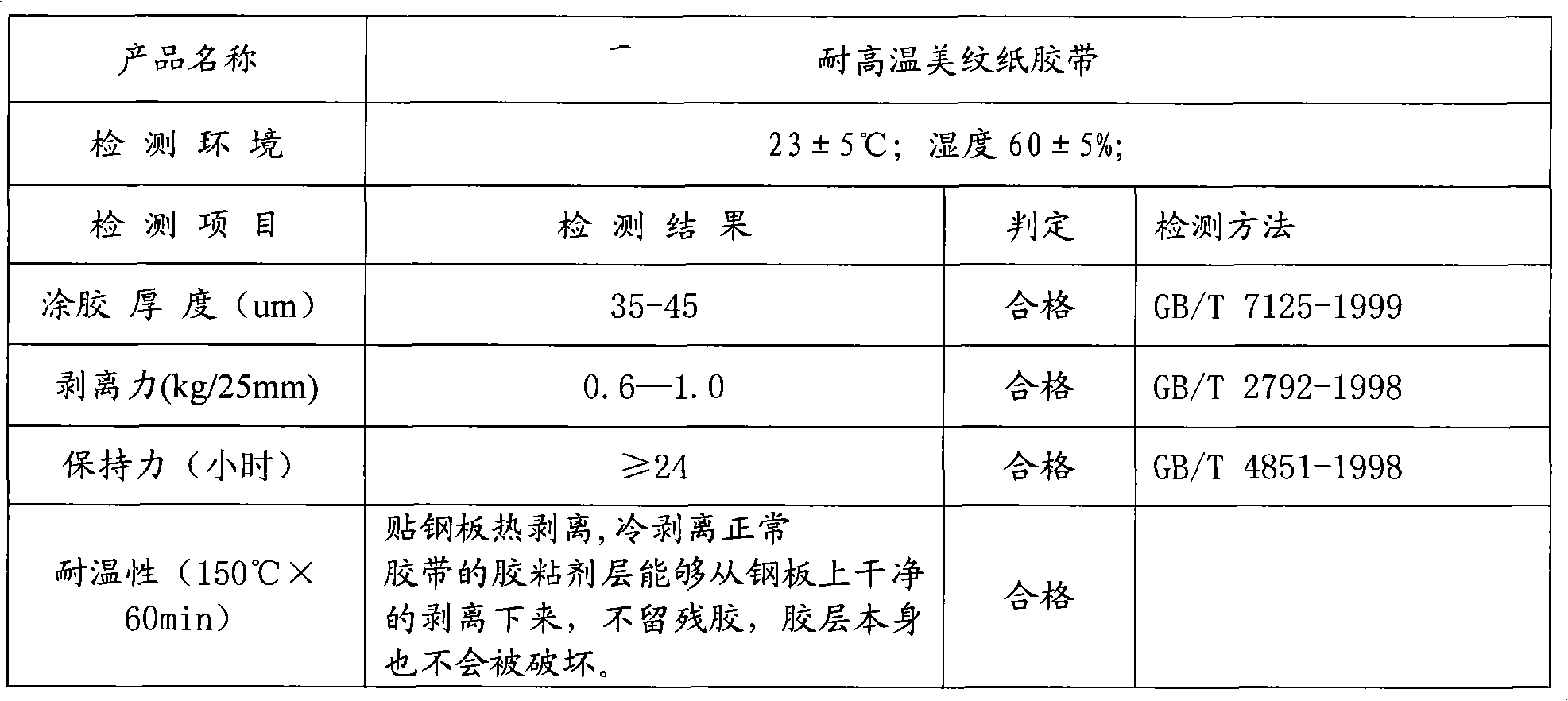

Adhesive for high-temperature-resistant masking tape and high-temperature-resistant masking tape

ActiveCN102120922AThermal peeling is normalCold peeling index is normalMineral oil hydrocarbon copolymer adhesivesNatural rubber adhesivesVulcanizationMasking tape

The invention discloses an adhesive for a high-temperature-resistant masking tape. The adhesive for the high-temperature-resistant masking tape is characterized by comprising the following components in percentage by weight: 30 to 50 percent of natural rubber, 10 to 20 percent of synthetic rubber, 4 to 20 percent of viscous resin, 0.5 to 4 percent of anti-aging agent, 1 to 5 percent of filler, 0.2 to 3 percent of vulcanization auxiliary agent, 2 to 5 percent of vulcanizing agent and the balance of solvent. The adhesive for the high-temperature-resistant masking tape has high temperature resistance and normal hot stripping and cold stripping indexes after being used continuously at the temperature of 150 DEG C for 60 minutes. The adhesive is applied to adhesion at the temperature of 150 DEG C without degumming and cracking and is particularly applied to high-temperature environments such as automobile baking varnish, an electronic circuit board and the like.

Owner:SHANGHAI SMITH ADHESIVE NEW MATERIAL

Method for producing wear-resistant composite roller

InactiveCN101412105ANo crackingImprove bindingRollsMetal rolling arrangementsInterference fitSurface layer

The invention relates to a method for manufacturing a wear resistant composite roll, which belongs to the technical field of steel rolling. The most difficult problems in the technology transfer of the prior combined composite roll are the improvement on the processability of an outer-layer roll sleeve and the improvement on the processing efficiency. The method comprises the following steps: opening a groove on the outer surface of a roll collar inner sleeve, washing the roll collar inner sleeve by using diluted hydrochloric acid and alcohol, then painting borax on the surface of the roll collar inner sleeve and in the groove, and air-drying the roll collar inner sleeve and placing the roll collar inner sleeve in a casting mould; pouring outer layer wear resistant molten metal through a bottom pouring method to obtain an imbedded composite roll sleeve; and combining the imbedded composite roll sleeve with a cast steel or forged steel rolling shaft through splines and integrating the imbedded composite roll sleeve and the cast steel or forged steel rolling shaft through interference fit so as to obtain the wear resistant composite roll. The composite roll has the advantages of high hardness for the outer surface layer, good wear resistance, high roll core strength, good tenacity, firm combinations between the roll sleeve and the roll core and between the roll sleeve outer surface layer and the roll collar inner sleeve and the like.

Owner:BEIJING UNIV OF TECH

Method for preparing ceramic material by process steps of powder green body dipping and precursor cracking

The invention provides a method for preparing a ceramic material by process steps of powder green body dipping and precursor cracking. The method comprises the following steps: (1) preparing ceramic powder into a required green body by using a conventional method; (2) drying the green body for 1-30 hours at the drying temperature of 80-150 DEG C to obtain a porous green body; (3) dipping the porous green body into a liquid ceramic precursor for 1 hour or more in vacuum or at a certain pressure; (4) placing the porous green body with the ceramic precursor in an airtight high-pressure kettle, introducing inert gas, raising the temperature to 60-300 DEG C at the pressure of 0.1-30 MPa, and then performing heat insulation for 10-55 hours so that the precursors in the holes of the powder green body are crosslinked and cured; and (5) placing the green body with the cured ceramic precursor in a high temperature furnace, protecting with nitrogen, heating to 1200-1400 DEG C, and then performing heat insulation for 50-70 minutes, so that the cured precursor is cracked and converted into ceramic. The method has the advantages of high production efficiency, high yield and low production cost, and can be used for preparing various ceramic materials such as silicon carbide, silicon nitride, silicon oxide, boron nitride, boron carbide, alumina, aluminium nitride, zirconia and the like.

Owner:NAT UNIV OF DEFENSE TECH

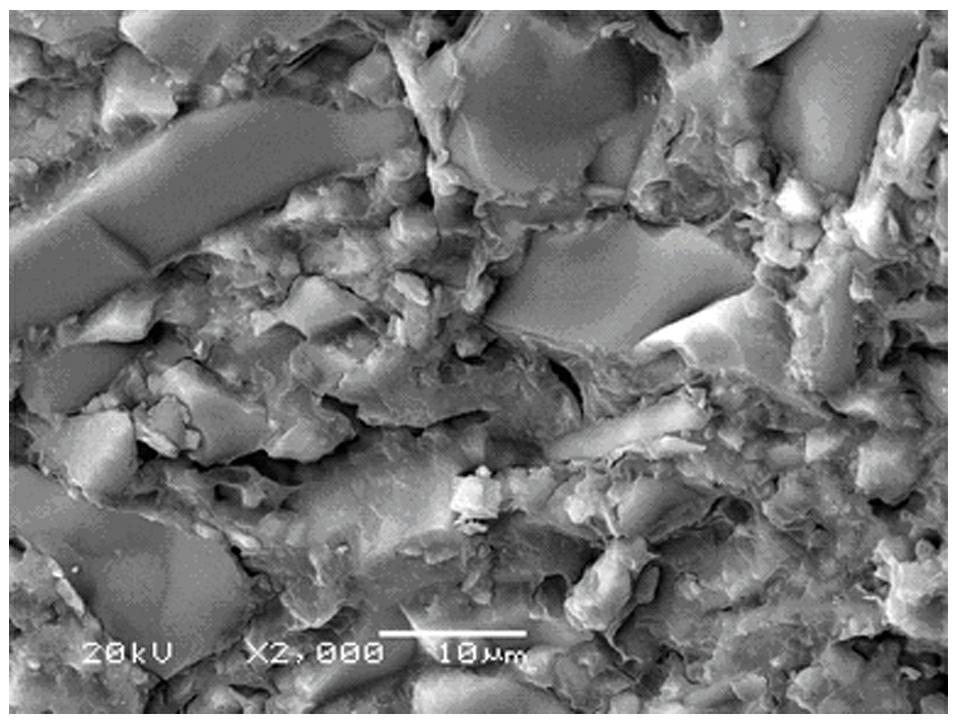

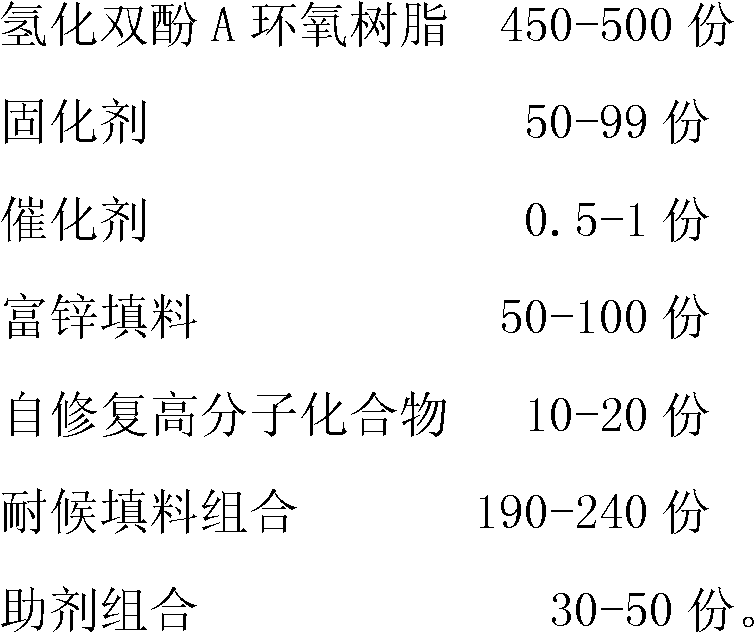

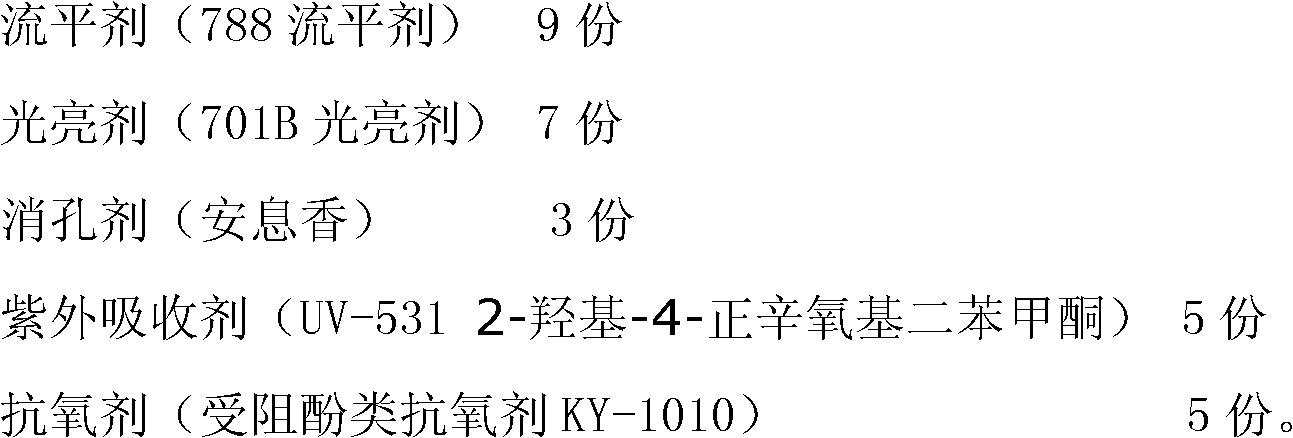

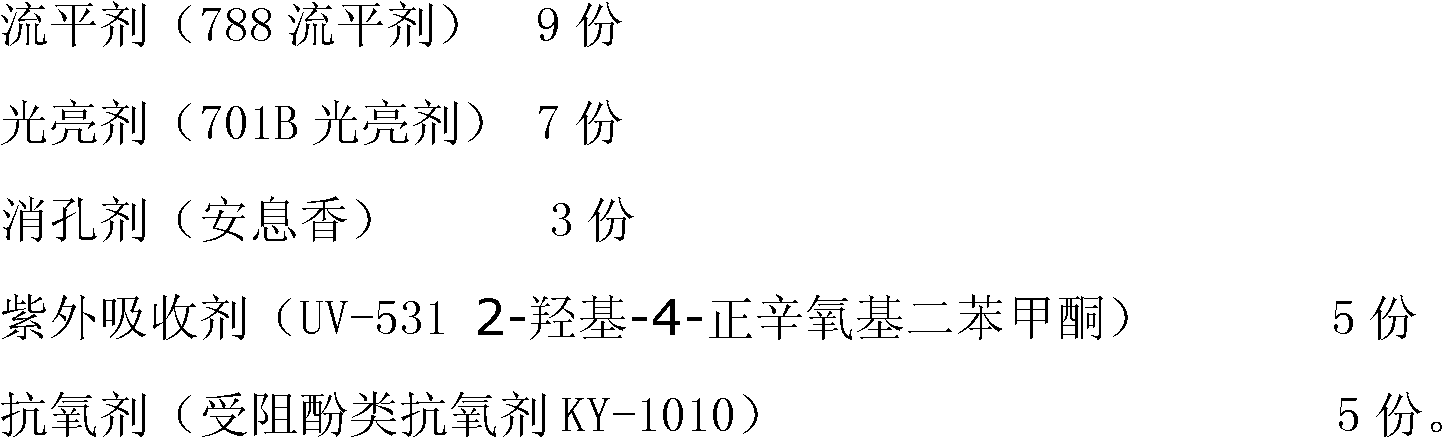

Weather-resistant heavy-duty anticorrosive powder coating

InactiveCN102634266AGood weather resistanceImprove corrosion resistanceAnti-corrosive paintsPowdery paintsDry mixingHeavy duty

The invention relates to a weather-resistant heavy-duty anticorrosive powder coating comprising the raw materials in parts by weight: 450-500 parts of hydrogenated bisphenol A epoxy resins, 50-99 parts of curing agents, 0.5-1 part of catalysts, 50-100 parts of zinc-rich fillers, 10-20 parts of self-repairing conductive macromolecule compounds, 190-240 parts of weather-resistant pigments and fillers and 30-50 parts of additives. A preparation method of the coating comprises the steps of putting the raw materials into a high-speed mixer, putting in an extruder after subjecting to dry mixing, carrying out fusion, mixing, cooling and preforming at an extrusion temperature of 80-90 DEG C, grinding by utilizing a grinder, grading, sieving and packaging to obtain finished products of the powder coating. The powder coating disclosed by the invention is mainly applied in the coating of outdoor heavy-duty anticorrosive environments, has excellent anticorrosive performance and weather-resistant performance and is an ideal heavy-duty anticorrosive coating capable of being used for outdoors. Proved by customer use and detection of relevant authoritative departments, the anticorrosive performance and the weather-resistant performance of the coating are excellent and can be completely up to indexes of imported similar products and certain indexes even exceed those of foreign products; the price of the coating is superior than that of the imported products; and therefore, the coating is well received by customers.

Owner:国润恒科(天津)防腐工程技术有限公司

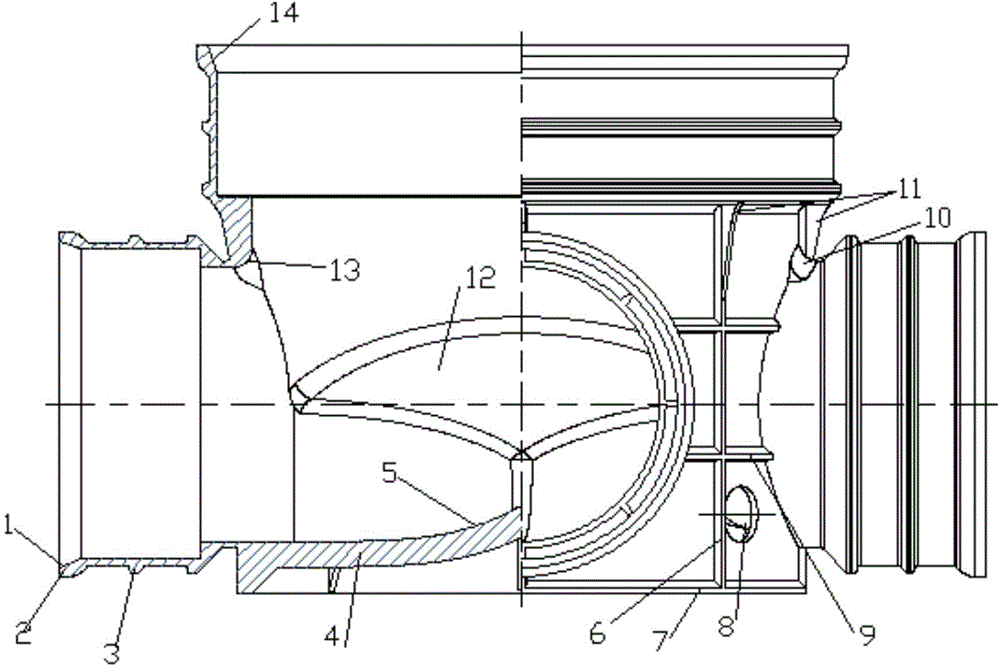

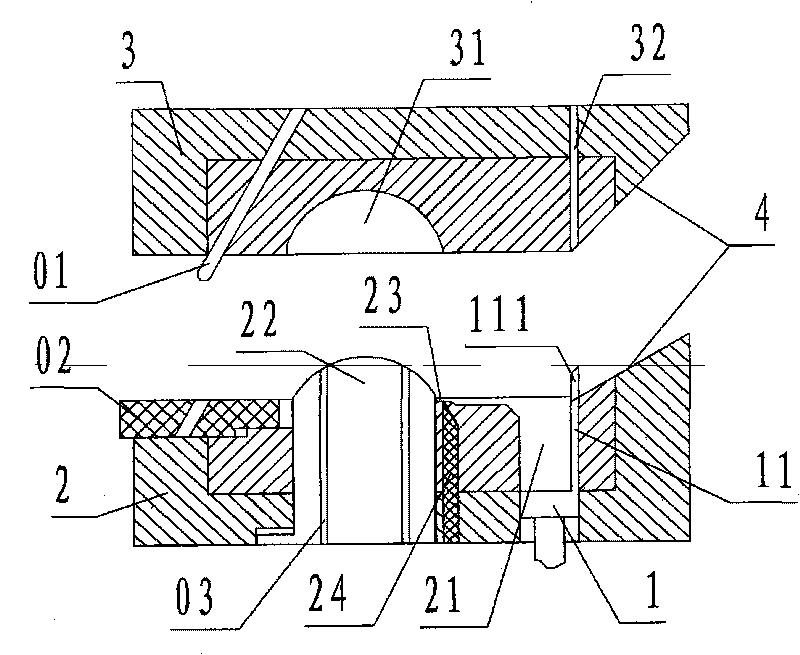

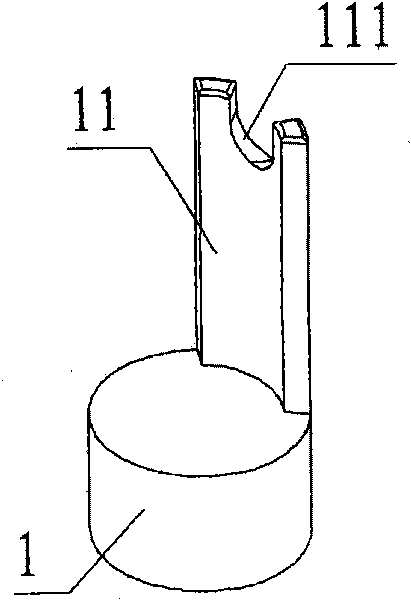

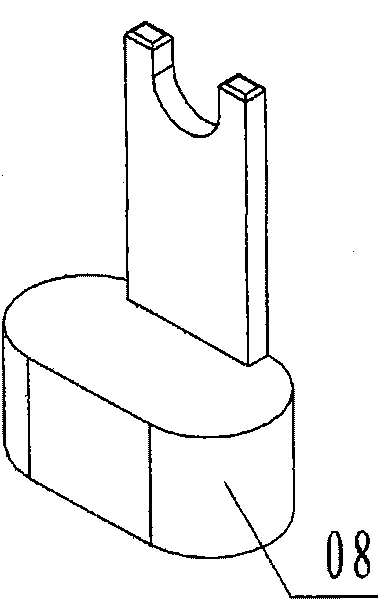

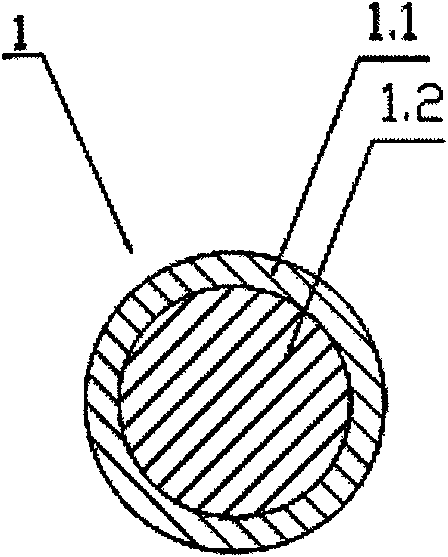

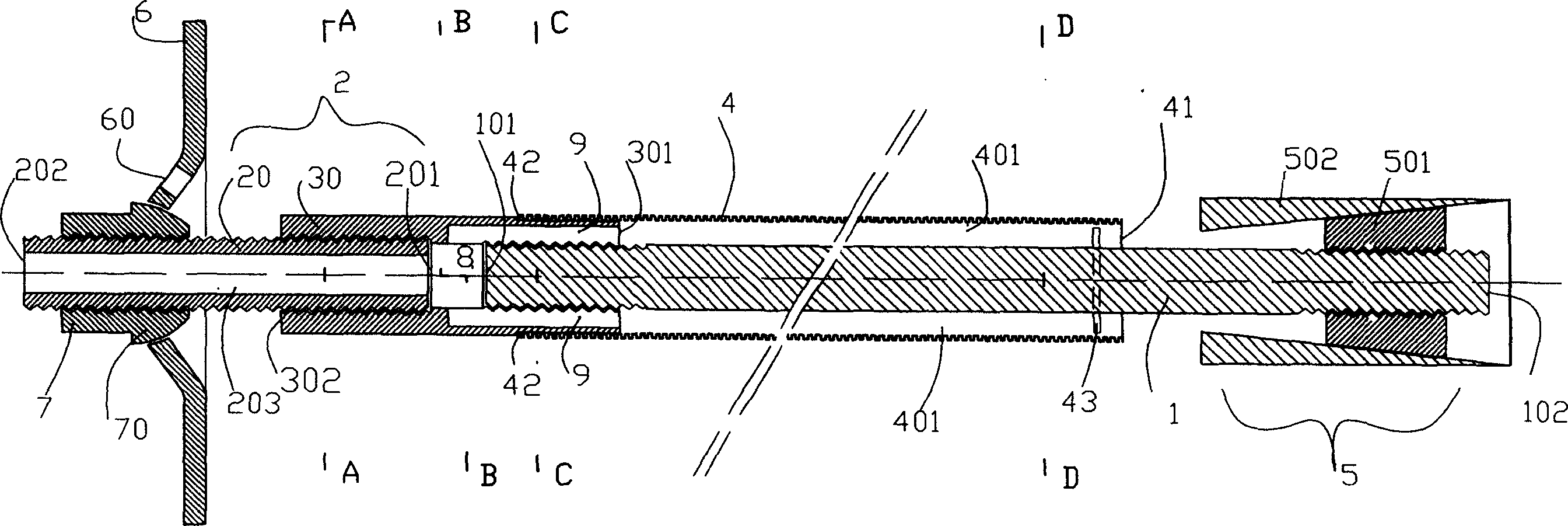

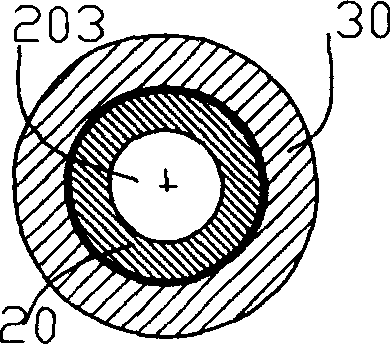

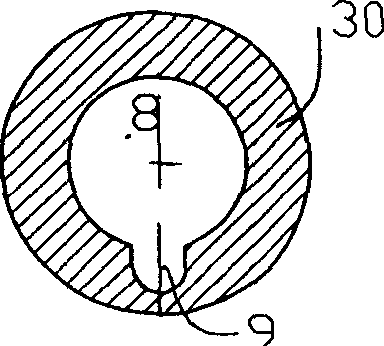

Alloy liquid extrusion casting forming device and process method thereof

The invention discloses an alloy liquid extrusion casting forming device which comprises a hammerhead (1), a static die (2), a movable die (3) and a pouring slot (4). The device adopts the technical scheme that a declined and downward funnel-shaped pouring slot occupied by both the movable die and the static die arranged respectively by half is arranged on the parting plane on one side of a vertical die casting mould; a cylinder chamber type feed liquid chamber and the piston type hammerhead with a sealing knife is arranged on the static die; the hammerhead is controlled to be pushed up, and simultaneously the sealing knife seals the pouring slot. Firstly, feed liquid is filled into the a die cavity at high speed with low pressure, then the semisolid feed filled into the die cavity is extruded at low speed with high pressure, and the semisolid feed is gradually condensed to be formed under high-pressure low-speed extrusion. The alloy liquid extrusion casting forming device and the process method thereof integrate full casting functions of low-pressure filling and high-pressure extrusion into a whole, ensure that forming of alloy casting achieves the purposes of no gas entrapment, no cast seam, no mis-run, no forging crack, no fash, compact texture, fine crystal grain, high mechanical property, capability of performing thermal treatment and sealing, high dimensional accuracy, energy saving and low cost.

Owner:中建投(绍兴)机械科技有限公司

Special thin anti-crack plastering mortar for autoclaved aerated concrete

The invention discloses a special thin anti-crack plastering mortar for autoclaved aerated concrete and belongs to the technical field of building materials. According to the special thin anti-crack plastering mortar disclosed by the invention, a dry material is added with water by a mass ratio that water to dry material ratio is equal to 1:4, and then stirred for 3-5 minutes to prepare mortar, wherein the dry material consists of the following components in mass by percentage: 20%-35% of cement, 10%-30% of 40-70-mesh quartz sand, 30%-50% of 80-100-mesh quartz sand, 2%-7% of 200-mesh coarse whiting powder, 1.5%-4% of redispersible emulsion powder; 0.15%-0.5% of water-retaining agent; 0.2%-0.7% of wood fiber and 0.11%-0.45% of short fiber. Being prepared by adopting quartz sand of 40-70 meshes or 80-100 meshes, the special thin anti-crack plastering mortar for the autoclaved aerated concrete disclosed by the invention has an excellent anti-crack performance, realizes effective control on contraction percentage of the mortar, causes no cracks during large-area construction, achieves good caking property, and realizes organic combination between the mortar and the surface layer of the autoclaved aerated concrete.

Owner:山东高阳建材有限公司

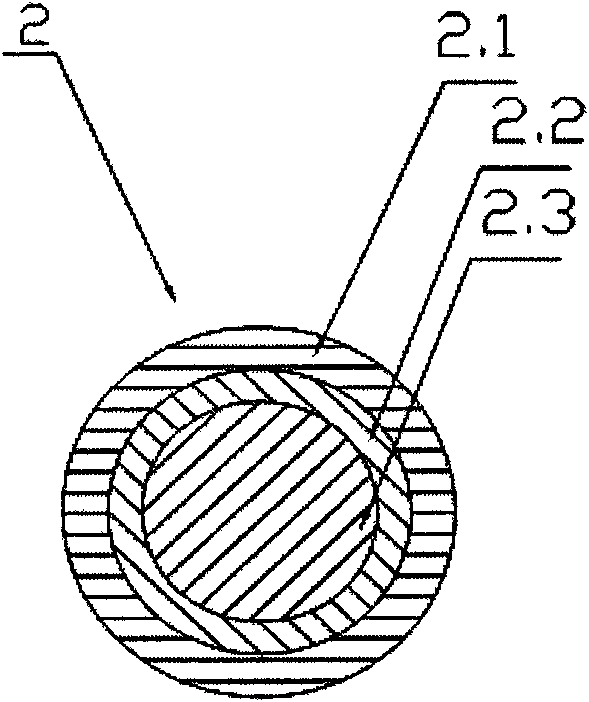

Continuous high-strength fiber resin-based compound core for overhead conductor and preparation method thereof

ActiveCN102136319AImprove bending performanceNo crackingInsulated cablesCable/conductor manufactureFiberInjury tolerance

The invention relates to an improved high-strength fiber resin-based compound core for an overhead conductor. The improved high-strength fiber resin-based compound core is characterized by being formed by twisting a plurality of single compound cores, wherein each single compound core is at least formed by concentrically compounding an inner layer fiber resin core and an outer layer fiber resin core; curing resin for outer layer fibers at least except a core layer is flexible resin the vitrified temperature of which is more than or equal to 180 DEG C; and the thickness of the outer layer is between 0.5 millimeter and 3 millimeters. By adopting the preparation method, the overall bending property of an obtained twisted compound core is remarkably improved, and the minimum bending radius is40 times of the diameter or smaller after twisting; the twisted compound core can bear radial compressive stress, has a high injury tolerance ratio and good using safety, can be directly connected byadopting ordinary hardware fitting and construction hardware fitting for a conductor in a compression joint way without cracking; the using and erecting costs and the construction cost are greatly lowered; and popularization and application are promoted. A single compound core is molded in a semi-curing mode, so that pulling and extruding speeds can be greatly increased and the production speed of the entire compound core can be increased by 20-50 percent compared with that of the conventional compound core adopting cured resin.

Owner:FAR EAST COMPOSITE TECH

Single system and composite fire retardant coating for tunnel

InactiveCN1687254AAvoid self-strength lossImprove performanceFireproof paintsCement coatingsAdhesiveUltimate tensile strength

The present invention relates to a production method of single system compounded tunnel fire-resisting paint. Its composition includes (by weight portion) 20.0-50.0 portions of adhesive formed from redispersible latex powder and aluminous cement, 55.0-85.0 portions of inorganic heat-insulating filler and 0.1-5.0 portions of adjuvant. Said fire-resisting paint not only has good fire-resisting property, but also has good water-proof and sound-insulating properties.

Owner:SICHUAN UNIV

Large compact zircon overflow brick and manufacturing method thereof

This invention relates to a large densed zircon overflow bricks containing TiO2 weighting 0.2-1.2% characterizing that the large densed zircon overflow brick is 1500-3100mm long, 100-600mm thick and 600-1000mm wide, which applies vacuumization first and molding later and rising and lowering the temperature slowly thus to overcome crack during the process of producing said bricks and produce overflow bricks used in the production system of liquid crystal glasses.

Owner:ZIBO GT INDAL CERAMICS

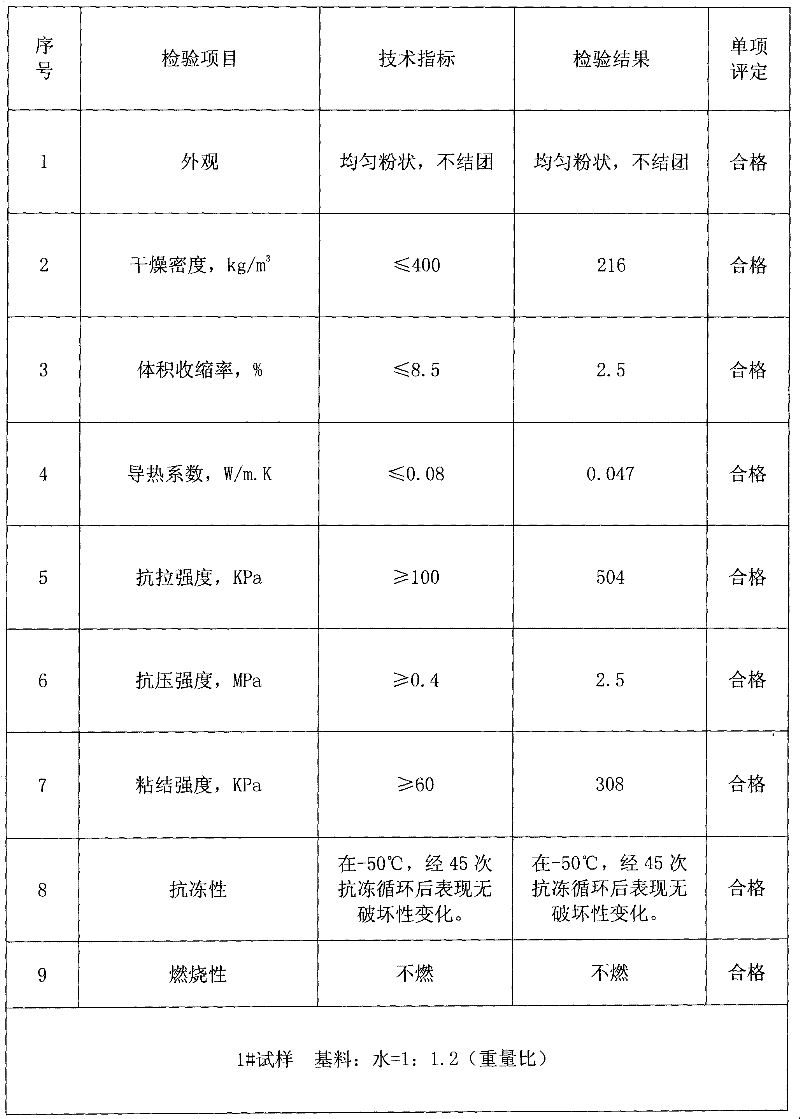

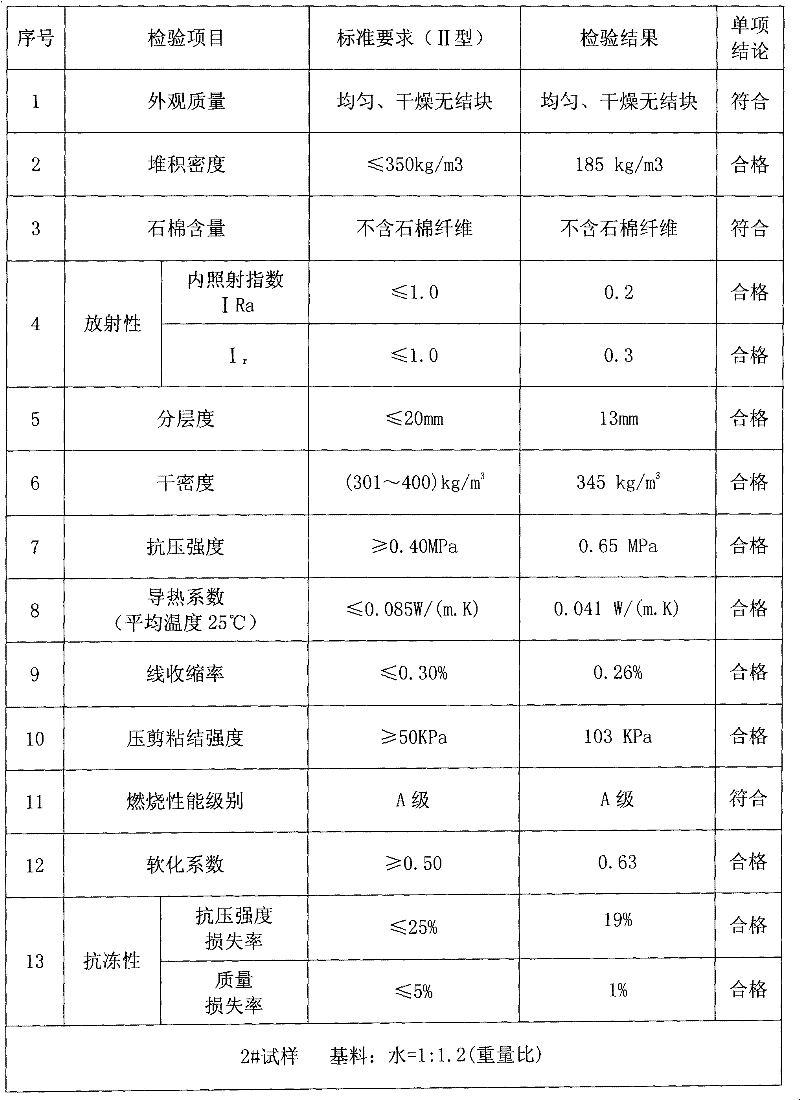

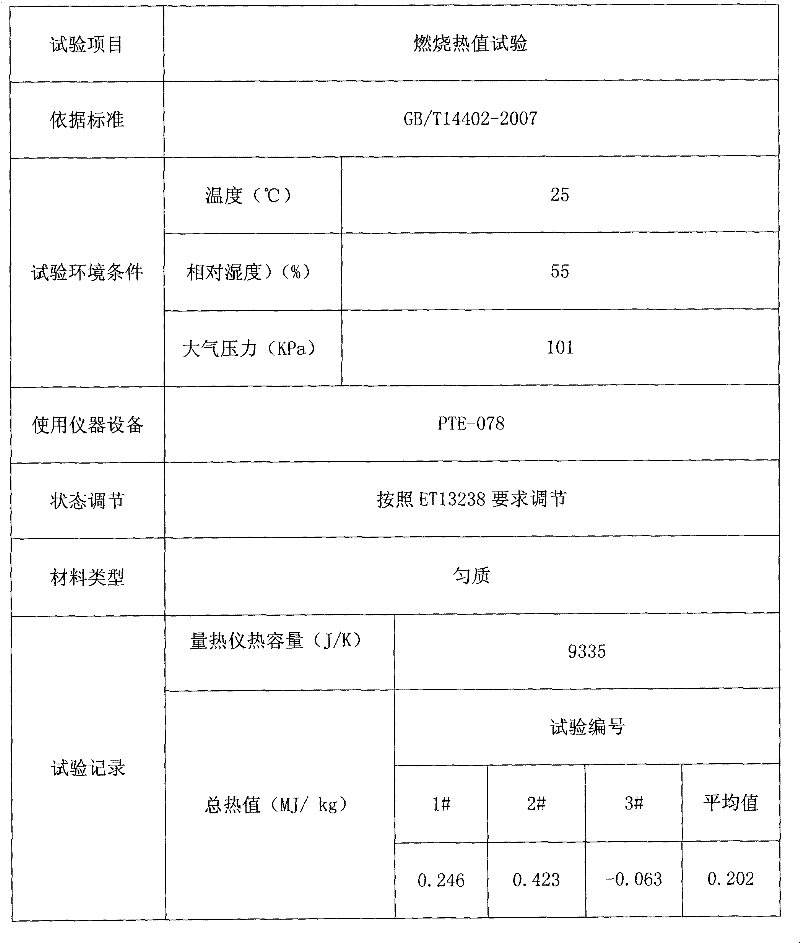

Siliceous heat-insulation composite material for wall

The invention relates to a siliceous heat-insulation composite material for a wall, which comprises base materials and water. The base materials mainly comprise closed-cell expanded perlite, cement, building gypsum, inorganic mineral substance fibers, high-viscosity attapulgite clay, redispersible rubber powder, hydroxypropyl methyl cellulose auxiliaries and a water repellent, wherein the inorganic mineral substance fibers comprise alumina silicate fibers, brucite fibers, mineral cotton fibers and the like, and when the material is used, the weight ratio of the base materials to the water is 1:1.2-1.3. The material as an amorphous powdery heat-insulation material is excellent in energy conservation, heat insulation, sound absorption, flame retardance reaching level A1, fireproofing, seismic resistance, crack control, flexibility and weatherability, does not chemically react with the wall, is high in strength and ageing resistance, avoids deformation, crack, hollowing, shedding and is the same as the wall in service life in use. The material is green, environment-friendly and non-toxic, is applicable to heat insulation of an inner wall and an outer wall made of various wall base materials, a splitting wall and heat-insulation energy-saving projects such as roofs, basements, garages, stairs, corridors, fire-fighting accesses and the like.

Owner:建平县德鑫外墙保温材料有限责任公司

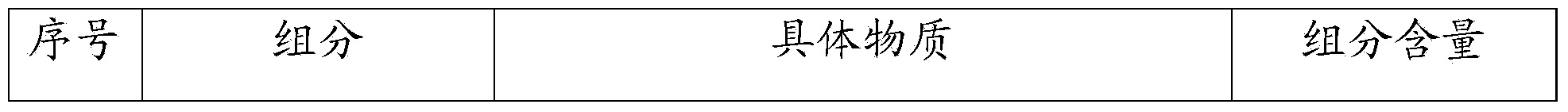

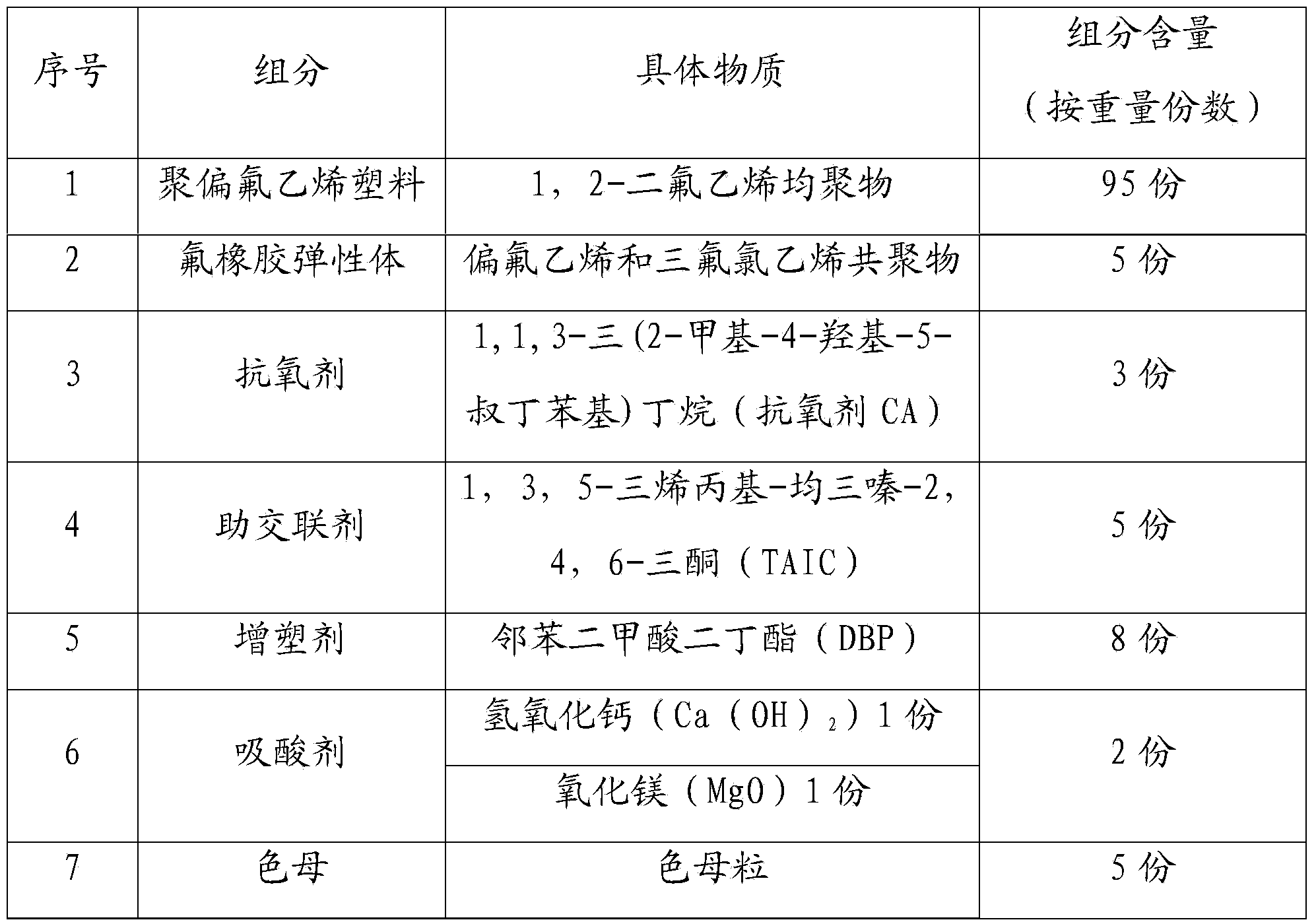

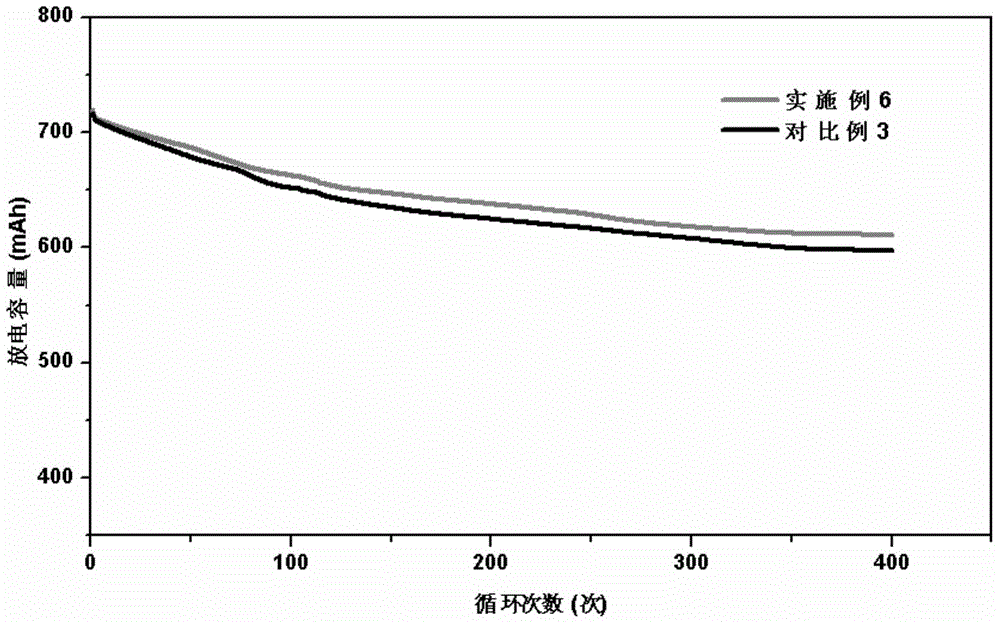

Elastic polyvinylidene fluoride heat-shrinkable sleeve and preparation method thereof

The invention relates to an elastic polyvinylidene fluoride heat-shrinkable sleeve which is composed of the following components in parts by weight: 85-95 parts of polyvinylidene fluoride plastic, 5-15 parts of fluororubber elastomer, 1-3 parts of antioxygen, 2-5 parts of assistant crosslinker, 3-8 parts of plasticizer, 0.5-2 parts of acid accepter and 2-5 parts of color master. The polyvinylidene fluoride plastic is one or two of the following matters: 1,2-difluoroethene homopolymer and 1,2-difluoroethene- hexafluoropropylene homopolymer. The fluororubber elastomer is one, two or more than two of the following matters: vinylidene fluoride and chlorotrifluor ethylene copolymer, vinylidene fluoride and hexafluoropropylene copolymer, vinylidene fluoride, tetrafluoroethylene and hexafluoropropylene terpolymer. According to the elastic polyvinylidene fluoride heat-shrinkable sleeve, such performances of fluoroplastic as wear resistance, mechanical damage resistance and the like are kept simultaneously, elasticity of the heat-shrinkable sleeve is improved, the elastic polyvinylidene fluoride heat-shrinkable sleeve has such specific performances of fluororubber as oil resistance simultaneously, application scope of the fluoride heat-shrinkable sleeve is broadened and risk in the process of use is reduced.

Owner:CHANGYUAN ELECTRONICS DONGGUAN +3

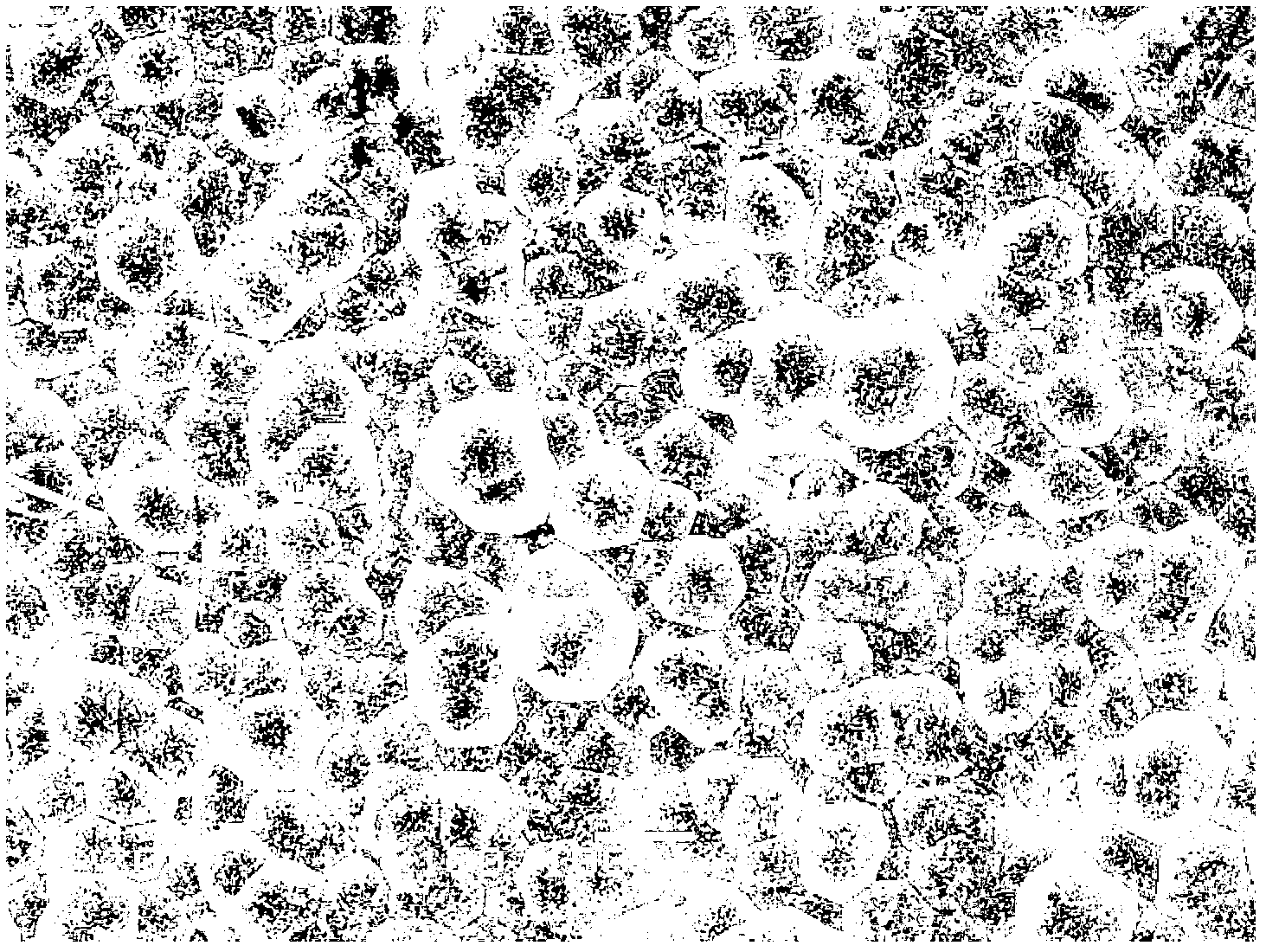

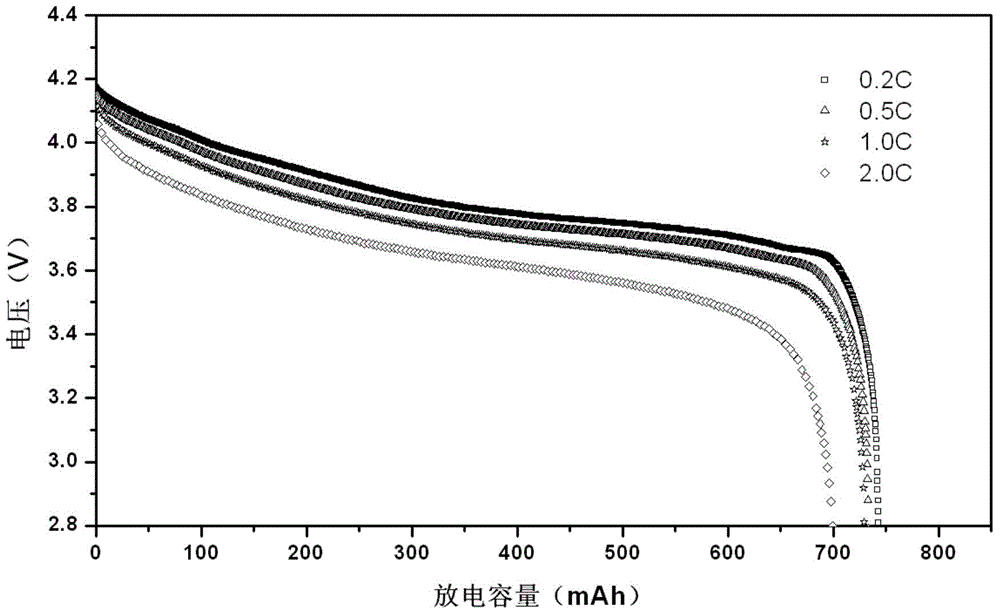

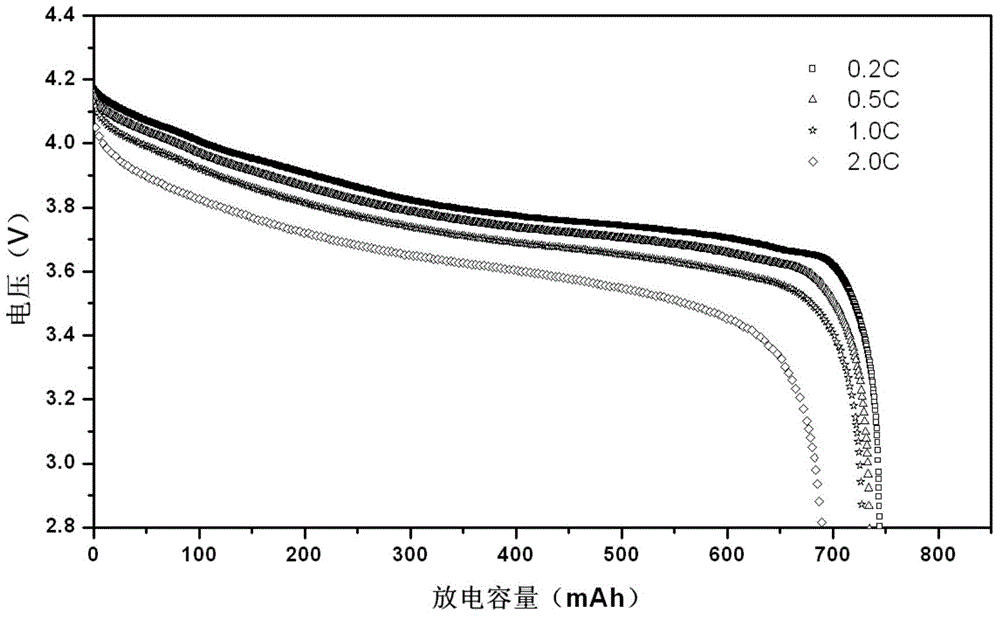

Aqueous binder used for lithium ion batteries, positive and negative electrode plates and coating membrane

ActiveCN105018001AEasy to manufactureImprove efficiencyMonocarboxylic acid ester polymer adhesivesCell electrodesPolyolefinEmulsion

The invention relates to an aqueous binder used for lithium ion batteries, positive and negative electrode plates and a coating membrane and belongs to the field of lithium ion battery manufacturing. The aqueous binder used for the lithium ion batteries comprises acrylic soap-free copolymerization aqueous emulsion and modifying agents, and the weight ratio of the acrylic soap-free copolymerization aqueous emulsion to the modifying agents is 100 to 5-50, wherein the modifying agents are selected from at least one of the compounds with the structural formulae being NR7R8CH2CH2CN or R9-(OCH2CH2)n-OCH2CH2CN or R10CONR11R12. The aqueous binder is suitable for modified coating of polyolefin diaphragms of the lithium ion batteries and high-temperature fast coating of the electrode plates, and the performance and the production efficiency of the lithium ion batteries can be improved.

Owner:SICHUAN INDIGO TECH CO LTD

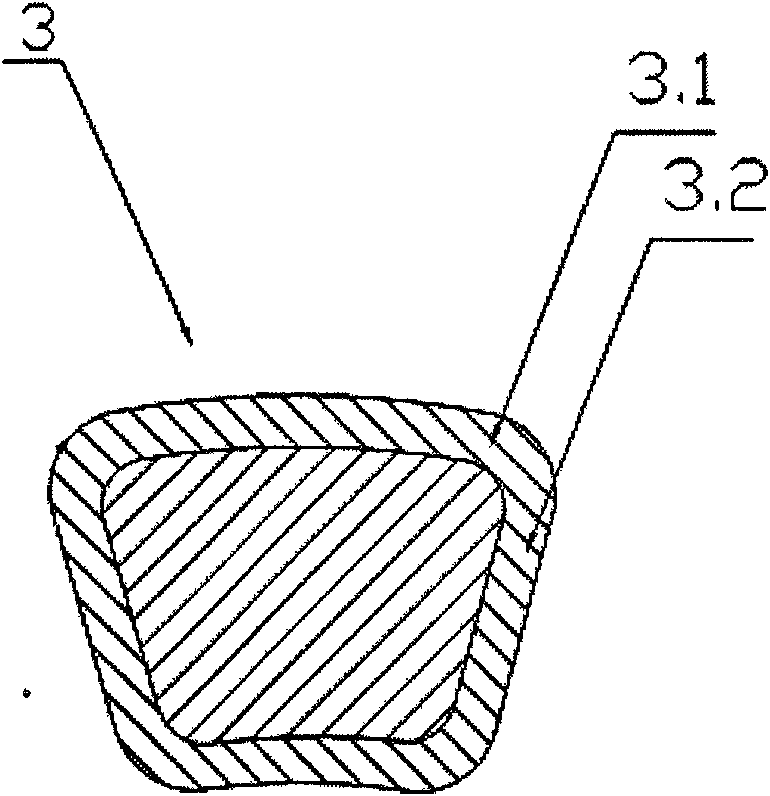

Slip casting roof bolt with anticorrosive casing pipe

InactiveCN1712670AIncreased durabilityExtended service lifeAnchoring boltsSupporting systemRock bolt

The invention opened an injected anchor arm with the antiseptic spigot, which is composed of the anchor arm body, the connection part of the porthole, the spigot, anchoring head, holding pad, the tight nut and the gasket. The invention can form the supporting anchorage power quickly to control the deforming of the terrene; also it can form a supporting system of multi-antiseptic barrier with the spigot and the double injected plasma.

Owner:吴德兴

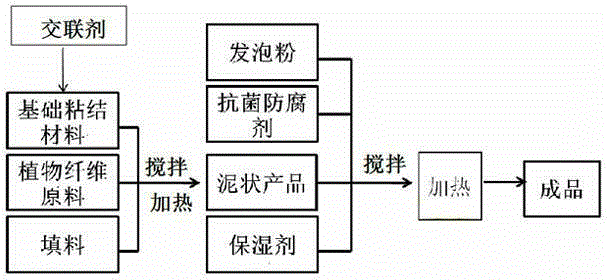

Ultralight paper clay and preparation method thereof

InactiveCN103951456AReduce the proportion of productsImprove strength and elasticityCeramicwareMineralogyPlant fibre

The invention discloses ultralight paper clay and a preparation method thereof. The preparation method comprises the following steps: adding a plant fiber raw material t0 a binder serving as a base material, and mixing with raw materials with specific effects, to produce novel paper clay which is soft and extremely good plasticity, wherein the novel paper clay is purely white in primary color, various non-toxic pigments are added during the preparation process to obtain paper clay of multiple colors, or the surfaces of formed objects can be dyed into various colors. The paper clay has the properties of a common kneaded-moulded material and has ultralight mass which is about one half of the specific gravity of water, and moreover the dry weight of the paper clay can reach a quarter of the wet paper clay. Besides, the raw materials adopt non-toxic and natural materials, thus having no harm to a human body, especially avoiding contact harm to children during playing.

Owner:SHAANXI UNIV OF SCI & TECH

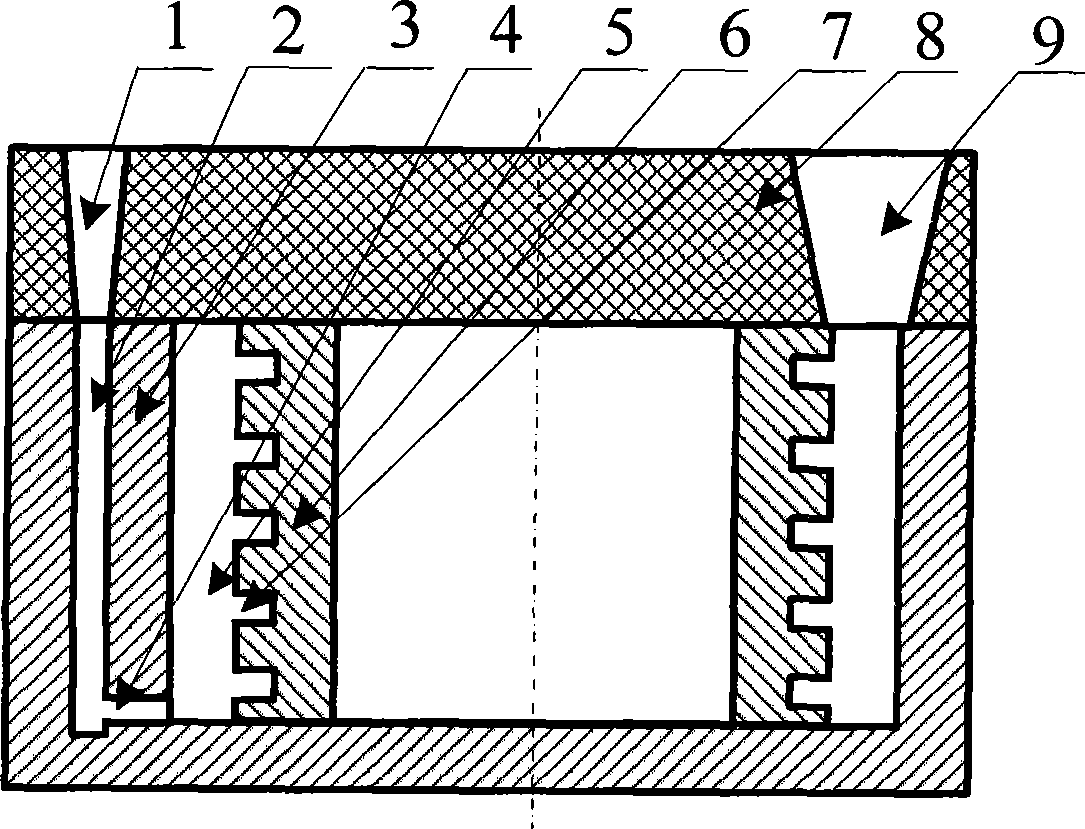

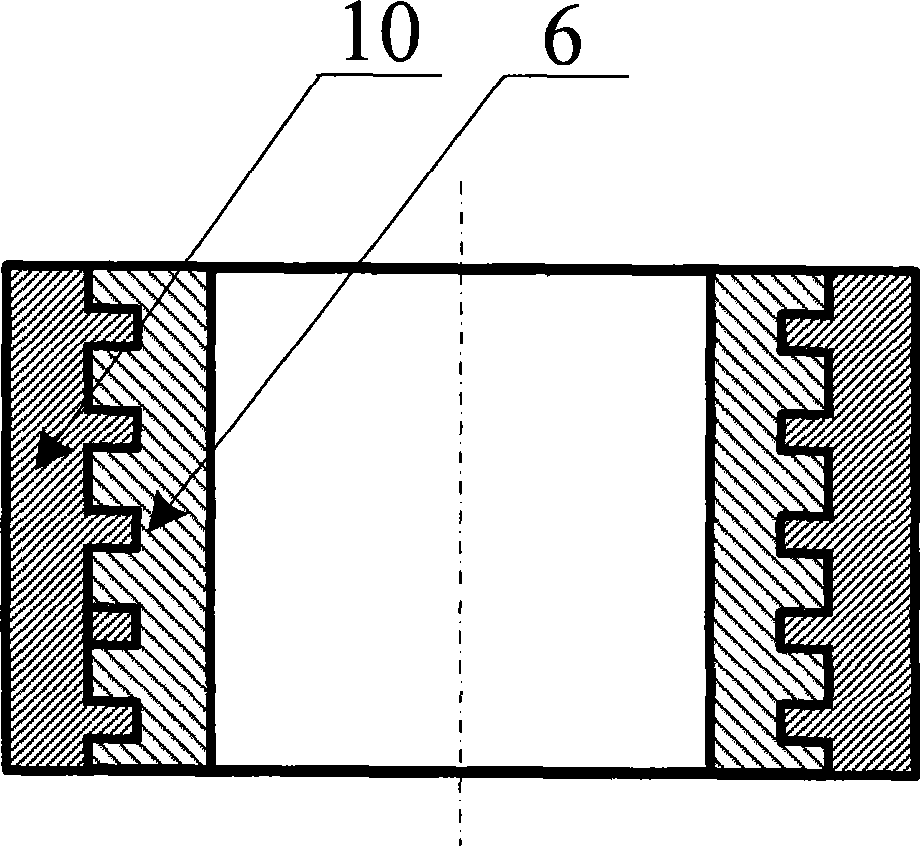

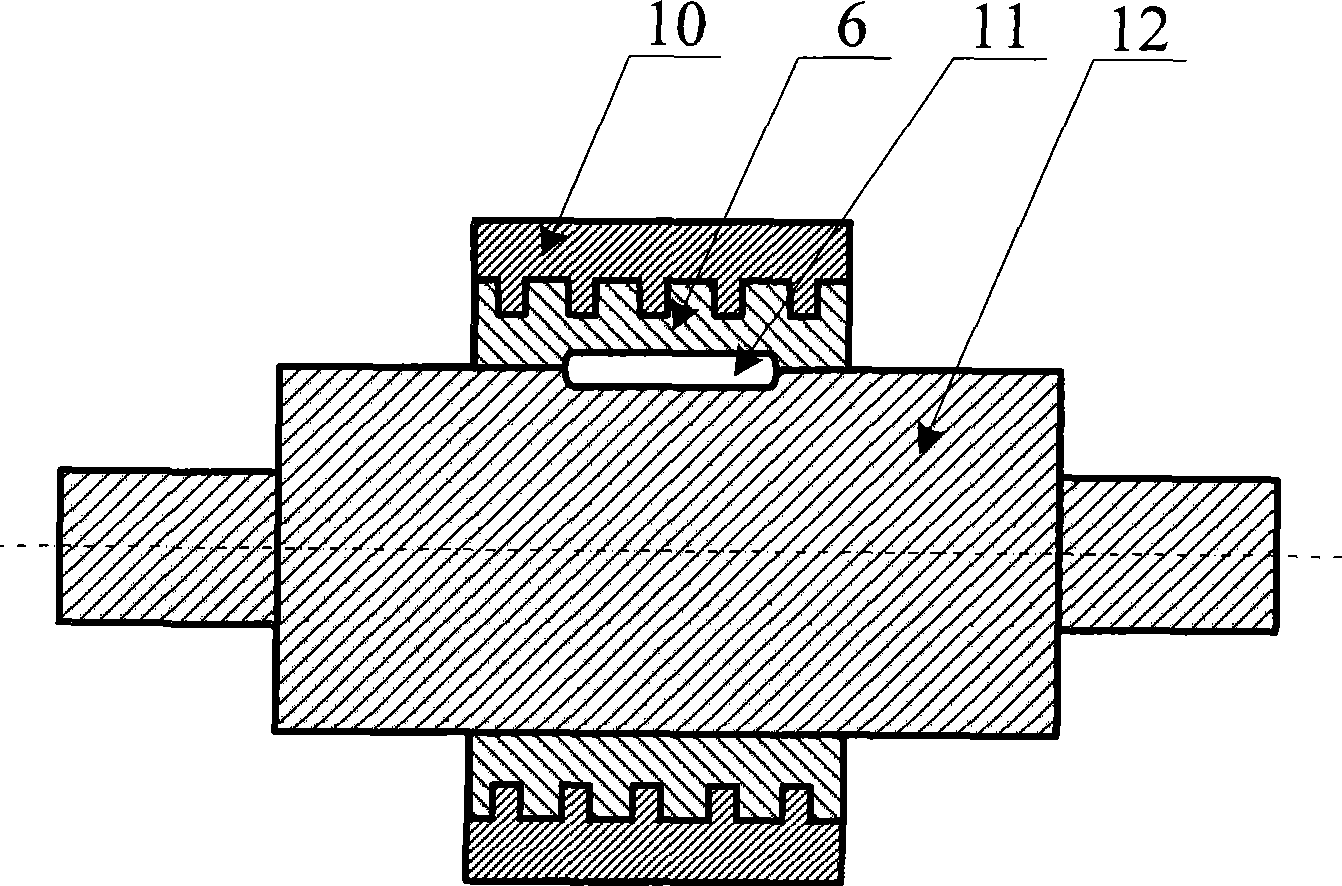

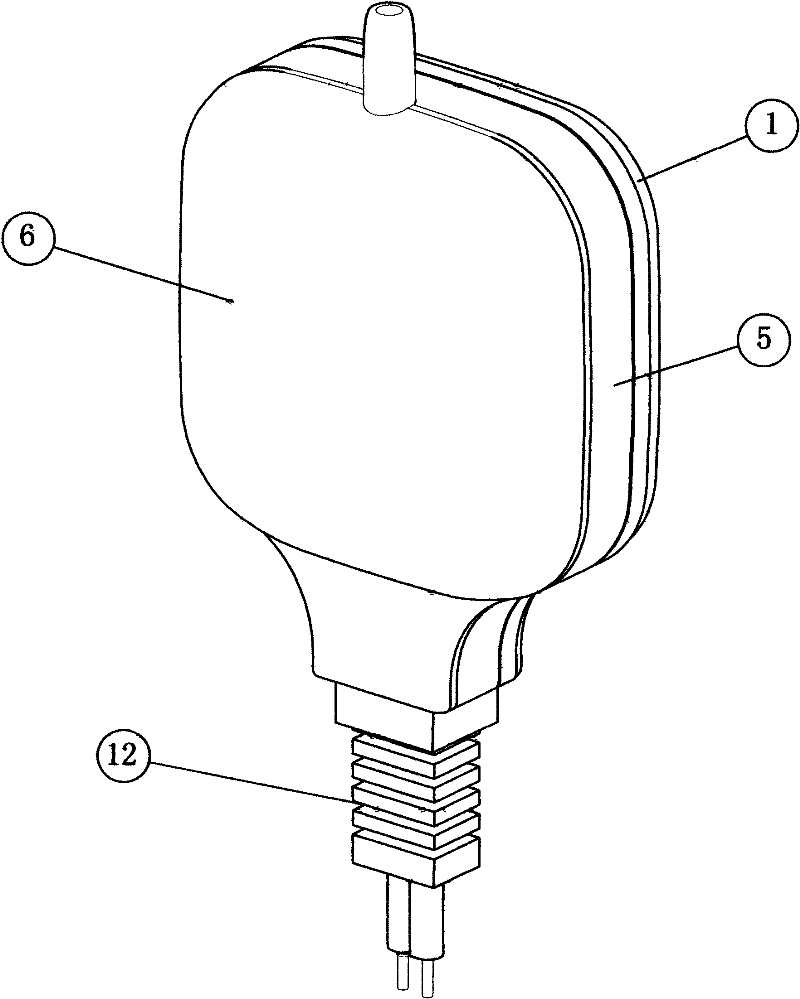

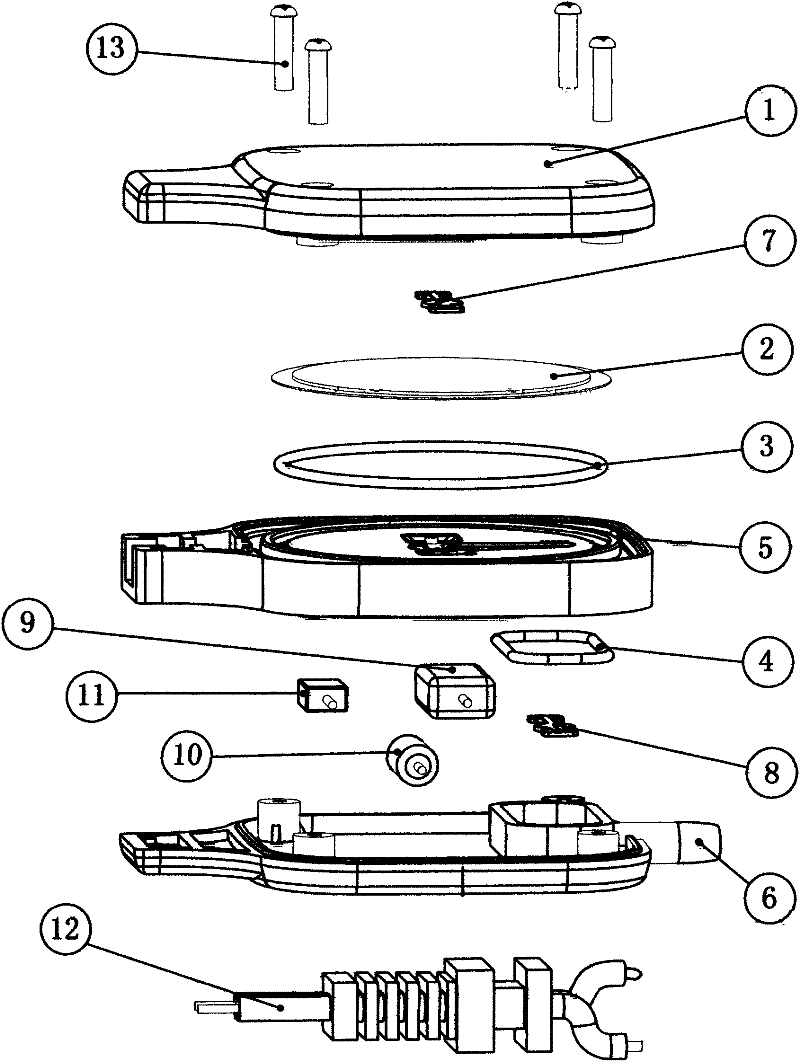

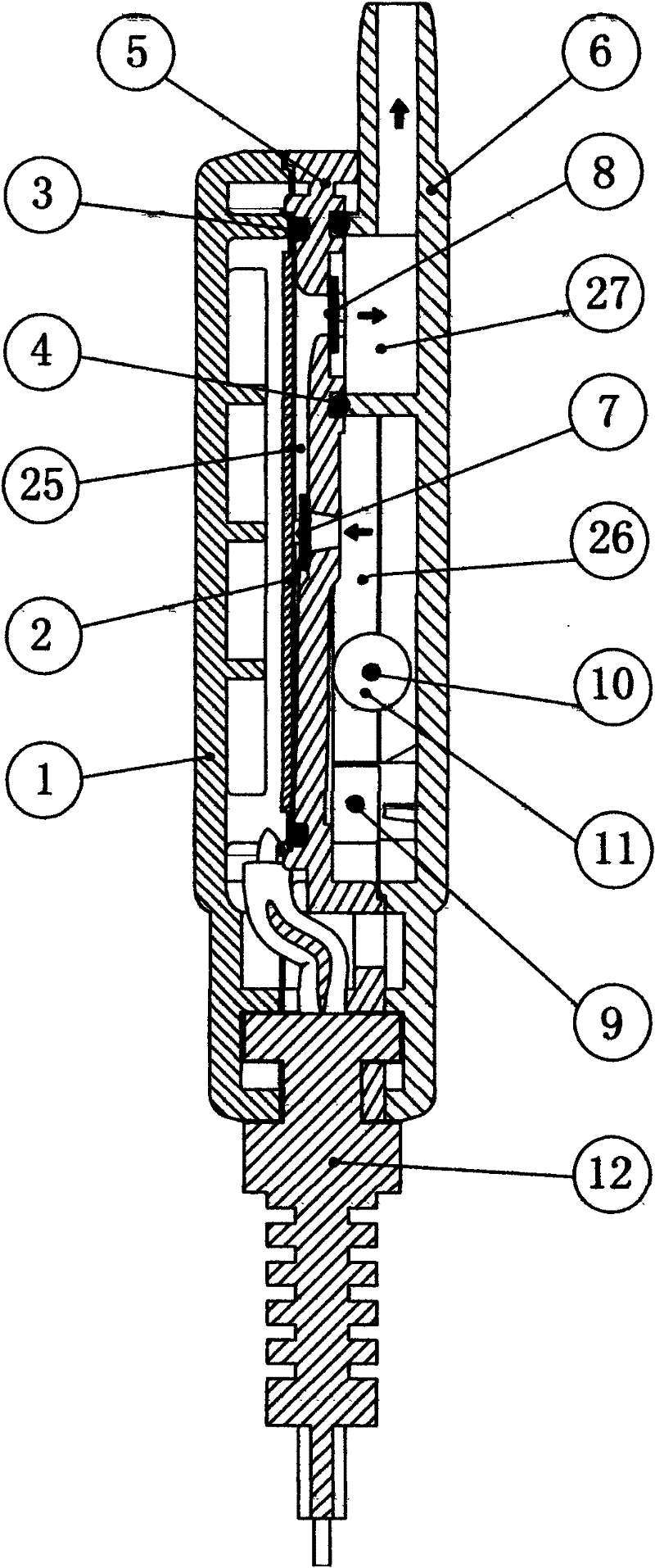

Piezoelectric ceramic drive type ultra-miniature air pump

ActiveCN102338072AExpand the scope of workPrevent fire and other hazardsFlexible member pumpsPositive-displacement liquid enginesLow noiseElectricity

The invention relates to a piezoelectric ceramic drive type ultra-miniature air pump. A working medium is gaseous, a miniature air pump in the prior art comprises a miniature negative pressure pump, a miniature vacuum pump and the like, and has the defects of large volume, limited working range and the like. The invention aims at designing the mechanical and electrical integration piezoelectric ceramic drive type ultra-miniature air pump with an ultra-miniature pump body by using a piezoelectric drive mode, which is formed by assembling a pump core in the pump body, wherein the pump body consists of a lower pump cover 1, a pump base 5 and a pump housing assembly, the lower pump cover 1 and the pump base 5 are fixedly connected with the pump housing assembly, the pump core is a piezoelectric ceramic transduction sheet 2 which is elastically fixed in the pump body in a circumference sealing manner, and a one-way inlet valve 7 and a one-way exhaust valve 8 are assembled in the pump body. Working principles of the traditional miniature diaphragm air pump, the miniature electromagnetic air pump and the like are thoroughly changed. The piezoelectric ceramic drive type ultra-miniature air pump has the effects of simple structure, miniature volume, energy consumption reduction, low noise lower than 30dB, energy saving, environment friendliness, convenience for installation and maintenance, reduction of production cost and wide application range.

Owner:SHENZHEN HEYI PRECISION PUMP TECH CO LTD

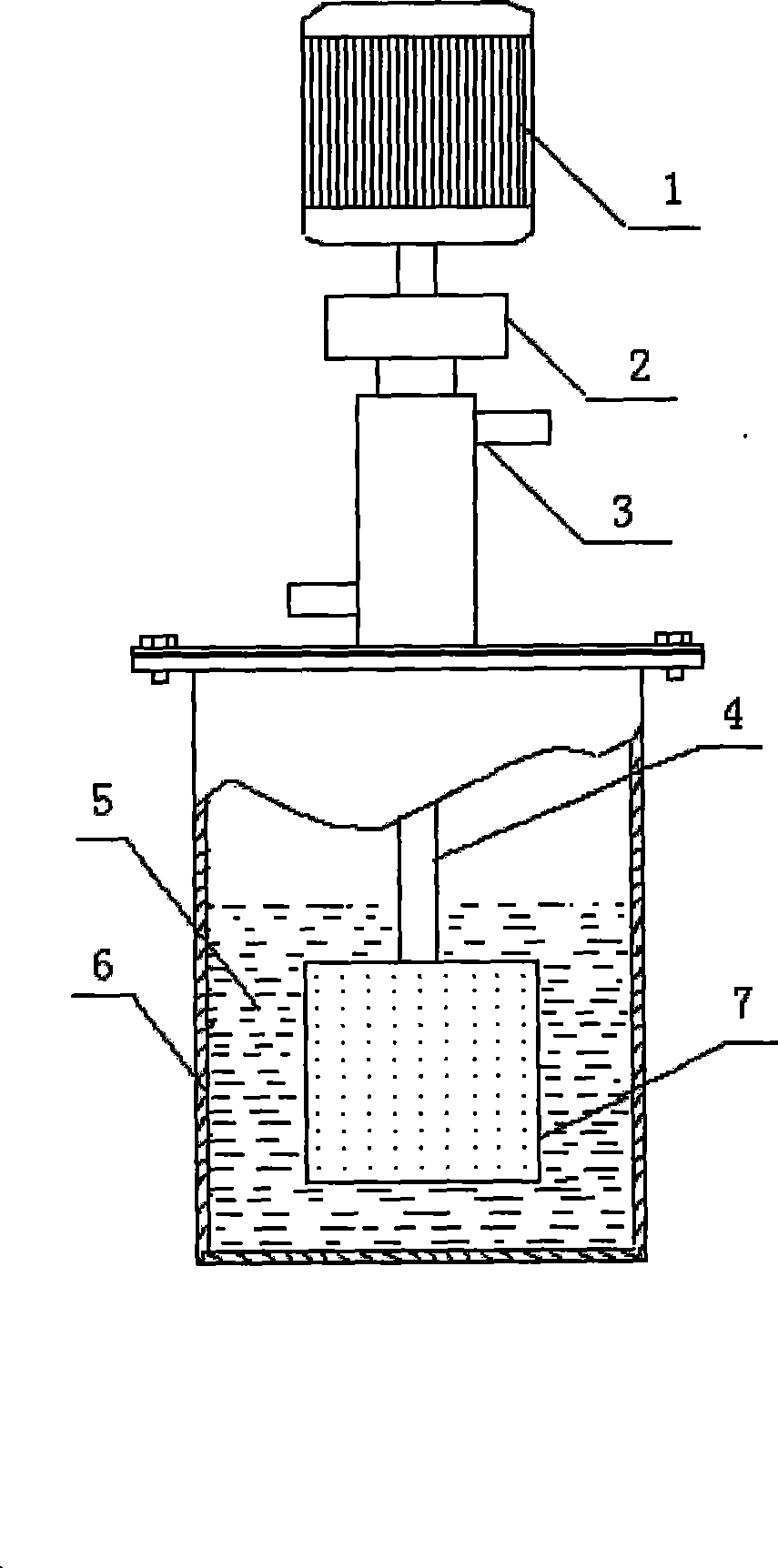

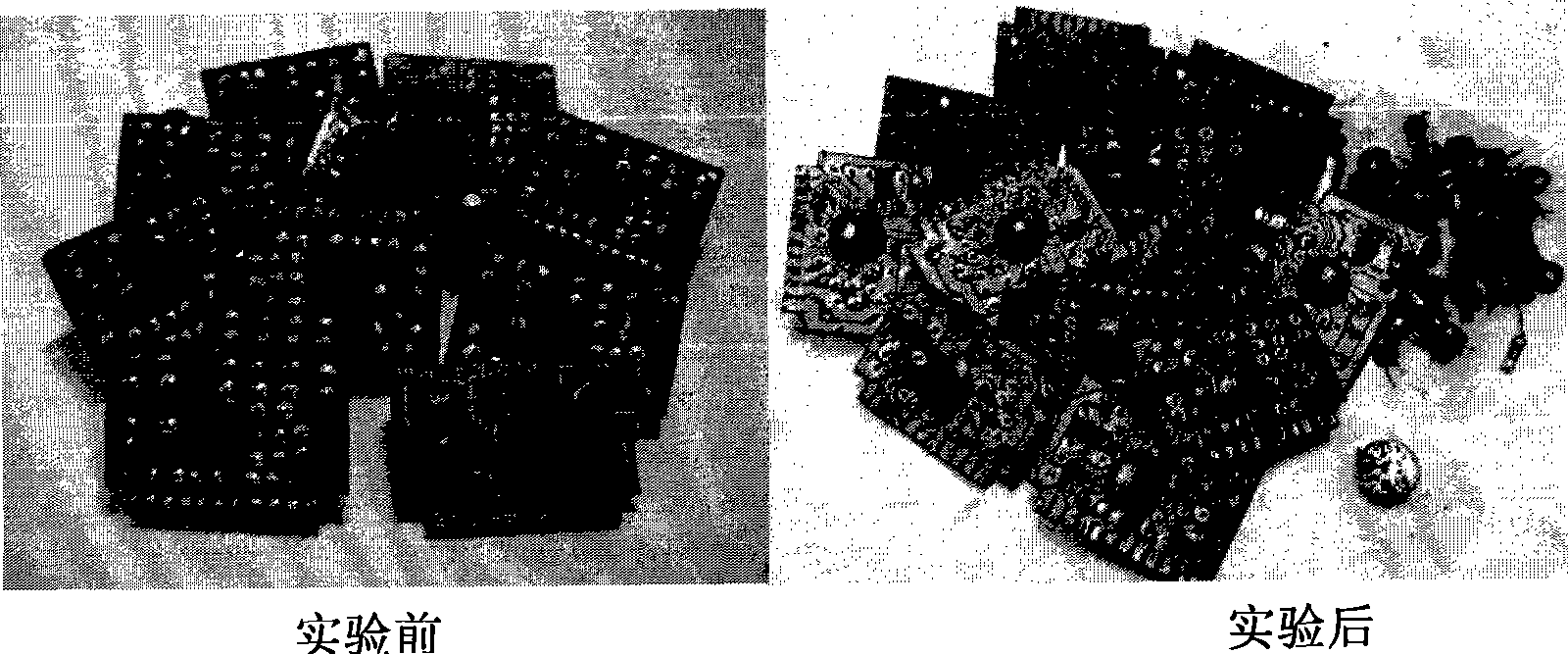

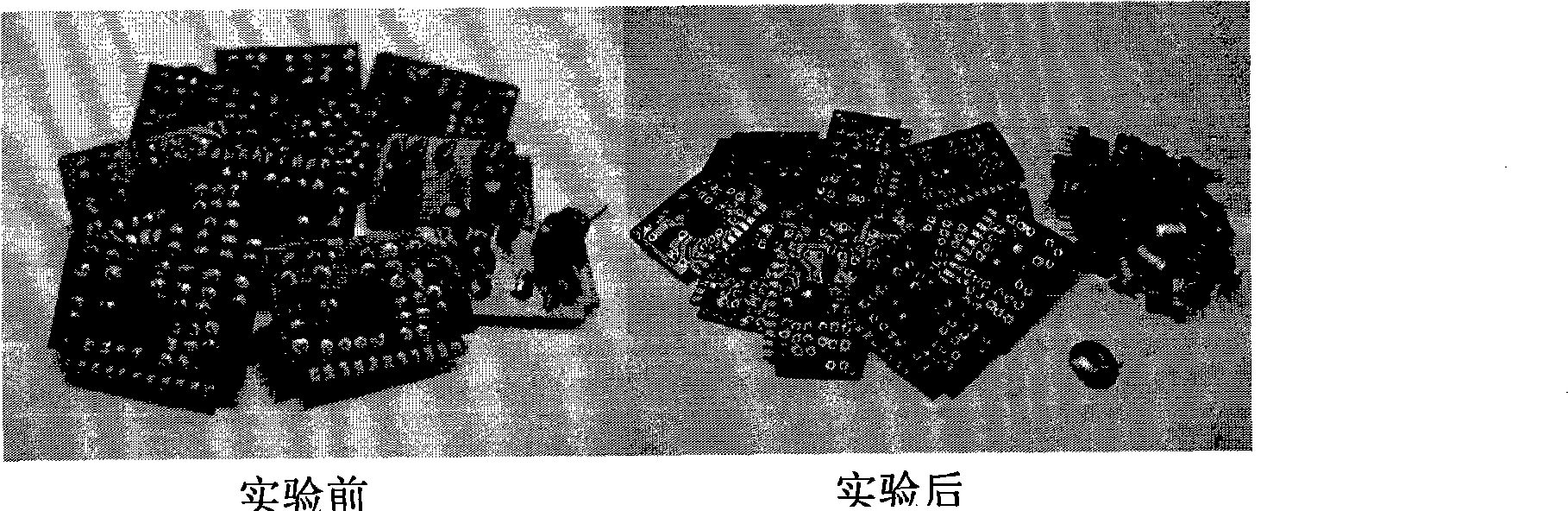

Technique and device for effectively recovering waste printed circuit boards solder

InactiveCN101362143ARealize separation and recoveryNo secondary pollutionSolid waste disposalSoldering apparatusHeat conductingIngot

The invention relates to a technology for high-efficiently recycling soldering tin of discarded printed circuit boards, and a device. In a sealed system, in which liquid heat conducting medium exists, discarded printed circuit boards to be processed and welded with electronic parts are put in a swivel which is provided with a plurality of filtering holes and immersed in the heat conducting medium, the temperature is risen until the soldering tin is melted, after the temperature is constant, the swivel is rotated to centrifugally separate solid and liquid, the soldering tin leaks from the filtering holes, deposits at the bottom and is cooled into ingot, and the electronic parts are separated from the discarded printed circuit boards correspondingly. The method for recycling the soldering tin of discarded printed circuit boards has no environmental pollution, low energy consumption and high efficiency, and can create good condition for high-efficiently recycling other metals.

Owner:CENT SOUTH UNIV

Log dyeing method

InactiveCN1672886ARetain structurePreserve textureWood treatment detailsPressure impregnationRoom temperatureVolumetric Mass Density

The log dyeing method is one circular hot pressing dyeing and normal temperature and pressure dyeing method on log with water content not higher than 8 % and in proper length. The log dyeing process includes the following steps: compounding acid dye aqua; soaking at room temperature for 120-480 min; dyeing at 25-120 deg.c and 10-15 Mpa under stirring for 30-60 min; lowering to room temperature; dyeing at 25-120 deg.c and 10-15 Mpa under stirring for 30-60 min; and so on until reaching the total dyeing time of 600-900 min; washing with water; drying at 25-120 deg.c to water content not higher than 8 %; and discharging. The log dyeing maintains the natural grains of log, raises the density of timber, homogenizes the color of timber, and raises the value of timber.

Owner:高凯

High-impact water-supply pipe granular material and preparation method thereof

InactiveCN101948594AReduce manufacturing costAuxiliary role in thermal stabilizationFlexible pipesWhole bodyPolyvinyl chloride

The invention discloses a high-impact water-supply pipe granular material and a preparation method thereof, wherein the high-impact water-supply pipe granular material is a blending system comprising PVC (Polyvinyl Chloride) resin and additives blended in the PVC resin; the additives comprise a toughening agent, stabilizing agents, a lubricant, a filling agent, a processing aid and titanium pigment; the stabilizing agents include an organic tin stabilizing agent and epoxidized soybean oil; and the contents of all the components in parts by weight are as follows: 100 parts of the PVC resin, 3.5-11 parts of the toughening agent, 2-4 parts of whole body of the two stabilizing agents, 1.5-3.5 parts of the lubricant, 4-12 parts of the filling agent, 1.5-6 parts of the processing aid and 0-0.5 part of the titanium pigment. A water-supply pipe produced by the granular material has good appearance and good toughness, the anti-impact strength is higher than 68kJ / m<2>, the Vicat heat deformation temperature is higher than 72 DEG C, and after being frozen for 60 minutes at the temperature of 0 DEG C, a cracking phenomenon can not occur when the water-supply pipe freely falls from a 10m high position.

Owner:JIANGSU UNIV OF TECH

Method for producing multi-layer nano composite proton exchange membrane with self-humidifying function

InactiveCN1610145AWill not cause self-discharge phenomenonSelf-humidifying abilityCell electrodesCell component detailsComposite filmProton

The present invention is the preparation process of multilayer nanometer composite proton exchange film with self-humidifying function, and features that porous PTFE film is first soaked in mixture of proton conducting resin and nanometer SiO2 or TiO2 to form water maintaining proton conducting layer, and then soaked in in mixture of proton conducting resin and nanometer Pt or Pd grain to form self-humidifying proton conducting layer. The composite film as the proton conducting film in proton exchanging film fuel cell has excellent self-humidifying and water-maintaining capacity.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com