Patents

Literature

285 results about "Heat-shrinkable sleeve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat-shrinkable sleeve (or commonly "shrink sleeve") is a corrosion protective coating for pipelines in the form of a wraparound or tubular sleeve that is field-applied.

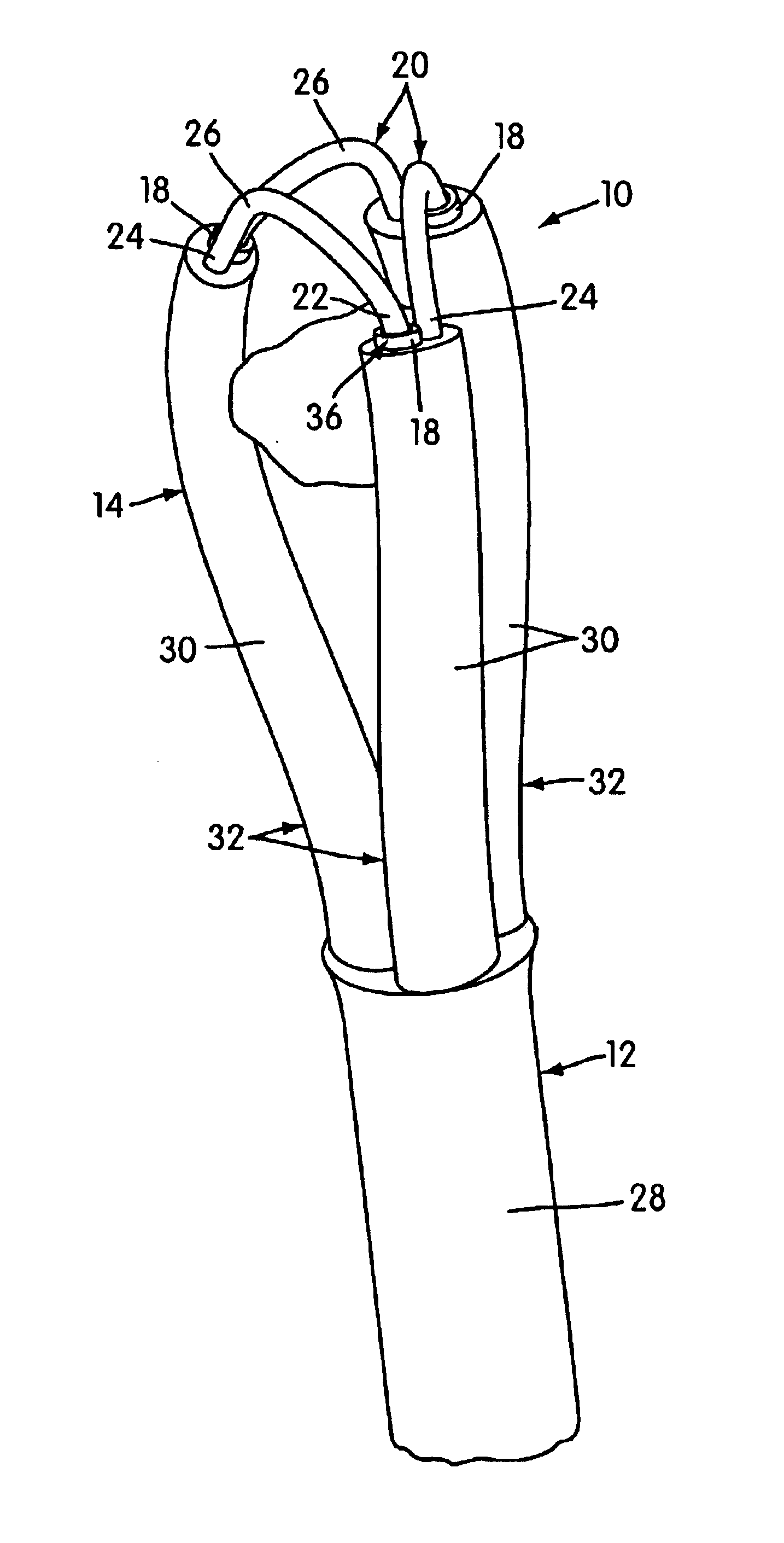

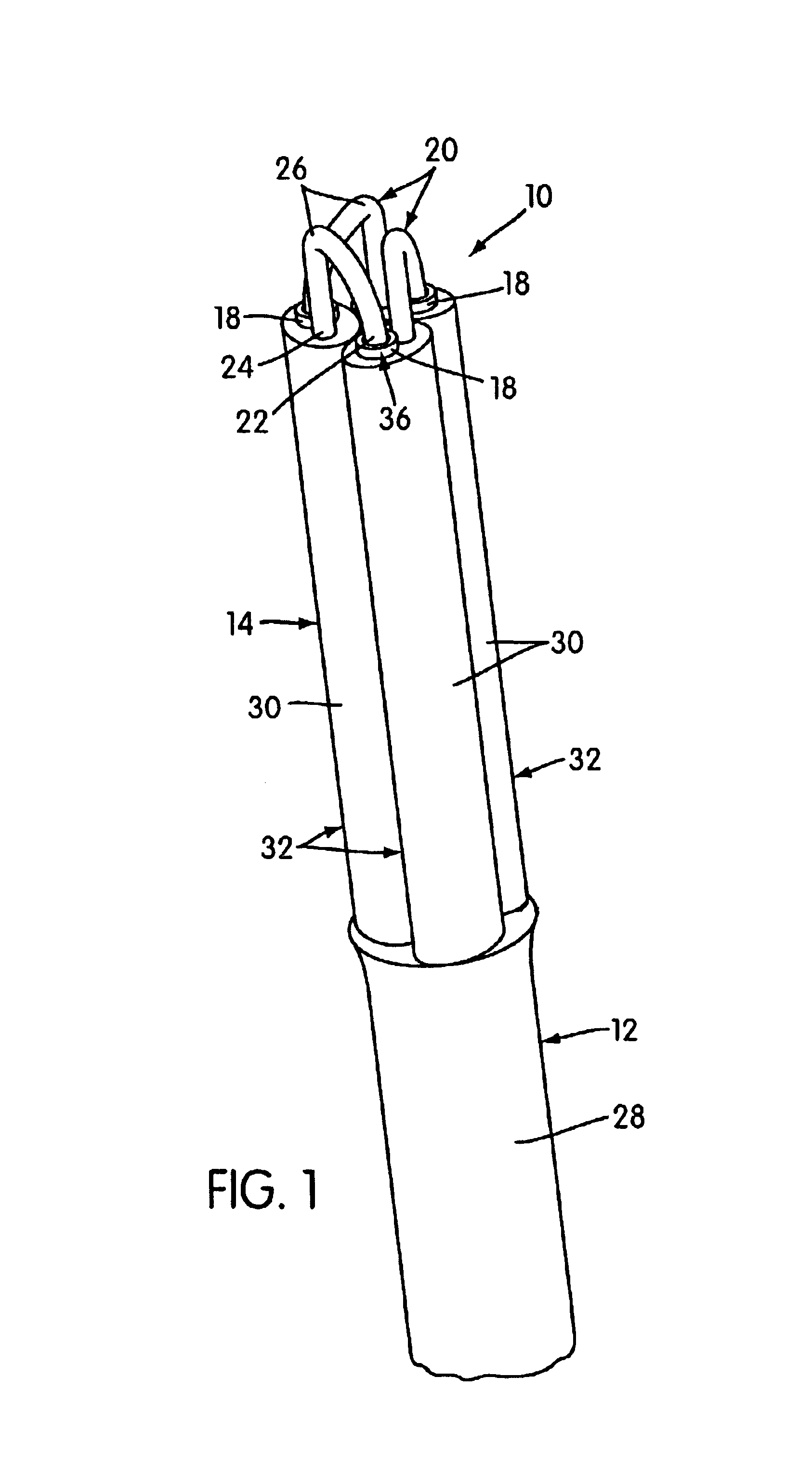

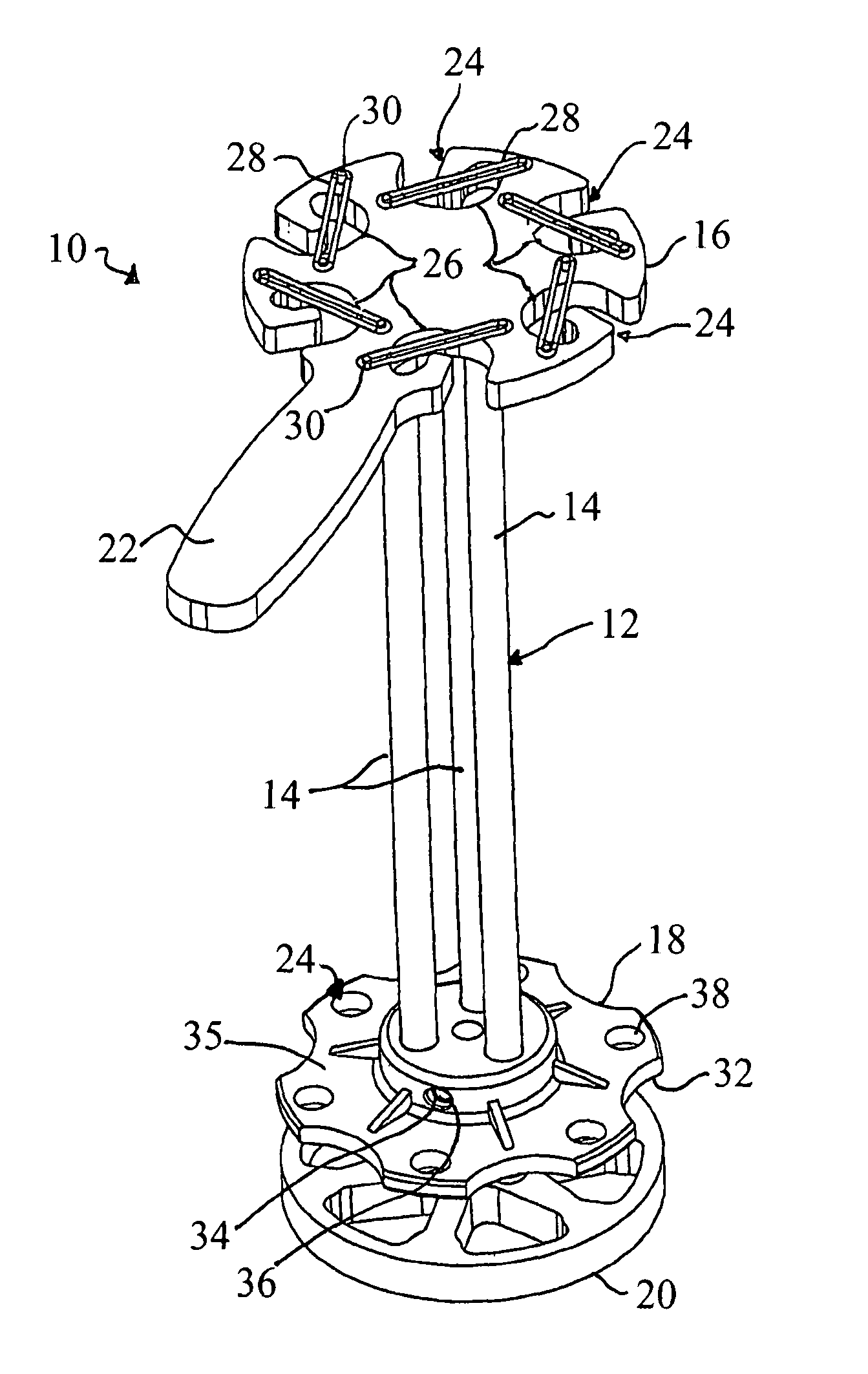

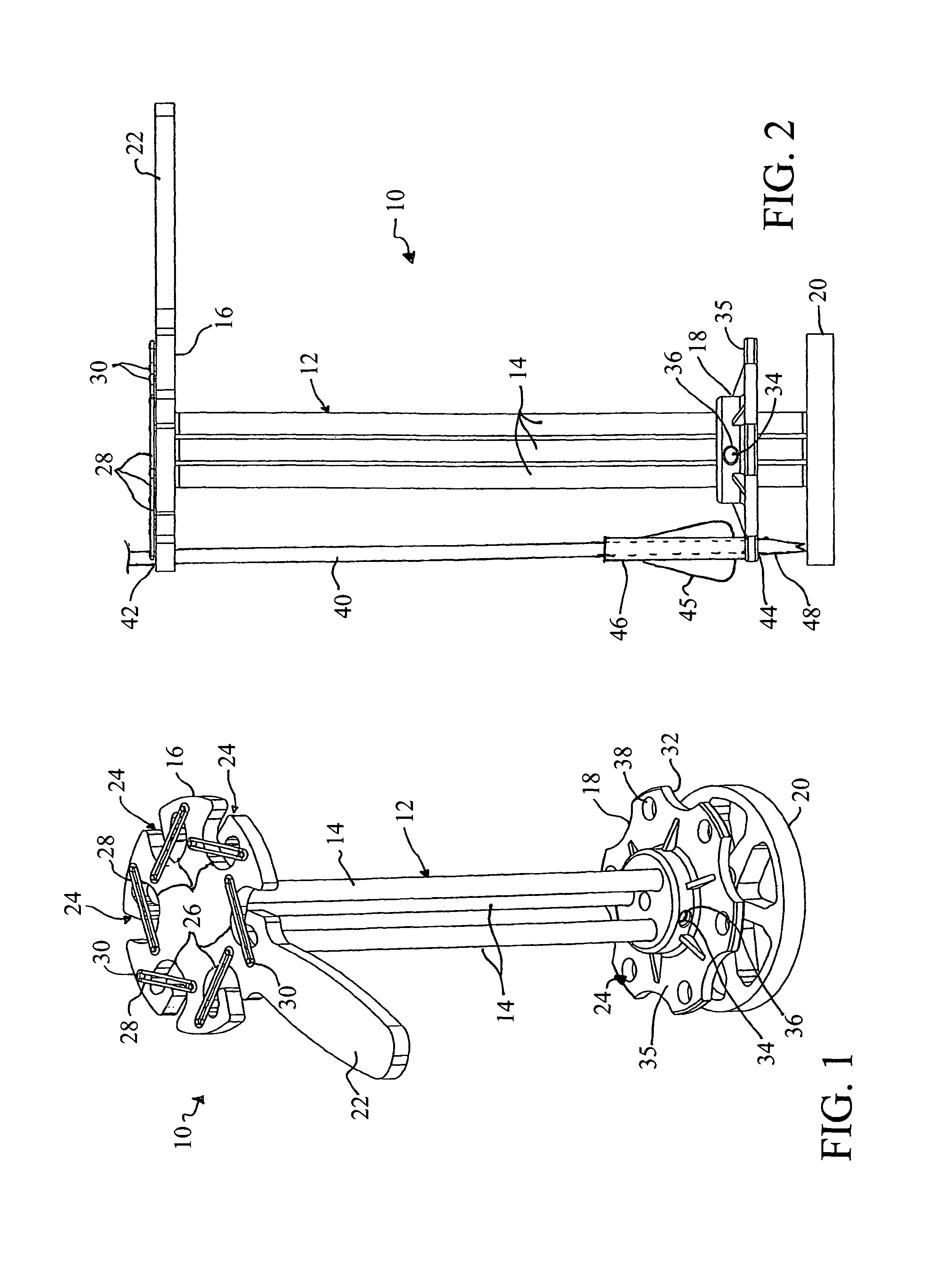

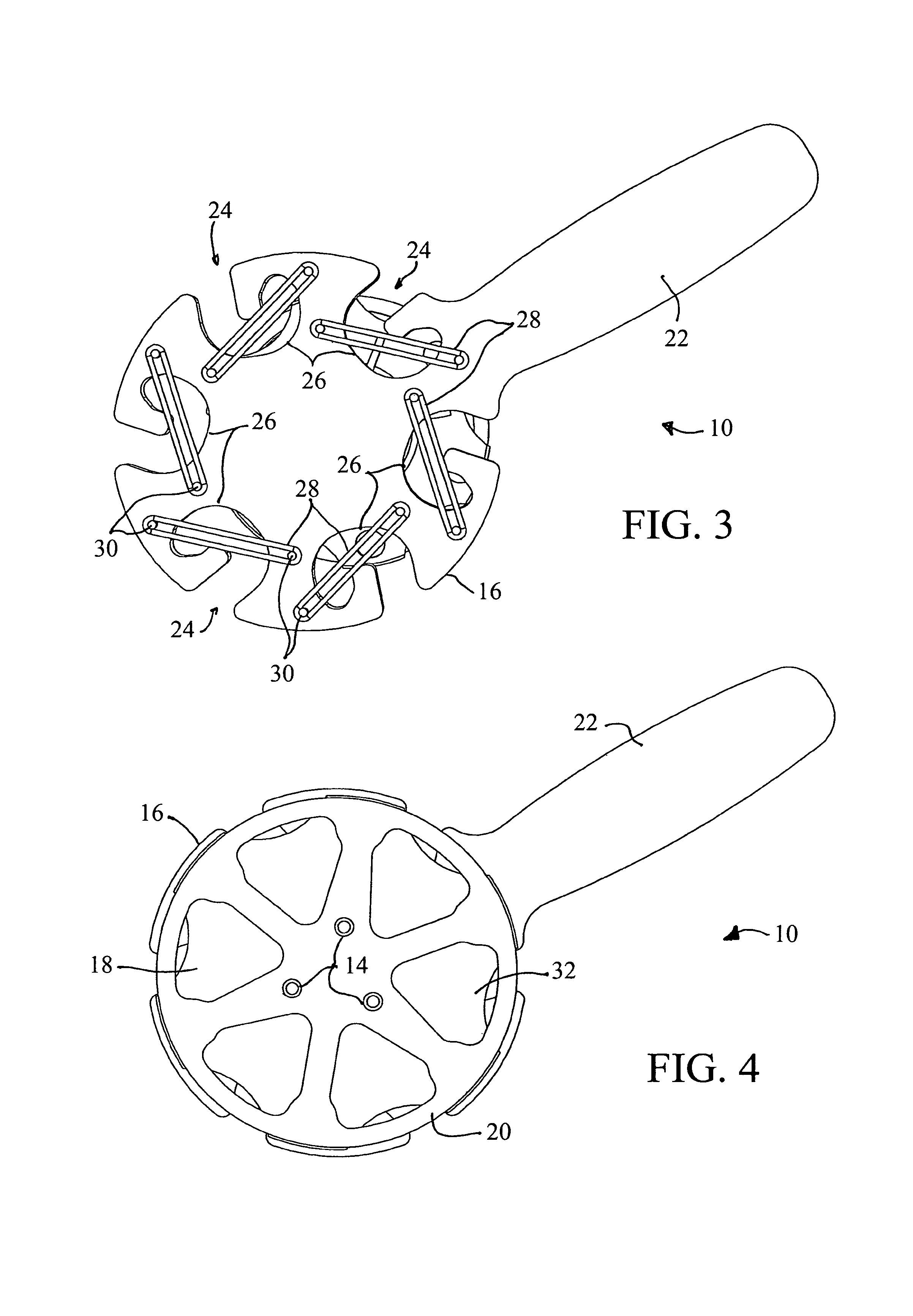

Method of making a medical grasper

A method of forming an annularly expanding and retracting gripping and releasing mechanism providing a series of flexible tubes, comprising providing (1) a series of flexible tubes, (2) a corresponding series of wires, each of which includes a movable wire section and relatively short fixed wire section integrally connected with one end of the movable wire section by a kink configured so that the wire sections extend in longitudinally coextensive relation therefrom; (3) a series of tubular elements of thermoplastic material; and (4) a series of heat shrinkable sleeves assembling a distal end portion of each flexible tube with a fixed wire section, a tubular element and a heat shrinkable sleeve so that the fixed wire section extends along the exterior periphery of the flexible tube with the kink disposed outwardly of the distal end thereof. The tubular element is disposed in surrounding relation to the fixed wire section and the flexible tube and the heat shrinkable sleeve is disposed in surrounding relation to the tubular element. The method further comprises applying heat to the exterior of each heat shrinkable sleeve at a temperature sufficient to contract the sleeve and soften the thermoplastic material of the tubular element surrounded thereby so that the contraction of the sleeve molds the softened thermoplastic material into adhered contact with the exterior surfaces of the surrounded fixed wire section and flexible tube.

Owner:COOK UROLOGICAL +1

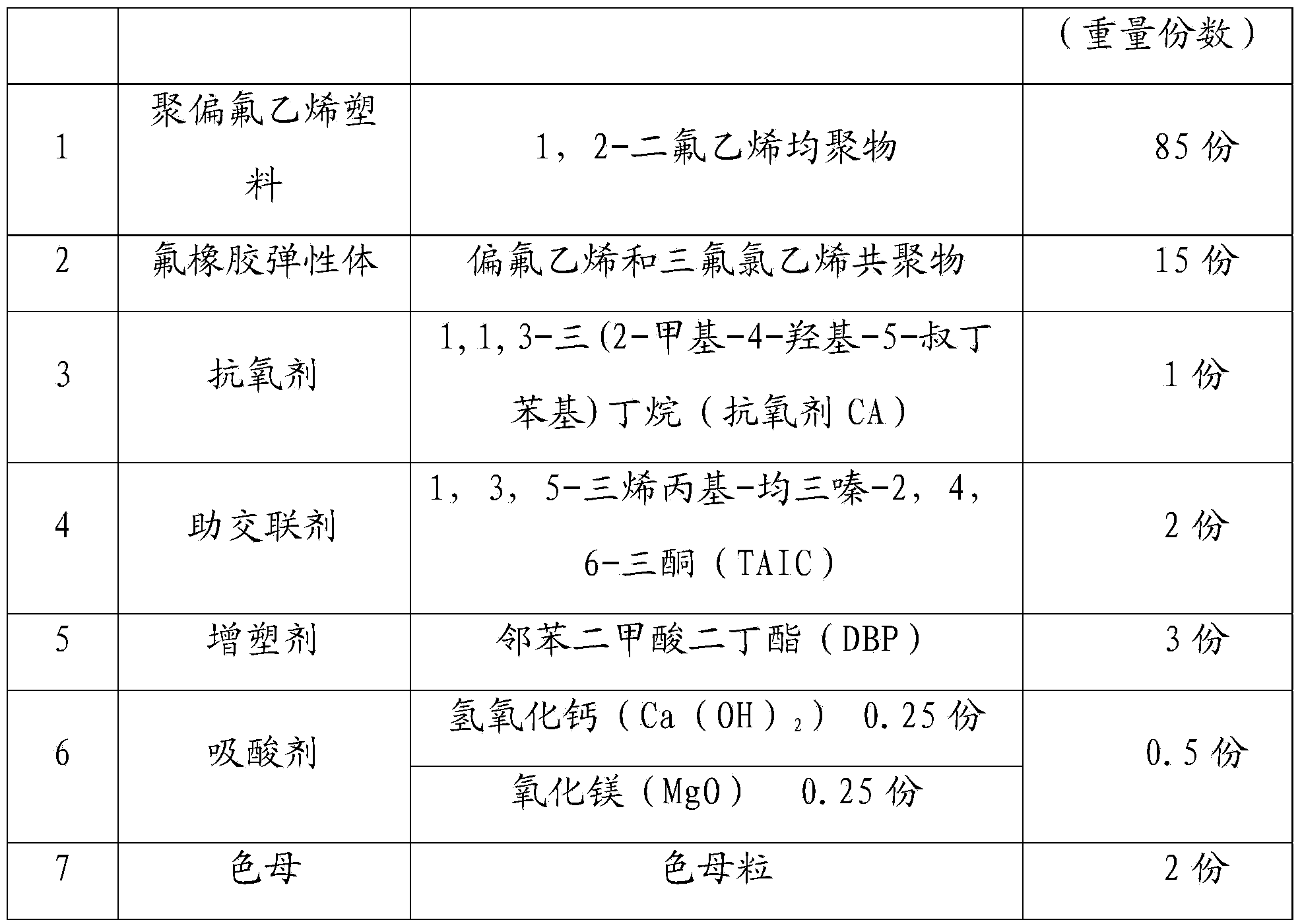

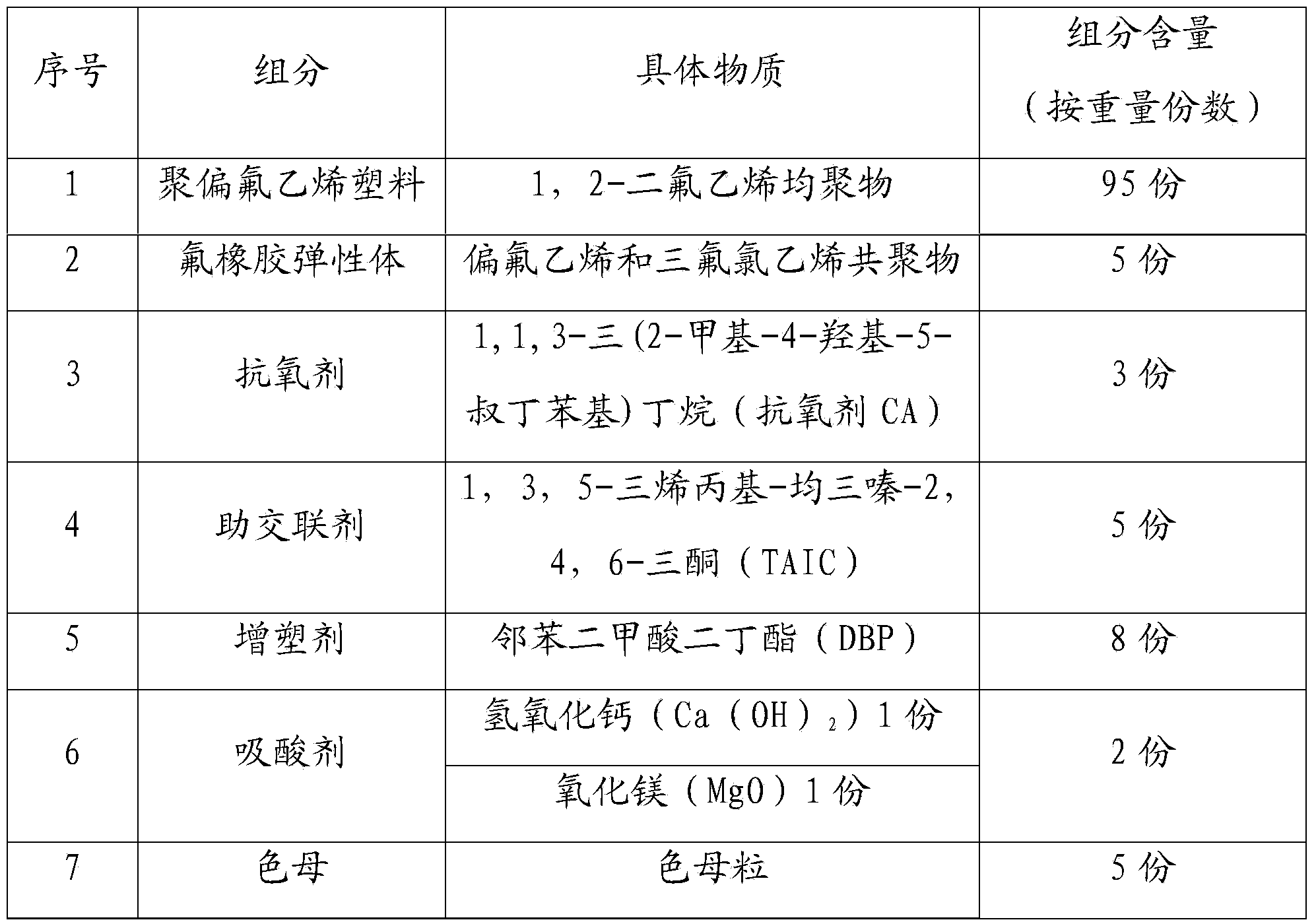

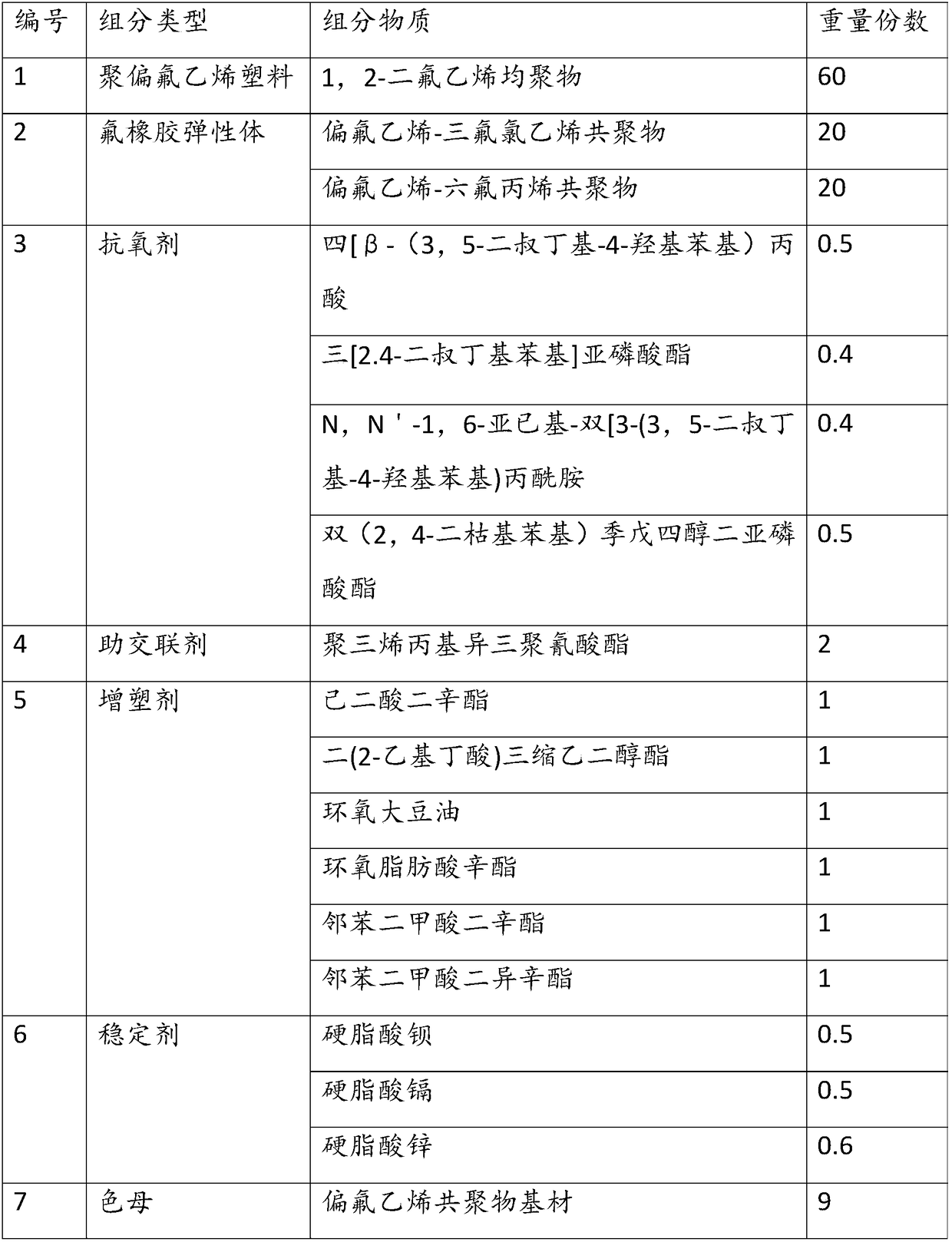

Elastic polyvinylidene fluoride heat-shrinkable sleeve and preparation method thereof

The invention relates to an elastic polyvinylidene fluoride heat-shrinkable sleeve which is composed of the following components in parts by weight: 85-95 parts of polyvinylidene fluoride plastic, 5-15 parts of fluororubber elastomer, 1-3 parts of antioxygen, 2-5 parts of assistant crosslinker, 3-8 parts of plasticizer, 0.5-2 parts of acid accepter and 2-5 parts of color master. The polyvinylidene fluoride plastic is one or two of the following matters: 1,2-difluoroethene homopolymer and 1,2-difluoroethene- hexafluoropropylene homopolymer. The fluororubber elastomer is one, two or more than two of the following matters: vinylidene fluoride and chlorotrifluor ethylene copolymer, vinylidene fluoride and hexafluoropropylene copolymer, vinylidene fluoride, tetrafluoroethylene and hexafluoropropylene terpolymer. According to the elastic polyvinylidene fluoride heat-shrinkable sleeve, such performances of fluoroplastic as wear resistance, mechanical damage resistance and the like are kept simultaneously, elasticity of the heat-shrinkable sleeve is improved, the elastic polyvinylidene fluoride heat-shrinkable sleeve has such specific performances of fluororubber as oil resistance simultaneously, application scope of the fluoride heat-shrinkable sleeve is broadened and risk in the process of use is reduced.

Owner:CHANGYUAN ELECTRONICS DONGGUAN +3

Formula and production method of radiation-crosslinked heat-shrinkable halogen-free flame-retardant marking sleeve product

The invention provides a formulation and a production method of a radiation cross-linked heat-shrinkable halogen-free flame-retardant marking sleeve product, which comprises: ethylene vinyl acetate copolymer 20-40; ethylene acrylate copolymer 0-10 ; Maleic anhydride graft polymer 1-15; Silicone masterbatch 1-15; Ultrafine surface treatment activated aluminum hydroxide 10-20; Ultrafine surface treatment activated magnesium hydroxide 10-20; Zinc borate 1-10; Surface treatment superfine red phosphorus 0-10; organic nitrogen phosphorus flame retardant 0-10; titanium dioxide 0-5; lubricant 0.2-1; antioxidant 0.5-1; sensitizing crosslinking agent 0.5-2; light stabilizer 0.5-2; color masterbatch 1-5. The manufactured label sleeve has good properties such as flame retardancy, machinery, insulation, wear resistance, corrosion resistance, and light aging resistance. Using thermal transfer printing, the writing is clear, the service life is more than 20 years, and the mark has good wipe resistance and solvent resistance. Easy to use, use nylon cable ties to bind large-size cables where they need to be marked. Radiation crosslinking greatly improves the mechanical properties and flame retardancy of the product.

Owner:HONGSHANG HEAT SHRINKABLE MATERIALS

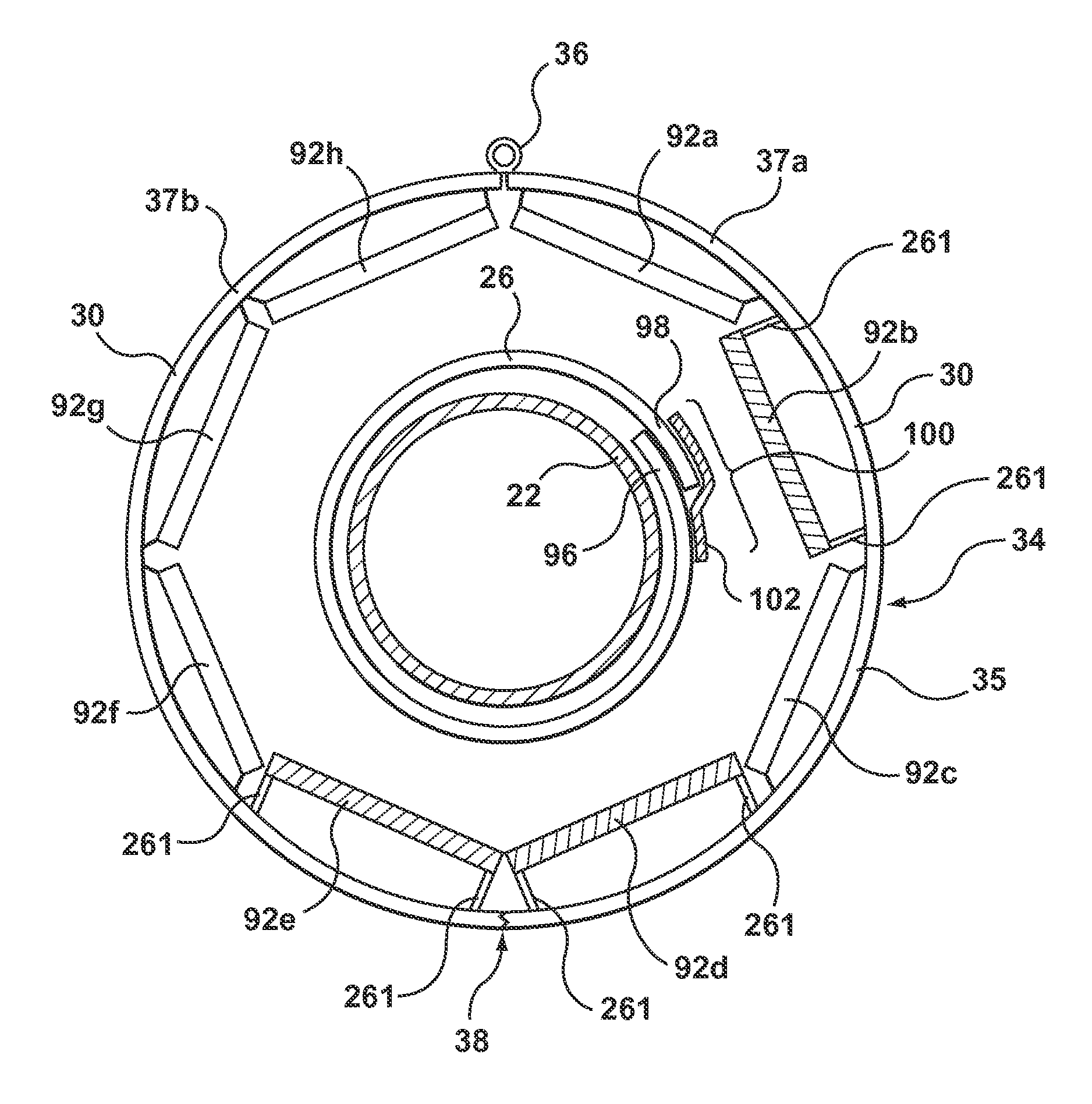

Fiducial marker with absorbable connecting sleeve and absorbable spacer for imaging localization

InactiveUS20080234572A1Enhance the imageEasily identifiableSurgeryDiagnostic markersHeat-shrinkable sleeveBiological body

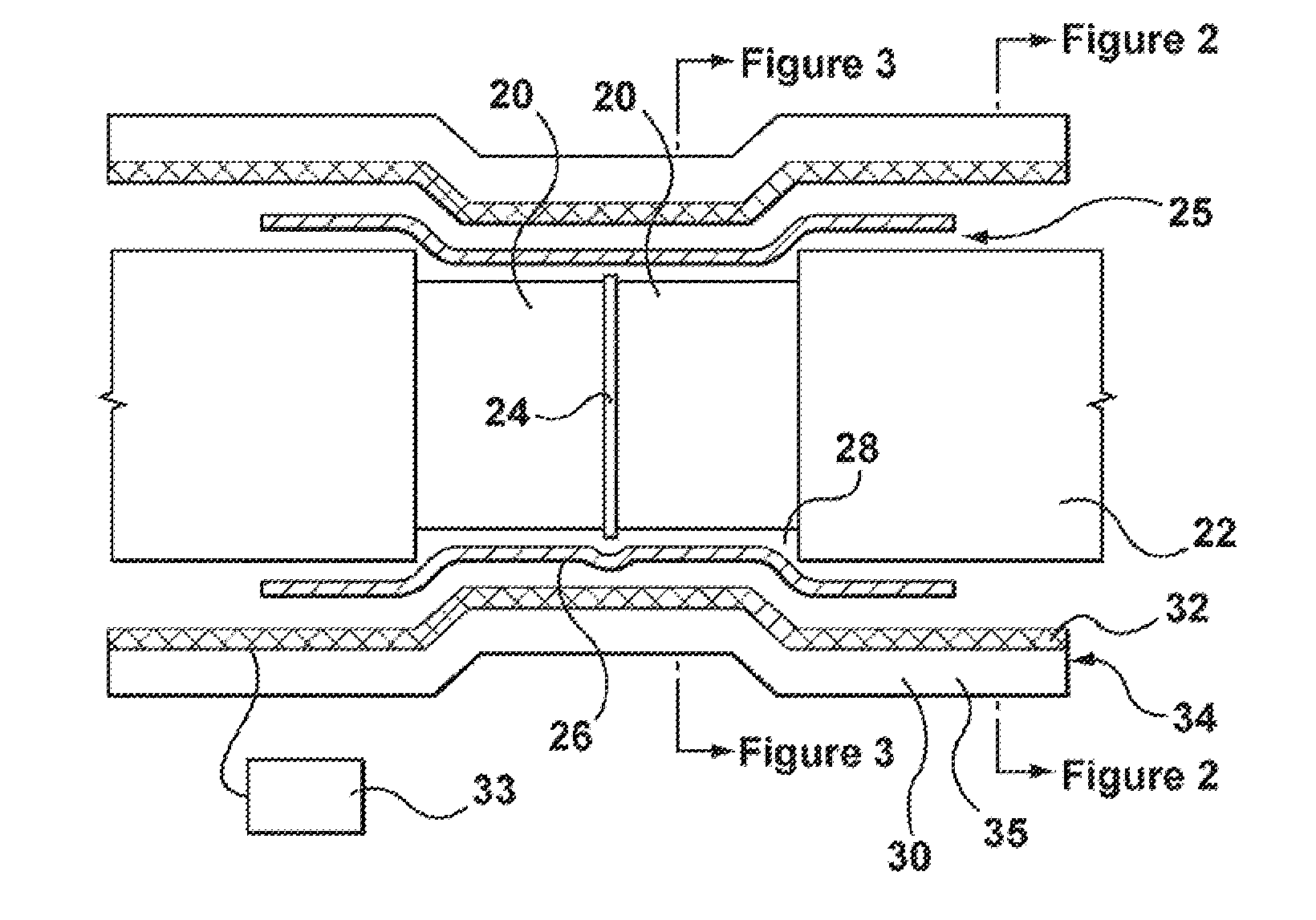

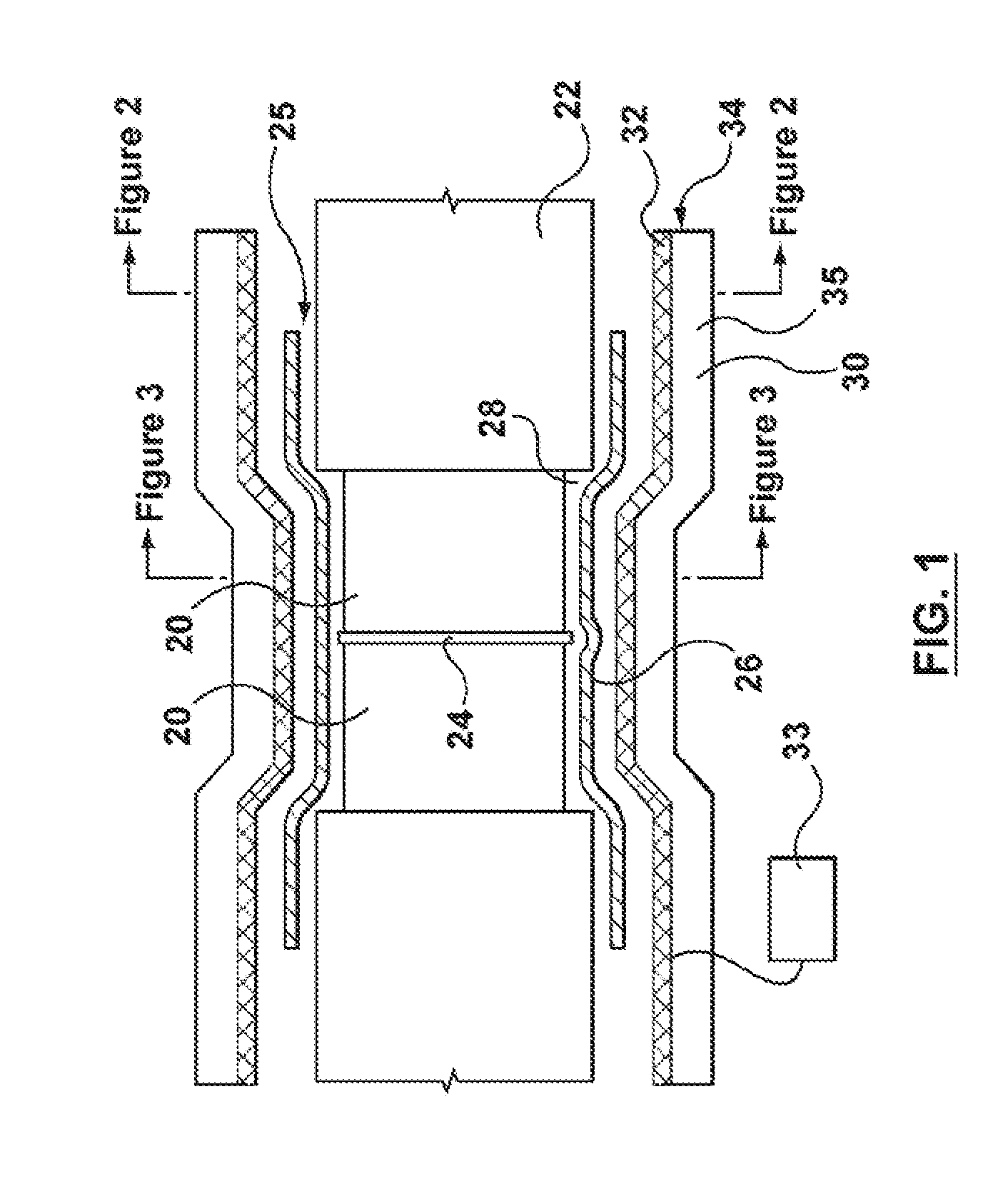

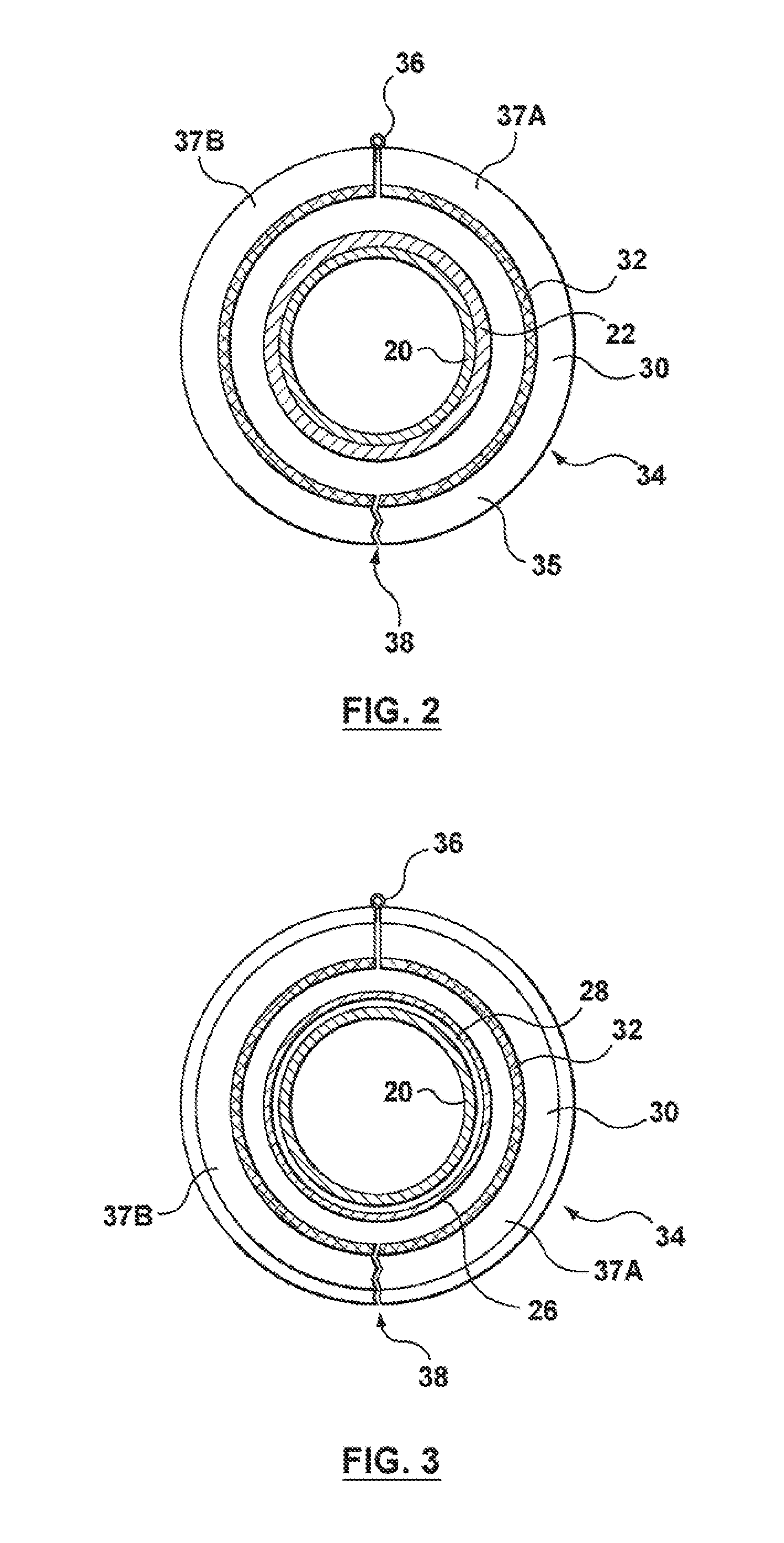

A fiducial marker for use in the body of a living being to enable the localization of targeted internal tissue. The implant is in the form of an elongated, e.g., rod-like, spacer located between pair of end members, e.g., gold cylinders, and held together by an elongated sleeve, e.g., a heat-shrinkable sleeve. When so connected portions of the end members are exposed, i.e., extend beyond the ends of the sleeve. The outer surface of the exposed portions of each of the end members is textured, e.g., grooved, to provide resistance to migration when the marker is implanted. The spacer and the sleeve are each be formed of an absorbable material.

Owner:CIVCO MEDICAL INSTR CO

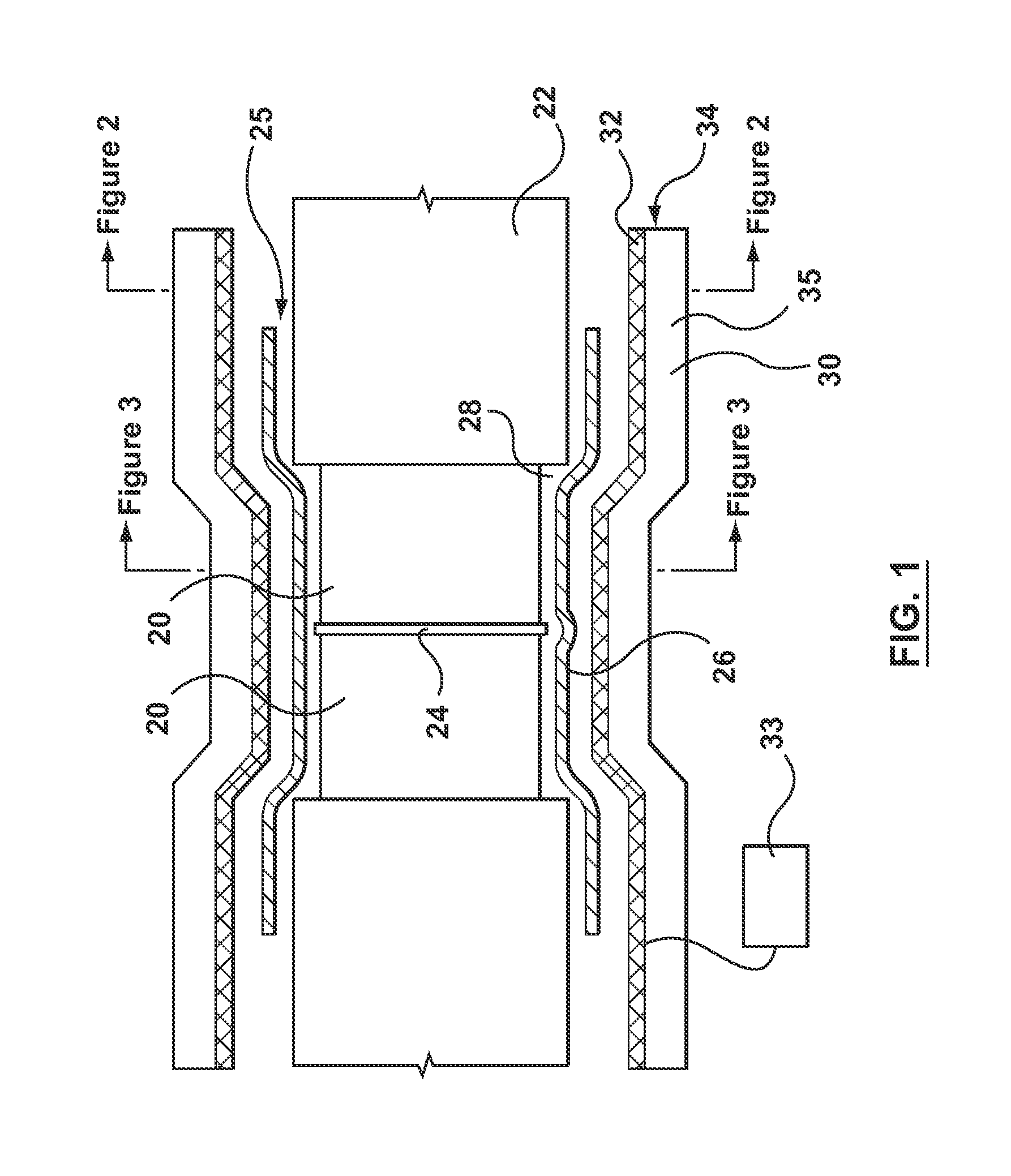

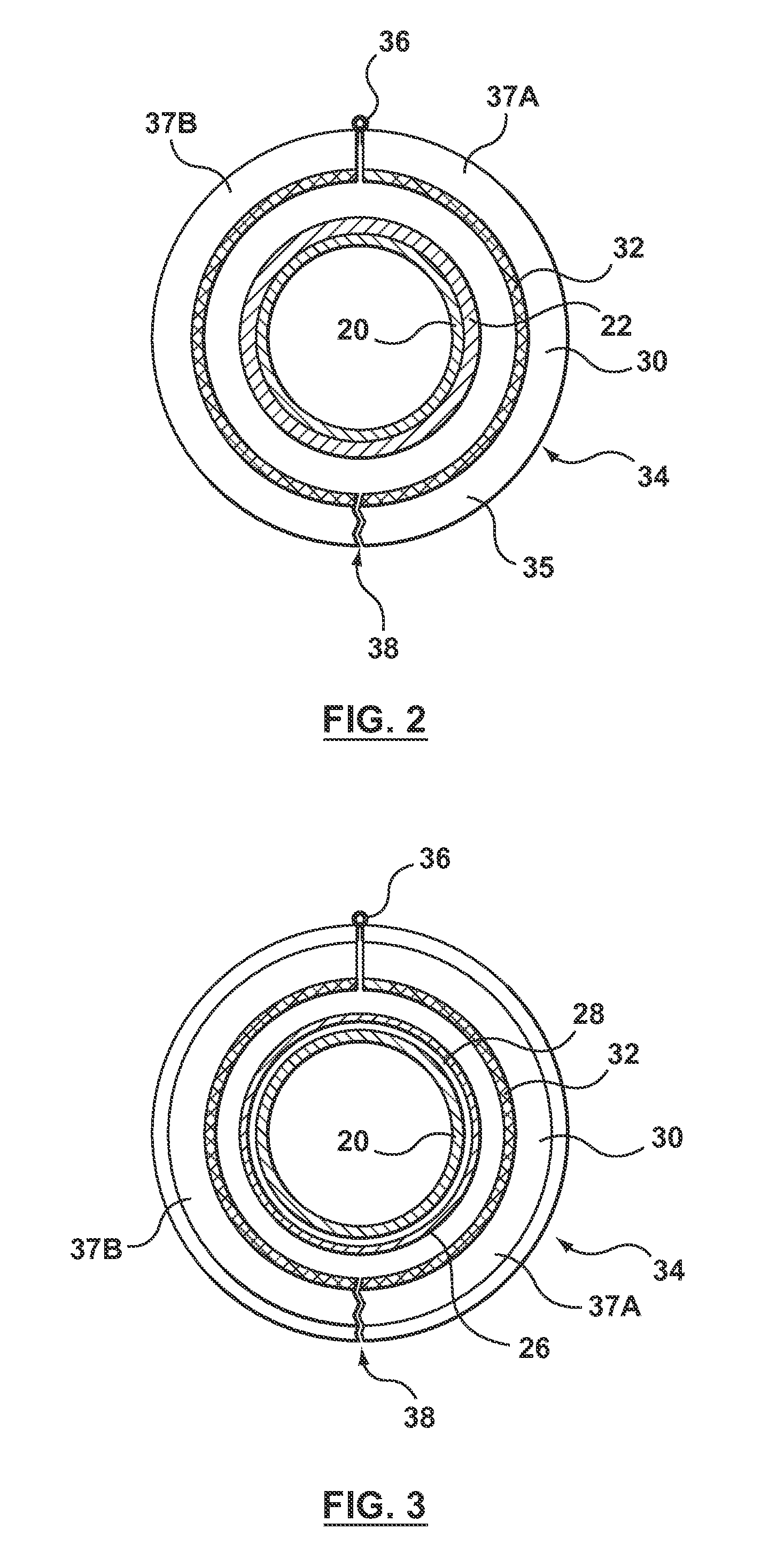

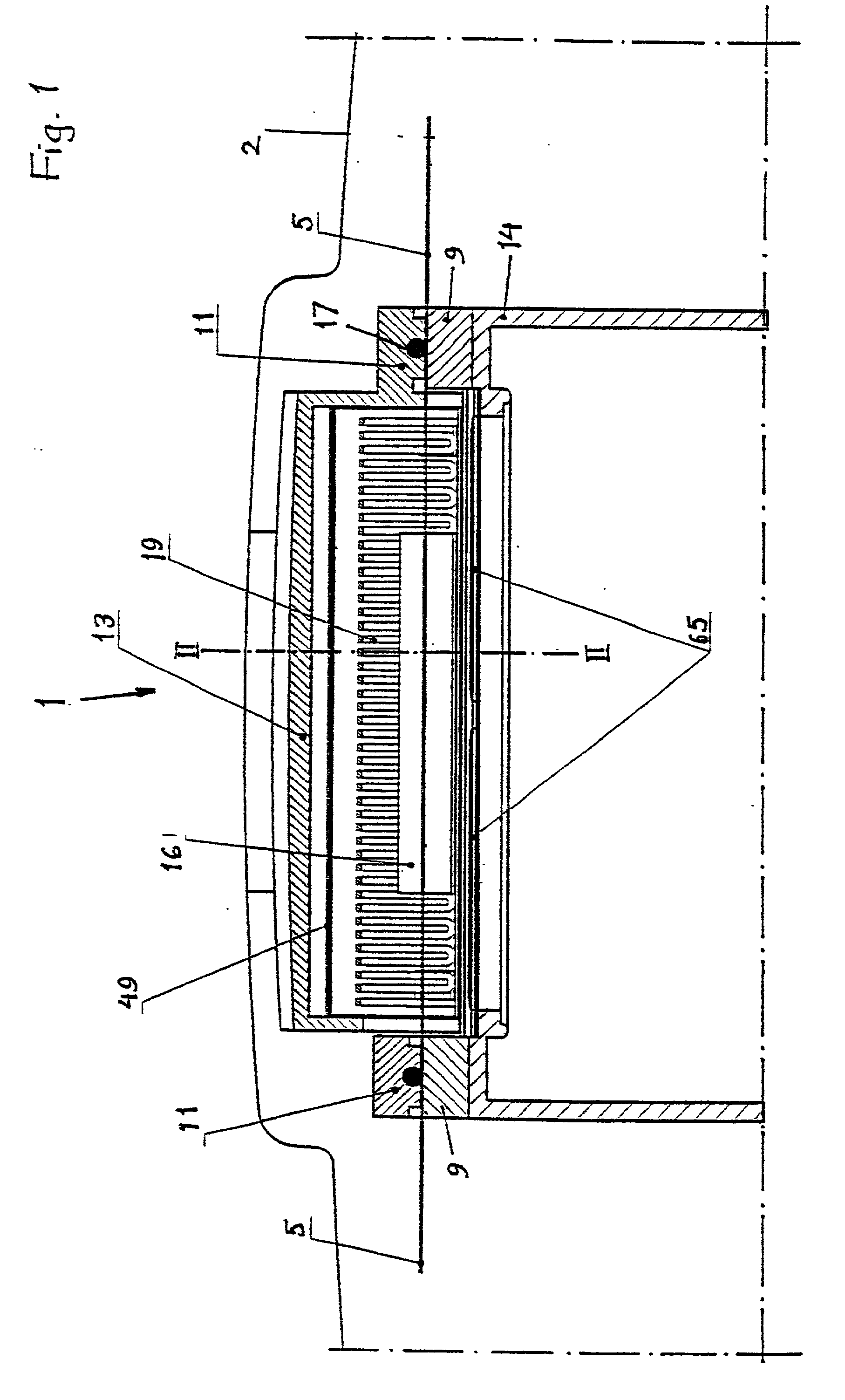

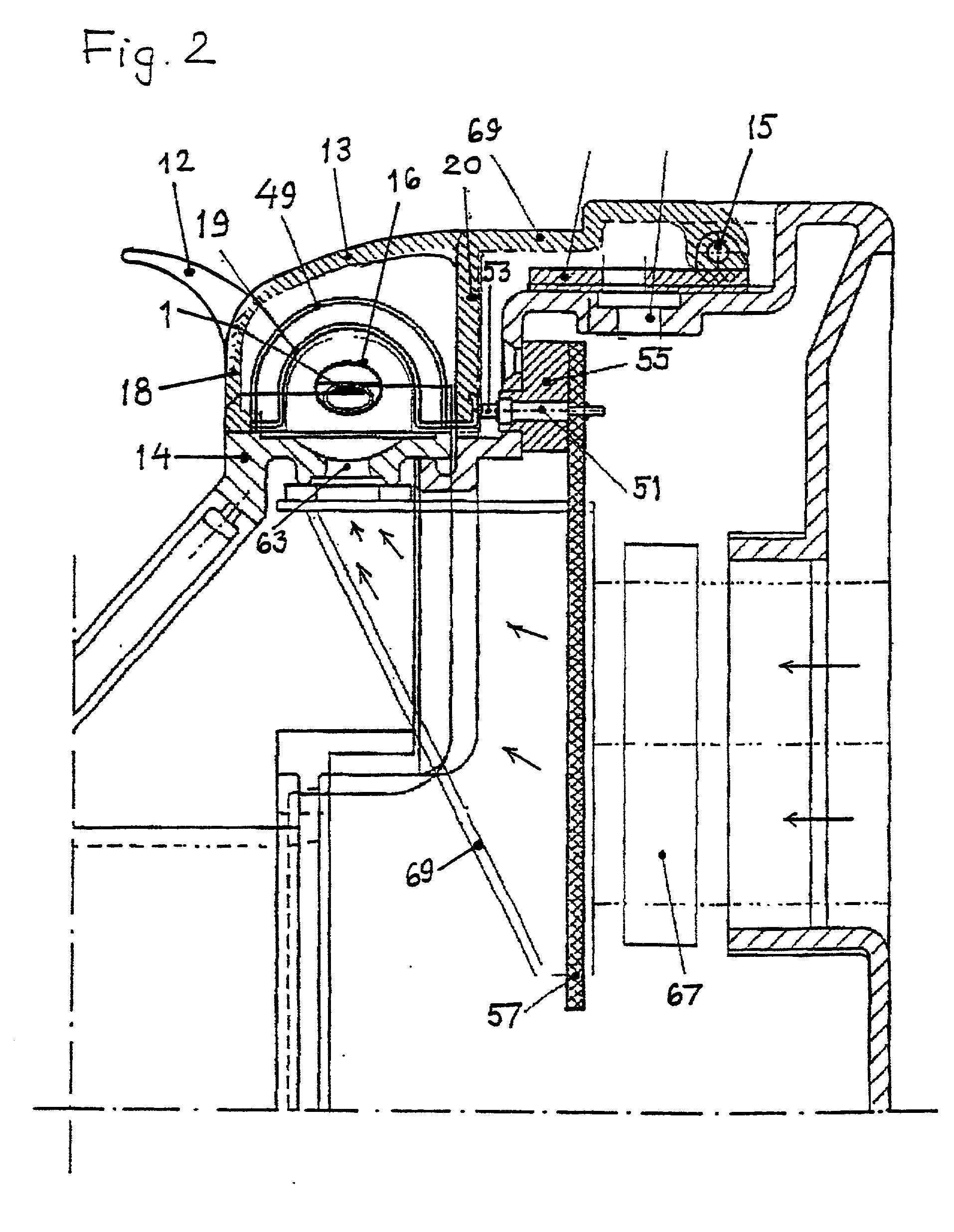

Apparatus for heating of elongate tubular article

InactiveUS20120090765A1Reduce quality problemsFast heating/coolingFurnace componentsLaminationHeat-shrinkable sleeveEngineering

The invention is directed to an apparatus for heating an elongate tubular article, comprising a frame member adapted to be disposed around said article, a heater with multiple heating zones and a controller for operating the heating device. The apparatus may be used to apply a heat shrinkable sleeve around a welded pipe joint. The heater may be infrared and also may use thin stamped sheets. If a heat shrinkable sleeve is used, the controller may activate the heating zones from the centre of the weld outward to eliminate pockets of air. The diameter of the interior of the frame may change along the length of the frame.

Owner:SHAWCOR LTD

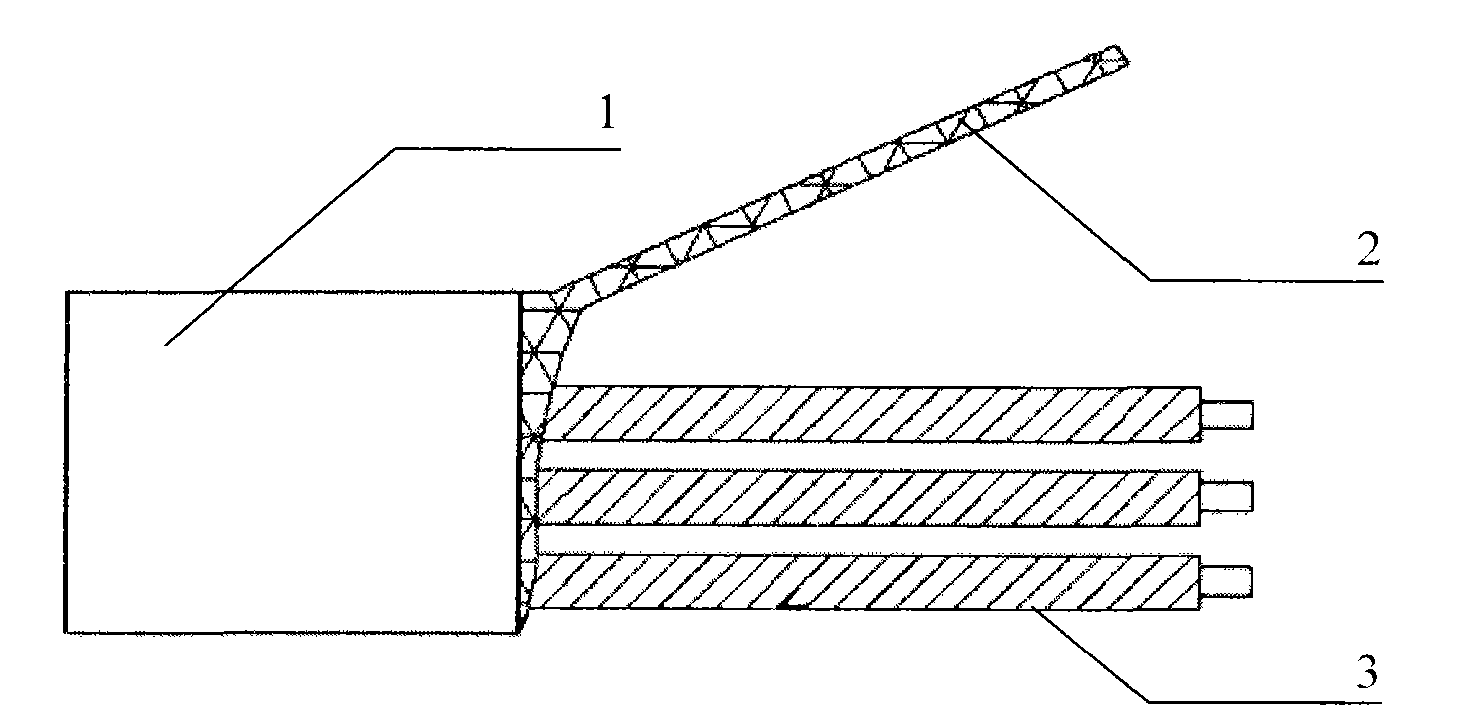

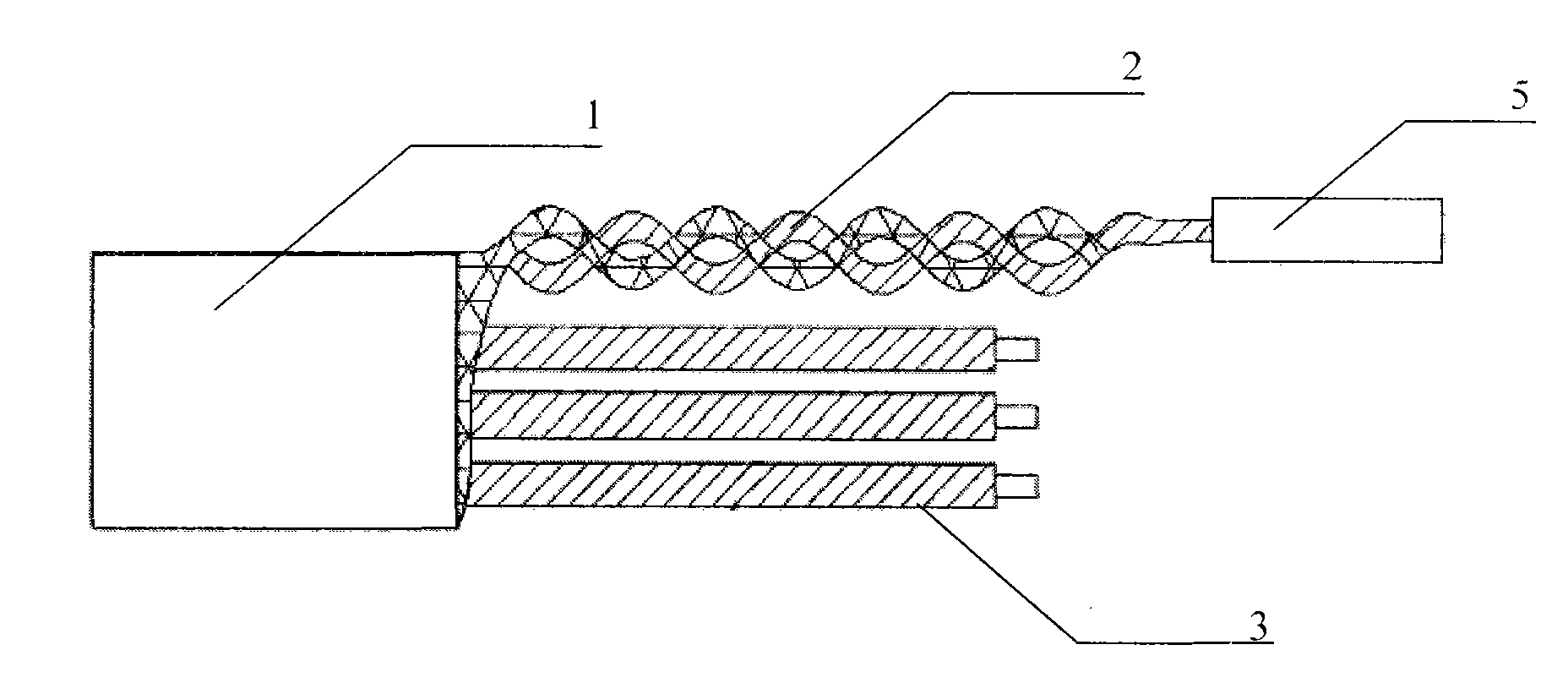

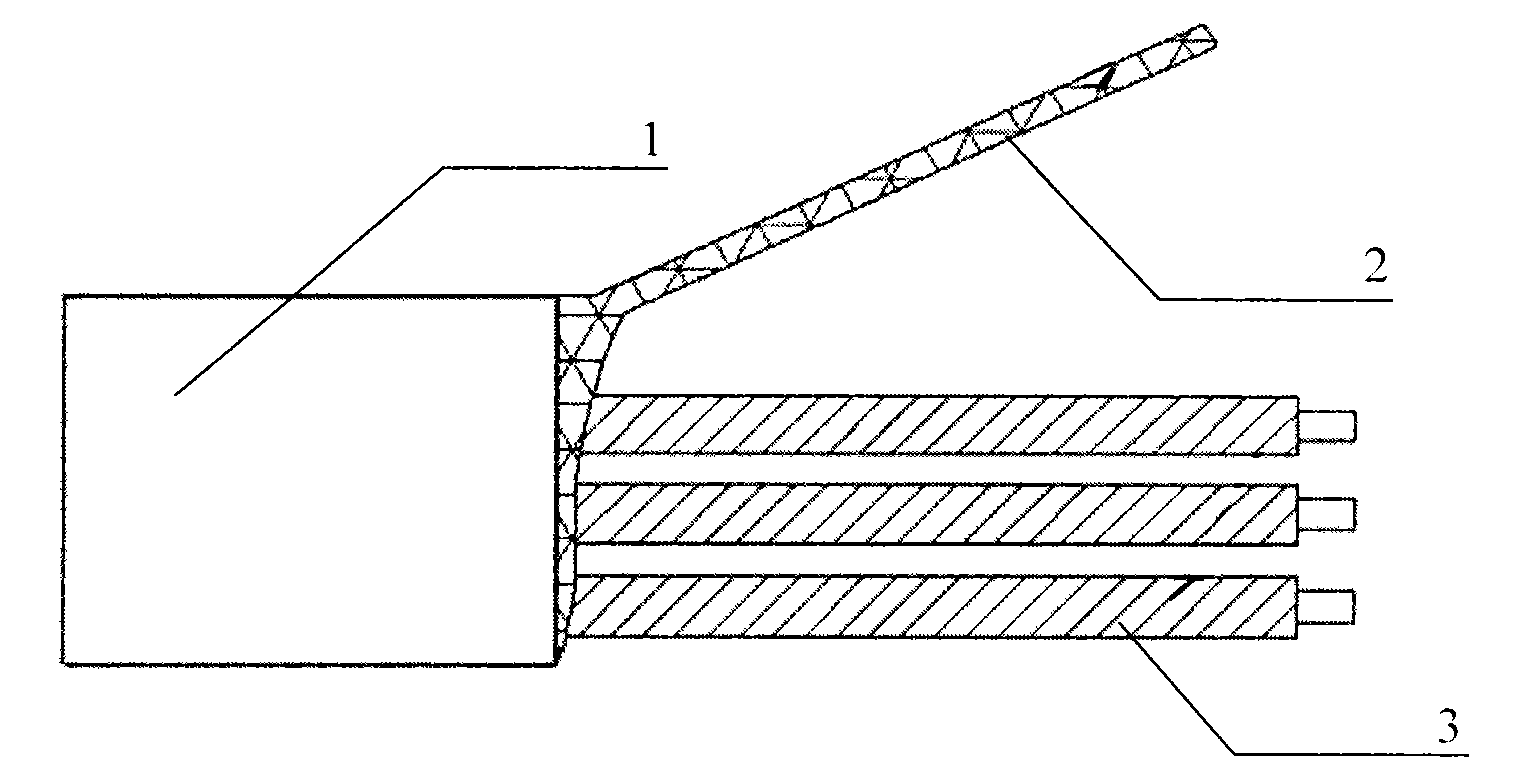

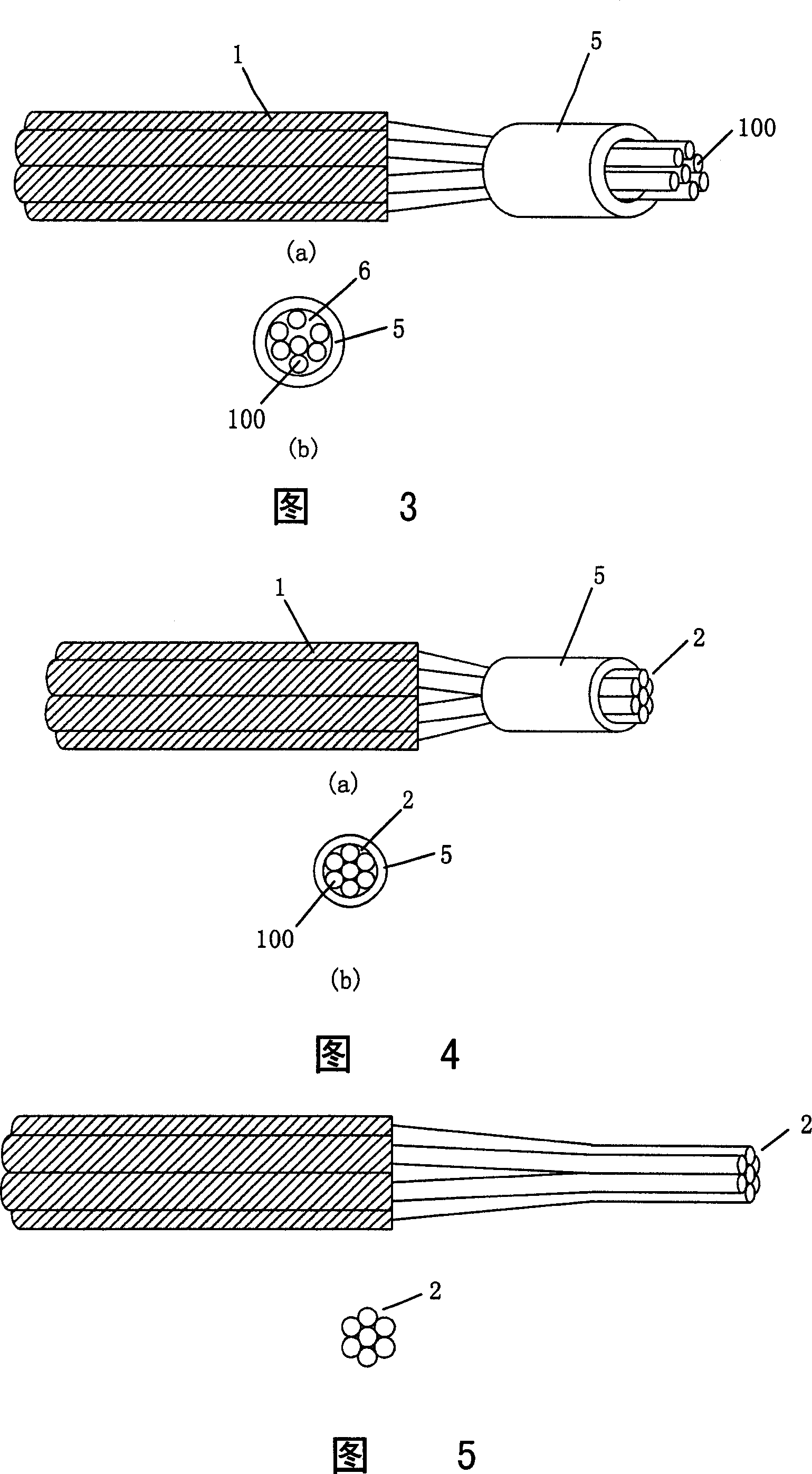

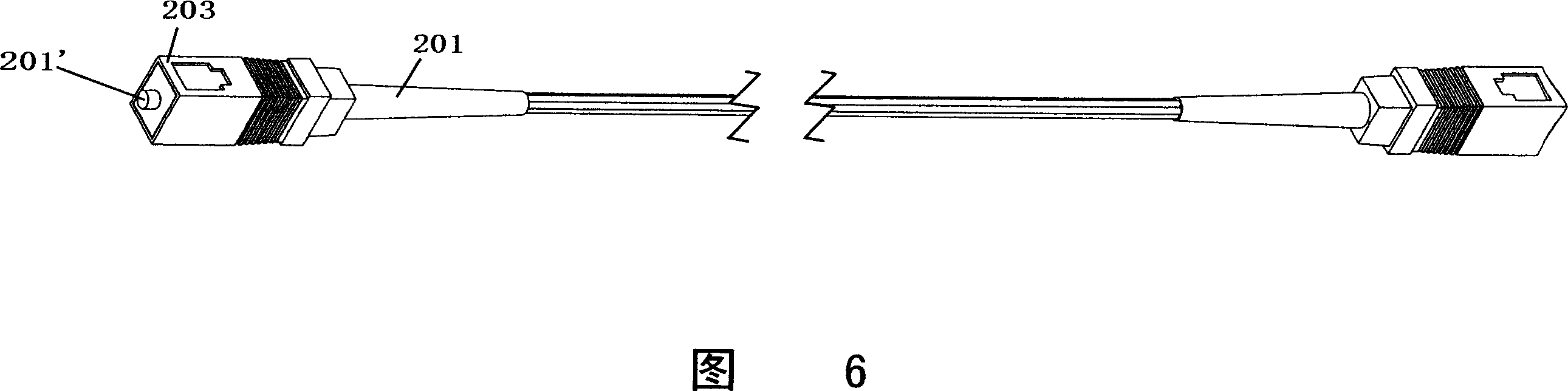

Shielded wire with lead wire and treatment process thereof

ActiveCN101834032ANot easy to fall offAvoid technical problems that require larger turning radiiLine/current collector detailsMulticonductor cable end piecesHeat-shrinkable sleeveEngineering

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

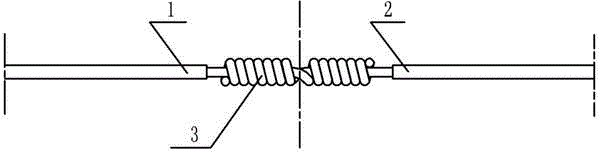

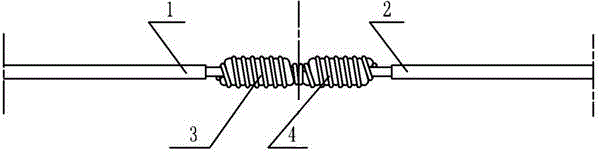

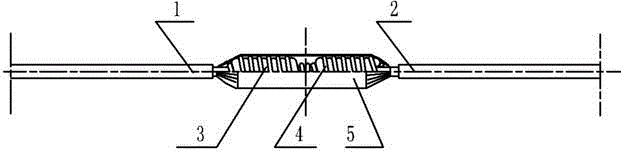

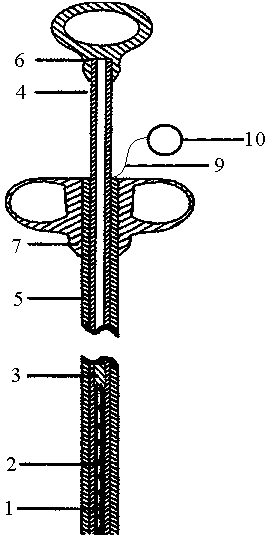

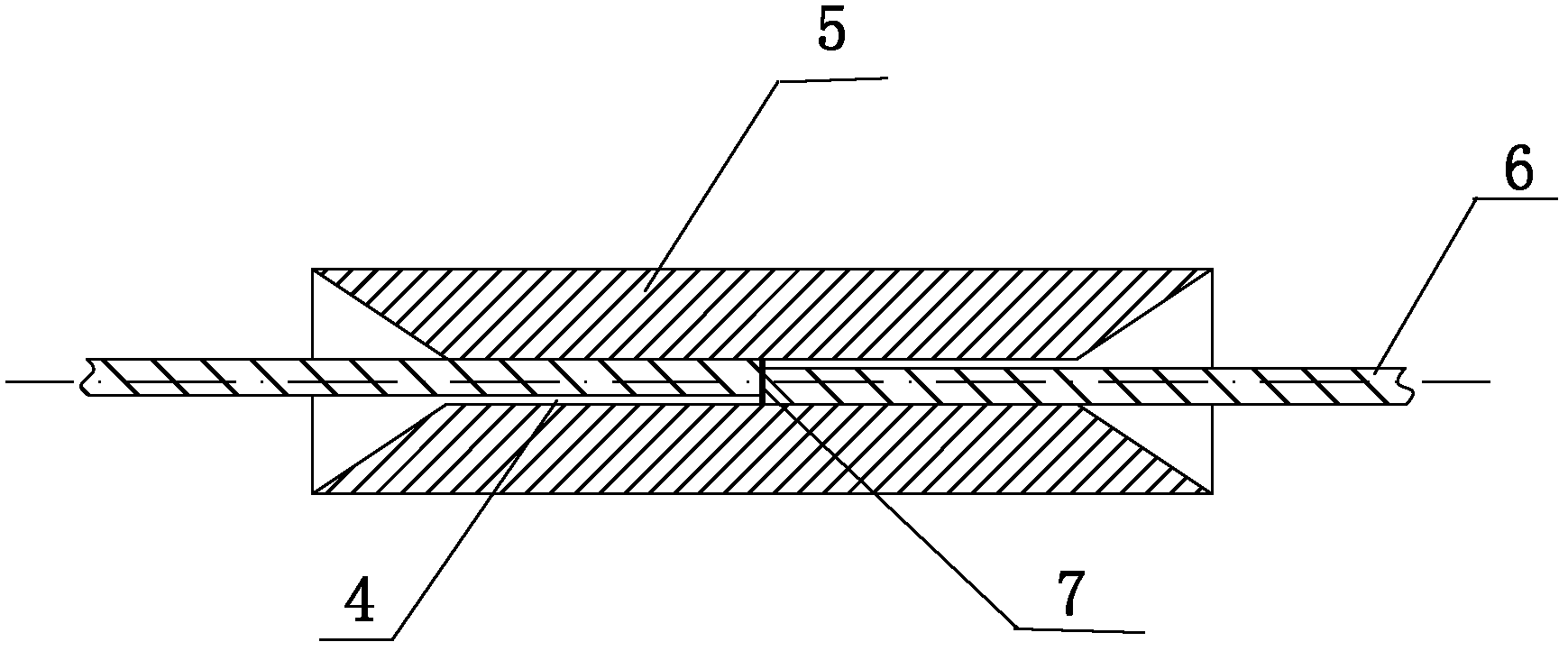

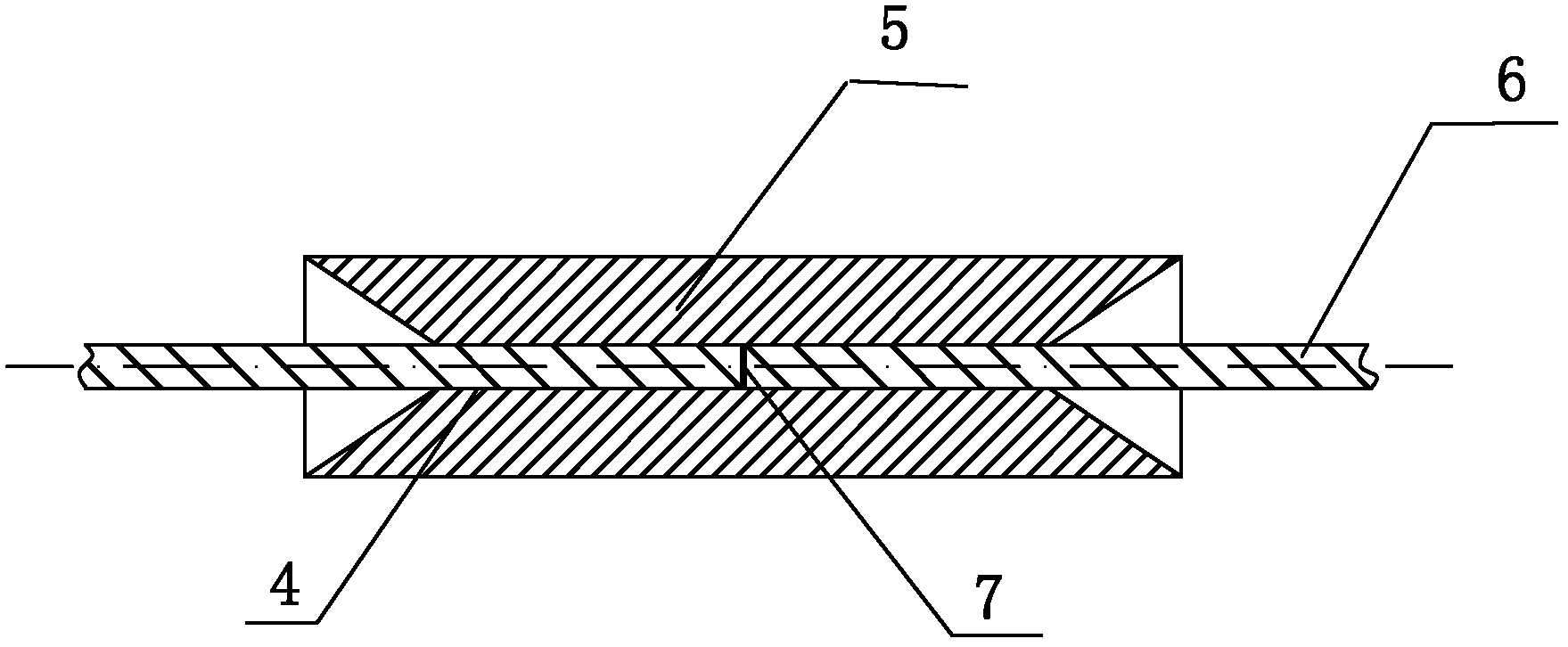

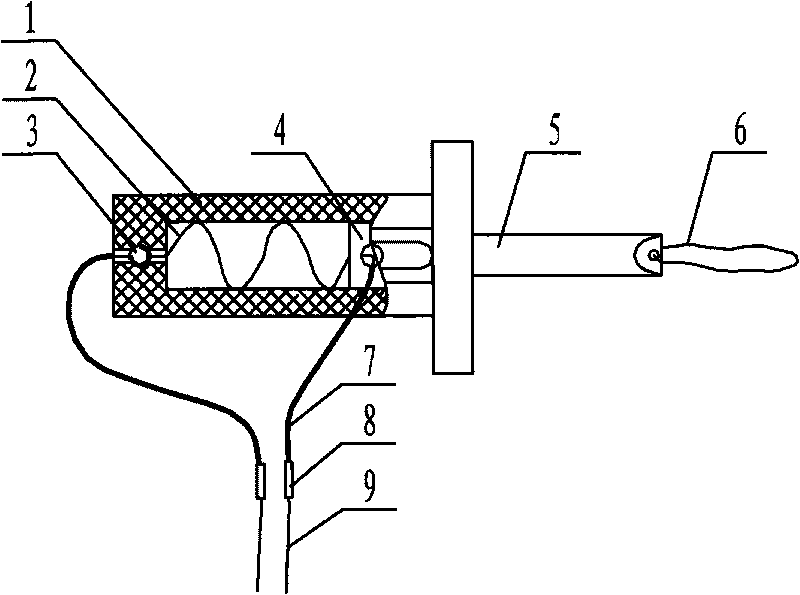

Production method of copper core cable soldered and sealed intermediate joint

The invention relates to a production method of a copper core cable soldered and sealed intermediate joint. The production method comprises the following steps that: 1) a cable, a wire 1 and a wire 2 are skinned, and the wires are made into a fixedly-connected bare joint 3; 2) the bare joint is wound with a solder wire 4; 3) the solder wire 4 is wrapped in aluminum foil paper 5; 4) a heat gun 6 is turned on to uniformly heat the aluminum foil paper, so that the solder wire can be indirectly heated to be soldered on the bare joint; 5) the joint is sleeved with a heat shrinkable sleeve 7, and the heat shrinkable sleeve 7 is uniformly heated with the heat gun; 6) the heat shrinkable sleeve shrinks and attaches to the bare joint; 7) the production of other wire joints of the cable is completed at a place where the above wire joint is not located according the step 1 to step 6; 8) cable sheaths at two ends of the joints are wrapped in hot-melt adhesive tapes 9 by one to two laps; and 9) the hot-melt adhesive tapes are sleeved with a large heat shrinkable sleeve 10, and the large heat shrinkable sleeve is uniformly heated with the heat gun, and therefore, the large heat shrinkable sleeve can shrink, and the hot-melt adhesive tapes in the large heat shrinkable sleeve can be melt, and the heat shrinkable sleeve can be bonded with the cable sheaths by the hot-melt adhesive, so that sealing and waterproof performance can be realized.

Owner:LEYARD LIGHTING CO LTD

Apparatus containing multiple sequentially used infrared heating zones for tubular articles

ActiveUS20150219264A1Reduce gapDrying solid materials with heatSpace heating and ventilationHeat-shrinkable sleeveAir cycle

An apparatus for heating an elongate tubular article, such as a heat shrinkable sleeve applied around a welded pipe joint during pipeline construction. The apparatus is in the form of a frame which can be disposed around the article, the frame having a heater device having both longitudinally disposed heating zones and radially disposed heating sectors, each of which can be independently controlled. Alternatively, or in combination, the apparatus can have an air circulation system. Also, a method for shrinking a heat shrinkable sleeve comprising use of said apparatus.

Owner:SFL CANUSA CANADA LTD

Halogen-free environment-friendly high-flame-retardant thermochromic material and application thereof

InactiveCN108485043AImprove mechanical propertiesPlay a protective effectPlastic/resin/waxes insulatorsInsulating bodiesEnvironmental resistanceHeat-shrinkable sleeve

The invention discloses a halogen-free environment-friendly high-flame-retardant thermochromic material and an application thereof. The thermochromic material comprises, by weight, 10 to 50 parts of ethylene and its copolymer, 5 to 30 parts of polyethylene / propylene, 5 to 40 parts of an elastomer, 3 to 10 parts of a compatibilizer, 30 to 70 parts of a flame retardant, 5 to 25 parts of color changing powder and 1 to 10 parts of an auxiliary agent. The invention also provides a method for producing a halogen-free environment-friendly high-flame-retardant thermochromic wire cable or heat shrinkable sleeve. The halogen-free environment-friendly high-flame-retardant thermochromic wire cable or heat shrinkable sleeve has environment-friendly characteristics of no halogen, no red phosphorus and no heavy metal bismuth, has the flame retardant grade reaching to the VW-1 level in the US UL standard, resists 105 or 125 DEG C, realizes the reversible thermochromic function at various temperatures,and can play the visual recognition function of operating temperature warning and over-temperature discoloration.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL +2

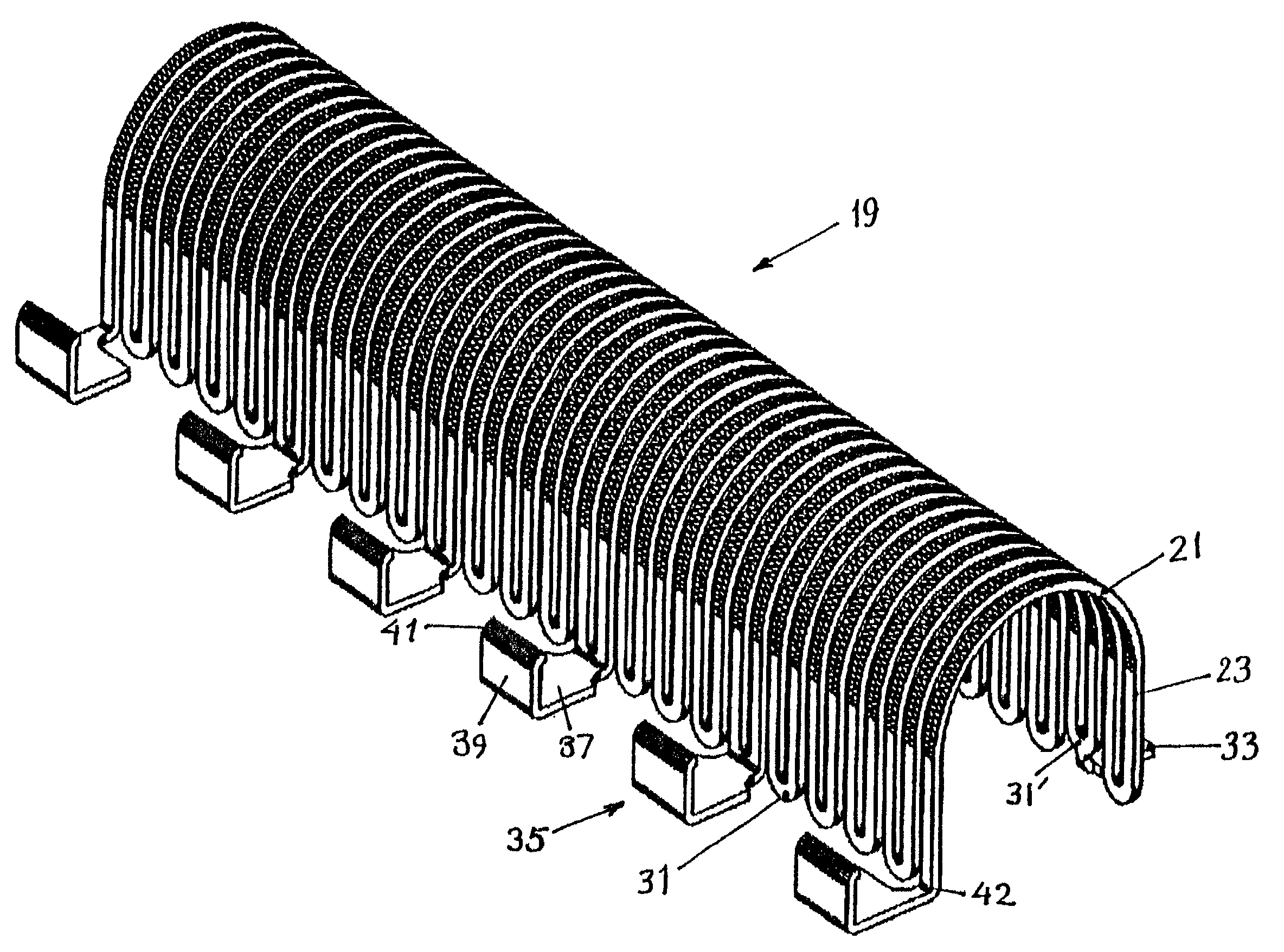

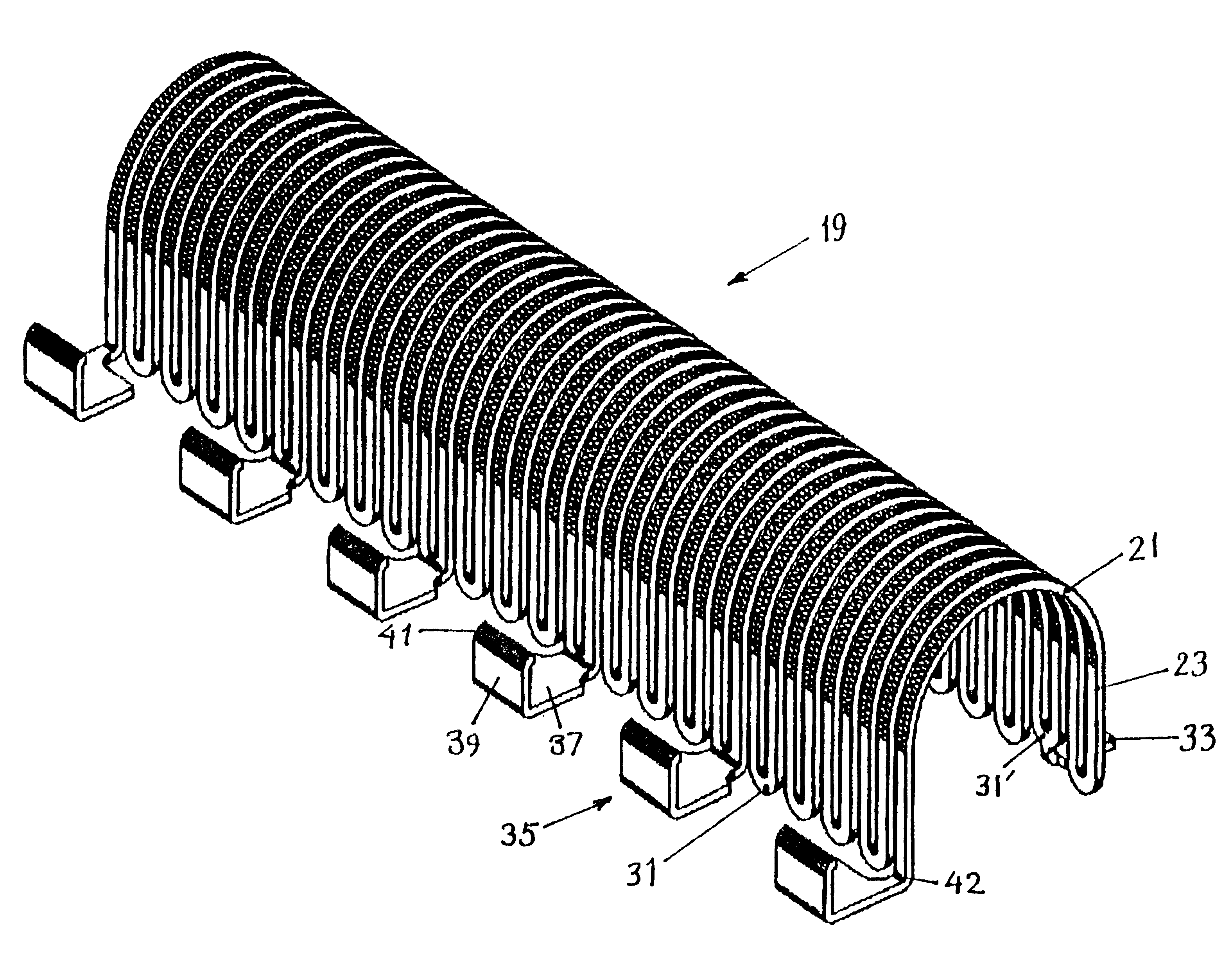

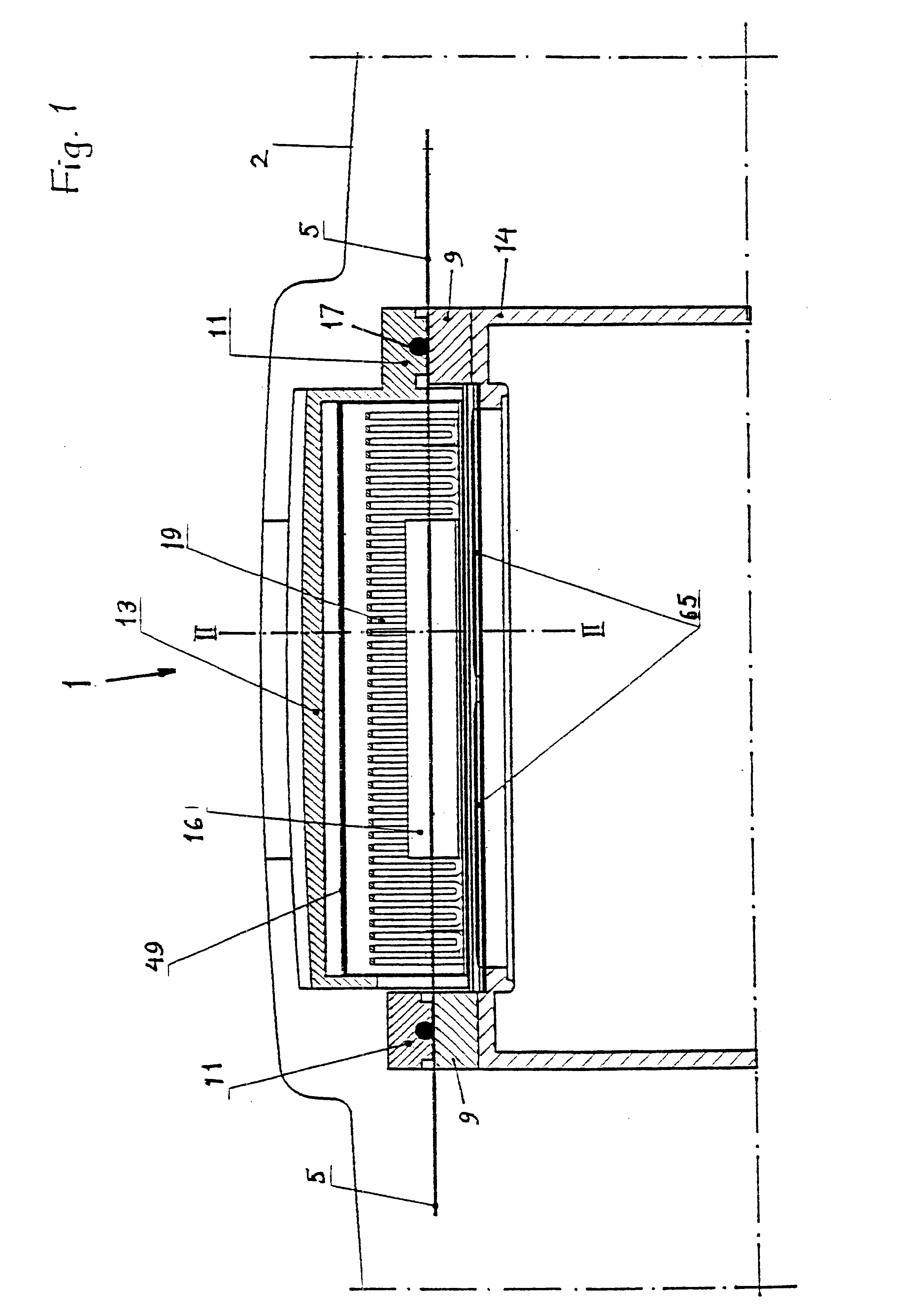

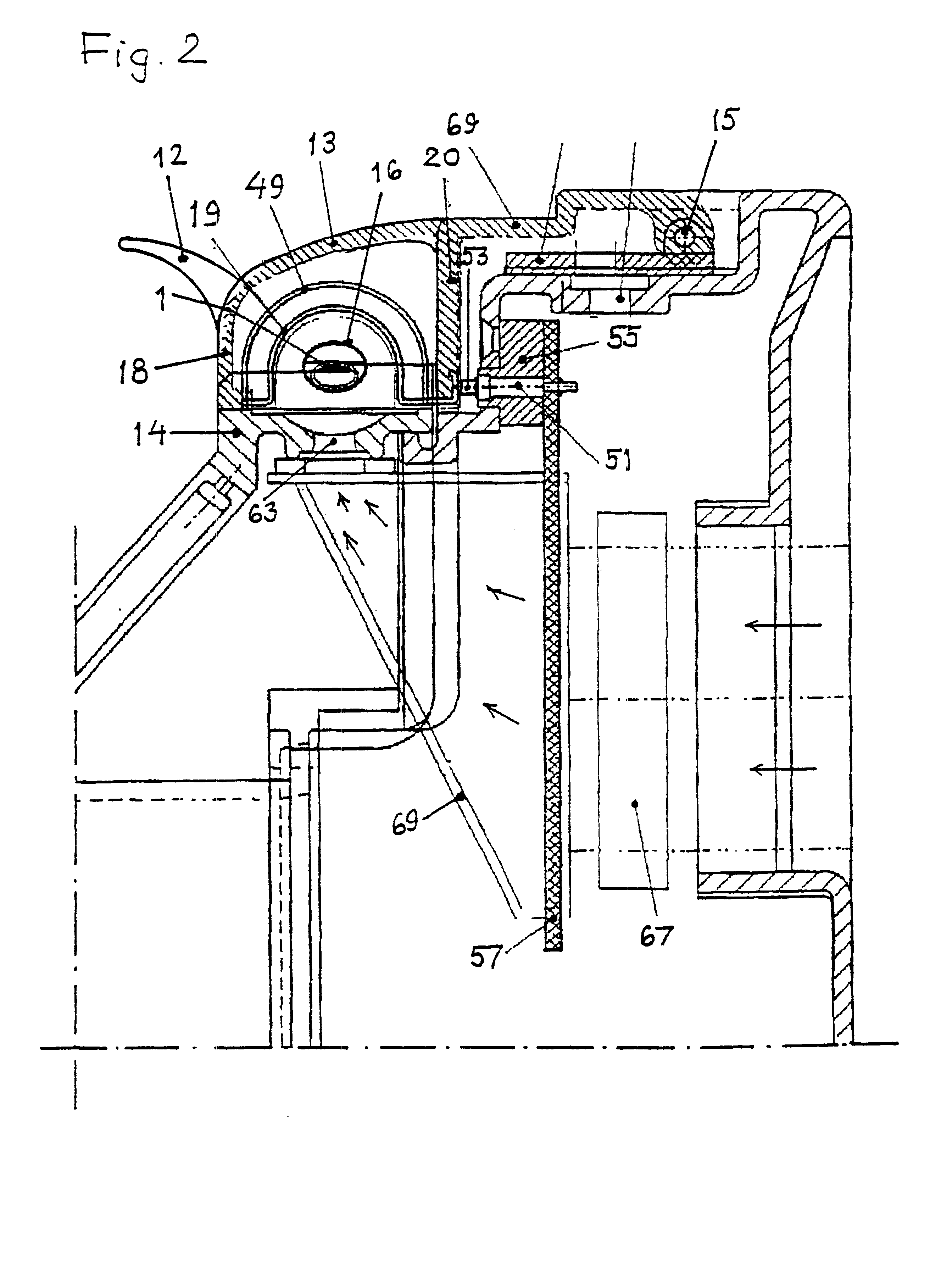

Device for heating shrinkable sleeves

InactiveUS20020088796A1Simple mounting attachmentIncrease contactElongated resistive elementHeater elementsHeat-shrinkable sleeveElectrical resistance and conductance

A resistance element (19) for a device for shrinking shrinkable sleeves comprises an elongate electrical conductor extending in a zigzag pattern and bent to a tunnel shape. The shrinkable sleeve including for example an optical fiber enclosed therein is placed in that region of the resistance element (19), which corresponds to approximately the geometric axis of the upper semi-cylindric portion of the tunnel shape. The resistance element (1) has attachment pins (33) and contact and attachment pins (35) at its front and rear sides respectively intended to be placed in corresponding recesses in a lid of the device. The rear contact and attachment pins (35) have portions (39) intended for contact with elastic, electrically conducting contact pins with which the resistance element (19) comes in contact, when the lid is folded down to perform the shrinking operation. The open and freely suspended design of the resistance element (19) including only small contact areas to the lid result in that the resistance element can be rapidly heated and thereafter rapidly cooled implying that a shrinking operation can be executed in a minimum of time.

Owner:TELEFON AB LM ERICSSON (PUBL)

Device for heating shrinkable sleeves

InactiveUS6570140B2Simple mounting attachmentIncrease contactElongated resistive elementHeater elementsHeat-shrinkable sleeveElectrical resistance and conductance

A resistance element (19) for a device for shrinking shrinkable sleeves comprises an elongate electrical conductor extending in a zigzag pattern and bent to a tunnel shape. The shrinkable sleeve including for example an optical fiber enclosed therein is placed in that region of the resistance element (19), which corresponds to approximately the geometric axis of the upper semi-cylindric portion of the tunnel shape. The resistance element (1) has attachment pins (33) and contact and attachment pins (35) at its front and rear sides respectively intended to be placed in corresponding recesses in a lid of the device. The rear contact and attachment pins (35) have portions (39) intended for contact with elastic, electrically conducting contact pins with which the resistance element (19) comes in contact, when the lid is folded down to perform the shrinking operation. The open and freely suspended design of the resistance element (19) including only small contact areas to the lid result in that the resistance element can be rapidly heated and thereafter rapidly cooled implying that a shrinking operation can be executed in a minimum of time.

Owner:TELEFON AB LM ERICSSON (PUBL)

Polyvinylidene fluoride heat-shrinkable sleeve and preparation method thereof

InactiveCN106633548AImprove mechanical propertiesImprove flame retardant performanceHeat-shrinkable sleeveAntioxidant

The invention discloses a polyvinylidene fluoride heat-shrinkable sleeve which contains the following components in parts by weight: 100 parts of polyvinylidene fluoride resin, 1-8 parts of antioxidant, 0.5-5 parts of light stabilizer, 5-10 parts of acid absorber, 0.5-3 parts of lubricant and 0-10 parts of coloring agent; the polyvinylidene fluoride resin is one or a mixture of more of the following substances: 1,2-vinyl difluoride homopolymer, 1,2-vinyl difluoride-hexafluoropropylene copolymer and 1,2-vinyl difluoride tetrafluoroethylene copolymer; the antioxidant is 4,4'-bis(alpha, alpha-dimethyl benzyl) diphenylamine; the light stabilizer is poly(1-hydroxyethyl-2,2,6,6-tetramethyl-4-hydroxypiperidine) succinate; and the acid absorber is one or a mixture of more of the following substances: magnesium oxide, calcium oxide and zinc oxide. The radiation crosslinked polyvinylidene fluoride heat-shrinkable sleeve disclosed by the invention can completely meet the requirements of UL224 and American military standard SAE-AMS-DTL-23053 / 18 in performance and can be widely applied to the fields such as locomotives, ships, aerospace and military industry.

Owner:CHANGYUAN ELECTRONICS DONGGUAN +4

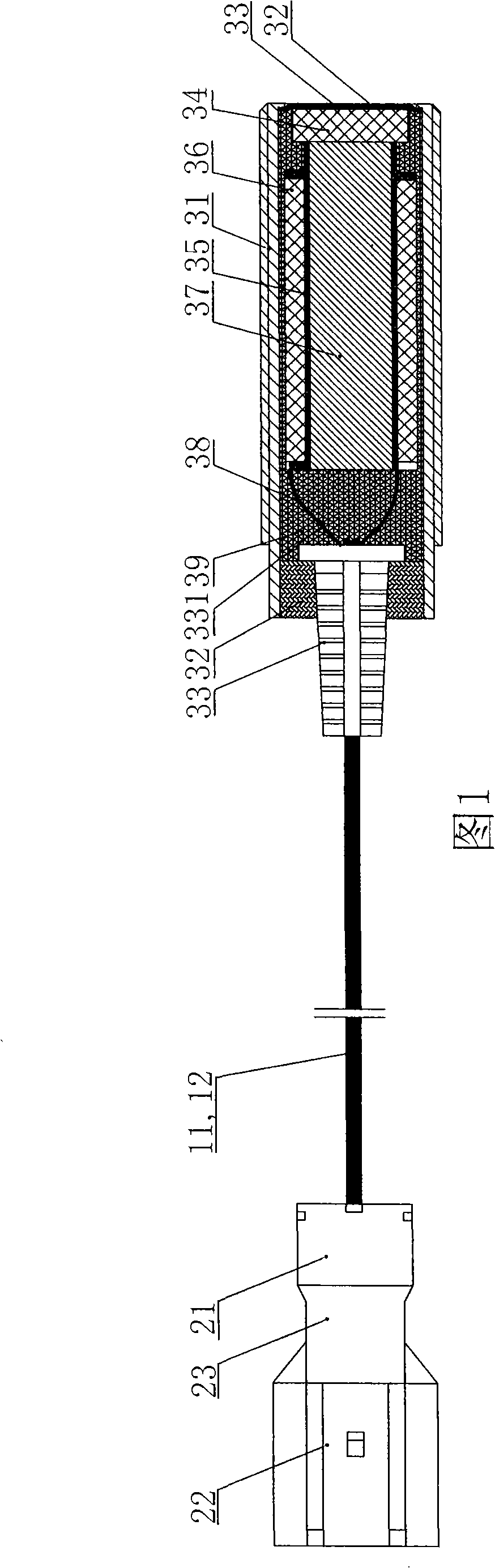

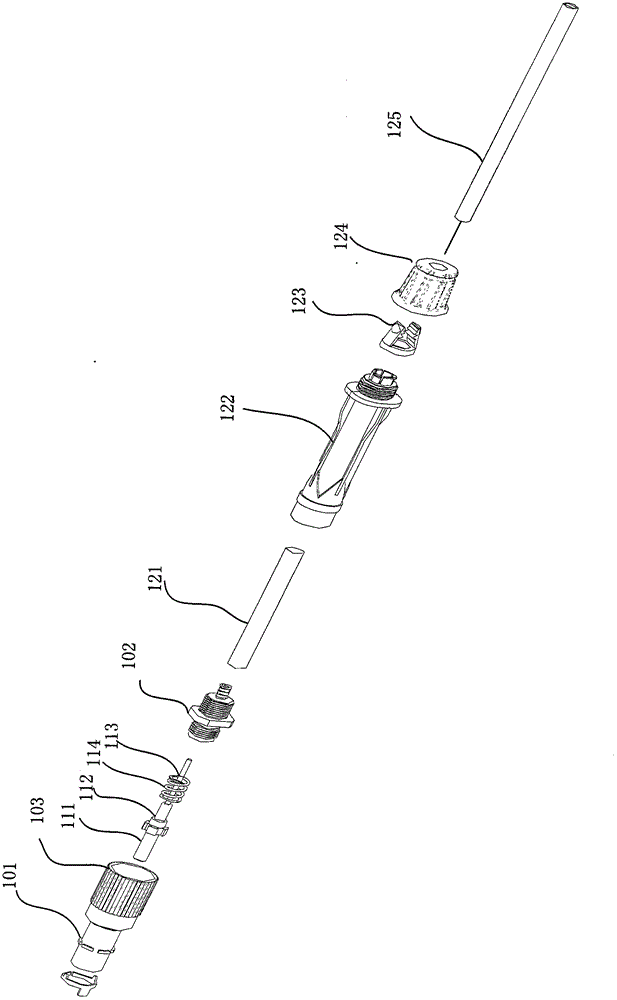

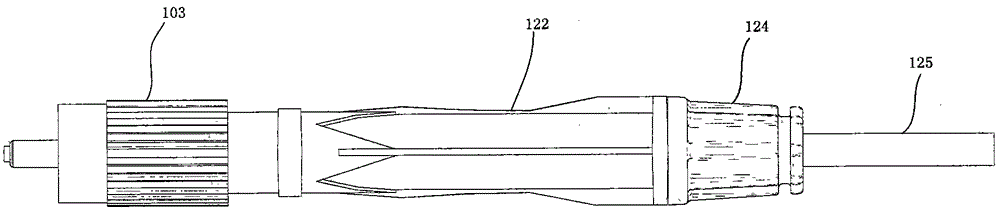

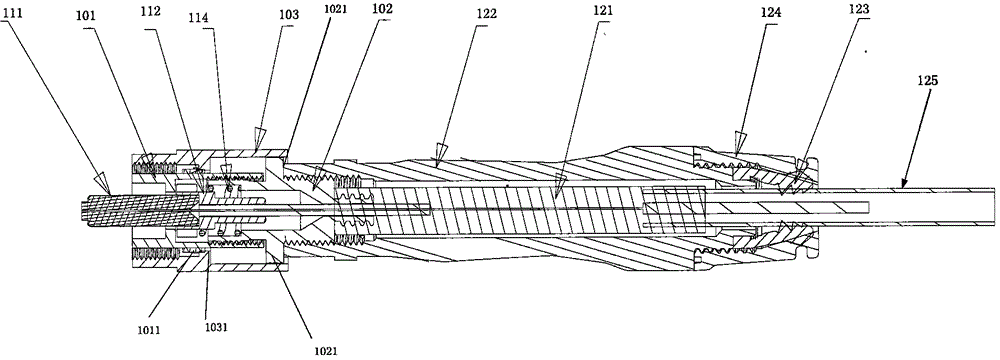

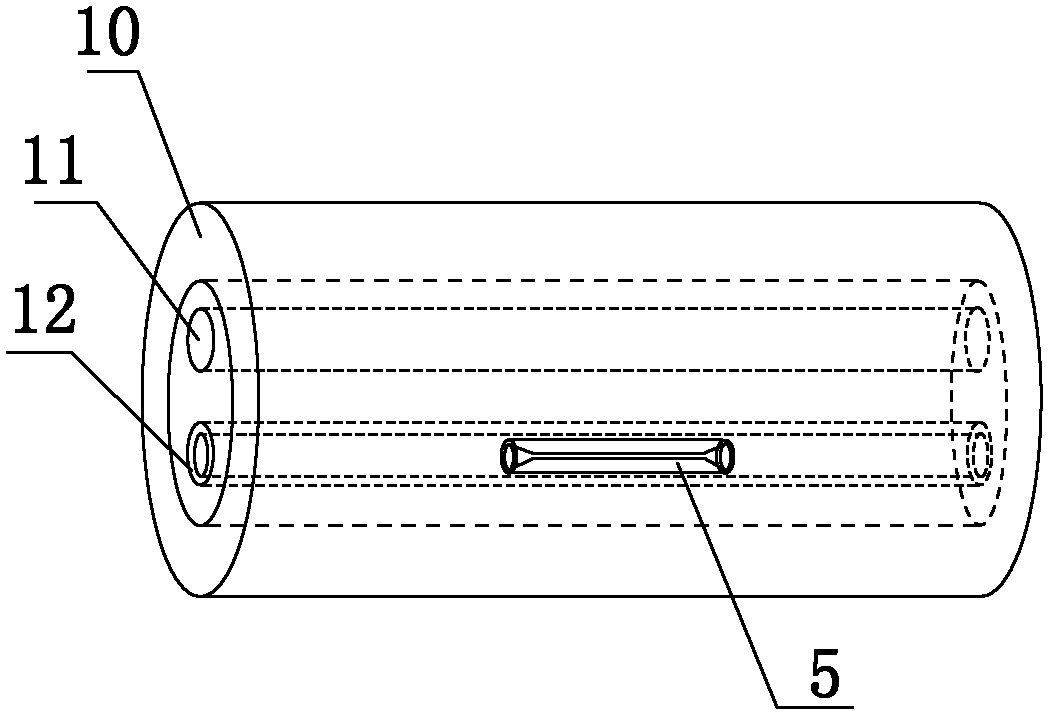

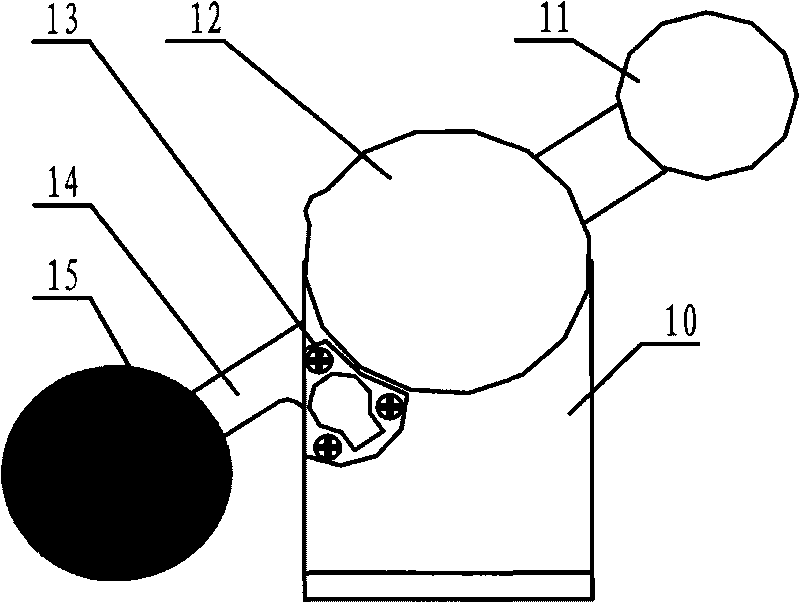

Magnetoelectricity type passive velocity transducer and manufacturing technology thereof

ActiveCN101315390AImprove high temperature resistanceLower working temperatureDevices using electric/magnetic meansHeat-shrinkable sleeveElectricity

The invention relates to a magnetoelectric passive speed sensor used for measuring the rotating speed of a dropping speed apparatus and the manufacturing technique thereof. The failure problem that the speed sensor of the dropping speed apparatus works in the high temperature environment can be effectively avoided. The magnetoelectric passive speed sensor is composed of a plug apparatus and a speed sensor which are respectively and fixedly arranged at both ends of an insulated wire sleeved in a heat shrinkable sleeve. The manufacturing technique comprises the steps as follows: a magnet, a mica sheet and a plug are fixed together by thin electronic silica gel; an iron core is arranged in a coil framework and wound on the coil framework through an enamel covered wire; the coil framework and the combination body of the magnet, the mica sheet and the plug are sleeved at the tail part of an outer shell in sequence; a wire button 30 is sleeved at the head part of the outer shell through the plug, and a double insulated wire led out by the wire button 30 is electrically connected with the coil framework through a leading wire; a layer of base coating solvent is coated in the outer shell; double components of silica gel are filled in the inner wall of the outer shell to perform the integral encapsulation in the cavity formed by the wire button 30, the coil framework and magnet; and the double insulated wire in a heat shrinkable pipe which is led out by the wire button 30 is connected to the plug apparatus.

Owner:深圳市大为创新科技股份有限公司

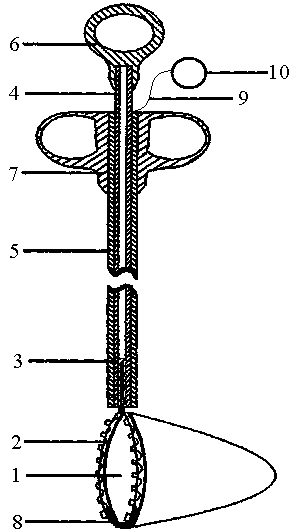

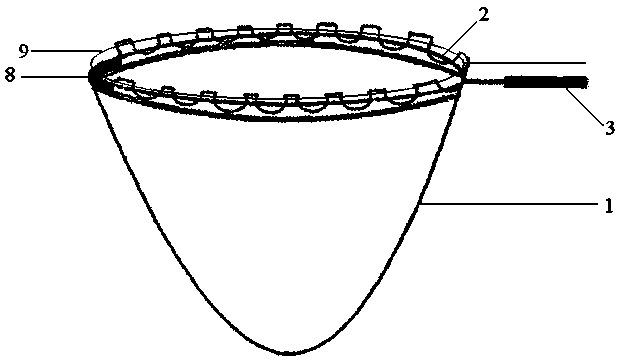

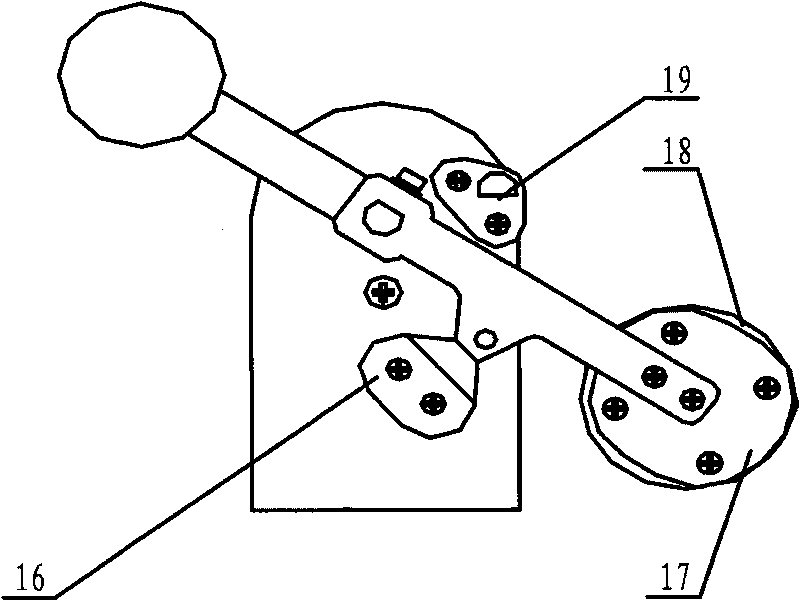

Excised tissue collector for laparoscopic operations

ActiveCN104287782AReduce the risk of injuryThere will be no deformation and saggingSurgeryVaccination/ovulation diagnosticsHeat-shrinkable sleeveShore

The invention discloses an excised tissue collector for laparoscopic operations. The excised tissue collector comprises two memory alloy flat clamps; one ends of the memory alloy flat clamps penetrate holes of two sides of a collecting bag and are connected at the confluence through a heat shrinkable sleeve, and a double-sheet memory alloy flat clamp ring is obtained; the other ends of the memory alloy flat clamps are connected to an inner connecting plug fixed to an inner sheath bar, the inner sheath bar is arranged in an outer sheath bar provided with a double-lug handle, and the inner sheath bar is provided with a signal-lug handle; the holes of the collecting bag are provided with a pull rope in a penetrated manner, and two ends of the pull rope penetrate the outer sheath rod to connect to a pull ring. The double-sheet memory alloy flat clamp ring is adopted, the bearing capacity is higher than that of a thin steel wire ring or elastic wire ring of the prior art, the connection of the double-sheet memory alloy flat clamp ring can be shore off during the clinical operation, instruments can be fetched from an operation channel, only the collecting bag and the pull rope are left inside a body, one operation channel can be omitted, doctor's operation is facilitated, and the pain of a patient can be reduced.

Owner:苏州鸿博医疗器械有限公司

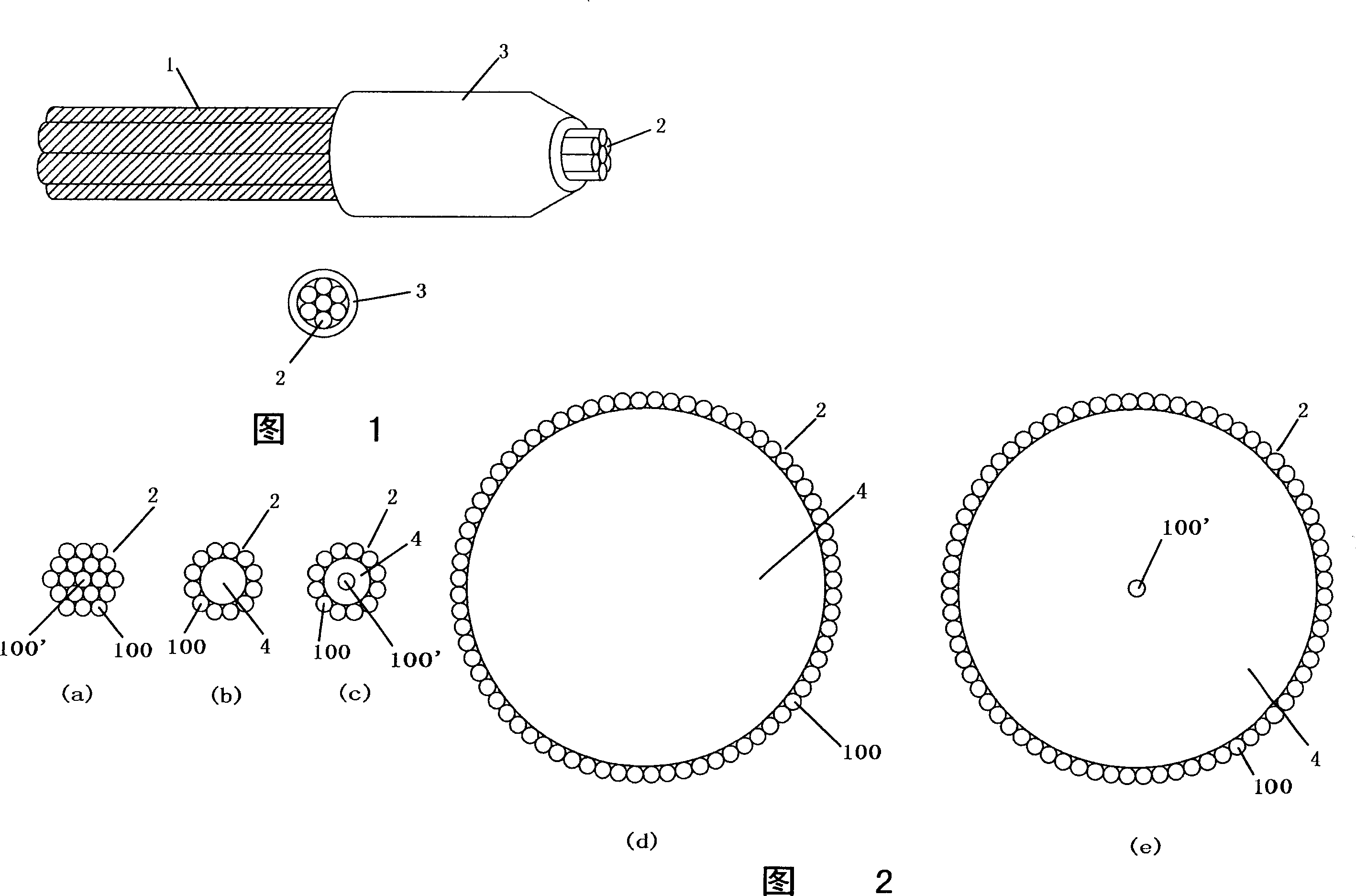

Multi-optical-fiber port platform and mfg. method

ActiveCN1936635AReduce stressReduce volumeCoupling light guidesBundled fibre light guideHeat-shrinkable sleeveFiber

The invention provides the multi-optical port table including the insert core and the optical fiber bundle which the space between the many optical fibers is the sub-micron grade. The method includes: first to remove the covered layer of the optical fiber and cover the heat-shrinkable sleeving on it, the overlapping region is coated with the optical hot setting adhesive; then to heat the heat-shrinkable sleeving until the space between the optical fiber is sub-micron grade; it removes the heat-shrinkable sleeving after cooling it and inserts it into the insert core and fixes it by the ultraviolet glue or the optical hot setting adhesive to construct the tail fiber of the multi-optical fiber; the ultraviolet glue can instead the optical hot setting adhesive, so it can be solidified by the violet solidifying lamp. Last to polish or cut the tail fiber of the optical fiber bundle to construct the multi-optical port table. The invention has the high reliability and small size, but cost little.

Owner:中贝光电科技(湖北)有限公司

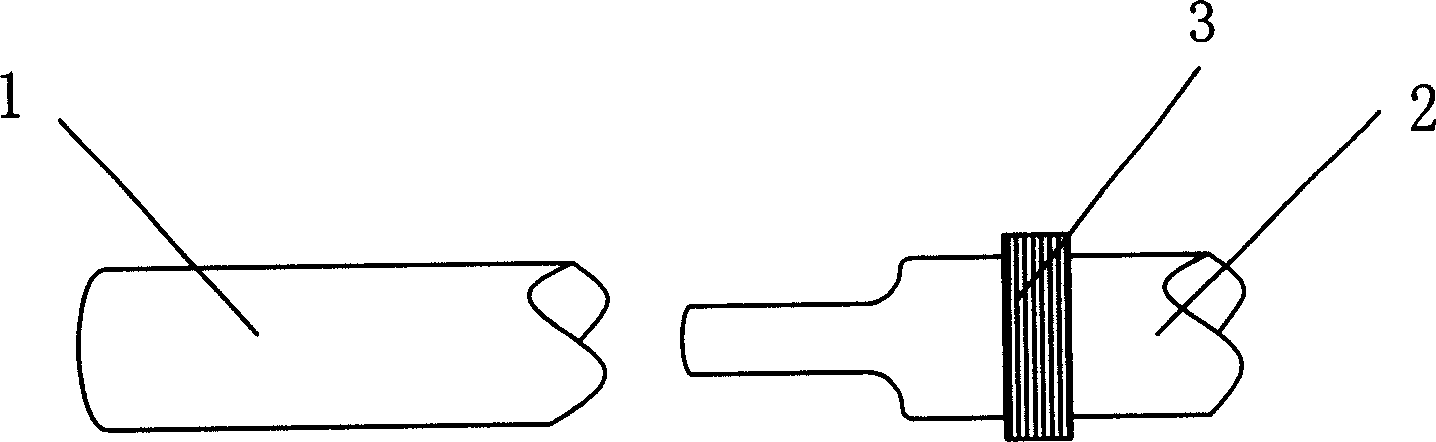

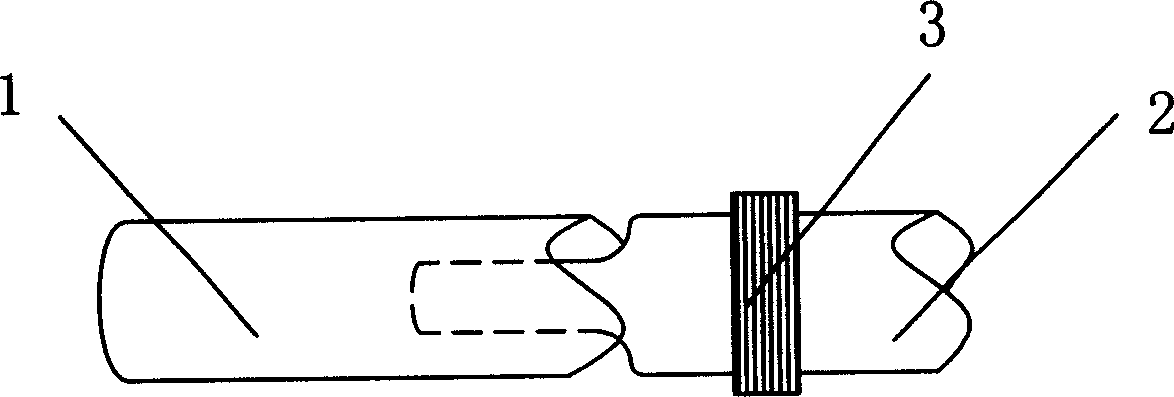

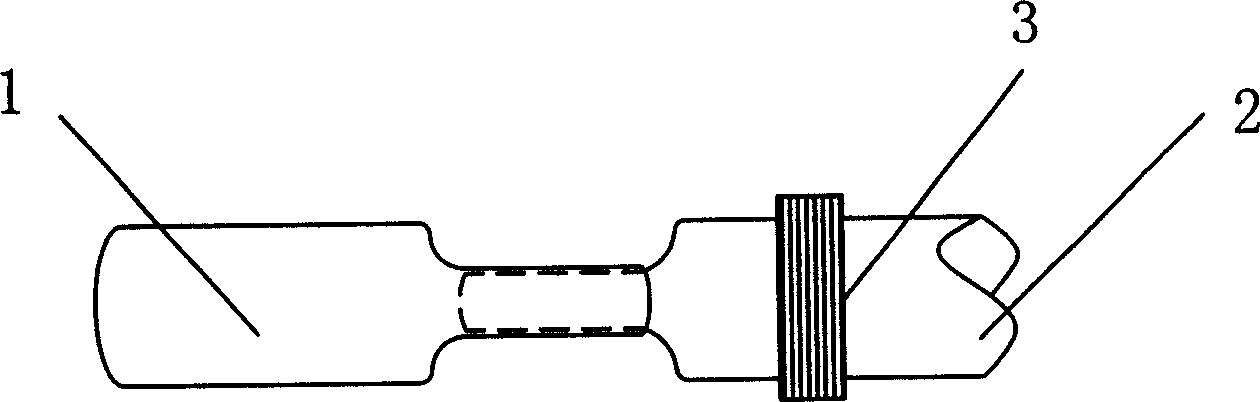

Connect method of heat-shrinkable sleeve

ActiveCN1623762AImprove sealingNo danger of crushingTubular articlesHeat-shrinkable sleeveThermal shrinkage

A method for connecting two thermal shrinkage sleeve tubes with each other includes such steps as heating one end of a sleeve tube for shrinking it, inserting it in the end of another sleeve tube, heating the connection position for shrinking it, heating the sealing end of external sleeve tube, and pressing for sealing.

Owner:深圳市沃尔热缩有限公司

Flame-retardant heat shrinkable sleeve

InactiveCN101280084AAvoid corrosionPrevent agingCable junctionsInsulating bodiesHeat-shrinkable sleevePolyolefin

Disclosed is a flame-retardant thermal-shrinking bushing, which is formed by crystal modified polyolefin material irradiated by high-energy gamma-rays through melting and extruding by special equipments; the crystal modified polyolefin material is prepared with the following components based on weight proportion: 100 portions of thermoplastic polyolefin, 15-30 portions of inorganic flame retardants, 30-60 portions of organic flame retardants, 1.5-5 portions of antioxidants, 1.5-8 portions of lubrication and processing aids, 1-8 portions of black color master batches, and 1-4 portions of cross-linking agent. The raw materials granulated and produced based on the formula of the invention have large mechanical strength and heat-resistant oxygen aging; the produced thermal-shrinking bushing can effectively prevent copper corrosion and thermal oxygen aging and enables insulation and wear-resistant protection to automotive wiring harness terminals.

Owner:SHANGHAI CHANGYUAN ELECTRONICS MATERIAL

Crimpable insulated electrical connector

InactiveUS9184517B1Quick and easy visual inspectionElectric connection structural associationsConnections effected by permanent deformationHeat-shrinkable sleeveElectrical conductor

An electrical connector electrically connects two or more conductors in end to end orientation such that a bared end of each conductor is positioned within a hollow crimp barrel and crimped therein. The crimp barrel is held within a heat shrinkable sleeve that is crystal clear. Openings on either side of a stop within the crimp barrel allow for visual access into the central channel within the crimp barrel to assure proper placement and subsequent crimping of the conductors.

Owner:ENDACOTT JOHN E

Magnetically-conductive plastic heat-shrinkable sleeve and preparation method thereof

ActiveCN101824181AMagnetic shielding is easy to operateLow costTubular articlesHeat-shrinkable sleeveConductive coating

The invention discloses a magnetically-conductive plastic heat-shrinkable sleeve and a preparation method thereof. As everyone knows, various electromagnetic components and parts generate magnetic fields in work so as to further influence peripheral instruments and equipment to a certain extent. In conventional methods, magnetically-conductive coatings or magnetically-conductive cups are adopted to magnetically shield the electromagnetic components and parts; however, the operation is time-consuming, labor-consuming, low in production efficiency and high in manufacturing cost. For overcoming the defects, the invention discloses the method for preparing the magnetically-conductive plastic heat-shrinkable sleeve by adding magnetic powder into the plastic heat-shrinkable sleeve. The magnetically-conductive plastic heat-shrinkable sleeve of the invention is directly sleeved on the outer surfaces of the electromagnetic components and parts, thereby effectively performing magnetic shielding and having the advantages of simple operation, low cost and high production efficiency.

Owner:深圳市沃尔热缩有限公司

Thermal setted coextruded heat shrinkable sleeving and method for producing same

ActiveCN102709007AImprove reliabilityImprove securityInsulating bodiesConnection insulationHeat-shrinkable sleeveThermoplastic

A thermal setted coextruded heat shrinkable sleeving comprises a reaction type hot melting adhesive inner layer (10), wherein an outer layer is a thermal shrinkage layer (20) which takes thermoplastics type polyolefin as a main material. The reaction type hot melting adhesive inner layer and the thermal shrinkage outer layer are coextruded into a composite sleeving, a high-energy electron accelerator is used to irradiate the sleeving, only the material of the outer layer is controlled for cross bonding, and the material of the inner layer is not cross bonded. The thermal setted coextruded heat shrinkable sleeving in the invention can completely substitute a common hotmelt double-walled heat-shrinkable sleeving under high temperature, high humidity, acid, alkali and other special working environments, so the insulation, sealing, moistureproof and shockproof effects are improved, moreover, the special materials of the inner layer and the outer layer belong to environmental protection materials, and the harmful substances and heavy metal control provisions of the Restriction of the use of Certain Hazardous Substances in Electrical and Electronic Equipment (ROSH) of the European union are satisfied.

Owner:深圳市博赛新材有限公司

General-purpose optical fiber connector

ActiveCN104316998AAffect the connection qualityImprove tensile propertiesCoupling light guidesHeat-shrinkable sleeveGeneral purpose

The invention relates to a general-purpose optical fiber connector. The general-purpose optical fiber connector comprises a hot melting connector assembly, a heat-shrinkable sleeve and a heat-shrinkable sleeve protective shell. The hot melting connector assembly comprises a hot melting head body, a ceramic pin, a ceramic pin holder base and an embedded optical fiber, wherein the ceramic pin, the ceramic pin holder base and the embedded optical fiber are arranged in the hot melting head body in a penetration mode. The tail portion of the heat-shrinkable sleeve protective shell is connected to an optical fiber locking device for locking the optical fiber and the locking device is arranged in separation from the heat-shrinkable sleeve protective shell. The general-purpose optical fiber connector is compatible with optical fibers in different sizes, the tensile property of the optical fiber connector is enhanced, and the heat-shrinkable sleeve protective shell can use the same mold for mass production rather than separate production for each type, so that the production efficiency is improved.

Owner:INNO INSTR (CHINA) INC +1

Optical fiber splicer

InactiveCN103163595ASimple structureReasonable designCoupling light guidesHeat-shrinkable sleeveOptical fiber cable

The invention discloses an optical fiber splicer which comprises an alignment tube composed of a memory alloy material. Two ends of the alignment tube are conic optical fiber introduction port. The relationships of the initial inner diameter DT1 of an inner hole of the alignment tube with optical fiber and the inner diameter DT2 of the inner hole of the alignment tube after the alignment tube expands at low temperature with the optical fiber are (1) [1-(1-S)*K]*DF<DT1<DF and (2) DF<DT2<DF*(1+S*K). DF is the outer diameter of the optical fiber when the optical fiber is in abutted connection. K is a shape memory strain coefficient of the alignment tube made of the memory alloy material. S is a selected proportionally coefficient. The optical fiber splicer further comprises a heat-shrinkable sleeve tube. A hot melting tube and a reinforcing piece arranged outside the hot melting tube and parallel to the hot melting tube are arranged inside the heat-shrinkable sleeve tube. The alignment tube is placed on the middle portion inside the hot melting tube. According to the optical fiber splicer, the memory alloy tube is mainly adopted and optical fiber end head connection is performed. The optical fiber splicer has the advantages of being low in cost, easy and convenient to use and good in long-term stability.

Owner:XIAN JINHE OPTICAL TECH

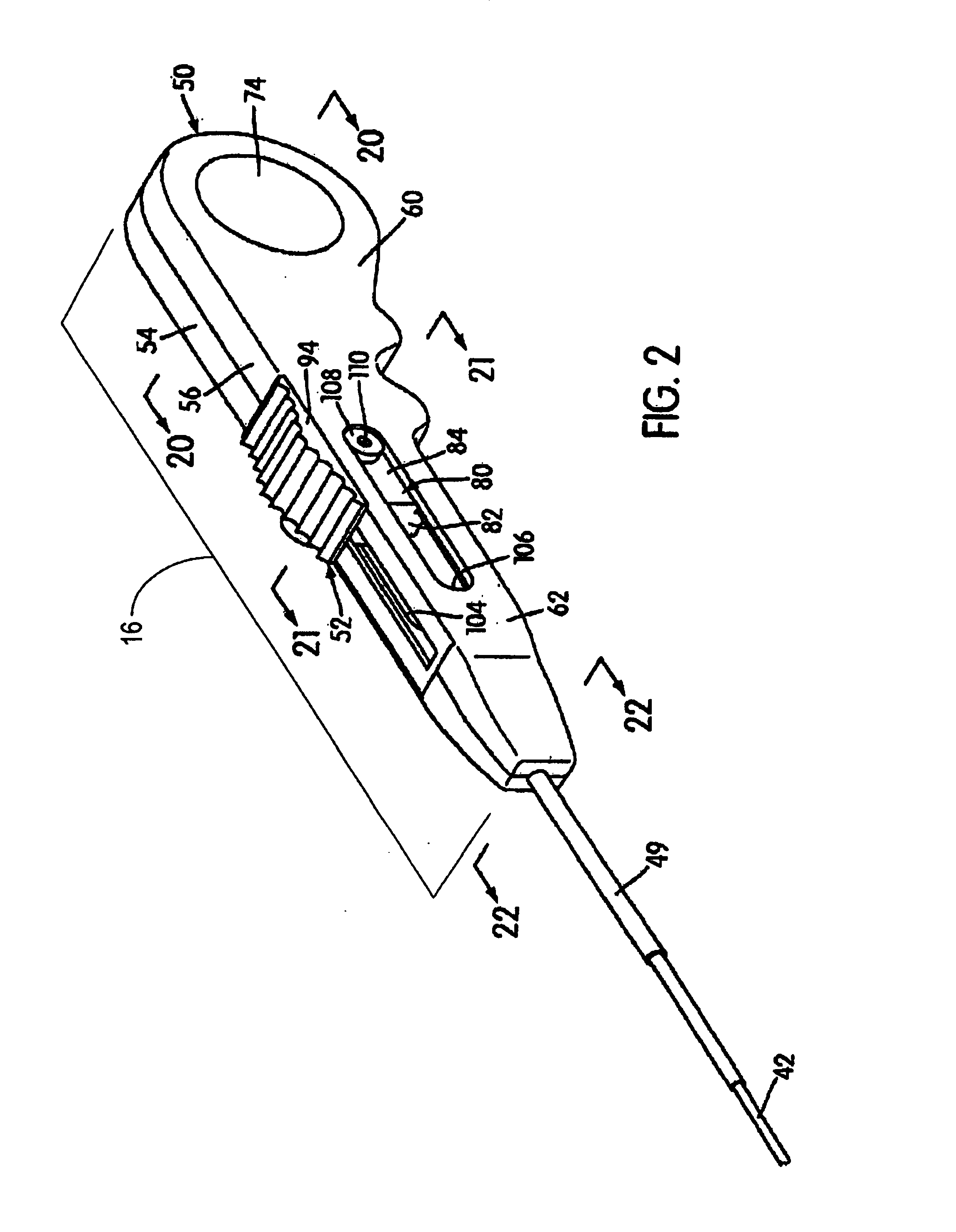

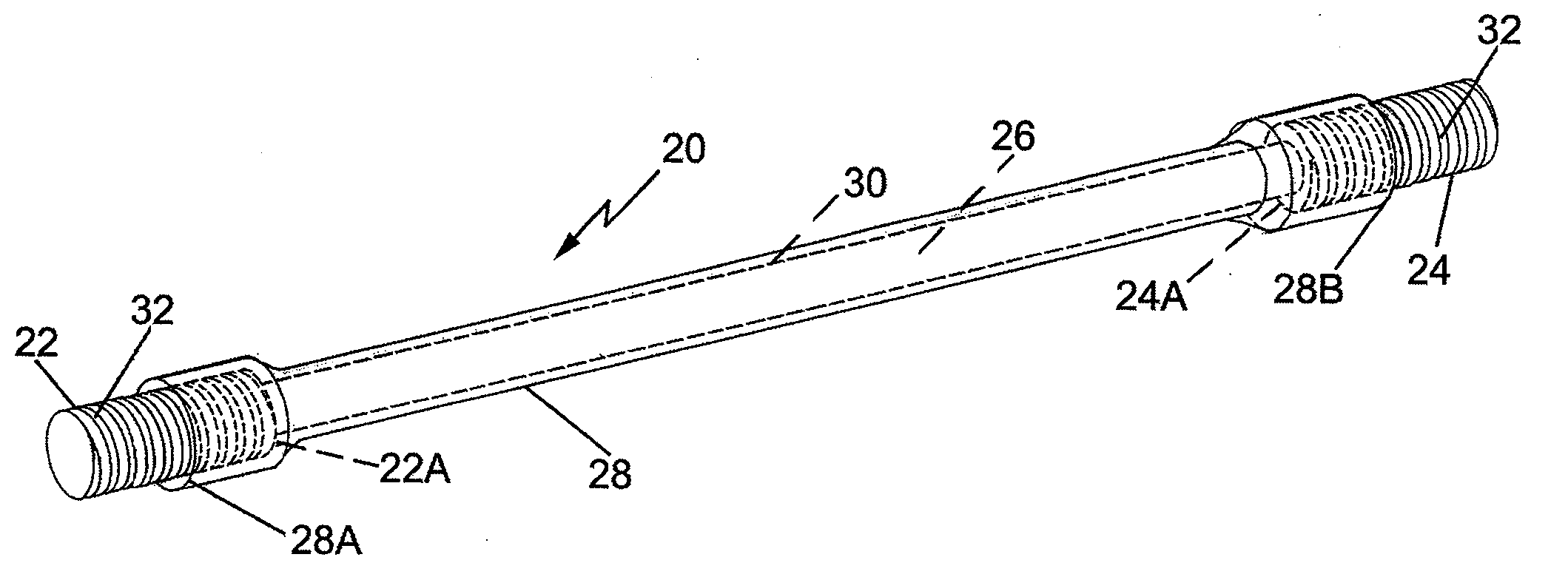

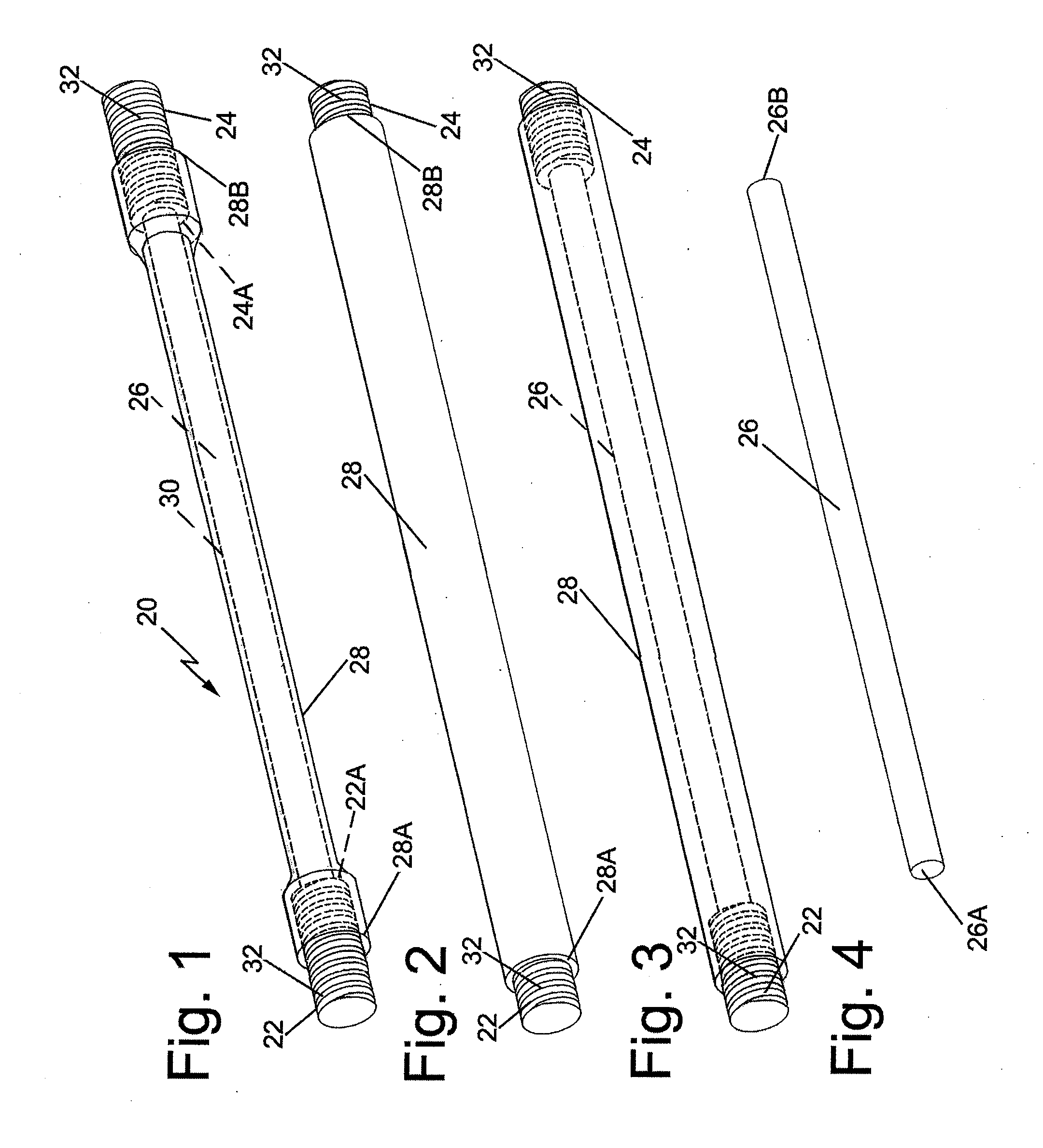

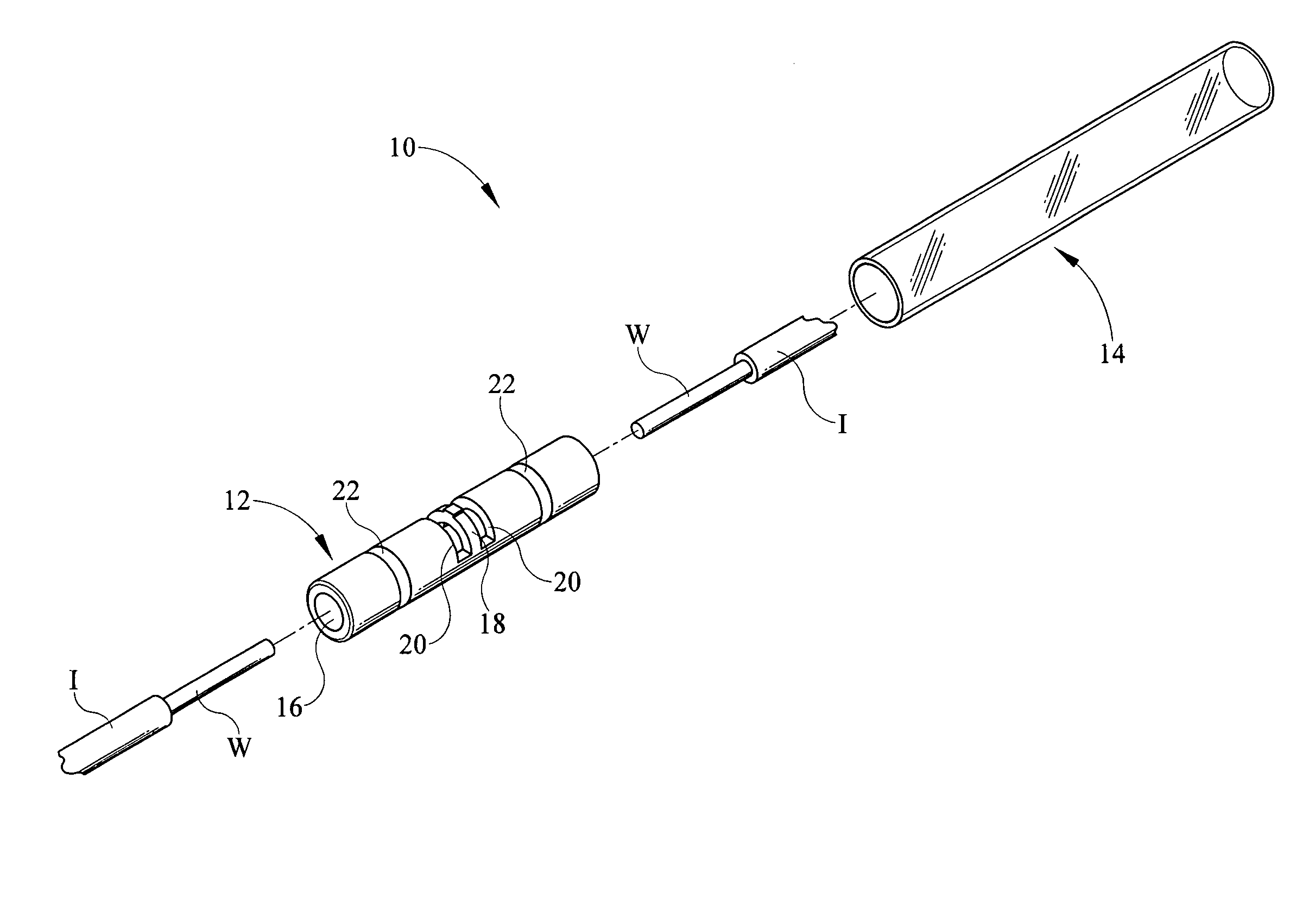

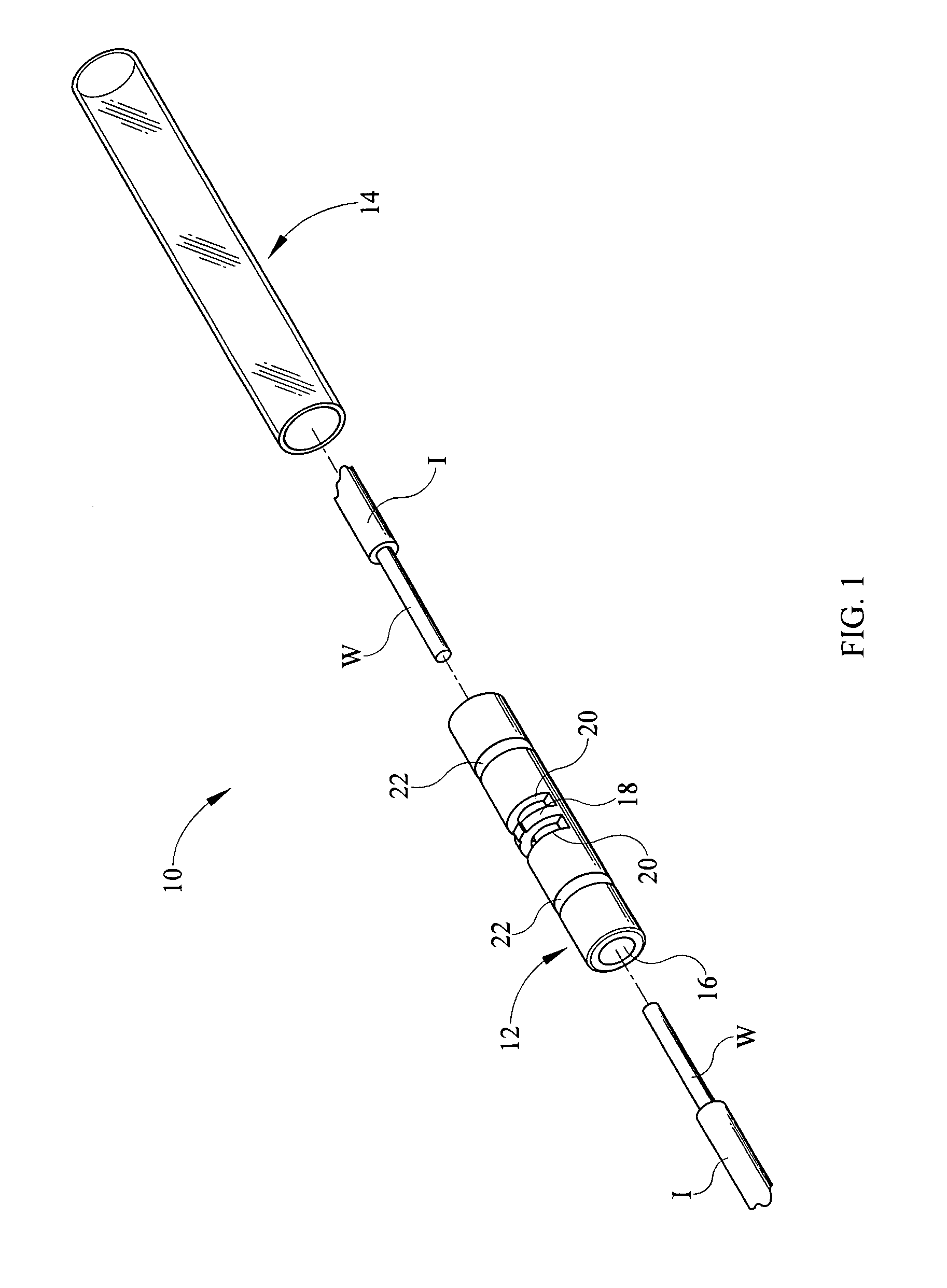

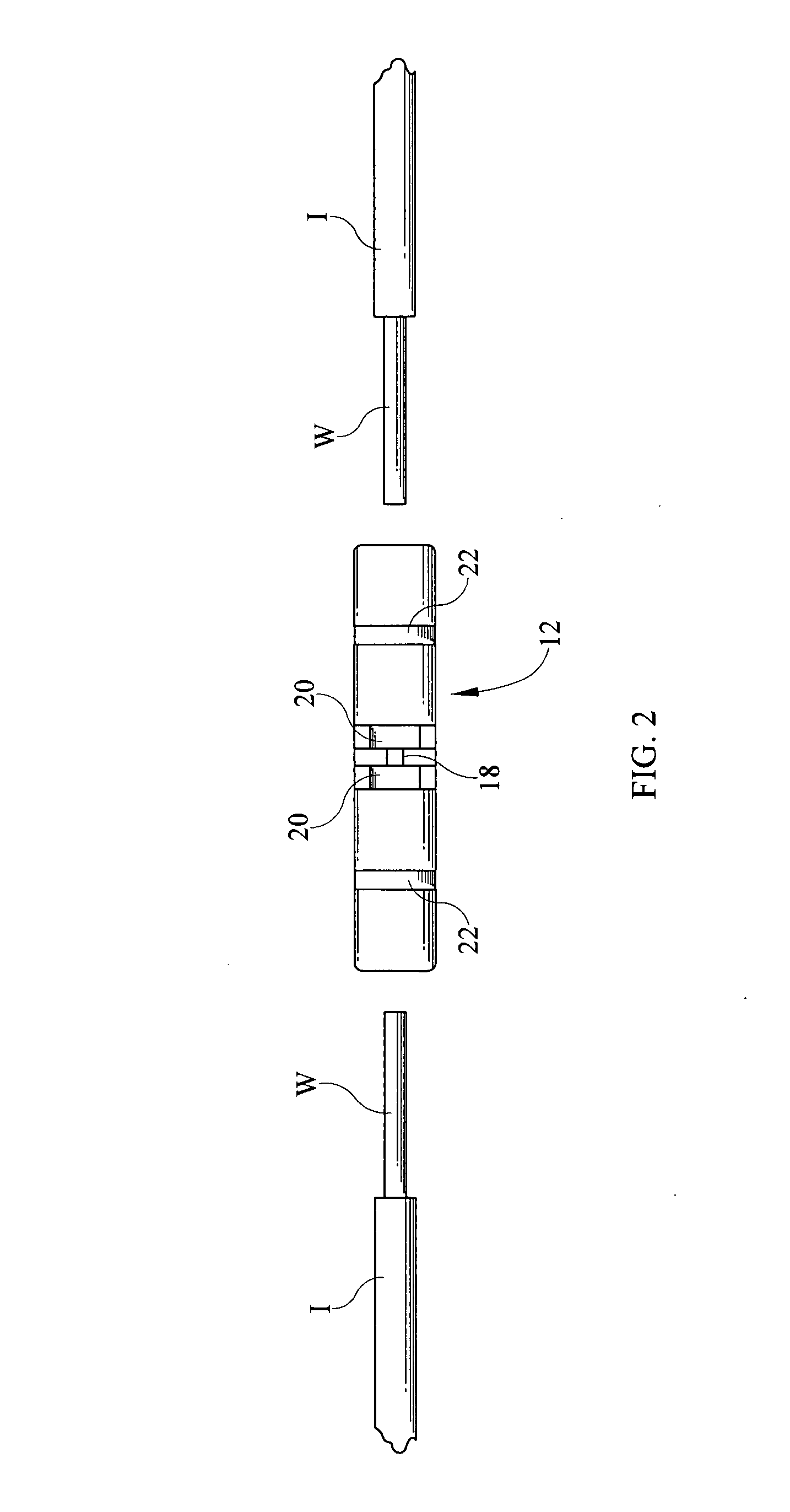

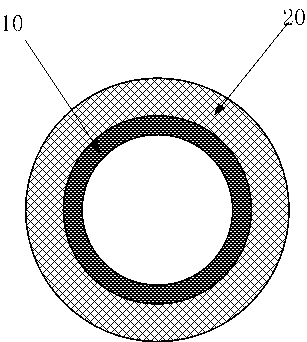

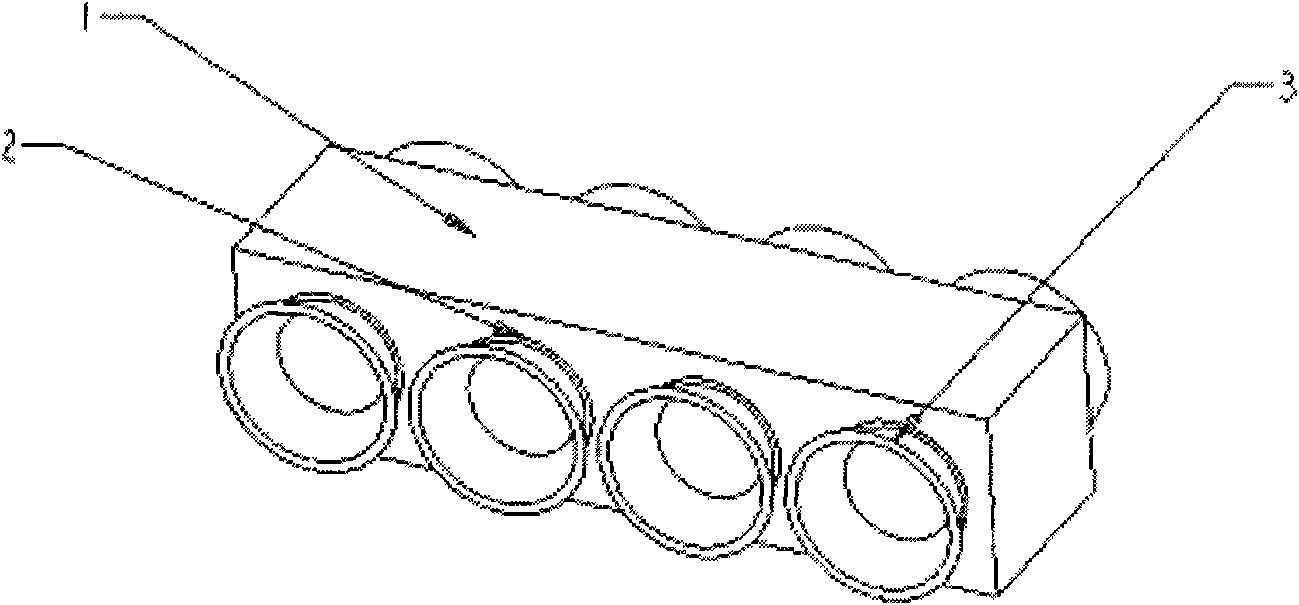

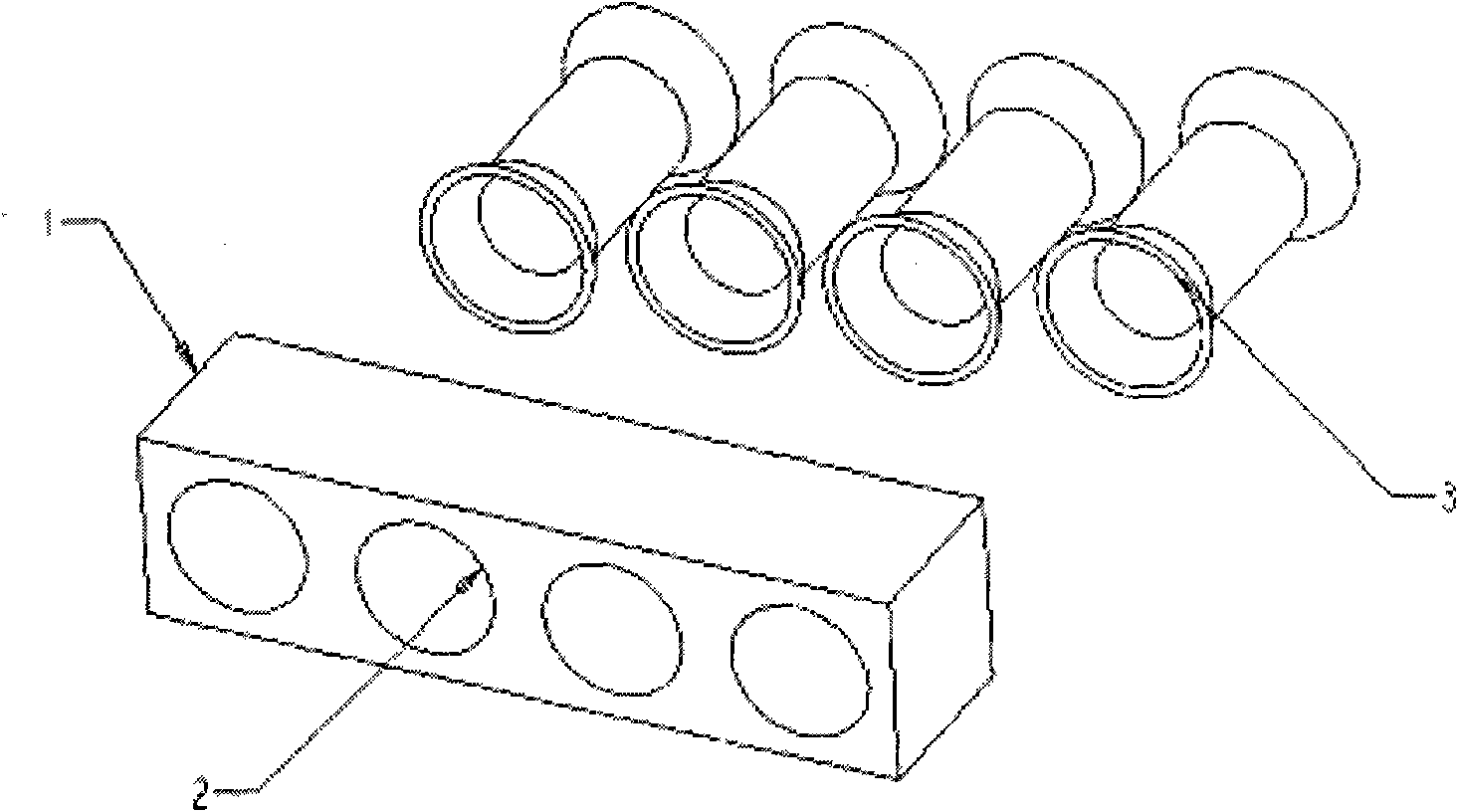

Alignment device and method for applying sleeves to arrow shafts

An apparatus and method for holding a plurality of arrow shafts in alignment for applying a heat-shrinkable sleeve thereto. The apparatus includes a support and an arrow holding assembly for holding more than one arrow shaft relative to the support. An adjuster ring is moveable along the support to hold the sleeves in the desired positions on the shafts. The apparatus and method of this invention allows for consistent positioning of shrinkable sleeves around multiple arrow shafts and simultaneous shrinking of sleeves onto the multiple arrow shafts.

Owner:NEW ARCHERY PRODS

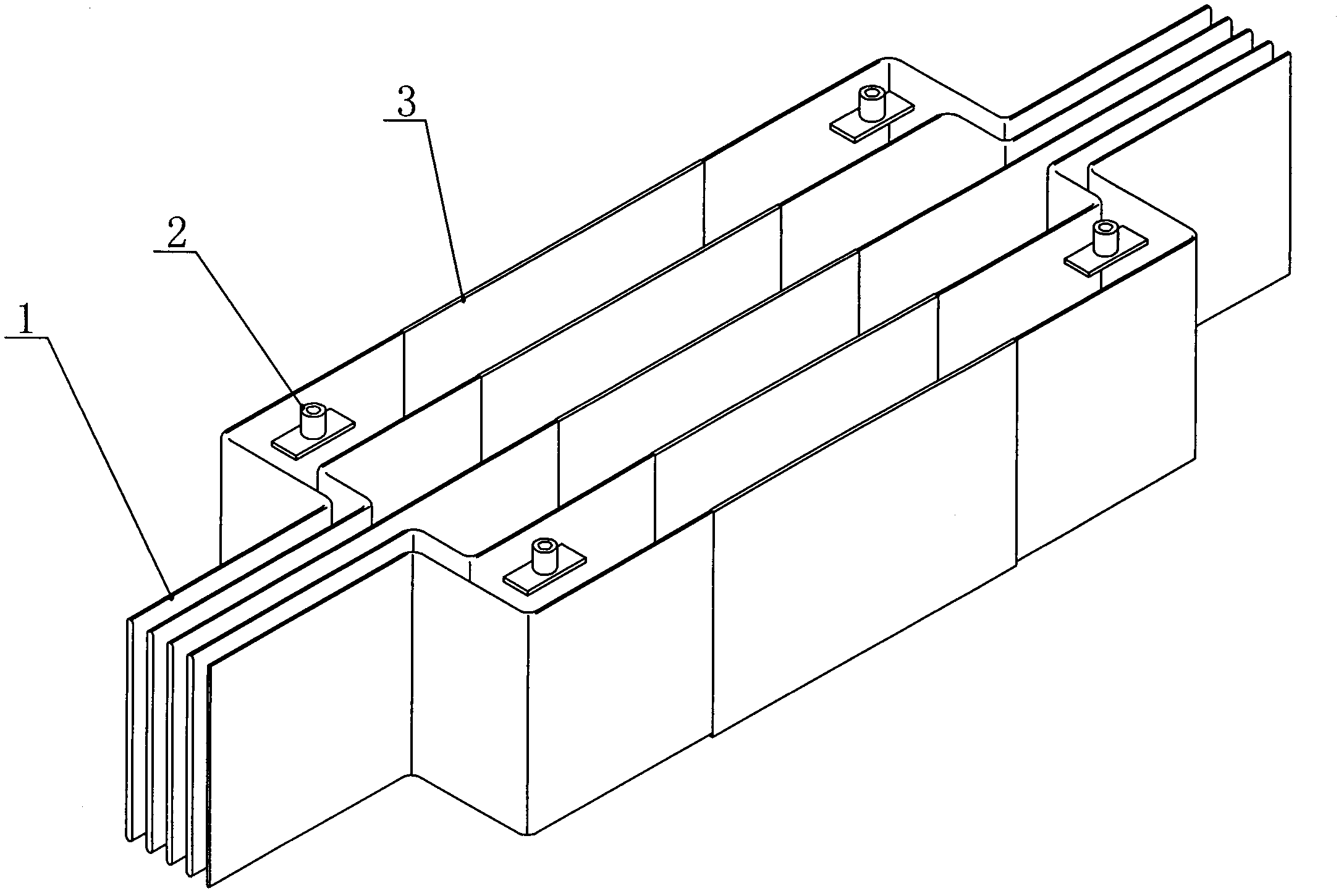

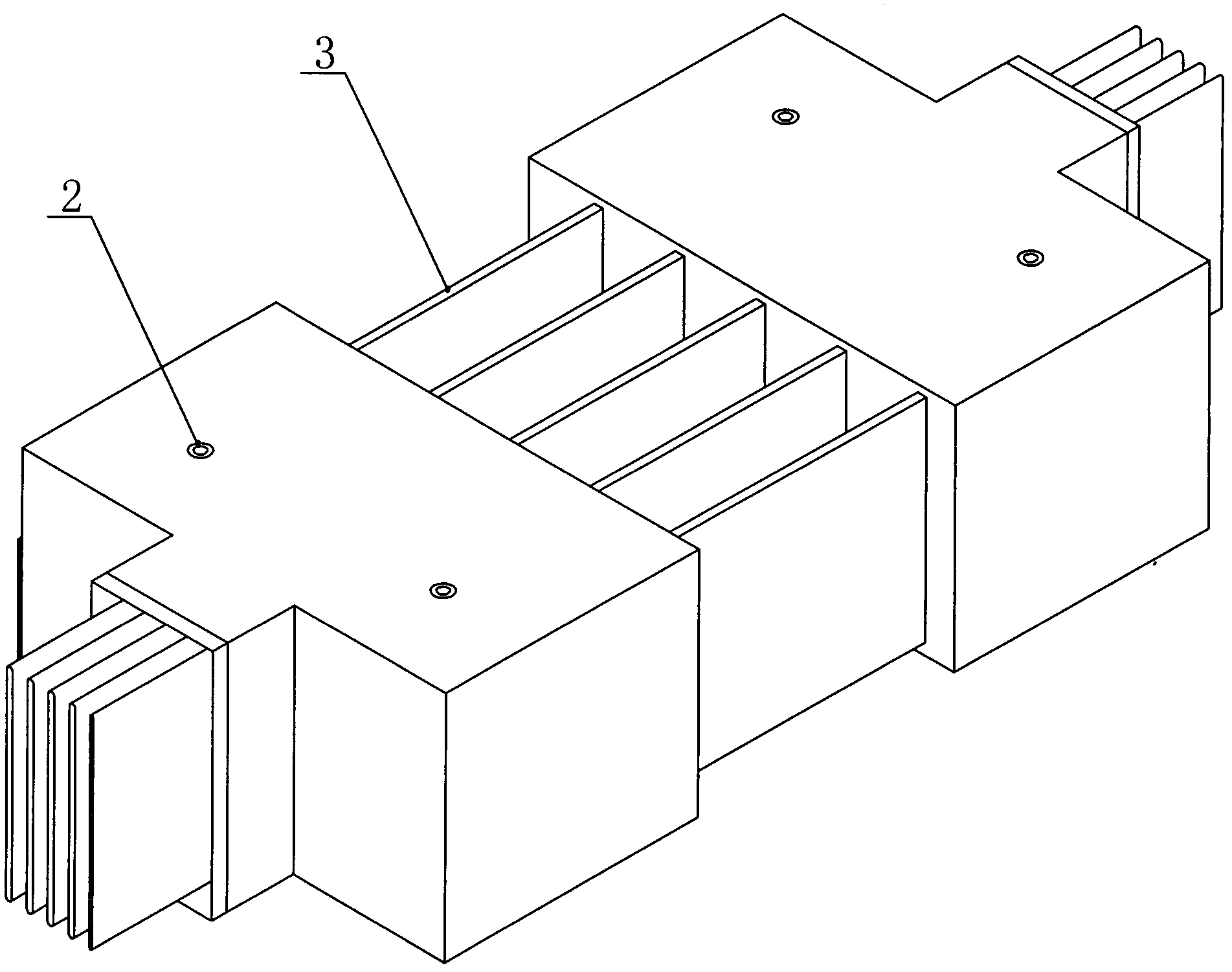

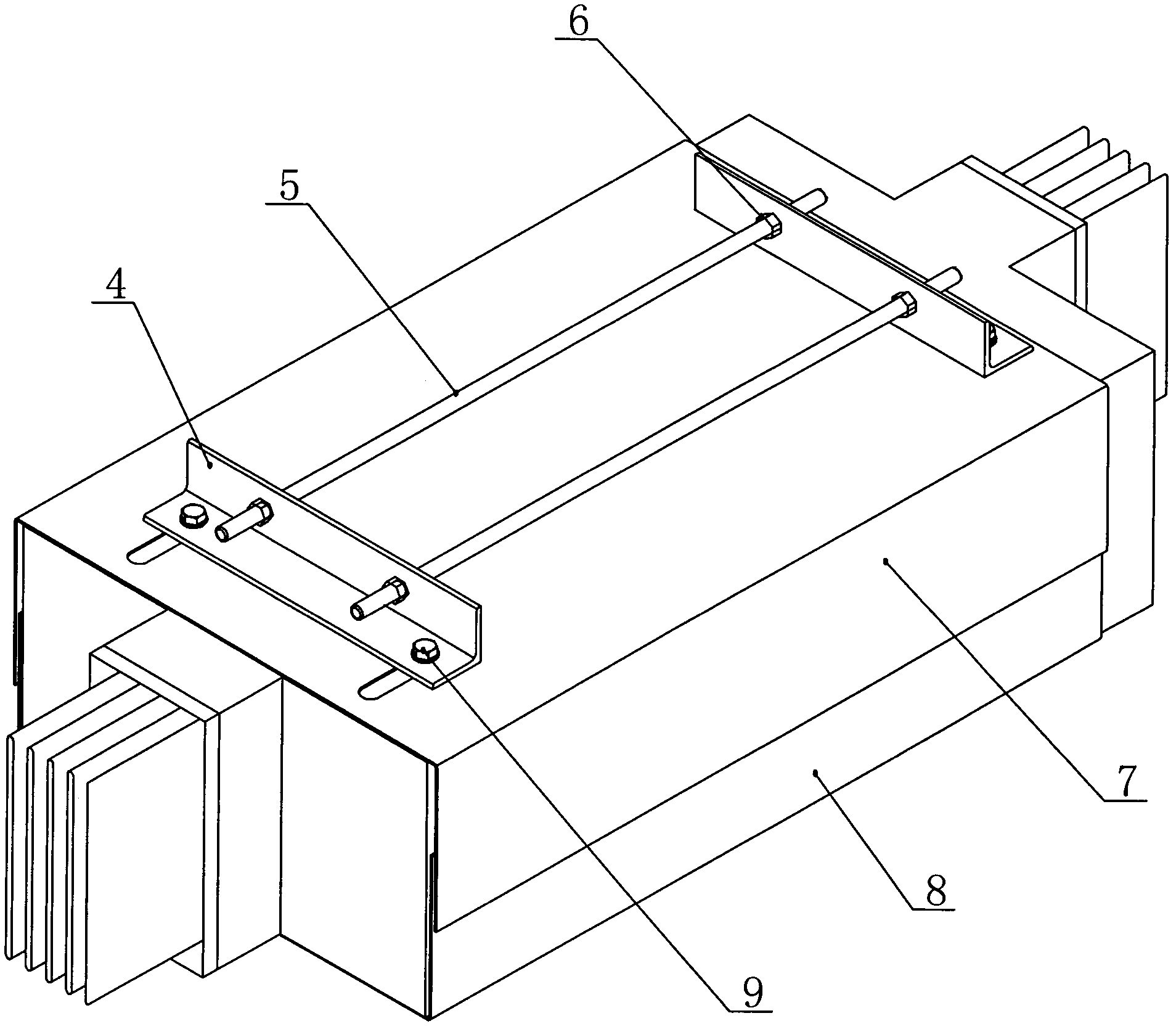

Resin bus expansion joint

InactiveCN103124057AHigh protection levelImprove power supply reliabilityTotally enclosed bus-bar installationsInsulating bodiesHeat-shrinkable sleeveElectrical conductor

The invention relates to a resin bus expansion joint, and belongs to the technical field of power transmission and distribution facilities. The resin bus expansion joint comprises a plurality of hard conductors located at two ends of the resin bus expansion joint, the hard conductors located at one end of the resin bus expansion joint are corresponding to the hard conductors located at the other end of the resin bus expansion joint, each hard conductor is wrapped by resin insulators, the resin insulators separate the hard conductors from one another, the hard conductors at two ends of the resin bus expansion joint are connected by banded flexible metal conductors in the middle of the resin bus expansion joint in a one-to-one correspondence mode, two ends of the flexible metal conductorare respectively welded with the hard conductors, an insulating film is wound around the periphery of each metal conductor, and a heat shrinkable sleeve is wrapped on the periphery of each the insulating film. The upper and the lower portions of the expansion joint are respectively covered with an upper protective cover and a lower protective cover which are sleeved with each other. Angle steels are respectively installed at two ends of the expansion joint, wherein the angle steels at two ends of the expansion joint are connected through adjusting screw rods, and the adjusting screw rod and the angle steels are fixed through adjusting nuts screwed on the adjusting screw rod. The expansion joint has a high ingress protection rating (IP) which can reach IP68, is compact in structure and small in size, and saves installation space, and furthermore inter-phase short circuit faults rarely occur.

Owner:WETOWN ELECTRIC GRP CO LTD

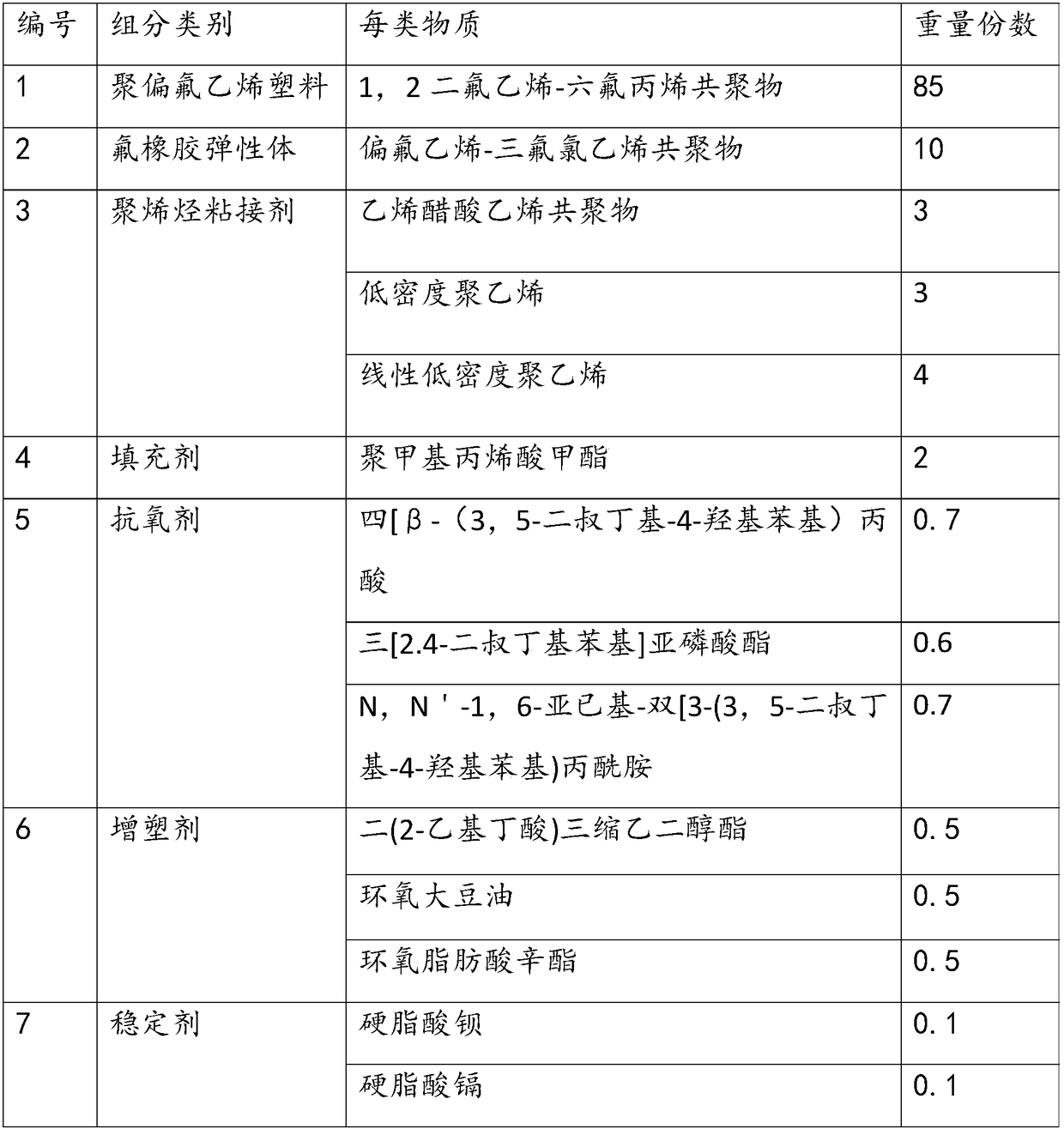

Fluoride elastic double-wall heat-shrinkable sleeve and preparation method thereof

ActiveCN108102260AIncrease elasticityWith reinforcementInsulating bodiesConnection insulationHeat-shrinkable sleeveElastomer

The invention discloses a fluoride elastic double-wall heat-shrinkable sleeve which comprises a sheath and an inner adhesive; the sheath is prepared from the following components in parts by weight: 60-98 parts of poly(vinylidene fluoride) plastics, 5-40 parts of a fluoro-rubber elastomer, 0.2-2.5 parts of an antioxidant, 2-6 parts of an auxiliary crosslinking agent, 1-6 parts of a plasticizer, 0.2-3 parts of a stabilizer and 1-9 parts of a color master; and the inner adhesive is prepared from the following components in parts by weight: 65-85 parts of the poly(vinylidene fluoride) plastics, 10-20 parts of the fluoro-rubber elastomer, 5-15 parts of a polyolefin adhesive, 2-8 parts of a filler, 0.5-2 parts of the antioxidant, 1-2 parts of the plasticizer, 0.2-3 parts of the stabilizer, 1-9parts of the color master and 3-10 parts of tackifying resin. The fluoride elastic double-wall heat-shrinkable sleeve provided by the invention can satisfy sealing, bending, the impact performance, insulation, piezoelectricity, machinery, ageing resistance, wear resistance, ultraviolet resistance and the like under the high-low temperature condition and also has the performances of wear resistance, mechanical damage resistance and the like.

Owner:SHANGHAI CHANGYUAN ELECTRONICS MATERIAL

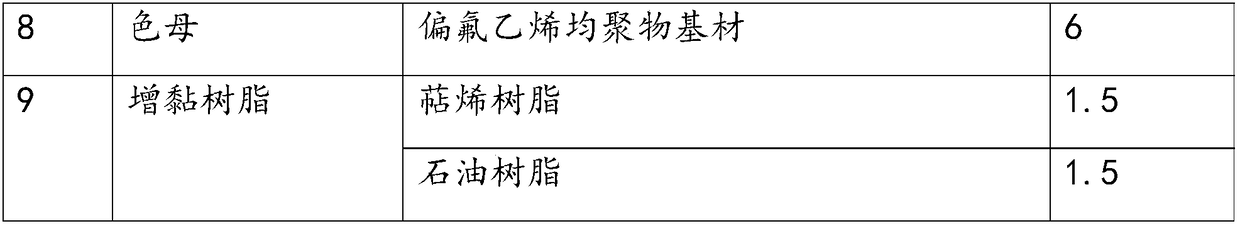

XLPE cable water tree accelerated aging tester and sample manufacturing method

The invention relates to the field of cable aging testing and particularly discloses an XLPE cable water tree accelerated aging tester and a sample manufacturing method. The tester comprises a voltagegeneration monitoring unit and an XLPE cable sample unit and is characterized in that the XLPE cable sample unit comprises a heat-shrinkable sleeve, a NaCl solution and an XLPE cable; the heat-shrinkable sleeve sleeves the XLPE cable, two ends of the heat-shrinkable sleeve are connected with two ends of the XLPE cable in a sealed manner, a gap exists between the middle of the heat-shrinkable sleeve and the XLPE cable to form a cavity, the cavity is filled with the NaCl solution, and the upper portion of the cavity is provided with a liquid injection hole; the outer semi-conductive layer of the XLPE cable located in the NaCl solution is provided with a plurality of defect needle holes, the power supply end of the voltage generation monitoring unit is connected with the core of the XLPE cable, and the grounding end of the voltage generation monitoring unit extends into the NaCl solution. By the tester, the water tree aging process of the cable in actual operation can be effectively simulated.

Owner:ELECTRIC POWER RES INST OF GUANGXI POWER GRID CO LTD

Small cable sealing module

The invention discloses a small cable sealing module applied to the field of cable module sealing. A tubular cylinder is arranged inside an elastic block which is provided with a plurality of through holes; and a through hole in the middle of the tubular cylinder allows a turn of small cable or a small cable coating thermoplastic tube to pass through. Liquid rubber is injected between the tubular cylinder and the small cable turn; the cured liquid rubber seals the small cable turn or the exterior of a heat-shrinkable sleeve; and the elastic block is compressed by a framework structure so as to seal a gap formed between the elastic block and the tubular cylinder. Therefore, the cable is sealed.

Owner:刘新月

Memory alloy calibrating lock and method for realizing locking and unlocking of satellite calibrating device by using same

InactiveCN101694523ASimple structureFew partsWave based measurement systemsHeat-shrinkable sleeveSatellite

The invention discloses a memory alloy calibrating lock, wherein one end of a memory alloy spring extends from a small hole at the bottom of a sleeve and is fixed by a screw at one side, and the other end is fixed on a limiting block and extends out of the side of the sleeve. A memory alloy wire outside the sleeve is provided with a heat-shrinkable sleeve and connected with leads of a control circuit through a pressure welding way. One end of a metal shaft is fixed on the limiting block and the other end is connected with a soft rope. The calibrating lock has the characteristics of small volume, light weight, simple structure and high reliability. When the calibrating device realizes the locking or the unlocking by the memory alloy calibrating lock, the assembly is fixed on a base of the calibrating device through the bolt. The soft rope is straightened for certain time, the metal shaft extends into a locking hole of a swinging rod of the calibrating device, and the spring has no restoring force to complete the locking. The control circuit electrifies the memory alloy spring when unlocking is needed, the spring restores the original shape of the memory after the phase-transition temperature is achieved, and the metal shaft is driven to retract towards the inner side of the sleeve so as to disengage from the locking hole of the swinging rod to realize the unlocking.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

Dry-type capacitor type composite insulating sleeve pipe production method

ActiveCN104900350AReduce generationAvoid breakdown phenomenonInsulating bodiesLead-in/lead-through insulatorsHeat-shrinkable sleeveVacuum pumping

The present invention relates to a dry-type capacitor type composite insulating sleeve pipe production method which comprises a step of taking a metal tube conductor and winding a layer of glass fiber cloth belt around the surface of the conductor, a step of sleeving outer side wall of the conductor wound by the cloth belt with a heat-shrinkable sleeve pipe, carrying out vacuum pumping processing on the space between the heat-shrinkable sleeve pipe and the conductor and pouring epoxy resin into the cavity between the heat-shrinkable sleeve pipe and the conductor from the resin poring port on the conductor, and a step of heating, drying and curing the conductor and winding a layer of semiconductor glass fiber on the outer wall of the heat-shrinkable sleeve pipe. The method has the advantages that an original glass fiber cloth belt layer is replaced by the staggered winding of glass fiber cloth belt and a semiconductor conformal material, and a breakdown phenomenon can be avoided well.

Owner:江苏沃能高压电气有限公司

Cold-shrinkable foamed sleeve pipe, patterned sleeve pipe and preparation method thereof

The invention discloses a cold-shrinkable foamed sleeve pipe which comprises the following raw materials in parts by weight: 100 parts of ethylene propylene diene monomer or silicone rubber, 10-120 parts of carbon black or white carbon black, 0-50 parts of inorganic fillers, 0.2-6 parts of a vulcanizing agent, 0.2-5 parts of an activating agent, 1-35 parts of a foaming agent and 0-10 parts of a foaming aid. A preparation process of the cold-shrinkable foamed sleeve pipe comprises the following steps of performing secondary vulcanization and foaming on the materials of the cold-shrinkable foamed sleeve pipe at 180-250 DEG C by adopting the foaming agent to form a foamed pipe material, performing decomposition reaction on the foaming agent, generating foams, and expanding, cooling and solidifying the foams. The process is simple, the production efficiency can be improved, and the production cost can be reduced. When the cold-shrinkable foamed sleeve pipe is applied, the negative phenomena of pricking of the hand and the like can be avoided, and the hand feel of the cold-shrinkable sleeve pipe held or gripped by people can be improved. The invention further provides a cold-shrinkable foamed anti-slip patterned sleeve pipe; a concave-convex pattern is arranged on the surface of the patterned sleeve pipe, so that the anti-slip effect can be further improved, and the hand feel of a heat-shrinkable sleeve pipe held or gripped by people can be improved.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com